Patents

Literature

68 results about "Tape speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

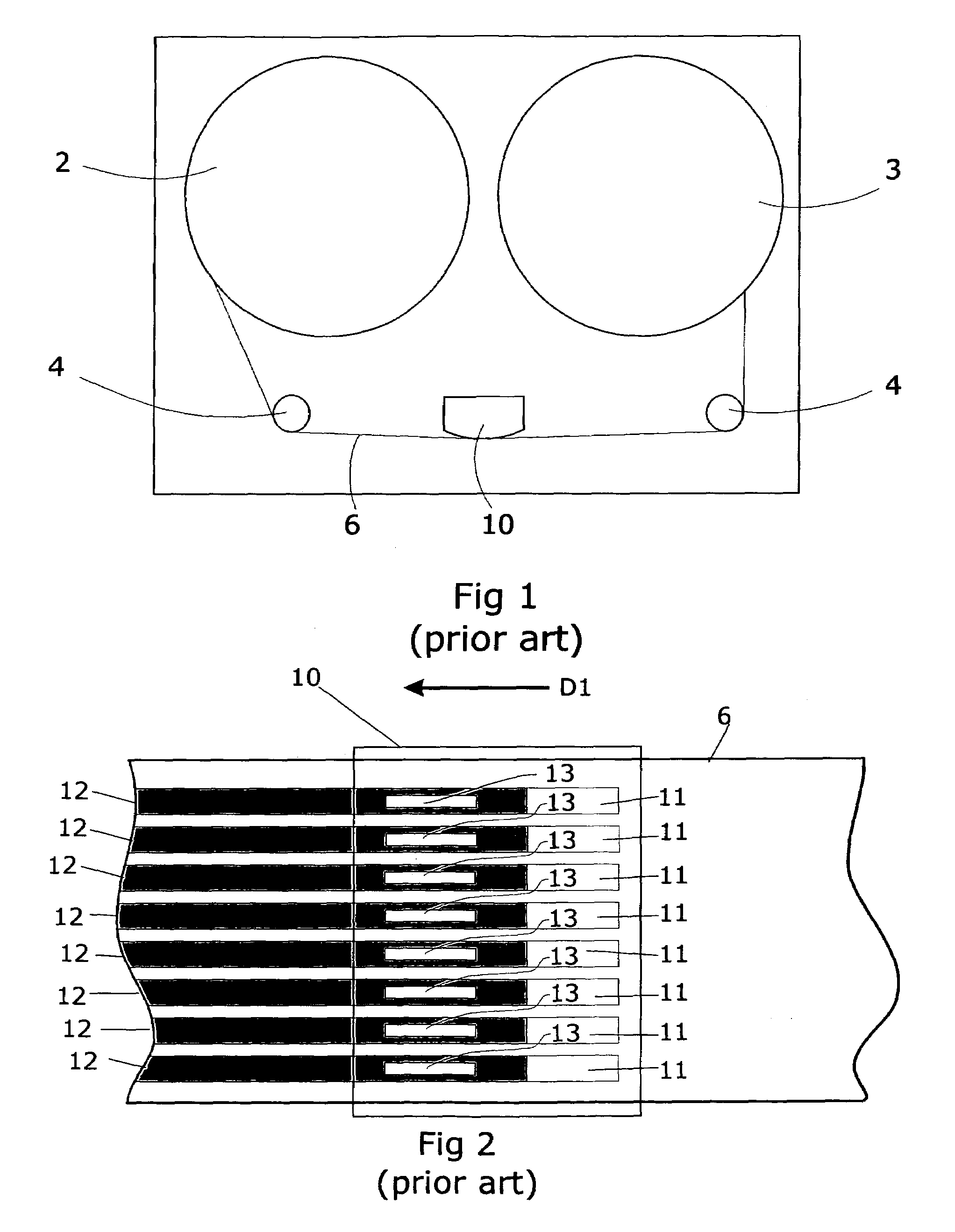

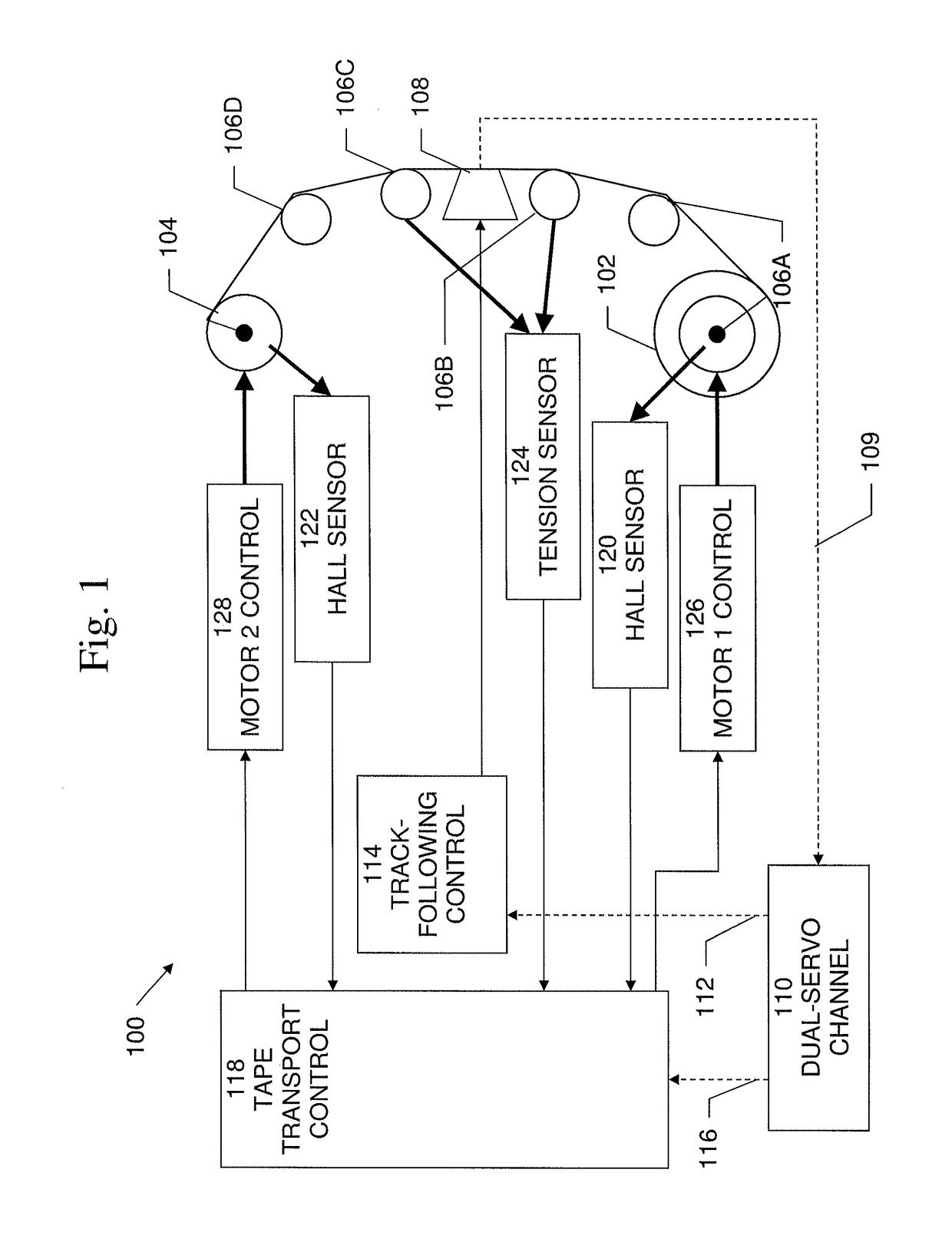

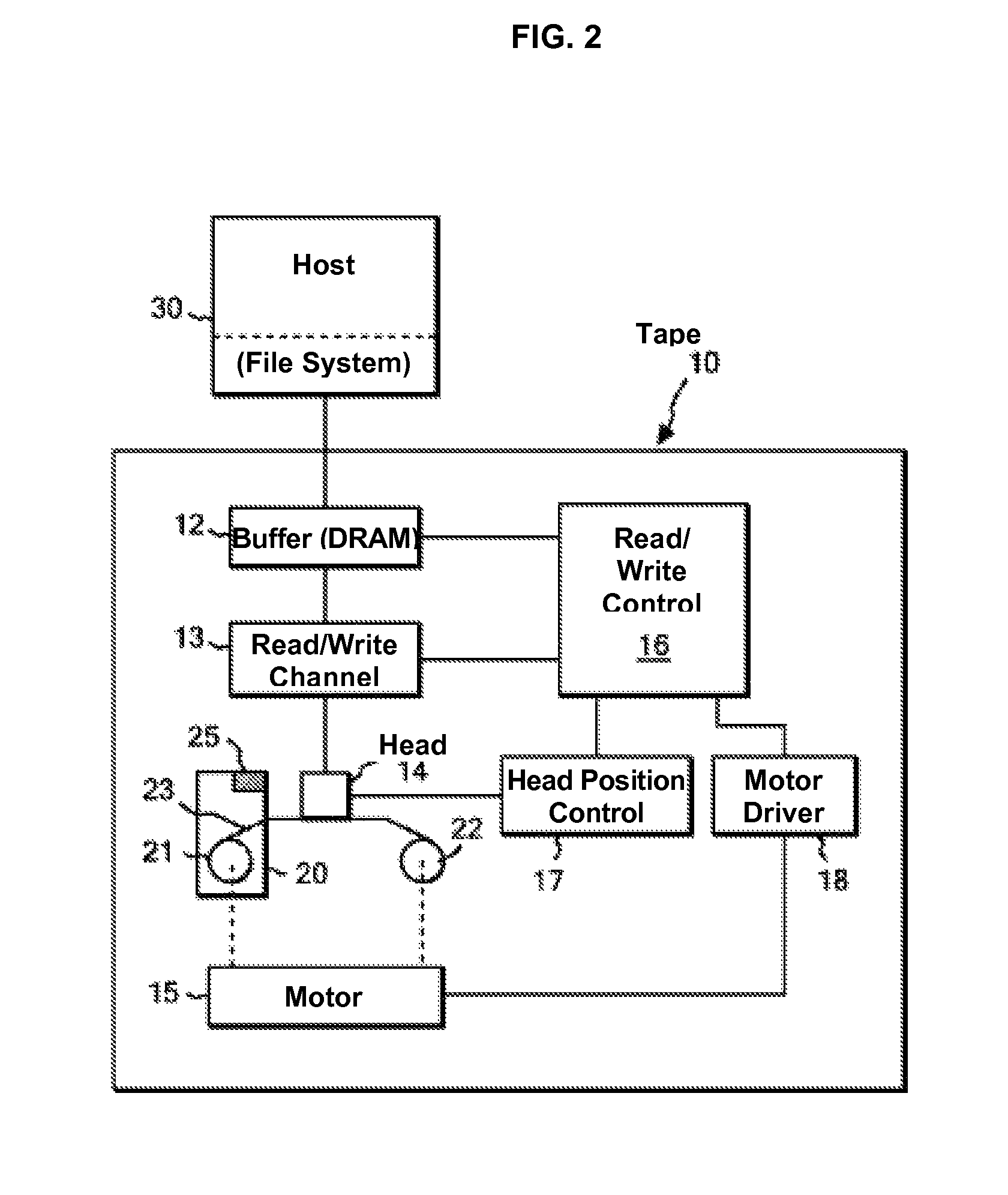

Tape transport servo system and method for a computer tape drive

InactiveUS6754026B1Alignment for track following on tapesRecord information storageTape speedTape drive

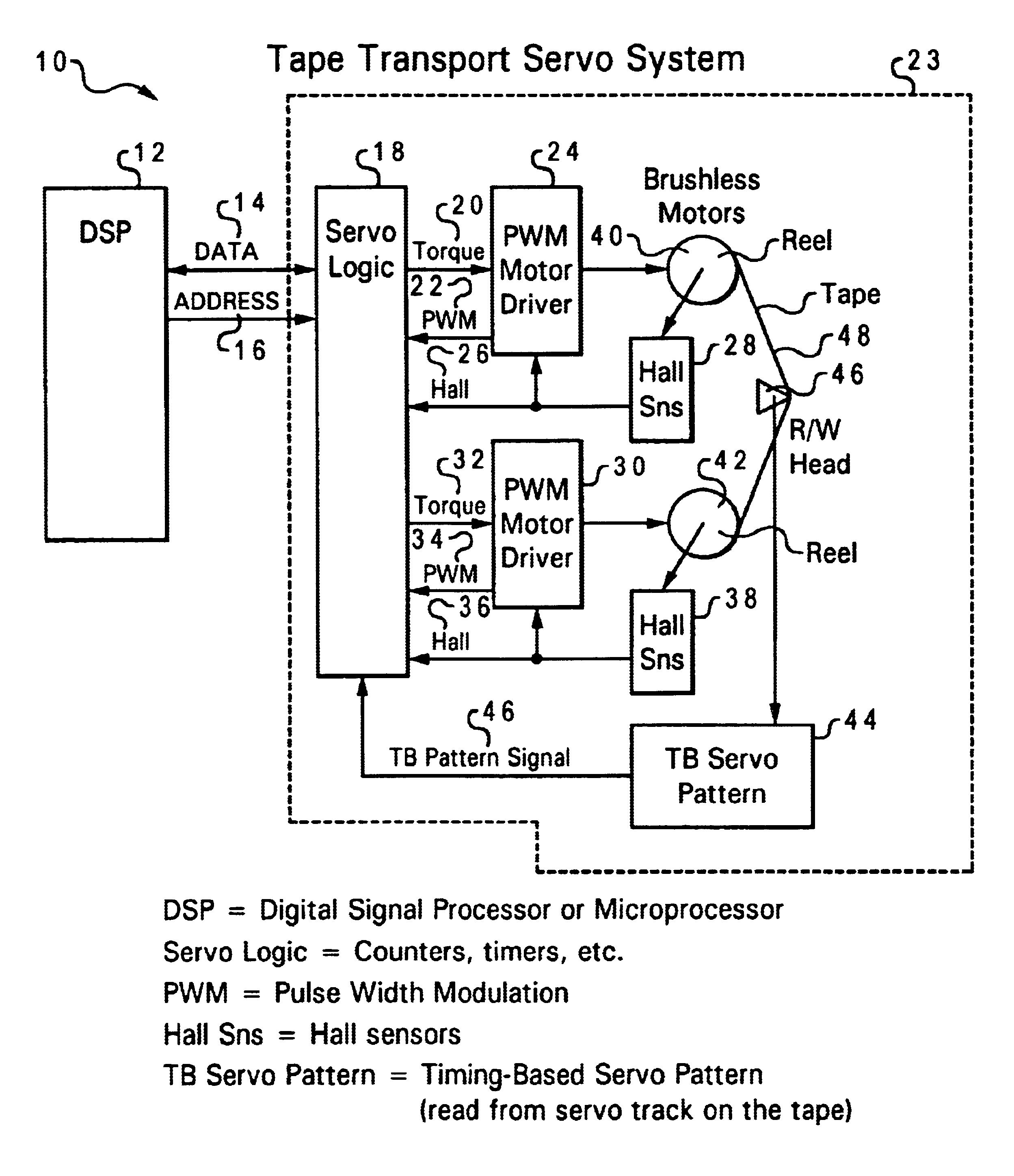

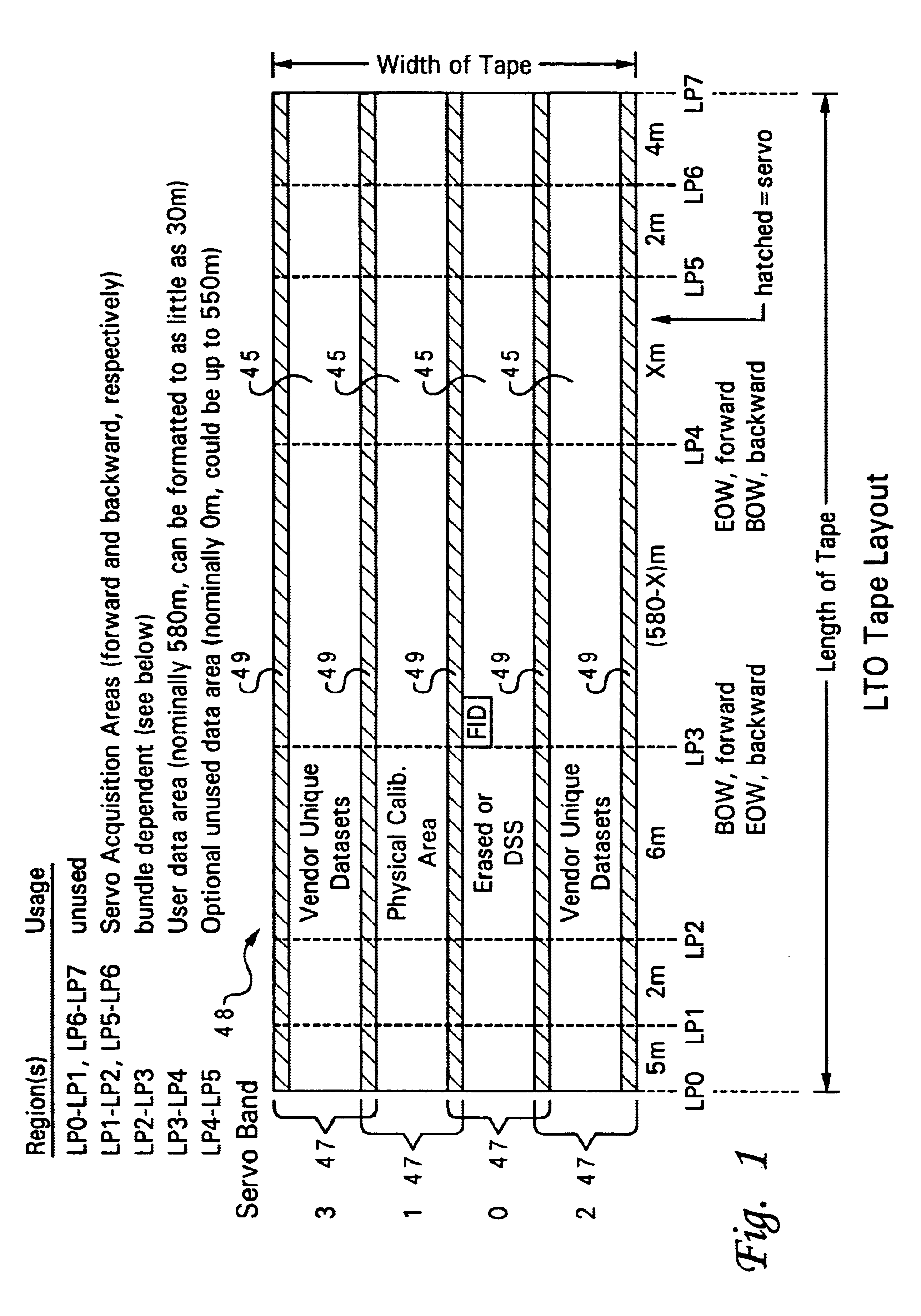

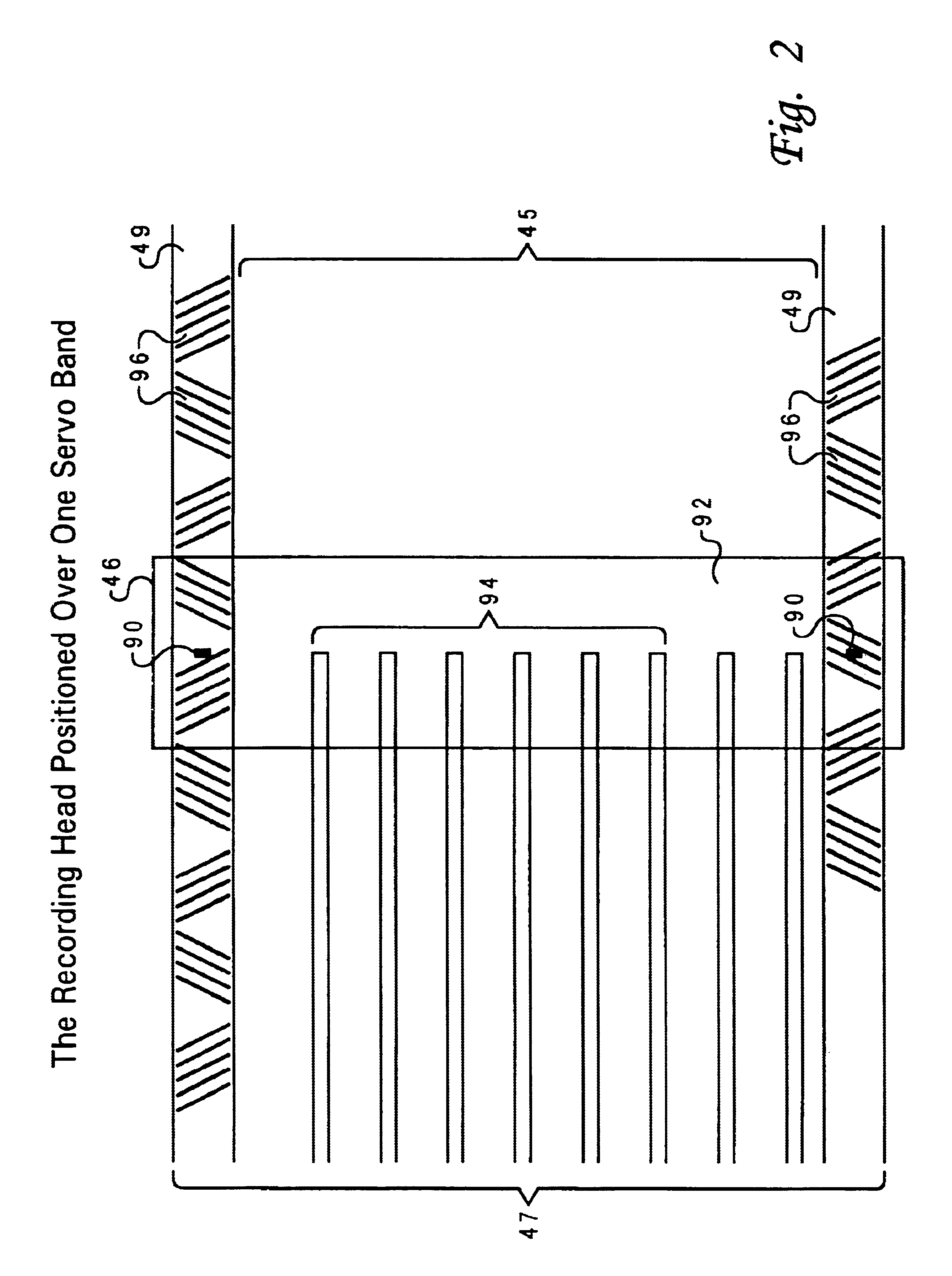

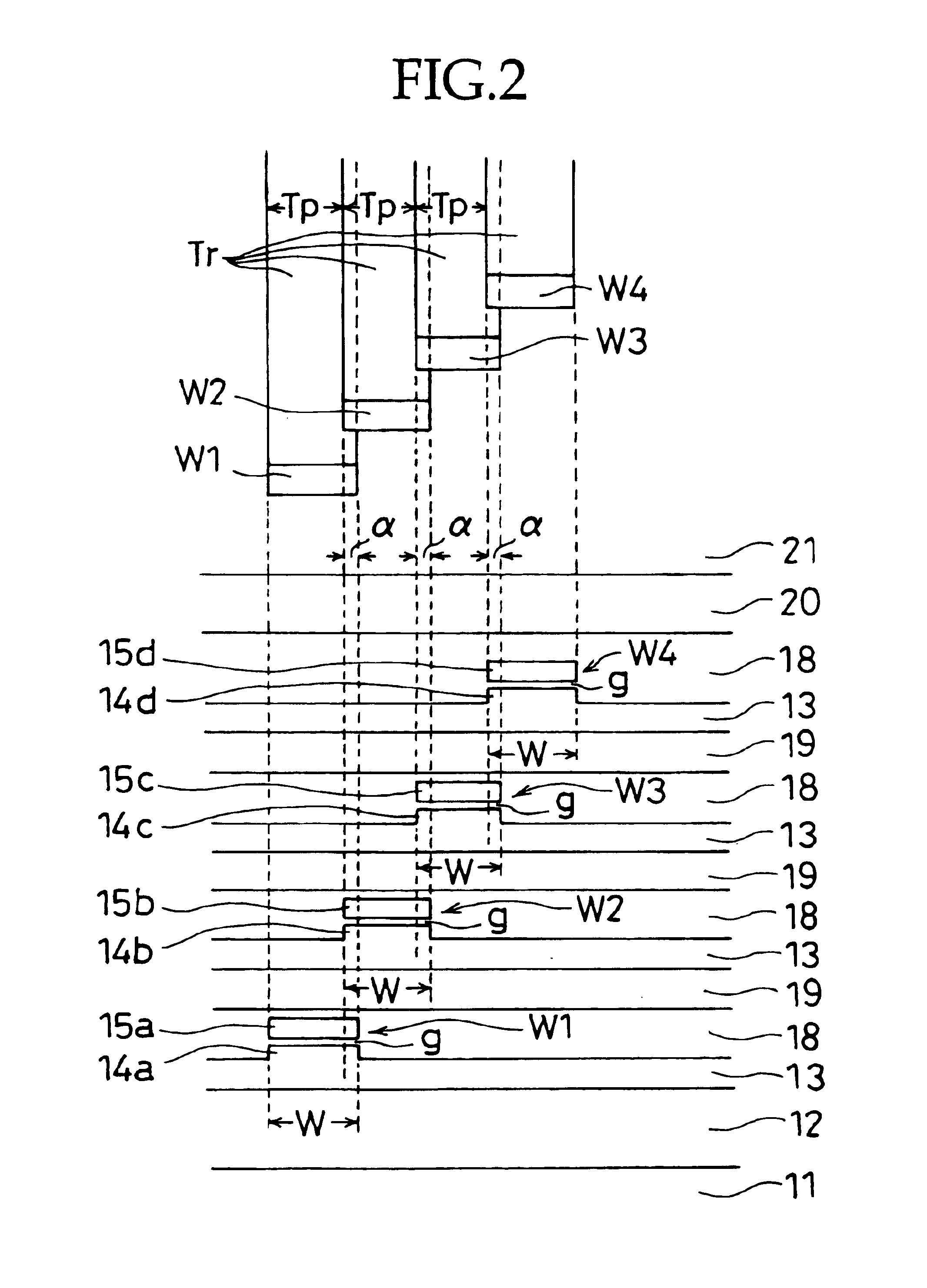

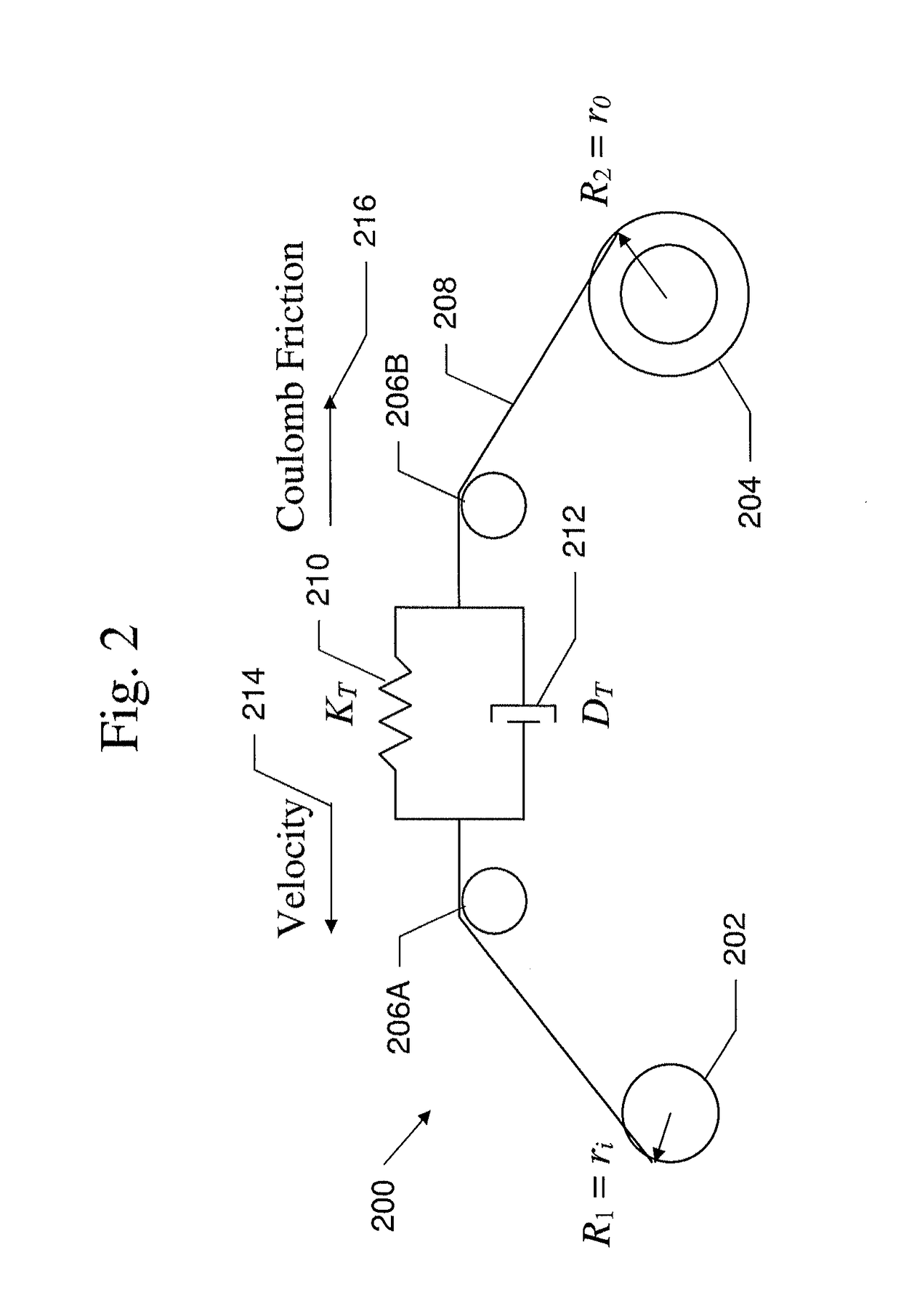

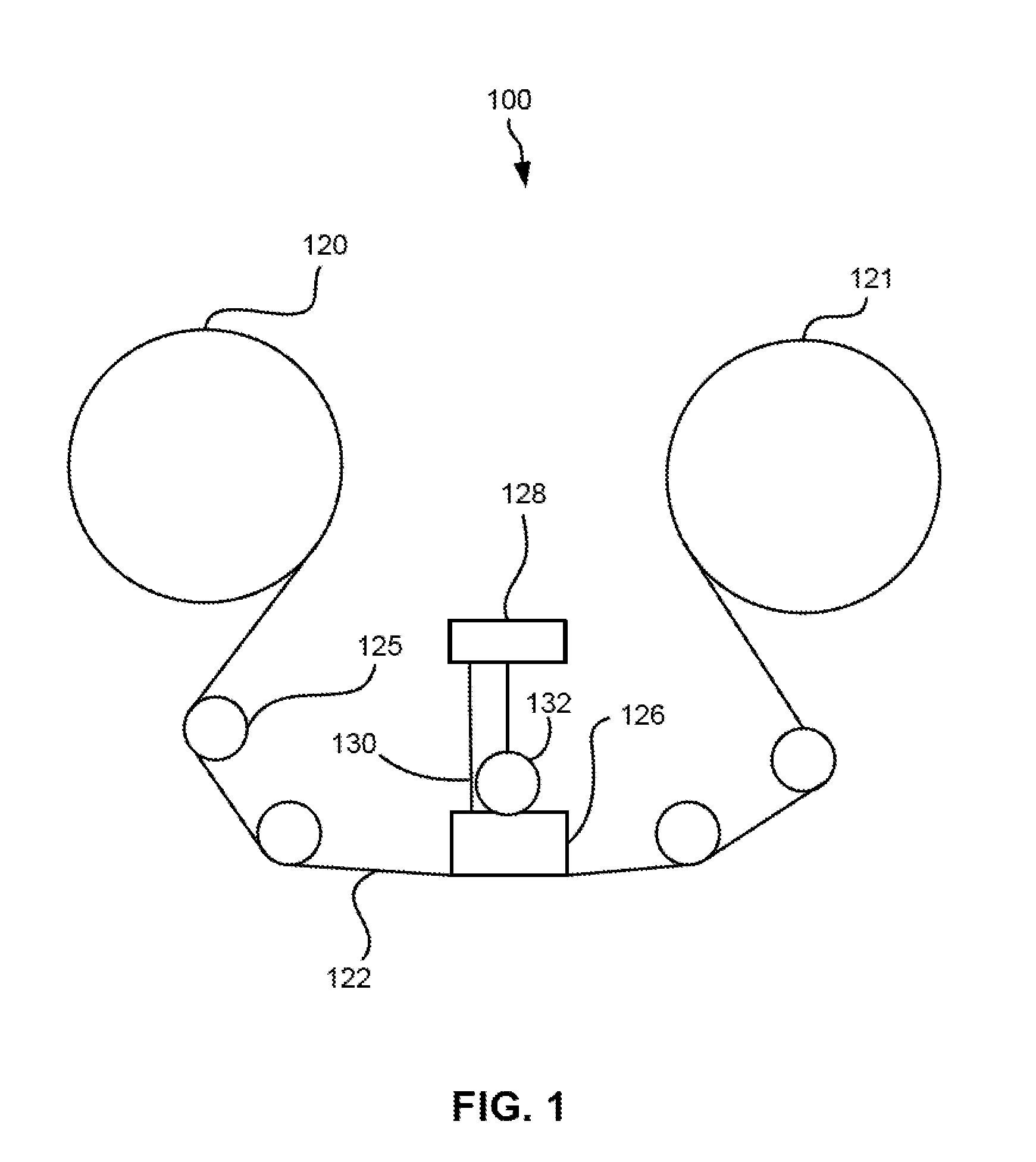

A tape transport servo system and method that do not make use of tachometers and / or encoders to derive tape velocity and position are provided. The tape transport servo system and method derive velocity and position of the tape from a primary and direct manner and also a secondary or alternative manner, especially when the primary or direct manner cannot be used. The tape transport servo system and method control a tape drive and moves a tape between one reel driven by one motor to another reel driven by another motor. The tape is read by a recording head composed of data readers, data writers and a dedicated set of servo read elements. A position and a velocity of the tape are determined from a primary velocity source when the tape is being read by the head. The position and the velocity of the tape are determined from a secondary velocity source when the tape is not being read by the head. The velocity of the tape is compared to a desired programmed reference velocity for the tape. The velocity of the tape is driven to the desired programmed reference velocity if the velocity is not equal to the desired velocity. The velocity of the tape is controlled by regulating the velocity and the driving currents of the motors. The tape transport servo system comprises a digital signal processor and a servo motor control system. The servo motor control system comprises a servo logic system, sensors, PWM motor drivers, power amplifiers, DACs, counters, computation systems, and a timing-based servo pattern monitoring system.

Owner:IBM CORP

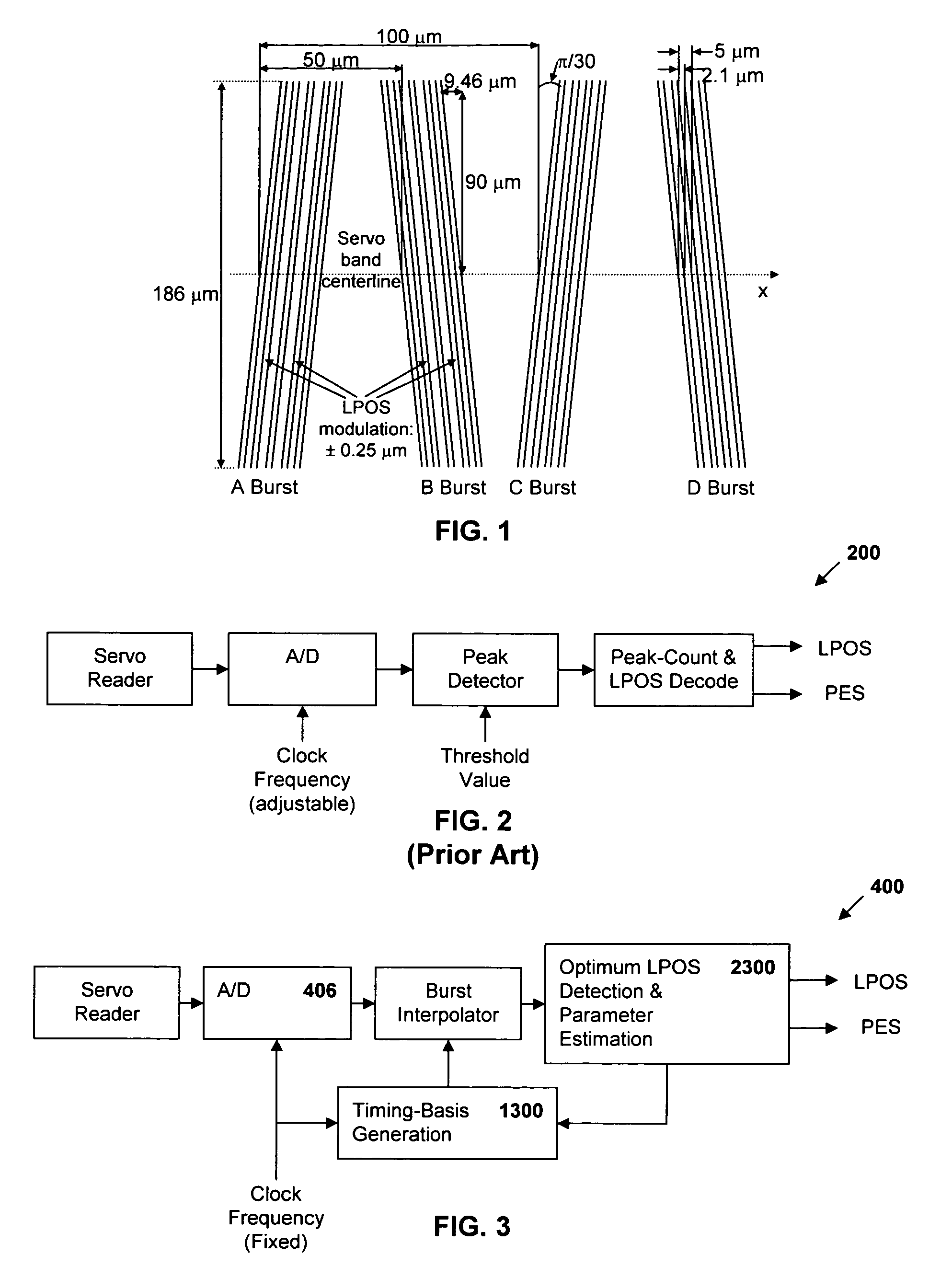

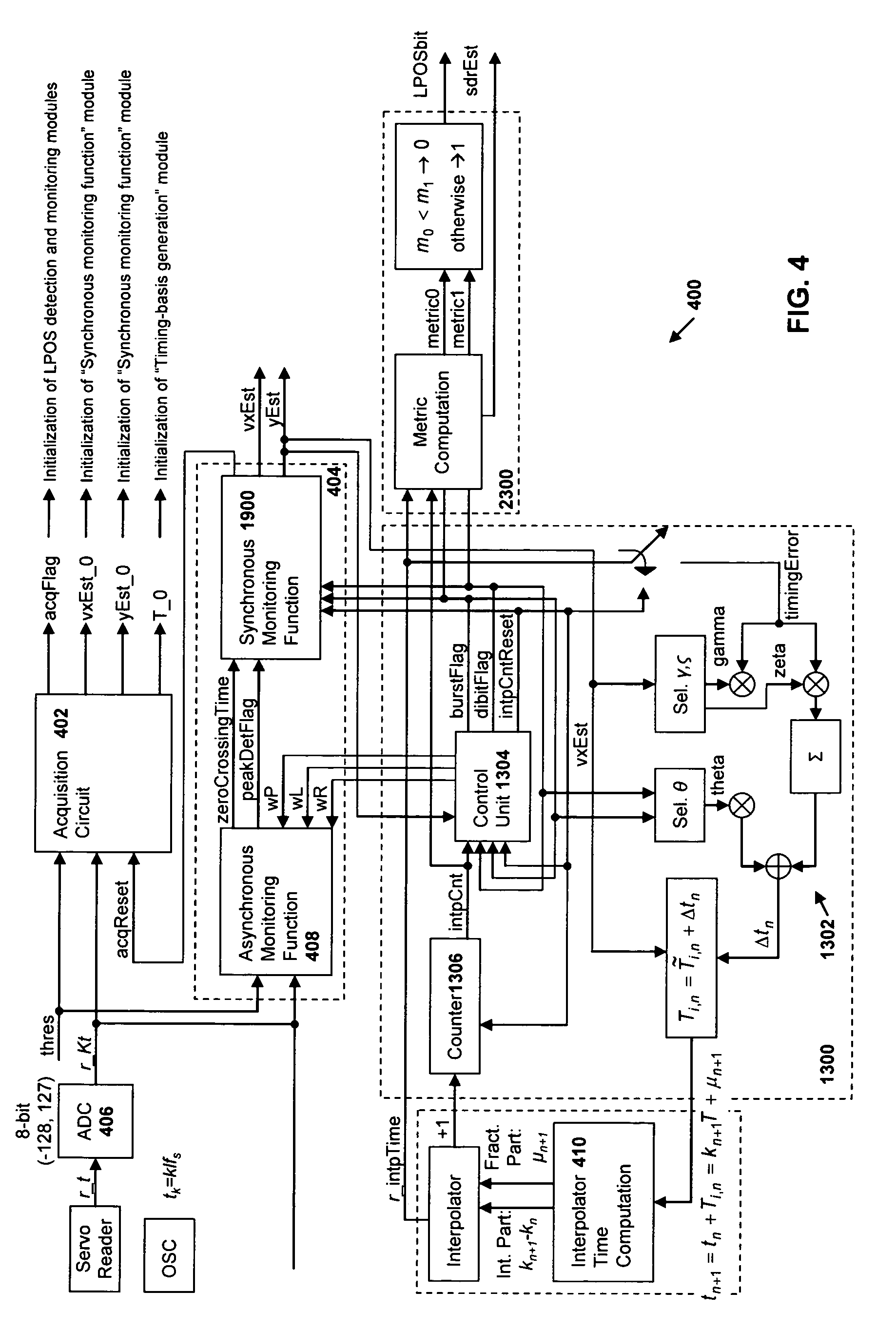

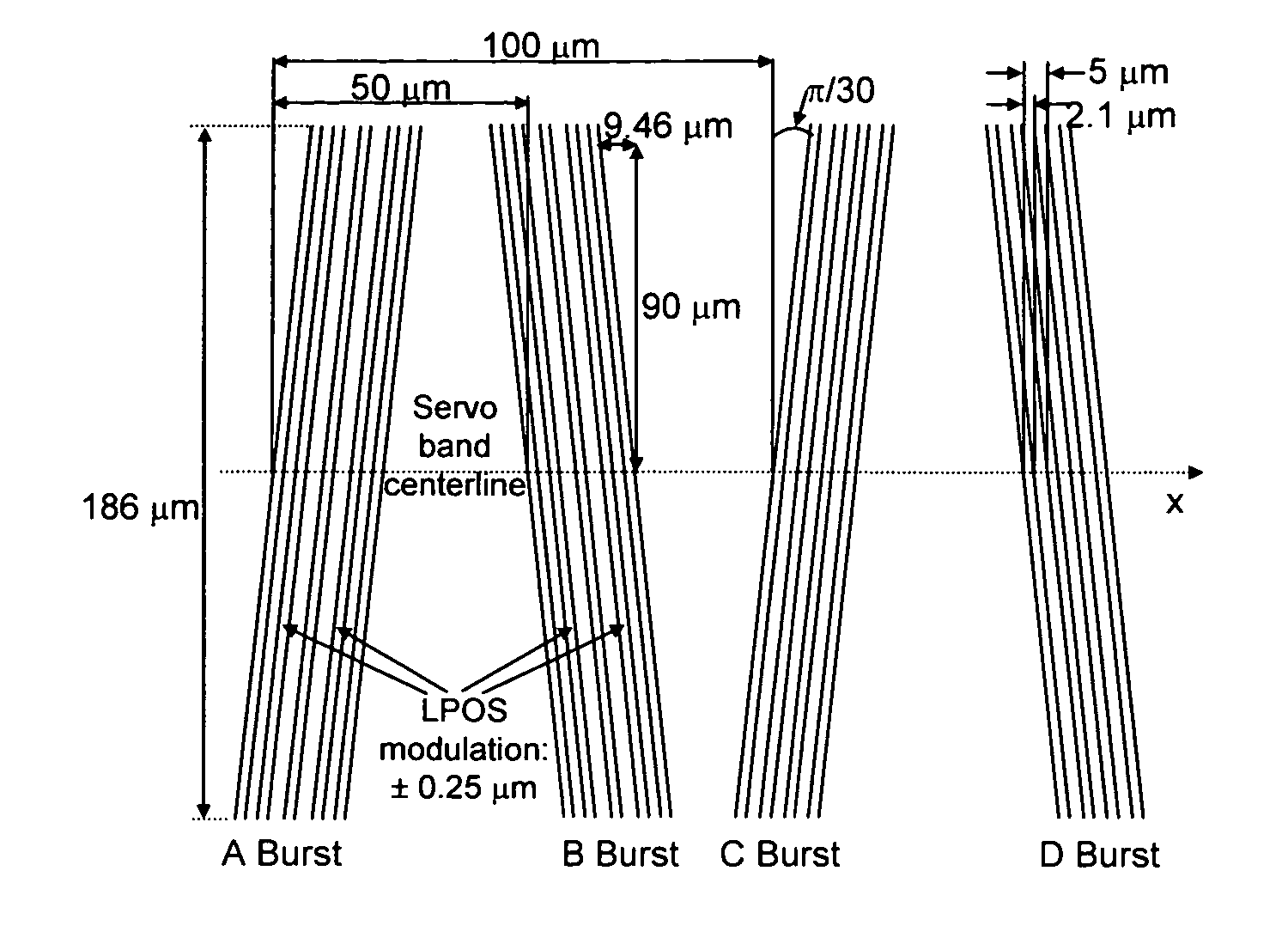

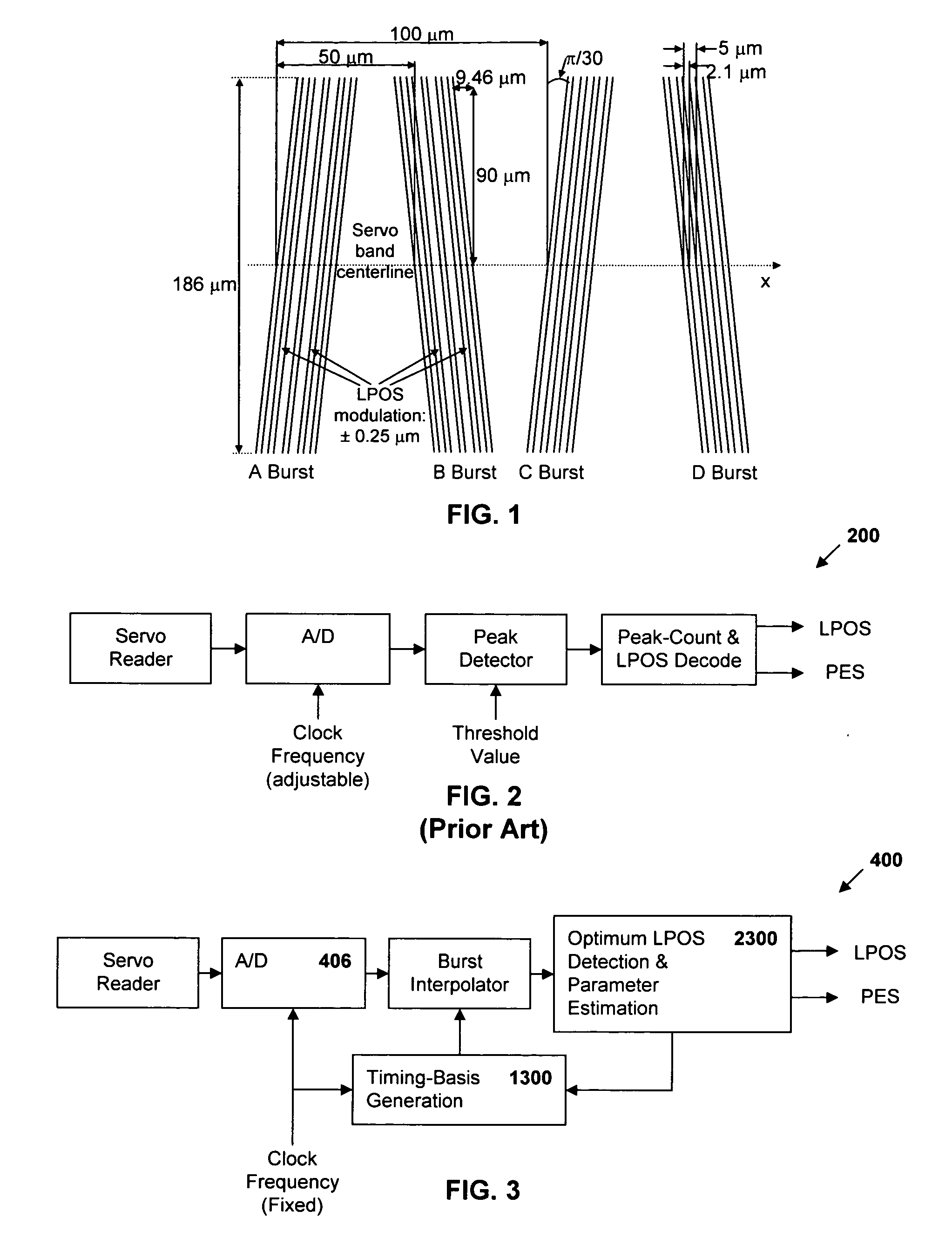

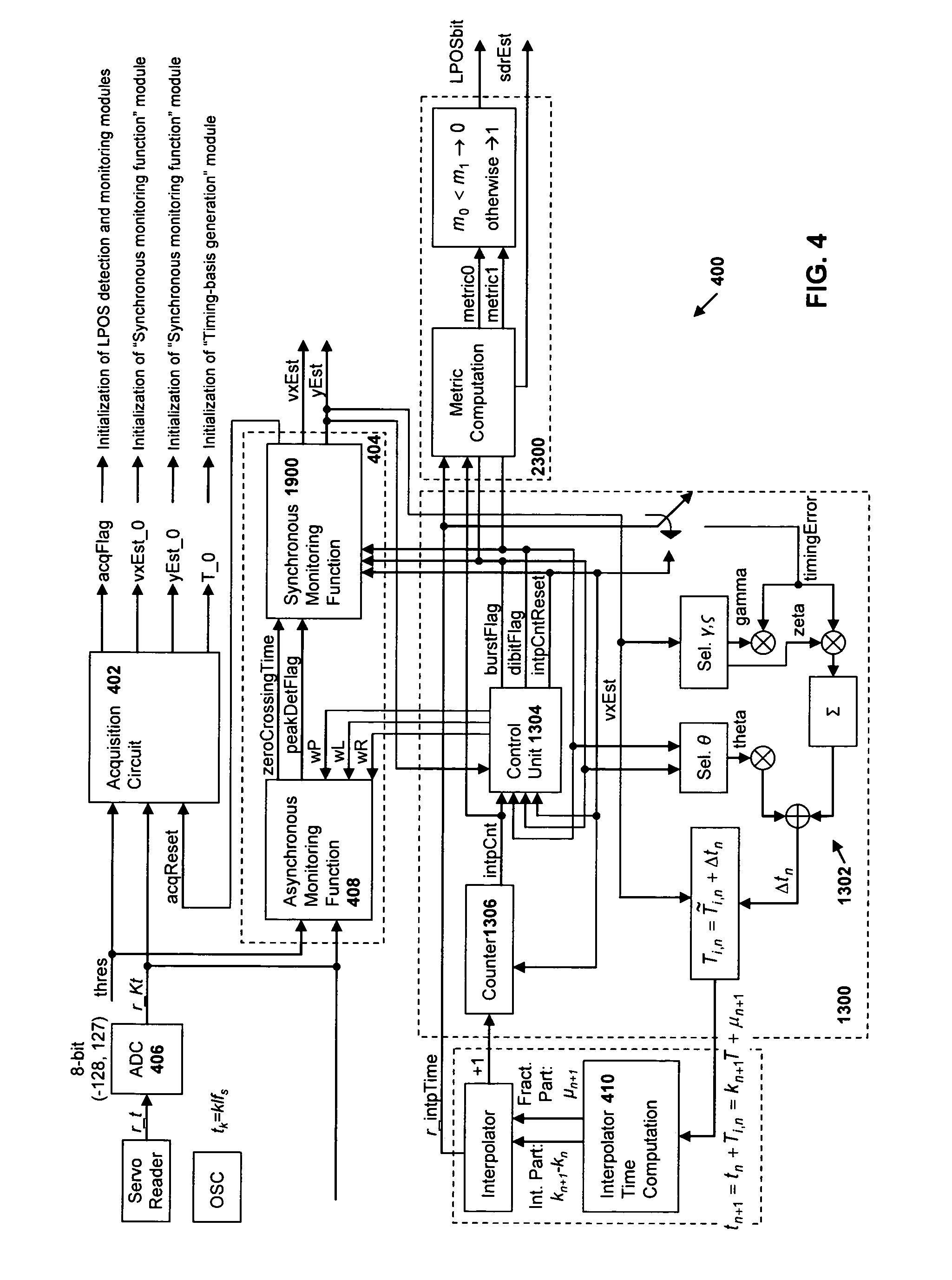

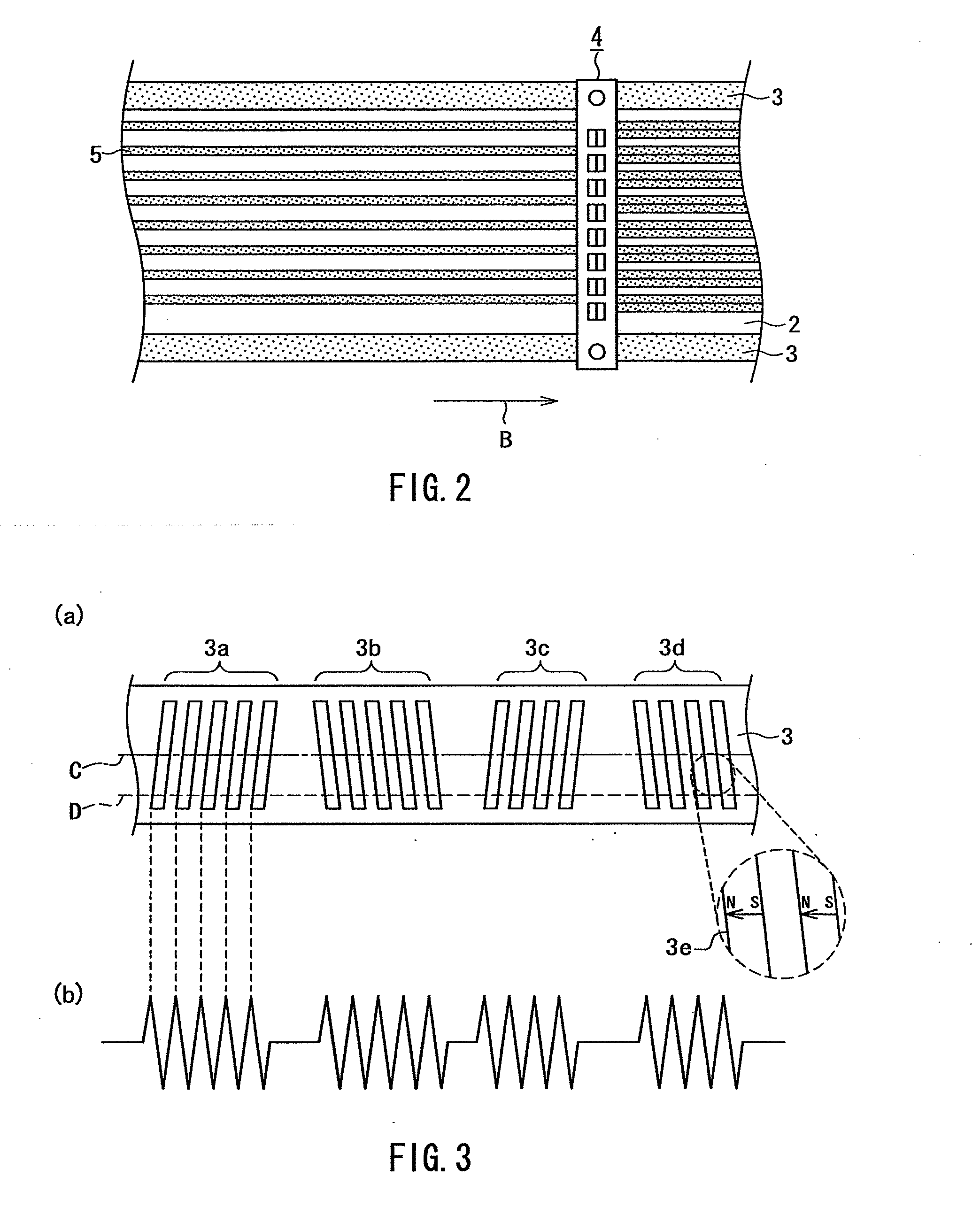

Synchronous servo channel for longitudinal position detection and position error signal generation in tape drive systems

InactiveUS7245450B1Improve reliabilityFilamentary/web record carriersAlignment for track following on tapesTape speedUnit of length

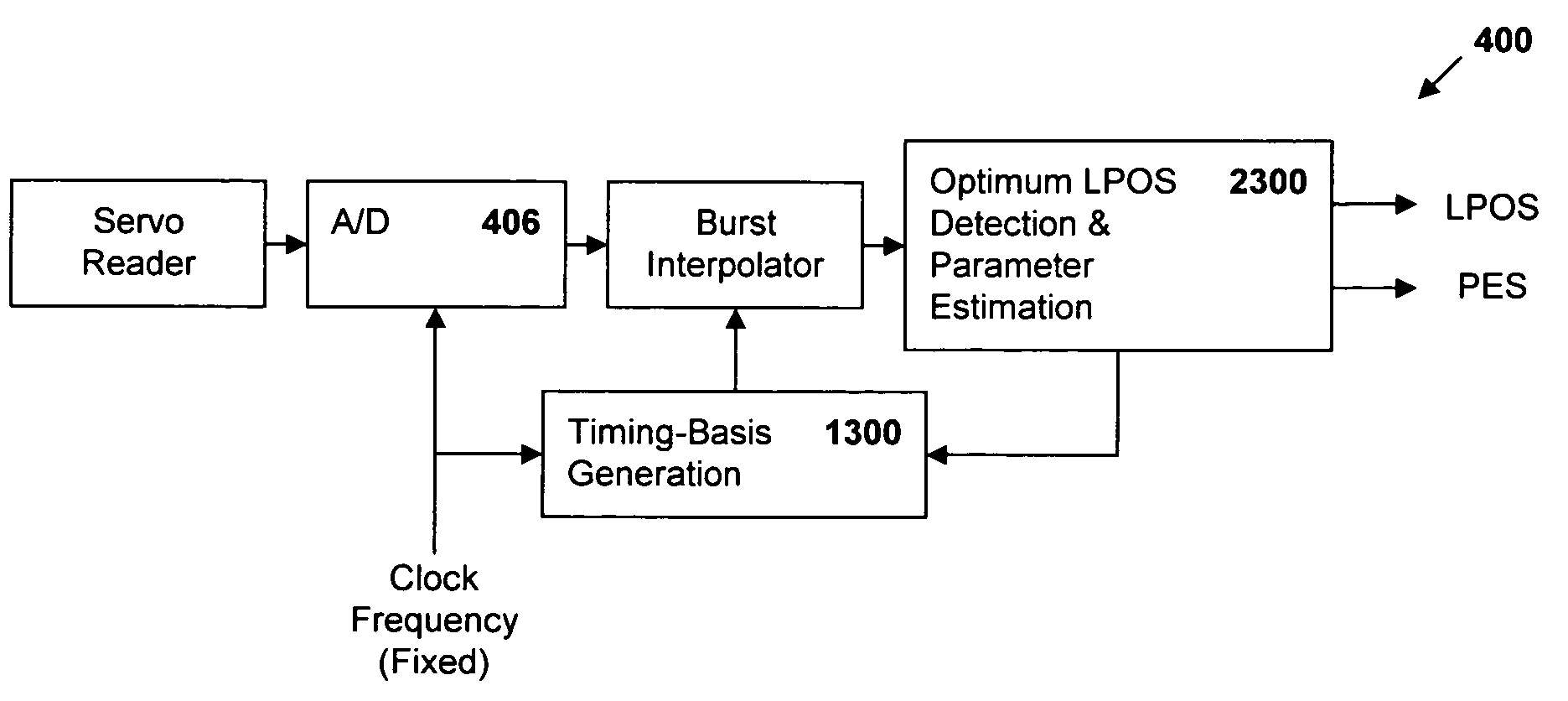

A fully synchronous longitudinal position (LPOS) detection system is provided for improving the reliability of servo channels in tape systems. The system is based on the interpolation of the servo channel output signal, which is sampled by an analog-to-digital converter (ADC) at a fixed sampling rate, using a clock at a nominal frequency, so that interpolated signal samples are obtained at a predetermined fixed rate, independent of tape velocity. This predetermined fixed rate is defined in terms of samples per unit of length, as opposed to samples per unit of time, which is the measure of the ADC sampling rate. The resolution with which the servo channel signal is obtained at the interpolator output is thus determined by the step interpolation distance.

Owner:IBM CORP

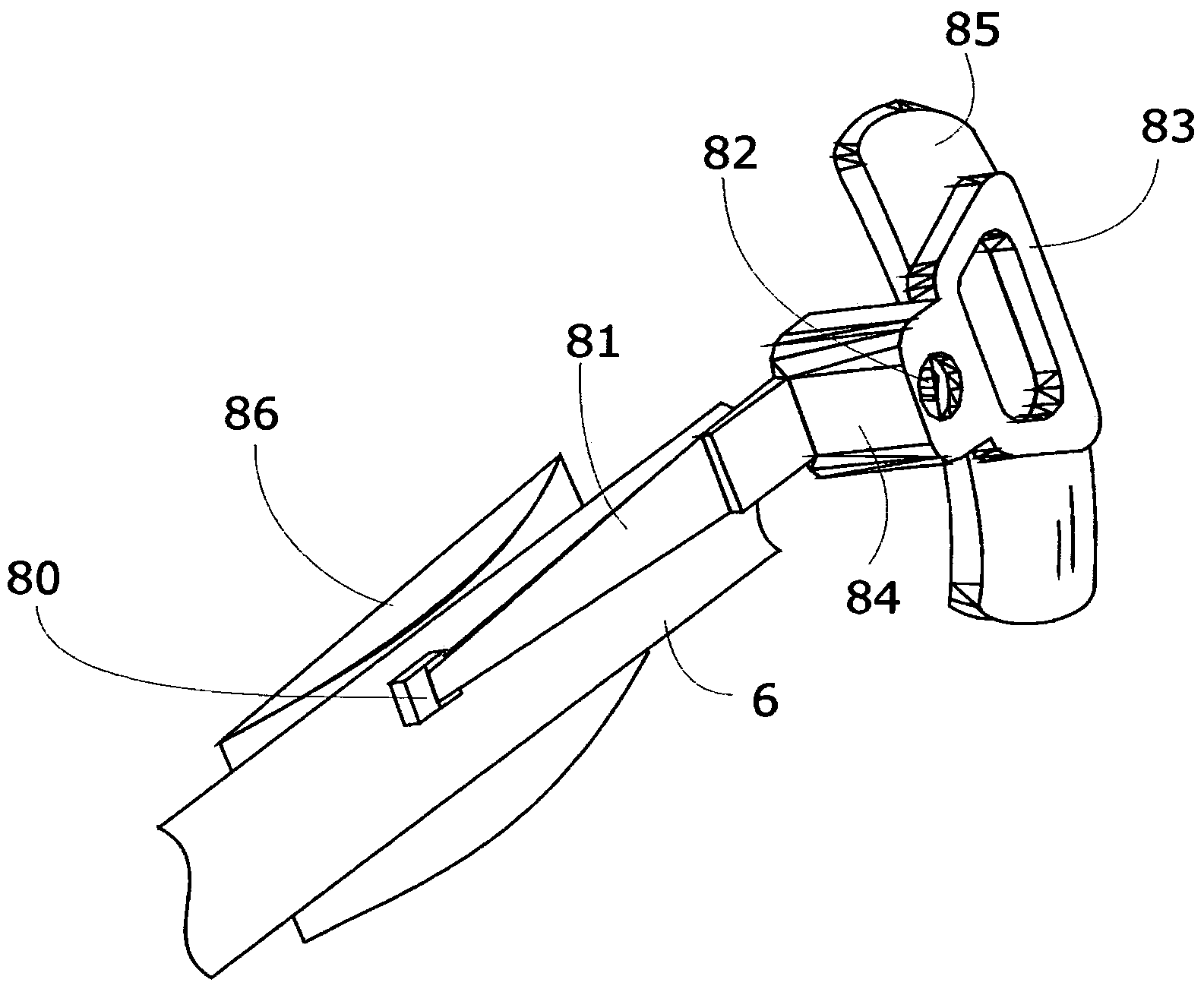

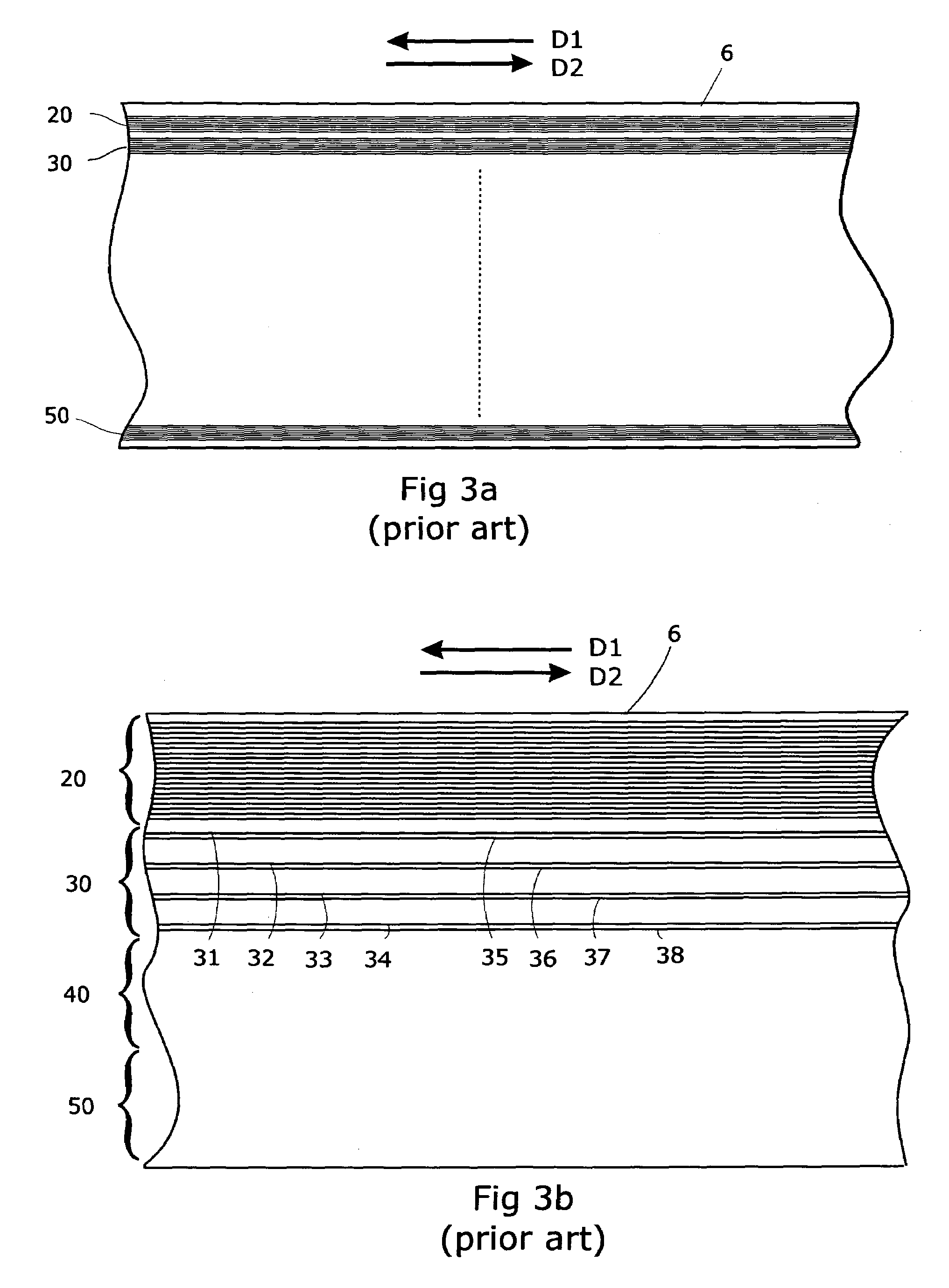

System for high density linear serpentine data recording

InactiveUS7054101B1Reduce tapeReduce head wearFilamentary/web record carriersAlignment for track following on tapesTape speedHigh density

A recording system comprises a read-write head with a length that is substantially smaller than the width of the tape, the small mass of the head allows high frequency track following. The head contacts only that area of the tape currently being accessed, significantly reducing the tape and the head wear. The head flies over the tape with the flying height tightly controlled even at high tape speed and low tape tension. Several methods to stabilize the tape in the recording area are disclosed. The stabilizer can be a second recording head allowing dual sided recording. A first implementation uses a linear actuator and a second implementation uses a rotary actuator. A mechanism moves the head from the path of a threading mechanism.

Owner:MOUNTAIN ENG II

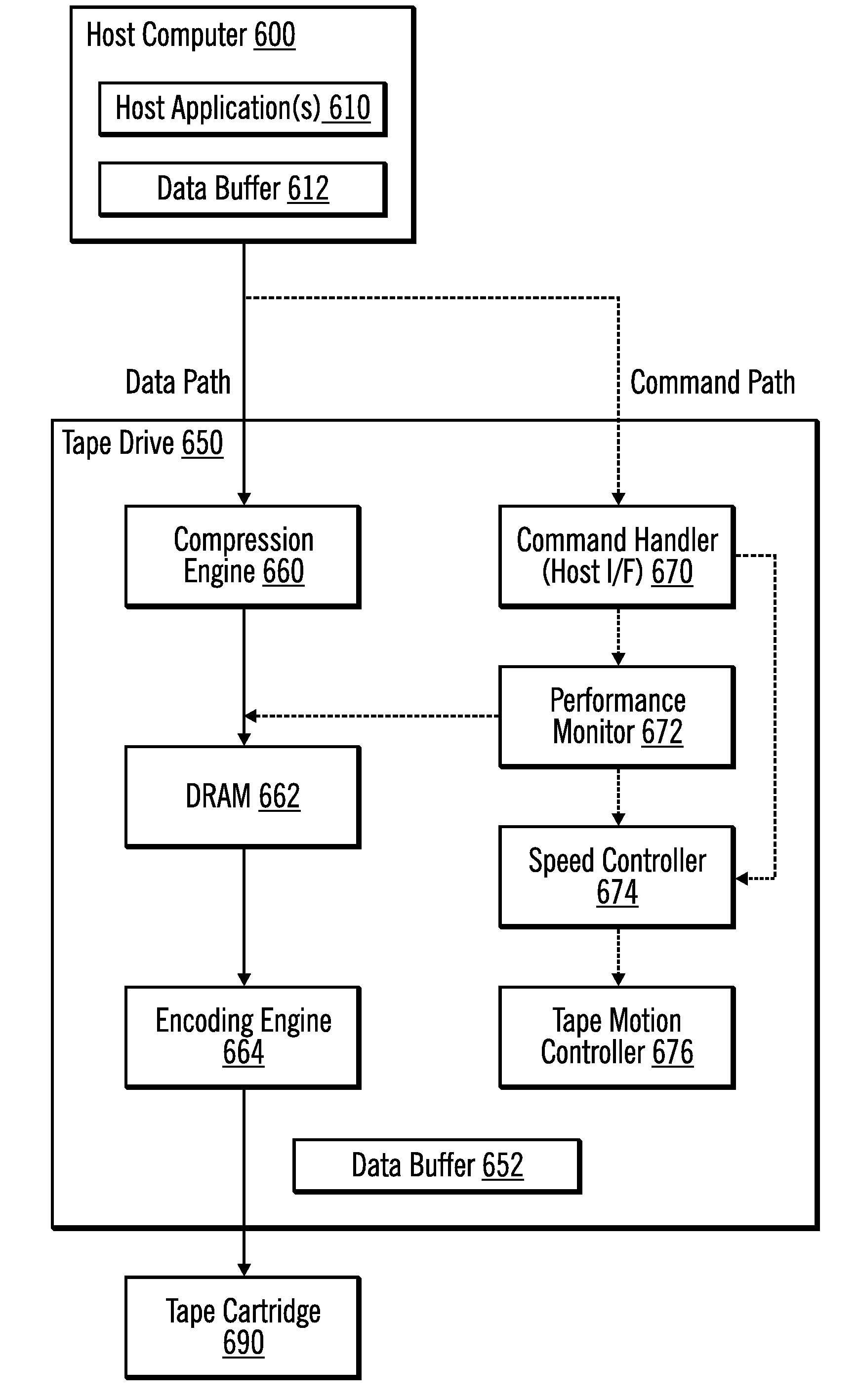

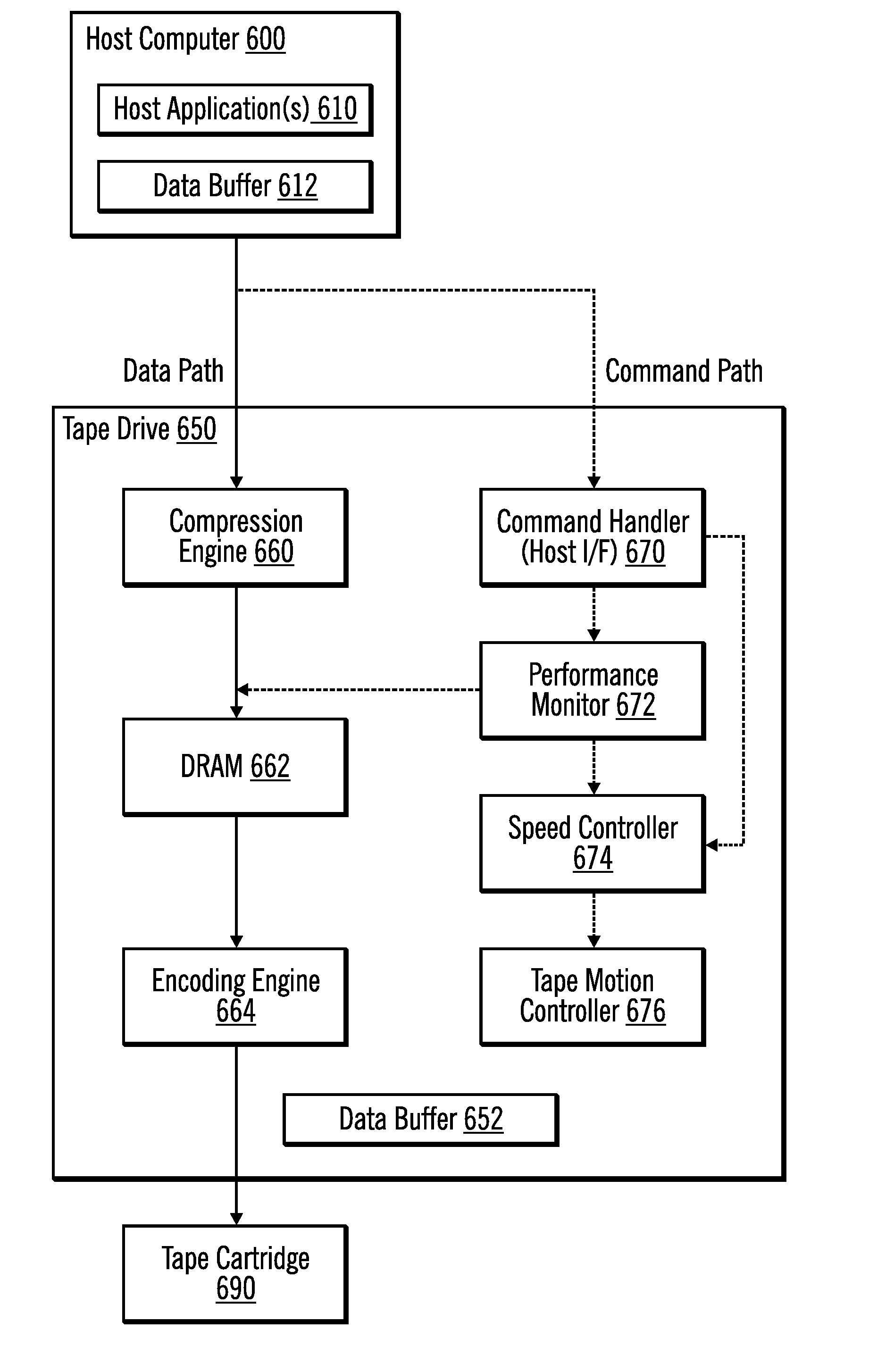

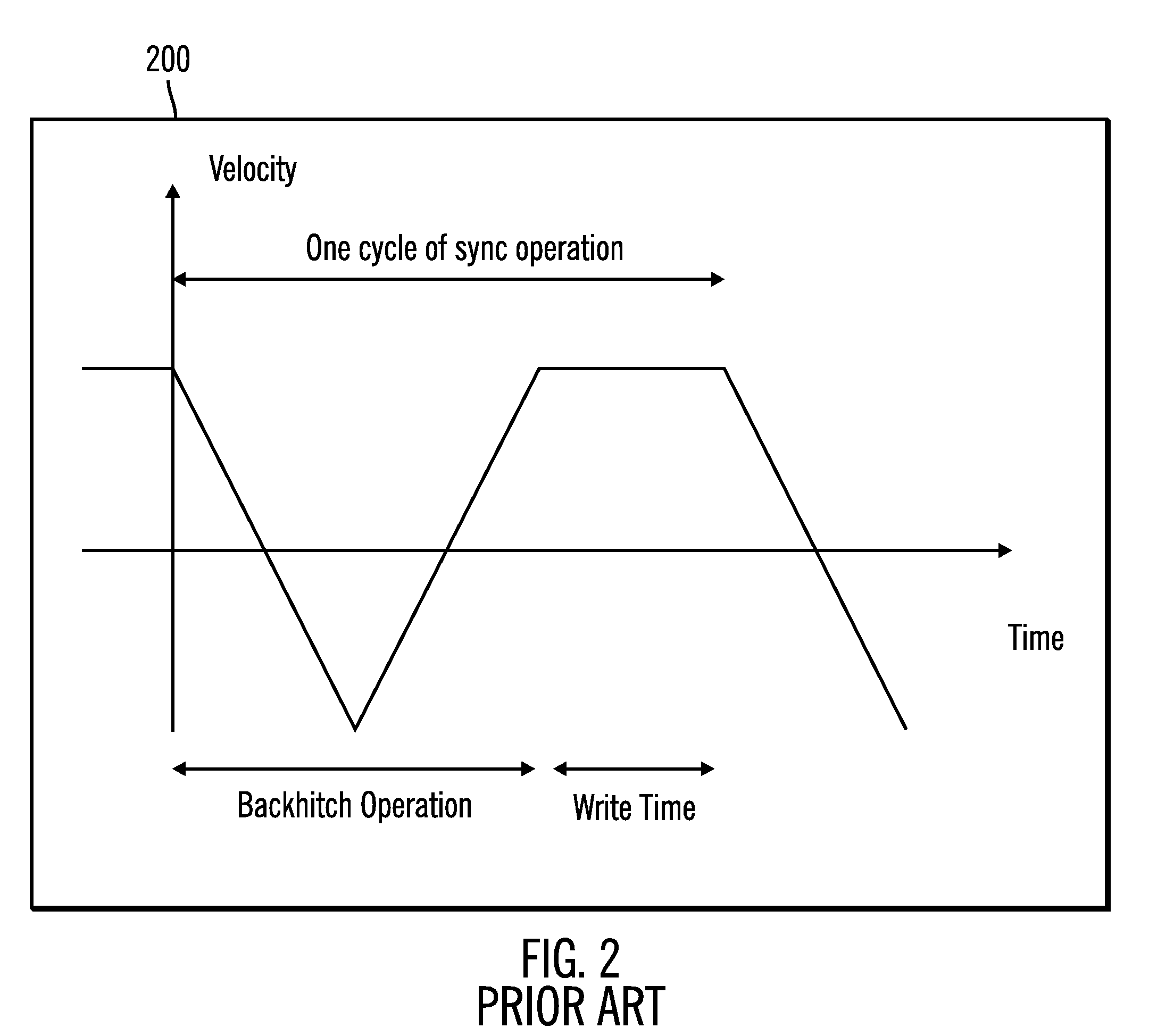

Optimizing tape speed for a sync operation

InactiveUS7710681B2Record information storageCarrier speed control/regulation/indicationComputer hardwareTape speed

Provided are techniques for determining a tape speed for a next sync operation. A sync command is received. An average transaction size and an average host transfer rate of a set of previous sync operations are calculated. The tape speed for the next sync operation is determined using the average transaction size, the average host transfer rate, and a backhitch time. Data is written to a tape cartridge using the determined tape speed.

Owner:IBM CORP

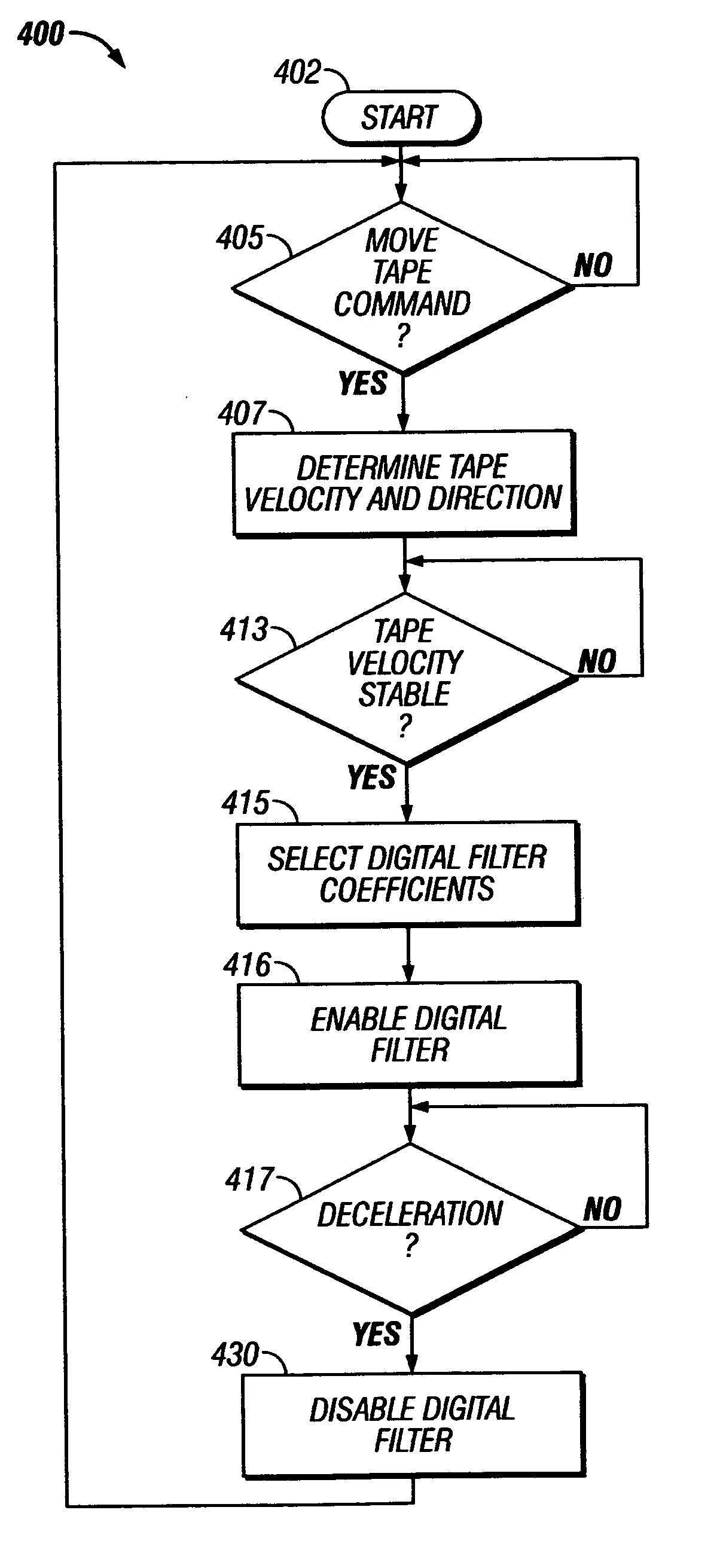

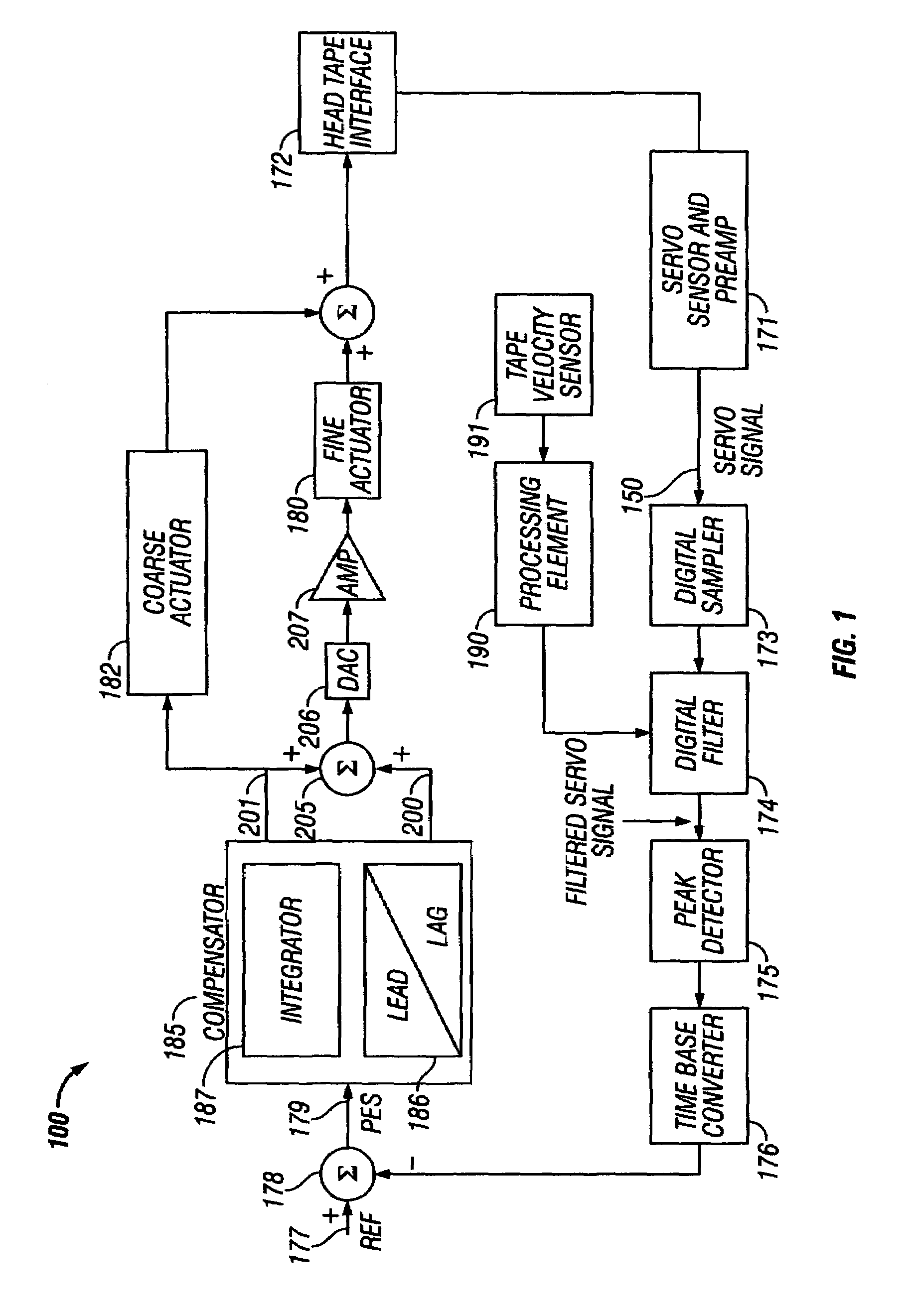

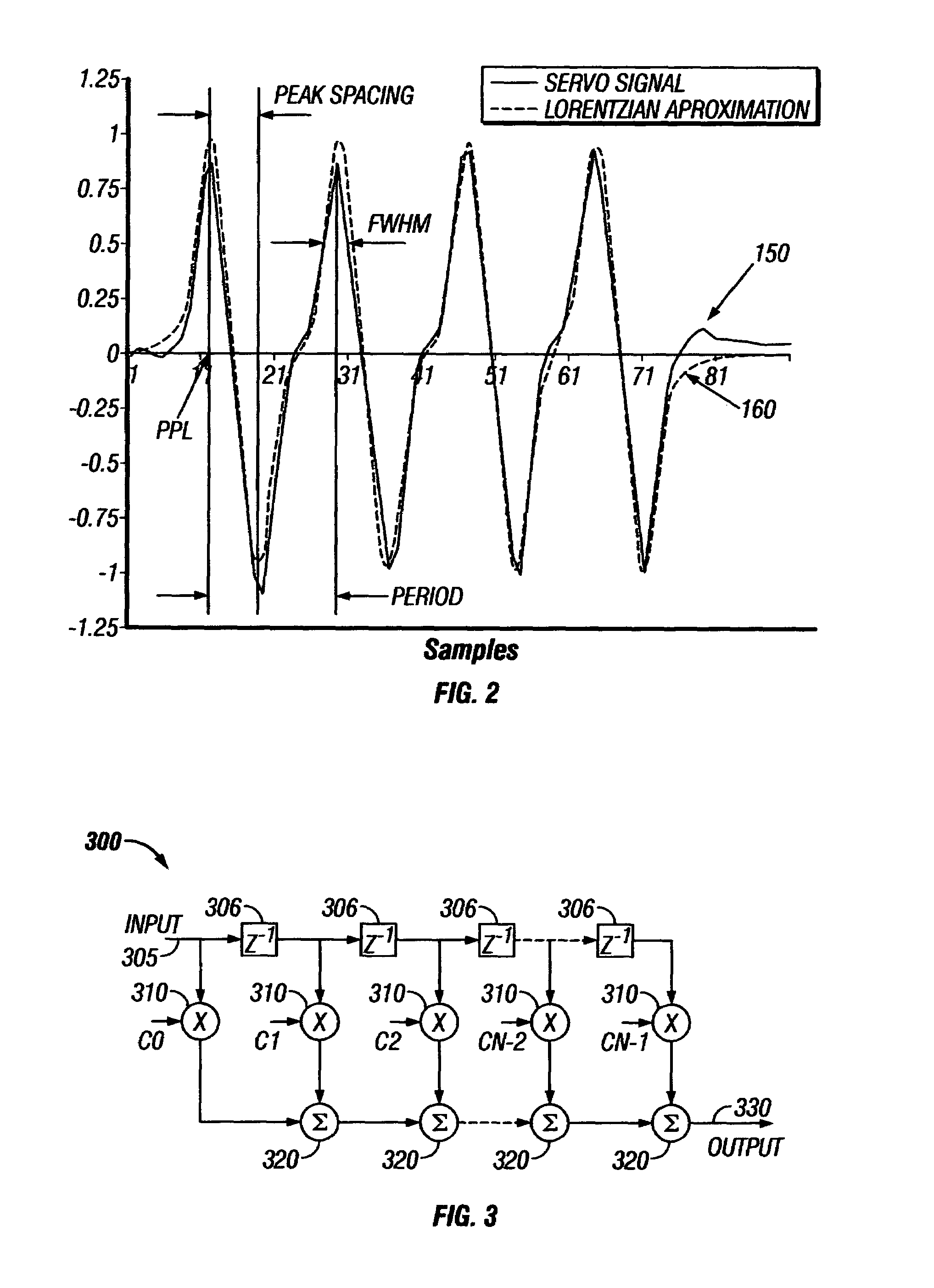

Matched filter detection for time based servo signals in a tape drive

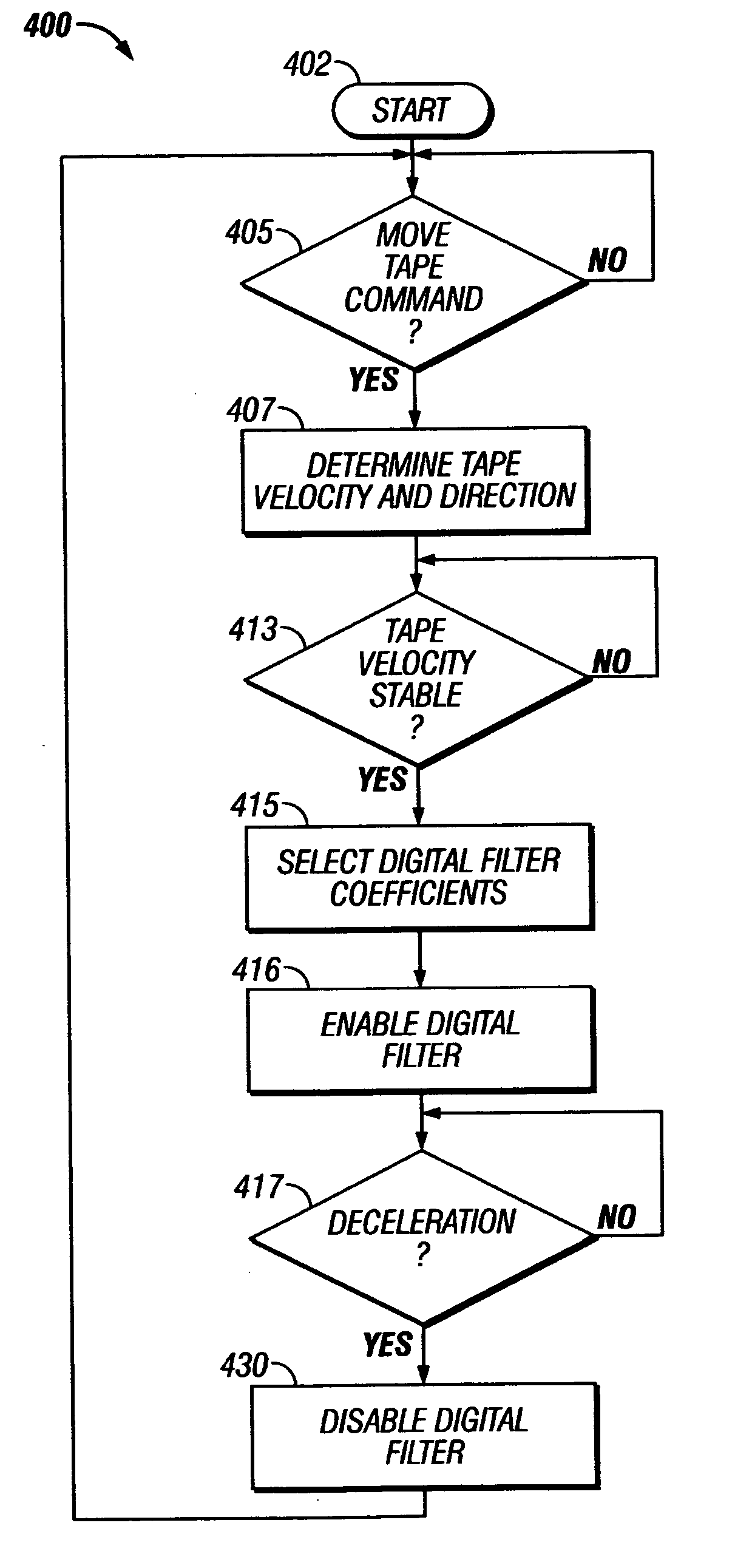

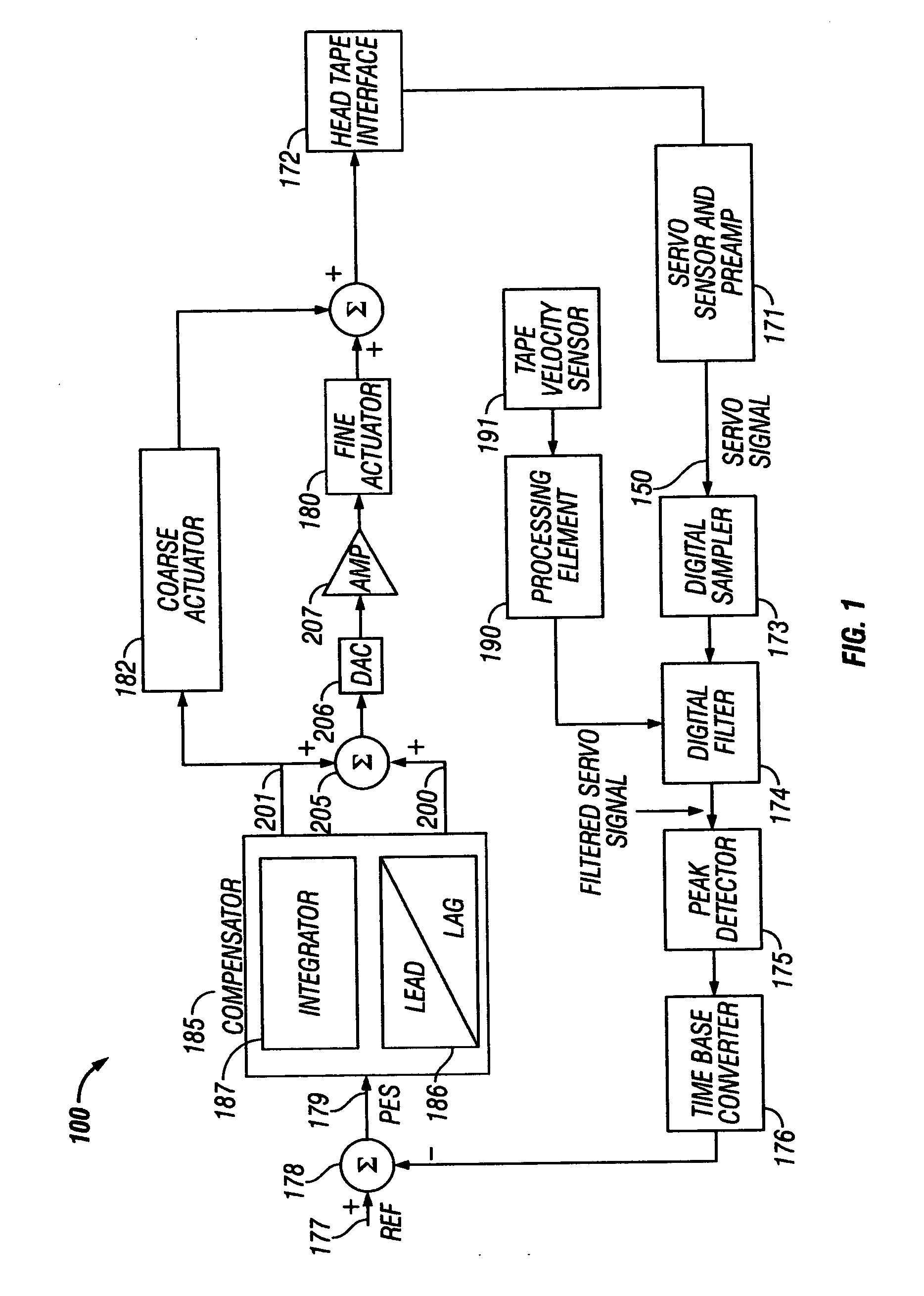

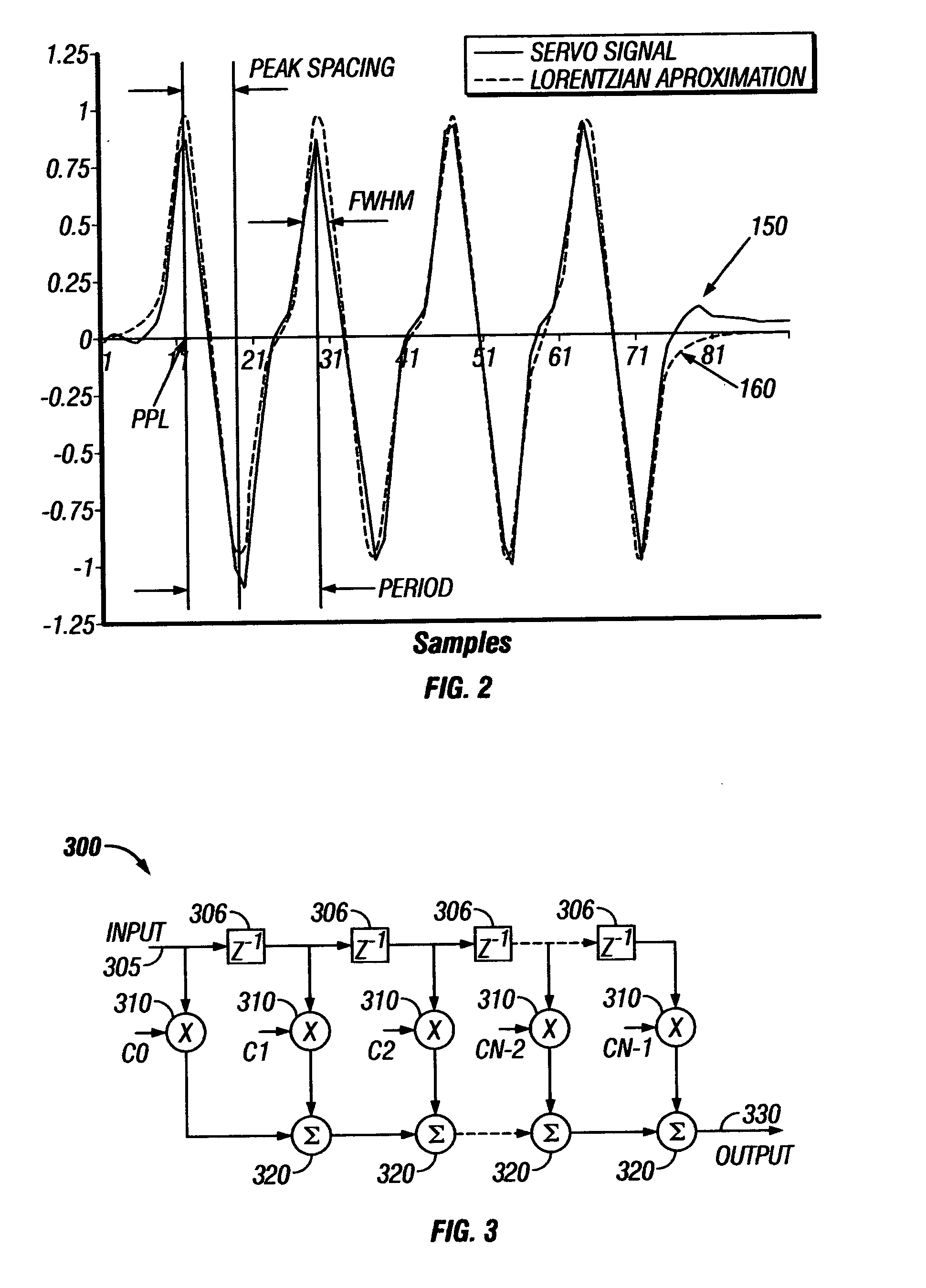

InactiveUS6940683B2Reduce noiseEasy to operateAlignment for track following on tapesRecord information storageTape speedDigital filter

Disclosed are a system, a method, and article of manufacture to provide for filtering a servo signal in a tape drive using a matched filter that is optimized for the operating tape velocity of the tape drive. A servo controller for track following on a tape uses a digital filter implementation of the matched filter to produce a filtered servo signal. The digital filter is optimized for different tape velocities by selecting digital filter coefficients for the digital filter that depend upon the tape velocity presently in use. The filtered servo signal is used by the servo controller to provide improved track following in a tape drive.

Owner:IBM CORP

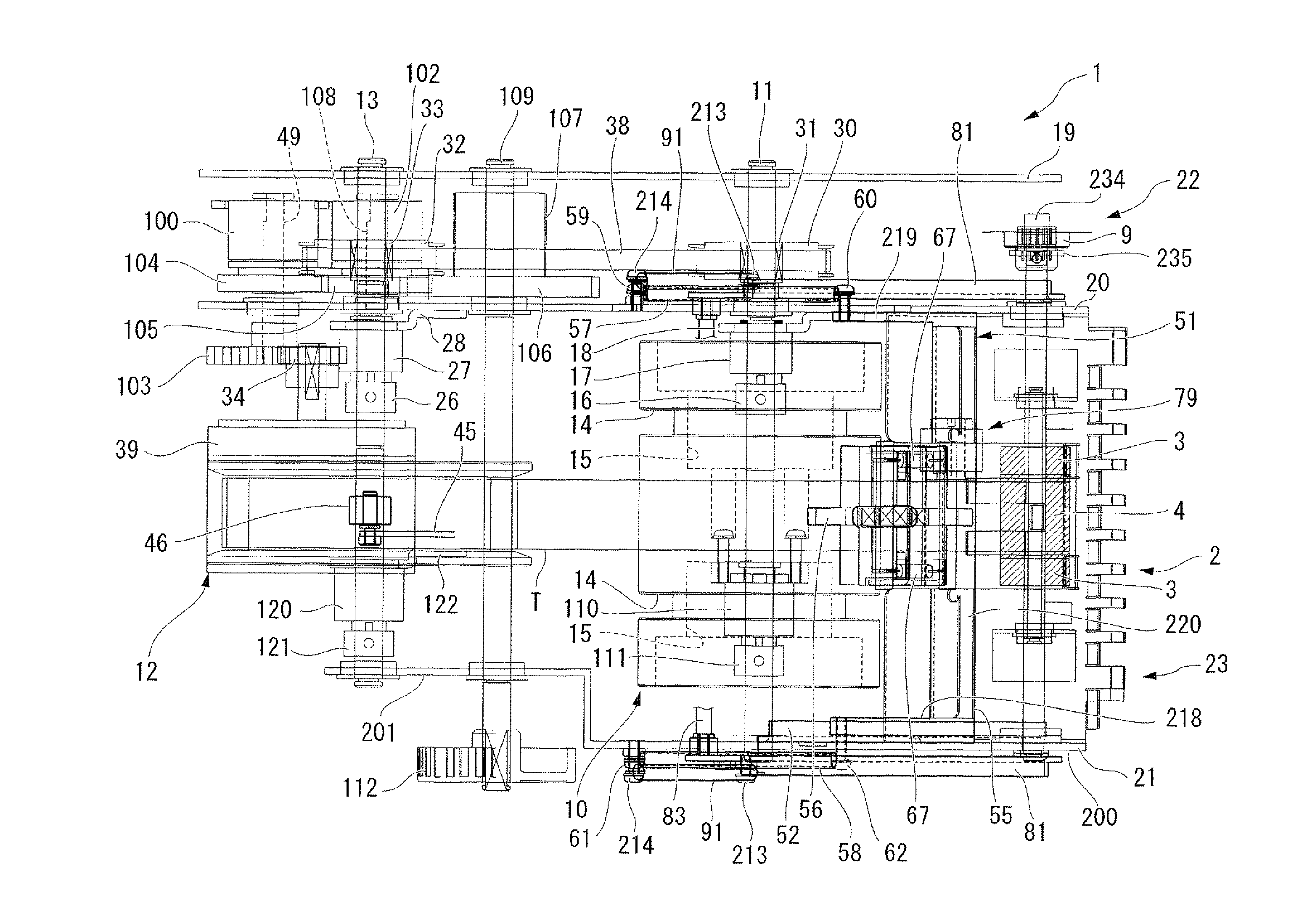

Sheet paper storage and dispensing device

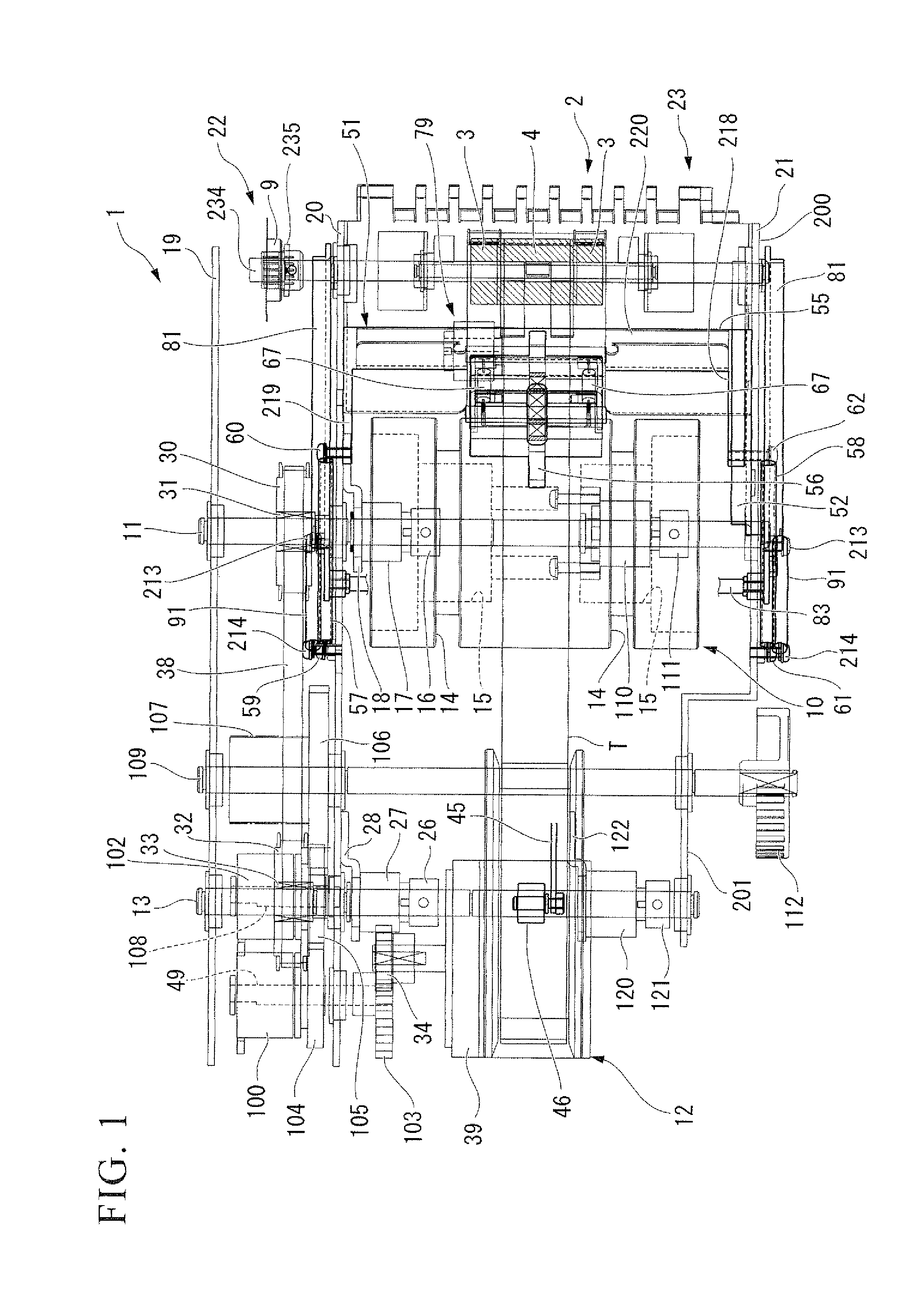

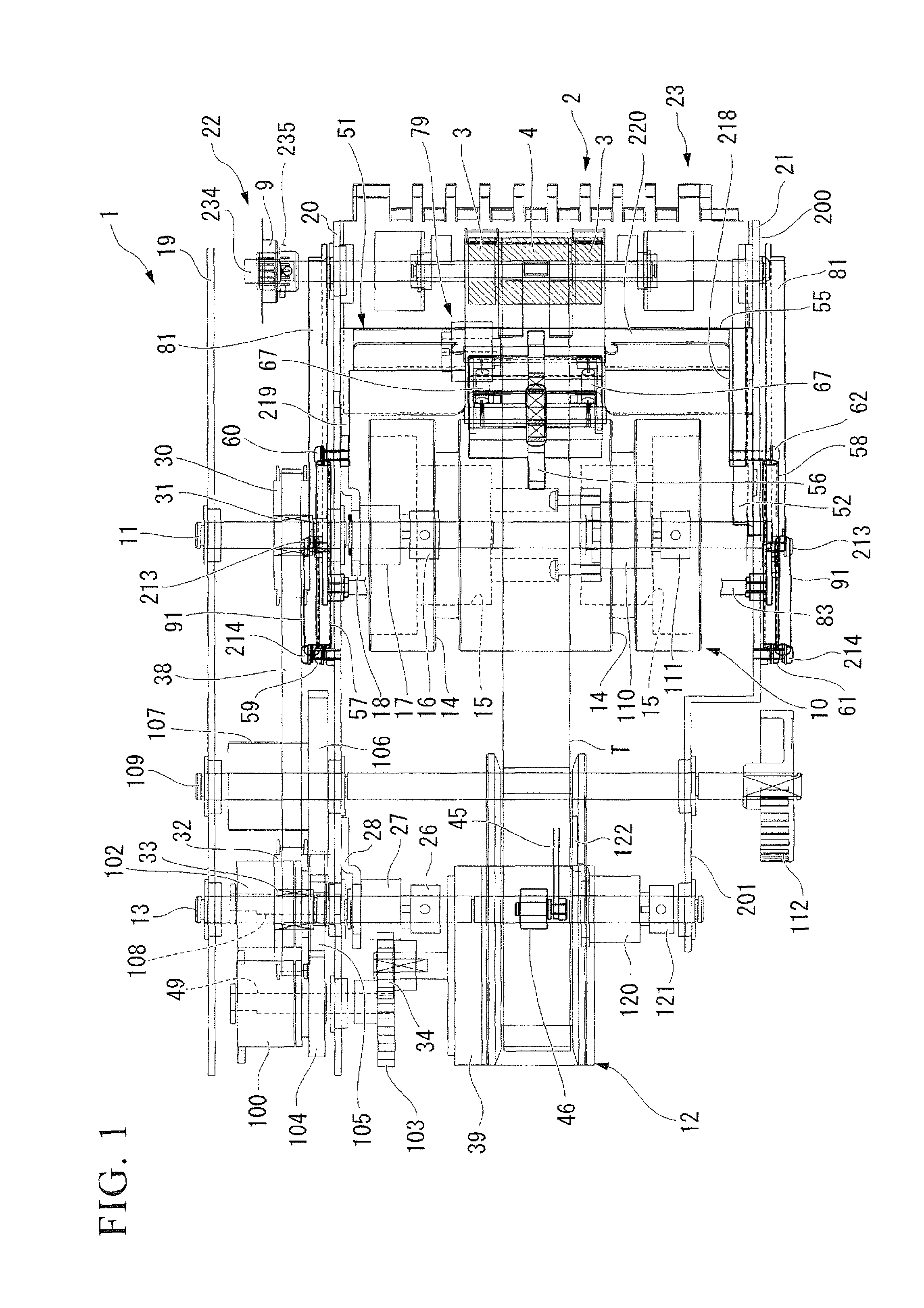

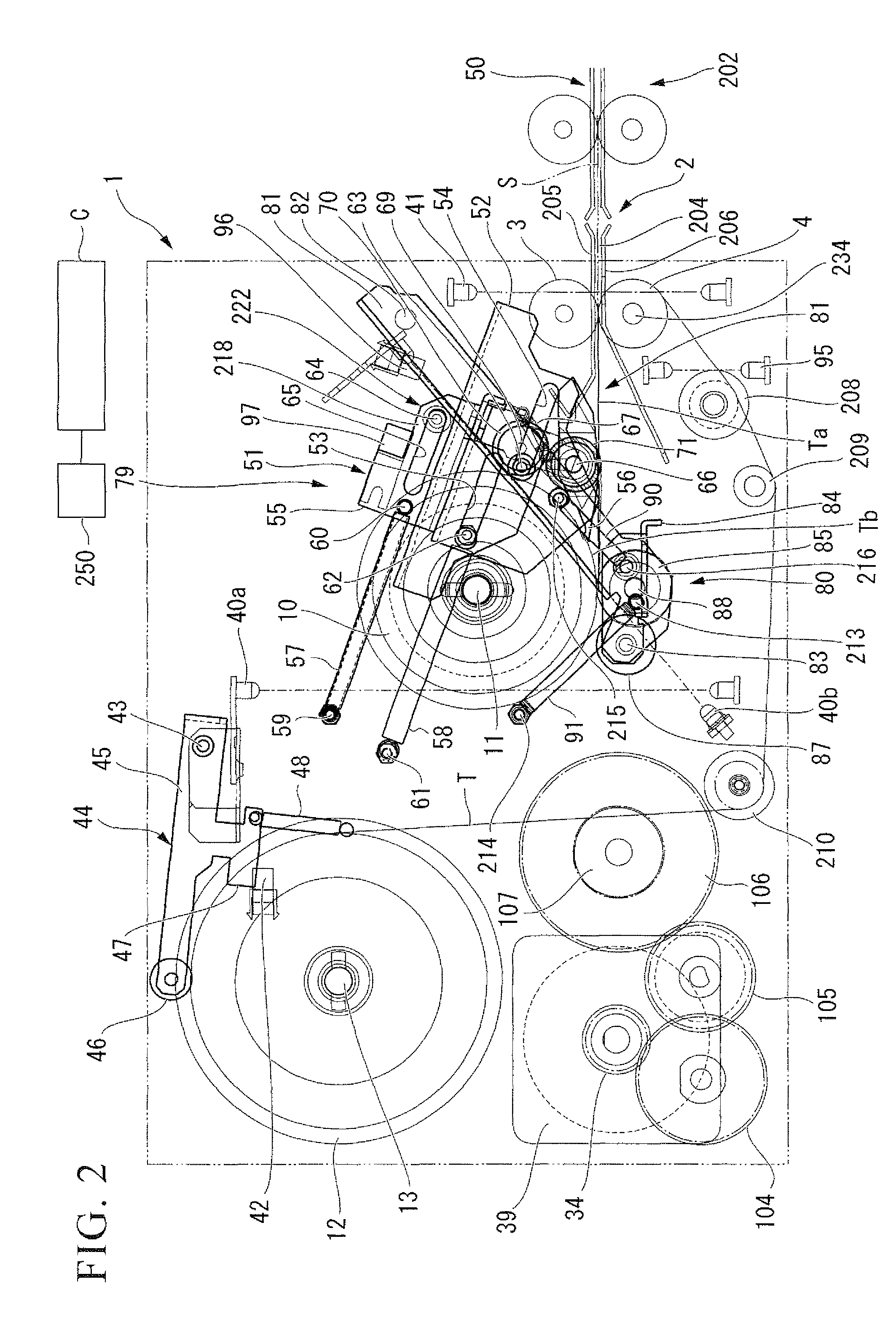

InactiveUS20100100245A1Accurate detectionEasily and accurately measureSampled-variable control systemsComputer controlTape speedMotor speed

A sheet paper storage and dispensing device according to the present invention stores and dispenses sheet paper, and includes: a first reel drum onto which a tape is wound from one side of the tape; a second reel drum on which sheet paper is stored by winding the tape thereon from an opposite side of the tape in a state in which the tape and sheet paper supplied from an external sheet paper transporting section to an intake / discharge port are mutually superimposed; a motor which drives the first reel drum and the second reel drum via a drive system; an electromagnetic clutch which switches between transmitting and interrupting drive force from the drive system; an electromagnetic brake which applies a brake to the drive system; a trigger sensor which detects supplying of the sheet paper from the sheet paper transporting section to the intake / discharge port; a tape speed detection section which detects a transporting speed of the tape at the intake / discharge port; a motor speed variation control unit which controls changes in a rotation speed of the motor; and a winding control unit which causes a winding operation by controlling the electromagnetic clutch so as to transmit the driving force of the motor when supplying of the sheet paper to the intake / discharge port is detected by the trigger sensor, the winding operation being a operation in which the tape is dispensed from the first reel drum while the tape is wound onto the second reel drum, so that the sheet paper supplied to the intake / discharge port is wound onto the second reel drum, the winding control unit controlling the motor speed variation control unit such that, during the winding operation, the transporting speed of the tape detected by the tape speed detection unit is held at a fixed speed which is faster by a predetermined amount than a transporting speed of the sheet paper transporting section.

Owner:LAUREL PRECISION MACHINES

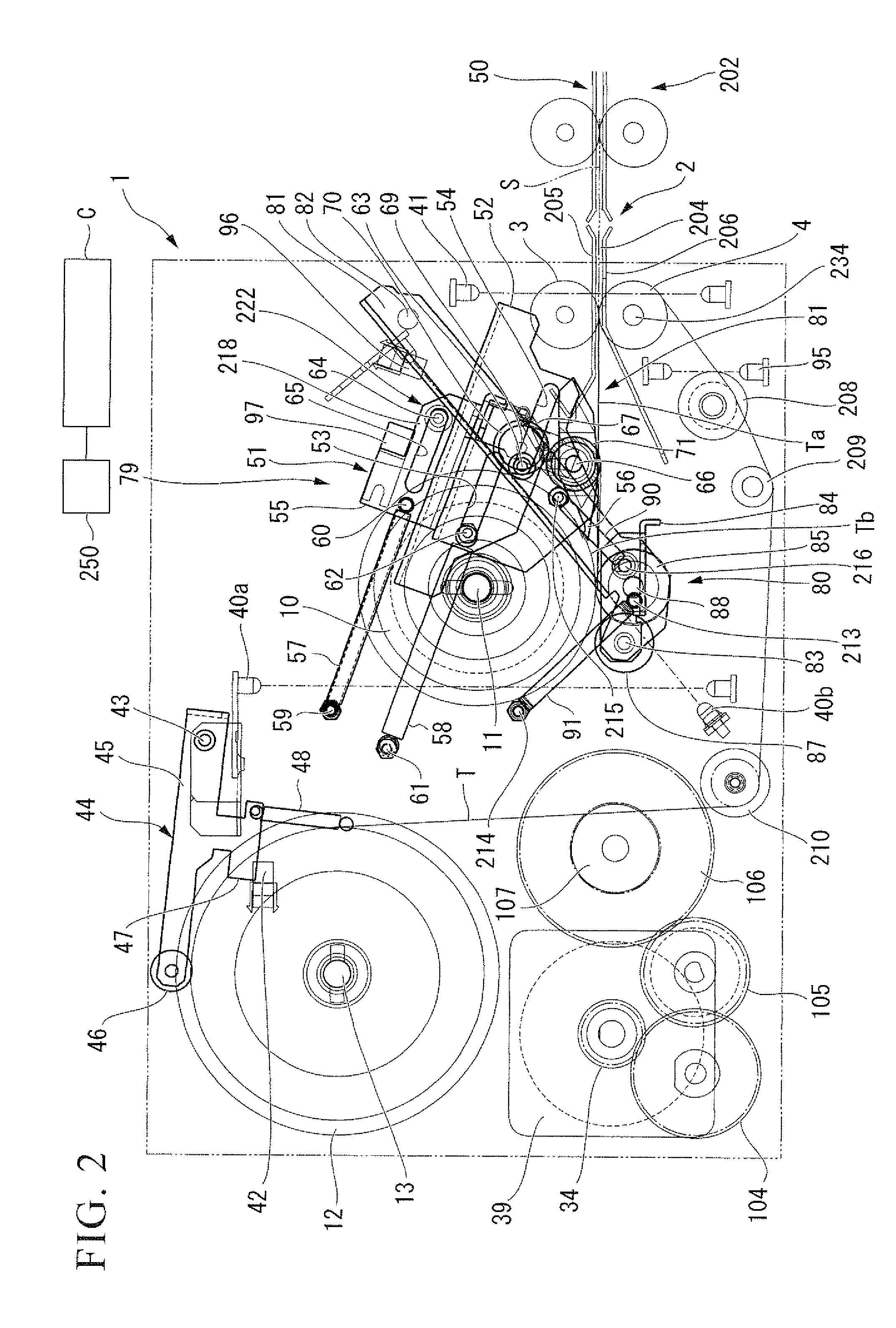

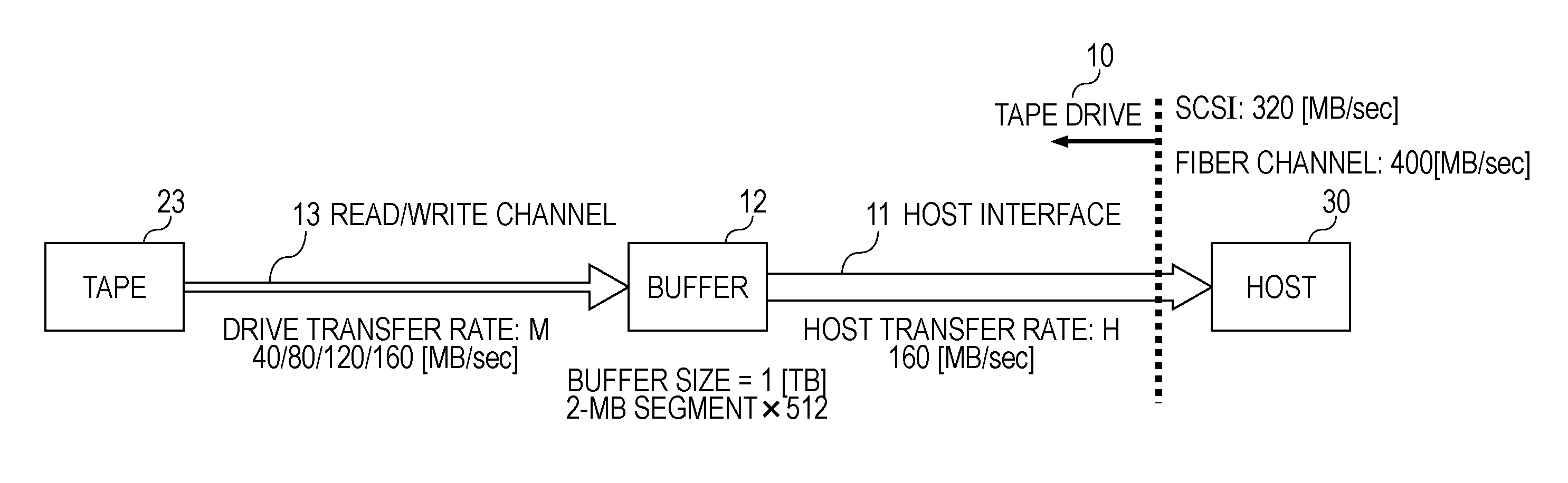

Tape drive, tape drive recording system, and method for selecting improved tape speed in response to intermittent read requests

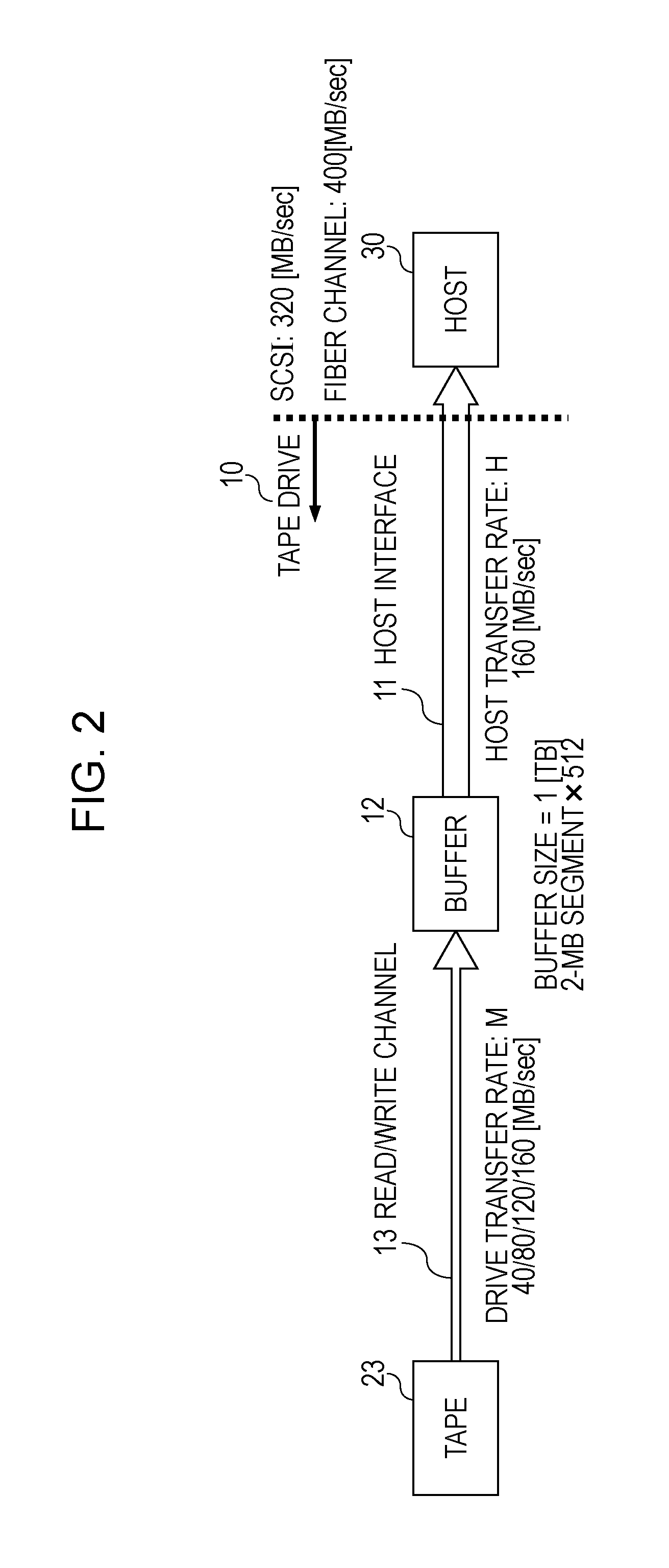

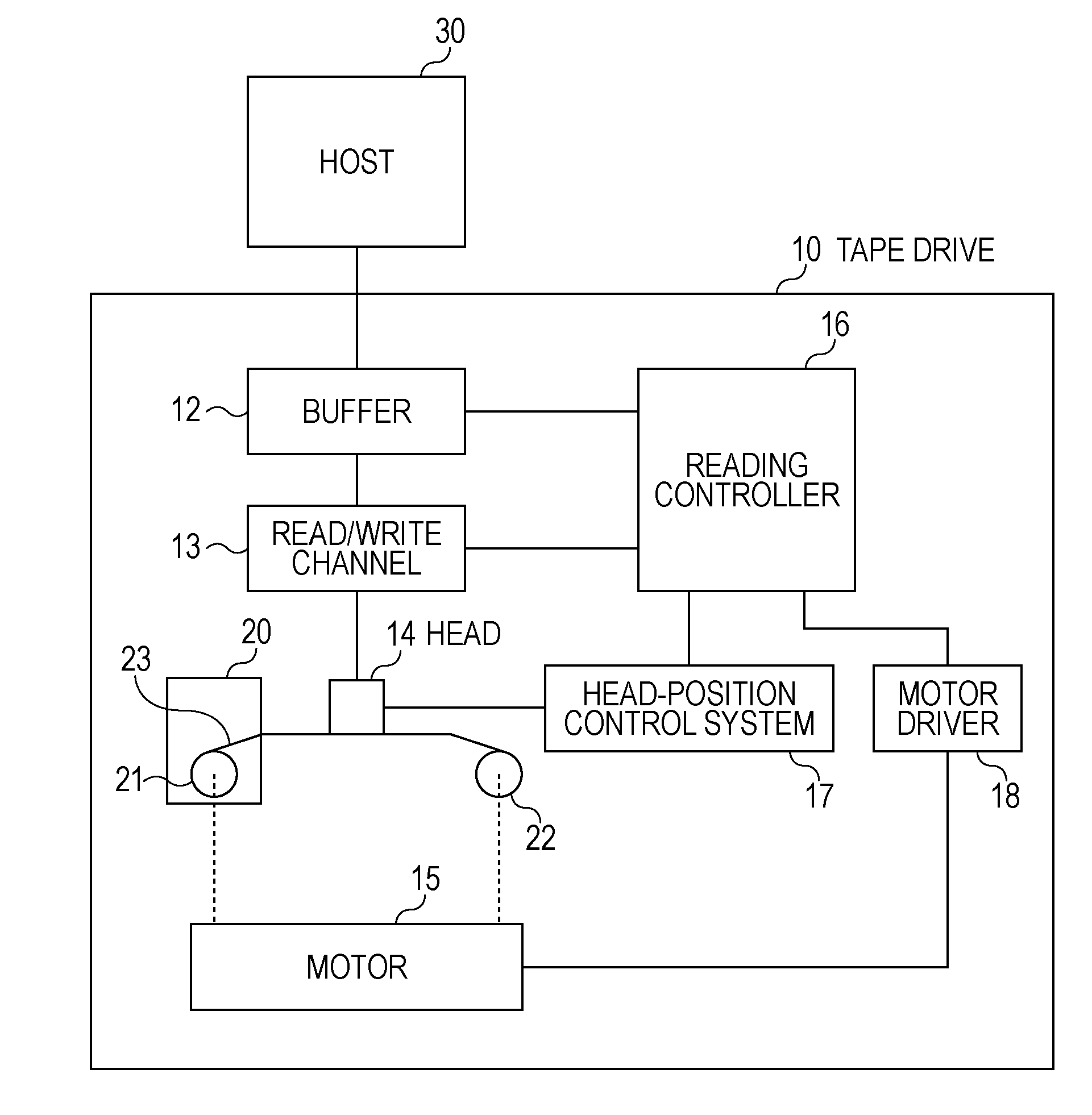

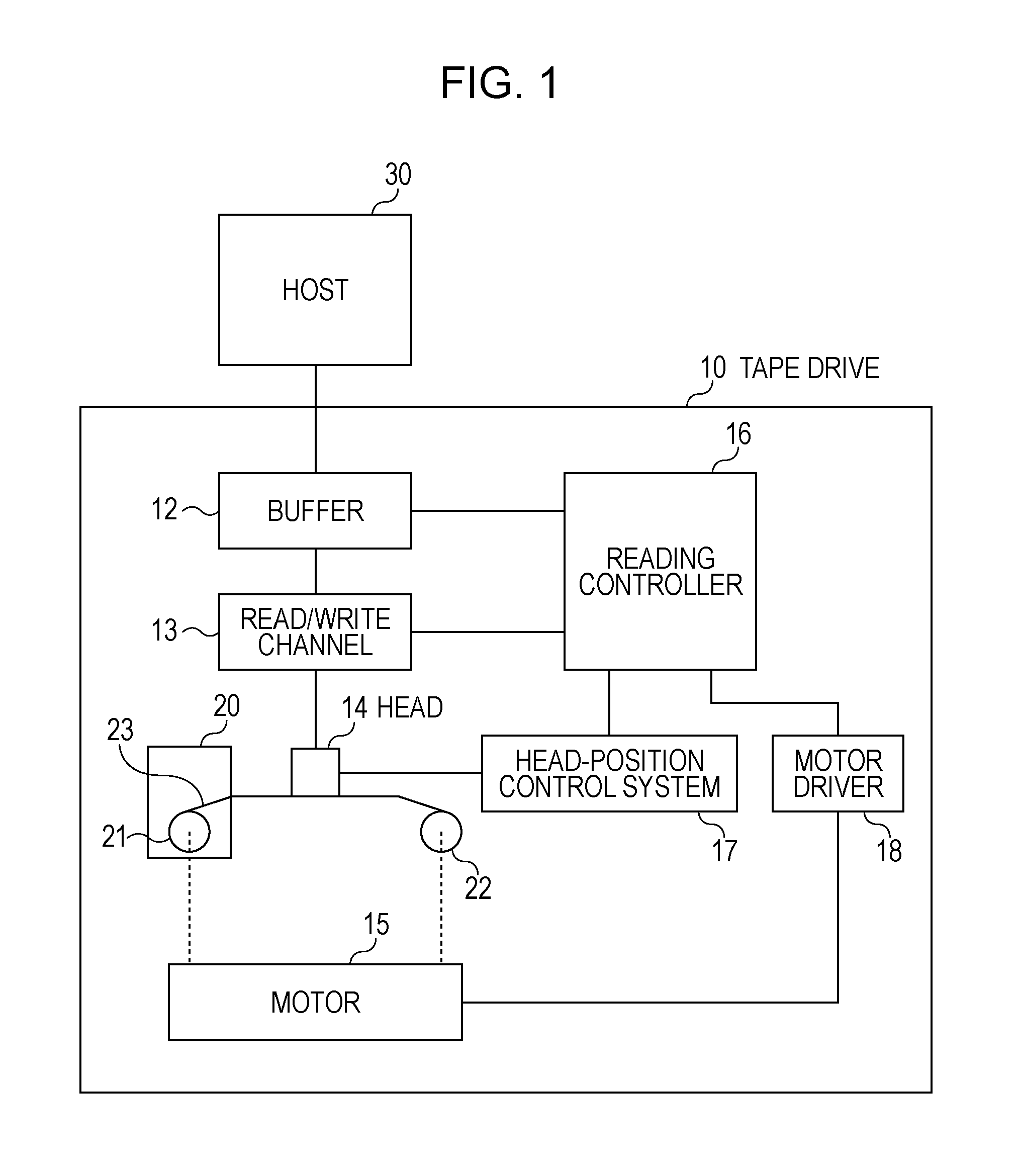

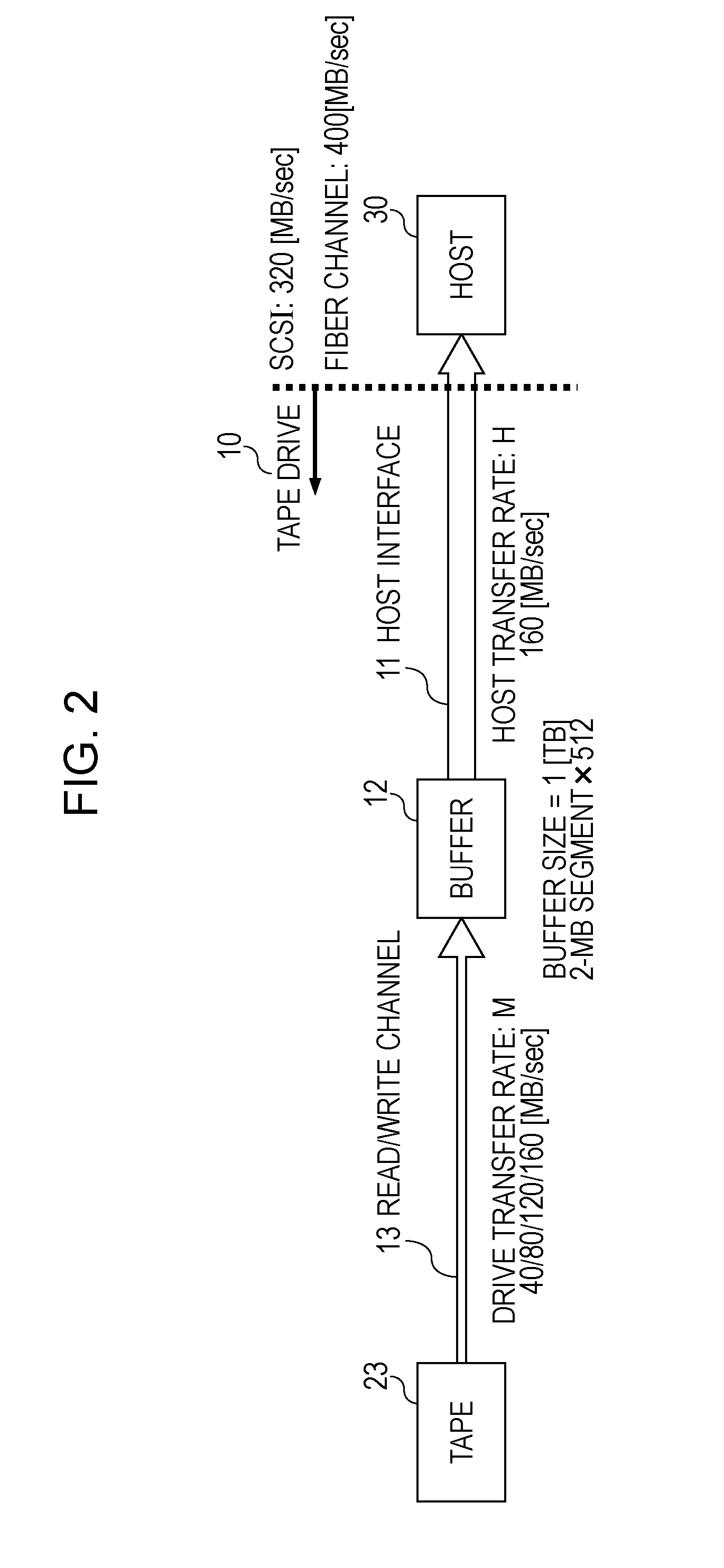

ActiveUS20100095029A1Reduce negative impactIncrease speedCarrier speed control/regulation/indicationInput/output processes for data processingTape speedData transmission

A tape drive, tape drive recording system, and method are provided for improving tape speed selection during data transfer. The tape drive comprises a buffer, a tape for recording the data to be temporarily stored in the buffer, and a read head. The tape drive further comprises a reading controller that initially sets a tape speed such that a drive transfer rate matches a host transfer rate as closely as possible and that drives the tape at the tape speed. To address backhitching caused by one or more host transfer halts, the reading controller subsequently adjusts the tape speed such that the drive transfer rate is lower than the host transfer rate by recalculating the host transfer rate in consideration of the host transfer and the host transfer halt and setting the tape speed such that the drive transfer rate matches the recalculated host transfer rate as closely as possible.

Owner:LENOVO GLOBAL TECH INT LTD

Matched filter detection for time based servo signals in a tape drive

InactiveUS20050174681A1Reduce noiseImprove operation of trackAlignment for track following on tapesRecord information storageTape speedDigital filter

Disclosed are a system, a method, and article of manufacture to provide for filtering a servo signal in a tape drive using a matched filter that is optimized for the operating tape velocity of the tape drive. A servo controller for track following on a tape uses a digital filter implementation of the matched filter to produce a filtered servo signal. The digital filter is optimized for different tape velocities by selecting digital filter coefficients for the digital filter that depend upon the tape velocity presently in use. The filtered servo signal is used by the servo controller to provide improved track following in a tape drive.

Owner:IBM CORP

Optimizing tape speed for a sync operation

InactiveUS20080304174A1Record information storageCarrier speed control/regulation/indicationTape speedComputer hardware

Provided are techniques for determining a tape speed for a next sync operation. A sync command is received. An average transaction size and an average host transfer rate of a set of previous sync operations are calculated. The tape speed for the next sync operation is determined using the average transaction size, the average host transfer rate, and a backhitch time. Data is written to a tape cartridge using the determined tape speed.

Owner:IBM CORP

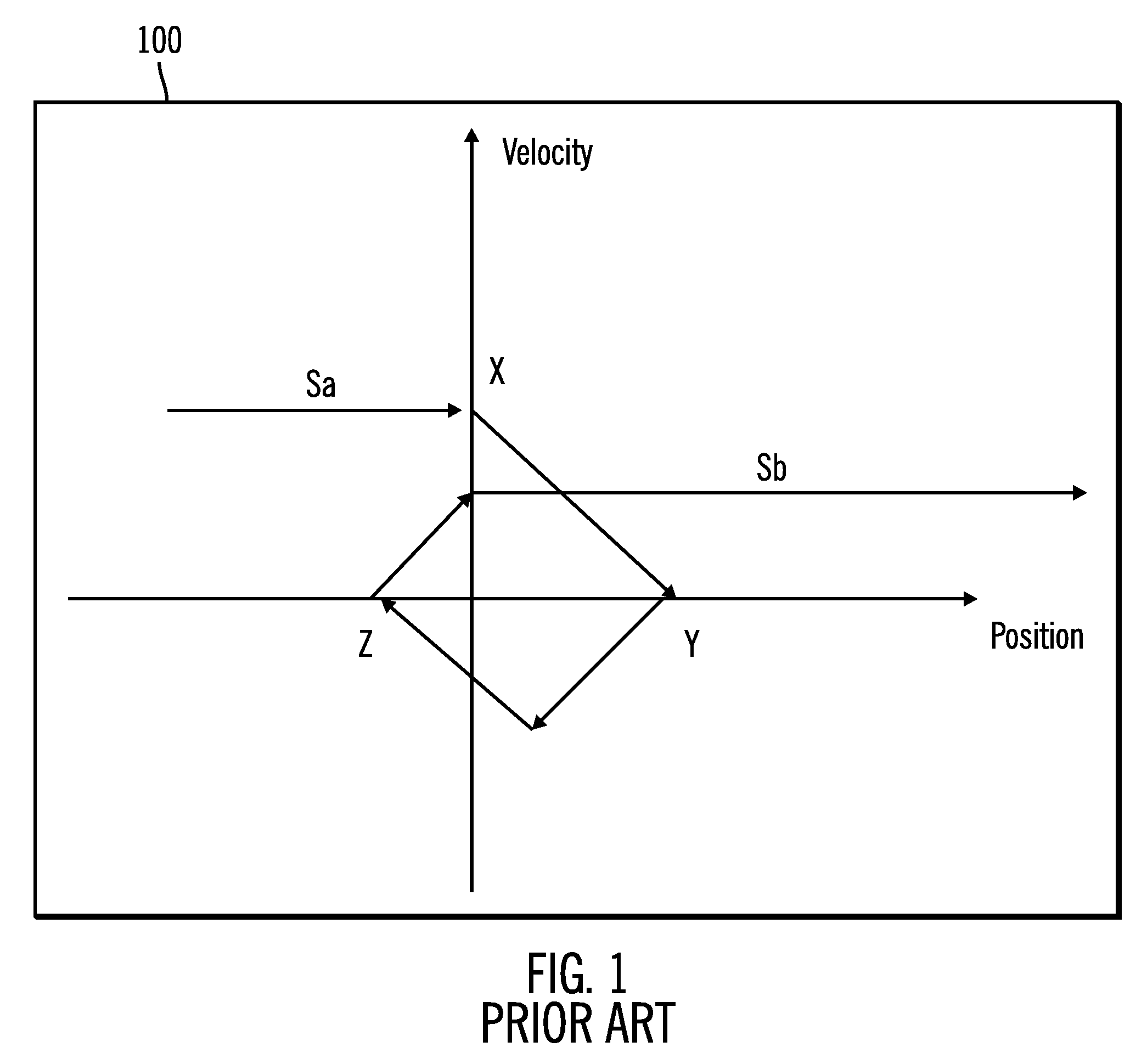

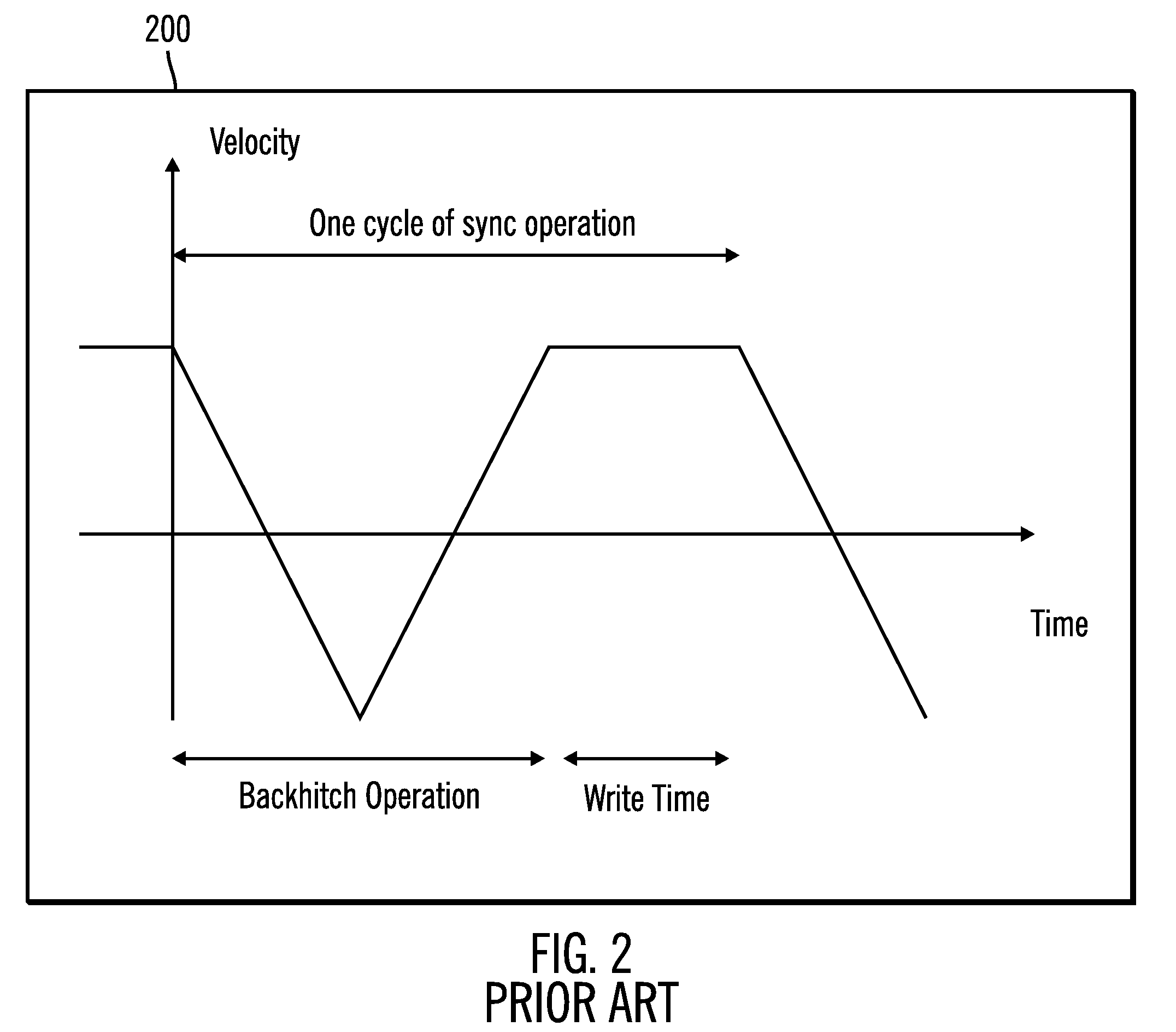

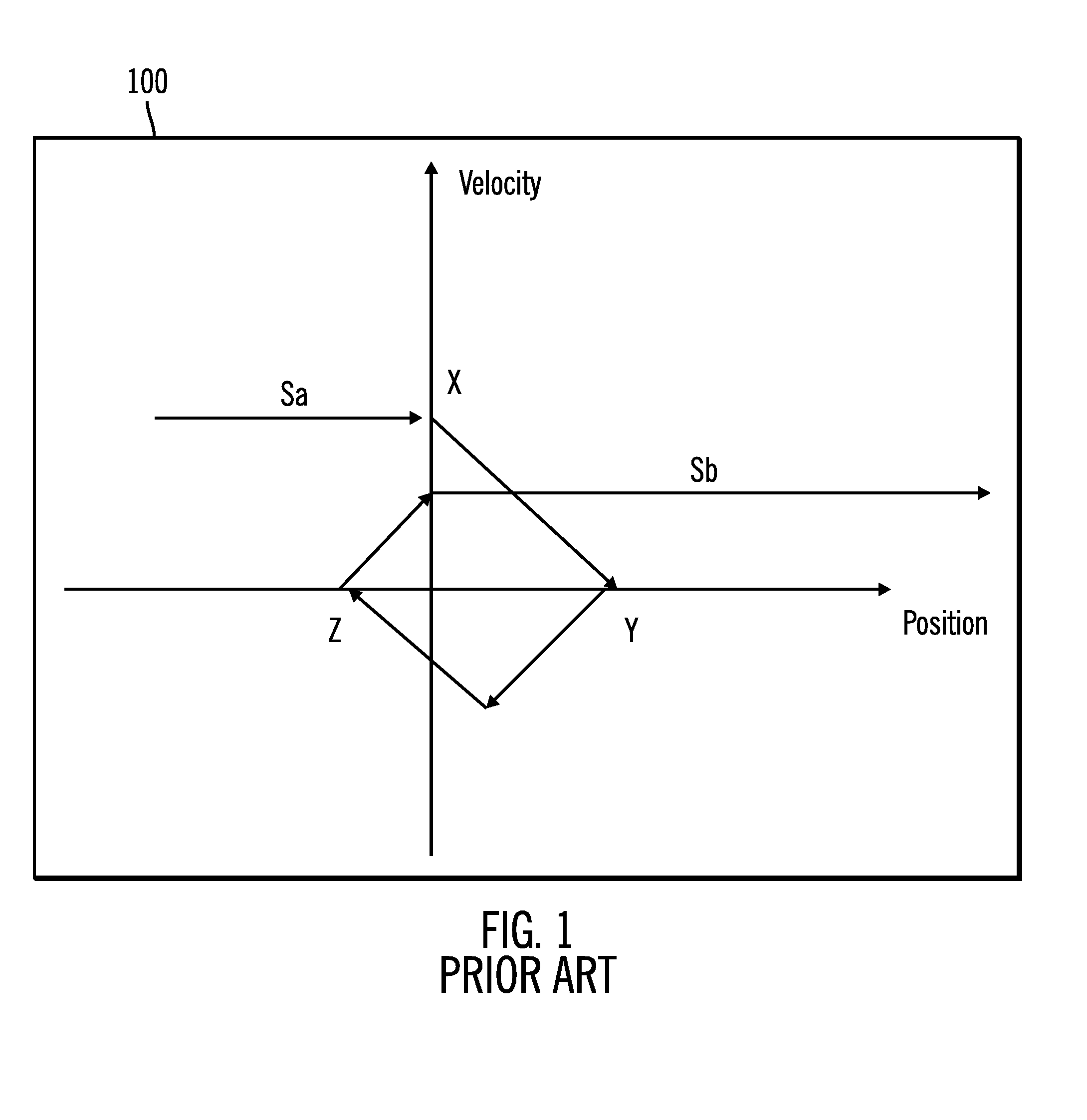

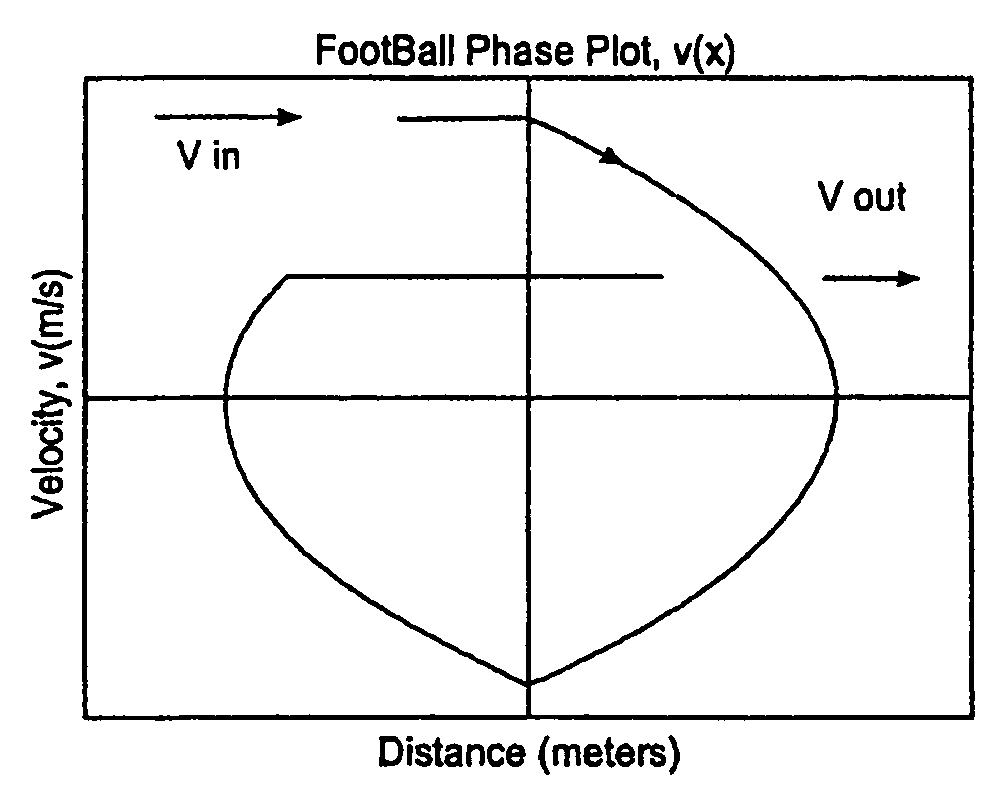

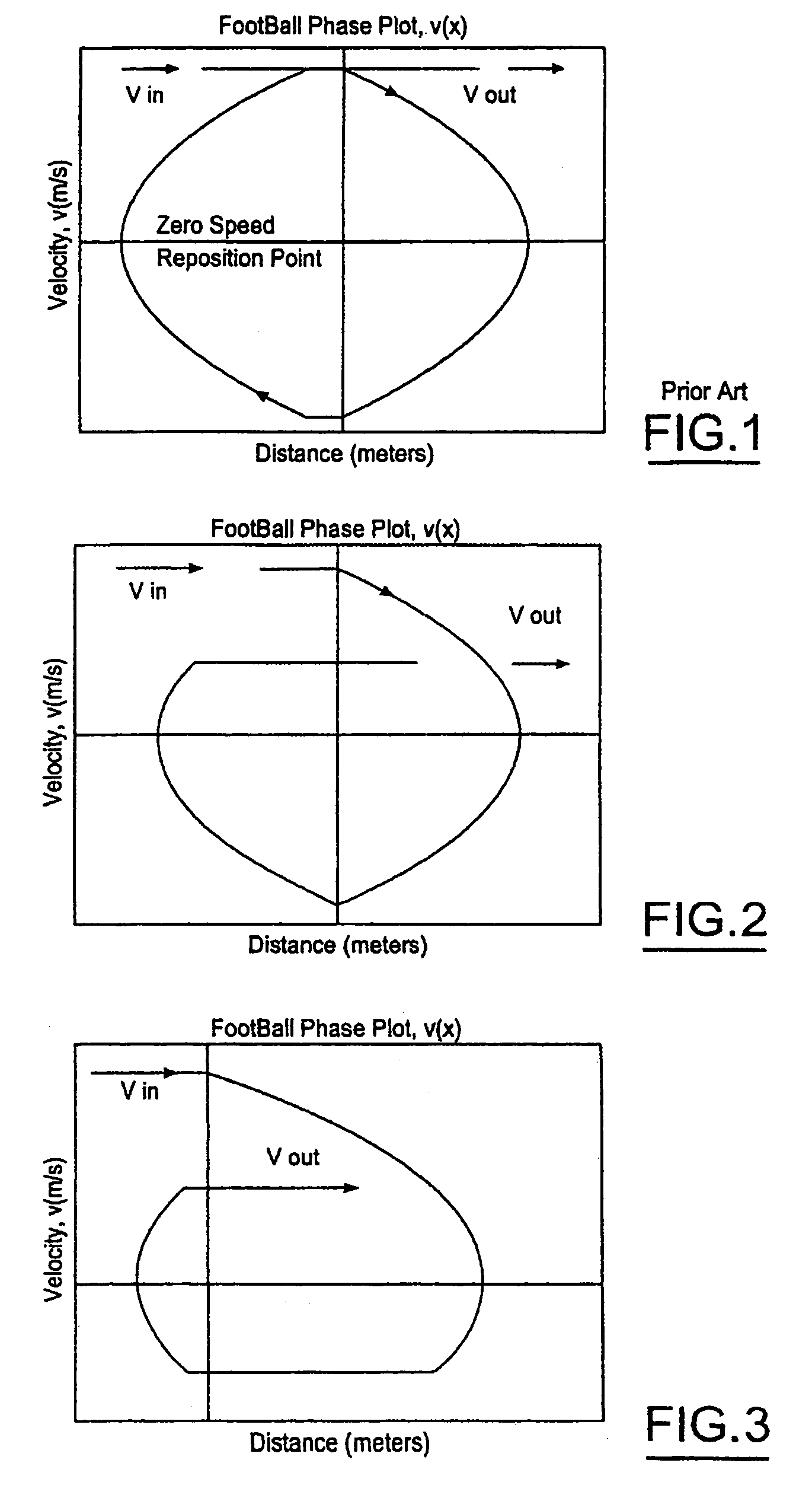

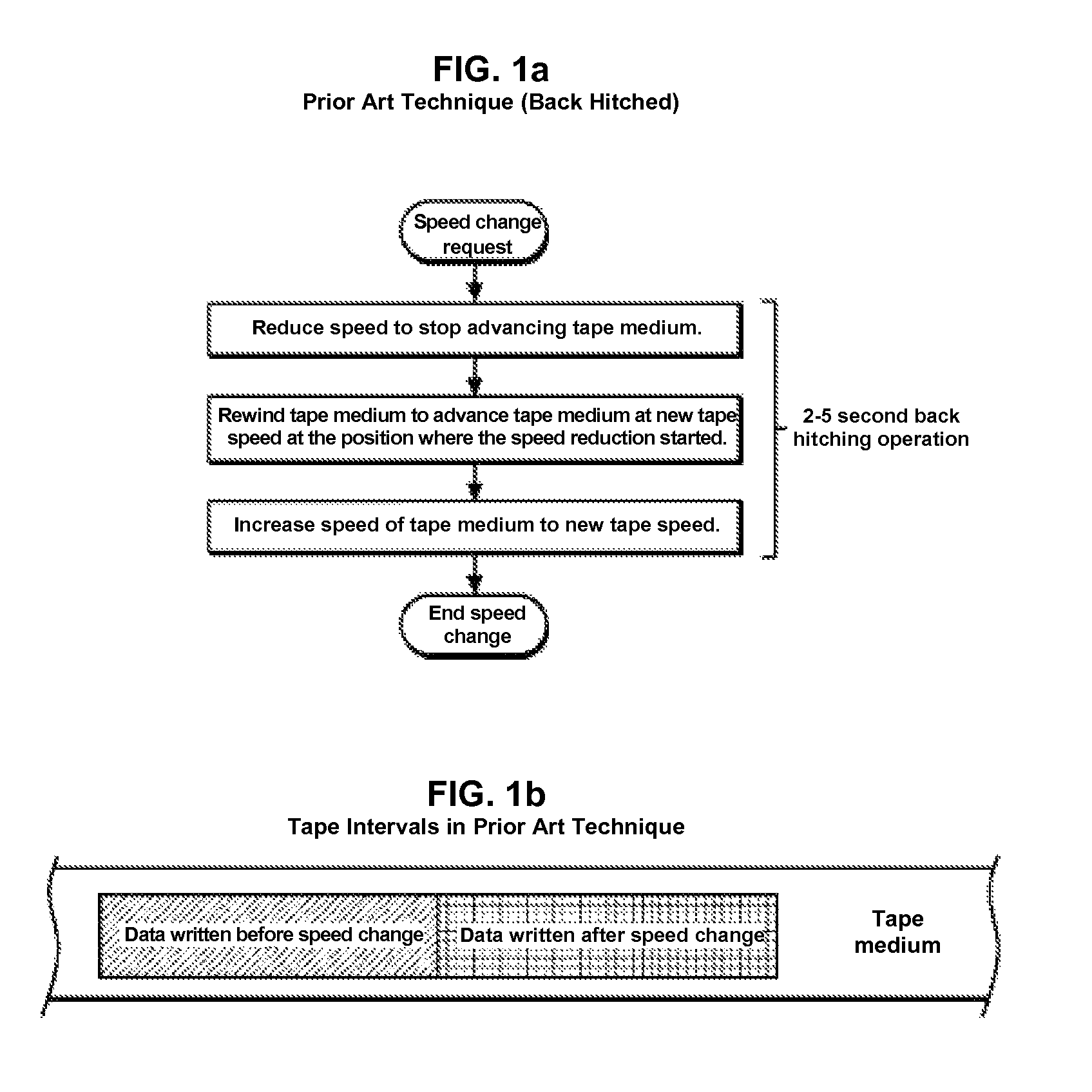

Reduction of tape velocity change backhitch time through use of an intermediate back velocity

ActiveUS7023651B1Shorten the timeRaise countAlignment for track following on tapesRecord information storageTape speedData rate

Modern tape drives can adjust their tape drive velocity between two or more read / write data rates to better match the data rate demands of the host. This velocity changing may provide improvements in drive performance and total backhitch counts. The transition from one tape velocity to another may involve a rate change backhitch which itself could impact performance. It is desirable to optimize these transitions. In one approach, a backhitch involves a backvelocity having a magnitude that is intermediate between the initial tape velocity and the final tape velocity. In another approach, a backhitch involves an intermediate forward velocity to quicken the approach toward the start R / W reposition point.

Owner:ORACLE INT CORP

Production method for aluminum nitride ceramic substrate for LED

The invention discloses a production method for an aluminum nitride ceramic substrate for an LED. The production method is characterized by comprising the following steps that firstly, burdening is conducted, high-purity directly-nitrided aluminum nitride powder or self-propagating aluminum nitride powder and three-component compound sintering aids are mixed; secondly, ball grinding is conducted, ethyl alcohol / methylbenzene or ethyl alcohol / butanone and glycerin or castor oil are added for ball grinding for 24-25 hours at the rotating speed of 482 rad / s, and polyvinyl butyral and polyethylene glycol are added for ball grinding for 26-27.5 hours at the rotating speed of 505 rad / s; thirdly, vacuum defoaming is conducted, and defoaming is conducted in the negative-pressure environment of 9.5*104-9.4*105 Pa; fourthly, tap casting is conducted; the height of a scraper is controlled to be 2.4-2.7 mm, and the casting tape speed is 0.1-0.3 m / minute; fifthly; rubber removing is conducted, and rubber removing is conducted in a continuous type rubber removing furnace continuously for 2-3 h at the temperature of 450-580 DEG C; sixthly, sintering is conducted, and sintering is conducted in a muffle furnace under the protection of the mixed atmosphere of hydrogen and nitrogen at the temperature of 1550-1680 DEG C. The aluminum nitride ceramic substrate for the LED has good heat conductivity, the reliable electric insulating property, the low dielectric constant and the low dielectric loss.

Owner:范红梅

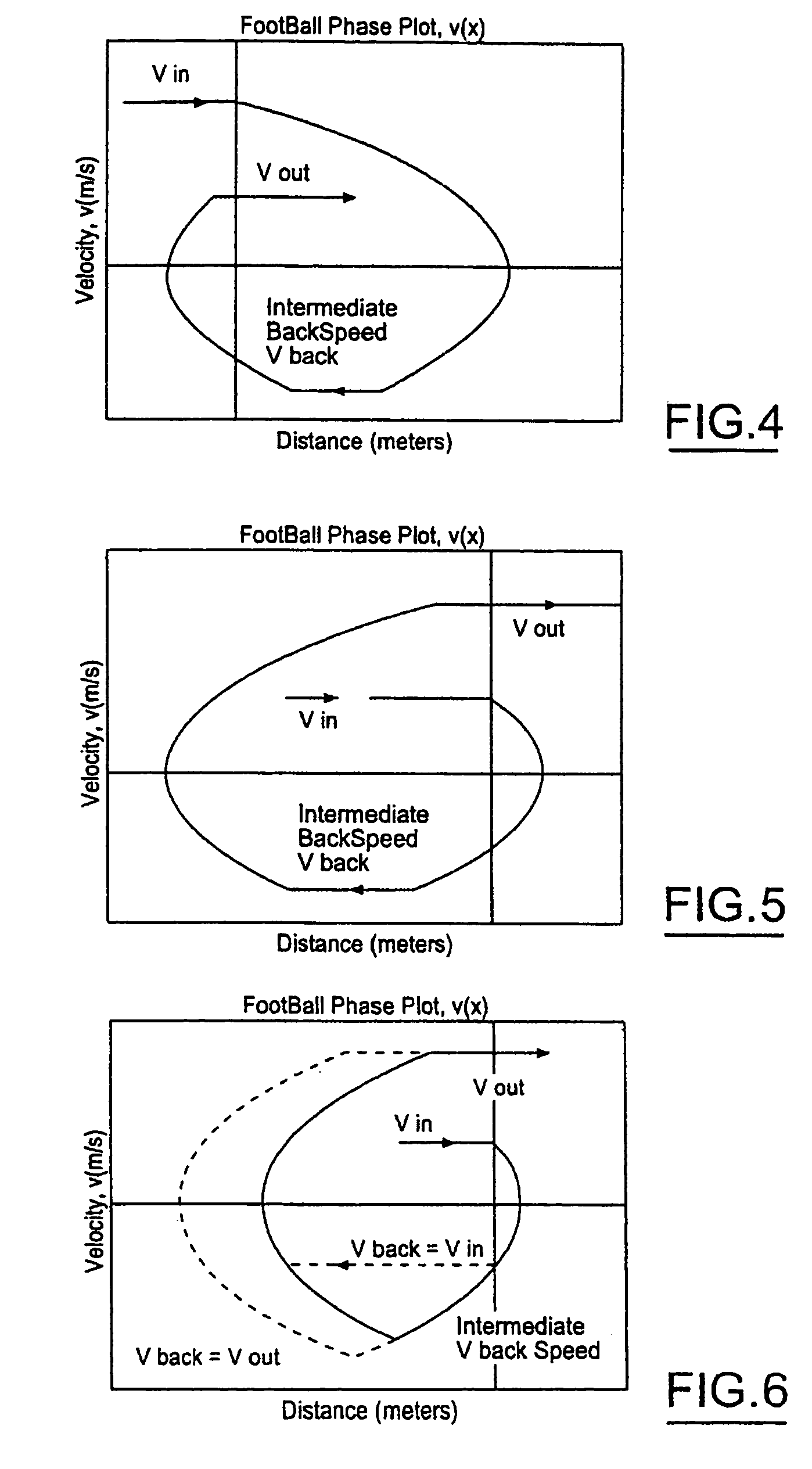

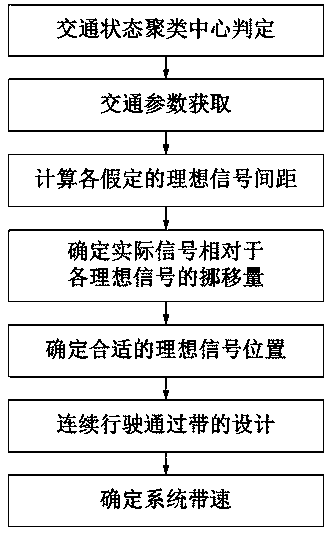

Dynamic bidirectional green wave control method based on traffic state identification

ActiveCN108806290ADrive stabilityImprove traffic capacityControlling traffic signalsDetection of traffic movementTape speedTraffic flow

The invention provides a traffic artery bidirectional dynamic green wave control method based on traffic state identification. The traffic artery bidirectional dynamic green wave control method basedon traffic state identification combines a traffic state identification method based on K-means clustering analysis method and a bidirectional green wave control model based on a number solution method, and can dynamically adjust a bidirectional green wave control scheme according to the change of traffic state of a road network. The traffic artery bidirectional dynamic green wave control method based on traffic state identification includes the steps: acquiring traffic parameters, discriminating the traffic state, calculating each assumed ideal signal spacing, determining the movement quantity of a practical signal, relative to each ideal signal, determining the appropriate ideal signal position, designing a non-stop running passage tape, and determining the system tape speed. The trafficartery bidirectional dynamic green wave control method based on traffic state identification can significantly reduce the delay and parking rate of urban road traffic flow, can improve the operationefficiency of urban roads, and can provide powerful technical support for urban road green wave control.

Owner:SOUTHEAST UNIV

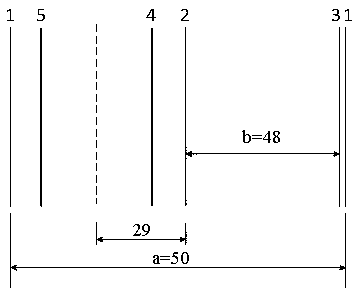

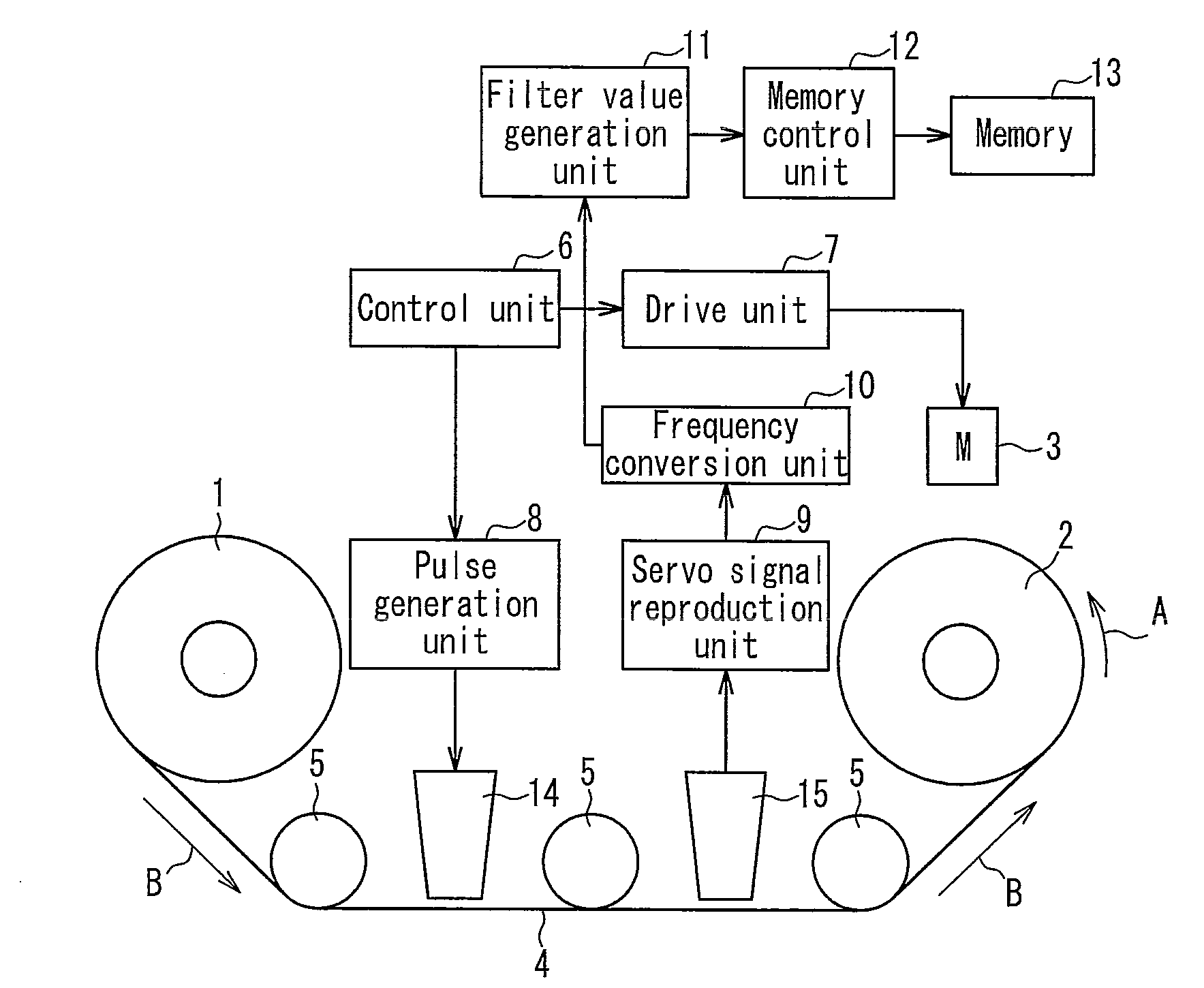

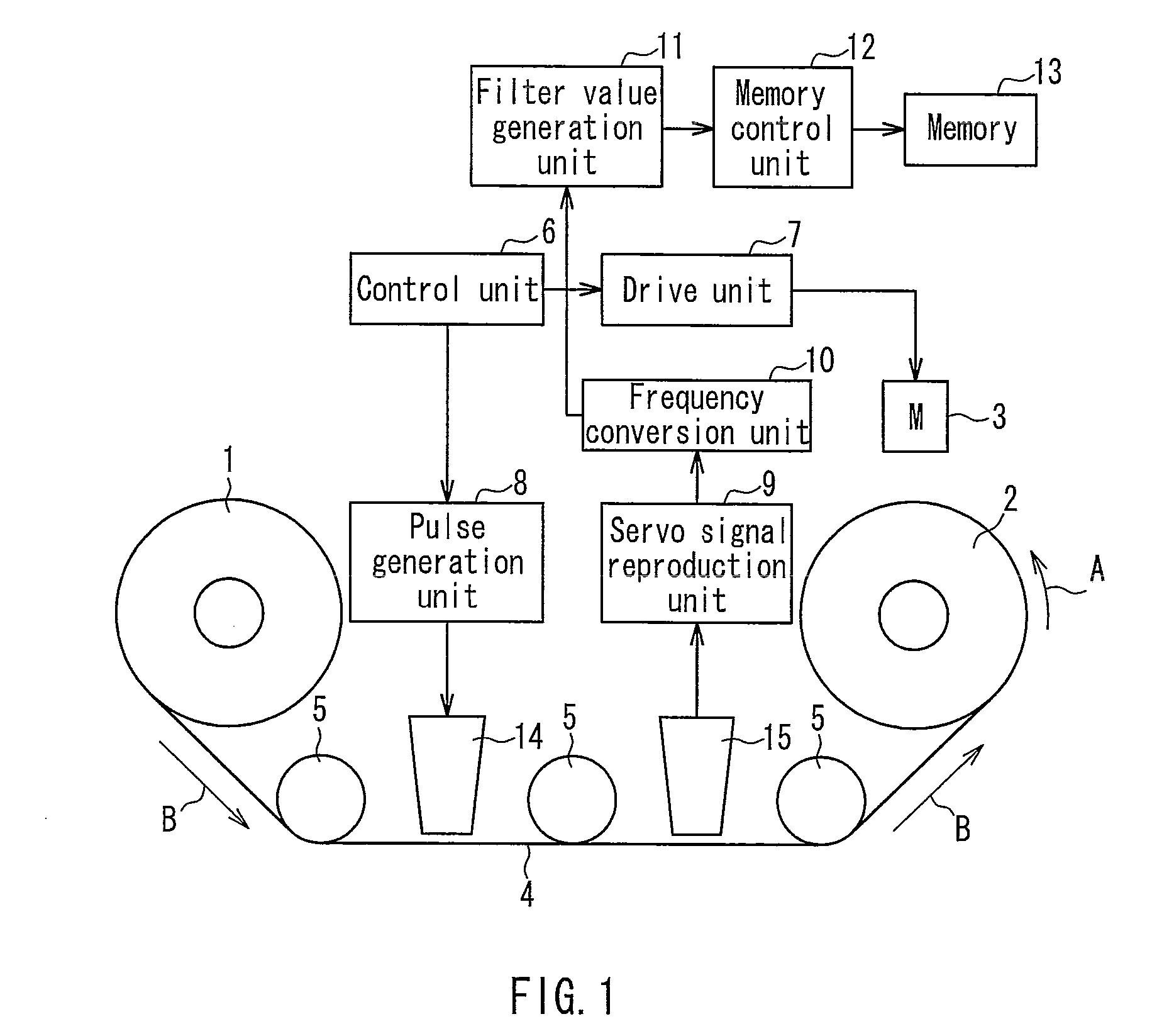

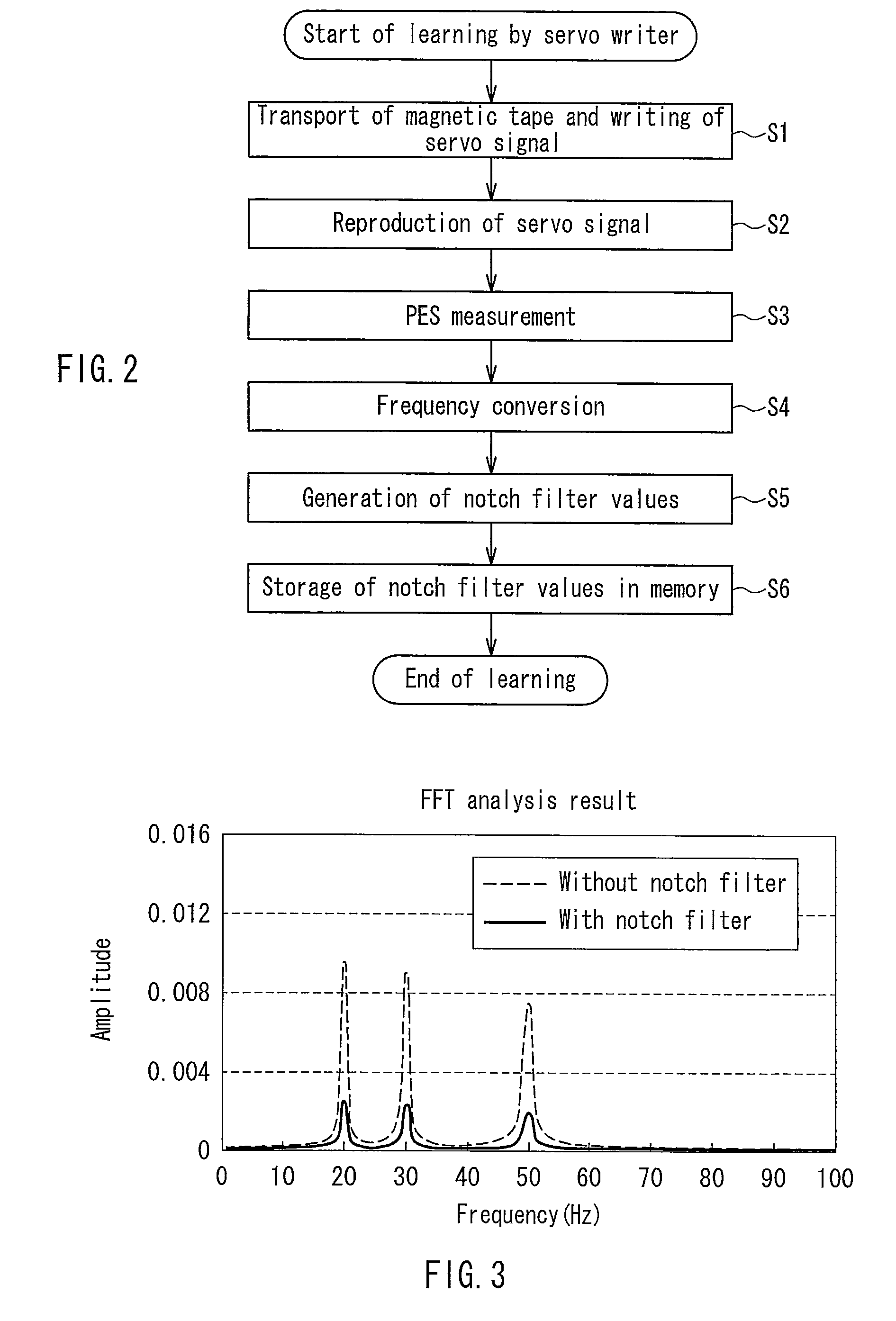

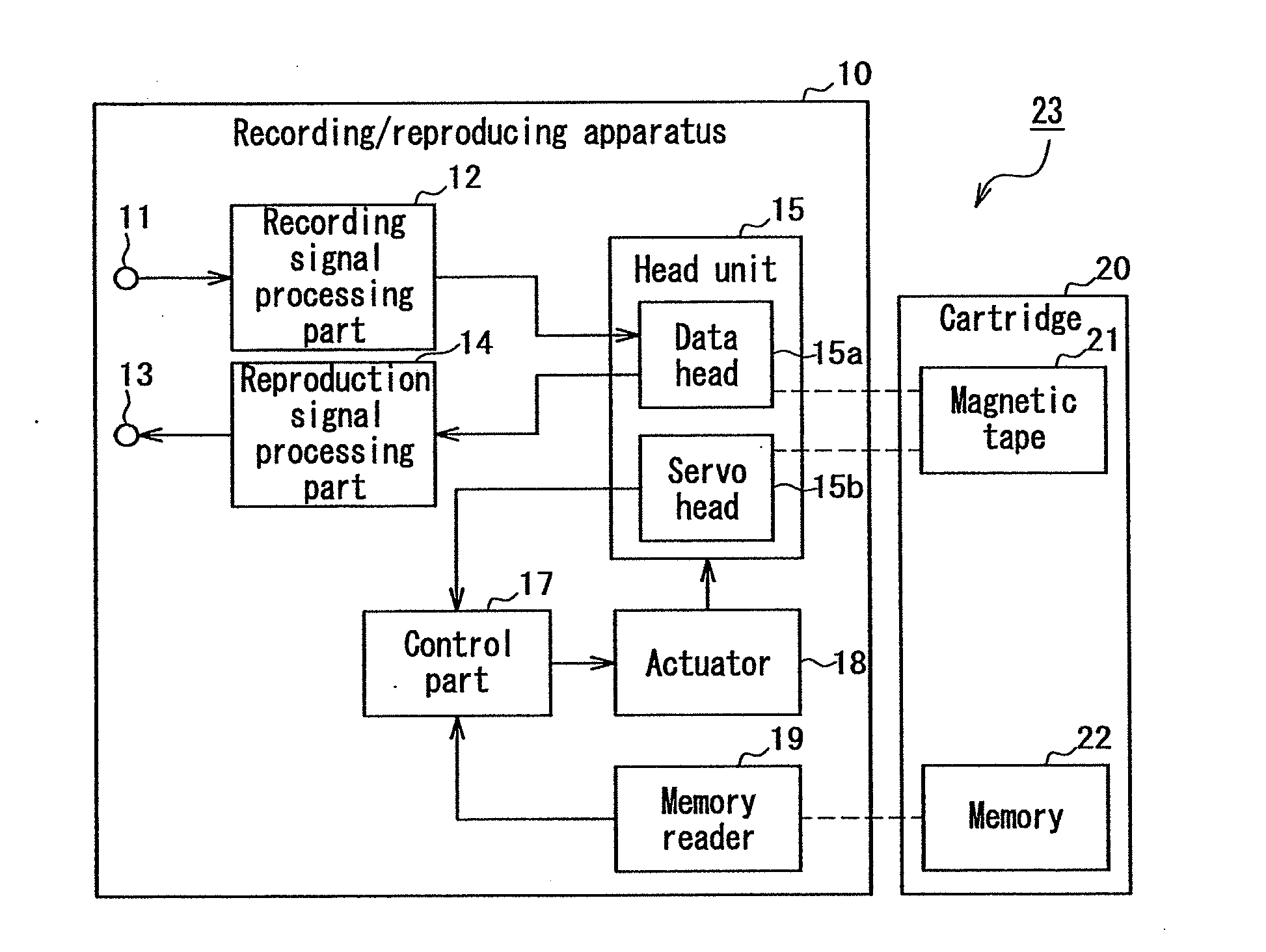

Servo signal recording apparatus, information recording apparatus, and tracking servo method

ActiveUS20090296269A1Reducing position error signalEliminate Periodic NoiseDriving/moving recording headsAlignment for track following on tapesTape speedEngineering

Owner:FUJIFILM CORP

Manufacturing process of automobile low-alloy high-strength steel cold-rolled sheet with high product of strength and elongation

The invention relates to a manufacturing process of an automobile low-alloy high-strength steel cold-rolled sheet with high product of strength and elongation, and belongs to the technical field of metallurgy. The technical scheme of the invention is as follows: the manufacturing process comprises a smelting process, a hot rolling process and a cold rolling process, wherein in the cold rolling process, the annealing temperature control is as follows: the soaking temperature is 840-860 DEG C, the slow cooling temperature is 670-700 DEG C, the rapid cooling temperature is 410-430 DEG C, and the aging finish temperature is 350-370 DEG C; and according to strip steel of different thickness specifications, different annealing tape speed target values are planed: the tape speed of the strip steel of 0.8mm specification is 205m / min, the tape speed of the strip steel of 1.0mm specification is 165m / min, the tape speed of the strip steel of 1.2mm specification is 137m / min, the tape speed of the strip steel of 1.5mm specification is 110m / min, the tape speed of the strip steel of 1.8mm specification is 92m / min, the tape speed of the strip steel of 2.0mm specification is 82m / min, and the tape speed of the strip steel of 2.5mm specification is 66m / min. The manufacturing process of the automobile low-alloy high-strength steel cold-rolled sheet with the high product of strength and elongation disclosed by the invention has the beneficial effects that the low-alloy high-strength steel cold-rolled sheet with high product of strength and elongation is produced by modifying the chemical elements and optimizing the hot rolling and cold rolling processes so that the product of strength and elongation of the low-alloy high-strength steel cold-rolled sheet reach 15GPa%, and simultaneously the quality is stably controlled.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

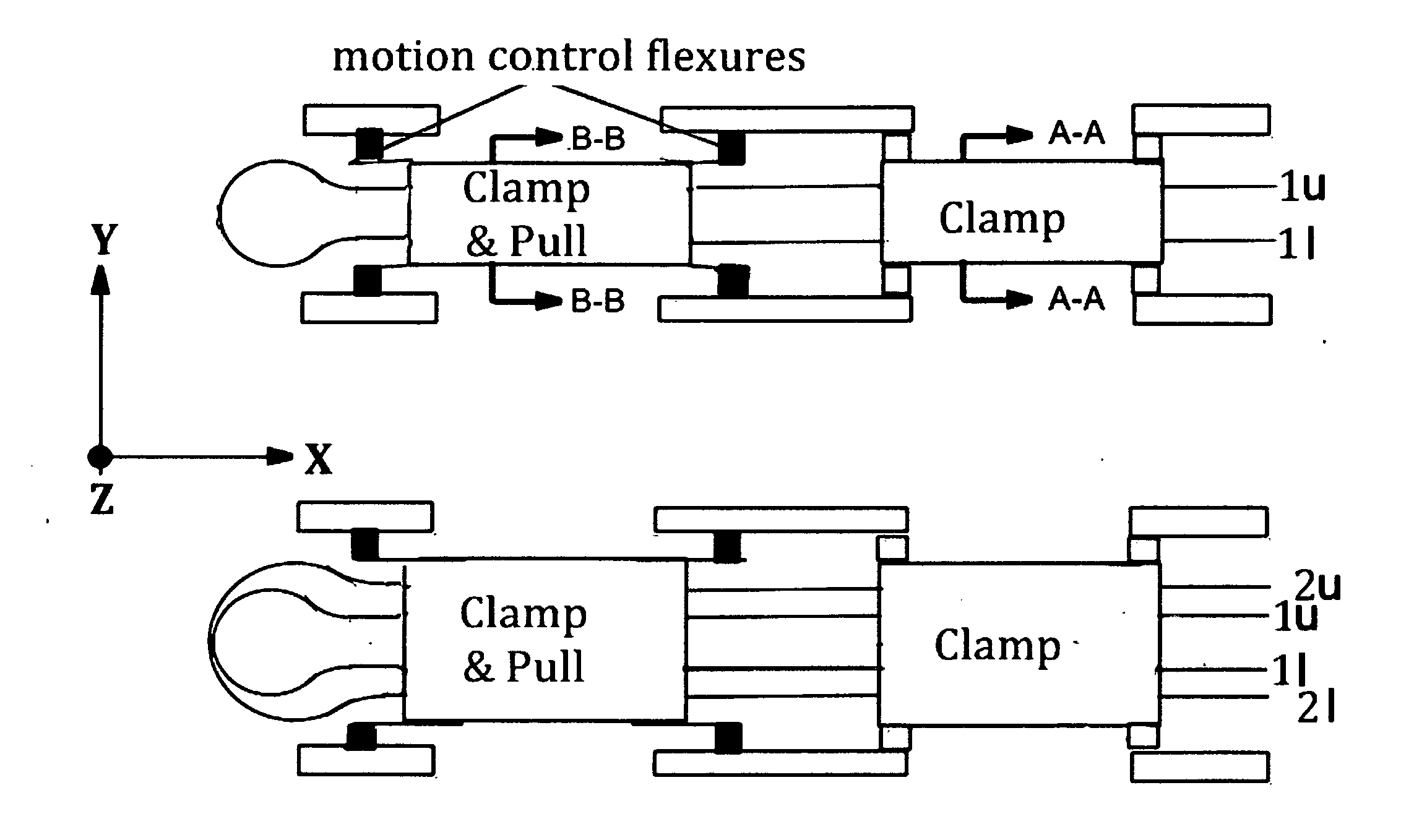

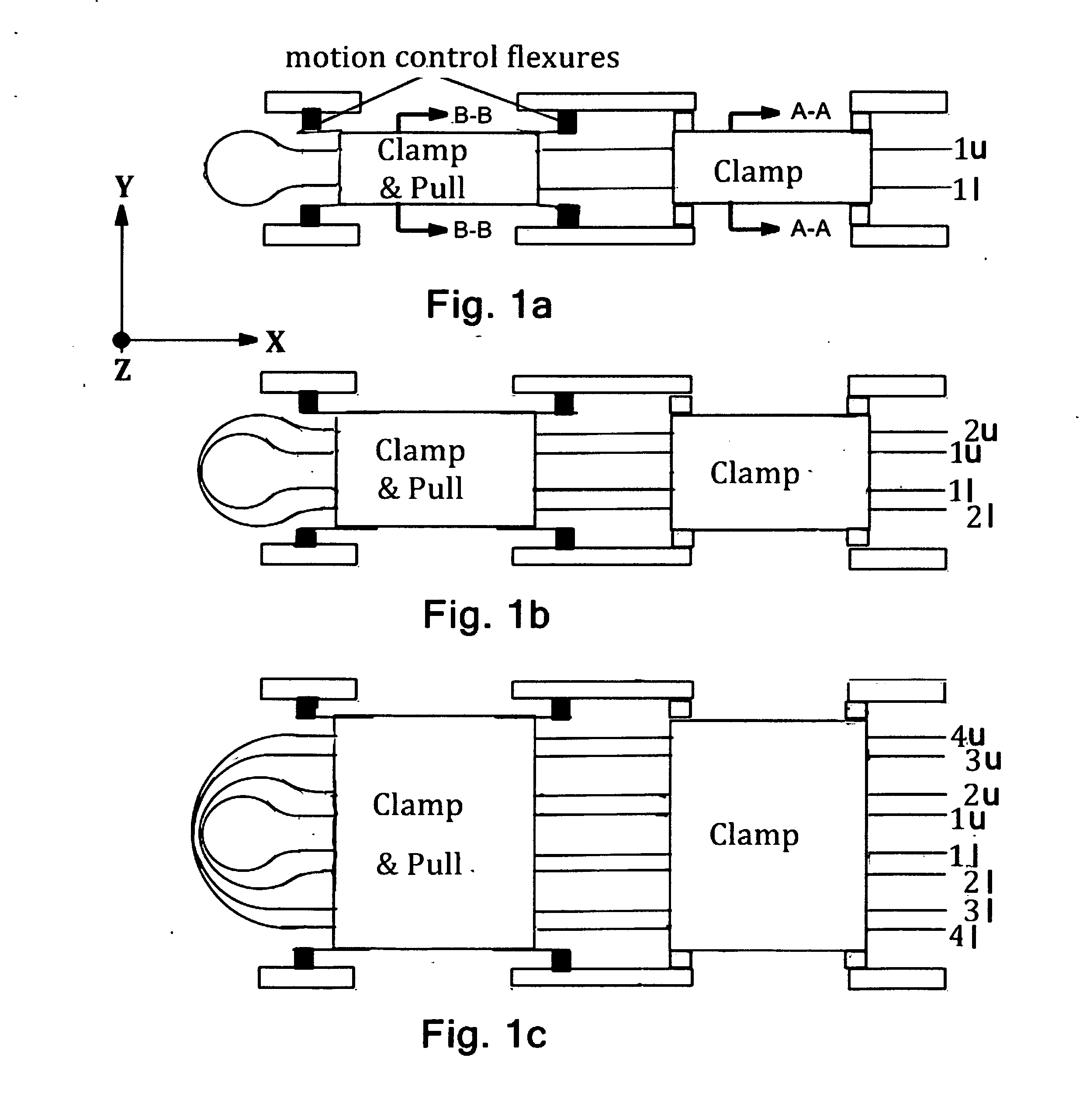

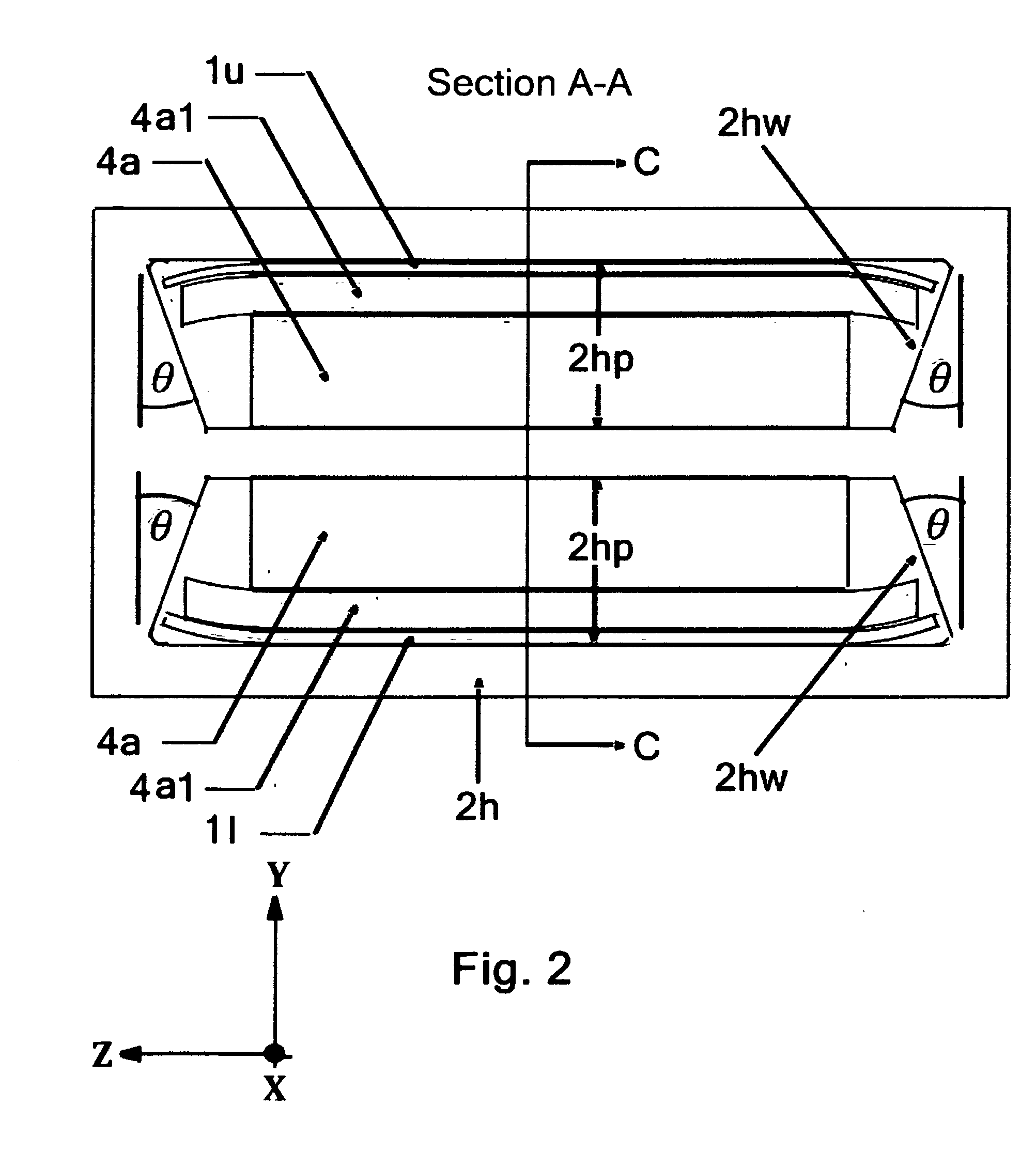

Tape muscle

InactiveUS20120228991A1Increase clamping forceLow costProgramme-controlled manipulatorElectrostatic generators/motorsTape speedComputer module

A Tape Muscle is described where multiple tape loops are independently driven by synchronized grasp and pull actions from a tandem of Clamp, Clamp & Drive modules. Each tape loop is elastically bent, with its open ends threaded through individual passageways in both modules. Tape loops are nested inside each other with all tape open ends on the same side. Each loop moves its open ends in equal, opposite directions, while the loop position remains fixed. Tape movements do not interfere with each other. The open ends of each loop attach to a shared appendage, which is pulled back and forth using tensile forces. Drive and hold forces use small angle flexure bending mechanical advantage and high force density electrostatic induction methods. Tape speed results from high frequency clock speed and novel hand-off methods. Governing equations, design details and performance estimates are provided.

Owner:VRANISH JOHN M

Sheet paper storage and dispensing device

InactiveUS8725297B2Easily and accurately measureSafe to takeTemperatue controlFilament handlingMotor speedTape speed

A sheet paper storage and dispensing device stores and dispenses sheet paper, and includes a first reel drum onto which a tape is wound; a second reel drum on which sheet paper is stored; a motor which drives the first and second reel drums via a drive system; an electromagnetic clutch which switches between transmitting and interrupting drive force from the drive system; an electromagnetic brake which applies a brake to the drive system; a trigger sensor which detects supplying of the sheet paper; a tape speed detection section which detects a transporting speed at the intake / discharge port; a motor speed variation control unit which controls changes in a rotation speed; and a winding control unit which causes winding by controlling the electromagnetic clutch so as to transmit the driving force when supplying of the sheet paper to the intake / discharge port is detected by the trigger sensor.

Owner:LAUREL PRECISION MACHINES

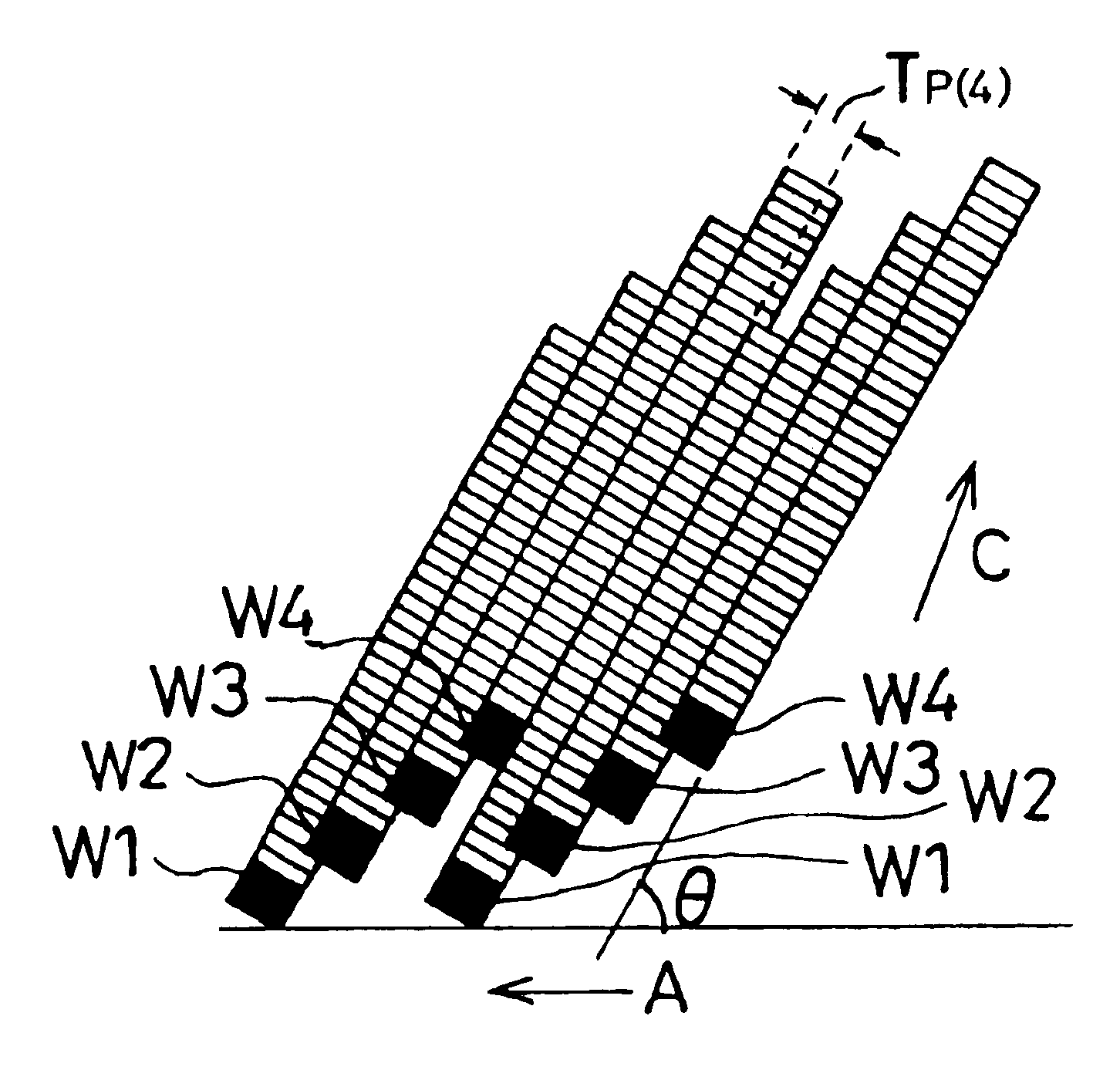

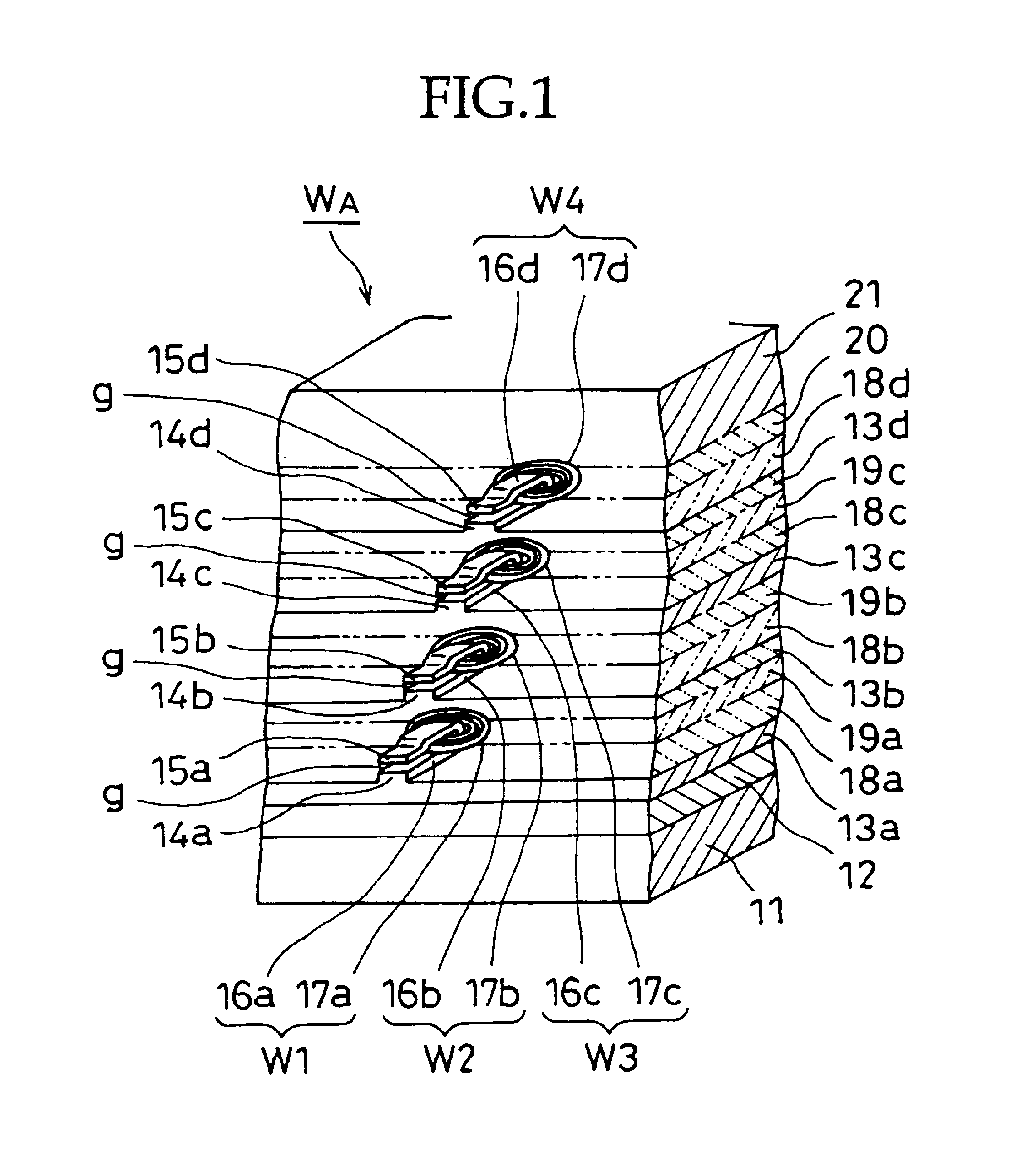

Magnetic tape recording apparatus for recording tracks having same track pitch

InactiveUS6922298B2Eliminating and reducing causeEliminate or reduce the cause of deterioration in accuracy of recording track widthFilamentary/web carriers operation controlDriving/moving recording headsHelical scanTape speed

In a helical scan type magnetic tape recording apparatus, one thin film multi-recording head is mounted on a rotary drum, wherein the multi-recording head includes N recording heads for recording N recording tracks at a predetermined track angle on a magnetic tape by one rotation of the rotary drum to perform recording for forming continuous recording tracks having the same track pitches, by determining rotary drum rotation and a tape speed in accordance with equation V1=Tp·N·(RPS) / sin θ, such that (N−1) recording tracks having the same track pitches narrower than the head width and one recording track having a wider track width than that are formed by a first rotation of the drum, then by a second rotation, a preceding recording head overwrites the recording track having the wider track width to form a recording track having a track width equal to the track width of the recording track.

Owner:SONY CORP

Synchronous servo channel for longitudinal position detection and position error signal generation in tape drive systems

InactiveUS20070171565A1Improve reliabilityAlignment for track following on tapesRecord information storageTape speedUnit of length

A fully synchronous longitudinal position (LPOS) detection system is provided for improving the reliability of servo channels in tape systems. The system is based on the interpolation of the servo channel output signal, which is sampled by an analog-to-digital converter (ADC) at a fixed sampling rate, using a clock at a nominal frequency, so that interpolated signal samples are obtained at a predetermined fixed rate, independent of tape velocity. This predetermined fixed rate is defined in terms of samples per unit of length, as opposed to samples per unit of time, which is the measure of the ADC sampling rate. The resolution with which the servo channel signal is obtained at the interpolator output is thus determined by the step interpolation distance.

Owner:INT BUSINESS MASCH CORP

Tape drive, tape drive recording system, and method for selecting improved tape speed in response to intermittent read requests

ActiveUS20120290784A1Reduce negative impactIncrease speedCarrier speed control/regulation/indicationMemory systemsTape speedData transmission

A tape drive, tape drive recording system, and method are provided for improving tape speed selection during data transfer. The tape drive includes a buffer, a tape for recording the data to be temporarily stored in the buffer, and a read head. The tape drive further includes a reading controller that initially sets a tape speed such that a drive transfer rate matches a host transfer rate as closely as possible and that drives the tape at the tape speed. To address backhitching caused by one or more host transfer halts, the reading controller subsequently adjusts the tape speed such that the drive transfer rate is lower than the host transfer rate by recalculating the host transfer rate in consideration of the host transfer and the host transfer halt and setting the tape speed such that the drive transfer rate matches the recalculated host transfer rate as closely as possible.

Owner:LENOVO GLOBAL TECH INT LTD

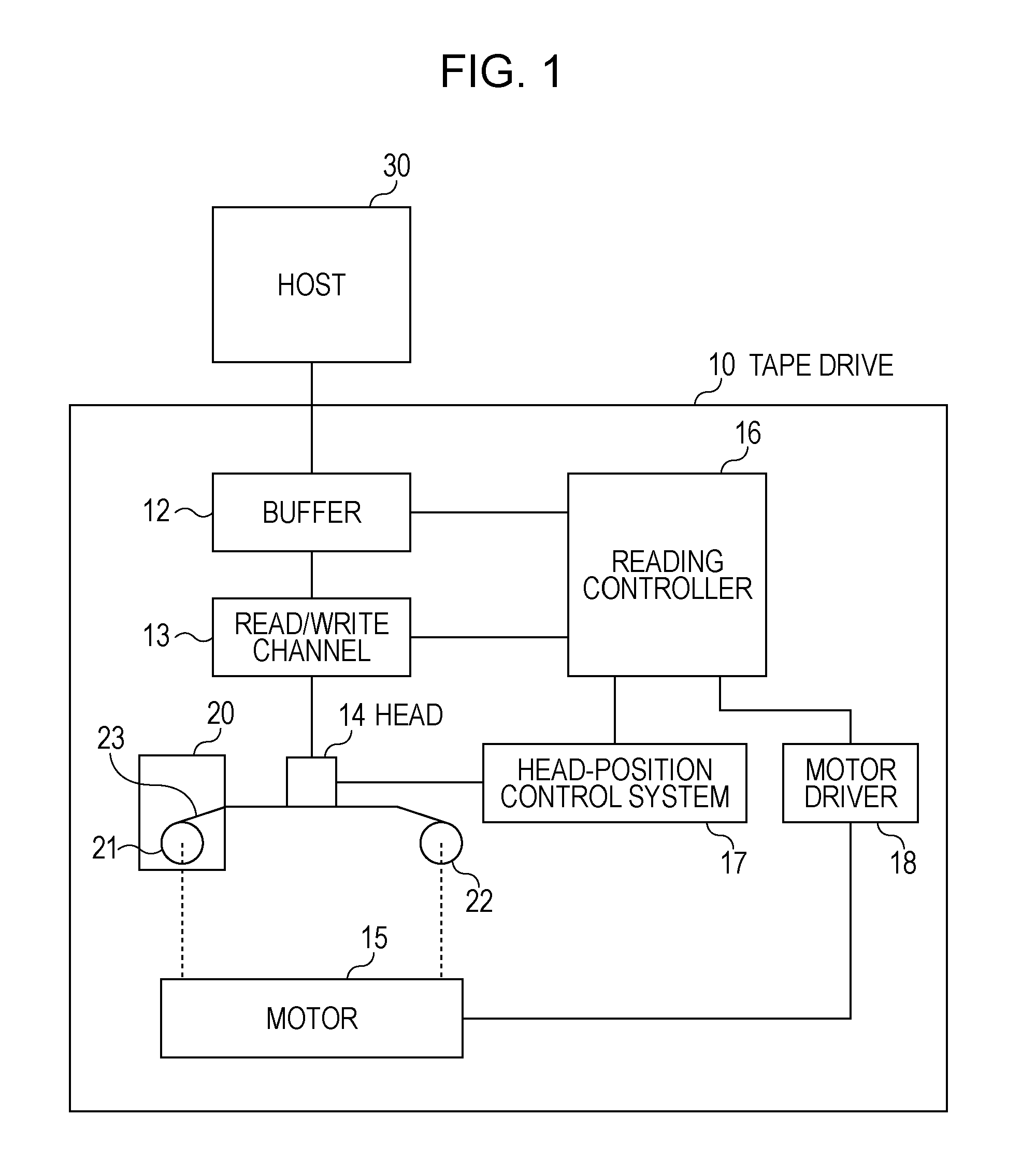

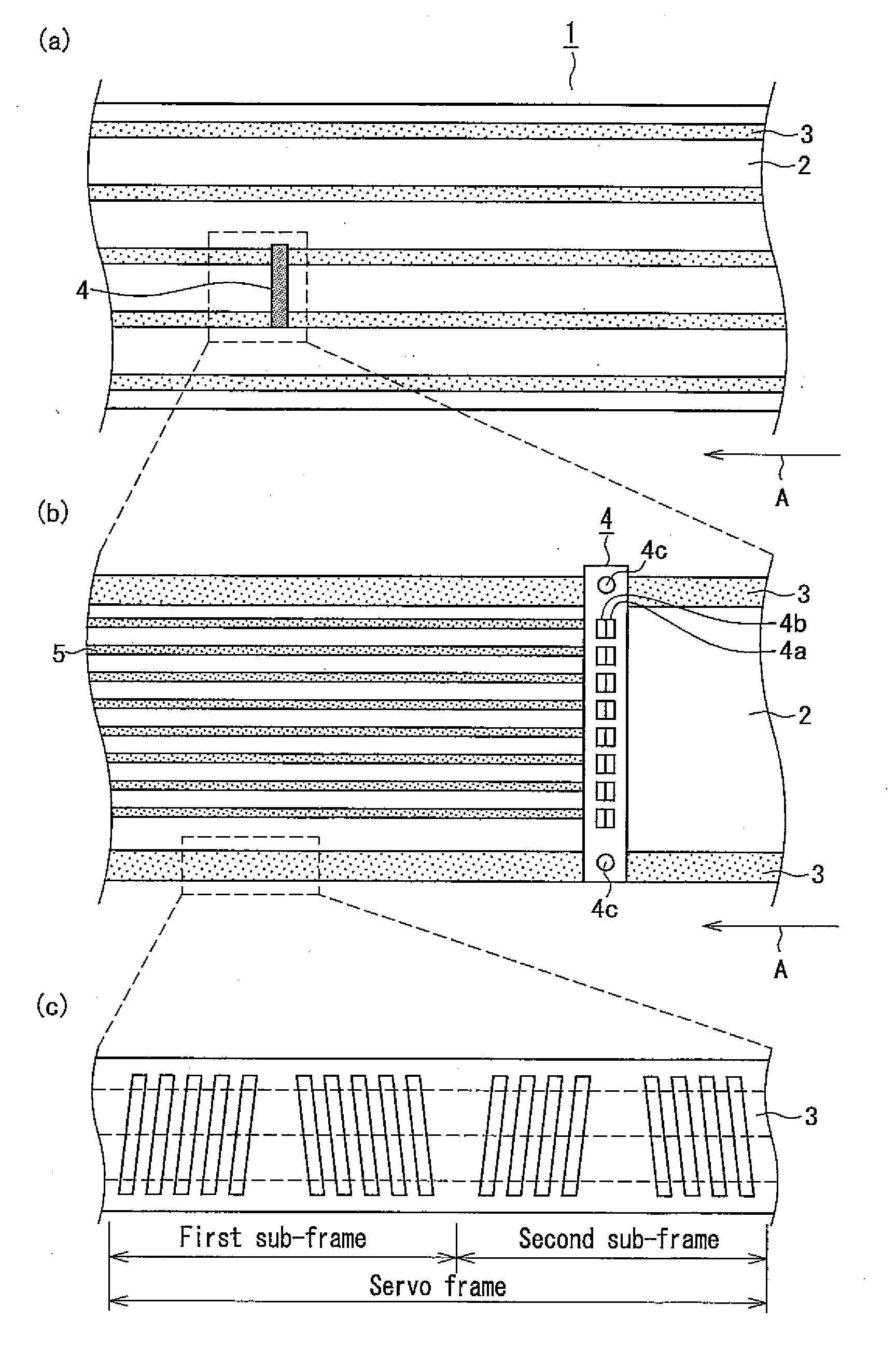

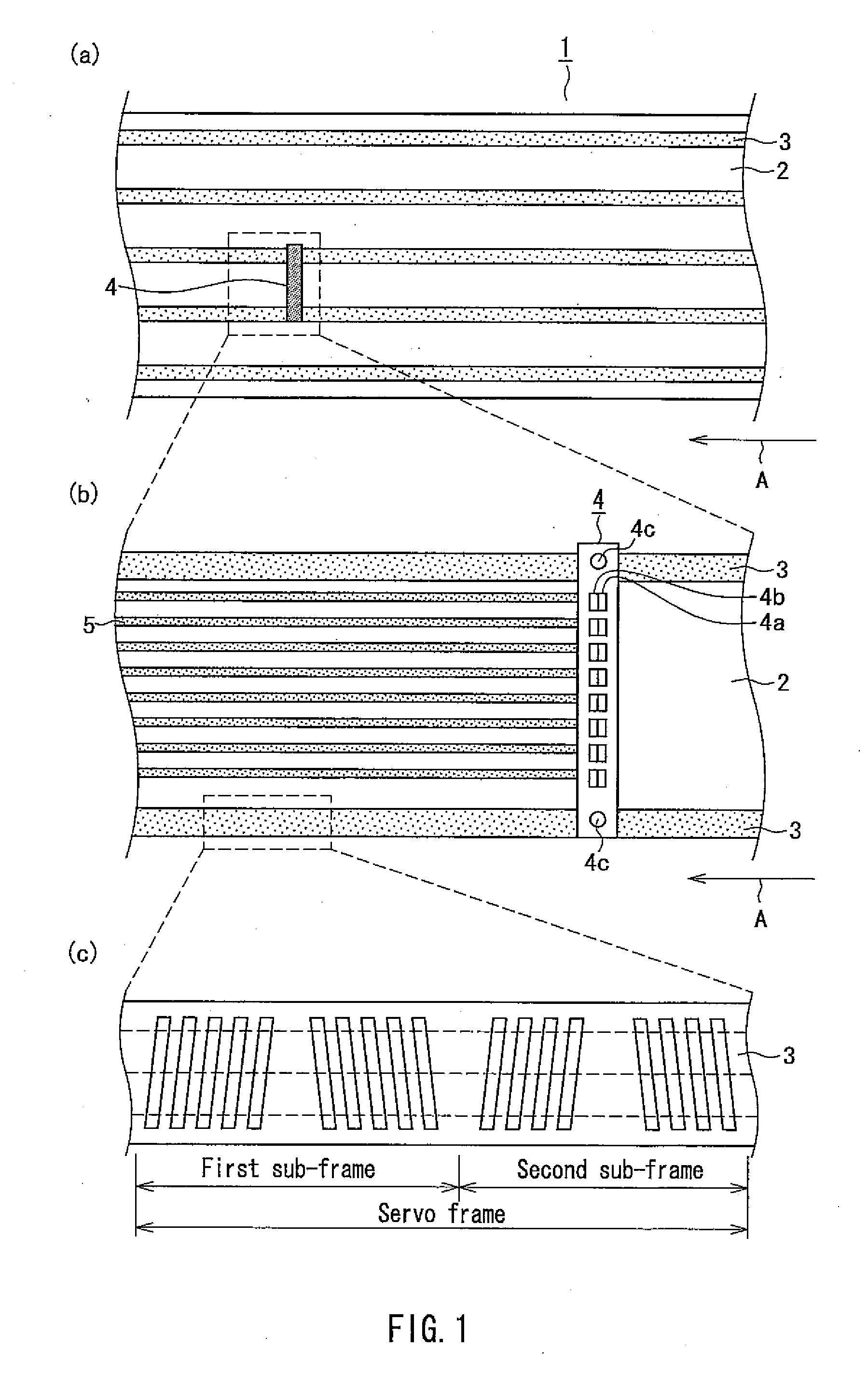

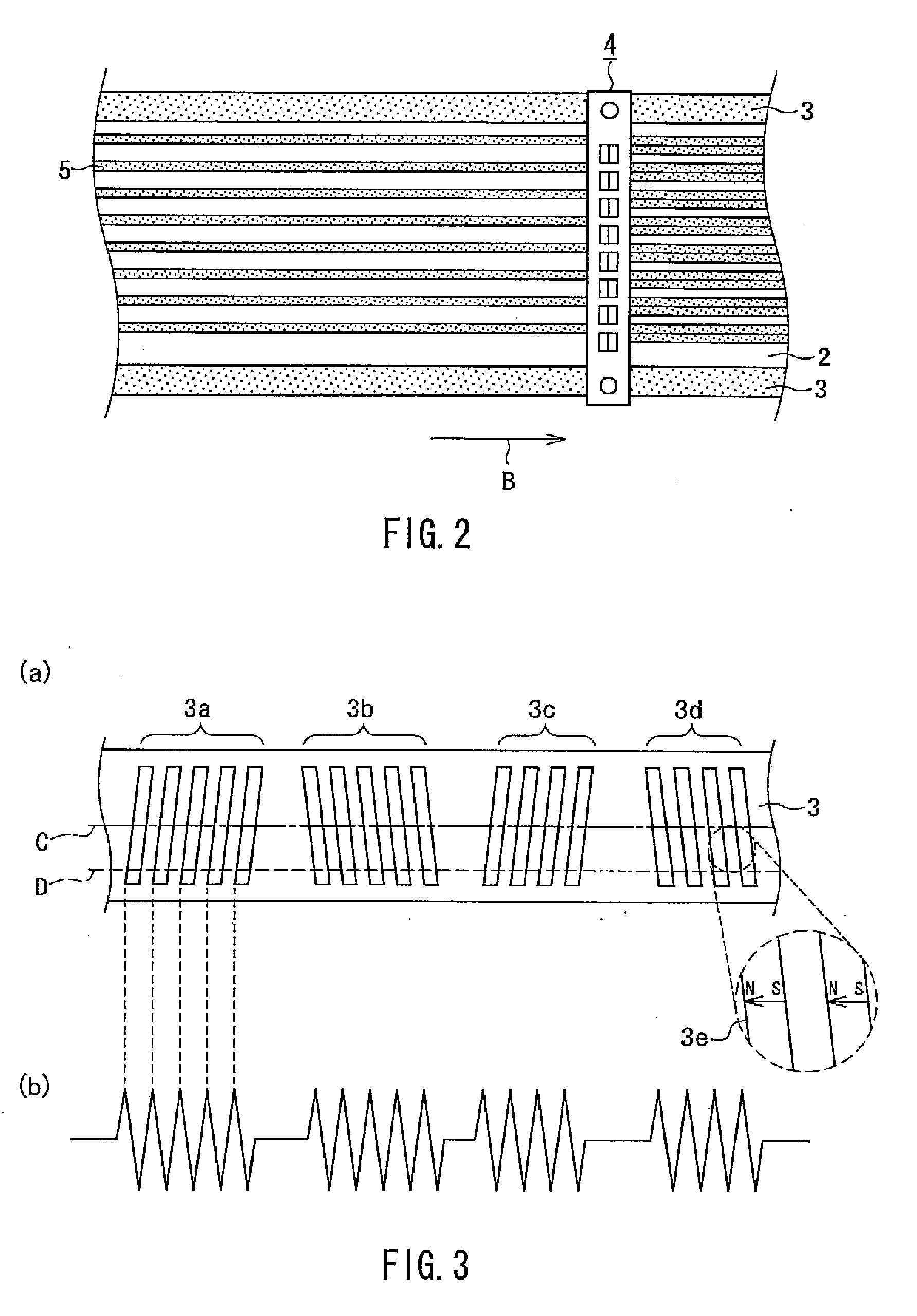

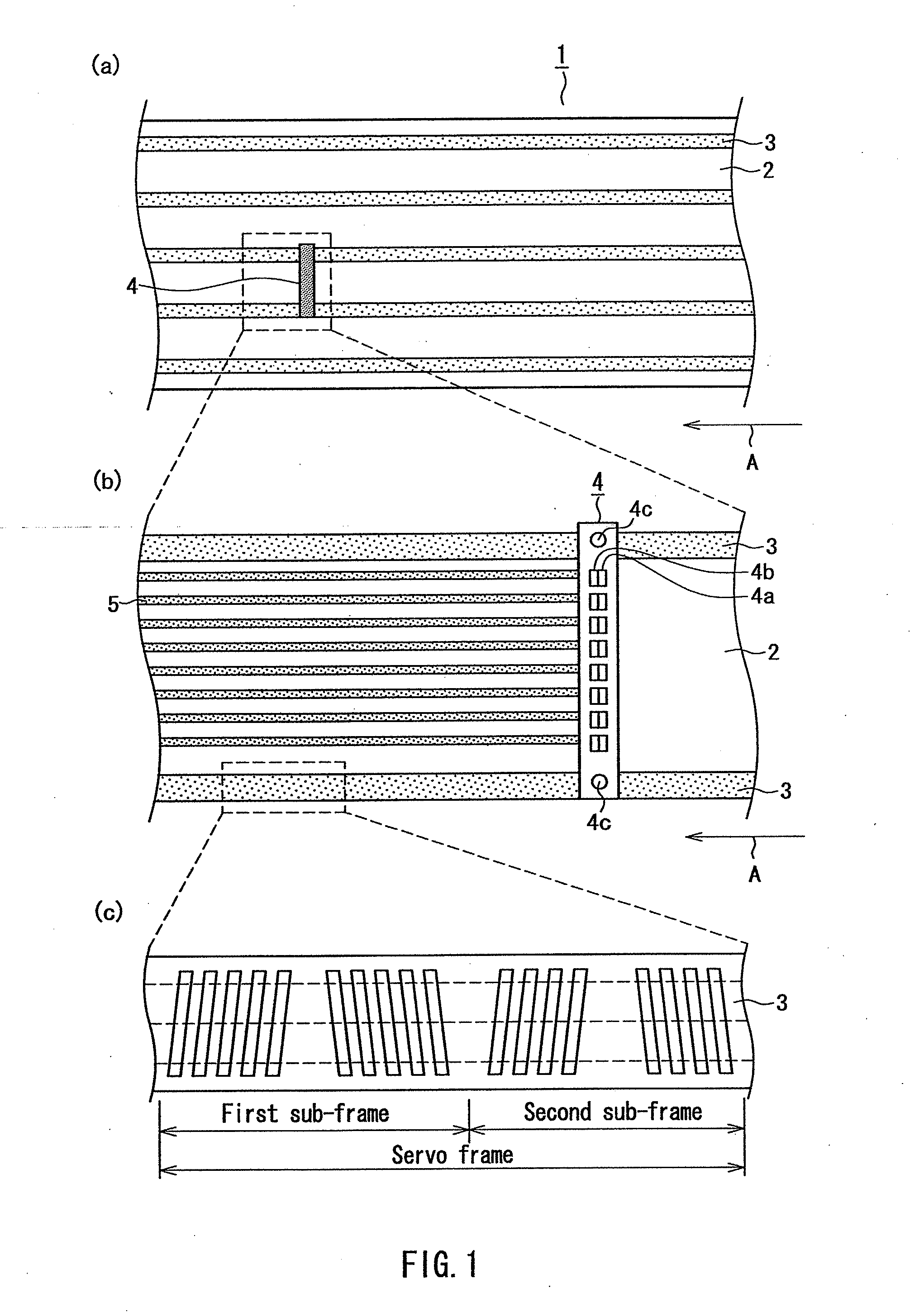

Servo controlling method, recording/reproducing apparatus, magnetic tape, and magnetic tape cartridge

ActiveUS20080278844A1Follow exactlyIncrease speedDriving/moving recording headsAlignment for track following on tapesTape speedEngineering

A servo controlling method of the present invention is a servo controlling method for controlling a position of a magnetic head against a magnetic tape that is accommodated in a cartridge and has at least a data track and a servo track, and the method includes the steps of: reading tape variance information from a magnetic tape cartridge 23 side, the magnetic tape cartridge 23 being composed of a cartridge 20 and a magnetic tape 21; reading a servo signal recorded in the servo track by the magnetic head and converting the servo signal into head position information; and controlling the position of the magnetic head according to an off-track value based on the tape variance information and an off-track value calculated from the head position information. With this configuration, even in the case where a recording track width is narrowed and a tape speed is increased, the magnetic head can follow a recording track accurately at a high speed

Owner:FUJIFILM CORP

Servo controlling method, recording/reproducing apparatus, magnetic tape, and magnetic tape cartridge

InactiveUS20100002338A1Follow exactlyDriving/moving recording headsCarrier storage meansTape speedControl theory

A servo controlling method of the present invention is a servo controlling method for controlling a position of a magnetic head against a magnetic tape that is accommodated in a cartridge and has at least a data track and a servo track, and the method includes the steps of: reading tape variance information from a magnetic tape cartridge (23) side, the magnetic tape cartridge (23) being composed of a cartridge (20) and a magnetic tape (21); reading a servo signal recorded in the servo track by the magnetic head and converting the servo signal into head position information; and controlling the position of the magnetic head according to an off-track value based on the tape variance information and an off-track value calculated from the head position information. With this configuration, even in the case where a recording track width is narrowed and a tape speed is increased, the magnetic head can follow a recording track accurately at a high speed.

Owner:HITACHT MAXELL LTD

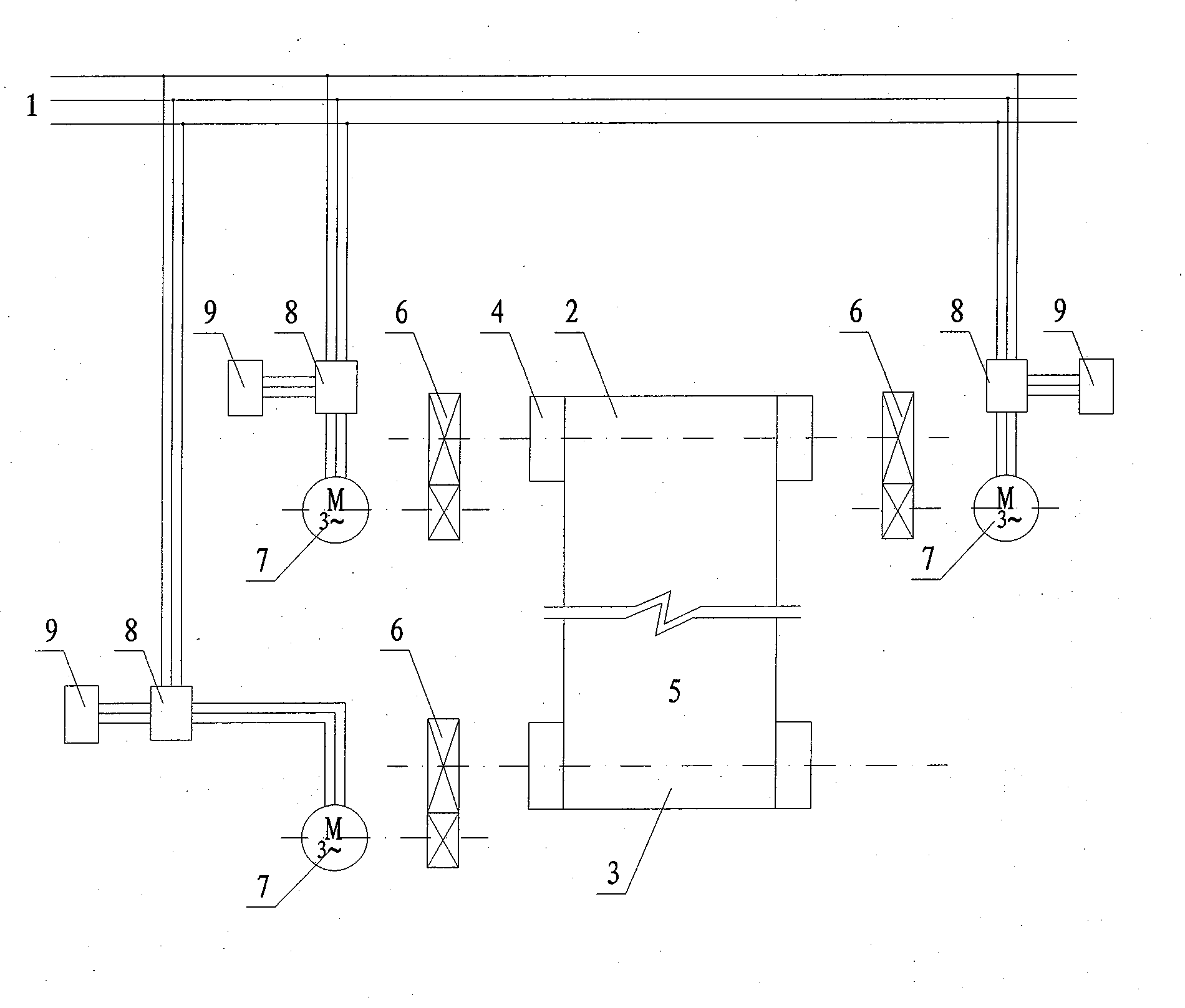

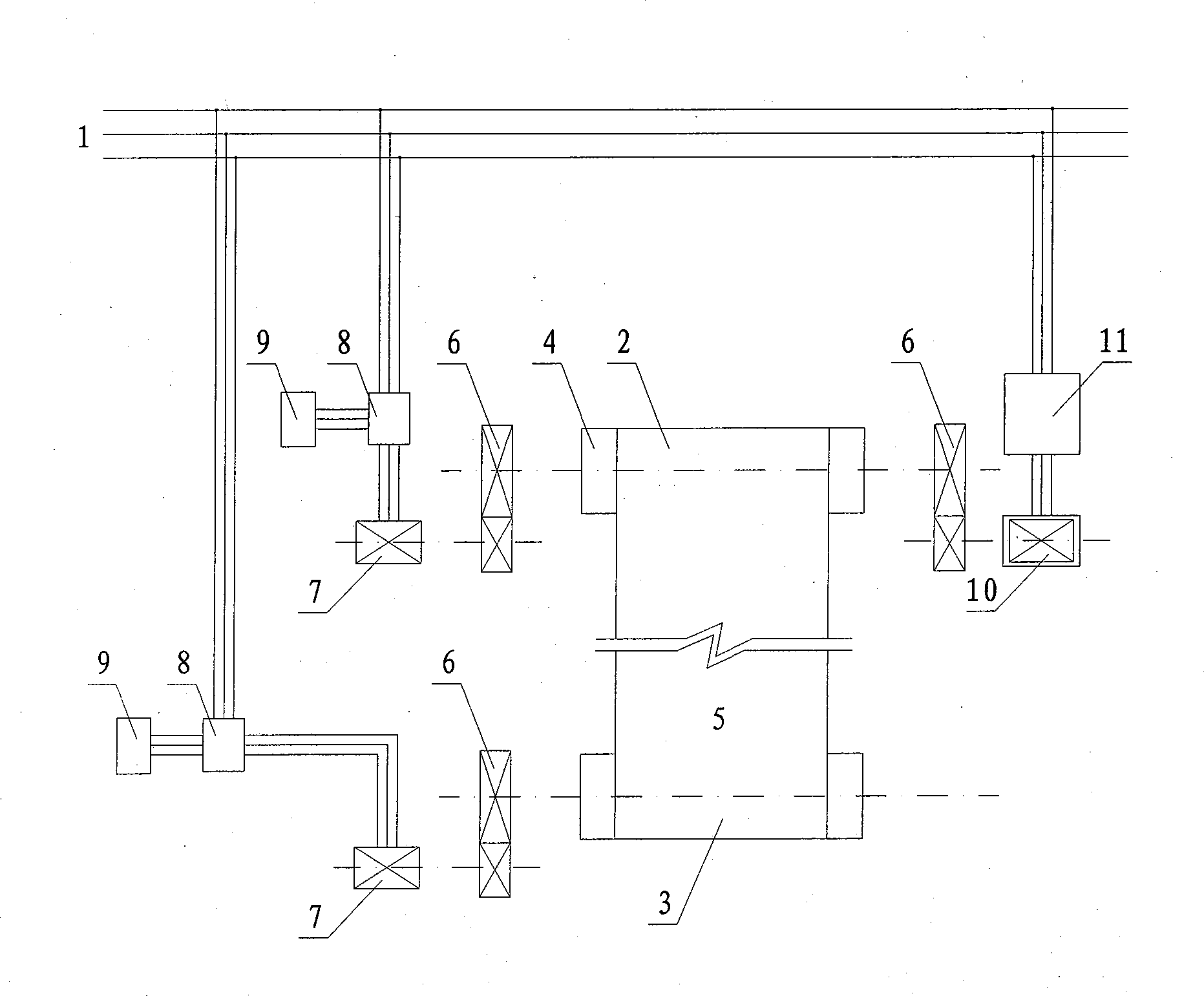

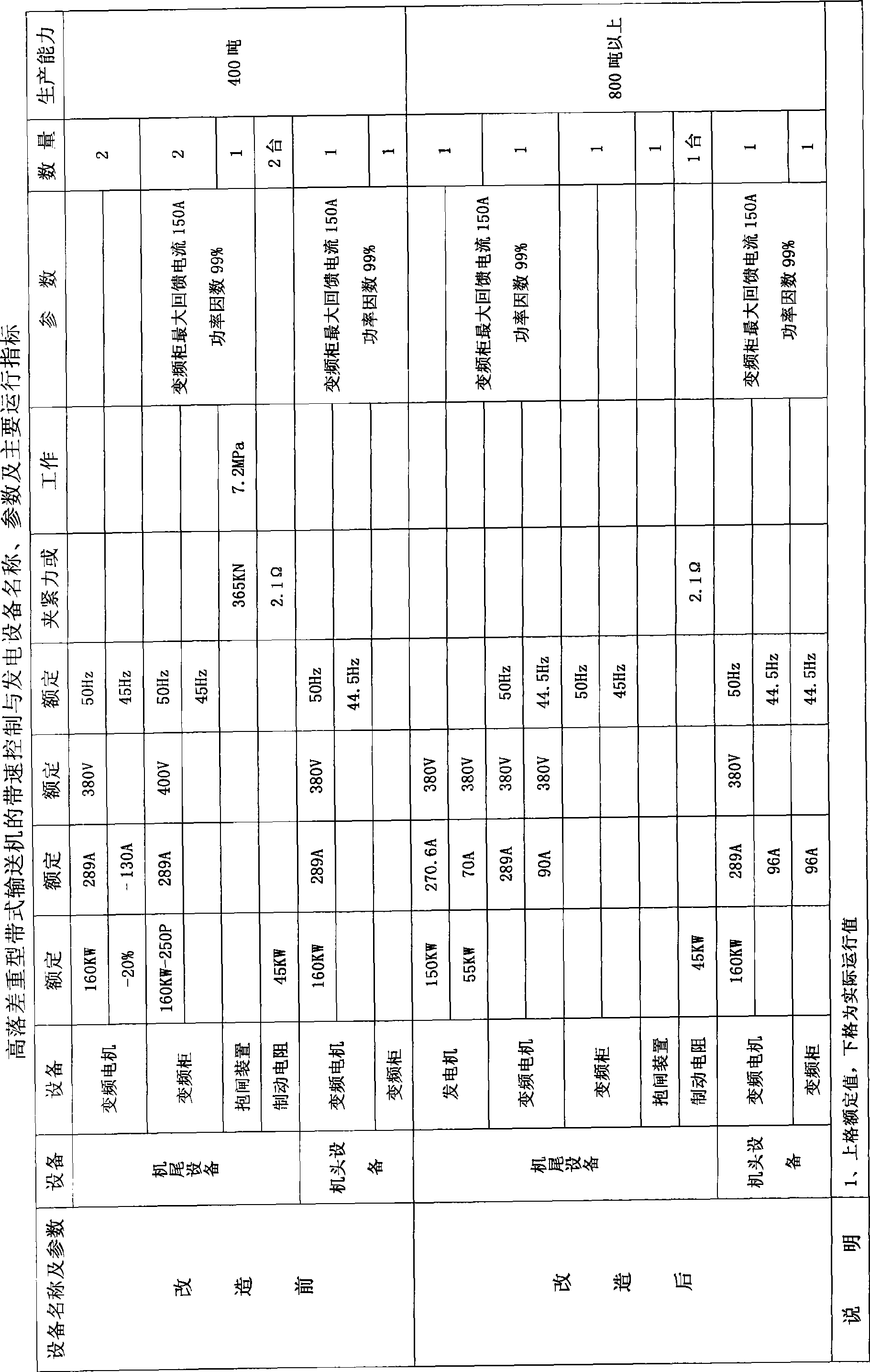

Tape speed control method for high drop height heavy type belt conveyor

InactiveCN101486407ASave equipmentSave moneyConveyorsControl devices for conveyorsFrequency changerTape speed

The invention discloses a belt speed control method of a heavy type belt conveyor with high drop height, which is mainly characterized in that: on the structural basis of the existing heavy type belt conveyor with high drop height which consists of a belt conveyor tail (2), a belt conveyor head (3), a belt conveyor roller (4), a conveyor belt (5), a speed reducer (6), an adjustable frequency motor (7), a frequency converter (8) and a resister (9) of the frequency converter, the belt conveyor tail (2) is configured with an electric generator (10) which rotates coaxially with the original adjustable frequency motor (7) so as to convert the potential energy generated by the belt conveyor when conveying materials of high drop height into electric energy and utilize the potential energy for generating electricity simultaneously when adjusting and controlling the belt speed of the belt conveyer. By utilizing the potential energy of the belt conveyer when conveying the materials of high drop height and converting the potential energy into the electric energy to replace the drive of the motive power motor through the electric generator, the invention realizes the purpose of utilizing the potential energy for generating electricity simultaneously when effectively controlling the belt speed of the belt conveyor.

Owner:LUOYANG HUANGHE TONGLI CEMENT

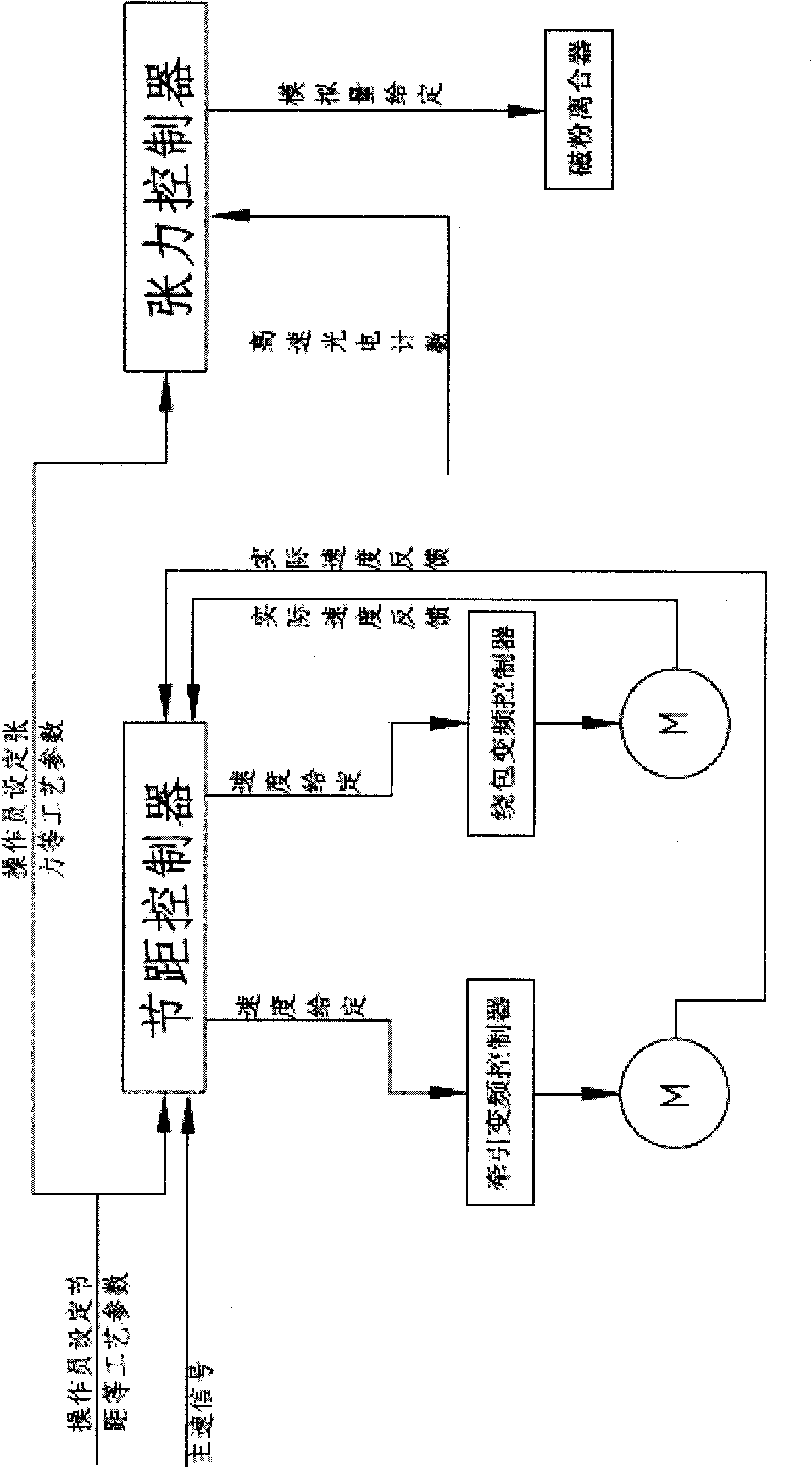

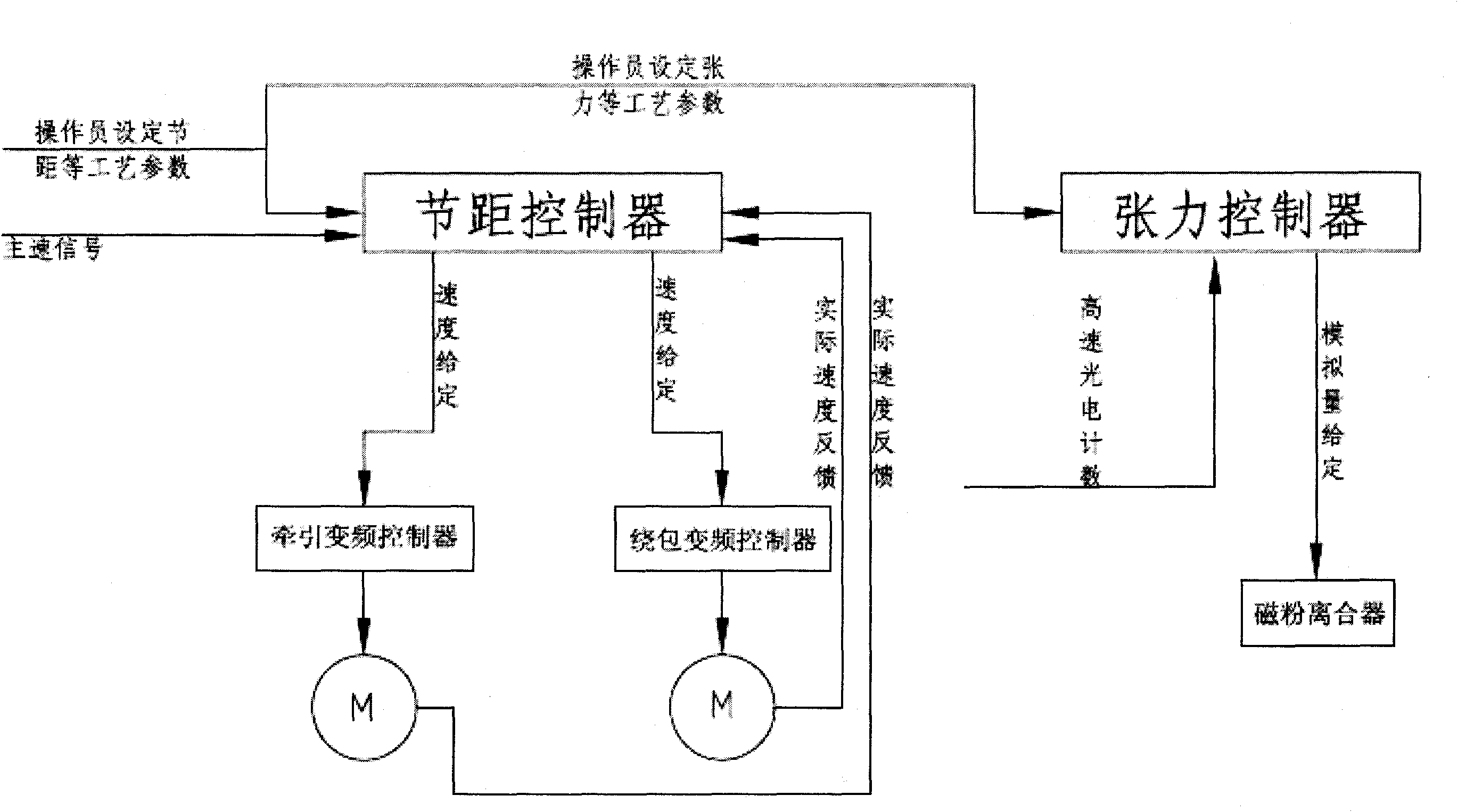

Winding wire taping method and winding wire taping control device

InactiveCN101819875AReal-time tracking output speedAccurate pitch controlElectronic commutation motor controlVector control systemsTape speedProportional control

The invention discloses a winding wire taping method. A synchronous controller is used to control taping device traction speed and taping speed in the same proportion, performs PID operation according to a specific speed and an actual acquisition speed, and tracks an output speed in real time, so that traction and taping motors are subjected to closed loop speed control and accurate pitch control is realized. Meanwhile, a compensation algorithm is built in the synchronous controller to automatically compensate the acceleration and deceleration of a system, and startup and stop so as to realize the accurate pitch control in the processes of acceleration and deceleration and startup and stop. A tension control system of a taping device automatically adjusts tension according to change of film materials; and a photosensitive switch is used to sense the insulating material consumption condition, the controller automatically calculates the diameter of an unwinding disk according to the feedback of the photosensitive switch and simultaneously automatically adjusts the taping tension according to the diameter change of the insulating material coil so as to fulfill the aim that the taping tension does not change along with the change of the insulating material coil.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

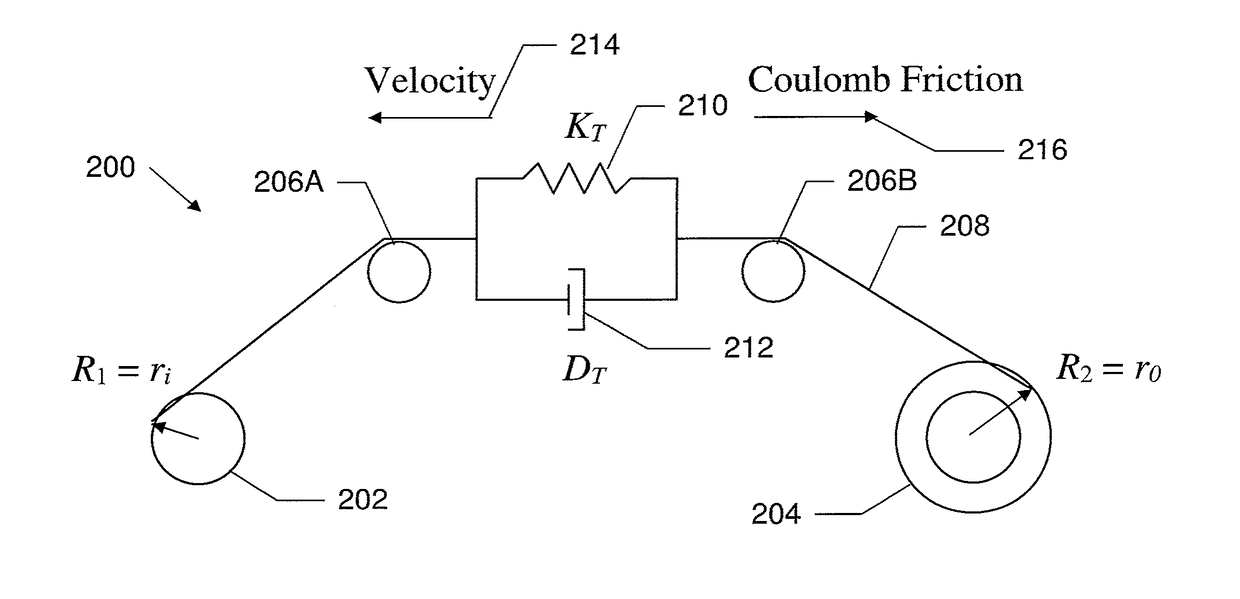

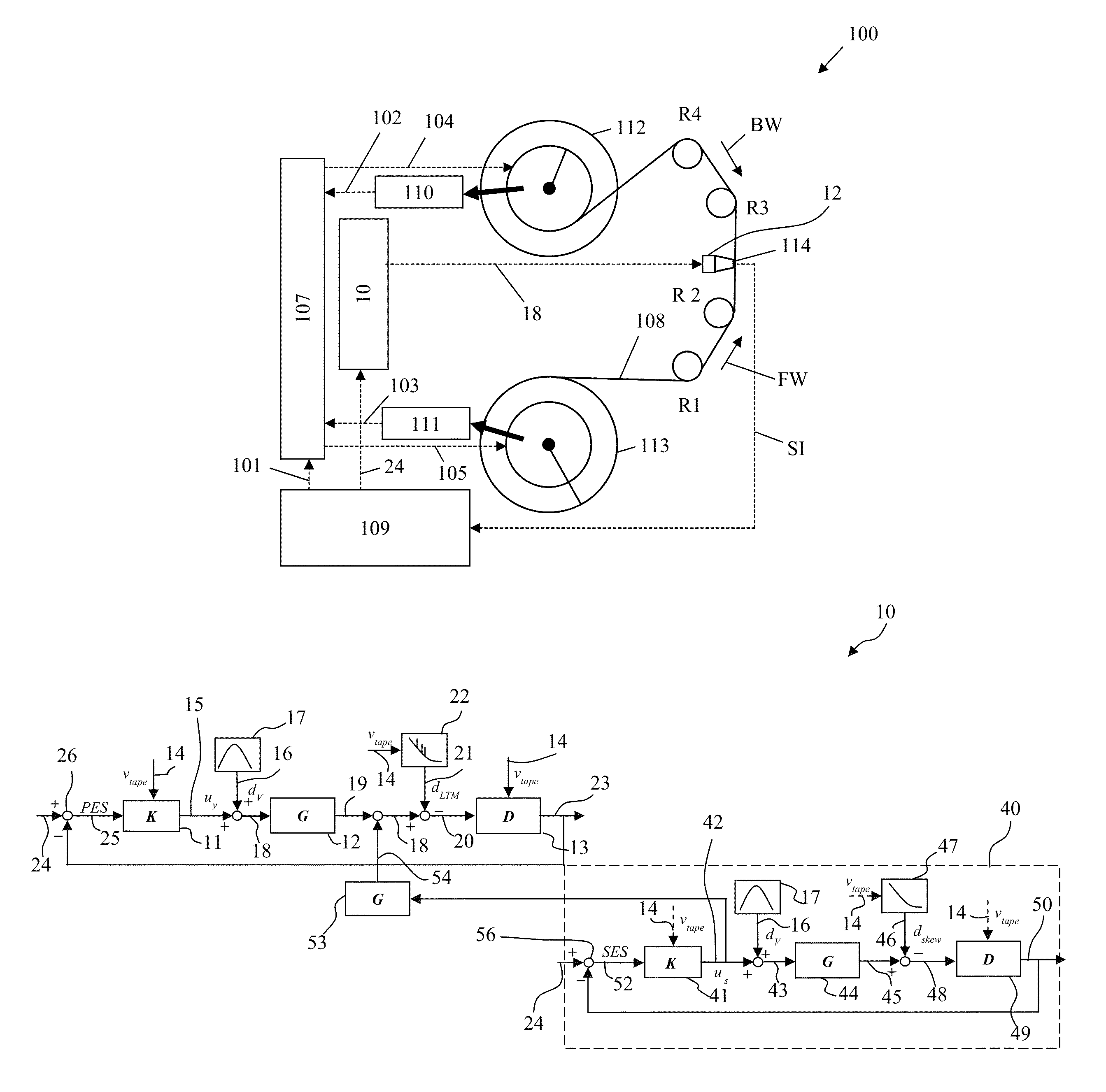

Tape transport control with feedback of velocity and tension

ActiveUS20180061448A1Easy to superviseReduce mechanical stressSimulator controlRecord information storageTape speedControl signal

A tape transport control system with enhanced regulation of tape tension and velocity over the entire length of the tape. For example, a closed-loop control system for controlling a tape transport includes circuitry adapted to output a signal representing a tape velocity at a tape head, circuitry adapted to output a signal representing a tape velocity at the first tape reel and a signal representing a tape velocity at the second tape reel, circuitry adapted to output a signal representing a tape tension, and circuitry adapted to, based on the received signals, generate control signals to control the tape velocity at least at one of the tape head, the first tape reel, the second tape reel, and the tension of the tape, using controller gains that depend on a longitudinal position of the tape, and to implement a system transfer function that is approximately independent of the longitudinal position.

Owner:IBM CORP

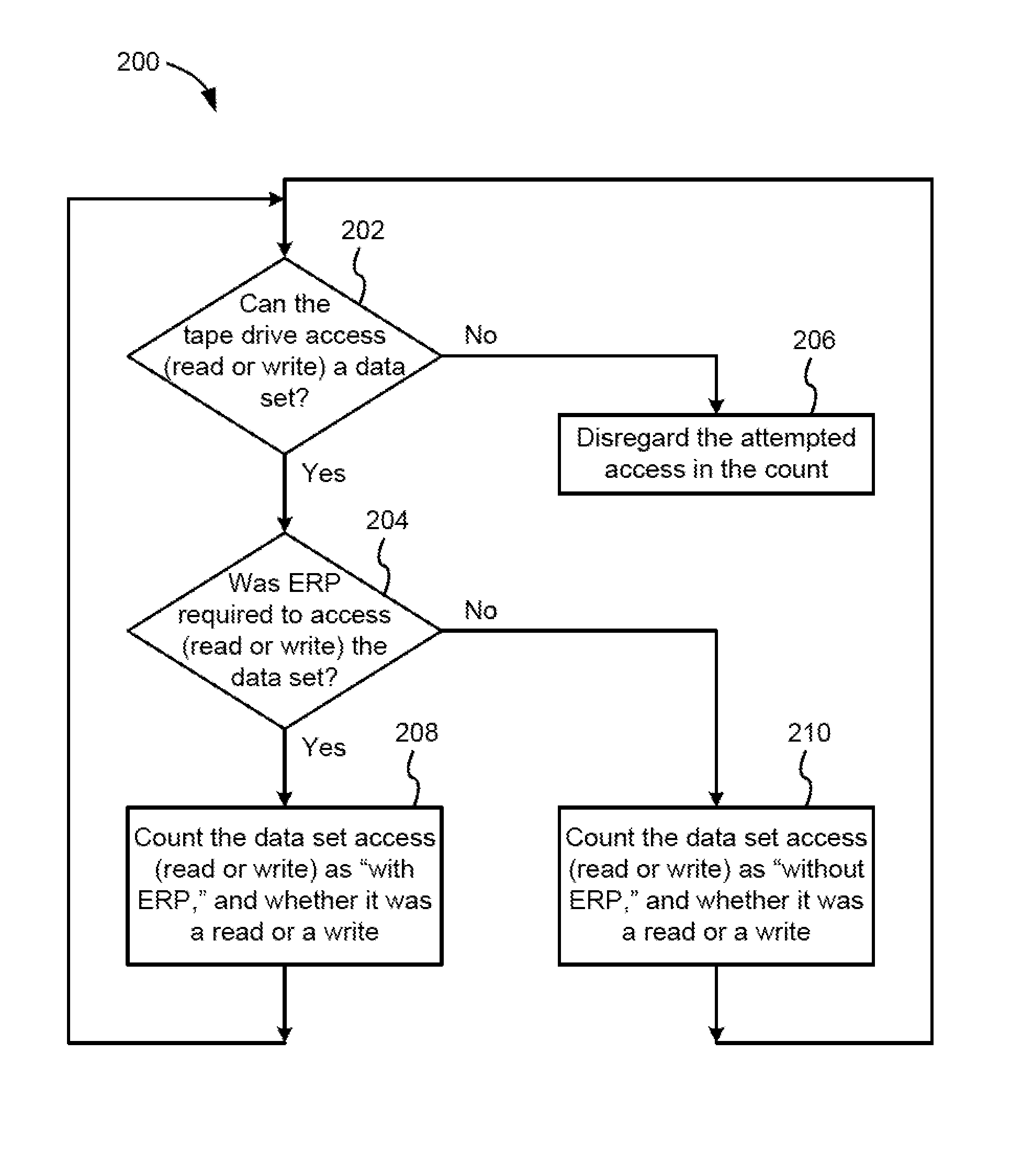

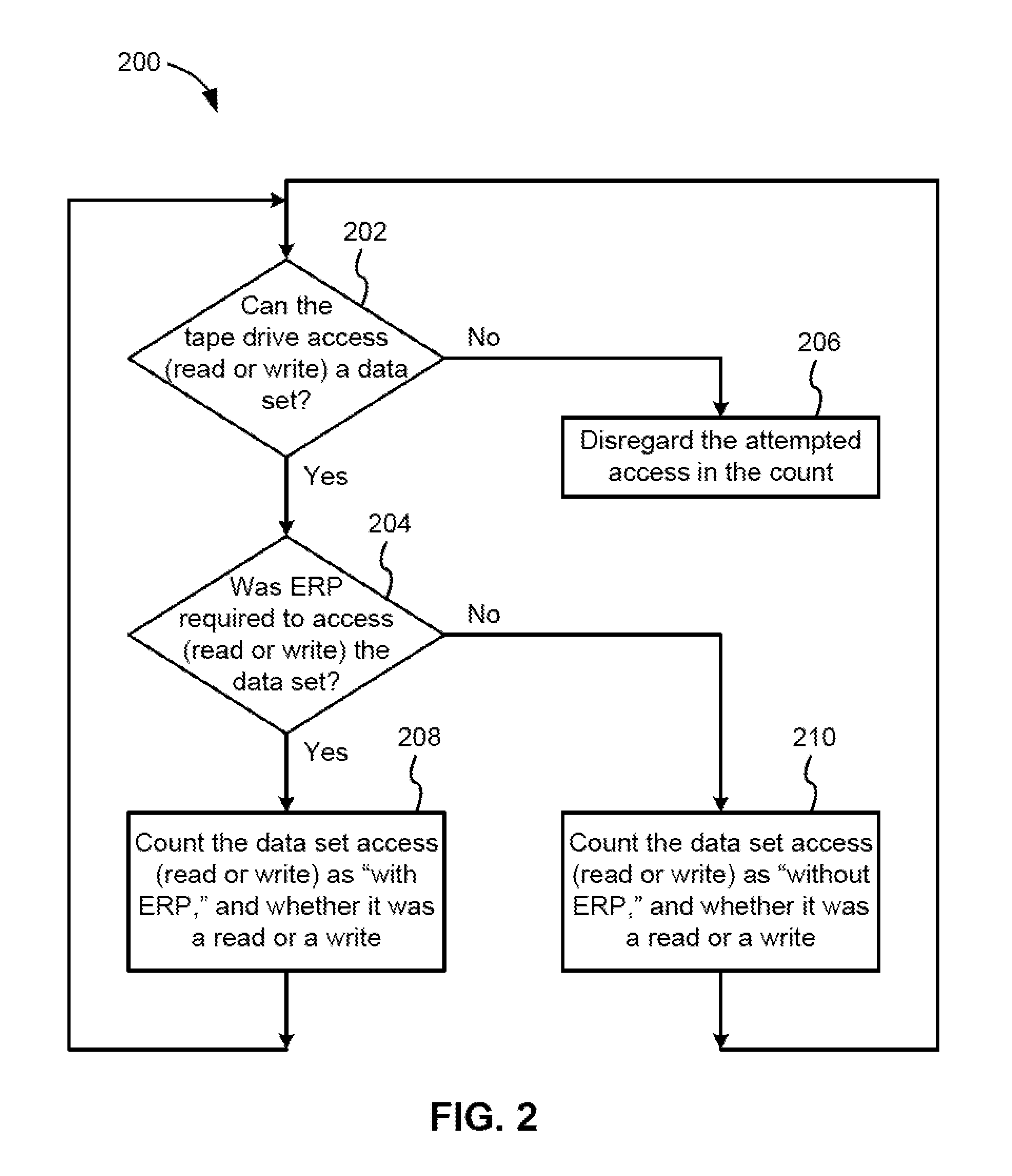

Error recovery procedure (ERP) using estimated best setting in first run

In one embodiment, a tape drive system includes a read channel, a write channel, logic adapted for accessing data sets using the read channel and / or the write channel, logic adapted for counting each data set access using the read channel that used error recovery procedure (ERP), logic adapted for counting each data set access using the read channel that did not use ERP, logic adapted for counting each data set access using the write channel that used ERP, logic adapted for counting each data set access using the write channel that did not use ERP, and logic adapted for accessing subsequent data sets using the read channel and / or the write channel, wherein any subsequent data set access that uses ERP is accessed using an initial ERP step characterized by a first tape speed, wherein the first tape speed is selected at least partially based on the counts.

Owner:IBM CORP

Load monitoring instrument and system of adhesive tape conveyor

PendingCN109665284AIncrease production capacityImprove efficiencyConveyorsControl devices for conveyorsTape speedCurrent load

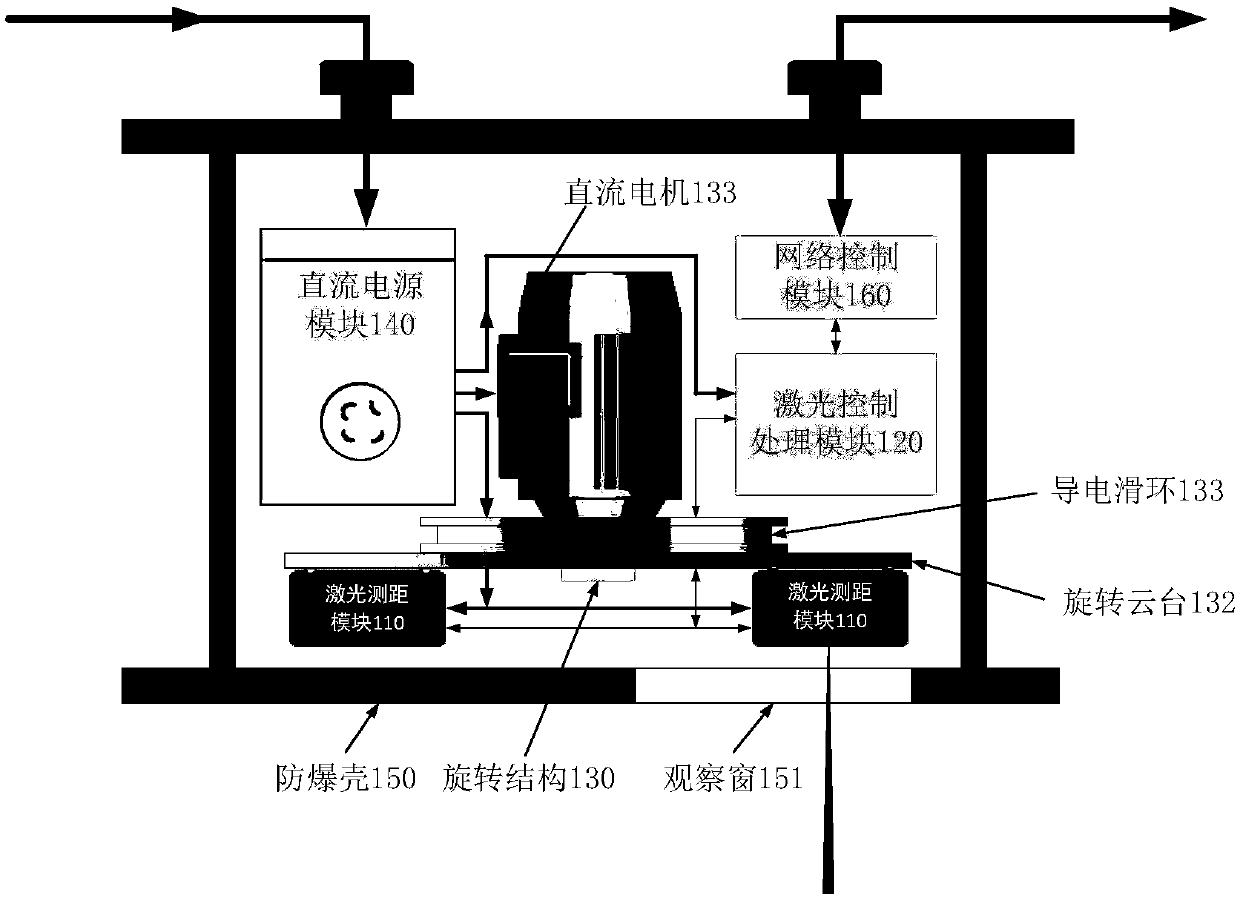

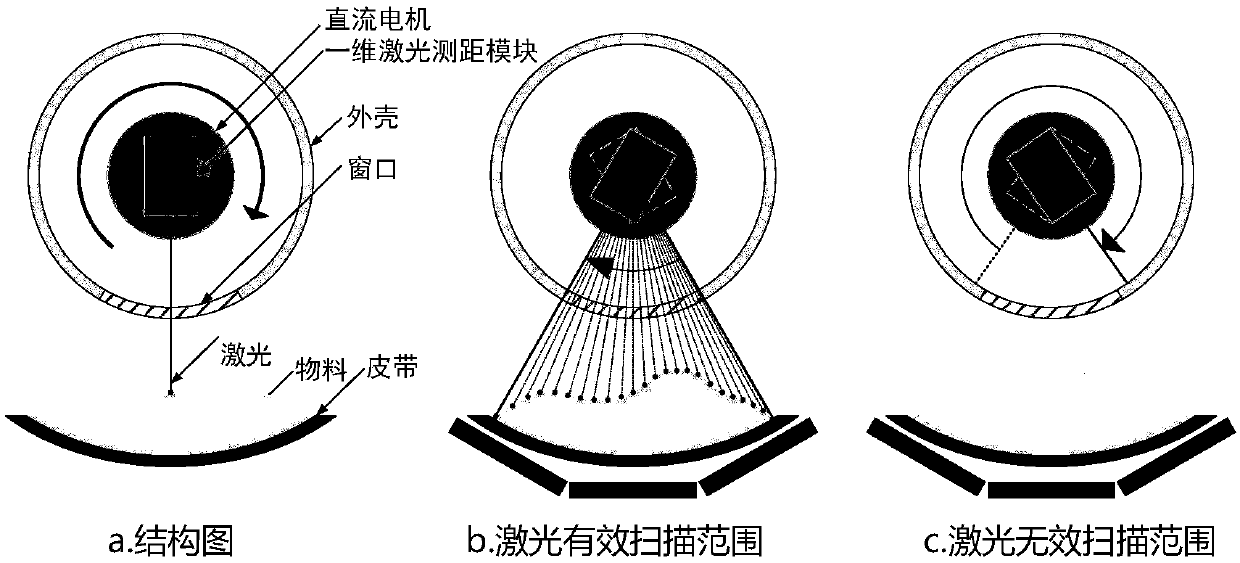

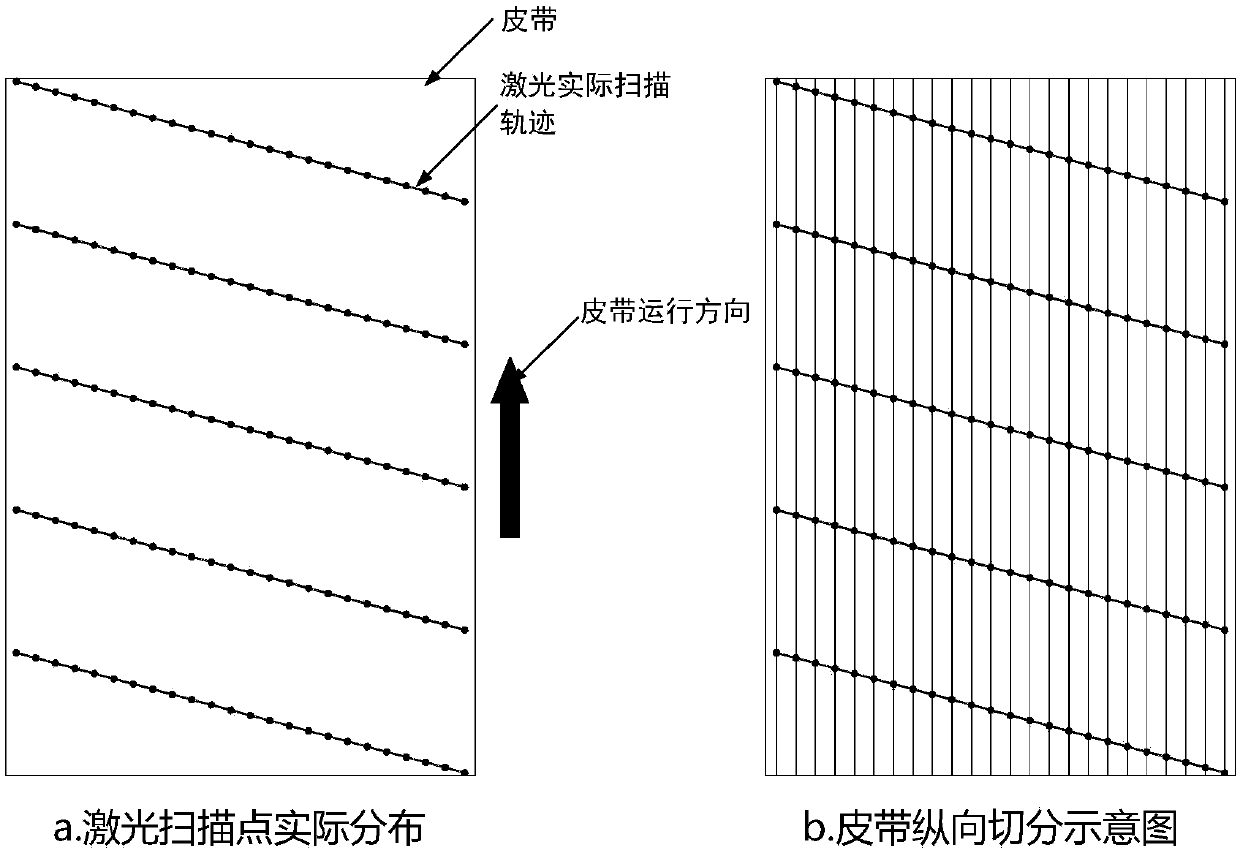

The invention discloses a load monitoring instrument and system of an adhesive tape conveyor. The monitoring instrument comprises one or more laser distance measurement modules, a laser control treatment module and a rotating structure. When the laser distance measurement modules rotate along with the rotating structure, raw coal on the adhesive tape conveyor is scanned, load distribution in unitlength on the adhesive tape conveyor can be obtained, and the current operating speed of the adhesive tape conveyor is calculated; the laser control treatment module determines the adjustment speed according to the load distribution in the unit length and the current operating speed, so that the adhesive tape conveyor operates according to the adjustment speed to achieve the purpose that the difference value between the load of a conveyer belt and rated load is in the preset range. When the monitoring instrument and system are applied, the distribution situation of coal current load on the adhesive tape conveyor can be safely and accurately monitored, so that the tape speed of the adhesive tape conveyor can be automatically adjusted according to the coal current load distribution of the adhesive tape conveyor, rated load operation can be performed, the transporting efficiency can be improved, and safe production management level of coal mines and economic benefits of the coal mines canbe increased.

Owner:BEIJING POLYTECHNIC COLLEGE +1

Controlling a tape speed to manage a tape drive buffer

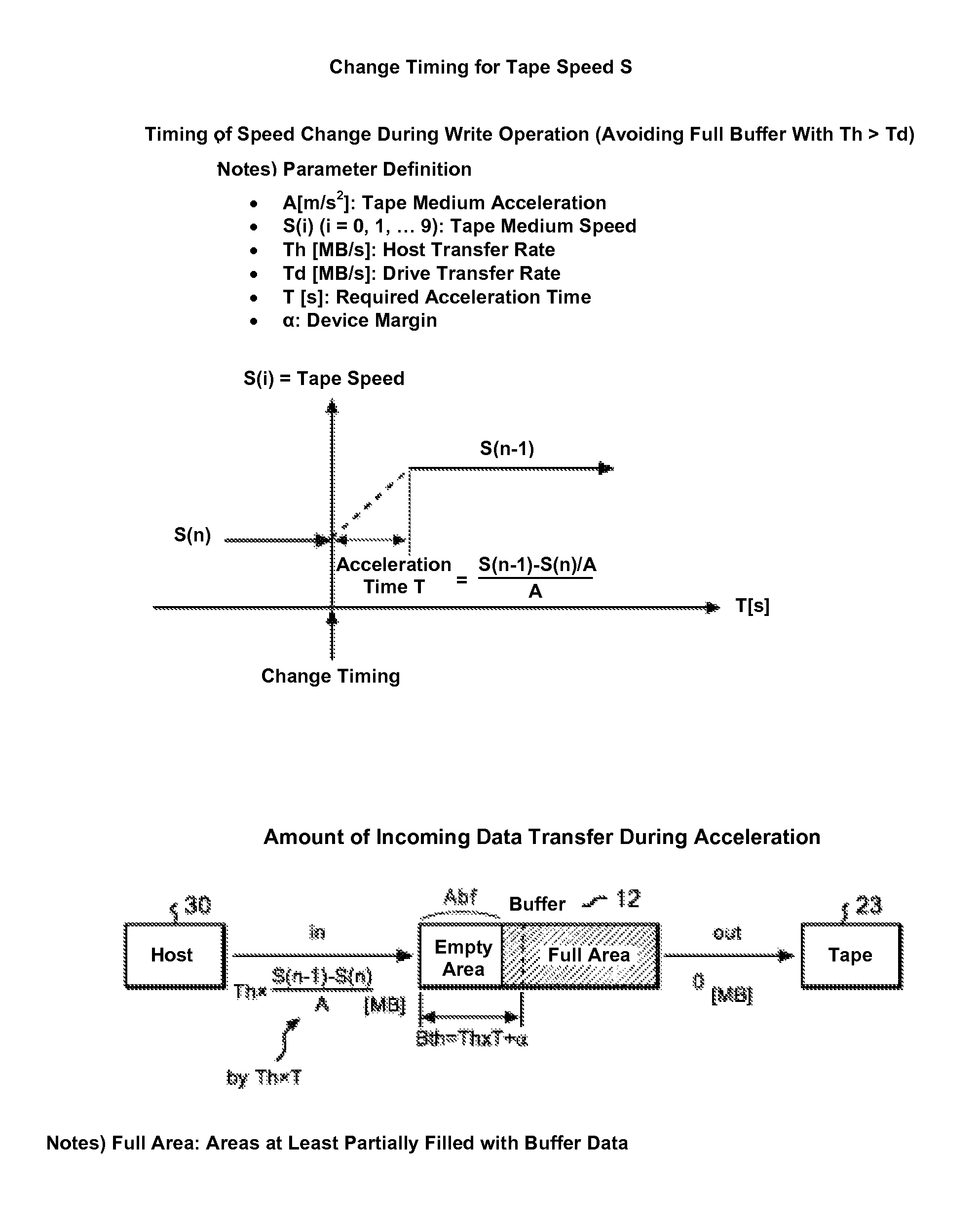

InactiveUS8917472B2Record information storageCarrier controlling using processorTape speedTape drive

Provided are a storage device, method, and program for controlling a tape speed to manage a tape drive buffer. A tape speed is increased from a current tape speed to a target tape speed on a predetermined speed-change timing to control the reading or writing of data between the buffer and the tape medium.

Owner:IBM CORP

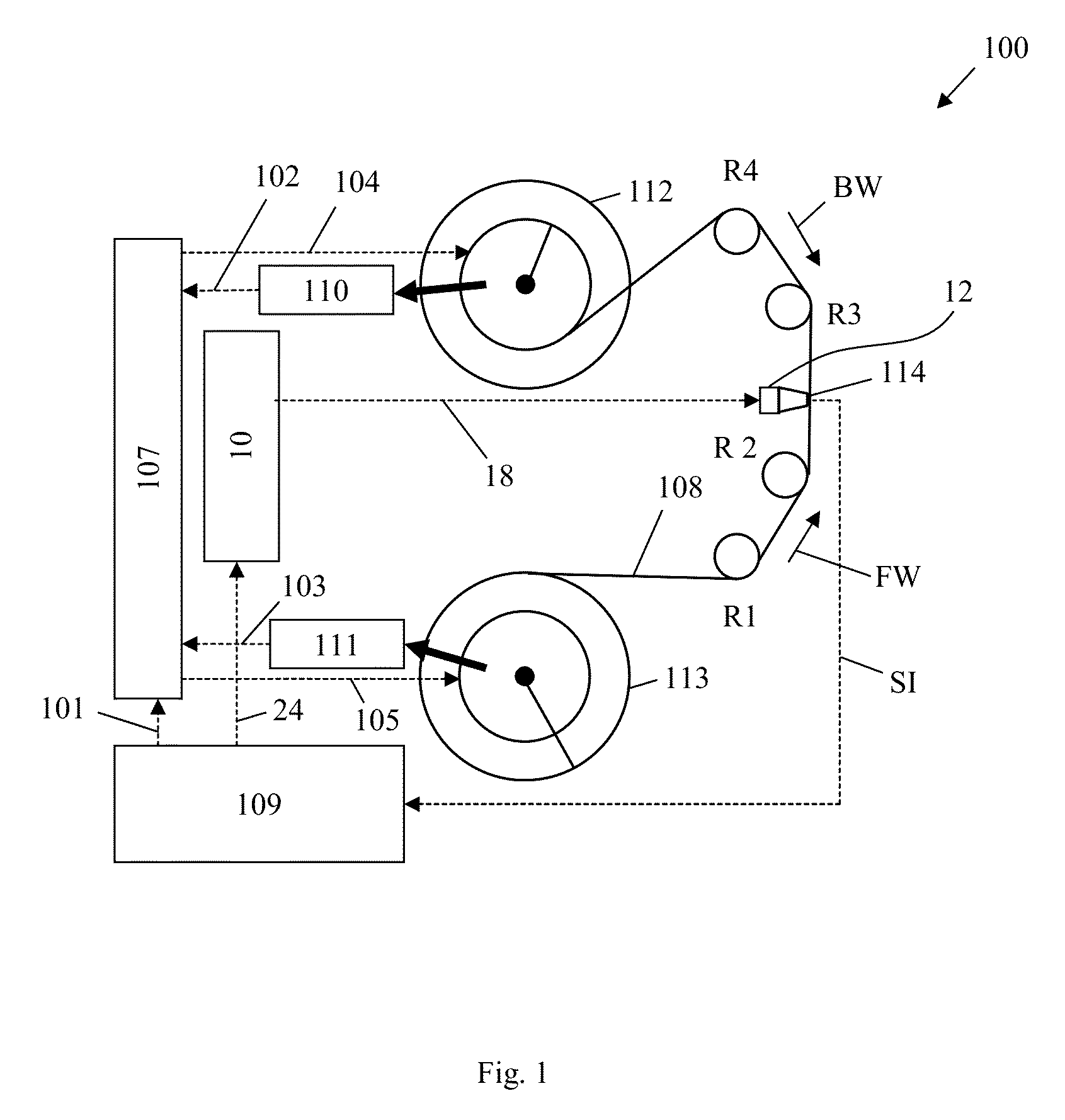

Device and method for controlling the position of a head relative to a tape within a tape transport system

InactiveUS9087539B2Filamentary/web record carriersAlignment for track following on tapesTape speedTransport system

Owner:INT BUSINESS MASCH CORP

Device and method for controlling the position of a head relative to a tape within a tape transport system

ActiveUS20150325262A1Driving/moving recording headsFilamentary/web record carriersTape speedTransport system

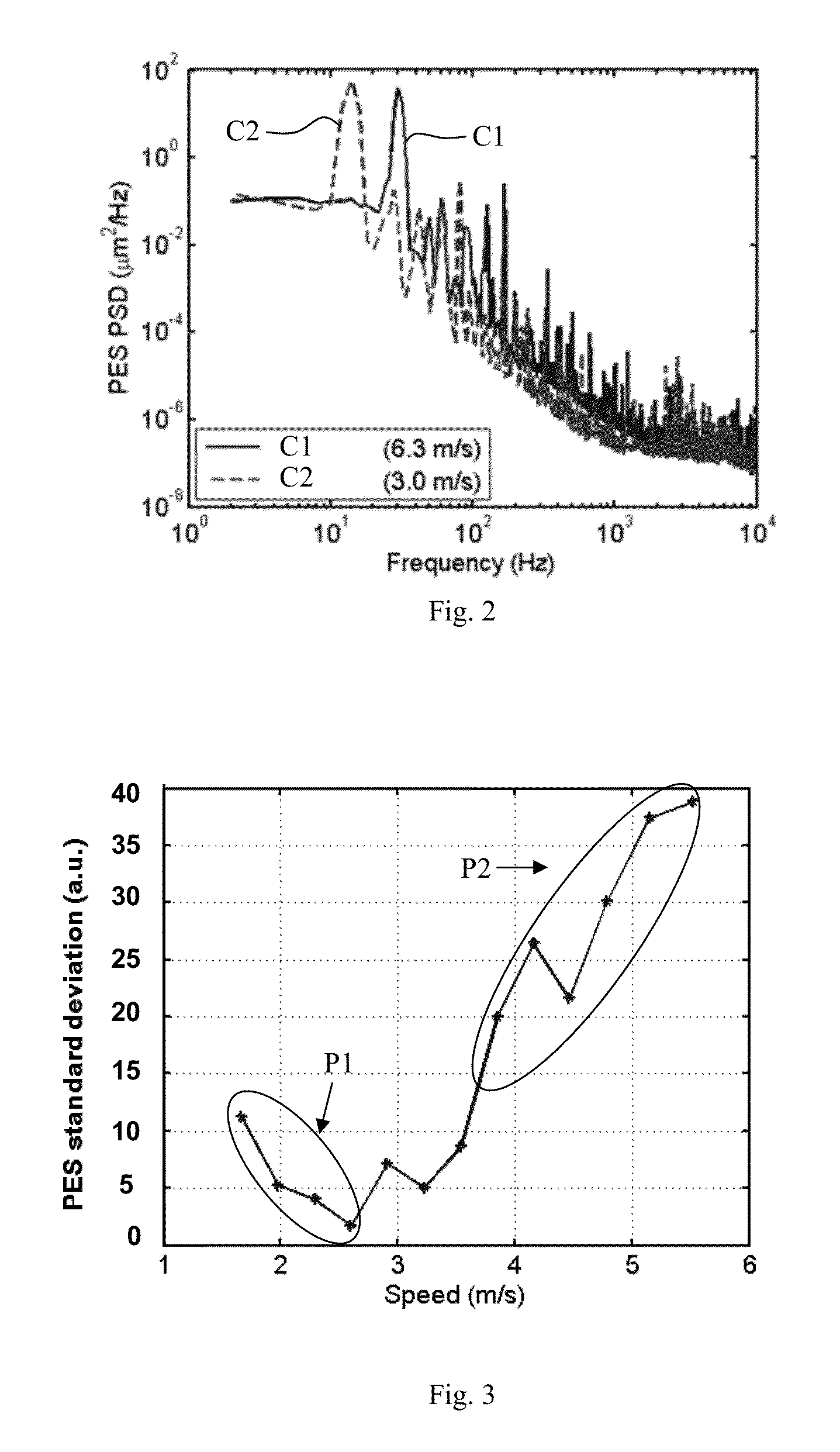

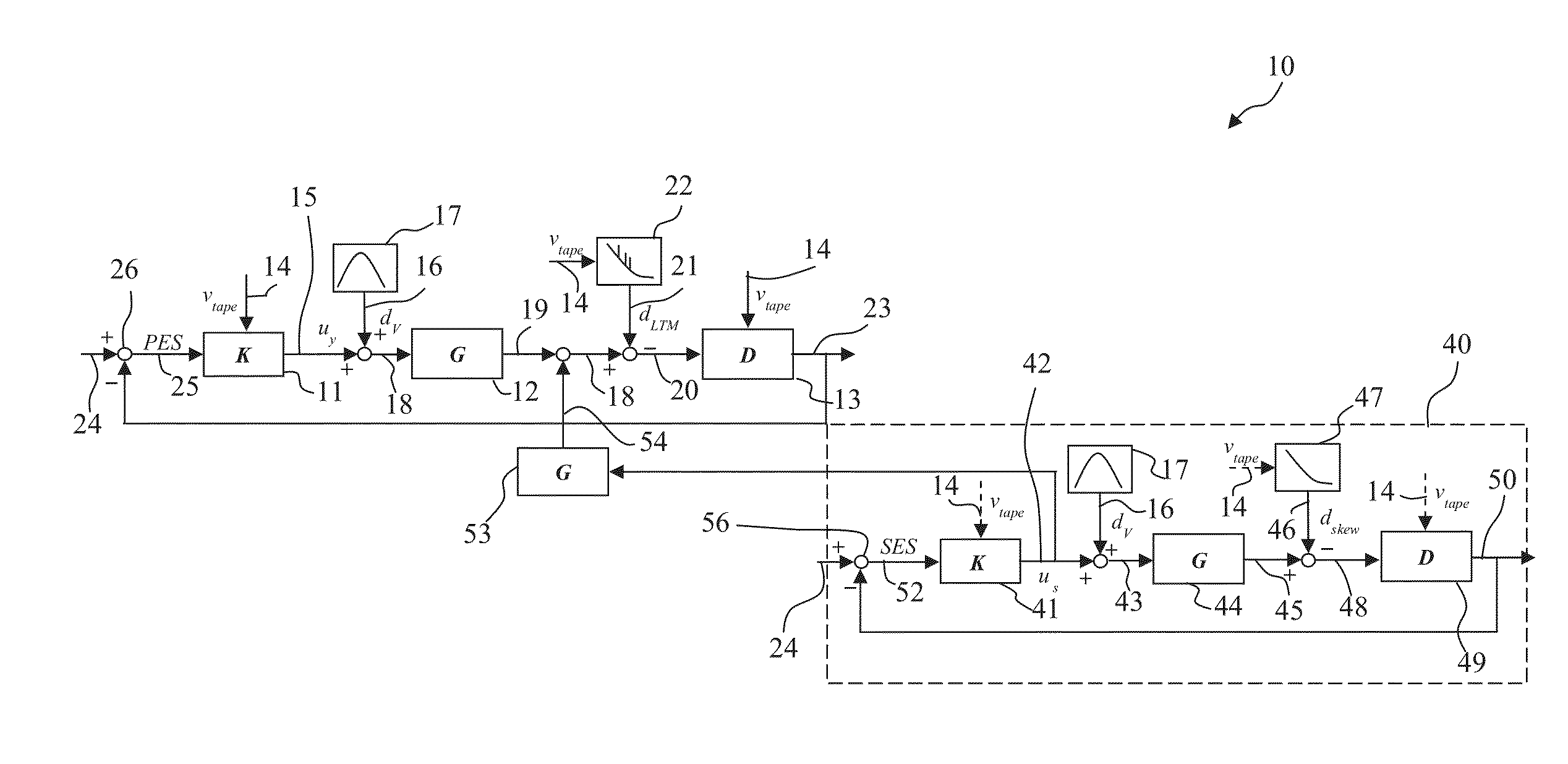

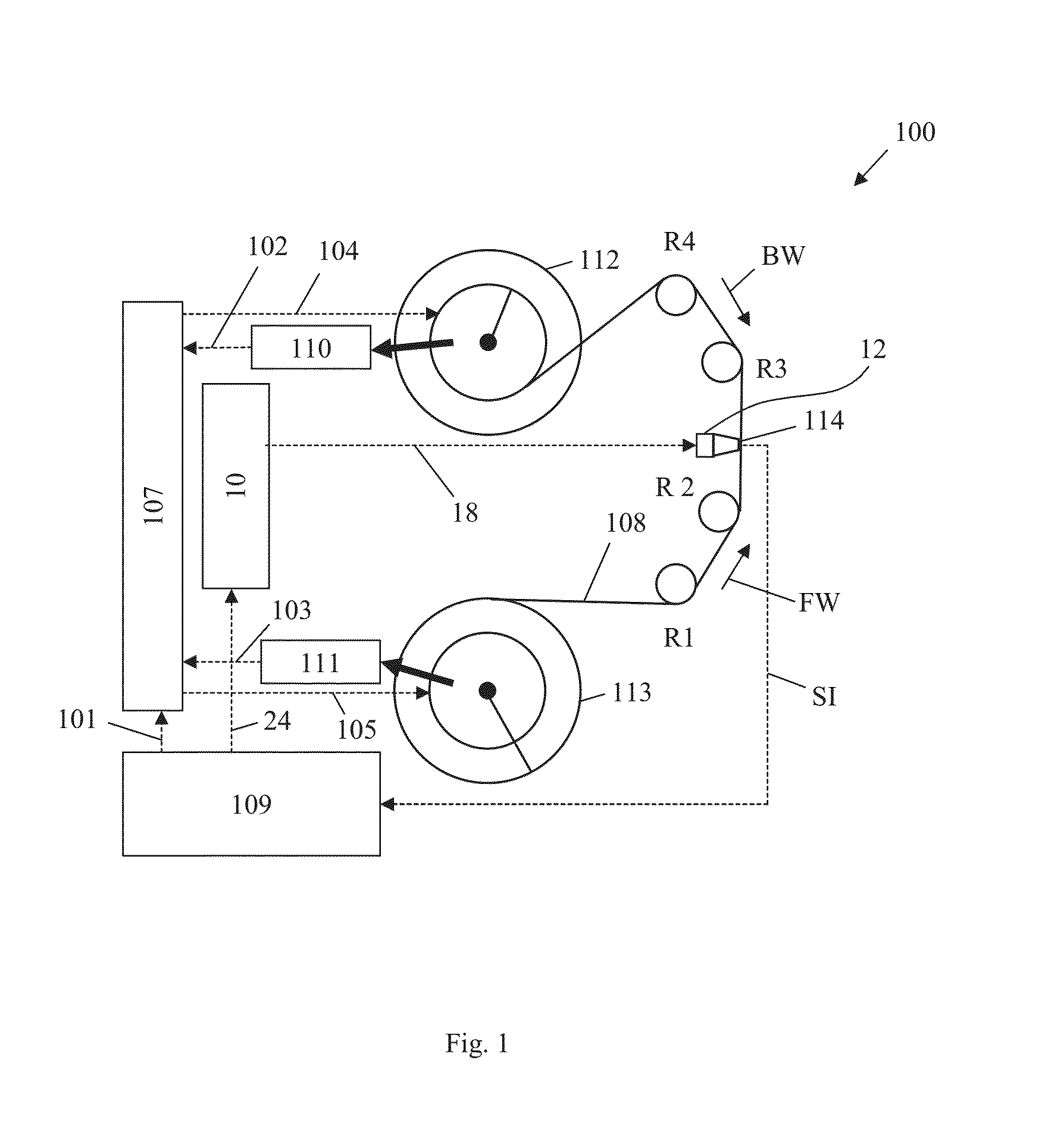

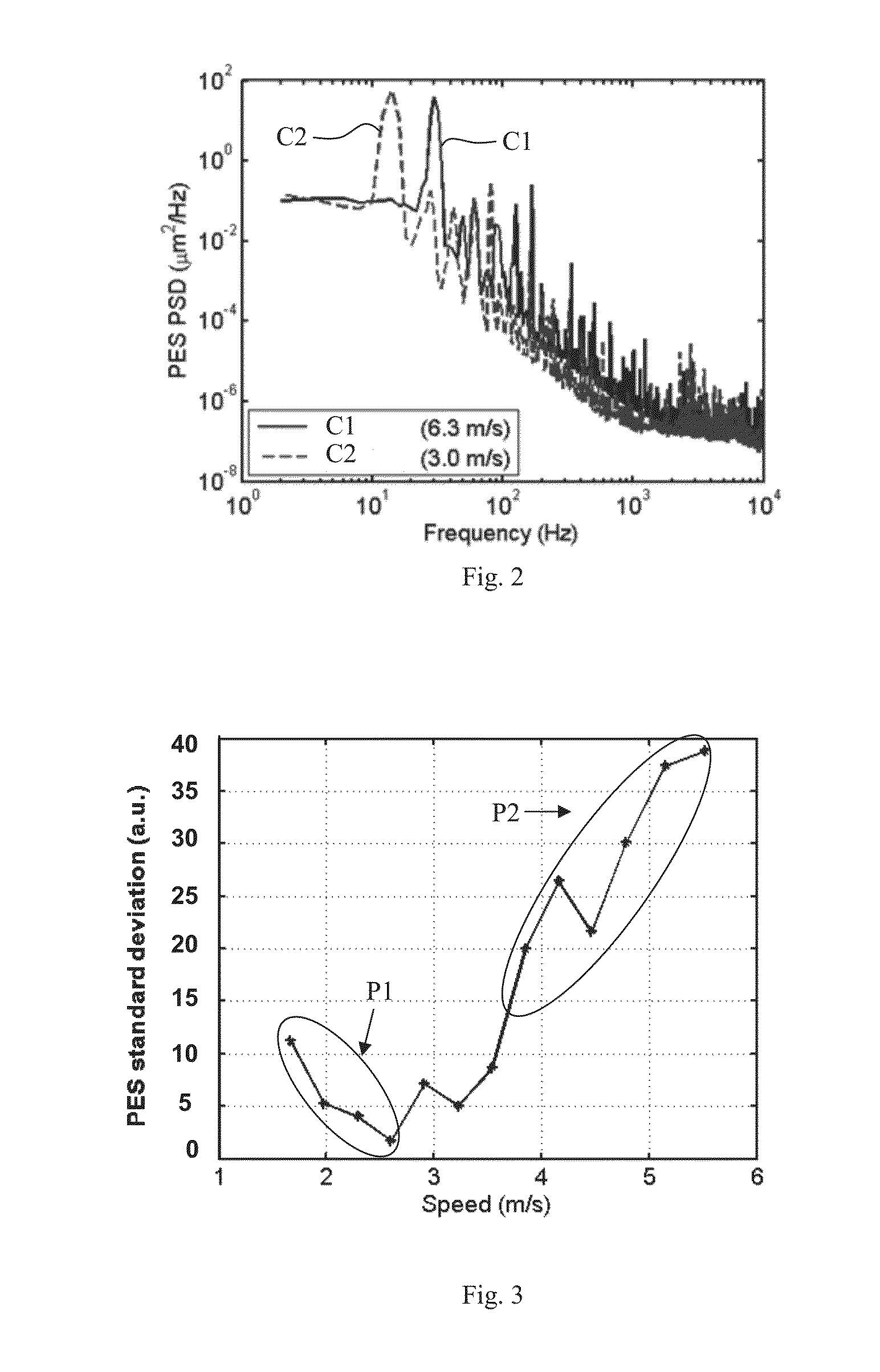

Controlling the position of a head within a tape transport system. A track-follow control system (TFCS) includes a controller device for generating a control signal as a function of a position error signal (PES), wherein the PES indicates a difference between the actual and target positions of the head relative to the tape, and an actuator for changing the actual position. The TFCS is adapted to select a controller device configuration from a plurality of configurations dependent on an operating tape speed. The configurations are predetermined depending on a vibration frequency domain profile indicative of environmental vibrations induced to the head and tape to determine the control signal for adjusting an actuator output signal relative to a lateral tape motion signal. The TFCS is also adapted to feed-back a signal depending on a difference of the actuator output signal and the lateral tape motion signal to generate the PES.

Owner:INT BUSINESS MASCH CORP

Device for monitoring operation speed of power line type fieldbus belt conveyor

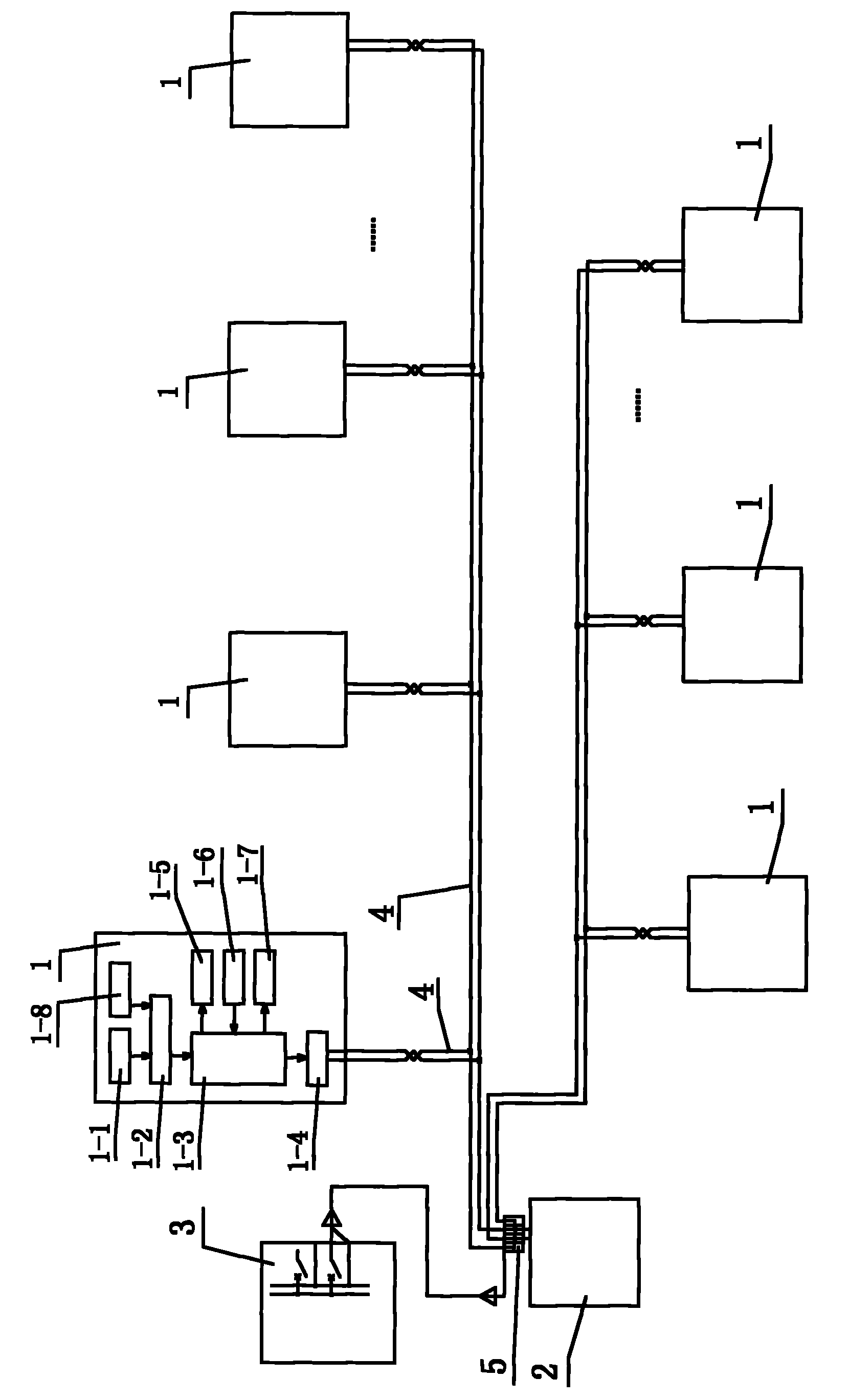

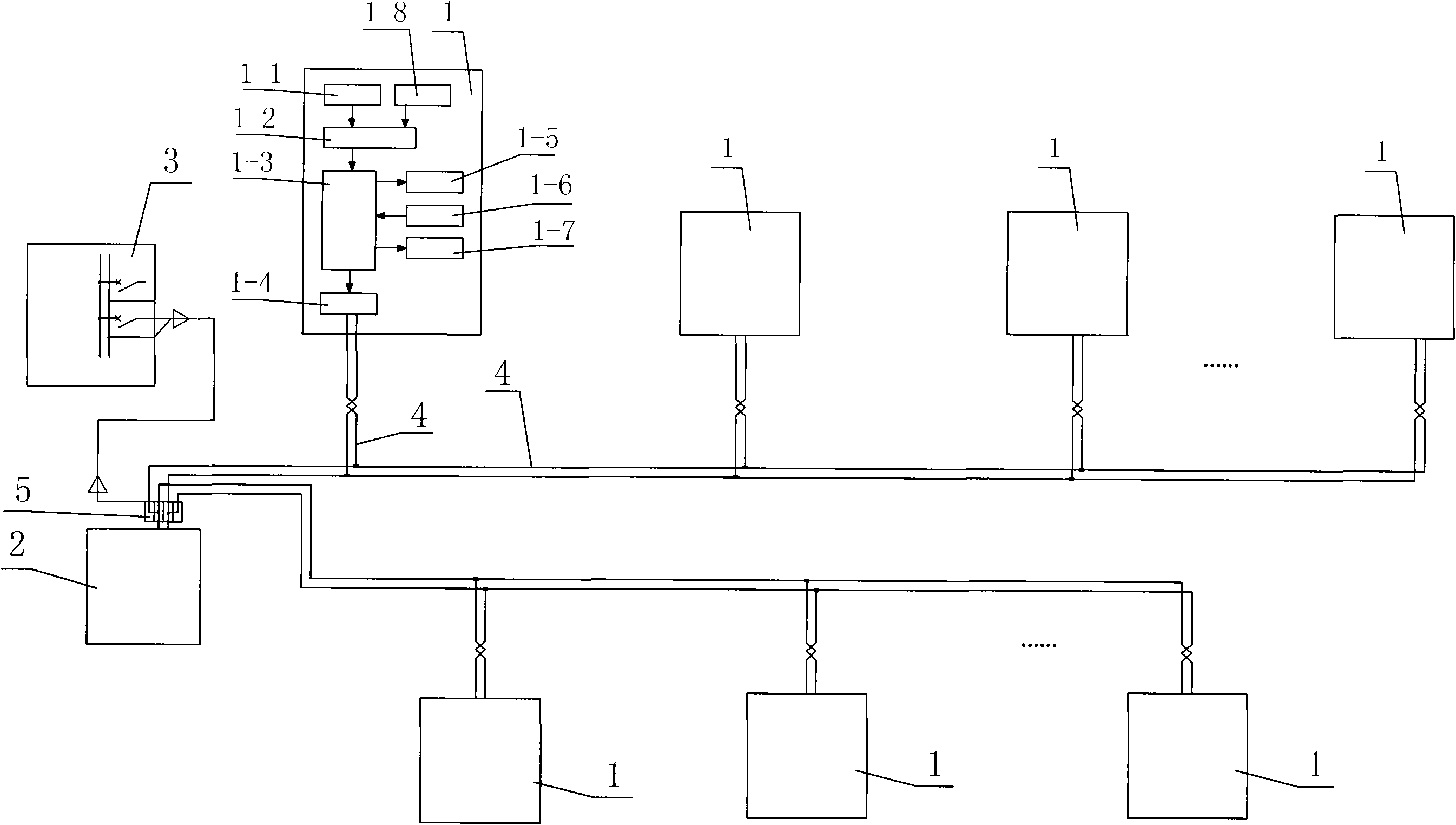

InactiveCN102050314ASolve the distance problemSolve difficultyControl devices for conveyorsLinear/angular speed measurementCommunication interfaceSignal conditioning circuits

The invention discloses a device for monitoring an operation speed of a power line type fieldbus belt conveyor, comprising a belt conveyor operation speed detection and treatment device and a dynamic power-supply system connected with the belt conveyor operation speed detection and treatment device, wherein the belt conveyor operation speed detection and treatment device comprises a sensor detection unit and an electric cabinet matched with the sensor detection unit; the electric cabinet comprises a control cabinet body, a signal conditioning circuit connected with the sensor detection unit, a microprogrammed control unit (MCU) processor and an input / output (I / O) communication interface connected with the MCU processor; the sensor detection unit comprises a tape speed sensor and / or rotate speed sensor; and the MCU processor is connected with a main programmable logic controller (PLC) control system through the I / O communication interface and a cable. The device is simple in structure, small in volume and convenient for installation, signal transmission is stable, intelligent level is high, operation and maintenance work load is less; and by using the device, the problems, existing in the current belt conveyor operation speed monitoring device in a thermal power plant, such as fussy wiring, far cable distance, extremely difficult construction and the like, are solved.

Owner:XIAN BOHENG INTELLIGENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com