Scroll compressor

a compressor and scroll technology, applied in the direction of machines/engines, rotary/oscillating piston pump components, liquid fuel engines, etc., can solve the problems of deterioration of reliability, increase of sliding loss, and rise of pressure in the compression chamber, so as to maintain the pressure in the back pressure chamber stably, the effect of high performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

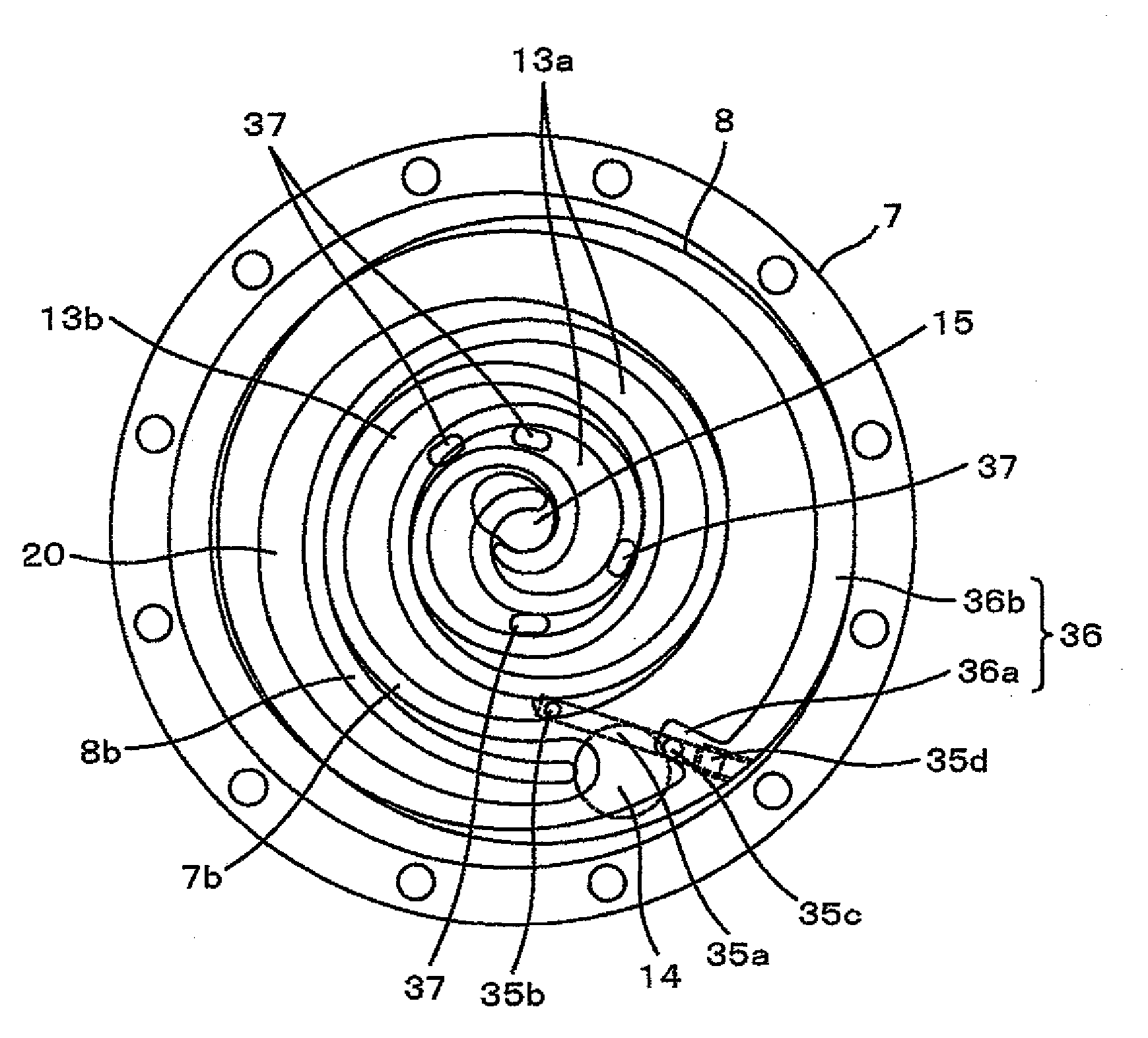

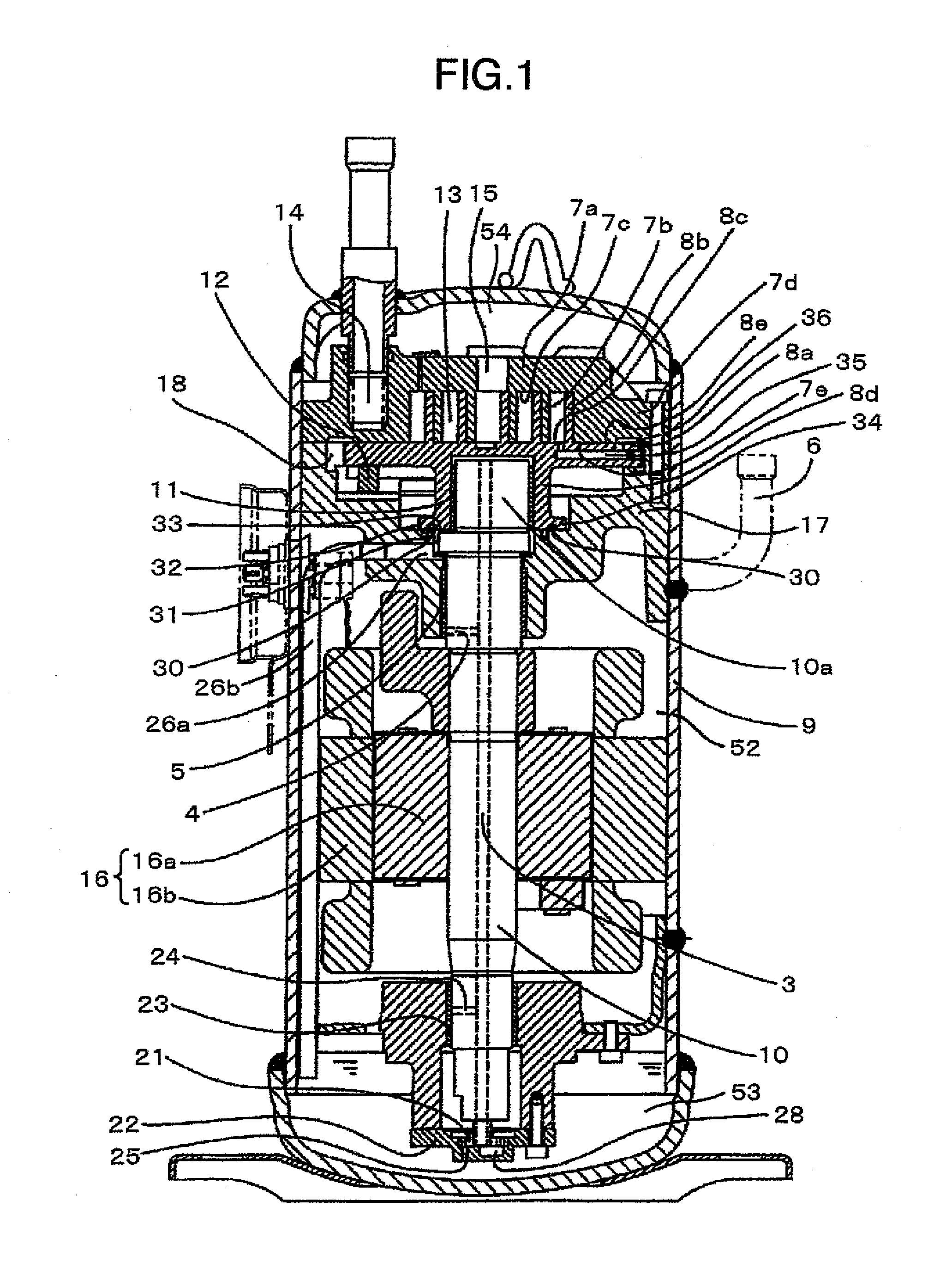

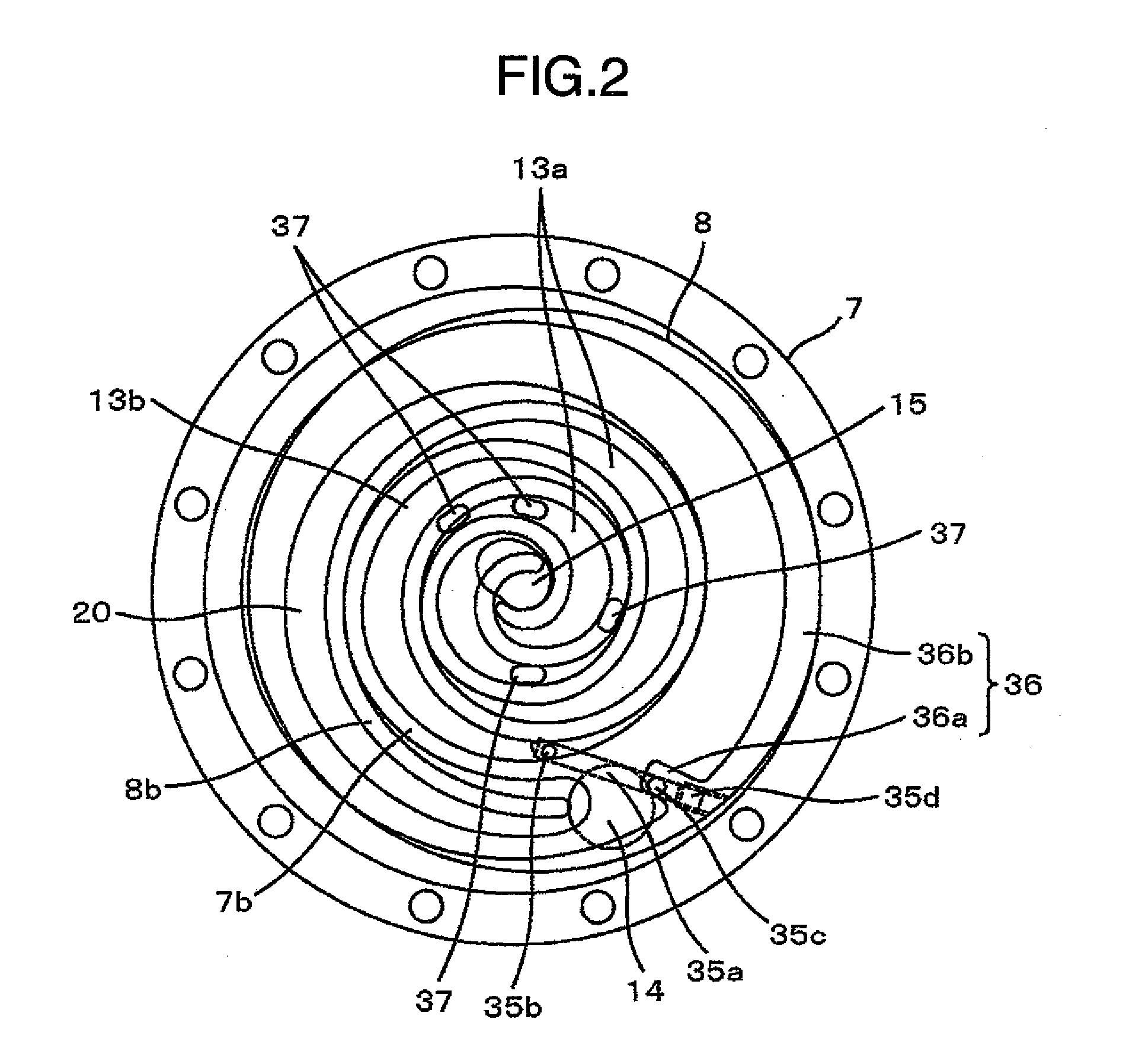

[0025]FIG. 1 is a longitudinal cross-sectional view of an entire scroll compressor illustrating Embodiment 1 of the present invention and FIG. 3 is an enlarged cross-sectional view of main parts showing an enlarged view of a scroll section made up of the fixed scroll member and the orbiting scroll member shown in FIG. 1.

[0026]As shown in FIG. 1 and FIG. 3, a fixed scroll (fixed scroll member) 7 includes a disk-shaped base plate 7a, a wrap 7b set upright in a spiral shape on the base plate 7a and a cylindrical support section 7d located on the outer peripheral side of the base plate 7a, that has an end plate surface contiguous to a distal end face of the wrap 7b and surrounds the wrap 7b.

[0027]The surface of the base plate 7a on which the wrap 7b is set upright is called a “tooth bottom 7c” because of its location between the wraps 7b.

[0028]Furthermore, the surface on which the support section 7d contacts an end plate 8a of a orbiting scroll (orbiting scroll member) 8 constitutes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com