Electro-wetting display unit and electro-wetting display system

An electrowetting display and electrode technology, applied in the direction of optical components, optics, instruments, etc., can solve the problems of reducing the contrast and transmittance of the display, affecting the display effect, and occupying non-polar fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the content of the present invention clearer and easier to understand, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

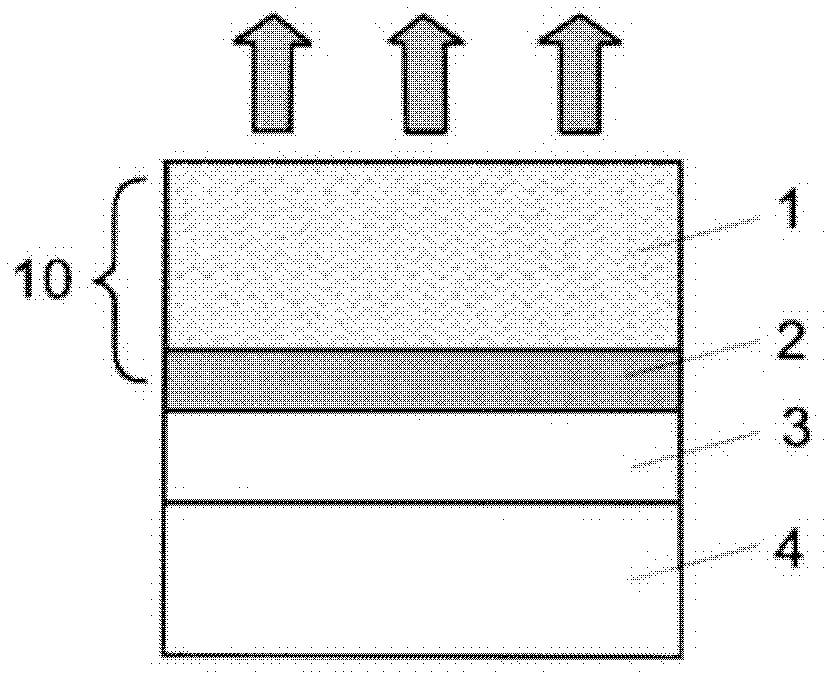

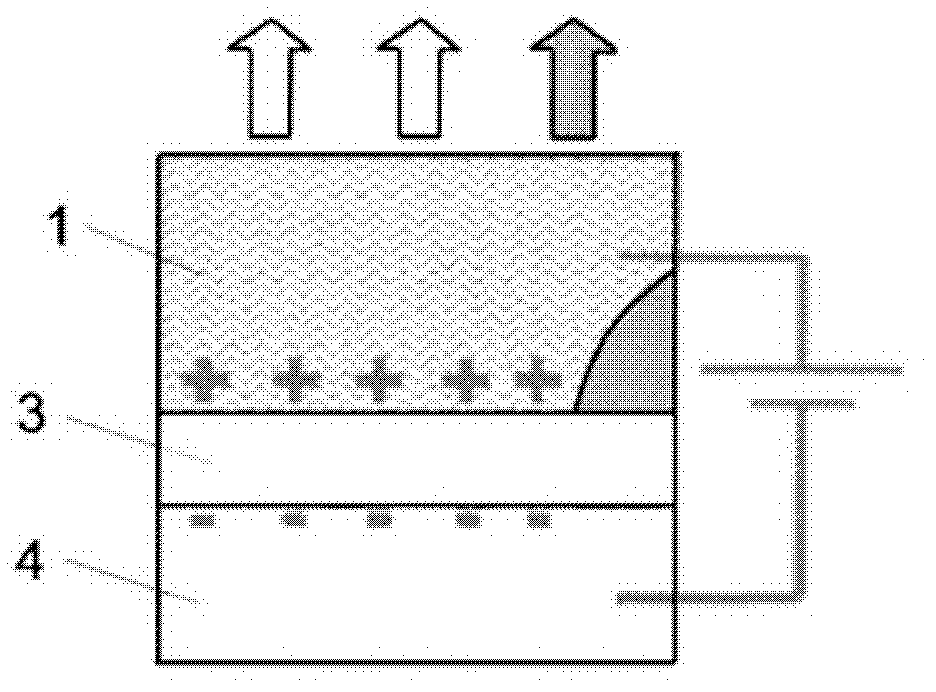

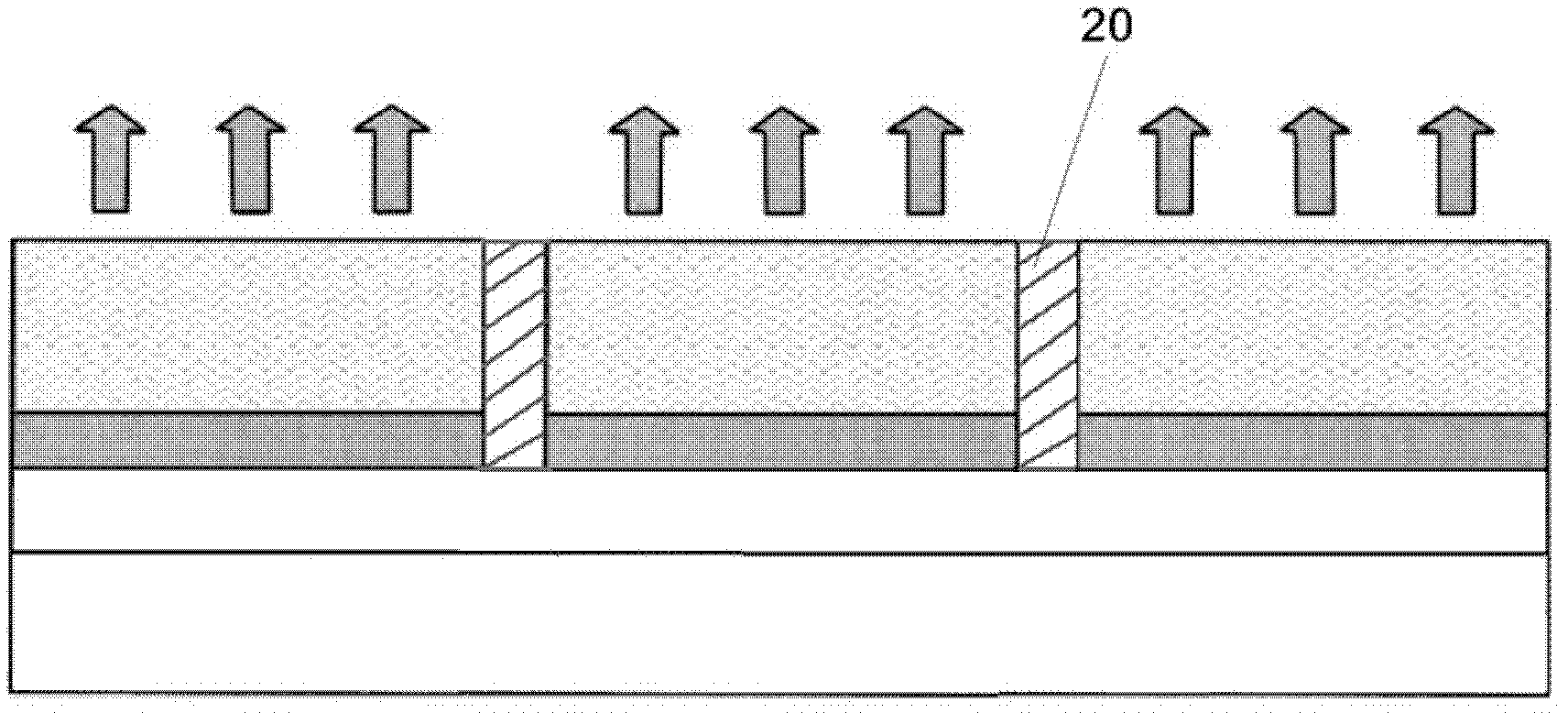

[0025] Figure 1a A cross-sectional view of an electrowetting display unit in the prior art is schematically shown. From Figure 1a It can be seen that the dielectric layer 3 is interposed between the fluid chamber 10 and the electrode 4 , and its contact surface with the non-polar fluid 2 is a flat surface. right Figure 1a When a voltage is applied to the electrowetting cell shown, the contact surface becomes more hydrophilic (wetted), since the previously water-resistant surface now becomes more water-absorbent, the non-polar fluid layer must not move under surface tension. Without changing its existing form, it changes from flat film to the corner of the display unit, such as Figure 1b shown. From Figure 1a and Figure 1b As can be seen from the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com