Device for monitoring operation speed of power line type fieldbus belt conveyor

A belt conveyor, running speed technology, applied in the direction of conveyor control device, linear/angular velocity measurement, measuring device, etc., can solve the problems of long cable distance, cumbersome wiring, difficult construction, etc., and achieve fast response and communication Long-distance and wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

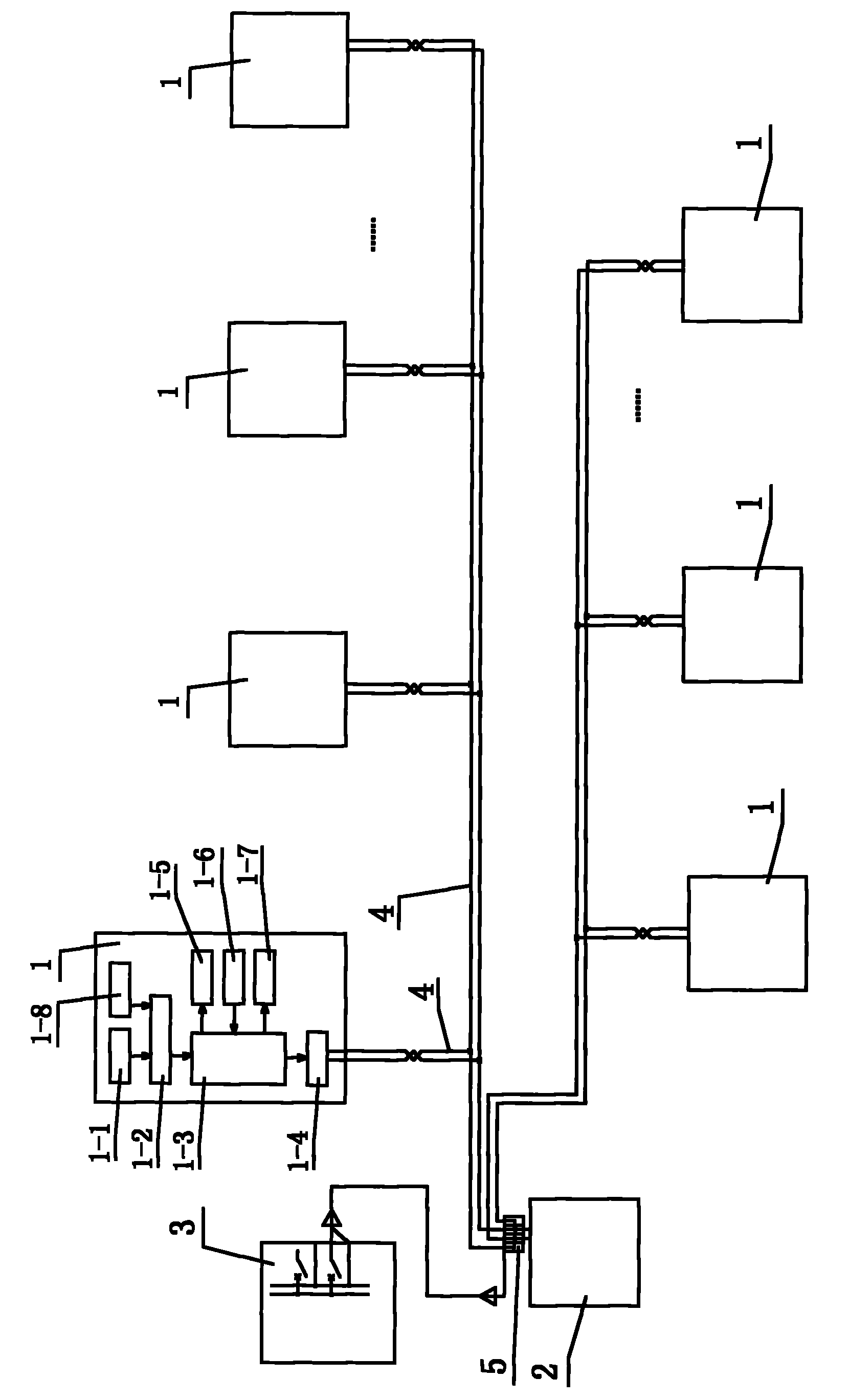

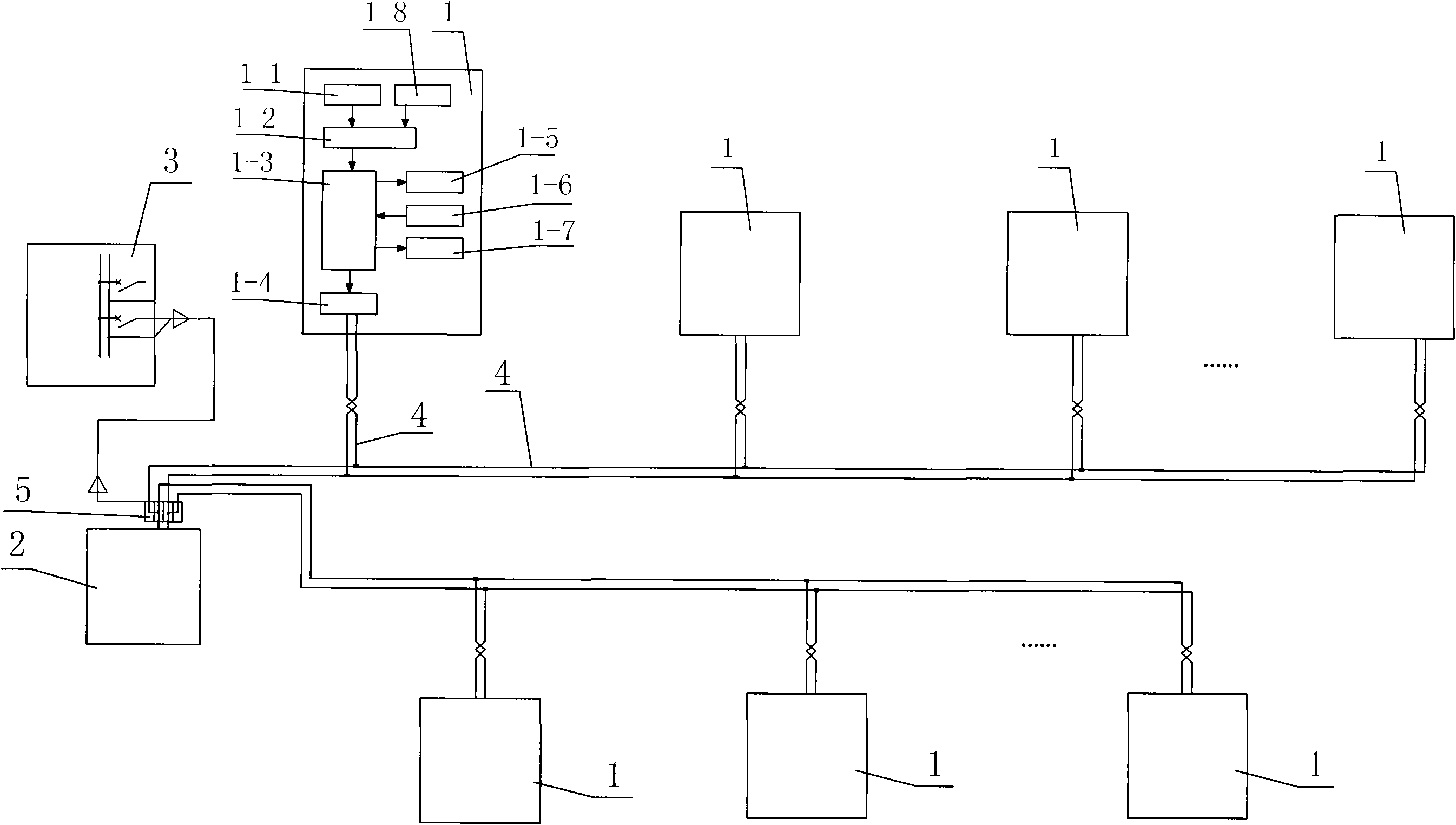

[0035] Such as figure 1 As shown, the present invention includes a running speed detection and processing device 1 for detecting and processing the running speed of the belt conveyor and a power supply system 3 connected with the running speed detection and processing device 1 . The running speed detection and processing device 1 includes a sensor detection unit and an electric control box used in conjunction with the sensor detection unit, and the electric control box includes a control box body and a signal conditioning circuit connected to the sensor detection unit 1-2. The MCU processor 1-3 connected with the signal conditioning circuit 1-2 and correspondingly controlling the motor of the belt conveyor and the I / O communication interface 1-4 connected with the MCU processor 1-3 . The signal conditioning circuit 1-2, the MCU processor 1-3 and the I / O communication interface 1-4 are all installed on the circuit board arranged in the control box. The sensor detection unit i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com