Pump-driven two-phase circuit device for heat dissipation of high heat flux electronic device

A technology of electronic devices and circuits, used in instruments, electrical digital data processing, digital data processing components, etc., can solve the problems of local temperature exceeding its working temperature, large scale of water cooling system, etc., to reduce fluid resistance and enhance heat transfer. effect, the effect of improving the heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below with reference to the accompanying drawings and examples.

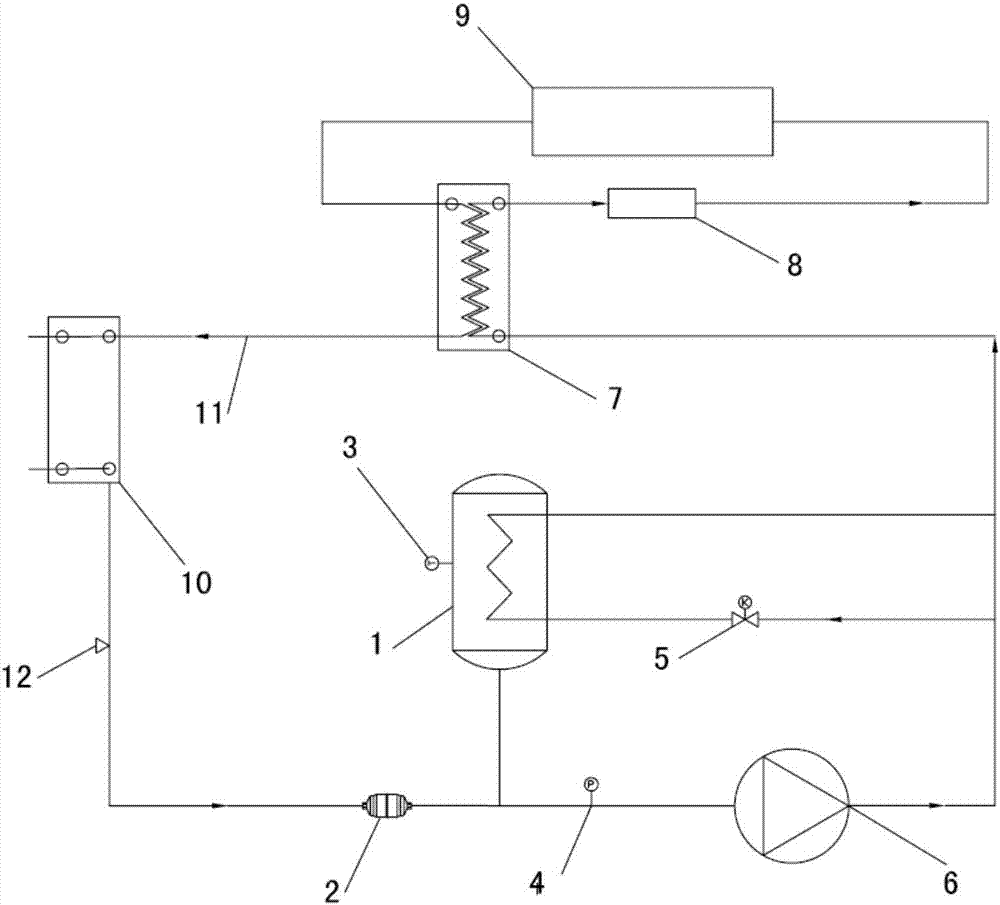

[0042] Such as figure 1As shown, it is a schematic flow diagram of a pump-driven two-phase circuit for heat dissipation of high heat flow electronic devices in the present invention, including a liquid reservoir 1, an evaporator 9, a condenser 10 and a fluid pipeline 11, and the working medium comes out from the evaporator 9 through the fluid After the pipeline 11 enters the condenser 10, it returns from the condenser 11 to the evaporator 9, and the lower end of the liquid receiver 1 communicates with the fluid pipeline 11 and exchanges the working medium; the working medium in the evaporator 9 is in the condenser Condensation in 10, the heat is dissipated from the pump-driven two-phase fluid circuit to the external environment; the fluid pipeline 11 is used to form a circuit in which the fluid can flow;

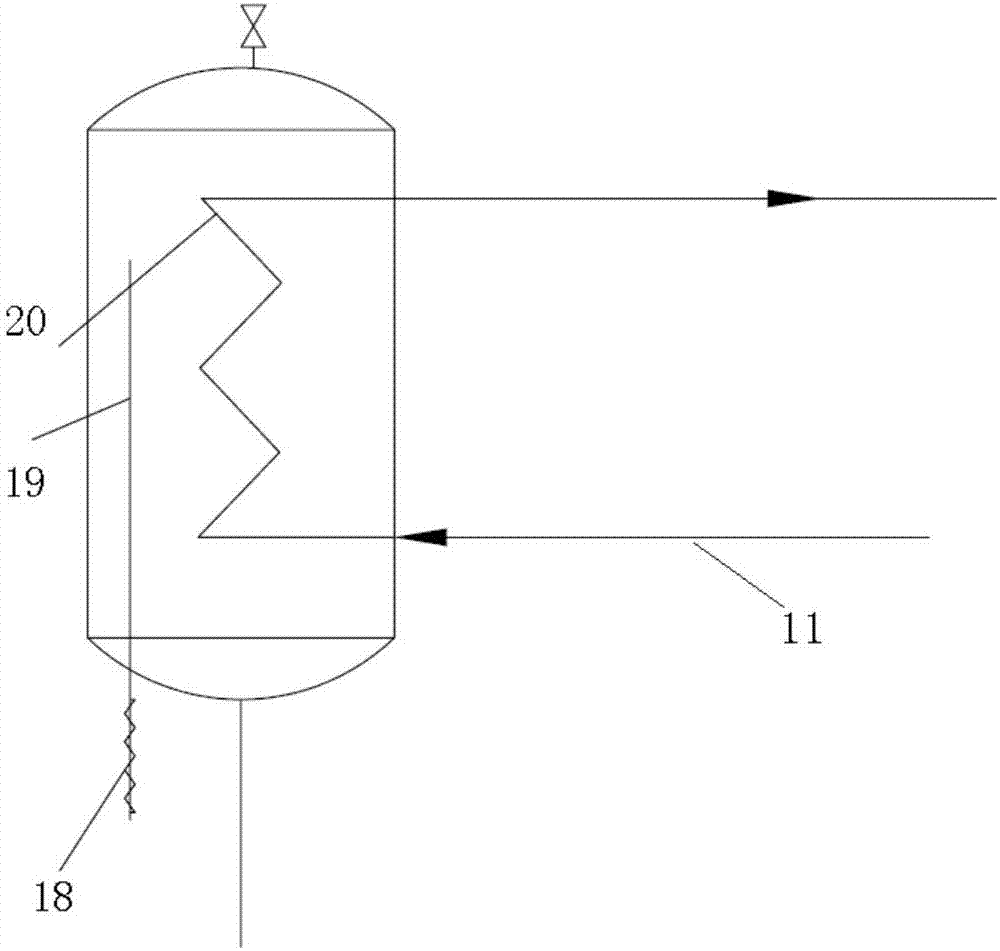

[0043] Such as figure 2 As shown, it is a schem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com