Patents

Literature

2887 results about "Scroll compressor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

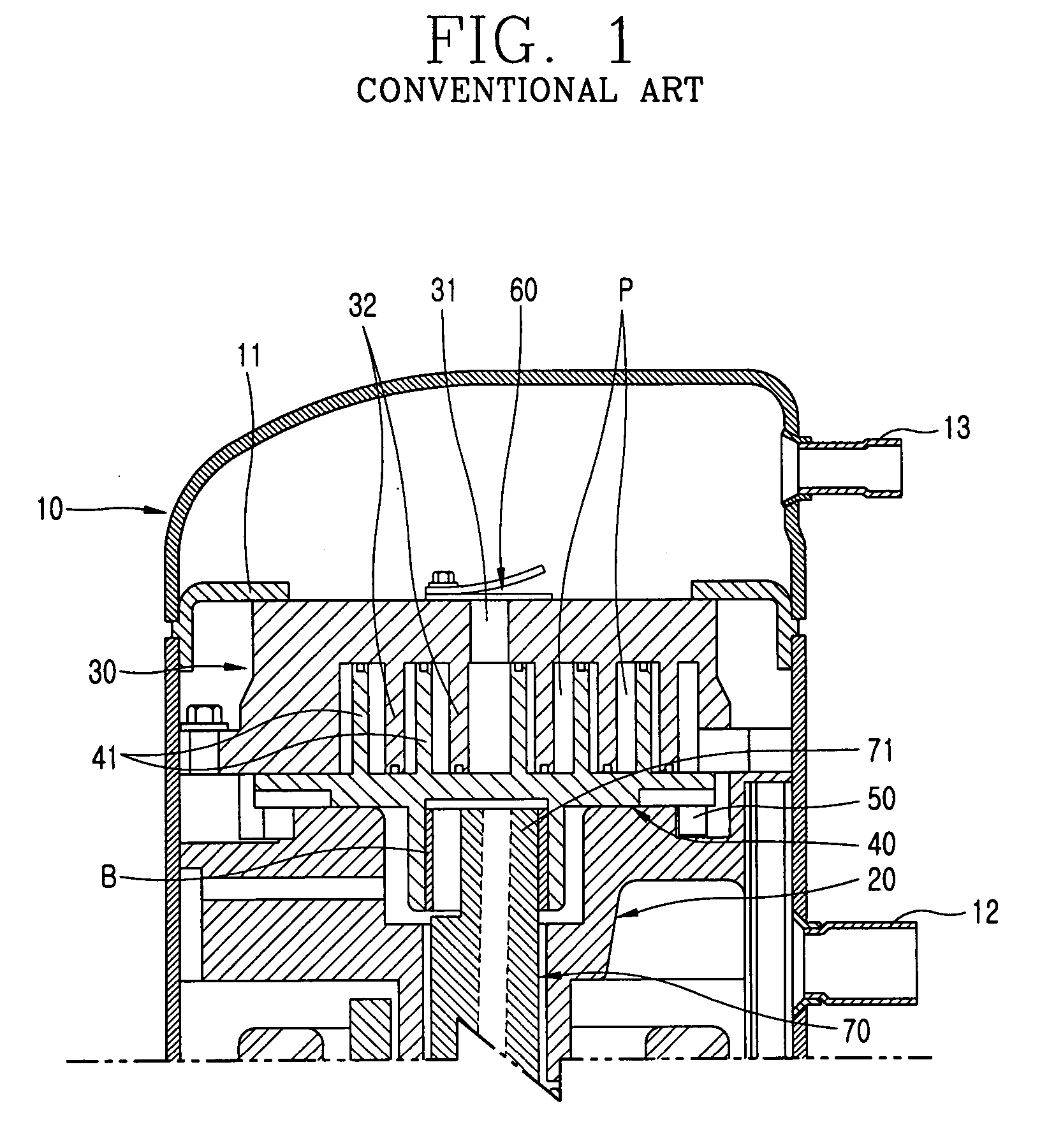

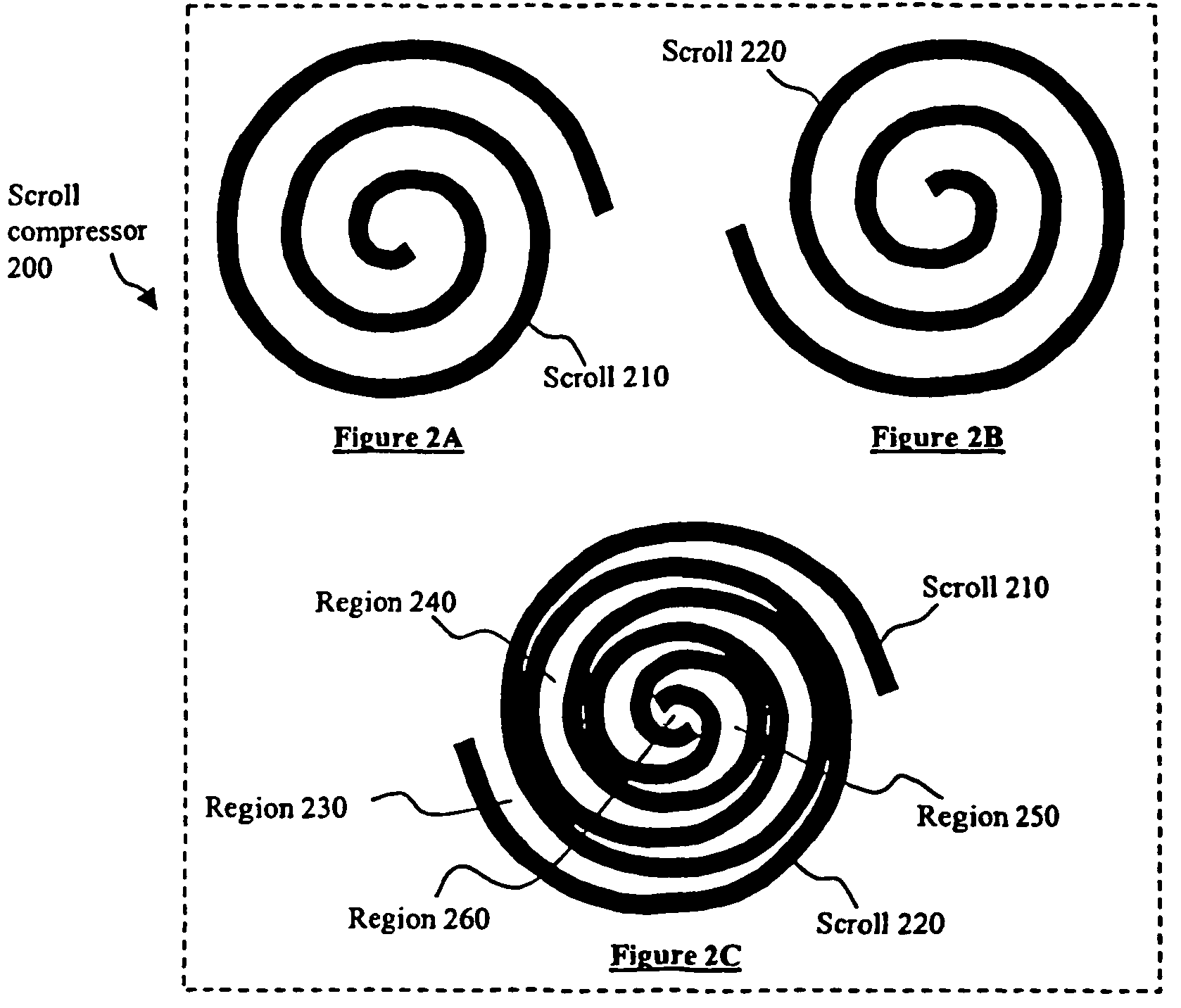

A scroll compressor (also called spiral compressor, scroll pump and scroll vacuum pump) is a device for compressing air or refrigerant. It is used in air conditioning equipment, as an automobile supercharger (where it is known as a scroll-type supercharger) and as a vacuum pump. Many residential central heat pump and air conditioning systems and a few automotive air conditioning systems employ a scroll compressor instead of the more traditional rotary, reciprocating, and wobble-plate compressors.

Compressor

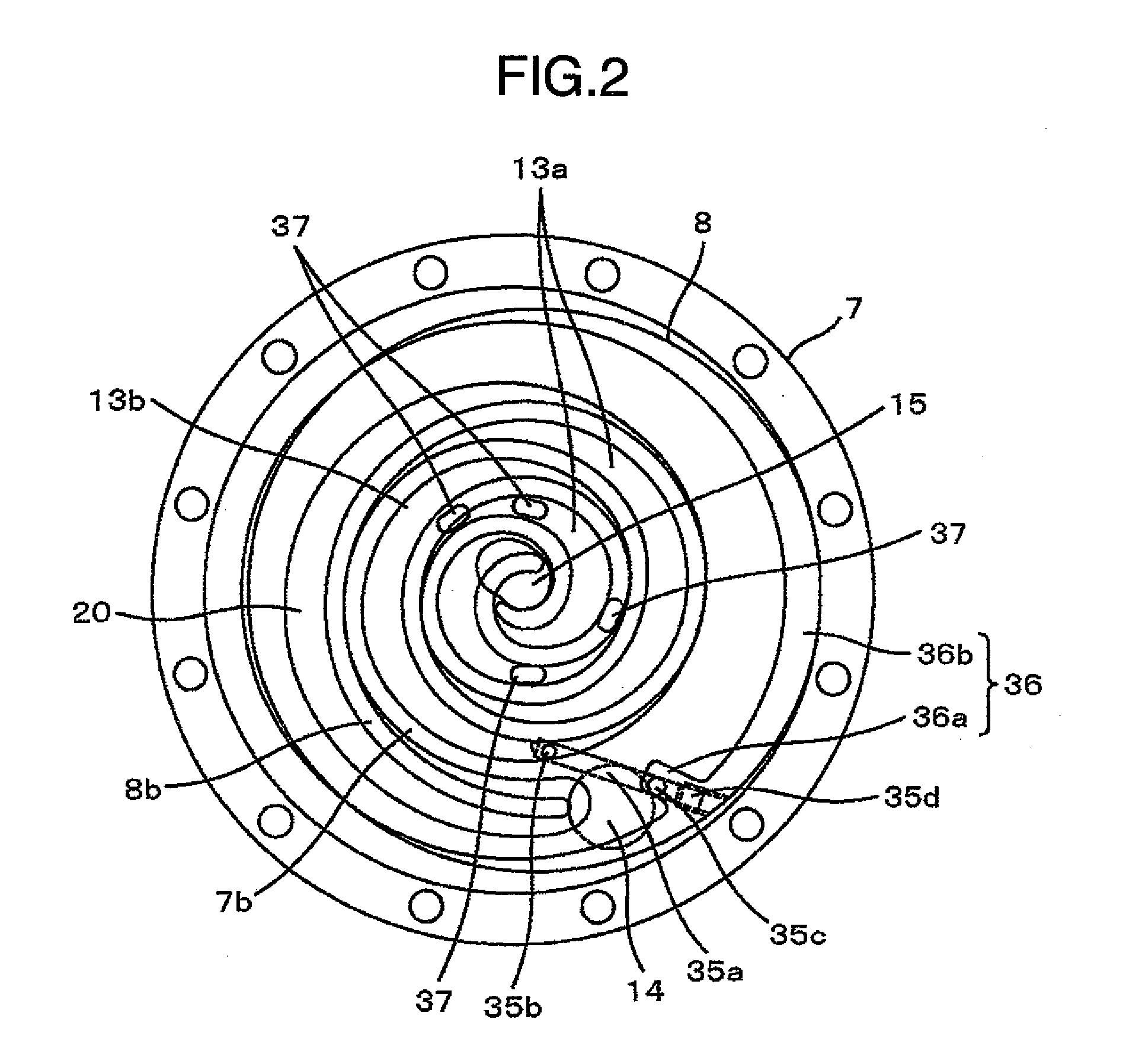

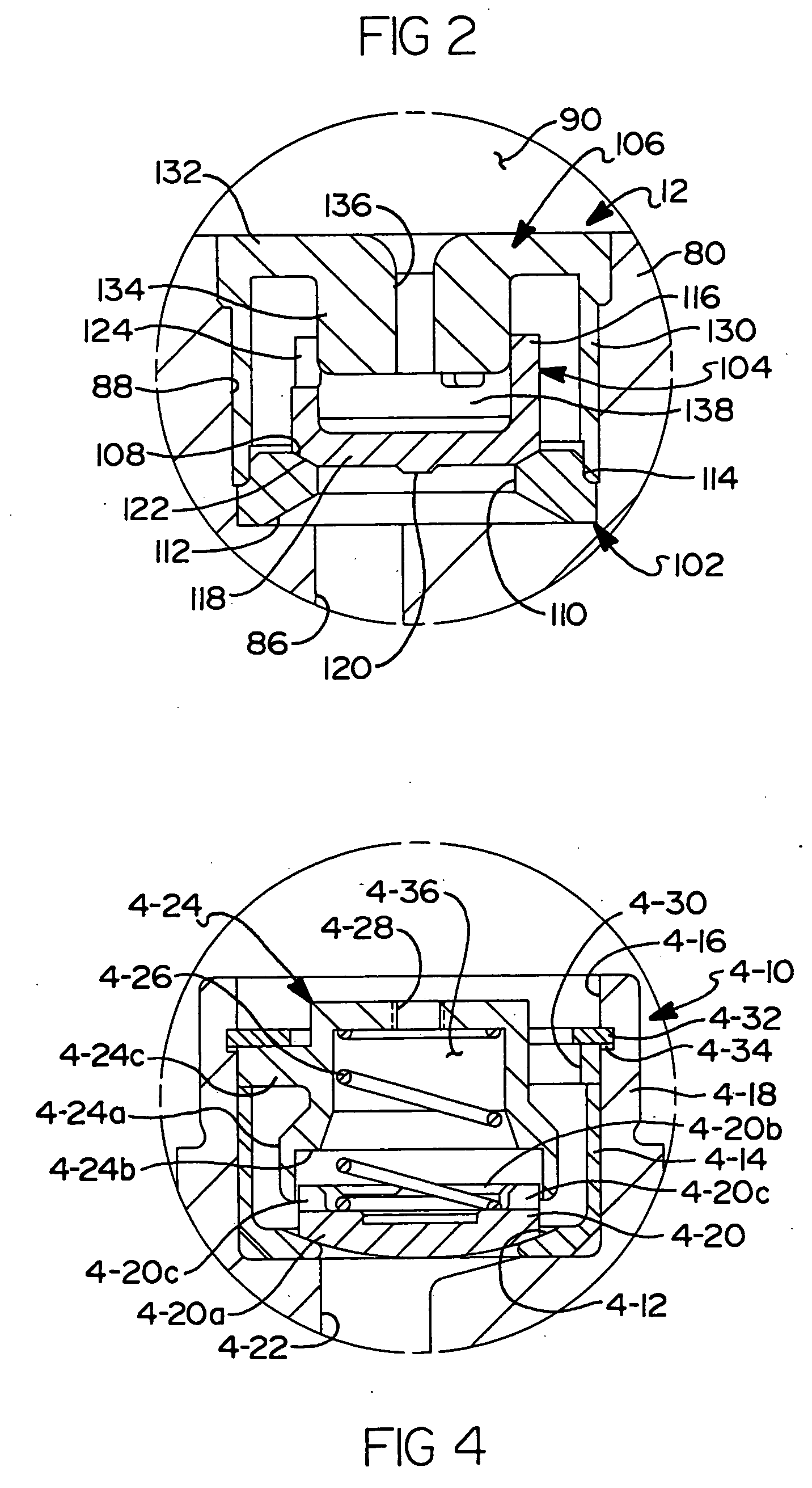

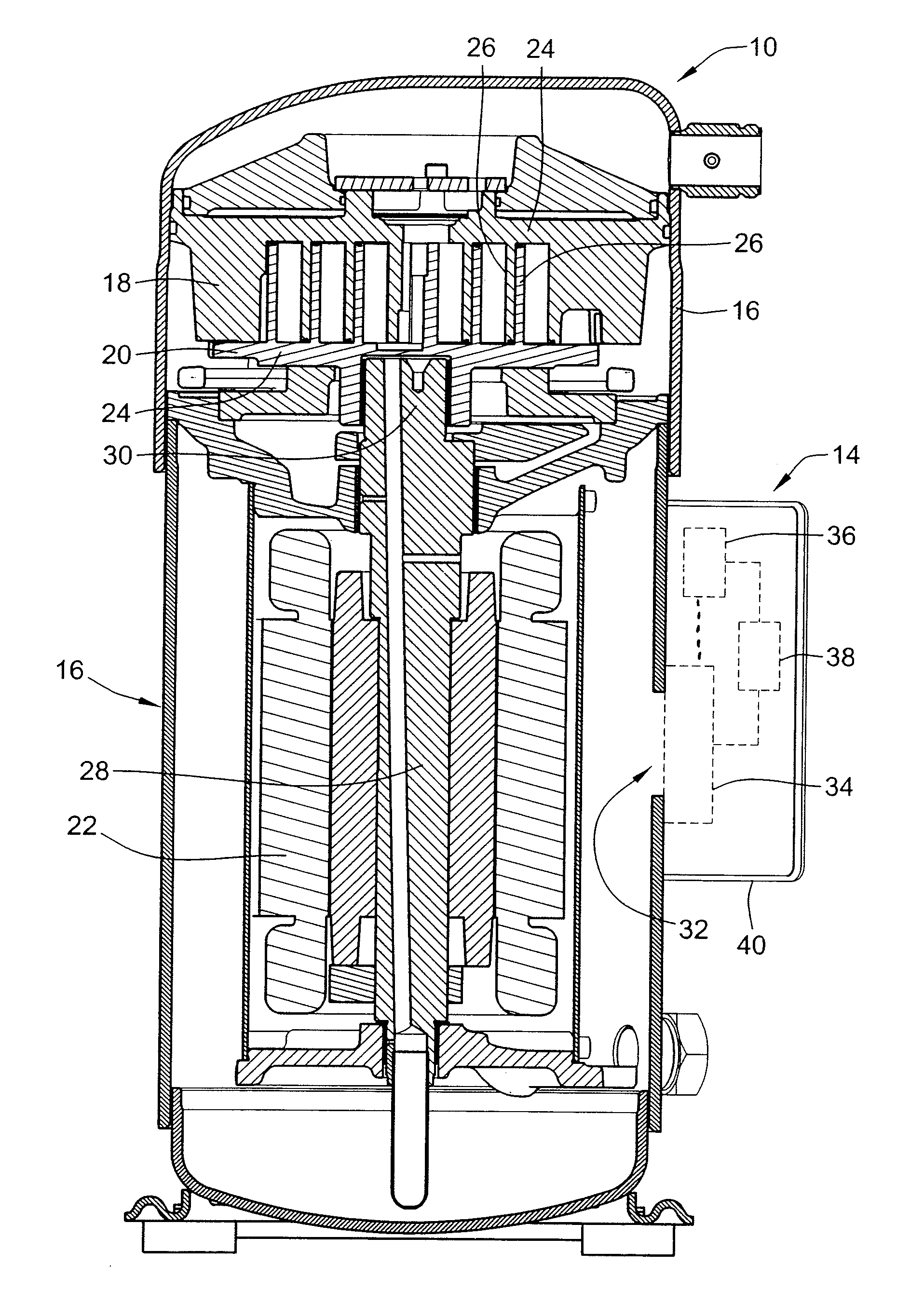

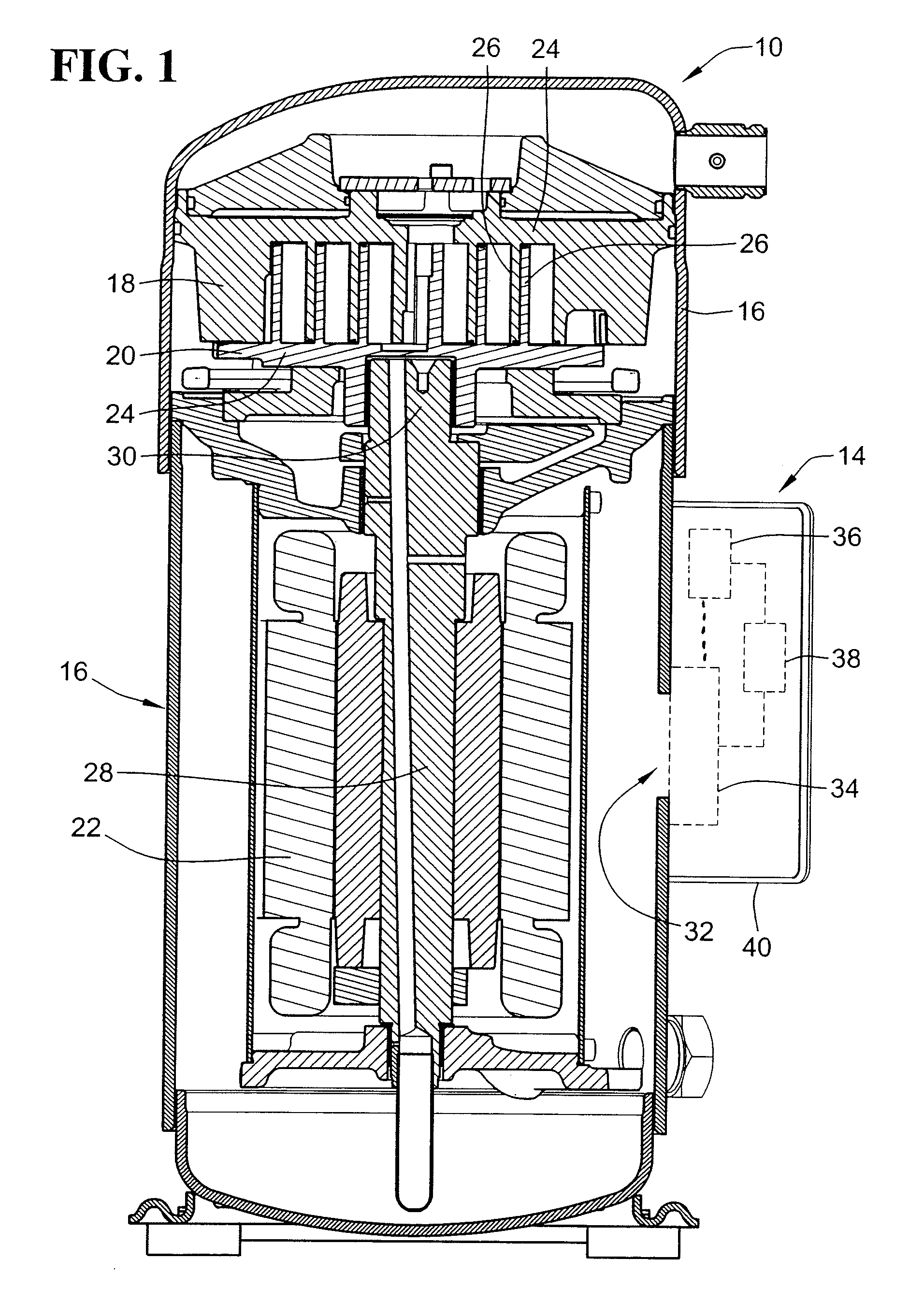

ActiveUS6960070B2Easy to fixPrecise alignmentRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeDrive shaftEngineering

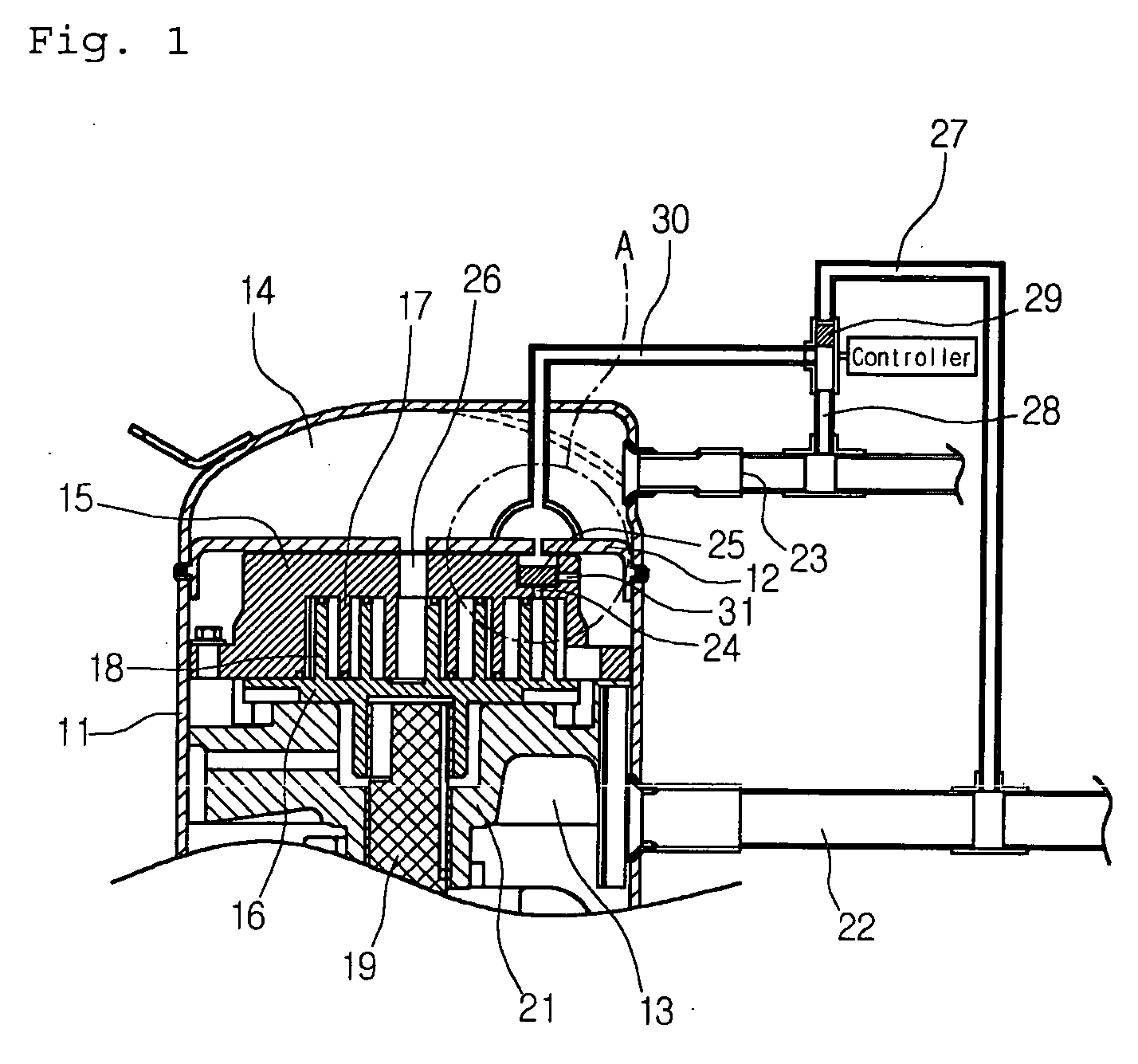

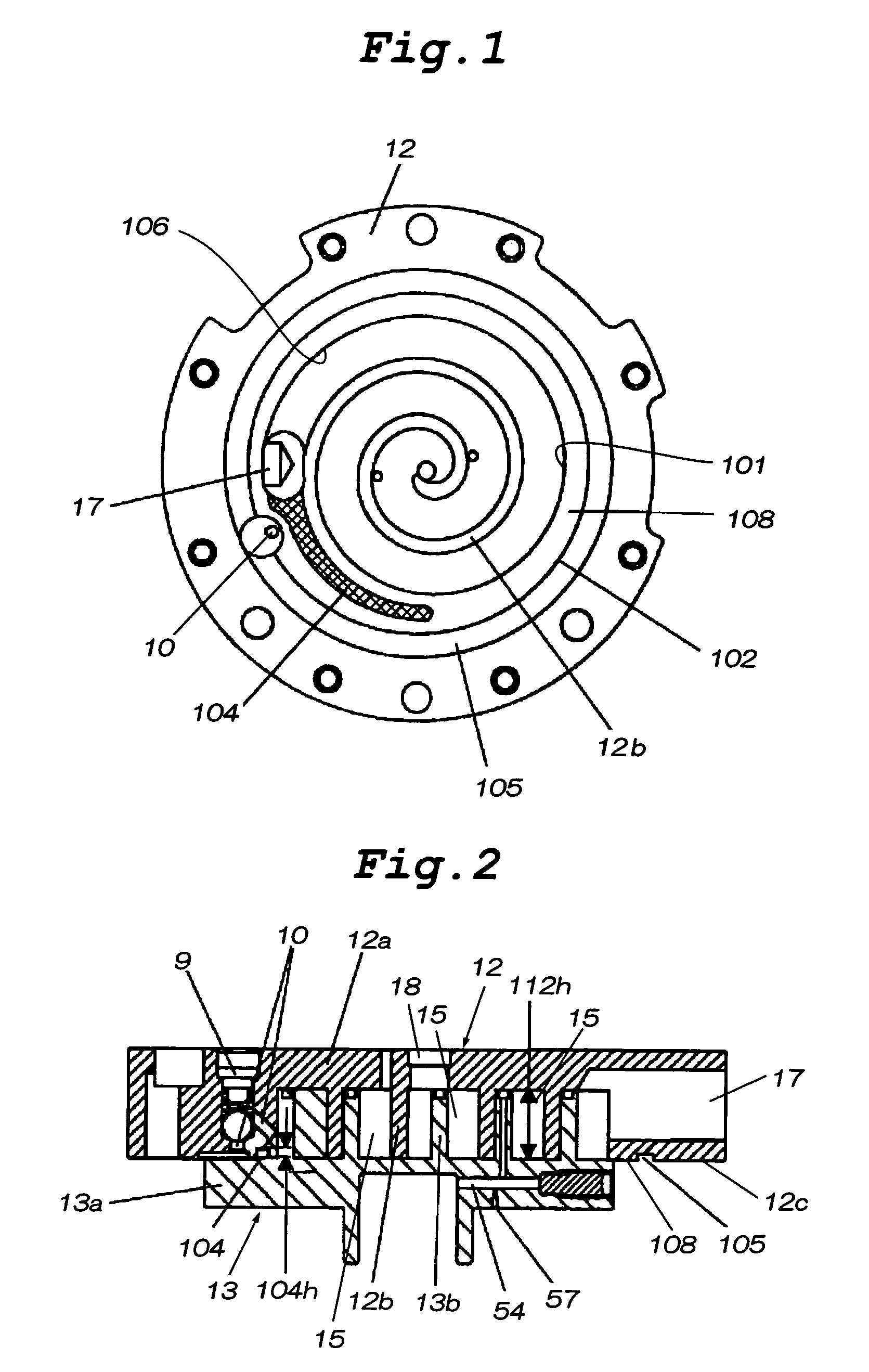

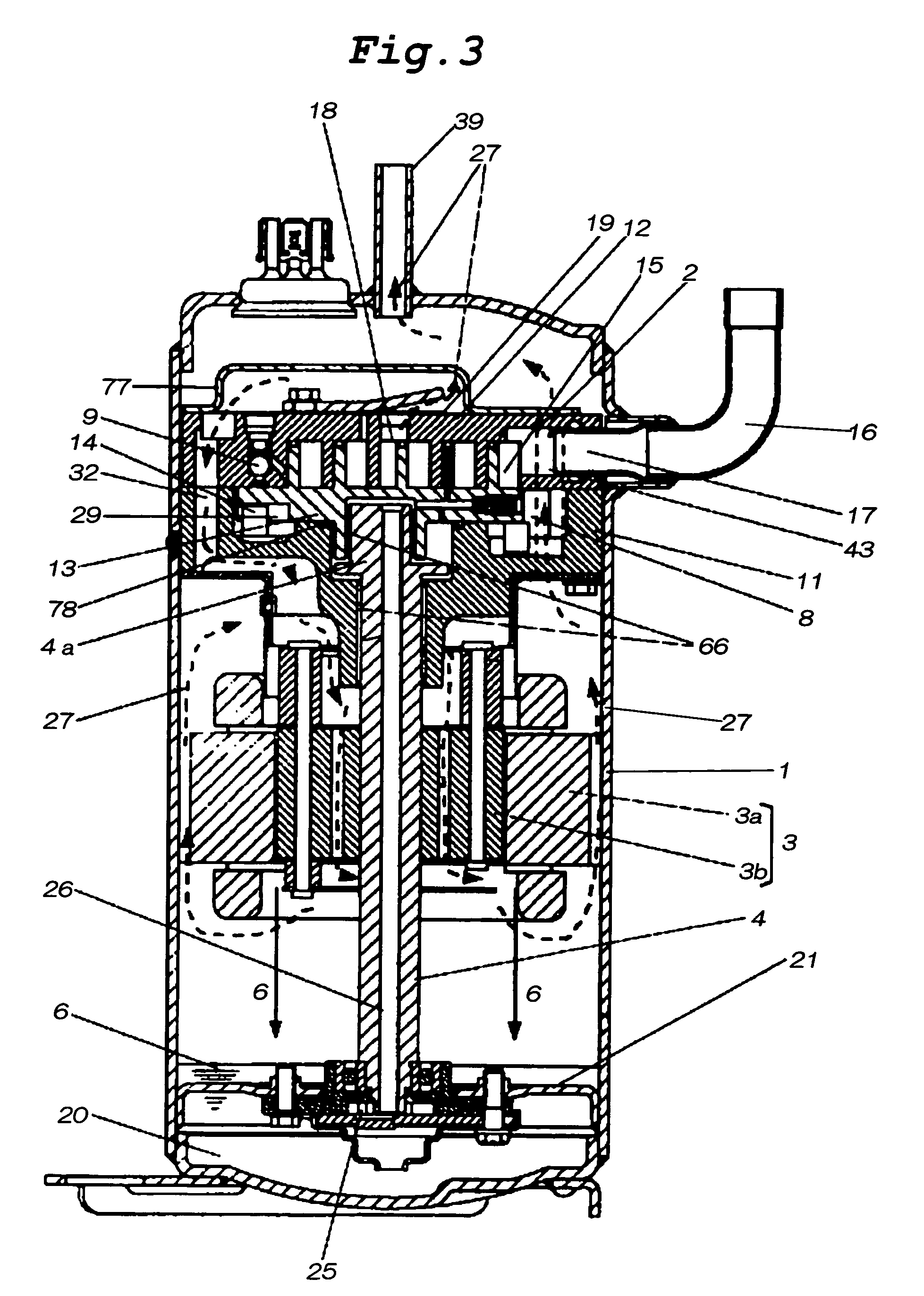

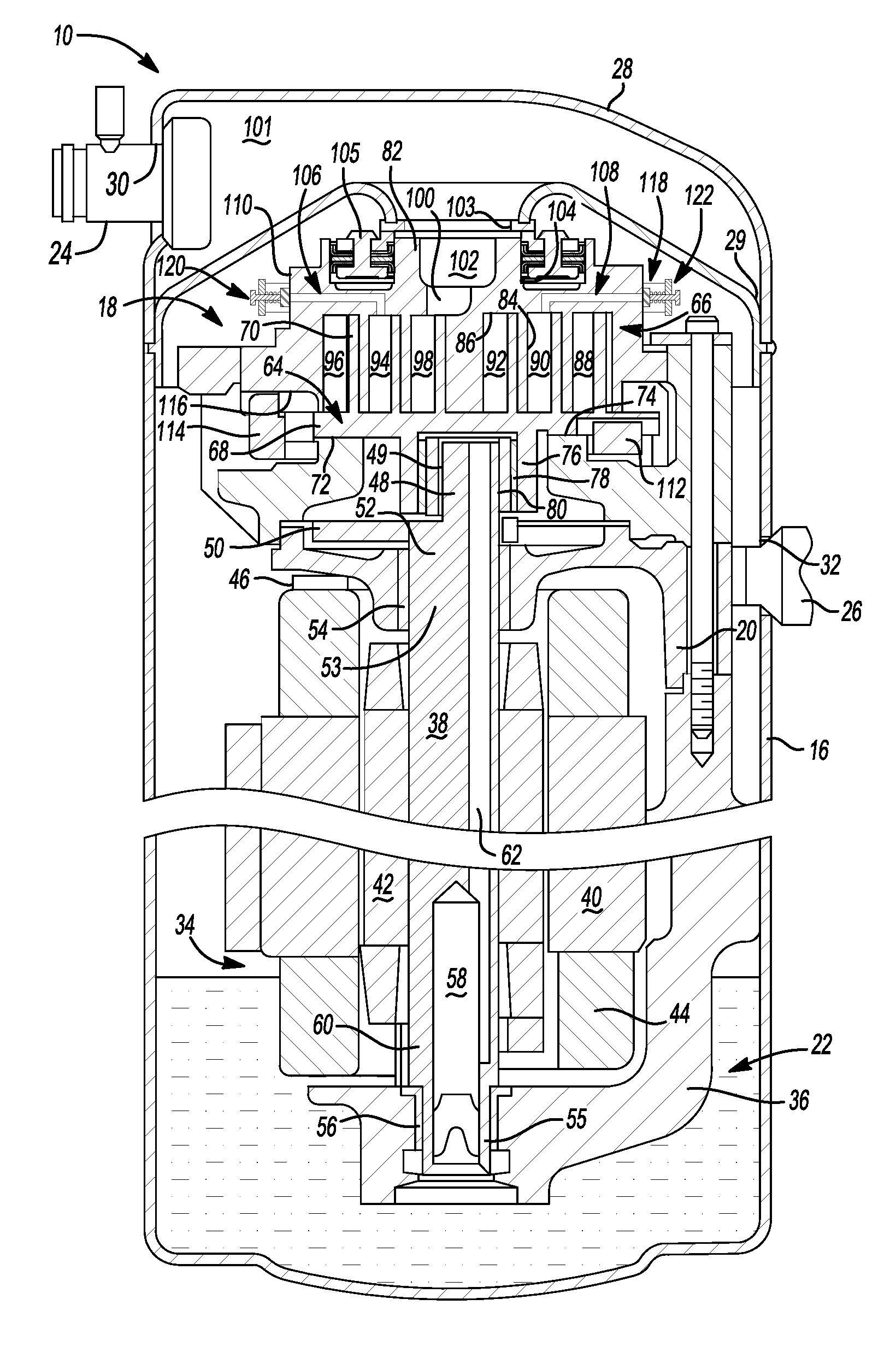

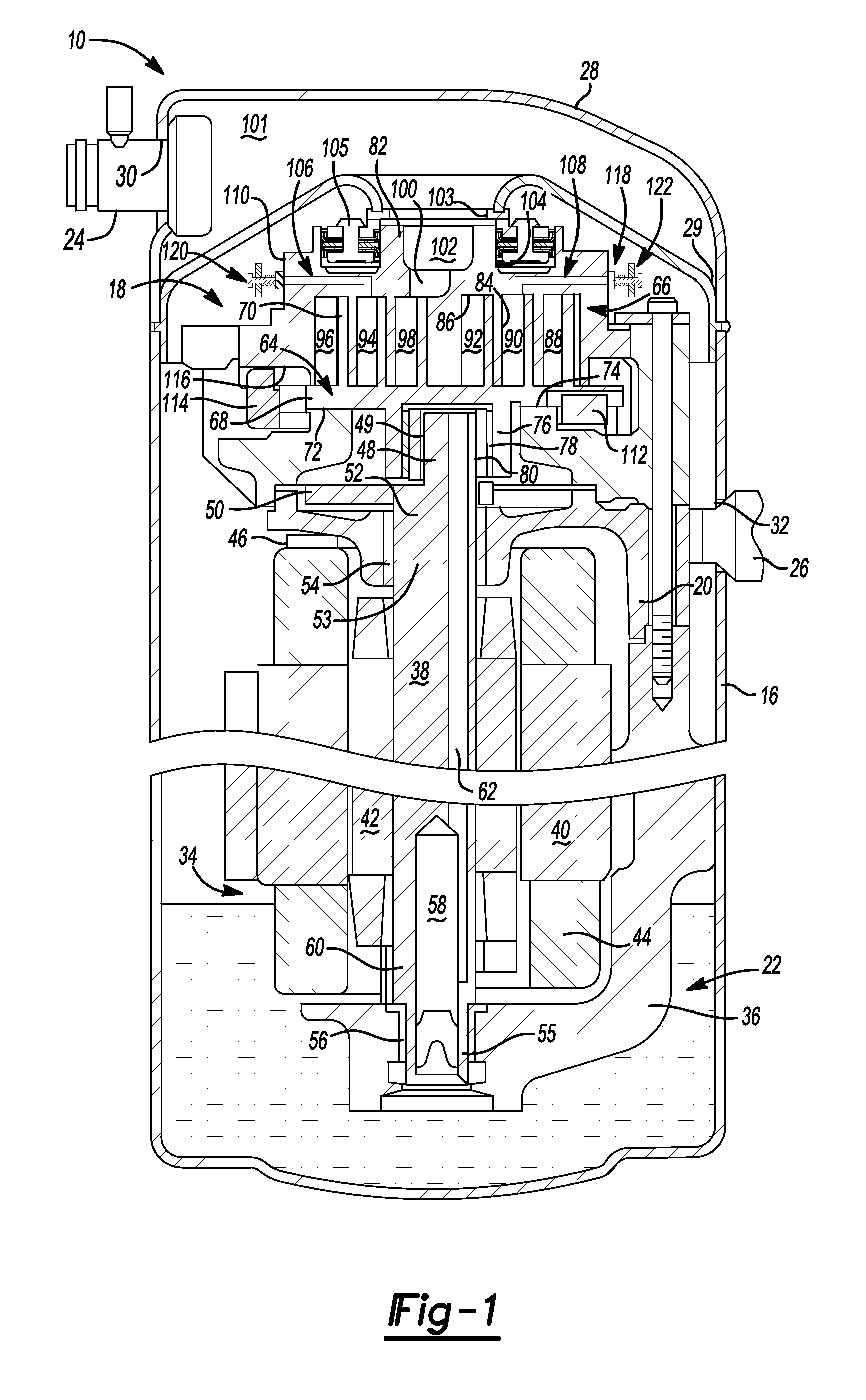

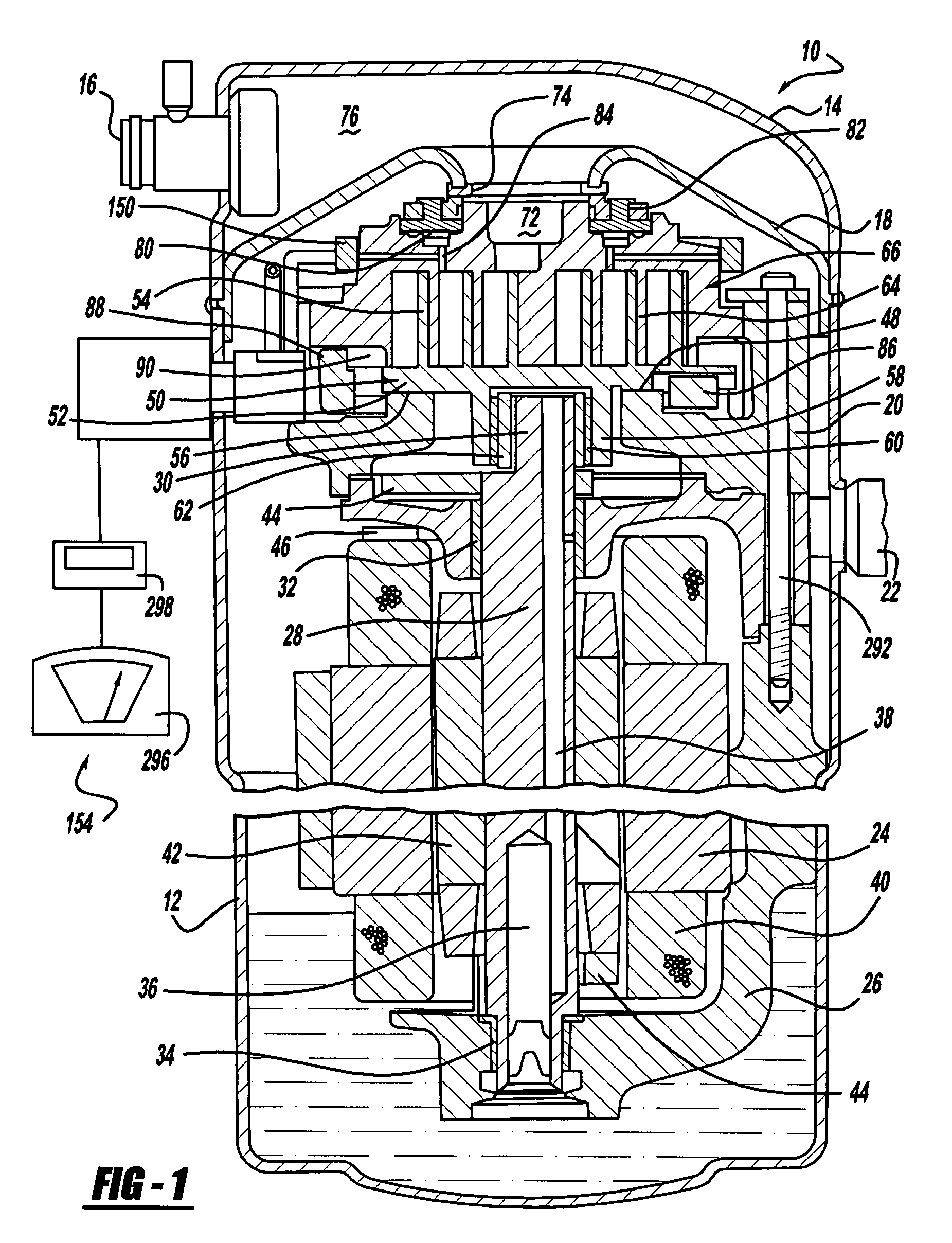

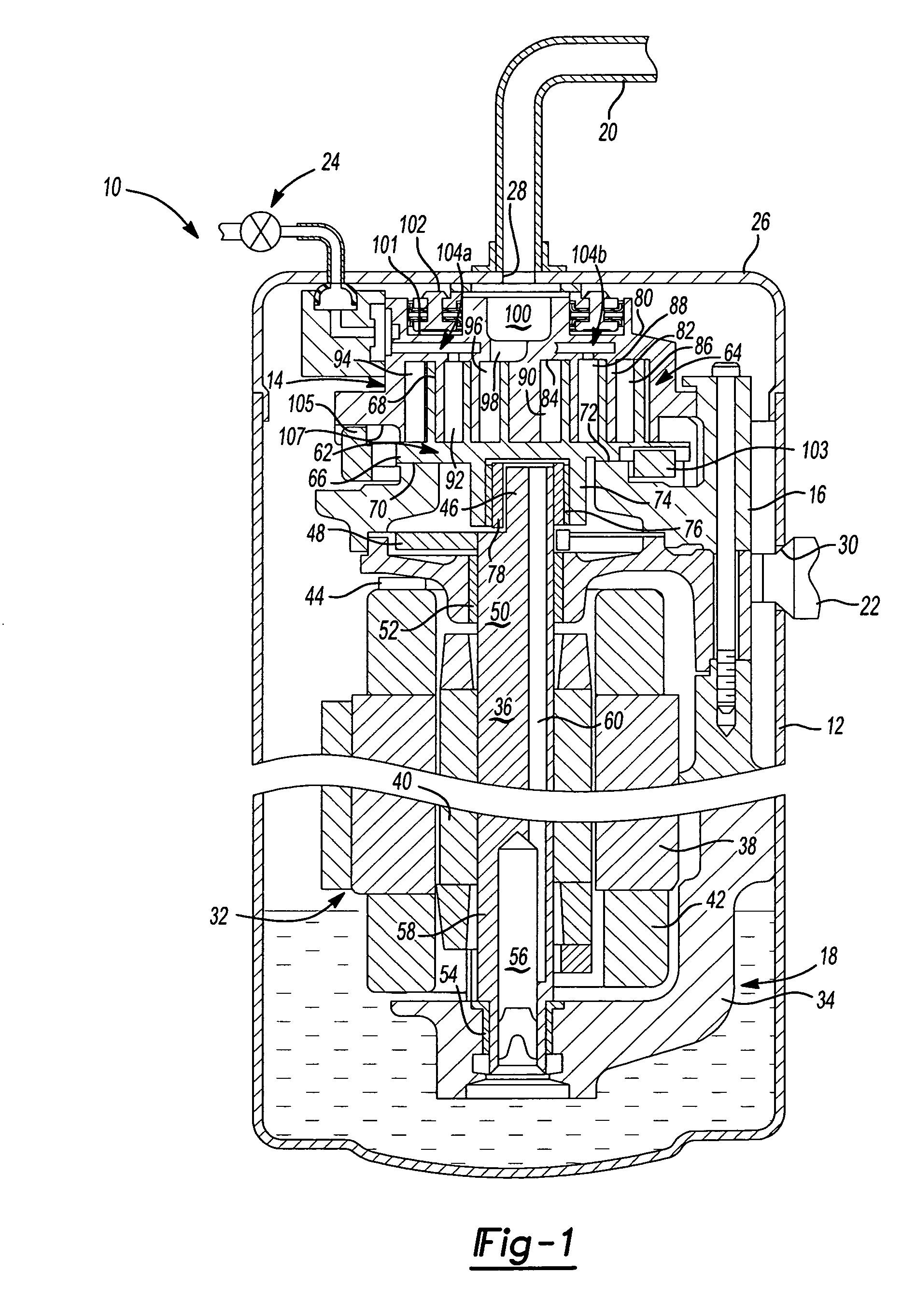

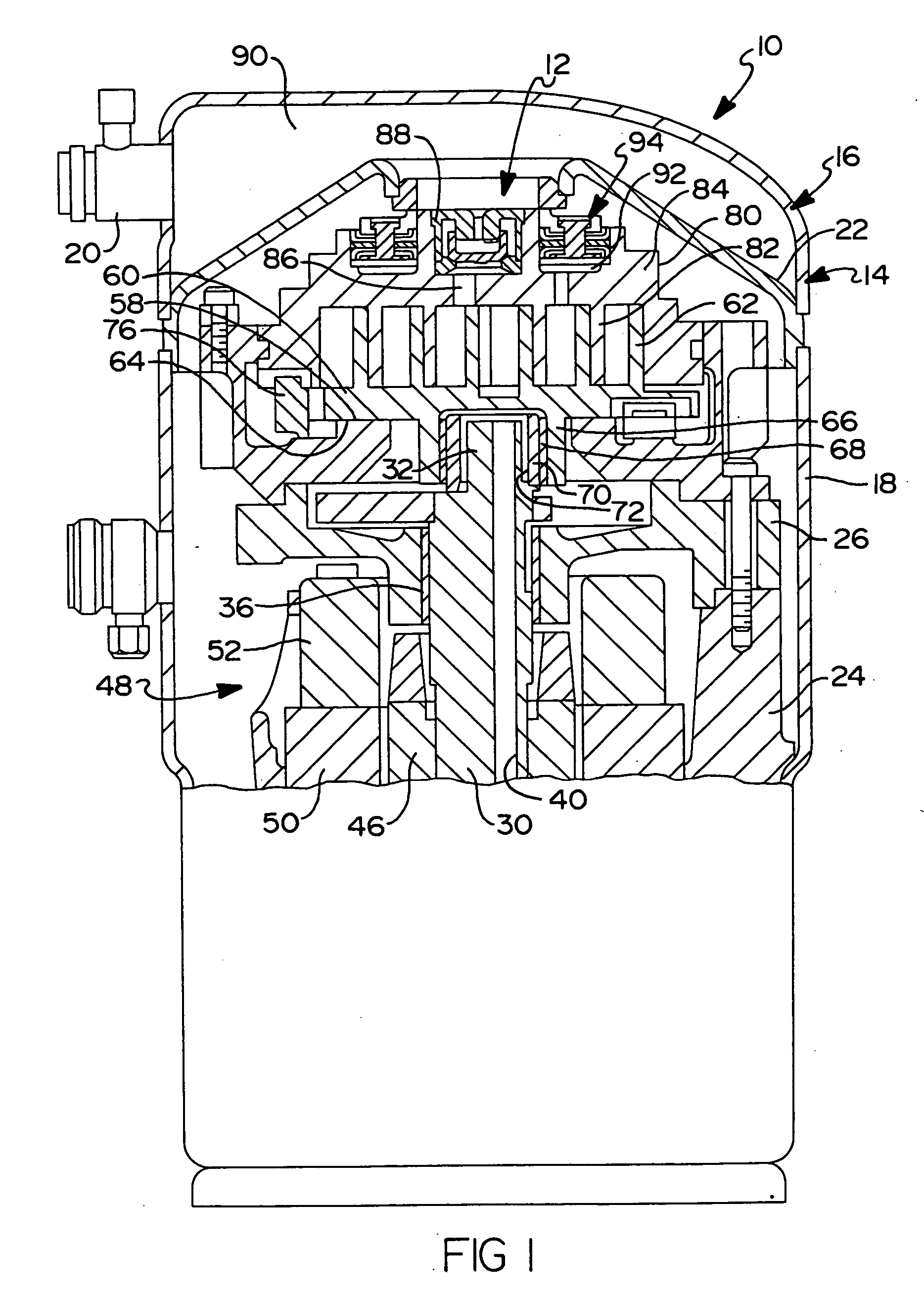

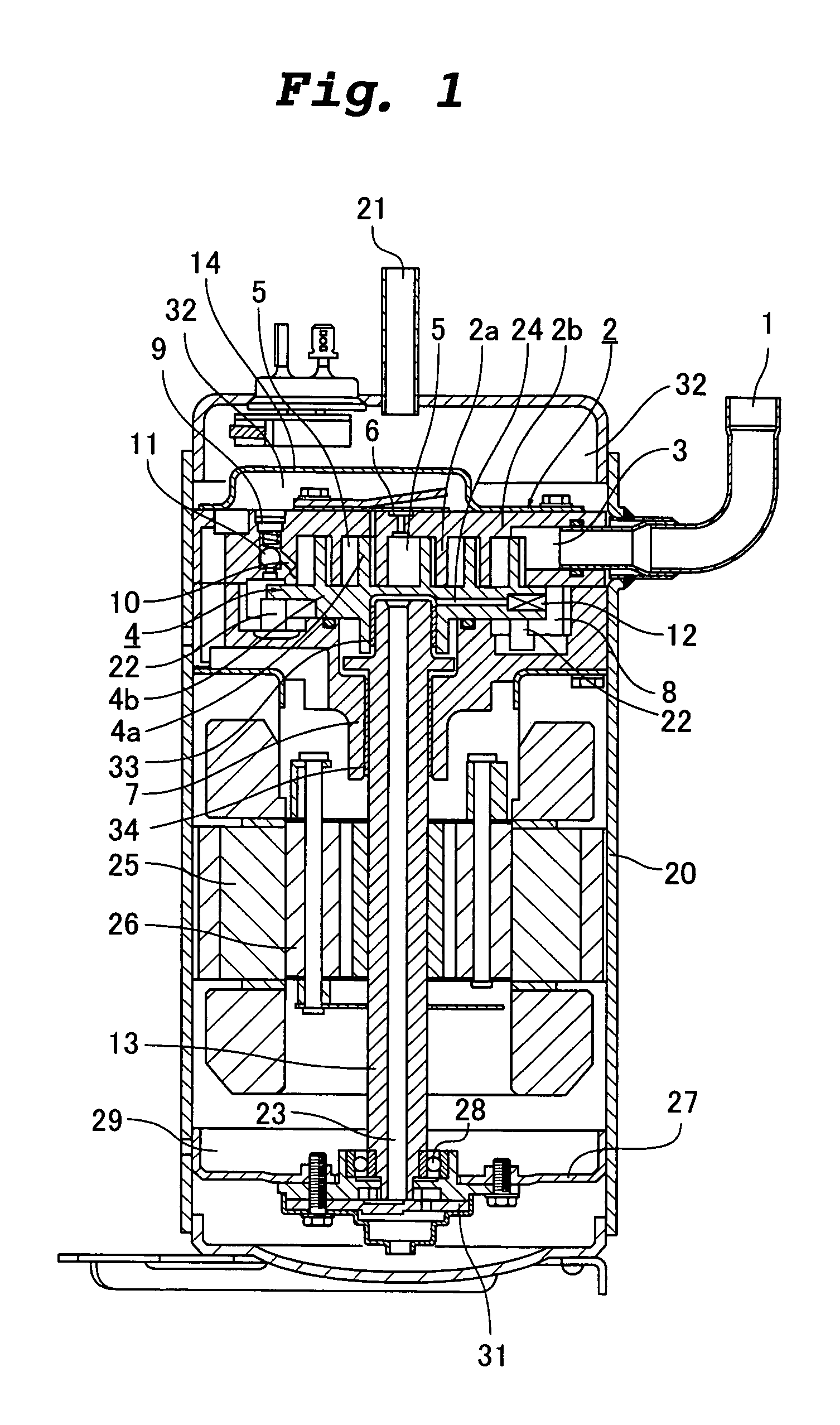

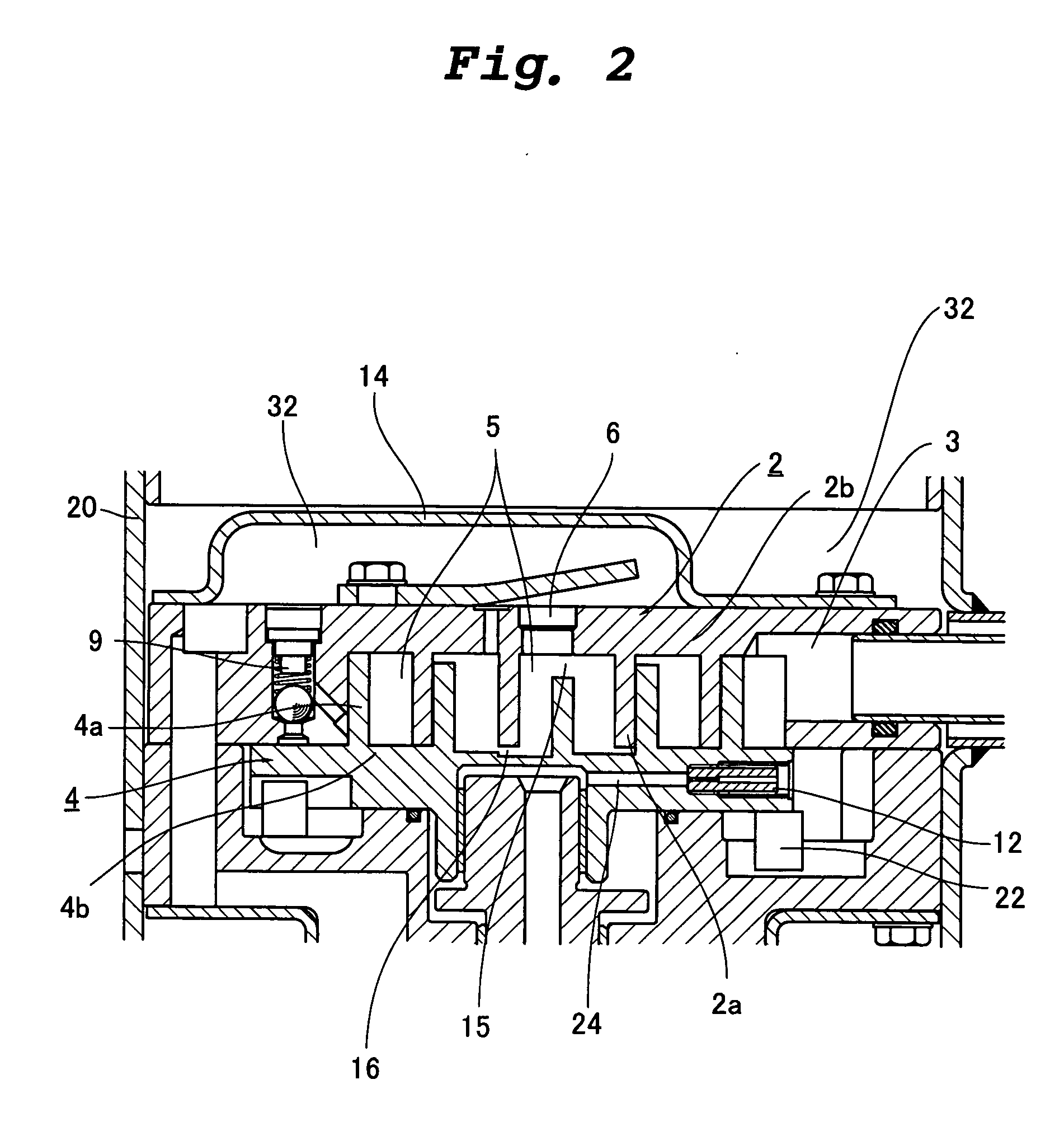

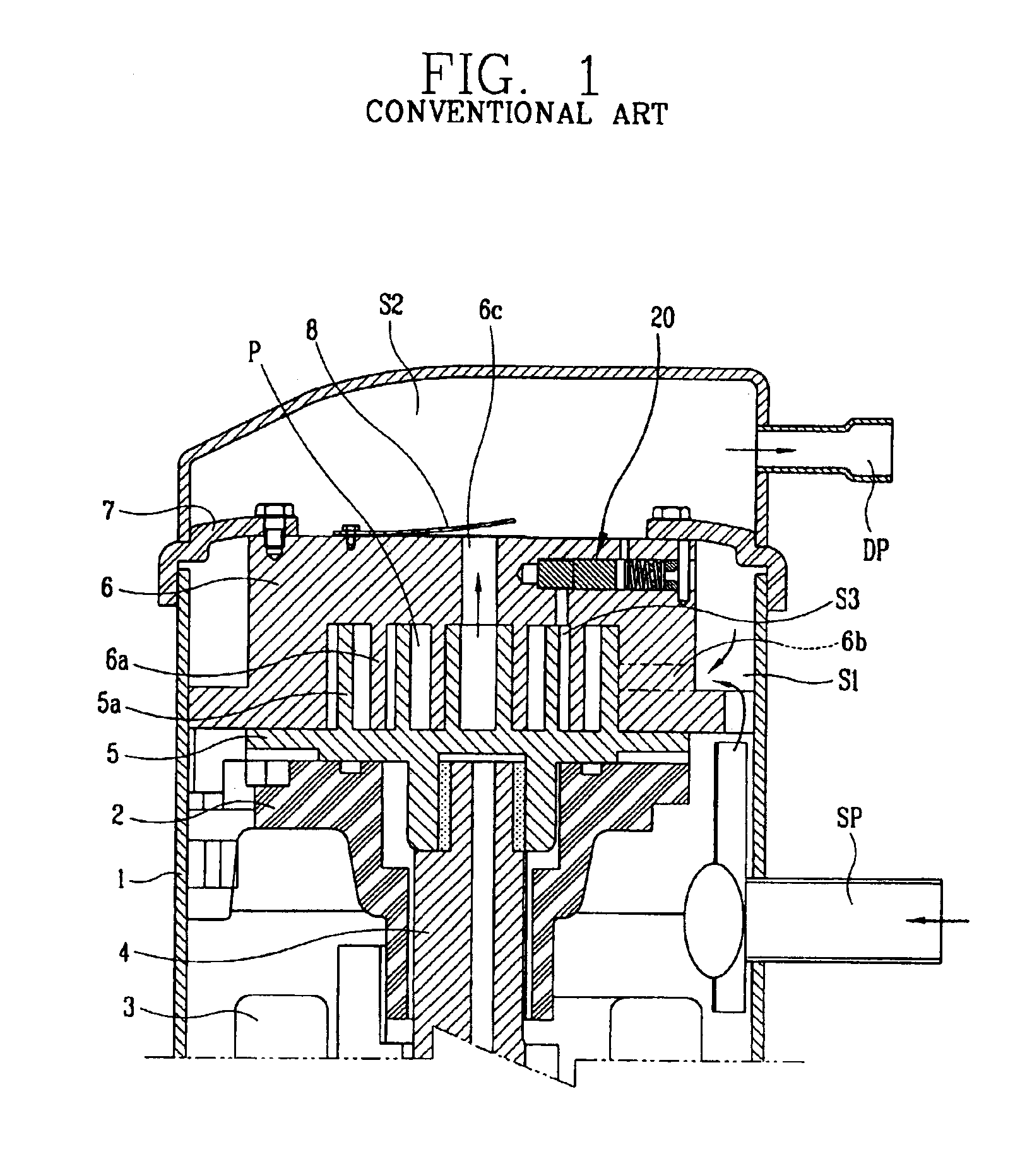

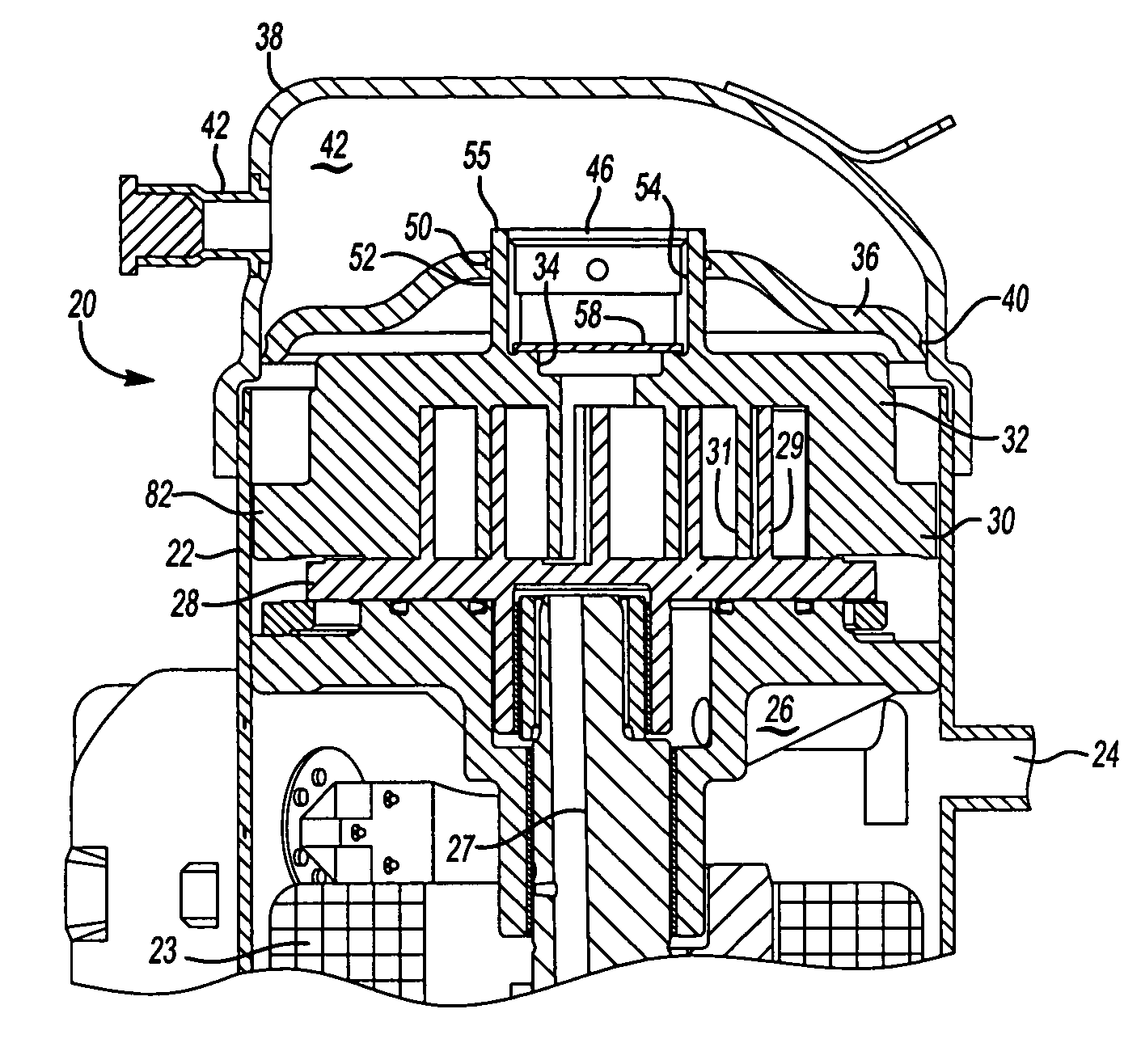

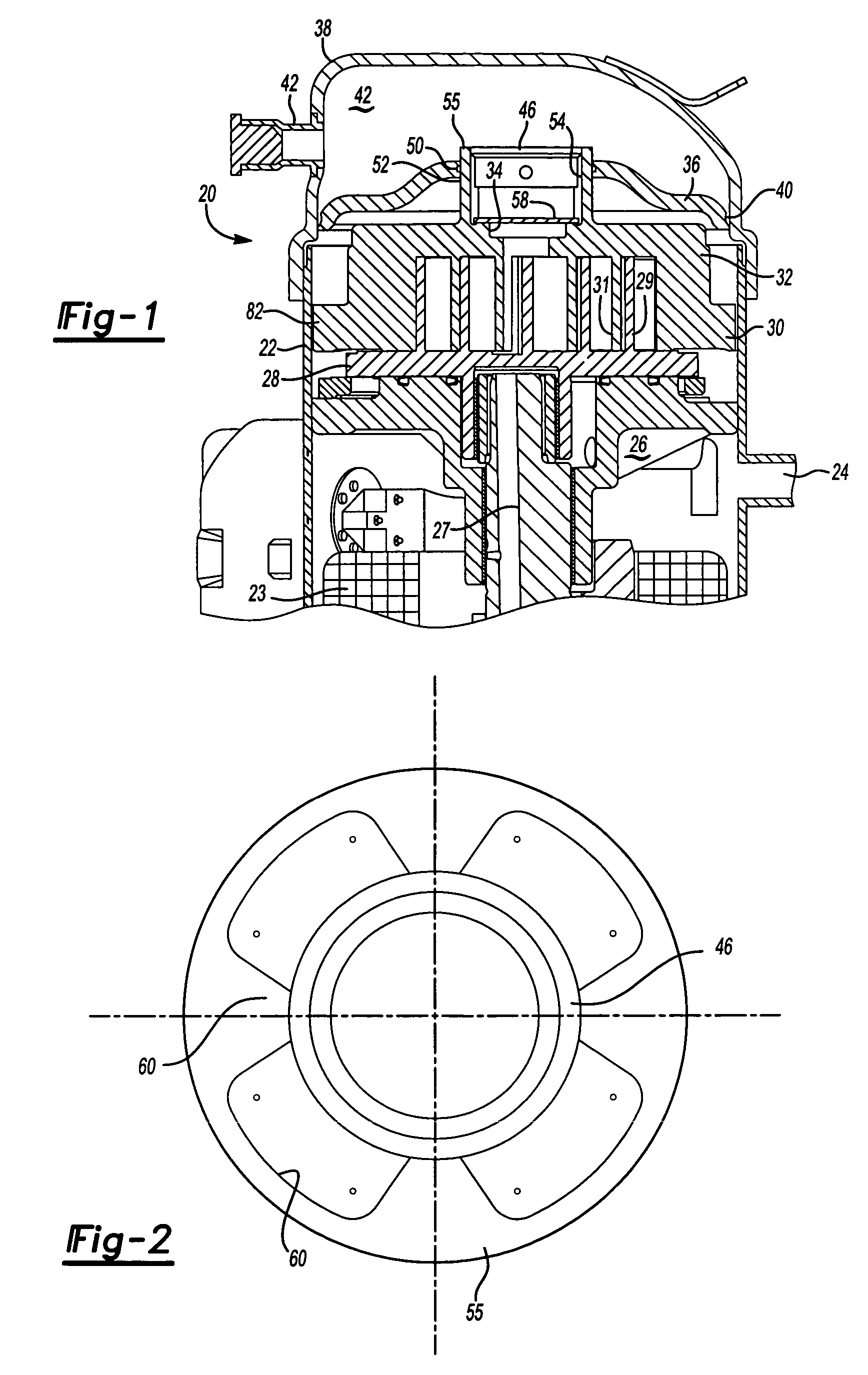

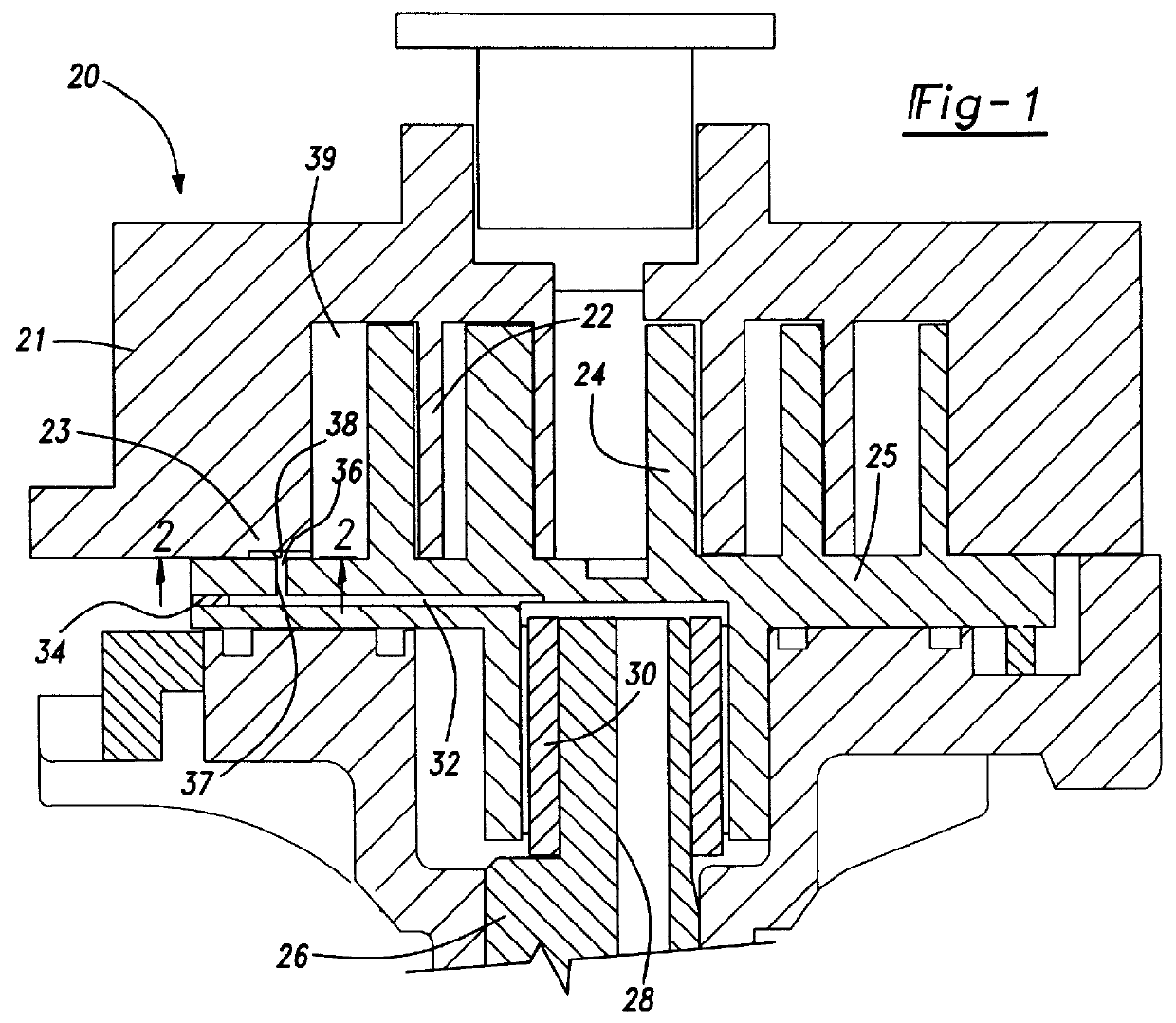

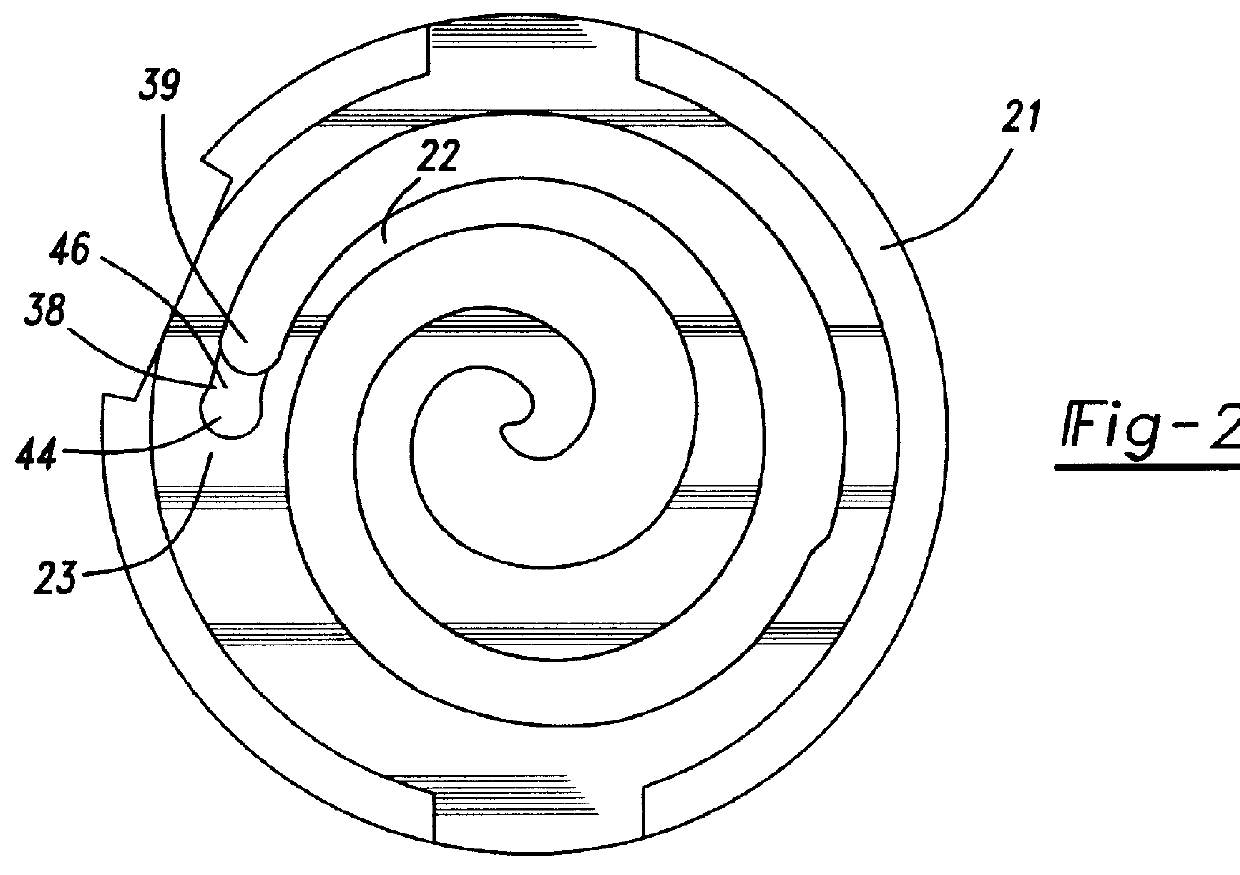

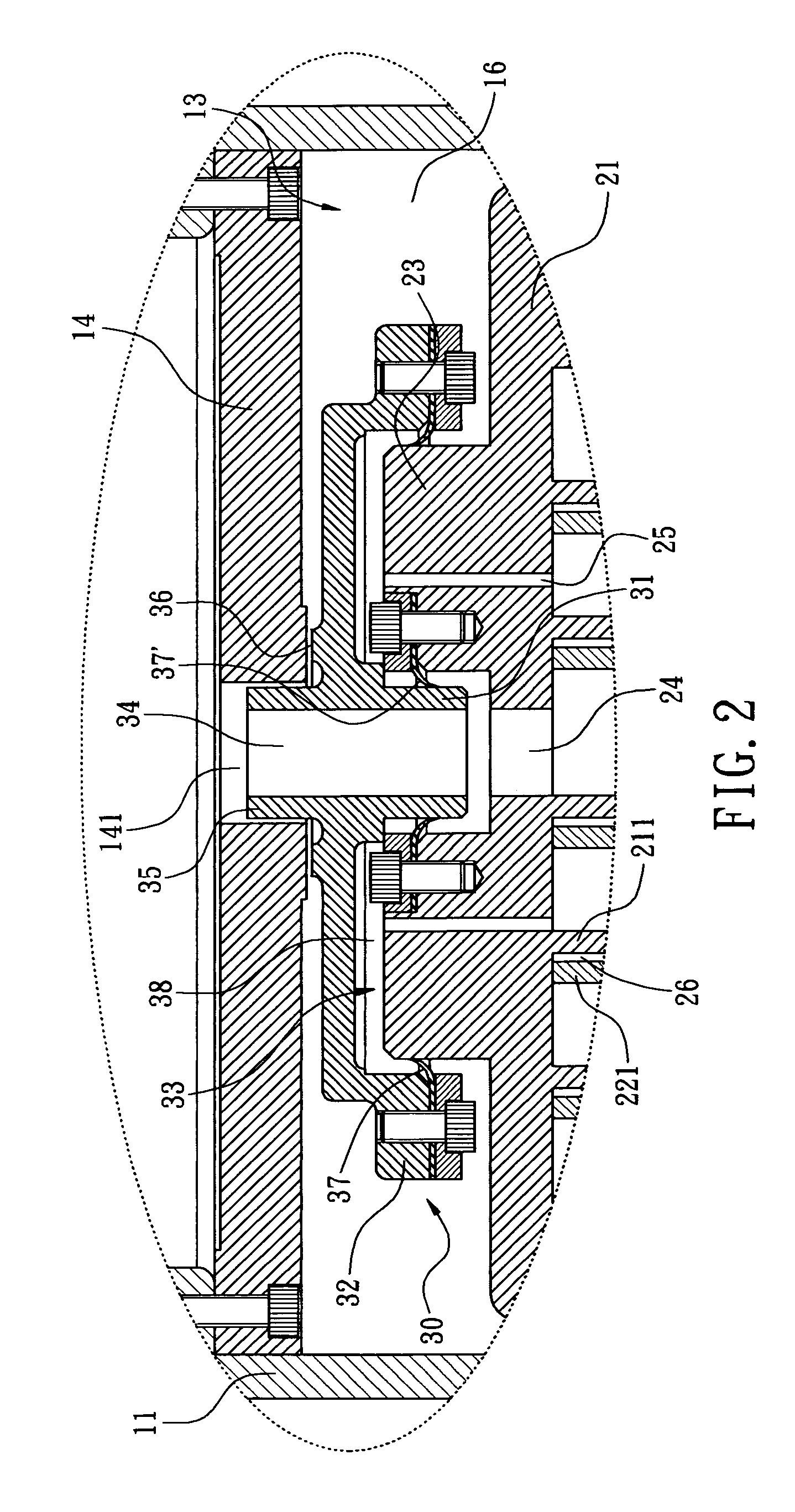

In order to improve a compressor for refrigerant, comprising an outer housing, a scroll compressor arranged in the outer housing and having a first compressor member arranged stationarily in the outer housing and a second compressor member which is movable relative to the first compressor member, the compressor members each having a base and first and second scroll ribs, respectively, which rise above the respective base and engage in one another such that the second compressor member is movable relative to the first compressor member on an orbital path about a central axis for the purpose of compressing the refrigerant, a drive unit for the second compressor member having an eccentric drive, a drive shaft, a drive motor arranged in a motor housing and having drawn-in refrigerant flowing around it as well as a bearing unit for the drive shaft which comprises a first bearing member connected to the outer housing, in such a manner that the refrigerant drawn in by the scroll compressor is free from lubricating oil to as great an extent as possible it is suggested that the refrigerant flow through an oil separator, which is arranged in the outer housing between this and the drive unit, after flowing around the drive motor and prior to entering the scroll compressor.

Owner:BITZER KUEHLMASCHINENBAU GMBH

Variable capacity scroll compressor

InactiveUS20050019177A1Easy to changeRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

Disclosed is a variable capacity scroll compressor including one or more bypass ports formed in a compression space, the bypass port being manipulated by intake / exhaust pressure of the compressor to control compression volume in multi-stages.

Owner:LG ELECTRONICS INC

Two-step self-modulating scroll compressor

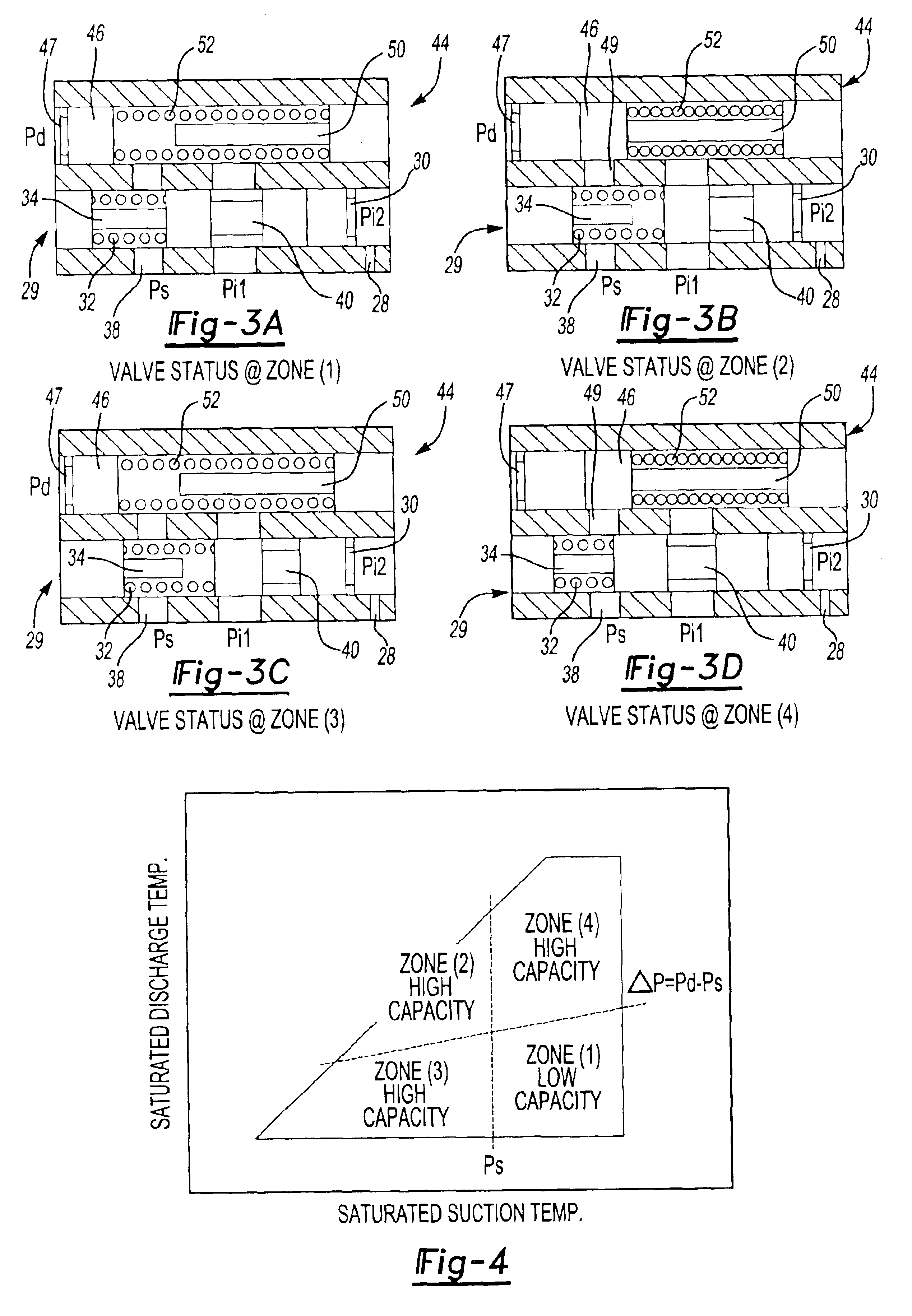

InactiveUS6884042B2Pump componentsEngine of arcuate-engagement typePressure differenceElectrical and Electronics engineering

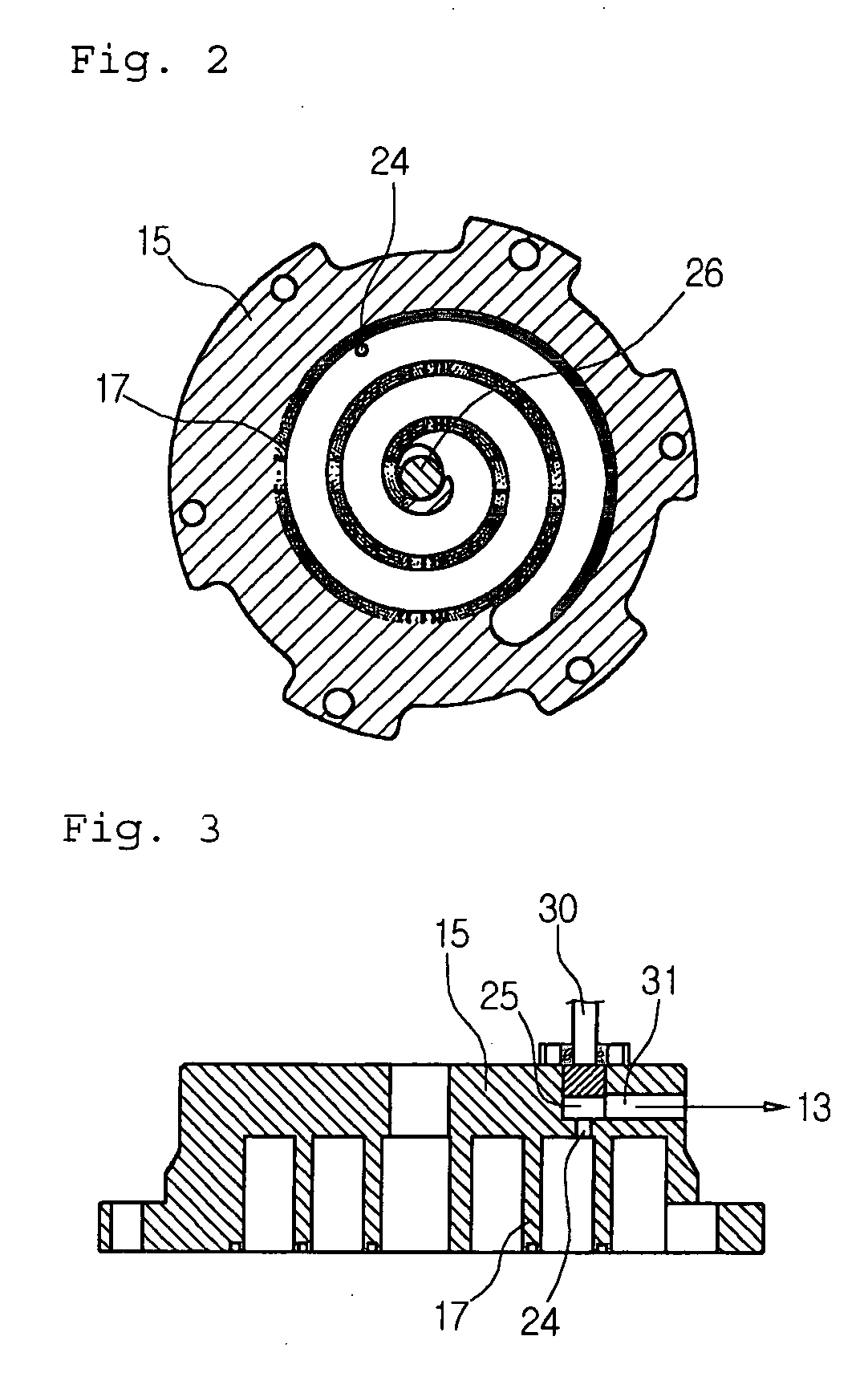

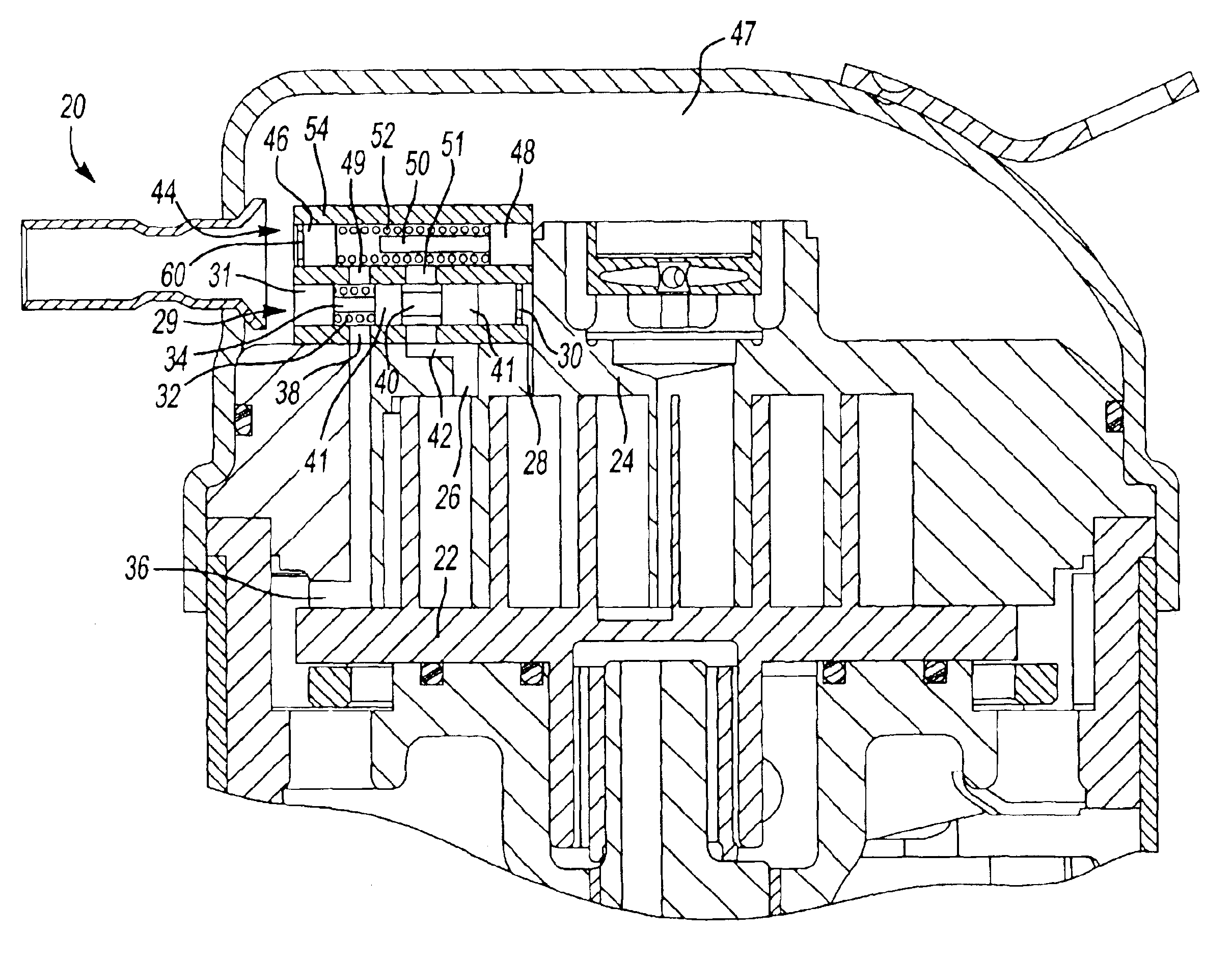

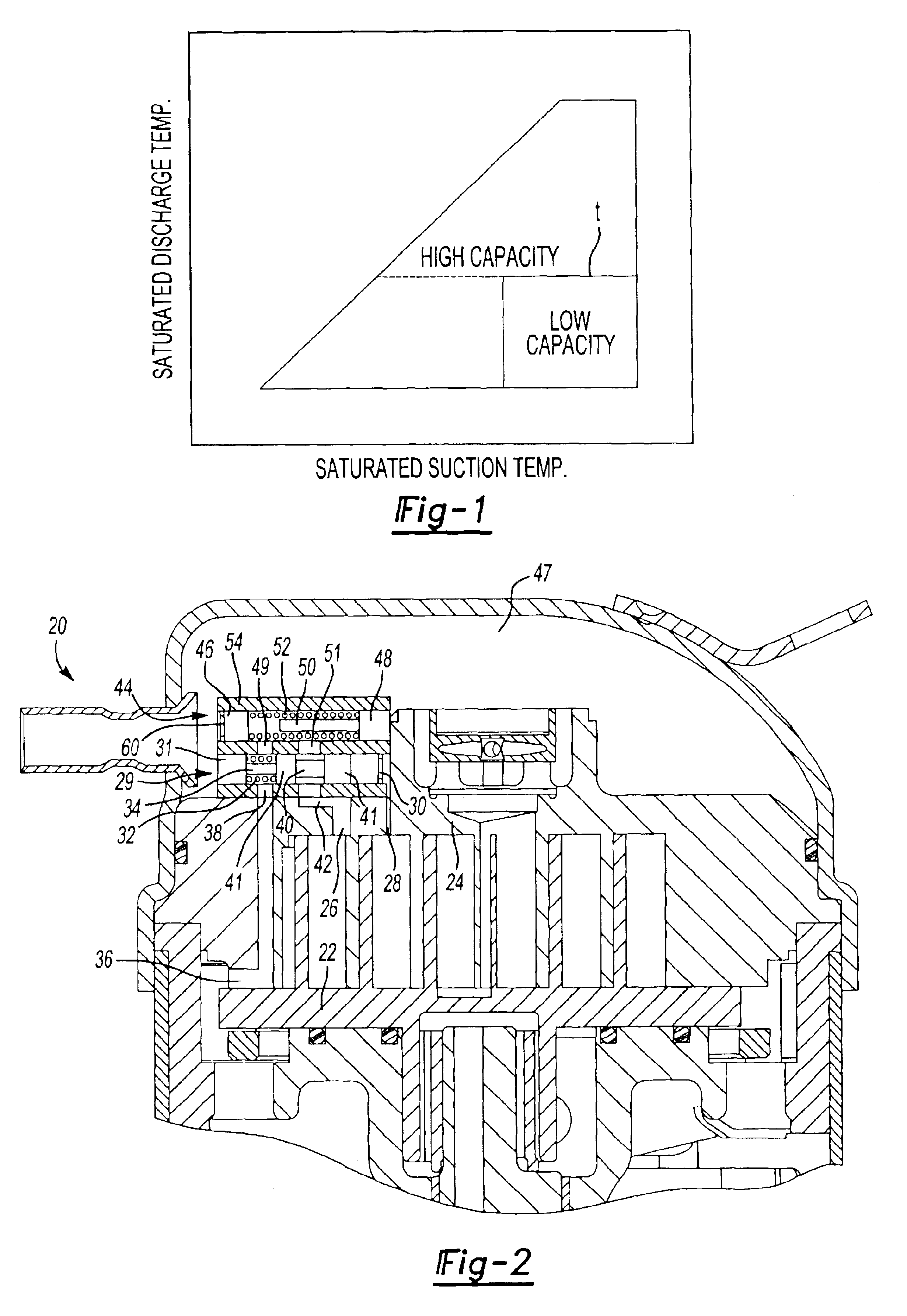

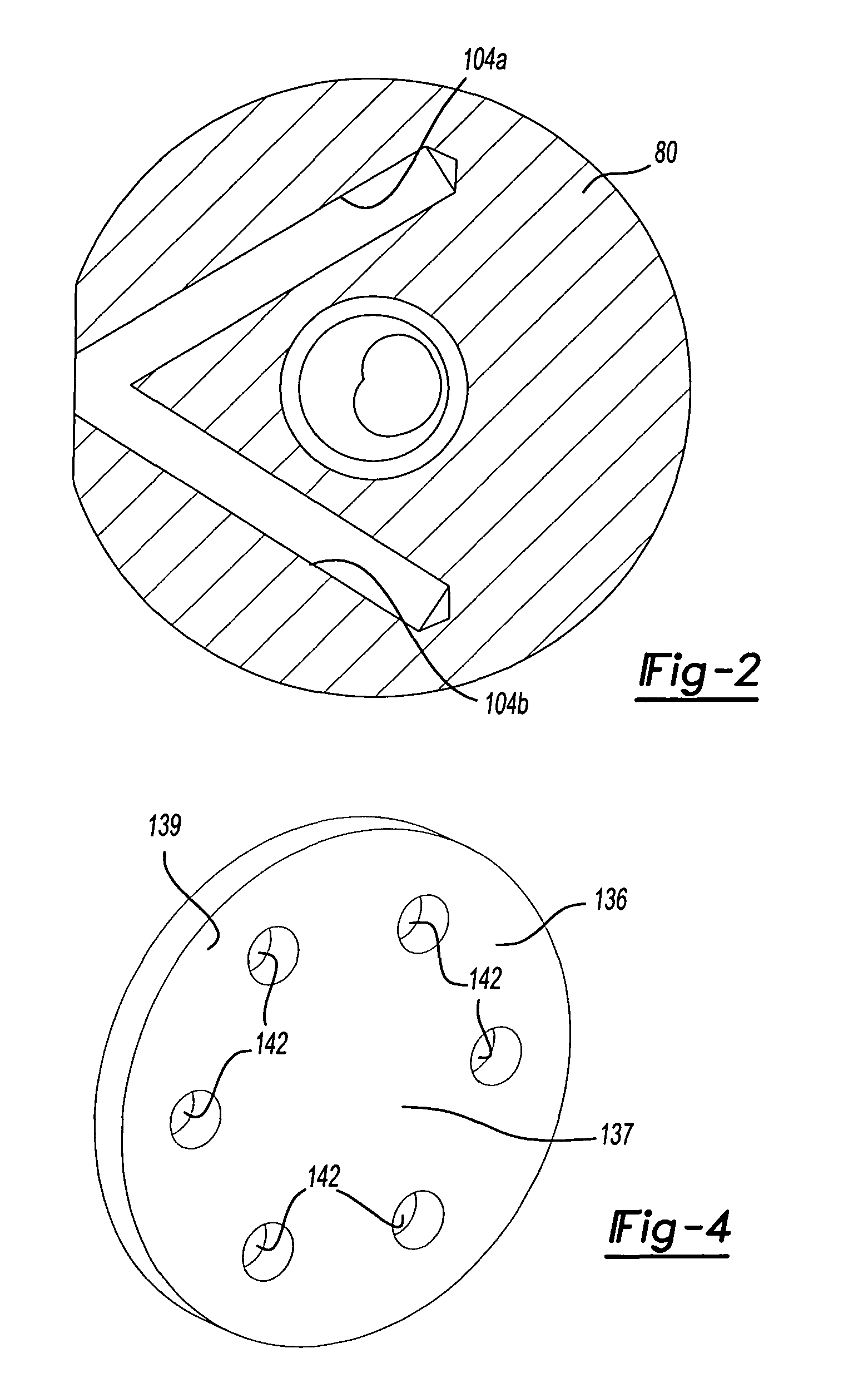

A self-modulating scroll compressor includes a pair of valves. A first valve moves to a low capacity position when the pressure differential is below a predetermined amount. A second valve moves to a low capacity position when the suction pressure is above a predetermined amount. Low capacity operation will only occur when both valves are open. The present invention thus provides a scroll compressor design with the ability to self-modulate and control the conditions under which low capacity operation occurs based upon two criteria.

Owner:SCROLL TECH

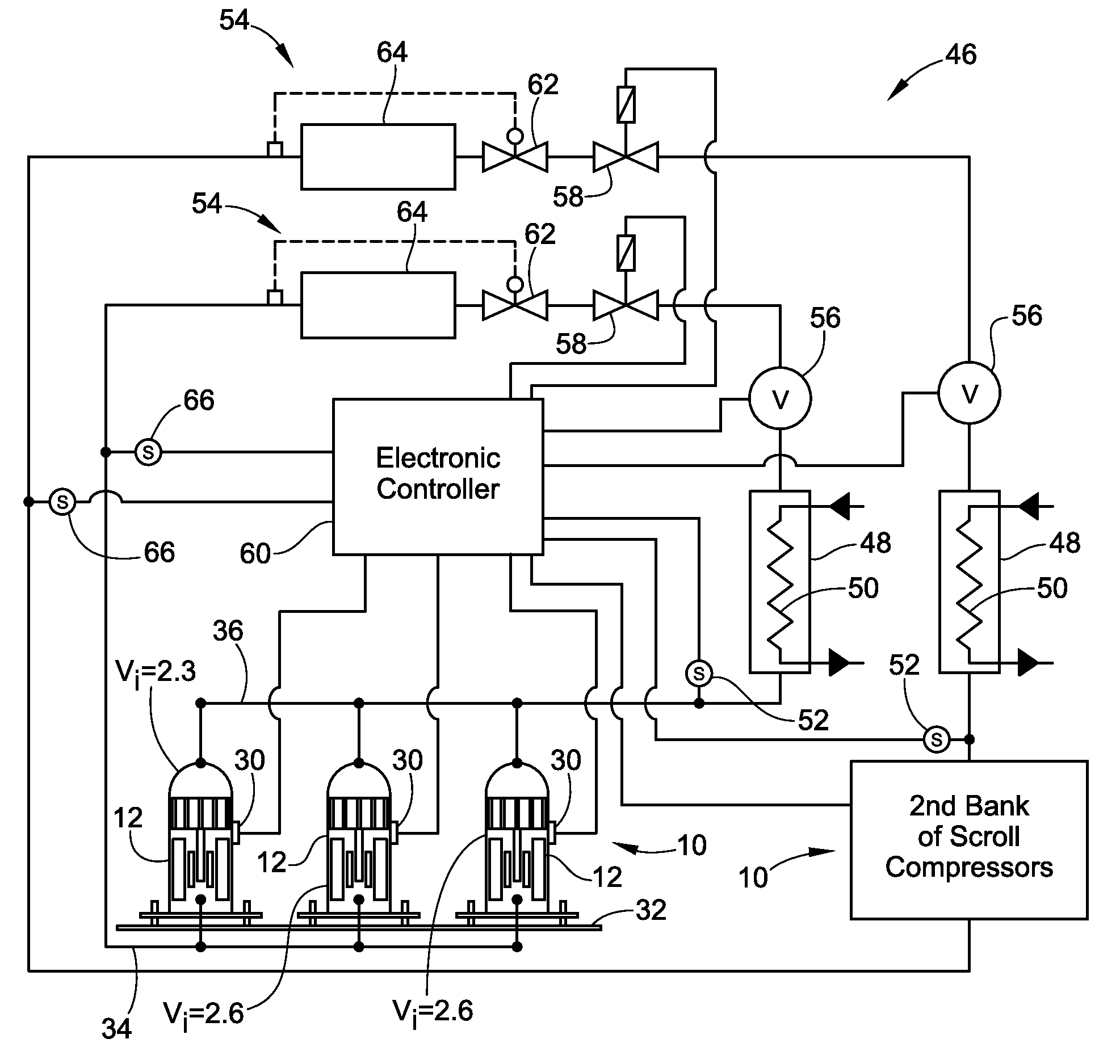

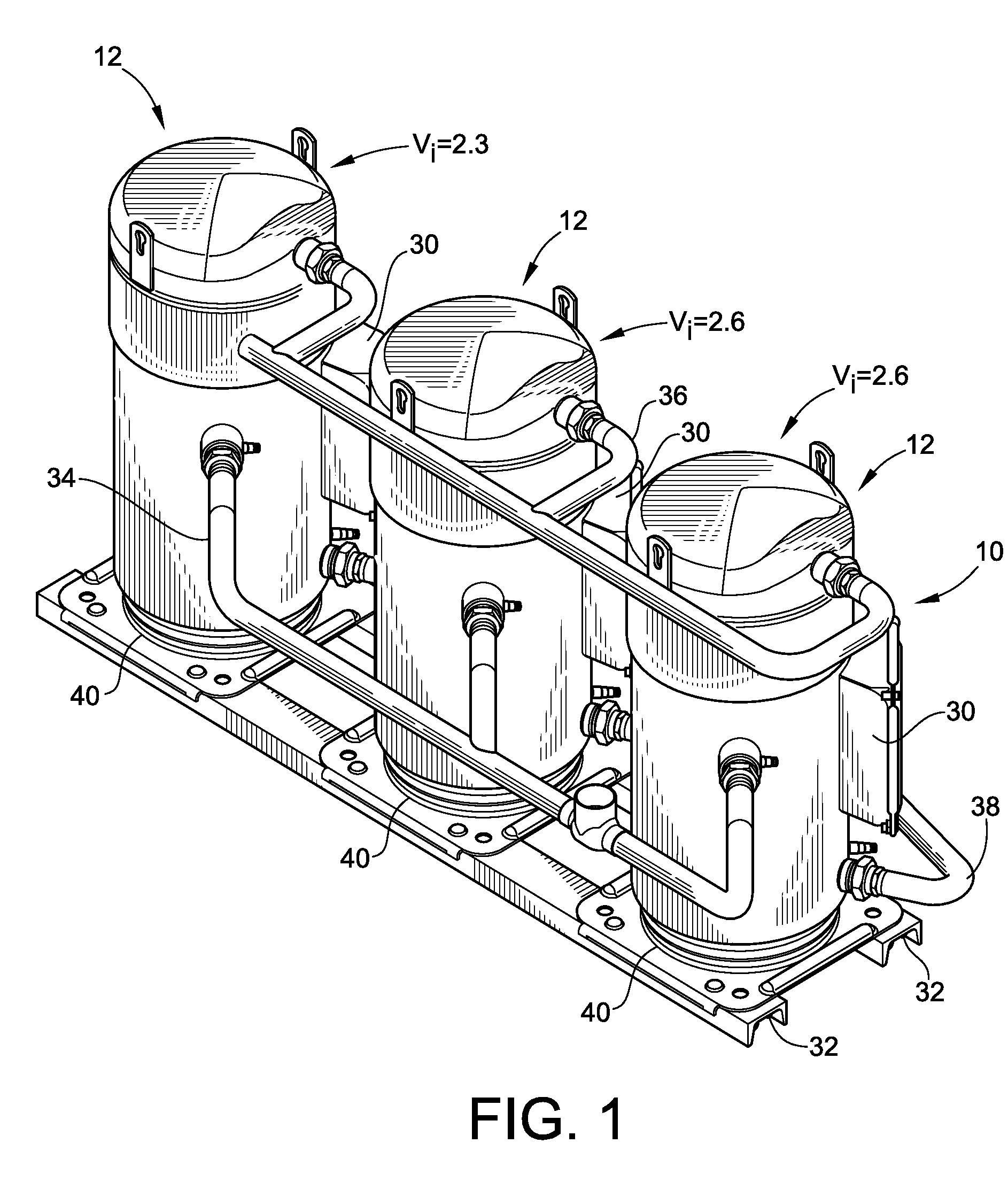

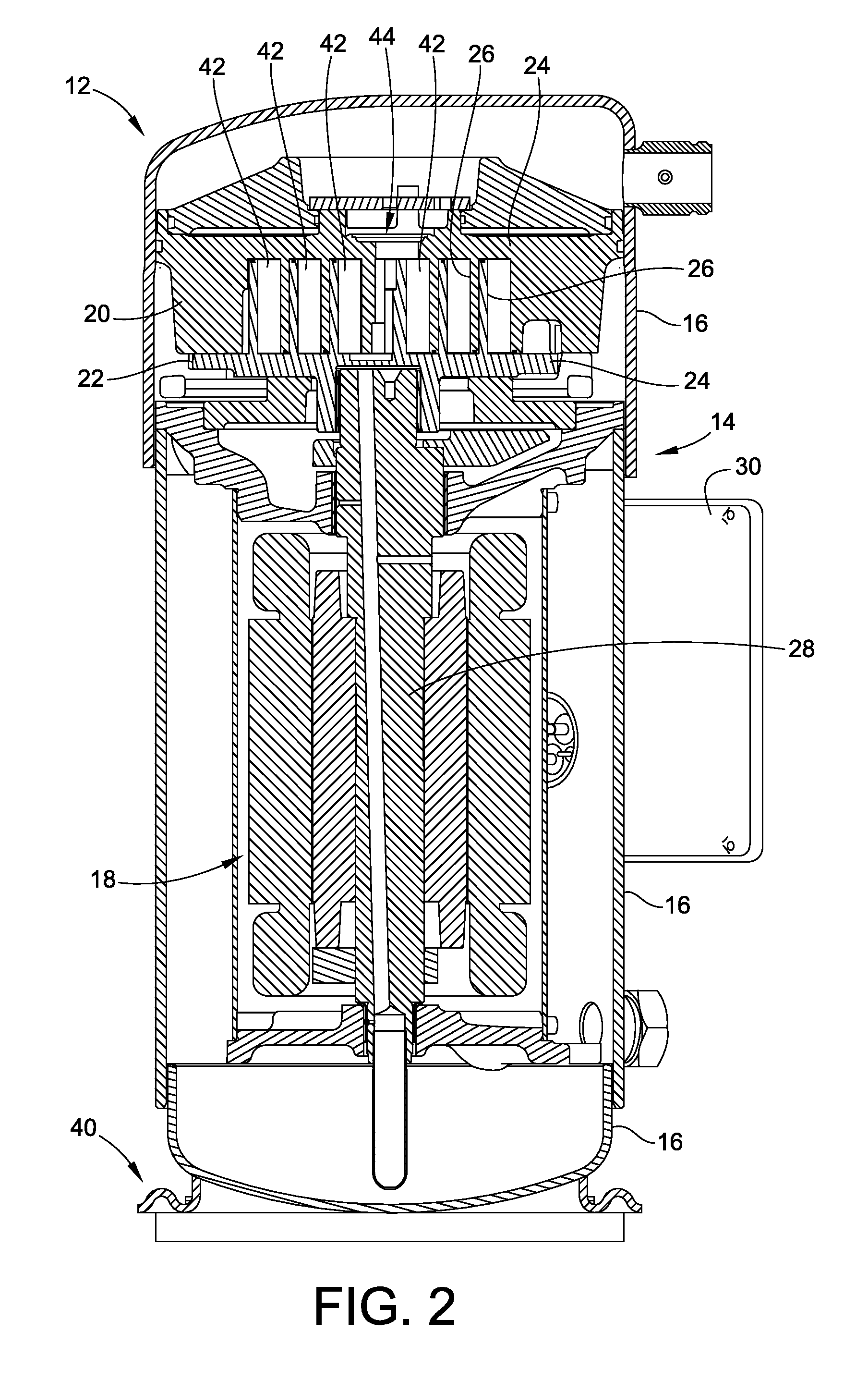

Scroll Compressors with Different Volume Indexes and Systems and Methods for Same

InactiveUS20100186433A1Improve efficiencyRotary/oscillating piston combinations for elastic fluidsCompressorEngineeringScroll compressor

Owner:BITZER KUEHLMASCHINENBAU GMBH

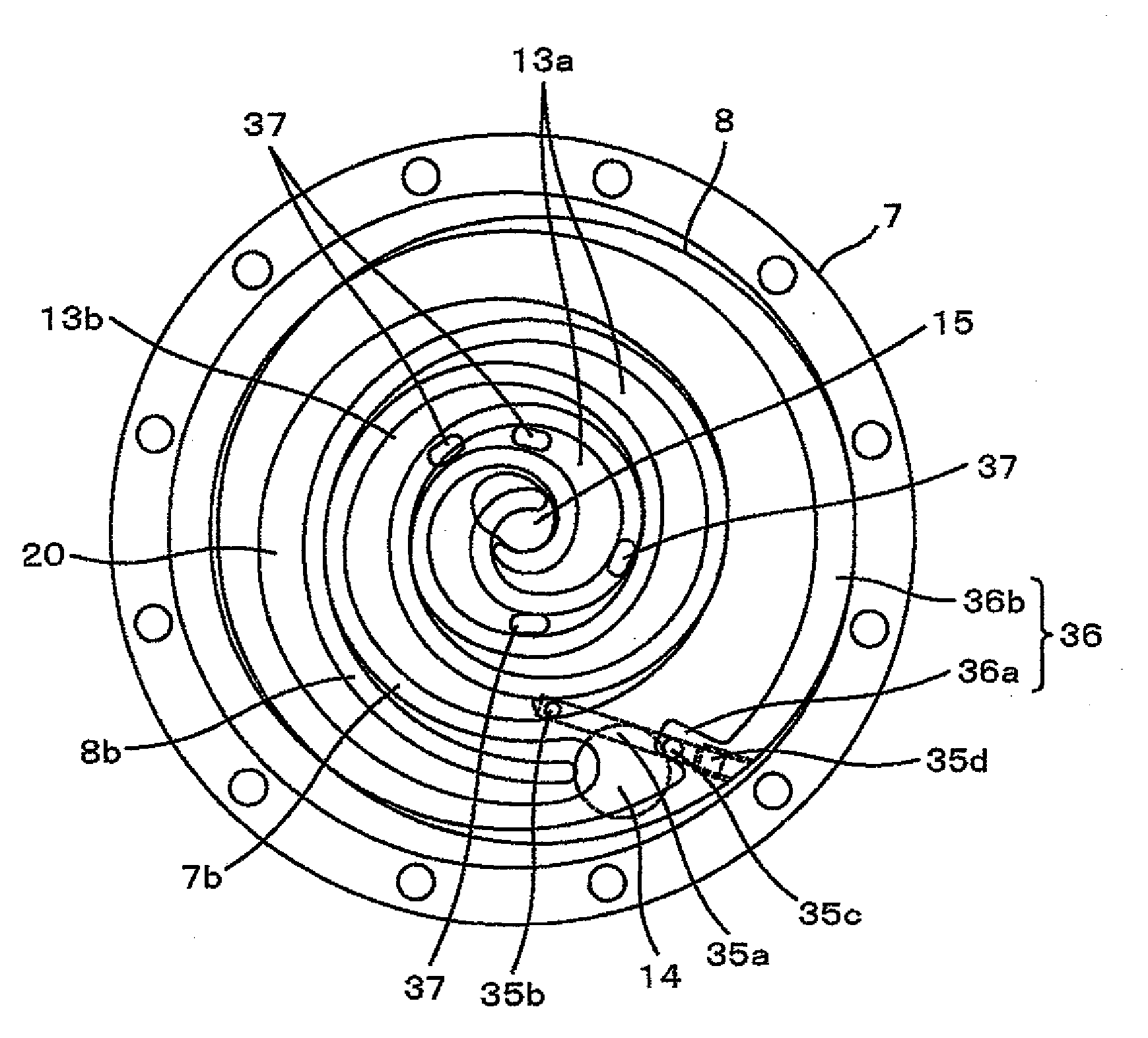

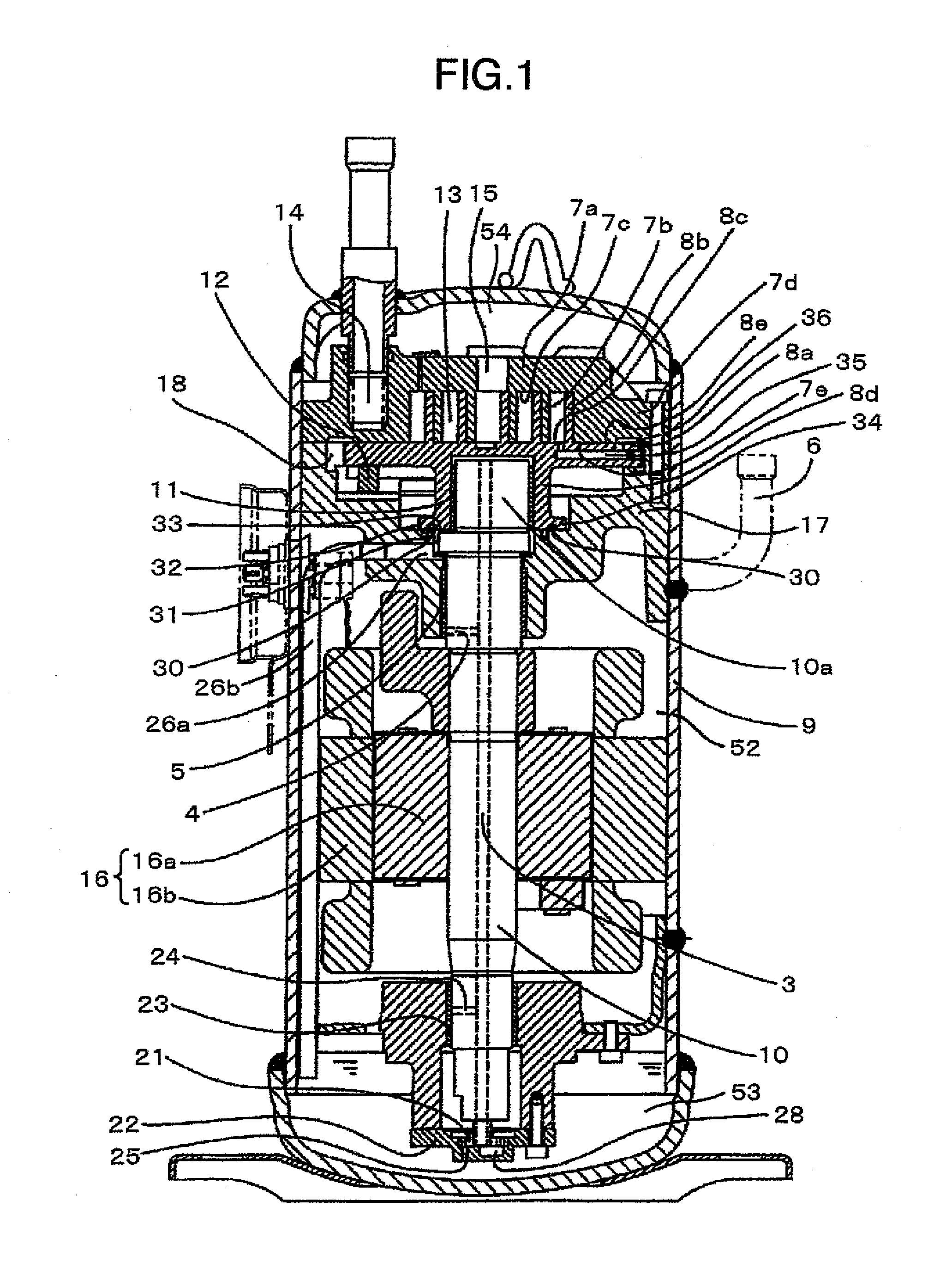

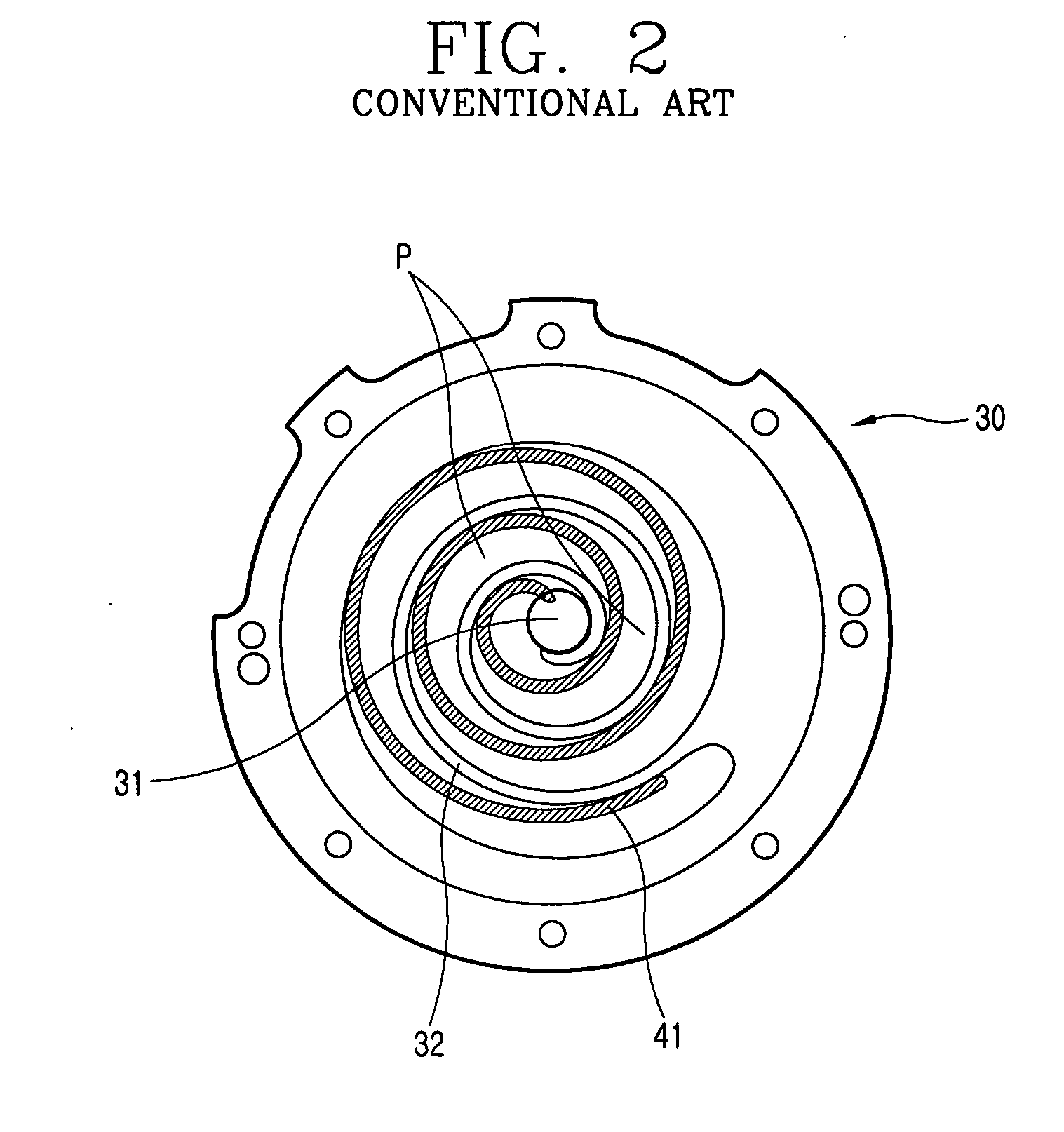

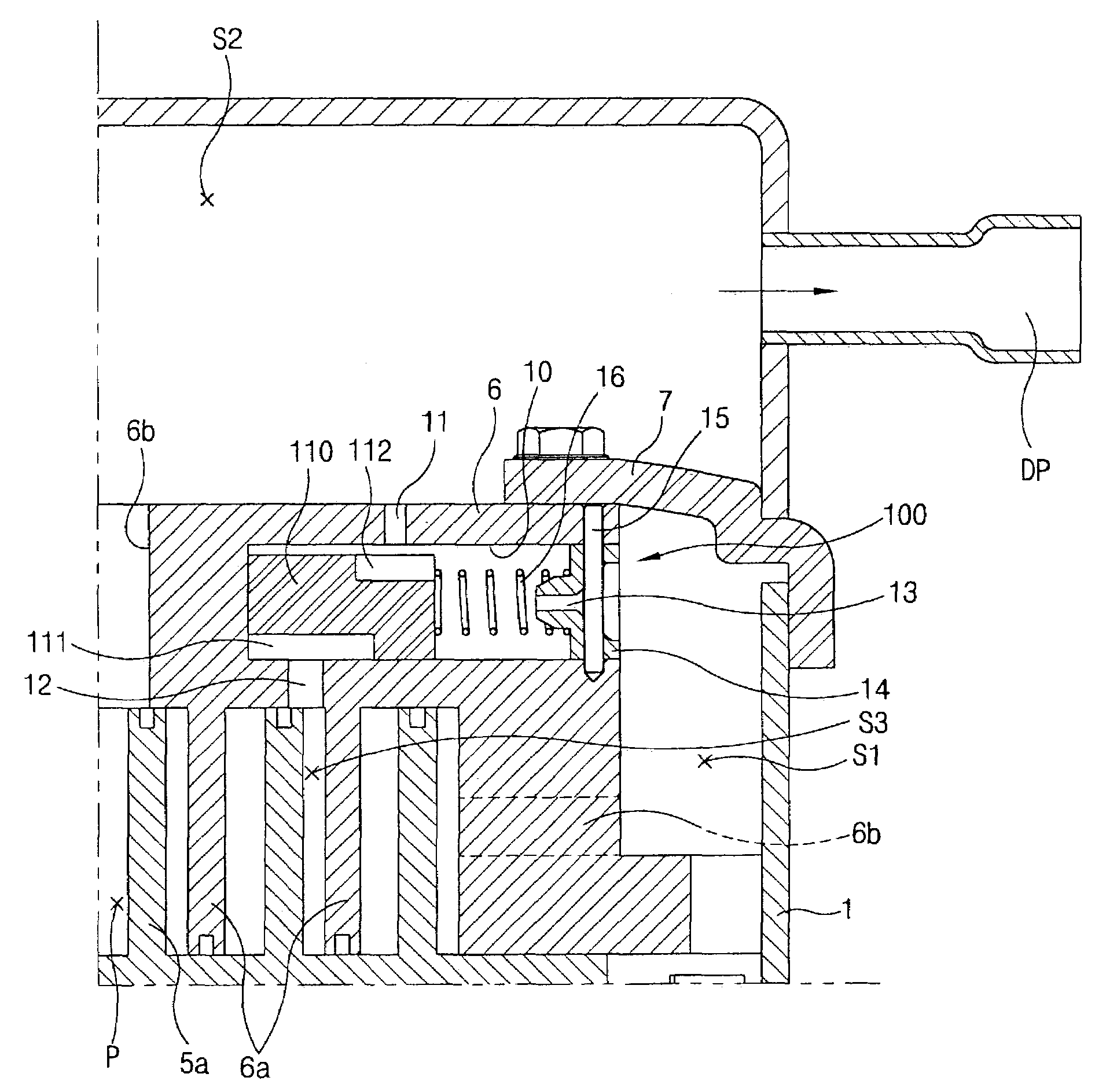

Scroll compressor having an annular recess located outside an annular seal portion and another recess communicating with suction port of fixed scroll

ActiveUS7229261B2Reduce back pressureSliding loss can be reducedEngine of arcuate-engagement typeOscillating piston enginesEngineeringSliding contact

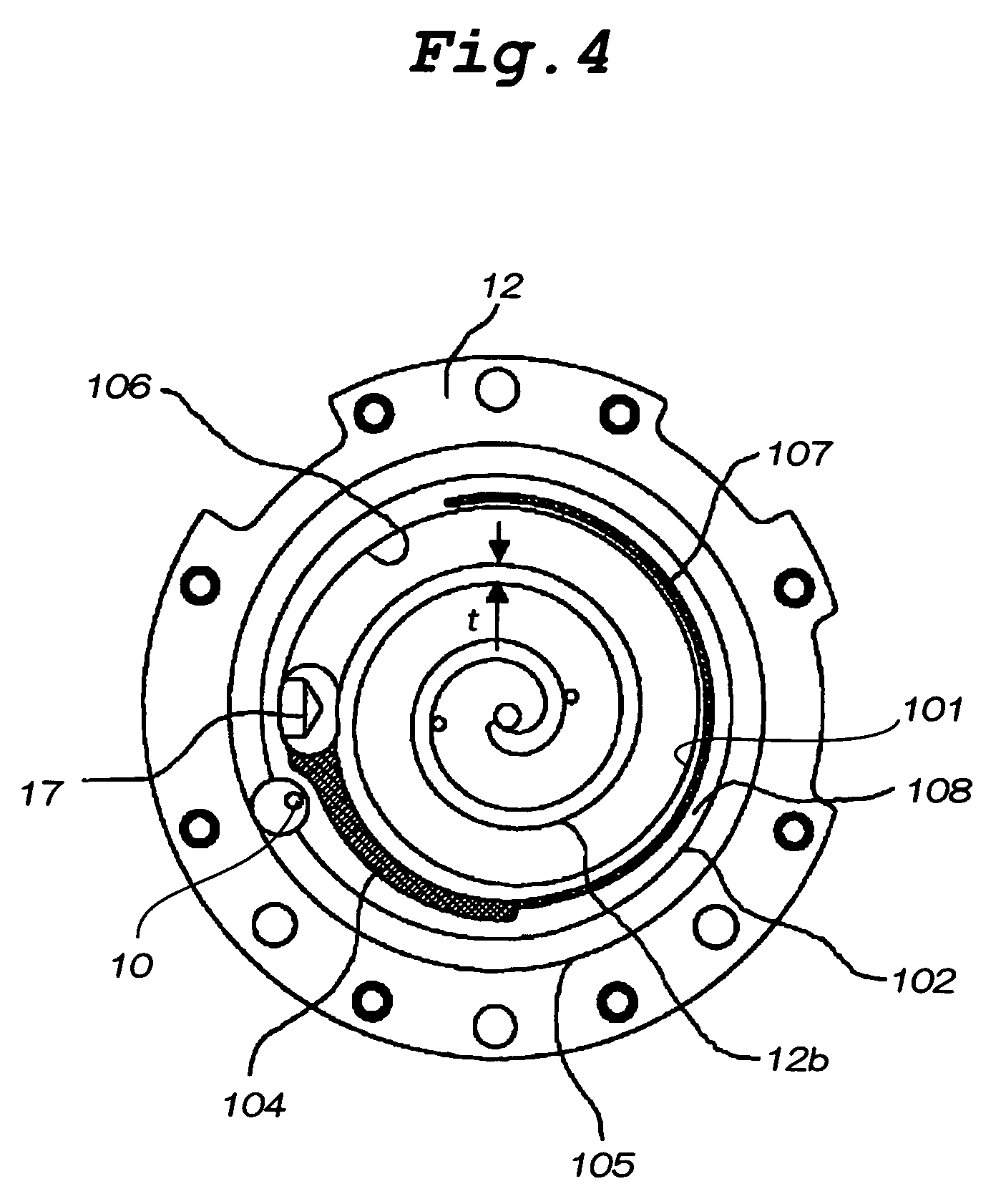

A surface of a fixed scroll which is opposed to a end plate of an orbiting scroll existing outside of a lap of the fixed scroll is formed with: a substantially annular seal portion which extends such as to have an outer wall surface of the fixed scroll outwardly extending from an inner wall surface of outermost periphery of the lap substantially along the inner wall surface, and which comes into slide contact with the end plate of the orbiting scroll; a substantially annular recess located outside of the substantially annular seal portion; and a recess which is brought into communication with an intake port of the fixed scroll independently from the substantially annular recess. With this, back pressure of the orbiting scroll is increased, and turning-over phenomenon of the orbiting scroll can be suppressed.

Owner:PANASONIC CORP

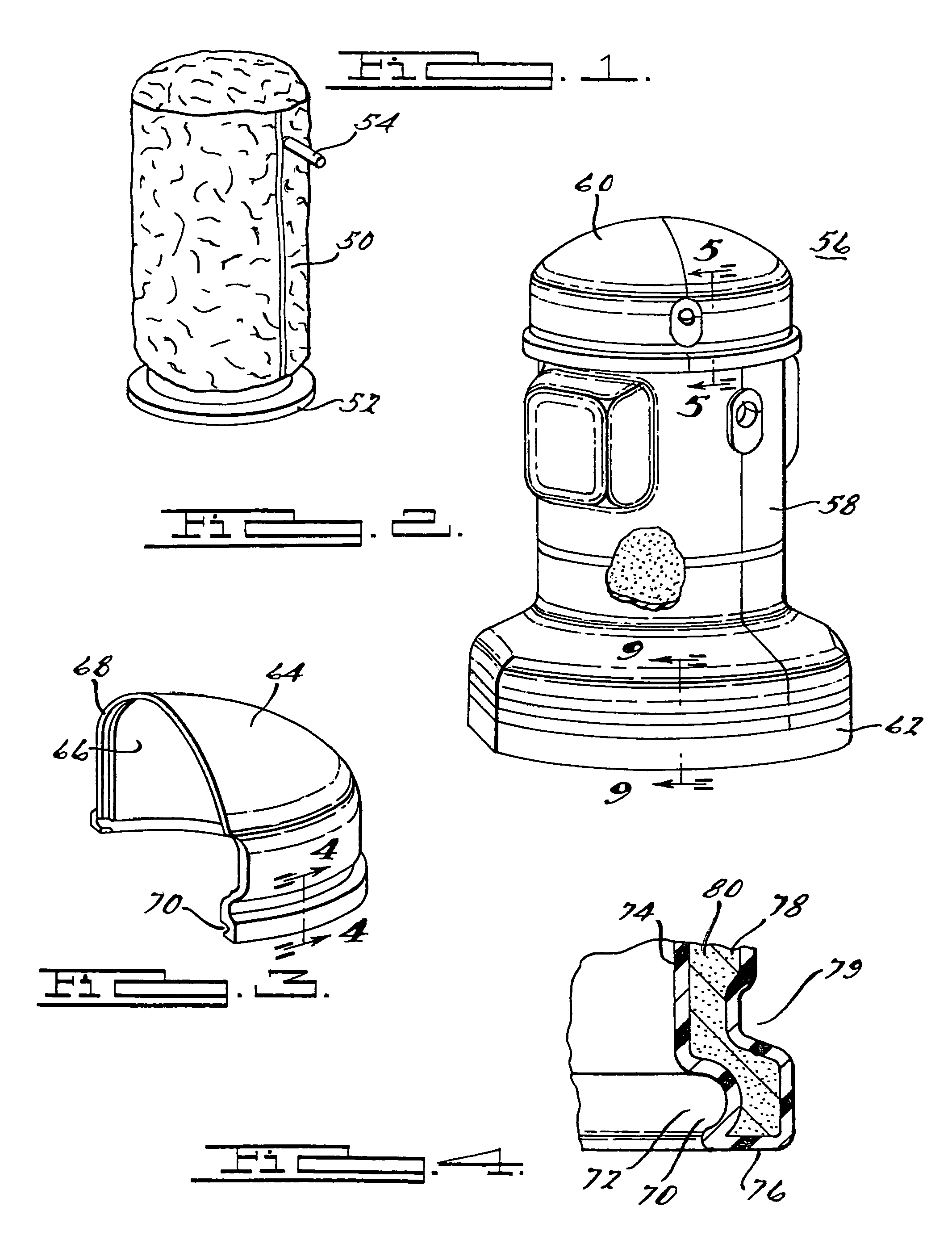

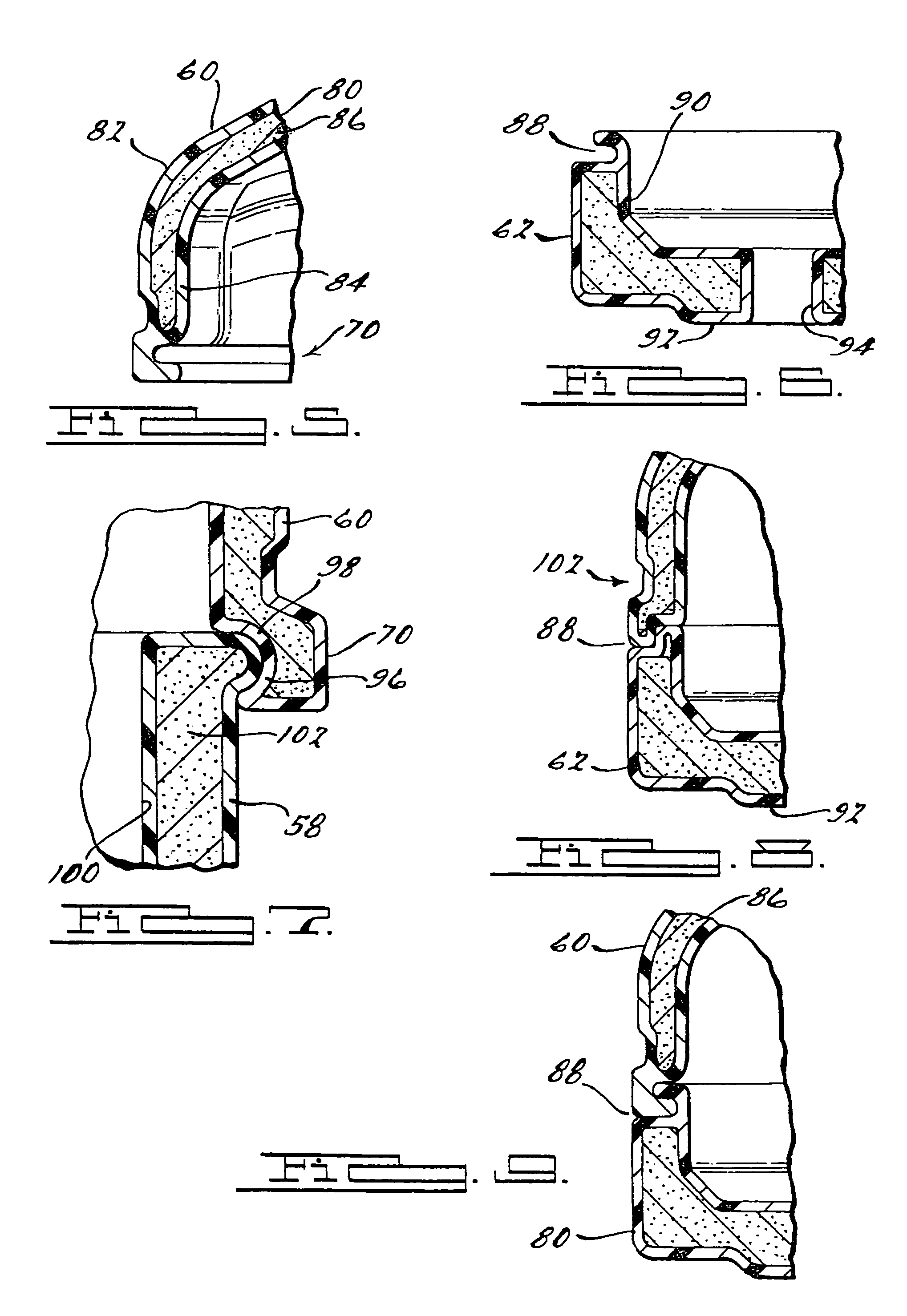

Compressor sound attenuation enclosure

InactiveUS7398855B2Improved sound attenuating shellImprove noiseRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsUltrasound attenuationEngineering

Owner:EMERSON CLIMATE TECH INC

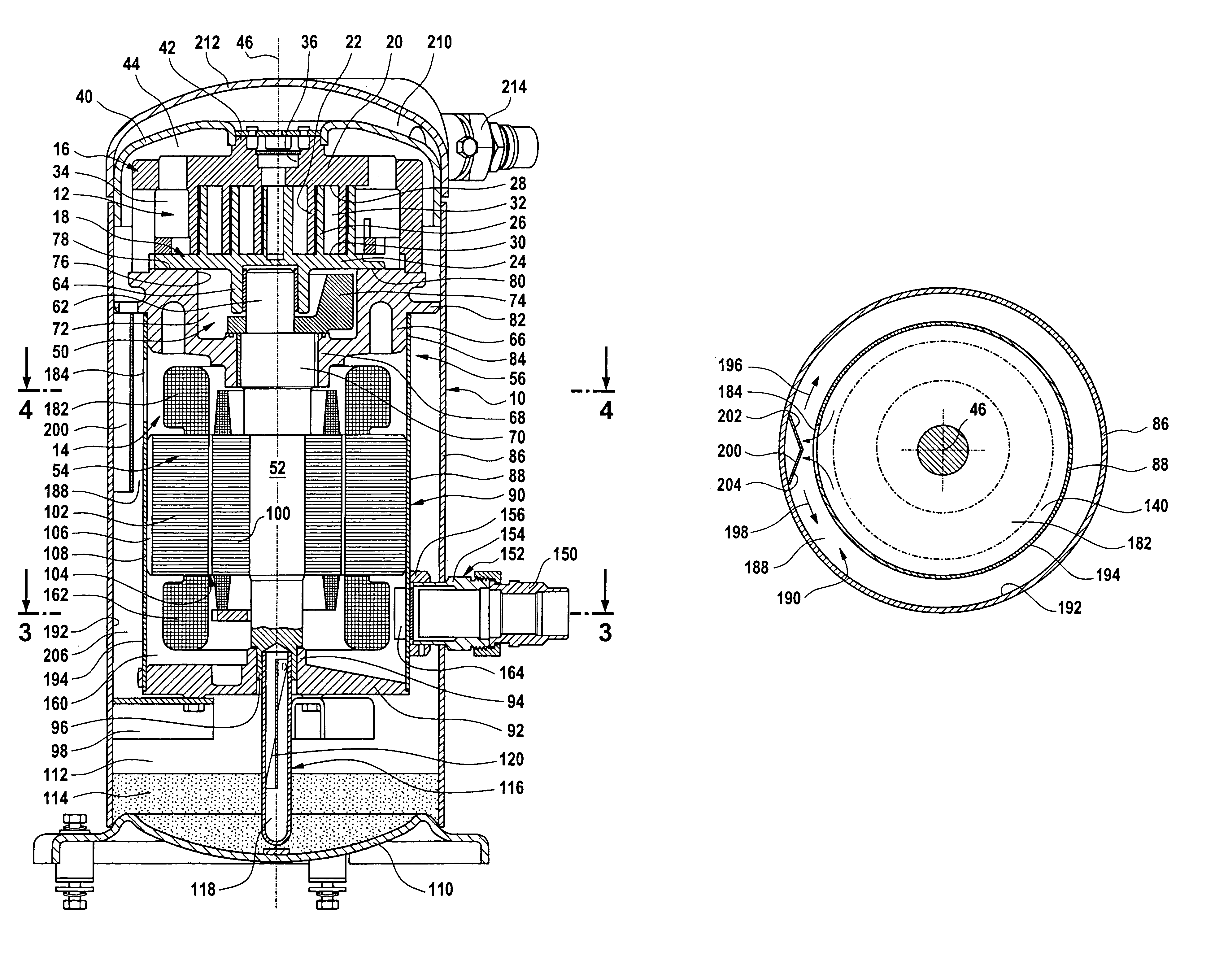

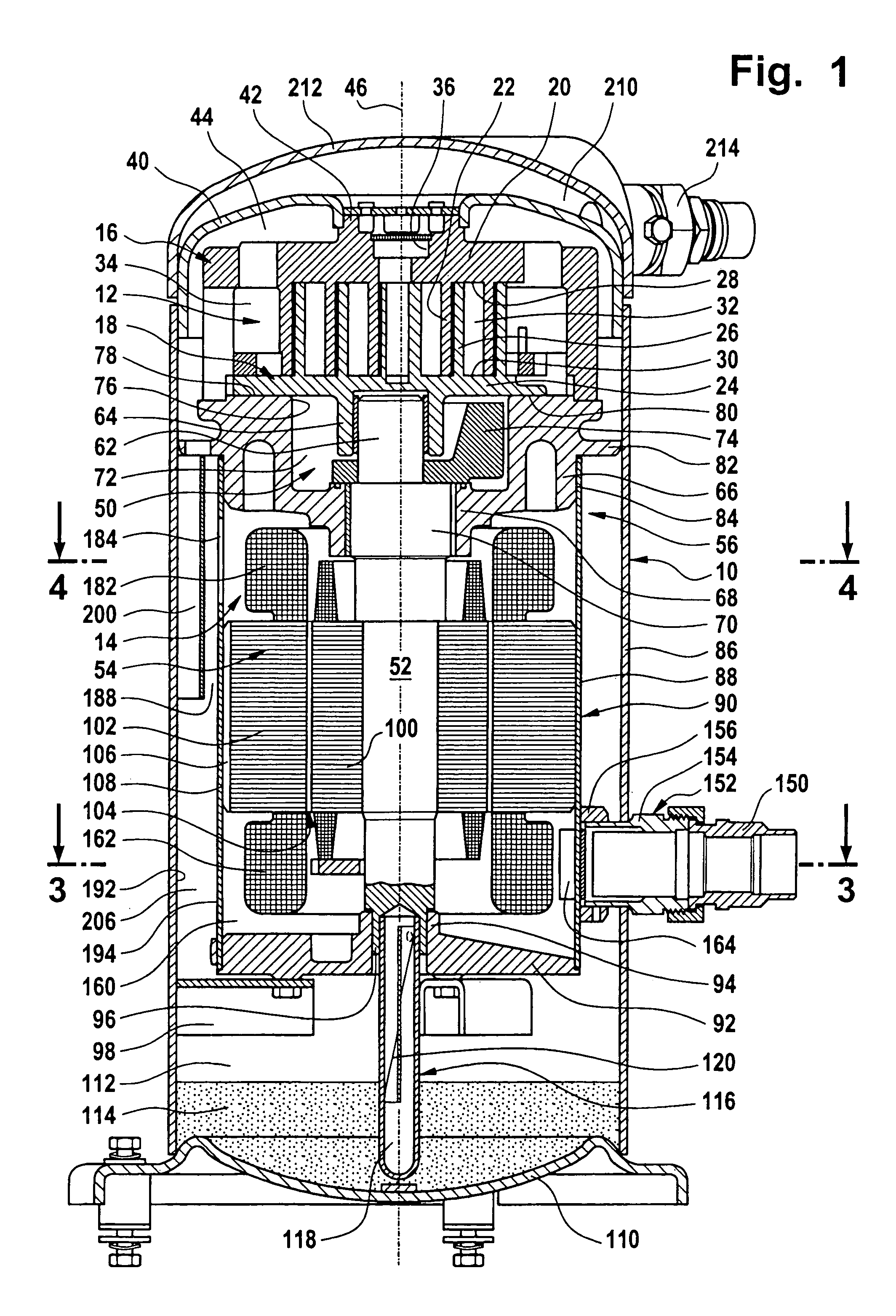

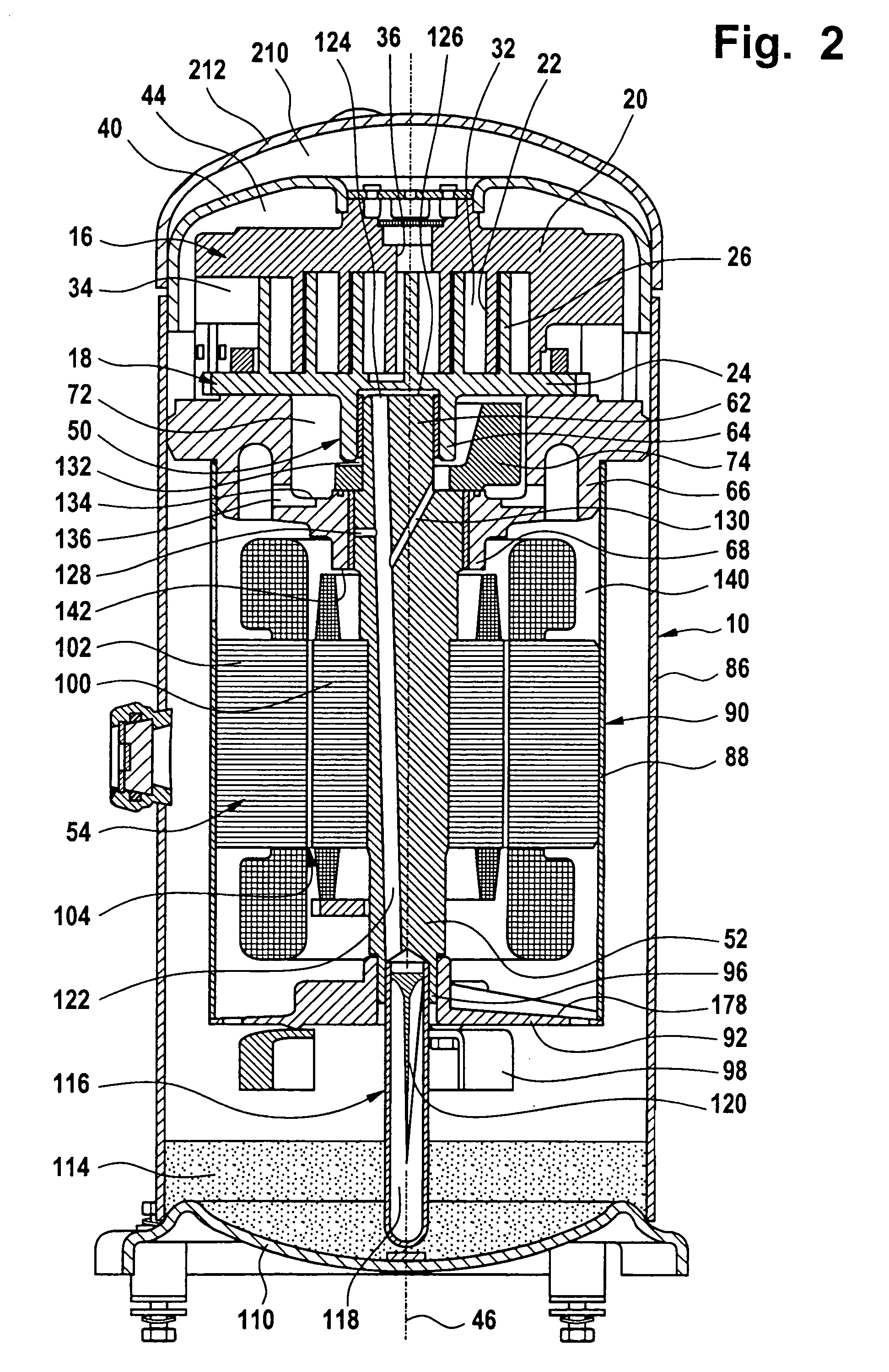

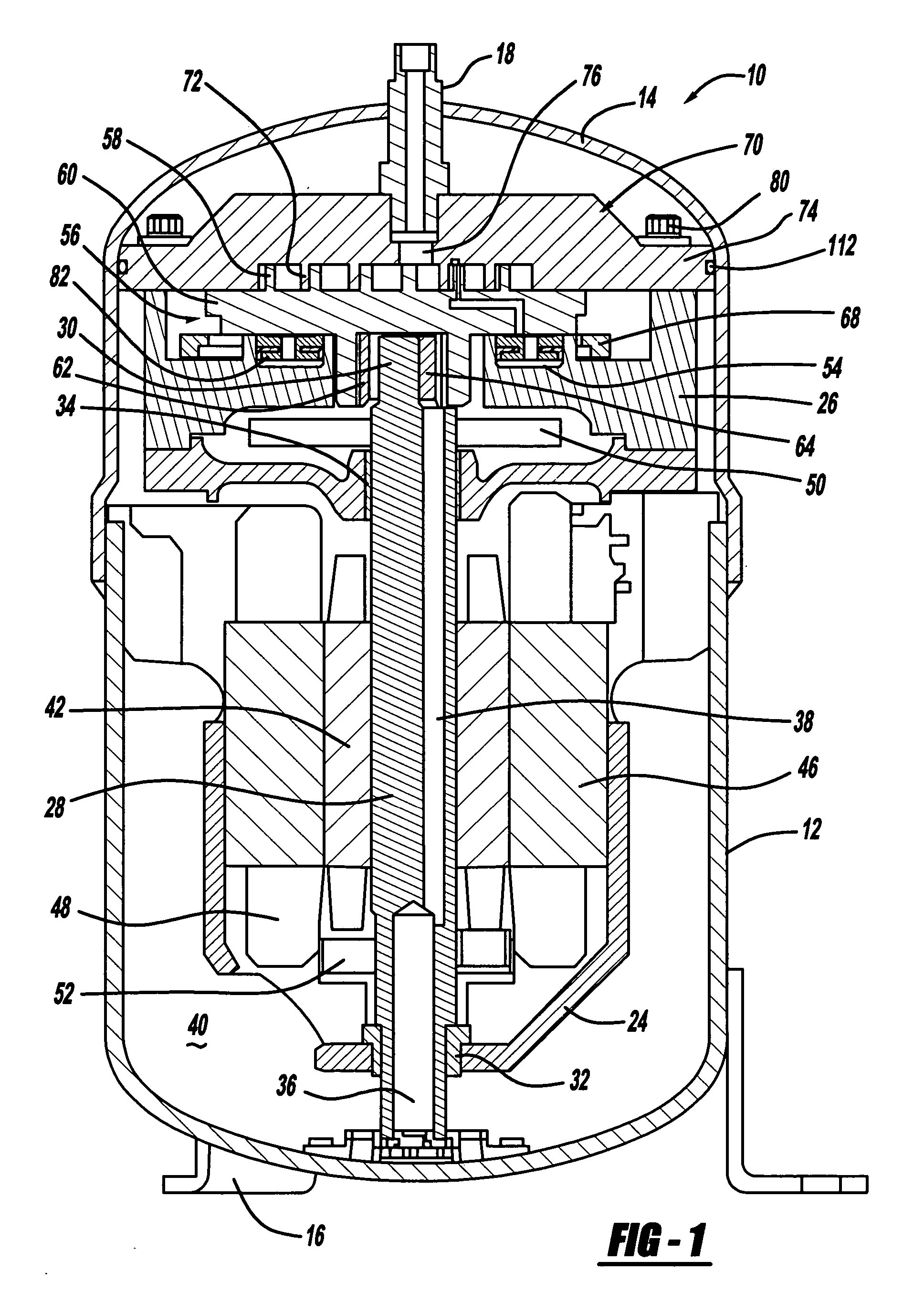

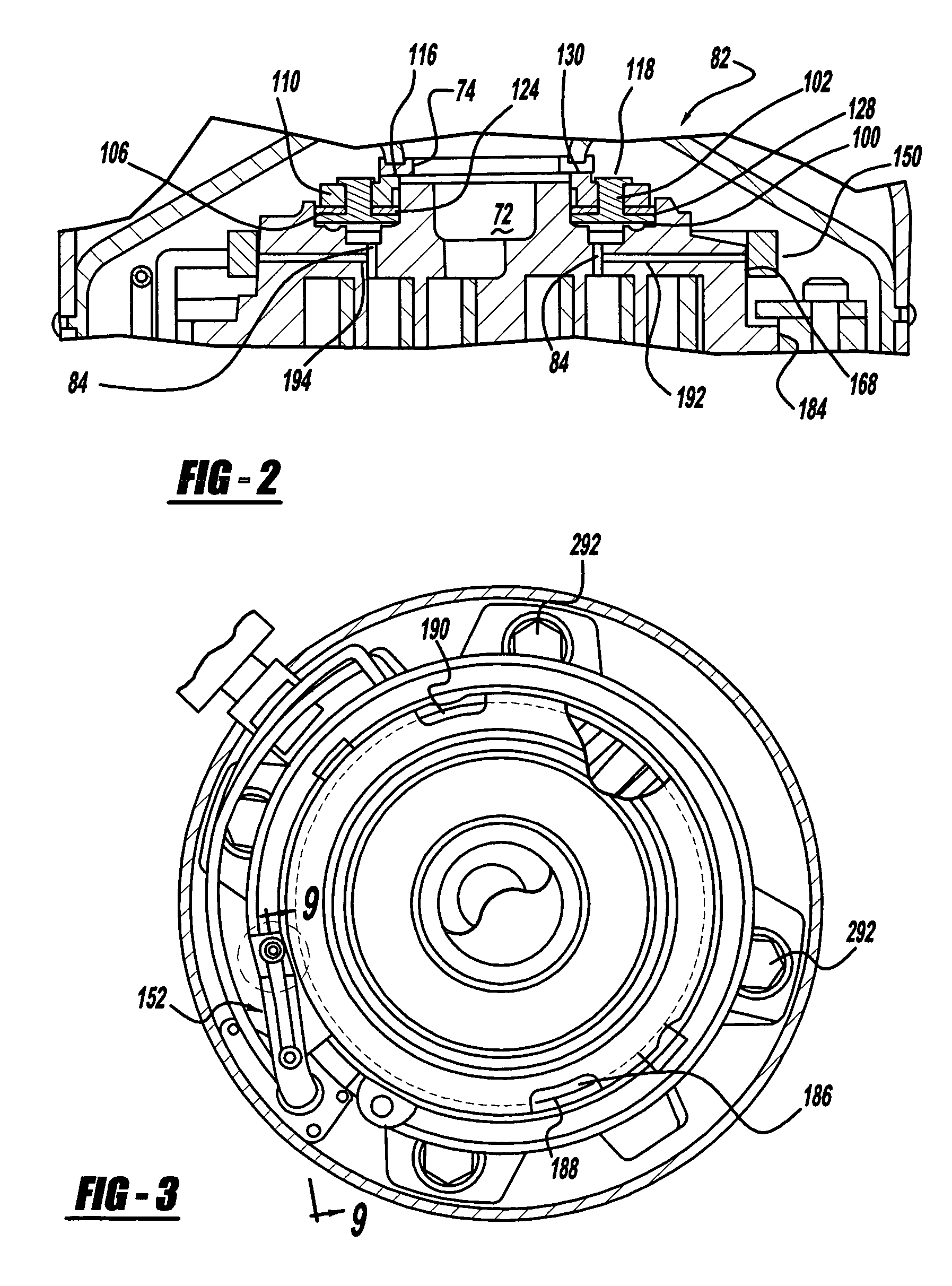

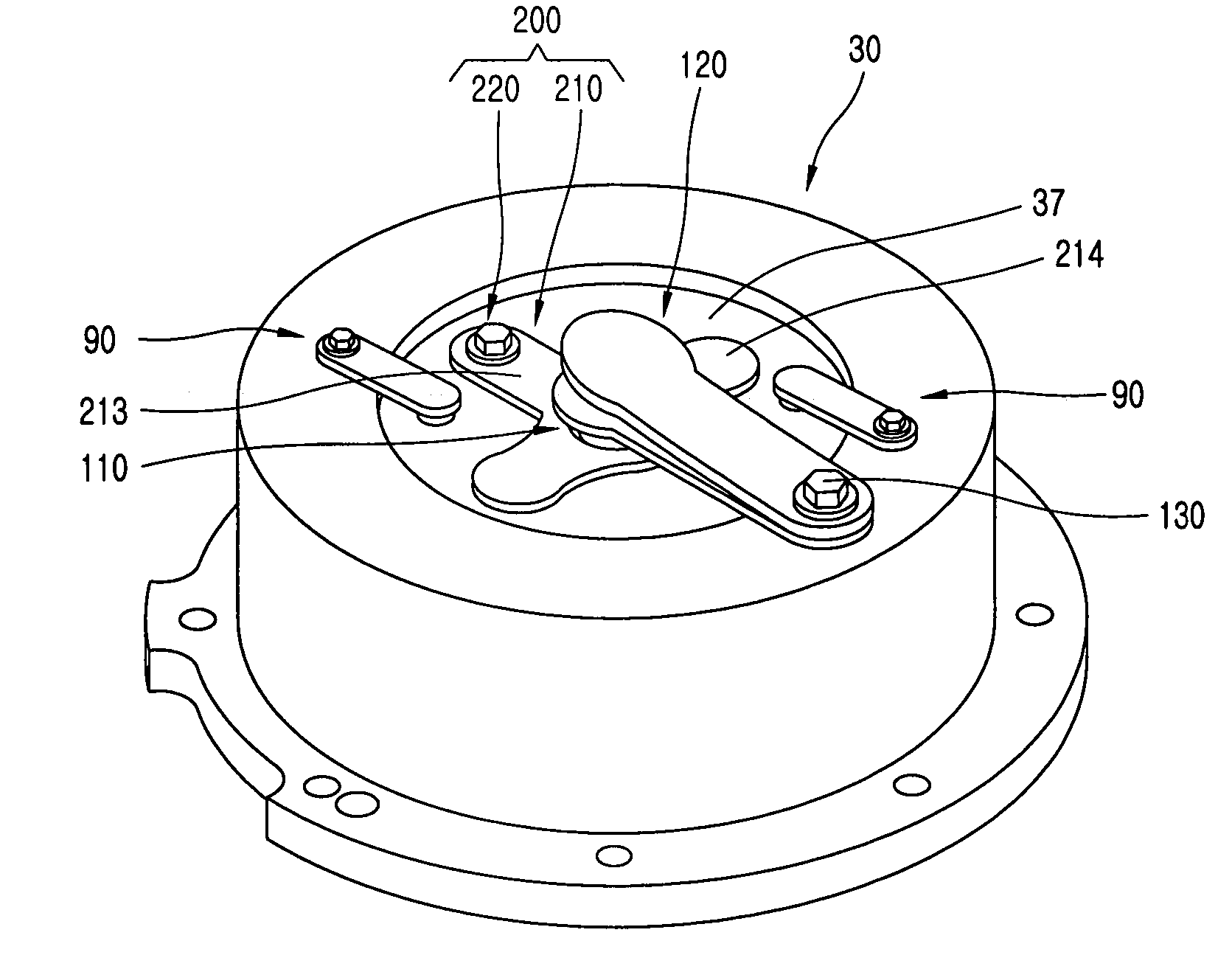

Scroll compressor with capacity modulation

ActiveUS7547202B2Rotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeActuatorCompression member

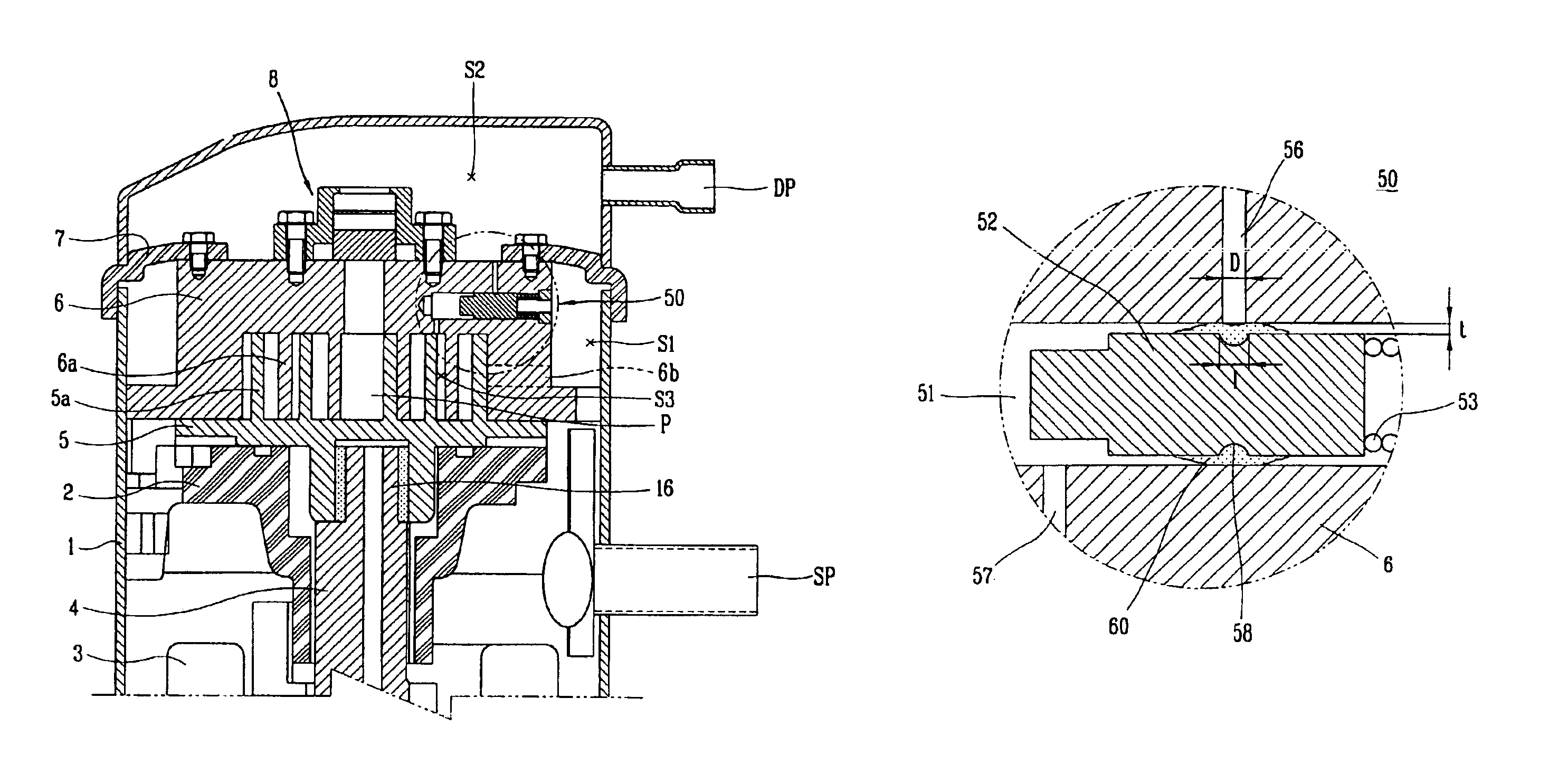

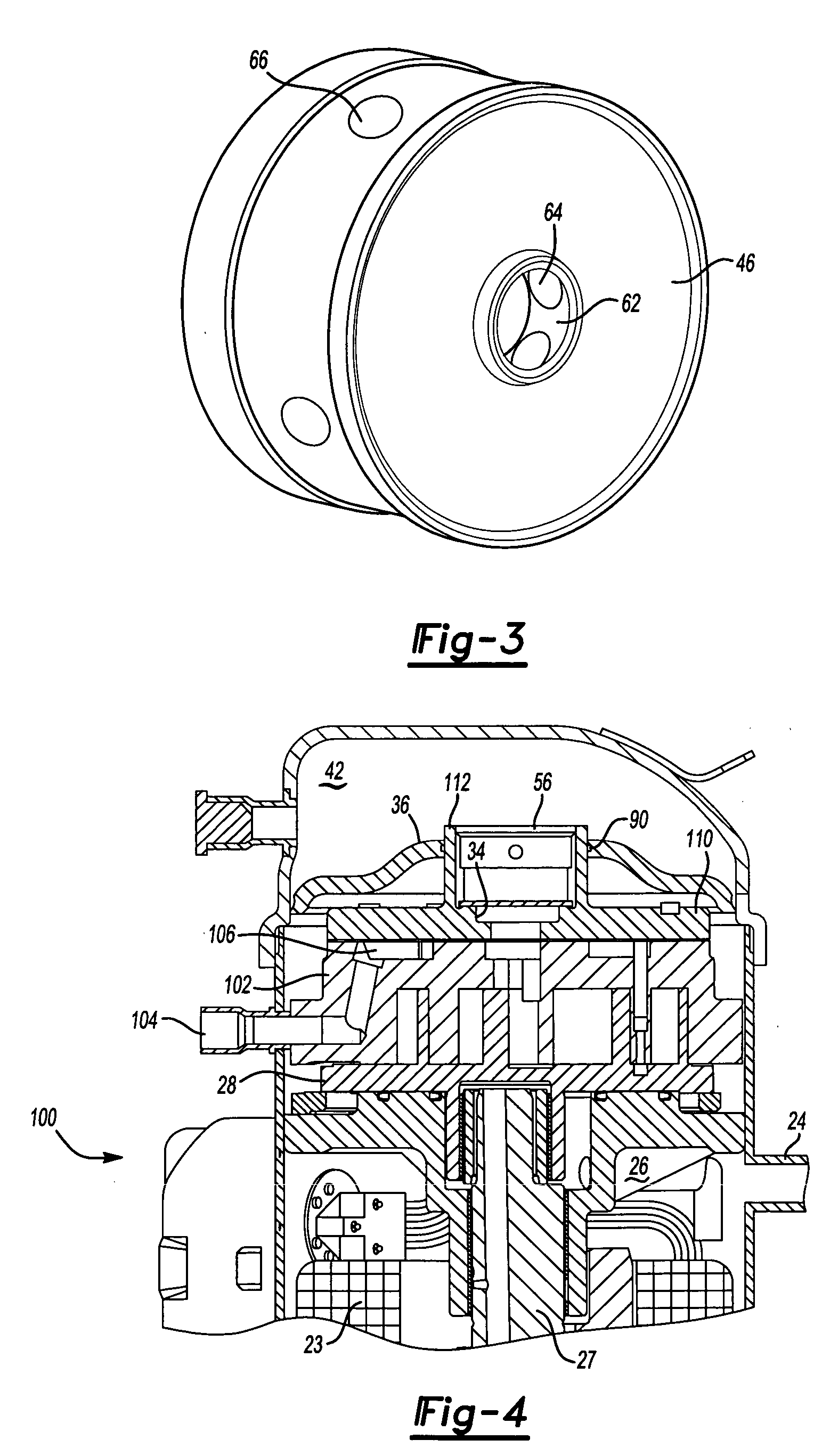

A scroll compressor may include a shell, a compression mechanism, and a sealing apparatus. The compression mechanism may be contained within the shell and include a compression member. The compression member may include an aperture extending radially there a surface. The sealing apparatus may be contained within the shell and include a first seal member and an actuator. The first seal member may be pivotally supported relative the compression member and may be movable from a first position wherein a sealing portion of the first seal member is in a sealing engagement with the surface and a second position wherein the sealing portion of the first seal member is displaced radially outwardly from the surface. The actuator may be engaged with the first seal member and configured to displace the first seal member from the first position to the second position.

Owner:COPELAND LP

Scroll compressor

InactiveUS20070092390A1Improve sealingImprove efficiencyRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringScroll compressor

A scroll compressor has a fluid pressure biasing system for both the orbiting scroll member and the non-orbiting scroll member. The biasing system can utilize a pressurized gas from the pocket of the scroll compressor or it can utilize an external pressurized oil source. In an additional embodiment, a hydrostatic bearing is located between the orbiting scroll member and the non-orbiting scroll member.

Owner:EMERSON CLIMATE TECH INC

Scroll compressor

InactiveUS20100111741A1Improve performanceImprove reliabilityRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringBack pressure

A scroll compressor comprises a fixed scroll, an orbiting scroll engaged with the fixed scroll to form a compression chamber therebetween, a back pressure chamber arranged at a back side of an end plate of the orbiting scroll, a back pressure hole formed in the end plate of the orbiting scroll to form a fluidal communication between the compression chamber and the back pressure chamber, and a release valve mechanism for discharging the fluid from the compression chamber to the discharge space when a pressure in the compression chamber is higher than the pressure in the discharge space, wherein the back pressure hole and the release flow path are arranged to prevent both of the fluidal communication and the another fluidal communication from being formed simultaneously.

Owner:HITACHI APPLIANCES INC

Capacity modulated scroll compressor

InactiveUS20070036661A1Reduce compressionCapacity modulationRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsElectrical and Electronics engineeringScroll compressor

A scroll compressor has a biasing chamber which contains a pressurized fluid. The pressurized fluid within the chamber biases the two scroll members together. A rotatable ring is attached to one of the scroll members to open and close a passage leading to this biasing chamber. When the ring opens the passage in one embodiment, this releases the pressurized fluid to remove the load, biasing the two scroll members together. When the biasing load is removed, the two scroll members separate, creating a leakage path between discharge and suction to reduce the capacity of the scroll compressor. When the ring opens the passage in another embodiment, a delayed suction passage is opened to reduce the capacity of the compressor.

Owner:EMERSON CLIMATE TECH INC

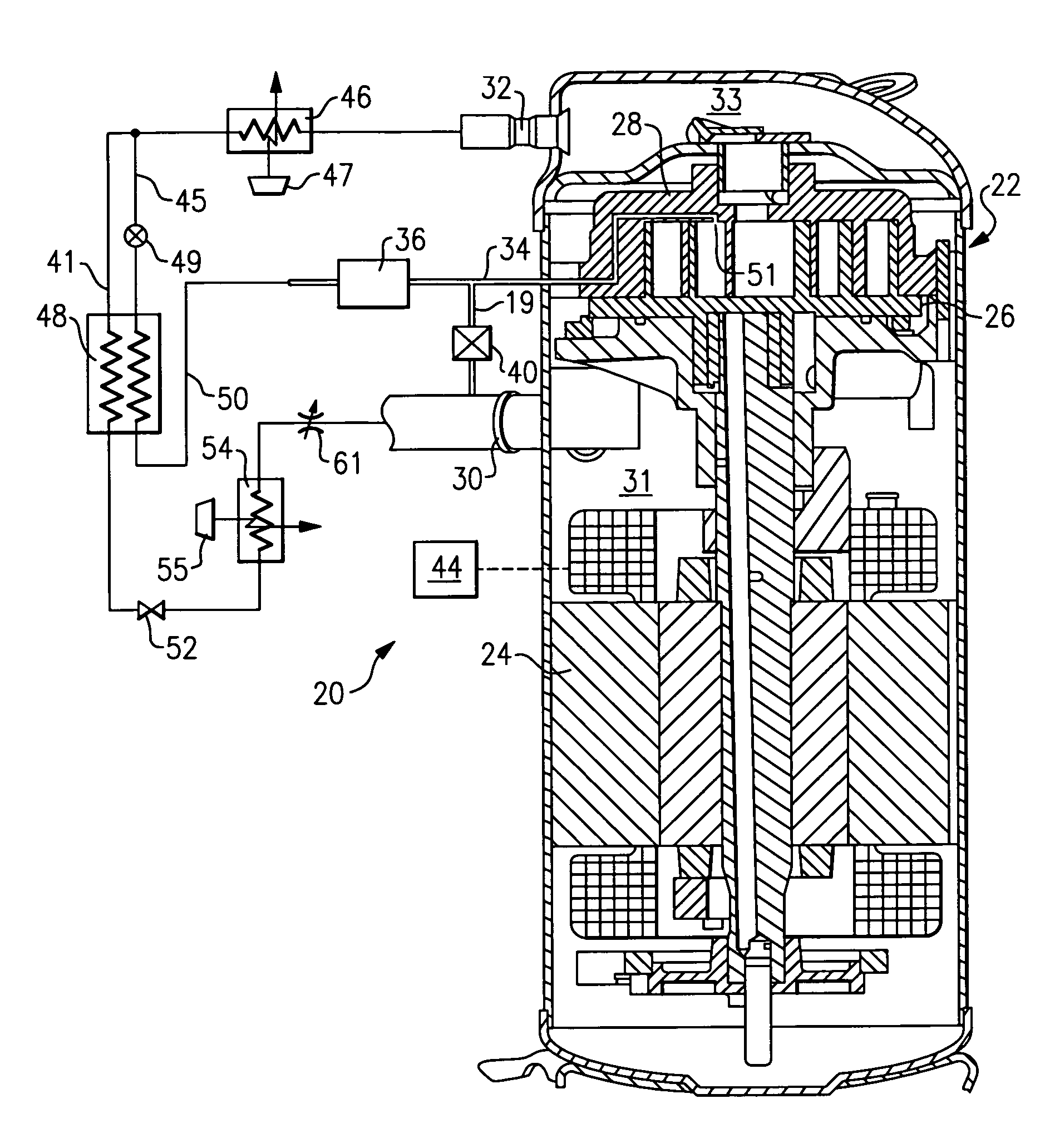

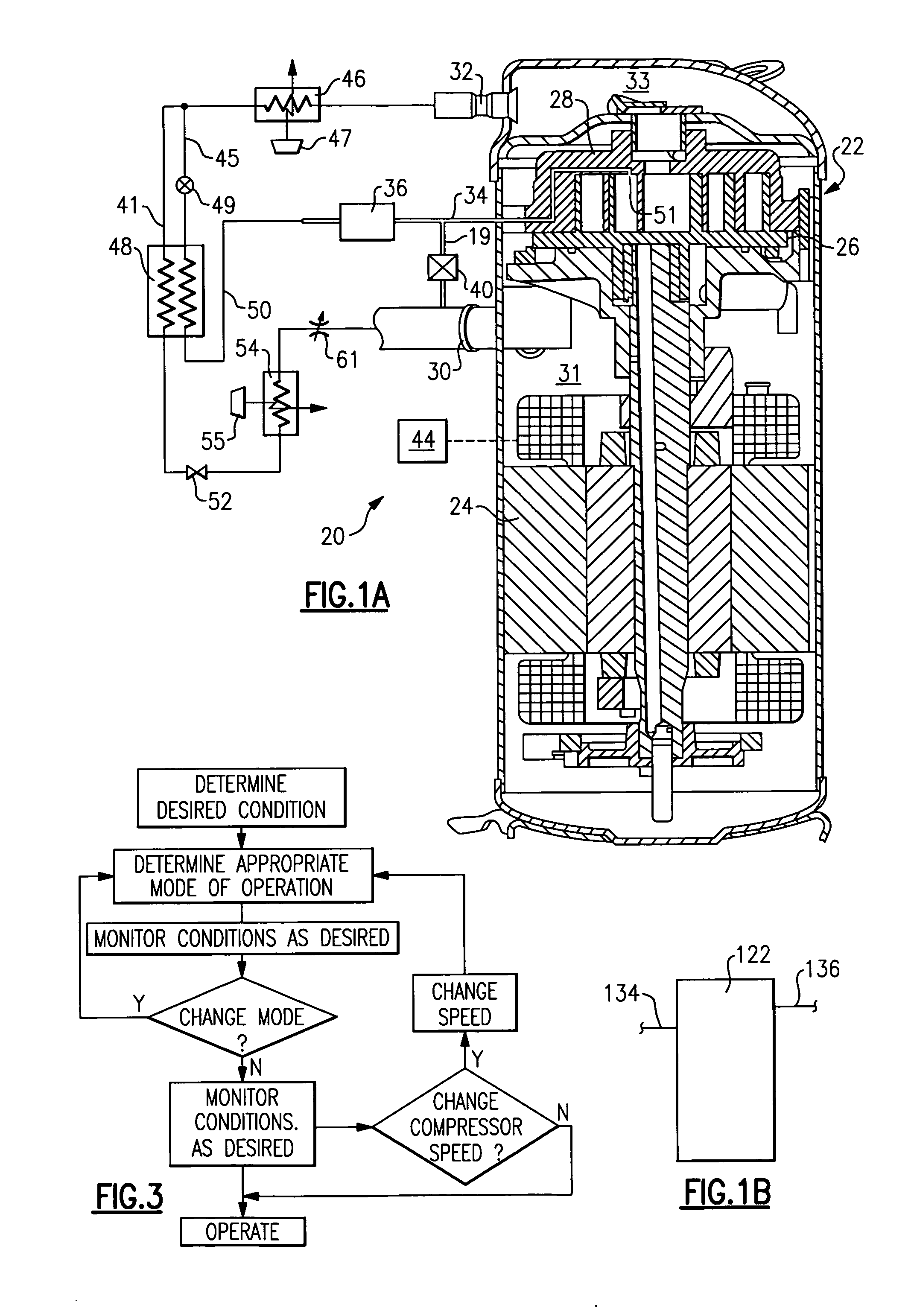

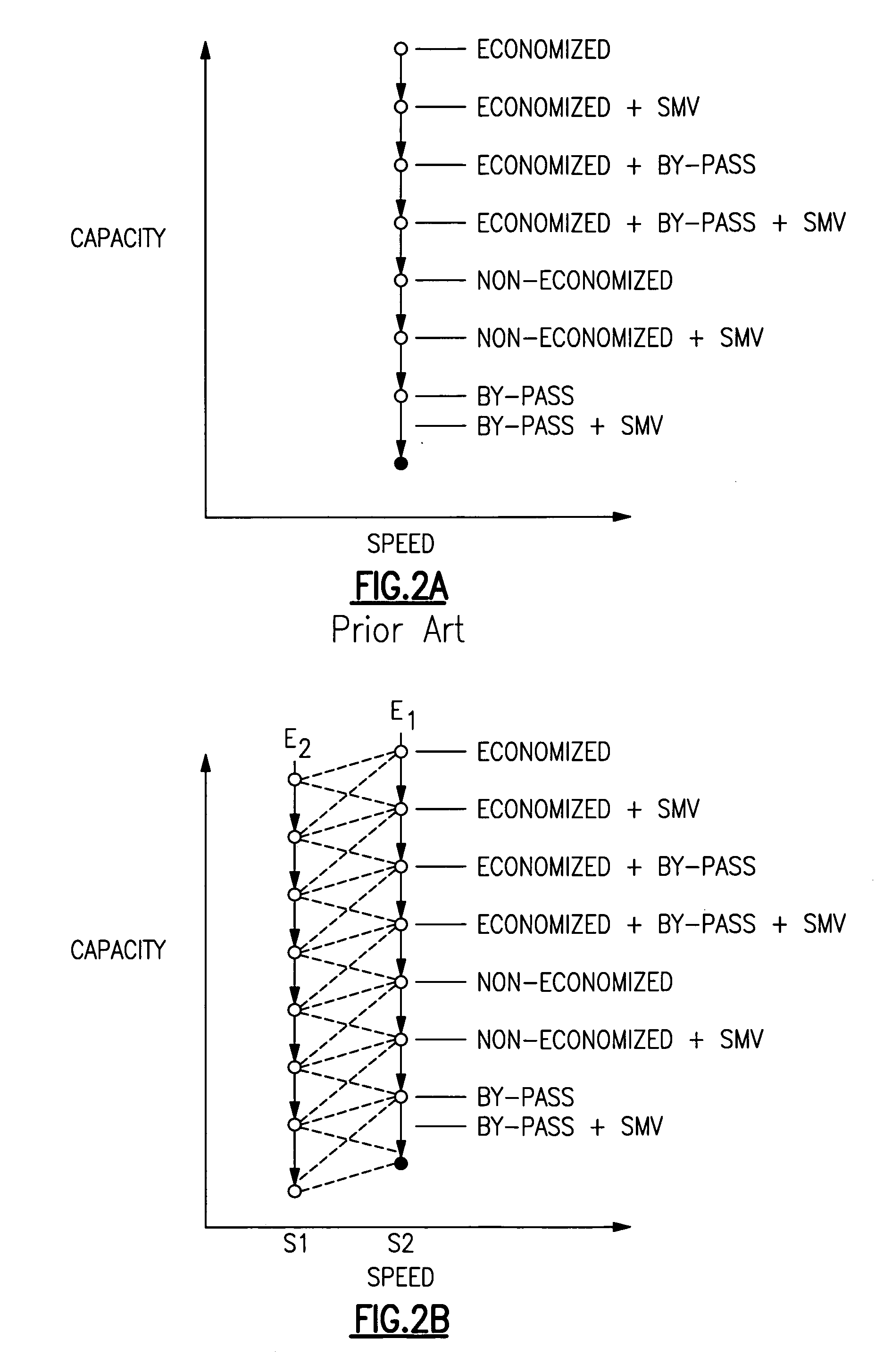

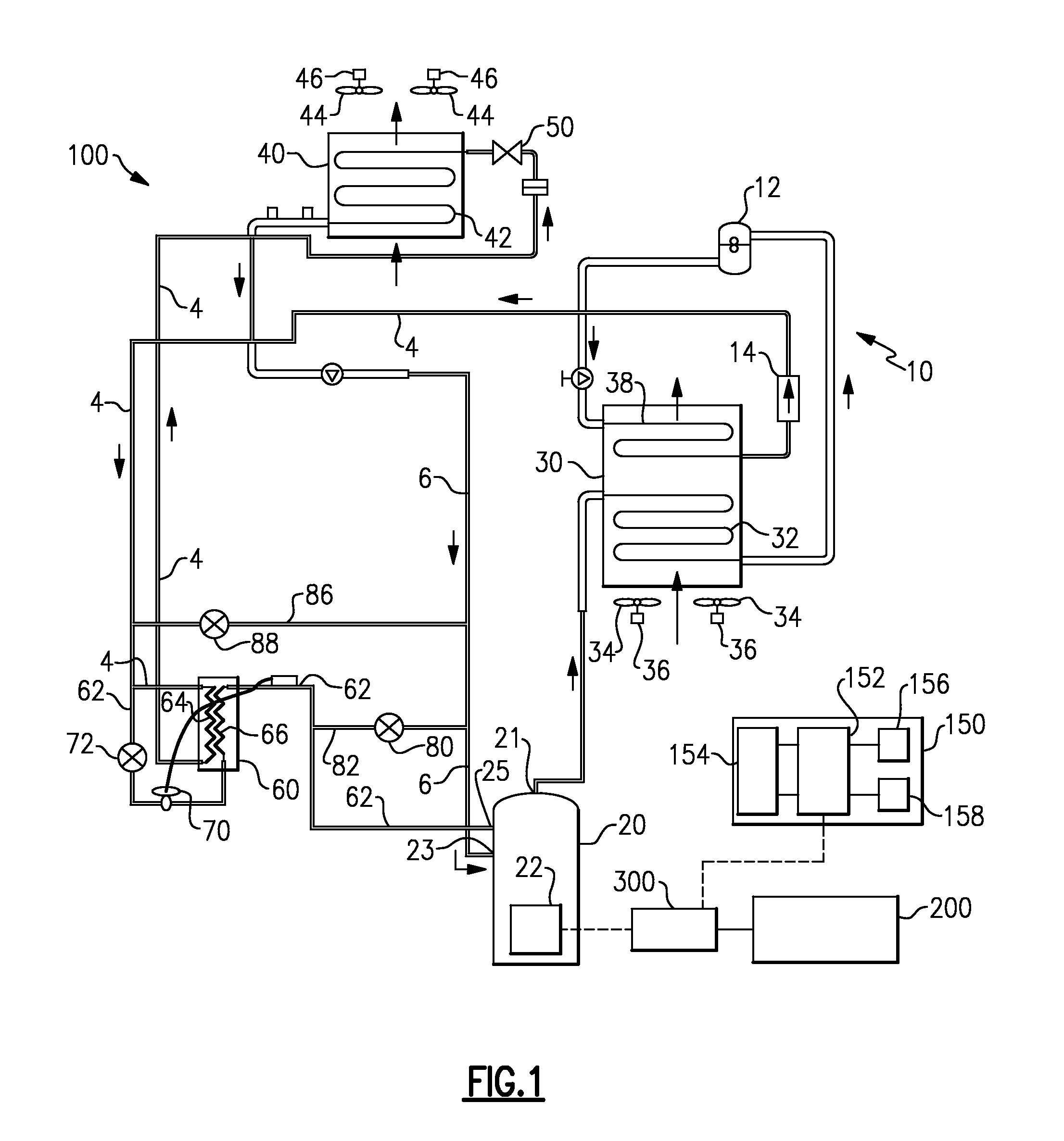

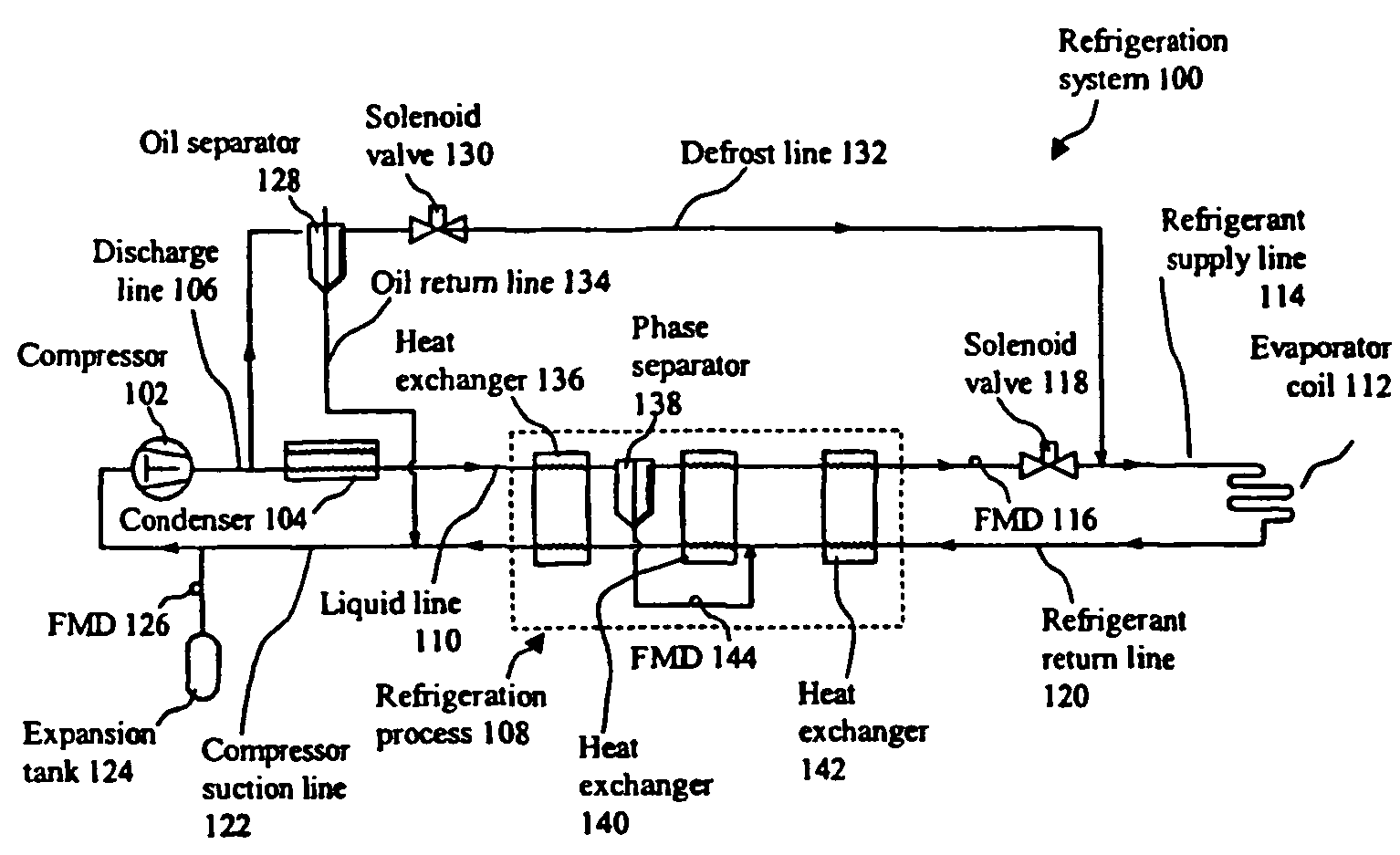

Refrigerant system with multi-speed scroll compressor and economizer circuit

InactiveUS20070130973A1Increase and decrease capacityIncrease control flexibilityCompression machines with non-reversible cycleVehicle heating/cooling devicesSystem capacityControl theory

A scroll compressor is provided with a multiple-speed motor. A control selects a speed for operating the motor, along with selecting between several available options for the system capacity adjustment to meet external load demands in a most efficient and reliable manner. The disclosed embodiment includes an economizer circuit, an unloader function, and an optional suction modulation valve. By utilizing each of these features in combination with the multi-speed motor for the compressor, the present invention is better able to tailor provided capacity to desired capacity.

Owner:SCROLL TECH

Variable capacity scroll compressor

ActiveUS20050019178A1Easy to changeRotary piston pumpsRotary piston liquid enginesEngineeringHigh pressure

Disclosed is a variable capacity scroll compressor in which a high-pressure fluid within a thermodynamic cycle is introduced into the inside of the compressor to increase the compression volume and also the fluid inhaled / exhausted from the compressor allows the fluid being compressed to be bypassed in multi-stages, thereby varying the capacity of the compression fluid.

Owner:LG ELECTRONICS INC

Discharge valve system of scroll compressor

ActiveUS20060099098A1Minimize the numberMaximize discharge amountEngine of arcuate-engagement typeOscillating piston enginesDischarge efficiencyProduction rate

A discharge valve system of a scroll compressor comprises: a fixed scroll having a discharge hole and discharge bypass holes; a discharge valve assembly mounted at the fixed scroll, for opening and closing the discharge hole by a pressure difference; and an integral bypass valve assembly mounted at the fixed scroll, for opening and closing the bypass holes and interworking the discharge valve assembly. According to this, a discharge amount of gas is maximized in a low pressure ration driving of the scroll compressor thereby to enhance a discharge efficiency. Also, the number of components is greatly reduced thus to reduce a fabrication cost. Also, the number of assembly processes is greatly reduced thereby to enhance an assembly productivity.

Owner:LG ELECTRONICS INC

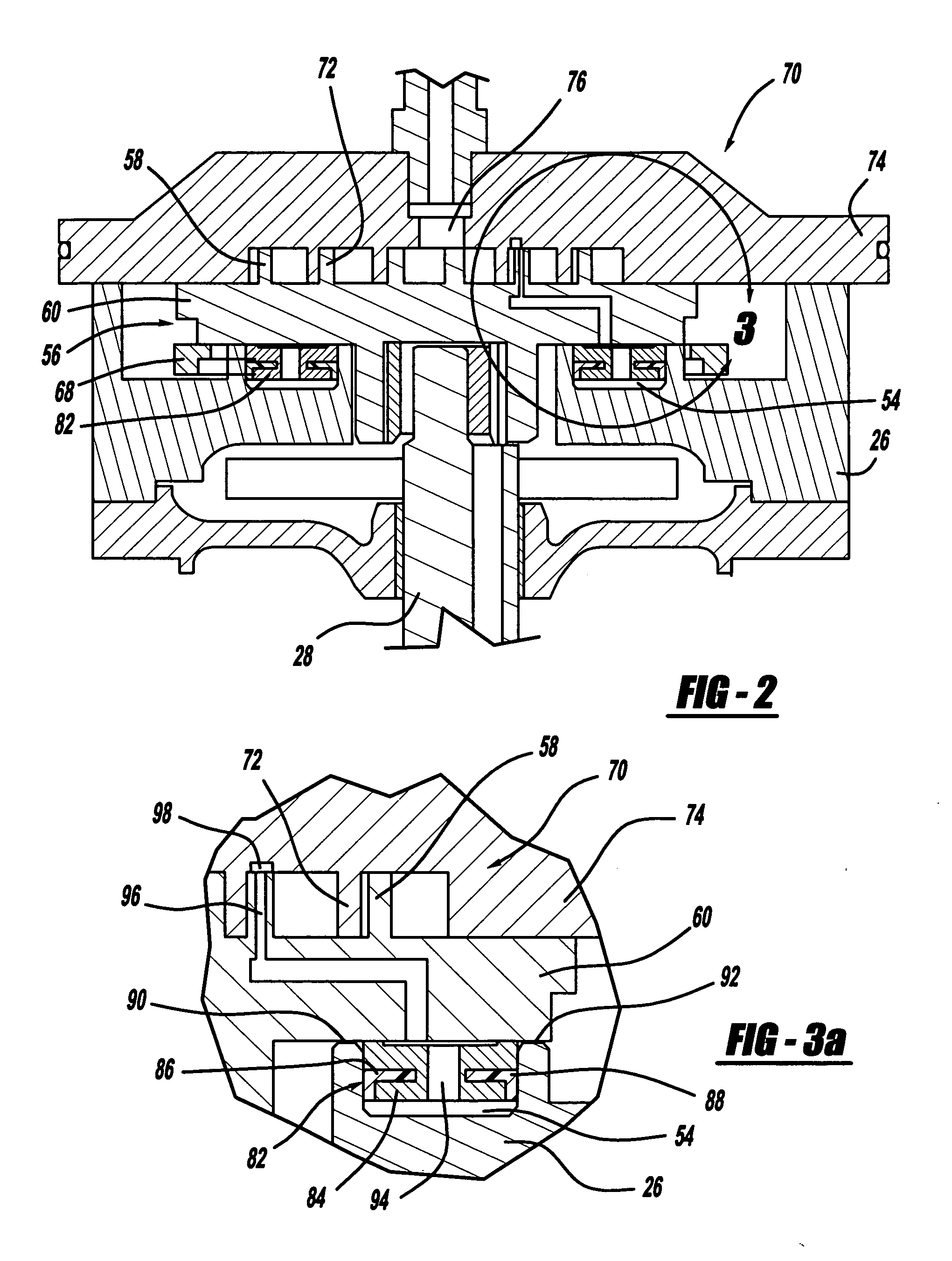

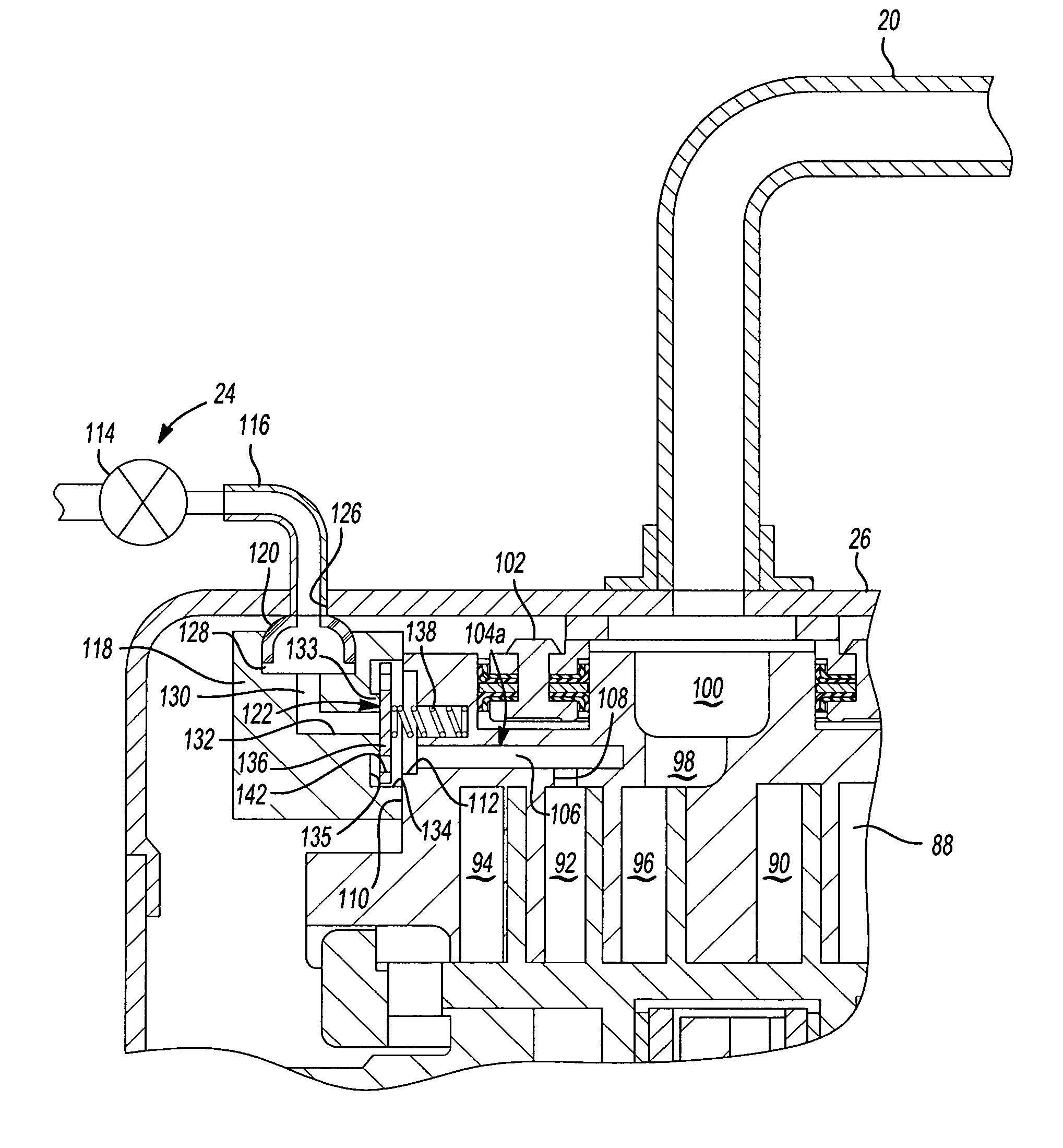

Vapor injection system for a scroll compressor

ActiveUS7771178B2Increase capacityImprove efficiencyRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeInjection deviceScroll compressor

A compressor may include a shell, a compression mechanism, a motor, and a vapor injection system. The compression mechanism may be contained within in the shell and include a non-orbiting scroll axially displaceably mounted to the shell. The non-orbiting scroll may have an exterior portion, an interior portion, and a vapor injection passage extending therethrough from the exterior portion to the interior portion. The motor may be contained within the shell and may be drivingly coupled to the compression mechanism. The vapor injection system may include a vapor injection device, a vapor injection fitting, and a vapor injection valve. The vapor injection fitting may be in communication with the vapor injection device and the vapor injection passage. The vapor injection valve may be disposed between the shell and the interior of the non-orbiting scroll.

Owner:COPELAND LP

Scroll machine

ActiveUS20060233657A1Quantity minimizationMinimize volume of compressedEngine of arcuate-engagement typeOscillating piston enginesCounter rotationVALVE PORT

A discharge valve assembly is provided for preventing reverse rotation of a scroll compressor. The discharge valve assembly includes a cup-shaped valve member slidably engaged with a central post of a retainer member. The cup-shaped valve member includes notches in communication between the central post of the retainer and the sidewalls of the cup-shaped valve member.

Owner:COPELAND LP

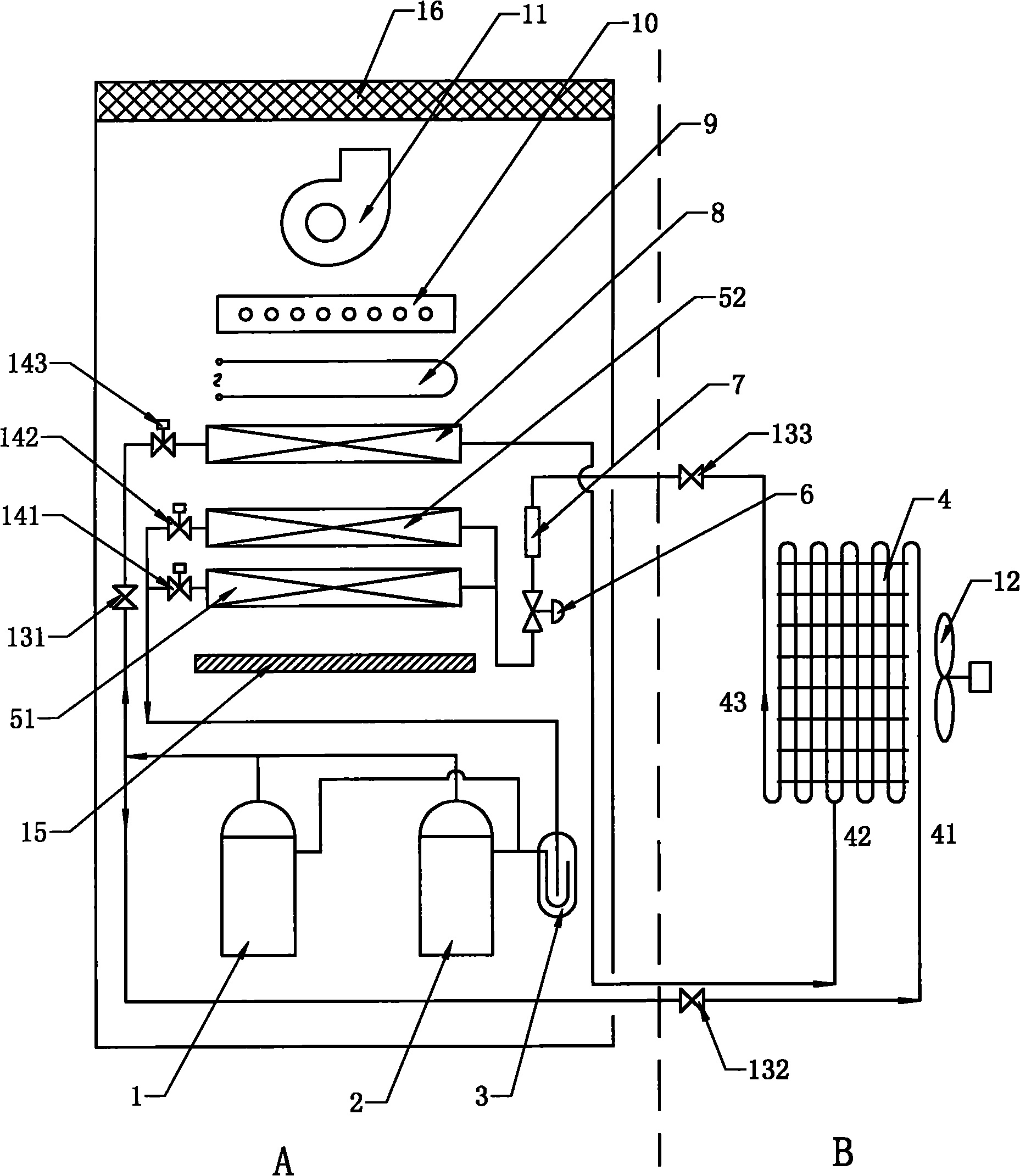

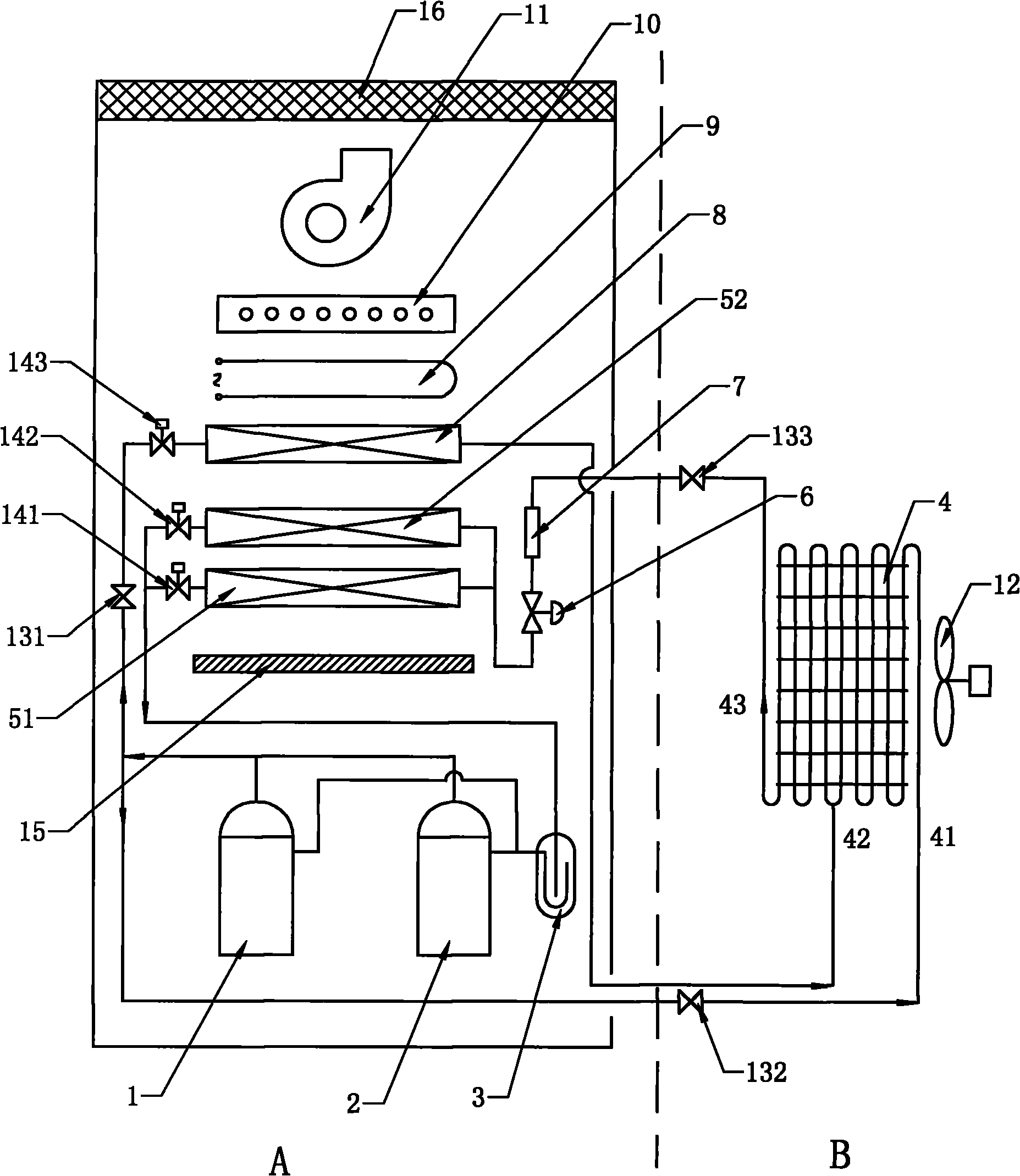

High-precision constant-temperature and humidity air conditioner operated in wide temperature range

InactiveCN101813343AAvoid energy wasteResolve delayCompressorEnergy recovery in ventilation and heatingConstant frequencyElectronic expansion valve

The invention relates to a high-precision constant-temperature and humidity air conditioner operated in a wide temperature range. The air conditioner comprises an outdoor machine and an indoor machine, wherein the outdoor machine is provided with a condenser and a condensing fan; the indoor machine comprises an evaporator, a thermal recovery exchanger, an electric heater, a humidifier and a blower; and a compressor is formed by connecting in parallel a constant-frequency compressor and a variable-frequency compressor (or a digital scroll compressor) and is arranged in the indoor machine. As the system adopts frequency conversion technology or digital vortex technology and electronic expansion valve technology and unique classified evaporator control, condenser fan frequency-conversion control technology and evaporator frostless structural design, the air condition broadens the use environment range, indoor temperature control environment (between 7 and 30 DEG C) and relative humidity control environment (between 35 and 70 percent RH), can be reliably operated in the outdoor high-temperature environment of 45 DEG C, also improves the controlling precision of indoor temperature and humidity, and is applicable to places with severe requirements on temperature and humidity and large environmental temperature change.

Owner:广东吉荣空调有限公司

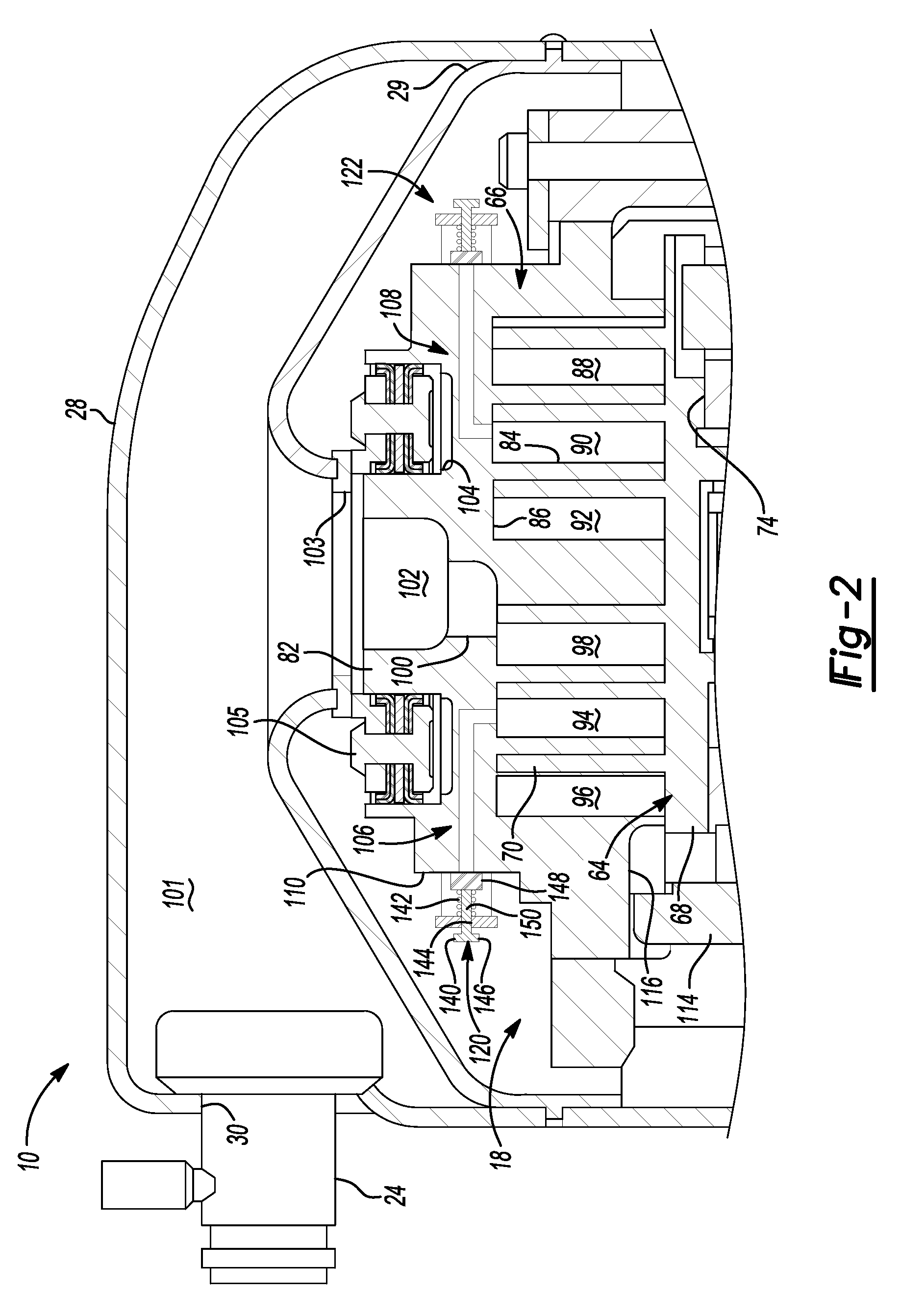

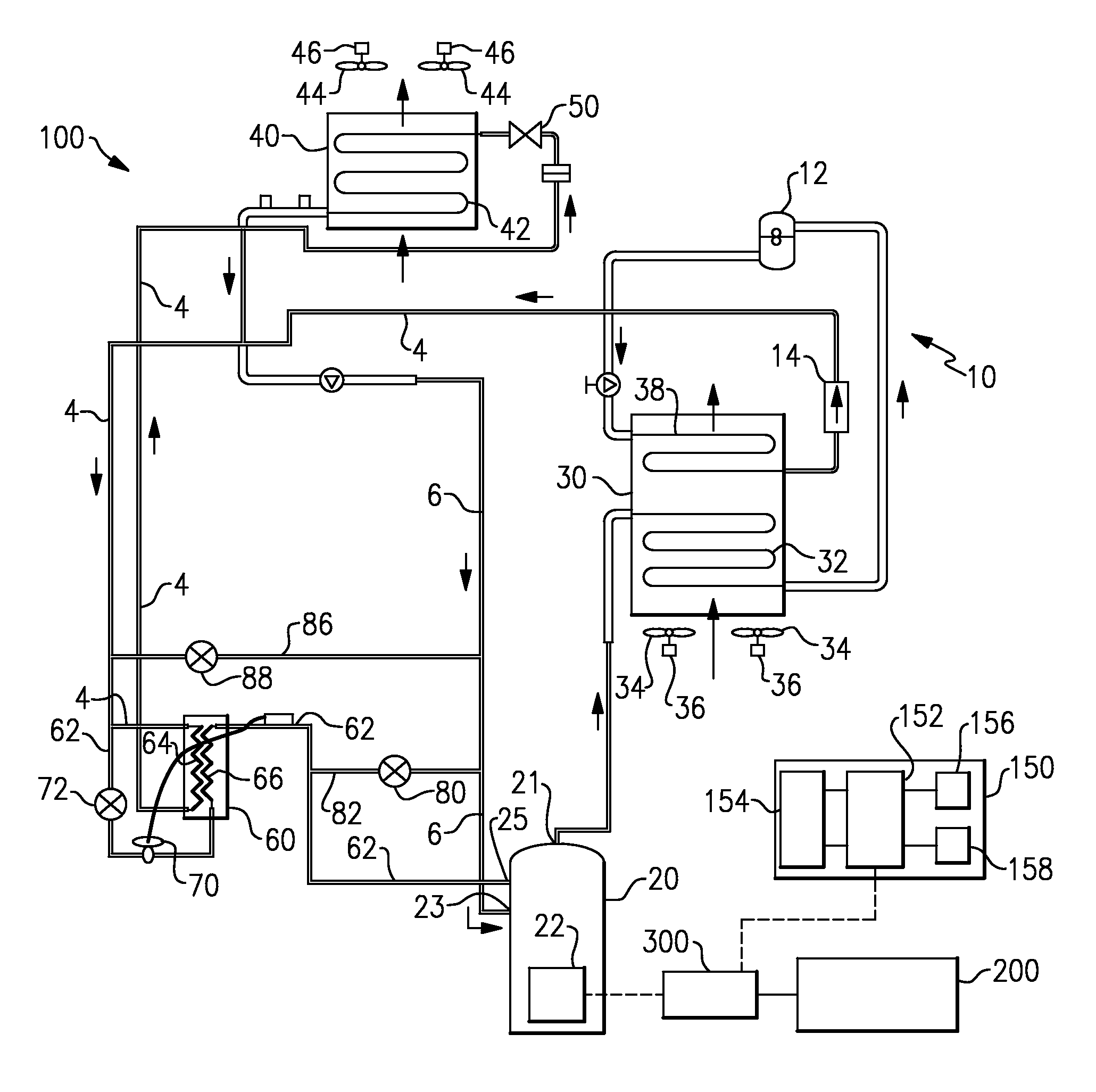

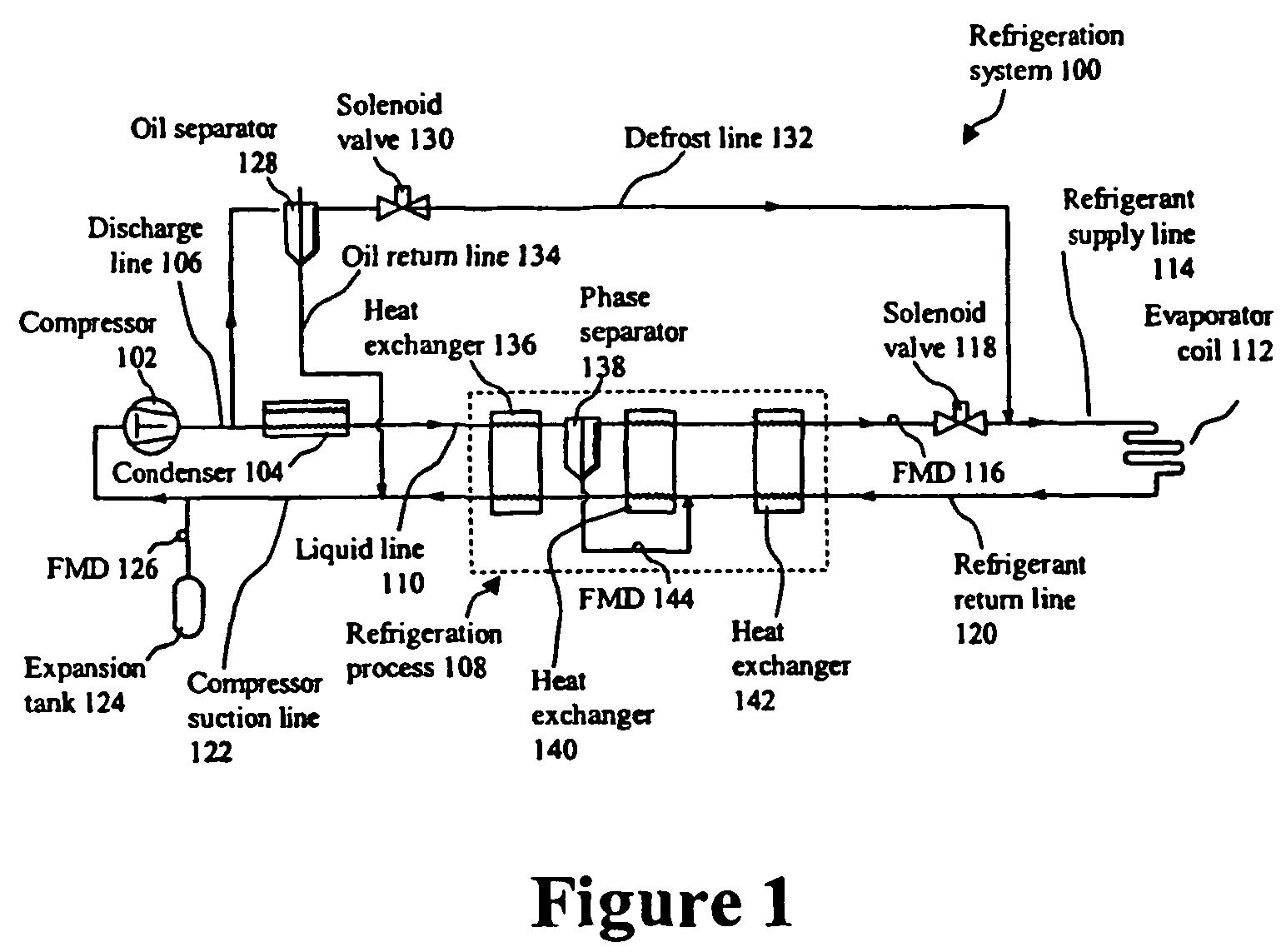

Truck trailer refrigeration system

ActiveUS20110247350A1Easy to operateCompression machines with non-reversible cycleDomestic refrigeratorsTruck-trailerPower flow

The refrigeration unit of an electrically powered trailer refrigeration system includes an economized scroll compressor and an economizer circuit selectively operable to inject refrigeration vapor into an intermediate stage of the scroll compressor. An engine driven generator produces AC current to power the scroll compressor and other electric components of the system. During operation of the refrigeration system at high capacity demand, a controller will operate the refrigeration system in an economized mode if sufficient electric power is available from the generator and in the non-economized mode if insufficient power is available to sustain operation of the refrigeration system in the economized mode.

Owner:CARRIER CORP

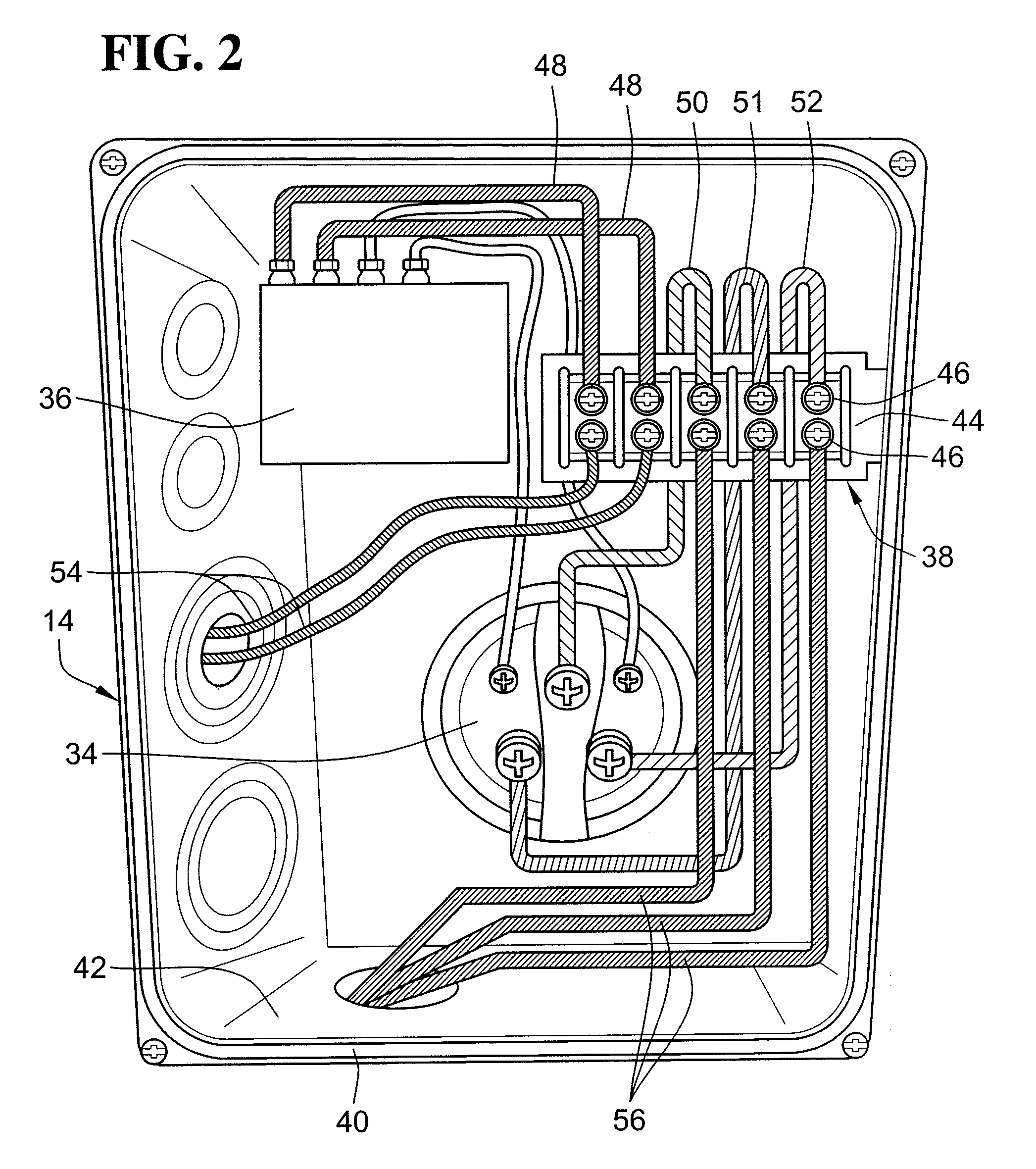

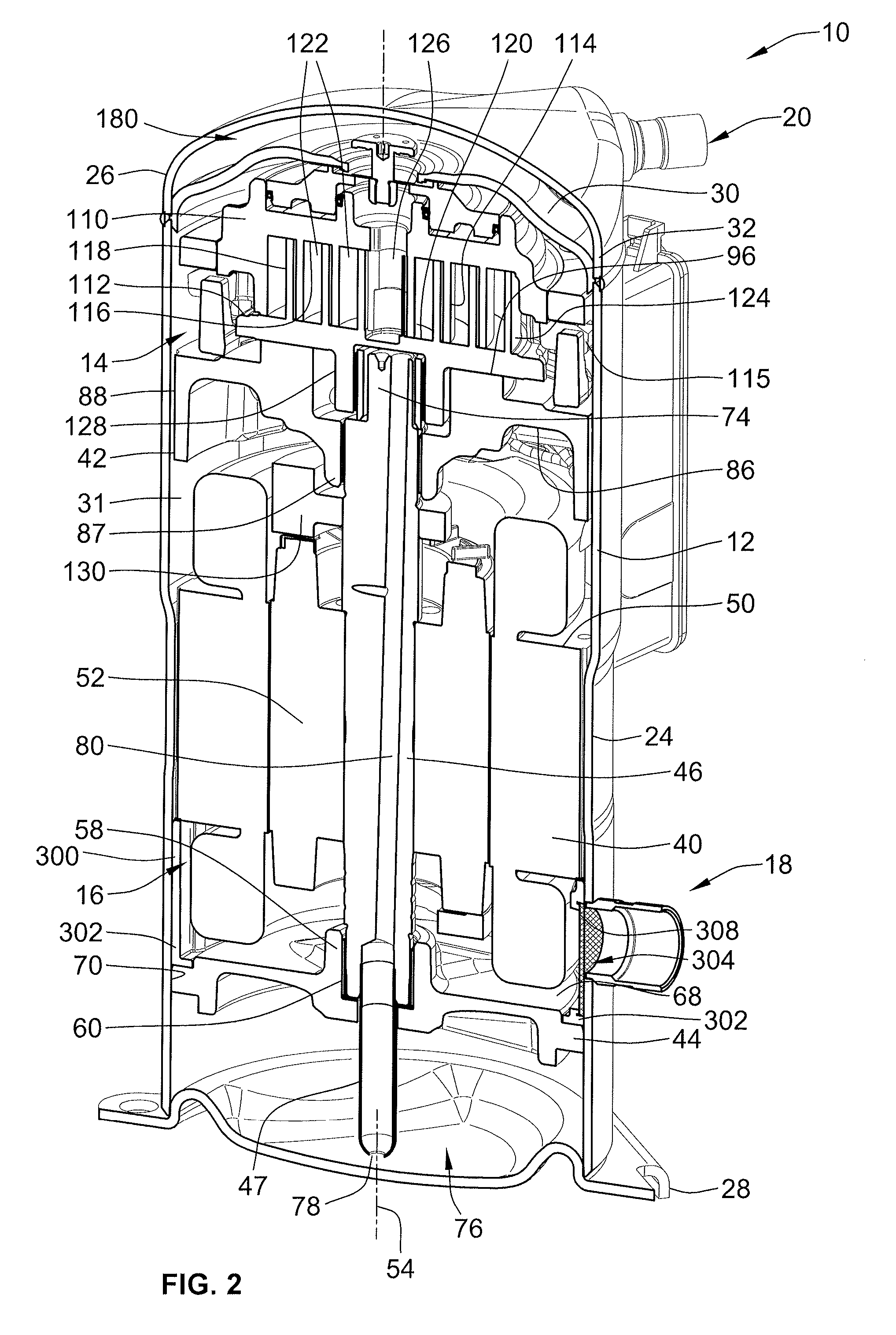

Scroll compressor having standardized power strip

A scroll compressor for compressing fluid has a common terminal block for electrical hook-ups. The compressor includes a compressor section; a drive unit operative to drive the compressor section for compressing fluid; a protection module; and a power connector for connecting electrical power to the drive unit to facilitate operation of the scroll compressor bodies. The common terminal block provides for connection to the protection module and the power connector for the compressor.

Owner:BITZER KUEHLMASCHINENBAU GMBH

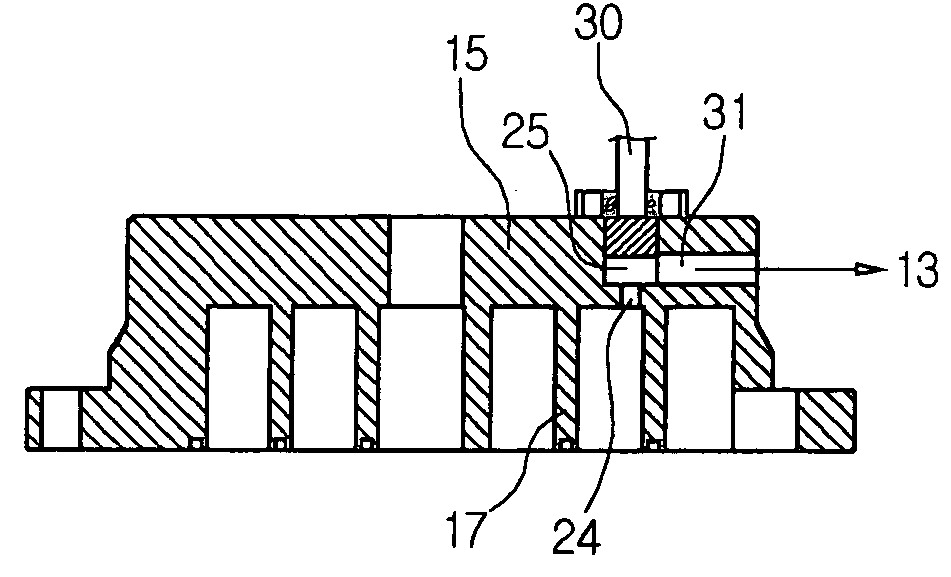

Scroll compressor

InactiveUS20070178002A1Avoid abnormal wearReliable scroll compressorEngine of arcuate-engagement typeOscillating piston enginesContact pressureScroll compressor

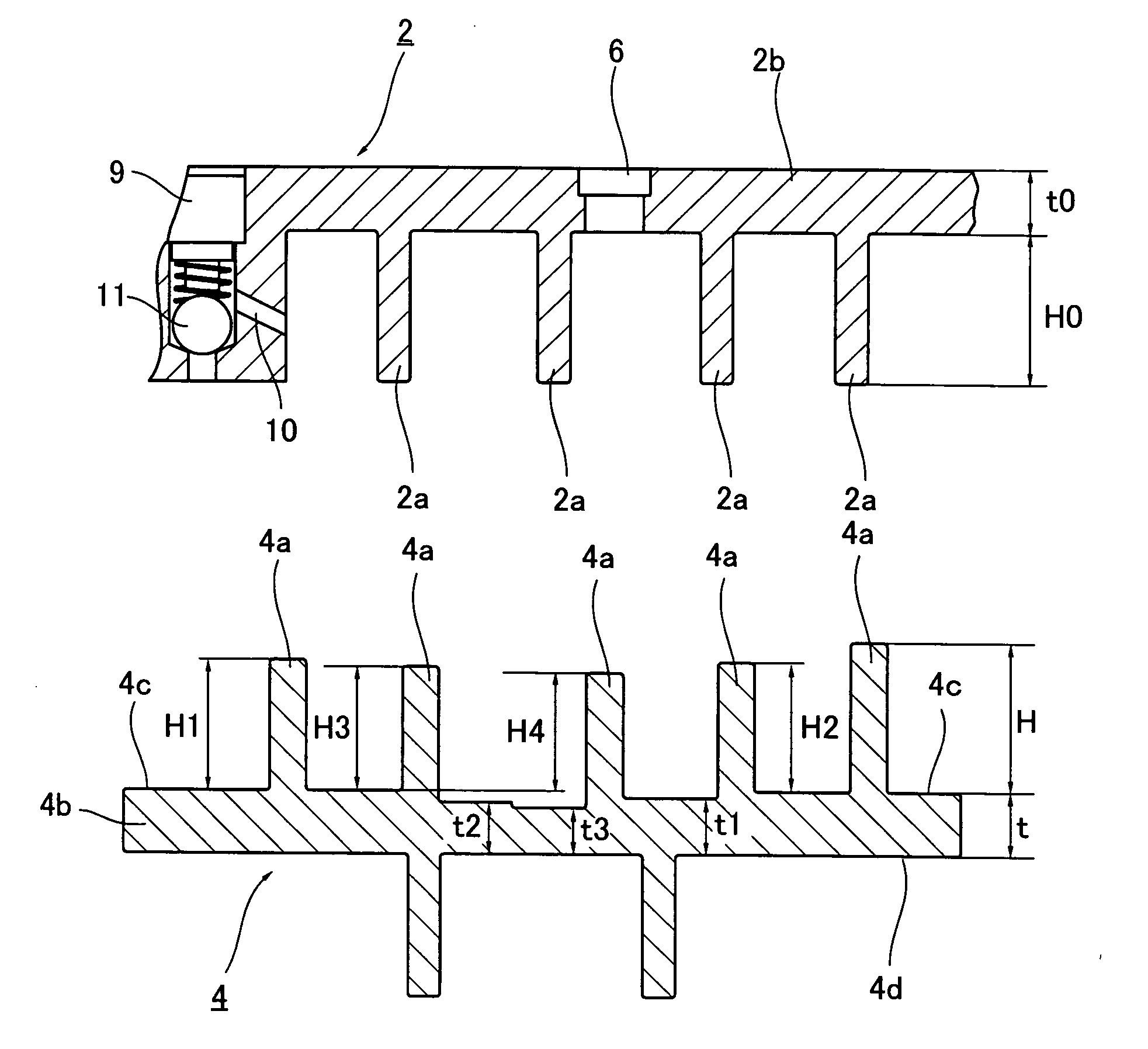

a First gap 15 in a thrust direction between teeth bottoms of a fixed mirror plate 2b and teeth tips of an orbiting lap 4a, and a second gap 16 in the thrust direction between teeth bottoms of an orbiting mirror plate 4b and teeth tips of a fixed lap 2a are formed such as to gradually increase from an outer peripheral side to an inner peripheral side of a scroll compressor, the first gap 15 is made greater than the second gap 16. Contact surface pressures of the laps 2a and 4a are kept low with respect to pressure deformation, contact pressure of the teeth tips of the fixed scroll part 2 and the teeth bottoms of the orbiting scroll part 4 are equally maintained. With this loads applied to the scroll parts 2 and 4 are equally received by a thrust surface.

Owner:PANASONIC CORP

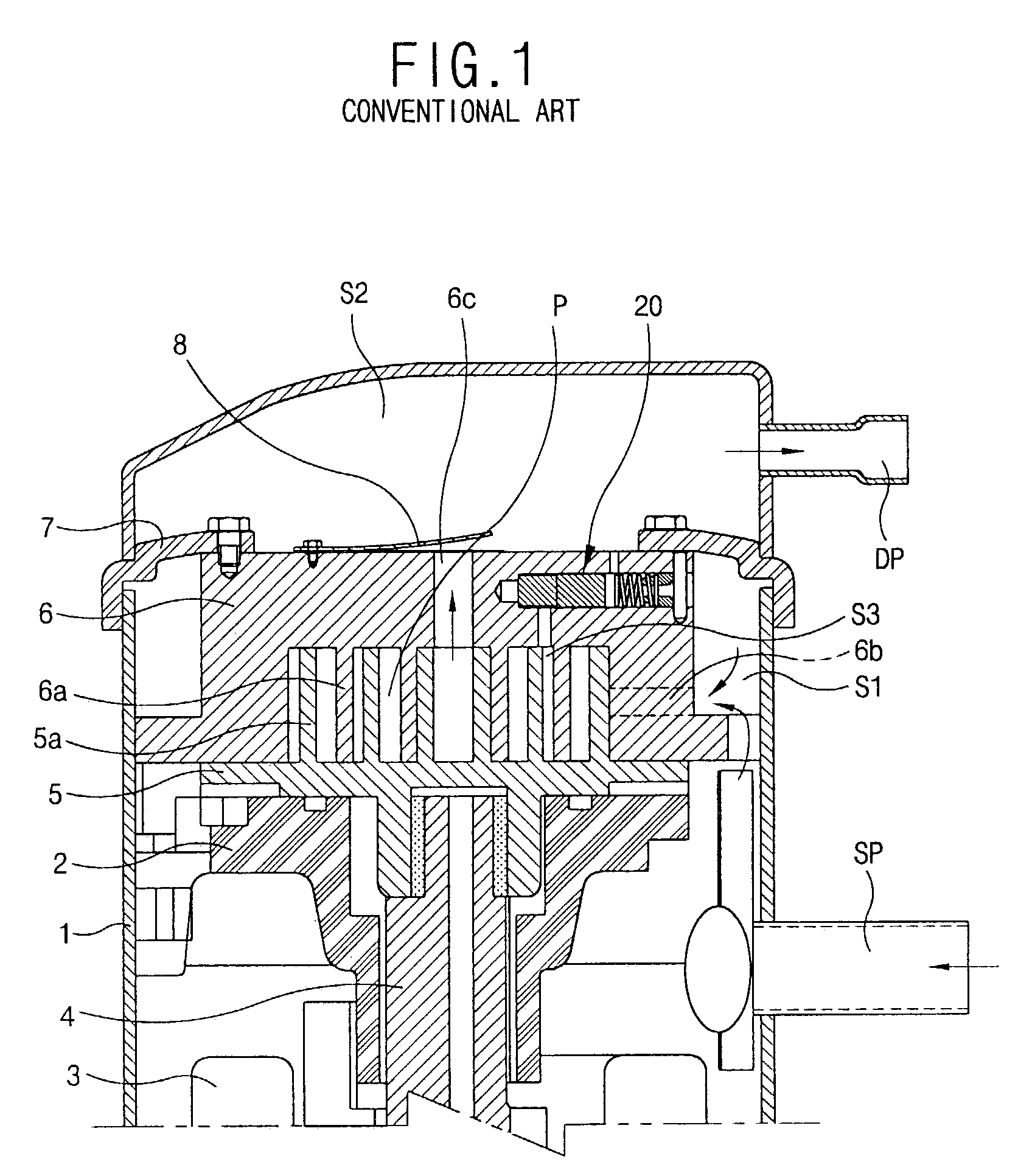

Vacuum preventing oil seal for scroll compressor

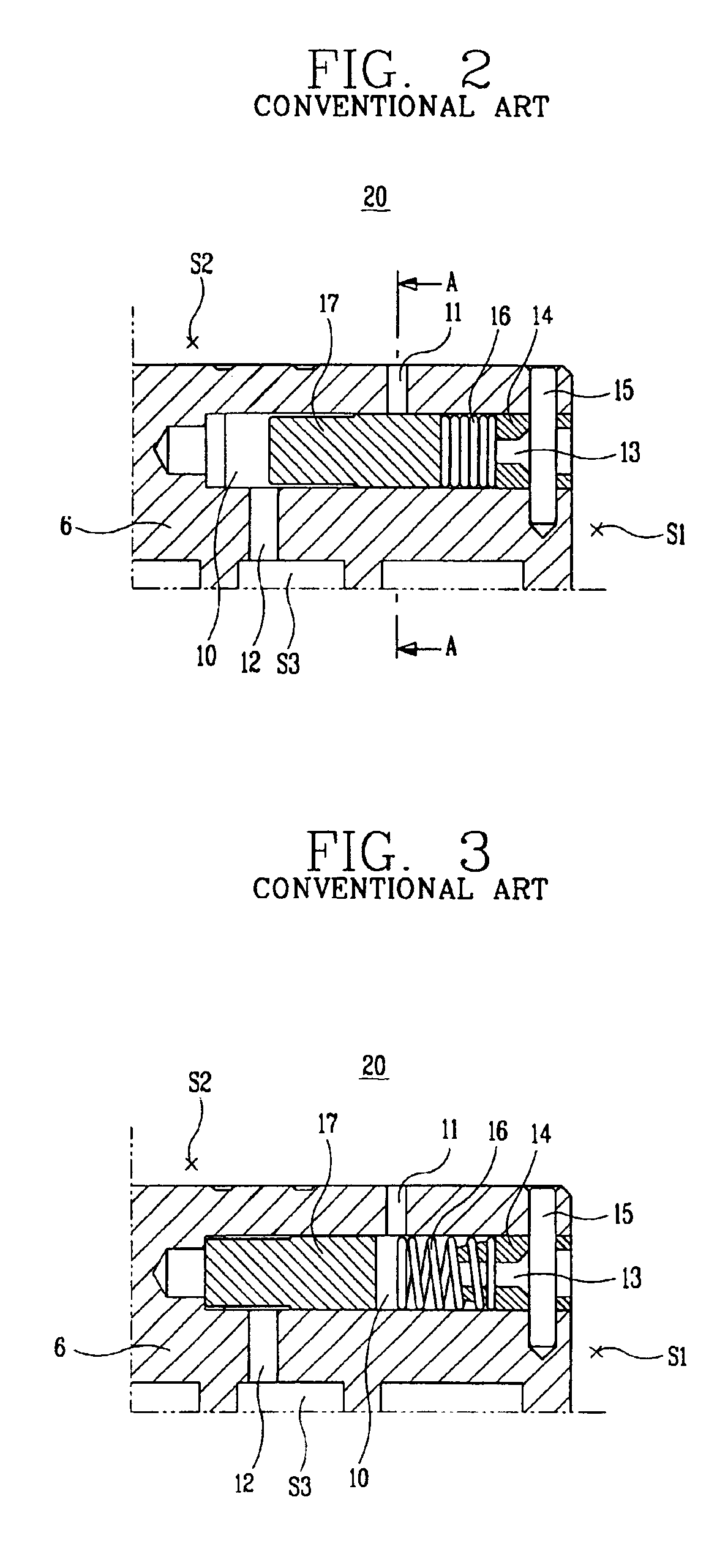

InactiveUS6863510B2Prevent gas leakageIncrease freedomRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeManufacturing cost reductionTolerance limit

Disclosed is a vacuum preventing device for a scroll compressor comprising: a chamber formed at one side of a fixed scroll and having a suction hole, a compression hole, and a discharge hole at an inner circumference surface thereof; an open / close member installed in the chamber and having a seal oil groove at an outer circumference surface thereof for selectively connecting the discharge hole to the suction hole; and an elasticity member installed in the chamber for providing an elasticity force to the open / close member. The device can enhance a compression efficiency of the compressor by preventing gas leakage efficiently and reduce a fabricating cost by improving a design of a clearance and enhancing a tolerance limit range.

Owner:LG ELECTRONICS INC

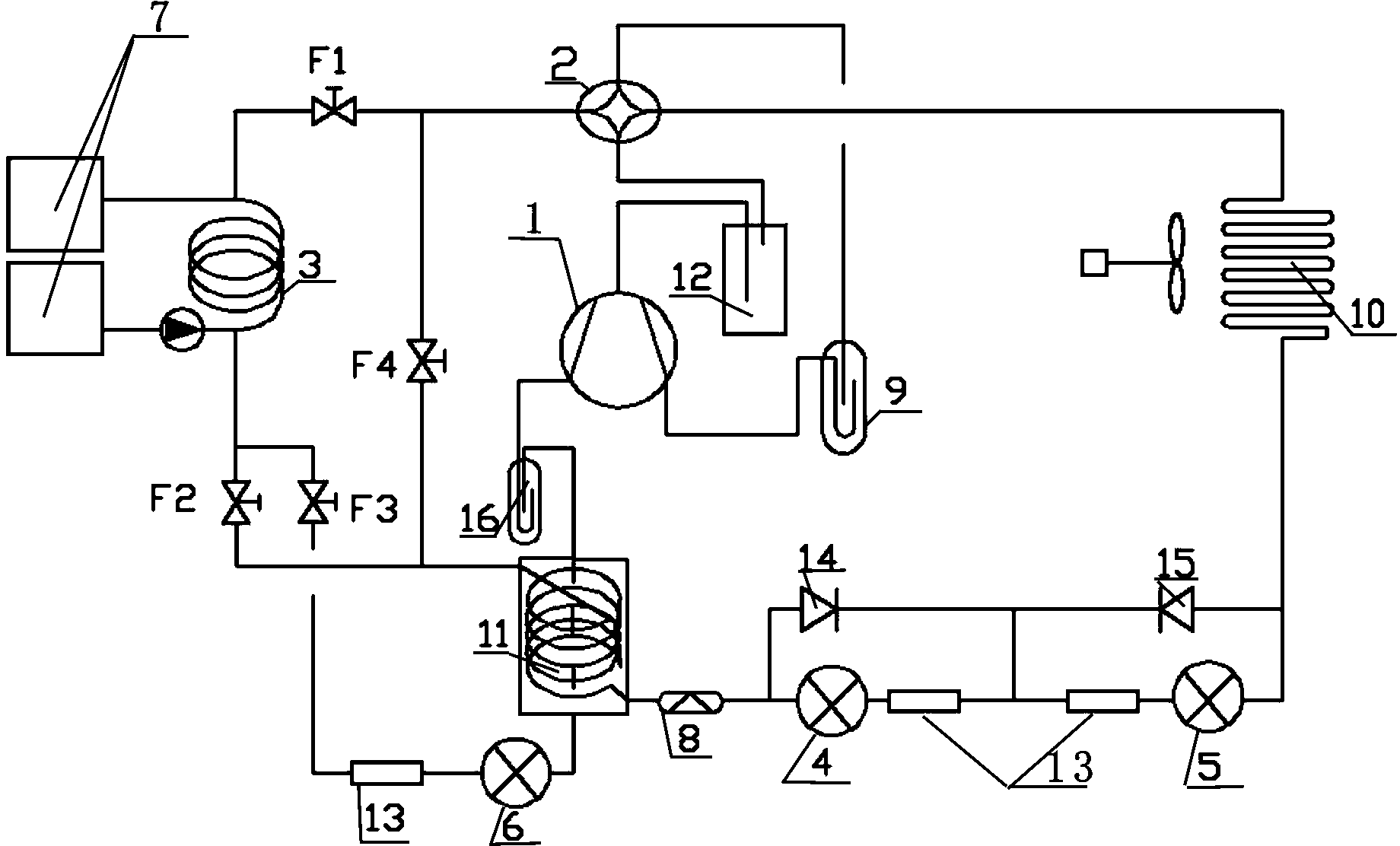

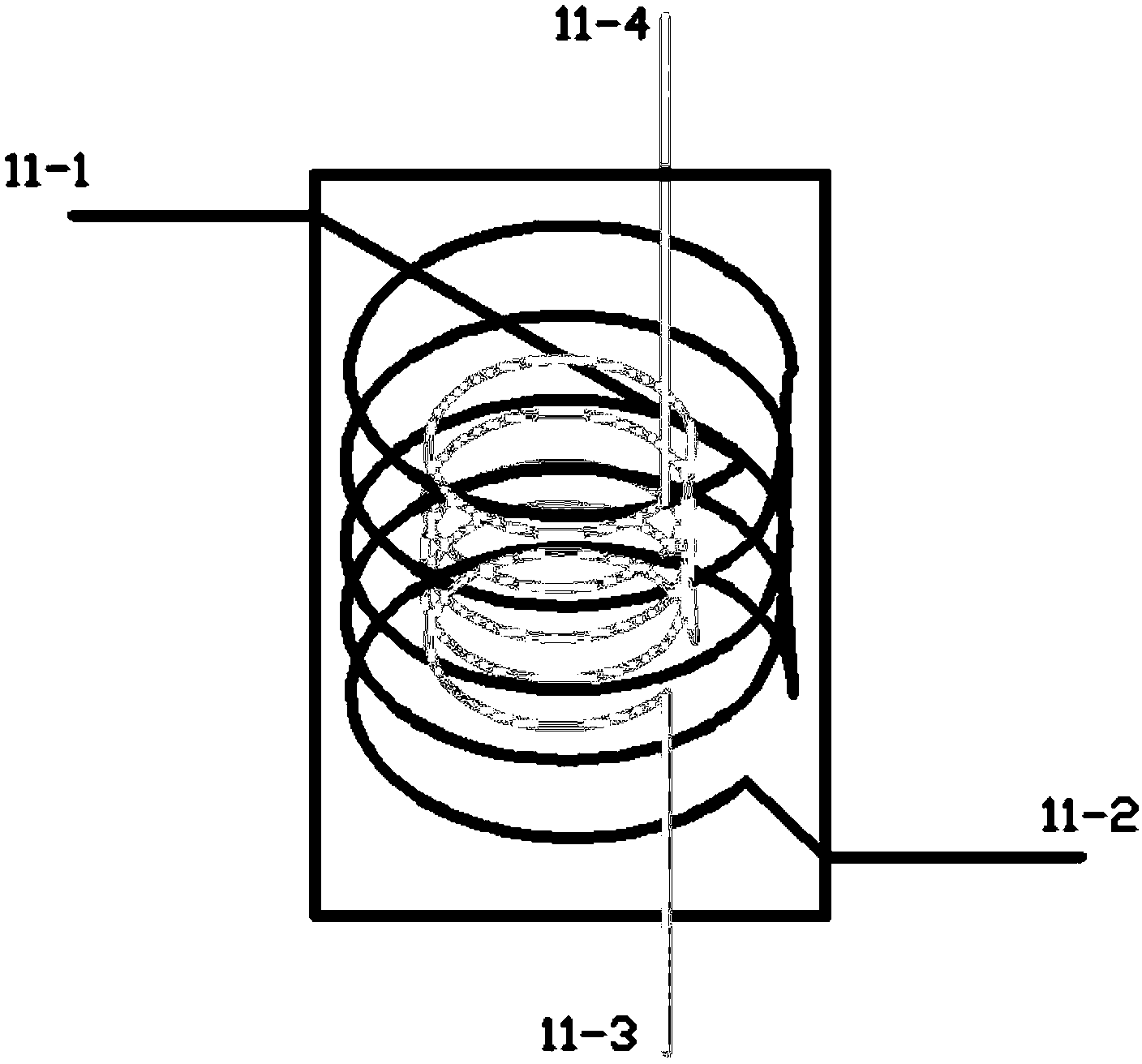

Air source heat pump water heater unit with phase change heat accumulation

InactiveCN102798214AIncrease steam flowIncrease heating capacityFluid heatersHeat storage plantsThermal expansionEngineering

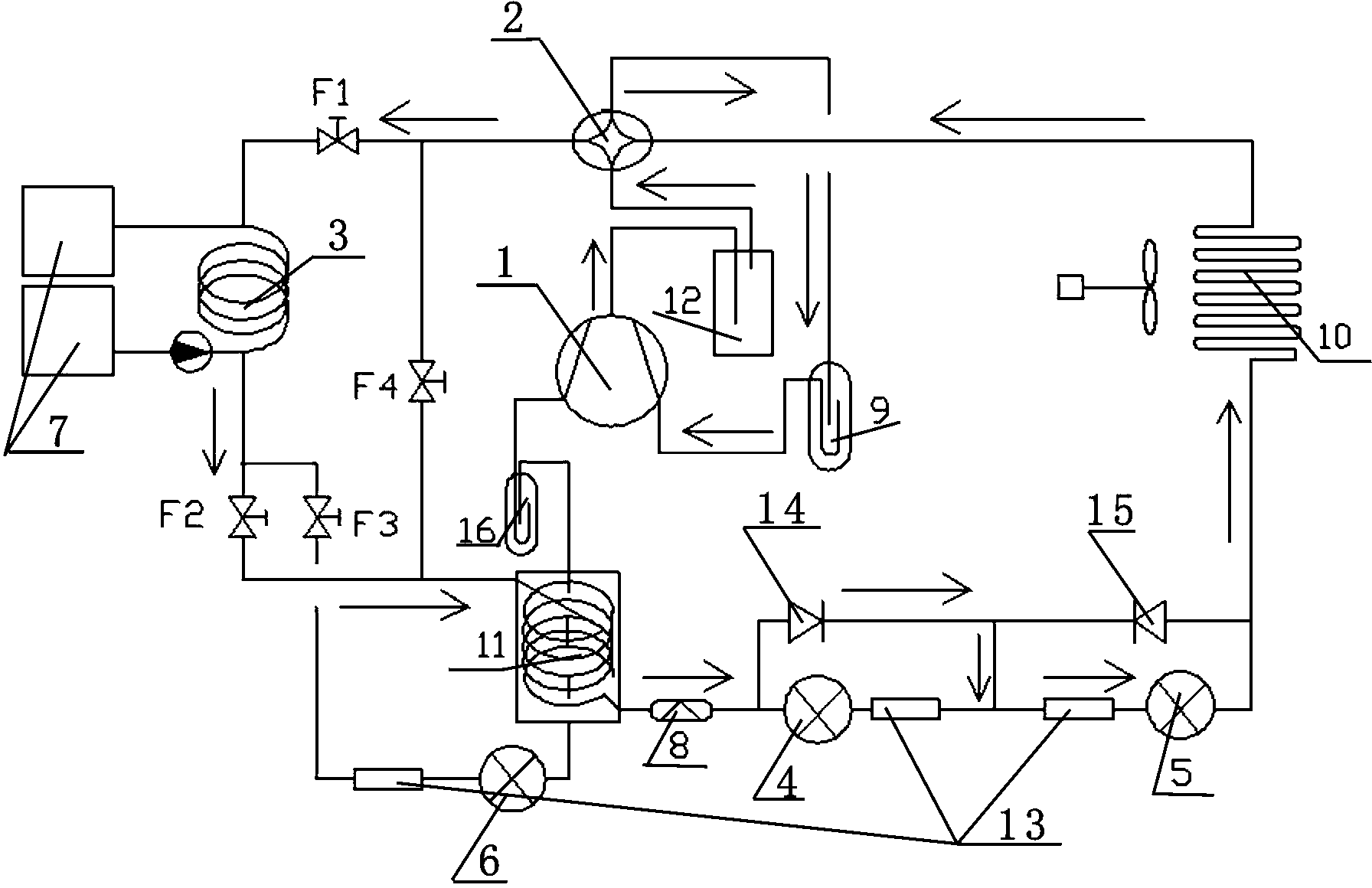

The invention relates to an air source heat pump water heater unit, and particularly to an air source heat pump water heater unit with a phase change heat accumulator. An air source heat pump water heater unit with phase change heat accumulation is provided, which comprises a scroll compressor, an oil separator, a plurality of gas-liquid separators, a four-way reversing valve, a plurality of electromagnetic valves, a plurality of check valves, a double-pipe condenser, a water tank, a phase change heat accumulator, an evaporator, a dry filter, a liquid sight glass, and a plurality of thermal expansion valves, wherein the scroll compressor is provided with an air suction port, an air supplement port and an air exhaust port, the air suction port is connected with the evaporator via a pipeline, the air supplement port is connected with the phase change heat accumulator via a pipeline, and the air exhaust port is connected with the double-pipe condenser via a pipeline. Even if in a low-temperature environment (of lower than minus 25 DEG C), because the phase change heat accumulator is used as an auxiliary evaporator for the system, for providing heat to the system and supplementing air to the compressor, thus increasing the air input of the compressor, optimizing the running working condition of the compressor, and ensuring the stable and safe low-temperature running of the compressor.

Owner:TAIYUAN UNIV OF TECH

Natural cold source cooling water chiller

InactiveCN101988722AReduce noiseSolution to short lifeLighting and heating apparatusSpace heating and ventilation detailsEvaporative coolerCooling tower

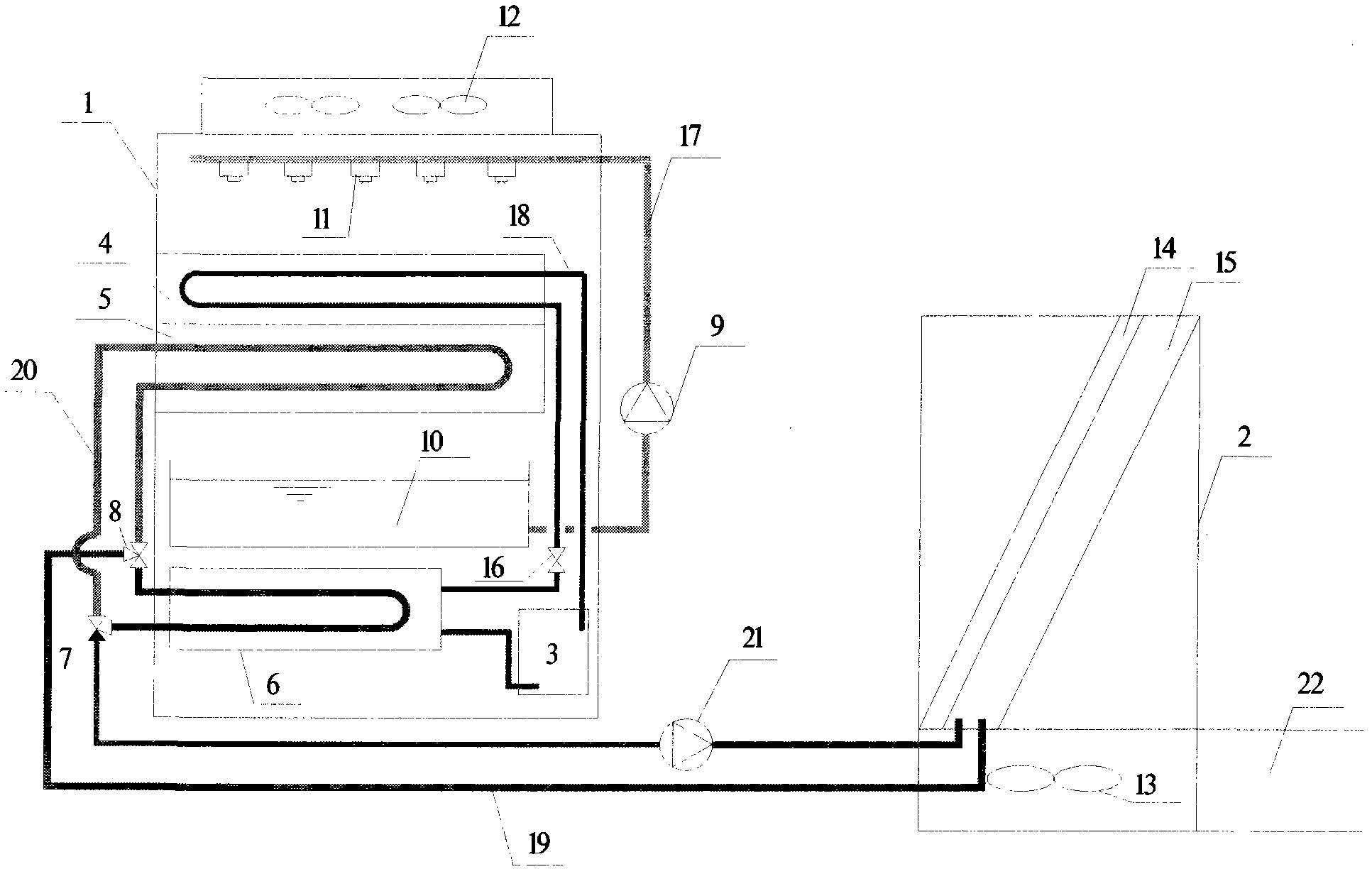

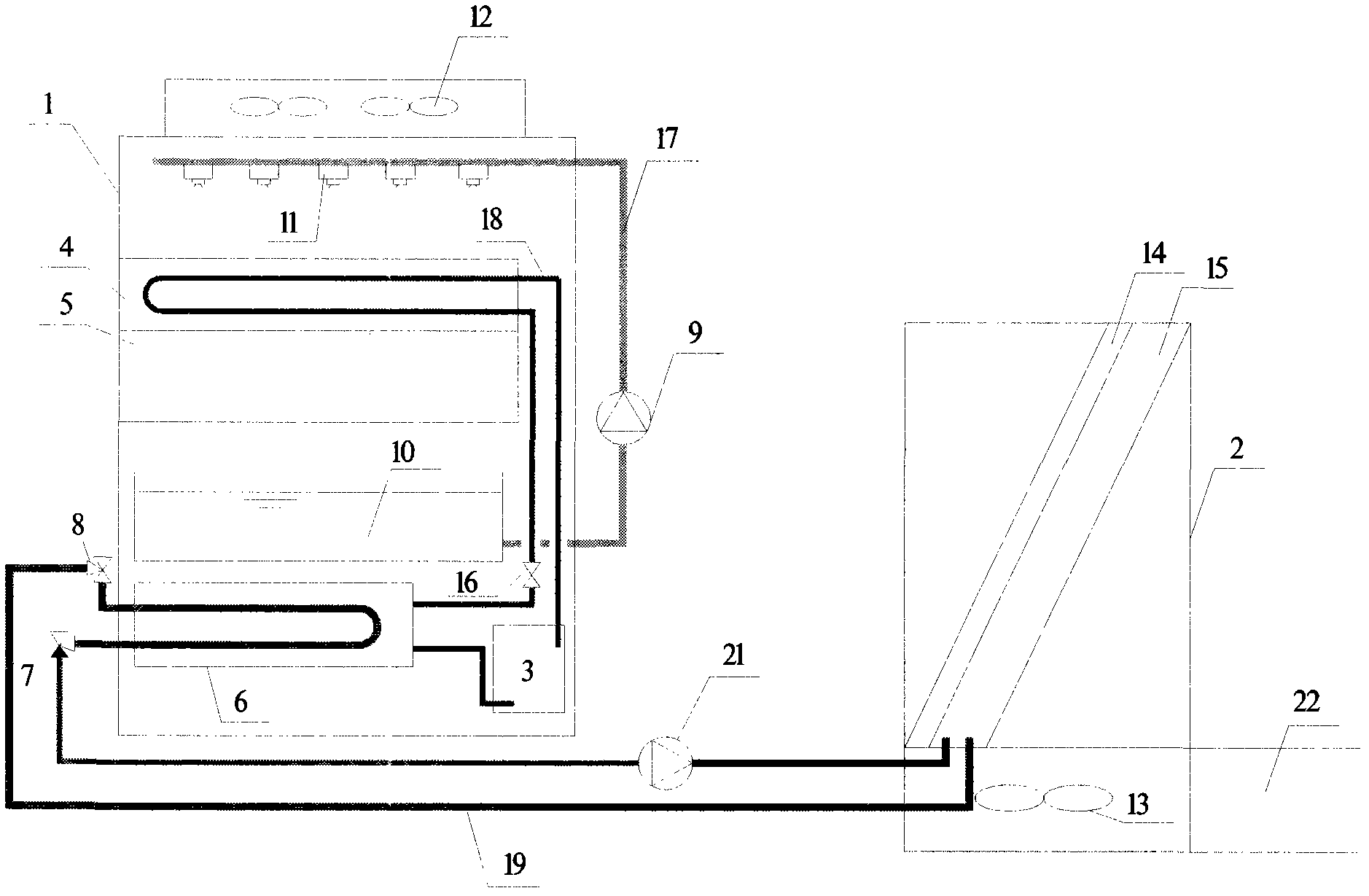

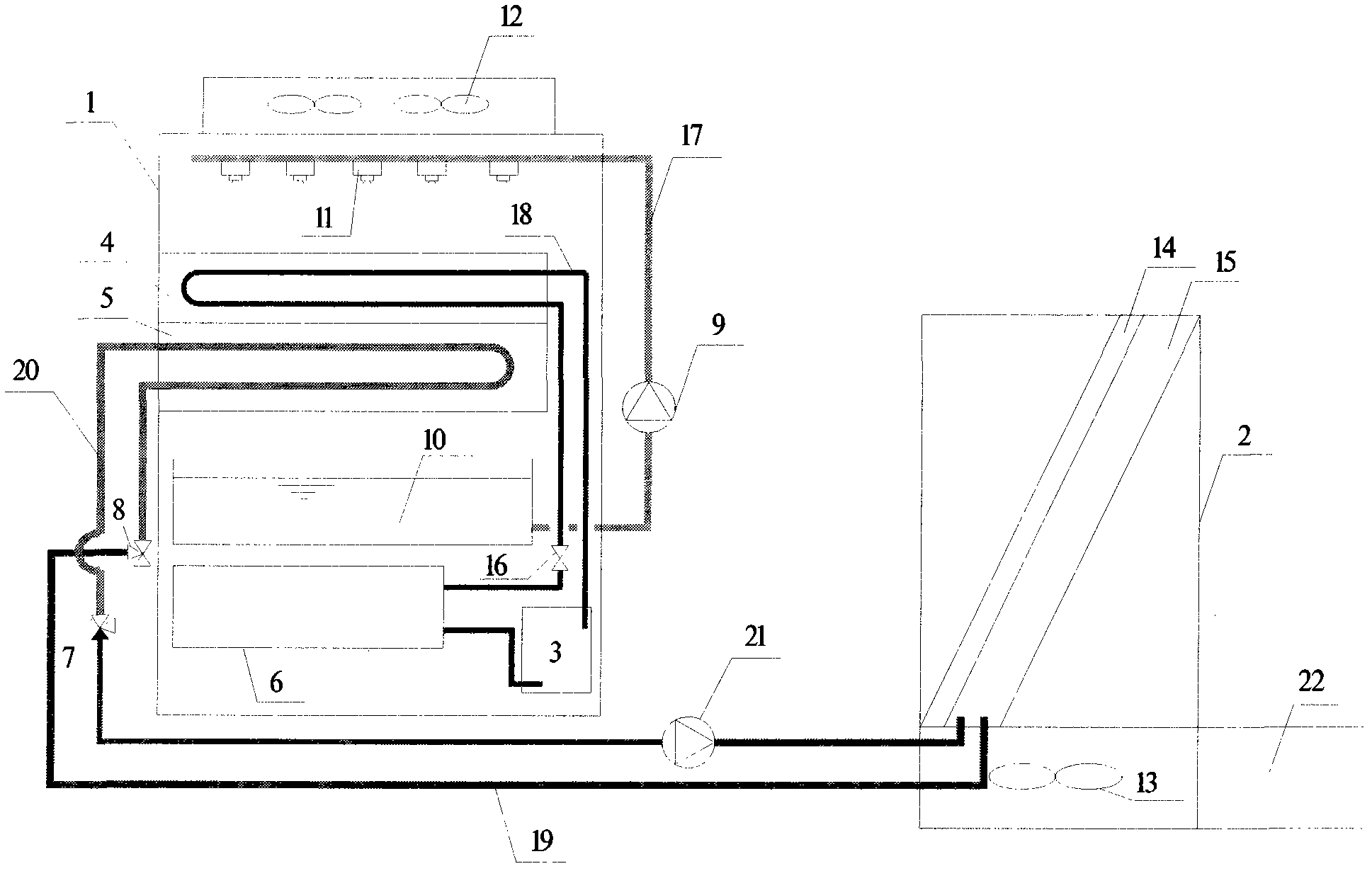

The invention relates to a natural cold source cooling water chiller which comprises an outdoor unit and an indoor unit, wherein the outdoor unit mainly consists of a refrigeration system composed of a totally-enclosed scroll compressor, an evaporator, an evaporative condenser and a natural cold source collection device, and a water channel circulating system with a three-way valve so as to realize the mechanical refrigeration of the evaporative condenser and the evaporative cooling and the air cooling of the natural cold source collection device. The water chiller is characterized in that the evaporative condenser and the high-efficiency natural cold source collection device are arranged simultaneously above a cooling circulating water pool, and an axial-flow fan is installed on upper space. When the outdoor wet-bulb temperature is higher than 6 DEG C to 8 DEG C, the evaporative condenser is mainly used to realize refrigeration, when the outdoor wet-bulb temperature is lower than 6 DEG C to 8 DEG C and higher than 0 DEG C and 2 DEG C, the natural cold source collection device which is in the form of cooling tower spraying is mainly used to realize the evaporative cooling, and when the outdoor wet-bulb temperature is lower than 0 DEG Cto 2 DEG C, the natural cold source collection device which is in the form of air cooling is mainly used to realize cooling.

Owner:郭海新 +1

Discharge valve structures for a scroll compressor having a separator plate

InactiveUS20060228243A1Quick closeRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeVALVE PORTScroll compressor

Owner:SCROLL TECH

Very low temperature refrigeration system having a scroll compressor with liquid injection

ActiveUS7234310B2Improve efficiencyIncrease mass flowCompressorCompression machines with non-reversible cycleEngineeringRefrigeration

Disclosed is a very low temperature or cryogenic refrigeration system with a scroll compressor and utilizing a mixed refrigerant that decreases refrigerant discharge temperature by refrigerant injection into the compressor.

Owner:EDWARDS VACUUM LLC

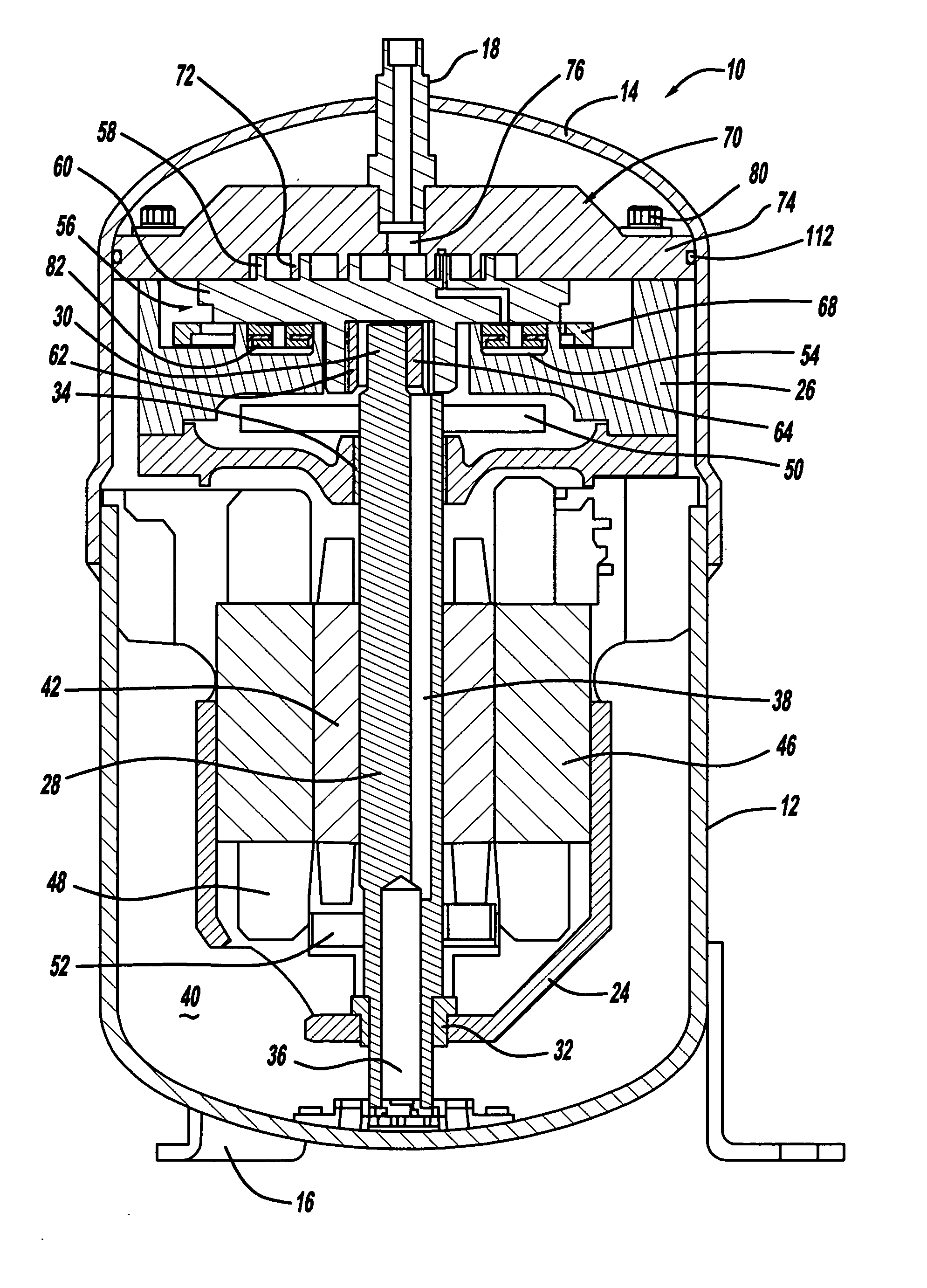

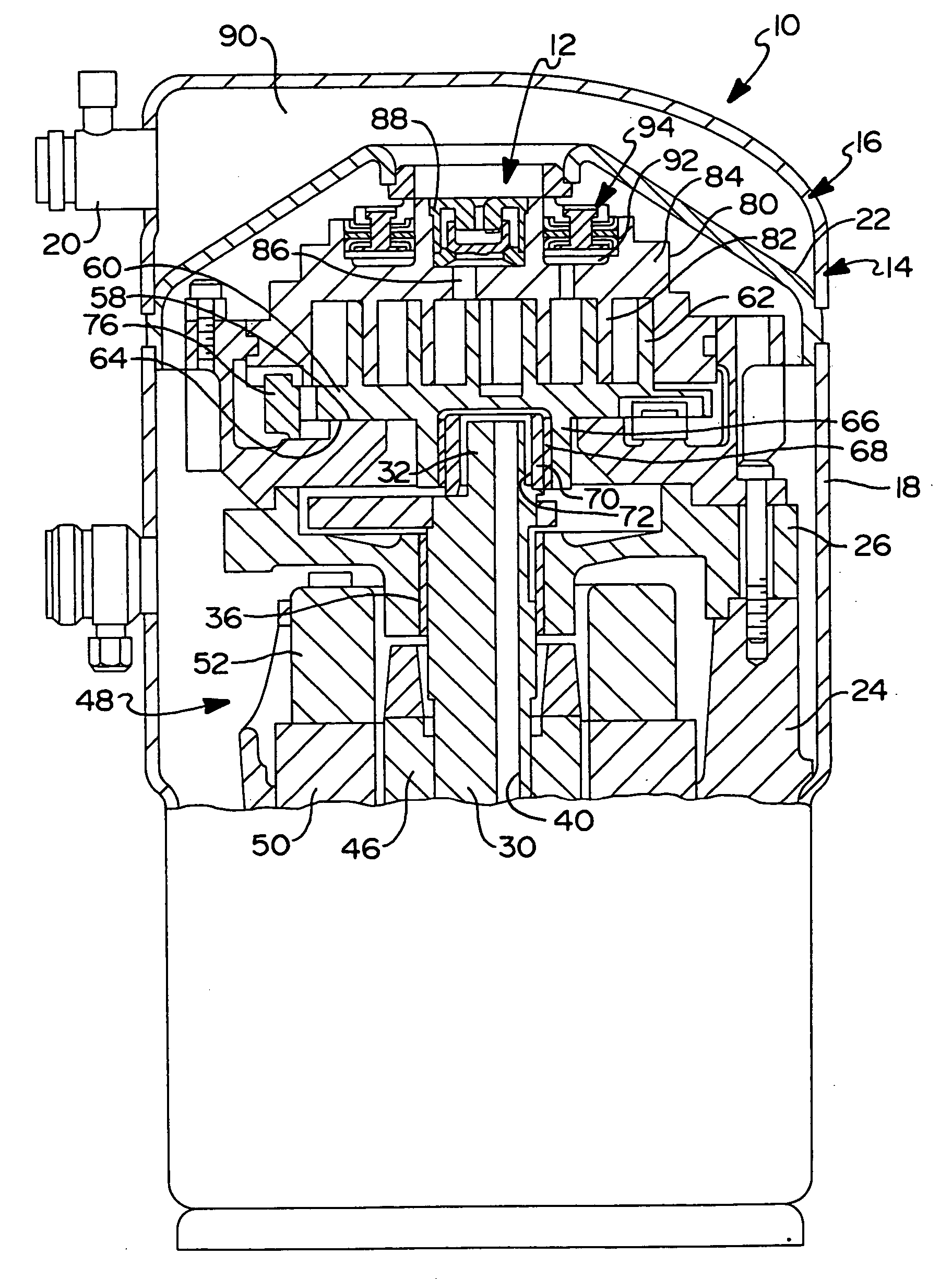

Lubrication systems for scroll compressors

An improved scroll compressor lubrication system includes a number of embodiments wherein a lubricant port in the orbiting scroll supplies lubricant to the compression chambers throughout its entire orbiting cycle. The lubricant port is aligned with a recess in a flange of the fixed scroll throughout its entire orbiting cycle. In a further embodiment, the lubricant port is exposed to the compression chamber throughout its entire cycle. In other embodiments, the fixed scroll is provided with recesses spaced from each other by approximately 180 DEG . The lubricant port moves sequentially into and out of communication with these spaced recesses to supply lubricant to the compression chambers.

Owner:CARRIER CORP

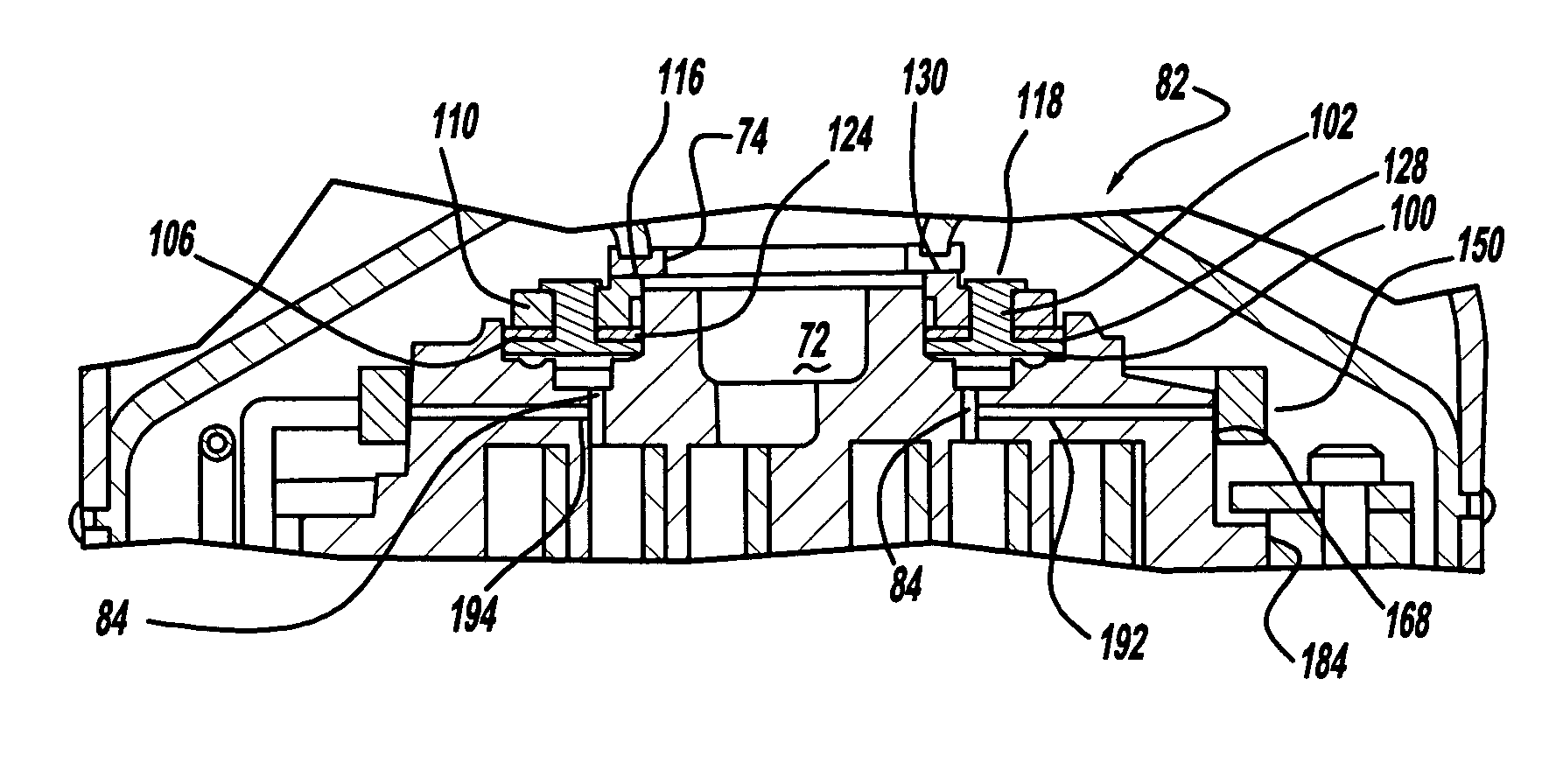

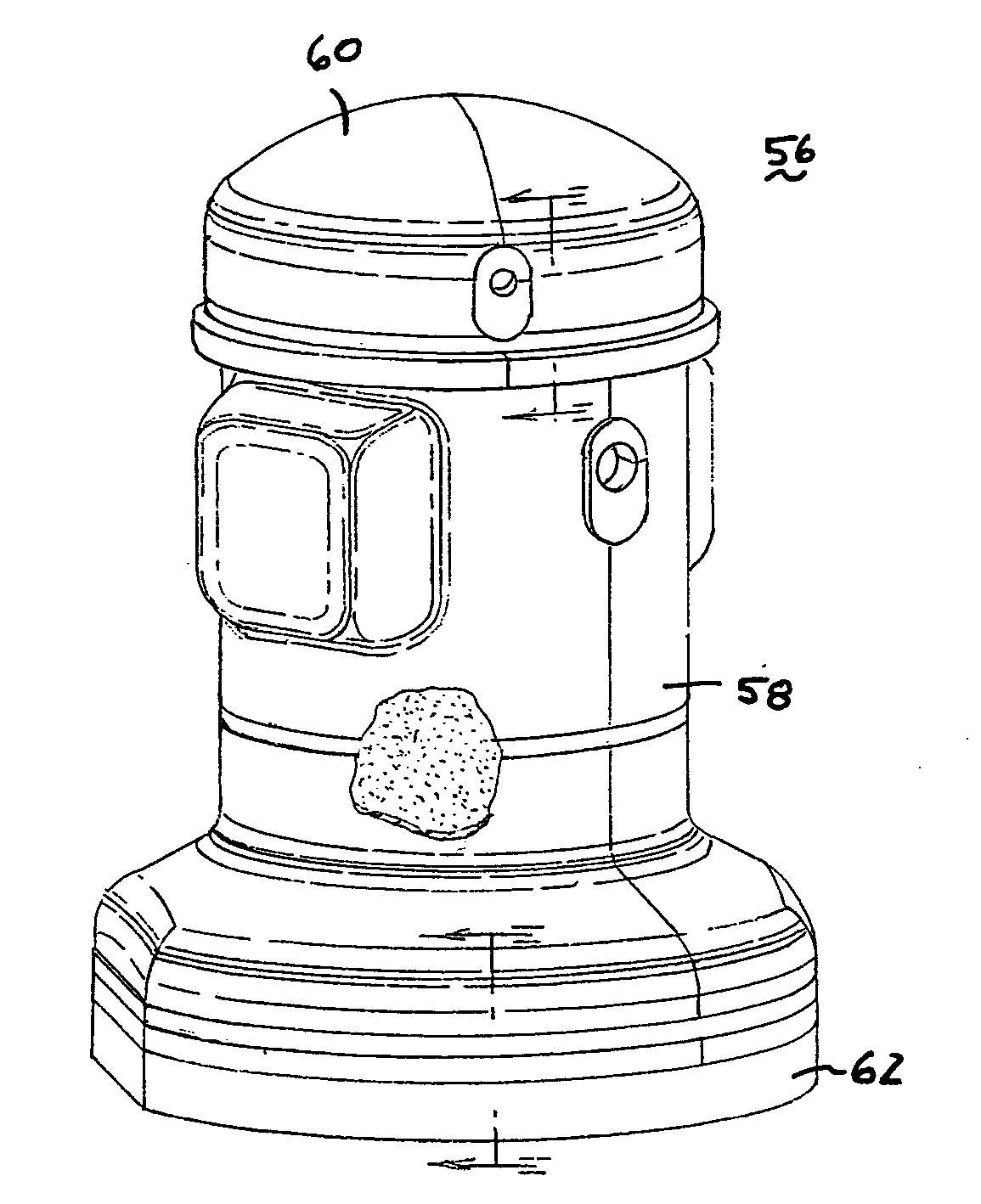

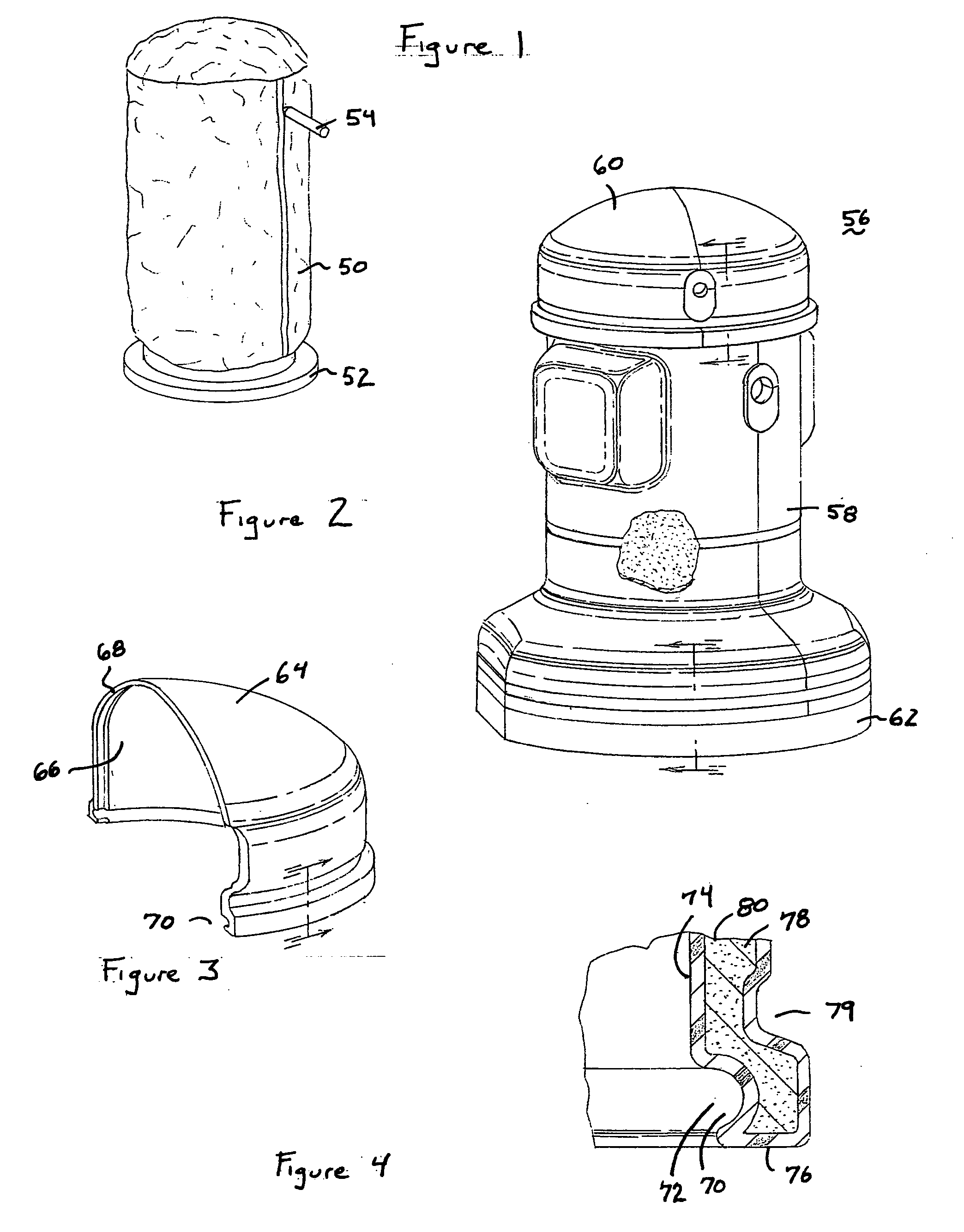

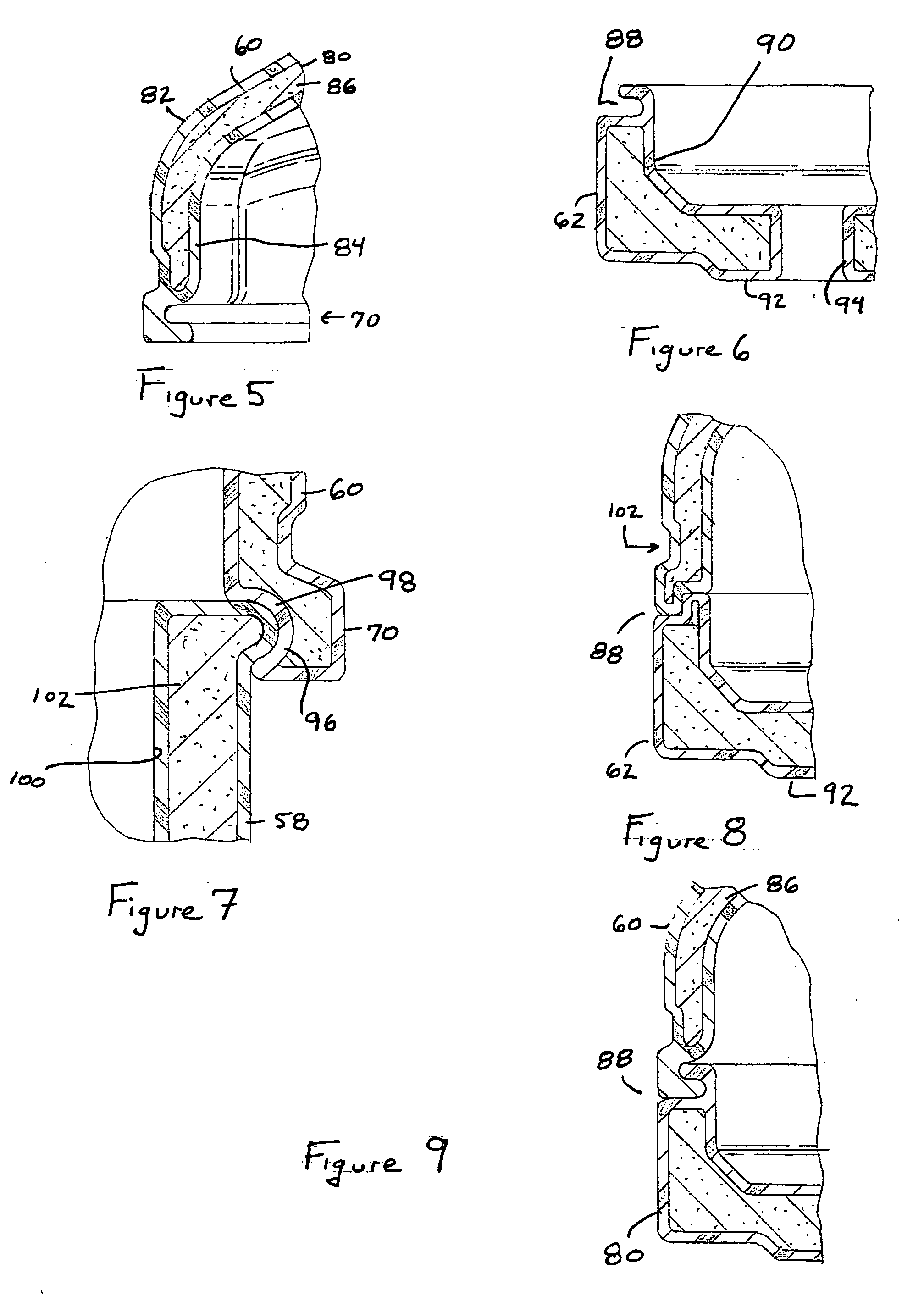

Compressor sound attenuation enclosure

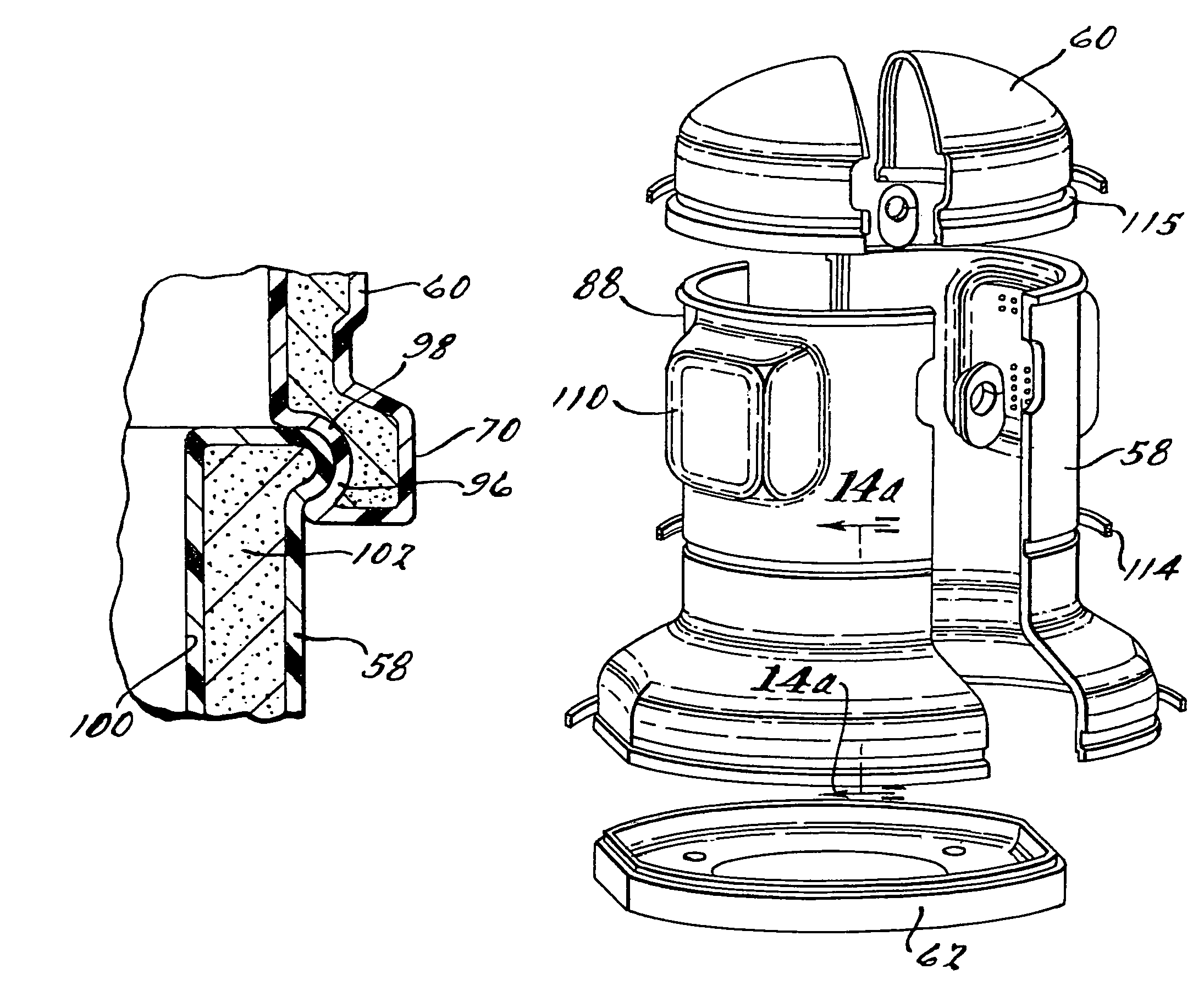

InactiveUS20050274569A1Low costSuperior sound transmission loss propertyRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsUltrasound attenuationEngineering

A sound attenuating cover for a scroll compressor is provided. The cover has a base member configured to support the compressor, the base defines a first chamber filled with a sound attenuating material. The sound attenuating chamber further has a cover member configured to cover the compressor and couple to the base, said cover member defines another chamber. This chamber is additionally filled with a sound attenuating material.

Owner:EMERSON CLIMATE TECH INC

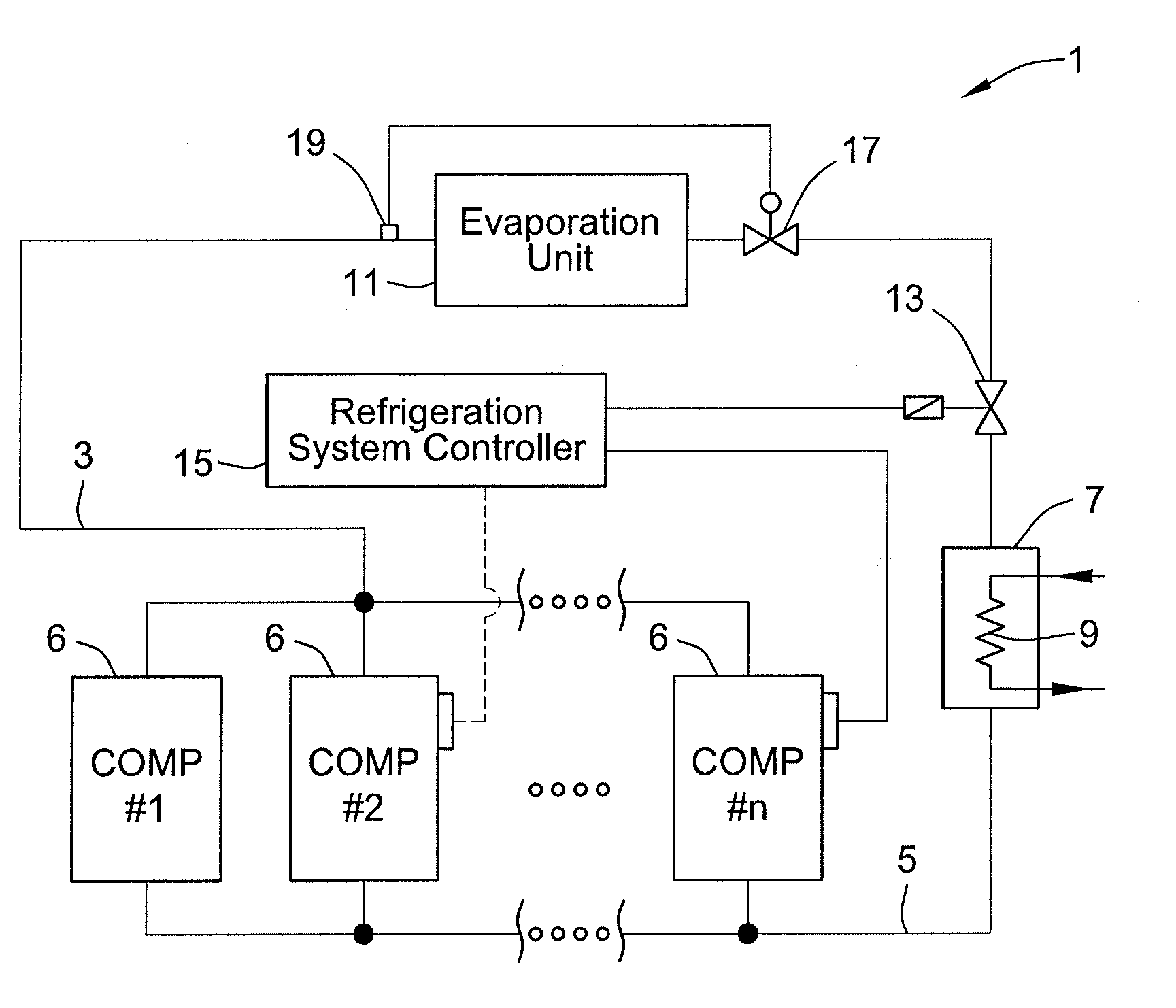

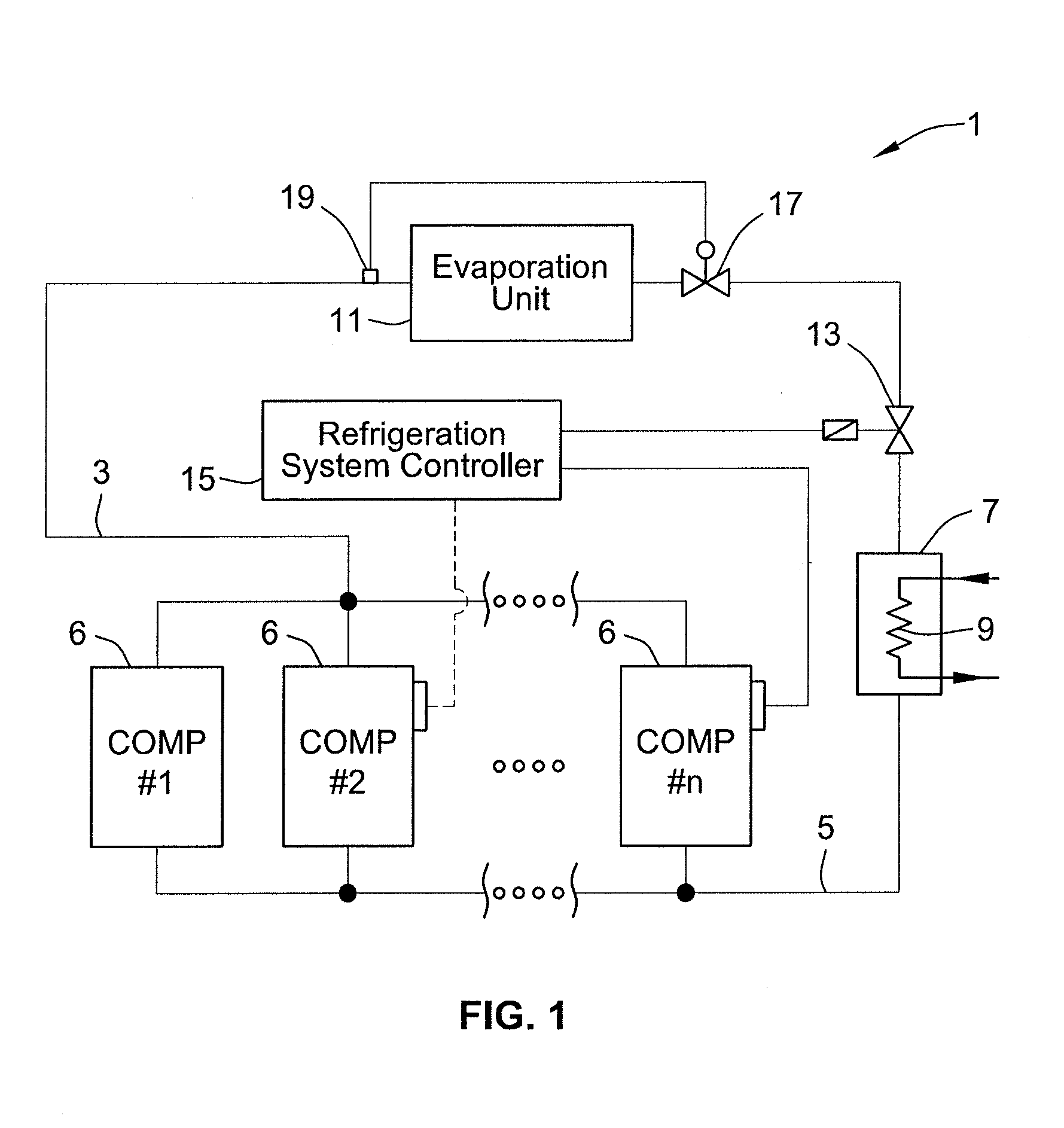

Apparatus and Method for Oil Equalization in Multiple-Compressor Systems

ActiveUS20140241926A1Promote sportsRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringEqualization

A method of operating a refrigeration system, that includes providing a plurality of compressors connected in parallel. The plurality of compressors includes a plurality of scroll compressors. The method further includes returning circulated refrigerant to the plurality of compressors, the circulated refrigerant having oil entrained therein. Returning circulated refrigerant to the plurality of compressors includes returning more oil to one of the plurality of compressors than to another of the plurality of compressors. The method also includes supplying oil from one of the plurality of compressors to at least one other of the plurality of compressors. Supplying oil from one of the plurality of compressors includes supplying oil from the one of the plurality of compressors having an opening in its housing. A fitting is assembled into the opening. The fitting protrudes through the housing into an interior portion of the housing.

Owner:BITZER KUEHLMASCHINENBAU GMBH

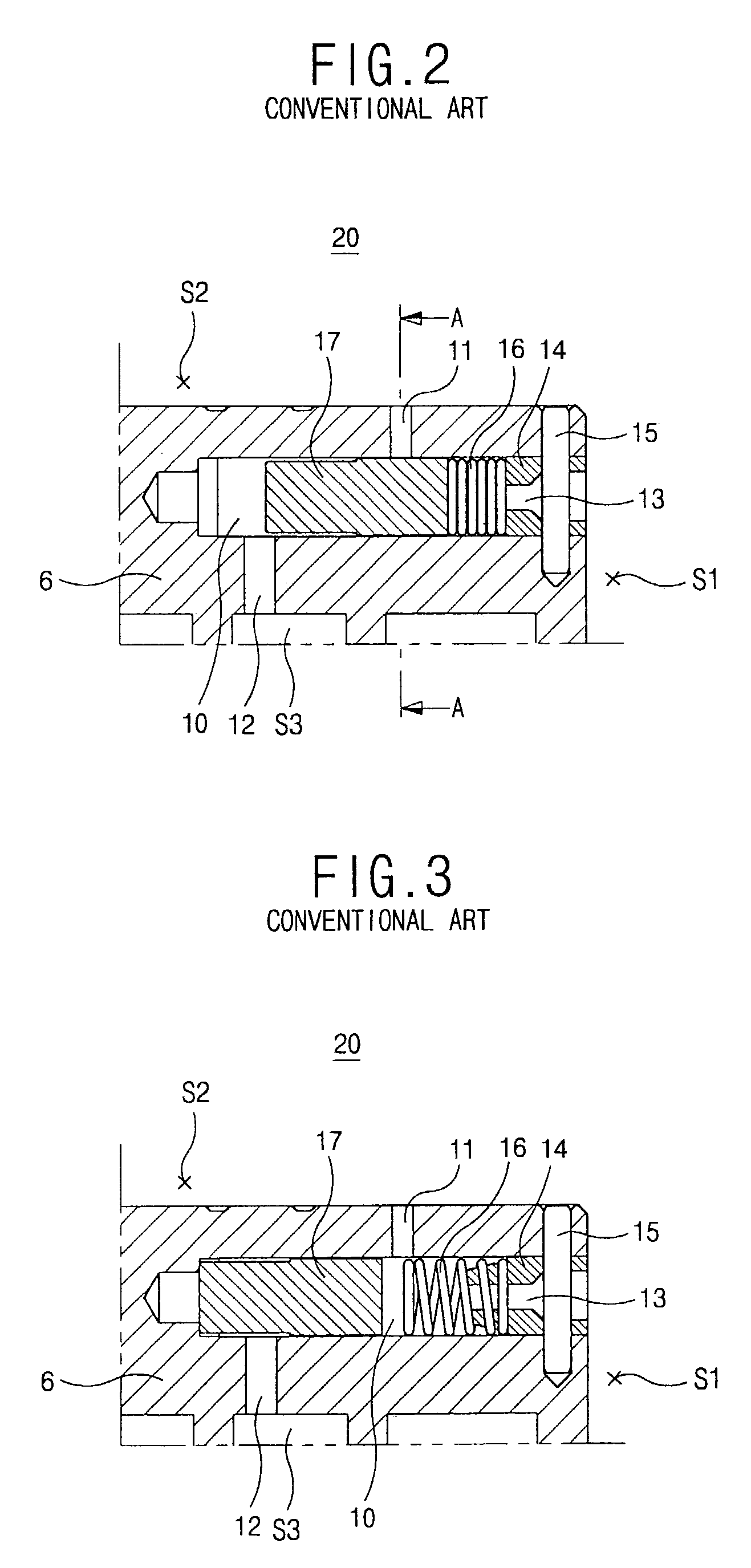

Vacuum preventing device of scroll compressor

InactiveUS7018180B2Improve compression efficiencyGap minimizationRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringAtmospheric pressure

A vacuum preventing device of a scroll compressor includes: a chamber formed at one side of a fixed scroll and having a suction pressure hole, a middle pressure hole and a discharge pressure hole communicating with a suction pressure zone, a middle pressure zone and a discharge pressure zone, each formed at a certain portion of an inner circumferential surface; an open and shut member installed inside the chamber and selectively communicating the discharge pressure hole and the suction pressure hole by virtue of a gas pressure of the middle pressure zone and an elastic force of a spring; and a gas leakage preventing unit for preventing a gas leakage in a normal operation by reducing a clearance between an inner wall of the chamber positioned at the side of the discharge pressure hole and the open and shut member.

Owner:LG ELECTRONICS INC

Axial sealing structure of scroll compressor

InactiveUS6984115B1Simplifying and reducing of assembling procedureImprove product qualityEngine sealsEngine of arcuate-engagement typeEngineeringMechanical engineering

An axial sealing mechanism of a scroll compressor includes a housing, a scroll device, and a floating seal member with a recess portion and a central channel. The housing includes a first shell and a second shell. The first shell has a receiving chamber. A partition is disposed inside the receiving chamber. The scroll device includes a fixed scroll and an orbiting scroll. A plurality of compression pockets is formed between the fixed scroll and the orbiting scroll. The fixed scroll has a protruding portion with a plurality of orifices. The recess portion of the floating seal member receives the protruding portion of the fixed scroll. Seal elements are respectively secured to the floating seal member and the fixed scroll. An intermediate pressure room is thereby formed between the float seal element and the fixed scroll.

Owner:NO 31 1 LANE 169 KANGNING ST +1

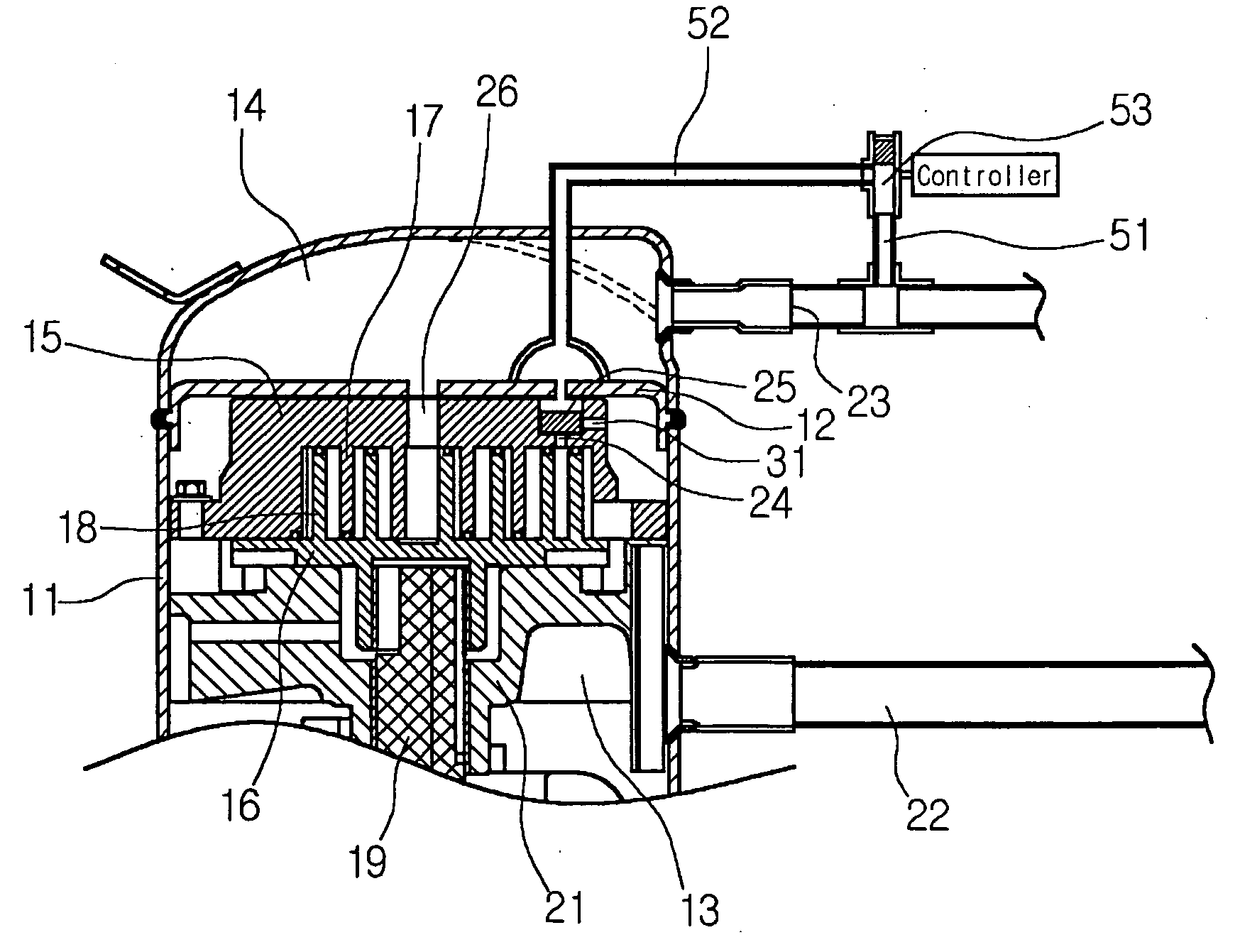

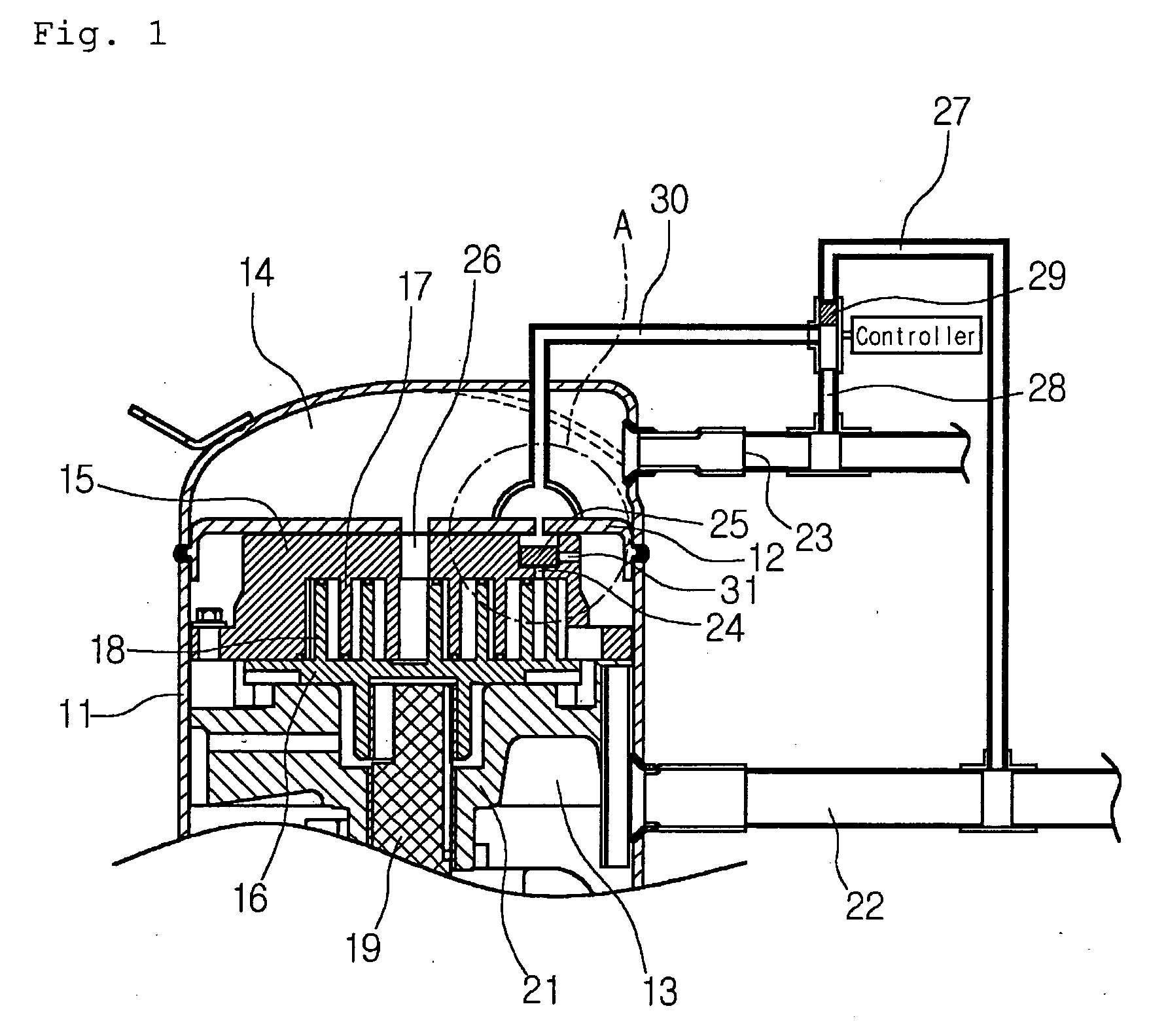

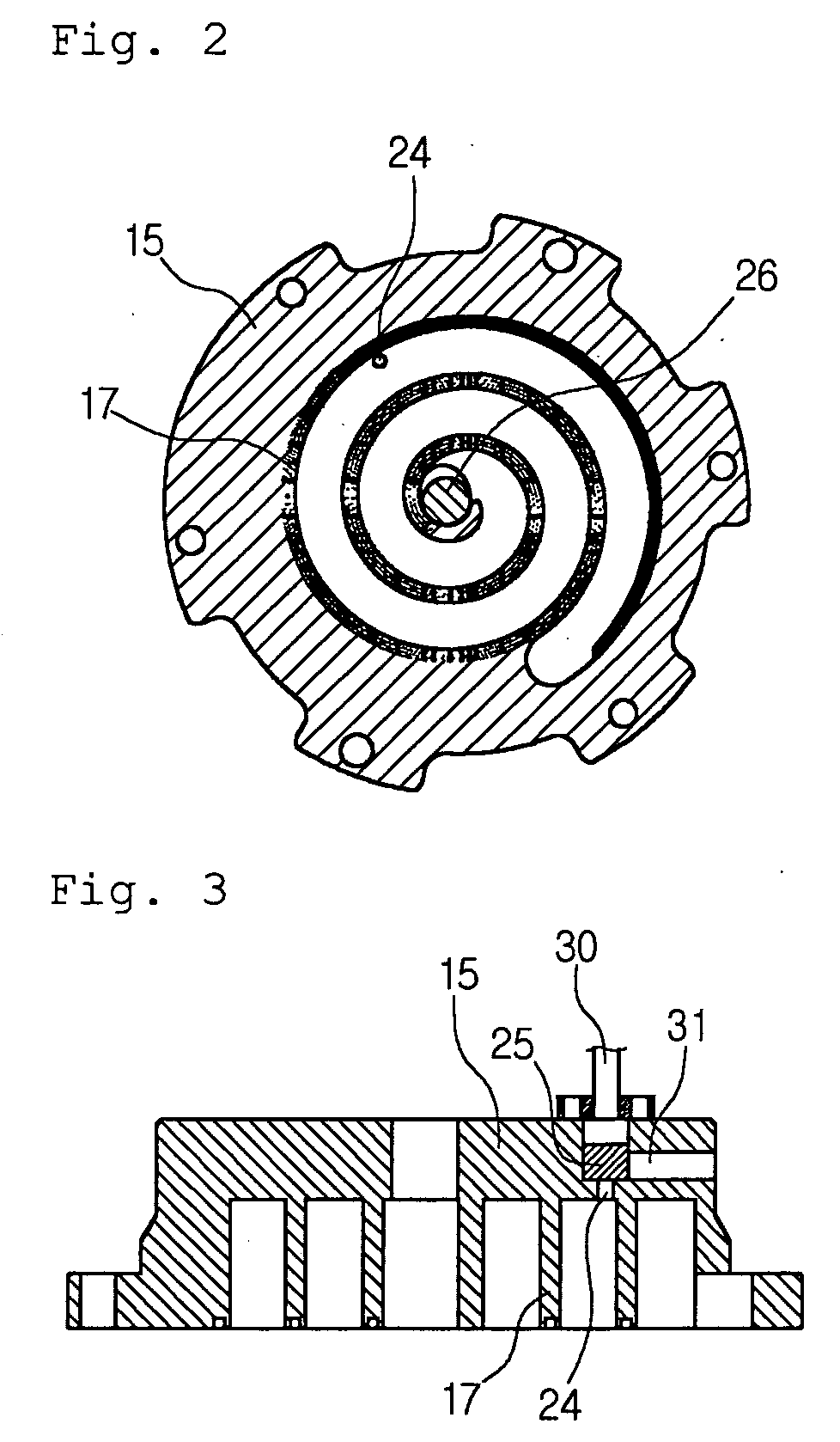

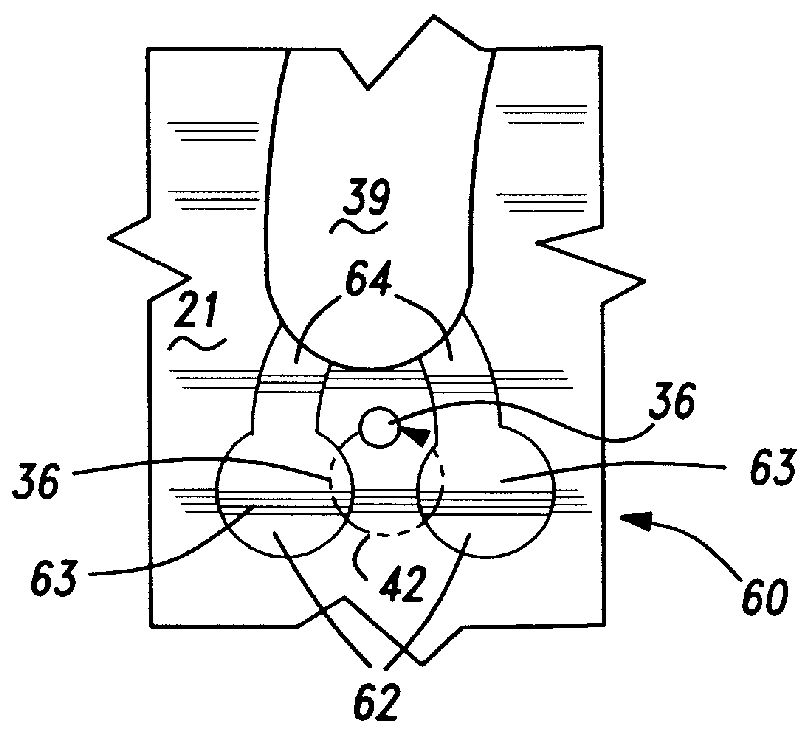

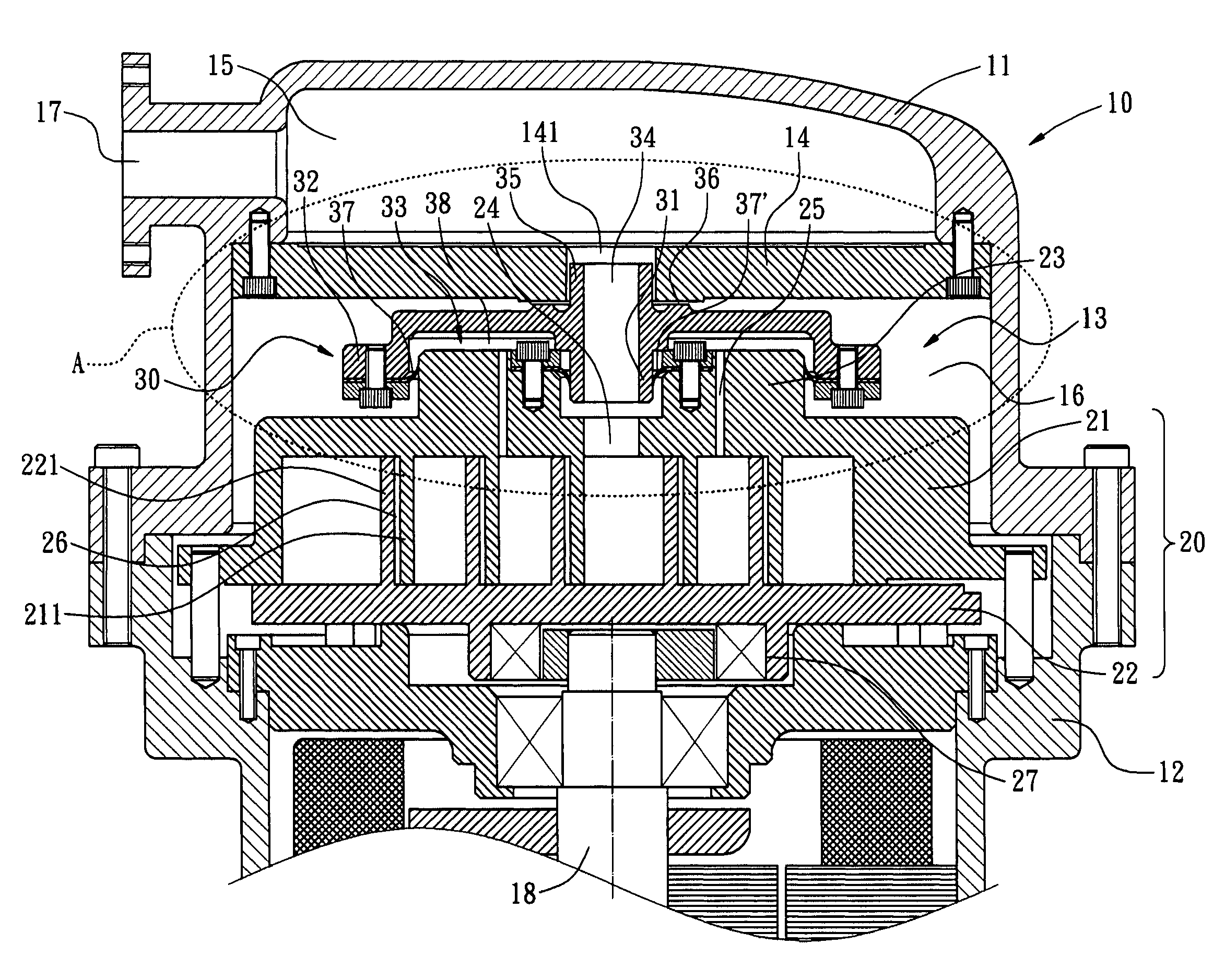

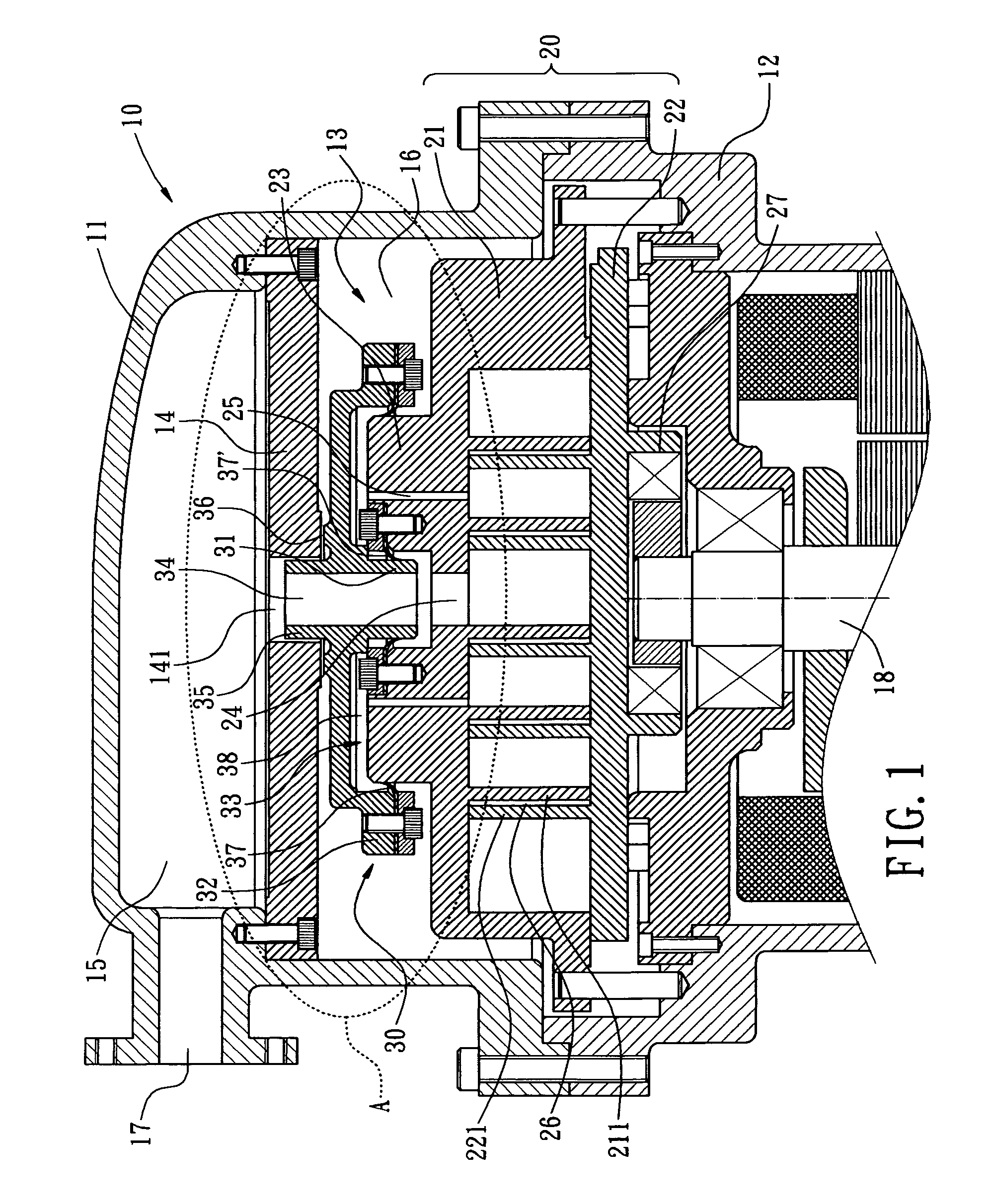

Variable capacity scroll compressor

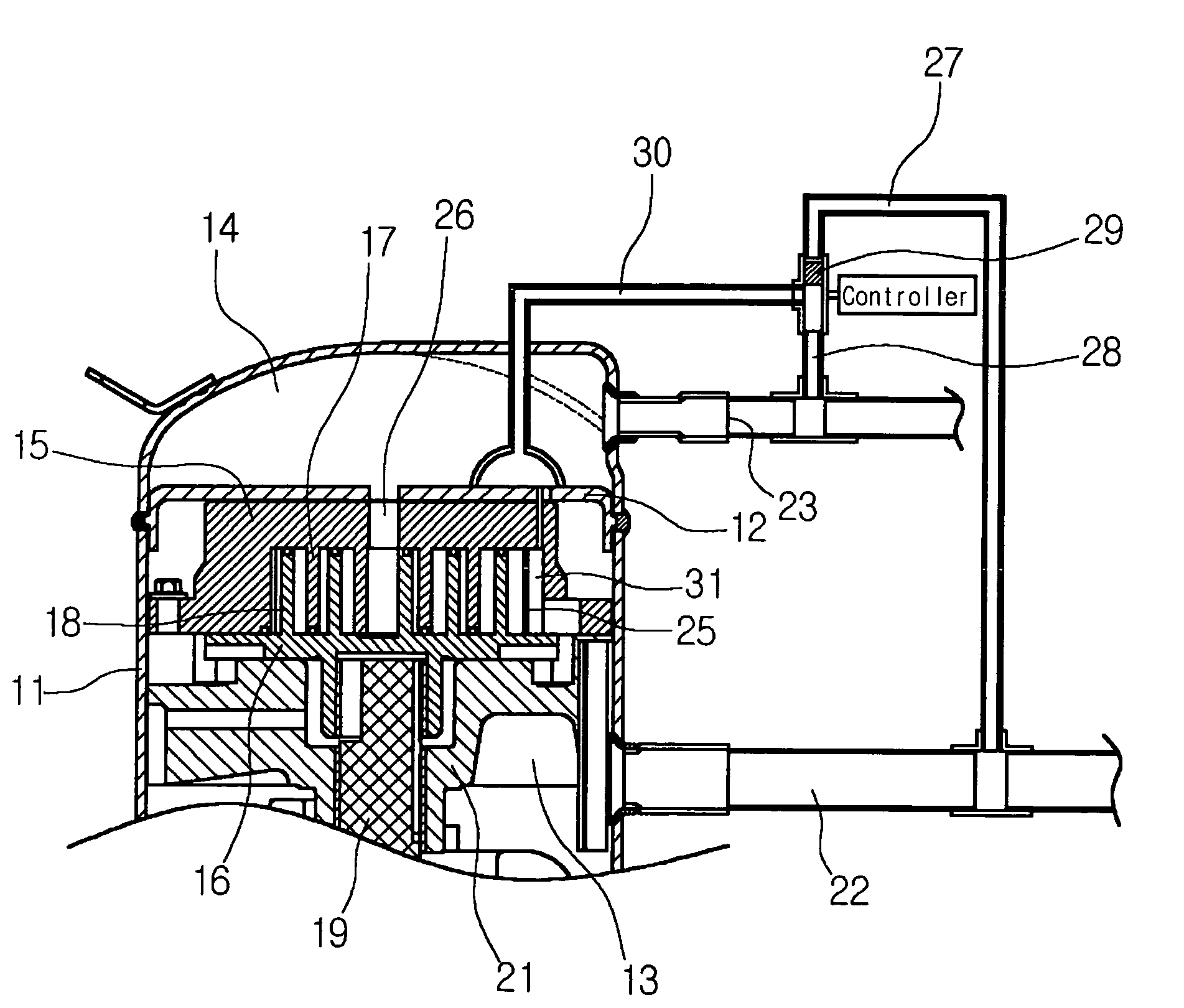

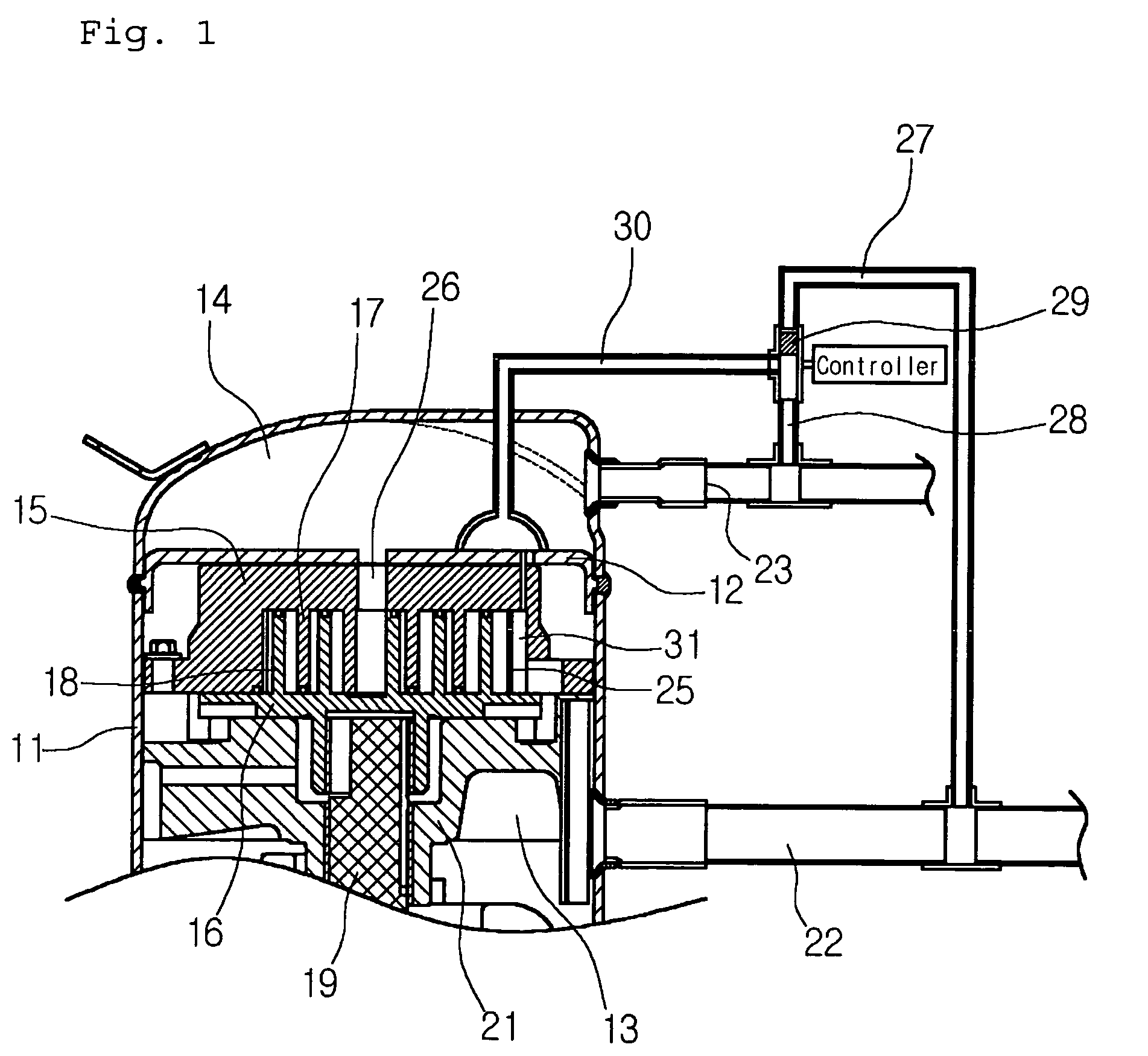

InactiveUS7371057B2Easy to changeEngine of arcuate-engagement typeRotary piston pumpsDrive shaftDrive motor

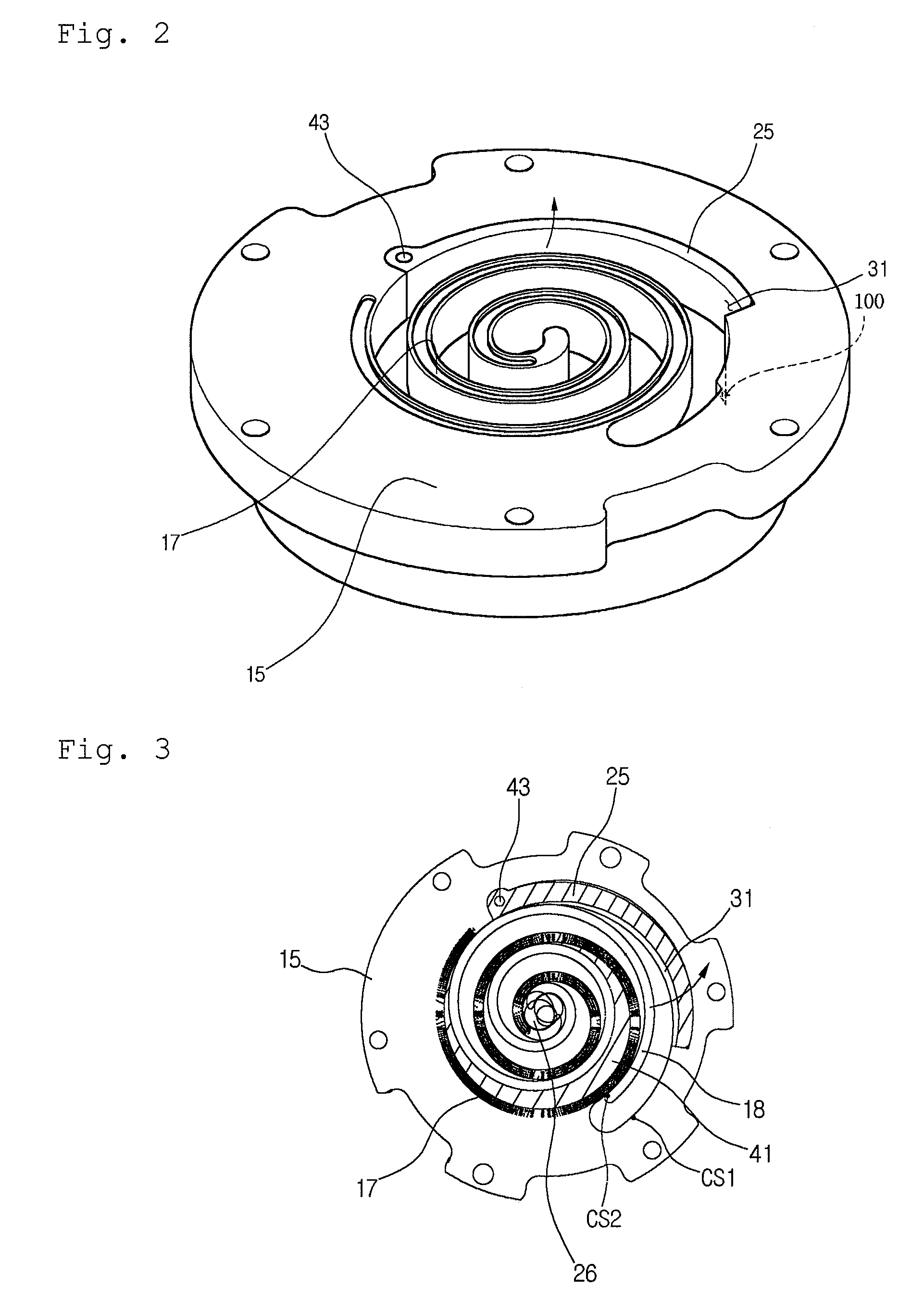

Disclosed is a variable capacity scroll compressor including a stationary scroll member on which a stationary spiral wrap is formed, an orbiting scroll member on which an orbiting spiral wrap is formed, the orbiting scroll member rotating while surface-contacting the stationary scroll, a driving motor, a driving shaft for rotating the orbiting scroll member using power transmitted from the driving motor, a control chamber formed on a predetermined portion of the stationary spiral wrap, a pivotal block disposed in the control chamber, and a controller for controlling a pivotal motion of the pivotal block.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com