Double-cylinder rotary compressor

A rotary compressor, double-cylinder technology, applied in the direction of rotary piston/oscillating piston pump components, mechanical equipment, machines/engines, etc., can solve the problem of the decrease of the rigidity of the middle partition, the distance between the main bearing and the auxiliary bearing Increased length, lower reliability and efficiency of the separator, etc., to prevent bending of the crankshaft and deformation of the separator, improve efficiency, and prevent the decline in reliability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

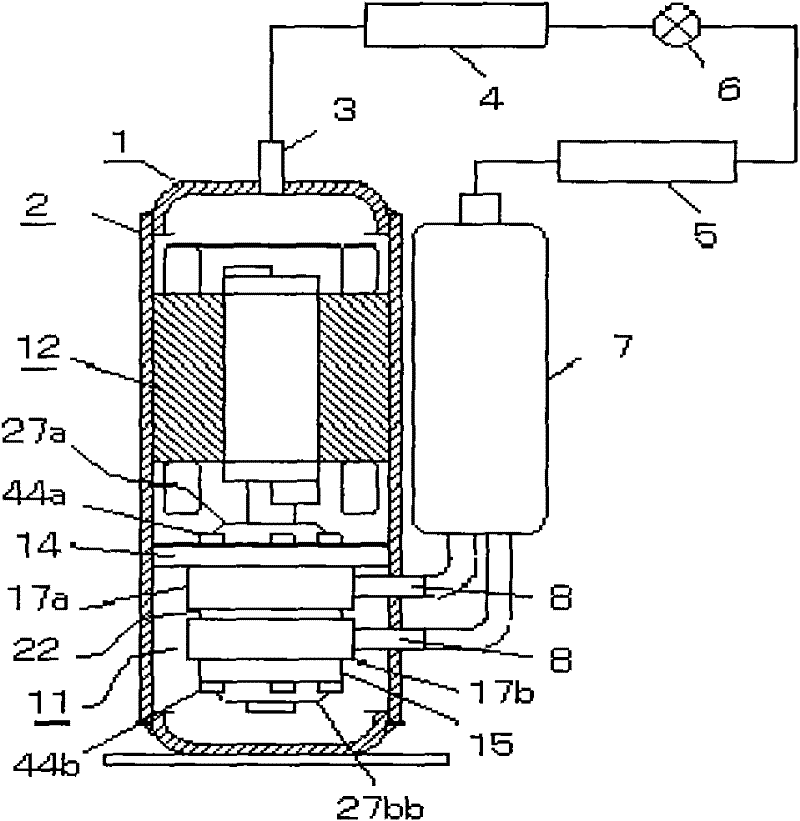

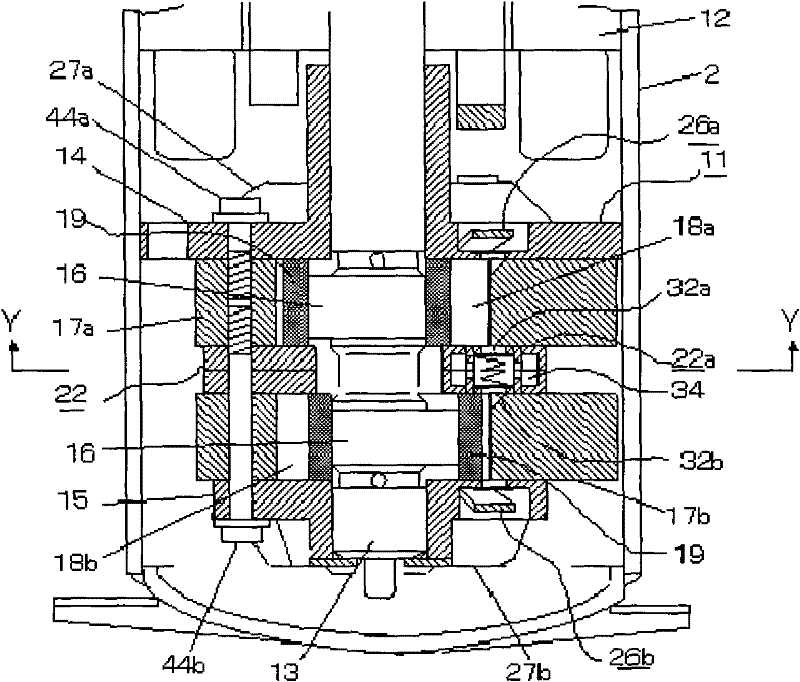

[0053] see Figure 1-Figure 2 , The two-cylinder rotary compressor 1 includes a compression mechanism part 11 installed in the sealed casing 2, and a motor part 12 arranged on the top thereof.

[0054] The compression mechanism part 11 includes a first cylinder 17a and a second cylinder 17b, a first middle partition assembly 22 located between the two cylinders and separating the compression chamber 18a of the first cylinder and the compression chamber 18b of the second cylinder, inside the compression chamber of the cylinder The eccentrically rotating piston 19, the sliding plate 20 synchronously reciprocating with the piston, and the two eccentric shafts 16 on the crankshaft 13 respectively drive the respective piston 19, the main bearing 14 and the auxiliary bearing 15 supporting the crankshaft. A first discharge muffler 27 a and a second discharge muffler 27 b are attached to the main bearing 14 and the sub bearing 15 , respectively.

[0055] The above components are assemb...

Embodiment 2

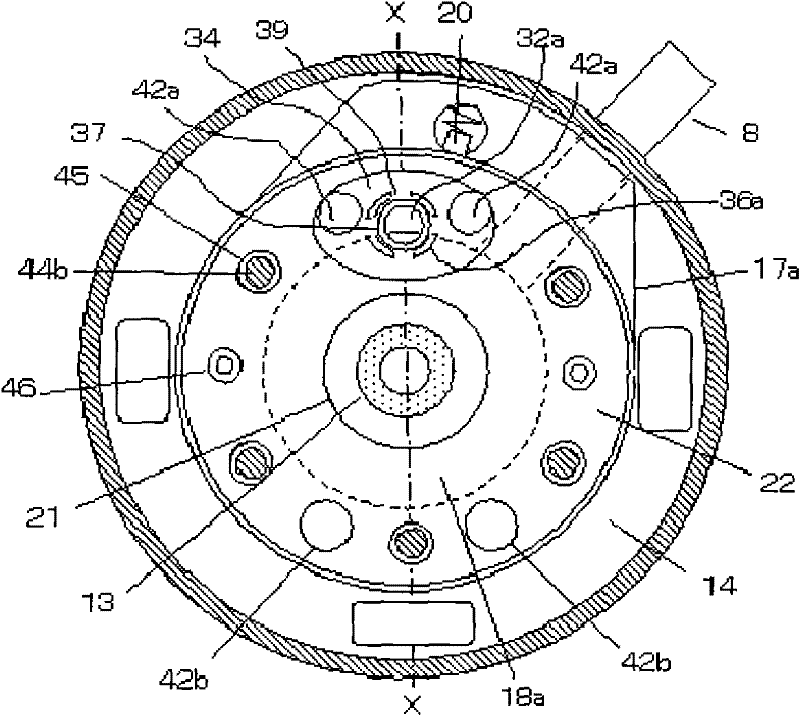

[0104] In embodiment 1, two flat plates are used to form the sound-absorbing cavity; as Figure 25-Figure 26 As shown, in this embodiment, a sound-absorbing cavity is formed in a flat body. The fourth flat body 23b of the second partition plate assembly 23 is formed using wear-resistant cast iron such as flake graphite. During the casting stage, the muffler cavity 34 can be designed using the core.

[0105] Thereafter, the outer peripheral portion of the fourth flat body 23b is processed simultaneously with the muffler center hole 23a, the second discharge hole 32b, and the valve seat 37. The inner diameter of the muffler center hole 23a is equal to the outer diameter of the second valve housing 23c.

[0106] The valve housing component here is the second valve housing component. The second valve housing 23c in the second valve housing assembly is formed by using the same material as the fourth flat body 23b, or by powder metallurgy or cold forging. After the second valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com