Patents

Literature

1334results about How to "Improve dehydration efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Press type sludge dehydration equipment

ActiveCN1837109AImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningPistonOutfall

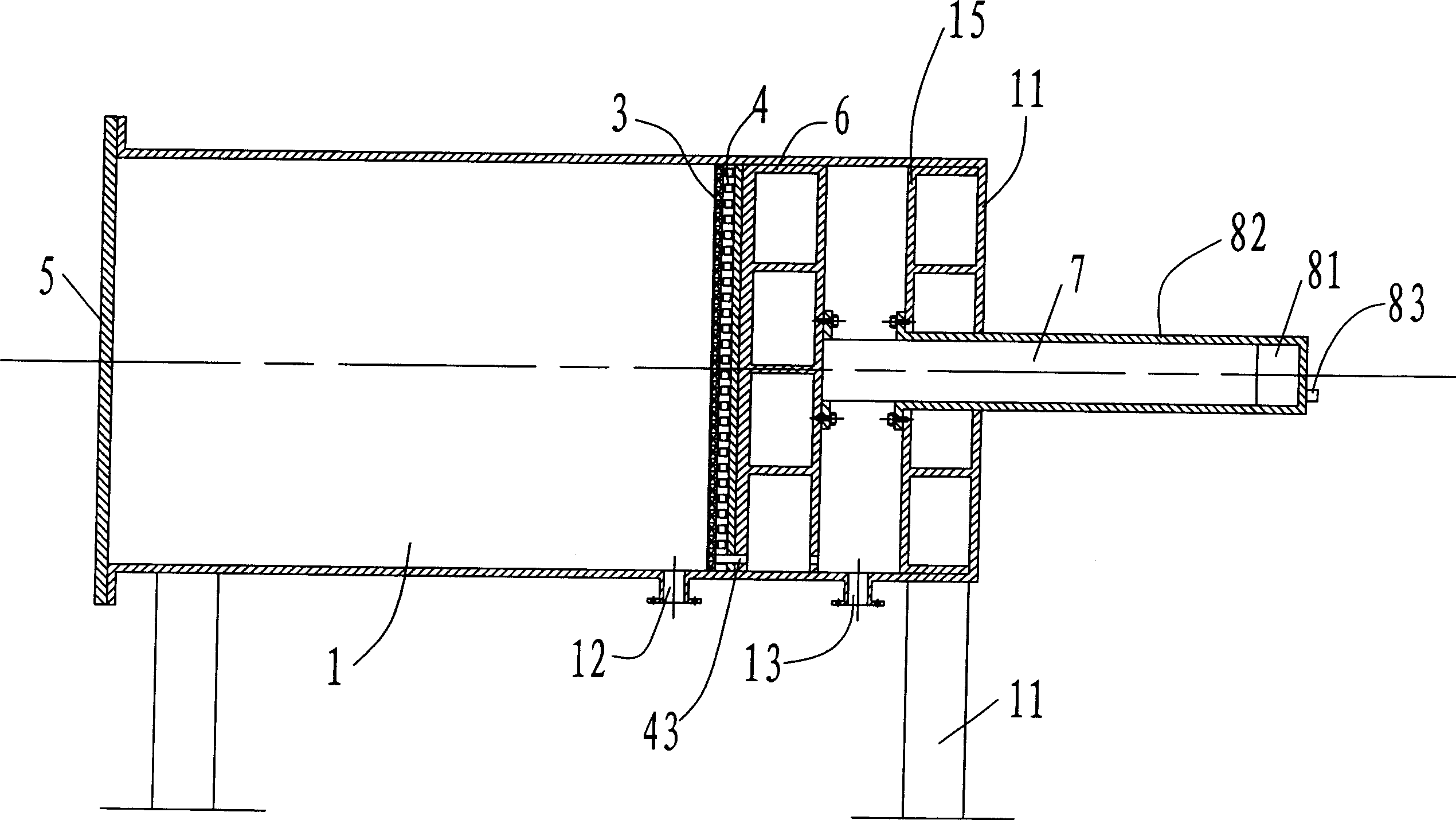

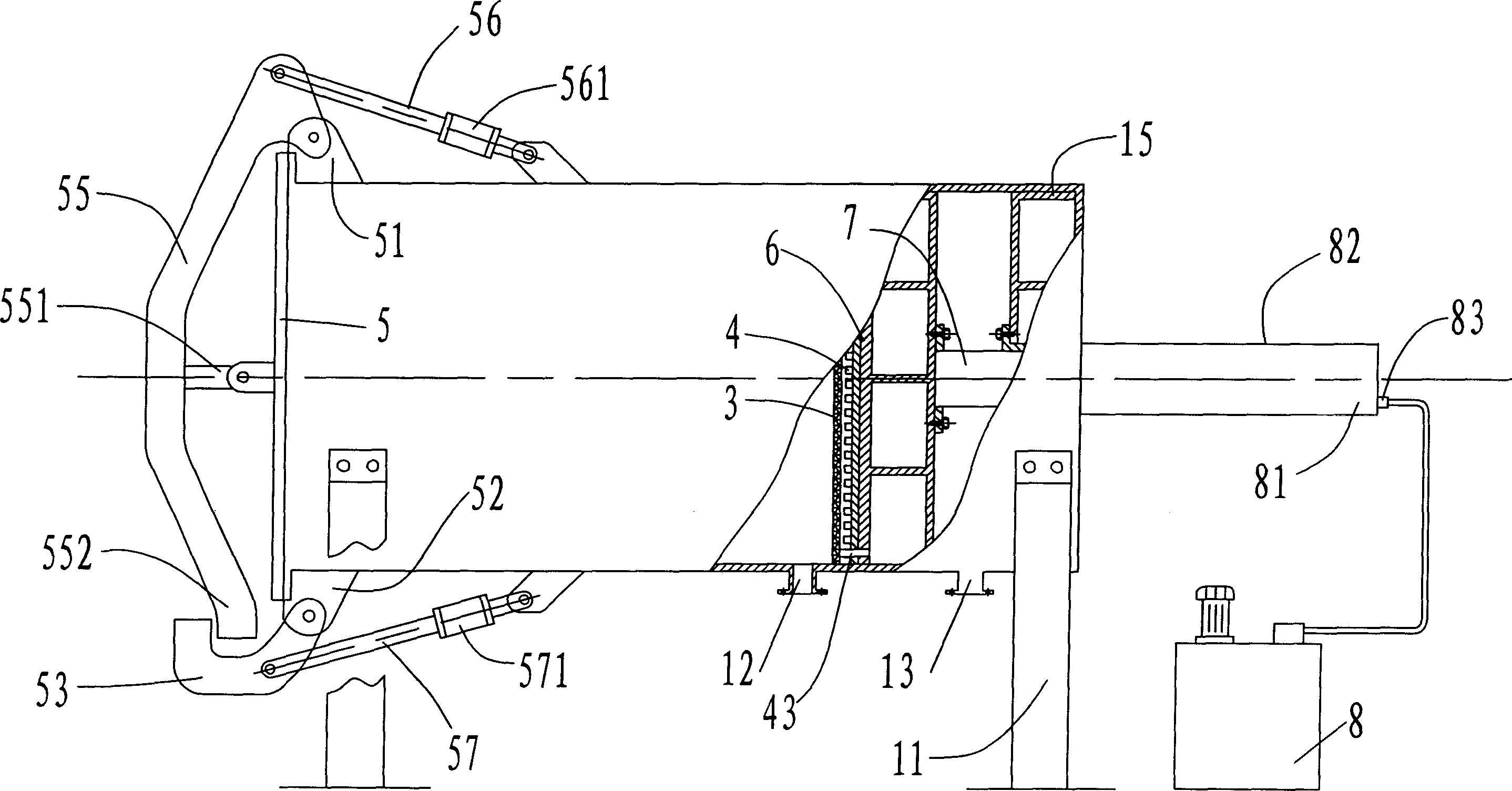

The invention discloses a pressing type sludge dewatering device, which comprises the straining chamber with feed head and outfall on the jamb wall, wherein the feed head connects to sludge transfer pump; the face side of filter pad is bundled by chain cloth; the filter pad installs colature discharging channel connecting to outfall; the straining chamber is cartridge-form straining chamber; the front end of straining chamber is sealed by openable thrust cover board; the rear end of straining chamber is sealed by the baffle; the filter pad is instaleed in straining chamber opposite thrust cover board; the circumferential of filter pad clings to cartridge-chamber of straining chamber; the opposite sides of filter pad connects to gas piston, which crosses the baffle and realizes the axial shuttle with connecting bar next to gas piston relying on the first propulsion plant; the outfall is between baffle and filter pad; the feed head is located between pulling-cover board and filter pad; the primary sludge is pressed by pressure of transfer pump; the sludge after primary pressing is pressed with more pressure by gas piston, so the squeeze ratio of sludge improves.

Owner:JIANGXI JDL ENVIRONMENTAL PROTECTION CO LTD

Quick preparation method for pickled vegetable containing biodiasmin

InactiveCN103120294AImprove production efficiencyIncrease productivityFood preparationVegetable processingSalt content

The invention provides a quick preparation method for a pickled vegetable containing biodiasmin. The quick preparation method comprises the following steps of: preparing biodiasmin liquor, preparing pickled vegetable fermentation liquor, preparing a seasoning fermentation liquor, pre-treating and preparing a finished pickled vegetable containing biodiasmin. According to the quick preparation method disclosed by the invention, the pickled vegetable fermentation liquor is independently prepared according to the conventional pickled vegetable production way, and the pickled vegetable fermentation liquor is treated by seasoning to form seasoning fermentation liquor; osmotic dehydration and the brittleness-keeping treatment are carried out on the fresh vegetable to obtain a semi-finished product; and the semi-finished product is pickled by the seasoning fermentation liquor, and the seasoning fermentation liquor is quickened up to permeate into the vegetable through the vacuum treatment to obtain the delicious finished pickled vegetable. The pickled vegetable is prepared by the preparation method disclosed by the invention is low in salt content, short in production time, high in calcium content and biodiasmin content and beneficial to the body health of a user; and moreover, the automation degree of the pickled vegetable processing is improved.

Owner:HEFEI UNIV

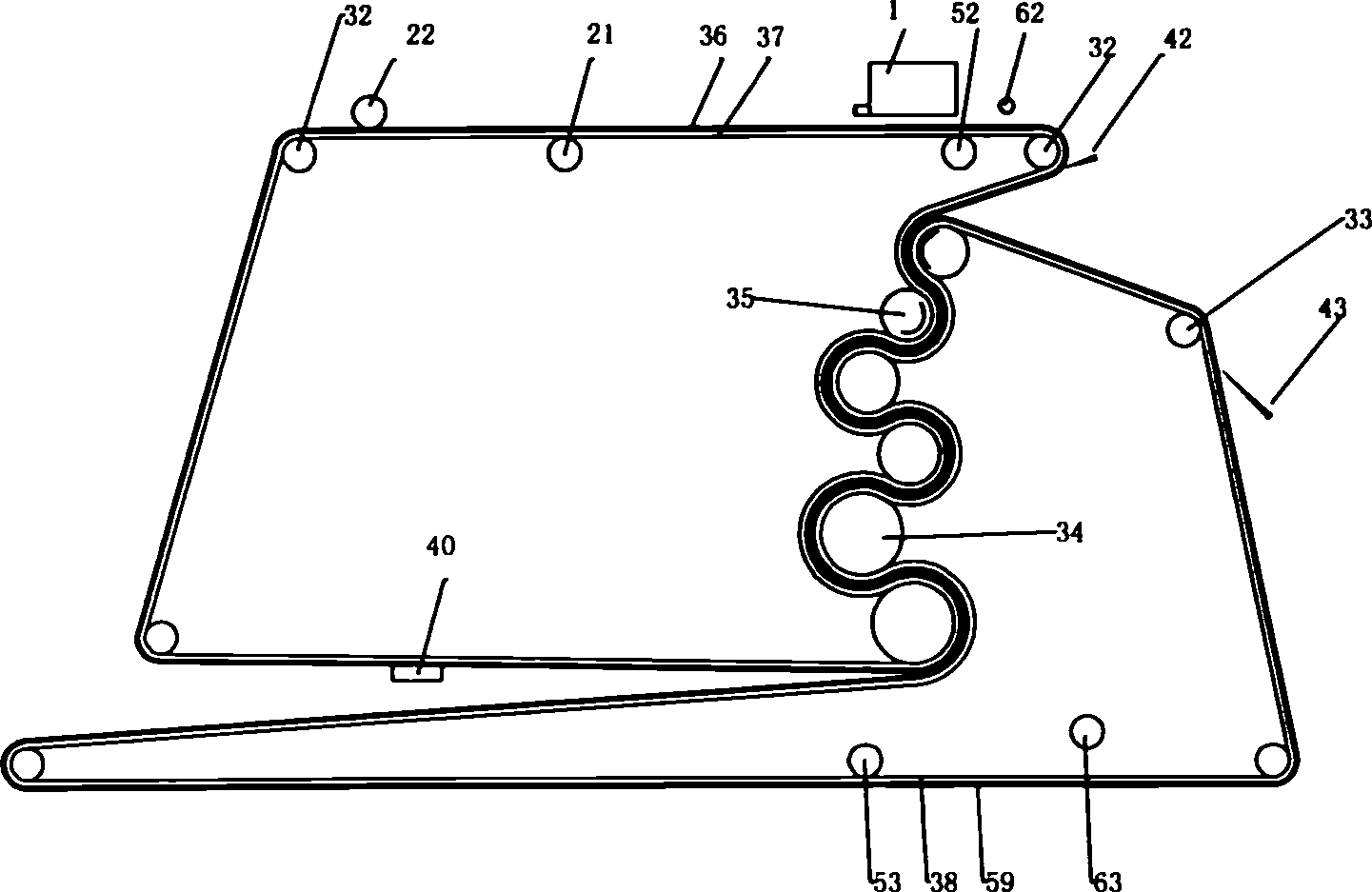

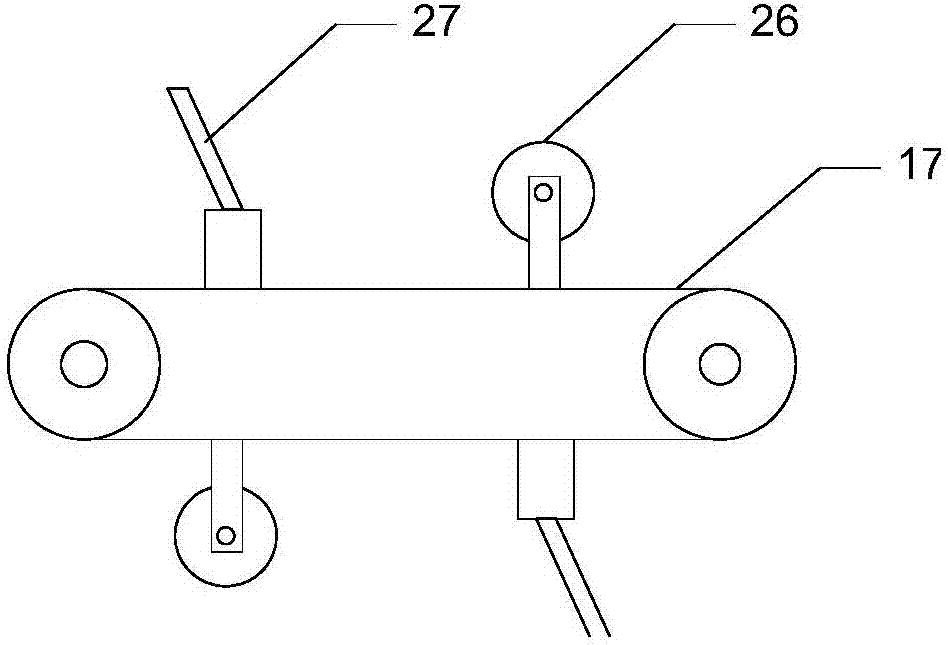

Belt type filter press

ActiveCN1879932AHigh filtration pressureHigh filter pressureMoving filtering element filtersEngineeringFilter press

The invention relates to a belt compress filter for dewatering the micro grains, wherein it is formed by a frame, a driver, a feeding device, a compress area and an auxiliary device; said compress area comprises a compress filtering roller and a filtering belt; the driver comprises a motor and a gear box; the auxiliary device comprises a tension roller, a scrape device, a water collector, a corrector, and a filter belt washer. The invention is characterized in that: the back of filter belt is lined with steel compress belt; the compress filtering rollers are compacted arranged. The invention can improve the filter pressure of compress filter to improve the balance point between the filter pressure and the filter resistance, to overcome the defects of present technique, while it can improve the dewatering efficiency and the yield.

Owner:ZHEJIANG HUAZHANG TECH

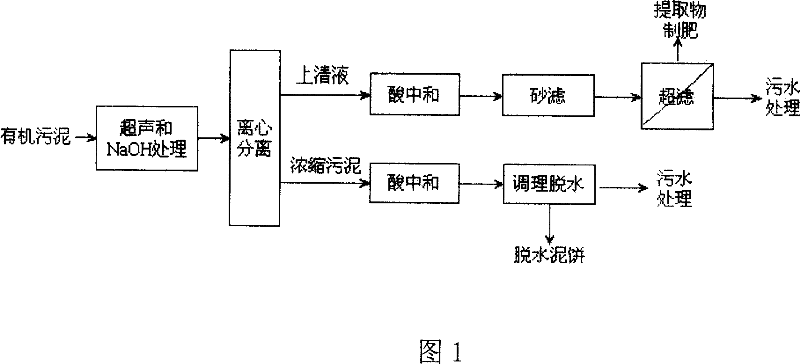

Method for producing liquid organic fertilizer by using organic fertilizer

InactiveCN101037354AImprove cracking efficiencyImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningClimate change adaptationUltrafiltrationHumic acid

The invention discloses method of producing liquid organic fertilizer by organic belonging to solid wastes disposal field, including: co-treating the residual sludge with 98 percent moisture content by ultrasound and sodium hydroxide to make the organic matters dissolve out; getting concentrated sludge and supernatant fluid after centrifugation; dehydrating the concentrated sludge after neutralization in a routine method; sand leaching and ultrafiltration treating the supernatant fluid twice after centrifugation to get a concentrated liquid containing macromolecule organic matter such as humic acid and the filtrate containing low molecular organic matter; the filtrate entering into the sewage treating plant for a primary treatment. Disposed dehydrated sludge cake has 70-80 percent moisture content and a reduction of the content of organic matter of 30-50%. The concentrated liquid by ultrafiltration is mainly composed of macromolecule organic matter and with a low content of heavy metal, and can be an organic liquid fertilizer, and complies the rule of using green food fertilizer. The invention is suitable for the sludge with a high organic matter content such as residual sludge and digested sludge.

Owner:TSINGHUA UNIV

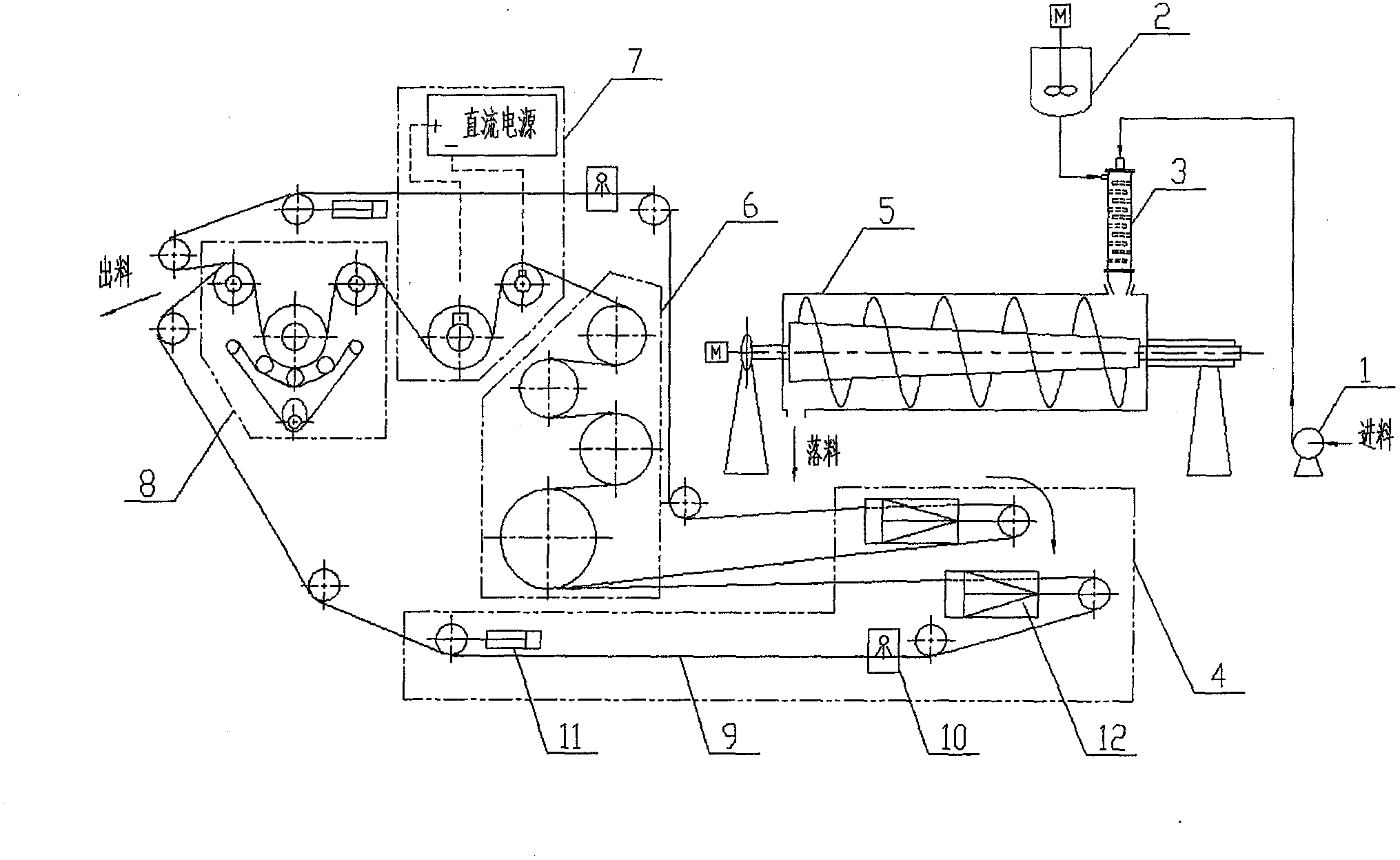

High dryness dewatering method and equipment for high moisture content sludge

InactiveCN103803775ACompact structureReduce volumeSludge treatment by de-watering/drying/thickeningSludgeWater resource management

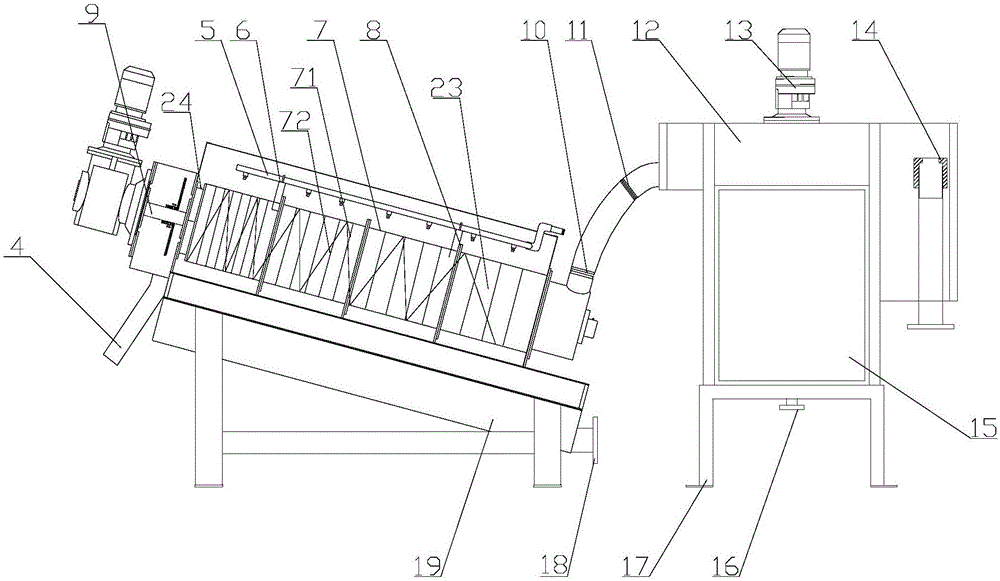

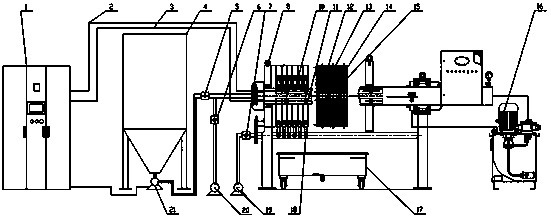

The present invention discloses a high dryness dewatering method for high moisture content sludge. According to the method, spiral belt type concentration electro-osmosis vibration pressing integrated equipment is adopted to carry out one time dewatering on sludge with a moisture content of 99.2-95.0% to achieve the moisture content of 60.0-55.0%, wherein the spiral belt type concentration electro-osmosis vibration pressing integrated equipment comprises a material feeding system, an agent adding system, a material mixing system, a conveying system, a spiral concentration dewatering system, a belt type pressing dewatering system, an electro-osmosis pressing dewatering system, and a vibration pressing dewatering system.

Owner:TIANJIN YUEQING ENVIRONMENT TECH

Roller centrifugal type environment-friendly treatment device for sludge dewatering

InactiveCN108033664AReasonable structureInnovative designSludge treatment by de-watering/drying/thickeningRotary centrifugesDrive shaftEngineering

The invention discloses a roller centrifugal type environment-friendly treatment device for sludge dewatering. The device comprises a fixing base plate; a first supporting frame is arranged on the left side of the upper end of the fixing base plate; a guide base is arranged at the upper end of the first supporting frame; a driving shaft is arranged in the middle of the guide base; a first rotatingdisc is arranged at the right end of the driving shaft; a second supporting frame is arranged on the right side of the upper end of the fixing base plate; a driven shaft is arranged in the middle ofthe second supporting frame through a bearing; a second rotating disc is arranged at the left end of the driven shaft; an outer cylinder is arranged between the first rotating disc and the second rotating disc; a first motor is arranged on the left side of the lower end of the outer cylinder; a driving belt wheel is arranged at the upper end of the first motor; a driven belt wheel is connected tothe right end of the driving belt wheel through a belt; a main shaft is arranged at the upper end of the driven belt wheel; an inner cylinder is arranged at the upper end of the main shaft; and a counter shaft is arranged in the main shaft. According to the device, sludge can be efficiently dewatered by utilizing the centrifugal force, the dewatering efficiency of the sludge can be improved, and meanwhile, the dewatered sludge can be quickly poured out.

Owner:TIANJIN ZHONGTIAN JINGKE SCI & TECH

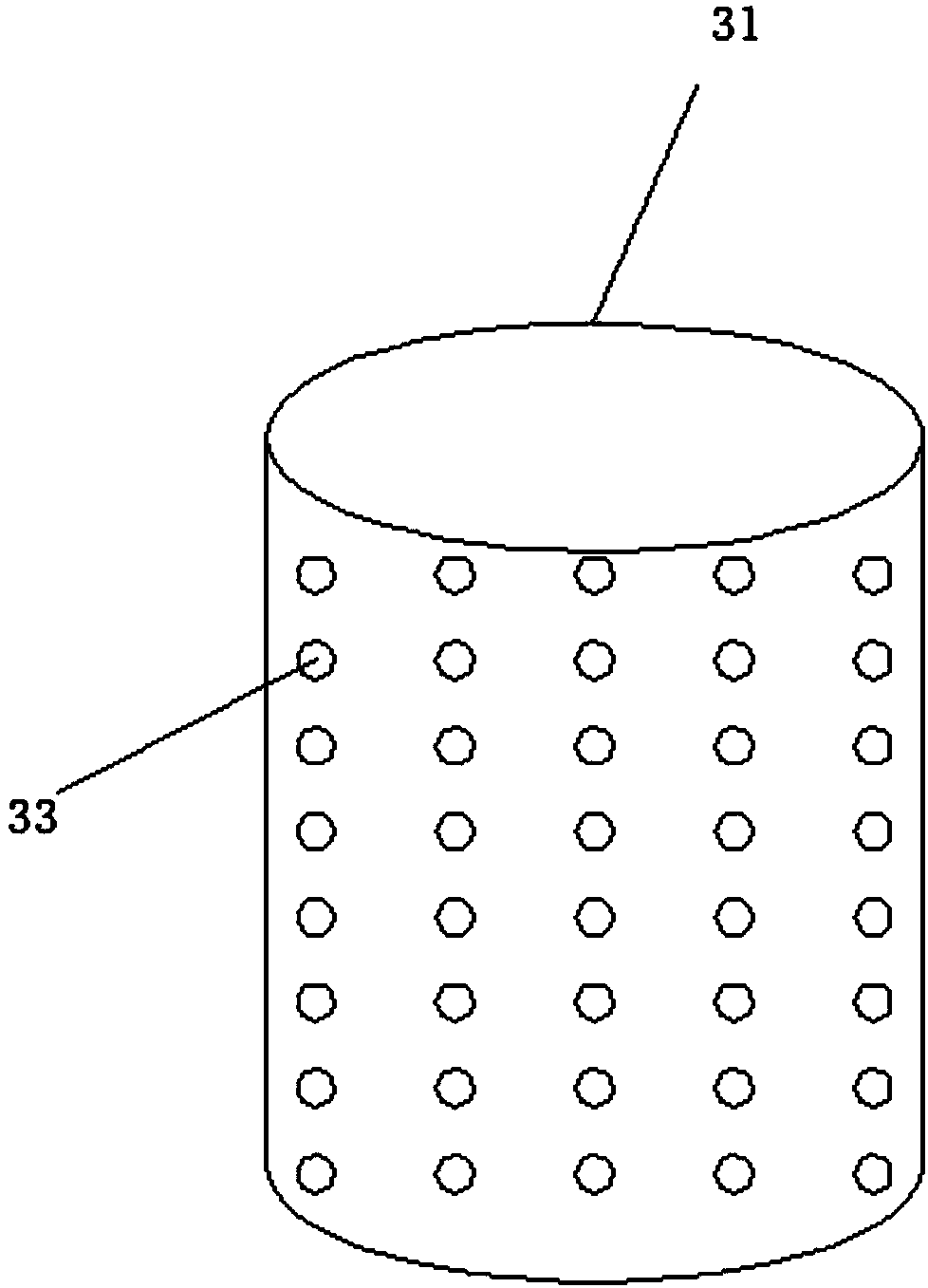

Continuous sludge treatment device

InactiveCN107176780AAvoid cloggingEfficient heatingSludge treatment by de-watering/drying/thickeningSludgePulp and paper industry

The invention discloses a continuous sludge treatment device. The continuous sludge treatment device comprises a feeding hopper, a first driving motor and a second driving motor, wherein the feeding hopper is communicated with a dewatering box, a screen drum is arranged in the dewatering box and sleeved with a rack ring, and the rack ring is rotationally connected with the screen drum through a bearing; strip-shaped brushes which are symmetrically arranged are fixedly connected with the right side wall of the rack ring; a drying box is communicated with the right side of the screen drum through a sludge pipe. With the arrangement of a screw extrusion dewatering device provided with the rotating brushes, sieve meshes are prevented from being blocked, continuous dewatering work is guaranteed, and the continuous sludge treatment device has higher dewatering efficiency; the continuous sludge treatment device is equipped with a drying device consisting of a heating plate, flat spreading rollers and scrapers, therefore, sludge is efficiently and uniformly heated, and drying efficiency is improved; an auxiliary drying device consisting of hot air spray nozzles, smashing blades and a turning plate is arranged, so that the sludge is thoroughly dried, and the drying effect is guaranteed.

Owner:李群珍

Production method for ready-to-eat instant nutritive edible fungus soup

The invention discloses a production method for ready-to-eat instant nutritive edible fungus soup, which belongs to the technical field of deep processing of agricultural products. The production method mainly comprises the steps of selecting, cleaning, precise cutting, mixed boiling, spreading, pre-freezing and microwave vacuum freeze drying on screened raw materials such as edible fungi, thus obtaining the product which is subjected to nitrogen-filled packaging after being taken out of storage. The raw materials of the edible fungus soup is dewatered by a microwave vacuum freeze drying technology according to a modern food nutrition principle, so that the original color, aroma, taste and nutrients of the product are kept to the hilt, and compared with those of a conventional process, the drying efficiency is remarkably improved, the production cycle is shortened, the production cost is effectively reduced, and the special sterilizing effect of microwaves further guarantees the product quality at the same time. The edible fungus soup produced by the method is flat in shape, bright in color and luster, rich in nutrition, good in water regaining effect and long in storage time, and a feasible new way is provided for deep processing and utilization of the edible fungi.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

Process for producing polyphenyl thioether

The invention relates to a process for producing polyphenyl thioether, comprising the following steps of:, mixing hydrogenous sodium sulfide, lithium chloride and N-methyl pyrrolidone in the weight ratio of (20-25): (2-6): (70-80), co-boiling the mixture and inert gases at 150-210 DEG C for distilling and dehydrating; separating solvent by refining; respectively adding santochlor, solvent and lithium chloride in anhydrous sodium sulfide, separating after complete reaction to obtain polyphenylene sulfide; compositely washing the polyphenylene sulfide to obtain pure polyphenylene sulfide; and reclaiming the lithium chloride by filtering, reclaiming the solvent and flashly evaporating dimethylbenzene solution in a two-period mode and cooling and crystallizing. The invention has the advantages of low cost, simple process, excellent performance of synthetic resin and high solvent recovering rate.

Owner:DUNHUANG XIYU MINING & CHEM

Organic high molecular composite flocculant and preparation method thereof

ActiveCN101973688ALow costSufficient sourceSludge treatment by de-watering/drying/thickeningChlorideSuspended matter

The invention discloses an organic high molecular composite flocculant which is mainly used for municipally or industrially dewatering sludge and a preparation method thereof, which solve the problems of complex treatment process, agent waste, secondary pollution and the like existing in the prior art. The flocculant comprises polyacrylamide, polydimethyldiallylammonium chloride and modified starch serving as raw materials and the dry weight ratio of polyacrylamide to polydimethyldiallylammonium chloride to modified starch is 4-9:0.5-5:0.5-5, wherein tap water or de-ionized water is used as a dispersing agent; and the liquid organic high molecular composite flocculant, of which the molecular weight is 4,000,000 to 12,000,000, the ionization degree is 40 to 80 percent and the effective content of the raw material is 1 to 5 percent based on dry weight, is prepared by dispersing the materials in a reactor at the temperature of between 10 and 50 DEG C with stirring and compounding for 0.5 to 3 hours. The flocculant has the advantages of sufficient raw material sources, low cost, simple process flow, stable performance and high suspension separation speed, is reasonably prepared and quickly dissolved and is safe to operate, and convenient to use, saves the amount, obviously improves the dehydration efficiency, expands the application range, prevents fluctuation of treatment effect and reduces secondary pollution.

Owner:国能辽宁环保产业集团有限公司材料分公司

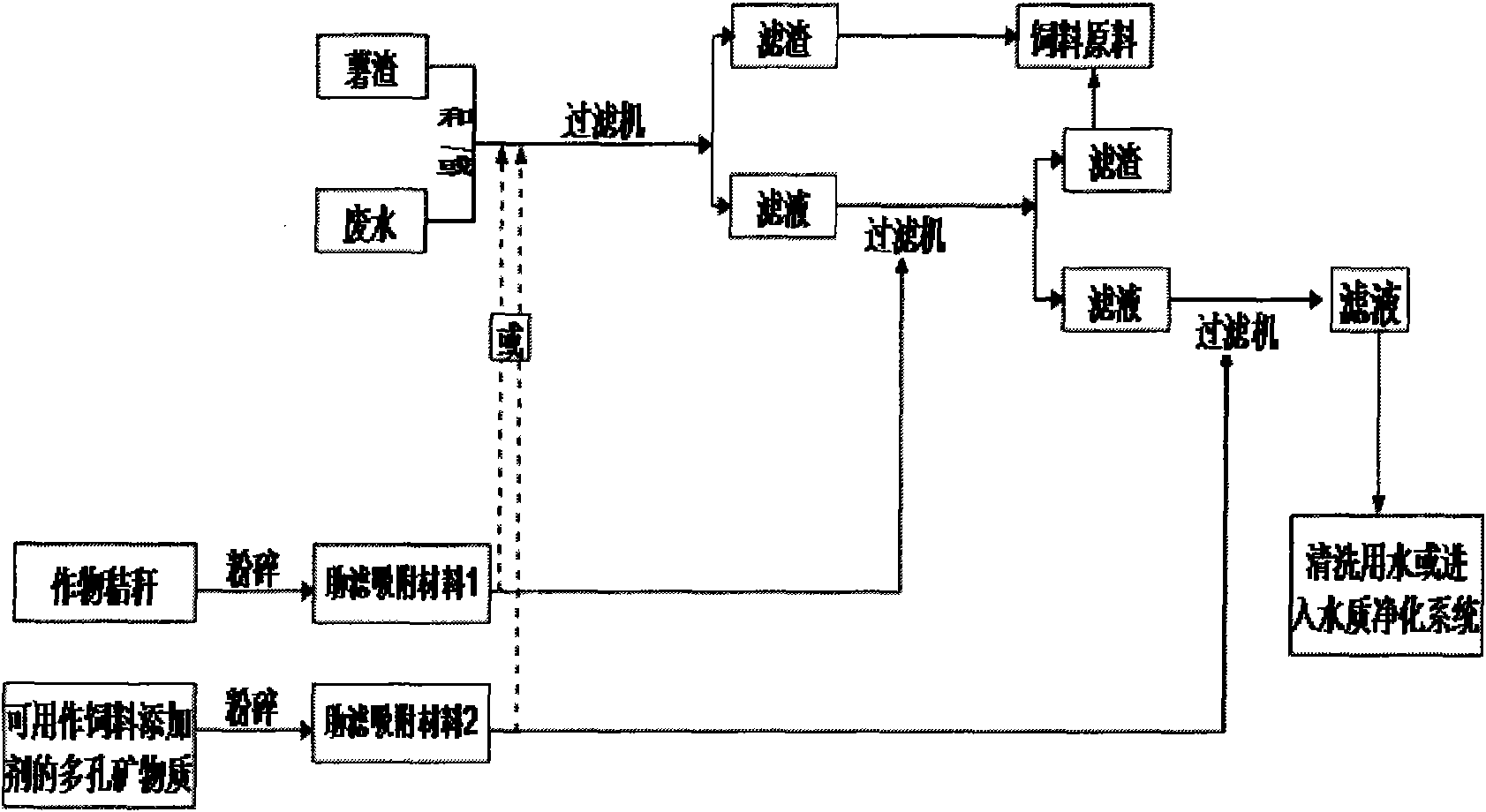

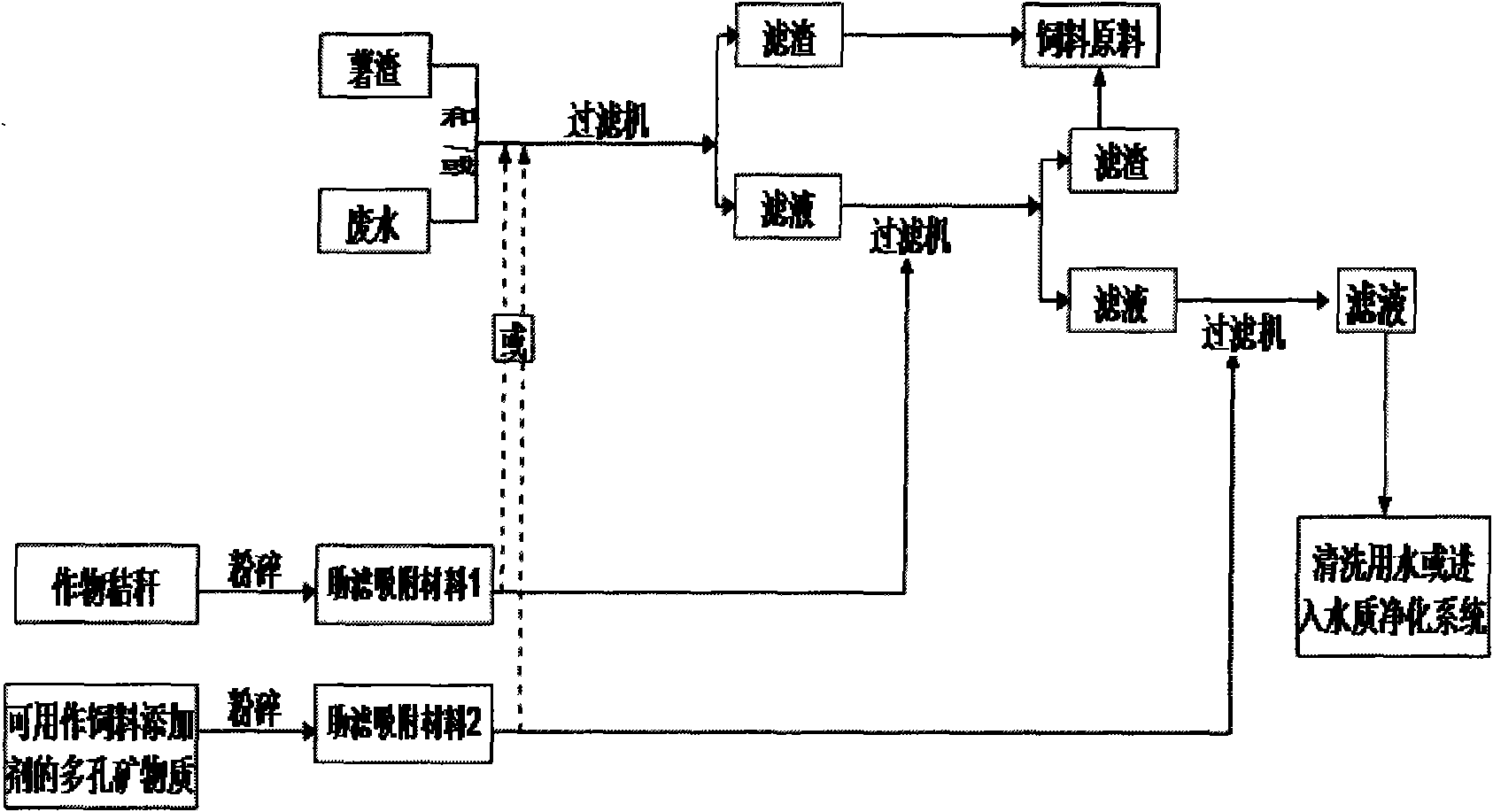

Method for recycling potato residue and waste water in production process of potato starch

InactiveCN101990987AReduce equipment costsLow running costOther chemical processesFood processingSubstance usePotato starch

The invention relates to the field of industrial production of potato starch and provides a method for recycling potato residue and waste water in the production process of potato starch. The method mainly comprises the following steps of: respectively pulverizing crop straws and porous mineral substances used as a feedstuff additive into certain size of particles as filtering-assisted adsorbing materials through a physical method; and carrying out filtering treatment by stages by utilizing the two filtering-assisted adsorbing materials in a process of recycling potato residue and waste water organic matters generated when processing the potato starch. The recycled organic matters, such as small particle starch, protein, polysaccharide, and the like and the filtering-assisted adsorbing materials can be together used as feedstuff materials, and the purpose of purifying the waste water is also achieved; and the purified water can be used as washing water for potato processing directly or through precipitating.

Owner:甘肃省农业科学院农产品贮藏加工研究所

Environment-friendly-type polluted oil processing agent

ActiveCN103820142AImprove dehydration efficiencyFor the purpose of separationDewatering/demulsification with chemical meansDewatering/demulsification with electric/magnetic meansSolventAluminium salts

The invention relates to an environment-friendly-type polluted oil processing agent, which is prepared by a surfactant, a flocculating agent and a solvent through uniformly mixing in a mechanical blending mode, the surfactant is a cationic surfactant and / or an anionic surfactant and / or a non-ionic surface active agent and / or an ampholytic surfactant, the flocculating agent is one of polyferric sulfate, polymeric aluminum ferric sulfate, polymeric aluminium and aluminum sulfate, and the solvent is a mixture of one or more of methyl alcohol, ethyl alcohol, ethylene glycol, propylene glycol, propanetriol or ethylene glycol butyl ether. According to the invention, a plurality of surfactants are employed for compounding, so that electrostatic neutralization effect can be generated on the surface of oil droplets, the stability of an emulsion is worse, so that the purposes of demulsification and oil-water separation can be reached, the flocculating agent has the effect for removing small impurity and mud, as well as demulsificating, so that oil removal efficiency can be increased. According to the invention, dewatering efficiency of the polluted oil processing agent is high, the crude oil can be effectively separated from the polluted oil, the pollution of the polluted oil to the environment can be reduced, and the administration cost is saved.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

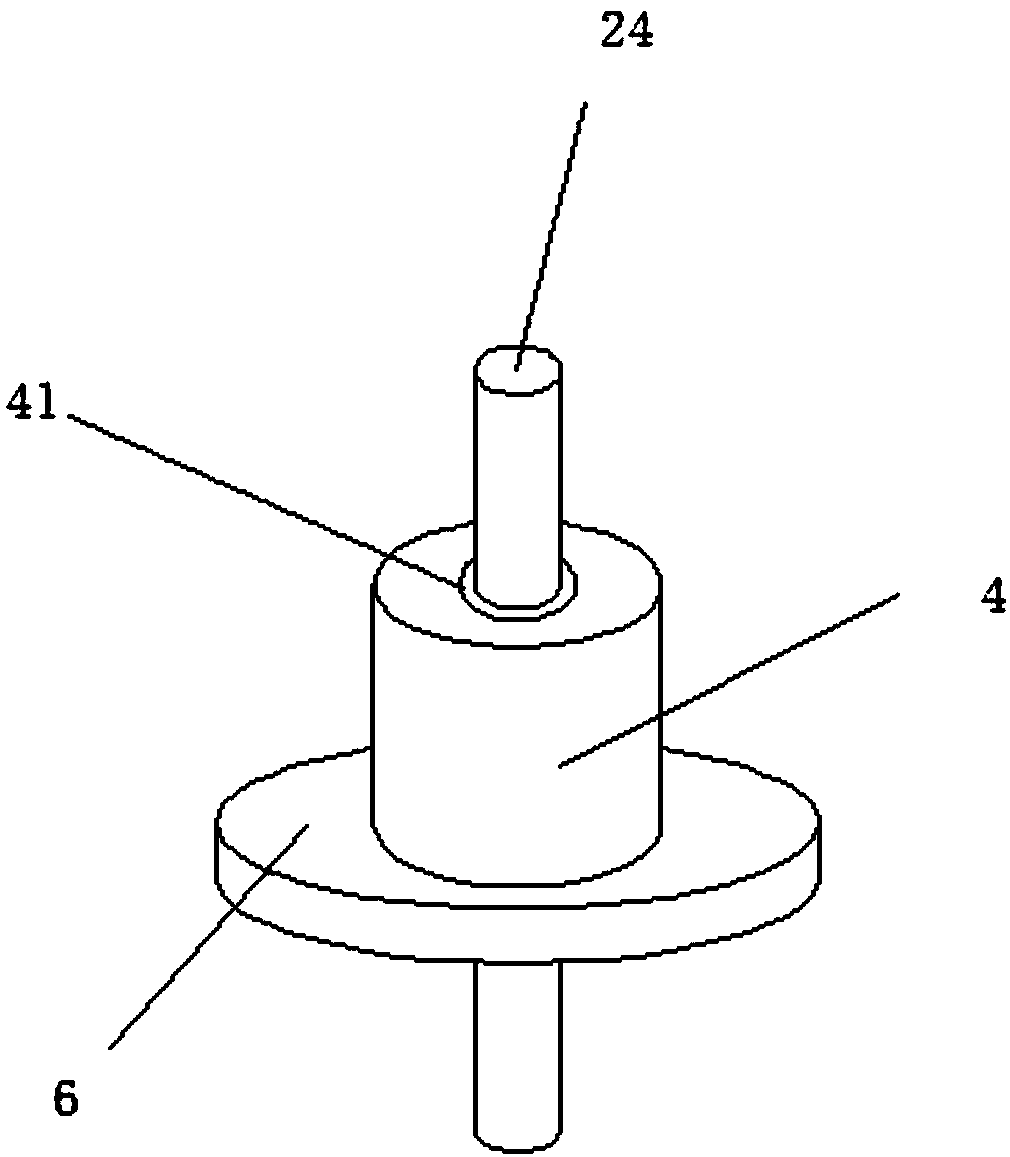

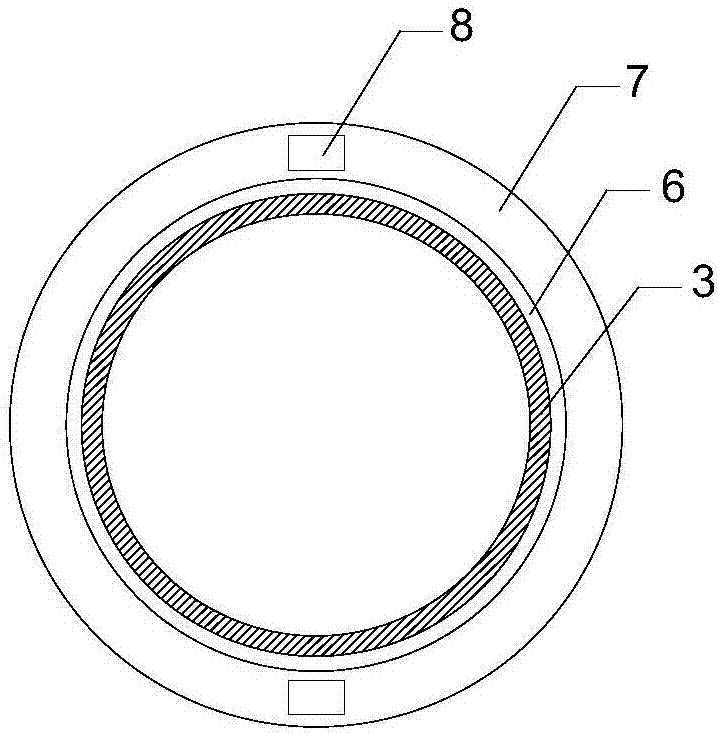

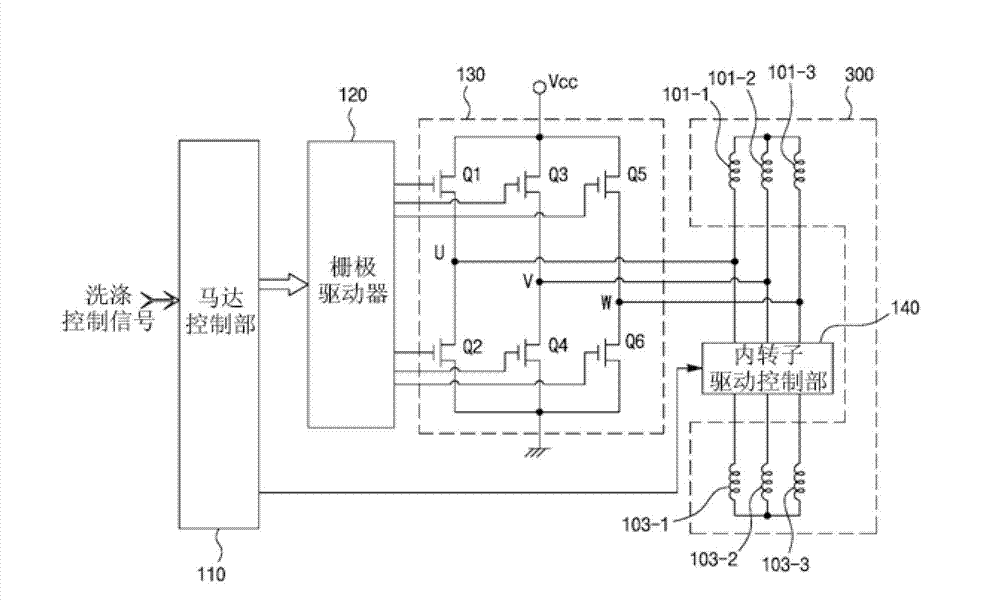

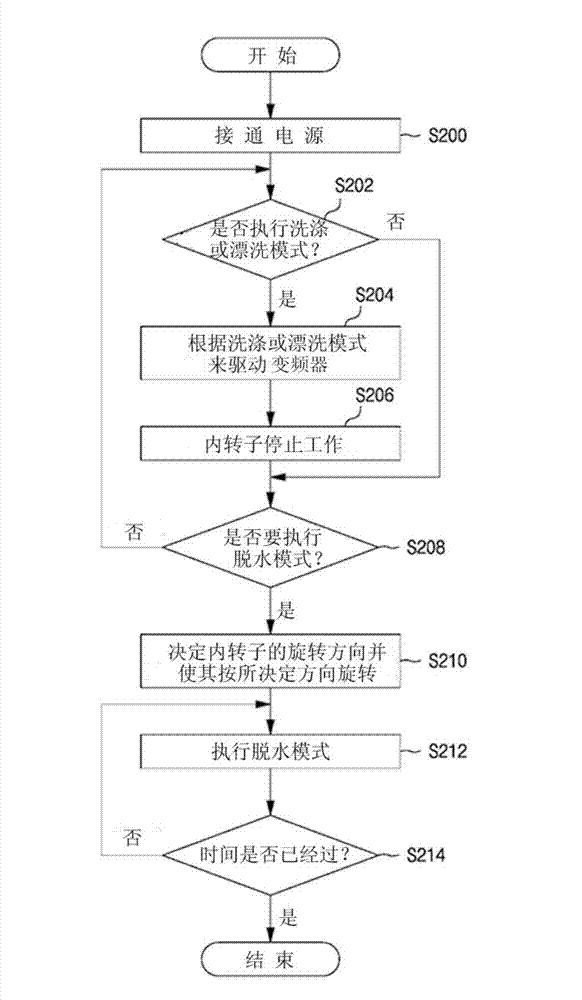

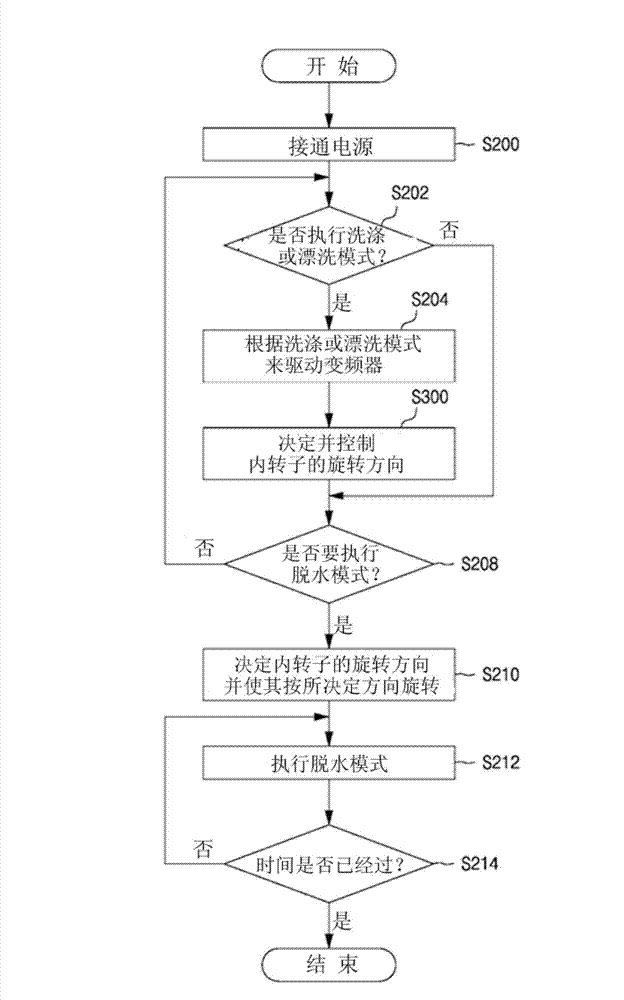

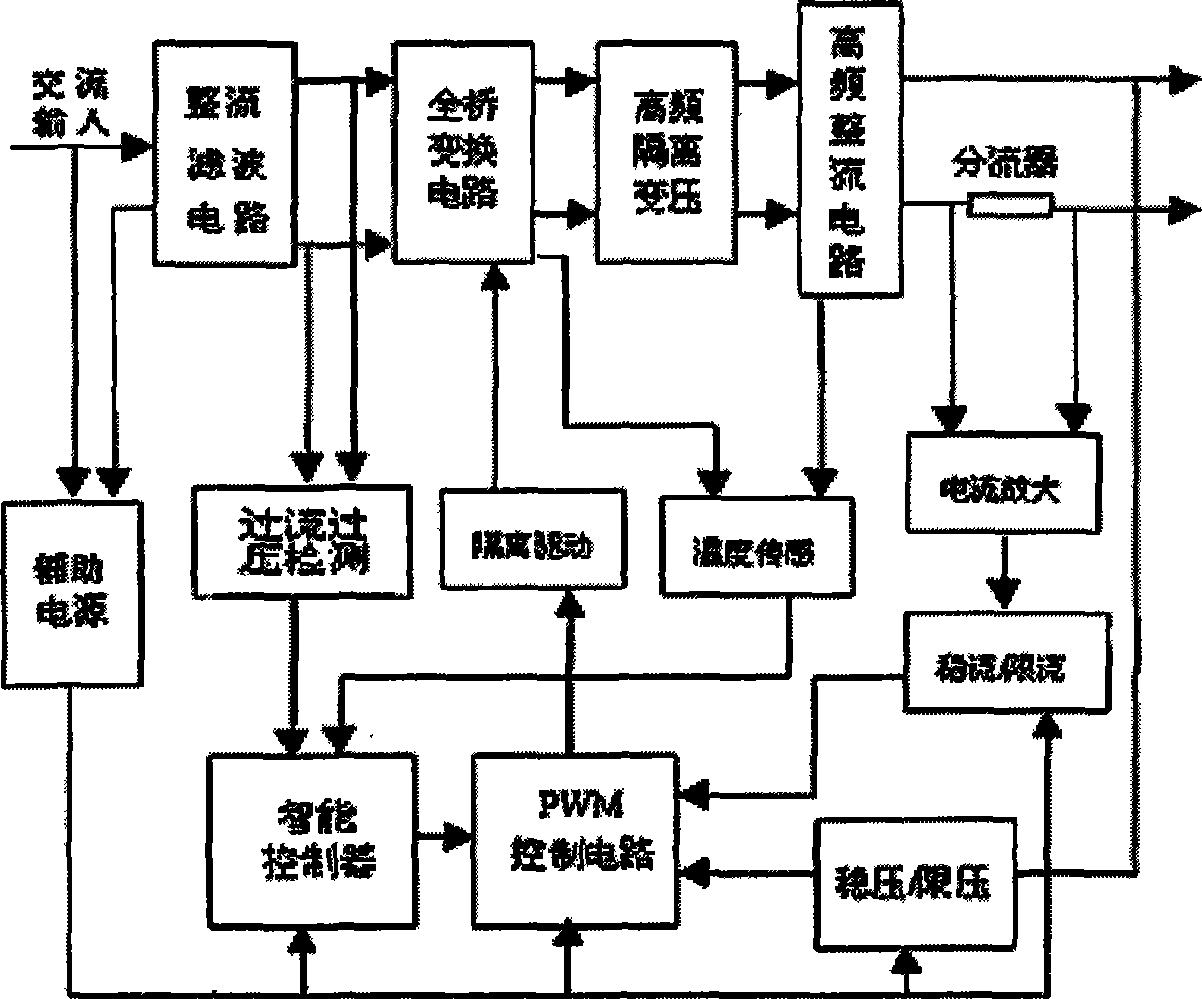

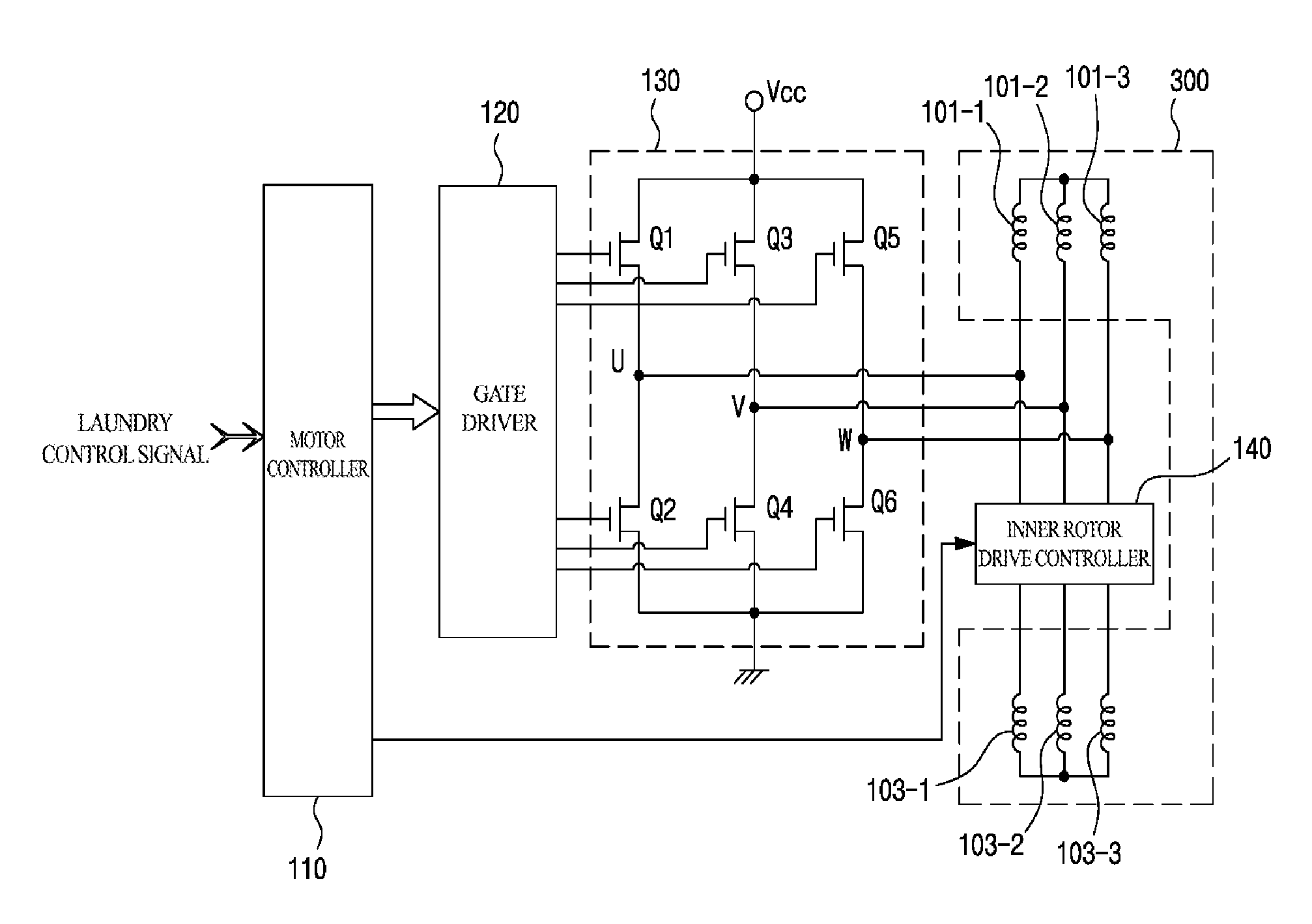

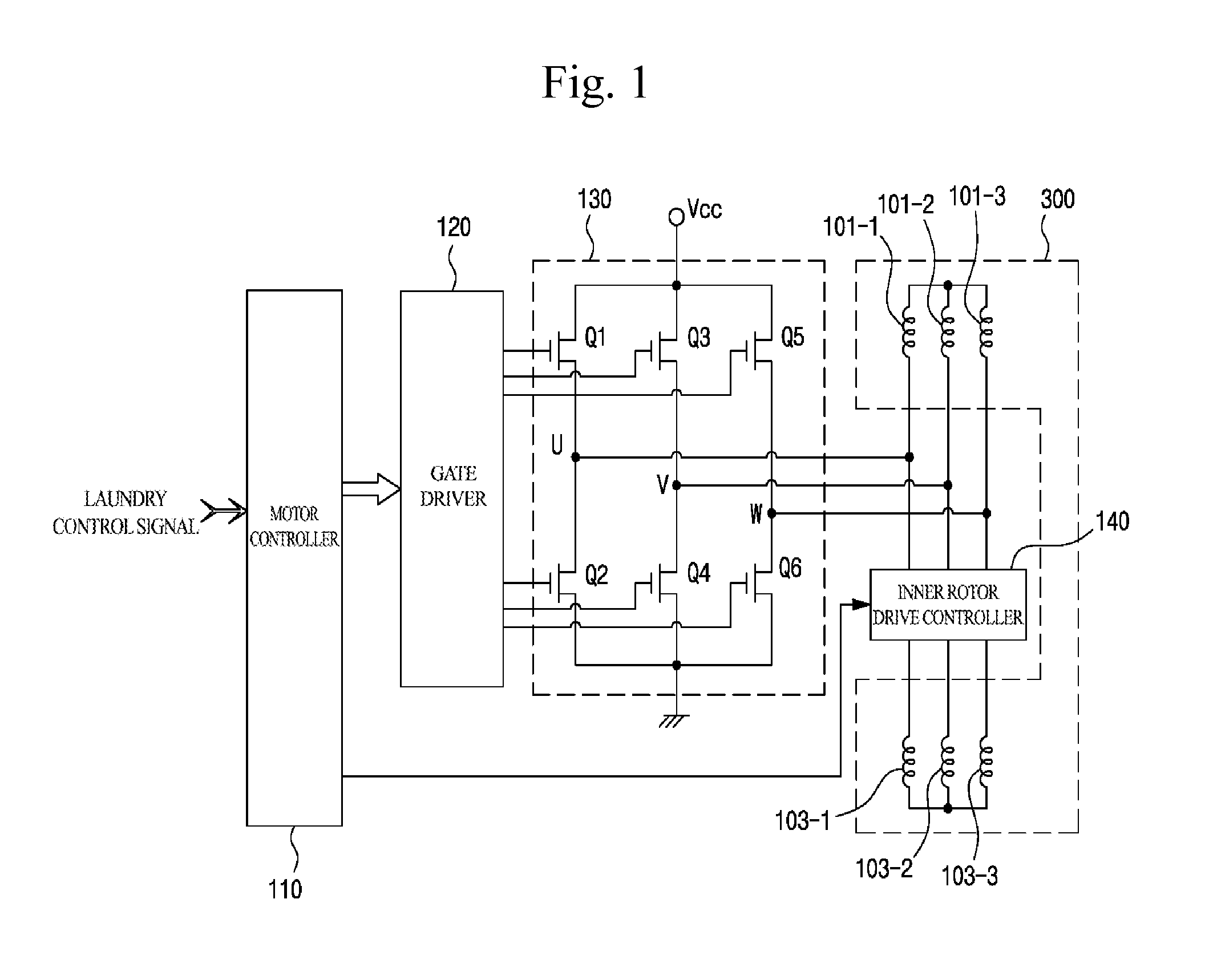

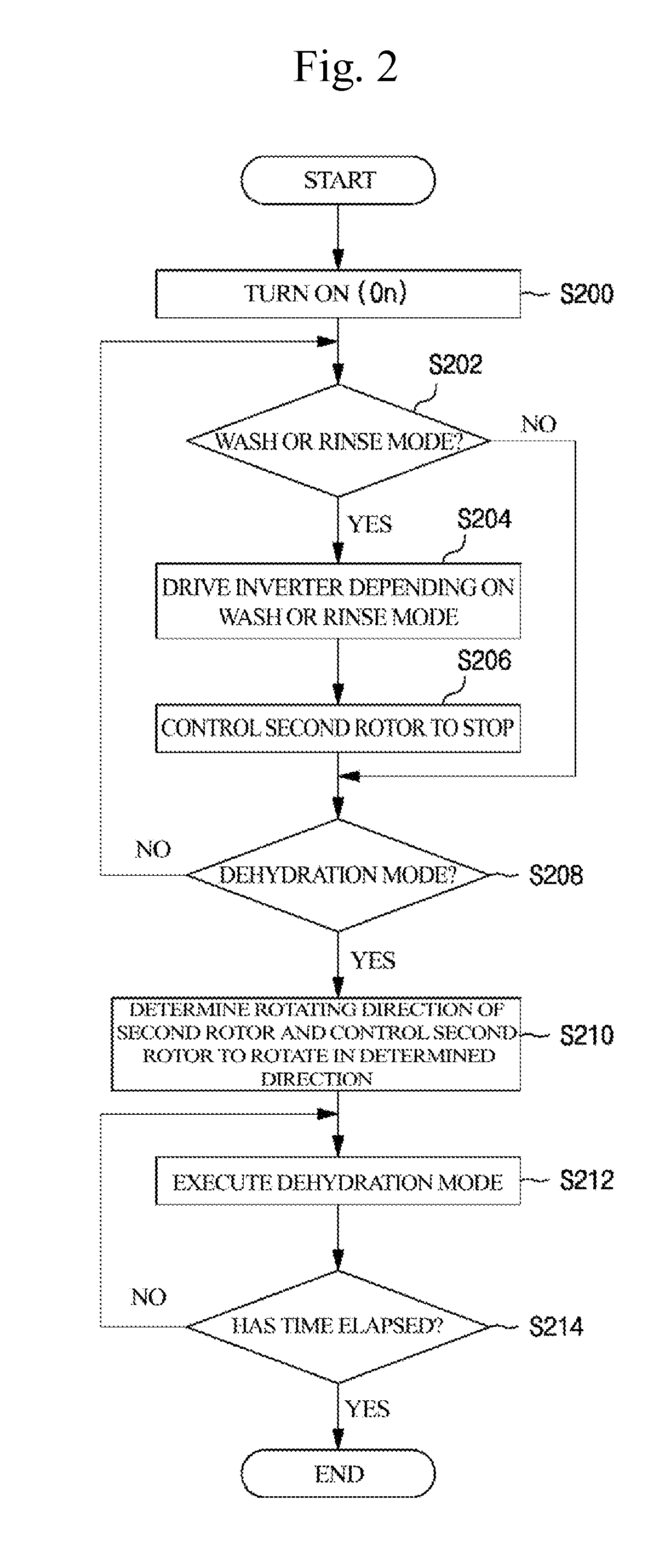

Motor driving device and driving method for washing machine

ActiveCN103051284AImprove washing efficiencyImprove dehydration efficiencyWashing controlling processesAC motor controlFrequency changerImpeller

The invention relates to a motor driving device and a driving method for driving the motor for a washing machine with a dual rotor-dual stator structure. The motor for a washing machine with a dual rotor-dual stator structure is provided with no independent clutch, and an impeller and a dewatering tank are selectively used. The invention includes the components as following: a motor control portion, a driving signal is generated according to a washing control signal, and the motor for the washing machine is controlled to be driven; a transducer, a three-phase alternating current is generated under the control of the motor control portion, and the three-phase alternating current is output to the thirteenth phase stator coil for driving the outer rotor of the motor to rotate and output to the twenty-third phase stator coil for driving the inner rotor of the motor to rotate; and a first rotor driving control portion, which is arranged between the transducer and the twenty-third phase stator coil and used for blocking or permitting the three-phase alternating current to pass under the control of the motor control portion, and the rotation direction of the inner rotor is controlled.

Owner:AMOTECH

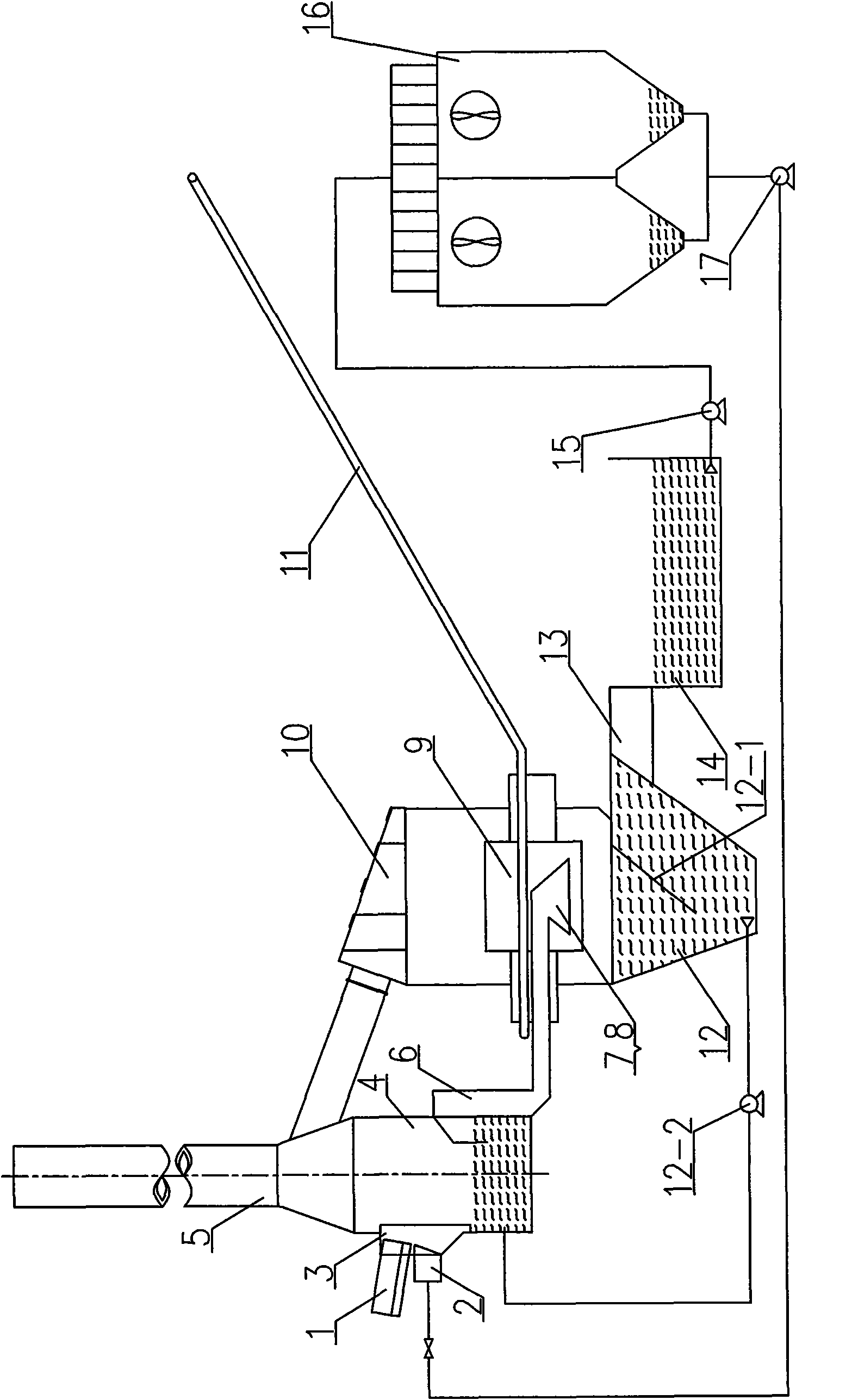

Blast furnace slag processing device

ActiveCN101649364ASmall footprintLow investment costRecycling and recovery technologiesProcess efficiency improvementSlagMaterials science

The invention relates to a blast furnace slag processing device. The processing device comprises a water-quenching cooling device, a slag-water separating device and a slag flush water circulating device, wherein the input end of the slag-water separating device is connected with the output end of the water-quenching cooling device, and the output end of the slag-water separating device is connected with the input end of the slag flush water circulating device; and the output end of the slag flush water circulating device is connected with the input end of the water-quenching cooling device. The blast furnace slag processing device is provided with a condensing and recycling device, reduces the ground occupation area, the investment and the production running cost and has high quality of water and slag.

Owner:CISDI ENG CO LTD

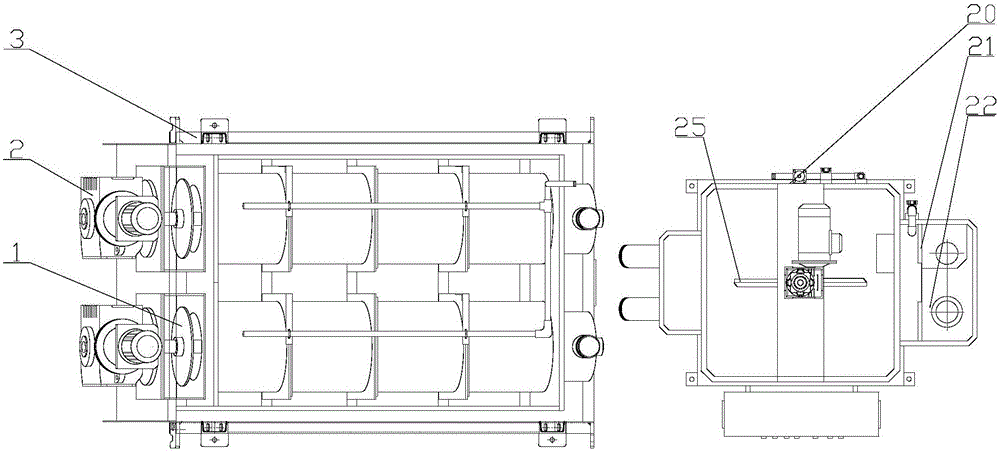

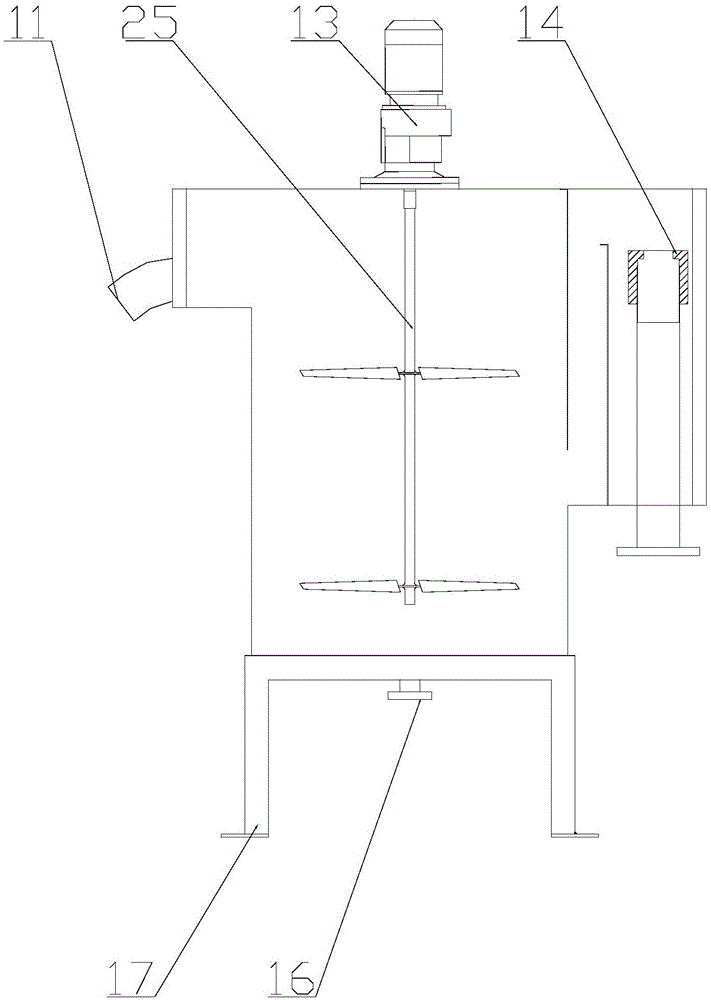

Stacked spiral type sludge dewatering machine

InactiveCN105084709ATurn slowlyImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningFlocculationPulp and paper industry

The invention relates to a sludge dewatering machine, in particular to a stacked spiral type sludge dewatering machine which comprises a stirring flocculation device and a dewatering device. The dewatering device comprises a first sludge inlet, a first sludge outlet, a stacked spiral body, a support plate, a spiral shaft, a rack and a first power device. The stacked spiral body comprises fixed rings and movable rings. The fixed rings are fixedly connected with the support plate. The spiral shaft is located in a cylindrical cavity formed by the fixed rings and the movable rings. The spiral shaft is fixedly connected with the first power device. The support plate and the spiral shaft are fixed to the rack. By the adoption of the structure, the sludge dewatering machine is not prone to being blocked, the dewatering rate is increased, and operation is very convenient.

Owner:江苏清木源环保科技有限公司

Oil-water separation system and separation method

ActiveCN109652117AReduce cloggingPrevent adhesionFatty/oily/floating substances removal devicesDewatering/demulsification with mechanical meansFiltrationDistributor

The invention discloses an oil-water separation system and a separation method. The oil-water separation system comprises a membrane filtration / demulsification system, a pre-separation system, a lightphase separation system and a heavy phase separation system; the membrane filtration / demulsification system comprises a membrane module and a circulating pump, and the pre-separation system comprisesa feeding tube, a hollow filter element and a steady flow zone; the light phase separation system sequentially comprises a material uniform distributor I, an upper coalescence separation zone and a light phase discharge port from bottom to top; and the heavy phase separation system sequentially comprises a material uniform distributor II, a lower coalescence separation zone, a light phase and heavy phase separation zone and a heavy phase discharge port from top to bottom. The separation system can be used to achieve continuous removal and preliminary of granular suspended matters in a material to be separated, rapid removal of free water drops or oil drops and demulsification and coalescence of a small amount of a heavy phase entrained in a light phase and a small amount of the light phase entrained in the heavy phase, has the advantages of short material residence time, high dewatering / deoiling efficiency and small device size, can realize deep removal of water, especially emulsifiedwater, in an oil product and deep removal of emulsified oil drops in sewage, has obvious advantages in oil-water separation of complex-composition and high-viscosity particle-containing severely emulsified oil products, and enables the moisture or oil removal rate to reach 99% or above.

Owner:CHINA PETROLEUM & CHEM CORP +1

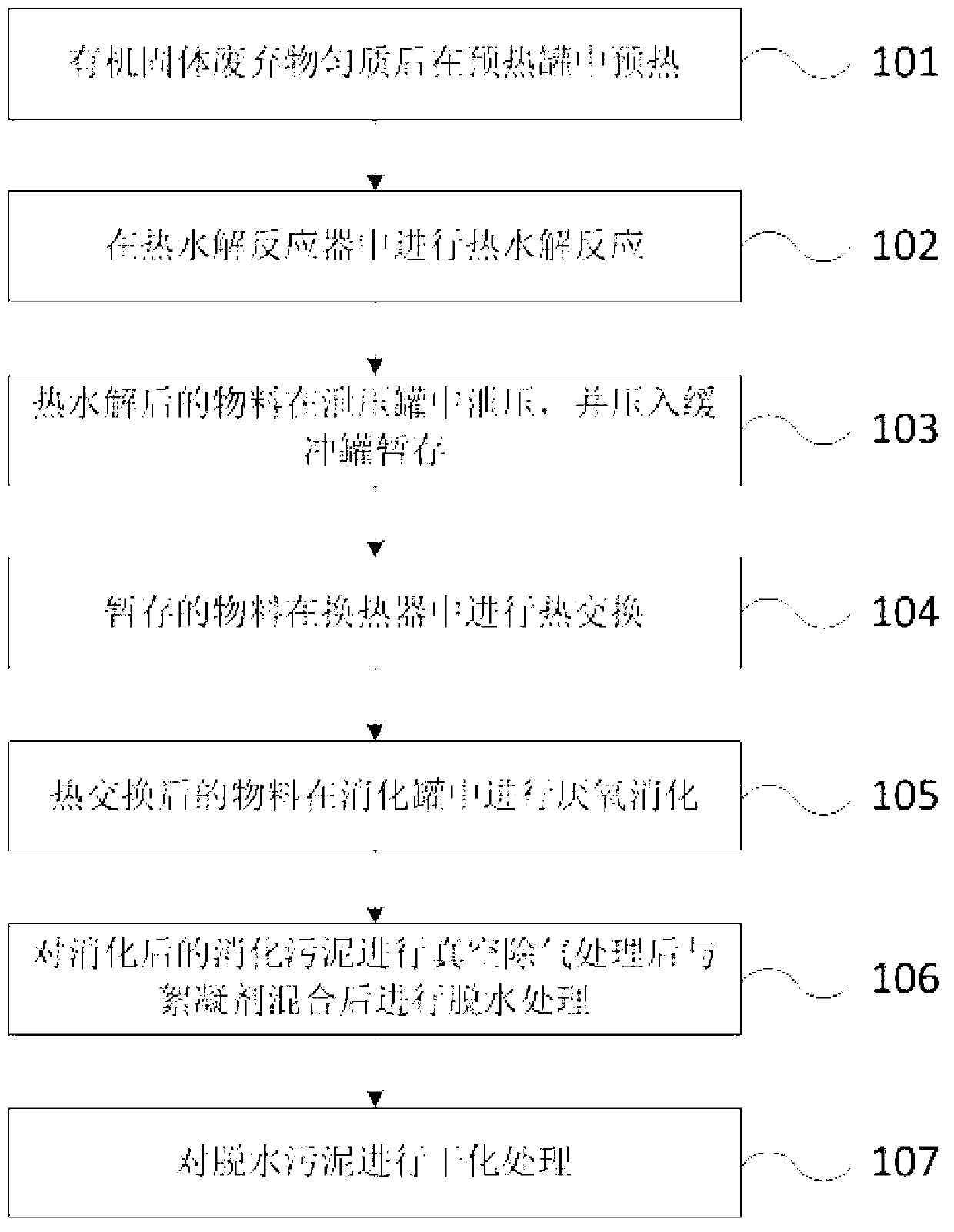

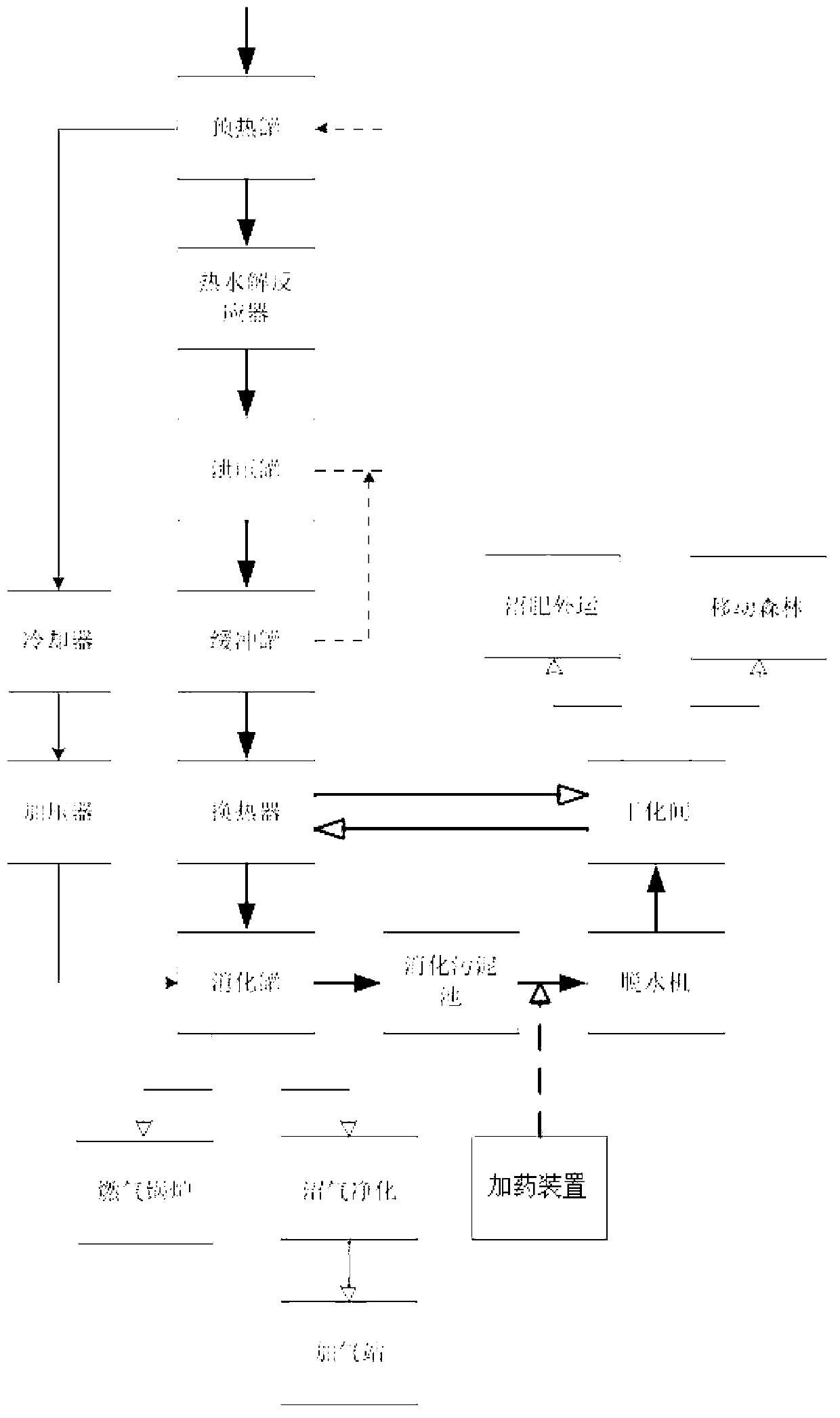

Treatment method of organic solid waste

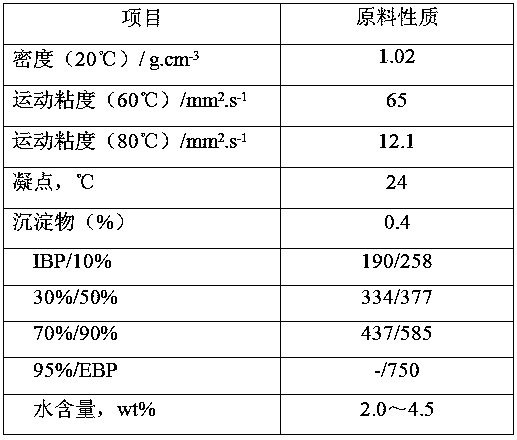

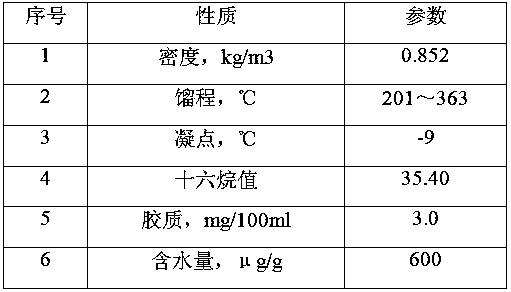

InactiveCN103274572AImprove dehydration efficiencyIncrease drynessSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisBuffer tankAerobic digestion

The invention relates to a treatment method of organic solid waste. The treatment method comprises the following steps of: homogenizing the organic solid waste and then preheating, carrying out a thermal hydrolysis reaction on the preheated organic solid waste, then pushing the material into a depressurization tank and a buffer tank to be subjected to primary depressurization and secondary depressurization and then temporary storage, then carrying out heat exchange on the material, carrying out anaerobic digestion on the material subjected to heat exchange, carrying out vacuum degassing treatment on digested sludge in a digested sludge tank, dehydrating the treated digested sludge to form dehydrated sludge, conveying the dehydrated sludge to a drying room to be dried, and producing dried biogas residue. According to the treatment method of the organic solid waste, high temperature hydrolysis and anaerobic digestion technologies are adopted, the problems that resource is wasted when a burning method is adopted and secondary pollution can be easily caused when a burying method is adopted can be avoided, digestive efficiency in follow-up anaerobic digestion is improved, standing time of an anaerobic digestion process is also reduced, and sludge subjected to anaerobic digestion is subjected to vacuum degassing, so that carbon dioxide and ammonium nitrogen in the digested sludge can be effectively removed, and sludge dehydration efficiency is improved.

Owner:HUBEI GUOXIN TIANHUI ENERGY

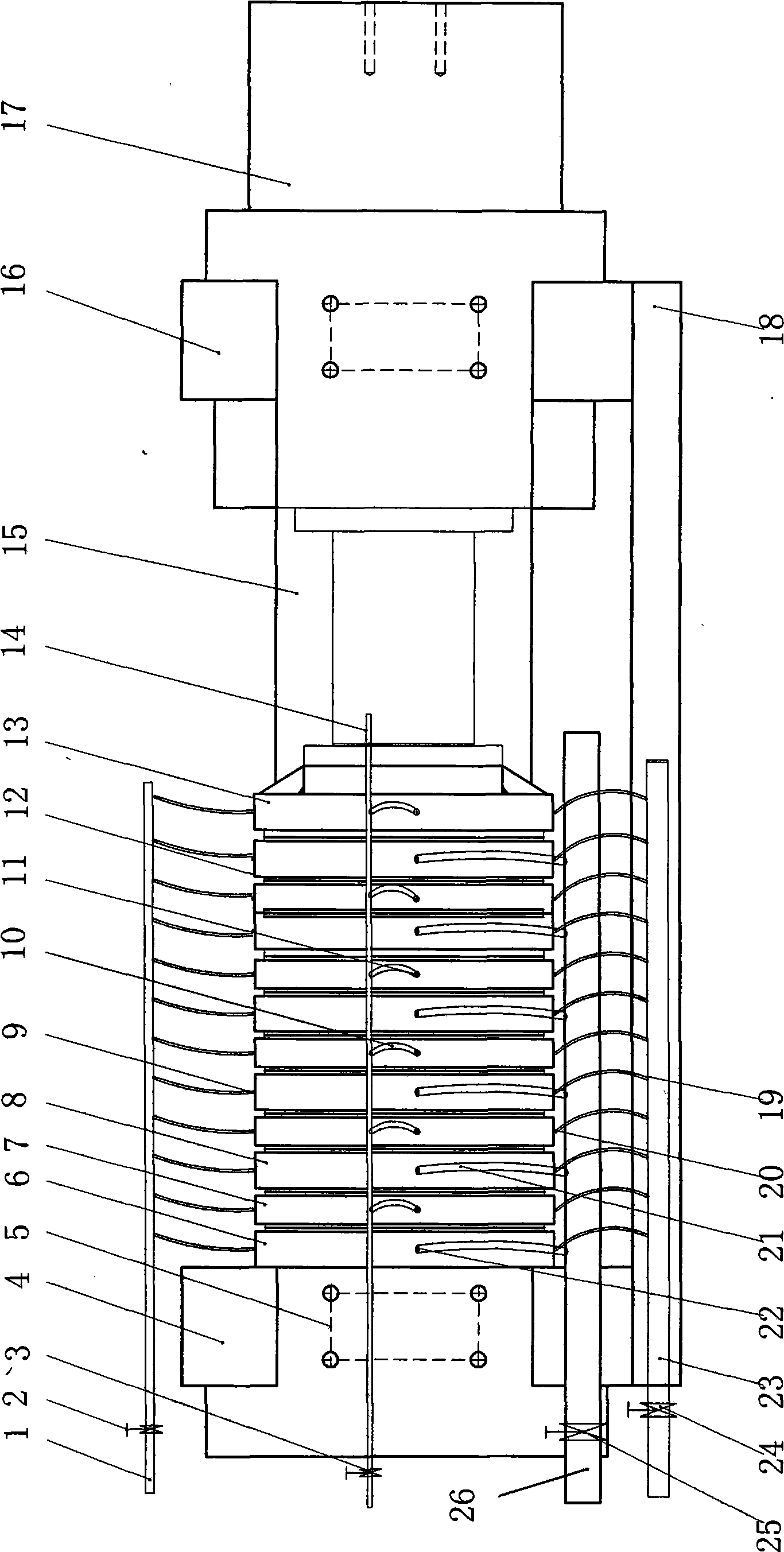

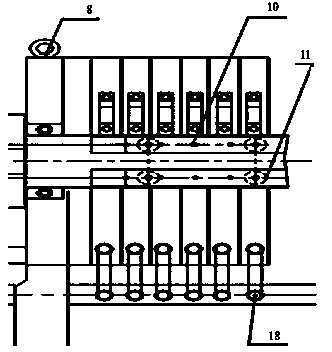

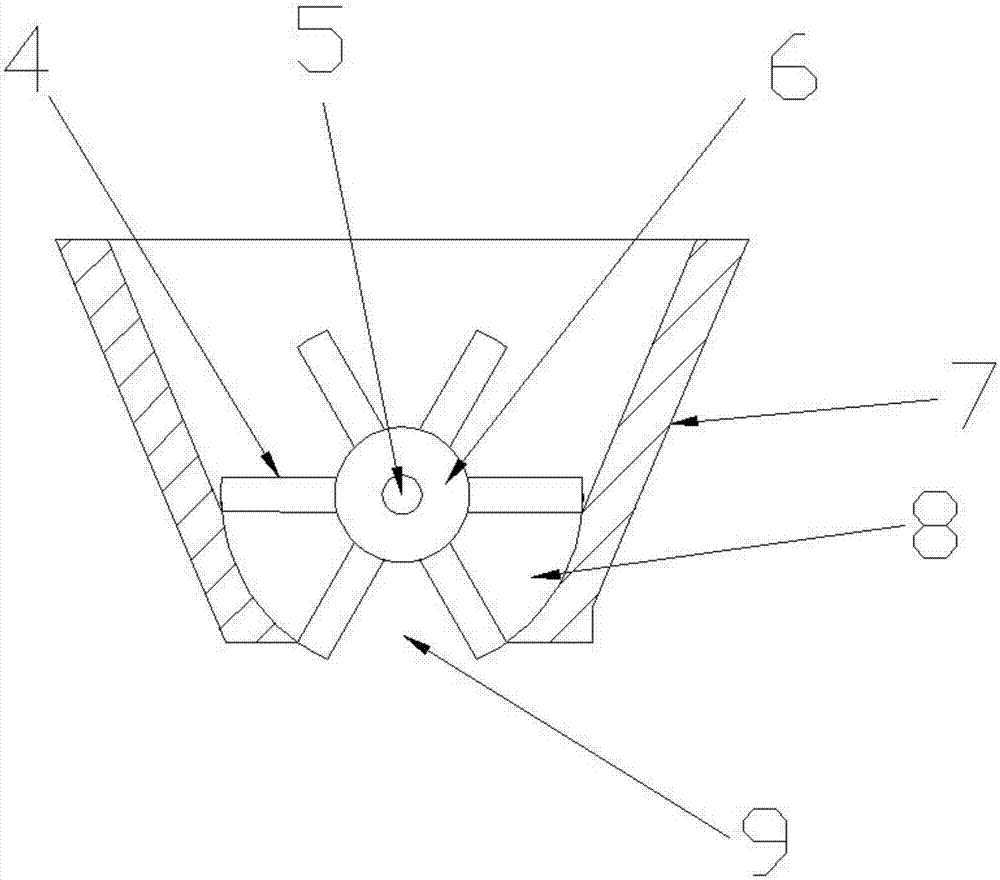

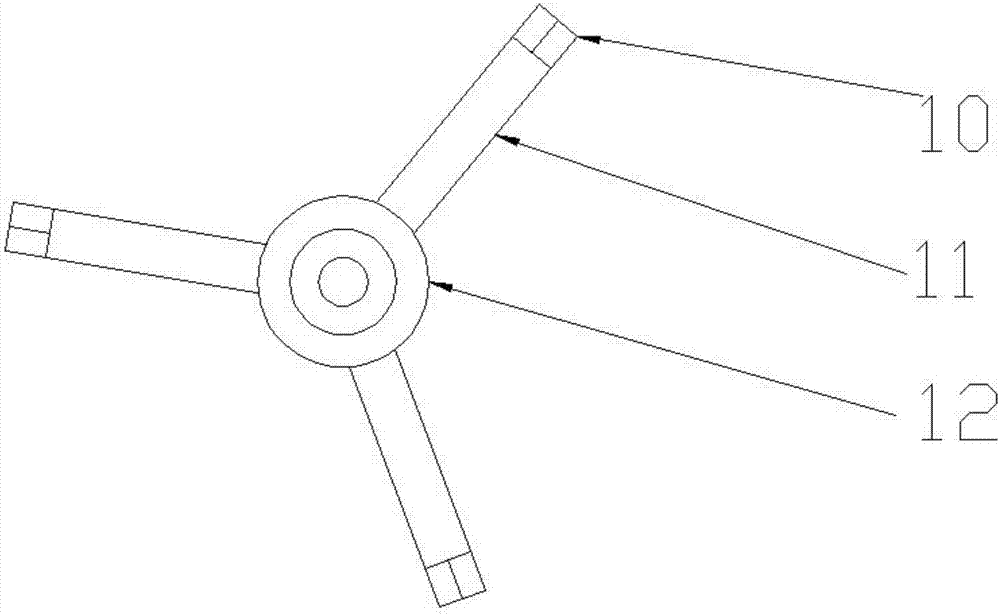

Plate-type sludge dewatering machine and dewatering method therefor

InactiveCN101544459AReasonable structureImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningElastomerHigh pressure

The invention discloses a plate-type sludge dewatering machine and a dewatering method therefore. The plate-type sludge dewatering machine adopts elastomers positioned among pressing filter plates, adjacent anti-thrust filter plates, air-inlet filter plates, feeding filter plates and thrust filter plates to form at least three hermetic pressing filter chambers variable in volume, utilizes the compression deformation and resilience of the elastomers to deep squeeze and dewater a filter cake, and adopts sealing plugs which are arranged in front of air-inlet holes of the air-inlet filter plates and the thrust filter plates and are on positions opposite to feeding holes on the feeding filter plates and the anti-thrust filter plates, wherein the feeding filter plates are adjacent and involutory to the air-inlet filter plates. After low-pressure filter dewatering is over and feeding is stopped, the sealing plugs block and seal the feeding holes so as to prevent sludge from flowing back and entering pipelines during pressing filtration. The dewatering method adopts the variable hermetic pressing filter chambers formed by the elastomers to perform pressing filtration and dewatering, and adds the operation of adopting the sealing plugs to block the feeding holes before high-pressure squeezing-dewatering operation. The invention has the advantages of high dewatering efficiency, strong adaptability, low energy consumption, low use cost and the like.

Owner:ZHEJIANG HUAZHANG TECH

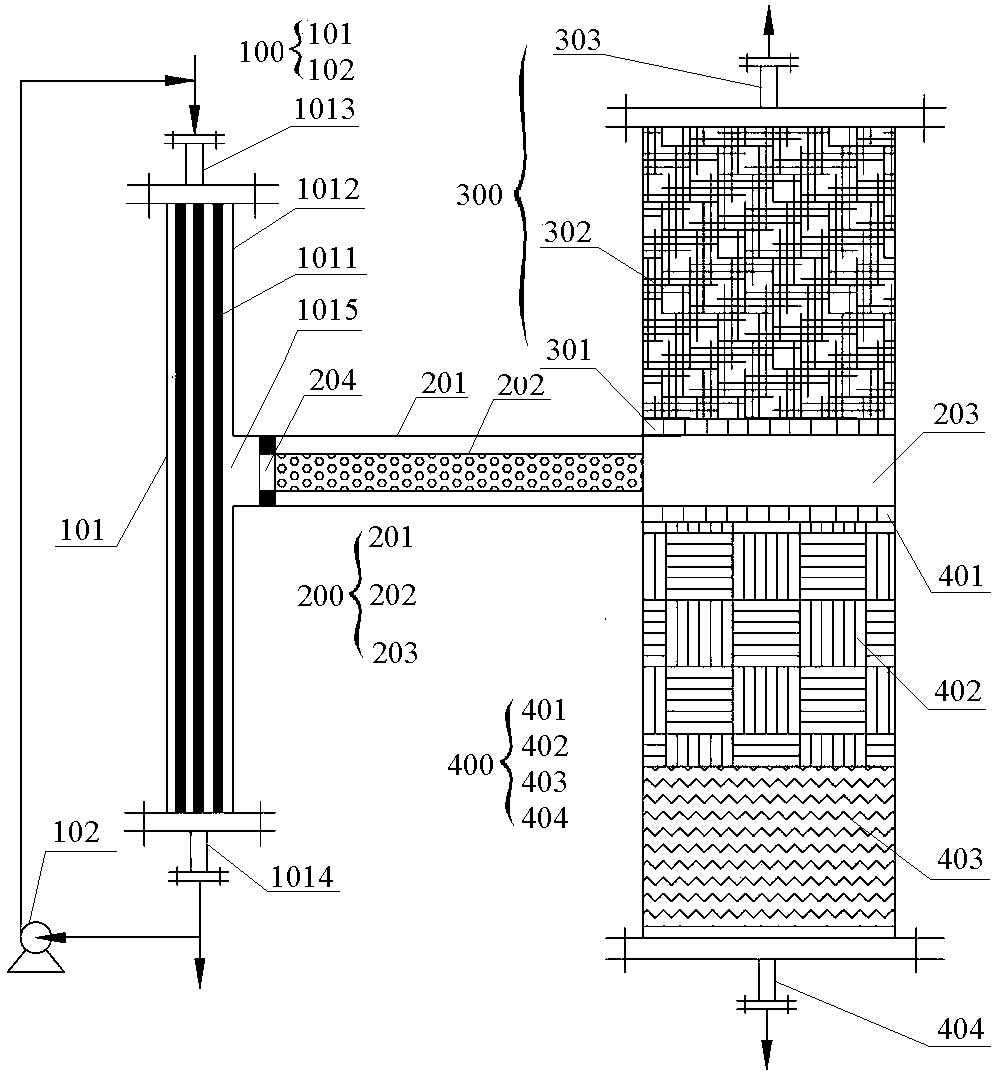

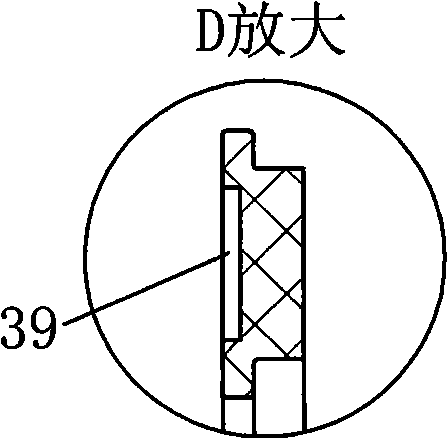

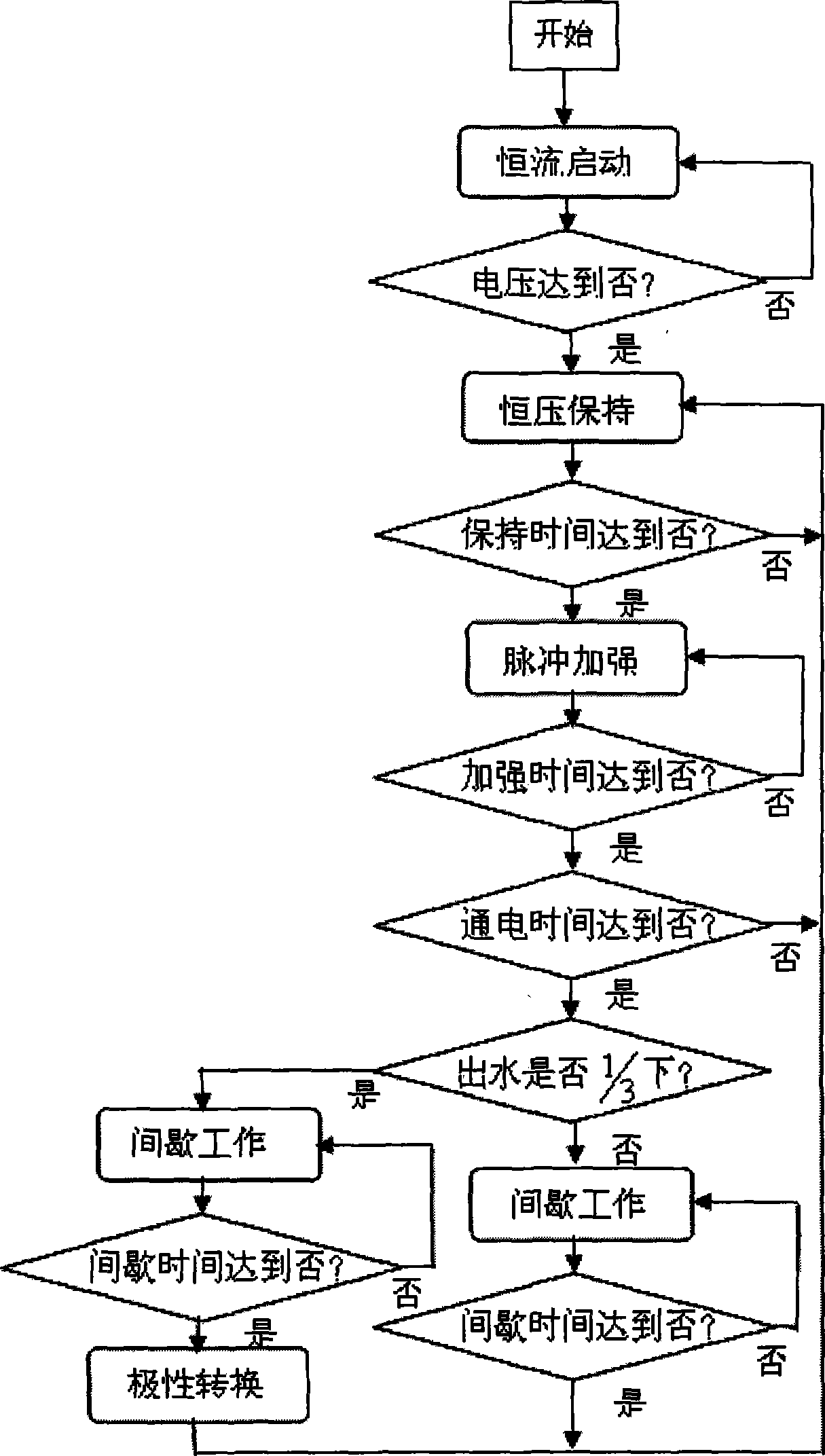

Electroosmosis method and apparatus for dehydration for large area high moisture percentage earth body

InactiveCN101457521AAddressing deficiencies in electroosmotic dehydration operationsImprove dehydration efficiencySoil preservationPower flowEngineering

The invention relates to an electroosmotic method used for dewatering the soil with large area and high water content and equipment thereof. The operation comprises the following steps of: (1) constant current starting: adopting a constant current output mode, namely the output current is constant and the output voltage is variable; (2) constant voltage holding: when the output voltage reaches a preset value, the output voltage is converted into stable voltage and then output, namely the output voltage is constant and the output current is variable, and the stable working condition is held for long time; (3) strengthening impulse: in the process of holding constant voltage, impulse voltage is superimposed by a certain interval; (4) energization at intervals: energization and power off are carried out alternatively; and (5) polarity convention: according to the change of water yield, the positive polarity and the negative polarity of output voltage of the special electroosmotic device are automatically changed. By improving the operation method to electroosmotic dewatering, the invention solves the defects in the prior art, improves dewatering efficiency and reduces the energy consumption.

Owner:JIAXING UNIV

Motor drive device for washing machine and motor control method thereof

ActiveUS20130160499A1Improve washing efficiencyImprove dehydration efficiencyWashing controlling processesMotor/generator/converter stoppersMotor driveControl signal

Provided is a motor drive device for a motor for a washing machine of a double-rotor / double-stator structure that can selectively rotate a pulsator and a dehydrator without having a separate clutch, and a motor control method thereof. The motor drive device includes: a motor controller that generates a drive signal according to a laundry control signal to thus control a motor for the washing machine to be driven: an inverter that generates three-phase alternating-current (AC) power under the control of the motor controller, and outputs the three-phase AC power to a first three-phase stator coil for rotating an outer rotor in the motor for the washing machine, and a second three-phase stator coil for rotating an inner rotor therein; and a rotor drive controller that is provided between the inverter and the second three-phase stator coil, to thus block or pass the three-phase AC power under the control of the motor controller and simultaneously change the direction of rotation of the inner rotor.

Owner:AMOTECH

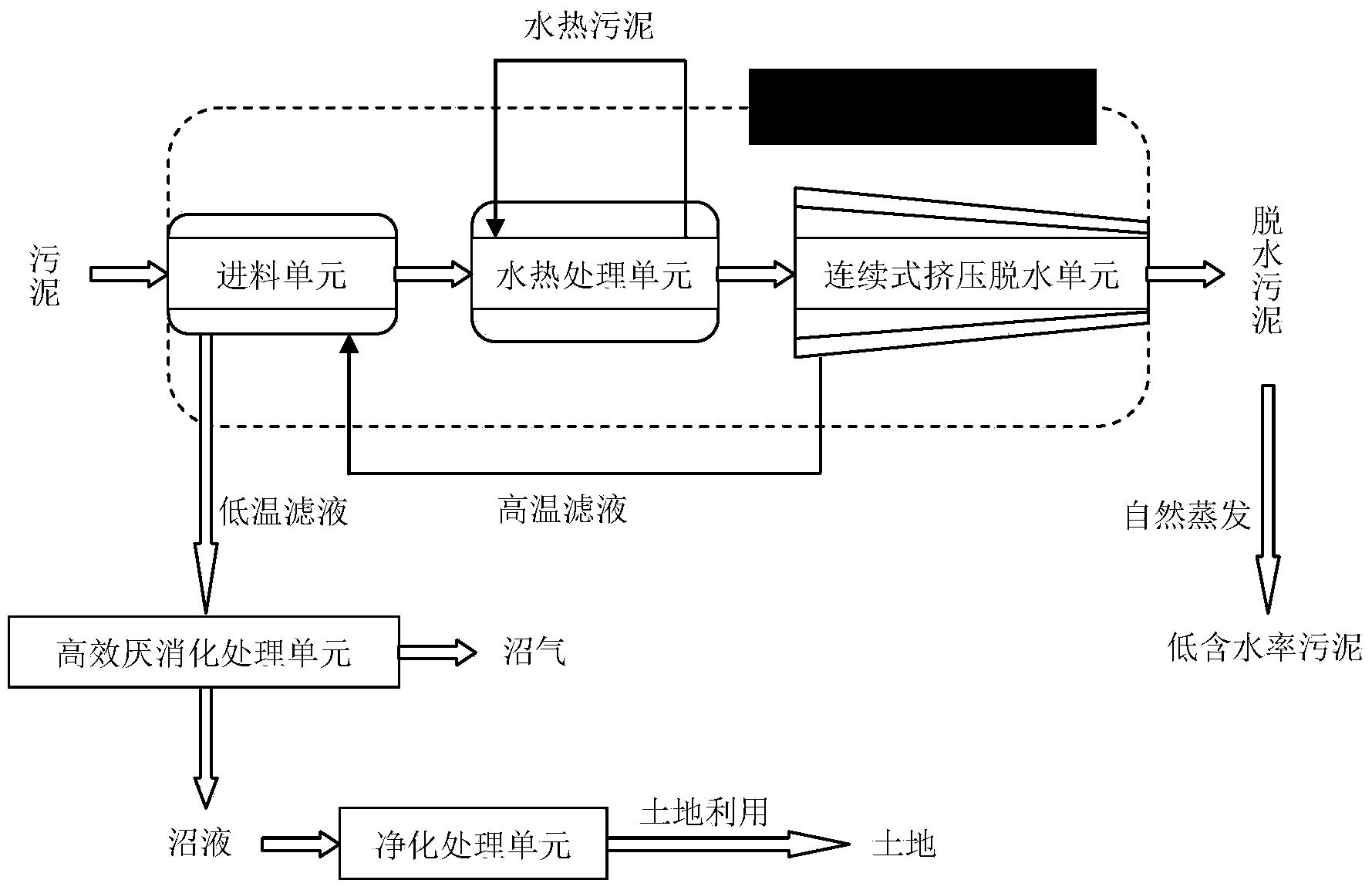

Continuous sludge dewatering method based on hydro-thermal treatment

ActiveCN103964662AAvoid heat consumptionHigh calorific valueSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningThermal treatmentThermal reaction

The invention relates to a continuous sludge dewatering method based on hydro-thermal treatment, and belongs to the field of sludge treatment. An external heat exchanger of a feeding unit is filled with high temperature filtrate, sludge is continuously introduced in the feeding unit, and the high temperature filtrate is used for preheating the sludge; the sludge after preheating enters a hydro-thermal treatment unit under the pushing of the feeding unit, and is heated to above 150 DEG C for a hydro-thermal reaction through a heating device arranged on the outside of the hydro-thermal treatment unit; the standing time of the sludge inside the hydro-thermal treatment unit is controlled by an accelerator arranged at the interior of the hydro-thermal treatment unit; partial sludge after hydro-thermal treatment is flown back to the hydro-thermal treatment unit; the sludge passing through the hydro-thermal treatment unit is introduced in a continuous extrusion dewatering unit to realize continuous dewatering of the hydro-thermal sludge, and a cavity in the dewatering process is at a sealed state. According to the dewatering method, based on the hydro-thermal treatment for improving the sludge structure and physicochemical characteristics, the energy sources are fully utilized and recycled while the energy consumption input is saved, and the sludge dewatering in a liquid form is realized continuously.

Owner:DALIAN UNIV OF TECH

A method for producing amino acid bio-organic fertilizer with cassava residue and starch waste liquid

InactiveCN102276317AHigh organic contentIncrease heightBio-organic fraction processingOrganic fertiliser preparationBacillus licheniformisBacillus megaterium

The invention belongs to the field of the manufacturing of organic fertilizers and discloses a method for producing an amino acid microbial organic fertilizer by using cassava residue and starch waste liquor. The method comprises the following steps of: dehydrating the cassava residue and the starch waste liquor until the final water content is 60 to 65 weight percent; adding 8 to 12 weight percent of humic acid, 3 to 7 weight percent of oil cake, 3 to 7 weight percent of rice bran and 0.3 to 0.5 weight percent of straw fermentation decomposing inoculant, and performing aerobic fermentation, wherein the fermentation temperature is 40 to 65 DEG C, and the fermentation cycle is 15 to 20 days; and uniformly mixing a functional strain which accounts for 3 to 5 percent of the total weight and is one or more of Bacillus mucilaginosus, bacillus subtilis, Bacillus licheniformis, Bacillus megaterium and Streptomyces jingyangensis, starch-containing waste liquor which accounts for 2 percent of the total weight and fermented residue, aerating the air and performing late curing for 5 to 7 days, and adding 1 to 3 percent of amino acid to obtain a finished product. Raw materials do not contain harmful bacteria and pathogens, harmful gas and odor are not generated in the fermentation, and the fertilizer can increase effect and stimulate plants to grow quickly.

Owner:云南金星化工有限公司

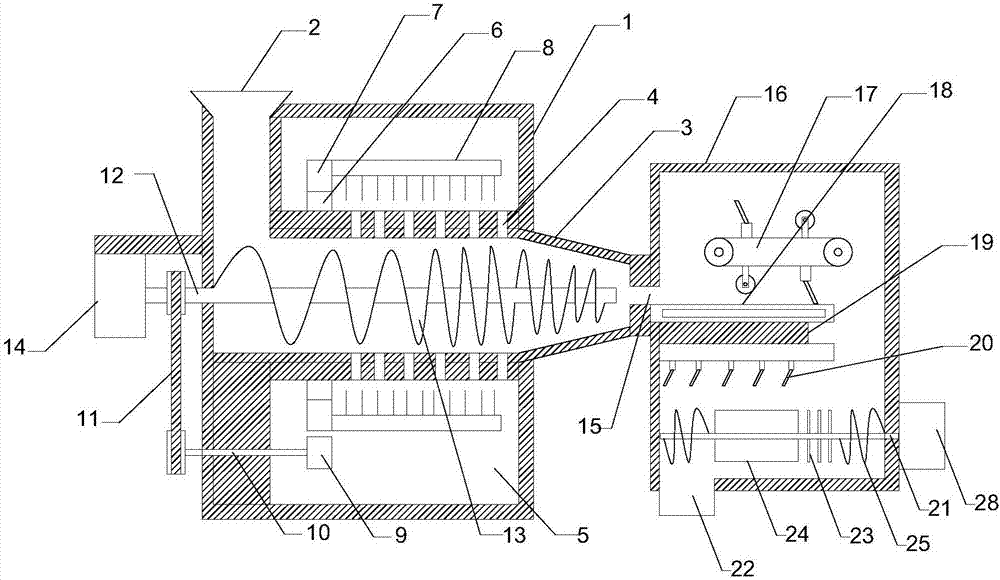

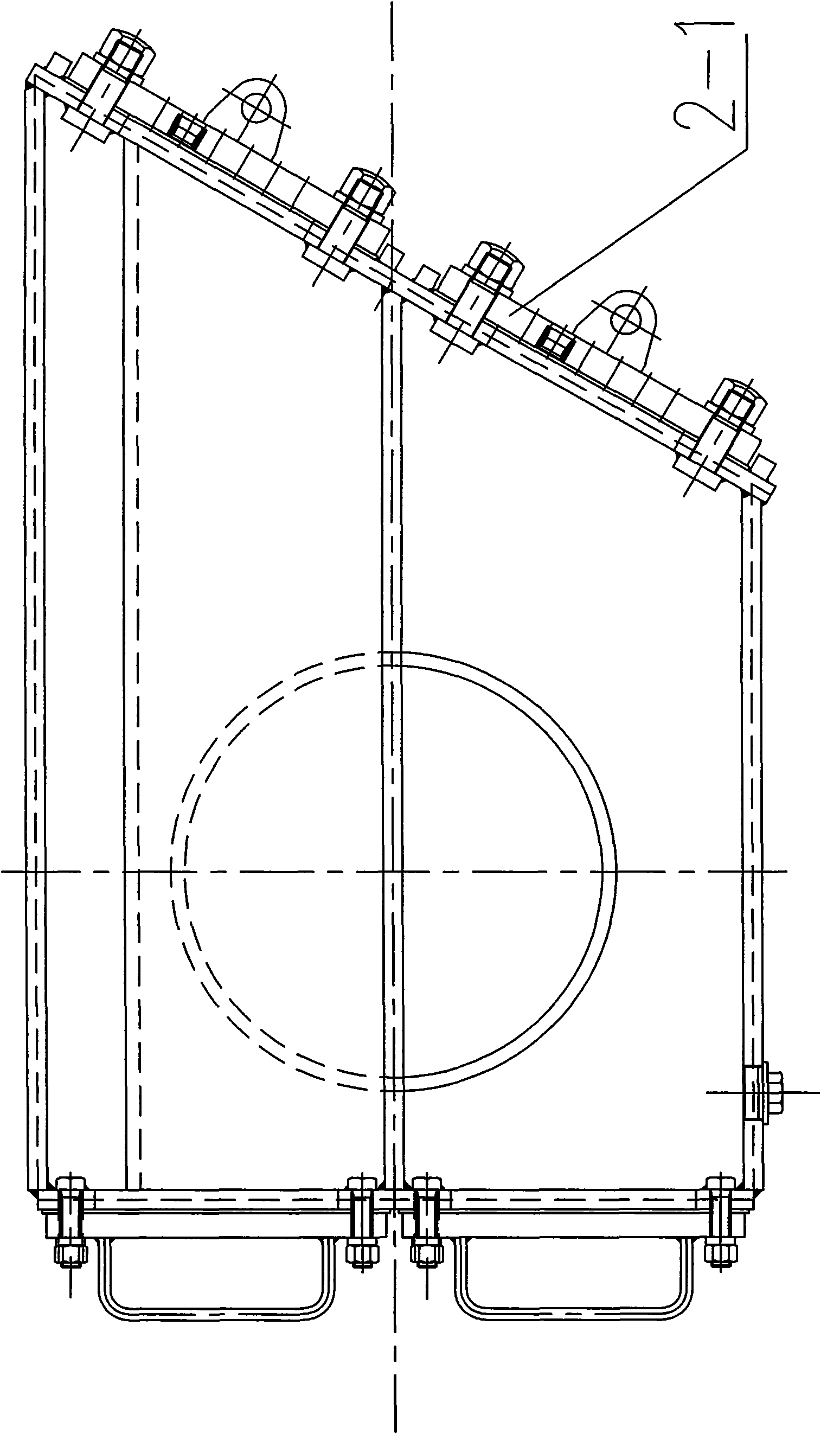

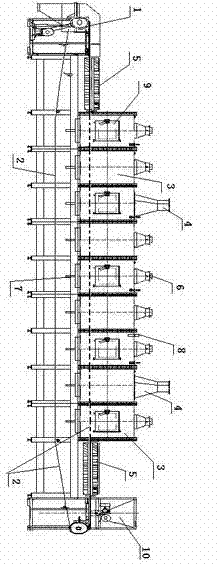

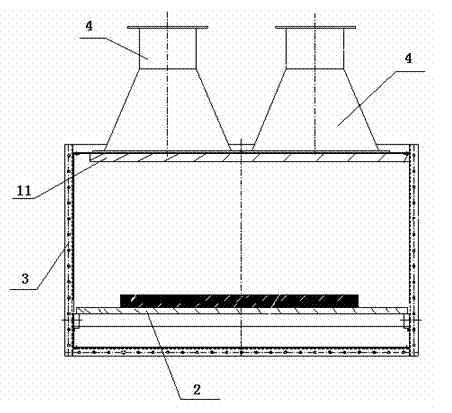

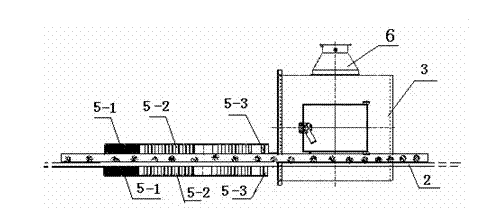

Coal quality improvement apparatus for microwave low temperature dehydration and desulfurization

InactiveCN102816623AReduce moisture contentQuality improvementDrying solid materials with heatSolid fuelsMicrowaveShielding gas

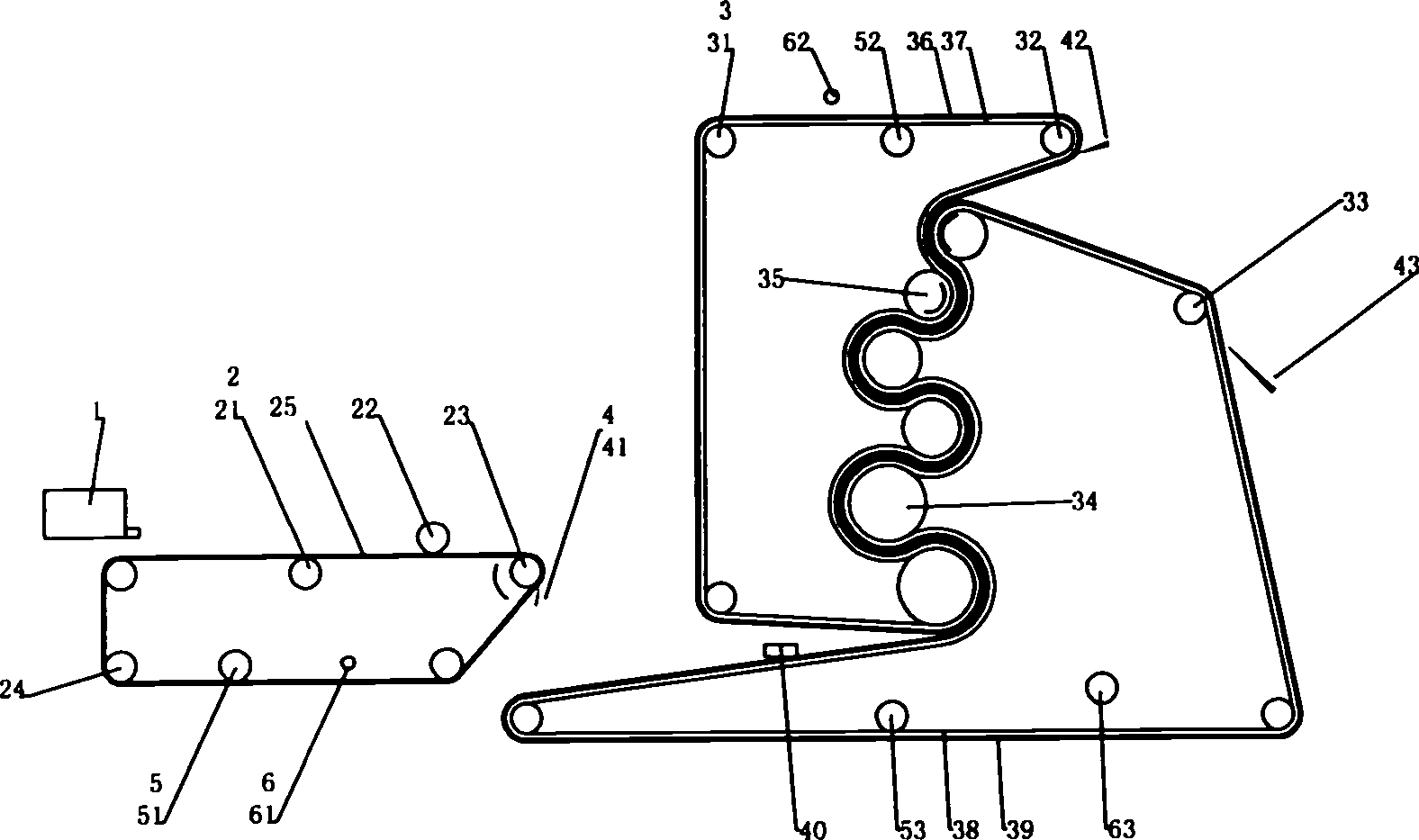

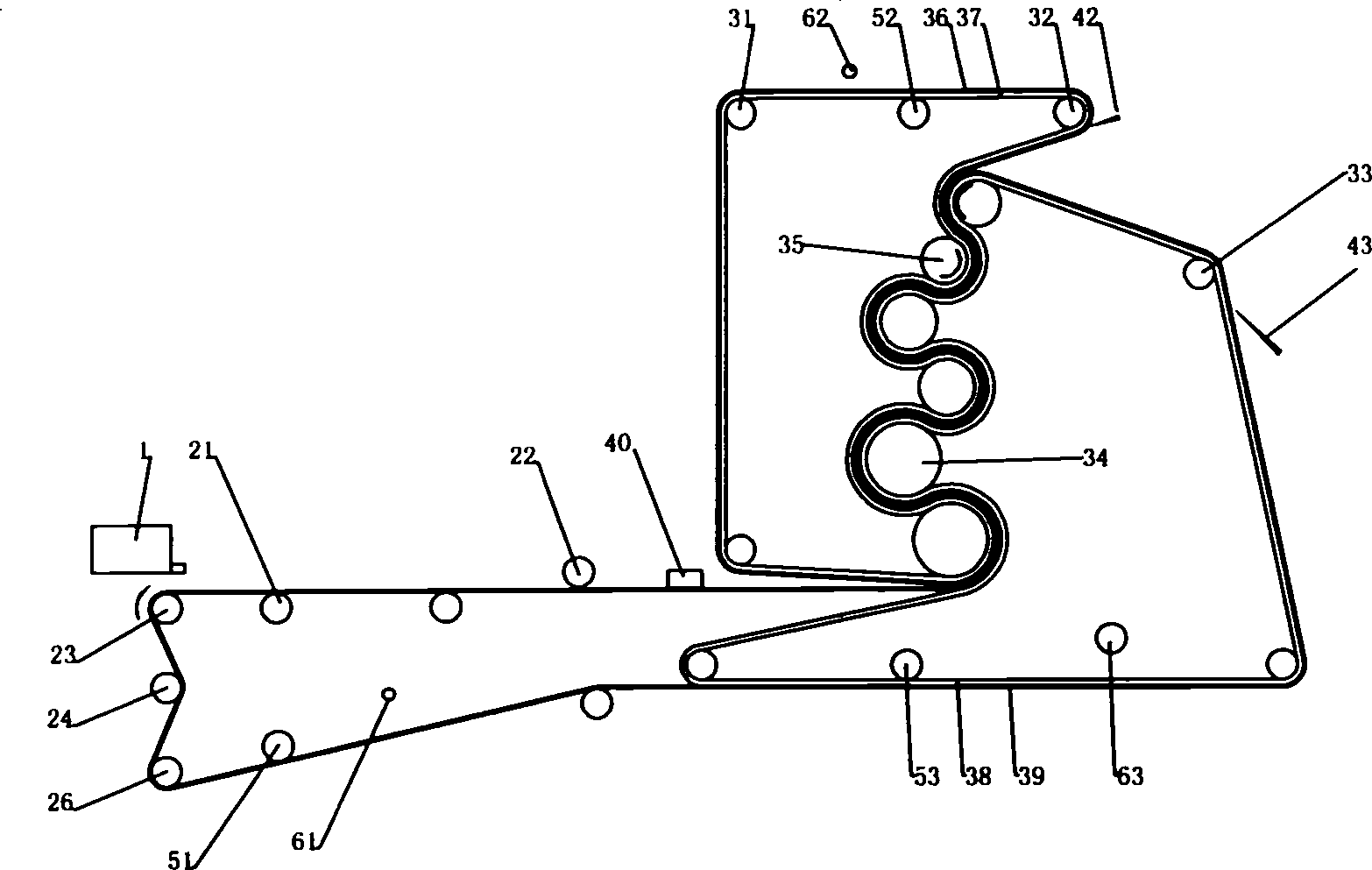

The present invention discloses a coal quality improvement apparatus for microwave low temperature dehydration and desulfurization. The apparatus comprises a continuous tunnel transportation device (1), a coal transportation belt (2), microwave line chambers (3), energy reclaiming ports (4) installed on the top of the microwave line chambers (3), and microwave leakage inhibition devices (5) installed on both ends of the microwave line chambers (3), wherein microwave energy of a continuous wave magnetron enters the microwave line chamber (3) through the energy reclaiming port (4), the upper parts of the microwave line chambers (3) are provided with pumping discharging ports (6), the bottom parts of the microwave line chambers (3) are connected with an inflation device (7) of protection air, and a plurality of the microwave line chambers (3) are continuously combined to form a microwave combination chamber. The coal quality improvement apparatus of the present invention has characteristics of reasonable structure design, high production efficiency, strong security, wide application range, concurrent performing of dehydration and desulphurization treatments, and high coal quality.

Owner:NANJING SANLE ELECTRONICS INFORMATION IND GRP +2

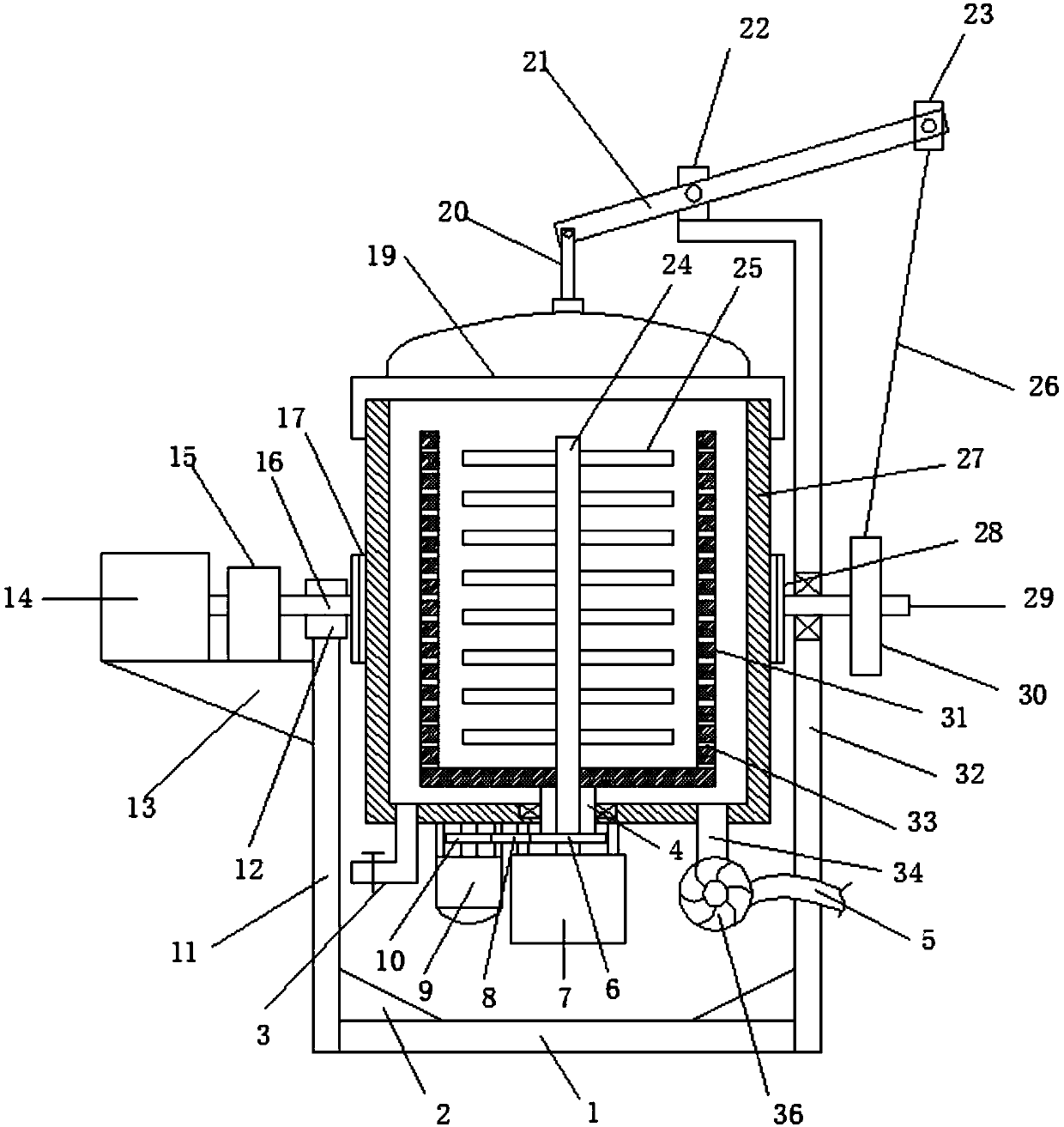

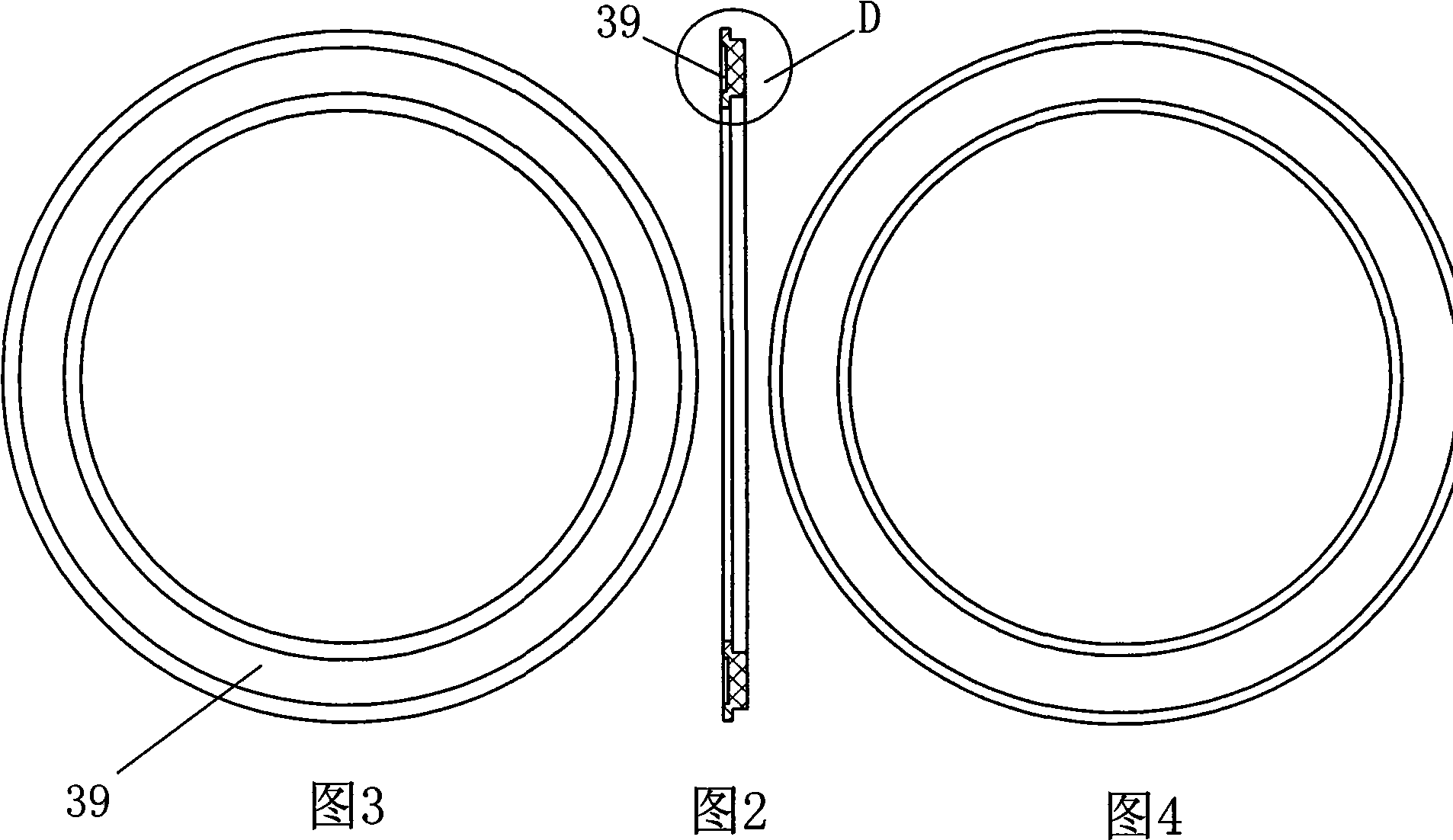

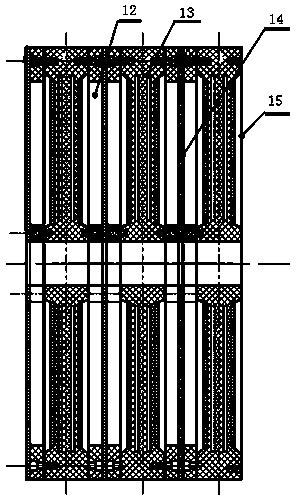

Membrane filter plates used for electro-osmosed sludge, membrane filter press and filter press

ActiveCN104030543AReduce moisture contentSimple structureSludge treatment by de-watering/drying/thickeningWater pipeMesh grid

The invention discloses membrane filter plates used for electro-osmosed sludge, a membrane filter press and a filter press. Each membrane filter plate is also provided with a relatively sealed membrane cavity formed by two membrane plates, wherein the membrane cavities are communicated with pressing water pipes; solid plates are arranged in the middle of the membrane cavities; filter cloths are arranged on the two sides of the membrane filter plates; cathode conductive filter screens are arranged on the backs of the filter cloths as liners and are connected with a cathode copper bar; grids of the cathode conductive filter screens are fit with sunk areas of the membrane filter plates; units are formed by the two parallel cathode membrane filter plates and form a relatively sealed sludge storage cavity; the sludge storage cavity is separated into two independent spaces by an anode plate connected with an anode copper bar. A sludge electro-osmotic dewatering device has a simple structure, operates reliably, can achieve reduction of the moisture content of the sludge below 50%, and improves the dewatering efficiency by 2-3 times compared with the membrane filter press.

Owner:SOUND ENVIRONMENTAL RESOURCES

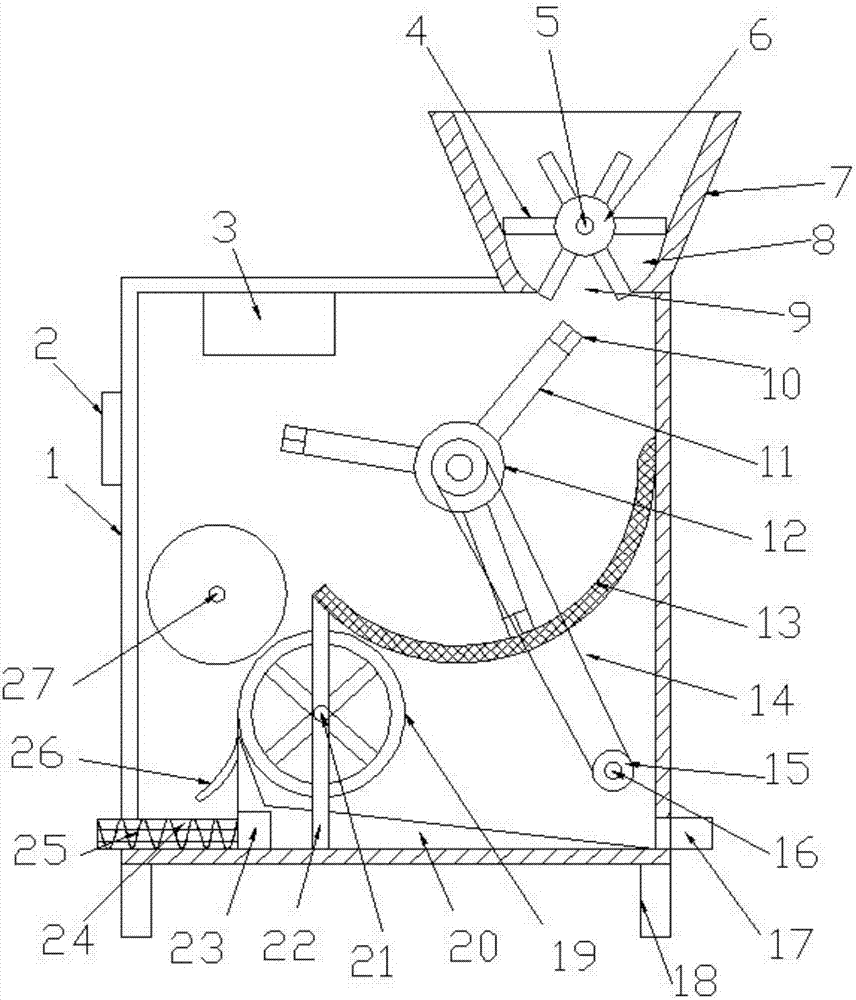

Quick efficient sludge dewatering device

InactiveCN107381992AImprove dehydration efficiencyDehydration achievedSludge treatment by de-watering/drying/thickeningSludge detoxificationPulp and paper industryDewatered sludge

The invention discloses a fast and high-efficiency sludge dewatering device, which comprises a shell, the bottom of the shell is symmetrically arranged with supporting feet, and a screen is arranged inside the shell, and the screen is in the shape of an arc groove. A turntable is set at the center of the arc, and the turntable is set on a rotating shaft in the casing. A rotating rod is arranged symmetrically on the center of the turntable, and a scraper is arranged at the end of the rotating rod. The top end of the right side of the screen is fixed on the casing. On the right side wall of the body, the left end of the screen is fixed to the inner bottom of the housing through a vertical rod; the top of the right side of the housing is provided with a feed port, and the housing on the left side of the screen is provided with an upper extrusion roller and a lower extrusion roller; The lower squeeze roller includes an outer drum, and the outer drum is a filter mesh drum; the invention skillfully arranges the screen structure and the scraping mechanism on the screen, which greatly improves the sludge dewatering efficiency, and at the same time, an upper squeeze roller is arranged corresponding to the bottom of the screen. The pressure roller and the lower squeeze roller, and clever use of the material hanging mechanism to scrape in the preliminary dewatered sludge to achieve further dehydration.

Owner:顾渠成

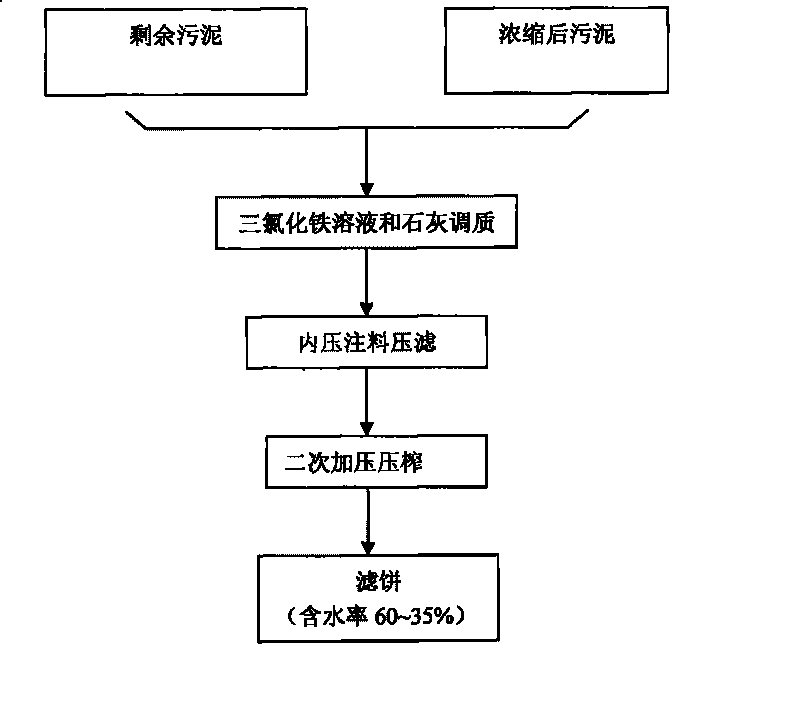

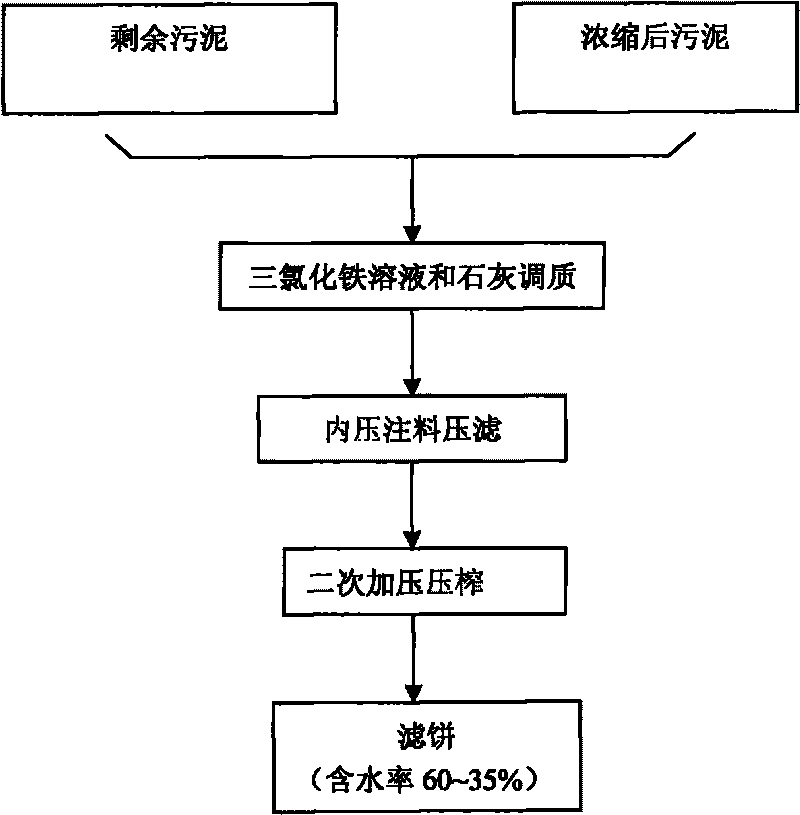

Secondary pressurizing and dehydrating method for sludge

ActiveCN101708941AImprove incompressibilityImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningTreatment burdenSludge

The invention discloses a secondary pressurizing and dehydrating method for sludge. The method comprises the following steps: modifying the sludge before dehydrating; pressing and filtering internally pressed feeding materials; and secondarily pressurizing and pressing. The method has the advantages that: sewage sludge is modified by inorganic medicament before dehydrating to improve the incompressibility of sludge particles, the hydrophilic sludge particles are modified to hydrophobic sludge particles so as to contribute to subsequent pressing, filtering and dehydrating; the filter cakes are subjected to secondary pressurizing and pressing after the internally pressed feeding materials are pressed and filtered; and the water content of the sludge filter cakes are further reduced through high pressure pressing so as to improve the dehydrating efficiency and reduce subsequent transportation and treatment burden.

Owner:SWISON CREATIVE ENVIRONMENTAL SOLUTIONS CO LTD

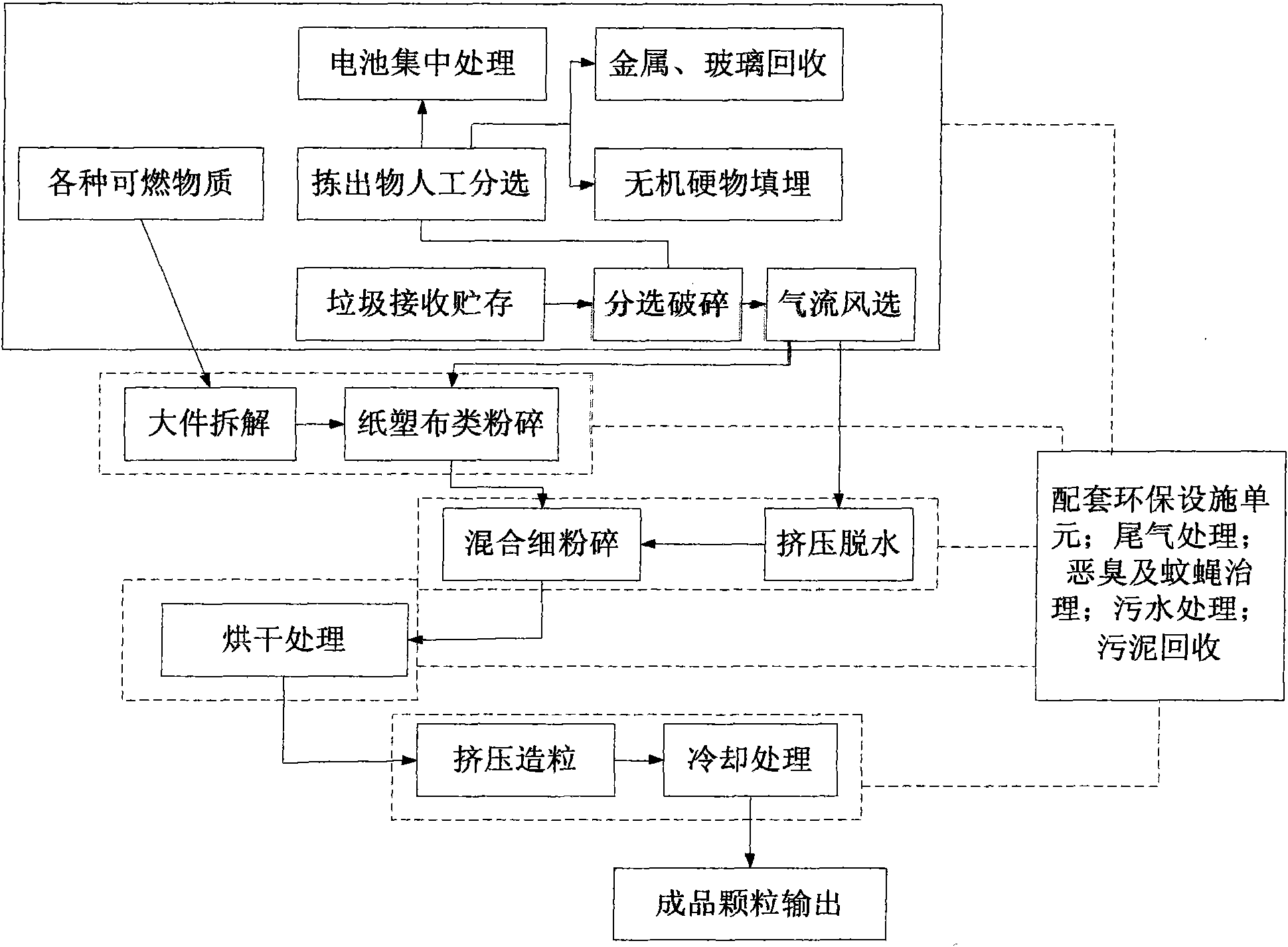

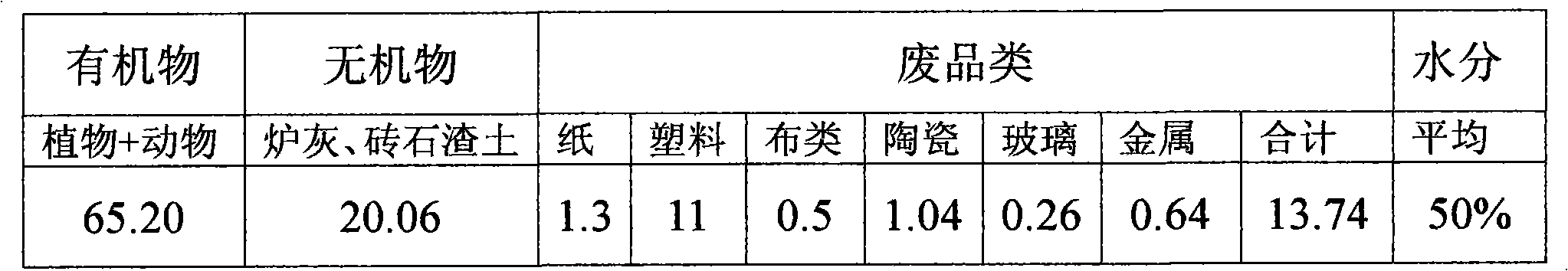

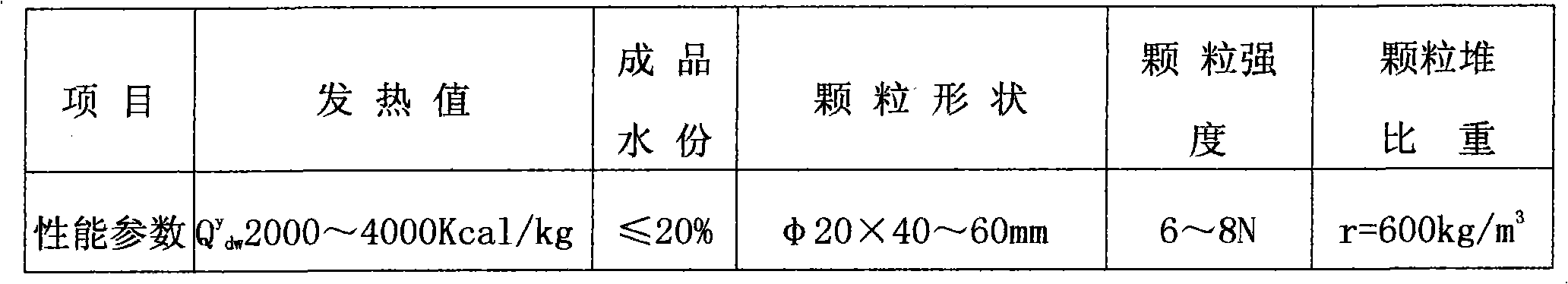

Method for preparing regeneration pellet fuel of urban household garbage

InactiveCN101886010AImprove recycling efficiencyReduce labor costsBiofuelsSolid fuelsLower limitLitter

The invention provides a method for preparing the regeneration pellet fuel of urban household garbage, which adopts the following steps of: comprehensive treatment of household garbage, burdening, secondary mixing and crushing, material drying, fuel forming, cooling and packaging and the like. The regeneration pellet fuel of the urban household garbage prepared by the method has the advantages that: the burdening process is adopted in the process of preparing garbage fuel to balance a heat value of the garbage fuel; the garbage fuel is prepared by adopting fully-mechanized assembly line operation, the process of garbage disposal has no phenomenon of material retention, no secondary pollution and no generation of garbage percolate and reduces mosquitoes and flies and the stench grade to the lowest limit, and simultaneously, the heat value of combustible matters in the processing process is not lost basically; and the fuel is dried first before forming, and has the high heat efficiency.

Owner:深圳市兖能环保科技有限公司

Nano highly effective amendment for sludge dehydration

InactiveCN1621370AHigh floc strengthLow floc strengthSludge treatment by de-watering/drying/thickeningWater/sewage treatment by flocculation/precipitationSulfateSludge

The present invention discloses one kind of Z's nanometer efficient sewage dewatering amendment. The Z's nanometer efficient sewage dewatering amendment consists of polymerized ferric sulfate 85-98 weight portions, polyacrylamide 0.5-6 weight portions, hydroxymethyl cellulose sodium 0.5-6 weight portions and nanometer material 0.5-3 weight portions. The present invention has powerful neutralizing capacity, bridging capacity and permeating capacity and thus has high sewage dewatering effect.

Owner:曾智勇 +1

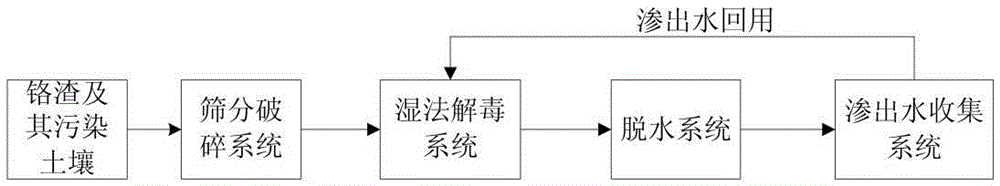

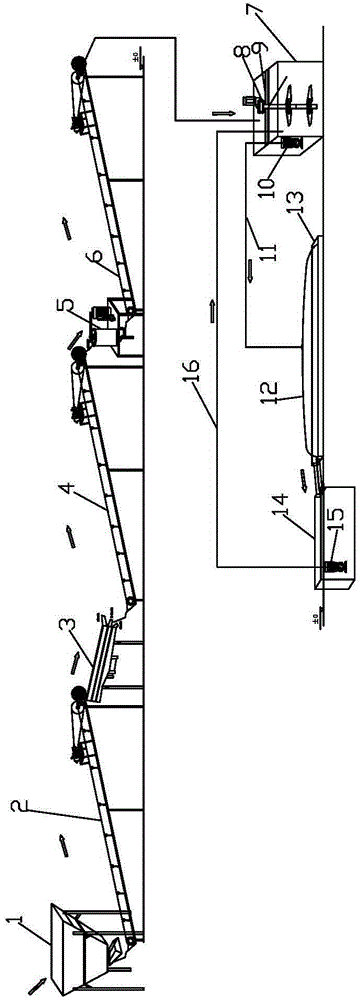

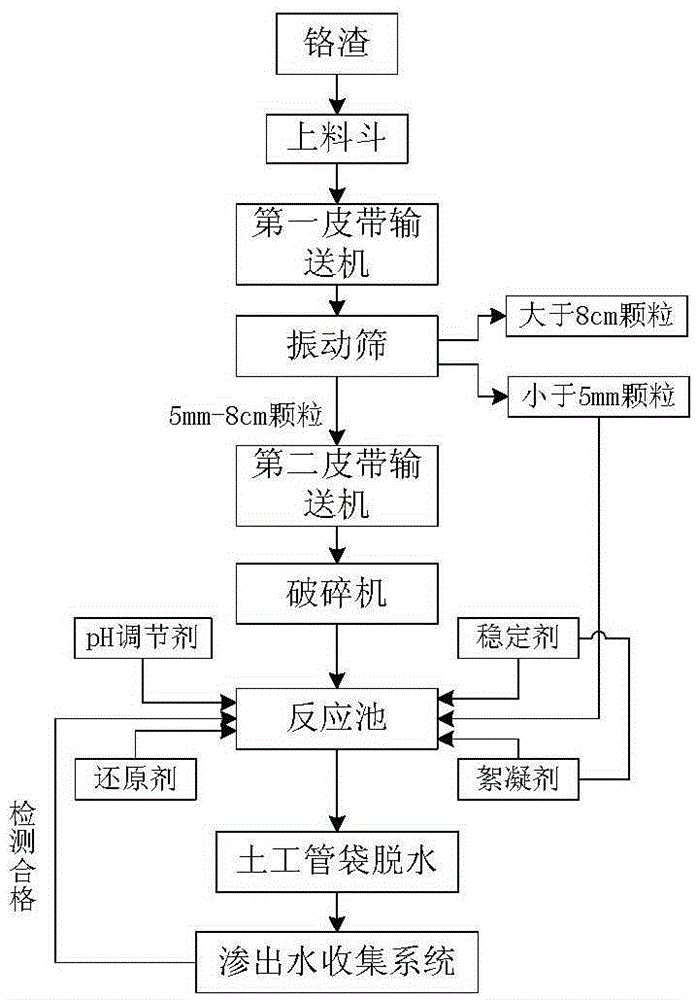

Wet process detoxifying processing device and method for chromium slag and contaminated soil of chromium slag

InactiveCN105396872AAchieving zero emissionsHigh degree of automationContaminated soil reclamationSlagWastewater

The invention discloses a wet process detoxifying processing device and method for chromium slag and contaminated soil of the chromium slag. The processing device comprises a screening and breaking system, a wet process detoxifying system, a water removing system and a seepage water collecting system. In the screening and breaking system, the chromium slag and the contaminated water of the chromium slag are conveyed to a vibrating screen by a feeding hopper through a belt conveyor and are conveyed to a breaker after being screened; after the chromium slag and the contaminated soil are broken to have the certain grain size through the breaker, the chromium slag and the contaminated soil are conveyed to the wet process detoxifying system; detoxifying chemicals are added into the wet process detoxifying system; after sufficient mixing and complete reacting are completed, a flocculating agent is added, and the mixture is conveyed to the water removing system through a submerged pump; a soil engineering pipe bag is adopted in the water removing system, after water removing of the water removing system is conducted, more than 99% of solid particles are reserved in the soil engineering pipe bag; and the seepage water is reused into the wet process detoxifying system after being collected. The wet process detoxifying processing device and method for the chromium slag and contaminated soil of the chromium slag have the beneficial effects that an operation effect is good, secondary pollution is avoided, and zero emission of waste water is achieved.

Owner:BEIJING GEOENVIRON ENG & TECH

Process for dehydrating activated sludge by waste alkaline residue/alkali liquor

InactiveCN101289268AImprove dehydration efficiencyEnable reuseSludge treatment by de-watering/drying/thickeningClimate change adaptationActivated sludgeSlag

The invention discloses a method for dewatering activated sludge by utilizing waste alkali slag / alkali liquor. The method of the invention mainly includes that the waste alkali slag / alkali liquor is first added with a certain amount of calcium oxide to be evenly mixed and then injected into activated sludge which goes through gravity settling, and evenly mixed; fully-dissolved polyacrylamide is then added and evenly mixed; the dry basis ratio of alkali slag, calcium oxide, polyacrylamide and activated sludge is 25 to 40 : 7 to 13 : 0.12 to 0.25:100; after being fermented and air-dried, dewatered sludge is served as agricultural fertilizer. The dewatering method of the invention has the advantages of low cost, high efficiency of sludge dewatering, good stability and low content of heavy metal in yielding sludge and achieves the purpose that the waste alkali slag is recycled to treat the waste by the waste; in addition, the alkali slag contains the elements of calcium, magnesium and a small amount of sodium, potassium, chloride, etc., which are necessary for the plant growth and can be used for making fertilizer in the agricultural production.

Owner:李肇忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com