Patents

Literature

3092results about "Mechanical diameter measurements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

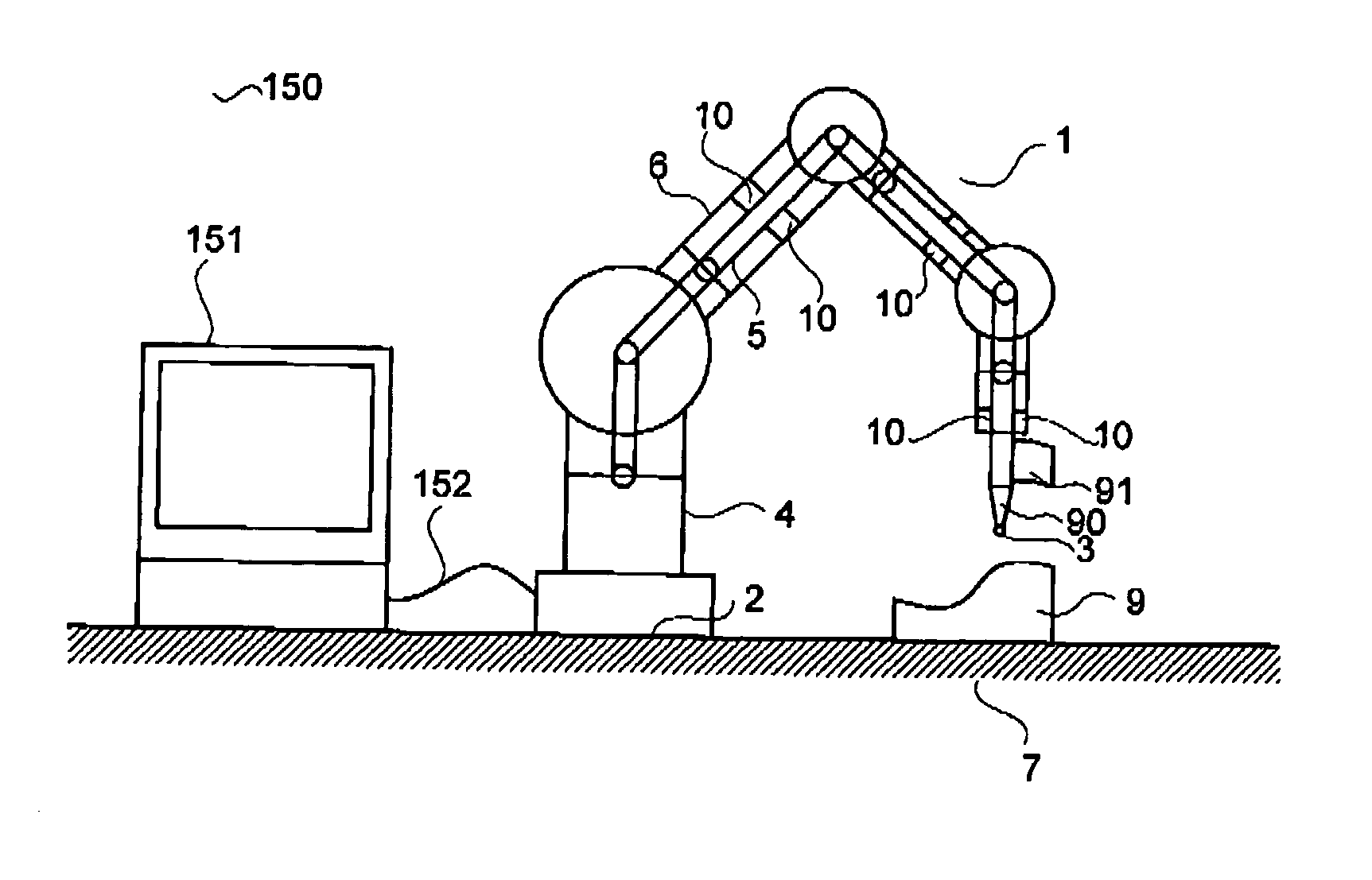

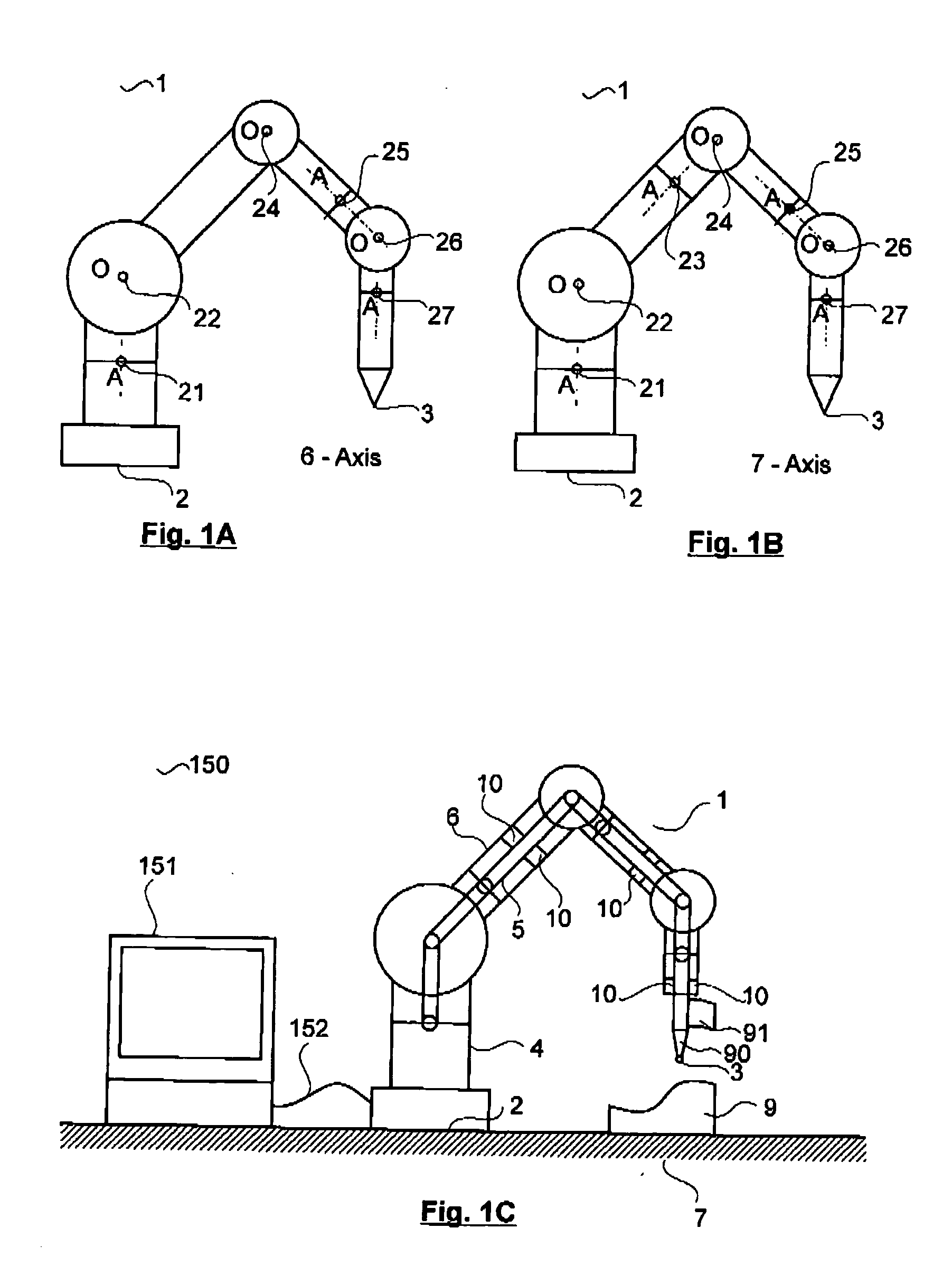

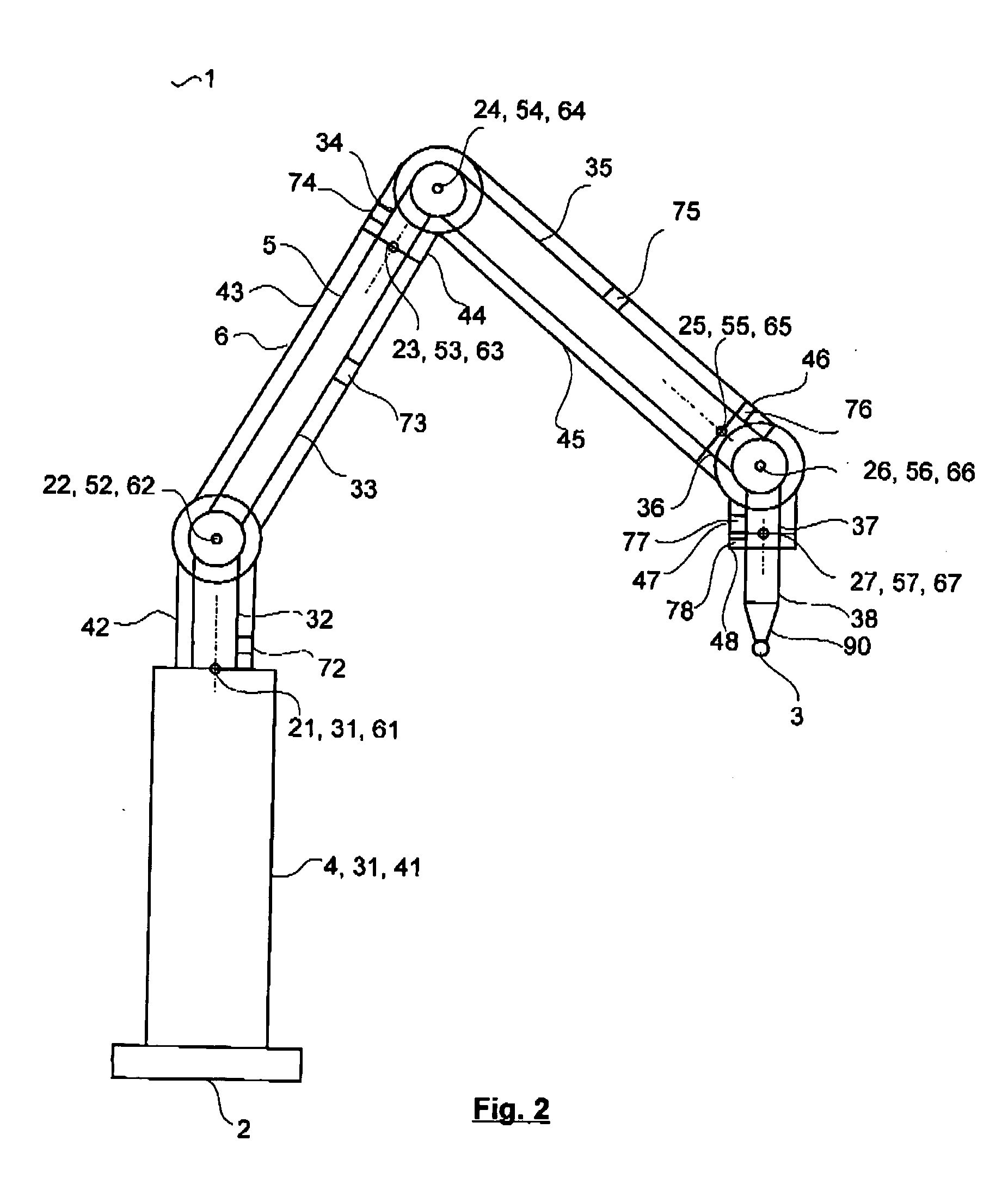

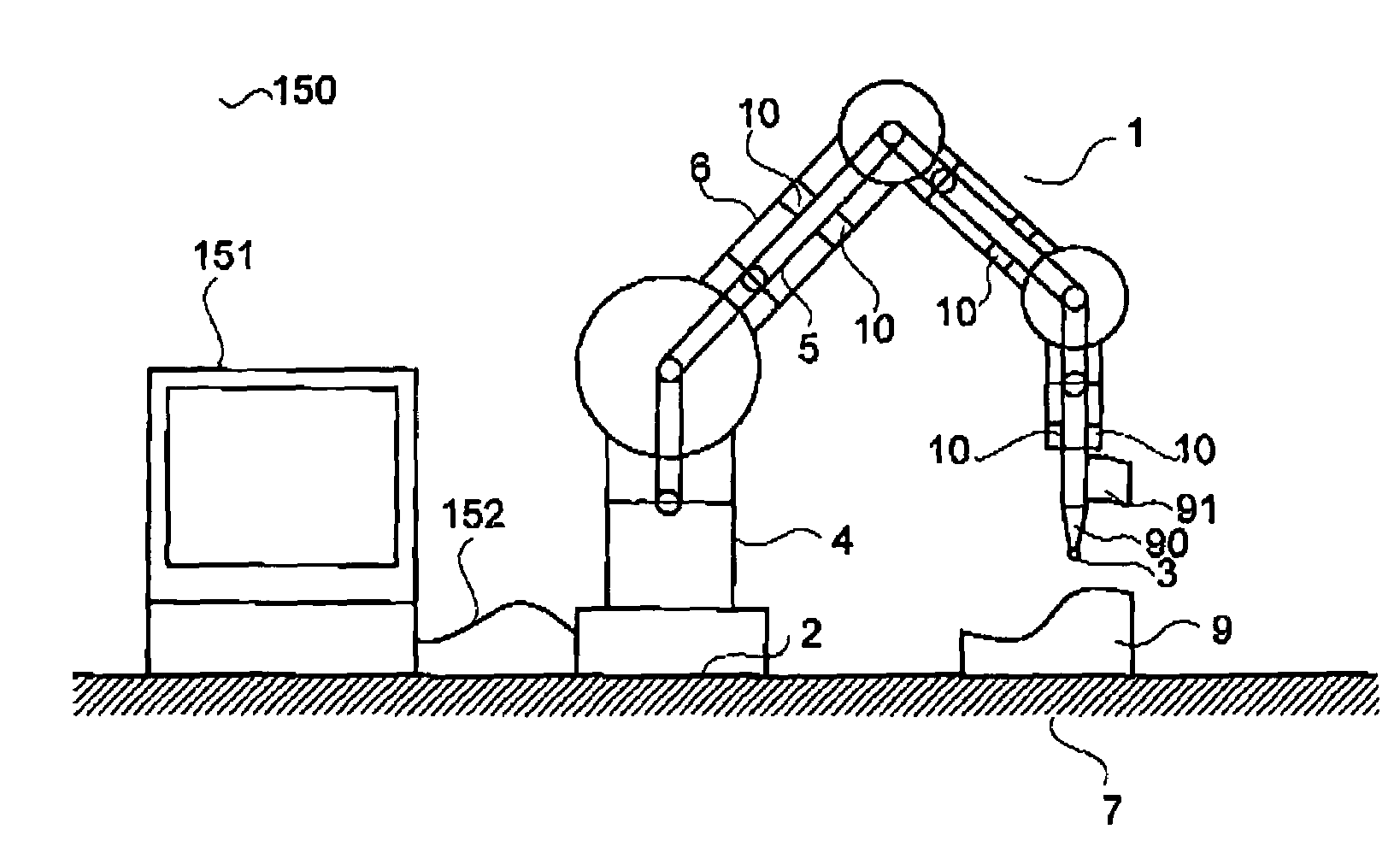

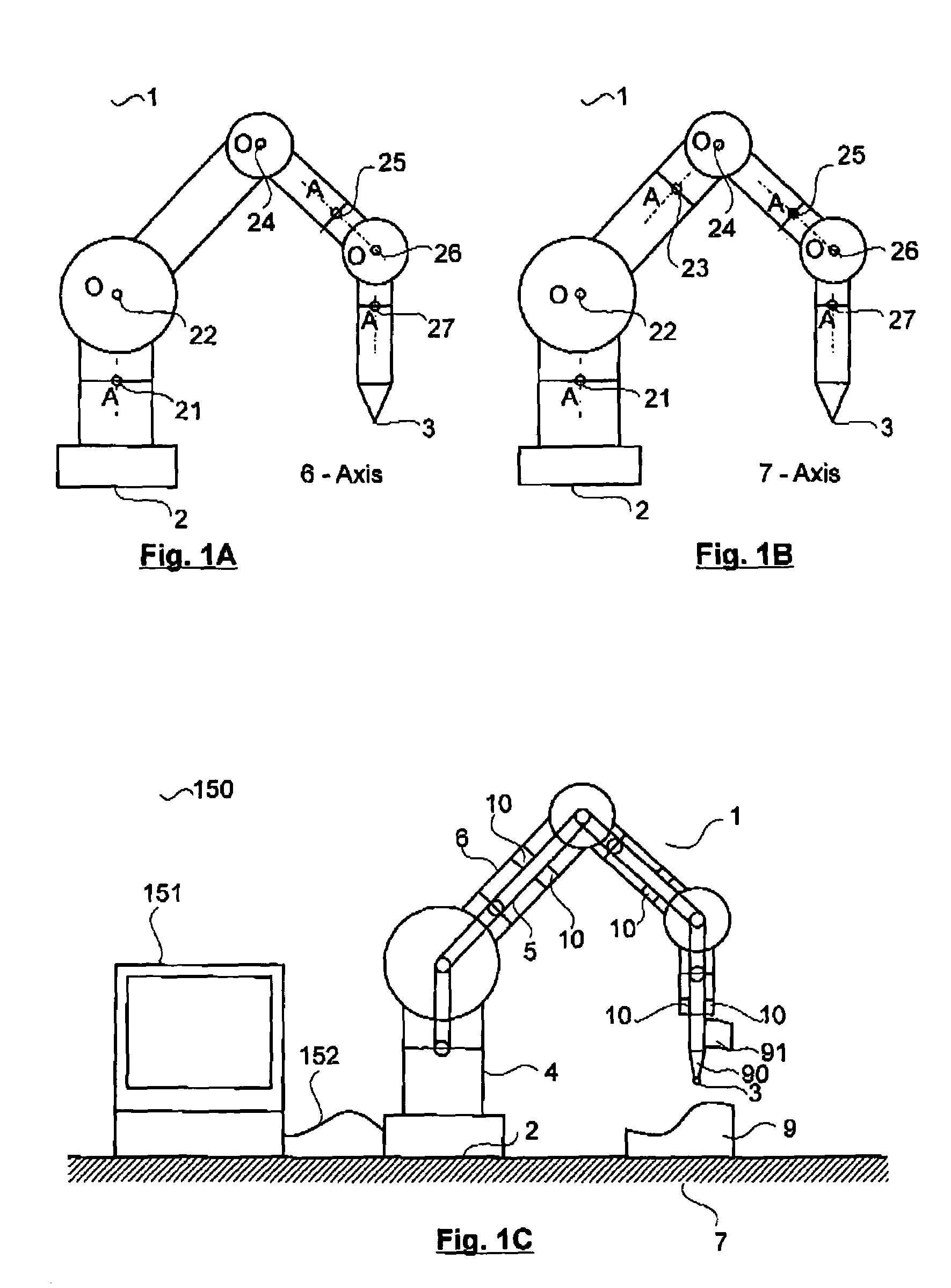

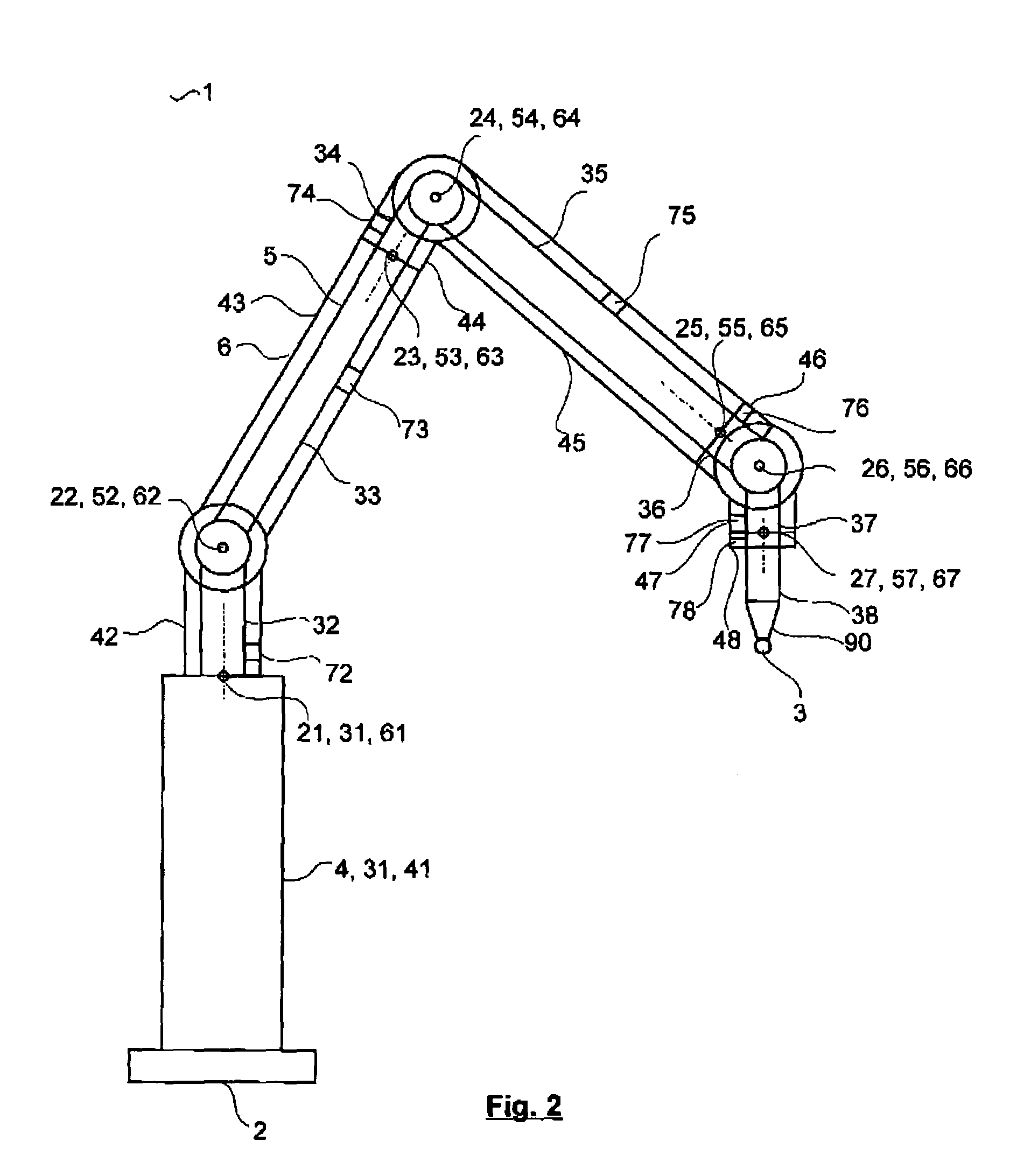

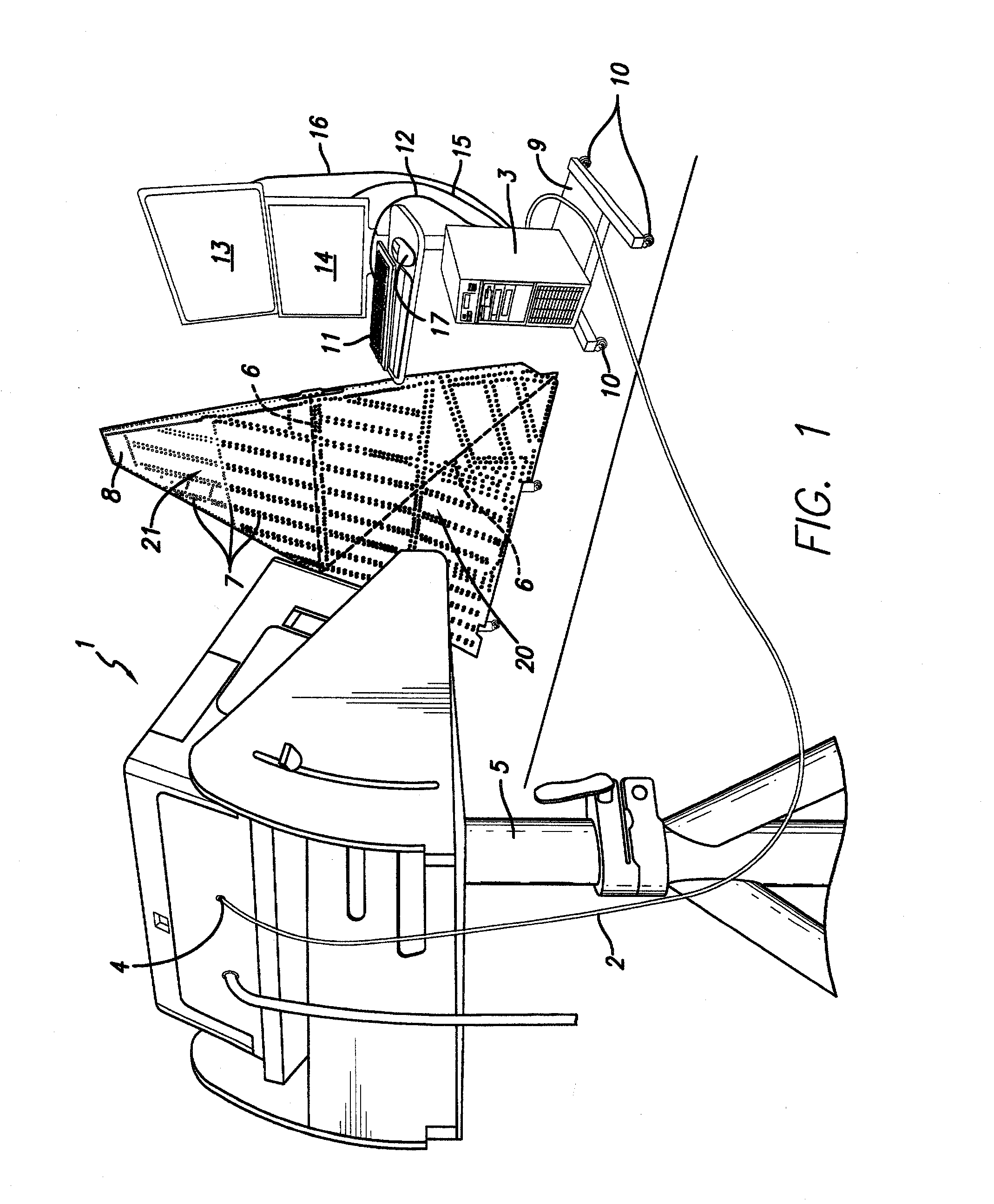

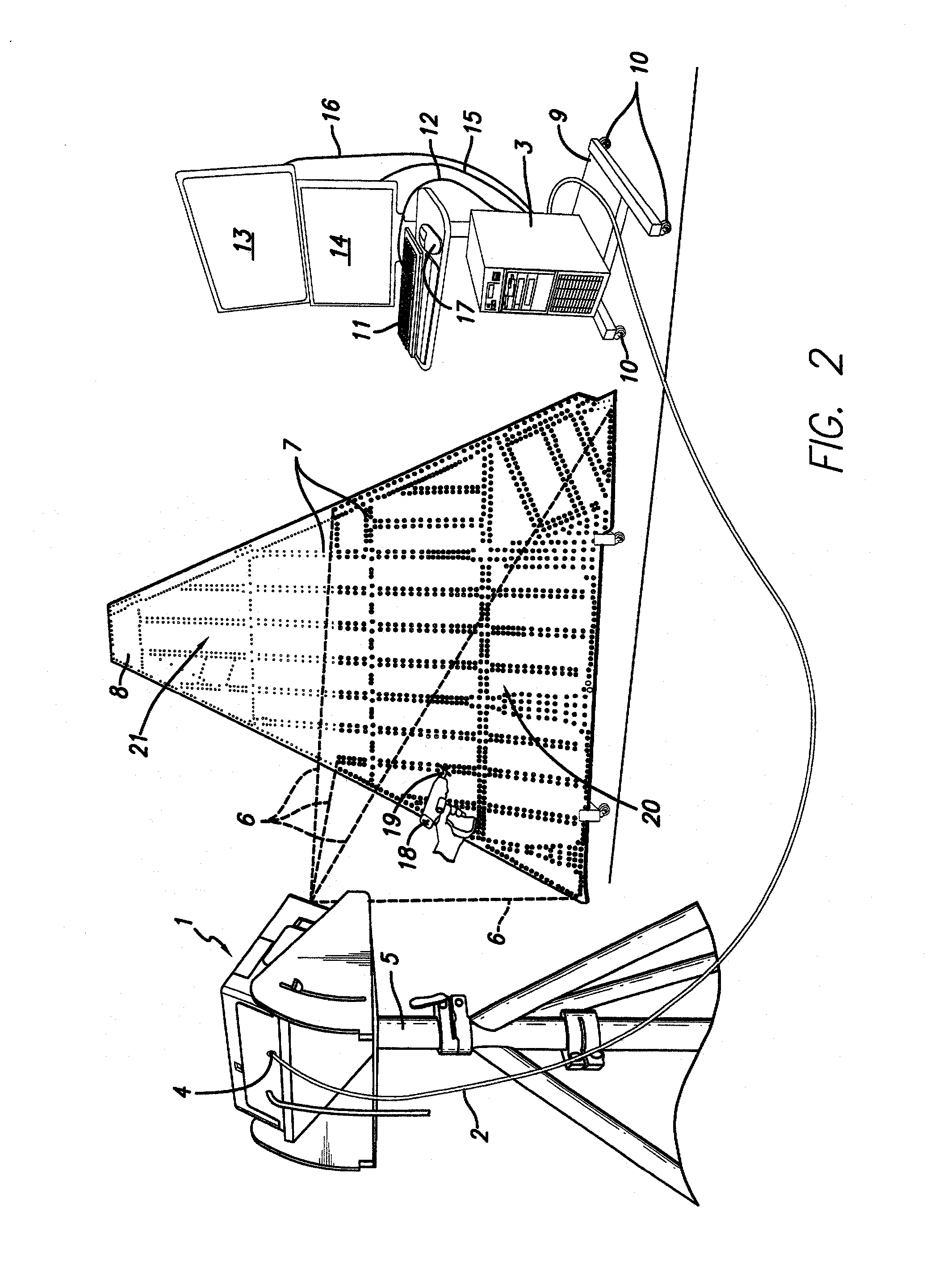

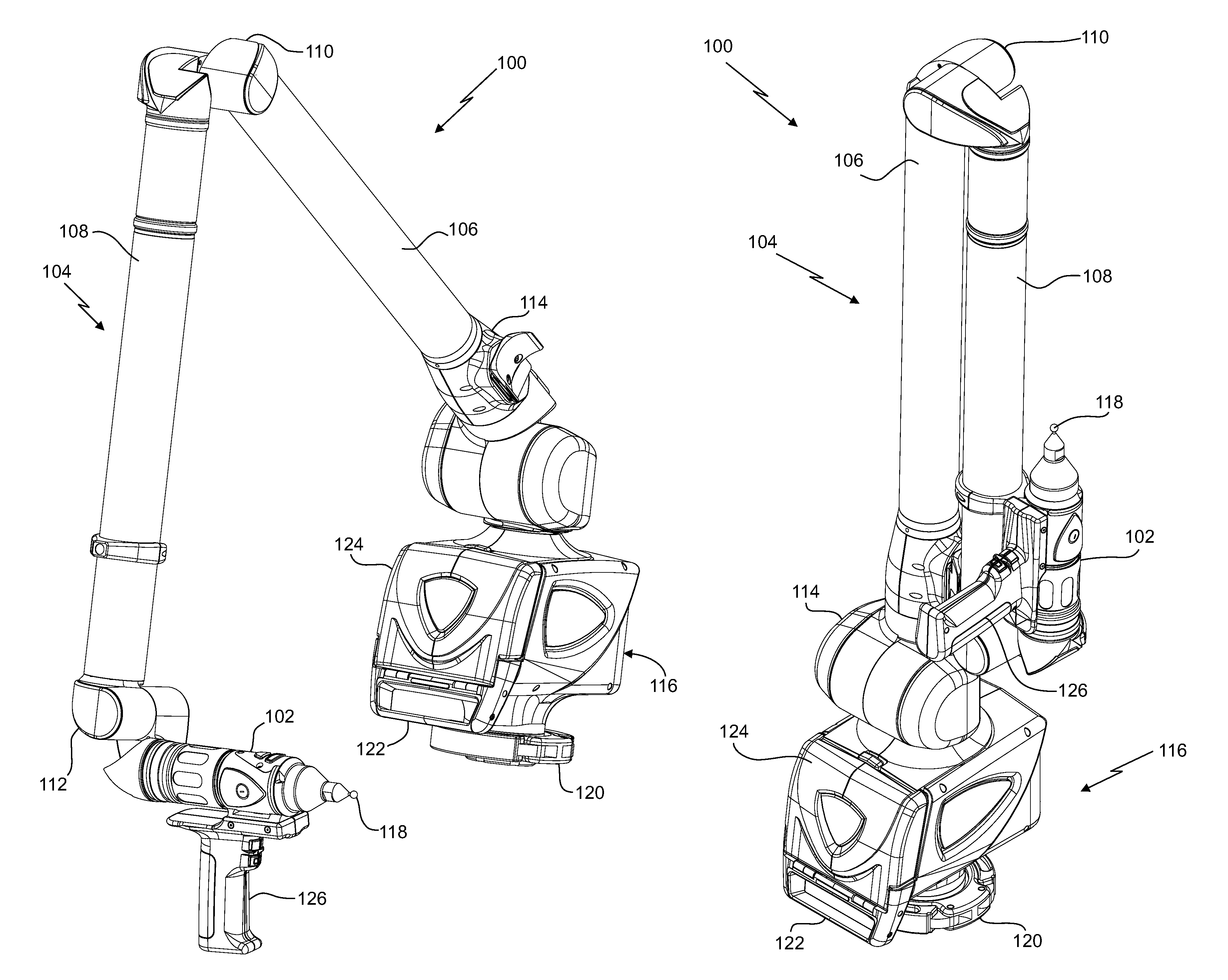

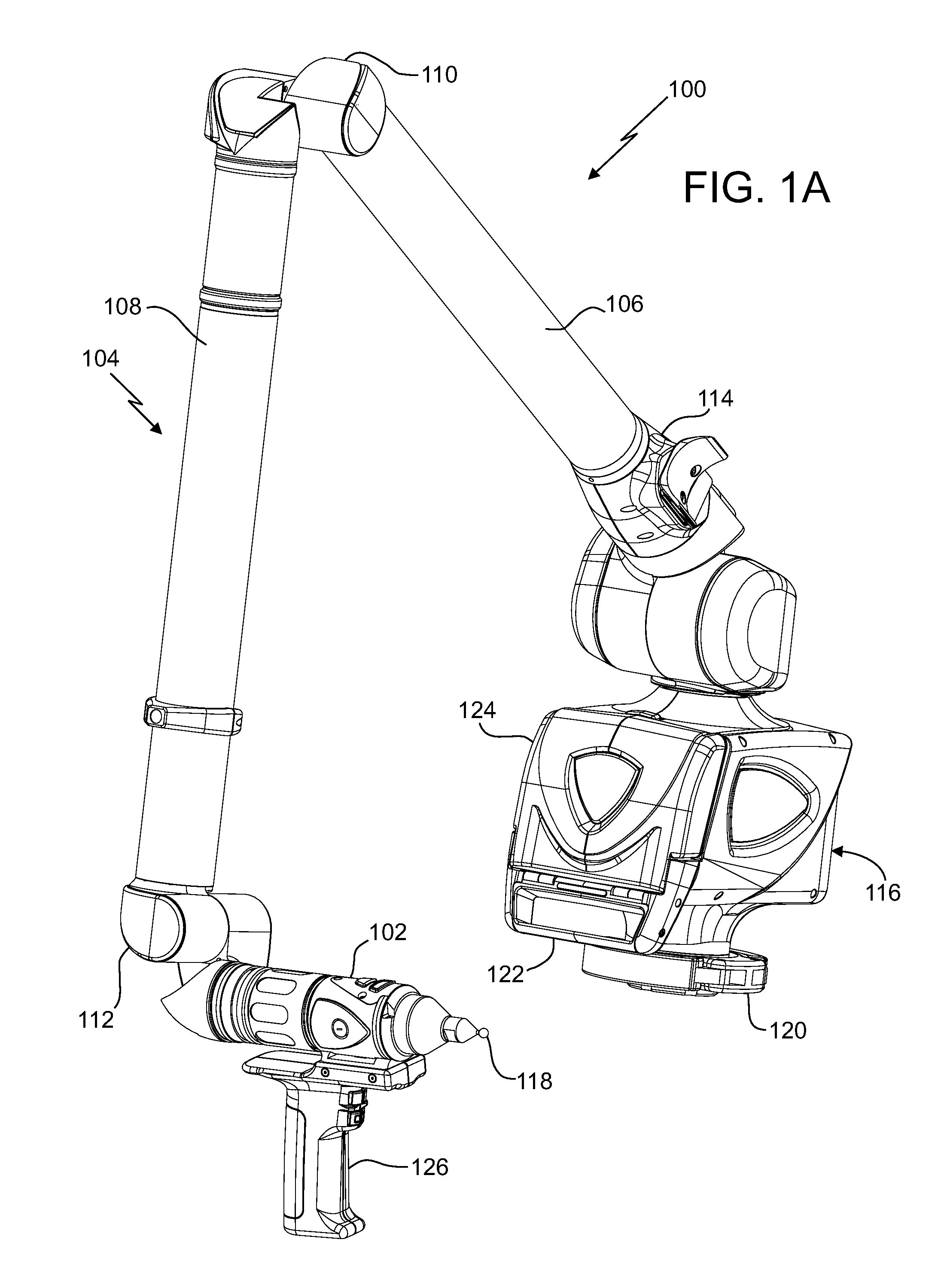

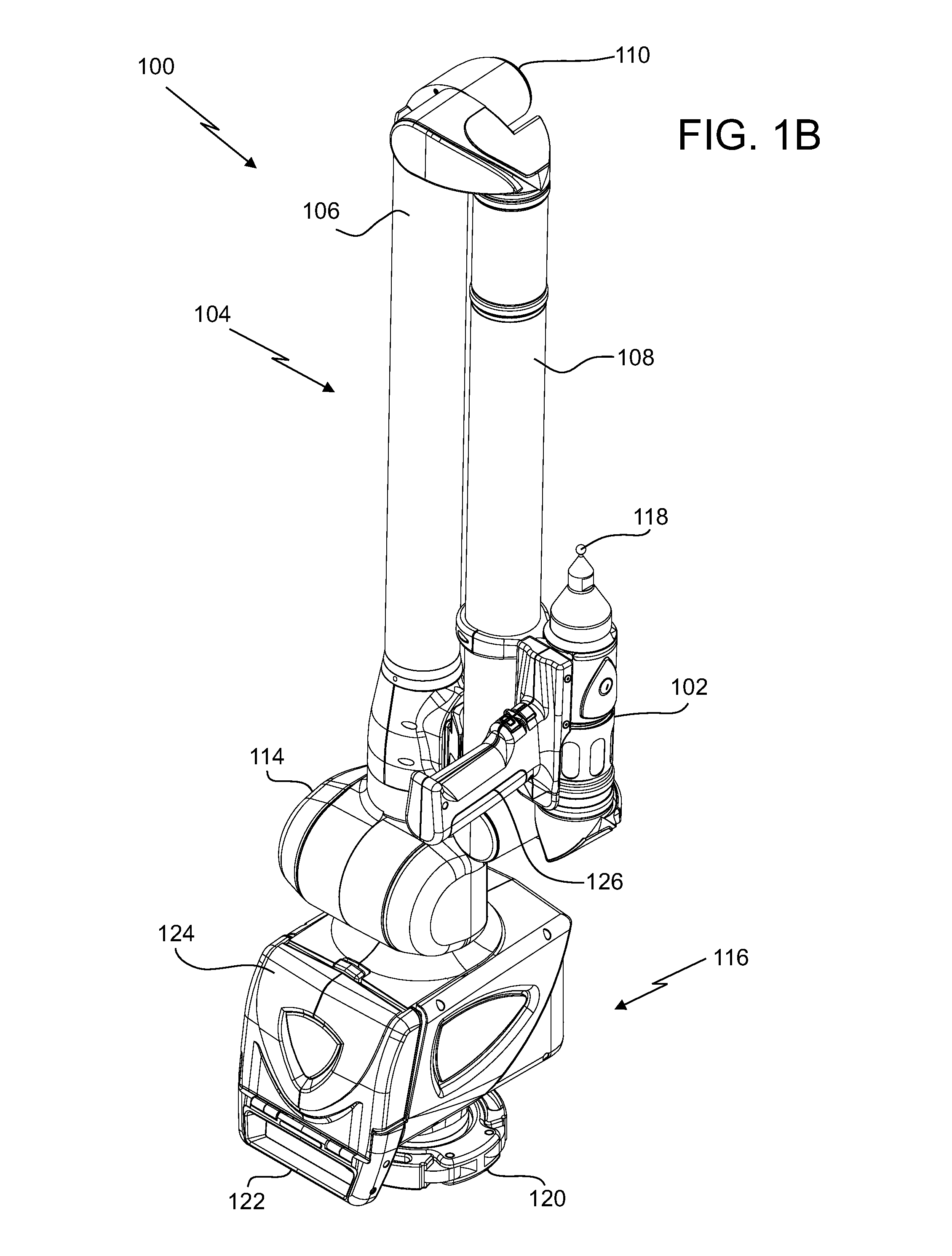

CMM arm with exoskeleton

ActiveUS20050166413A1Significantly accurateSignificantly robustProgramme controlProgramme-controlled manipulatorEngineeringCoordinate-measuring machine

Apparatus for a CMM Arm with Exoskeleton is provided comprising an Internal CMM Arm with a base end and a probe end, and an Exoskeleton driving the Internal CMM Arm through a plurality of transmission. One or more contact probes, optical probes and tools are mounted on the probe end. The CMM Arm with Exoskeleton is provided in manually operable and automated embodiments. The CMM Arm with Exoskeleton is operable for accurate measurement or for performing accurate operations. Methods are provided for operation of the CMM Arm with Exoskeleton.

Owner:NIKON METROLOGY

CMM arm with exoskeleton

ActiveUS7395606B2Significantly accurateSignificantly robustProgramme controlProgramme-controlled manipulatorEngineeringExoskeleton

Apparatus for a CMM Arm with Exoskeleton is provided comprising an Internal CMM Arm with a base end and a probe end, and an Exoskeleton driving the Internal CMM Arm through a plurality of transmissions. One or more contact probes, optical probes and tools are mounted on the probe end. The CMM Arm with Exoskeleton is provided in manually operable and automated embodiments. The CMM Arm with Exoskeleton is operable for accurate measurement or for performing accurate operations. Methods are provided for operation of the CMM Arm with Exoskeleton.

Owner:NIKON METROLOGY

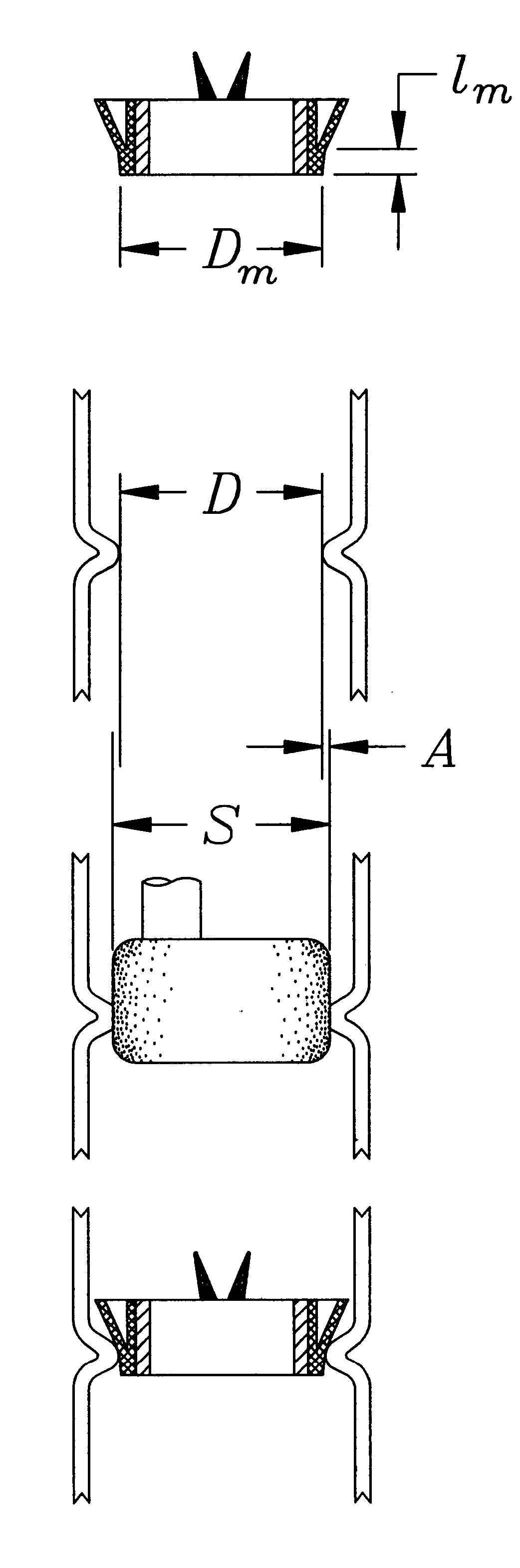

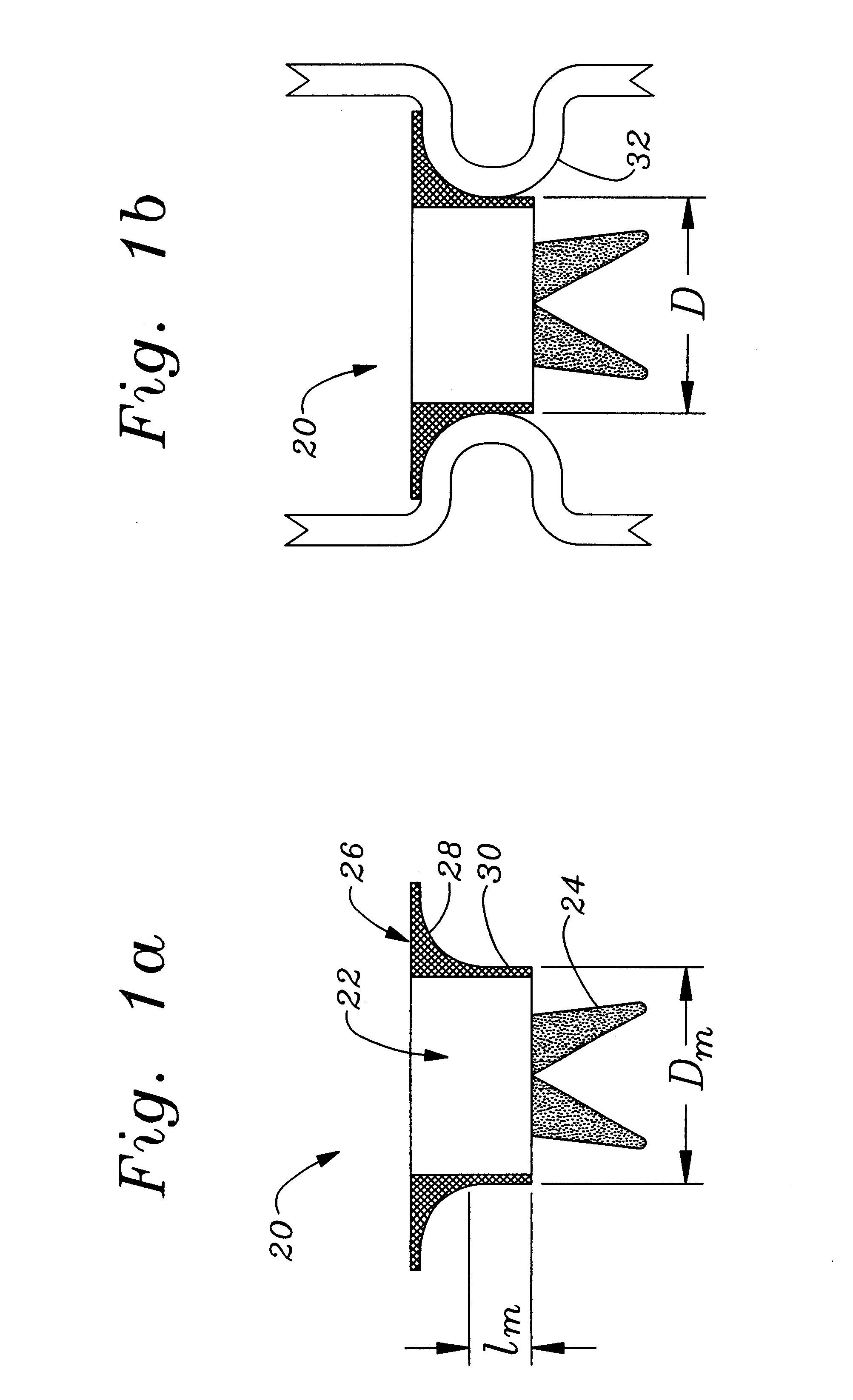

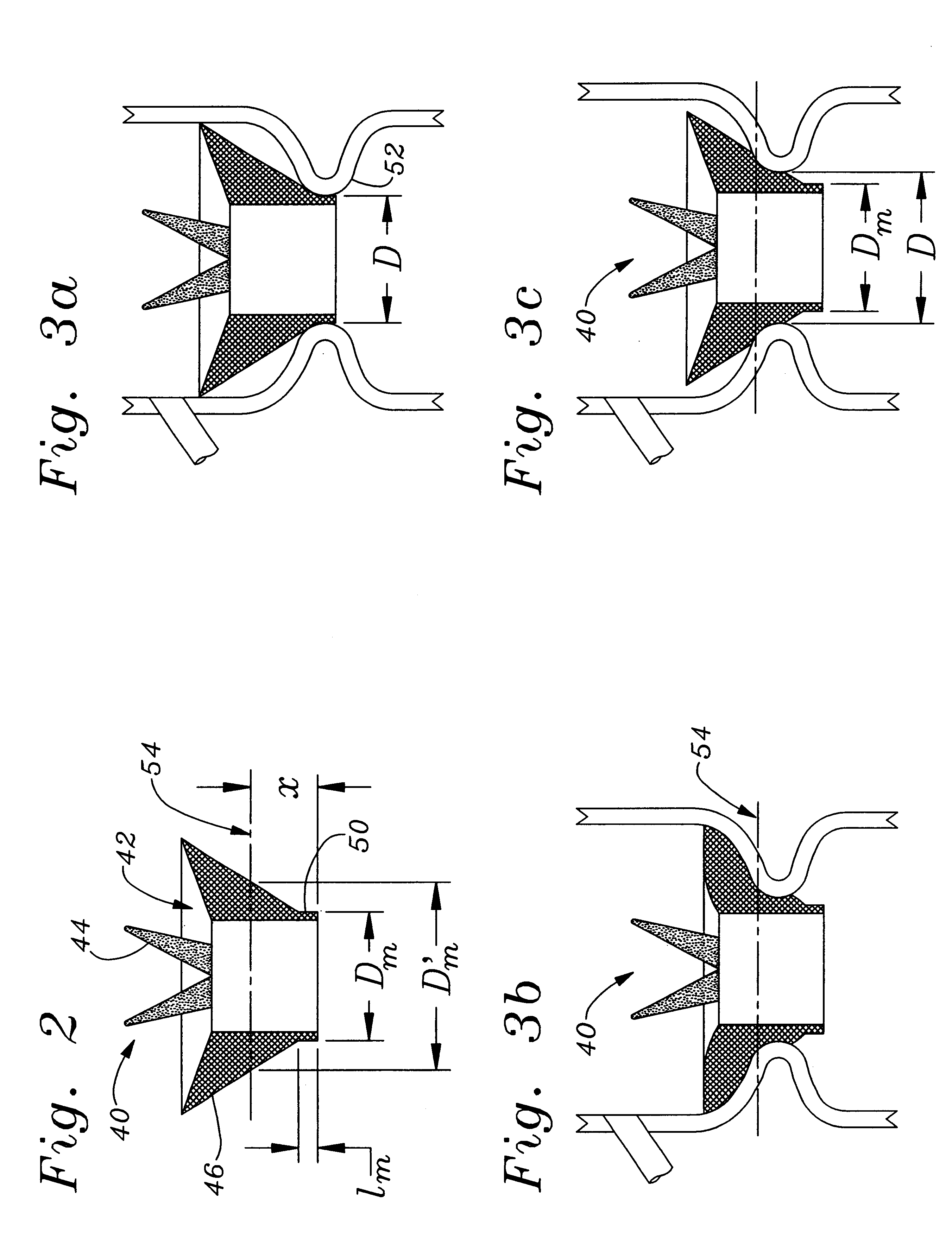

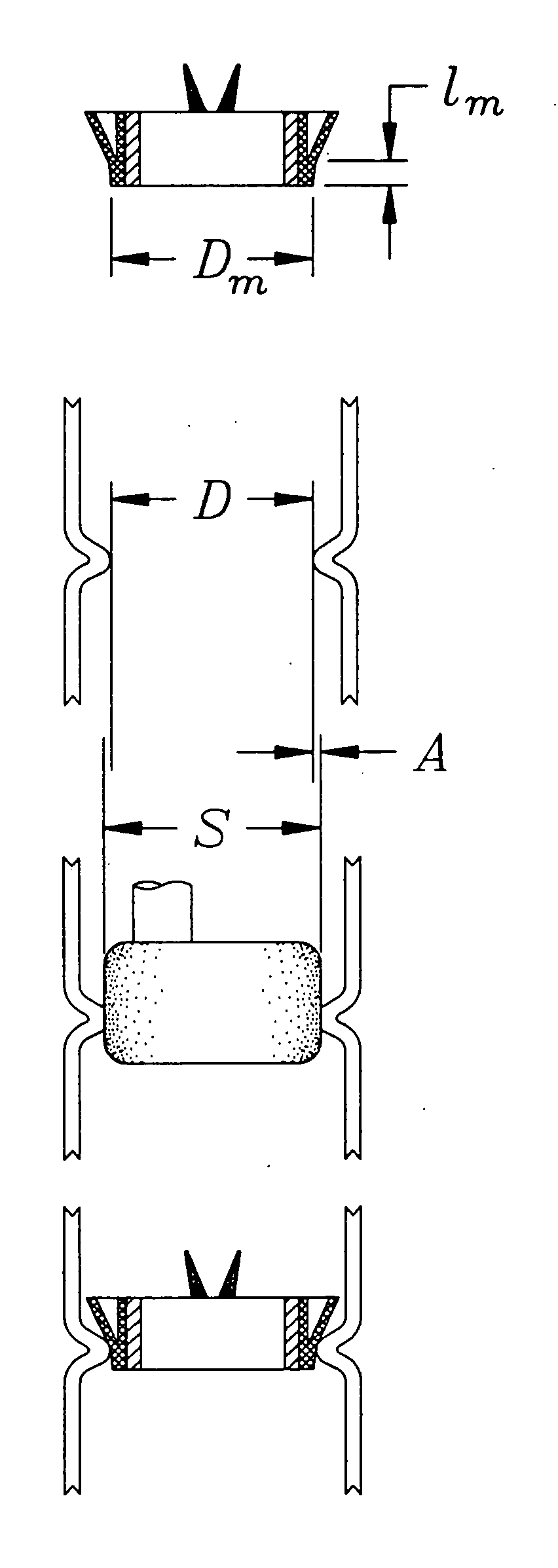

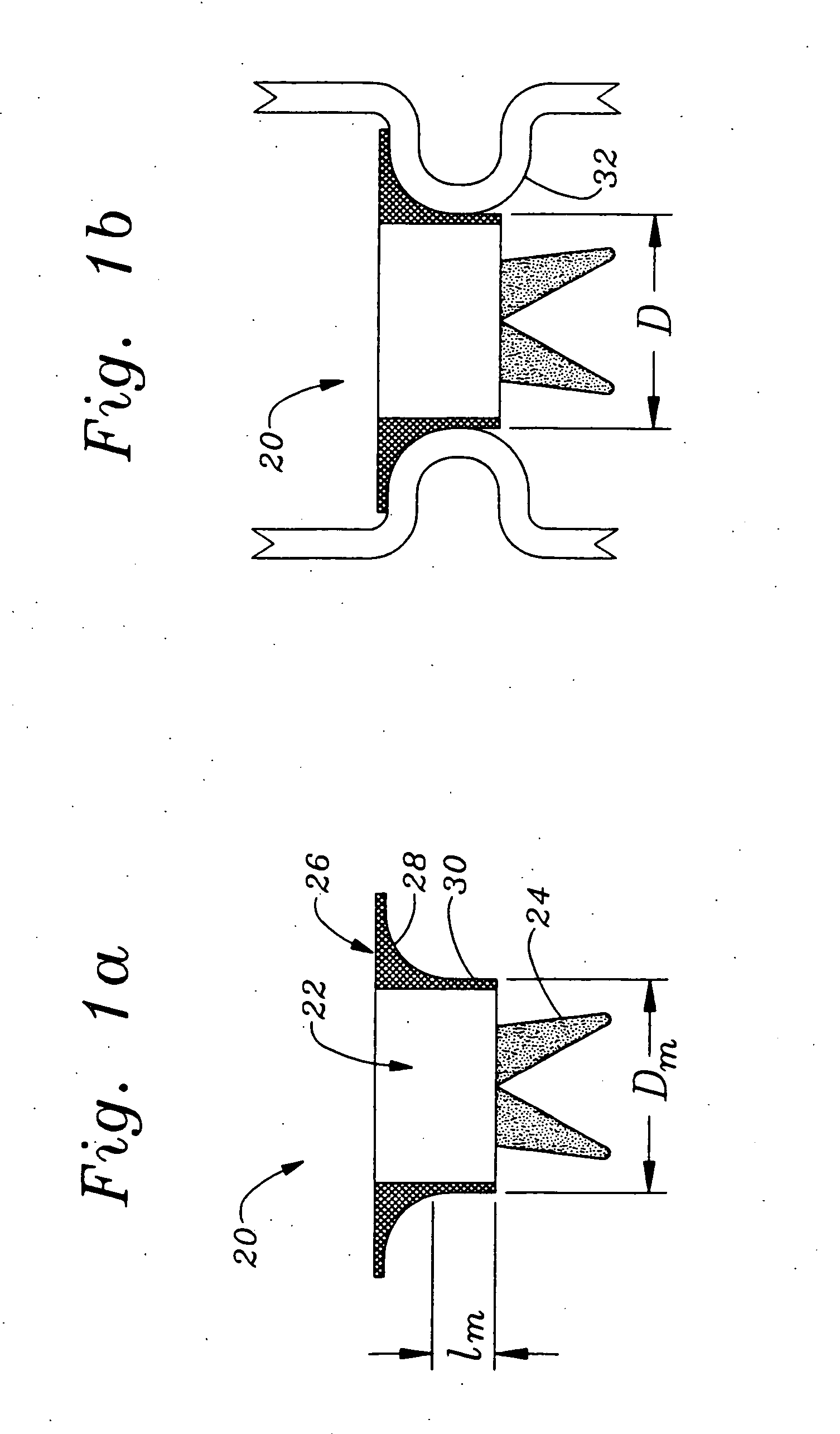

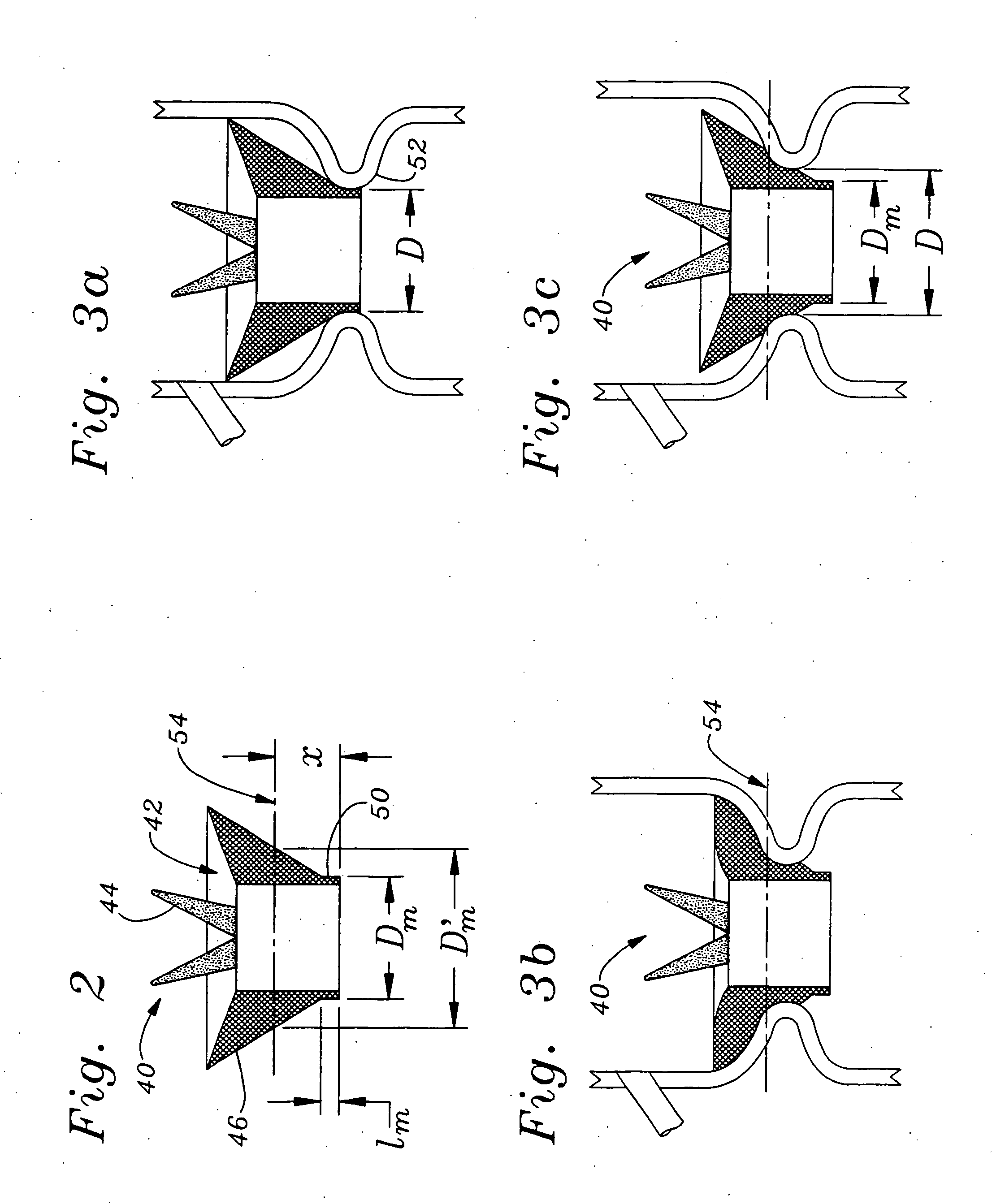

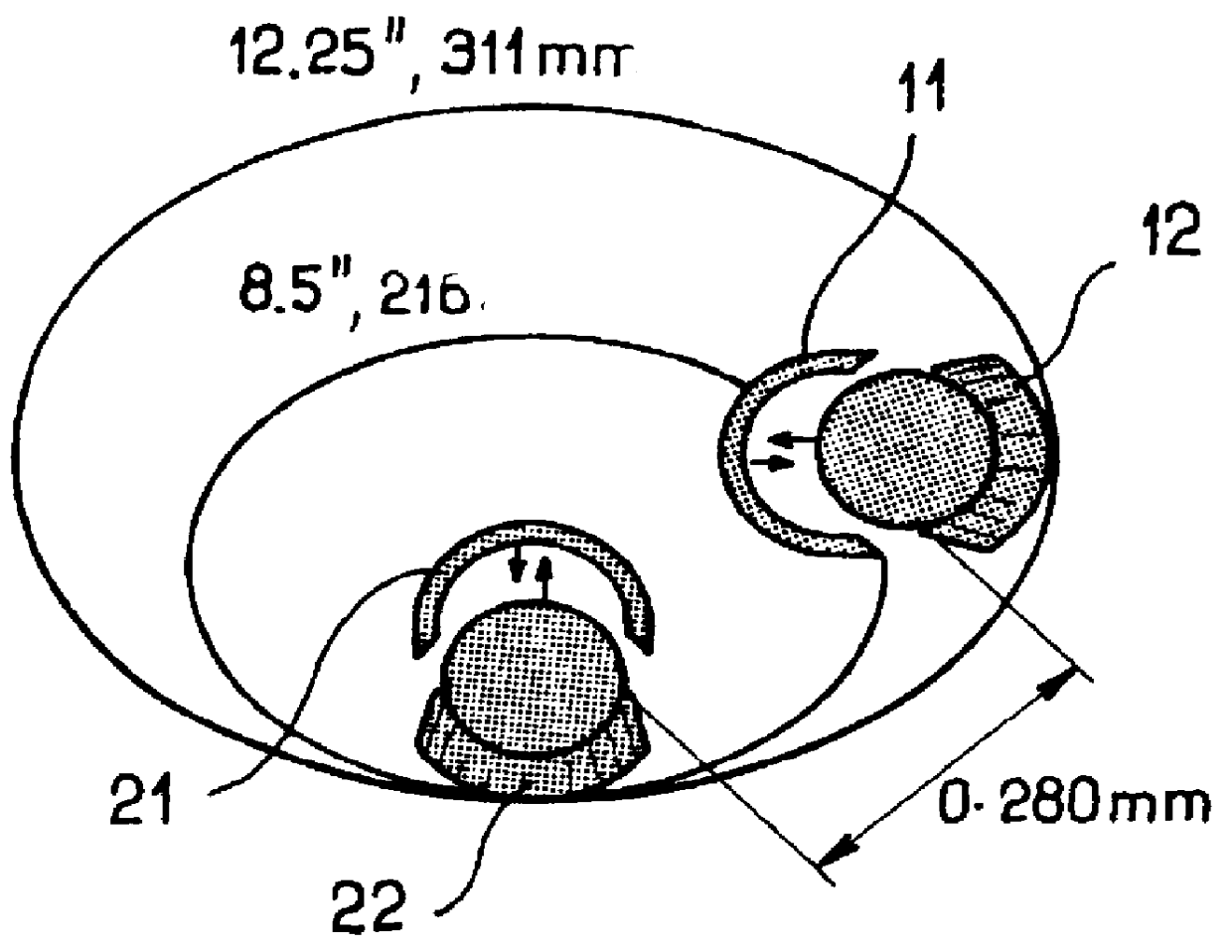

Combination anatomical orifice sizer and heart valve

Anatomical orifice sizers that are optimally proportional to an associated prosthetic device such as a heart valve, and methods of use are provided. The sizers are desirably slightly larger than the rigid mounting diameter of the corresponding heart valve. The heart valve sizer may be cylindrical and have a diameter about 0.3 mm larger than the valve mounting diameter. The sizer preferably has a length of between about 19 mm to 22 mm, and the edges are desirably rounded to a minimum 1 mm radius. The method includes providing a set of cylindrical sizers having varying diameters; sequentially inserting at least two of the sizers through the annulus; measuring the push force needed to pass each sizer through the annulus; selecting a valve corresponding to the sizer for which the measured push force is between about 150 and 300 grams.

Owner:EDWARDS LIFESCIENCES CORP

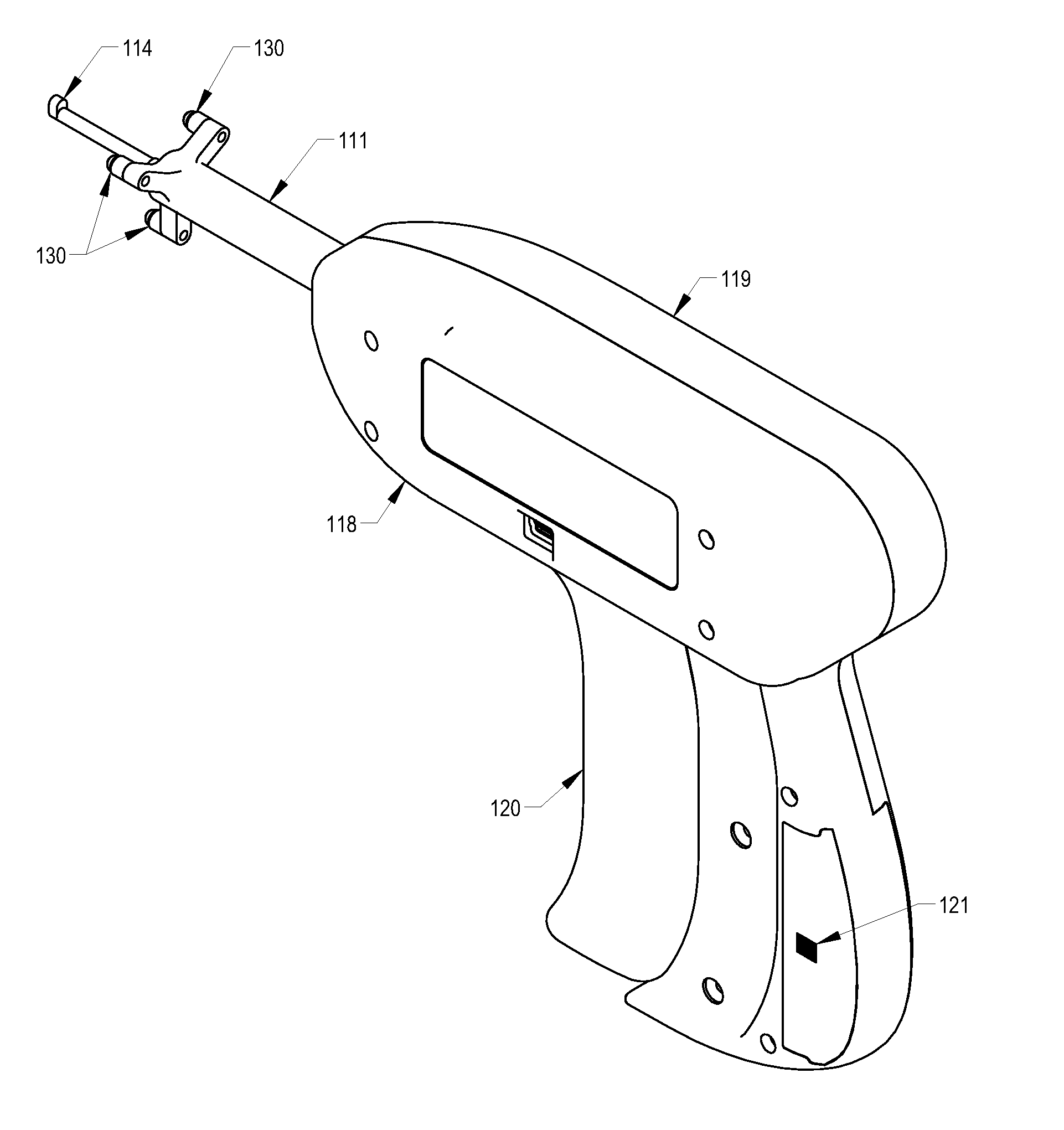

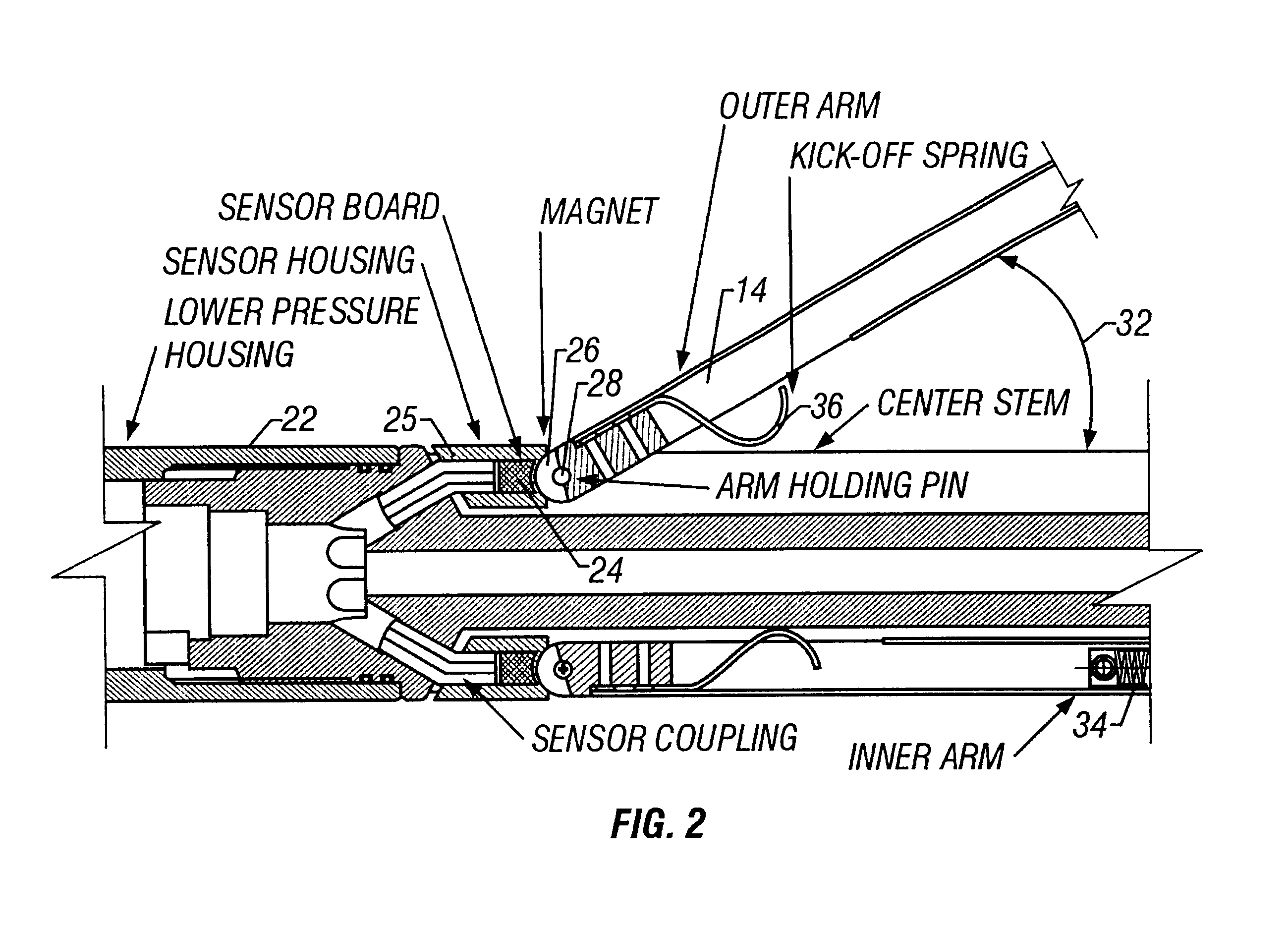

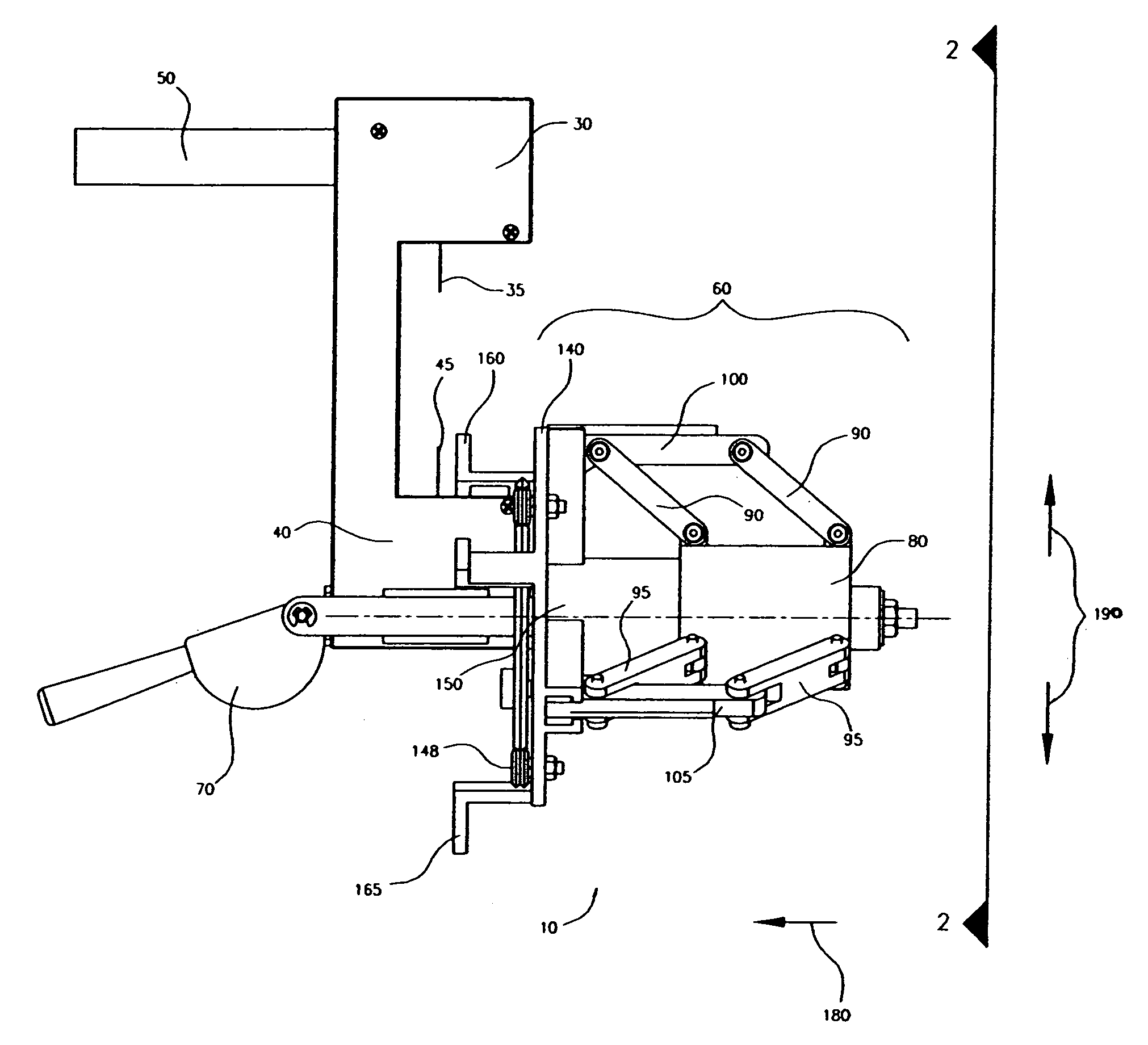

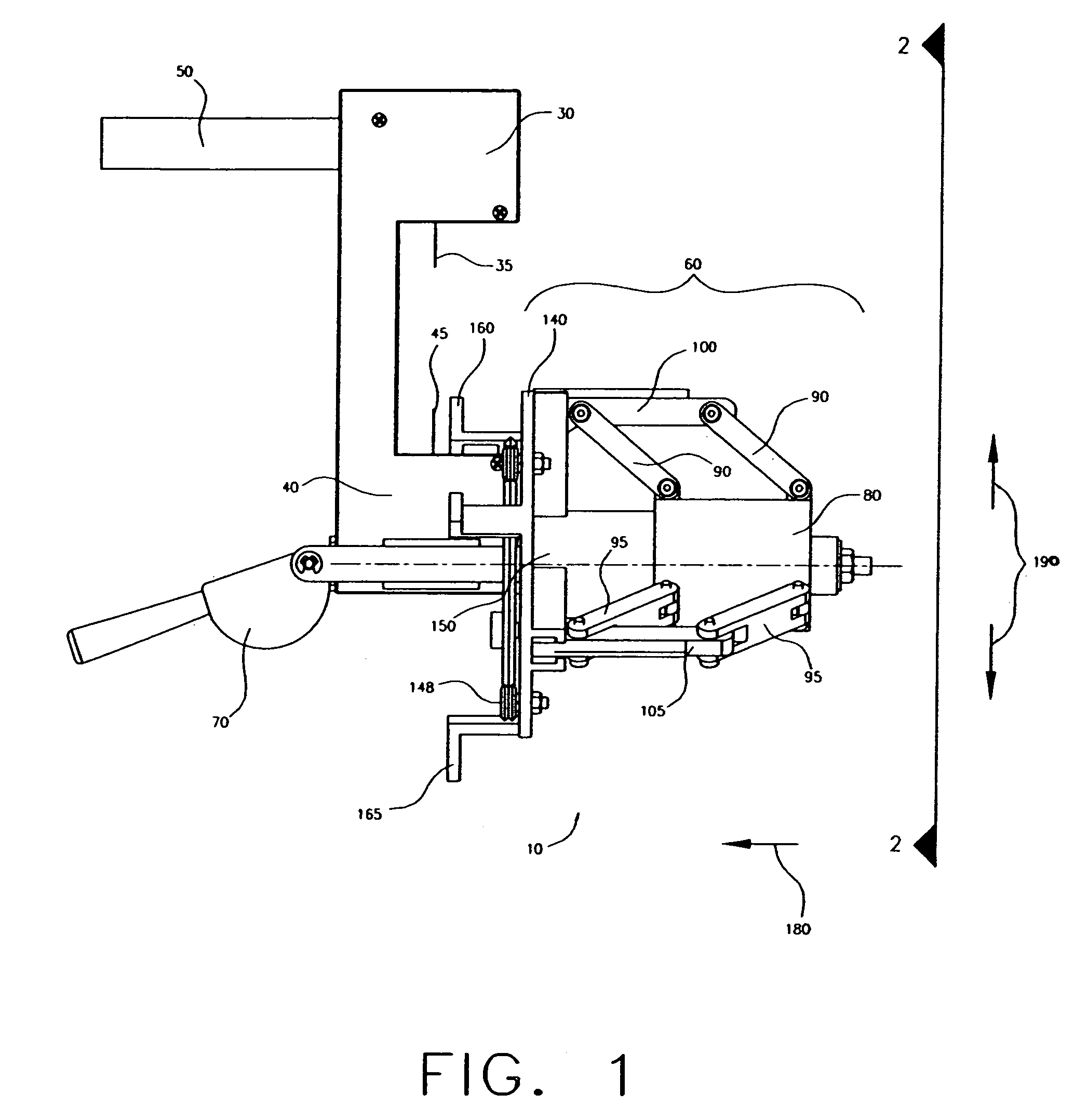

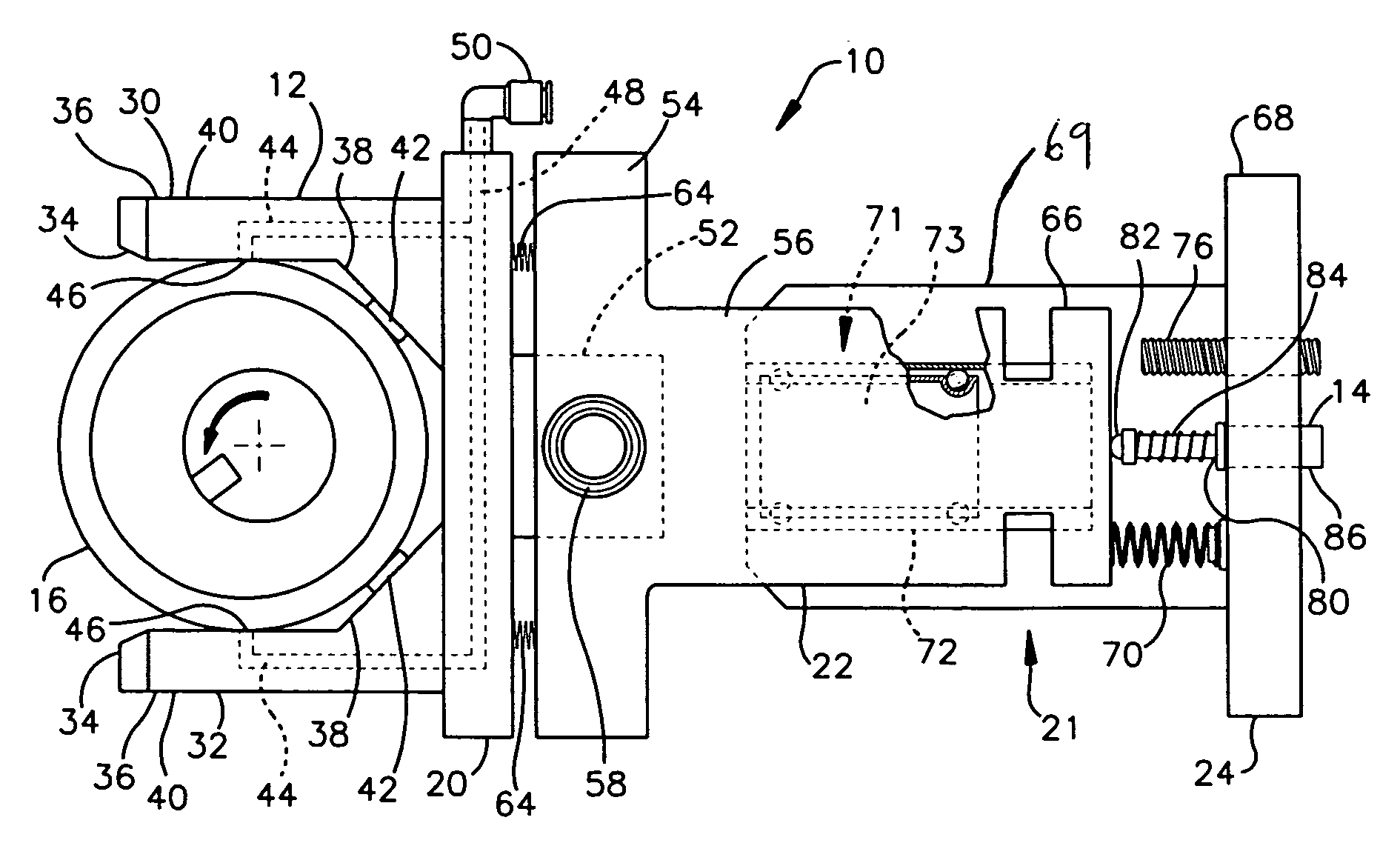

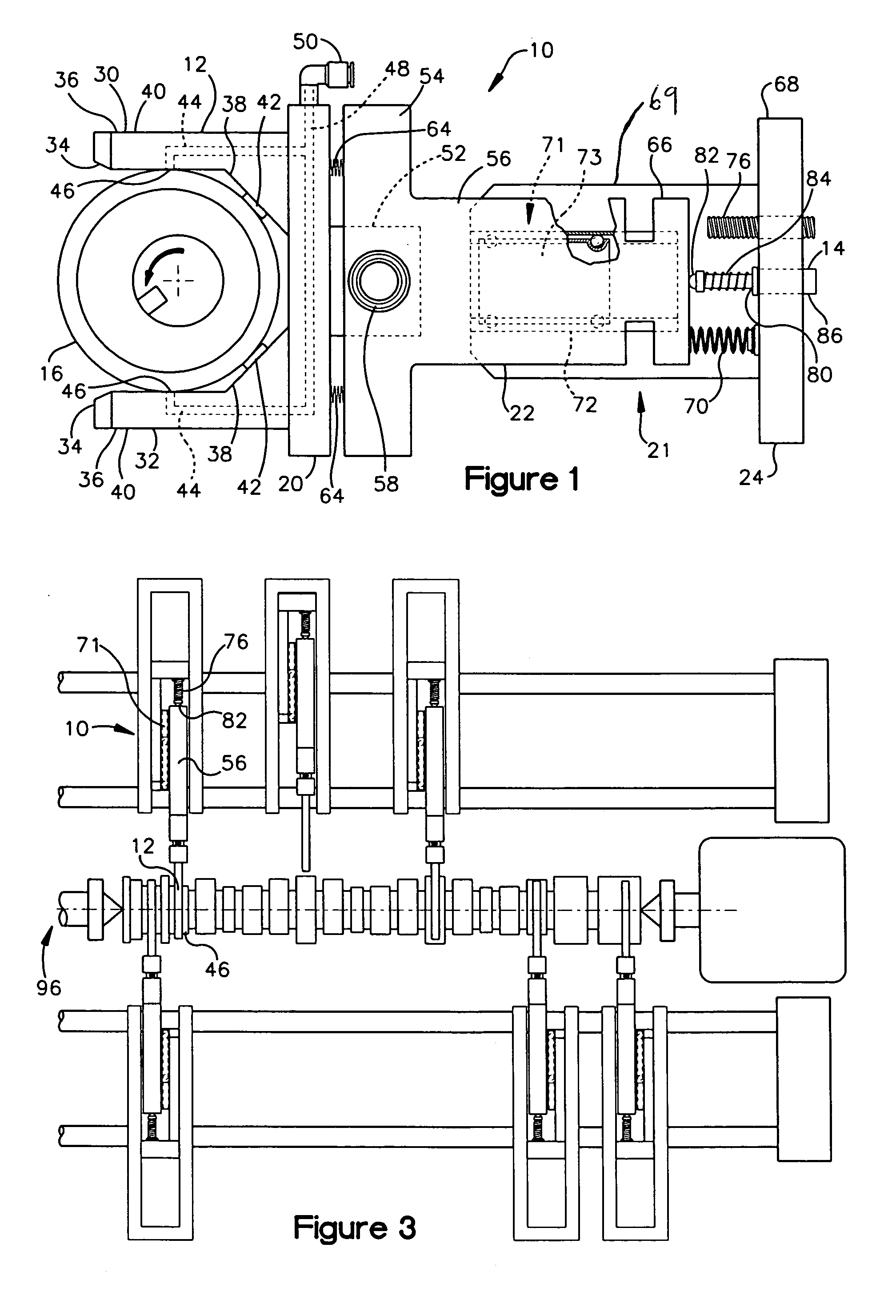

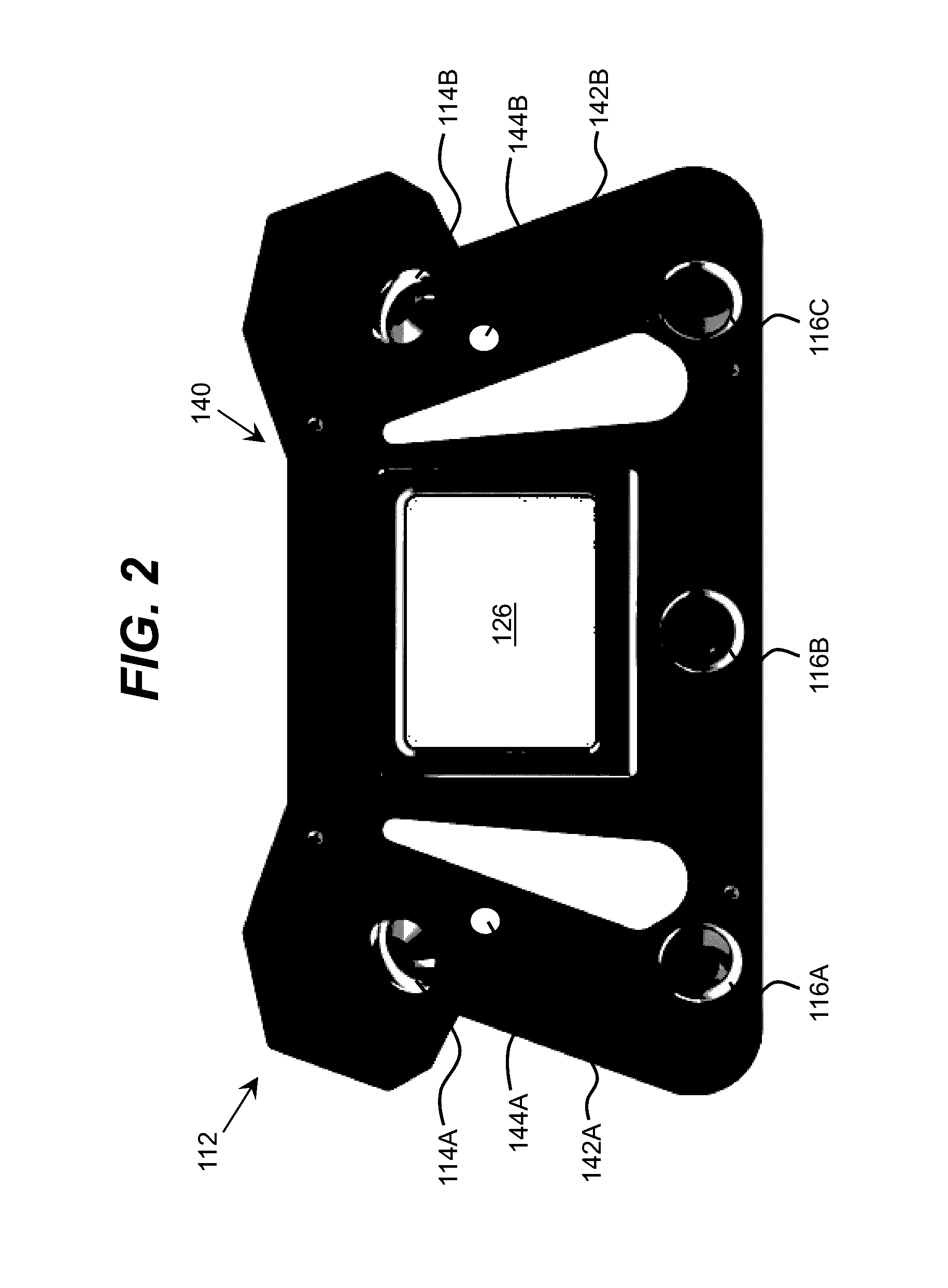

Hole Measurement Apparatuses

ActiveUS20110166824A1Increase productionIncrease workforceElectric/magnetic depth measurementElectrical/magnetic diameter measurementsEngineeringDiameter measurement

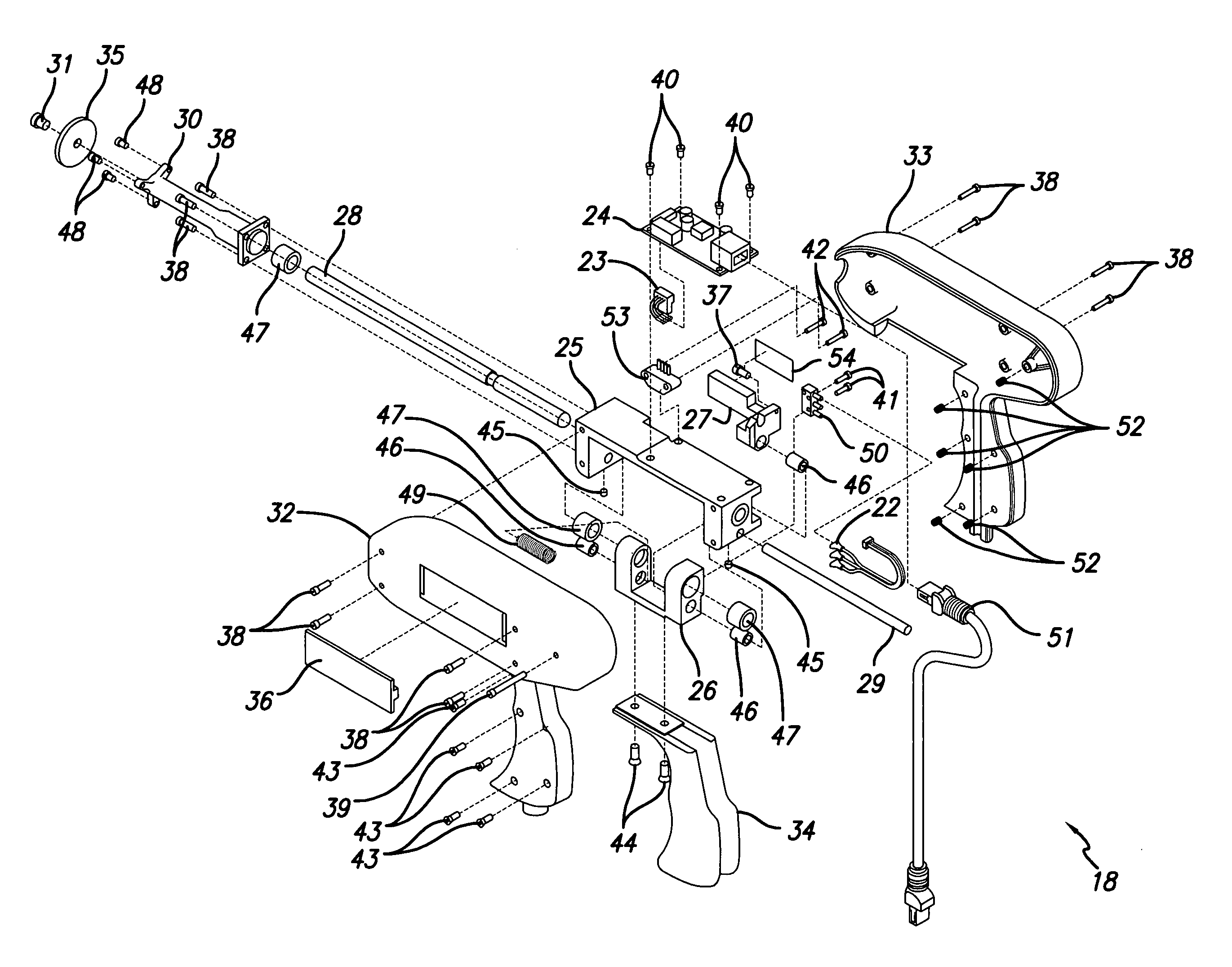

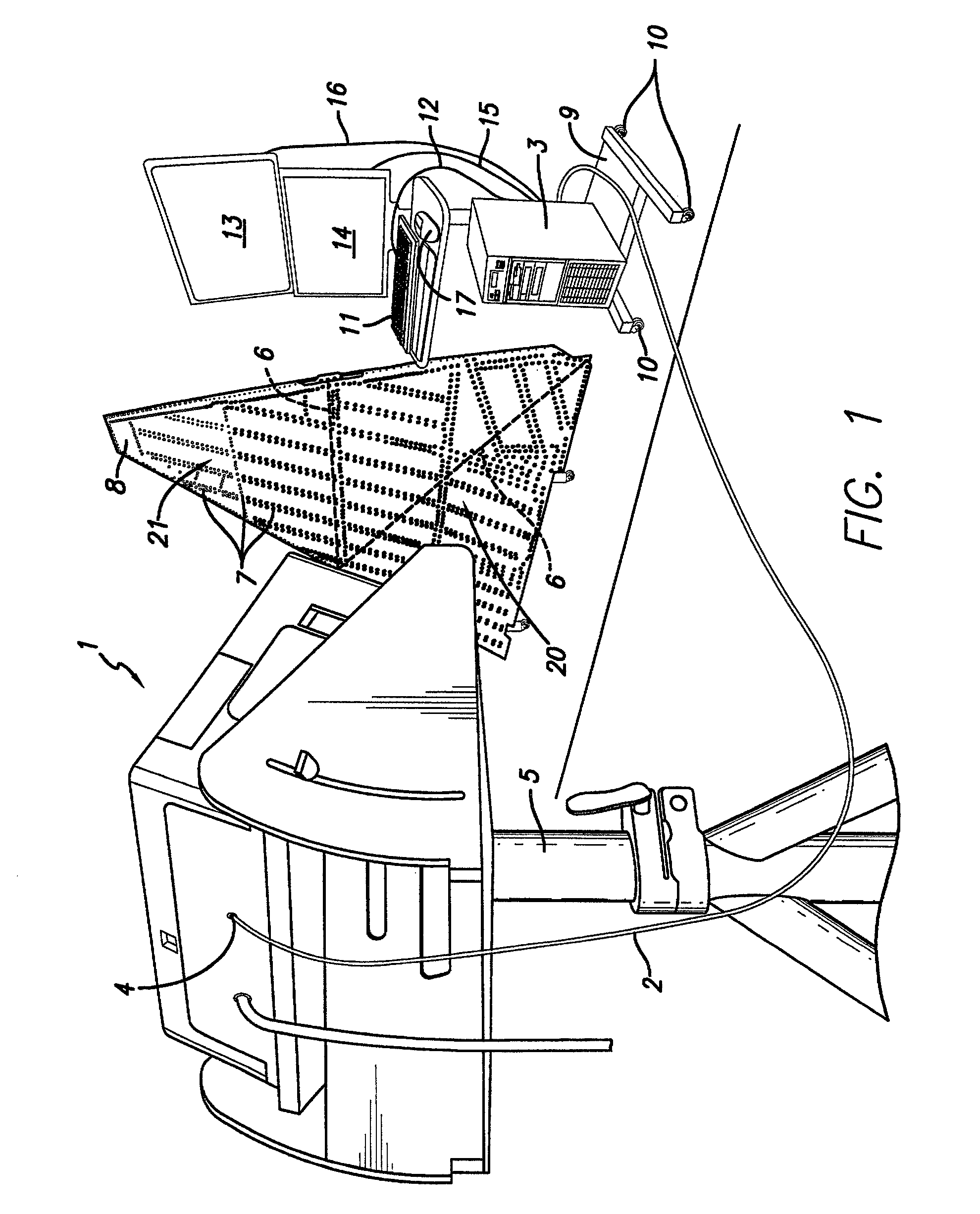

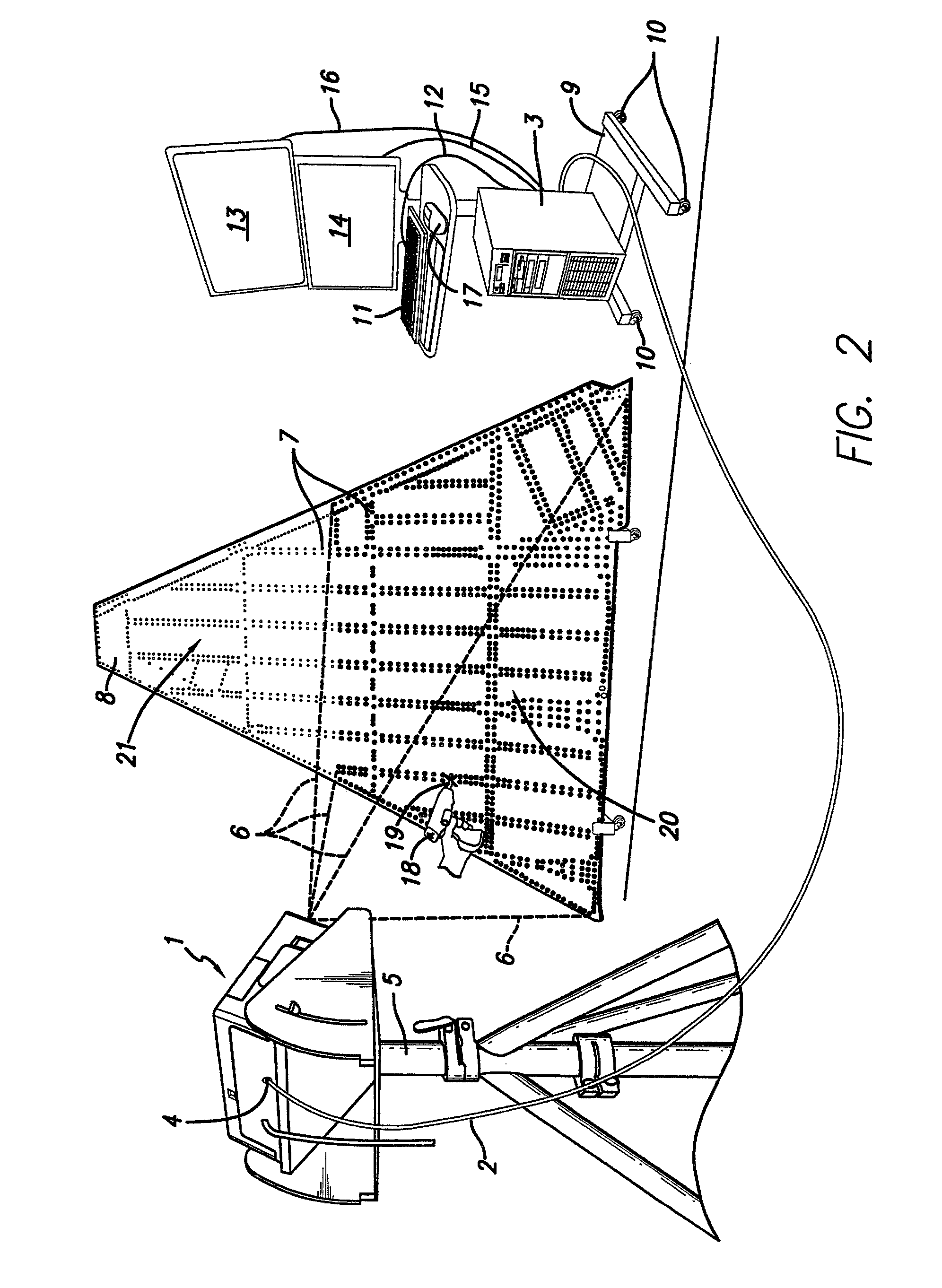

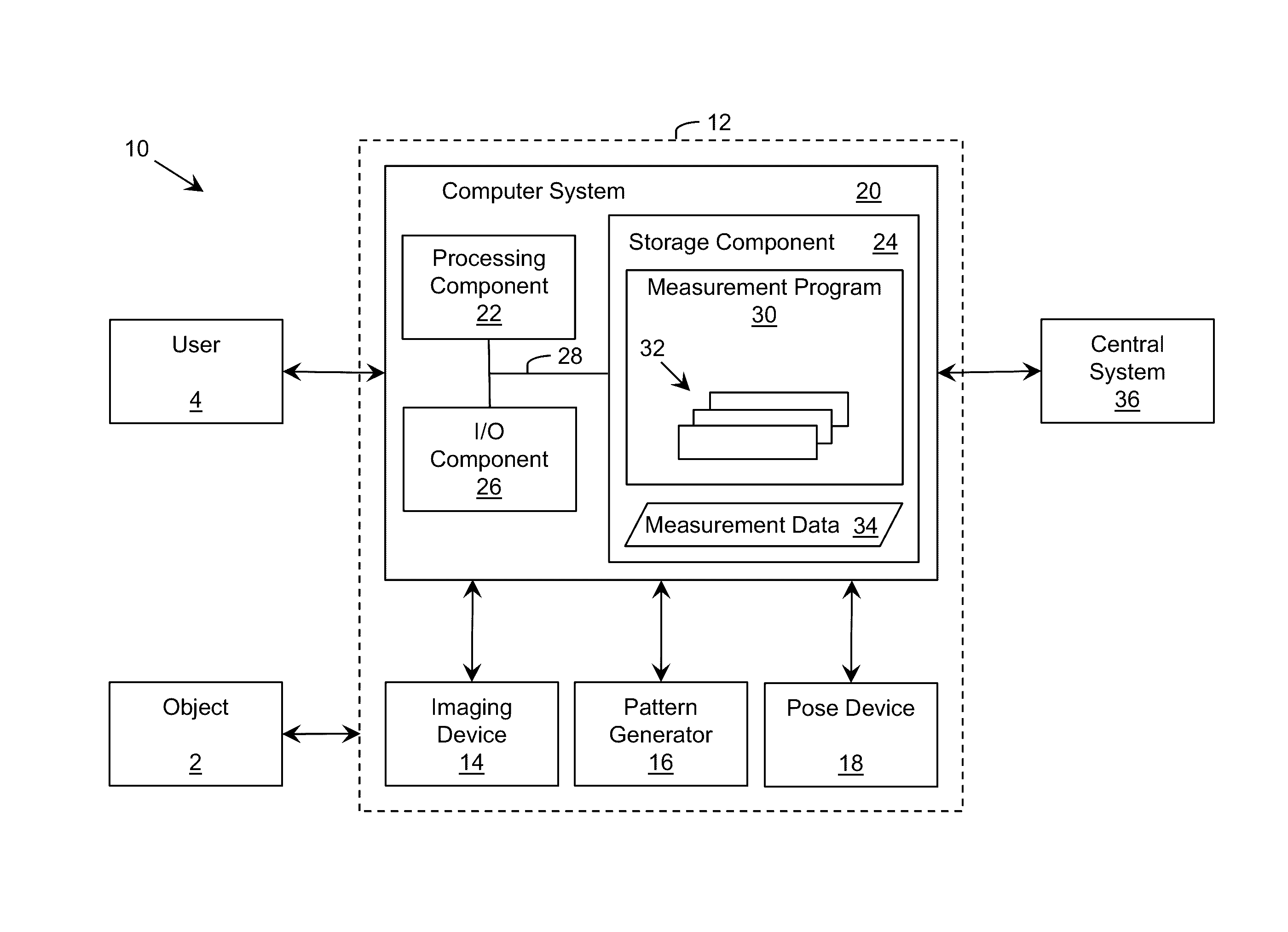

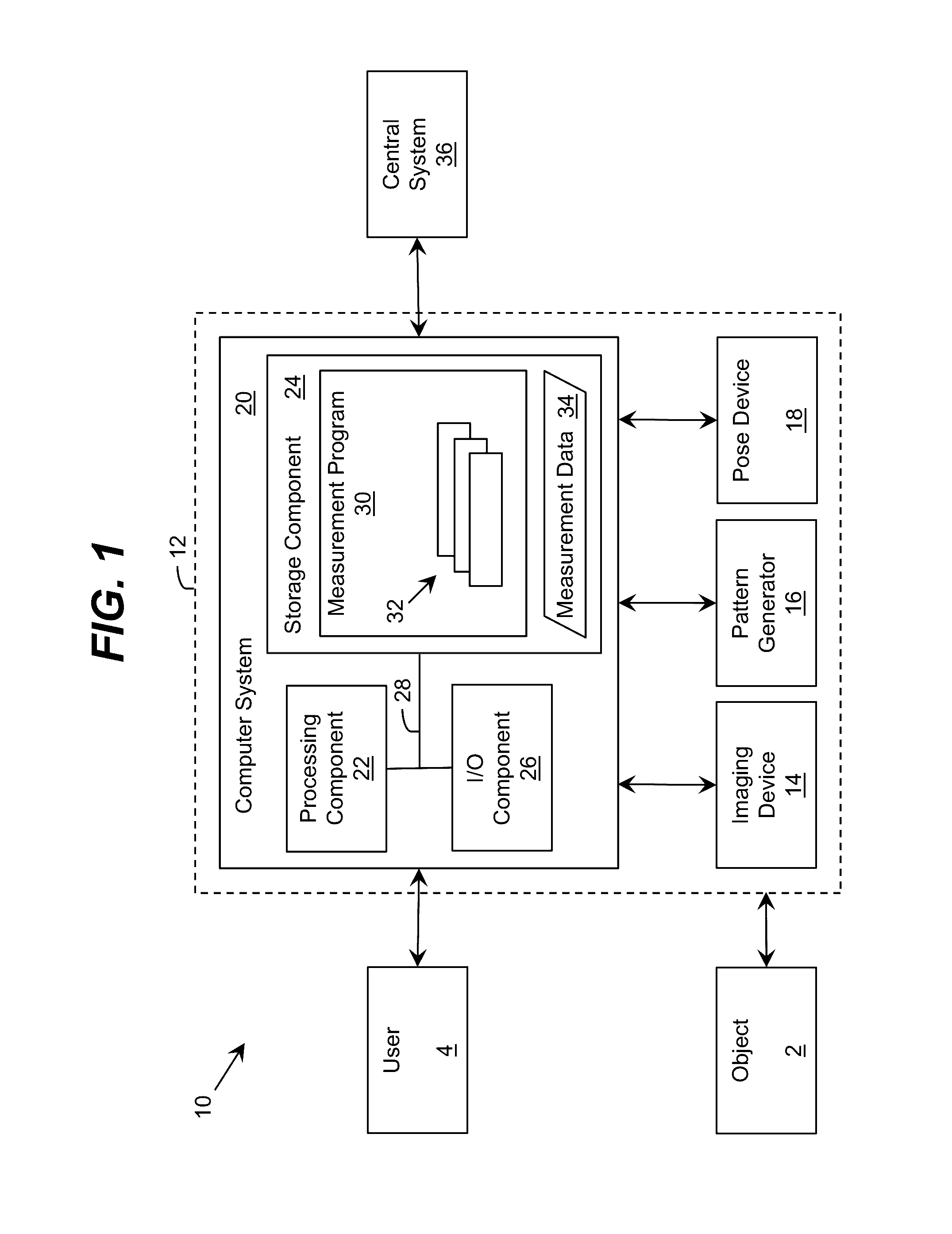

The present invention is directed to automated apparatuses and methods for measuring fastener hole depth, fastener length, countersink depth and / or hole diameters in a workpiece (or other object) in an automated and extremely rapid, efficient and accurate manner. The apparatuses may be operably connected with a power source and with one or a plurality of computers or other data collection devices to transmit fastener hole depth, countersink depth and / or hole diameter measurement data and / or information to them each time that a fastener hole is measured, while the apparatus is continuously measuring fastener holes (i.e., with no interruptions). Extremely advantageously, using only one hand, and by only squeezing a trigger only one time, an operator of such an apparatus may successfully and very rapidly and accurately perform more than one, or all three, of the following functions: (i) normalize the apparatus relative to one or a plurality of fastener holes and / or workpiece surfaces; (ii) make one or a plurality of accurate measurements; and (iii) transmit the one or more measurements from the apparatus to one or a plurality of computers and / or other data collection devices for, for example, recordation, storage, manipulation, other use and / or the like.

Owner:DELTA SIGMA

Hole measurement apparatuses

ActiveUS8606540B2Fast, efficient and accurate measurementEasy transferElectric/magnetic depth measurementElectrical/magnetic diameter measurementsDiameter measurementBiomedical engineering

The present invention is directed to automated apparatuses and methods for measuring fastener hole depth, fastener length, countersink depth and / or hole diameters in a workpiece (or other object) in an automated and extremely rapid, efficient and accurate manner. The apparatuses may be operably connected with a power source and with one or a plurality of computers or other data collection devices to transmit fastener hole depth, countersink depth and / or hole diameter measurement data and / or information to them each time that a fastener hole is measured, while the apparatus is continuously measuring fastener holes (i.e., with no interruptions). Extremely advantageously, using only one hand, and by only squeezing a trigger only one time, an operator of such an apparatus may successfully and very rapidly and accurately perform more than one, or all three, of the following functions: (i) normalize the apparatus relative to one or a plurality of fastener holes and / or workpiece surfaces; (ii) make one or a plurality of accurate measurements; and (iii) transmit the one or more measurements from the apparatus to one or a plurality of computers and / or other data collection devices for, for example, recordation, storage, manipulation, other use and / or the like.

Owner:DELTA SIGMA

Heart valve sizers dimensioned larger than corresponding heart valves

Anatomical orifice sizers that are optimally proportional to an associated prosthetic device such as a heart valve, and methods of use are provided. The sizers are desirably slightly larger than the rigid mounting diameter of the corresponding heart valve. The heart valve sizer may be cylindrical and have a diameter about 0.3 mm larger than the valve mounting diameter. The sizer preferably has a length of between about 19 mm to 22 mm, and the edges are desirably rounded to a minimum 1 mm radius. The method includes providing a set of cylindrical sizers having varying diameters; sequentially inserting at least two of the sizers through the annulus; measuring the push force needed to pass each sizer through the annulus; selecting a valve corresponding to the sizer for which the measured push force is between about 150 and 300 grams.

Owner:EDWARDS LIFESCIENCES CORP

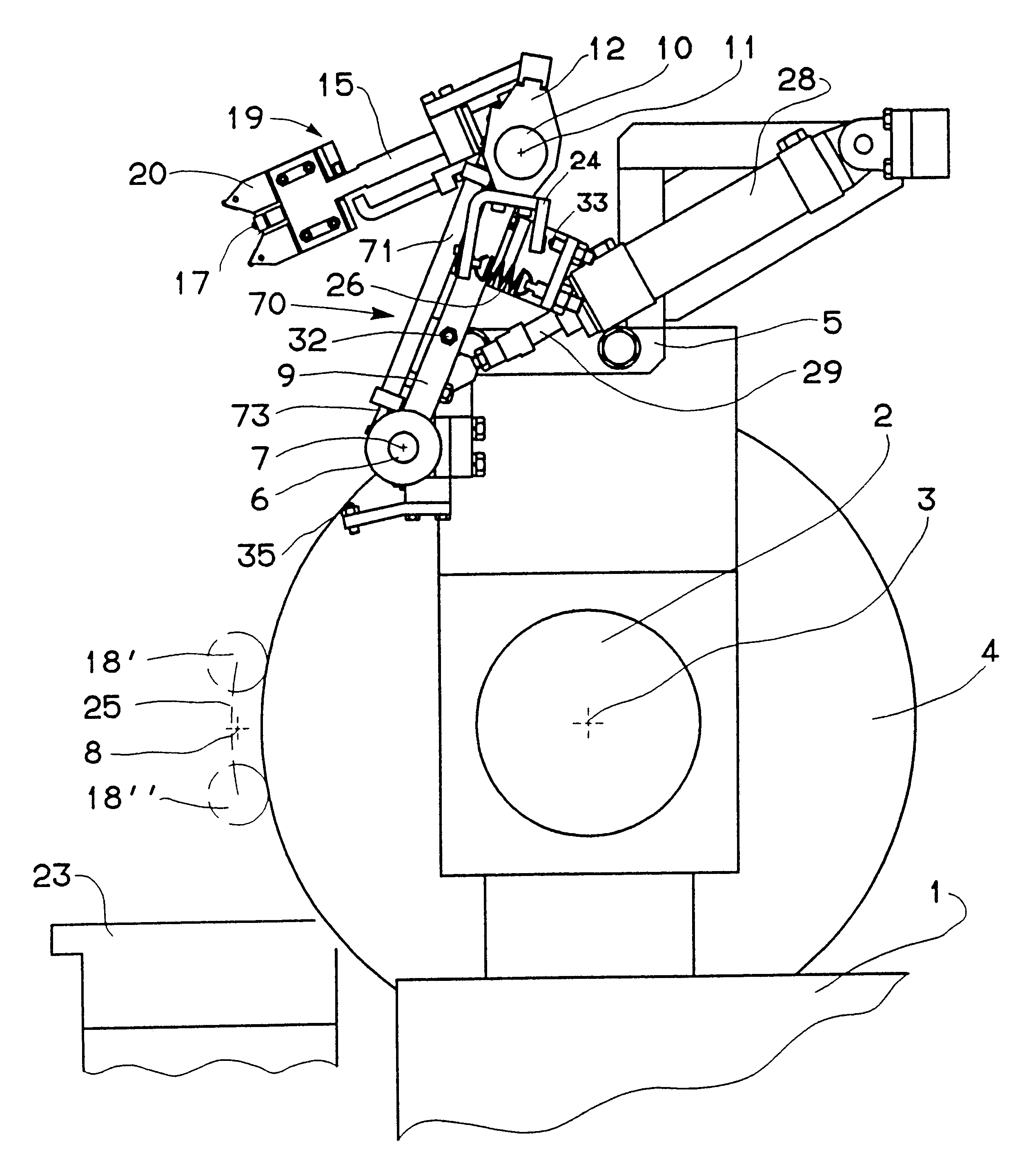

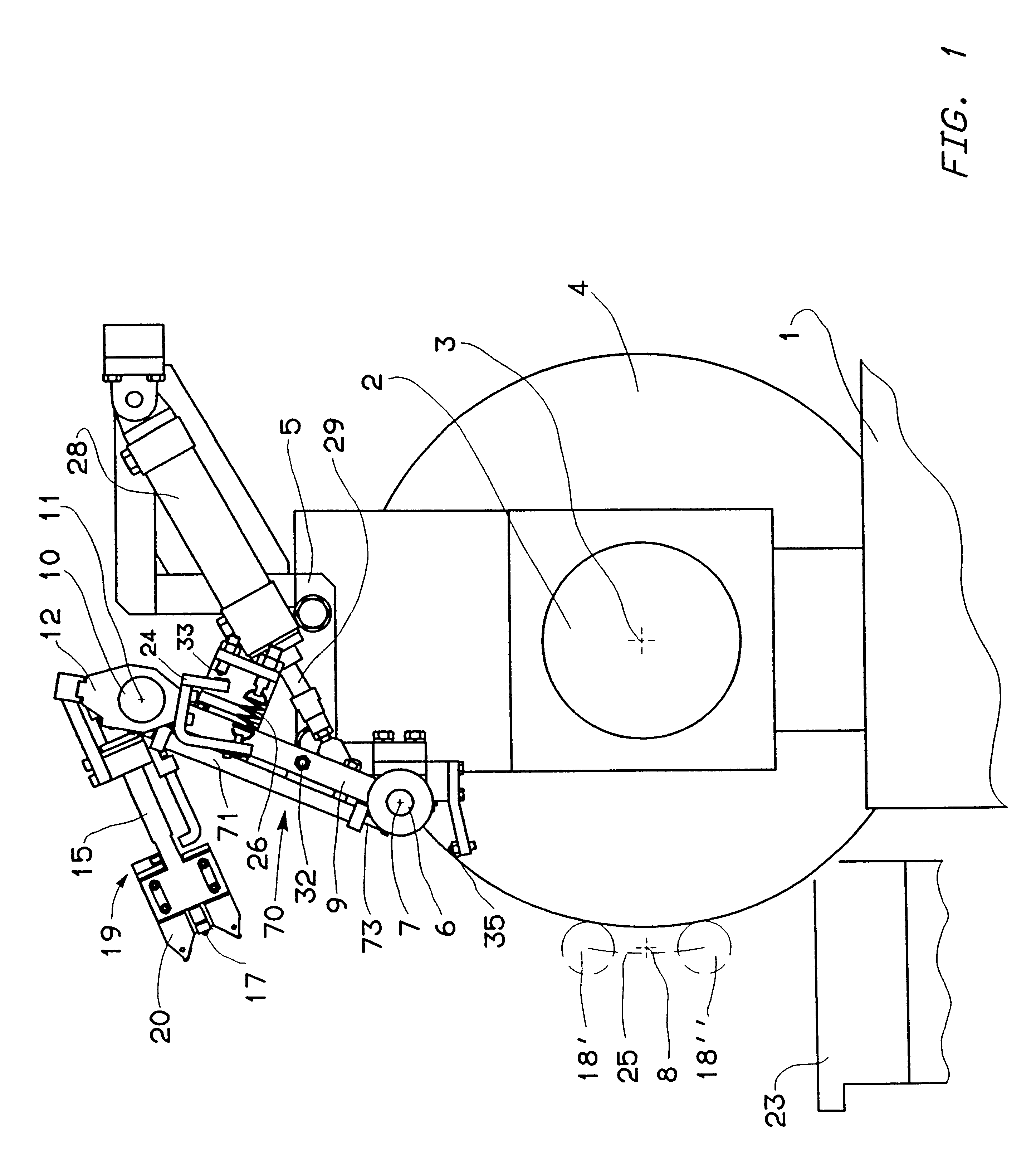

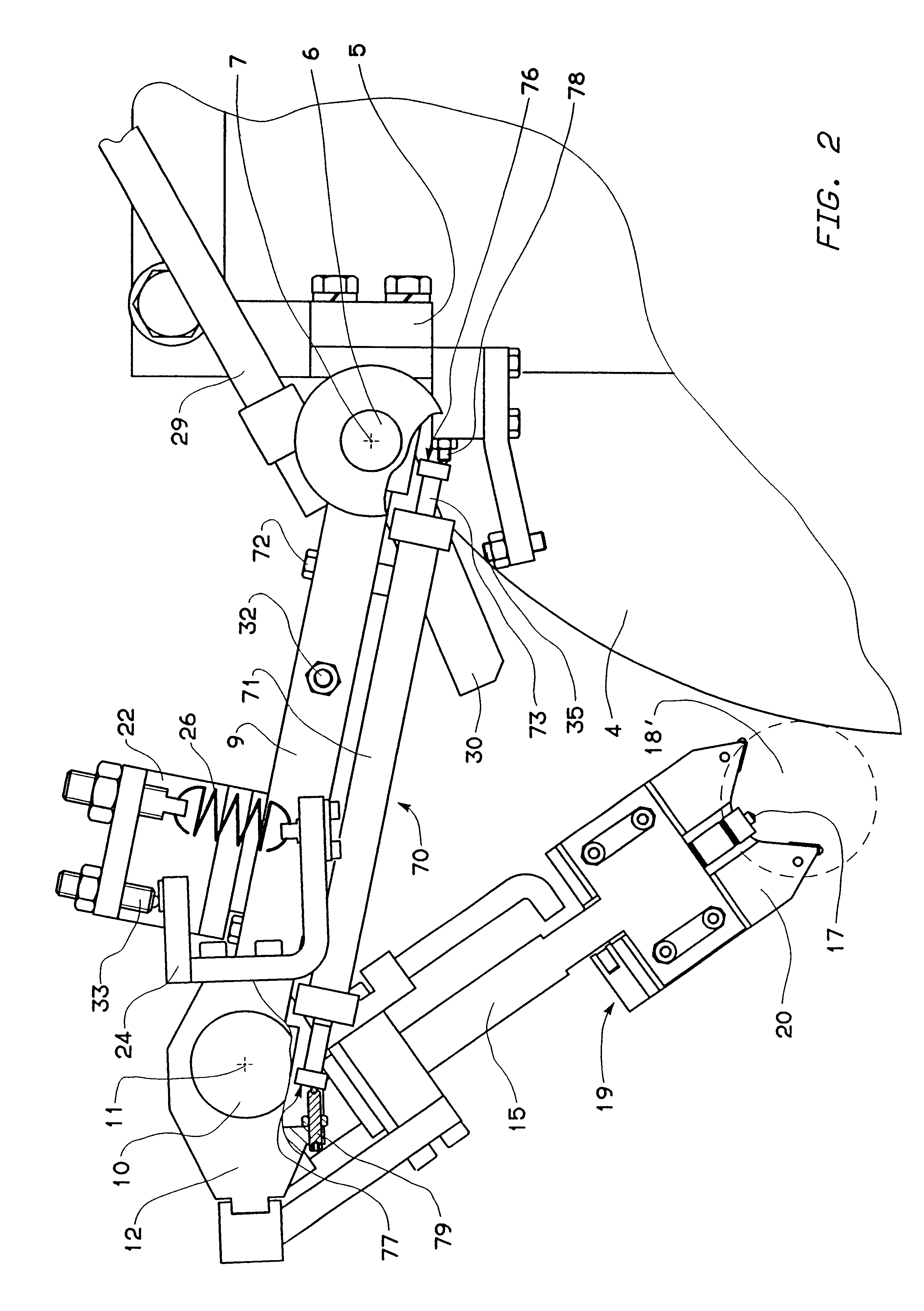

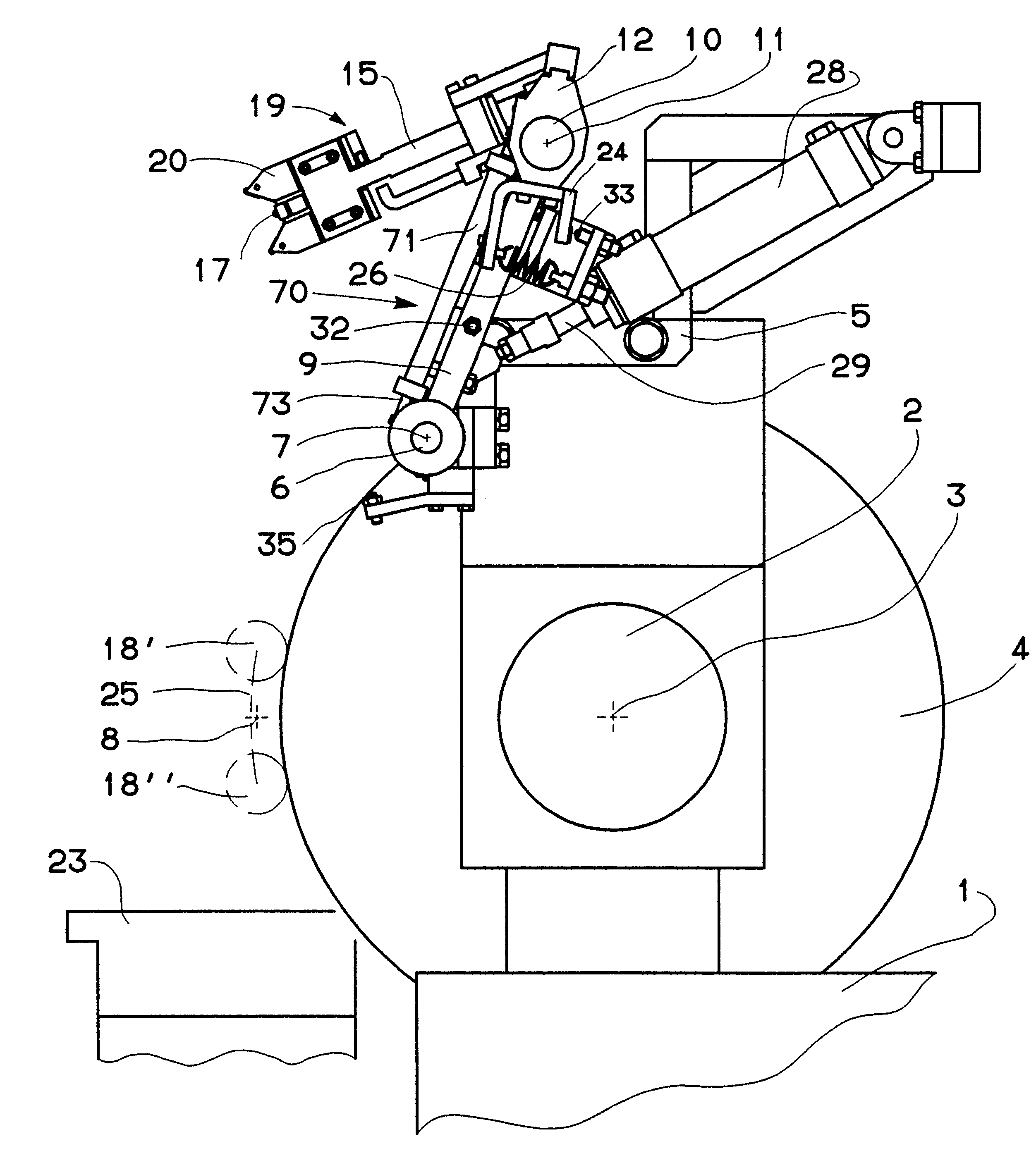

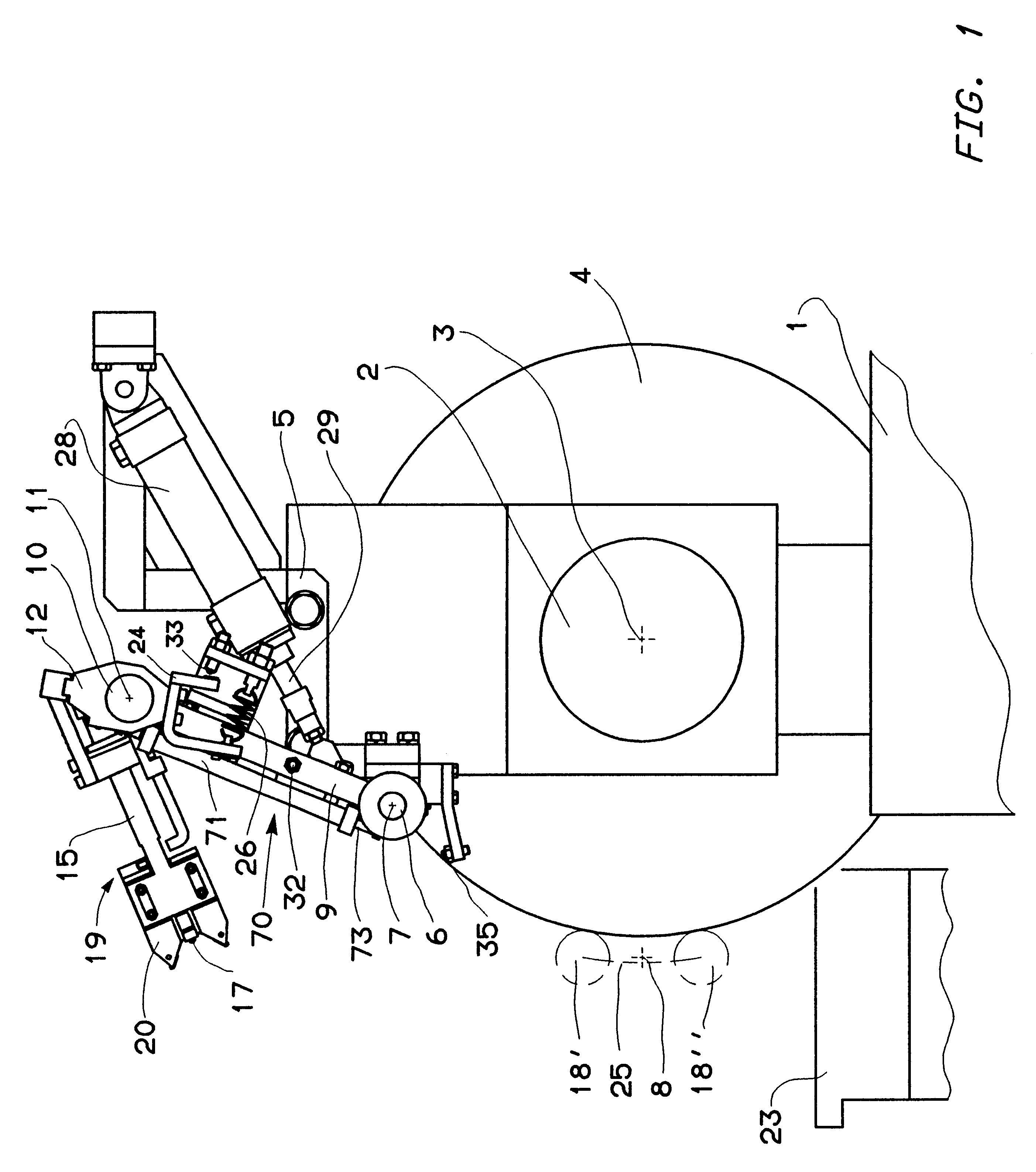

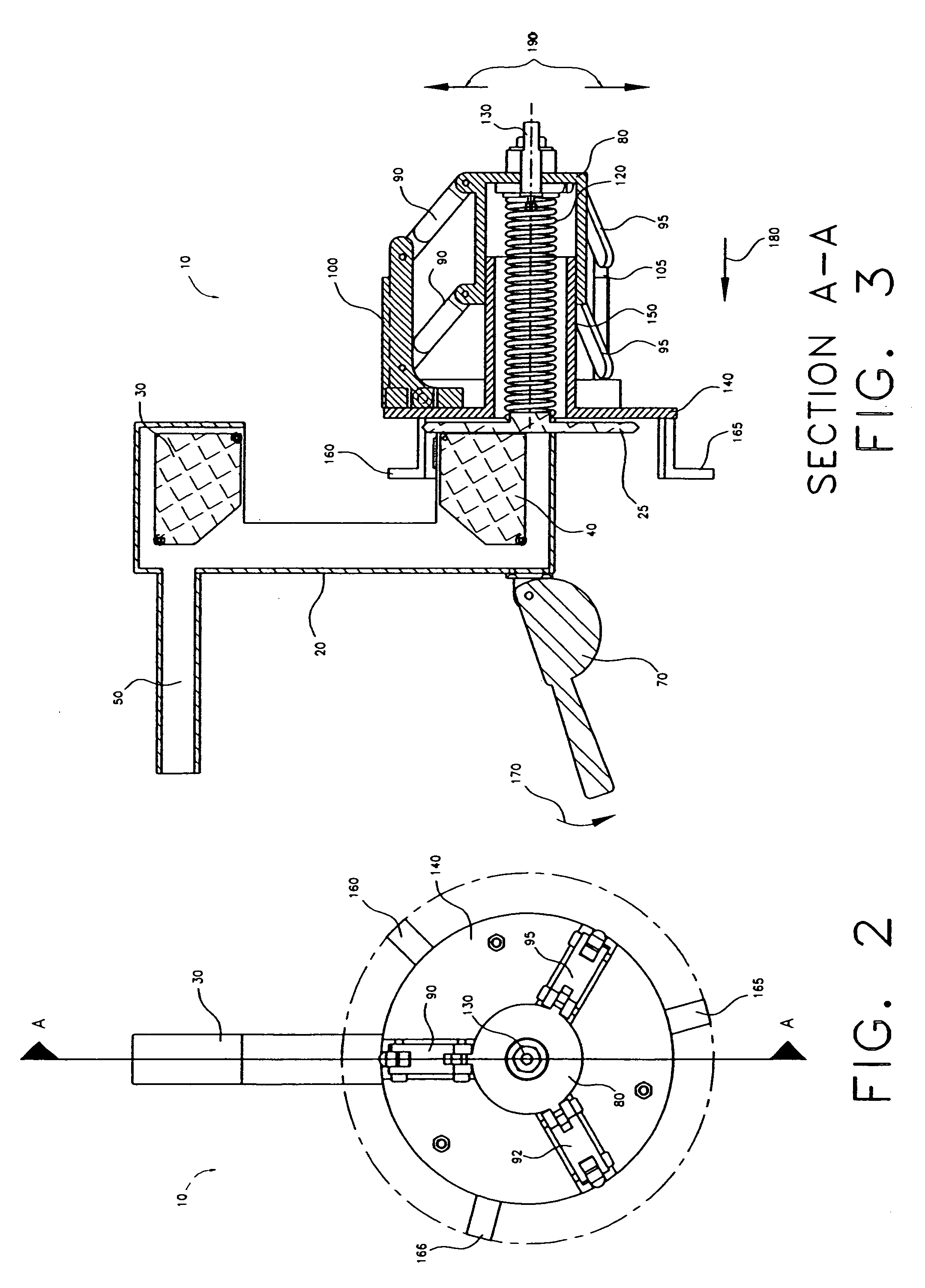

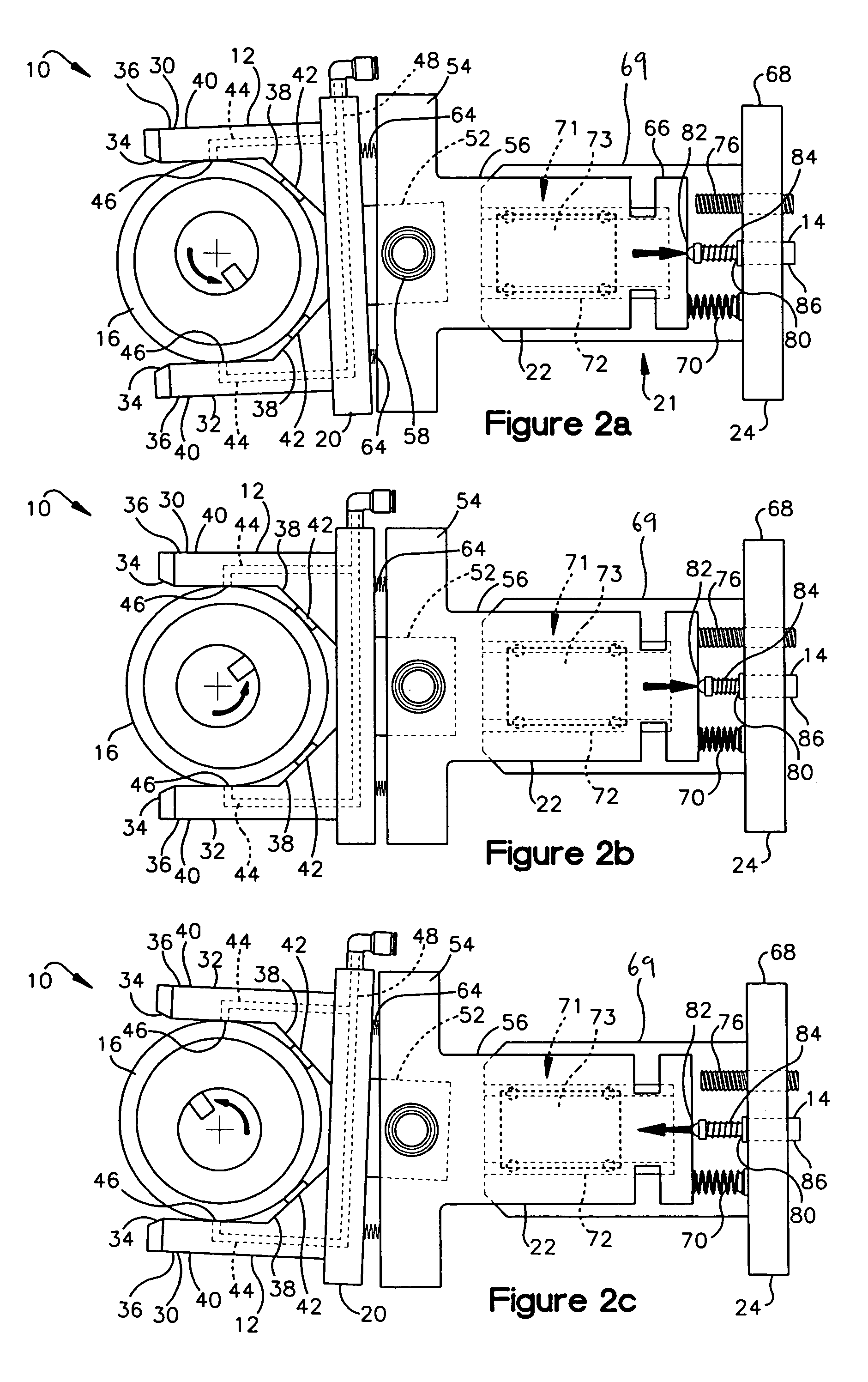

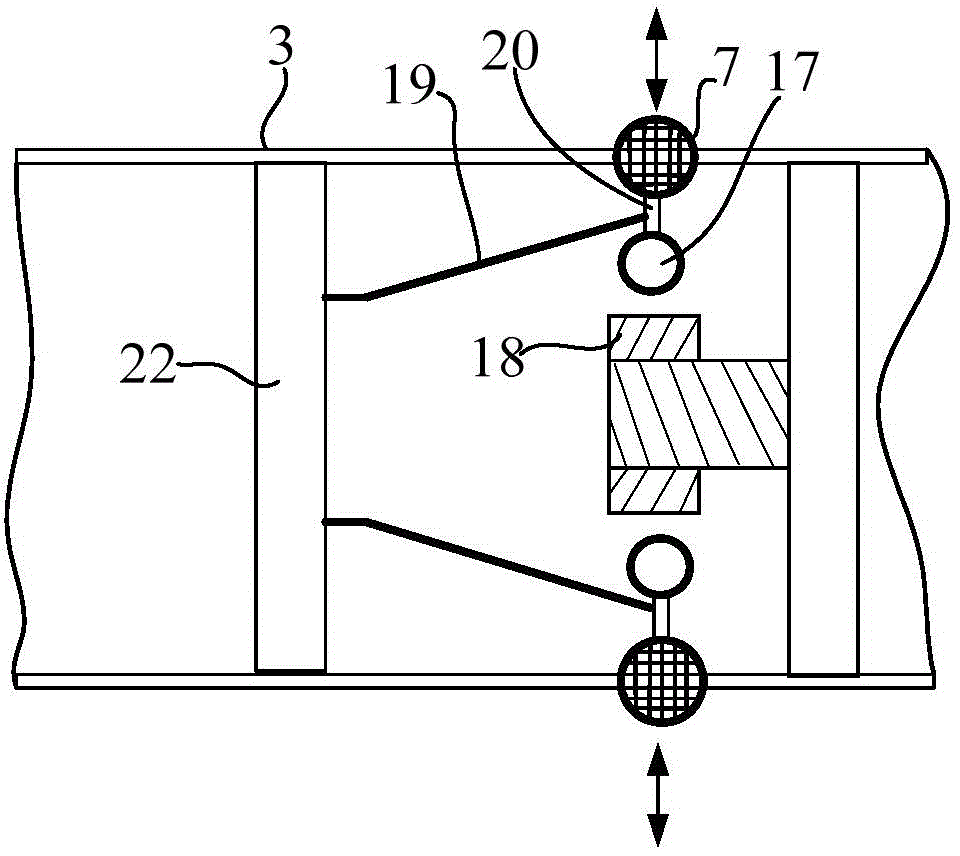

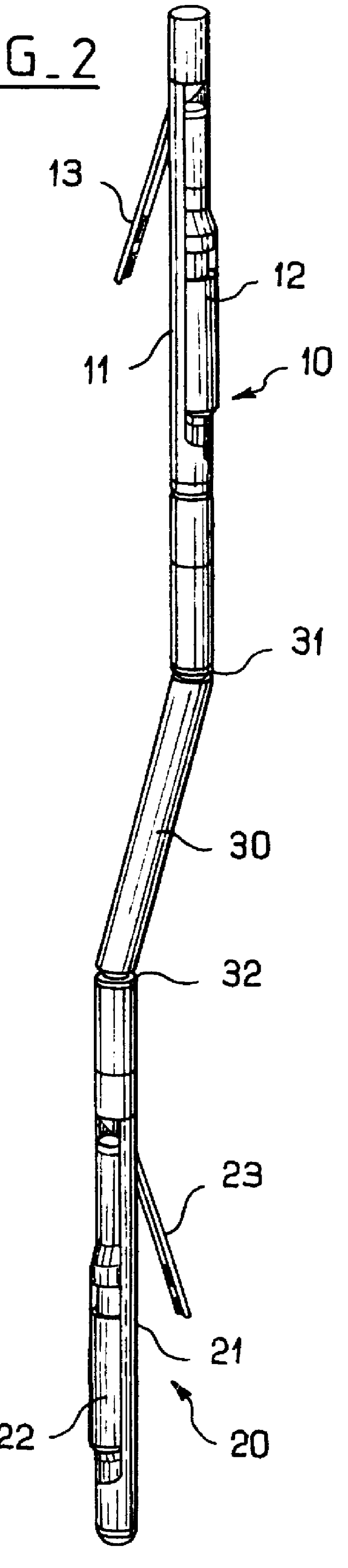

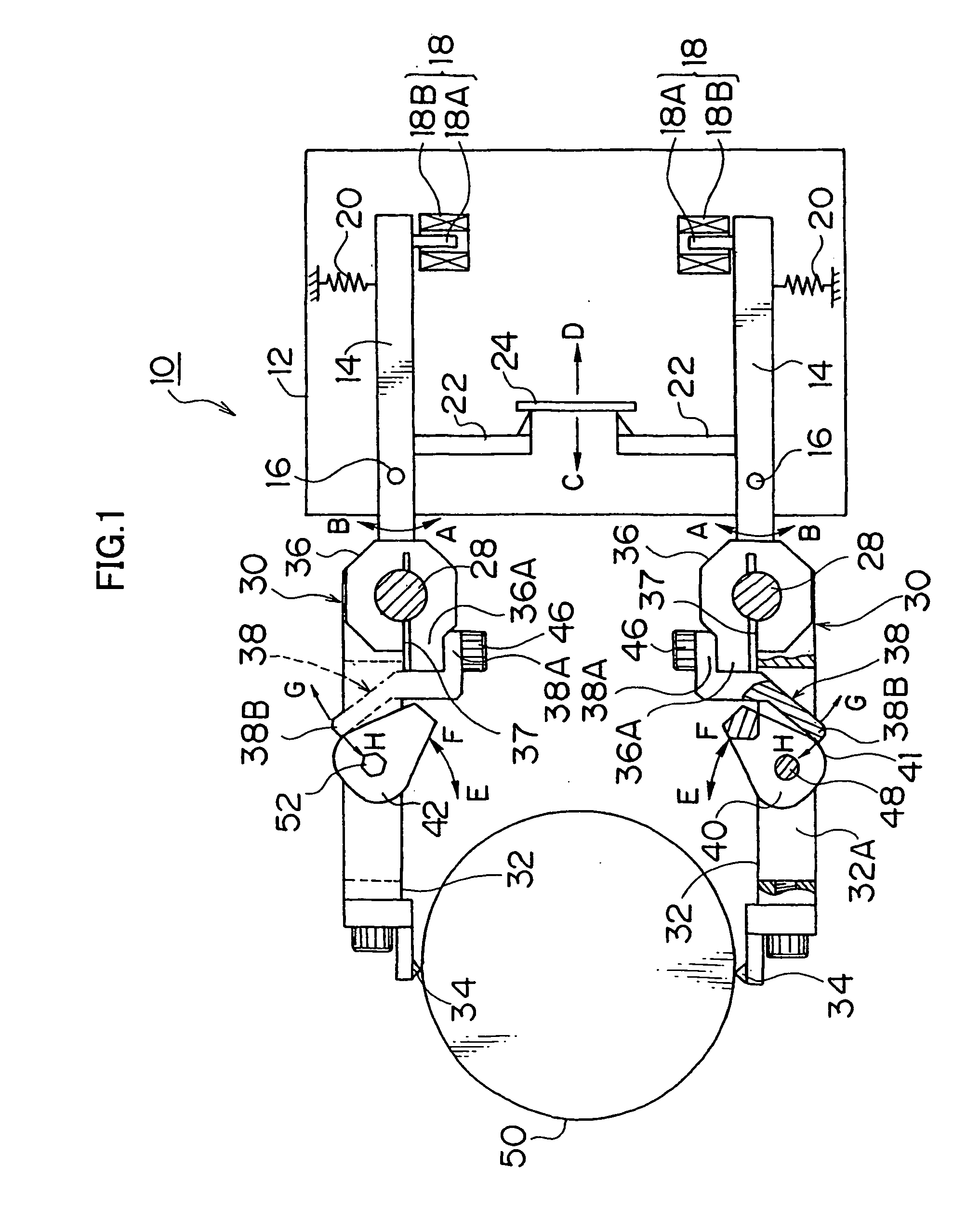

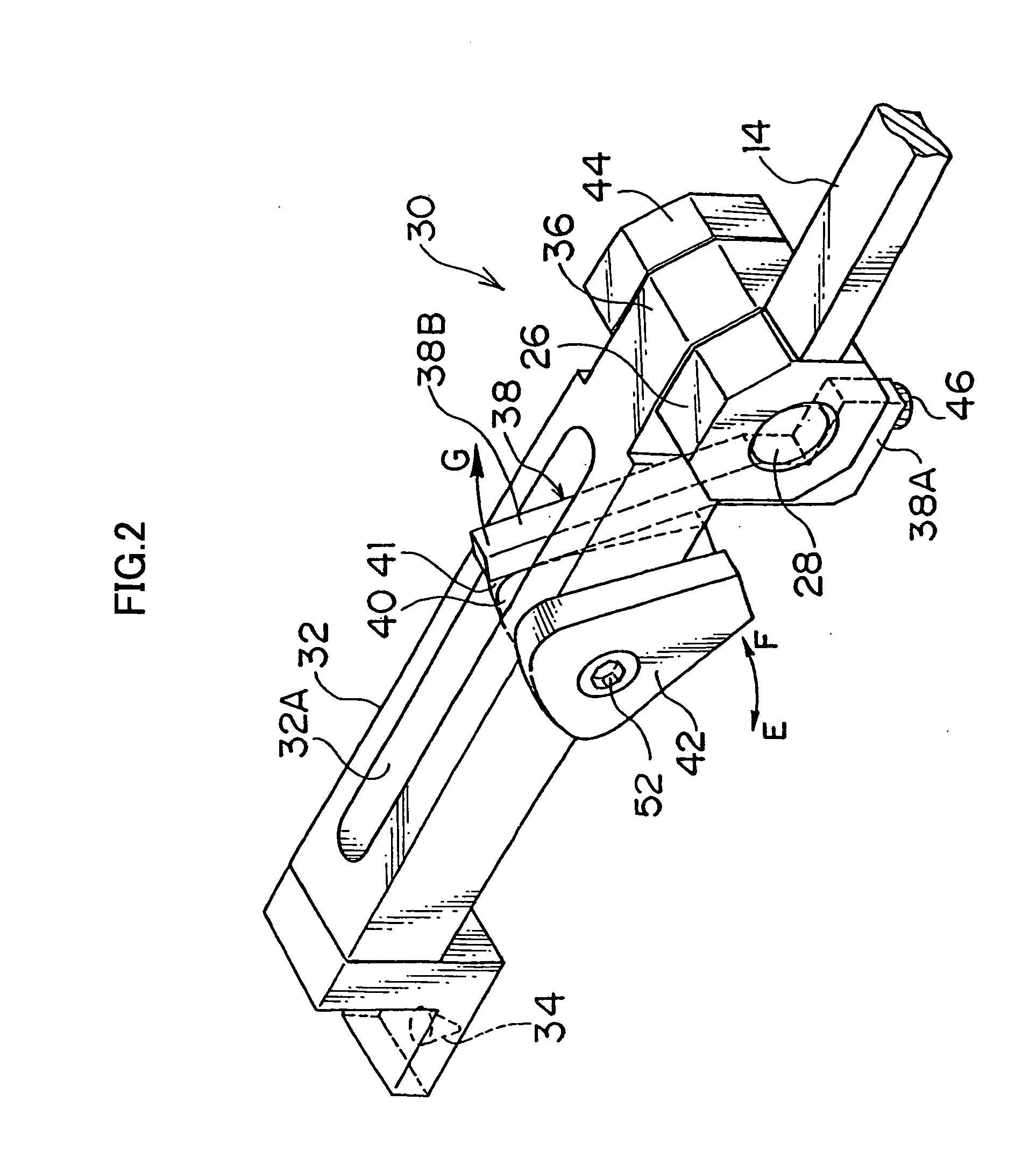

Apparatus for the in-process dimensional checking of orbitally rotating crankpins

InactiveUS6643943B2Revolution surface grinding machinesMechanical diameter measurementsReference deviceCrankpin

An apparatus for checking the diameter of crankpins of a crankshaft in the course of the machining in a grinding machine includes a Vee-shaped reference device, a measuring device associated with the reference device and including a feeler axially movable along the bisecting line of the Vee-shaped reference device, and a support device with a first arm rotating with respect to a support arranged on the grinding-wheel slide and a second arm rotating with respect to the first and carrying the Vee-shaped reference device.A guiding mechanism includes a limiting device, with mutually abutting surfaces and coupled to the support device, that guides the displacement of the reference device along a trajectory substantially parallel to the profile of the grinding wheel, allows the engagement of the reference device on a crankpin to be checked while the latter is orbitally moving, and does not interfere with the displacements of the support device caused by the orbital motion of the crankpin in the checking condition.

Owner:MARPOSS SPA

Use of magneto-resistive sensors for borehole logging

Owner:BAKER HUGHES INC

Apparatus for the in-process dimensional checking of cylindrical parts

InactiveUS6430832B1Revolution surface grinding machinesMechanical diameter measurementsReference deviceCrankpin

An apparatus for checking the diameter of crankpins of a crankshaft in the course of the machining in a grinding machine includes a Vee-shaped reference device, a measuring device associated with the reference device and including a feeler axially movable along the bisecting line of the Vee-shaped reference device, and a support device with a first arm rotating with respect to a support arranged on the grinding-wheel slide and a second arm rotating with respect to the first and carrying the Vee-shaped reference device.A guiding mechanism includes a limiting device, with mutually abutting surfaces and coupled to the support device, that guides the displacement of the reference device along a trajectory substantially parallel to the profile of the grinding wheel, allows the engagement of the reference device on a crankpin to be checked while the latter is orbitally moving, and does not interfere with the displacements of the support device caused by the orbital motion of the crankpin in the checking condition.

Owner:MARPOSS SPA

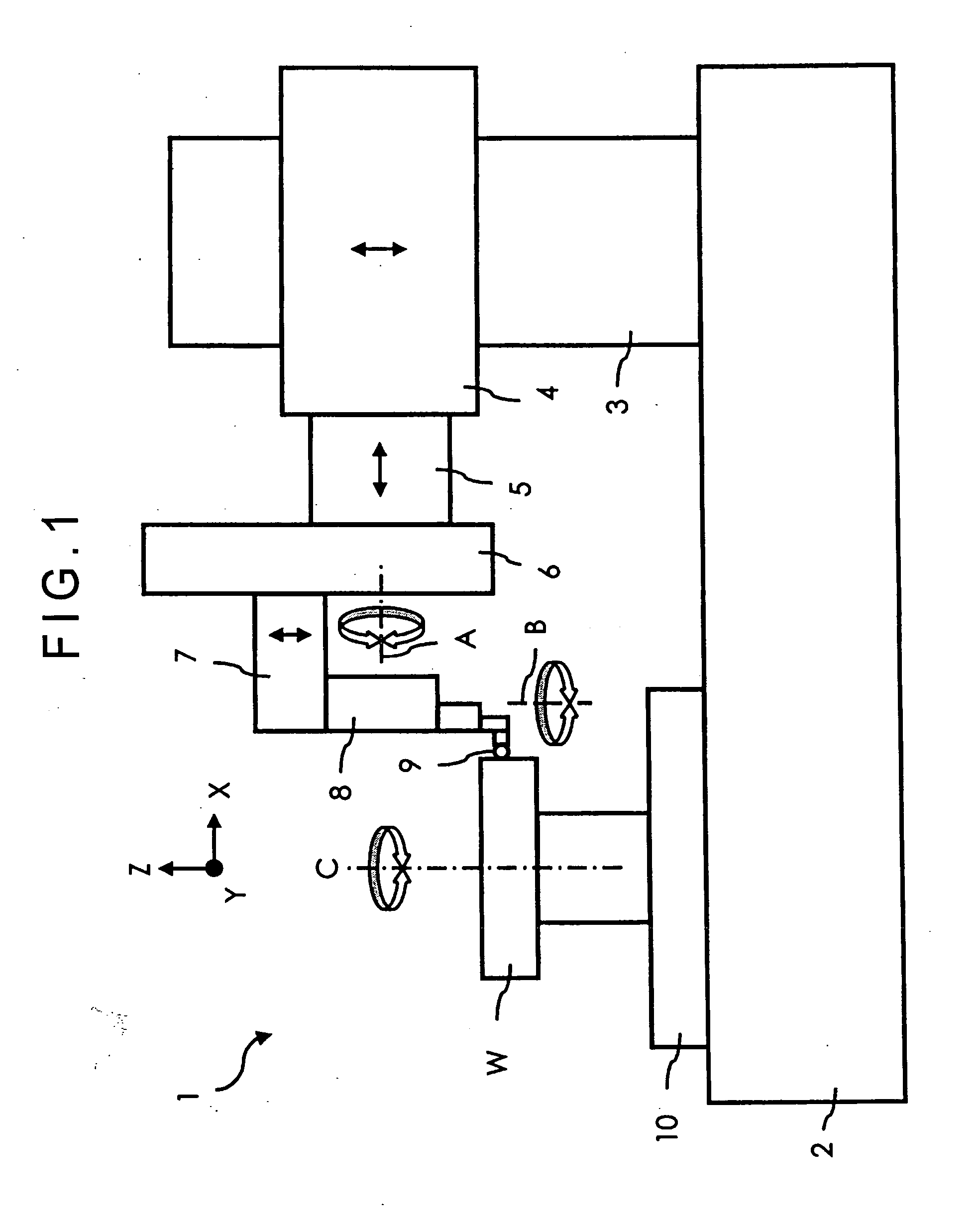

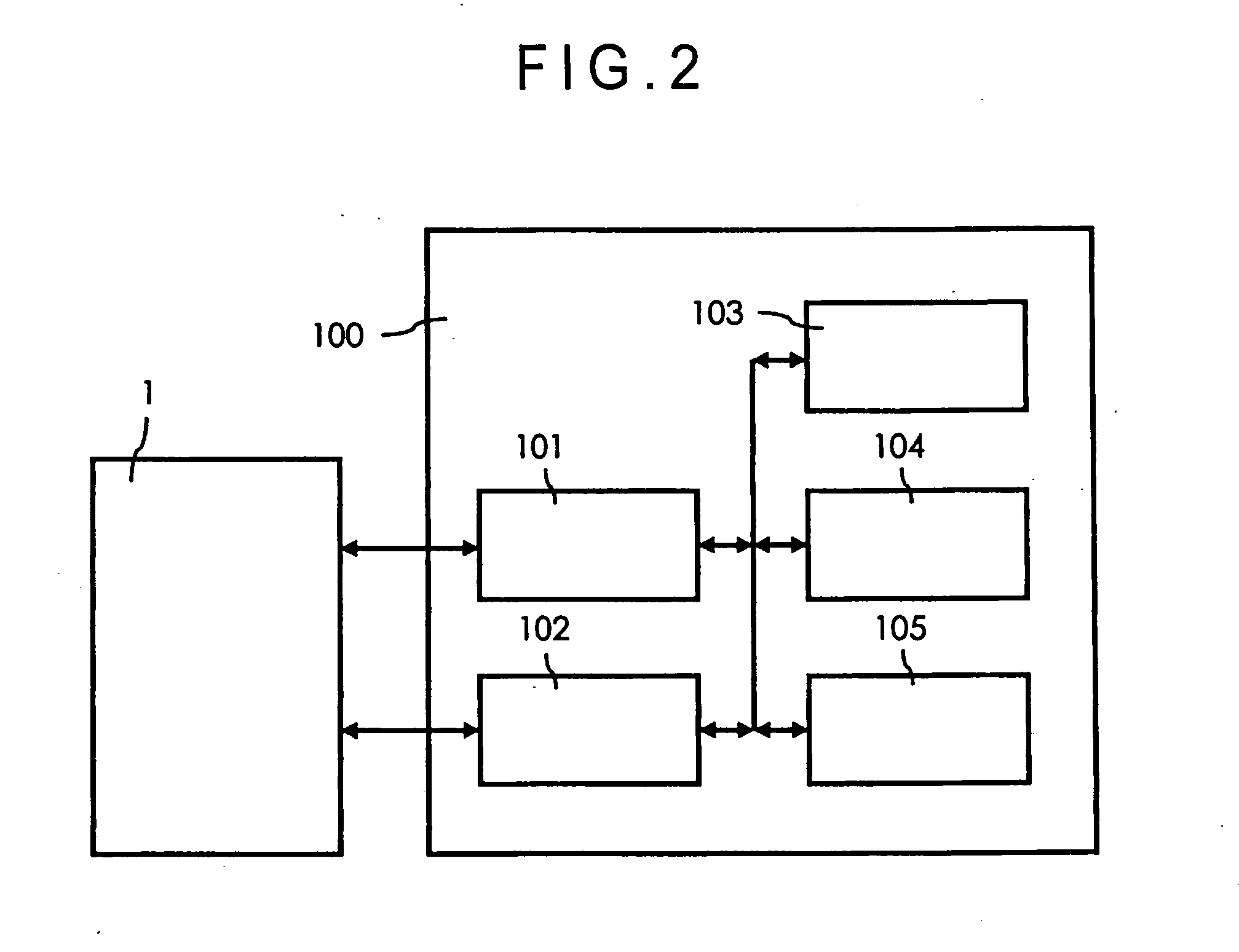

Width-measuring method and surface texture measuring instrument

ActiveUS20050132591A1Easy to measureSimple and accurate measurementMechanical counters/curvatures measurementsMechanical diameter measurementsMeasuring instrumentSurface roughness

A surface texture measuring instrument has a rotary table on which a workpiece is rotatably mounted, a Z-axis slider capable of moving in a Z-axis direction parallel to a rotation axis of the rotary table, an X-axis slider that is held by the Z-axis slider and is advanceable and retractable in an X-axis direction orthogonal to the rotation axis, a first arm that is held by the X-axis slider and is rotatable around a center line parallel to the X-axis, a second arm that is held by the first arm and is advanceable and retractable in a direction orthogonal to the X-axis, and a detector held by the second arm to measure a surface texture of the workpiece.

Owner:MITUTOYO CORP

Portable articulated arm coordinate measuring machine with multi-bus arm technology

ActiveUS8683709B2Programme controlMechanical diameter measurementsMeasurement deviceCoordinate-measuring machine

A portable articulated arm coordinate measuring machine (AACMM) with multi-bus arm technology that includes a manually positionable articulated arm portion, a measurement device, and an electronic circuit. The electronic circuit is configured to receive a position signal from the arm portion and to provide data corresponding to a position of the measurement device. The AACMM further includes a probe end, an accessory device, an encoder data bus, and a first device data bus. The encoder data bus is coupled to the arm portion and the electronic circuit, and the encoder data bus is configured to send the position signal to the electronic circuit. The first device data bus is coupled to the accessory device and the electronic circuit. The first device data bus is configured to operate simultaneously with and independently of the encoder data bus for sending accessory device data from the accessory device to the electronic circuit.

Owner:FARO TECHNOLOGIES INC

Method and apparatus for best fitting two or more items

InactiveUS7086169B1Mechanical counters/curvatures measurementsMechanical diameter measurementsAlgorithmEngineering

Owner:PROJECT CONSULTING SERVICES

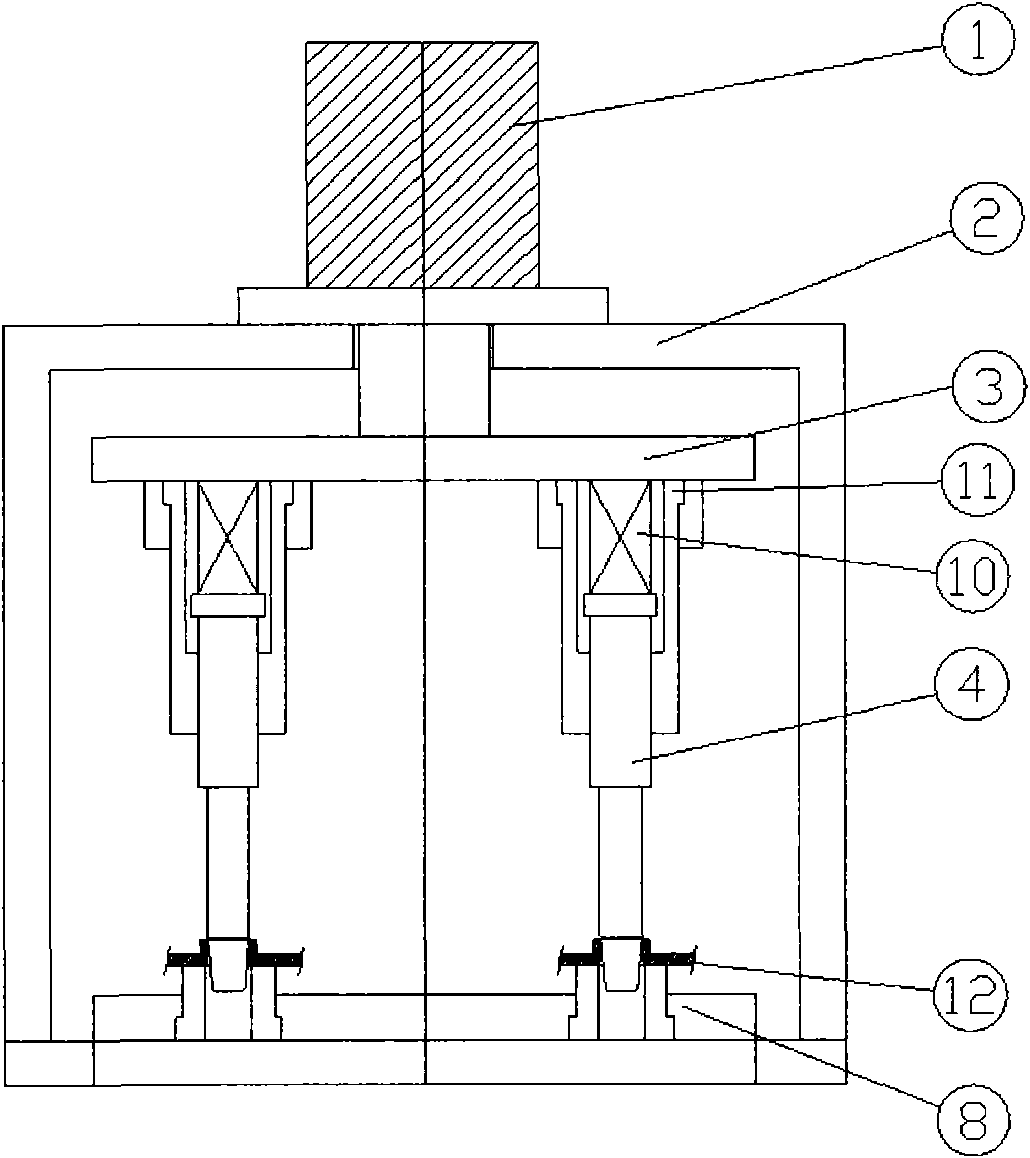

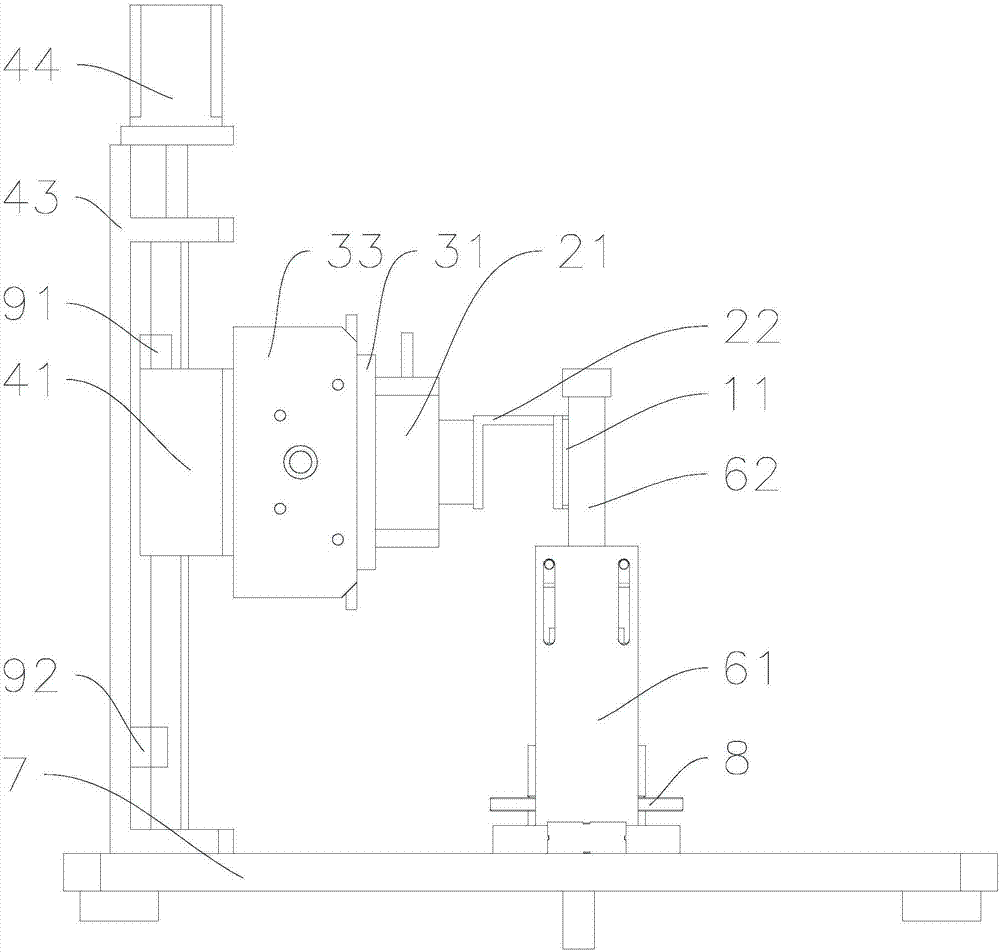

Screw thread automatic detecting equipment and method

InactiveCN101603804AImprove satisfactionFacilitate the realization of assembly line operationMechanical diameter measurementsFixed frameVia device

The invention relates to screw thread automatic detecting equipment and a method thereof; the main frame of the equipment is a fixing frame, a screw thread detecting pin is driven by a working air cylinder fixed at the center of the outer part of the top side to move downwards to carry out detection, a product detecting fixture is arranged on a base of the fixing frame, and the position of a screw thread hole of the product to be detected is arranged right below the screw thread detecting pin; a sensor is arranged at one side of the screw thread detecting pin, the front end part of the sensor is vertical to the screw thread detecting pin and is arranged at a distance from the screw thread detecting pin, the sensor is triggered to carry out detection by the insertion of a screw thread detecting rod at the front end of the screw thread detecting pin or by different working states generated by preventing from moving downwards. The equipment fully utilizes the difference of pore diameter of an extruding and tapping product before tapping and after tapping to carry out judgment and identification, and full-inspection identification and marking are automatically carried out by the equipment, thereby being beneficial to realizing assembly line work, avoiding changing or lagging the production flow, reducing the risk on producing defective products in the process and having remarkable economic benefit.

Owner:无锡雄伟精工科技有限公司

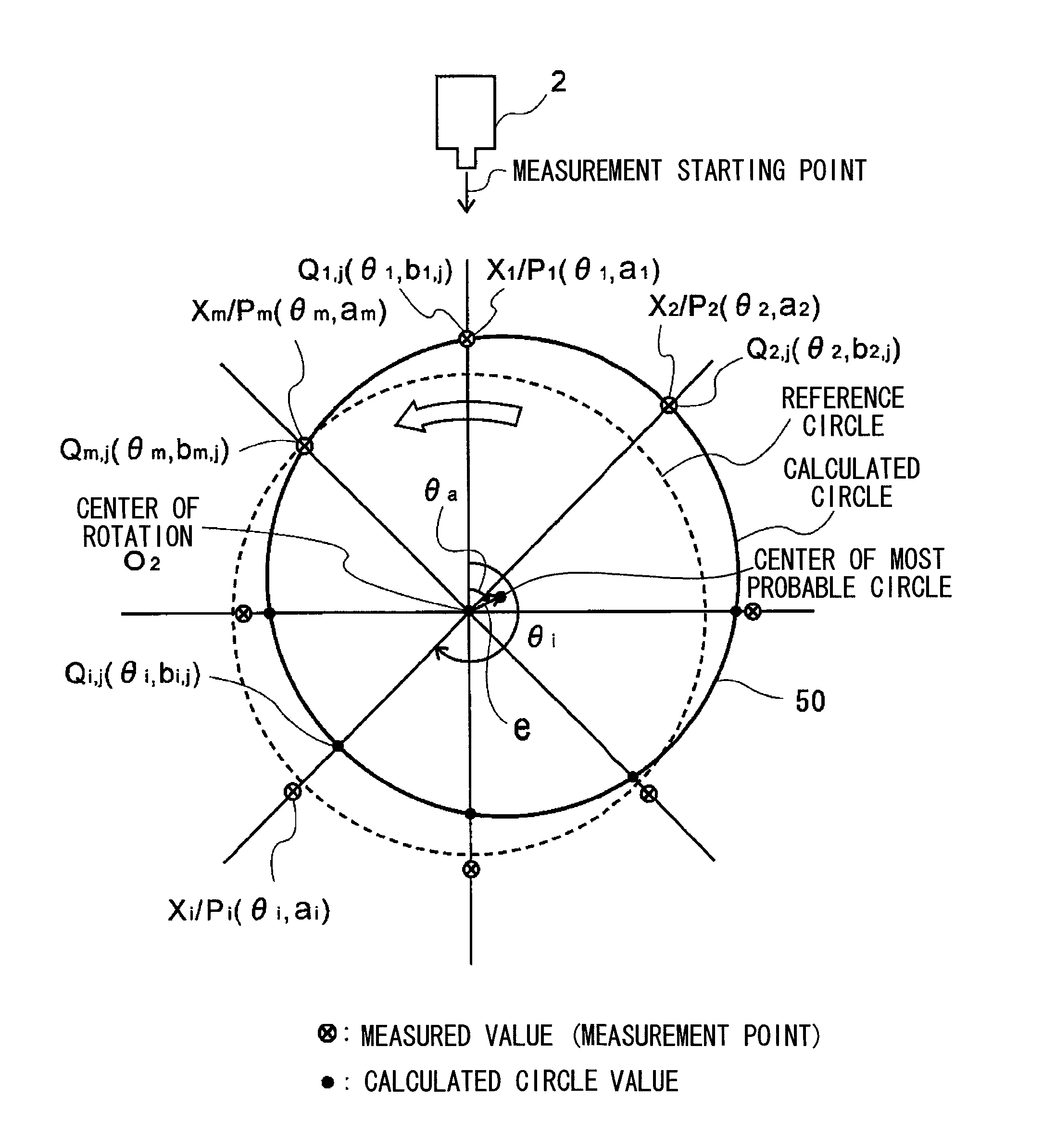

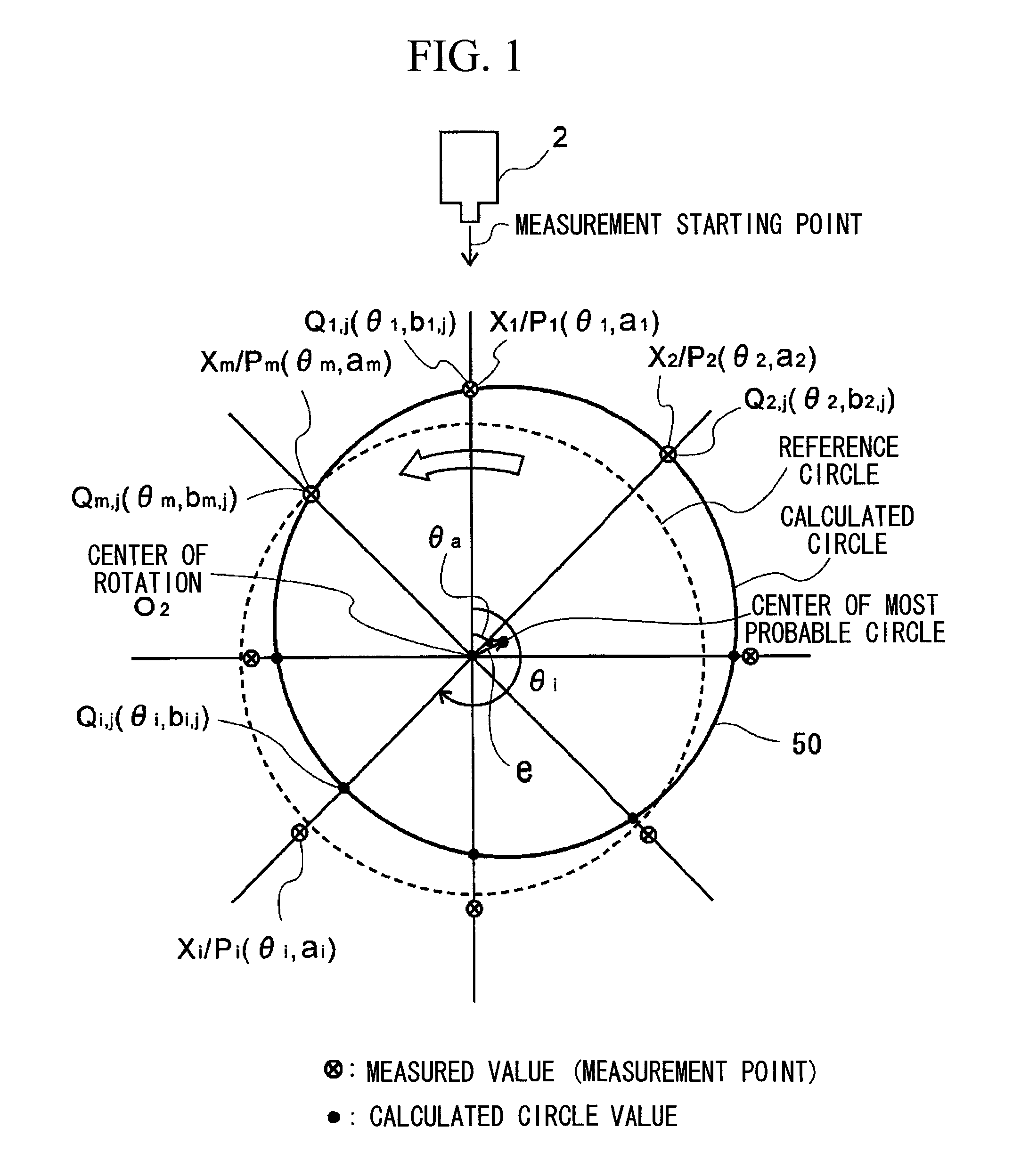

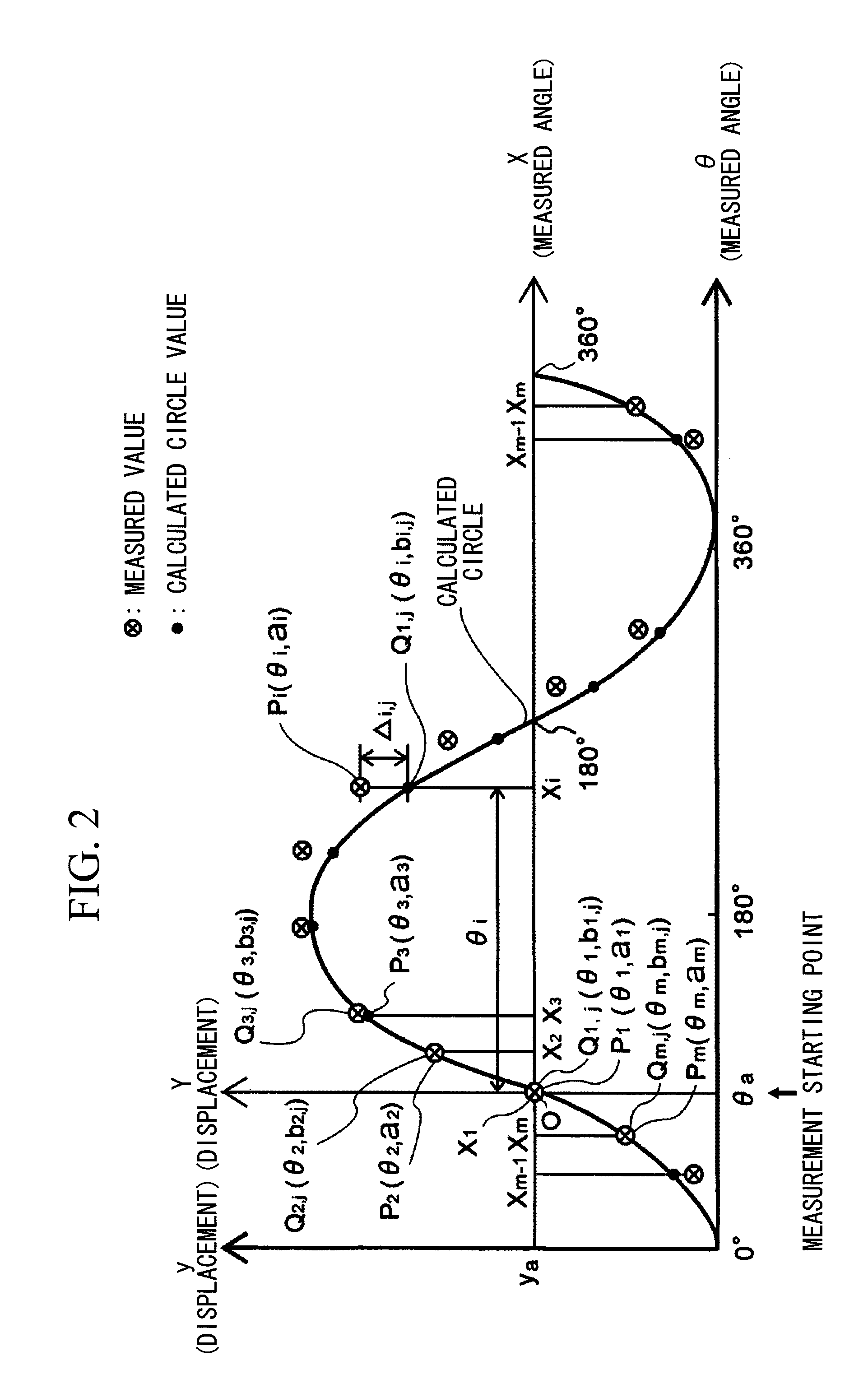

Method and system for calculating misalignment of rotational body

ActiveUS8306776B2Quick and reliable maintenanceElectrical/magnetic diameter measurementsIncline measurementMeasurement pointRepeating circle

In a method of calculating misalignment of a rotational body, radial displacement values are measured using a displacement gauge. A calculation part performs the steps of deriving radial displacement amounts of the rotational body for at least four or more measurement points along an outer surface while rotating the rotational body, selecting three arbitrary points to calculate a circle, calculating circle values for all the measurement points, calculating differences between the calculated circle values and the radial displacement amounts as error amounts, summing the error amounts to derive a total error amount, repeating circle calculation for different combinations and calculating a total error amount for each calculated circle, selecting a circle with a minimum total error amount as a most probable circle, and calculating deviation between the center of the most probable circle and the center of rotation of the rotational body.

Owner:MITSUBISHI POWER LTD

Wall contact caliper instruments for use in a drill string

Owner:SCHLUMBERGER TECH CORP

Gauge assembly for measuring diameter and total indicated runout

InactiveUS7197837B1Short timeOvercome disadvantagesCompasses with pivoted armsMechanical diameter measurementsLinear motionAerodynamic drag

The invention is directed to a gauge assembly that is used to measure parameters of camshaft journals or other objects with cylindrical surfaces. The gauge assembly includes two gauges, the first is an air snap gauge and the second a linear variable differential transducer. The air snap gauge is slidingly attached to the base and the second gauge is attached to a base as well. Air resistance measurements, taken through the air snap gauge provide a measure of diameter of the journal while relative linear motion between the base and air snap gauge, measured by the second gauge, provides a measure of journal runout relative to the center axis of the camshaft. Control logic is used to calculate other parameters such as runout of a journal relative to another journal on a common camshaft.

Owner:HONDA MOTOR CO LTD

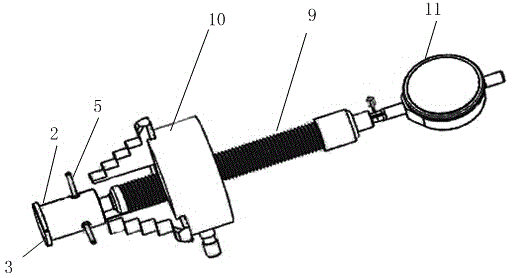

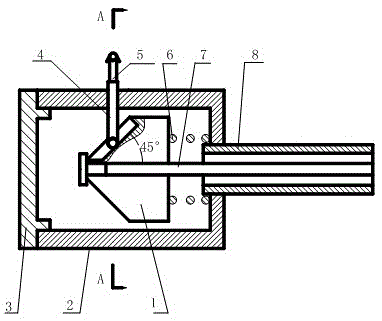

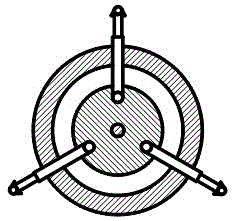

Depth aperture internal diameter measurement device

ActiveCN105547106AGuaranteed backingGuaranteed measurement accuracyMechanical diameter measurementsMeasurement deviceCircular cone

The invention discloses a depth aperture internal diameter measurement device, comprising a tapered block, a sleeve, three measurement rods, a spring, a push rod, a sleeve rod, a thread sleeve rod, a three-claw chuck and an internal diameter dial indicator. The conical surface of the tapered block is uniformly provided with three sliding grooves which are formed along the generatrix direction of the tapered block; the included angle between each sliding groove and the axis of the tapered block is 45 degree; the wall of the sleeve is provided with three through holes which are uniformly distributed along the circumference; three measurement rods pass through the through hole in the wall of the sleeve; and one end of the measurement rod is clamped inside a sliding groove. In the invention, the included angle between the sliding groove and the axis of the tapered block is 45 degrees and the displacement of the measurement rod along the radial direction is turned into an axial direction, which avoids the intermediate transfer between the levers in the traditional measurement, has more accurate measurement and can measure the maximum and minimum diameter of any cross section.

Owner:NANJING COLLEGE OF INFORMATION TECH

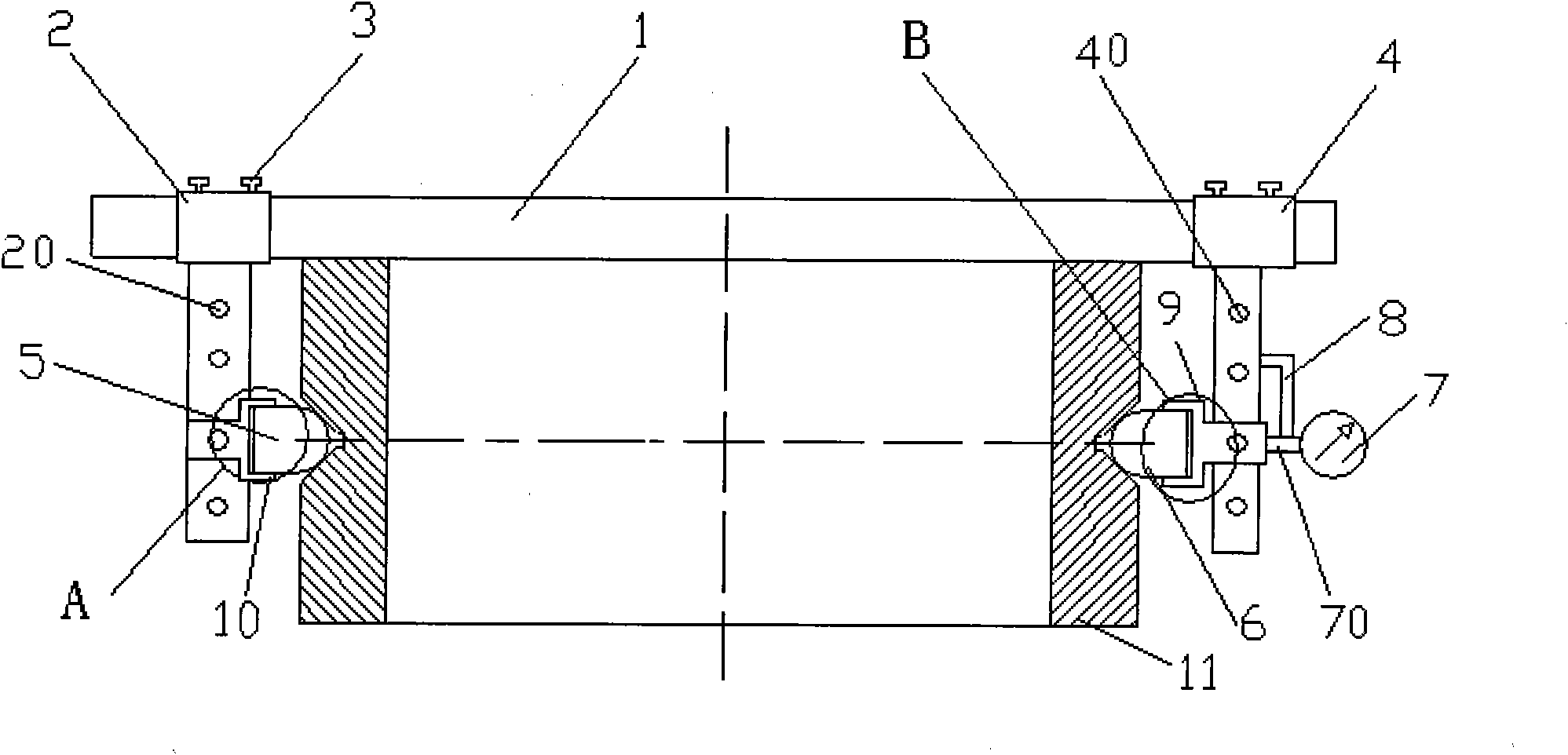

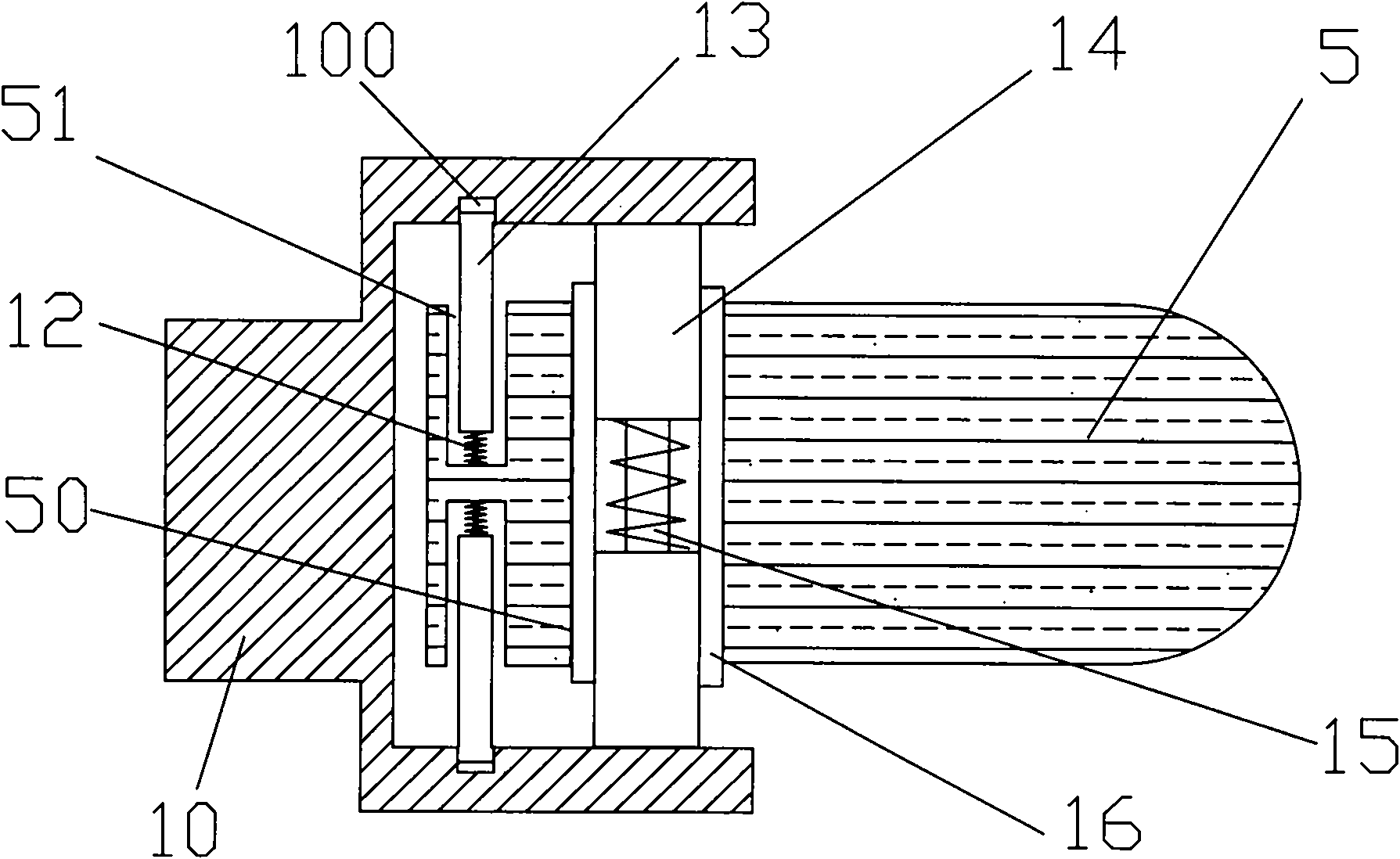

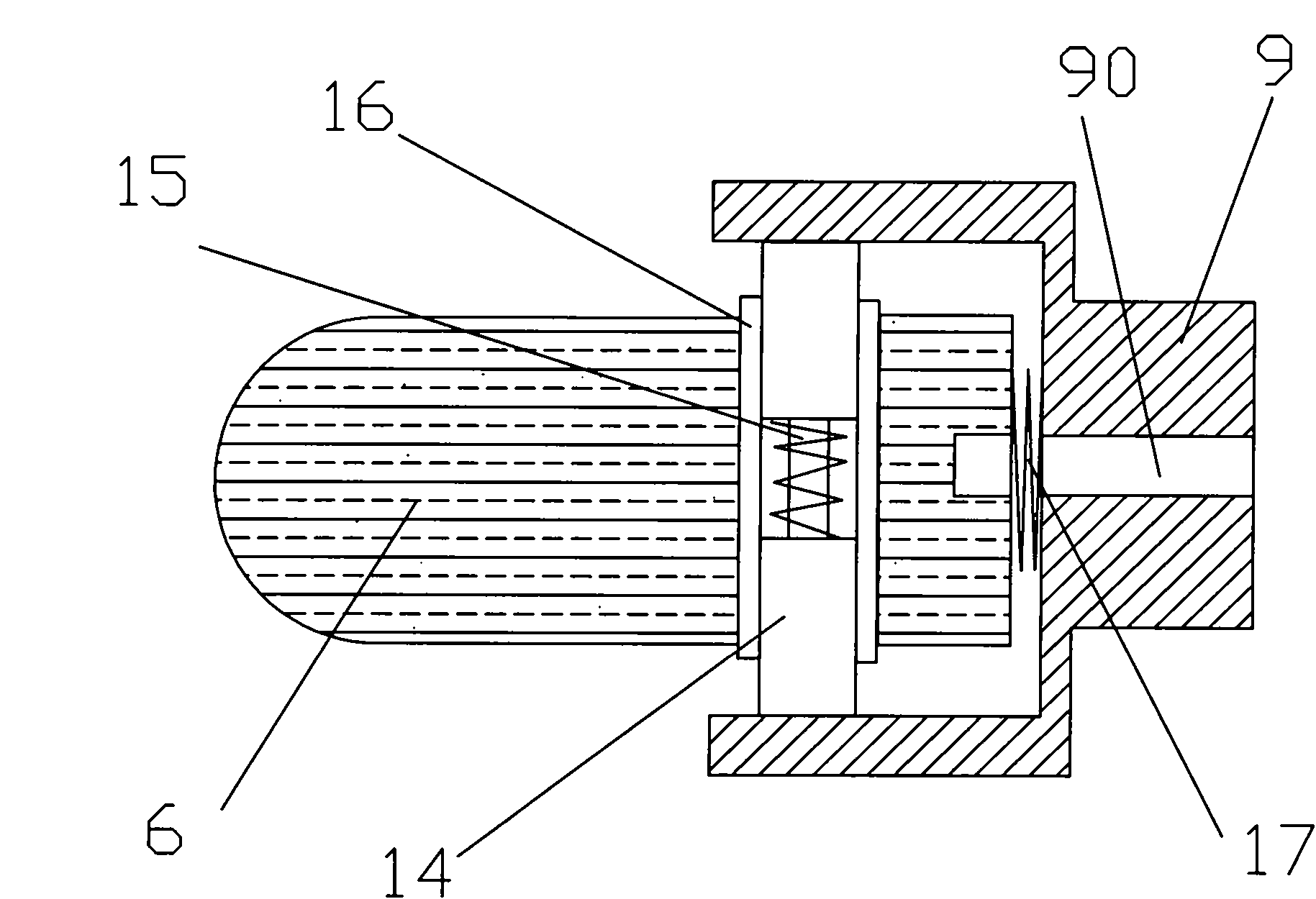

Device and method for measuring diameters of internal and external raceways of wind power bearing

The invention discloses a device and method for measuring diameters of internal and external raceways of a wind power bearing. The device comprises a ruler and a meter, wherein the left side and the right side of the ruler are respectively provided with a measuring bar, i.e. a left measuring bar and a right measuring bar respectively; the left measuring bar and the right measuring bar can be moved and fixed on the ruler; the left measuring bar and the right measuring bar can also be arranged on the ruler in the reverse direction for measuring; the left measuring bar and the right measuring are vertical to the ruler; the left measuring bar is provided with a fixed measuring head through a left fixed mount; the right measuring bar is provided with a moving measuring head through a right fixed mount; the meter is fastened and connected with the right measuring bar through a fixed bar; and a contact of the meter and the right end surface of the moving measuring head are in elastic contact. The method comprises the steps of adjusting the measuring device, actually measuring and judging whether the diameters of the raceways are qualified or not. The device can be used for measuring the diameters of the internal and the external raceways of the bearing, thereby improving the efficiency and the convenience of the measuring work.

Owner:SHANGHAI UNITED BEARING

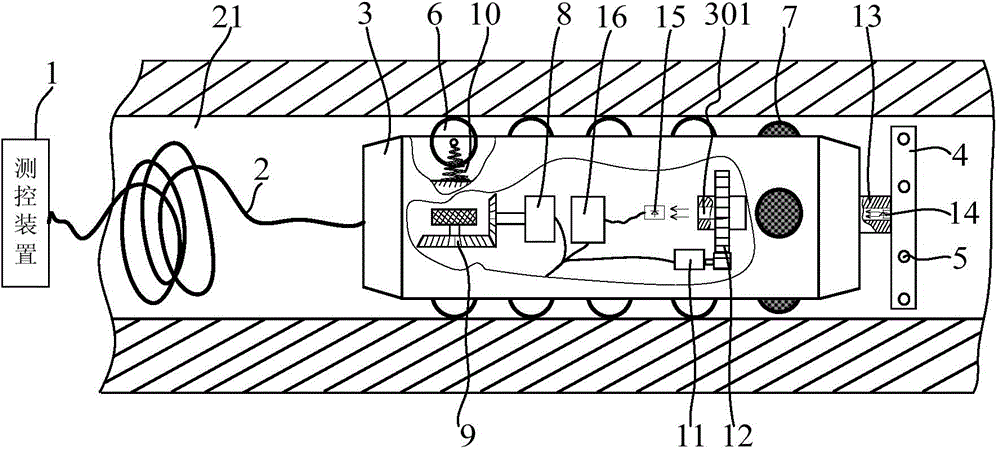

Deep hole inner diameter measuring system

ActiveCN104089561ASimple structureImprove stabilityMechanical diameter measurementsPhysicsMicrometer

The invention discloses a deep hole inner diameter measuring system which comprises a measuring main body moving in the axial direction of a deep hole and a measuring control device connected with the measuring main body. The measuring main body comprises a cavity, at least three rows of supporting rolling wheels, at least two stopping balls and a rotating measuring disc, wherein the supporting rolling wheels are evenly distributed outside the cavity, one supporting rolling wheel is provided with a driving wheel for driving, the stopping balls are evenly distributed outside the cavity, the rotating measuring disc is arranged at one end of the cavity, a plurality of eddy current displacement sensors for measuring the inner diameter of the deep hole are arranged in the radial direction of the rotating measuring disc, and the eddy current displacement sensors are designed to achieve high sensitivity of 20 mv / micrometer within the 1mm measuring range on the basis of the simple series resonance principle. The stopping balls, the driving wheel and the rotating measuring disc are driven by corresponding driving devices respectively. The measuring control device comprises a first control module, a second control module, a third control module and a measuring calculation module for processing voltage signals output by the eddy current displacement sensors and calculating the inner diameter of the deep hole. According to the system, the inner diameter of the deep hole can be measured, and the measuring precision of the inner diameter of the deep hole can be improved.

Owner:NAT INST OF METROLOGY CHINA

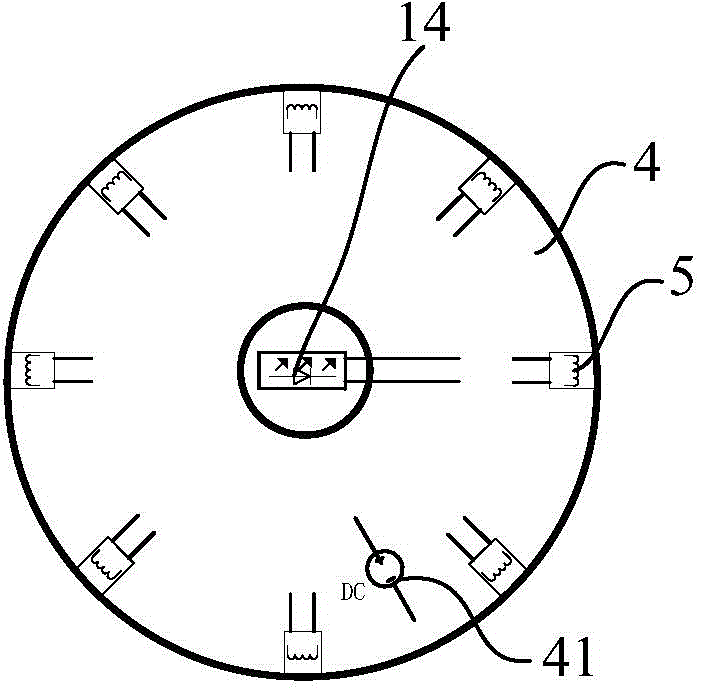

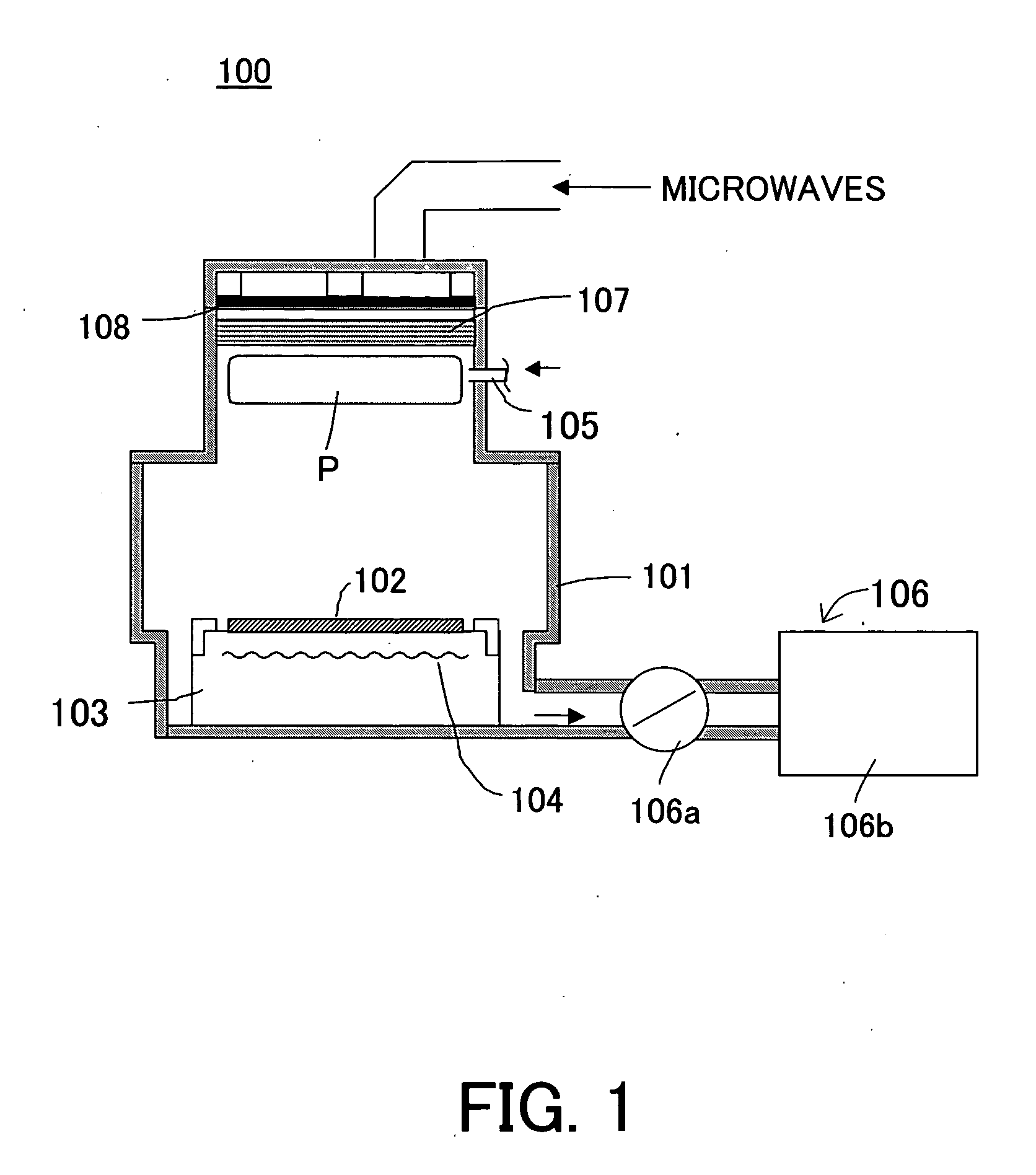

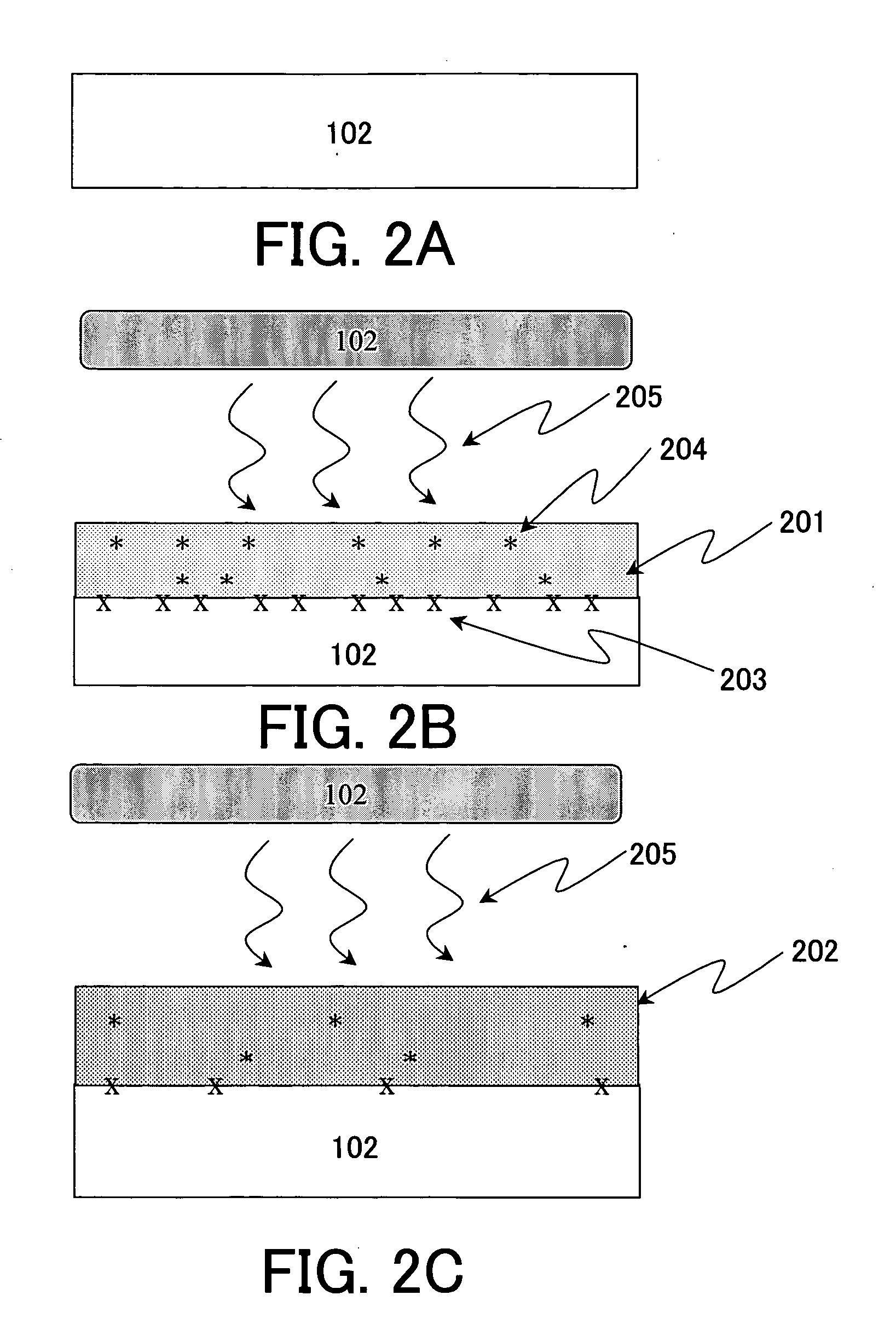

Processing apparatus and method

InactiveUS20050106896A1Mechanical diameter measurementsSemiconductor/solid-state device manufacturingNitrogenOxygen

A processing method for forming an insulated film on a surface of a substrate to be processed, through an oxynitriding treatment includes the steps of nitriding a surface of the substrate by irradiating plasma containing nitrogen atoms onto the substrate, and oxidizing the surface of the substrate, which has been nitrided, by irradiating plasma containing oxygen atoms.

Owner:CANON KK

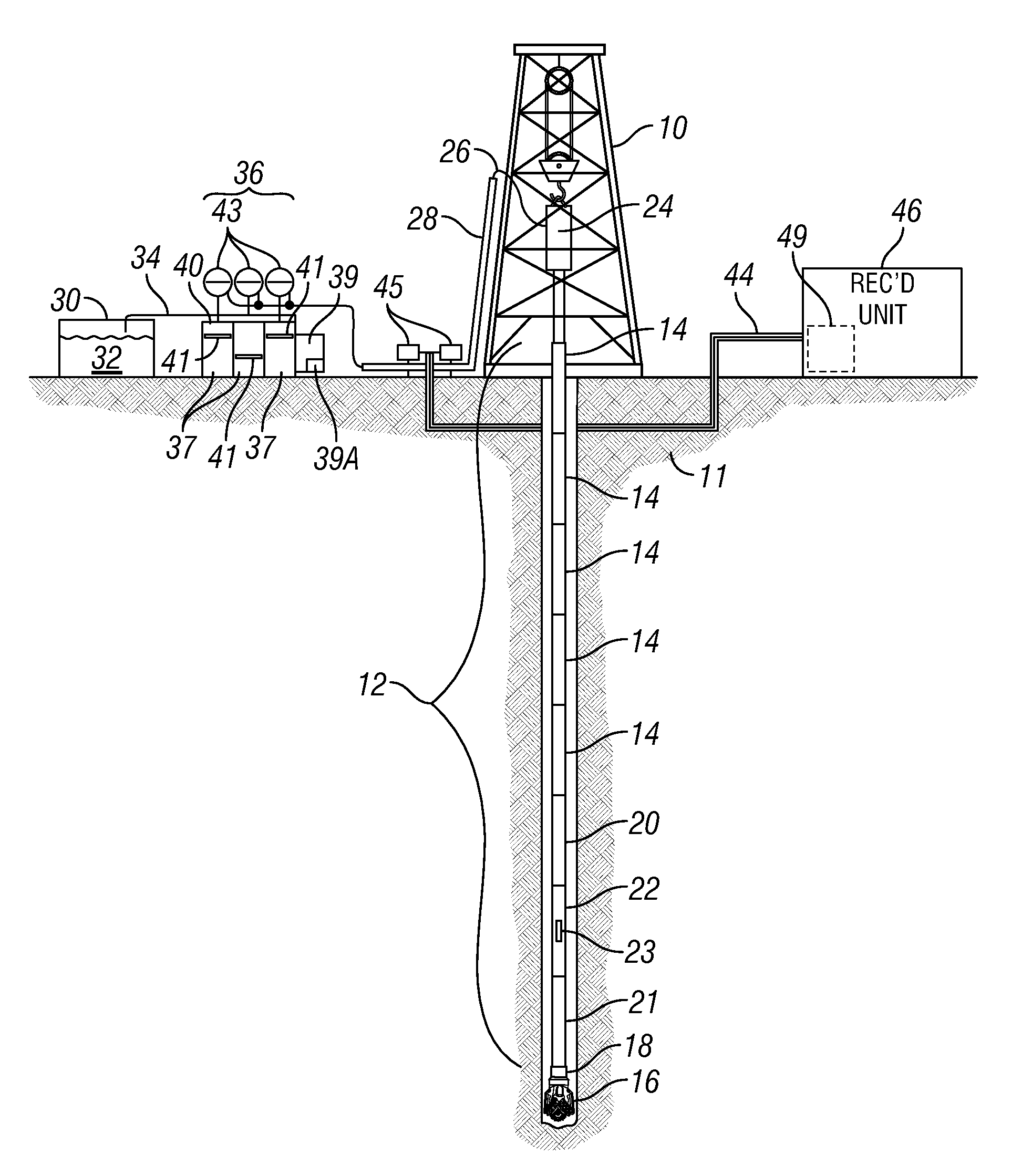

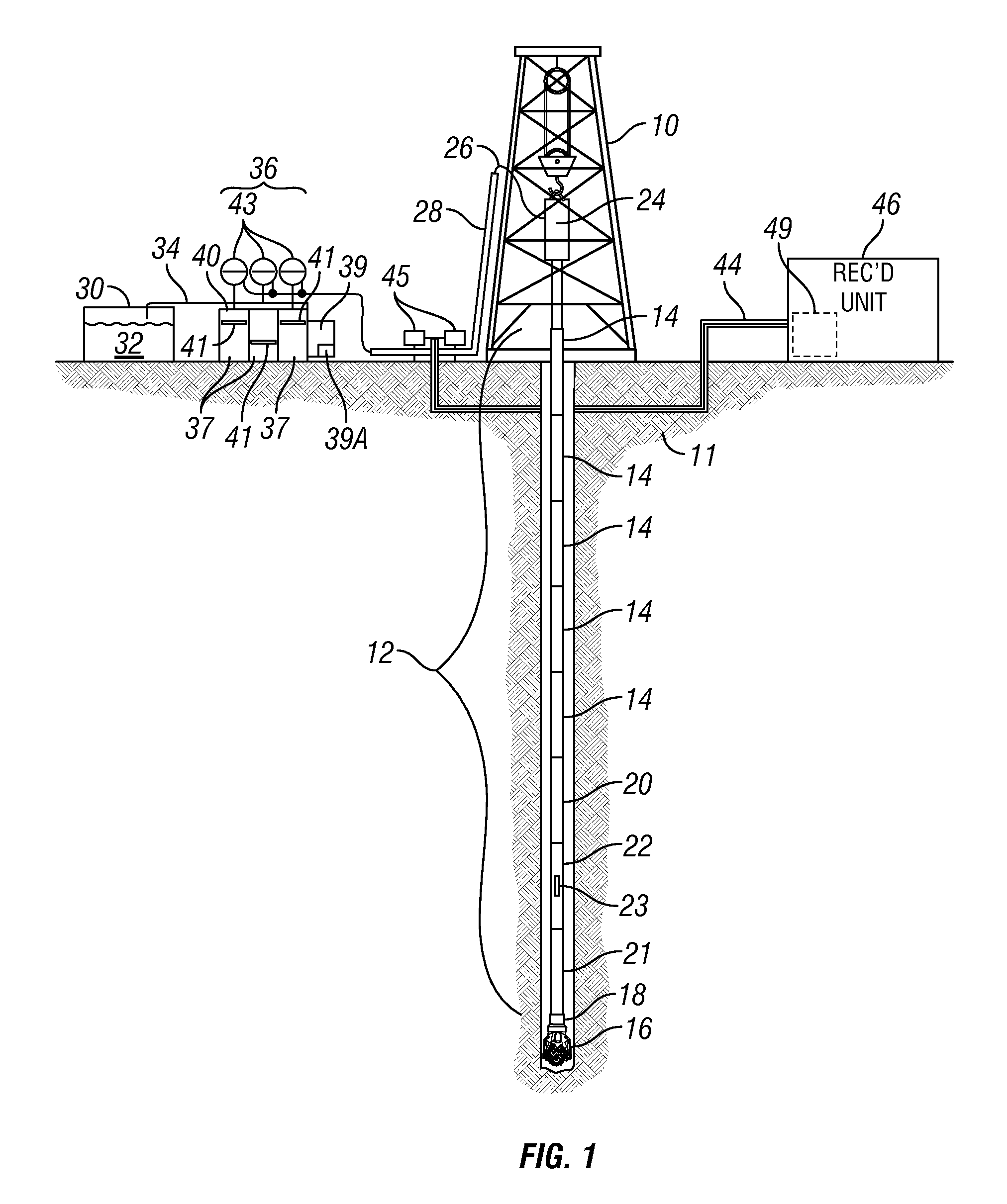

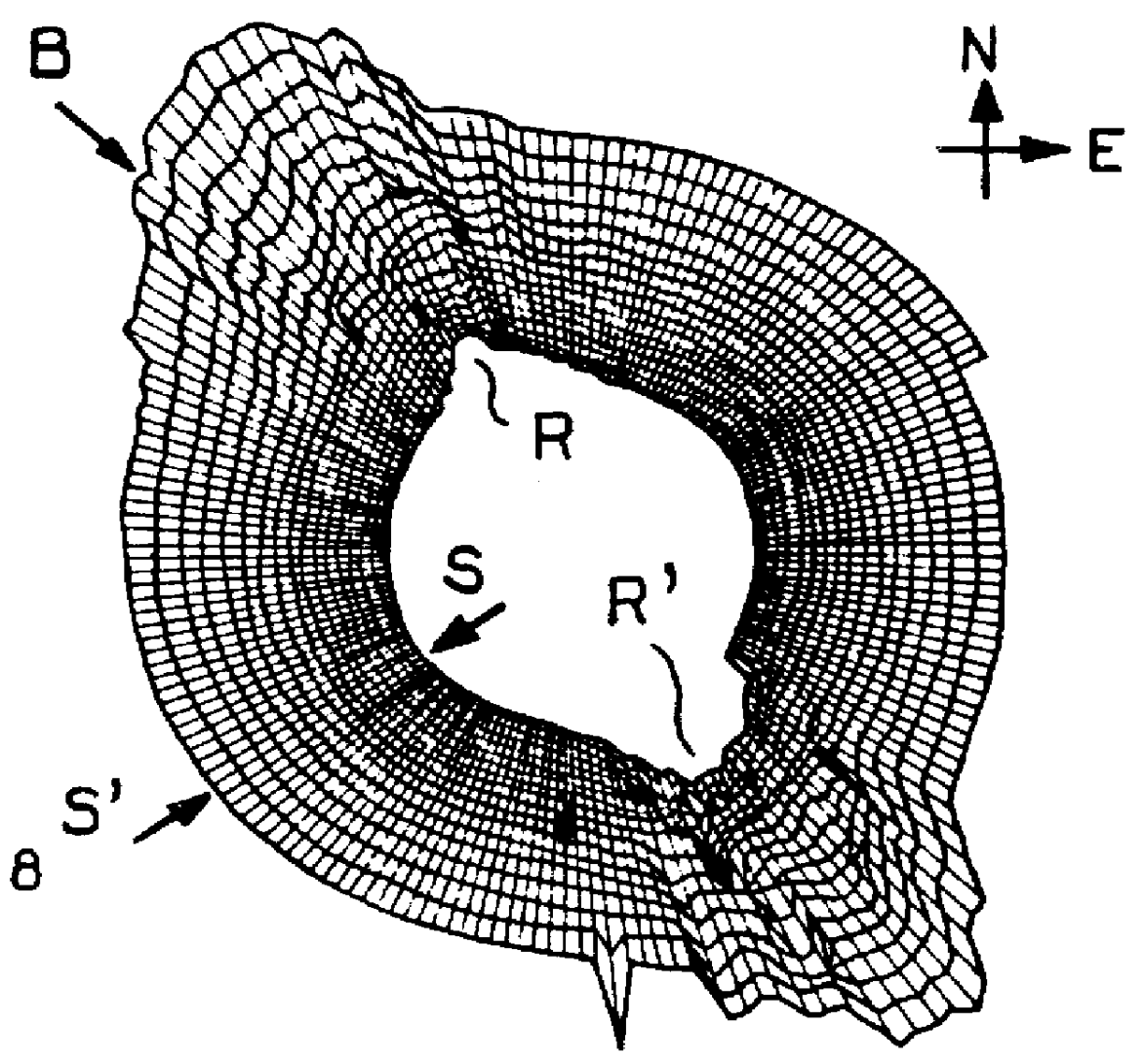

Method and apparatus for logging non-circular boreholes

The invention relates to a logging method and apparatus adapted for use in non-circular boreholes which, in one embodiment, comprises the use of a first and a second sonde, each sonde having: a pad adapted for contact with the borehole wall, at least a sensor on each pad, and an extendable arm for keeping the pad against the wall of the borehole. The first and second sonde produce measurements related to the same property of the formations, and the first and the second sonde are connected so as to keep the pads aligned with a 90 DEG azimuthal spacing therebetween.

Owner:SCHLUMBERGER TECH CORP

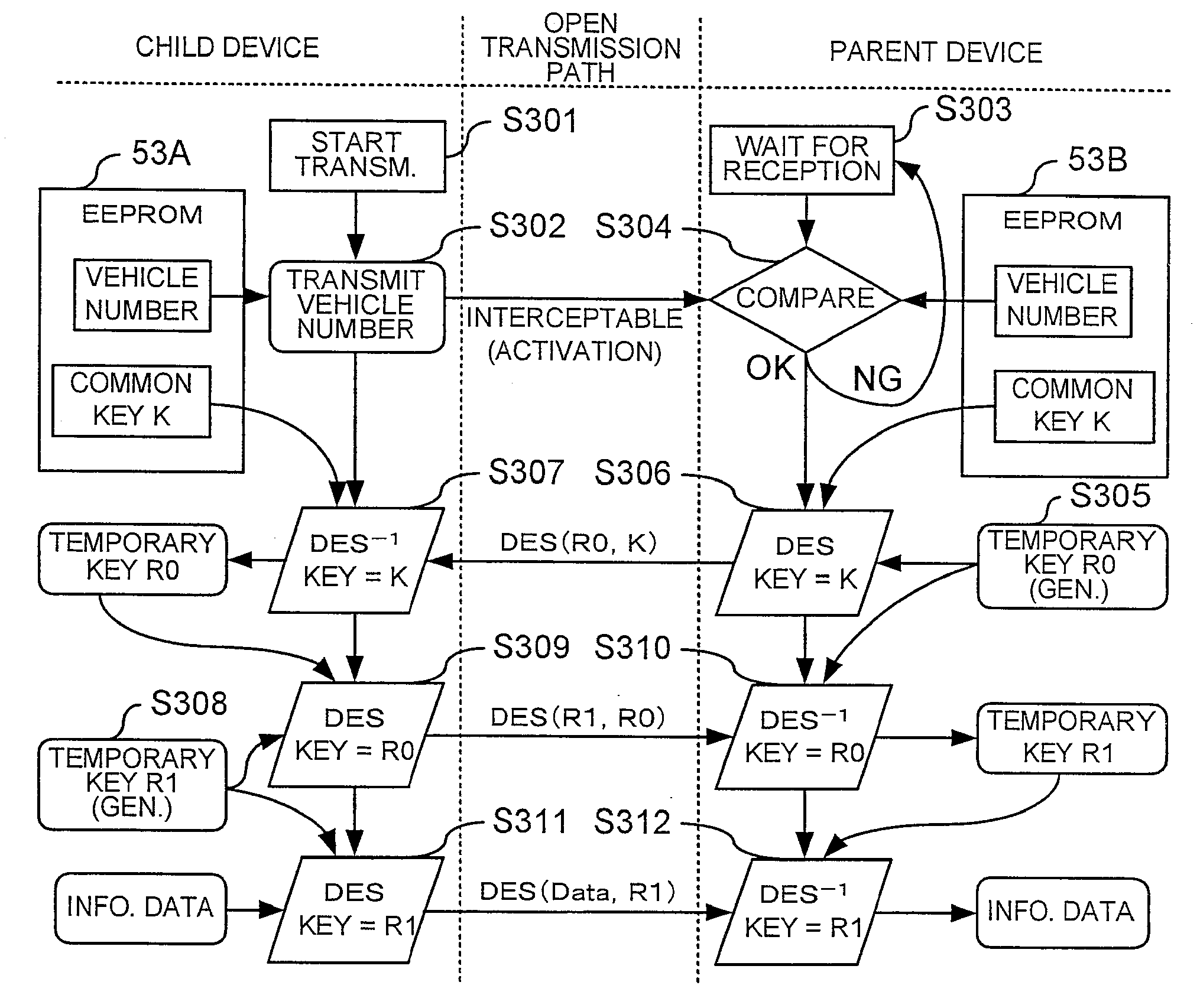

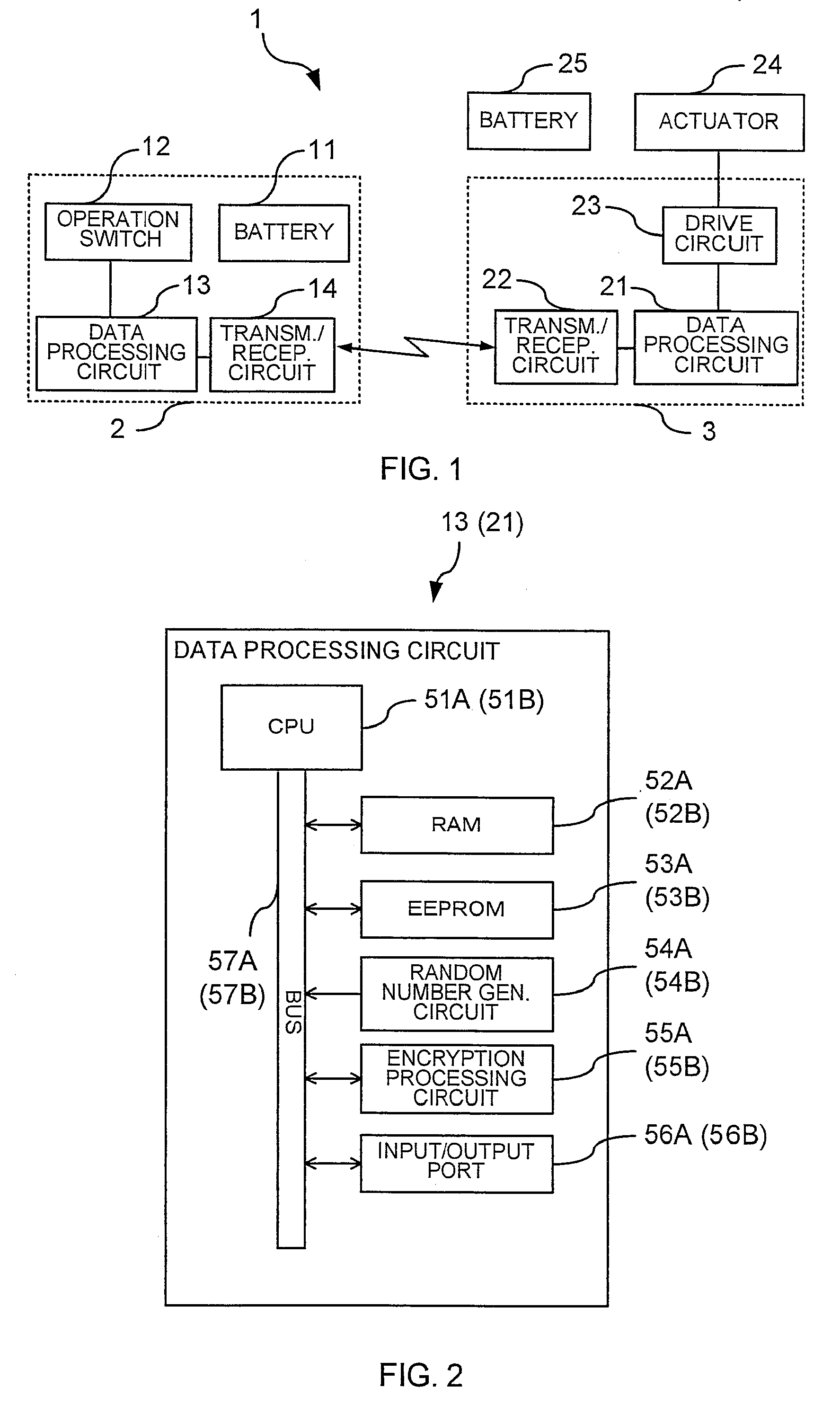

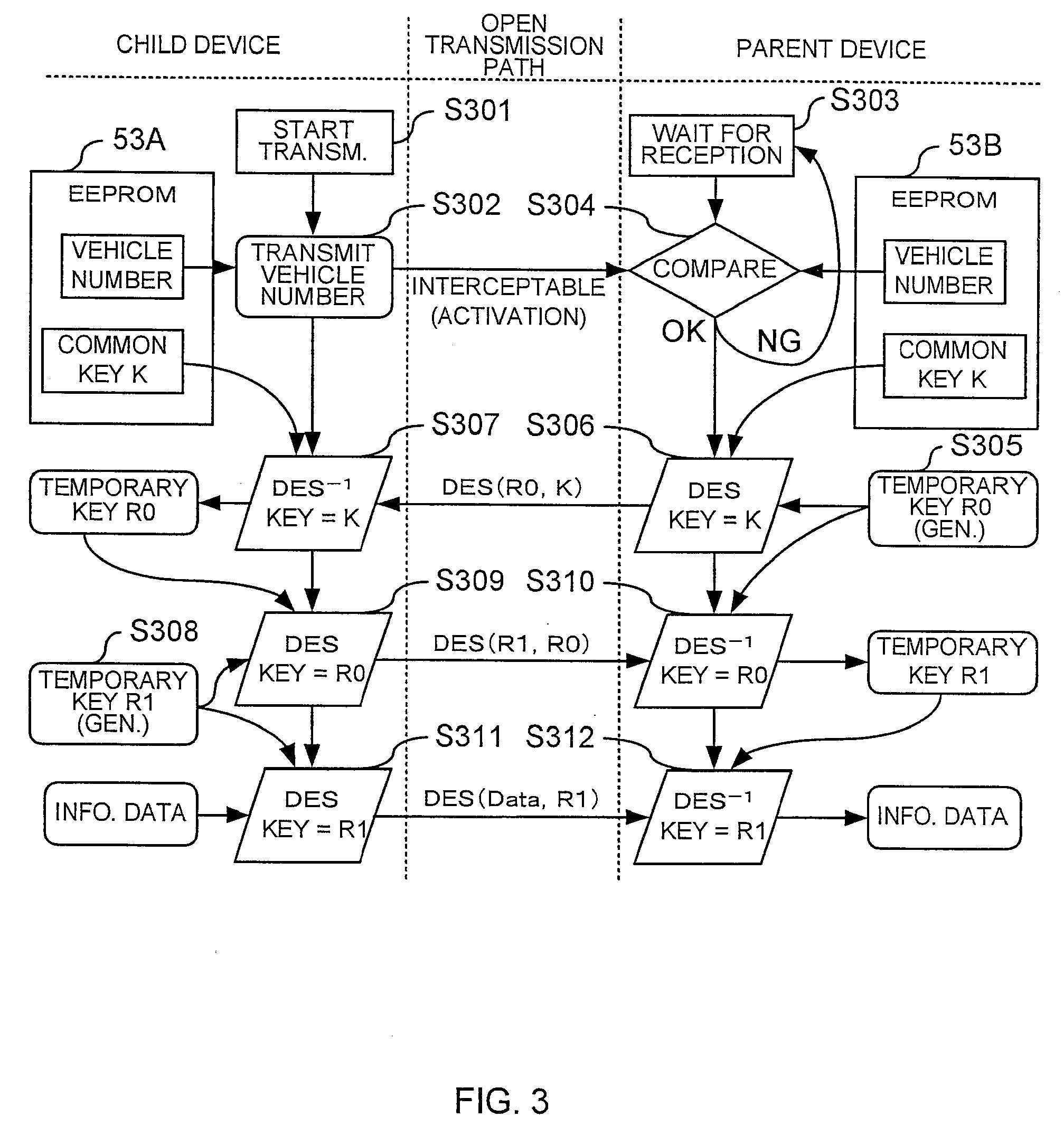

Random Number Generating Circuit

InactiveUS20070067374A1Difficult to predictRandom number generatorsEncryption apparatus with shift registers/memoriesPseudo random number generationComputer science

Owner:SANYO ELECTRIC CO LTD

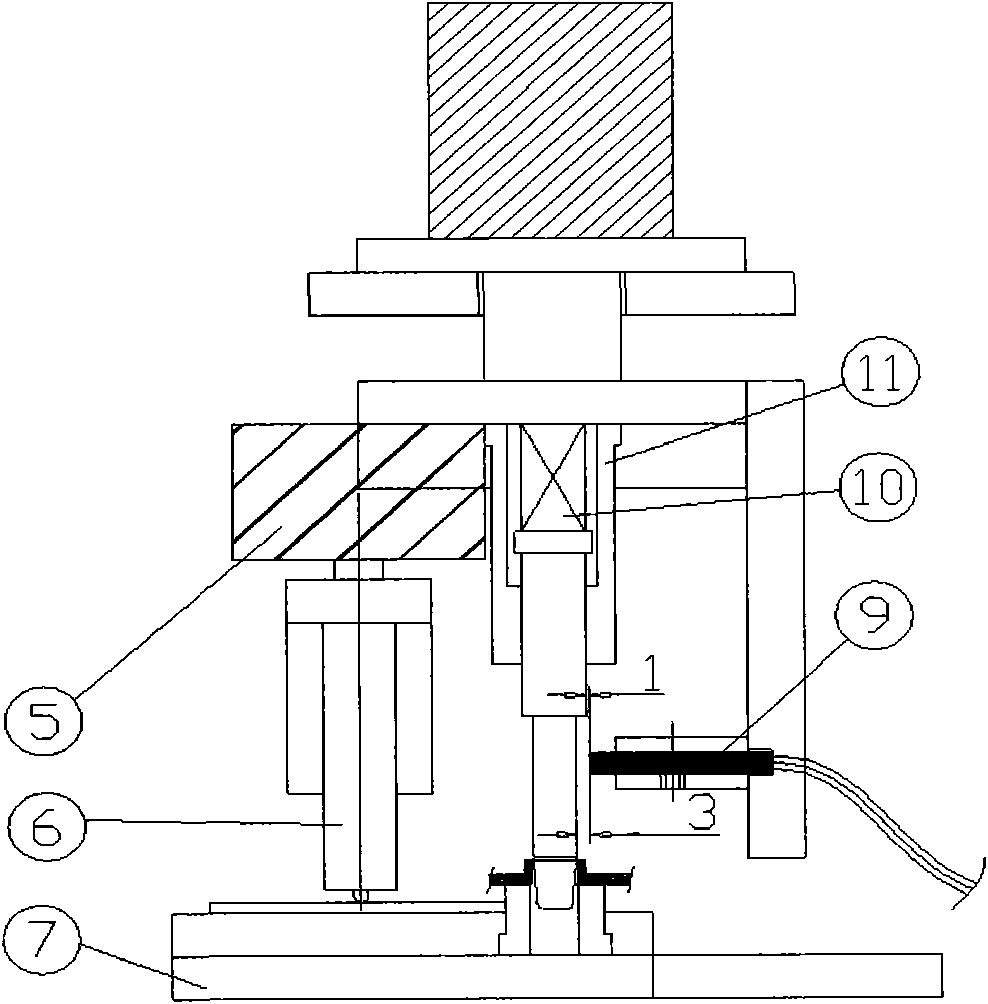

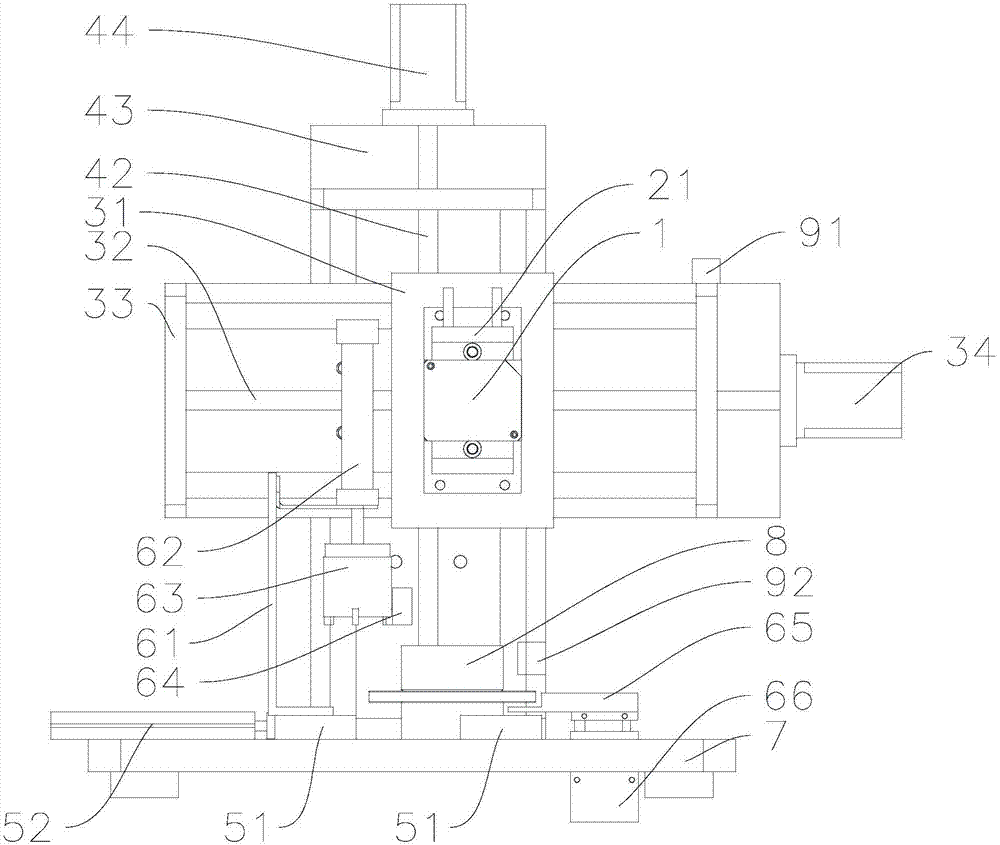

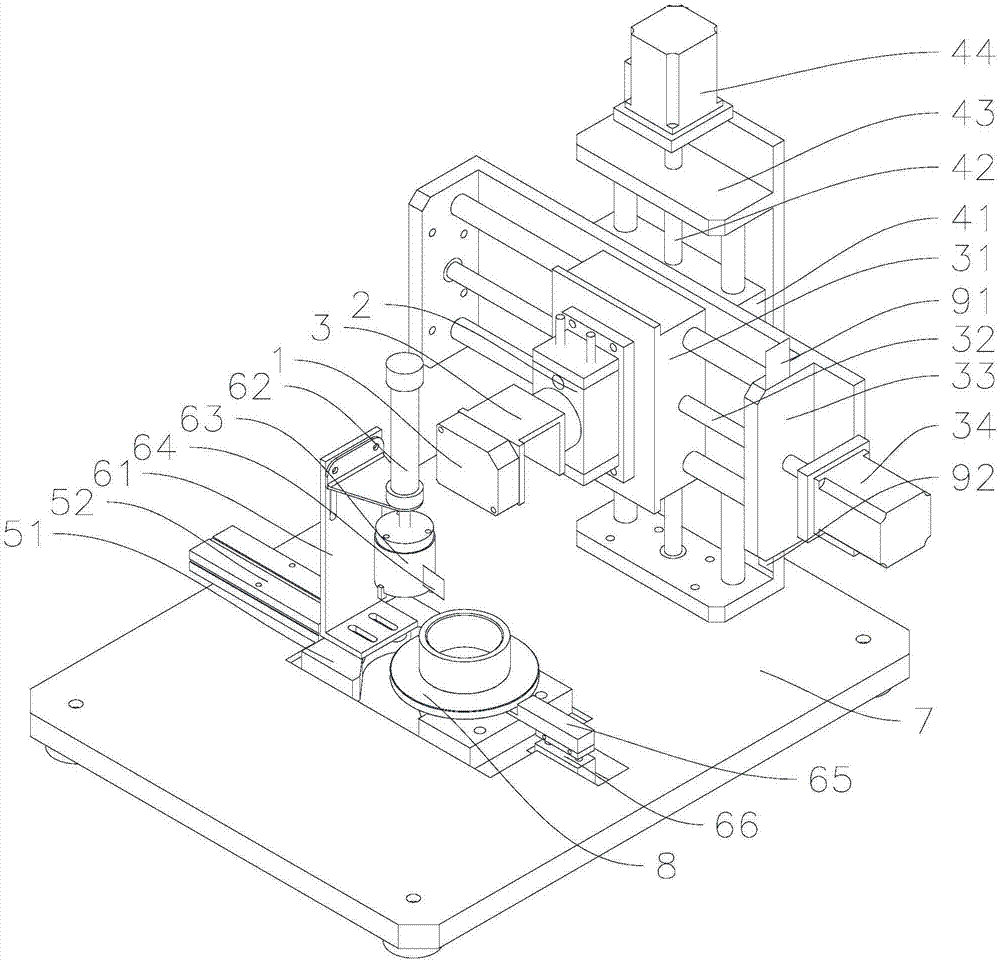

Laser multi-dimension servo detection device and detection system thereof

ActiveCN107345791ARealize high-precision detectionFully automatedMechanical diameter measurementsUsing optical meansProduction lineLaser

The invention relates to the technical field of workpiece measurement and in particular relates to a laser multi-dimension servo detection device. According to the laser multi-dimension servo detection device, a laser displacement sensor serves as a measuring tool; in order to realize multi-dimension precision detection, multi-dimension detection in the axial and radial directions and on multiple step surfaces can be performed by adopting an X-direction movement component, a Y-direction movement component, a rotary movement component clamping mechanism and a measuring block component. The problems that manual detection serves as a main manner and the workpiece detection efficiency is extremely low are solved, and automation of the detection process of processing parts on a production line is realized. Time and labor can be saved, the part processing quality and the processing efficiency are improved, and the device disclosed by the invention has far-reaching significances for promoting development of the processing and measuring integrated technology.

Owner:JIANGSU LEAP MACHINE

Noncontact measuring device

Owner:INT ELECTRONICS MACHINES

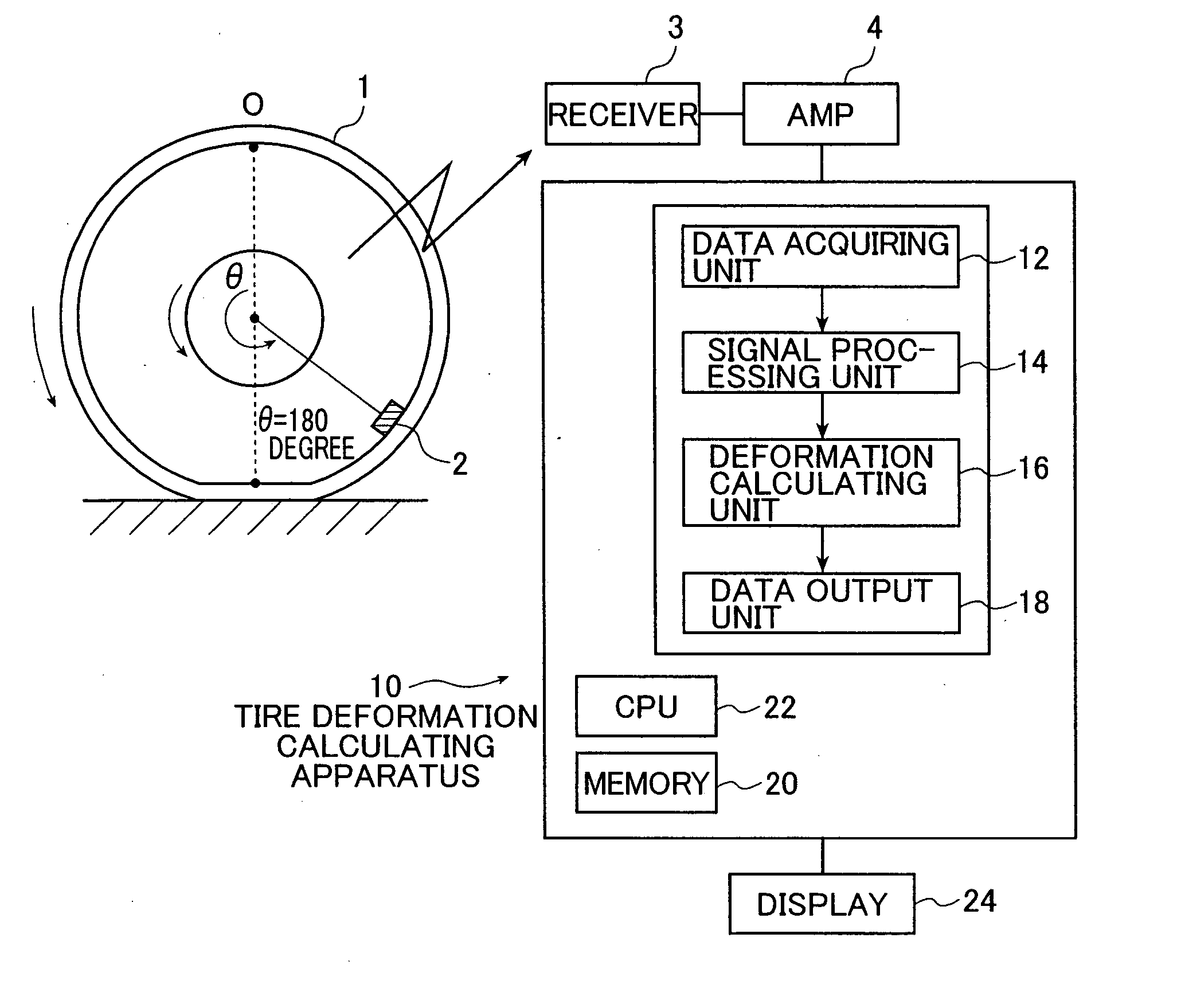

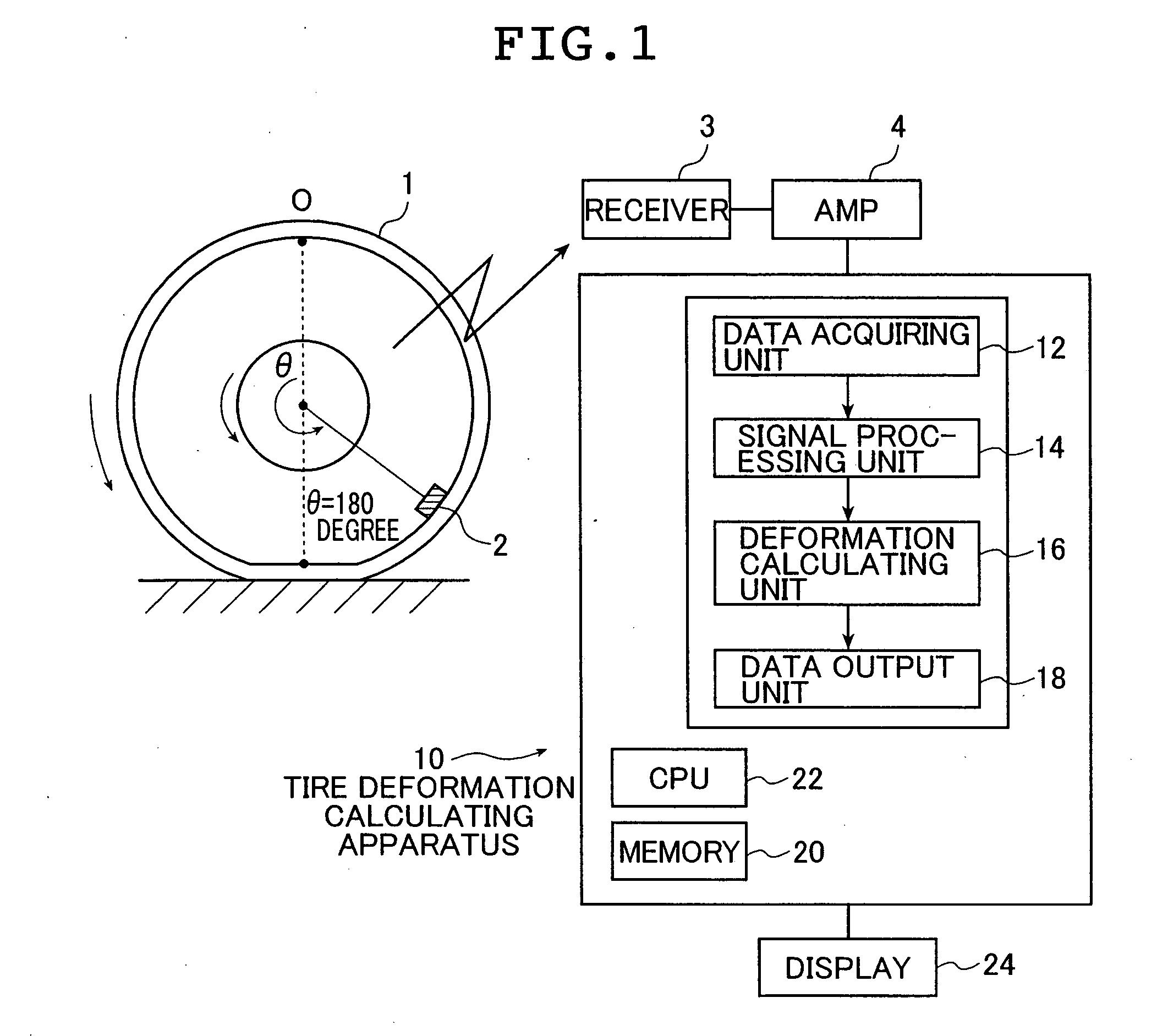

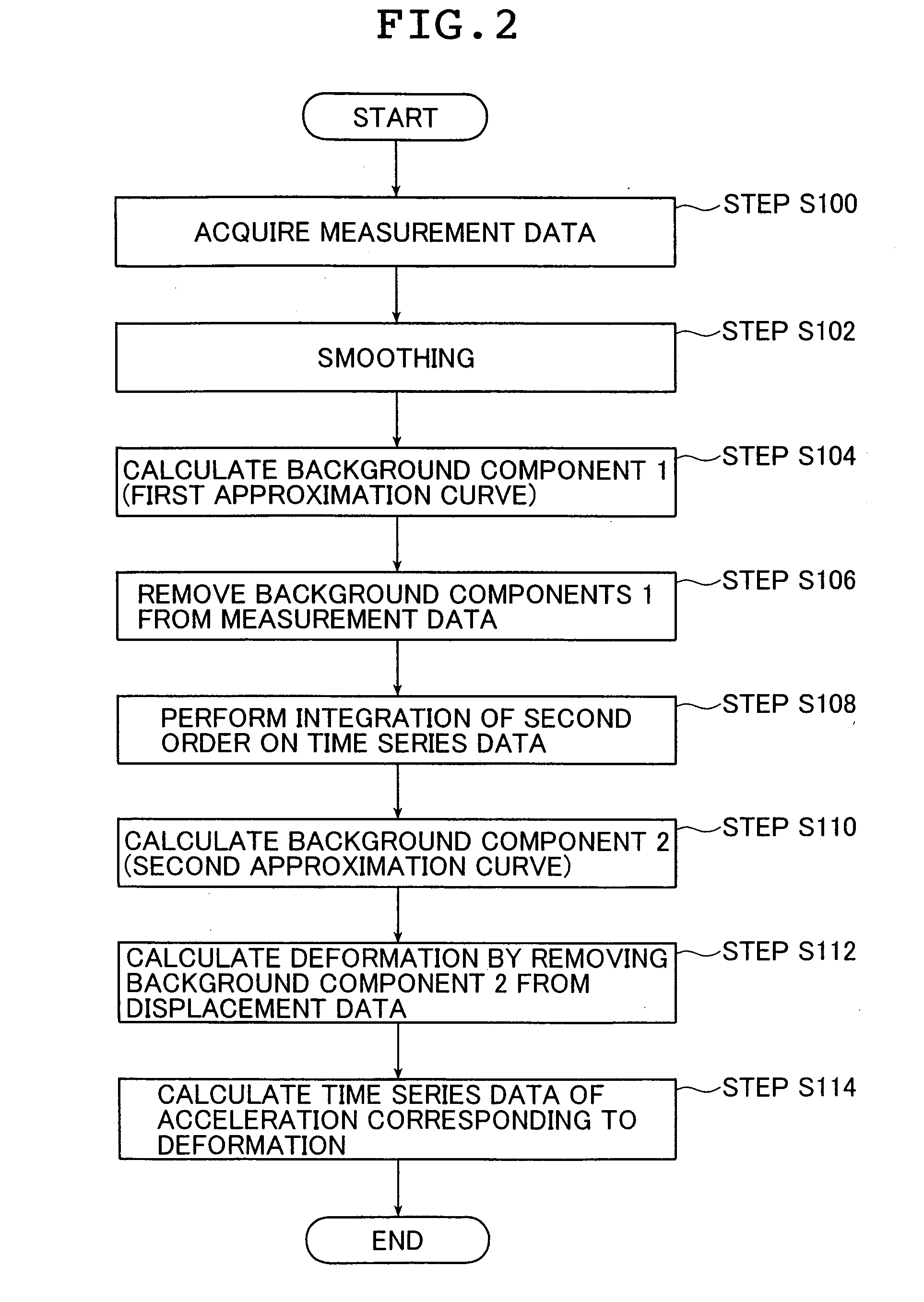

Tire Deformation Calculating Method And Tire Deformation Calculating Apparatus

InactiveUS20070213953A1Good coefficientImprove accuracyMeasurement arrangements for variableOptical signallingEngineeringRoad surface

A deformation of a rotating tire on a road surface is calculated the following. At first, time series data of acceleration extracted from measurement data of acceleration corresponding to one round of tire rotation is subjected to a time integration of second order to obtain displacement data so as to calculate the deformation at the tread portion. The time series data of acceleration and the displacement data in the non-contact region excluding a road surface contact region on the tire circumference at the tread portion are respectively approximated to calculate a first and a second approximation curves. The two approximation curves are subtracted respectively from the time series data of acceleration and the calculated displacement data, thereby extracting time series data of acceleration due to tire deformation and obtaining the deformation at the tread portion.

Owner:THE YOKOHAMA RUBBER CO LTD

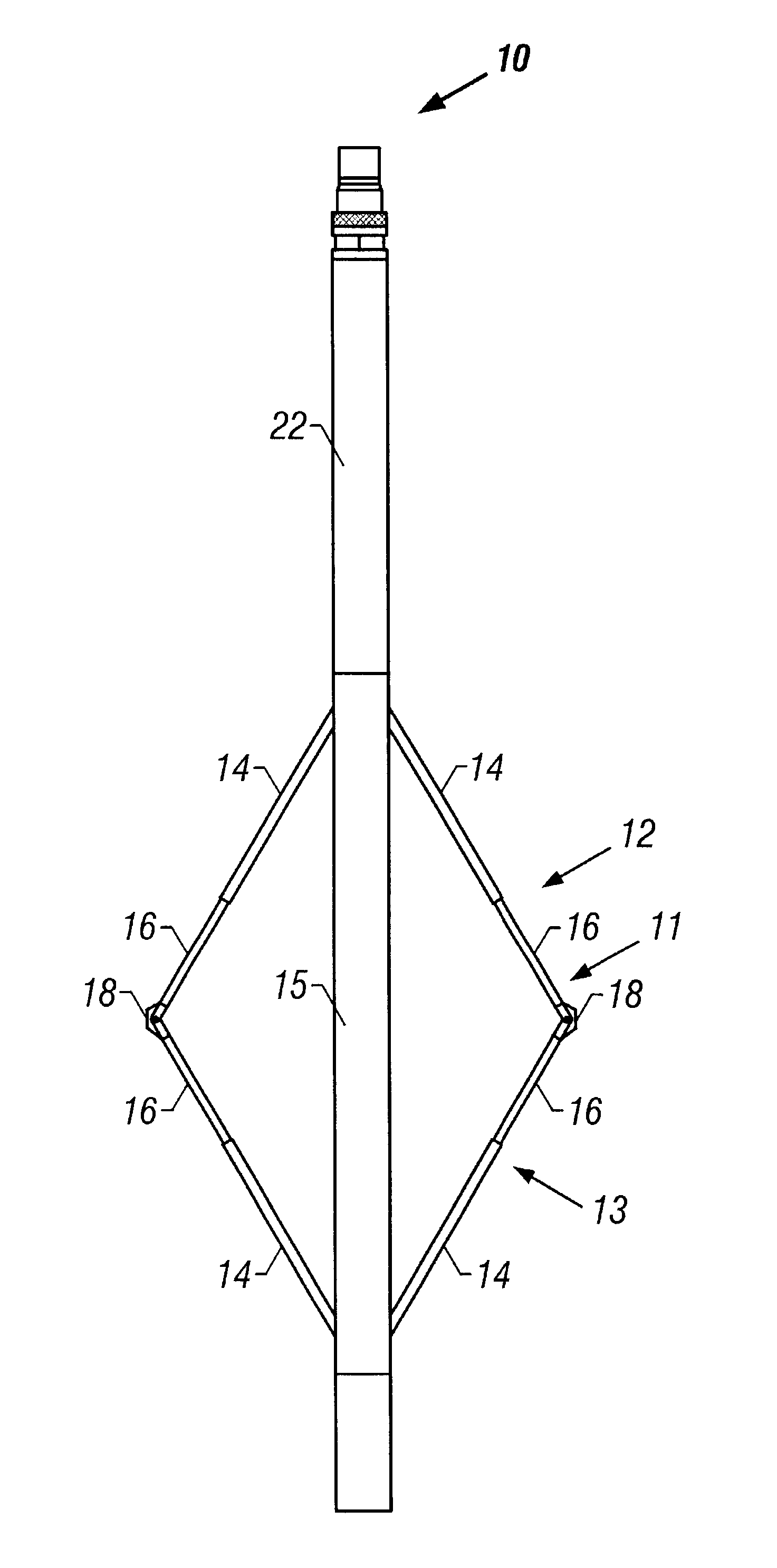

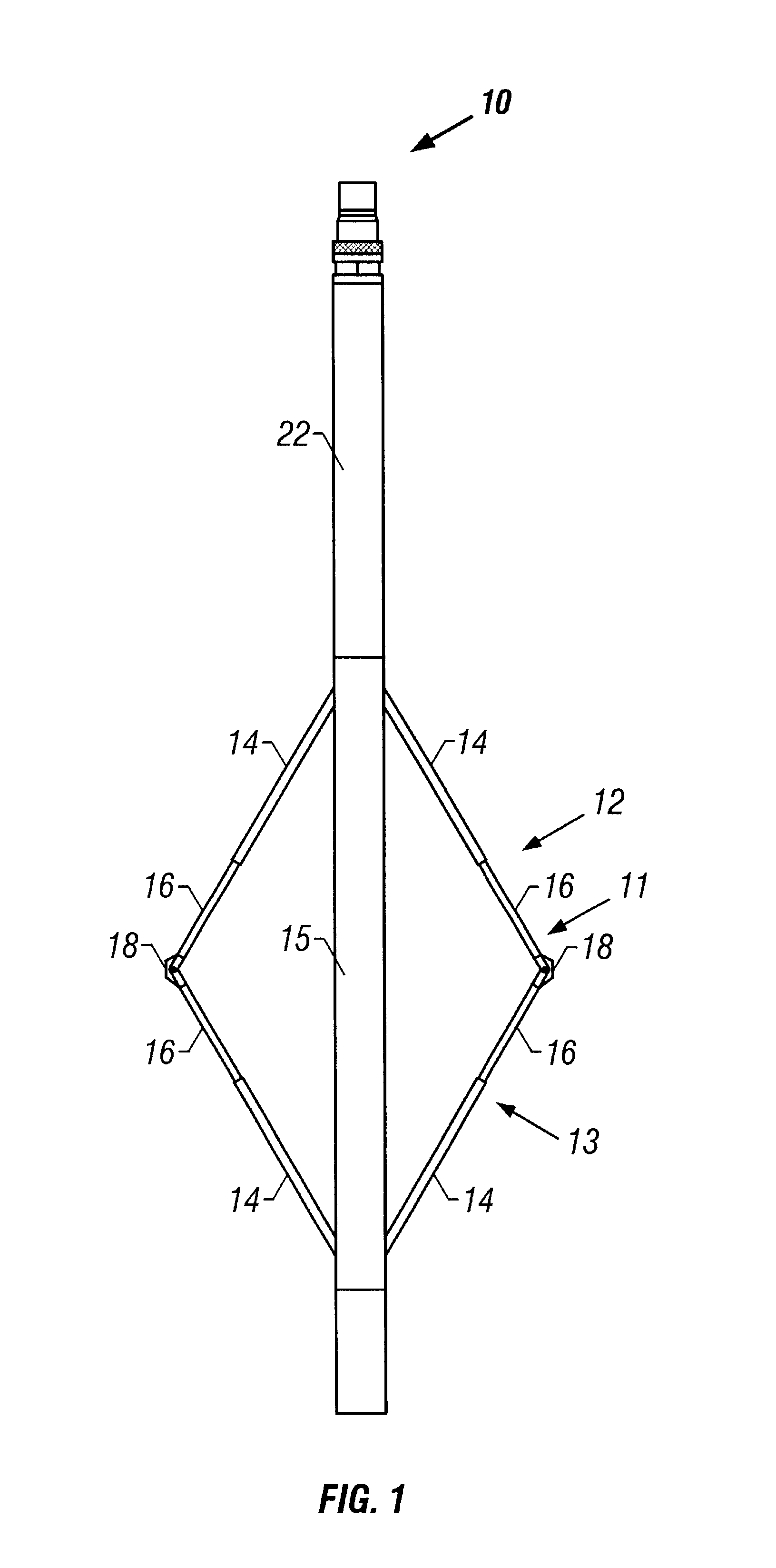

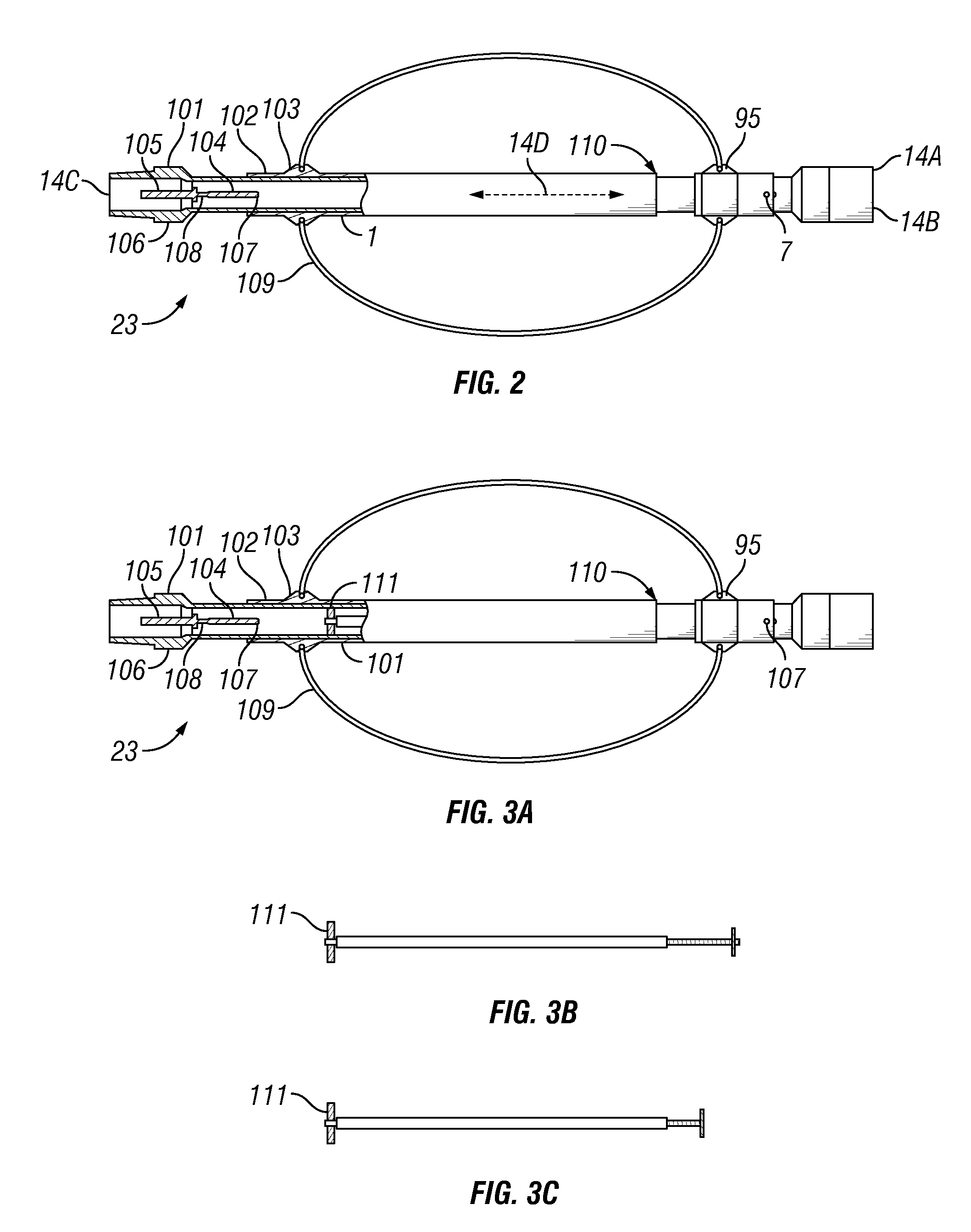

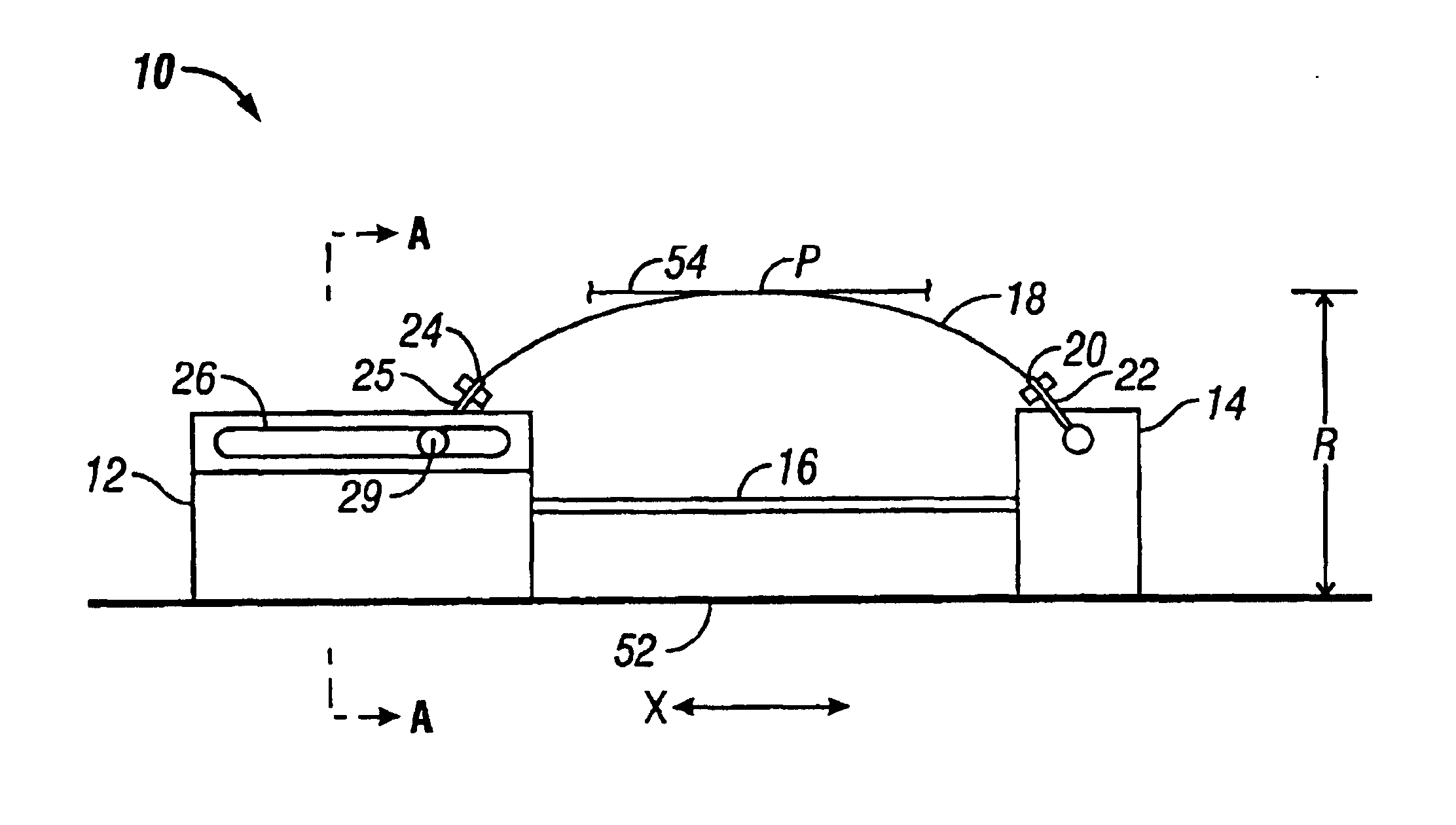

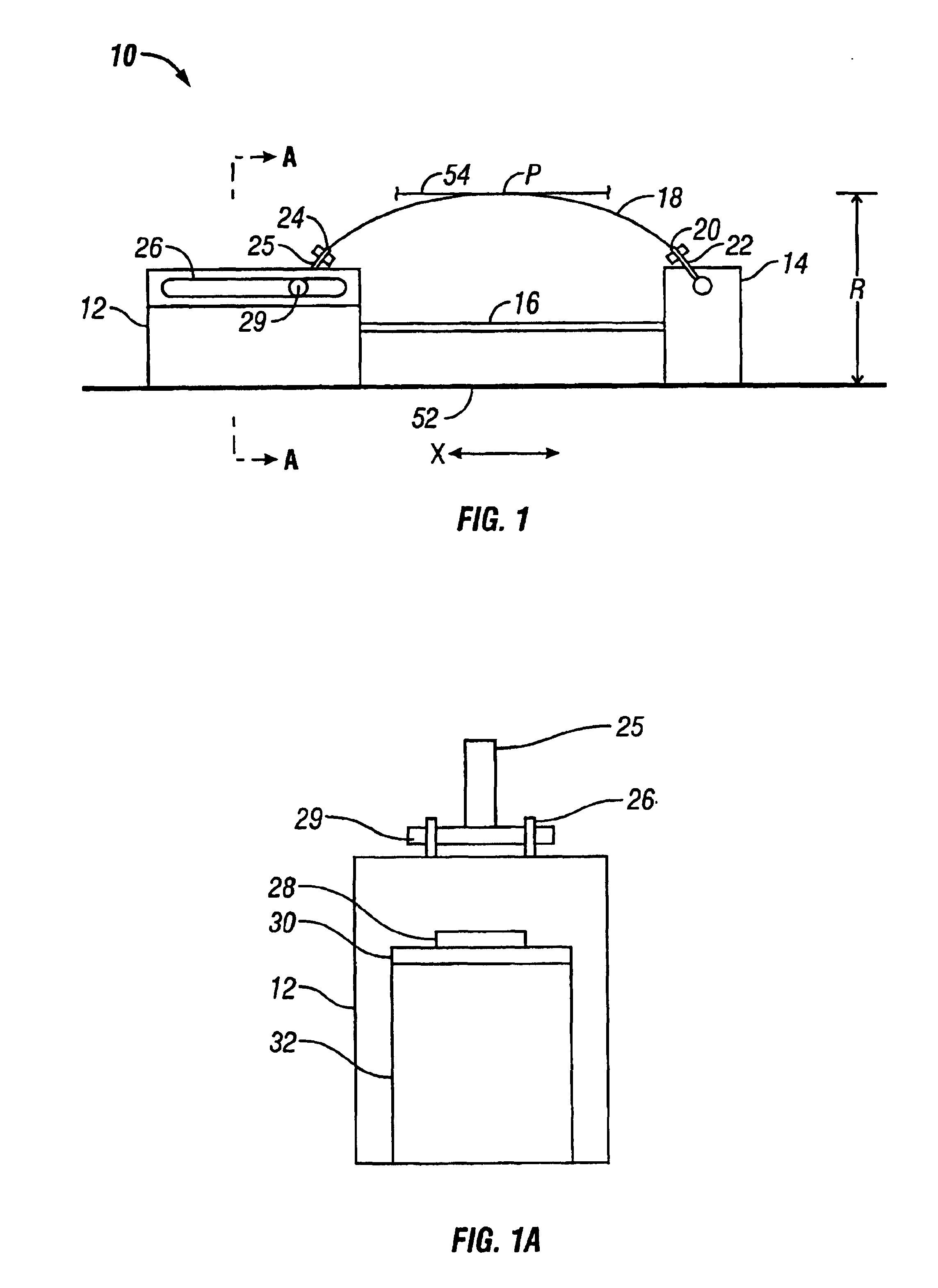

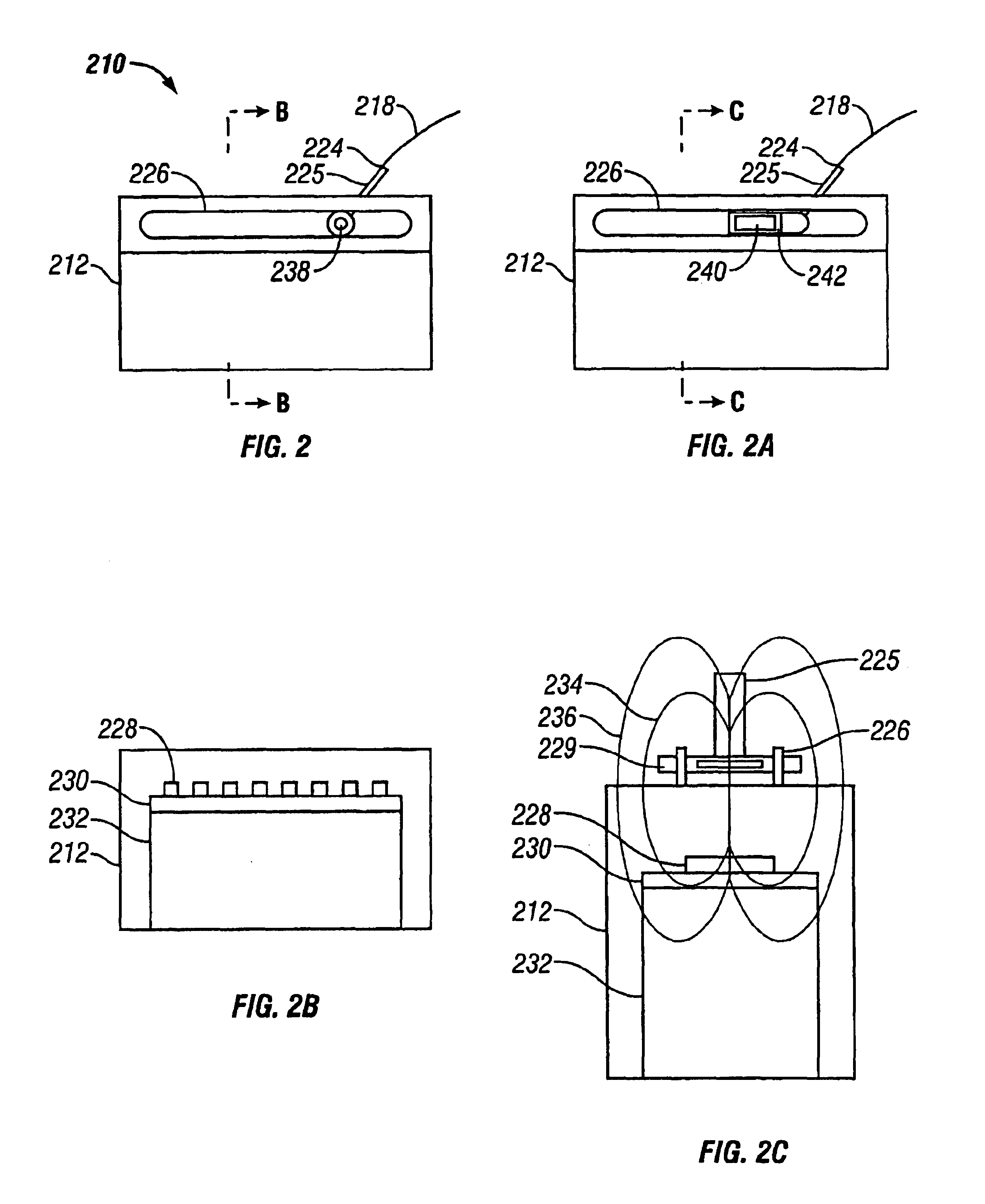

Method and apparatus for measuring a distance

InactiveUS6848189B2Easy maintenanceSurveyMechanical diameter measurementsEngineeringDistance measurement

A distance measurement device and method for measuring a distance between two reference points comprising a housing, a base, and a flexible member curving therebetween. The flexible member housing end is allowed to slide in a slide track in the housing. The housing also comprises sensors that detect the position of the flexible member housing end relative to the housing. The distance measurement device measures the distance between the two reference points by engaging the first reference point with the housing and engaging the second reference point with the flexible member apex. As the distance from the housing to the flexible member apex changes, the flexible member housing end slides in the housing slide track. There is a unique correlation between the location of the flexible member housing end and the distance to flexible member apex, and thus the second reference point. Using the information gathered by the sensors and the known dimensions of the housing, the distance measurement device thus measures the distance from the first reference point to the second reference point.

Owner:HALLIBURTON ENERGY SERVICES INC

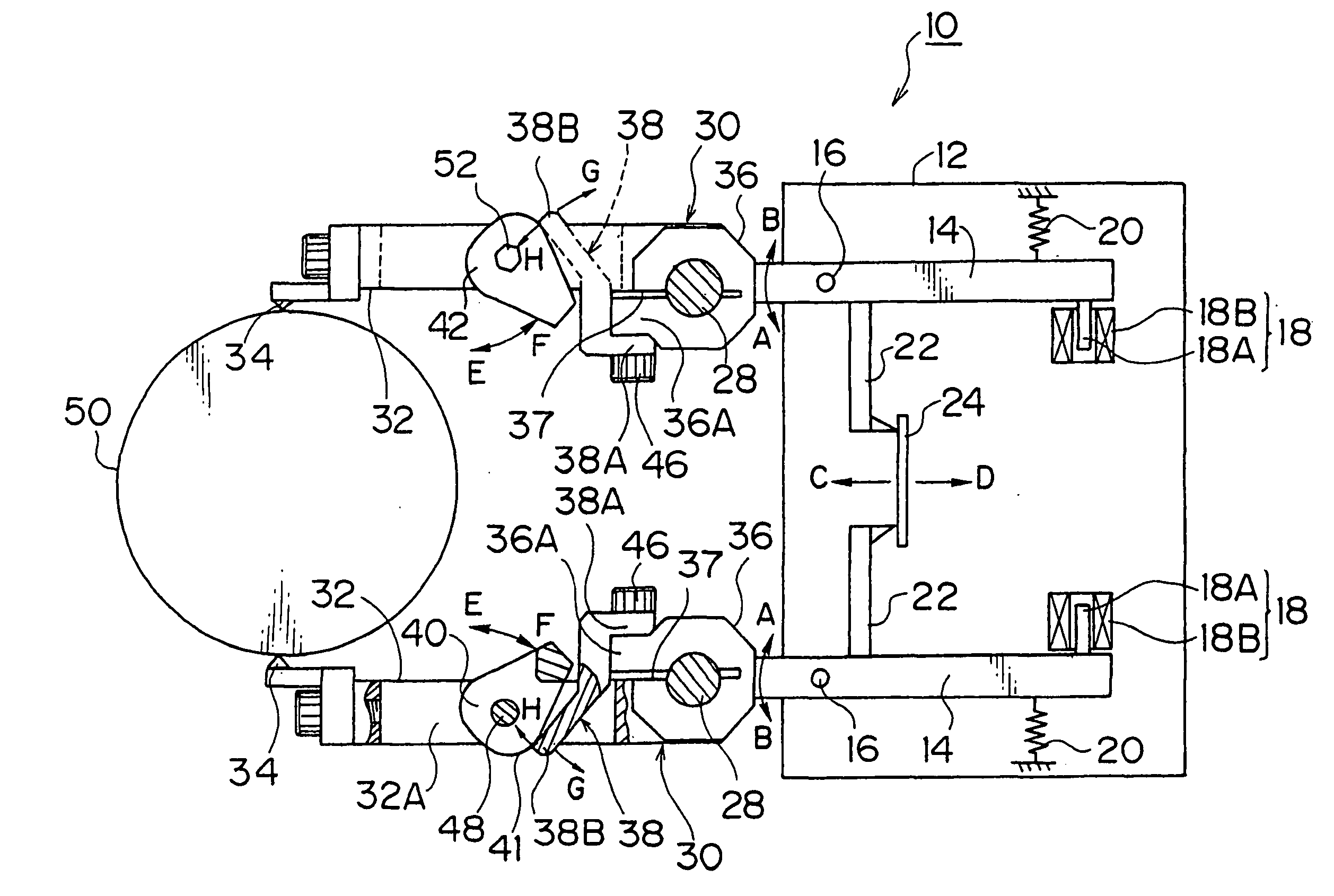

Measuring head

InactiveUS20060042109A1Increase flexibilityProlong lifeMechanical diameter measurementsElectrical/magnetic diameter measurementsEngineeringRestoring force

According to the measuring head, the zero point and the amount of front travel settings are facilitated. Firstly, the amount of front travel is set by allowing contacts 34, 34 to abut a master 50. Then, rotating the lever 42 in a direction indicated by an arrow E, or a close position, causes the bearing member 36 to be fastened to the swinging support shaft 28. At this time, a restoring force, or a force caused by reaction, of the bearing member 36 transferred from the bearing member 36 through the arm 38, cam plate 40 and shaft 48 to the measurement lever 32 causes the measurement lever 32 to deflect by an amount that equals to the amount of front travel, and therefore from the position where the amount of front travel is set to the zero point position. This automatically sets the zero point position.

Owner:TOKYO SEIMITSU

Coordinate measurement machine with distance meter used to establish frame of reference

ActiveUS8898919B2Programme controlMechanical diameter measurementsCoordinate-measuring machine3d coordinates

A portable articulated arm coordinate measuring machine includes a distance meter to measure 3D coordinates of at least three targets to establish a position and orientation of the articulated arm within a frame of reference established by the at least three targets.

Owner:FARO TECH INC

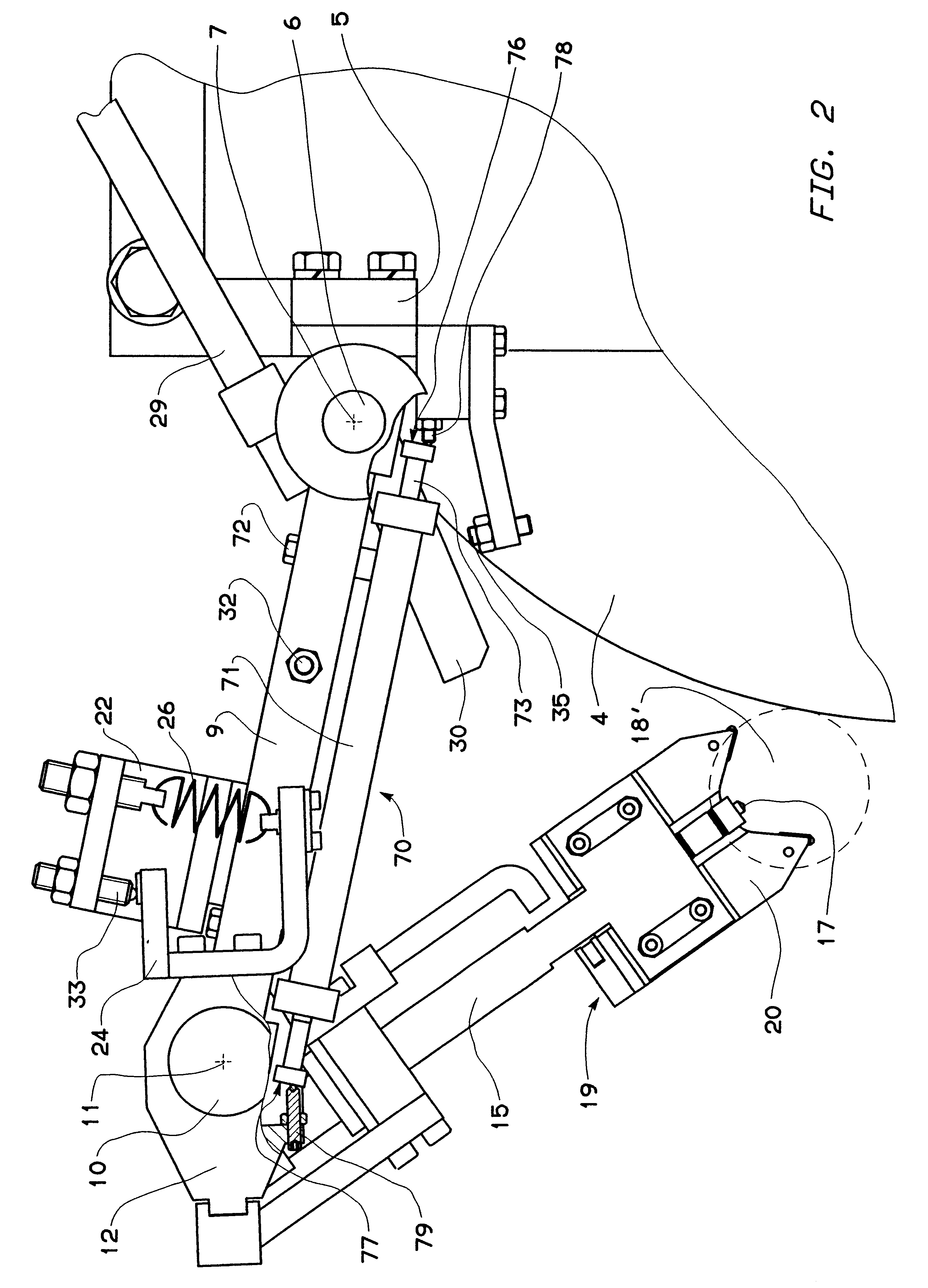

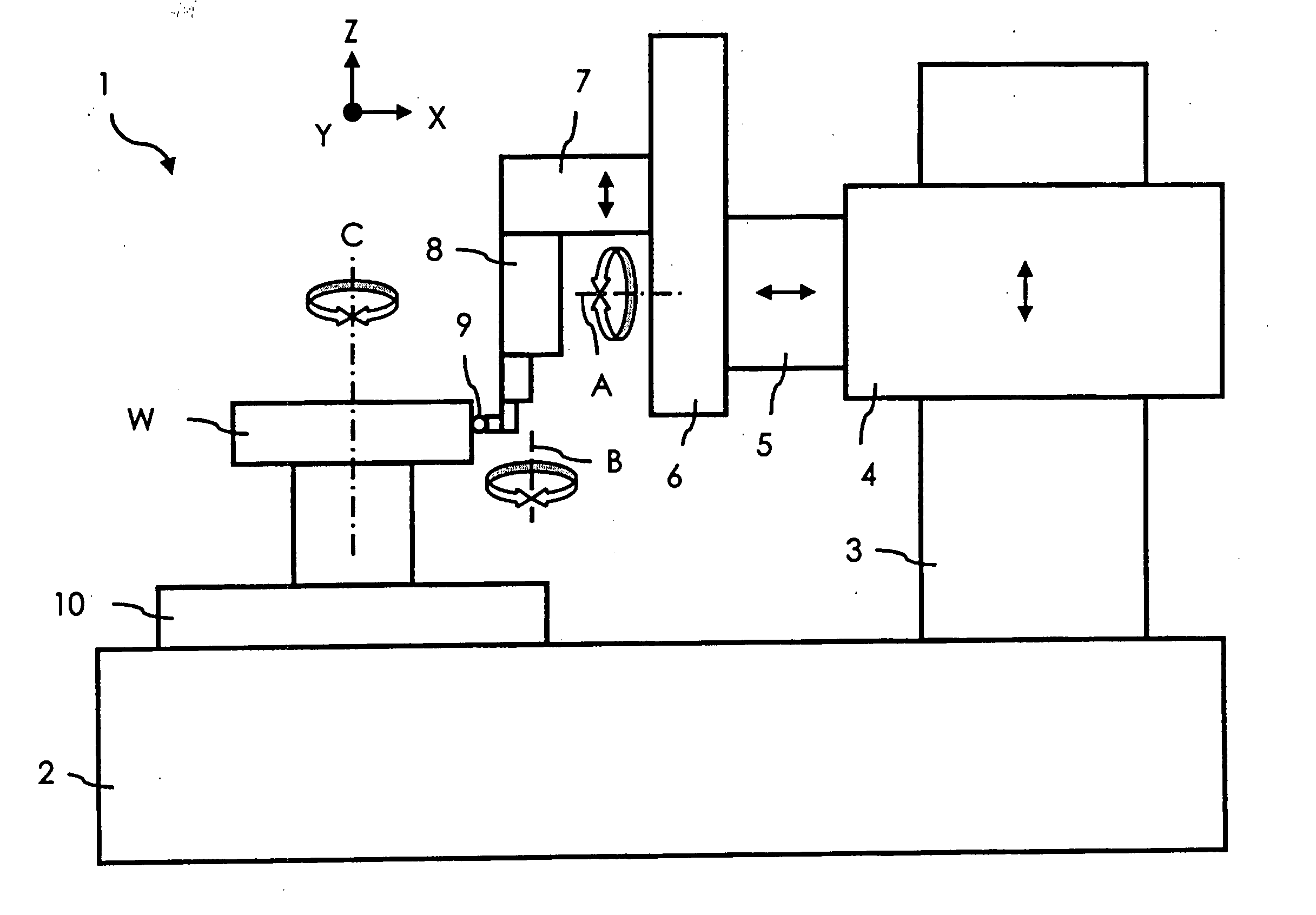

Measuring instrument, probe for the same, and measuring method

InactiveUS6065220AAvoid insufficient lengthImprove accuracyMechanical diameter measurementsMechanical clearance measurementsMeasuring instrumentEngineering

A body 1 placed thereon with a table 35 put thereon with an object to be measured W, and a portal frame 41 supporting both ends of rail 43 to the body through pillars 42A and 42B, the rail being placed above the table 35 and extending along a moving direction of a pair of probes 91A and 91B, are provided. A pair of sliders 51A and 51B are movably supported by the rail 43. The pair of the probes are extended downward from the sliders 51A and 51B to be abutted to the object W put on the table 35. The flexural deformation of the probes 91A and 91B is decreased due to the shorter length of the probes 91A and 91B, so that the high accurate measurement is achieved and a relative measurement is omitted.

Owner:MITUTOYO CORP

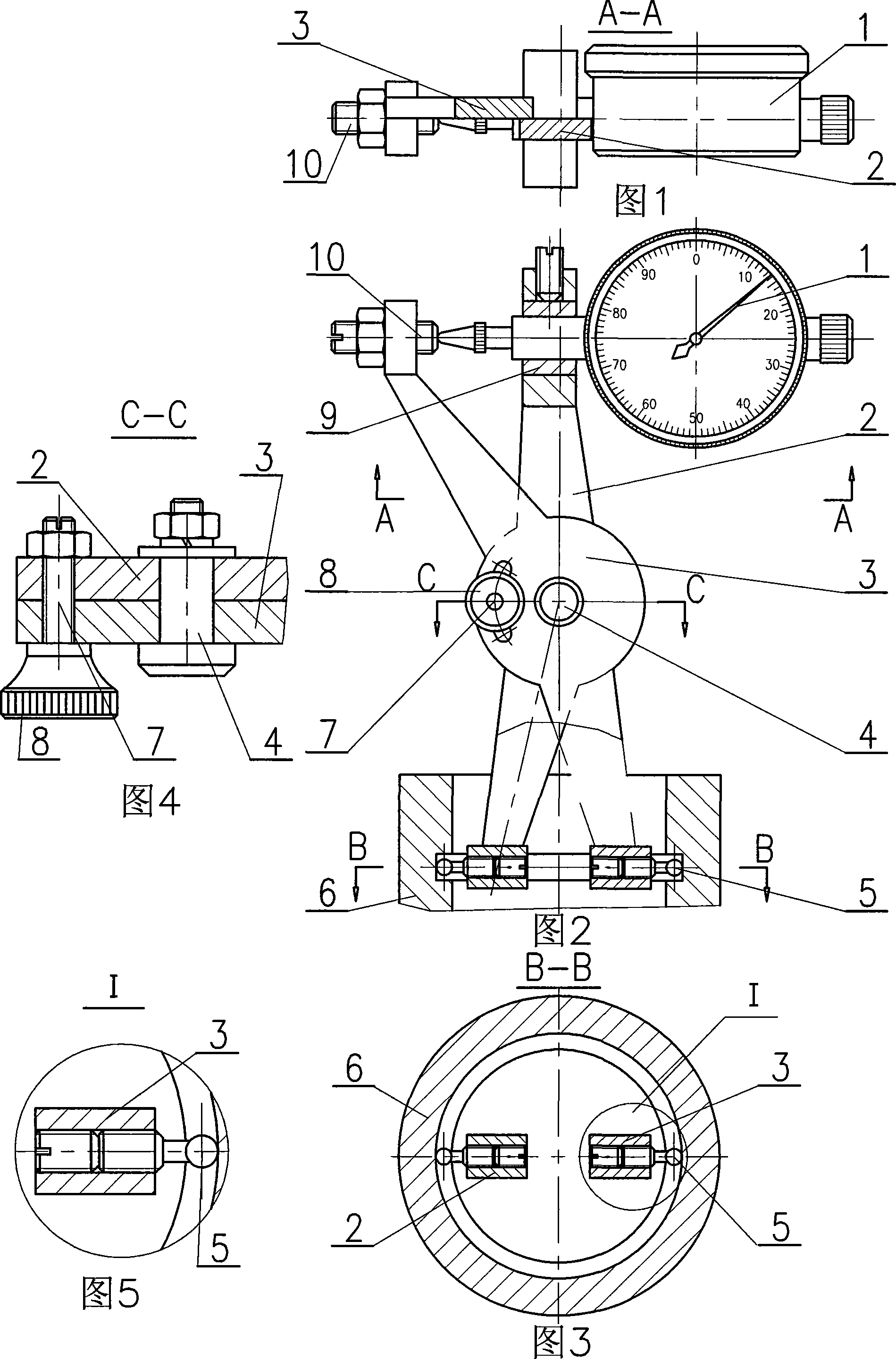

Inner hole groove diameter gauge

A diameter measure tool for a groove of an inner hole is provided. A pin pierces through middle holes of an upper stent and a lower stent and is linked with the upper stent and the lower stent through a flat washer, a spring washer and a nut. A locking stud pierces through a ring groove which centers on the axis of a pin hole on the upper stent and is installed in a thread hole of the lower stent to be locked through a nut. The end of the locking stud exposing out of the upper stent is equipped with a knurl high nut for locking the upper stent and the lower stent. Two probes are respectively fixed in the screw holes on the same ends of the upper stent and the lower stent. A percent meter is fixed in a hole on the other end of the lower stent. A measuring stud is fixed in the screw hole on the other end of the upper stent. The two probes are put into a groove of a work piece hole by holding the upper stent and the lower stent with hands. Under the elastic function of the percent meter probe, the two probes of the measure tool are arranged on the diameter position of the groove. With the match of a percent scale or a standard hole, the diameter of groove of the inner hole can be measured rapidly and precisely according to the number indicated by the pointer of the percent meter. The measure tool also can substitute a common inner diameter scale to measure the inner hole of a common part.

Owner:陈焕春

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com