Patents

Literature

182results about How to "Simple and accurate measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

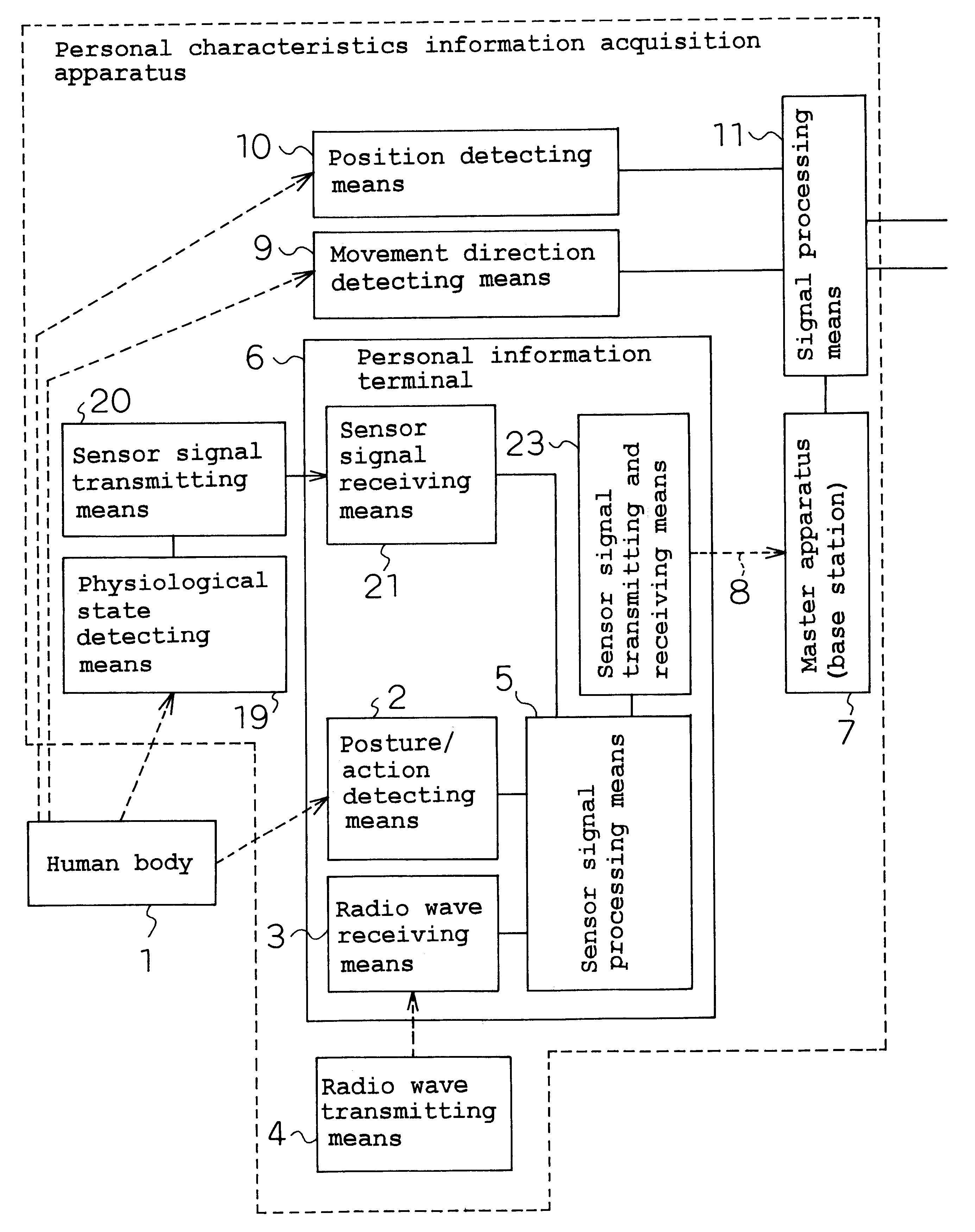

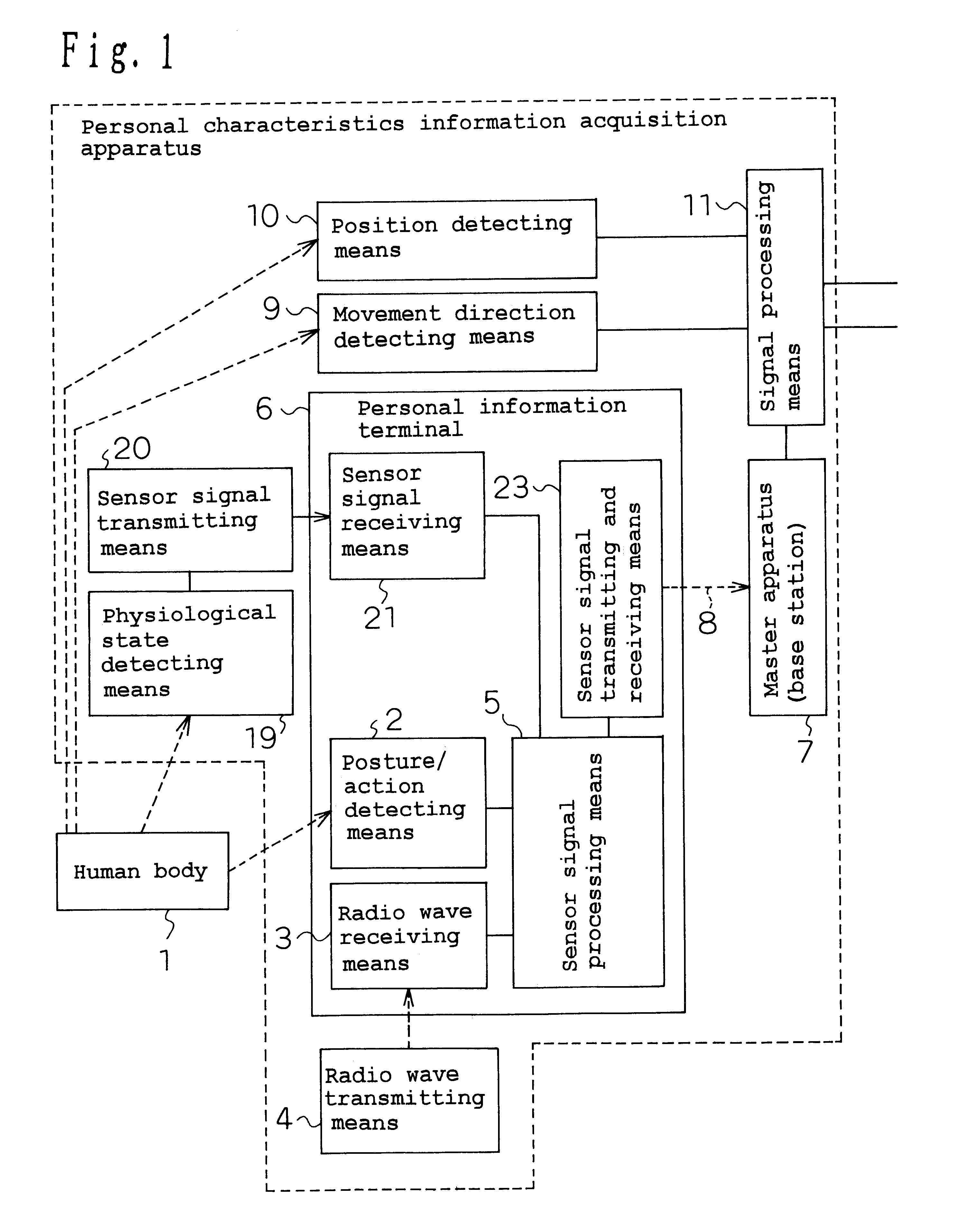

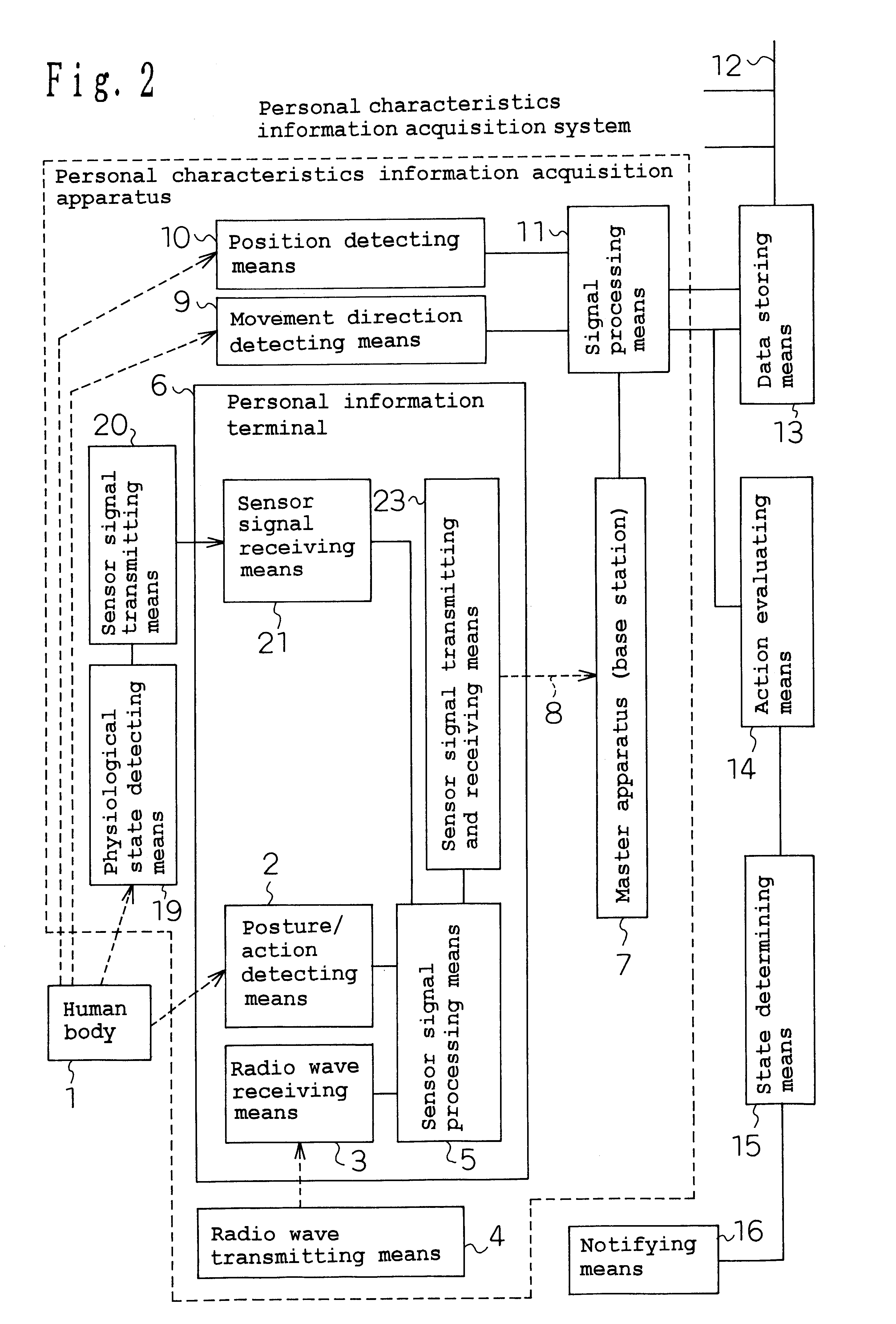

State information acquisition system, state information acquisition apparatus, attachable terminal apparatus, and state information acquisition method

InactiveUS6616607B2Reduce data volumeSimple and accurate measurementSurgeryPerson identificationPhysiologic StatesTerminal equipment

A state information acquisition system hasa terminal which has physiological state detecting means of detecting the physiological state of a person or animal, posture / action detecting means of detecting the posture and / or action state of the person or animal, and detection signal transmitting means of transmitting detection signals based on the detection of (1) the physiological state and (2) the posture and / or action state, and is attachable to the person or animal; andsignal receiving and processing means which receives and processes a signal transmitted from the terminal and is located in a predetermined region; andthereby obtaining state information indicating the state of the person or animal on the basis of the detection signal.

Owner:PANASONIC CORP

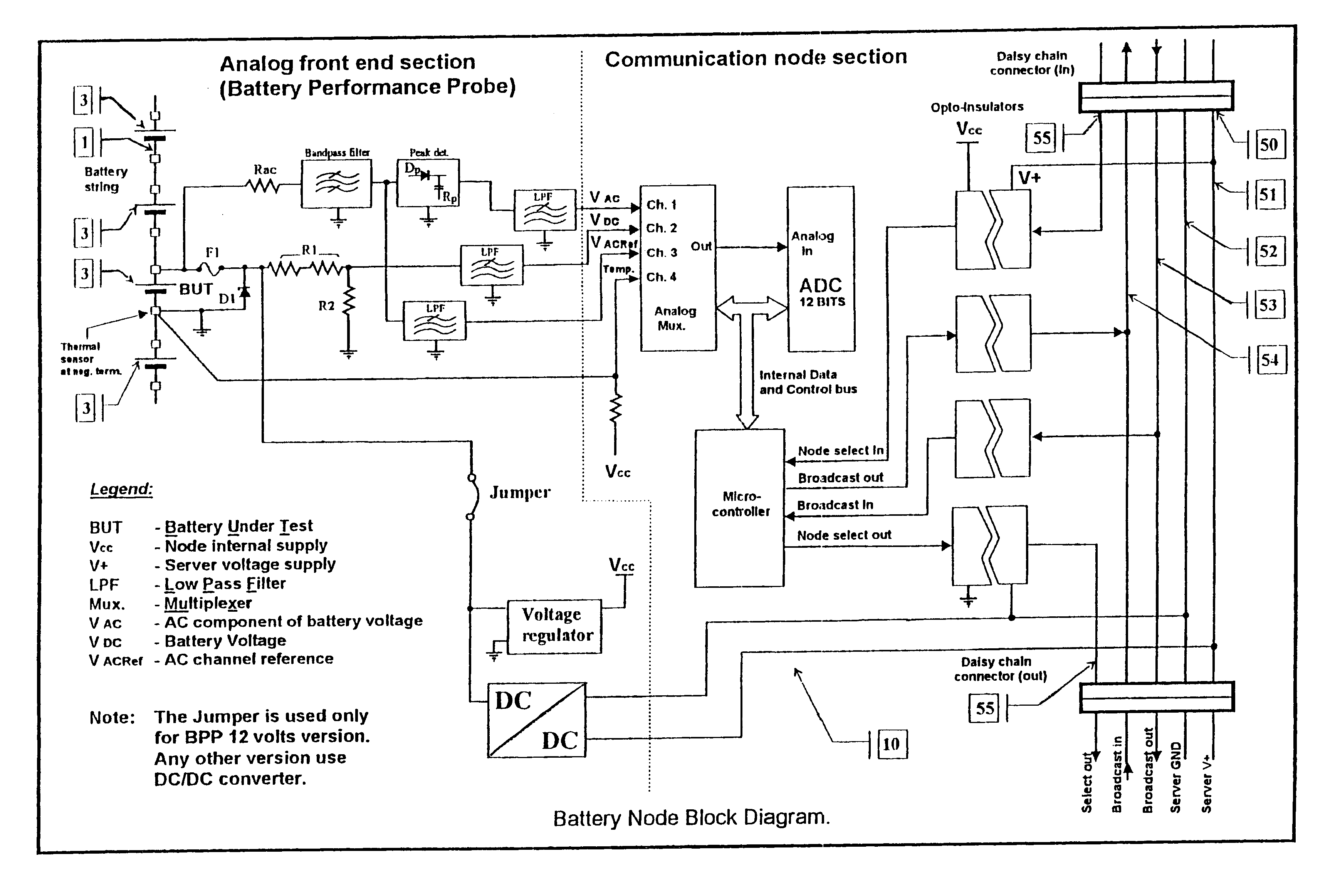

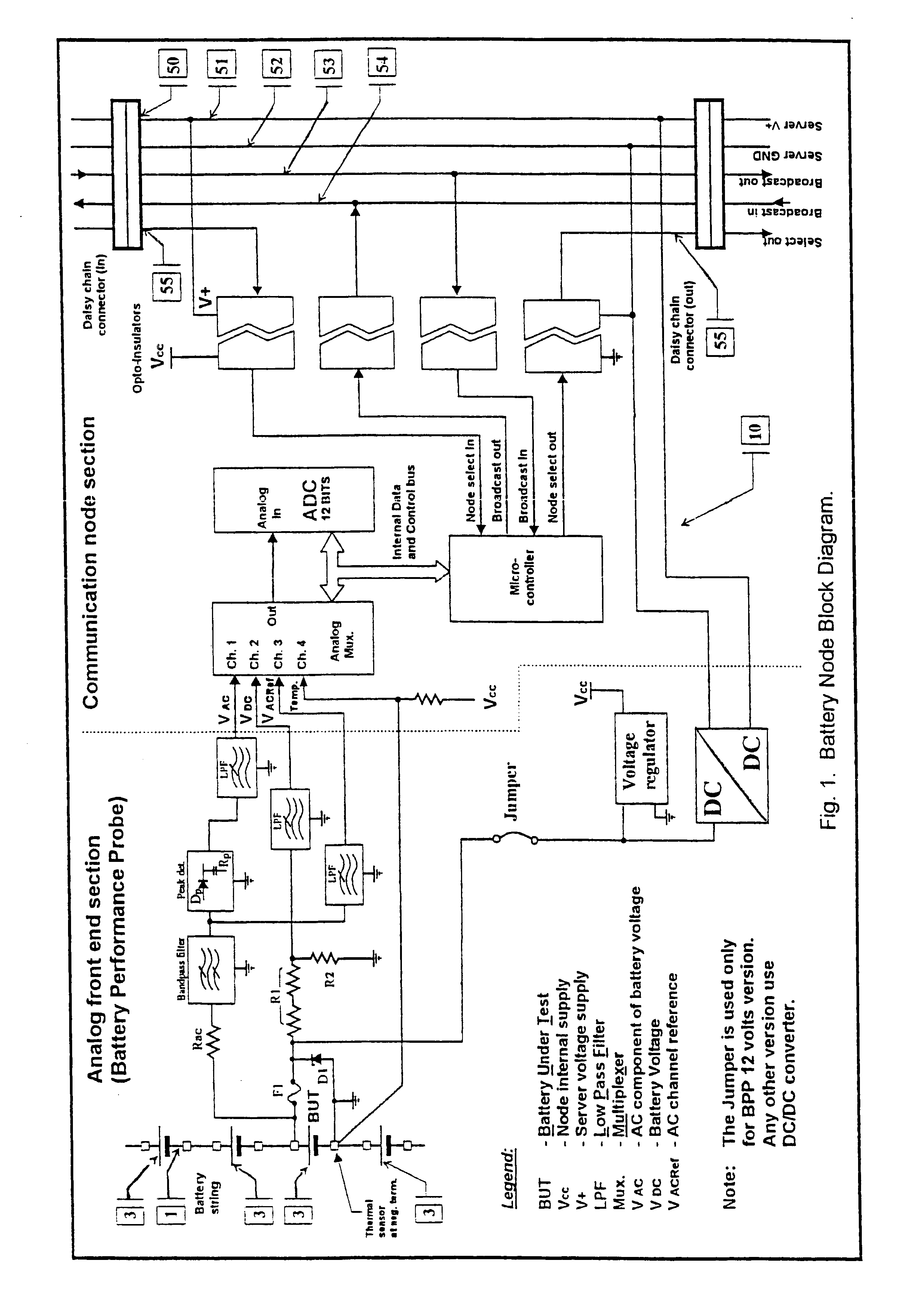

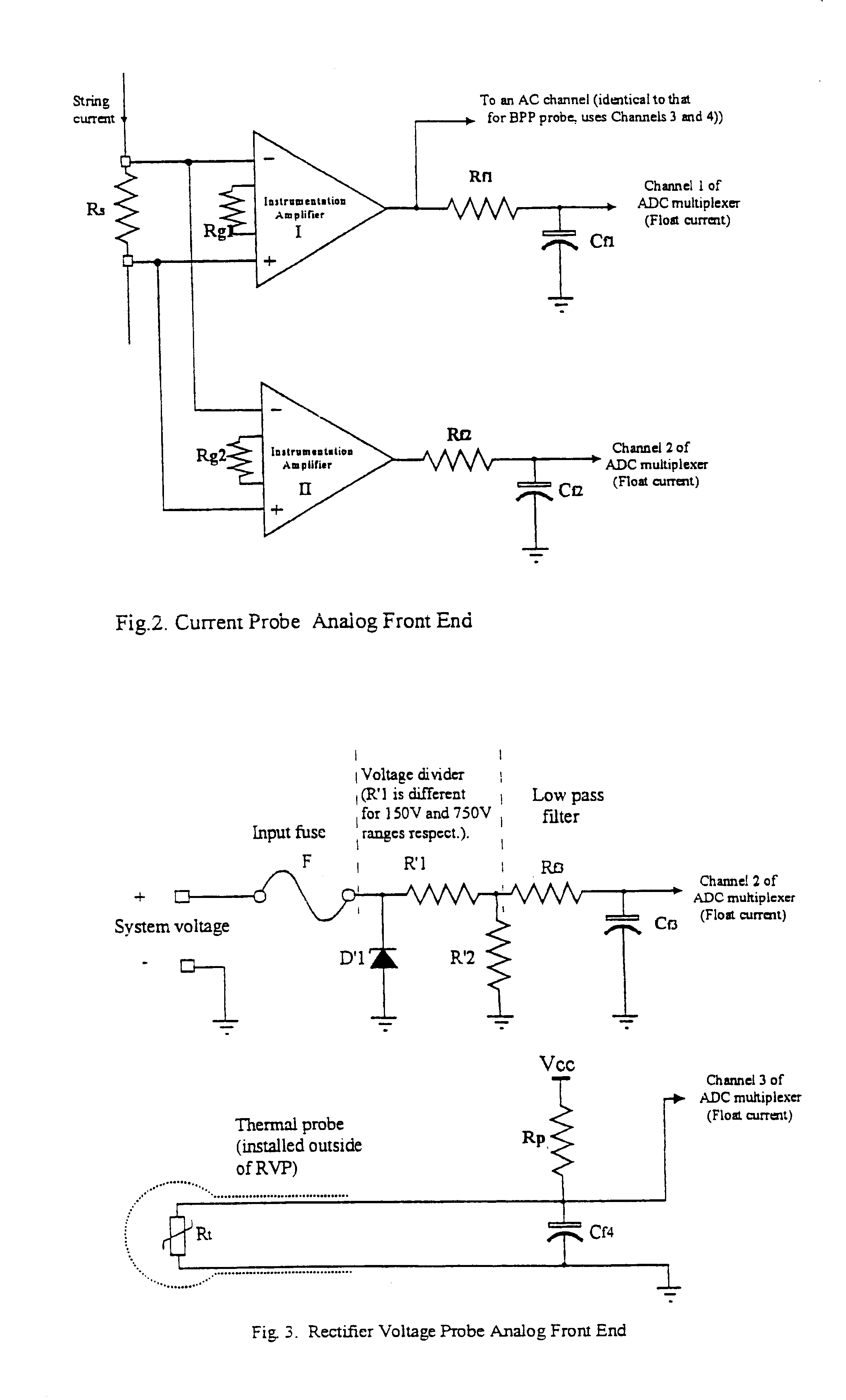

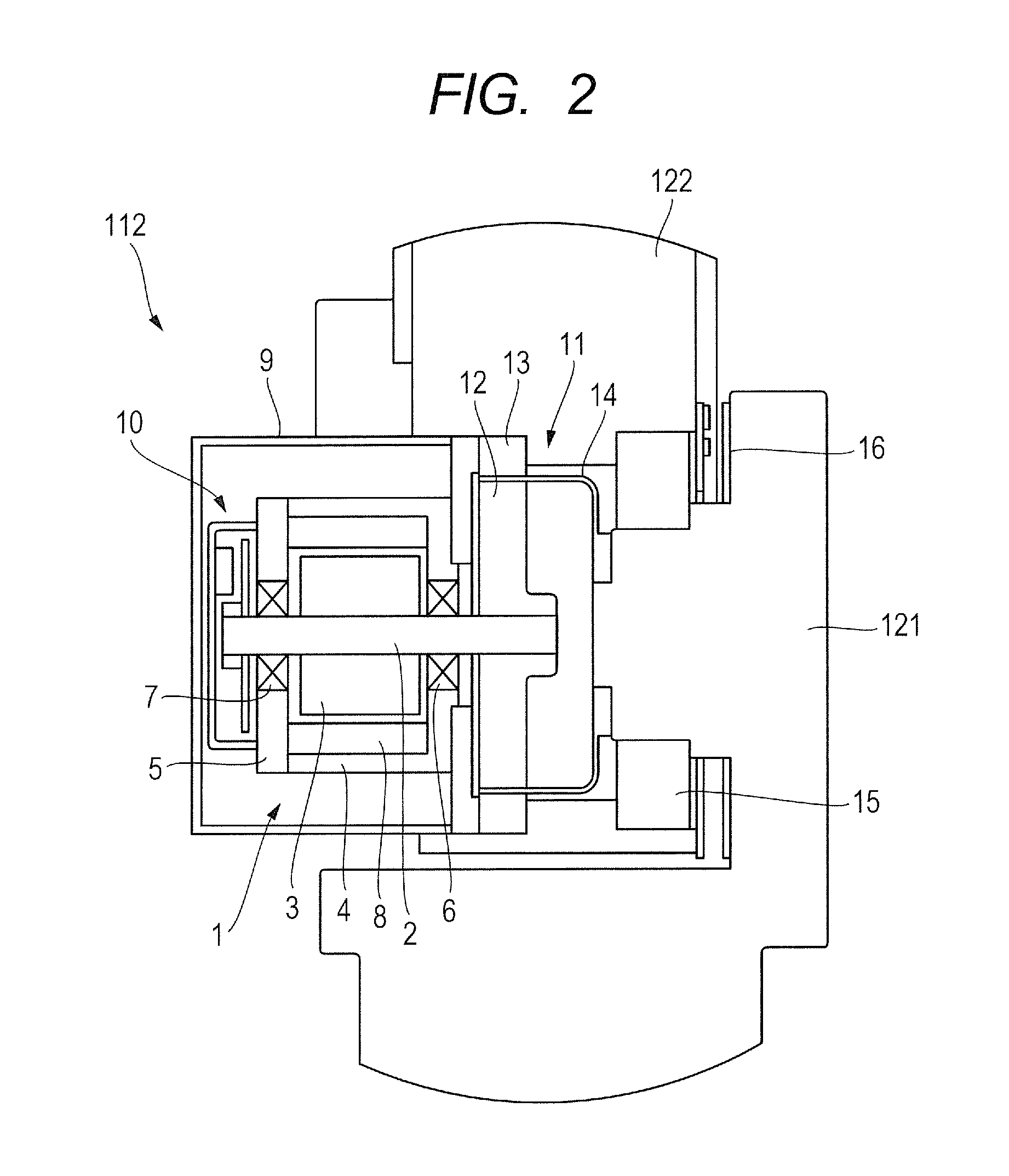

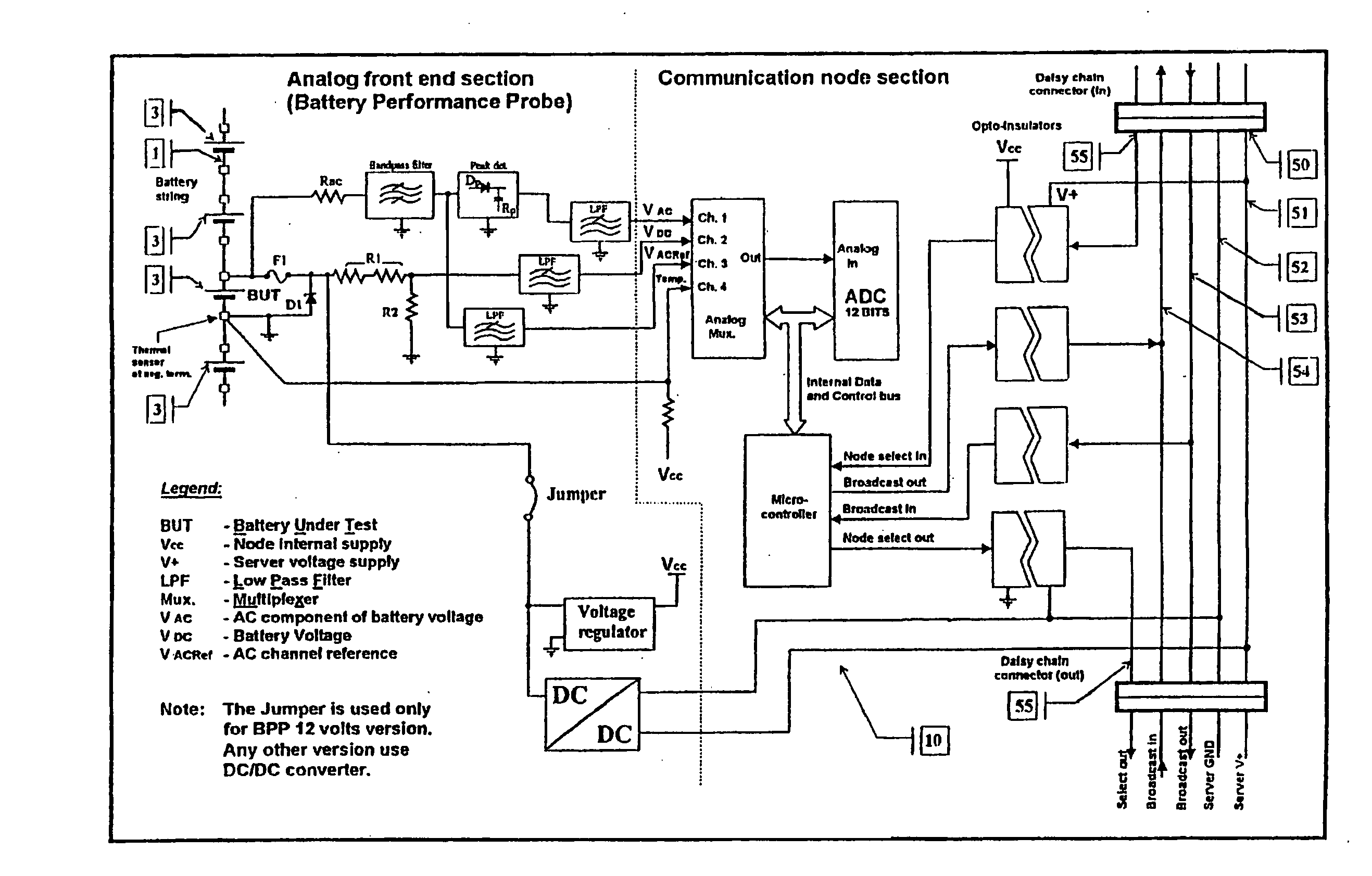

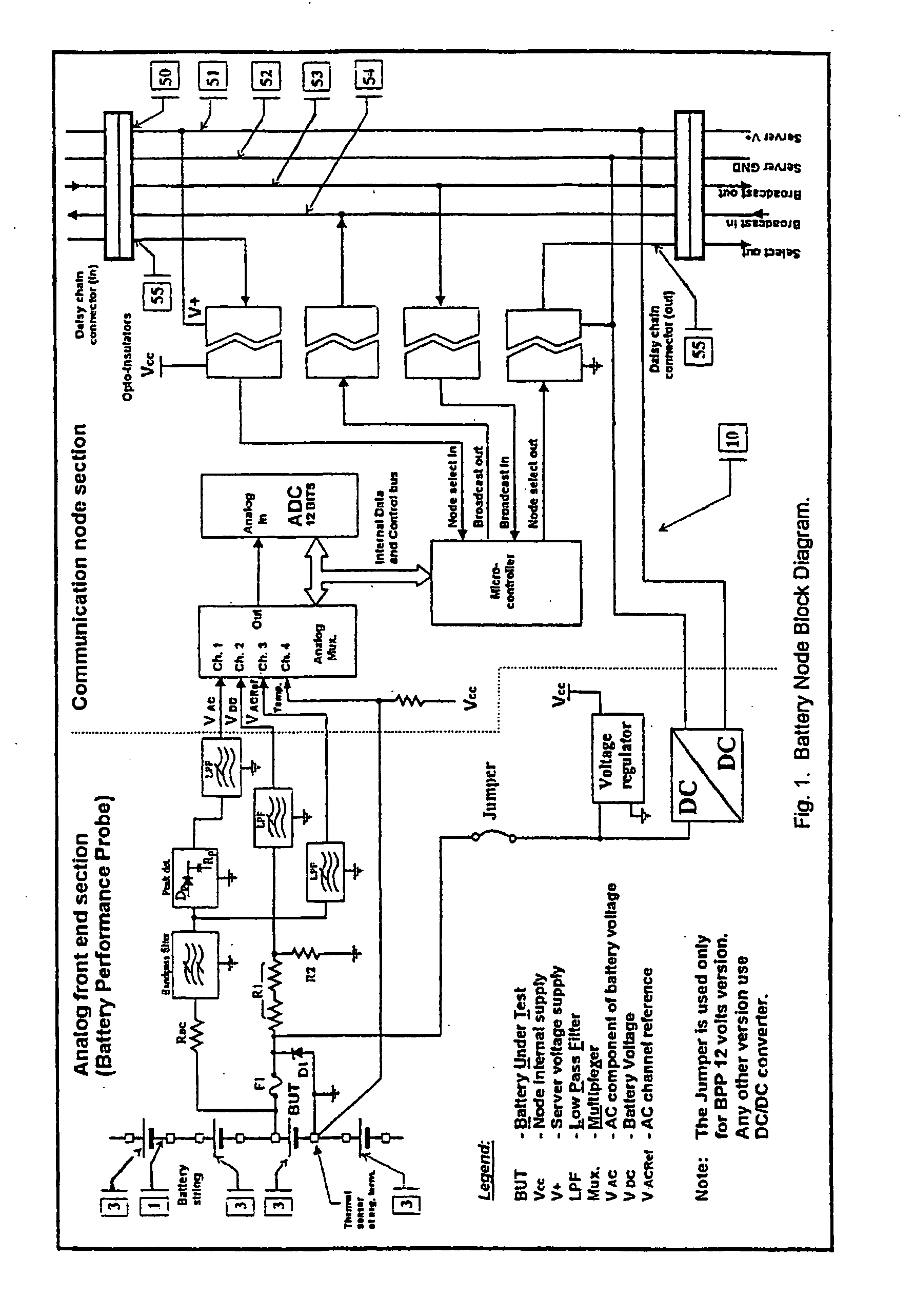

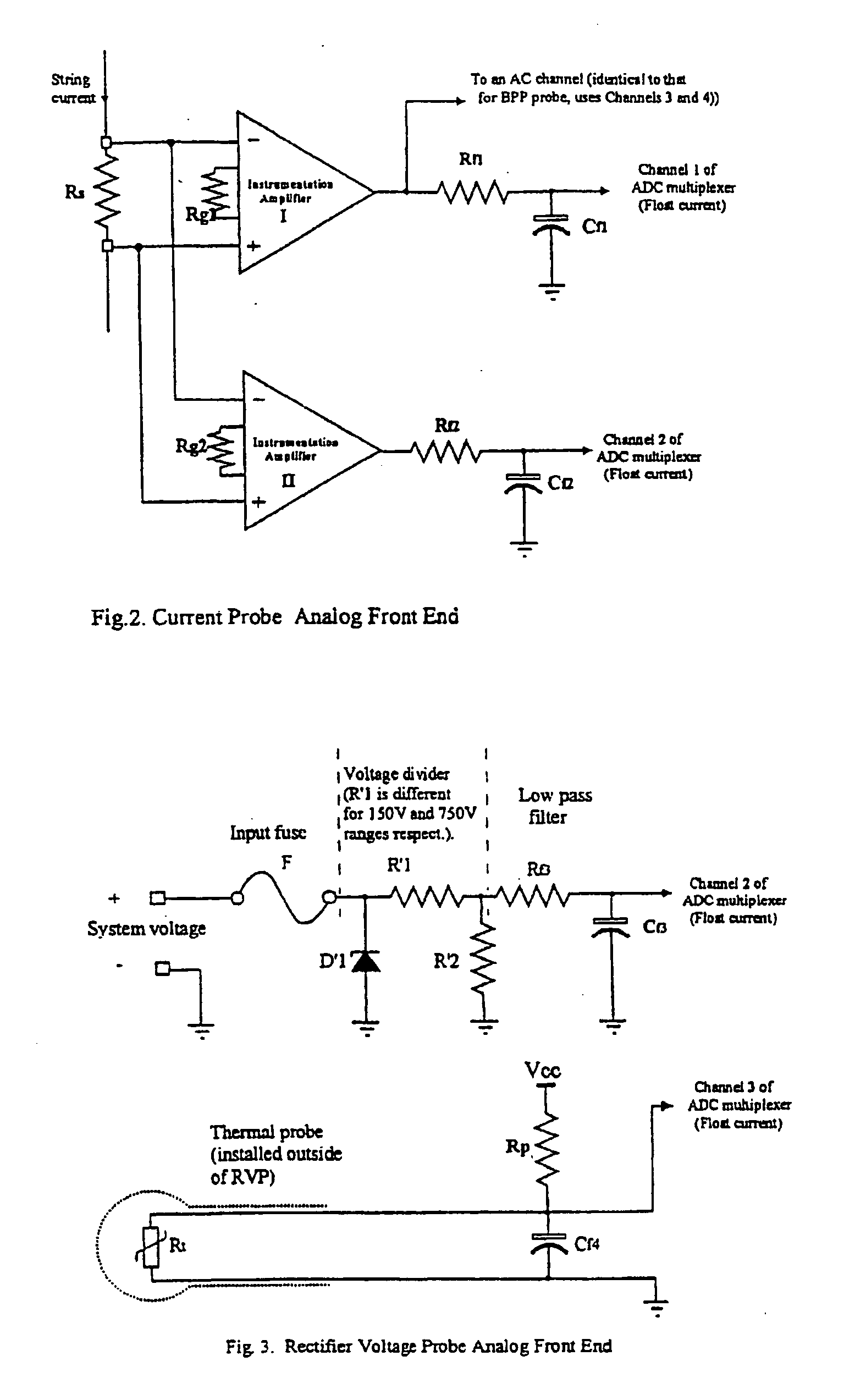

Method and apparatus for the continuous performance monitoring of a lead acid battery system

InactiveUS6611774B1Simple and accurate measurementBatteries circuit arrangementsElectrical testingDaisy chainMonitoring system

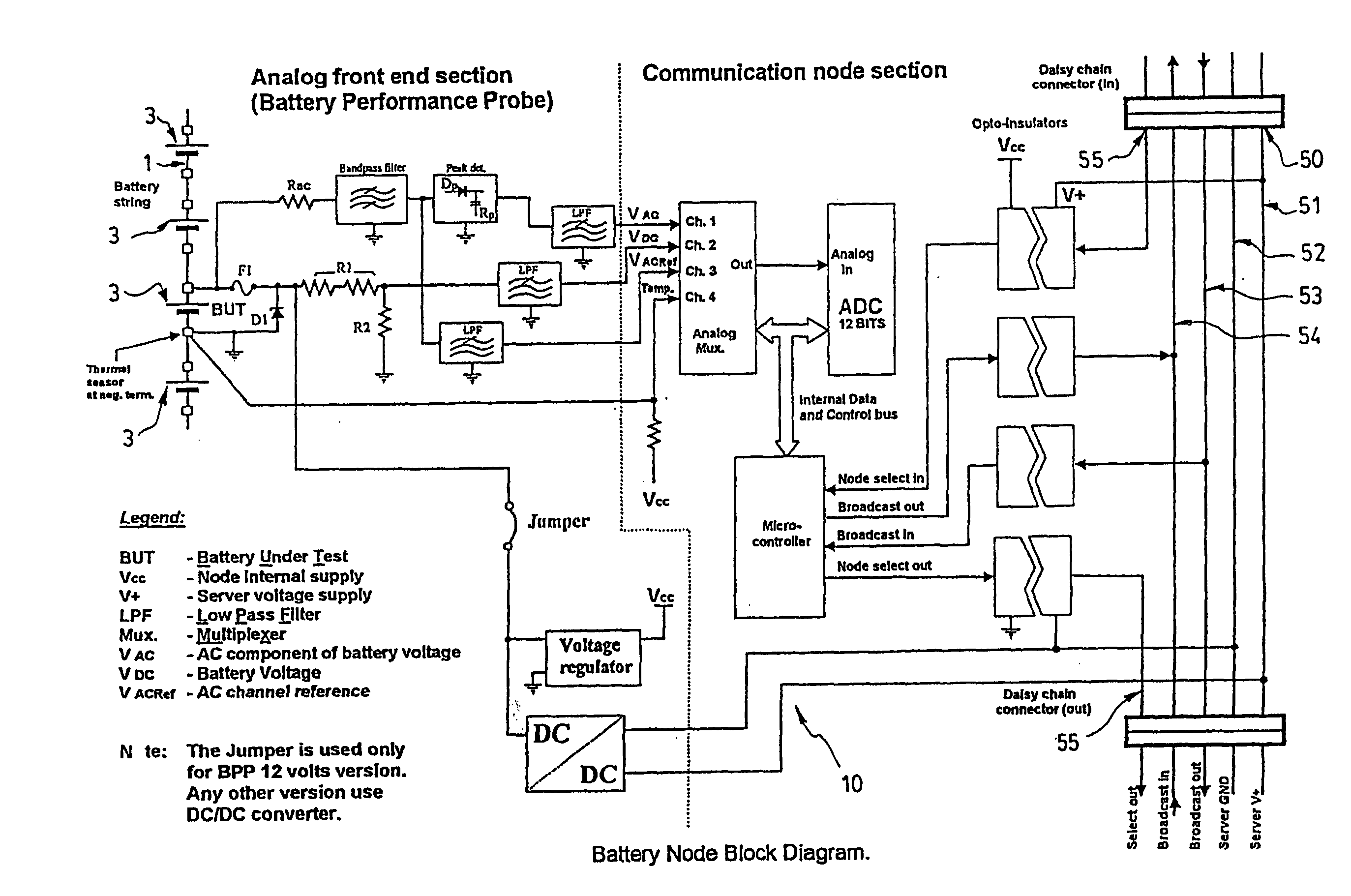

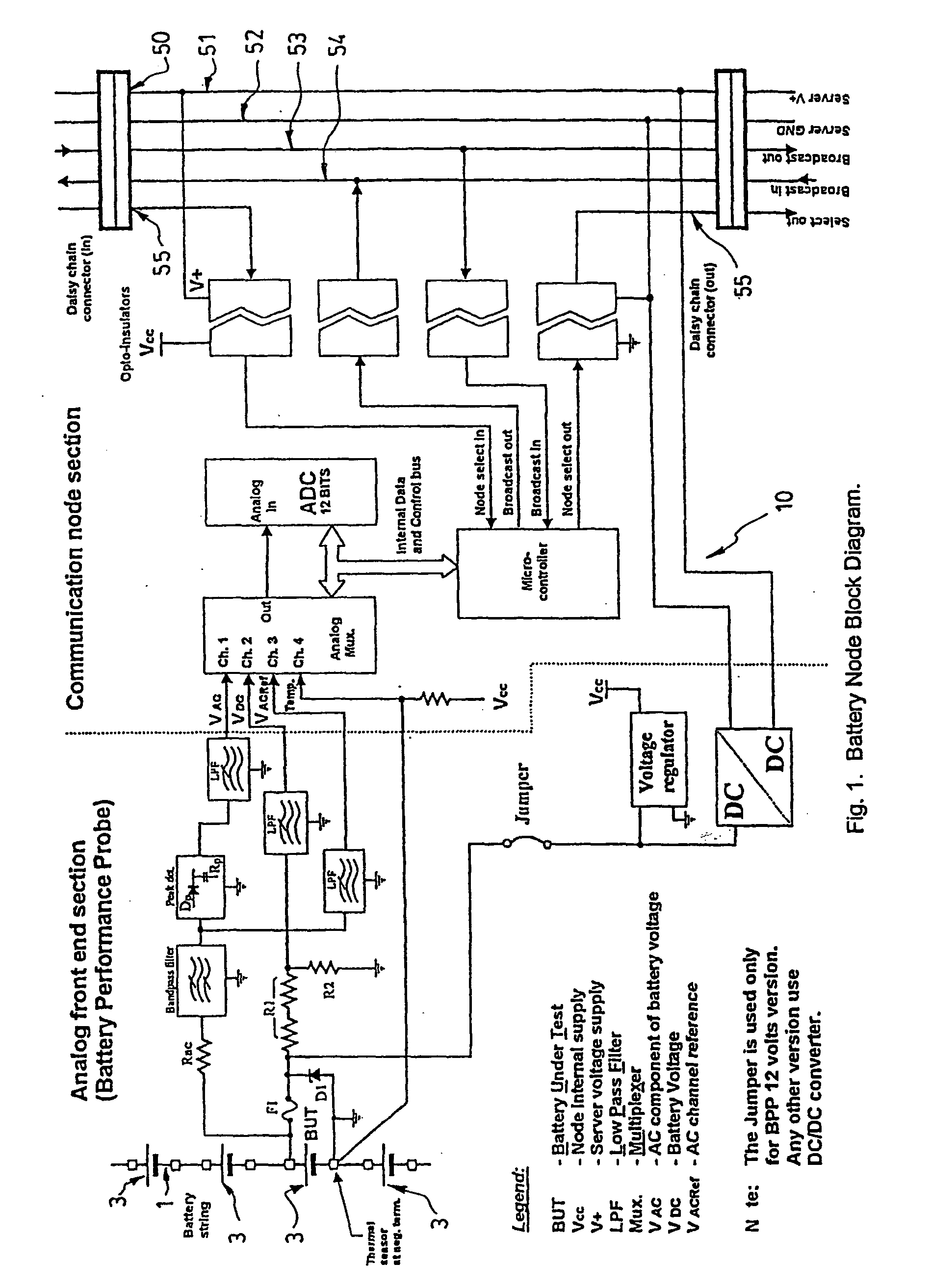

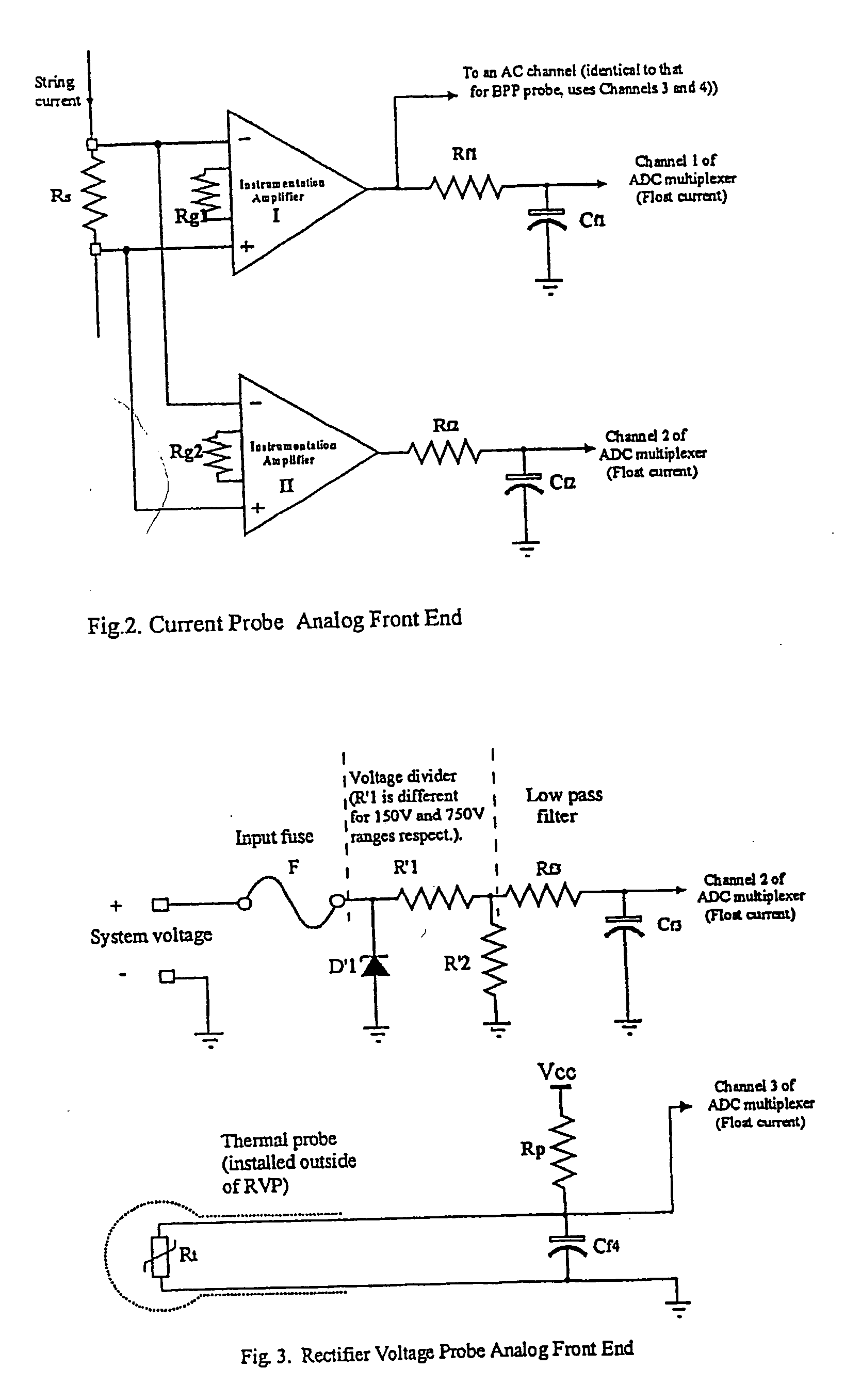

The present invention concerns a battery monitoring system for monitoring a plurality of batteries serially connected to form a string. The battery monitoring system includes a number of probes connected to at least a portion of the string, a daisy chain bus having a select channel for serially interconnecting the probes, the bus having other, parallel channels for data communication and power, and a system server. The probes each have a sensing module and a communication module. The sensing module senses characteristics of at least a portion of the string, such as voltage or current. The communication module receives the sensed characteristics and converts them into digital form for broadcast to the system server over the bus. The communication module of the probes have a memory for storing an address assigned to the corresponding probe upon reception of an initialization signal sent by the system server via the bus.

Owner:ENERSAFE

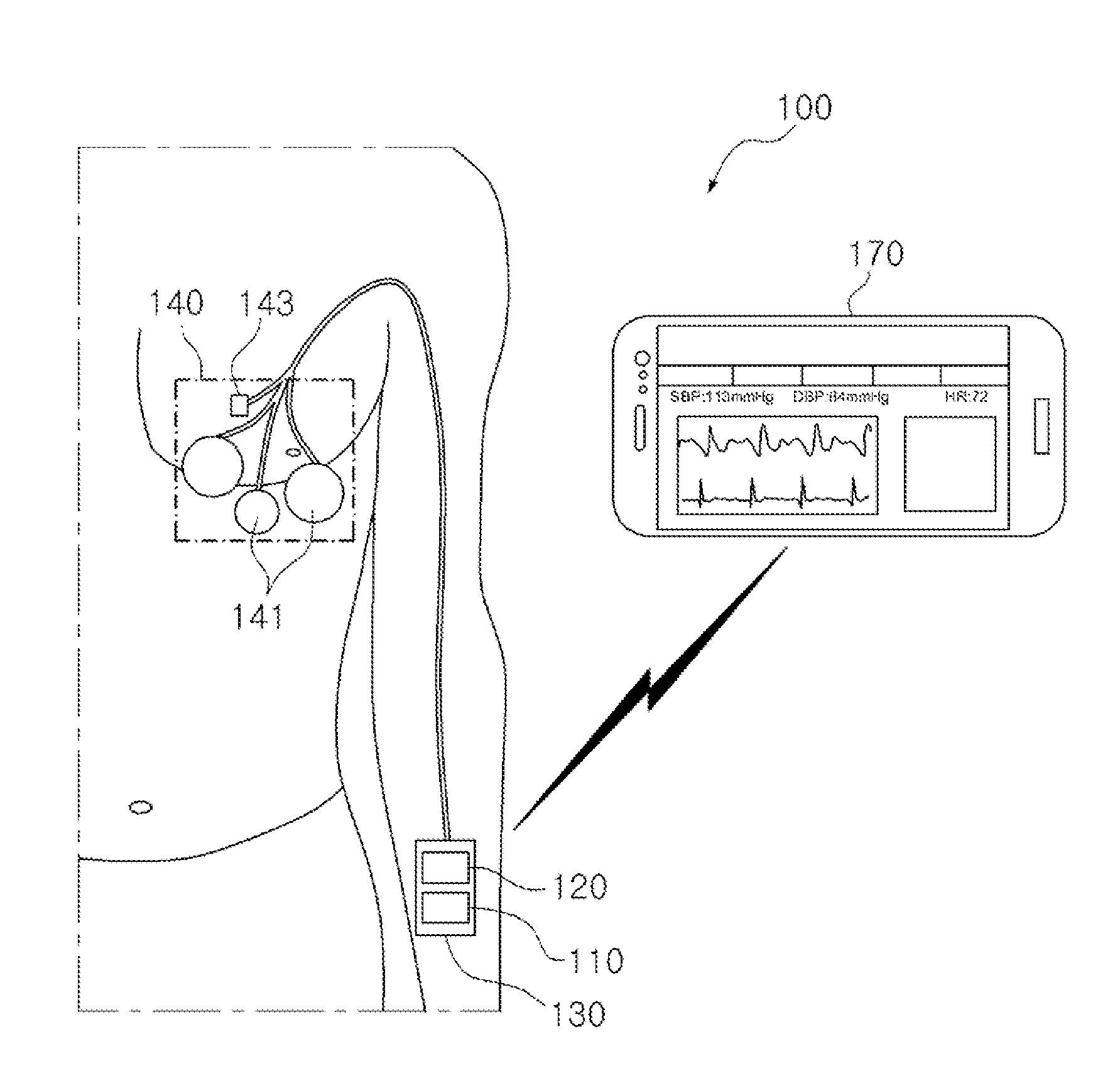

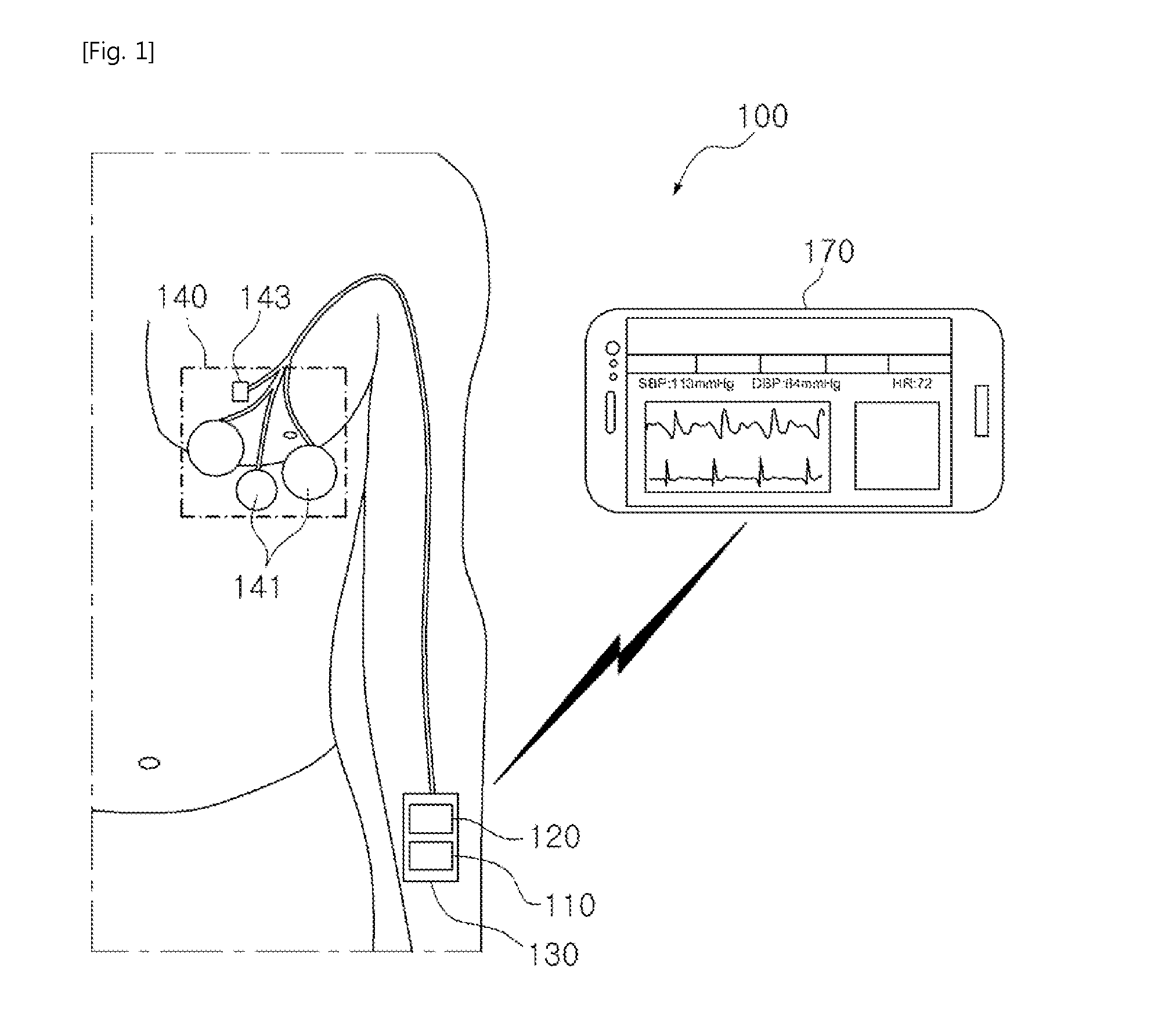

Apparatus for continuously and automatically measuring pulse wave and method for measuring blood pressure

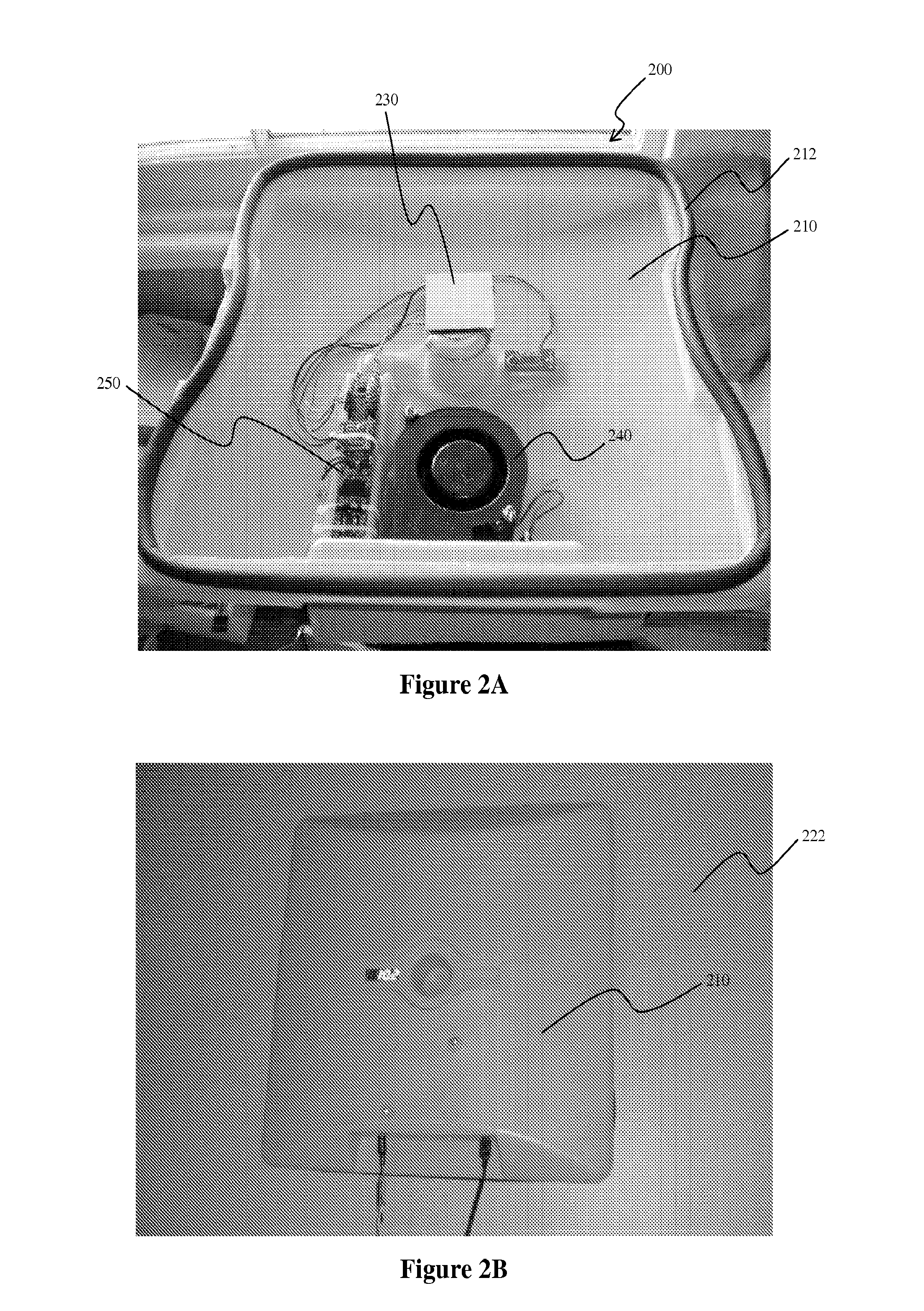

InactiveUS20150374244A1Easy to installSimple configurationElectrocardiographyStethoscopePotential differenceHeart sounds

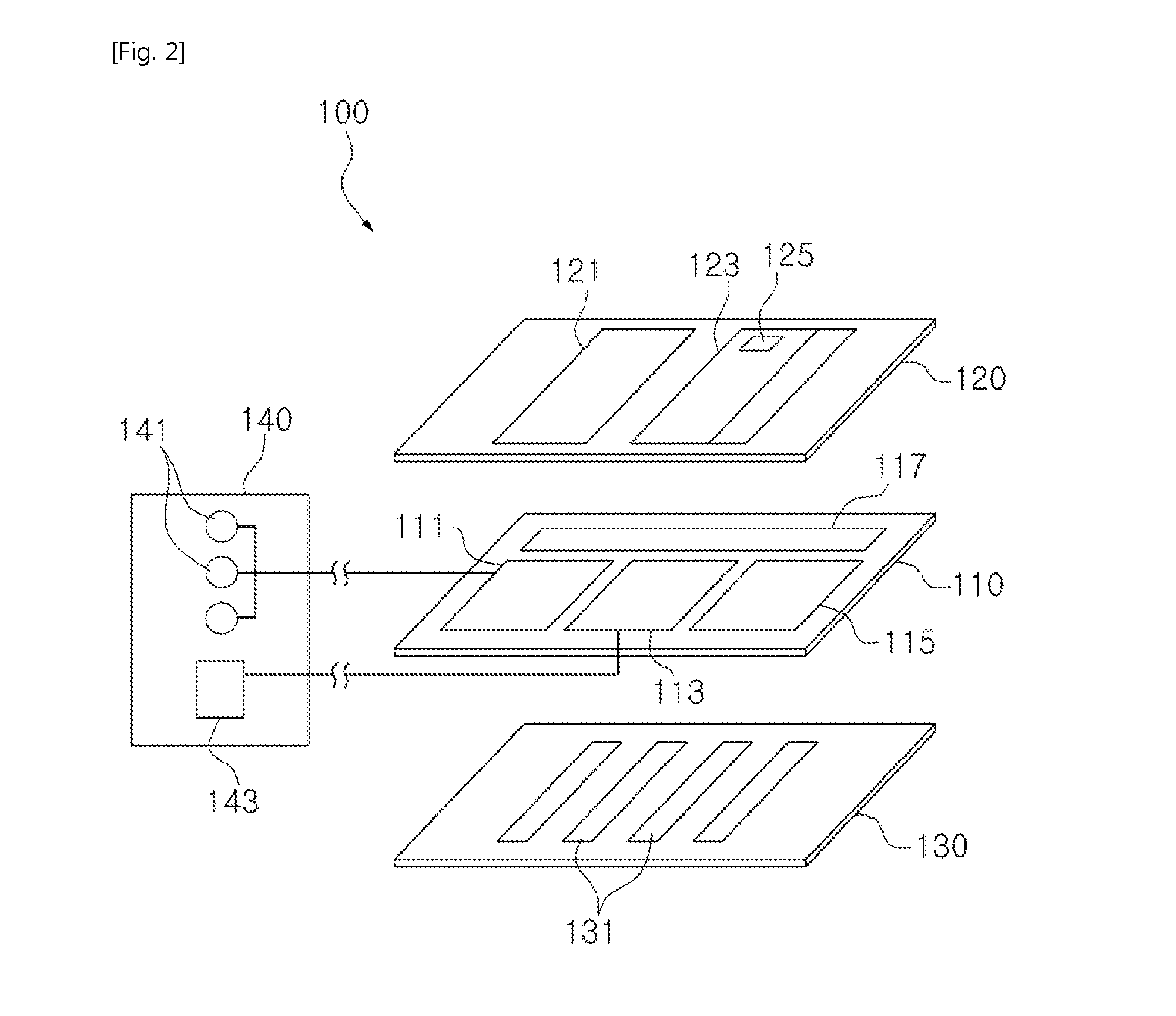

Disclosed is an apparatus for continuously and automatically measuring a pulse wave by a non-invasive method to know the state of a cardiovascular system. The apparatus includes an integrated measurement module, a communication power module, and a bio-measurement pad. The integrated measurement module includes an electrocardiogram measurement portion for measuring the electrocardiogram of a subject, a bioelectrical impedance measurement portion for measuring the bioelectrical impedance of the subject by a potential difference, a heart sound measurement portion for measuring the heart sound of the subject, and a controller for measuring and controlling the state of the cardiovascular system of the subject on the basis of a pulse transit time calculated by the electrocardiogram signal measured at the electrocardiogram measurement portion, the bioelectrical impedance signal measured at the bioelectrical impedance measurement portion, and the heart sound signal measured at the heart sound measurement portion.

Owner:K HEALTHWEAR

Method and apparatus for the continuous performance monitoring of a lead acid battery system

InactiveUS20040095249A1Simple and accurate measurementTelemetry/telecontrol selection arrangementsElectrical testingSignal onMonitoring system

The present invention concerns a battery monitoring system for monitoring a plurality of batteries serially connected to form a string. The battery monitoring system includes a number of probes connected to at least a portion of the string, a daisy chain bus having a select channel for serially interconnecting the probes, the bus having other, parallel channels for data communication and power, and a system server. The probes each have a sensing module and a communication module. The sensing module senses characteristics of at least a portion of the string, such as voltage or current. The communication module receives the sensed characteristics and converts them into digital form for broadcast to the system server over the bus. The communication module of the probes have a memory for storing an address assigned to the corresponding probe upon reception of an initialization signal sent by the system server via the bus. In order to readdress all of the probes, a reset signal is transmitted to all of the probes. The probes clear the present address, and wait until they are selected through the select channel. Once the probe has been selected, it receives an address from the system server, stores the address in its memory, acknowledges this to the system controller, and sends a signal on the select channel to the next probe. Accordingly, initialization of a battery monitoring system is easily performed. The invention also lies in an interface device for use with a battery monitoring system.

Owner:ZACCARIA ROBERT

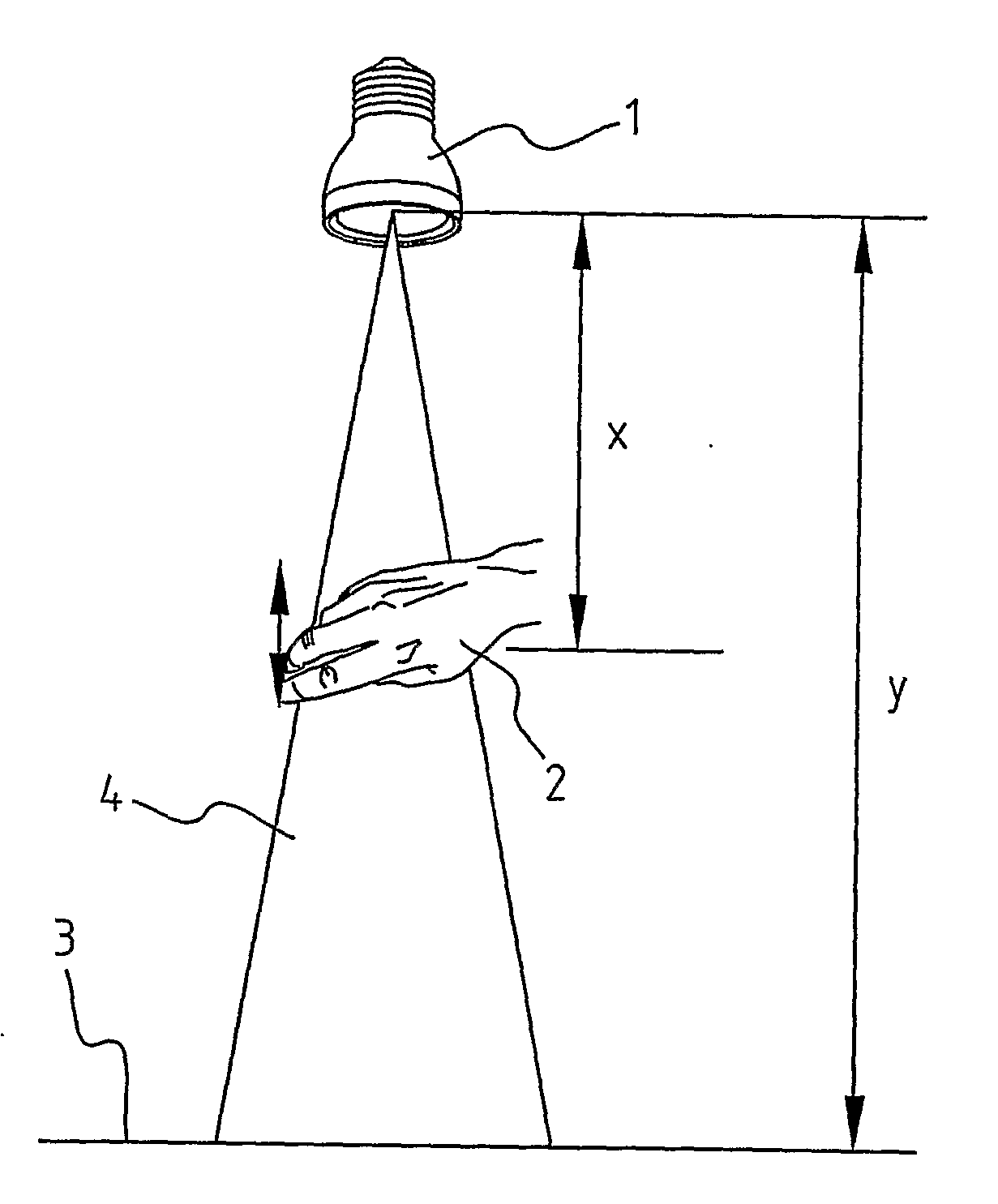

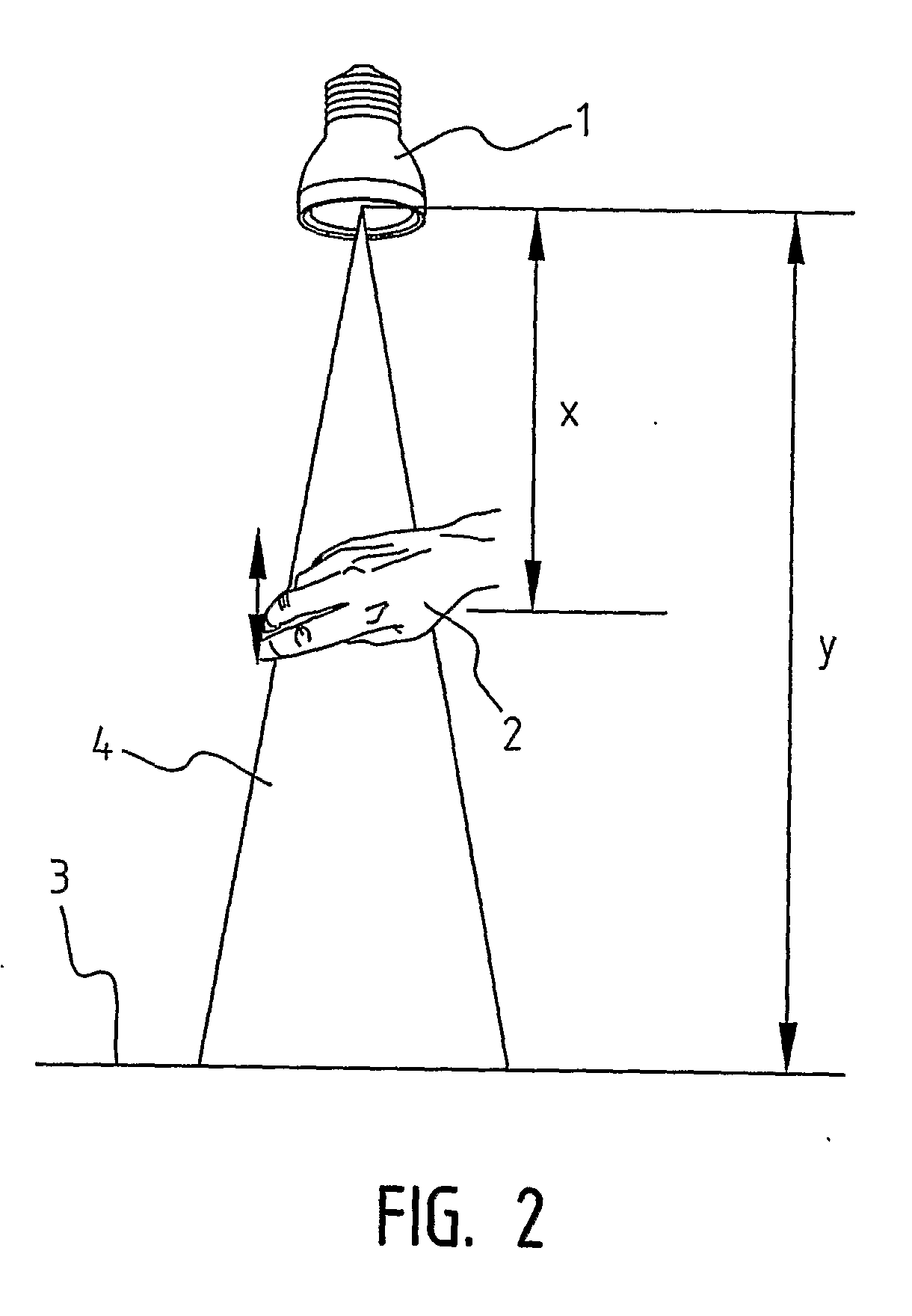

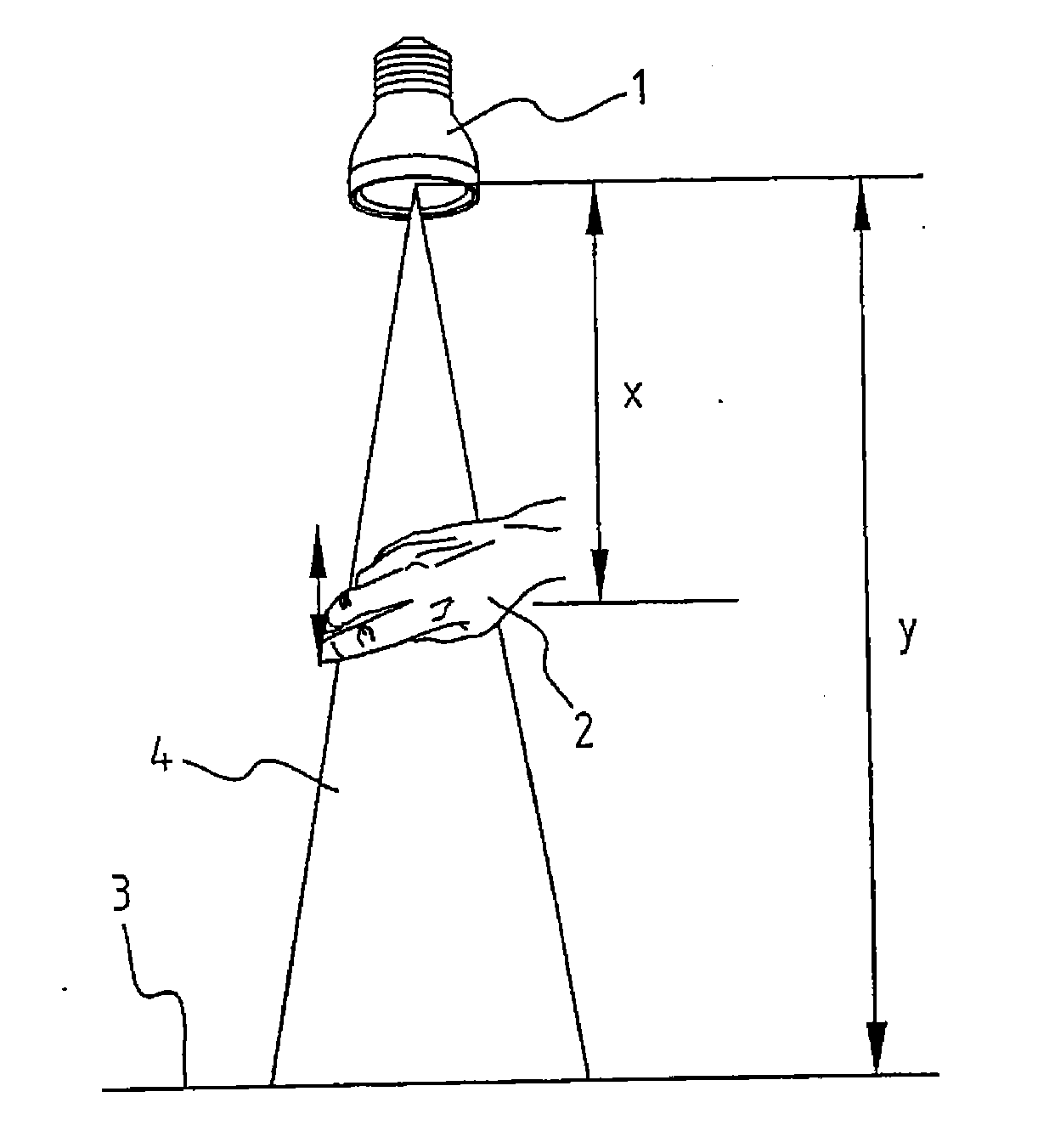

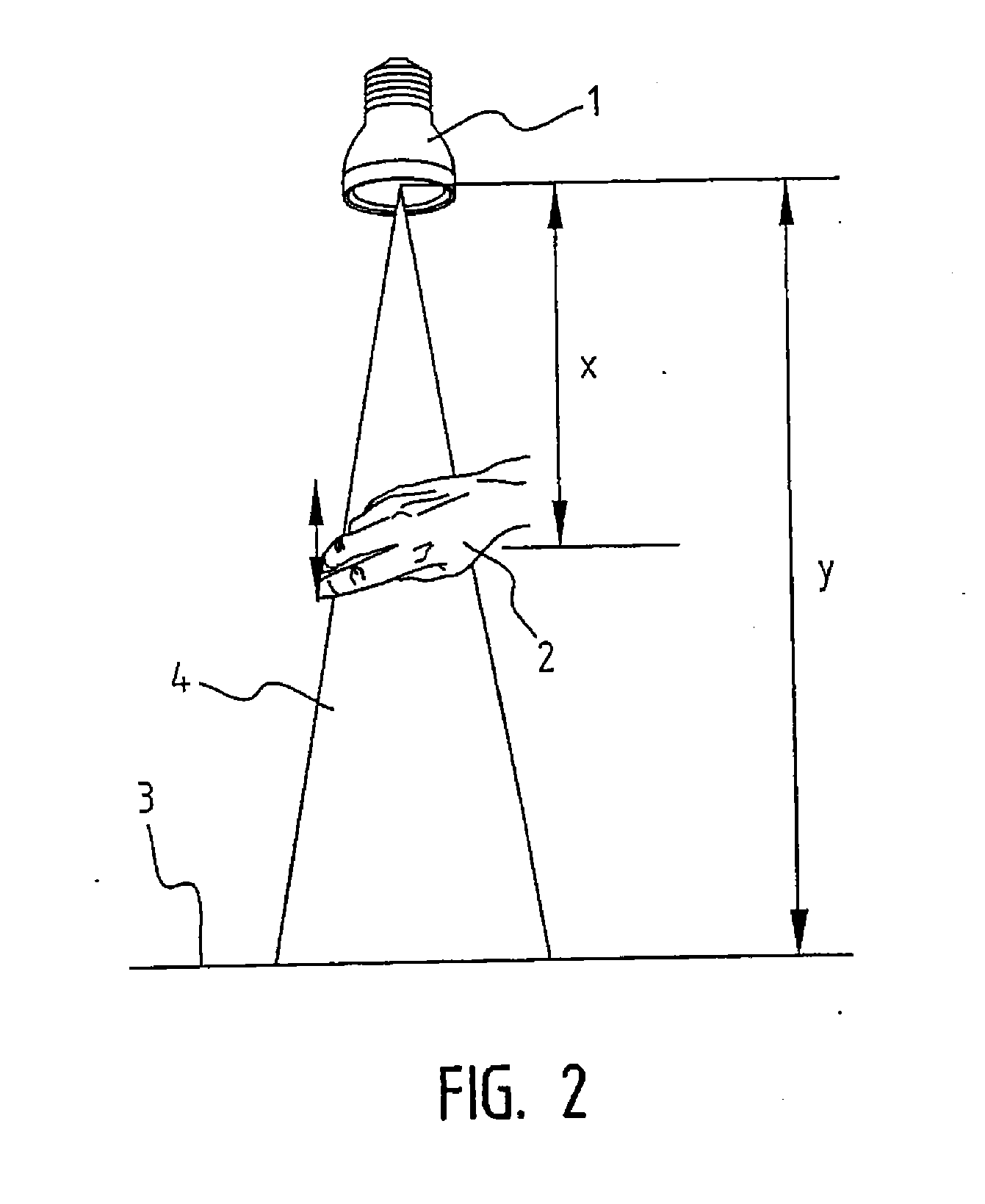

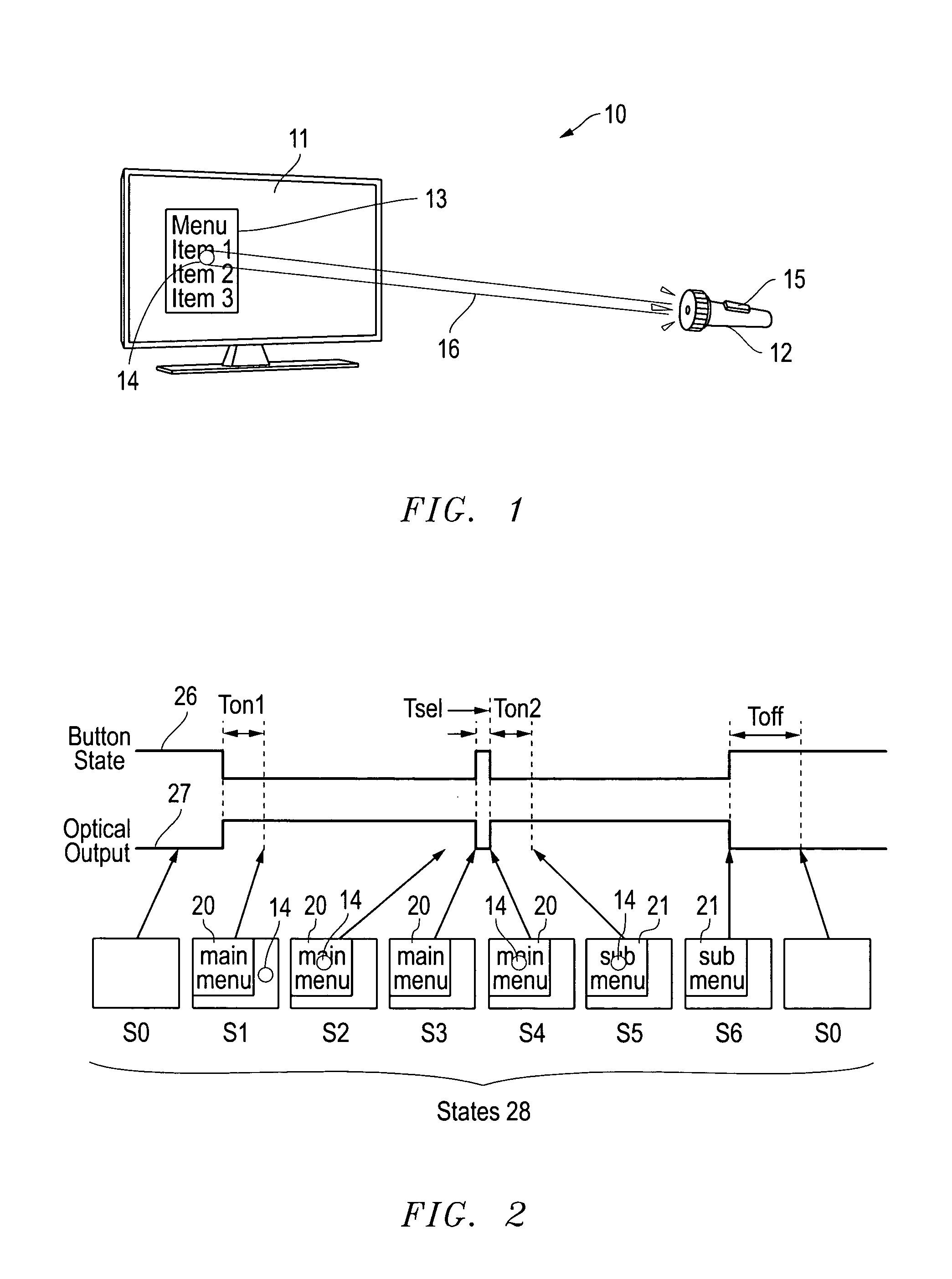

Low Cost System Concept for Gesture Light Control

InactiveUS20100253241A1Low costSimple and accurate measurementElectroluminescent light sourcesElectronic switchingControl signalTime of flight

A lighting system comprising a lamp comprising an array of LEDs arranged to transform electricity into a light beam having properties such as intensity, colour, colour temperature; a fight control means comprising a LED driver and a pulse width modulator arranged to adjust said light beam properties; a DA-converter, an ultrasound driver and an ultrasonic transmitter arranged to convert a digital transmit signal into the transmission of an ultrasonic pulse; an ultrasonic receiver and an amplifier arranged to receive reflected ultrasonic signals and transform said ultrasonic signal in a voltage, and a comparator arranged to generate a digital receive signal if said voltage is greater than a predetermined threshold; a processing means arranged to derive a time-of-flight signal representing the time differences between said digital transmit and receive signals and to send control signals to said light control means in dependence of said time-of-flight signal.

Owner:LITE ON TECH CORP

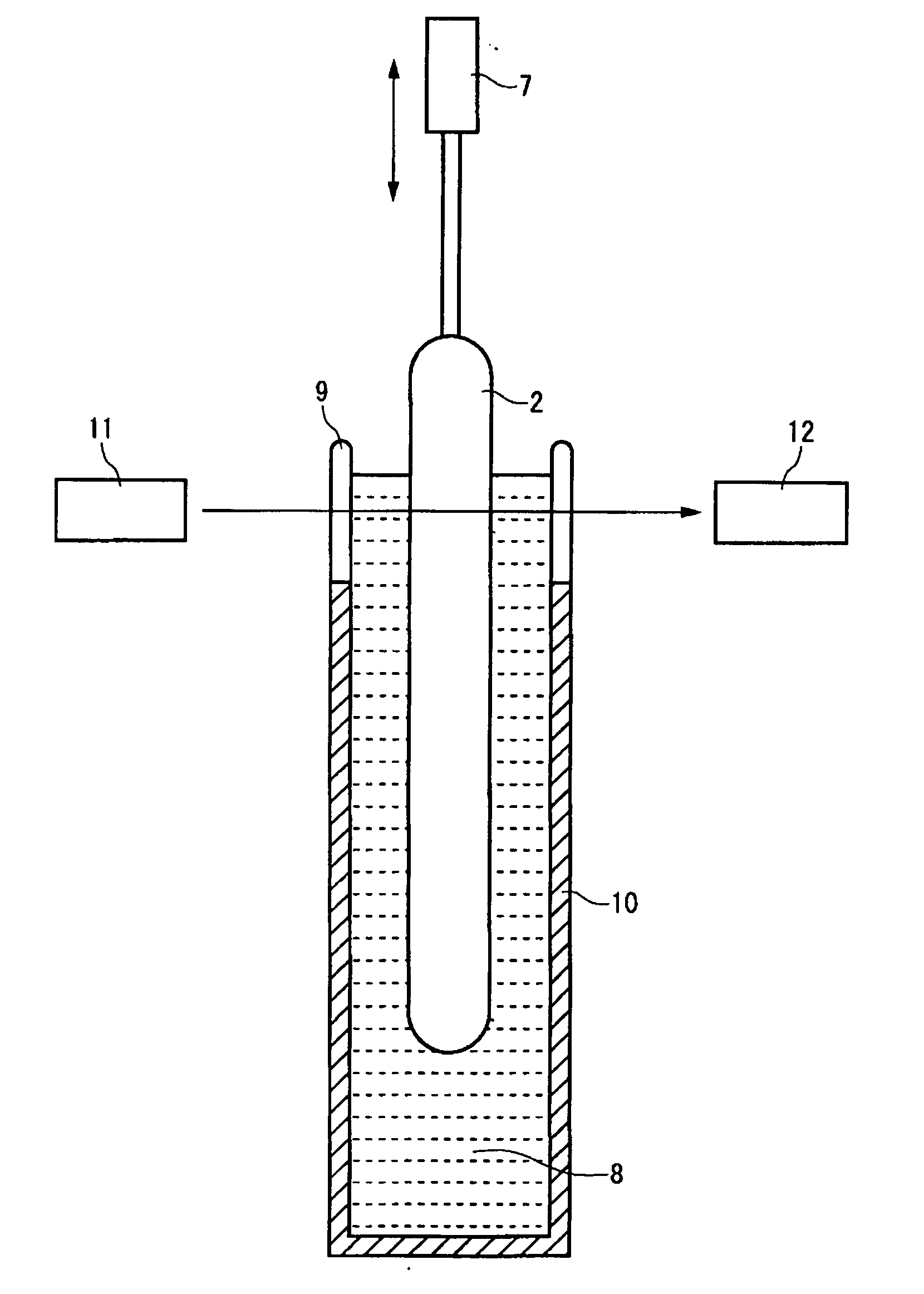

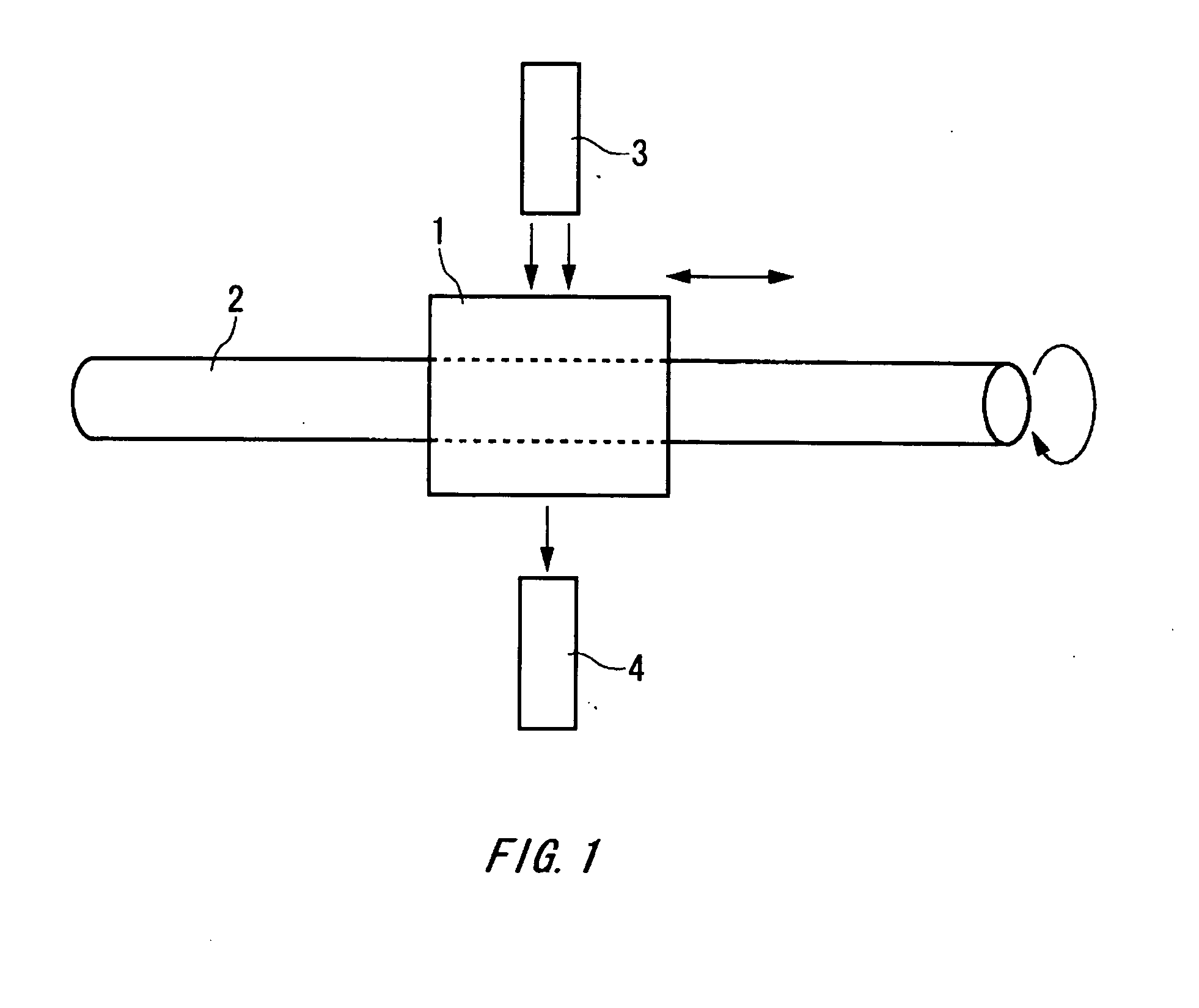

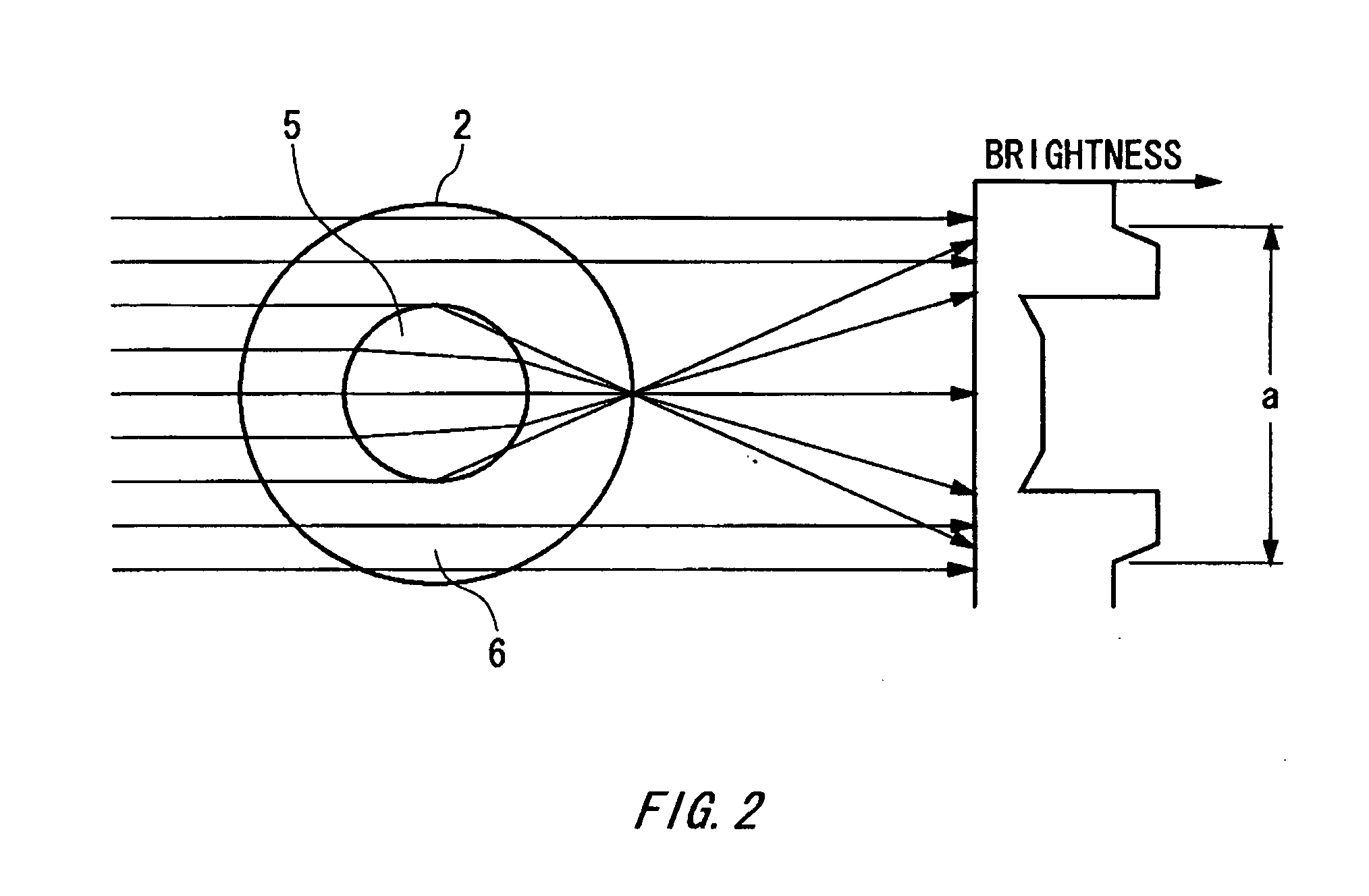

Measurement Method of Non-Circularity of Core Optical Fiber Base Material and Apparatus Therefor

ActiveUS20080192239A1Simple and accurate measurementInvestigating moving sheetsUsing optical meansRefractive indexUltimate tensile strength

There is provided a measurement method of non-circularity of a core part of an optical fiber base material and an apparatus therefor, which can accurately and easily measure non-circularity of the core part, regardless of a refractive index difference between a core and a clad and an interval between a light projector and a photoreceiver. The method for measuring non-circularity of a core part of an optical fiber base material having the core part and a clad part includes the steps of: immersing the optical fiber base material in liquid having a refractive index substantially equal to that of the clad part of the optical fiber base material; irradiating parallel light from a side face of the optical fiber base material to measure intensity distribution of transmitted light; measuring a width of a dark space caused by light passing the core part on intensity distribution to obtain a relative value for a core diameter; rotating the optical fiber base material to further obtain the relative value for the core diameter at plural points for a circumferential direction; and obtaining non-circularity of the core part based on the obtained plurality of relative values for the core diameter.

Owner:SHIN ETSU CHEM IND CO LTD

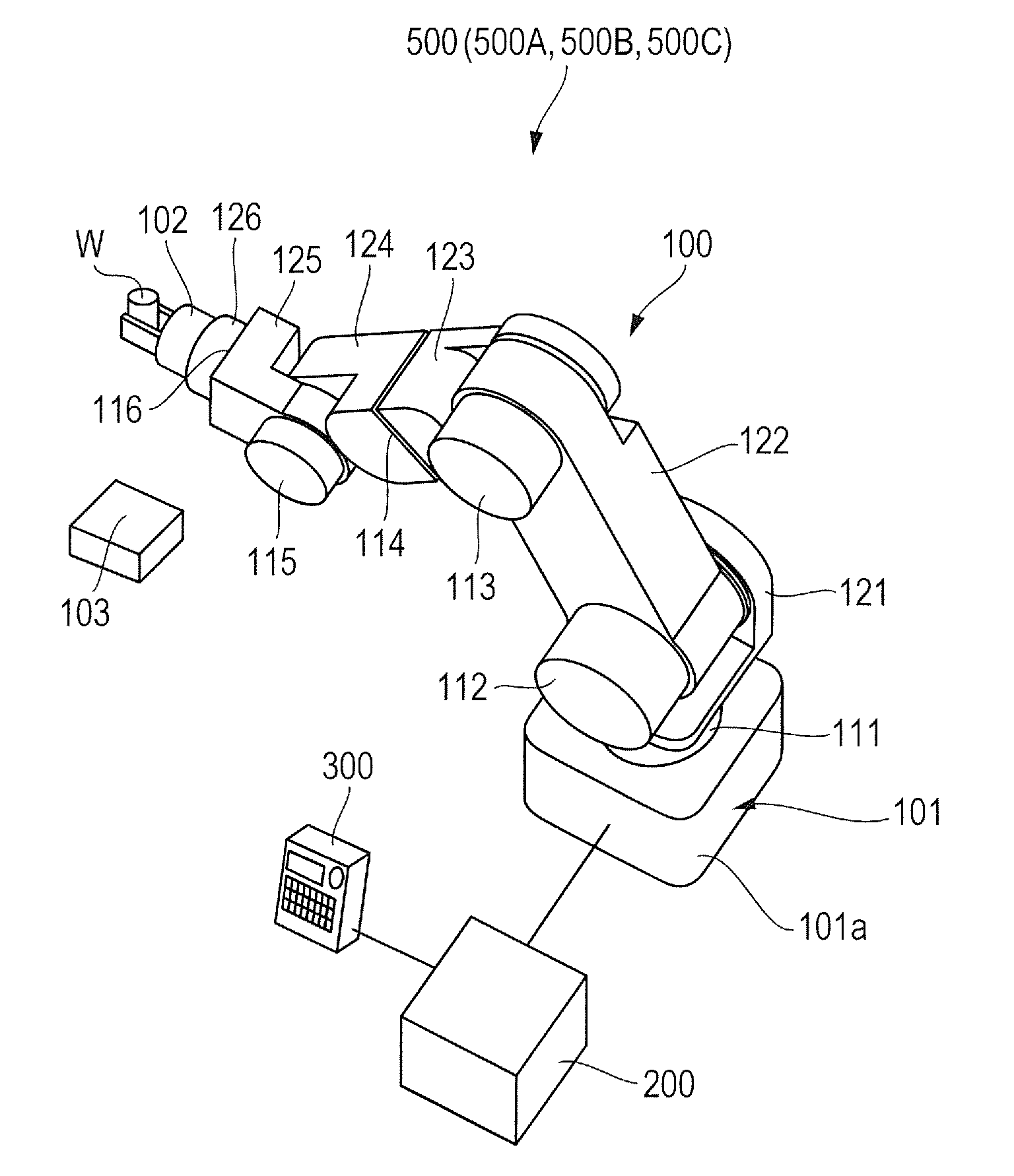

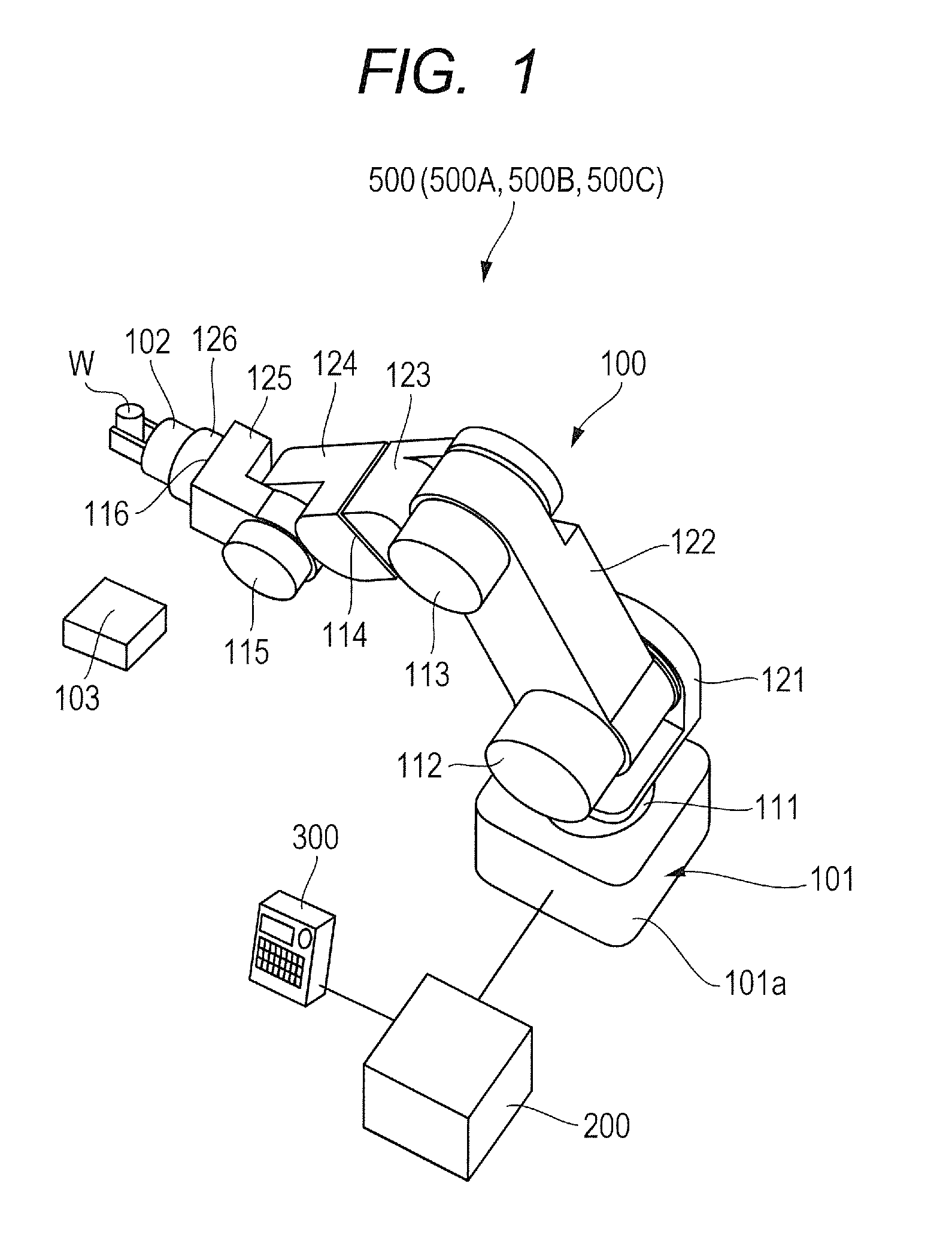

Robot apparatus, and measuring method of rotation driving apparatus

ActiveUS20170015004A1Simple and accurate measurementProgramme controlProgramme-controlled manipulatorLife lengthEngineering

The present invention enables to easily and accurately measure a joint of a robot apparatus, in particular, a lost motion of a driving system of the joint, and, to easily and accurately perform a diagnosis of a lifetime or a life expectancy of a joint mechanism of the robot apparatus based on a measured result.

Owner:CANON KK

Method and apparatus for the continuous performance monitoring of a lead acid battery system

InactiveUS20060259280A1Easy to installMinimal manipulationTelemetry/telecontrol selection arrangementsError detection/correctionSignal onElectrical battery

The present invention concerns a battery monitoring system for monitoring a plurality of batteries serially connected to form a string. The battery monitoring system includes a number of probes connected to at least a portion of the string, a daisy chain bus having a select channel for serially interconnecting the probes, the bus having other, parallel channels for data communication and power, and a system server. The probes each have a sensing module and a communication module. The sensing module senses characteristics of at least a portion of the string, such as voltage or current. The communication module receives the sensed characteristics and converts them into digital form for broadcast to the system server over the bus. The communication module of the probes have a memory for storing an address assigned to the corresponding probe upon reception of an initialization signal sent by the system server via the bus. In order to readdress all of the probes, a reset signal is transmitted to all of the probes. The probes clear the present address, and wait until they are selected through the select channel. Once the probe has been selected, it receives an address from the system server, stores the address in its memory, acknowledges this to the system controller, and sends a signal on the select channel to the next probe. Accordingly, initialization of a battery monitoring system is easily performed. The invention also lies in an interface device for use with a battery monitoring system.

Owner:ZACCARIA ROBERT

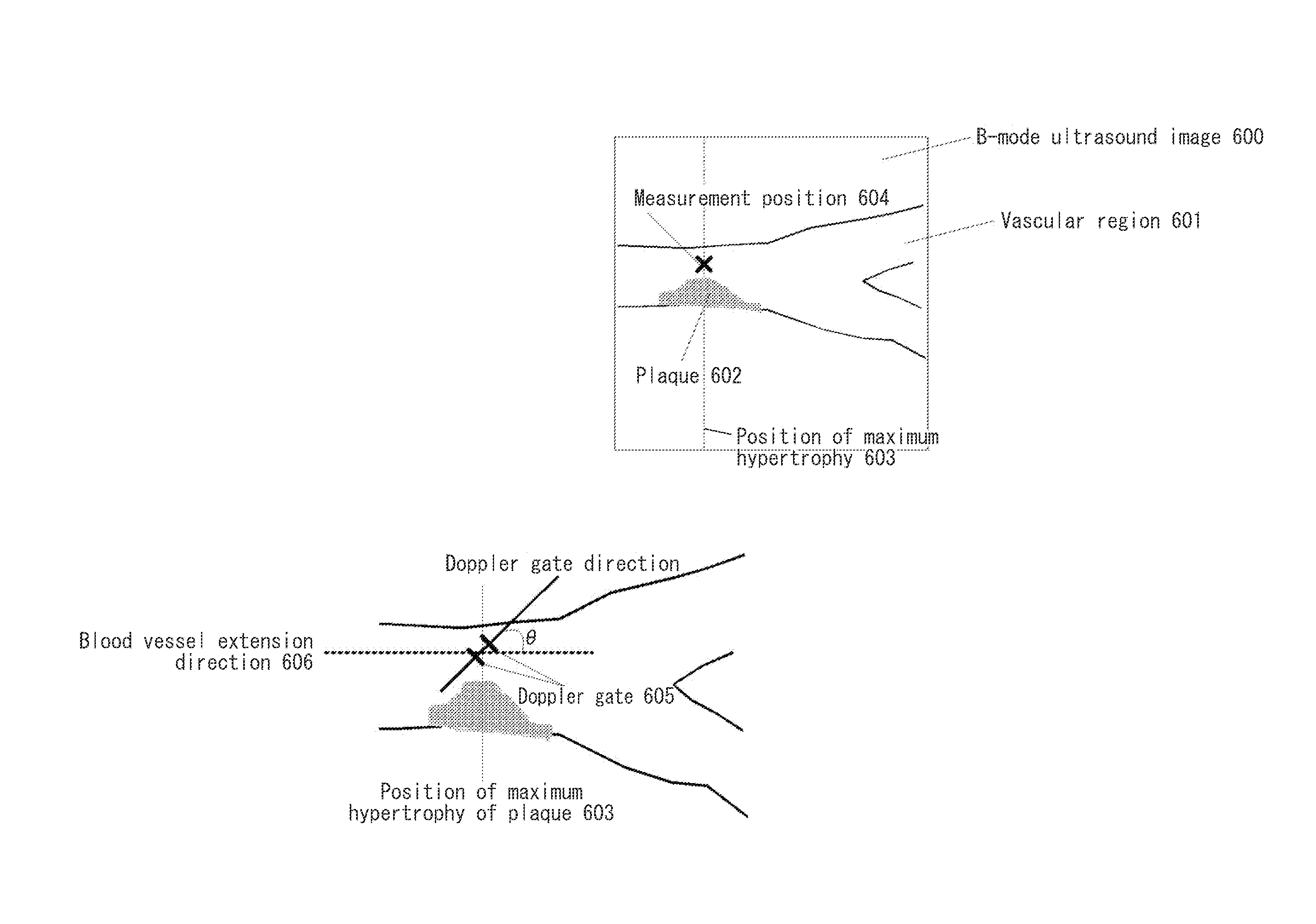

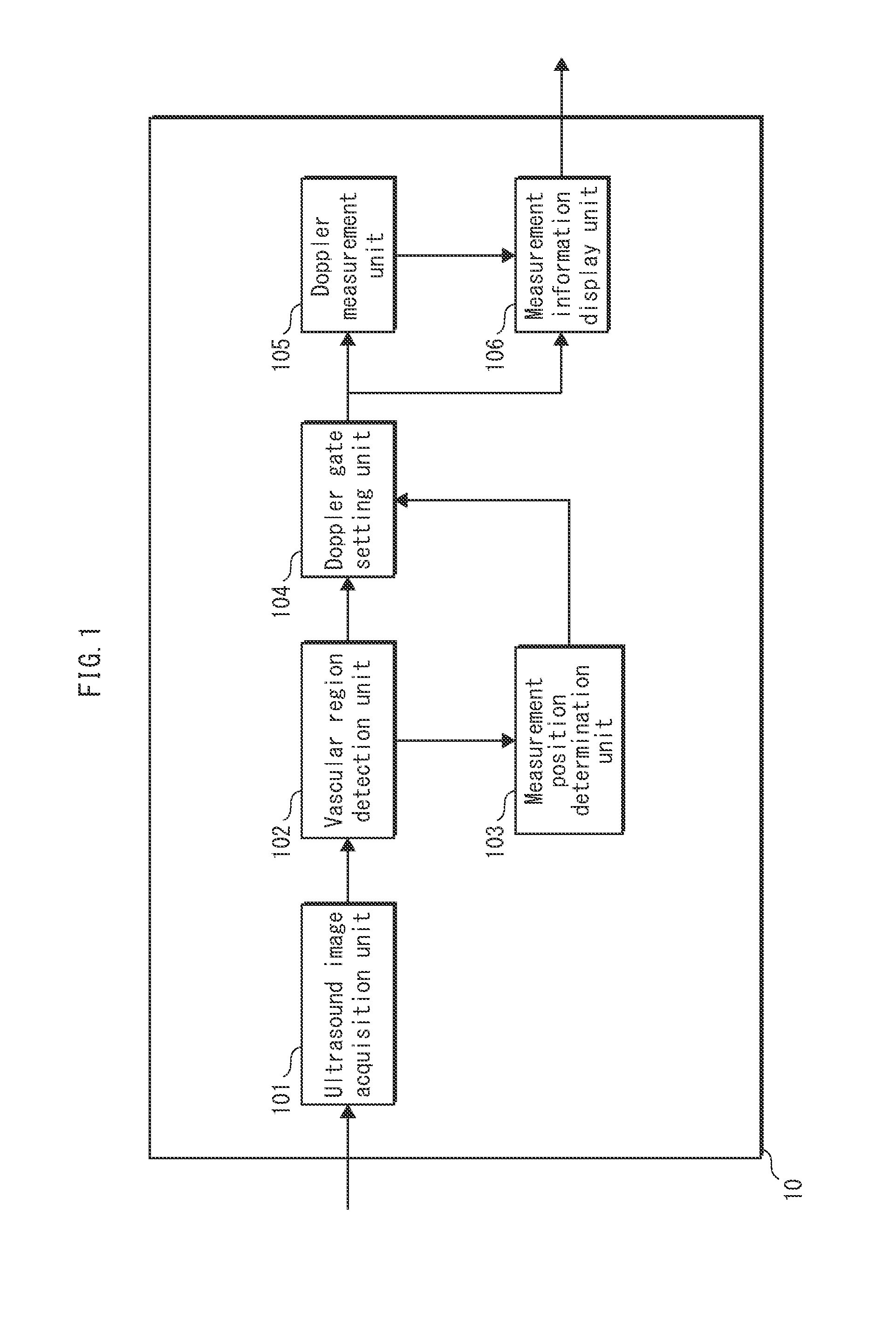

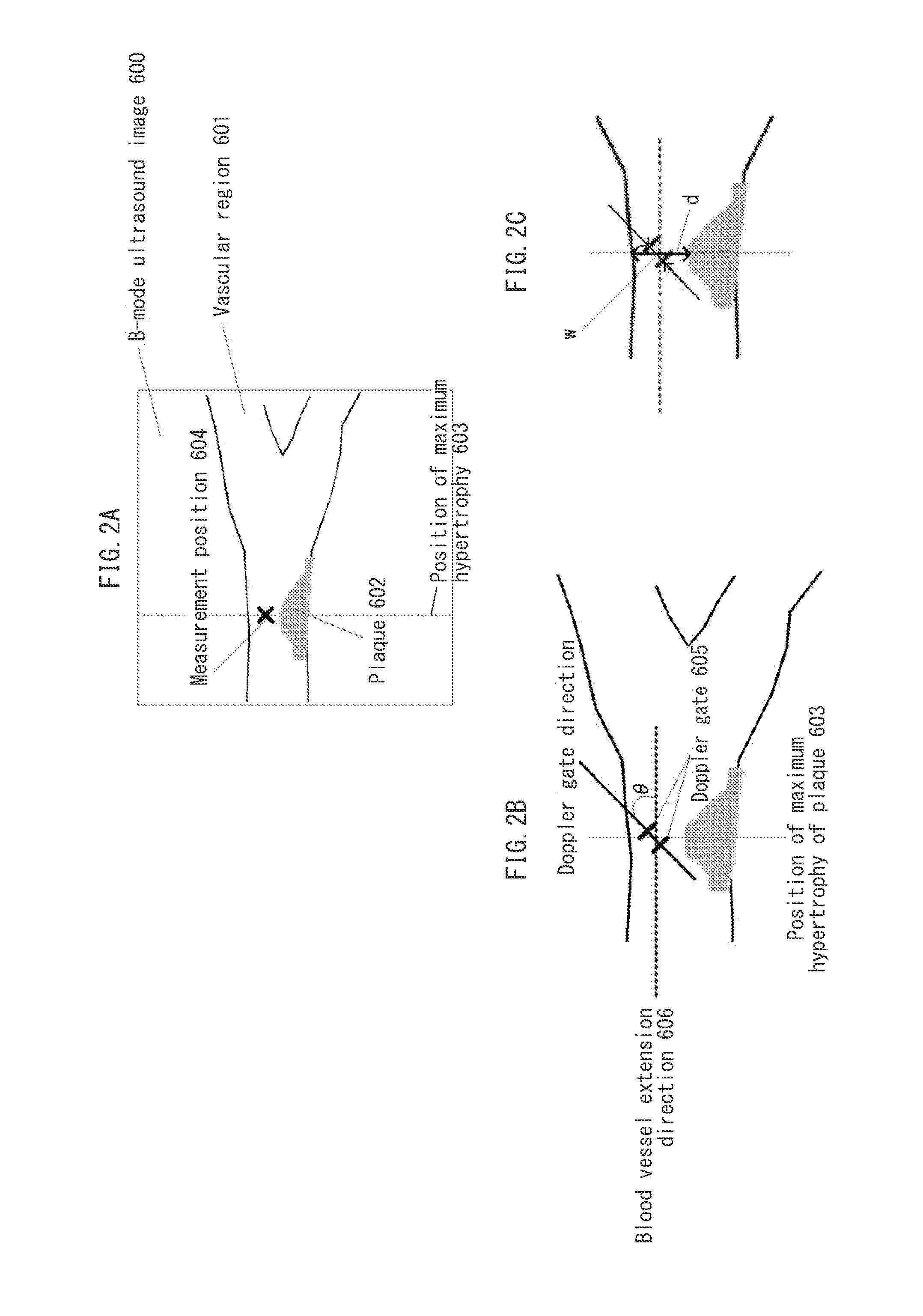

Ultrasound diagnostic apparatus and method for controlling the same

InactiveUS20140303499A1Simple and accurate measurementBlood flow measurement devicesHealth-index calculationThree vesselsRegion detection

An ultrasound diagnostic apparatus measures blood flow velocity by emitting ultrasound towards a measurement target and receiving a reflected wave, via an ultrasound probe. The ultrasound diagnostic apparatus includes an ultrasound image acquisition unit, a vascular region detection unit, a measurement position determination unit, and a Doppler gate setting unit. The ultrasound image acquisition unit acquires an ultrasound image which has been captured of the measurement target. The vascular region detection unit detects, from the ultrasound image, a vascular region corresponding to a blood vessel. The measurement position determination unit detects a specific part of the vascular region based on vascular region shape and determines, in accordance with the specific part, one or more measurement positions in the vascular region in terms of longitudinal direction thereof. The Doppler gate setting unit sets, with respect to each measurement position, a Doppler gate in a lumen region of the vascular region.

Owner:KONICA MINOLTA INC

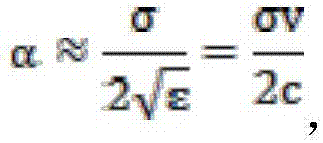

Method for measuring soil compaction degree based on ground penetrating radar

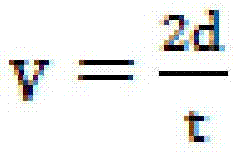

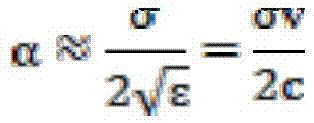

InactiveCN107576674ASimple and accurate measurementMaterial analysis using microwave meansRadio wave reradiation/reflectionAttenuation coefficientTime domain

The invention discloses a method for measuring soil compaction degree based on ground penetrating radar. The method comprises the following steps: adopting a ground penetrating radar cross-section method to measure the volume weight of soil; processing an acquired measurement signal, and defining a zero point measured by an electromagnetic wave to obtain accurate time domain information; extracting electromagnetic wave propagation speed, and establishing a regression equation of reverting the volume weight of soil in combination with the electromagnetic wave propagation speed and other soil factors; extracting the amplitude of the electromagnetic wave, using the correlation between the amplitude energy value of the electromagnetic wave and soil penetration resistance to proof the feasibility of the soil compaction degree measured by the ground penetrating radar; calculating the decay rate of the electromagnetic wave, using the correlation between the decay factor of the electromagneticwave and the soil penetration resistance to proof the feasibility of the soil compaction degree measured by the ground penetrating radar; using the average speed of propagation of the electromagneticwave to calculate the average volume weight of a soil body, and using the amplitude of the electromagnetic wave and the decay factor to reflect the characteristic that the soil compaction degree gradually changes along with the depth. The method disclosed by the invention is accurate, simple and fast.

Owner:QUFU NORMAL UNIV

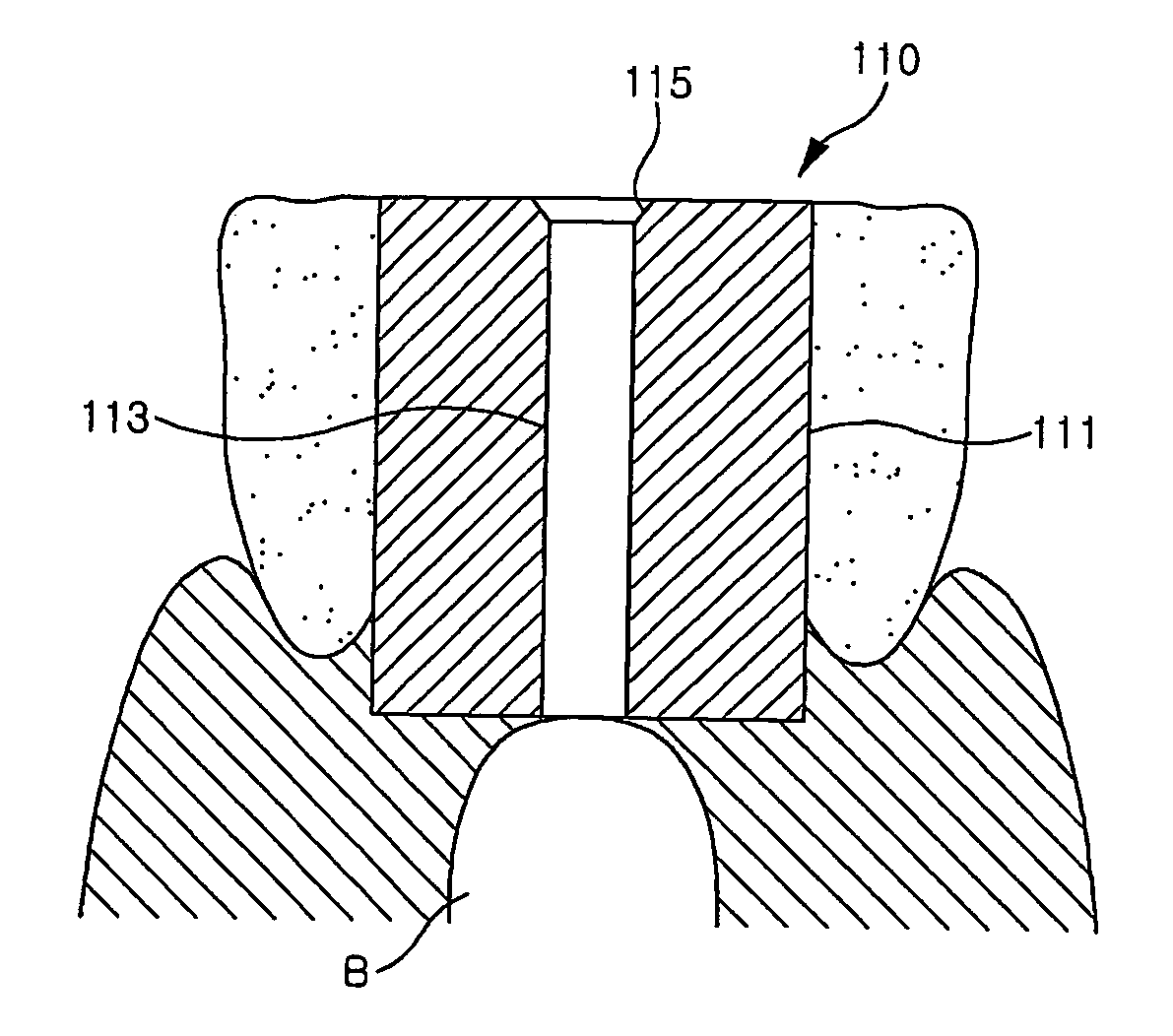

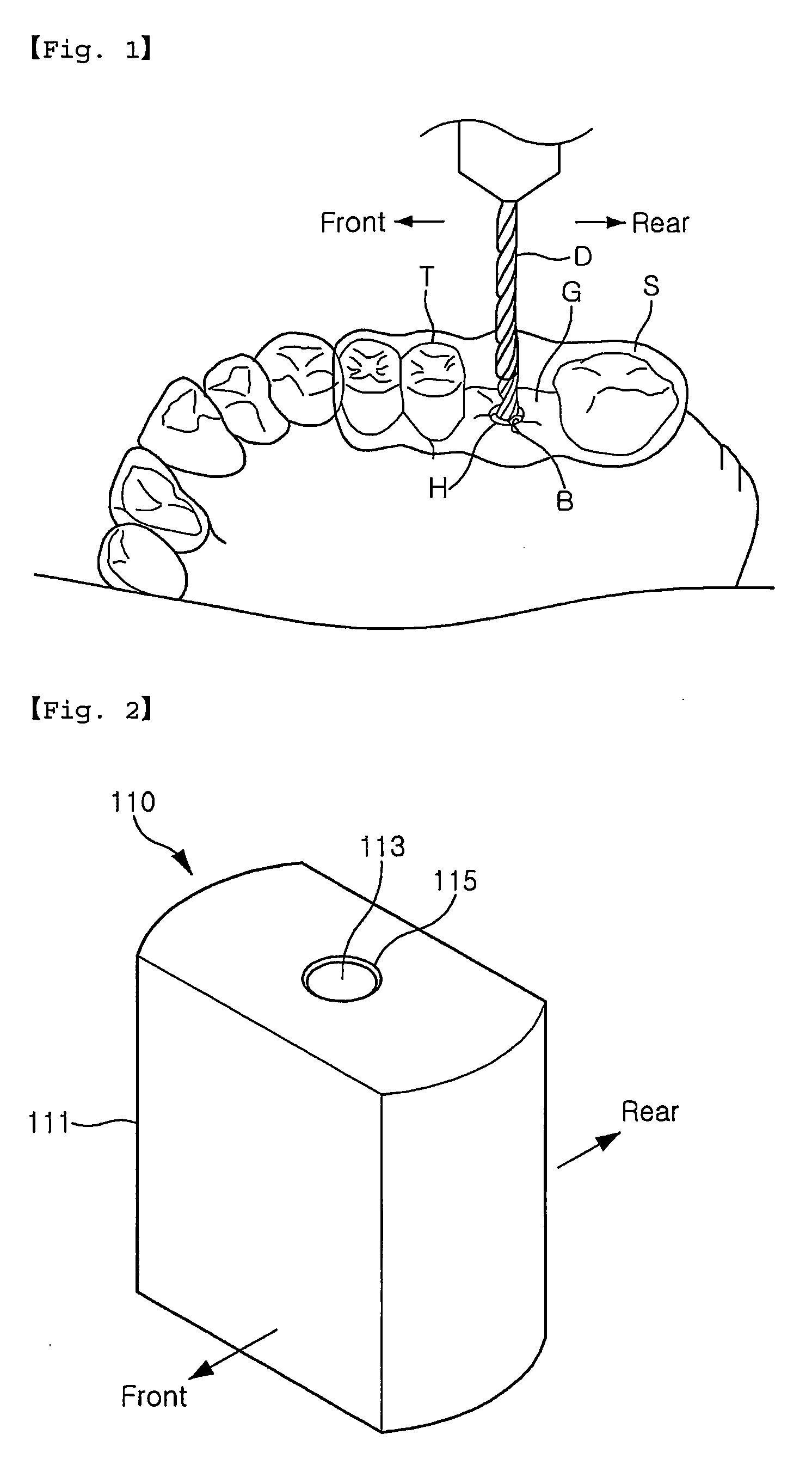

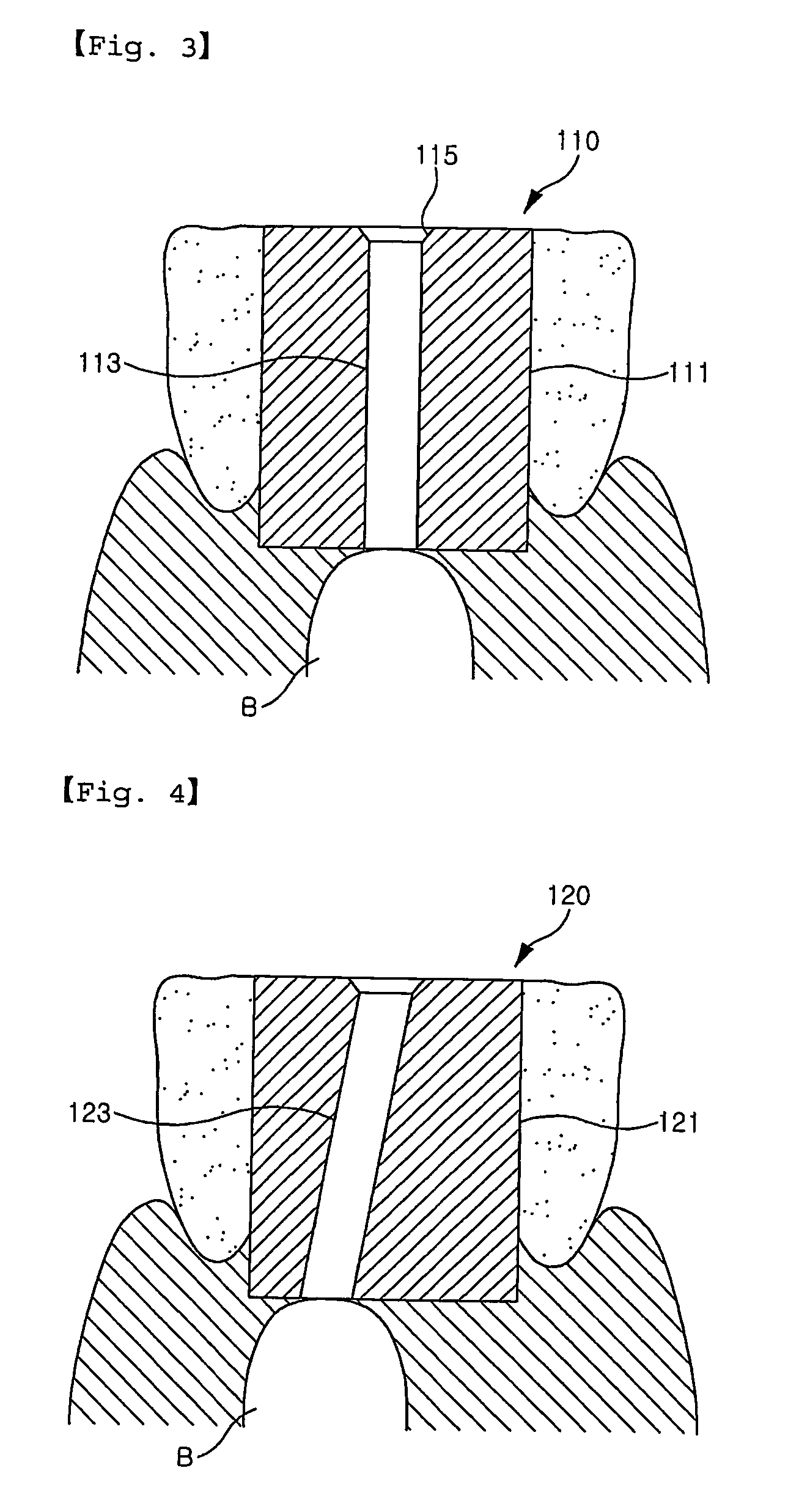

Assistant for implant stent

InactiveUS20070154862A1Operate rapidly and accuratelySimple and accurate measurementDental implantsBoring toolsBiomedical engineeringDrill bit

The present invention relates to an assistant for implant stent. The assistant for implant stent of the present invention comprises a body with a predetermined length and a drill insertion hole bored through the body from a top surface to a bottom surface thereof. The body comprises a support portion with a predetermined thickness and a sectional area greater than that of the body. The support portion is formed on the top surface of the body.

Owner:KIM JONG PIL

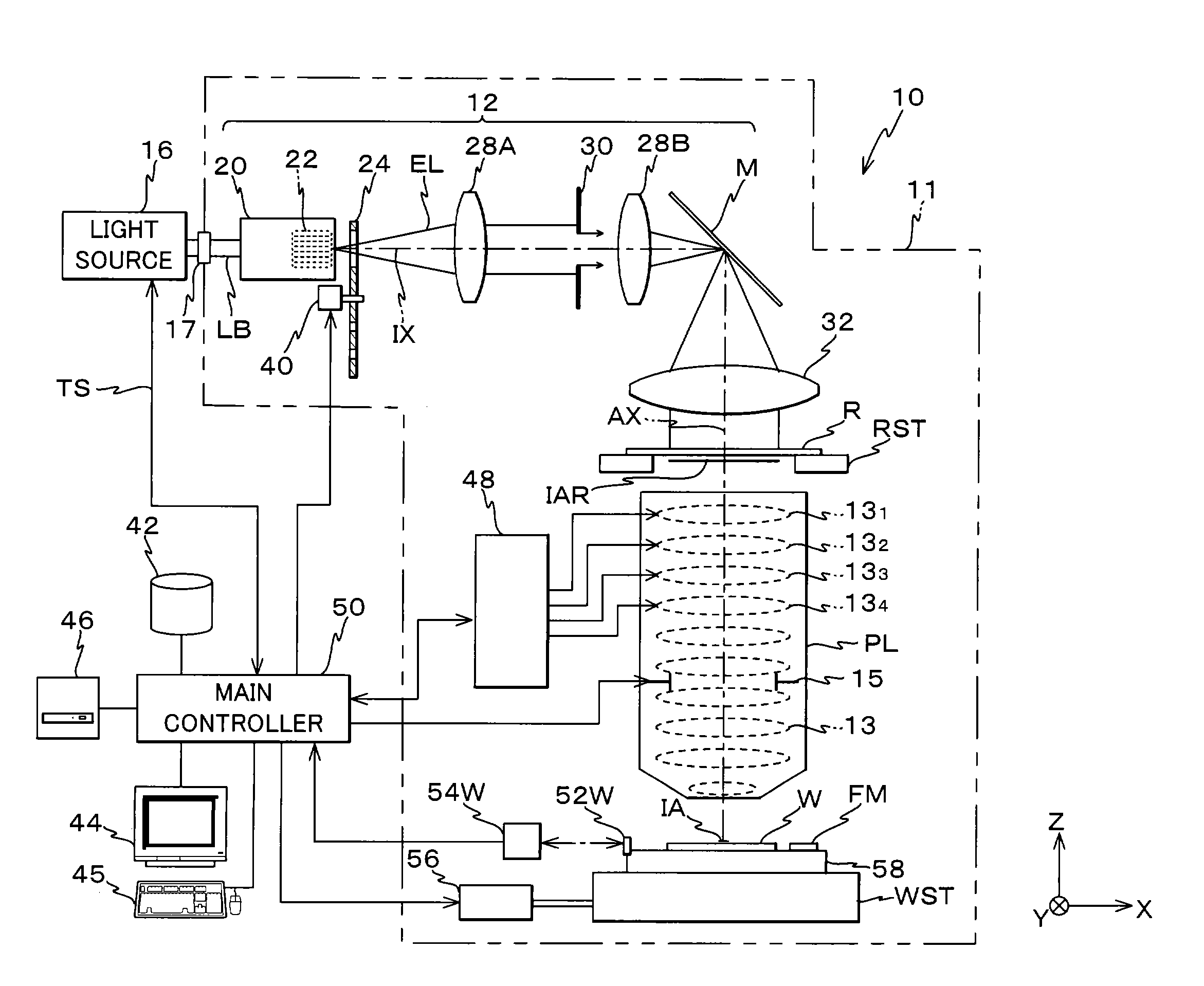

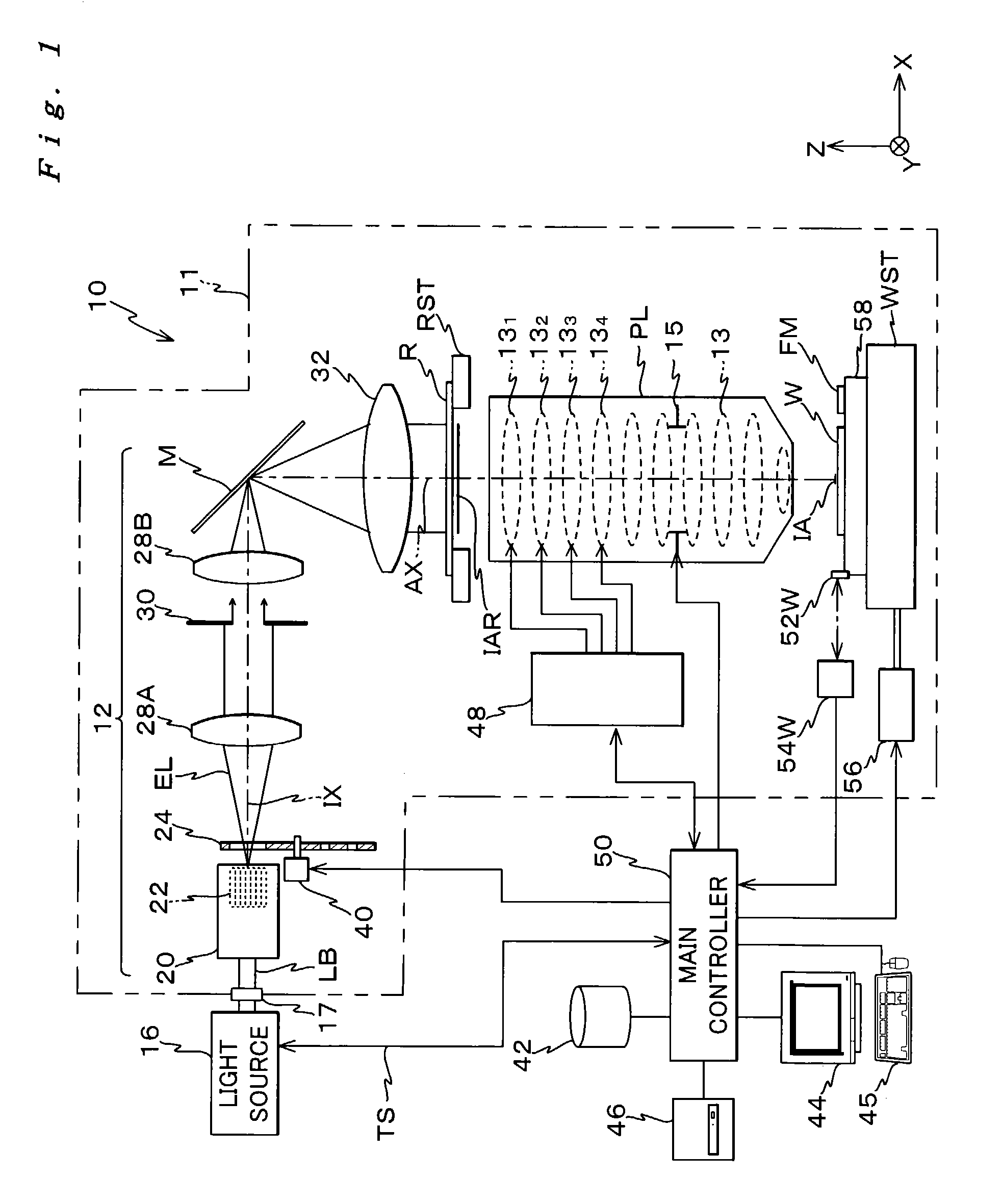

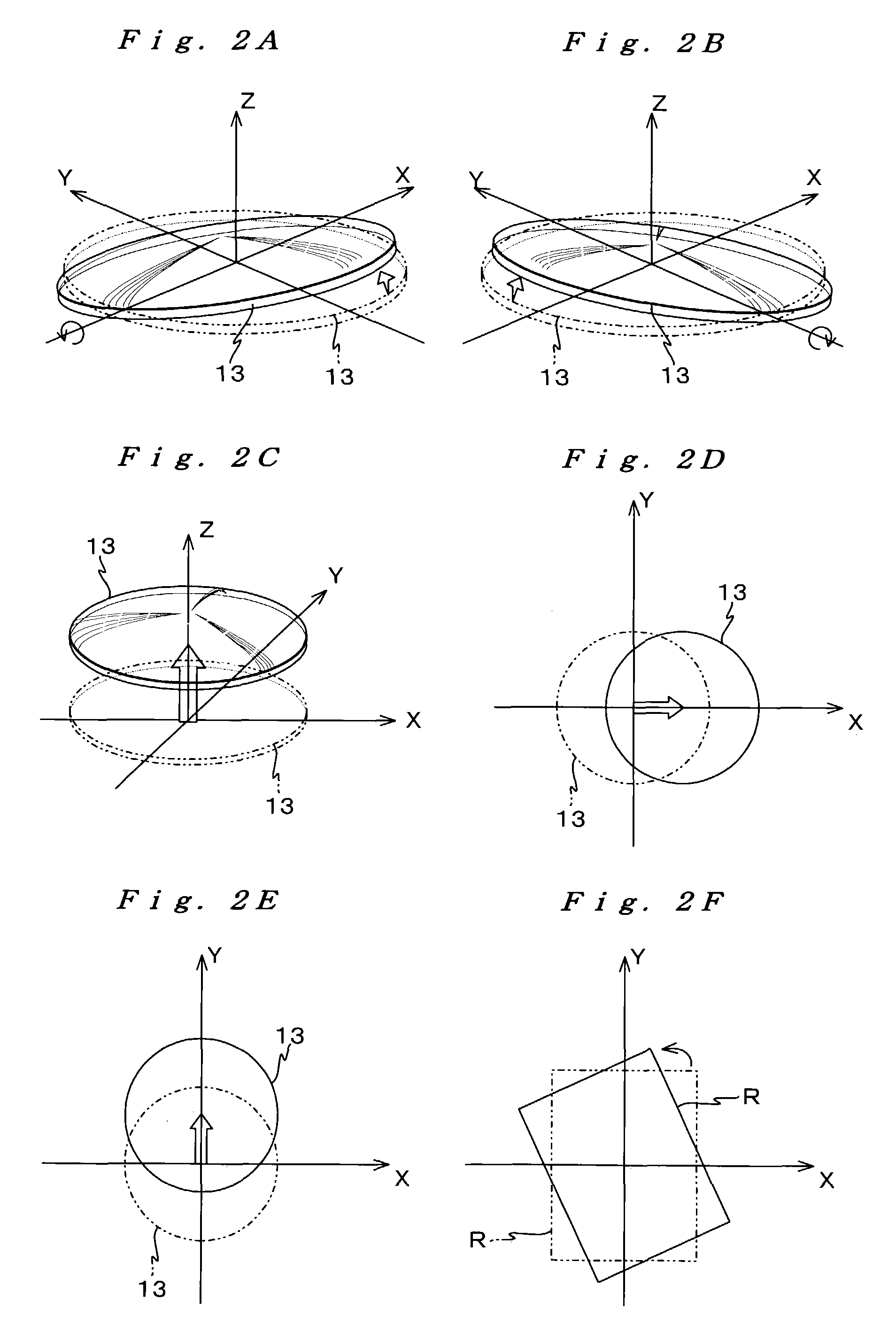

Image forming characteristics measuring method, image forming characteristics adjusting method, exposure method and apparatus, program and storage medium, and device manufacturing method

InactiveUS7075651B2Simple and accurate measurementEasy to adjustComputer controlSimulator controlImage formationMaster controller

When actual measurement data of a wavefront aberration of a projection optical system is input, a main controller calculates a targeted image forming characteristic of the projection optical system based on the data and a Zernike sensitivity table of the image forming characteristic that is made prior to the input. By using the Zernike sensitivity table, the targeted image forming characteristic can be calculated with only one measurement of wavefront aberration. Moreover, parameters that denote a relation between an adjustment of an adjustable specific optical element and a change in the image forming characteristics of the projection optical system is obtained in advance, and are stored in advance in a storage unit. Then, when the measurement data of the image forming characteristic of the projection optical system is input, the main controller calculates a targeted adjustment amount of the specific optical element using a relation expression between the measurement data, the parameters, and the targeted adjustment amount of the specific optical element, and adjusts the specific optical element based on the calculation results.

Owner:NIKON CORP

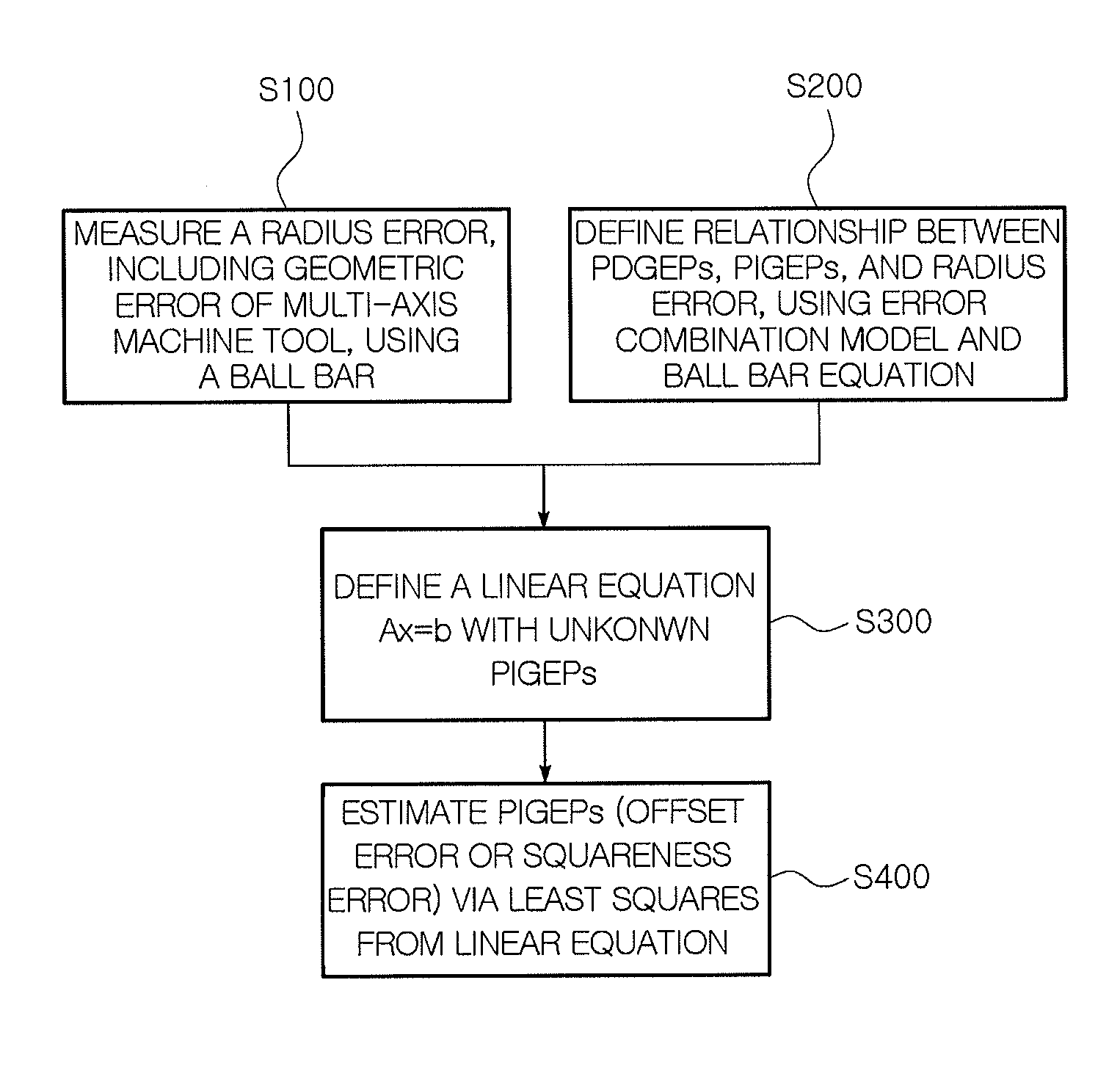

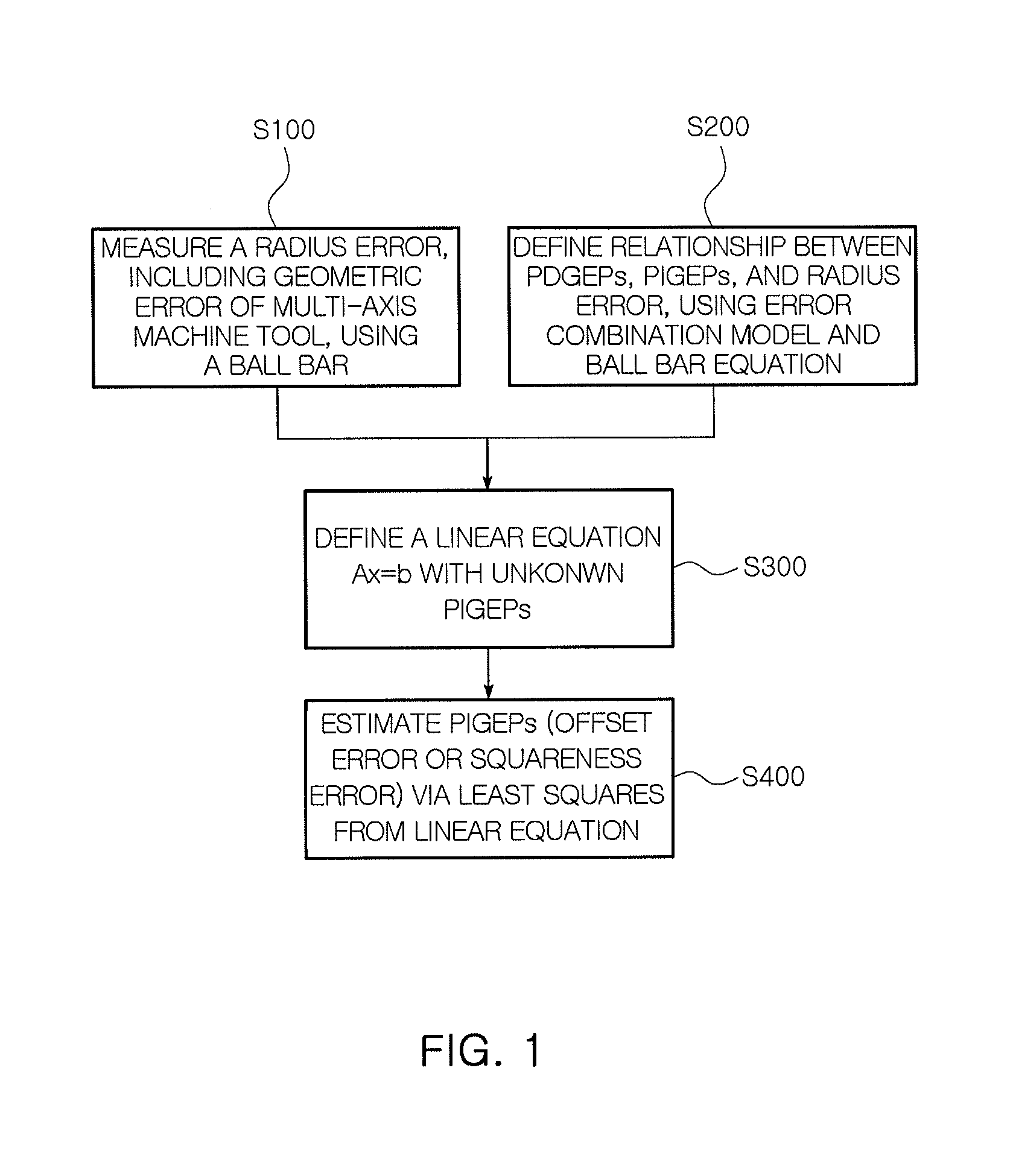

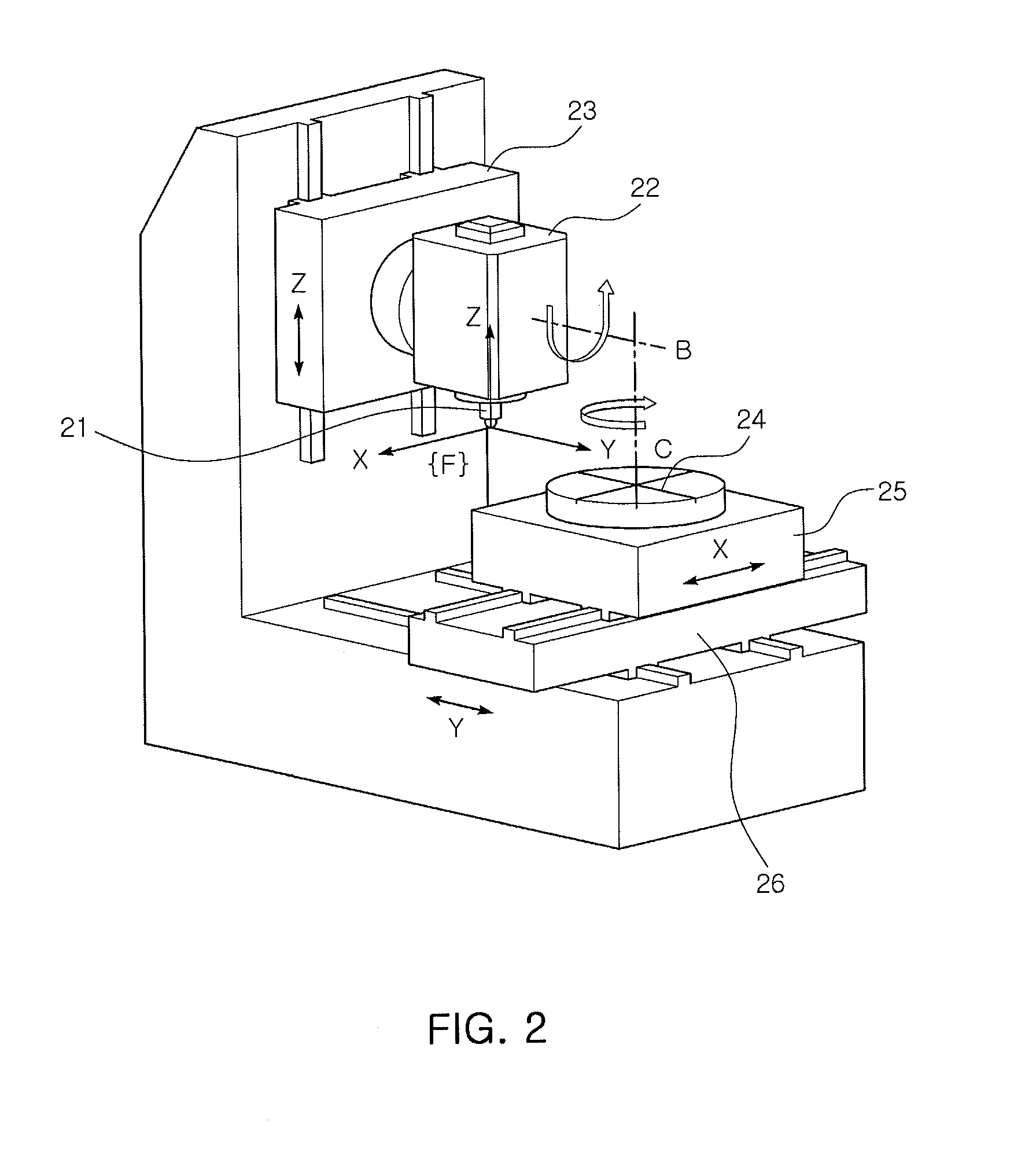

Method for Estimating Geometric Error Between Linear Axis and Rotary Axis in a Multi-Axis Machine Tool

InactiveUS20110178782A1Simple and accurate measurementMeasurement devicesComputation using non-denominational number representationLeast squaresRotational axis

A method of estimating a geometric error between a linear axis and a rotary axis in a multi-axis machine tool is provided, the method including creating a circular path under the control of one or more drive axes and measuring a radial error of the circular path using a ball bar, defining the relationship between position-dependent geometric error parameters and position-independent geometric error parameters and measured data using an error synthesis model and an equation of a ball bar, defining a linear equation with unknown position-independent geometric error parameters by removing higher order terms of the position-dependent geometric error parameters and position-independent geometric error parameters, and obtaining the position-independent geometric error parameters through least squares from the linear equation.

Owner:KYUNGPOOK NAT UNIV IND ACADEMIC COOP FOUND

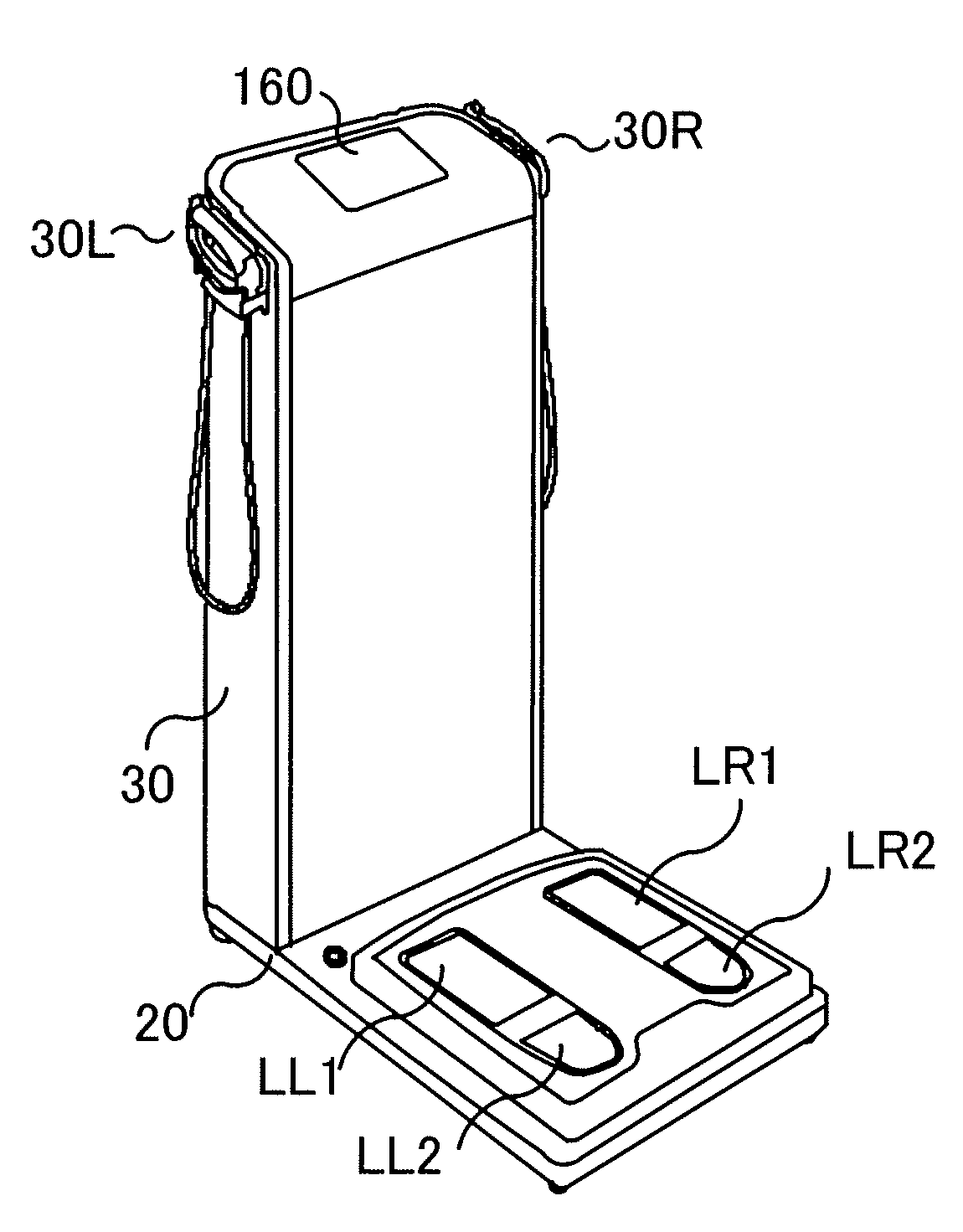

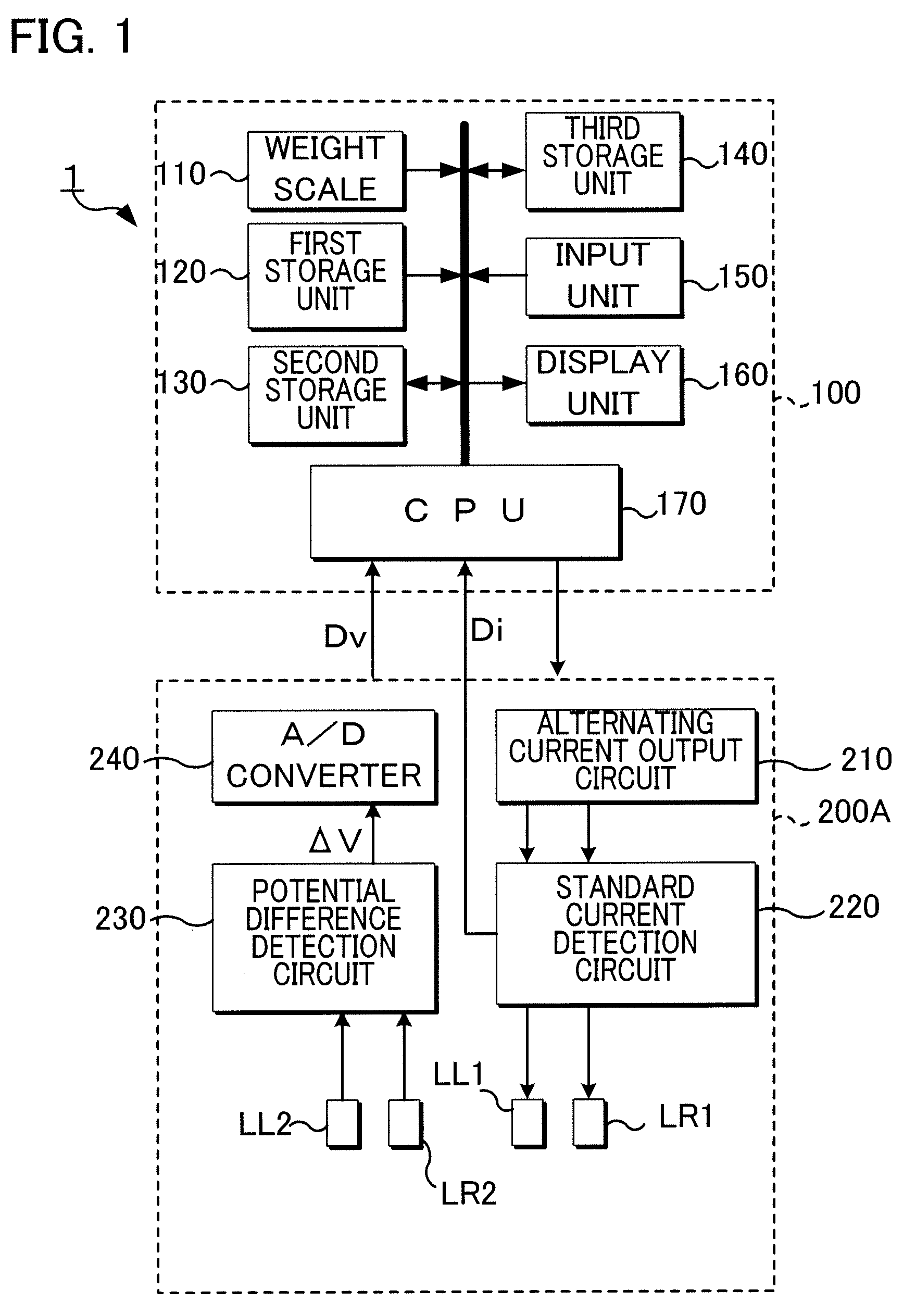

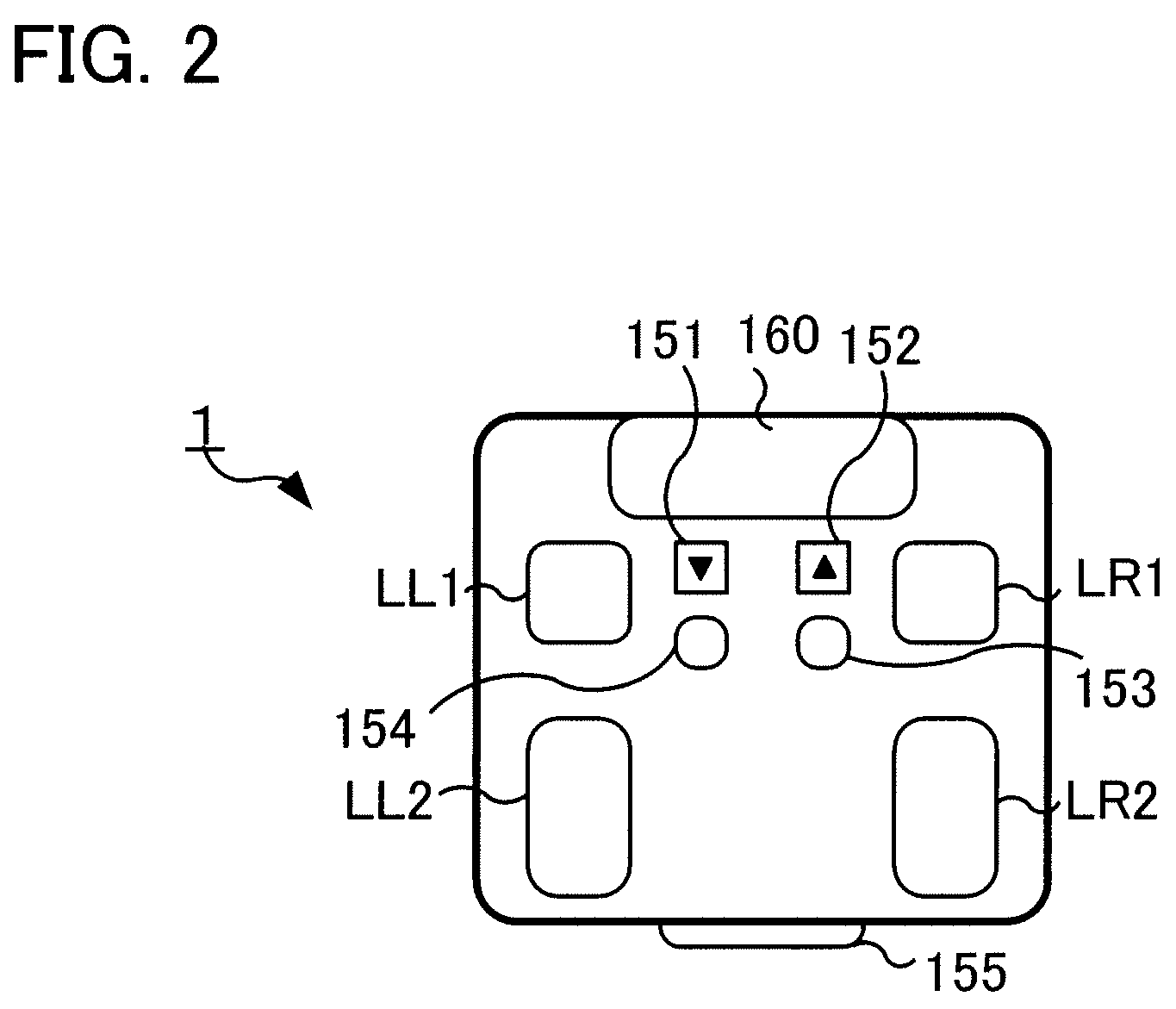

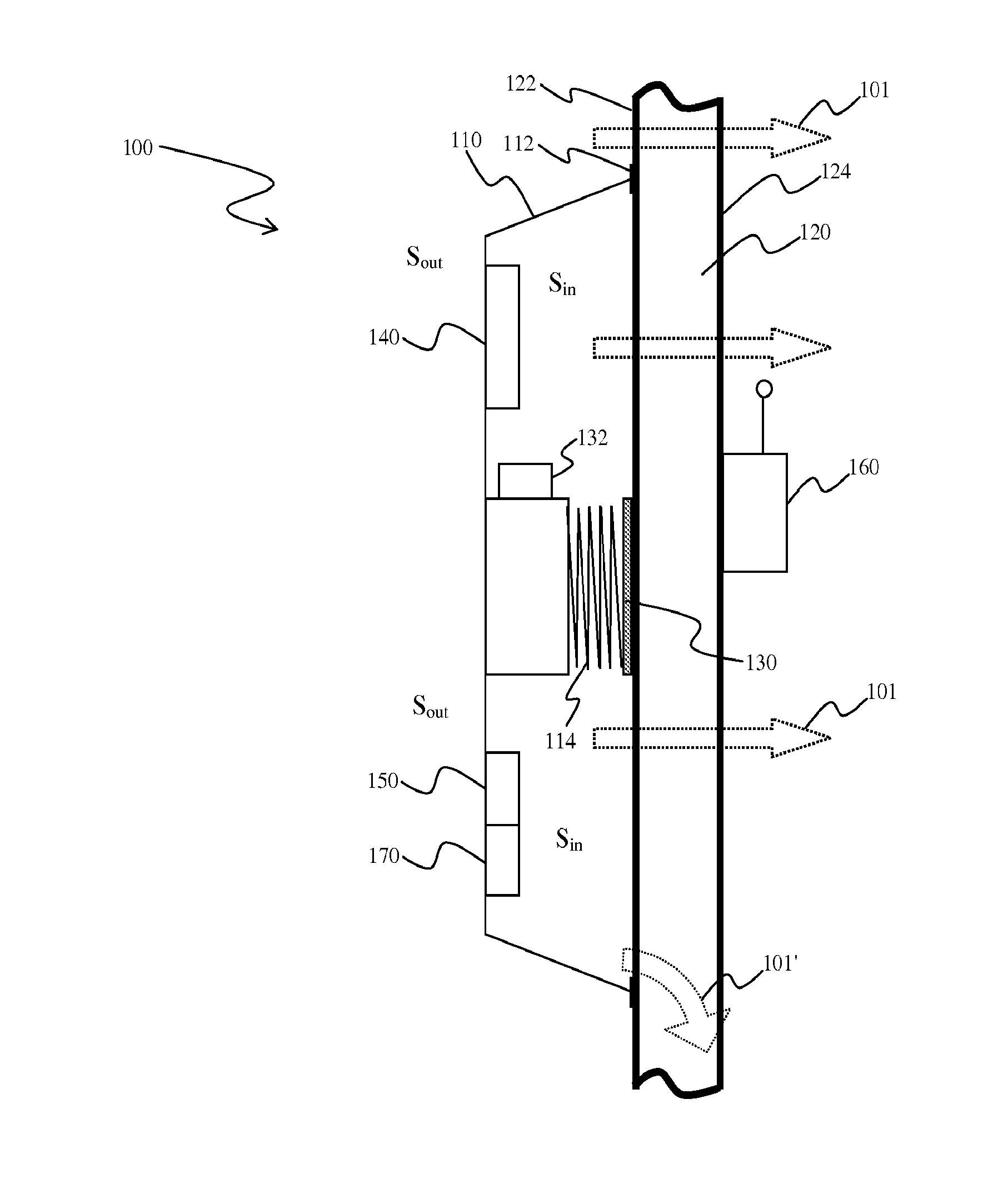

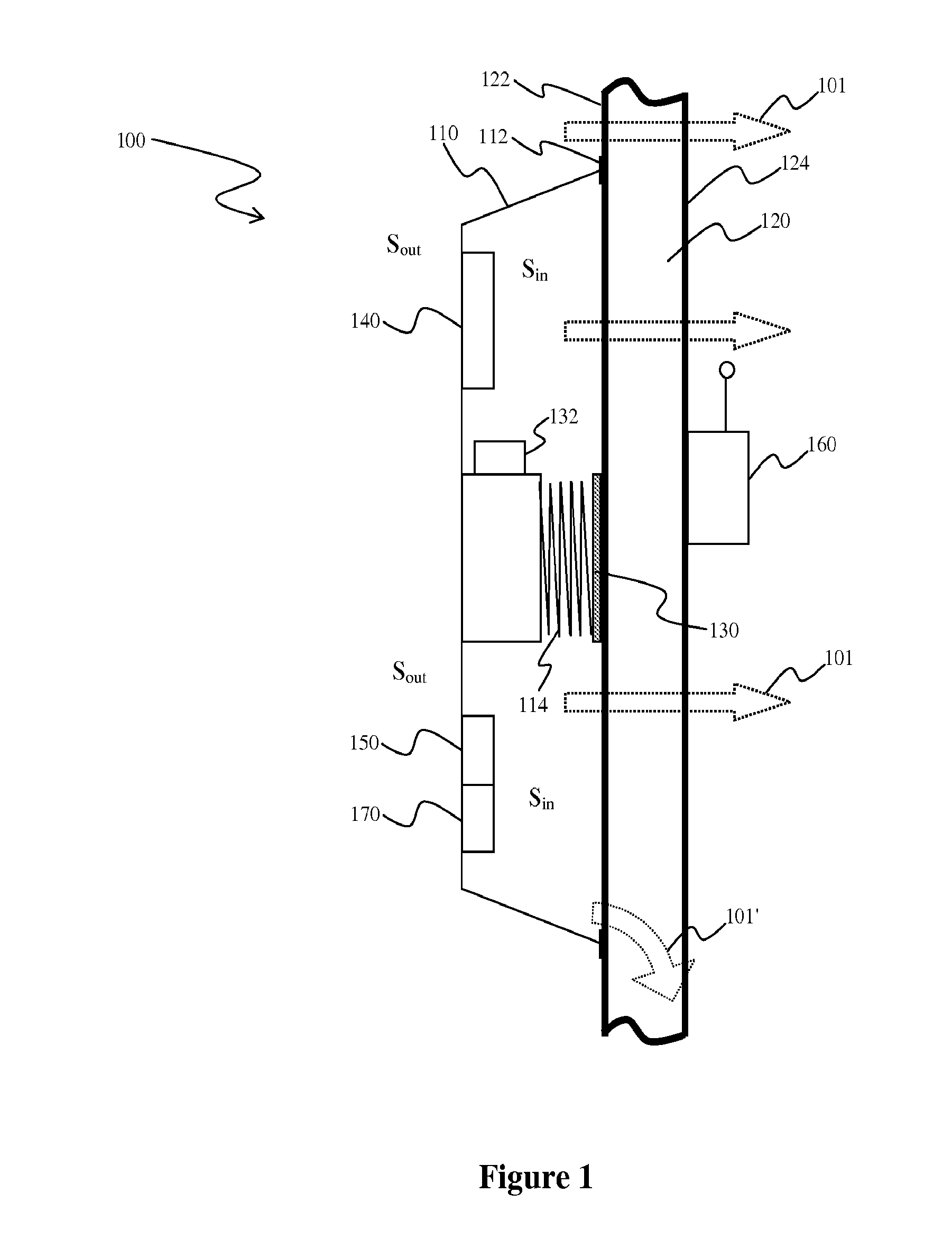

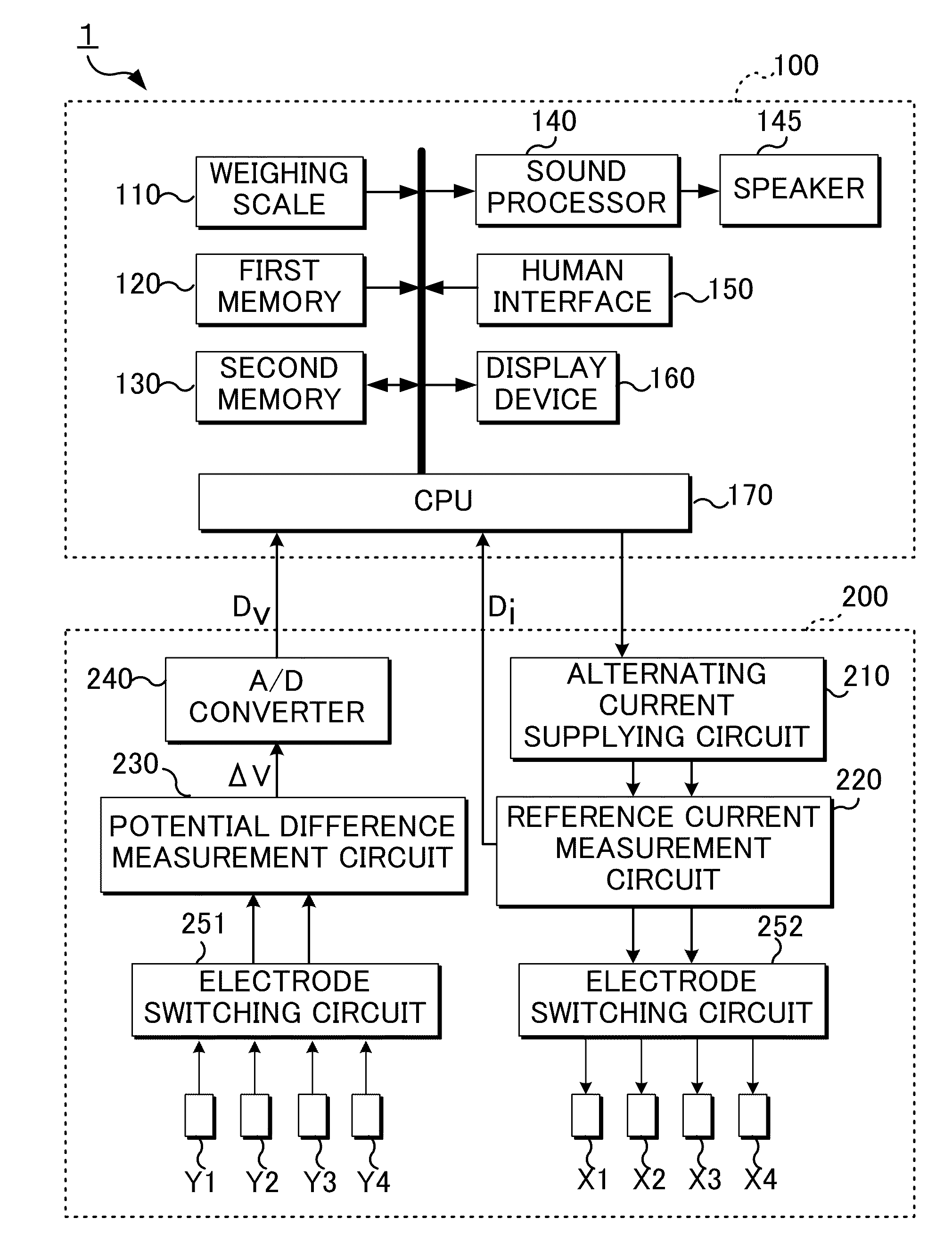

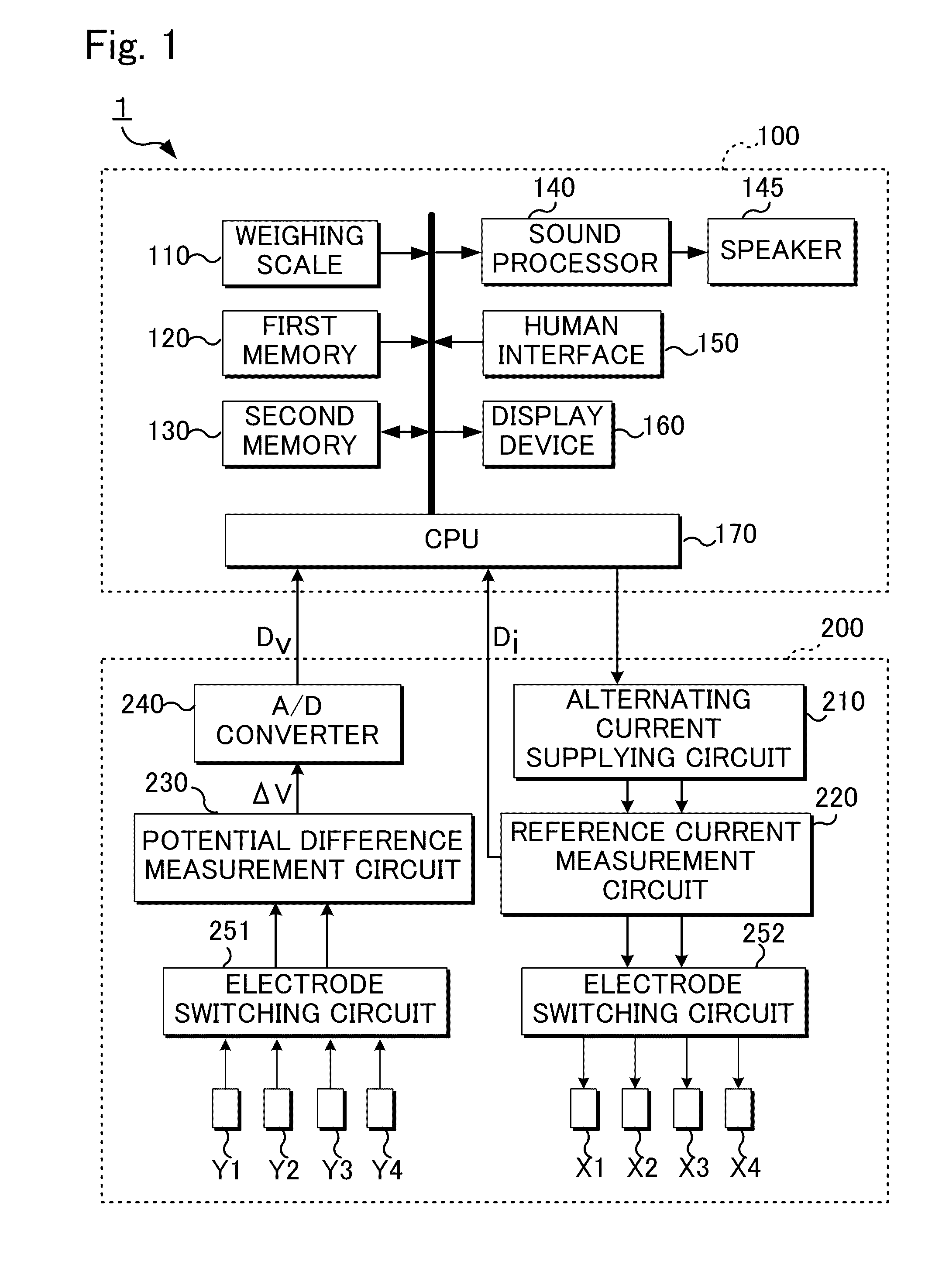

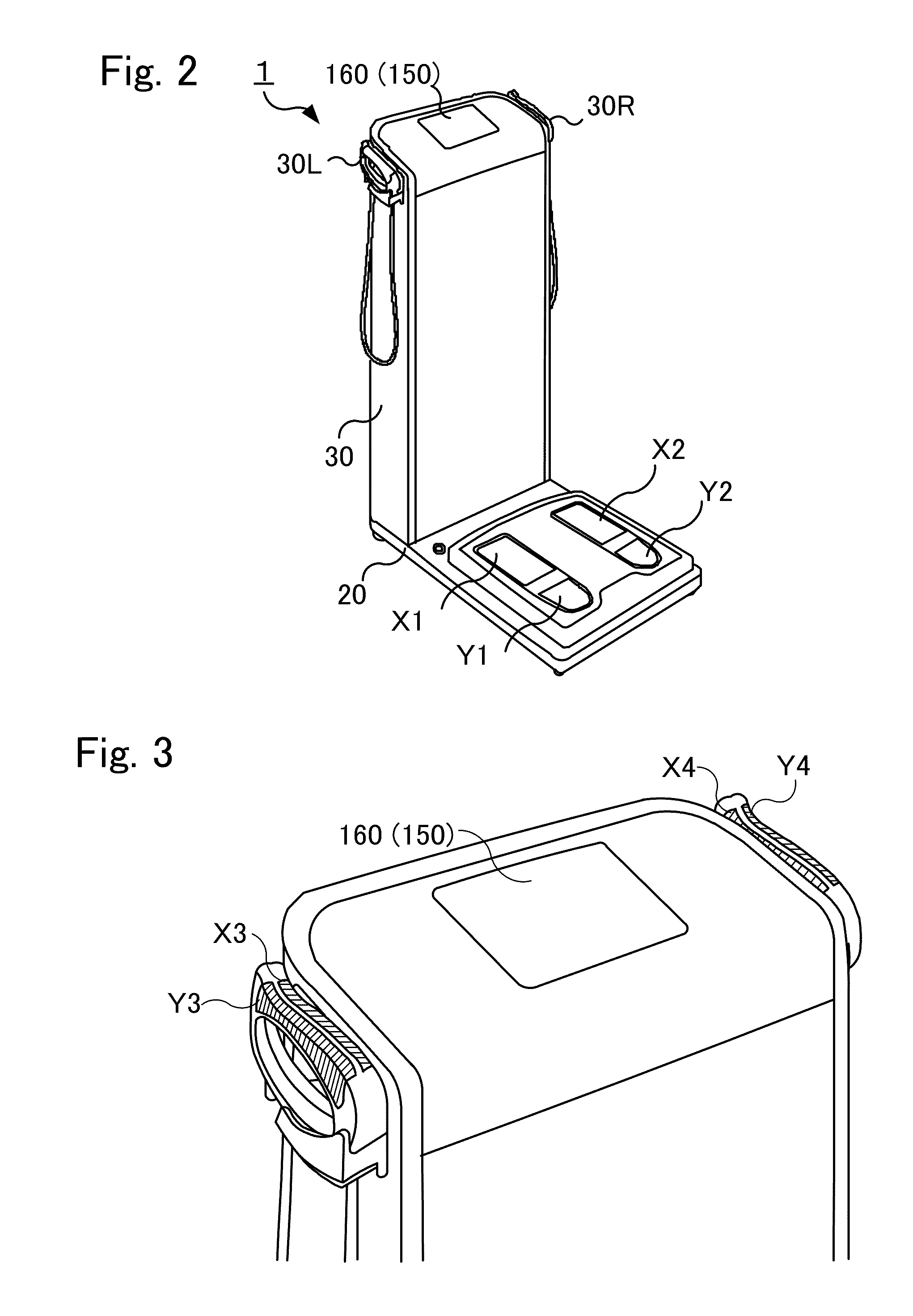

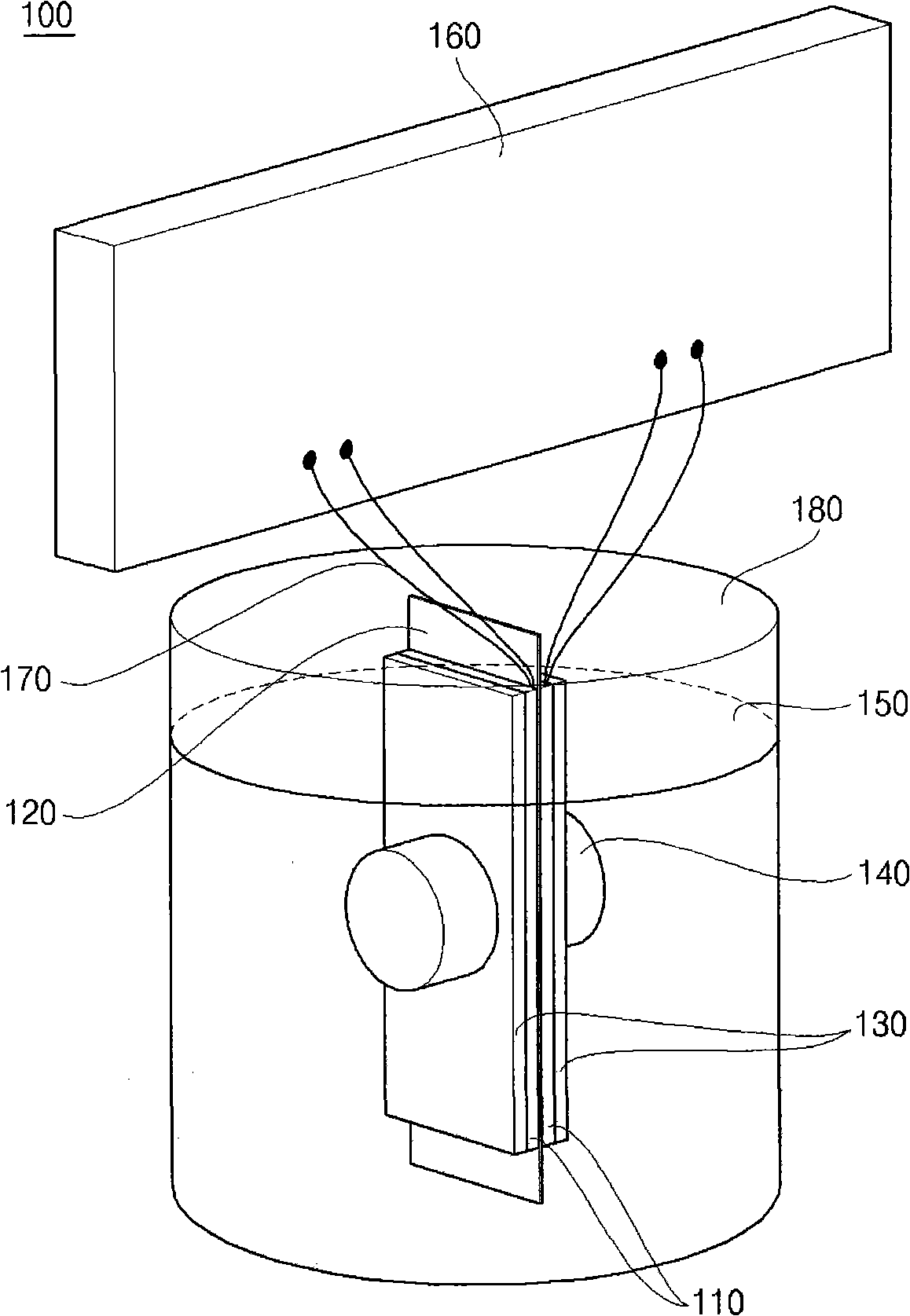

Human Subject Index Estimation Apparatus and Method

InactiveUS20080146961A1Improve accuracySimple and accurate measurementAfter-treatment detailsPerson identificationBody weight measureEngineering

A CPU (170) of a human subject index estimation apparatus (1) computes a waist circumference based on body weight measured by a weight scale (110) and bioelectric impedance measured by a bioelectric impedance measurement unit (200A), and information such as age and height which was input through input unit (150). The computed waist circumference is stored, along with the information such as age and height, in a third storage unit (140) that is a rewritable non-volatile memory. The CPU (170) displays the waist circumference on display unit (160).

Owner:TANITA CORP

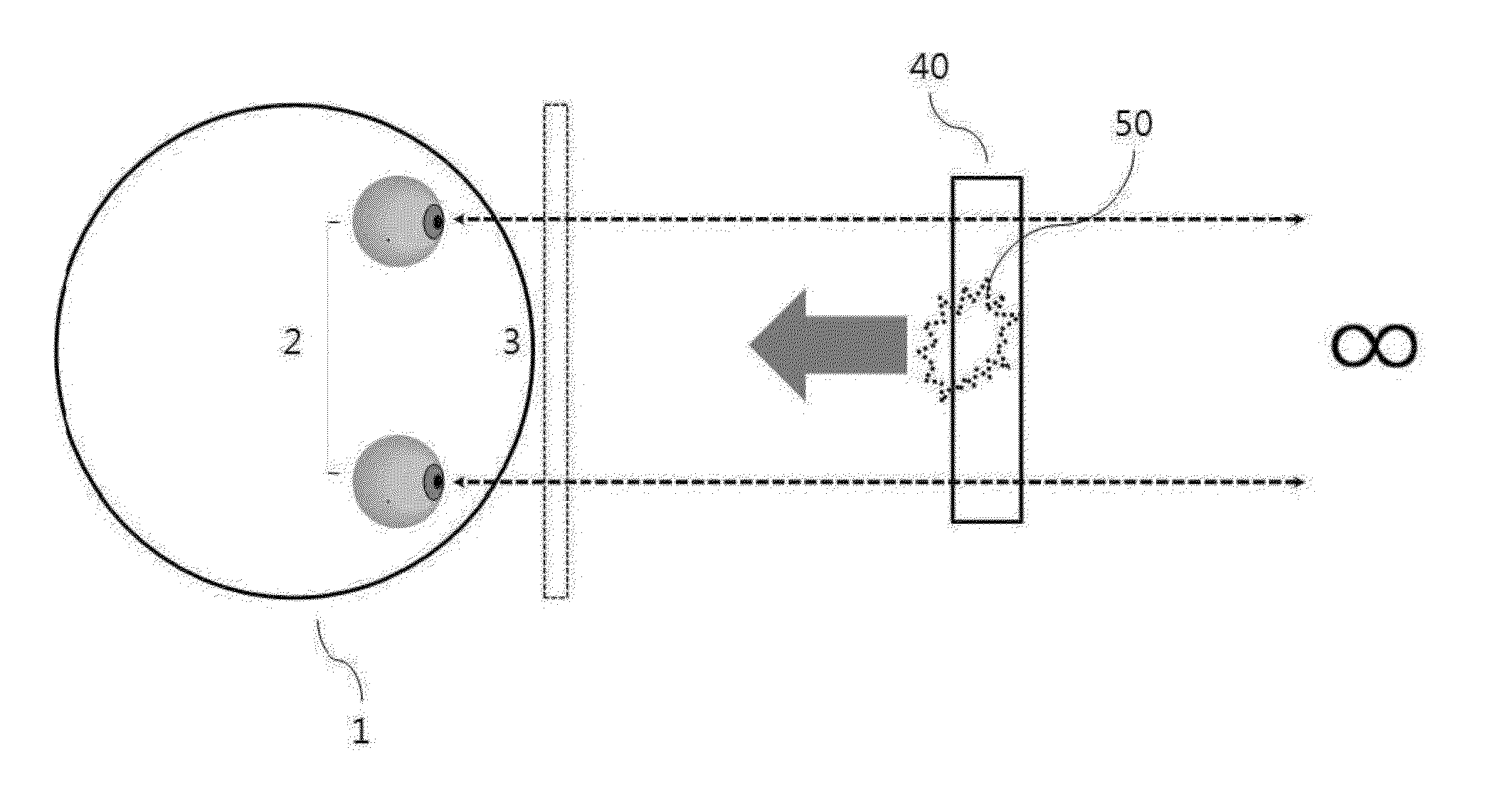

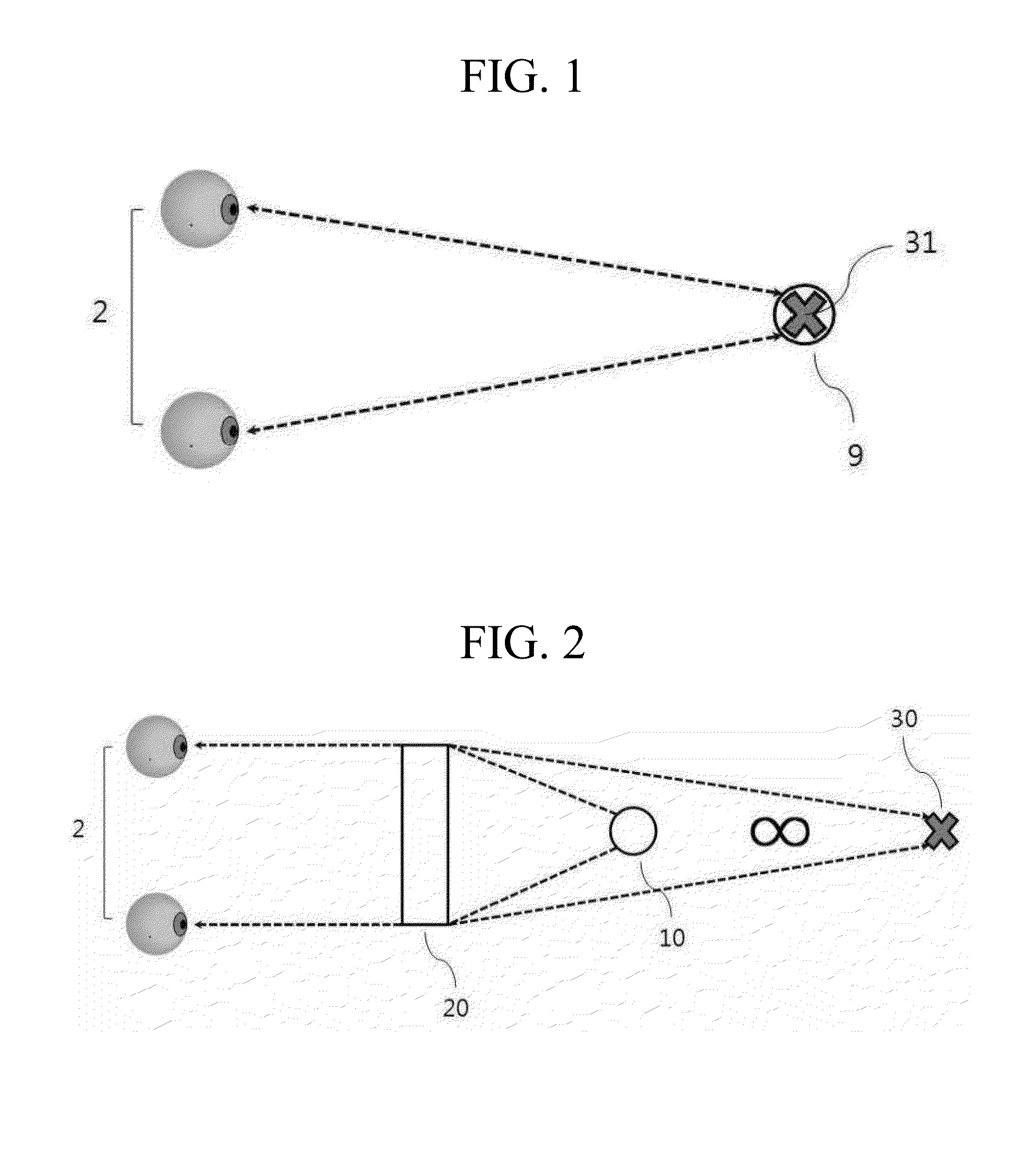

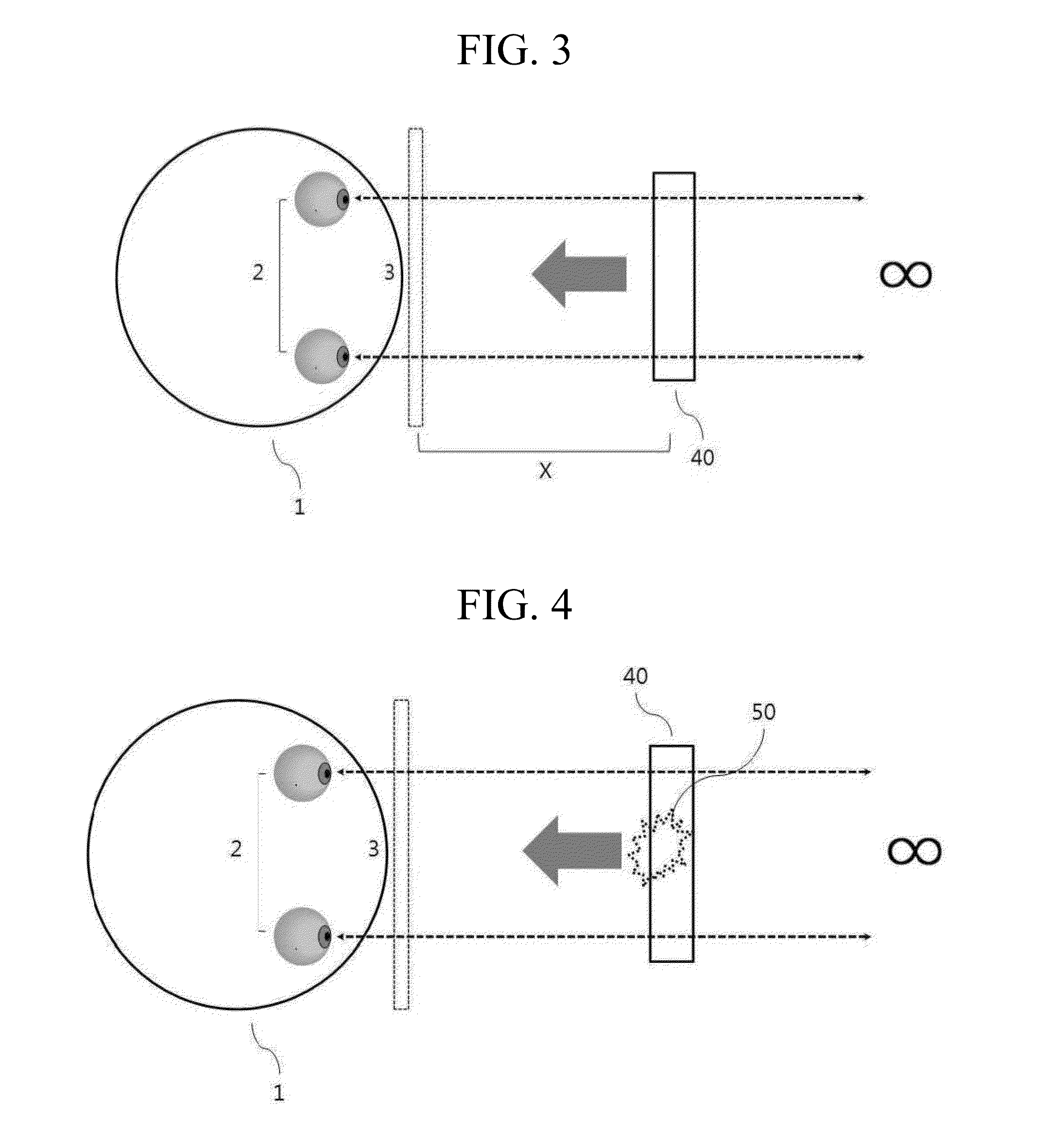

Method for measuring parameters for manufacturing spectacle lens and device for realizing the same

InactiveUS20140009737A1Easily manipulatedEasy to manufactureSpectales/gogglesEye diagnosticsOphthalmologyEyewear

A method for measuring the parameters for manufacturing spectacle lenses and a device for realizing the same. The measuring method can precisely and easily measure the parameters for manufacturing spectacle lenses by reflecting the measurement subject's physical features and spectacle-wearing habits through the naturally captured image of the measurement subject who looks at the infinite distance focus. The device for measuring the parameters for manufacturing spectacle lenses can be easily manufactured and manipulated through various simple modules, such as the infinite distance focus providing means, the near distance focus providing means, the camera means, the flash means, and so on, can be manufactured in a small size in such a fashion that a user can carry it. The auxiliary device for measuring the parameters for manufacturing spectacle lenses can accurately and easily measure various parameters for manufacturing spectacle lenses by being connected with the portable tablet computer.

Owner:VIEWITECH

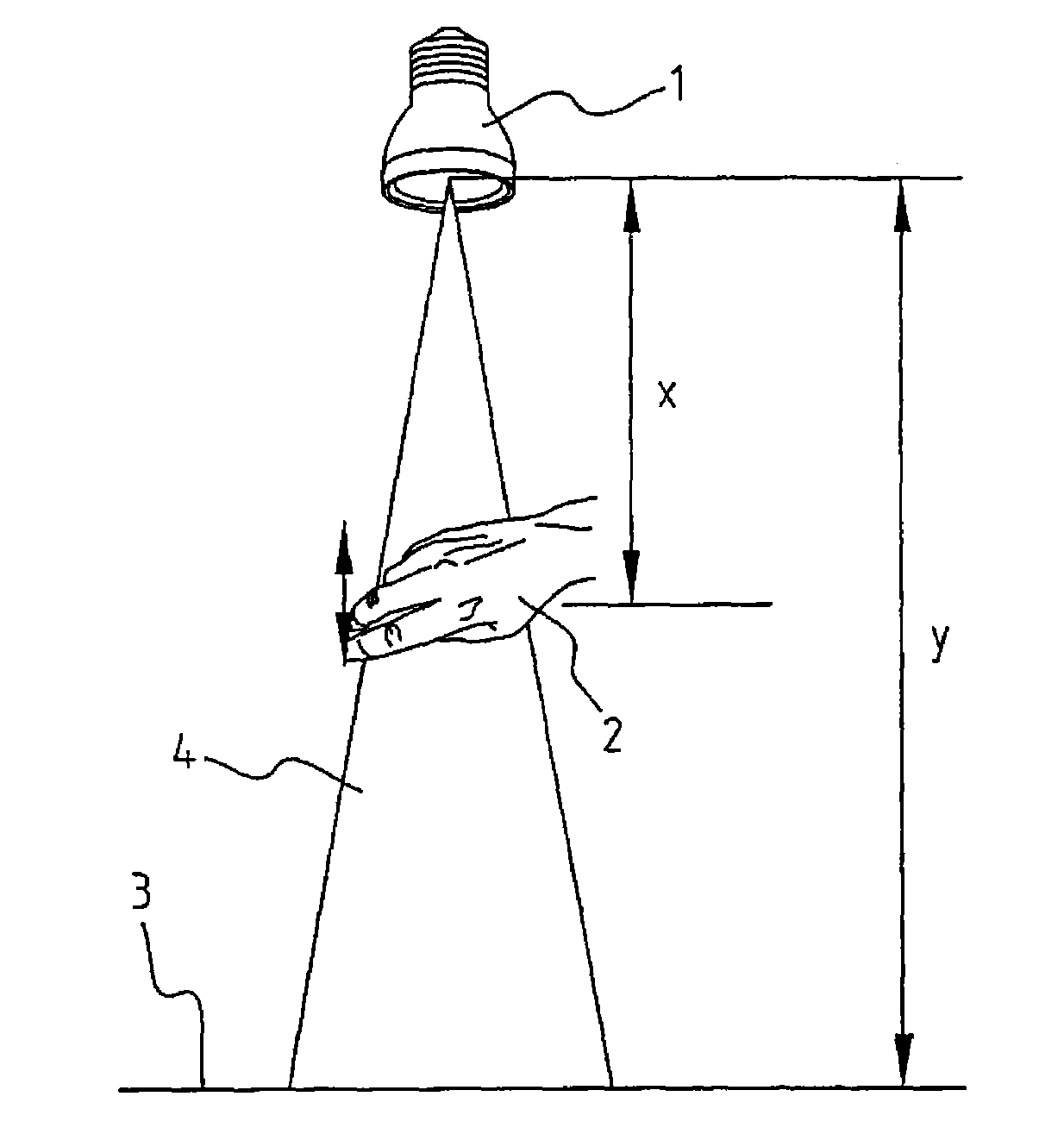

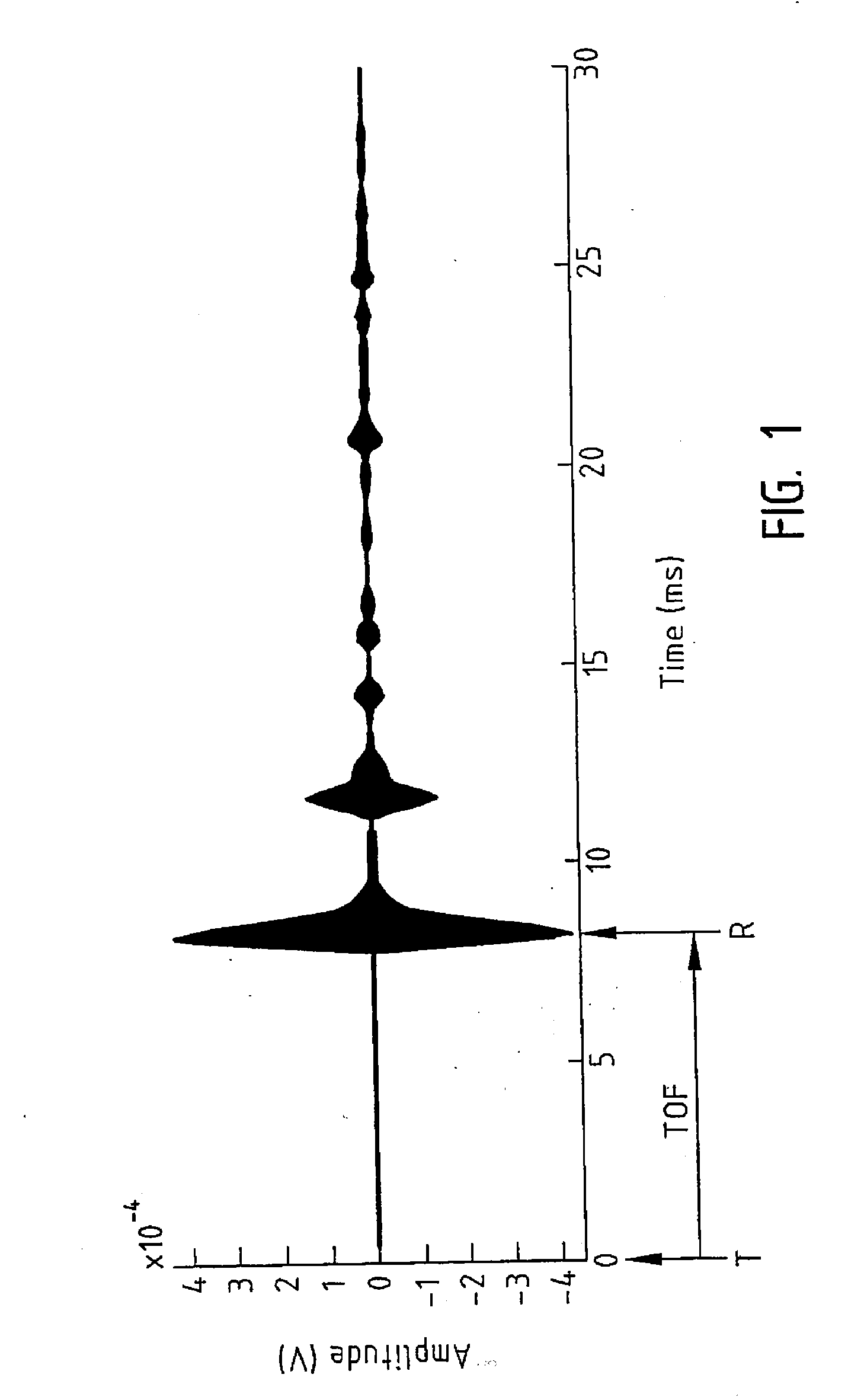

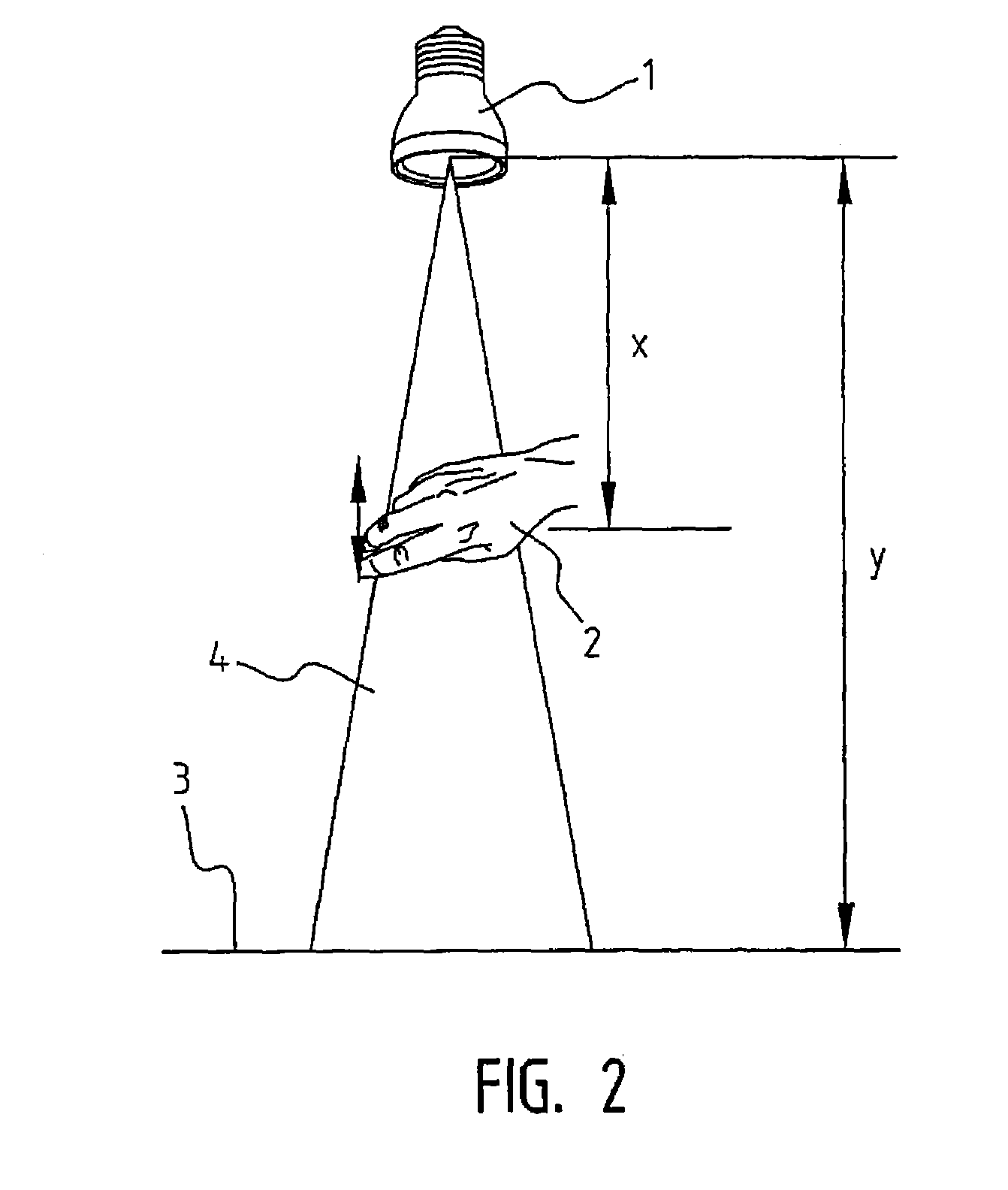

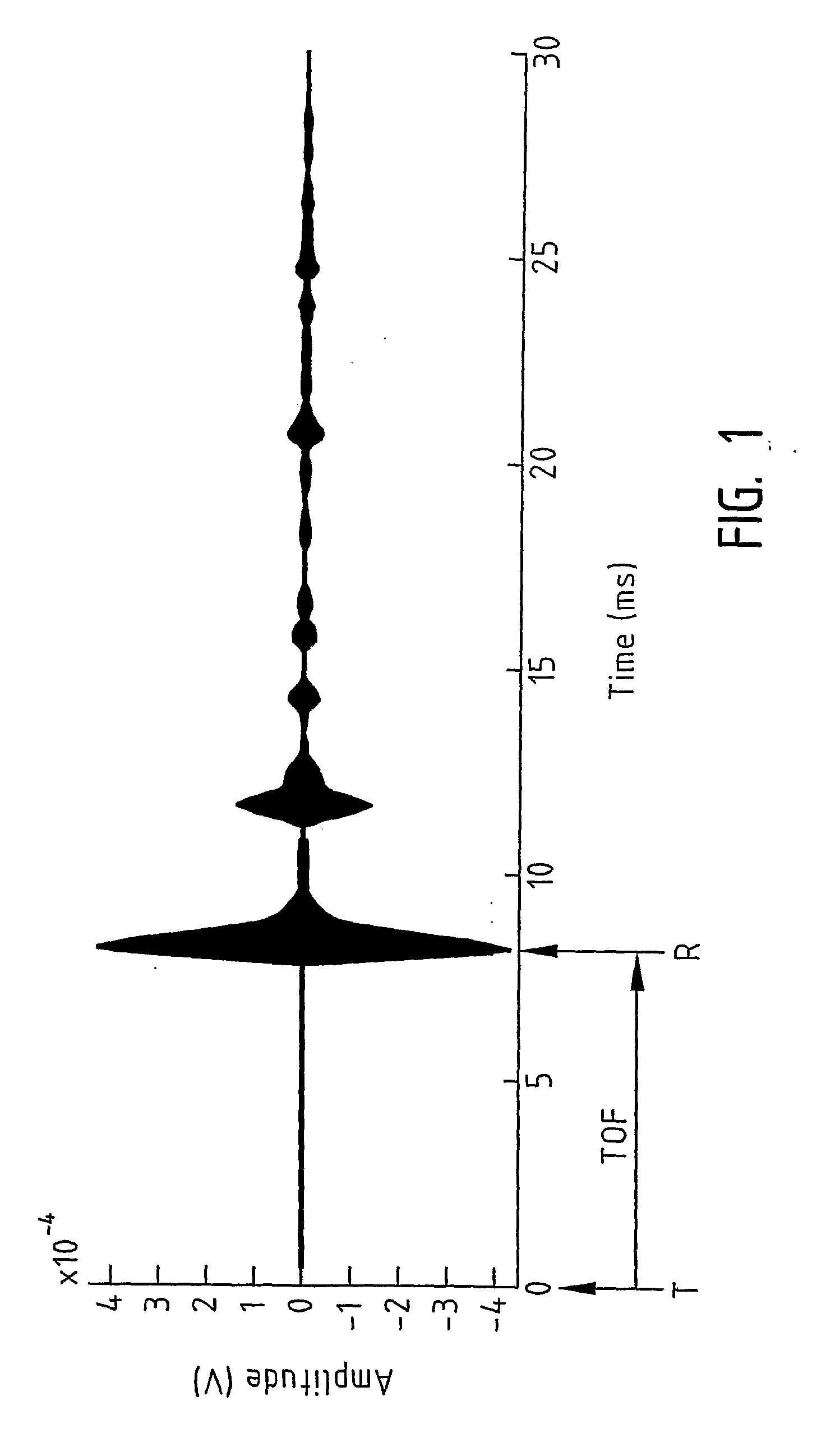

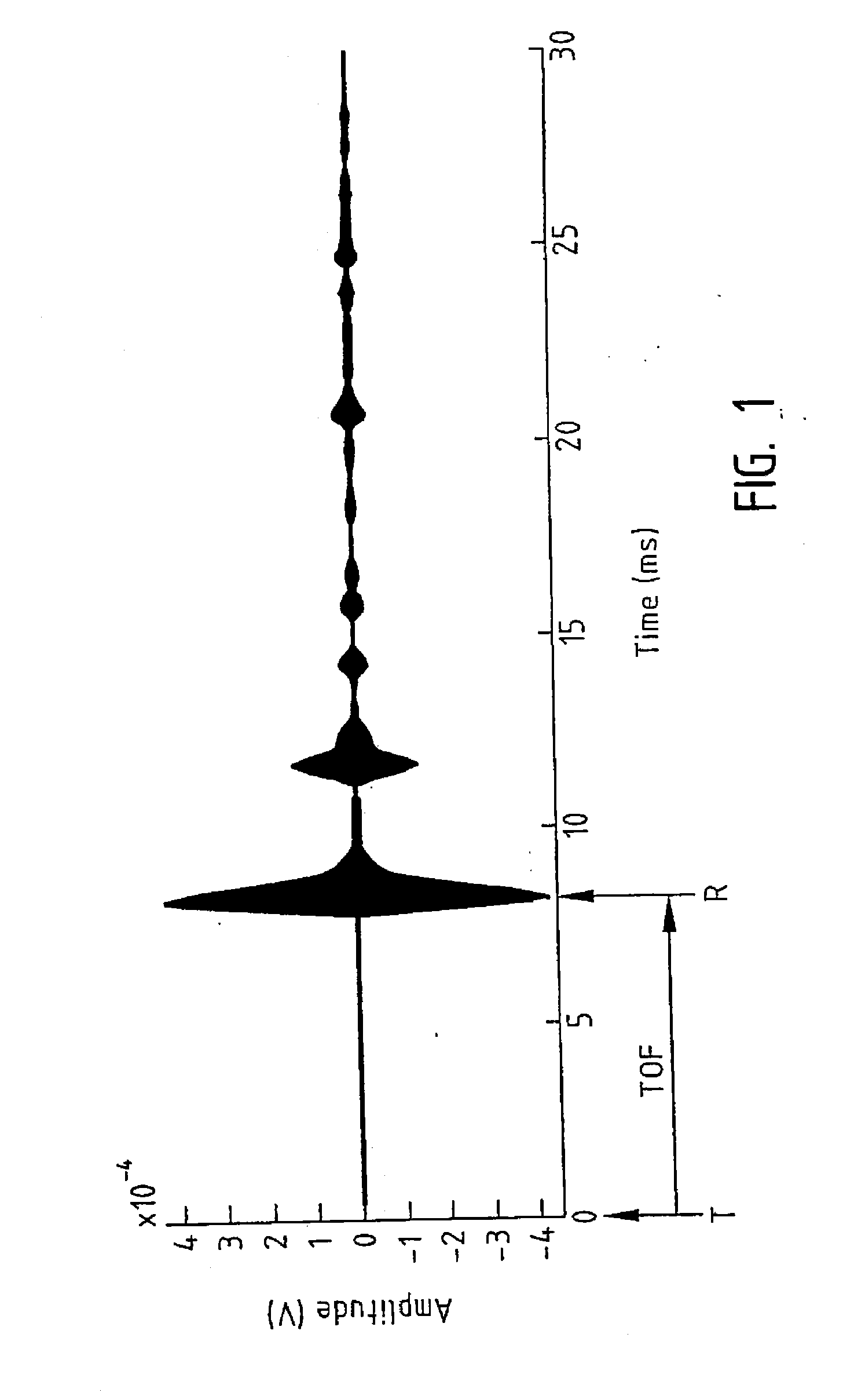

1d gesture light control

InactiveUS20100277073A1Low costSimple and accurate measurementElectroluminescent light sourcesMaterial analysis by optical meansElectricitySonification

A lighting system comprising a lamp arranged to transform electricity into a light beam having properties such as intensity, colour, colour temperature, direction and beam cone angle, a light control means arranged to adjust said light beam properties, an ultrasonic transmitter arranged to transmit ultrasonic signals, an ultrasonic receiver arranged to receive reflected ultrasonic signals, and a processing means arranged to derive a time-of-flight signal representing the time differences between said transmitted and received ultrasonic signals and to send control signals to said light control means in dependence of said time-of-flight signal.

Owner:LITE ON TECH CORP

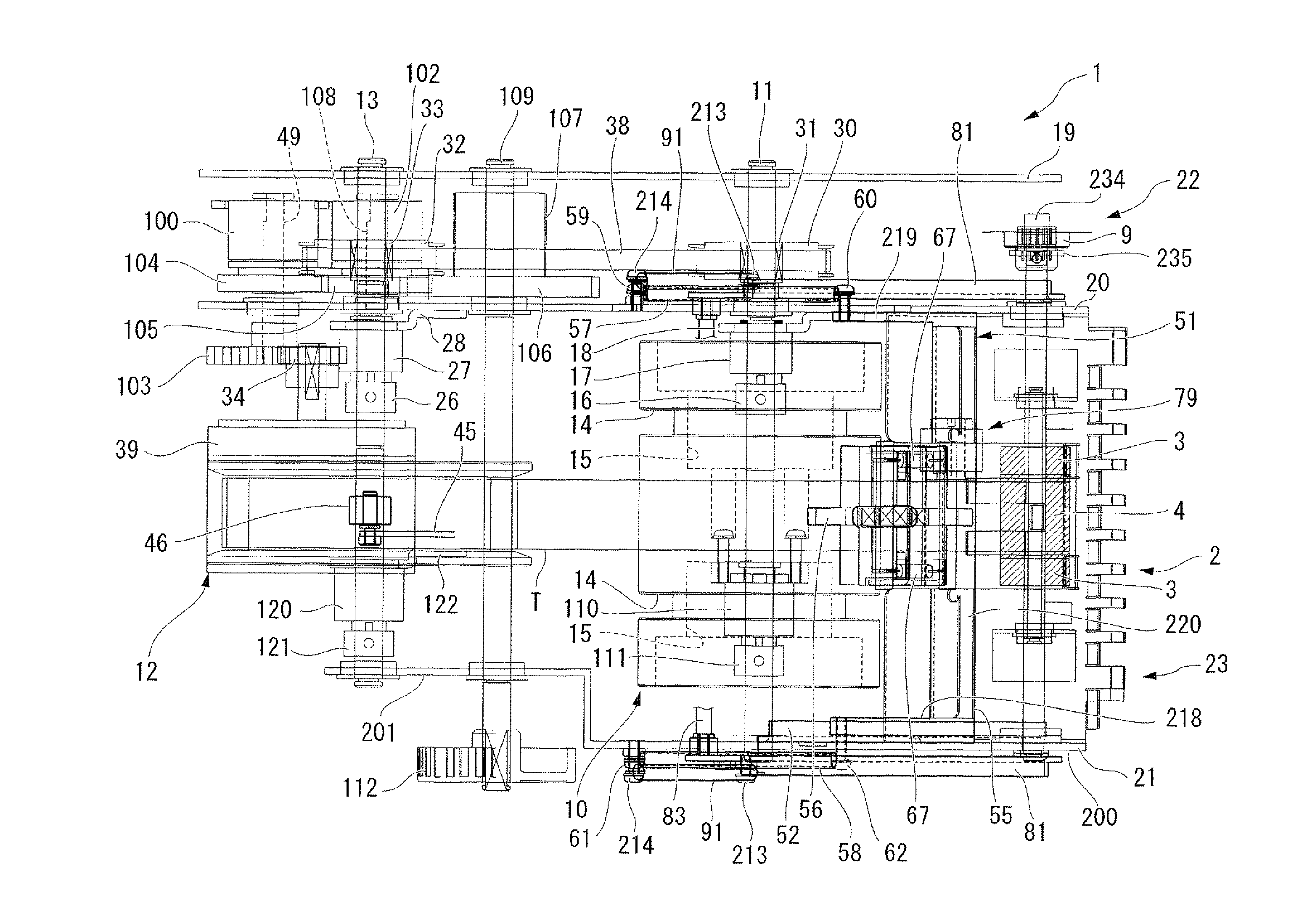

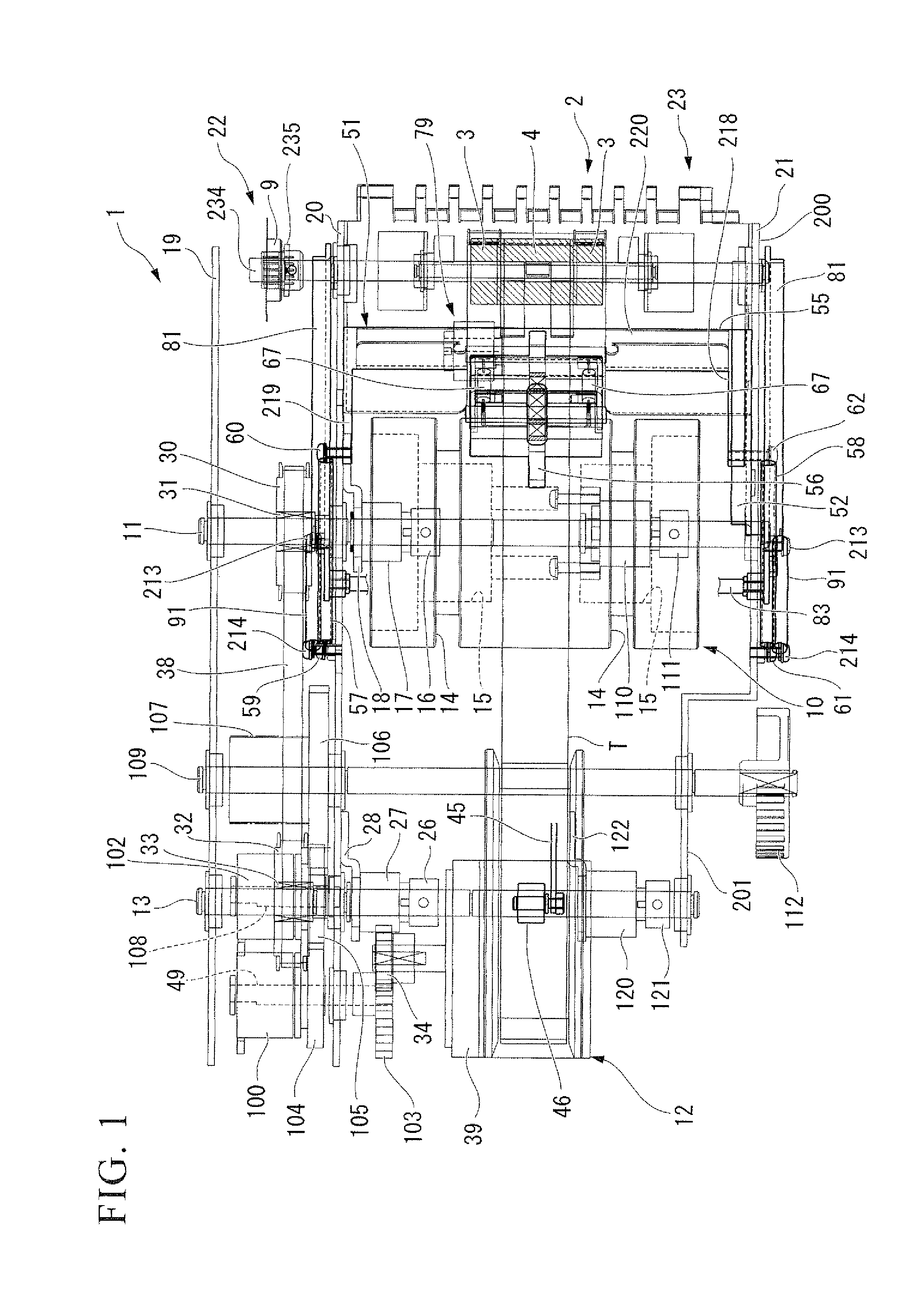

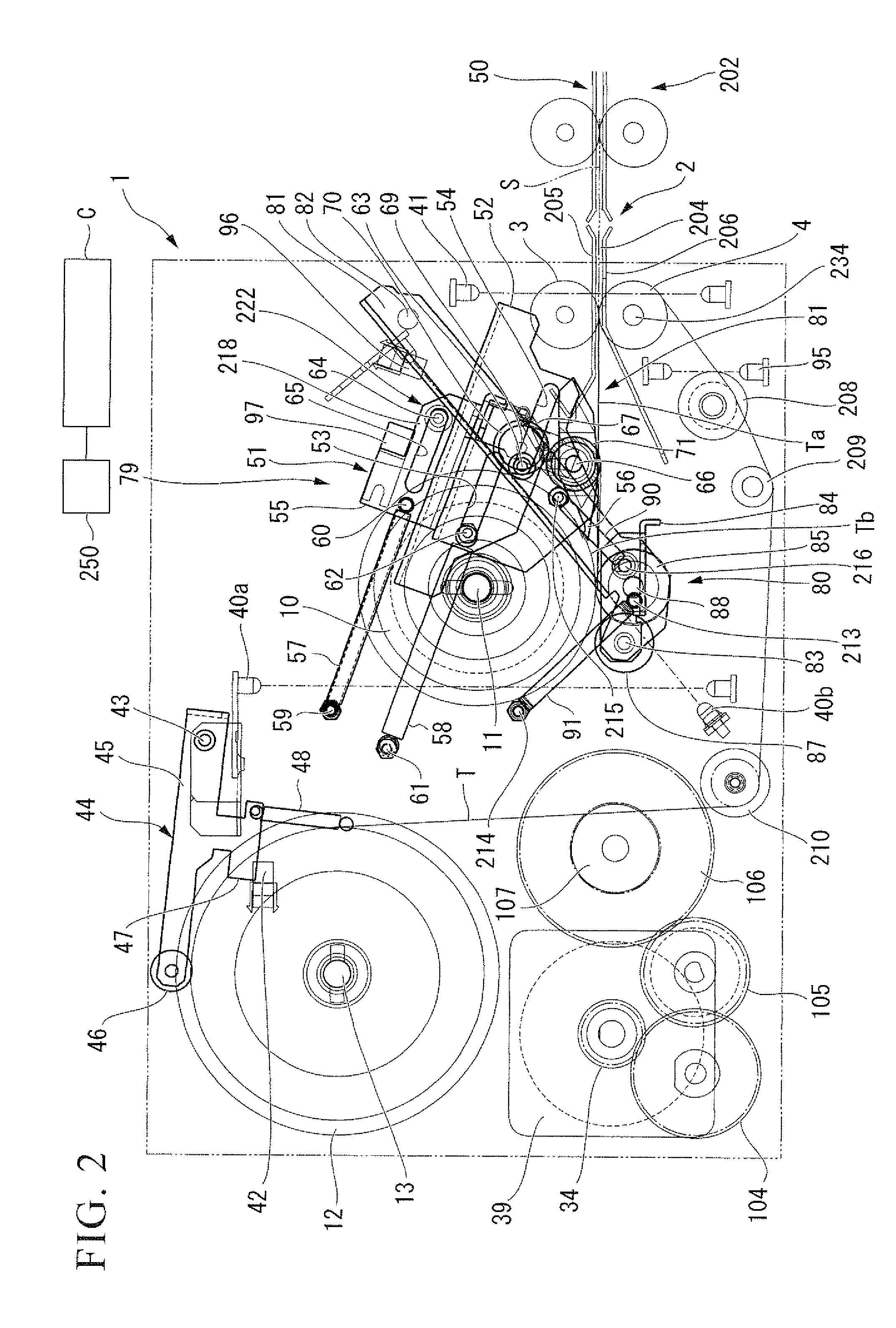

Sheet paper storage and dispensing device

InactiveUS20100100245A1Accurate detectionEasily and accurately measureSampled-variable control systemsComputer controlTape speedMotor speed

A sheet paper storage and dispensing device according to the present invention stores and dispenses sheet paper, and includes: a first reel drum onto which a tape is wound from one side of the tape; a second reel drum on which sheet paper is stored by winding the tape thereon from an opposite side of the tape in a state in which the tape and sheet paper supplied from an external sheet paper transporting section to an intake / discharge port are mutually superimposed; a motor which drives the first reel drum and the second reel drum via a drive system; an electromagnetic clutch which switches between transmitting and interrupting drive force from the drive system; an electromagnetic brake which applies a brake to the drive system; a trigger sensor which detects supplying of the sheet paper from the sheet paper transporting section to the intake / discharge port; a tape speed detection section which detects a transporting speed of the tape at the intake / discharge port; a motor speed variation control unit which controls changes in a rotation speed of the motor; and a winding control unit which causes a winding operation by controlling the electromagnetic clutch so as to transmit the driving force of the motor when supplying of the sheet paper to the intake / discharge port is detected by the trigger sensor, the winding operation being a operation in which the tape is dispensed from the first reel drum while the tape is wound onto the second reel drum, so that the sheet paper supplied to the intake / discharge port is wound onto the second reel drum, the winding control unit controlling the motor speed variation control unit such that, during the winding operation, the transporting speed of the tape detected by the tape speed detection unit is held at a fixed speed which is faster by a predetermined amount than a transporting speed of the sheet paper transporting section.

Owner:LAUREL PRECISION MACHINES

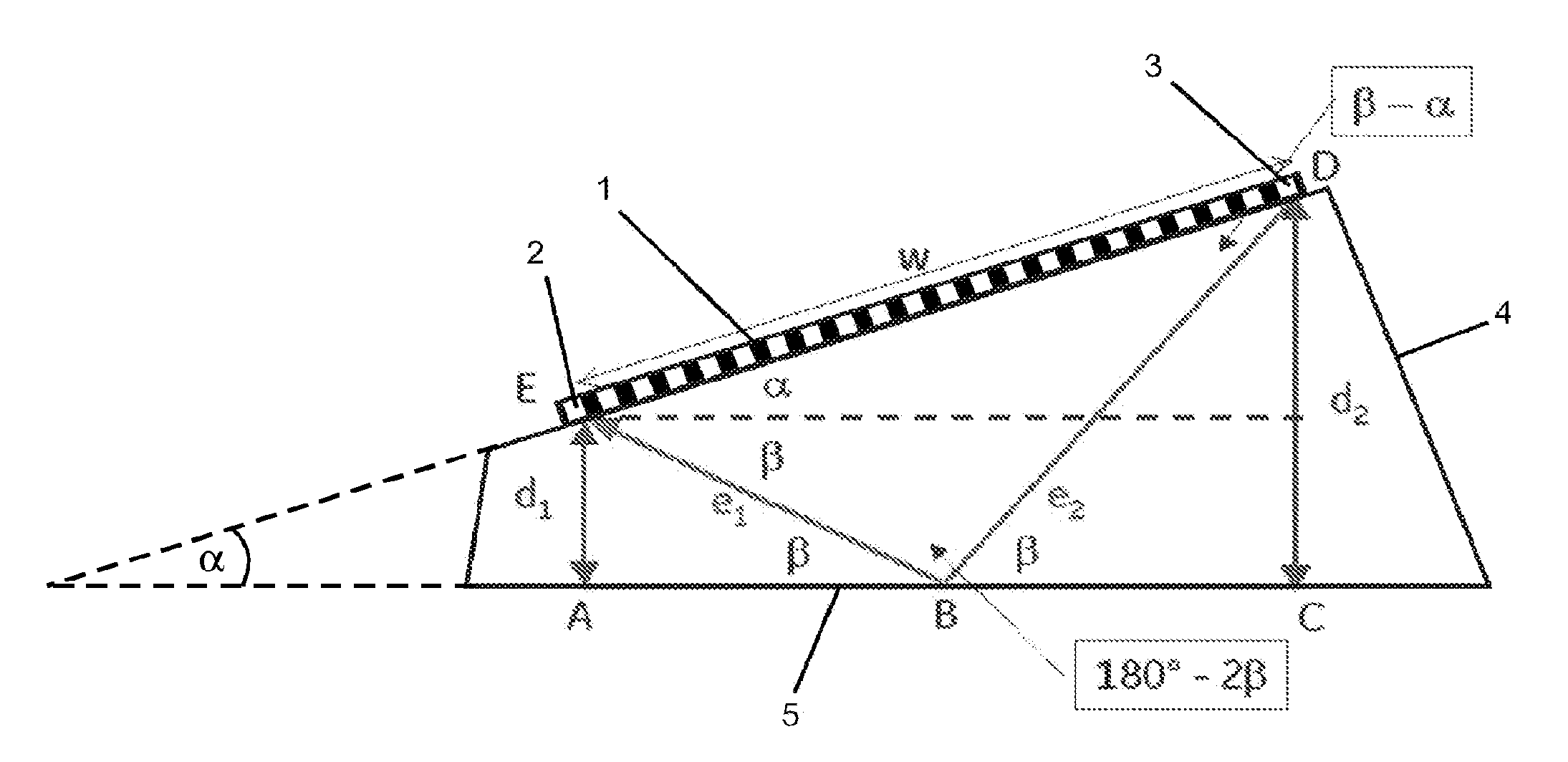

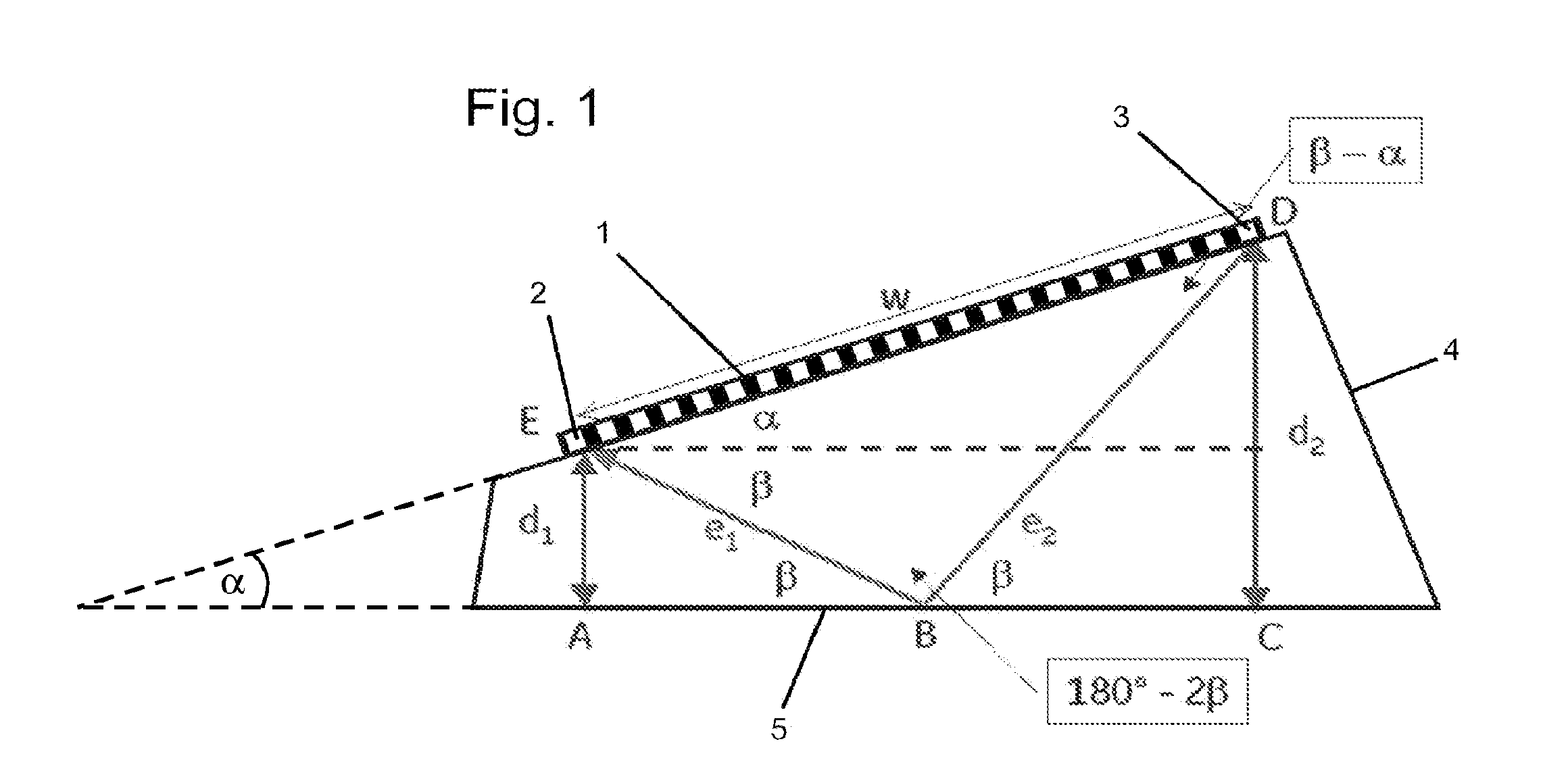

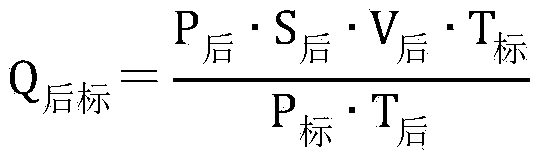

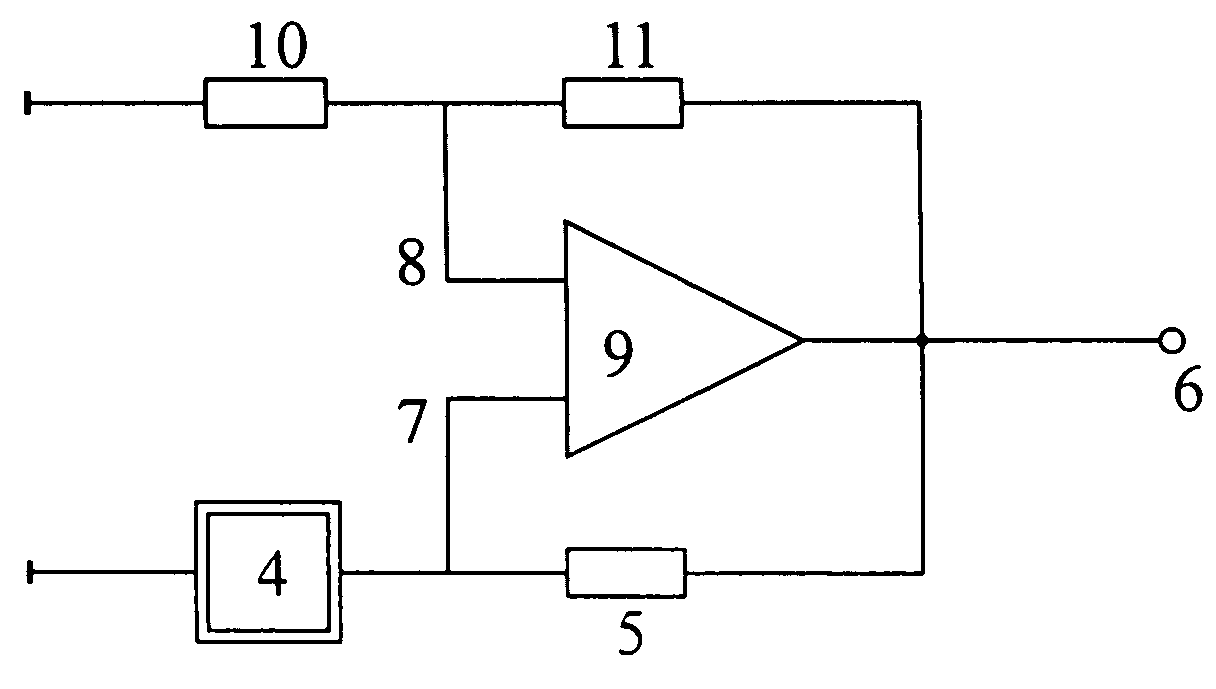

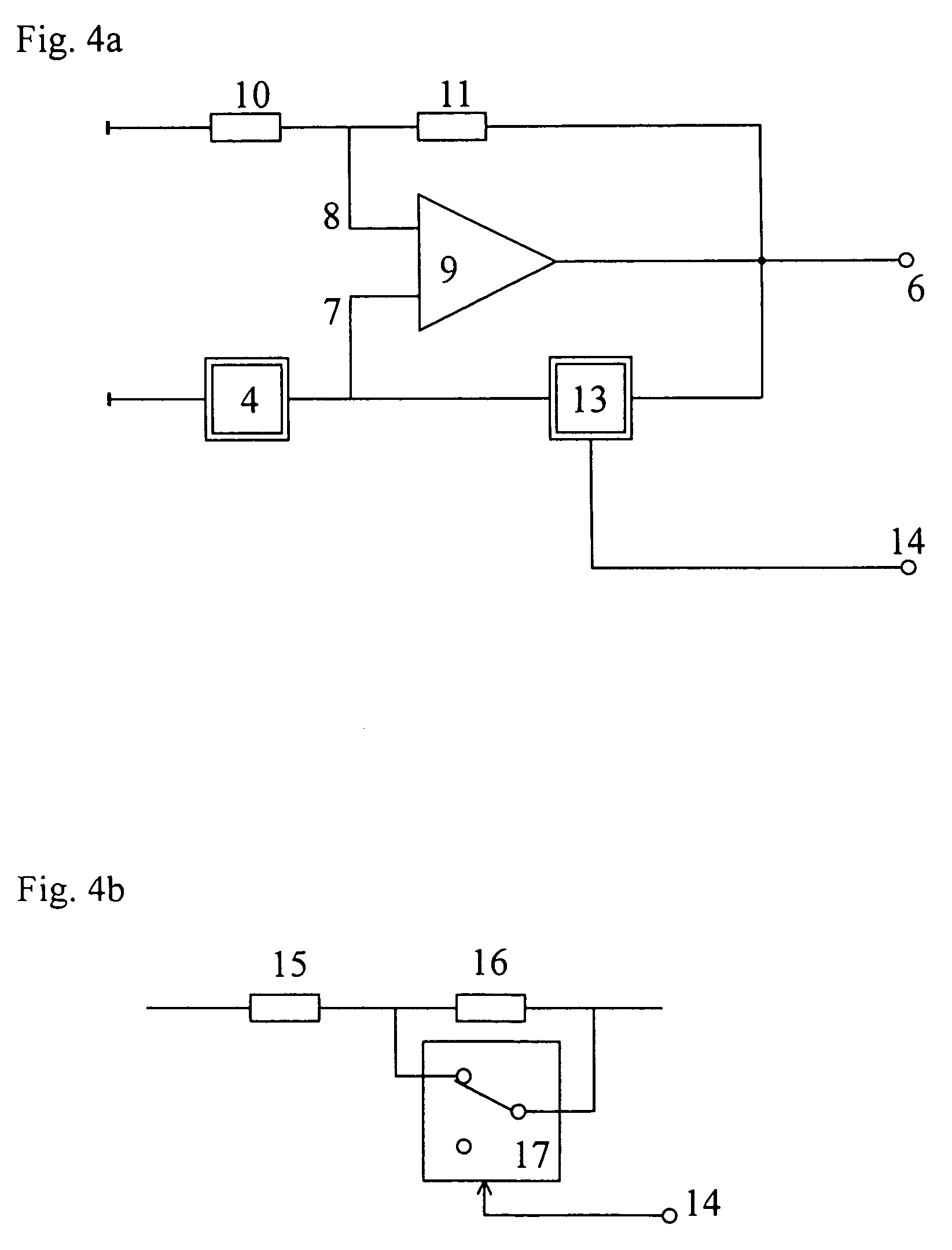

Pulse-echo method by means of an array-type probe and temperature compensation

ActiveUS20110247417A1Easy to adaptHigh measurement accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesMagnetic property measurementsShortest distancePropagation time

The invention relates to a nondestructive ultrasonic test method in which at least one ultrasonic pulse is emitted into a workpiece under test by means of at least one ultrasonic transmitter (3), the ultrasonic pulse is reflected on boundary surfaces within the workpiece, the reflected ultrasound is received by at least one ultrasonic receiver (2), and the associated signals are evaluated, the ultrasound penetrating a damping block (4) that is arranged between the workpiece and the transmitter or receiver. Said method is characterized in that it includes at least one step for determining the sound velocity in the damping block (4) by means of an array-type probe (1) comprising selectively controllable transducers; in said step, at least one first transducer (3) of the array-type probe (1) is used as the transmitter of at least one ultrasonic pulse, while at least one second transducer (2) of the array-type probe (1) is used as the receiver of the ultrasonic pulse, and the sound velocity in the damping block (4) is determined at least by measuring the propagation time of the ultrasound along the shortest distance (e1, e2) of the ultrasound between the respective transducers (2, 3) that are placed at a distance from each other.

Owner:GE SENSING & INSPECTION TECH GMBH

Thermal Resistance Measuring Device

InactiveUS20140286373A1Simple and accurate in situ measurementAvoids drawbackMaterial thermal conductivityCalorimeterElectrical resistance surveyEngineering

Contemplated devices and methods allow for simple and accurate measurement of static and dynamic heat flux and heat capacity of a structure in situ. Especially preferred devices and methods use a thermally equilibrated housing that encloses a thermoelectric sensor and an associated microprocessor and external temperature sensor.

Owner:CAMBRIA

Respiration characteristic analysis apparatus and respiration characteristic analysis system

InactiveUS20120016255A1Simple and accurate measurementEffective trainingEvaluation of blood vesselsSensorsElectrical resistance and conductanceRadiology

A respiration characteristic analysis apparatus includes a bioelectrical impedance determiner adapted for determining bioelectrical impedance at a part including the right lung of a human subject and for determining bioelectrical impedance at a part including the left lung of the human subject; and a respiration depth calculator adapted for calculating a right lung respiration depth related to a respiration capability of the right lung of the human subject on the basis of change over time in the bioelectrical impedance at the part including the right lung determined by the bioelectrical impedance determiner, and for calculating a left lung respiration depth related to a respiration capability of the left lung of the human subject on the basis of change over time in the bioelectrical impedance at the part including the left lung determined by the bioelectrical impedance determiner.

Owner:TANITA CORP

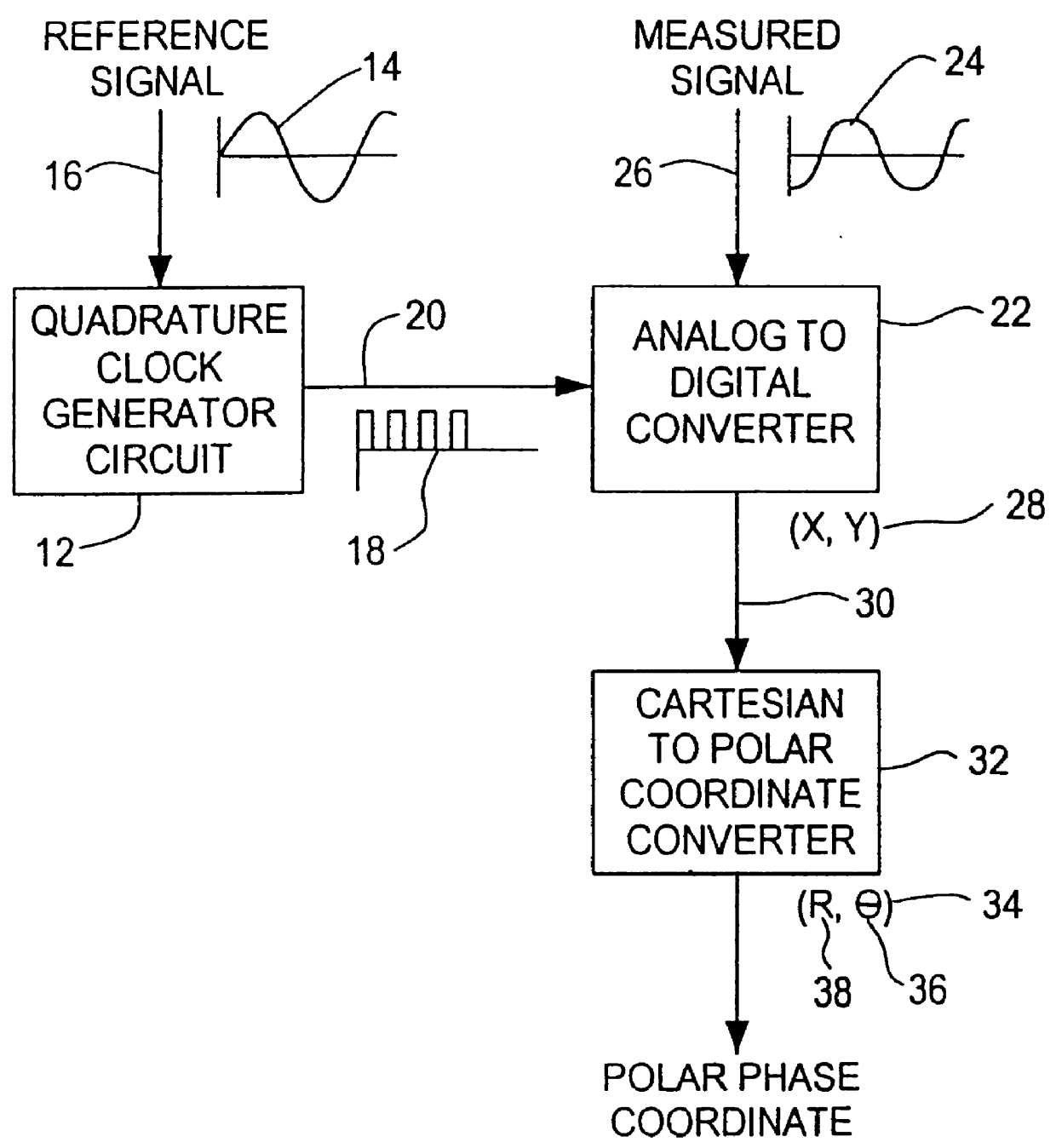

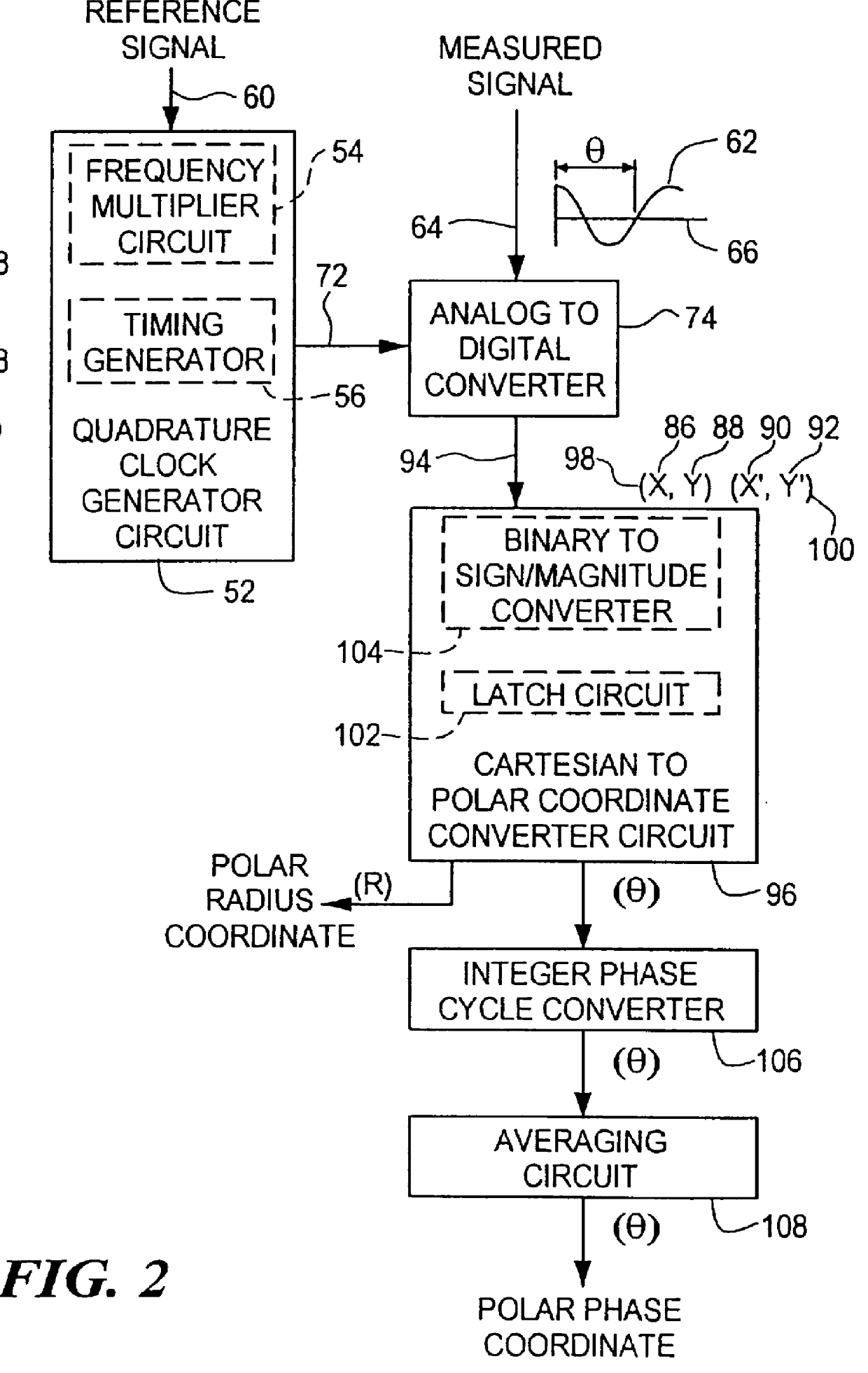

Digital phase measuring system and method

InactiveUS6049297ALow costFast processingElectric signal transmission systemsVoltage-current phase anglePhase differencePhysics

A digital phase measuring system and method for measuring the phase difference between two signals including generating quadrature clock signals for a first reference signal, converting a second measured signal from analog to digital form by sampling the second measured signal using the quadrature clock signals to produce quadrature cartesian samples of the measured signal, and converting the quadrature cartesian samples to polar coordinates to define the polar phase coordinate representative of the phase difference between the two signals.

Owner:VISIDYNE

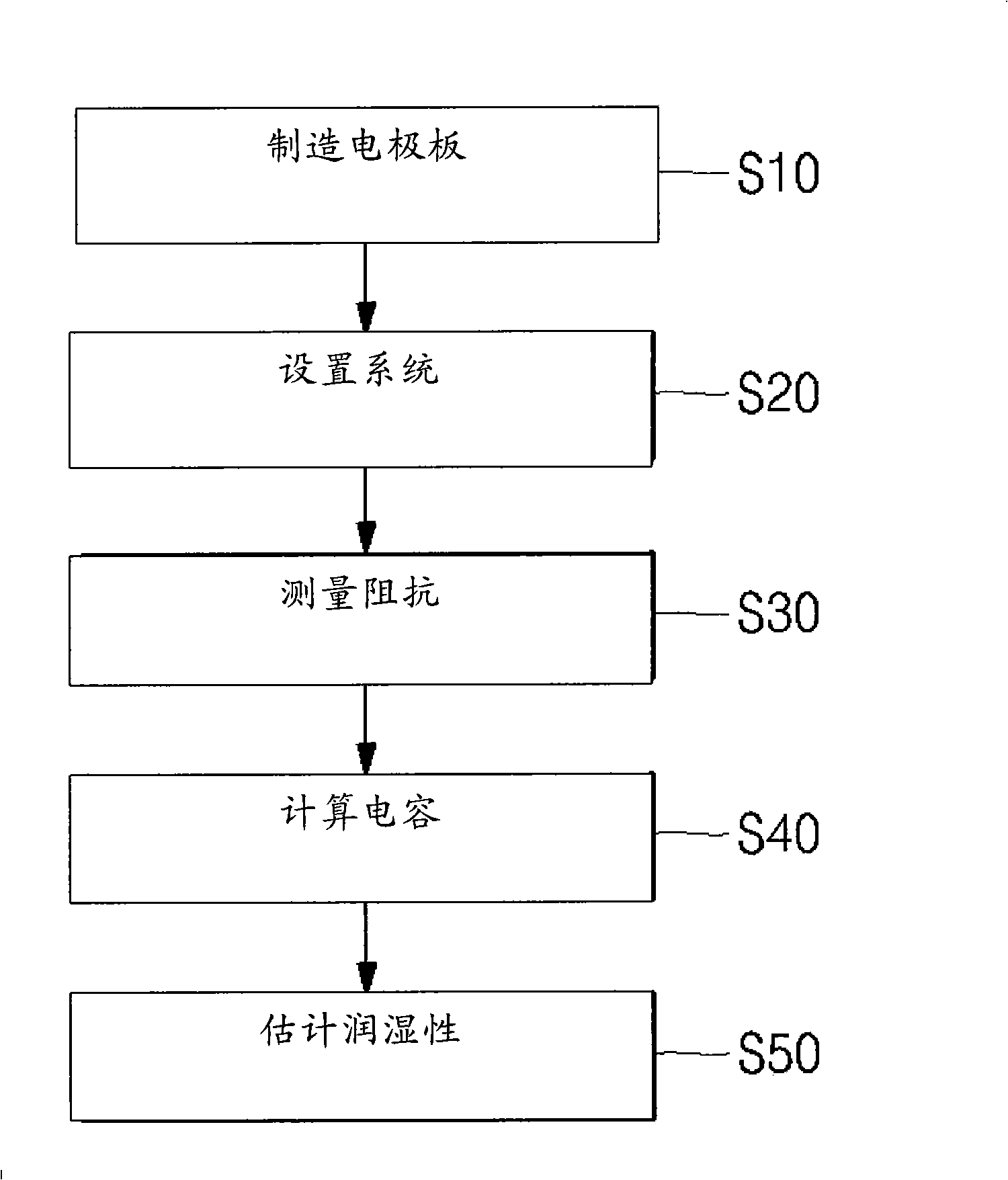

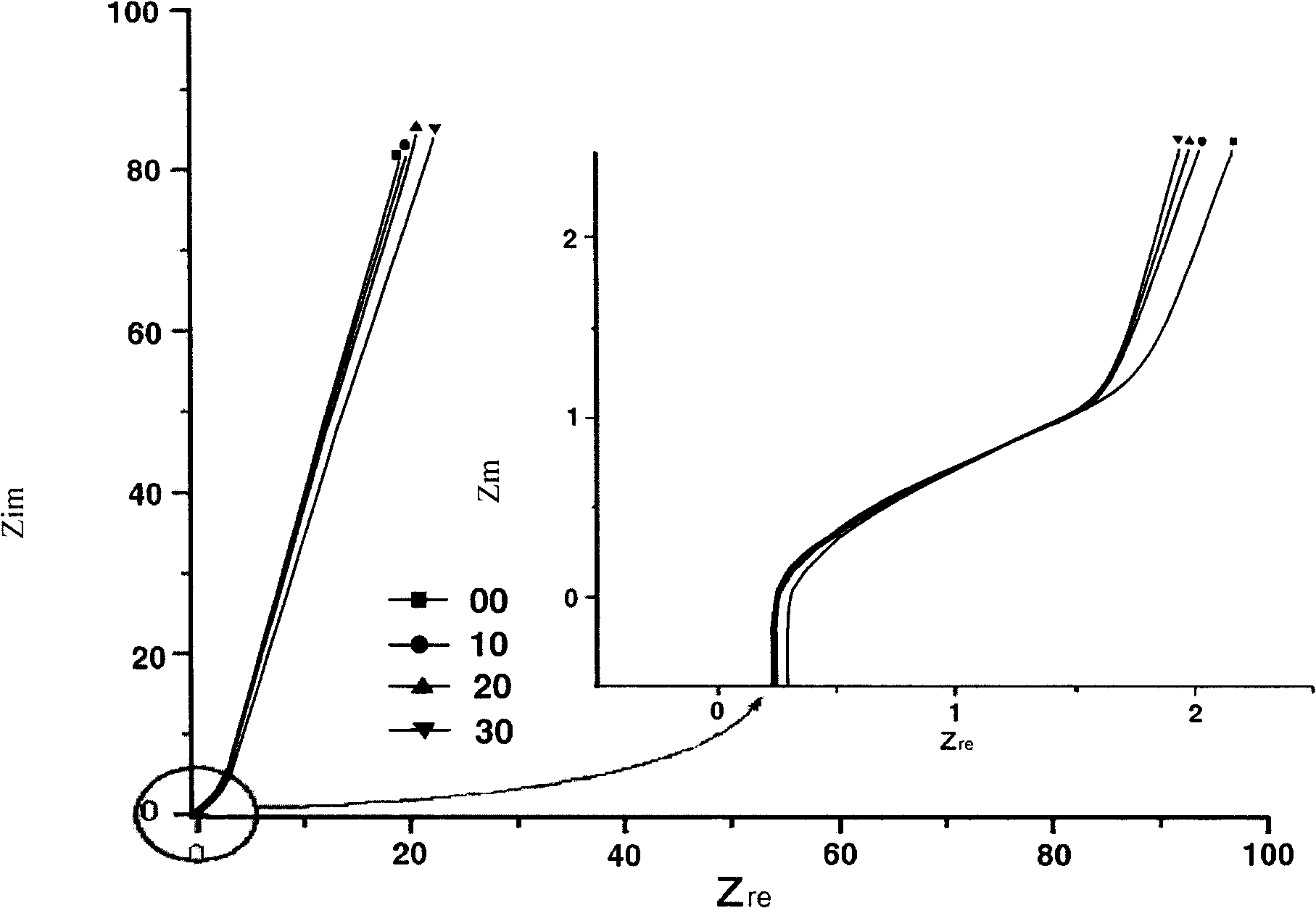

Method and device for measuring non-aqueous electrolyte battery moisture

InactiveCN101311703AQuick measurementSimple and accurate measurementSurface/boundary effectSecondary cells testingElectricityCapacitance

The invention discloses a method for measuring wettability of a non-aqueous electrolyte cell and a device thereof, comprising: enclosing an electrode module into a case, and injecting electrolyte into the case equipped with the electrode module; after injecting the electrolyte, for certain scheduled time, infusing the electrolyte; after injecting the electrolyte, measuring capacitance value between an anode and a cathode through electrically connecting measuring terminals of a capacitance spectrometer with the anode and the cathode of the electrode module; estimating the wettability of the electrolyte in the electrode module through measured capacitance value.

Owner:SAMSUNG SDI CO LTD

Robust 1d gesture light control algorithm

InactiveUS20110215733A1Reduce the impactLow costElectrical apparatusDirection finders using ultrasonic/sonic/infrasonic wavesElectricitySonification

A lighting system comprising a lamp arranged to transform electricity into a light beam having different properties; a light control means arranged to adjust said light beam properties; an ultrasonic transmitter arranged to transmit ultrasonic signals; an ultrasonic receiver arranged to receive reflected ultrasonic signals; and a processing means arranged to derive a time-of-flight signal representing the time differences between said transmitted and received ultrasonic signals and to send control signals to said light control means in dependence of said time-of-flight signal. The processing means performs a reference calibration step: the time-of-flight is repeatedly measured a multitude of times, and calculates the average of said measured time-of-flight values and stores the average in memory means as a reference time-of-flight value if said deviation of the majority of the measured time-of-flight values of said multitude of measurements is lower than a predetermined threshold.

Owner:LITE ON TECH CORP

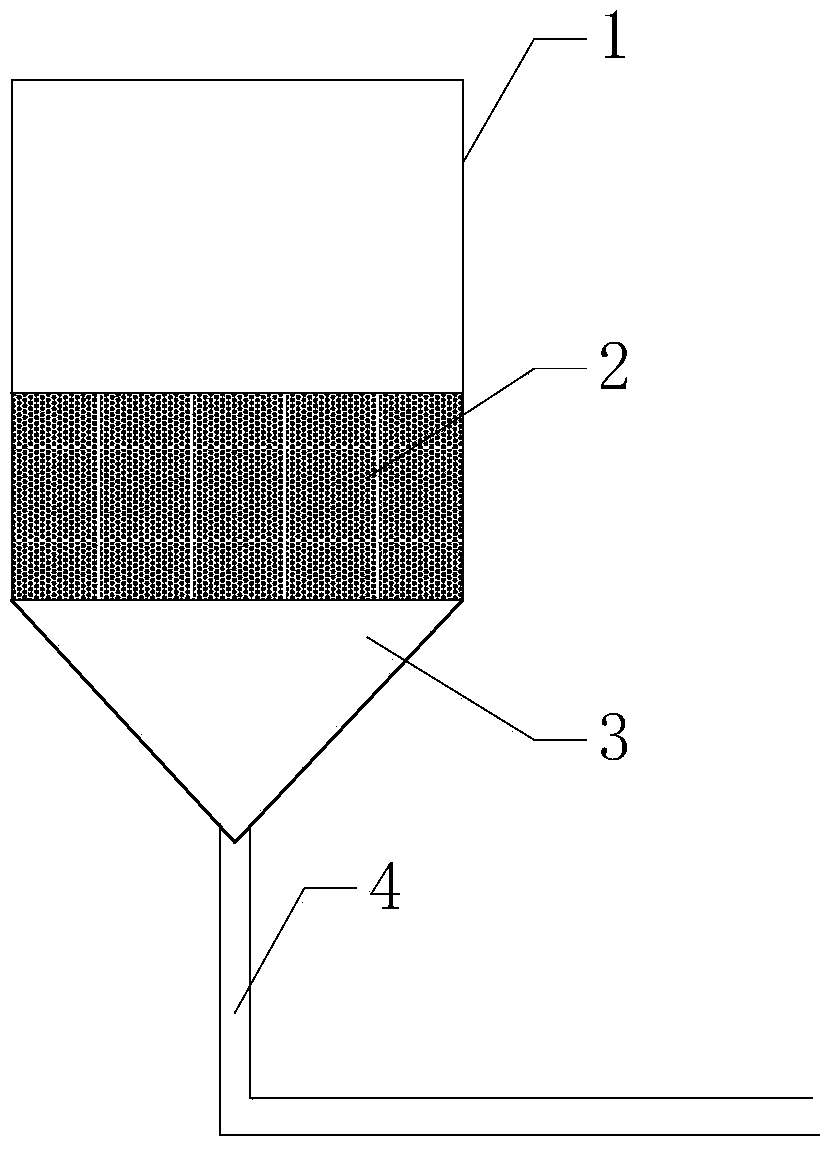

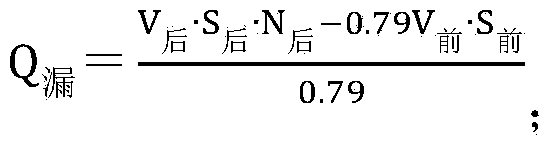

Method for measuring gas leakage rate of sintering machine system

ActiveCN104034371ASolve the situation where the air inlet velocity is seriously unevenEasy to measureVolume/mass flow measurementFlue gasMetallurgy

The invention discloses a method for the measuring gas leakage rate of a sintering machine system. The method is on the basis that N2 is not involved in the reaction in the sintering process and adopts N2 balance for gas leakage measurement. The method includes the steps of 1, extending the side plate of a sintering machine trolley upwardly, and guaranteeing a no-material space between the sintering material surface and the upper edge of the side plate of the sintering machine trolley; 2, measuring gas incoming speed of the sintering material layer on the sintering material, and measuring the flue gas velocity, the flue gas temperature, the flue gas pipeline nitrogen concentration and the flue gas pressure; 3, calculating the gas leakage rate according to the measured data by the formulas (img file = 'DDA0000523955380000011.TIF' wi = '75' he = '38' / ) (img file = 'DDA0000523955380000012.TIF' wi = '752' he = '' / 136). The method has the advantages that the gas leakage rate of the sintering machine system can be measured simply and accurately, and disadvantages that an existing measuring technology is inconvenient to operate, errors are large, and only partial gas leakage rate can be measured by a gas leakage spot gas velocity measuring method are solved.

Owner:LAIWU IRON & STEEL GRP

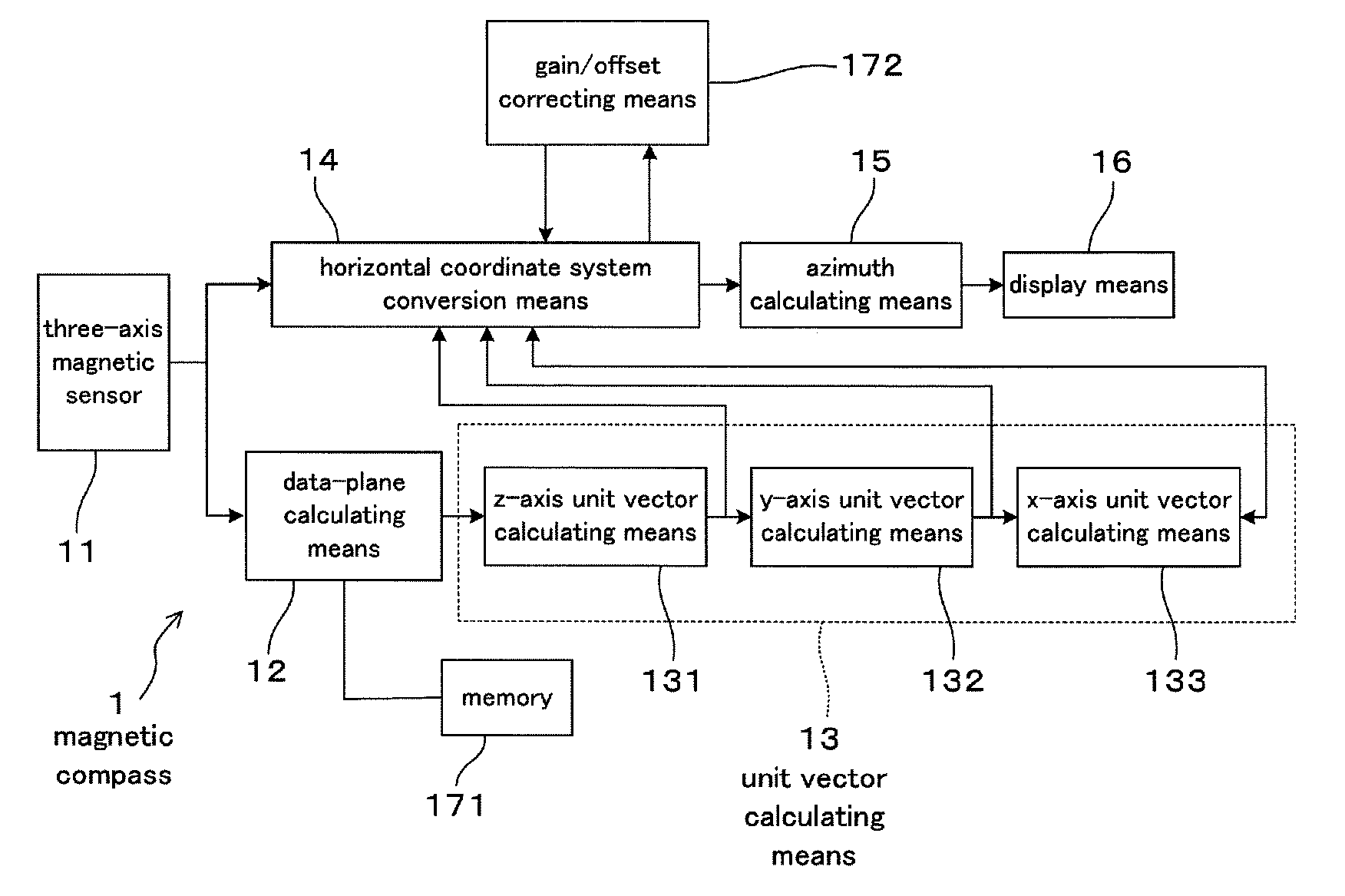

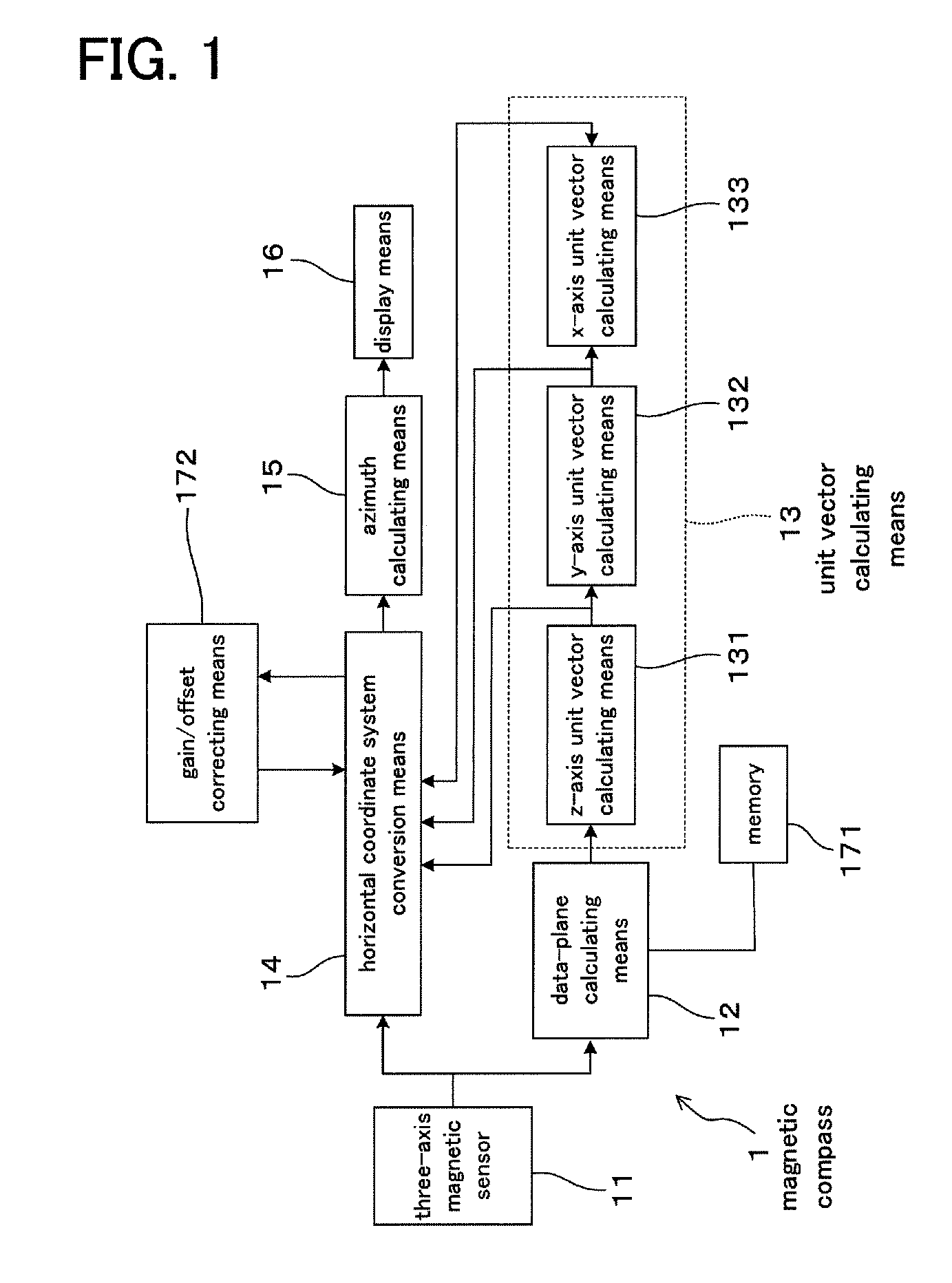

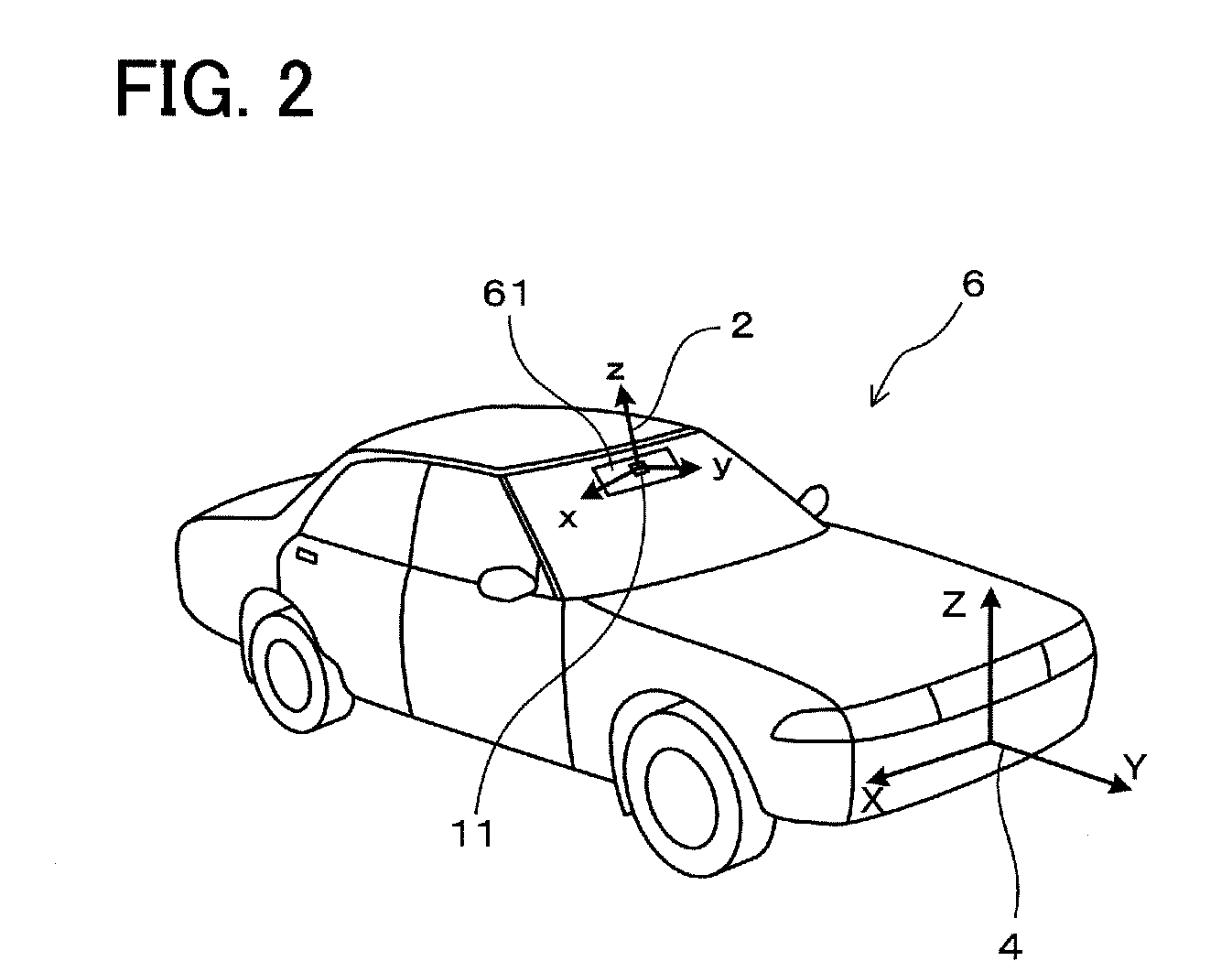

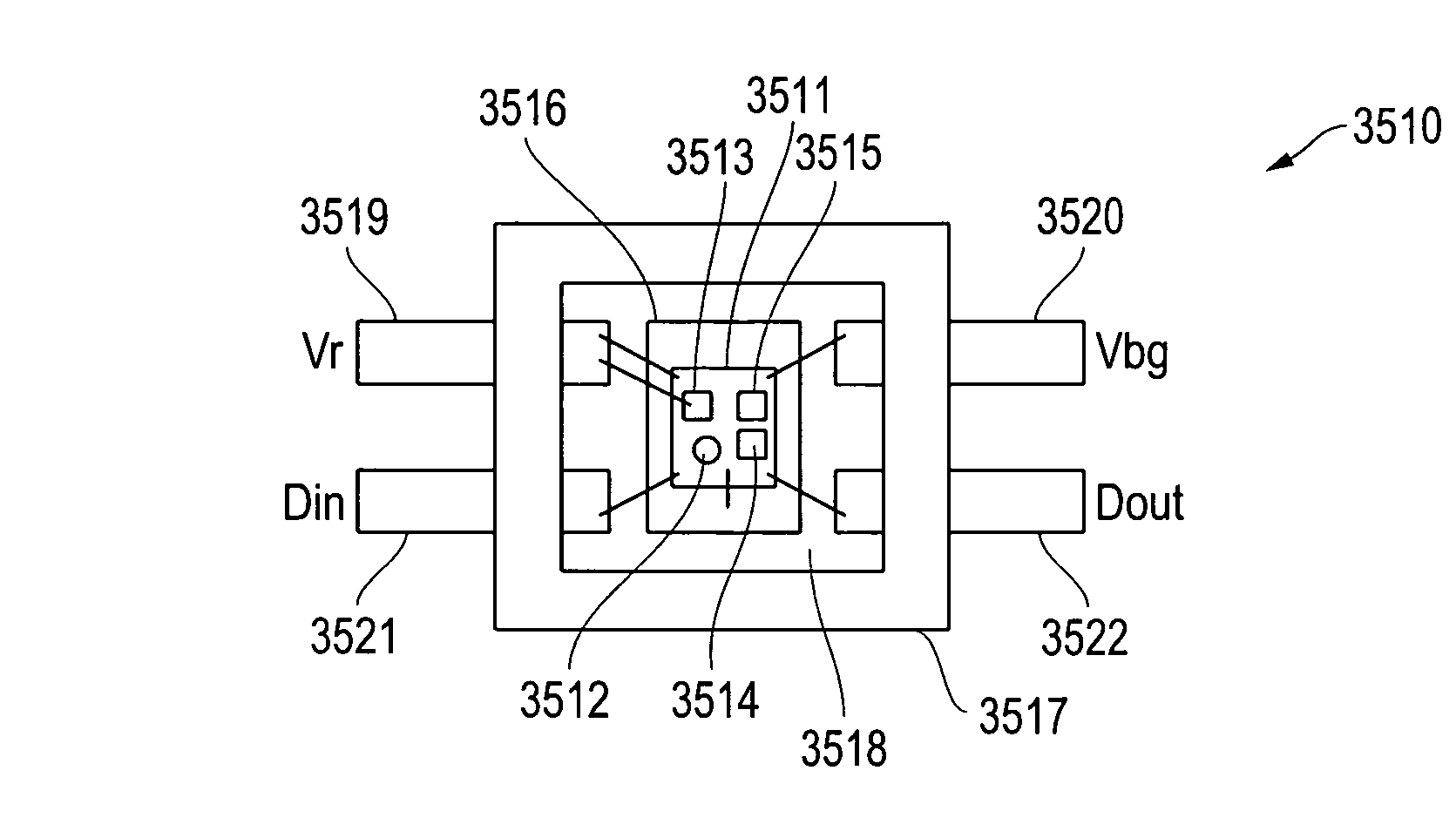

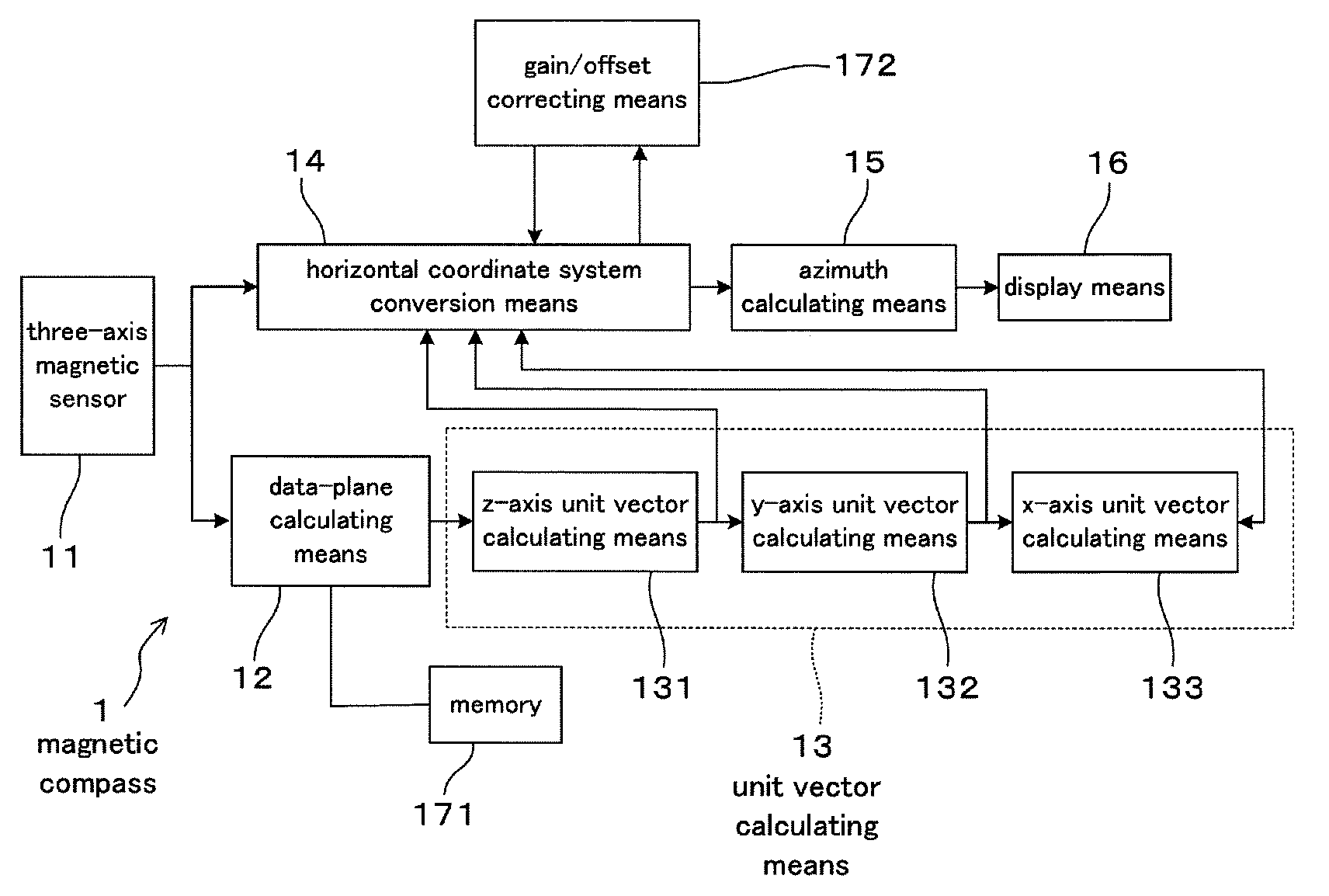

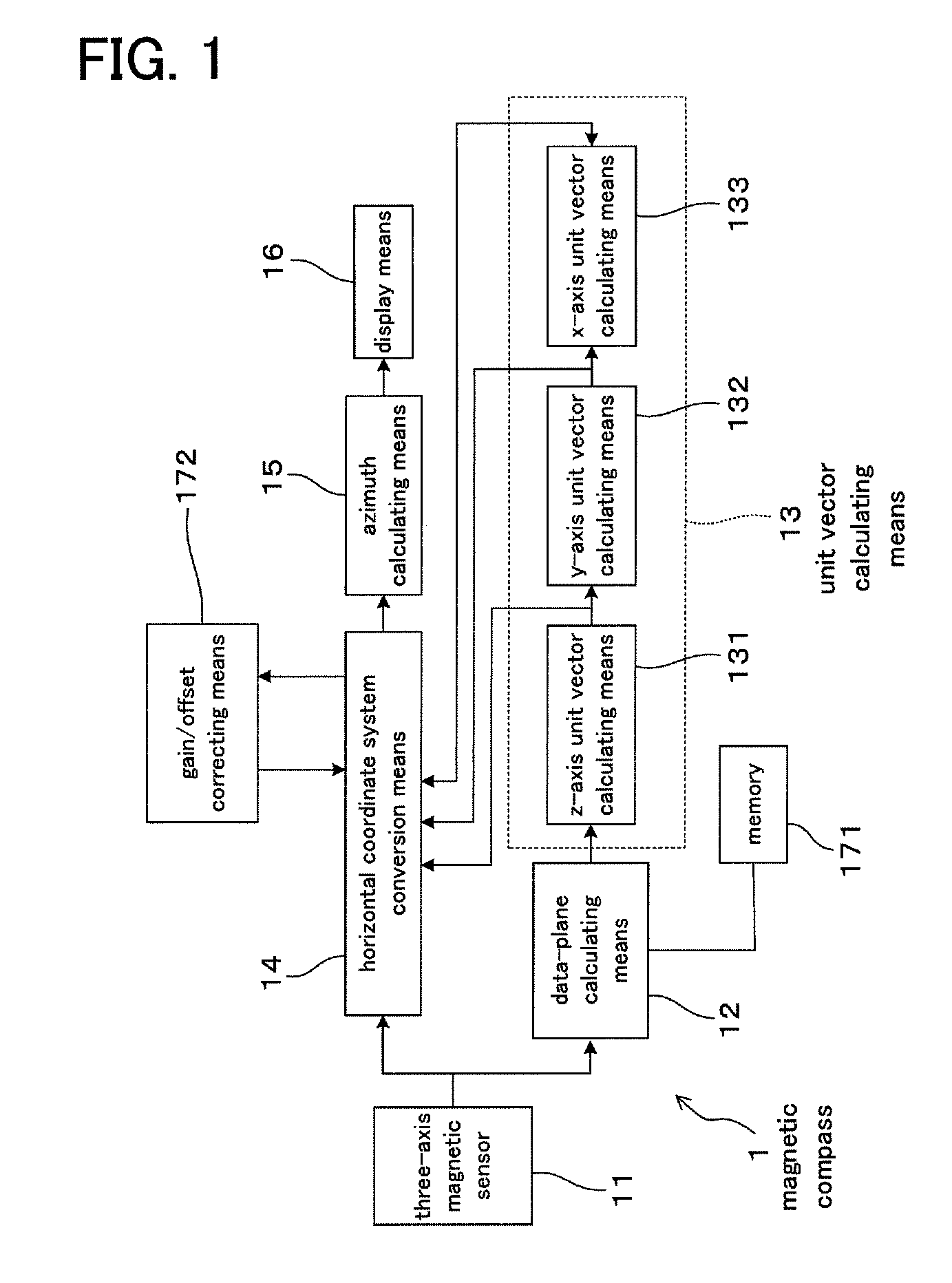

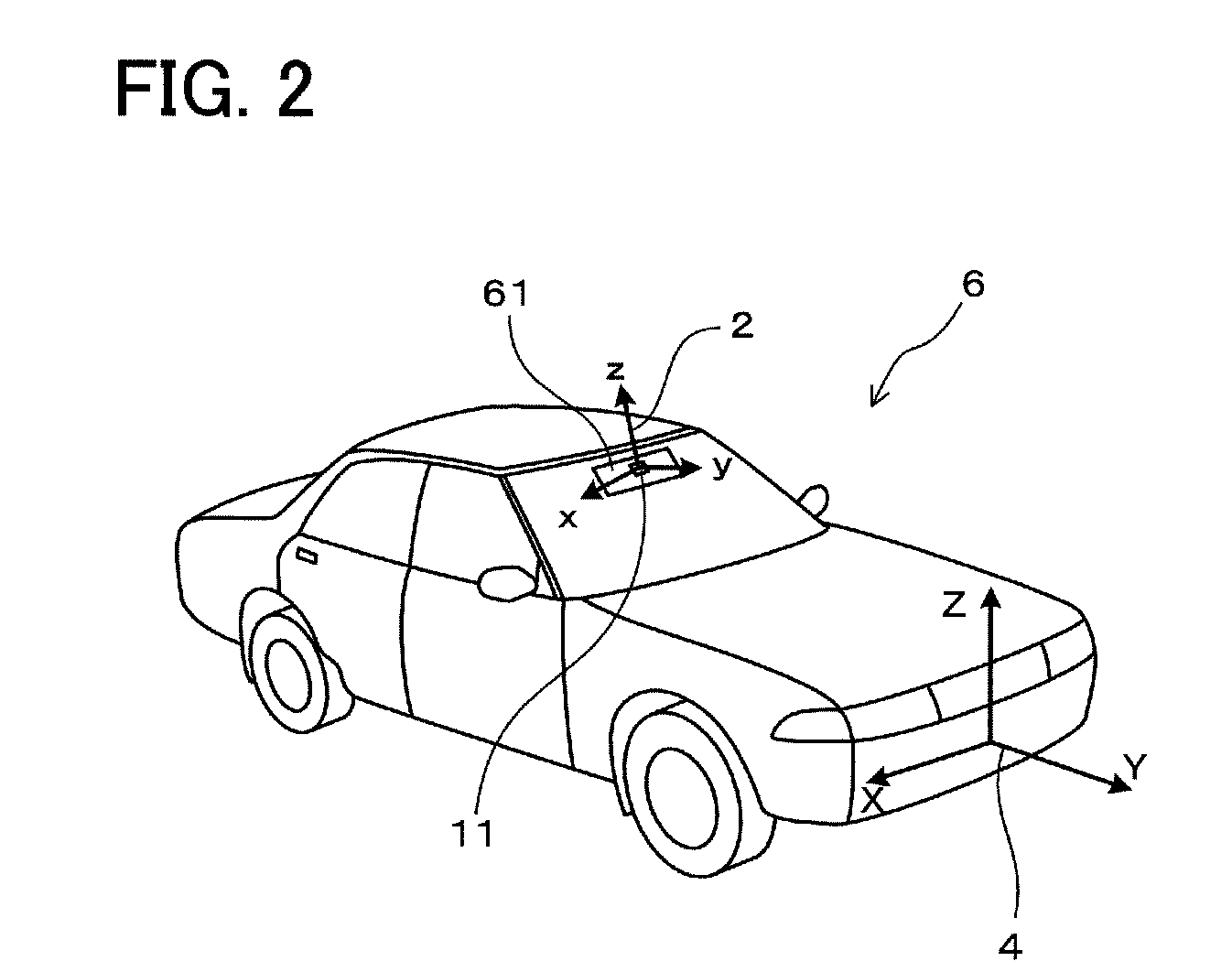

Magnetic compass

InactiveUS20070084070A1Easy and accurate azimuth measurementLow costCompassesClassical mechanicsCompass

A magnetic compass includes: a three-axis magnetic sensor for detecting geomagnetic vector as geomagnetic components in directions of three orthogonal axes x, y, and z; a data-plane calculating unit for calculating a data plane on which output data of the three-axis magnetic sensor are present in a sensor coordinate system of the three axes x, y, and z; a unit vector calculating unit for calculating unit vectors of a horizontal coordinate system of three orthogonal axes X, Y, and Z whose Z-axis runs vertically and X-Y plane defines a horizontal plane relative to the earth; a horizontal coordinate system conversion unit for converting geomagnetic components in the sensor coordinate system detected by the three-axis magnetic sensor into geomagnetic components in the horizontal coordinate system; an azimuth calculating unit for calculating azimuth based on the converted geomagnetic components in the horizontal coordinate system; and a display unit for displaying the calculated azimuth.

Owner:AICHI MICRO INTELLIGENT

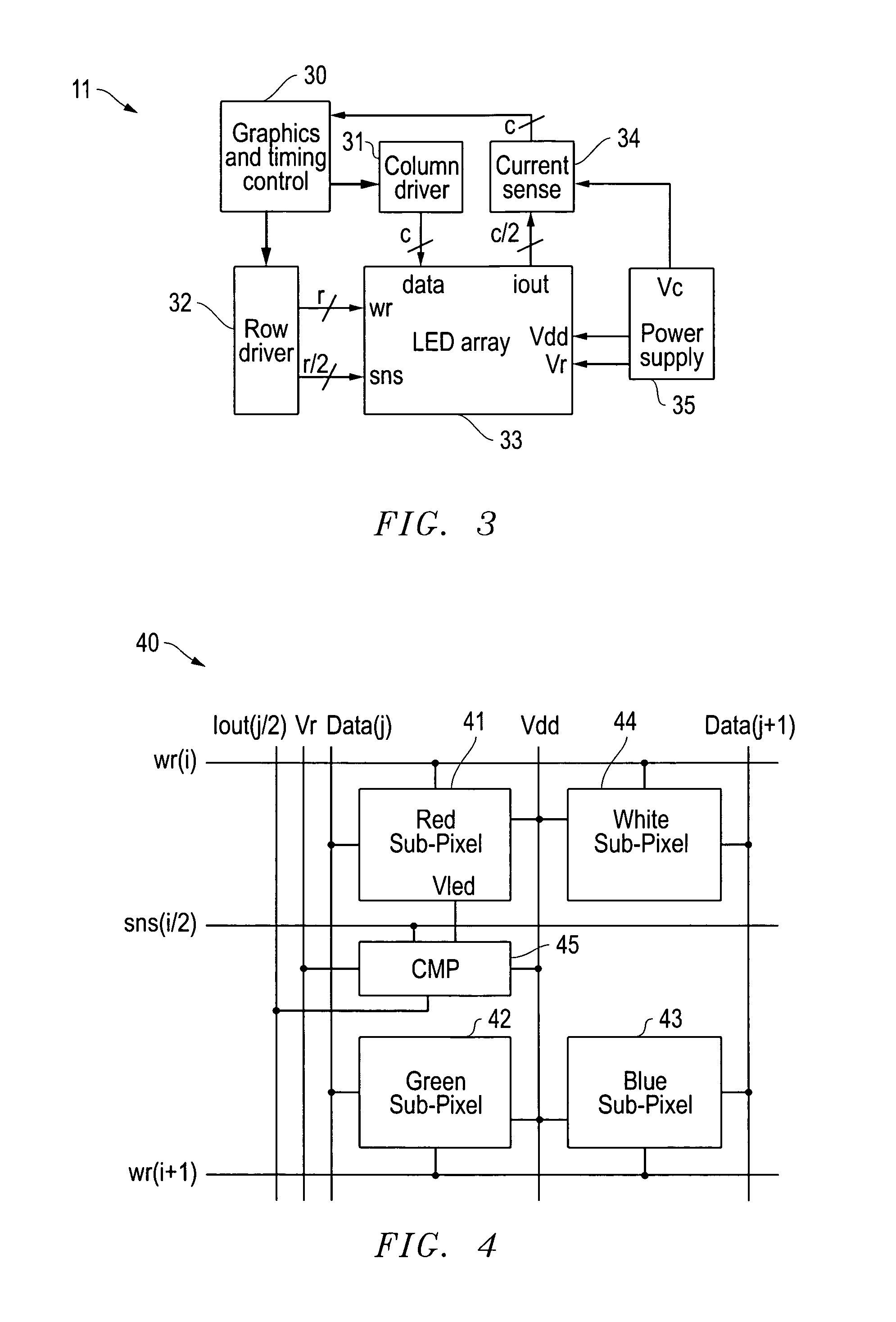

Illumination devices and related systems and methods

ActiveUS8773336B2Accurate measurementSimple and accurate measurementTelevision system detailsPhotometry using reference valueLight equipmentPower flow

Illumination devices and related systems and methods are closed that can be used for LCD (Liquid Crystal Display) backlights, LED lamps, or other applications. The illumination devices can include a photo detector, such as a photodiode or an LED or other light detecting device, and one or more LEDs of different colors. A related method can be implemented using these illumination devices to maintain precise color produced by the blended emissions from such LEDs. One application for the illumination devices is backlighting for FSC (Field Sequential Color) LCDs (Liquid Crystal Displays). FSC LCDs temporally mix the colors in an image by sequentially loading the red, green, and blue pixel data of an image in the panel and flashing the different colors of an RGB backlight. Precise and uniform color temperature across such a display can be advantageously maintained by continually monitoring ratios of photodiode currents induced by the different colored LEDs in each illumination device as each color is flashed.

Owner:LUTRON TECH CO LLC

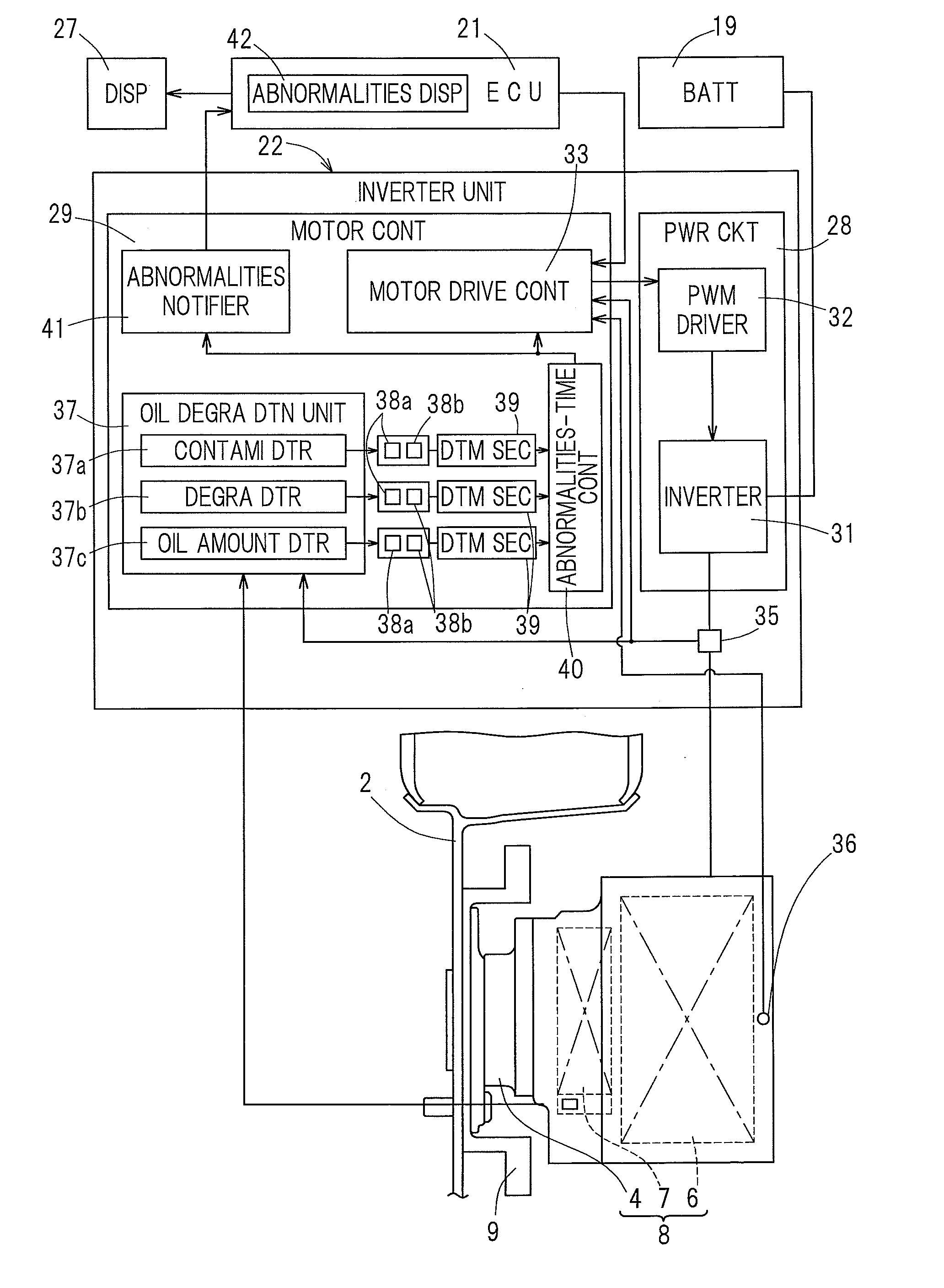

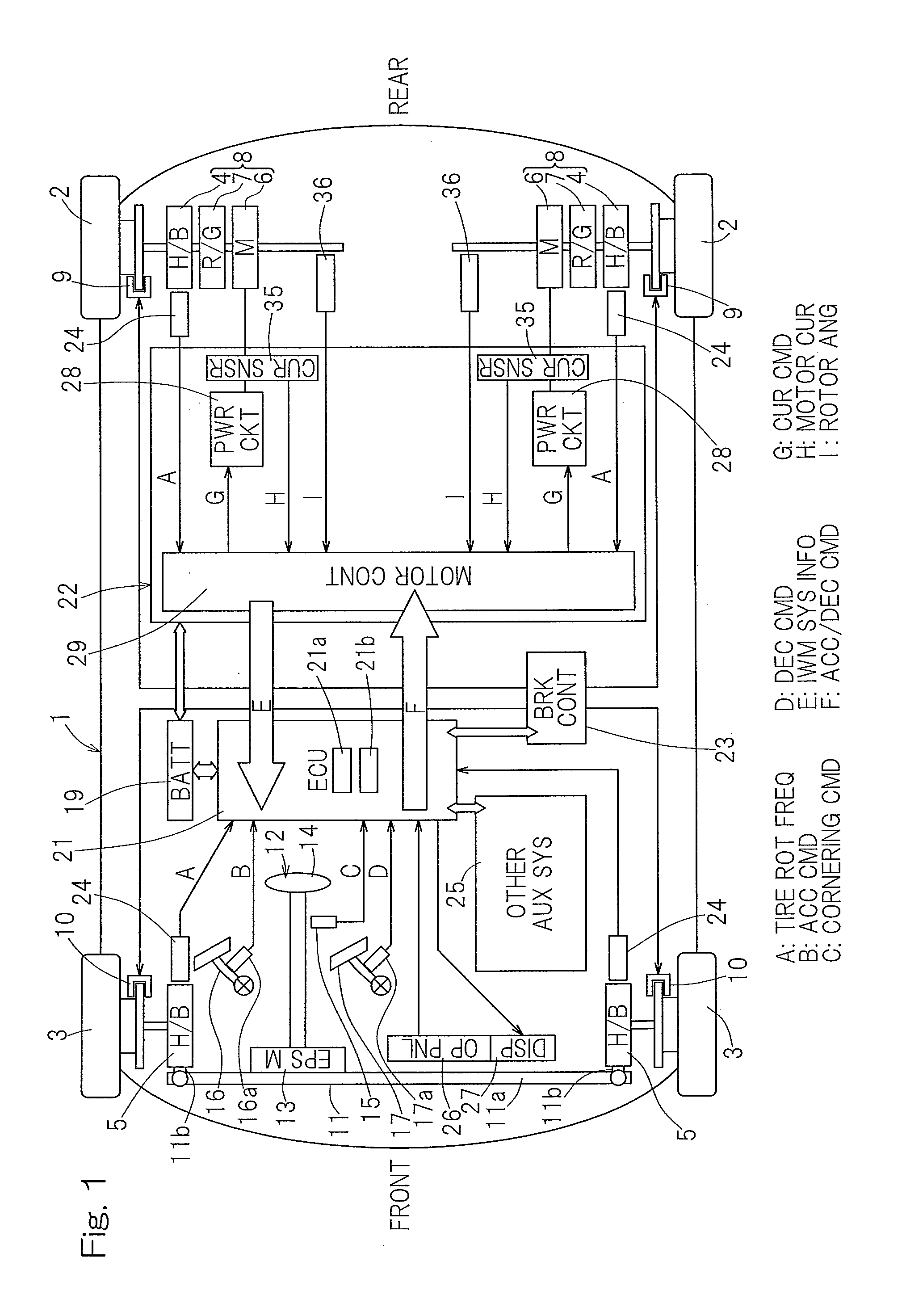

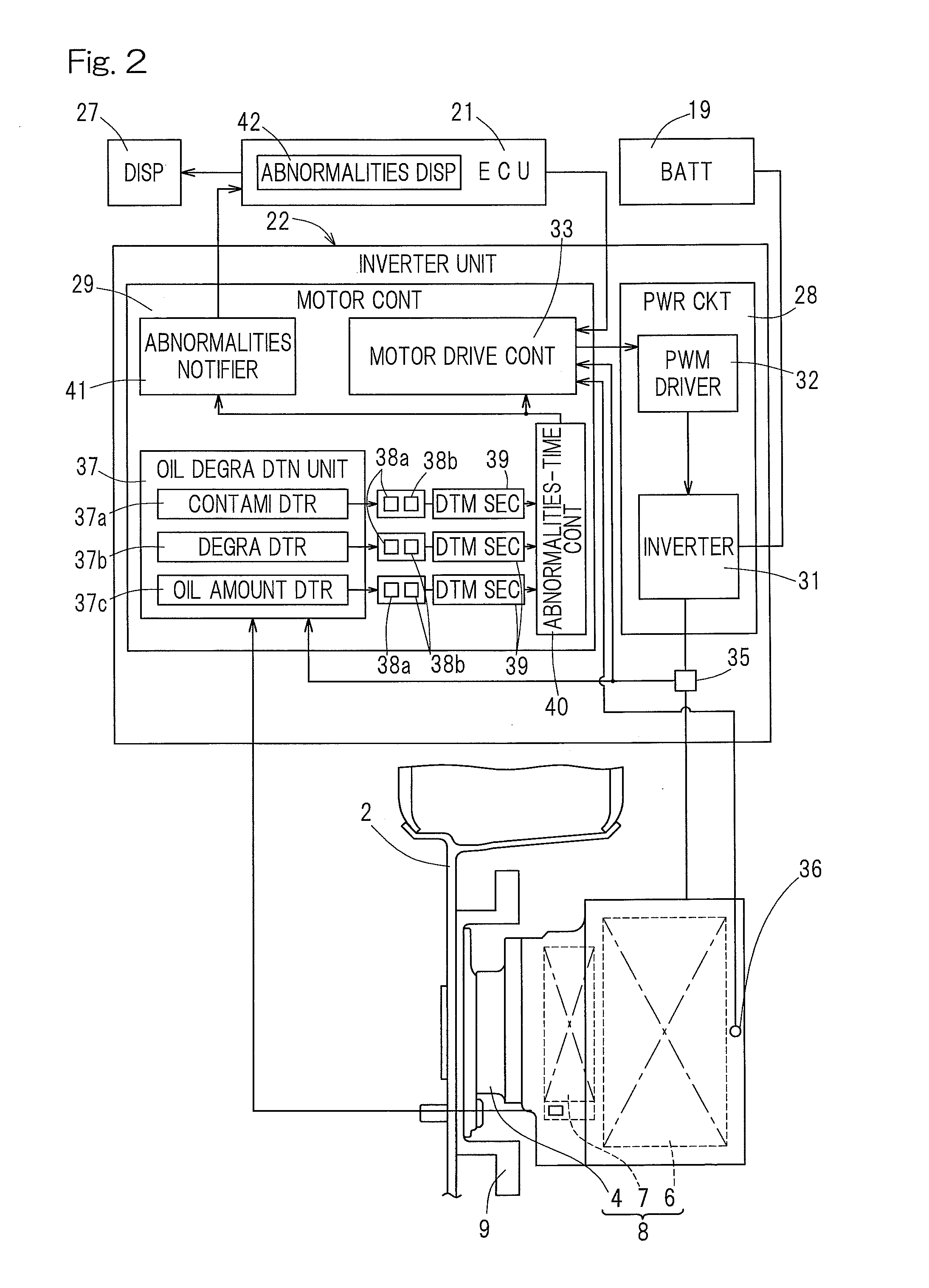

Diagnostic method for motor

InactiveUS20130342150A1Easy to measureVery high cooling effectDC motor speed/torque controlElectrical testingTime controlElectric vehicle

In a diagnostic device and a diagnostic method for a motor unit of an electric vehicle, an oil degradation / others detection unit is provided which is configured to detect at least any one detection item of a contamination degree, a degradation degree, and an oil amount of an oil used for cooling a motor unit or a reduction gear unit during a non-traveling period when the vehicle is powered on. An abnormalities-time control unit is provided which is configured to send notice of abnormalities of an oil supply system or not permit start of rotation of the motor unit when a detection value detected by the oil degradation / others detection unit is out of a setting range.

Owner:NTN CORP

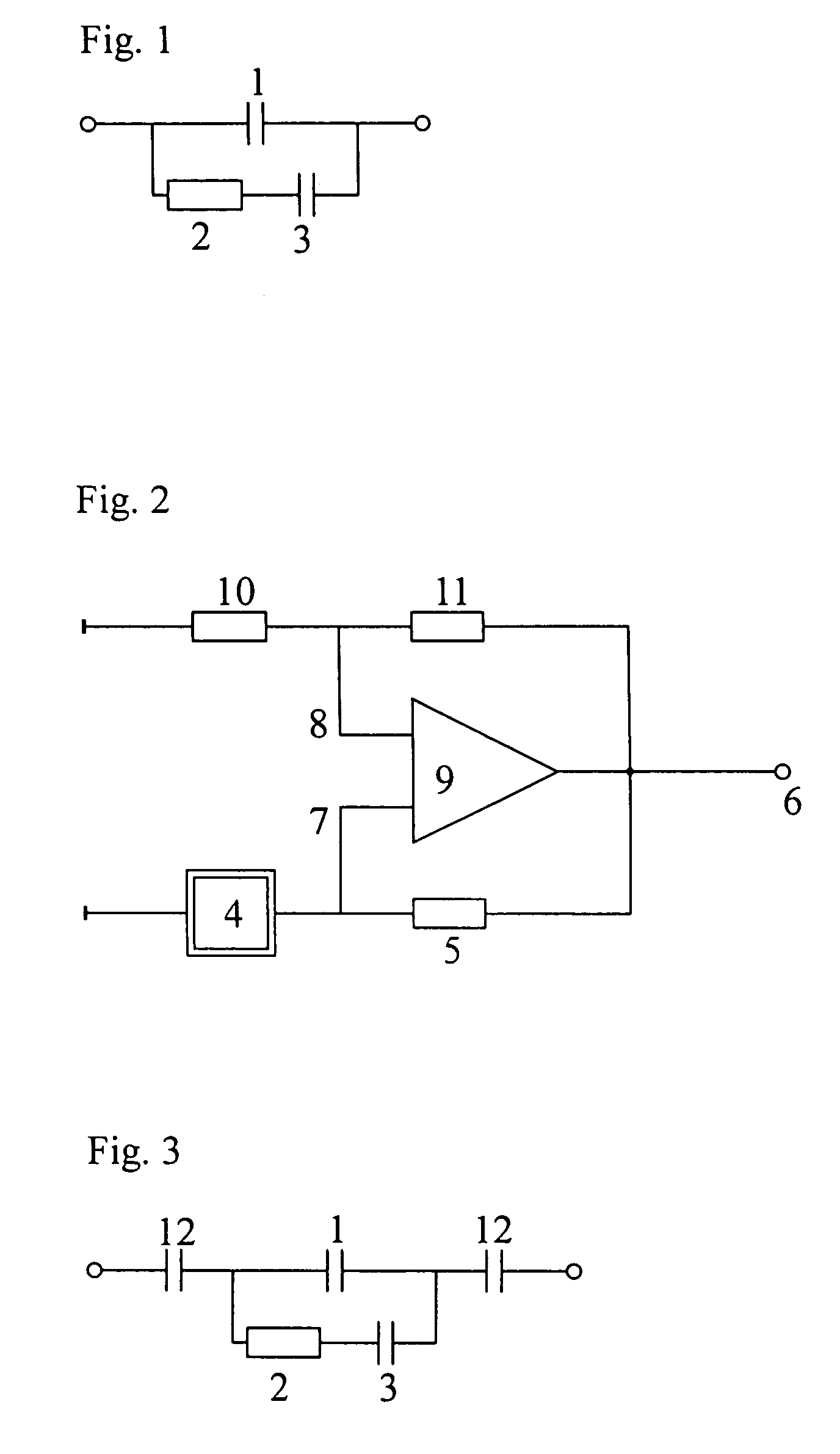

Method and device for determining the moisture content and conductivity in the ground and in bulk materials

InactiveUS7126352B2Simple and accurate measurementDisturbances can be eliminatedResistance/reactance/impedenceEarth material testingVoltage sourceMoisture

In a method and device for determining the moisture content and conductivity in the ground and in bulk materials, a capacitive sensor is disposed in the ground or the bulk material, the sensor is charged from a constant external voltage supply with a given initial current from a given first voltage threshold value to a given second voltage threshold value and either a voltage / time diagram is determined or a first charging time required for charging the sensor from the first to the second voltage threshold values by the constant external voltage supply is determined and a second charging time is determined wherein either the initial current and / or at least one of the two voltage threshold values are altered and the water content and the conductivity are determined by verification of the two charging times or of the voltage / time diagram.

Owner:GSF FORSCHUNGSZENT FUR UMWELT & GESUNDHEIT

Magnetic compass

A magnetic compass includes: a three-axis magnetic sensor for detecting geomagnetic vector as geomagnetic components in directions of three orthogonal axes x, y, and z; a data-plane calculating unit for calculating a data plane on which output data of the three-axis magnetic sensor are present in a sensor coordinate system of the three axes x, y, and z; a unit vector calculating unit for calculating unit vectors of a horizontal coordinate system of three orthogonal axes X, Y, and Z whose Z-axis runs vertically and X-Y plane defines a horizontal plane relative to the earth; a horizontal coordinate system conversion unit for converting geomagnetic components in the sensor coordinate system detected by the three-axis magnetic sensor into geomagnetic components in the horizontal coordinate system; an azimuth calculating unit for calculating azimuth based on the converted geomagnetic components in the horizontal coordinate system; and a display unit for displaying the calculated azimuth.

Owner:AICHI MICRO INTELLIGENT

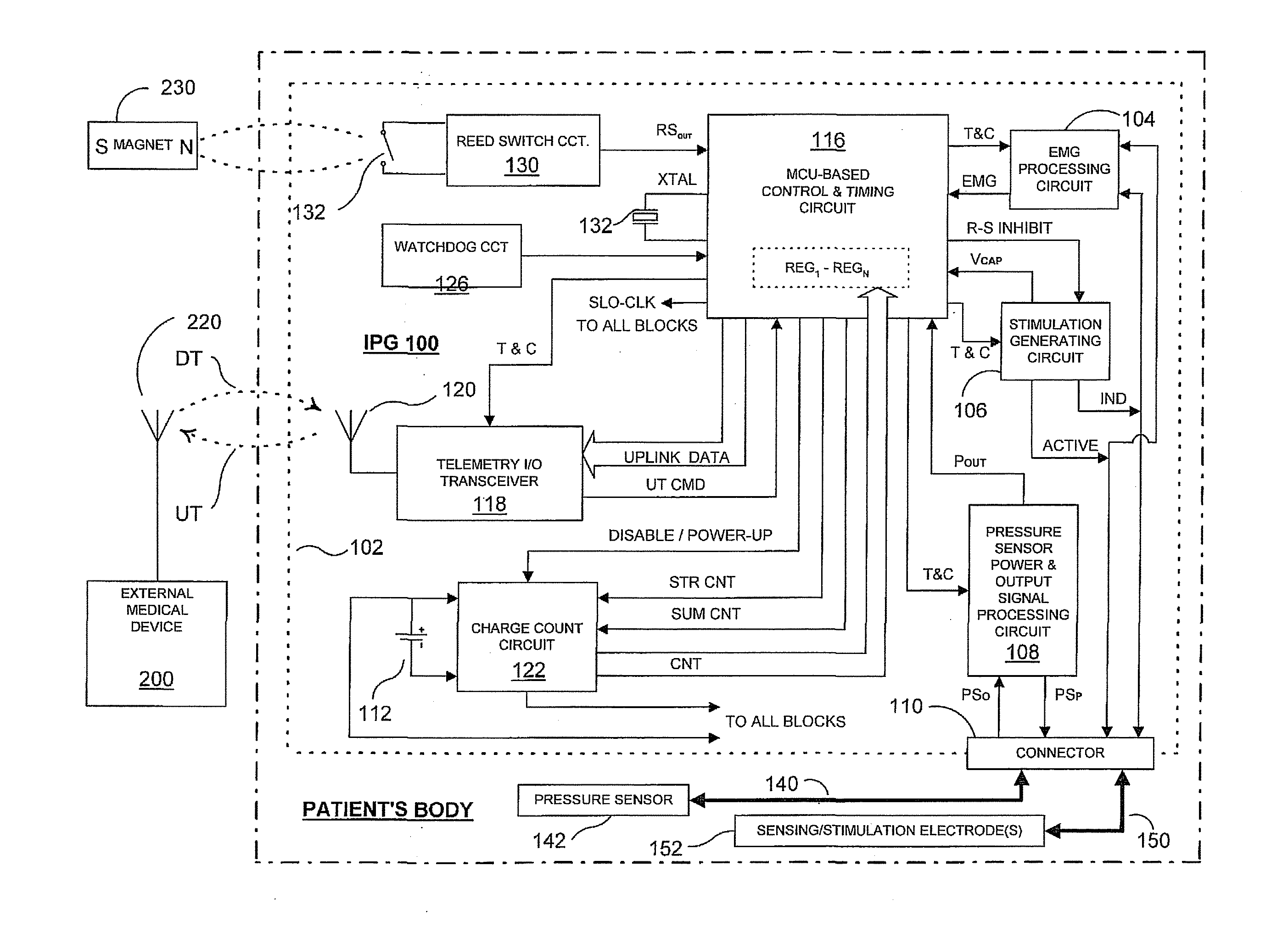

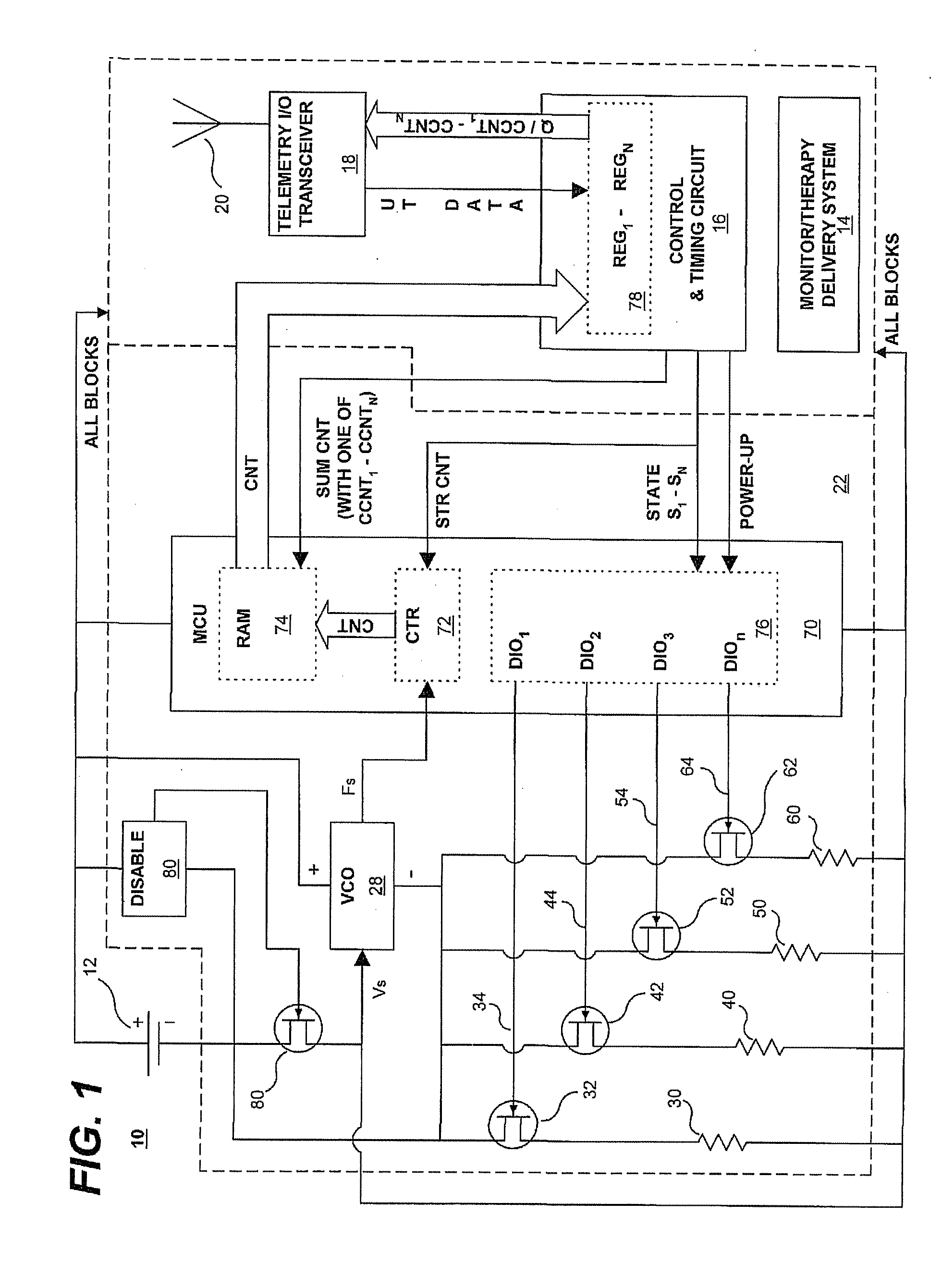

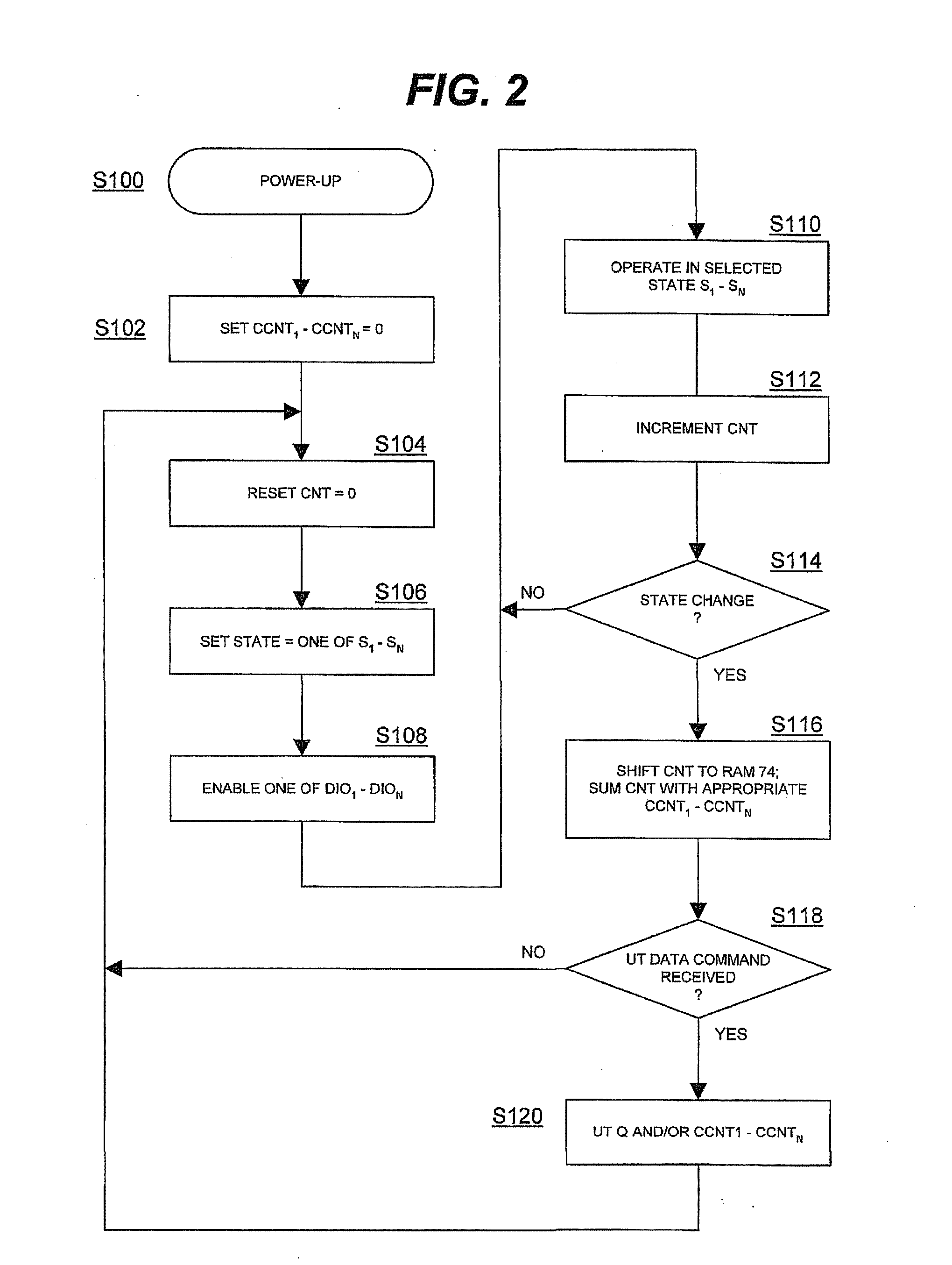

Methods and apparatus for monitoring battery charge depletion

InactiveUS20100114510A1Simple and accurate measurementMinimizing battery chargeElectric devicesMaterial analysis by electric/magnetic meansElectrical resistance and conductanceState dependent

A system and method of monitoring the amount of charge consumed from a battery powering a device, e.g., an implantable medical device, operable in at least first and second current drain states are disclosed. In each drain state, a current-sensing resistance correlated to the drain state is connected with the battery to develop a respective current drain state voltage that is converted to a current drain state count established over the duration of the drain state. The first and second current drain state counts are accumulated as cumulative first and second current drain state counts that are indicative of the amount of charge consumed from the battery. A battery charge state may be estimated from the cumulative first current drain state count and the first current state resistance and the cumulative second current drain state count and second current state resistance.

Owner:BOSTON SCI SCIMED INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com