Sludge deep dehydration method

A deep dewatering and sludge technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of high moisture content of mud cake wrapping, high operating cost of sludge treatment, and increased post-treatment cost, etc. effect of chemical treatment, reducing sludge treatment cost and improving sludge treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

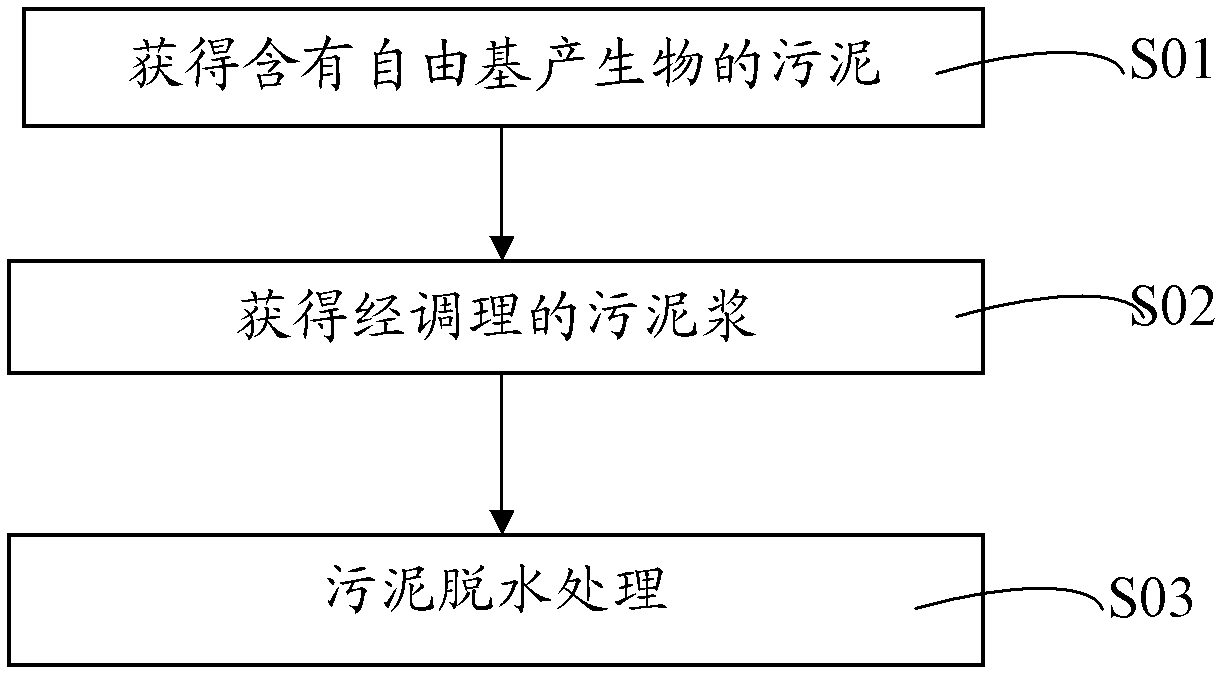

[0050] A method for deep dewatering of sludge, the process steps are as follows:

[0051] S11: Starting from the remaining sludge with an organic matter content of 55.2wt% and a moisture content of 97wt%, add peracetic acid free radical generators of 5wt% on a dry basis to the sludge, and stir thoroughly;

[0052] S12: Add 5 wt% manganese salt transition metal salt on a dry basis to the sludge treated in step S11, and stir for 10 minutes to complete sludge conditioning;

[0053] S13: dehydrating the sludge conditioned in step S12 through plate and frame dehydration.

[0054] After testing, the specific resistance of sludge filtration is changed from the original 1.88×10 13 m / kg down to 1.24×10 11 m / kg, the capillary water absorption time of the sludge decreased from 156.2s of the original sludge to 42.5s, the moisture content of the conditioned sludge was 55.2%, and the organic matter of the sludge cake was 52.4% after dehydration by the plate and frame.

Embodiment 2

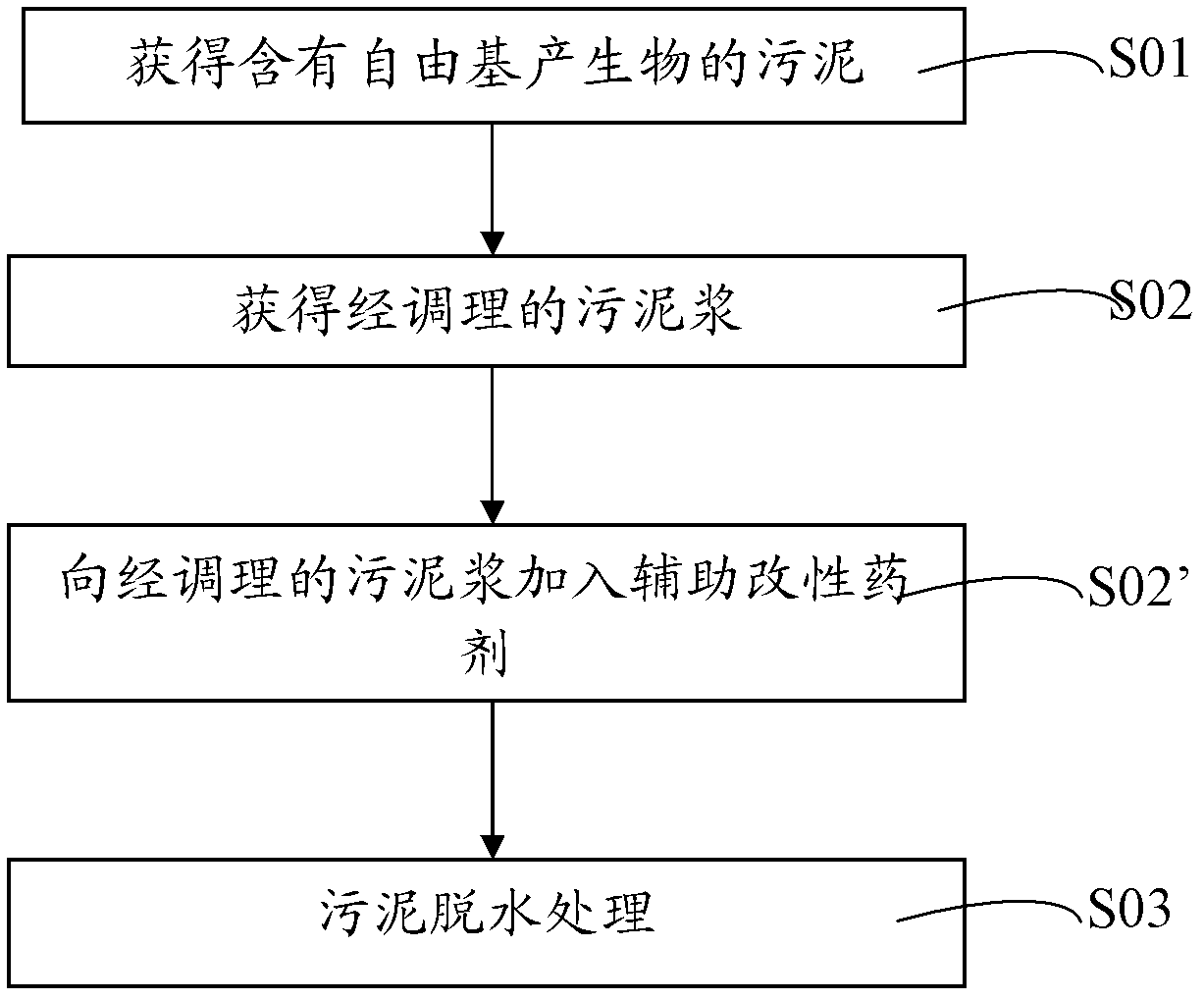

[0056] A method for deep dewatering of sludge, the process steps are as follows:

[0057] S21: Starting from the remaining sludge with an organic matter content of 55.2wt% and a water content of 97.1wt%, add hydrogen peroxide and peroxodisulfate with a mass ratio of 1:1 to the sludge at 5wt% on a dry basis Mixture free radical generator, stir well;

[0058] S22: Add 10wt% cobalt salt transition metal salt on a dry basis to the sludge treated in step S21, and after stirring for 10 minutes, add 10wt% slag powder with a particle size ≤ 1.0mm on a dry basis Auxiliary modifier, stirring to fully complete sludge conditioning

[0059] S23: dehydrating the sludge conditioned in step S22 through plate and frame dehydration.

[0060] After testing, the specific resistance of sludge filtration is changed from the original 1.88×10 13 m / kg down to 3.12×10 10 m / kg, the capillary water absorption time of the sludge decreased from 156.2s of the original sludge to 30.6s. After the conditio...

Embodiment 3

[0062] S31: Starting from the centrifuge dewatered cake with an organic content of 50.6wt% and a water content of 82.2wt%, adding water to slurry it to a water content of 93wt%, and then adding 10wt% of the sludge on a dry basis to the sludge Peroxobisulfate free radical generator, fully stirred;

[0063] S32: Add 10%wt aluminum salt transition metal salt on a dry basis to the sludge treated in step S31, and after stirring for 15min, add 5wt% isomeric alcohol polyoxyethylene polyoxypropylene ether to assist in improving Active agent, stirring to fully complete the sludge conditioning;

[0064] S33: dehydrating the sludge conditioned in step S32 through plate and frame.

[0065] After testing, the sludge filtration specific resistance is 2.82×10 when the slurry water content is 93%. 13 m / kg down to 6.5×10 11 m / kg, the capillary water absorption time of the sludge decreased from 194.5s to 34.5s when the slurry moisture content was 93%, the conditioned sludge was dehydrated by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com