Patents

Literature

6147results about "Rotary/oscillating piston combinations for elastic fluids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compressor

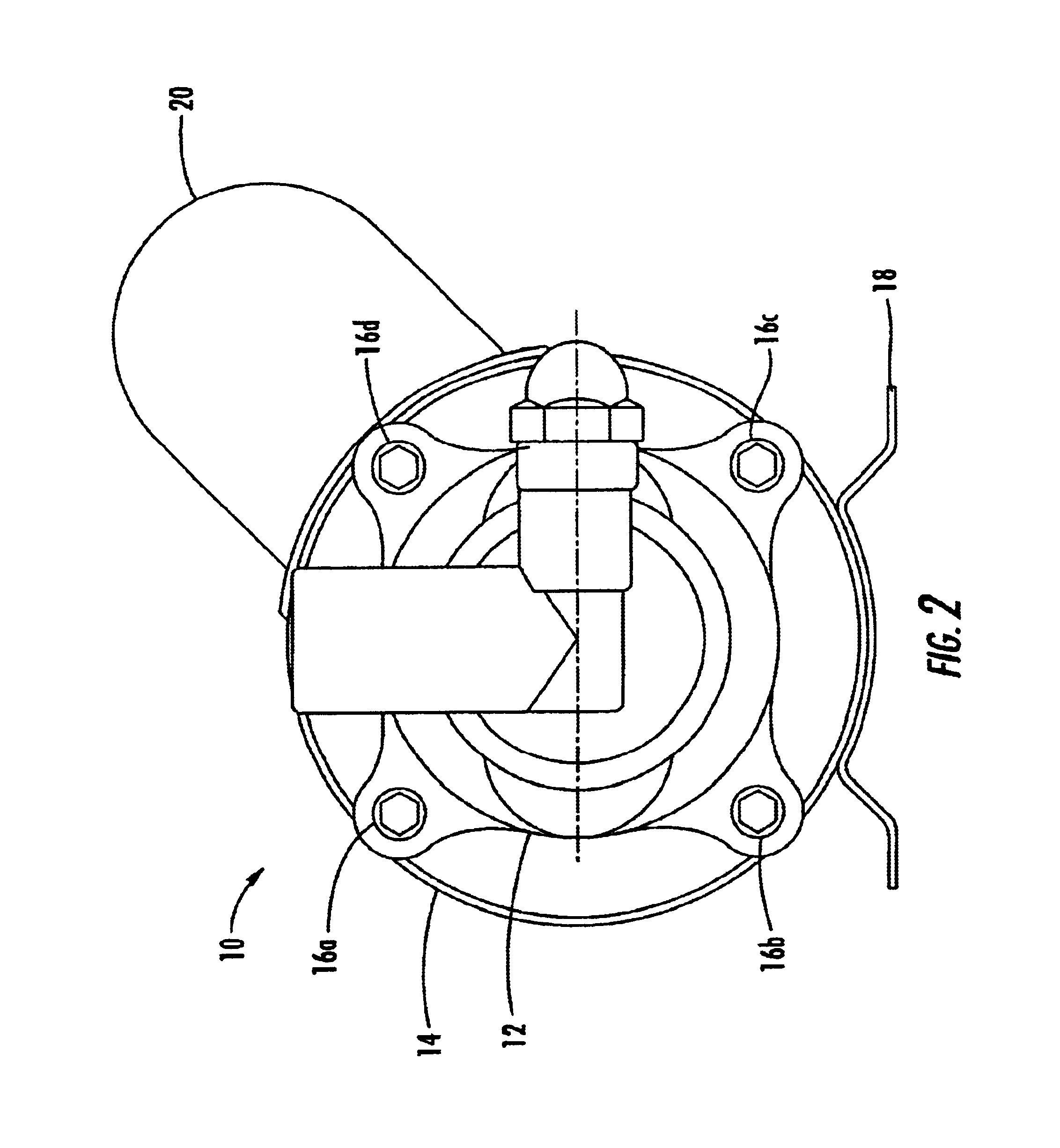

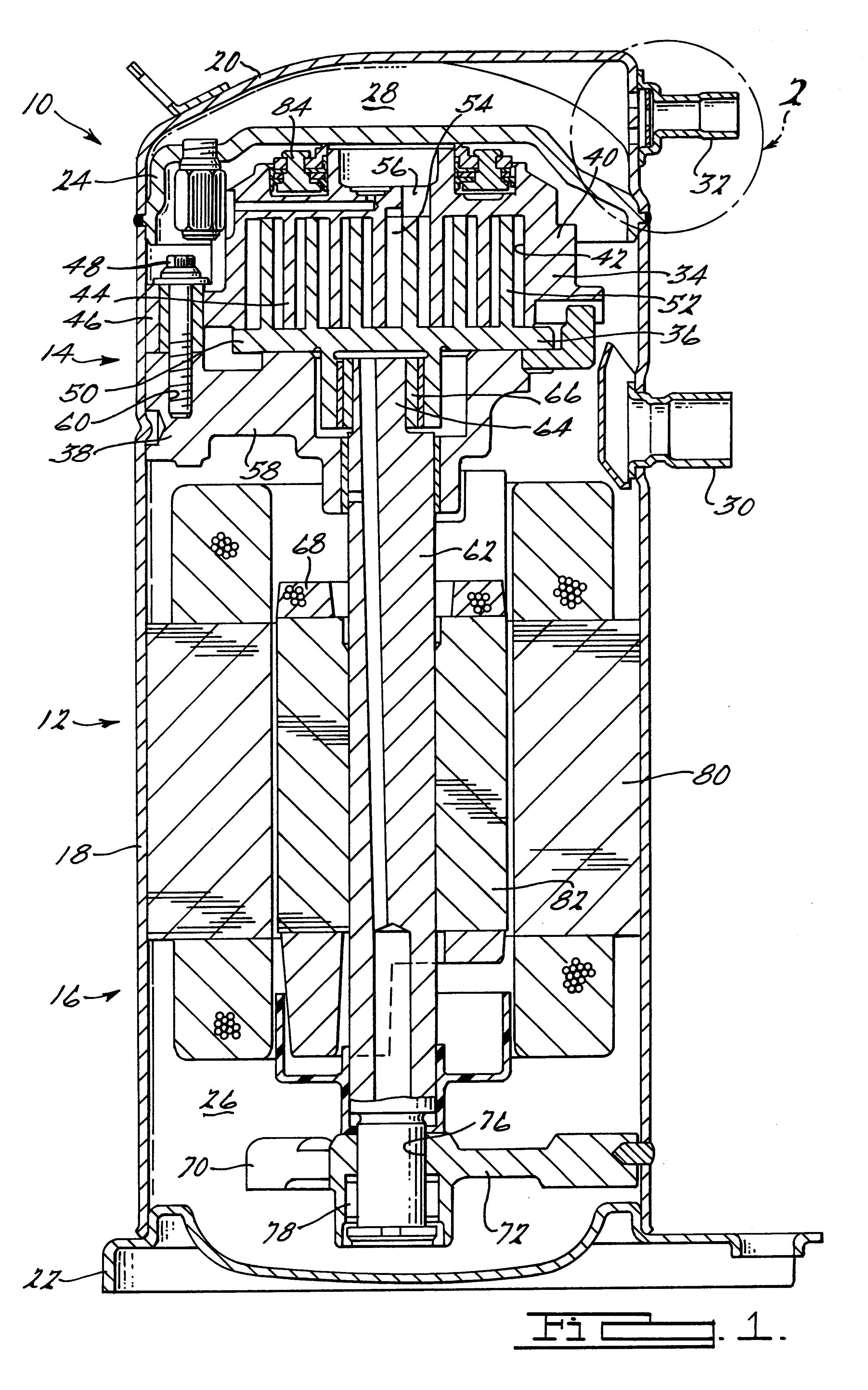

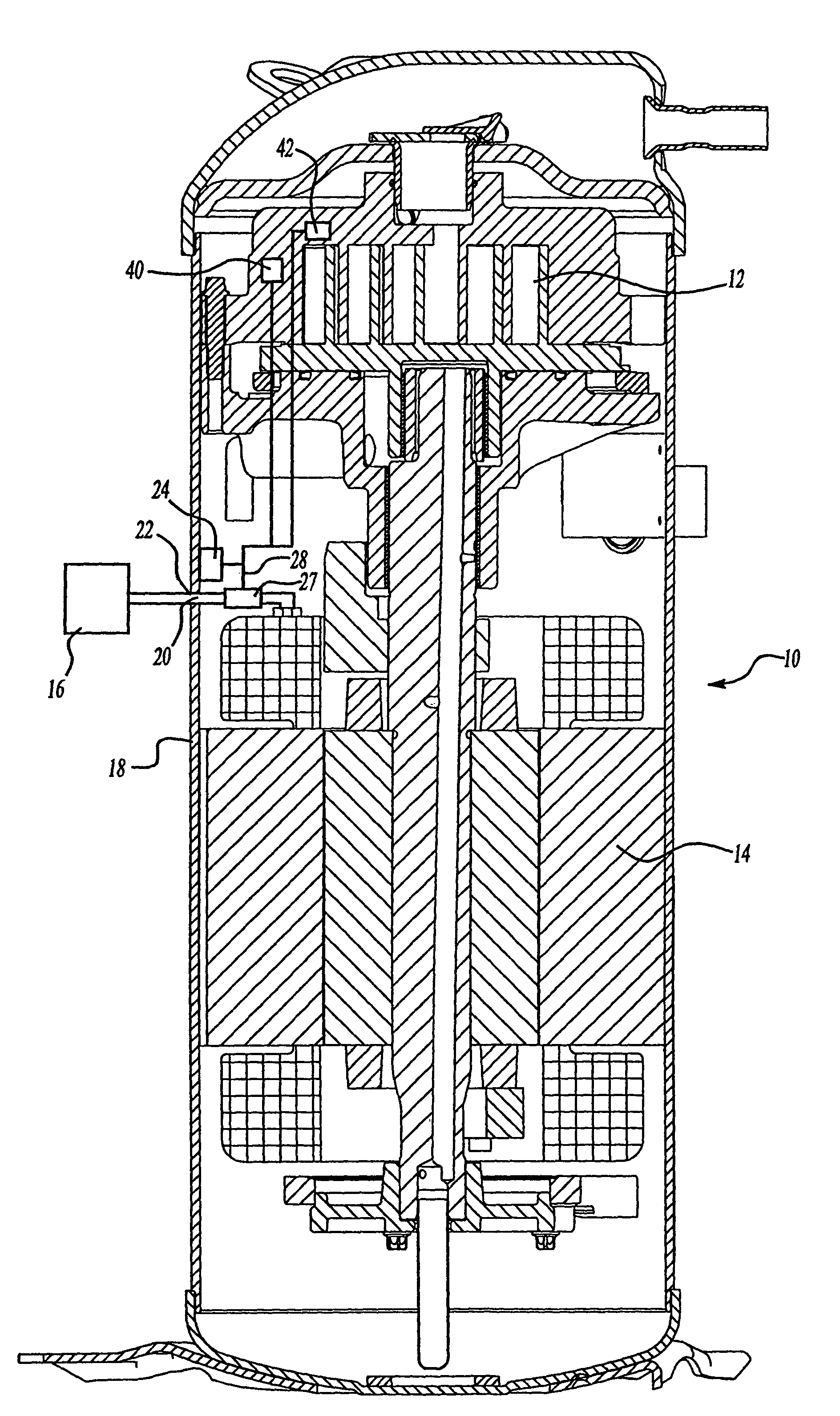

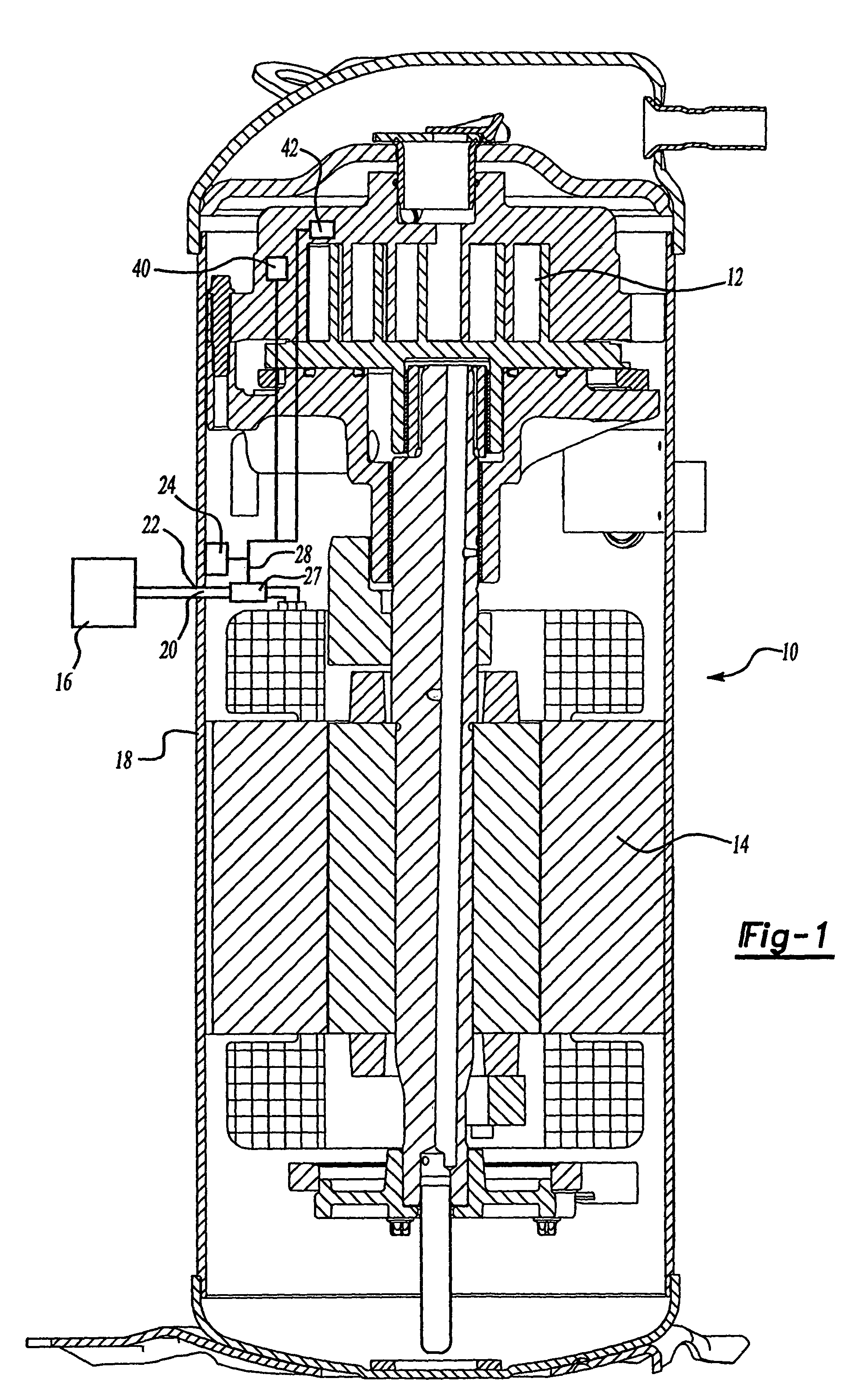

ActiveUS6960070B2Easy to fixPrecise alignmentRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeDrive shaftEngineering

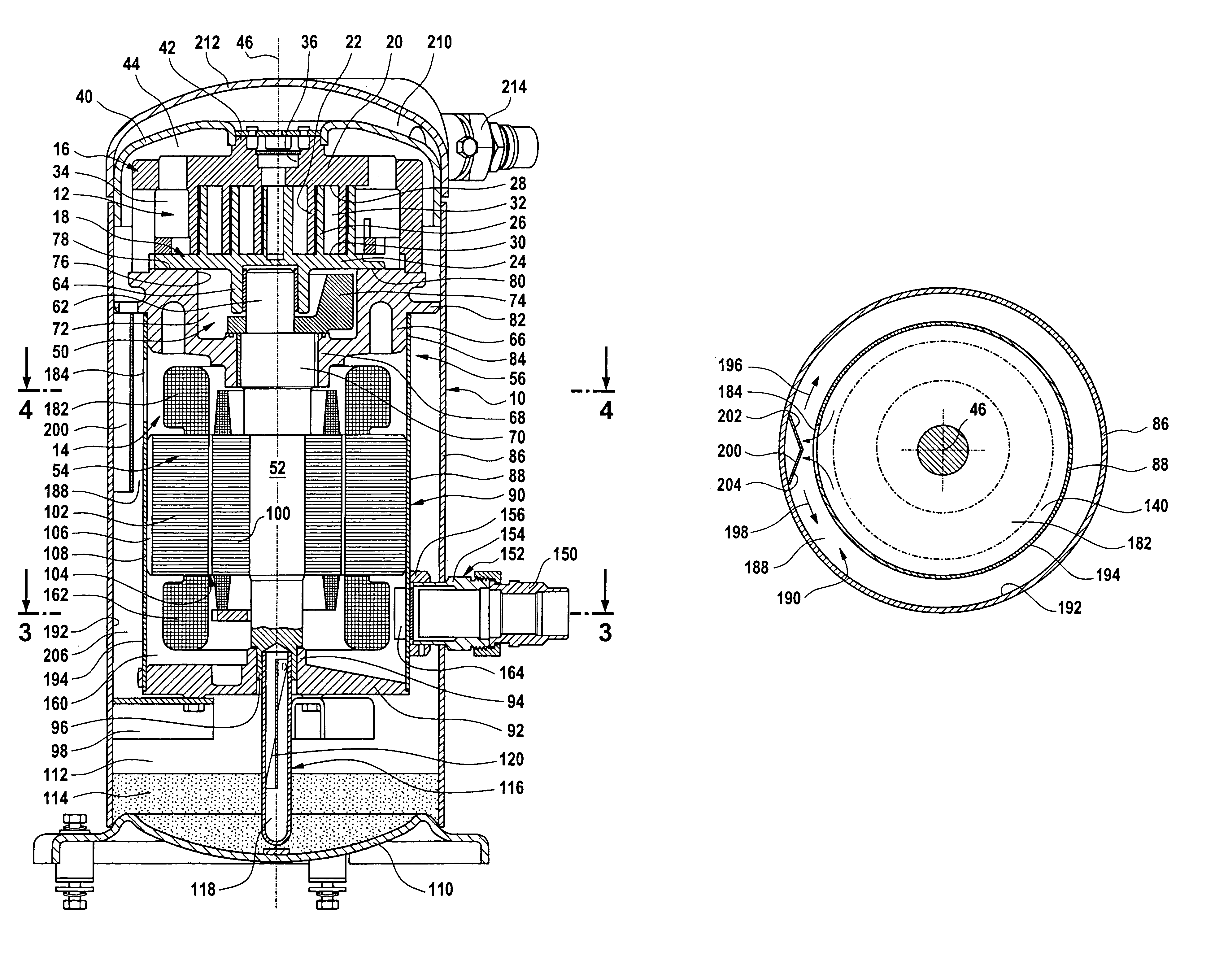

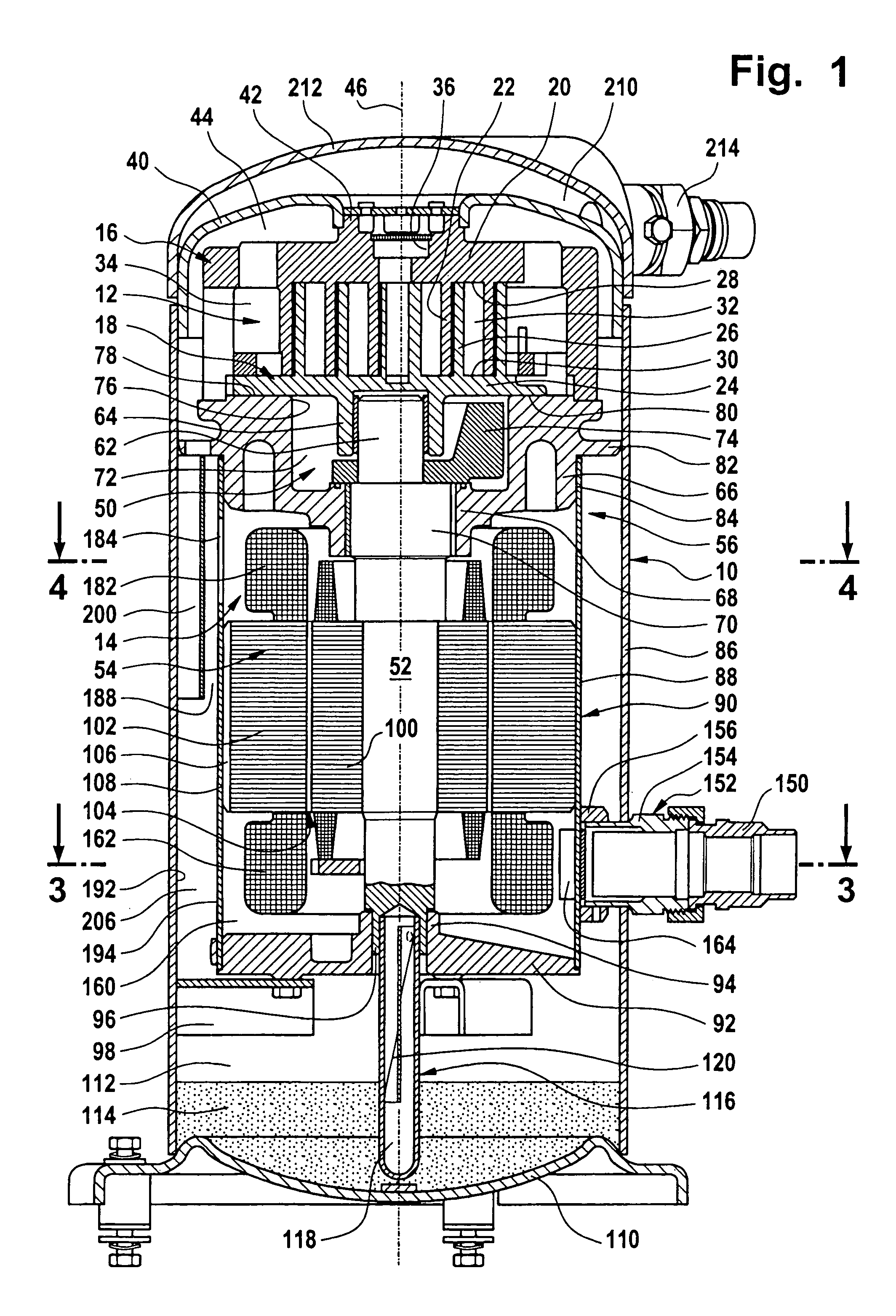

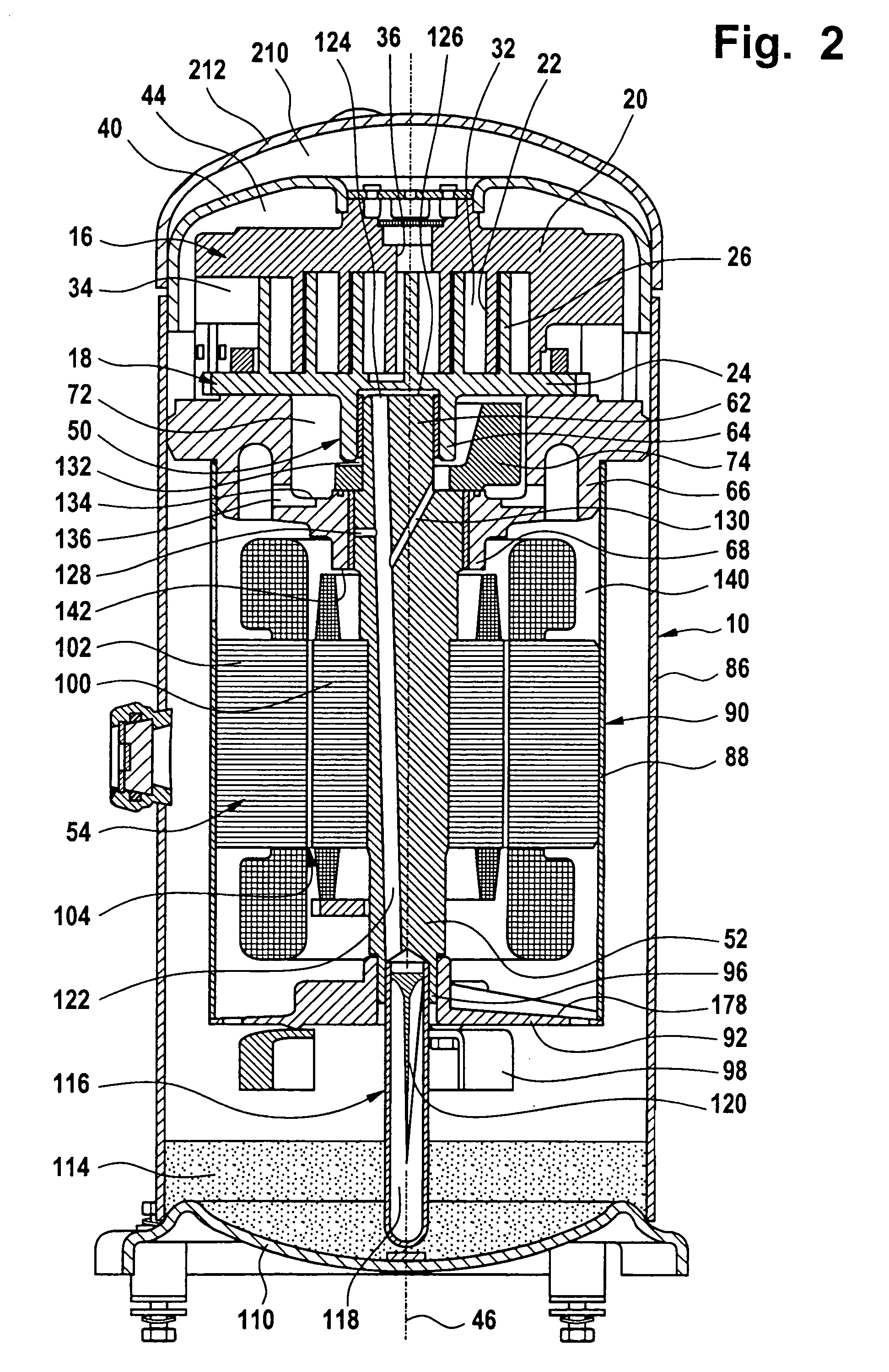

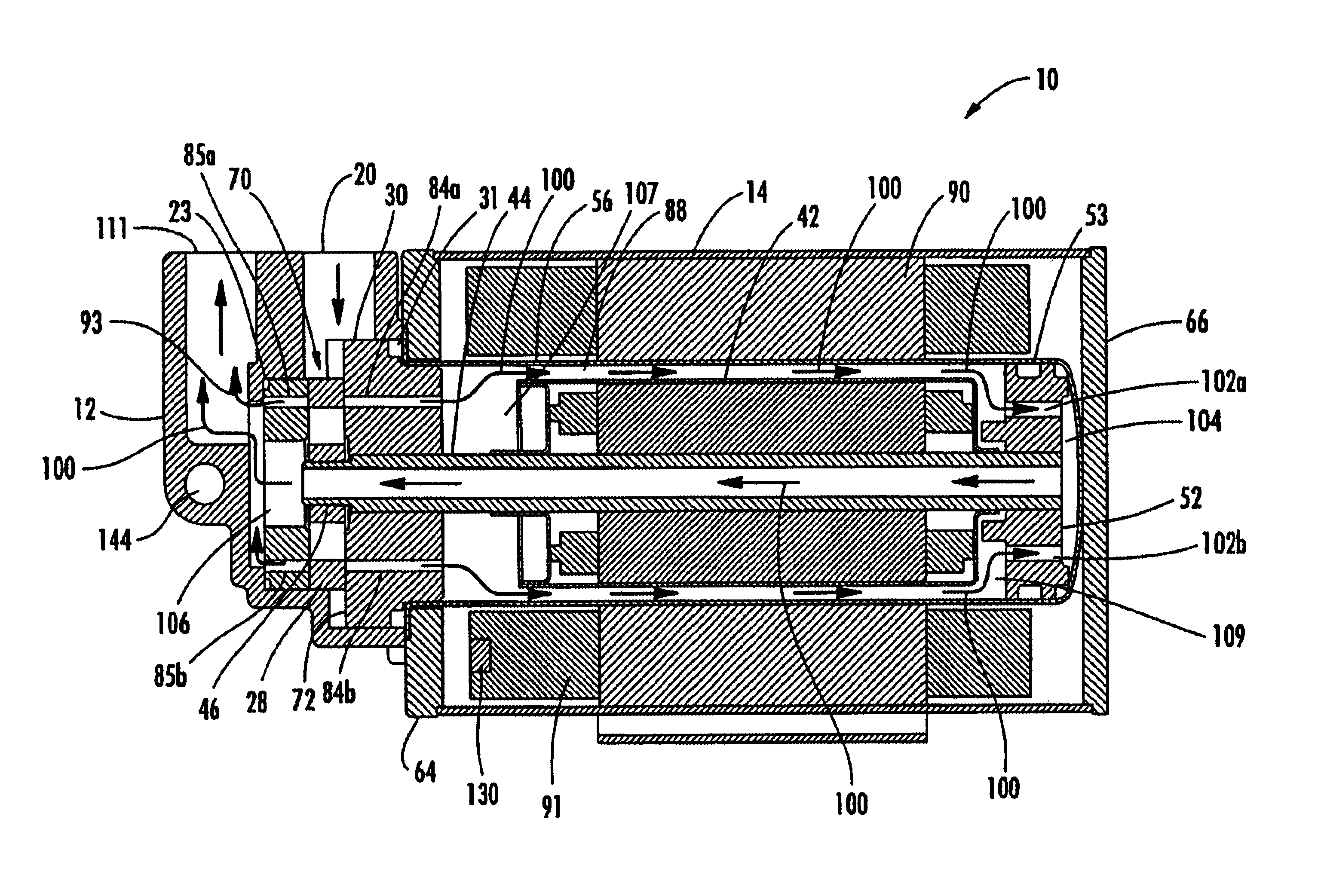

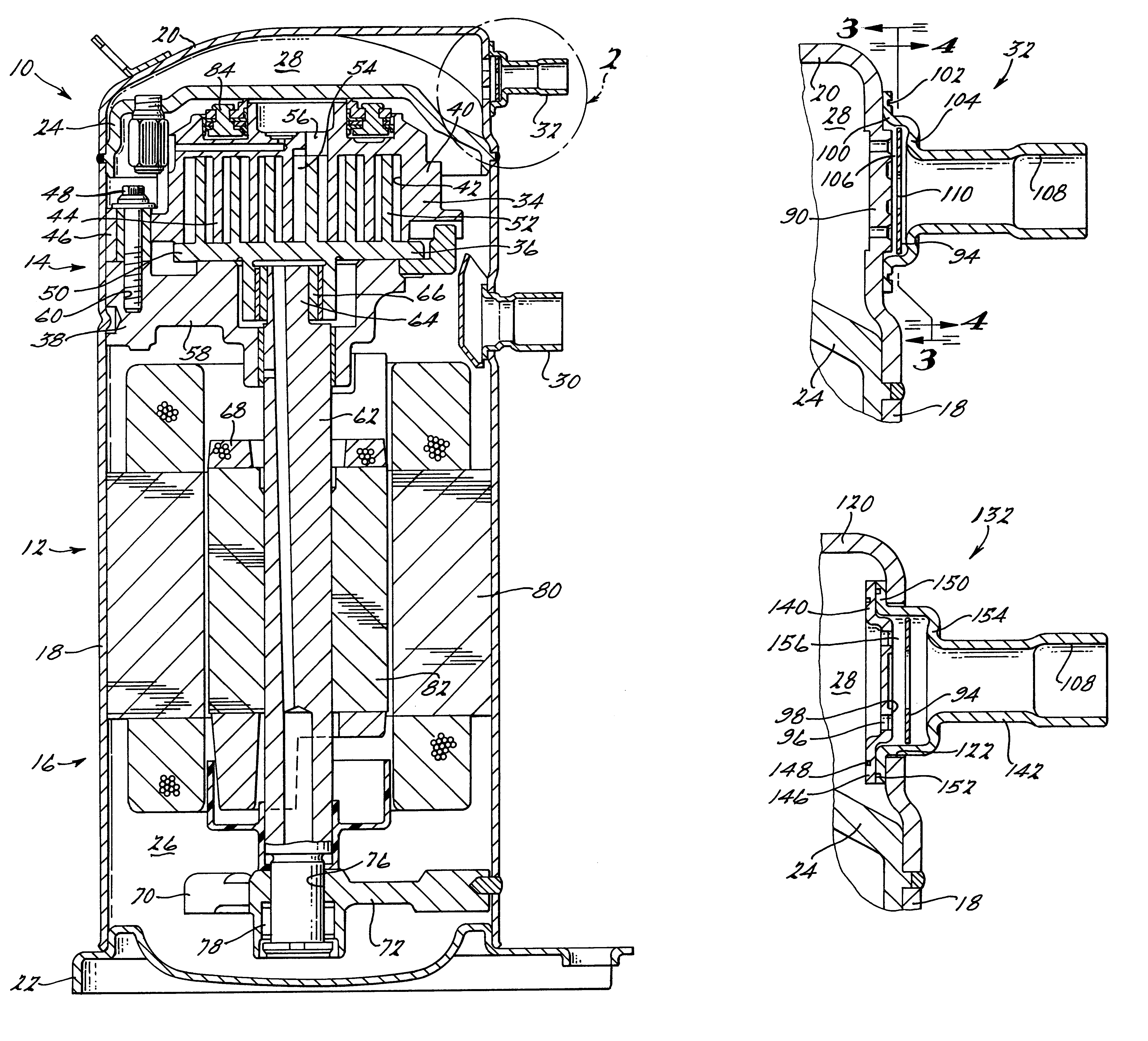

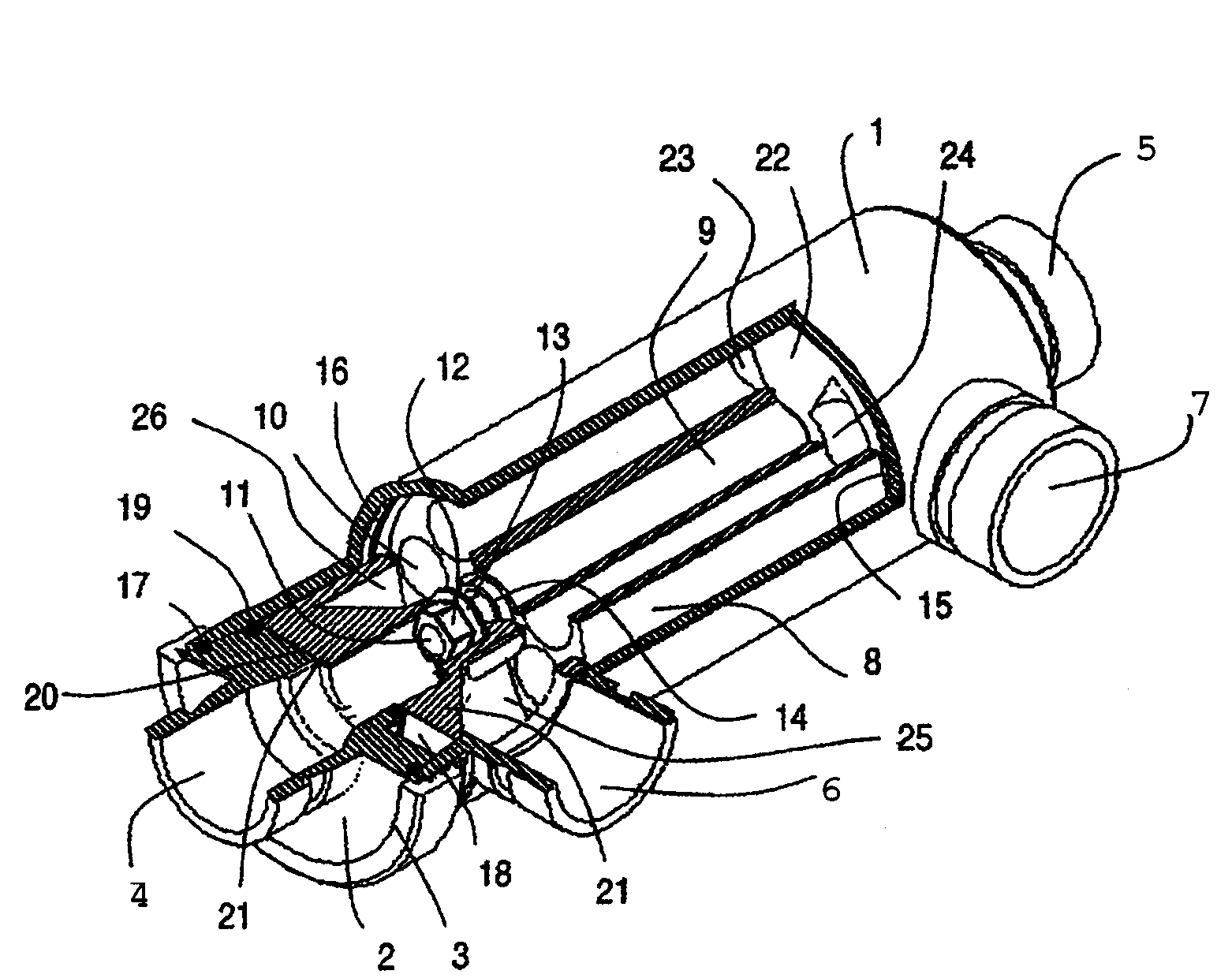

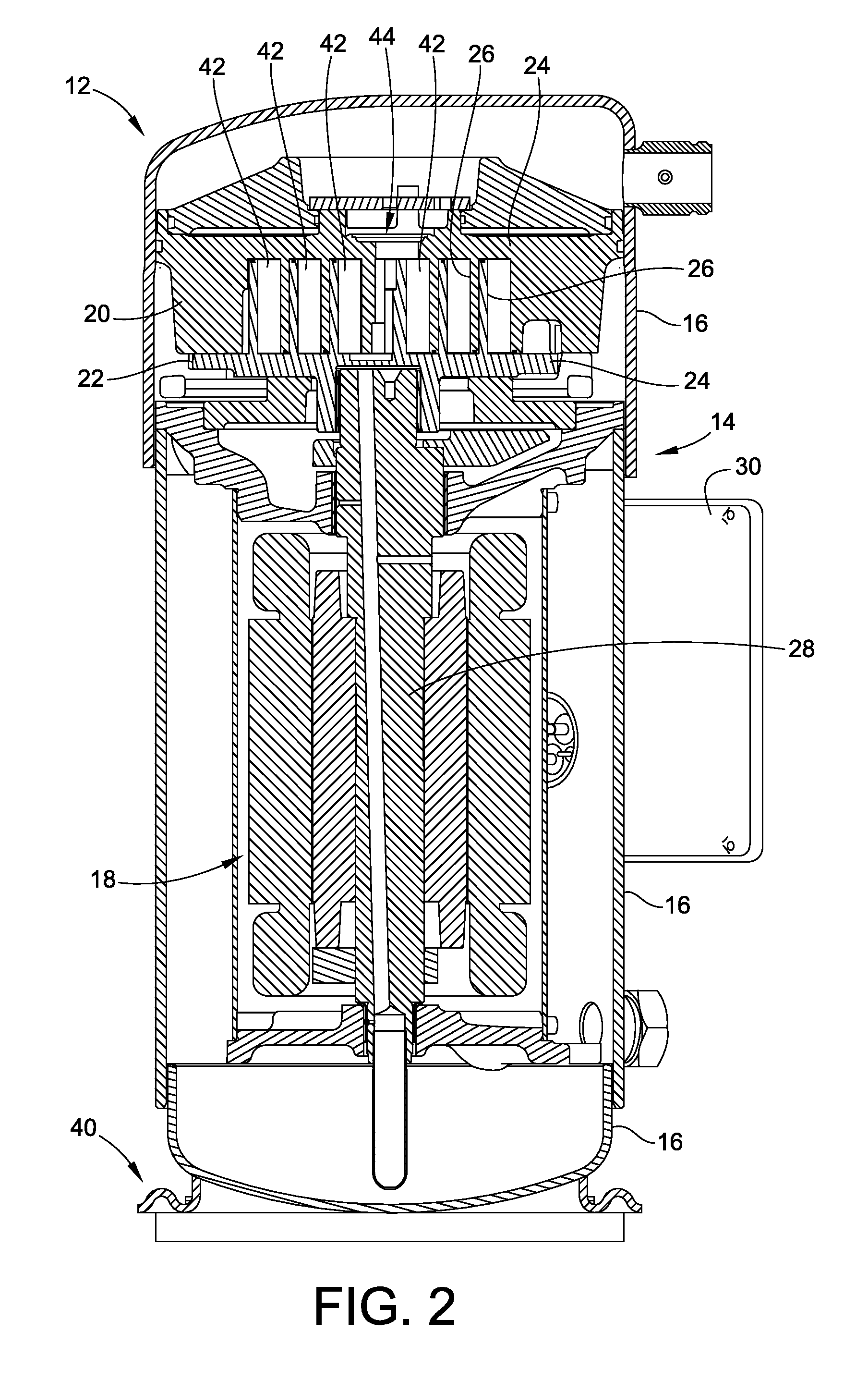

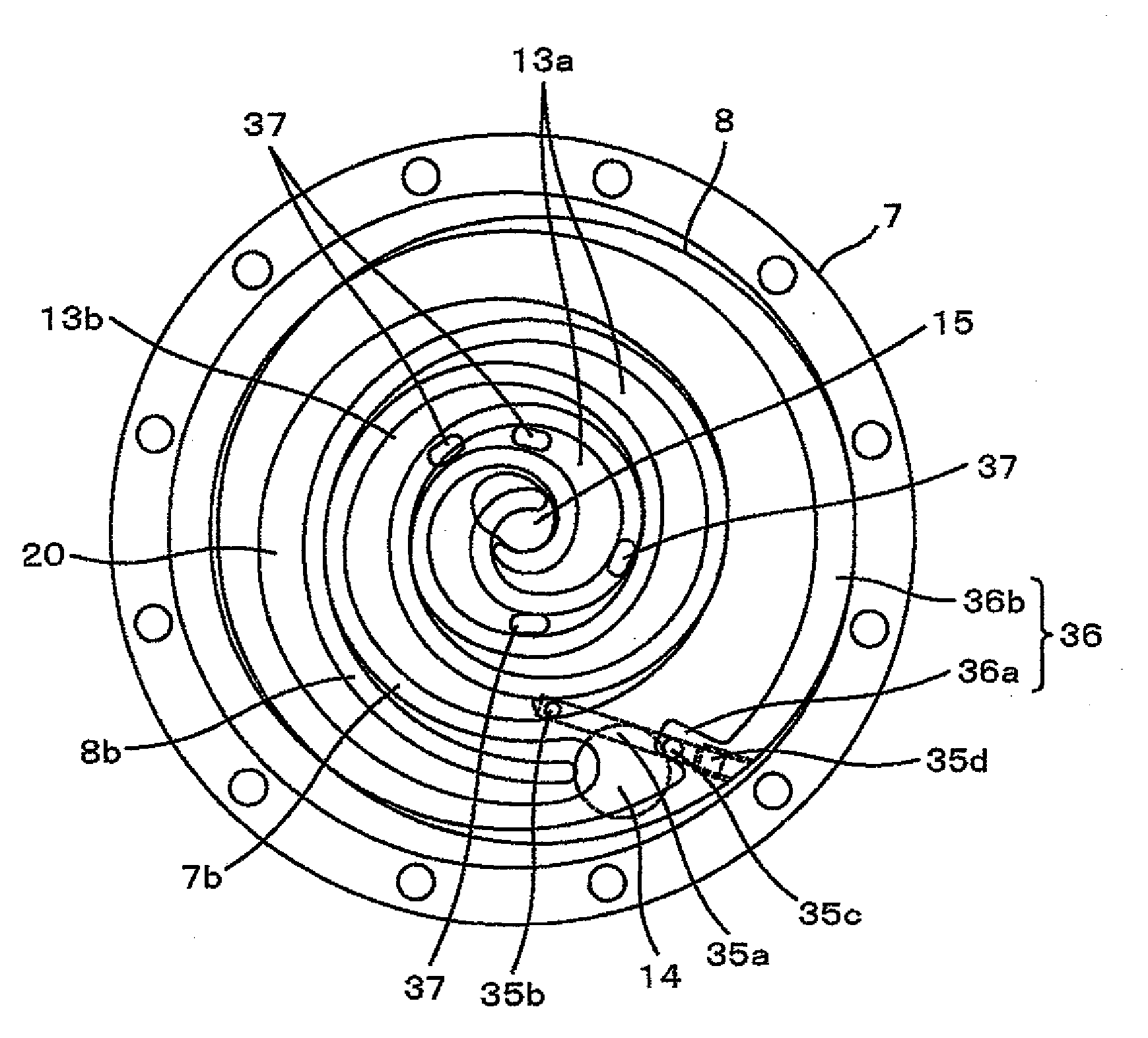

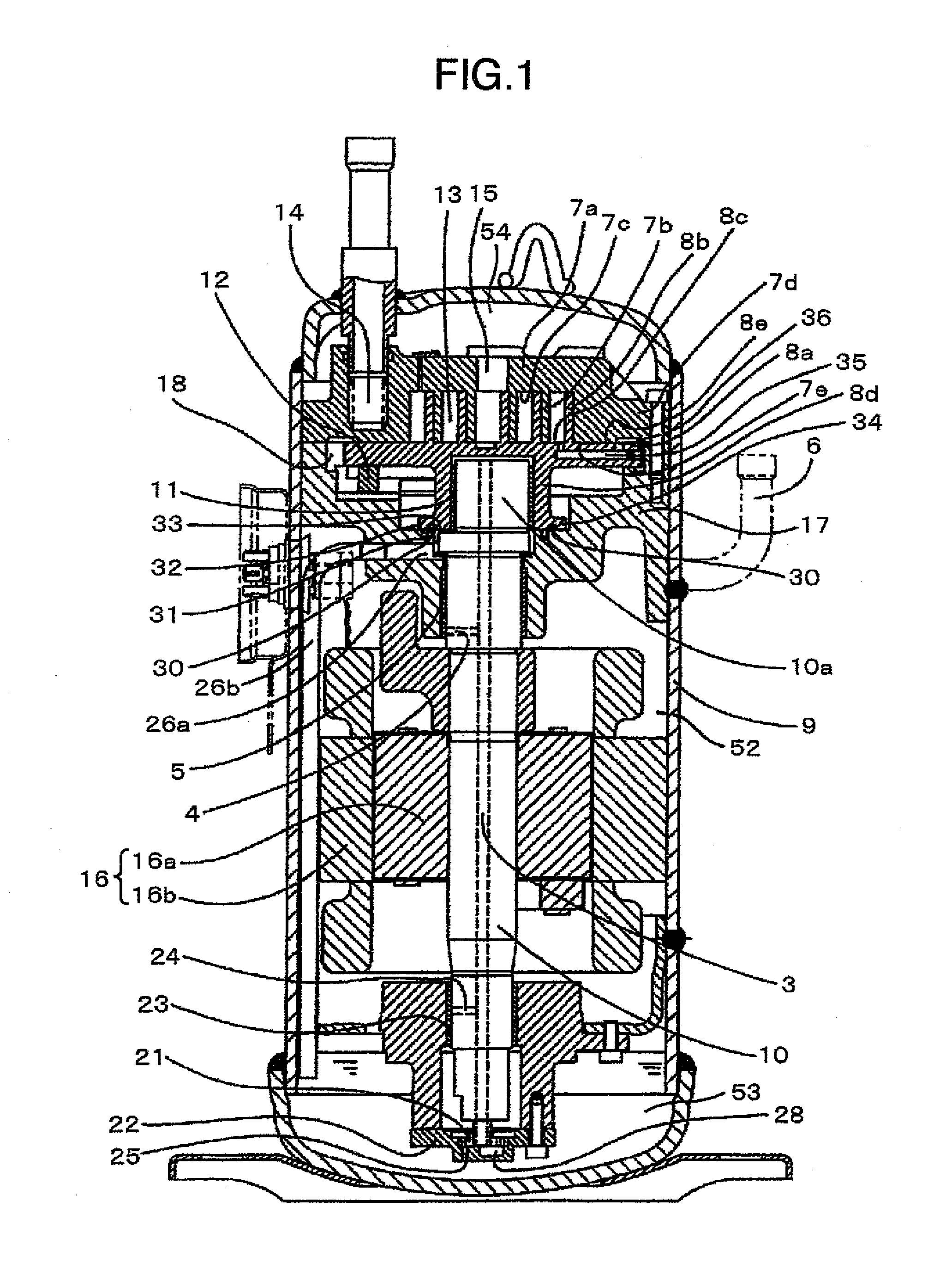

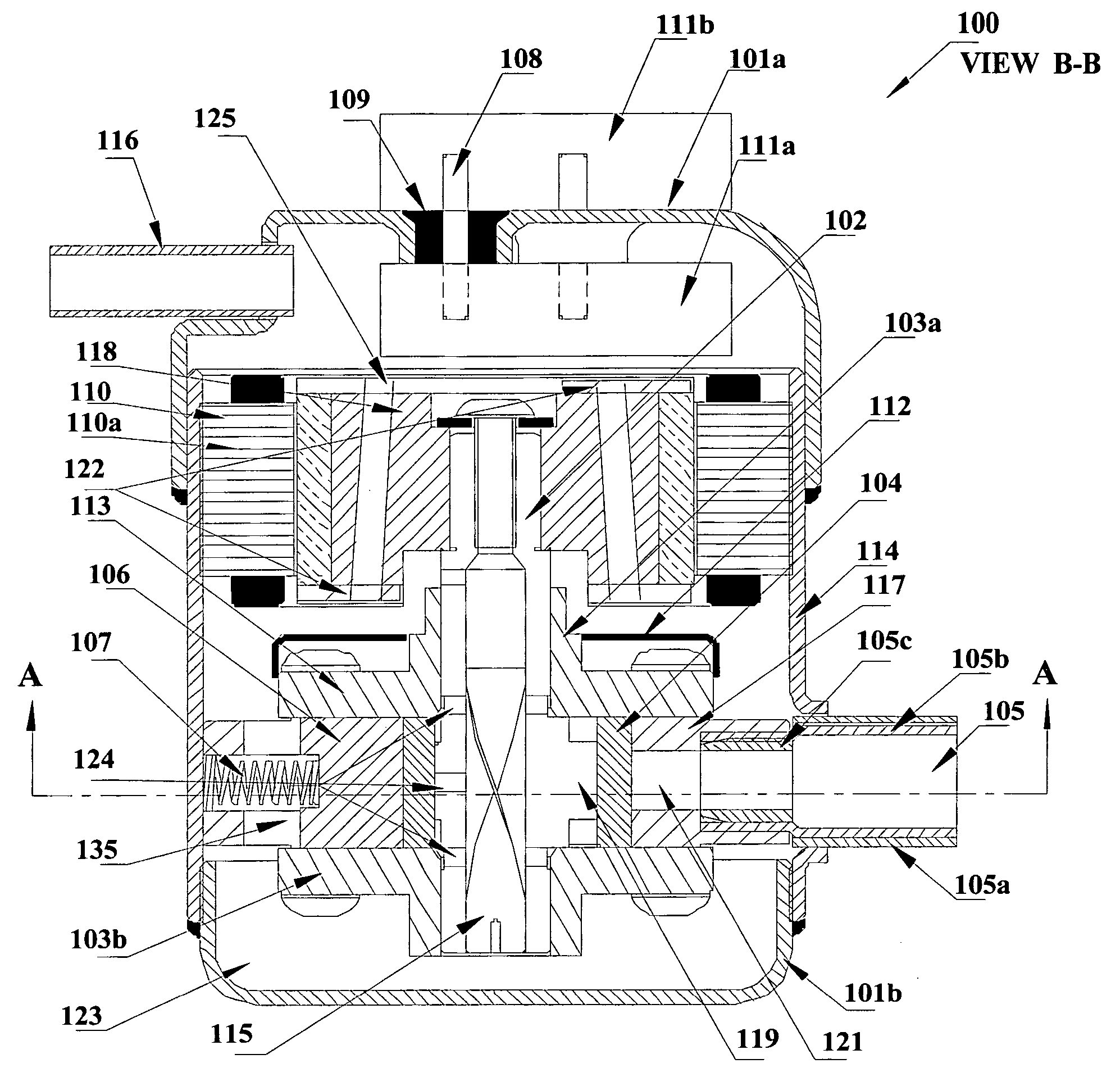

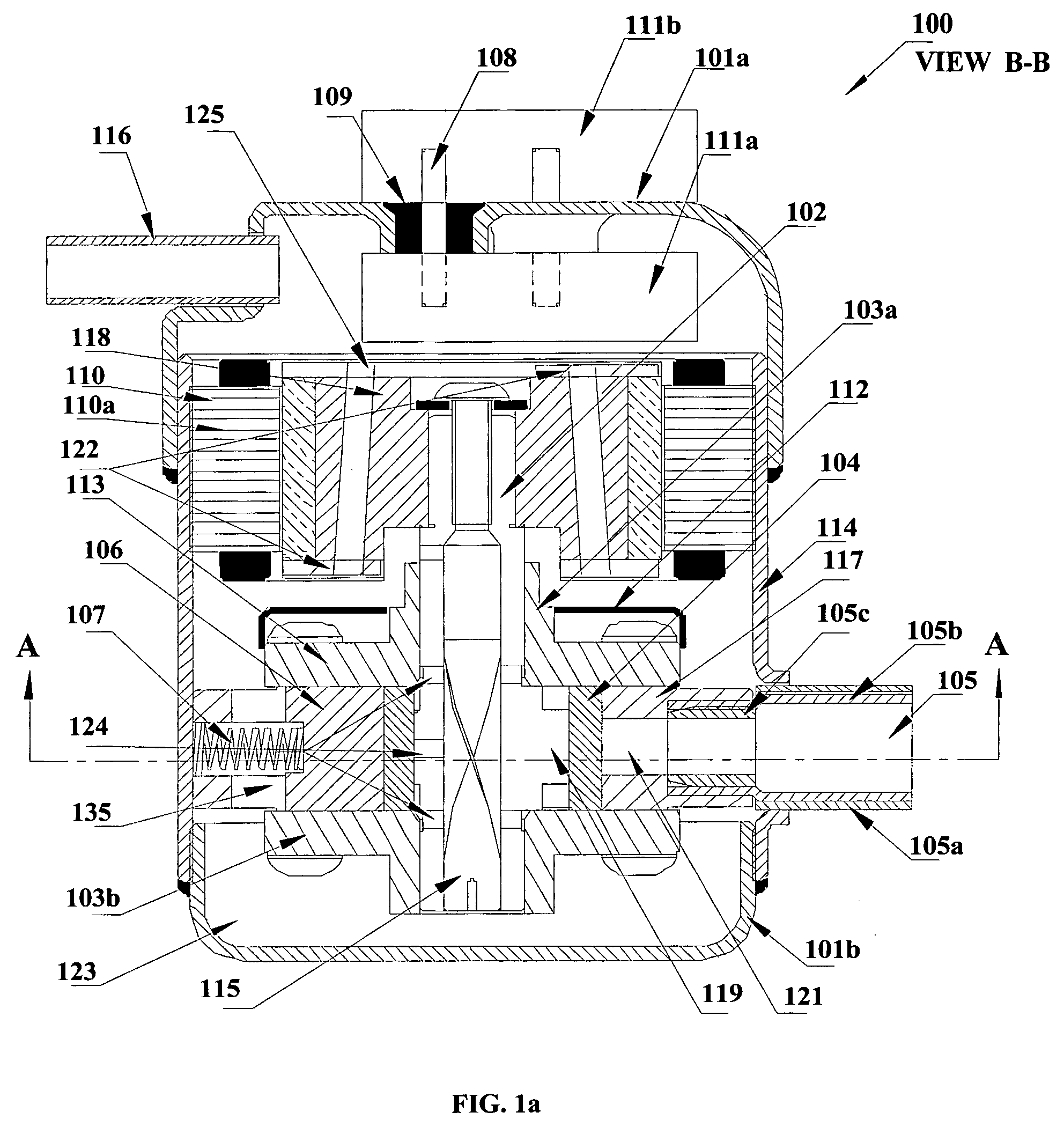

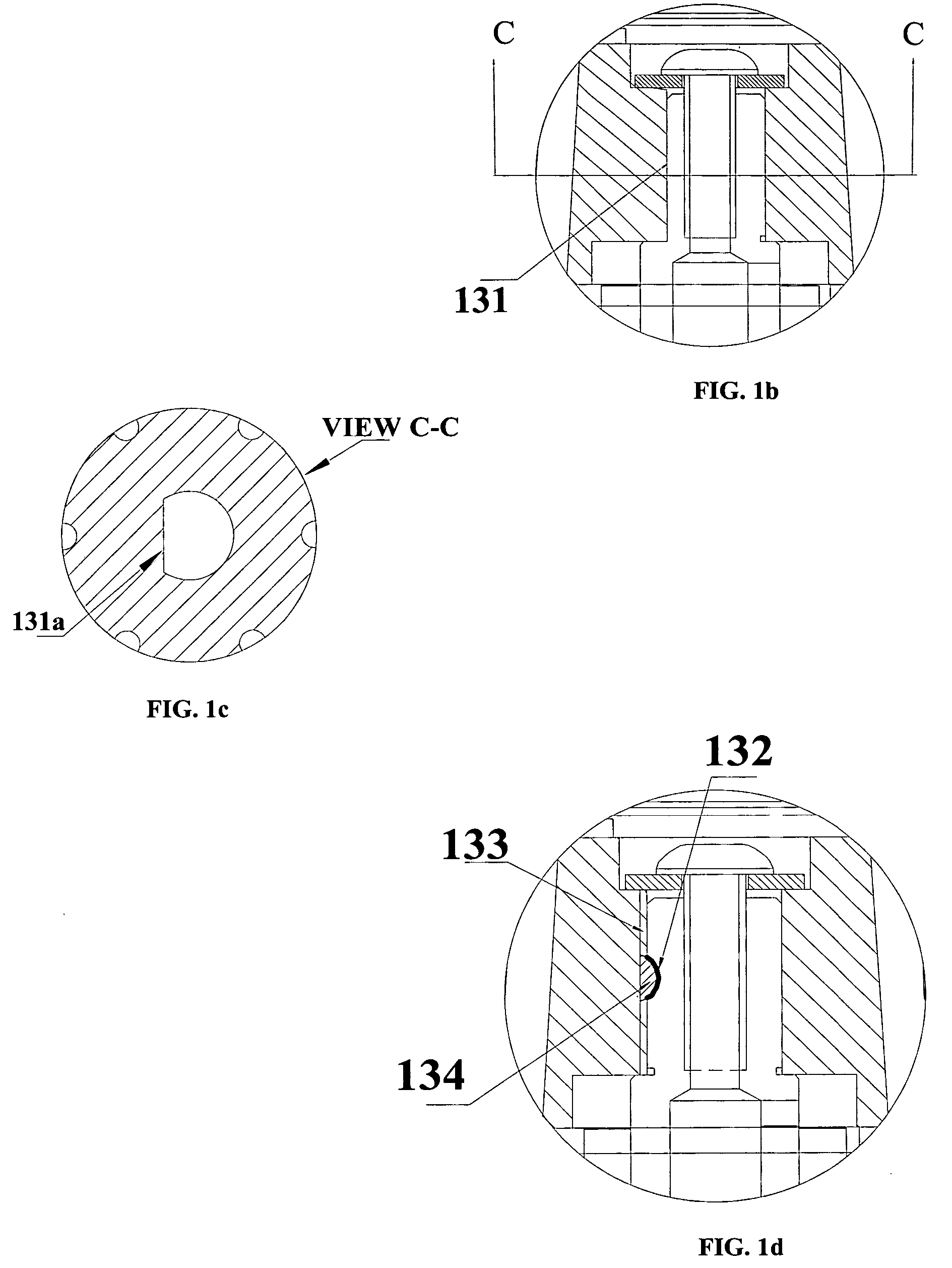

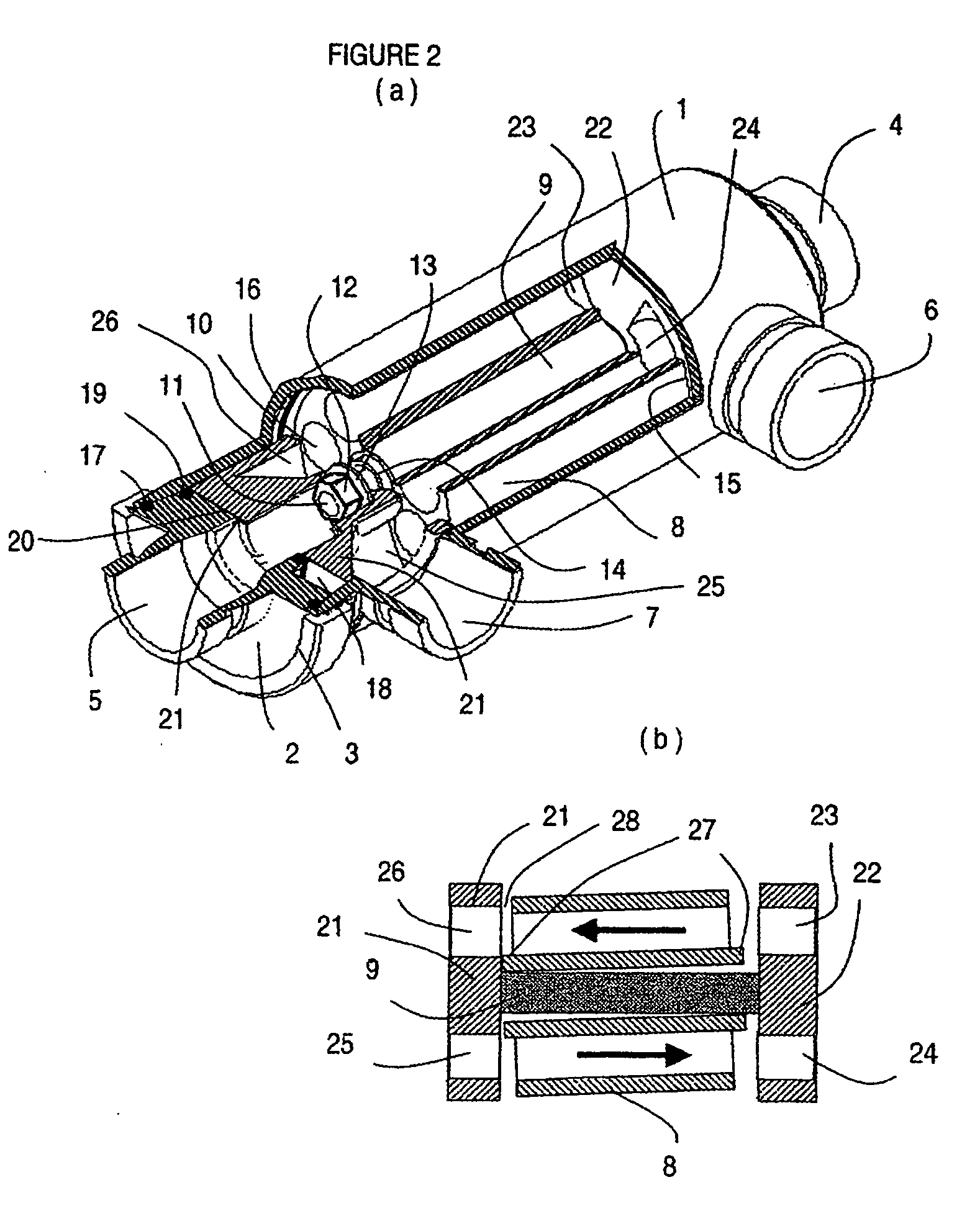

In order to improve a compressor for refrigerant, comprising an outer housing, a scroll compressor arranged in the outer housing and having a first compressor member arranged stationarily in the outer housing and a second compressor member which is movable relative to the first compressor member, the compressor members each having a base and first and second scroll ribs, respectively, which rise above the respective base and engage in one another such that the second compressor member is movable relative to the first compressor member on an orbital path about a central axis for the purpose of compressing the refrigerant, a drive unit for the second compressor member having an eccentric drive, a drive shaft, a drive motor arranged in a motor housing and having drawn-in refrigerant flowing around it as well as a bearing unit for the drive shaft which comprises a first bearing member connected to the outer housing, in such a manner that the refrigerant drawn in by the scroll compressor is free from lubricating oil to as great an extent as possible it is suggested that the refrigerant flow through an oil separator, which is arranged in the outer housing between this and the drive unit, after flowing around the drive motor and prior to entering the scroll compressor.

Owner:BITZER KUEHLMASCHINENBAU GMBH

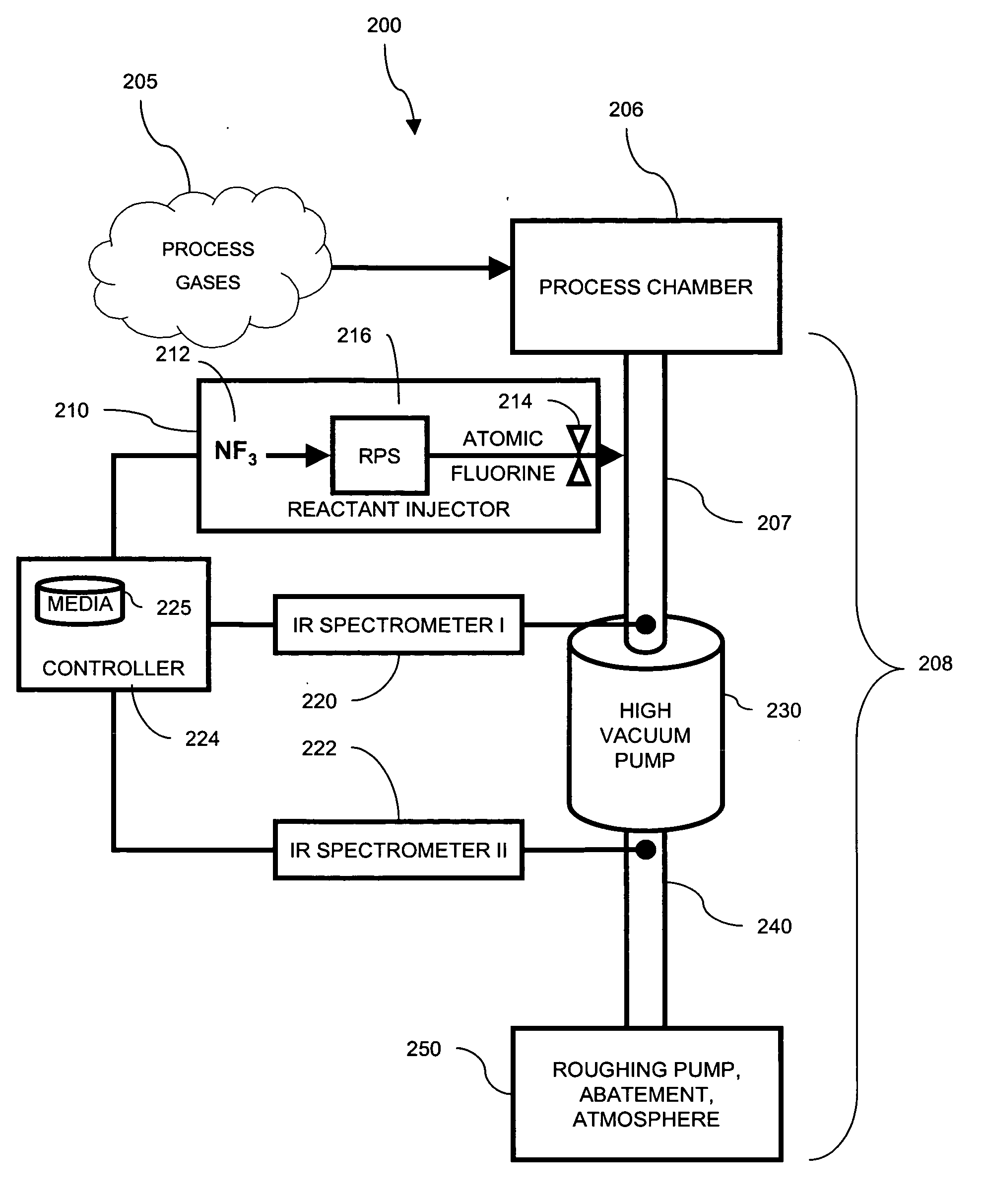

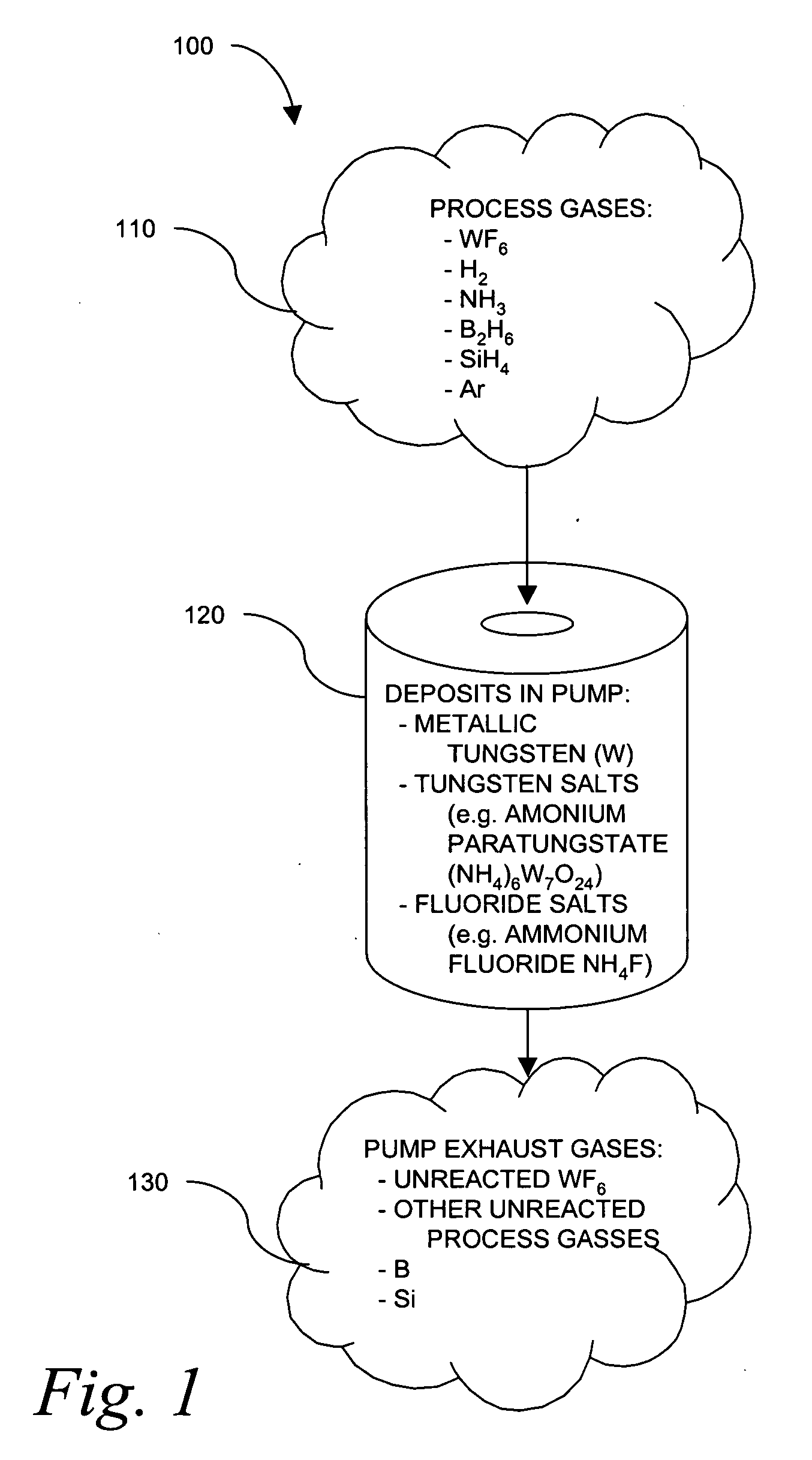

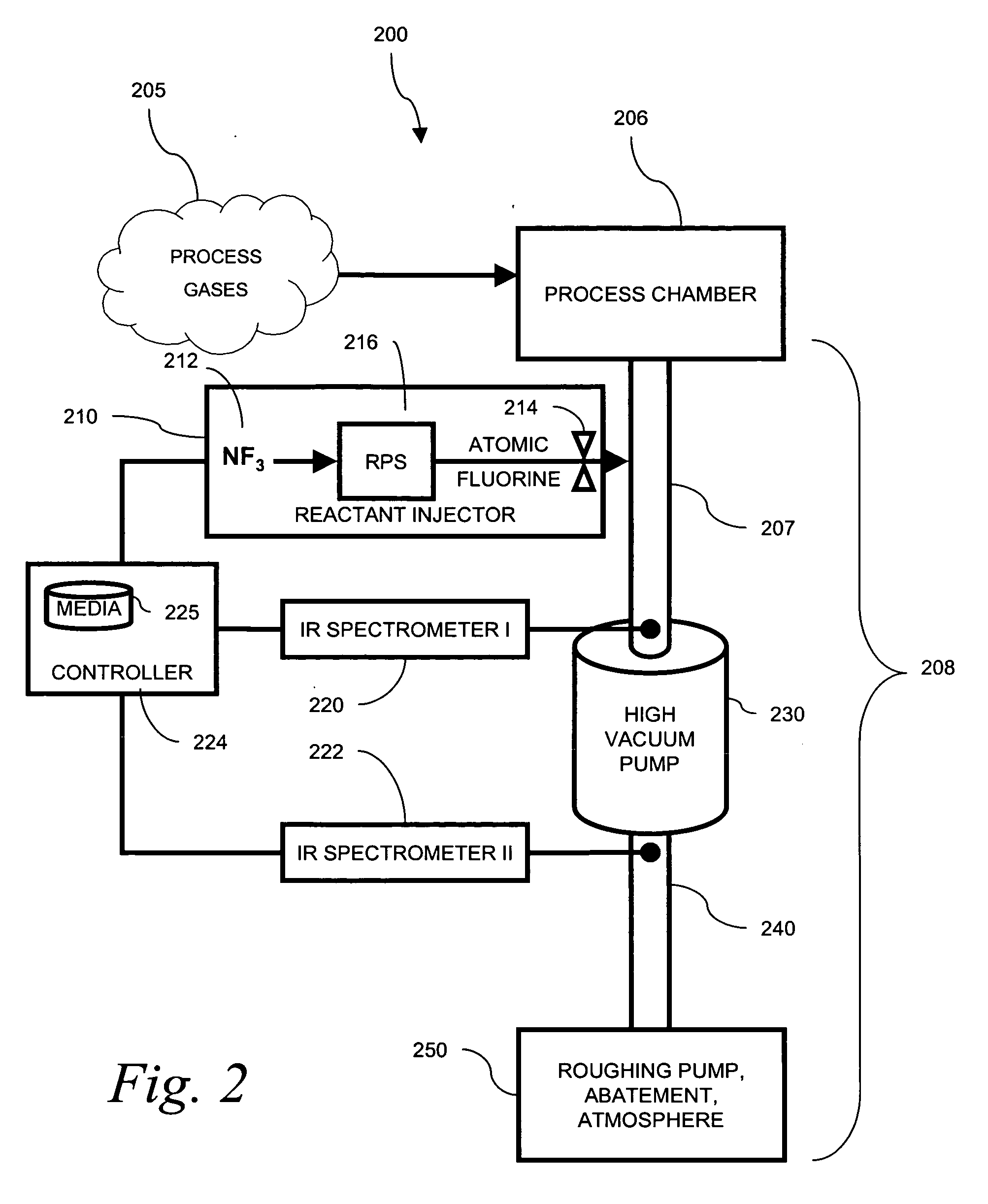

Use of spectroscopic techniques to monitor and control reactant gas input into a pre-pump reactive gas injection system

ActiveUS20090320881A1Produce some attenuationTrend downRotary/oscillating piston combinations for elastic fluidsHollow article cleaningGas phaseReactive gas

The present invention relates to vacuum processing systems in which process gases are introduced in a process chamber and are exhausted through a vacuum processing system exhaust path. Deposits made by the exhausted gas are reduced or eliminated by introducing a reactive gas upstream of the device affected by deposits. The amount of introduced reactive gas is controlled by measuring gas phase concentrations of exhausted gas components upstream and downstream of the affected device, and, from those measurements, determining whether the components are being consumed in deposits on the affected device.

Owner:EDWARDS VACUUM LLC

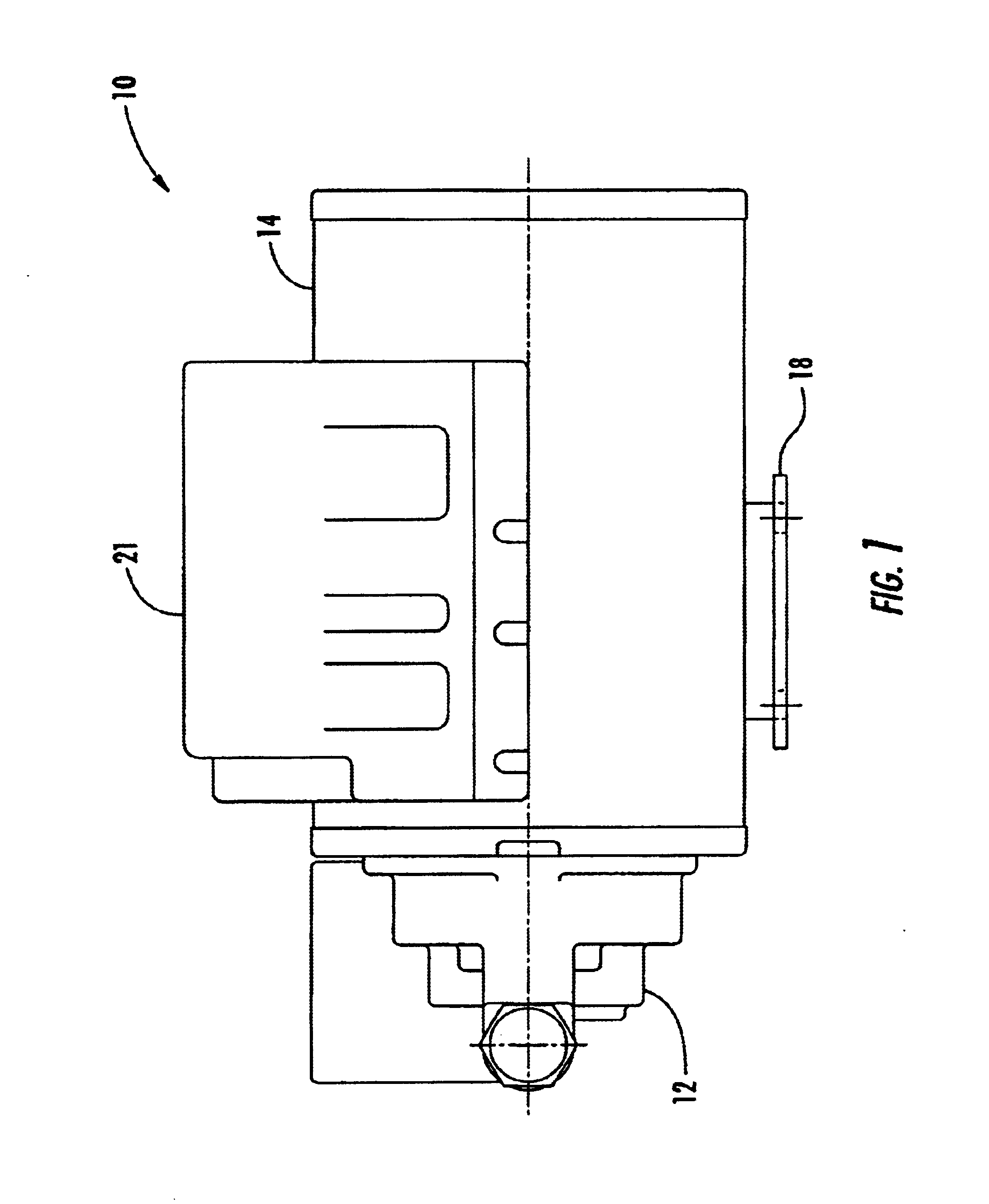

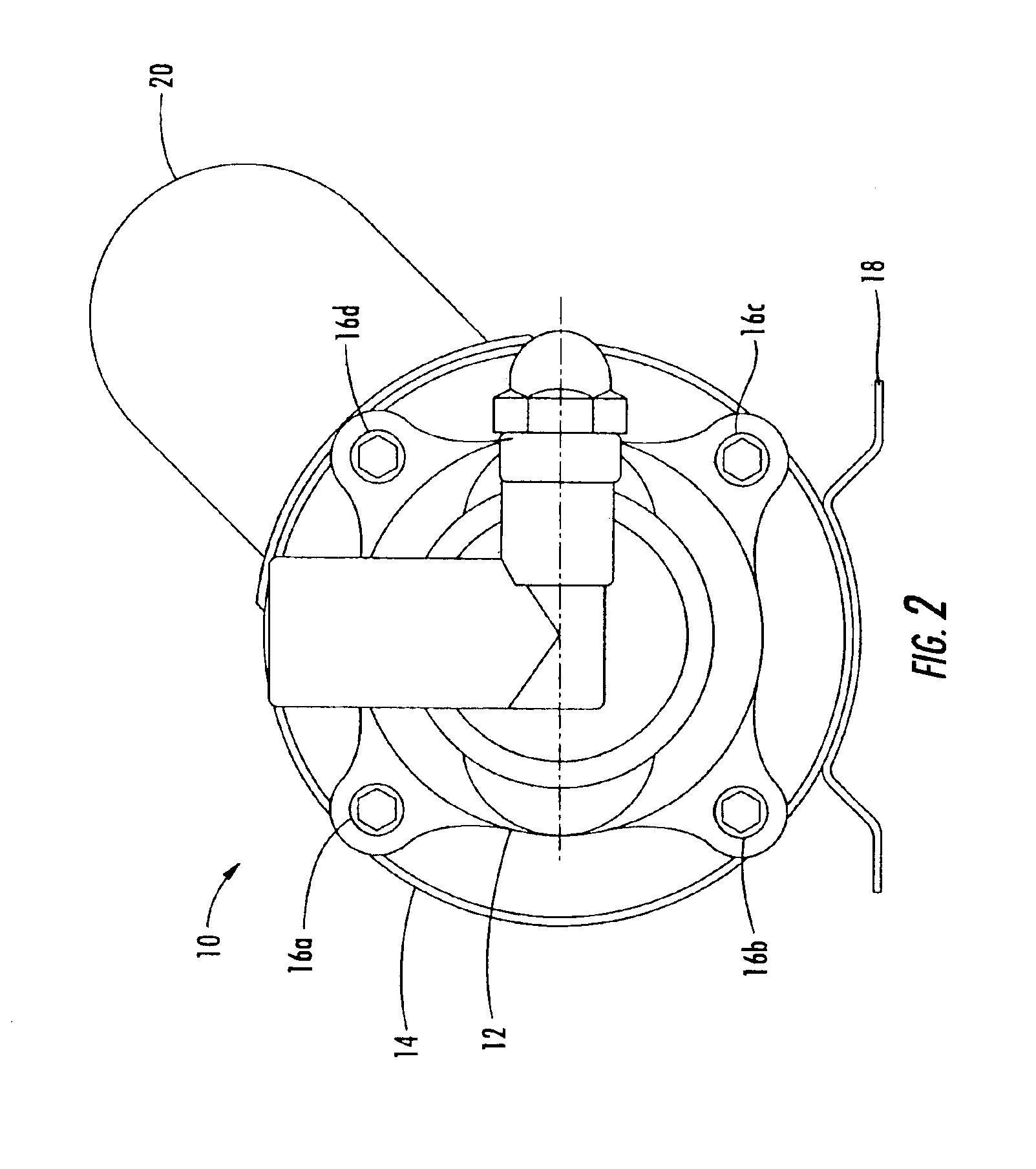

Overheat protection for fluid pump

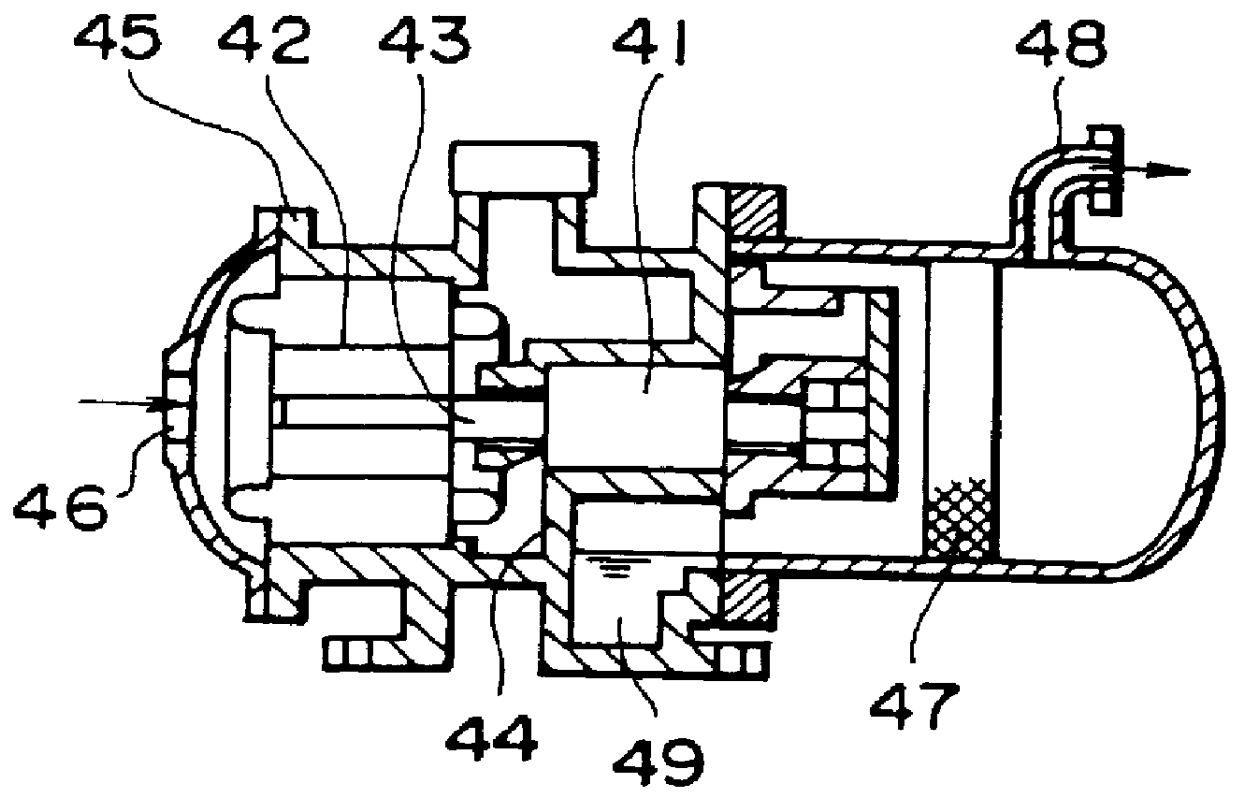

InactiveUS6837688B2Avoid damageReduce stepsRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsPump headThreshold temperature

An apparatus for detecting the presence of an overheat condition in a fluid pump includes a pump head for receiving a fluid at a first pressure and outputting the fluid at a second pressure that is greater than the first pressure. A motor is positioned adjacent the pump head to drive the pump head to pressurize the fluid. A single overheat sensor senses an overheat condition in the pump head and an overheat condition in the motor. When a threshold temperature is sensed by the overheat sensor, a switch is activated to prevent operation of the motor. In one embodiment, the overheat sensor and switch are integral and may, for example, take the form of a bi-metal switch formed in the stator windings of the motor. In alternate embodiments, the overheat sensor and switch are separate.

Owner:STANDEX INT CORP

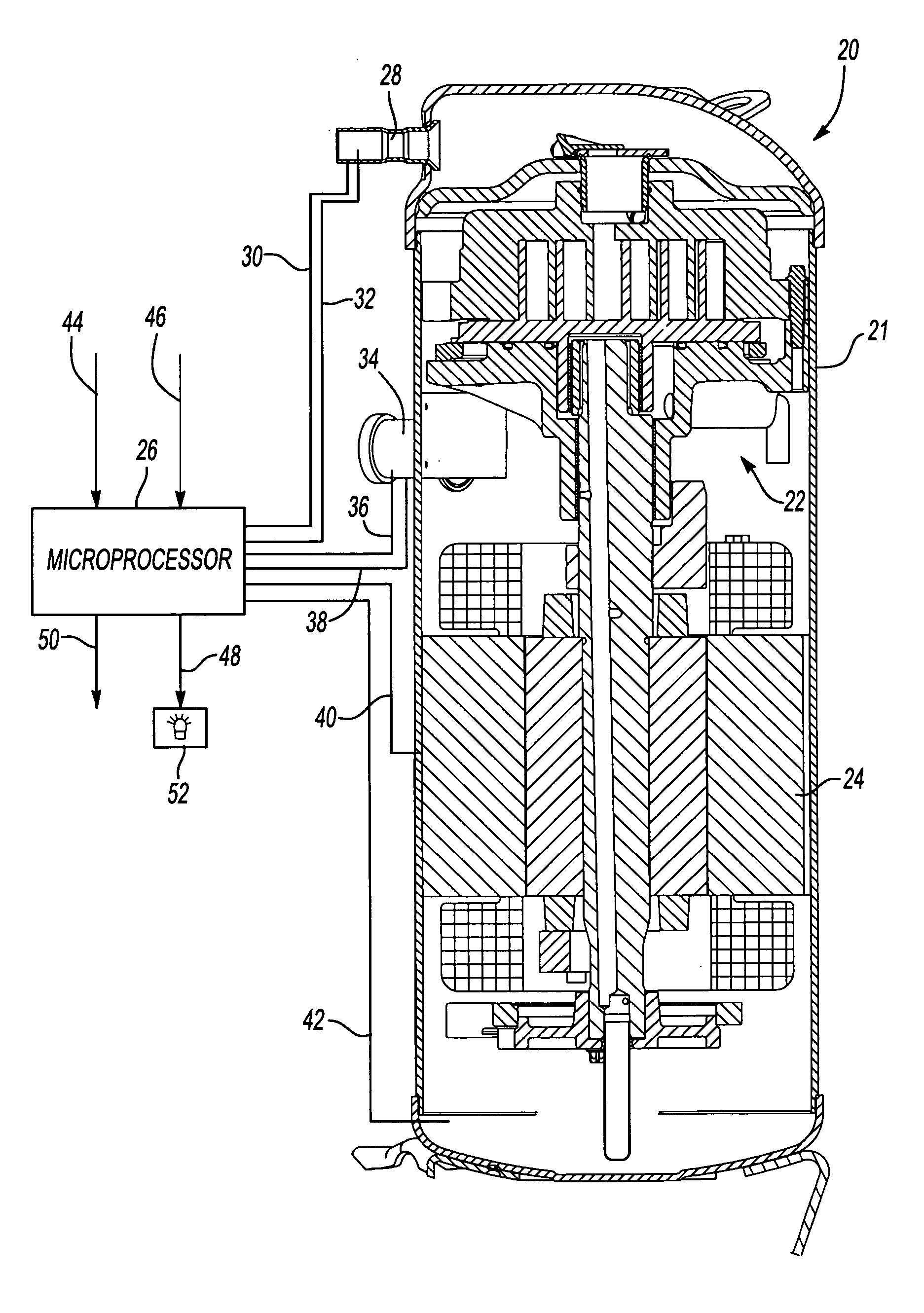

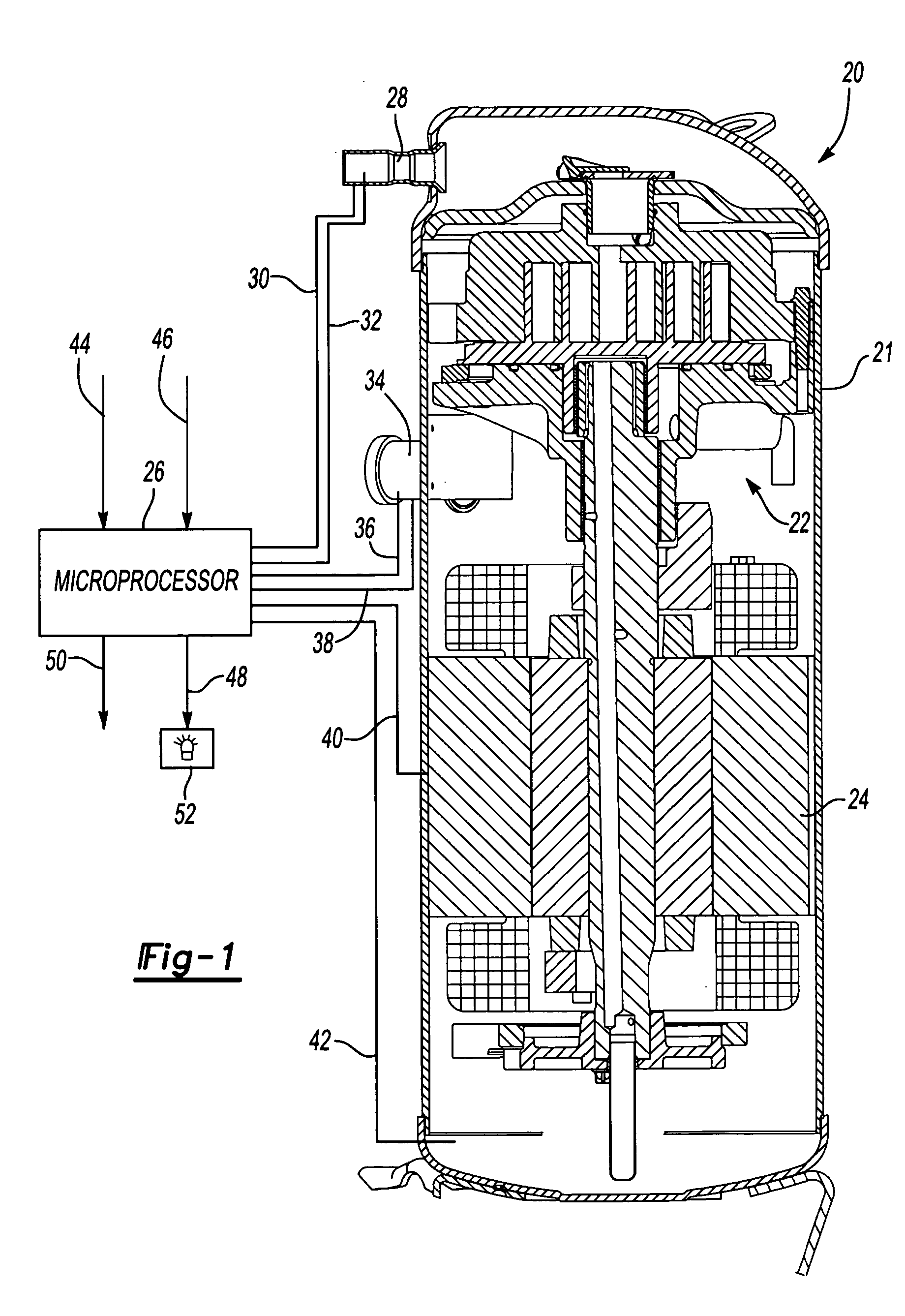

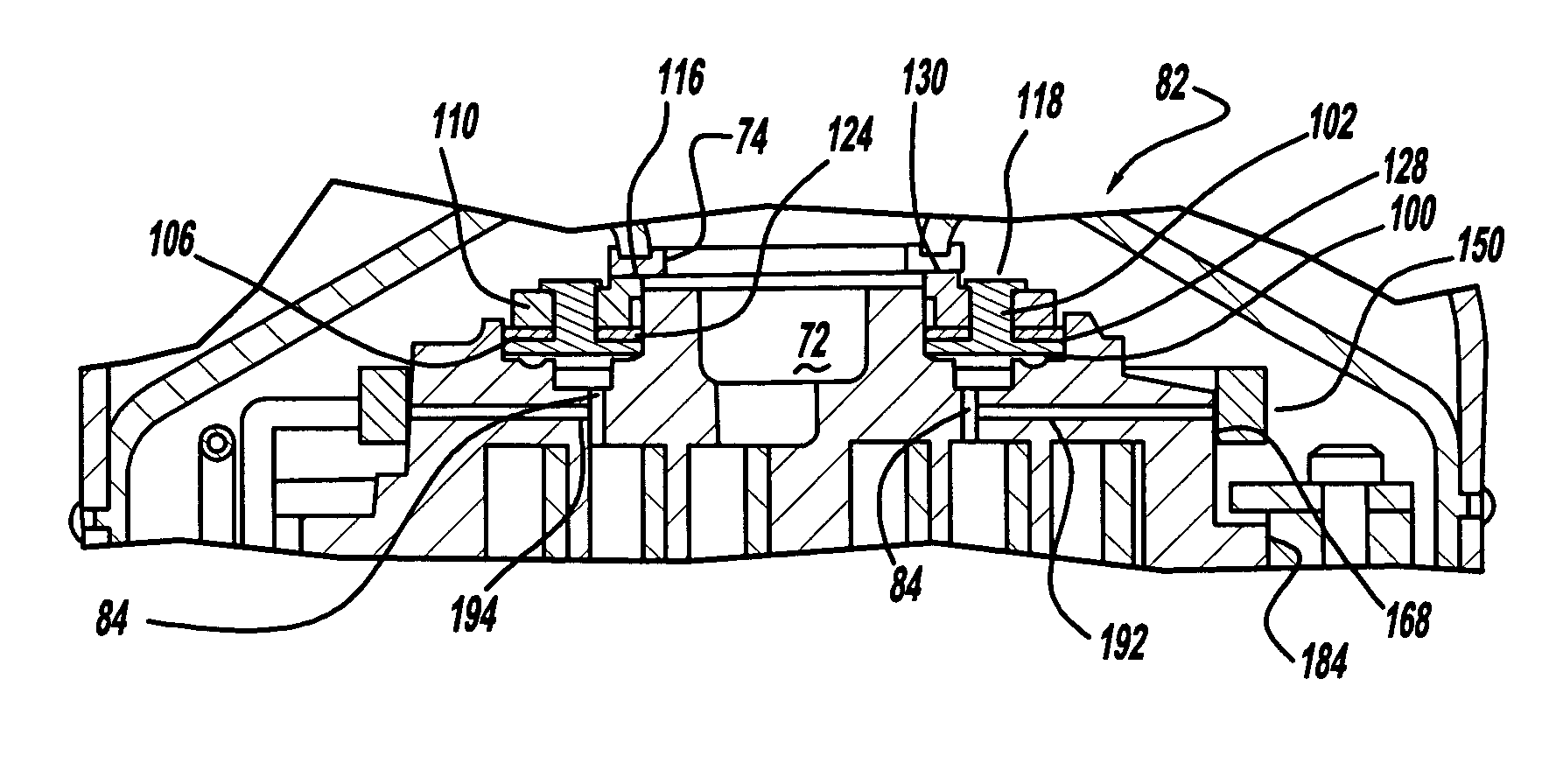

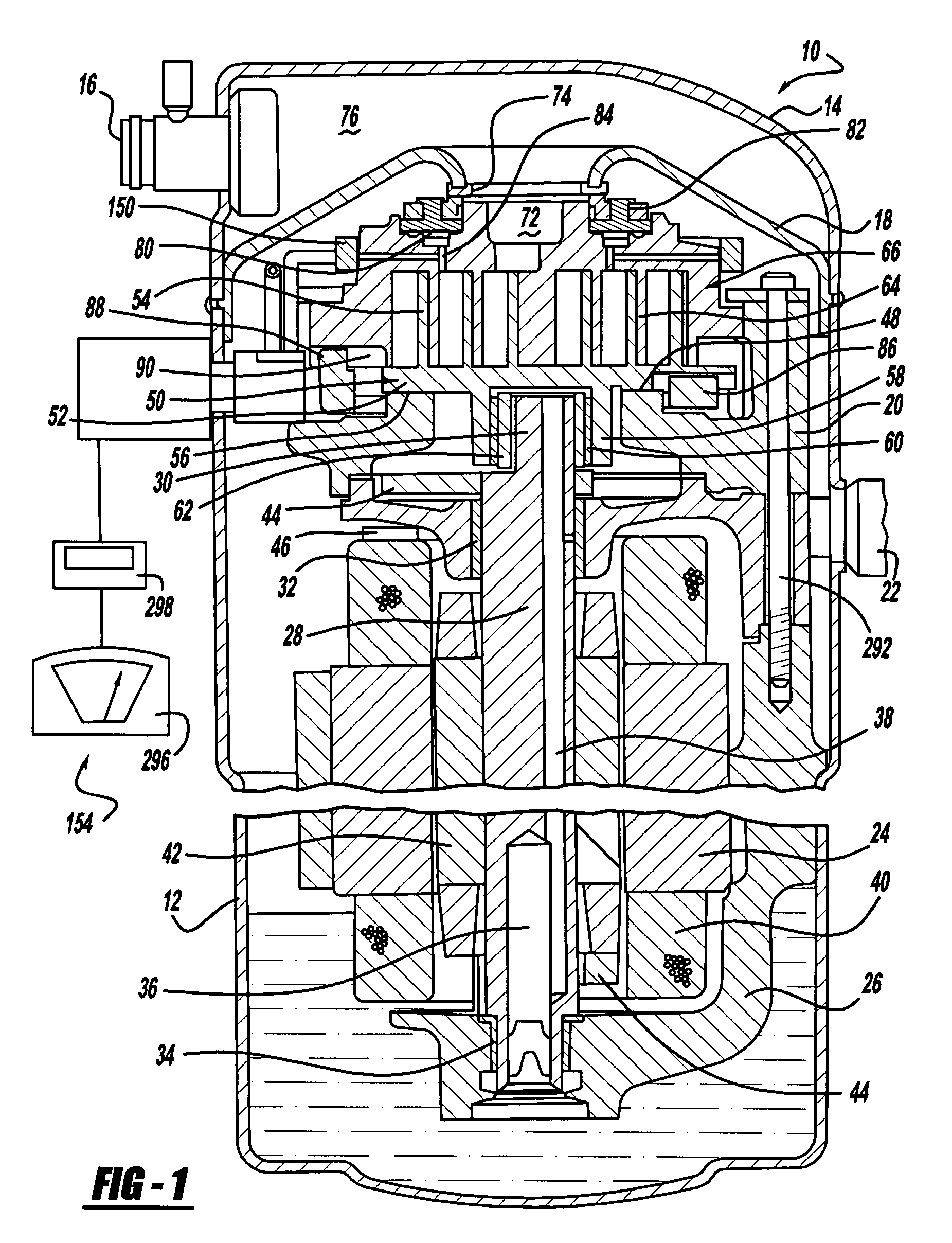

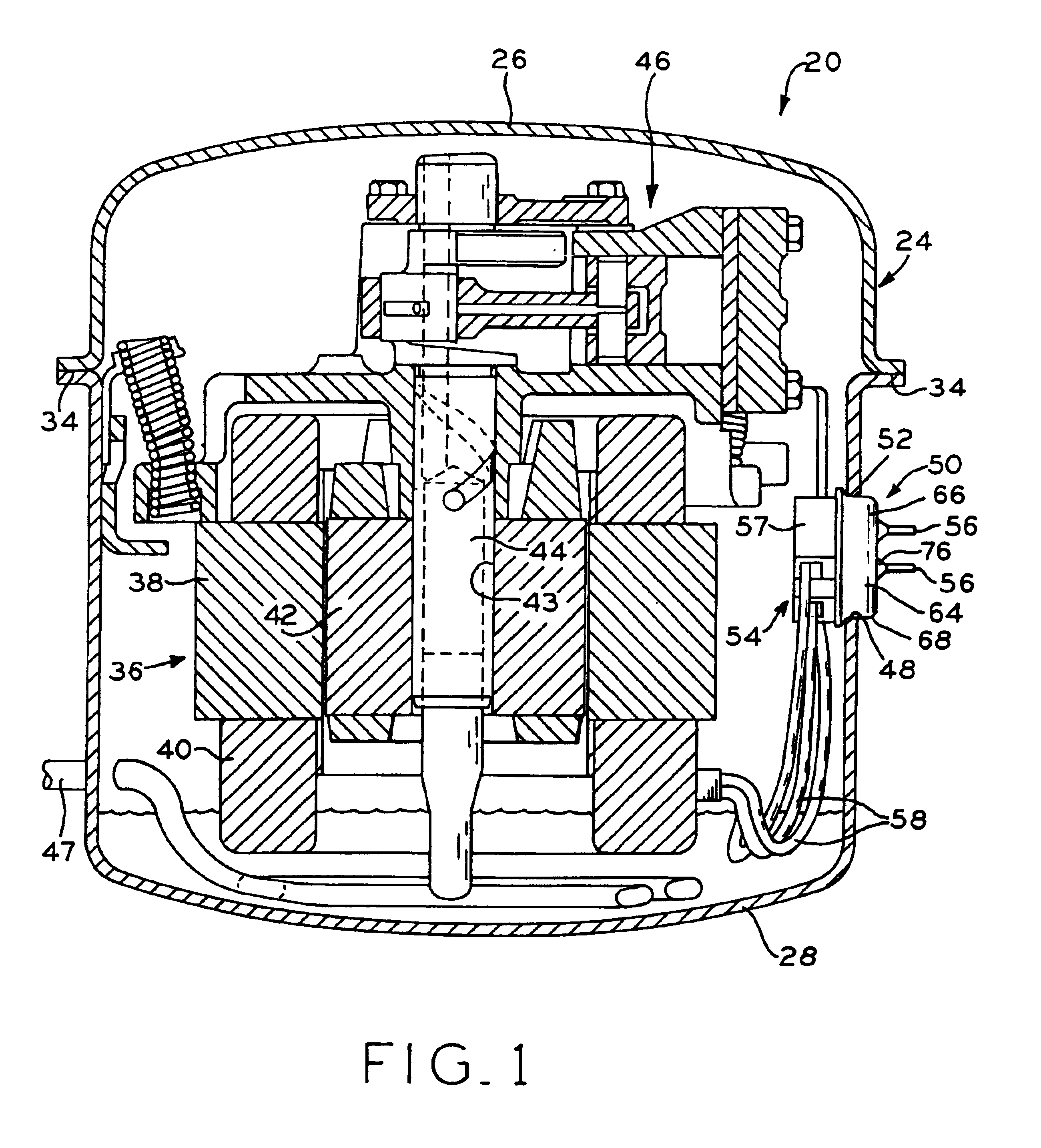

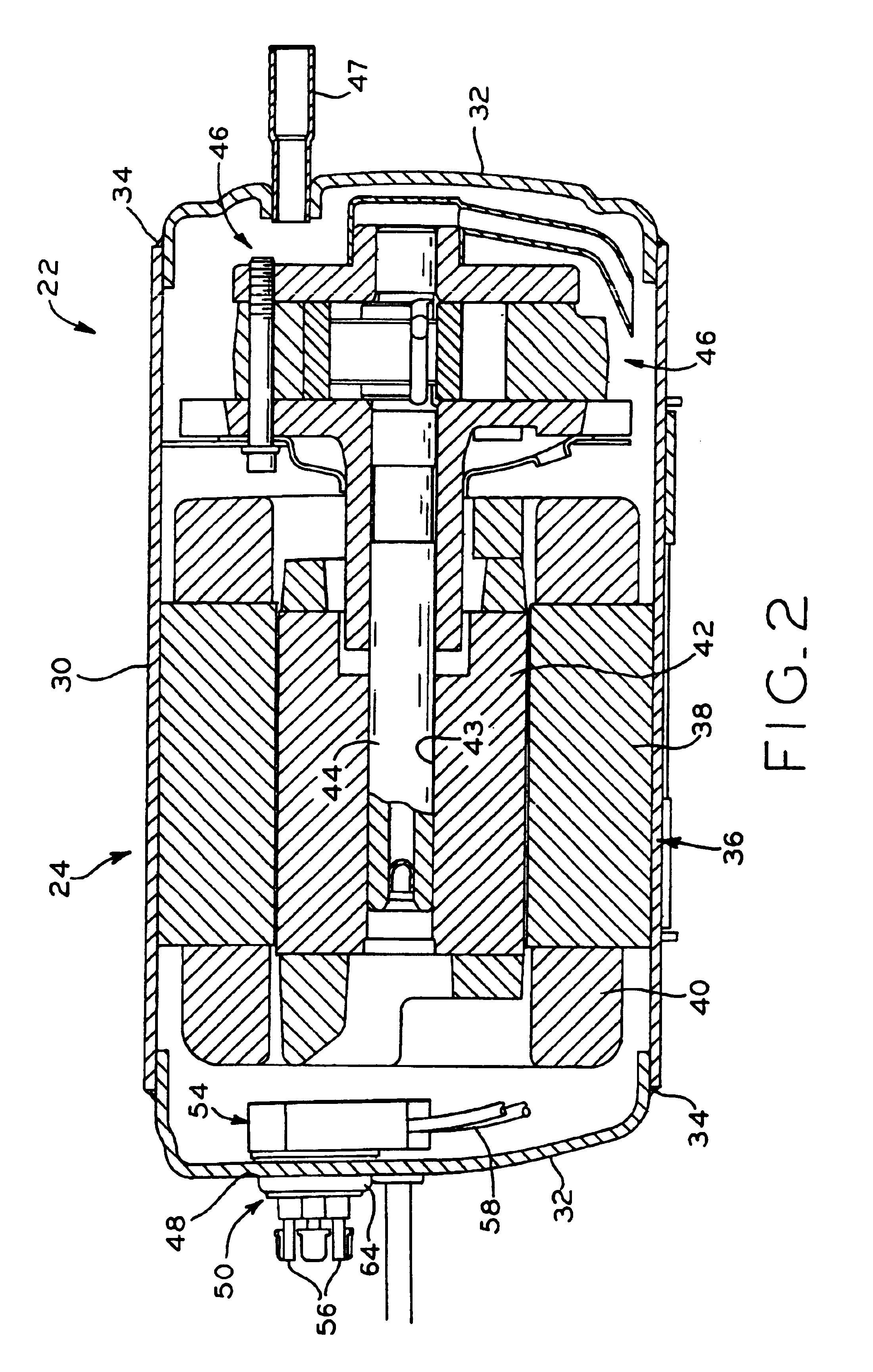

Compressor diagnostic and recording system

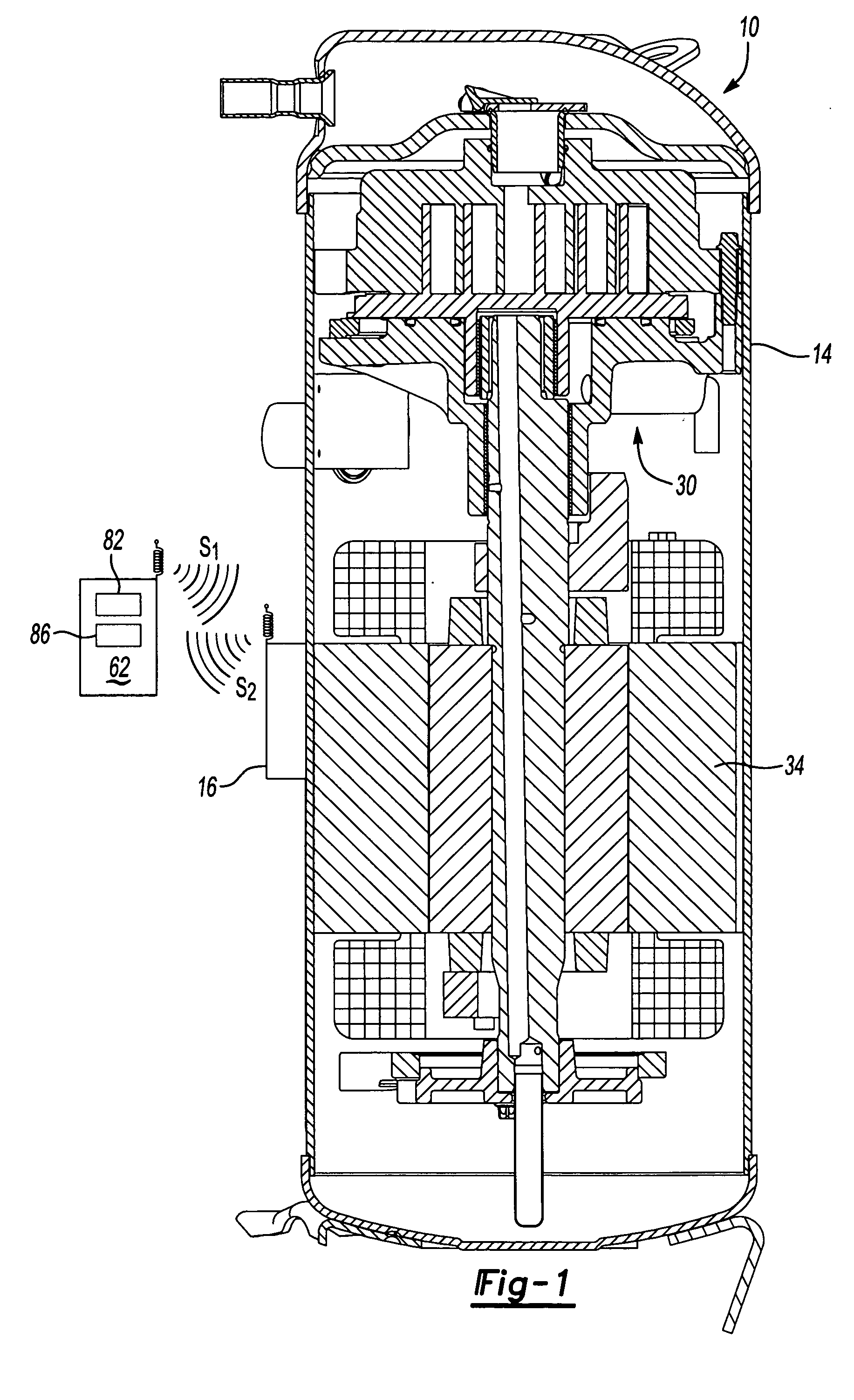

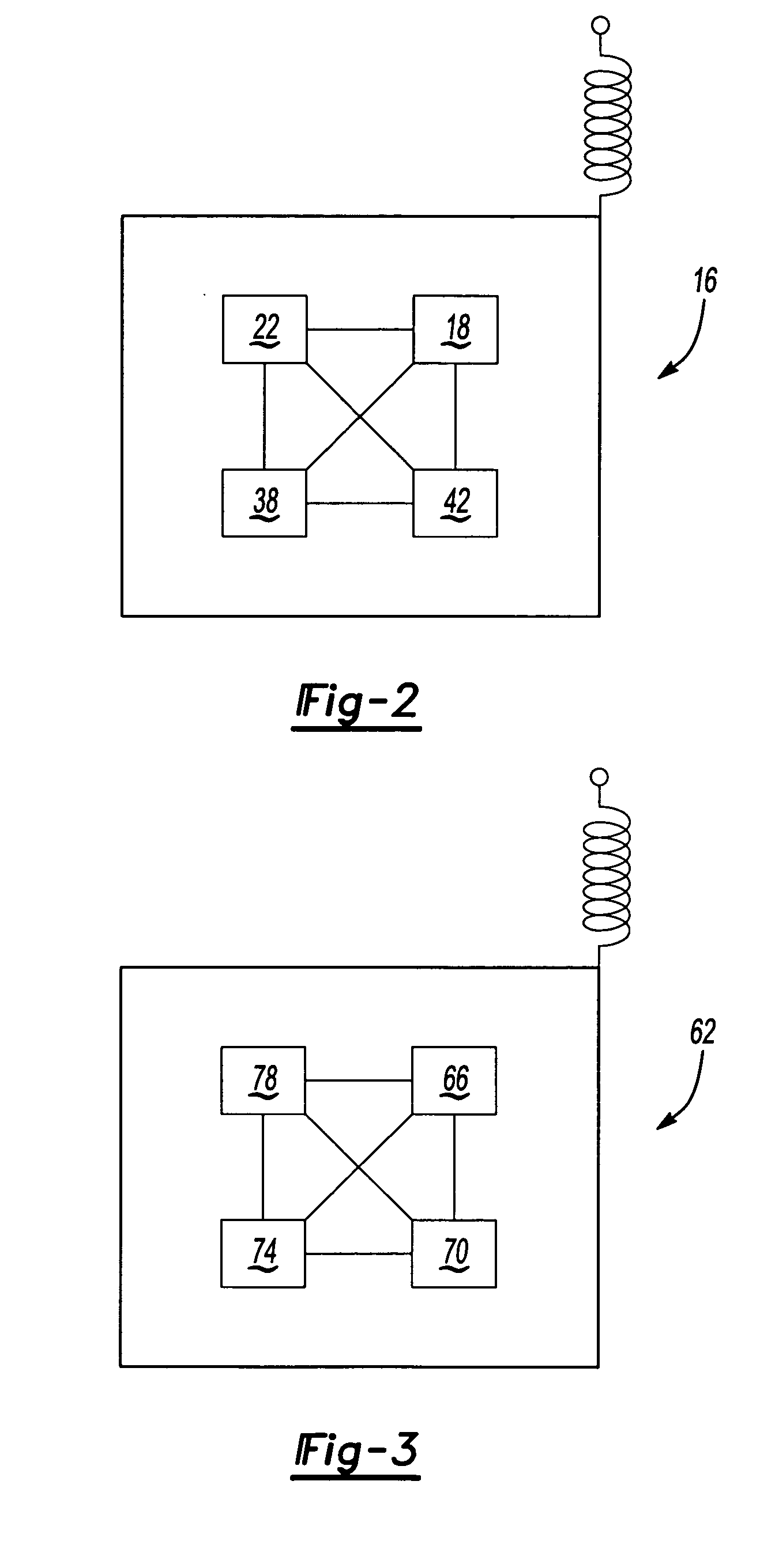

InactiveUS20020127120A1Rotary/oscillating piston combinations for elastic fluidsPump componentsData streamEngineering

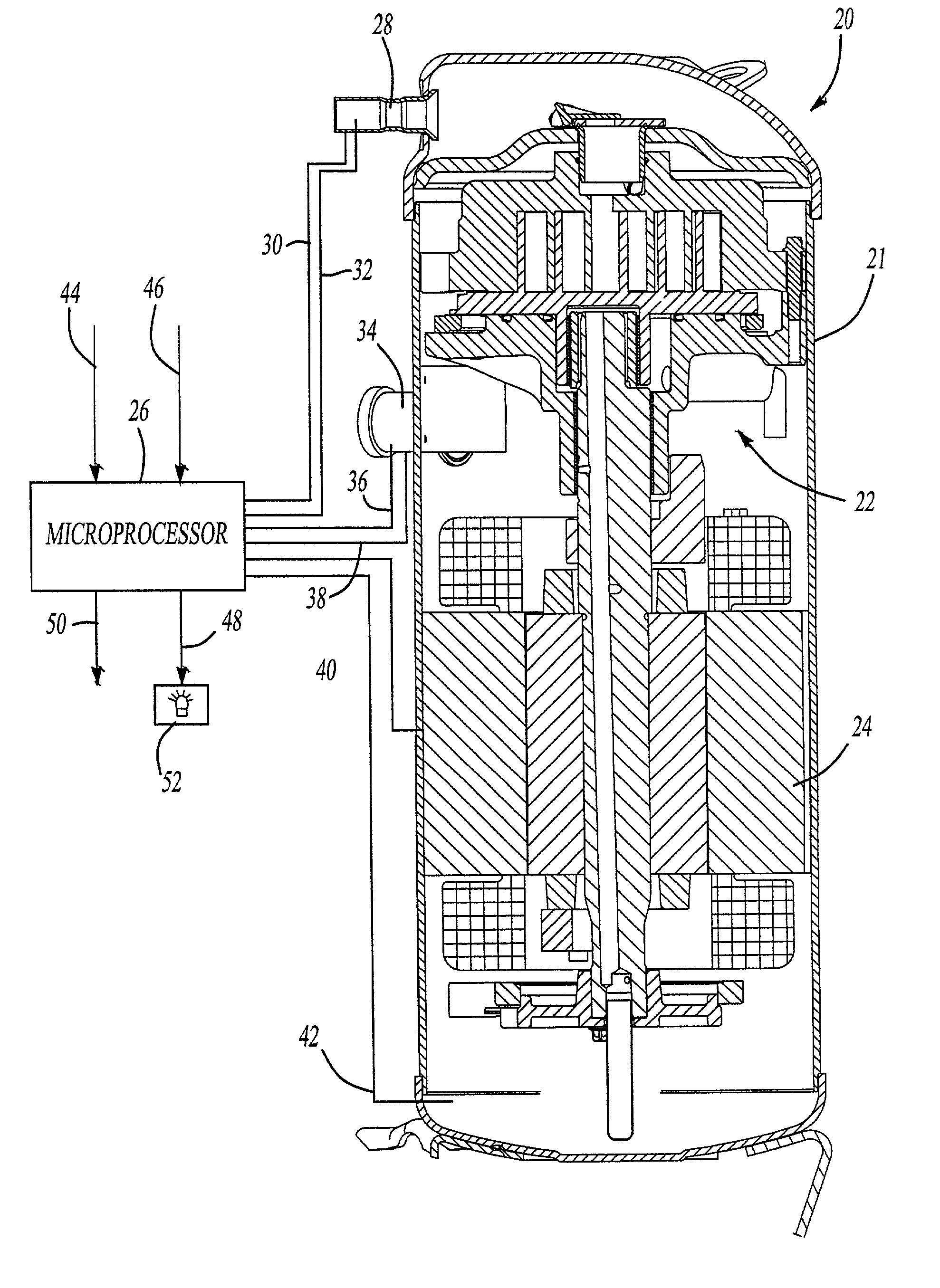

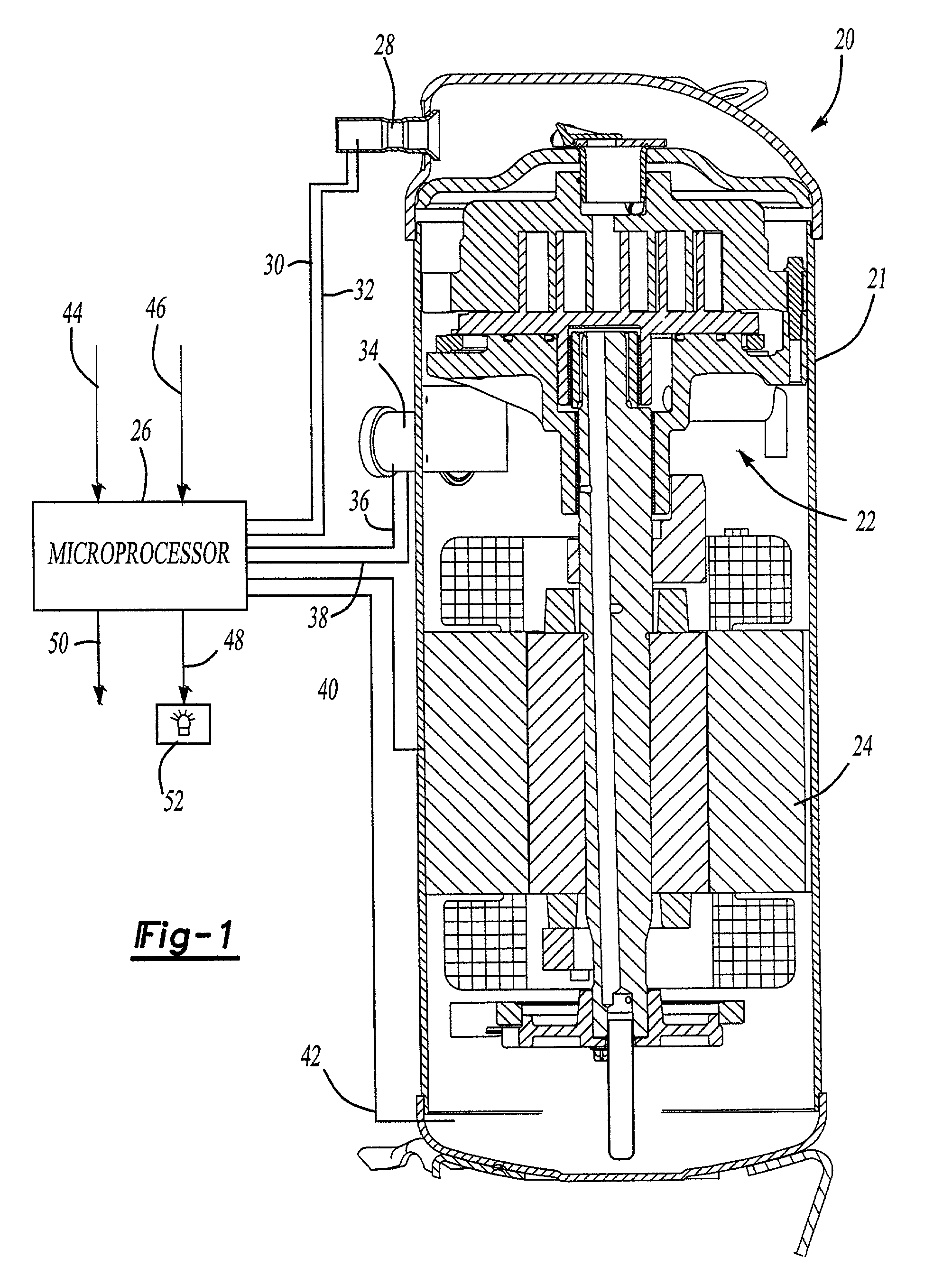

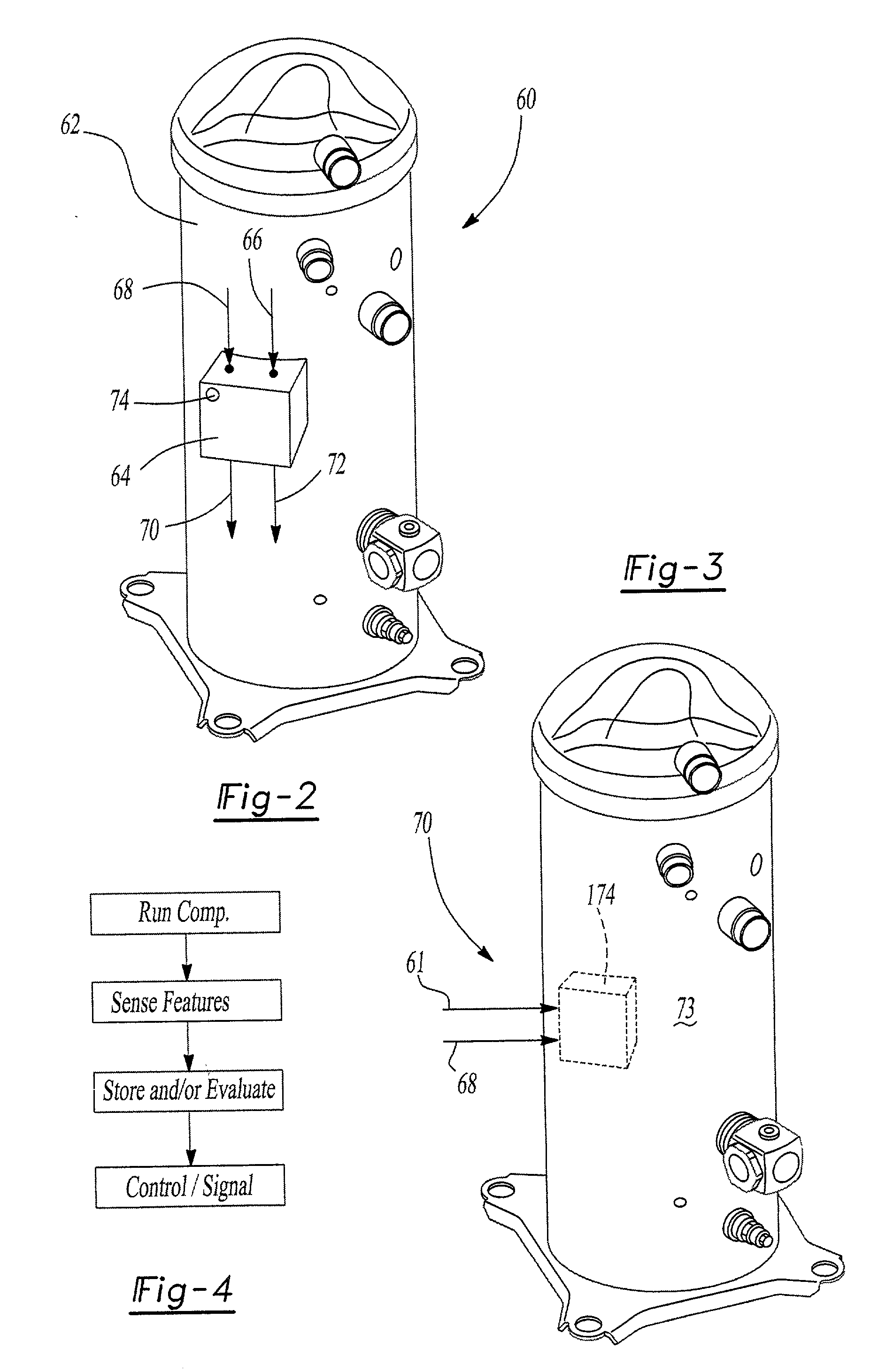

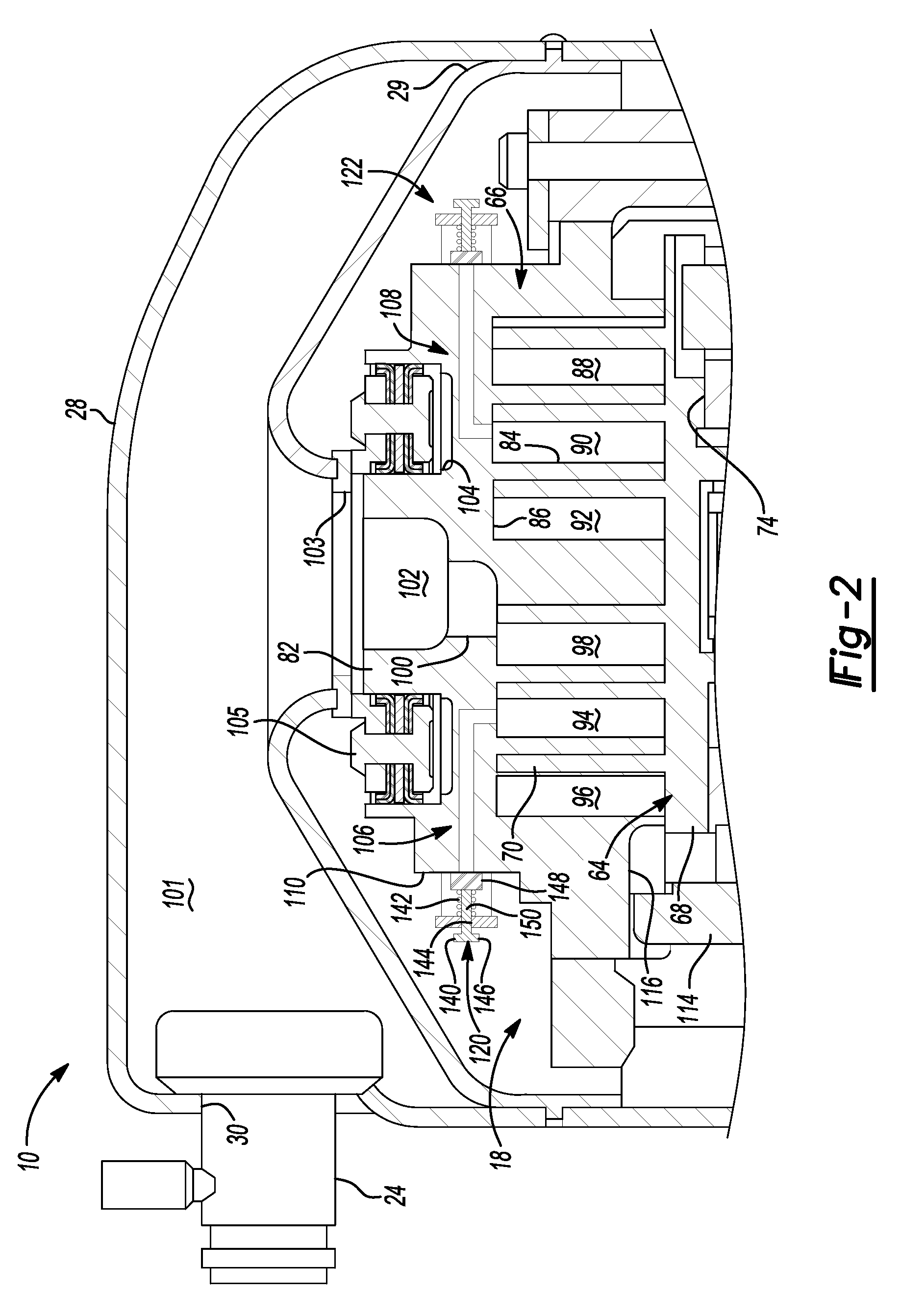

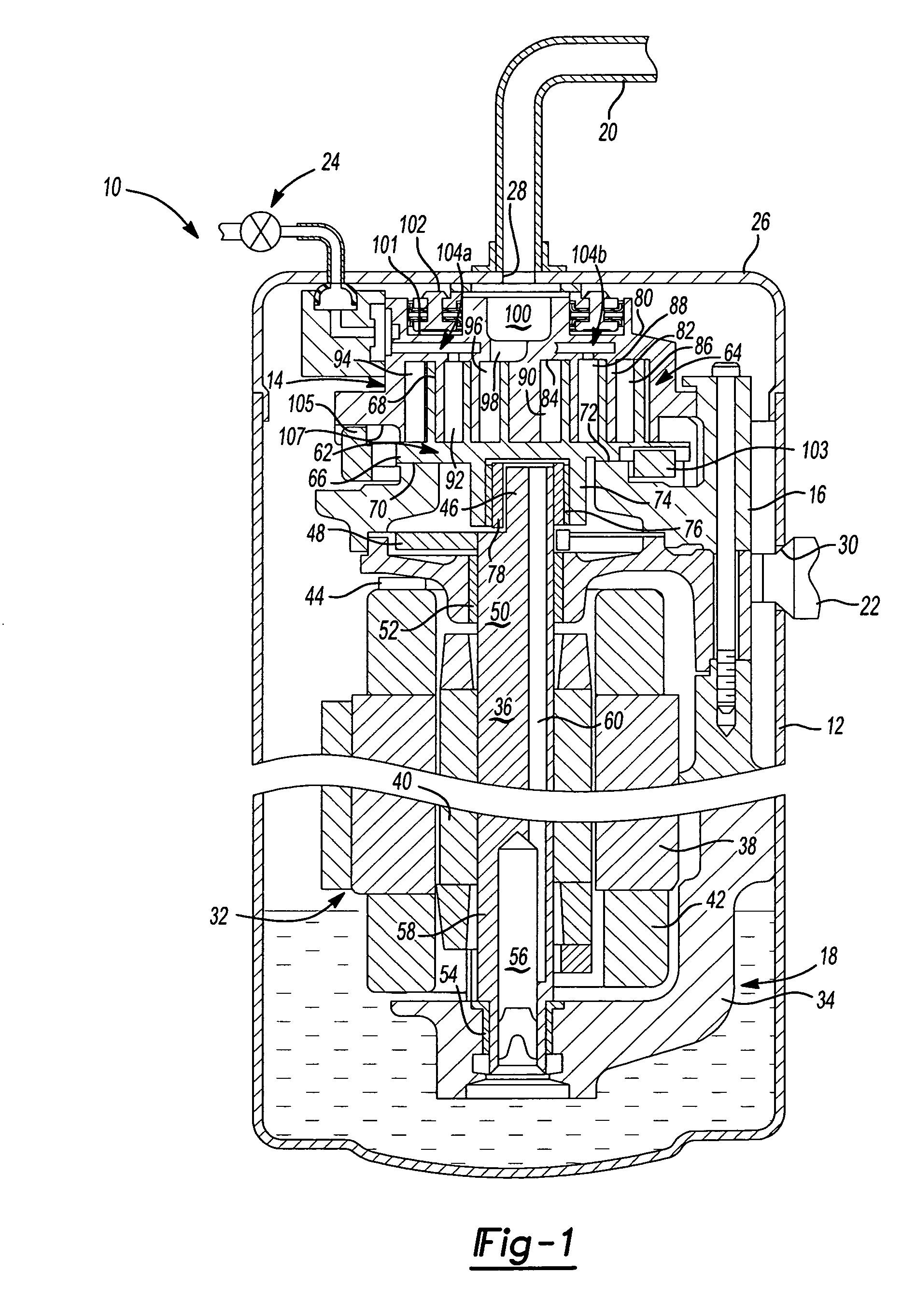

A compressor diagnostic system incorporates a control which receives a plurality of data streams about various operational features of the compressor. As an example, both temperature and pressure of the suction and discharge refrigerant are taken and sent to the control. Moreover, information with regard to the power being supplied to the motor is taken and stored. All of this information is utilized at a control which compares the information to expected values and determines a fault based upon the evaluation. Moreover, in another feature of this invention, much of this data is stored, and maintained at the compressor. In the event of a compressor failure, this stored information will provide a maintenance worker with a good indication of why the compressor failed.

Owner:HAHN GREG +7

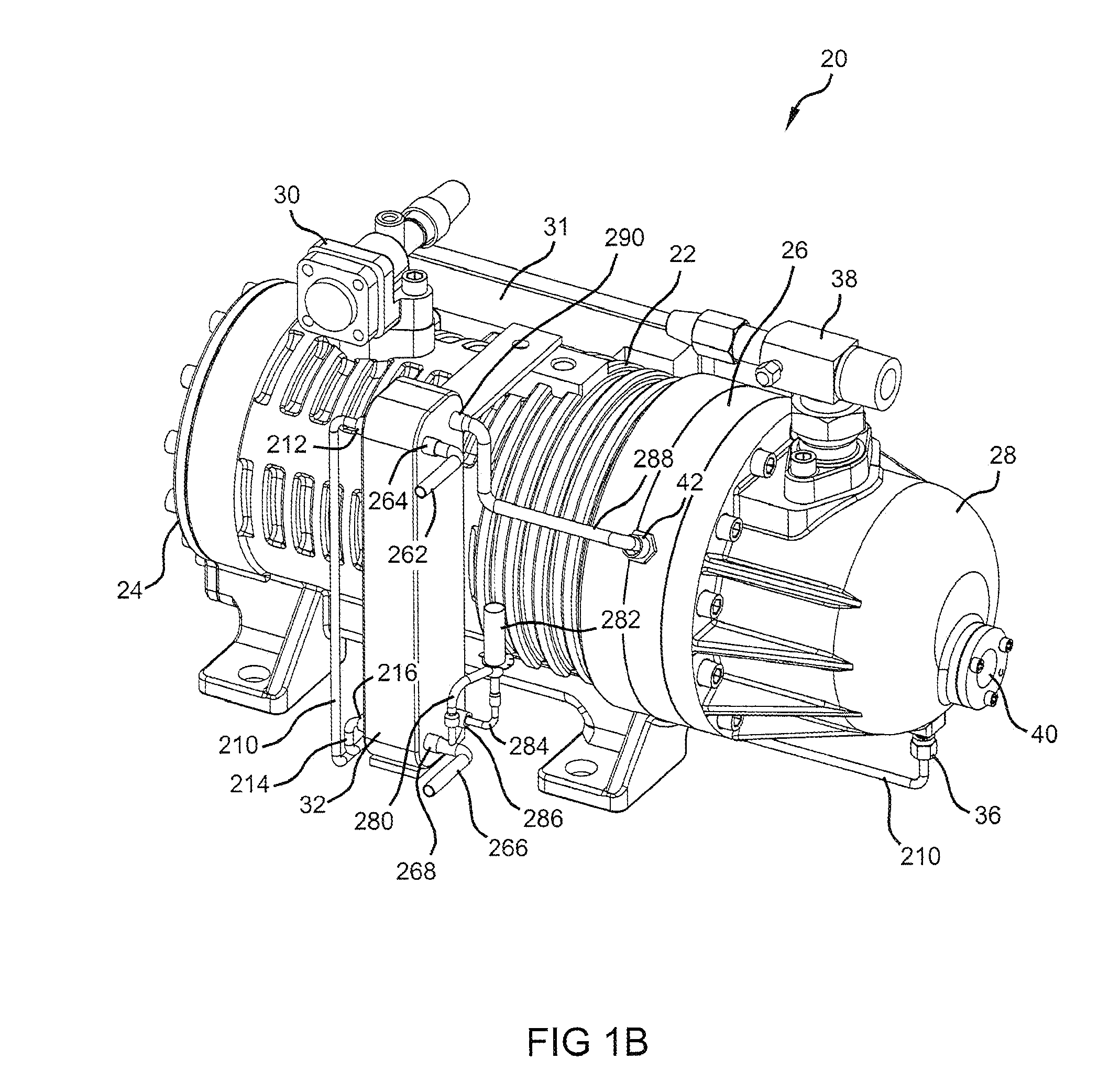

Lubricant cooled integrated motor/compressor design

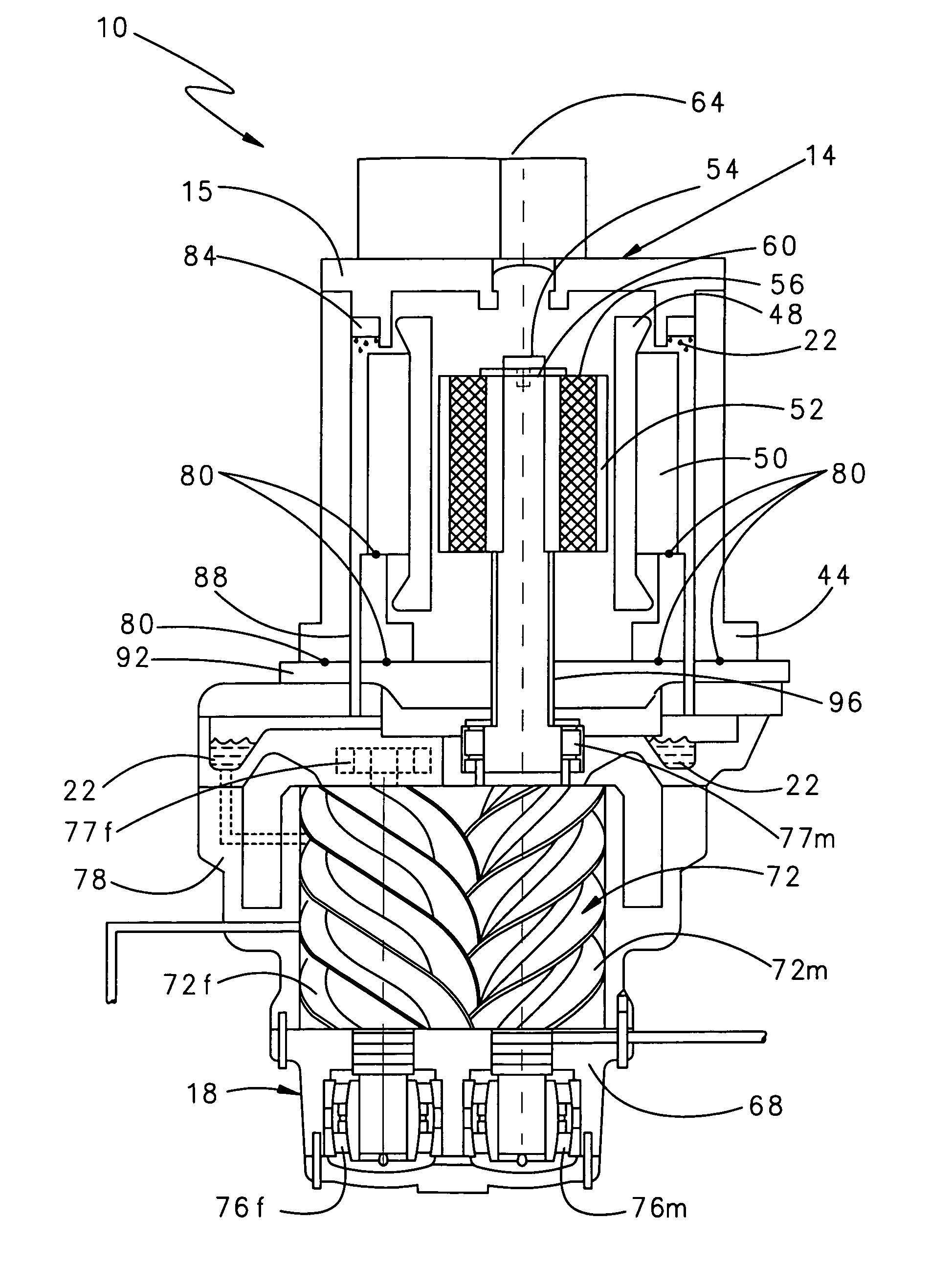

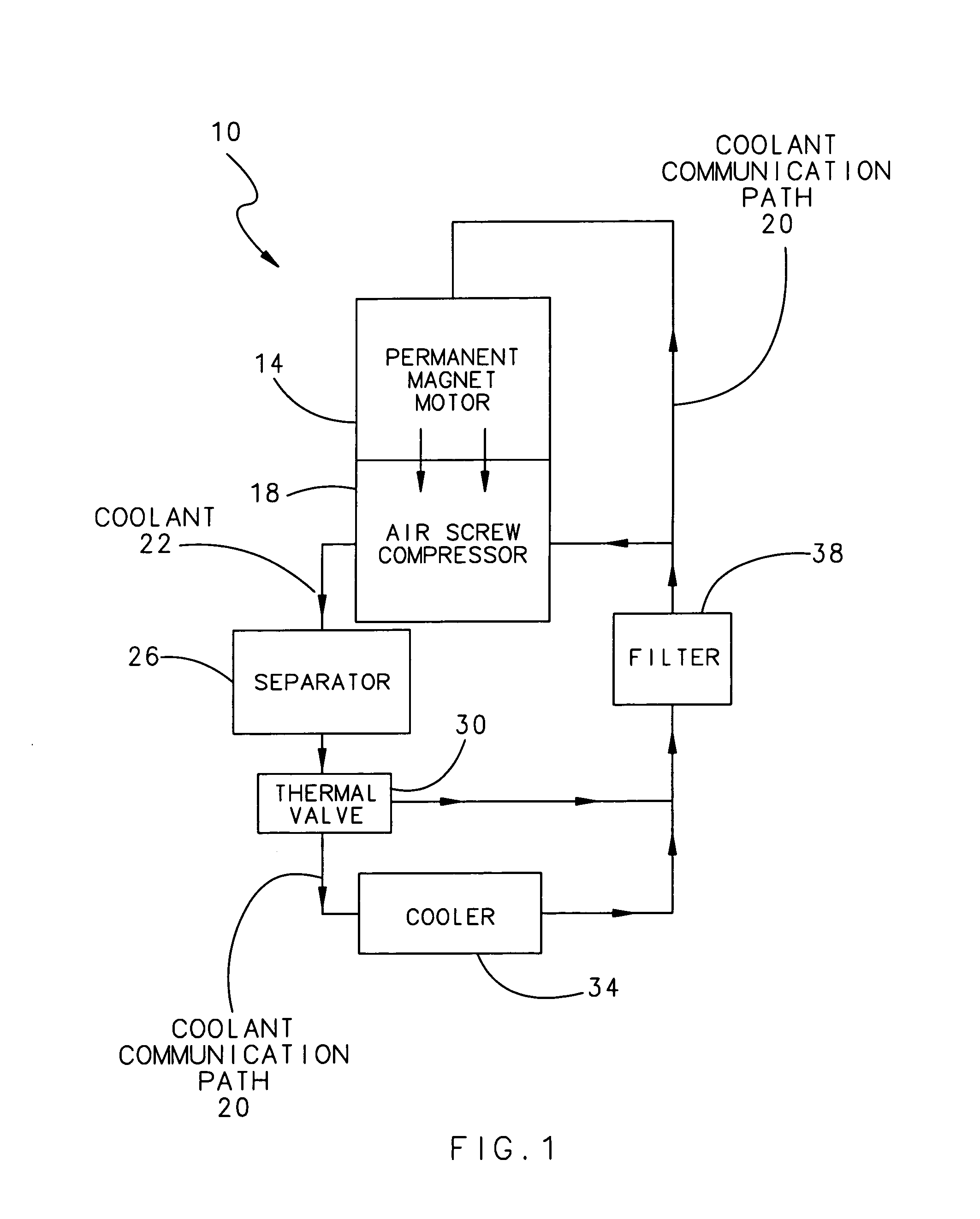

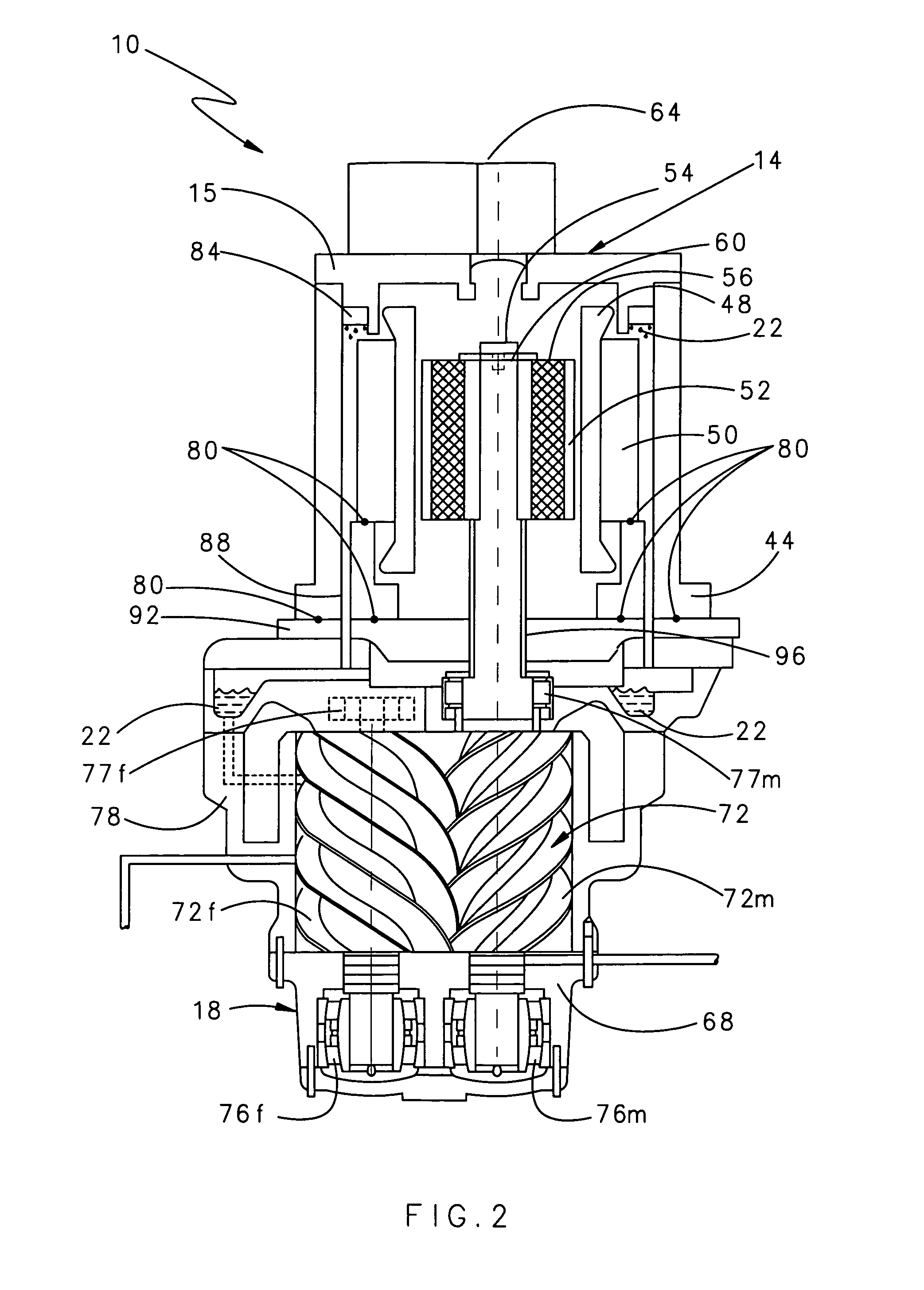

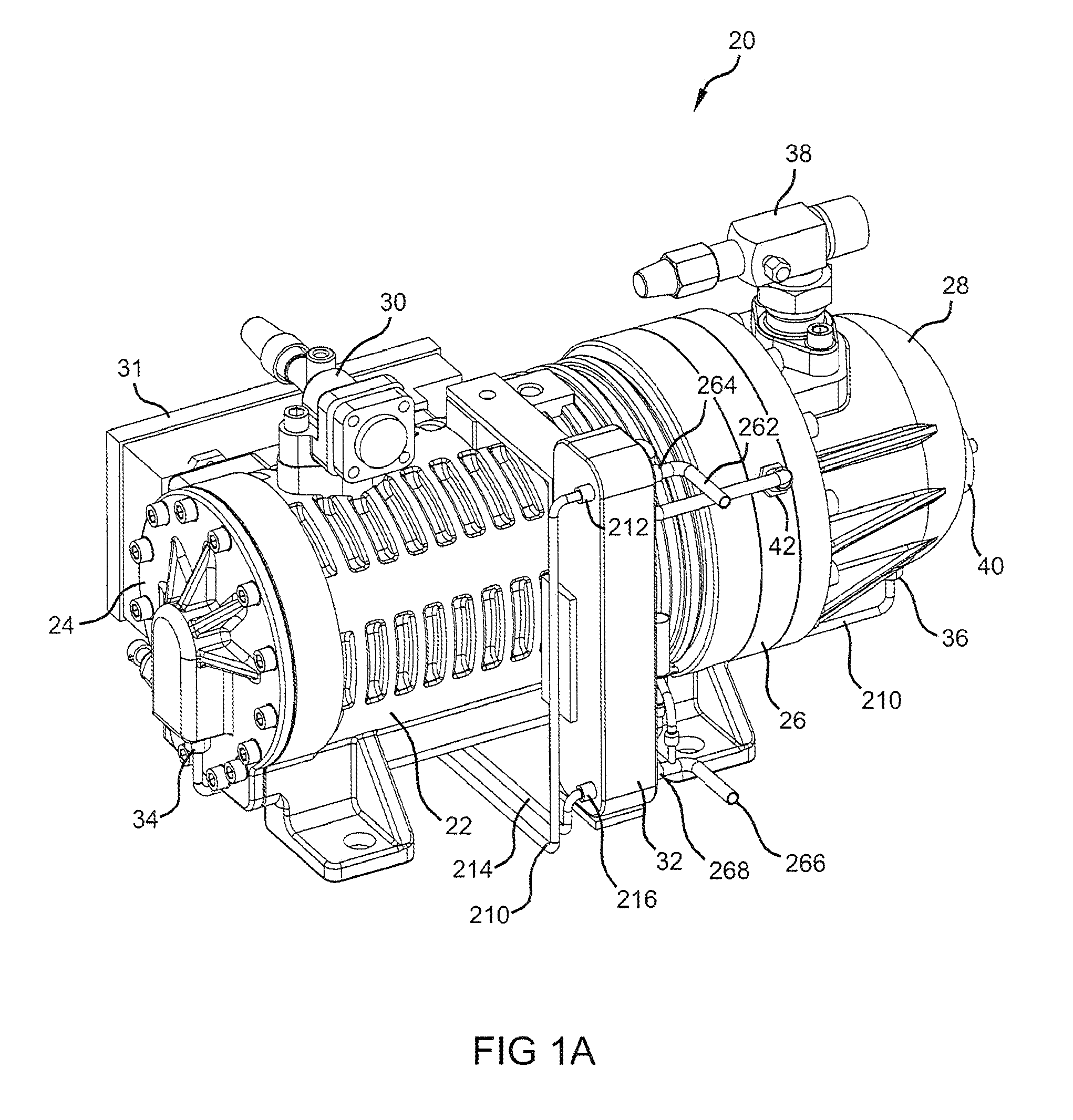

InactiveUS20070241627A1Prevent overboard leakageThe process is compact and efficientRotary/oscillating piston combinations for elastic fluidsEngine of counter-engagement typePermanent magnet motorGear train

A compressor system according to the present invention utilizes direct rotational input from a permanent magnet motor to generate compressed air. The permanent magnet motor is mounted directly to an air screw compressor. The rotational input is provided by the permanent magnet motor to the air screw compressor without a gear train. The permanent magnet motor and associated variable speed drive controls the rotational speed of the permanent magnet motor and hence the screw compressor. Differing motors may selectively mount, and provide rotational input to, the air screw compressor.

Owner:SULLAIR CORP

Discharge valve

InactiveUS6171084B1Easy to operateRaise the possibilityRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringValve seat

A compressor assembly includes a shell which defines a discharge chamber. A discharge valve assembly is attached to the shell in communication with the discharge chamber. The discharge valve assembly includes a stamped or coined valve seat, a drawn tubular element and a stamped valve member. The stamping, drawing and coining operations used to manufacture the discharge valve assembly significantly reduce the manufacturing costs for the discharge valve assembly.

Owner:EMERSON CLIMATE TECH INC

Compressor diagnostic and recording system

InactiveUS20050100449A1Rotary/oscillating piston combinations for elastic fluidsPump componentsData streamEngineering

A compressor diagnostic system incorporates a control which receives a plurality of data streams about various operational features of the compressor. As an example, both temperature and pressure of the suction and discharge refrigerant are taken and sent to the control. Moreover, information with regard to the power being supplied to the motor is taken and stored. All of this information is utilized at a control which compares the information to expected values and determines a fault based upon the evaluation. Moreover, in another feature of this invention, much of this data is stored, and maintained at the compressor. In the event of a compressor failure, this stored information will provide a maintenance worker with a good indication of why the compressor failed.

Owner:SCROLL TECH

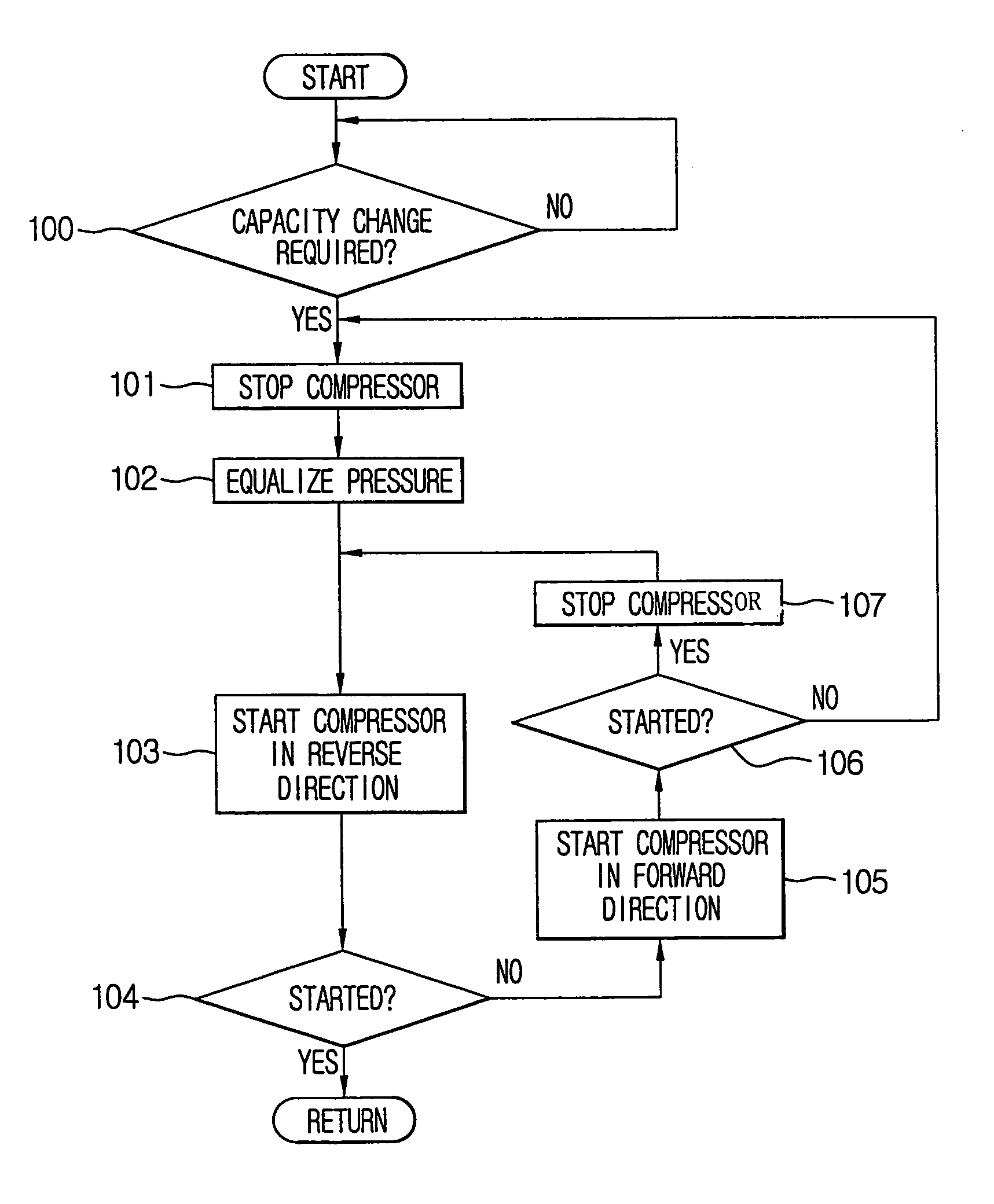

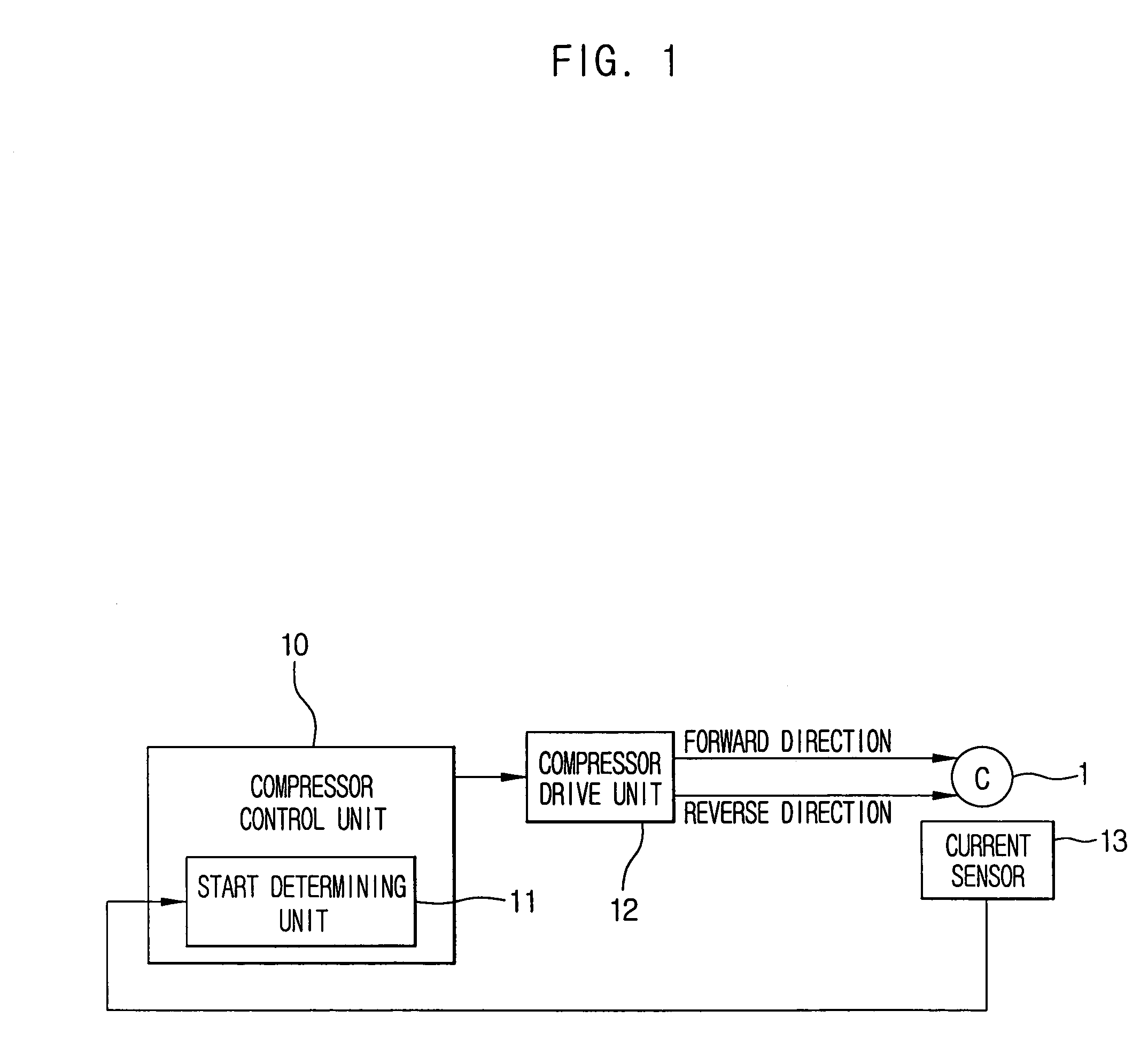

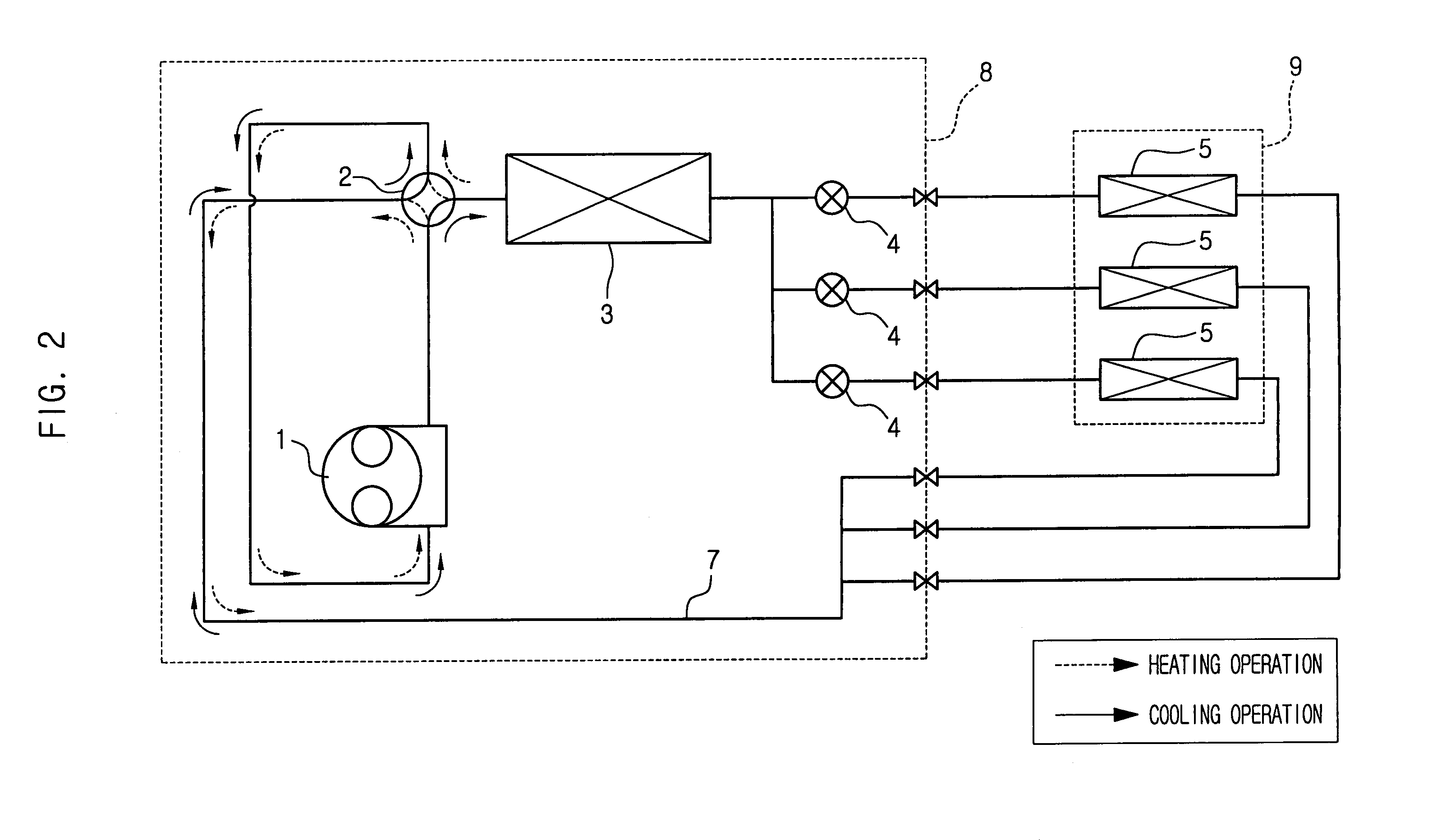

Air conditioner and method of controlling the same

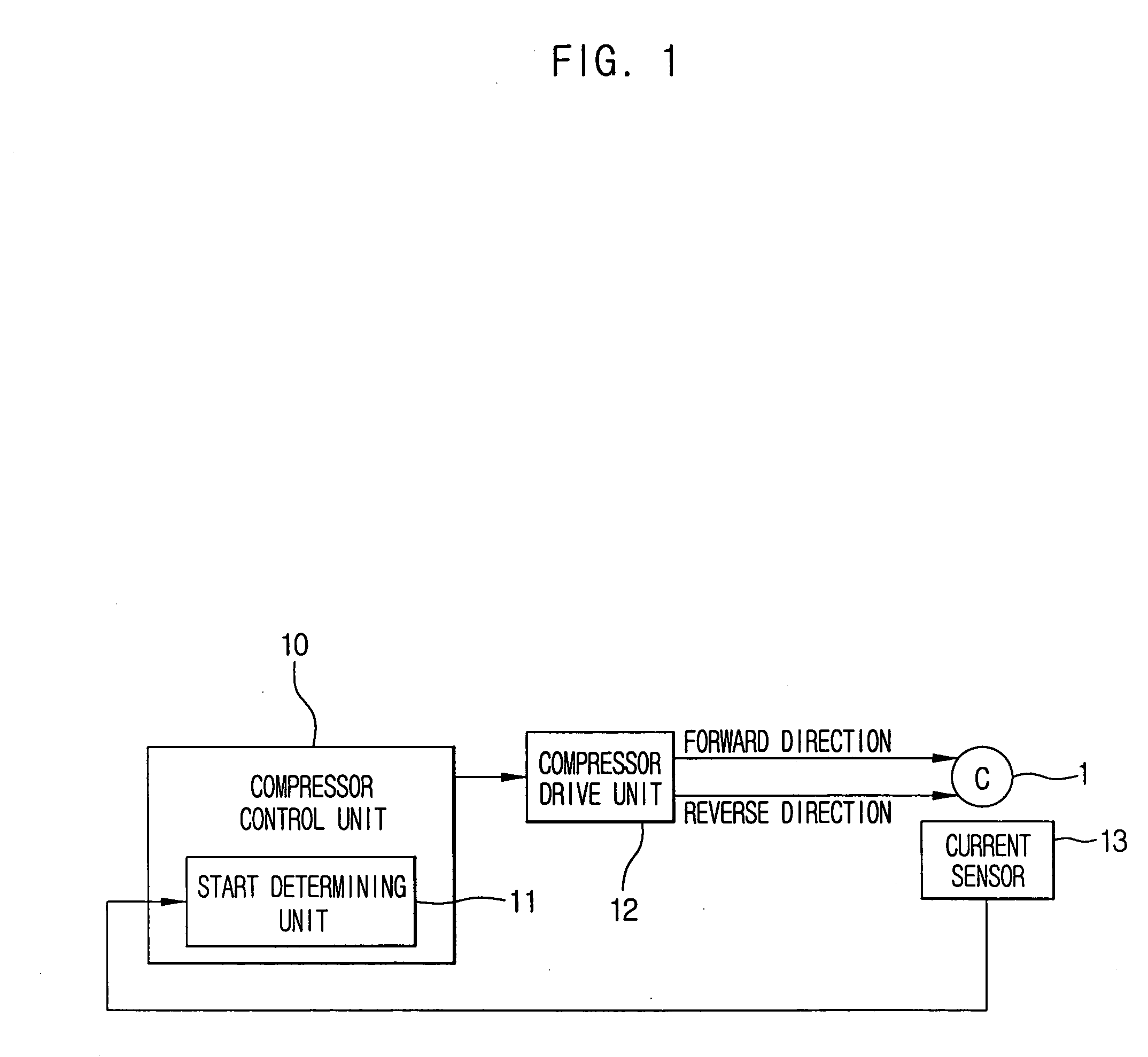

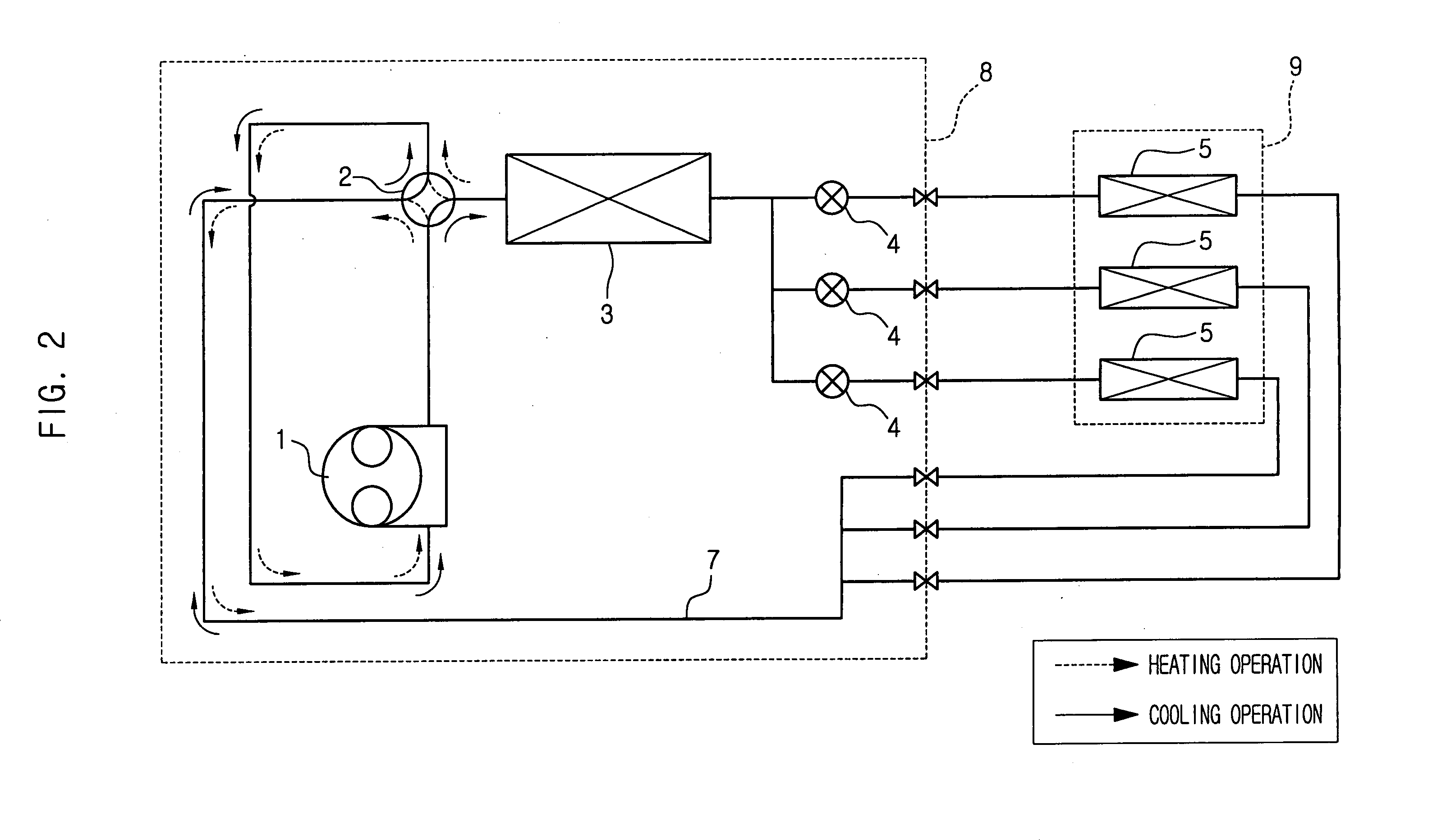

InactiveUS20050050908A1Smooth startImprove startup reliabilityRotary/oscillating piston combinations for elastic fluidsSpace heating and ventilation safety systemsEngineeringControl theory

An air conditioner has a variable capacity rotary compressor, which allows the compressor to be smoothly re-started, thus increasing start reliability of the compressor. The air conditioner includes a compressor rotated in opposite directions. A drive unit rotates the compressor in a forward or reverse direction. A start determining unit determines whether the compressor has started to rotate in a forward direction or not. A control unit operates the drive unit so as to rotate the compressor in a direction opposite to the forward direction, and then re- start the compressor in the forward direction, when the compressor has failed to start. The air conditioner and a method of controlling the air conditioner allow the compressor to be smoothly and rapidly re-started even when the compressor has failed to re-start, thus increasing start reliability, and shortening a time required to re-start the compressor.

Owner:SAMSUNG ELECTRONICS CO LTD

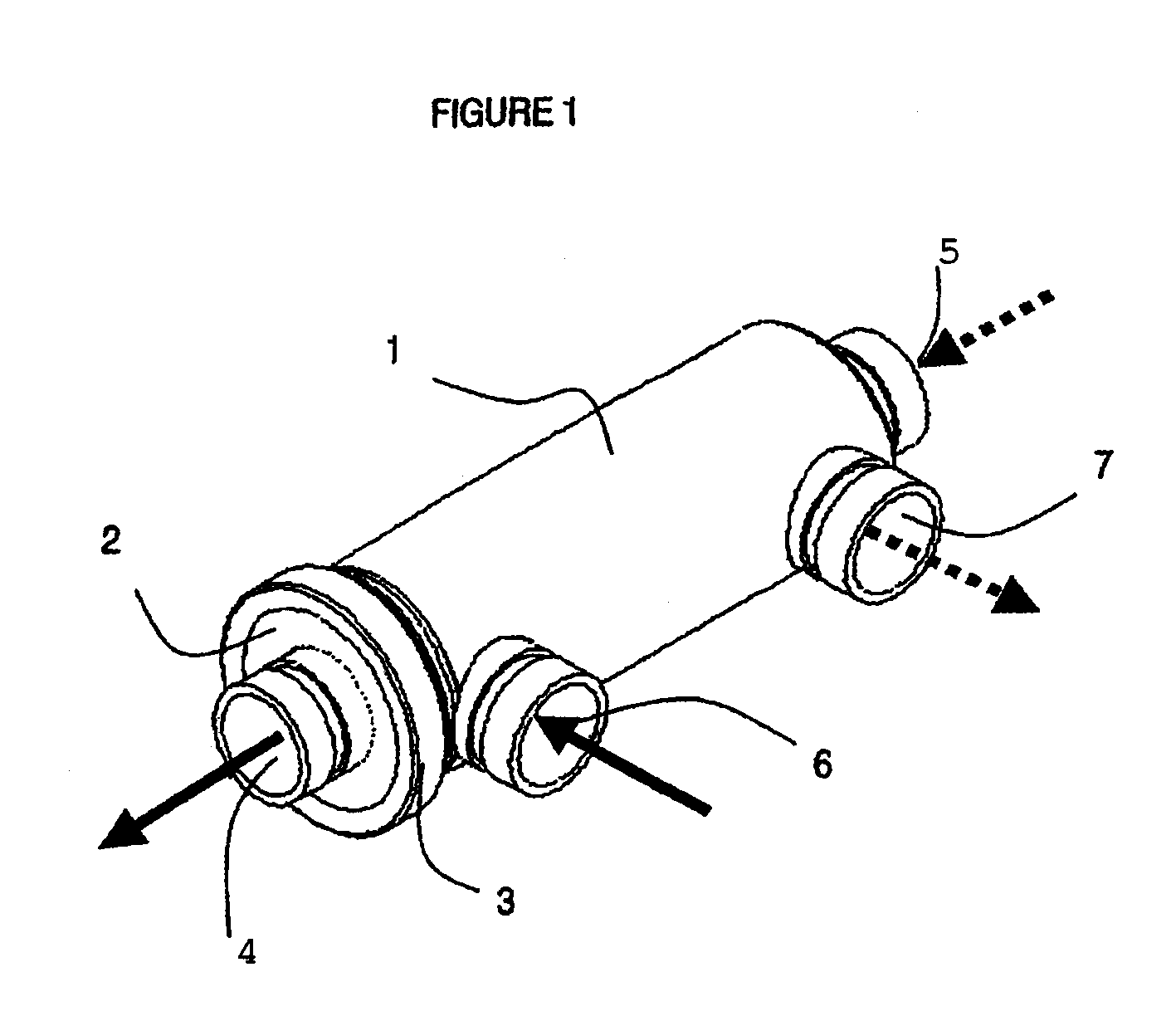

Pressure exchanger

ActiveUS7306437B2Increase capacityIncrease momentumRotary/oscillating piston combinations for elastic fluidsGeneral water supply conservationCavitationMomentum

Owner:ISOBARIC STRATEGIES INC

Oil pump

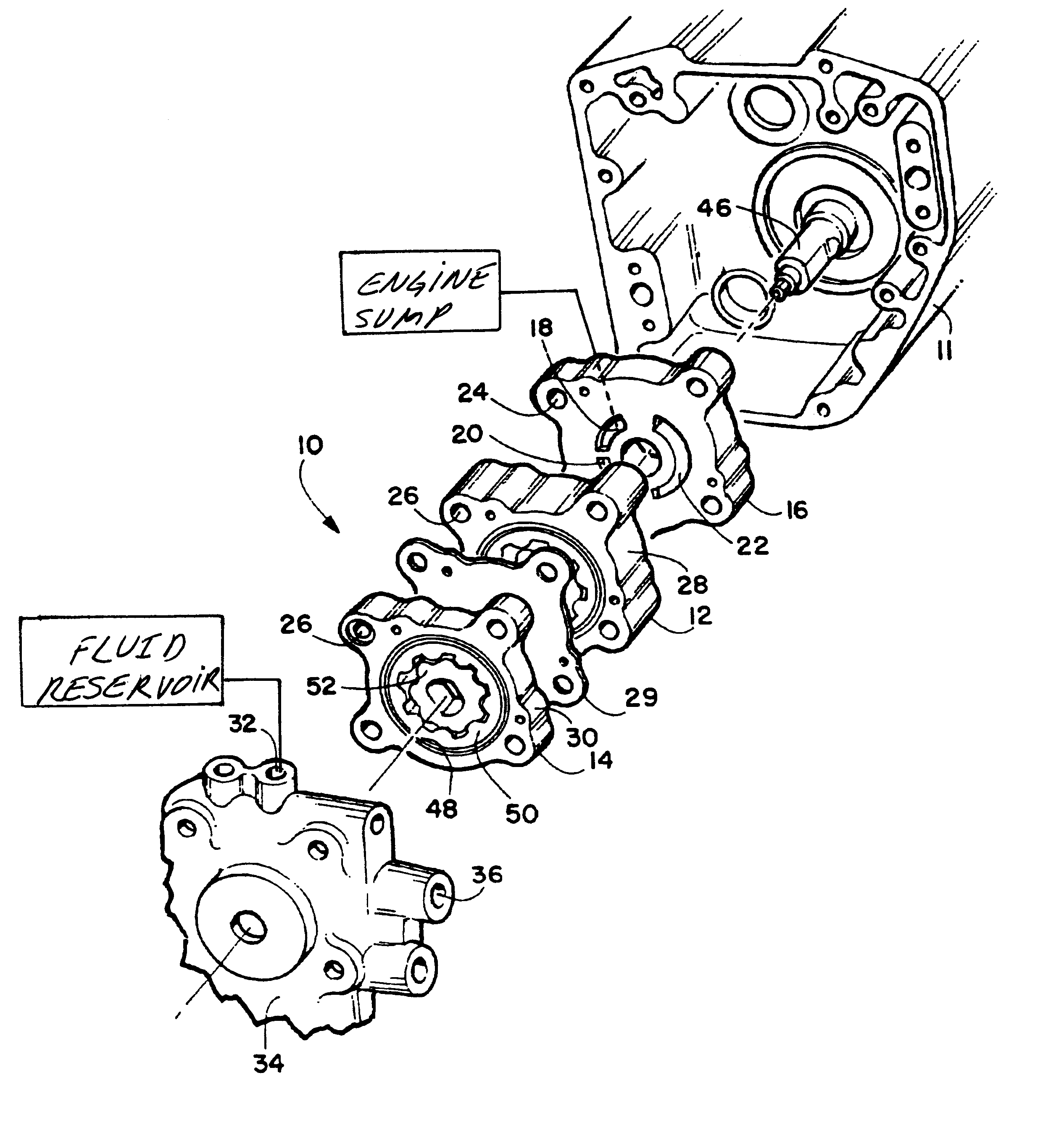

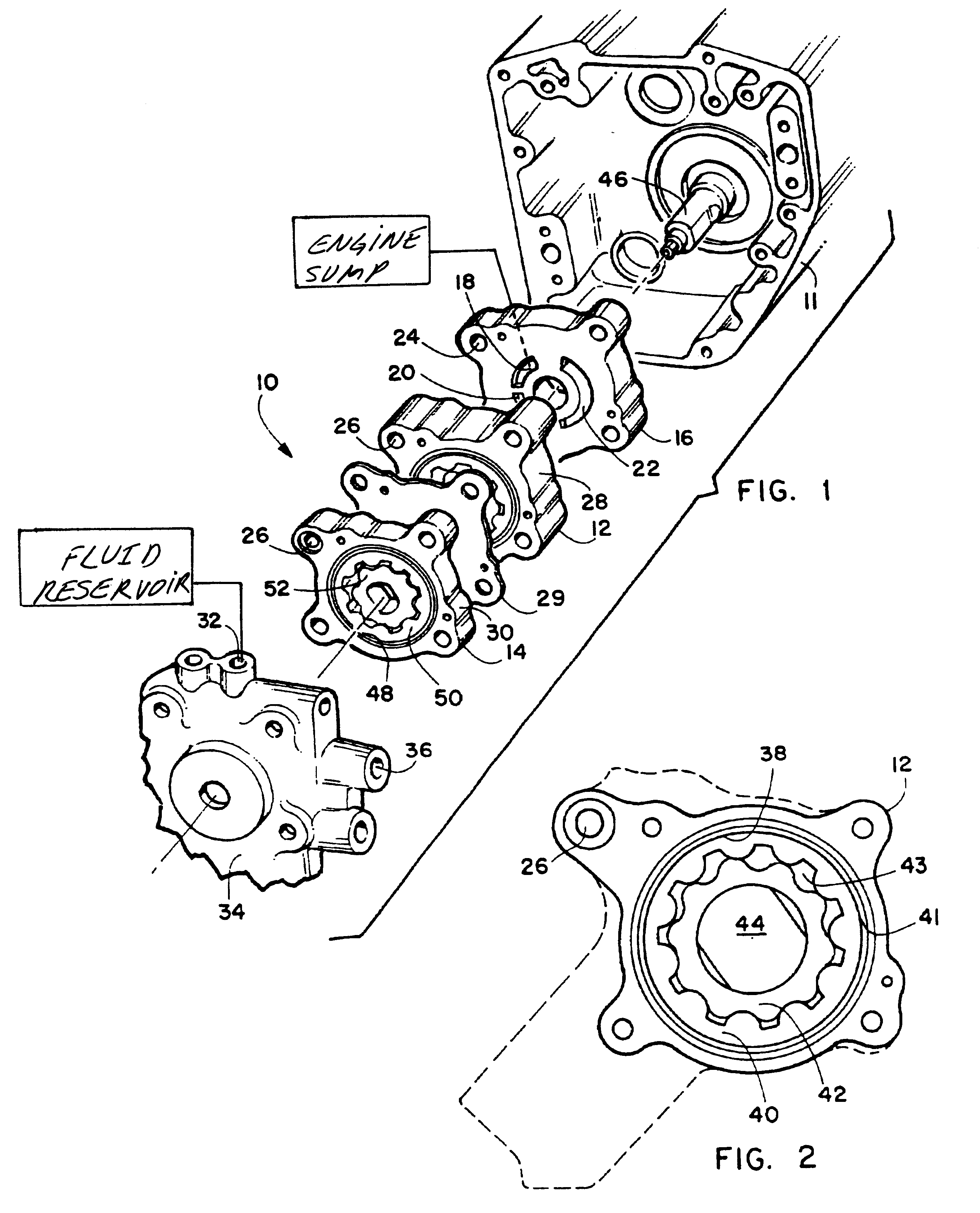

InactiveUS6679692B1Easy to replacePromote repairRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesFuel tankEngineering

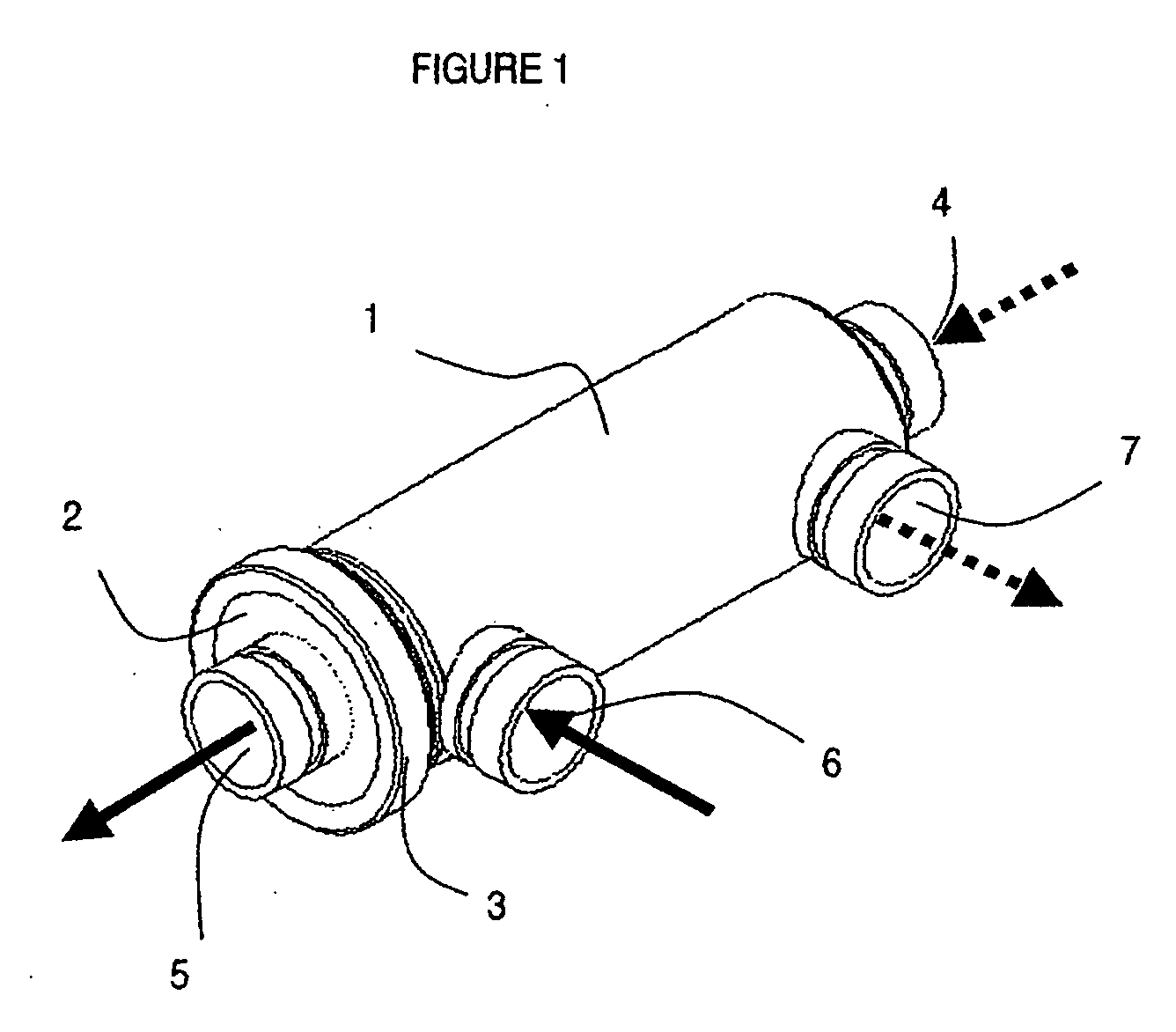

A modular oil pump for use in combination with an internal combustion engine having a dry sump lubrication system. The device features a first gerotor pump having an intake port engageable in communication with at least one engine sump and having an discharge port engageable in sealed communication with a fluid reservoir for the dry sump system. A second gerotor pump, engageable in sealed communication with the fluid reservoir has a discharge port fluidly engageable with the engine lubrication system oil supply conduit. Both the first pump and second pump are assembled from separate housings, and cooperatively engaged inner and outer gears sized for rotation and in line mounting on the engine crankshaft inside a cavity in the housings. The volume pumping capacity of the first pump at a ratio to efficiently drain fluid and gas from the engine sumps and supply the reservoir with a constant supply of lubrication fluid. The device may be assembled from a kit having a plurality of different sized components to adjust the ratio of the pumping volume of the first pump to the second pump.

Owner:FEULING JAMES J

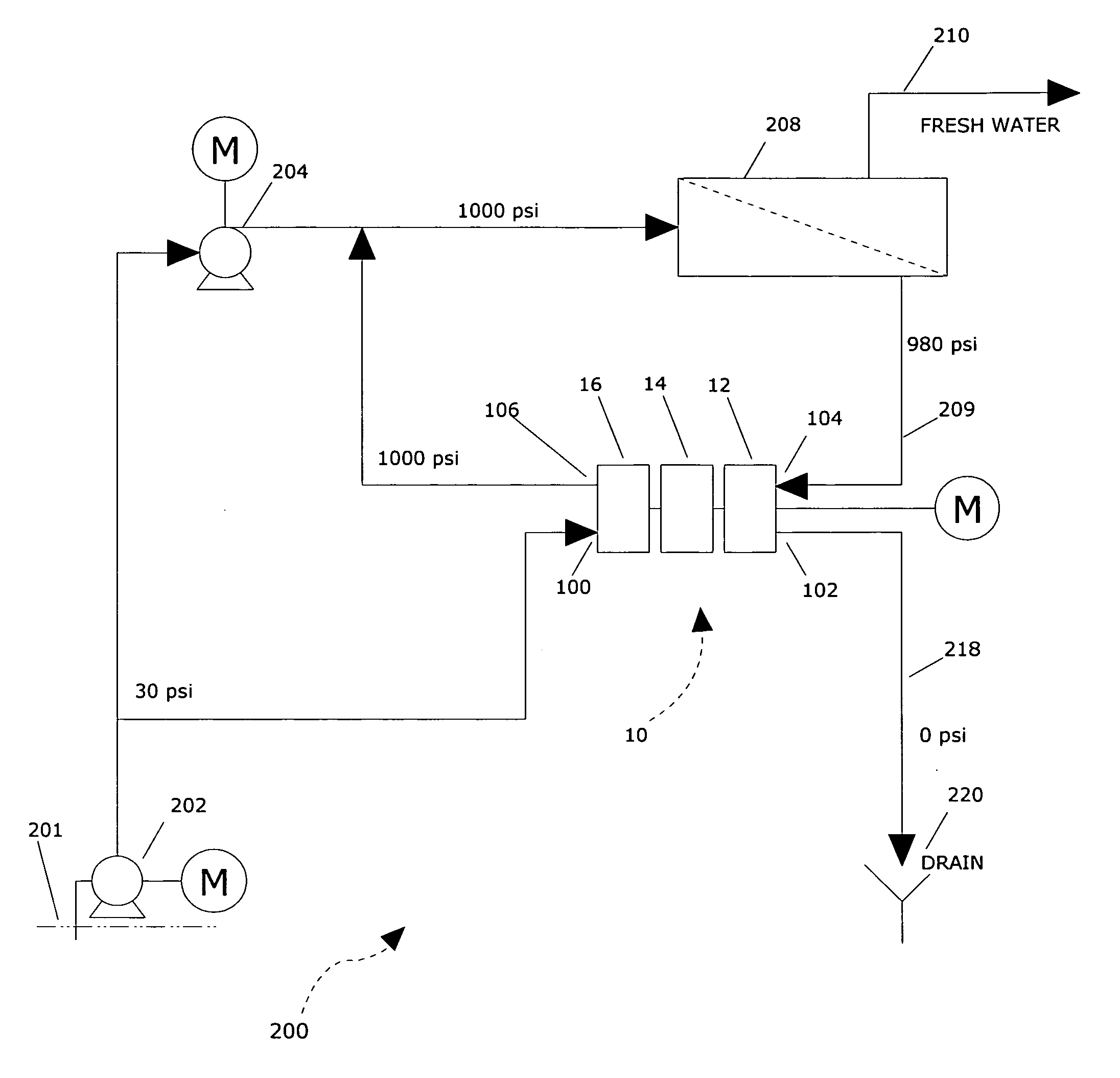

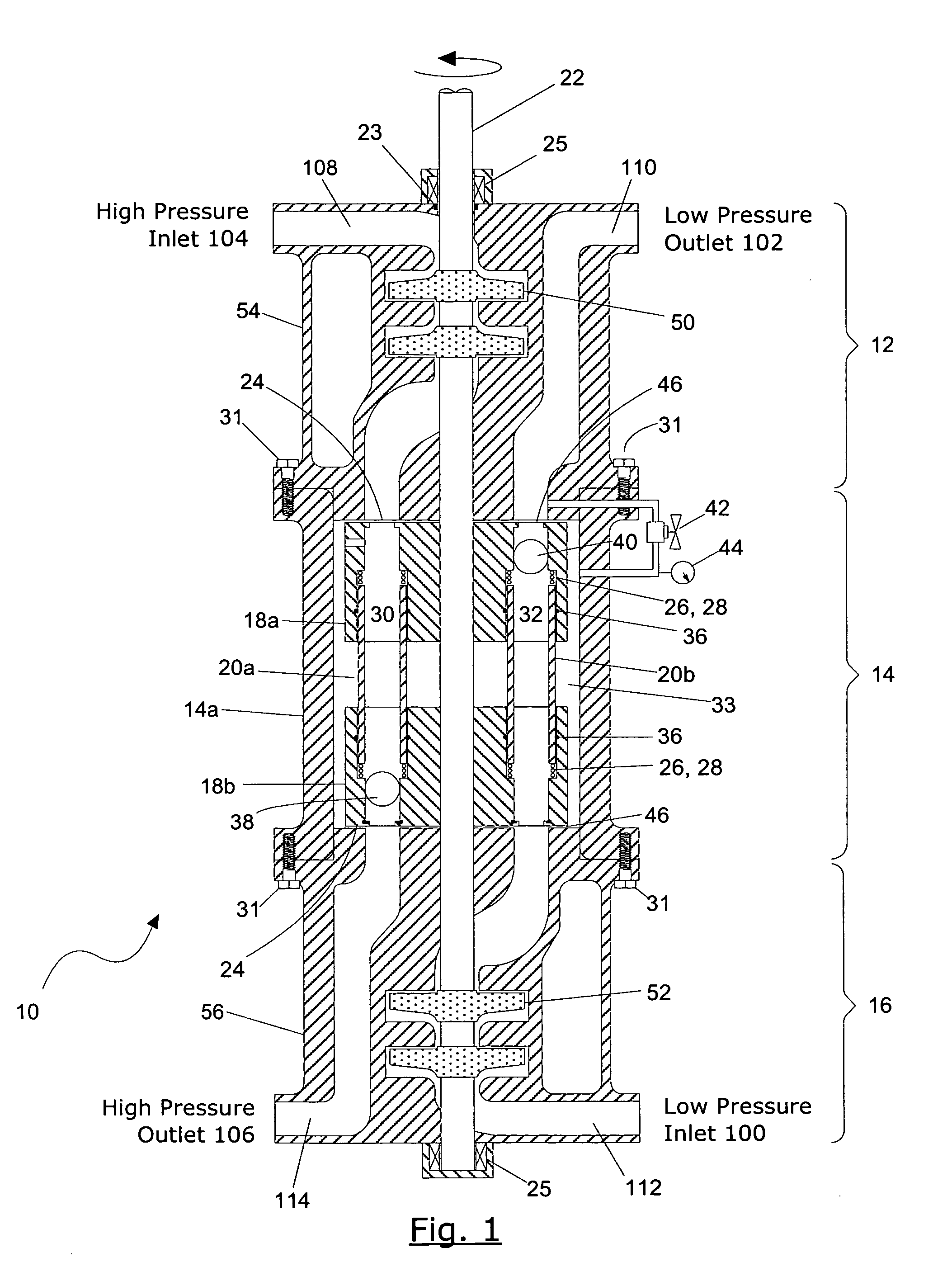

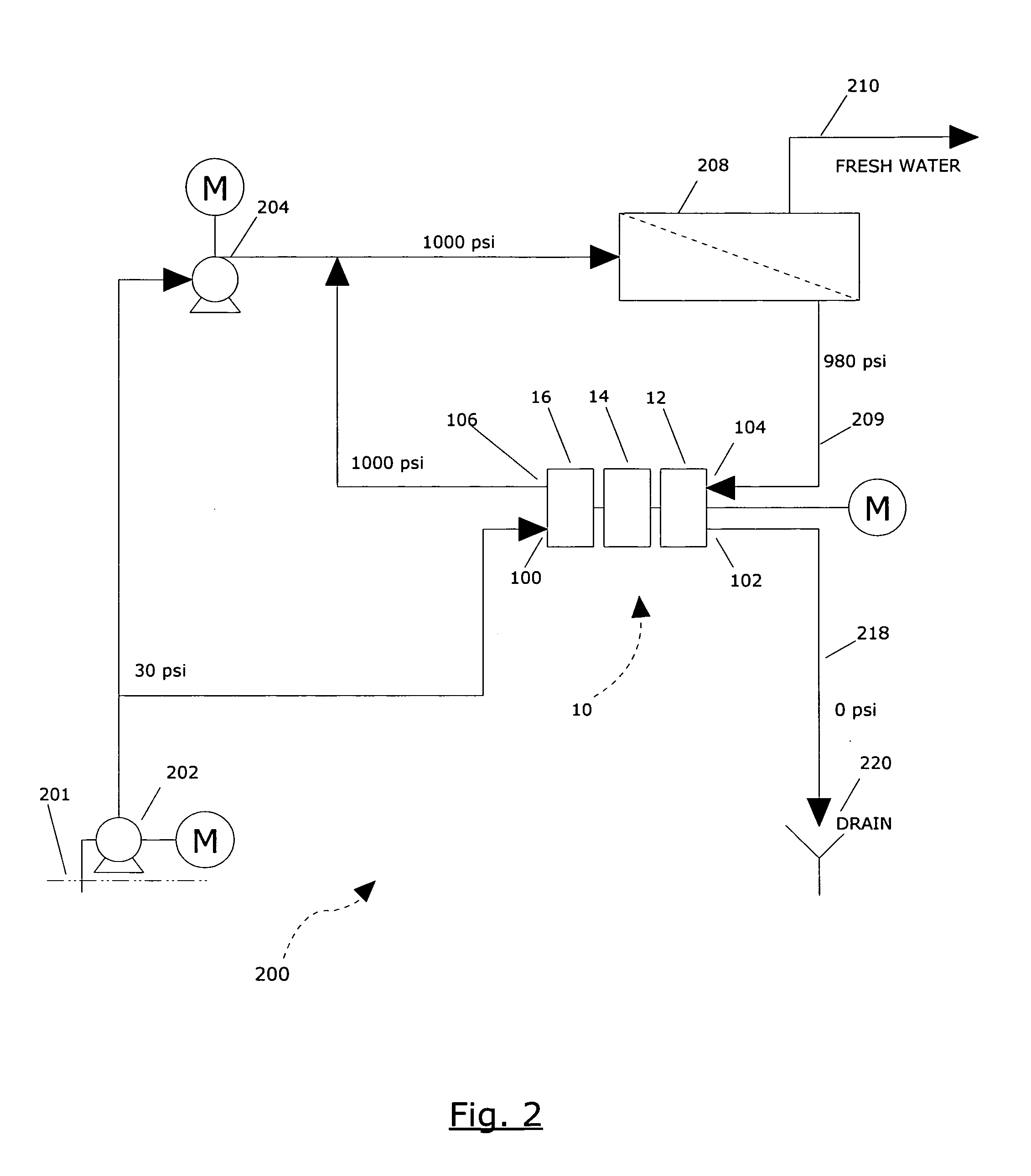

Pressure exchange apparatus with integral pump

InactiveUS20060037895A1Increase pressureRotary/oscillating piston combinations for elastic fluidsPump componentsEngineeringMechanical engineering

A pressure exchange device is provided that utilizes an integral high pressure boost pump that is in fluid communication with a pressure exchange unit. An optional low pressure boost pump unit may also be provided. The pressure exchange unit comprises a rotating rotor assembly inside a housing to transfer the pressure of a fluid from one high pressure fluid to another low pressure fluid.

Owner:SHUMWAY SCOTT

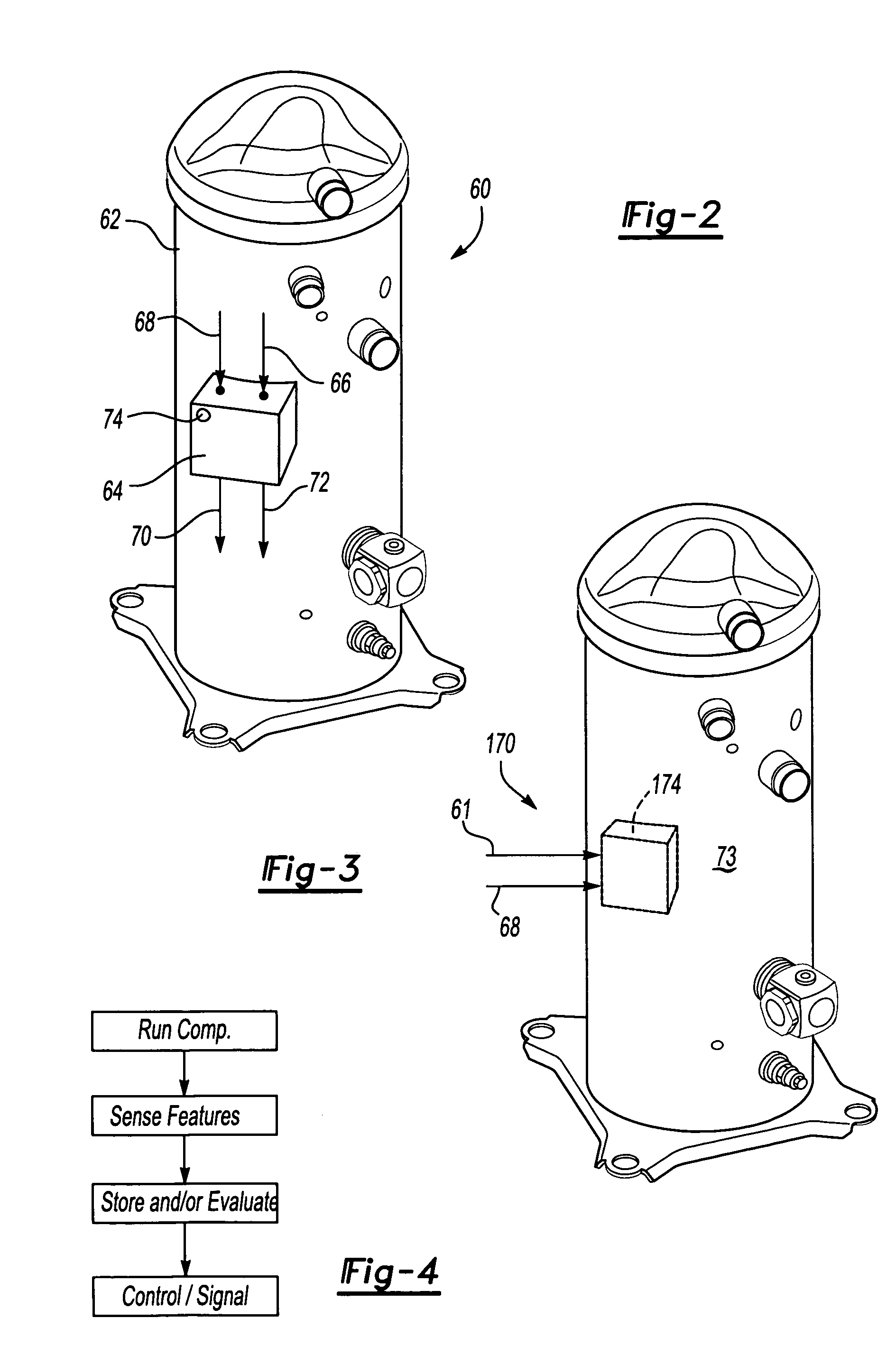

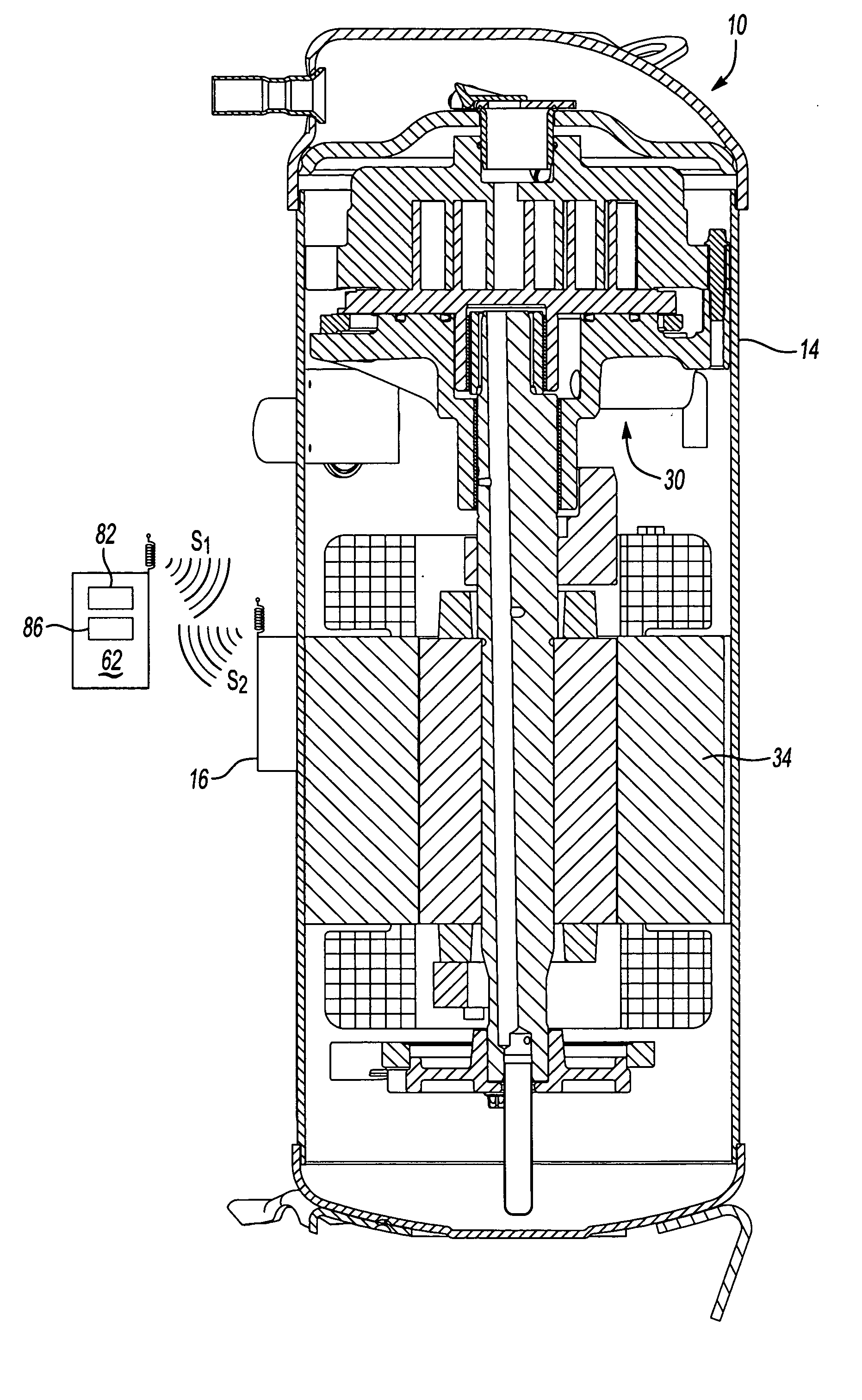

Permanent low cost radio frequency compressor identification

InactiveUS20050232781A1Fast readWrite quicklyRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringRadio frequency

Owner:SCROLL TECH

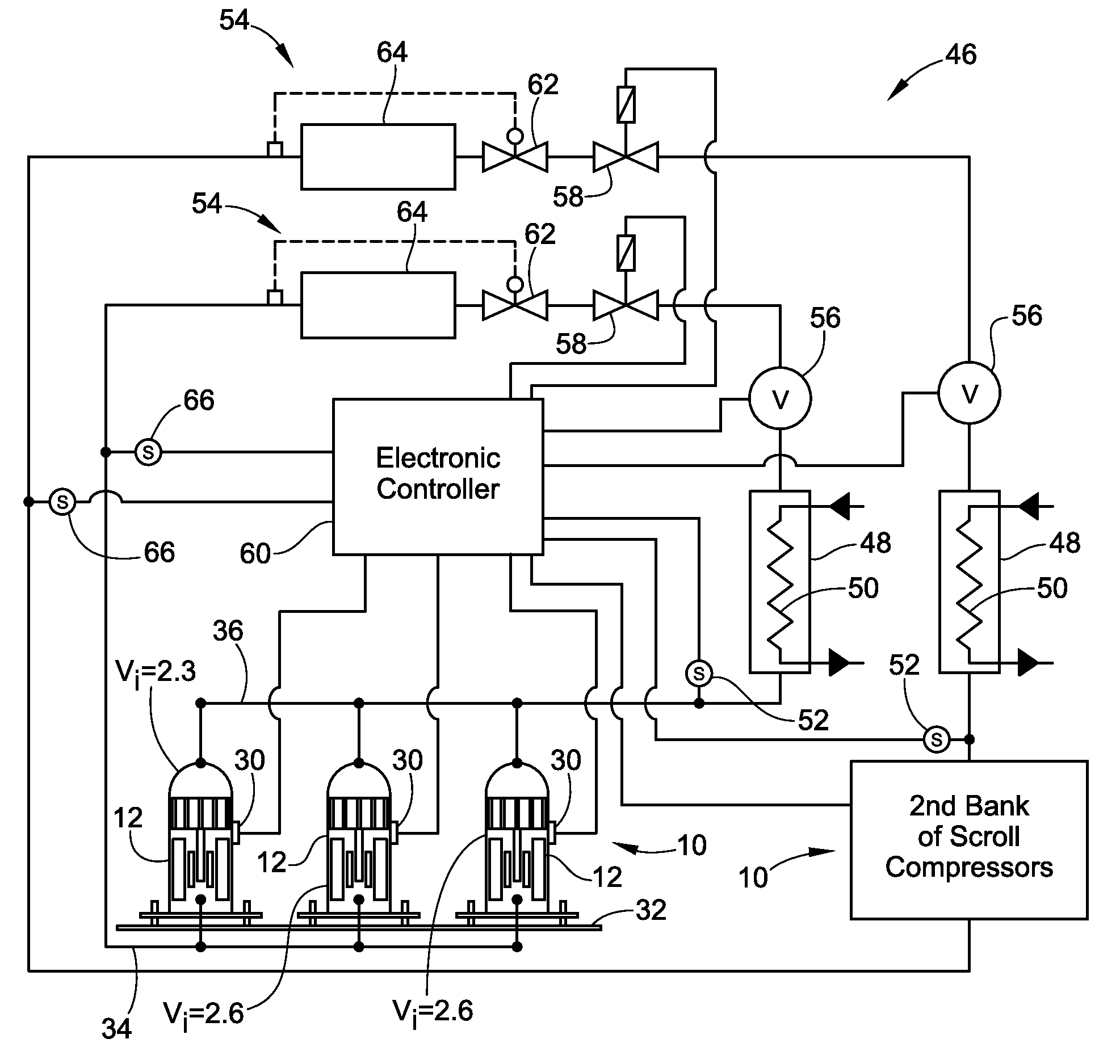

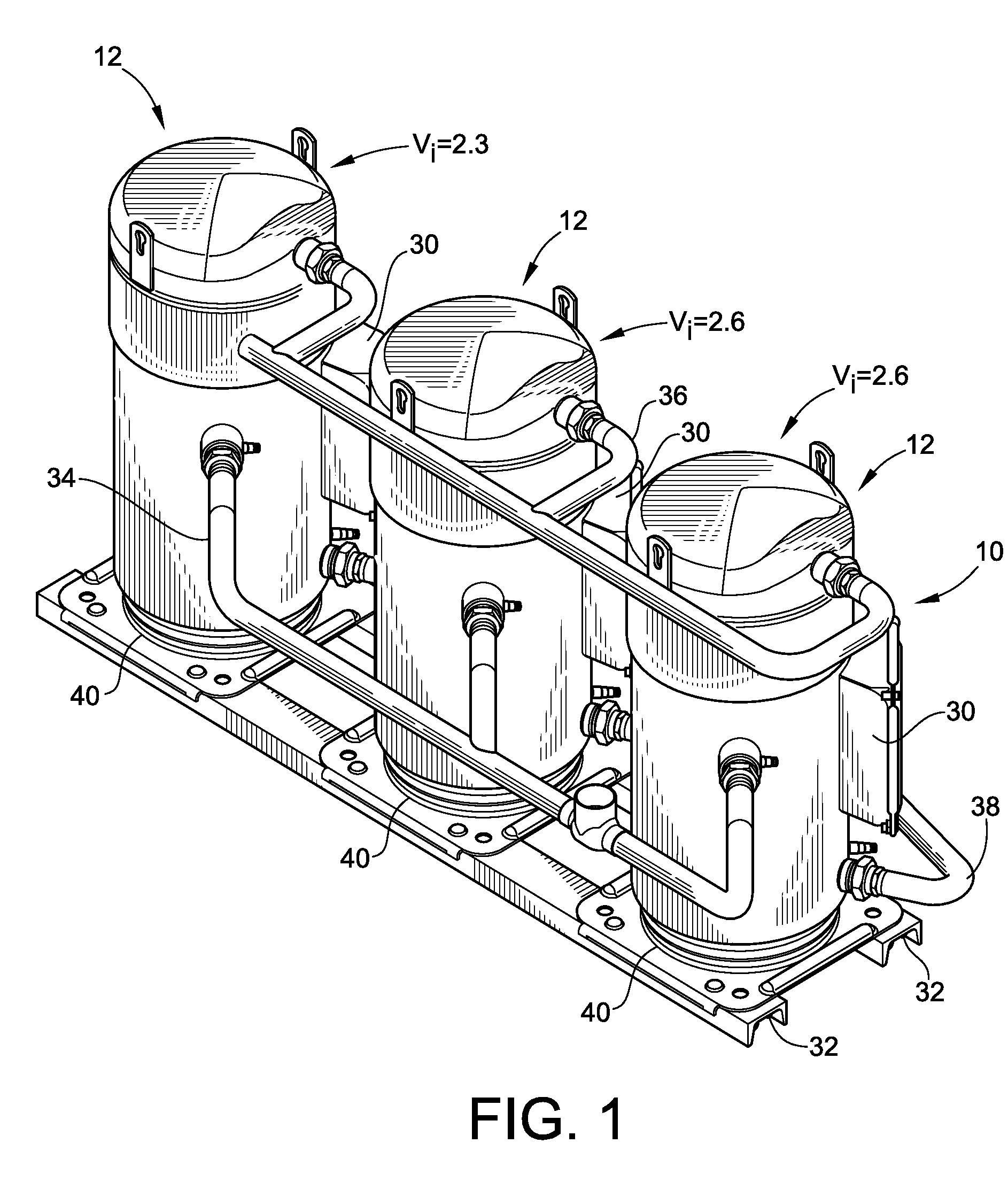

Scroll Compressors with Different Volume Indexes and Systems and Methods for Same

InactiveUS20100186433A1Improve efficiencyRotary/oscillating piston combinations for elastic fluidsCompressorEngineeringScroll compressor

Owner:BITZER KUEHLMASCHINENBAU GMBH

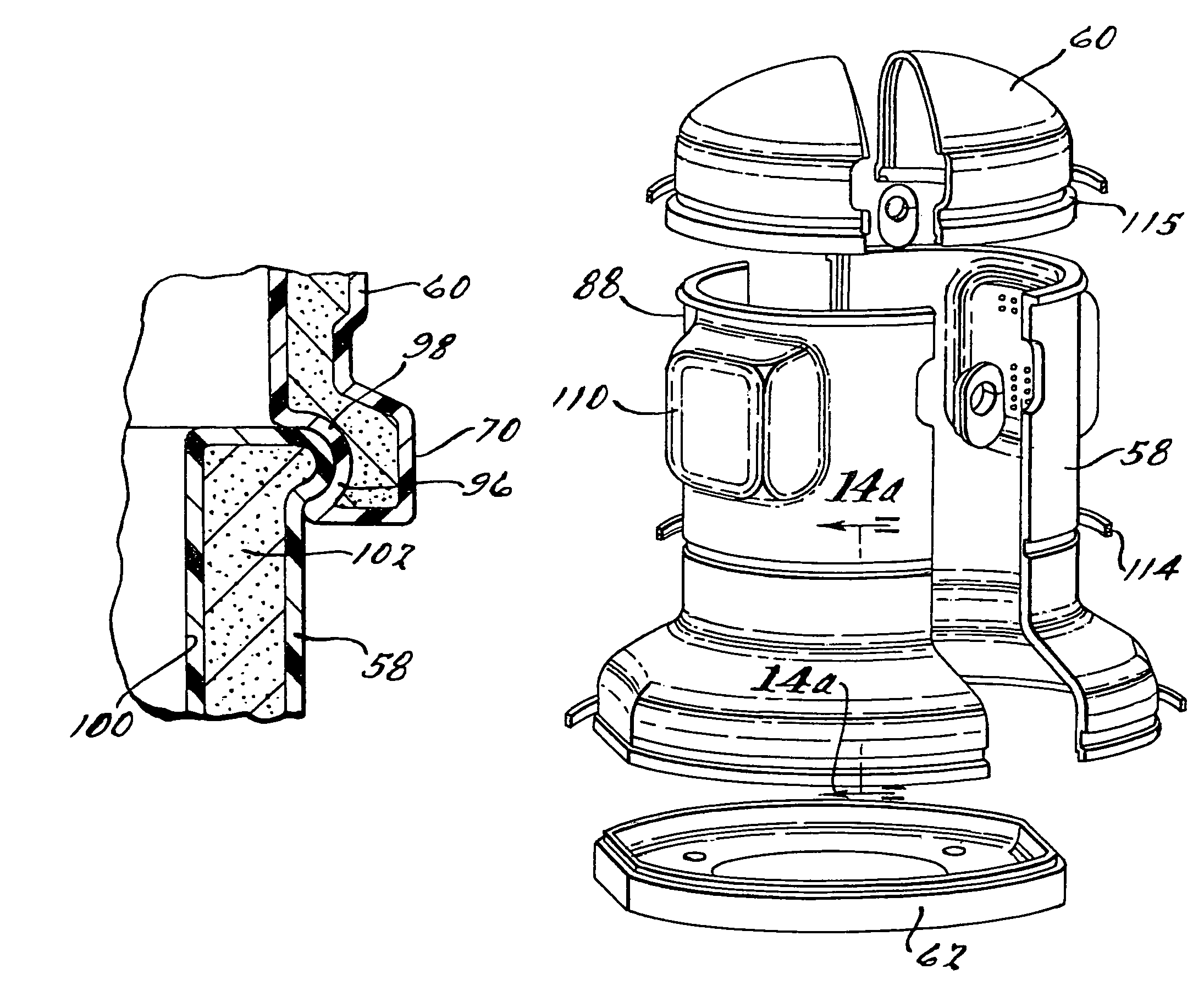

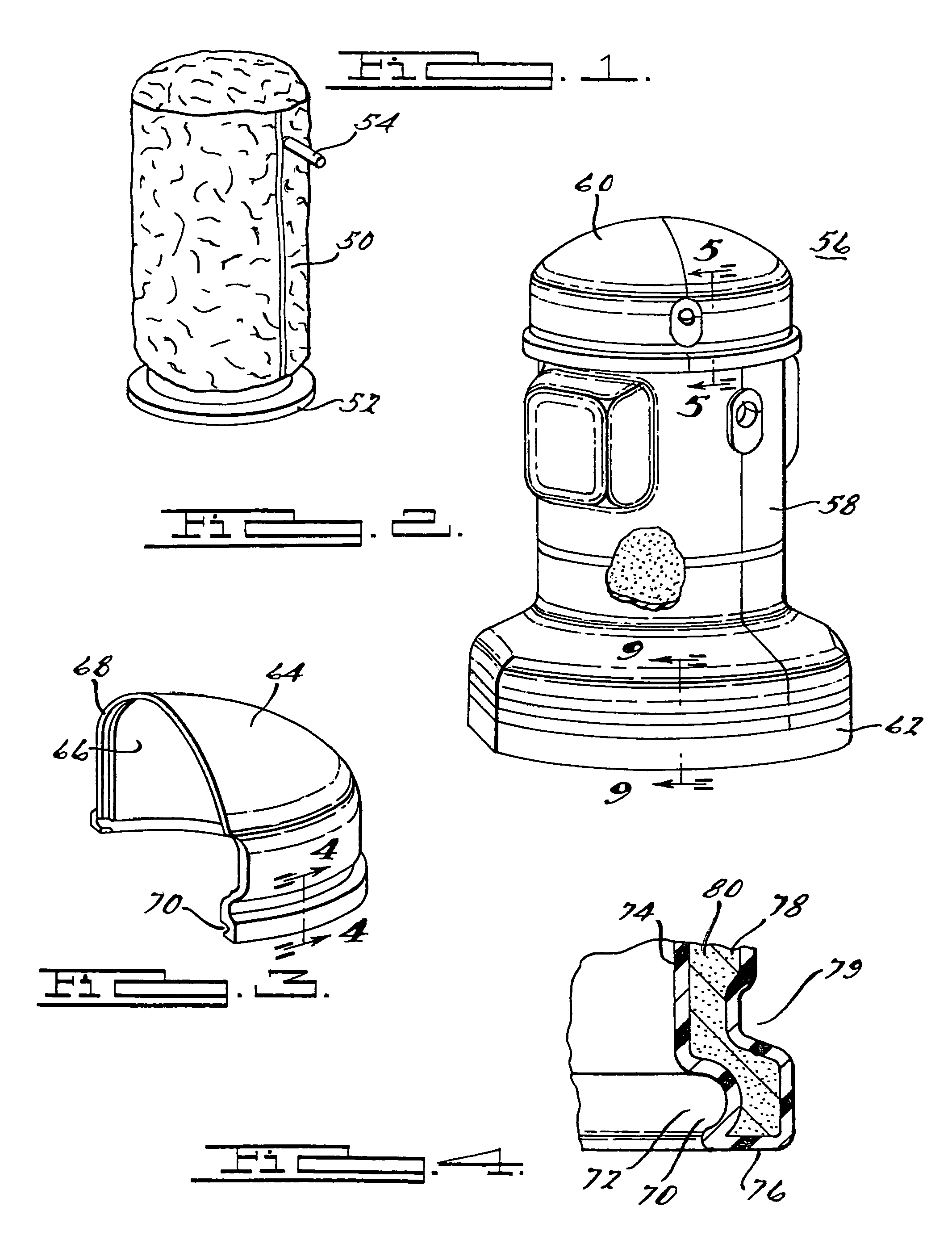

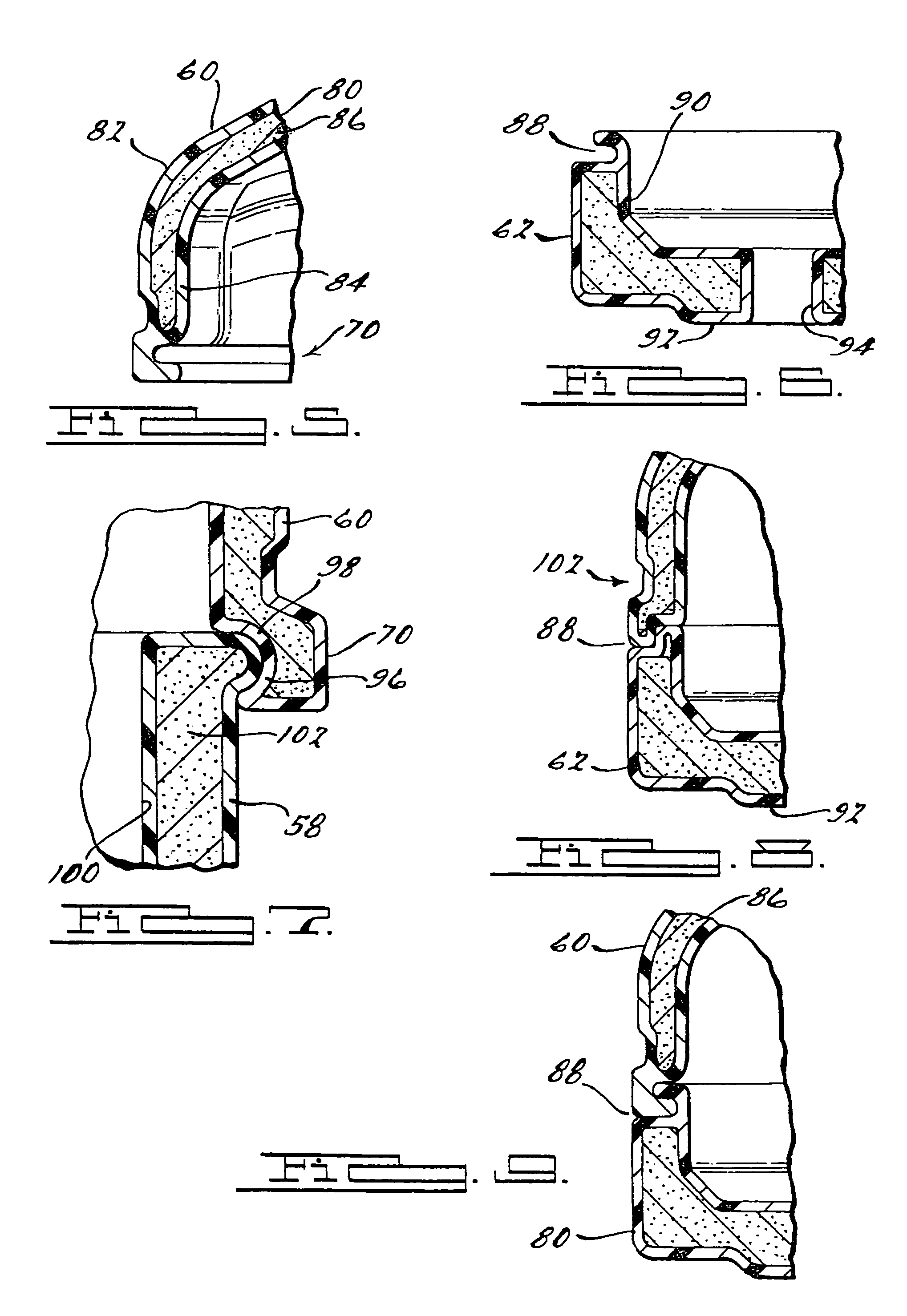

Compressor sound attenuation enclosure

InactiveUS7398855B2Improved sound attenuating shellImprove noiseRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsUltrasound attenuationEngineering

Owner:EMERSON CLIMATE TECH INC

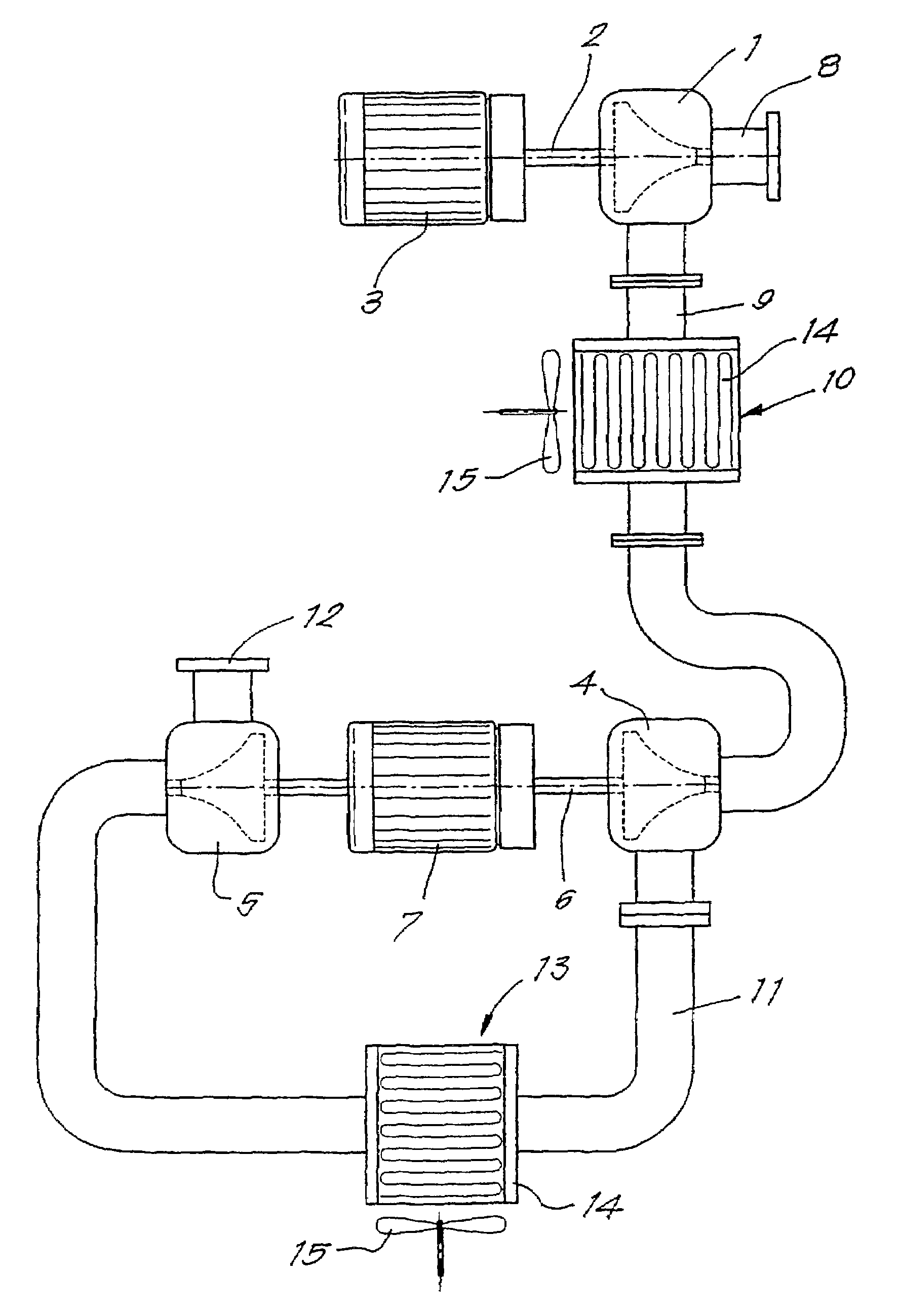

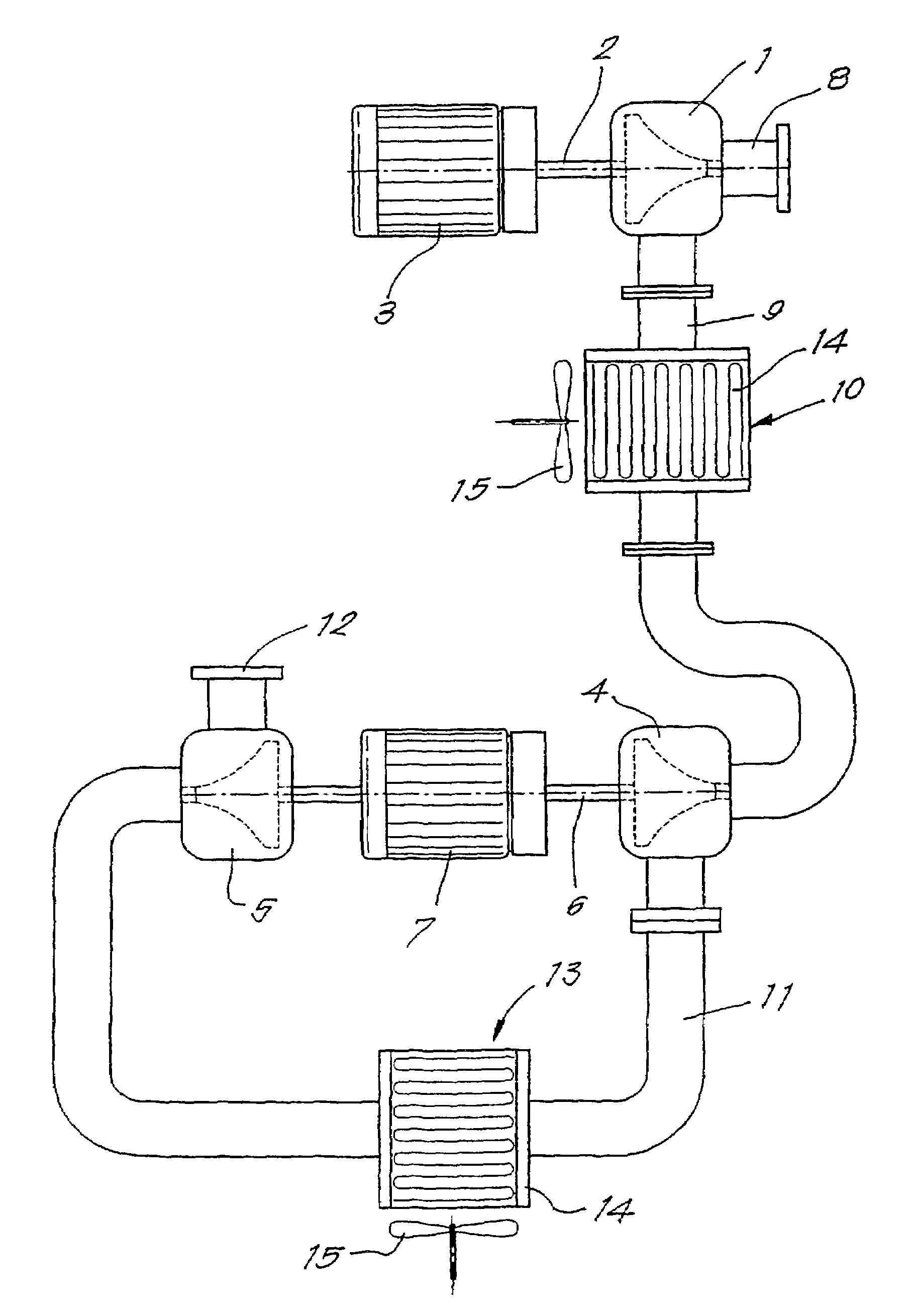

High-pressure multi-stage centrifugal compressor

InactiveUS7044716B2Reduce the ratioShorten speedRotary/oscillating piston combinations for elastic fluidsPump componentsEngineeringHigh pressure

A high-pressure multi-stage centrifugal compressor is provided containing at least three compressor elements which are arranged in series as compressor stages, and at least two electric motors to drive these compressor elements. At least one compressor element forms a low-pressure stage which is driven by an electric motor. At least two compressor elements form high-pressure stages, and are arranged in series and driven by one and the same second electric motor.

Owner:ATLAS COPCO AIRPOWER NV

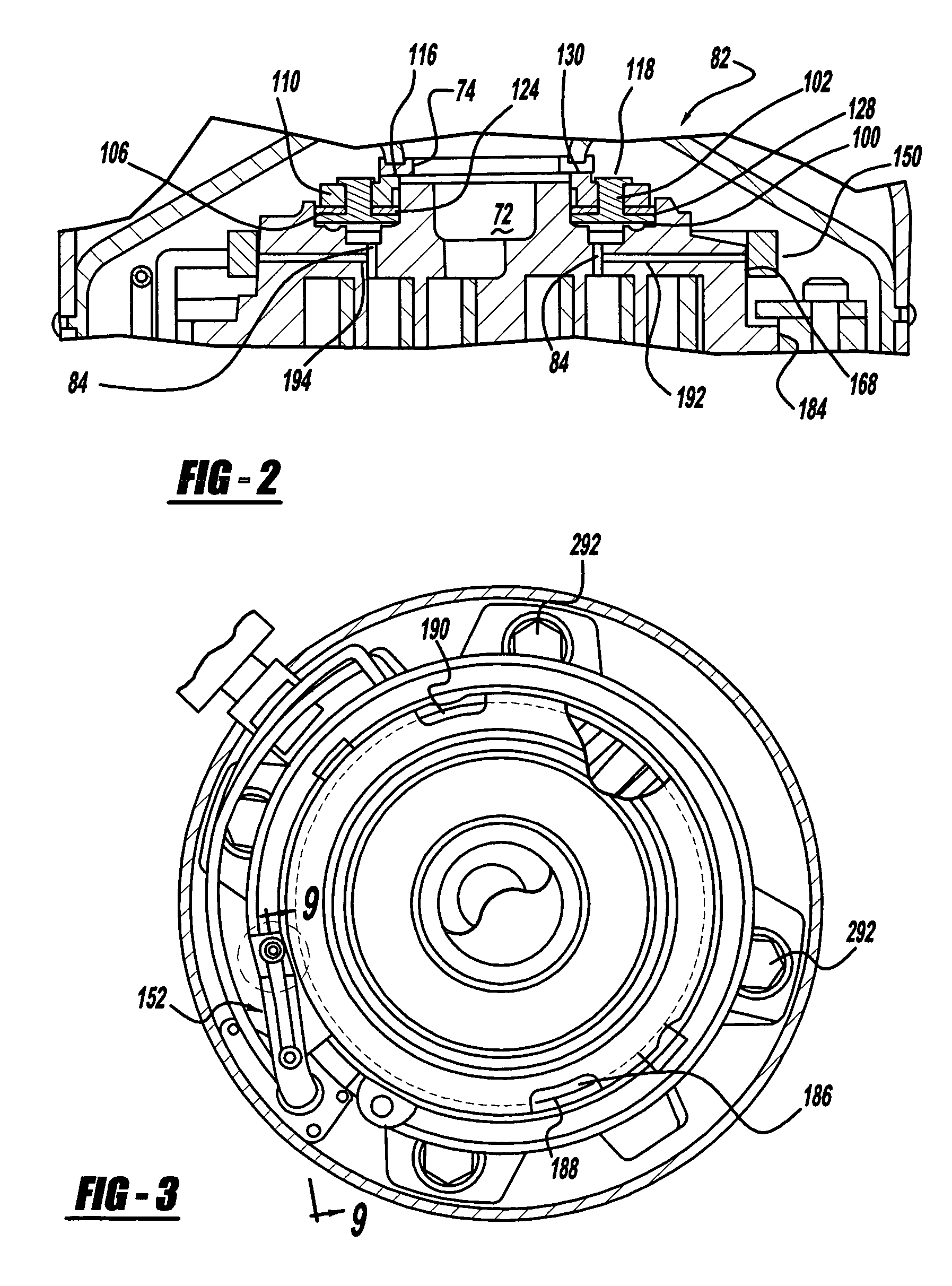

Scroll compressor with capacity modulation

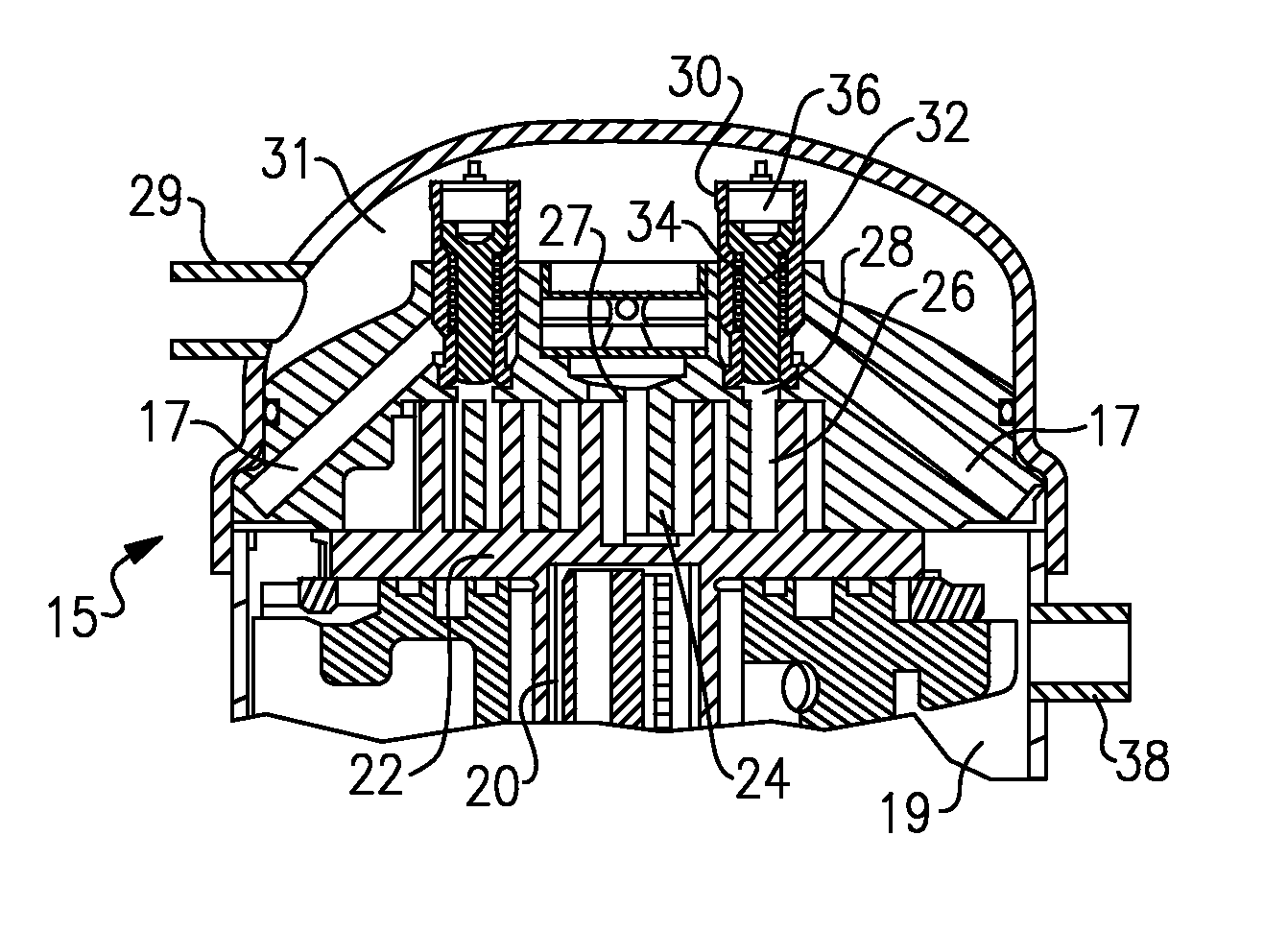

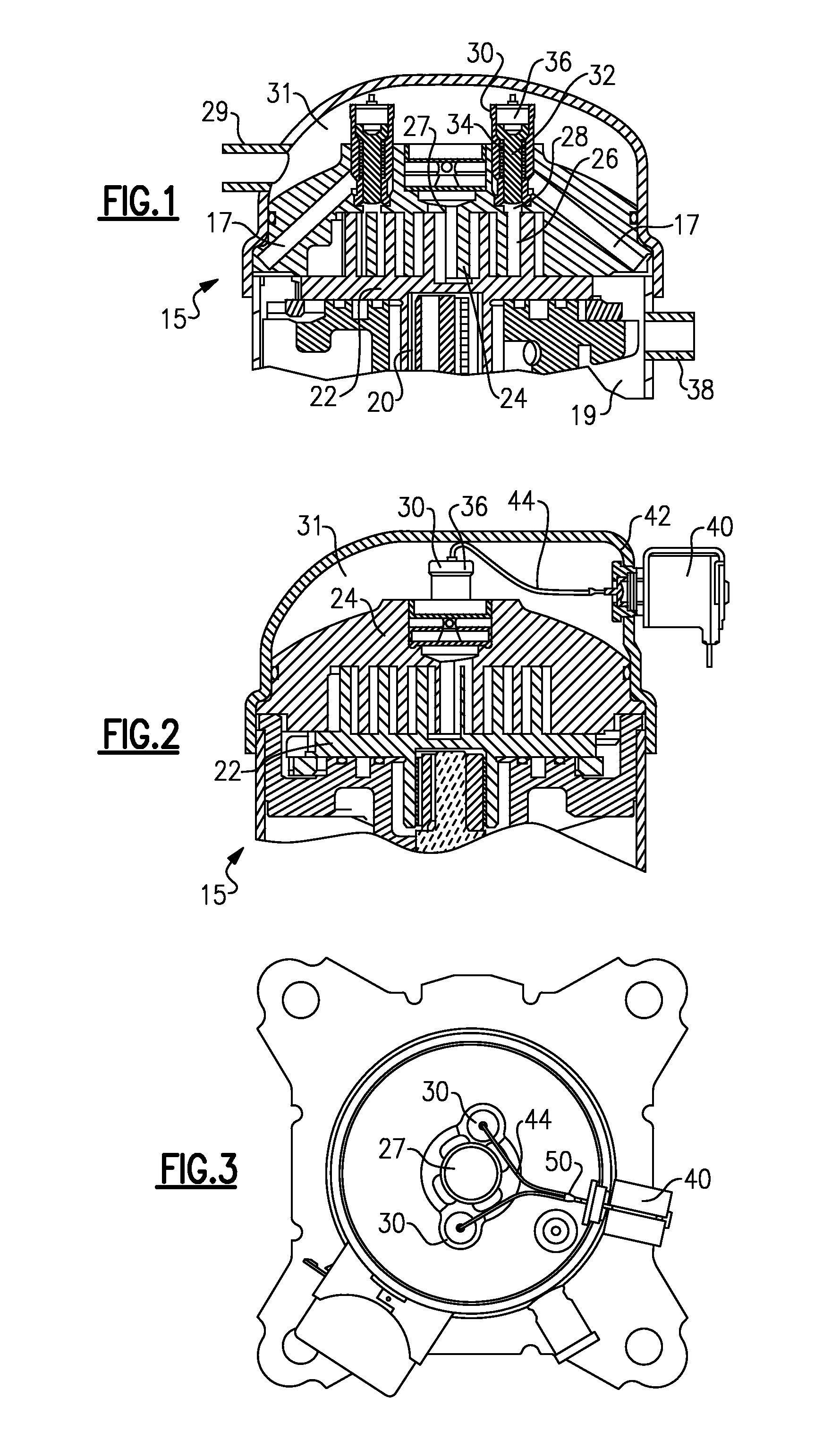

ActiveUS7547202B2Rotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeActuatorCompression member

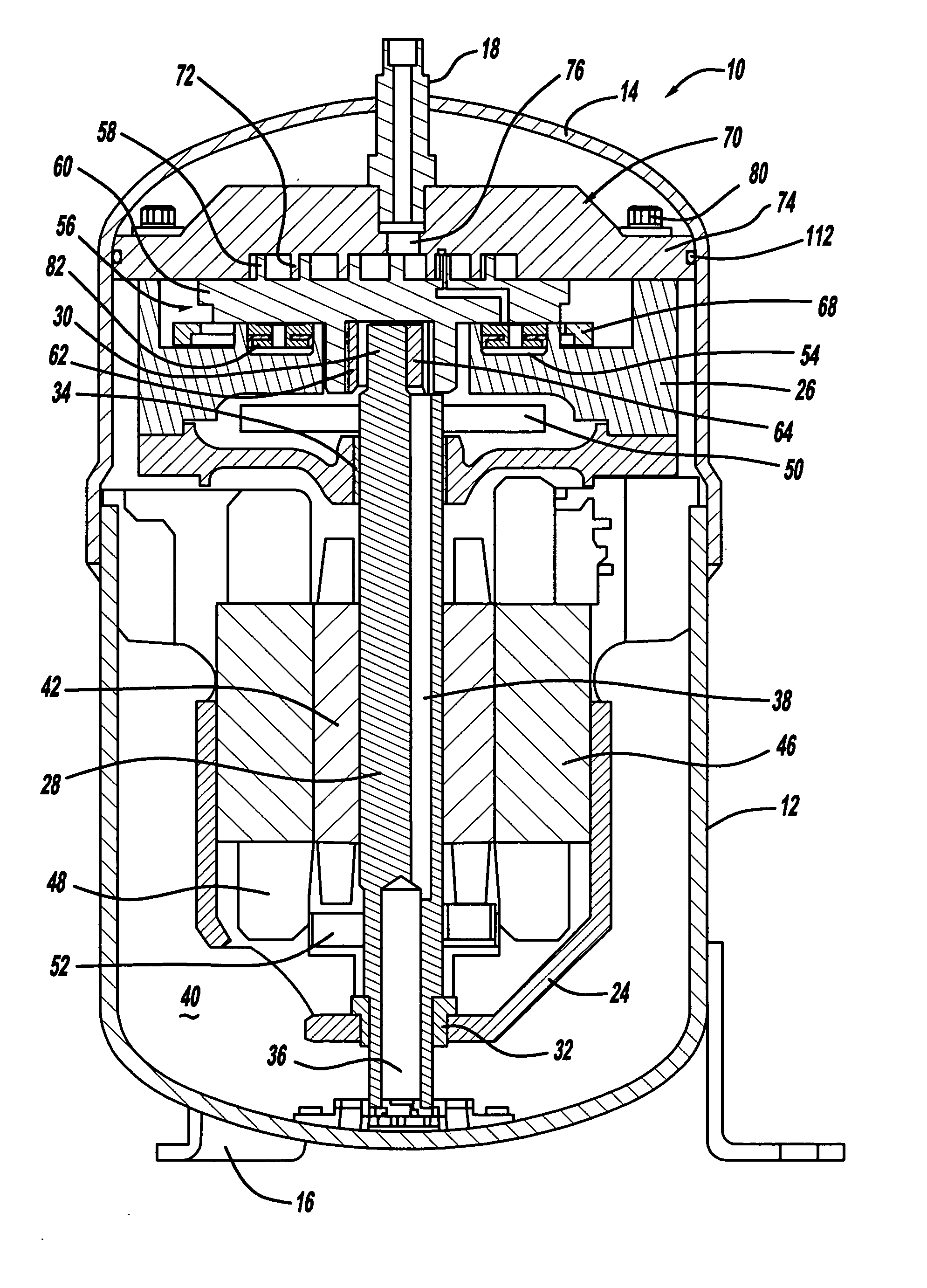

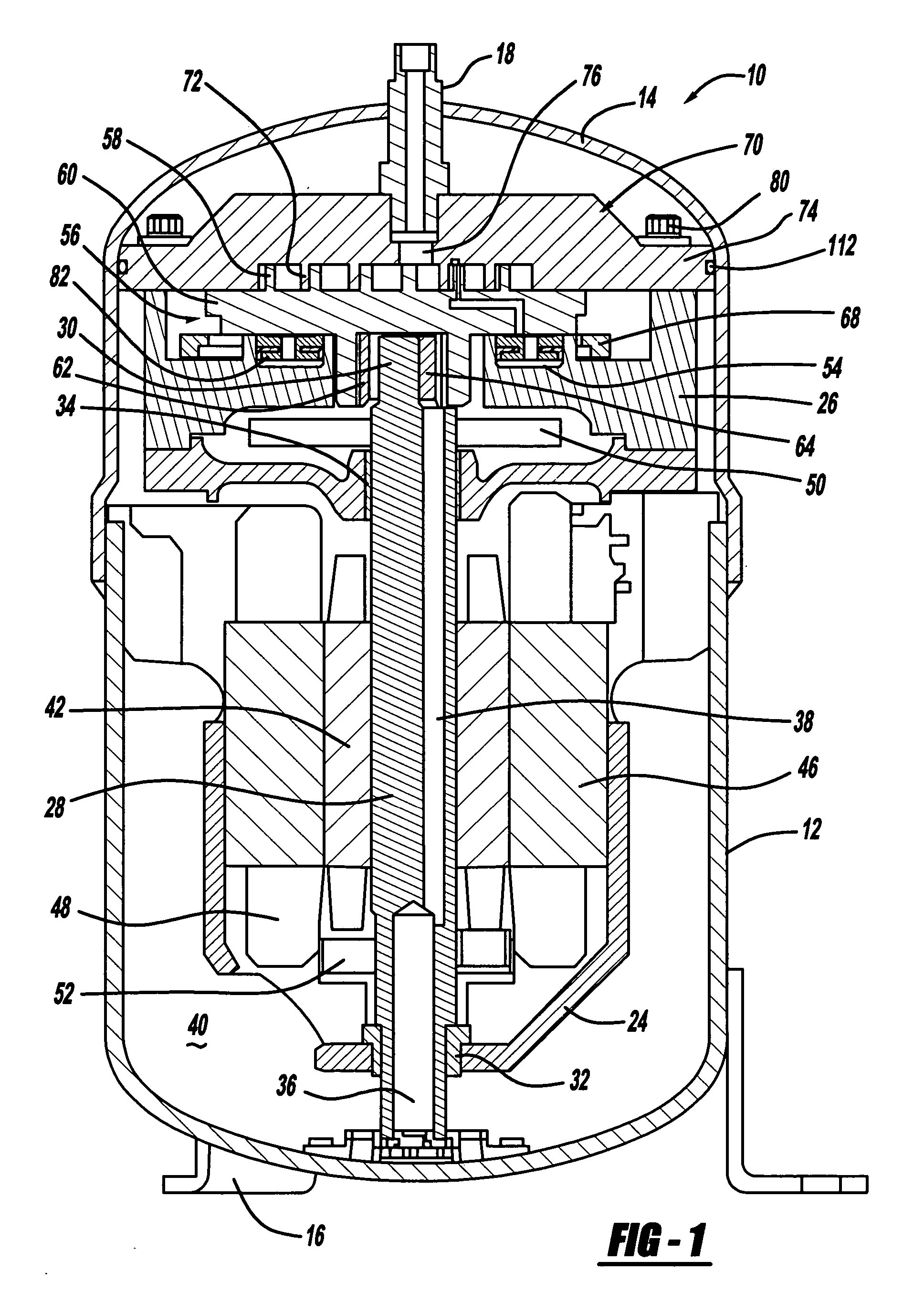

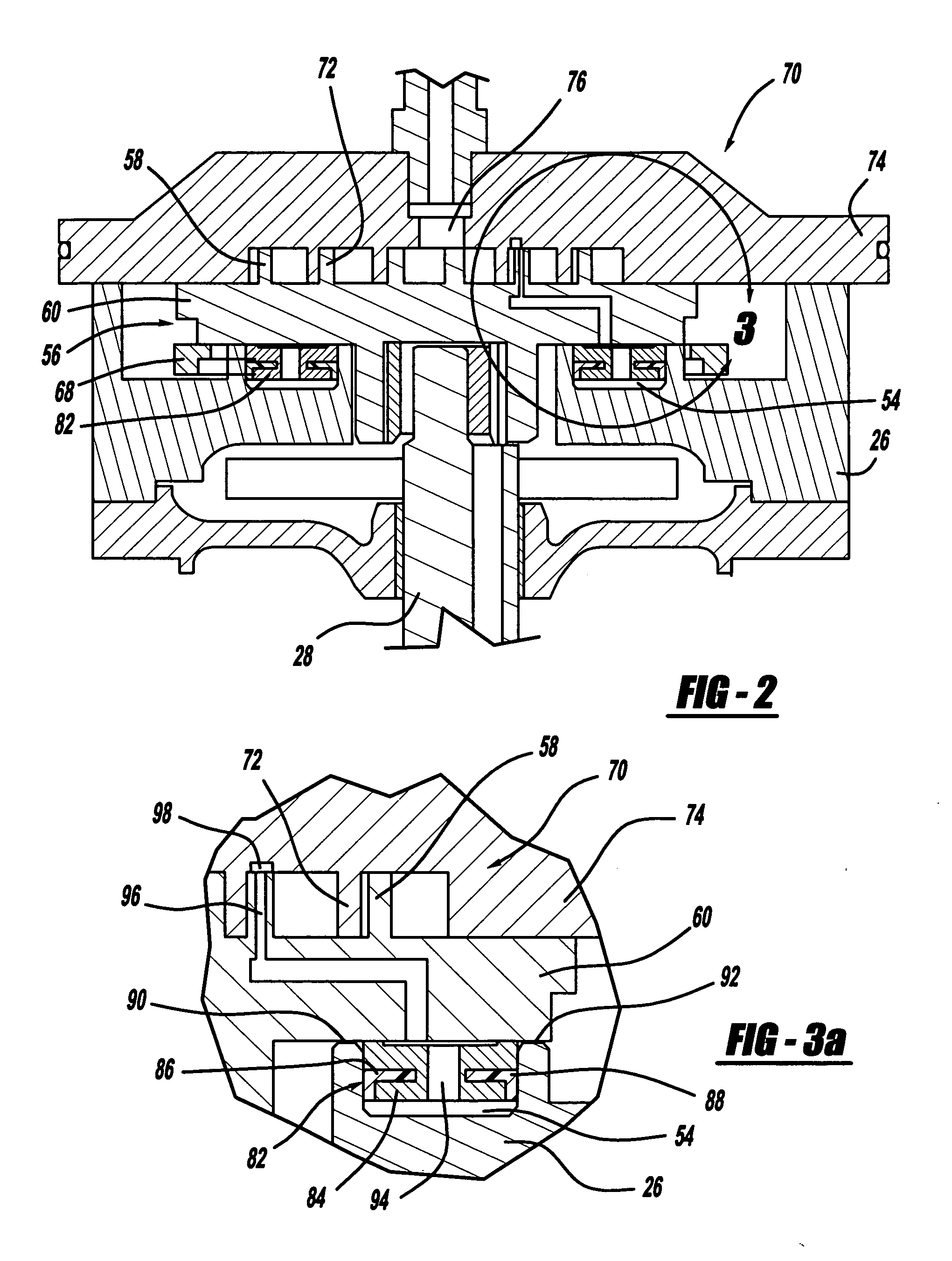

A scroll compressor may include a shell, a compression mechanism, and a sealing apparatus. The compression mechanism may be contained within the shell and include a compression member. The compression member may include an aperture extending radially there a surface. The sealing apparatus may be contained within the shell and include a first seal member and an actuator. The first seal member may be pivotally supported relative the compression member and may be movable from a first position wherein a sealing portion of the first seal member is in a sealing engagement with the surface and a second position wherein the sealing portion of the first seal member is displaced radially outwardly from the surface. The actuator may be engaged with the first seal member and configured to displace the first seal member from the first position to the second position.

Owner:COPELAND LP

Scroll compressor

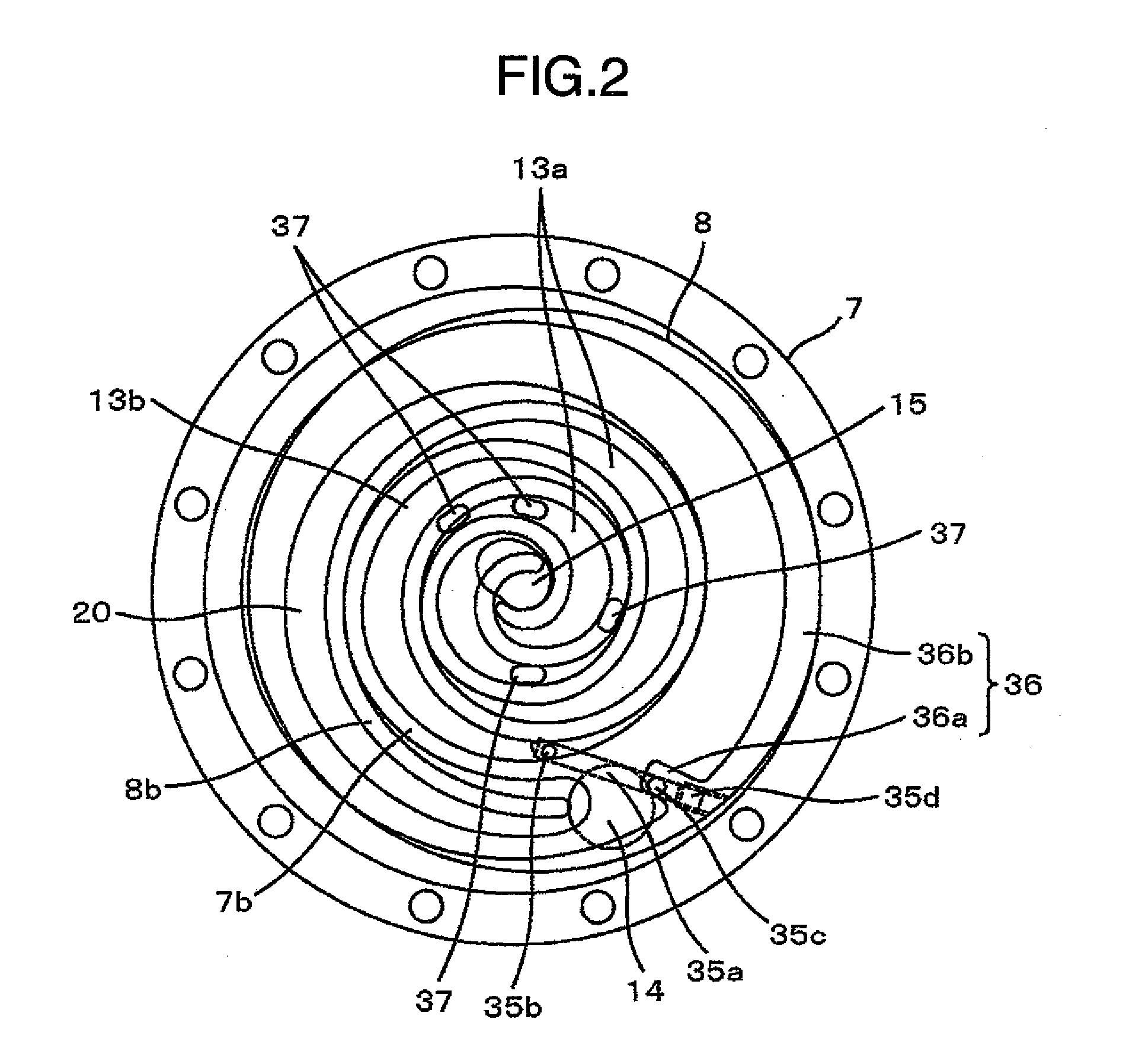

InactiveUS20070092390A1Improve sealingImprove efficiencyRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringScroll compressor

A scroll compressor has a fluid pressure biasing system for both the orbiting scroll member and the non-orbiting scroll member. The biasing system can utilize a pressurized gas from the pocket of the scroll compressor or it can utilize an external pressurized oil source. In an additional embodiment, a hydrostatic bearing is located between the orbiting scroll member and the non-orbiting scroll member.

Owner:EMERSON CLIMATE TECH INC

Air conditioner and method of controlling the same

InactiveUS7040107B2Smooth startImprove startup reliabilityRotary/oscillating piston combinations for elastic fluidsSpace heating and ventilation safety systemsCounter rotationVariable capacity

An air conditioner has a variable capacity rotary compressor, which allows the compressor to be smoothly re-started, thus increasing start reliability of the compressor. The air conditioner includes a compressor rotated in opposite directions. A drive unit rotates the compressor in a forward or reverse direction. A start determining unit determines whether the compressor has started to rotate in a forward direction or not. A control unit operates the drive unit so as to rotate the compressor in a direction opposite to the forward direction, and then re-start the compressor in the forward direction, when the compressor has failed to start. The air conditioner and a method of controlling the air conditioner allow the compressor to be smoothly and rapidly re-started even when the compressor has failed to re-start, thus increasing start reliability, and shortening a time required to re-start the compressor.

Owner:SAMSUNG ELECTRONICS CO LTD

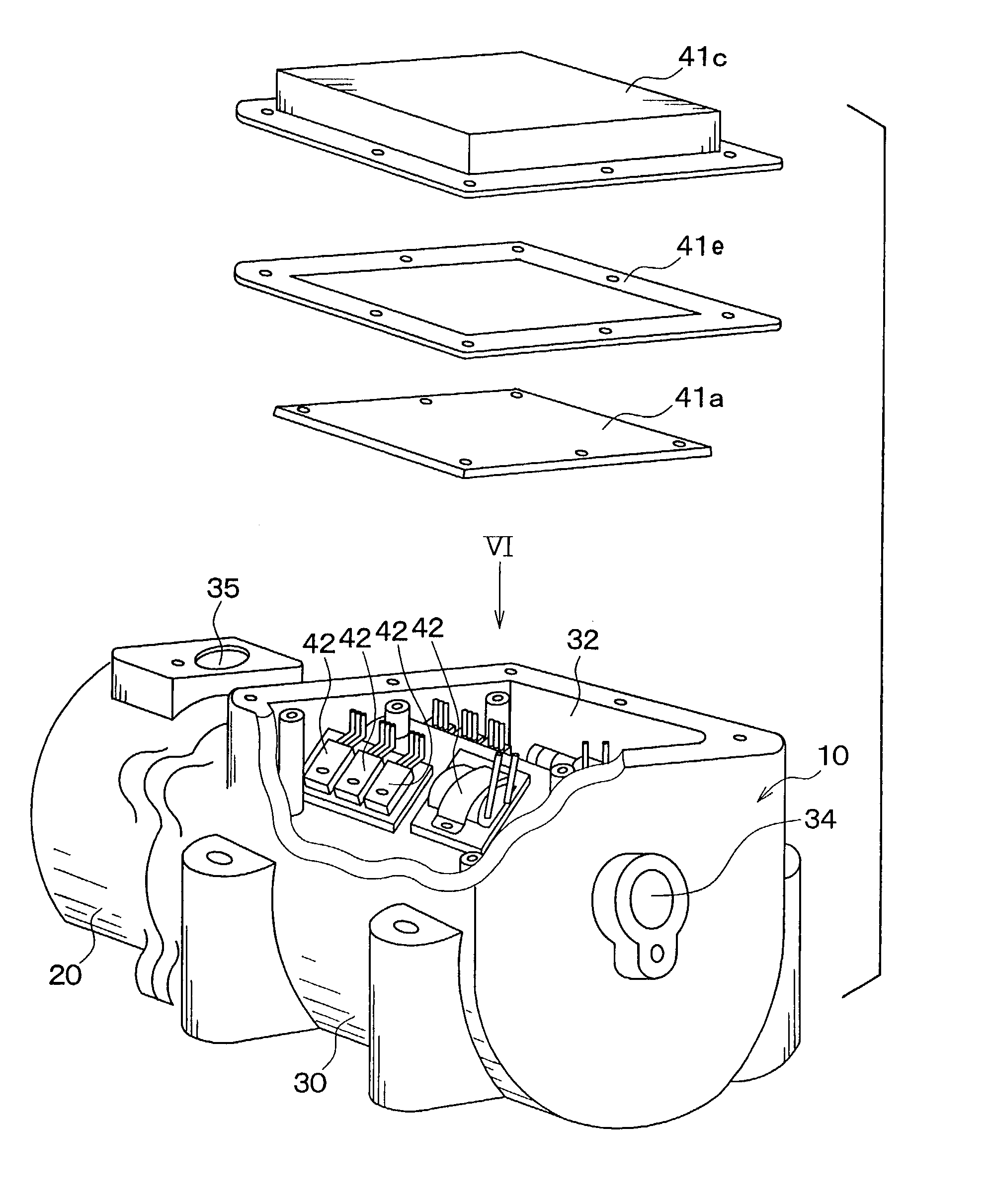

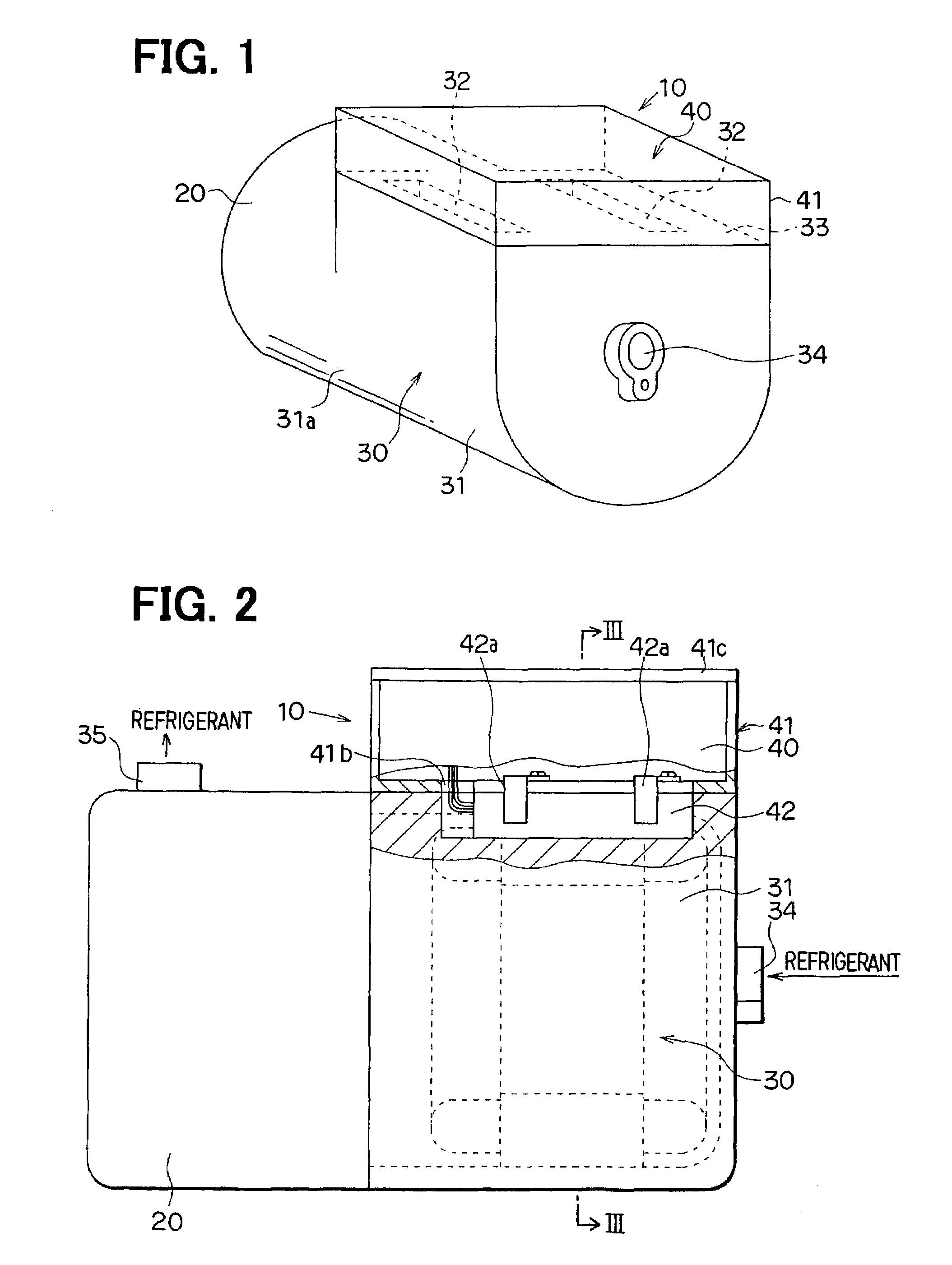

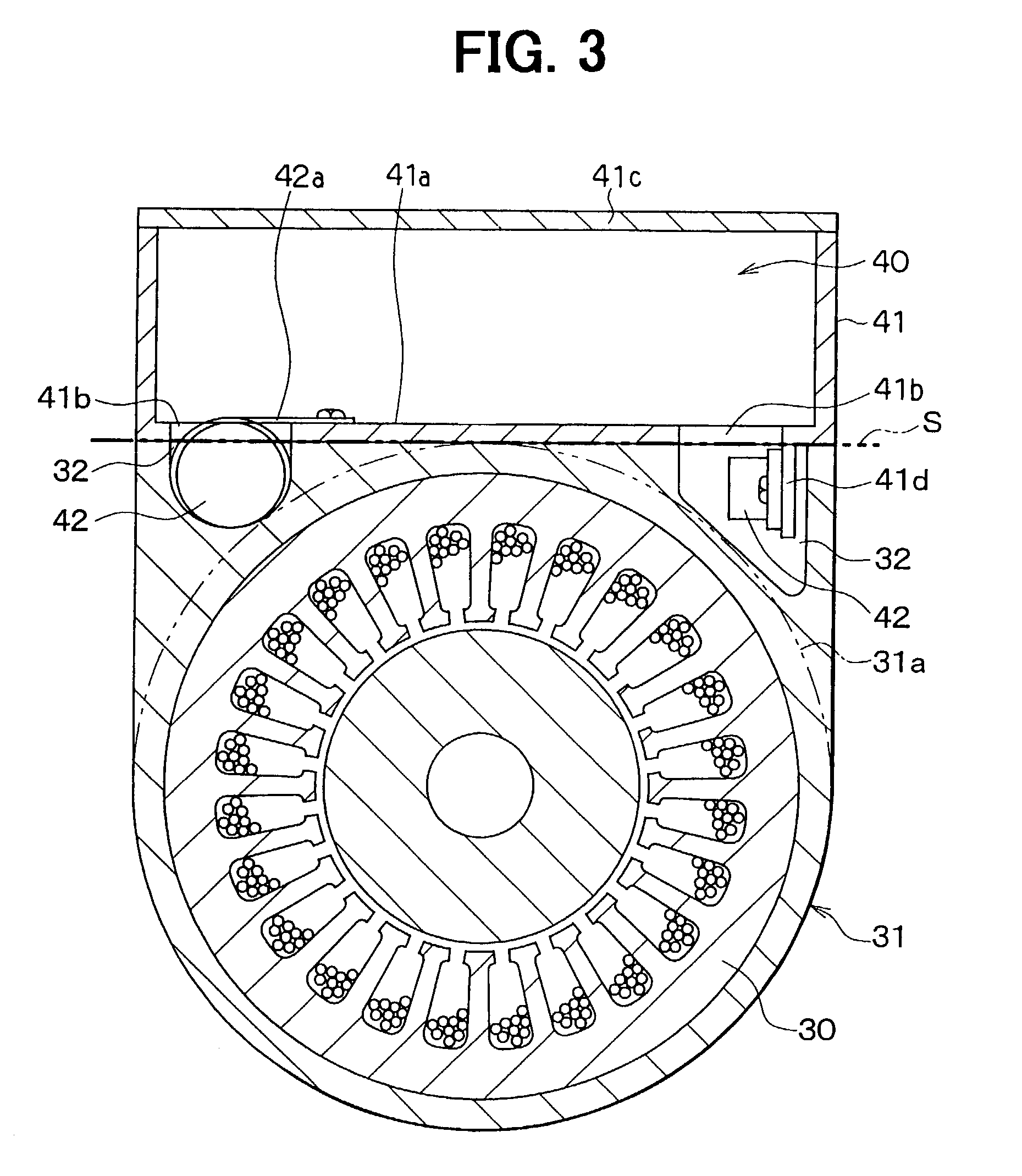

Electric refrigeration compressor having a cooling system for an electrical circuit

InactiveUS7009318B2Small sizeReduce weightRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsElectric motorRefrigeration compressor

In an electrical compressor having a motor and an electrical circuit integrated with a compression portion, a part of electrical components of the electrical circuit is disposed in spaces between a cylindrical outer surface of a motor housing and an imaginary flat surface that imaginarily contacts the cylindrical outer surface. Therefore, the spaces can be used effectively, and the electrical compressor can be downsized. Further, the part of the electrical components can be effectively cooled by refrigerant in the motor housing. On the other hand, the outer surface of the motor housing is used as one surface defining an inner space of a casing for accommodating the electrical circuit. In this case, the electrical circuit can be effectively cooled by refrigerant in the motor housing.

Owner:DENSO CORP

Scroll compressor

InactiveUS20100111741A1Improve performanceImprove reliabilityRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringBack pressure

A scroll compressor comprises a fixed scroll, an orbiting scroll engaged with the fixed scroll to form a compression chamber therebetween, a back pressure chamber arranged at a back side of an end plate of the orbiting scroll, a back pressure hole formed in the end plate of the orbiting scroll to form a fluidal communication between the compression chamber and the back pressure chamber, and a release valve mechanism for discharging the fluid from the compression chamber to the discharge space when a pressure in the compression chamber is higher than the pressure in the discharge space, wherein the back pressure hole and the release flow path are arranged to prevent both of the fluidal communication and the another fluidal communication from being formed simultaneously.

Owner:HITACHI APPLIANCES INC

Capacity modulated scroll compressor

InactiveUS20070036661A1Reduce compressionCapacity modulationRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsElectrical and Electronics engineeringScroll compressor

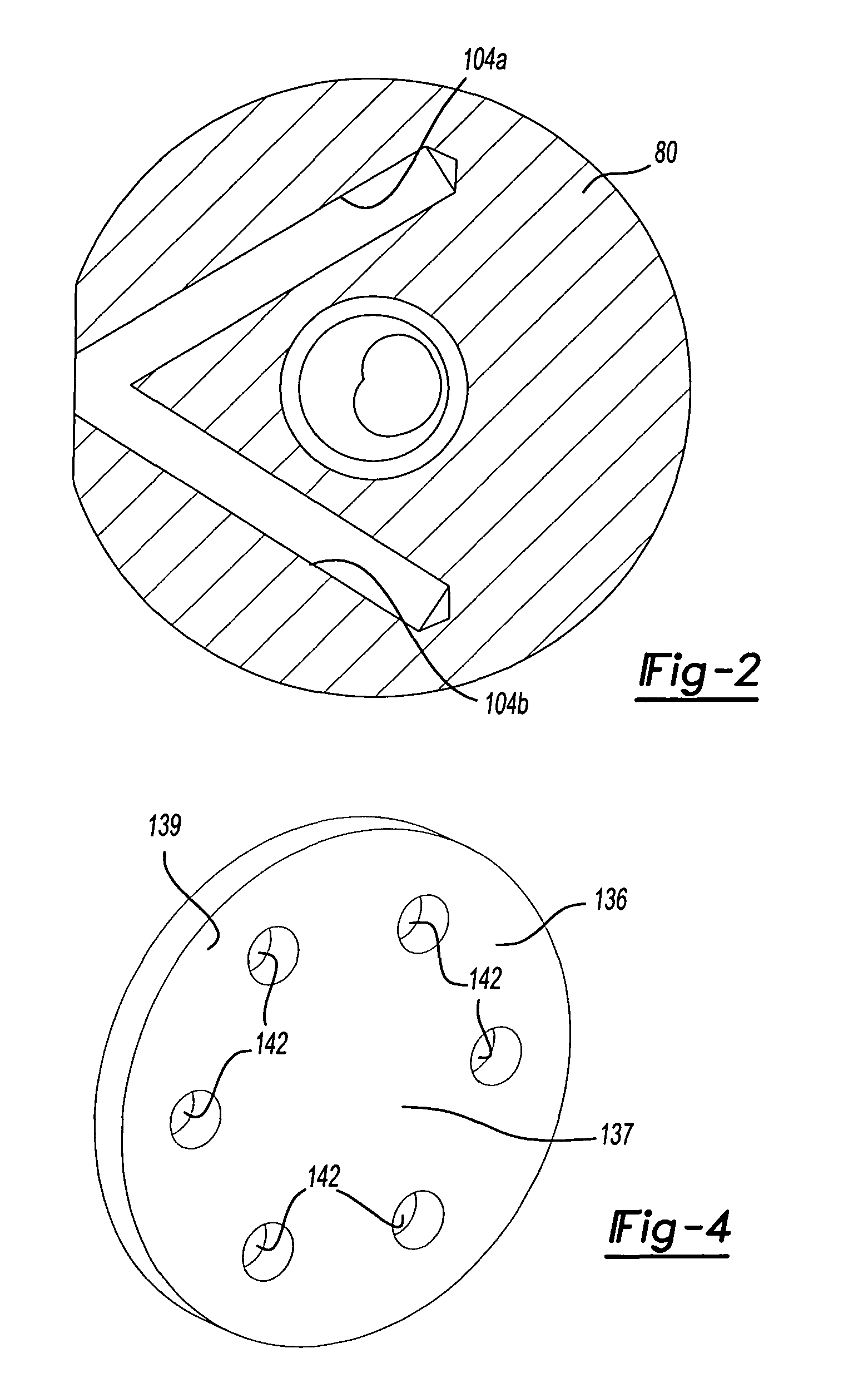

A scroll compressor has a biasing chamber which contains a pressurized fluid. The pressurized fluid within the chamber biases the two scroll members together. A rotatable ring is attached to one of the scroll members to open and close a passage leading to this biasing chamber. When the ring opens the passage in one embodiment, this releases the pressurized fluid to remove the load, biasing the two scroll members together. When the biasing load is removed, the two scroll members separate, creating a leakage path between discharge and suction to reduce the capacity of the scroll compressor. When the ring opens the passage in another embodiment, a delayed suction passage is opened to reduce the capacity of the compressor.

Owner:EMERSON CLIMATE TECH INC

Compressor utilizing low volt power tapped from high volt power

InactiveUS6964558B2Reduce voltage gainRotary/oscillating piston combinations for elastic fluidsAssociation with control/drive circuitsLow voltageEngineering

Low voltage electrical power is supplied to a diagnostic control device in a sealed compressor. Electrical power is tapped from a high voltage power line and transformed to low voltage power that in turn operates the diagnostic control device. The diagnostic control device and the electric voltage transforming system are housed within the sealed compressor shell, thus eliminating the need for additional openings in the compressor shell. Other low voltage devices can be powered in this way.

Owner:SCROLL TECH

Fluid circulation path for motor pump

InactiveUS6884043B2Rotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringPump head

A fluid pump includes a pump head having an inlet for receiving fluid at a first pressure and an outlet for outputting fluid at a second pressure greater than the first pressure. Pressurized fluid is directed through a first passage to the outlet without the pressurized fluid leaving the pump head prior to reaching the outlet. A second passage directs pressurized fluid to a fluid circulation path which is at least partially external to the pump head with the fluid circulation path terminating adjacent the outlet. Pressurized fluid passing through the first and second passages is directed to the outlet without being re-pressurized by the pump head. The first and second passages are in opposed relation to one another to provide balancing of thrust produced by the flow of pressurized fluid through the passages. An electric motor drives the pump head. The fluid circulation path may include portions of the electric motor.

Owner:STANDEX INT CORP

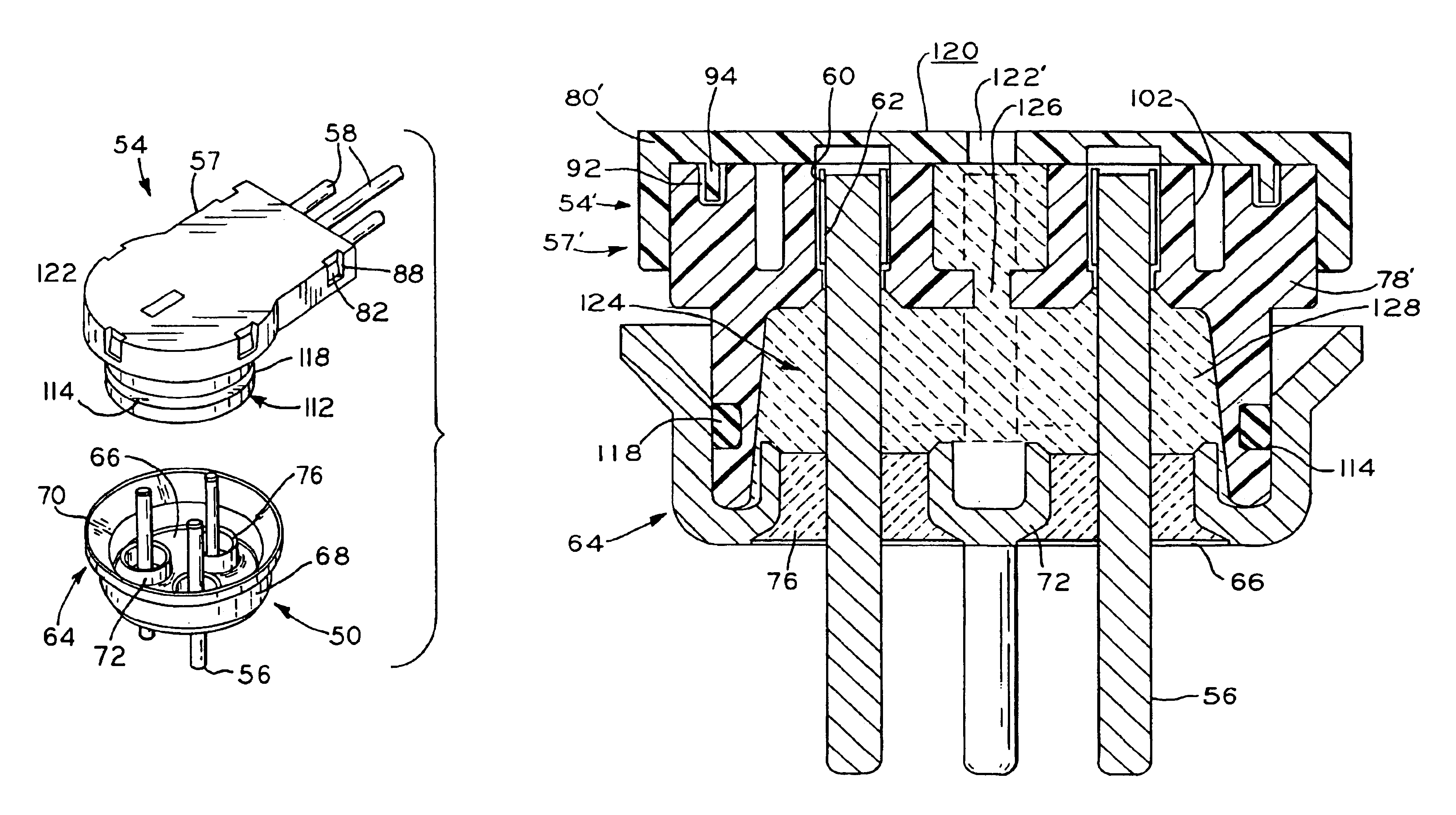

Compressor with terminal assembly having dielectric material

InactiveUS6910904B2Potential for leakageRotary/oscillating piston combinations for elastic fluidsRelieving strain on wire connectionHermetic sealEngineering

Owner:TECUMSEH PROD CO

Miniature rotary compressor, and methods related thereto

InactiveUS20060140791A1High densityImprove efficiencyProgramme controlCompressorMiniaturizationEngineering

Disclosed is a rolling piston rotary compressor for use with primary refrigerants that is miniaturized for portable and mobile applications for which size and weight are often crucial. The miniature rotary compressor comprises a compressor mechanism, a brushless DC motor and a casing. The compressor mechanism comprises, a cylinder, a shaft having an eccentric part, one or more bearings to support the shaft, a roller, a vane, an oil sump, openings for communicating with lubricant oil and refrigerant, and inlet and discharge ports. The compressor mechanism and the motor are housed in a hermetically sealed or semi-hermetically sealed casing. The configuration and design of the present invention allow the realization of an ultralight miniature compressor. The miniature rotary compressor provides a higher power density and comparable efficiency as compared to state-of-the-art refrigerant-based rotary compressors. Also disclosed are methods of manufacturing the miniature rotary compressor.

Owner:ASPEN COMPRESSOR

Vapor injection system for a scroll compressor

ActiveUS7771178B2Increase capacityImprove efficiencyRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeInjection deviceScroll compressor

A compressor may include a shell, a compression mechanism, a motor, and a vapor injection system. The compression mechanism may be contained within in the shell and include a non-orbiting scroll axially displaceably mounted to the shell. The non-orbiting scroll may have an exterior portion, an interior portion, and a vapor injection passage extending therethrough from the exterior portion to the interior portion. The motor may be contained within the shell and may be drivingly coupled to the compression mechanism. The vapor injection system may include a vapor injection device, a vapor injection fitting, and a vapor injection valve. The vapor injection fitting may be in communication with the vapor injection device and the vapor injection passage. The vapor injection valve may be disposed between the shell and the interior of the non-orbiting scroll.

Owner:COPELAND LP

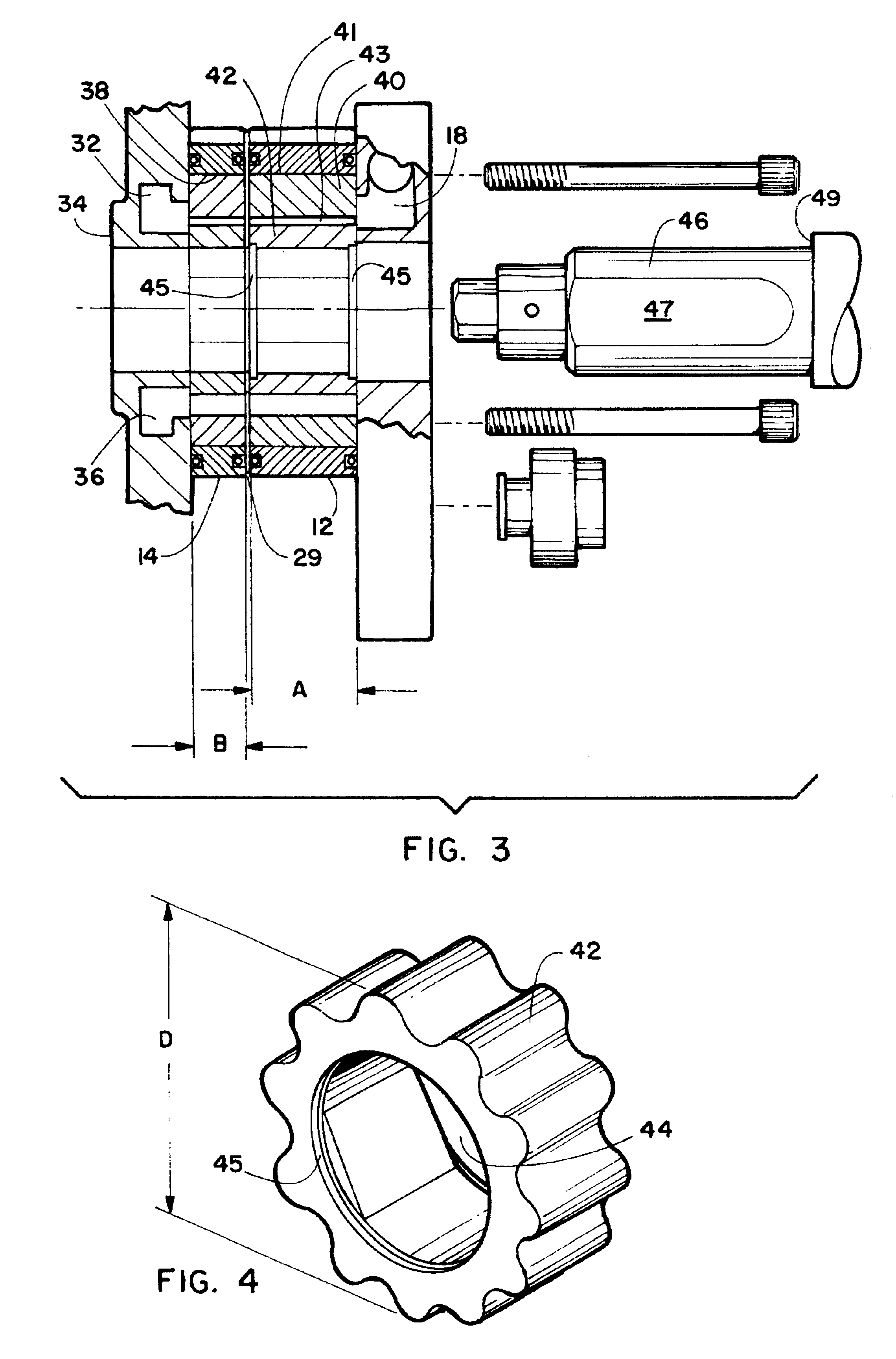

Pressure exchanger

ActiveUS20060032808A1Improve flow capacityIncrease momentumRotary/oscillating piston combinations for elastic fluidsGeneral water supply conservationCavitationMomentum

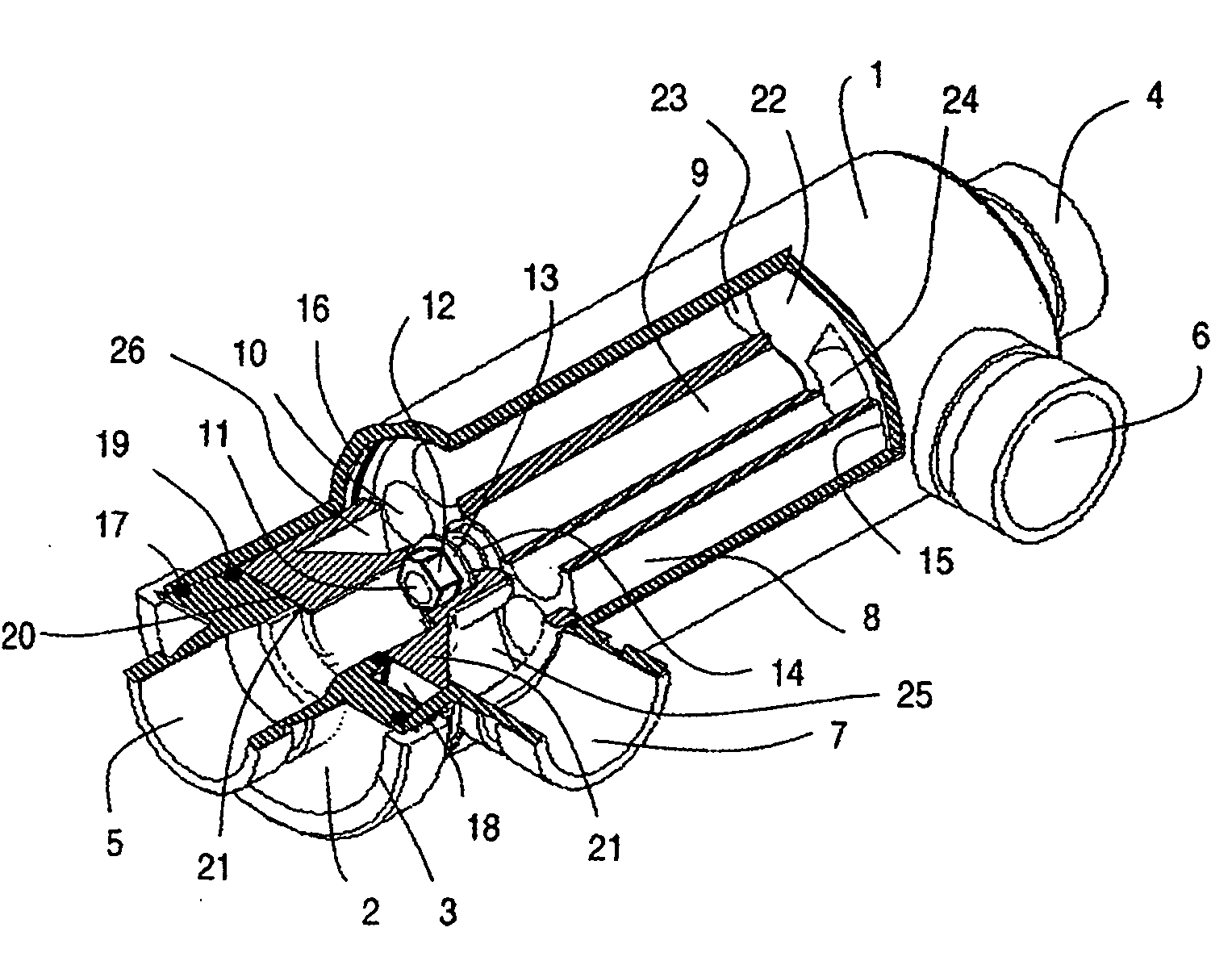

A pressure exchanger for transferring pressure energy from a relatively high-pressure fluid stream to another relatively low-pressure fluid stream is provided. A ducted rotor is positioned on a central axle between two end covers inside a pressure vessel with a coaxial inlet and outlet pair that is in communication with a pair of low pressure ports having inclination forming an inlet tangential velocity vector in the direction of rotor rotation and an outlet tangential velocity vector in opposite direction imparting a rotational momentum on rotor. A pair of high-pressure ports is adapted for flow without inclination and imparts no momentum to rotor and flow can be varied without impacting the rotor's RPM. The end covers have a sloped surface following a flat sealing area that increases the clearance in the direction of rotation causing increased outflow during depressurization and lower duct pressure before duct is exposed to low pressure port and furthermore causing increased inflow during the pressurization phase before duct is exposed to the high pressure port, which will dissipate pressure energy as opposed to producing cavitation or pressure waves with result wear and noise.

Owner:ISOBARIC STRATEGIES INC

Oil-cooled type screw compressor

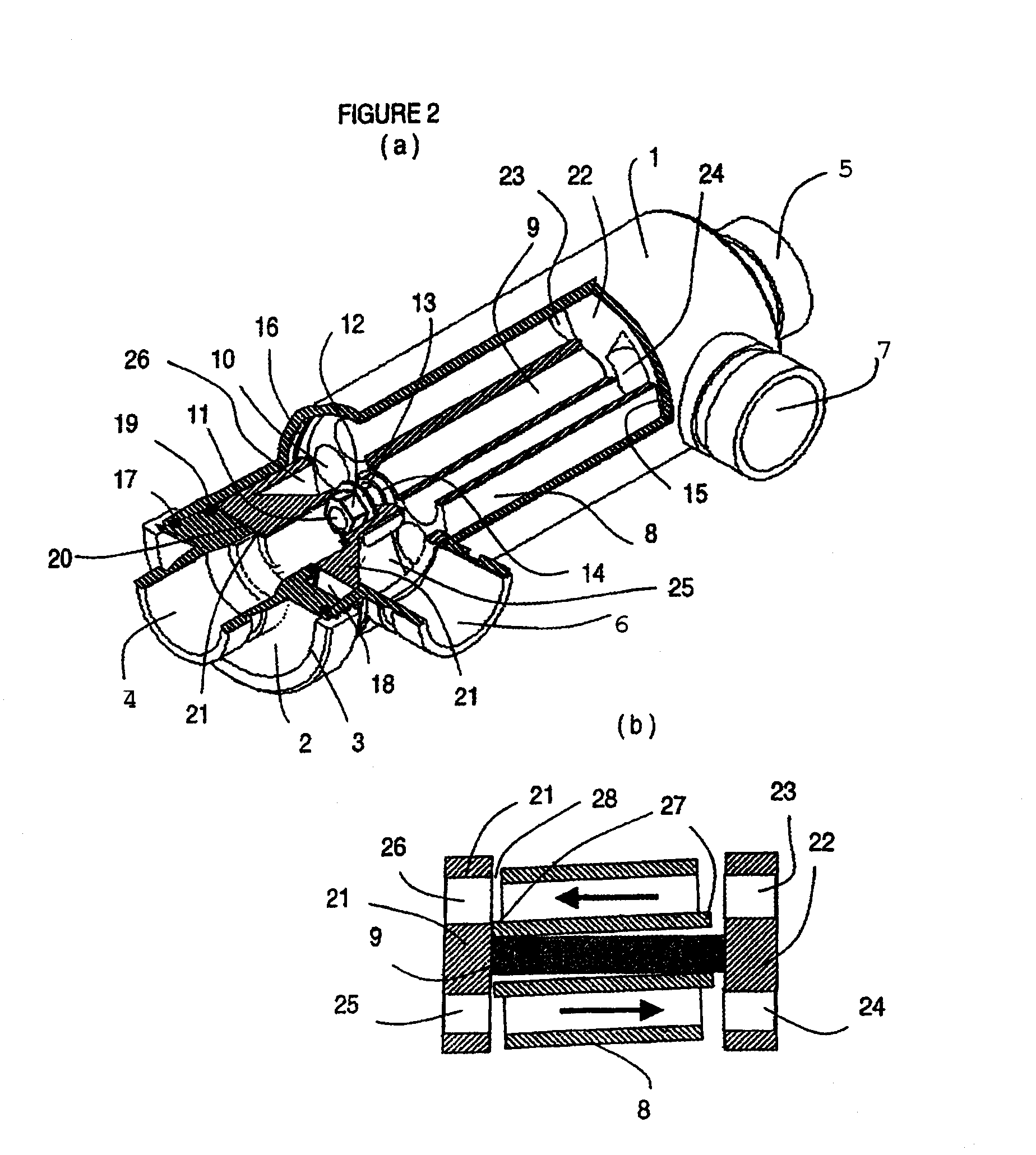

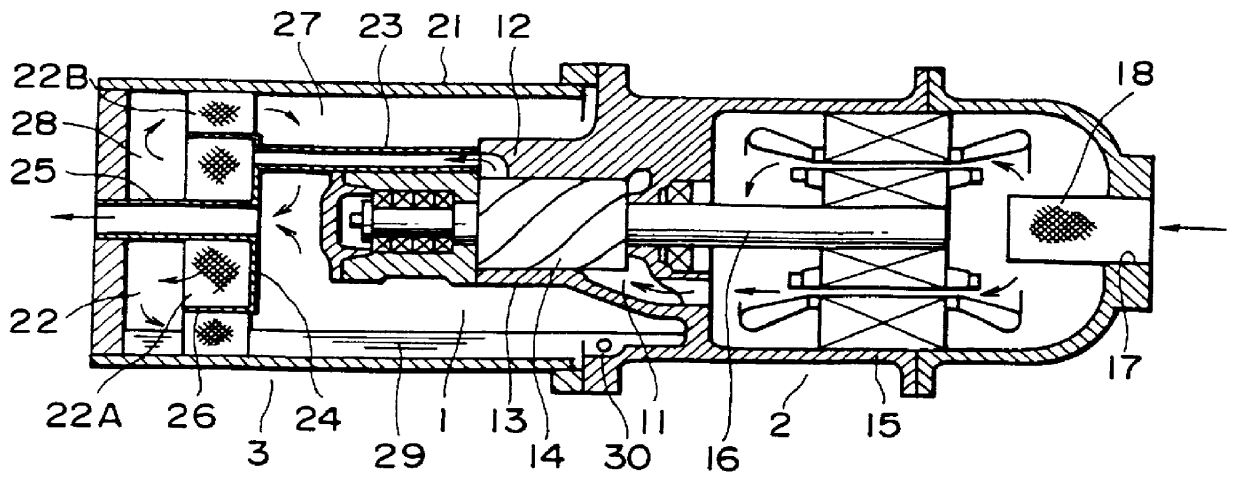

InactiveUS6045344ARotary/oscillating piston combinations for elastic fluidsOscillating piston enginesInterior spaceEngineering

An oil-cooled type screw compressor capable of improving the oil separating efficiency is provided. The oil-cooled type screw compressor includes an outer casing 21 which encloses at least a bearing portion on a discharge port 12 side of a compressor body 1 in an isolated state from a suction port 11, an oil separating element 22 which comprises an inside portion 22A and an outside portion 22B partitioned from each other by an annular partition plate 26 and which bisects the inside space of the outer casing into a space 27 on the compressor body side and a space 28 on the side opposite to the compressor body, a first discharge pipe 23 which conducts a compressed gas discharged together with oil from the discharge port 12 to the inside portion 22A, a shielding plate 24 for isolating the inside portion 22A from the compressor body-side space 27, and a second discharge pipe 25 extending through both the oil separating element 22 and the portion of the casing 21 which covers the space 28 on the side opposite to the compressor body, to conduct the compressed gas which has entered the compressor body-side space 27 from the opposite-side space 28 to the exterior.

Owner:KOBE STEEL LTD +1

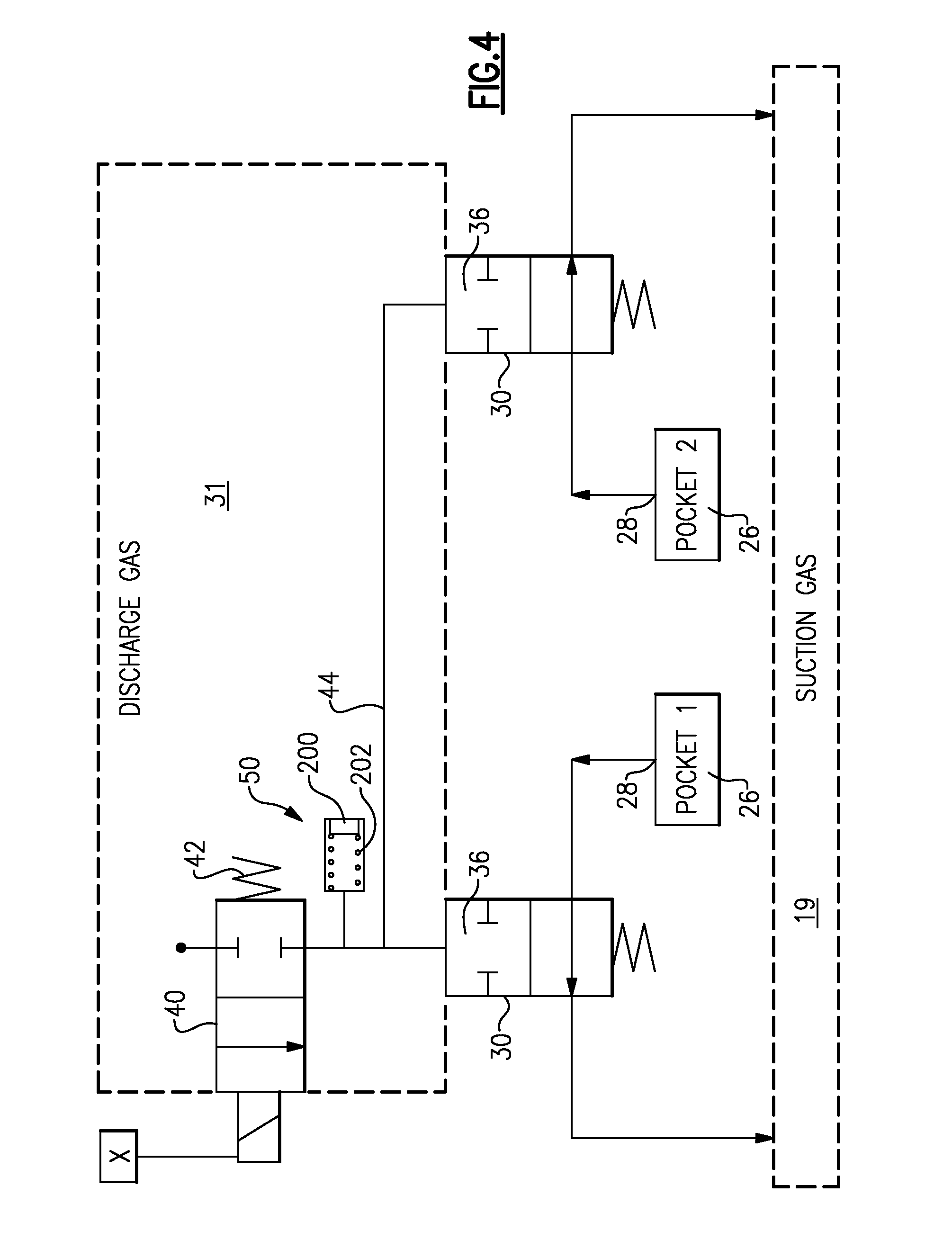

Scroll compressor capacity modulation with hybrid solenoid and fluid control

InactiveUS20110135509A1Control movementRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeReducing capacityFluid control

A scroll compressor includes a compressor shell having first and second scroll members. The scroll members each have a base and a generally spiral wrap extending from its base. The generally spiral wraps of the first and second scroll members interfit to define compression chambers. A shaft causes the second scroll member to orbit relative to the first scroll member. At least one bypass port is formed in a base of one scroll member, and communicates with at least one of the compression chambers. The bypass port communicates with a passage leading to a suction pressure chamber within the compressor shell. A solenoid valve is movable between a reduced capacity position and a full capacity position, and selectively supplies a pressurized fluid to a fluid valve associated with the bypass port, such that movement of the solenoid can control whether the bypass port is open or closed.

Owner:DANFOSS SCROLL TECH

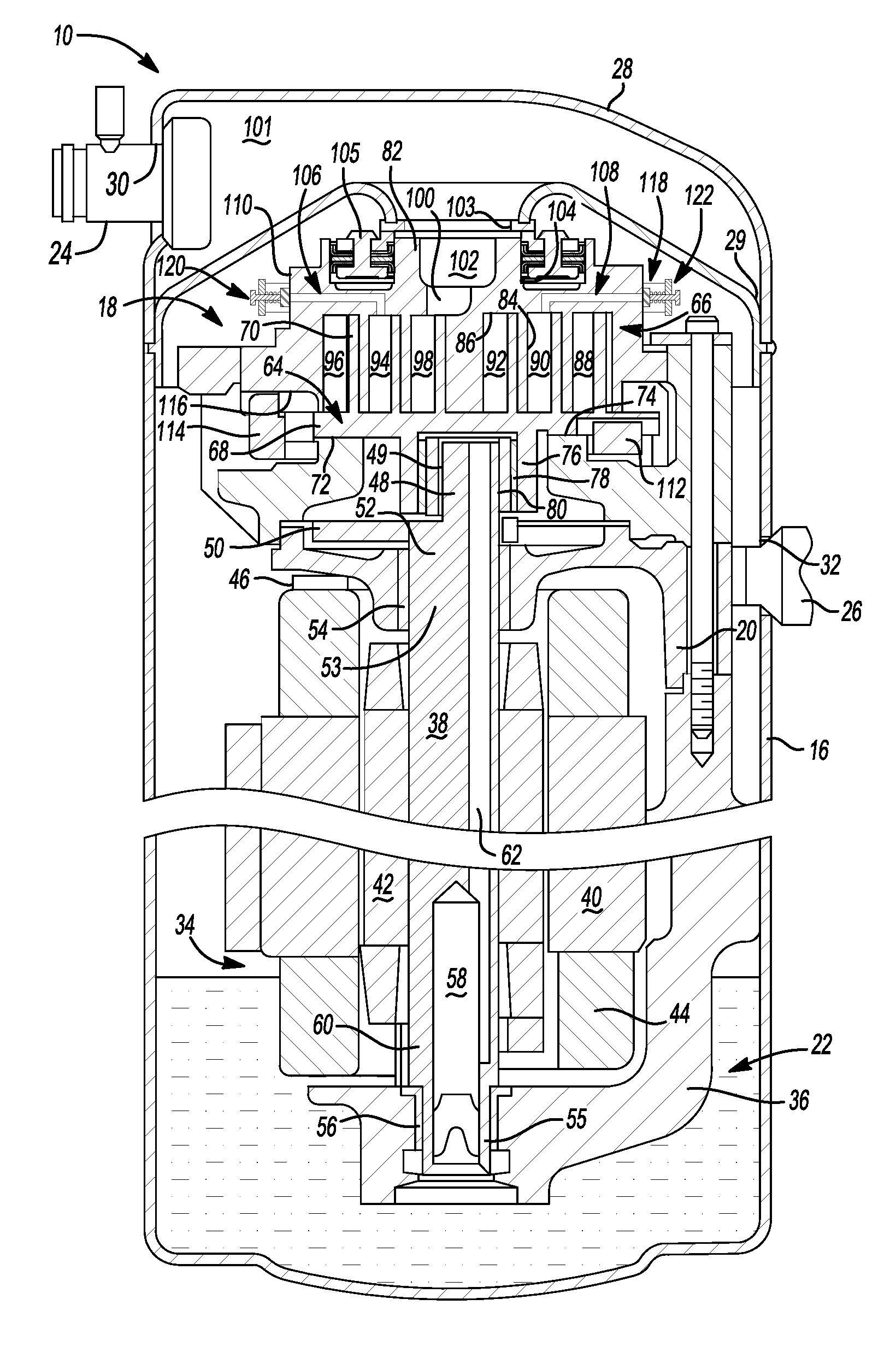

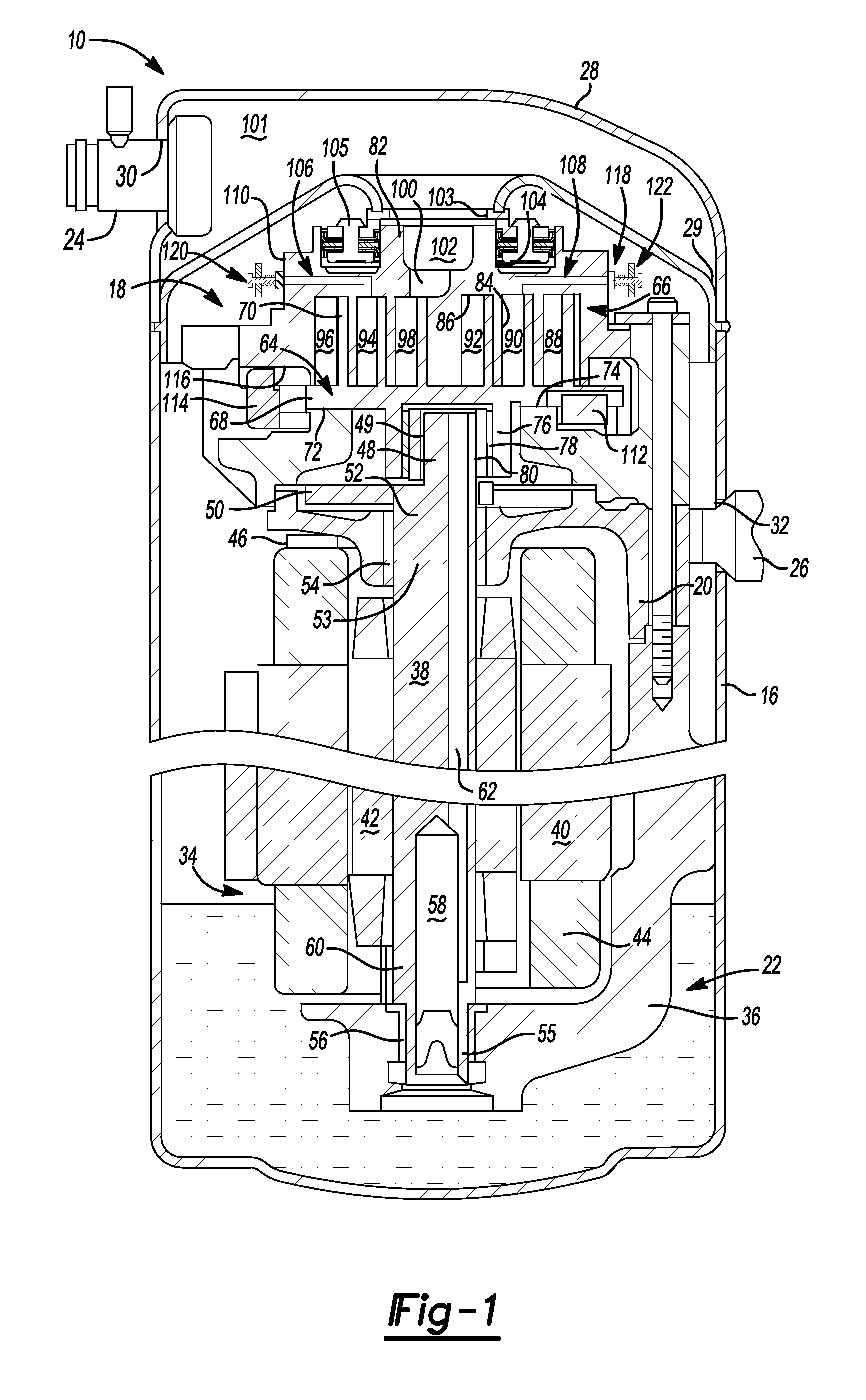

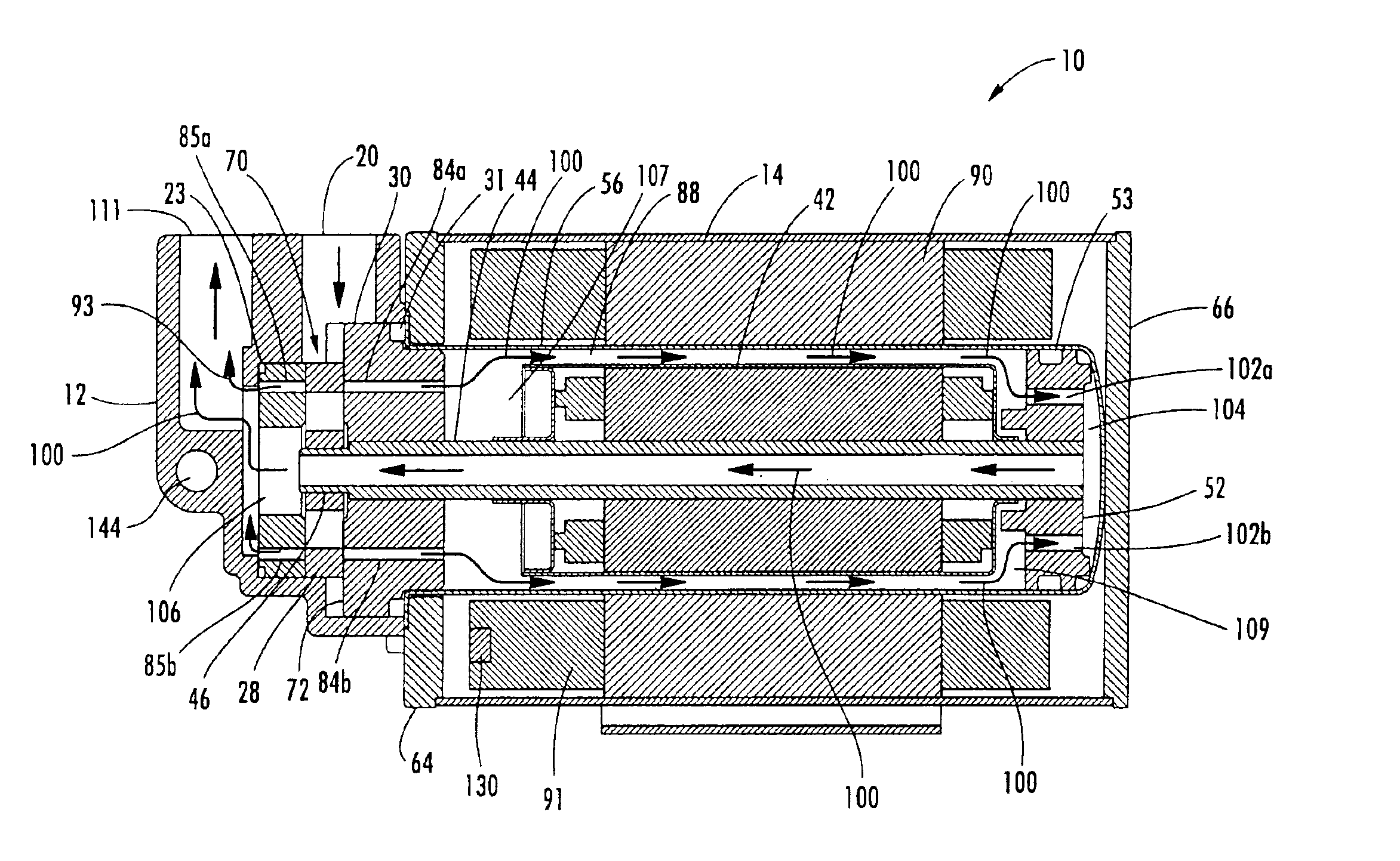

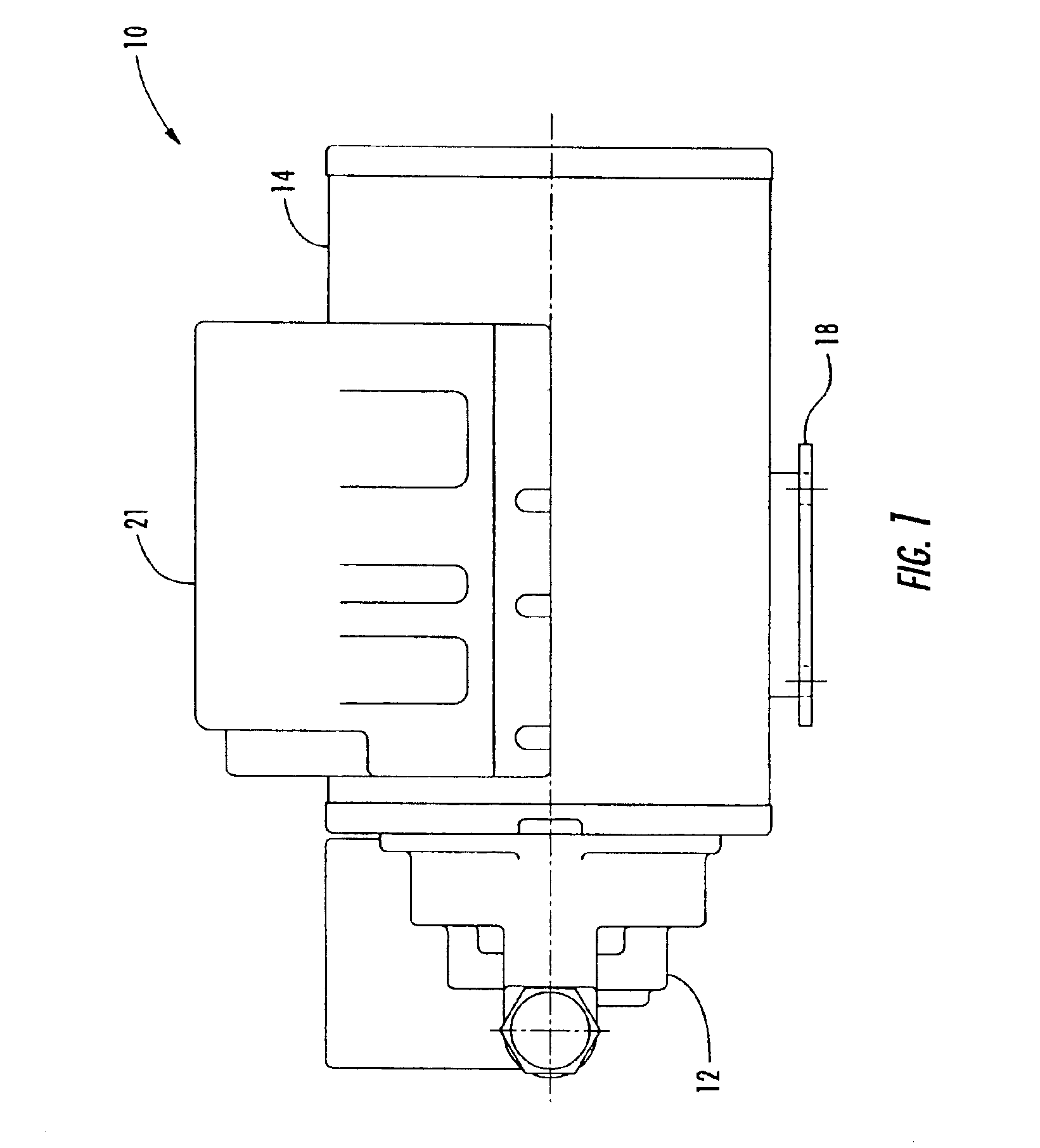

Compressor and oil-cooling system

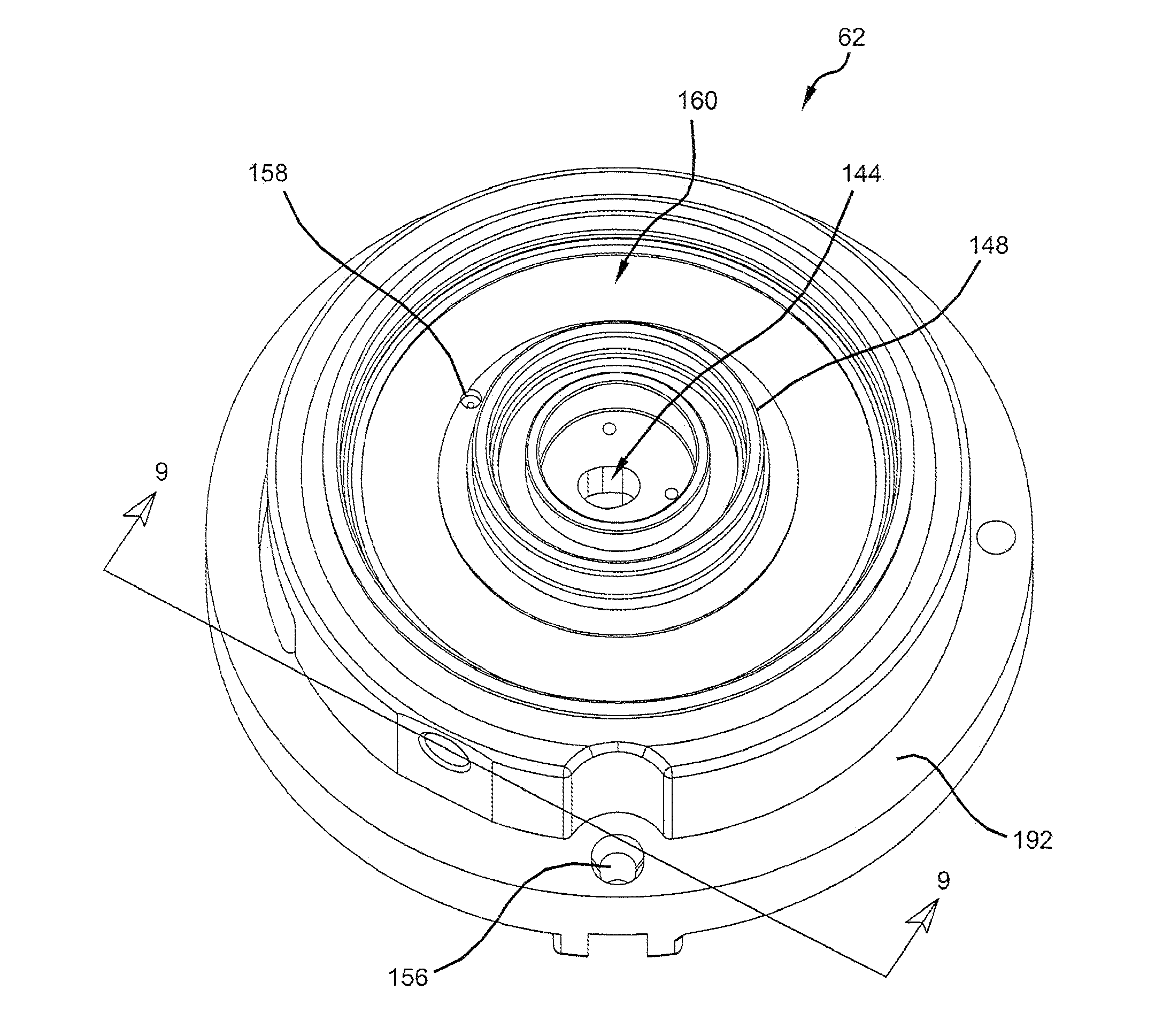

ActiveUS20100307173A1Reduce suction superheatImproving compressor volumetric efficiencyCompressorRotary/oscillating piston combinations for elastic fluidsWorking fluidEngineering

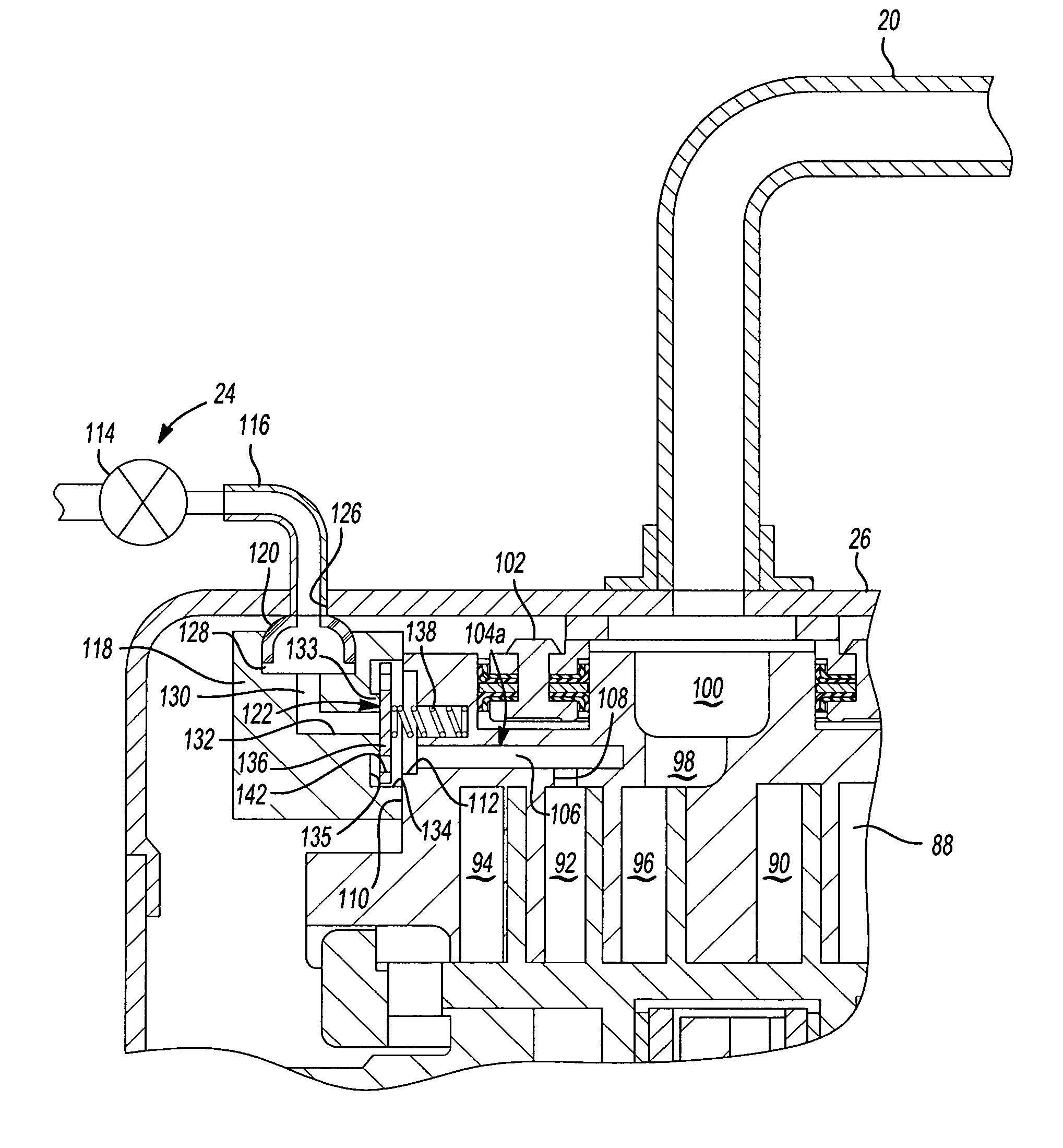

An external heat exchanger is used to transfer heat from a compressor lubricant to an expanded working fluid, thereby cooling the lubricant. The heat exchanger may also be used to sub-cool condensed working fluid with the same flow of expanded working fluid. A horizontal scroll-type compressor includes an intermediate lubricant sump between a main bearing support and a scroll member. A counterweight on the crankshaft can travel through the lubricant in the intermediate sump to splash the lubricant around. A horizontal scroll-type compressor can include multiple machined surfaces that are utilized to precisely center and align components of the compressor.

Owner:COPELAND LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com