Electrolytic filtering/squeezing integrated sludge dewatering machine

A sludge dewatering machine and sludge technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of unsatisfactory, unsatisfactory efficiency, and no sequential increase of filter belt tension, etc., to achieve low investment and high production efficiency , The effect of small equipment occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

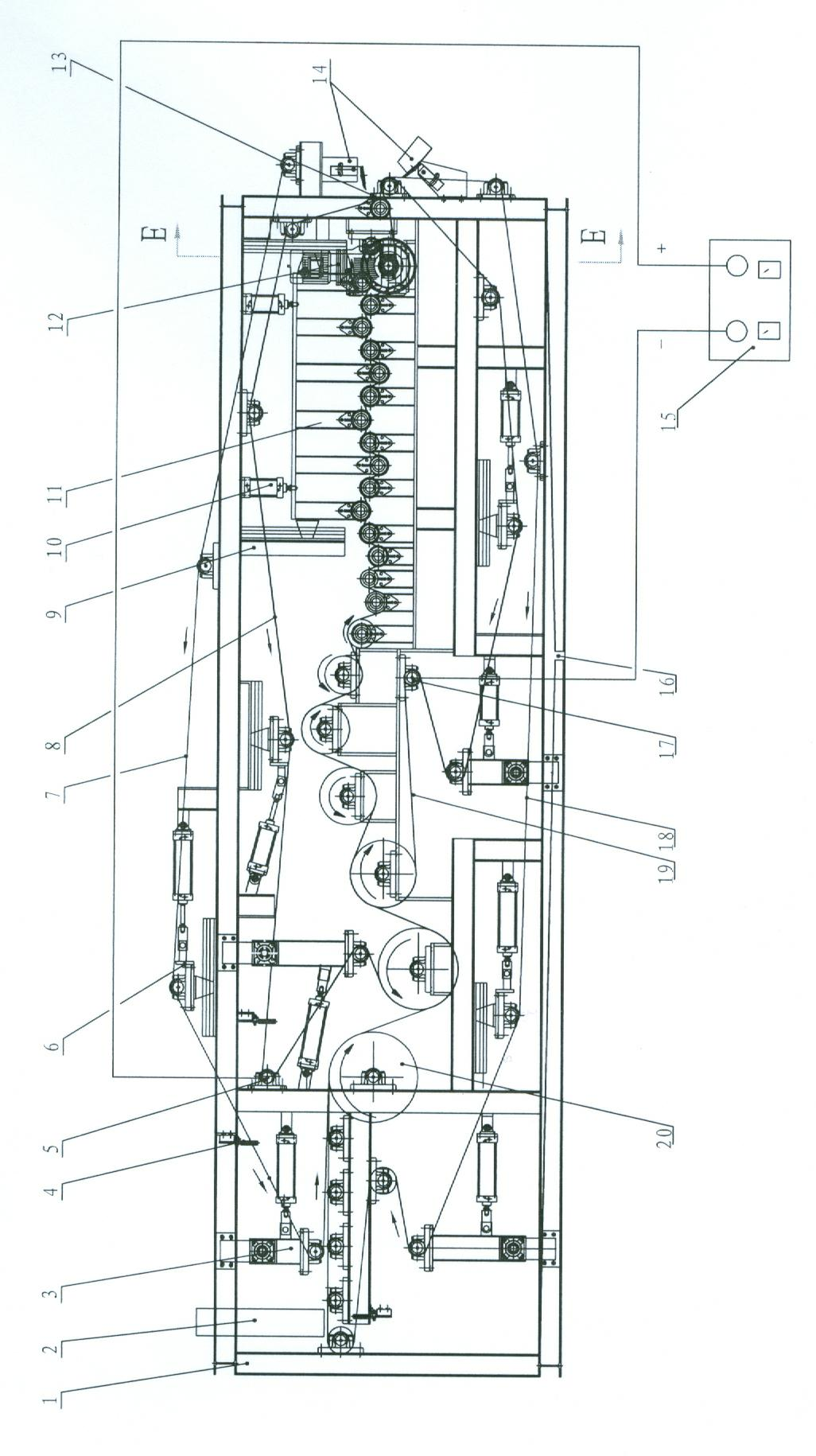

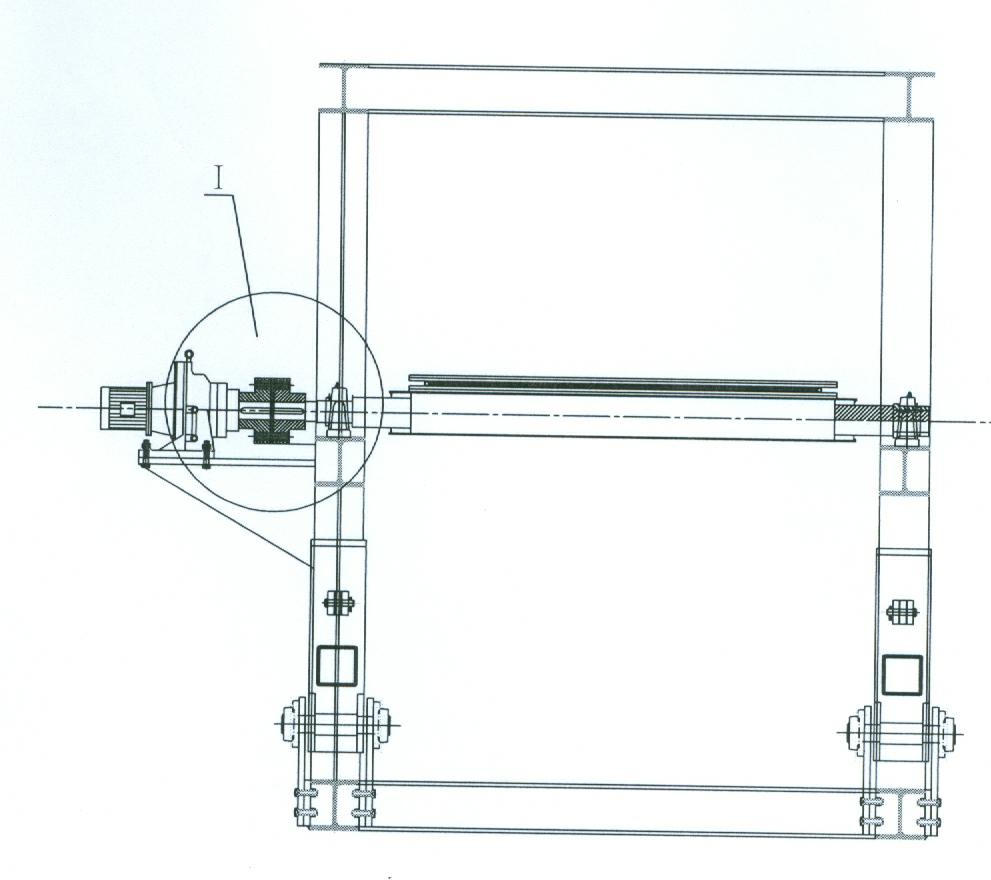

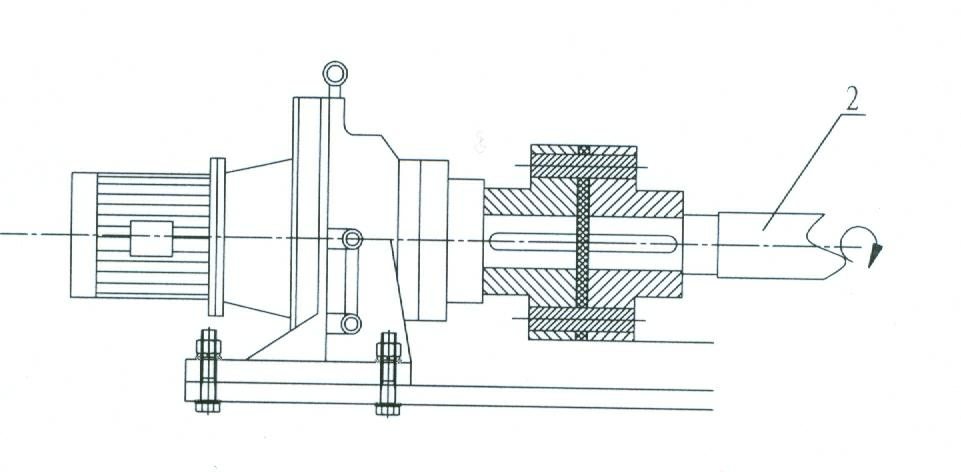

[0019] The accompanying drawing is a structural schematic diagram of an embodiment of an electrolytic filter press integrated sludge dewatering machine that processes 20 tons of sludge per day. It includes an initial pressure filter area, an electrolytic filter press, and area and electrolytic pressing area, and an external DC power supply 15. The frame 1 is a rectangular frame in a lying position, with stepped structural brackets installed in order to install horizontal roller shafts 20, and a water accumulation tray 16 is provided at the bottom. The upper and lower parts of the frame 1 are respectively equipped with a tensioning device 3, a deviation correcting device 6 and a guide wheel 13 to jointly support the flexible ring-shaped upper filter belt 7, upper press belt 8, lower filter belt 18, lower press belt 19 and sequentially ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com