Manufacturing method for interlocked armored aluminum alloy flat cable

A technology of interlocking armoring and manufacturing methods, applied in the direction of cable/conductor manufacturing, flat/ribbon cables, insulated cables, etc., which can solve the problems of difficult control of annealing temperature and annealing time, poor ability to resist external mechanical damage, and conductor conduction In order to achieve the effects of long-term stable operation, strong resistance to external mechanical damage, and good bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

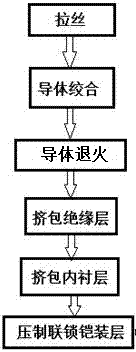

[0033] A method for manufacturing an interlocking armored aluminum alloy flat cable. The manufacturing process includes the following steps: wire drawing—conductor stranding—conductor annealing—extruded insulation layer—extruded inner lining layer—pressed interlocking armor layer, the conductor The annealing step refers to heating the stranded conductor to 370°C through the stuffy-tank heating annealing step, and then cooling down to room temperature naturally after 4 hours in an environment of 370°C; the step of pressing the interlocking armor layer It refers to the "Z"-shaped interlocking armor form that uses aluminum alloy strips with a thickness of 0.5mm on the surface of the inner lining layer and presses them into a bow-shaped height of 2mm at a pitch of 6mm.

[0034] In the present invention, the stuffy-tank heating annealing includes the following steps: charging—vacuumizing—inflating—heating and heat preservation—out of the furnace and cooling, the charging step is to ...

Embodiment 2

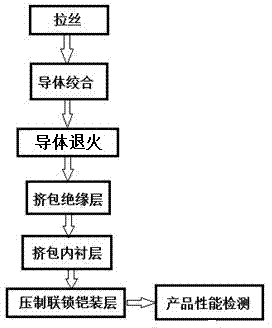

[0042] A method for manufacturing an interlocking armored aluminum alloy flat cable. The manufacturing process includes the following steps: wire drawing—conductor stranding—conductor annealing—extruded insulation layer—extruded inner lining layer—pressed interlocking armor layer, the conductor The annealing step refers to heating the stranded conductor to 390°C through a stuffy-tank heating annealing step, and then cooling down to room temperature naturally after 4 hours in an environment of 390°C; the step of pressing the interlocking armor layer It refers to the "Z"-shaped interlocking armor form that uses aluminum alloy strips with a thickness of 0.5mm on the surface of the inner lining layer and presses them into a bow-shaped height of 3mm at a pitch of 12mm.

[0043] In the present invention, the stuffy-tank heating annealing includes the following steps: charging—vacuumizing—inflating—heating and heat preservation—out of the furnace and cooling, the charging step is to h...

Embodiment 3

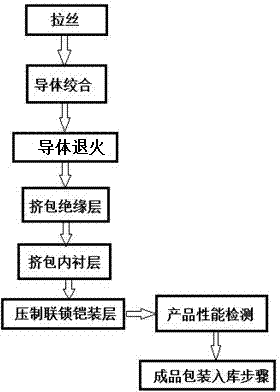

[0058] A method for manufacturing an interlocking armored aluminum alloy flat cable. The manufacturing process includes the following steps: wire drawing—conductor stranding—conductor annealing—extruded insulation layer—extruded inner lining layer—pressed interlocking armor layer, the conductor The annealing step refers to heating the stranded conductor to 400°C through a stuffy tank heating annealing step, and then cooling down to room temperature naturally after 5 hours in an environment of 400°C; the step of pressing the interlocking armor layer It refers to the "Z"-shaped interlocking armor form that uses aluminum alloy strips with a thickness of 0.6mm on the surface of the inner lining layer and presses them into a bow-shaped height of 4mm at a pitch of 24mm.

[0059] In the present invention, the stuffy-tank heating annealing includes the following steps: charging—vacuumizing—inflating—heating and heat preservation—out of the furnace and cooling, the charging step is to h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com