Method for measuring diameter of ring groove

A measurement method and detection method technology, applied in the direction of mechanical diameter measurement, etc., can solve the problems of inaccurate size measurement, inaccurate measurement, tilt measurement, etc., and achieve the effect of meeting the detection needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

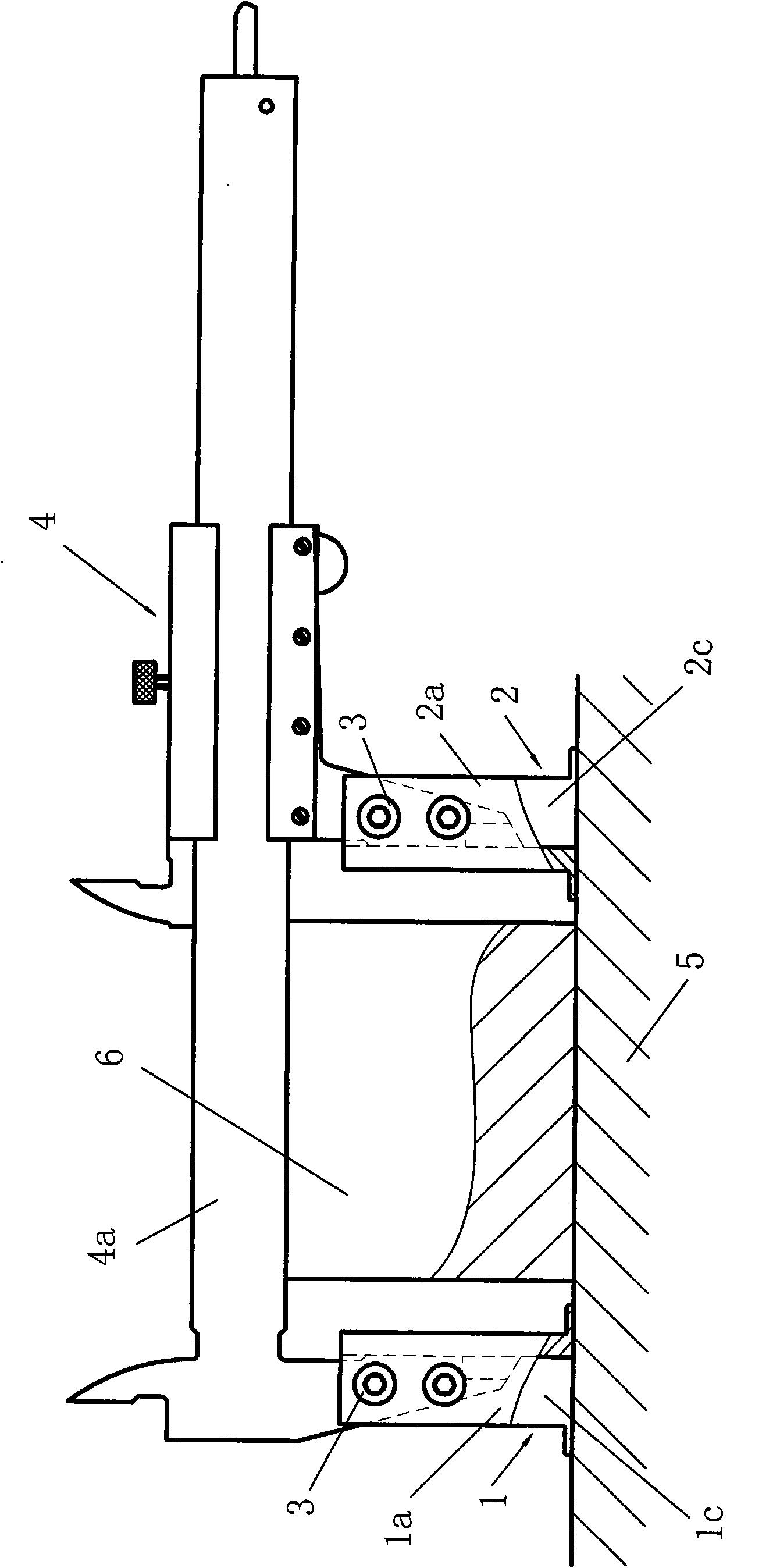

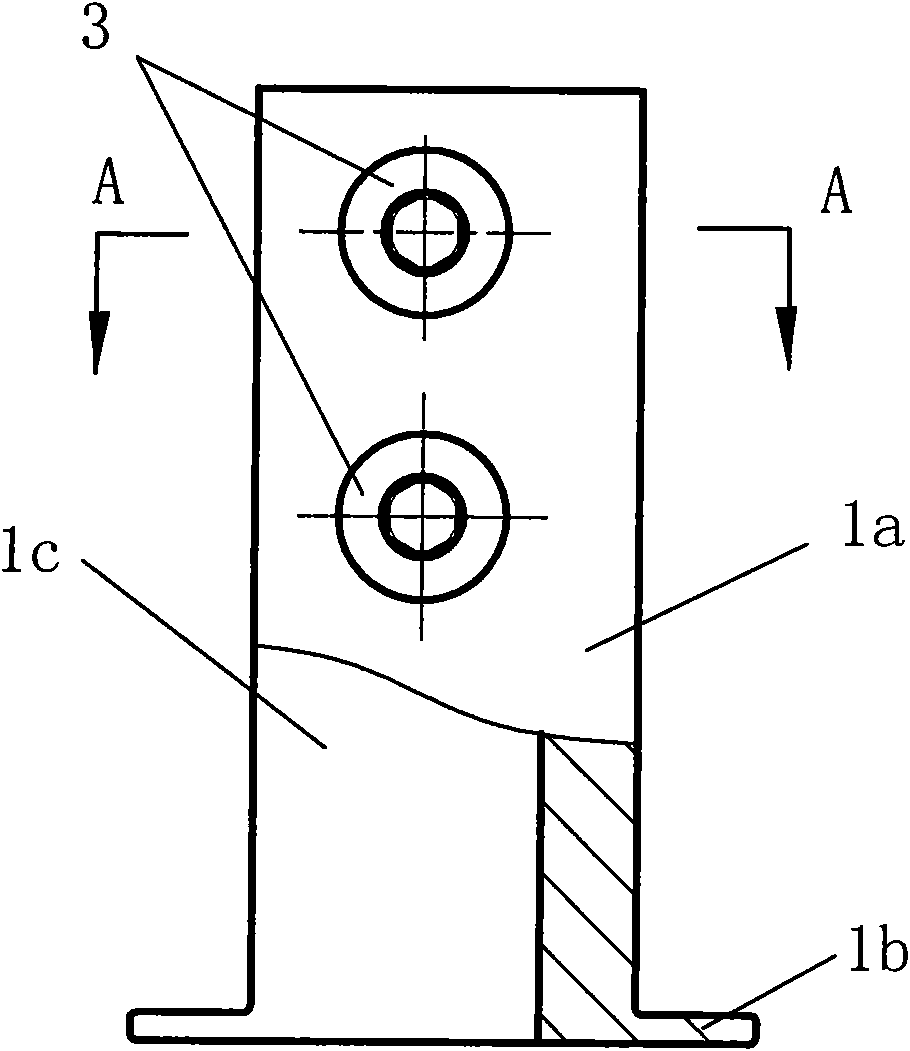

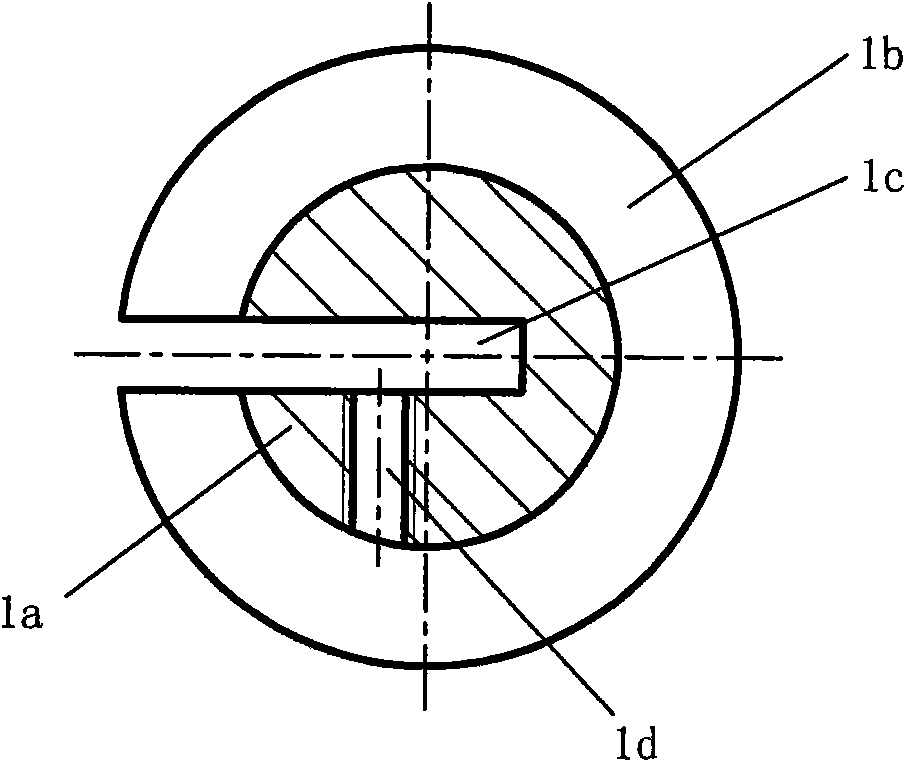

[0016] Embodiment 1: as figure 1 Shown, a kind of measuring method of ring groove diameter comprises installation method and detection method, carries out according to the following steps: (1) installation method, A, place a piece of contour pad iron 6 on flat plate 5, the external measurement of vernier caliper 4 The clips are respectively inserted into the through grooves of the left measuring pin 1 and the right measuring pin 2 with the same structure, so that the two measuring pins are set on the external measuring pins of the vernier caliper 4, and the height of the contour pad 6 is the length of the external measuring pins 1.4 times; B, place the lower surface of the ruler body 4a of the vernier caliper 4 on the top surface of the contour pad iron 6, and make the two external measuring pins vertically suspended on both sides of the contour pad iron 6, adjust The two measuring feet make the bottom surface of the flange at the lower end of the measuring feet stick to the f...

Embodiment 2

[0021] Embodiment 2: In the method for measuring the ring groove diameter described in this embodiment, the measuring foot used has the same structure as the measuring foot in Embodiment 1, and the measuring method is basically the same as that of Embodiment 1. The difference is that in During detection, the block gauge group formed by the combination of multiple block gauges is replaced by a block gauge close to the nominal size of the bottom diameter of the measured ring groove, and the length of the block gauge is first measured with the vernier caliper 4 equipped with the measuring feet, Note down the reading D 0 , and then use the method to measure the bottom diameter D of the tested ring groove 2 , the difference Δ obtained by subtracting the nominal size of the block gauge from the nominal size of the measured ring groove bottom diameter D Compensated to reading D 2 , get the value D 3 , ie Δ D +D 2 =D 3 , and finally the value D 3 with reading D0 Compare to dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com