Patents

Literature

32results about How to "Lower working fluid temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

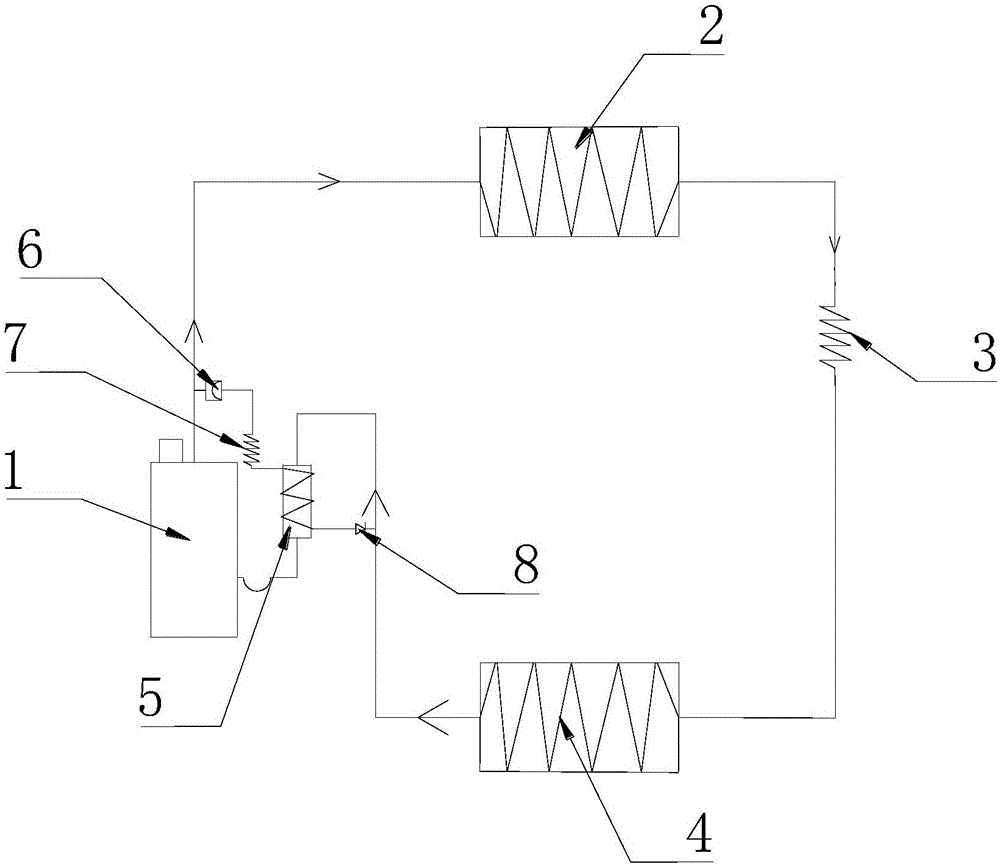

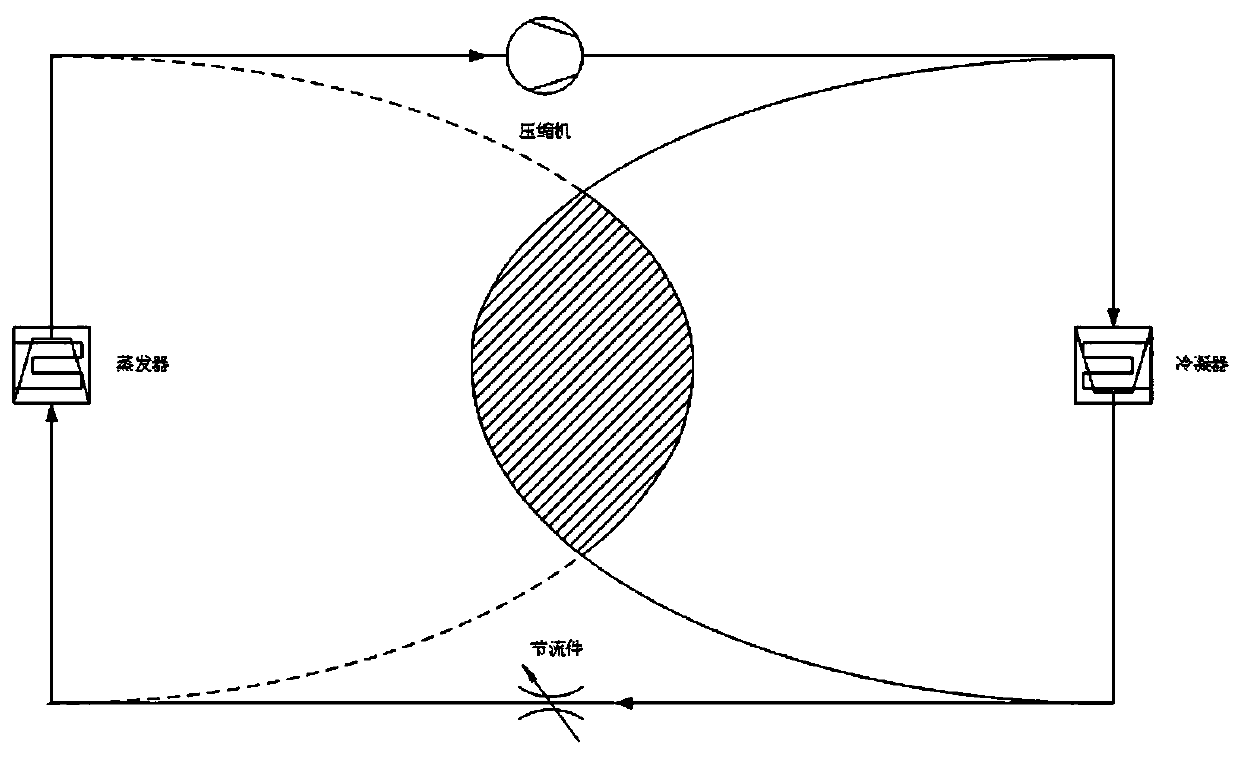

Steam compression type refrigeration cycle device of approximate ideal inverse Carnot cycle efficiency

InactiveCN1683842ALower working fluid temperatureLittle change in thermal perfectionCompression machines with non-reversible cycleCarnot cycleEngineering

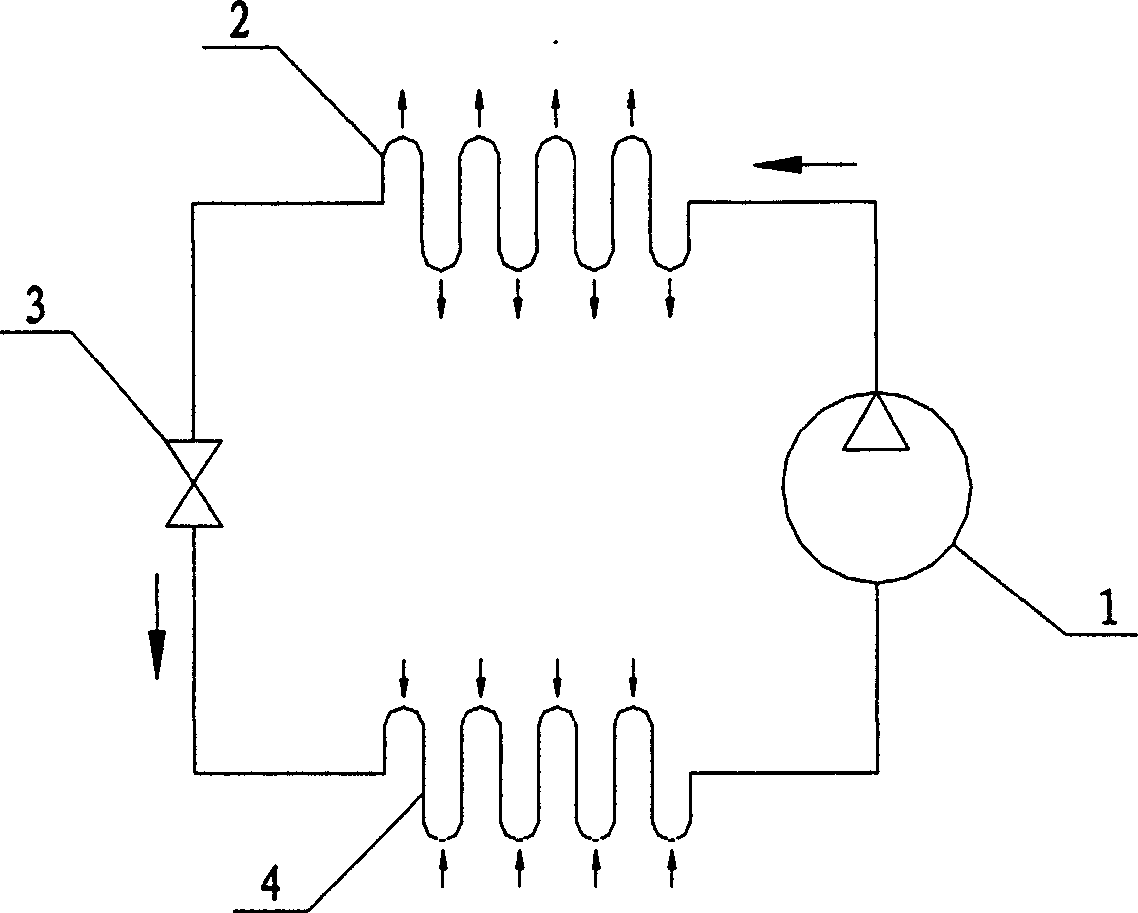

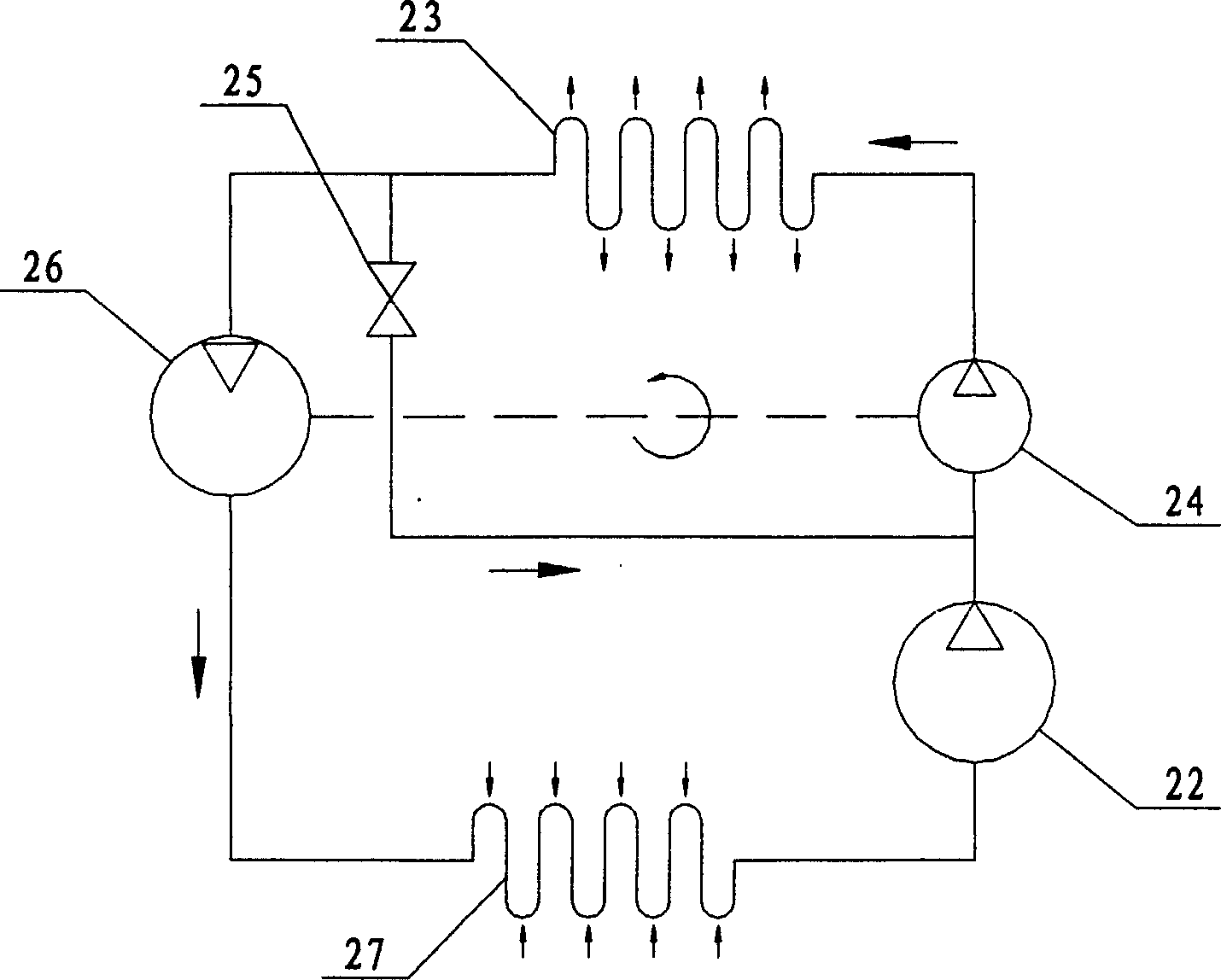

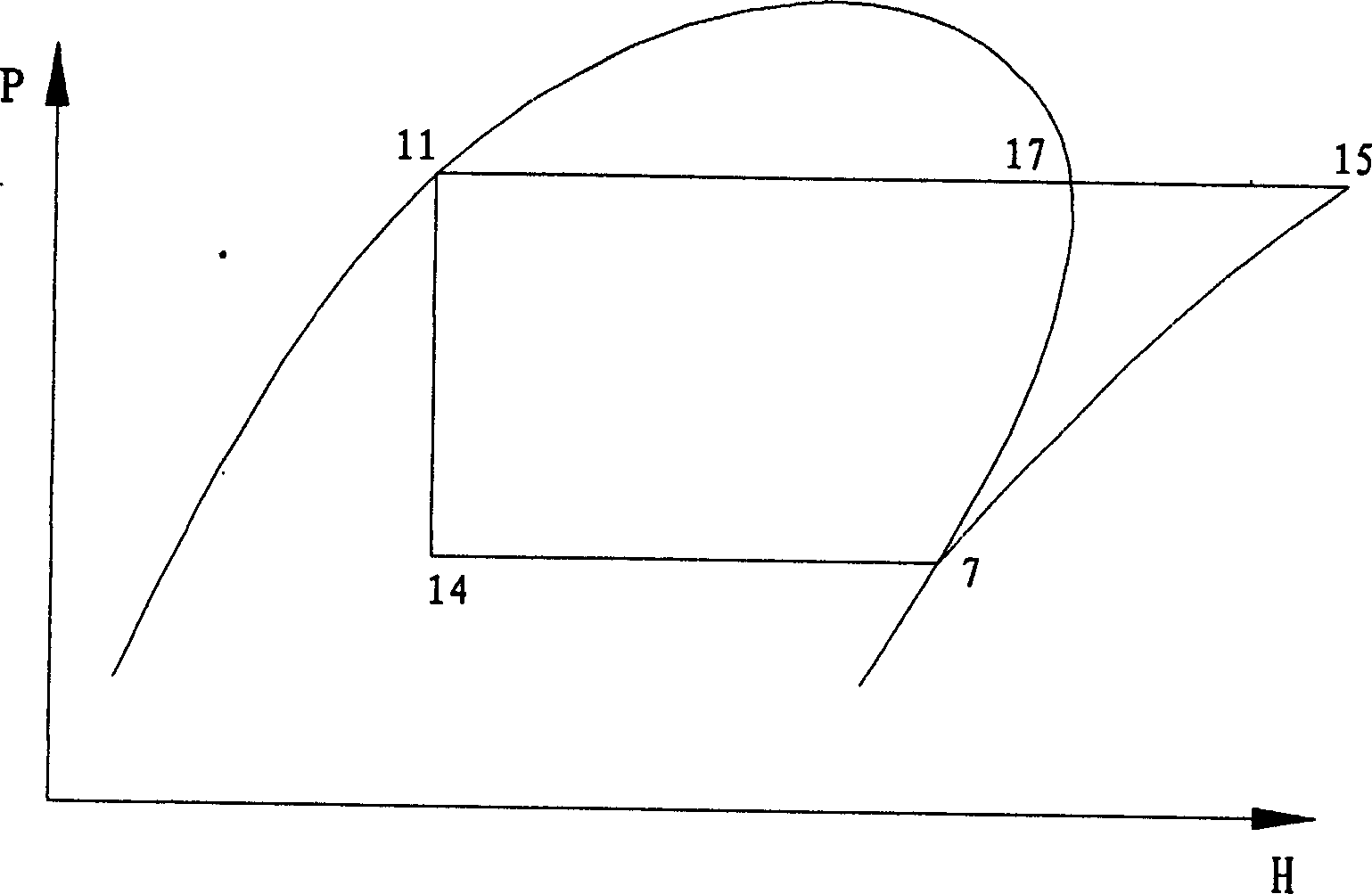

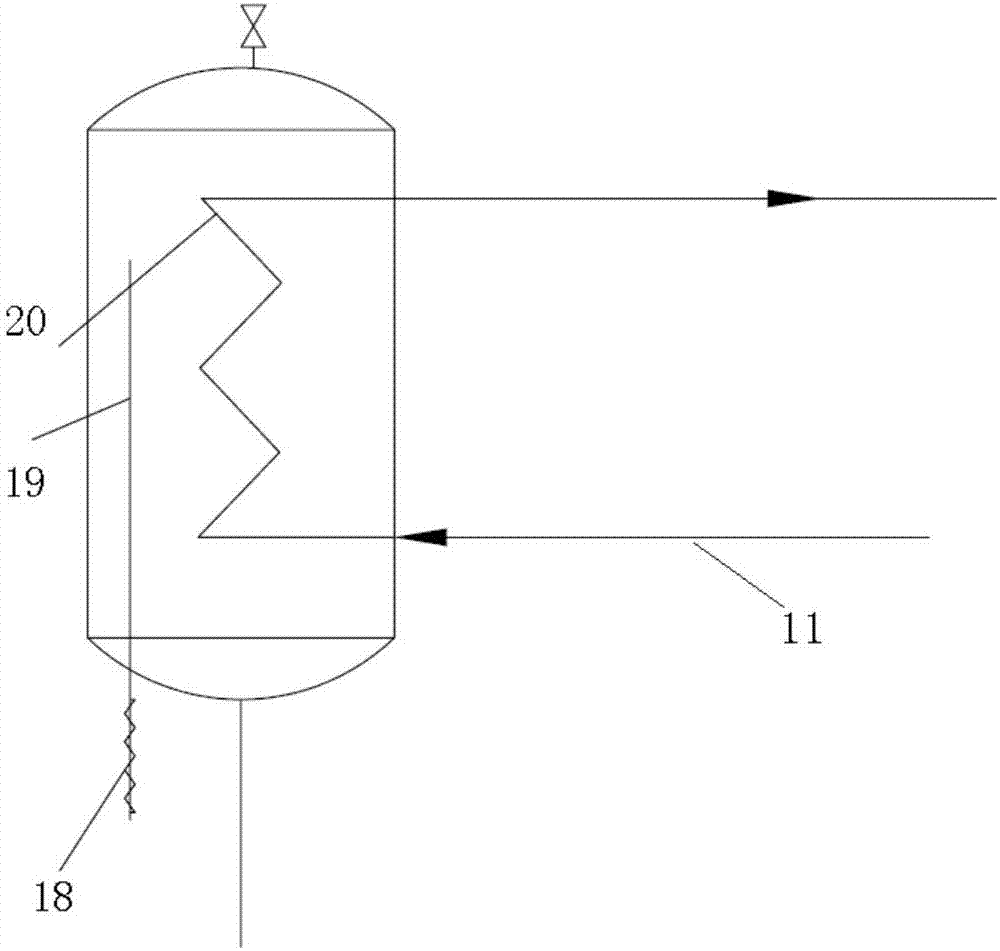

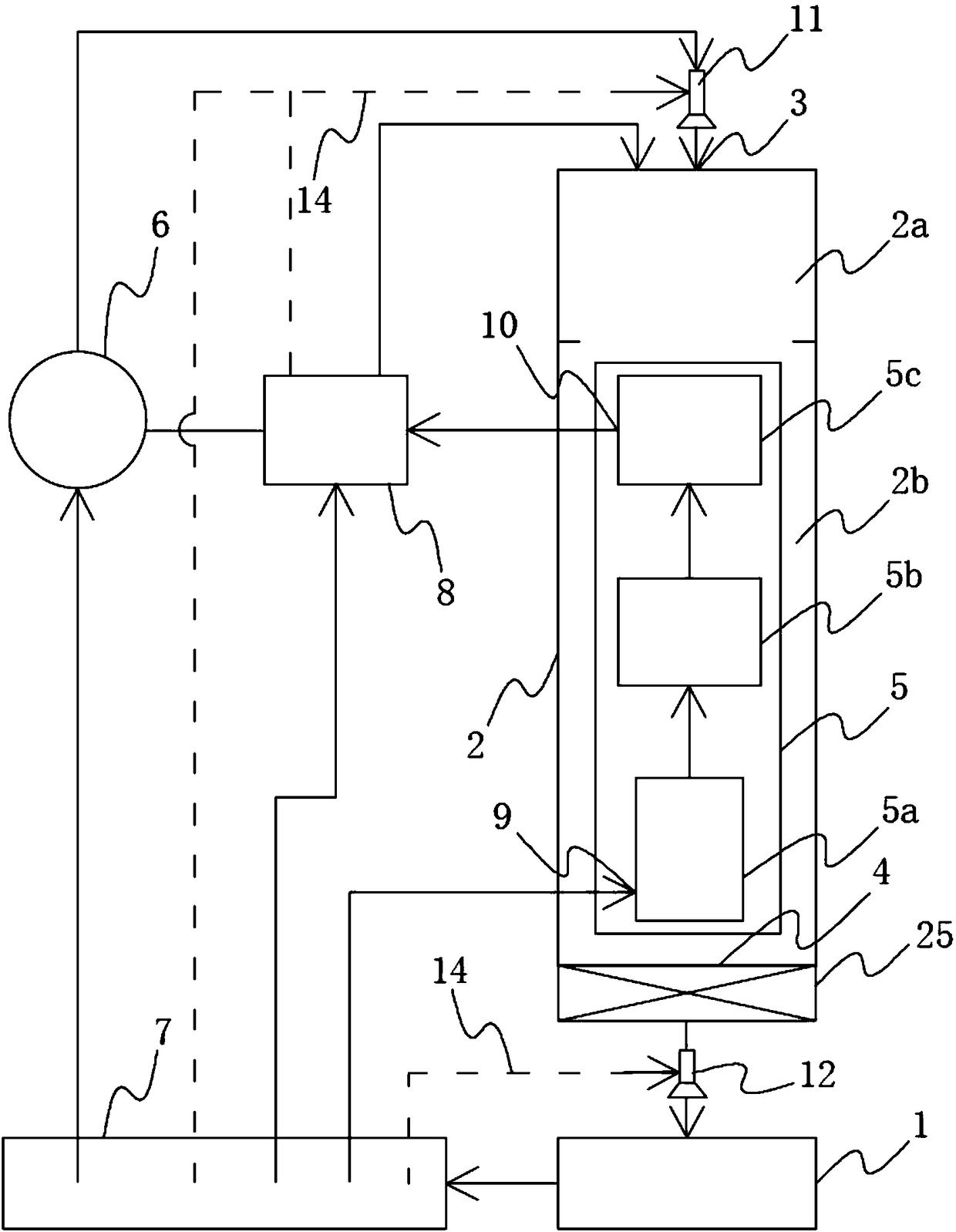

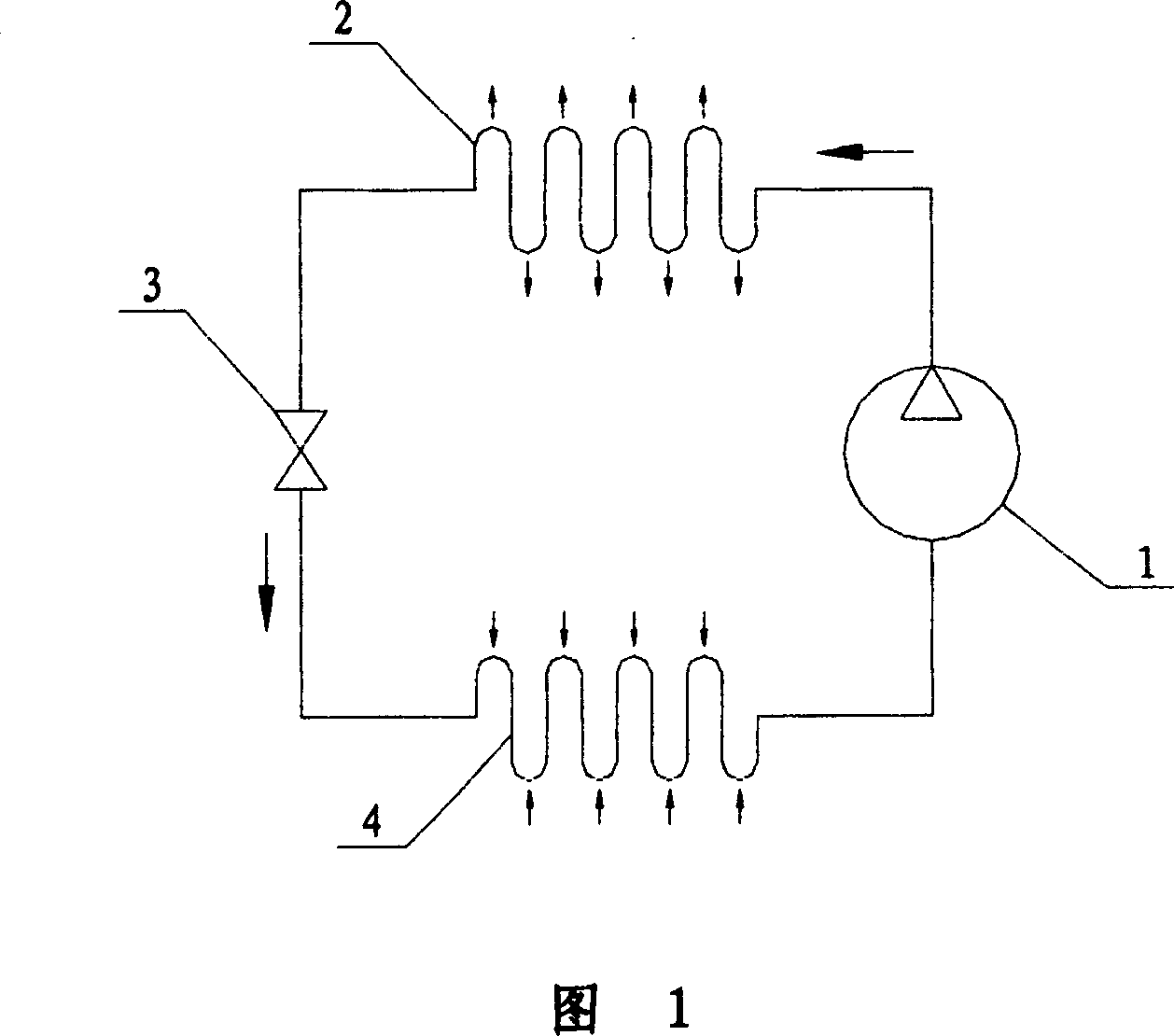

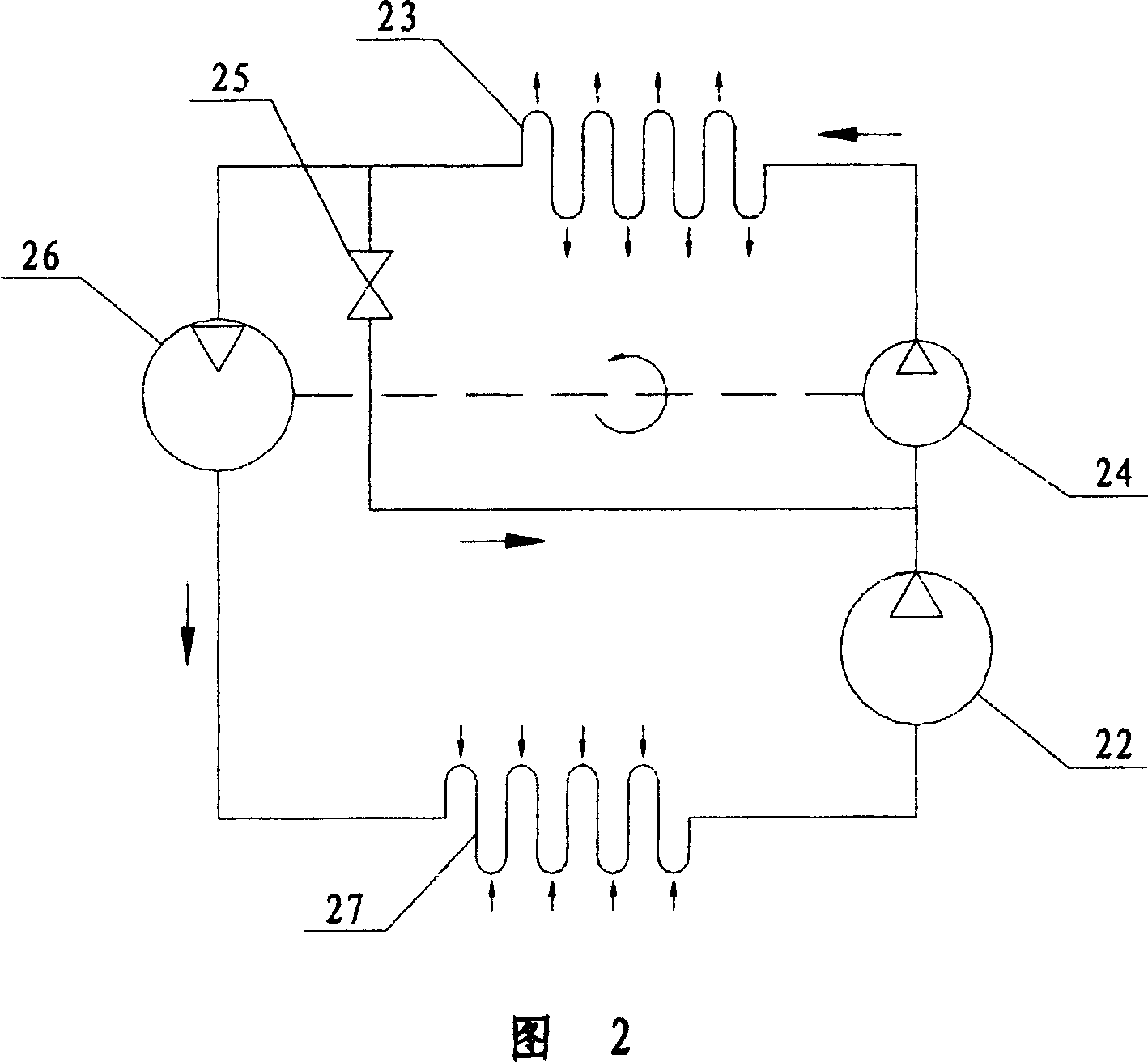

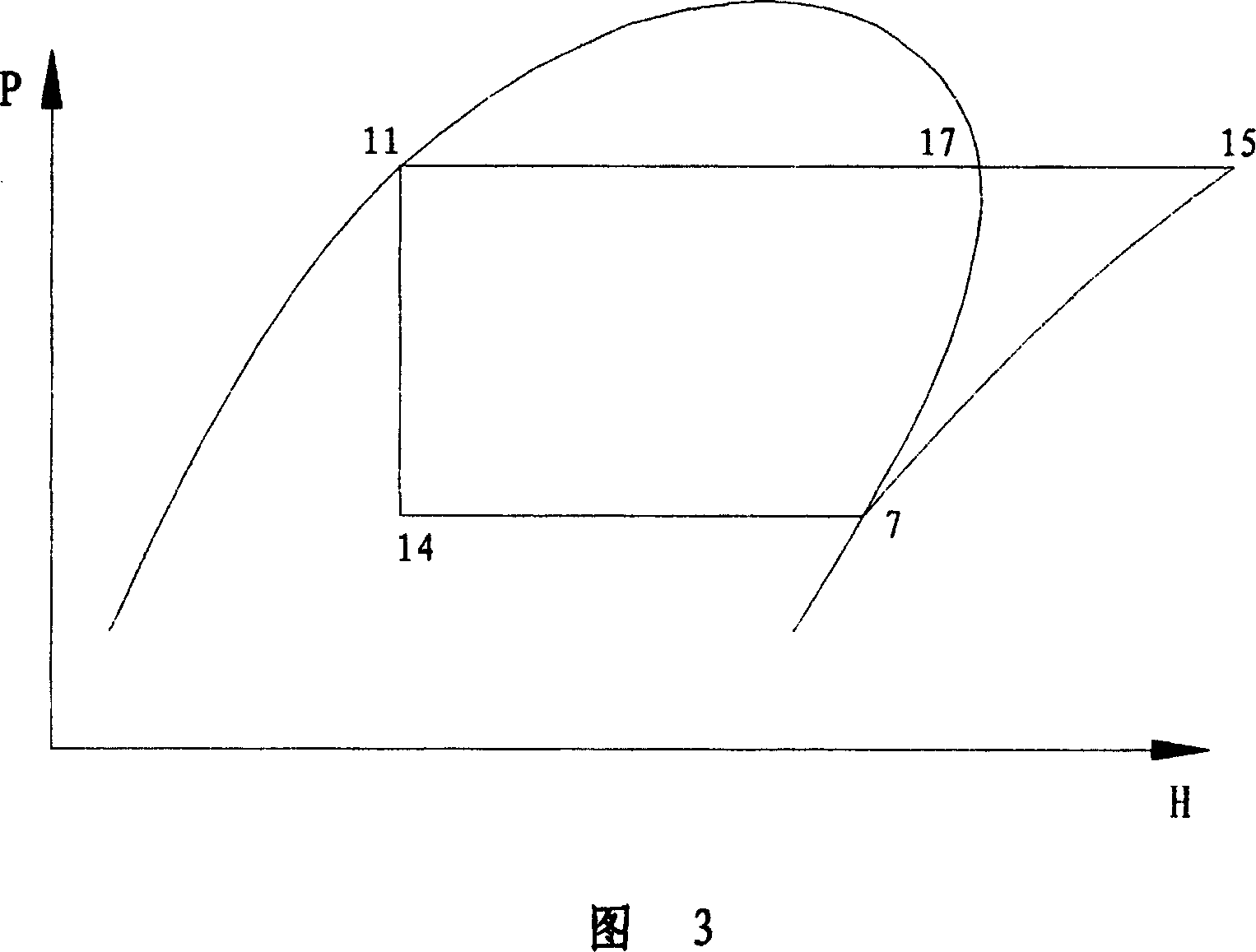

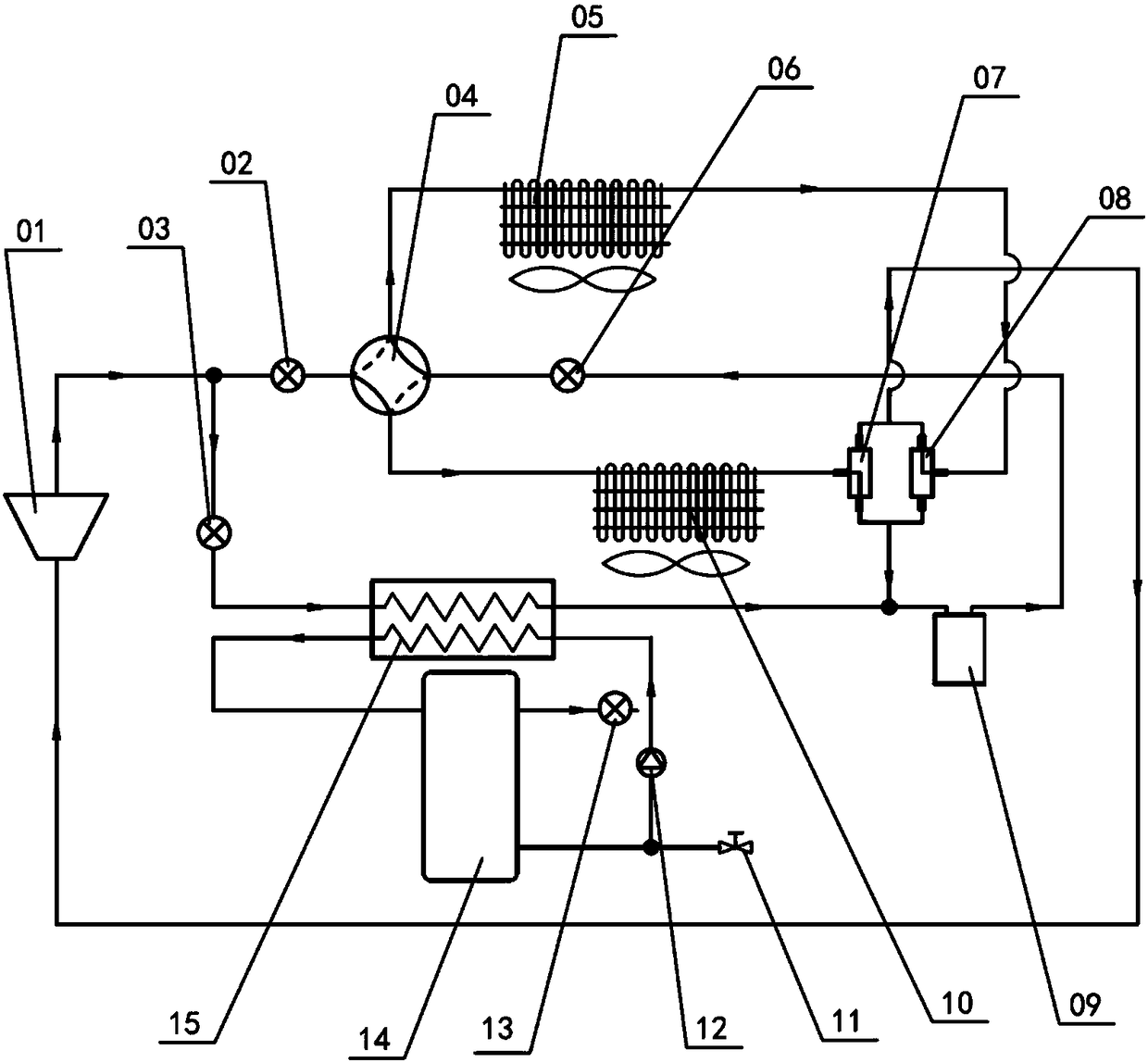

The steam compressing refrigeration cycle device includes main cycle system comprising booster pump, condensator, expansion motor, evaporator and compressor connected successively with pipeline to output cold; and secondary cycle system comprising throttle connected across the inlet of the booster pump and the outlet of the condensator as well as the booster pump and the condensator, to further lower the temperature of the work medium in the outlet of the compressor. The expansion motor has its output torque rotating the booster pump and has isoentropic expansion to reduce the entropy of the work medium entering the condensator. The booster pump reduces the operation pressure difference and the power consumption of the compressor. Therefore, the present invention has energy efficiency near ideal inverse Carnot cycle and low hot load one compressor, and may be used widely in refrigeration cycle in air conditioner, refrigerator, etc.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

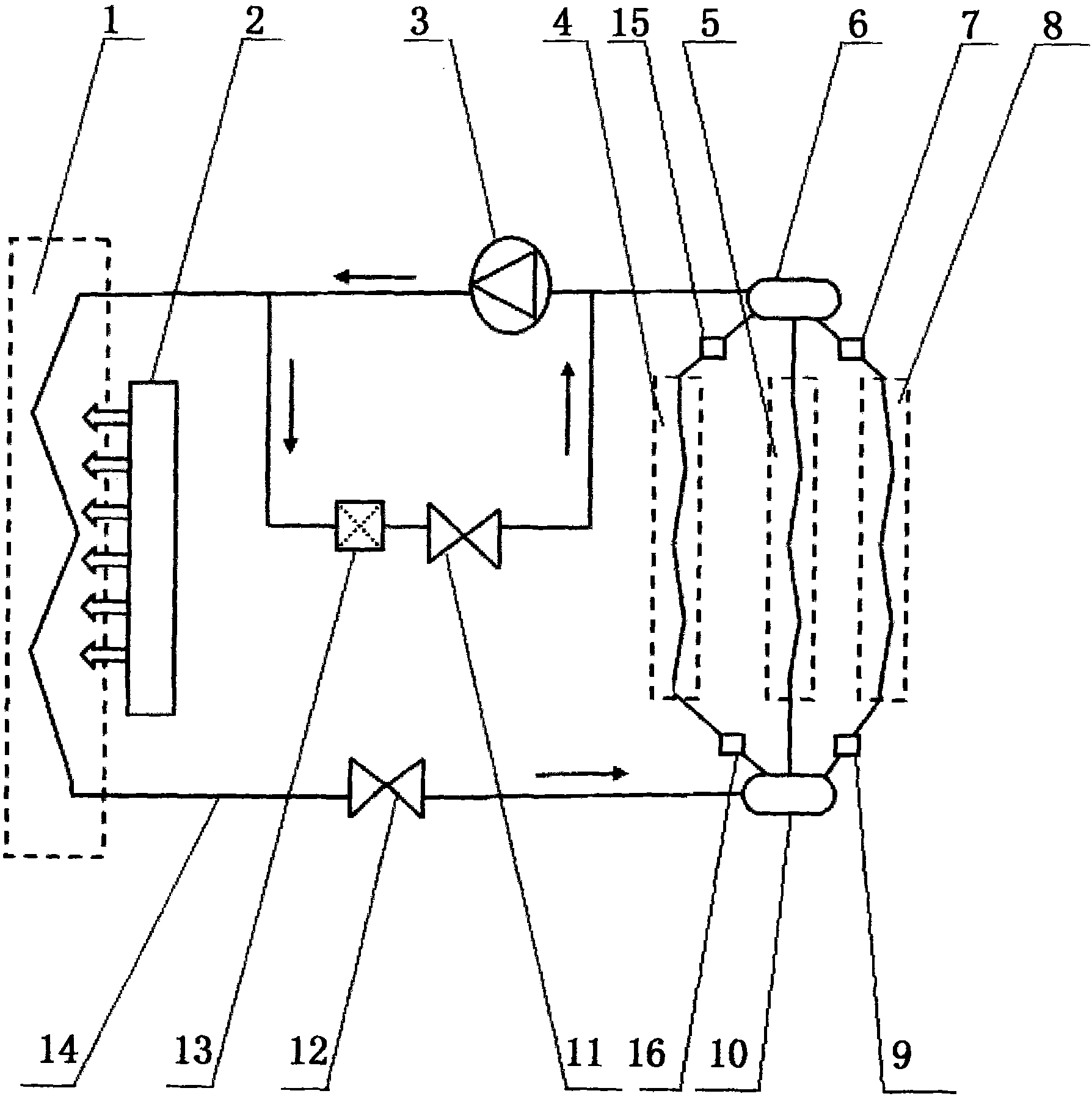

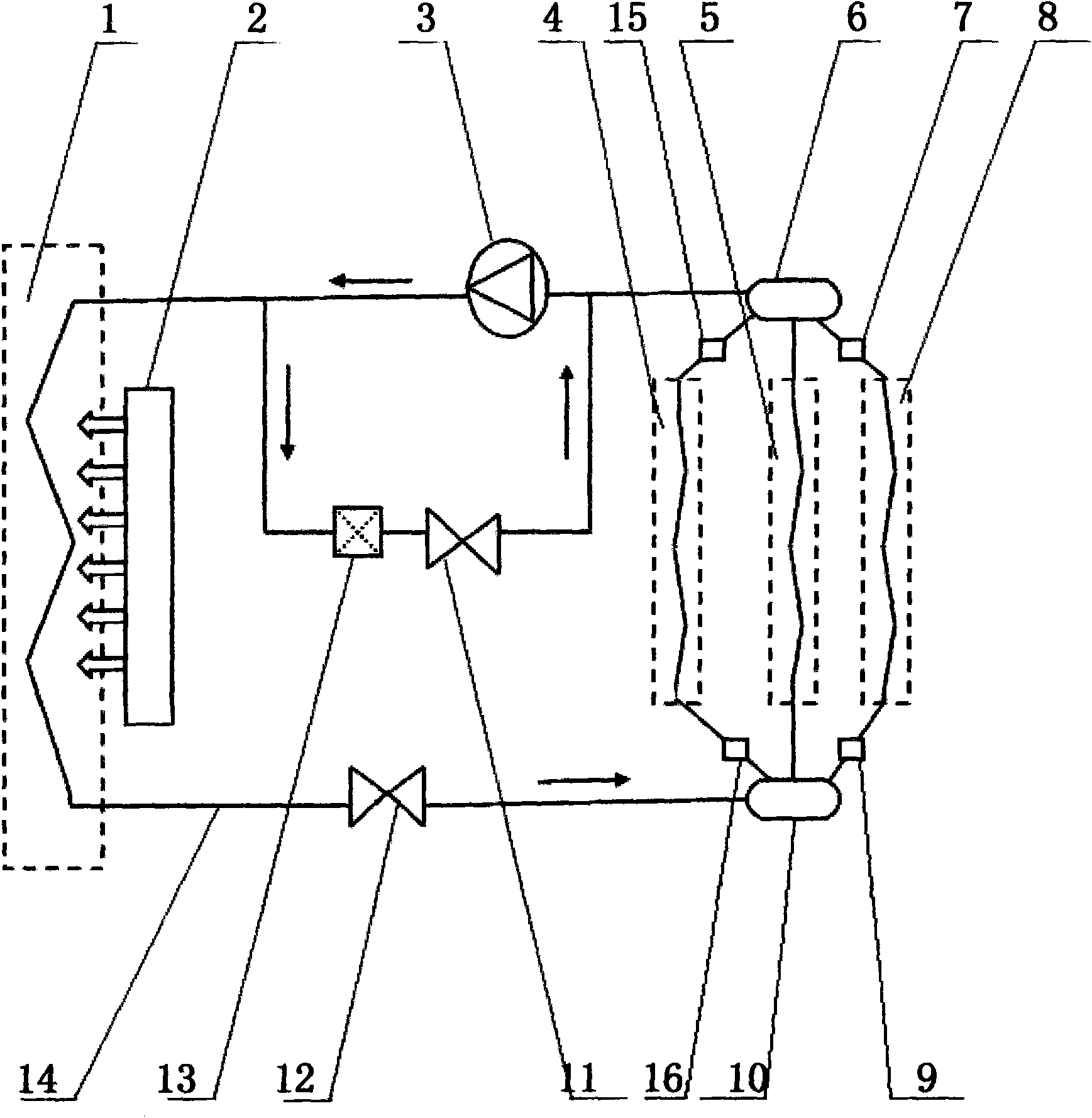

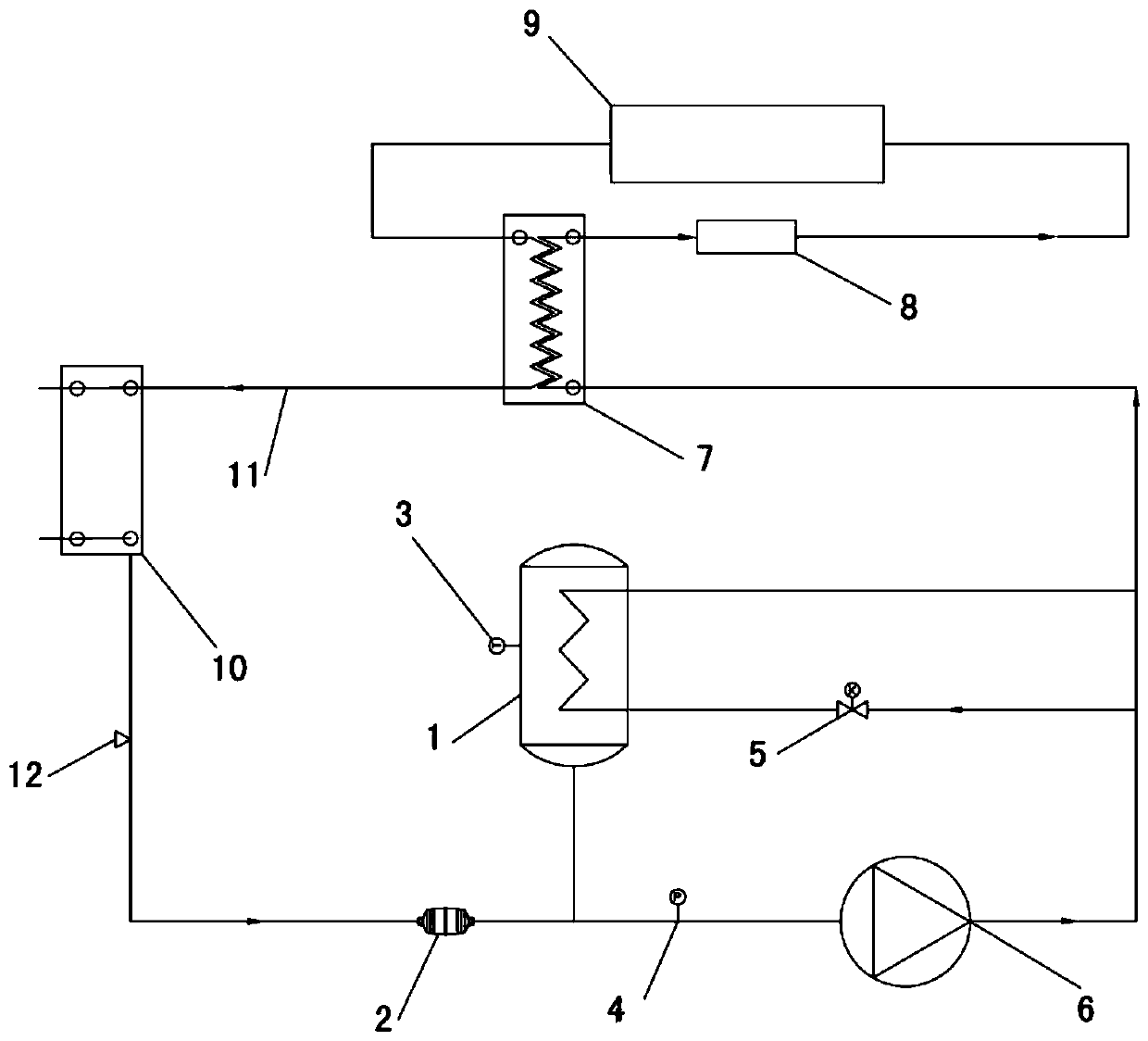

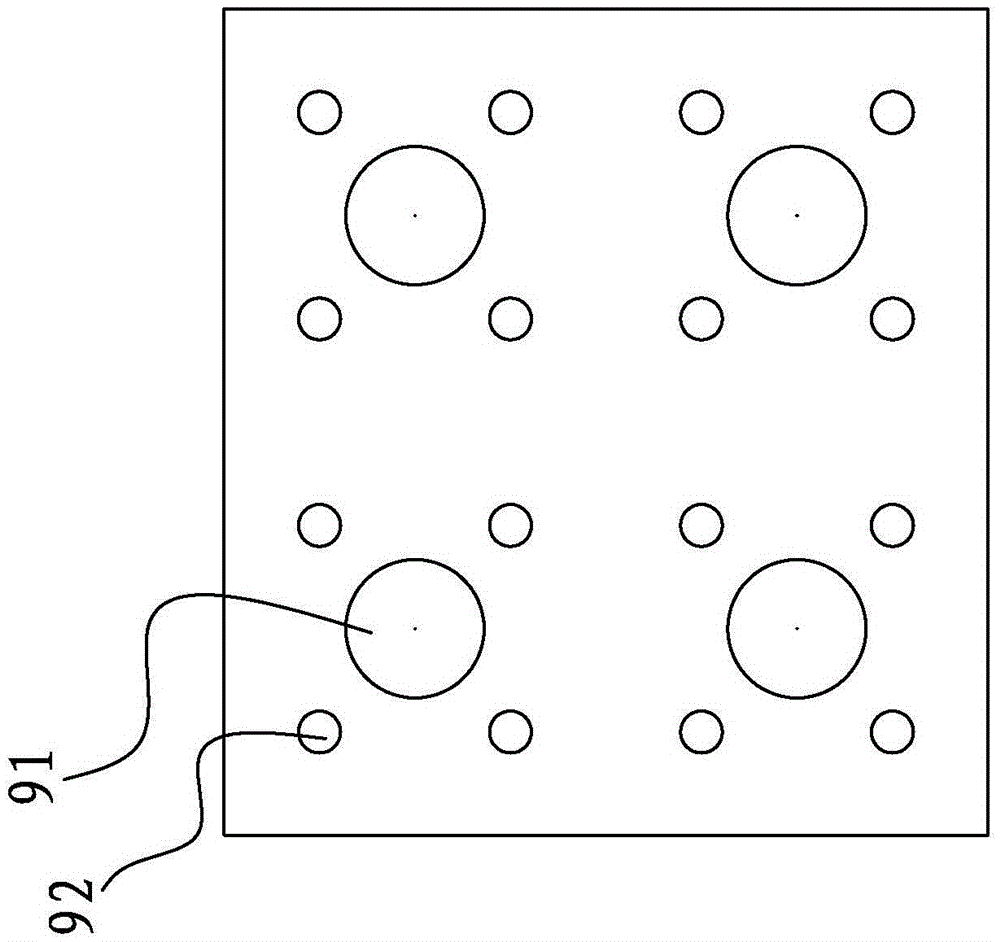

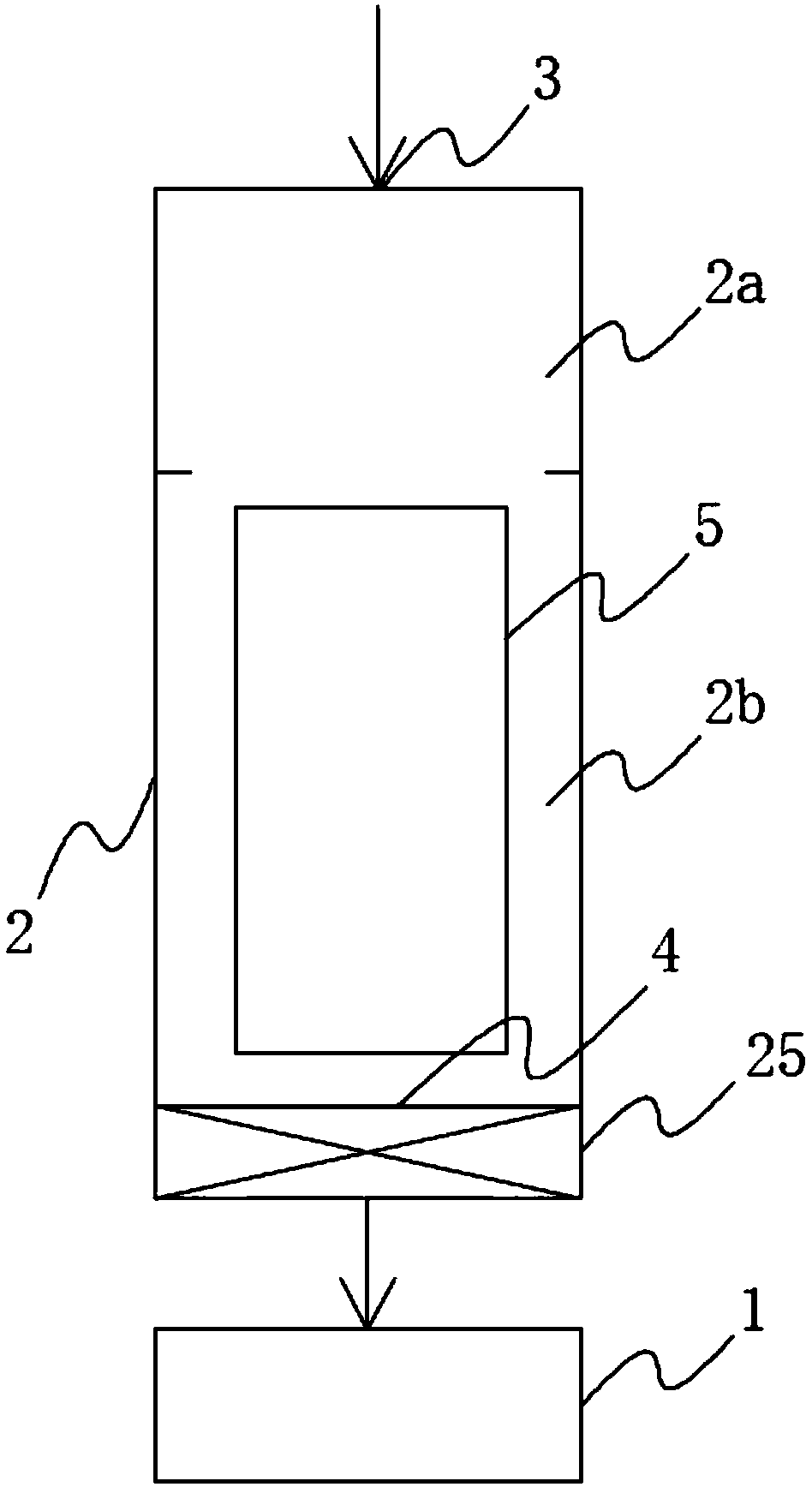

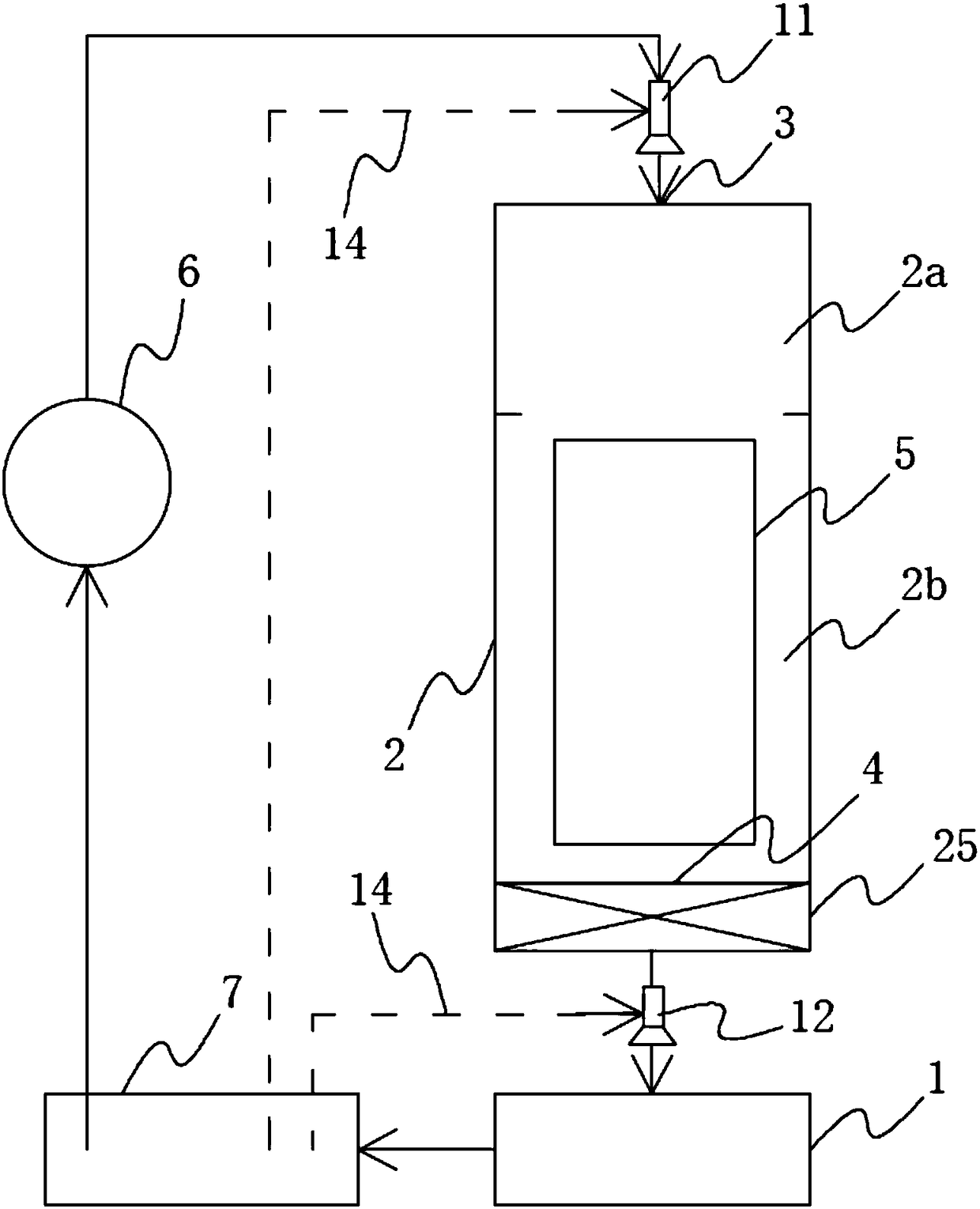

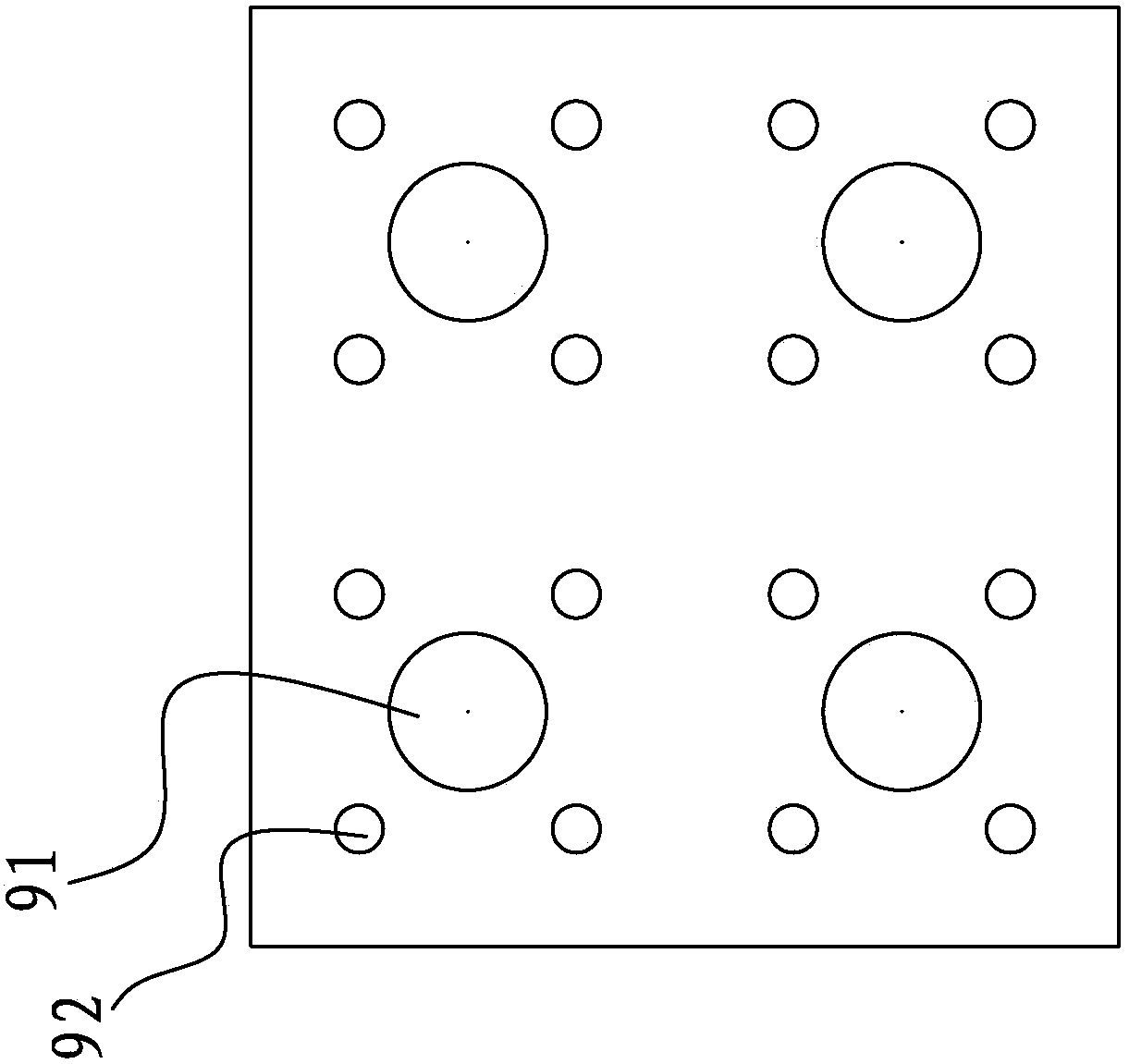

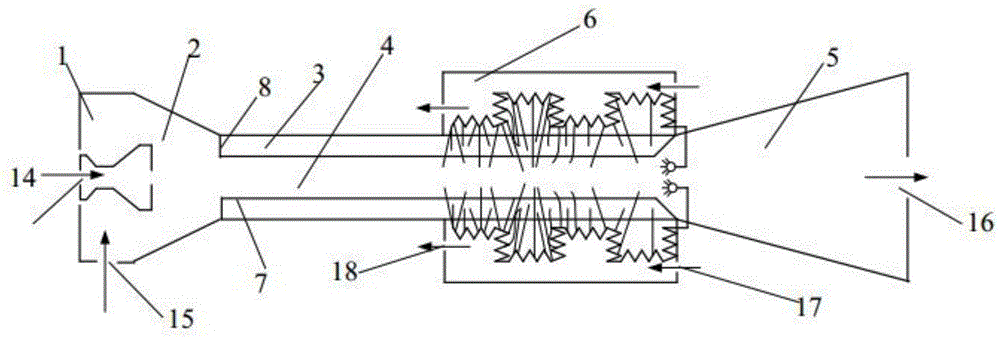

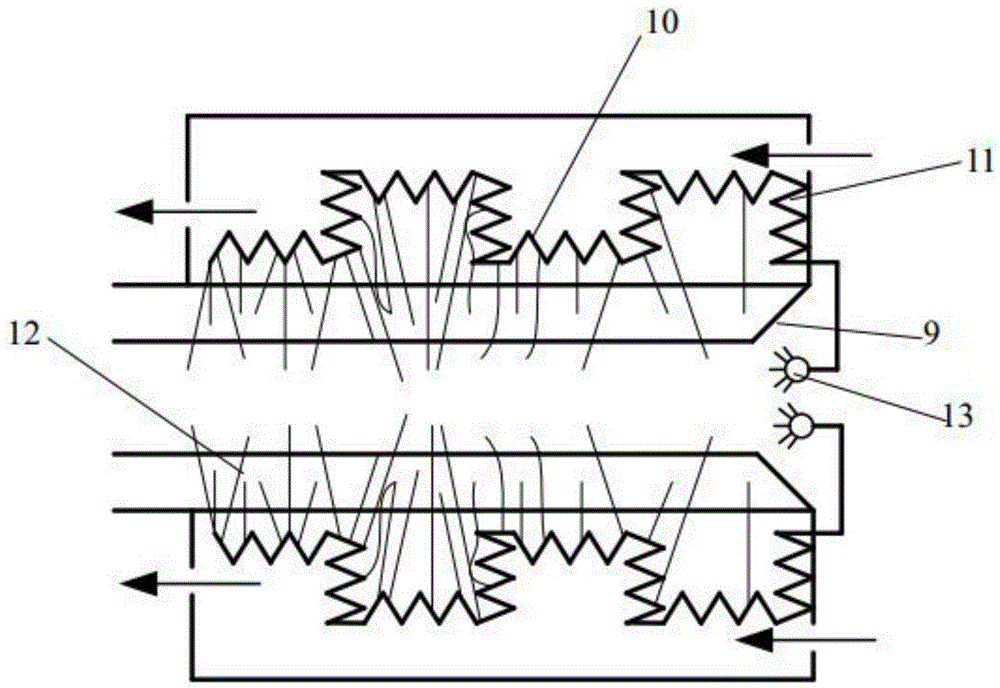

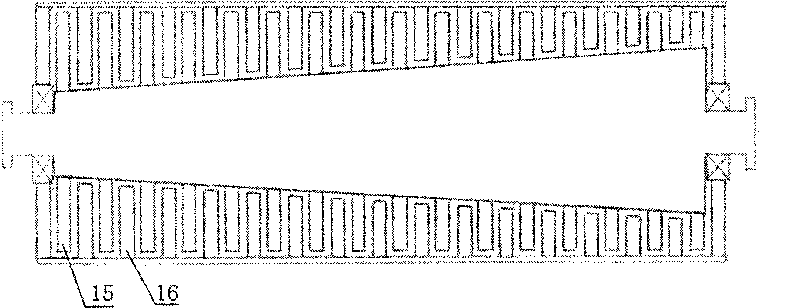

Pump-driven two-phase circuit device for heat dissipation of high heat flux electronic device

ActiveCN107454797AMeet job needsImprove cooling effectDigital data processing detailsCooling/ventilation/heating modificationsHeat fluxEvaporation

The invention provides a pump-driven two-phase circuit device for heat dissipation of a high heat flux electronic device. Heat is collected and transported by using an endothermic process in evaporation and an exothermic process in condensation during a circulation flow process of a working medium. An evaporator for the circuit device comprises micro-channels and fins. In an area of high heat flux, the micro-channels are used to dissipate heat and increase a heat transfer coefficient of a partial area, while in an area of low heat flux, the fins are used. Due to great area difference between the micro-channel area and the fin area in the evaporator, when the working medium in the micro-channels enters the fin area, volume quickly expands and temperature of the working medium reduces, so as to help heat dissipation of the device in the fin area. By using different structures and with little resources, heat dissipation problems of devices with different powers are solved. The pump-driven two-phase circuit device for heat dissipation of the high heat flux electronic device can adapt to heat dissipation of electronic devices with different heat flux densities and can satisfy working requirements of electronic devices with a heat flux density of 50 W / cm<2> or above.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

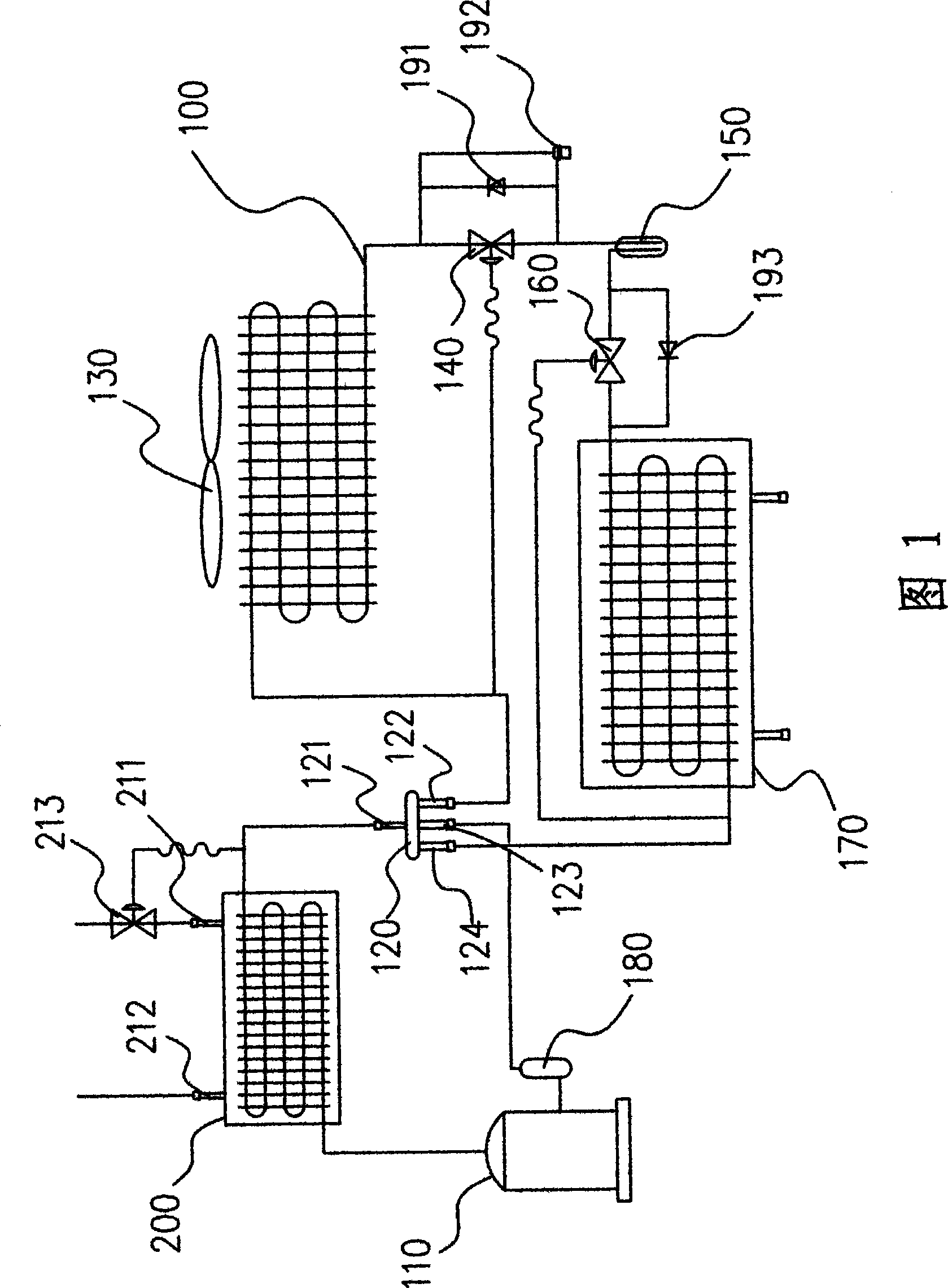

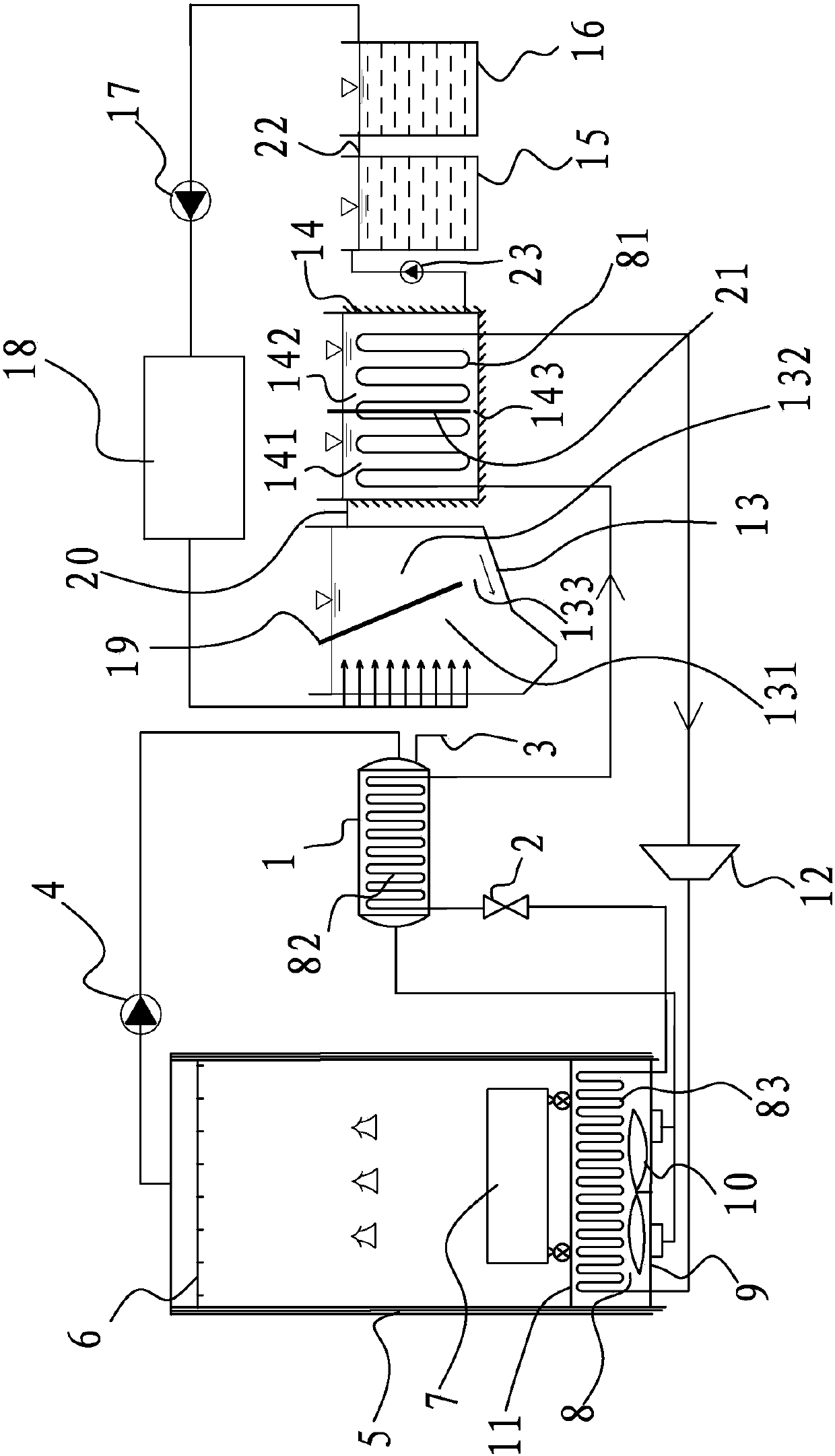

Air-source heat-pump air heater adopting parallel-type evaporator

InactiveCN101936601AImprove energy efficiency ratioIncrease wind speedFluid heatersCompression machines with several evaporatorsBusiness efficiencyEngineering

The invention discloses an air-source heat-pump air heater adopting a parallel-type evaporator, comprising an air source heat pump and a condenser fan. The evaporator of the air source heat pump comprises a group of working evaporators and at least one group of spare evaporators, the refrigerant input ends and the refrigerant outputs of the evaporators are connected in parallel by a manifold, the refrigerant input ends of the spare evaporators are controlled by an electromagnetic valve, a ratio of the heat exchange area of a condenser to the input power of a compressor is 5.6-13.5 m<2> / kw, and the condenser fan has the total pressure of 80-400 Pa. The invention fully exerts the heating potential of the air source heat pump to improveso the energy efficiency ratio of the system and satisfy the need for drying materials or heating in life, improves the working capacity and the environmental change suitability of the air-source heat-pump air heater so that the system stably operates, ensures that the application range of the air source heat pump is greatly enlarged, and has wide geographic or climatic suitability range and positive significance in saving energy and protecting environment.

Owner:湖南省浏阳市择明热工器材有限公司

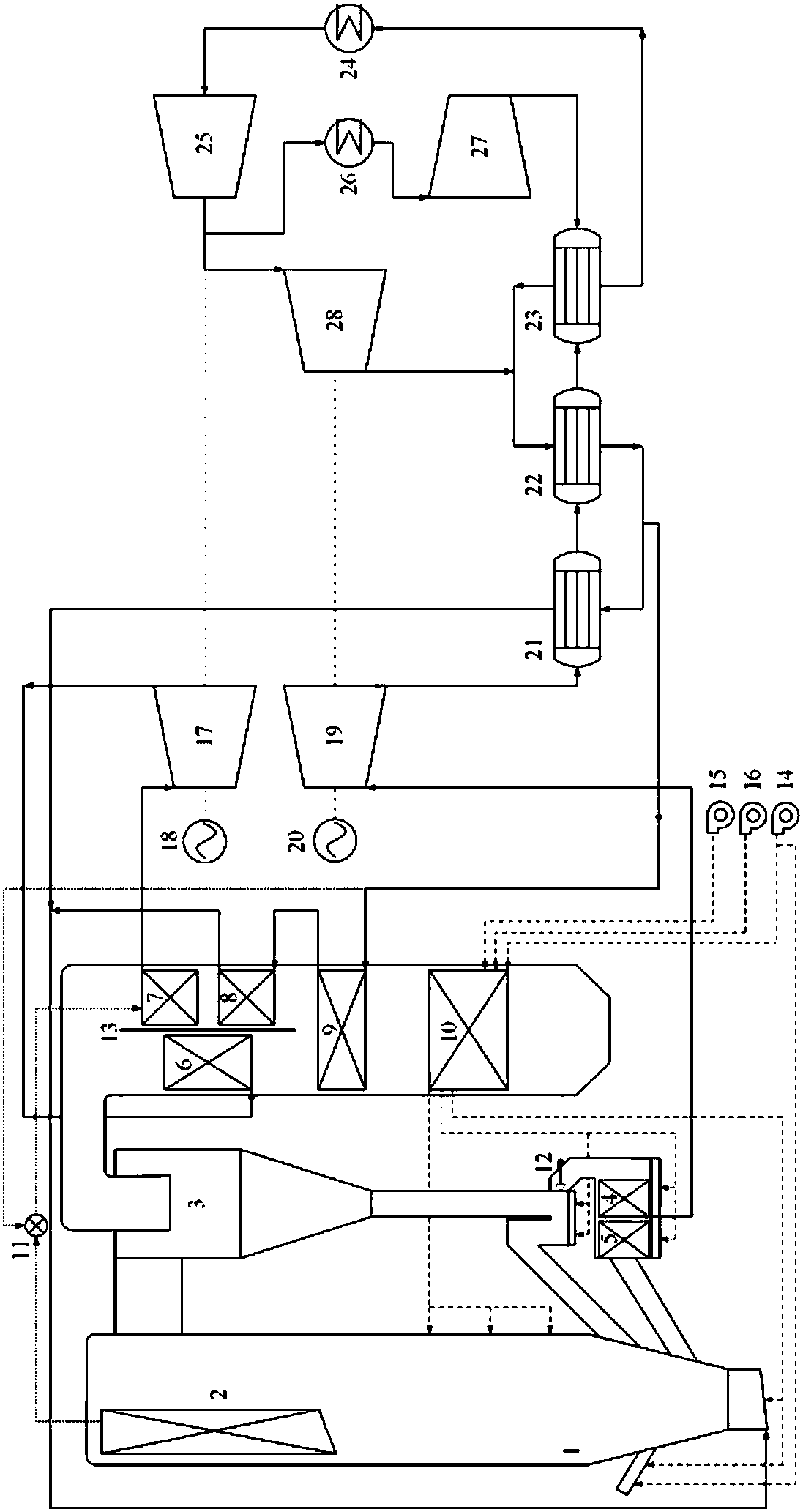

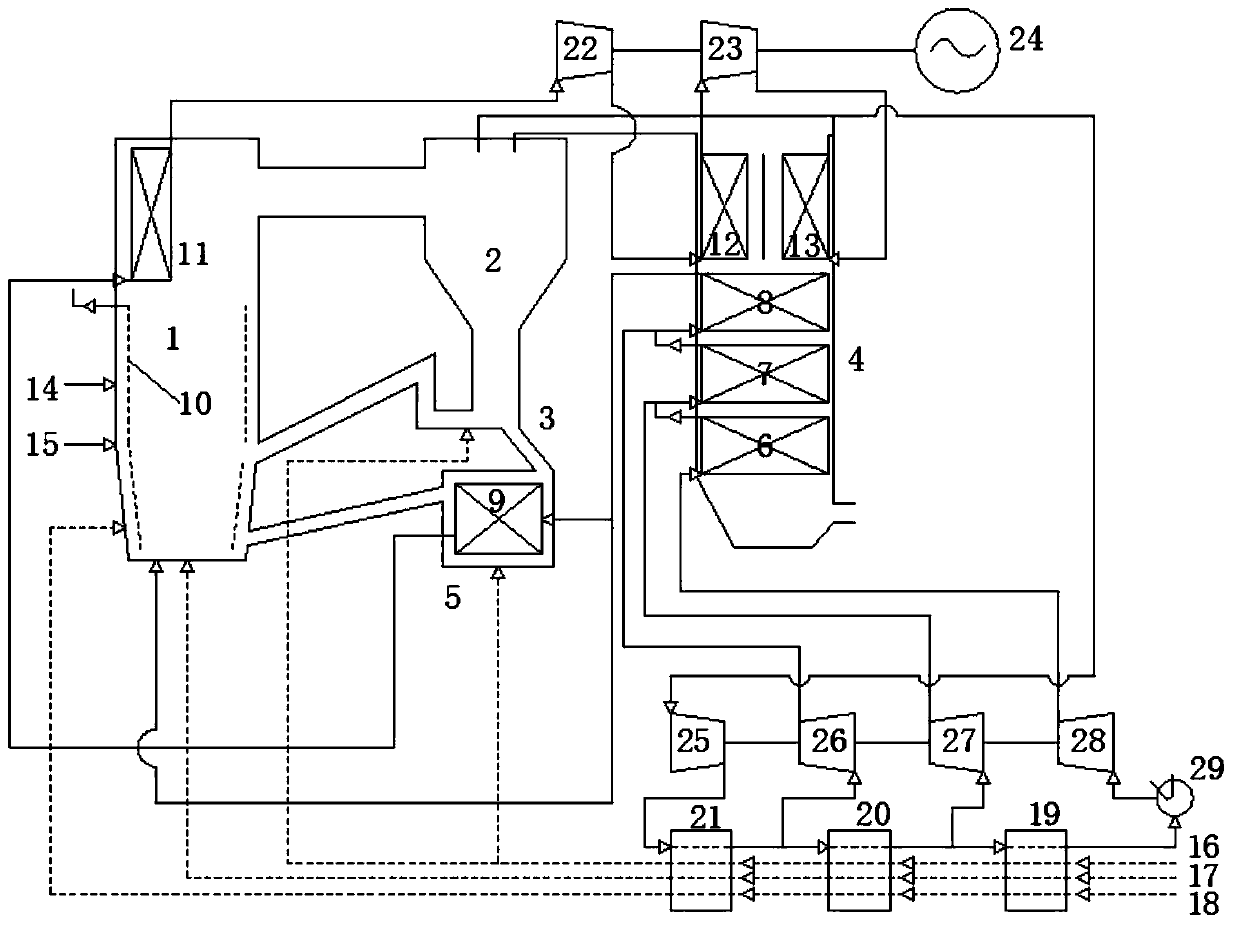

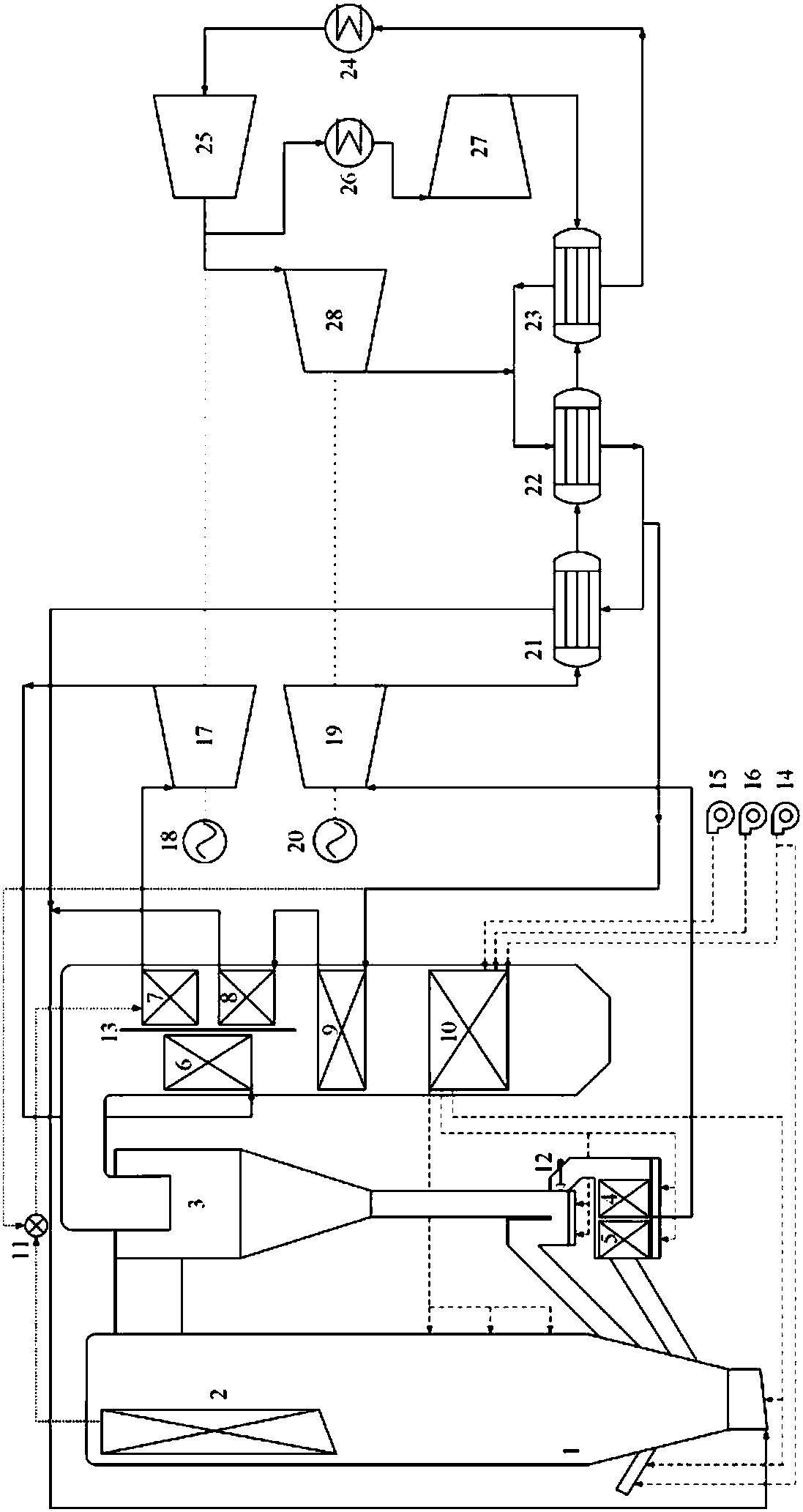

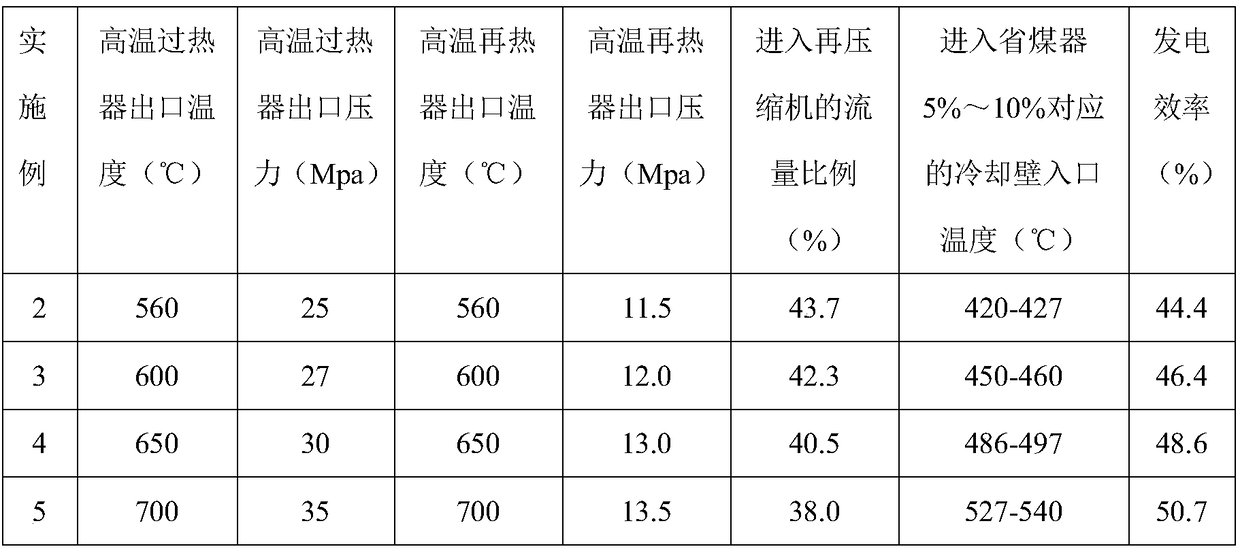

Supercritical carbon dioxide coal-fired circulating fluidized bed boiler, power generation system and power generation method

ActiveCN108180470AReduce thermal deviationGuaranteed uptimeFluidized bed combustionSteam engine plantsAir preheaterSuperheater

The invention discloses a supercritical carbon dioxide coal-fired circulating fluidized bed boiler, a power generation system and a power generation method. The supercritical carbon dioxide coal-firedcirculating fluidized bed boiler comprises a hearth, a separator, a tail flue and an externally-arranged type heat exchanger located in a material back section of the separator. A cooling wall and anintermediate-temperature overheater are arranged in the hearth. A high-temperature reheater and a low-temperature overheater are arranged in the externally-arranged type heat exchanger, wherein the low-temperature overheater communicates with the cooling wall and the intermediate-temperature overheater. A low-temperature reheater, a high-temperature overheater, an upper-level economizer, a lower-level economizer and an air preheater are arranged in the tail flue, wherein the high-temperature overheater communicates with the intermediate-temperature overheater, the low-temperature reheater communicates with the high-temperature reheater. The working medium of the boiler is supercritical carbon dioxide. By the adoption of the supercritical carbon dioxide coal-fired circulating fluidized bedboiler, the wall temperature of the cooing wall can be effectively controlled, it is guaranteed that the boiler safely and reliably operates, and the heat efficiency is high; a power generator set tends to be miniature, a higher load response speed is obtained, the deep peak load regulation adaptability is high, the advantages of coal resources are taken into full play, the energy utilization rate is improved, and energy safety is guaranteed.

Owner:SOUTHEAST UNIV

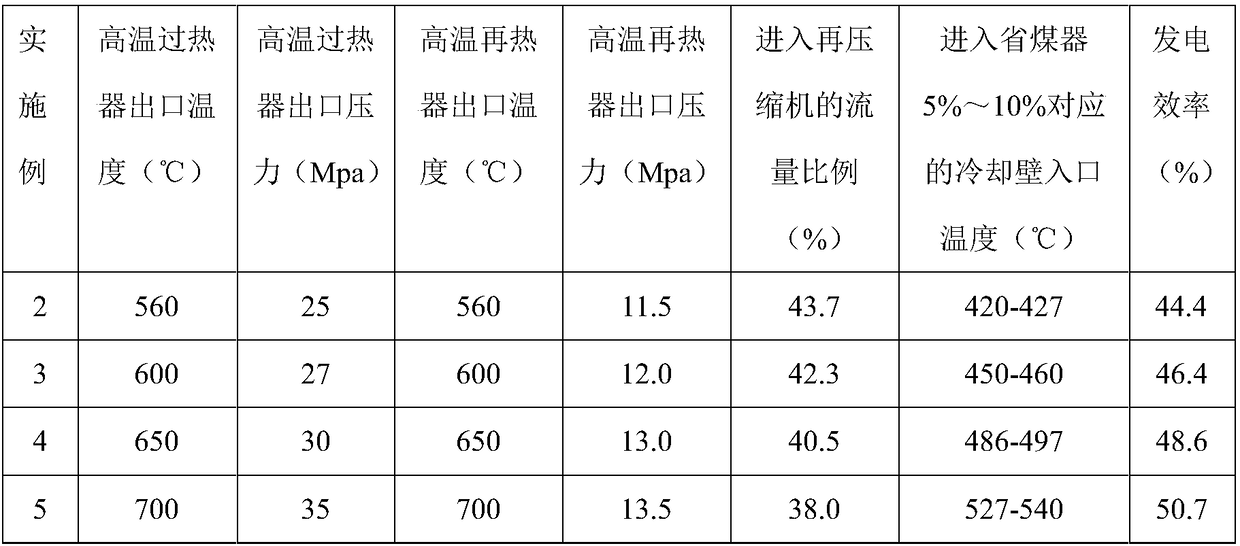

Supercritical carbon dioxide circulating coal-fired power generation system

PendingCN110080848AEliminate manufacturing difficultiesReduce boiler exhaust gas temperatureCombustion processSteam useSuperheaterCirculating fluidized bed boiler

The invention relates to a supercritical carbon dioxide circulating coal-fired power generation system. The supercritical carbon dioxide circulating coal-fired power generation system comprises a hearth and a primary reheater, a membrane type wall is arranged on the inner wall of the hearth, a secondary superheater is arranged at the upper end of the hearth, a separator is connected to the outer end of the top of the hearth, the bottom end of the separator is connected with a return valve, one end of the bottom of the return valve is connected into the hearth, the other end of the bottom of the return valve is connected with an external heat exchanger, and an outlet of the external heat exchanger is connected to one end of the bottom of the hearth. The supercritical carbon dioxide circulating coal-fired power generation system has the beneficial effects that the supercritical carbon dioxide circulation is combined with a circulating fluidized bed boiler, the fuel flexibility of the circulating fluidized bed boiler is good, high-sulfur coal and low-calorific-value fuel can be efficiently utilized, the up-to-standard emission can be realized only through the desulfurization and low-temperature combustion nitrogen inhibiting in the furnace, the heat efficiency of the circulating fluidized bed boiler can achieve 90% or more, and compared with a pulverized coal fuel boiler, the circulating fluidized bed boiler has better economical advantages.

Owner:SHANGHAI POWER EQUIP RES INST

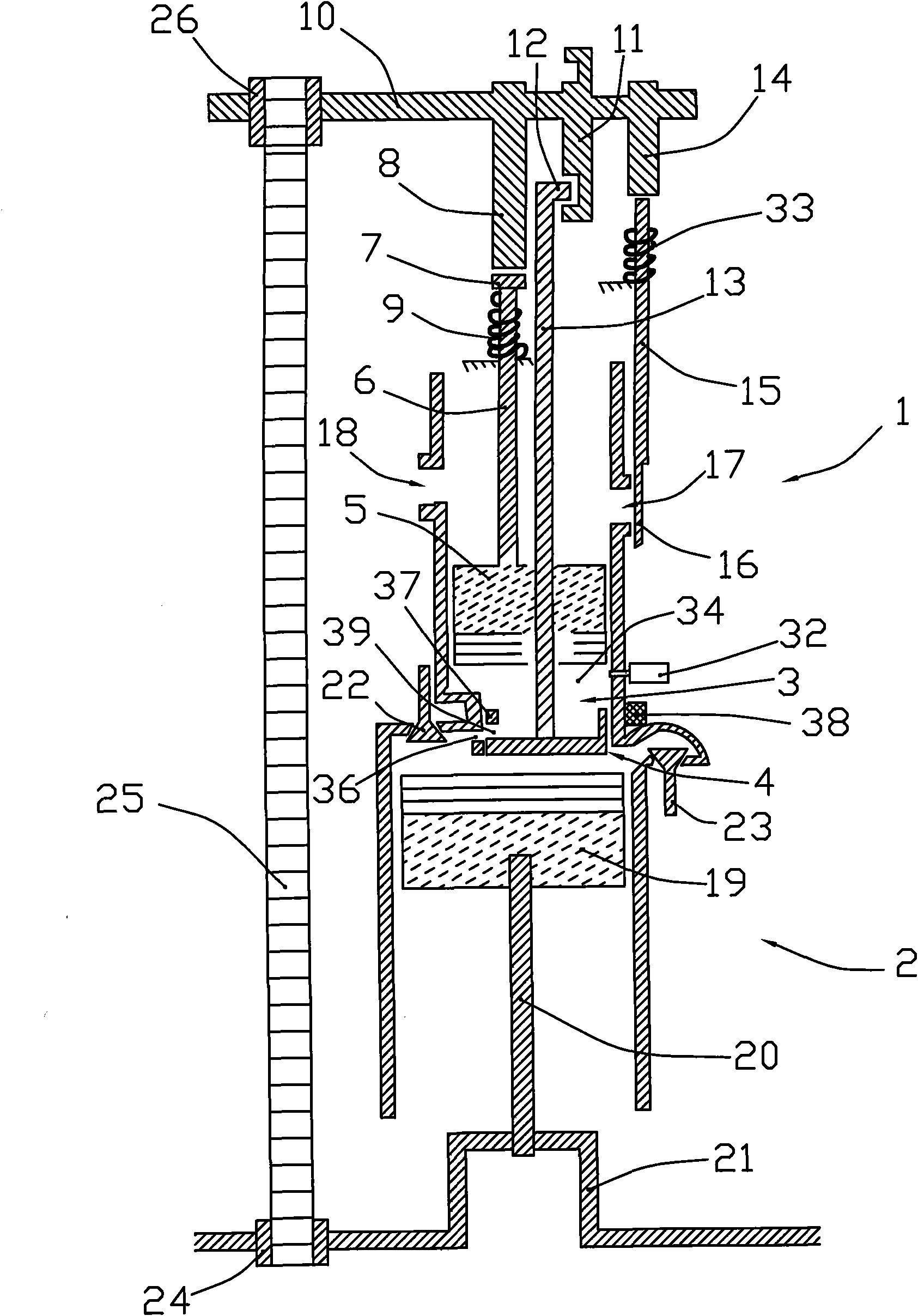

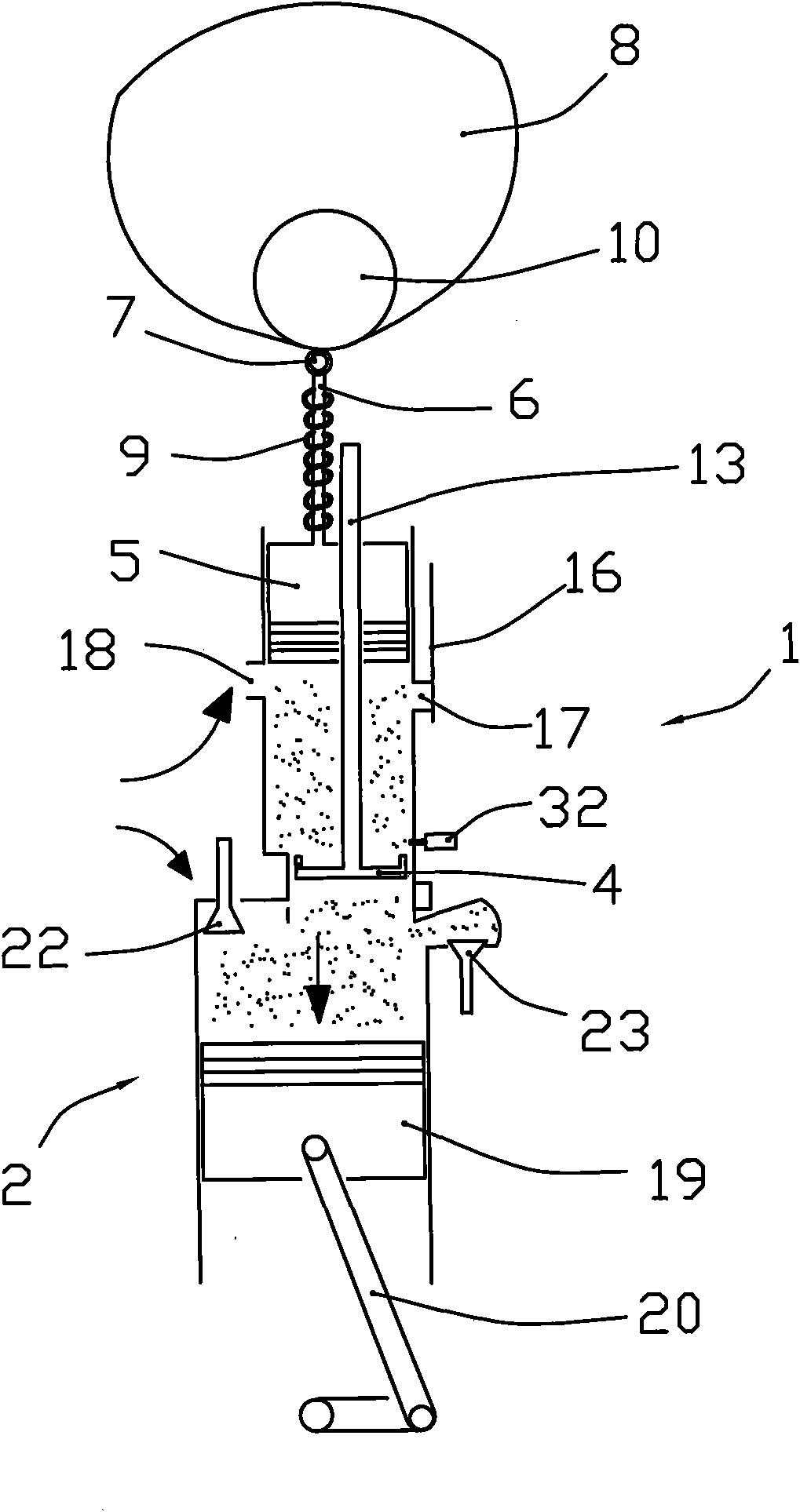

Reciprocating type internal-combustion engine with low fuel oil and micro discharge

InactiveCN101566091AReduced clearance volumeIncrease the compression ratioInternal combustion piston enginesIgnition delayFuel oil

The invention discloses a reciprocating type internal-combustion engine with low fuel oil and micro discharge, which comprises a combustion cylinder, a power output cylinder, a communication cylinder and a blocker which is controlled by a blocking control mechanism and can reciprocate between the combustion cylinder and the power output cylinder so as to open and close the communication cylinder. The blocker reciprocating in the communication cylinder of the reciprocating type internal-combustion engine is used for controlling different working substances of the combustion cylinder and the power output cylinder to separately or cooperatively work. When the power output cylinder has a smallest clearance volume, fuel gas close to a highest temperature period after doing work in the combustion cylinder is put in the power output cylinder, and pure air which is compressed isothermally and compressed with a high-pressure compression ratio and is several times or even tens of times of the amount of the fuel gas in the power output cylinder is isasterically heated. The processes and the power of the ignition delay period and the rapid combustion period of the reciprocating type internal-combustion engine are similar to those of a conventional internal-combustion engine, and the thermal efficiency of the reciprocating type internal-combustion engine is improved by multiples. The reciprocating type internal-combustion engine has micro discharge, low fuel oil, large push moment and flexible working.

Owner:王建全

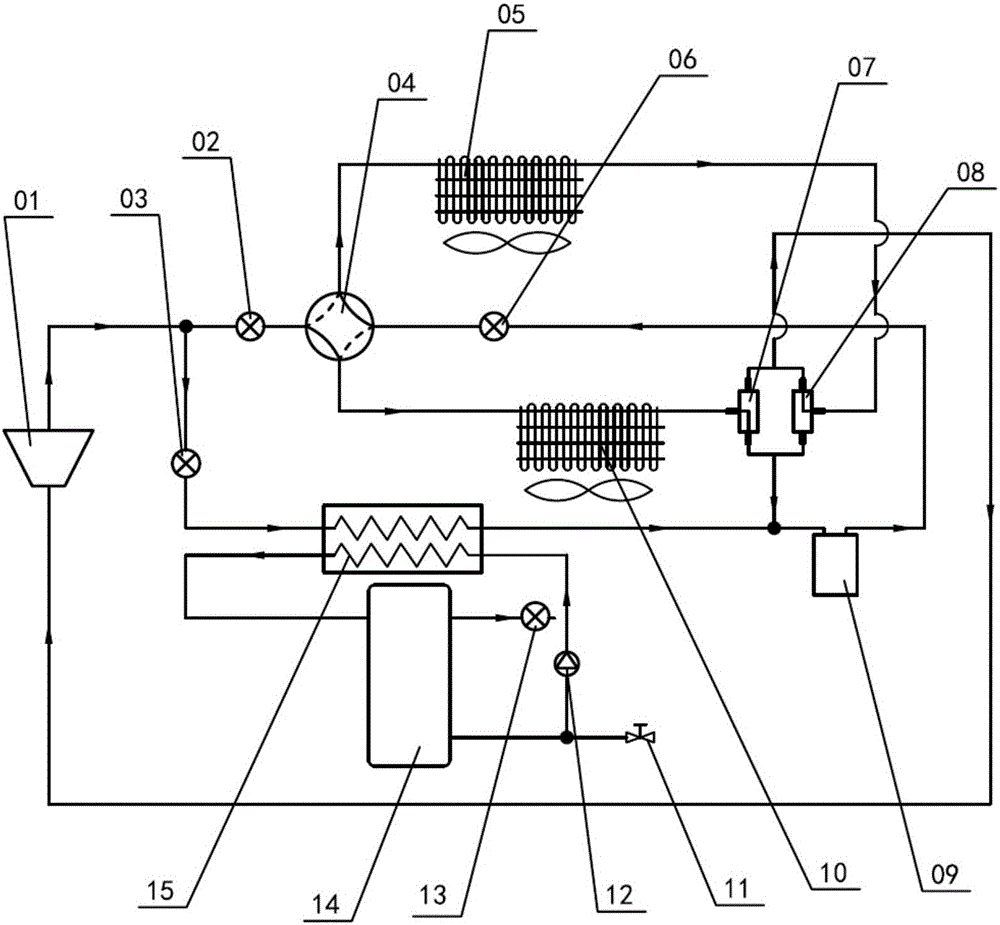

Transcritical CO2 heat pump air conditioner system

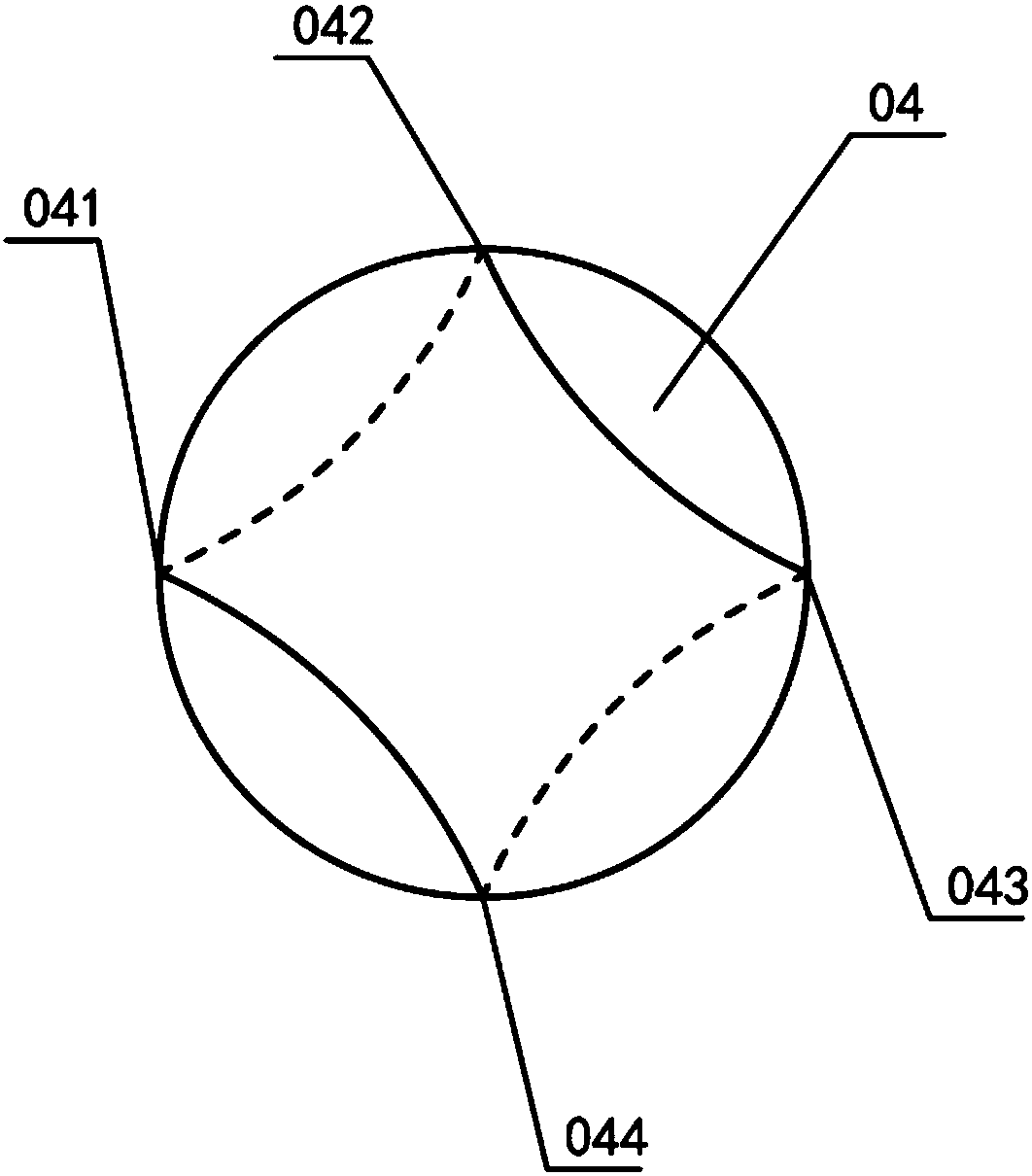

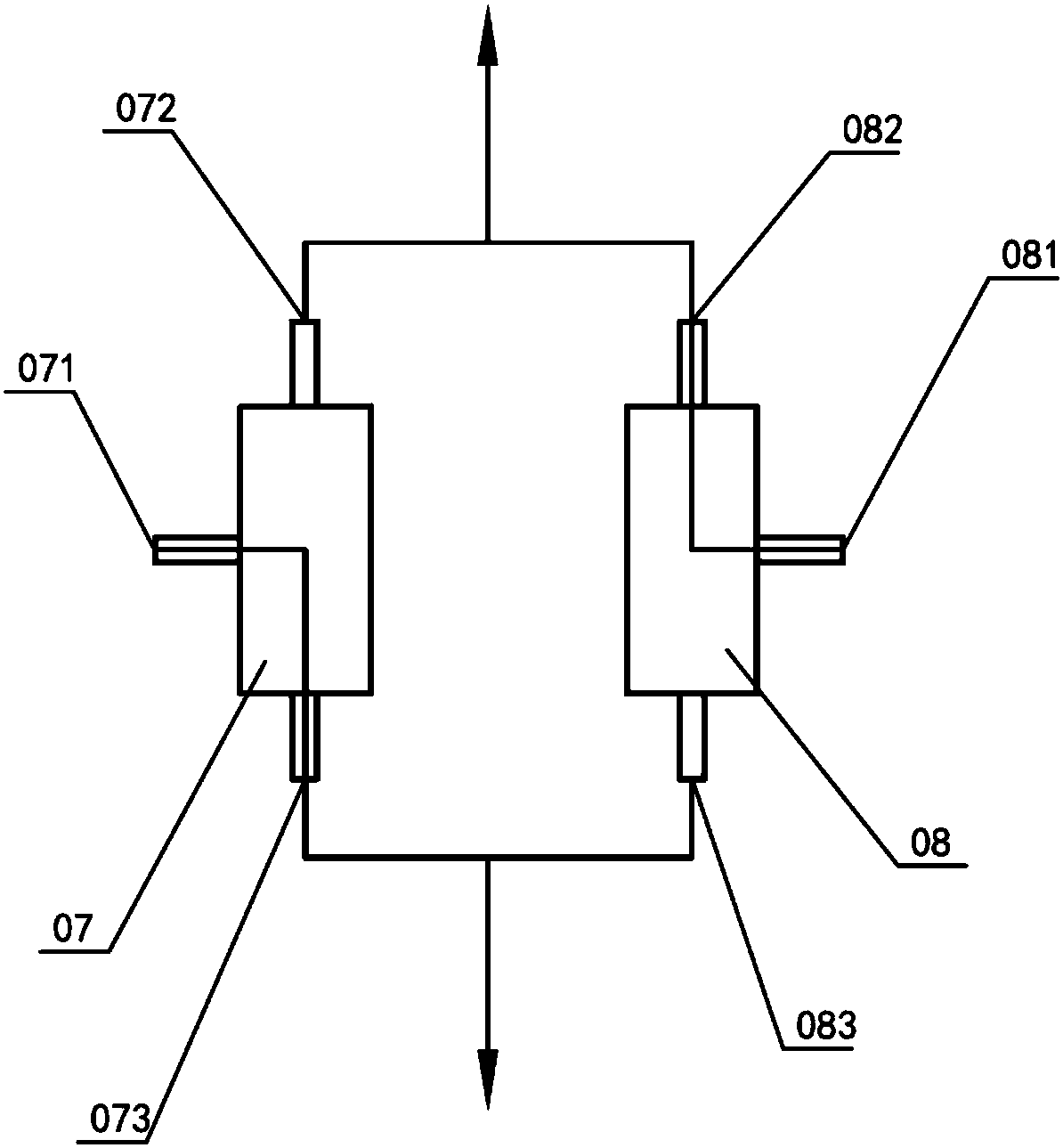

ActiveCN104990169AImprove reliabilityRealize the cooling effectFluid heatersMechanical apparatusCold airFour-way valve

The invention relates to a transcritical CO2 heat pump air conditioner system. The transcritical CO2 heat pump air conditioner system comprises a compressor, a four-way valve, a hot water air cooler, a throttling component, an indoor cold air heat exchanger, an outdoor air cooing heat exchanger and a liquid storage tank. A first three-way valve second port and a second three-way valve second port in the system are communicated and form a first common output end. A first three-way valve third port and a second three-way valve third port are communicated and form a second common output end. The output end of the indoor cold air heat exchanger is connected with the first three-way valve first port. The output end of the outdoor air cooling heat exchanger is connected with a second three-way valve first port. The first common output end is connected with the compressor. The second common output end is connected with the liquid storage tank. In the system, two three-way valves are used for replacing a four-way valve, and in the heating and refrigerating converting process, one three-way valve is enough to independently work every time, wherein one path of work media do not affect the other path of work media, the problem of valve leakage cannot happen, and the reliability of the transcritical CO2 heat pump air conditioner system is improved.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

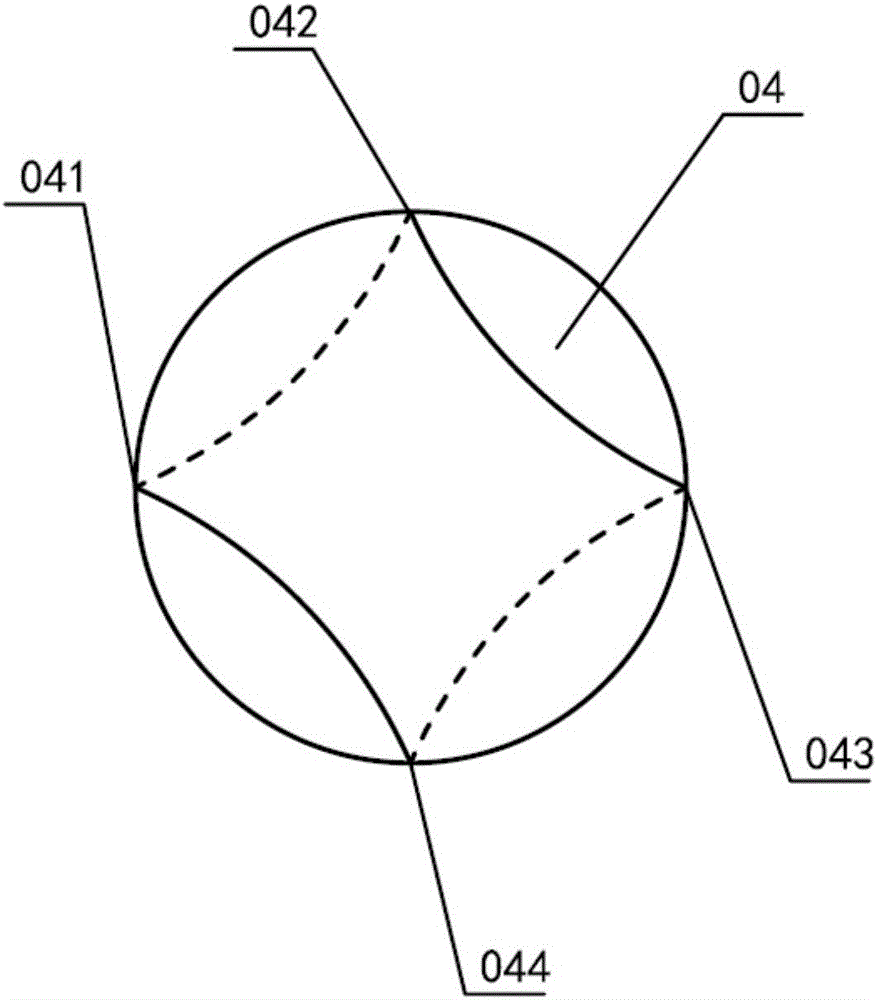

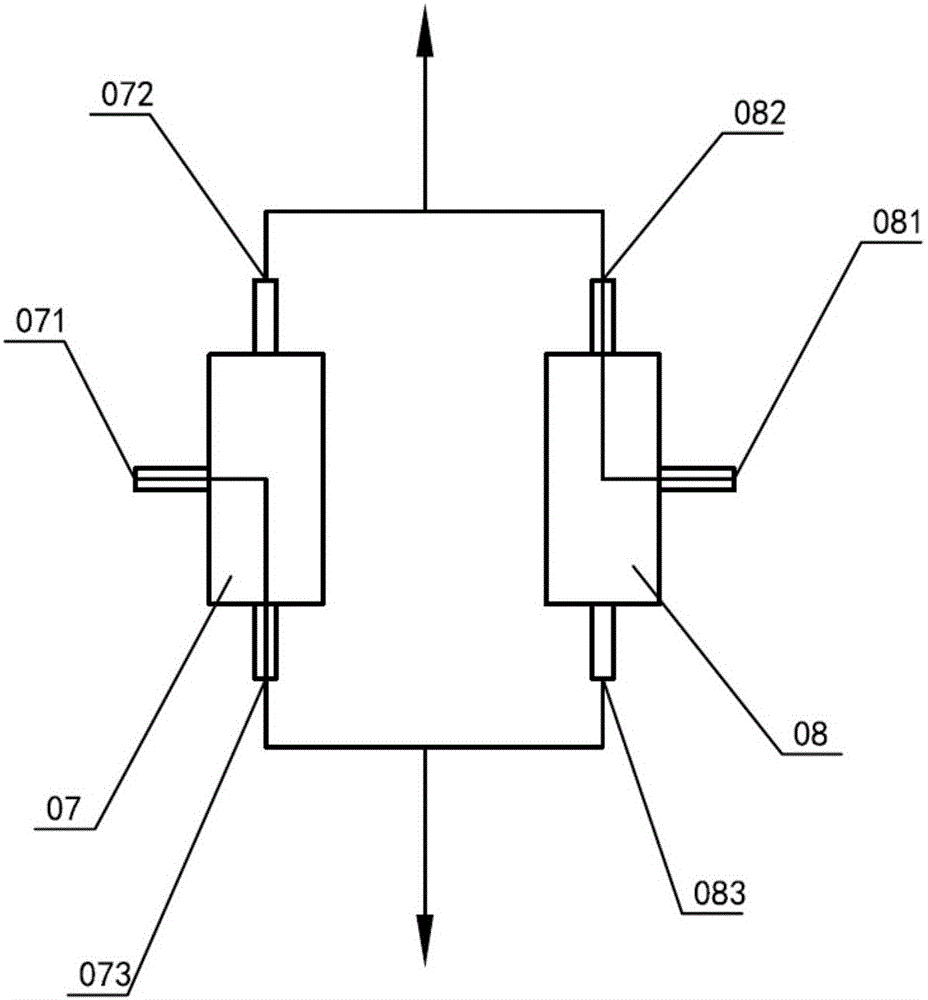

Condensation ejector

ActiveCN104190572ARelieve pressureReduce the temperatureLiquid spraying apparatusEngineeringMixing chamber

The invention discloses a condensation ejector which comprises an accepting chamber, a throat chamber, a mixing chamber, a dispersion chamber, a condensing chamber and an atomizing mechanism, wherein the accepting chamber is provided with a first inlet and a second inlet; one end of the throat chamber is communicated with the accepting chamber, and the throat chamber is located on the down stream of the second inlet; one end of the mixing chamber is communicated with the other end of the throat chamber, one end of the dispersion chamber is communicated with the other end of the mixing chamber, and a first outlet is formed in the other end of the dispersion chamber; the condensing chamber is arranged close to the outer side of the down stream of the mixing chamber in a surrounding mode and comprises a third inlet formed in the down stream end of the condensing chamber, a second outlet formed in the upstream of the condensing chamber, a plurality of main condensing pipes and a plurality of branch condensing pipes, one end of each of the condensing pipes extends into the mixing chamber, the extending directions of the branch condensing pipes are different, the other end of each of the branch condensing pipes is communicated with a main condensing pipe, one end of the main condensing pipe is sealed, and the other end of the main condensing pipe is communicated with the dispersion chamber through a fourth inlet in the dispersion chamber; the atomizing mechanism is provided with a plurality of nozzles formed in the position of the fourth inlet, and the atomizing mechanism is used for atomizing fluid in the main condensing pipe and spraying the fluid in the dispersion chamber.

Owner:广西海岛生态投资有限公司

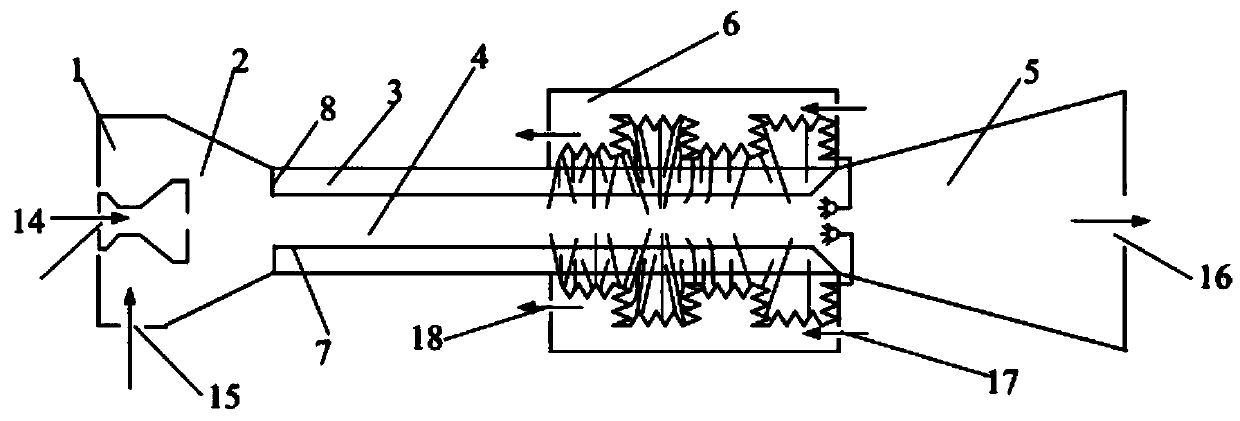

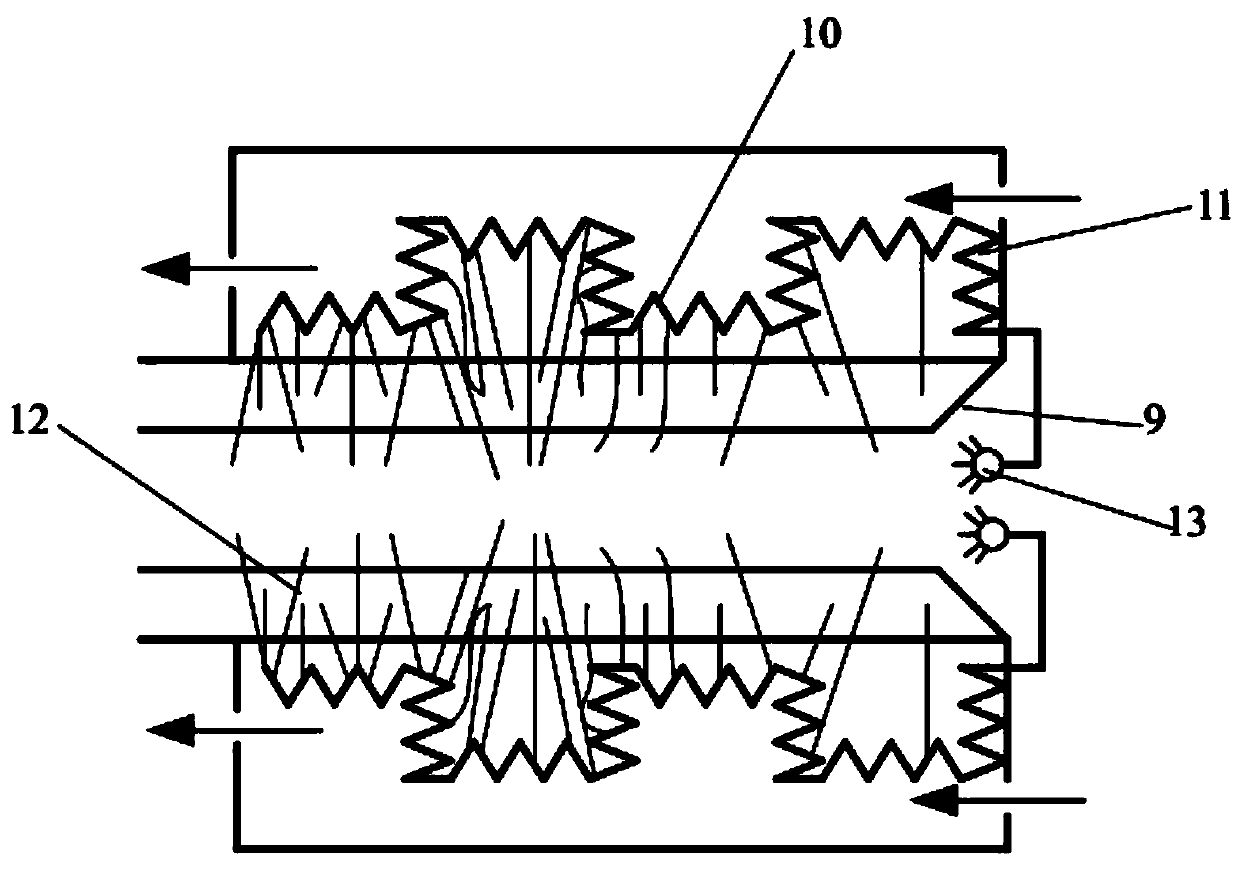

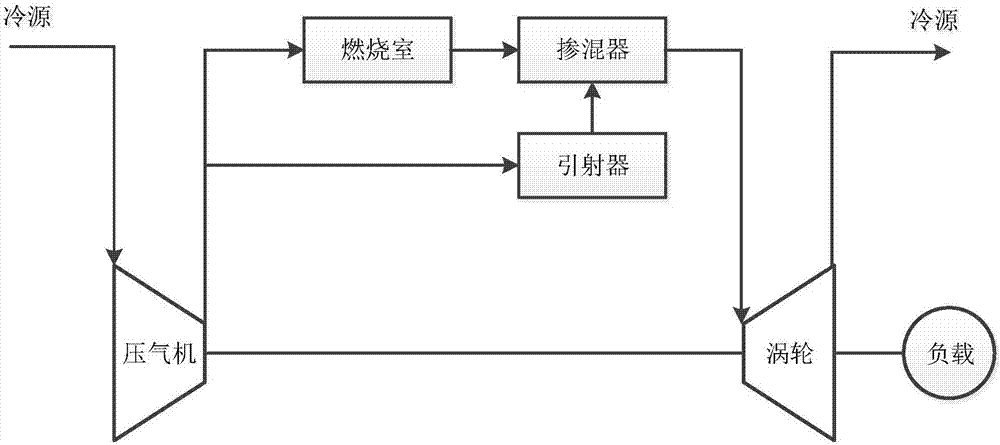

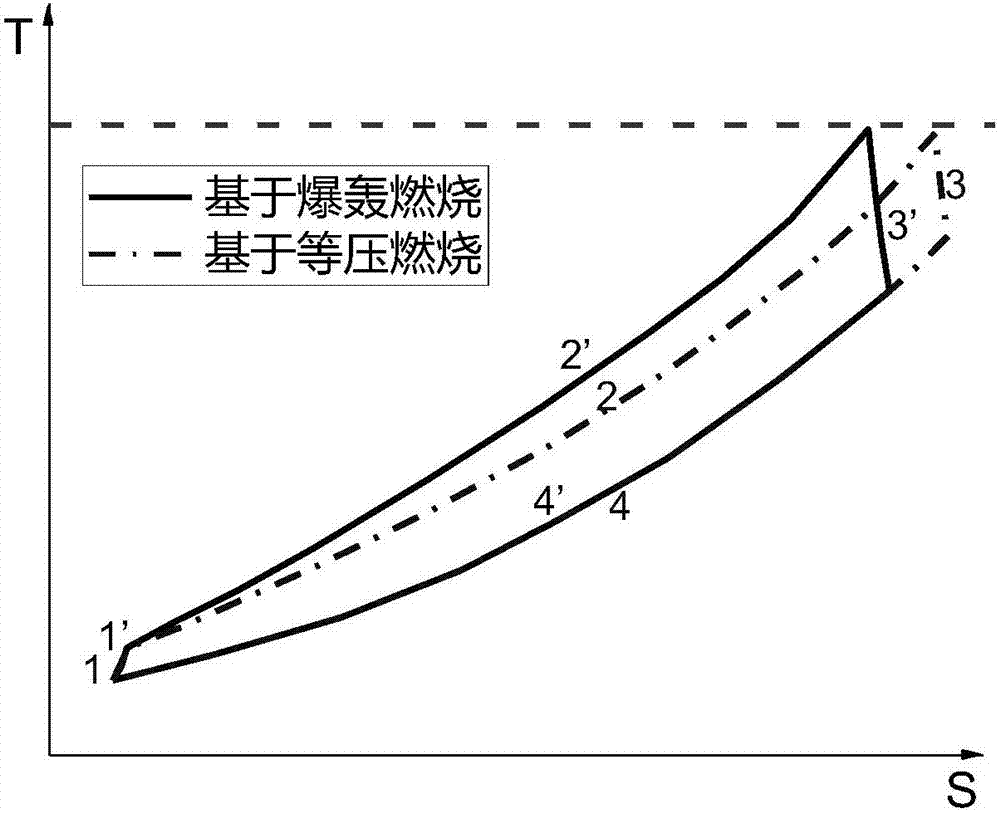

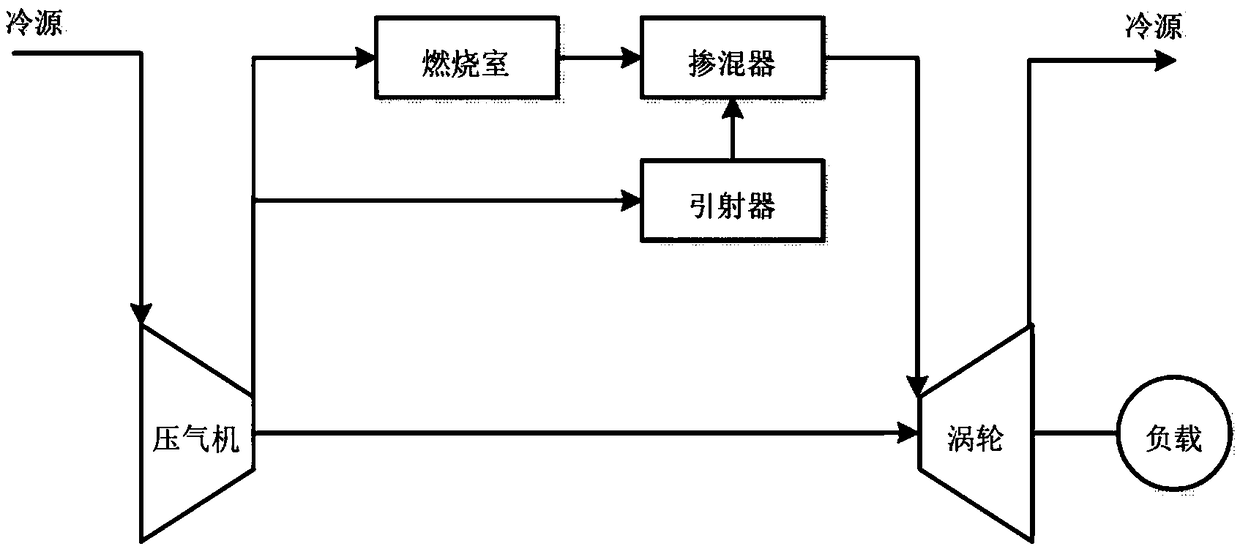

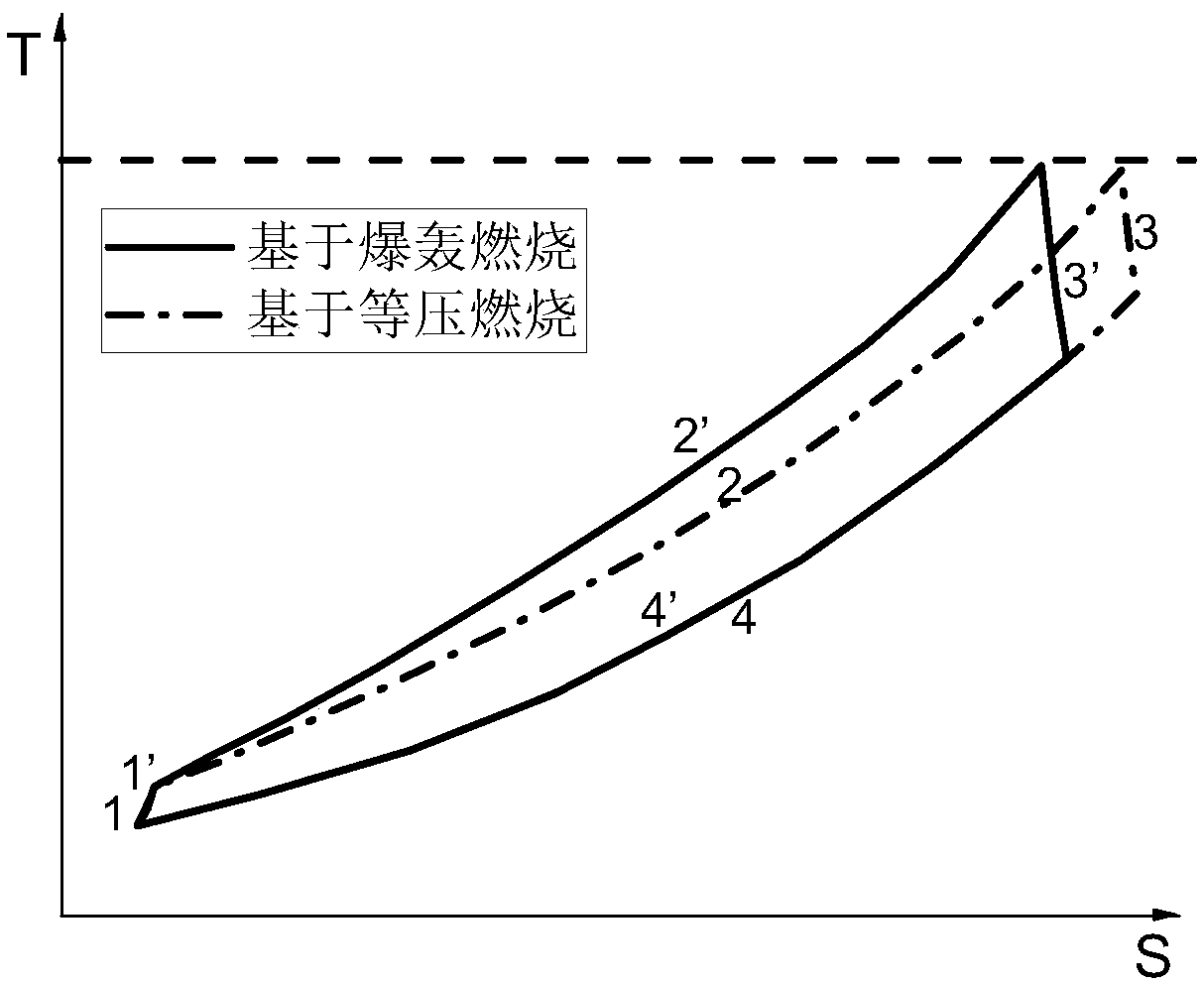

Simple cyclical gas turbine based on rotary detonation combustion

ActiveCN107120189AImprove cycle thermal efficiencyOvercoming the problem of excessive entropy increaseContinuous combustion chamberTurbine/propulsion engine coolingAxial compressorDetonation

The invention provides a simple cyclical gas turbine based on rotary detonation combustion. The simple cyclical gas turbine based on the rotary detonation combustion comprises a gas compressor, a rotary detonation combustion room, a thermojet priming tube, an ejector, a mixing set, a turbine, a load and a cold source. The rotary detonation combustion room is applied to the simple cyclical gas turbine, and the mixing set is added at the tail part of the combustion room to ensure that working medium at an inlet of the turbine does not overheat. Through utilizing the pressurizing characteristic of the rotary detonation combustion room, the power capability of the working medium at an inlet of the turbine is improved, and under the conditions that the temperature, the efficiency of assembly unit, the pressure ratio of the gas compressor are uniform, the circulation heat efficiency of the gas turbine is improved 5%-10%.

Owner:HARBIN ENG UNIV

Refrigerating circulation system of high-temperature air conditioner and high-temperature air conditioner

ActiveCN106802036AReduce workloadReduce loadMechanical apparatusFluid circulation arrangementVapor–liquid separatorEngineering

The invention relates to a refrigerating circulation system of a high-temperature air conditioner and the high-temperature air conditioner. The refrigerating circulation system comprises a compressor, an outdoor heat exchanger, a caterpillar tube, an indoor heat exchanger and a gas-liquid separator, all of which are sequentially connected to form a loop. The refrigerating circulation system further comprises a pressure releasing device, and the two ends of the pressure releasing device communicate with a working medium outlet of the compressor and a working medium inlet of the gas-liquid separator through pipelines correspondingly. Due to the fact that the pressure releasing device is arranged between the working medium outlet of the compressor and the working medium inlet of the gas-liquid separator, part of working media can be converged with outlet working media of the indoor heat exchanger through the pressure releasing device when the exhaust pressure of the compressor is increased, and the workload of the outdoor heat exchanger can be reduced.

Owner:MIDEA GRP CO LTD +1

A pump-driven two-phase circuit device for heat dissipation of high heat flow electronic devices

ActiveCN107454797BMeet job needsImprove cooling effectDigital data processing detailsCooling/ventilation/heating modificationsHeat flowHeat flux

The invention provides a pump-driven two-phase circuit device for heat dissipation of a high heat flux electronic device. Heat is collected and transported by using an endothermic process in evaporation and an exothermic process in condensation during a circulation flow process of a working medium. An evaporator for the circuit device comprises micro-channels and fins. In an area of high heat flux, the micro-channels are used to dissipate heat and increase a heat transfer coefficient of a partial area, while in an area of low heat flux, the fins are used. Due to great area difference between the micro-channel area and the fin area in the evaporator, when the working medium in the micro-channels enters the fin area, volume quickly expands and temperature of the working medium reduces, so as to help heat dissipation of the device in the fin area. By using different structures and with little resources, heat dissipation problems of devices with different powers are solved. The pump-driven two-phase circuit device for heat dissipation of the high heat flux electronic device can adapt to heat dissipation of electronic devices with different heat flux densities and can satisfy working requirements of electronic devices with a heat flux density of 50 W / cm<2> or above.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

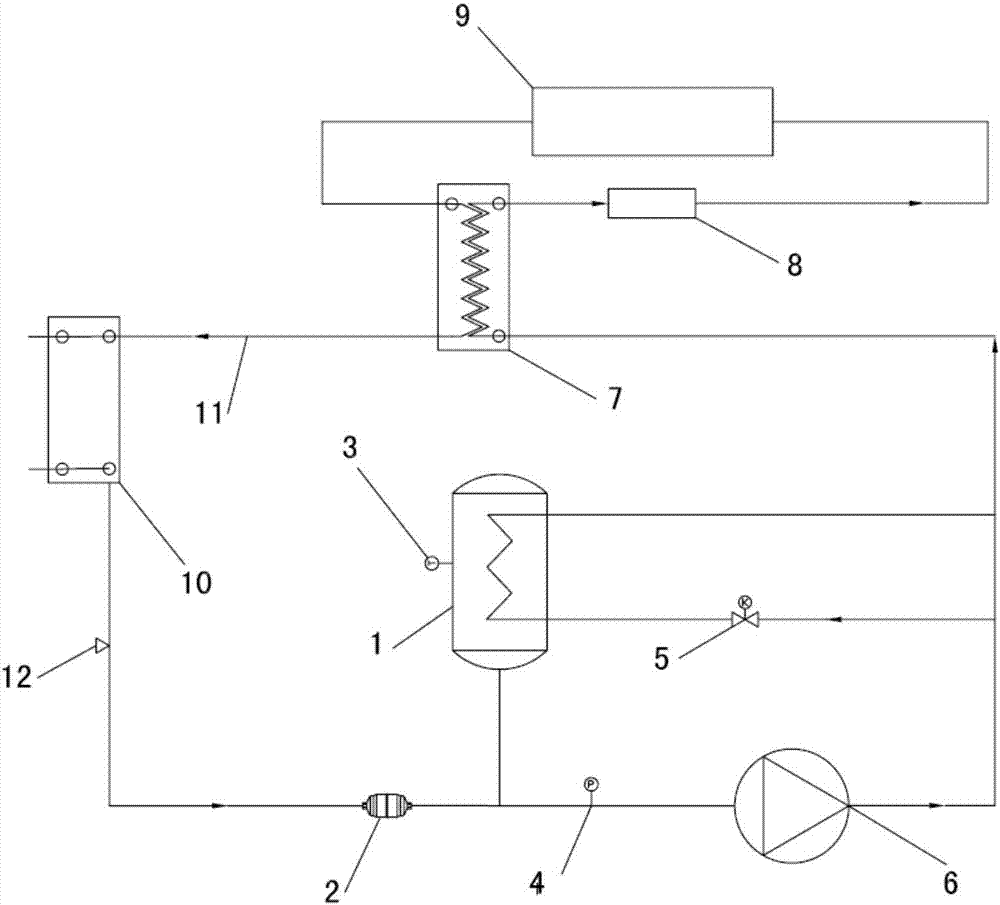

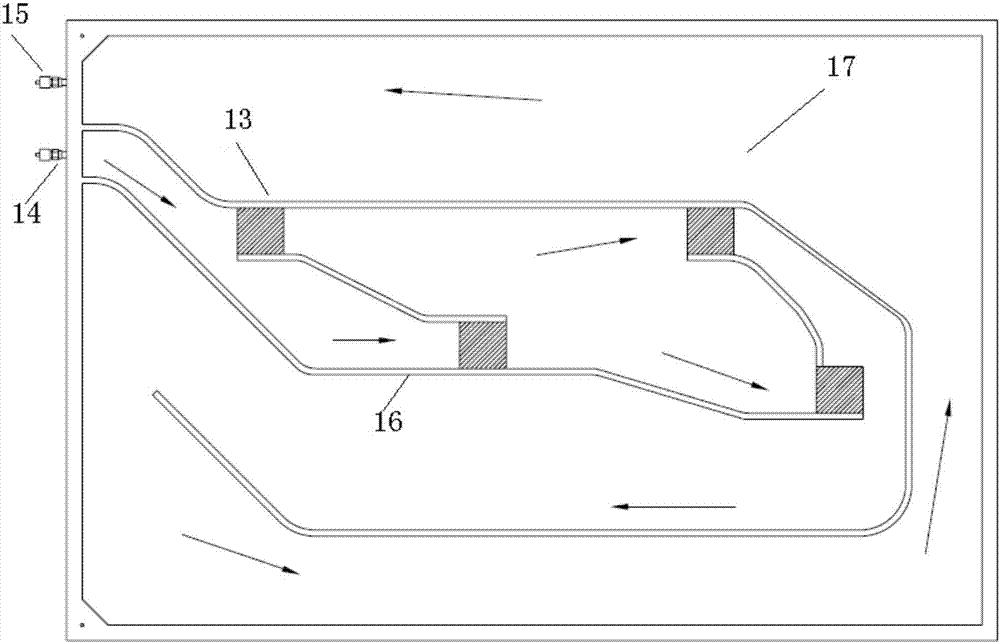

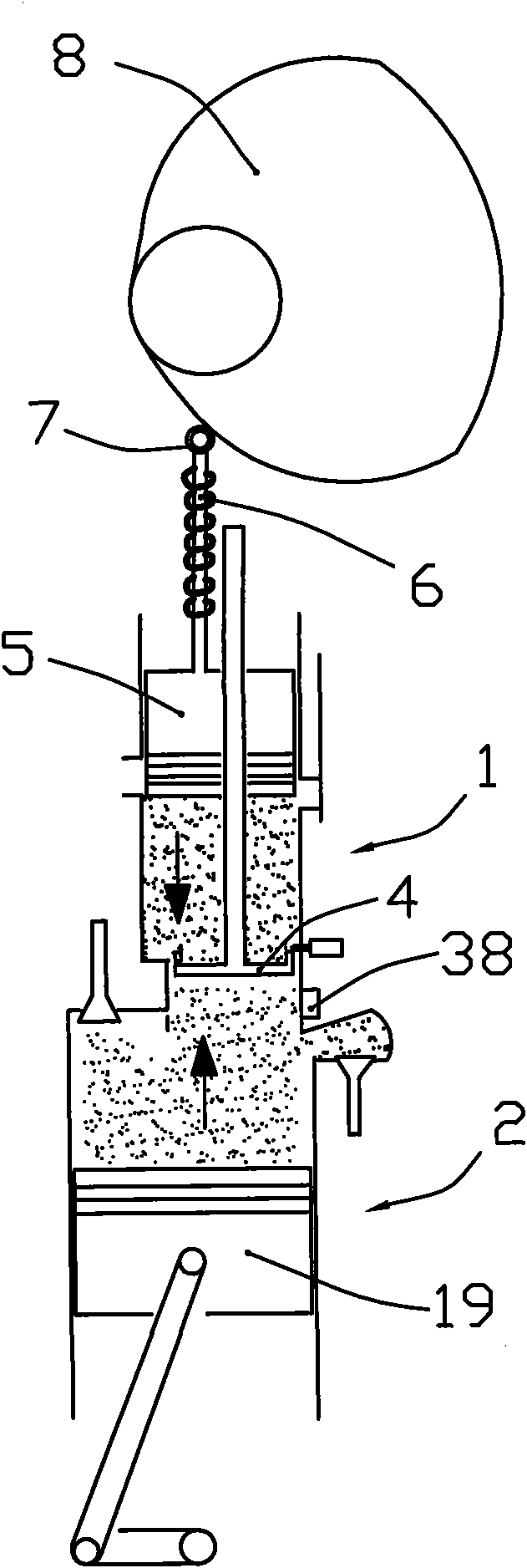

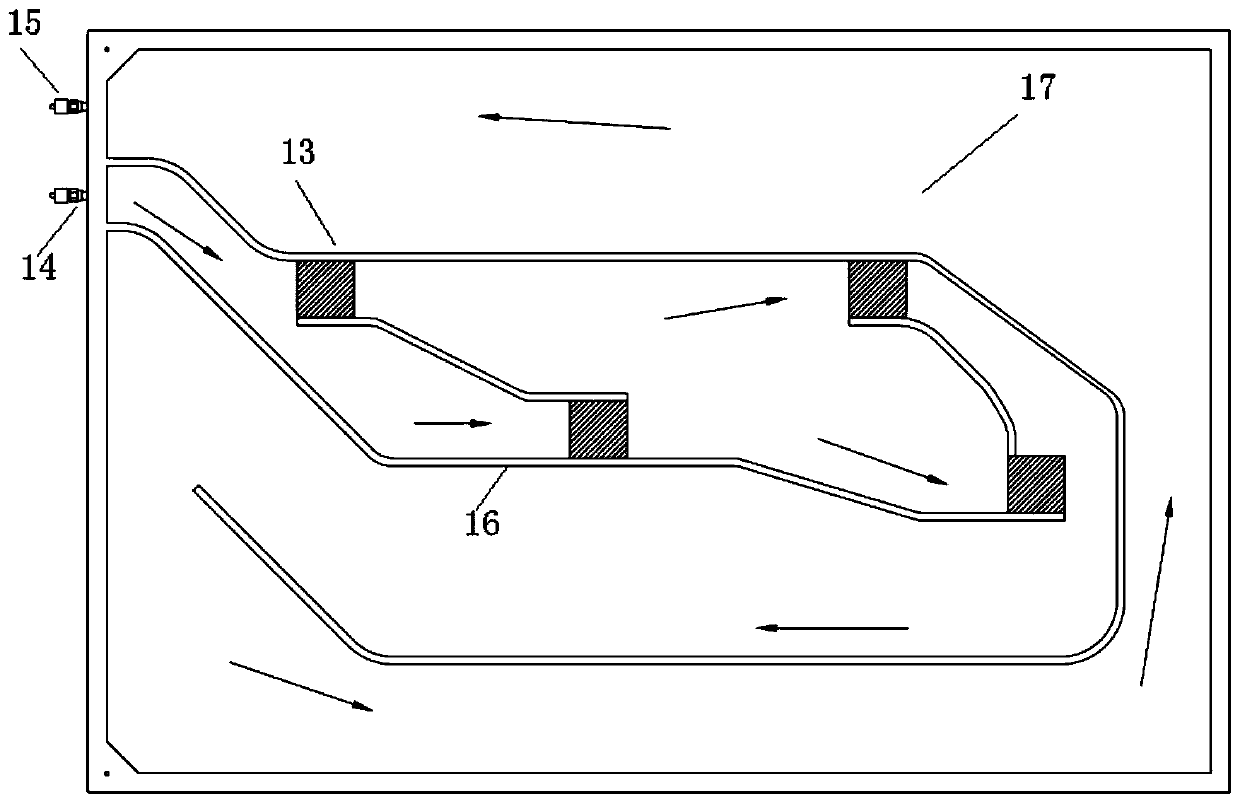

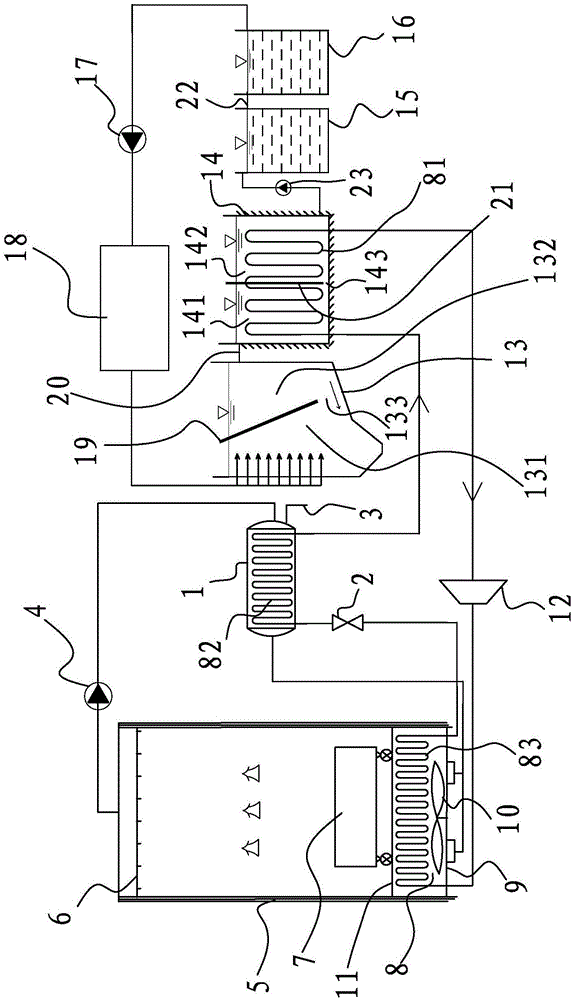

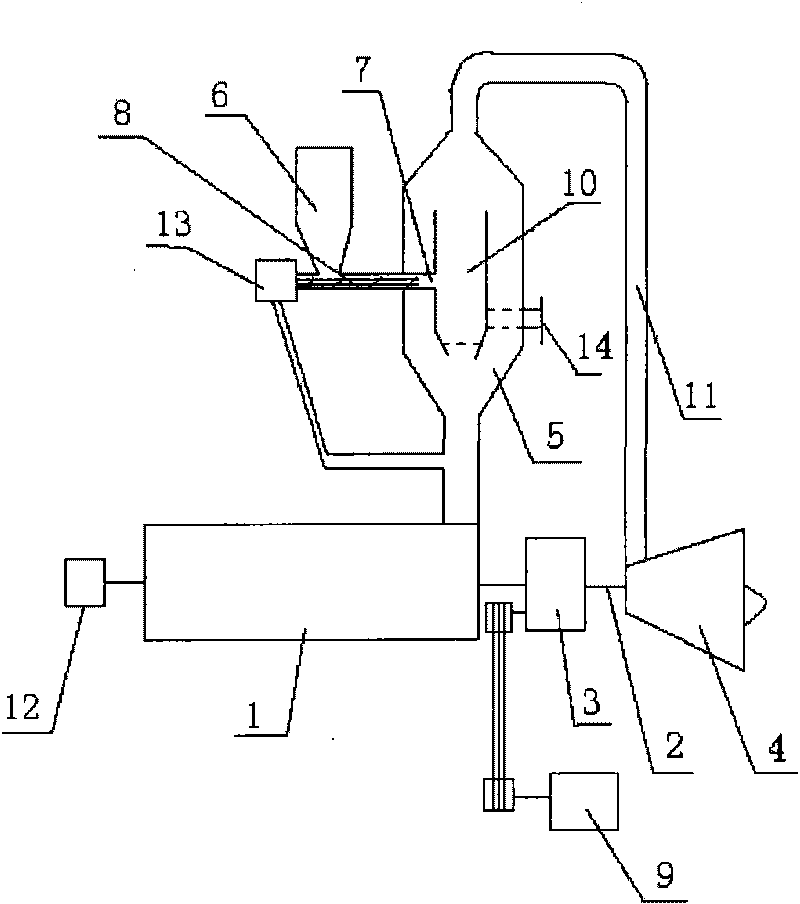

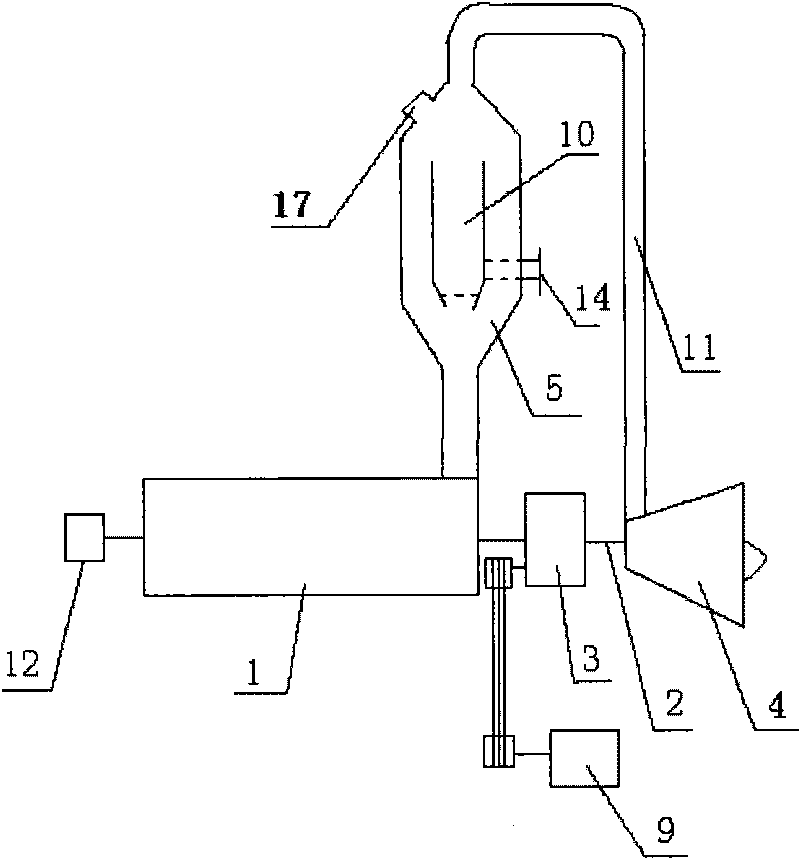

Heat pump drying system adopting industrial circulating water as heat source

ActiveCN105627702AFully extractedIncrease profitHeat pumpsHeat recovery systemsHeat conductingEngineering

The invention relates to a heat pump drying system adopting industrial circulating water as a heat source. The heat pump drying system comprises a drying case, a condenser, a compressor, an evaporator, a throttle and a fan, wherein the drying case is provided with an air inlet and an air outlet. The system further comprises a primary settling pond, a heat recovery pond and a settling pond, wherein a first heat conducting portion is arranged in the heat recovery pond, a second heat conducting portion is arranged in the evaporator, and the condenser is provided with a third heat conducting portion corresponding to the air inlet. The inlet end of the compressor communicates with the outlet end of the first heat conducting portion, and the outlet end of the compressor communicates with the inlet end of the third heat conducting portion. The inlet end of the throttle communicates with the outlet end of the third heat conducting portion, and the outlet end of the throttle communicates with the inlet end of the second heat conducting portion. The outlet end of the second heat conducting portion communicates with the inlet end of the first heat conducting portion. The inlet end of the evaporator communicates with the air outlet, and the outlet end of the evaporator communicates with the air inlet. The heat pump drying system can reduce energy consumption, improve the energy utilization rate and reduce environment pollution.

Owner:QUANZHOU INST OF EQUIP MFG

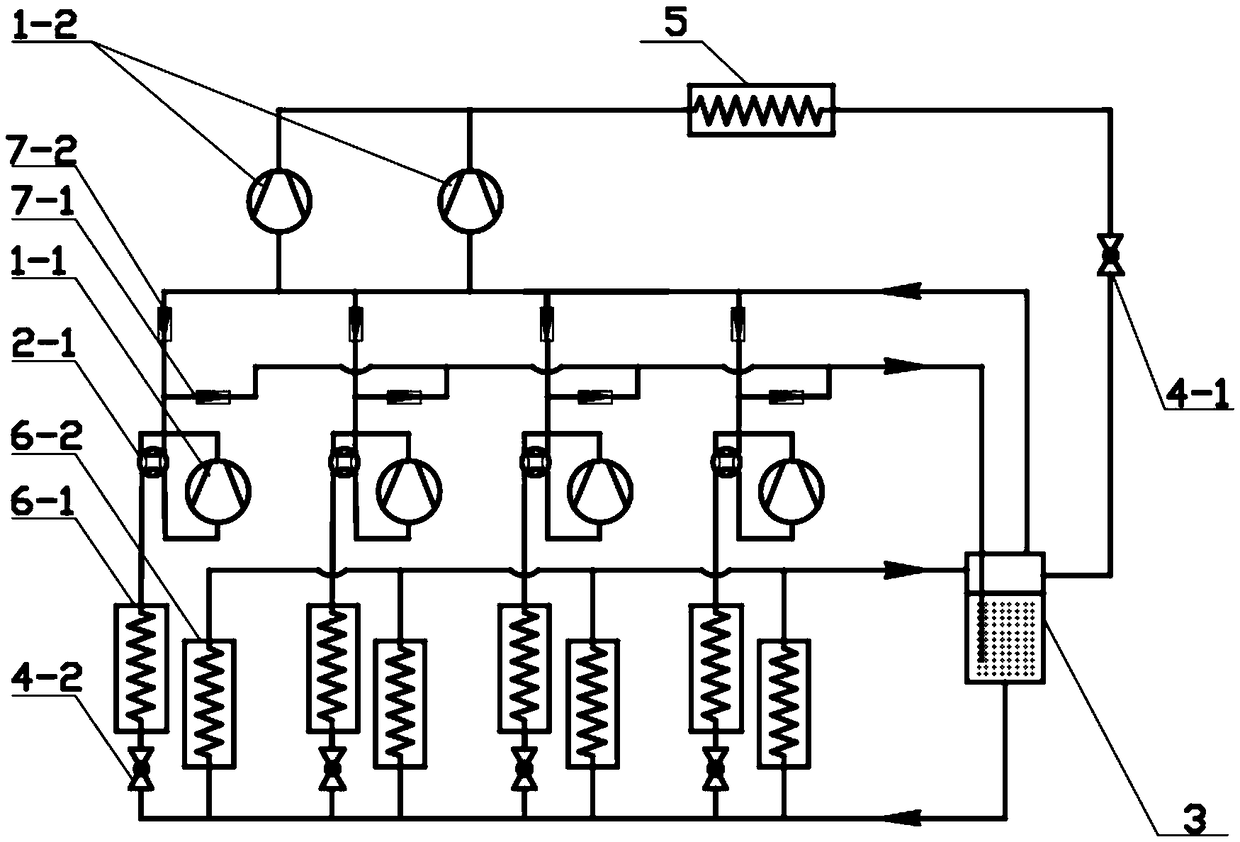

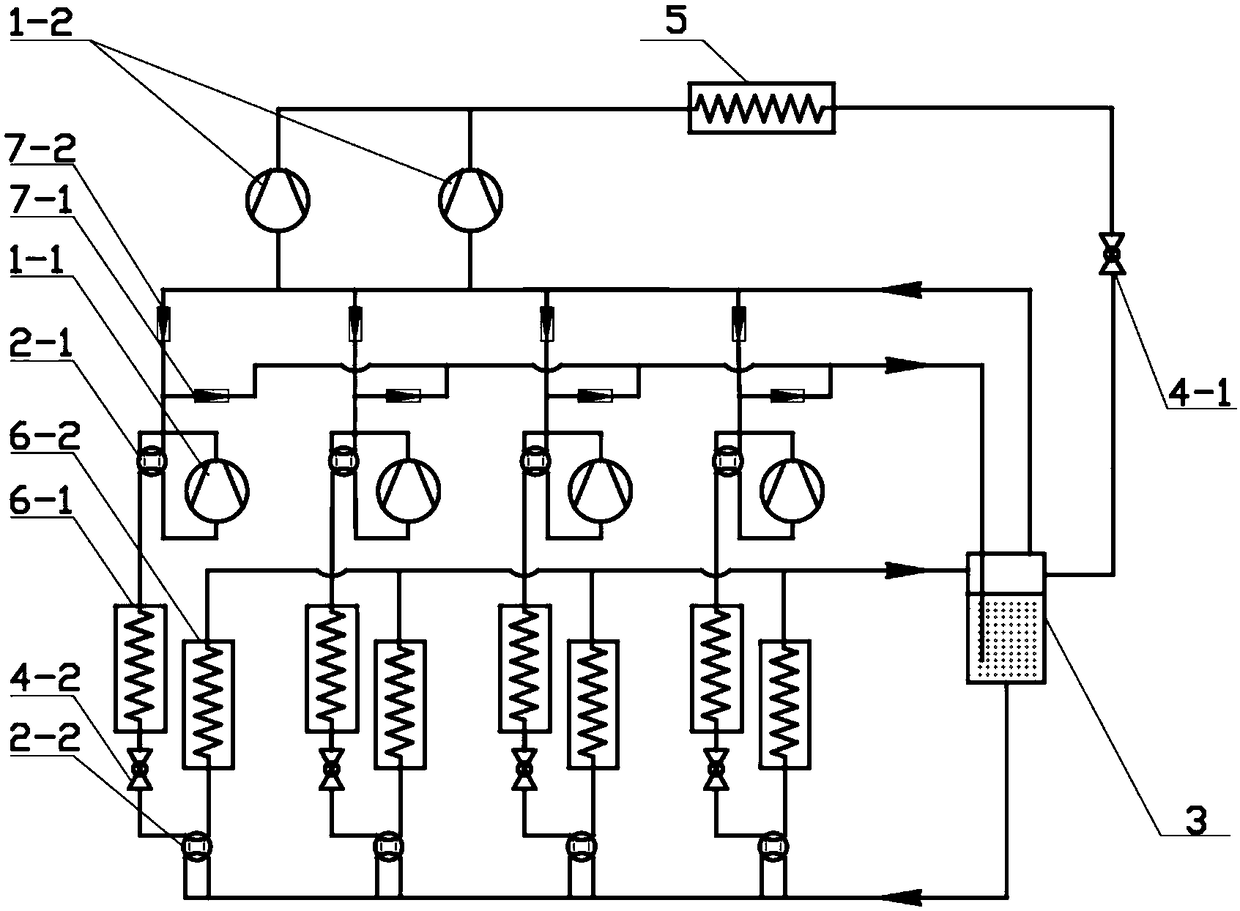

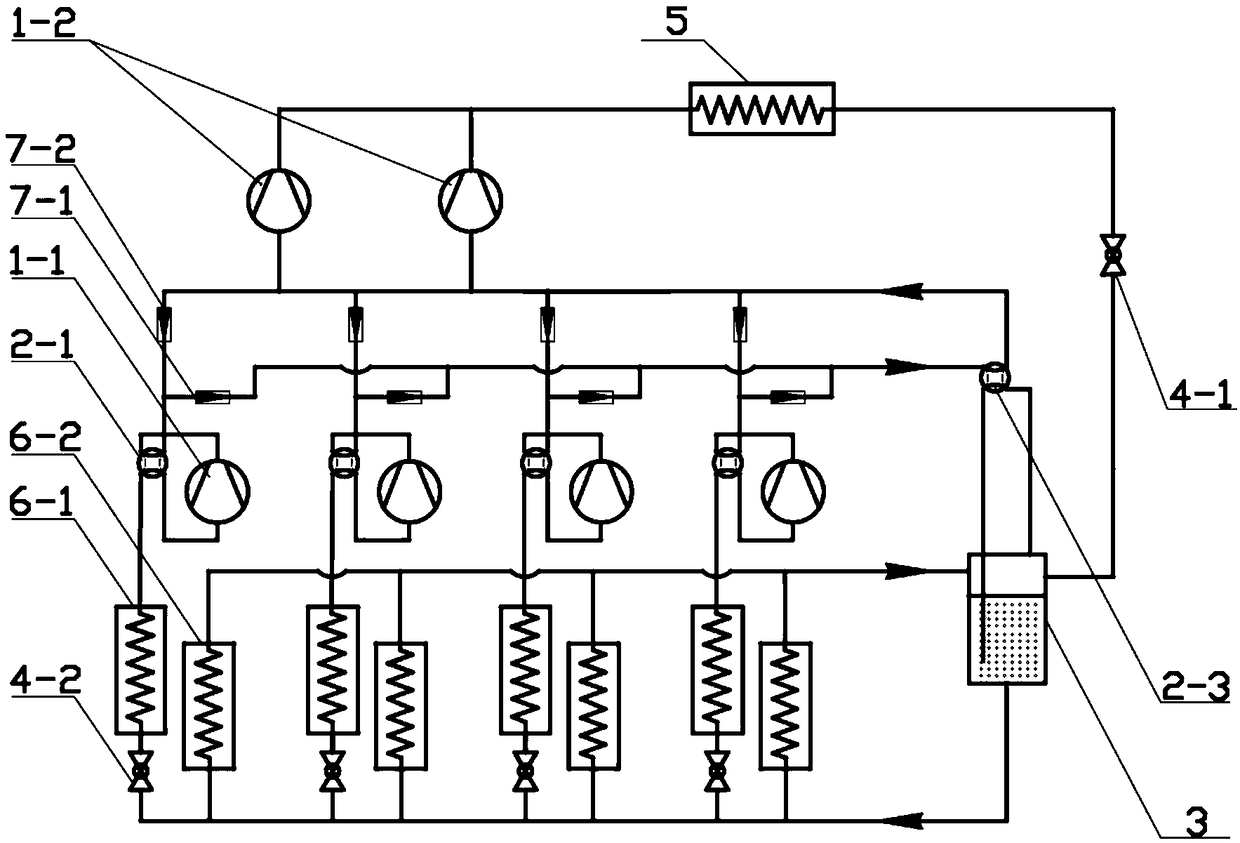

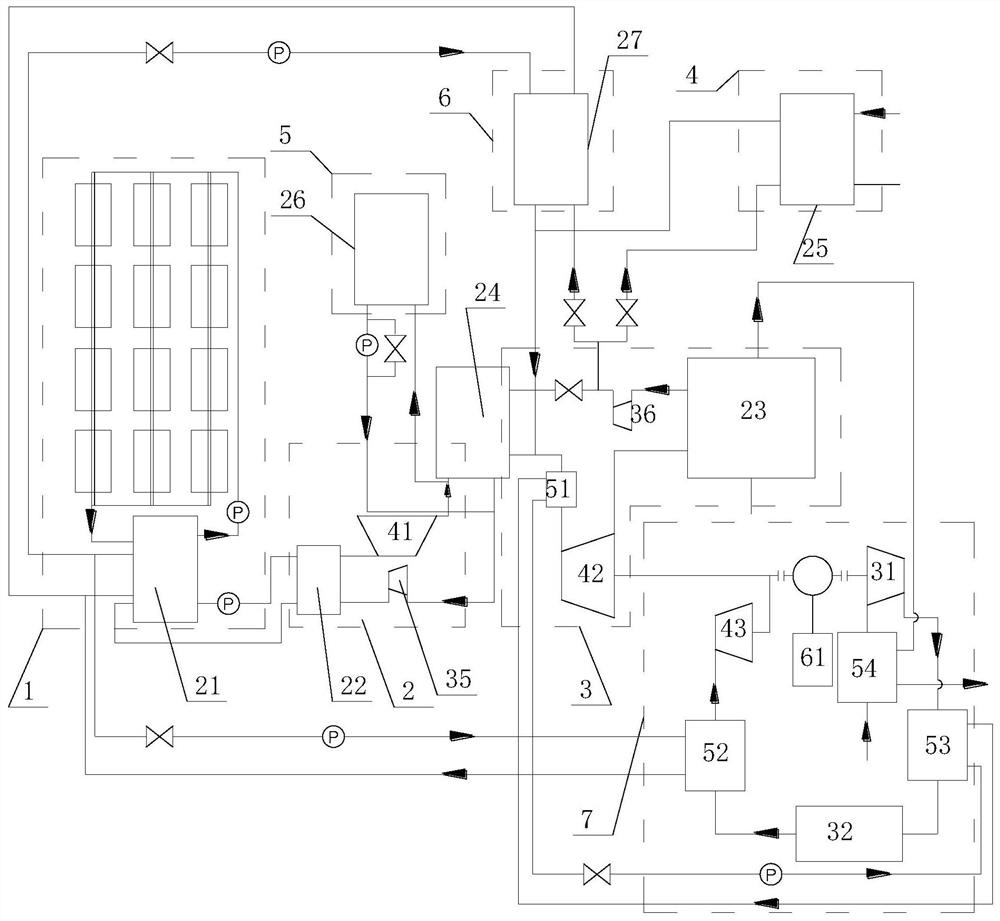

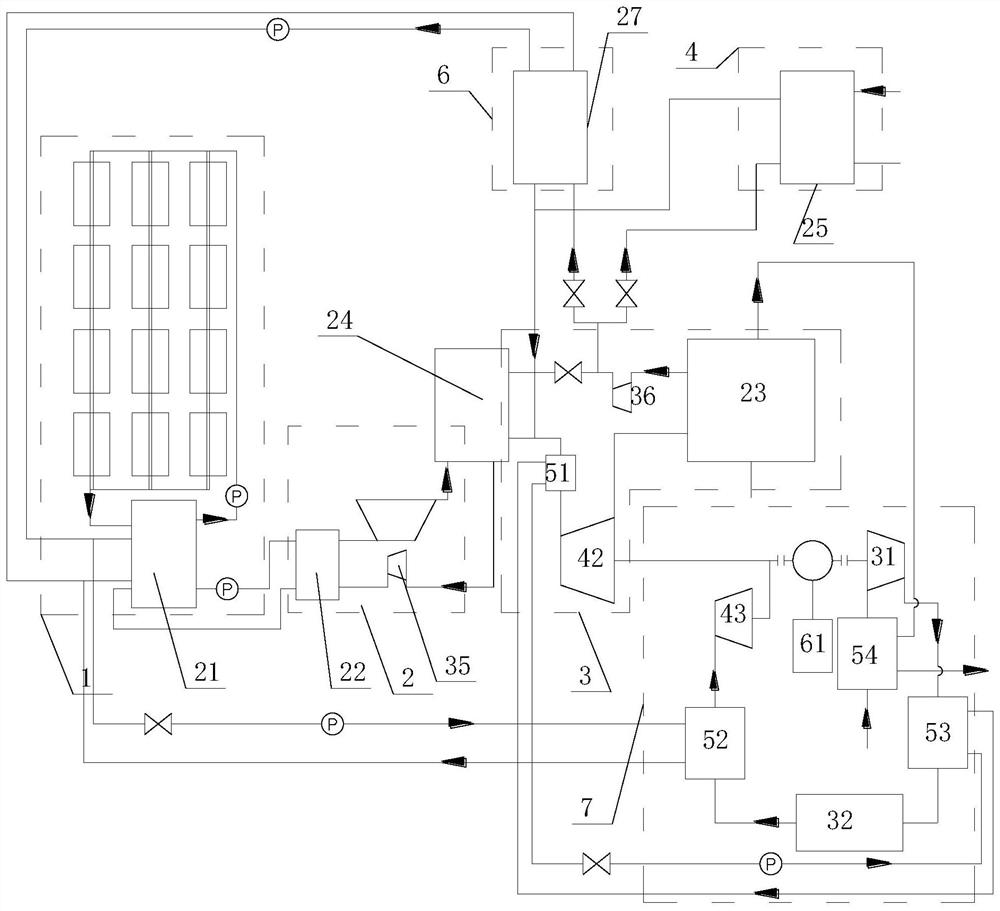

Operation method of two-stage-throttling intermediate complete cooling type refrigeration system and two-stage-throttling intermediate complete cooling type refrigeration system

ActiveCN108709333AGuaranteed uptimeImprove defrosting efficiencyMechanical apparatusCorrosion preventionEngineeringHigh pressure

The invention discloses an operation method of a two-stage-throttling intermediate complete cooling type refrigeration system and the two-stage-throttling intermediate complete cooling type refrigeration system. The operation method of the two-stage-throttling intermediate complete cooling type refrigeration system and the two-stage-throttling intermediate complete cooling type refrigeration system aim to achieve that a low-pressure-grade compressor heat pump circulation is used for wheel gear defrosting of low-temperature evaporators. An intermediate temperature evaporator and a low-temperature evaporator are arranged in each low-pressure-grade unit, wherein the intermediate temperature evaporator is used for achieving intermediate temperature refrigeration, and the low-temperature evaporator is used for achieving low-temperature refrigeration or defrosting. The operation method comprises the steps that when one low-temperature evaporator needs defrosting, through valve switching, a low-pressure-grade compressor having the defrosting function is converted into a high-pressure-grade compressor to operate, the low-pressure-grade compressor in the low-pressure-grade unit achieving the defrosting function sucks a working medium from the low-pressure-grade compressor achieving the refrigeration function, after the working medium is compressed, the working medium condenses to heat the low-temperature evaporator to be defrosted, and then defrosting is achieved; when multiple low-temperature evaporators need defrosting, wheel gear type defrosting is adopted. According to the two-stage-throttling intermediate complete cooling type refrigeration system and the two-stage-throttling intermediate complete cooling type refrigeration system, the defrosting circulation and the refrigeration circulation are both double-grade compression circulations, the temperature fluctuation of a cold storage is small, the structure is simple, and the efficiency is high.

Owner:TIANJIN UNIV OF COMMERCE

Self-heat-absorption type heat exchanger combination

InactiveCN106705020AIncrease vacuumImprove efficiencyEngine componentsSteam engine plantsRiver waterElectricity

A self-heat-absorption type heat exchanger combination belongs to the field of thermoelectric technology of a heat exchanger combination, is a combination of two heat exchangers and a refrigerator and is used for thermal power generation, nuclear power generation and exhaust steam heat power generation with media in closed circulation. According to the self-heat-absorption type heat exchanger combination, a working medium before a circulating pump absorbs the heat of a working medium behind the circulating pump to achieve absorption and reutilization of waste heat and improve the heat utilization rate; an external cold source is only used for cooling the last heat exchanger and carries away a little heat, the deposition of river water dirt is reduced to avoid cleaning of a steam condenser, and a low-temperature heater and a high-temperature heater are omitted; and the heat-electricity conversion efficiency is greatly improved.

Owner:王运举

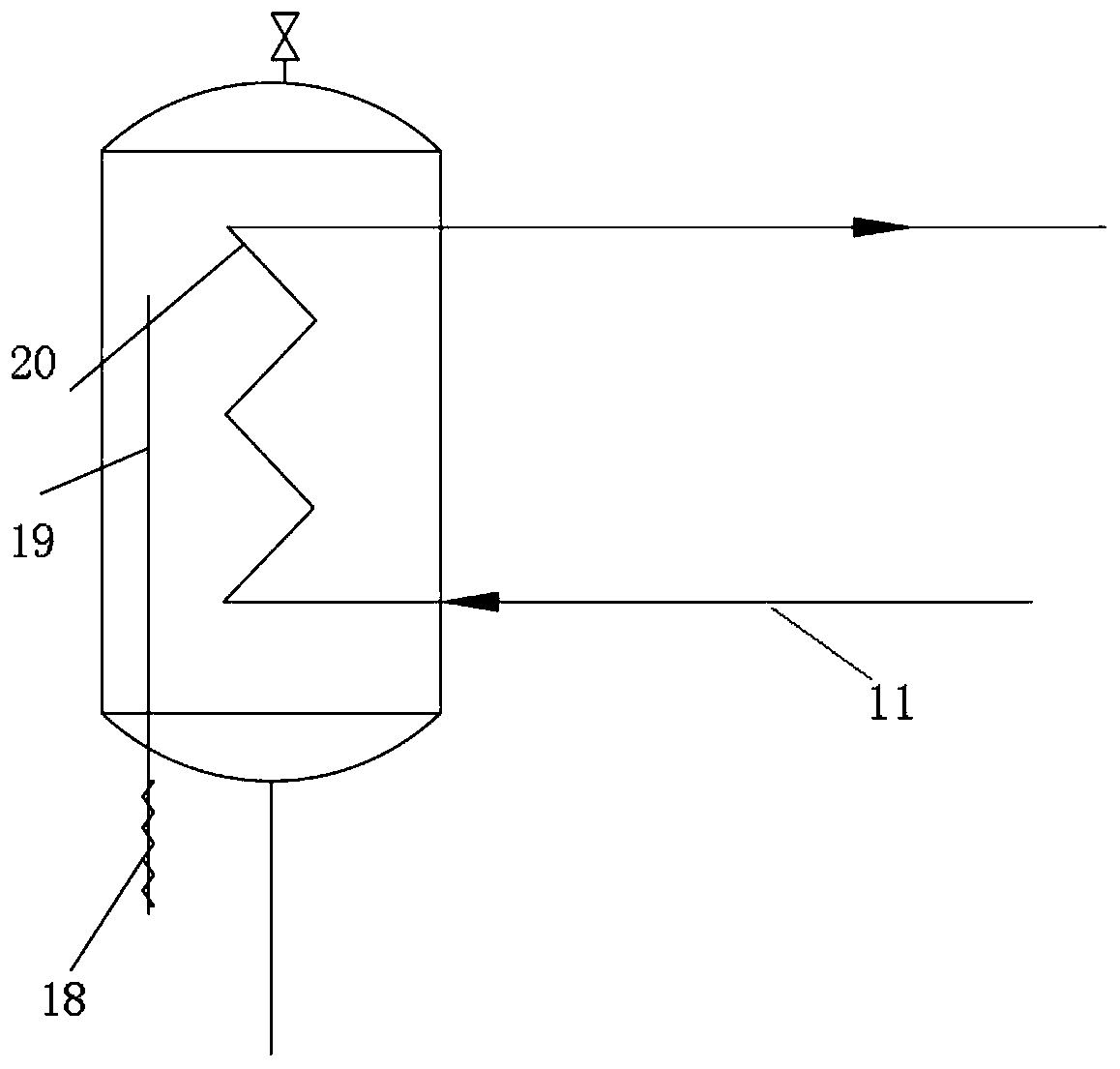

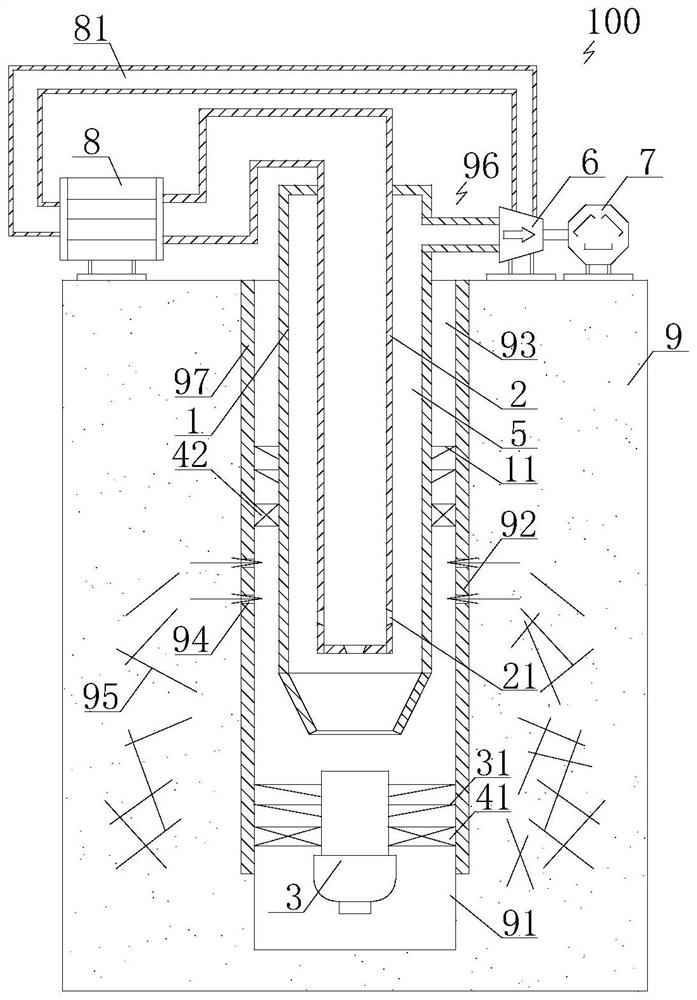

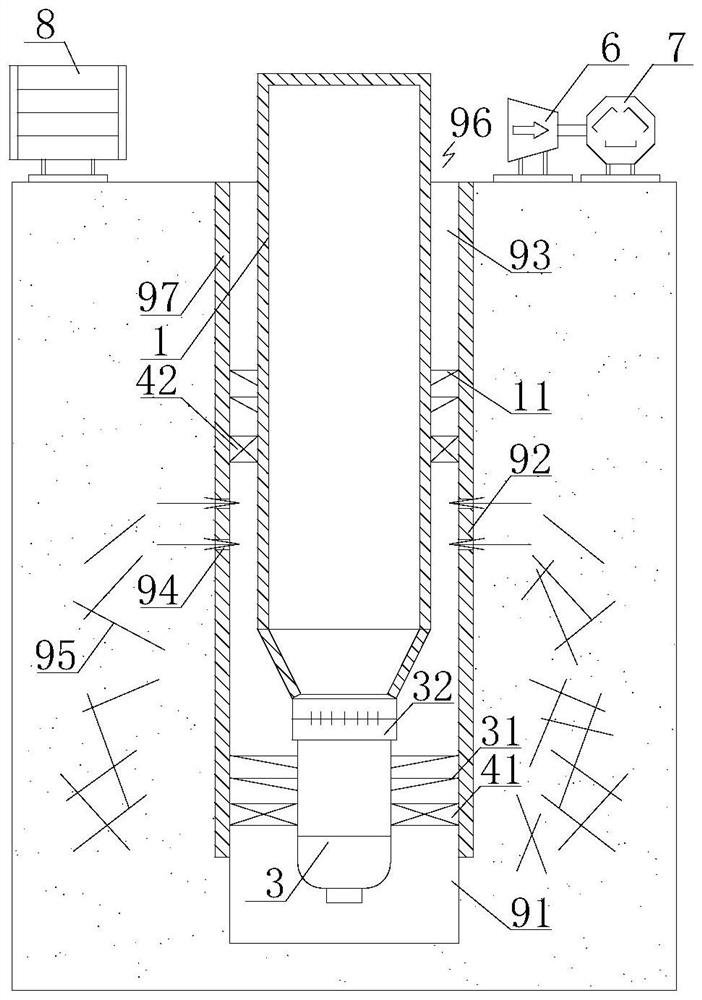

Method for achieving geothermal power generation through double-working-medium underground heat exchange and heat exchange production structure

PendingCN113882836AReduce dissipationLower working fluid temperatureGeothermal energy generationFluid removalThermodynamicsHeat energy

The invention discloses a method for achieving geothermal power generation through double-working-medium underground heat exchange and a heat exchange production structure. The method comprises the following steps that an open hole section, a perforation section and a well section annulus are formed in a well from bottom to top; an electric submersible pump and a first packer are put into a geothermal production well through a production pipe column, and the open hole section and the perforation section are sealed and separated through the first packer in a setting mode; the production pipe column is separated from the electric submersible pump, and a second packer on the production pipe column sets and packs the perforation section and the well section annulus; a heat removal working medium injection pipe column is put down into the production pipe column, and high-pressure gas is injected into the annulus of the pipe column to replace accumulated liquid in the pipe column in a reverse circulation mode; the electric submersible pump is started to circulate geothermal fluid of a stratum, meanwhile, a liquid heat removal working medium, a gaseous heat removal working medium and the geothermal fluid are injected into the heat removal working medium injection pipe column to complete double-working-medium heat exchange at the well bottom, heat energy of the geothermal fluid is converted into heat removal working medium pressure energy, and the gaseous heat removal working medium is output from a well opening; and when the wellhead stably generates the gaseous heat removal working medium, the wellhead is switched to a turbine to drive a generator set to generate power.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Air Conditioner system

InactiveCN101377341AImprove job stabilityReduce current loadEnergy recovery in ventilation and heatingLighting and heating apparatusCurrent loadPower flow

The invention discloses an air-conditioning system, which comprises a refrigeration device which is provided with a compressor, wherein, a heat recovery heat exchanger used to absorb heat of condensation released from the refrigeration device is arranged at the compressor of the refrigeration device; the heat recovery heat exchanger is provided with a water inlet and a water outlet. Therefore, through supplying tap water to the heat recover heat exchanger to absorb the heat of condensation released by the working medium in the refrigeration device, the heat exchange efficiency is improved, the temperature of the working medium after heat exchange is low, the load of the refrigeration device is too low, thus the working stability of the air-conditioning system is improved, the current load of the air-conditioning system is lowered, and the service life is prolonged.

Owner:赵福龙

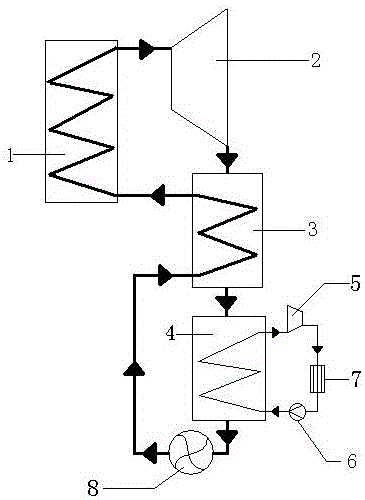

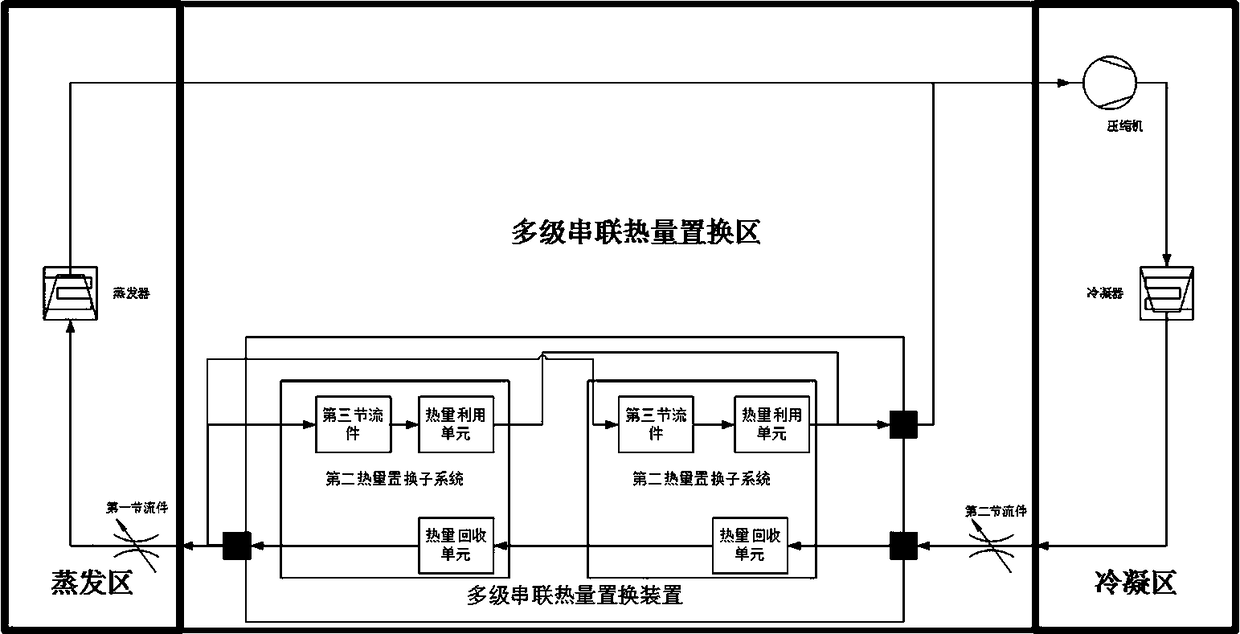

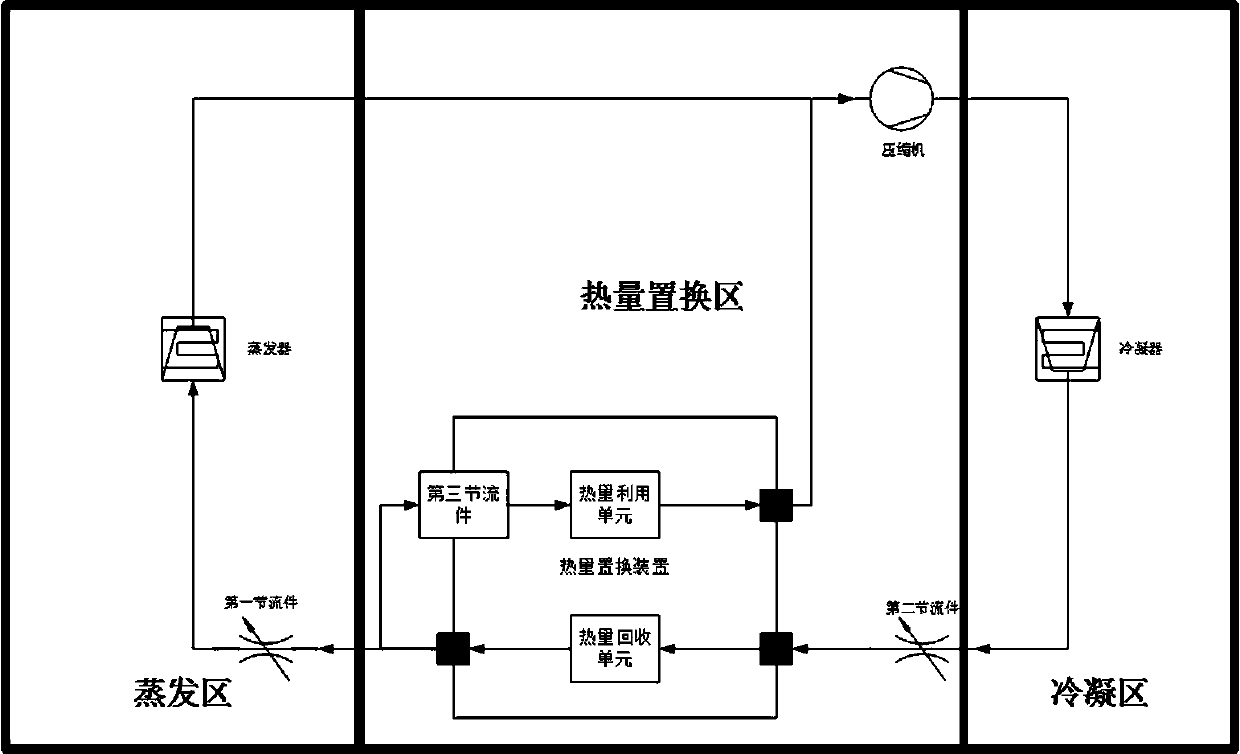

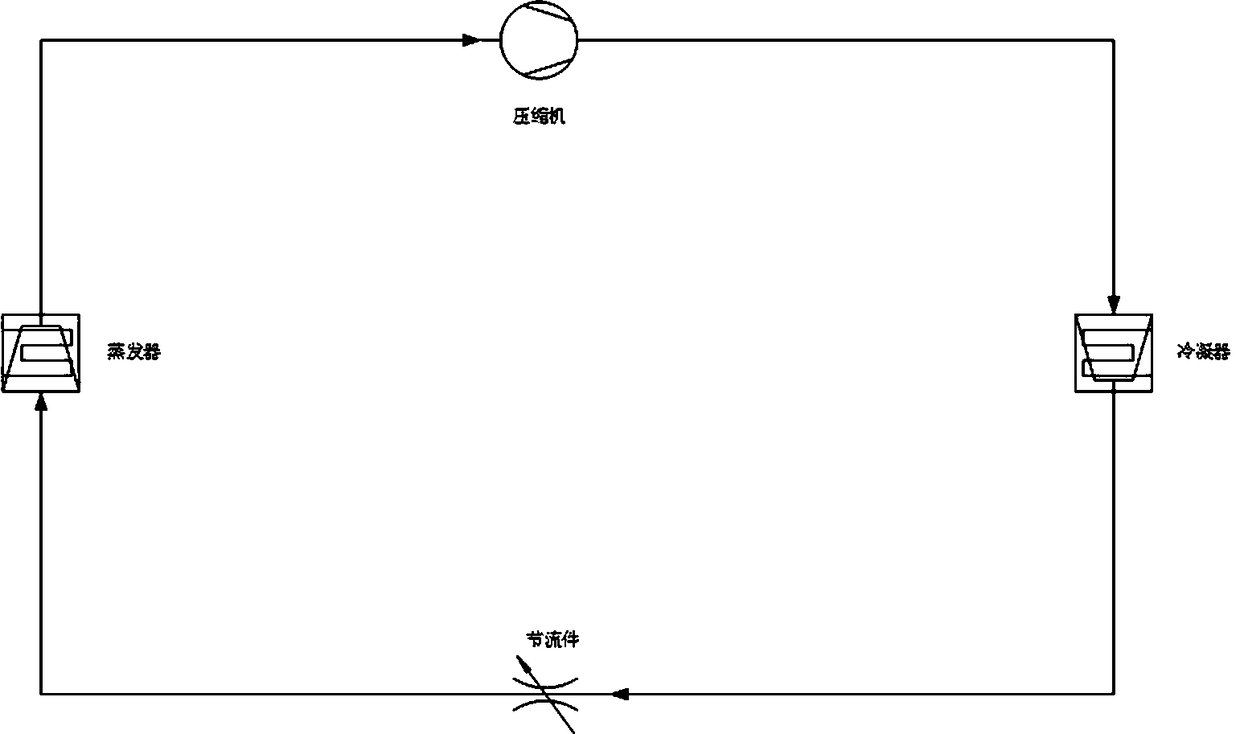

A multi-stage series displacement heat exchange system

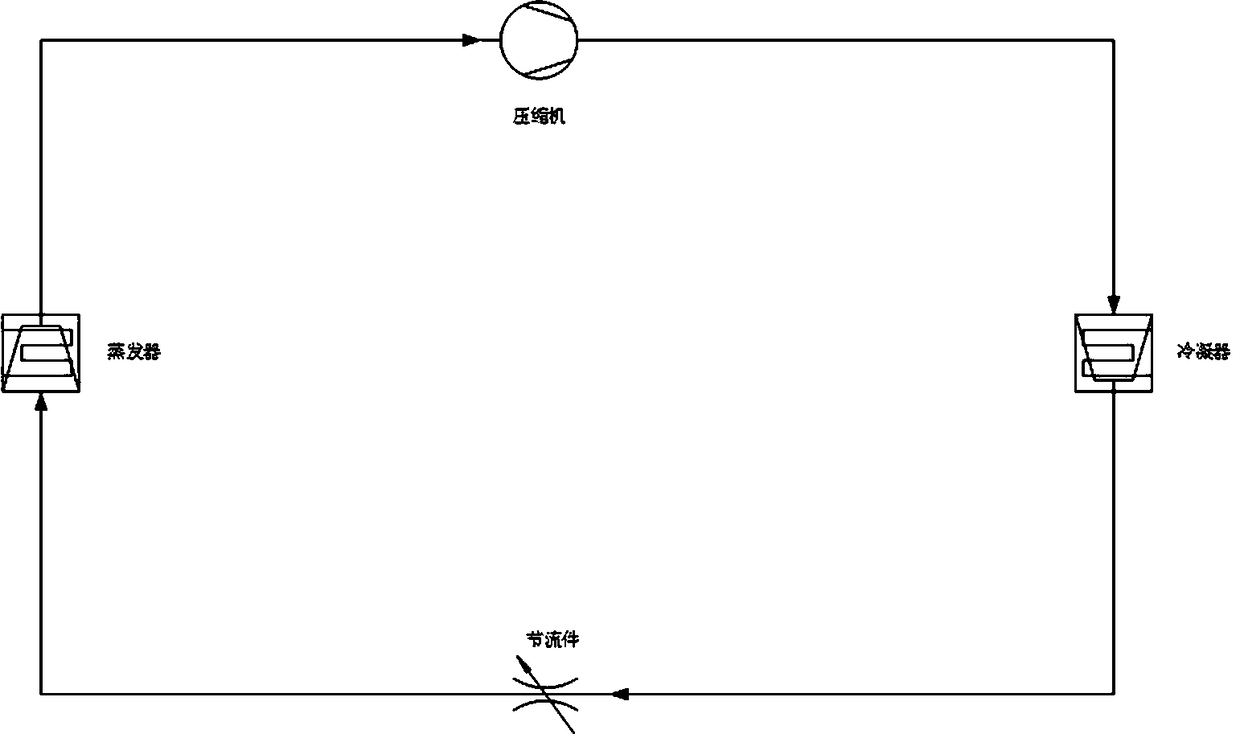

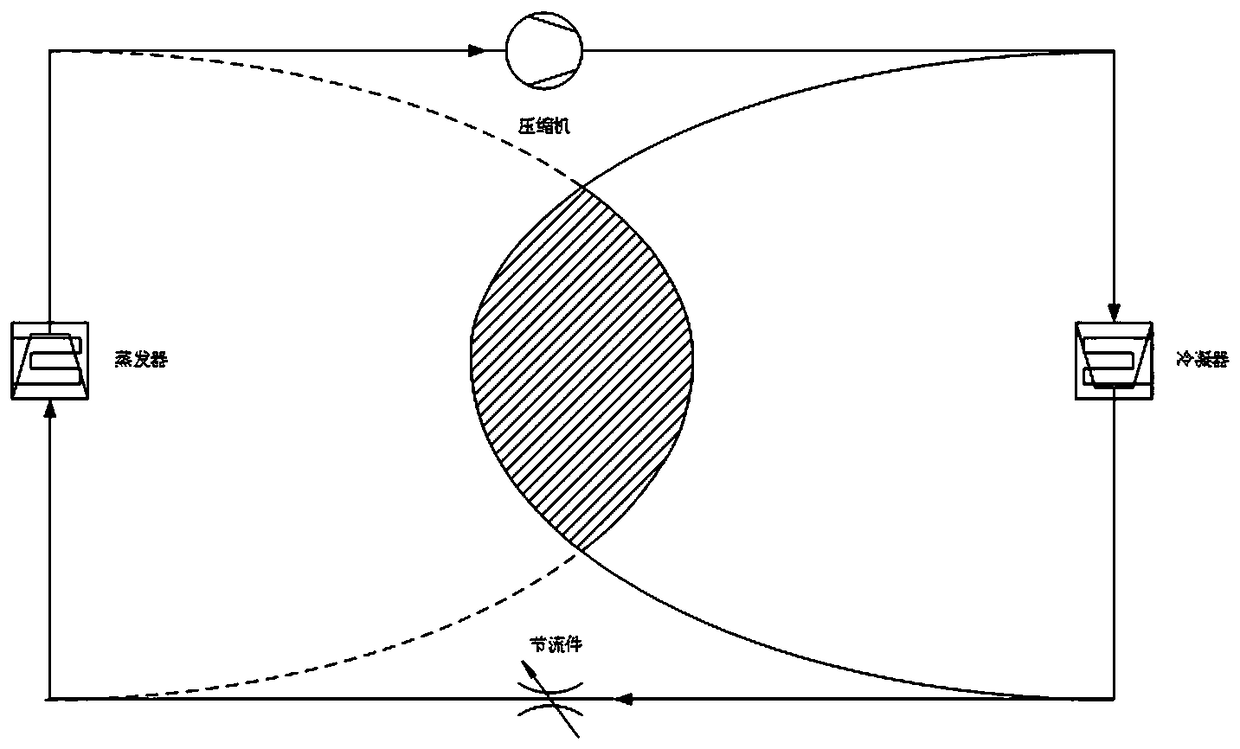

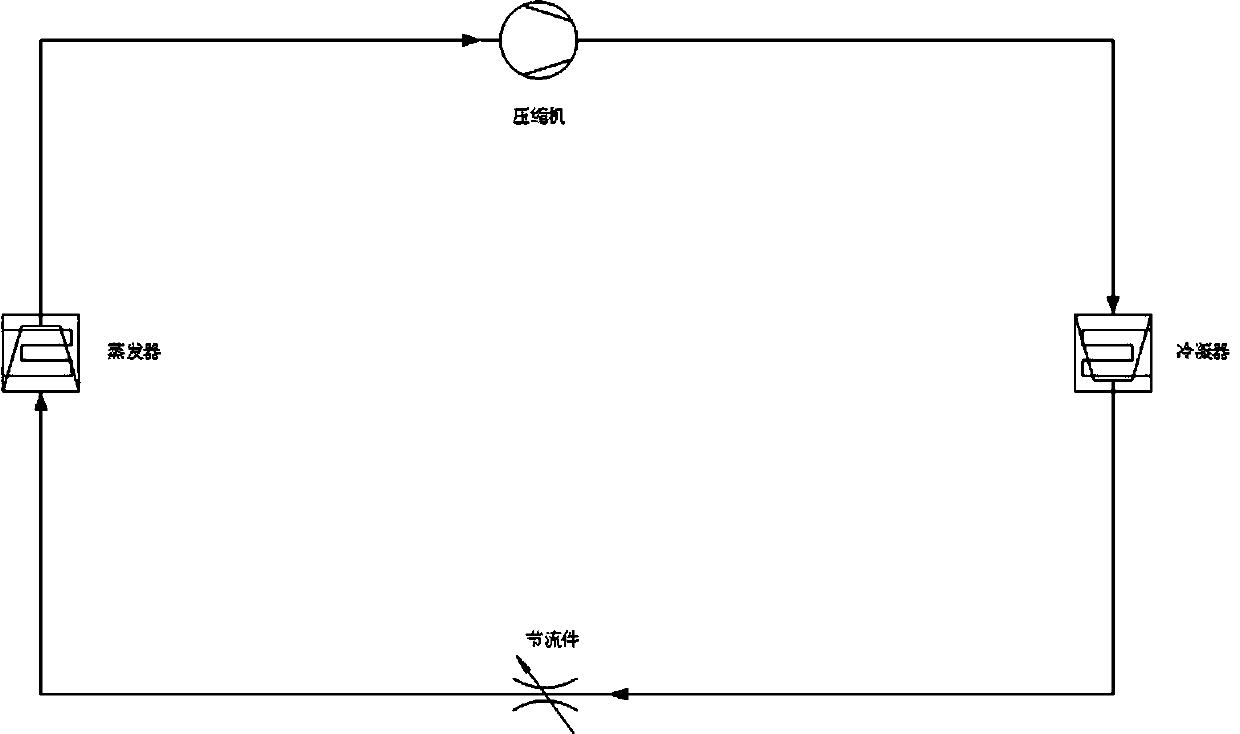

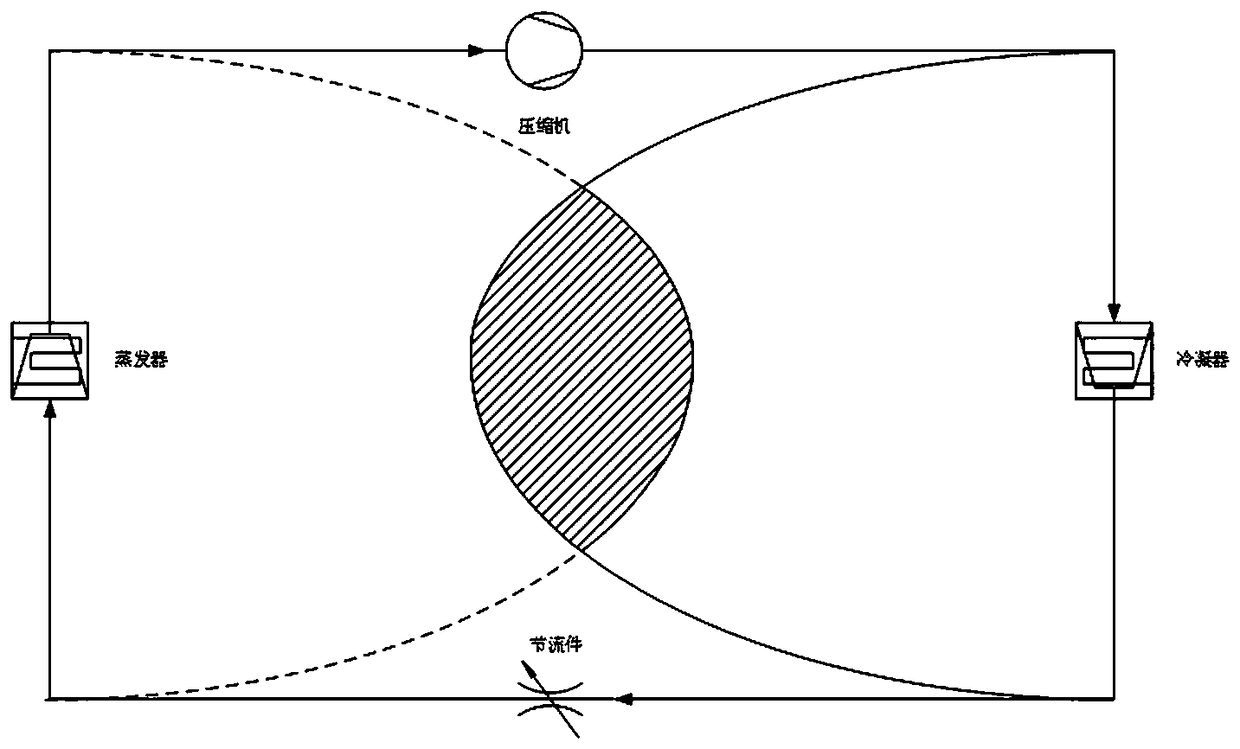

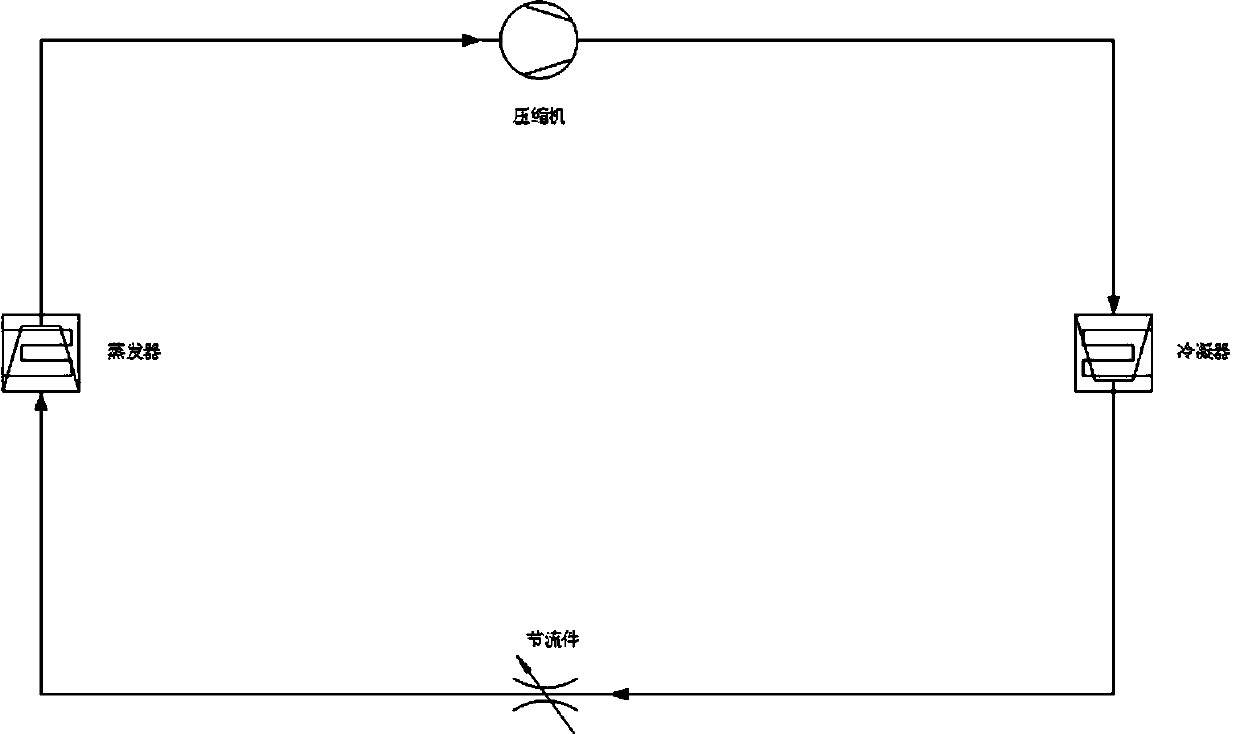

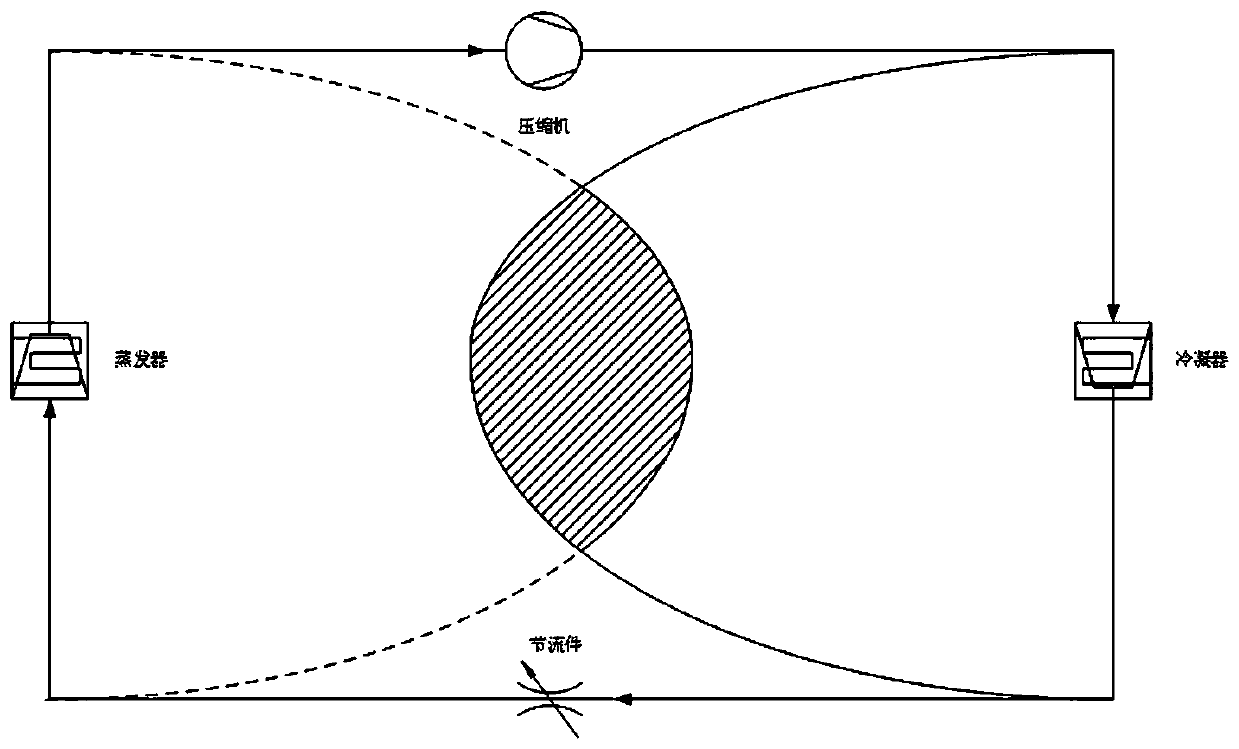

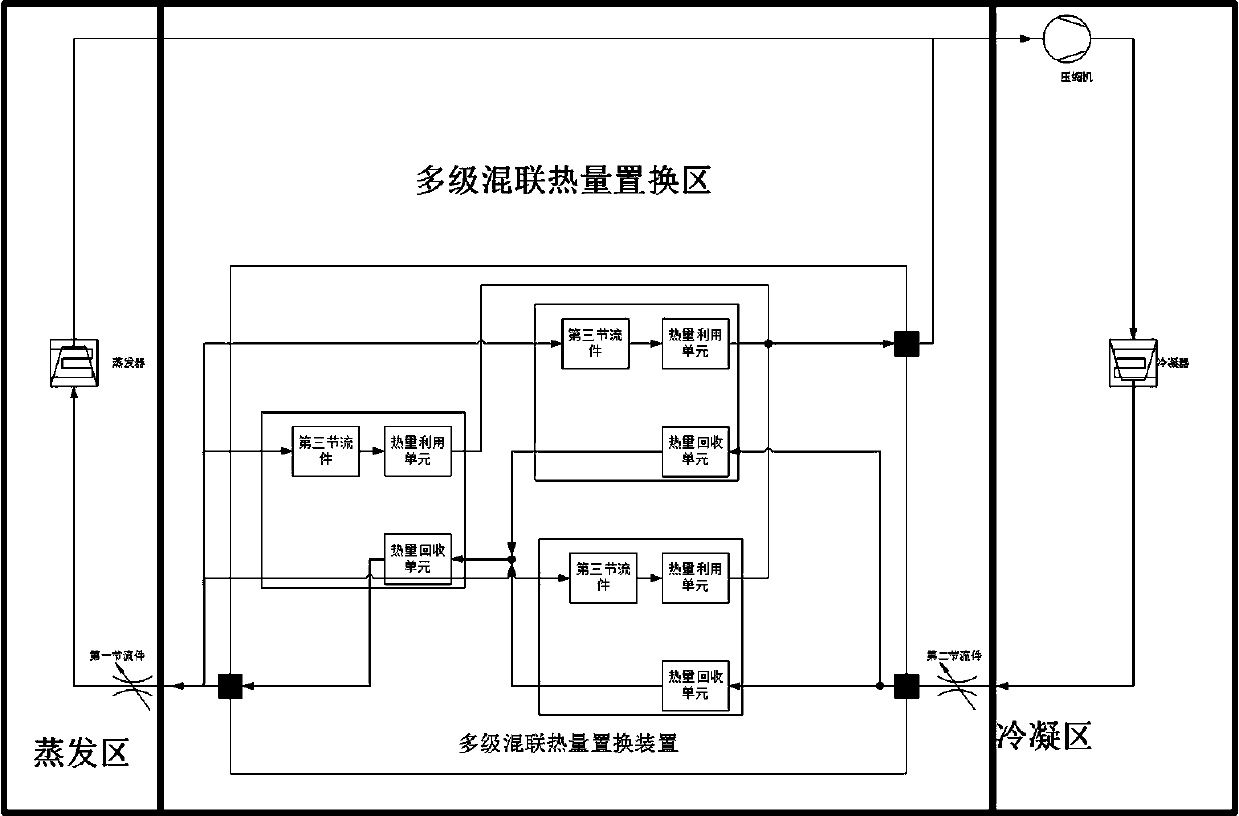

ActiveCN105928231BImprove energy efficiencyDestroying the Evaporation SceneMechanical apparatusCompression machines with non-reversible cycleWorking fluidEngineering

The invention relates to the technical field of heat exchange, in particular to a multi-stage series displacement heat exchange system. It includes an evaporator, a compressor, a condenser, and a first throttling member connected through a working fluid channel; the outlet of the evaporator is connected to the inlet of the compressor, and the outlet of the compressor is connected to the condenser Inlet, the outlet of the condenser is connected to the inlet of the first throttle, and the outlet of the first throttle is connected to the inlet of the evaporator; it is characterized in that: the outlet of the condenser and the first A multi-stage series heat exchange area is arranged between the inlets of the throttling element. The multi-stage series heat replacement area established between the condenser and the first throttling member isolates the condensation area and the evaporation area of the system, and at the same time enhances condensation, isolates the influence of condensation waste heat on the evaporation area, making the system Energy efficiency is greatly improved.

Owner:浙江柿子新能源科技有限公司

Supercritical carbon dioxide coal-fired circulating fluidized bed boiler, power generation system and power generation method

ActiveCN108180470BGuaranteed uptimeHas emissionsFluidized bed combustionSteam engine plantsAir preheaterSuperheater

Owner:SOUTHEAST UNIV

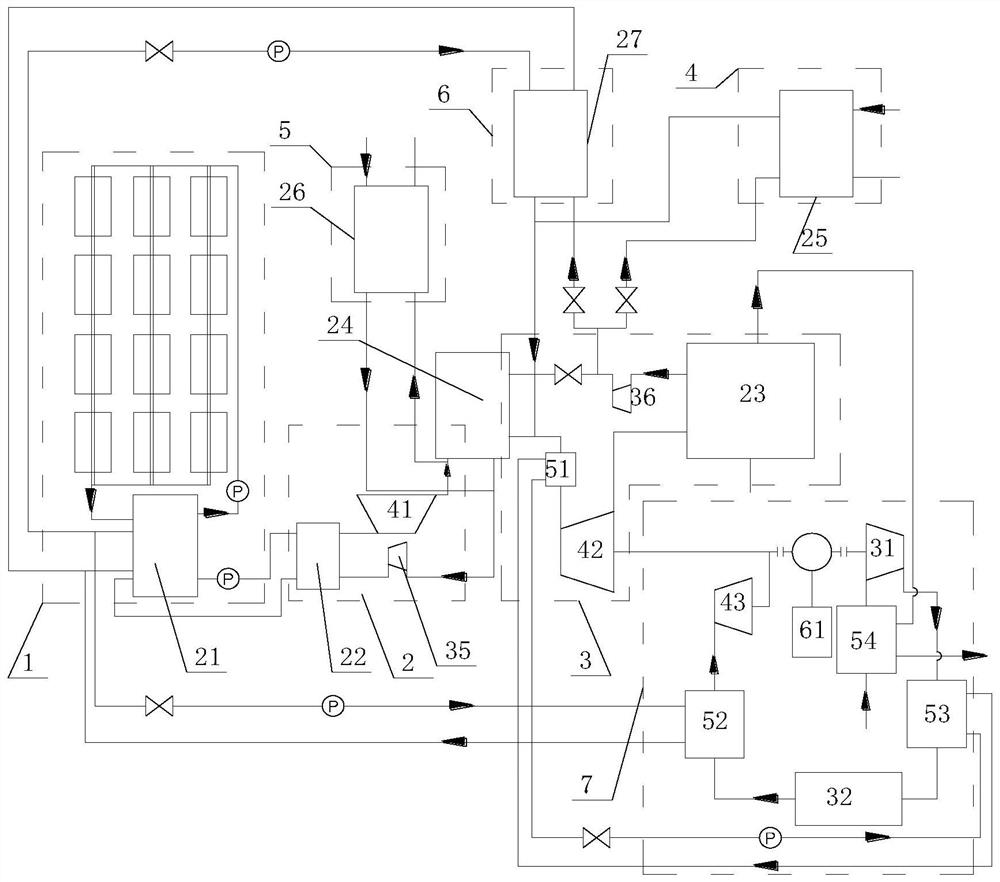

A method and device for combined supercritical power generation and energy storage coupled utilization of solar energy and natural gas cold energy

ActiveCN110985318BAchieving Demand ResponseStable power outputFrom solar energyEnergy storageEngineeringProcess engineering

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

A system that drives a liquid working medium to do work by vapor pressure

ActiveCN106437909BLower working fluid temperatureHigh thermal efficiencySteam engine plantsWorking fluidSteam pressure

Owner:镇江市恒利低温技术有限公司

Steam compression type refrigeration cycle device of approximate ideal inverse Carnot cycle efficiency

InactiveCN1304797CImprove cooling energy efficiencyLower working fluid temperatureCompression machines with non-reversible cycleCarnot cycleEngineering

The steam compressing refrigeration cycle device includes main cycle system comprising booster pump, condensator, expansion motor, evaporator and compressor connected successively with pipeline to output cold; and secondary cycle system comprising throttle connected across the inlet of the booster pump and the outlet of the condensator as well as the booster pump and the condensator, to further lower the temperature of the work medium in the outlet of the compressor. The expansion motor has its output torque rotating the booster pump and has isoentropic expansion to reduce the entropy of the work medium entering the condensator. The booster pump reduces the operation pressure difference and the power consumption of the compressor. Therefore, the present invention has energy efficiency near ideal inverse Carnot cycle and low hot load one compressor, and may be used widely in refrigeration cycle in air conditioner, refrigerator, etc.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

A heat pump drying system using industrial circulating water as heat source

ActiveCN105627702BFully extractedIncrease profitHeat pumpsHeat recovery systemsWater source heat pumpHeat conducting

The invention relates to a heat pump drying system adopting industrial circulating water as a heat source. The heat pump drying system comprises a drying case, a condenser, a compressor, an evaporator, a throttle and a fan, wherein the drying case is provided with an air inlet and an air outlet. The system further comprises a primary settling pond, a heat recovery pond and a settling pond, wherein a first heat conducting portion is arranged in the heat recovery pond, a second heat conducting portion is arranged in the evaporator, and the condenser is provided with a third heat conducting portion corresponding to the air inlet. The inlet end of the compressor communicates with the outlet end of the first heat conducting portion, and the outlet end of the compressor communicates with the inlet end of the third heat conducting portion. The inlet end of the throttle communicates with the outlet end of the third heat conducting portion, and the outlet end of the throttle communicates with the inlet end of the second heat conducting portion. The outlet end of the second heat conducting portion communicates with the inlet end of the first heat conducting portion. The inlet end of the evaporator communicates with the air outlet, and the outlet end of the evaporator communicates with the air inlet. The heat pump drying system can reduce energy consumption, improve the energy utilization rate and reduce environment pollution.

Owner:QUANZHOU INST OF EQUIP MFG

a heat exchange system

ActiveCN105928240BImprove energy efficiencyAvoid destructionMechanical apparatusFluid circulation arrangementWorking fluidWaste heat

A heat exchange system, comprising an evaporator, a compressor, a condenser, and a first throttling member connected through a working fluid channel; the outlet of the evaporator is connected to the inlet of the compressor, and the outlet of the compressor connected to the inlet of the condenser, the outlet of the condenser is connected to the inlet of the first throttling member, and the outlet of the first throttling member is connected to the inlet of the evaporator; it is characterized in that: the condenser A heat replacement zone is provided between the outlet and the inlet of the first restrictor. The heat replacement area established between the condenser and the first throttling member isolates the condensation area and the evaporation area of the system, while improving condensation, it also isolates the influence of condensation waste heat on the evaporation area, so that the energy efficiency of the system is greatly improved .

Owner:唐玉敏 +1

a condensation injector

ActiveCN104190572BRelieve pressureReduce the temperatureLiquid spraying apparatusEngineeringMixing chamber

The invention discloses a condensation ejector which comprises an accepting chamber, a throat chamber, a mixing chamber, a dispersion chamber, a condensing chamber and an atomizing mechanism, wherein the accepting chamber is provided with a first inlet and a second inlet; one end of the throat chamber is communicated with the accepting chamber, and the throat chamber is located on the down stream of the second inlet; one end of the mixing chamber is communicated with the other end of the throat chamber, one end of the dispersion chamber is communicated with the other end of the mixing chamber, and a first outlet is formed in the other end of the dispersion chamber; the condensing chamber is arranged close to the outer side of the down stream of the mixing chamber in a surrounding mode and comprises a third inlet formed in the down stream end of the condensing chamber, a second outlet formed in the upstream of the condensing chamber, a plurality of main condensing pipes and a plurality of branch condensing pipes, one end of each of the condensing pipes extends into the mixing chamber, the extending directions of the branch condensing pipes are different, the other end of each of the branch condensing pipes is communicated with a main condensing pipe, one end of the main condensing pipe is sealed, and the other end of the main condensing pipe is communicated with the dispersion chamber through a fourth inlet in the dispersion chamber; the atomizing mechanism is provided with a plurality of nozzles formed in the position of the fourth inlet, and the atomizing mechanism is used for atomizing fluid in the main condensing pipe and spraying the fluid in the dispersion chamber.

Owner:广西海岛生态投资有限公司

A Simple Cycle Gas Turbine Based on Rotating Detonation Combustion

ActiveCN107120189BImprove cycle thermal efficiencyOvercoming the problem of excessive entropy increaseContinuous combustion chamberTurbine/propulsion engine coolingDetonationPower capability

The invention provides a simple cyclical gas turbine based on rotary detonation combustion. The simple cyclical gas turbine based on the rotary detonation combustion comprises a gas compressor, a rotary detonation combustion room, a thermojet priming tube, an ejector, a mixing set, a turbine, a load and a cold source. The rotary detonation combustion room is applied to the simple cyclical gas turbine, and the mixing set is added at the tail part of the combustion room to ensure that working medium at an inlet of the turbine does not overheat. Through utilizing the pressurizing characteristic of the rotary detonation combustion room, the power capability of the working medium at an inlet of the turbine is improved, and under the conditions that the temperature, the efficiency of assembly unit, the pressure ratio of the gas compressor are uniform, the circulation heat efficiency of the gas turbine is improved 5%-10%.

Owner:HARBIN ENG UNIV

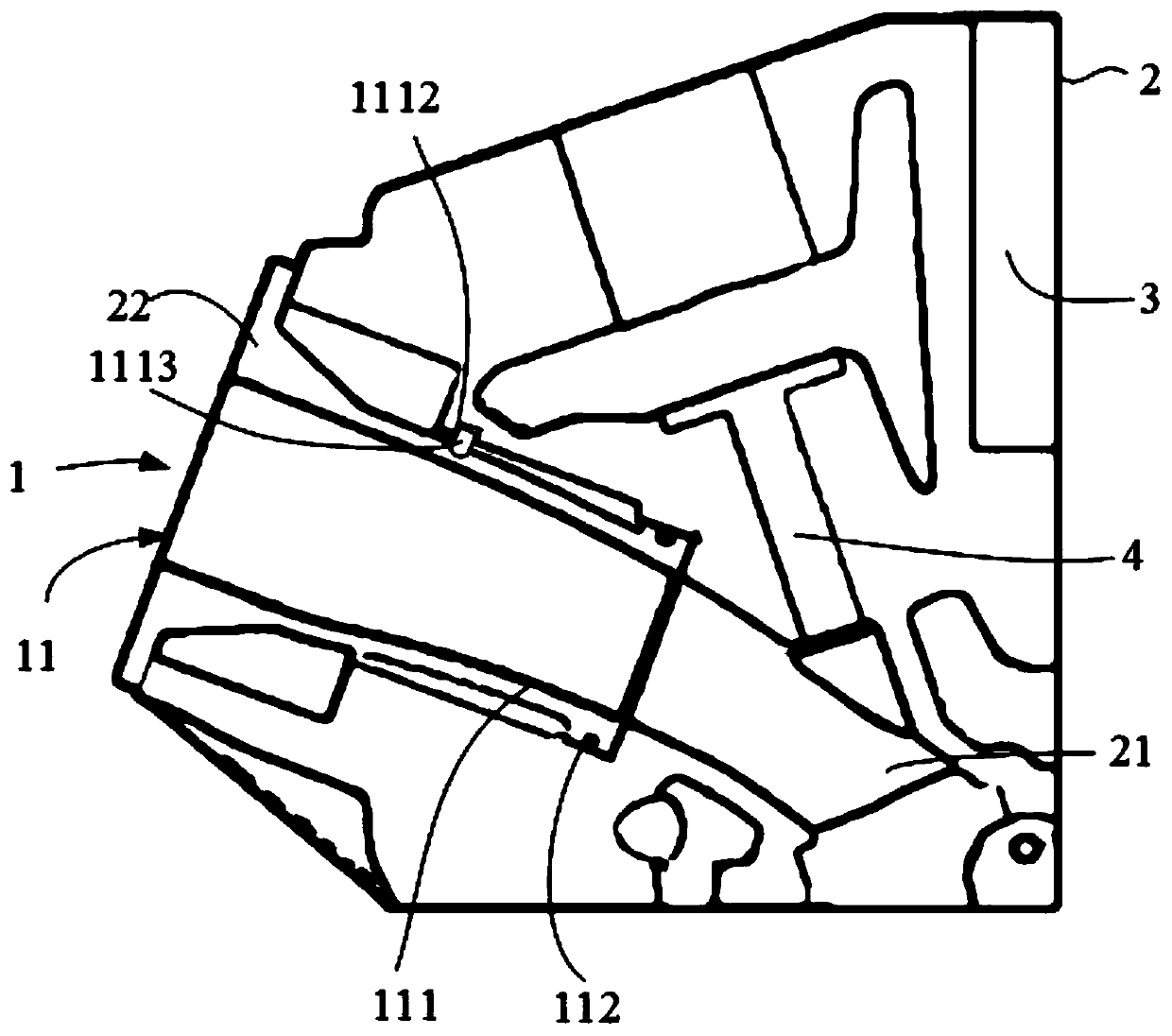

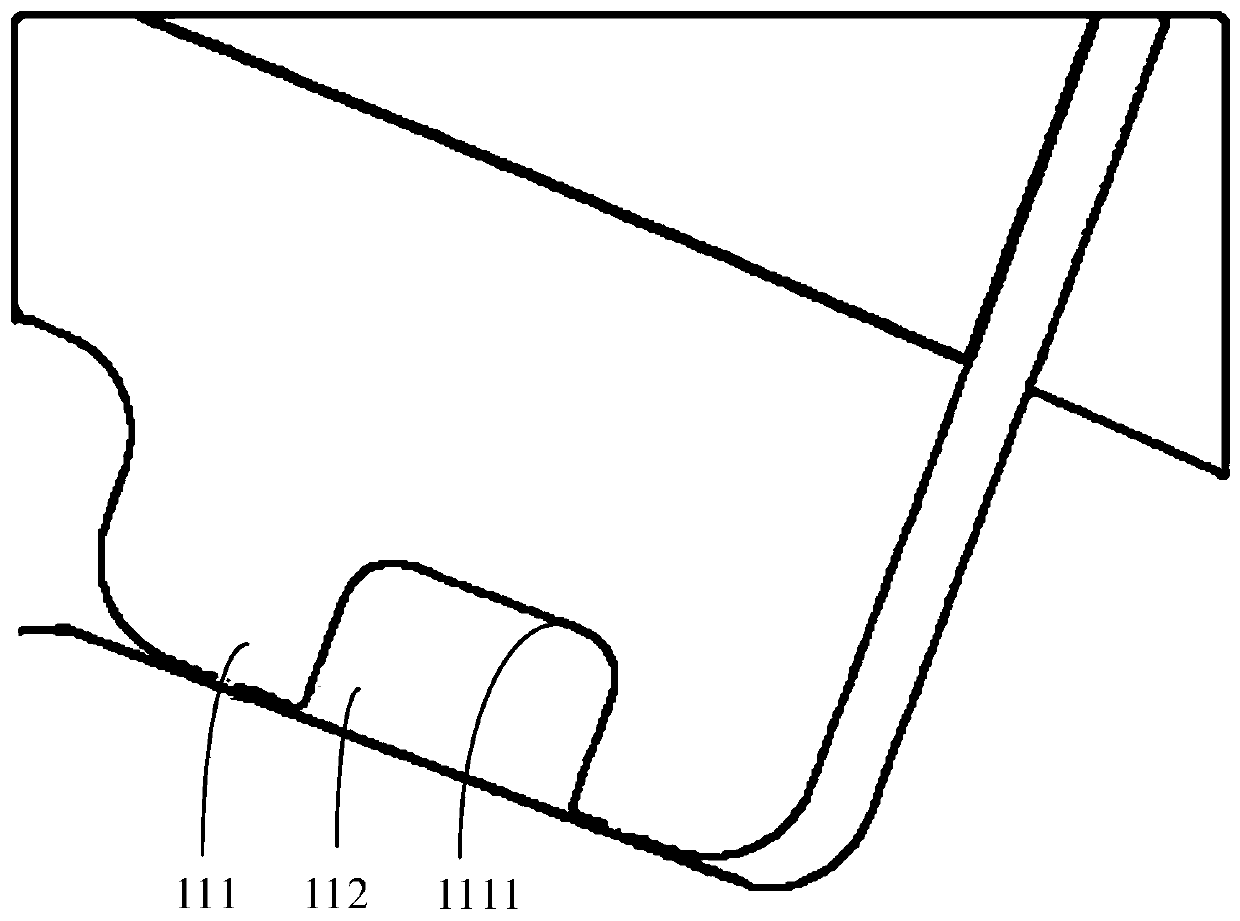

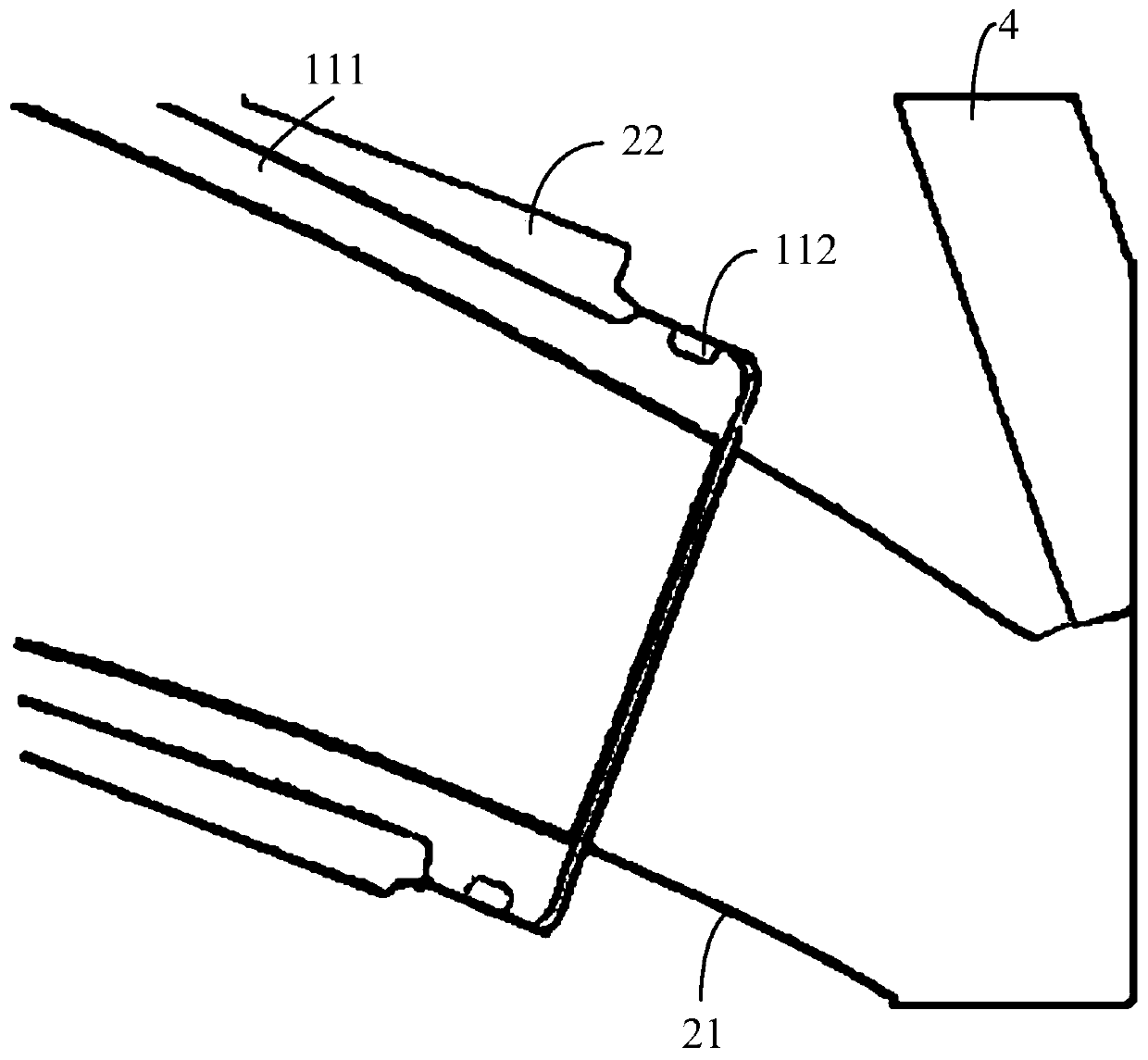

Air intake system of engine

InactiveCN110594057AImprove volumetric efficiencyLower initial temperatureCombustion-air/fuel-air treatmentMachines/enginesRam-air intakeEngineering

The invention discloses an air intake system of an engine. The air intake system of the engine comprises an air intake manifold and an air cylinder cover, wherein the air intake manifold comprises aninternal insertion air channel and an air intake manifold body, a first end of the internal insertion air channel communicates with an air outlet of the air intake manifold body, a second end of the internal insertion air channel is inserted in an air intake channel of the air cylinder cover, the internal insertion air channel is made of a material with low heat conductivity coefficient, and the air intake manifold body is fixed on the outer wall of the air cylinder cover. The internal insertion air channel with low heat conductivity coefficient is used as one part of the air intake channel ofthe air cylinder cover of the engine, as the heat conductivity coefficient of the internal insertion air channel, the heating effect of the air intake channel of the air cylinder cover of the engineon air can be reduced, and the volume coefficient of the engine can be enhanced.

Owner:CHERY AUTOMOBILE CO LTD

A Transcritical CO2 Heat Pump Air Conditioning System

ActiveCN104990169BImprove reliabilityRealize the cooling effectFluid heatersMechanical apparatusCold airFour-way valve

The invention relates to a transcritical CO2 heat pump air-conditioning system, including a compressor, a four-way valve, a hot water air cooler, a throttling component, an indoor cold air heat exchanger, an outdoor air-cooled heat exchanger and a liquid storage tank. The second port of the first three-way valve communicates with the second port of the second three-way valve to form a first common output port, and the third port of the first three-way valve communicates with the third port of the second three-way valve to form a second common output port ; The output end of the indoor cold air heat exchanger is connected to the first port of the first three-way valve, the output end of the outdoor air-cooled heat exchanger is connected to the first port of the second three-way valve, and the first common output end is connected to the compressor. The second common output end is connected with the liquid storage tank. In the system, two three-way valves are used instead of one four-way valve. In the conversion process of heating and cooling, only one three-way valve works independently each time. The problem of valve body leakage occurs, which improves the reliability of the transcritical CO2 heat pump air conditioning system.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

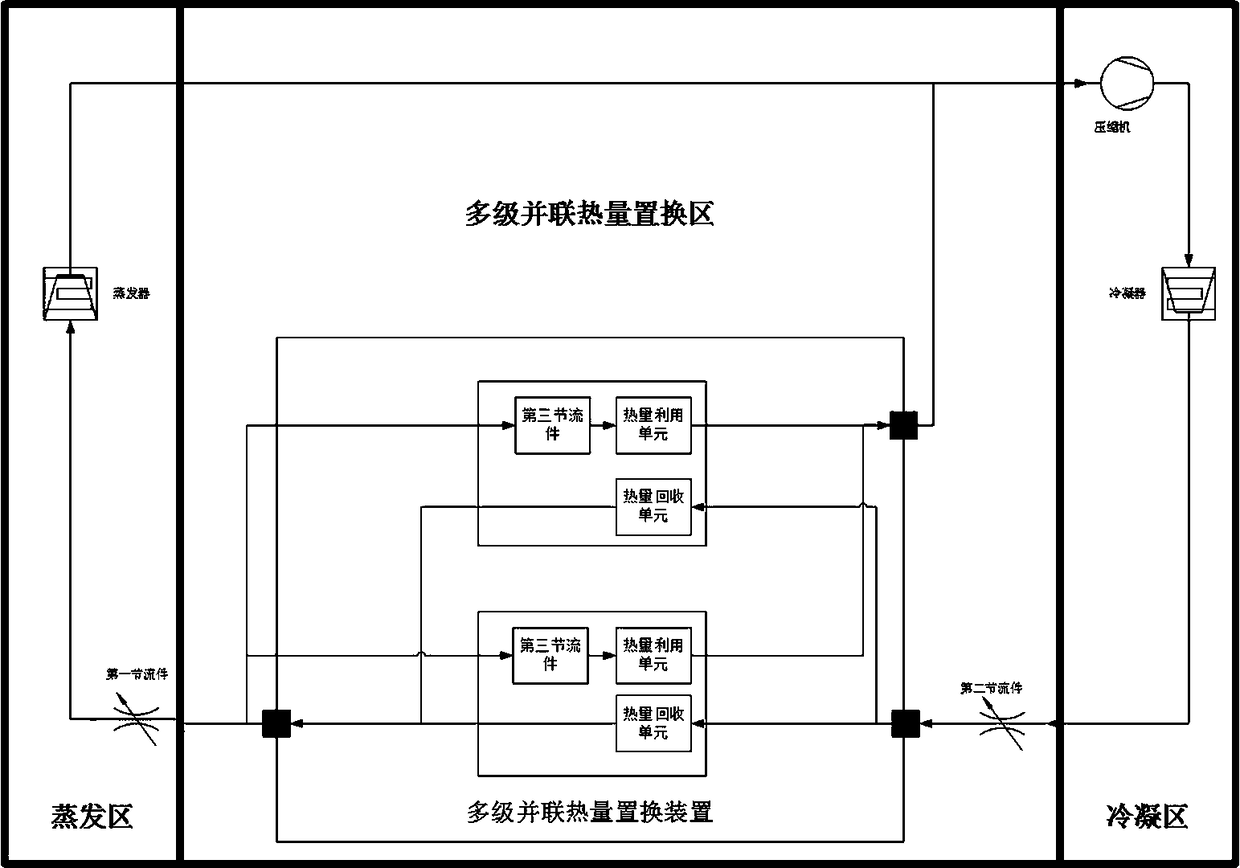

A multi-stage parallel displacement heat exchange system

ActiveCN105928267BImprove energy efficiencyDestroying the Evaporation SceneMechanical apparatusClimate change adaptationWorking fluidEngineering

The invention relates to the technical field of heat exchange, in particular to a multi-stage parallel displacement heat exchange system. It includes an evaporator, a compressor, a condenser, and a first throttling member connected through a working fluid channel; the outlet of the evaporator is connected to the inlet of the compressor, and the outlet of the compressor is connected to the condenser Inlet, the outlet of the condenser is connected to the inlet of the first throttle, and the outlet of the first throttle is connected to the inlet of the evaporator; it is characterized in that: the outlet of the condenser and the first A multi-stage parallel heat displacement zone is provided between the inlets of the throttling element. The multi-stage parallel heat replacement area established between the condenser and the first throttling member isolates the condensation area and the evaporation area of the system, and at the same time enhances condensation, isolates the influence of condensation waste heat on the evaporation area, making the system Energy efficiency is greatly improved.

Owner:唐玉敏 +1

Hot gas turbine

InactiveCN101761395AReasonable structural designLower working fluid temperatureTurbine/propulsion fuel supply systemsTurbine/propulsion engine coolingCold airCombustion chamber

The invention relates to a hot gas turbine, which belongs to the technical field of hot gas turbine structures. The hot gas turbine comprises a gas compressor, wherein the gas compressor is connected with driving equipment; rotor vanes and stator vanes are densely distributed in the gas compressor; the output end of the gas compressor is communicated with a cold air channel in which a fuel combustion chamber is arranged; the combustion chamber is provided with a fuel delivery device; the cold air channel is communicated with the hot gas turbine through a fuel gas and cold air mixed hot-gas pipeline; and a speed reducer is arranged between the hot gas turbine and the gas compressor and is connected with a load. The hot gas turbine has the characteristics of rational structural design, low cost, high heat efficiency and durability.

Owner:姜文岐

A multi-stage series series displacement heat exchange system

ActiveCN105928397BImprove energy efficiencyDestroying the Evaporation SceneMechanical apparatusEvaporators/condensersWorking fluidEngineering

The invention relates to the technical field of heat exchange, in particular to a multi-stage series series displacement heat exchange system. It includes an evaporator, a compressor, a condenser, and a first throttling member connected through a working fluid channel; the outlet of the evaporator is connected to the inlet of the compressor, and the outlet of the compressor is connected to the condenser Inlet, the outlet of the condenser is connected to the inlet of the first throttle, and the outlet of the first throttle is connected to the inlet of the evaporator; it is characterized in that: the outlet of the condenser and the first A multi-stage series connection heat displacement area is arranged between the inlets of the throttling parts. The multi-stage series heat replacement area established between the condenser and the first throttling member isolates the condensation area and the evaporation area of the system, and at the same time enhances condensation, isolates the influence of condensation waste heat on the evaporation area, making the system Energy efficiency is greatly improved.

Owner:陕西柿子元能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com