Continuous carbon fiber composite material 3D printing device and method with modifying and dipping synchronization function

A 3D printing and composite material technology, applied in the field of carbon composite fiber 3D printing devices, can solve problems such as inability to eject resin and incomplete combination of model fibers and resin, reduce cost and process complexity, and improve 3D printing quality , improve the effect of the combined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

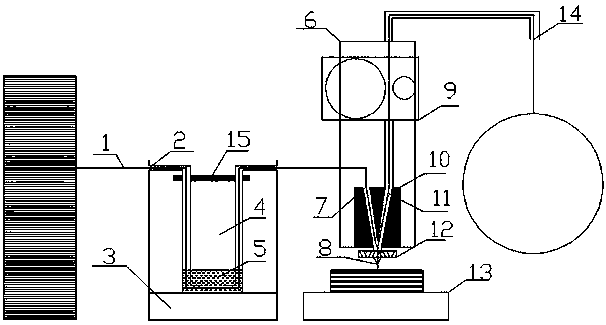

[0029] Example 1: A continuous carbon fiber composite material 3D printing device that can be simultaneously modified and impregnated, such as figure 1 As shown, it includes a synchronous modification container 4, a print head 10, a fiber conduit 2, a resin conduit, a stepping motor 9, a heating block 12 and a copper nozzle 8, and the stepping motor 9 and the print head 10 are fixed on the bracket 6 up and down.

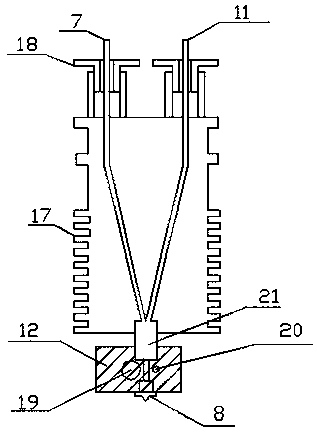

[0030] Among them, such as figure 2 As shown, the print head 10 includes a print head body and two wire feed channels 7, 11 that run through the body longitudinally. There are several layers of horizontal sheet-shaped raised cooling fins 17 . The two wire feeding holes 7 and 11 are left-right symmetrical, the top of the left wire feeding hole 7 is connected to the fiber conduit 2, and the top of the right wire feeding hole 11 is connected to the resin conduit. The resin in the resin conduit is promoted by the stepping motor 9, and the inlet of the right side chann...

Embodiment 2

[0036] Embodiment 2: roughly the same as Embodiment 1, the difference is the configuration of the modified solution, the volume ratio of PLA particles and methylene chloride liquid is 1:8, and the rotation time on the magnetic stirrer is 35min; after printing starts, The heating temperature of the heating block 12 was 225°C.

Embodiment 3

[0037] Embodiment 3: roughly the same as Embodiment 1, the difference is the configuration of the modified solution, the volume ratio of PLA particles and methylene chloride liquid is 1:10, and the rotation time on the magnetic stirrer is 40min; after printing starts, The heating temperature of the heating block 12 was 235°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com