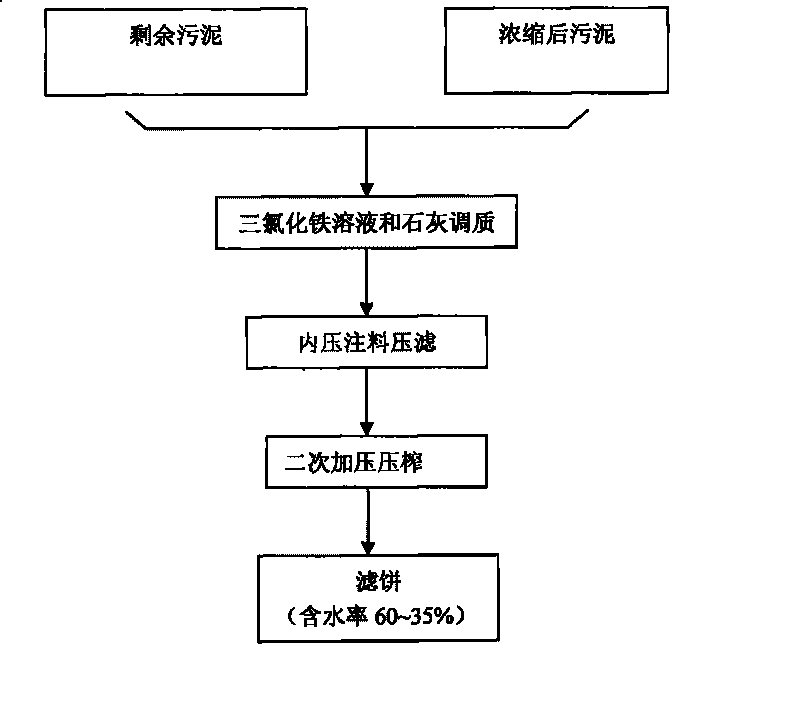

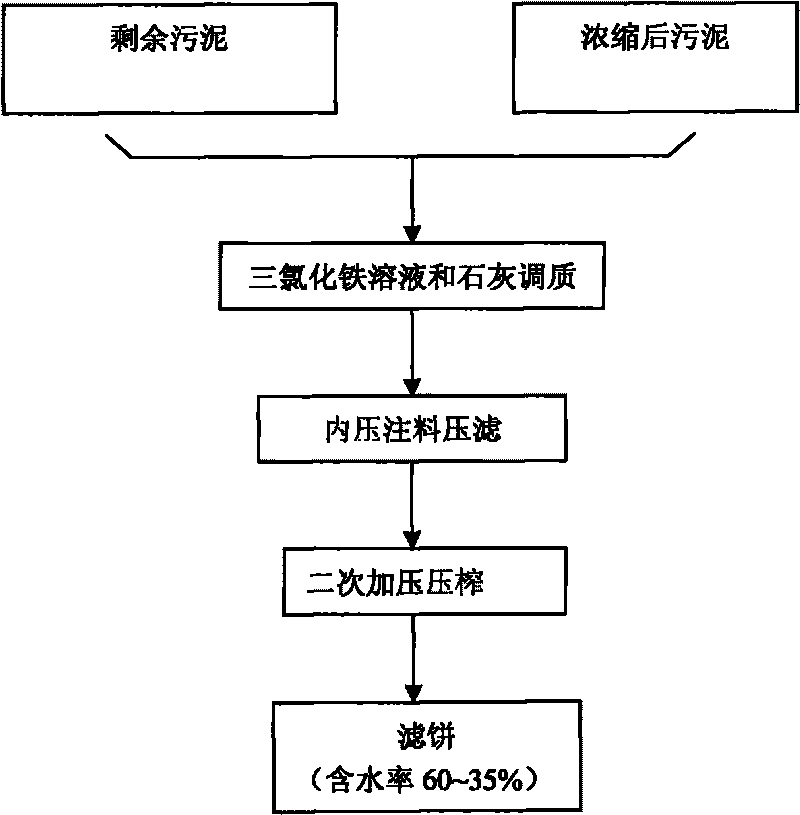

Secondary pressurizing and dehydrating method for sludge

A technology of secondary pressurization and sludge, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problem of high moisture content of sludge, reduce moisture content, improve dehydration efficiency, and reduce the burden of transportation and disposal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The concentrated sludge with a water content of 95% is transported to the inorganic conditioning and tempering tank, and the ferric chloride solution with a concentration of 38.8% is first added to the sludge and fully stirred for 30 seconds. The dosage is 4.5% of the dry basis mass of the sludge; then add lime particles to the sludge and fully stir for 10 minutes, the calcium oxide content in the lime particles is 70%, and the dosage of lime particles is 12.5%.

[0023] The conditioned sludge to be pressed is transported to the plate and frame filter press through the screw pump, and the hydraulic station provides a compression pressure of 25MPa for the plate and frame filter press. The sludge particles are trapped in the filter chamber and gradually form a filter cake, and the filtrate is discharged through the filtrate collection system. When the pressure in the plate and frame filter press reaches 1.2 MPa, the pressurizing equipment stops feeding, and a filter cake...

Embodiment 2

[0026] Transport the concentrated sludge with a water content of 97% to the inorganic conditioning and tempering tank, first add ferric chloride solution with a concentration of 38.8% to the sludge and fully stir for 30 seconds. The dosage is 5% of the dry mass of the sludge; then add lime particles to the sludge and fully stir for 10 minutes, the calcium oxide content in the lime particles is 70%, and the dosage of lime particles is 15%.

[0027] The conditioned sludge is transported to the plate and frame filter press through a screw pump, and the hydraulic station provides a compression pressure of 25MPa for the plate and frame filter press. The sludge particles are trapped in the filter chamber and gradually form a filter cake, and the filtrate is discharged through the filtrate collection system. When the pressure in the plate and frame filter press reaches 1.0 MPa, the pressurizing equipment stops feeding, and a filter cake with a thickness of 30 mm is formed at this ti...

Embodiment 3

[0030] Transfer the remaining sludge with a moisture content of 99.3% to the inorganic conditioning and tempering tank, first add ferric chloride solution with a concentration of 38.8% to the sludge and fully stir for 30 seconds, the addition of ferric chloride solution The amount is 6.5% of the dry weight of the sludge; then add lime particles to the sludge and stir for 10 minutes. The calcium oxide content in the lime particles is 70%, and the dosage of lime particles is 20% of the dry weight of the sludge. %.

[0031] The conditioned sludge is transported to the plate and frame filter press through a screw pump, and the hydraulic station provides a compression pressure of 25MPa for the plate and frame filter press. The sludge particles are trapped in the filter chamber and gradually form a filter cake, and the filtrate is discharged through the filtrate collection system. When the pressure in the plate and frame filter press reaches 0.8 MPa, the pressurizing equipment stop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com