Patents

Literature

157 results about "Tolerance limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tolerance limits consist of the the upper and lower limits of a particular environmental condition which allows a certain species to survive.

Method and device for monitoring and controlling network risks

ActiveCN102111307AAchieve precise monitoringGuaranteed normal operationData switching networksTolerance limitStatistical analysis

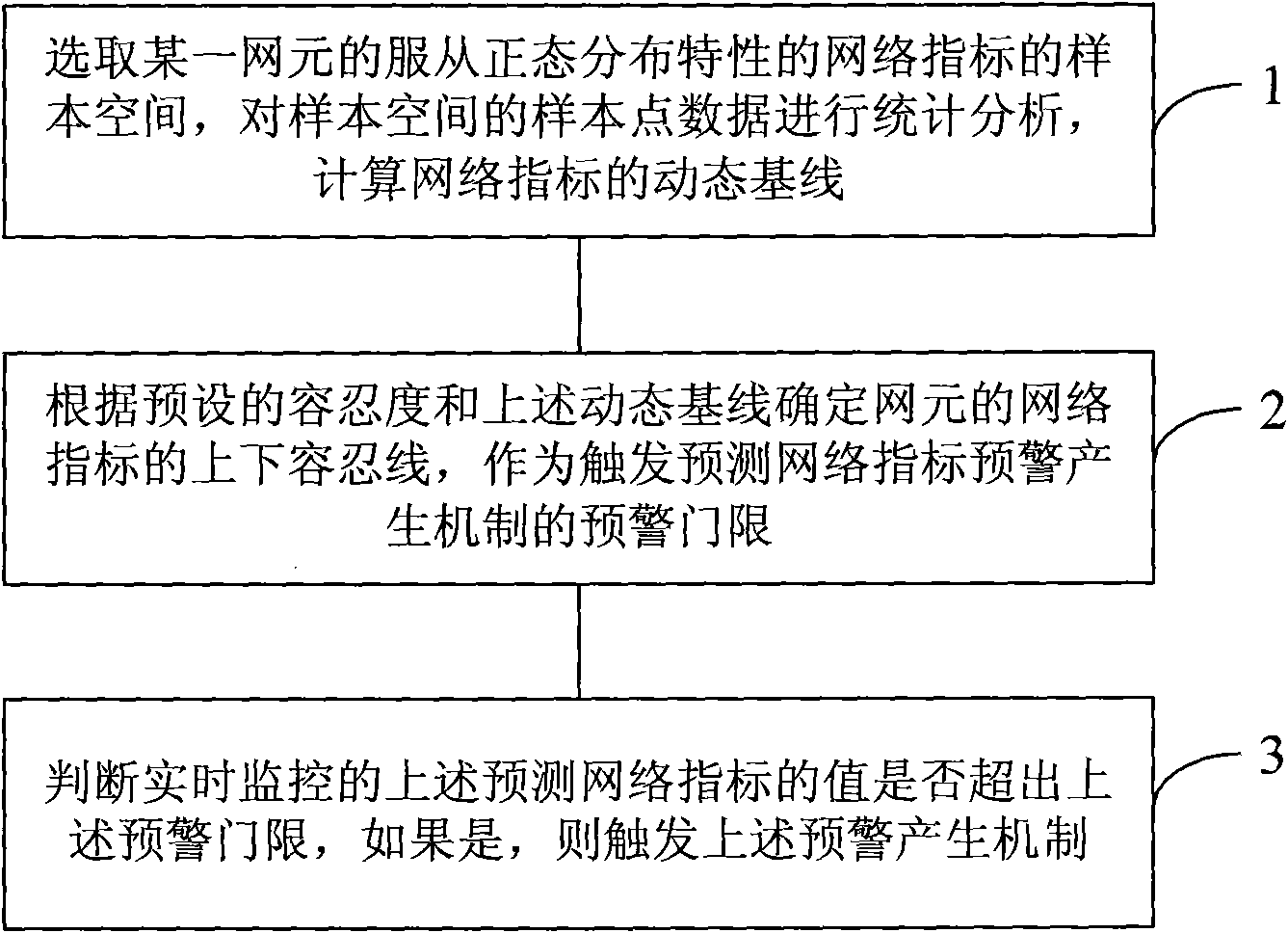

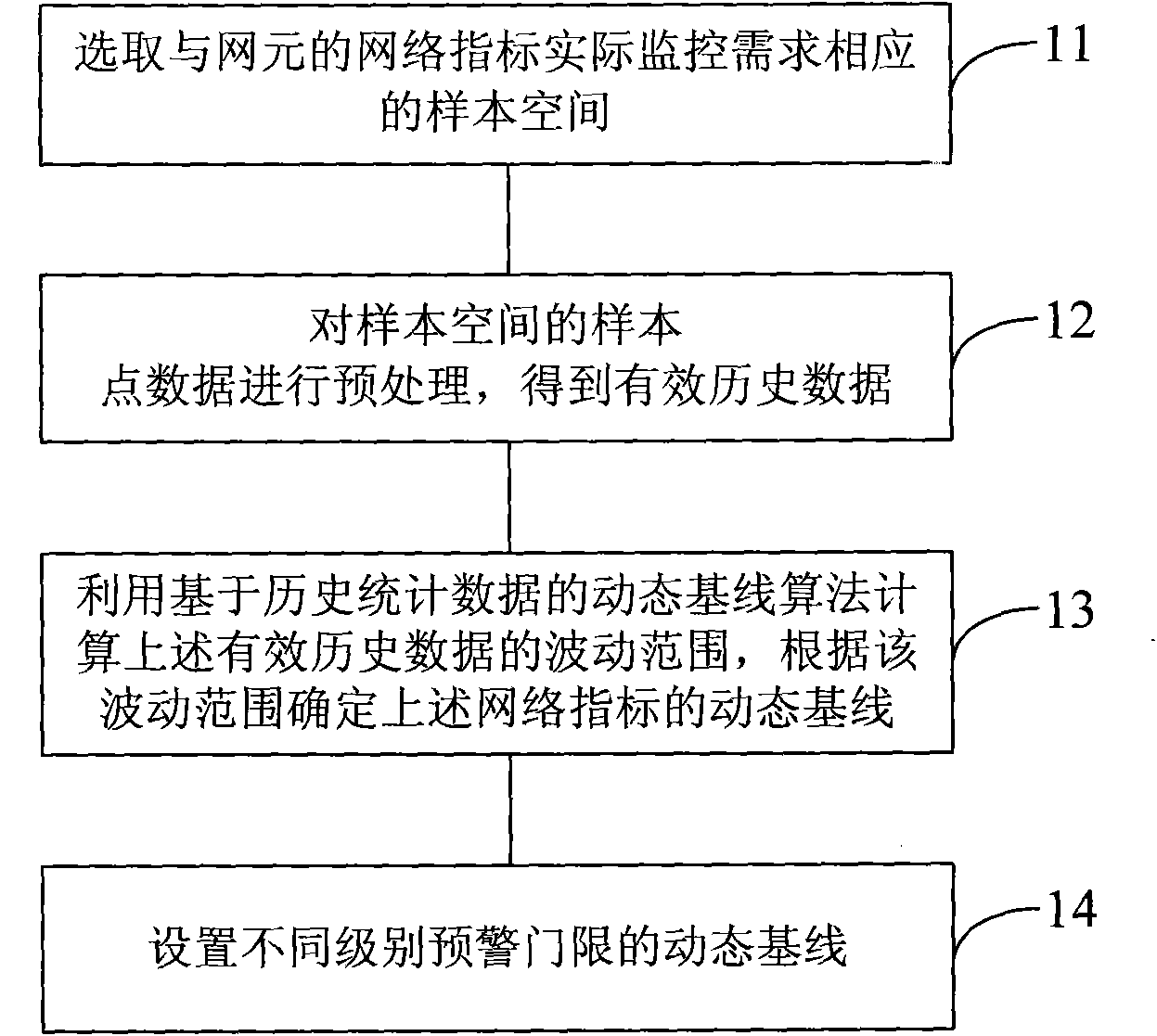

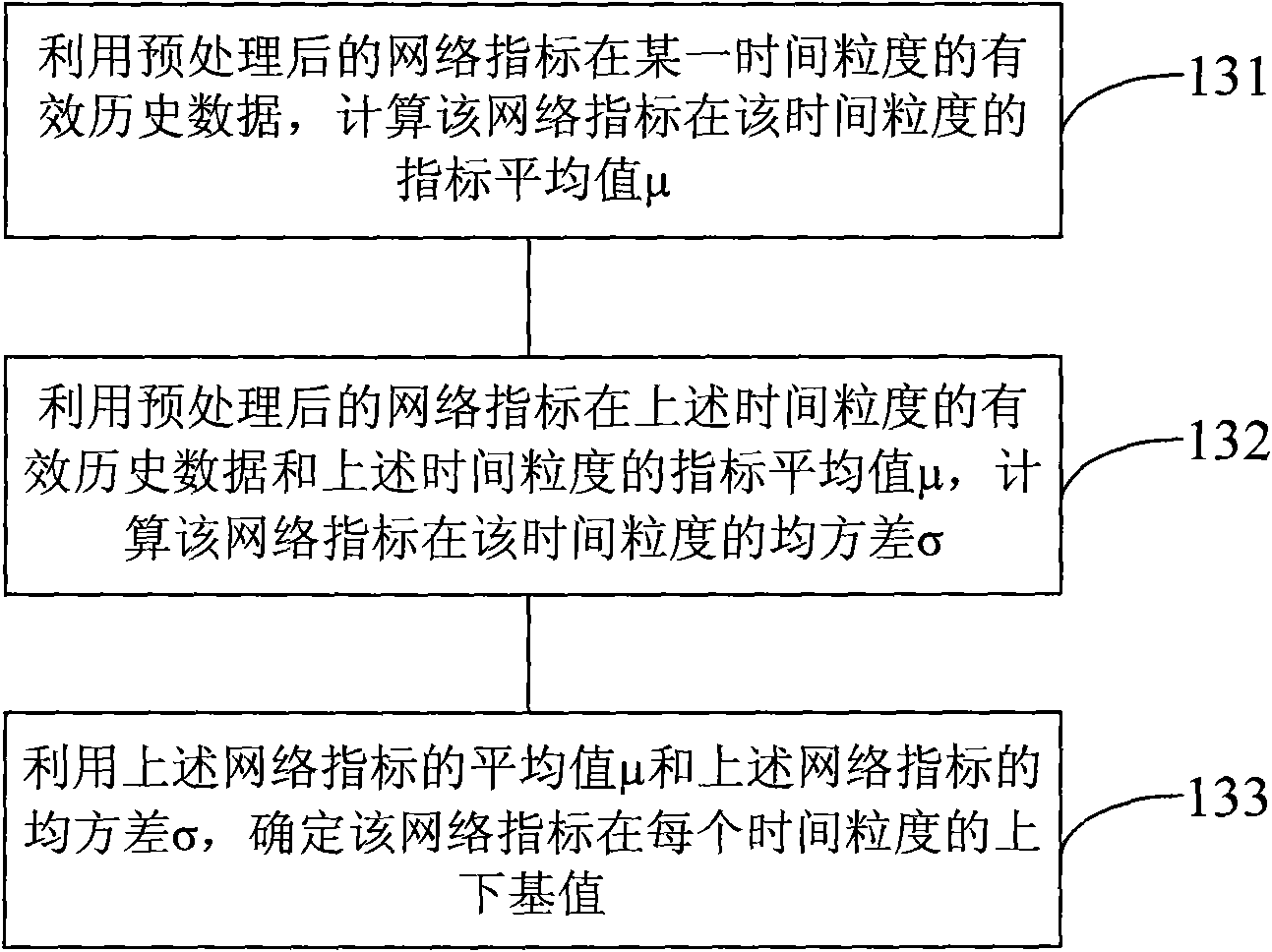

The invention provides a method and device for monitoring and controlling network risks. The method comprises the following steps: step one, selecting the sample space of network objectives of some network element (NE), carrying out statistic analysis on the sample point data of the sample space, and calculating a dynamic baseline, wherein the network objectives comply with a normal distribution character; step two, according to preset tolerability and the dynamic baseline, determining the upper tolerance limit and the lower tolerance limit of the network objectives as early warning thresholds for triggering an early warning generating mechanism of the predictive network objectives; and step three, judging whether values of the predictive network objectives which are monitored and controlled in real time exceed the early warning thresholds; and if the values exceed the early warning thresholds, triggering the early warning generating mechanism. By realizing a dynamic threshold method, the threshold values can be set more reasonably and accurately, multiple early warning grades can be triggered, accurate monitoring and control for networks is reached, hidden failures in the networks are found, and finally after-event problem analysis of the prior art for the network failures is changed into initiative monitoring and controlling of the network objectives before problems generate, thus effectively ensuring the normal operation of the networks.

Owner:成都亿阳信通信息技术有限公司

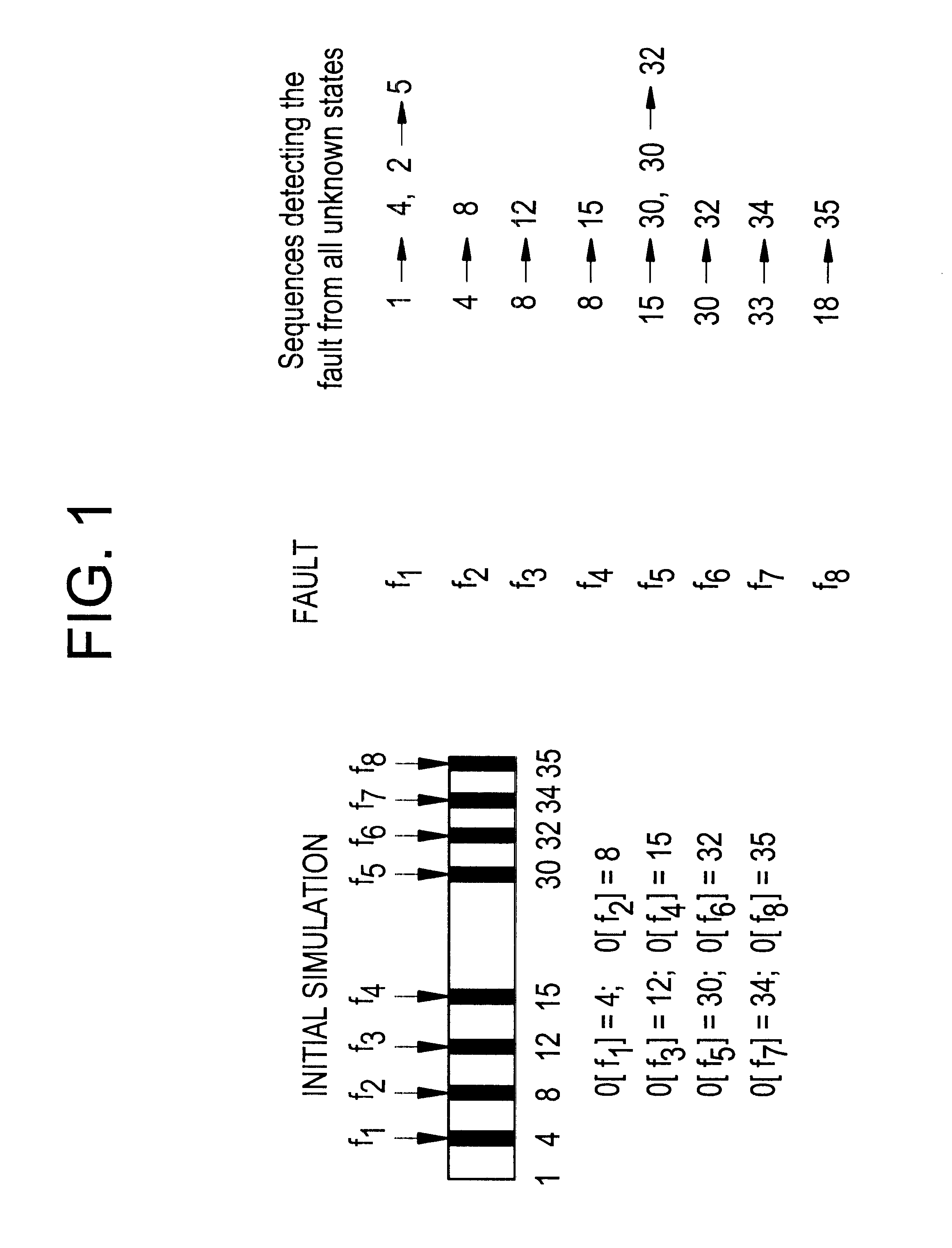

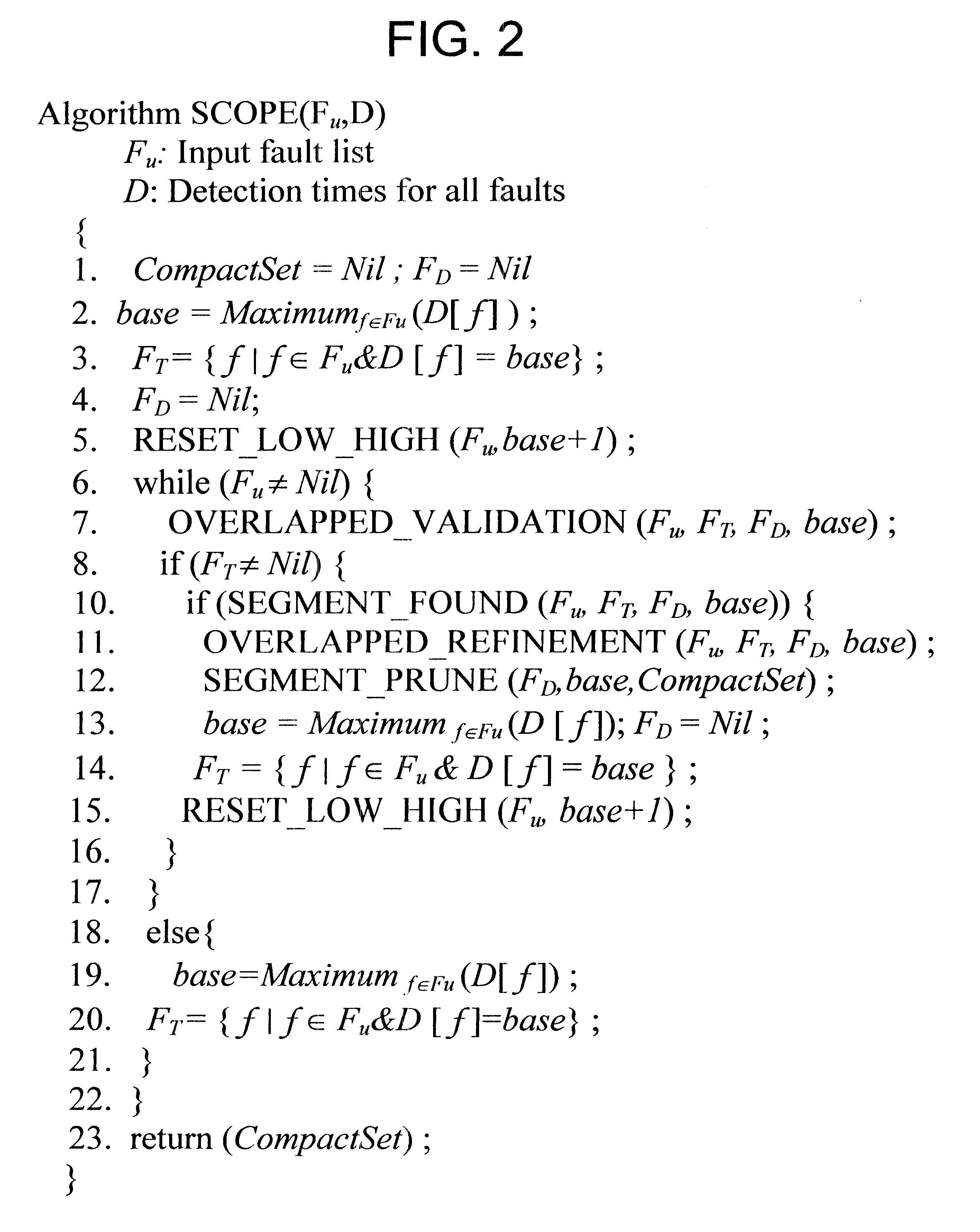

Segmented compaction with pruning and critical fault elimination

InactiveUS6467058B1Electronic circuit testingDetecting faulty computer hardwareTolerance limitFault modeling

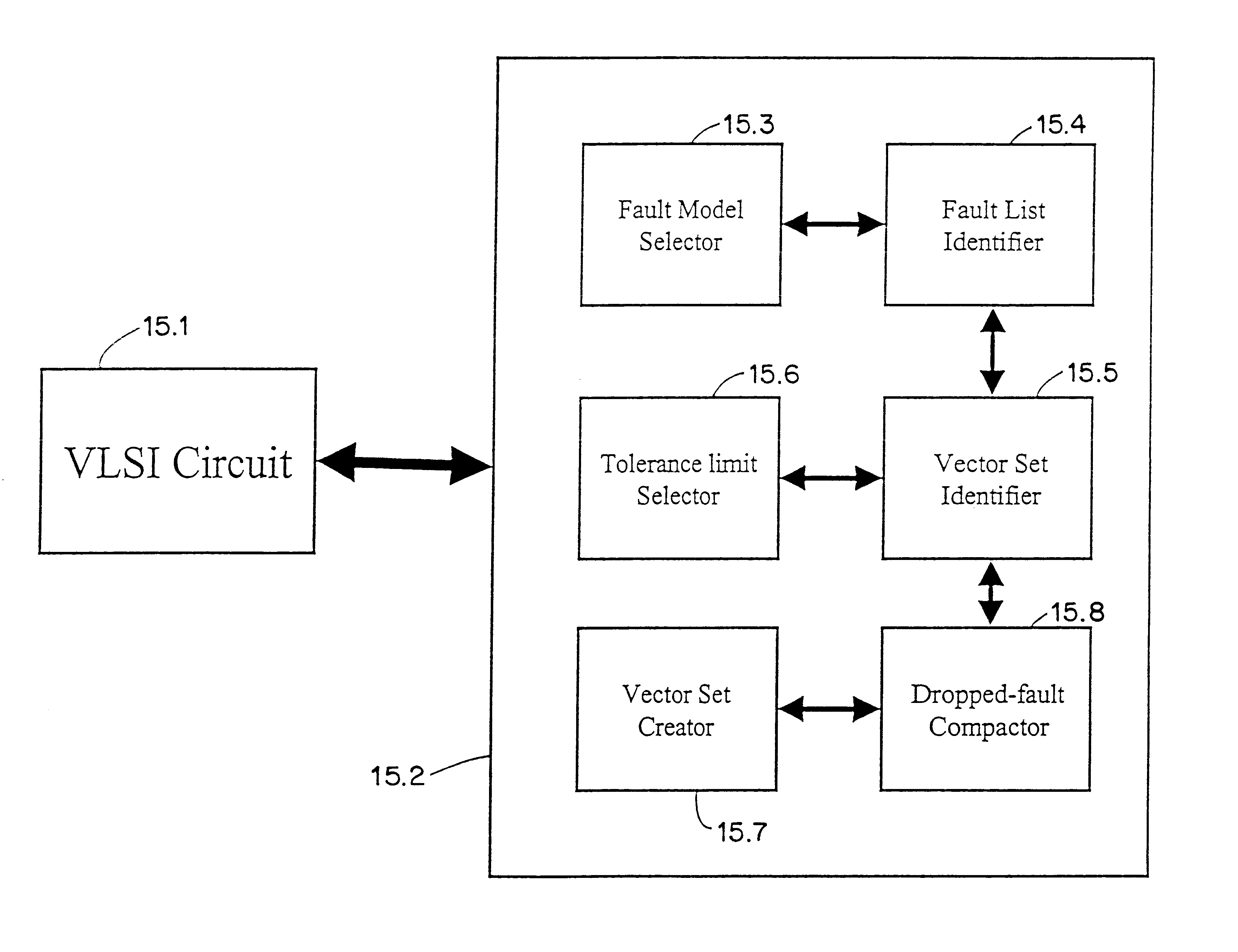

A method of generating a vector set, said vector set being used for testing sequential circuits. The method comprises selecting a plurality of fault models, identifying a fault list each for each of said plurality of fault models, identifying a vector set each for each of said fault lists, selecting a tolerance limit each for each of said fault lists, thereby each fault model having an associated fault list, an associated vector set and an associated tolerance limit, compacting each of said vector set such that the compacted vector set identifies all the faults in the associated fault list or a drop in fault list coverage is within the associated tolerance limit; and creating a vector set by combining all vector sets compacted. A system and a computer program product for testing circuits with a compacted vector set where the compacted vector set is created by dropping faults based on a tolerance limit.

Owner:NEC CORP

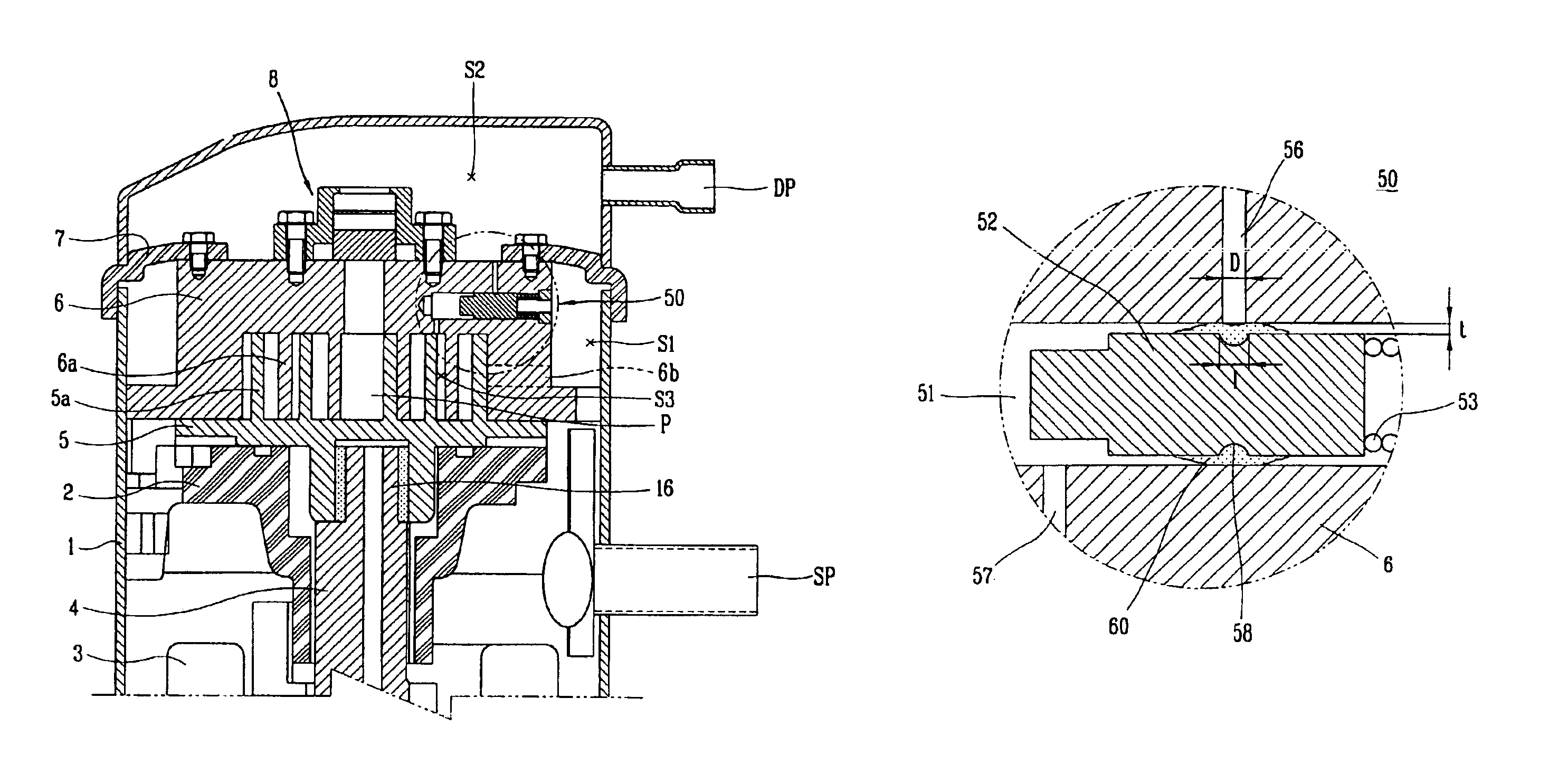

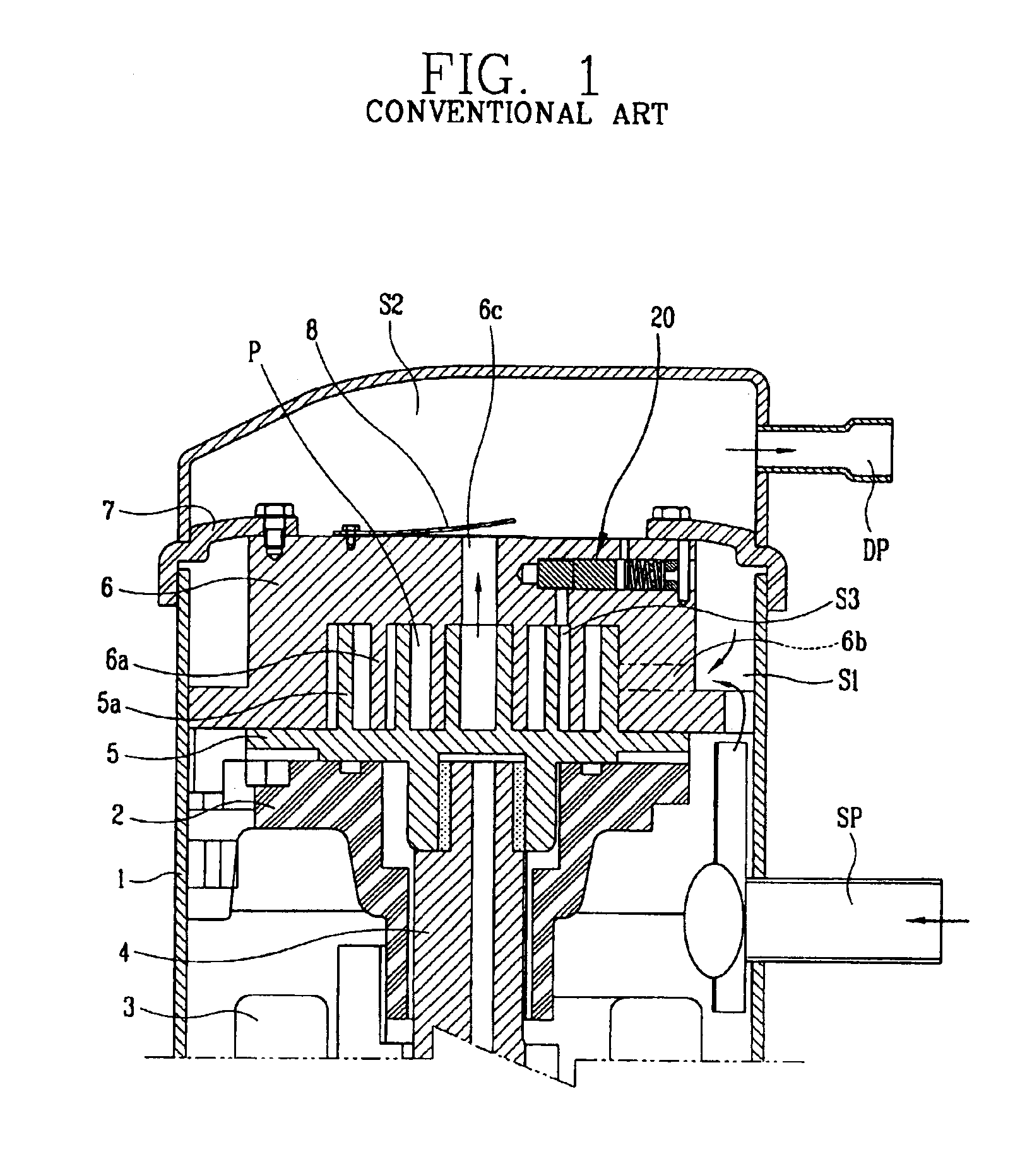

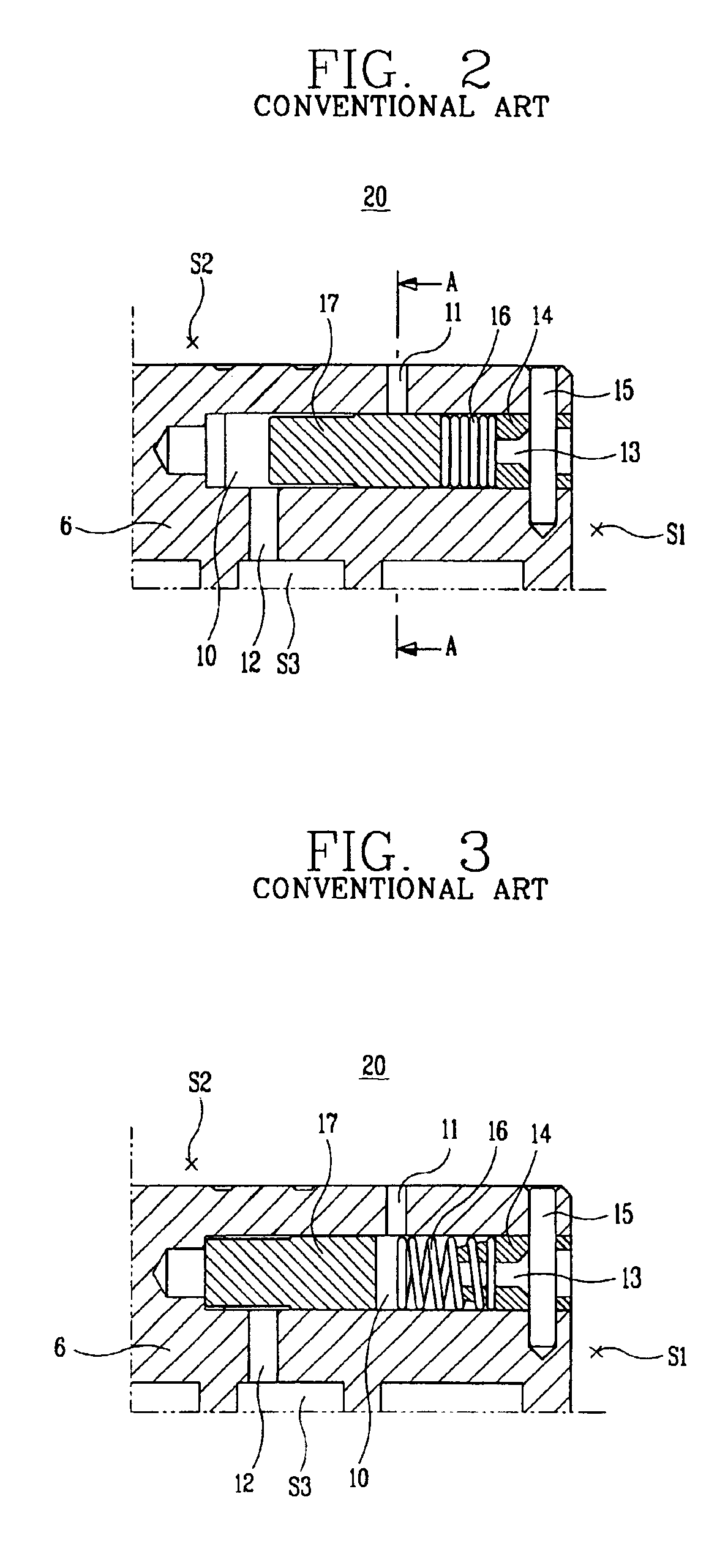

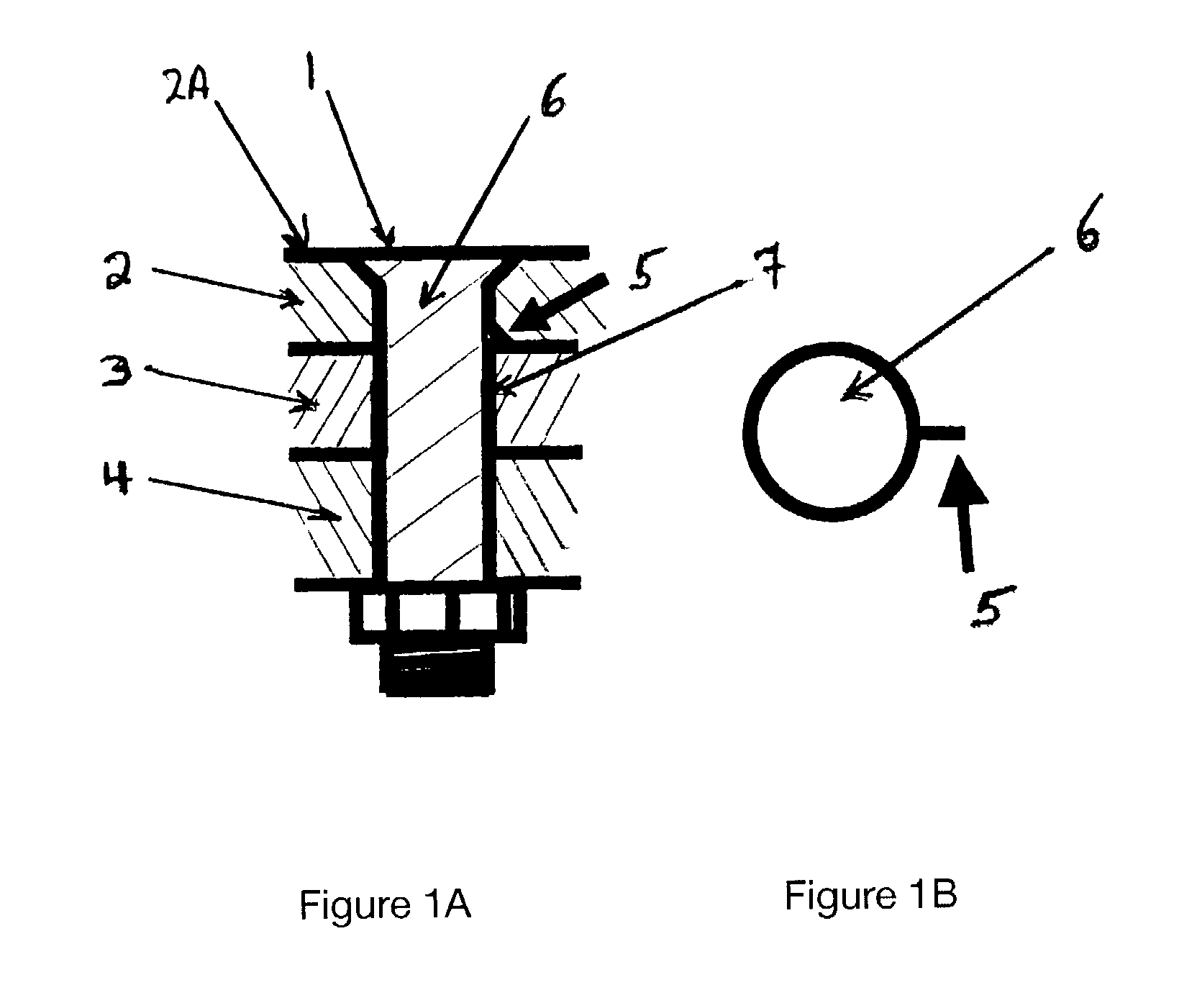

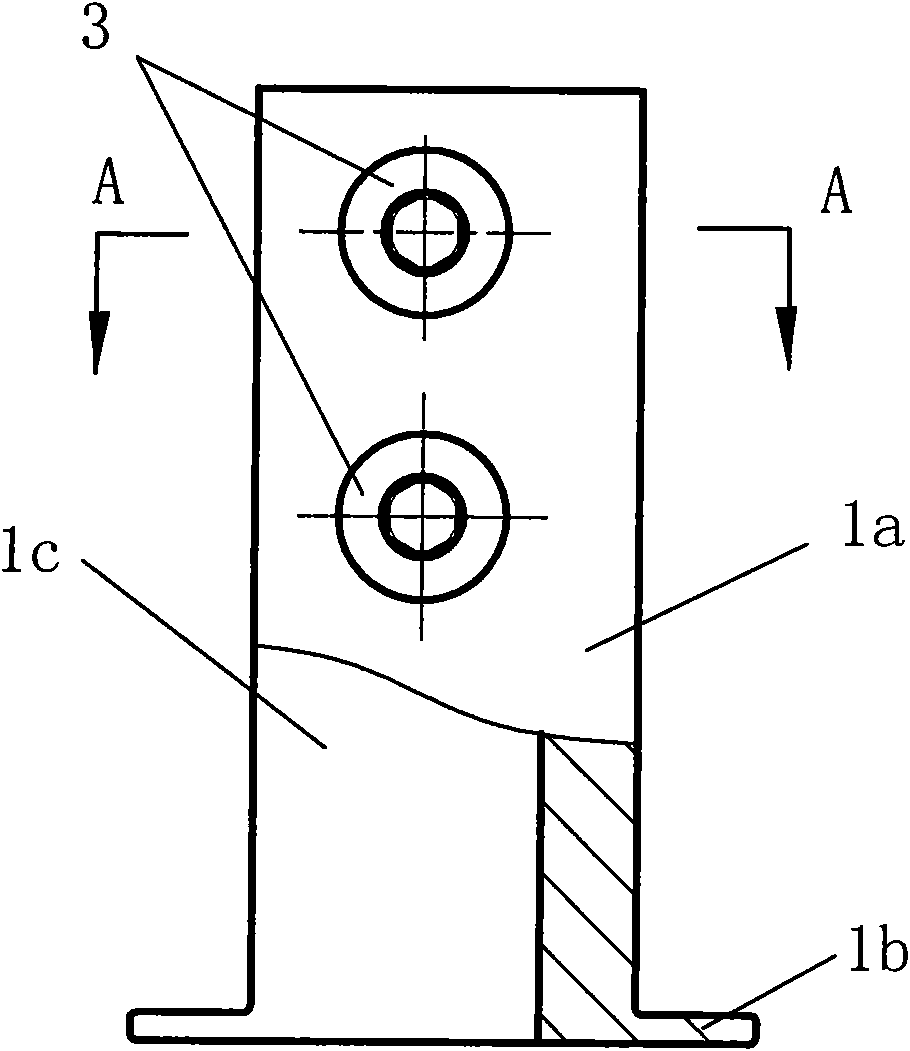

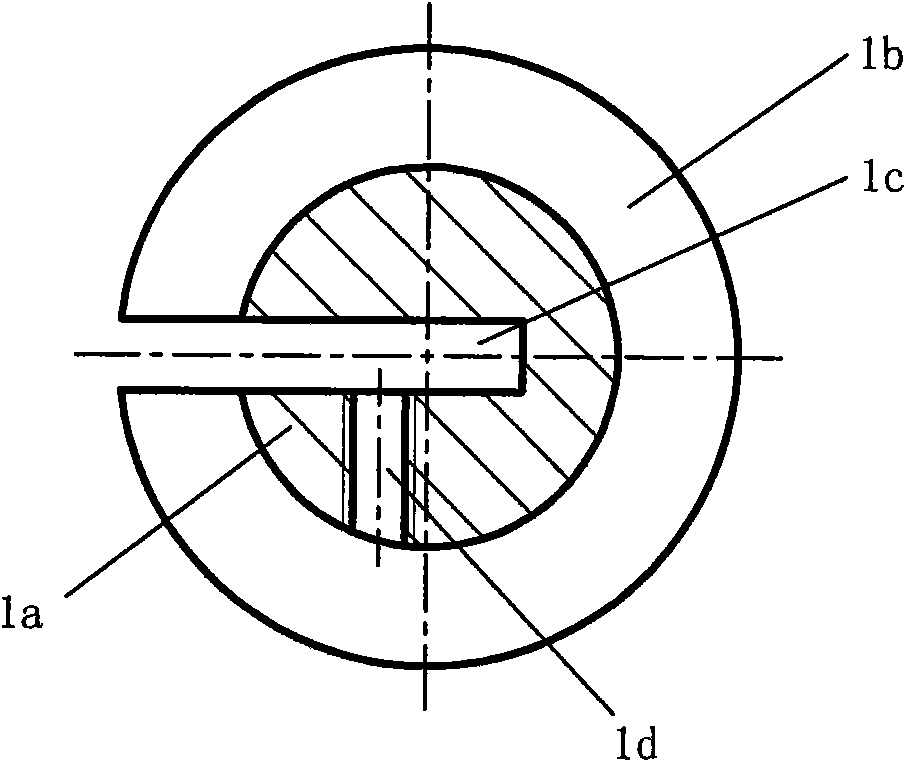

Vacuum preventing oil seal for scroll compressor

InactiveUS6863510B2Prevent gas leakageIncrease freedomRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeManufacturing cost reductionTolerance limit

Disclosed is a vacuum preventing device for a scroll compressor comprising: a chamber formed at one side of a fixed scroll and having a suction hole, a compression hole, and a discharge hole at an inner circumference surface thereof; an open / close member installed in the chamber and having a seal oil groove at an outer circumference surface thereof for selectively connecting the discharge hole to the suction hole; and an elasticity member installed in the chamber for providing an elasticity force to the open / close member. The device can enhance a compression efficiency of the compressor by preventing gas leakage efficiently and reduce a fabricating cost by improving a design of a clearance and enhancing a tolerance limit range.

Owner:LG ELECTRONICS INC

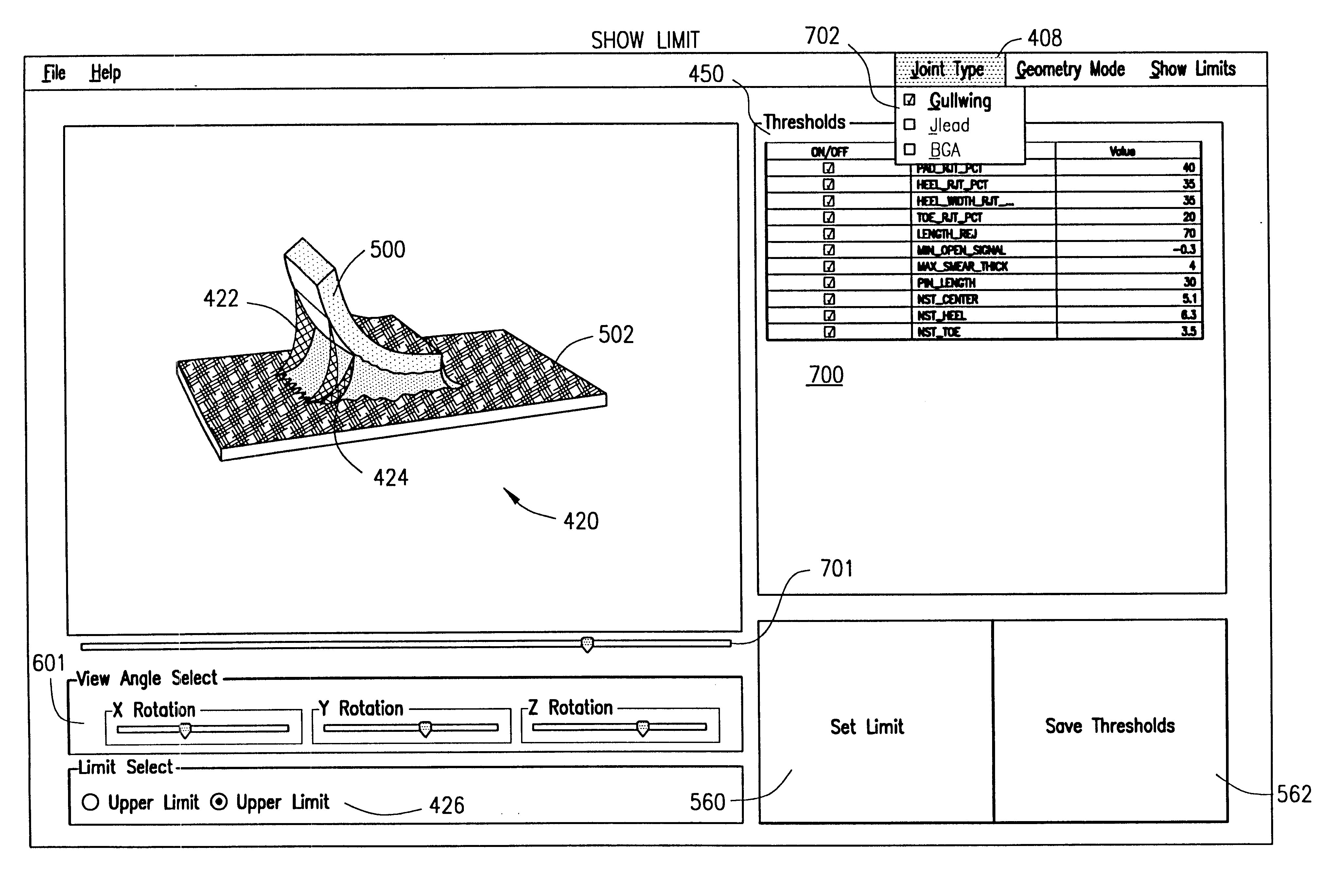

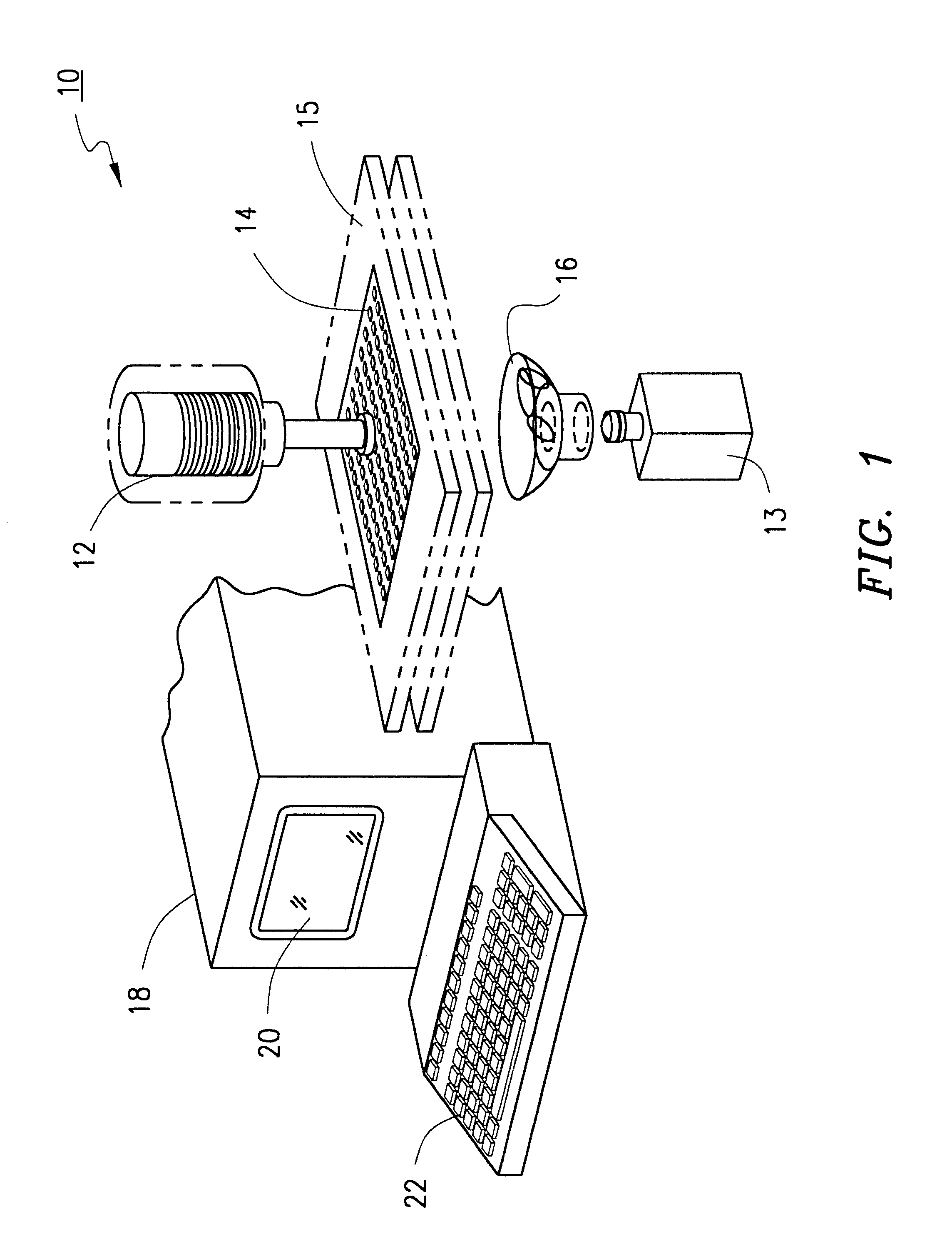

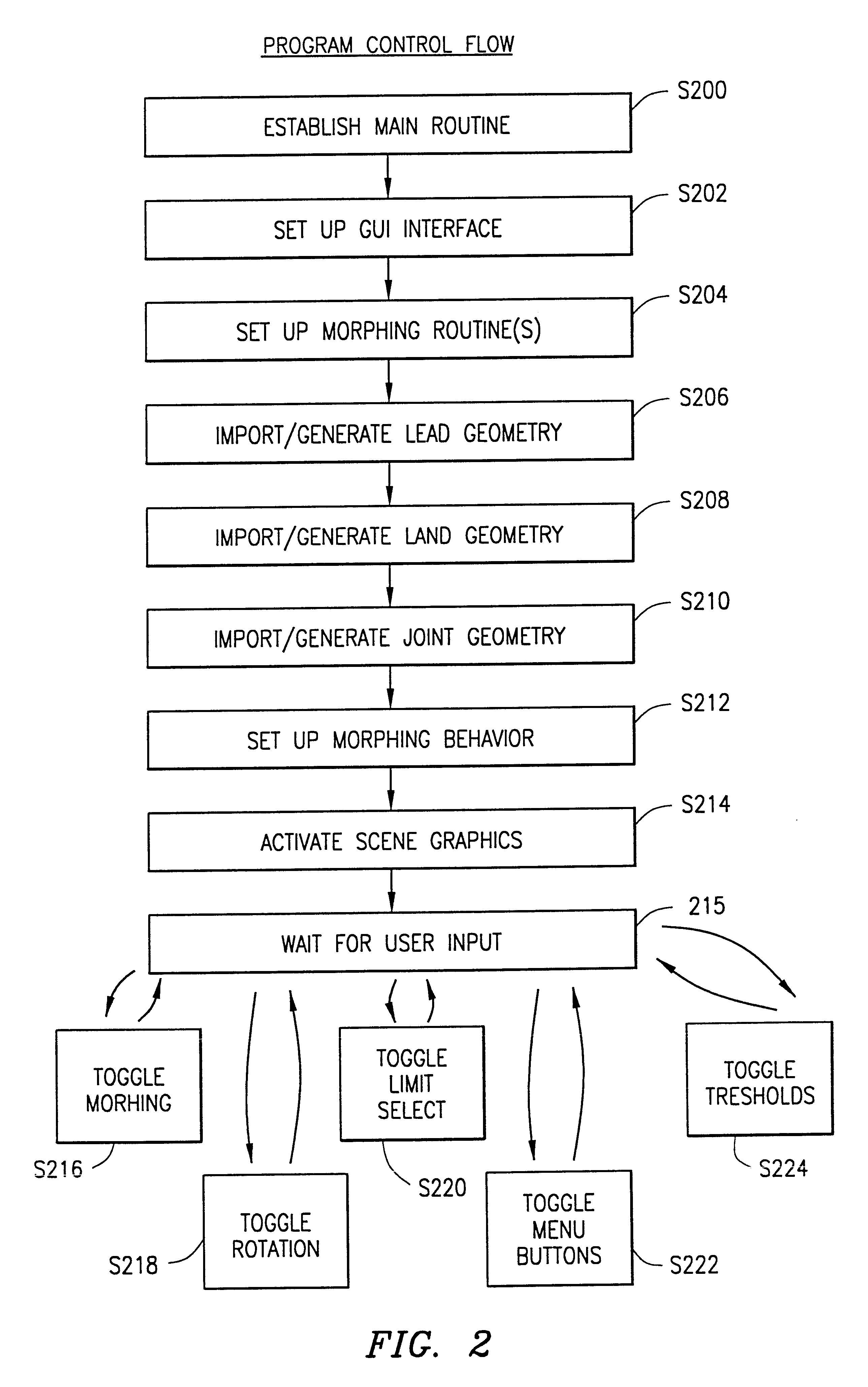

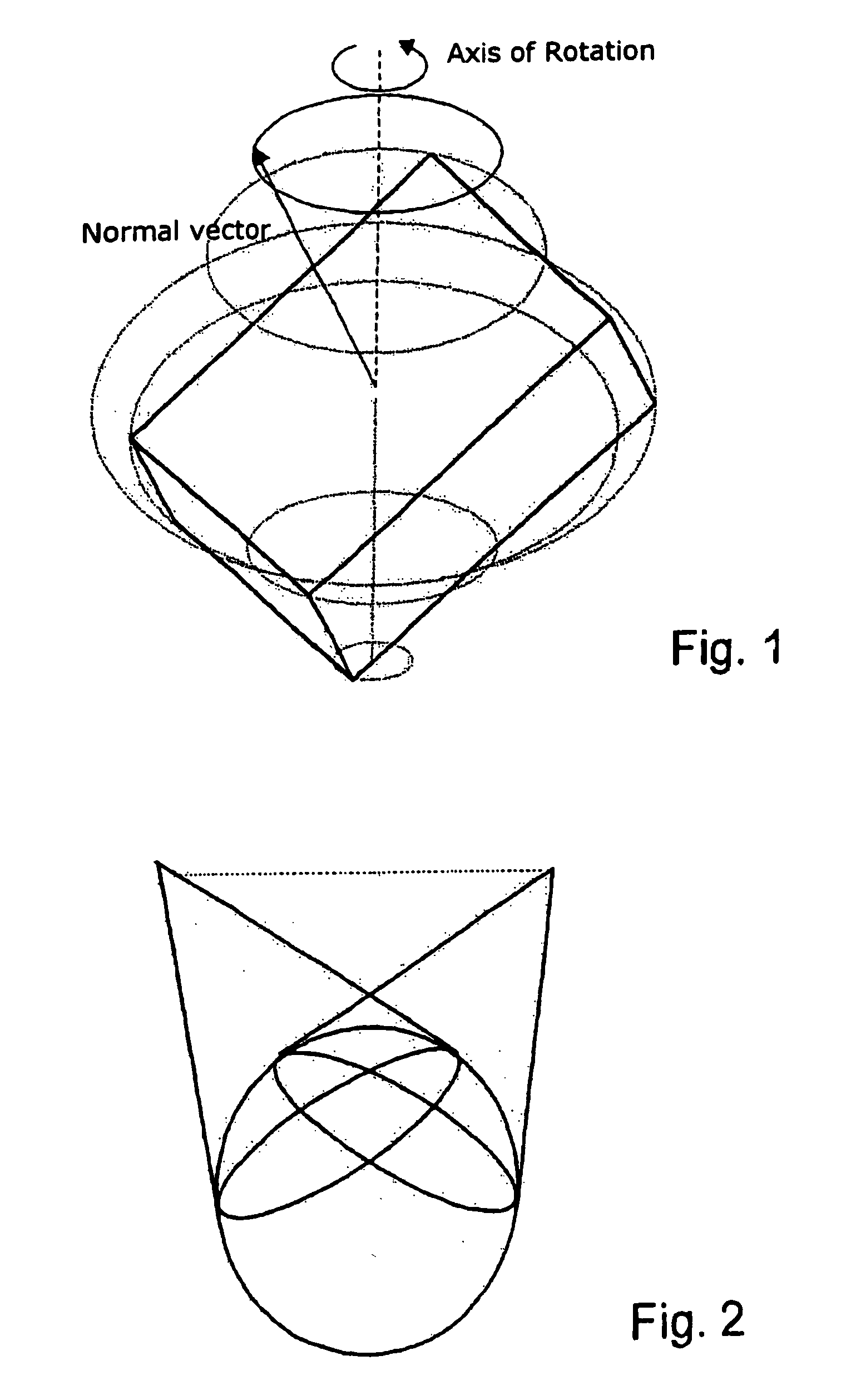

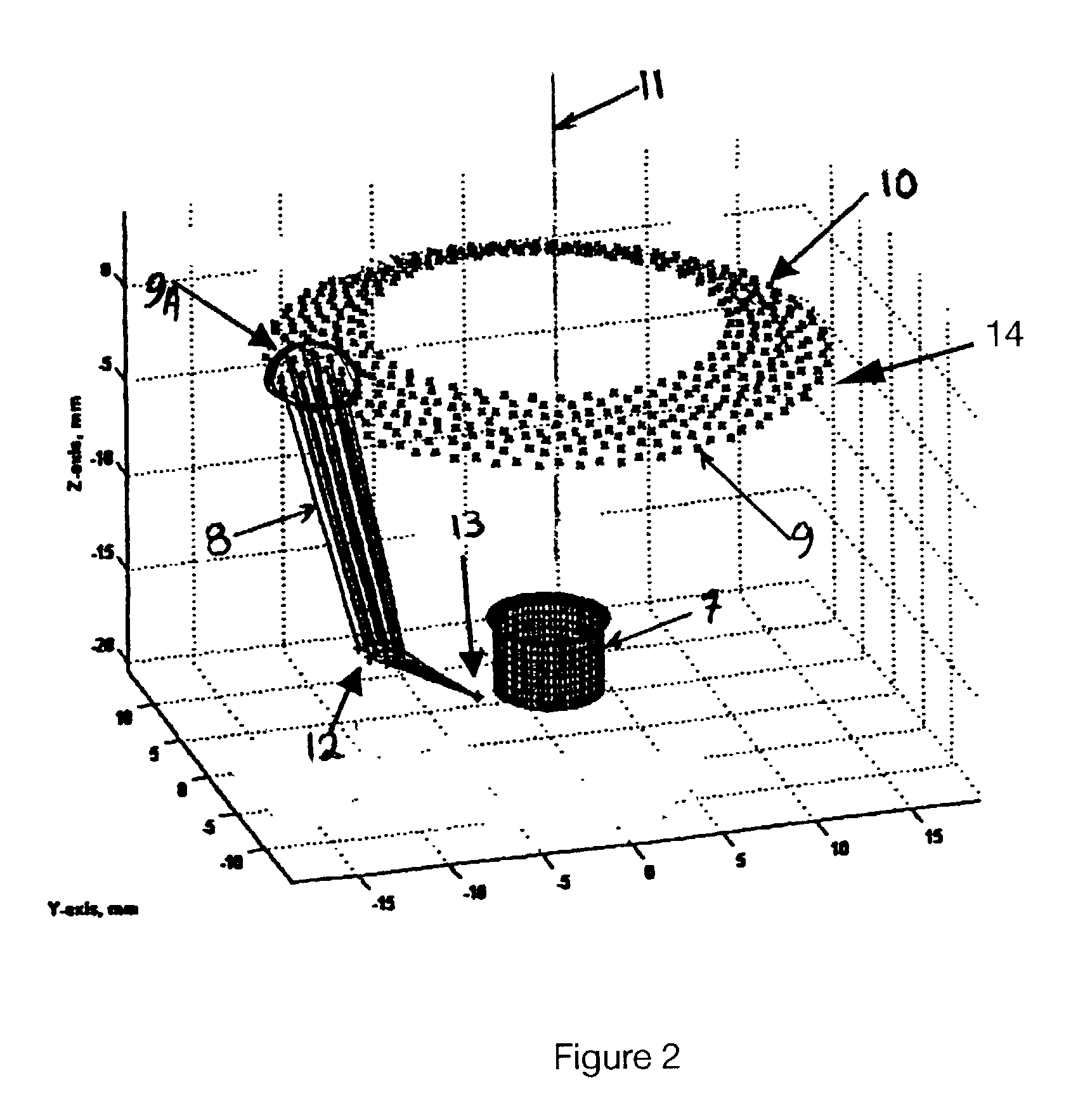

Method and apparatus for extracting measurement information and setting specifications using three dimensional visualization

The present invention provides an apparatus and method for viewing a depiction of an object (for example a solder joint) in a multi-dimensional manner, morphing the object's depiction using a graphical user interface to upper and lower acceptable tolerance limits and storing the tolerance limits for use in a test / inspection apparatus. The invention relates to the translation of human visual inspection-analysis of an object into physical quantifiable parameters used in an inspection device via a graphical user interface.

Owner:AGILENT TECH INC

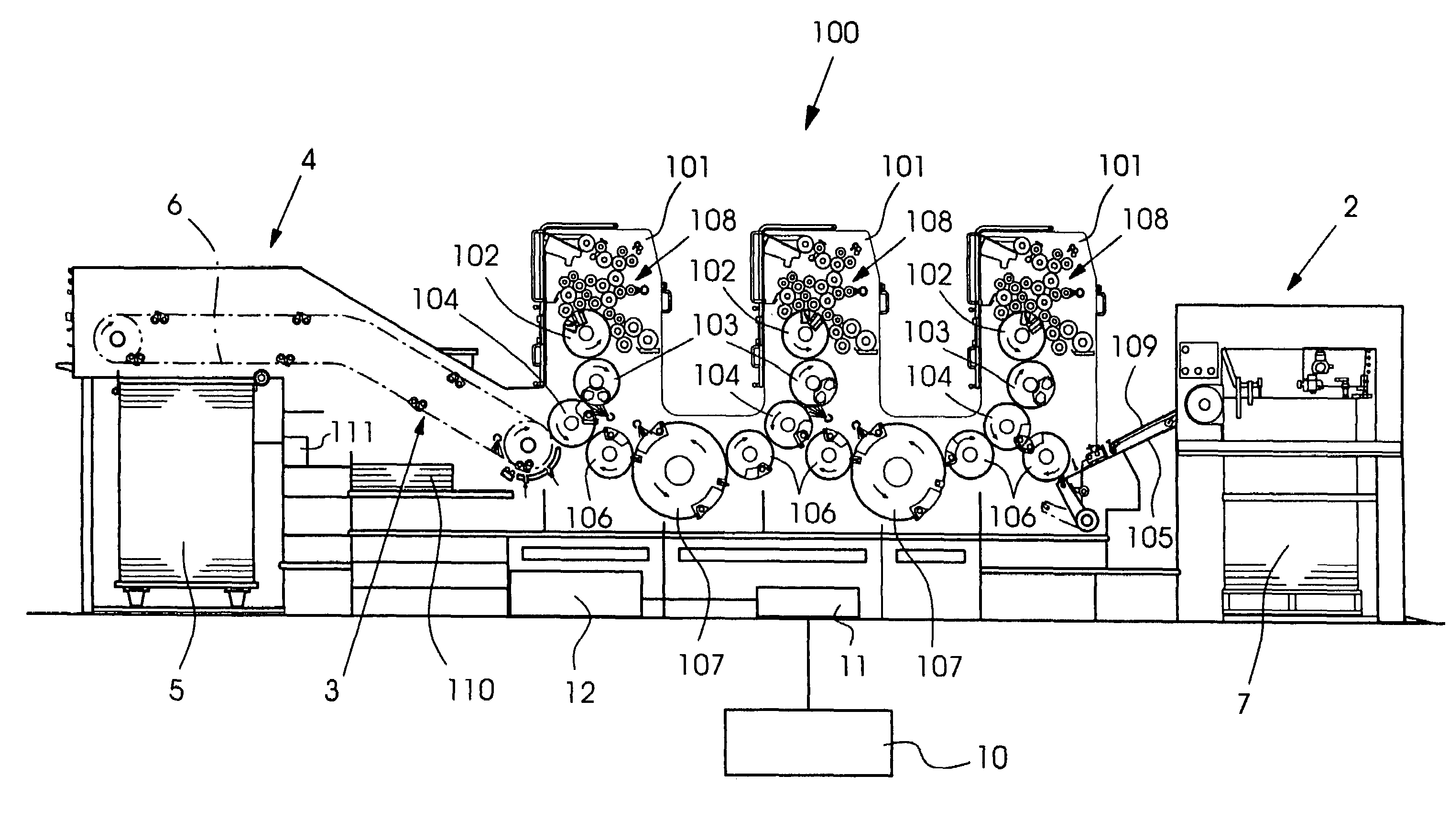

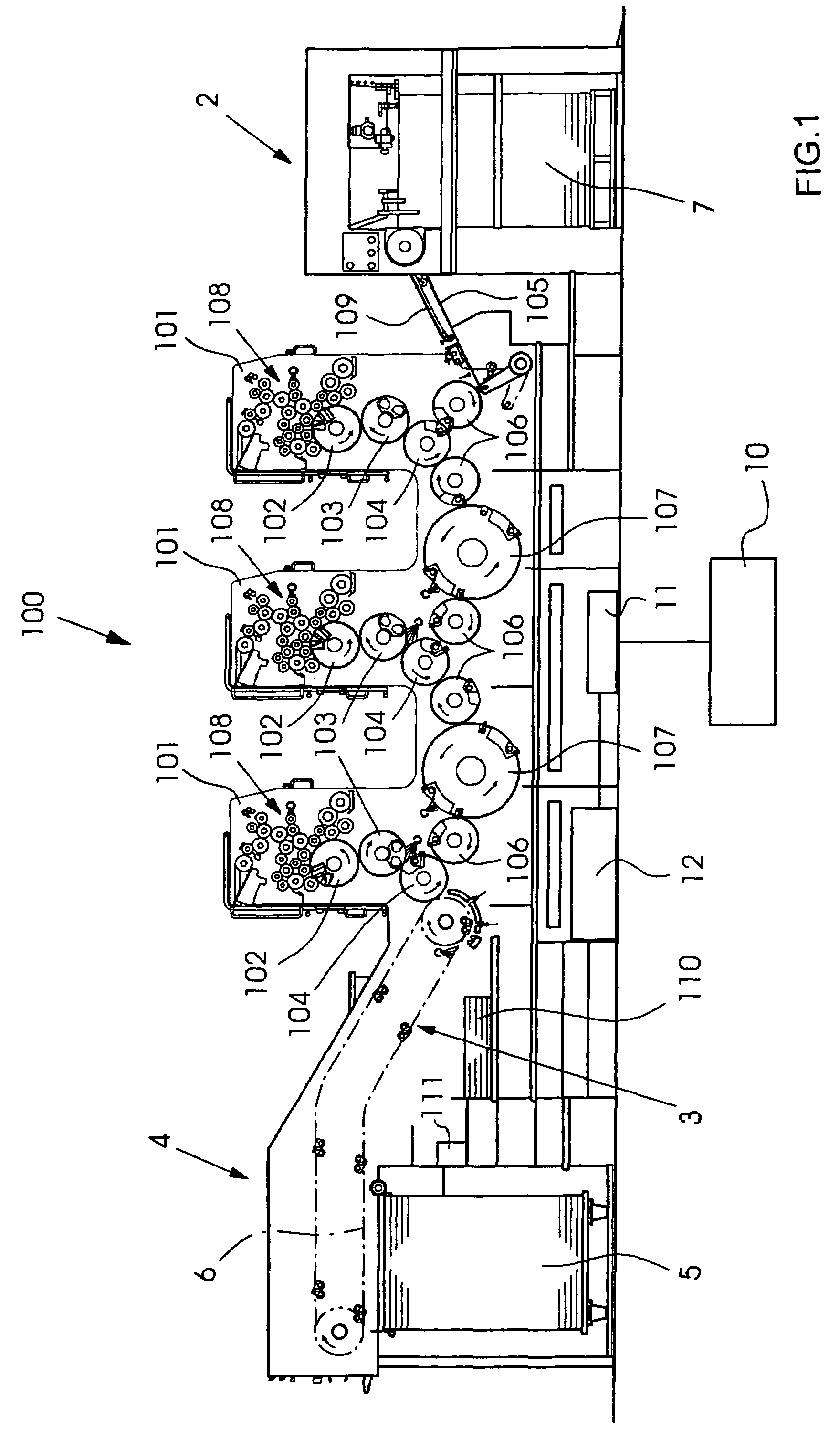

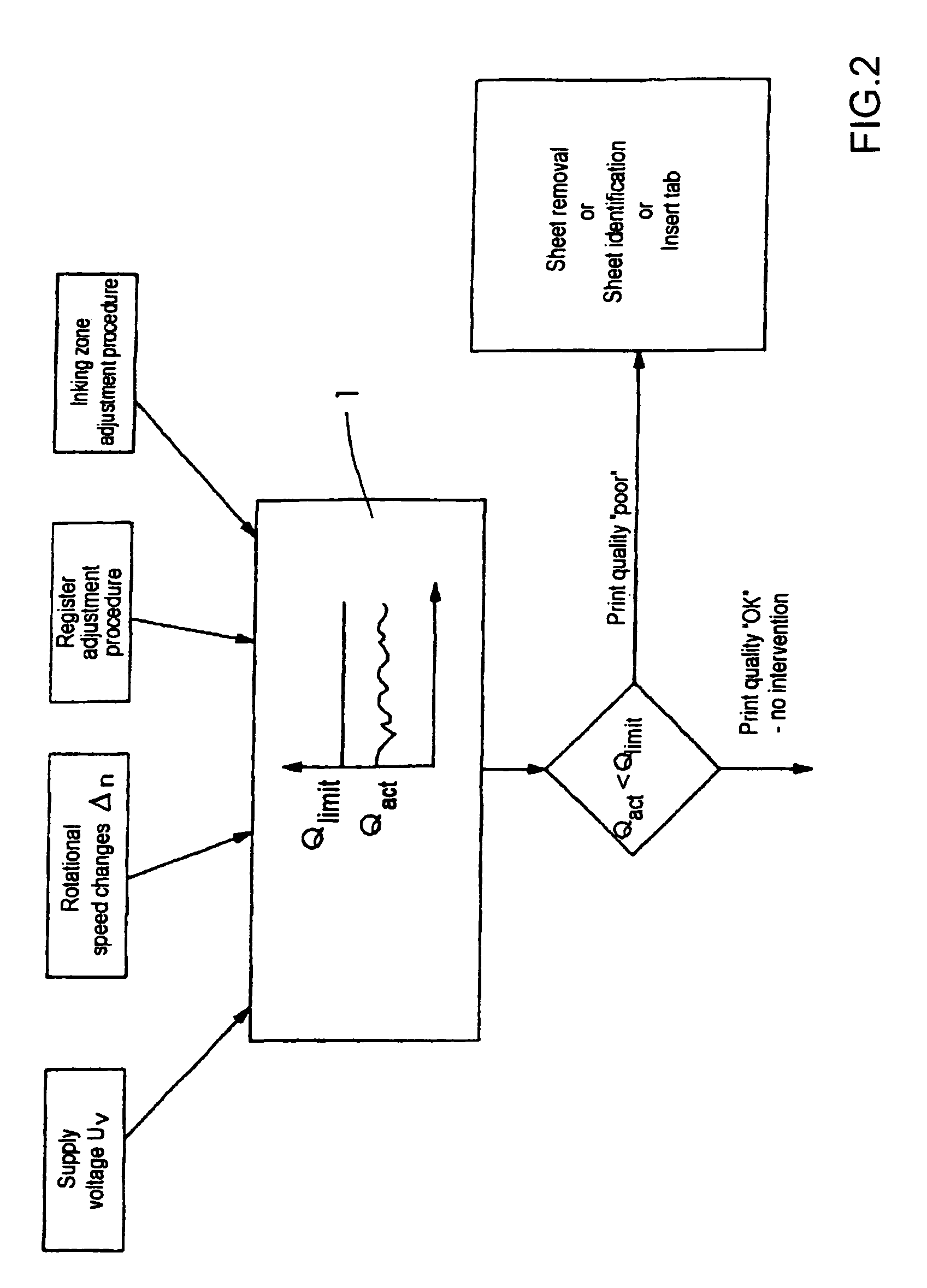

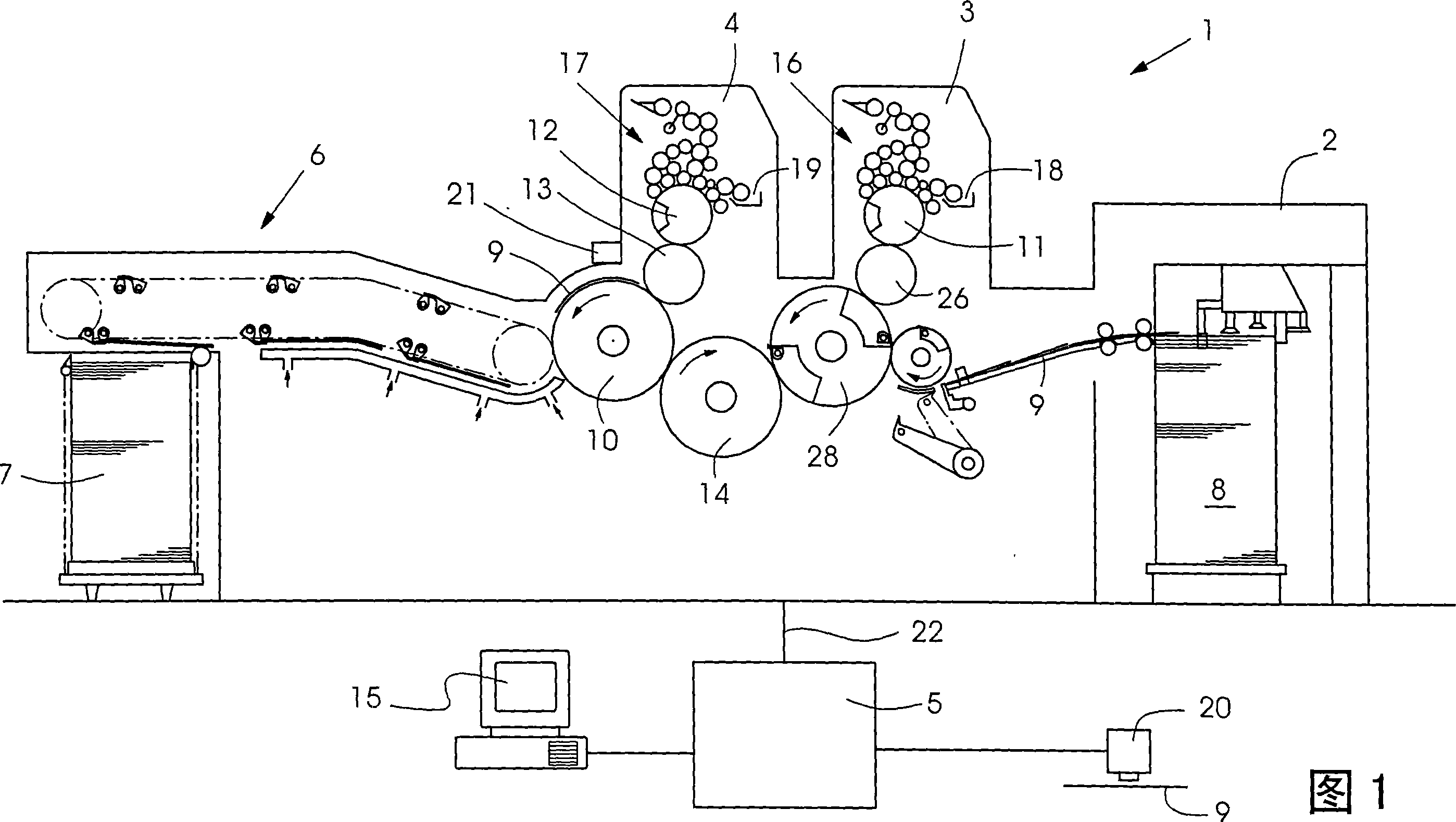

Method for selecting printing material in a printing press and printing press

InactiveUS7287473B2Accurate predictionEasy to separateAddressographsPlaten pressesTolerance limitPrinting press

An apparatus and a method for the selection of printing materials in a machine processing printing materials has at least one control computer. The operating data of the machine processing the printing materials is logged by the computer and a tolerance limit corresponding to the operating data registered is stored in the computer. When the tolerance limit is exceeded during a time interval, the printing materials produced in this time interval are registered in the control computer.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

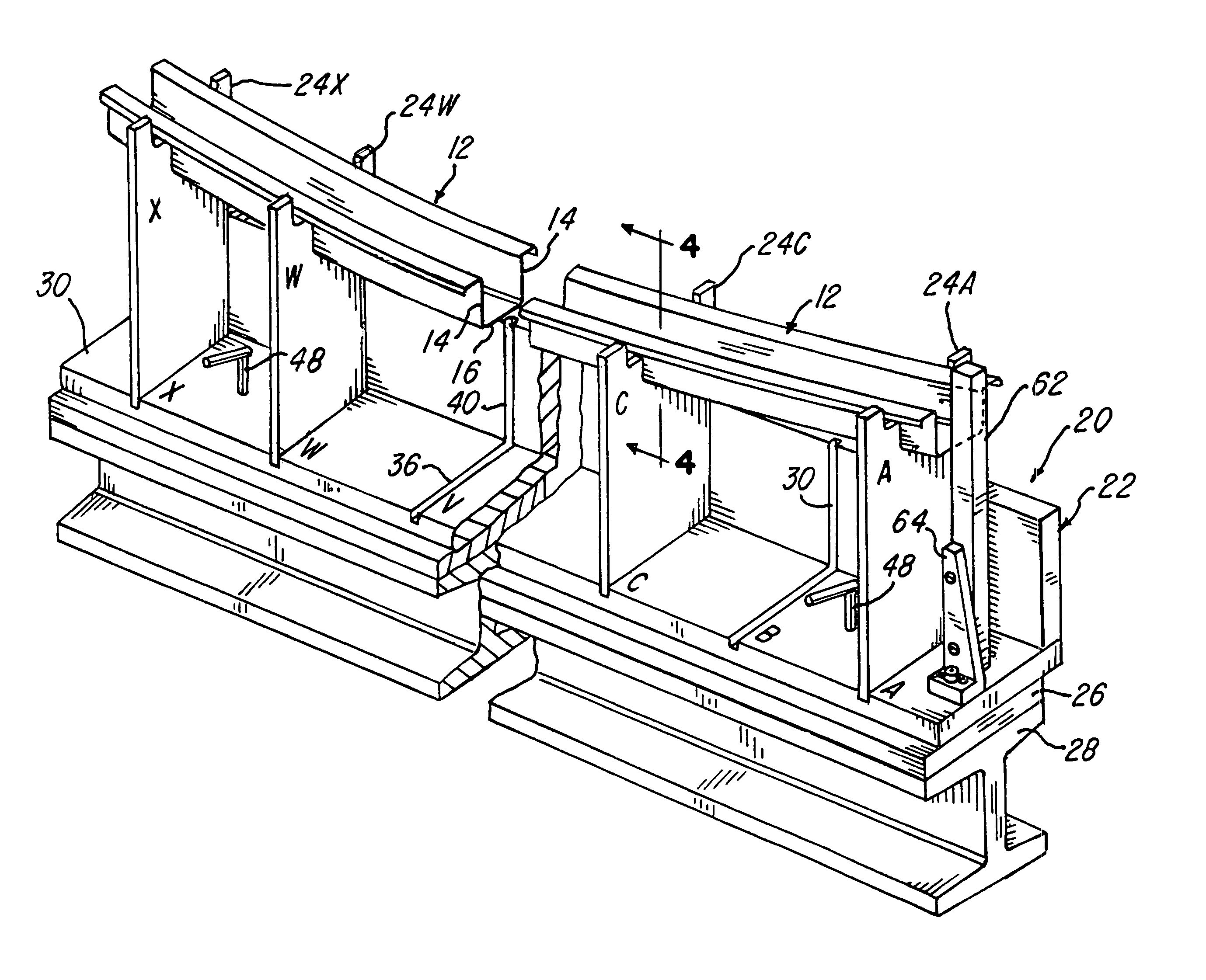

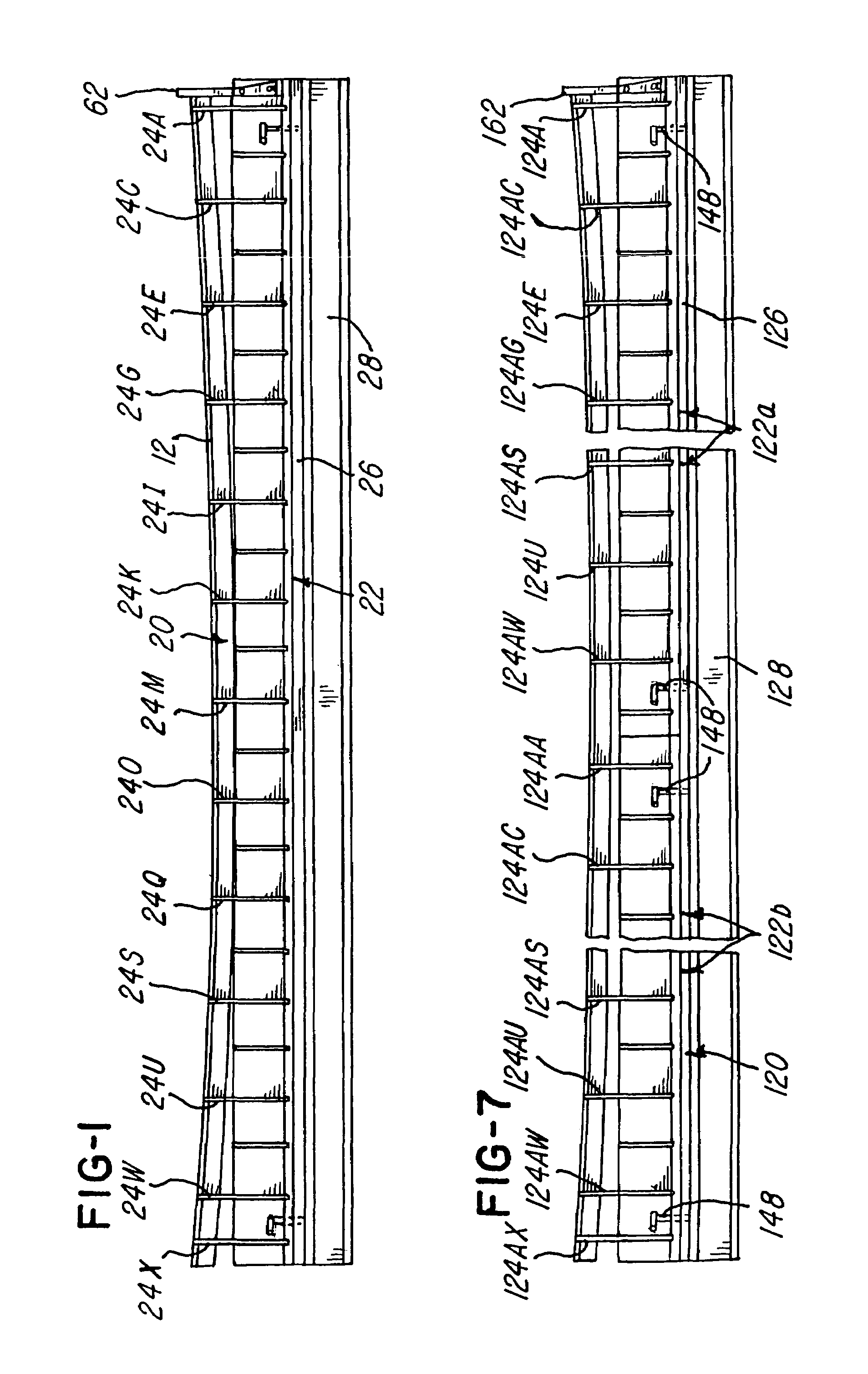

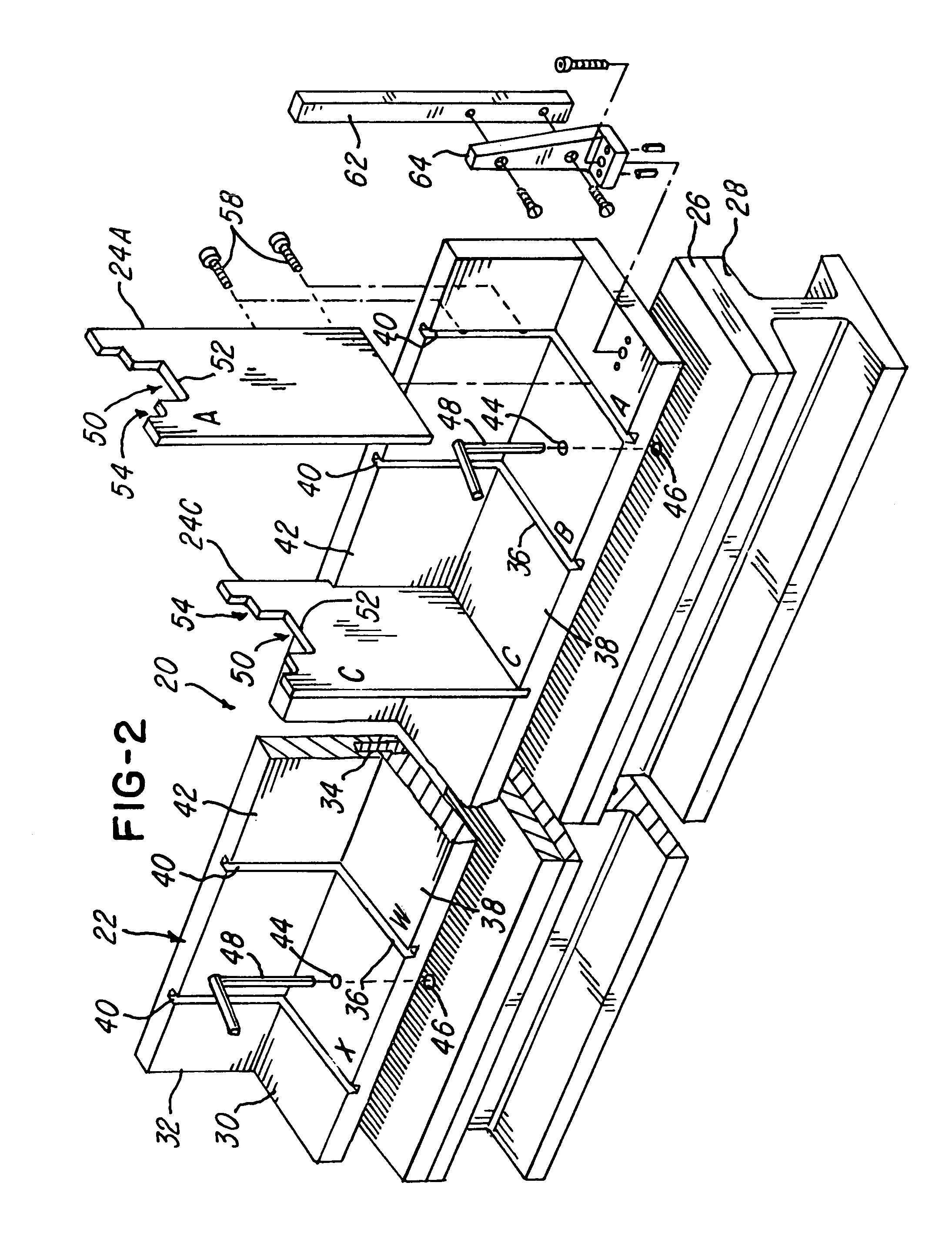

Stringer check fixture and method

An aircraft frame stringer is checked against designed specifications using a set of templates with stringer-engaging, upwardly-facing surfaces that match the designed contours of sections of the stringer at different locations along the length of the stringer. The templates are removably supported in mutually aligned and spaced relationship on a base assembly. The stringer is placed on the templates and measurements are made to determine if the stringer contours at the different locations match, within acceptable tolerance limits, the template contours at those locations. A computer model is used to determine the contours of the sections of the stringer at the desired locations thereon and to control the operation of a CNC machine for machining the templates.

Owner:ROLL FORMING CORP

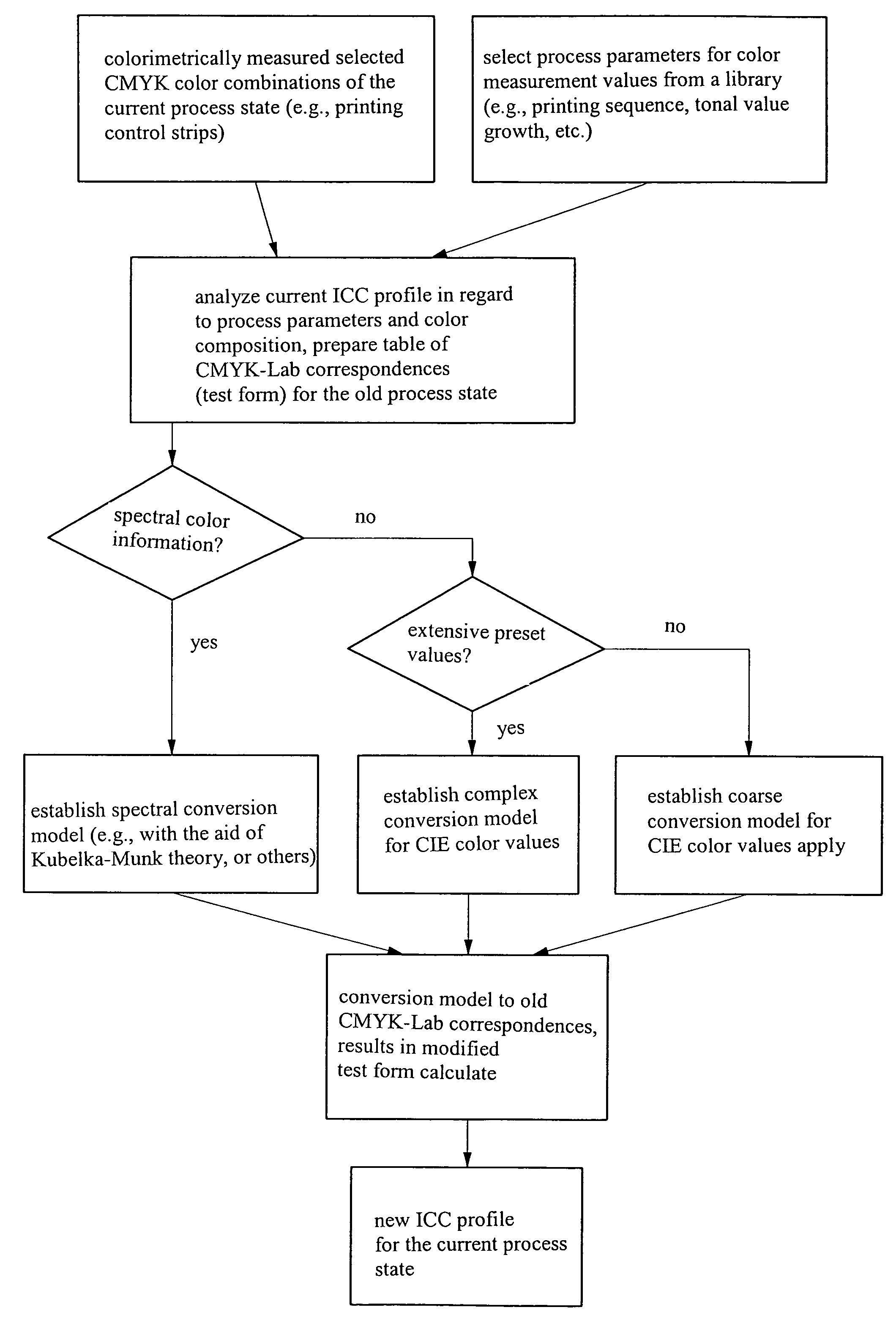

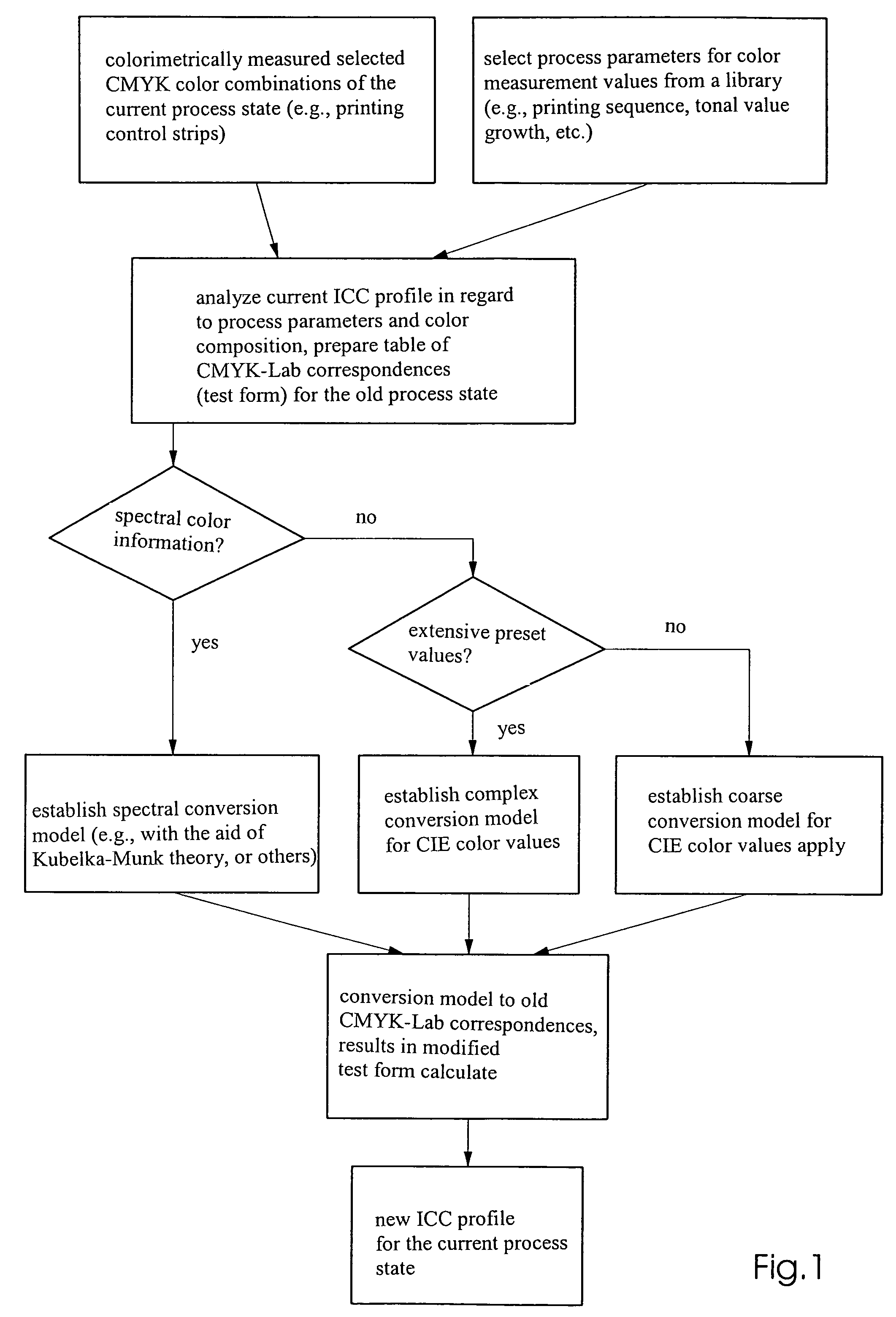

Method for correcting unadjusted printing data on the basis of colormetrically measured reference sheet

InactiveUS7307755B2Avoid unnecessary wasteGuaranteed predictive effectDigitally marking record carriersDigital computer detailsTolerance limitPrinting press

A method for correcting digitized image data in the prepress stage when using printing presses having a device-independent color profile in the main printing stage, having the following method steps:colorimetric measurement of a reference sheet and production of an image file in a device-independent color space,conversion of an image file belonging to the reference sheet in a device-dependent color space into a further image file in a device-independent color space using the device-independent color profile belonging to the printing press to be used,comparison of the two device-independent image files.performing alterations on the device-dependent image file associated with the reference sheet or alteration of the printing process in the selected printing press if tolerance limits are exceeded.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

Plating solution for high-speed electrotinning

Owner:HARBIN INST OF TECH

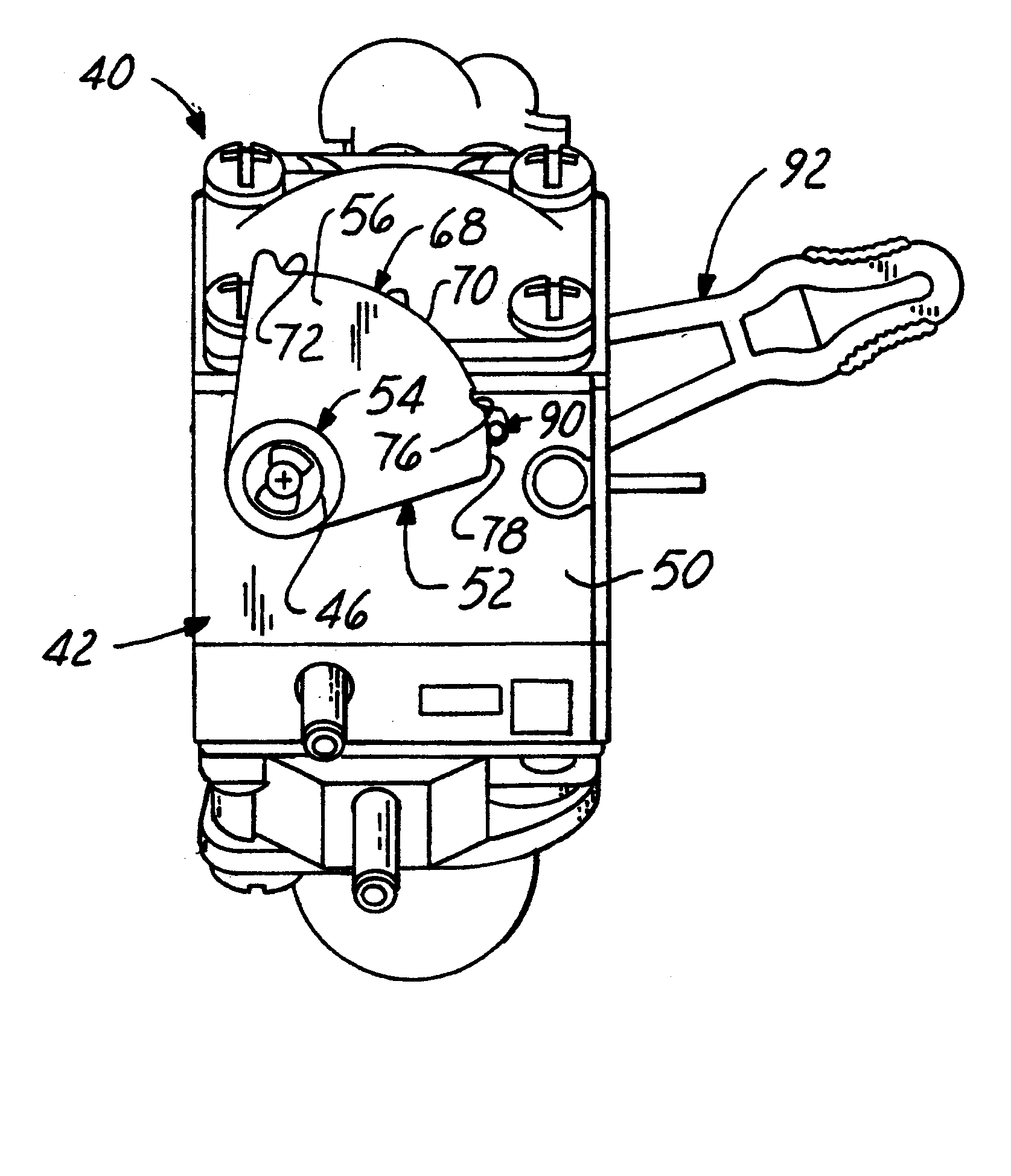

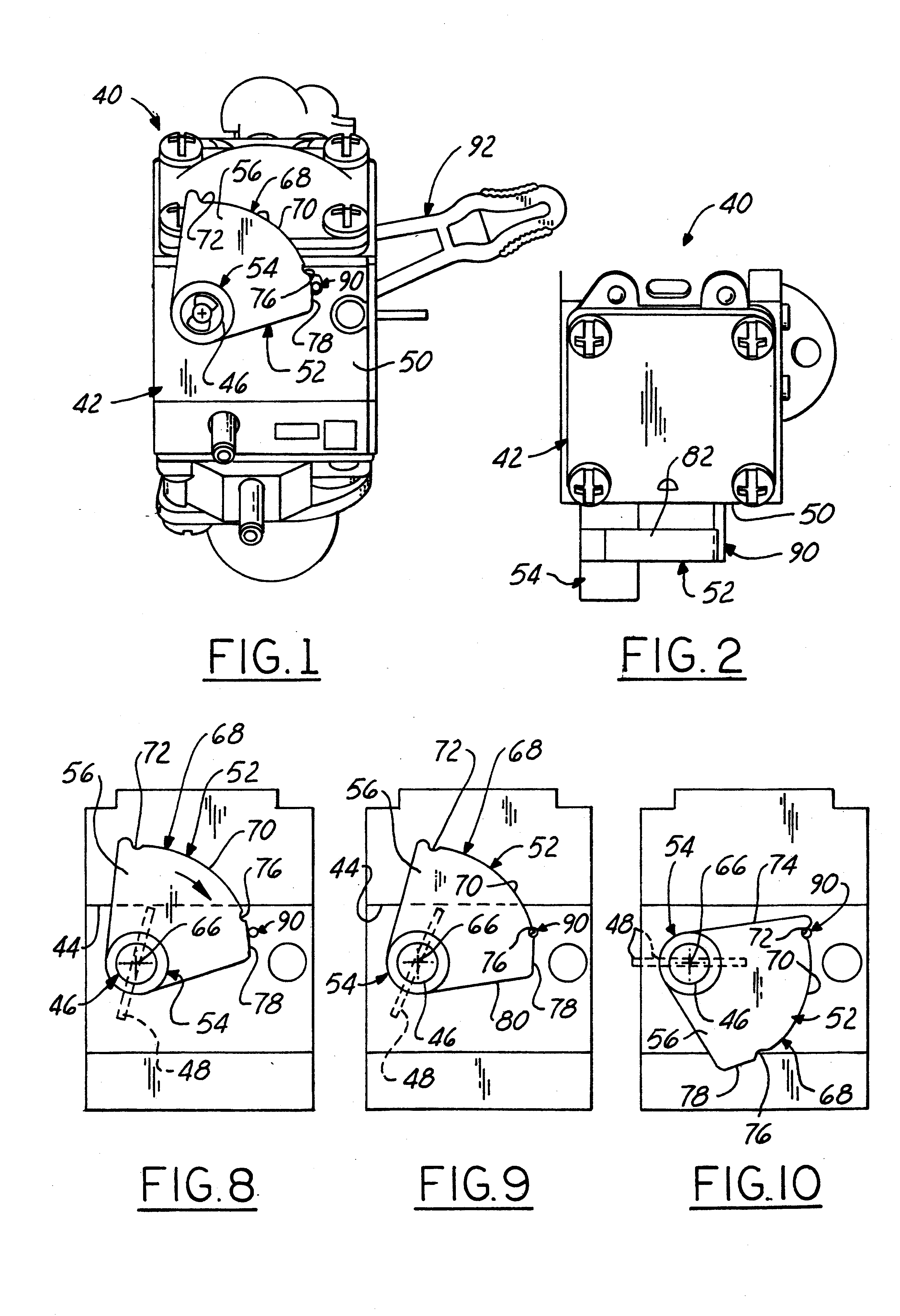

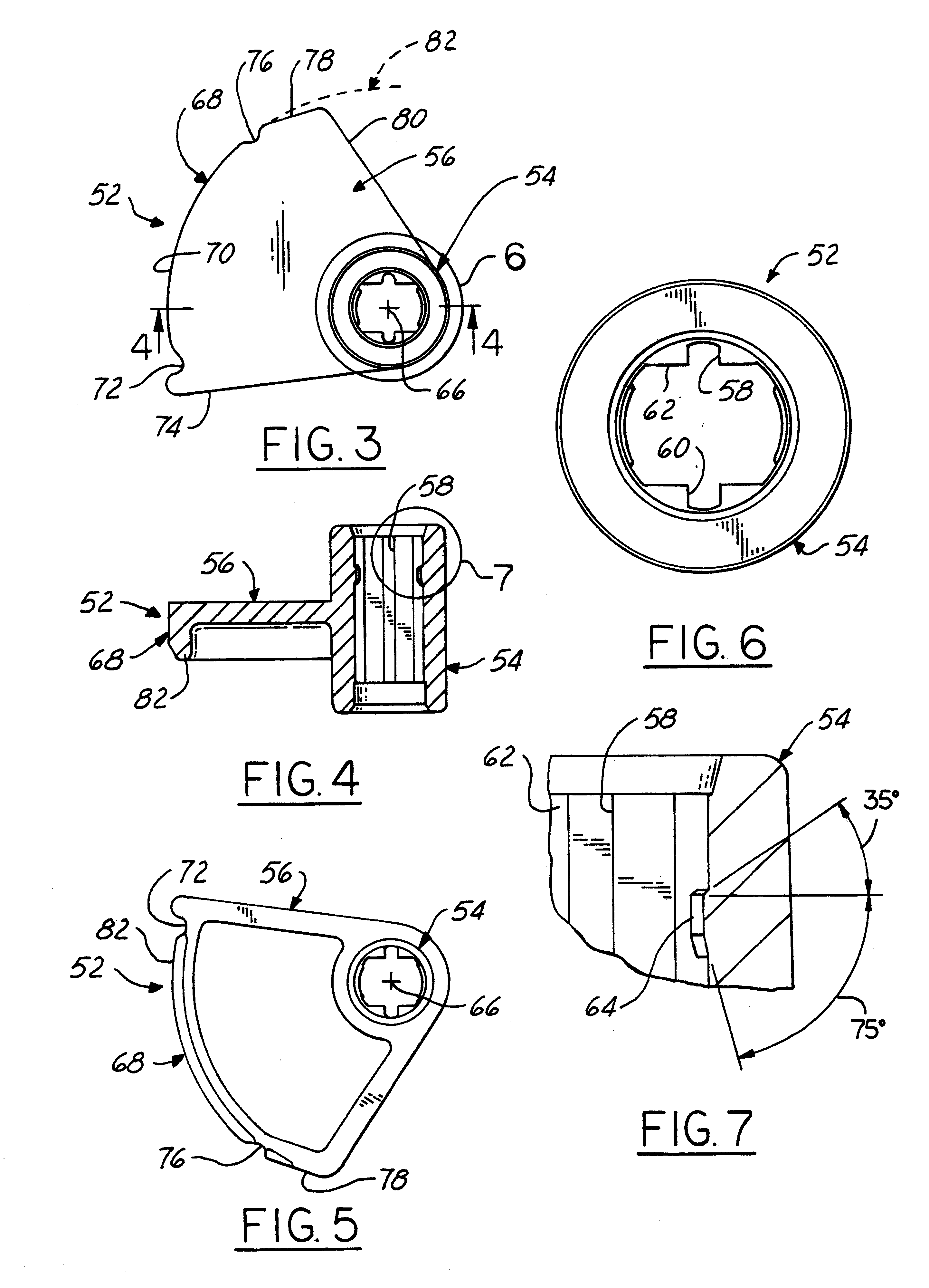

Carburetor throttle control detent mechanism

InactiveUS6561496B2Reduce assemblyLow costLighting and heating apparatusUsing liquid separation agentThrottle controlRotational axis

A carburetor having a throttle valve co-rotatable with a small diameter throttle shaft having a free end protruding from an exterior side surface of the associated carburetor body. A throttle lever detent arm is co-rotatable on and with the throttle shaft free end adjacent each body surface. Interengageable detents on the detent arm and body surface are spaced radially away from the throttle shaft rotational axis by a distance, for example, of about three times the shaft diameter. The arm and body detents are releasably engageable with one another for thereby yieldably holding the detent arm and hence the throttle shaft and associated throttle valve in any one of a plurality of selected angular settings. Hence, the angular tolerance variation on the set positions of the throttle valve blade as controlled by the detents is now, for example, approximately three times more precise so that the tolerance limits for such positions are now rendered three times tighter than otherwise would be possible when utilizing the prior art. Hence manufacturing tolerances do not need to be tightened up in order to achieve the exemplary three-fold improvement in operational tolerances of the carburetor throttle control detent mechanism. The invention thus provides a low cost throttle control detent mechanism that enables fine increment, positive stops at predetermined valve blade settings, such as the W.O.T. (wide-open throttle), idle and closed valve positions.

Owner:WALBRO ENGINE MANAGEMENT

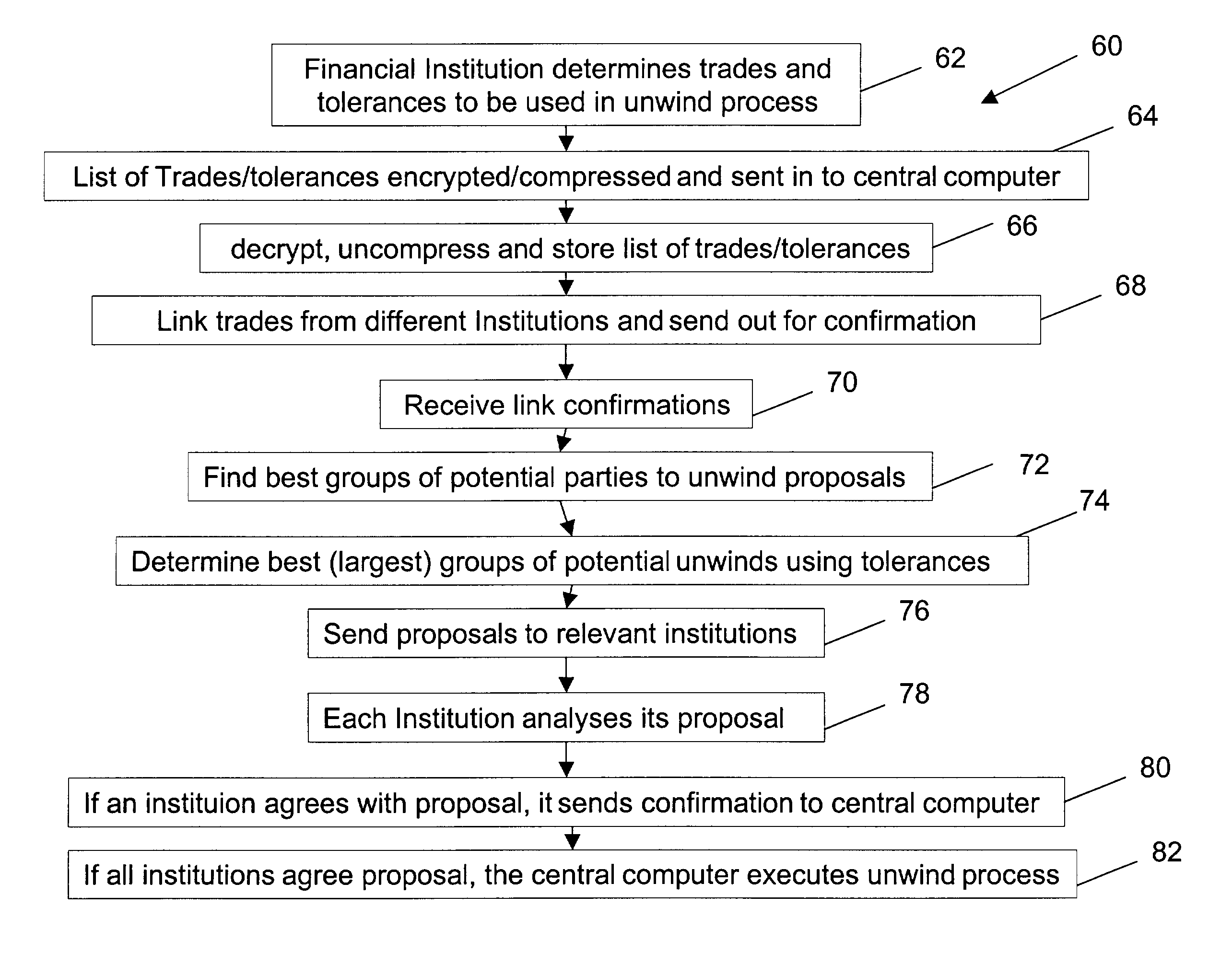

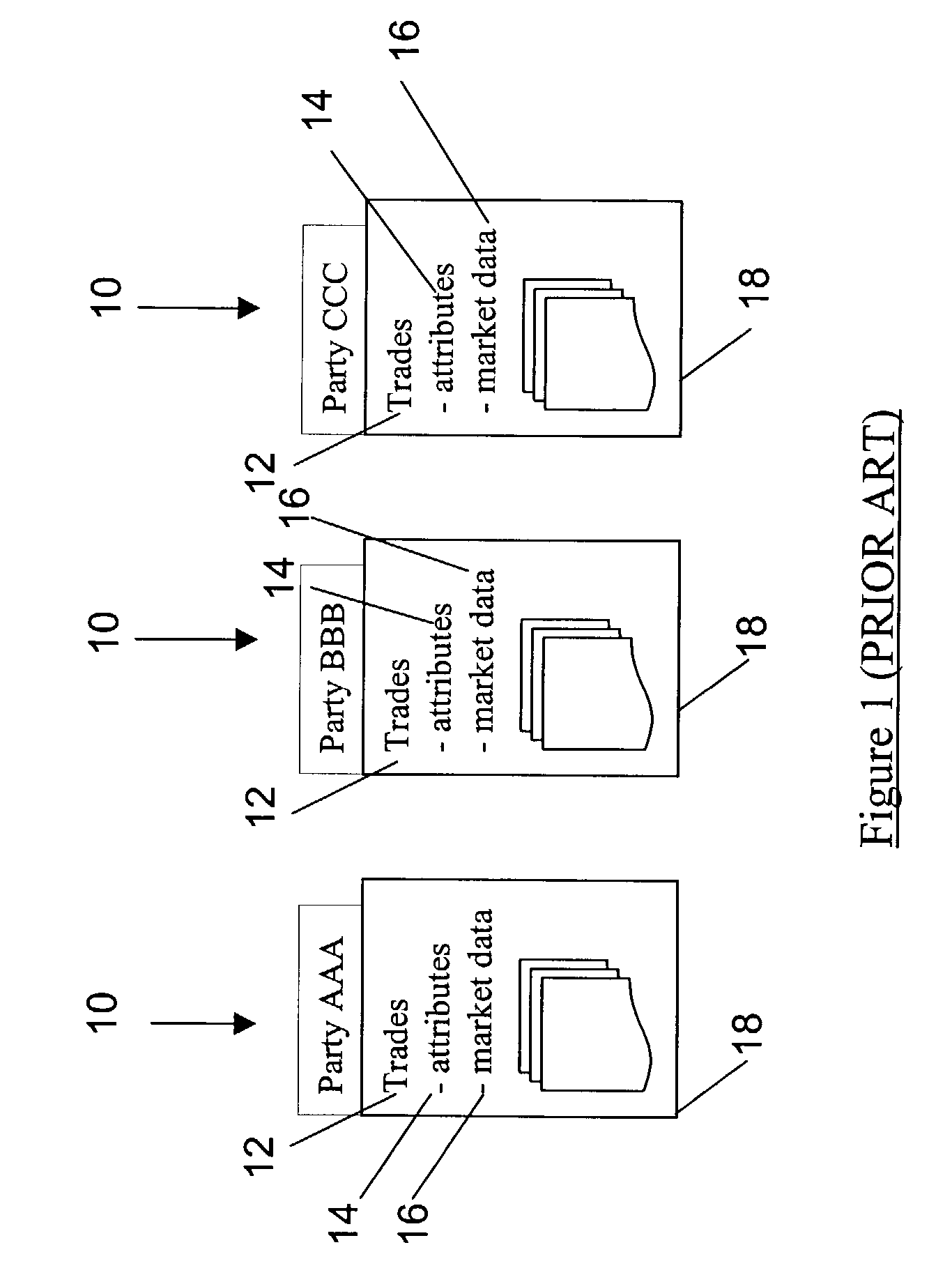

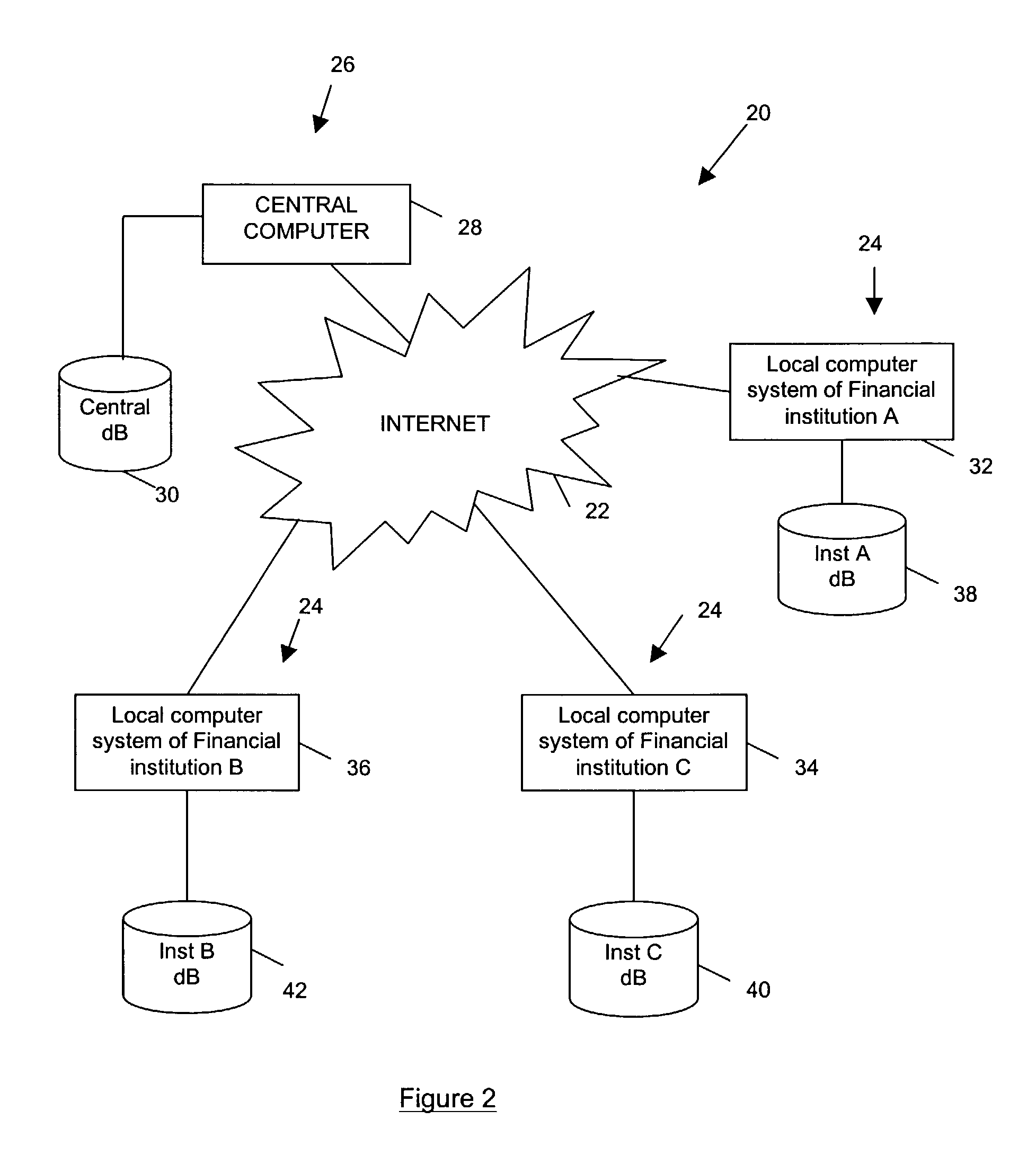

System and method of implementing massive early terminations of long term financial contracts

A method of and system for terminating or assigning outstanding OTC derivative transactions between a plurality of financial institutions (banks). The system comprises: a processing station arranged to receive transaction data describing a plurality of transactions from a plurality of banks via the Internet. The processing station comprises: a linking module for linking different versions of the same transaction received from different parties to that transaction; an analysis module for determining a set of linked transactions between a plurality of different banks, wherein each bank has debts and claims towards other banks in the set; a calculation module arranged to calculate an aggregated value of each set of linked transactions and select the set of linked transactions which has an aggregated value within bank-specified tolerance limits acceptable for executing a termination; and an execution module for executing a termination or assignment of the selected set of linked transactions.

Owner:CME GRP +1

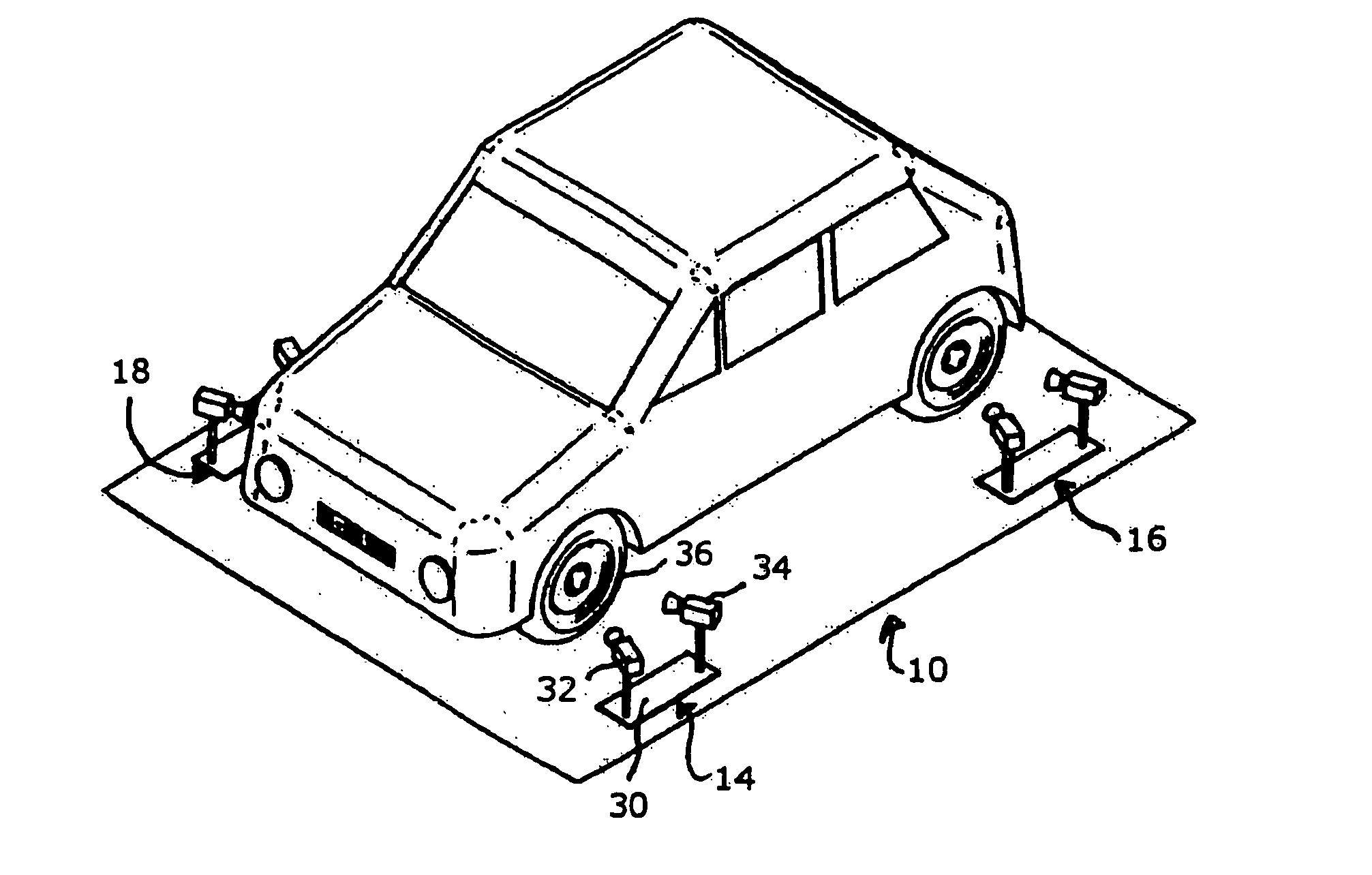

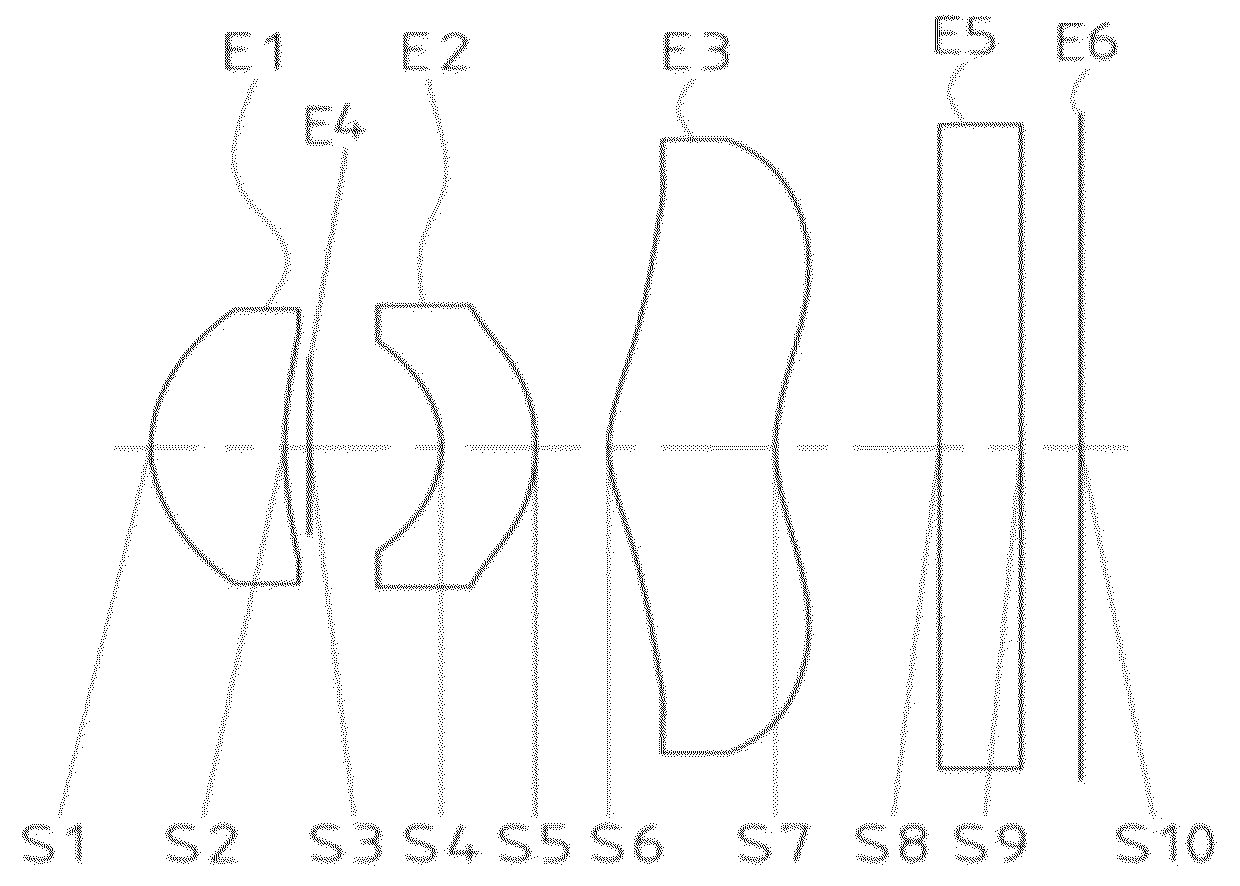

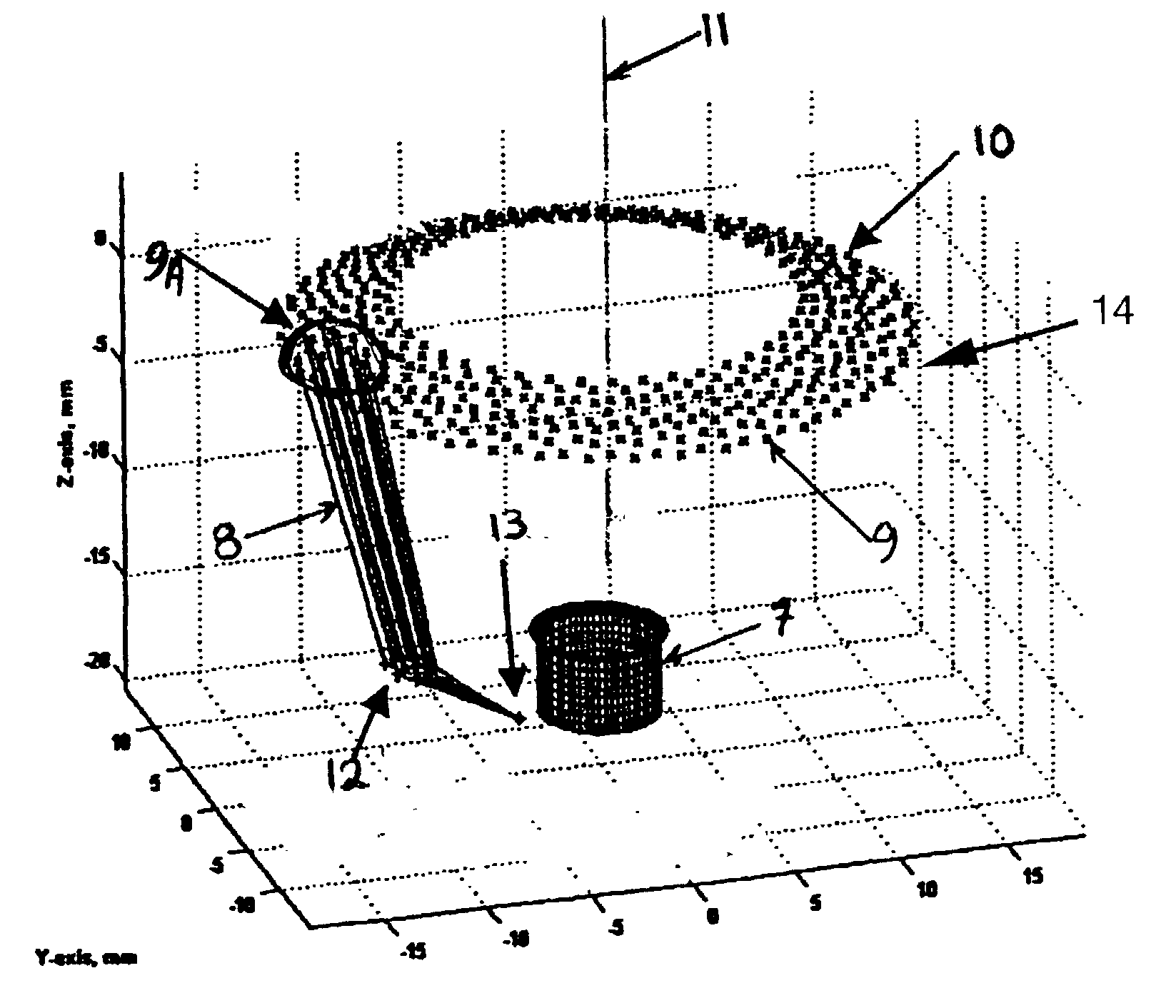

Measuring method and measuring unit for determining the spatial position of a wheel rim as well as a wheel alignment measuring system

InactiveUS7860295B2Accurate measurementAvoid mistakesCharacter and pattern recognitionColor television detailsTolerance limitEngineering

A method and a unit for determining the spatial position of a wheel rim with respect to a measuring unit having at least one camera, wherein the wheel rim lies in the viewing field of the camera, including making available of a model, that describes a model body of a localizable wheel rim geometry detail as well as the spatial position of the model body with respect to the measuring unit, through model parameters, capturing of a picture of the wheel rim geometry detail of the wheel rim with the camera, fitting the image of the model body resulting from the model parameters to the picture of the wheel rim geometry detail through changing the model parameters of the model, and tracking the changes of the model parameters upon the fitting, whereby the data related to the position of the model body of the wheel rim geometry detail reflect the spatial position of the wheel rim-geometry detail and, thereby, the wheel rim itself, when the image resulting from the model parameters, of the wheel rim-geometry detail fits to the captured picture of the wheel rim geometry detail within the asserted tolerance limits. The invention also relates to a wheel alignment measuring method and to a wheel alignment measuring system that uses said method and said unit.

Owner:BEISSBARTH

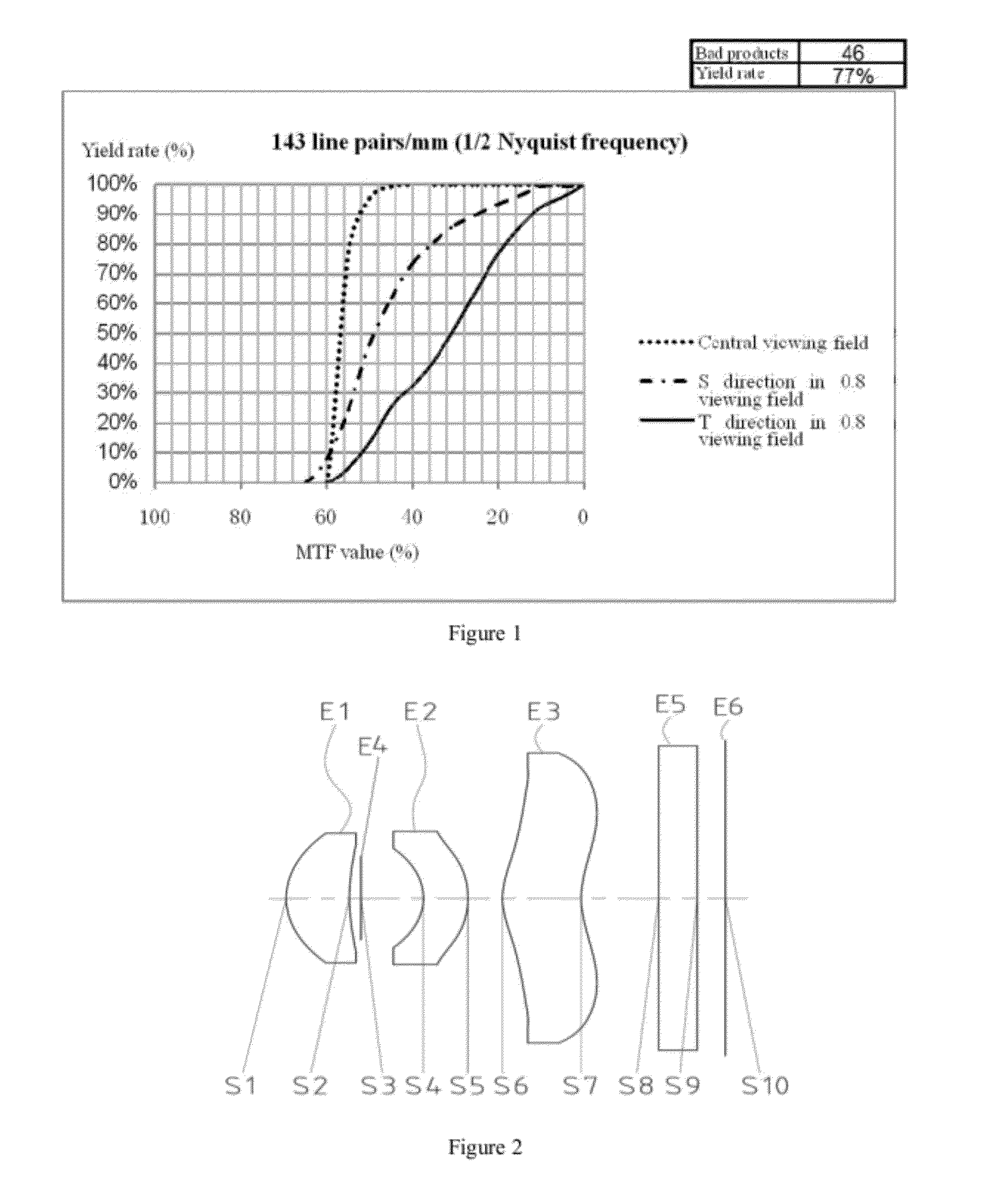

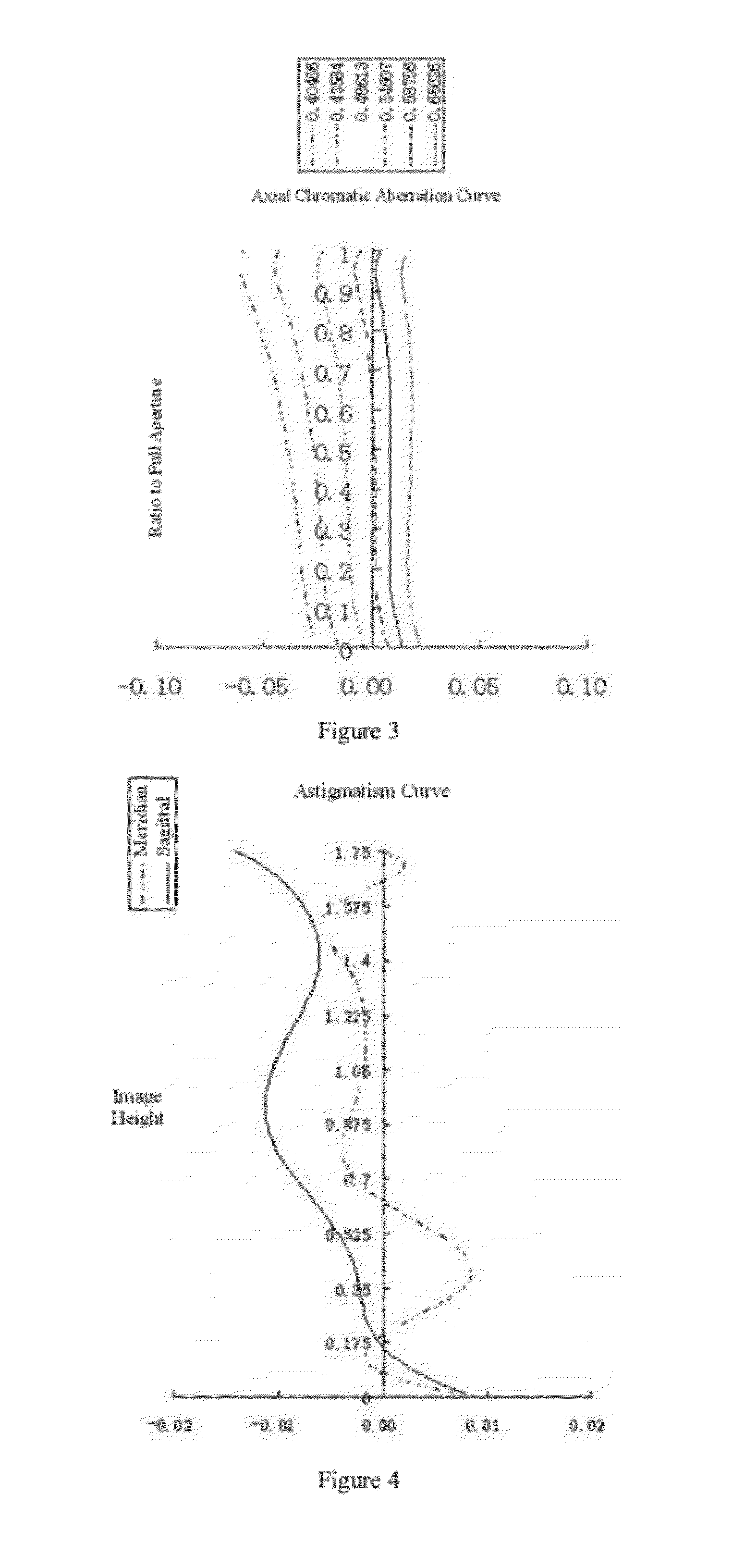

Micro camera lens

InactiveUS20120050888A1Improve image qualityReduce Tolerance SensitivityLensCamera lensTolerance limit

The present invention discloses a micro camera lens, comprising three aspheric lenses and a diaphragm, wherein, the three lenses have positive diopter, negative diopter, and positive diopter, respectively, and meet the following expression: VP1>50 and VP2<35; Where, VP1 and VP2 are Abbe numbers of the first lens and second lens, respectively. Since the micro camera lens provided in the present invention employs a combination of aspheric lens, the resolving power of the entire lens is enhanced, and the lens has excellent imaging quality; in addition, in an appropriate optical parameter design, the lens has lower tolerance sensitivity and improved tolerance limit, and can be produced reliably by mass production. Thus, the micro camera lens provided in the present invention attains favorable technical efficacies.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

Automatic height adjustment in an altimeter

InactiveUS6678630B1Inflated body pressure measurementFluid pressure measurement by electric/magnetic elementsTolerance limitEngineering

The invention relates to an altimeter for detecting and displaying the altitude above the sea level of a location by measuring the ambient atmospheric pressure. In order to compensate for changes in air pressure due to meteorological reasons, such as temperature, an adjustment or reset mechanism is provided with the purpose of adjusting or resetting the altimeter to a given stored height at a given moment. This is only effected if at that moment, the air pressure that has been measured indicates height coinciding with the given stored height within a predetermined tolerance limit.

Owner:FLYTEC

Method for processing color measurement in printing machine

A color measurement on printed materials produced by a printing press is performed by at least a first color measuring device installed in the printing press and at least a second color measuring device. A signal is output by the first color measuring device in the printing press when the measured color values registered on the printing materials are located within a predefined tolerance limit for a predefined period and that, after the signal has been output, a color measurement on one of the printed materials thus produced is performed with the second color measuring device.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

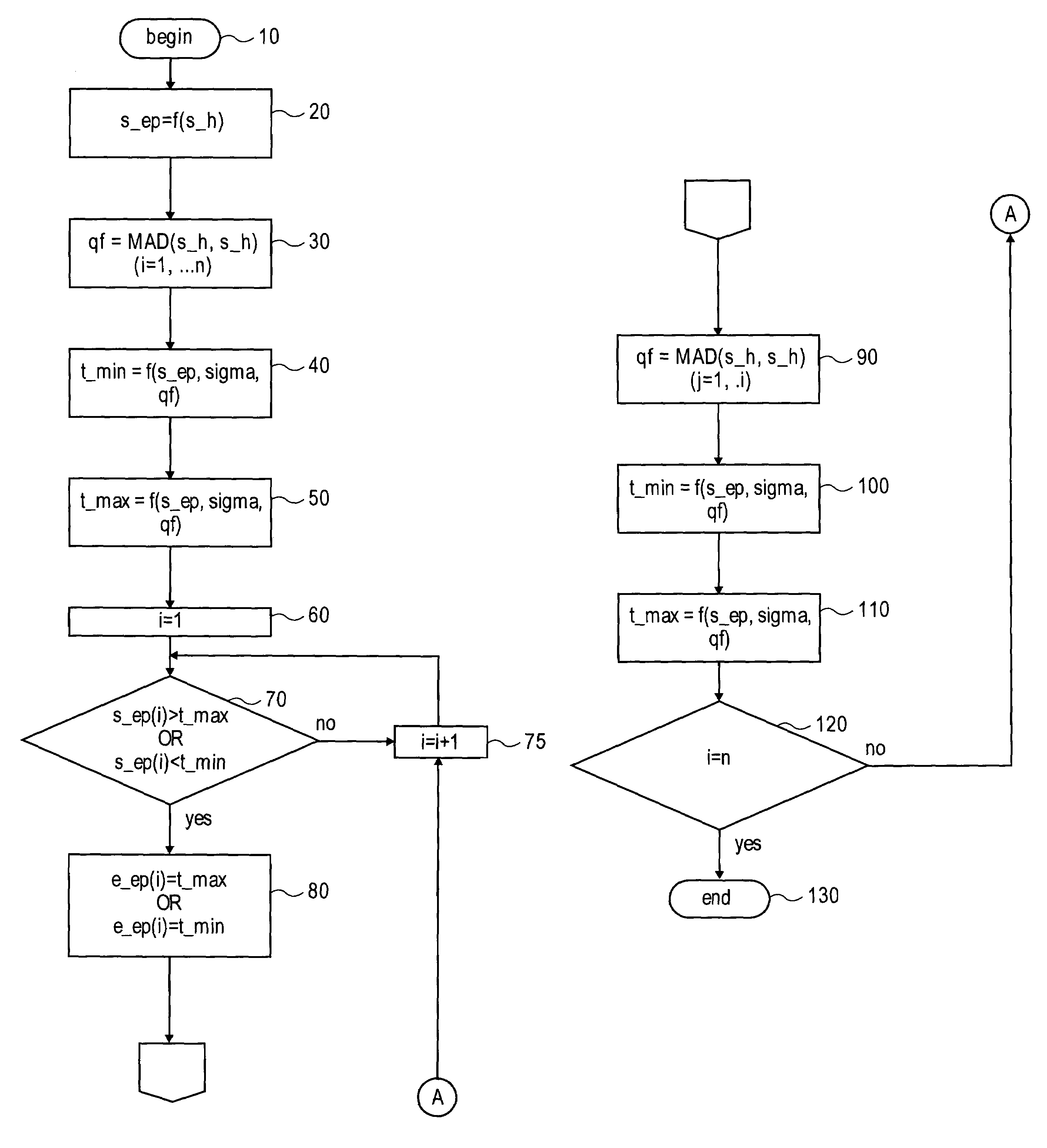

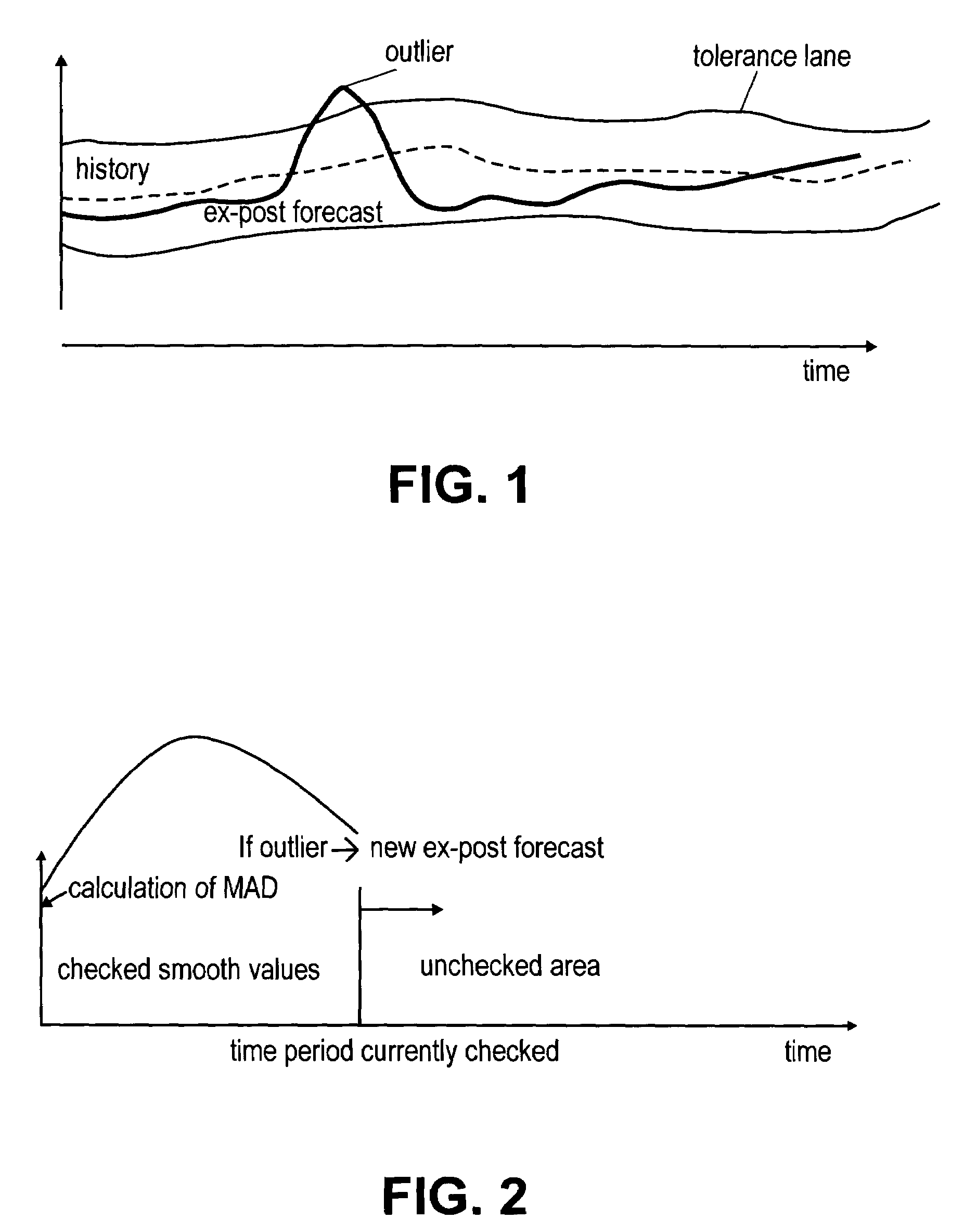

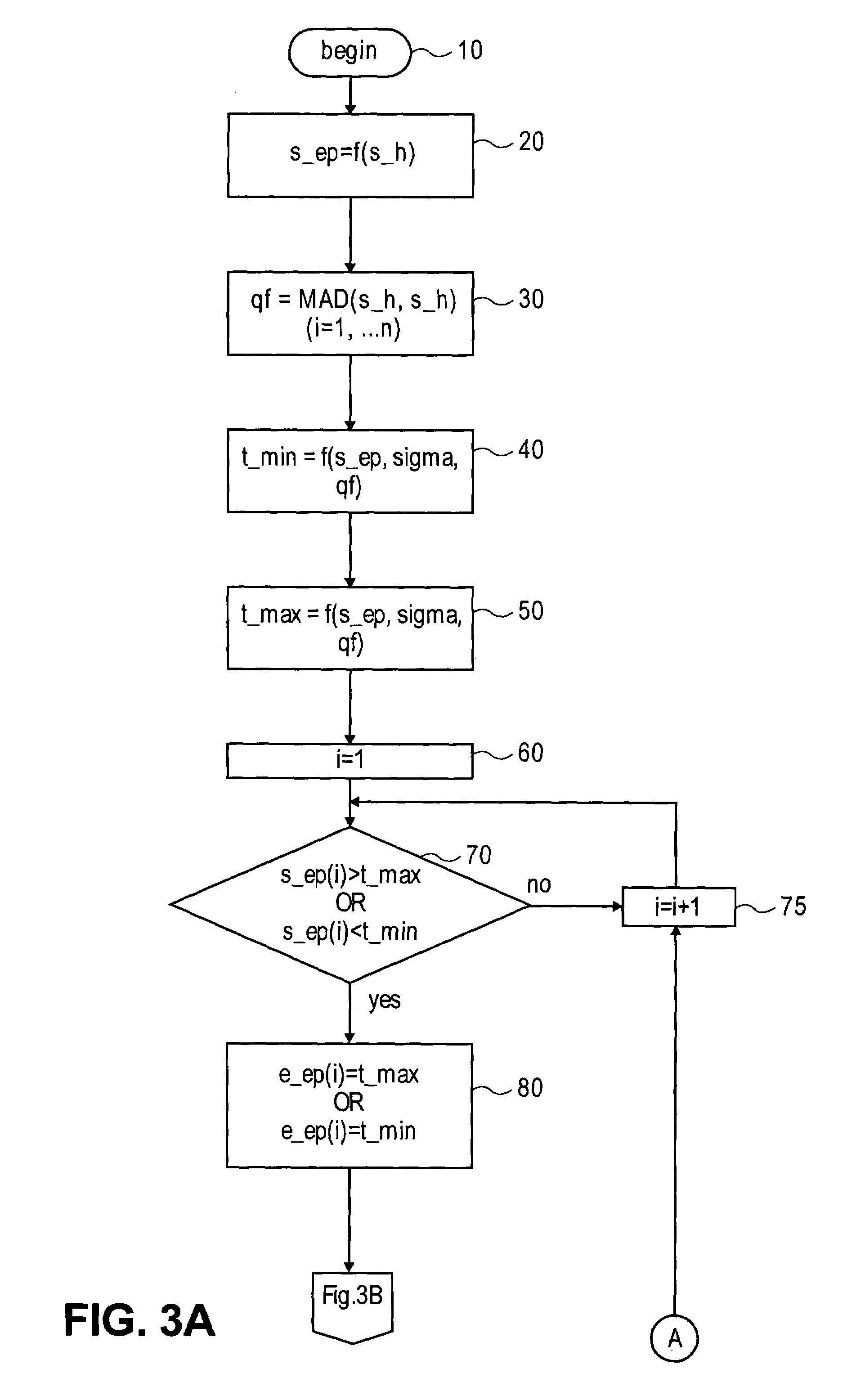

Outlier correction

ActiveUS7239984B2Minimize impactAmplifier modifications to reduce noise influenceDigital computer detailsTolerance limitOutlier

Owner:SAP AG

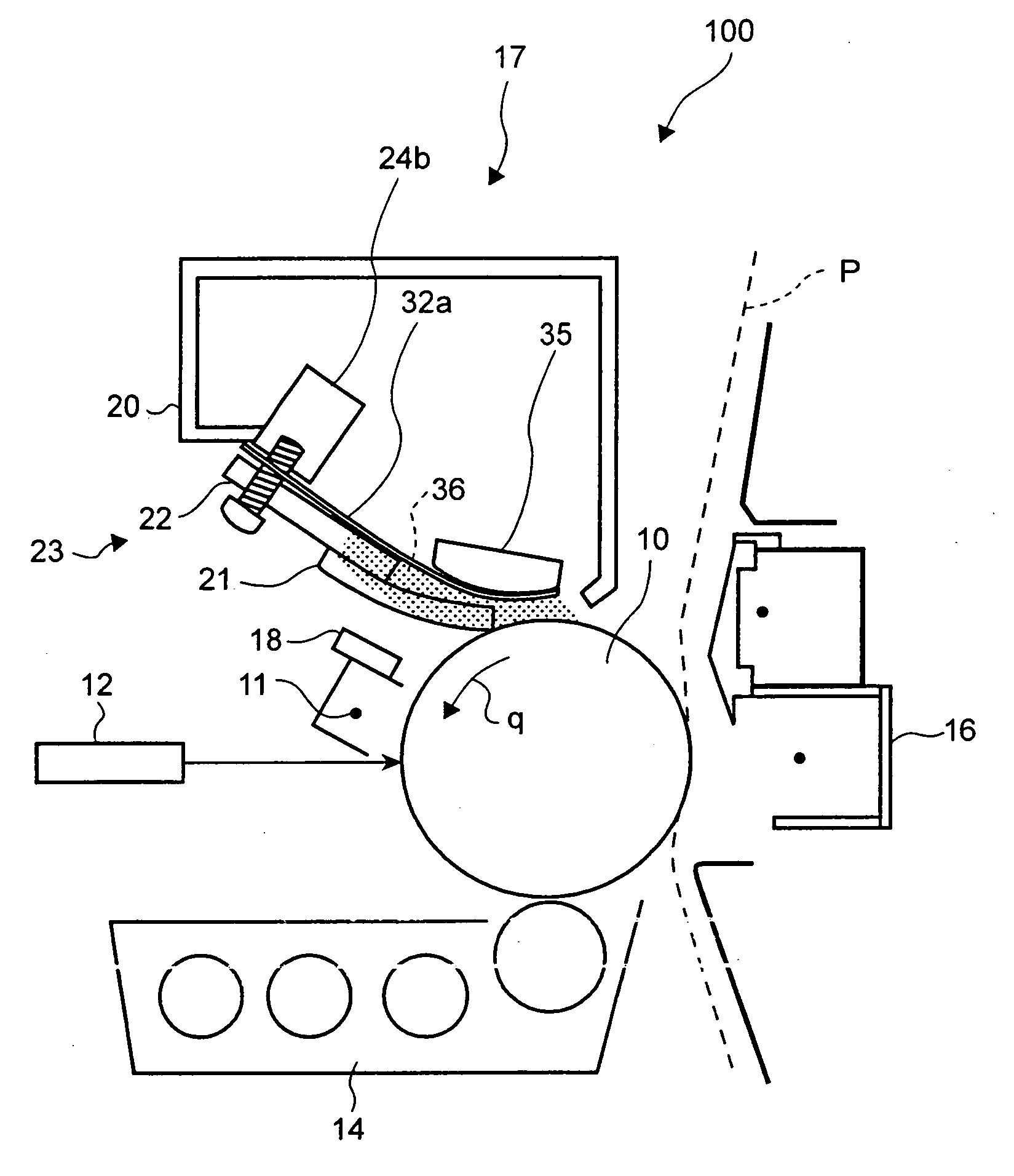

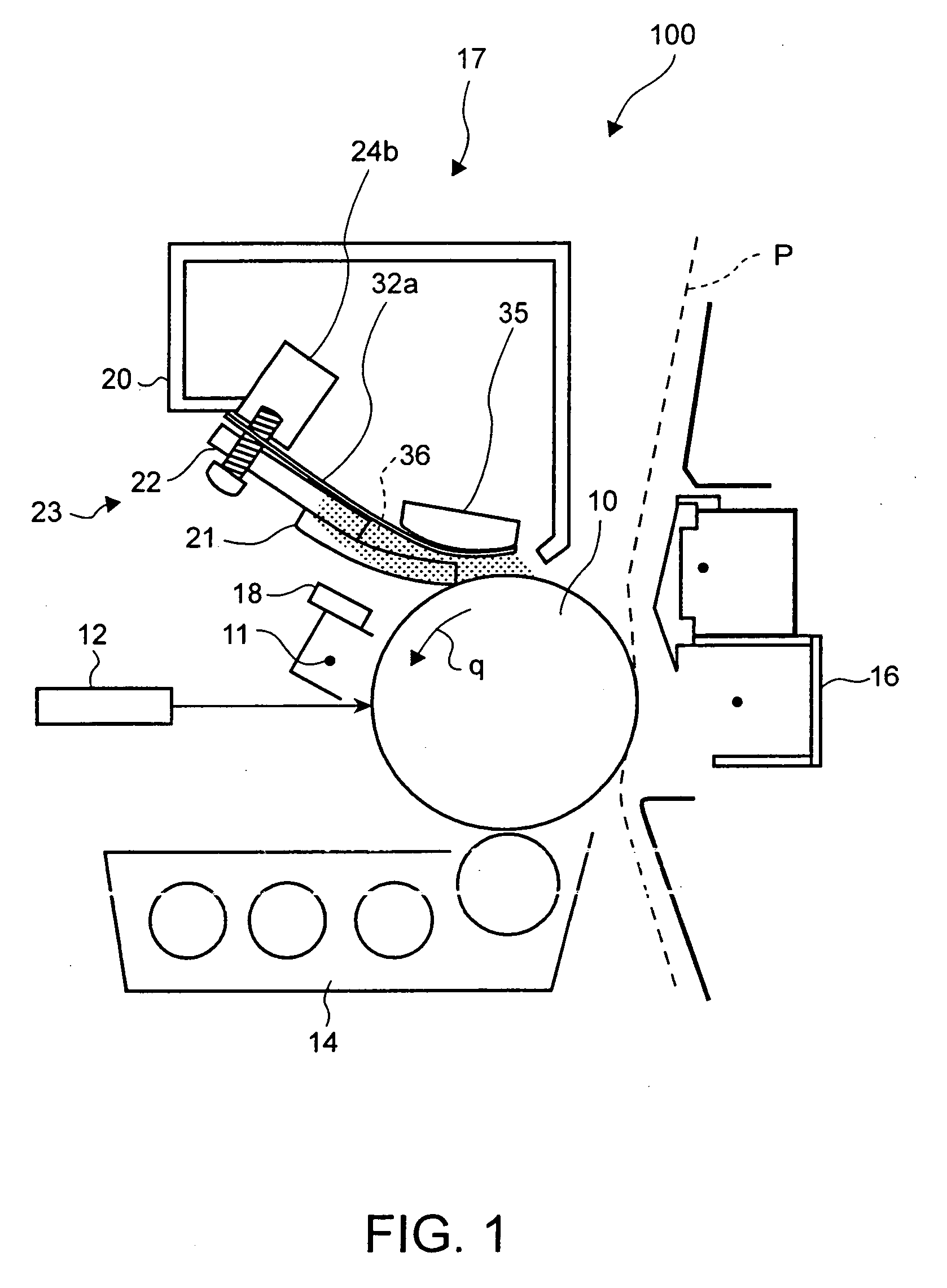

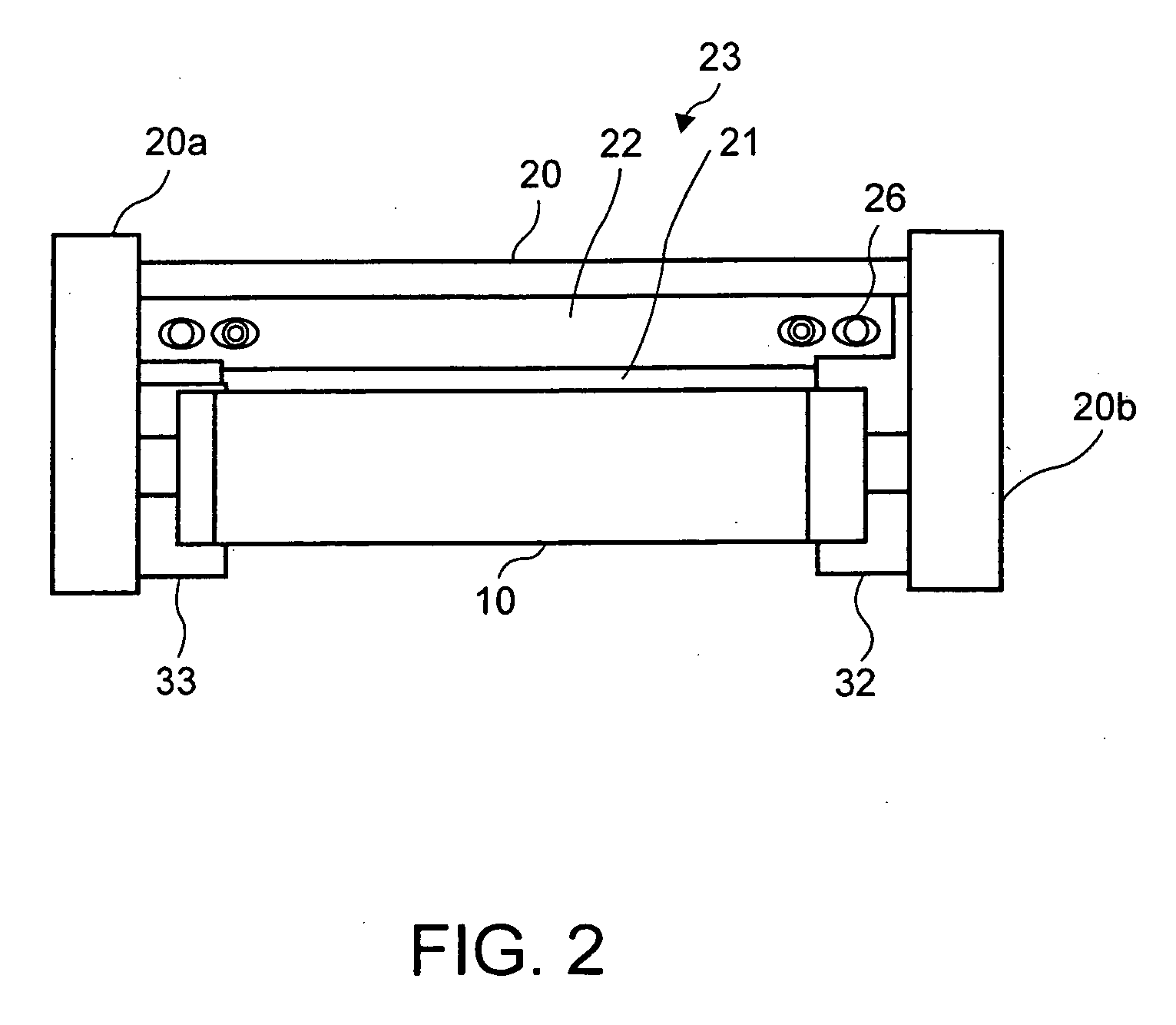

Blade-cleaning device and blade member supporting method

InactiveUS20060188286A1Improve yieldEnabling useElectrographic process apparatusTolerance limitEngineering

A blade cleaning device of the present invention fixes a blade to a blade support member in a state of sliding and moving it in the longitudinal direction and fixes a second side seal member to the blade support member in a state of sliding and moving it in the longitudinal direction on the second side of the blade support member. By doing this, even if the dimensional tolerance limits of the blade are varied, the gap between the blade support member and the blade member can be sealed surely, and the manufacturing accuracy of the blade as a change part is moderated, and the yield rate of defective products is improved.

Owner:KK TOSHIBA +1

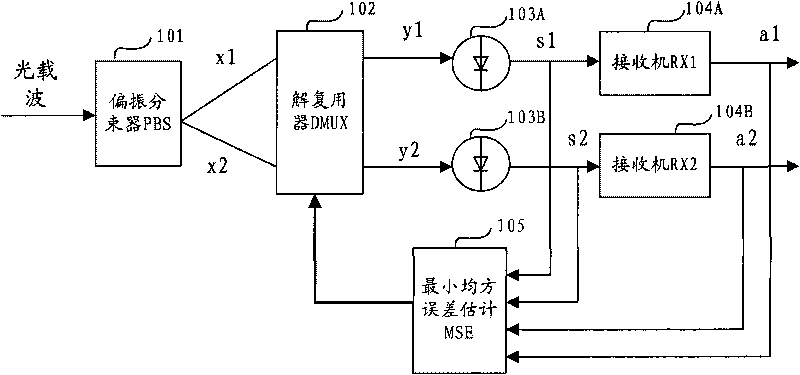

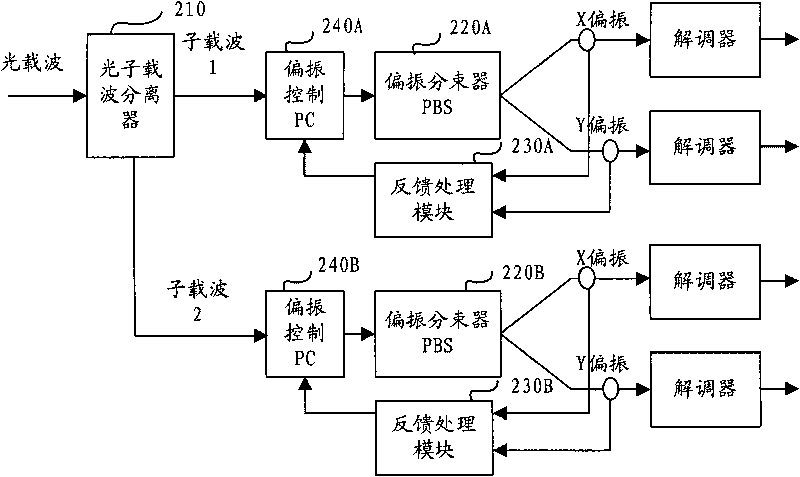

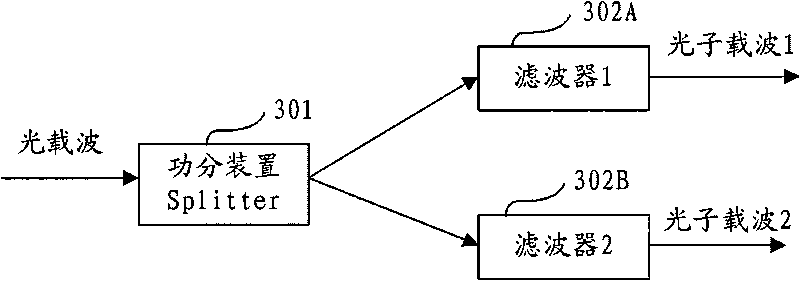

Method, device and system for photolyzing, polarizing and multiplexing optical carrier

InactiveCN101729149ALower requirementReduce complexityPolarisation multiplex systemsOptical transmission with multiple stagesMultiplexingFrequency spectrum

The embodiment of the invention discloses a method, a device and a system for photolyzing, polarizing and multiplexing an optical carrier, which relate to the technical field of optical communication, and can improve the frequency spectrum utilization ratio of the system, improve the tolerance limits of chromatic dispersion CD and polarization mode dispersion PMD, and simultaneously reduce the device requirement and the complexity of a receiving end. The method provided by the embodiment of the invention comprises the following steps of: separating the optical carrier into more than two paths of photon carriers at the receiving end; respectively photolyzing, polarizing and multiplexing each path of photon carrier into two paths of optical signals to be demodulated; and using the optical signals to be demodulated as feedback input signals, and respectively correspondingly regulating the incident angle of each path of photon carrier. Through the device photolyzing more than two paths of photon carriers and combining photolysis, polarization and multiplexing, the embodiment of the invention enables an optical carrier signal to be decomposed into more than four paths in an optical modulation format to be processed, and a DQPSK demodulator can be directly used on an optical wave for carrying out time delay interference detection to obtain an output signal.

Owner:HUAWEI TECH CO LTD

Phased array ultrasonic NDT system for fastener inspections

InactiveUS7328619B2Analysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansTolerance limitBeam search

An ultrasonic probe suited for testing the integrity of sheet metal surfaces around fastener openings is provided with means to center the probe over such openings. Both a mechanical centering rod and an electronic display assist the user in centering such probe. Once positioned within tolerance limits, phased array ultrasonic beams search for defects within the metal surfaces, allowing for residual offsets in the centering of the probe. Also described are test fixtures for calibrating the probe.

Owner:R D TECH +1

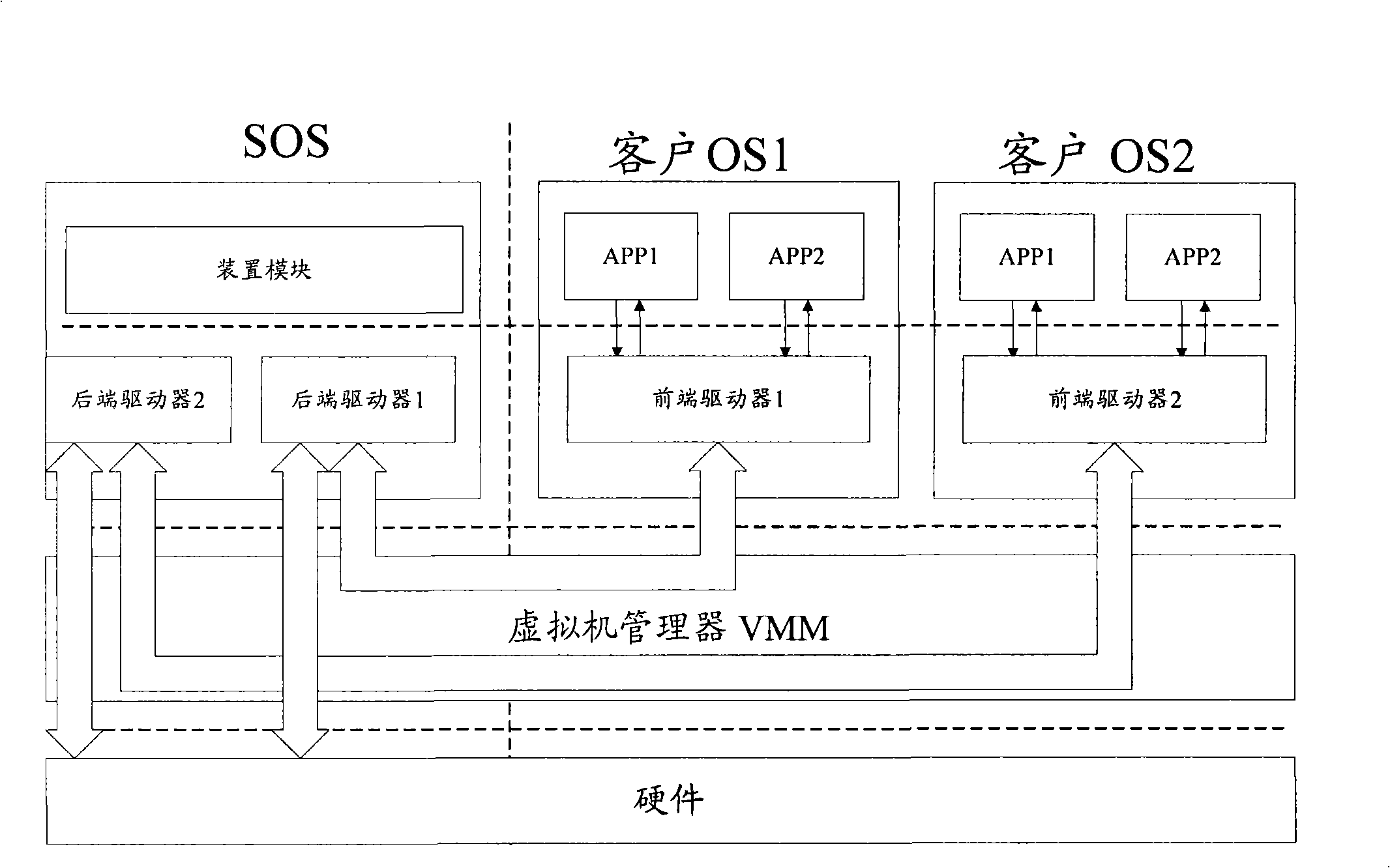

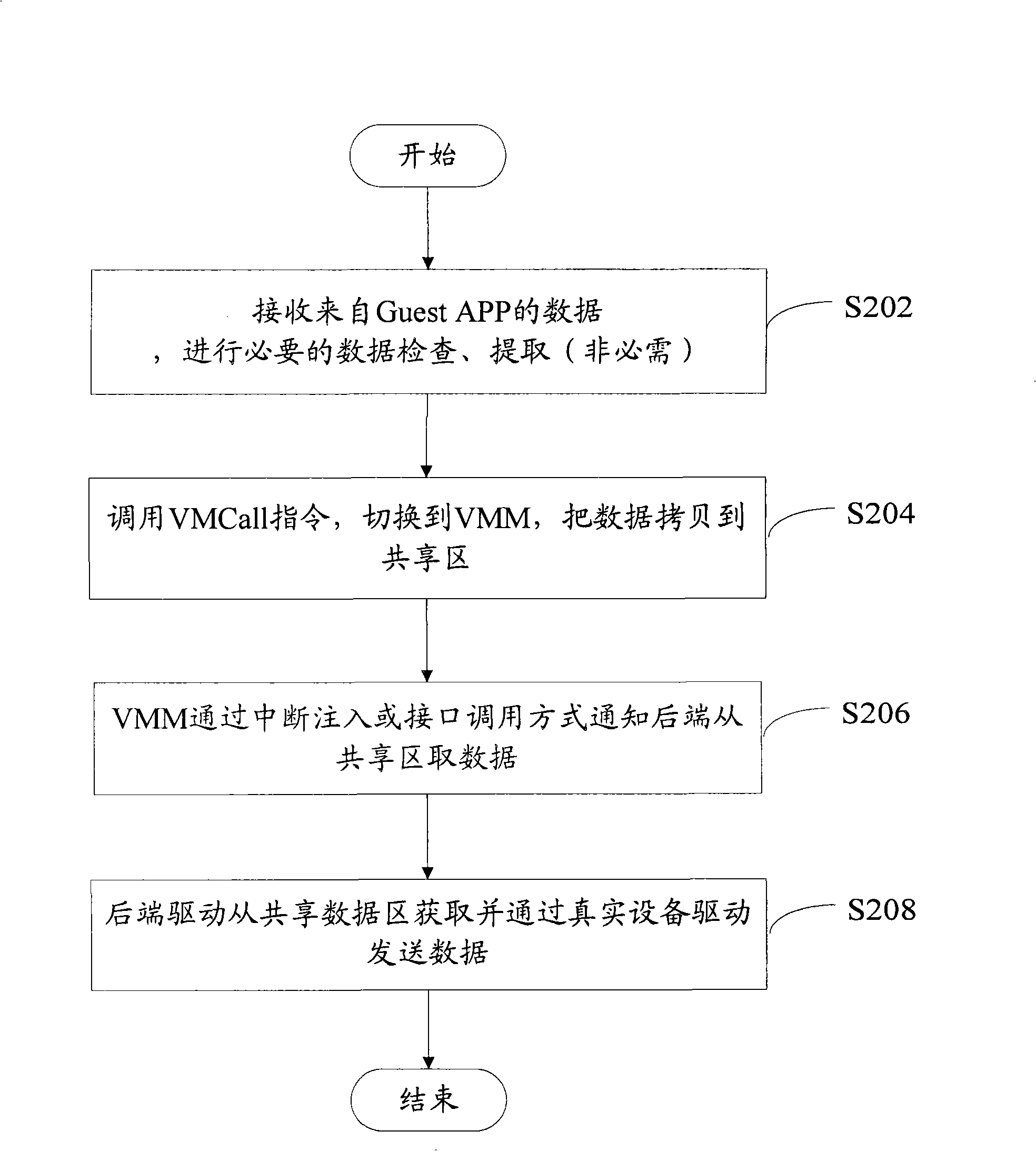

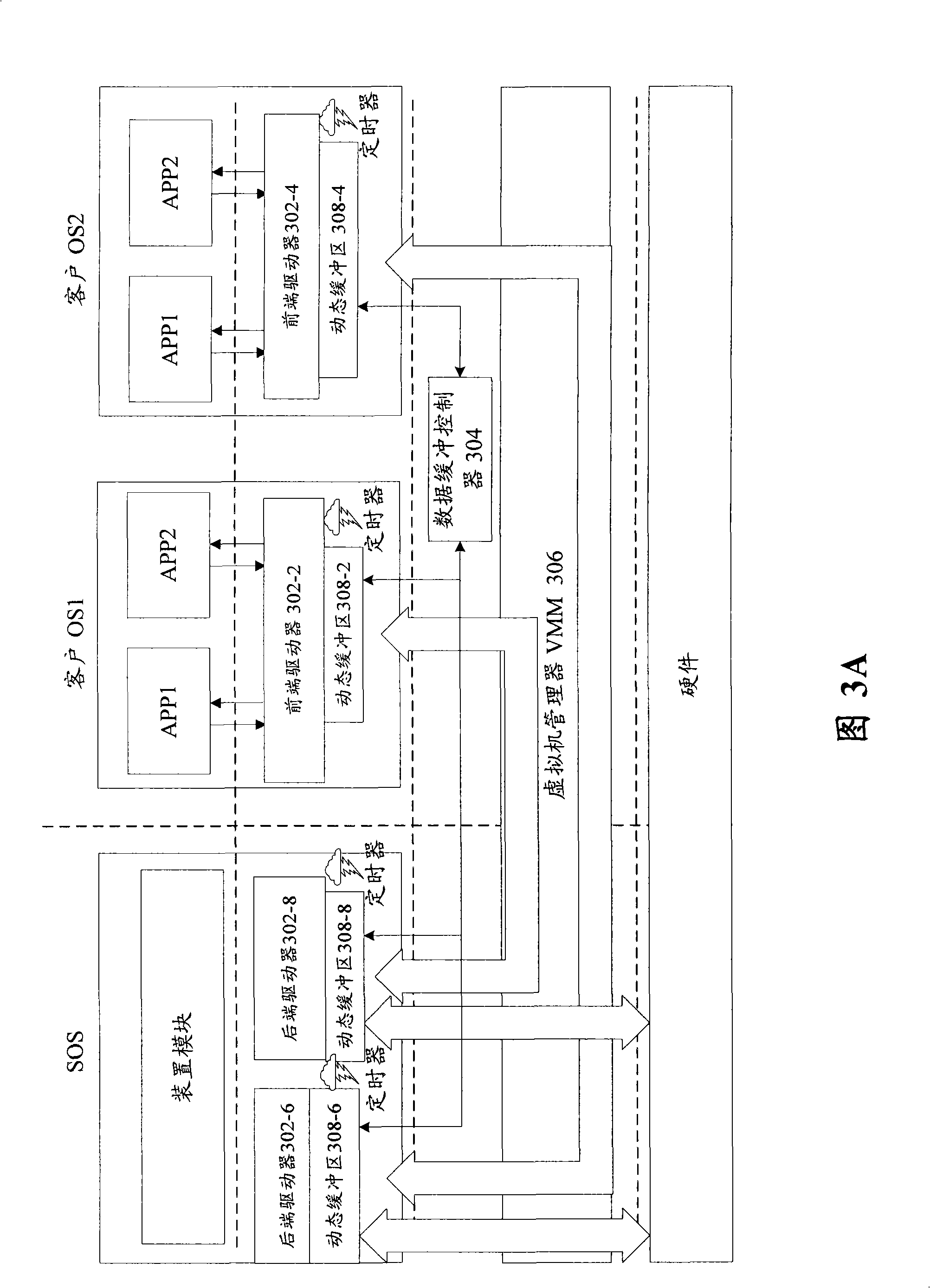

Interrupt handling method and system

ActiveCN101335694AEfficient data transferImprove performanceData switching networksTolerance limitNetwork packet

The invention provides an interruption processing method and a system thereof, wherein, the method comprises the following steps: Step S402, a buffer area and a timer are arranged in a virtual machine; the buffer area is used for buffering a data packet received by the front end or the rear end of the virtual machine; the timer is used for timing data buffering time; Step S404, after receiving the data packet from the front end or the rear end, the buffer area determines that whether the received data packet is an interactive data packet and determines whether the timer is started or postponed; under the condition that the data packet is not the interactive data packet, the buffer area caches the received data packet and starts the timer; and Step S406, under the condition that the buffer area reaches the largest tolerance limit or the time reaches a preset time, the cached data packet is sent to the rear end or the front end of the virtual machine for processing by a manager of the virtual machine.

Owner:LENOVO (BEIJING) LTD

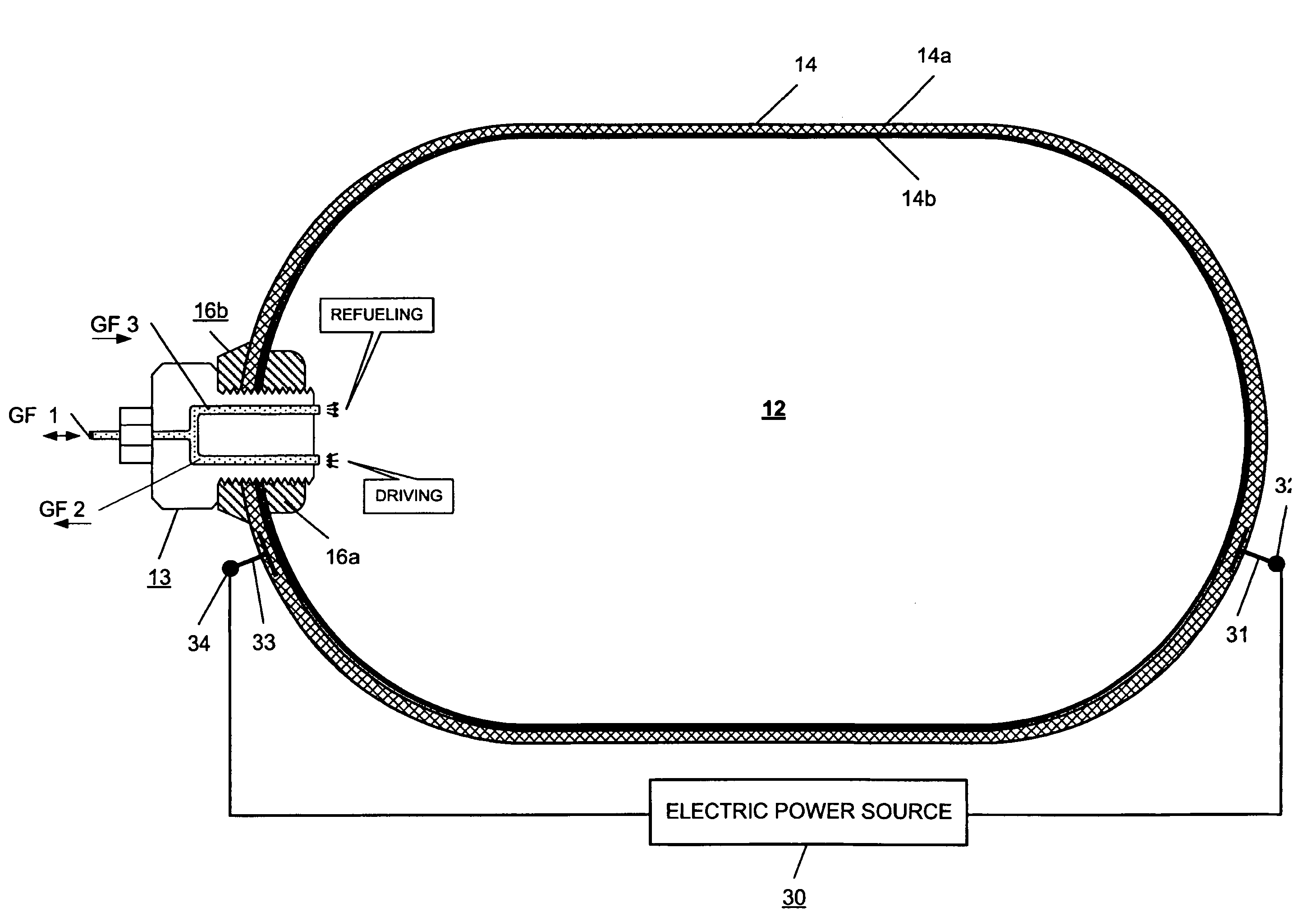

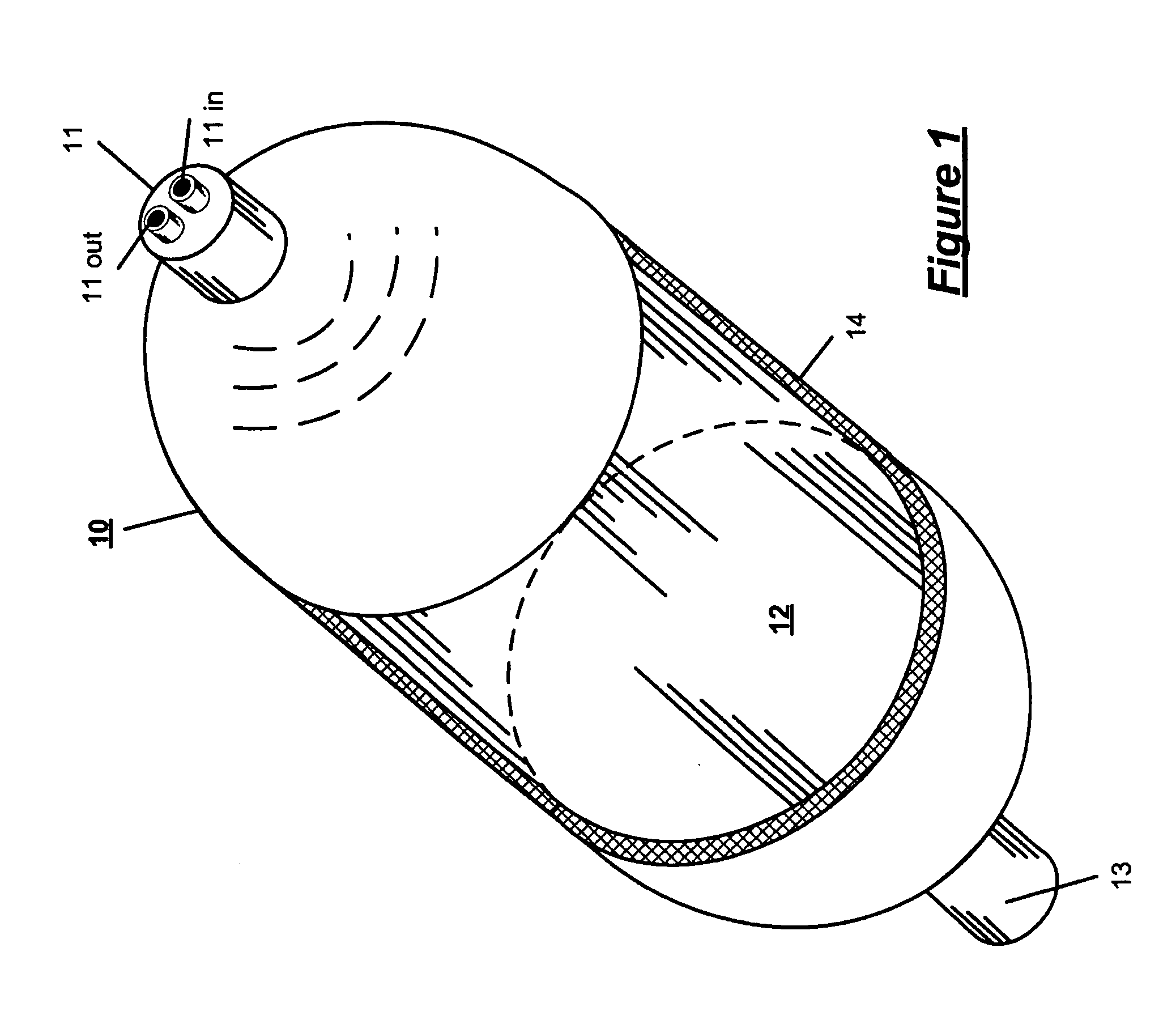

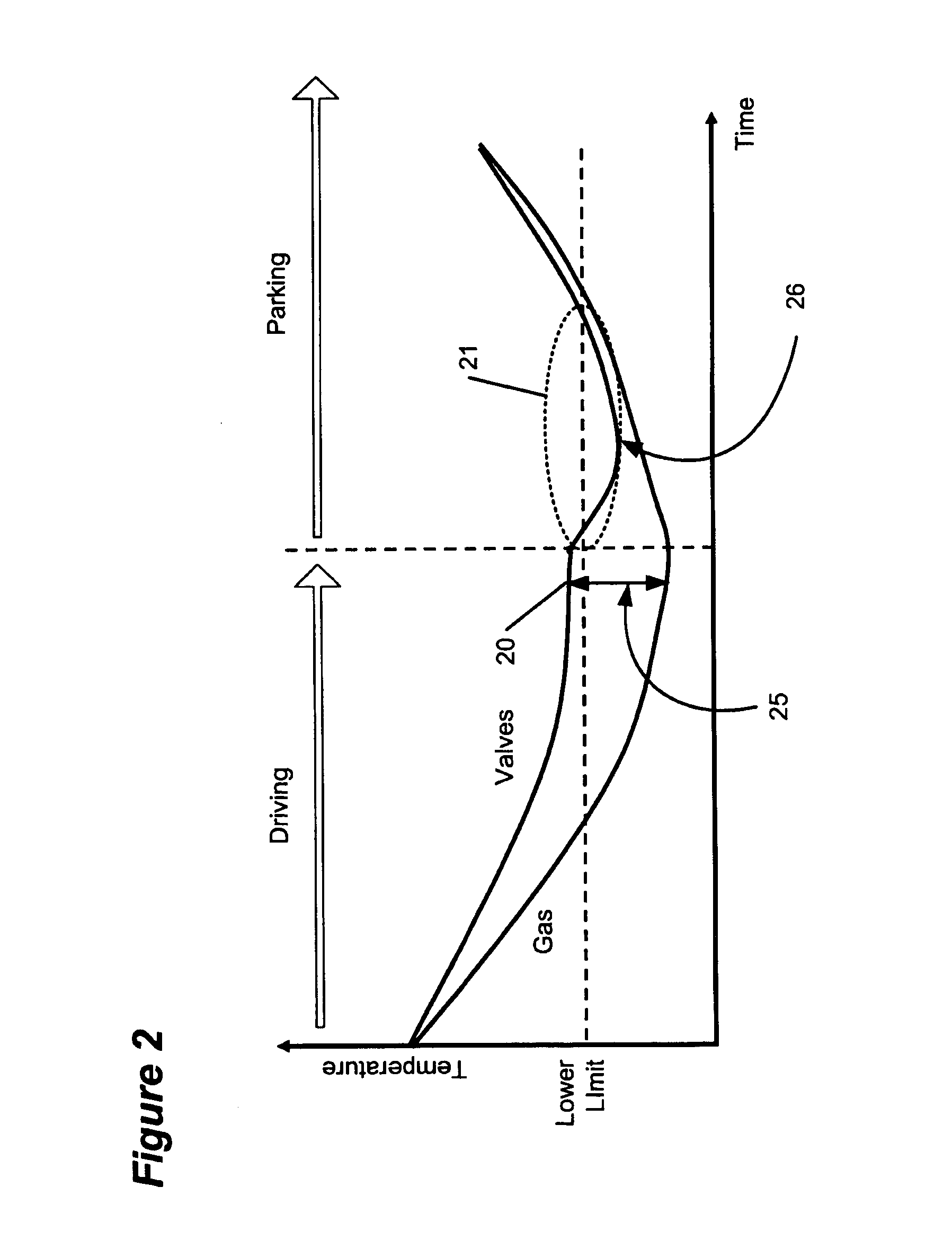

Carbon Fiber Warming System for Fiber Composite Gas Storage Cylinders

InactiveUS20090142636A1Reduce riskIncreased durabilityVessel mounting detailsReactant parameters controlFiberCarbon fibers

Owner:HONDA MOTOR CO LTD

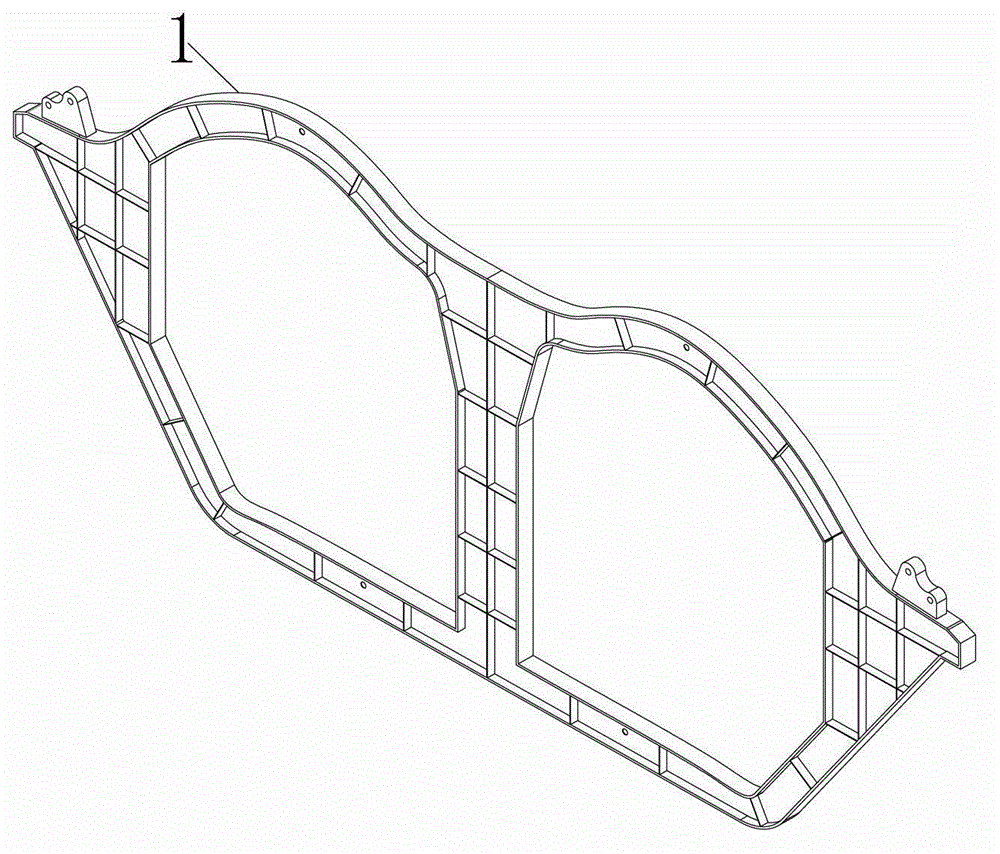

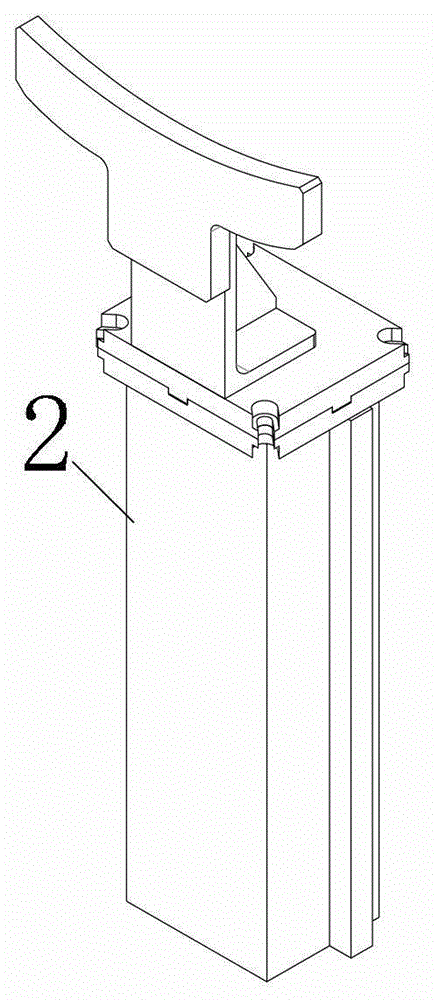

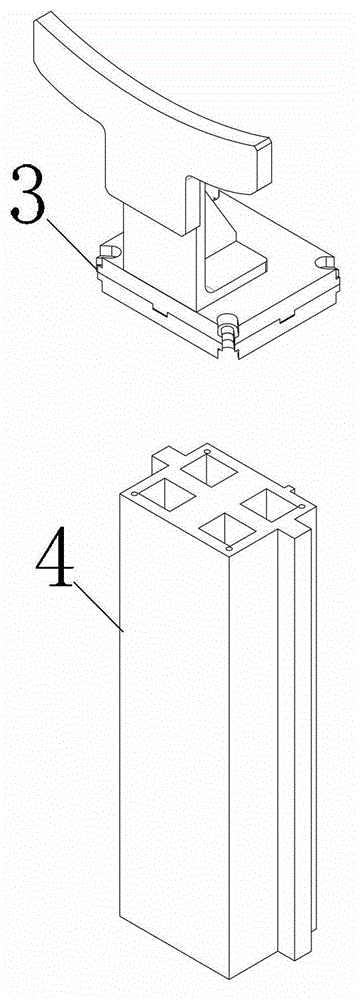

Airplane frame part assembly stress detection and control method

InactiveCN103063333ARealize real-time detectionControl assembly stress levelsForce measurementMechanical pressure/force controlTolerance limitProcess Measures

Provided is an airplane frame part assembly stress detection and control method. The airplane frame part assembly stress detection and control method includes fix steps: step 1, determining installation positions and quantity of three-way force sensors; step 2, determining assembly stress tolerance limits of frame parts through quantitative analysis; step 3, designing an assembly stress detection component, namely a three-way force sensor; step 4, installing the three-way force sensor into a locator of the frame parts; step 5, observing assembly stress change of the frame parts; and step 6, adjusting assembly process measures so as to control levels of frame part assembly stress. The airplane frame part assembly stress detection and control method solves the assembly difficult problem that the assembly stress is excessive of the airplane frame parts in the process of assembly of airplane body components because of forced assembly, and achieves the purpose of detecting and controlling of the airplane frame part assembly stress.

Owner:BEIHANG UNIV

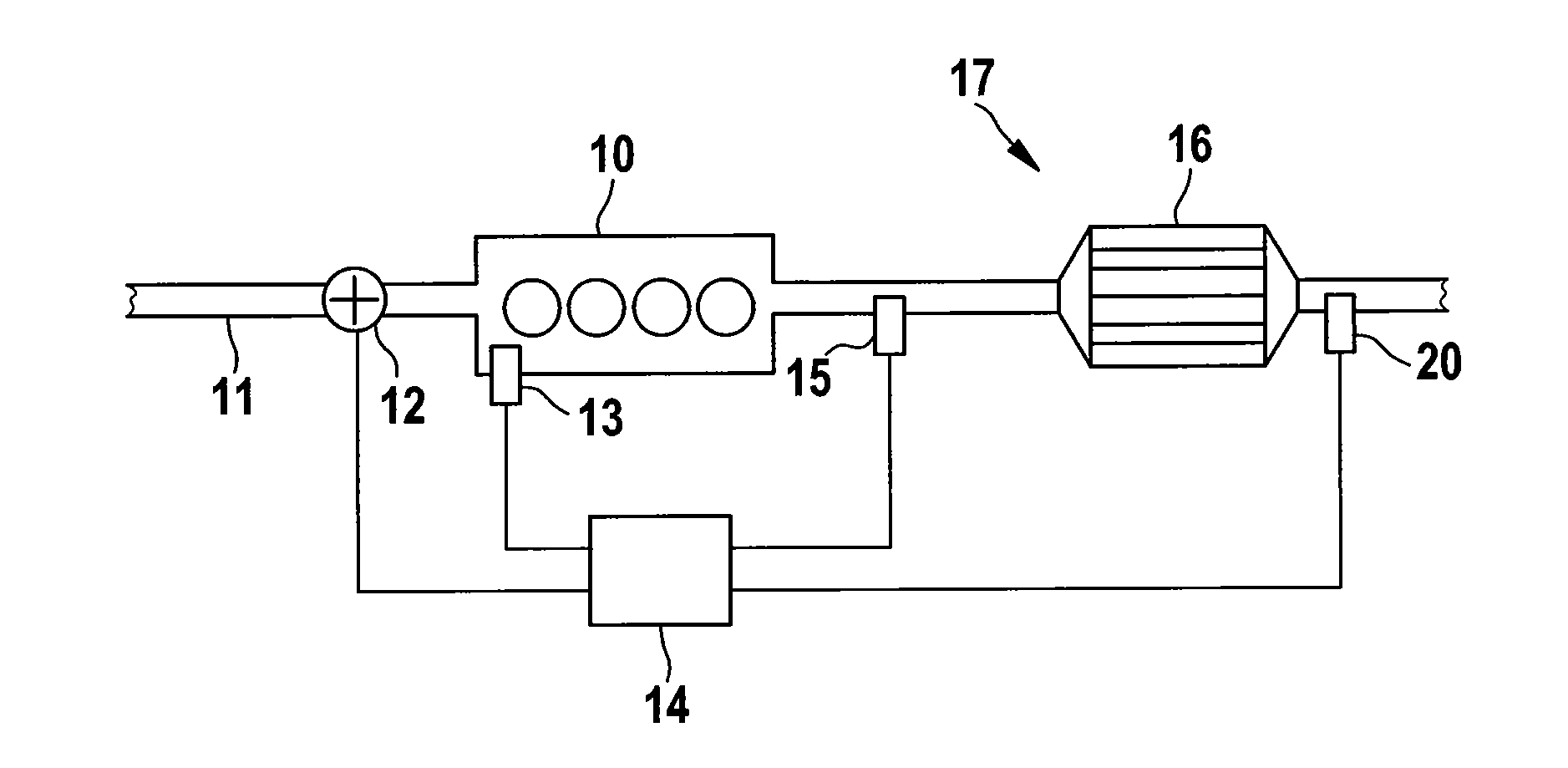

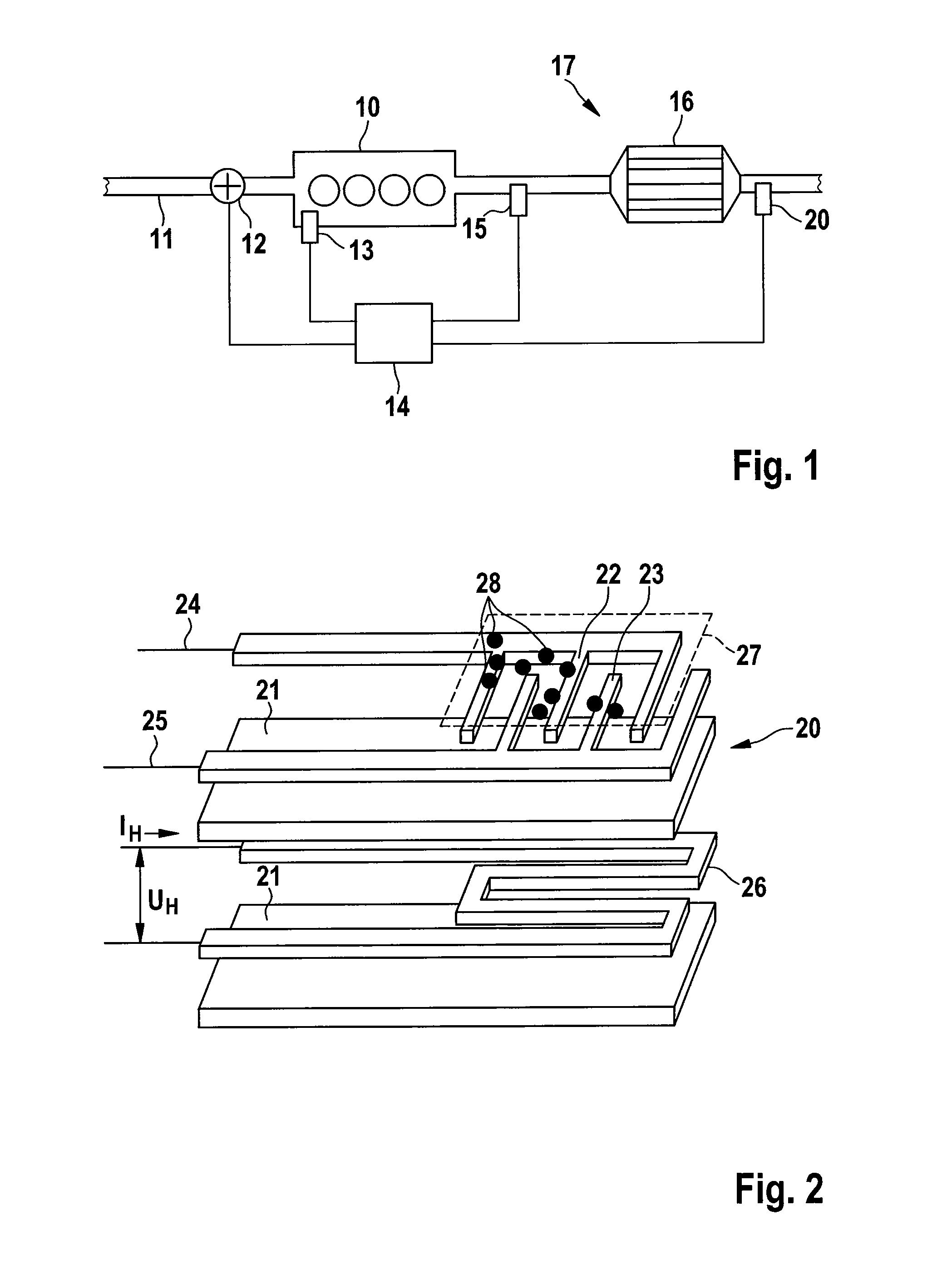

Method and apparatus for the self-diagnosis of an exhaust gas probe

ActiveUS20110252768A1Improve self-diagnosisGuaranteed uptimeInternal combustion piston enginesExhaust apparatusTolerance limitProcess engineering

A method for the self-diagnosis of an exhaust gas probe (20). The exhaust gas probe (20) has at least one heating element (26). The method includes a modeled heat output PH is determined for the heating element (26) by means of a computer program comparing parameters of the gas stream with a measured heat output, and determining, when the parameters of the gas stream exceeds the measured heat output by more than a defined tolerance limit, that one of the exhaust gas probe (20) is defective, and an exhaust gas section (17) in which the exhaust gas probe (20) is installed is faulty.

Owner:ROBERT BOSCH GMBH

Ageing life testing method for O-shaped rubber sealing ring

InactiveCN108088786APrecise prediction of service lifeAccurate predictionWeather/light/corrosion resistanceTolerance limitMechanical equipment

Owner:CHINA AERO POLYTECH ESTAB +1

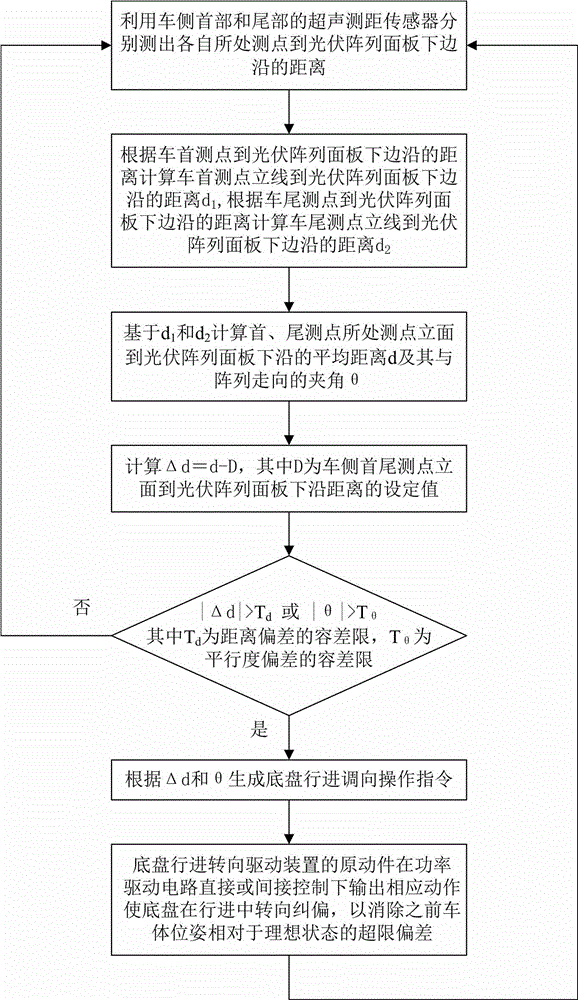

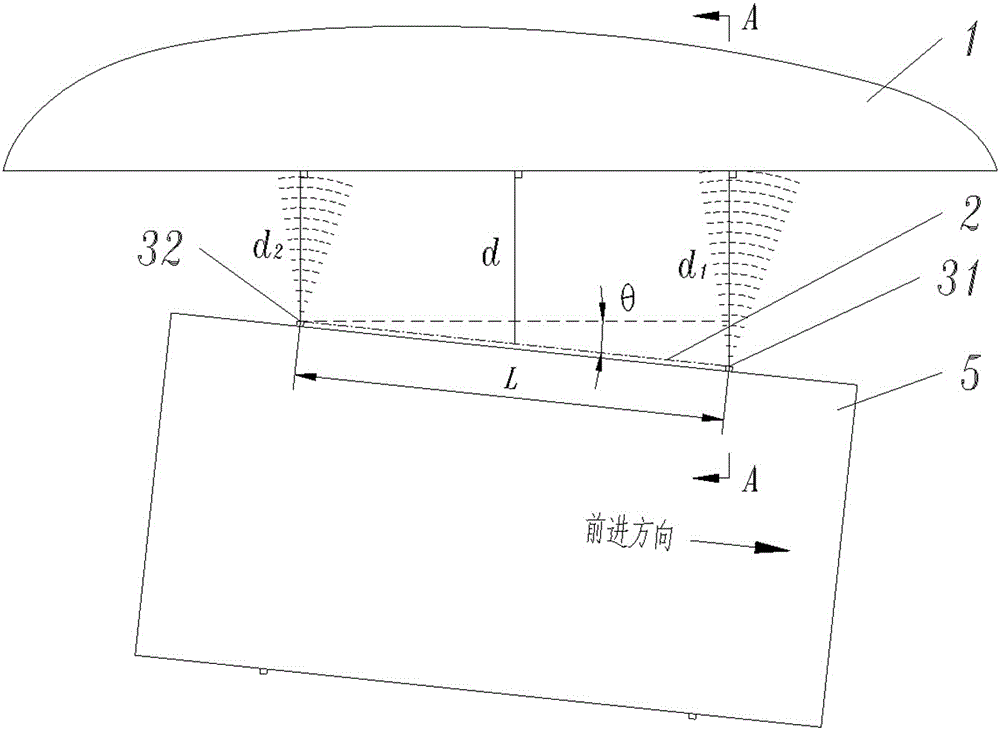

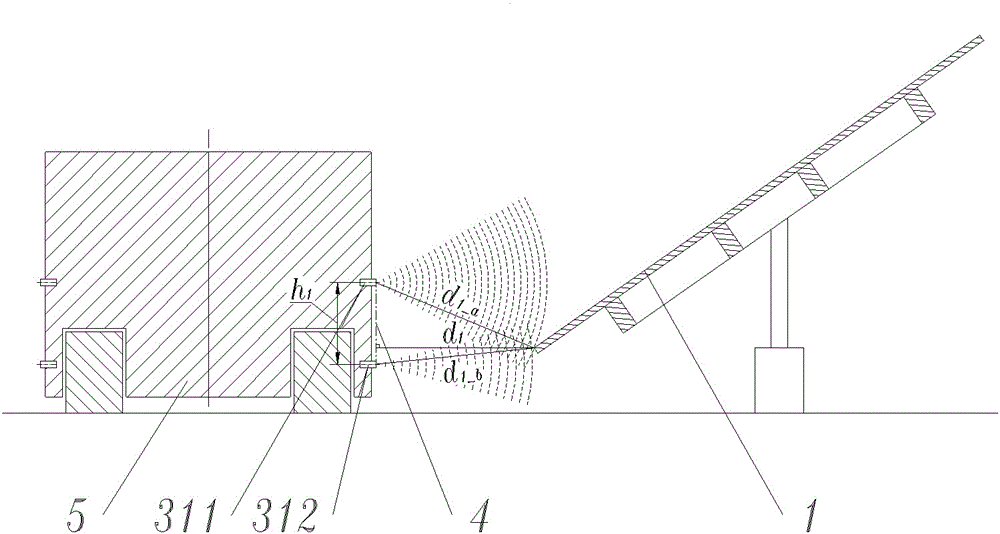

Automatic deviation rectifying method and automatic deviation rectifying system for advancement of solar panel cleaning vehicle

ActiveCN105057301AImprove travel qualityReduce work intensityFlexible article cleaningOperating instructionTolerance limit

The invention discloses an automatic deviation rectifying method for the advancement of a solar panel cleaning vehicle. The automatic deviation rectifying method comprises the following steps of using ultrasonic range finder sensors arranged at the head and the tail of one side of a vehicle body to respectively measure the distance between a measuring point vertical line of the head and the lower edge of a photovoltaic array panel and the distance between a measuring point vertical line of the tail and the lower edge of the photovoltaic array panel; calculating the average distance between a measuring point vertical surface and the lower edge of the photovoltaic array panel and an included angle between the measuring point vertical surface and the trend of a photovoltaic array according to the distances; calculating the distance deviation of the average distance relative to a preset value; when the distance deviation and the parallelism exceed the control tolerance limit, generating a chassis advancement steering operating instruction; controlling a driving link of a chassis advancement steering driving device to realize steering deviation rectification of a crawler chassis in the advancing process. The invention also provides an automatic deviation rectifying system which can implement the method. According to the deviation rectifying method and the deviation rectifying system disclosed by the invention, automatic deviation rectification of the cleaning vehicle in the advancing process is realized by using intrinsic characteristics of the photovoltaic array and an ultrasonic range finding method, and the reform on the photovoltaic array is unnecessary; the deviation rectifying process is realized quickly, accurately and stably, and the cleaning quality can be improved while the working intensity of a driver is reduced.

Owner:CSIC HAIWEI ZHENGZHOU HIGH TECH CO LTD

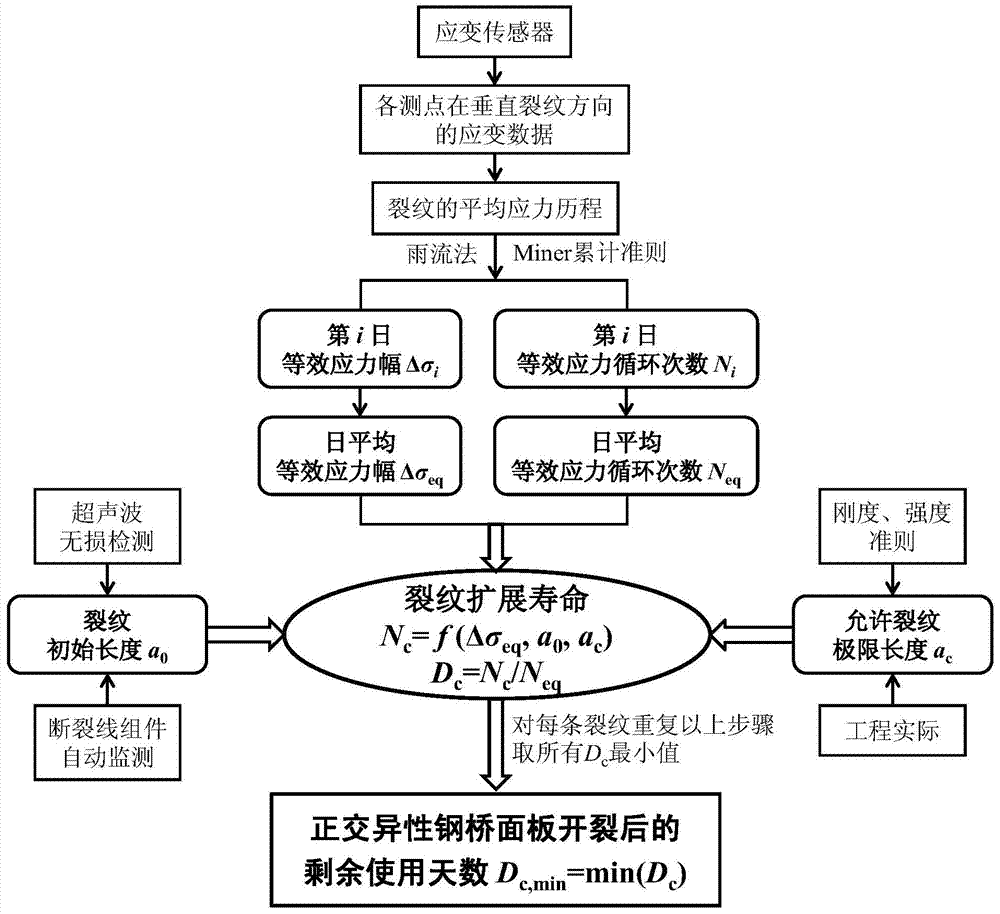

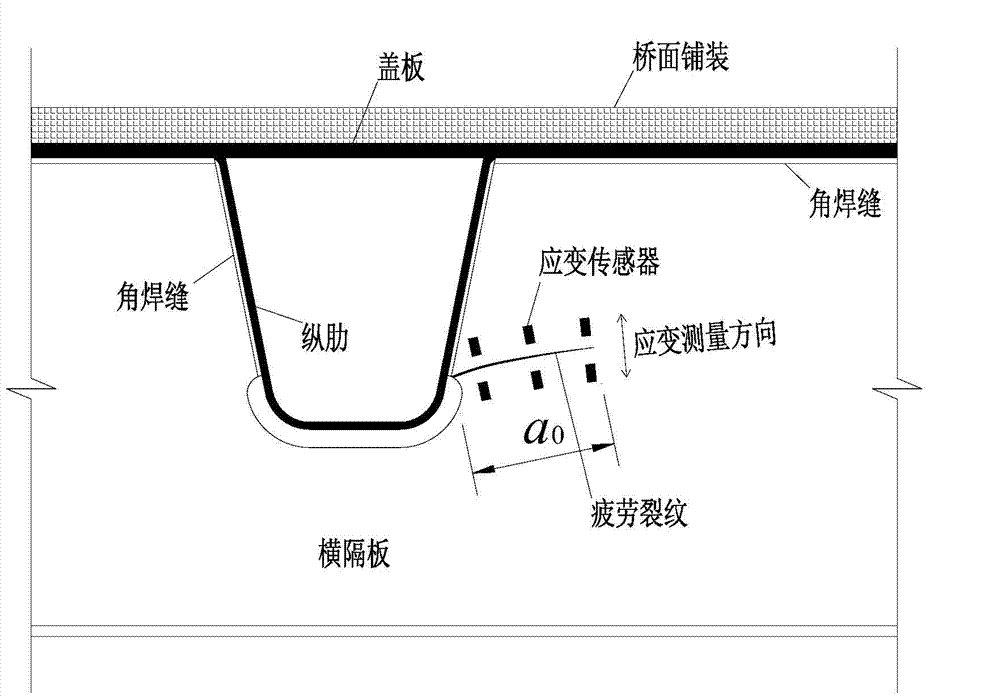

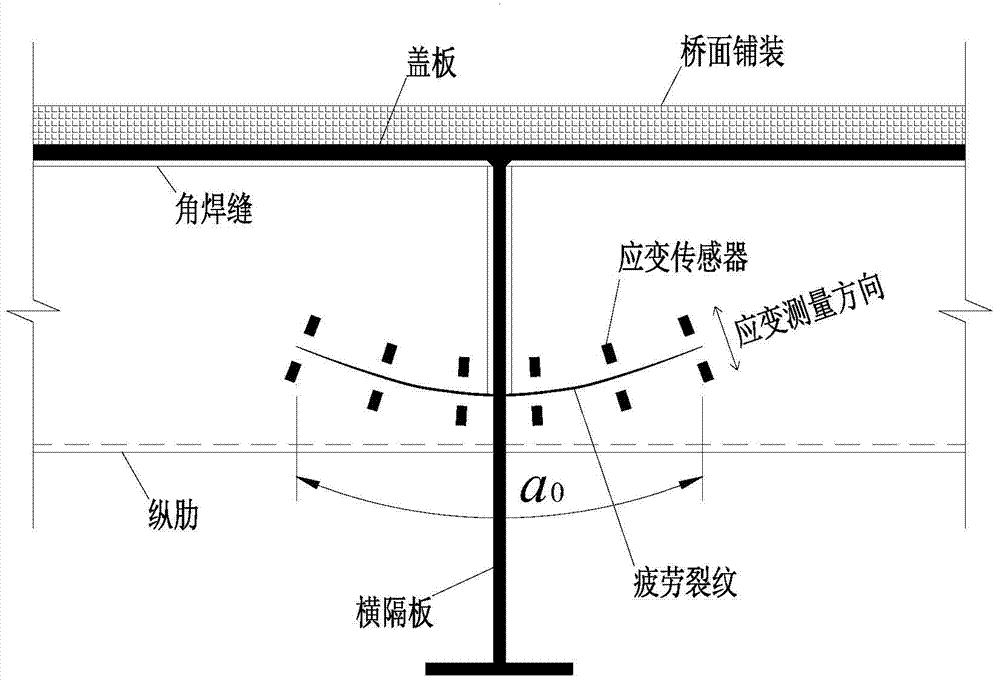

Method for evaluating remaining service life of orthotropic steel deck slab on active service after fatigue cracking

ActiveCN103940626ACan check security operation statusControllable security operation statusStructural/machines measurementNon destructiveTolerance limit

The invention provides a method for evaluating the remaining service life of an orthotropic steel deck slab on active service after fatigue cracking. The method specifically comprises the steps of (1) measuring the actual length a0 of each crack by adopting a non-destructive testing technology, (2) monitoring actual strain data of the two sides of each crack by adopting strain sensors, (3) obtaining stress process data of each crack, (4) calculating the daily mean equivalent stress amplitude delta sigma eq and the daily mean equivalent stress cycle index Neq according to a rain flow method and a Miner accumulation criterion, (5) determining the tolerance limit length ac of each crack by combining actual situations on the basis of rigidity and strength criterions, (6) calculating the propagation life Nc and Dc of each crack on the basis of a Paris formula, and (7) taking the minimum value of the Dc of all the cracks as the remaining fatigue life Dc, min of the steel bridge deck slab. The method for evaluating the remaining service life of the orthotropic steel deck slab on active service after the fatigue cracking is reliable in theory, clear in logic, and simple in detection means and method.

Owner:SHANGHAI JIAO TONG UNIV

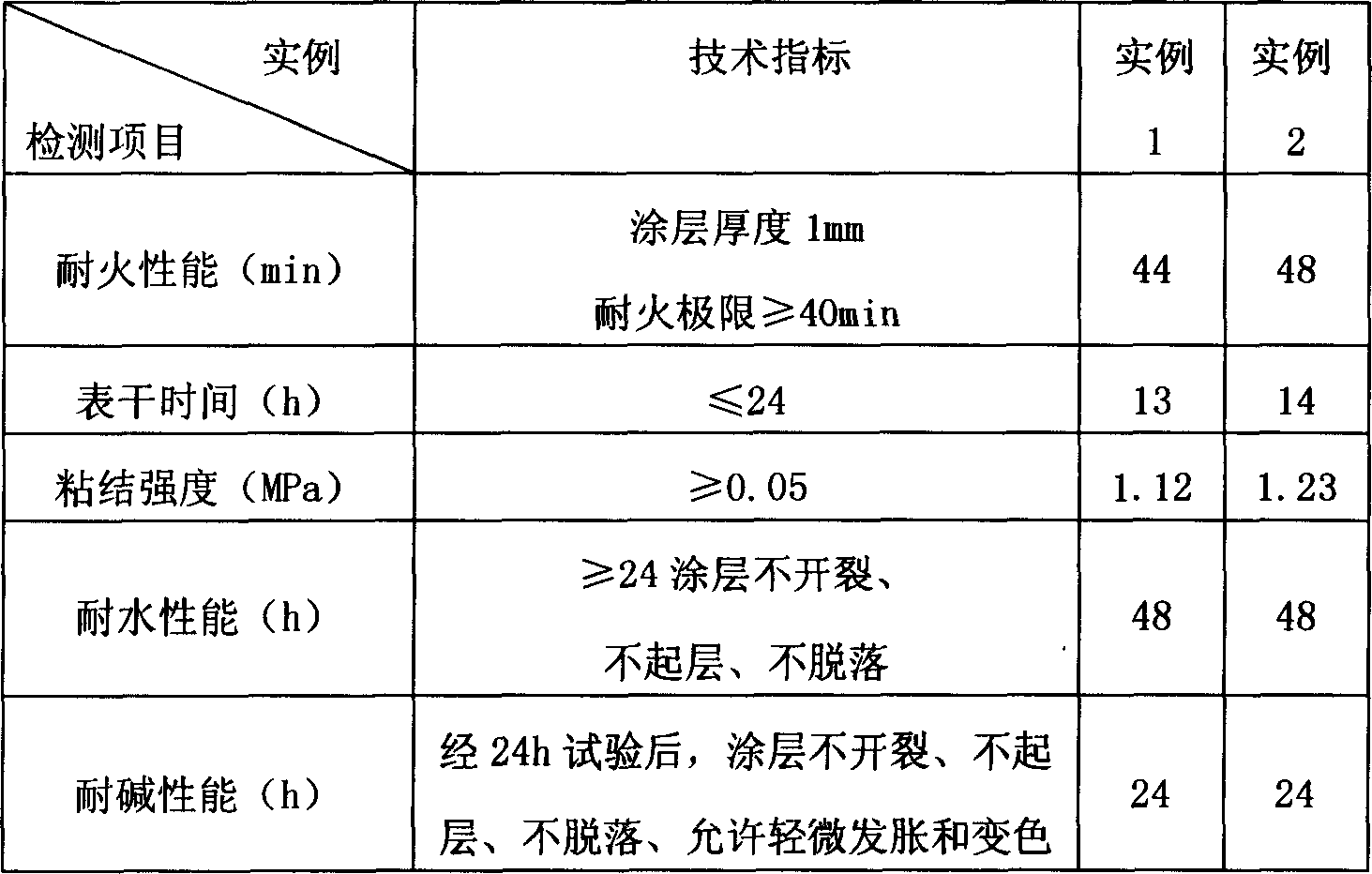

Expandable graphite-glue powder system thin layer tunnel fire-proof paint

InactiveCN1858123ASolve thick problemsGuaranteed oxygen concentrationFireproof paintsTolerance limitThin layer

The present invention discloses the preparation process of thin layer tunnel fire-proof paint of expandable graphite-glue powder system. The paint consists of dispersible latex powder 40-50 weight portions, expandable graphite 30-50 weight portions, aluminum hydroxide 5 weight portions, magnesium hydroxide 10-15 weight portions and water-proof powder 5-10 weight portions. The paint has dispersible latex powder as adhesive and expandable graphite as fire-proof and smoke isolating material, so that it has high coating adhesion strength, short coating curing period, high construction efficiency, high fire tolerance limit of the coating and high environment friendship. In addition, the paint is dry powder product and is used after adding water in the site, and this facilitates the packing, transportation and use.

Owner:SICHUAN UNIV

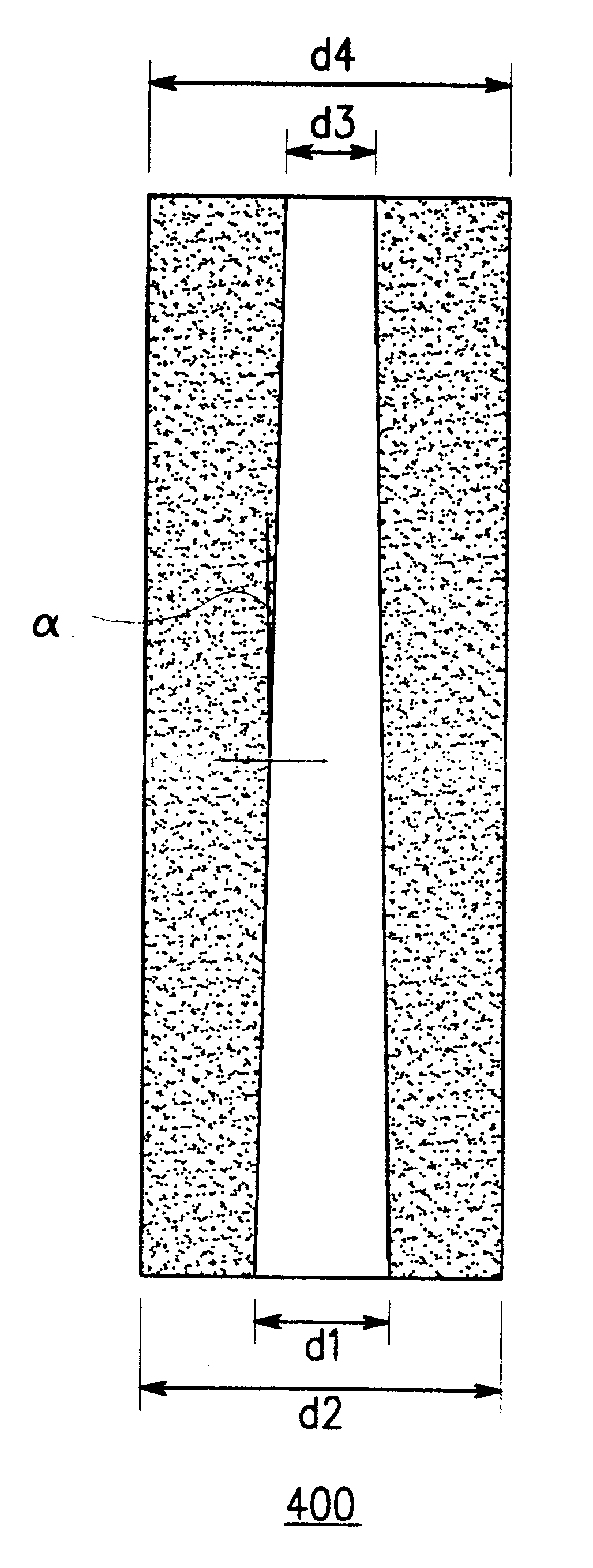

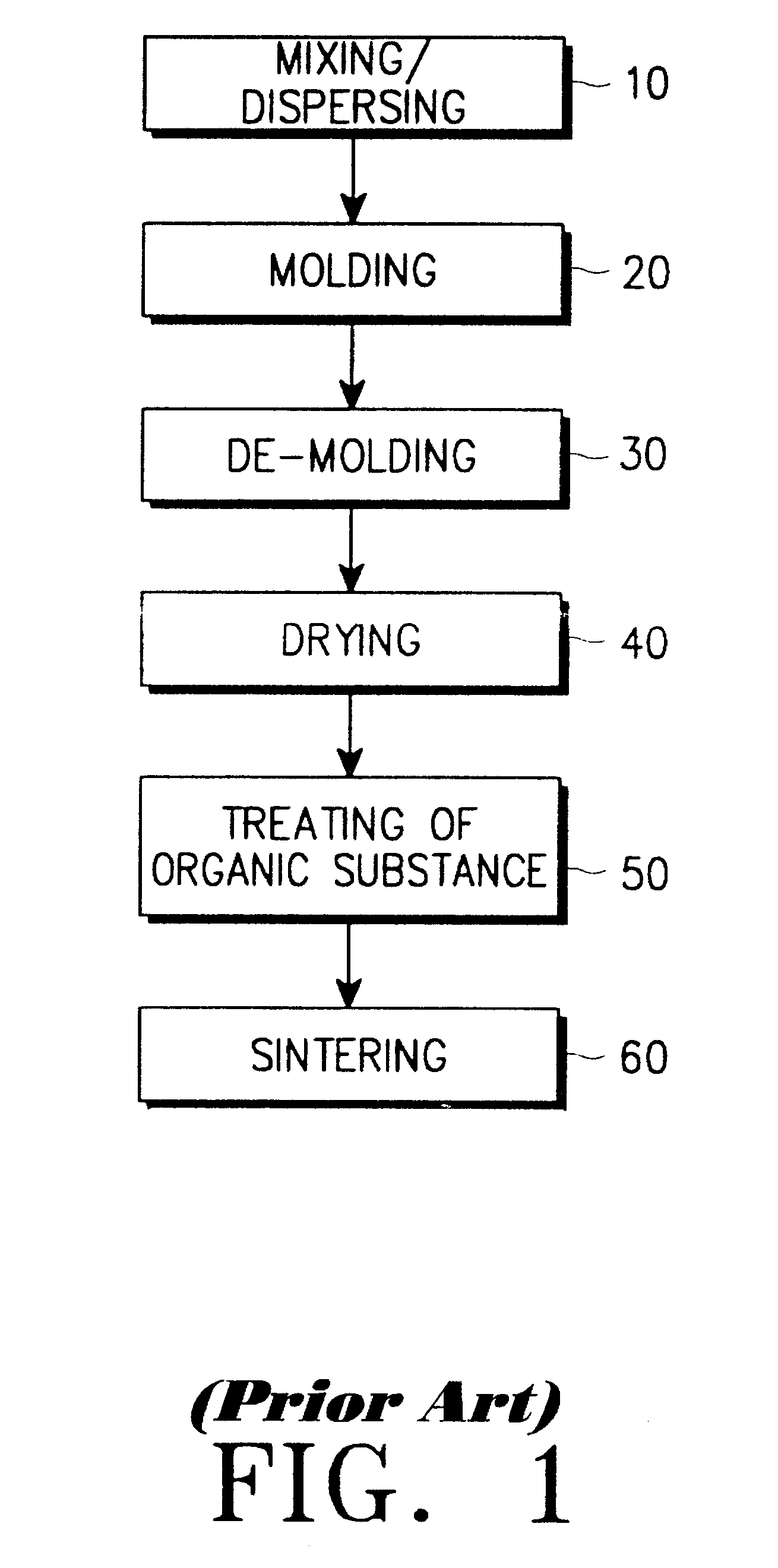

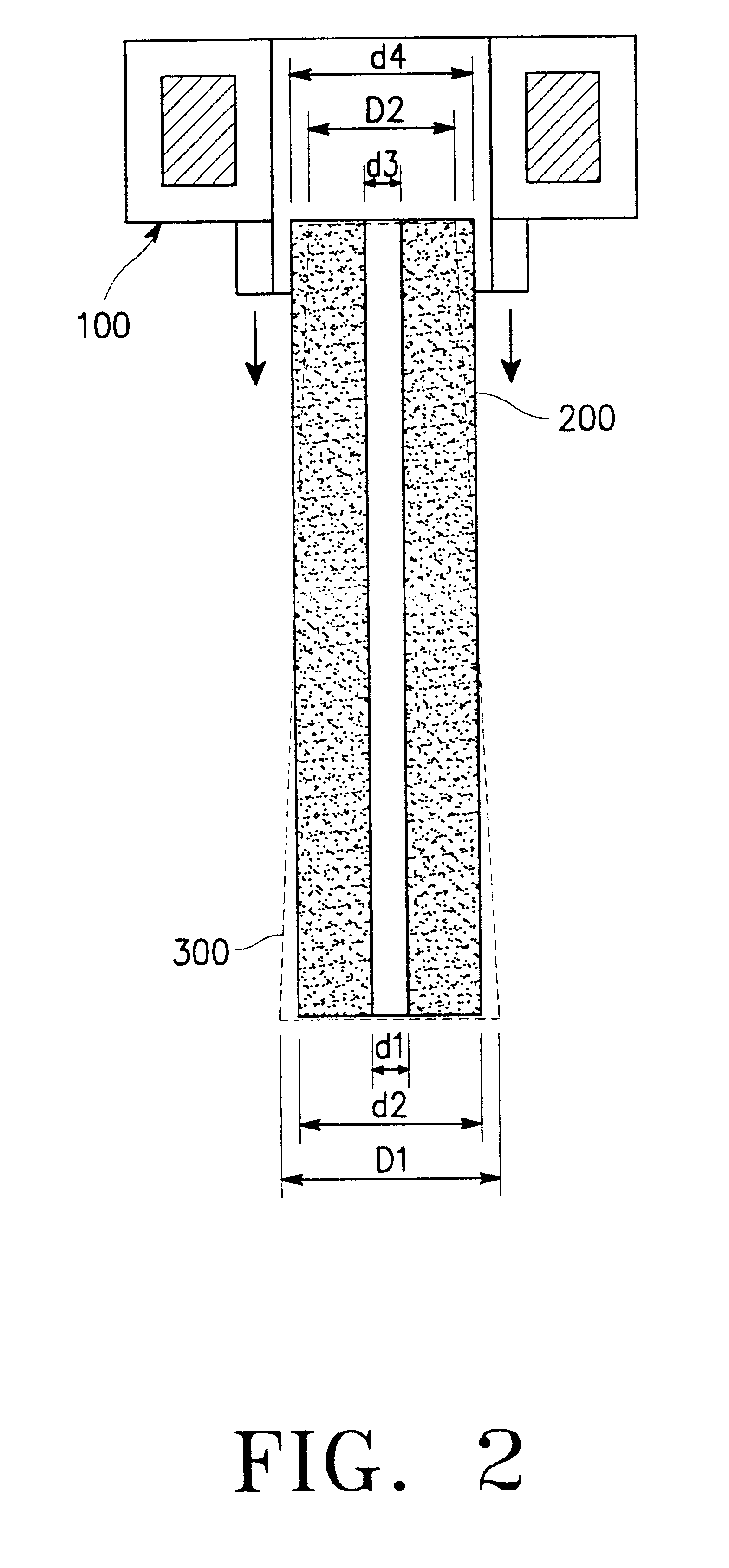

Method for manufacturing tube-shaped silica glass product

InactiveUS6555048B1Avoid distributingImproved transfer loss characteristicGlass shaping apparatusCeramic shaping apparatusTolerance limitSilicon dioxide

A silica product, method and apparatus for manufacturing a tube-shaped silica glass product using a molded green body having a hollow rod structure. A molded green body having a hollow rod structure has a uniform outer diameter and has a bore having an inner diameter increasing gradually from one end to the other. When sintered in a vertically movable sintering furnace, a tube-shaped silica glass product having a longitudinal cross section distribution less than a tolerance limit may be obtained. Optical fiber manufactured using the silica glass tube according to the present invention may have a uniform longitudinal geometrical structure, thereby exhibiting superior transmission characteristics.

Owner:SAMSUNG ELECTRONICS CO LTD

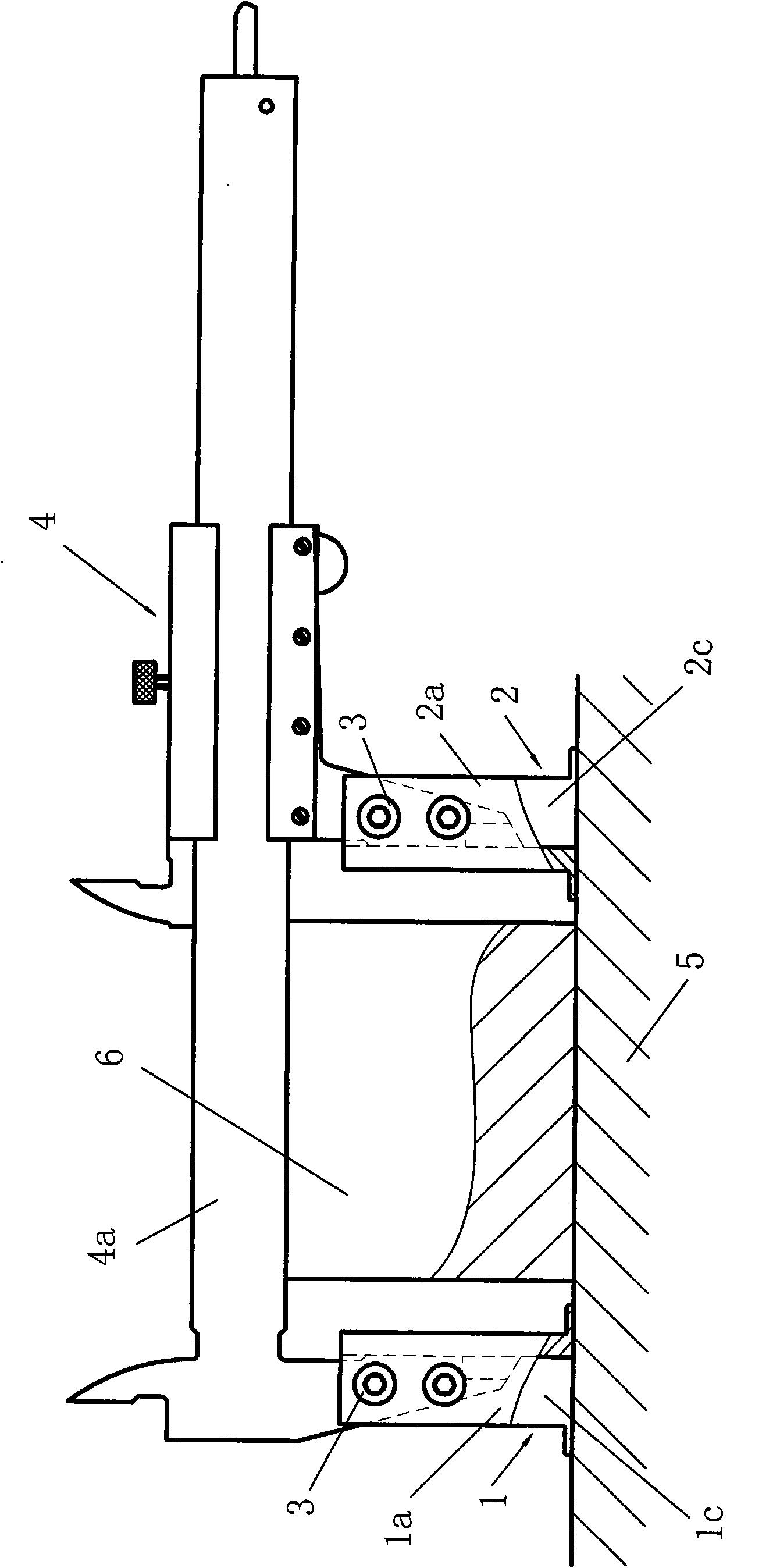

Method for measuring diameter of ring groove

InactiveCN101551222AAccurate detectionEasy to detectMechanical diameter measurementsVernier scaleTolerance limit

The invention relates to a method for measuring the diameter of a ring groove, which comprises an installing method and a detecting method. The measuring method comprises the following steps: placing the lower surface of the body of a vernier caliper on the top surface of a sizing block positioned on a flat plate, and making two outside tips vertically hang at two sides of the sizing block; fitting the bottom surface of the lower flanges of the measuring tips sleeved on the tips with the flat plate, and tightly screwing fastening bolts; when detecting, inserting the flanges of the two measuring tips from two sides of a measured ring groove until the flanges touch the bottom of the groove; finding the maximum value D2 generated when the shaft axis of the two measuring tips and the shaft axis of the measured ring groove are in the same plane; comparing the reading D2 with the standard value D1 of a block gage which is previously measured; and then, judging whether the measured value is within the tolerance limit or not. Each measuring tip comprises a column shaft provided with an axial through groove, and a coaxial thin disc-shaped flange positioned at the bottom end of the column shaft. The invention can accurately and conveniently detect the diameters of inner ring grooves and outer ring grooves of different sizes to meet the detection requirements of various workpieces.

Owner:力帆科技(集团)股份有限公司

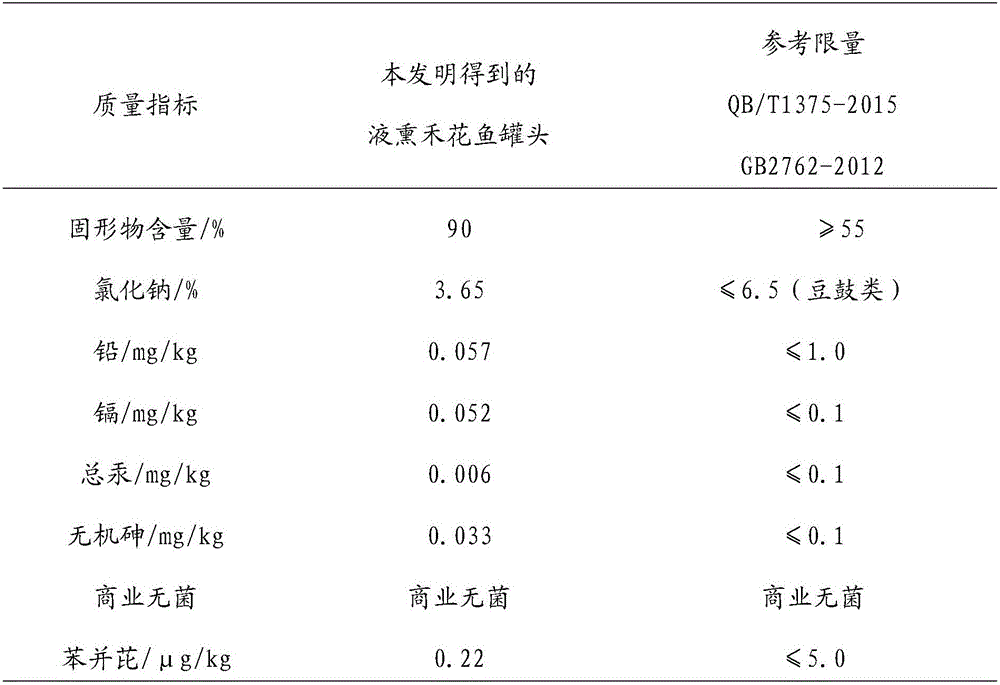

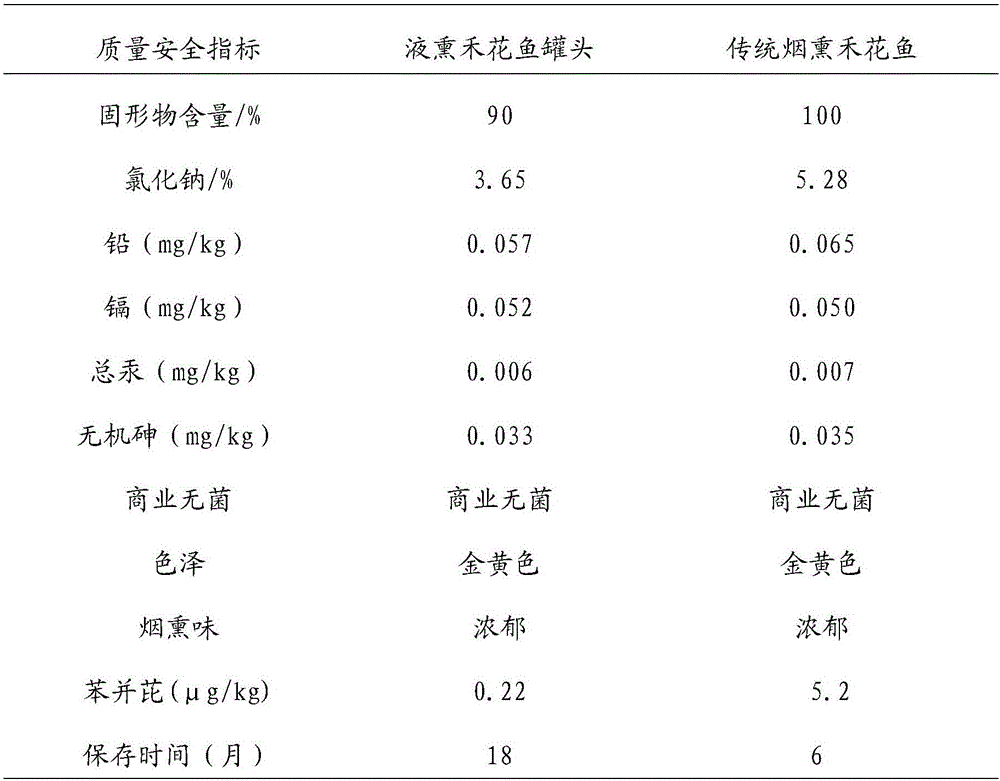

Preparation method of canned liquid-smoked procypris mera

InactiveCN105995628AAttractive smoky colorAttractive aromaFood ingredient as antioxidantFood ingredient as taste affecting agentTolerance limitLiquid smoke

The invention discloses a preparation method of canned liquid-smoked procypris mera and belongs to the technical field of processing of aquatic products. The preparation method comprises the following steps: (1) treatment of fish serving as a raw material; (2) liquid smoking; (3) frying; (4) canning and sealing; (5) sterilization; (6) cooling and packaging. The procypris mera is processed with a liquid smoking method, the attractive smoked color and fragrance can be obtained, and the functions of resisting bacteria, resisting oxidation and prolonging the guarantee period are realized; with the adoption of the smoking process, nutrients of the procypris mera are seldom damaged, processing is easy, time is saved, the efficiency is improved, the flavor of the product is good, and the canned liquid-smoked procypris mera has a golden color and a strong smoking flavor, is safe to take due to the fact that the content of residual BaP (benzopyrene) is lower than a national tolerance limit, and is very characteristic.

Owner:GUANGXI NORMAL UNIV

Method and apparatus for testing hollow pieces for impermeability

InactiveUS20010015091A1Achieve improvementShorten test timeMeasurement of fluid loss/gain ratePermeability/surface area analysisTemperature controlTolerance limit

The impermeability of a test piece, e.g., a pipe made of concrete, clay, stoneware, etc., is tested using negative pressure air. Air in a compensation tank is maintained at negative pressure and also at a temperature that correspond to the temperature of the inside wall of the test piece. Then, the test piece, sealed on both ends, has a negative pressure is generated therein that corresponds to the negative pressure inside the compensation tank. Subsequently, the air inside the test piece is replaced with the temperature-controlled air from inside the compensation tank, and then the negative pressure inside the test piece is adjusted to a predetermined testing level. The progression of the negative pressure over a time period in the test piece is monitored. If the measured negative pressure drops below a prescribed tolerance limit, the pipe is considered too leaky.

Owner:MESSMANN ANNEMARIE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com