Patents

Literature

856results about How to "Increase squeeze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

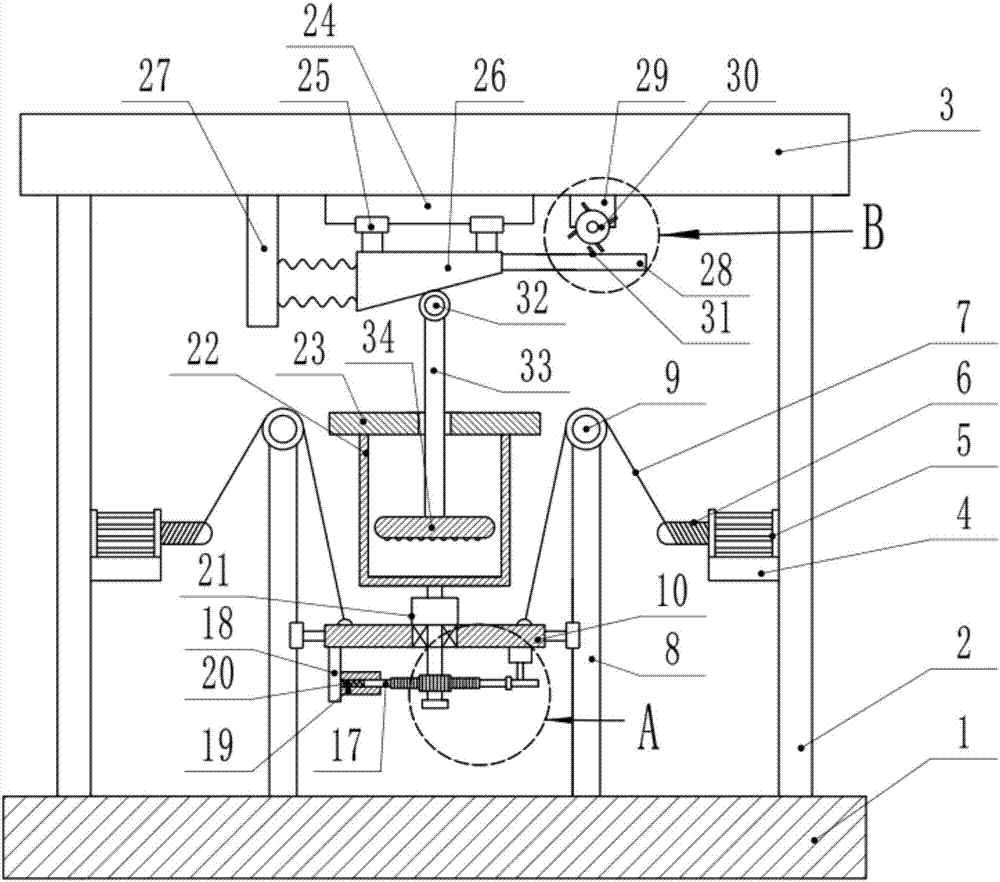

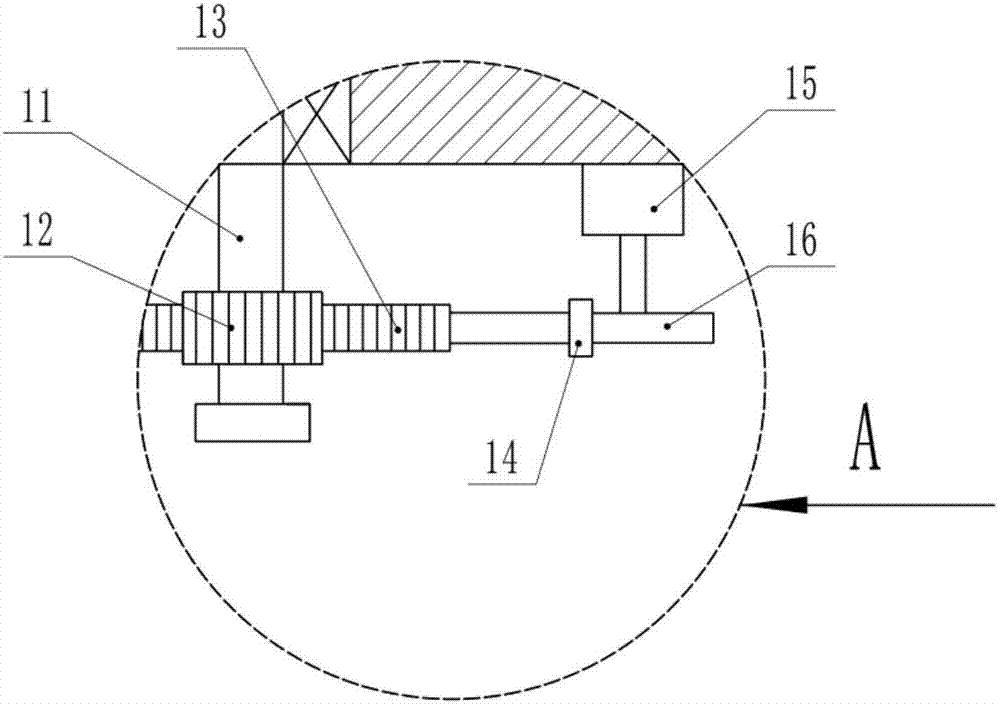

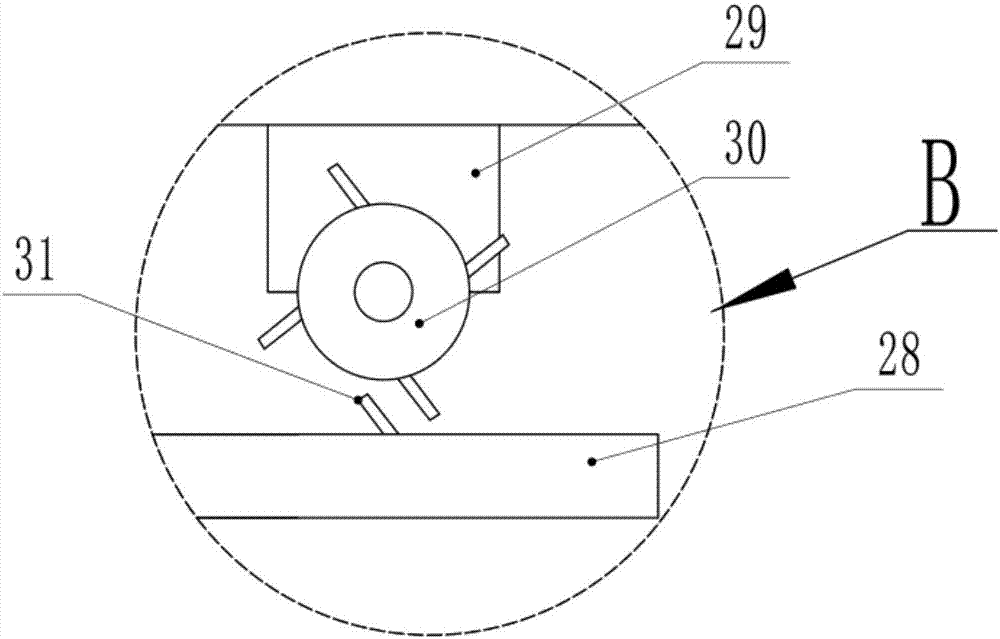

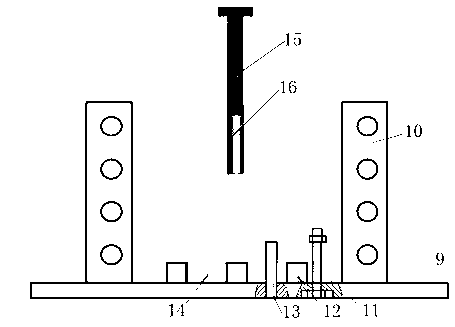

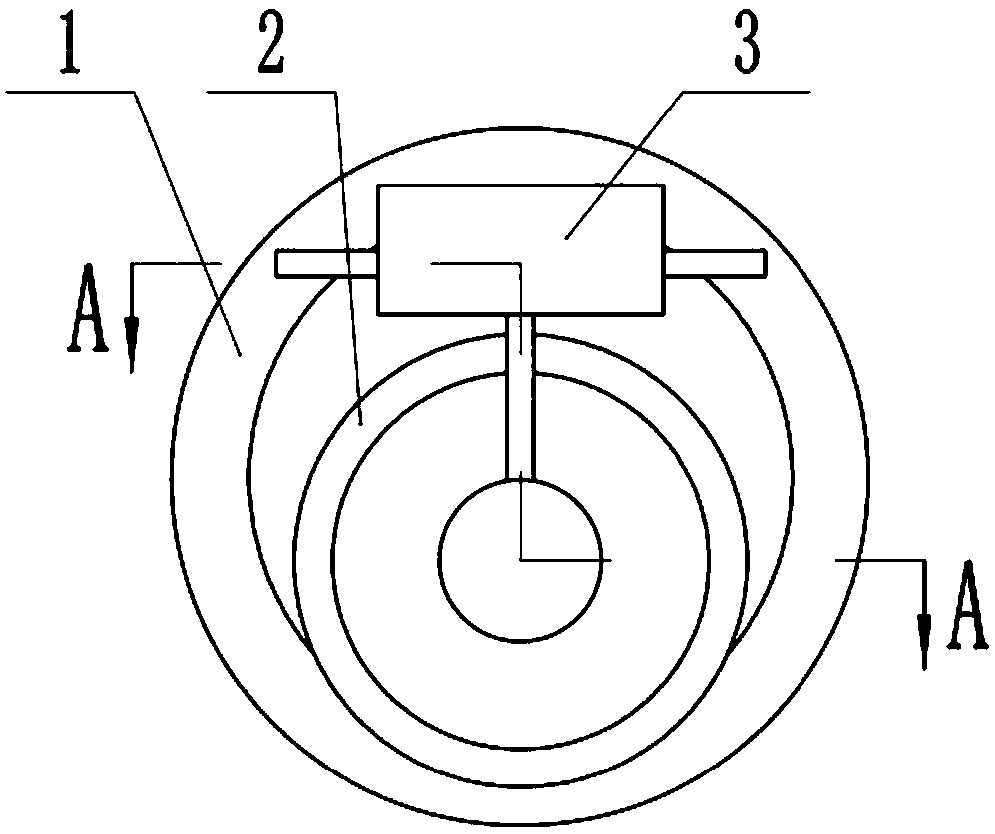

Traditional Chinese medicinal material fine grinding device for pharmacy

The invention discloses a fine grinding device for Chinese medicinal materials used in a pharmacy, which comprises a base, a lifting motor, a rope winding shaft, a lifting slide plate, a first driving motor, a cam, a grinding bucket, a wedge block and a second driving motor. The lifting motor outputs A rope winding shaft is fixedly connected to the shaft, and a rotating shaft is installed in the center of the lifting slide, and a grinding bucket is connected to the upper end of the rotating shaft; several groups of sliders are slidably installed on the slide rail, and a The wedge-shaped block, the output shaft of the second driving motor is forward and is fixedly connected with a toggle wheel block to cooperate with the toggle wheel. Adjust the distance between the grinding head and the bottom of the grinding bucket through the lifting motor to adjust the size of the extrusion force, so as to obtain Chinese herbal medicine powder with different grinding degrees; through the cooperation between the wedge block and the roller, the grinding rod drives the grinding head down intermittently Movement, so as to increase the extrusion force between the grinding head and the Chinese herbal medicine, so as to make the grinding more fully and improve the grinding effect.

Owner:袁润栋

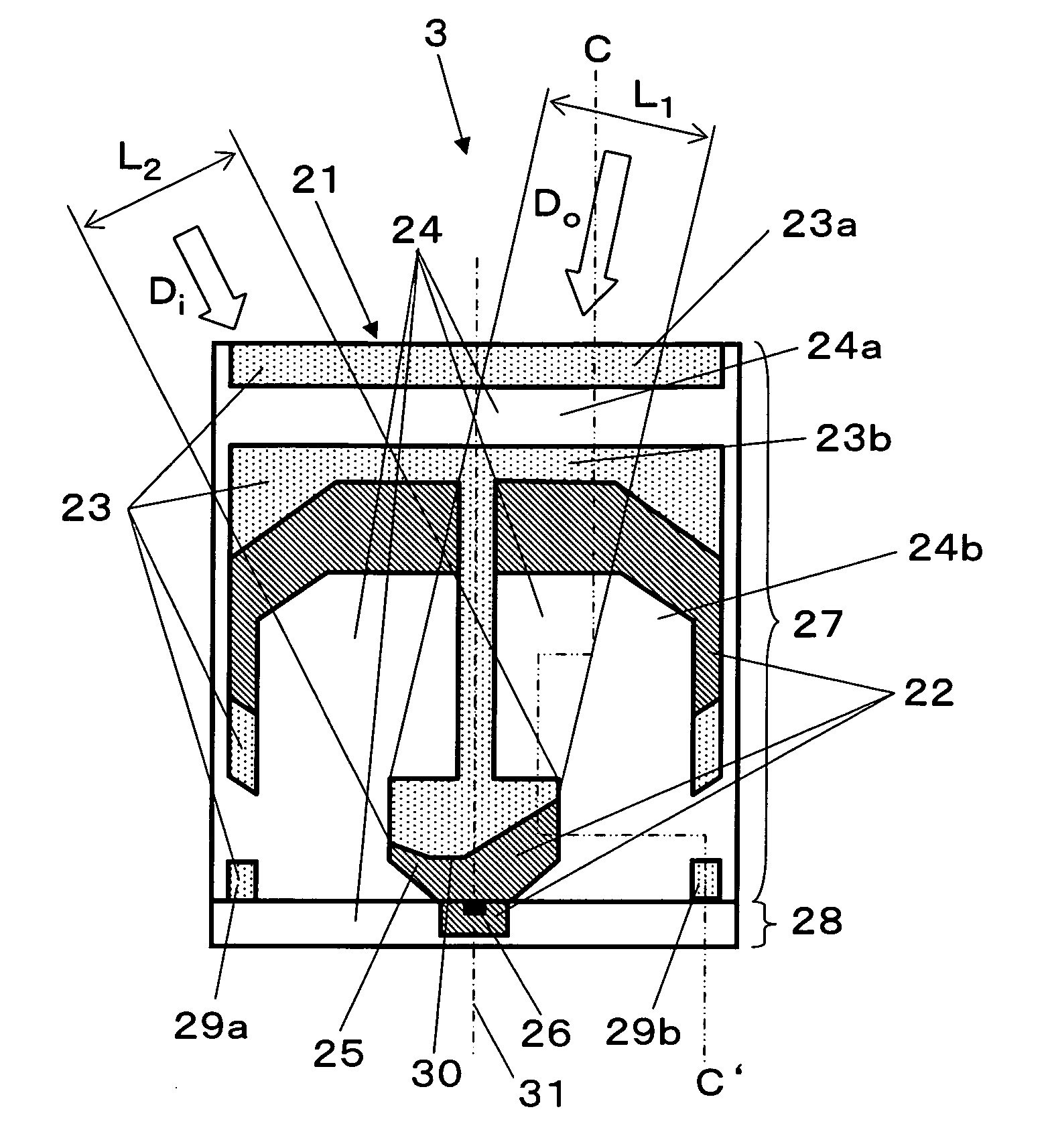

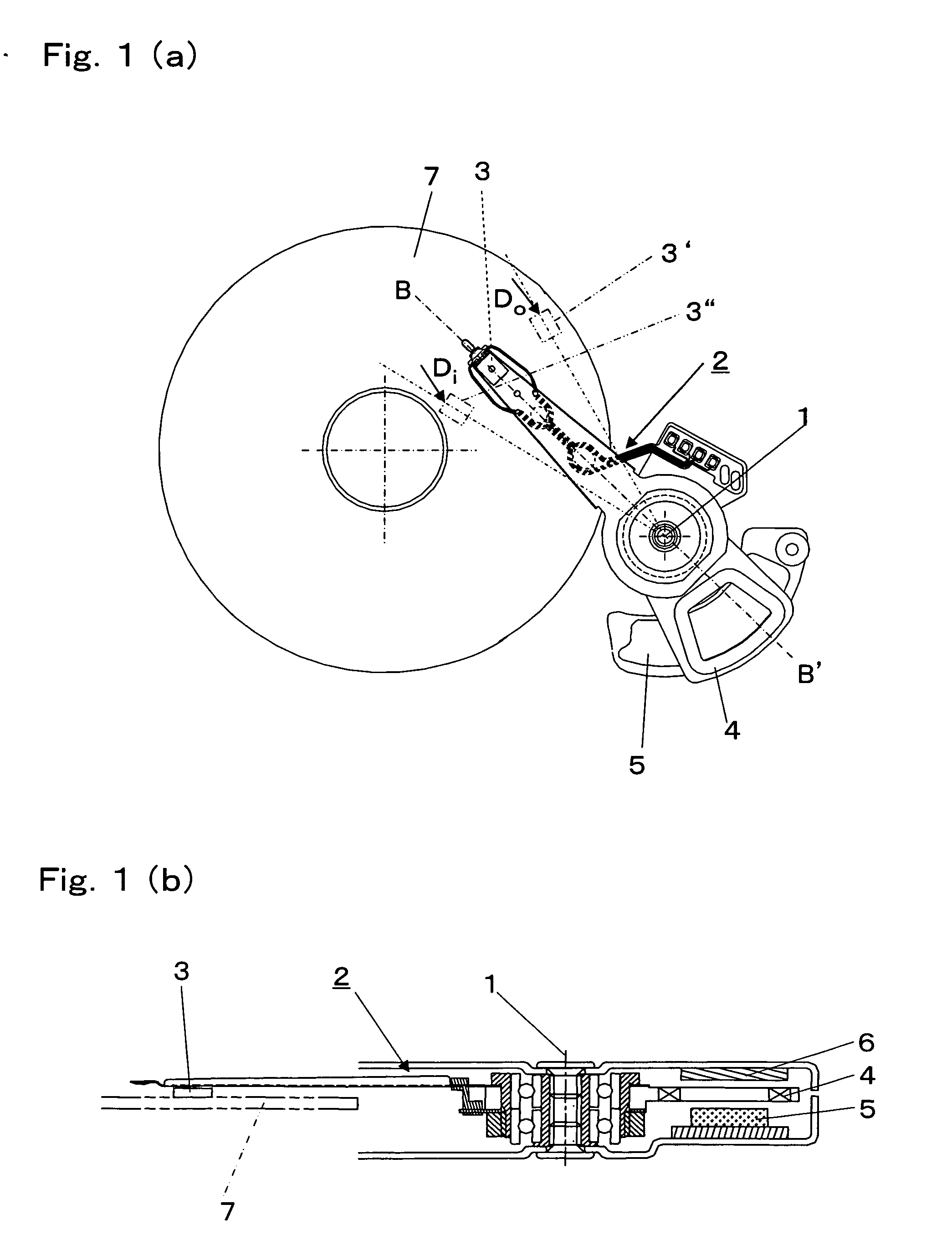

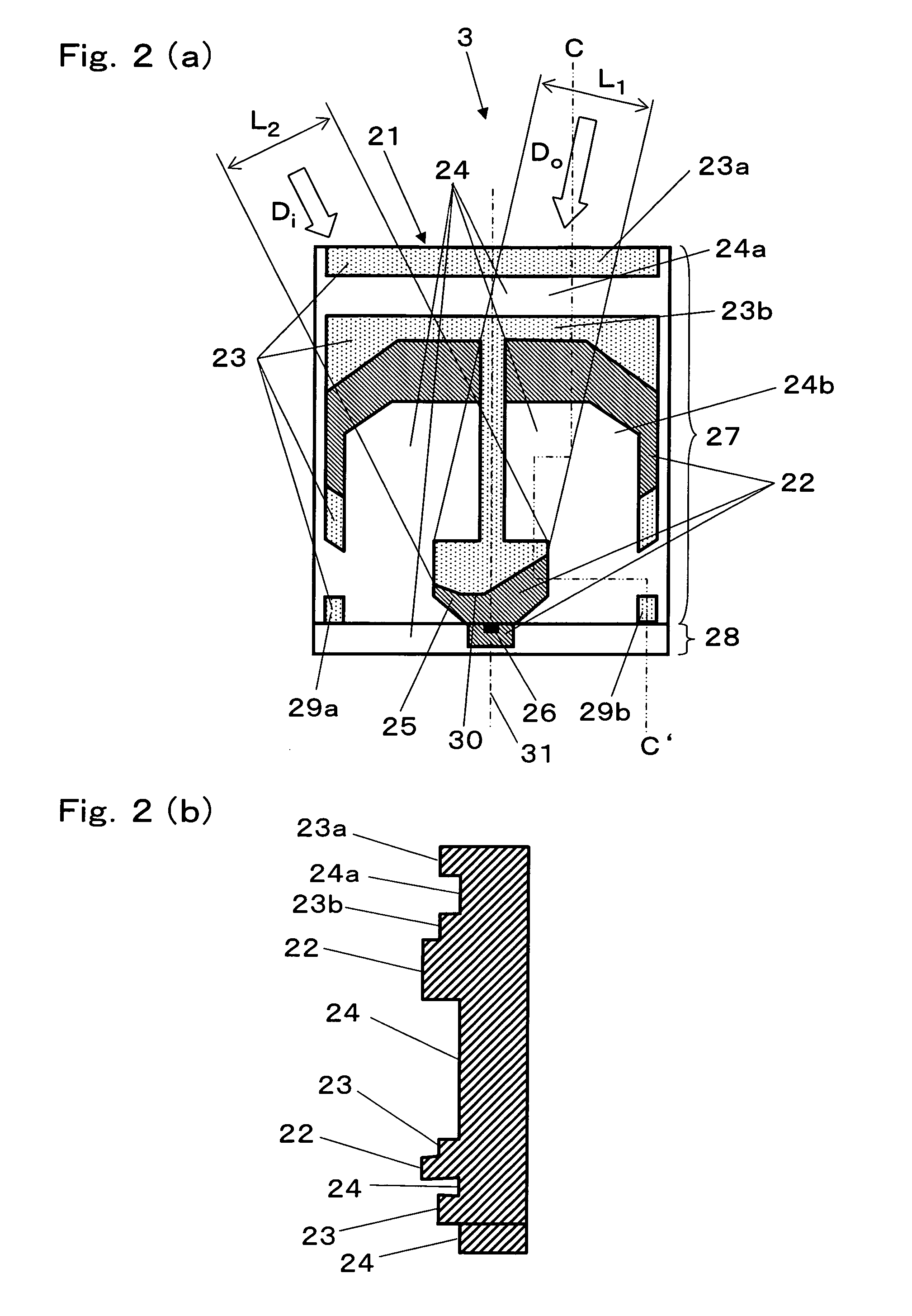

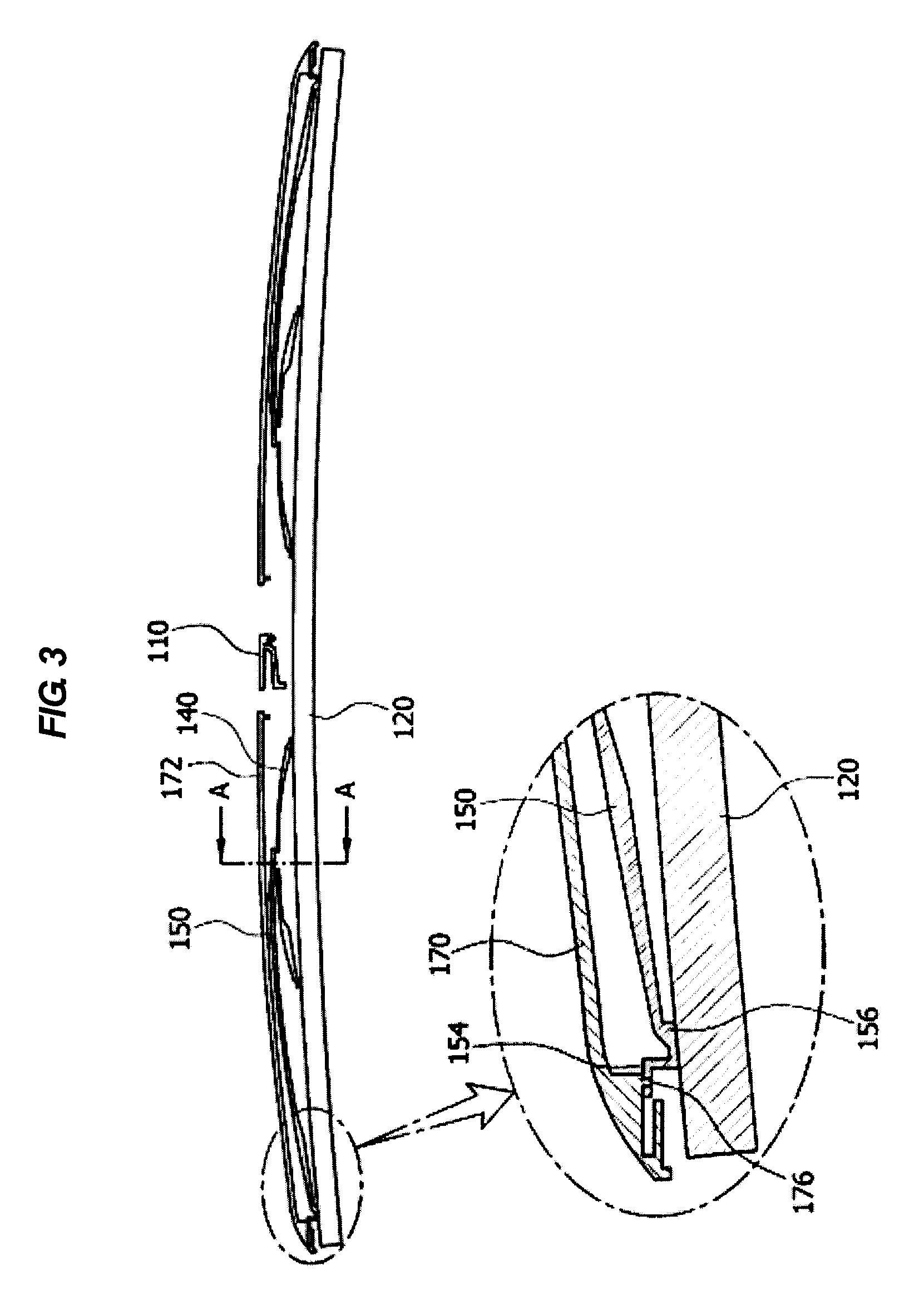

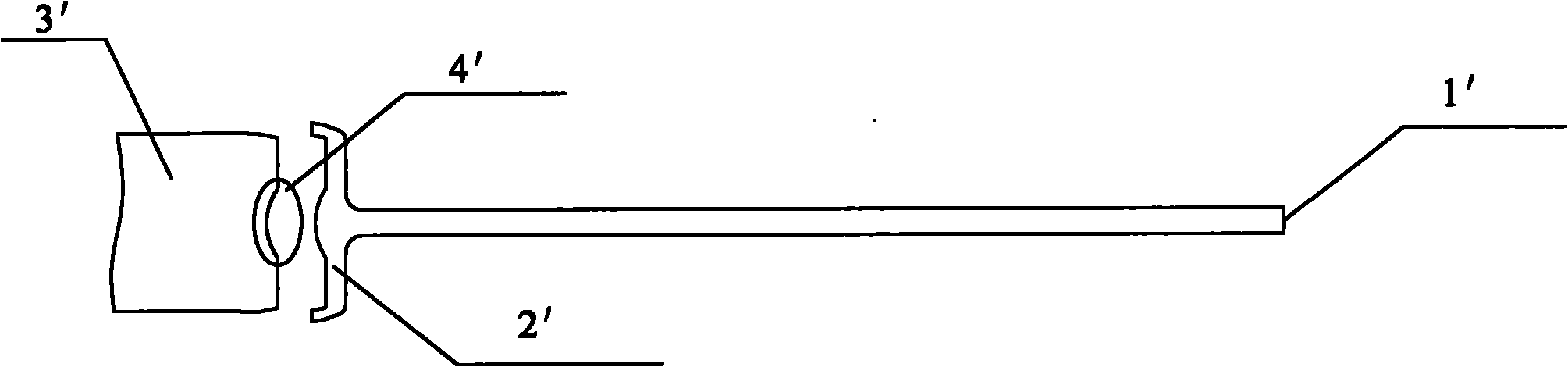

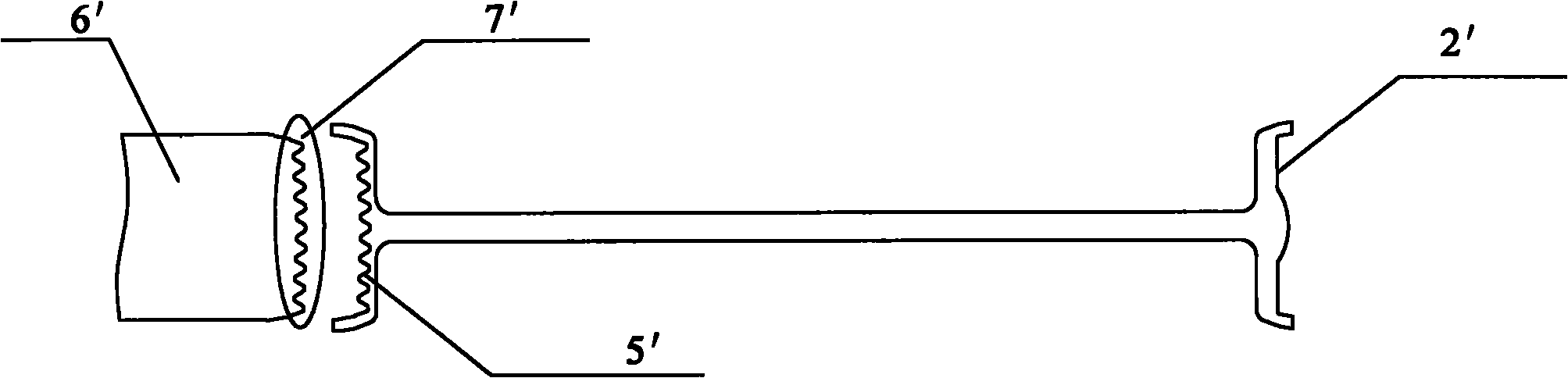

Head slider and disk drive with the same

InactiveUS20050105216A1Suppress mutationIncrease squeezeRecord information storageFluid-dynamic spacing of headsPositive pressureEngineering

A head slider is designed to prevent collision against a surface of a disk due to an external impact and the like while a device is in use to avoid damages on an air bearing surface (“ABS”) of the head slider and the surface the disk. This is achieved by a structure of the head slider which produces a large positive pressure on a positive dynamic pressure generating section when the head slider comes close to the disk. More specifically, the ABS of the head slider comprises three surfaces of different positional heights, and the positive dynamic pressure generating section having a height equivalent to a mid level surface of the second highest position is provided on a portion of the head slider made of a material of high brittleness at each of locations near both side edges lateral to a tracking width of a magnetic head. In addition, a head mounting pad bearing the magnetic head is so configured that a boundary between a high level surface in the highest position and a mid level surface is asymmetrical with respect to the lateral center of the head slider in a direction of the tracking width of the magnetic head.

Owner:WESTERN DIGITAL TECH INC

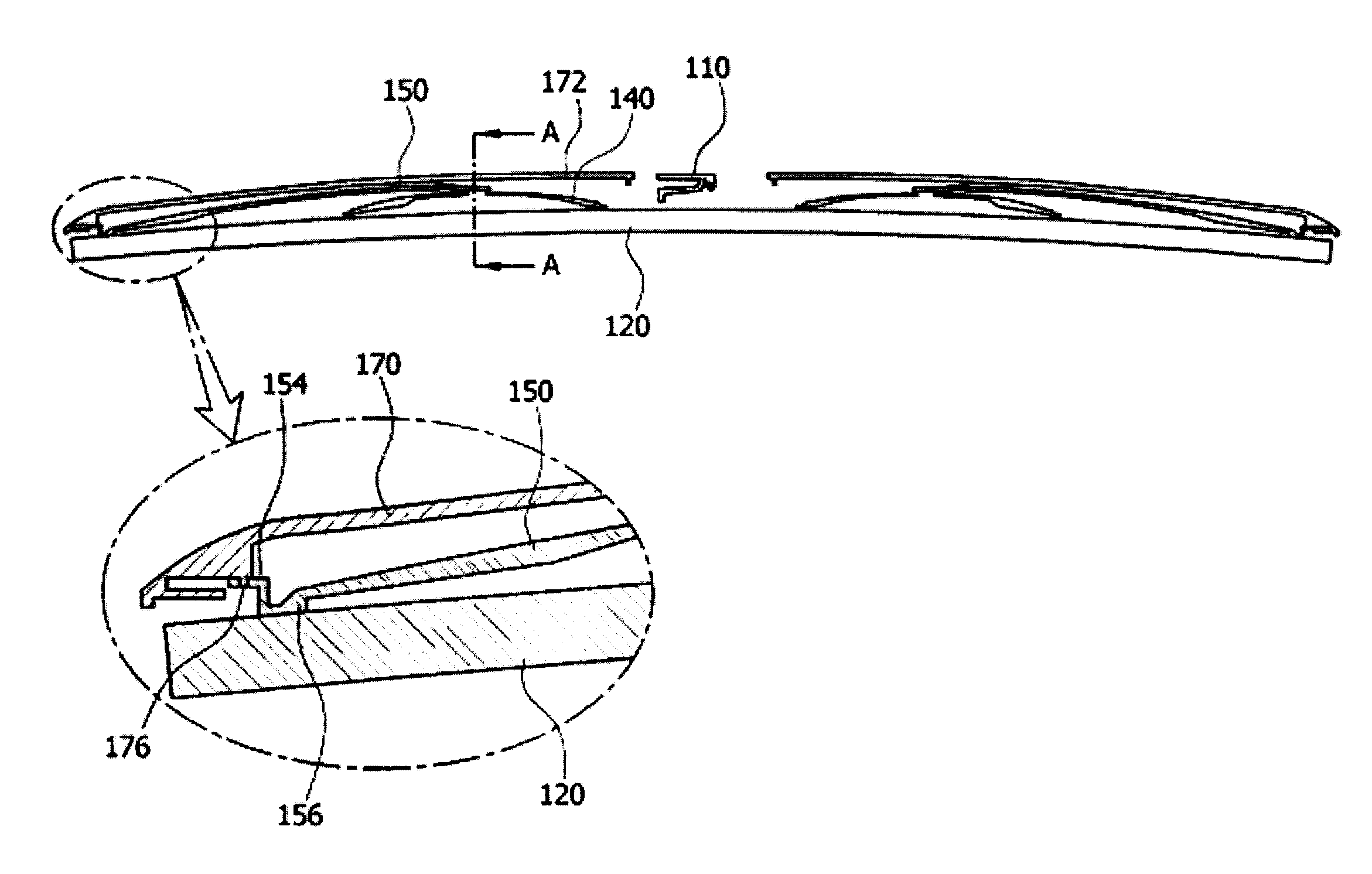

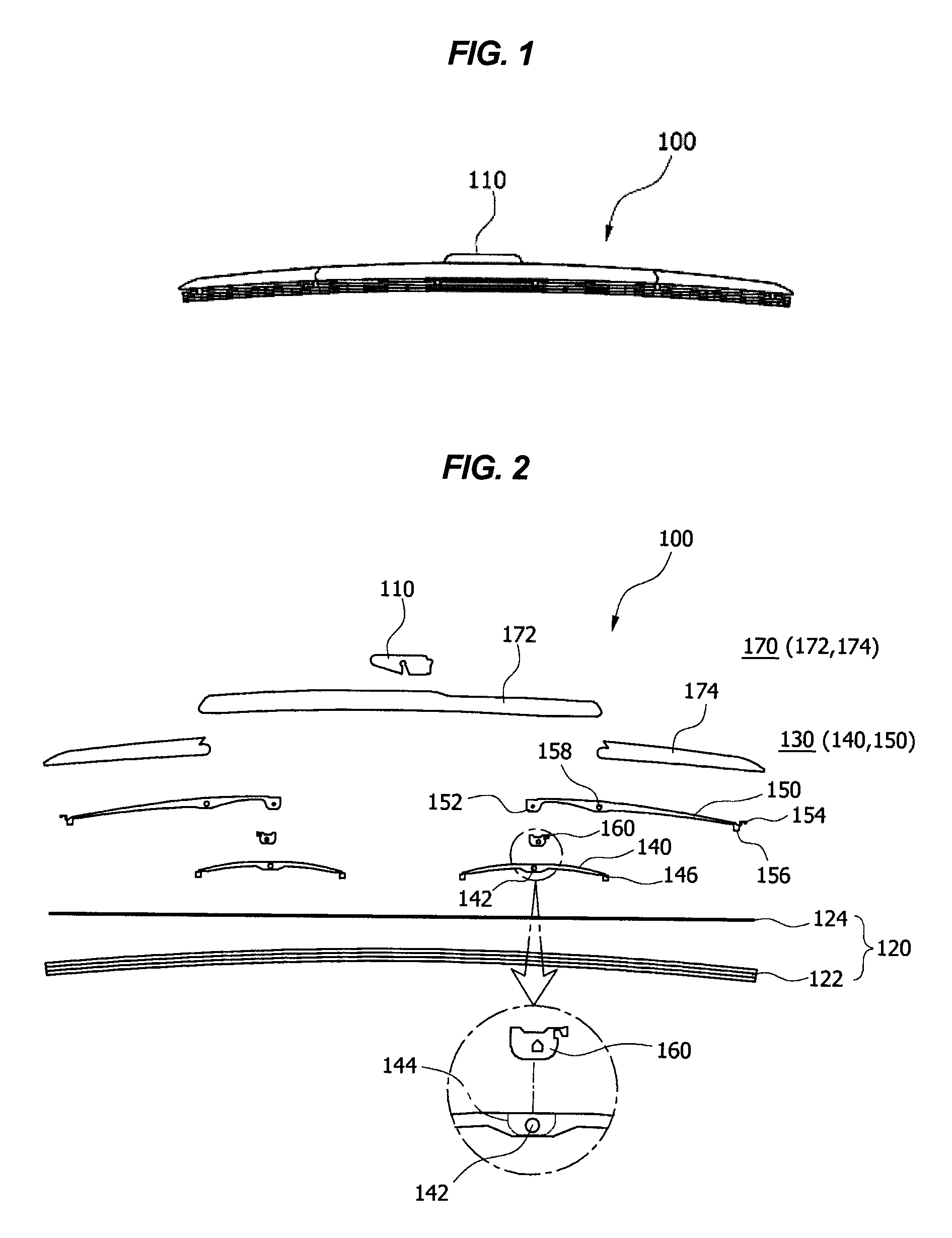

Wiper Blade

ActiveUS20100139027A1Increase squeezeNot chatterWindow cleanersVehicle cleaningHinge angleEngineering

A wiper blade includes a wiper strip for contacting a windshield glass of a vehicle, a lever assembly supporting the wiper strip to squeeze onto the windshield glass, and a cover member containing the lever assembly, wherein the lever assembly includes, a pair of first levers, each with both ends engaged with and point-supporting the wiper strip to form an engaging portion on the wiper strip respectively, and a pair of the second levers, each with one end hinge-coupled to a corresponding one of the first levers and with the other end coupled with the cover member and the wiper strip.

Owner:HYUNDAI MOTOR CO LTD +2

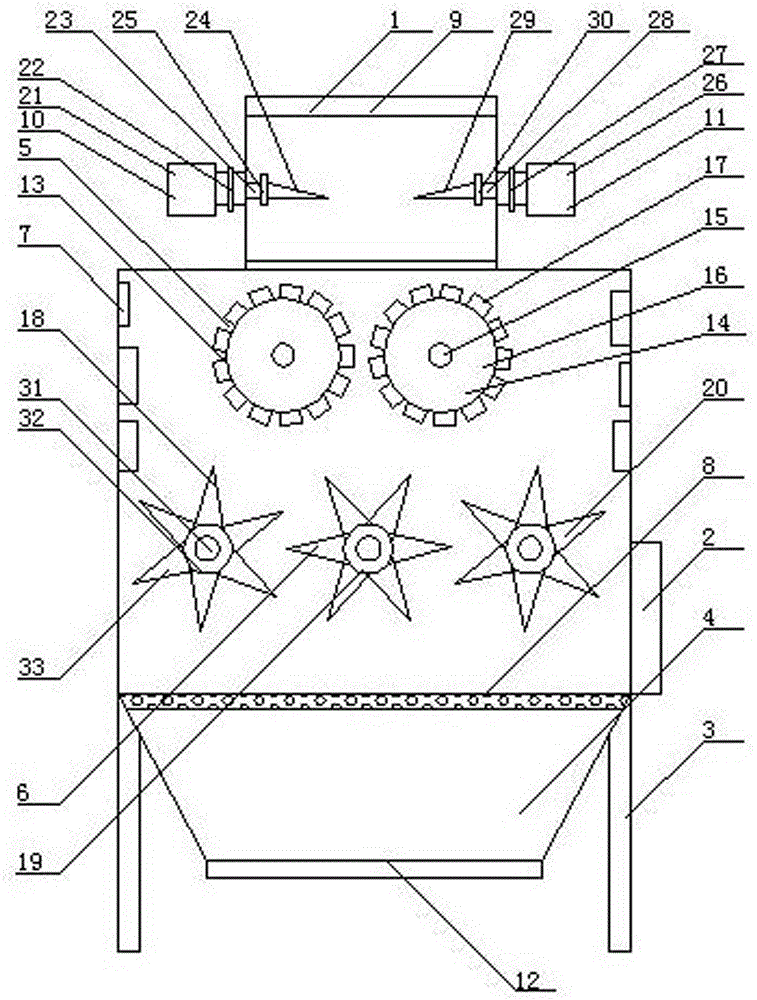

Biomass fuel crushing device

InactiveCN106732996AIncrease squeezePromote fragmentationGrain treatmentsPulp and paper industryCrusher

The invention discloses a biomass fuel crushing device which comprises a machine body; a feeding mechanism is arranged at the top end of the machine body; a discharge door is arranged at the lower end of the right side of the machine body; a supporting leg is arranged at each of the left side and the right side of the bottom end of the machine body; the bottom end of the machine body is equipped with a tapered discharge bin; a double-roller crusher is arranged at the upper end inside the machine body; a combined type crusher is arranged at the lower end inside the machine body; the upper ends of the left side and the right side inside the machine body are each provided with a plurality of irregular baffle plates; and the bottom end inside the machine body is equipped with a stainless steel filter screen. The biomass fuel crushing device disclosed by the invention solves the problems that biomass fuel crushing equipment in the prior art is low in crushing efficiency and is low in crushing speed. The biomass fuel crushing device adopts a multi-stage type crushing design, performs cutting, extruding and crushing and pulverizing treatment on biomass fuels, is high in crushing speed, is good in crushing effect, and is very convenient to charge and discharge.

Owner:南京恒誉名翔科技有限公司

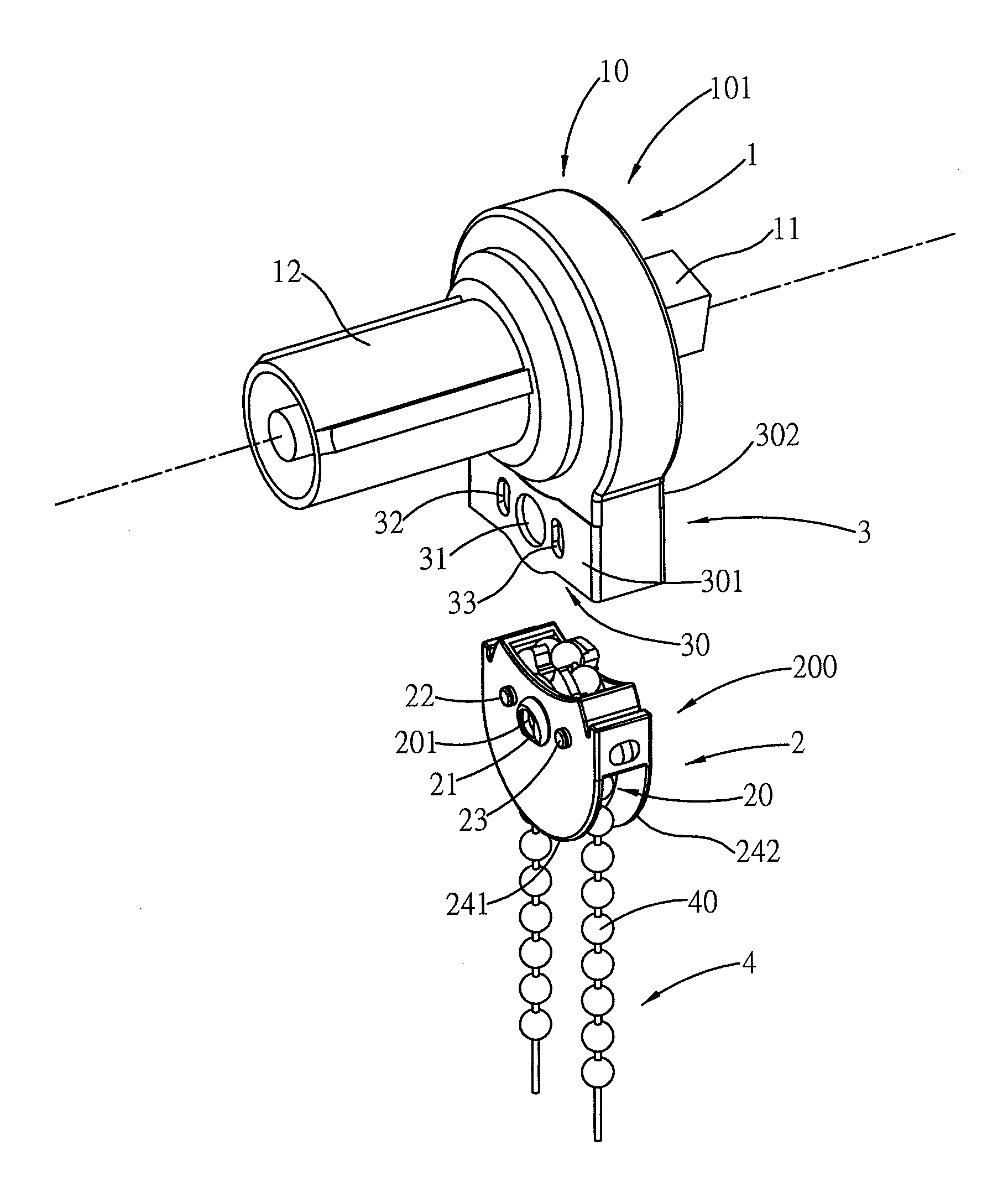

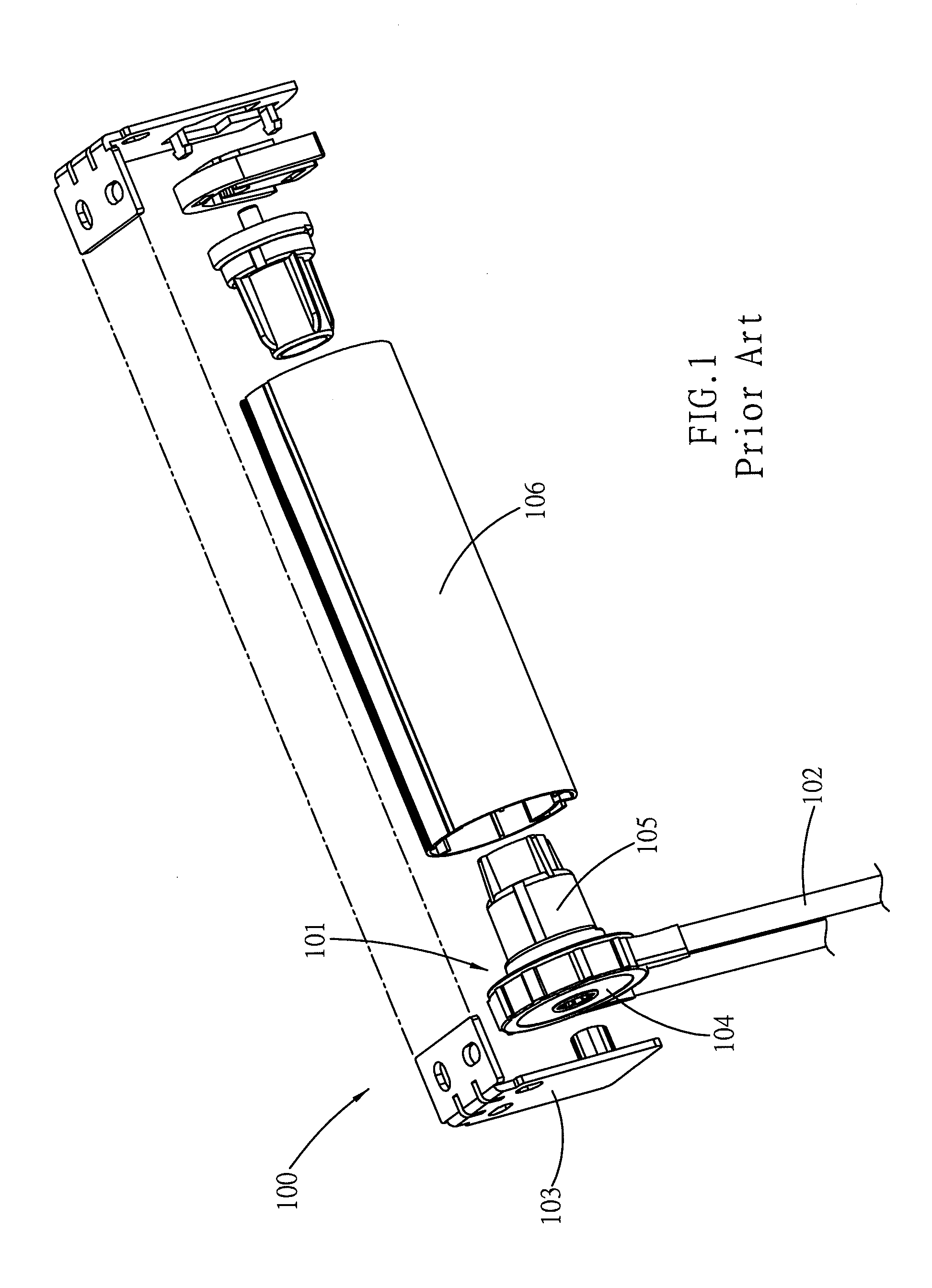

Safety curtain structure

InactiveUS20120017399A1Good effectIncrease squeezeRopes and cables for vehicles/pulleyLight protection screensEngineeringMechanical engineering

In a safety curtain structure, an assembly of a pulling string and a curtain brake mechanism can be separated easily when a force is applied onto the curtain pulling string by accident, such that a binding force of the pulling string can be released quickly to assure the safety for protecting children's limbs at a certain height, and allowing the pulling string to fully apply a force to a brake mechanism to satisfy the requirement of moving or stopping a reasonable load when a curtain is rolled normally.

Owner:HUANG HSIEN TE

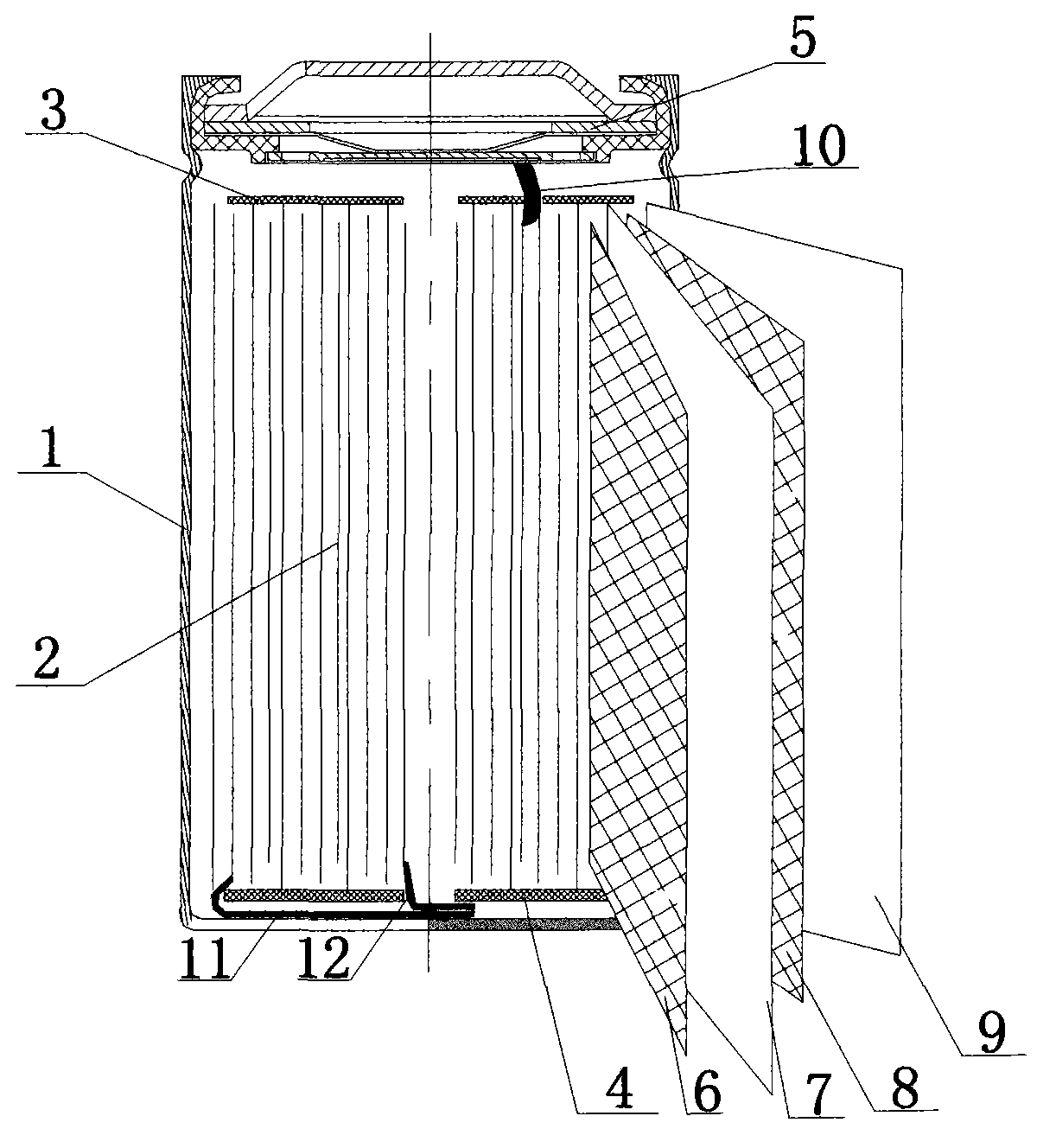

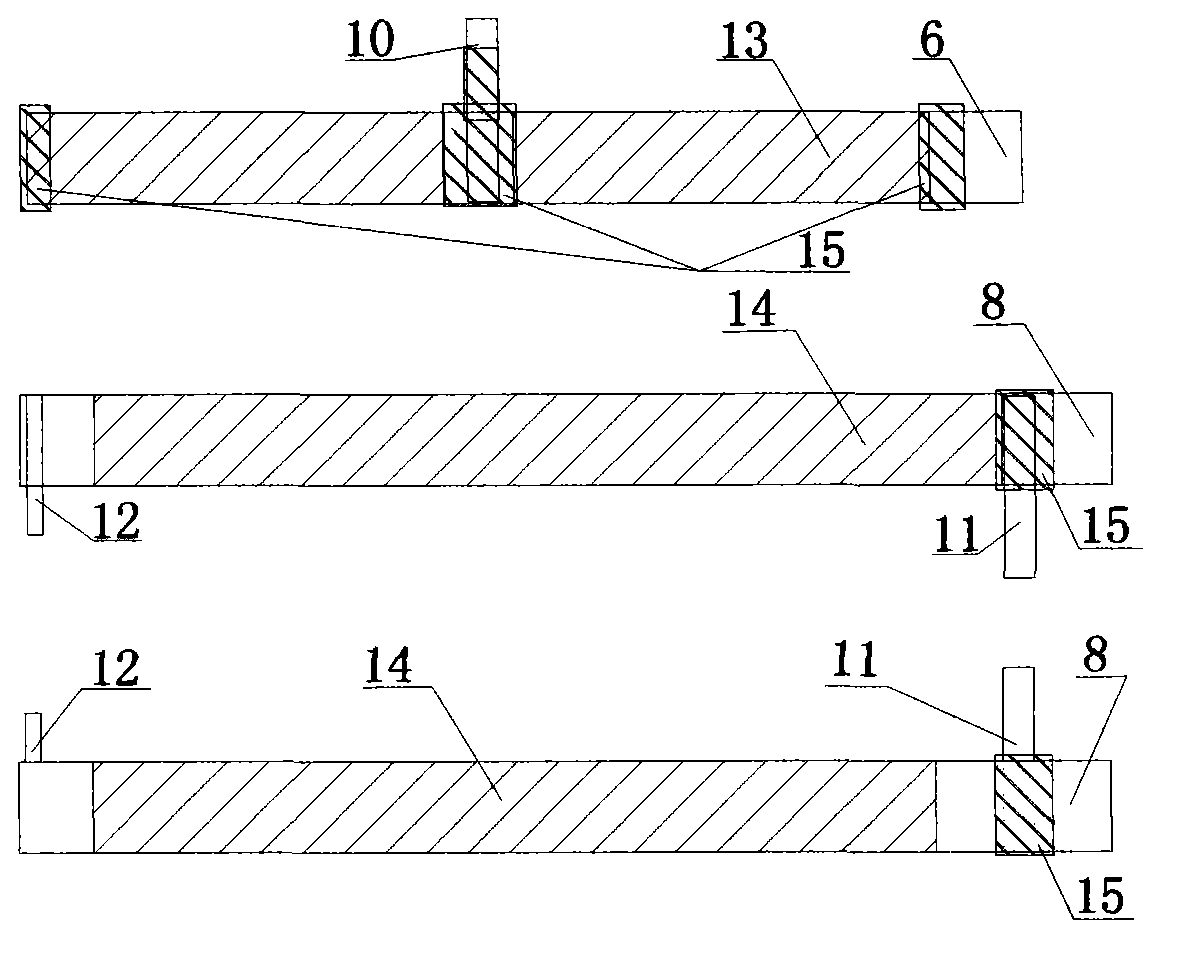

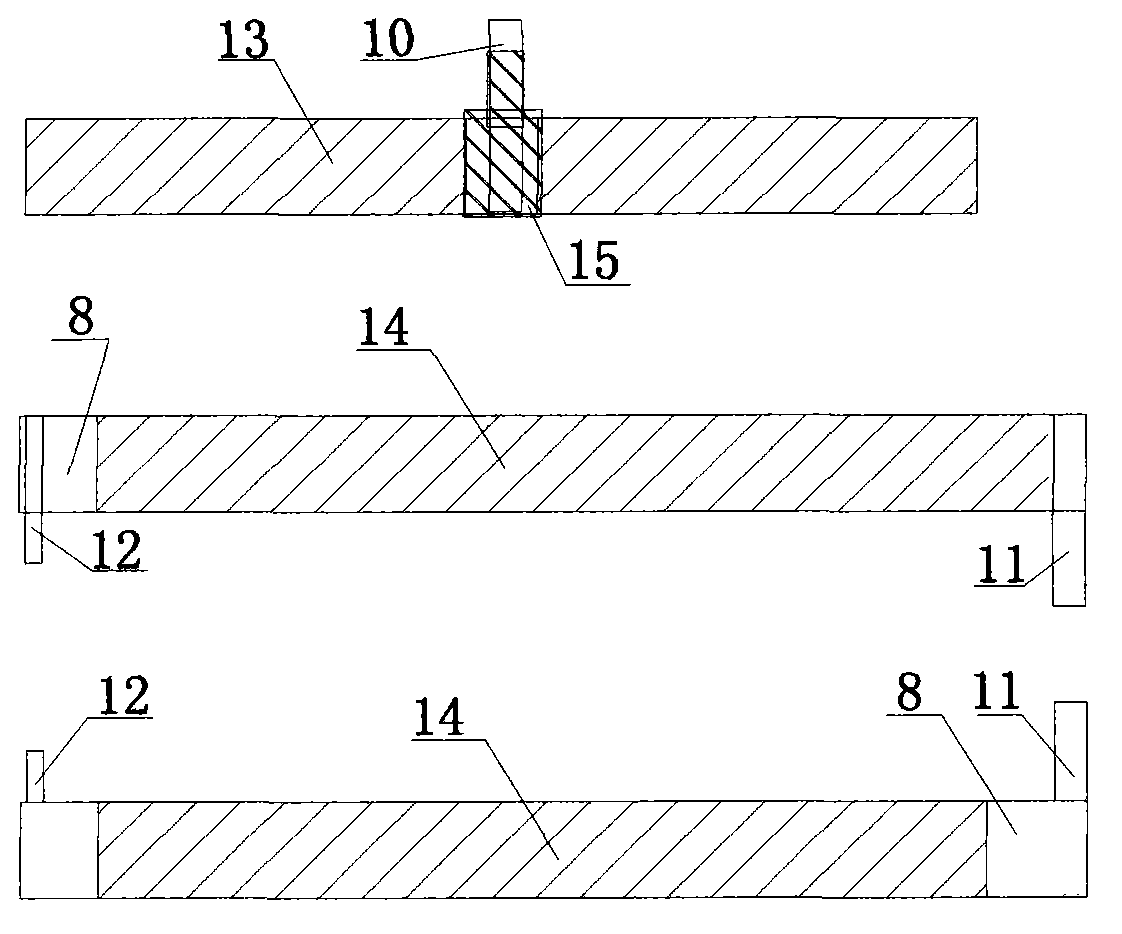

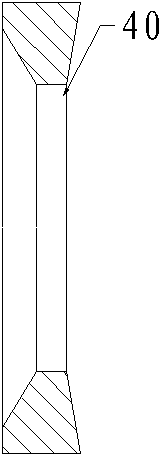

Lithium nickel cobalt manganate cylindrical high-rate battery and preparation method thereof

ActiveCN103413975AIncrease productivityImprove overcharge resistanceFinal product manufactureCell component detailsHigh rateAdhesive

The invention belongs to a high-safety lithium nickel cobalt manganate cylindrical high-rate battery and a preparation method thereof. The battery comprises a nickel-plated steel case and a lithium ion battery cell in the nickel-plated steel case, wherein an upper insulating strip and a lower insulating strip are respectively arranged at the upper part and the lower part of the lithium ion battery cell; a cap is arranged on a mechanical seal port in the upper part of the nickel-plated steel case; the lithium ion battery cell comprises a positive plate, a first diaphragm, a negative plate and a second diaphragm which are superposed in sequence and reeled; by setting the positions of a positive pole leading-out end and a negative pole leading-out end and setting the sticking position and manner of a high-temperature adhesive tape, the battery production efficiency can be effectively improved and defects in a processing procedure can be reduced; as the first diaphragm and the second diaphragm are used in combination and electrolytes containing special additives are selected and used to coordinate with one another, the destructive safety performance test of the battery is 100% qualified. The battery has the advantages that the assembly is simple, the yield is high, the cycle performance is good, and the safety performance of resistance to overcharge, short circuit, needling, squeezing, impact and the like can be improved.

Owner:河南比得力高新能源科技有限公司

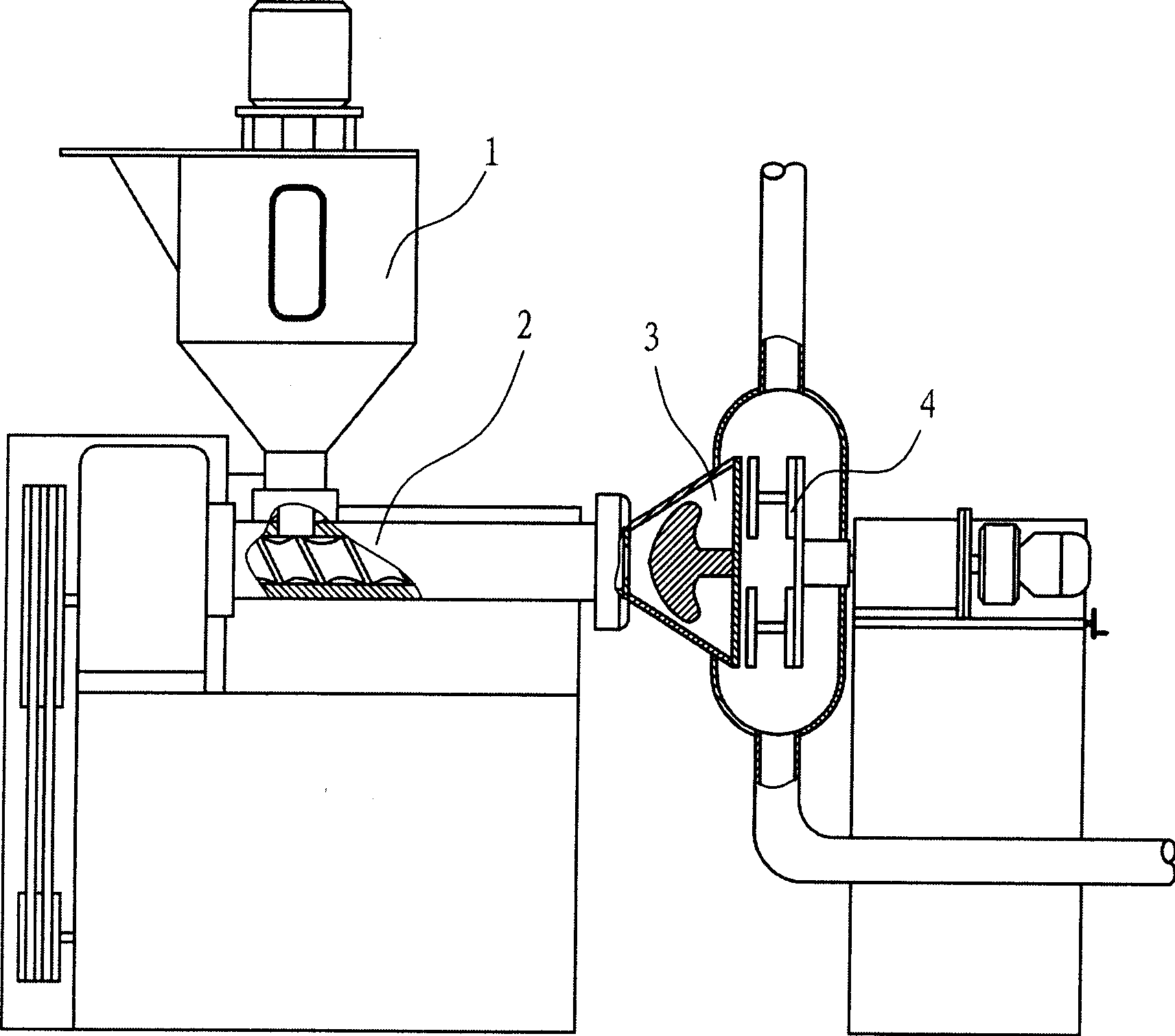

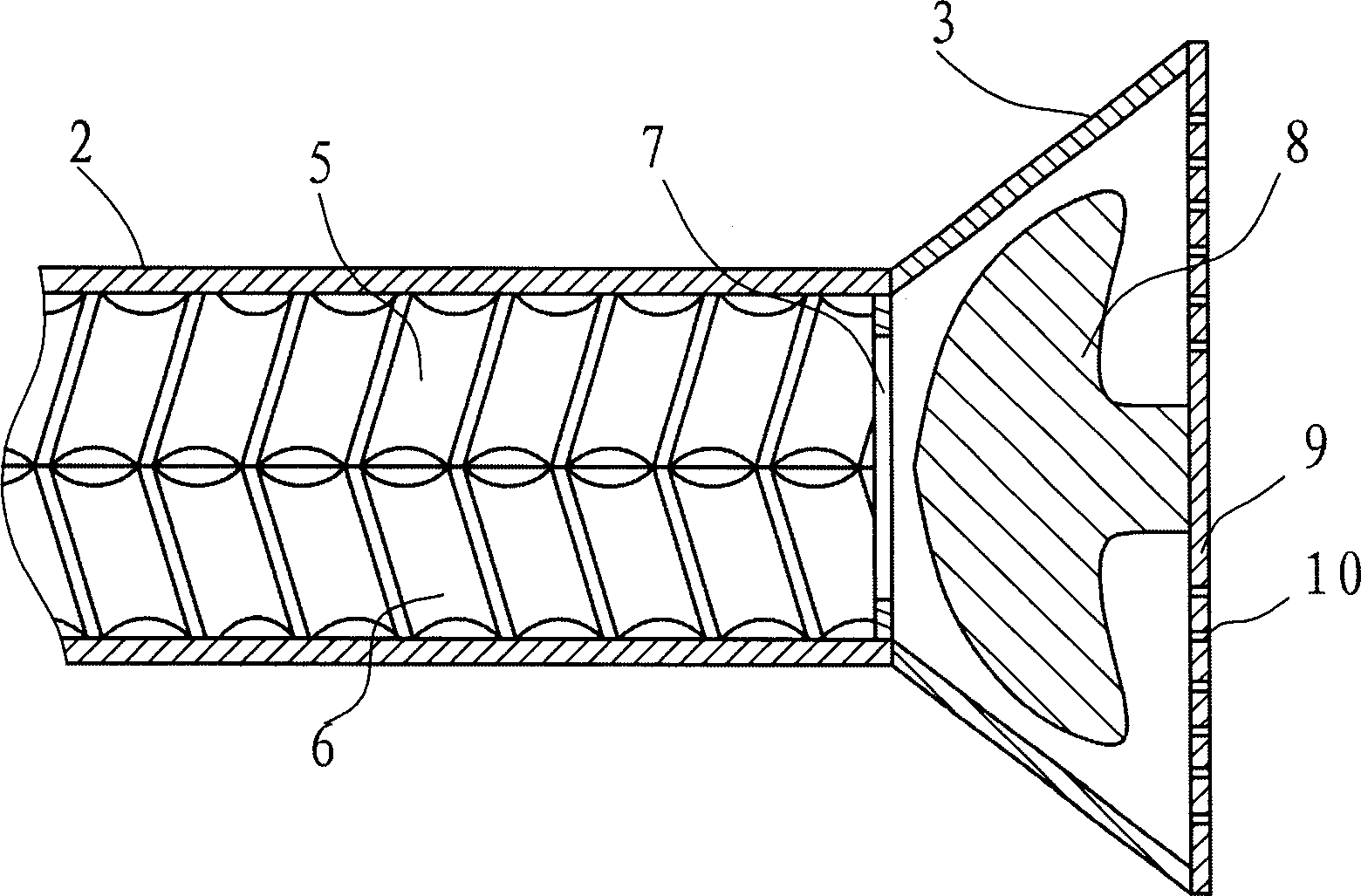

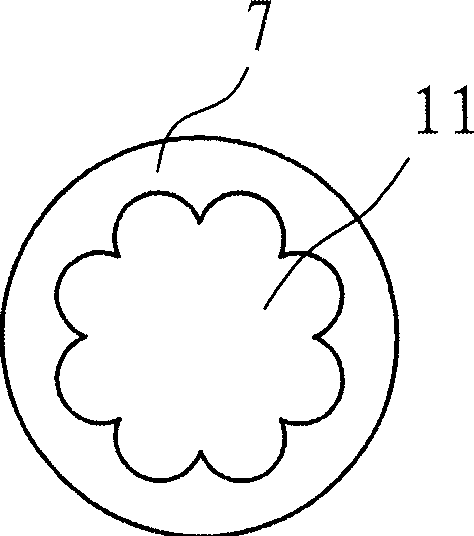

Granulate device for tiny pills in Chinese herbal medicine

InactiveCN1444917AThe effect of decompression and diversion is obviousQuality assurancePharmaceutical product form changeGranulation by pressingMixing chamberMedicine

A pelletizer for preparing Chinese-medicinal micropills is composed of is composed of mixing chamber, screw conveyer, flow-splitting chamber containing a splitting cone, flow-splitting plate between flow-splitting chamber and outlet, and a perforated discharge template at the end of flow-splitting chamber.

Owner:高庆凌 +1

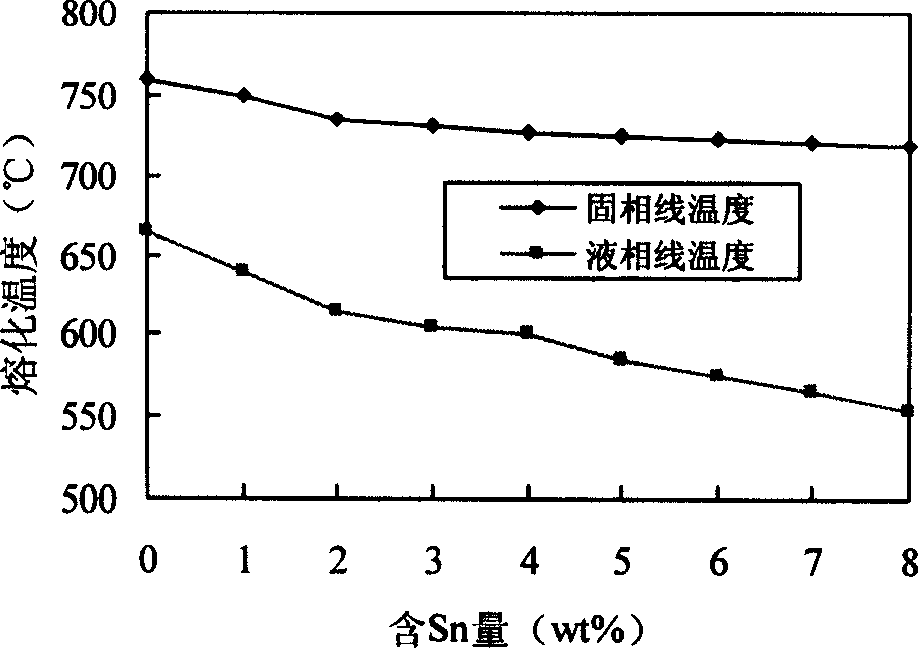

Medium temperature Ag base brazing filler metal and its preparing method

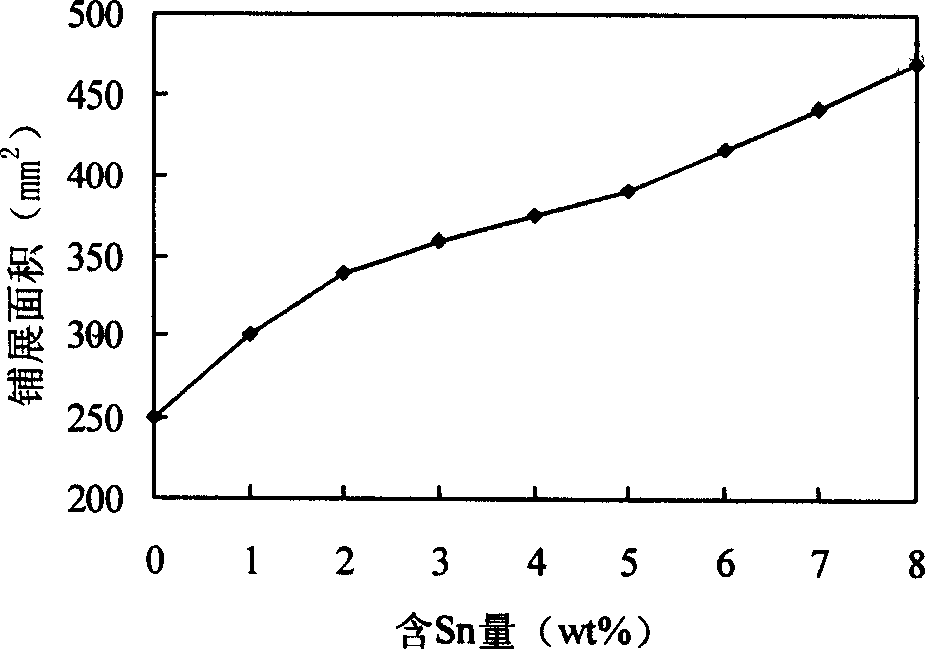

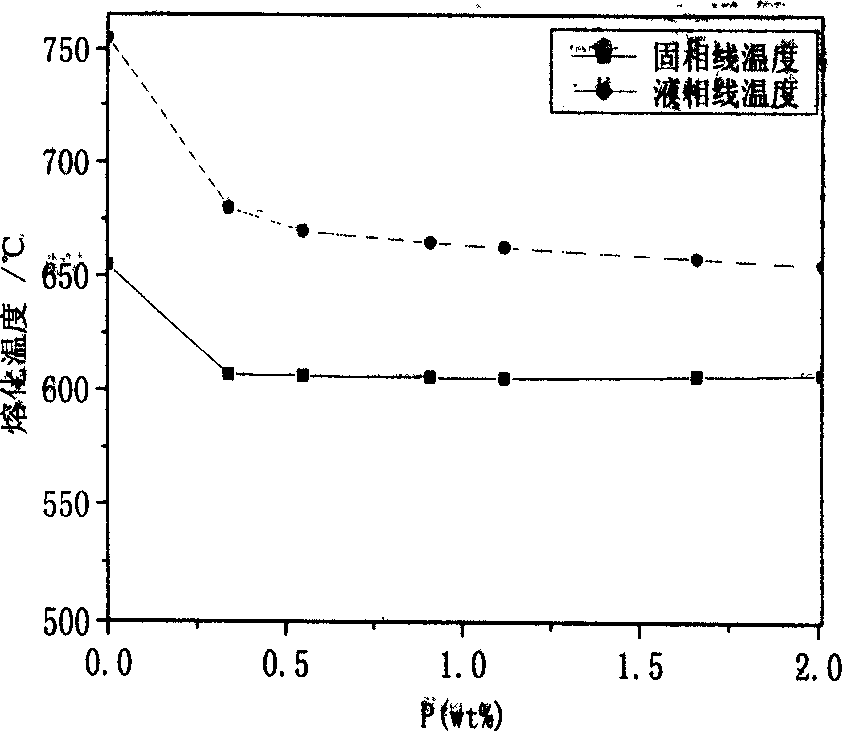

InactiveCN1616182ALower melting temperatureImprove wettabilityWelding/cutting media/materialsSoldering mediaCopperFiller metal

The medium temperature silver base brazing filler metal consists of: Ag 29.5-30.5 wt%, Zn 31.5-32.5 wt%, Mn 2.5-3.5 wt%, Sn 2.5-3.5 wt%, P 0.4-0.8 wt% and La 0.2-0.4 wt% except Cu. The preparation process includes the following steps: selecting material, material throwing and smelting, casting, extrusion and drawing. During the step of material throwing and smelting, electrolytic copper and P-Cu alloy are first heated quickly inside furnace for complete melting, covering agent is added, Zn, Cu-Mn alloy are added successively, Ag and Sn-La are added after lowering the temperature, and the temperature is finally raised to 1050-1100 deg.c while stirring before tapping. The product has the features of no harmful elements contained, relatively low cost, short production process, stable quality and raised extrusion and drawing finished product rate.

Owner:HARBIN INST OF TECH

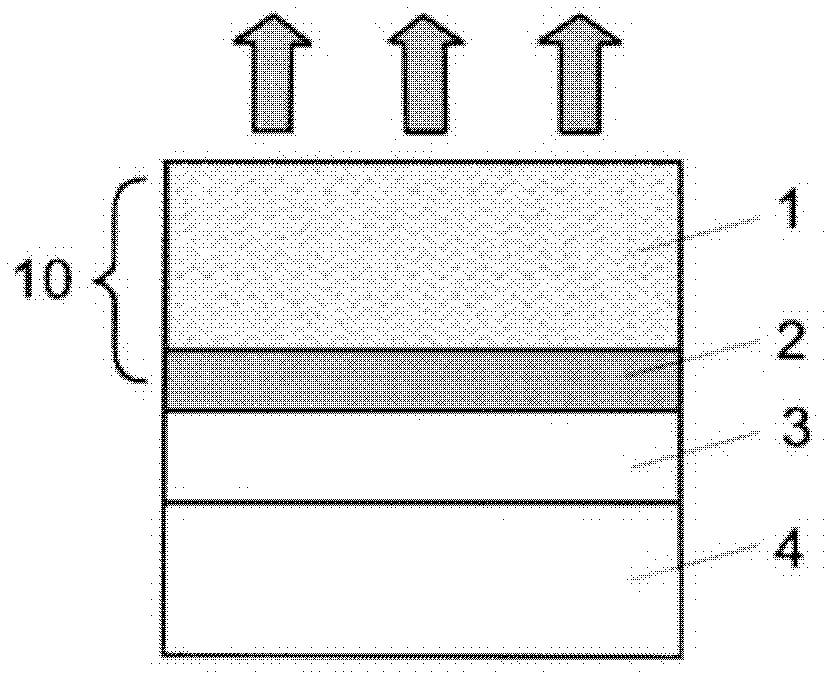

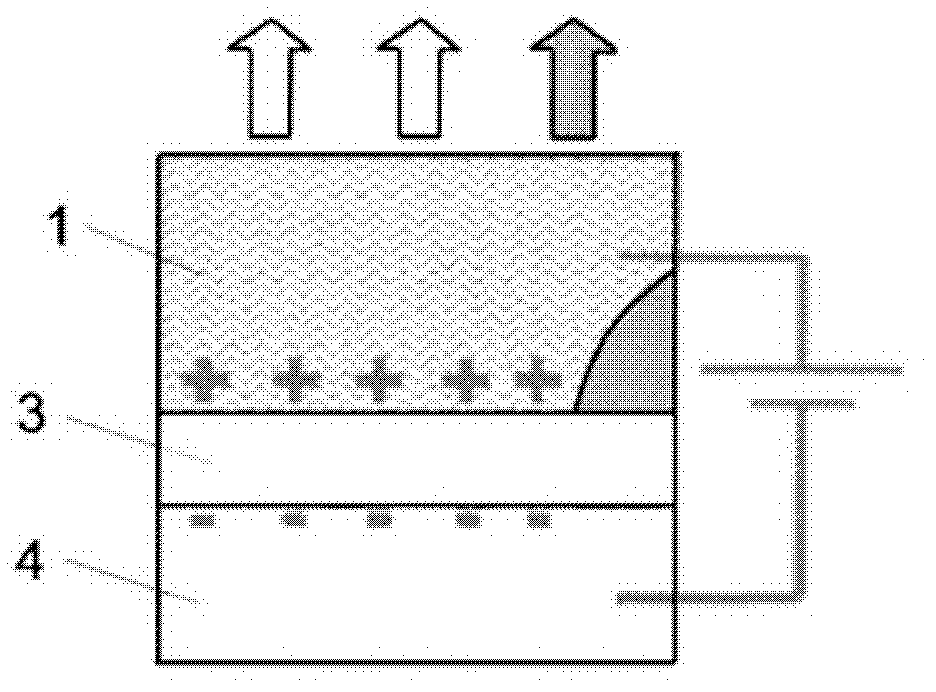

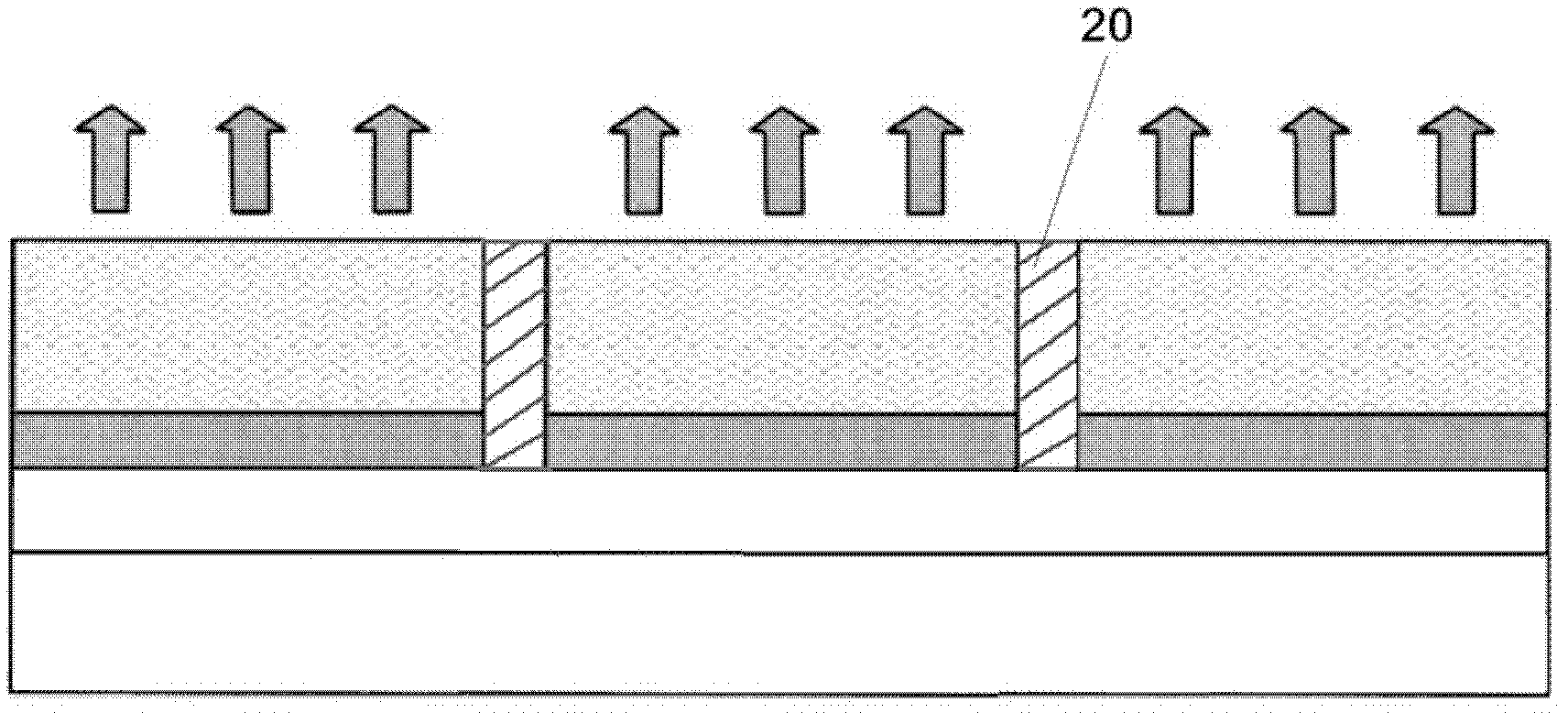

Electro-wetting display unit and electro-wetting display system

The invention provides an electro-wetting display unit and an electro-wetting display system. The electro-wetting display unit comprises a fluid layer, a dielectric layer and an electrode, wherein the fluid cavity comprises polar fluid, colored non-polar fluid and a partition wall used for surrounding the polar fluid and the non-polar fluid; the dielectric layer is positioned below the fluid cavity and is contacted with the non-polar fluid or the polar fluid in the fluid cavity; and the electrode is positioned below the dielectric layer. The electro-wetting display unit is characterized in that a hollow groove is arranged in the partition wall, is provided with an opening facing to the dielectric layer and is used for completely or partly storing the non-polar fluid when the voltage is applied between the polar fluid and the electrode. The electro-wetting display system comprises the electro-wetting display unit. When the electro-wetting display unit trends to be in the bright state in display, and the non-polar fluid paved above the dielectric layer originally enters the hollow groove by the assistance of the extrusion force on the non-polar fluid caused by the polar fluid controlled by the electrode, and is not attached at one corner or the middle area of the bottom surface.

Owner:BOE TECH GRP CO LTD

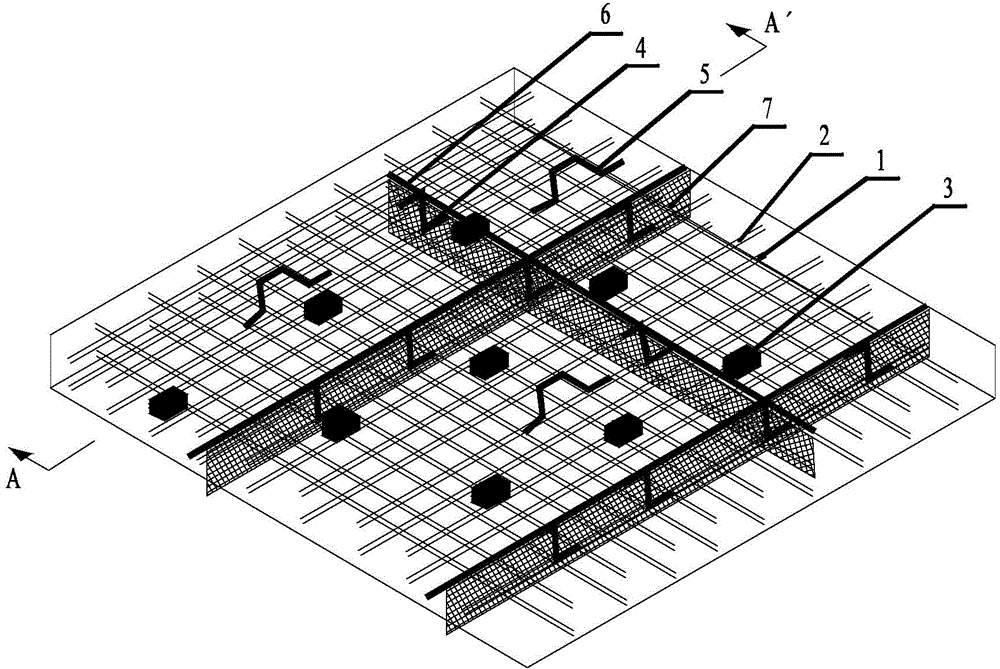

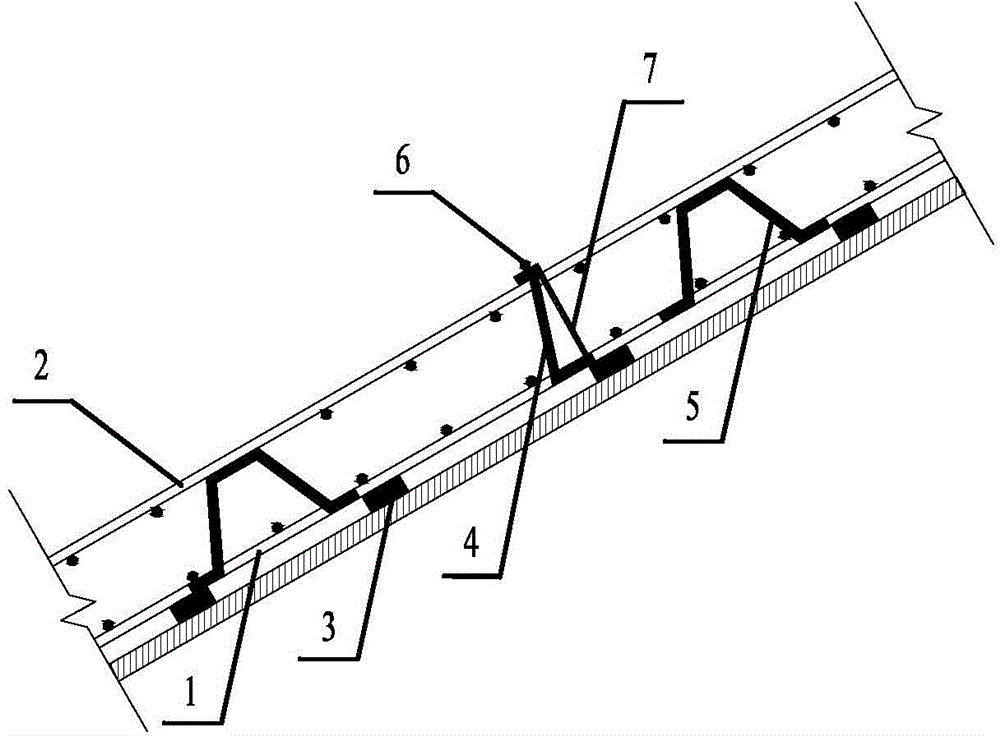

Guiderail device and method for pouring slope roof

ActiveCN104100092APrevent slippingPouring is easyBuilding roofsBuilding material handlingRebarWire mesh

The invention discloses a guiderail device and method for pouring a slope roof and relates to the technical field of building engineering construction. The guiderail device comprises plate-bottom steel reinforcing bars laid on the top surface of the form board of the slope roof. Plate-surface steel reinforcing bars opposite to the plate-bottom steel reinforcing bars are disposed above the plate-bottom steel reinforcing bars. A plurality of cushion blocks are disposed between the plate-bottom steel reinforcing bars and the form board of the slope roof. A plurality of horse stool steel reinforcing bars and a plurality rows of guiderail support steel reinforcing bars are disposed between the plate-bottom steel reinforcing bars and the plate-surface steel reinforcing bars. A guiderail steel reinforcing bar is fixedly connected to the top surface of each row of guiderail support steel reinforcing bars, and a steel wire mesh is fixedly connected to the bottom of the guiderail steel reinforcing bar. When the guiderail device is used for pouring, the plate-bottom steel reinforcing bars are laid first, the cushion blocks are placed between the plate-bottom steel reinforcing bars and the form board, then the horse stool steel reinforcing bars are fixed and the plate-surface steel reinforcing bars are laid, the guiderail support steel reinforcing bars are disposed and the guiderail steel reinforcing bars are laid, the steel wire meshes are mounted below the guiderail steel reinforcing bars, and finally concrete pouring can be performed. The guiderail device has the advantages that the guiderail device is easy in concrete pouring and dense in vibration, construction progress is accelerated, and construction cost is lowered.

Owner:WUHAN HANYANG MUNICIPAL CONSTR GRP CO LTD

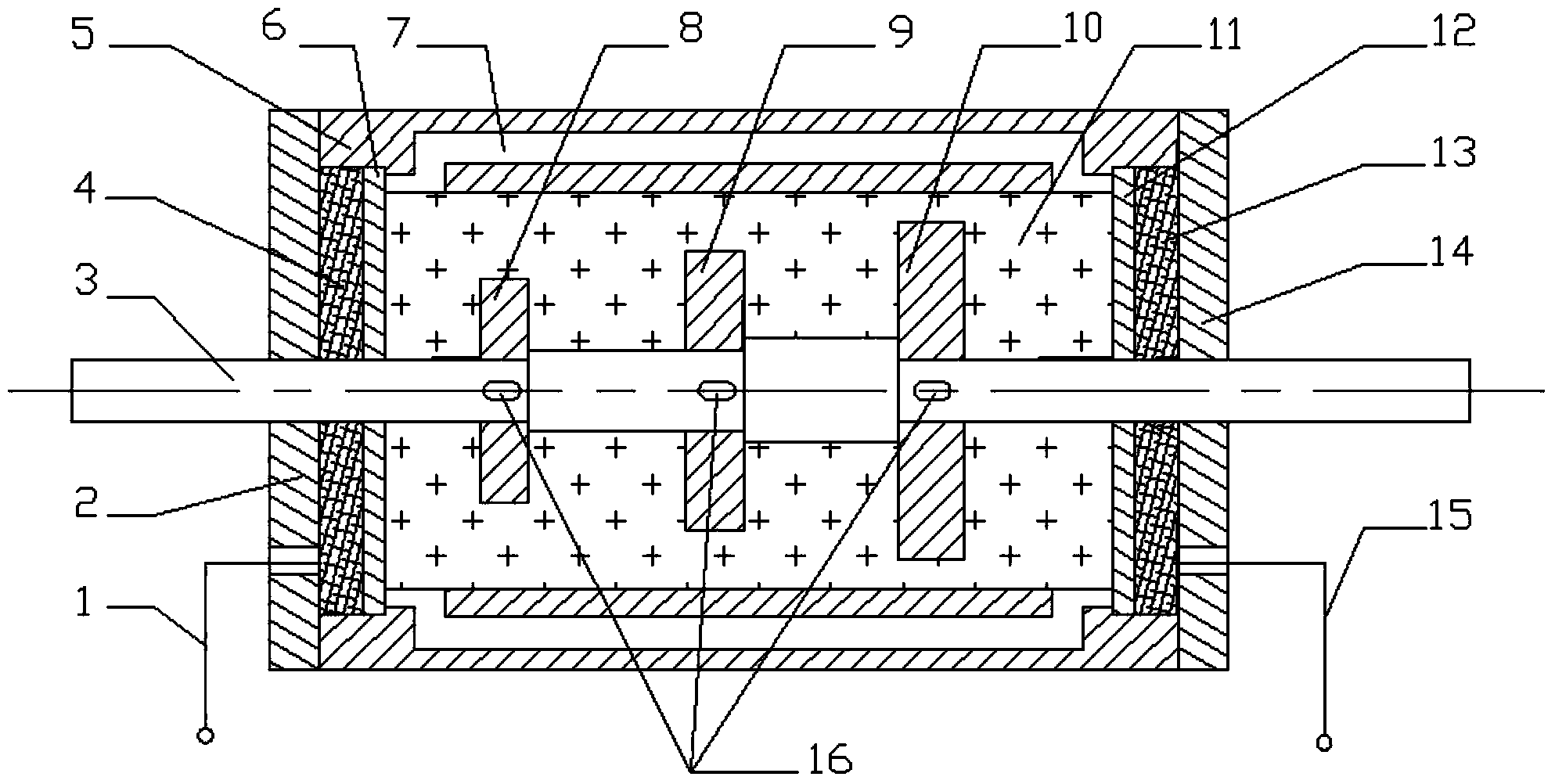

Seven-level adjustable reciprocating type electrorheological fluid damper

InactiveCN103591209AIncrease structural flexibilityLarge damping forceNon-rotating vibration suppressionLiquid based dampersThrottle controlApparent viscosity

A seven-level adjustable reciprocating type electrorheological fluid damper mainly comprises a positive-pole conducting wire, a negative-pole conducting wire, a positive-pole piston cylinder cover, a negative-pole piston cylinder cover, positive-pole conducting rubber, negative-pole conducting rubber, a piston rod, an insulating piston cylinder, a positive pole, a negative pole, a backflow control path, a small piston, a middle piston, a large piston and electrorheological fluid. The positive-pole conducting rubber and the negative-pole conducting rubber replace sealing materials and play a role in sealing and conducting. Installation forms of the small piston, the middle piston and the large piston are determined by borne damping force, wherein when the damping force is large, stress is not clear, and movement speed is high, the dual-piston or three-piston form is adopted; when the damping force is small, the single-piston form is adopted. The backflow control path replaces a throttling control valve, no external electric field exists, the electrorheological fluid bears the force and flows between the positive pole and the negative pole through the backflow control path, and the seven-level adjustable reciprocating type electrorheological fluid damper is a hydraulic damper; when an external electric field is applied and shearing efficiency is high, apparent viscosity of the electrorheological fluid of the backflow control path changes, the section area of the backflow control path becomes smaller, the backflow control path is even blocked completely, and the electrorheological fluid effectively controls an engineering system by proving shearing force and extruding force.

Owner:QINGDAO AGRI UNIV

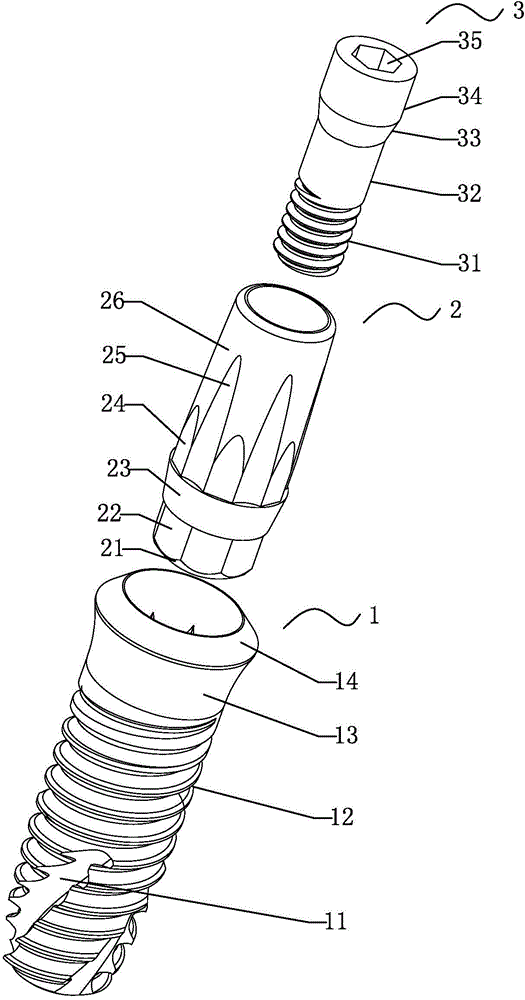

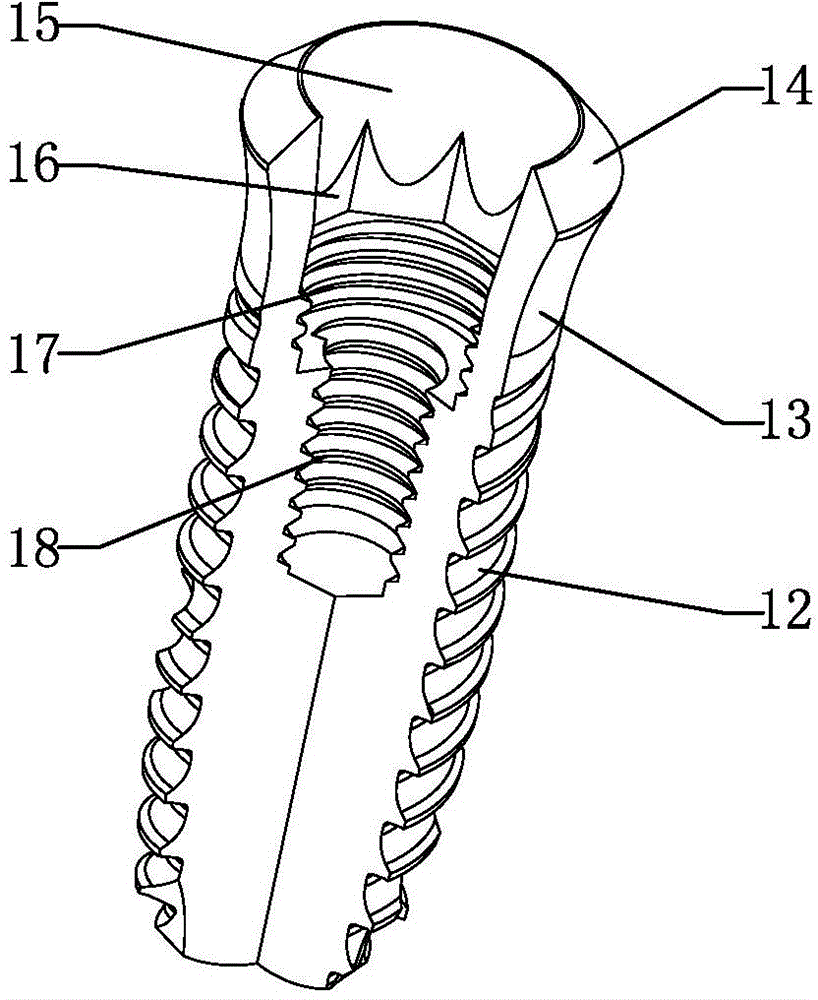

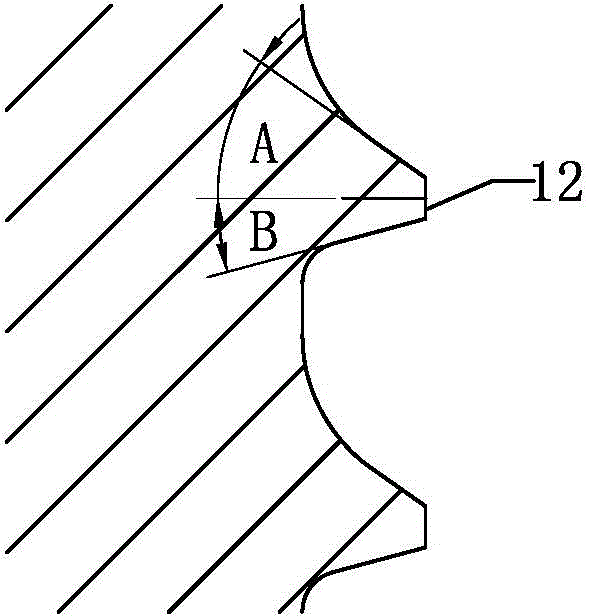

Easily-removing implant device and screwing-out tool thereof

InactiveCN103550003AReduce the risk of absorbingAvoid secondary surgeryDental implantsNeck partsImplanted device

The invention discloses an easily-removing implant device and a screwing-out tool thereof. The easily-removing implant device comprises an implant, a base station and a central bolt; the easily-removing implant device is characterized in that the implant comprises a gum-penetrating neck part and a head part, wherein a thread is formed on the outer surface of the head part, at least two spiral self-tapping grooves are also formed in the outer surface of the head part, a connecting hole coaxial with the implant is formed in the implant, the connecting hole comprises a tapered hole, an anti-rotation hole, an implant taking-out section and a blind threaded hole, which are sequentially connected coaxially, the base station comprises a dental crown connecting section and an implant connecting section, the implant connecting section comprises a conical table and an anti-rotation column, a stepped hole matched with the central bolt is formed in the base station, and the central bolt penetrates through the stepped hole to be connected with the blind threaded hole, so that the base station and the implant are fixed integrally. According to the easily-removing implant device, the implant taking-out section with a reverse thread is additionally arranged in the implant, the problem that a part of the implant, which is remained in dentale due to fracture of the implant, is difficult to take out is solved, and the easily-removing implant device has the advantages of simple structure, strong practicability, and the like.

Owner:DALIAN SANSHENG SCI & TECH DEV

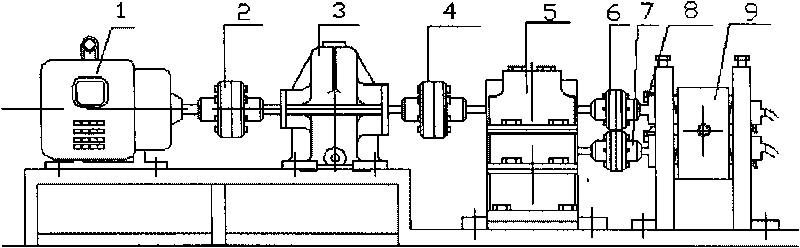

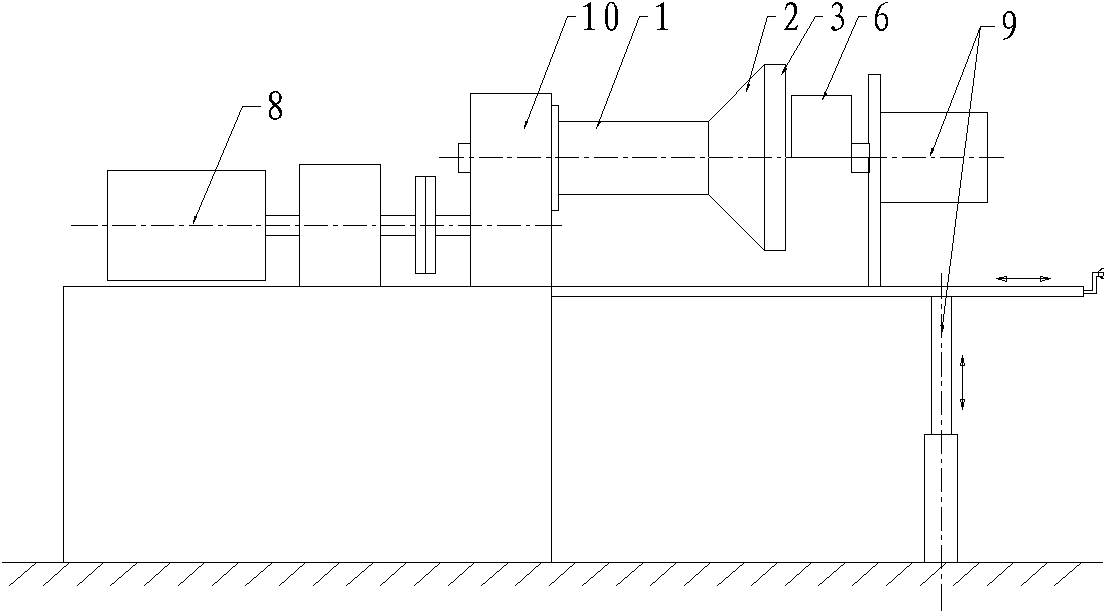

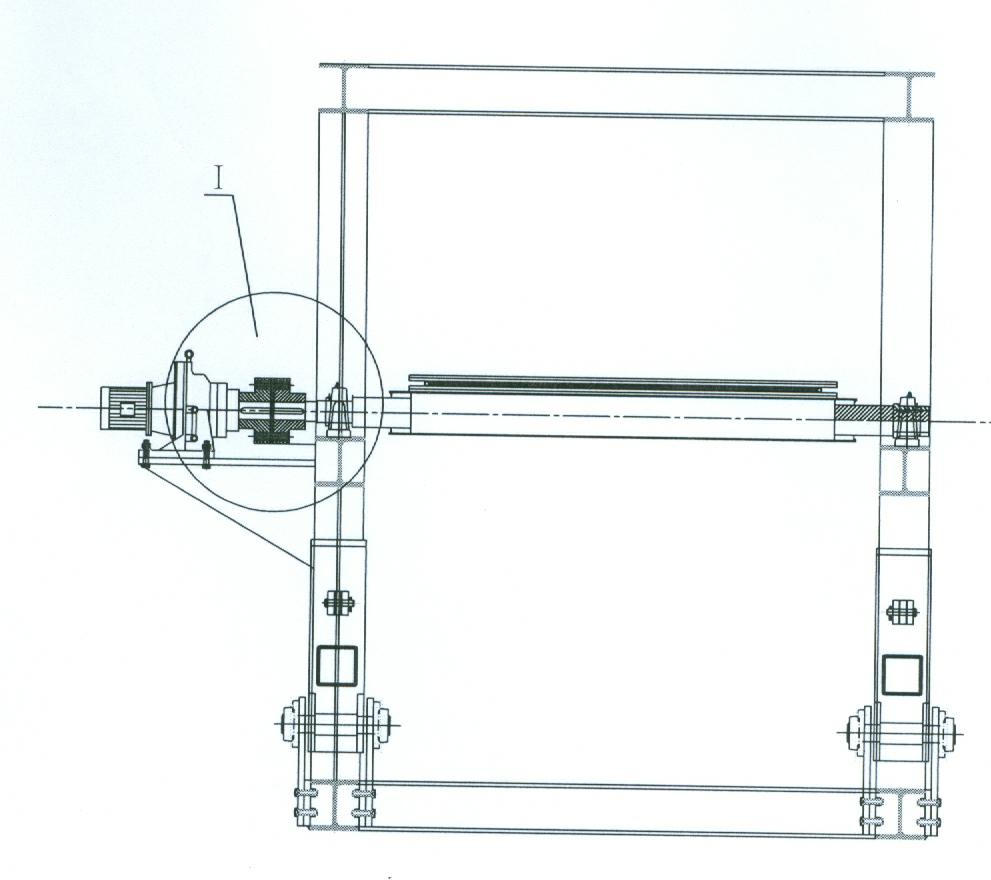

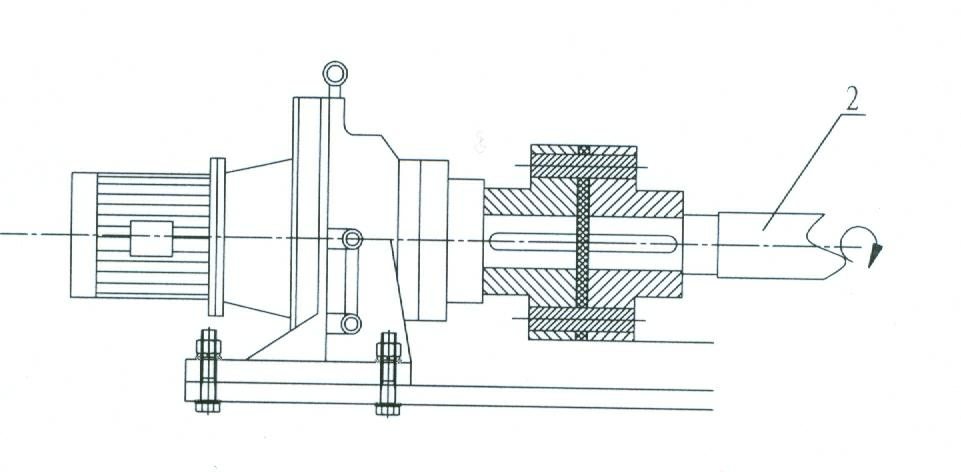

Multi-purpose double-roll continuous rheological forming device for liquid metal

InactiveCN101690941AIncrease productivitySolve low production efficiencyMetal rolling arrangementsLiquid stateCoupling

The invention discloses a multi-purpose double-roller continuous rheological forming device for liquid metal, which is mainly used for double-roller continuous rheological forming of plates, strips, pipes, profiles, wires, composite materials and wrapping materials. The device consists of a motor, a half coupling, a decelerator, a gear box, a main machine, a cooling water tank and a coiling machine, wherein the main machine consists of a stander, an upper working roller, a lower working roller, a feeding shoe, an extrusion shoe, a die in a cavity of the extrusion shoe, and rotating speed sensors at shaft heads of the upper working roller and the lower working roller of the main machine. An annular groove of the upper working roller is mutually matched with an annular lug boss of the lower working roller. The feeding shoe is arranged at the feeding end of the main machine, and the feeding shoe and the annular groove of the upper working roller form a feeding cavity. A metal material enters into a roller gap between the two working rollers through the feeding cavity. When producing pipes, profiles, wires and wrapping materials, the extrusion shoe is arranged at the discharging end of the main machine, and an extrusion forming die can be arranged in the cavity of the extrusion shoe. The device can realize quick continuous rheological forming of the liquid metal, and can also be used for direct forming of a semi-solid metal material.

Owner:NORTHEASTERN UNIV

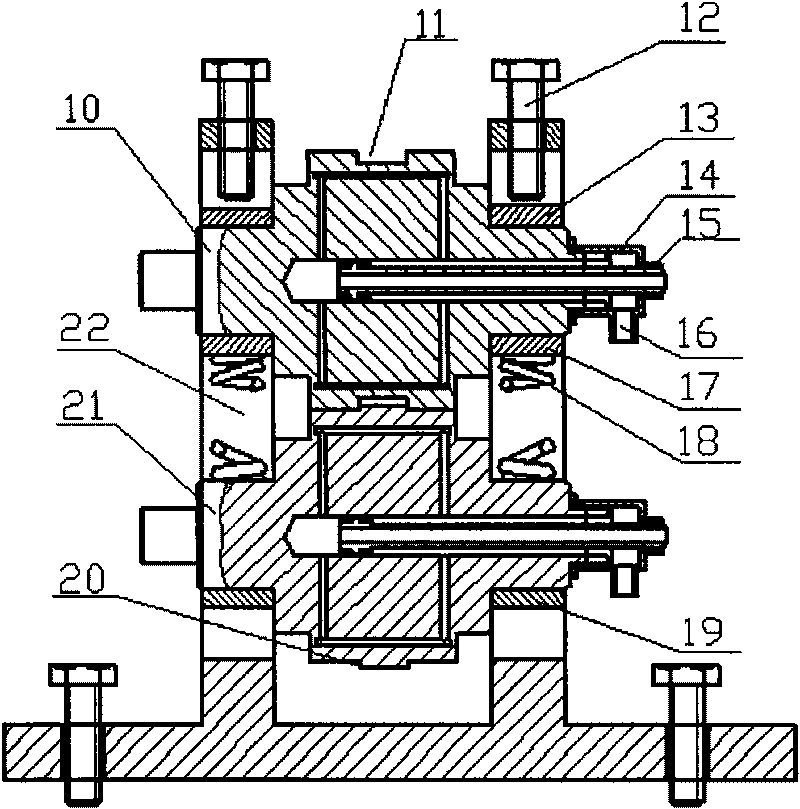

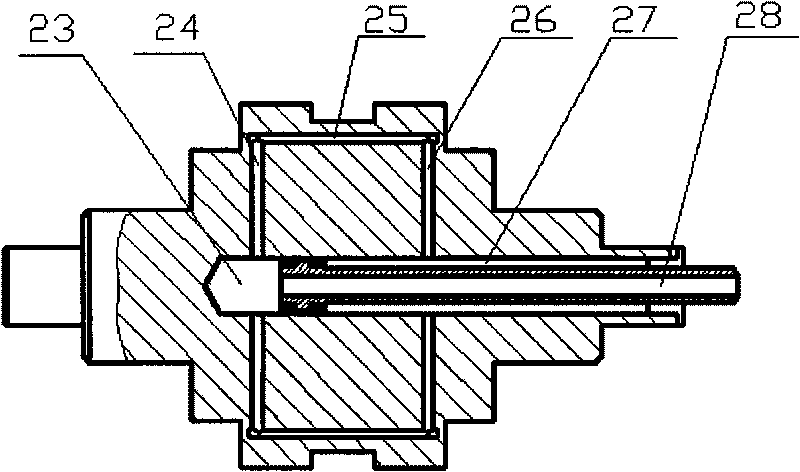

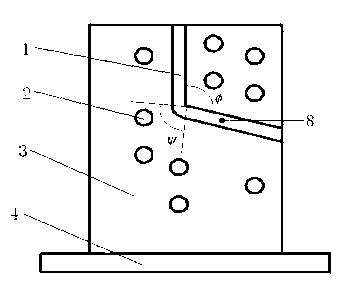

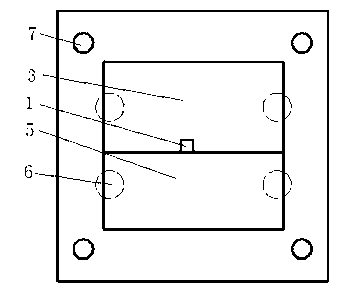

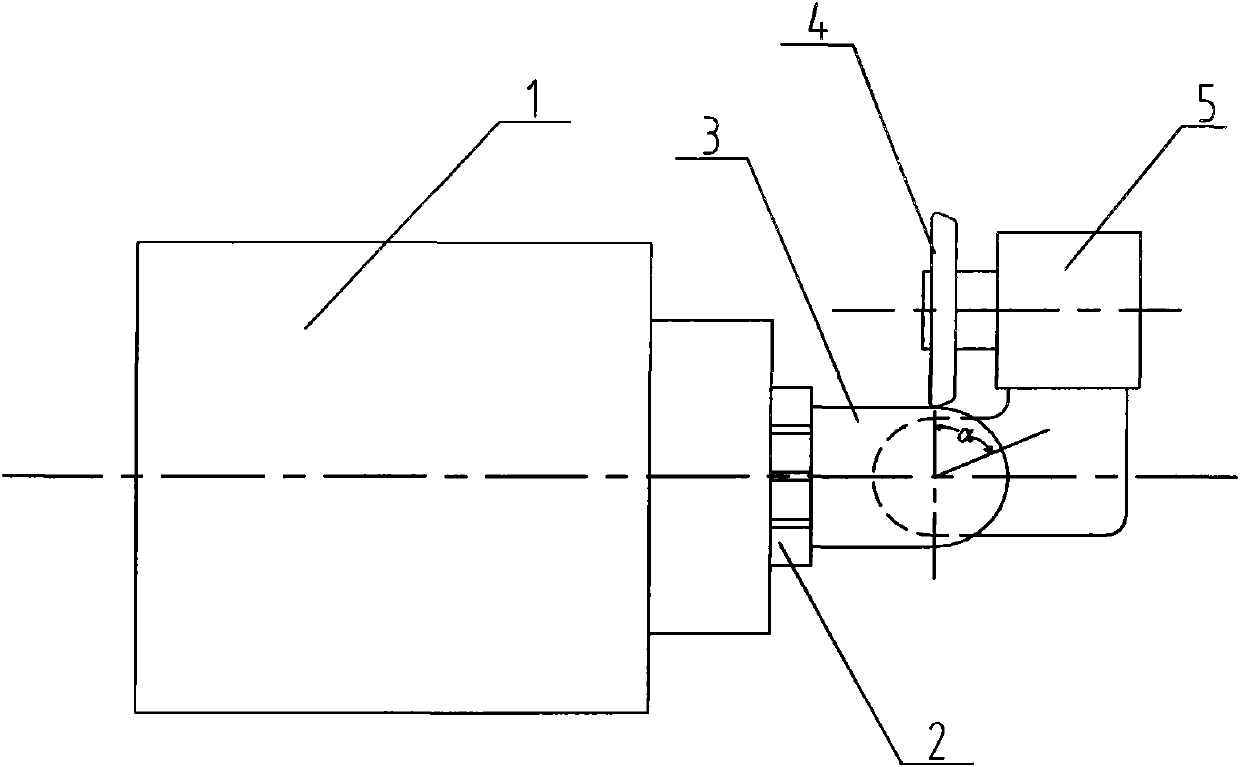

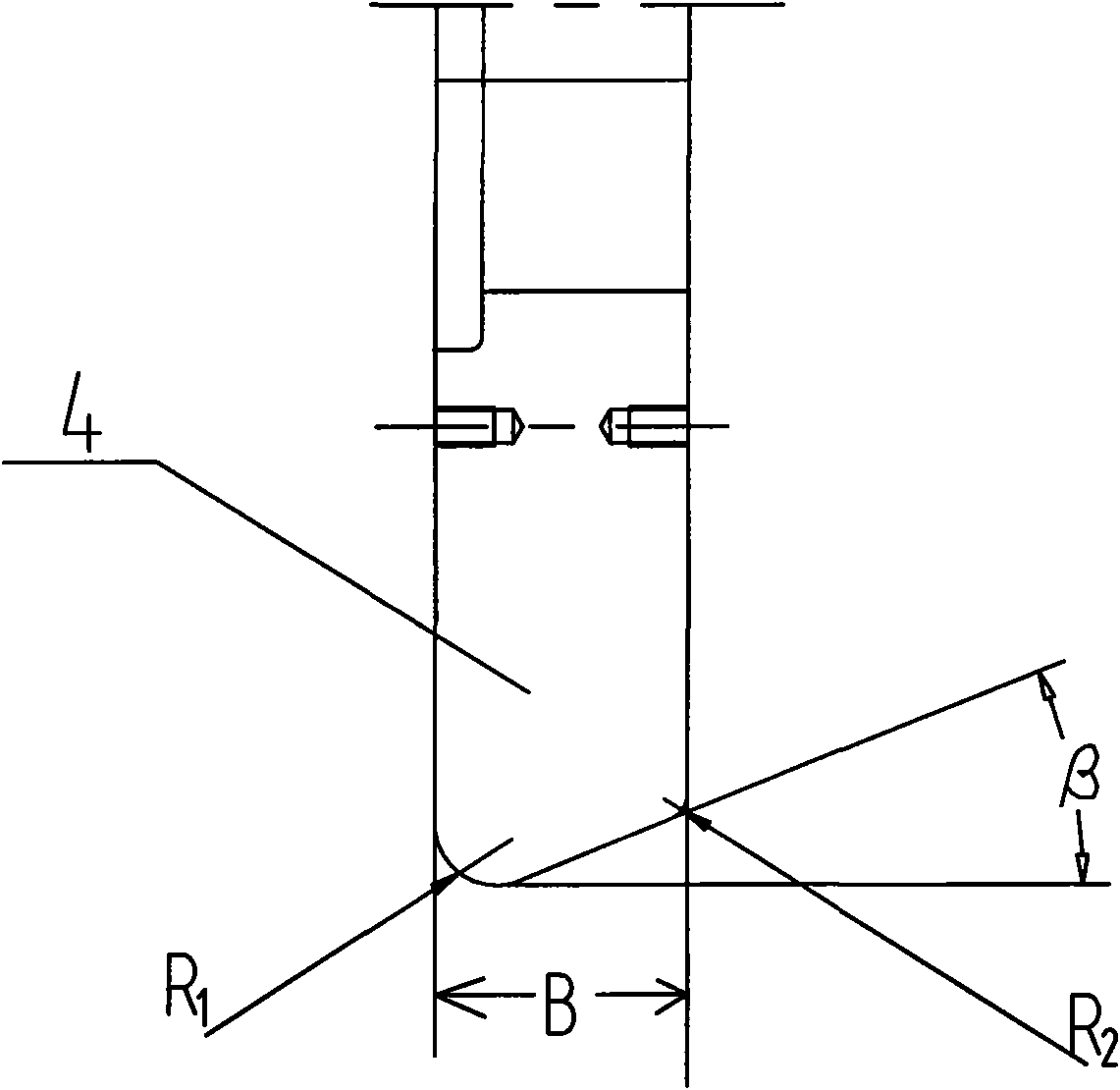

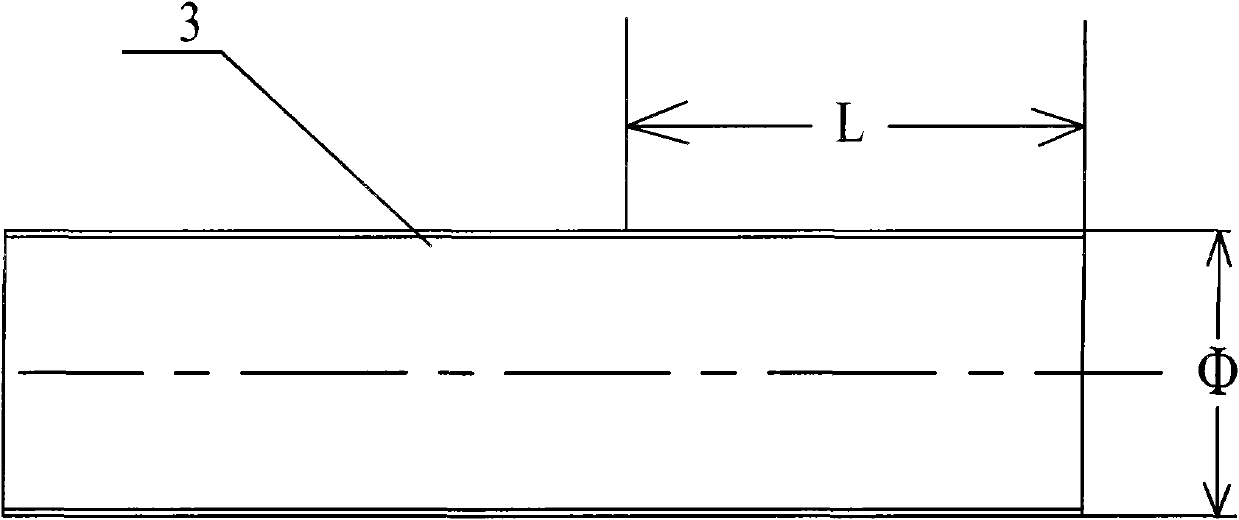

Mould of pure titanium equal channel angular extrusion and process method

InactiveCN103252377AIncrease squeezeSqueeze to meetExtrusion diesTitaniumEqual channel angular extrusion

The invention provides a mould of pure titanium equal channel angular extrusion and a process method. An integral concave mould design is adopted. A concave mould comprises a concave mould main body, a concave mould base and a concave mould cover plate; the mould of the pure titanium equal channel angular extrusion comprises an equal angular channel; the concave mould main body comprises the equal angular channel; the concave mould cover plate comprises a side face of the equal angular channel; and the concave mould main body and the concave mould cover plate are fastened by a bolt and a nut. The mould of the pure titanium equal channel angular extrusion disclosed by the invention adopts a novel mould structure of the integrated concave mould so that the extrusion force capable of being borne by the mould is increased; with the adoption of an isothermal extrusion technology, the extrusion of pure titanium with a close-packed hexagonal structure, higher rigidity and lower plasticity and the equal angular channel of an alloy thereof can be met; the mould is relatively simple in structure, and lubrication and fault treatment of the channel are convenient to carry out; and the service life of the mould can be prolonged to a certain extent.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Flowerpot

ActiveCN108633543AIncrease squeezePrevent rotSelf-acting watering devicesPressurised distribution of liquid fertiliserEngineeringAirbag

The invention relates to the technical field of cleaning devices, and particularly relates to a flowerpot. The flowerpot comprises an inner pot, an outer pot and a water replenishing mechanism; a plurality of water absorbing pipes which contain water absorbing resin are installed in the outer pot; the water replenishing mechanism comprises a floating block and an airbag, the floating block is arranged in the outer pot, a weight balancing block is fixedly connected with the floating block, and a pressing rod is fixedly connected with the weight balancing block; the airbag is communicated with awater pipe, a nozzle is communicated with the airbag, and a pressure valve is arranged in the airbag. At the beginning, water is added to the outer pot manually, the water is delivered into soil in the inner pot through the water absorbing resin to provide moisture for flowers; the pressing rod is driven by the floating block to move downwards with the lowering of water level, the airbag is pressed by the pressing rod, the pressure valve in the airbag is turned on, and water is discharged from the nozzle to water the flowers. According to the flowerpot, water only needs to be added to the outer pot manually at the very beginning, watering the flowers manually is not needed in the subsequent process, and automatic watering can be achieved by the flowerpot. After the soil is moisturized, the inner pot is moved up and down, the water absorbing pipes are moved up and down in the inner pot, soil loosening can be conducted on the soil in the inner pot, and the growing of roots of the flowers is promoted.

Owner:台州蛙弟互联网科技有限公司

Hot spinning bottom-finishing method of seamless gas cylinder by positive roller

The invention discloses a hot spinning bottom-finishing method of a seamless gas cylinder by a positive roller, comprising the following steps of: 1), heating the bottom-finishing section of a steel pipe to 1050 to 1100 DEG C; 2), performing standard semispherical positive sealing and spinning to the bottom-finishing section of the steel pipe for 7 to 8 times, obtaining a semispherical gland; 3), performing the semispherical gland forming and the bottom thickening and spinning to the semispherical gland for 7 to 10 times, obtaining a semispherical gland with a thickened bottom; 4), finally smoothening and spinning the gland surface, and finishing the hot spinning bottom-finishing of the seamless air cylinder. The method finishes the bottom and forms the seamless air cylinder by the positive roller hot spinning, thereby reducing the self-pressure welding material temperature of the steel pipe material in the central melt area of the air cylinder bottom, improving the centre thickening effect of the gland bottom and distinctly reducing the device cost.

Owner:国营江北机械厂

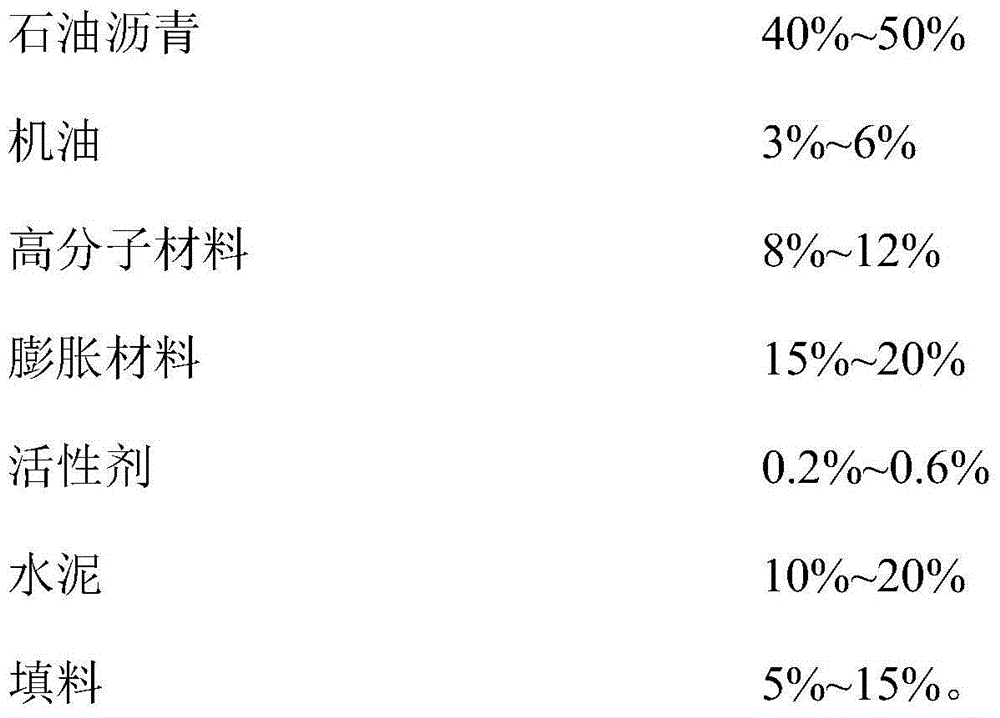

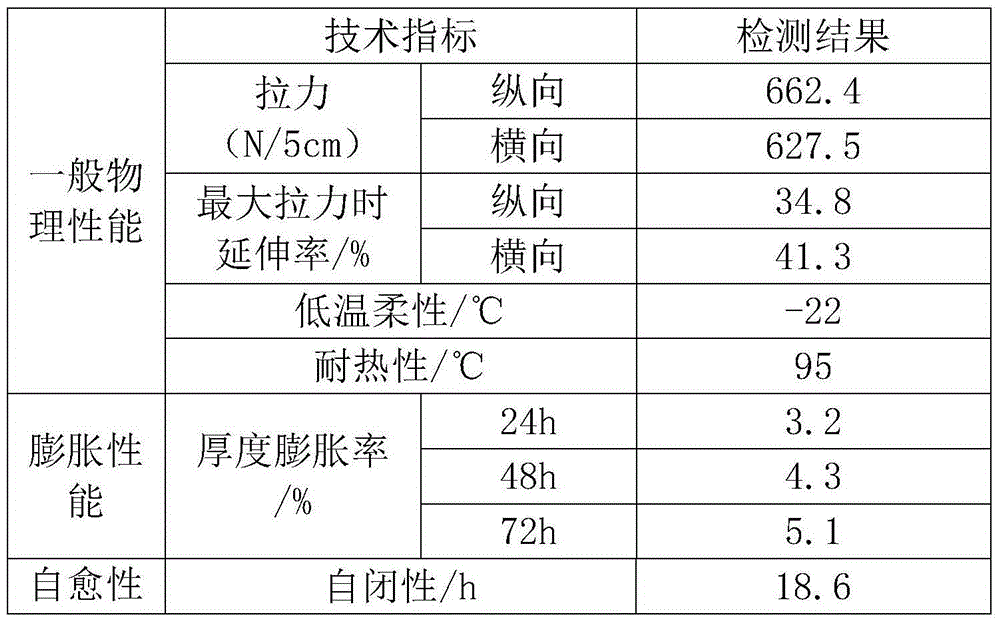

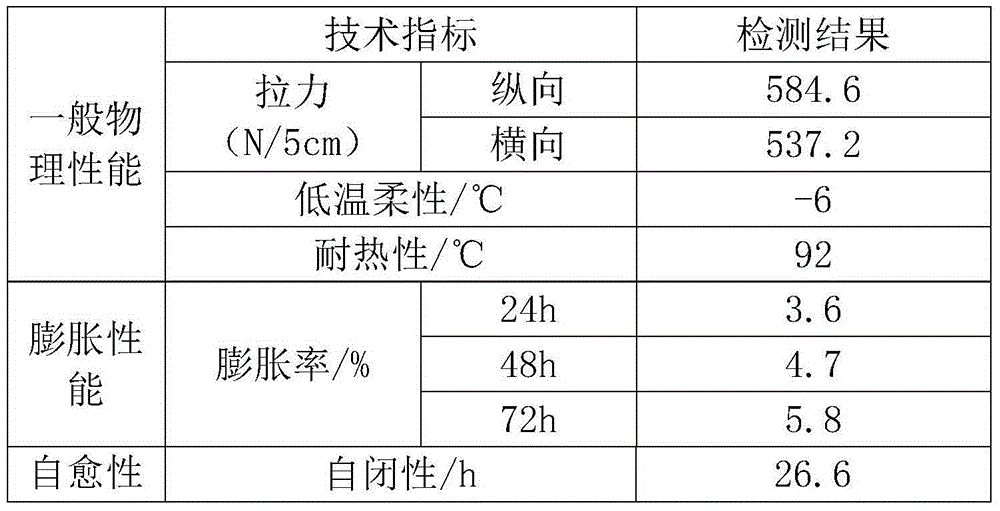

Self-healing type non-self-adhesive modified asphalt waterproof coiled material and preparation method thereof

ActiveCN104312174AEasy to produceGood physical propertiesBuilding insulationsSelf-healingBituminous waterproofing

The invention discloses a self-healing type non-self-adhesive modified asphalt waterproof coiled material which is characterized by consisting of a modified asphalt coating material, a tire body and an isolation material, wherein the modified asphalt coating material consists of the following components in percentage by mass: 40-50% of petroleum asphalt, 3-6% of machine oil, 8-12% of high polymer material, 15-20% of expanding material, 0.2-0.6% of active agent, 10-20% of cement and 5-15% of filler. During preparation, the coating material is uniformly mixed and then is coated on the tire body, and then the tire body is covered with the isolation material to obtain the self-healing type non-self-adhesive modified asphalt waterproof coiled material. By virtue of tests performed according to relevant national or industrial test methods, the waterproof coiled material disclosed by the invention has good mechanical properties and excellent self-healing performance.

Owner:苏州市姑苏新型建材有限公司

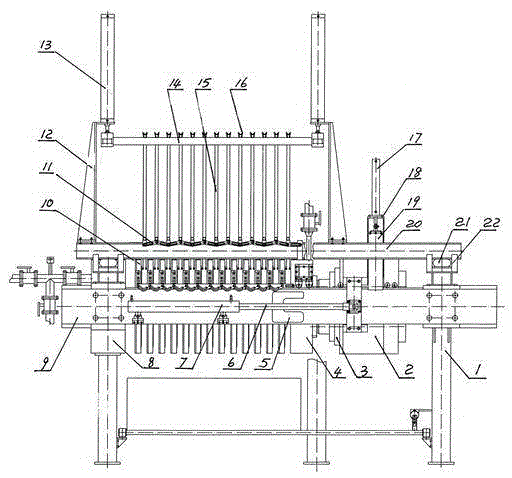

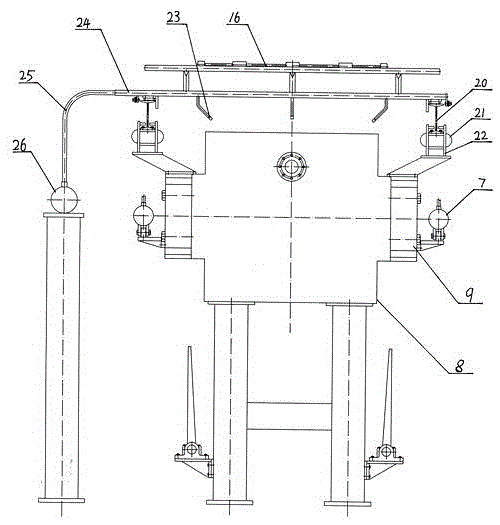

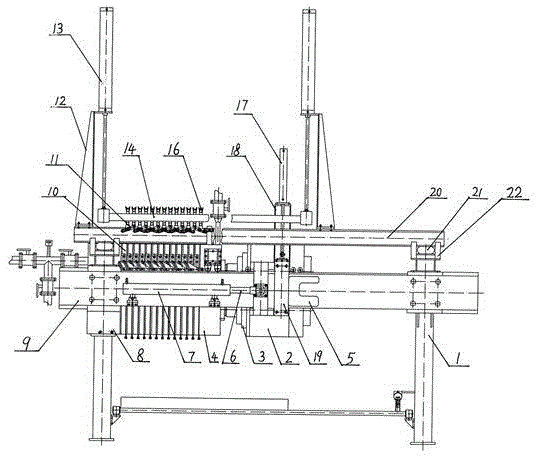

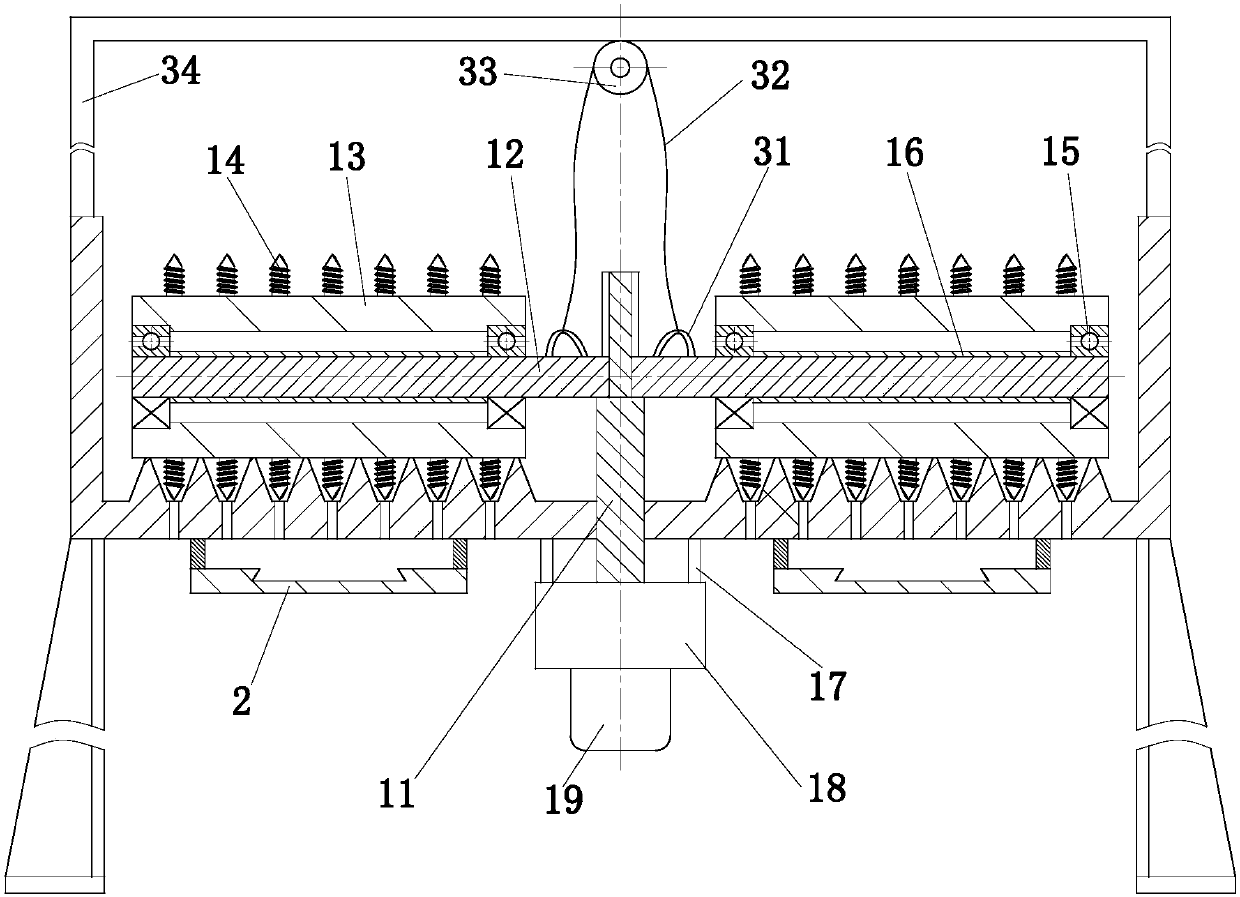

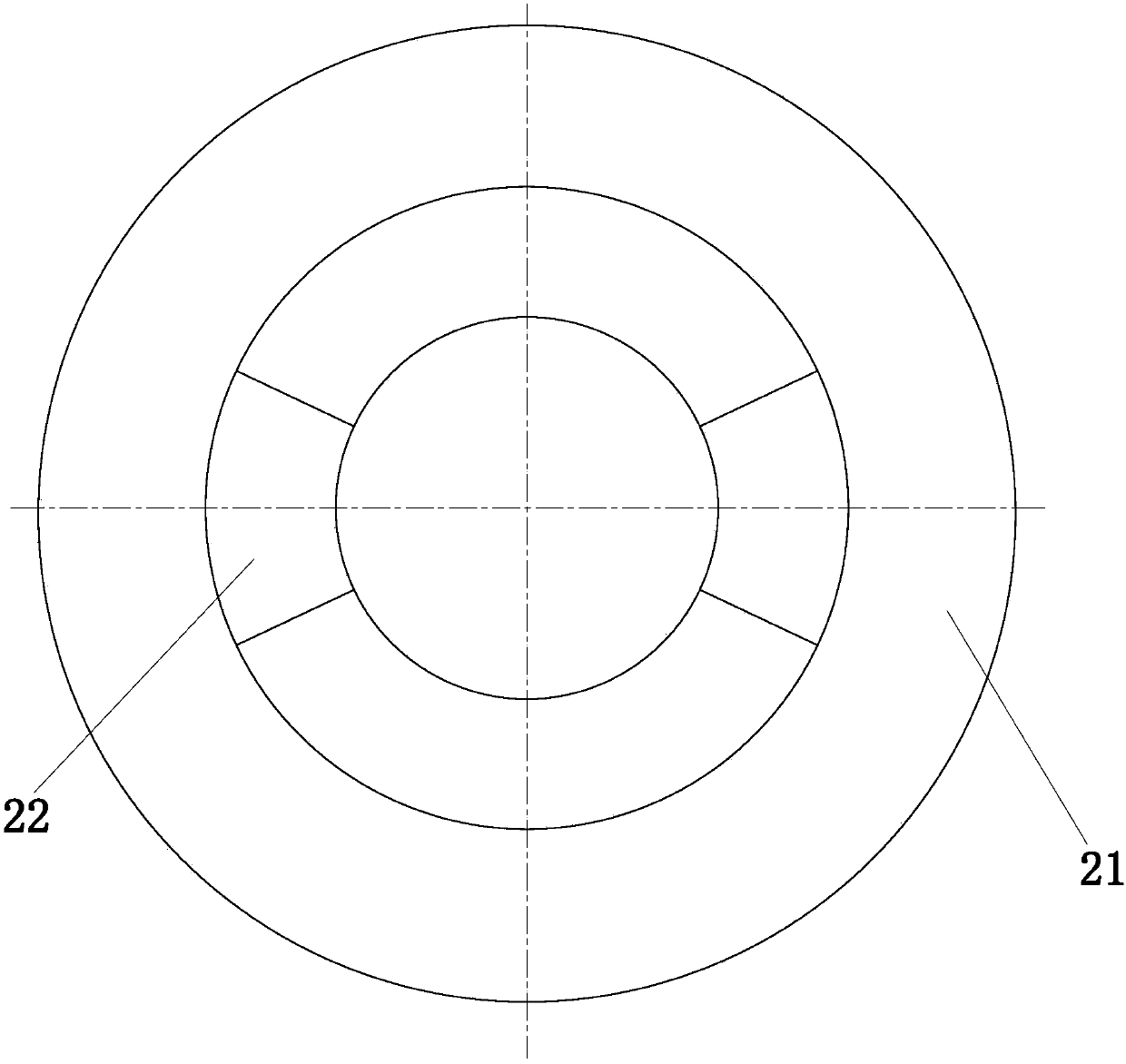

Press filter

The invention discloses a press filter. The press filter comprises hydraulic cylinders, filter plates and a thrust plate, wherein a main is fixed to a main hydraulic cylinder base; a guide roller on the base is arranged on guide rails of main beams; a piston rod of the main hydraulic cylinder is connected with a push plate connected with the filter plate at the right end of the plurality of variable capacity filter plates; the filter plate at the left end of the plurality of variable capacity filter plates is in contact with the thrust plate; the variable capacity filter plates are connected with one another through lower connecting boards; a quick-opening hydraulic cylinder is fixed to one end of the left end of the corresponding main beam, and piston rods of the quick-opening hydraulic cylinders are connected with the hydraulic cylinder base; an insert plate lifting hydraulic cylinder is fixed to the main hydraulic cylinder base; the upper end of an n-shaped insert plate is connected with a piston rod of the insert plate lifting hydraulic cylinder; the main beams are arranged in the opening of the n-shaped insert plate; a limiting plate is fixed to the side surface of one main beam and opposite to the insert plate. The press filter has the remarkable advantages that the compression is high, the material containing solid rate reaches 50% or above, and cleaning of filtering cloth is quick and clean.

Owner:HENAN BAIHUI ENVIRONMENTAL PROTECTION TECH CO LTD

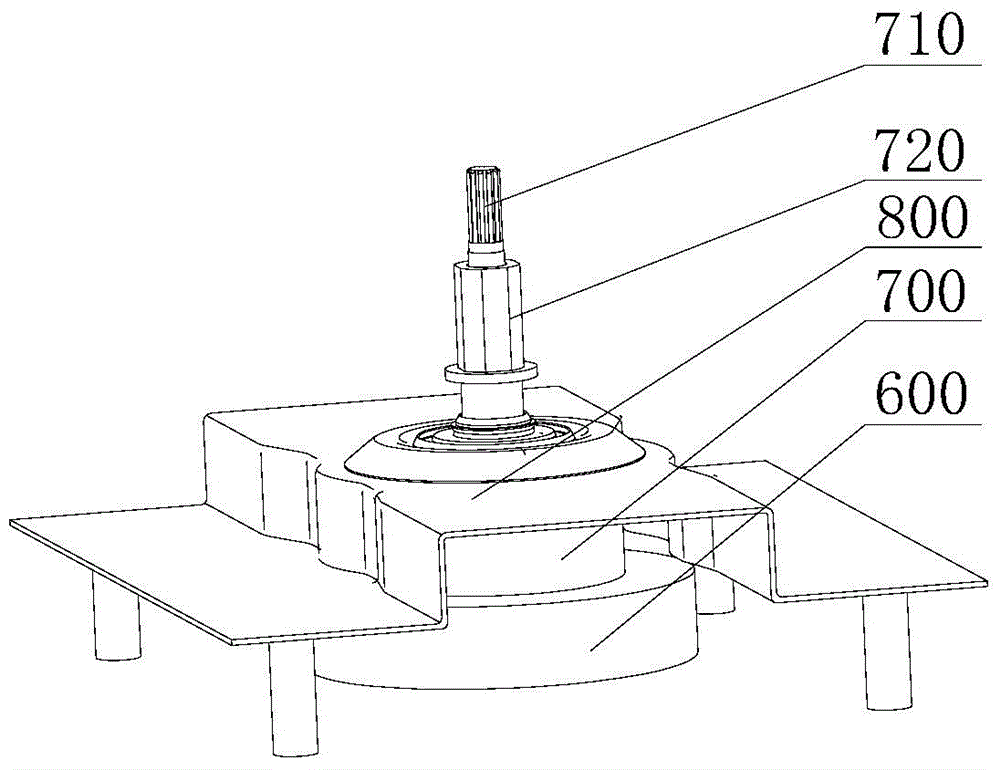

Wire taking device of waste radial steel wire tire circle opening

ActiveCN107694720AIncrease squeezeImprove the effectSolid waste disposalGrain treatmentsEngineeringSeparation problem

The invention belongs to the field of tire recovering, and particularly relates to a wire taking device of a waste radial steel wire tire circle opening. The wire taking device of the waste radial steel wire tire circle opening comprises a grinding module, an attraction module, a lifting module, a machine basin and stabilizer blades; the machine basin is of a barrel-shaped structure, a plurality of circles of upwards-protruding cones are arranged at the bottom of the machine basin, cylindrical material discharging holes are formed in the bottom faces of the adjacent cones, and a through hole for the grinding module to penetrate is formed in the middle portion of the machine basic; the grinding module is installed in the machine basin and grinds and crushes rubber at the tire circle openingin the machine basin; the attraction module is installed below the machine basin and generates downward action force on the grinding module; and the lifting module is installed above the machine basin and is used for lifting the grinding module. The waste radial steel wire tire circle opening wire taking device is mainly used for solving the problem about separation of the rubber in the radial steel wire tire circle opening and a steel wire, grinding and crushing of the tire circle opening are achieved through the grinding module, the attraction module increases extrusion force of the grinding module on the tire circle opening, and separation of the steel wire and the rubber is achieved.

Owner:解波

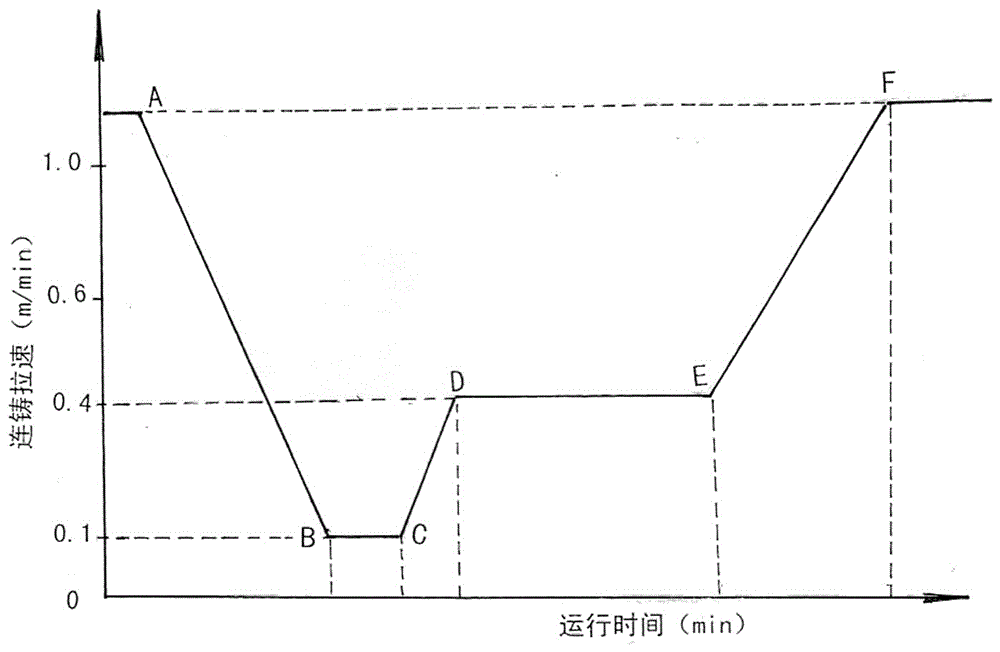

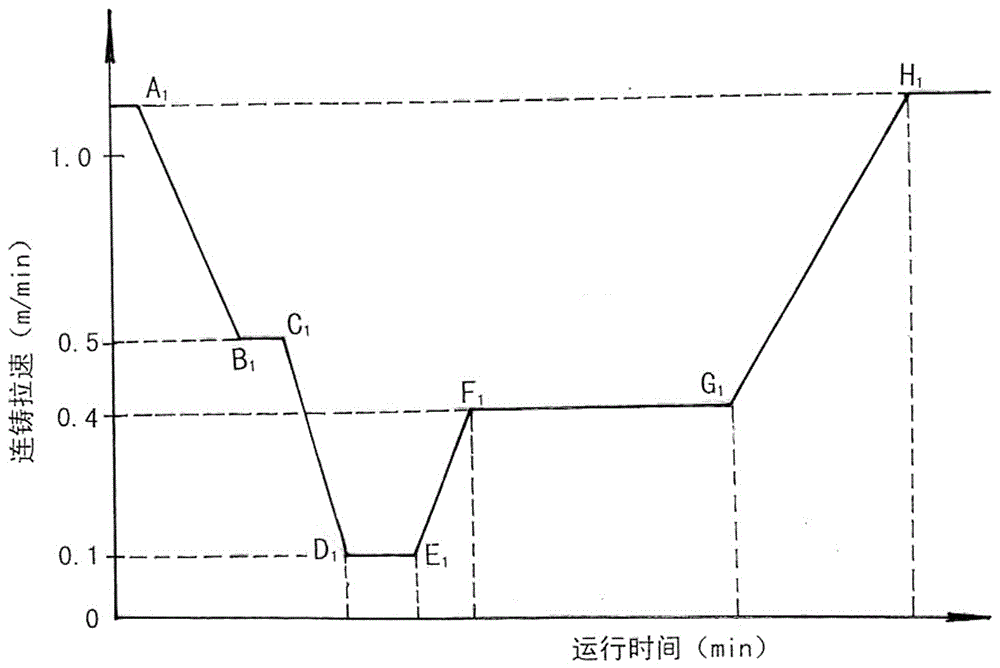

Continuous casting stop-casting blank tail discharge and top sealing method

The invention discloses a continuous casting stop-casting blank tail discharge and top sealing method. First and second stopper rods of a tundish of a two-machine and two-current continuous casting machine are opened; and first and second currents of molten steel flow into first and second crystallizers. When the height of the molten steel of the tundish is from 1130 mm to 680 mm, the continuous casting pull speeds of the first and second currents of molten steel in continuous casting are both reduced to 0.09-0.11 m / min at different accelerations; at this time, after the first and second stopper rods in the tundish are respectively closed, first and second blind plates are pushed in; first and second casting water ports are taken out from the first and second crystallizers; first and second cooling rods are put in the first and second crystallizers; and the continuous casting pull speeds are increased to 0.38-0.42 m / min for keeping by not shorter than 2 min. When the tail part of a continuous casting blank is discharged from lower ports of the crystallizers, and a foot roll section casting blank totally enters the tail part of the casting blank, the tail part of the casting blank is shrunk to form a recess area, and the tail discharge and the top sealing of the casting blank are finished. The top sealing method is excellent in tail discharge and top sealing of the casting blank, increases the molten steel yield, and has the popularization value.

Owner:湖南华菱涟源钢铁有限公司

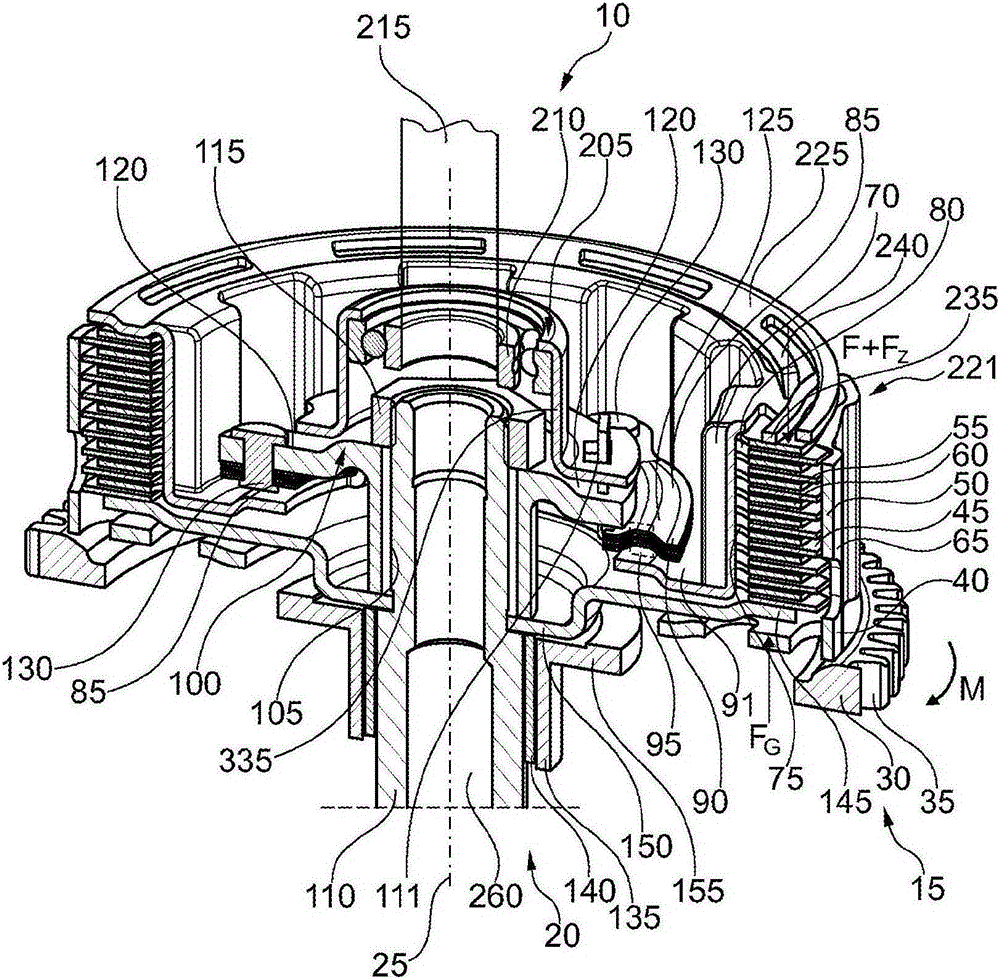

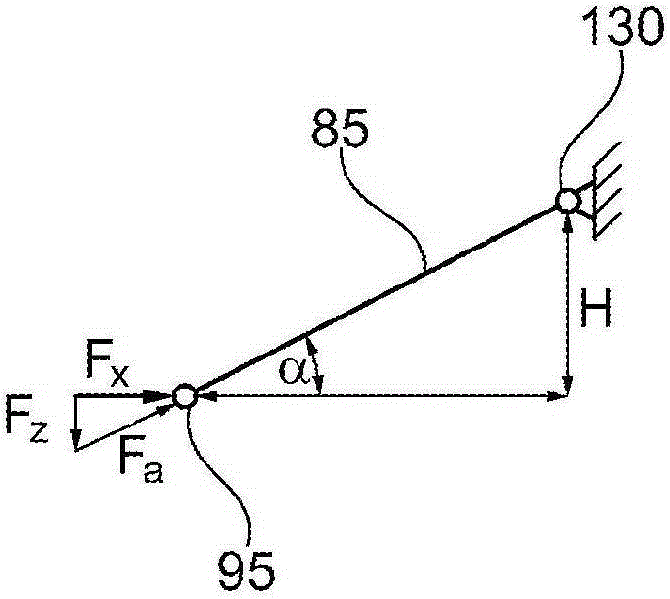

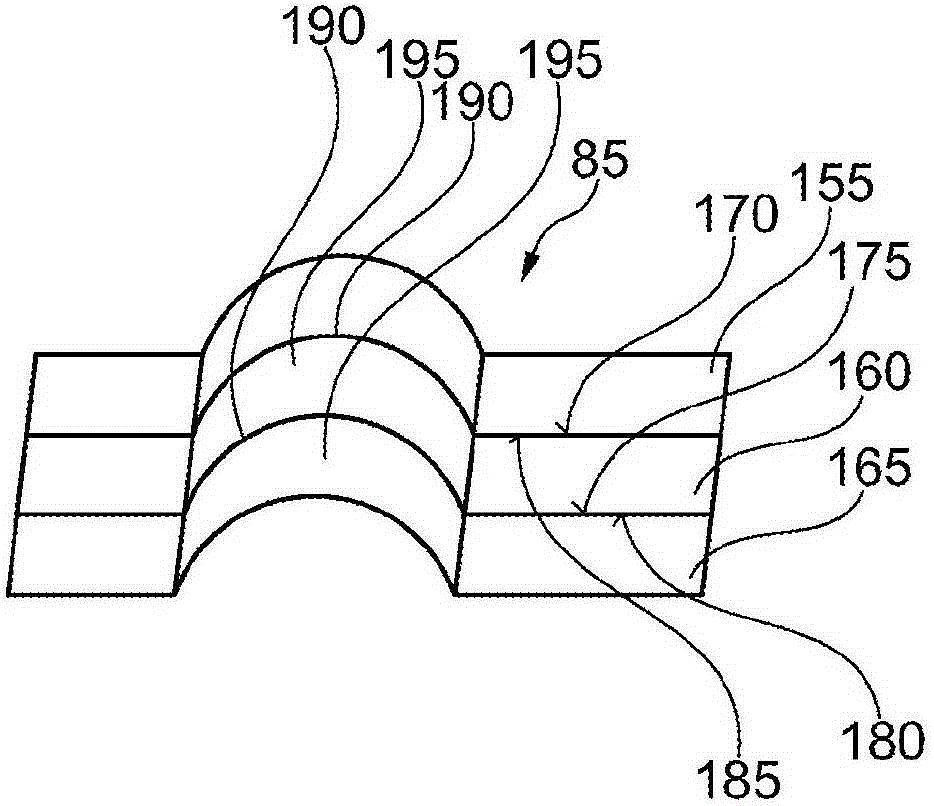

Clutch system

InactiveCN105229326AIncrease squeezeReduce extrusion pressureFriction clutchesRotational axisContact pressure

The invention relates to a clutch system (10) comprising an input side (15) and an output side (20), which sides are arranged so as to be rotatable about a rotational axis (25), and at least one friction element (55) and at least one second friction element (60), the first friction element being connected to the input side for torque transmission, and the second friction element being connected to the output side for torque transmission. The first and the second friction element can be brought in frictional engagement with each other by a contact pressure to transmit torque between the input side and the output side, at least one spring element (85) being provided that is designed to boost the contact pressure.

Owner:SCHAEFFLER TECH AG & CO KG

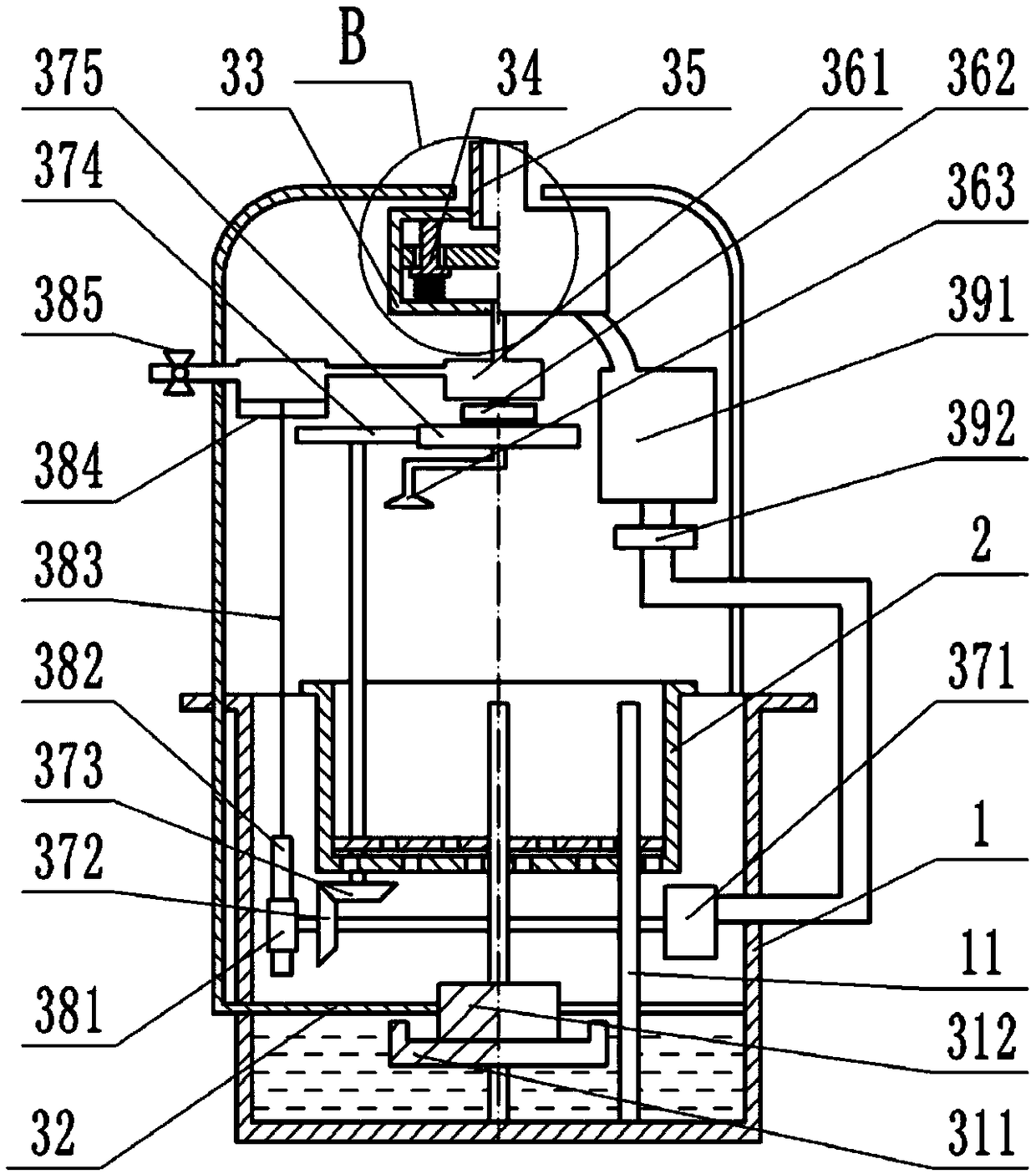

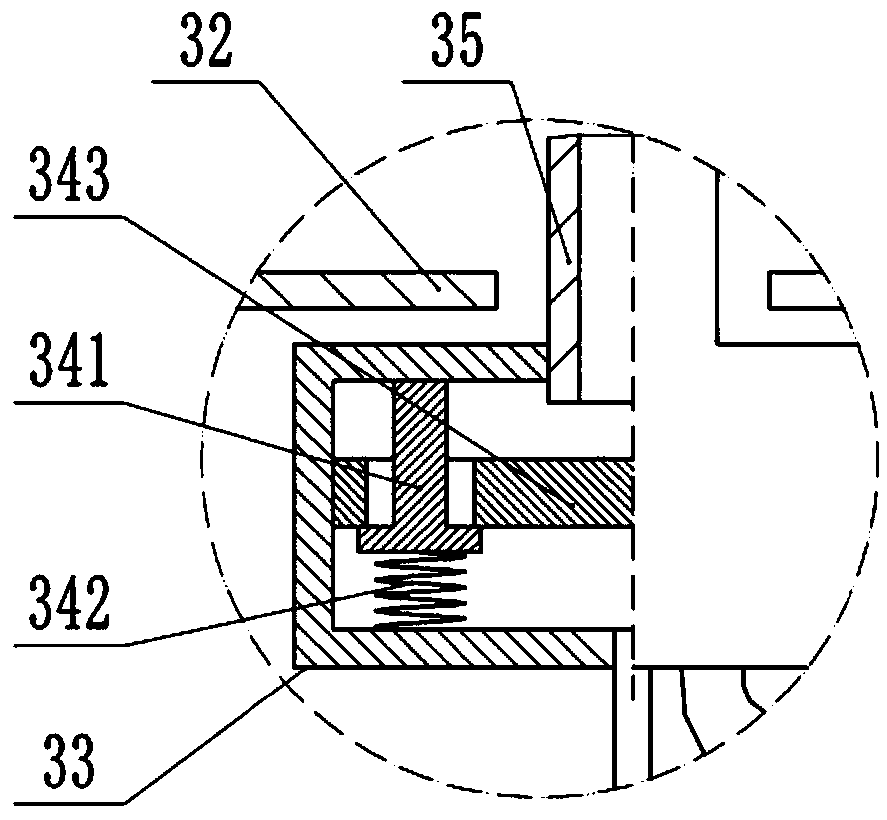

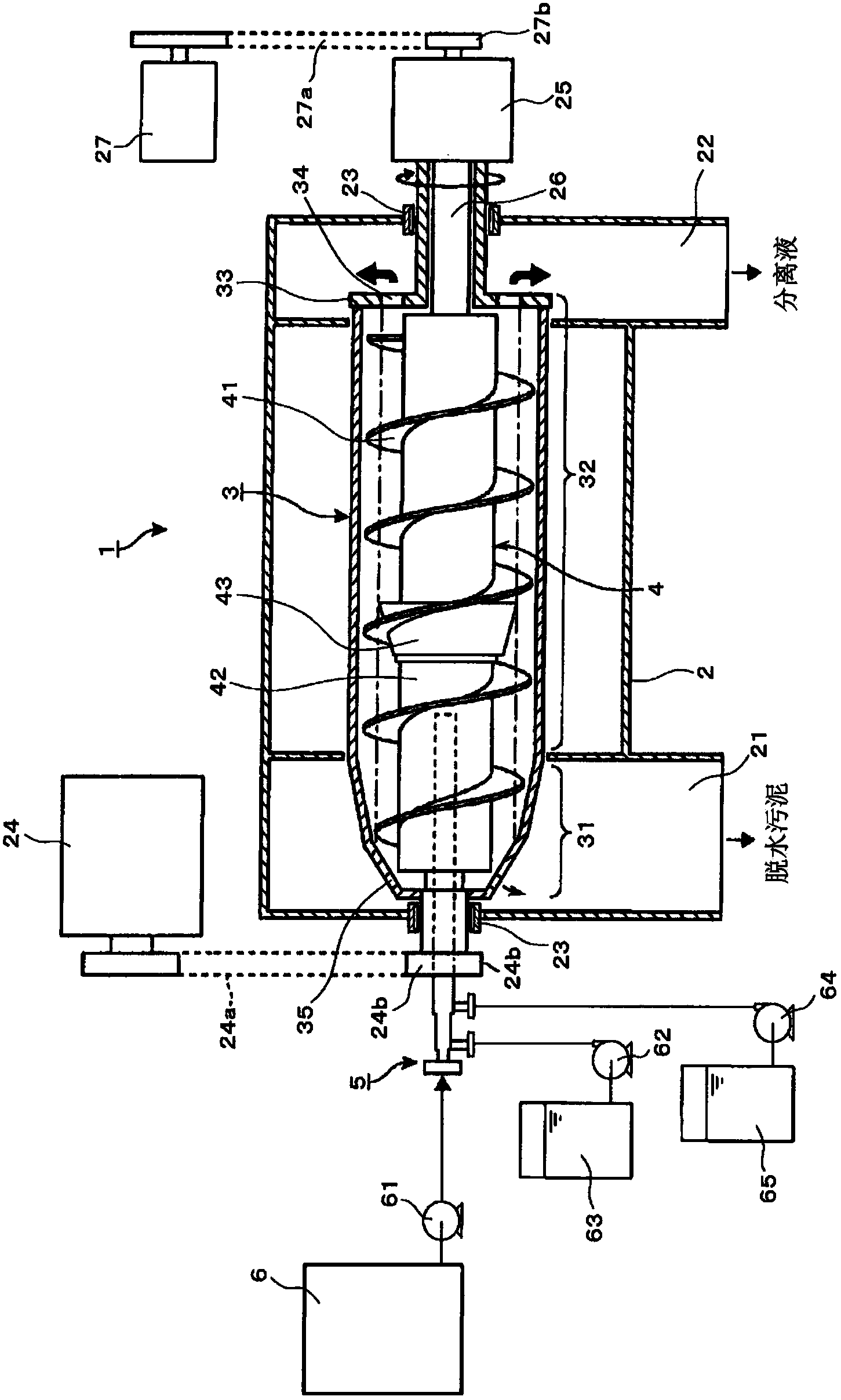

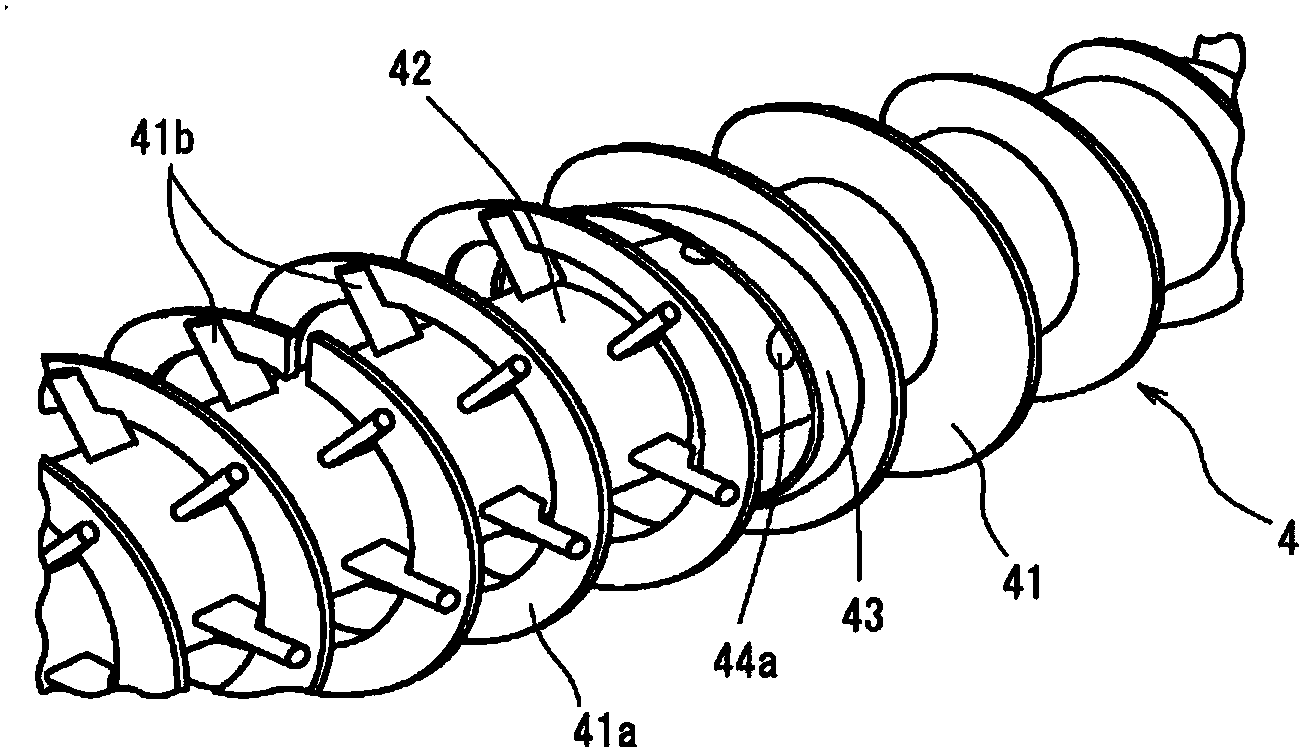

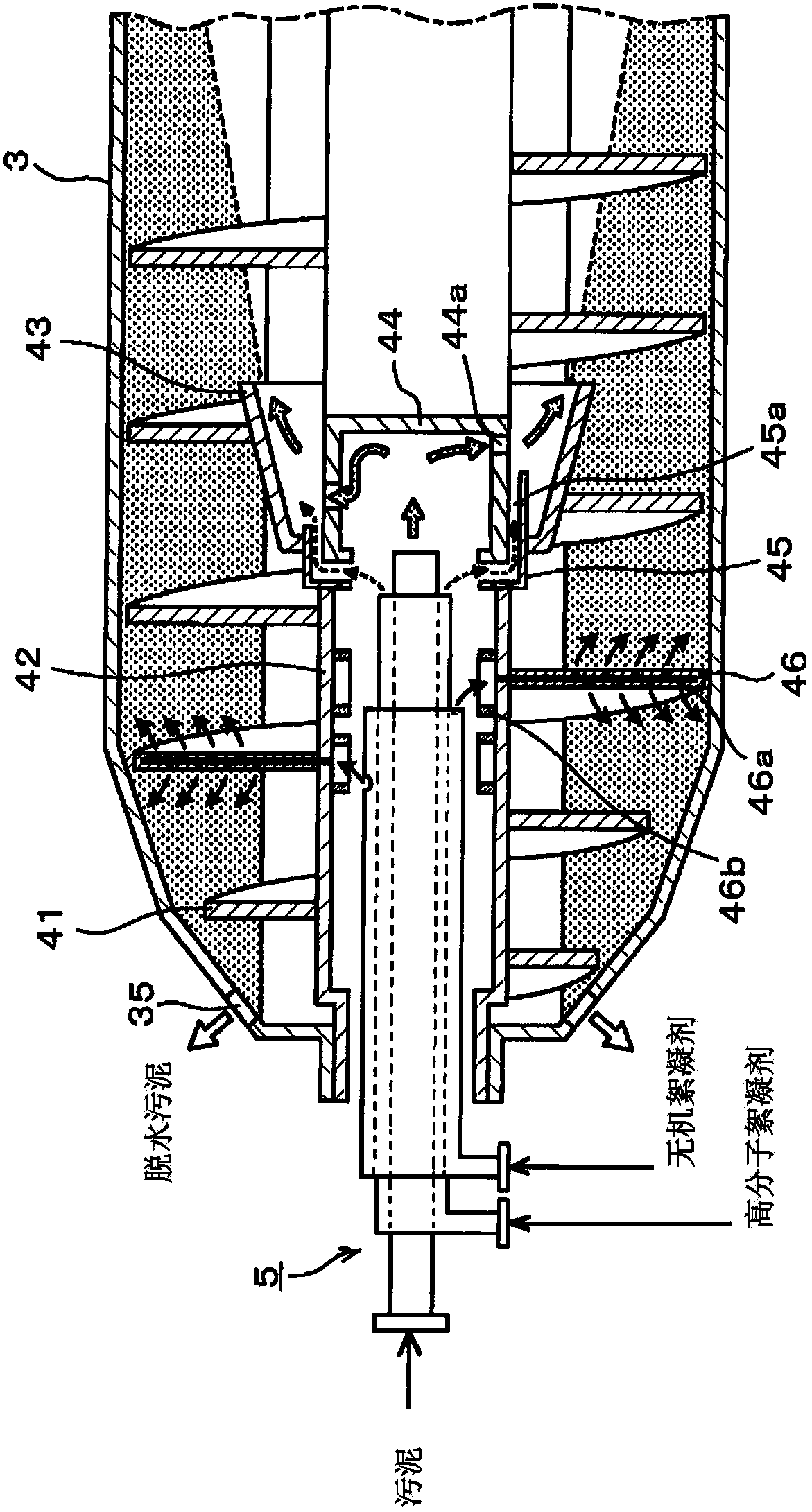

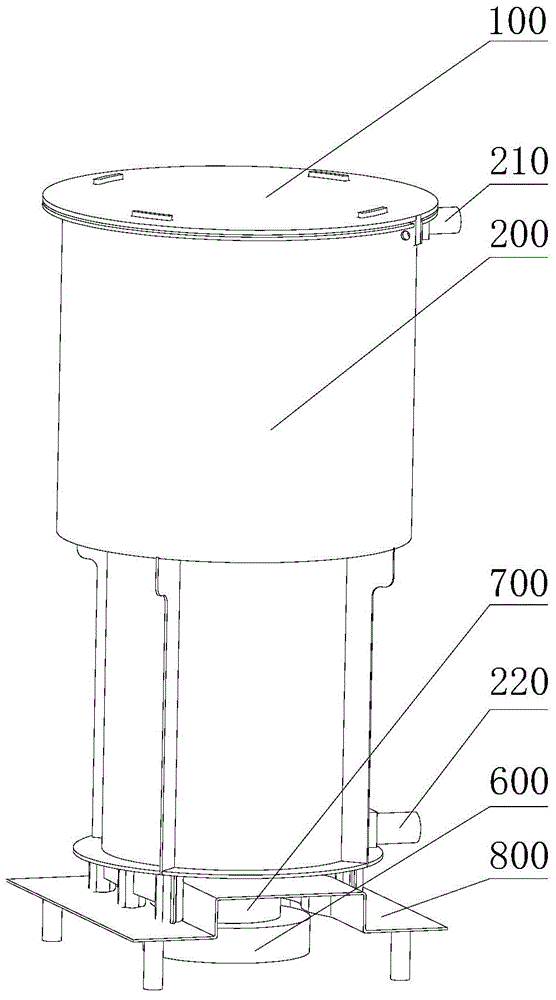

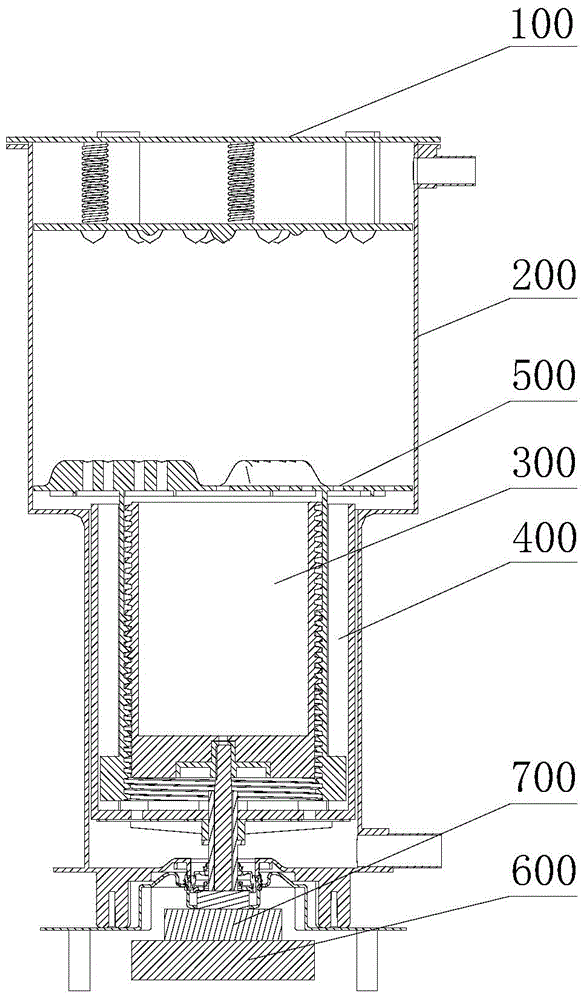

Centrifuging device and sludge dehydrating method

InactiveCN103420556AEvenly dispersedAdequate responseSludge treatment by de-watering/drying/thickeningRotary centrifugesPulp and paper industryCentrifugal force

A polymer flocculant and an inorganic flocculant are added in sludge dehydration as dehydration assistants, and the inorganic flocculant is uniformly dispersed in sludge to improve the dehydration efficiency. A centrifuging device disclosed in the invention is characterized in that the centrifuging device comprises: a rotating cylinder having a hollow cylinder portion and used for separating the sludge into dehydrated sludge and a separation liquid through utilizing the centrifuging force; a screw conveyer arranged in the rotating cylinder to rotate relative to the rotating cylinder in a relative rotating speed difference mode; a unit for supplying the sludge into the rotating cylinder; a first flocculant adding unit for adding a first flocculant into the sludge supplied into the rotating cylinder; and a second flocculant adding unit for adding a second flocculant to the sludge conveyed to the outlet of the dehydrated sludge formed in the rotating cylinder by the screw conveyer, wherein the second flocculant adding unit has an adding part partially or fully dipped in the sludge in the rotating cylinder, and the outlet of the second flocculant is arranged at the position of the part dipped in the sludge.

Owner:TOMOE ENGINEERING CO LTD

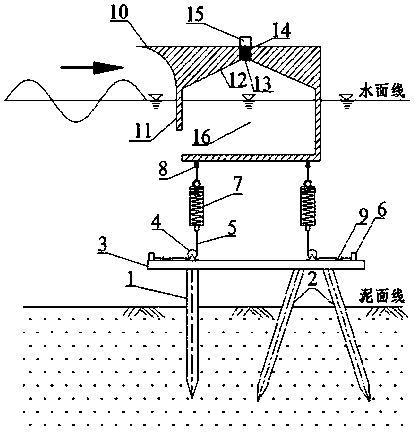

Breakwater and floating type oscillating water column generating device suitable for silty sea areas

InactiveCN108397339AReduced workload and material consumptionThe overall stability of the structure is strongBreakwatersQuaysWater columnElectric energy

The invention discloses a breakwater and floating oscillating water column type wave energy conversion device, which is especially suitable for silty seashores. The breakwater and floating oscillatingwater column type wave energy conversion device is composed of a plurality of breakwater structural units, wherein each breakwater structural unit is provided with a pile foundation so as to adapt tothe condition of insufficient bearing capacity of foundations of the silty seashores, the pile foundation formed by single straight piles and braced piles is adopted, a cylinder is used as a major structure, an extended cylinder wall is used in the cylinder, and an inverse arc-shaped front slope is designed on the front end of the cylinder structure, so that the function of wave prevention and dissipation of the breakwater is realized. A spring is arranged between the upper major structure and the lower foundation so as to realize up-and-down floating of the whole oscillating water column device. According to the breakwater and floating oscillating water column type wave energy conversion device, on the basis that original wave prevention and blocking functions of the breakwater are guaranteed, the conversion and storage of wave energy, mechanical energy and electric energy are realized, and the breakwater and floating oscillating water column type wave energy conversion device has the advantages of greenness and high environment friendliness.

Owner:ZHEJIANG UNIV

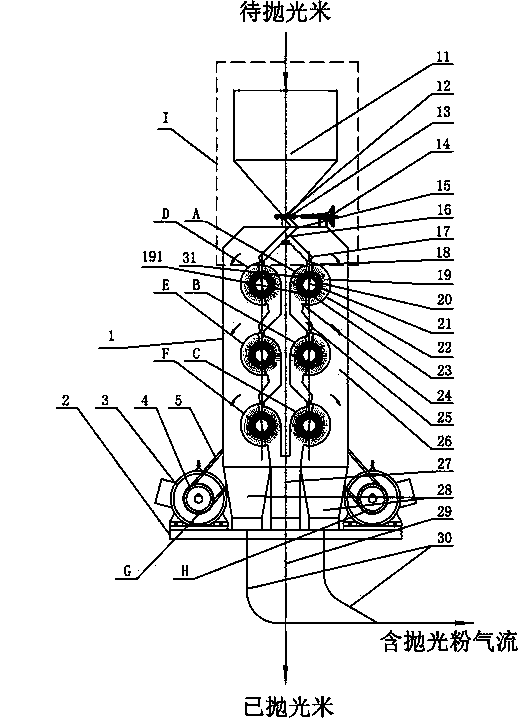

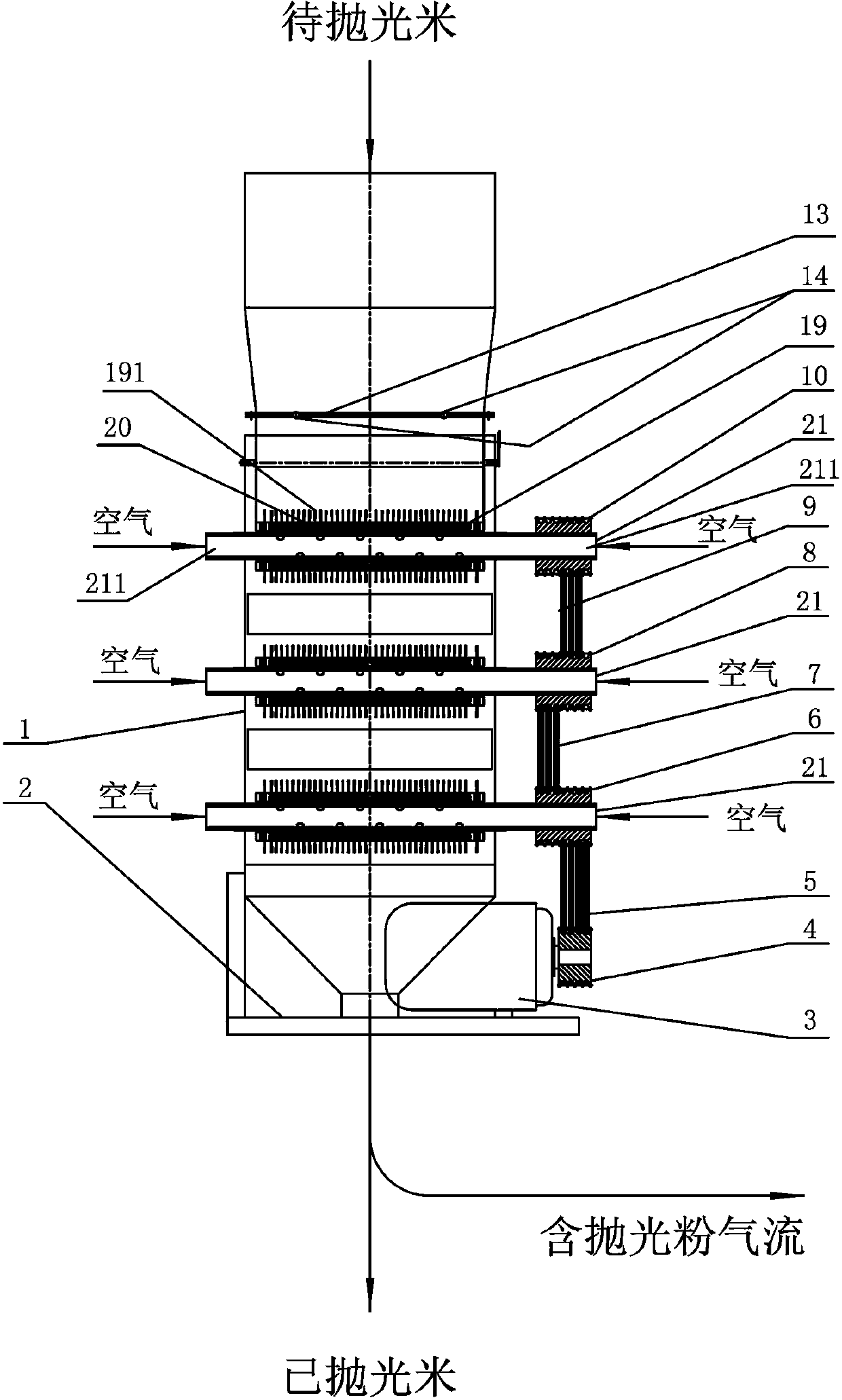

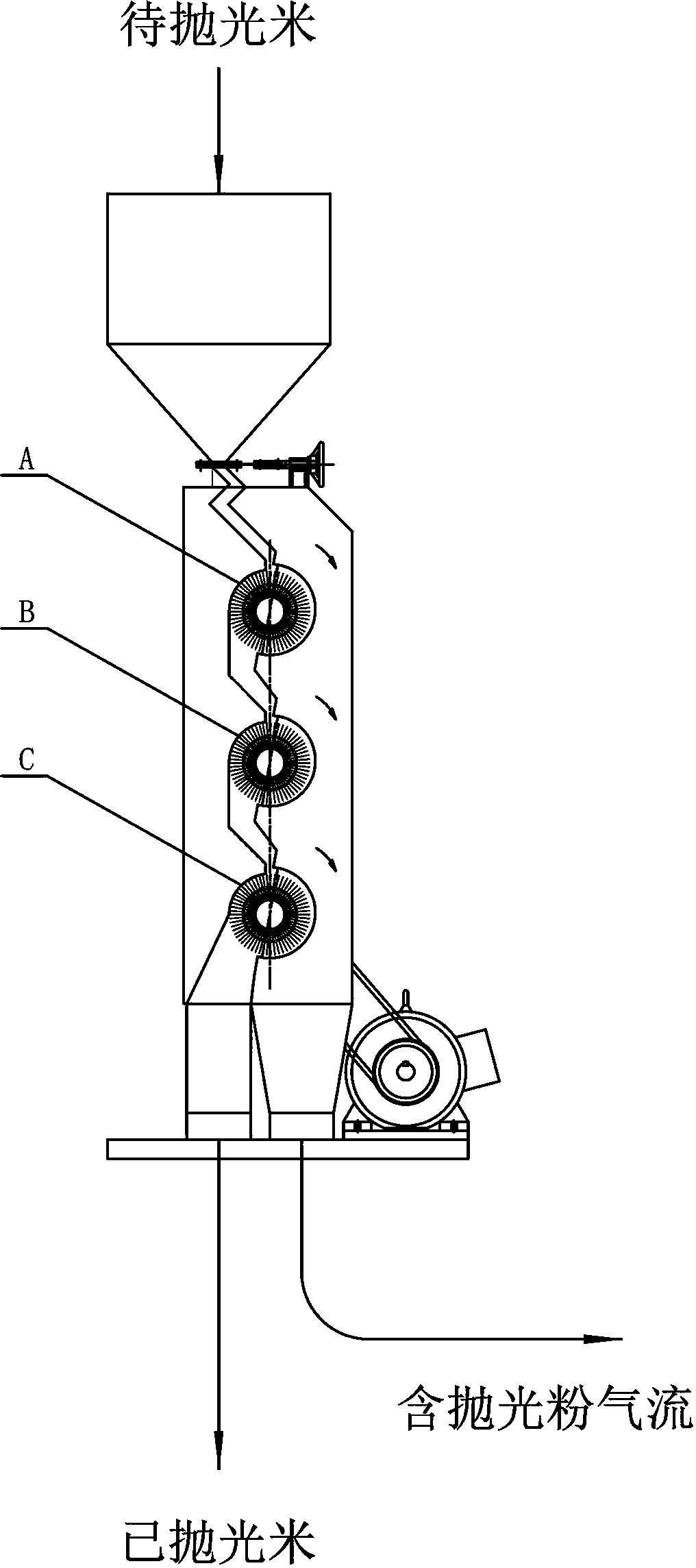

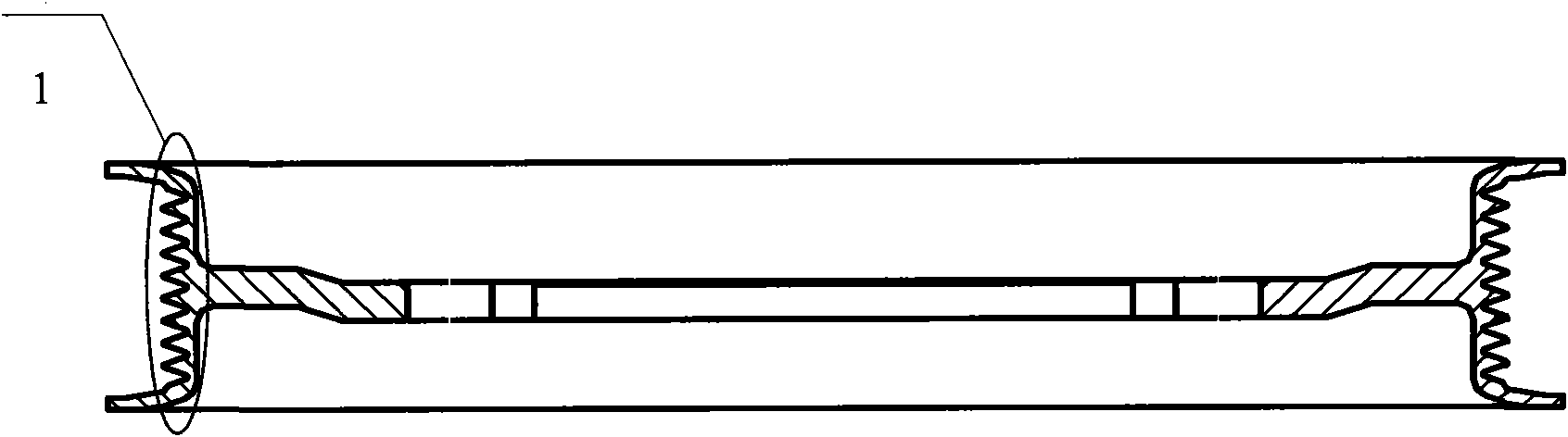

Flexible polishing device for granulated grains

ActiveCN104209156AAchieve moderate processingImprove the rice yieldGrain huskingGrain polishingFriction effectEngineering

The invention provides a flexible polishing device for granulated grains. The flexible polishing device comprises a shell, a feeding device, at least one flexible polishing unit, a bran discharging device and a rice outlet, wherein the flexible polishing unit comprises a radial gravity self-flowing flexible polishing chamber; the feeding device, the flexible polishing chamber and the rice outlet are sequentially arrayed from top to bottom along the gravity direction. According to the flexible polishing device for the granulated grains, the shear effect of the granulated grains in the polishing chamber is avoided, the flexible friction effect is improved, the damage to rice in the polishing process is greatly reduced while rice bran is cleaned and the rice is polished, the rice yield is improved and the energy consumption is reduced.

Owner:周颖

Spinning process of plate-made belt pulley and forming roller used for same

ActiveCN101879546ASlow down the flowIncrease squeezePortable liftingGearing elementsEngineeringUltimate tensile strength

The invention relates to a spinning process of a plate-made belt pulley and a forming roller used for the same. The spinning process comprises the following steps of: (1) installing a preforming roller and enabling a groove at the middle part of the preforming roller to be in T-shaped correspondence with a center line of base metal, rotating the preforming roller to be in the horizontal motion, carrying out stacked spinning and stacking the base metal outwards along the center line; (2) installing a primary-forming roller and enabling a primary-forming tooth groove of the primary-forming roller to be in T-shaped correspondence with the center line of the base metal which finishes the step (1), rotating the primary-forming roller to be in the horizontal motion, carrying out spinning on thebase metal which finishes the step (1) and enabling a groove shape of the base metal to begin to take shape; and (3) installing a finishing roller and enabling a shaped tooth groove of the finishing roller to be in correspondence with the groove shape of the base metal which finishes the step (2), rotating the finishing roller to be in the horizontal motion, and carrying out fine spinning and finishing to achieve the final groove shape of the product. The invention ensures that an aluminum magnesium alloy material is suitable for batched production and application of the plate-made spinning belt pulley, effectively reduces the product weight, solves the problems of low strength and low processing performance of the aluminum magnesium alloy material, solves the strength problem, and realizes the stable spinning production.

Owner:东风襄阳旋压技术有限公司

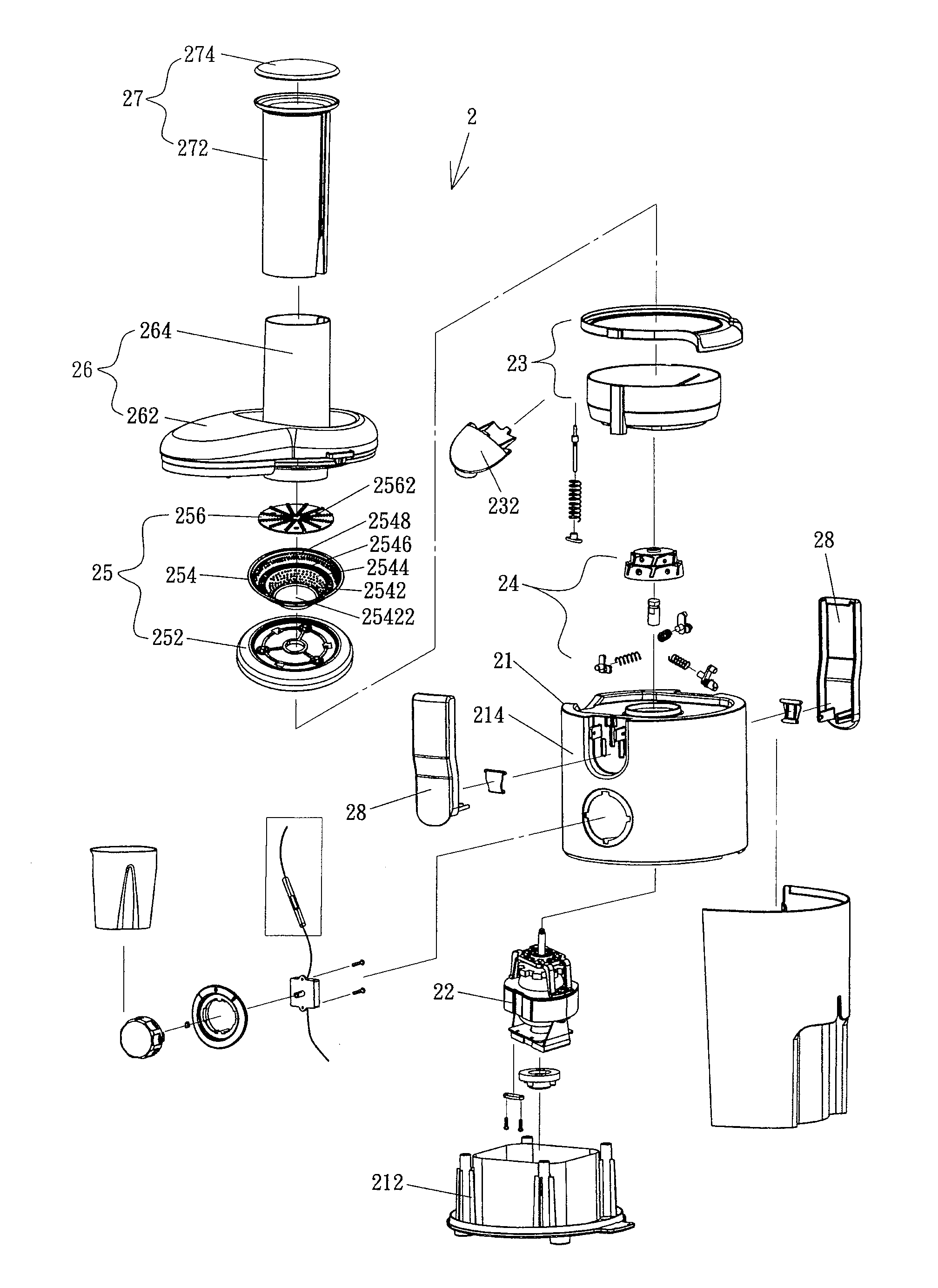

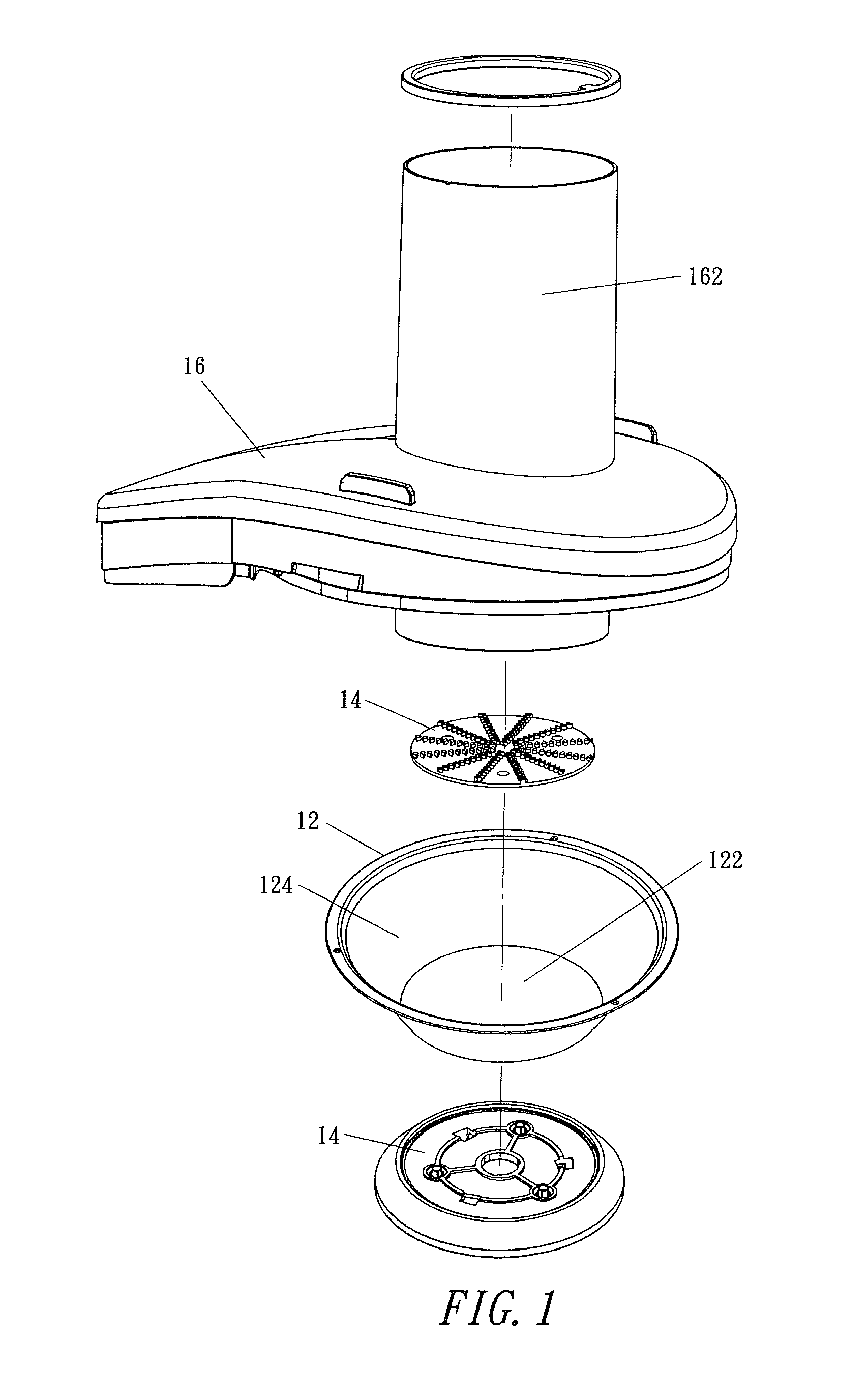

Juice Machine and Filter Thereof

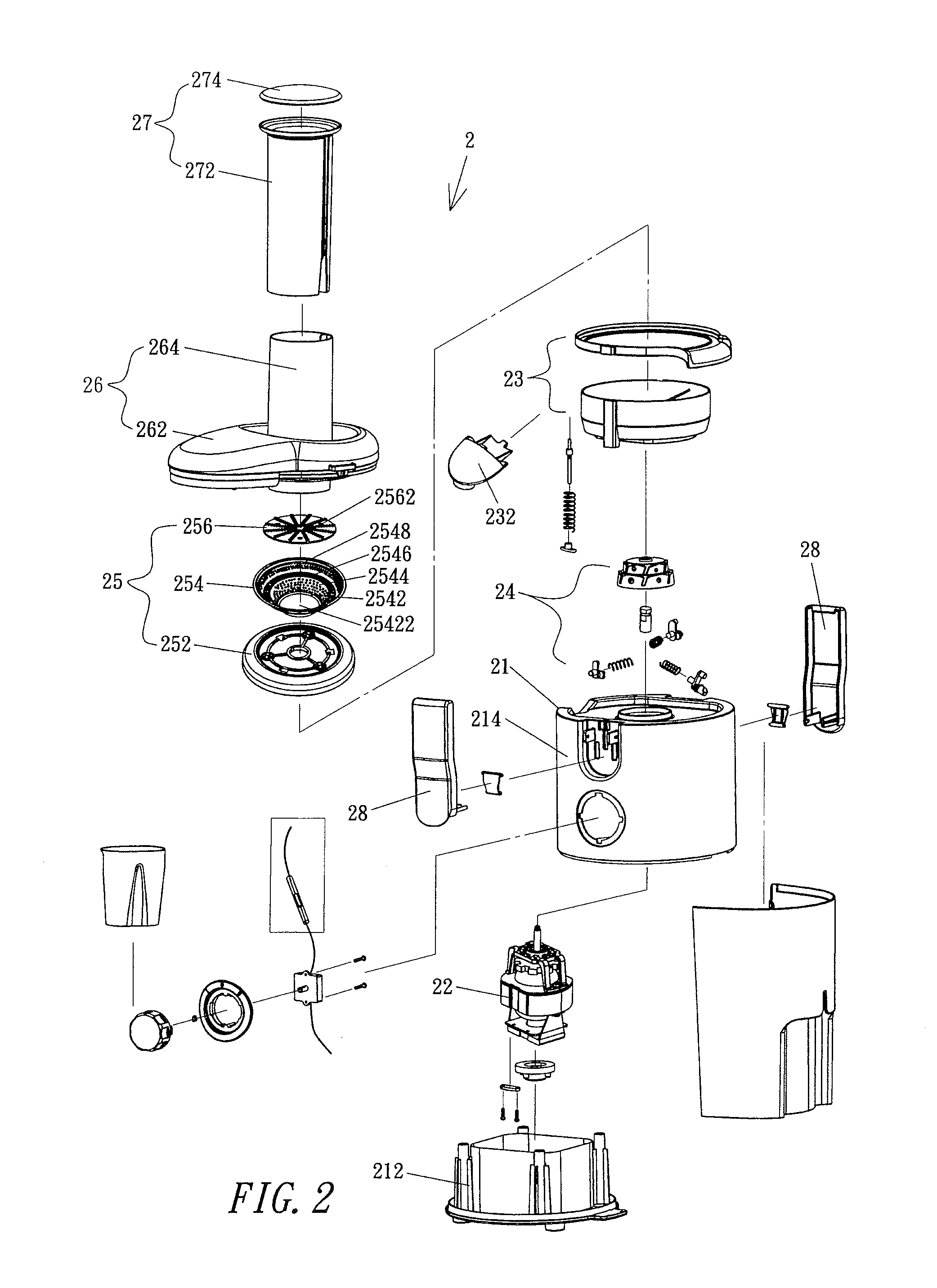

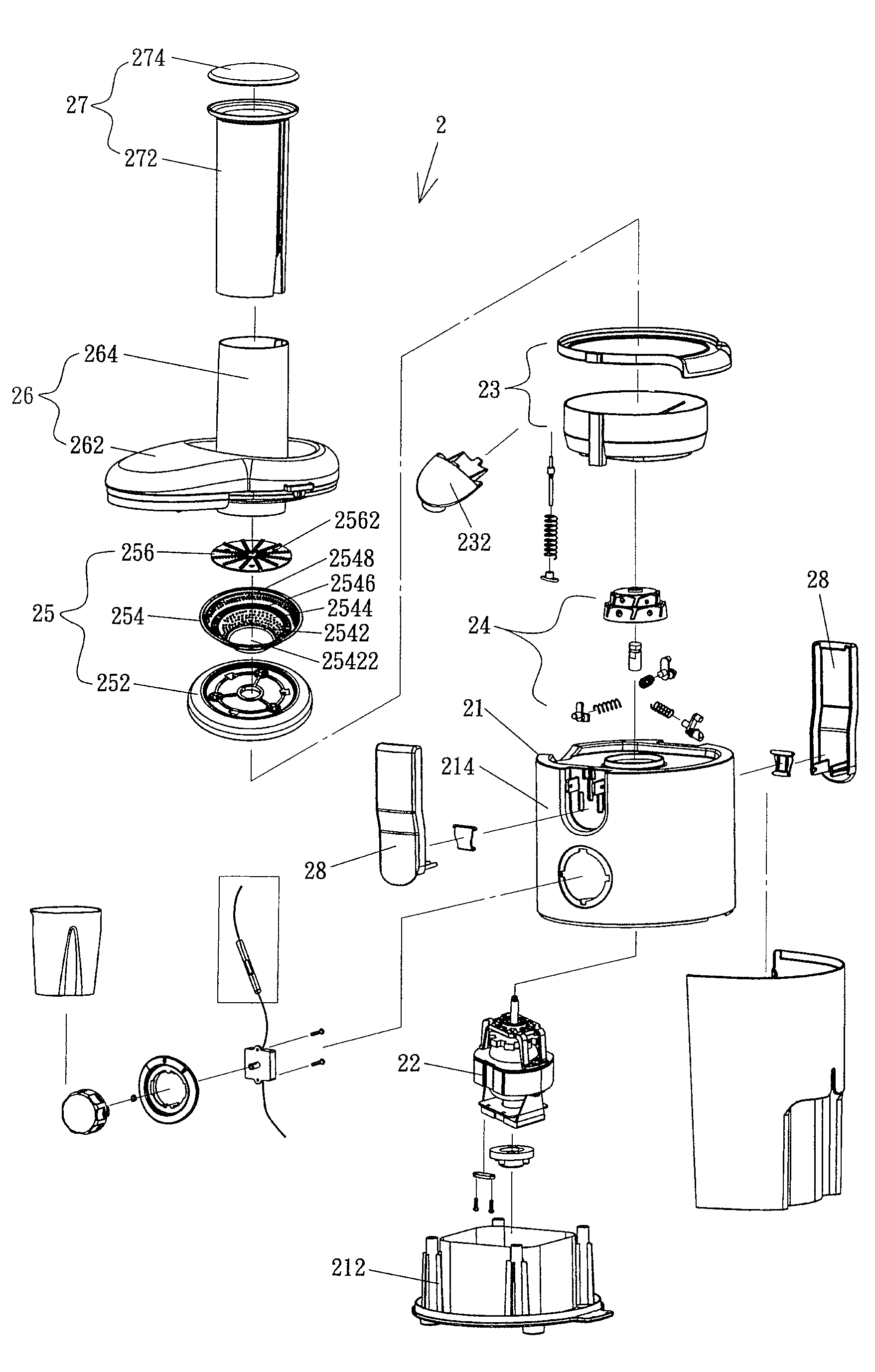

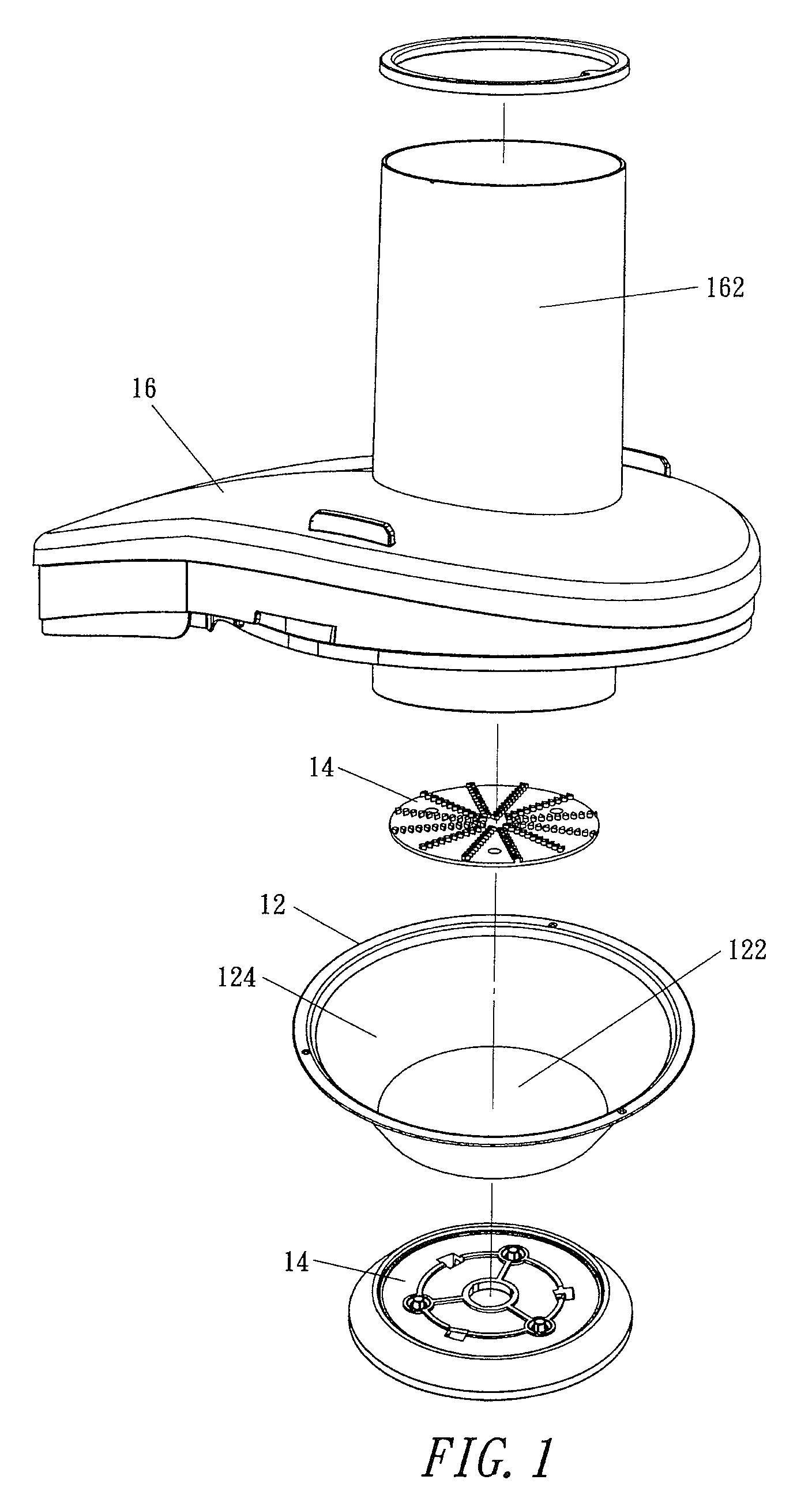

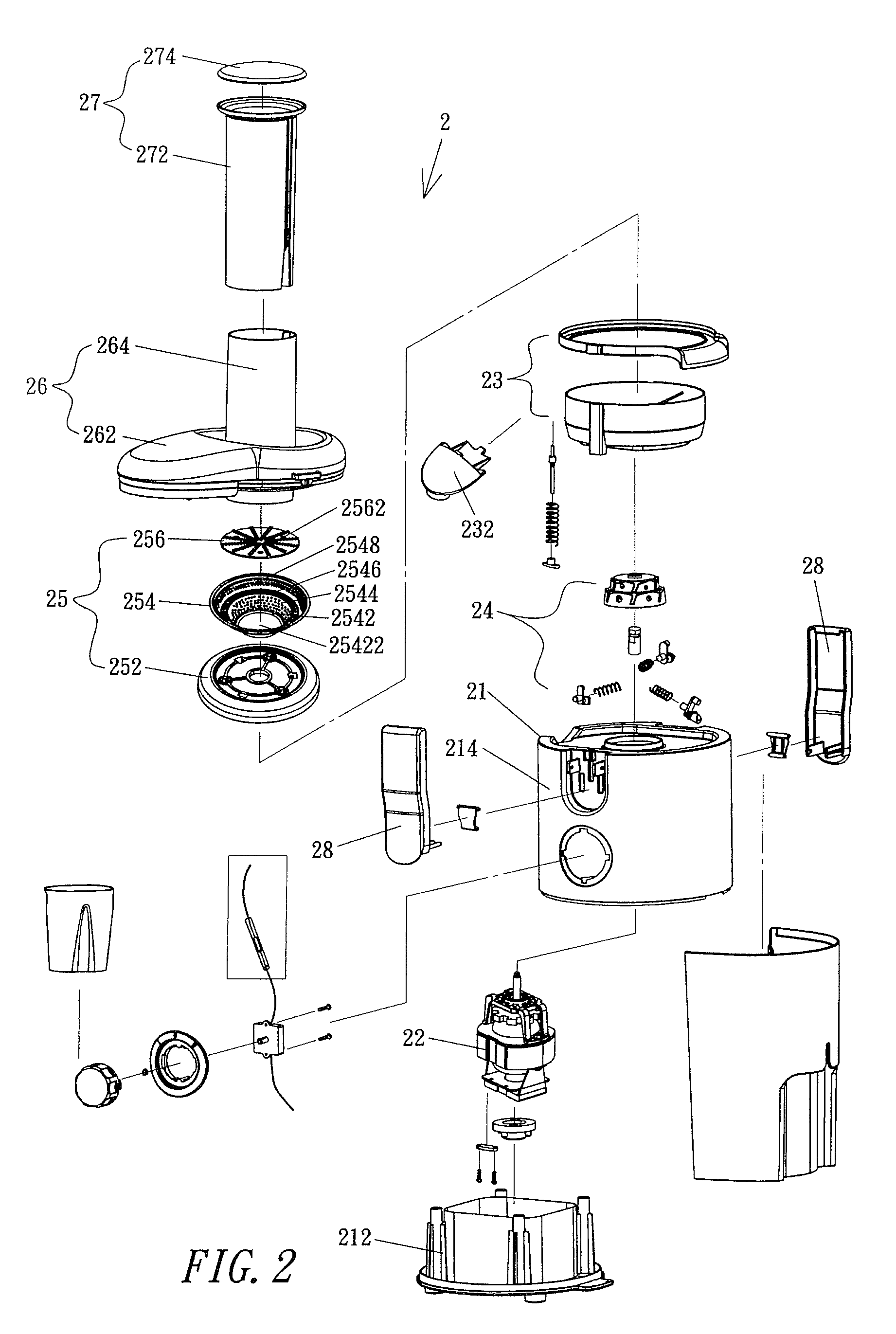

InactiveUS20120192729A1Increase the juice yieldEnhance juice juice squeezing efficiencyJuice extractionCentrifugesEngineeringFlywheel

A juice machine includes a cutter module, and the cutter module includes a cutter turntable, a filter, and a cutter flywheel. The filter includes a bottom plate, a first side plate protruded and tilted upwardly from an external periphery of the bottom plate, a filter plate horizontally extended from the top of the first side plate, a tilted second side plate protruded upwardly from an edge of the filter plate, an opening formed at the center of the bottom plate, a plurality of first meshes formed on the first side plate, a plurality of second meshes formed on the filter plate, a plurality of third meshes formed on the second side plate. Therefore, the weight of the filter can be decreased to provide a stable filter and reduce vibrations and noises. The juice machine can enhance both juice squeezing efficiency and juice yield.

Owner:YA HORNG DONG GUAN ELECTRONICS +1

Juice Machine and Lid Thereof

A juice machine includes a lid, and the lid includes an upper casing, a feeding barrel, and a block member. The feeding barrel is installed on the upper casing, and the feeding barrel is hollow inside. The block member is surrounded around an external side of the bottom of the feeding barrel. The juice machine can enhance both juice squeezing efficiency and juice yield.

Owner:YA HORNG DONG GUAN ELECTRONICS +1

Compression granulator

InactiveCN102727384AImprove molding qualityLarge processing viscosityPharmaceutical product form changeEngineeringViscosity

The invention discloses a compression granulator which granulates more uniformly, and comprises a double-screw type extrusion feeding device in a handpiece and a discharging barrel which is matched with the extrusion feeding device, wherein the discharging barrel is sequentially provided with a collection tray with a central hole, a distribution part and an extrusion plate, the outer part of the extrusion plate is provided with a rotary cutter with an elastic part, distribution chutes are uniformly distributed at the feeding side of the distribution part, the discharging side of the distribution part is provided with a central boss and a support block, all the distribution chutes are converged at a discharging chute, the central hole has gradual diameter change, the discharge hole of the extrusion plate also has gradual diameter change, and cooling structures are respectively arranged on screws and spiral tubes of the double-screw type extrusion feeding device. The compression granulator uniformly discharges, can adapt to larger extrusion force, processes materials with larger viscosity, operates stably, has good reliability, and is particularly suitable for processing pharmaceutical particles.

Owner:SICHUAN JINSUIFANG PHARMA

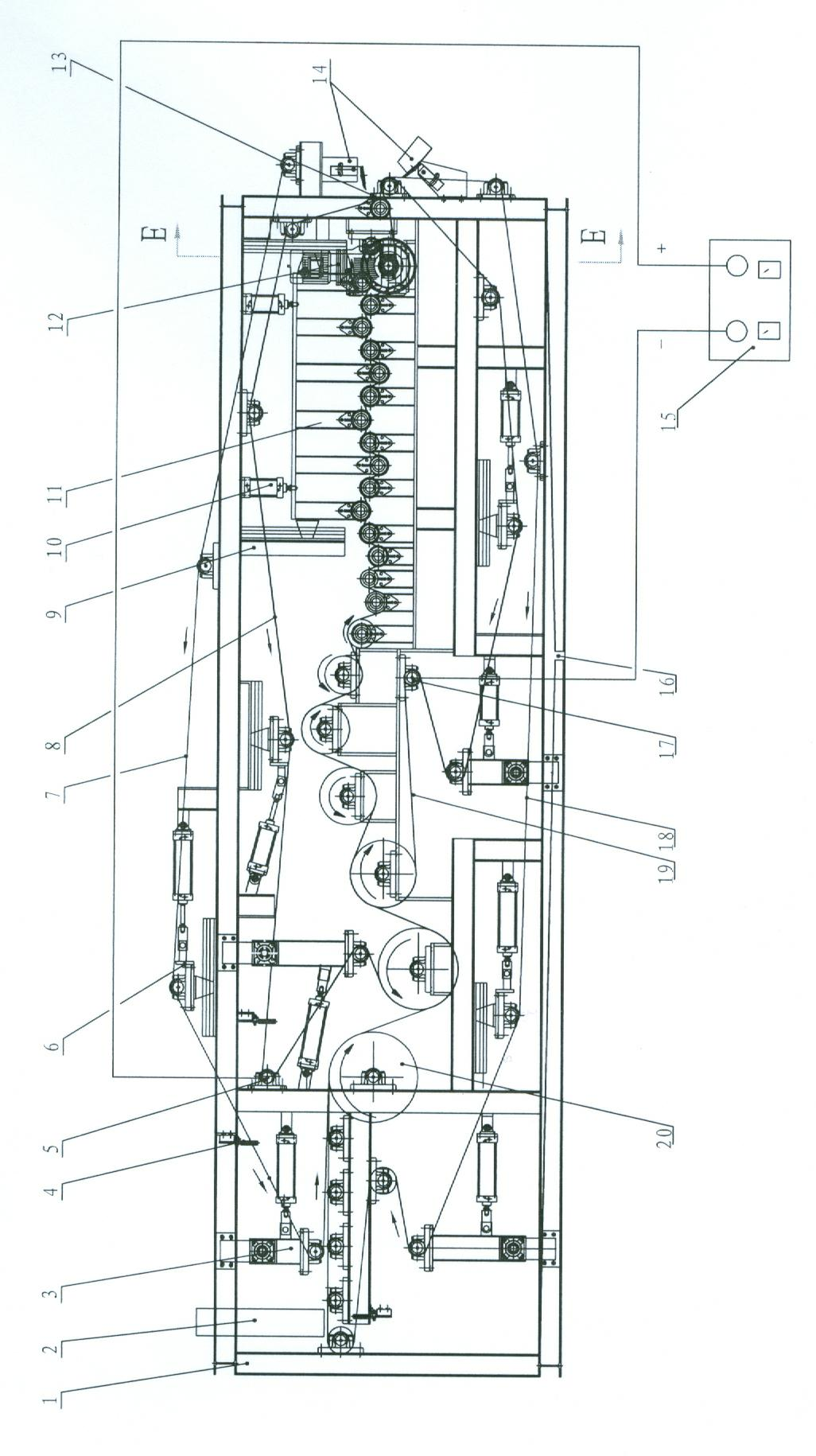

Electrolytic filtering/squeezing integrated sludge dewatering machine

ActiveCN102115302AIncrease productivitySmall footprintSludge treatment by de-watering/drying/thickeningSludge cakeInterstitial water

The invention discloses an electrolytic filtering / squeezing integrated sludge dewatering machine which comprises a primary squeezing and filtering region, an electrolytic filtering region, an electrolytic squeezing region and an external direct current power source, wherein the primary squeezing and filtering region, the electrolytic filtering region and the electrolytic squeezing region are sequentially arranged with one anther by taking a frame as a carrier. The sludge fallen from a hopper is primarily squeezed and filtered to remove the free water contained in the sludge. A driven upper filter strip and a driven lower filter strip are respectively and externally leaned against an upper squeezing strip and a lower squeezing strip connected the two poles of a direct current power source, so that the sludge clamped between the upper squeezing strip and the lower squeezing strip is electrolyzed, and the interstitial water and the cellular water in the sludge flow to the negative pole when the electric charge flows, i.e. the electrophoresis. The incompletely-dried sludge is carried into the electrolytic squeezing region and is forced under the condition that the sludge is stilled electrolyzed to accelerate the dewatering. By sequentially reducing the diameters of a plurality of the roll shafts and by adopting an installation technology measure that the adjoining roll shafts are installed in a misplaced way up and down, the machine can dewater by sequentially forcing, so that the dryness of a sludge cake is improved. The machine is particularly suitable for treating the biochemical active sludge precipitated by the urban domestic sewage or the industrial sewage.

Owner:江苏百新环境工程有限公司

A reciprocating squeezing type and rotation type washing machine

ActiveCN105088605AImprove washing effectImprove cleanlinessOther washing machinesTextiles and paperPistonEngineering

The invention provides a reciprocating squeezing type and rotation type washing machine comprising an outer barrel. The outer barrel comprises a washing cavity in the upper portion and a control cavity in the lower portion; a piston is arranged in the washing cavity; the control cavity is internally provided with a flange barrel and a transmission mechanism arranged in the flange barrel; the piston is connected with the transmission mechanism and the flange barrel; the transmission mechanism can drive the piston to reciprocate up and down; the flange barrel can drive the piston to rotate. The invention provides the washing machine washing clothes by using the piston to squeeze the clothes in a reciprocating manner; at the same time, the piston rotates in the process of reciprocating, so that the clothes is also washed through rotation. The washing machine integrates the reciprocating squeezing mode and the pulsator rotation mode of the conventional washing machines, thereby being capable of washing clothes through squeezing and improving the washing effect through rotation. Thus, the clothes washing degree is increased.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com