Patents

Literature

83results about How to "Not easy to cause deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Packaging method

InactiveCN105355569AEliminate driftDrift suppressionSolid-state devicesSemiconductor/solid-state device manufacturingPlastic packagingNon functional

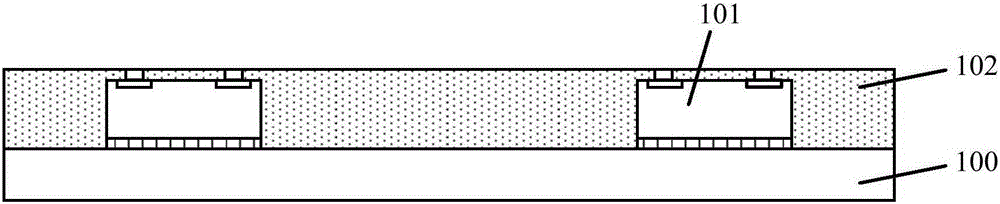

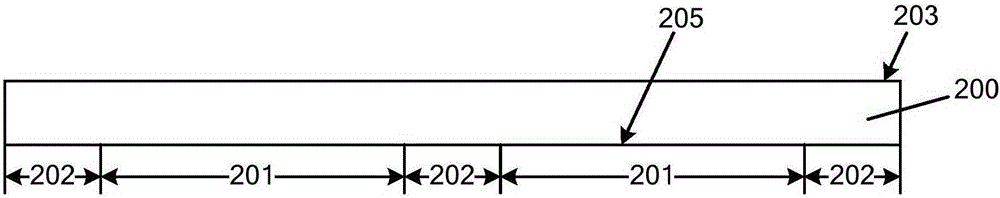

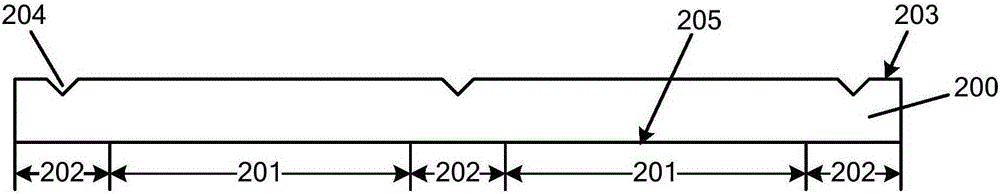

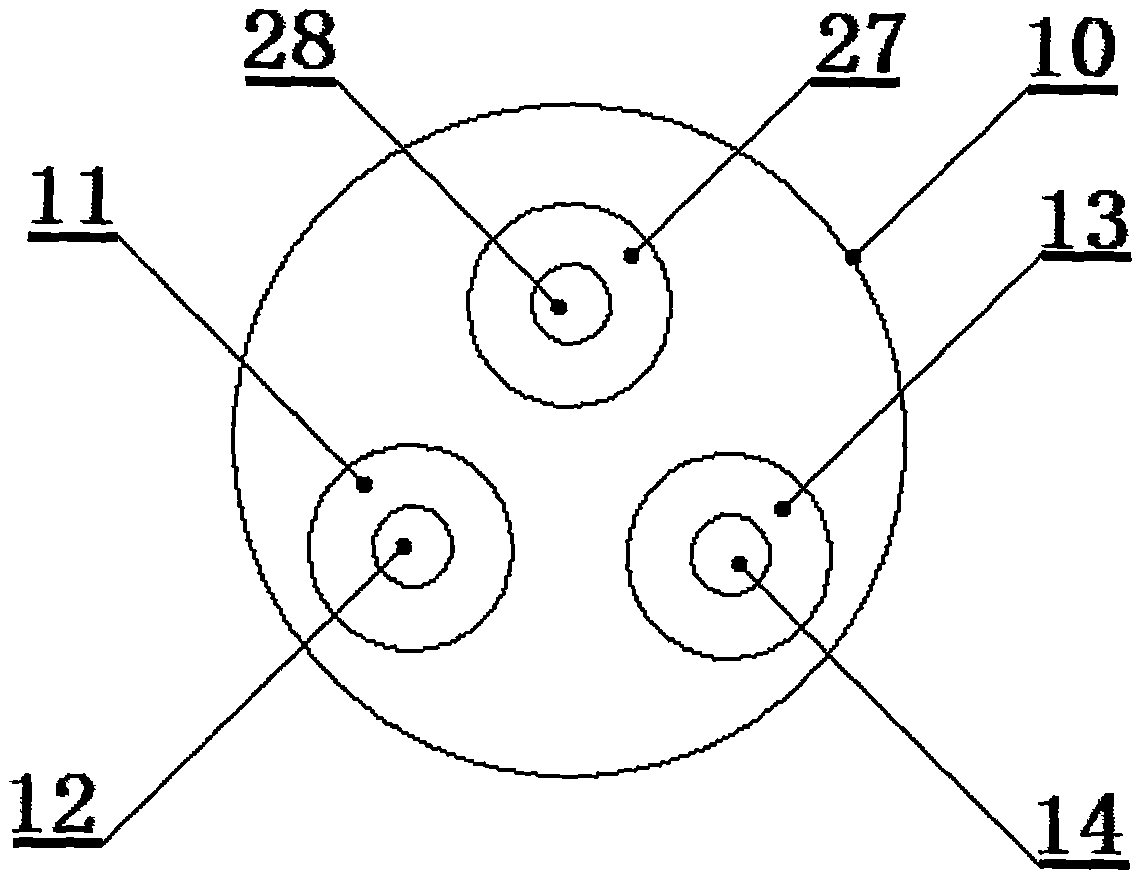

A packaging method comprises the steps of: providing a carrier plate, wherein the carrier plate comprises a plurality of chip regions and cutting regions arranged between the adjacent chip regions, the carrier plate further comprises a first surface, and a plurality of grooves are formed in the cutting regions in the first surface of the carrier plate; providing chips, wherein each chip comprises a functional surface and a non-functional side surface which are opposite to each other, the surface of each functional surface is provided with bumps, and the bumps protrude out of the functional surfaces; fixing the non-functional side surfaces of the chips with the first surface of the carrier plate in the chip regions; forming a plastic packaging layer on the first surface of the carrier plate and the surfaces of the chips, wherein the plastic packaging layer exposes top part surfaces of the bumps; removing the carrier plate after forming the plastic packaging layer; forming a rewiring structure on the surface of the plastic packaging layer and the functional surfaces of the chips; and cutting the plastic packaging layer and the rewiring structure, so that the plurality of chips are separated from one another, thereby forming an independent packaging structure. The yield and reliability of the formed packaging products are improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

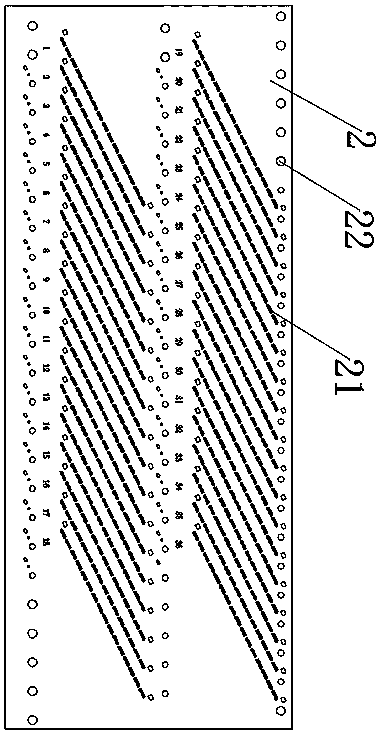

Manufacturing technique of flour-linen jacquard interval fabric mesh cloth

ActiveCN106560538AHigh pattern precisionImprove stabilityFabric breaking/softeningWarp knittingFiberYarn

The invention discloses a manufacturing technique of flour-linen jacquard interval fabric mesh cloth. The manufacturing technique comprises the first step of production and manufacturing of chemical fiber yarn, the second step of flower-type process design of the flour-linen jacquard interval fabric mesh cloth, the third step of weaving and manufacturing, and the fourth step of dyeing and finishing and sizing, wherein in the second step, the upper layer of the flour-linen jacquard interval fabric mesh cloth is knitted through the control of guide bar GB1 to guide bar GB3; the middle layer of the flour-linen jacquard interval fabric mesh cloth is knitted through the control of guide bar GB4; the lower layer of the flour-linen jacquard interval fabric mesh cloth is knitted through the control of guide bar GB5 and guide bar GB6. According to the flour-linen jacquard interval fabric mesh cloth prepared through the manufacturing technique, distortion or deformation of the flower-type are not easily caused, the precision of the flower-type is high, the stability is good, after dyeing treatment of half matt gloss polyester yarn and terylene CD yarn on the upper layer of the mesh cloth, the surface of the finished product mesh cloth presents an effect of two-tone flour-linen, dyefastness is good, and a very good overall dyeing effect is achieved.

Owner:SINCETECH FUJIAN TECH CO LTD

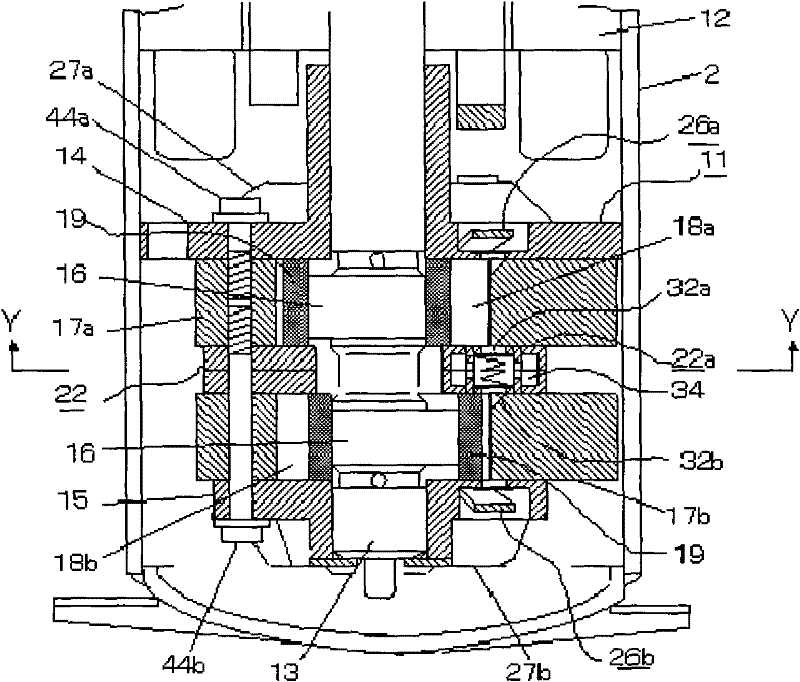

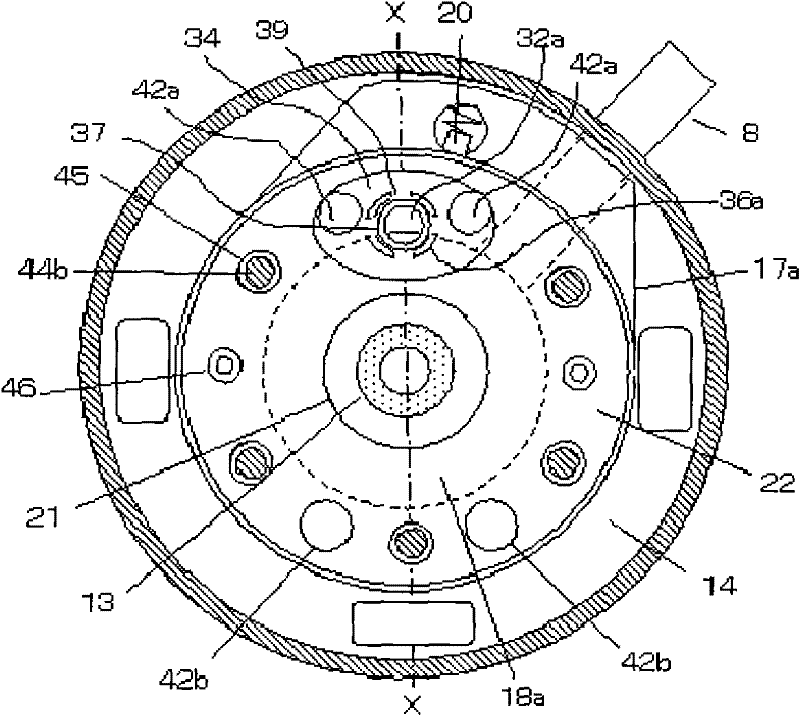

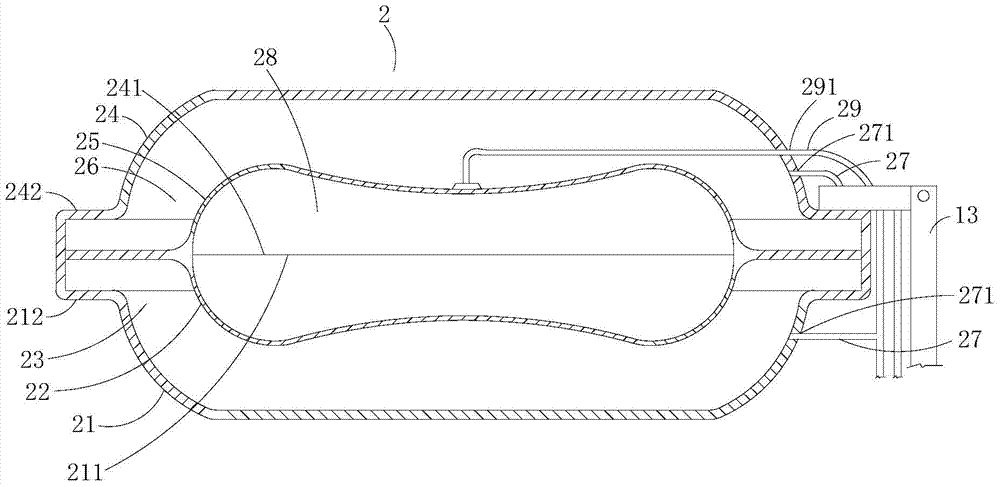

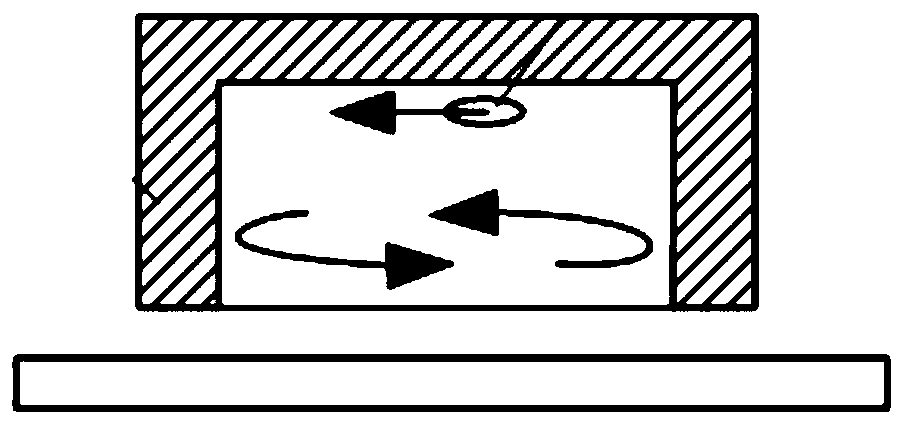

Double-cylinder rotary compressor

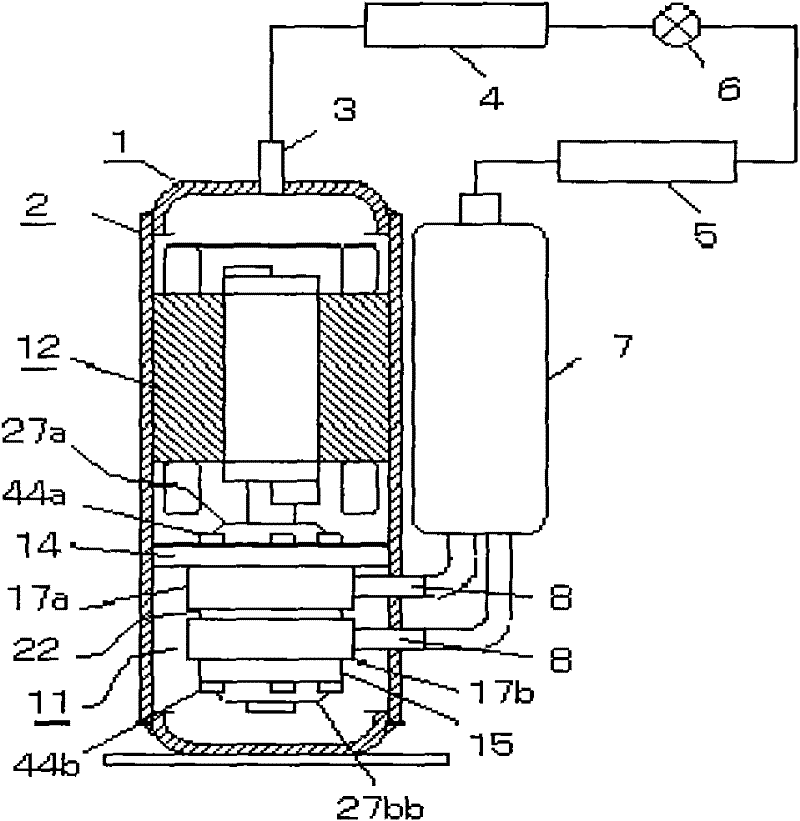

InactiveCN102235360AImprove rigidityReduce thicknessRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsEngineeringCrankshaft

The invention relates to a double-cylinder rotary compressor. An electric engine section and a compressor section are arranged in a sealed housing. The compressor section comprises: a first cylinder, a second cylinder, a middle partitioning plate assembly arranged between the first cylinder and the second cylinder, a silencing cavity arranged on the middle partitioning plate, and a middle partitioning plate discharging apparatus arranged in the silencing cavity. The middle partitioning plate discharging apparatus comprises: two discharging ports arranged in the silencing cavity, wherein the discharging ports are respectively provided on the first cylinder compressing cavity and the second cylinder compressing cavity; two valve seats respectively arranged on the peripherals of the discharging ports; two discharging valves respectively arranged on the valve seats for opening and closing the discharging ports; a valve spring arranged between the two discharging valves for elastically adjusting the gap between the two discharging valves; cylinder walls or stop columns arranged on the outer sides of the two valve seats for limiting the scopes of the horizontal movements of the discharging valves. The double-cylinder rotary compressor provided by the invention is characterized in that: the rigidness of the middle partitioning plate assembly is high, the thickness of the middle partitioning plate assembly is small, crankshaft bending and middle partitioning plate deformation are not easy to occur, the product is easy to produce, and the application scope of the product is wide.

Owner:GUANGDONG MEIZHI COMPRESSOR

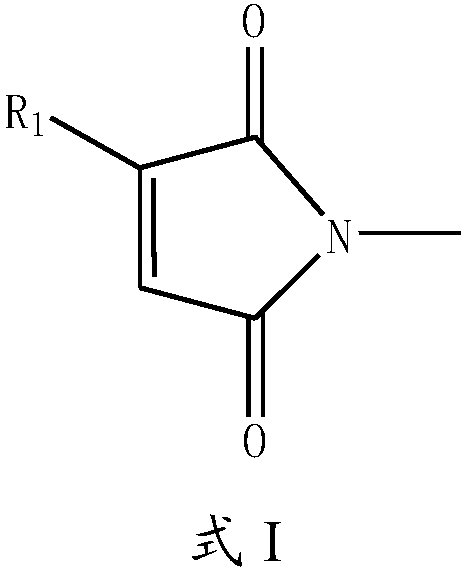

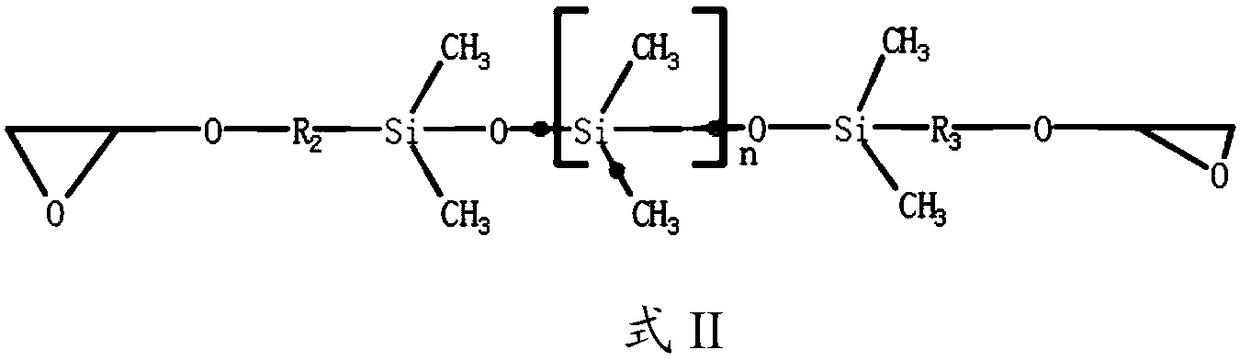

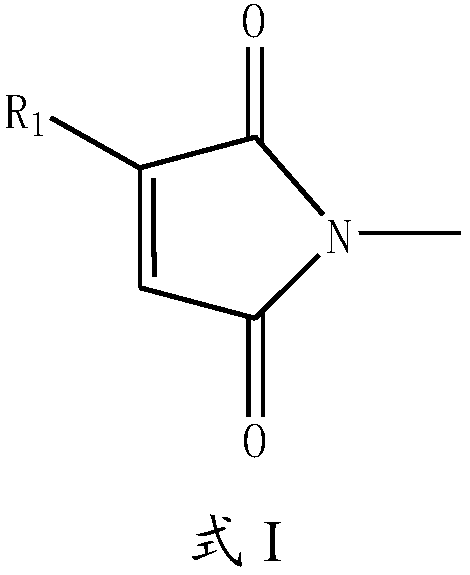

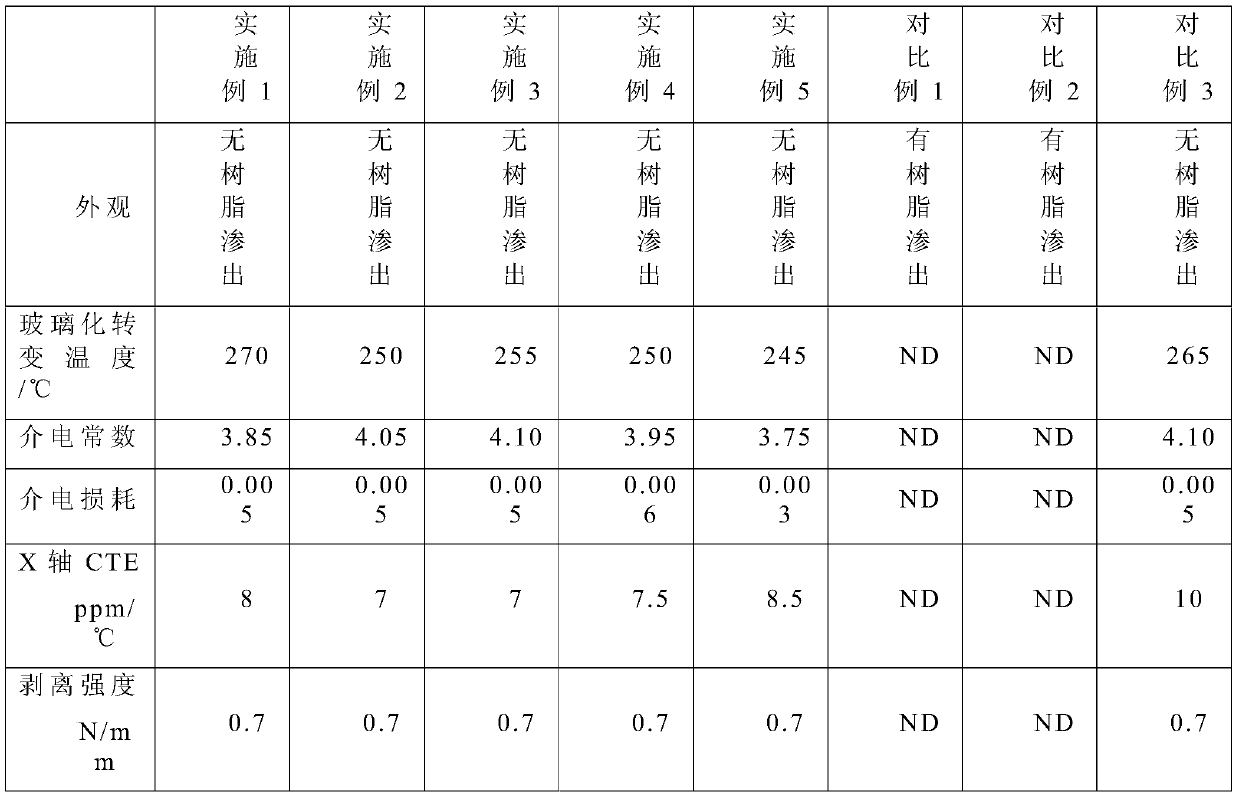

Modified maleimide resin composition and prepreg and laminate prepared therefrom

The invention provides a modified maleimide resin composition, which is prepared from epoxy siloxane-modified maleimide prepolymer, thermosetting resin, and inorganic filler; maleimide compound and aromatic amine compound react in advance, so that maleimide-modified aromatic amine compound is prepared, epoxy siloxane is then added into the maleimide-modified aromatic amine compound to react, and thereby the epoxy siloxane-modified maleimide prepolymer is obtained. The invention further provides a prepreg prepared from the modified maleimide resin composition and a laminate prepared by laminating the prepregs. The modified maleimide resin composition and the prepreg and the laminate prepared therefrom which are provided by the invention have the advantages of low thermal expansibility, highbinding property, high heat resistance, excellent reactivity, low moisture absorption rate and high flame-retardant property, can be applied in the field of IC (integrated circuit) packages, such asCSP (Chip Scale Package), PoP and SIP (System in Package), and have a broad application prospect.

Owner:SHENGYI TECH SUZHOU

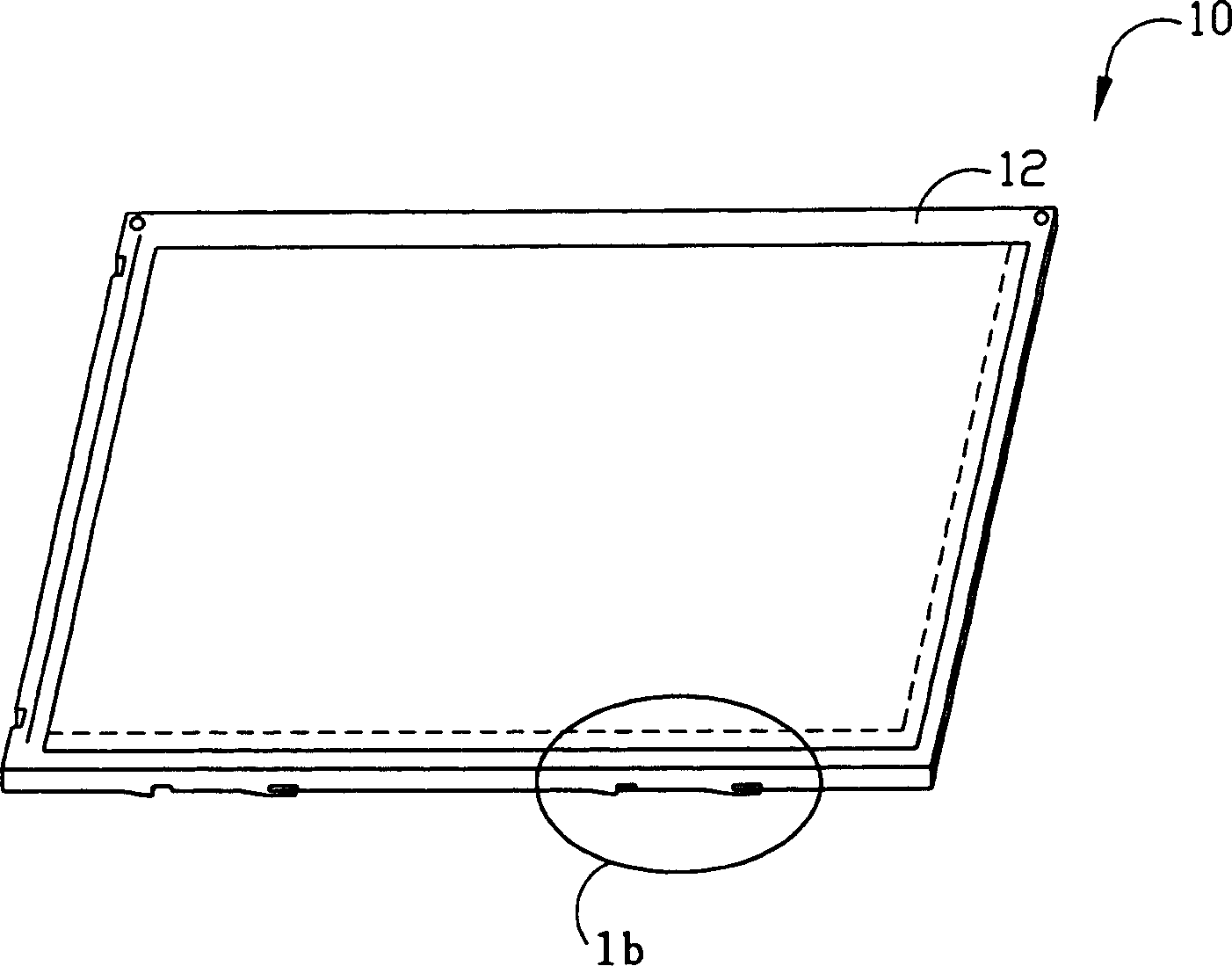

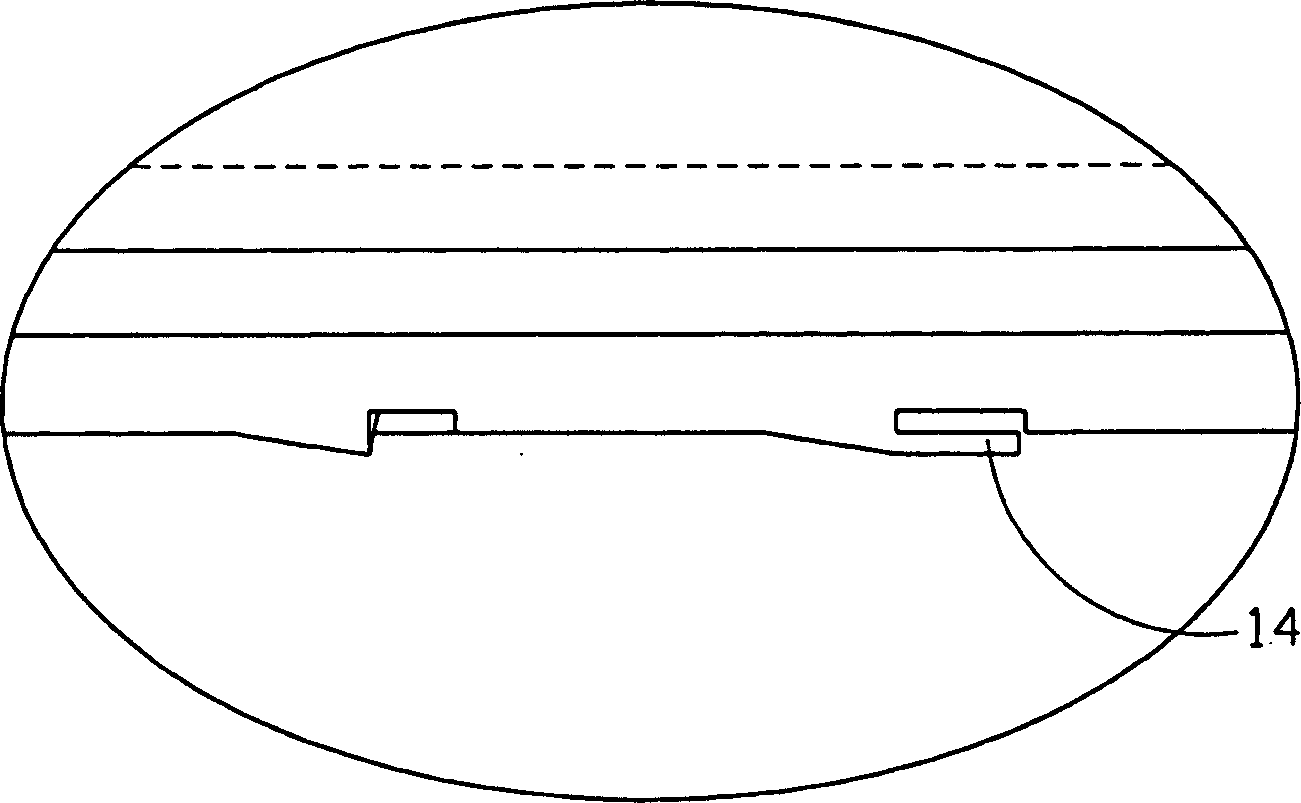

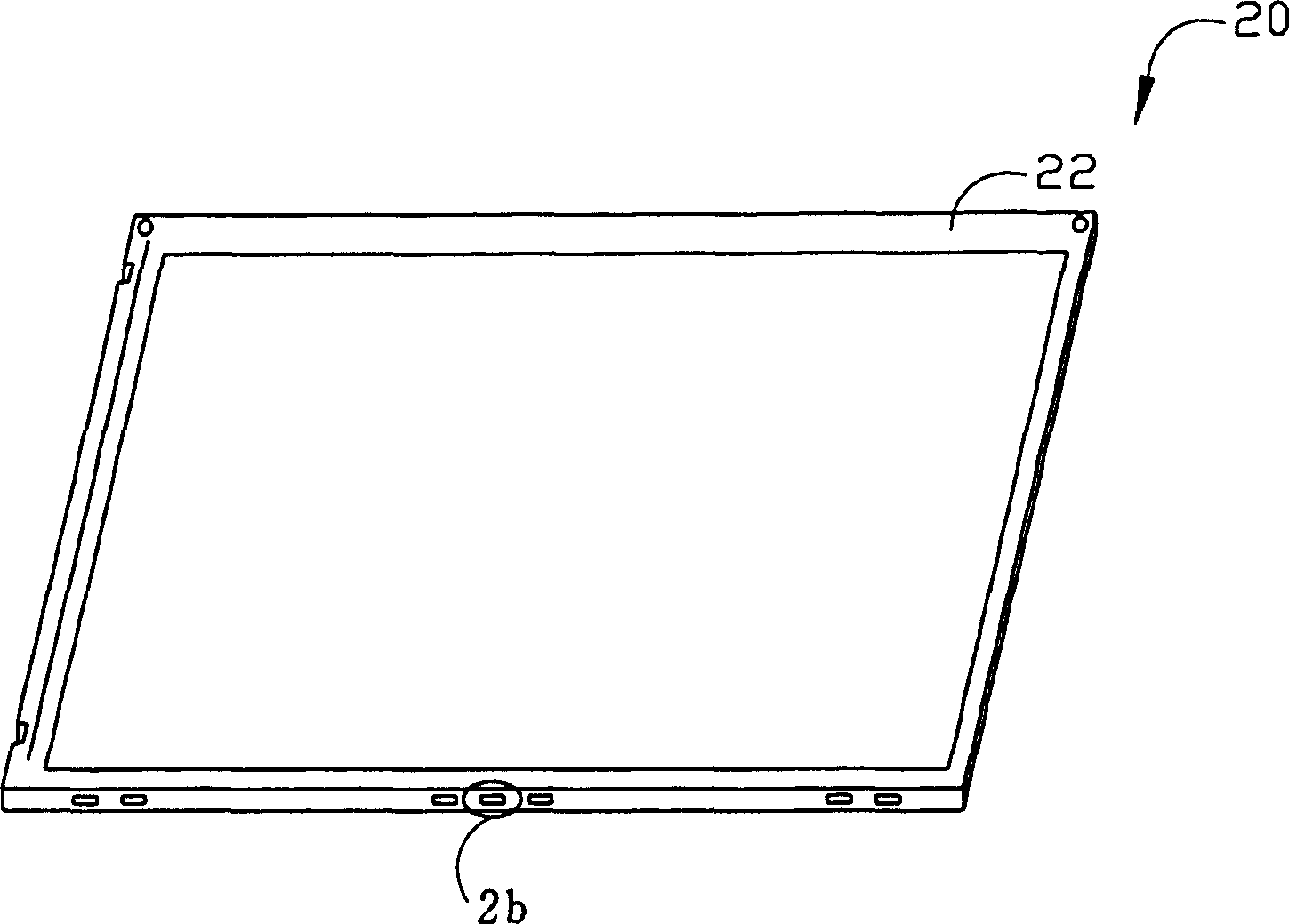

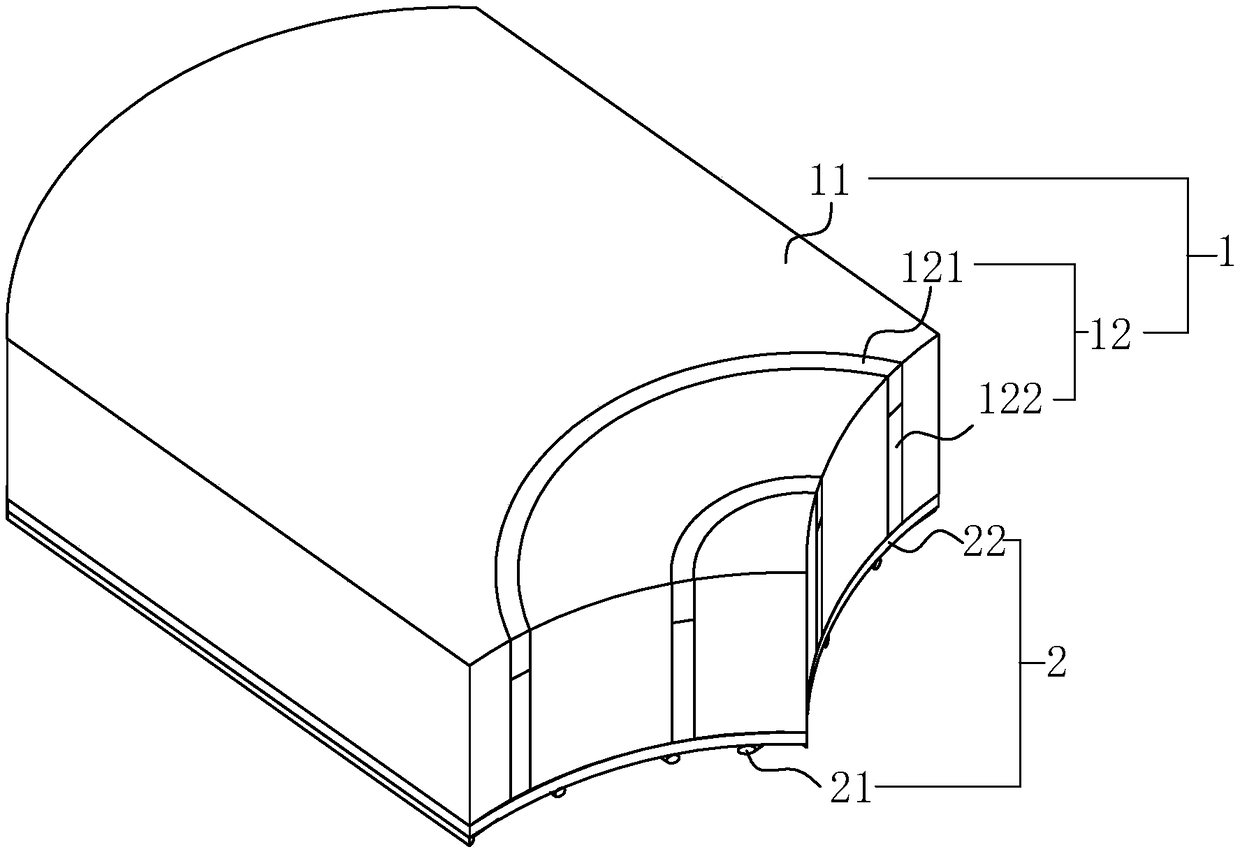

Liquid crystal display outer frame possessing elastic snapin mechanism

InactiveCN1558275ANot easy to cause deformationNot easy to cause scratchesNon-linear opticsLiquid-crystal displayEngineering

Owner:AU OPTRONICS CORP

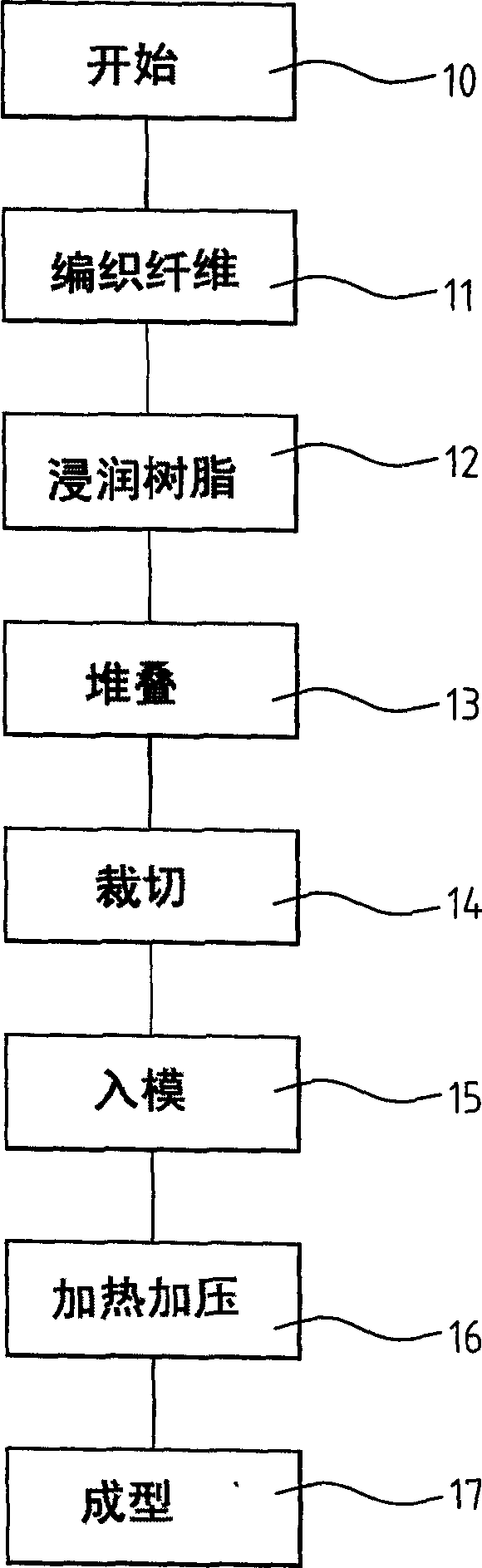

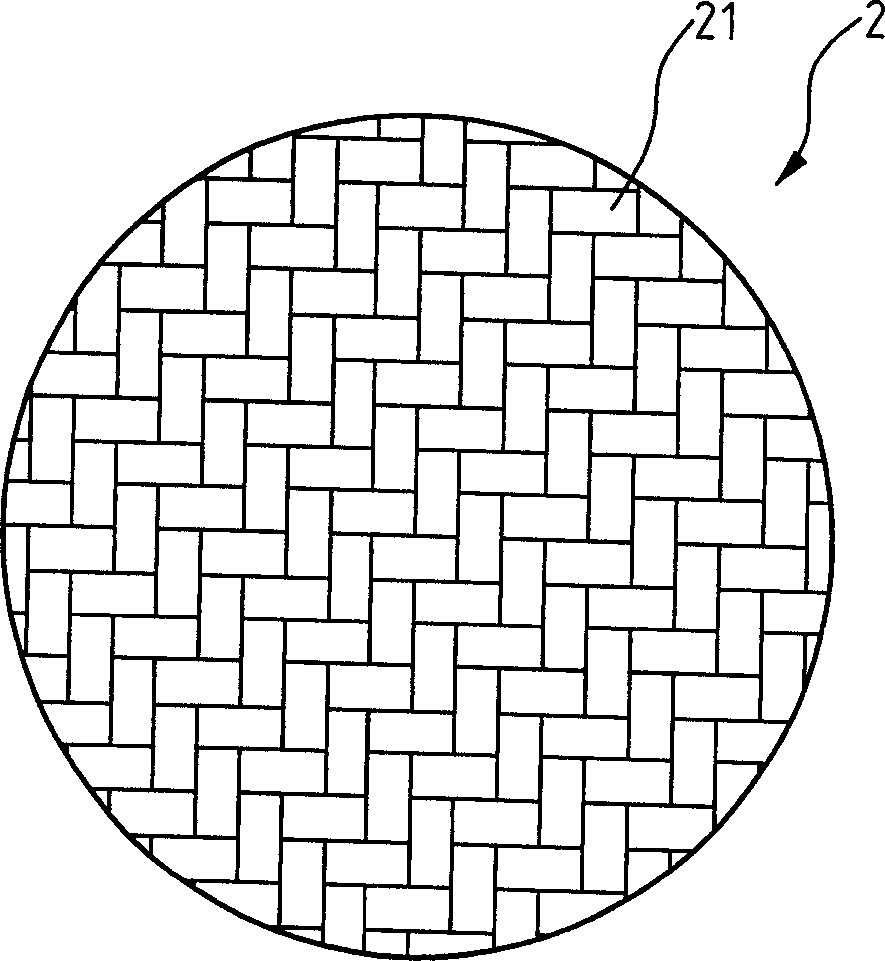

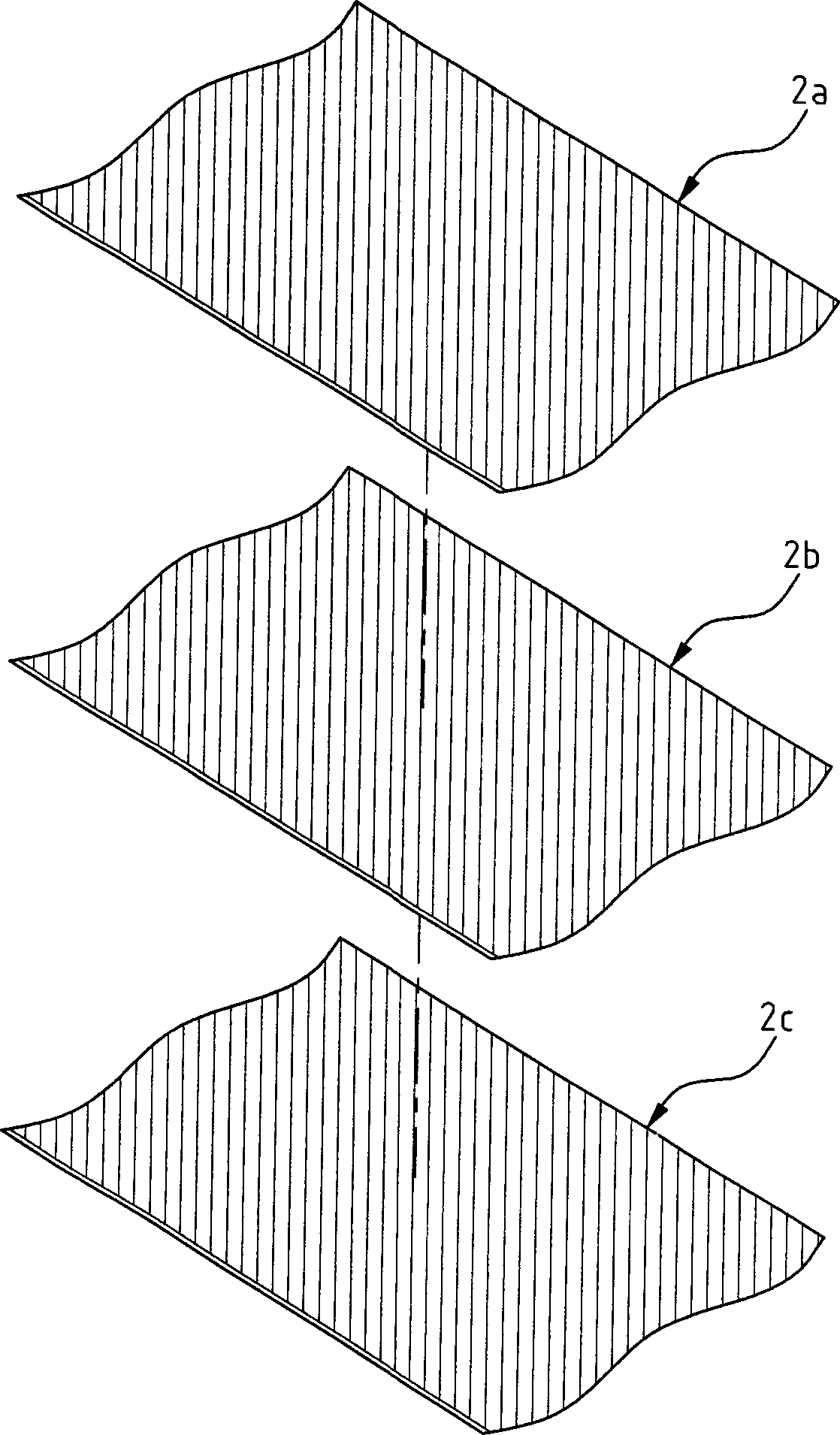

Fabricating method for laptop outer casing with fibrage texture

InactiveCN1704226AHigh strengthNot easy to cause deformationDigital data processing detailsFiberEngineering

The invention provides a method for making laptop cover with fibrage lines which comprises the following steps: (a) providing fiber and forming fibrage; (b) immersing the fibrage into resin; (c) stacking the fibrage and completely the making the angle of top and bottom fibrage lines in order with one direction; (d) heat-pressing the fibrage; (e) hardening and one time shaping the fibrage to form laptop cover with fibrage lines.

Owner:CATCHER TECH

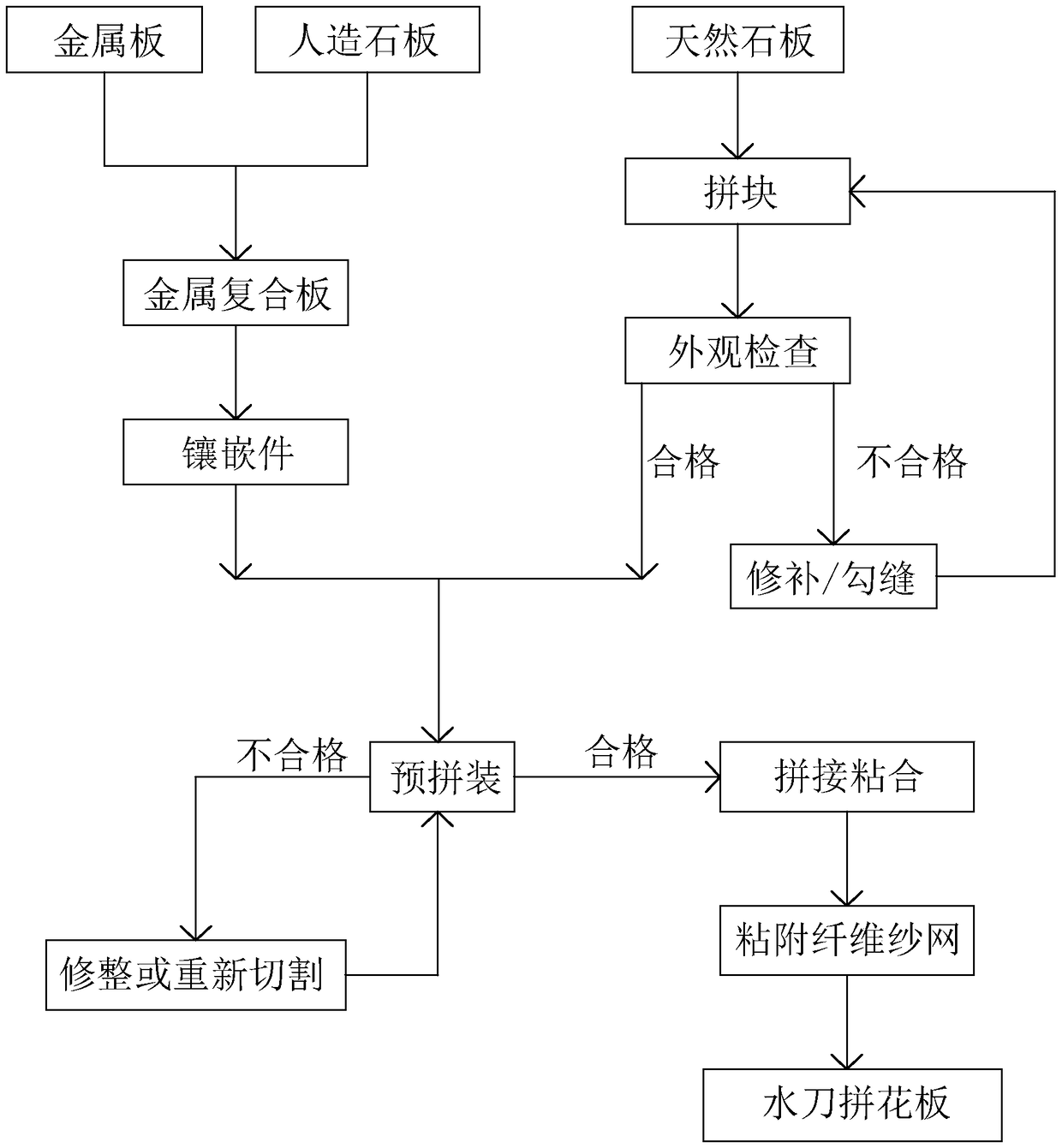

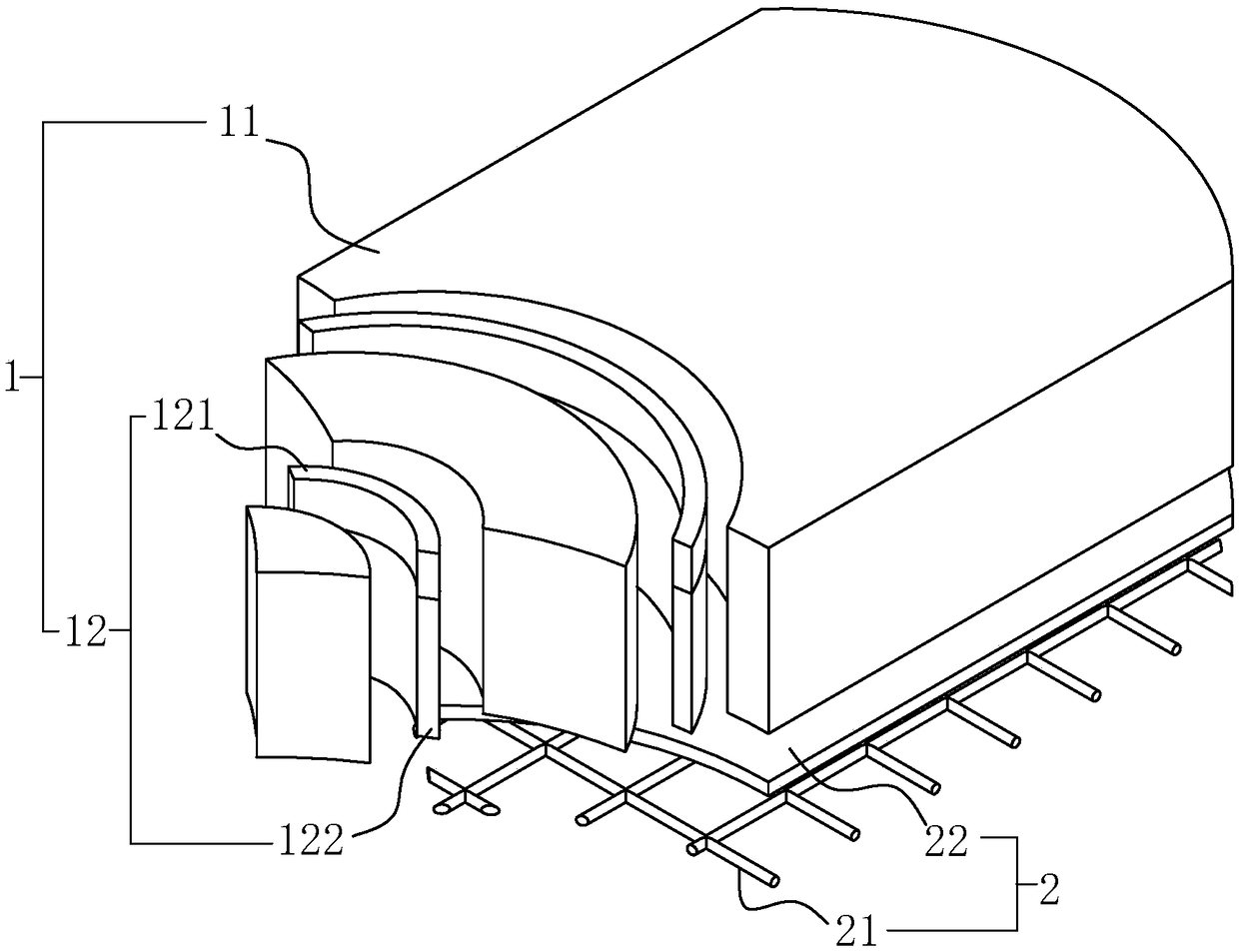

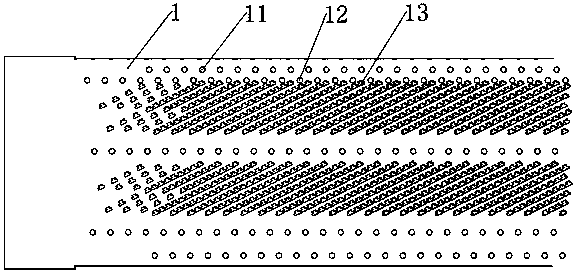

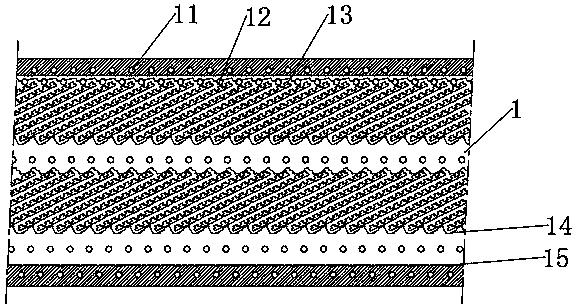

Water-jet match board manufacturing method and water-jet scalpel match paving construction method

InactiveCN109017109AControllable shapeAccuracy controllableOrnamental structuresSpecial ornamental structuresArtificial stoneAbnormal shaped

The invention discloses a water-jet scalpel match board manufacturing method and a water-jet scalpel match paving construction method, belongs to the technical field of building decoration and construction, and aims to solve the problem that water-jet scalpel match construction difficulty for the specially-shaped metal inlaid effect is great. According to the key point of the technical scheme, thewater-jet scalpel match board manufacturing method comprises the following steps of: manufacturing blocks, manufacturing inlaid parts, jointing and bonding, and reinforcing match boards; and the water-jet scalpel match paving construction method comprises the following steps of: base layer leveling, appearance checking, paving and curing. After being compounded, a metal plate / artificial stone plate is cut by a water jet scalpel to manufacture the inlaid parts which are jointed with the blocks to manufacture the water-jet scalpel match boards, so that manufacturing is not limited by design shape, and therefore, efficient combination, in decorative engineering, of metal and stone products is realized, and the constraint of means of artistic expression of a designer in a conventional processis avoided. The method disclosed by the invention is adopted to perform water-jet scalpel match paving construction, has the advantages of being simple in process, low in construction difficulty, high in construction efficiency and good in quality, and can reduce the design effect to the greatest extent.

Owner:SUZHOU GOLD MANTIS EXHIBITION DESIGN ENG

PCB rubberizing method

PendingCN108601221AHigh precisionEasy to fixCircuit board tools positioningPrinted circuit simultaneous processingPunchingEngineering

The invention discloses a PCB rubberizing method. The method is characterized by comprising the specific steps of S1, performing manufacturing of a whole PCB, and manufacturing the whole PCB comprising multiple single boards; S2, performing connected film punching, punching an alignment hole and an avoidance hole in the connected film by a hardware die according to the appearance design of the whole PCB, wherein each connected film comprises multiple units corresponding and consistent to the PCB; S3, performing edge cutting on each connected film, and carrying out edge cutting treatment on theconnected film according to the set appearance through a cutter die; S4, performing lamination of each film and the PCB, and enabling each connected film to be aligned to and laminated on the whole PCB; and S5, performing PCB punching, and cutting the rubberized whole PCB into single PCBs. By virtue of the method, the rubberizing yield of the PCB is improved.

Owner:SHENZHEN BAOMING TECH

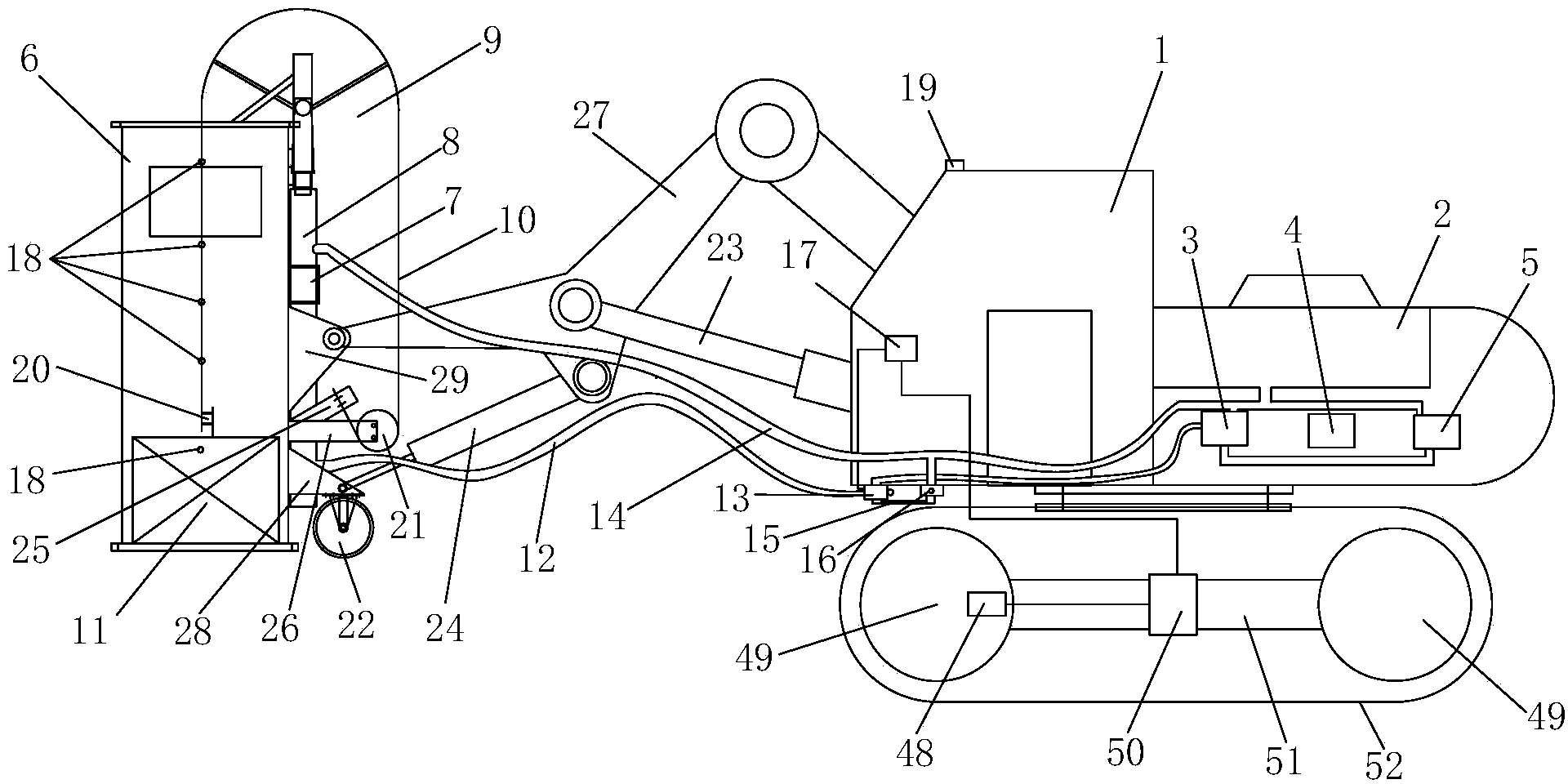

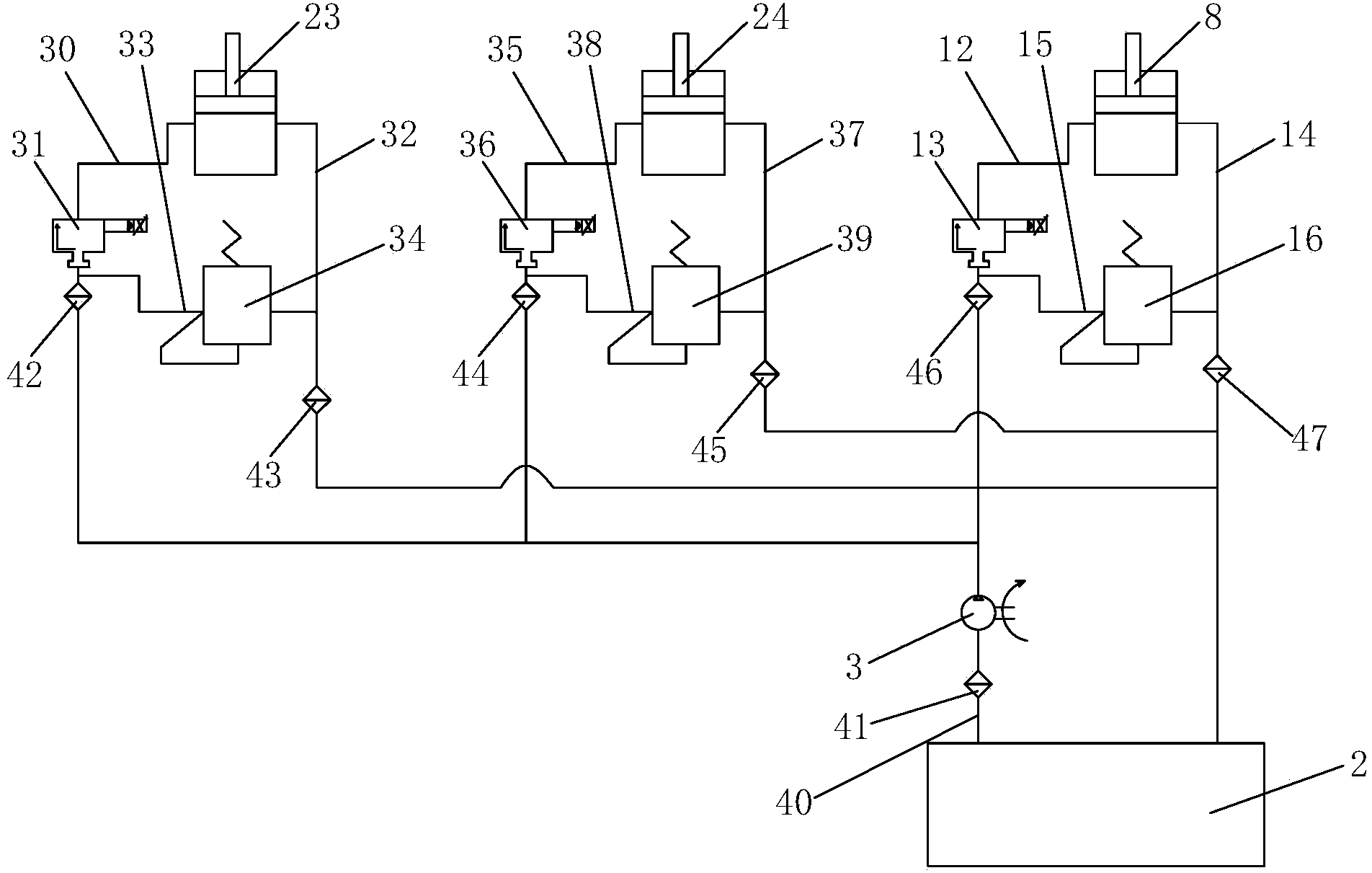

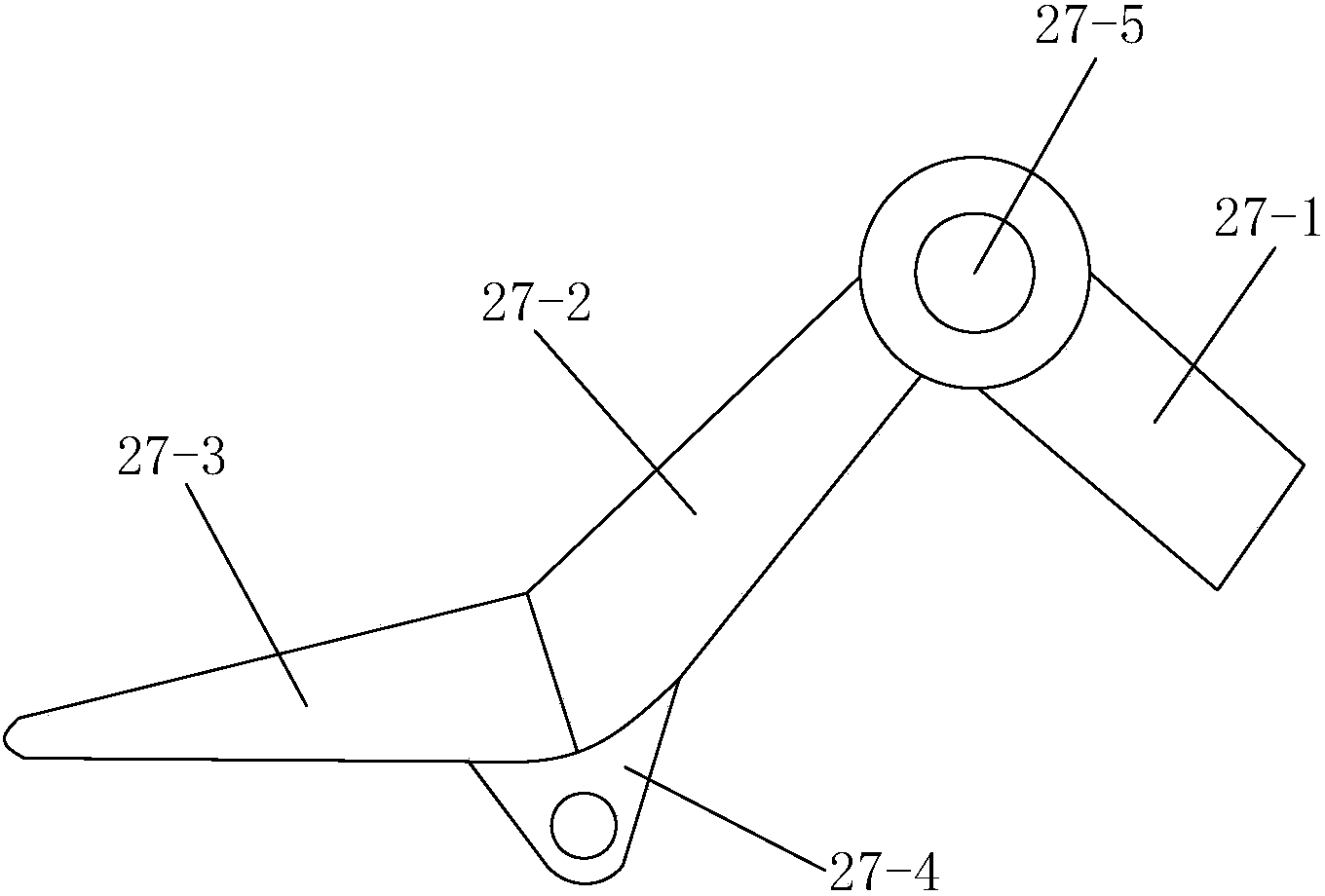

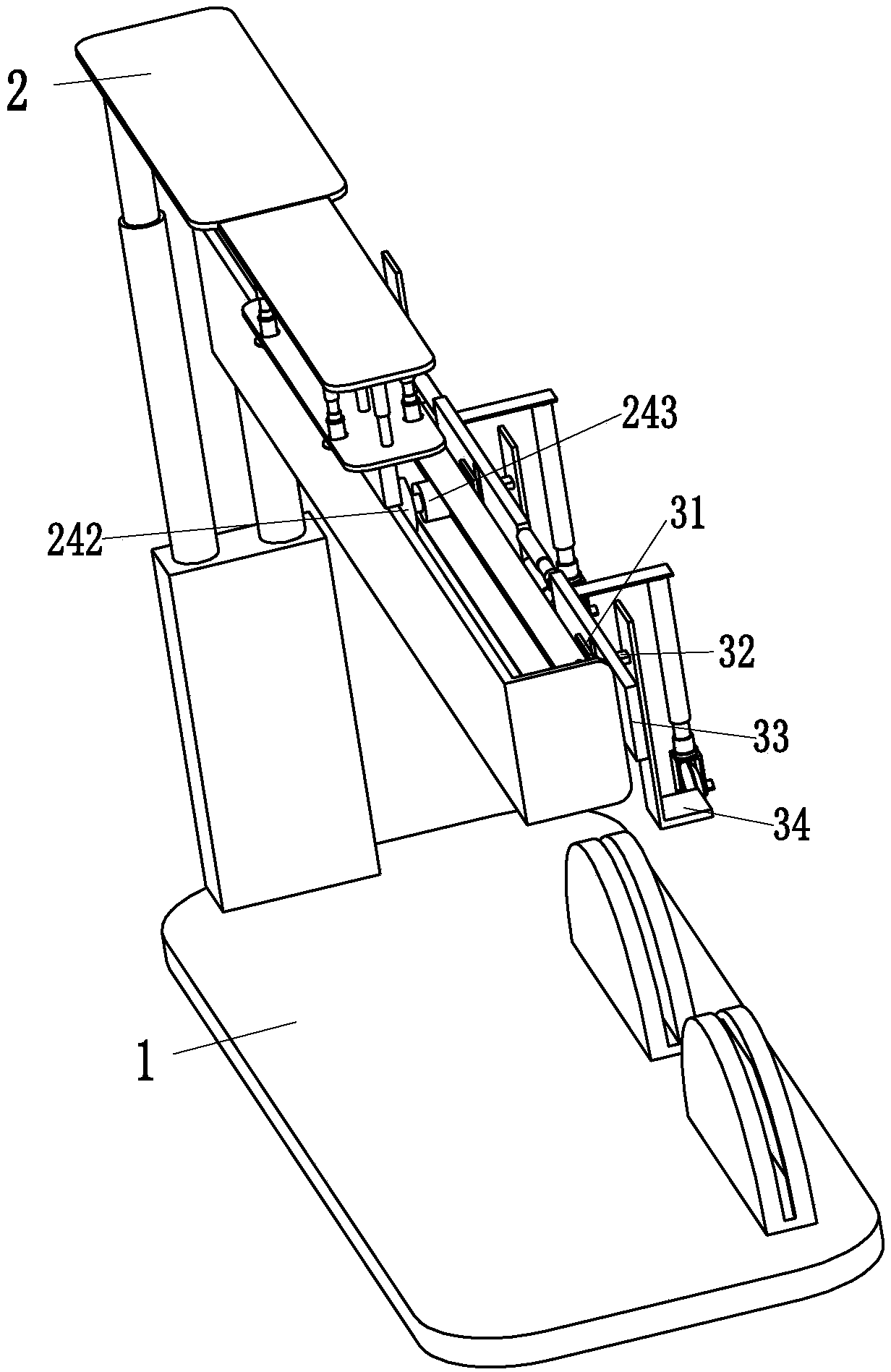

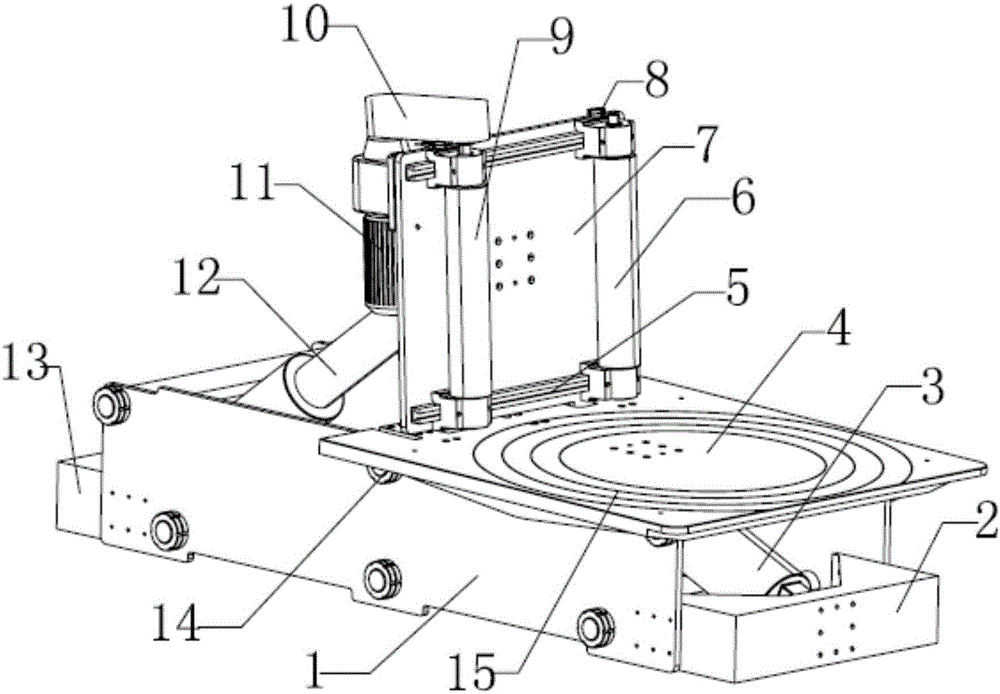

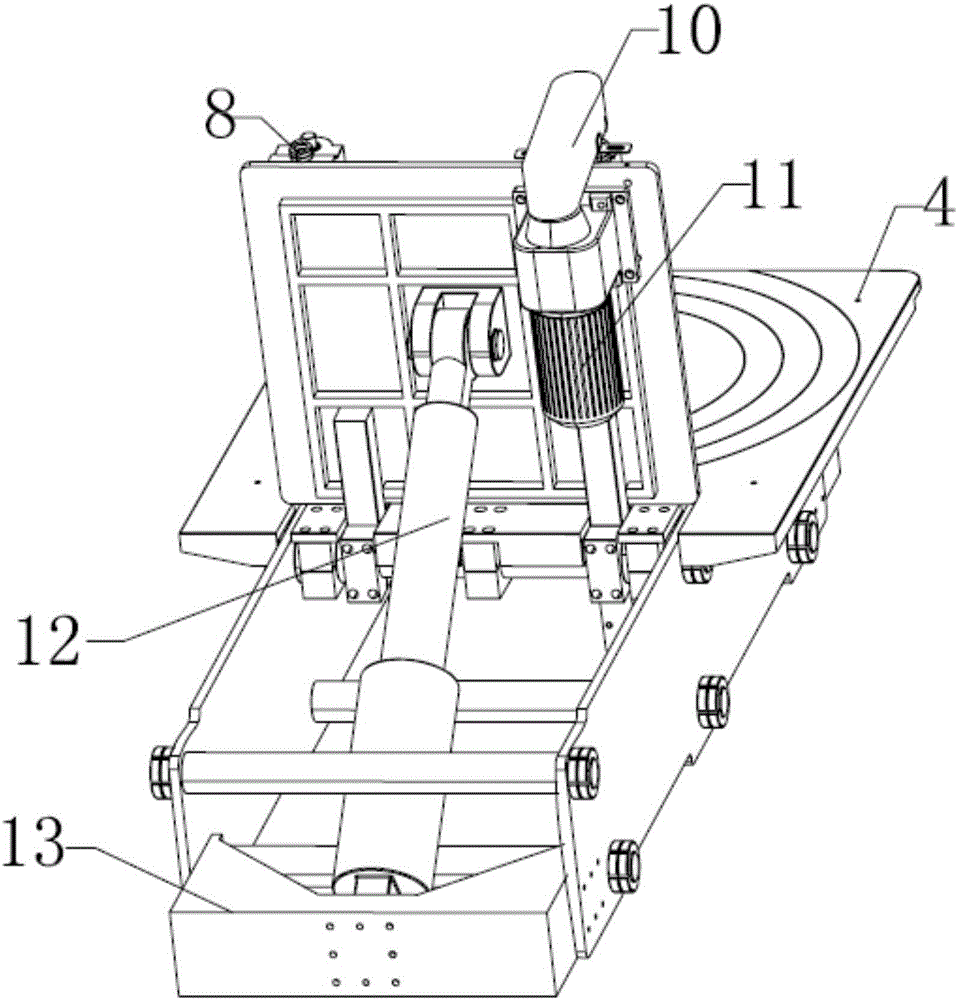

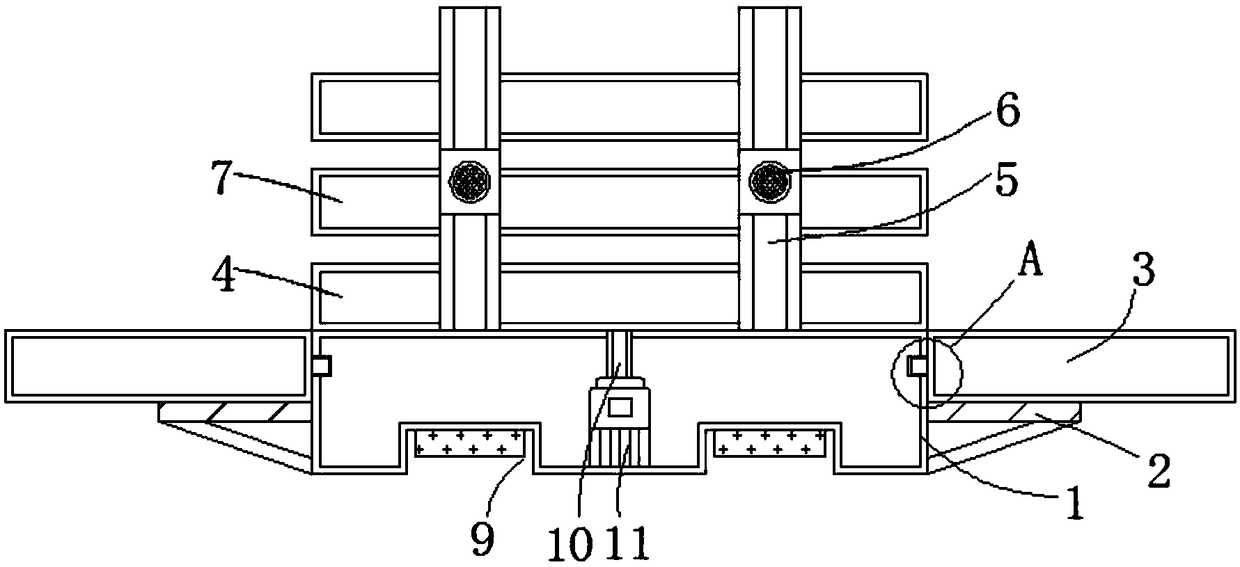

Self-traveling type intelligent continuous dynamic compactor

ActiveCN103741669ACompact structureNovel and reasonable designIn situ soil foundationSoil preservationAgricultural engineeringExcavator

The invention discloses a self-traveling type intelligent continuous dynamic compactor which comprises a crawler excavator, a crawler excavator power system, a crawler excavator self-traveling mechanism and a compaction mechanism, wherein the crawler excavator power system comprises an oil tank, an oil pump, a heat dissipater and an engine; the crawler excavator self-traveling mechanism comprises a traveling frame, traveling wheels, a traveling crawler and a self-traveling control system; the compaction mechanism comprises a stander, a third oil cylinder, a movable pulley, a soft connection body, a fixed pulley and a rammer; a stander is connected with a supporting wheel and is provided with a compaction density detection system; a hydraulic system and an intelligent control system are arranged on the crawler excavator; a third connection plate is connected to the stander; one end of a connection arm is connected with the crawler excavator, and the other end of the connection arm is connected with the third connection plate. The self-traveling type intelligent continuous dynamic compactor is easy to use and operate, has a self-traveling function and can intelligently realize continuous compaction; furthermore, the compaction power is higher, and the compaction thickness and the compaction influence depth are large; the self-traveling type intelligent continuous dynamic compactor can accurately detect the compaction density and work stably and reliably.

Owner:西安长大公路养护技术有限公司

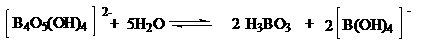

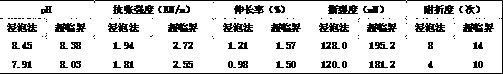

Method for deacidifying through utilizing soluble tetraborate in supercritical CO2 state

ActiveCN102828443ALow viscosityIncrease the diffusion coefficientOld paper after-treatmentPaper sheetAqueous solution

The invention discloses a method for deacidifying through utilizing a soluble tetraborate in a supercritical CO2 state. The method comprises the following steps: putting paper, especially aged and acidified paper in a supercritical CO2 processing apparatus, and processing with an alcohol-water solution containing the soluble tetraborate. The method enables the pH of the paper to be controlled in an optimum range and the deacidifying agent application amount to be reduced. Compared with other methods, the method disclosed in the invention has the advantages of obvious improvement of the paper strength because of the soluble tetraborate in the supercritical CO2 state, and great increase of various mechanical strengths.

Owner:GUANGDONG UNIV OF TECH

Cutting-off equipment for color steel tile machining

InactiveCN109365898APlay a buffer roleAvoid damageShearing machinesShearing toolsEngineeringMachining

The invention relates to cutting-off equipment for color steel tile machining. The cutting-off equipment comprises a bottom plate, an adjusting device and cutting-off devices. The adjusting device ismounted on the upper side of the right end of the bottom plate, and the cutting-off devices are evenly mounted at the front end of the adjusting device. The problems that during existing color steel tile machining, color steel tiles need to be cut off, during cutting-off of existing cutting equipment, the color steel tiles are not cut along cambered surfaces, deformation is easily caused, cuttingis not smooth, during pre-cutting, the color steel tiles are usually directly cut over by cutting knives, and the cutting knives are easily damaged after long-time work can be solved. The function ofsmoothly cutting the color steel tiles of different specifications can be achieved, the color steel tiles of different specifications are adjusted to enable the cutting knives 6 to be always attachedto the surfaces of the color steel tiles for work, deformation is not likely to be caused, during pre-cutting, the cutting knives 6 are buffered through a buffer mechanism, knife bits are prevented from being damaged, and the consumed time is short.

Owner:合肥巍华钢结构有限公司

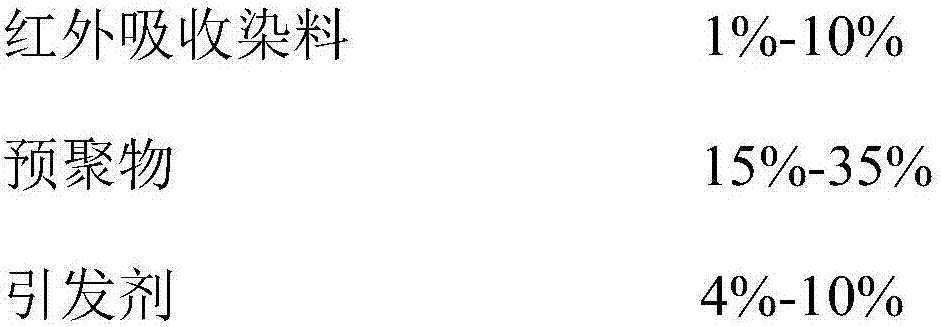

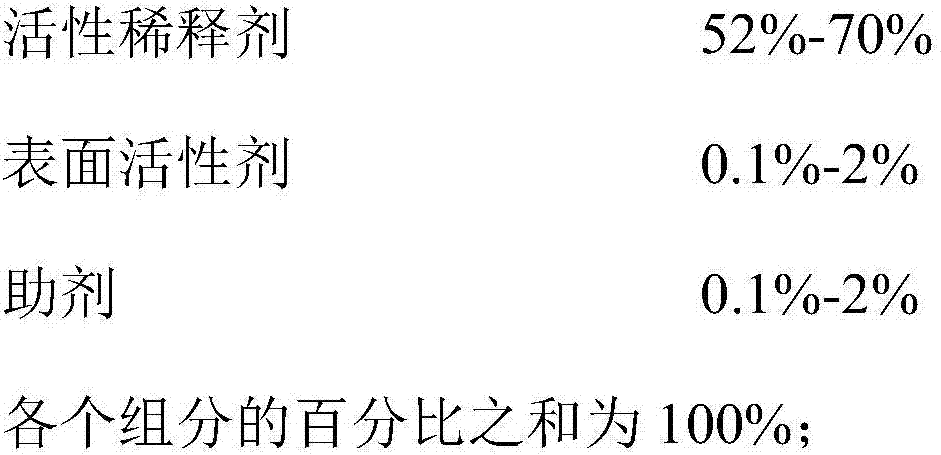

Light-colored infrared absorbing UV-LED ink-jet ink and preparation method thereof

The invention discloses light-colored infrared absorbing UV-LED ink-jet ink and a preparation method thereof. The light-colored infrared absorbing UV-LED ink-jet ink is composed of the following ingredients (by weight): 1-10% of an infrared absorbing dye, 15-35% of a prepolymer, 4-10% of an initiator, 52-70% of a reactive diluent, 0.1-2% of a surfactant and 0.1-2% of an auxiliary agent. The ink-jet ink can be used in industrial production. For one pass ink-jet printing, printing speed is 80 m / min-100 m / min. Smooth printing is guaranteed. The ink-jet ink has characteristics of no misting, rapid solidification, low energy, good light resistance and the like.

Owner:CHINA BANKNOTE INK +1

Soft material sticking structure device

The utility model discloses a soft material sticking structure device. The soft material sticking structure device comprises a power component, a sticking component and a locking component, wherein the power component can open and close the sticking component and vacuumize an inner cabin and an outer cabin of the sticking component; the sticking component is mainly provided with an upper cover and a lower shell; a flexible sticking sheet and an upper outer cabin are arranged in the upper cover; a flexible lower sticking sheet and a lower outer cabin are arranged in the lower shell; the inner cabin is formed between the upper sticking sheet and the lower sticking sheet; the upper cover and the lower shell are buckled through the locking component, so that the upper sticking sheet and the lower sticking sheet can be tightly stuck to two flexible articles to be stuck when preset negative pressure is reached in the inner cabin, and the two articles can be tightly stuck within preset time. The surfaces of the flexible articles are not easily damaged in a processing process, and deformation is not easy to cause, so that the yield of finished products is high and the soft material sticking structure device has industrial utilization value.

Owner:LI DE MACHINERY +1

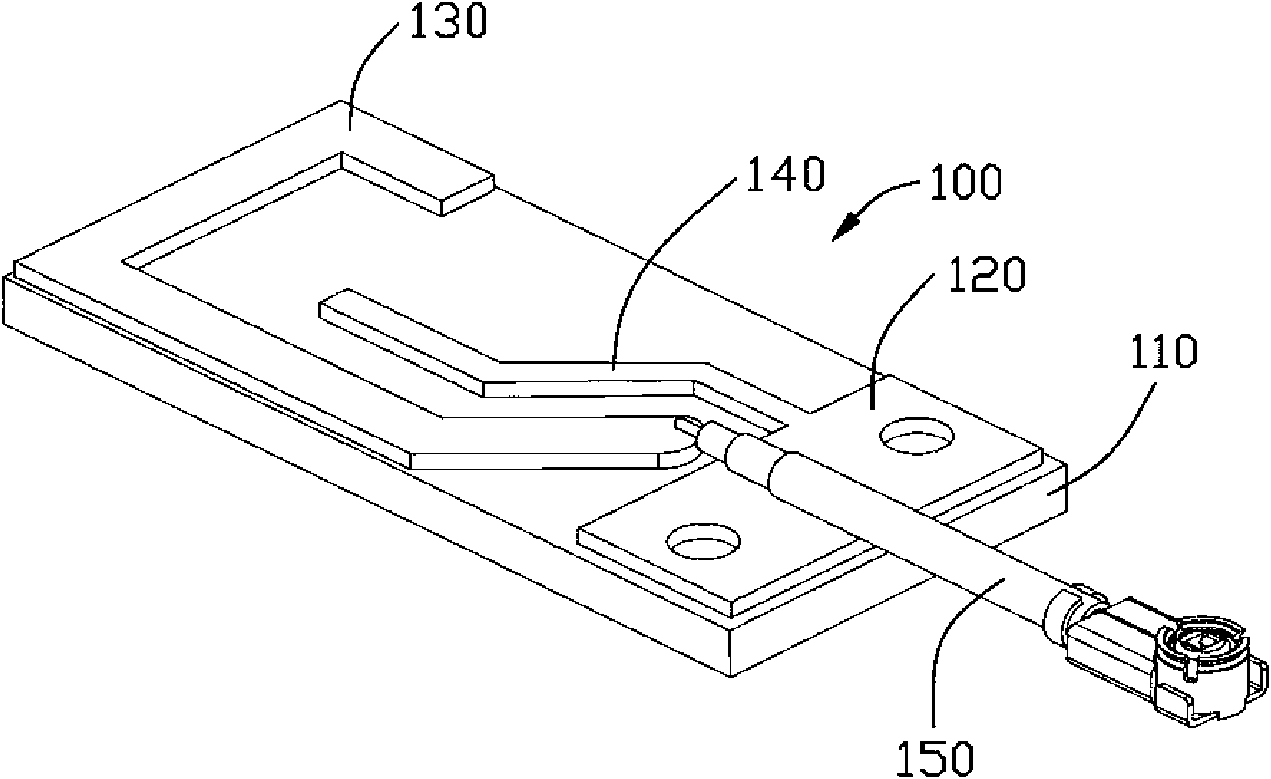

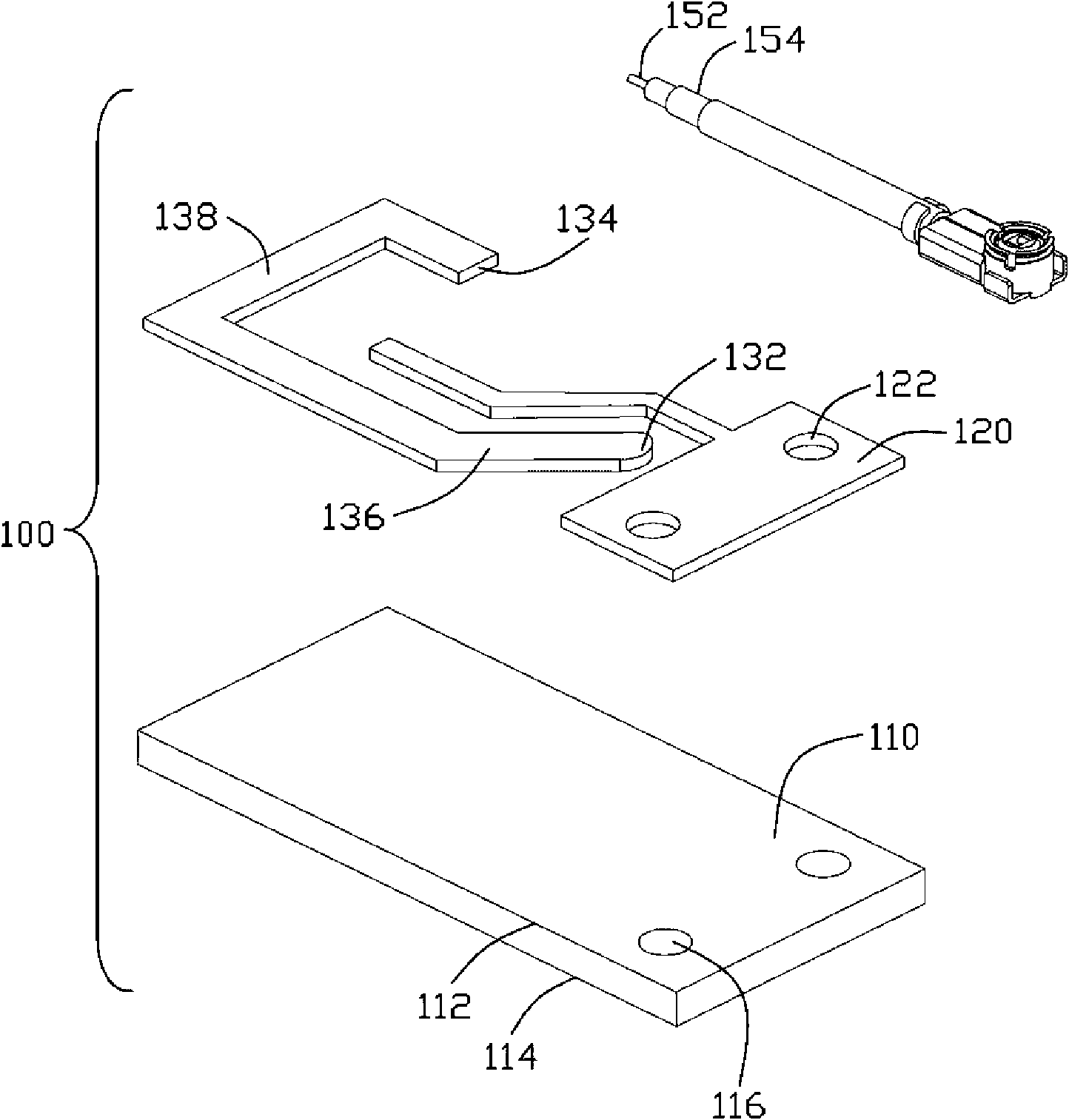

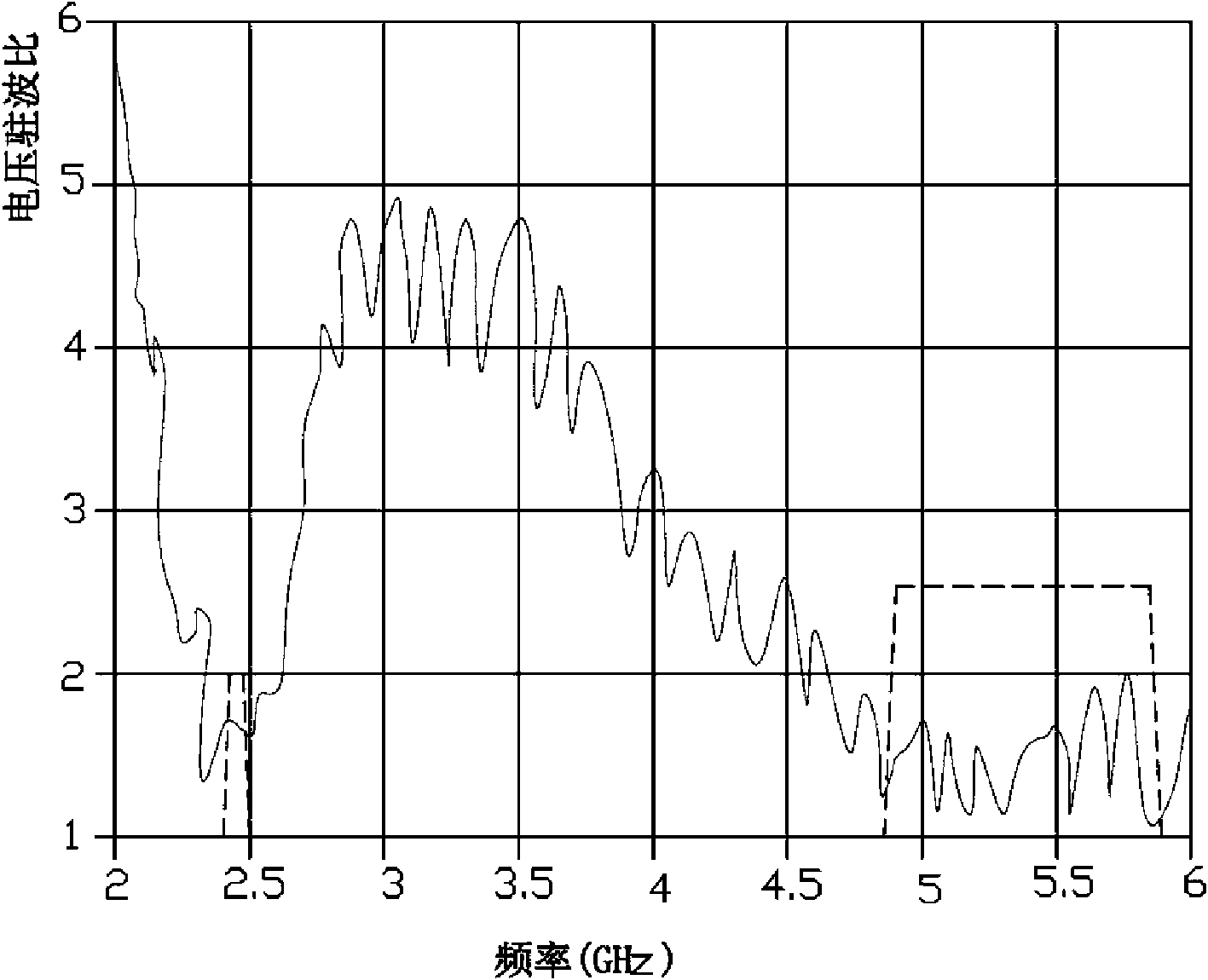

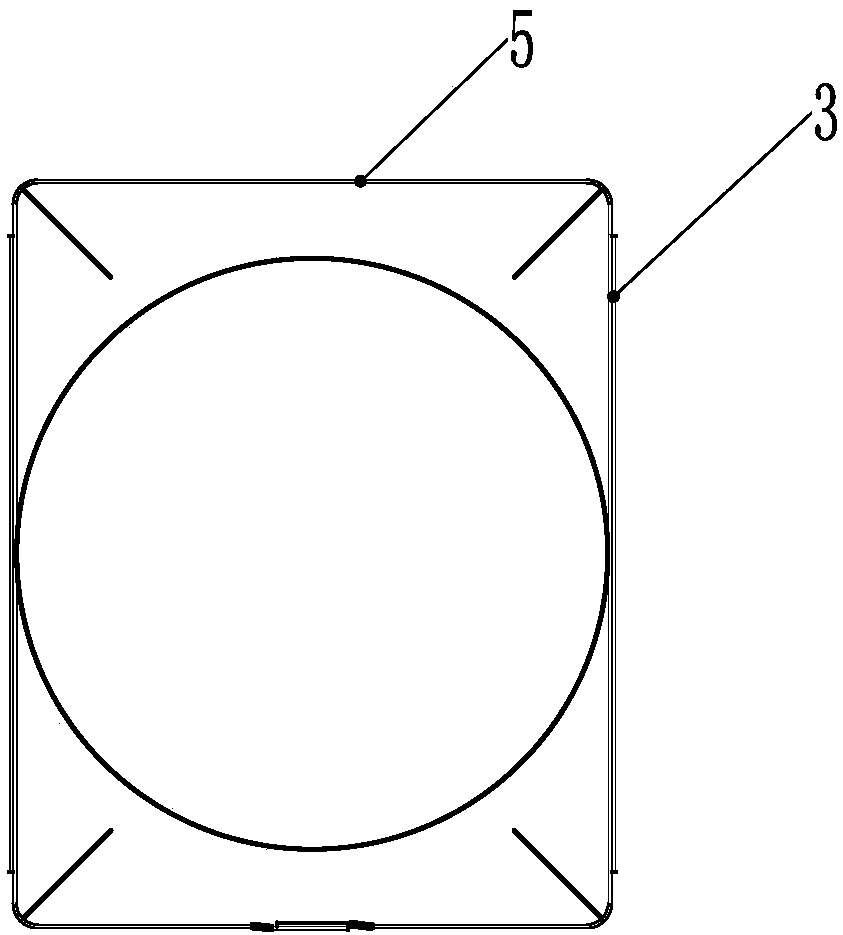

Slice antenna and manufacturing method thereof

InactiveCN101800351AEasy to prepareNot easy to cause deformationAntenna supports/mountingsElectrically short antennasMetallic foilEngineering

The invention discloses a slice antenna and a manufacturing method thereof. The slice antenna comprises a substrate, an electric conduction foil pasted on the substrate and a feeder line, wherein the electric conduction metallic foil can work at least on a first working frequency band, and the feeder line is welded on corresponding position on the metallic foil.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

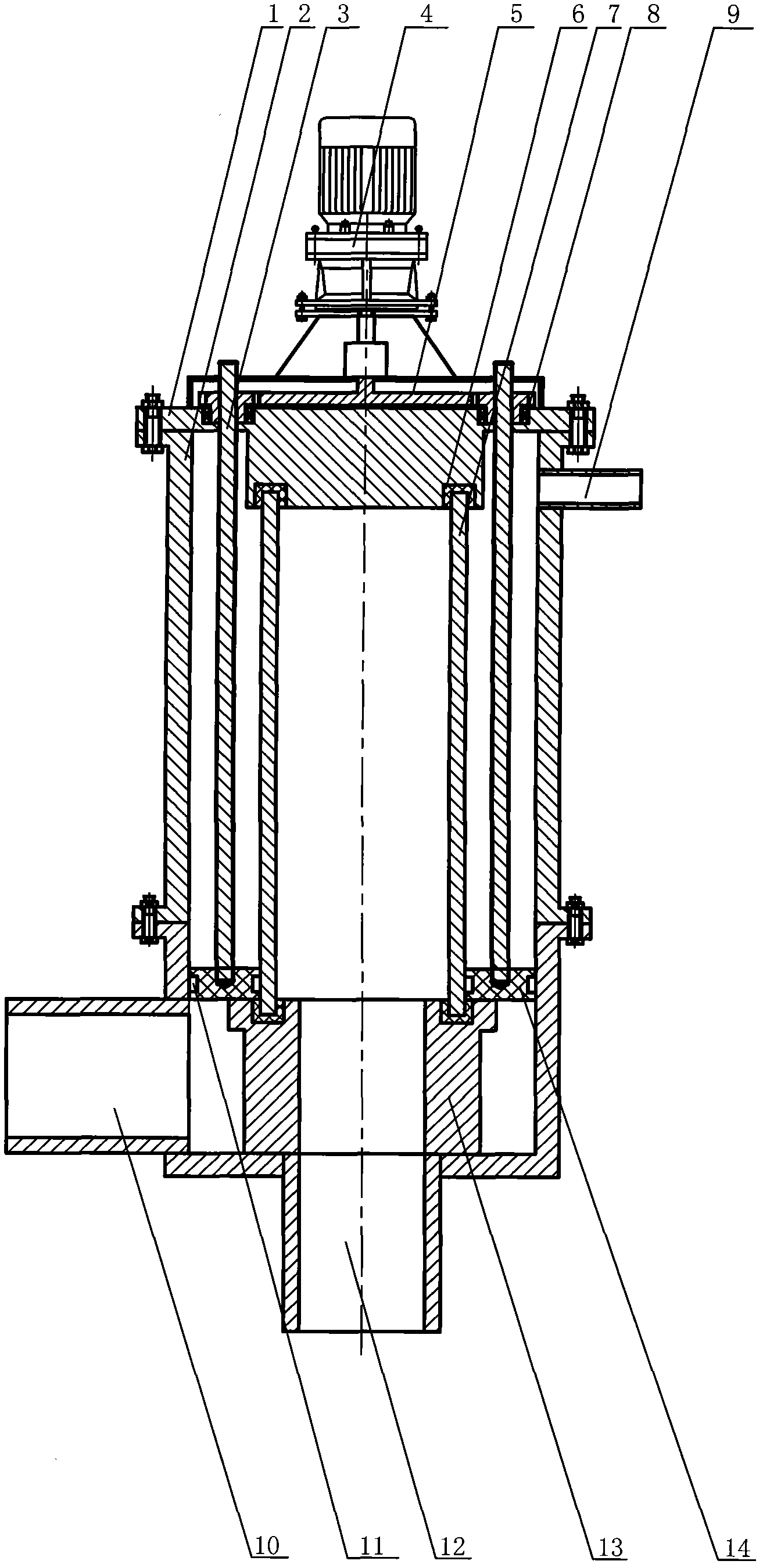

Movable turn-taking backwash net type filter

InactiveCN103100249ANot easy to cause deformationAvoid damageStationary filtering element filtersRubber ringGear transmission

The invention discloses a movable turn-taking backwash net type filter which comprises a shell, an upper gland, a base, a water inlet, a water outlet, a blow-off pipe and a net type filter element. The movable turn-taking backwash net type filter is characterized in that the upper gland and the base are arranged at two ends of the shell; the blow-off pipe is arranged on an outer wall of the shell and close to the upper gland; a gear transmission device is arranged on the upper gland; the bottom end of the base is connected with a water outlet, and a water inlet is connected to an outer wall of the base; the net type filter element is arranged inside the shell; two ends of the net type filter element are sleeved in a U-shaped rubber ring in an annular groove on the upper gland and the base; a circular ring clapboard is arranged between the outer wall of the net type filter element and an inner wall of the shell; the circular ring is connected with a power pull rod; the power pull rod is connected with the gear transmission device; and the circular ring clapboard moves under the action of the power pull rod. Compared with the prior art, the movable turn-taking backwash net type filter has the advantages that the circular ring clapboard is arranged between the inner wall of the shell and the net type filter element, the circular ring clapboard moves to perform turn-taking backwash on different sections of the net type filter element, and the filter is simple in structure and has obvious effect.

Owner:XINJIANG TIANYE GRP

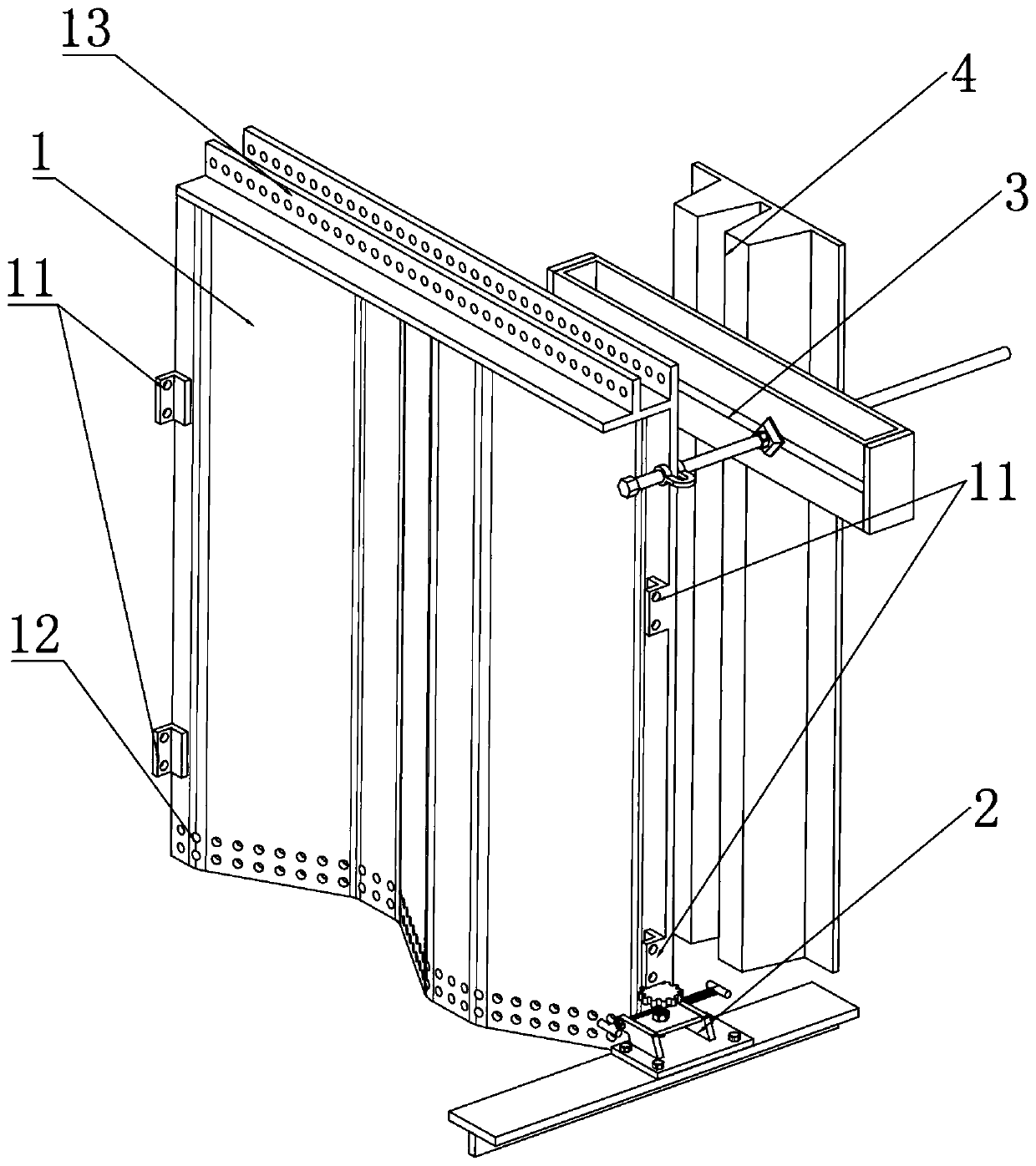

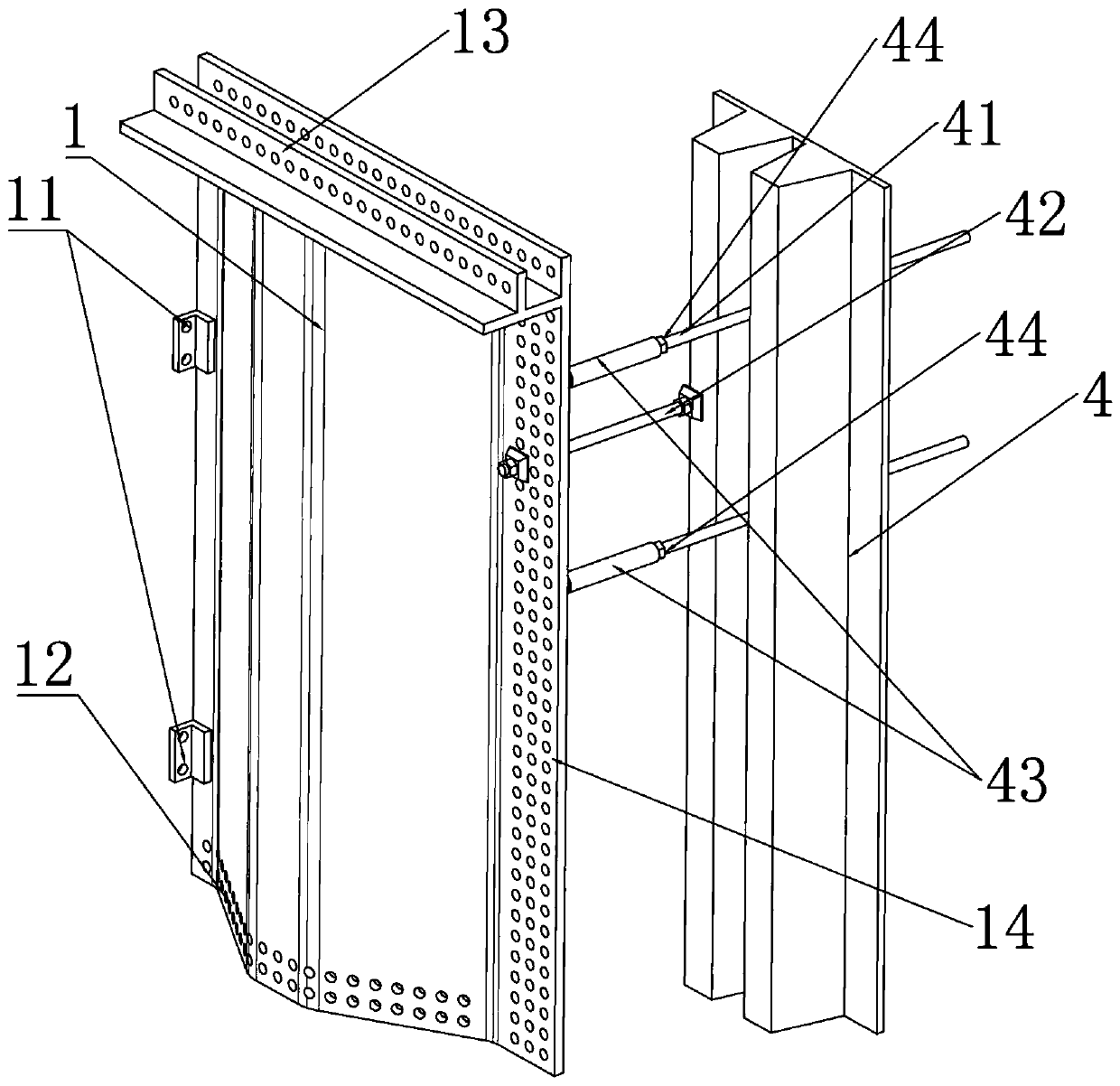

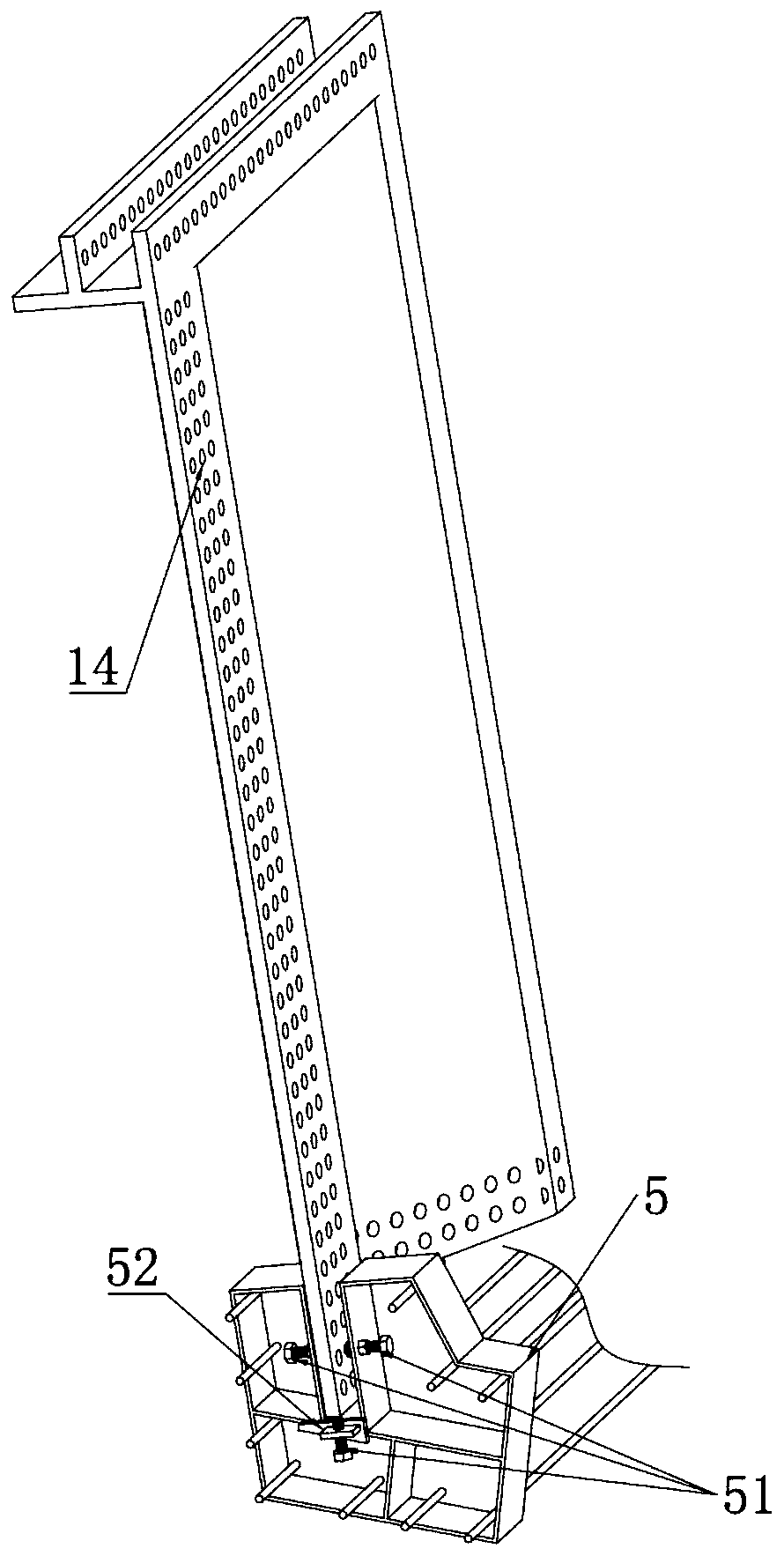

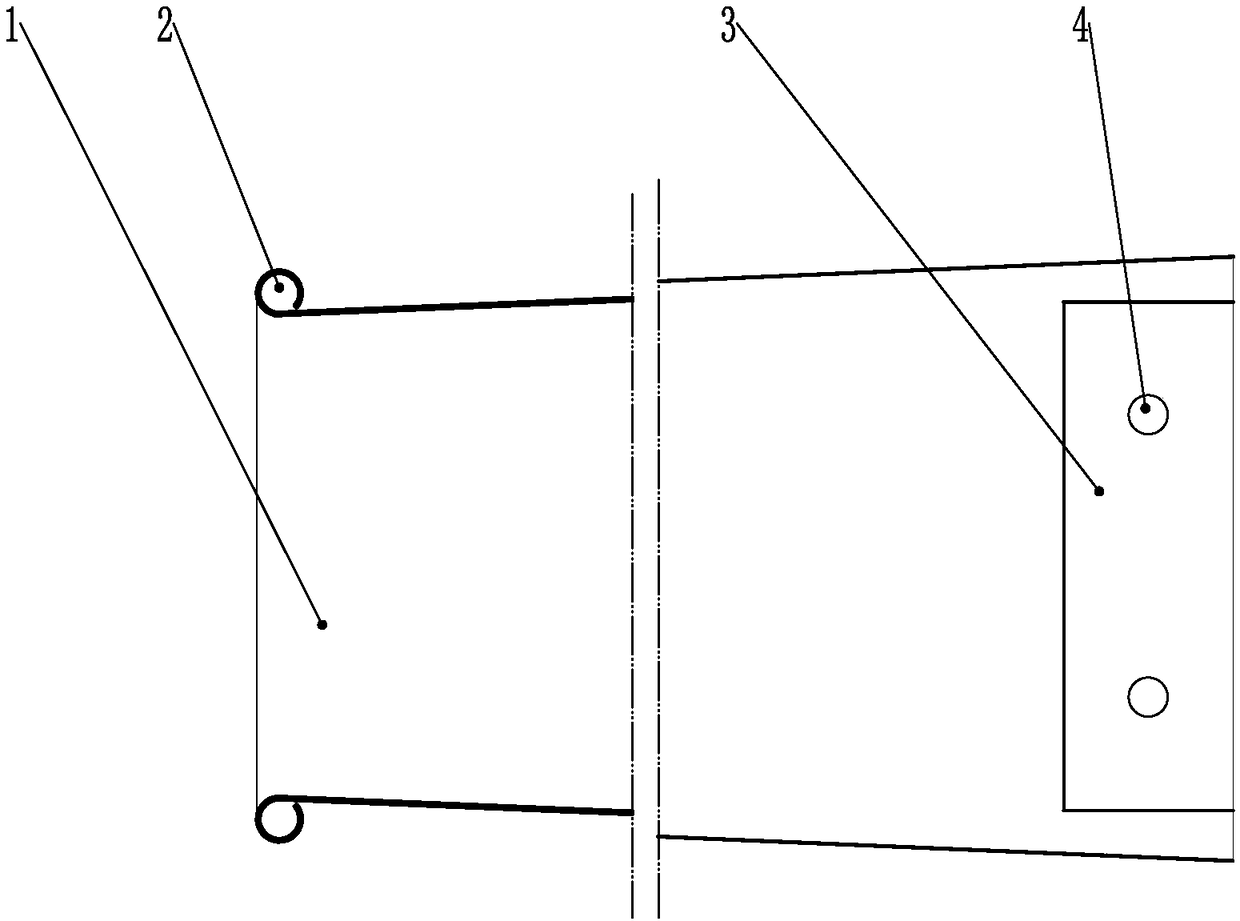

Corrugated steel web positioning method and adopted bidirectional adjusting and positioning device

ActiveCN110747744AAccurate locationPrecise positioningBridge erection/assemblyEngineeringStructural engineering

The invention discloses a corrugated steel web positioning method and an adopted bidirectional adjusting and positioning device. The corrugated steel web positioning method comprises the following steps of S1, mounting the bidirectional adjusting and positioning device of a corrugated steel web at a fixed end die; S2, obliquely hoisting the corrugated steel web into the die according to a designedslope; S3, adjusting and positioning the corrugated steel web at the fixed end die side in height direction and transverse direction of a bridge; and S4, adjusting and positioning the corrugated steel web 1 at a matched beam side opposite to the fixed end die side in height direction and transverse direction of the bridge. The corrugated steel web positioning method is convenient and quick to position, can reduce influence of external factors such as wind power and is more accurate and reliable to position.

Owner:CCCC SHEC FOURTH ENG

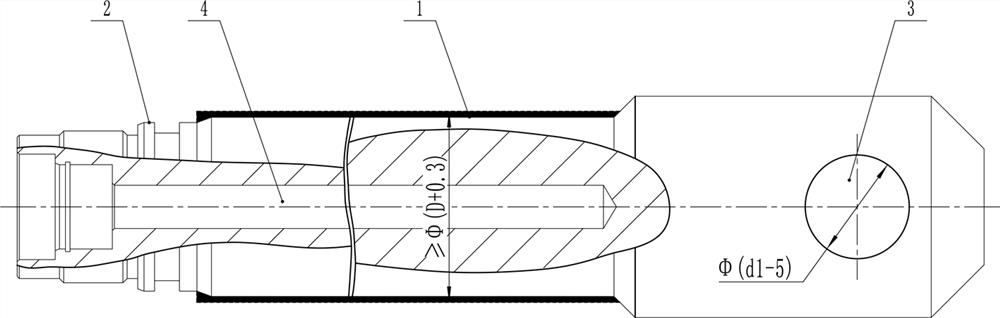

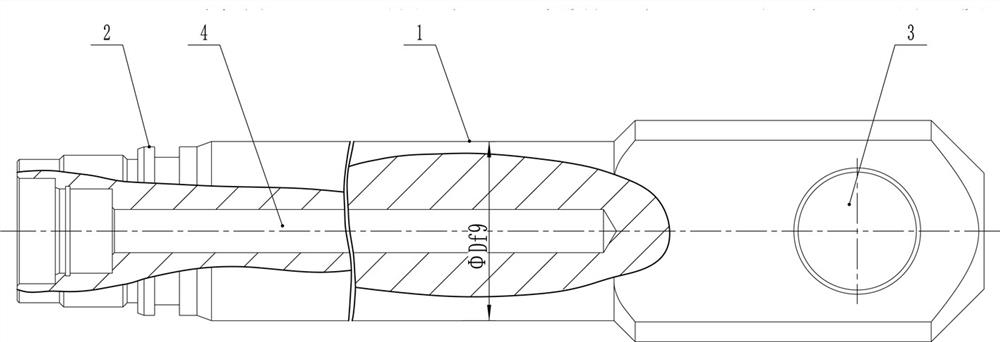

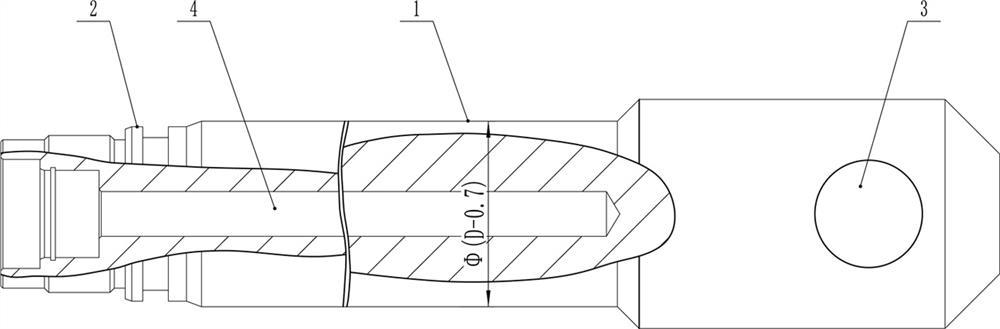

Laser cladding deformation control method for slender piston rod

InactiveCN112059545ANot easy to cause deformationHighlight substantive featuresMetallic material coating processesPolishingDeformation control

The invention provides a laser cladding deformation control method for a slender piston rod. The laser cladding deformation control method comprises the following steps of rough turning, wherein the reserved size is larger than or equal to phi(D+n) mm; drilling a hinge hole; hardening and tempering; straightening, wherein the jerk value of the slender piston rod is less than or equal to 1mm; Semi-finish turning, wherein the reserved size is larger than or equal to phi(D+n1) mm; finish turning, specifically, carrying out further finish machining on the outer circle of the slender piston rod bytaking a semi-finish-turned outer circle as a benchmark; high-speed laser cladding, specifically, detecting the jerk value of a sealing surface; size detection, specifically, detecting the diameter ofeach part of the slender piston rod; and carrying out milling-flattening, excircle grinding and polishing in order to complete the laser cladding process of the slender piston rod. The laser claddingdeformation control method for the slender piston rod has the advantages that severe workpiece deformation caused by excessive heat generated in the laser cladding process is avoided, and the processflow and time are saved.

Owner:ZHENGZHOU COAL MINING MACHINERY GRP

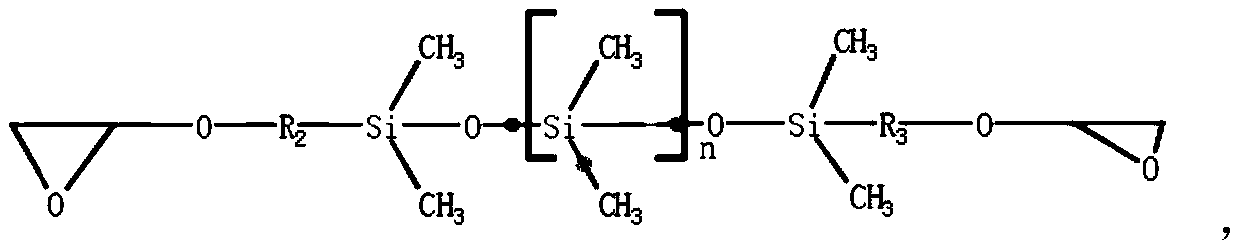

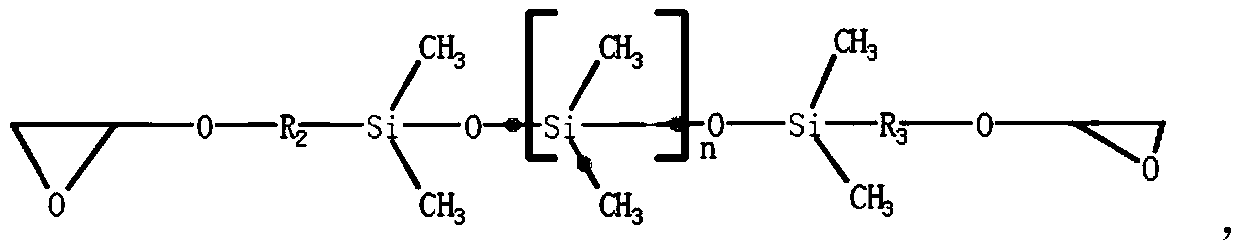

Modified maleimide resin composition as well as prepreg and laminated board prepared from modified maleimide resin composition

ActiveCN109971175AFix compatibility issuesGood compatibilitySynthetic resin layered productsElectrical equipmentEpoxyDielectric loss

The invention discloses a modified maleimide resin composition. A maleimide compound, epoxy polysiloxane and maleic anhydride modified polybutadiene react by adopting a method of simultaneously prepolymerizing three components to obtain an epoxy polysiloxane modified maleimide prepolymer, so that the problem of compatibility of siloxane and polybutadiene in a maleimide compound is solved; a prepreg and a laminated board which are prepared from the modified maleimide resin composition disclosed by the invention have a relatively low X / Y-axis thermal expansion coefficient, and board deformationcaused by temperature change is not easy to generate, so that the problem of poor connection between a semiconductor element and a substrate and between the substrate and a PCB is avoided to a certainextent; and meanwhile, the relatively low dielectric constant and dielectric loss are also beneficial to increment of transmission speed of a signal and reduction of transmission loss of the signal,and therefore, the modified maleimide resin composition has a wide application prospect.

Owner:SHENGYI TECH SUZHOU

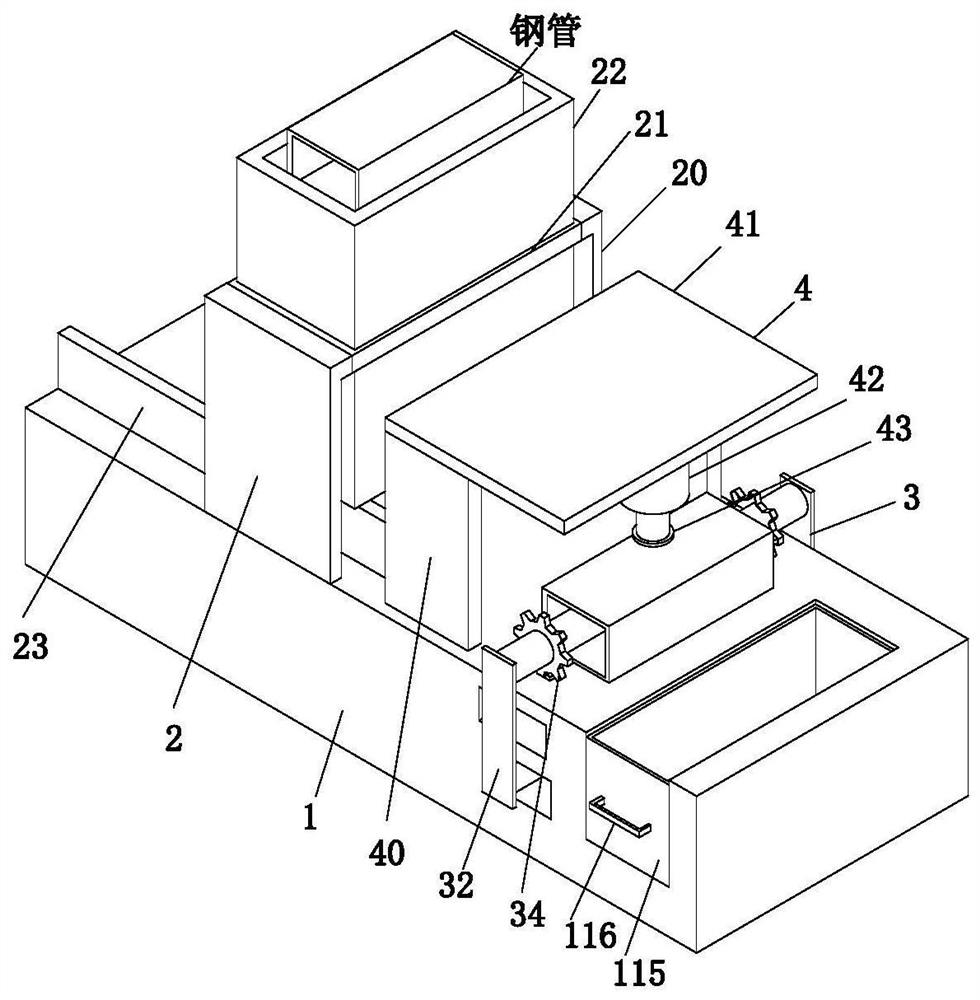

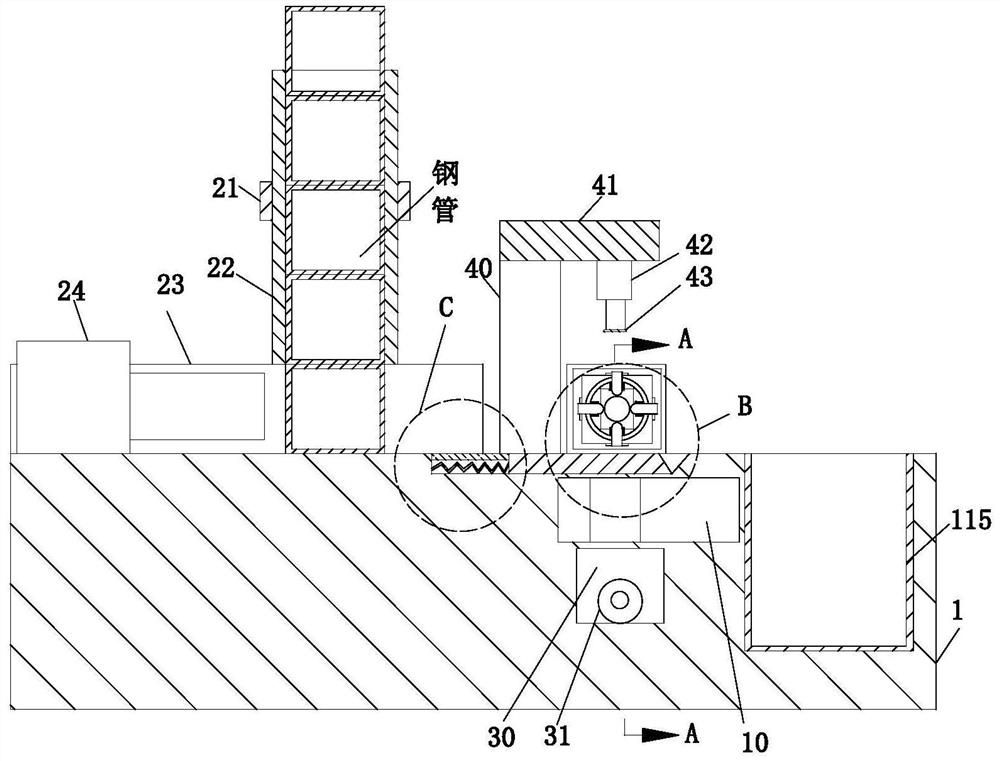

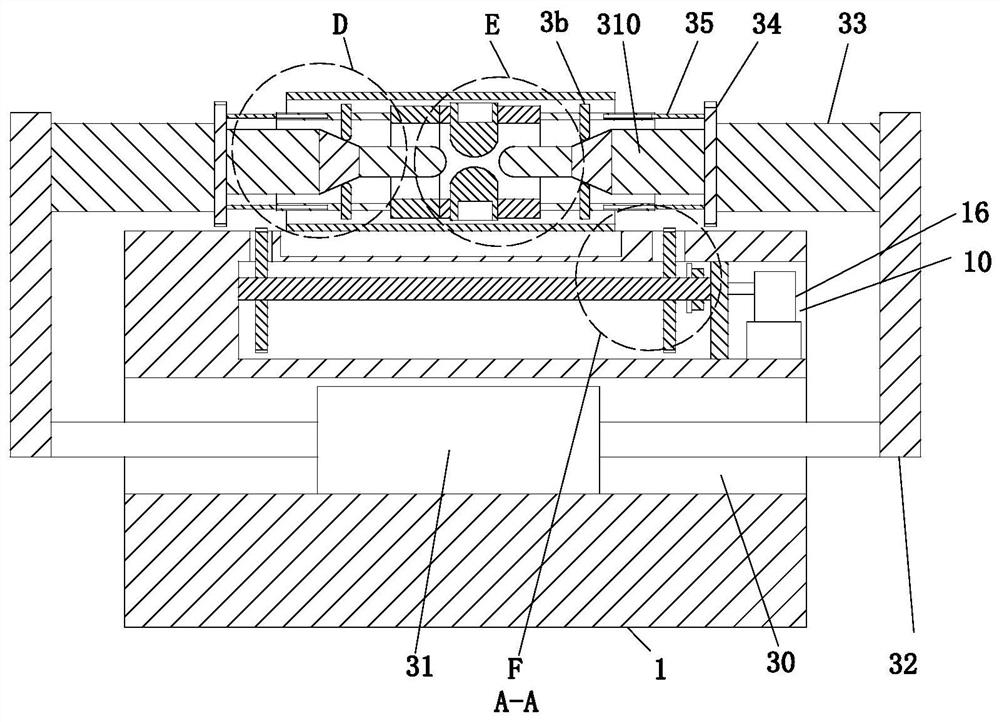

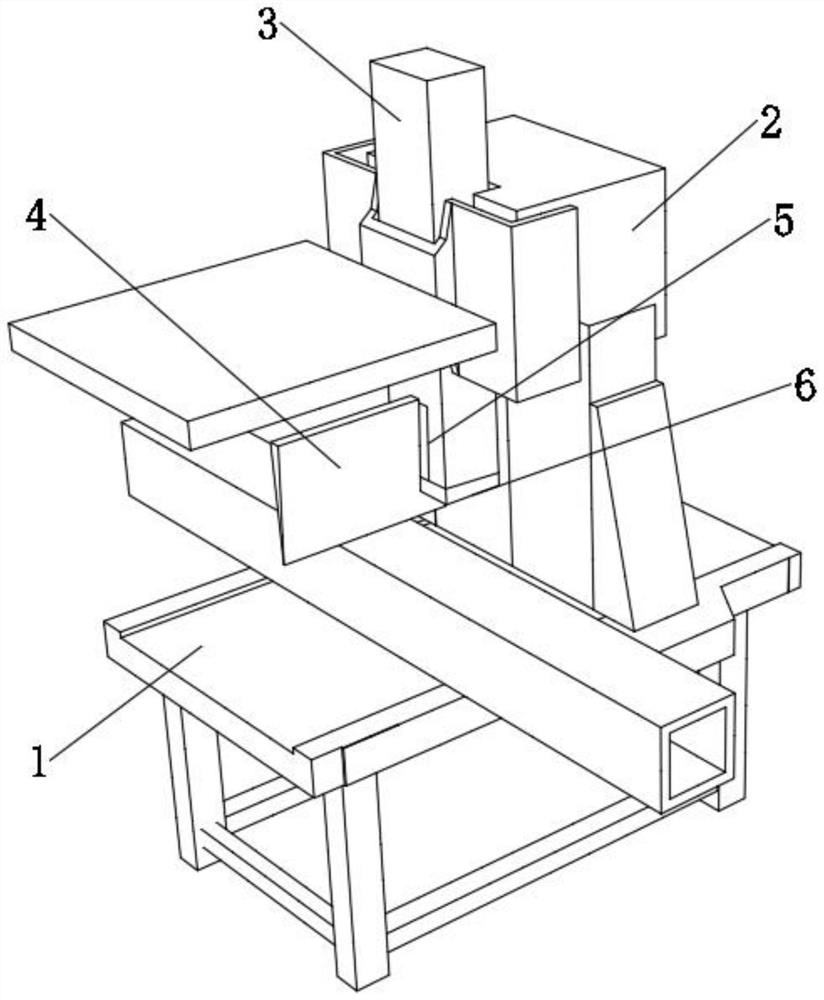

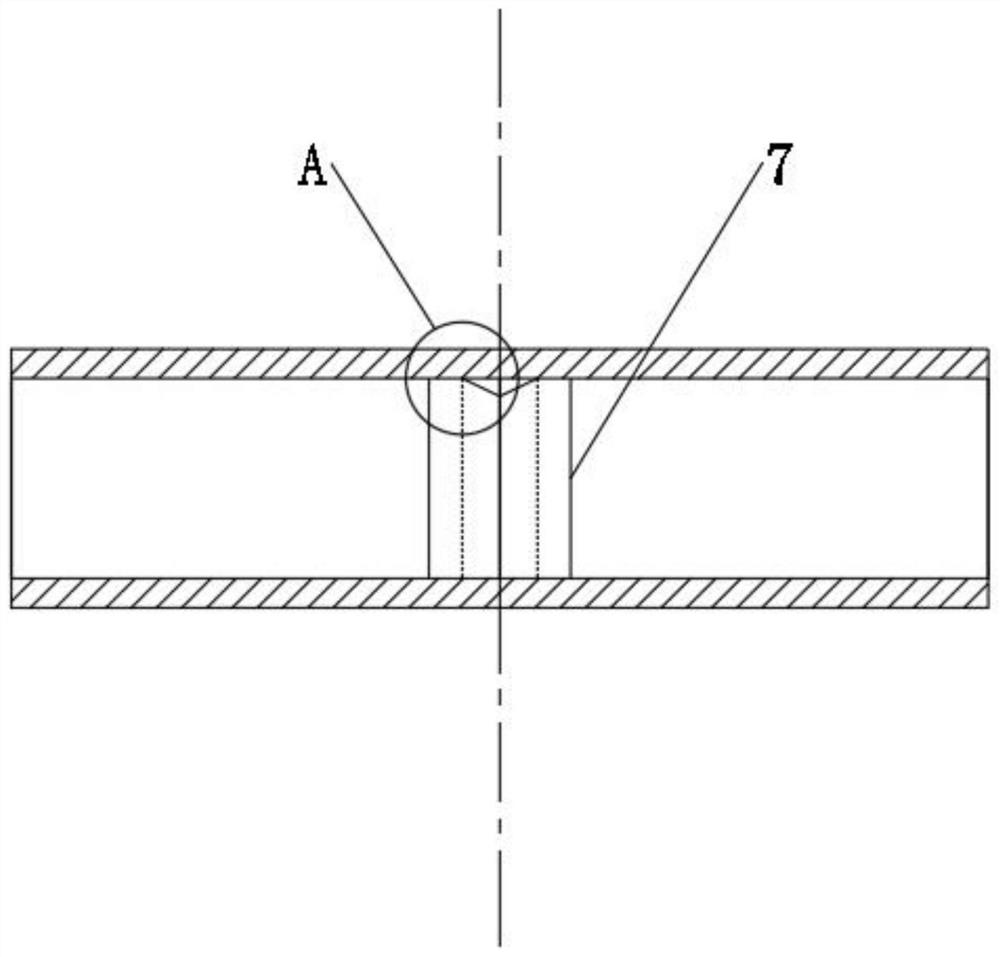

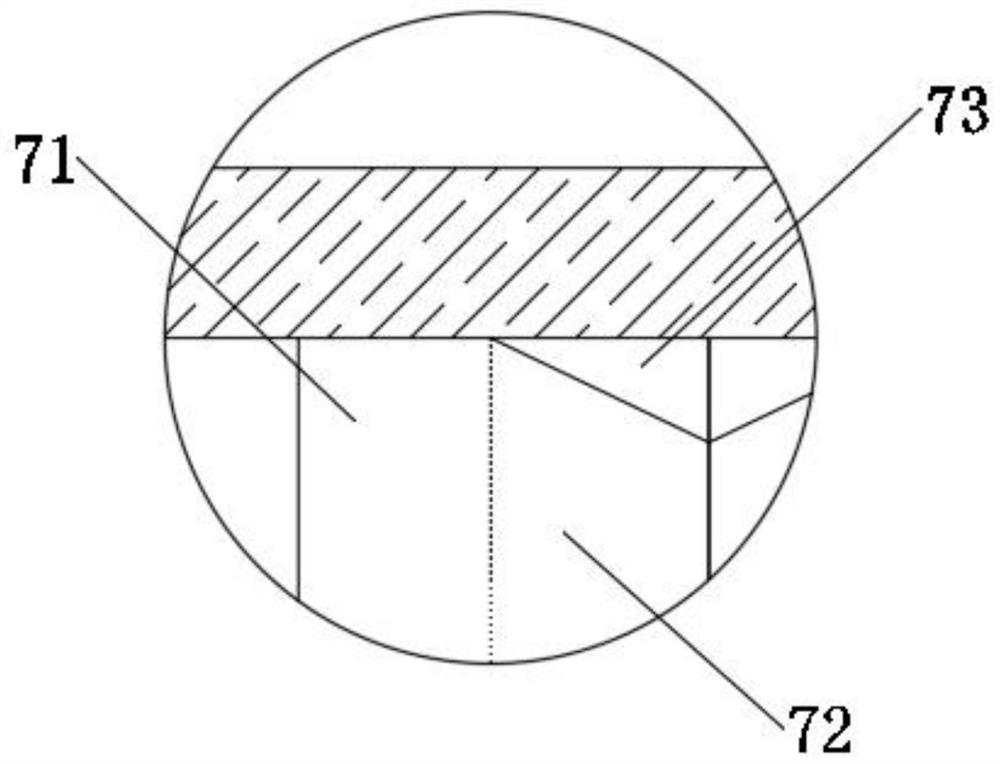

Vertical machining stamping equipment

InactiveCN112453192ANot easy to cause deformationConvenient for multi-face punchingPerforating toolsMetal-working feeding devicesPunchingMachining

The invention relates to vertical machining stamping equipment. The vertical machining stamping equipment comprises a workbench, a moving mechanism, a fixing mechanism and a stamping mechanism, wherein the moving mechanism is installed on the left side of the upper end surface of the workbench, the fixing mechanism is installed on the right side of the upper end surface of the workbench, and the stamping mechanism is arranged between the fixing mechanism and the moving mechanism. According to the vertical machining stamping equipment, when a steel pipe is fixed by the fixing mechanism, the inside of the steel pipe can be supported, so that the steel pipe has supporting force during stamping, and the deformation of the steel pipe is not prone to being caused; meanwhile, the fixing mechanismcan further turn over the steel pipe, so that multi-end-surface punching of the steel pipe is facilitated, the use effect of multiple purposes of one machine is achieved, and the punching position ofthe steel pipe is more accurate; and a moving plate moves when the steel pipe is turned over, so that the steel pipe moves without resistance, and the steel pipe is reset under the action of a supporting spring after being turned over so as to support the lower end of the steel pipe.

Owner:盐城市科瑞达科技咨询服务有限公司

Carbonizing method for thin wood board

ActiveCN106182307ASpeed up evaporationImprove consistencyRadiation/waves wood treatmentWood treatment detailsCrack resistanceMaterial selection

The invention discloses a carbonizing method for a thin wood board. The method comprises the following steps of (1) material selection, (2) drying treatment, (3) carbonizing treatment and (4) cooling treatment. The thin wood board manufactured through the method is good in stability and uniform in color and luster, the thickness of an effective carbonized layer is increased by 1 to 1.5 times, the properties such as crack resistance, bending resistance, impact toughness and nail-holding capacity of the thin wood board are greatly improved, and the using value is high.

Owner:阜南县永盛工艺品有限公司

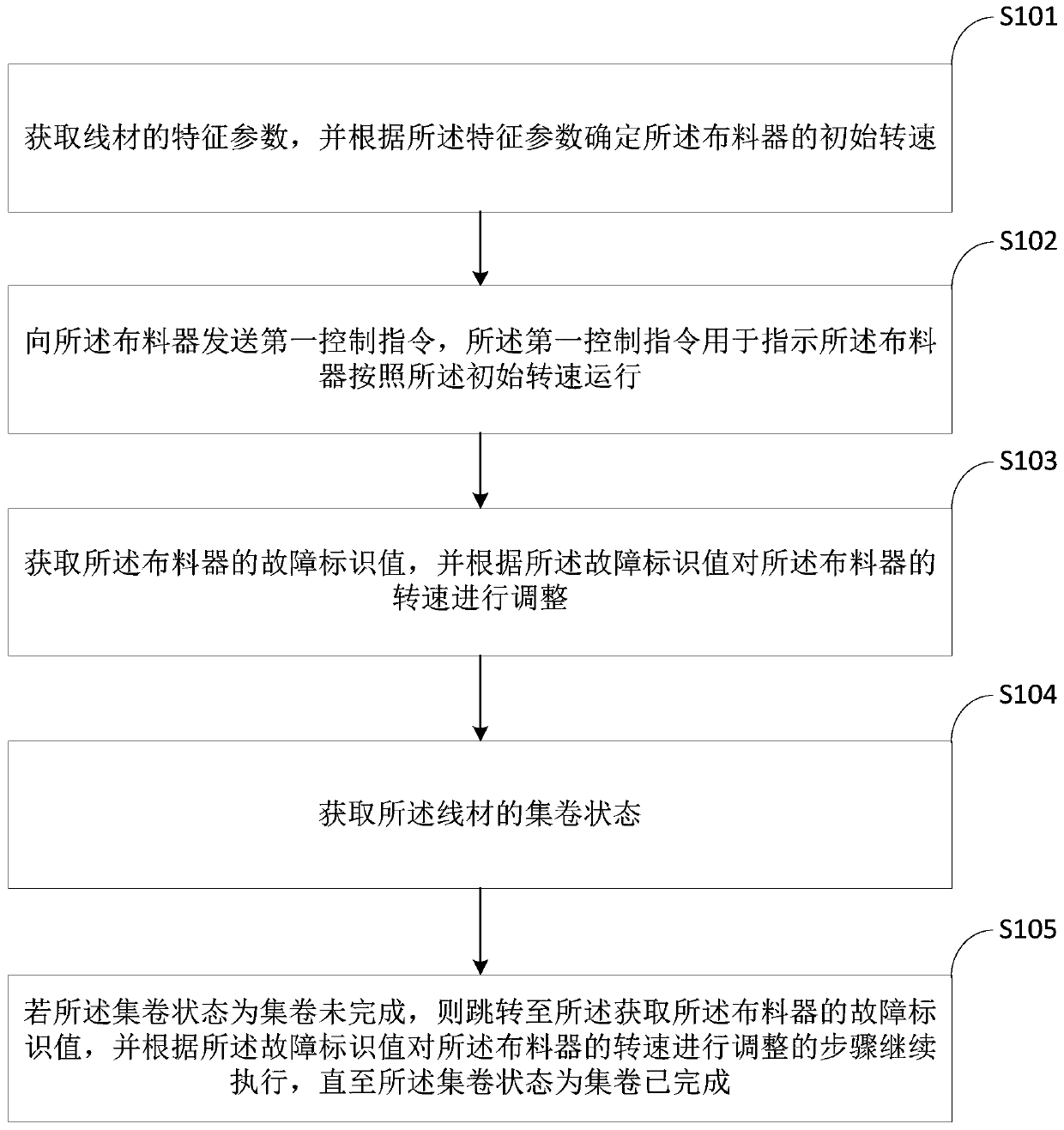

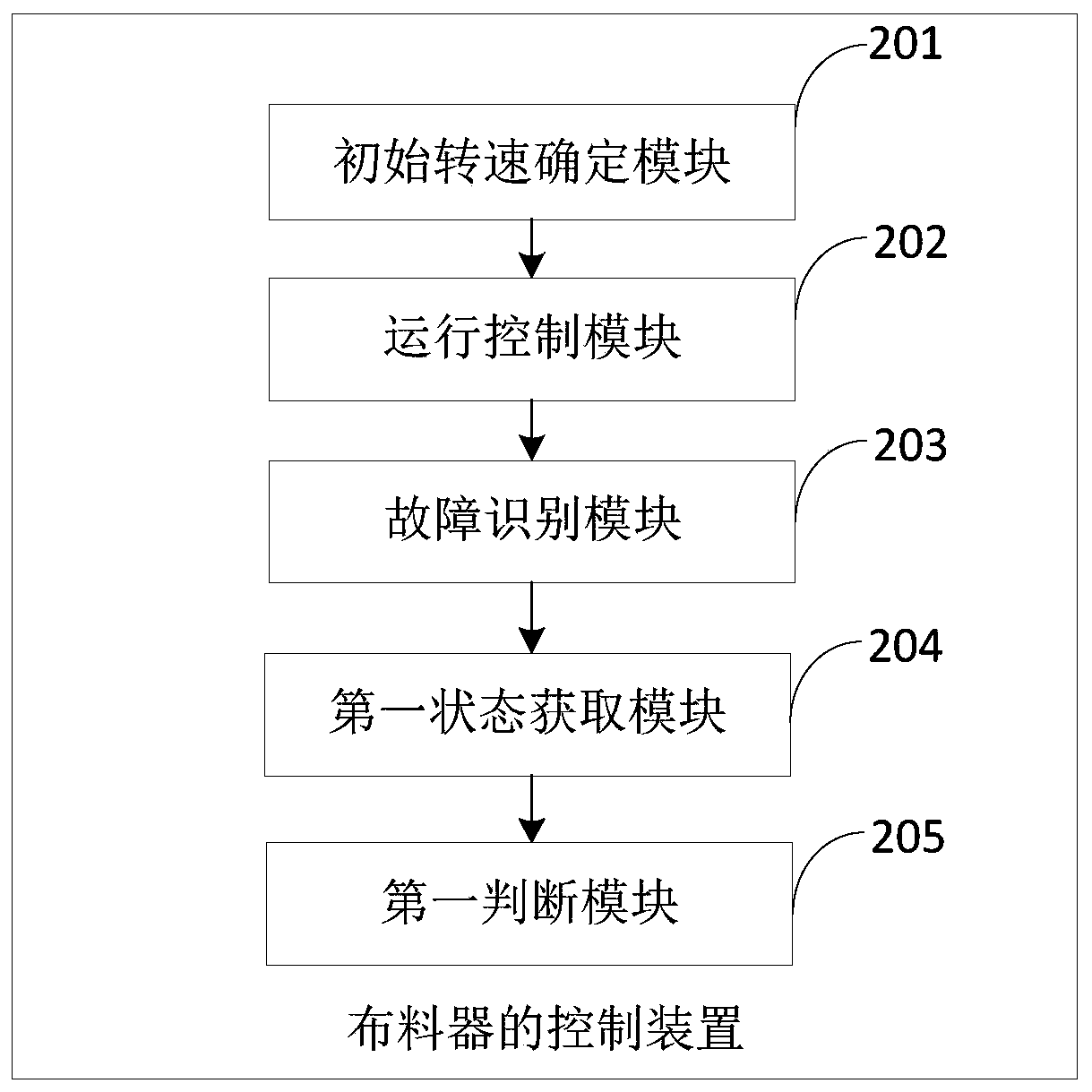

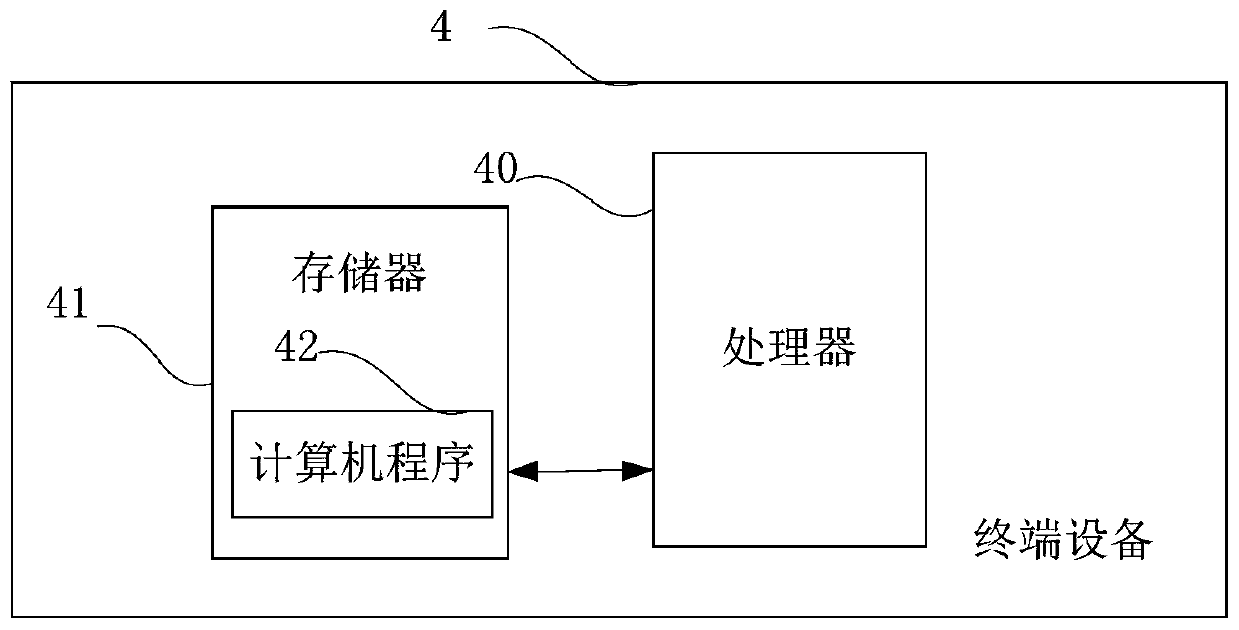

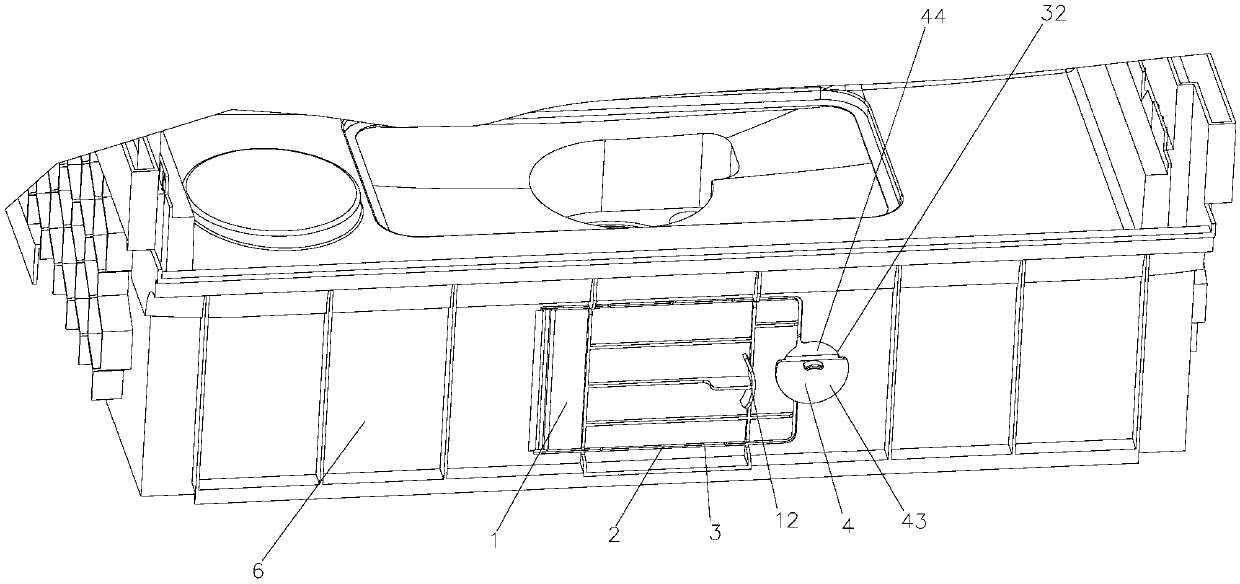

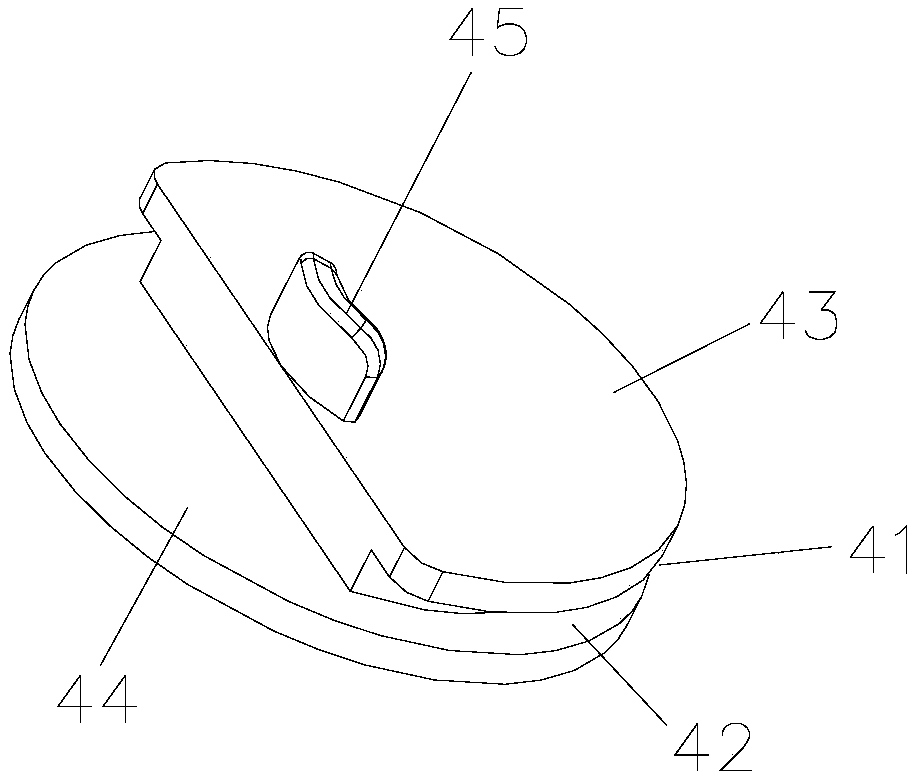

Distributor control method and terminal equipment

ActiveCN111203446ANot easy to cause deformationReduce the influence of human factorsRoll mill control devicesFlexible work arrangmentsWire rodAutomatic control

The invention is applicable to the technical field of automatic control and provides a distributor control method and terminal equipment. The method comprises the following steps of obtaining the characteristic parameters of a wire rod, and determining the initial rotating speed of a distributor according to the characteristic parameters; sending a first control instruction to the distributor, wherein the first control instruction is used for indicating the distributor to operate according to the initial rotating speed; obtaining a fault identification value of the distributor, and adjusting the rotating speed of the distributor according to the fault identification value of the distributor; acquiring a coil collection state of the wire rod; and if the coil collecting state is that coil collecting is not completed, continuous executing the step of obtaining the fault identification value of the distributor. According to the method, an original blade type distributor is used, on the premise that hardware does not need to be improved, the influence of human factors is reduced, the coil collecting control precision is improved, the cost is saved, and meanwhile the advantages that theblade type distributor is not prone to causing finished product deformation and good in coil collecting effect are reserved.

Owner:HEBEI IRON AND STEEL

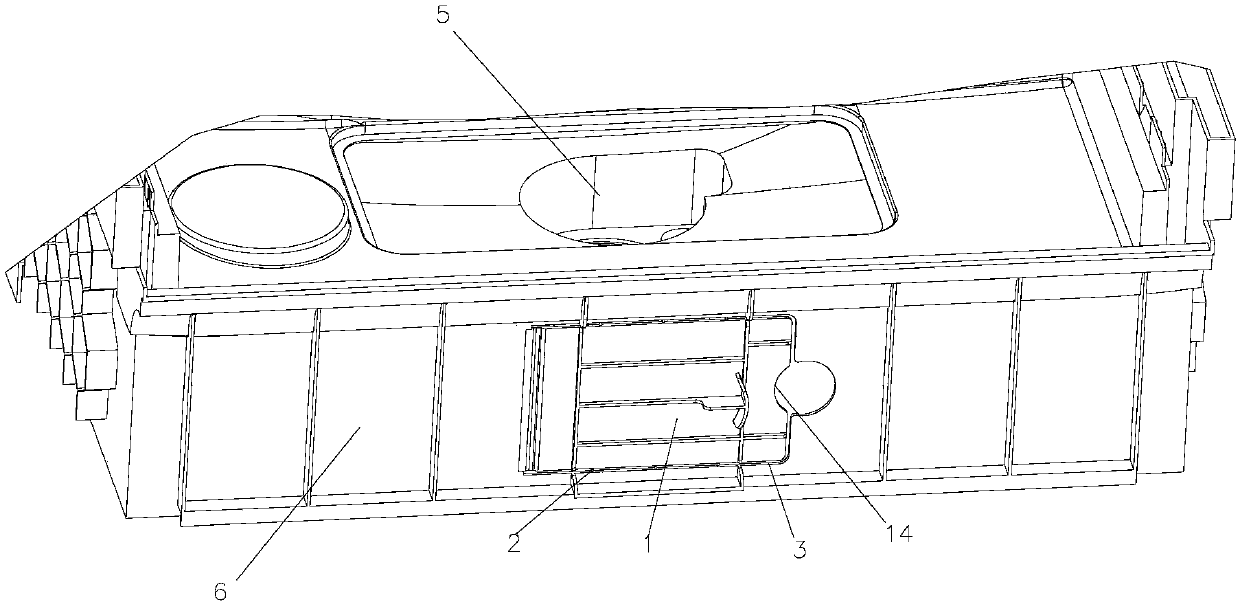

Dish washing machine

ActiveCN110680255ARealize repair and maintenanceRealize limitTableware washing/rinsing machine detailsEngineeringMechanical engineering

The invention discloses a dish washing machine comprising a shell; the shell is provided with an access hole, an access door capable of opening / closing the access hole and a limiting device rotatablyarranged between the access hole and the access door; and the limiting device is provided with a limiting clamping part, and the limiting clamping part is in limiting clamping connection with the edgeof the access door and the edge of the access hole by rotating the limiting device so as to achieve limiting after the access door is closed. According to the dish washing machine in the invention, the rotatable limiting device is used for realizing the limiting after the access hole and the access door are closed, so that the access door can be limited to be opened towards one side and a presetnotch can also be enclosed; and meanwhile, the limiting clamping part of the limiting device can automatically fall to the lower side under the action of gravity, and the access door is fixed to a state that cannot be opened, such that the closing state can be kept at all times when the access door is not in use, sealing of a base accommodating cavity is guaranteed, and equipment damage caused byforeign matters entering the base accommodating cavity is prevented.

Owner:QINGDAO HAIER DISHWASHER

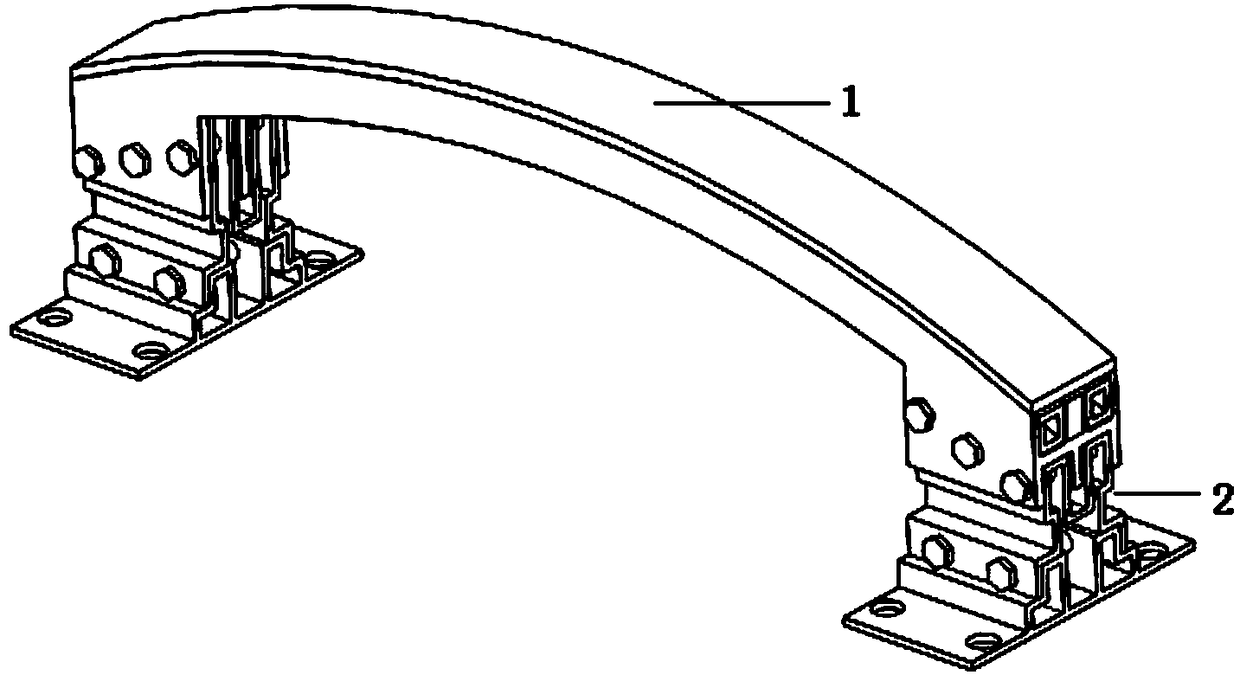

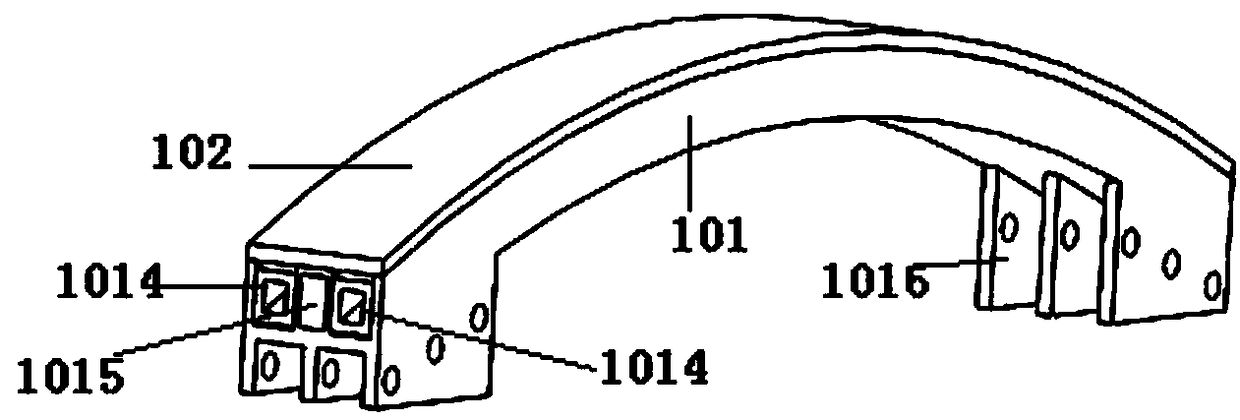

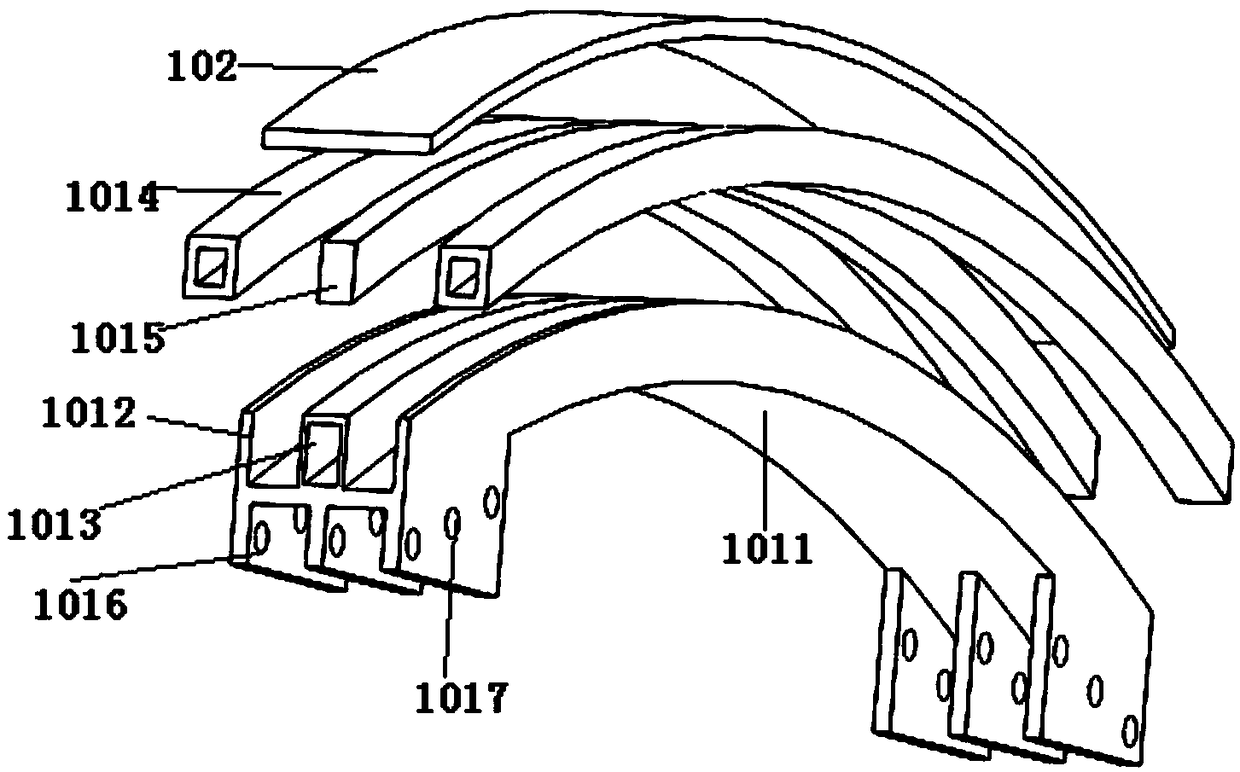

Automobile anti-collision protection mechanism and anti-collision material thereof

The invention discloses an automobile anti-collision protection mechanism. The automobile anti-collision protection mechanism comprises an anti-collision cross beam and buffering energy absorbing boxes which are fixed on the two sides of the anti-collision cross beam; the anti-collision cross beam comprises a cross beam body; a rigid outer plate is fixed on the surface of the cross beam body; andthe rigid outer plate is prepared from an anti-collision material. According to the automobile anti-collision protection mechanism, by arranging the anti-collision cross beam and the buffering energyabsorbing boxes, the outside force is dispersed by using an arc cross beam plate of the anti-collision cross beam; and meanwhile, by using the cross beam body to further disperse the outside force, partial outside force is eliminated, and the dispersed and eliminated outside force is further eliminated and dispersed under buffering and dispersing effects of the buffering energy absorbing boxes; and therefore, the outside force transmitted to an automobile falls within an acceptable range so that no damage cannot be caused to the automobile and passengers in the automobile.

Owner:ANHUI SANLIAN UNIV

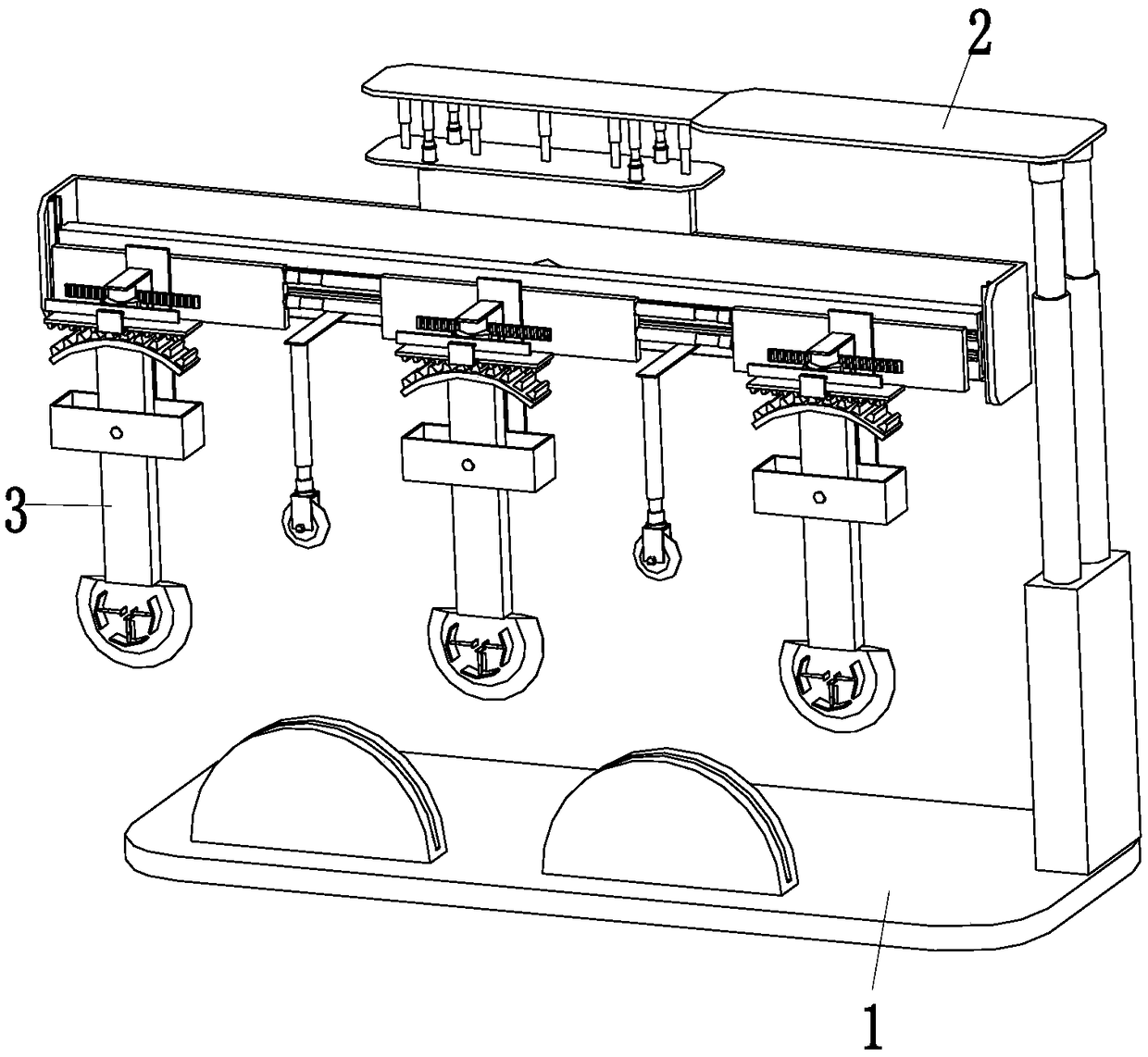

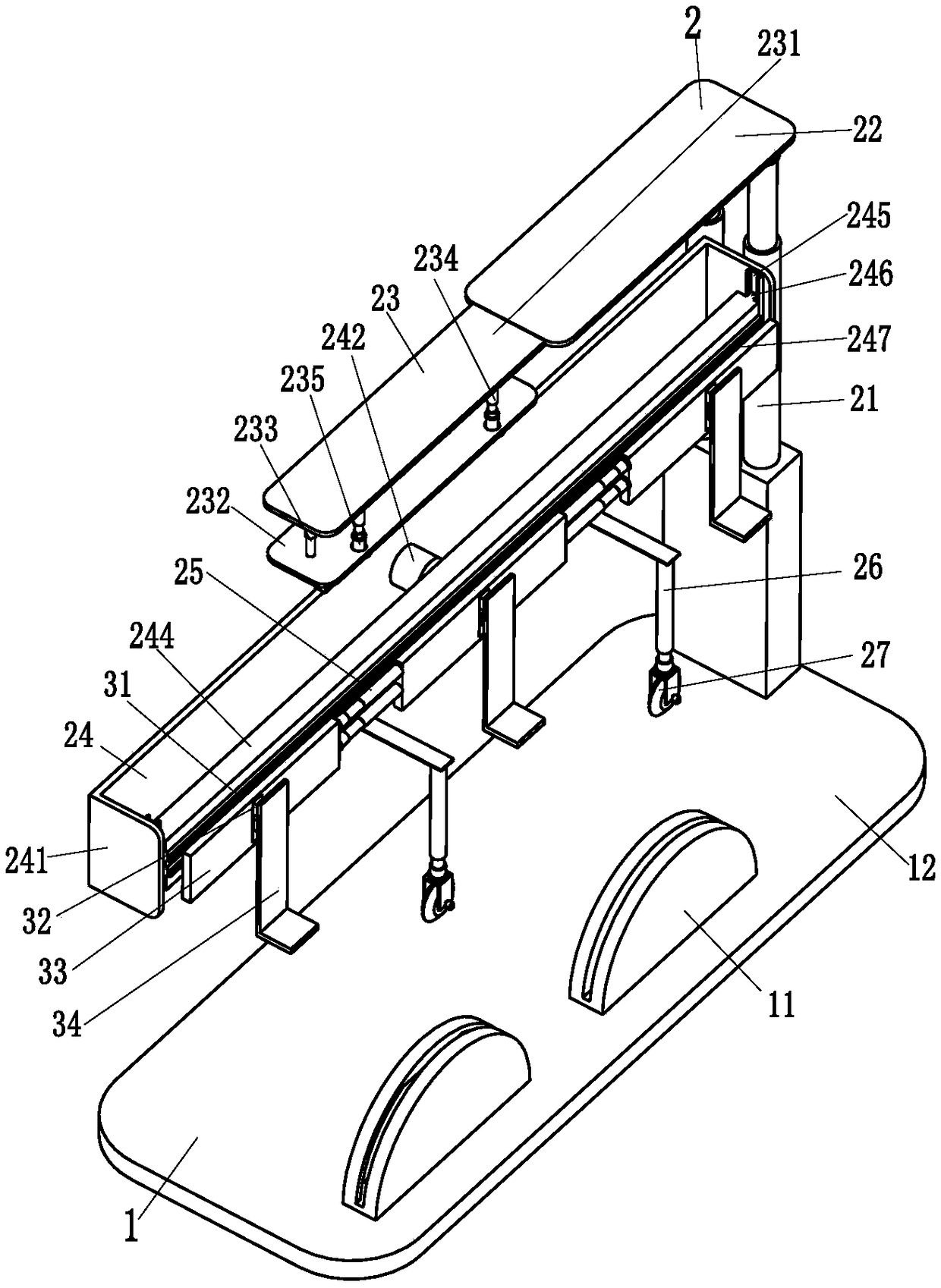

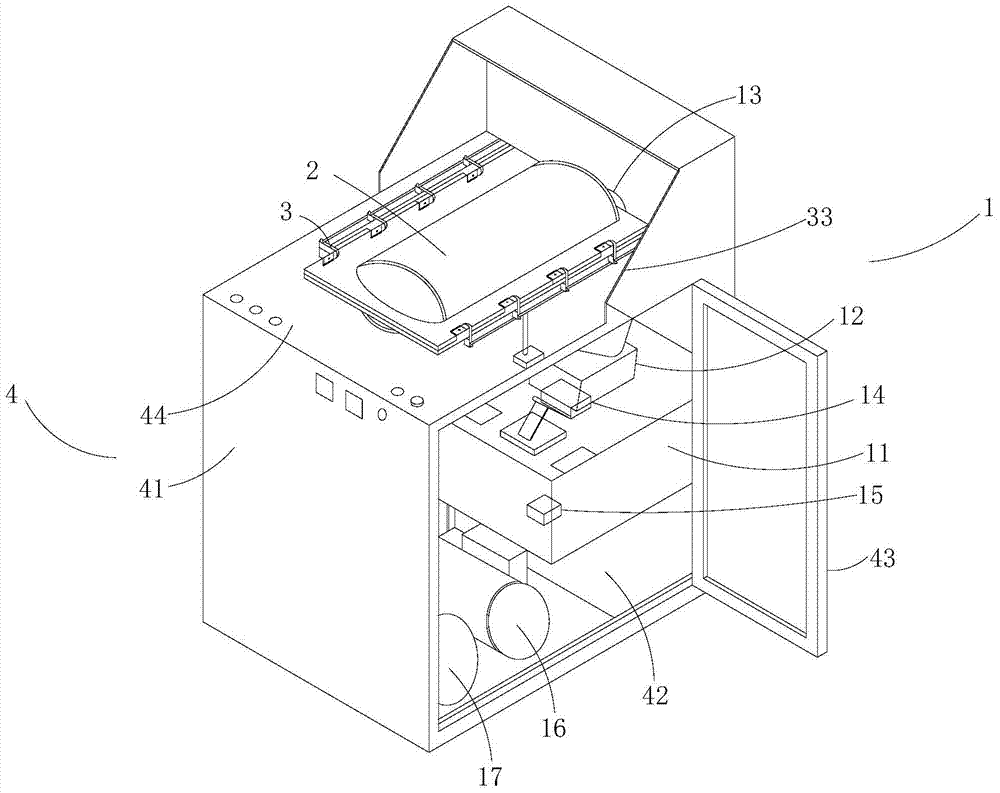

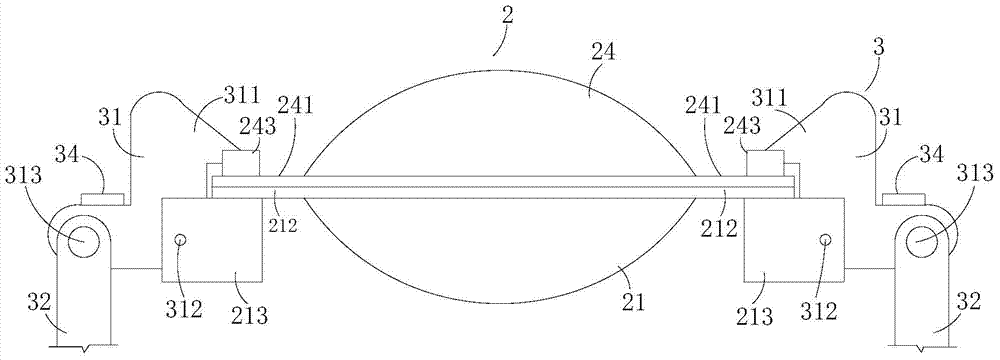

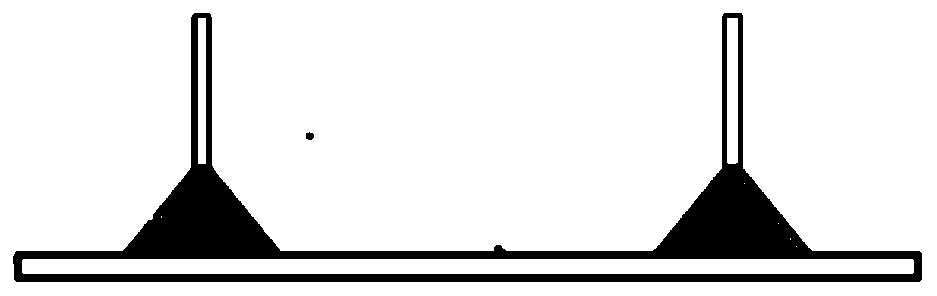

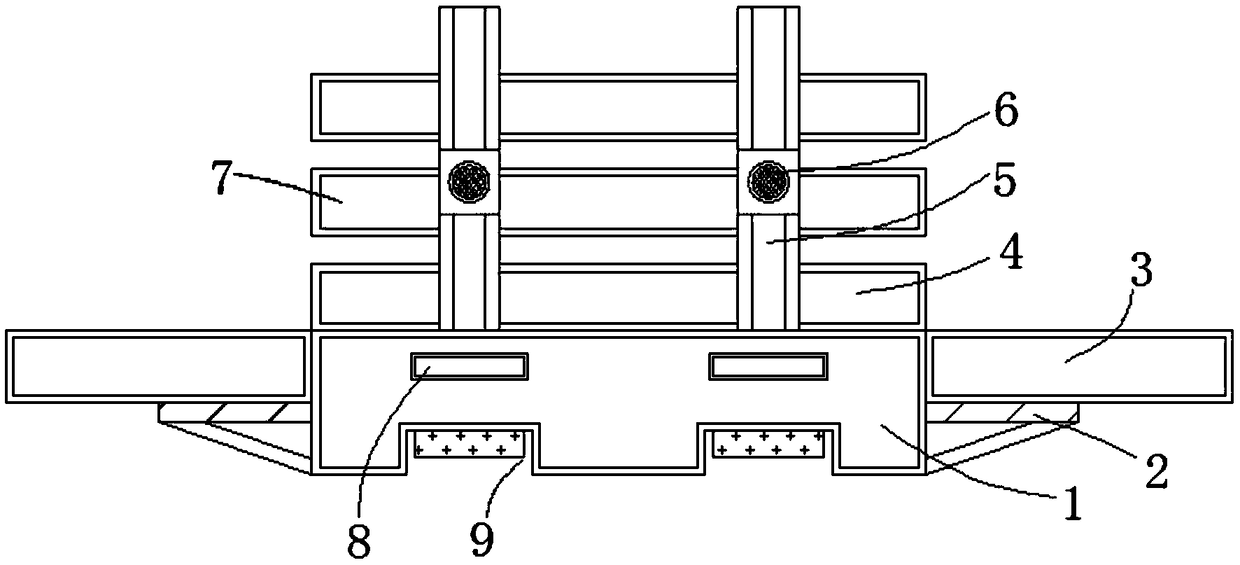

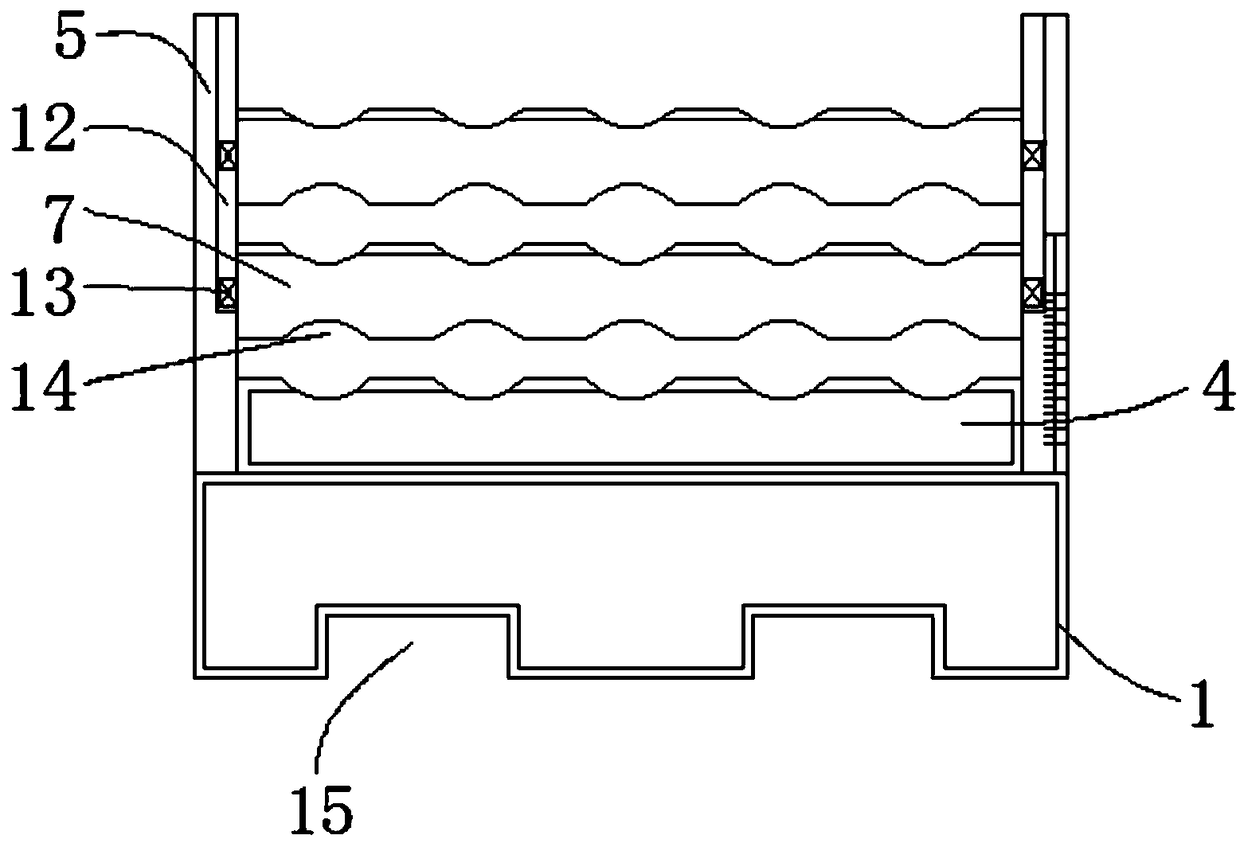

Large-scale stator core turnover welding device

InactiveCN106181208ASolve uncontrollable factorsSolve manpowerWelding/cutting auxillary devicesAuxillary welding devicesStatorMechanical engineering

The invention relates to a large-scale stator core turnover welding device which comprises a bracket, a bottom plate and a backup plate, wherein a rotary shaft is mounted at the upper end of the bracket; the bottom plate and the backup plate are rotatably mounted on the rotary shaft; a front turnover air cylinder fixing seat is mounted at the front end of the bracket and is rotatably connected with a front turnover air cylinder; a piston rod of the front turnover air cylinder is rotatably connected with the middle of the lower end face of the bottom plate; a rear turnover air cylinder fixing seat is mounted at the rear end of the bracket and is rotatably connected with a rear turnover air cylinder; a piston rod of the rear turnover air cylinder is rotatably connected with the middle of the rear end face of the backup plate; a plurality of sliding rails are transversely arranged on the front end face of the backup plate; driven rollers and driving rollers are mounted on the sliding rails in a sliding manner; lock screws are mounted at the upper end and the lower end of each of the driven rollers and the driving rollers and are propped against two sides of the sliding rails; a motor is mounted on the rear end face of the backup plate; and a rotary shaft of the motor is connected with the driving rollers. The large-scale stator core turnover welding device eliminates the process that a worker manually turns over and rotates a workpiece.

Owner:NINGBO PHASE MOTION CONTROL

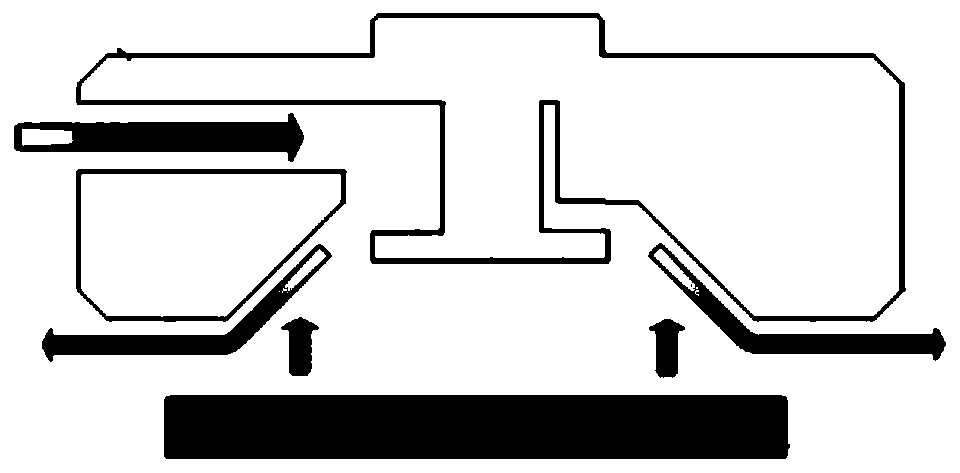

Non-contact mobile operating device and control method

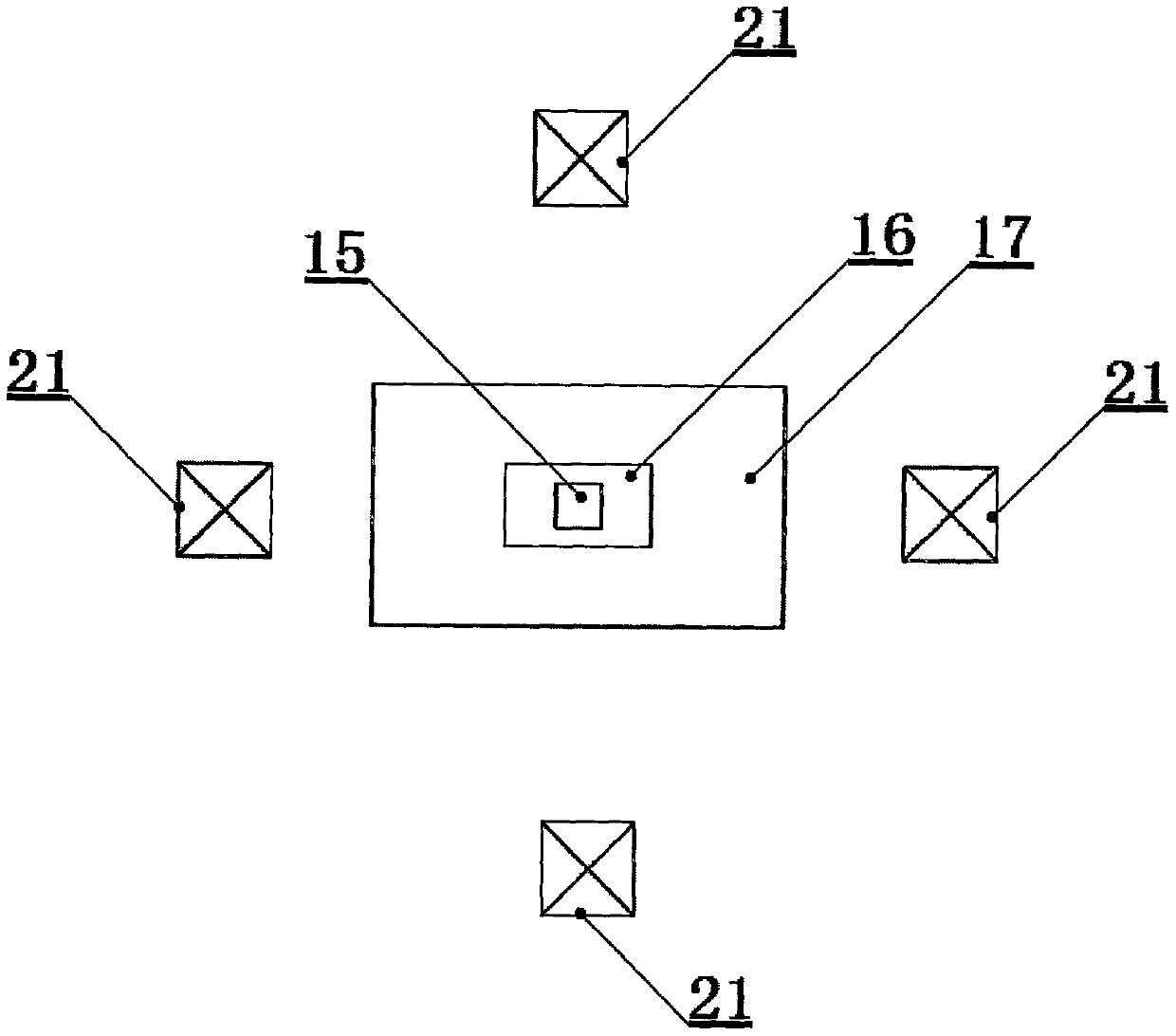

The invention discloses a non-contact mobile operating device. The non-contact mobile operating device comprises a round upper-layer plate, a round lower-layer porous medium plate and position sensors; a groove is formed in the upper-layer plate; the lower-layer porous medium plate and the upper-layer plate are fixedly connected to form a cavity; four first through holes are evenly formed in the circumferential direction of the upper-layer plate; corresponding second through holes are formed in the corresponding positions of the lower-layer porous medium plate; the first through holes are connected with a first vacuum pump; another two opposite first through holes are connected with a second vacuum pump; a third through hole is formed in the center of the upper-layer plate; an air inlet joint is mounted on the third through hole; four supports are evenly mounted on the side wall of the upper-layer plate; a two-position three-way electromagnetic reversing valve, a position sensor and anair spraying opening are mounted on each support; the first vacuum pump and a second vacuum pump are connected with the two-position three-way electromagnetic reversing valves through pipelines; andthe two-position three-way electromagnetic reversing valves are connected with the air spraying openings. According to the device, the strength and the direction of the air flow on the surface of an object are changed through pumping of the miniature vacuum pumps, so that the object moves, and the complete non-contact effect can be realized.

Owner:JIANGSU UNIV OF SCI & TECH

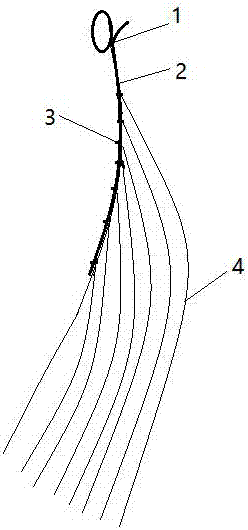

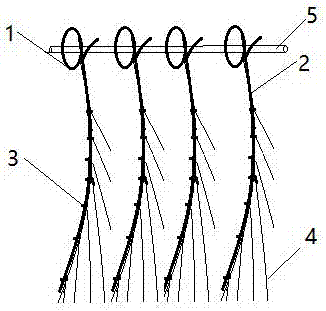

Efficient hair extension method

ActiveCN107232670AImprove comfortNot easy to cause deformationNon-macromolecular adhesive additivesWigsHair streamsEngineering

The invention discloses an efficient hair extension method. The method comprises the following steps that every 5-8 hairs are neatened into one wisp, a fiber rope is used as a base rope in each wisp of hair, and the hair of a wig is bonded on the base rope by using glue; a dislocation connection mode is used for a junction in bonding, and the tail end of one side of the base rope of each wisp forms one fiber ring or above; every 3-10 wisps of hair are neatened into one row, the glue is used for bonding all wisps of hair, and the distance between the bonding points among wisps and the top ends of all wisps is 3-10 mm; a support rod is used for connecting the fiber rings in series in sequence during hair extension, the wig is arrayed in a row mode, then the rowed wig is connected with the human hair, and hair extension is achieved. According to the efficient hair extension method, hair extension is more natural, the method has no negative effect on human basically, and the hair extension efficiency is higher.

Owner:安徽金润发制品有限公司

Intelligent anti-rolling forklift bracket for carrying building pipes

InactiveCN108946588AFast storage workLess prone to rollingLifting devicesForklift truckArchitectural engineering

The invention discloses an intelligent anti-rolling forklift bracket for carrying building pipes, and relates to the technical field of building construction assistance. The intelligent anti-rolling forklift bracket for carrying the building pipes comprises a support frame and a bearing plate, wherein bearing frames are connected to the left side and the right side of the outer wall of the supportframe; the bearing frames are connected with the support frame through screws; and the bearing plate is placed on the top part of the support frame. The intelligent anti-rolling forklift bracket forcarrying the building pipes provided by the invention has the beneficial effects that a first limiting groove, a second limiting groove and a limiting plate are arranged, and the inner side radian ofthe second limiting groove is equal to the inner side radian of the first limiting groove, so that when a forklift is used for bearing and carrying the building pipes through the device, under the actions of the first limiting groove and the second limiting groove arranged equidistantly, and under the actions that the first limiting groove and the second limiting groove are distributed relatively,the building pipes clamped by the first limiting groove and the second limiting groove are not easy to roll during the transportation work, and the influence on the balance of the device at a forklift arm part is avoided.

Owner:GUIZHOU RUIHANG INTELLIGENT TECH CO LTD

Wind fire-extinguishing machine air duct

The invention discloses a wind fire-extinguishing machine air duct, which is formed by welding sheet iron, wherein one port of the wind fire-extinguishing machine air duct is circular, the circular opening is provided with a round flipping edge from inside to outside, the other port of the wind fire-extinguishing machine air duct is a square port, and both edges of the square port are provided with a reinforcing plate with round holes. According to the present invention, the wind fire-extinguishing machine air duct has the effectively enhanced strength so as not easily to cause deformation ordamage, can reduce wind quantity loss, and can improve fire extinguishing efficiency.

Owner:任成岩

Full-automatic square tube cutting machine

InactiveCN113210714AImprove cut qualityNot easy to cause deformationTube shearing machinesMetal working apparatusThermal deformationEngineering

The invention discloses a full-automatic square tube cutting machine, and belongs to the technical field of cutting. According to the full-automatic square tube cutting machine, a matched thermal deformation shaping block is placed in a square tube, then a cutting position is determined based on magnetic force guidance, and then the square tube is cut through a heated cutting blade in a vertical cutting manner, so that the cutting power can be reduced, meanwhile, large-amplitude deformation of a notch is not prone to being caused, after the upper end face is cut, after short remaining, position adjustment is conducted, and even if errors exist in the position of the thermal deformation shaping block, the thermal deformation shaping block automatically triggers the deformation action under heating of the cutting blade; and the cutting blade is guided until the thermal deformation shaping block indirectly moves to the optimal position, the square tube is completely and integrally cut under shaping and limiting of the thermal deformation shaping block, and compared with an abrasive wheel cutting machine adopted in the prior art, the cutting machine has the advantages that the cutting quality of the square tube can be remarkably improved, the shape of the notch can be well controlled, and subsequent processing is facilitated.

Owner:广东欧丽仕智能科技有限公司

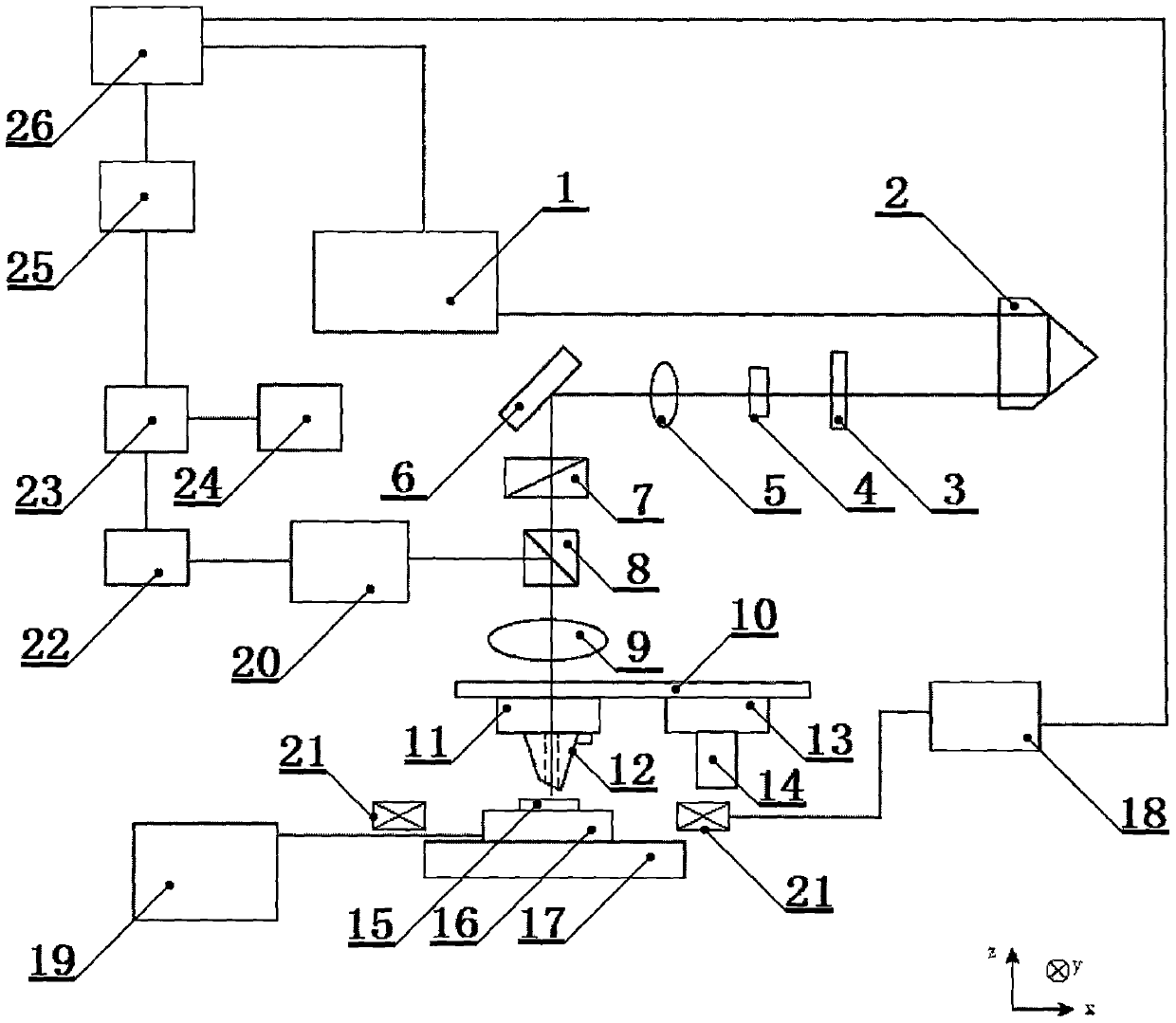

Method for measuring magnetism of surface nanostructure

ActiveCN108680510AExtended service lifeNot easy to cause deformationPolarisation-affecting propertiesScanning probe microscopyMeasurement deviceBeam splitter

The invention relates to a magnetism measuring method in the field of optical technology measurement. A method for measuring magnetism of a surface nanostructure adopts a measuring device comprising alaser, a delayer, a quarter wave plate, a concave lens, a convex lens I, a plane mirror, a polarizer, a beam splitter, a convex lens II, a lens table, an atomic force microscope I, a probe I, a lensholder, an objective lens, a sample, a Hall plate, a sample table, a signal generator, an oscilloscope, a detector, a magnet, a preamplifier, a differential amplifier, a compensator, an analog-digitalconverter, a computer, an atomic force microscope II and a probe II, wherein the magnet is formed by connecting four identical sub-magnet cables. A high-precision positioning device is used to obtainmagnetization information of a surface of a nanometer sample, so that the single nanostructure can be measured; the measurement on magnetization dynamics of the surface of the sample can achieve a spatial resolution at a sub-micron level; nanoscale magnetization dynamic characteristics can be obtained without extracting information of micro-magnetization fluctuation of the surface of the sample by depending on a phase sensitivity detection technology.

Owner:嘉兴诺恩医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com