Patents

Literature

1553results about How to "Avoid breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

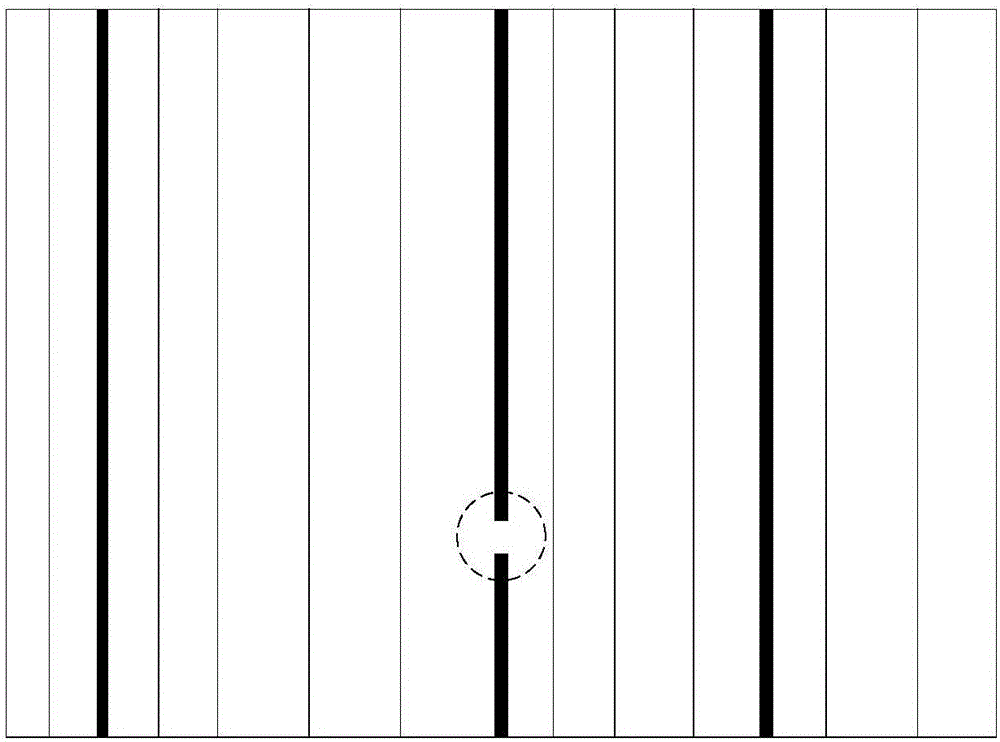

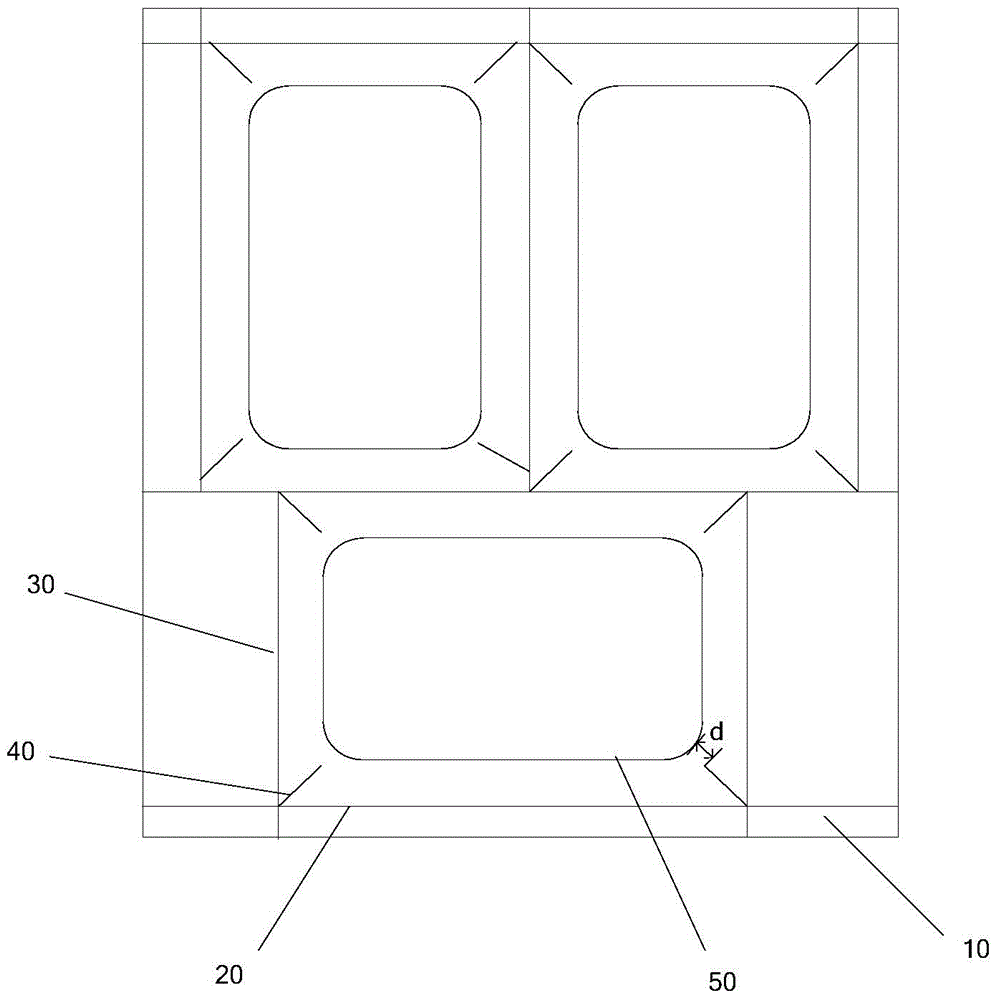

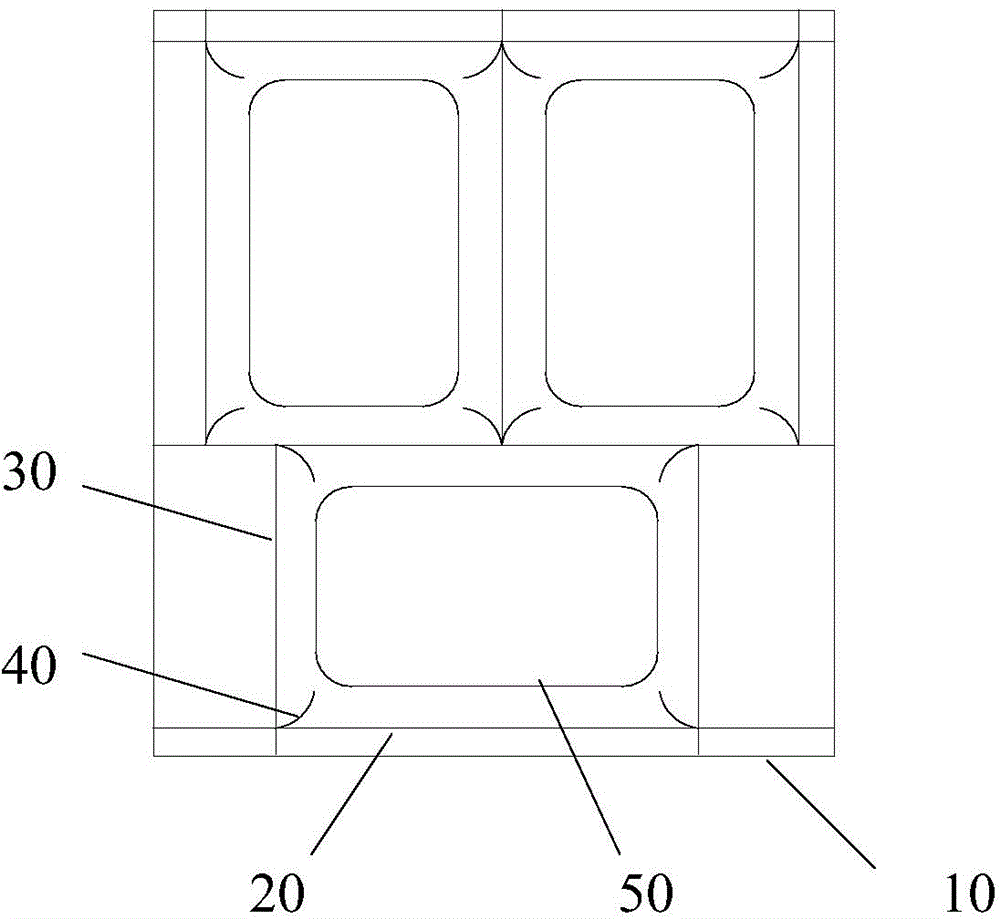

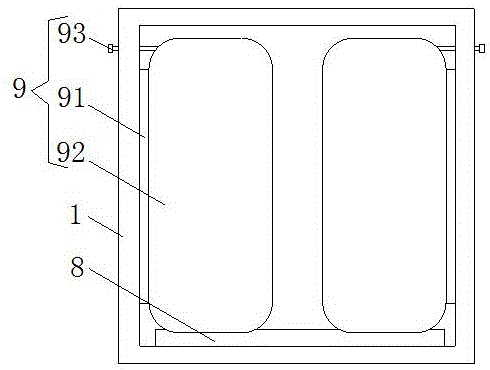

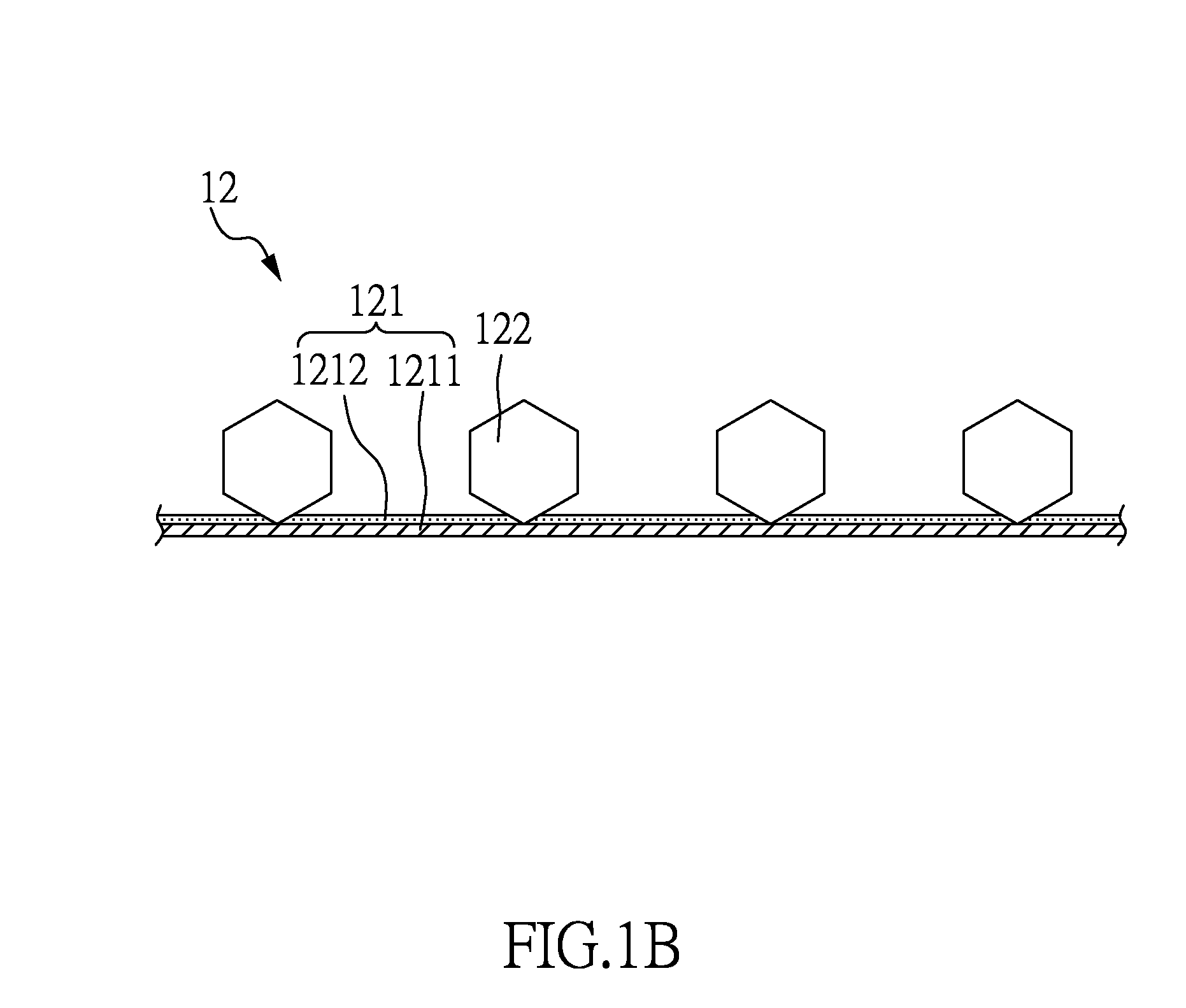

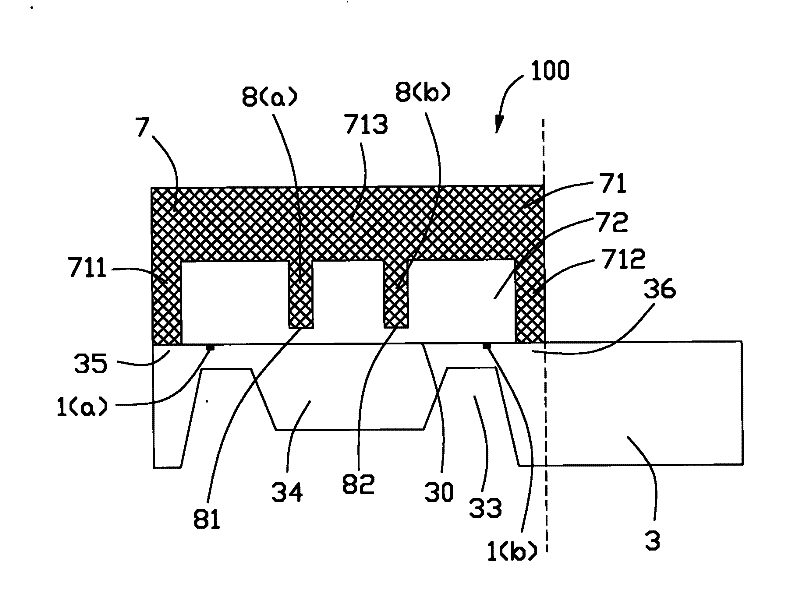

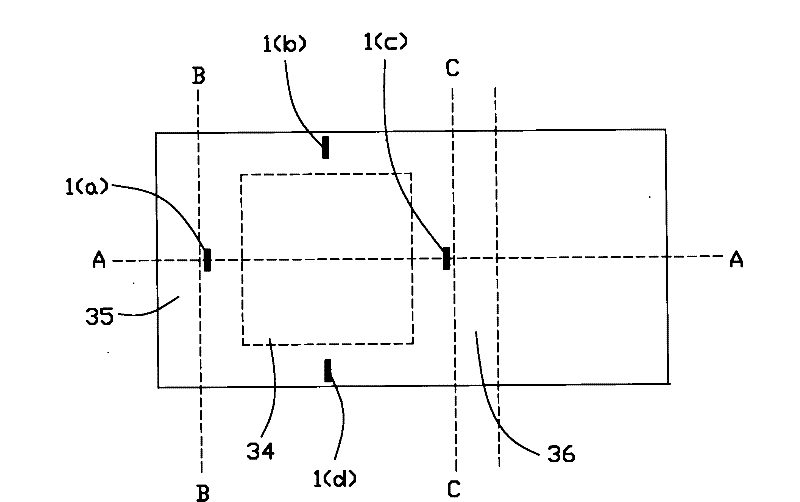

Supporting structure and display device

ActiveCN110767096AImprove bending resistanceBending Resistance GuaranteeCasings with display/control unitsPhotovoltaic energy generationDisplay deviceEngineering

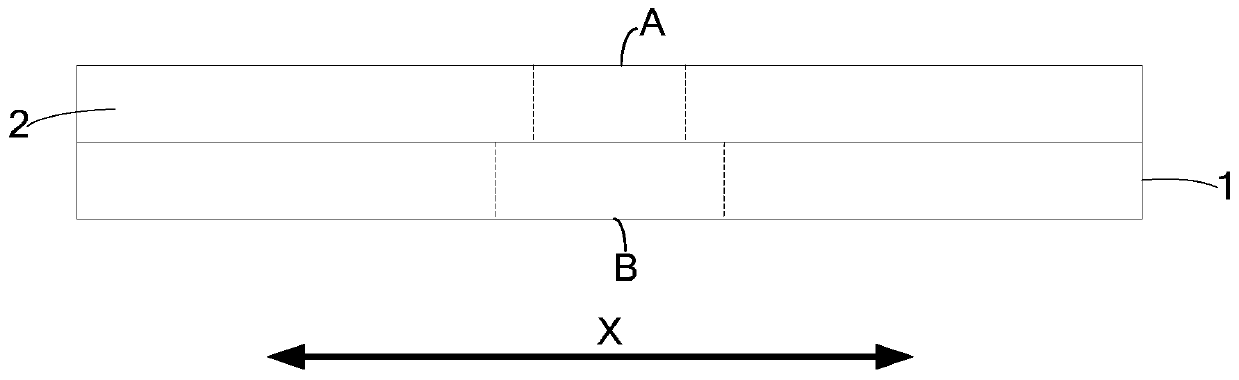

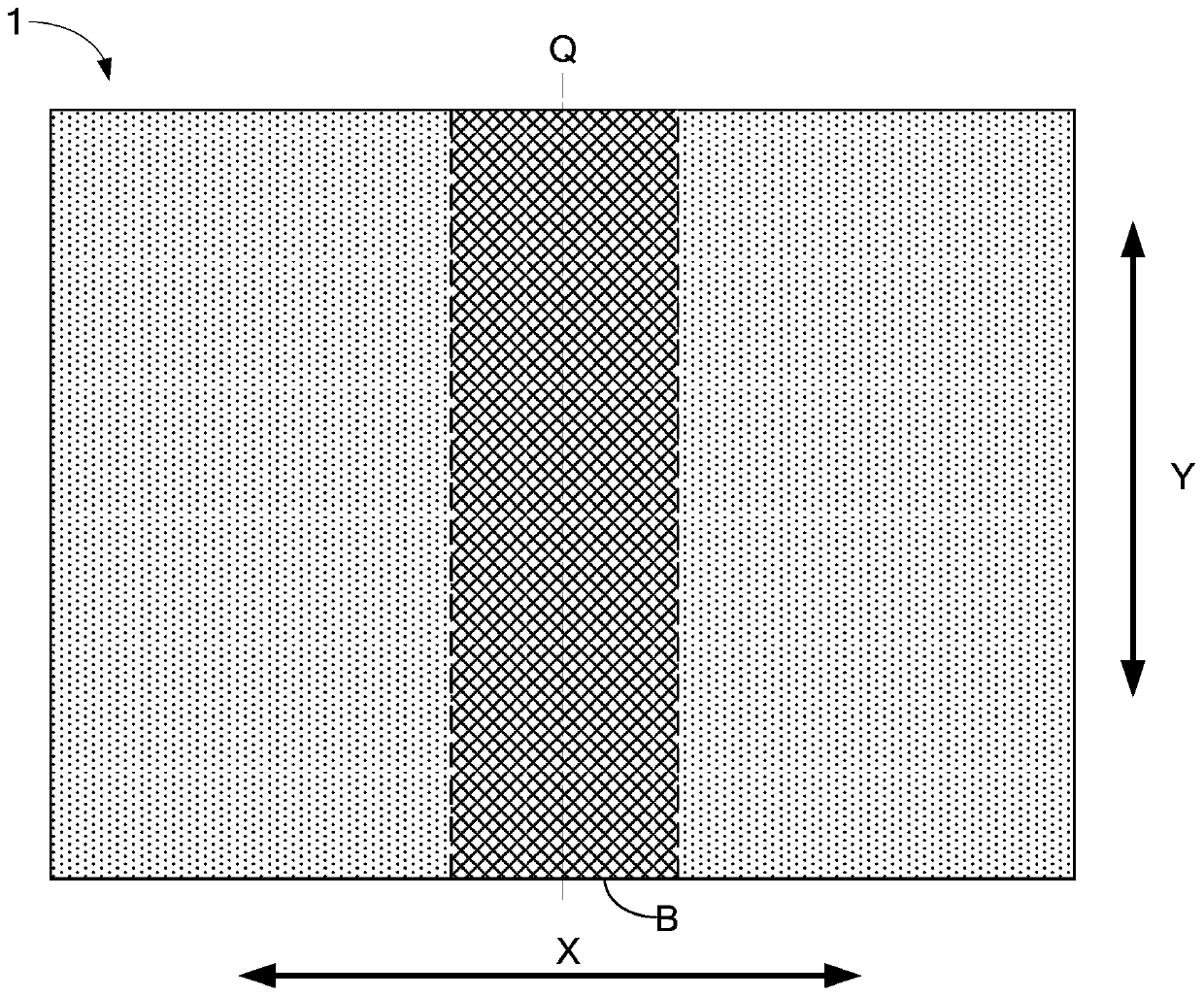

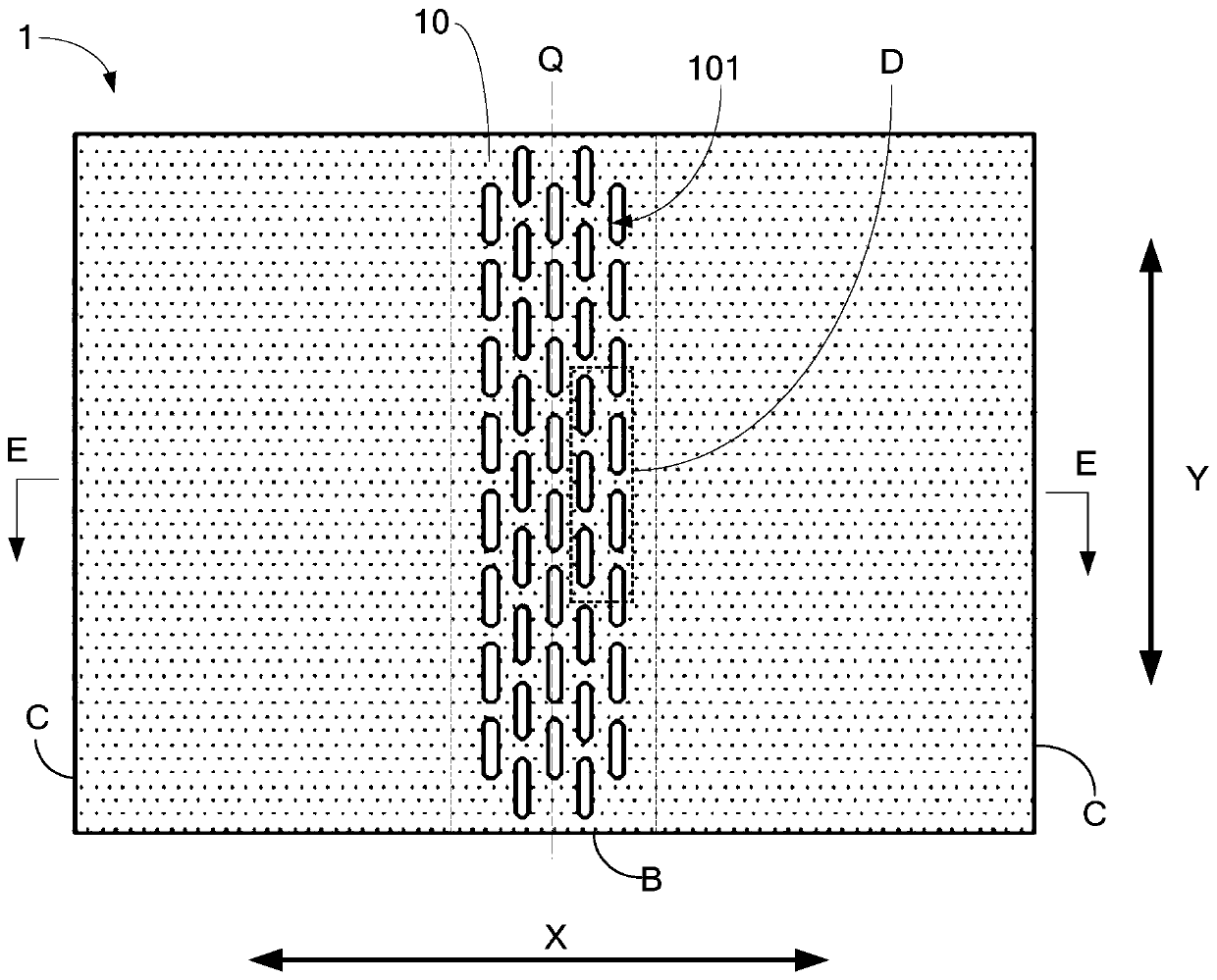

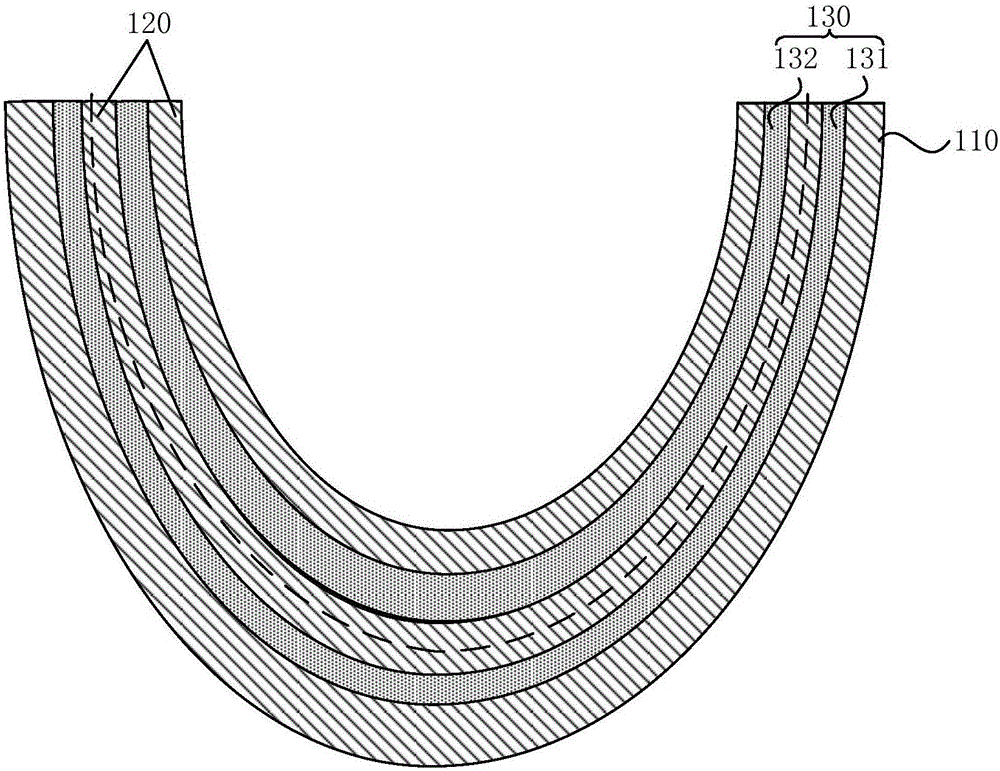

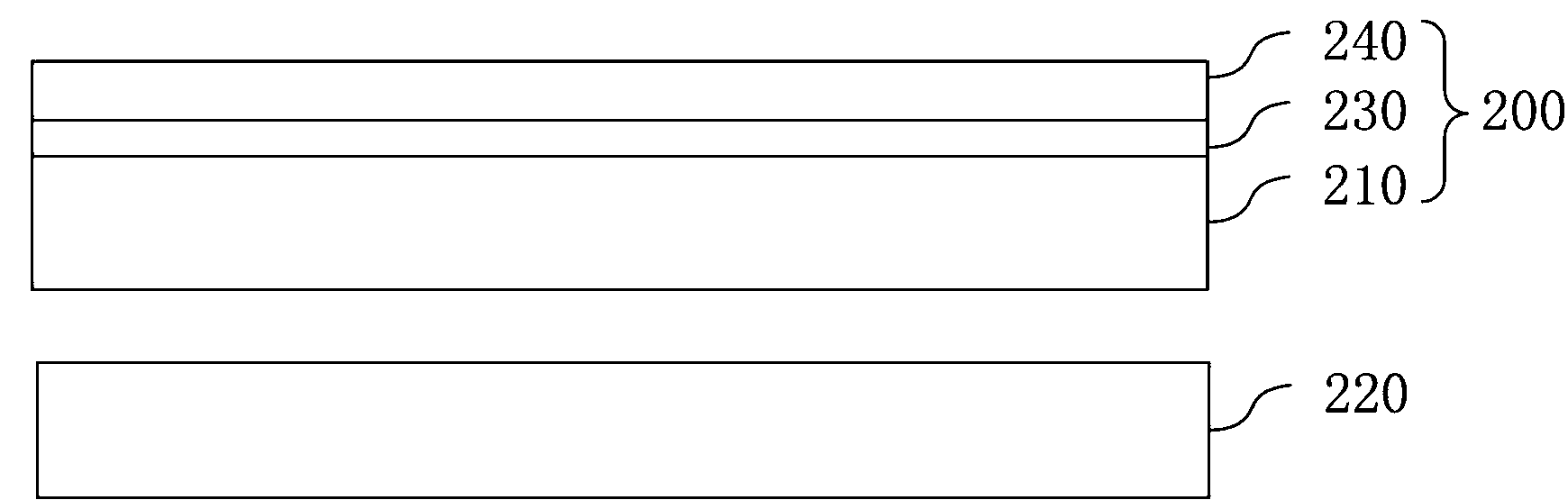

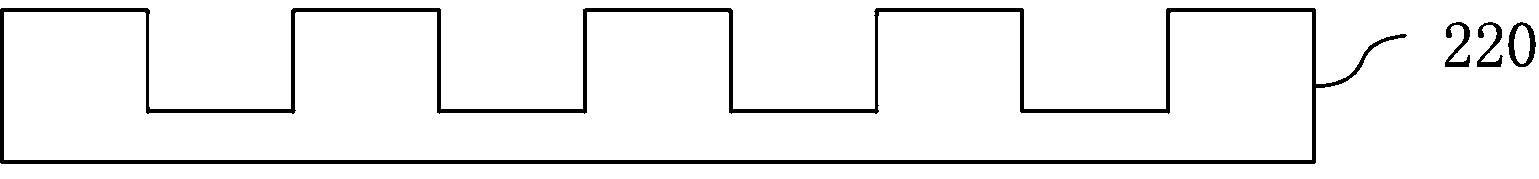

The application relates to a supporting structure and a display device. The supporting structure is arranged at one side of a flexible display panel, the flexible display panel comprises a bendable area, a bending axis corresponding to the bendable area extends on a first direction, wherein the supporting structure comprises a hollow-out area with a positive projection capable of completely covering the bendable area on the display panel, the hollow-out area comprises a first part formed with multiple first hollow-out holes, second parts located at two opposite sides of the first part on the first direction, wherein multiple second hollow-out holes are formed on the second parts; a specific value of the total area of multiple second hollow-out holes and the total area of the second parts is different from that of the total area of multiple first hollow-out holes and the first part, thereby guaranteeing the structure stability of the supporting structure and enhancing the shock resistance and bending resistance of the flexible display panel.

Owner:BOE TECH GRP CO LTD

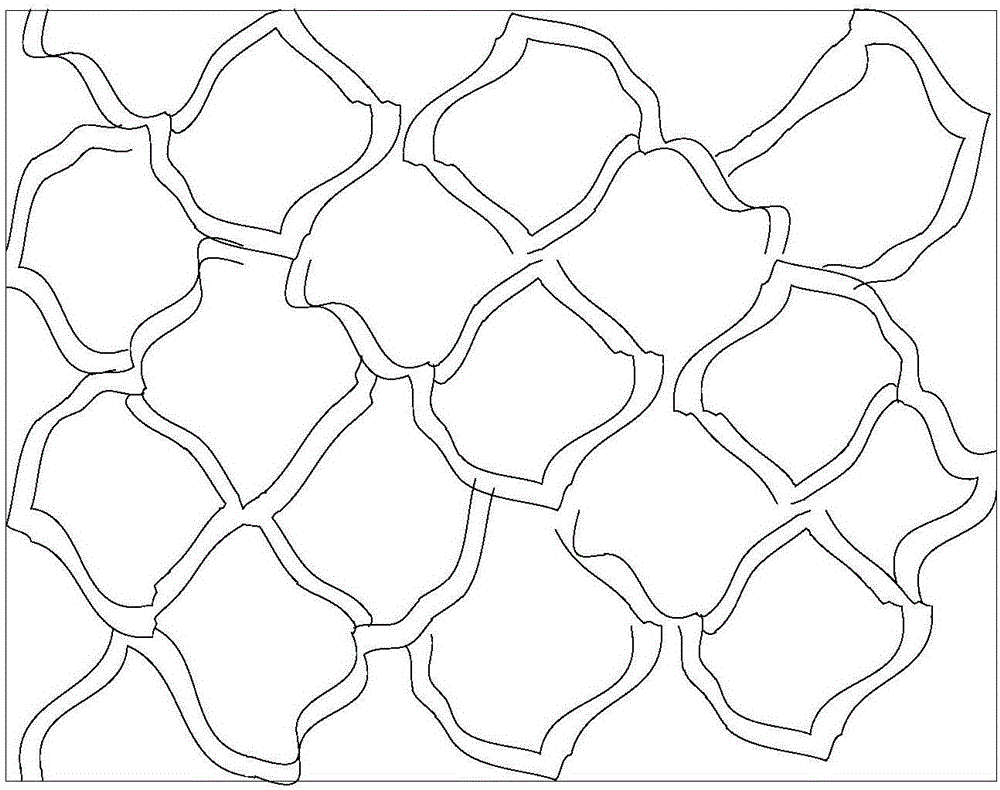

Curved-surface display device

ActiveCN106530973AIncrease elasticityIncrease stickinessIdentification meansSurface displayComputer science

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

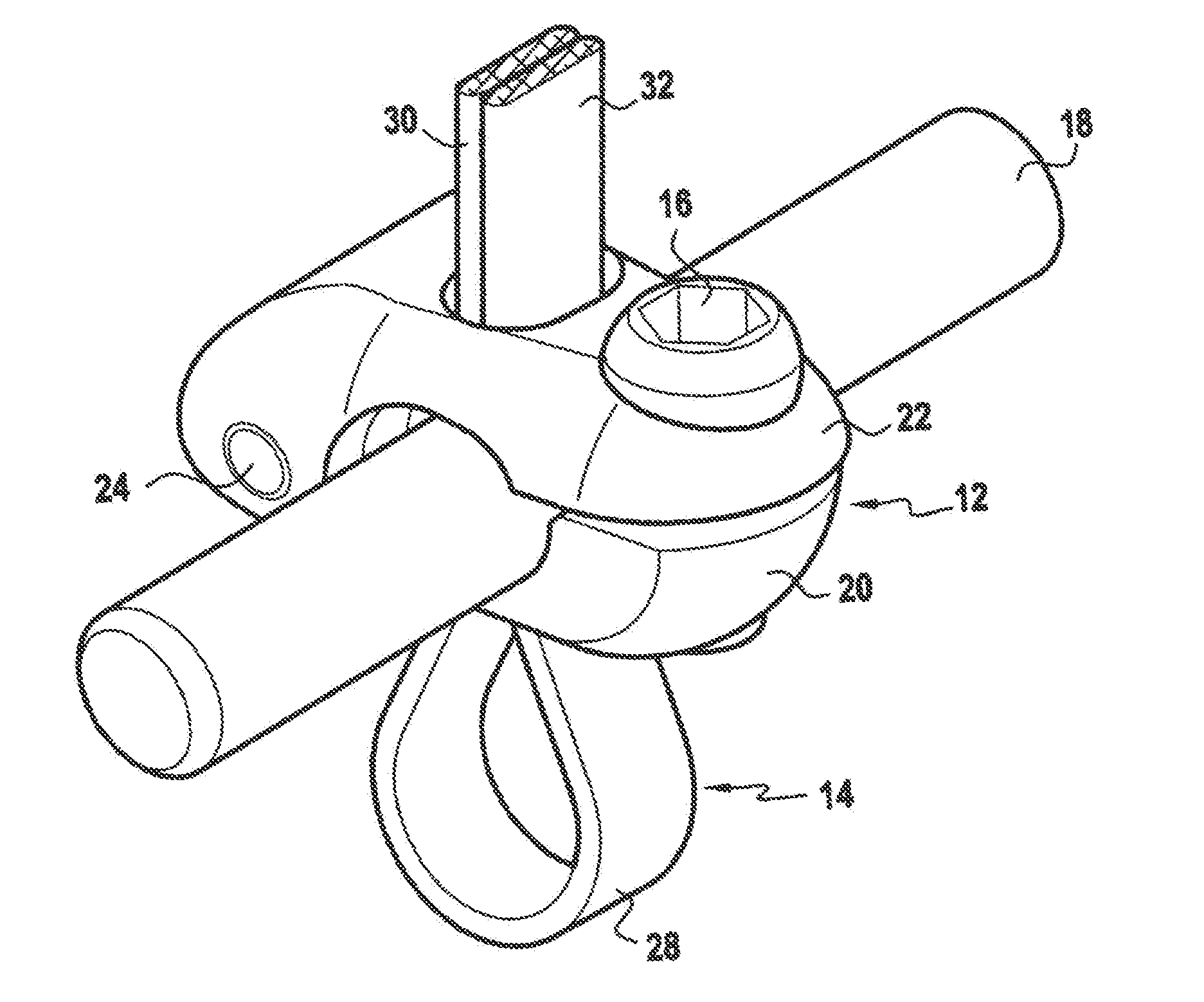

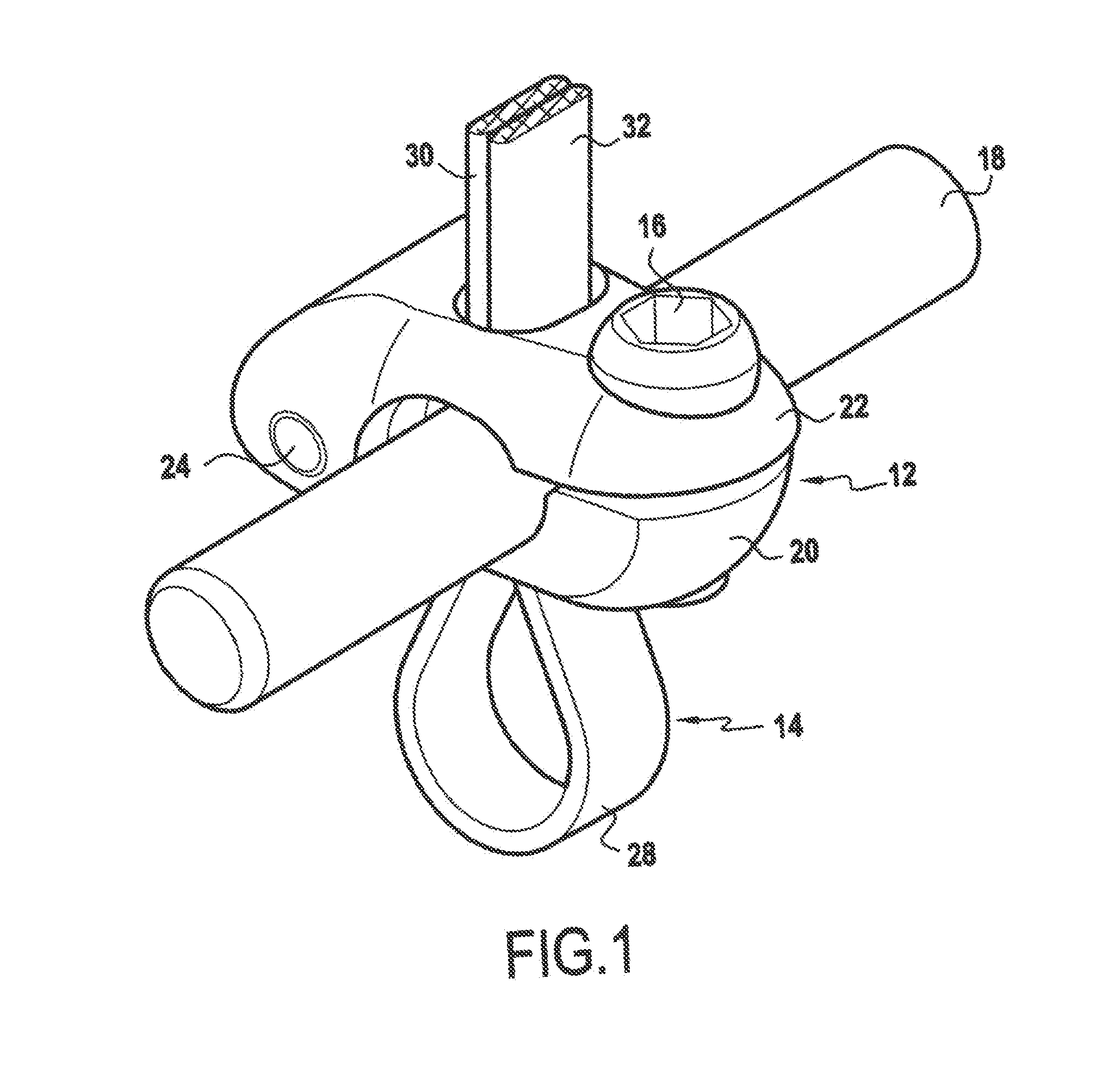

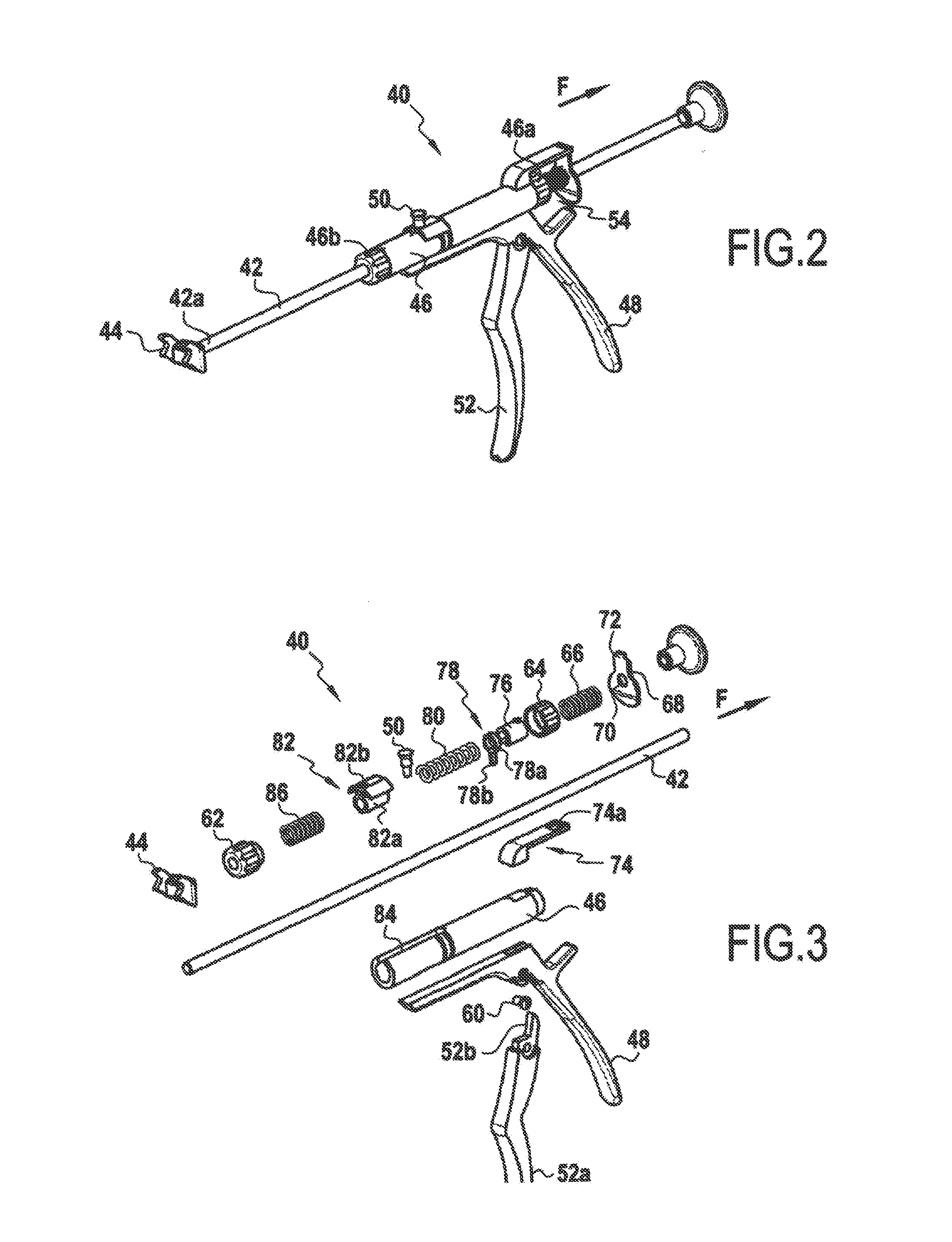

Spinal implant with flexible tie

ActiveUS20110238118A1Avoid breakageReduce riskInternal osteosythesisJoint implantsSpinal implantFixed position

A spinal implant can be fastened on a bony element of a patient via a flexible tie. In some embodiments, the spinal implant has two jaws, each having a recess and an opening. The recess is configured to receive a portion of a rod. A portion of the flexible tie is passed through the opening and between a wall of the recess and a surface of the rod to form a loop that can be placed around the bony element. The two jaws are hinged at one end and engaged at the opposite end via a locking member. The locking member can be adjusted to simultaneously hold the jaws together in a fixed position relative to the rod and lock the flexible tie, which has been properly tensioned, in translation relative to the spinal implant.

Owner:ZIMMER SPINE SAS

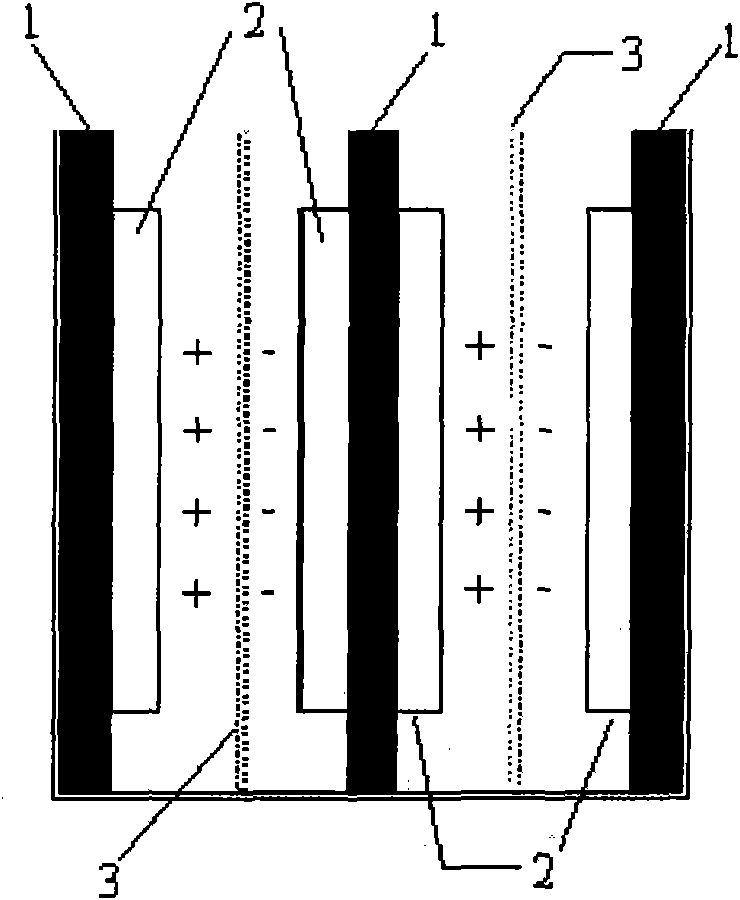

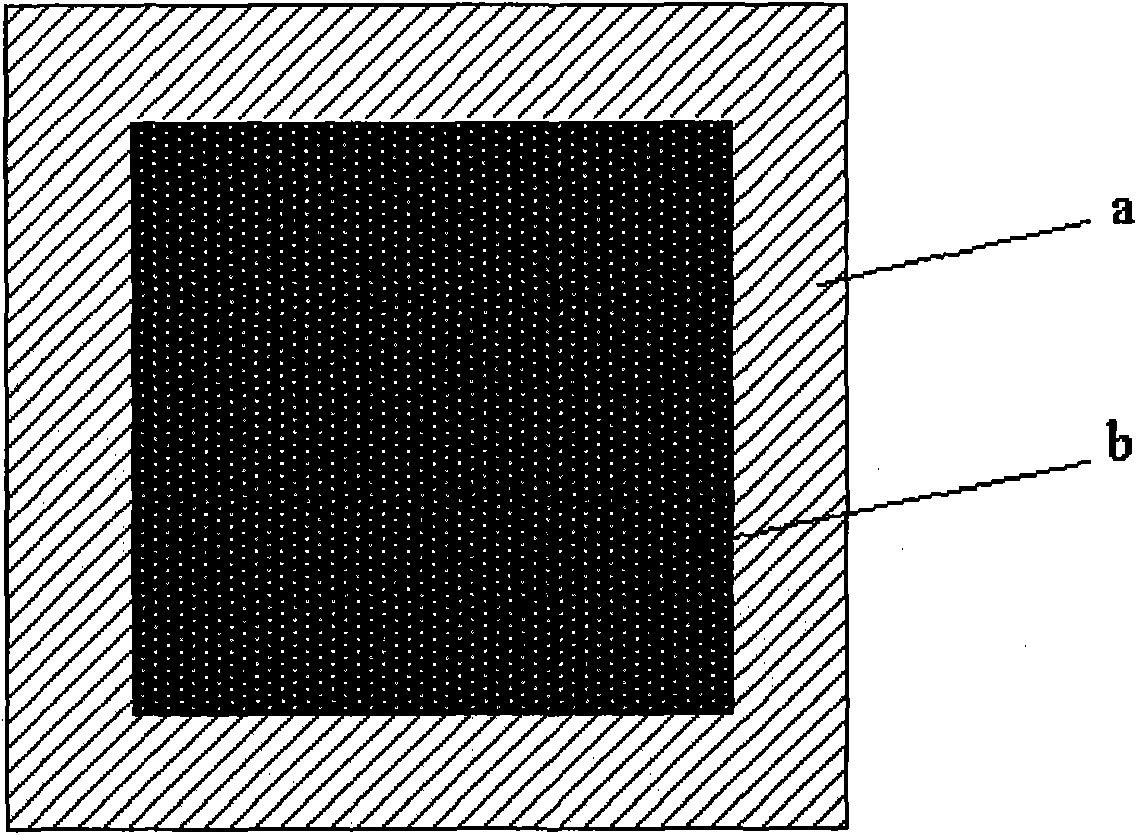

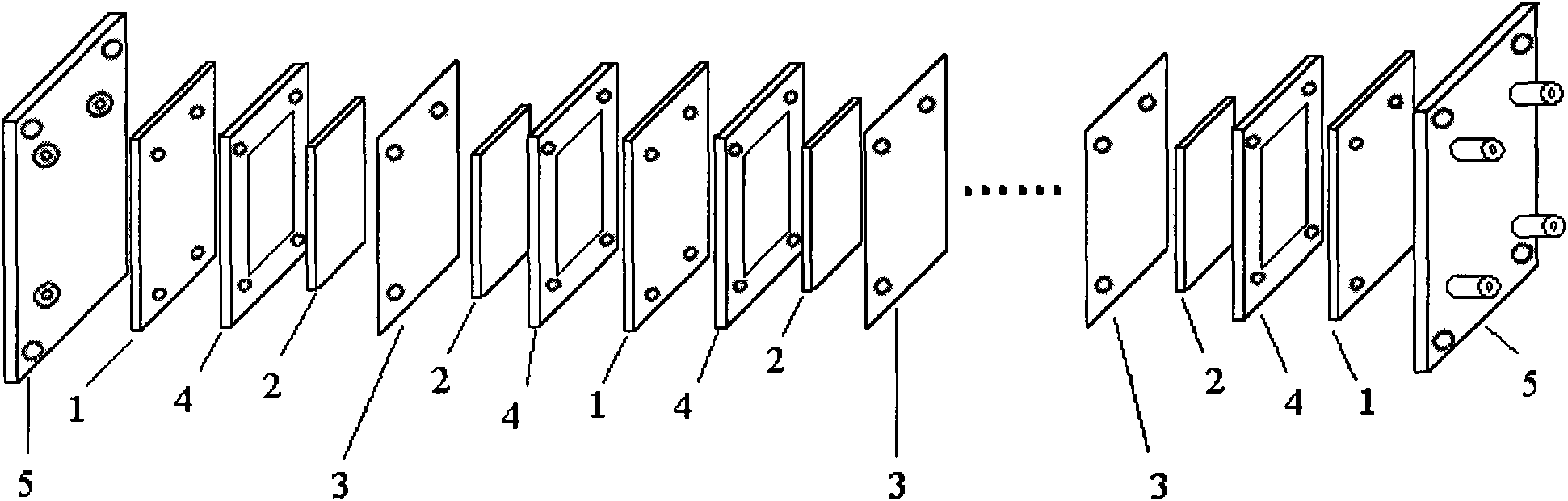

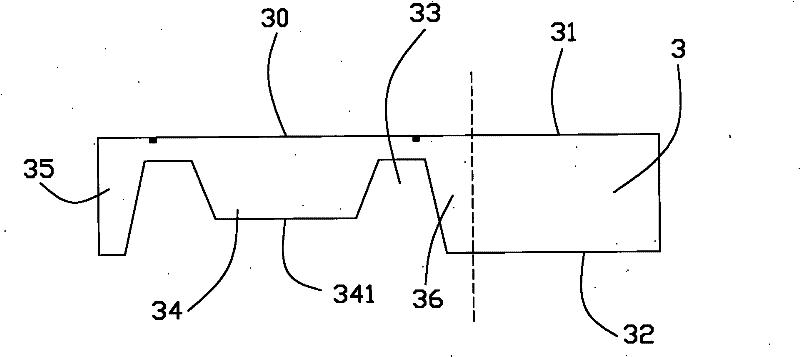

Current collector of liquid flow battery and liquid flow battery

ActiveCN101877408AImprove toughnessIncrease elasticityRegenerative fuel cellsElectrode carriers/collectorsStress concentrationEngineering

The invention provides a current collector of a liquid flow battery. The current collector comprises a conductive plastic plate and a graphite plate attached to the surface of the conductive plastic plate, wherein the area of the graphite plate is 20 to 90 percent of that of the conductive plastic plate; and the edges of the graphite plate are all positioned in the surface of the conductive plastic plate. The invention also provides the liquid flow battery, which comprises the current collector provided by the invention. Because conductive plastic has high toughness, elasticity and corrosion resistance, the current collector only comprising the graphite plate is prevented from being broken due to concentrated stress during processing; and the graphite plate is integrated with a conductivepart on the surface of the conductive plastic plate so as to increase effective current path. Therefore, the current collector of the liquid flow battery solves the problems of detachment of an electrode felt and high contact resistance in a using process.

Owner:BYD CO LTD

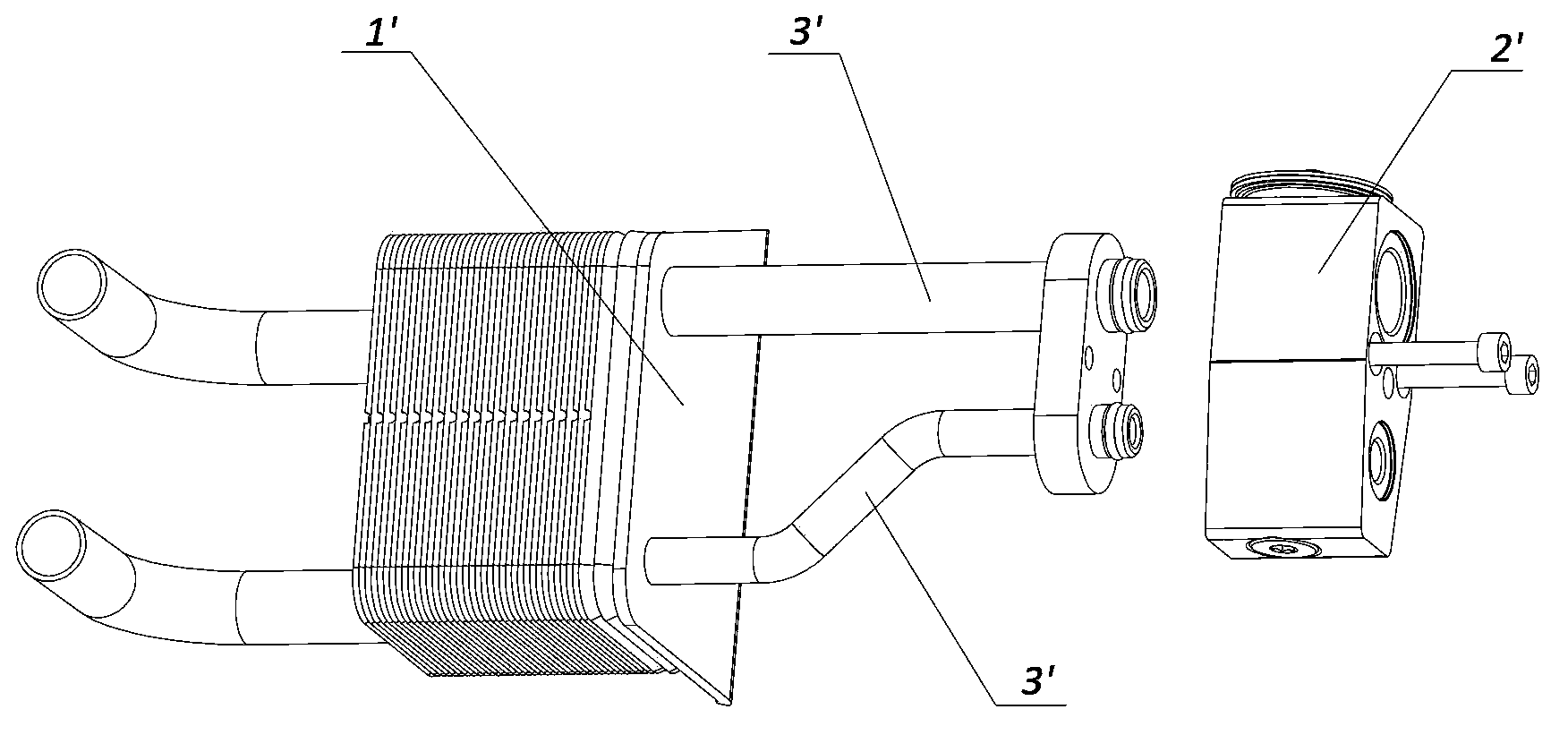

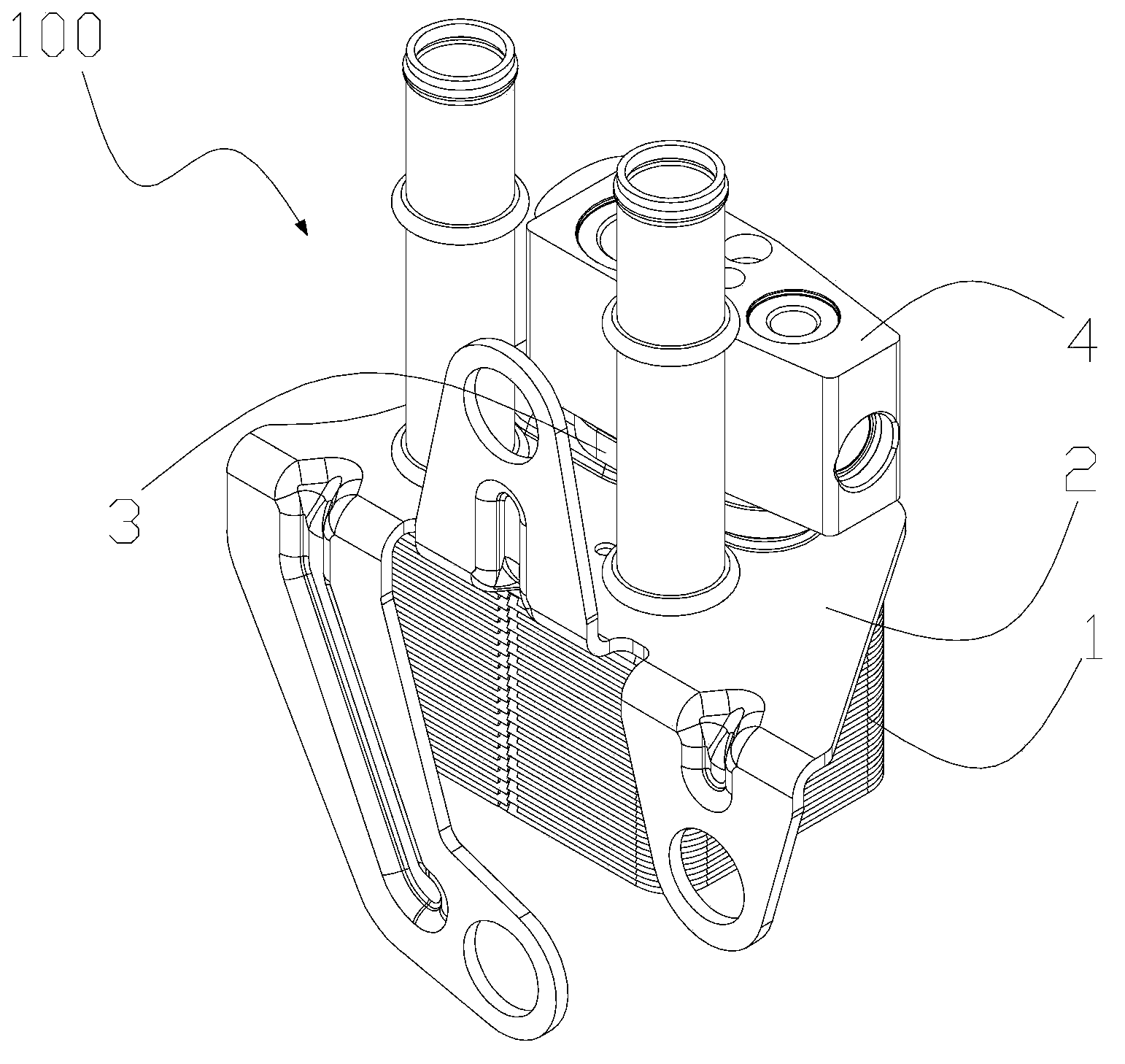

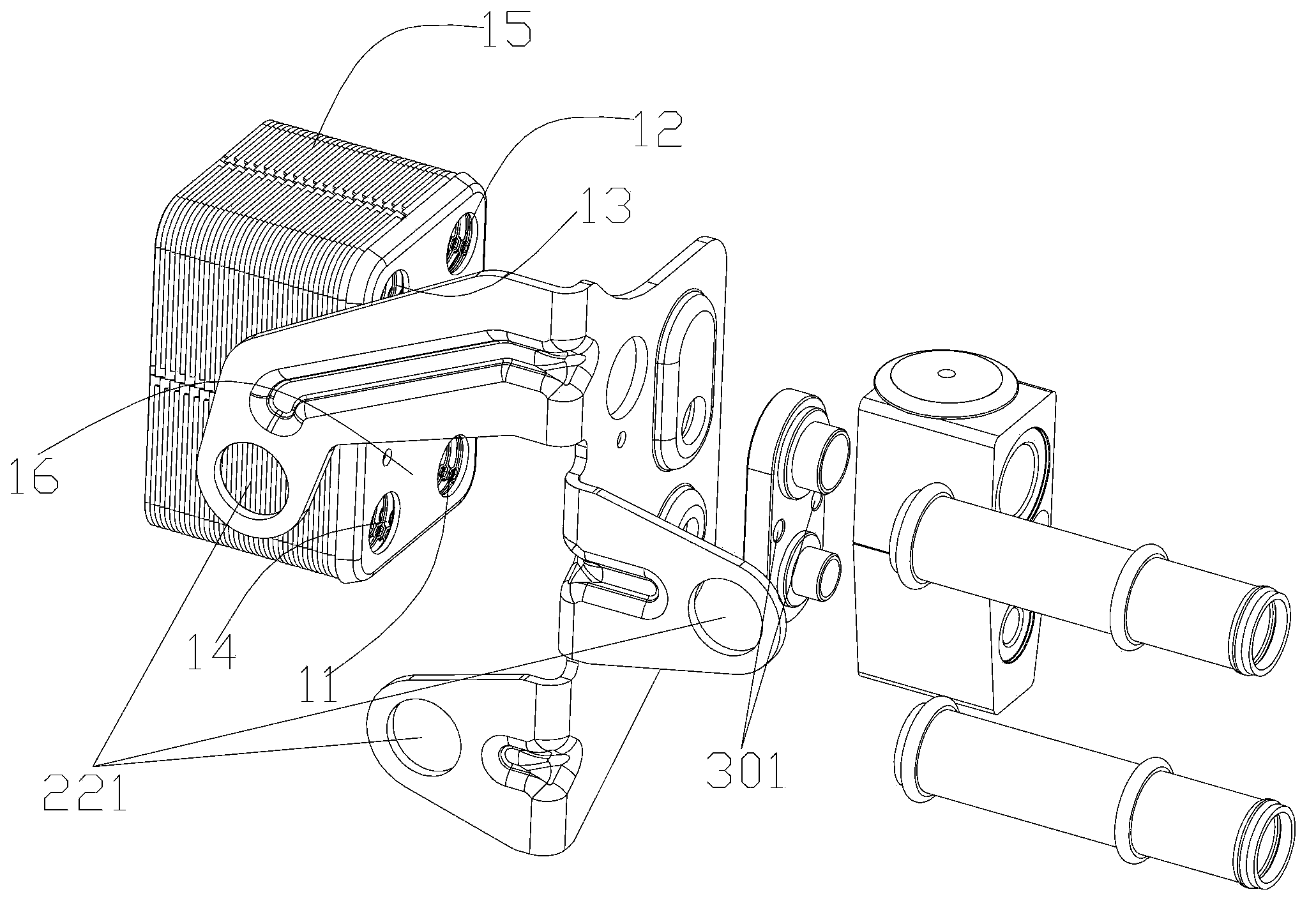

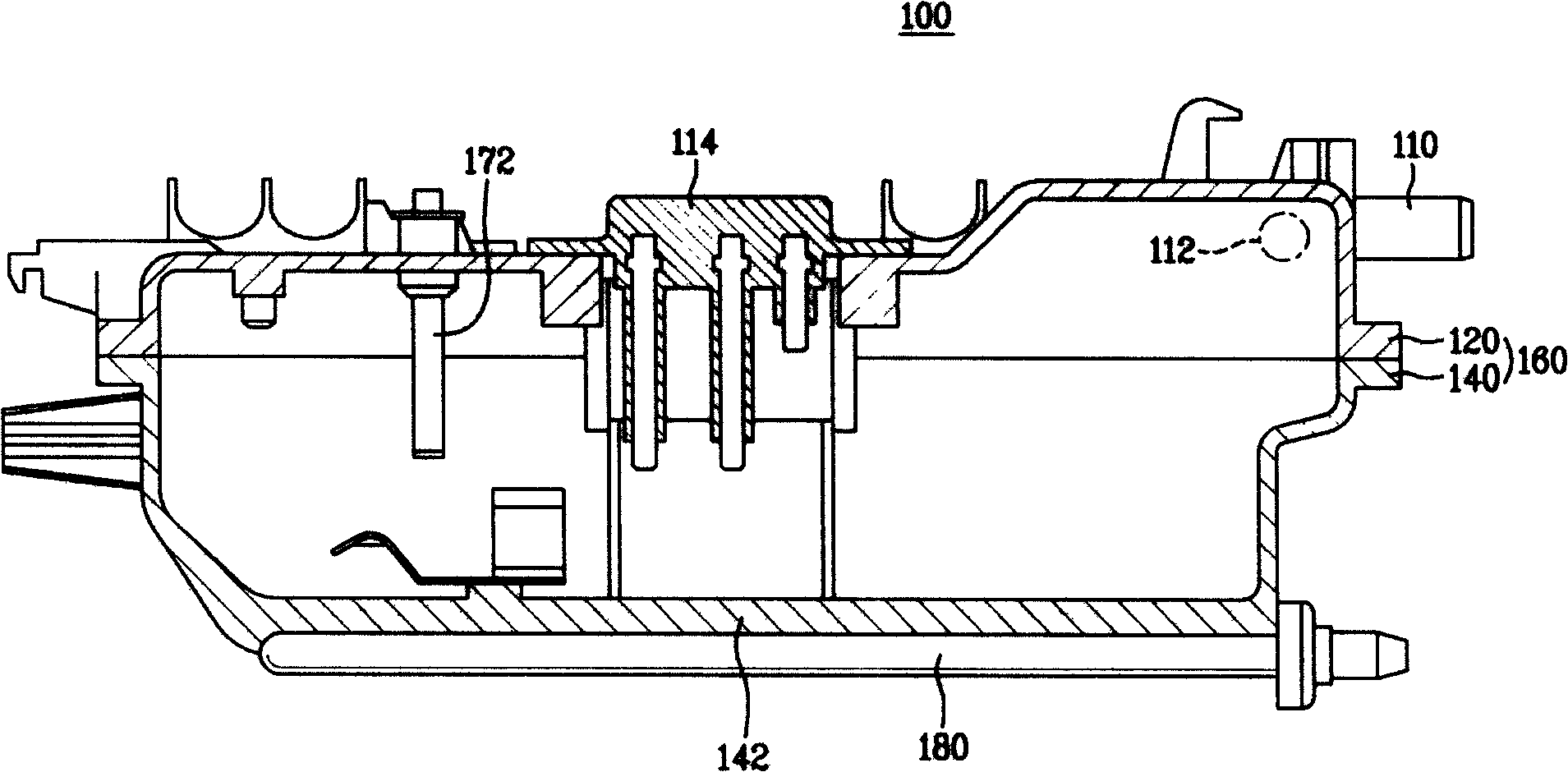

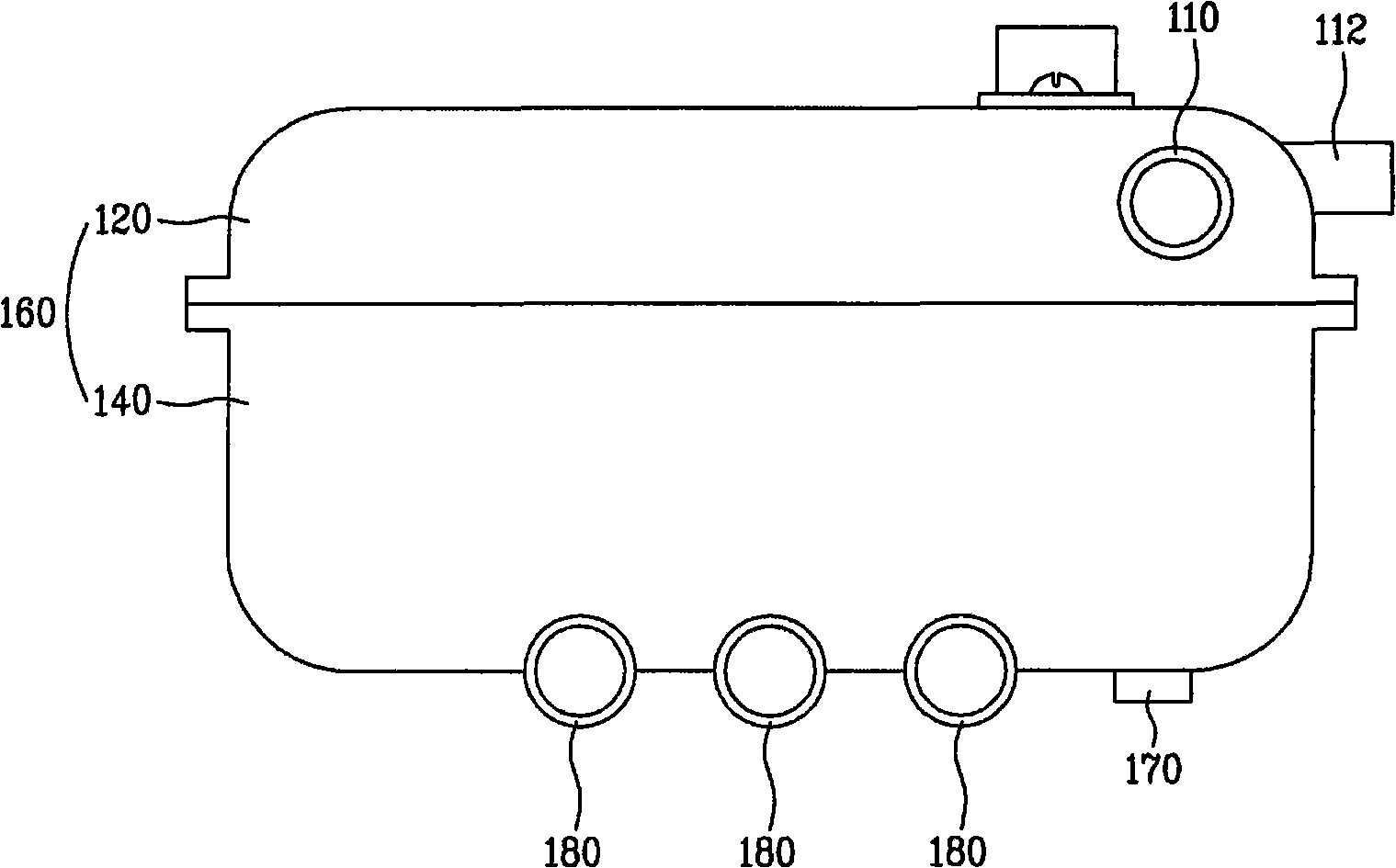

Heat exchanger integrated assembly

ActiveCN104296422AReduce volumeSimple connection structureMechanical apparatusEvaporators/condensersSoftware engineeringRefrigeration

The invention provides a heat exchanger integrated assembly. The heat exchanger integrated assembly comprises a heat exchanger, an adaptation connecting device and an installation supporting frame used for fixing the integrated assembly, wherein one end of the adaptation connecting device is fixed to a matching part, and an outwards protruding third pipeline and an outwards protruding fourth pipeline are arranged at the other end of the adaptation connecting device; the installation supporting frame comprises an installation part bent at an included angle with the matching part, the installation part comprises at least two installation plates, at least one installation plate is located on the side, opposite to the side where the other installation plate is located, of the matching part, or the installation part comprises one installation plate and at least two connecting parts, and the gap between at least two adjacent connecting parts is larger than the gap between other adjacent connecting parts. Each installation plate is provided with a plurality of installation holes, and the installation holes are completely exposed outside the heat exchanger and the adaptation connecting device in the installation direction penetrating through the installation holes. The heat exchanger integrated assembly is simple in structure, good in refrigeration effect, high in stability of the installation supporting frame and high in vibration strength.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

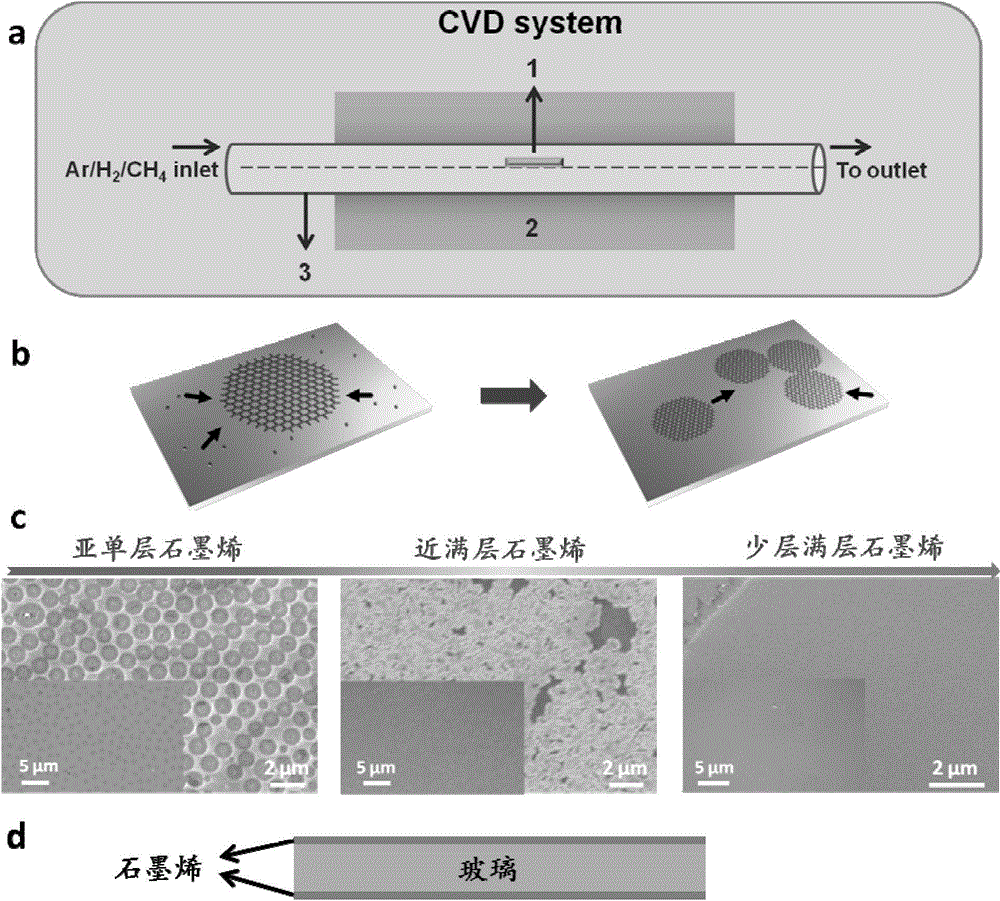

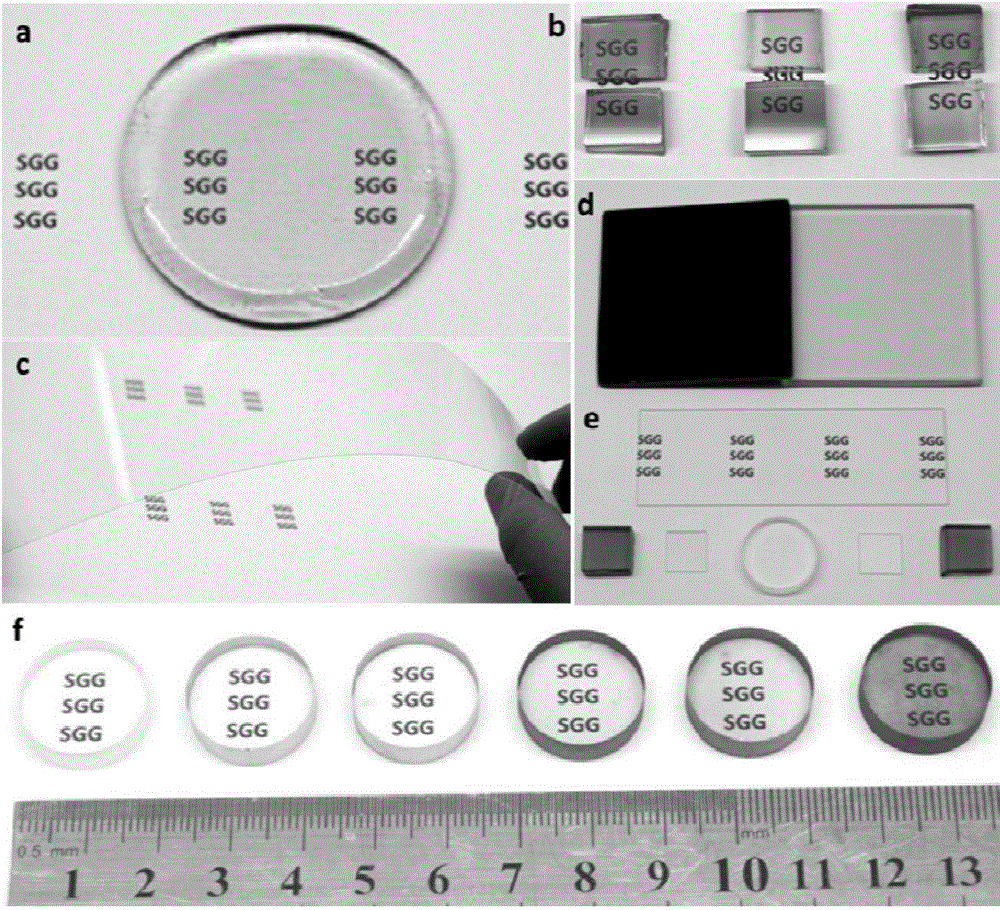

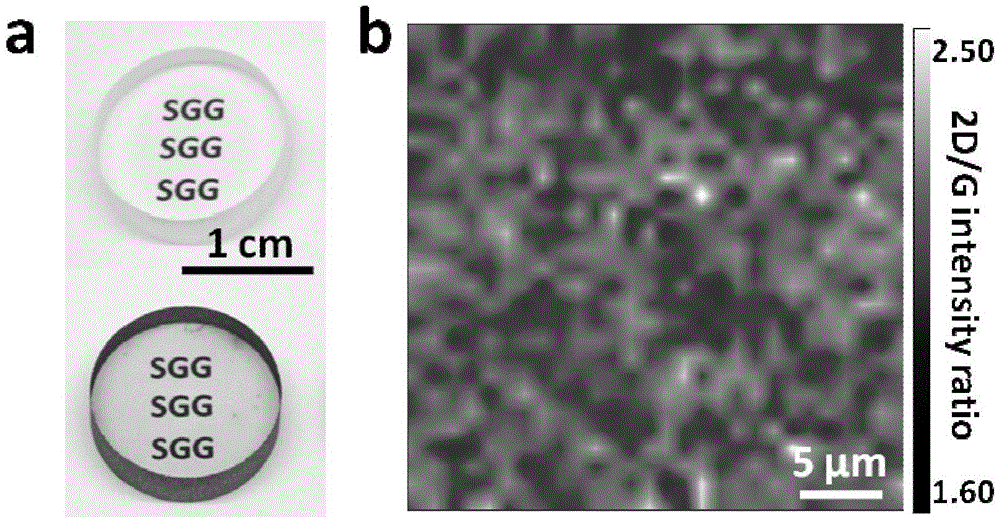

Super graphene glass, and preparation method and applications thereof

The invention discloses a super graphene glass, and a preparation method and applications thereof. The preparation method comprises following steps: glass taken as a substrate is washed and dried, and is delivered into a chemical vapor deposition system for chemical vapor deposition; and after deposition, temperature is reduced to room temperature so as to obtain the super graphene glass. Selective use of different chemical vapor deposition methods can be realized based on the kinds of glass, and direct growth of high quality graphene with controllable layer number can be realized on the selected glass substrate so as to realize preparation of the super graphene glass. The preparation method is capable of realizing direct preparation of graphene films with controllable thickness on various glass substrates, and the prepared super graphene glass possesses super properties. Preparation of the super graphene glass is disclosed in the invention for the first time, so that the preparation method possesses significant importance on fundamental researches and large scale application of graphene glass.

Owner:北京石墨烯研究院有限公司

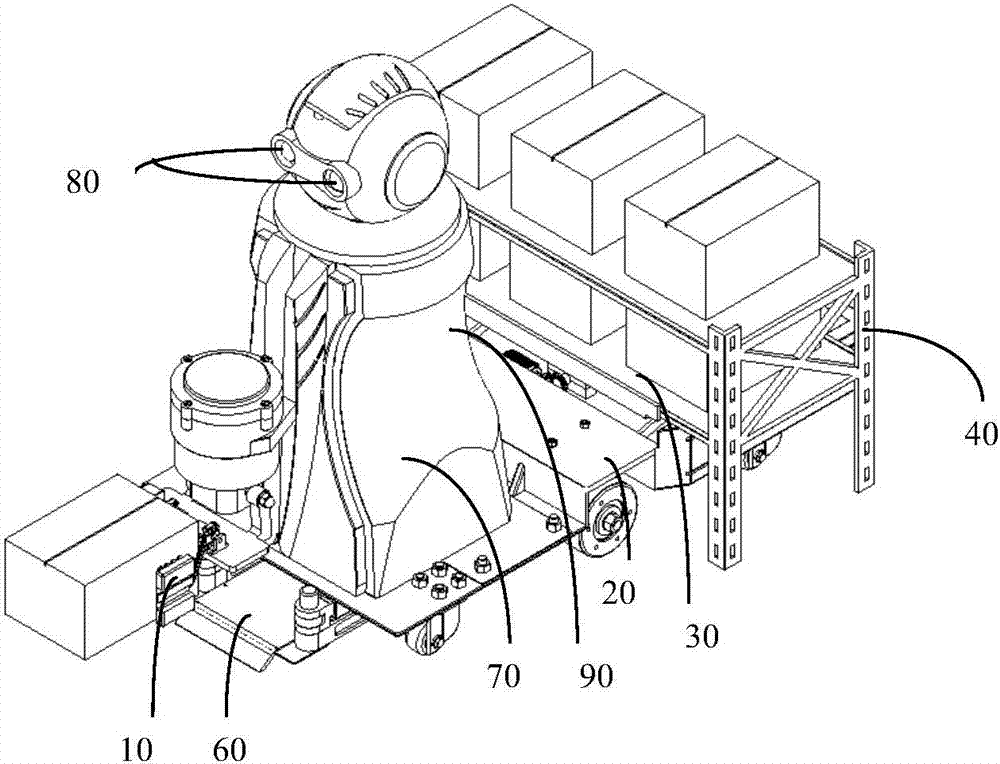

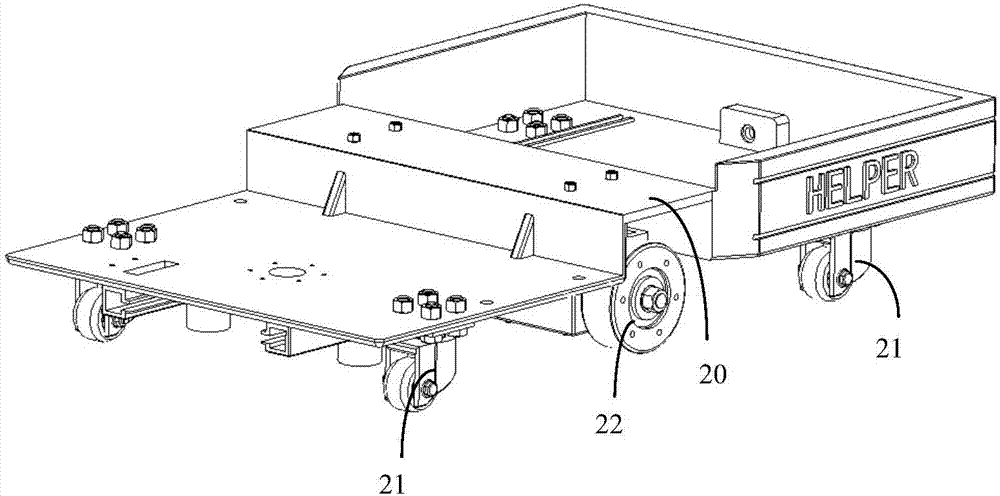

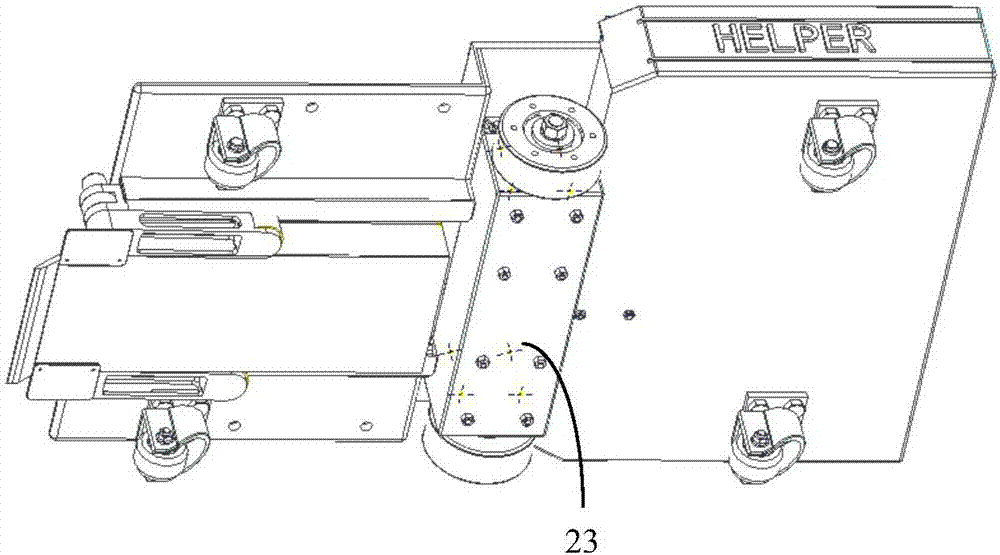

Carrying and conveying robot

ActiveCN106985145AAdapt to different working conditionsAdapt to working conditionsProgramme-controlled manipulatorMagnetic tapeComputer module

The invention relates to a carrying and conveying robot comprising a bearing table, execution mechanisms and a control module. The bearing table is provided with a drive device. The drive device regulates the speed and direction of the bearing table on the basis of control information of the control module so that the bearing table can be used in cooperation with the execution mechanisms for carrying goods on the basis of the control information of the control module. The robot further comprises a magnetic belt guide unit and a vision guide unit. The control module determines at least one route on the basis of a first position parameter and a second position parameter of a carrier in an assigned area and indicates the drive device to move along the at least one route preset according to guidance of the magnetic belt guide unit so that the carrier in the unloaded state can be carried to the first position from the second position, and the control module controls the bearing table to carry the carrier, fully loaded through the execution mechanisms according to placement morphological parameters of the goods in a corresponding movement manner, to the assigned second position according to the preset at least one route. By means of the dual manner of magnetic belt guidance and vision guidance, positioning of the robot can be more accurate, and efficiency can be higher.

Owner:HEFEI UNIV OF TECH

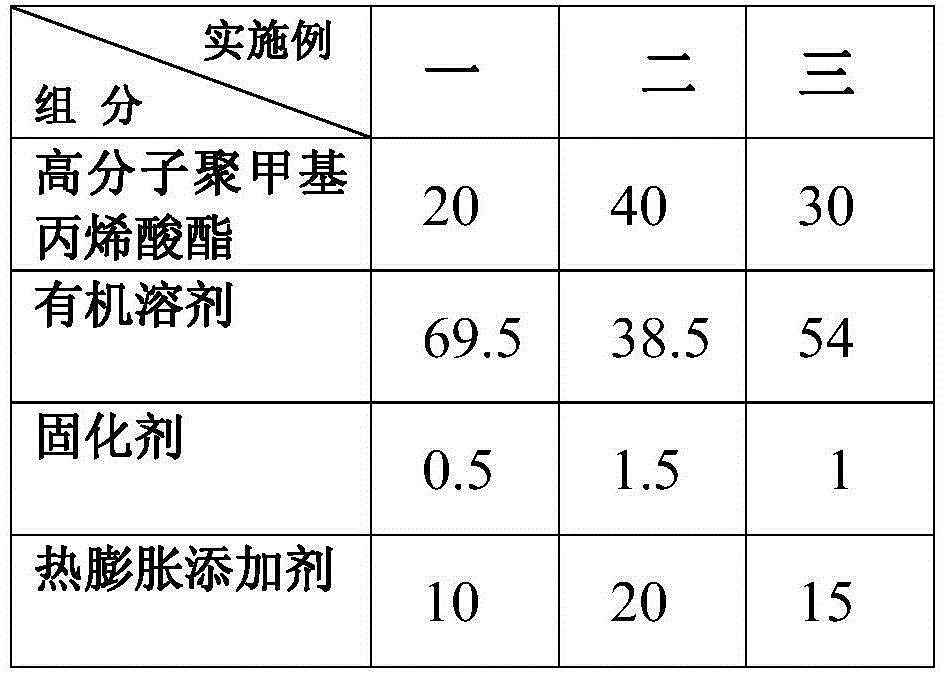

Thermal viscosity loss pressure-sensitive adhesive, thermally peelable adhesive tape and preparation methods of thermal viscosity loss pressure-sensitive adhesive and thermally peelable adhesive tape

InactiveCN105131869AImproved thermal peel performanceAvoid breakageNon-macromolecular adhesive additivesFilm/foil adhesivesPressure sensitivePoly methacrylate

The invention discloses a thermal viscosity loss pressure-sensitive adhesive, which is prepared from the following ingredients in percentage by weight: 20.0 percent to 40.0 percent of macromolecular polymethacrylate, 69.5 percent to 38.5 percent of an organic solvent, 0.50 percent to 1.50 percent of a curing agent and 10.0 percent to 20.0 percent of a thermal expansion additive, wherein the weight percentage of solid content in the thermal viscosity loss pressure-sensitive adhesive is 20 percent to 40 percent. The invention also discloses a thermally peelable adhesive tape and a preparation method of the thermally peelable adhesive tape. When the thermally peelable adhesive tape is adhered onto an adhered object and is heated to foam so that micro spheres expand, the viscosity of a thermal viscosity loss pressure-sensitive adhesive layer is greatly reduced. When the thermally peelable adhesive tape is applied for temporary fixation in electronic devices, the damage of elements can be effectively prevented, and the product yield is improved.

Owner:SHENZHEN MEIXIN ELECTRONICS

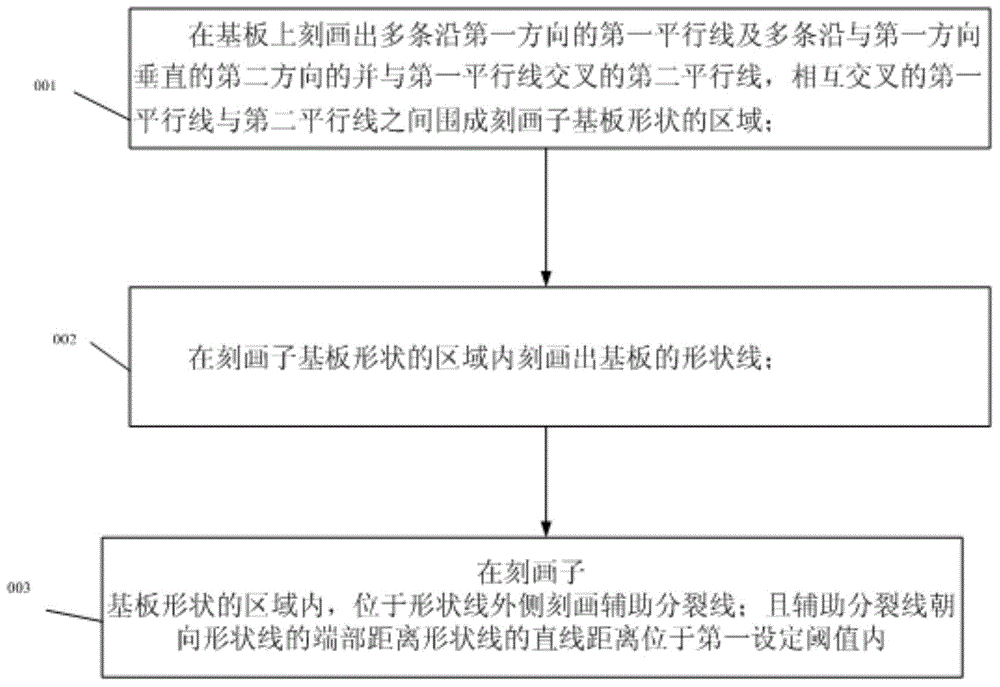

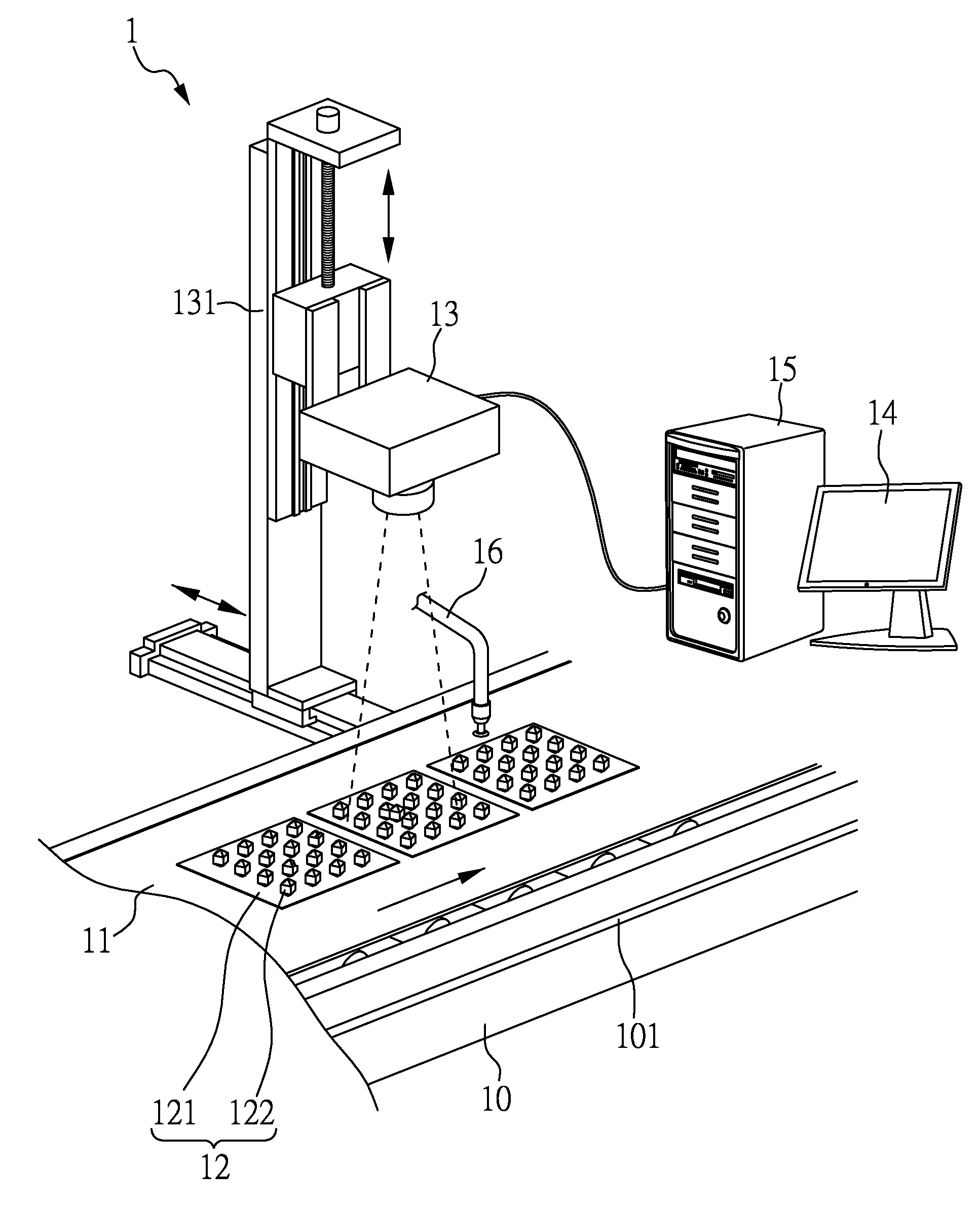

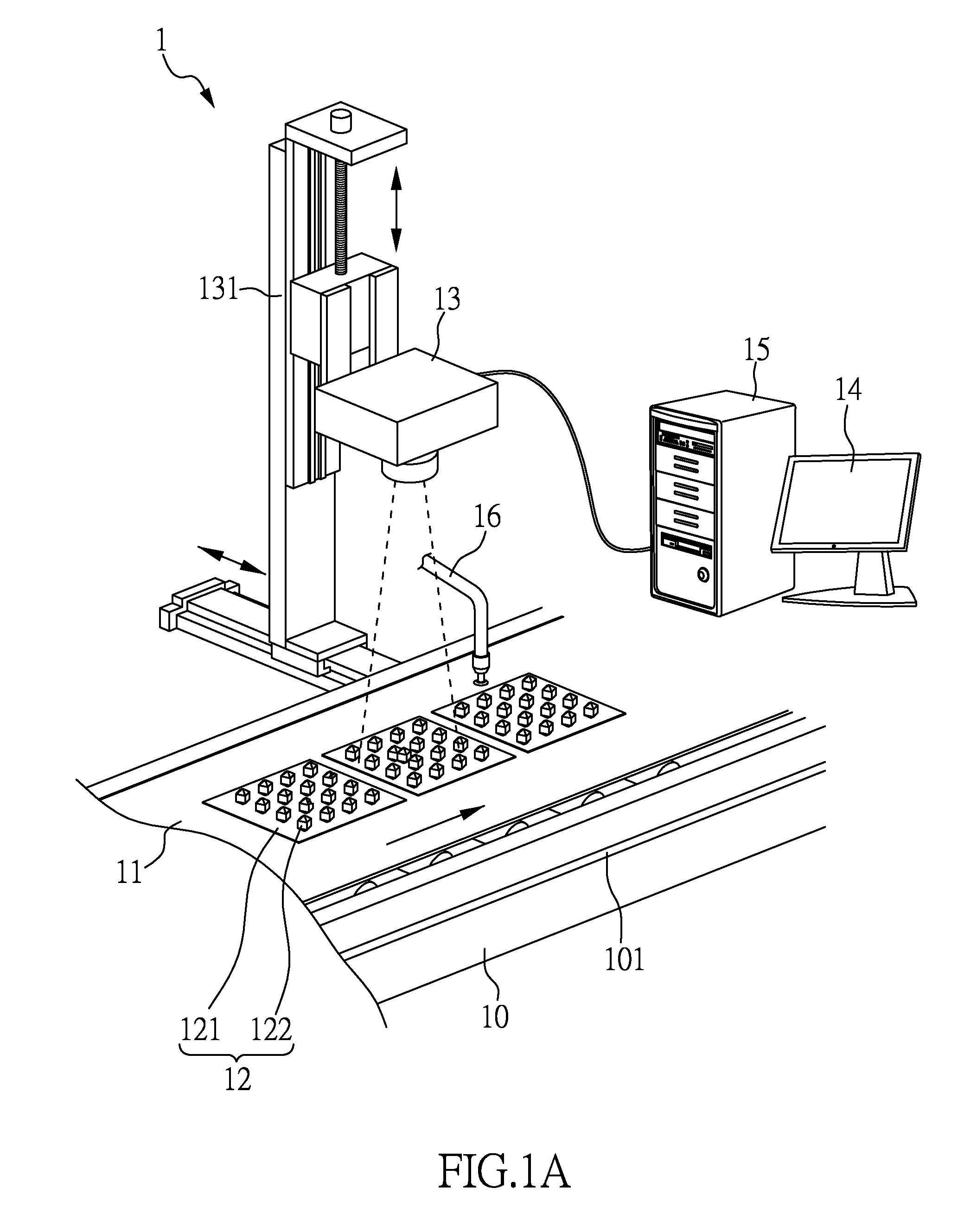

Method for cutting base plate by laser and laser cutting equipment

InactiveCN104310779AImprove yieldAvoid breakageGlass severing apparatusWelding/soldering/cutting articlesDisplay deviceLaser cutting

The invention relates to the technical field of production of display devices and discloses a method for cutting a base plate by laser and laser cutting equipment. The method comprises the following steps: a plurality of crossed first parallel lines and second parallel lines are engraved on the base plate, an area engraved with a subbase plate shape is defined by the first parallel lines and the second parallel lines, and an outline is positioned in the area with the subbase plate shape; an auxiliary splitting line is engraved outside the outline in the area engraved with the subbase plate shape; and the minimum distance from the end part of the auxiliary splitting line, facing the outline line, to the outline line is within a first set threshold. The parallel lines and the auxiliary splitting line are set to help split the base plate, the stress damage points of the base plate during cutting are increased, a phenomenon that the glass base plate is broken when being cut is avoided and the finished product rate of base plate cutting is effectively improved; and besides, the cutting path is designed reasonably and skillfully, the cut base plate can be completely separated and an automatic taking-out condition can be achieved.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

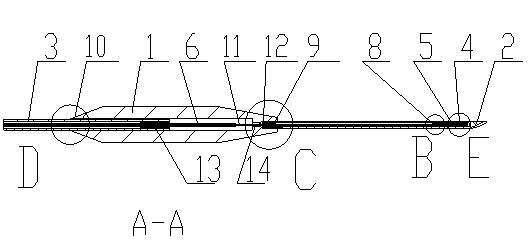

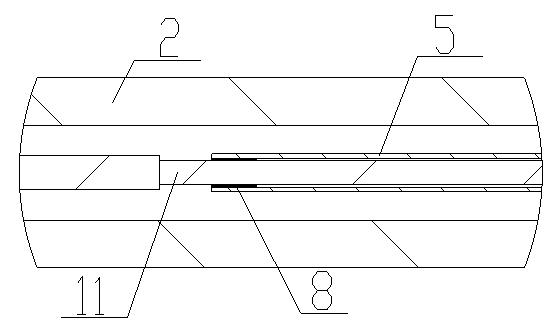

Fiber Bragg Grating Temperature Sensor and Its Probe

InactiveCN102274006AAccurate heating and temperature controlExtended service lifeThermometers using physical/chemical changesMicrowave therapyFiberMicrowave

The invention relates to a fiber grating temperature sensor which comprises a probe and a demodulating system connected with the probe, wherein the probe comprises a needle head and a handle which are connected together. The fiber grating temperature sensor is characterized in that the needle head is an austenitic stainless steel round bar with a needle point, the center of the bottom surface at one end of the austenitic stainless steel round bar is provided with a blind hole, and the blind hole extends close to the other end of the austenitic stainless steel round bar; and a fiber bragg grating is arranged in the blind hole. The invention is mainly used for manufacturing fiber grating temperature sensors for microwave thermotherapy of bone tumors.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI +1

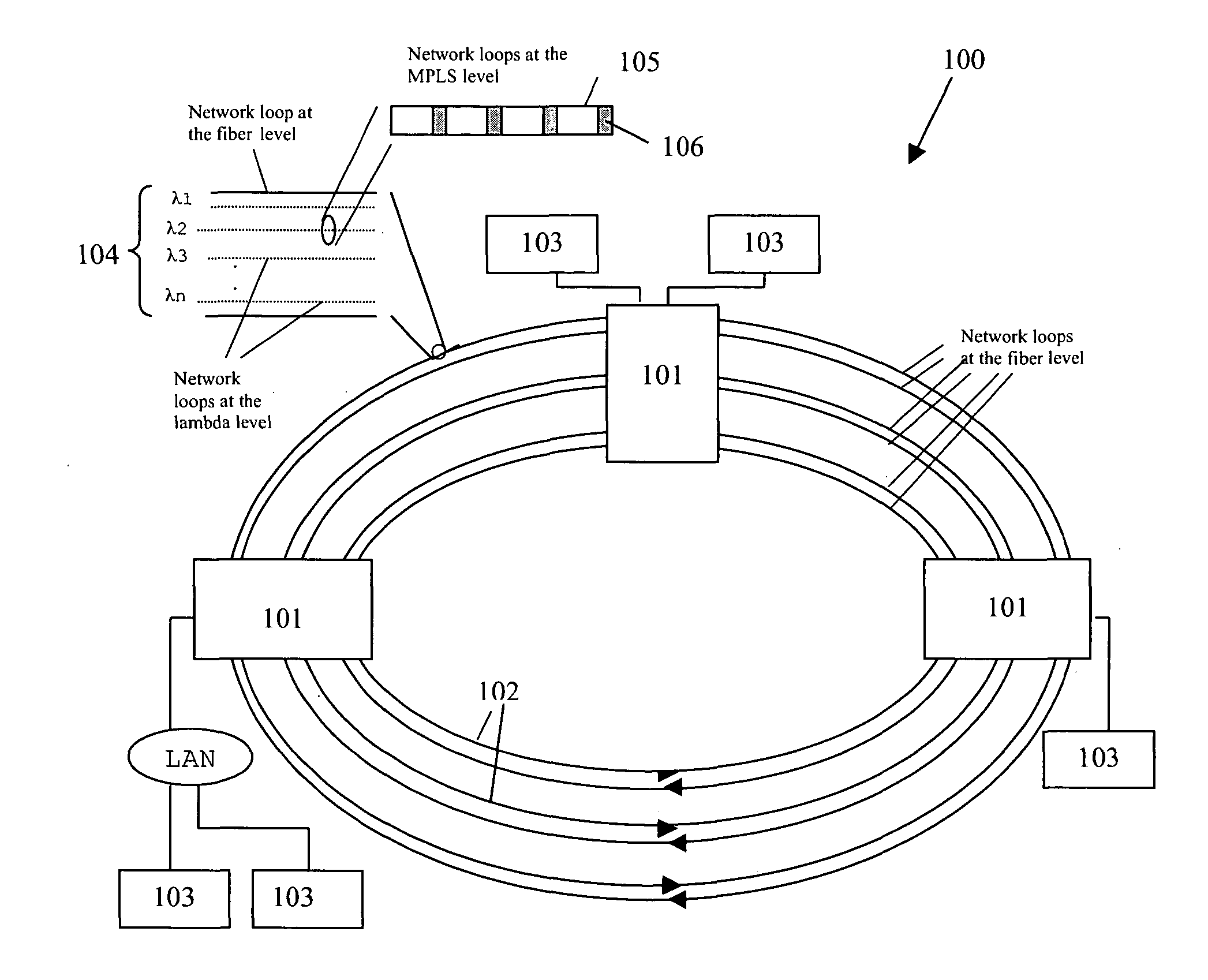

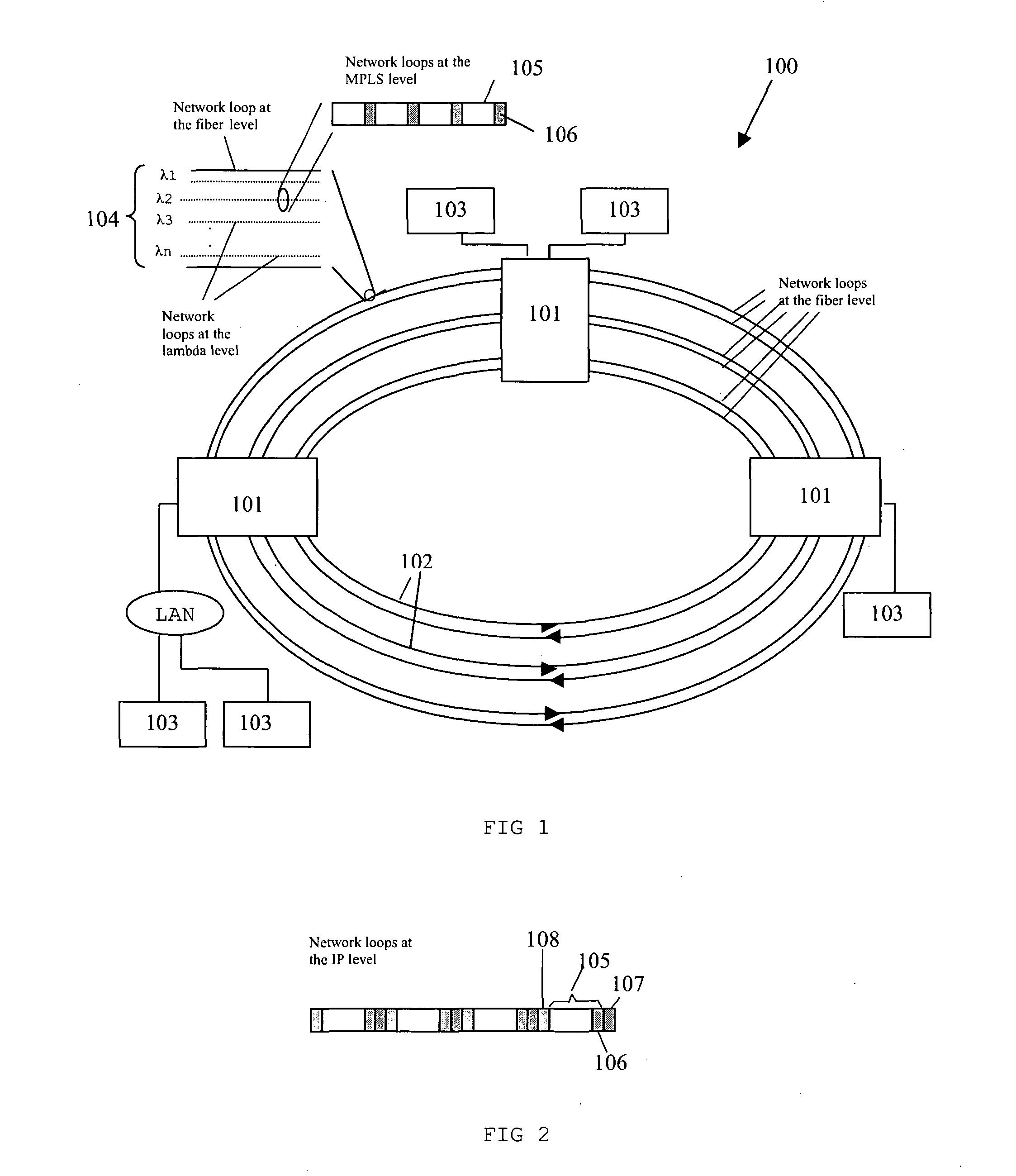

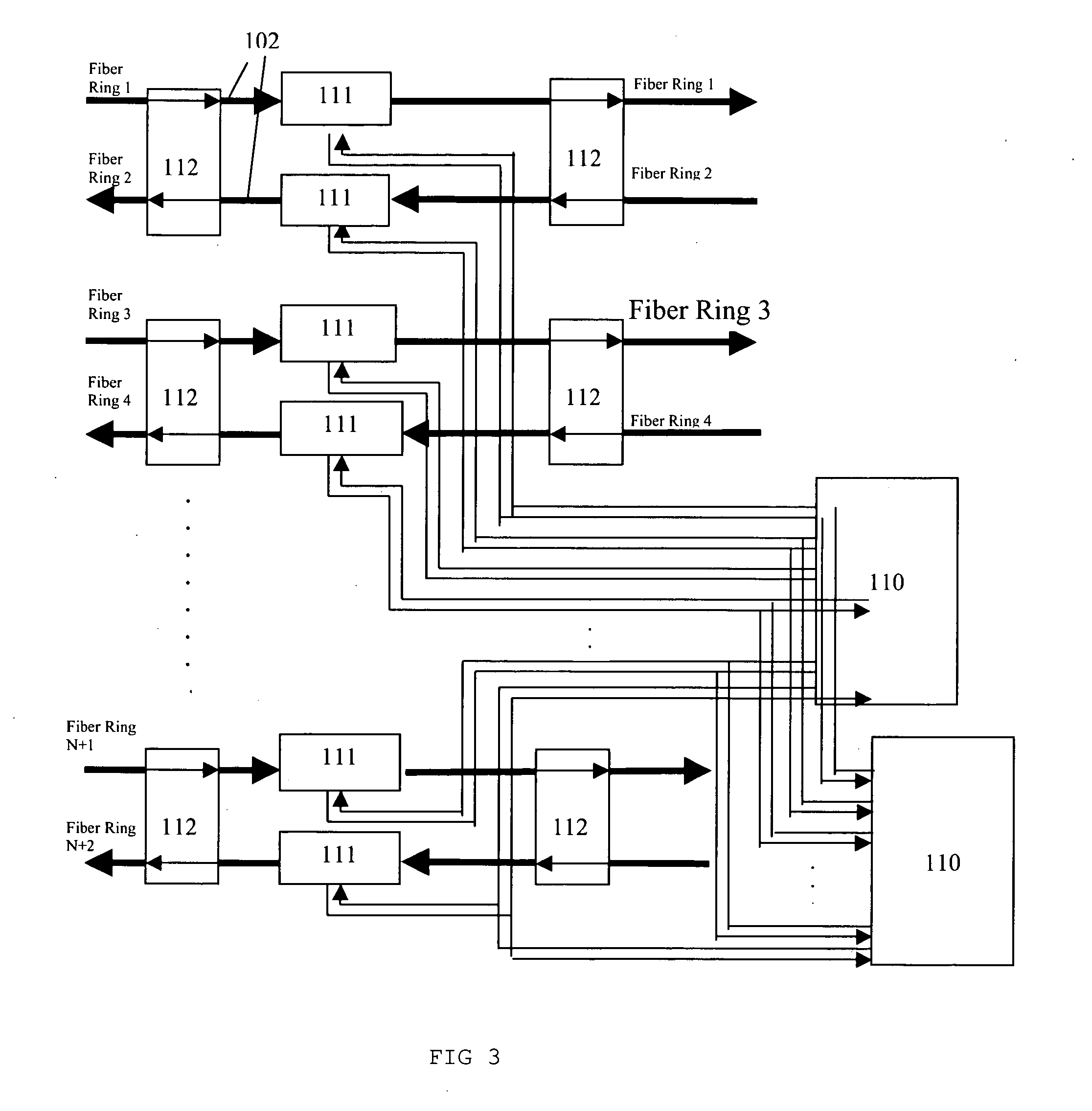

Method and system for enabling recovery of data stored in a computer network; a method and a system for recovering data stored in a computer network

InactiveUS20050022046A1Avoid breakageEasy to implementFrequency-division multiplex detailsTransmission systemsData storeData loss

A method for enabling recovery of data stored in a computer network, the computer network comprises a plurality of computer nodes, the method comprising the steps of generating a set of redundancy data based on a predetermined relationship between a first set of data and a second set of data, injecting the first set of data, the second set of data and the set of redundancy data into separate looping paths of the computer network, wherein a looping path is a path along a plurality of computer nodes in which data is transported, and the looping paths are defined in separate communication channels between the computer nodes and pass through at least one common node of the computer network, such that the redundancy data and the second set of data can be used to reconstruct the first set of data based on the predetermined relationship between the first and second set of data when the first set of data is lost, thereby enabling the recovery of data stored in the computer network.

Owner:AGENCY FOR SCI TECH & RES

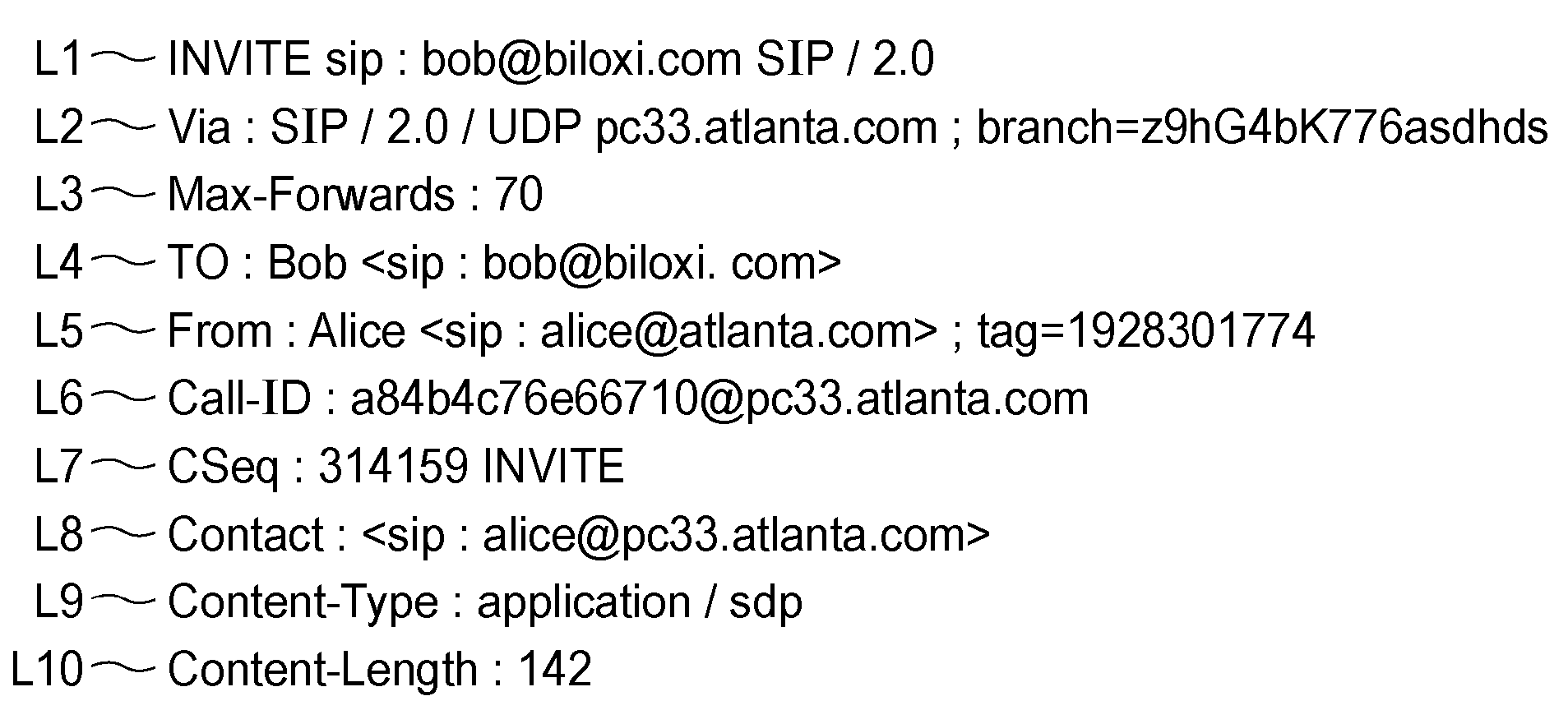

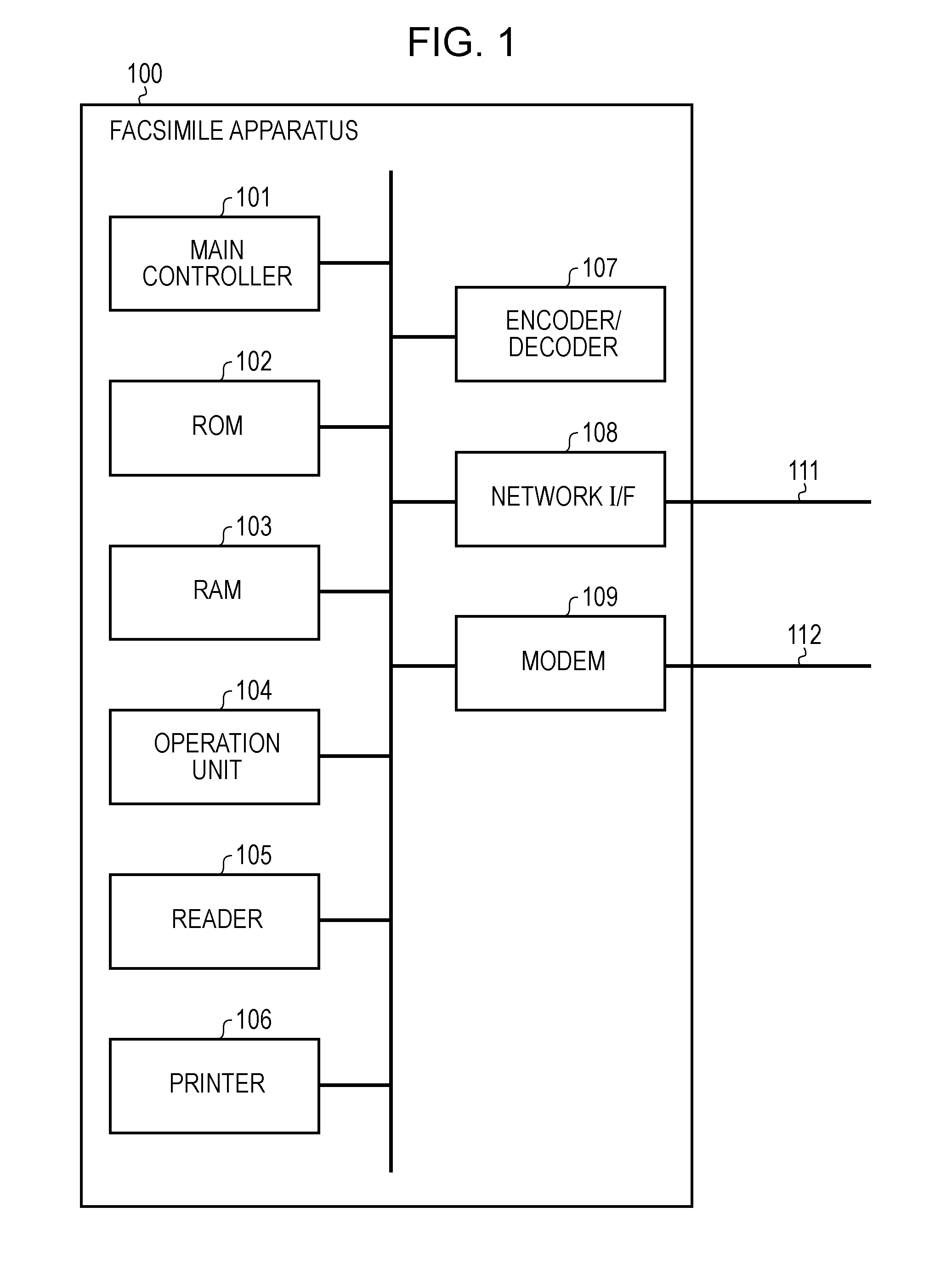

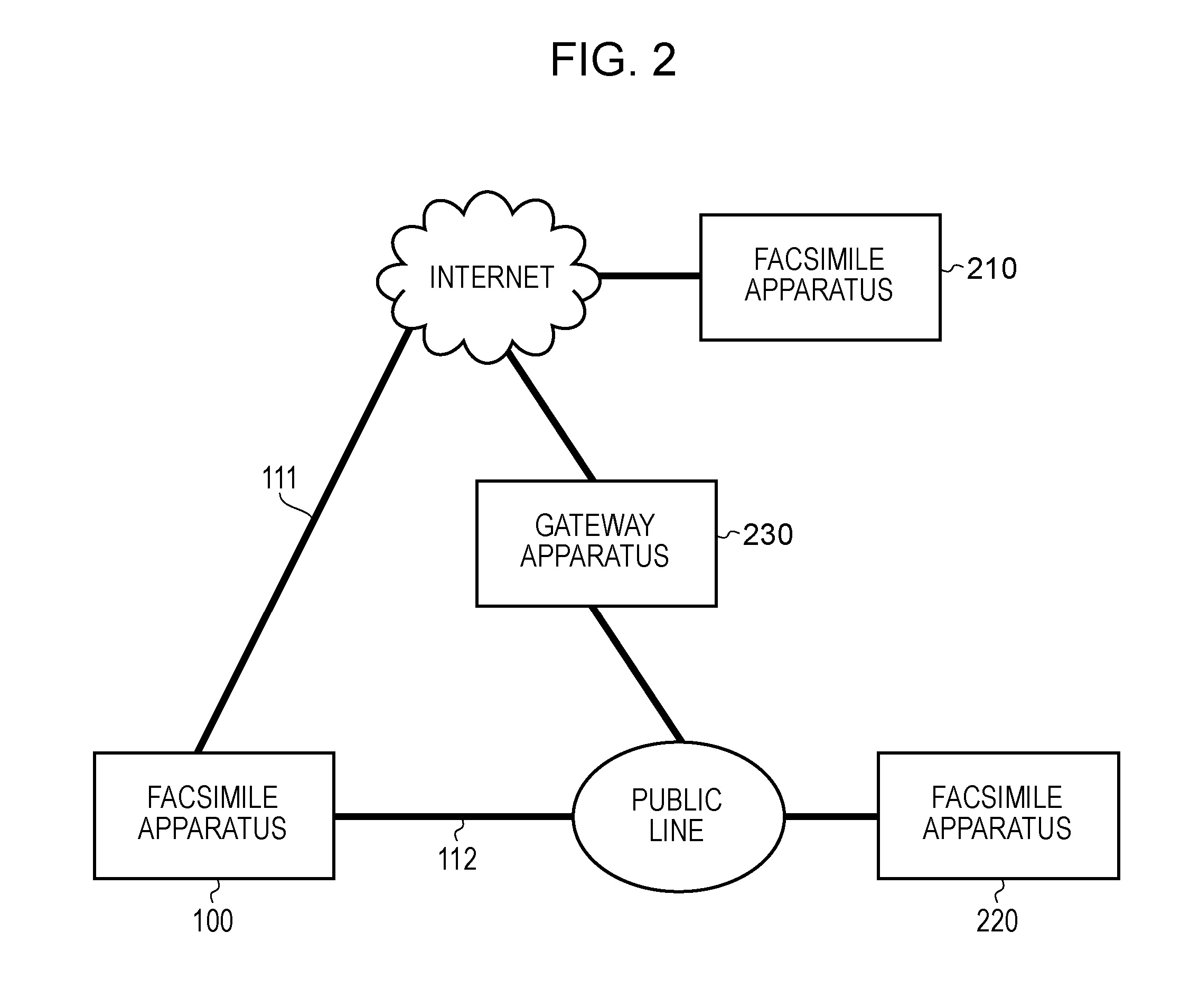

Facsimile apparatus and control method therefor

InactiveUS20080117477A1Avoid breakageAvoid breakingPictoral communicationReal-time computingFacsimile

A facsimile apparatus performs facsimile communication with a partner apparatus using a first communication path including a public line or a second communication path not including the public line, detects whether facsimile communication using the first communication path and facsimile communication using the second communication path are in contention with each other, selects which of facsimile communication using the first communication path and facsimile communication using the second communication path is to be given priority in the case where it is detected that facsimile communication using the first communication path and facsimile communication using the second communication path are in contention with each other, and gives priority to facsimile communication selected from facsimile communication using the first communication path and facsimile communication using the second communication path.

Owner:CANON KK

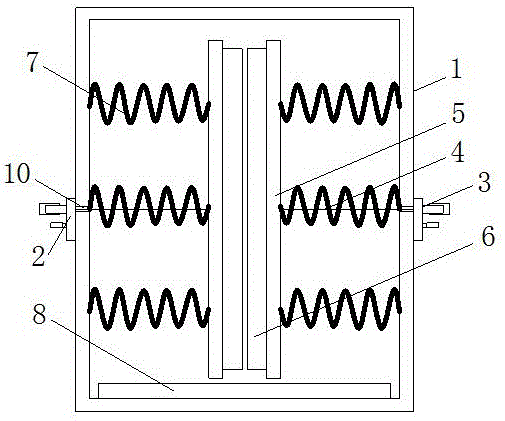

Steam generator

PendingCN101290111AIncrease the heating areaImprove the heating effectBoiler drums/headersSteam generation heating methodsEngineeringHeating effect

Owner:NANJING LG PANDA APPLIANCES

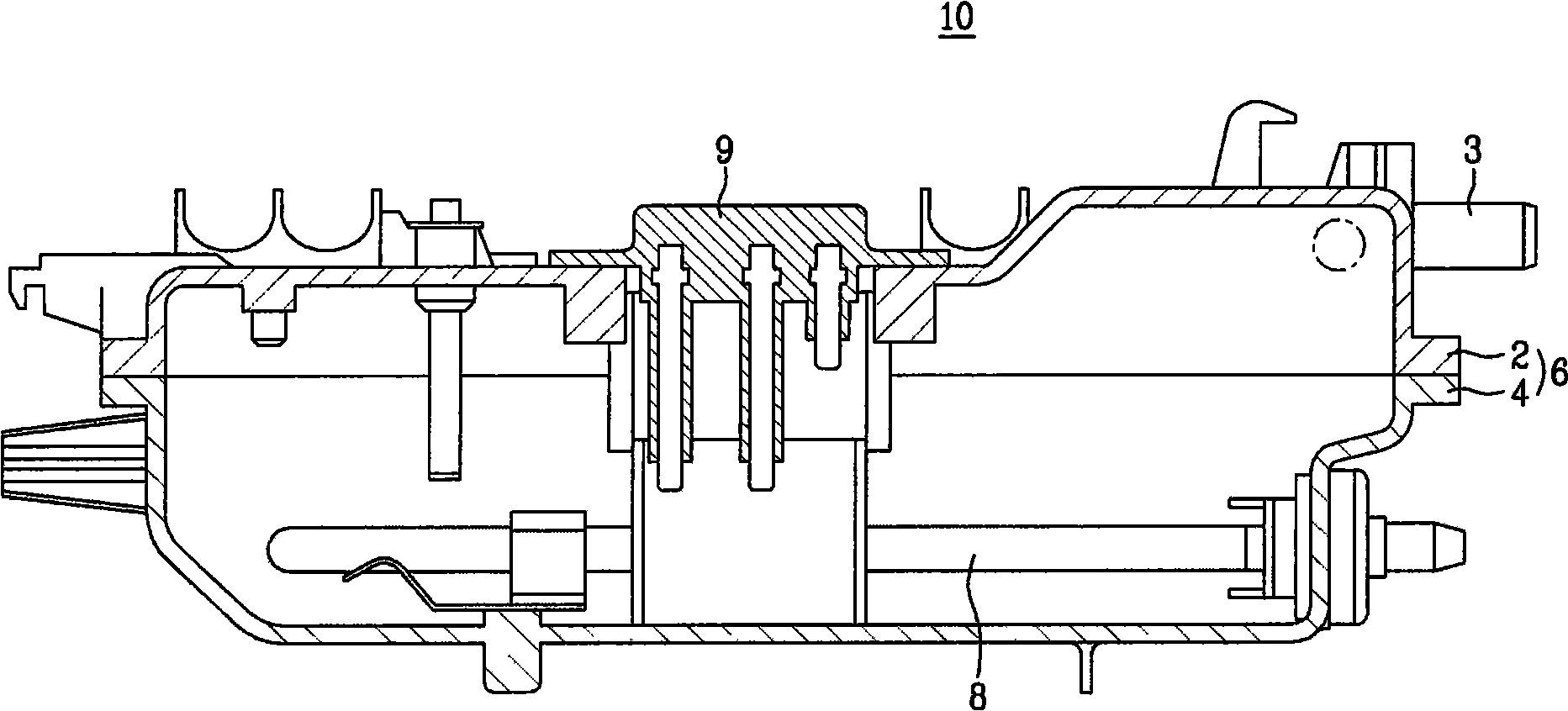

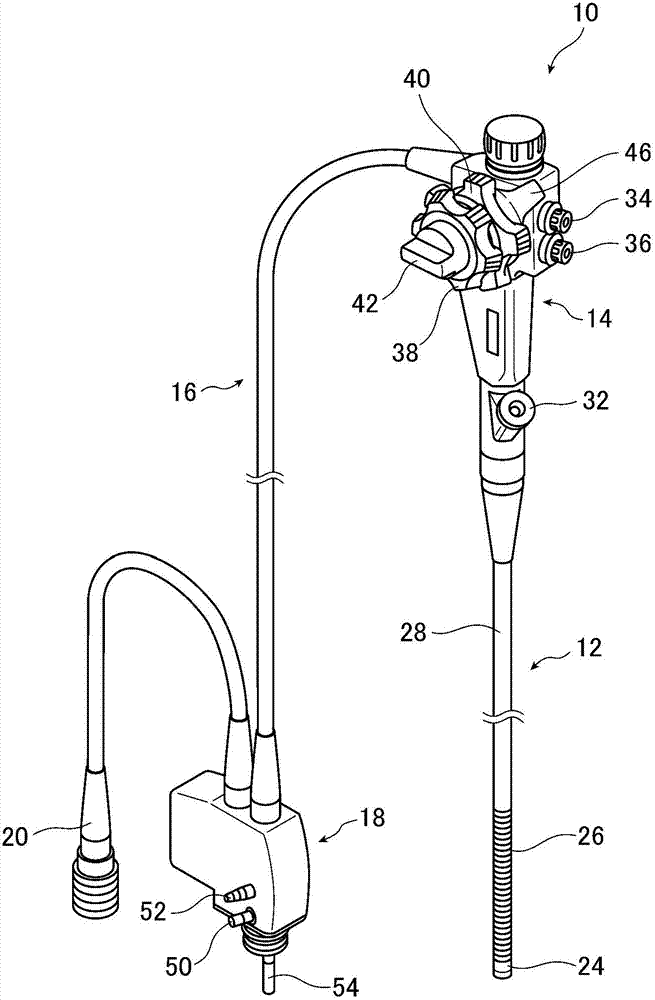

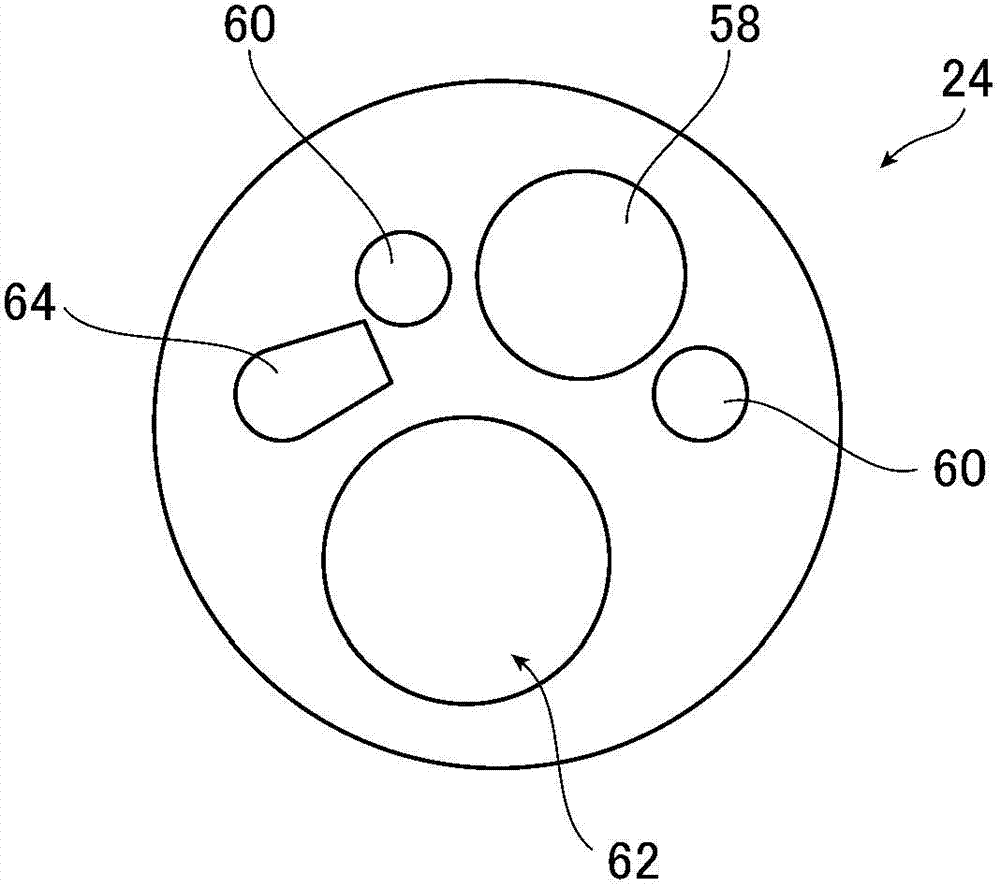

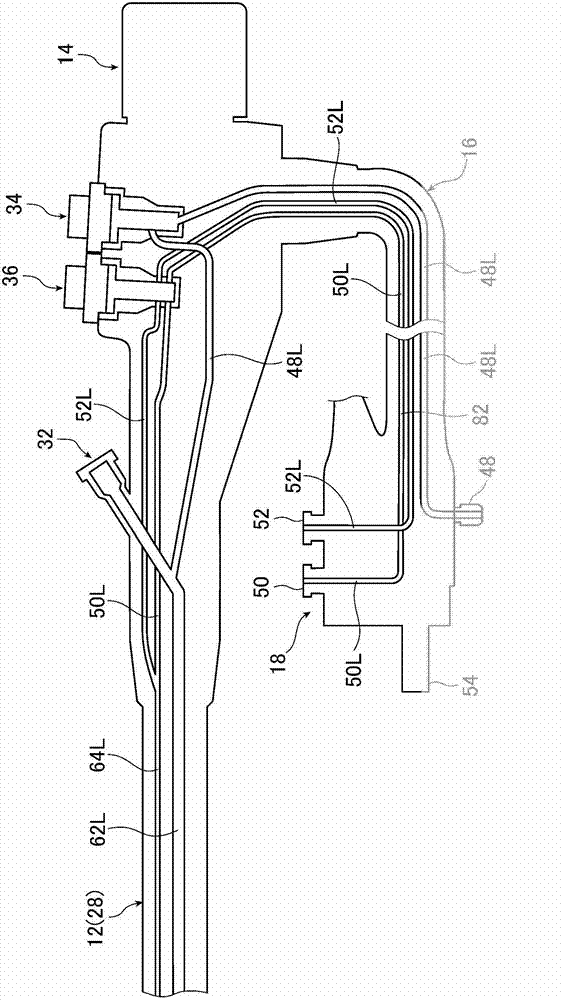

Fluid pipeline switching device and endoscope

The present invention provides a fluid pipeline switching device. In the fluid pipeline switching device for an endoscope, when a piston is detached, contact between the filter and connecting holes formed on an operating cylinder can be prevented, thereby preventing filler damage. The fluid pipeline switching device is provided with the following components: a press button which is provided with a piston and a plurality of sealing components; the operating cylinder which gradually necks in an insertion direction of the piston and is provided with the connecting holes connected with the fluid pipeline; and a limiting member which is used for limiting the lower position of the piston. The plurality of sealing components gradually thins to the front end and separates the space in the operating cylinder along the axis direction. The diameter of the sealing component is smaller than the inner diameter of the upper segment of the segment of the piston, which is in slidable contact with the sealing component. Furthermore the positions of the connecting holes for connecting each fluid pipeline with the operating cylinder are closer to the front end than the lower-end position of the sealing components which slidably contact with corresponding components, thereby settling the task of the invention.

Owner:FUJIFILM CORP

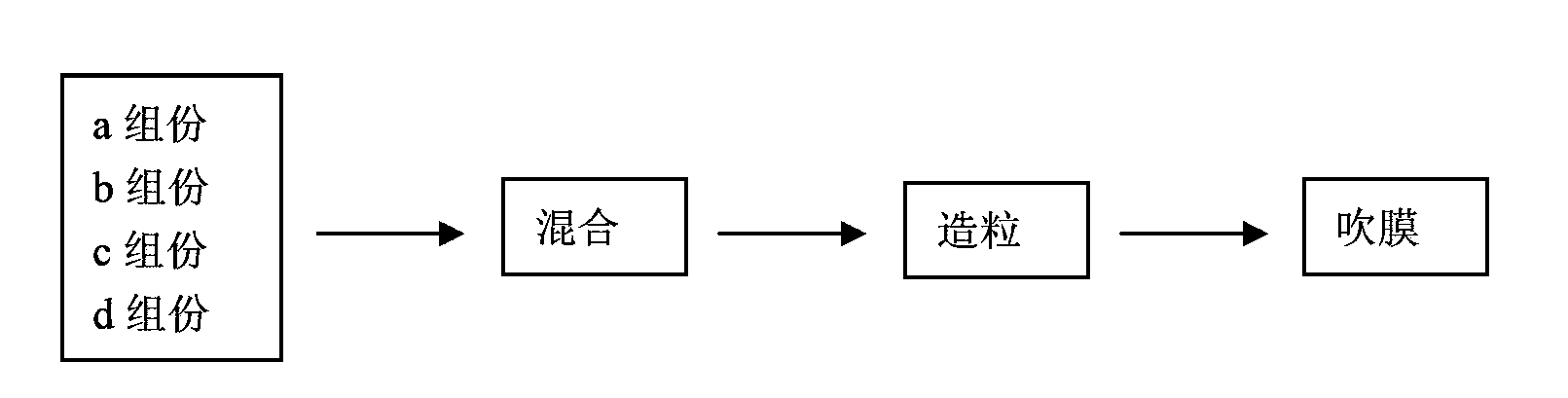

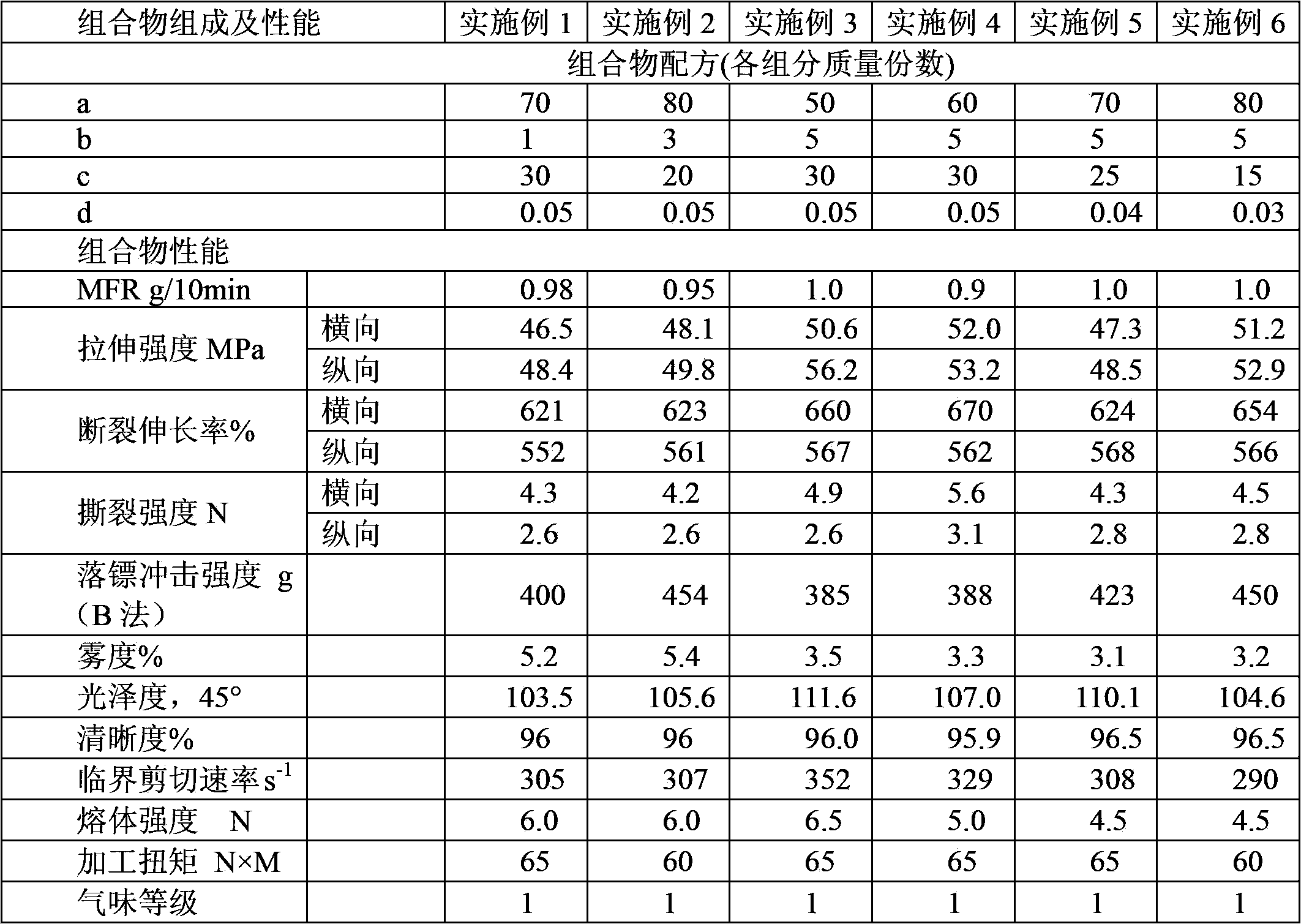

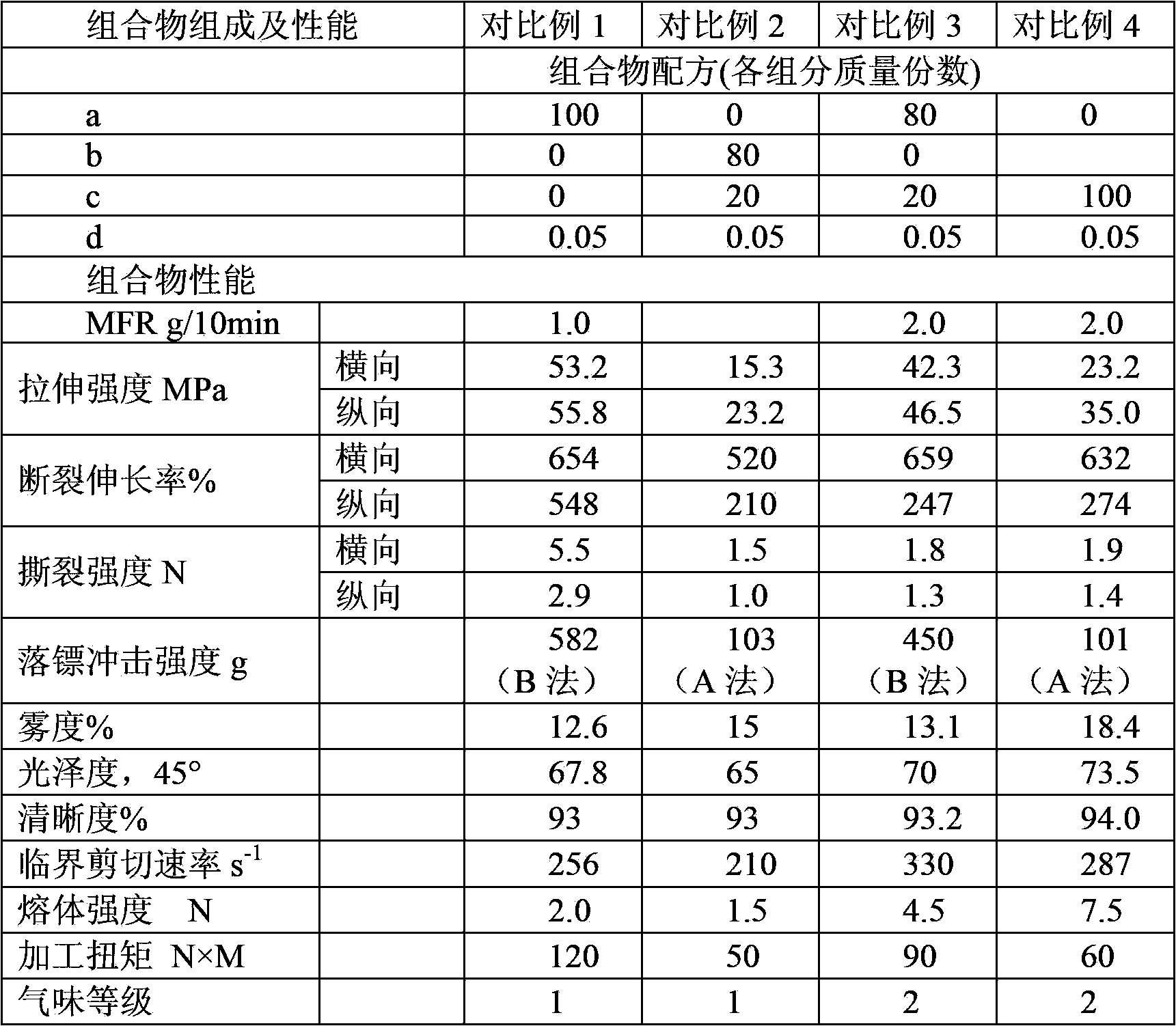

Highly-transparent polyethylene composition and preparation method thereof

The invention relates to a polyethylene composition, specifically to a highly-transparent polyethylene composition and a preparation method thereof. The highly-transparent polyethylene composition comprises a matrix resin and a processing auxiliary agent, wherein the matrix resin is prepared by co-mixing first mLLDPE, second mLLDPE and high pressure LDPE. The composition has characteristics of good strength, good flexibility, good processability, good aging resistance, low odor, excellent gloss, excellent impact strength, excellent tensile strength and excellent tear strength, can be used for preparing composite package films with excellent comprehensive performances, and can be provided for avoiding phenomena such as scratch, puncture and breaking by external force due to insufficient performances such as tear resistance and the like during the use process. In addition, after the mLLDPE resin and the normal resin are blended, the thickness of the film is reduced, the comprehensive performance is excellent, the product cost is reduced, and the processability of the composition is improved.

Owner:CHINA PETROLEUM & CHEM CORP

Thimble device

ActiveCN1851898AAvoid skippingAvoid low productivitySemiconductor/solid-state device manufacturingManipulatorResidual charge

This invention relates to a semiconductor etching device, in which, the thimble device includes a thimble containing a main body and a mandril, a slot is set in the main body and plugged with the mandril and a space is set between the bottom surface of the mandril and the bottom wall of the slot and a height deformer and a position sensor are set in the space, the deformed volume of the deformer is 0.05-1.2mm, which applies an telescopic thimble to test the deformation volume of a spring contacting with a wafer when the thimble rises to test the residual charge of the wafer then puts up the wafer to finish the transmission of the manipulator.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

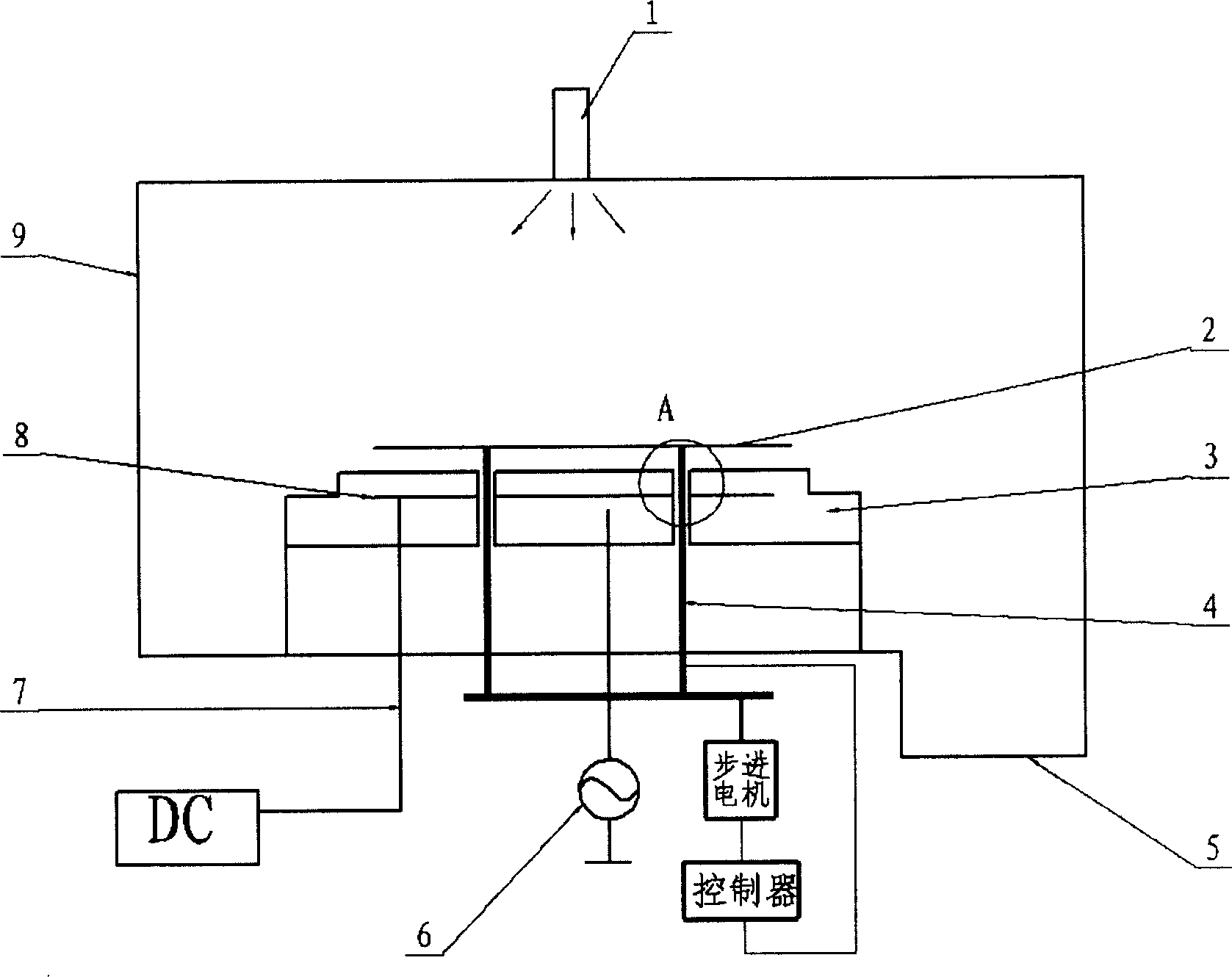

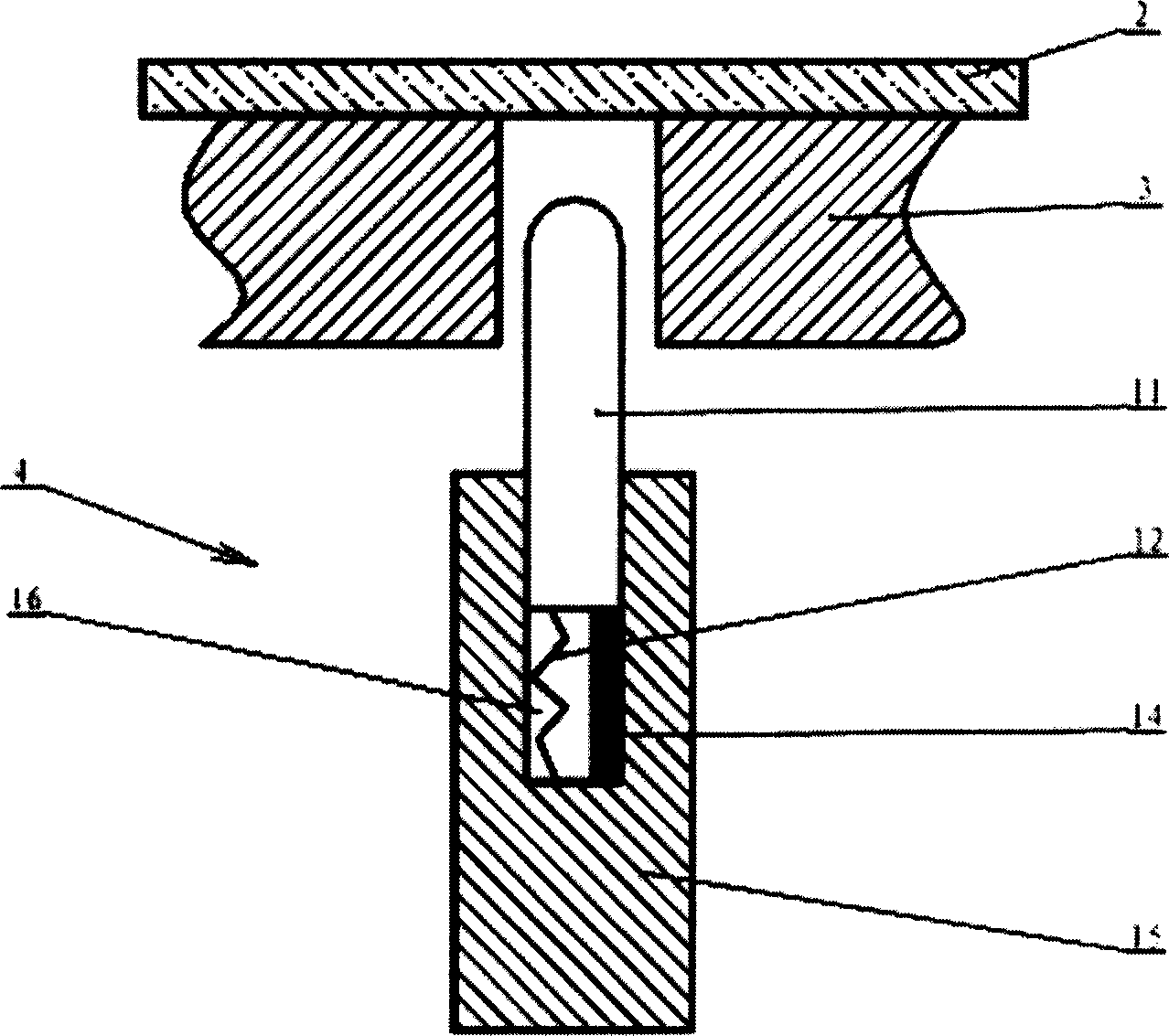

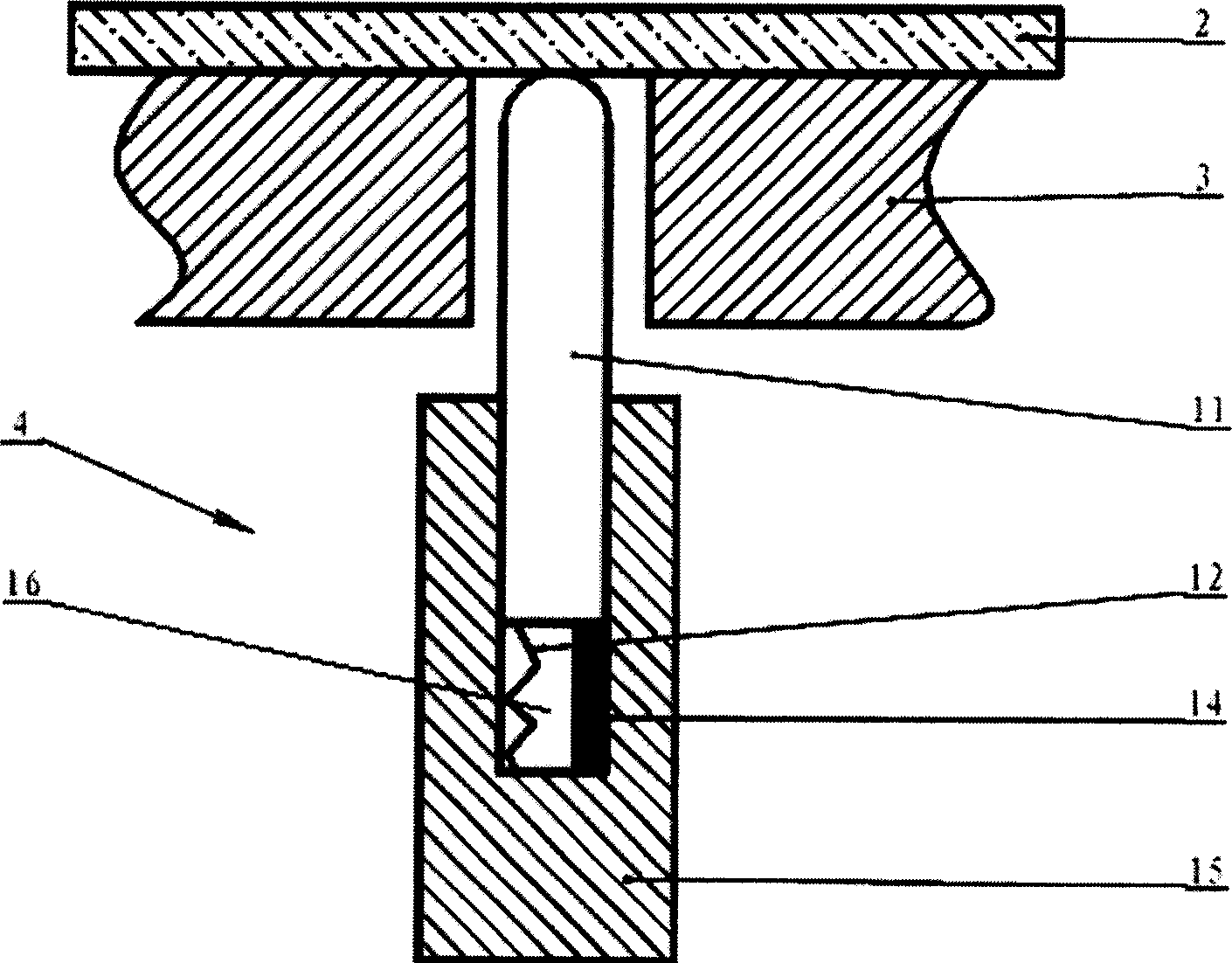

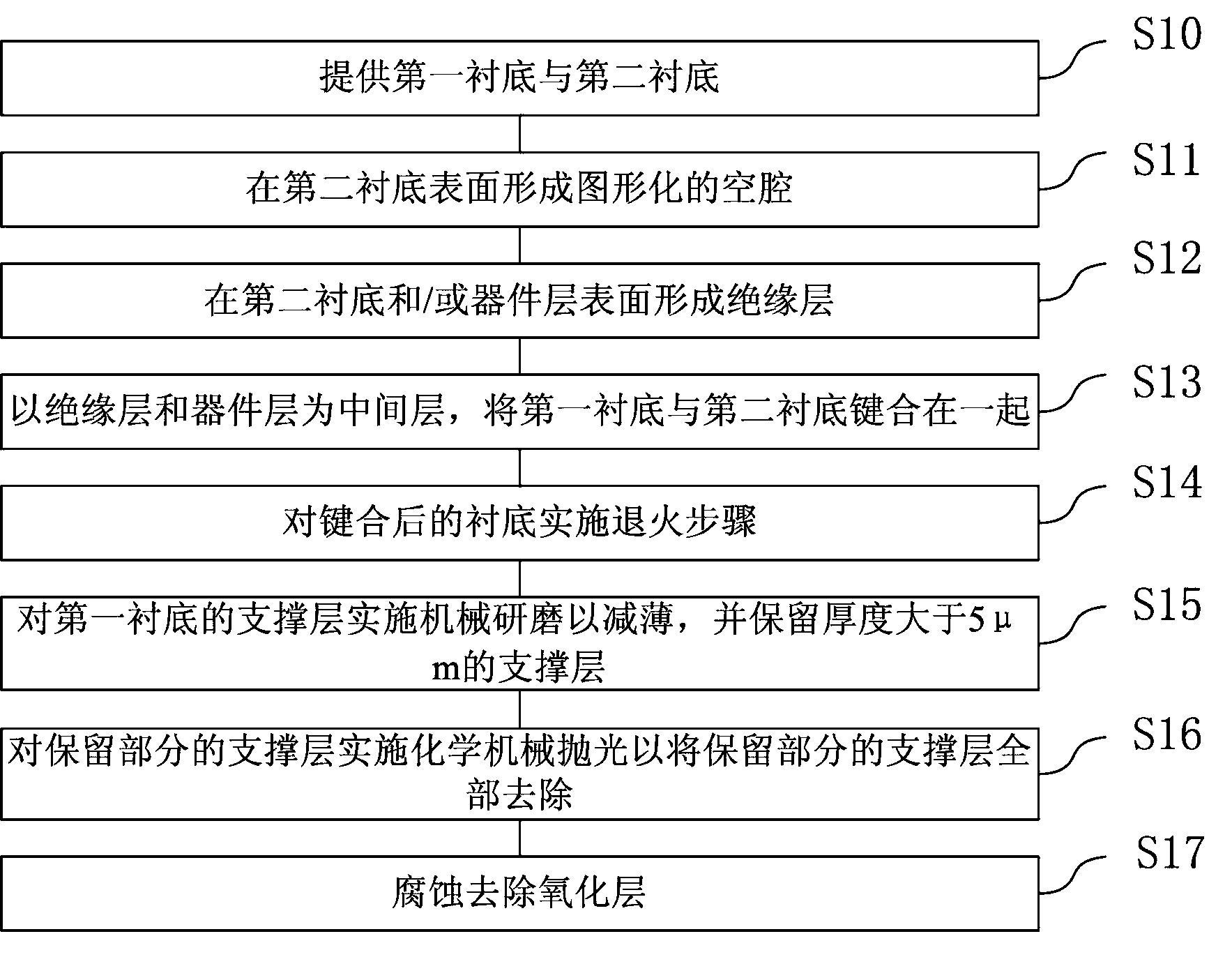

Preparation method of semiconductor substrate with cavity

ActiveCN103400797AGood top silicon uniformity and defect controlAvoid breakageSemiconductor/solid-state device manufacturingCorrosionSemiconductor

The invention provides a preparation method of a semiconductor substrate with a cavity. The preparation method comprises the following steps: a first substrate and a second substrate are provided, wherein the first substrate comprises a support layer, an oxidation layer on the surface of the support layer and a device layer on the surface the oxidation layer; the graphical cavity is formed on the surface of the second substrate; an insulating layer / insulating layers is / are formed on the surface / surfaces of the second substrate or / and the device layer; the first substrate and the second substrate are bonded together by taking the insulating layer and the device layer as middle layers; the annealing is performed on the bonded substrate; the mechanical lapping is performed on the support layer of the first substrate so as to reduce the thickness of the support layer, and the support layer with the thickness more than 5 um is reserved; the chemically mechanical polishing is performed on the support layer of a reserved part so as to completely remove the support layer of the reserved part; the oxidation layer is removed through corrosion so as to form semiconductor substrate with the cavity. The preparation method has the advantage that the combination method of the mechanical lapping, the chemically mechanical polishing and the corrosion is adopted, so that the crush of a top layer and a silicon layer due to only partial support during the process of mechanical lapping is prevented.

Owner:SHANGHAI SIMGUI TECH

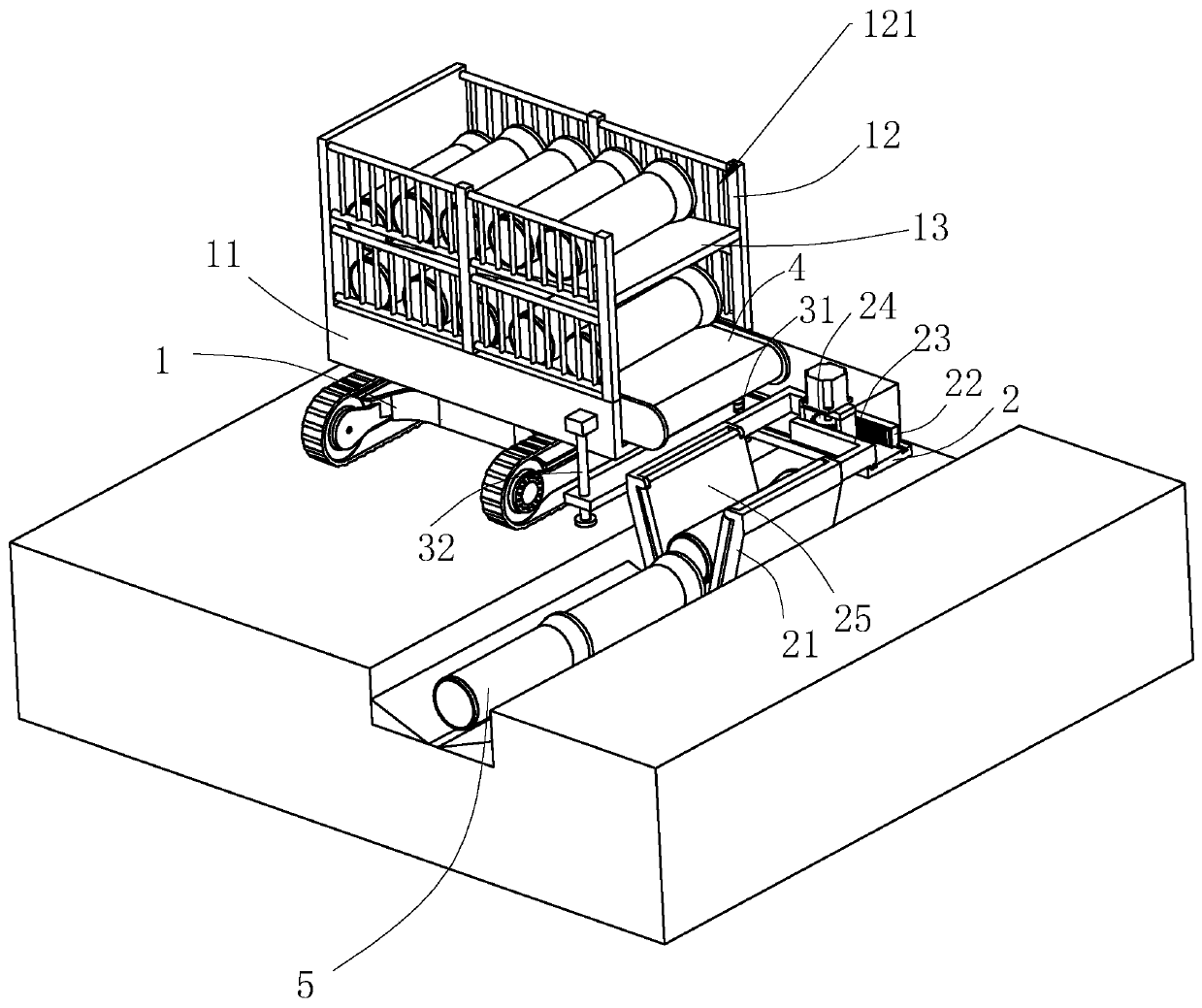

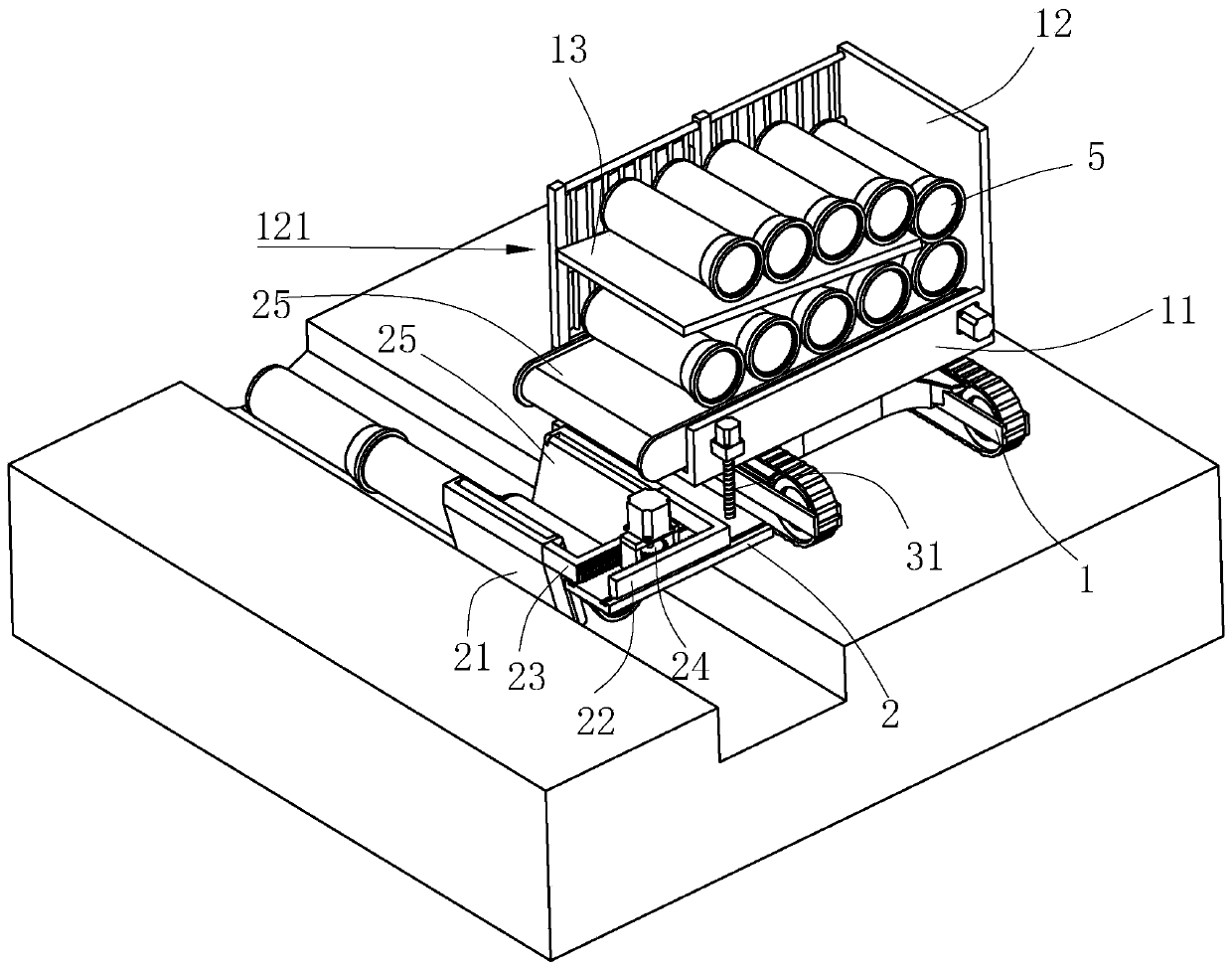

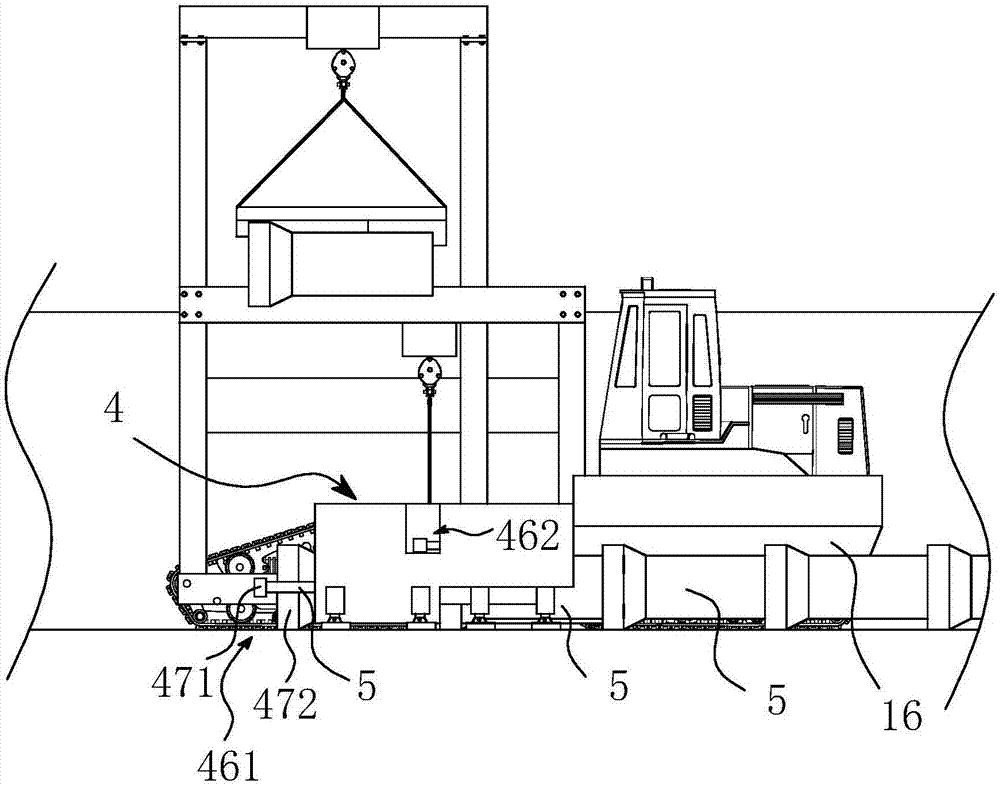

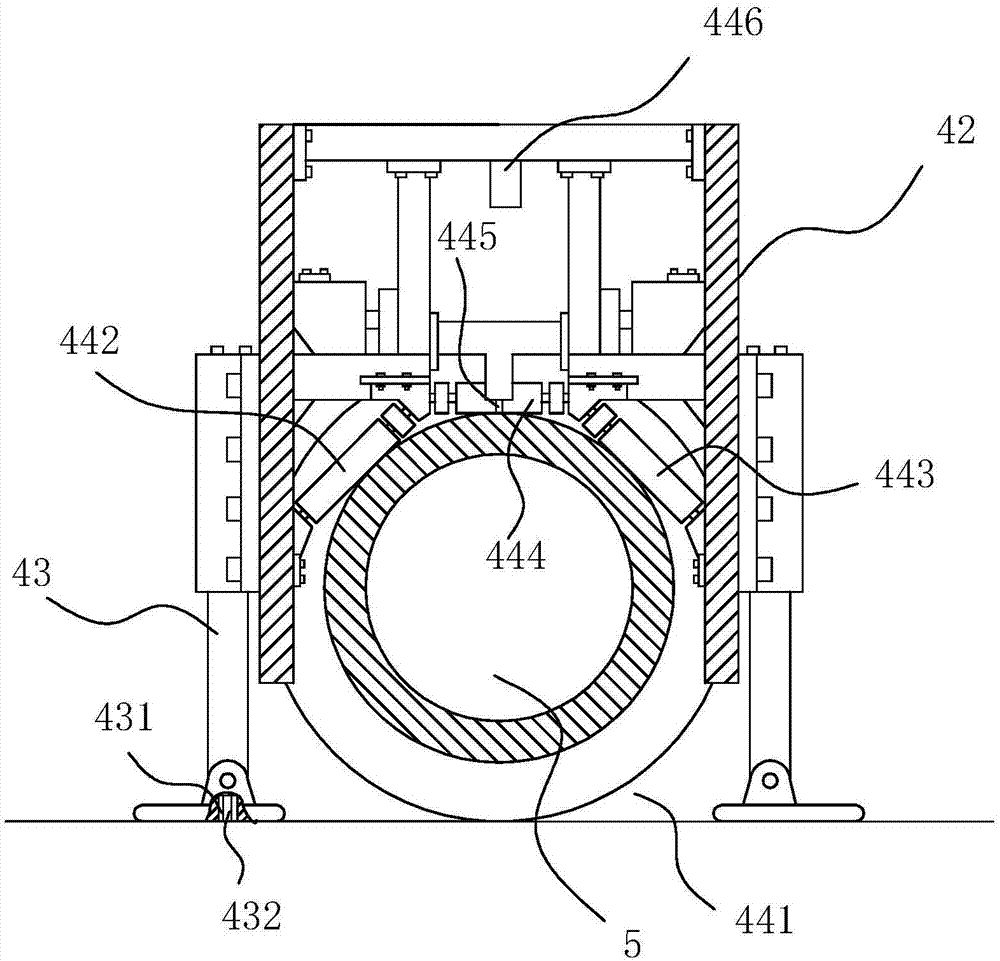

Municipal administration path sewer pipeline construction equipment and method

ActiveCN111456195AEasy to adjustAvoid collisionSewer pipelinesArchitectural engineeringStructural engineering

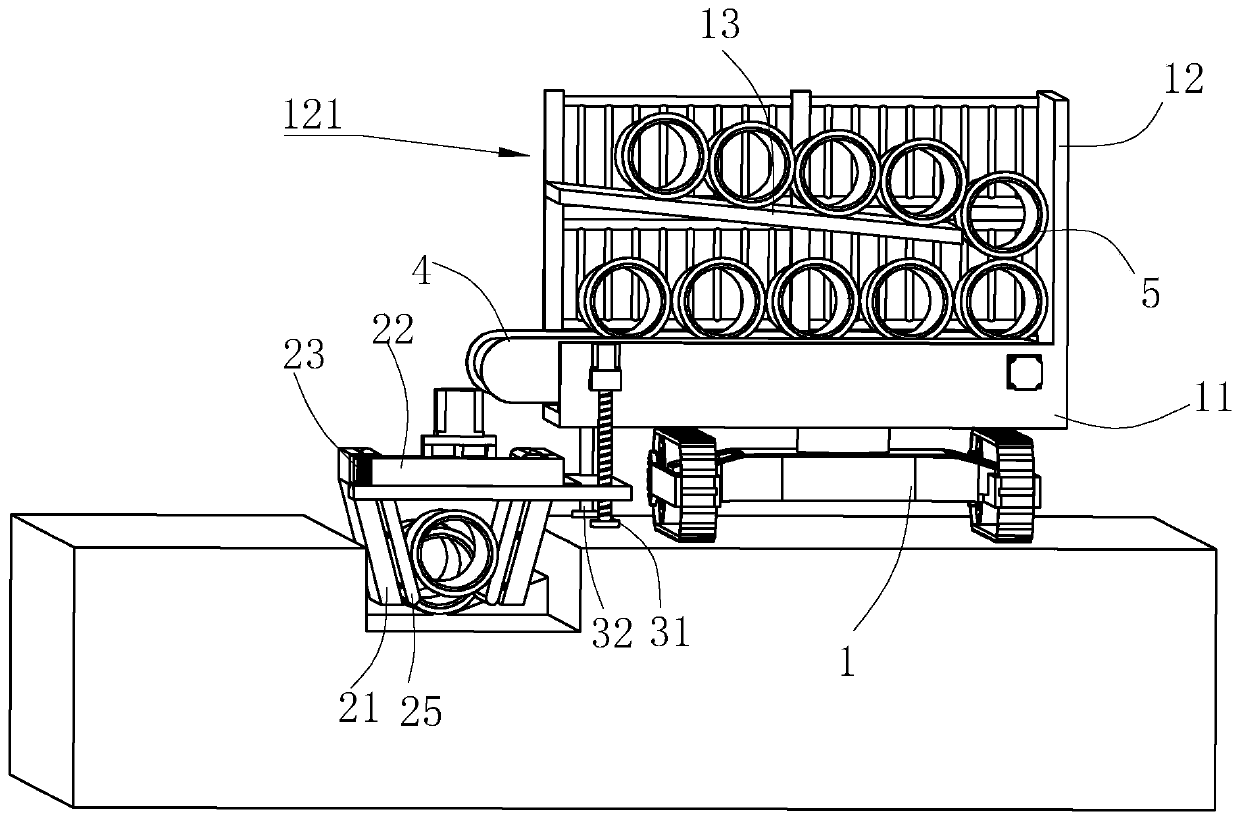

The invention relates to municipal administration path sewer pipeline construction equipment and a method. The municipal administration path sewer pipeline construction equipment comprises a movable base, wherein a rack is rotatably connected above the base; a rotation axis of the rack is perpendicular to the base; the rack is provided with a pipe storage tank for stacking single pipelines; an opening is formed in one side of the pipe storage tank; a conveying device for conveying the single pipelines toward the opening direction is arranged on the bottom part of the pipe storage tank; the rack is provided with a clamping device at one side of the opening; the clamping device stretches into a pipe groove and is used for clamping each single pipeline; the clamping device is located under the opening; and a lifting device for lifting the clamping device is arranged between the clamping device and the rack. Through adopting the technical scheme, through the cooperation of the pipe storagetank, the conveying device and the clamping device of the equipment, one batch of single pipelines can be sequentially downwards placed in a groove, so that the time spent on sequentially lifting thesingle pipelines through a crane is shortened, the occurrence of the phenomenon that the single pipelines are easy to break when being downwards placed manually is further avoided, and an effect on quickly paving sewer pipelines is achieved.

Owner:广东城华工程咨询有限公司

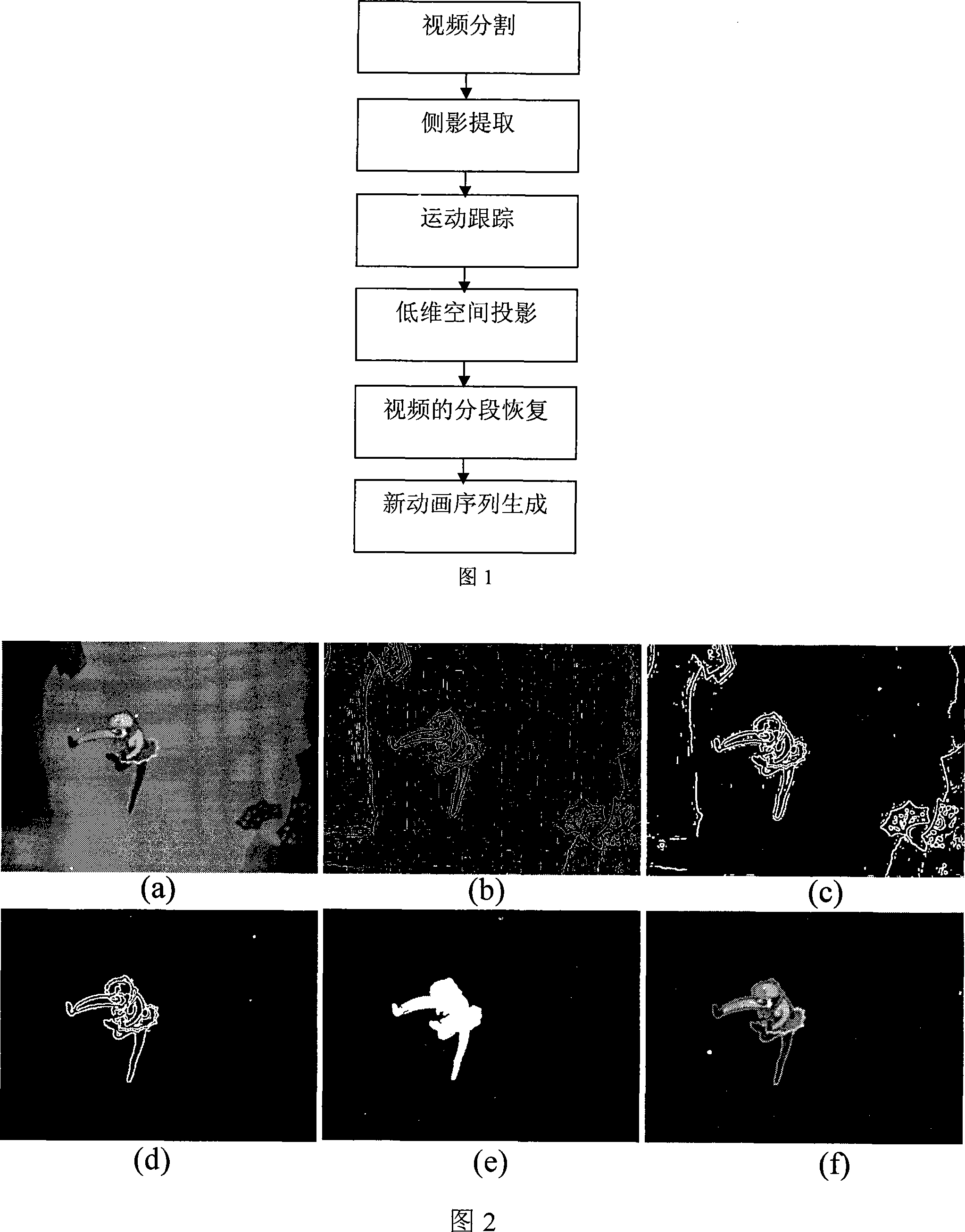

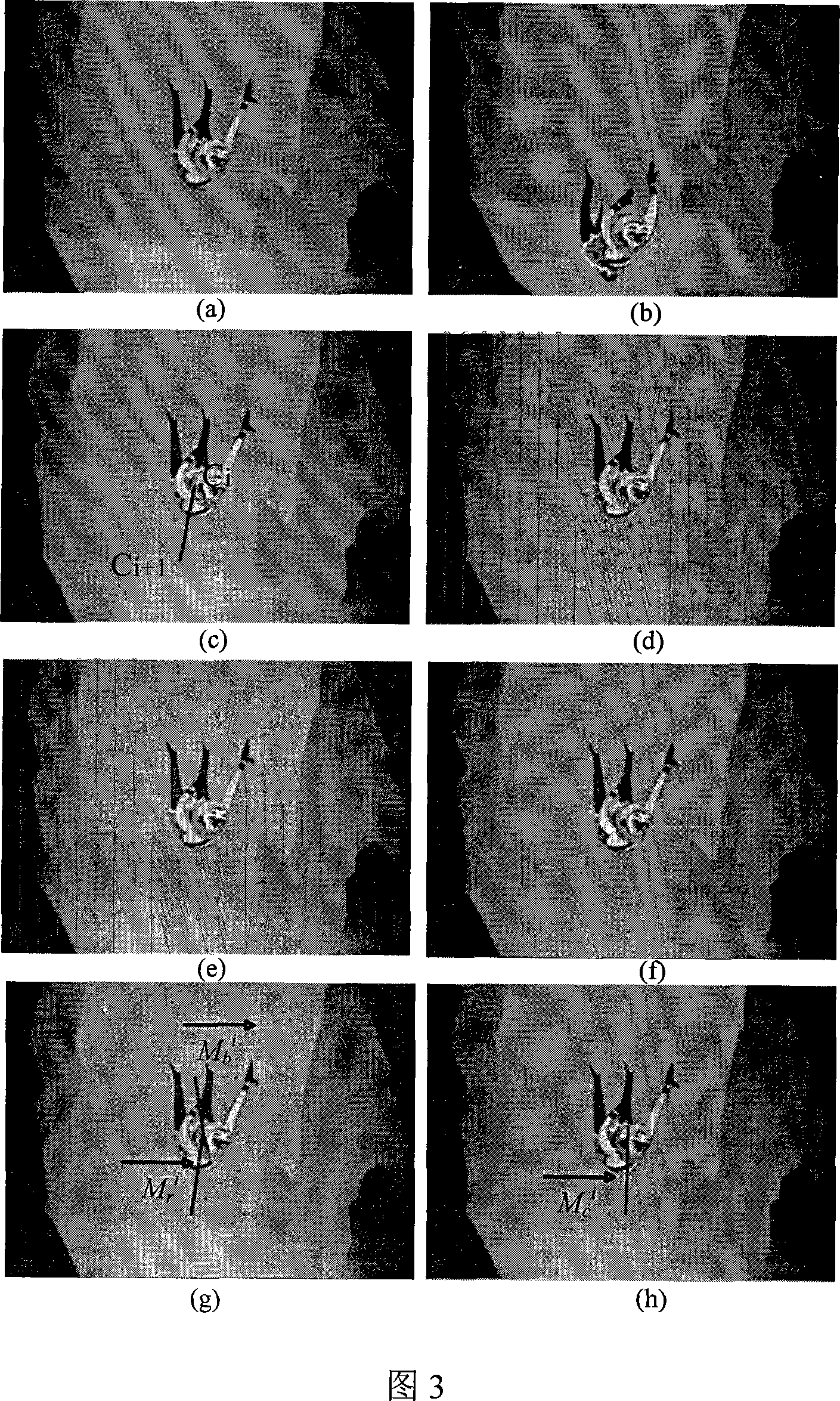

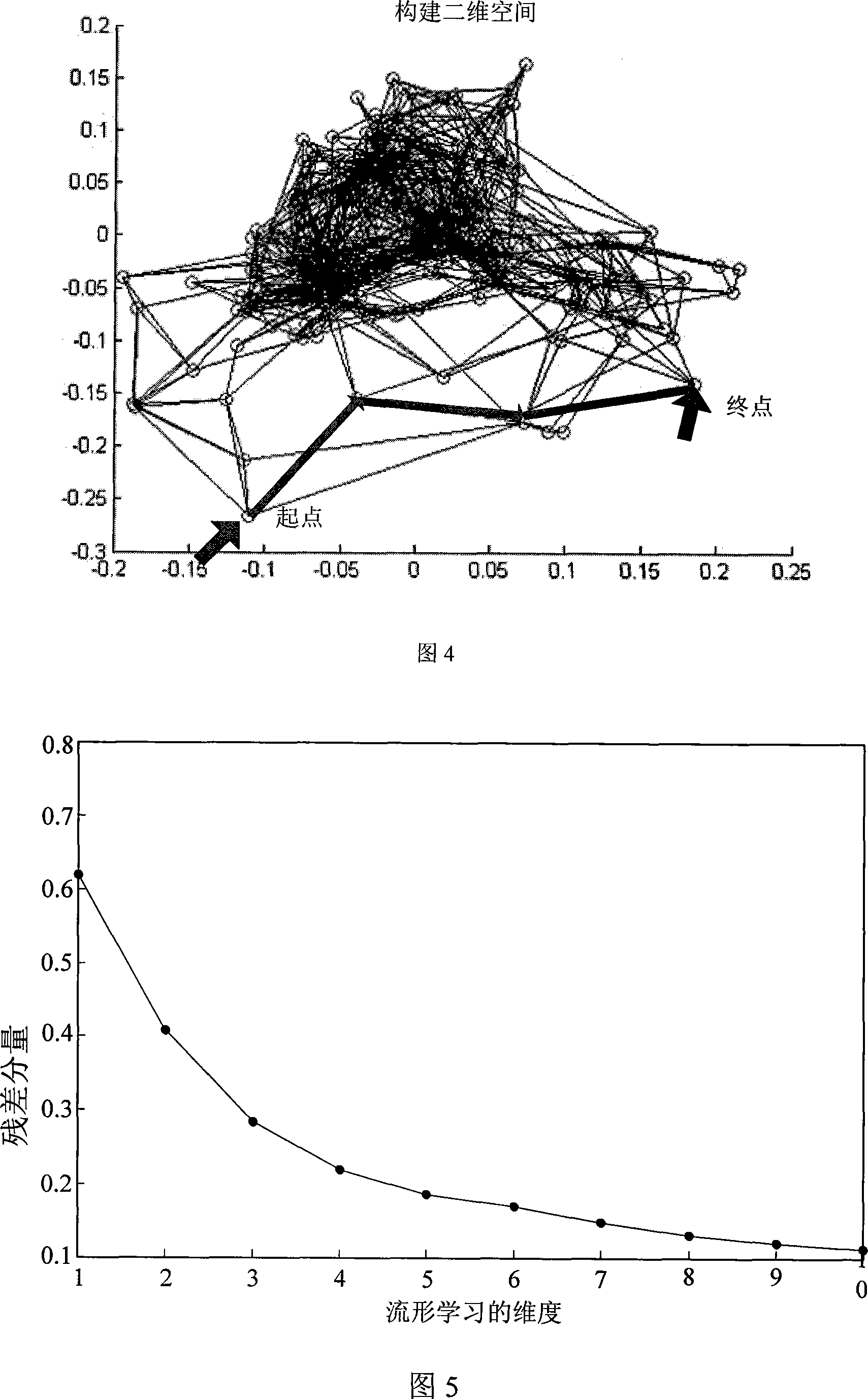

Cartoon animation fabrication method based on video extracting and reusing

The invention discloses a cartoon animation producing method based on video extraction and reuse. The invention comprises the following steps of: firstly dividing a cartoon video into cartoon frames; next, extracting cartoon roles via the foreground dividing technique based on the boundary; then, calculating the distance between any two frame roles and obtaining a distance matrix via using the role similarity on the boundary; then constructing an undirected graph via using the manifold learning arithmetic according to the obtained distance matrix; finally, appointing any two points in the undirected graph and establishing the shortest path between the two points which comprises the frames to form a smooth cartoon frame sequence. The method has the advantages of: effectively extracting the cartoon roles from the complex background via designing a foreground extraction technique based on boundary; making the similarity between roles more accurately by calculating the movement attribute of the roles in every frame via optical flow tracking technique; and constructing a cartoon data reuse platform to facilitate a user to produce cartoon animations conveniently and rapidly via manifold learning.

Owner:ZHEJIANG UNIV

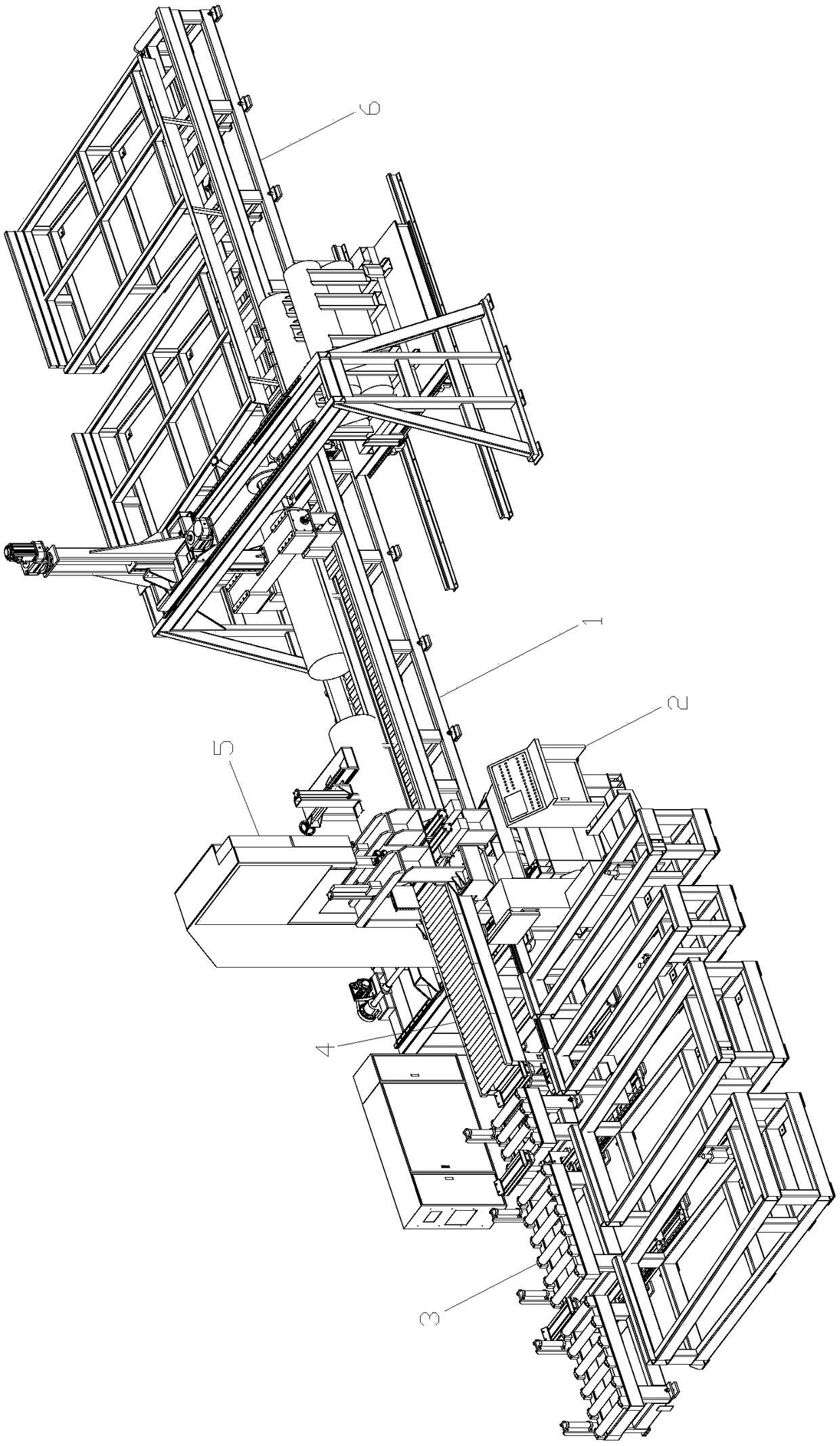

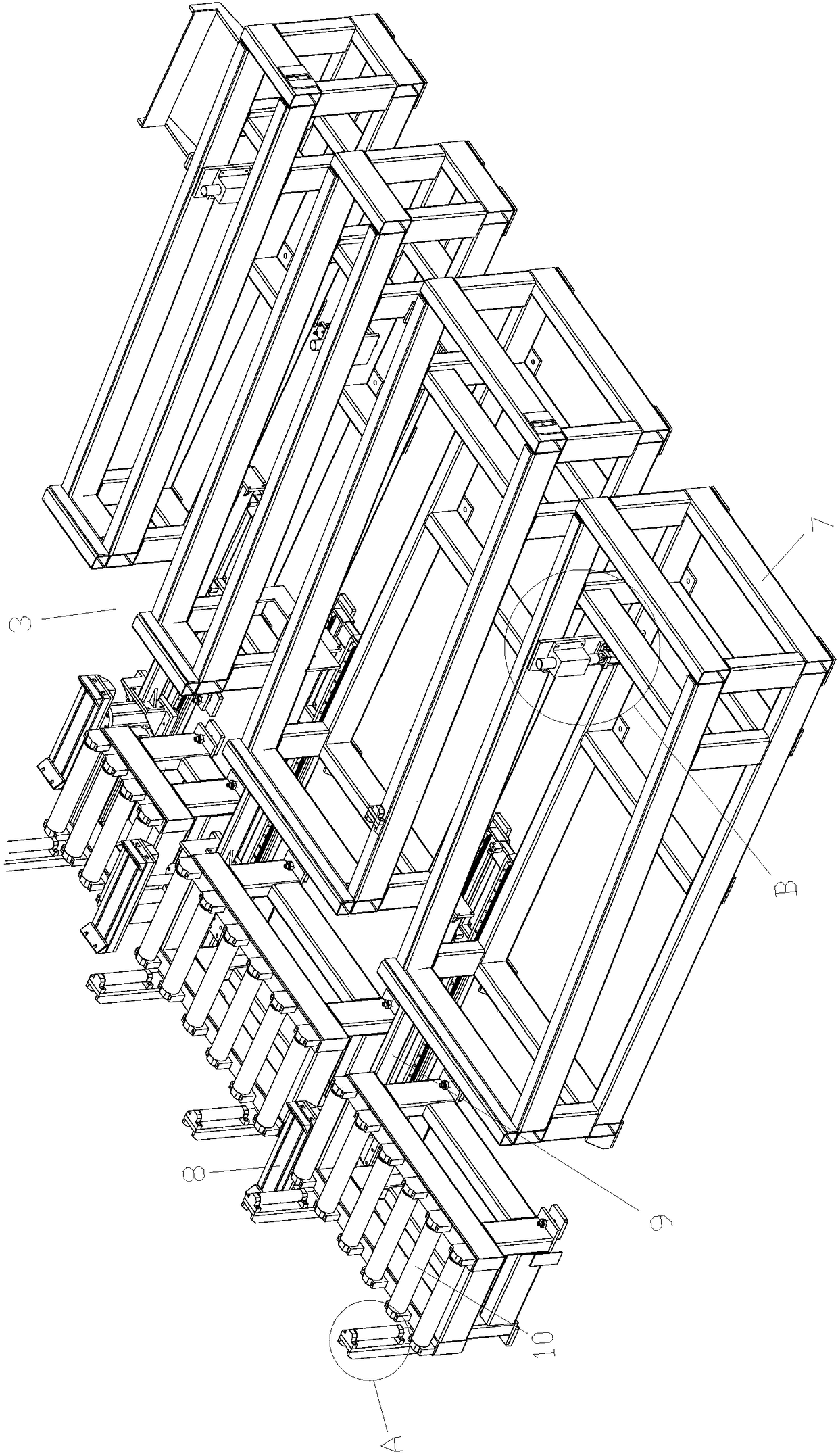

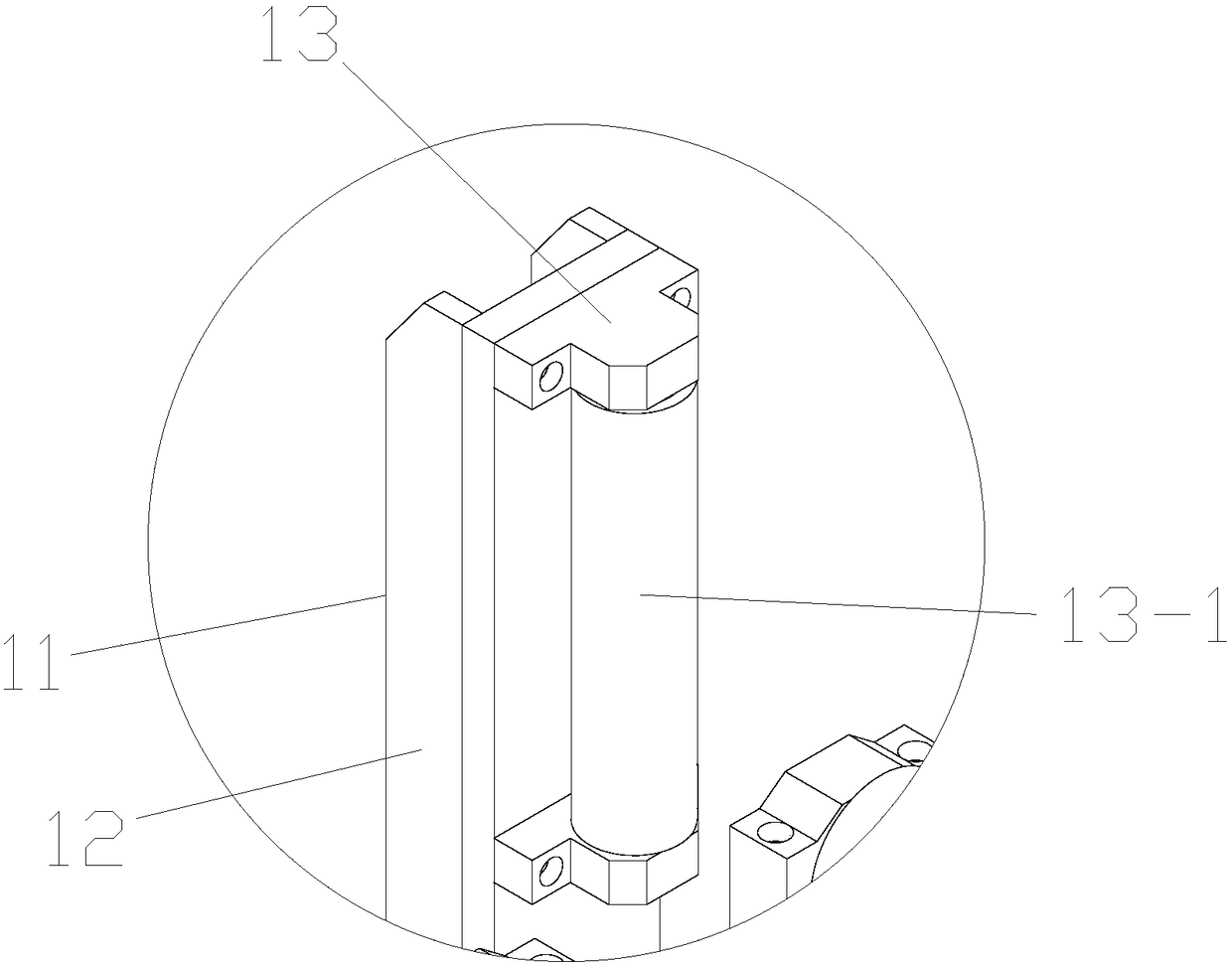

Intelligent production line for high-speed aluminum bar saw cutting

The invention relates to an intelligent production line for high-speed aluminum bar saw cutting. The intelligent production line comprises a machine body and an operation table used for controlling the machine body to run; the machine body comprises a feeding device used for conveying aluminum bars, a feeding sizing device used in cooperation with the feeding device, a main machine saw cutting device used in cooperation with the feeding sizing device and a discharging device used for discharging after saw cutting is completed. According to the intelligent production line for high-speed aluminum bar saw cutting, monomer project research and development and system organic sets of series functions including batch automatic feeding, numerical control sizing, saw cutting clamping, finished product numerical control stacking, weighing, coding and the like of workpieces are studied, overall process numerical control problems (controllable beat) of a series of motions such as feeding, positioning, clamping, hoisting, weighing and coding are solved, and the production line is worthy of popularization.

Owner:浙江锯力煌工业科技股份有限公司

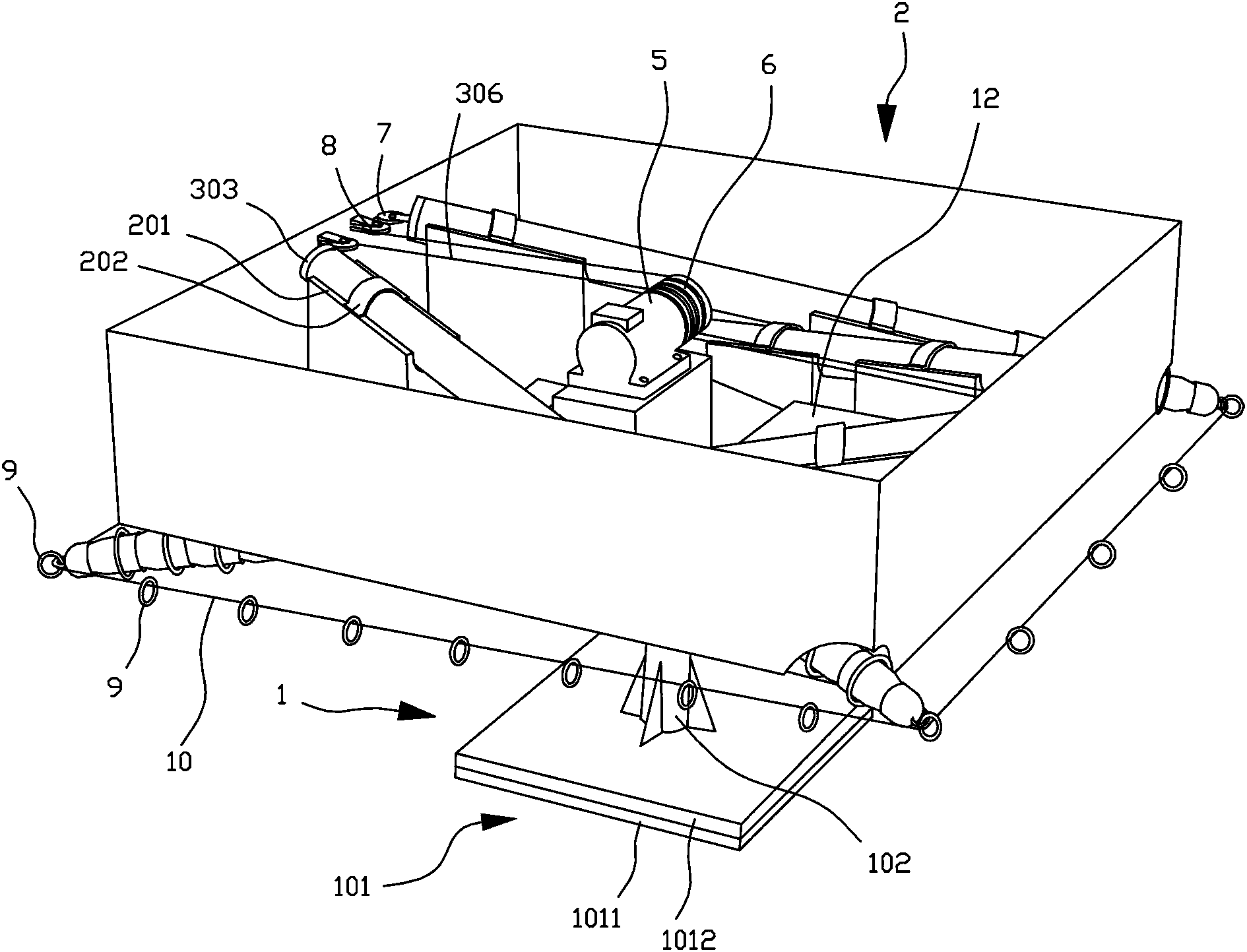

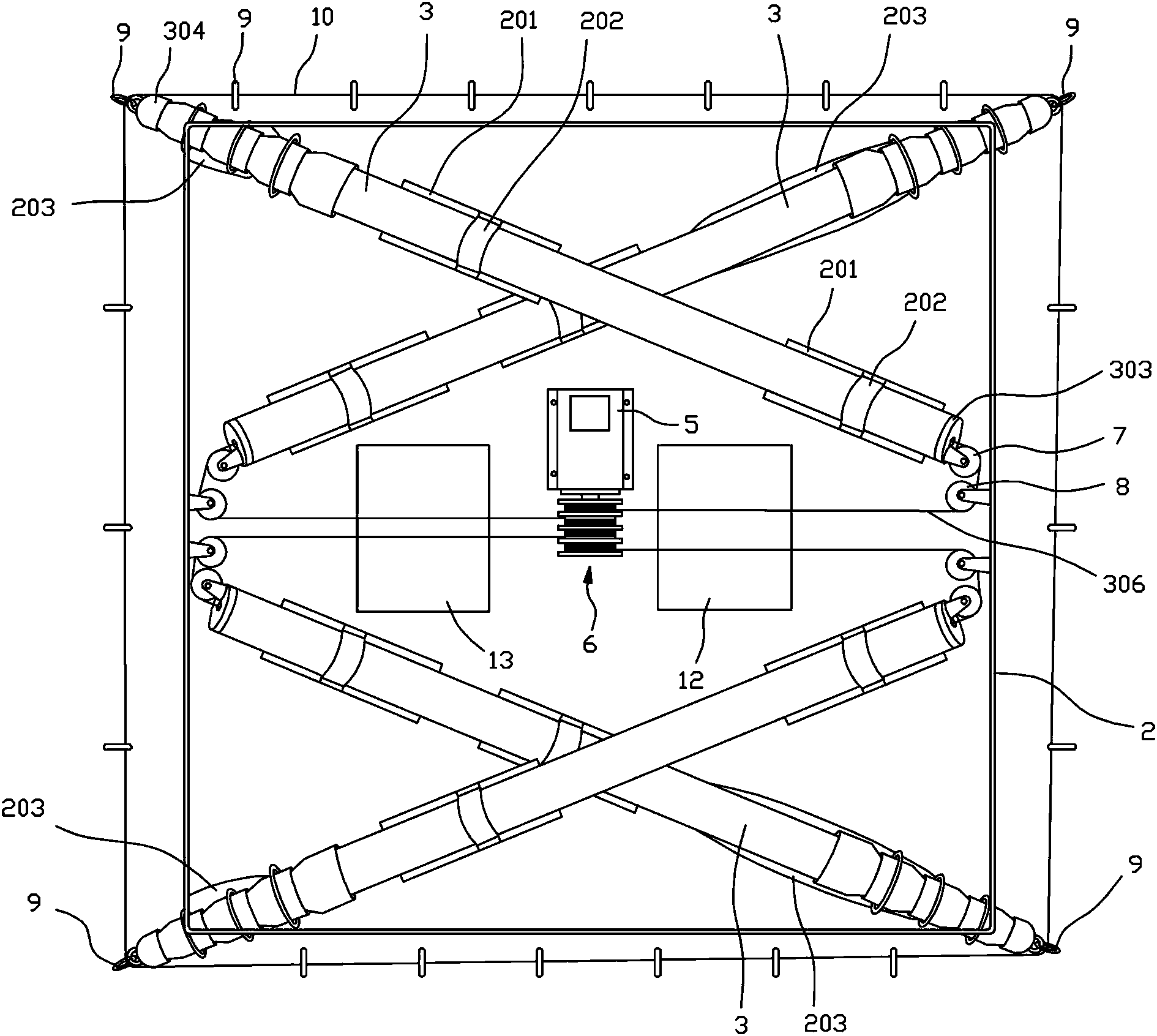

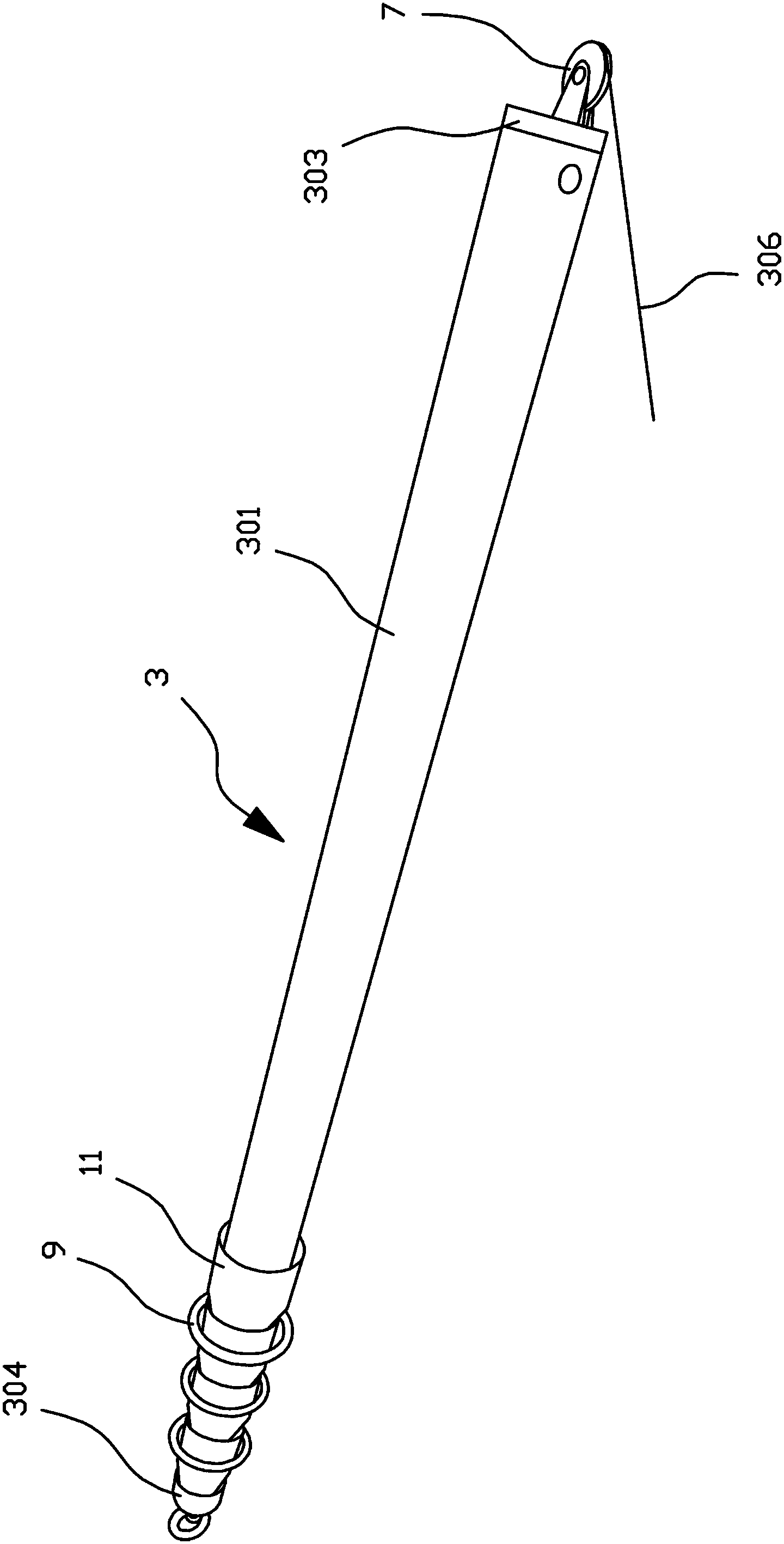

Safety recyclable transportation packaging box not prone to breaking up

ActiveCN106395148AGuaranteed fixed effectEnsure safetyPackage recyclingContainers to prevent mechanical damageMechanical engineeringMultiple stages

The invention discloses a safety recyclable transportation packaging box not prone to breaking up. The safety recyclable transportation packaging box not prone to breaking up comprises a box body. A winding device fixedly installed on the outer portion of the box body is movably connected with a fixing plate through a dragging steel wire, and the fixing plate is located in an inner cavity of the box body. The side, close to the winding device, of the fixing plate is elastically connected with one end of a spring, the other end of the spring is elastically connected to the inner wall of the box body, a sponge block is fixedly installed on the other side of the fixing plate, an air charging device is fixedly installed on the side face of the sponge block as well as the inner wall of the box body, and a clamping device is movably connected to the side face of the winding device as well as the outer portion of the box body. The safety recyclable transportation packaging box not prone to breaking up has the advantages that the clamping distance is adjusted according to the size of cargos, the effect that the cargos are fixed through the optimal clamping force is ensured, impact force caused by clamping is relieved in time, the situation that no other protection measures are taken when the cargos topple over, and consequently the cargos break up is avoided, recycling is achieved, and by adoption of multiple stages of protection measures, the cargos are safer.

Owner:重庆益弘防务科技有限公司

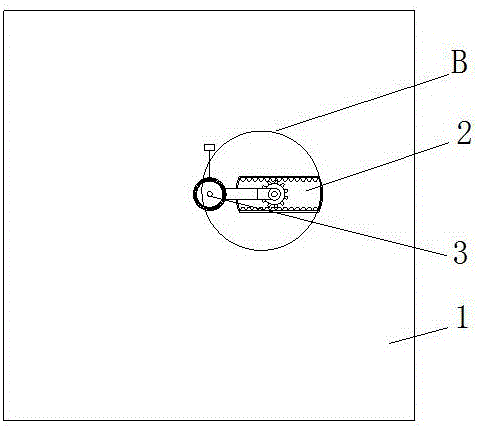

Diamond Screening Apparatus

ActiveUS20150041372A1Avoid breakageAvoid breakingProgramme controlProgramme-controlled manipulatorImage captureDisplay device

The present invention relates to a diamond screening apparatus, comprising: a working platform comprising a working plane; a conveyer disposed on the working plane of the working platform for carrying a diamond matrix unit; an image capture device forming one or a plurality of captured images in different regions of the diamond matrix unit; a display device; and an image recognition module, which is electrically connected to the image capture device and the display device, performs a geometric feature parameter analysis on the captured images to determine one or a plurality of risk diamonds of the diamond matrix unit.

Owner:KINIK

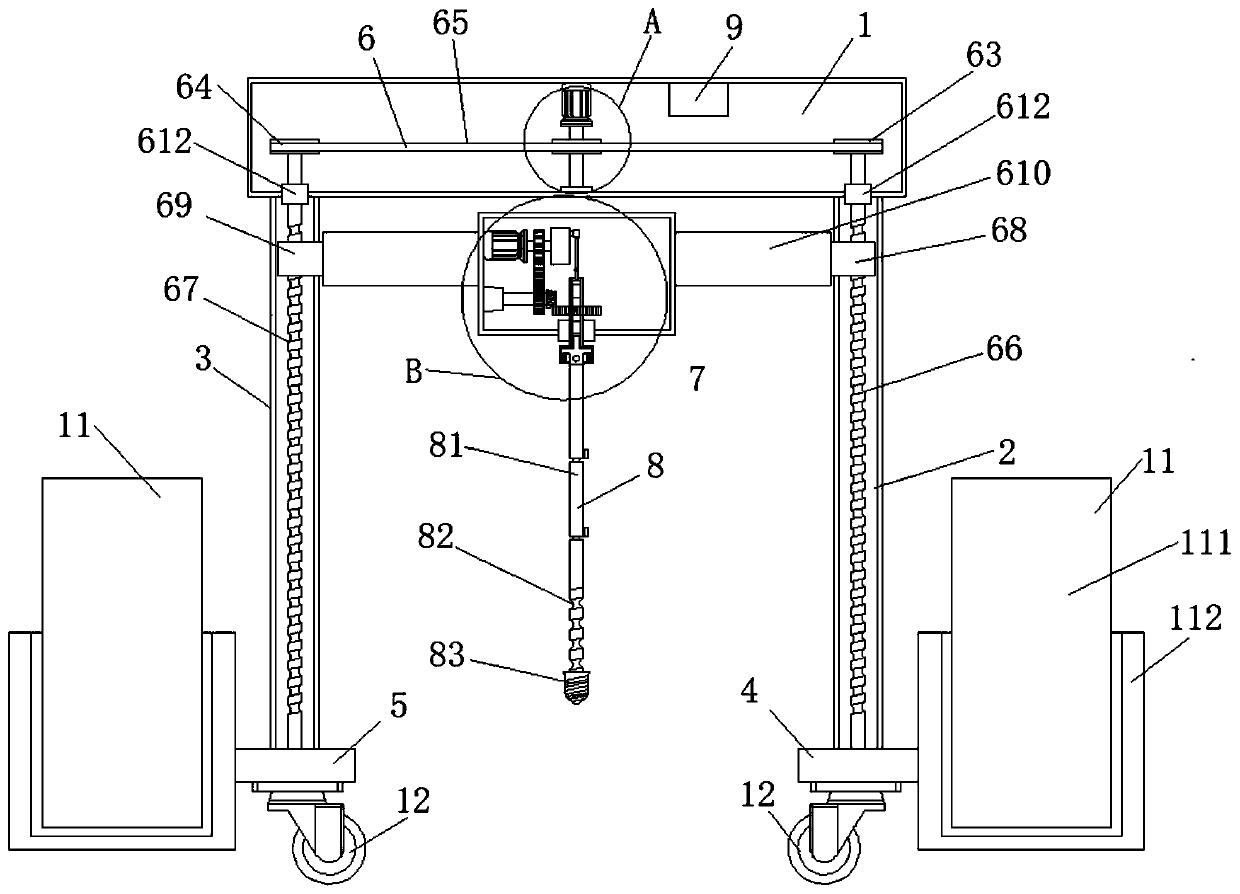

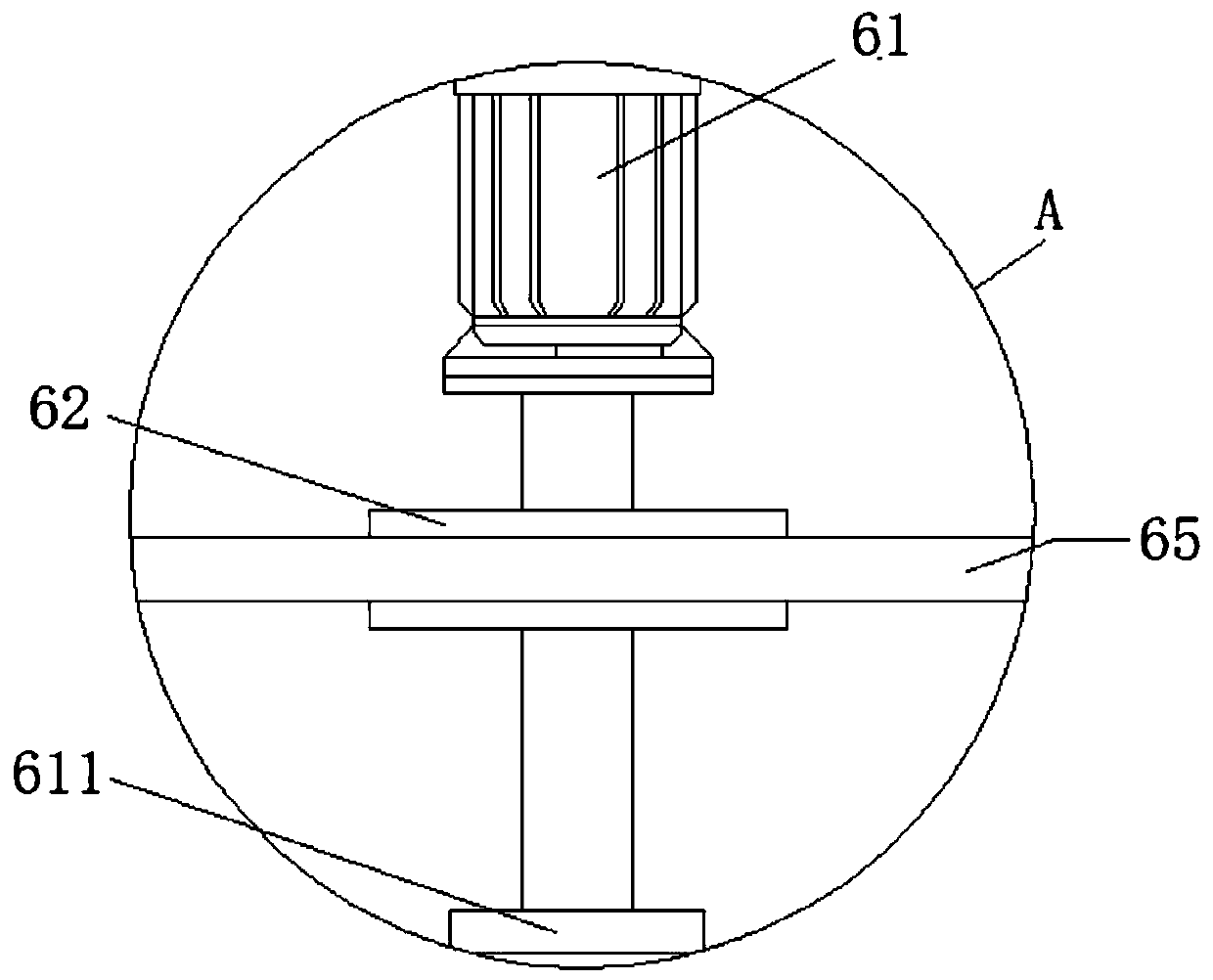

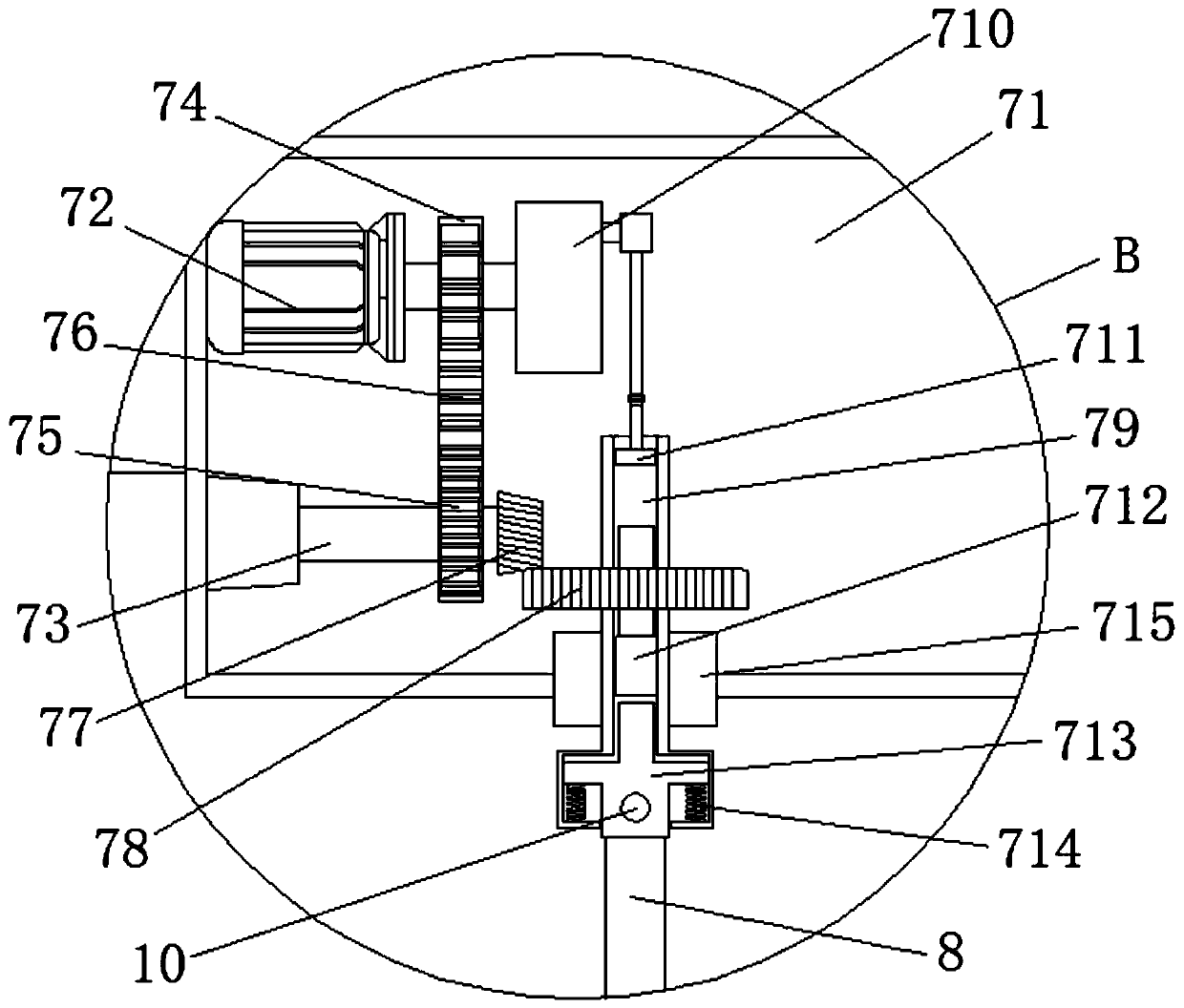

Sampling device and method for geological exploration rock-soil body

InactiveCN110261168AGuaranteed uptimeAvoid bendingWithdrawing sample devicesEngineeringGeological exploration

The invention discloses a sampling device and method for a geological exploration rock-soil body. The device comprises a mounting seat which is arranged at the upper end of a support seat, wherein the bottom portion of the support seat is provided with a base; a first motor is fixedly installed at the top portion of the inner cavity of the mounting seat, and a driving belt pulley is fixedly mounted at the output end of the first motor; a driving screw is vertically arranged in the support seat, a driven belt pulley is fixedly arranged at the top end of the driving screw, and the driven belt pulley is connected with the driving belt pulley through a driving belt; and moving seats slidingly sleeve transmission screws, and the moving seats sleeve the transmission screws; a moving seat connecting plate is horizontally arranged between the two moving seats, a second power mechanism is arranged on the moving seat connecting plate, and a sampling drill rod is connected with the output end of the second power mechanism. By cooperation of the first motor, the driving belt pulley and the driven belt pulley, the operation of the moving seats are stable, so that the sampling drill rod is kept in a vertical state in the running process and is prevented from being bent.

Owner:CHANGAN UNIV

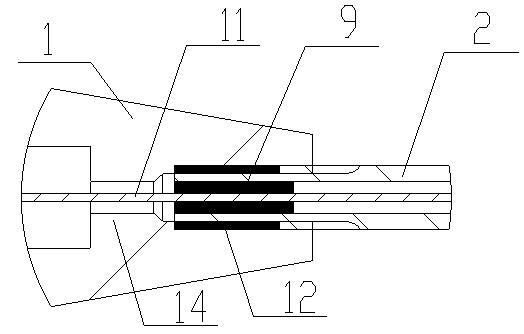

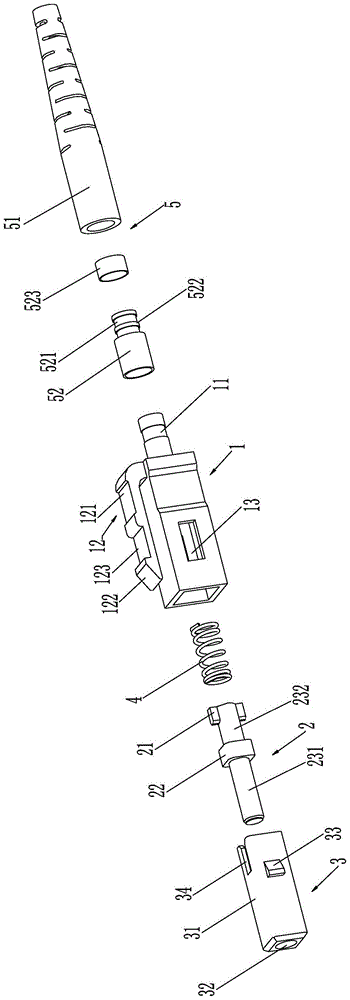

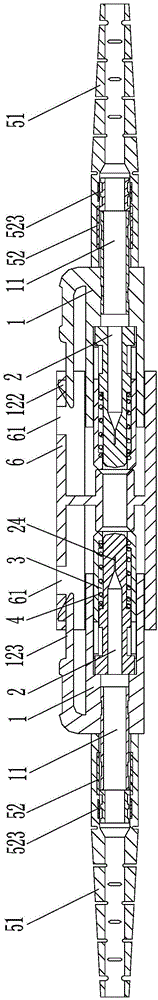

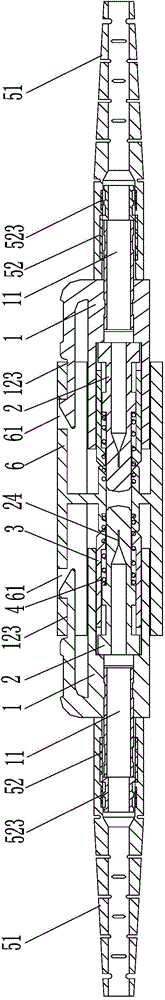

Optical fiber connector and manufacturing method thereof

ActiveCN104965262AReduce assembly requirementsLow matching accuracy requirementsCoupling light guidesFiberElastic component

The invention relates to an optical fiber connector and a manufacturing method thereof. The optical fiber connector comprises a housing and a fiber insertion core arranged in the housing. The end surface of the fiber insertion core is provided with at least one lens. The cavity at one end of the housing is equipped with an insertion core protection structure for protecting the end surface of the insertion core so as to prevent the lens surface at the end surface of the fiber insertion core from being damaged or scraped. The insertion core protection structure is internally provided with the fiber insertion core and an elastic component sleeved on a fiber insertion core tubular body to ensure free telescoping of the insertion core protection structure. The other end of the housing is provided with an extension pipe. The extension pipe is connected with a tail sheath assembly which carries out bending protecting on an optical cable and guarantees that the optical fiber connector can transmit optical signals normally under the bending pressure condition. An elastic buckle structure for enabling the optical fiber connector to be buckled to a corresponding insertion hole of an adapter is integrated to the outer wall of the housing.

Owner:SHENZHEN EPLU SCI TECH

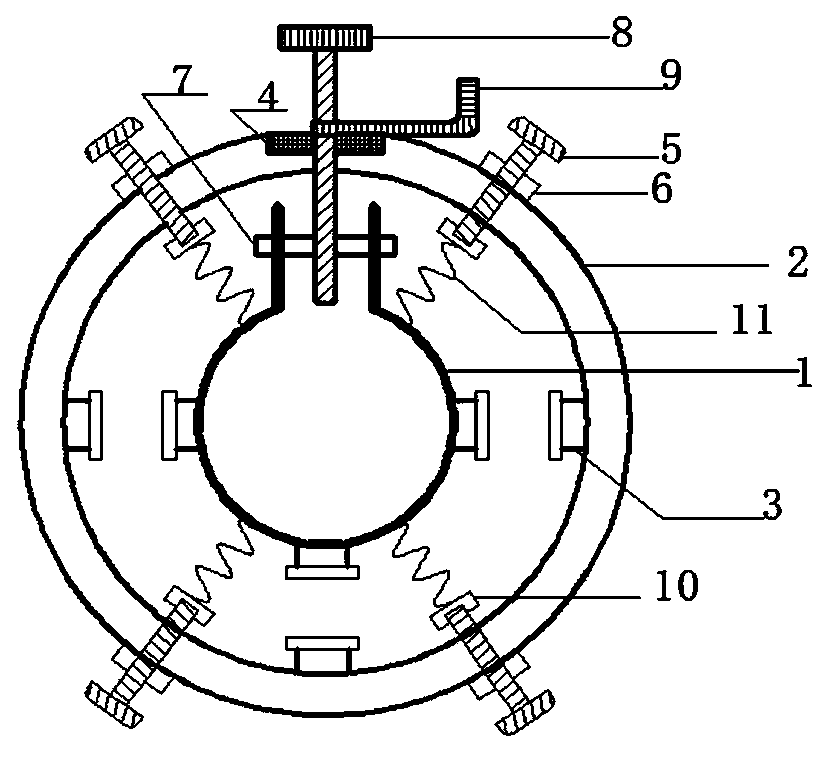

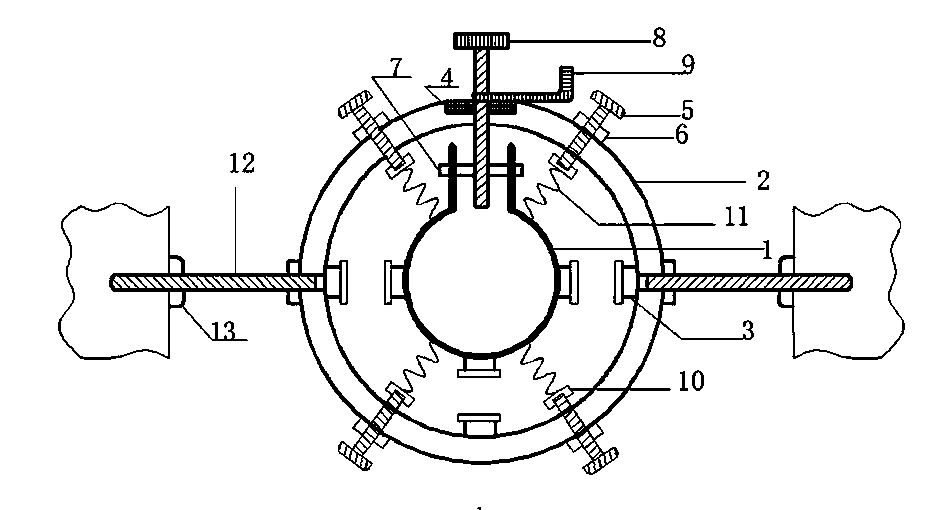

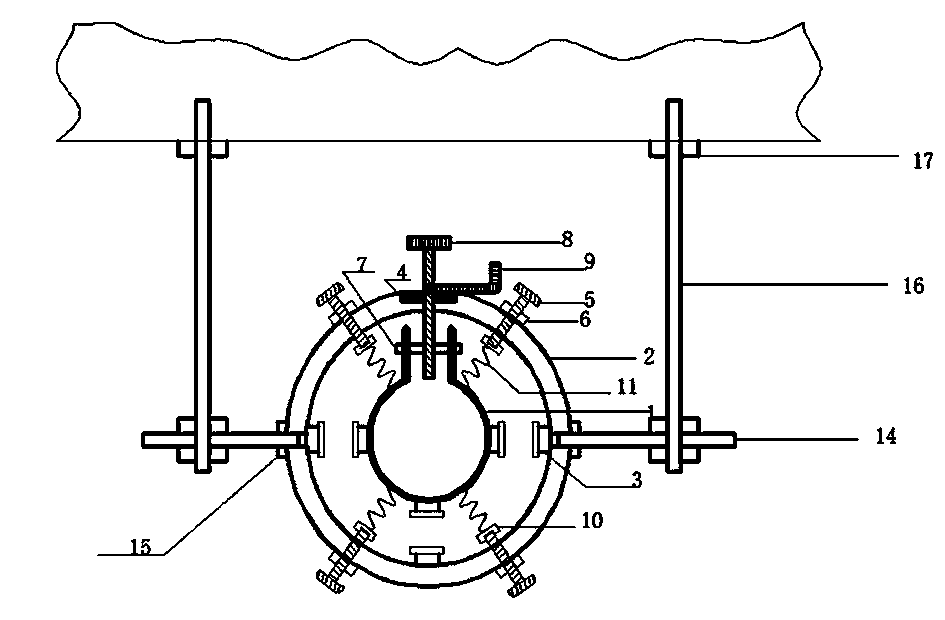

Adjustable ship pipeline shock resistance lantern ring device

InactiveCN103803033ATimely Limit OffsetLimit offsetVessel safetyPipe elementsFixed-functionRing device

The invention discloses an adjustable ship pipeline shock resistance lantern ring device which comprises a first adjusting ring covering a pipeline and a second ring arranged on the periphery of the first adjusting ring. The first adjusting ring is a non-closed ring and an allowance is reserved in a body of the first adjusting ring. The allowance of the ring body can be collected or released through an adjusting bolt and a connecting piece, and therefore the first adjusting ring can be used for pipelines with different diameters. The adjustable ship pipeline shock resistance lantern ring device is wide in application range and capable of reducing cost. When a casing pipe works normally, a pipeline system has the restraining function and the fixing function, when the pipeline system is shocked and vibration is generated, the pipeline is protected against large excursion, and the impact resistance of the ship pipeline is enhanced.

Owner:JIANGSU MARITIME INST +1

Low-range piezoresistive pressure sensor for vacuum measurement and manufacturing method thereof

ActiveCN102261979AMeet low range measurementAvoid breakageTelevision system detailsImpedence networksPhysicsPhotoresist

The invention discloses a method for manufacturing a low-range piezoresistive pressure sensor for vacuum measurement comprising the following steps: (a) providing a silicon wafer, covering a silicon oxide and a silicon nitride as a mask on the back of the silicon wafer, and etching the silicon oxide and silicon nitride as the mask by using RIE to form a membrane structure opening; (b) removing a photoresist and corroding or etching the silicon wafer so as to form a certain depth at the opening of the membrane structure; (c) photoetching an island structure, and etching the silicon oxide and the silicon nitride on the island structure by using RIE; (d) removing the photoresist and keeping on corroding or etching the silicon wafer, obtaining a pressure sensing film with the desired depth; (e) corroding the remaining silicon oxide and silicon nitride by using BOE; (f) providing a bonding layer, and fixing the bonding layer at the front of the silicon wafer, arranging a cavity communicated with the pressure sensing film and a stop block downwardly extending to the cavity on the bonding layer, and reserving a gap between the stop block and the pressure sensing film for limiting excessive deformation of the pressure sensing film; also comprising a step of making a plurality of piezoresistive bars which can connect a Wheatstone bridge at a stress concentration area of the pressure sensing film. The design of the stop block limits the maximum displacement of the pressure sensing film so as to realize the functions of ordinary pressure protection and overload protection of the sensor.

Owner:MEMSENSING MICROSYST SUZHOU CHINA

Automobile sun shade

InactiveCN103448523AEasy to storeEasy to use automaticallyRemovable external protective coveringsAutomotive engineeringElectric power

Owner:俞幸芳

Continuous carbon fiber composite material 3D printing device and method with modifying and dipping synchronization function

ActiveCN108454084AChange surface propertiesImprove bindingAdditive manufacturing apparatus3D object support structuresMolten stateFiber

The invention provides a continuous carbon fiber composite material 3D printing device and method with a modifying and dipping synchronization function. A fiber guide pipe is partially immersed in a solution of a synchronous modification container, and the immersed part is provided with a notch for the solution to flow; the fiber guide pipe and a resin guide pipe are connected with two inlets of aprinting head respectively, an outlet of the printing head is connected with a heating block, and a nozzle is arranged at the bottom of the heating block. According to the device and method, 3D printing of the fiber composite material which is synchronously modified and dipped is achieved; through the design of a mechanical structure, the modified continuous fiber enters the heating block along with resin to be printed, the unmodified resin is conveyed into a modification solution to be soaked and modified so that printed carbon fibers can be modified all the time, and synchronization of fiber modification and printing is effectively achieved; after the carbon fibers are soaked with the modified solution, original cellosilk which is easy to disperse in the carbon fibers is combined more tightly; the surfaces of the carbon fibers are coated with a layer of resin, so that the binding effect of the carbon fibers and the resin in the molten state is improved, and the continuous carbon fiber material is not easy to break in the printing process.

Owner:NANJING NORMAL UNIVERSITY +1

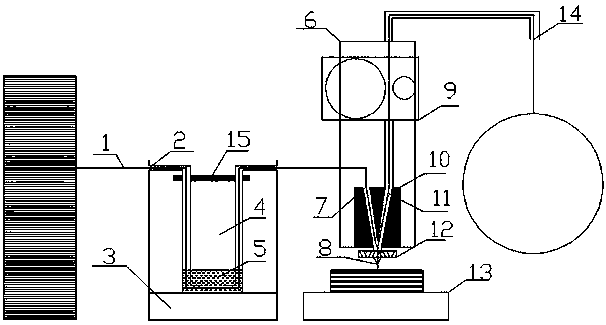

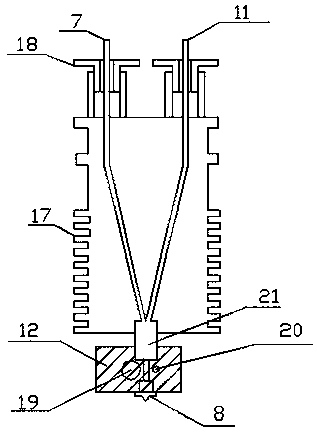

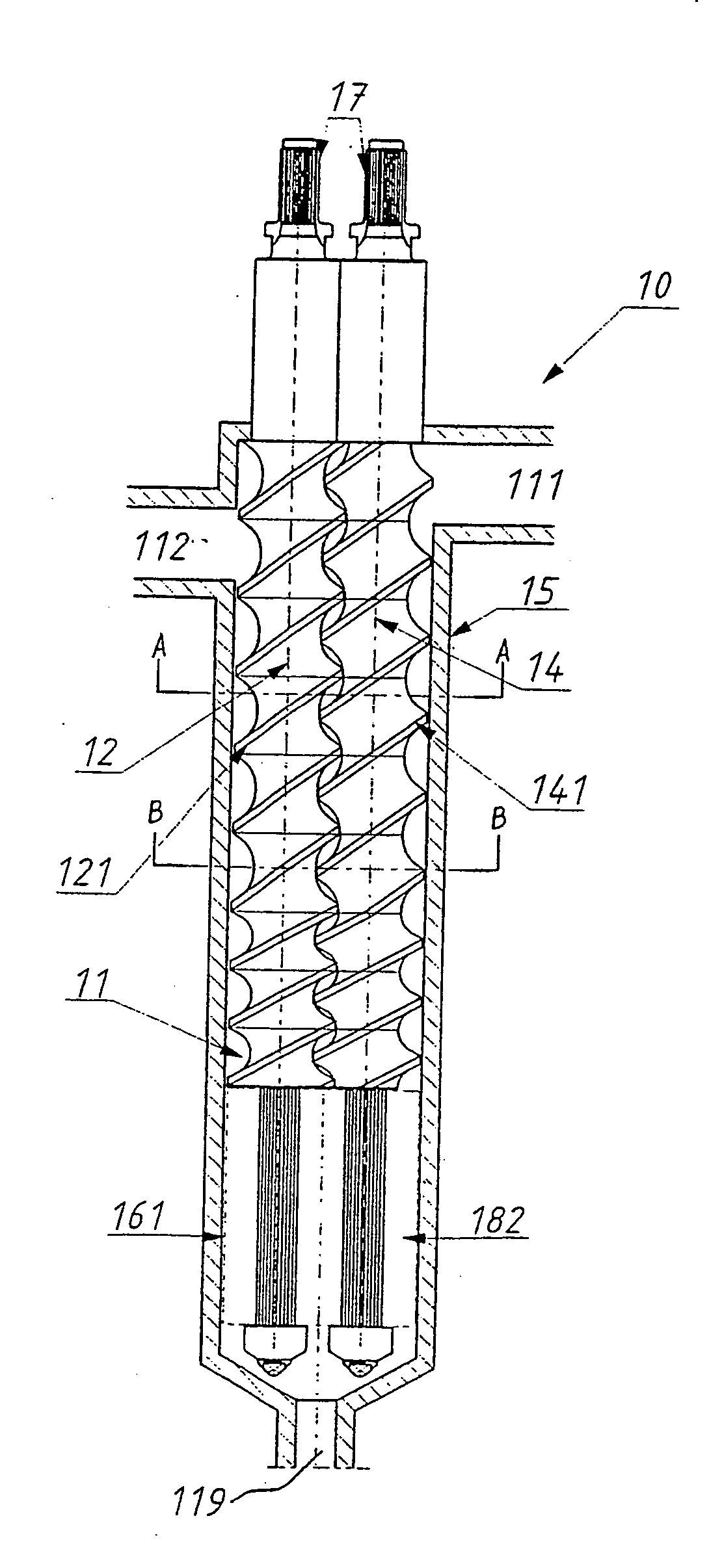

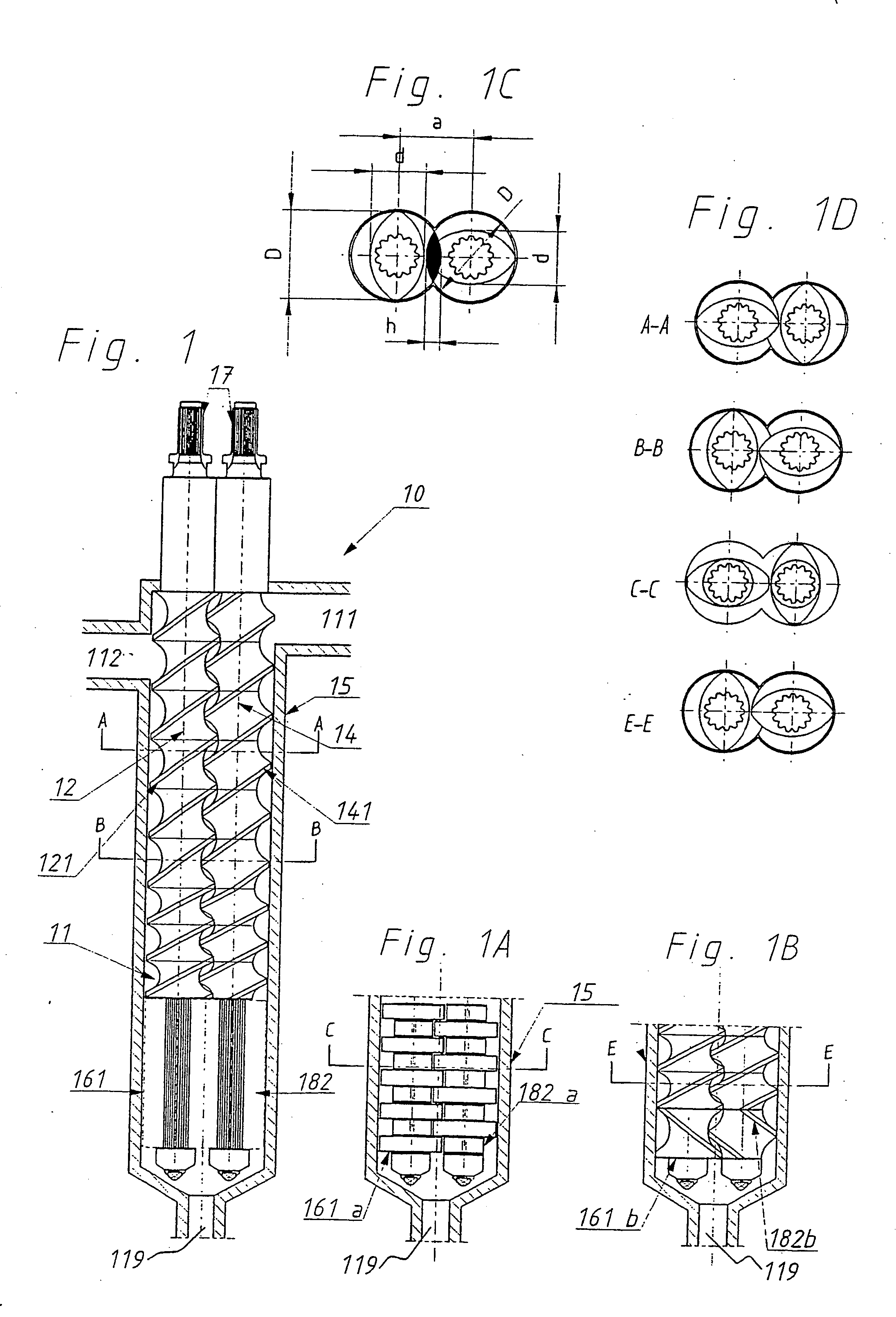

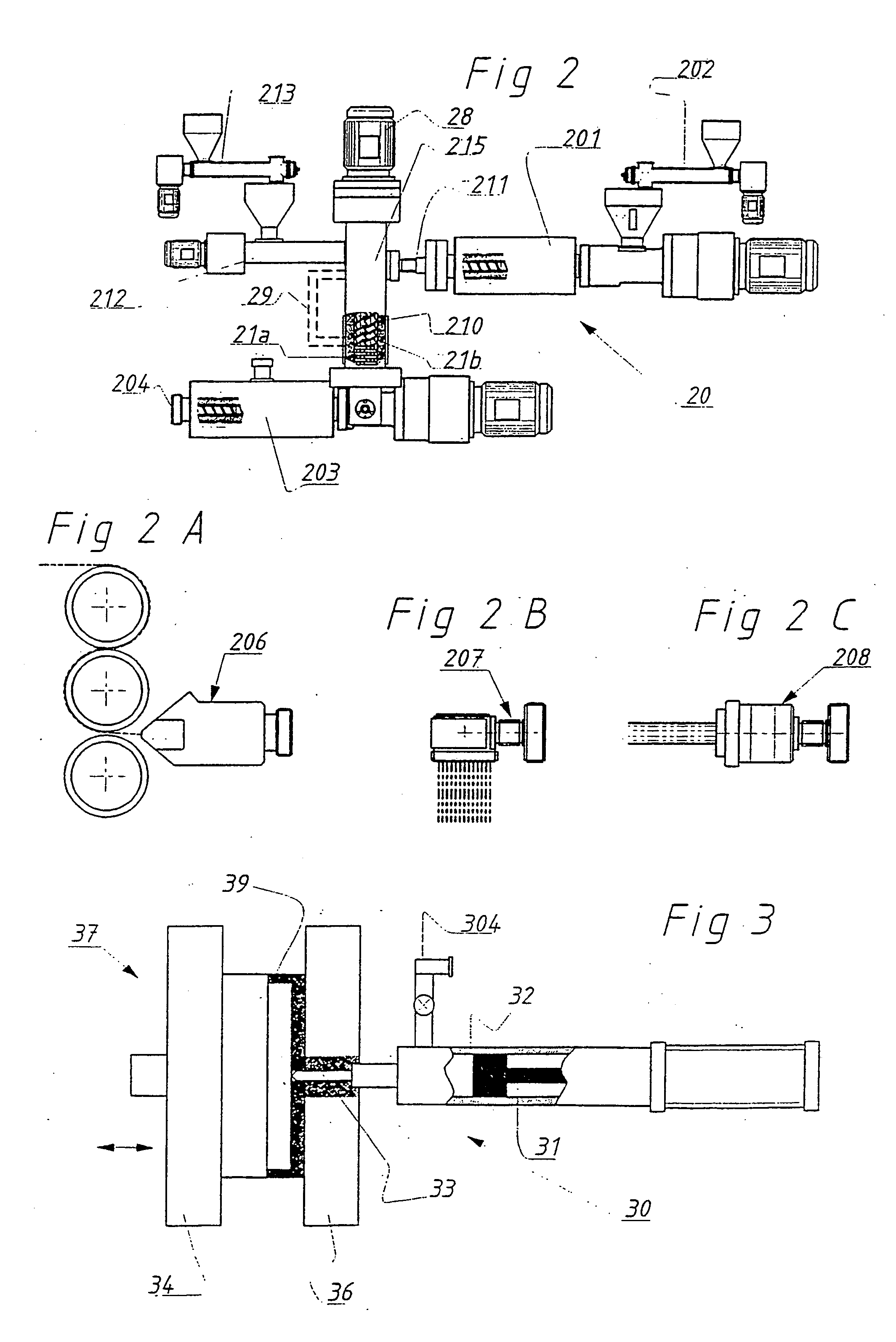

Mixing and kneading device for polymer compositions

InactiveUS20050063246A1Avoid breakageMinimize stressRotary stirring mixersFrozen sweetsEngineeringPolymer composition

A mixing / kneading device (10) for receiving a viscous composition and for admixing at least one additional constituent therewith, said device comprising: an elongated cavity (11) formed by an enclosure (15) and having a length and a diameter, and including a first inlet (112) for introducing said viscous composition into said device, and at least one second inlet (111) for introducing said at least one 10 additional constituent; and an outlet end (119) downstream of said first and said second inlet for connecting said mixing / kneading device with a processor; a pair of elongated rotors (12,14) for co-rotation within said cavity (11); said elongated rotors each having a first and mutually inter-matching flight portion (121;141) closely fitting into said cavity (11) and being adapted to forcingly convey said viscous composition and said at least one additive distributed therein through said cavity (11) towards said outlet end (119) thereof; and at least one non-conveying portion (161;182) downstream of each of said first portions (121;141) adapted to improve said distribution of said at least one additive in said viscous composition.

Owner:PONZIELLI GUISEPPE

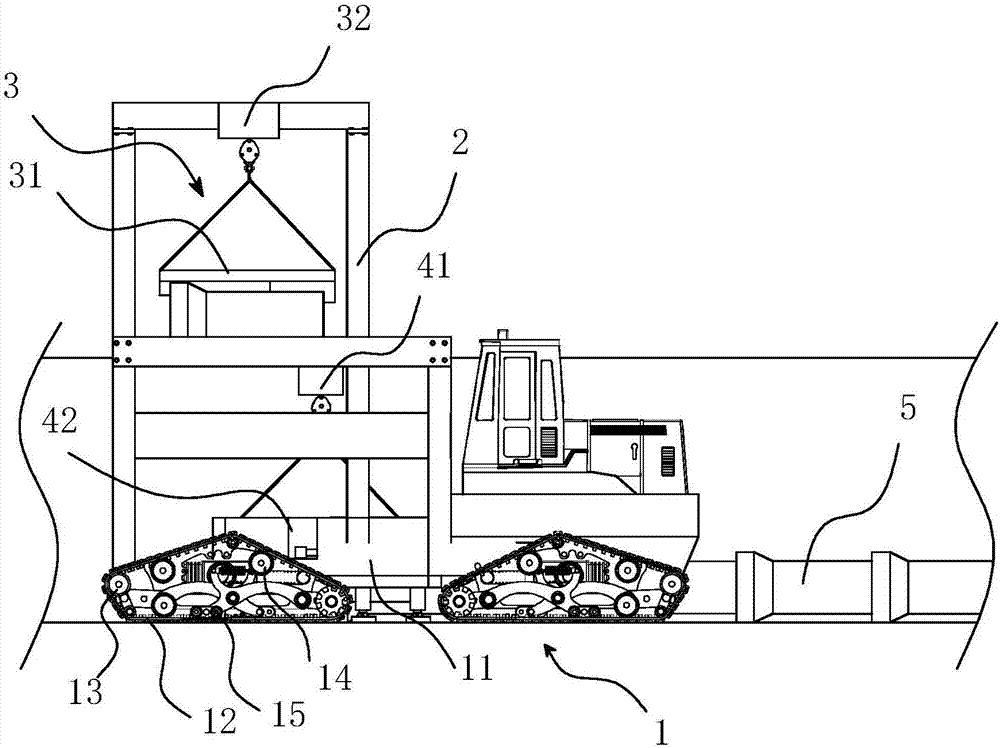

Automatic pipe laying device

ActiveCN107387870AAvoid breakageAvoid offsetPipe laying and repairLoad-engaging elementsMechanical engineeringHydraulic pressure

The invention discloses an automatic pipe laying device which is characterized in that the automatic pipe laying device comprises a positioning pipe laying device and a pipe hoisting device, the positioning pipe laying device comprises a positioning traveling crane, a device support, hydraulic pressure supporting legs and a rear-end positioning mechanism, the hydraulic pressure supporting legs are fixed on two sides of the device support, a rear-end positioning space is formed in the device support and used for covering a pipe body from top to bottom, the rear-end positioning mechanism comprises a rear-end left side pipe, a rear-end right side pipe and a rear-end middle side pipe which are rotatably mounted in the rear-end positioning space, a front-end positioning space is formed in the device support and used for carrying falling pipe bodies, guide plates are obliquely fixed on two sides of the front-end positioning space, a front-end positioning mechanism comprises a front-end left side pipe, a front-end right side pipe, a front-end pushing mechanism, a left side pipe driving mechanism and a right side pipe driving mechanism, the left side pipe driving mechanism is used for unfolding the front-end left side pipe, and the right side pipe driving mechanism is used for unfolding the front-end right side pipe. According to the automatic pipe laying device, rapid positioning can be achieved, abutting joint is convenient and rapid, opening efficiency is improved, and potential safety hazards are avoided.

Owner:黄山云天建筑工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com