Light-colored infrared absorbing UV-LED ink-jet ink and preparation method thereof

A UV-LED, infrared absorption technology, used in inks, household appliances, applications, etc., can solve the problems of inability to better protect anti-counterfeiting characteristics, poor light fastness, and limited application fields of infrared inkjet inks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

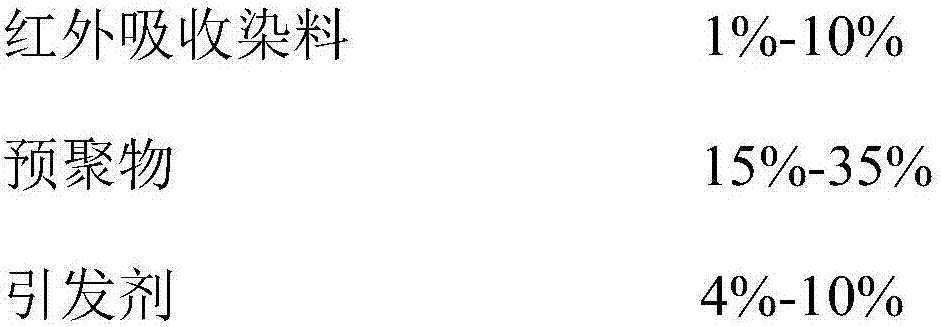

[0028] Light color infrared absorbing UV-LED inkjet ink, its formula is as follows:

[0029]

[0030]

[0031] Preparation method: mix the various components, let stand, filter with a positive pressure filter device, the filter membrane pore size is 0.45 μm, and obtain light-color infrared absorption UV-LED inkjet ink after filtering.

[0032] Measure the physical properties of the ink, as follows:

[0033] Viscosity (25°C): 21mpa·s

[0034] Surface tension: 22mN / m

[0035] Particle size: Z-Average 122nm, PDI 0.135

[0036] This ink is used for printing with Ricoh nozzle GEN4. The printing speed is 50m / min. It has good printing fluency and no ink flying.

Embodiment 2

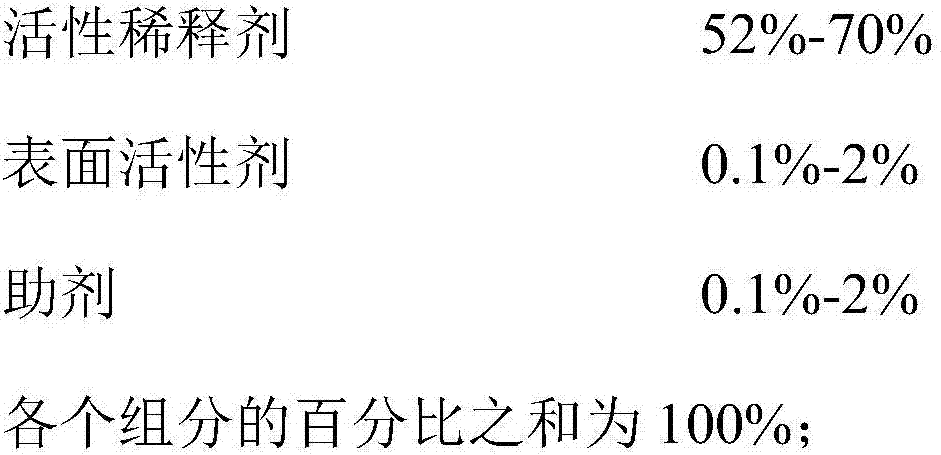

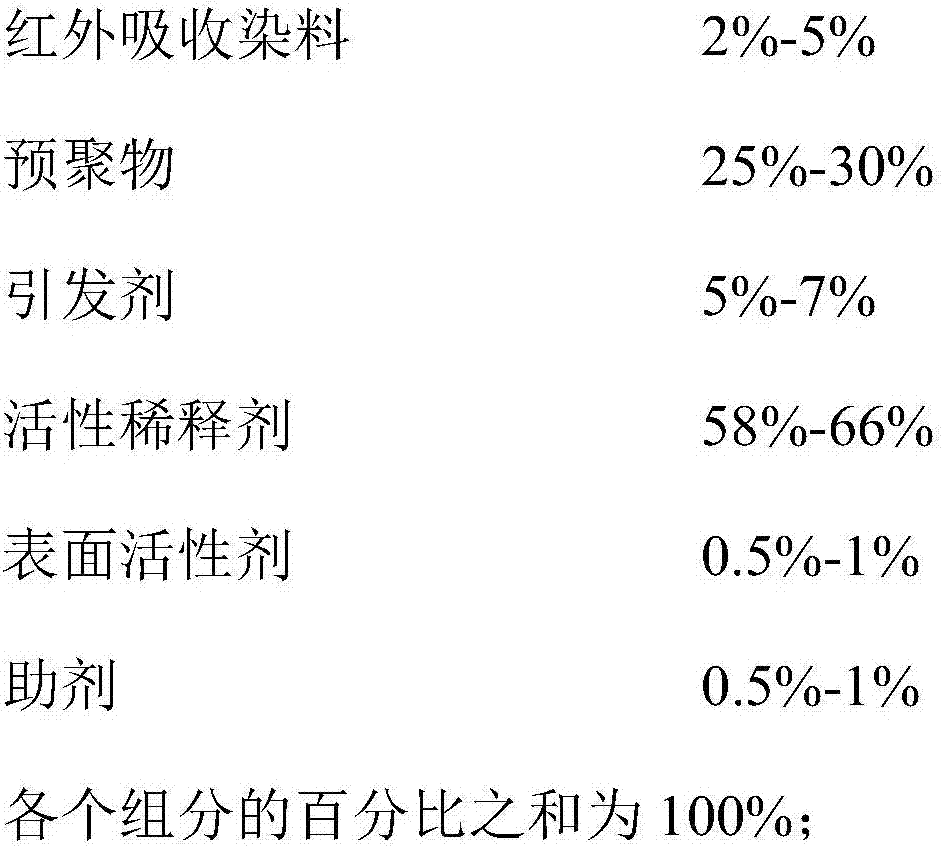

[0038] Light color infrared absorbing UV-LED inkjet ink, its formula is as follows:

[0039]

[0040]

[0041] Preparation method: according to the formula, mix perylene-based infrared absorbing dyes, tetrahydrofuran acrylate, dipropylene glycol acrylate, polyethylene glycol acrylate, monoacyl phosphine, α-amino ketone, surfactant, and auxiliary agents in sequence Add it into the container, stir for 30 minutes, and control the speed at 500r / min. After mixing, the system becomes uniform and transparent blue. After stirring, let it stand for 30 minutes, filter with a positive pressure filter device, the filter membrane has a pore size of 0.45 μm, and obtain a light-colored infrared-absorbing UV-LED inkjet ink after filtering.

[0042] Measure the physical properties of the ink, as follows:

[0043] Viscosity (25°C): 24mpa·s

[0044] Surface tension: 21mN / m

[0045] Particle size: Z-Average 110nm, PDI 0.120

[0046] The ink is used for printing with Ricoh nozzle GEN4, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com