Non-contact mobile operating device and control method

A technology of moving operation and control method, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of object contamination, inability to drive objects to move horizontally, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

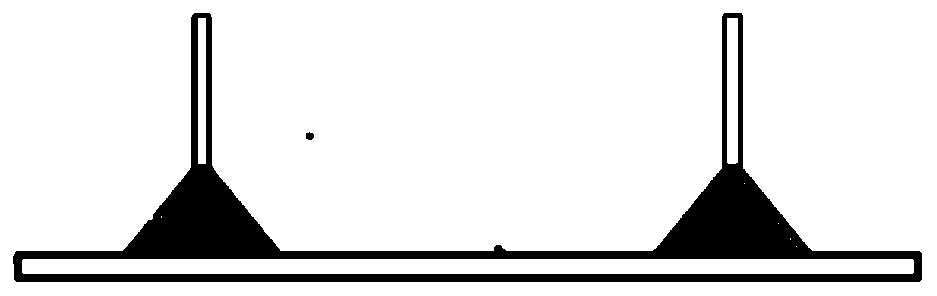

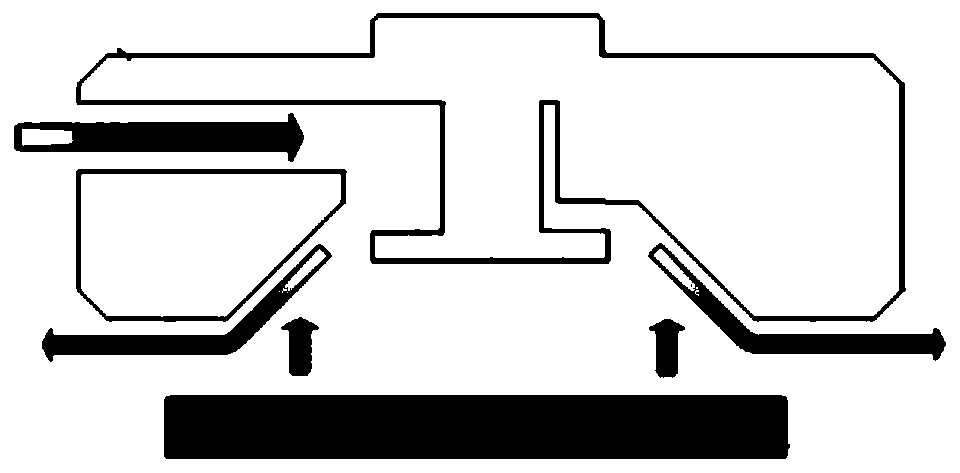

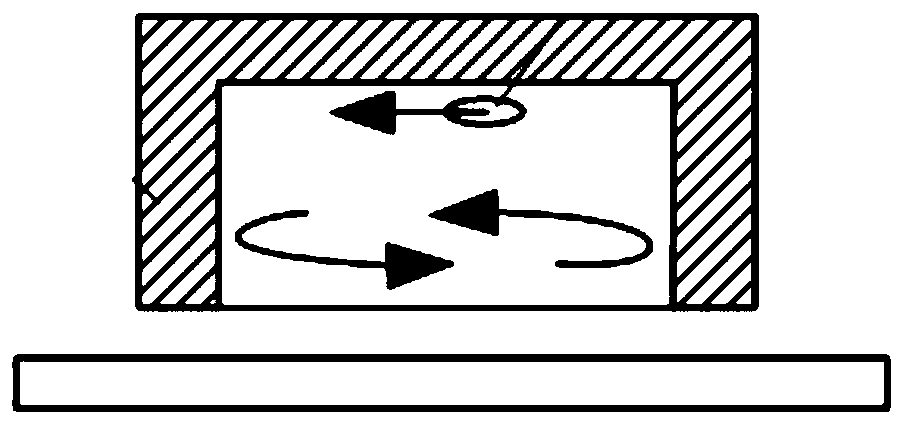

[0048] Such as Figure 1 to Figure 14 As shown, a non-contact mobile operation device of the present invention includes a circular upper plate 1, a circular lower porous medium plate 2 and a position sensor 5, the upper plate 1 is provided with a groove, and the lower porous medium plate 2 It is fixedly connected with the upper plate 1 to form a cavity, and there are four first through holes evenly arranged in the circumferential direction of the upper plate 1, and corresponding second through holes are provided at the corresponding positions of the lower porous medium plate 2, and the opposite two first through holes The hole is connected to the first vacuum pump 7, and the other two relative first through holes are connected to the second vacuum pump. The center of the upper plate 1 is provided with a third through hole, and an air inlet joint 8 is installed on the third through hole. Four brackets 3 are evenly installed on the side wall of the upper plate 1, and each bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com