Patents

Literature

57results about How to "Lower initial temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comprehensive processing recycling process and device of bromine-contained high temperature flue gas

InactiveCN103292339ANo disposition problemAvoid de novo synthesisLighting and heating apparatusVapor condensationHigh concentrationCombustion chamber

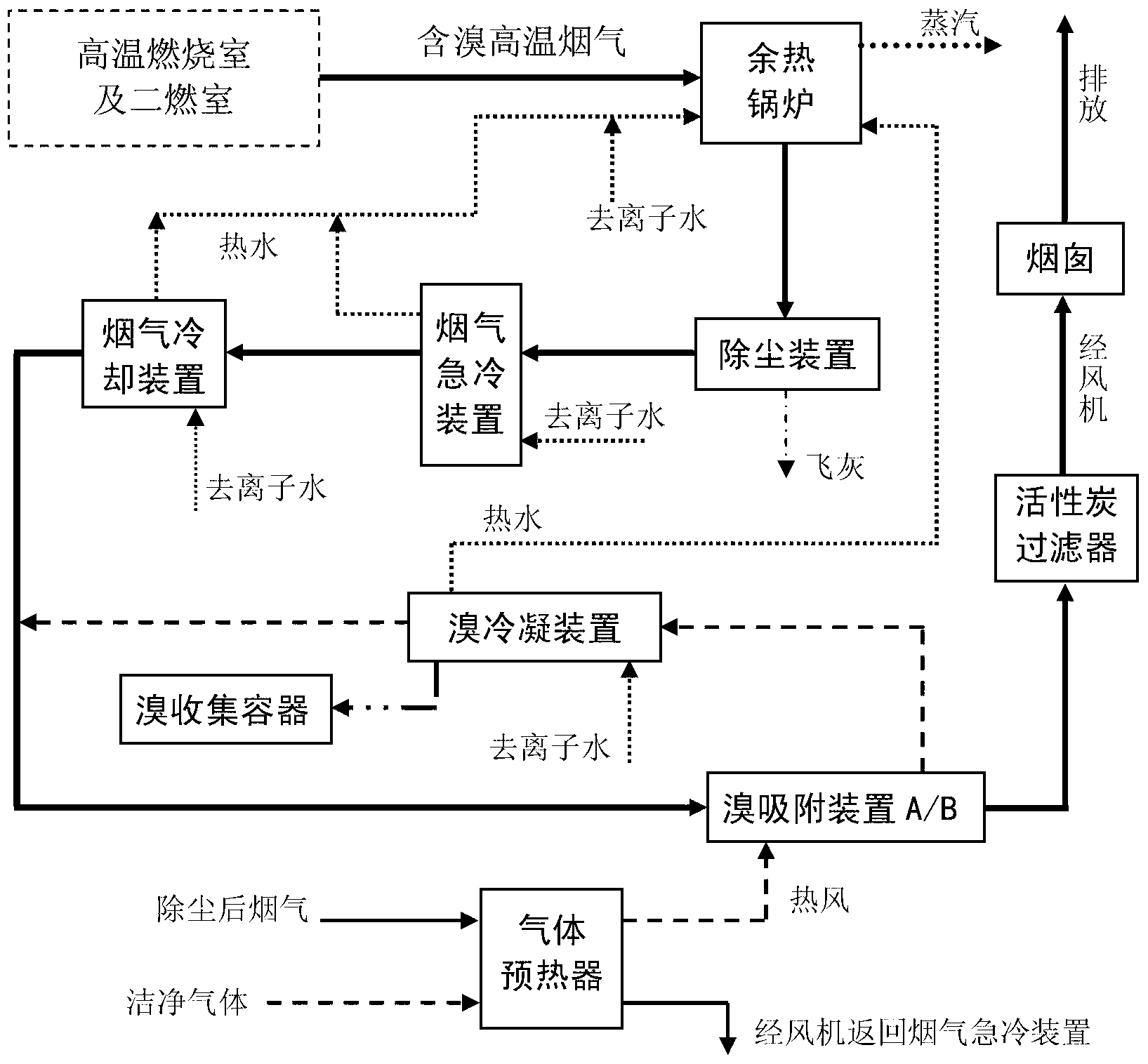

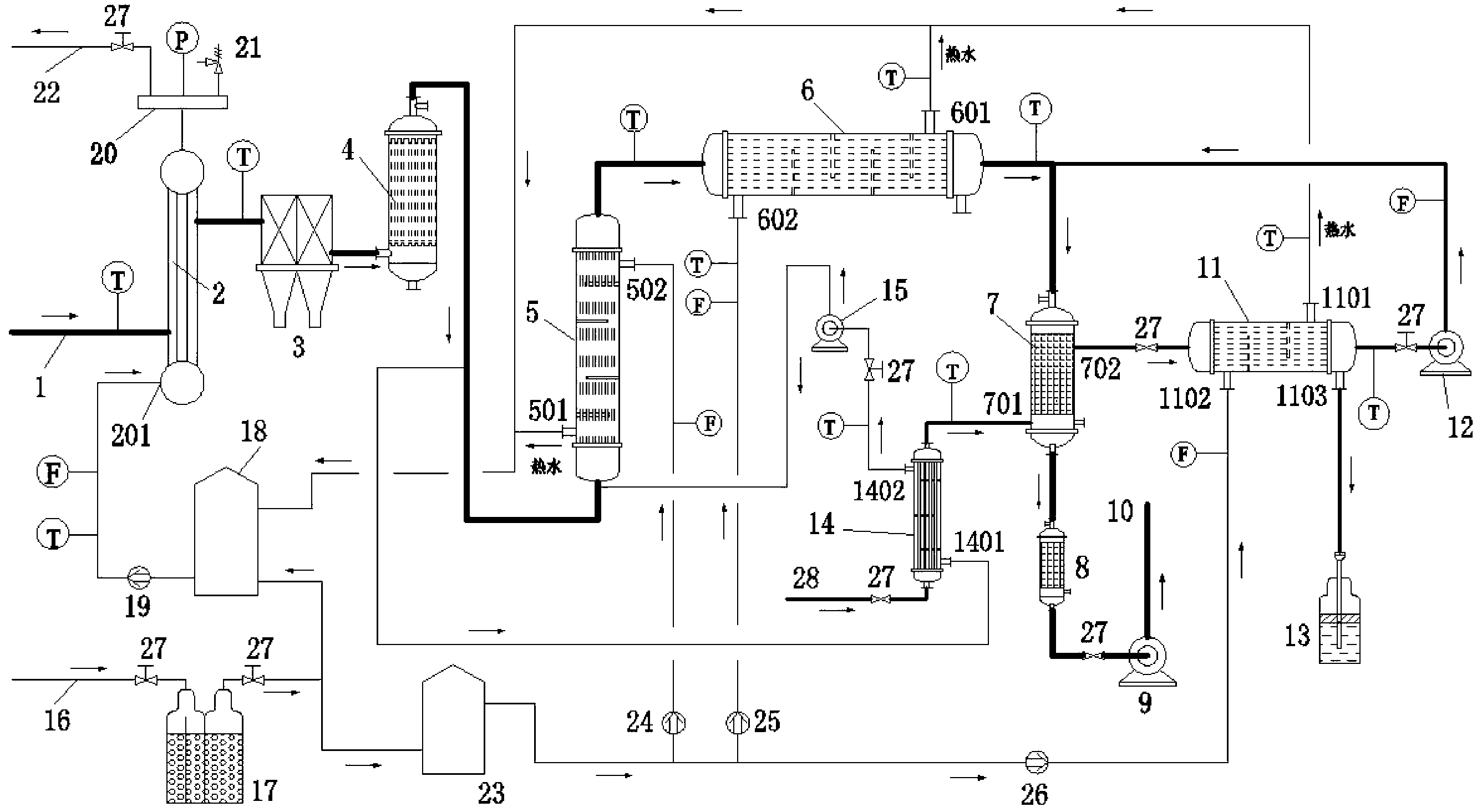

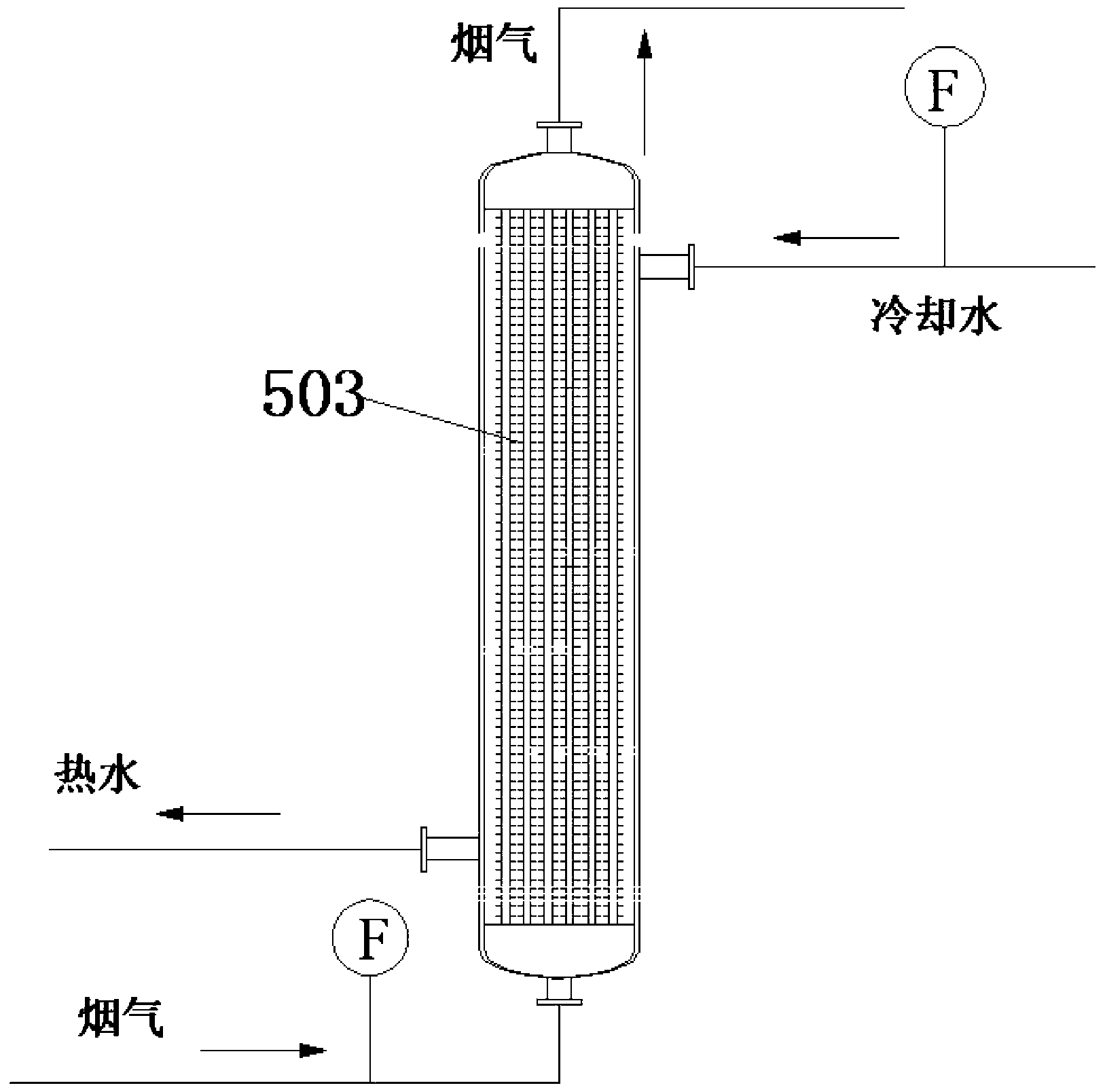

The invention discloses a comprehensive processing recycling process and device of bromine-contained high temperature flue gas. The comprehensive processing recycling process mainly includes the steps of enabling the high temperature flue gas coming from a high temperature combustor and a second combustor to enter a waste heat boiler for cooling, enabling steam generated by the waste heat boiler to be outwards supplied to users needing the stream for use, enabling the high temperature flue gas to enter a dust removal device so as to remove flying ash in the flue gas, enabling the high temperature flue gas to pass through a flue gas rapid cooling device so that the temperature of the flue gas can be reduced, enabling the flue gas to enter a flue gas cooling device, enabling the sufficiently-cooled flue gas to enter a bromine adsorption device, after the bromine adsorption device is saturated, adopting a small amount of hot air to regenerate adsorption media, enabling high-concentration bromine-contained gas generated by the regeneration to enter a bromine condensing device, enabling the cooled flue gas to be discharged by a chimney, and enabling condensed liquid bromine to be collected by a bromine recycling container which is connected with the bromine condensing device placed in an inclined mode. According to the comprehensive processing recycling process and device of the bromine-contained high temperature flue gas, inorganic bromine in the flue gas is recycled, meanwhile, new waste liquid or new waste residues are avoided, heat energy in the flue gas is recycled to the maximum degree, and the flue gas cooling process is controlled to regenerate dioxin without addition of new chemical reagents.

Owner:HUNAN UNIV OF SCI & TECH

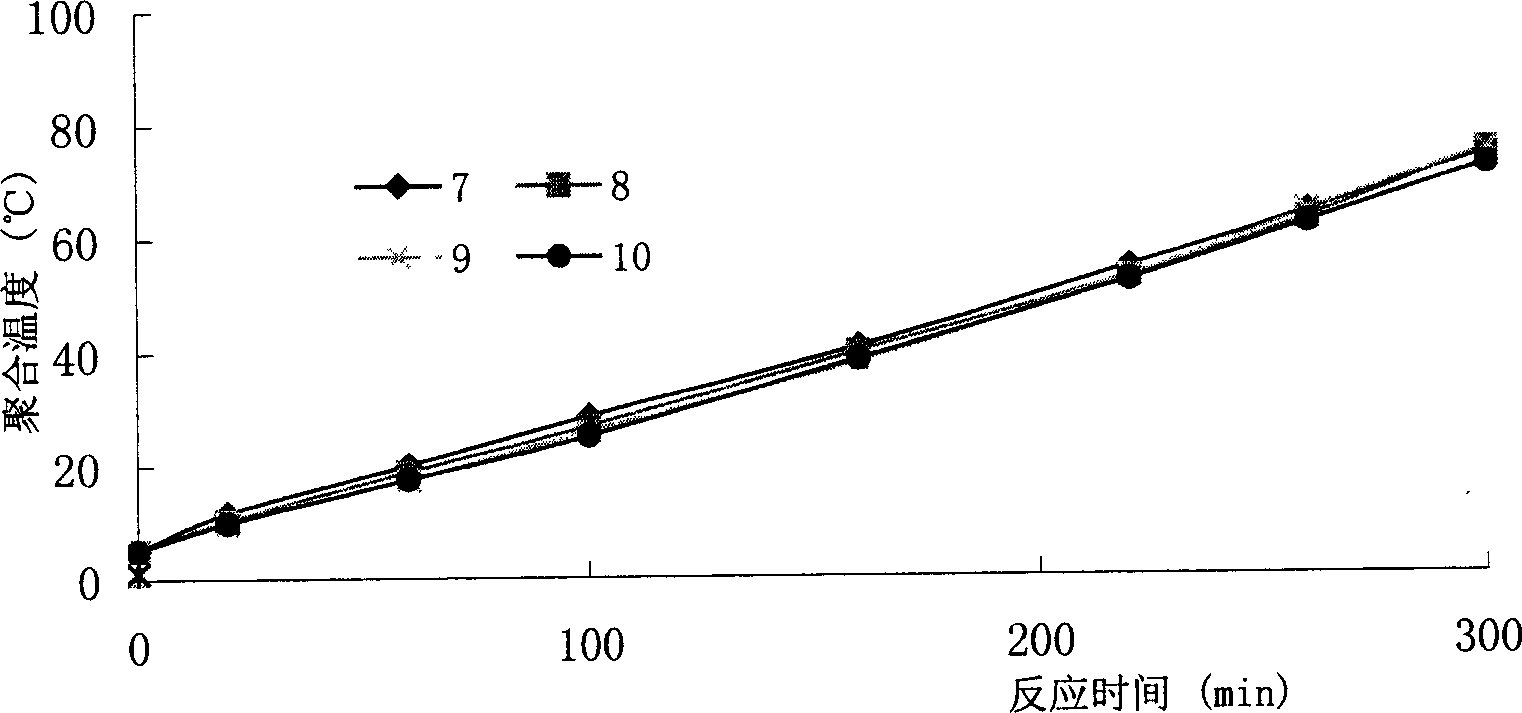

Trisegment composite initiator for synthesizing super high molecular weight polyacrylamide

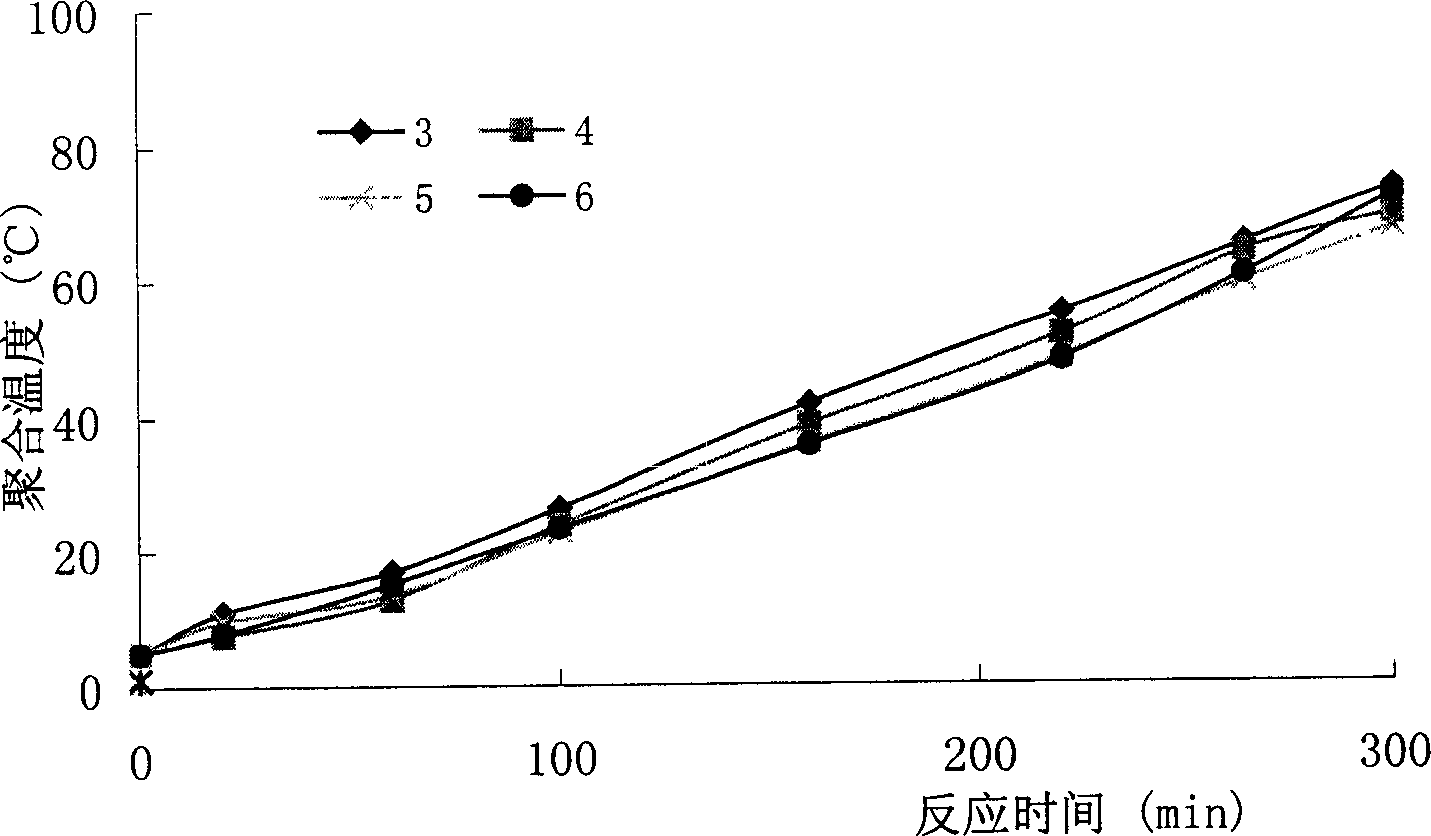

The invention discloses a three-segmented composite initiator of super-molecular weight polyacrylamide, which is characterized by the following: three-segmented initiator system is composed of reacting speed control agent, solutizer, one-segmented, two-segmented, three-segmented initiator according to certain proportioning; the polyacrylamide with over 25,000 thousand molecular weight can be synthesized stably in the industrial manufacturing, whose reacting speed can be controlled effectively.

Owner:PETROCHINA CO LTD

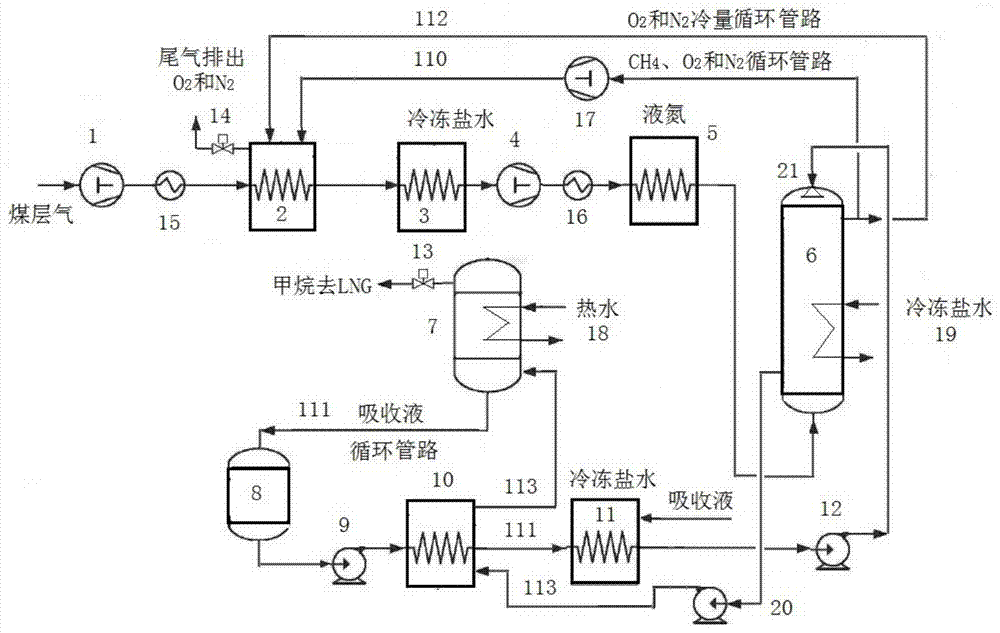

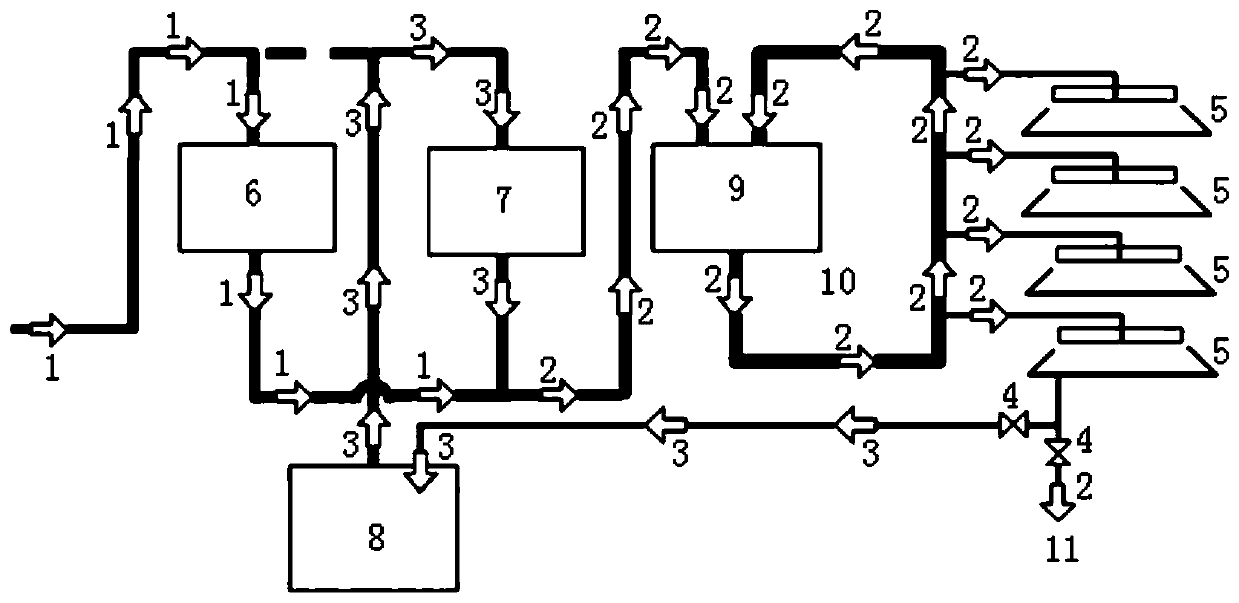

Preparation and energy recycling system of coal-bed gas hydrate

The invention provides a preparation and energy recycling system of coal-bed gas hydrate. The preparation and energy recycling system comprises a coal-bed gas booster pump, a refrigerant heat exchanger, a tail gas cooling capacity recycler, an un-reacted coal-bed gas cooling capacity recycler, a hydrate reactor, a hydrate decomposer, a saturated absorption liquid cooling capacity recycler, an absorption liquid circulating pump, and the like. A coal-bed gas is pressurized, cooled by saline water and liquid nitrogen through multiple steps; the coal-bed gas is ventilated from the bottom of the reactor to carry out countercurrent contact reaction with the adsorption liquid sprayed from the top of the reactor; saturated methane adsorption slurry is pumped into the decomposer by a discharging pump from the lower part of the reactor; the saturated absorption slurry carries out countercurrent indirect heat exchange with the absorption liquid entering the decomposer, and is re-pumped into the hydrate reactor after being cooled by the saline water; and methane discharged by the hydrate decomposer through a vent valve enters an LNG (liquefied natural gas) production system. Production cost of extracting methane from the coal-bed gas hydrate is greatly lowered by recycling the cooling capacity in the tail gas exhaustion gas, the cooling capacity in the un-reacted coal-bed gas, and cooling capacity in the statured absorption liquid.

Owner:ANHUI UNIV OF SCI & TECH

Method for cladding TiC enhanced Ni3Al based composite coating on surface of aluminum alloy

InactiveCN103233223AThe preparation process is stableIncrease productivityMetallic material coating processesLaser beam welding apparatusExothermic reactionAlloy surface

The invention relates to a method for cladding TiC enhanced Ni3Al based composite coating on the surface of aluminum alloy. The method comprises the following steps of: (1) cleaning the surface of aluminum alloy matrix metal and removing greasy dirt and an oxidation layer; (2) uniformly mixing a Ni-based material with TiC powder to serve as a coating material, wherein the weight content of the Ni element of the Ni-based material is over 75 percent; (3) forming a molten bath on the surface of the aluminum alloy matrix metal by using laser beams in an argon protection device; and (4) conveying the coating material into the molten bath to form metallurgical bonding with the aluminum alloy matrix metal, and performing chemical exothermic reaction between Ni and Al to form the TiC enhanced Ni3Al based composite coating. The method has the characteristics of stable preparation process, basic avoidance of sputtering or burning loss, high production efficiency and the like. The prepared TiC enhanced Ni3Al based composite coating cladded on the surface of aluminum alloy has the advantages of good surface quality, uniform TiC distribution and diffusion, tiny crystal particles, metallurgical bonding with the matrix, high wear resistance and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

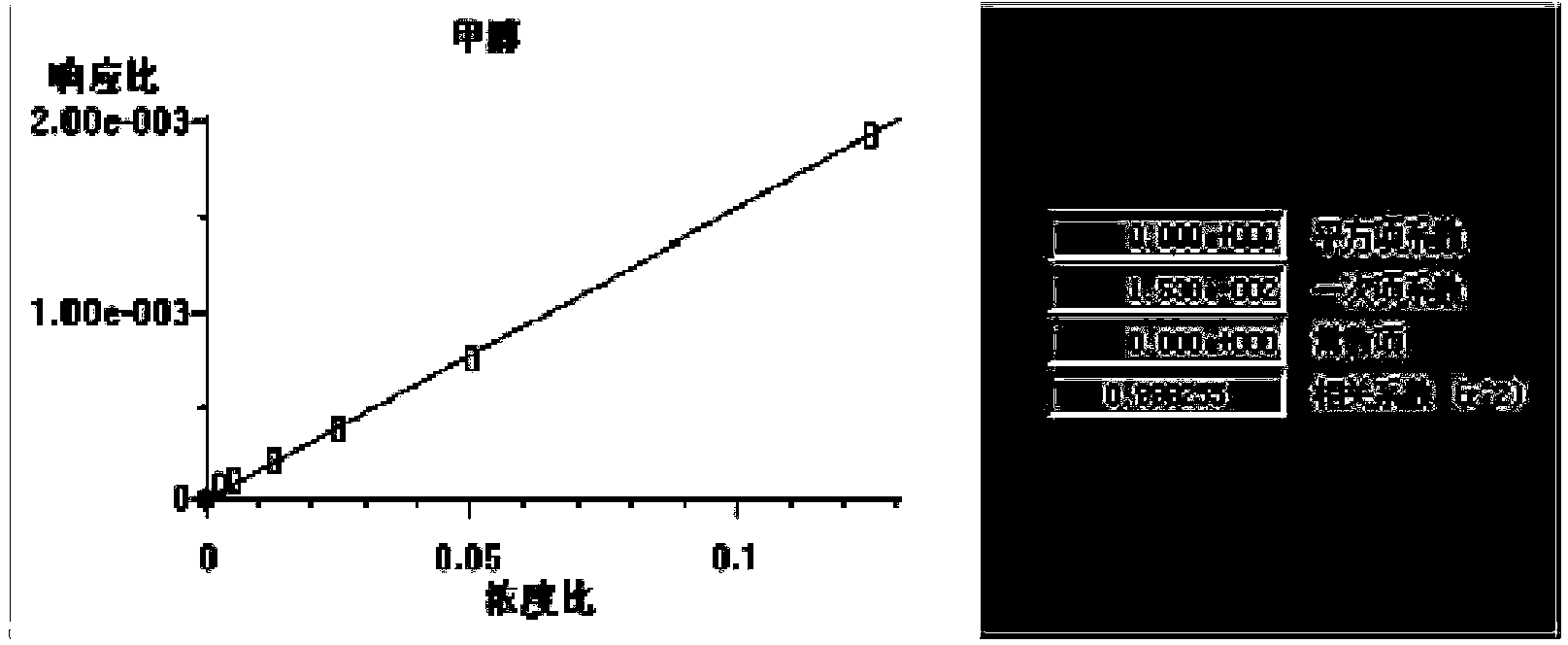

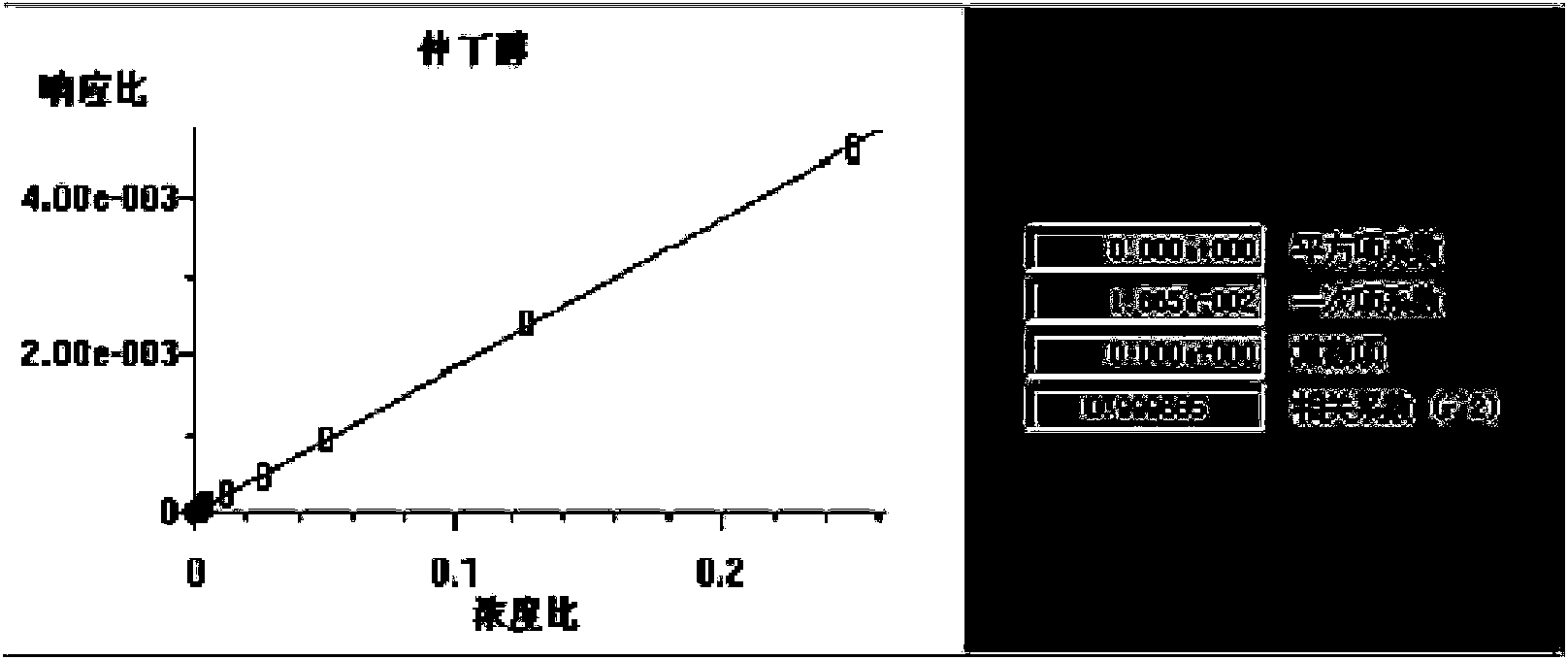

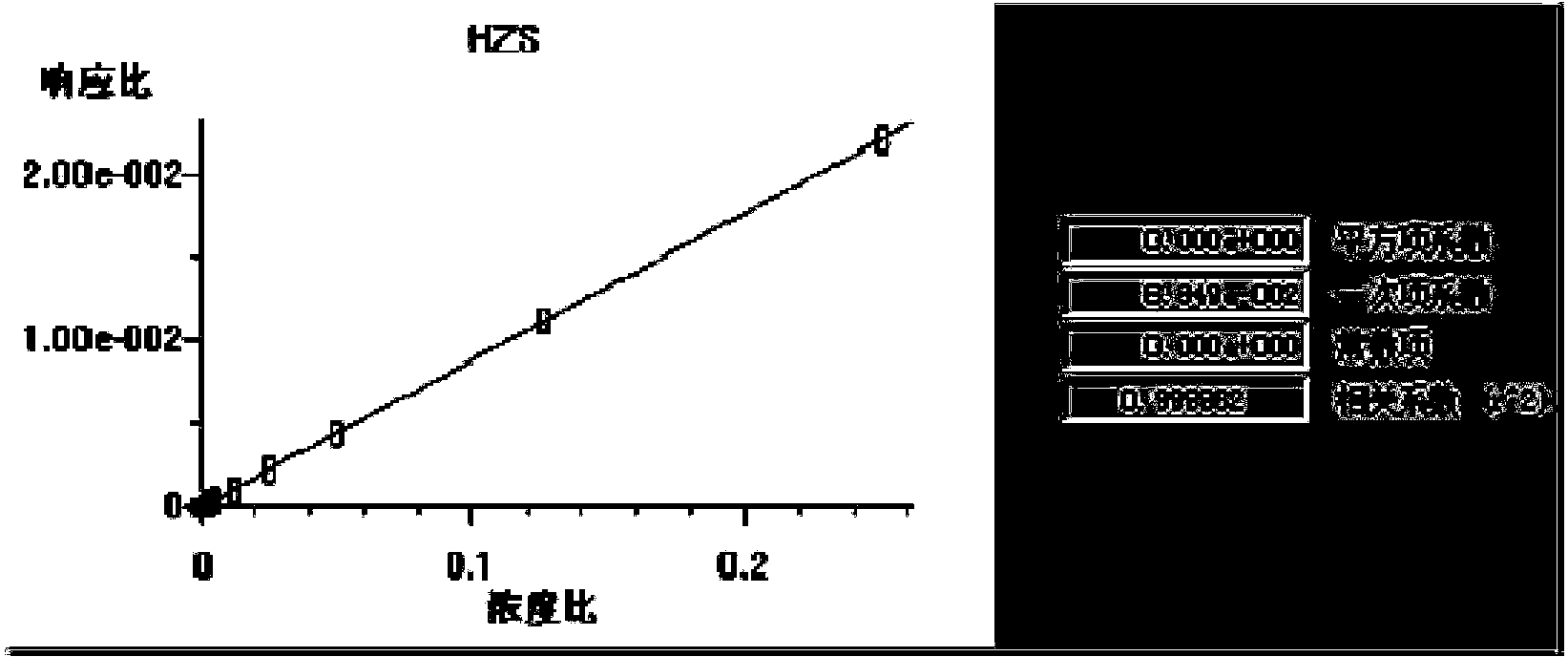

Method for detecting seven prohibited compounds in flavors and fragrances

ActiveCN103869039AEfficient detection methodModerate polarityComponent separationChemical industrySolvent

The invention discloses a method for detecting seven prohibited compounds in flavors and fragrances. The seven prohibited compounds are methanol, sec-butyl alcohol, safrole, imidazole, coumarin, musk xylene and sesamol. The detection method can accurately and rapidly detect the contents of the seven prohibited compounds in flavors and fragrances, is suitable for quality safety control of fragrance raw liquid and auxiliary solvents in the industries such as food, daily-use chemical industry, tobacco and pharmacy, and the has the characteristics of simple operation, rapidness, accuracy, good repeatability, high sensitivity and the like.

Owner:CHINA TOBACCO FUJIAN IND +1

Cryoablation apparatus and cryoablation method

ActiveCN109009406ALow temperature requirementNot prone to explosionCatheterSurgical instruments for coolingTemperature controlProcess engineering

The invention discloses a cryoablation apparatus and a cryoablation method, belonging to the technical field of cryoablation. The cryoablation apparatus includes a refrigeration capsule, a conduit, amedium storage tank, a medium supply pipeline, a medium recycling pipeline and a refrigeration assembly. The cryoablation method includes four steps: pre-refrigeration, ablation, recycling and rewarming. The cryoablation apparatus and the cryoablation method have the advantages of being low in the danger coefficient, being simple in operation, being convenient to use, being high in the cooling capacity utilization efficiency, and being accurate in temperature control at the same time.

Owner:PIEDMONT MEDSYST ZHUHAI CO LTD

Preparation method of red mud sinking agent

ActiveCN101735376AUniform temperature riseGood solubilitySludge treatment by de-watering/drying/thickeningIonUrea

The invention relates to a preparation method of a red mud sinking agent, which comprises the following steps of mixing acrylamide, acrylic acid and urea with deionized water in weight percent, cooling and regulating the pH value to end the material preparation; mixing the ingredients, chelating agent and chain transfer agent in a reaction kettle, sequentially adding a third section oxidant, a second section oxidant, a first section oxidant, a reducer and an auxiliary reducer in nitrogen introducing process, continuously introducing nitrogen, and than stopping nitrogen introduction, sealing, and carrying out insulation polymerization reaction; opening a reaction kettle bottom valve after being placed, pressing out a rubber block by compressed air and disintegrating the rubber block into colloidal particles by a granulator; and hydrolyzing the colloidal particles, and preparing a product through treatments of granulation, drying, crushing, screening and packaging. The aluminum oxide plant red mud sinking agent has the advantages of high molecular weight, fast dissolving speed, high hydrolysis degree and low cost.

Owner:安徽省天润功能高分子工程研究有限公司

Amorphous copper catalyst and preparation method and application thereof

ActiveCN101733130AImprove belt yieldLow costOrganic compound preparationAmino-carboxyl compound preparationDehydrogenationAlloy

The invention relates to an amorphous copper catalyst and a preparation method and application thereof. The preparation method comprises the following steps: heating copper, aluminum, and an alloy consisting of a transition metal M and aluminum to melt; rapidly cooling and curing the melts; and performing extraction treatment on the cured alloy by using alkali solution so as to extract most aluminum to obtain the catalyst. The catalyst prepared by the method has high catalytic activity and stability and excellent abrasion resistance, and can be applied to catalytic dehydrogenation oxidation reaction of diethanol amine.

Owner:CHINA PETROLEUM & CHEM CORP +1

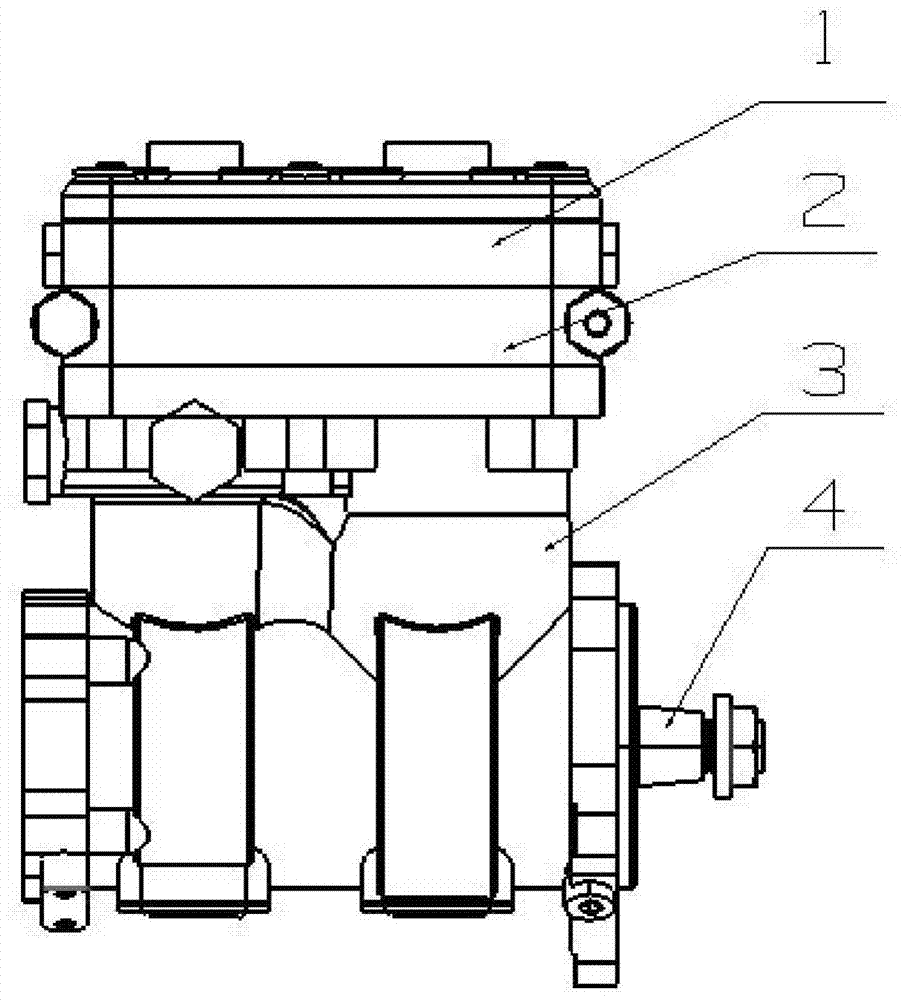

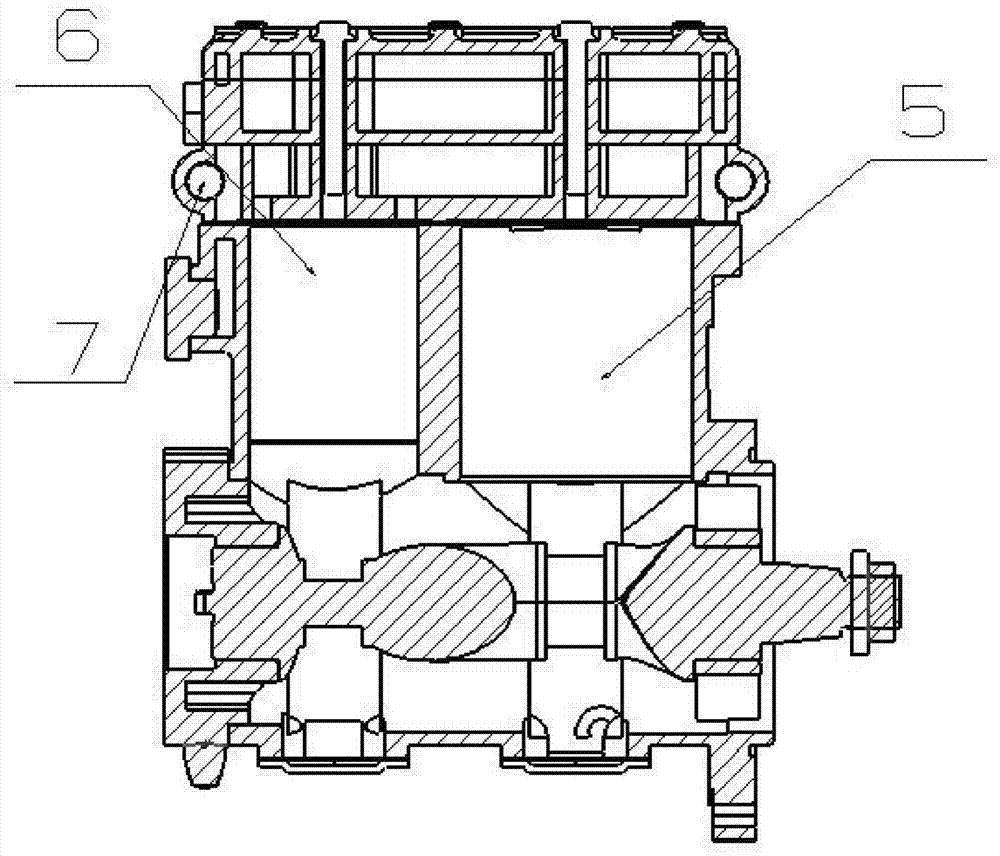

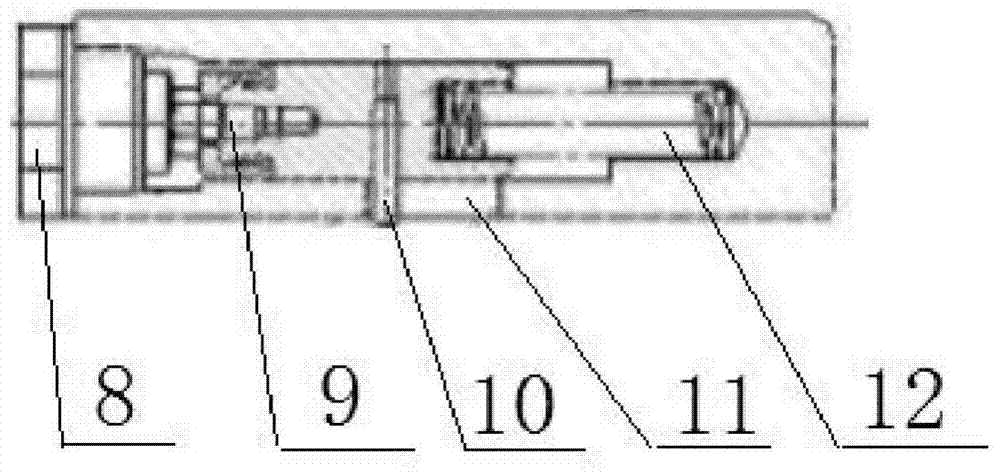

Two-stage supercharging vehicle-mounted air compressor

InactiveCN103758732AReduce power consumptionReduced service lifePositive displacement pump componentsPump installationsGas compressorLinear compressor

The invention discloses a two-stage supercharging vehicle-mounted air compressor and aims at providing an automotive two-stage supercharging air compressor which is low in power consumption, high in reliability and low in exhaust temperature. The two-stage supercharging vehicle-mounted air compressor comprises a cylinder cover, wherein the cylinder cover is connected with a cylinder body through a valve plate assembly, a crankshaft is arranged under the cylinder body, a primary air cylinder and a secondary air cylinder are arranged in the cylinder body in parallel, and an unloading mechanism is arranged on the valve plate assembly and comprises an unloading hole, a plunger piston, a pin, a rack, a spring and gear. The plunger piston is fixedly connected with the rack through the pin, one end of the plunger piston faces the unloading hole, the other end of the plunger piston is connected with the spring, the rack is meshed with the gear, a cooling system is arranged in the cylinder cover, air discharged by the primary air cylinder is cooled by the cooling system and then flows into the secondary air cylinder. The two-stage supercharging vehicle-mounted air compressor is suitable for modification of brake systems of large automobiles and existing automobiles.

Owner:GUANGXI YUCHAI MASCH CO LTD

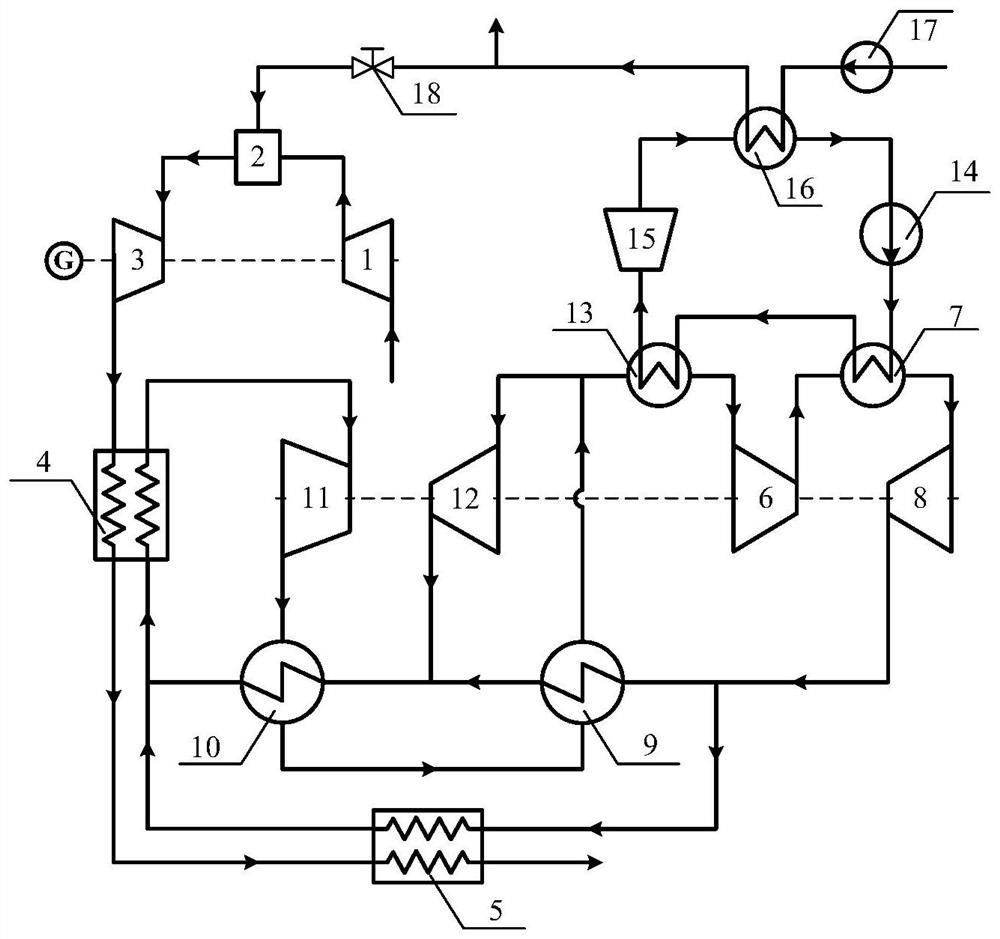

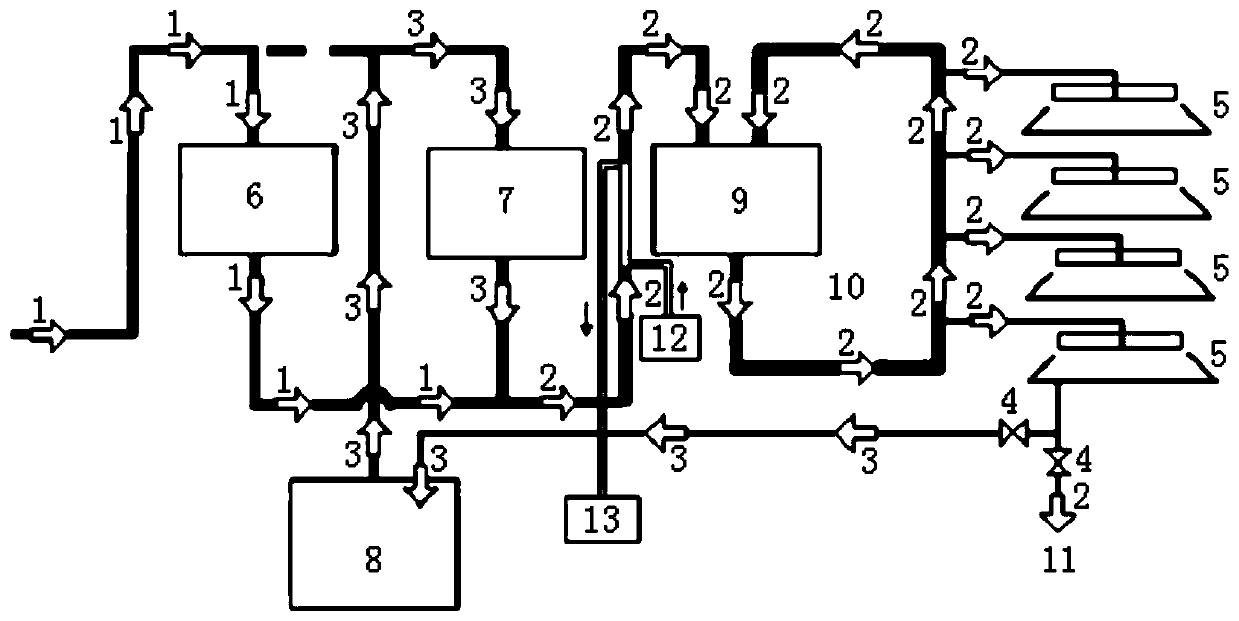

Gas supercritical carbon dioxide combined cycle power generation system based on LNG cold source and operation method

PendingCN111810297AImprove thermal efficiencyLower initial temperatureTurbine/propulsion fuel supply systemsSteam regenerationThermodynamicsProcess engineering

The invention discloses a gas supercritical carbon dioxide combined cycle power generation system based on an LNG cold source and an operation method. The system comprises a gas turbine power generation system, a supercritical carbon dioxide power generation system and a bottom cycle power generation system, wherein the cold end of the supercritical carbon dioxide power generation system can improve the cycle efficiency through an interstage cooling mode, and meanwhile, reduces the temperature of a working medium at an outlet of a compressor, and is used for completely recycling exhaust smokewaste heat of a gas turbine; and the bottom cycle power generation system generates power by recycling the cold source loss of the supercritical carbon dioxide power generation system and cold energyof fuel LNG of the gas turbine power generation system. According to the gas supercritical carbon dioxide combined cycle power generation system, energy quality-divided gradient utilization is achieved, the energy utilization rate can be greatly increased, and therefore the power generation efficiency of the system is effectively improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

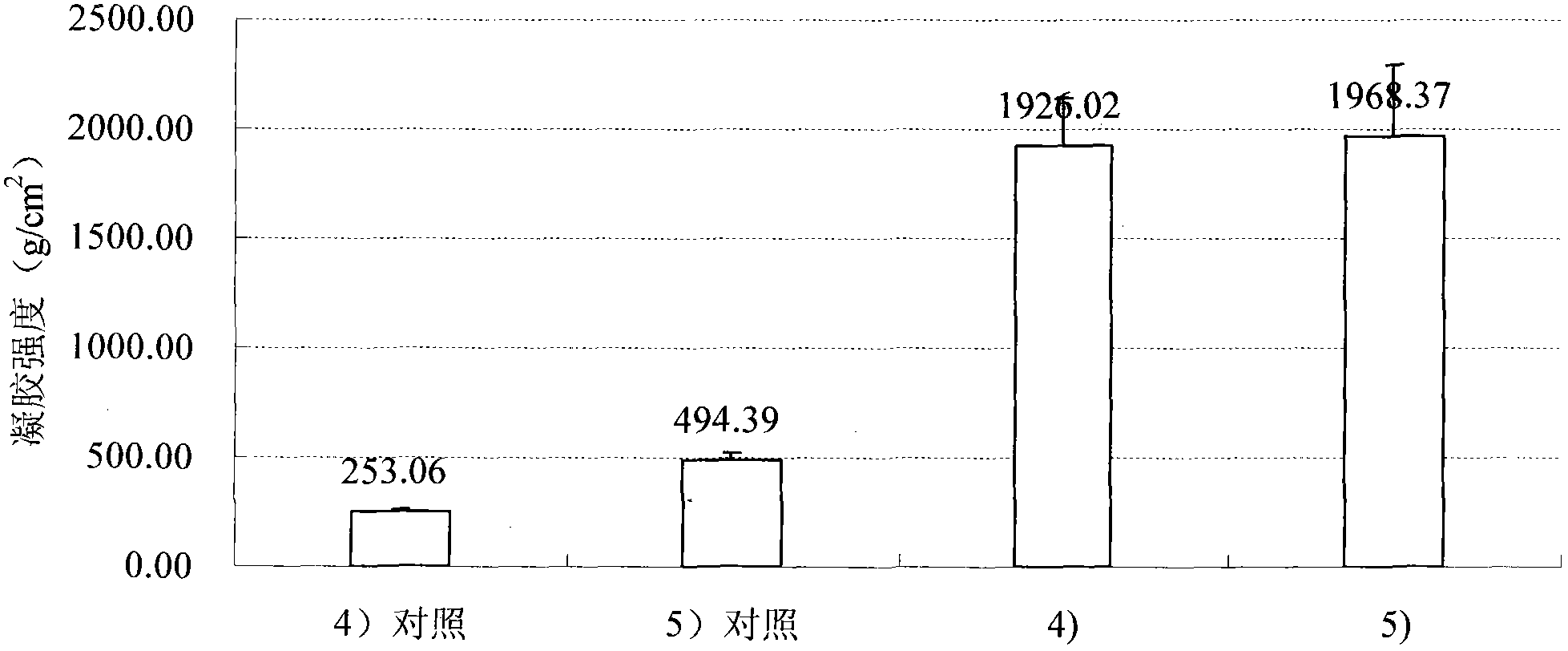

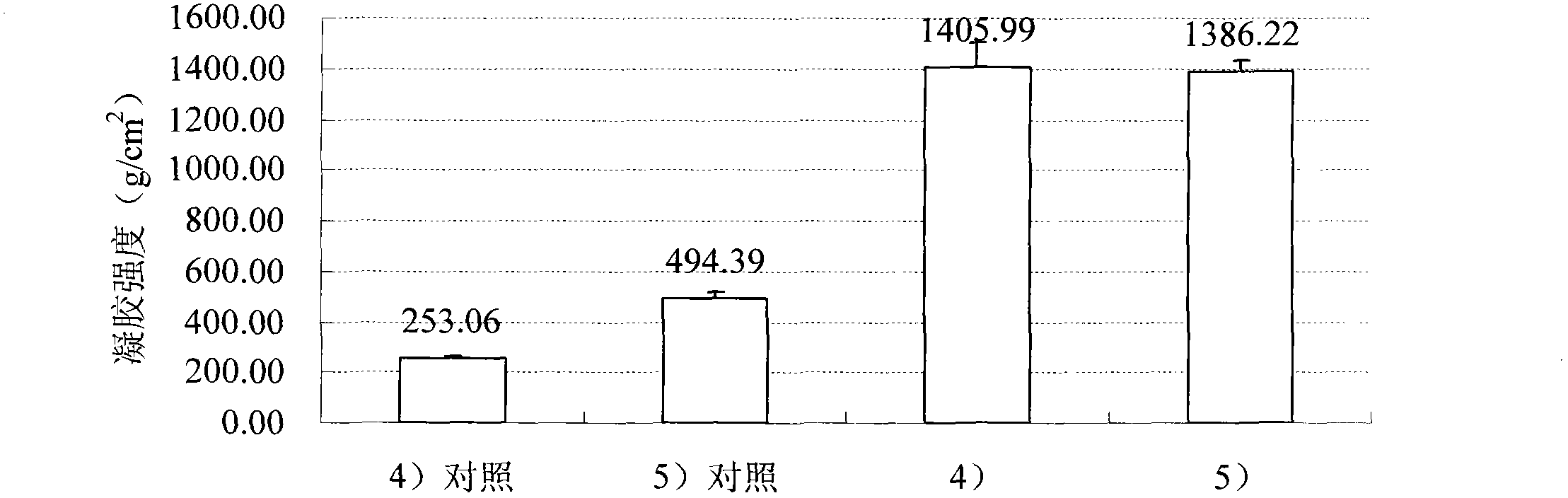

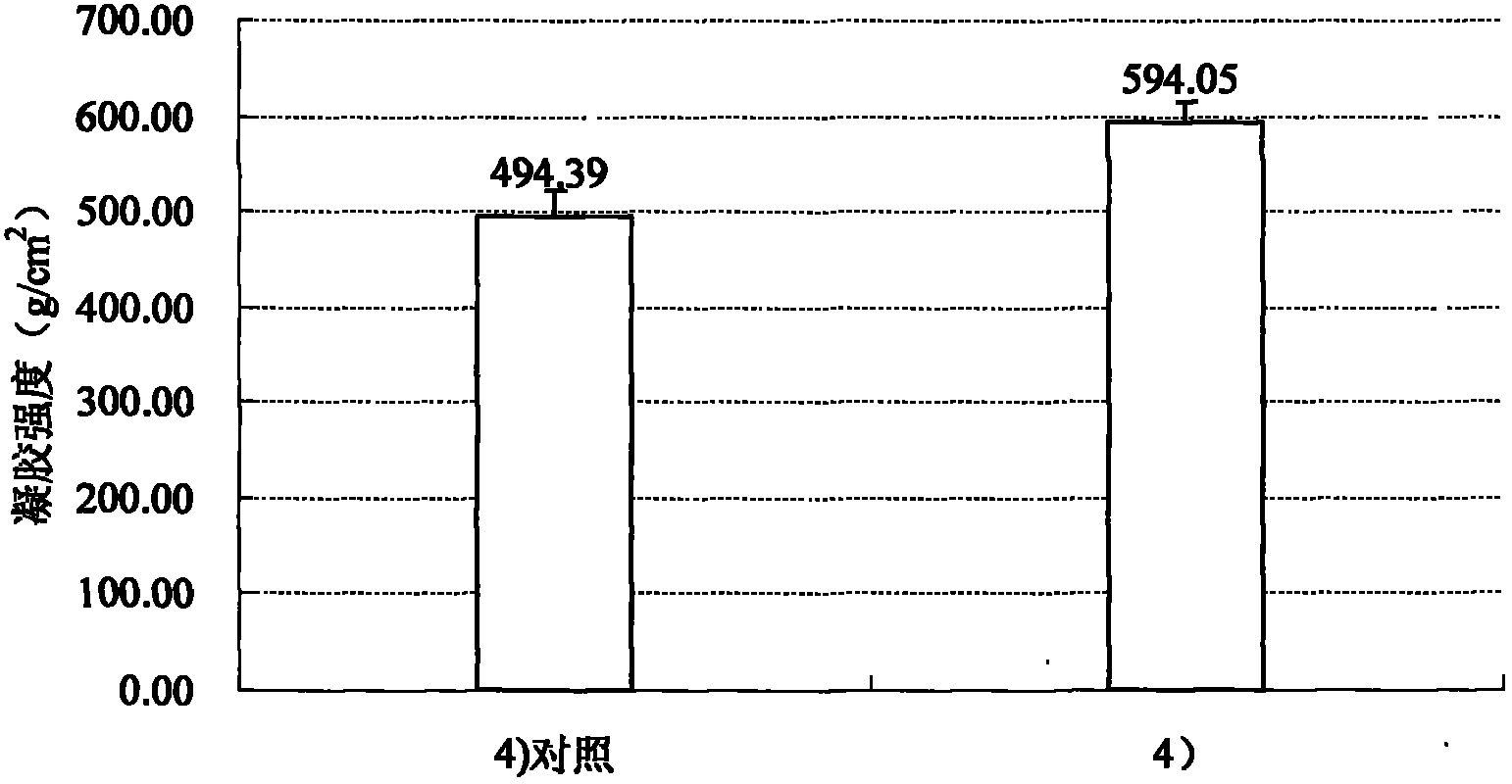

Method capable of improving gel strength of curdlan

The invention provides a method capable of improving gel strength of curdlan. The method includes: compounding microbial polysaccharide curdlan and hydrogen bond binding force promoting agents or microbial polysaccharide curdlan and coagulant aids, dissolving the mixture in water, and performing gel on the obtained solution at the temperature of 45-95 DEG C for 8-12 minutes. The jelly strength of the curdlan is obviously improved, and the hydrogen bond promoting agents can enhance the hardness at the high temperature state and the brittleness at the low temperature state, and obviously improve transparency of the colloid. The coagulant aids can reduce the gel initial temperature of the curdlan and improve the hardness and brittleness of the colloid at the low temperature state. When the hydrogen bond promoting agents and the coagulant aids act synergistically, the strengthening effects of the various aspects of the curdlan are improved.

Owner:SHANDONG FOOD & FERMENT IND RES & DESIGN INST

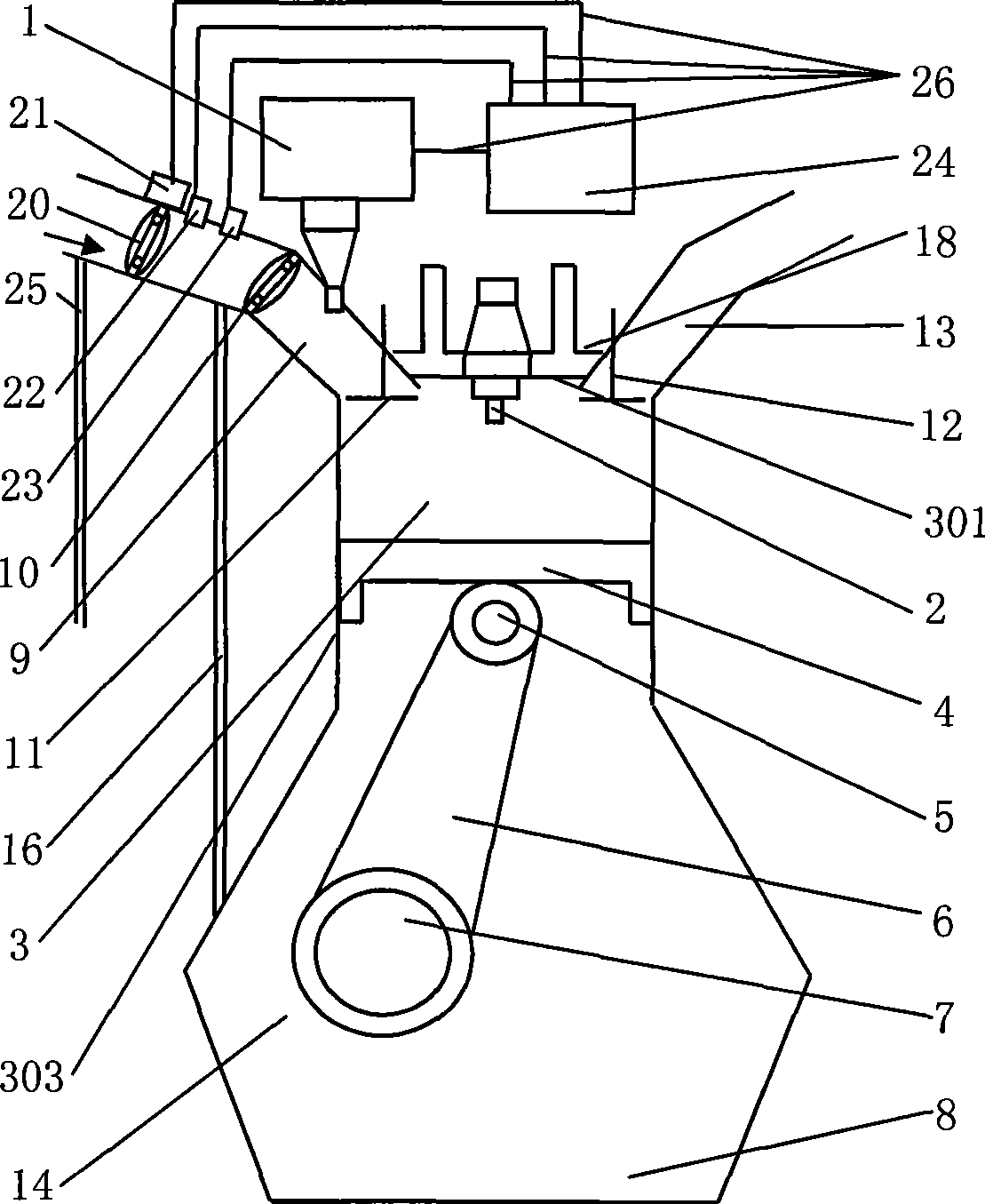

Pressure reducing air inlet high compression ratio internal-combustion engines

InactiveCN101498246ALow densityReduce the temperatureInternal combustion piston enginesCylinder headsExhaust valveExternal combustion engine

The invention relates to a four-stroke gasoline engine, in particular to a decompressed gas-intake internal combustion engine with high compression ratio, belonging to an engine. The decompressed gas-intake internal combustion engine with high compression ratio comprises an oil spout system, a spark plug, an gas cylinder, a piston, a piston pin, a connecting bar, a crank, an oil bottom shell, an intake pipe, an intake valve, an exhaust valve, an exhaust pipe and a crank case and also comprises a gas-intake decompressed valve, a valve drive of the gas-intake decompressed valve, an air pressure sensor and a flow sensor which are all arranged on the upper part of a motion valve and an extract opening of the crank case along a gas-intake direction to be used for restricting gas-intake quantity; the decompressed gas-intake internal combustion engine is improved in compression ratio and can not generate abnormal combustion such as deflagration, surface ignition, and the like. In addition, the decompressed gas-intake internal combustion engine with high compression ratio saves a water cooling system for a prior internal combustion engine. The invention reduces the exhaust emission, saves the energy, and also simplifies the structure of an internal combustion engine, decreases the part number and lowers the production cost on the basis of enhancing the heat efficiency of the internal combustion engine.

Owner:周同庆

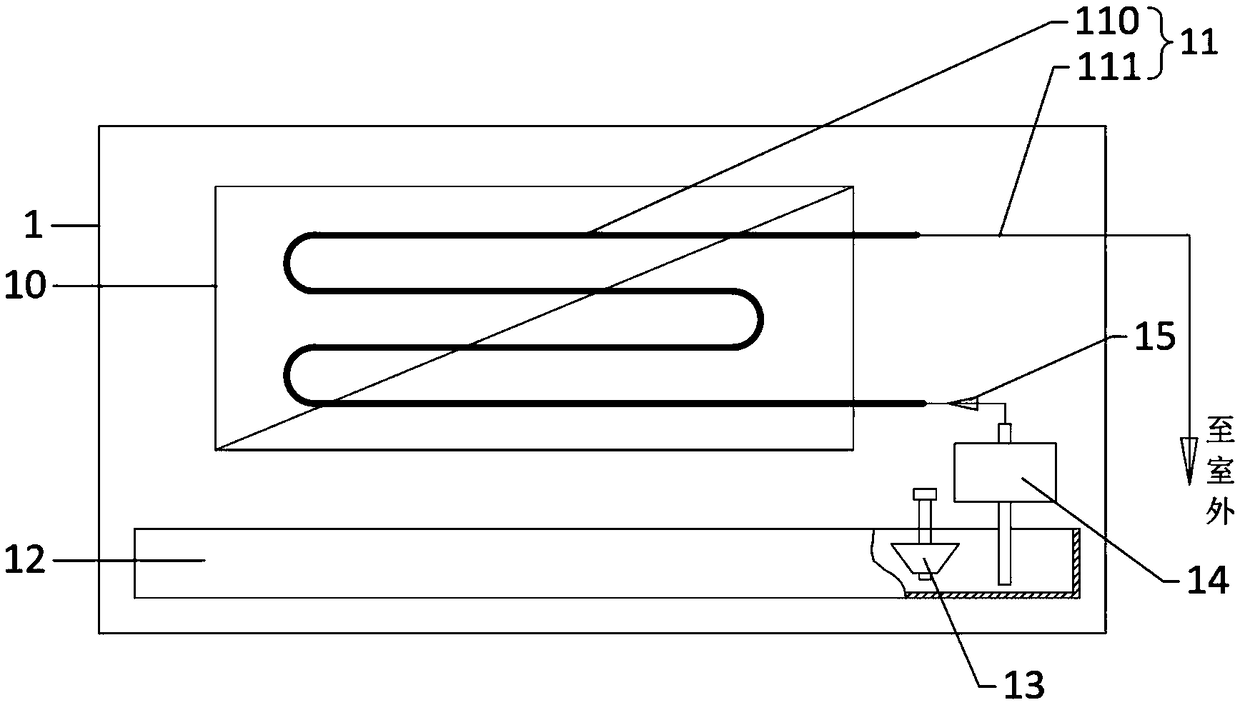

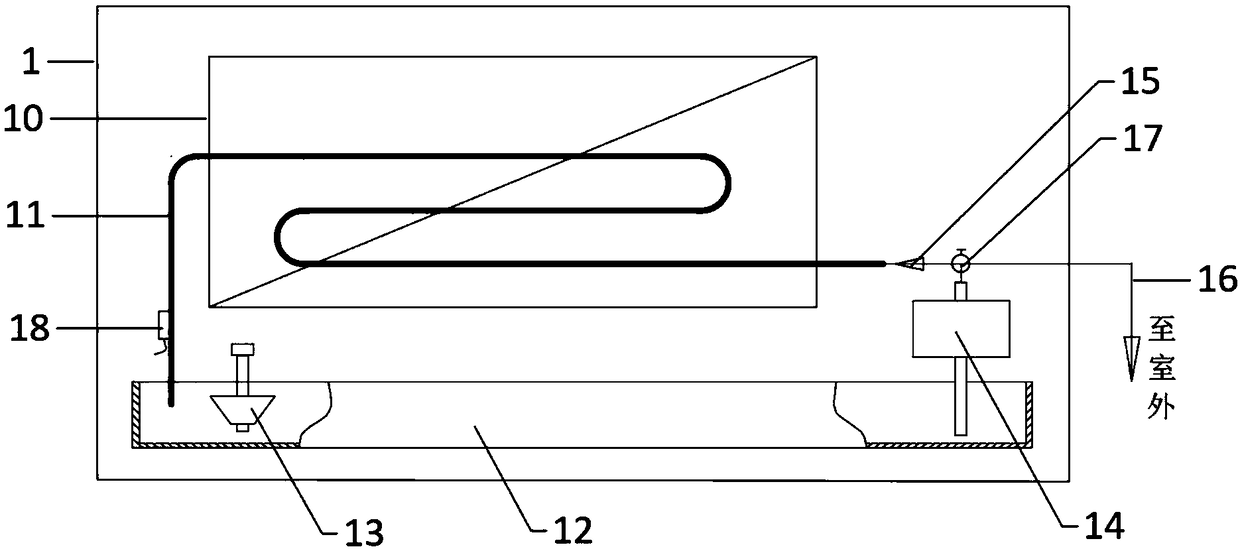

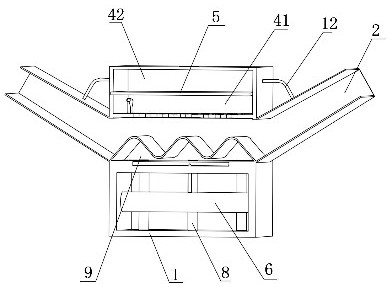

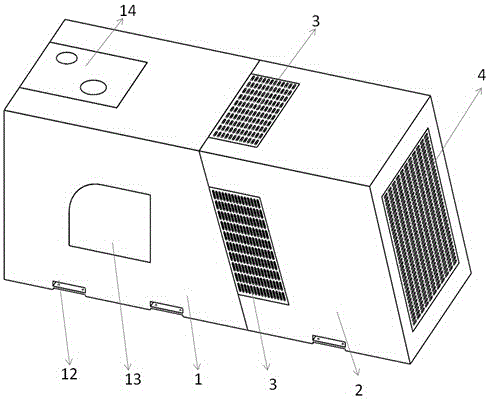

Air conditioner indoor unit and air conditioner

PendingCN109340920AImprove cooling efficiencyReduce the temperatureCondensate preventionLighting and heating apparatusWater flowAir conditioning

The invention relates to the technical field of air conditioners and aims to solve the problem that existing air conditioners have low utilization rate of the cooling capacity in condensate water generated by indoor units, and for this reason, the invention provides an air conditioner indoor unit and an air conditioner. The indoor unit comprises an air supply passage and an evaporator arranged inside the air supply passage and further comprises a water receiving tray, a water pump and a condensate water pipeline, wherein the water receiving tray is arranged below the evaporator and used for receiving the condensate water flowing out of the evaporator; the water pump is used for pumping and conveying the condensate water inside the water receiving tray; and an inlet of the condensate waterpipeline is connected to a water outlet of the water pump, the condensate water pipeline comprises a heat exchanging pipe segment, and the heat exchanging pipe segment is arranged inside the air supply passage to perform heat exchanging with air inside the air supply passage conveniently. By means of the air conditioner indoor unit and the air conditioner, the cooling capacity in the condensate water generated by the indoor unit can be utilized sufficiently, the air conditioning refrigeration efficiency is improved, cooling capacity waste is avoided, special equipment of a long distance transportation pipeline is not needed, and the air conditioner indoor unit and the air conditioner are low in cost and good in effect.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD

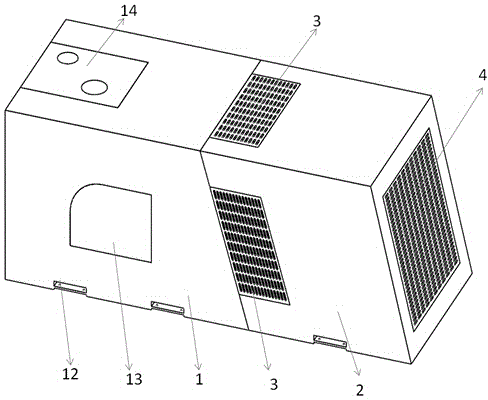

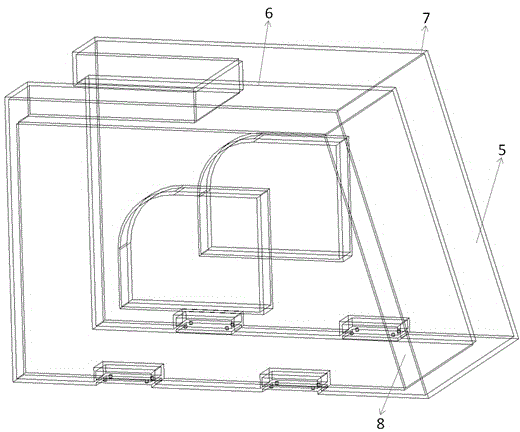

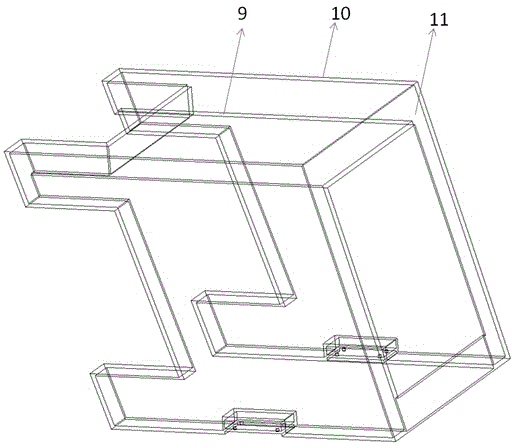

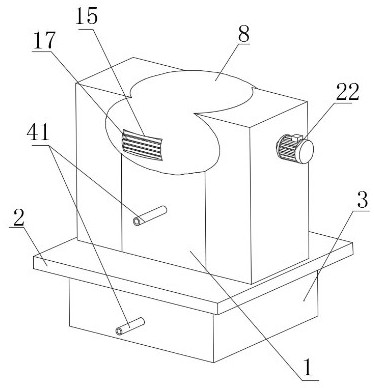

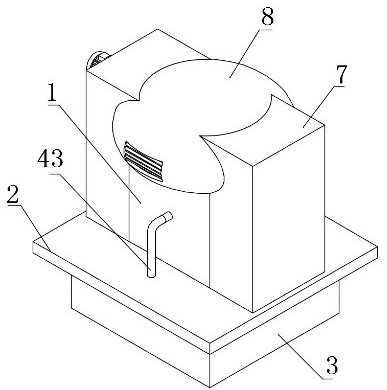

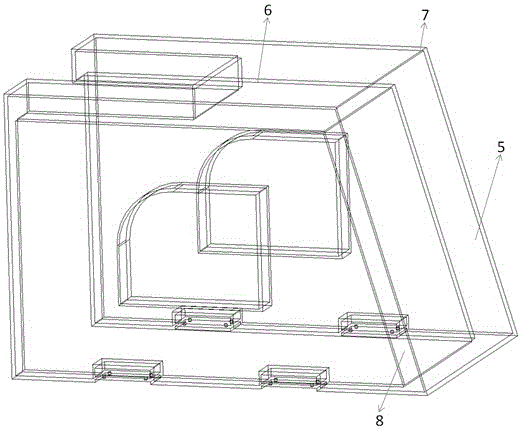

Combined machine cover for engineering machine

ActiveCN104149859AImprove sound insulationImprove vibration resistanceSuperstructure subunitsPropulsion coolingEngineeringClosed cavity

The invention discloses a combined machine cover for an engineering machine. The combined machine cover comprises an engine compartment cover body and a heat dissipation compartment cover body, and the heat dissipation compartment cover body is provided with an air inlet grid and an air exhaust grid; the heat dissipation compartment cover body is connected to the tail portion of the engine compartment cover body, and the heat dissipation compartment cover body and the engine compartment cover body are isolated through a tail end plate of the engine compartment cover body; the engine compartment cover body comprises an engine compartment inner cover unit and an engine compartment outer cover unit located on the outer side of the engine compartment inner cover unit, the engine compartment inner cover unit is fixedly connected with the engine compartment outer cover unit, and a first closed cavity is formed between the engine compartment inner cover unit and the engine compartment outer cover unit; the heat dissipation compartment cover body comprises a heat dissipation compartment inner cover unit and a heat dissipation compartment outer cover unit located on the outer side of the heat dissipation compartment inner cover unit, the heat dissipation compartment inner cover unit is fixedly connected with the heat dissipation compartment outer cover unit, and a second closed cavity is formed between the heat dissipation compartment inner cover unit and the heat dissipation compartment outer cover unit. The combined machine cover has good sound insulation performance and shock resistance.

Owner:JIANGSU NANGAO INTELLIGENT EQUIP INNOVATION CENT CO LTD

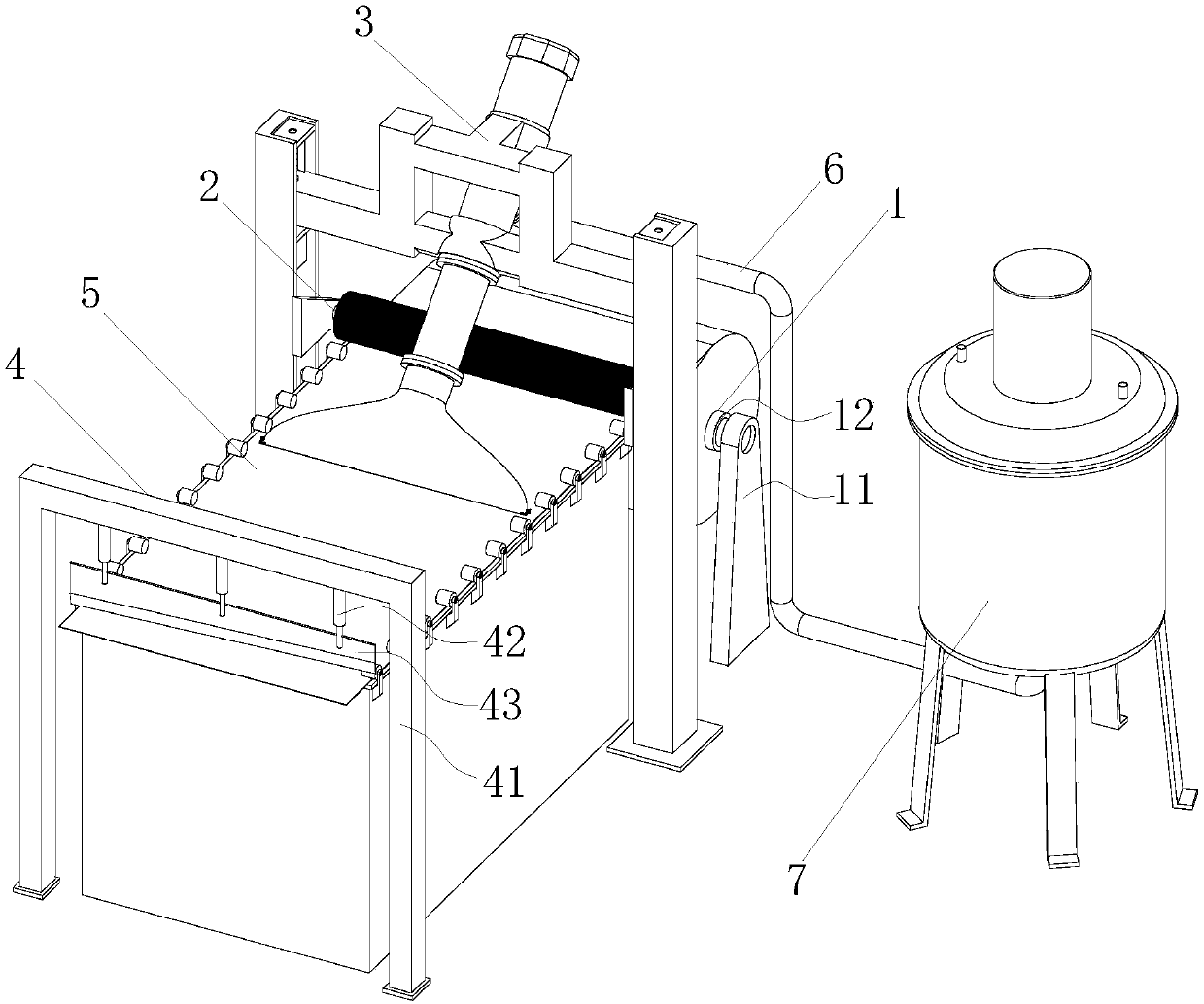

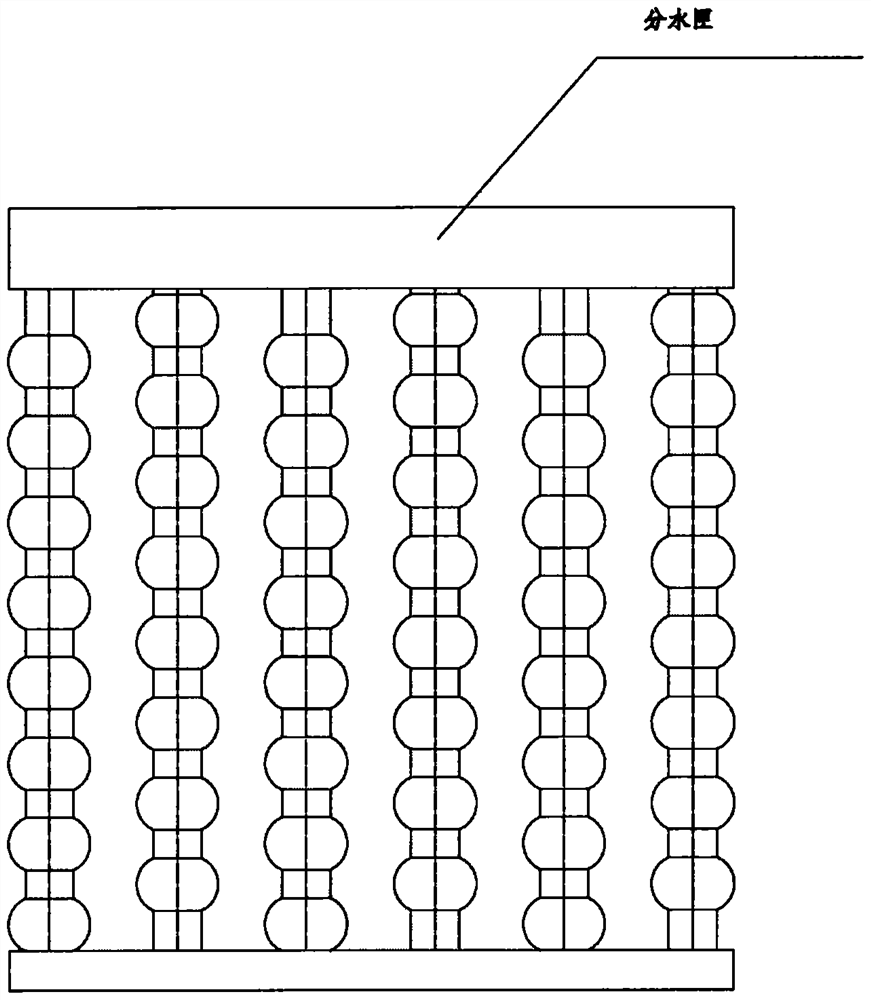

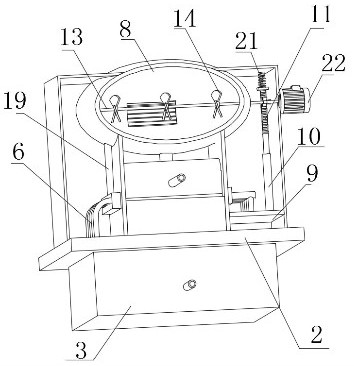

Urea granulating column with high yield

ActiveCN109126633AEasy to recycleIncrease contact areaGranulation by liquid drop formationGranulation by pressingEngineeringDistributor

The invention relates to a urea granulating column with high yield, comprising a column body and a distributor, as well as a squeezing disc that is arranged in the upper portion of the column body; ahollow shaft is arranged in the center of the squeezing disc; a plurality of horizontal center shafts are fixed evenly on the outer periphery of the hollow shaft, each horizontal hollow shaft is hinged to a squeezing roller in penetrating manner, and the bottom edges of each squeezing rollers are attached to the upper surface of the squeezing disc. The granulating blocking problem can be effectively solved by making use of squeezing granulation; each urea granule is squeezed to freely fall in an independent cooling tube; the urea granules are full and solid and have a stable falling trajectory; the urea granules never collide with and stick to other granules; column sticking to the granules is never caused, a water film on a film mesh spreads water so that contact area of the water with urea powder is enlarged, and dust collection effect is significant; the dissolved urea is easy to recycle; humidity in the column herein is unaffected and dust emission is reduced.

Owner:SHANDONG HUALU HENGSHENG CHEM IND

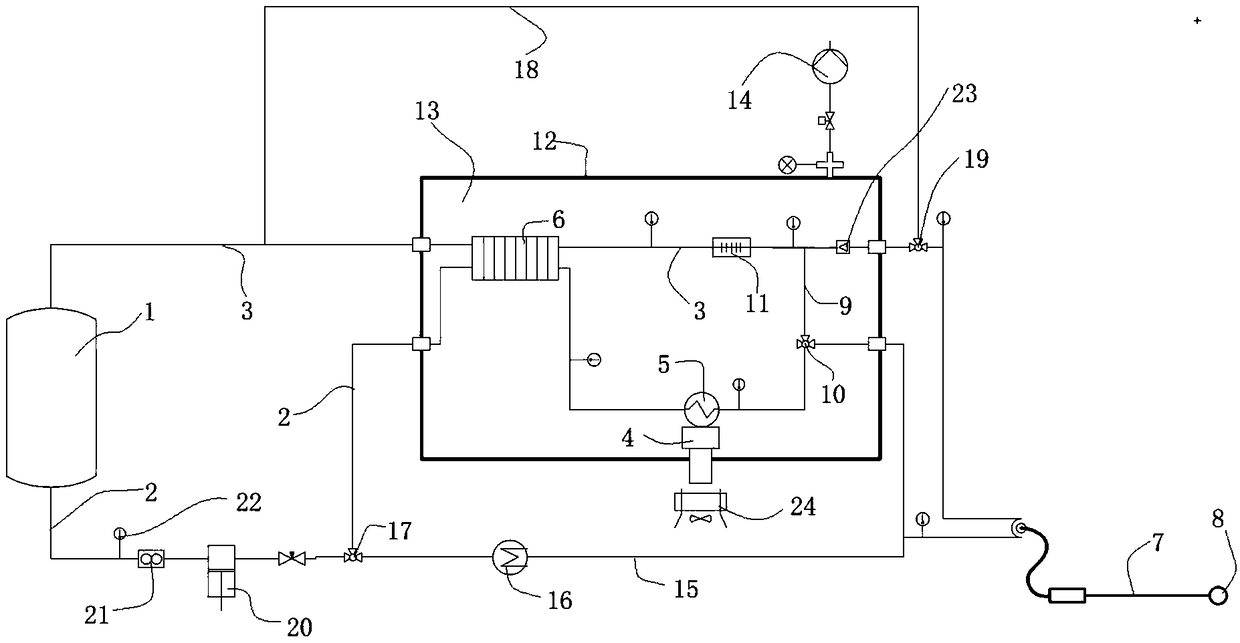

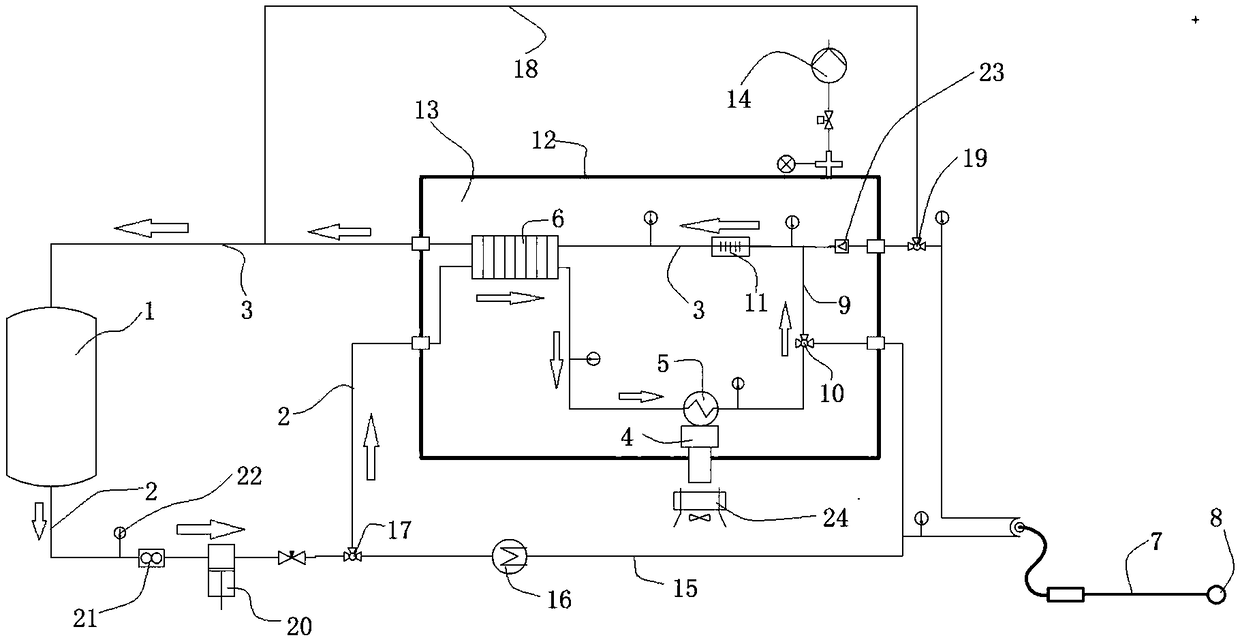

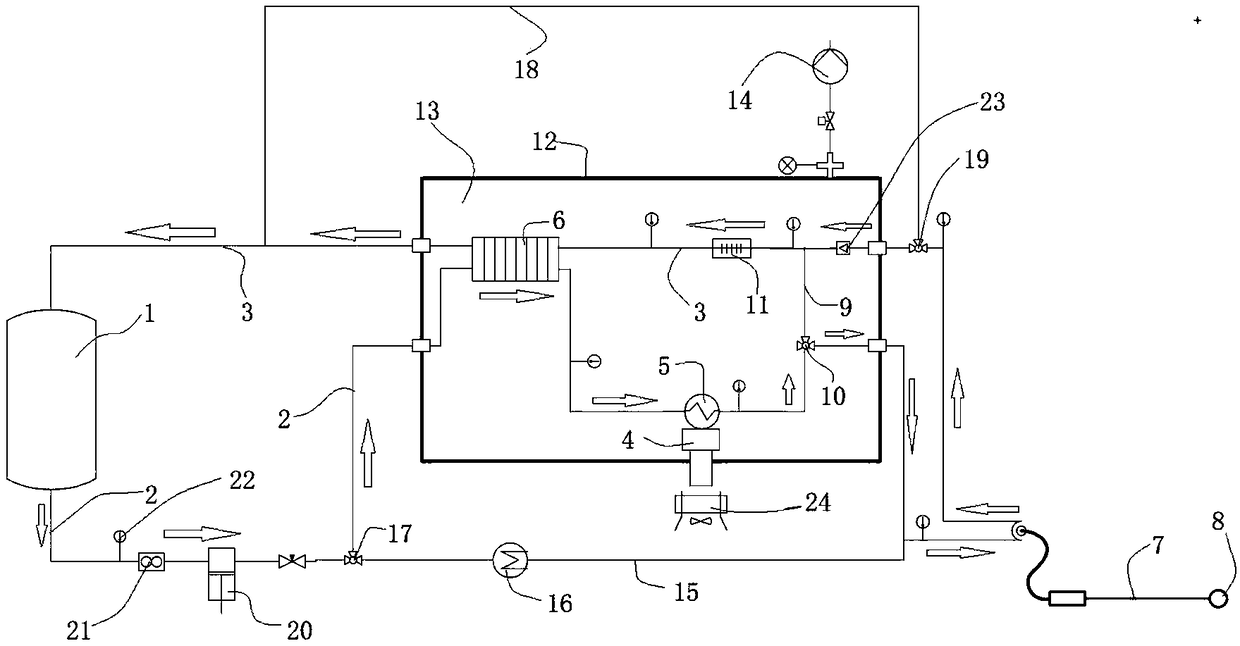

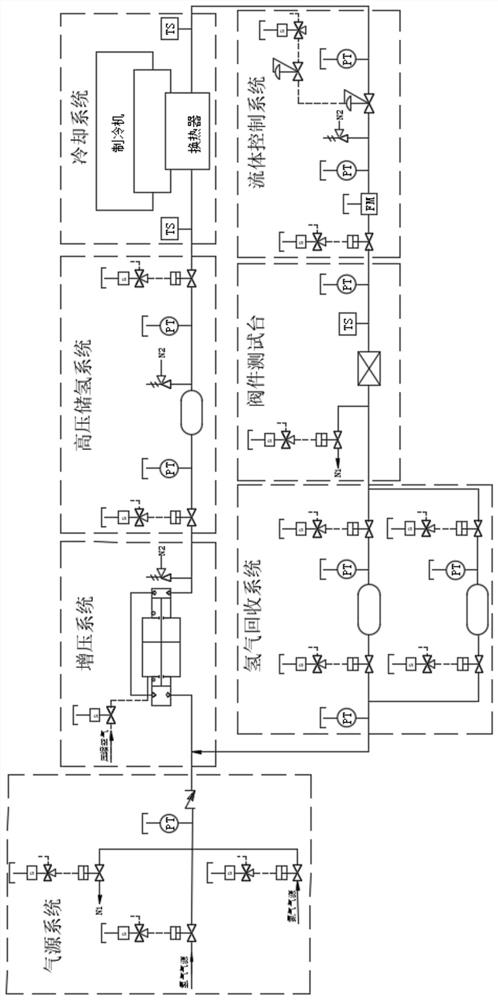

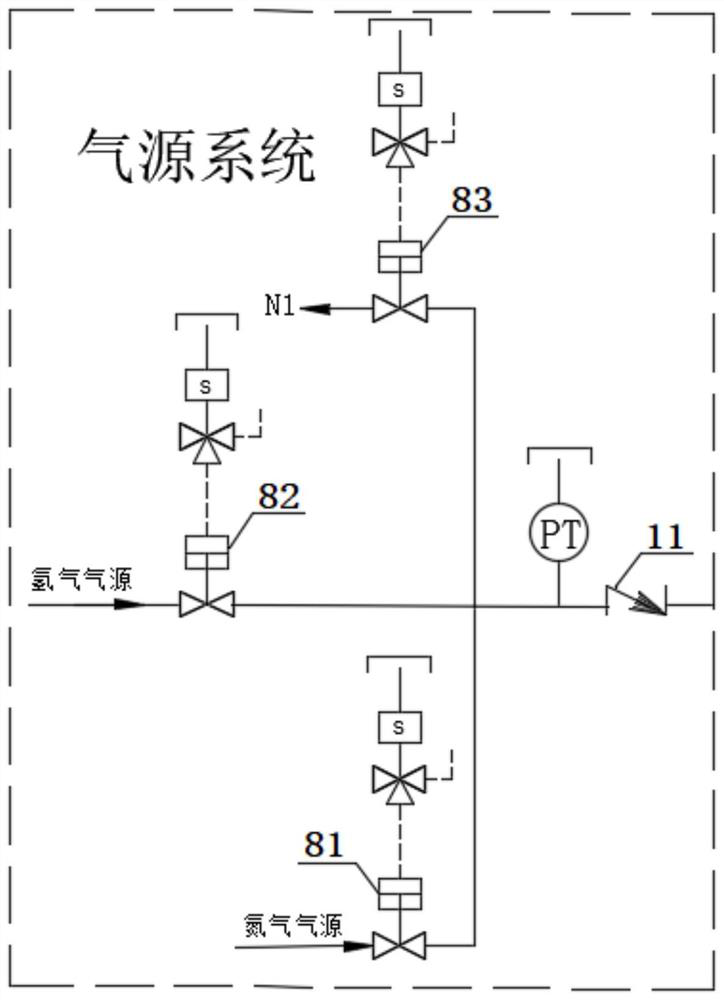

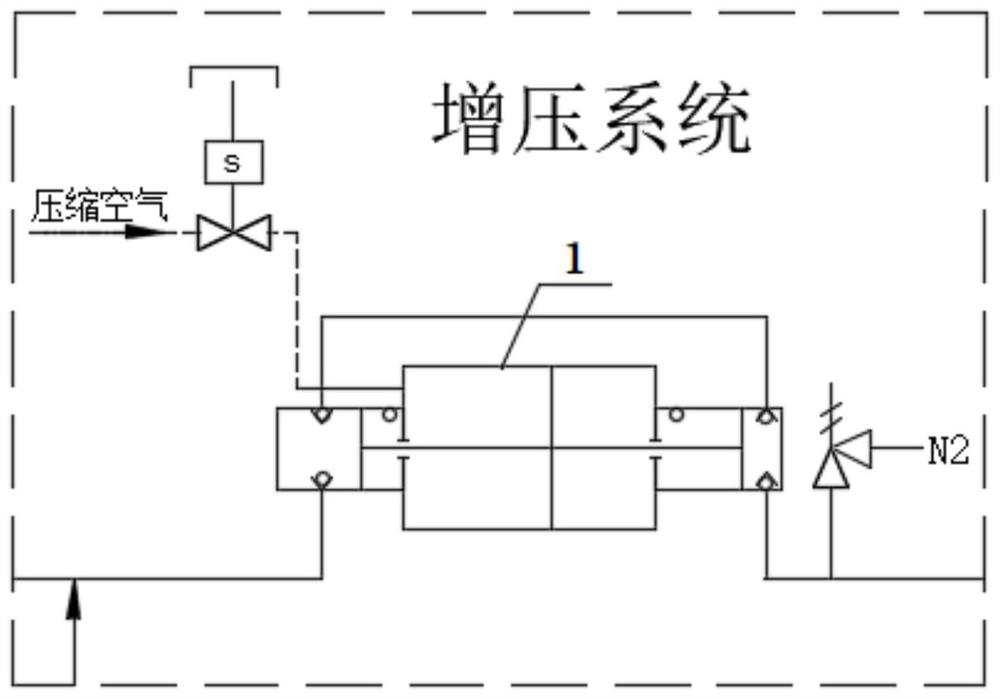

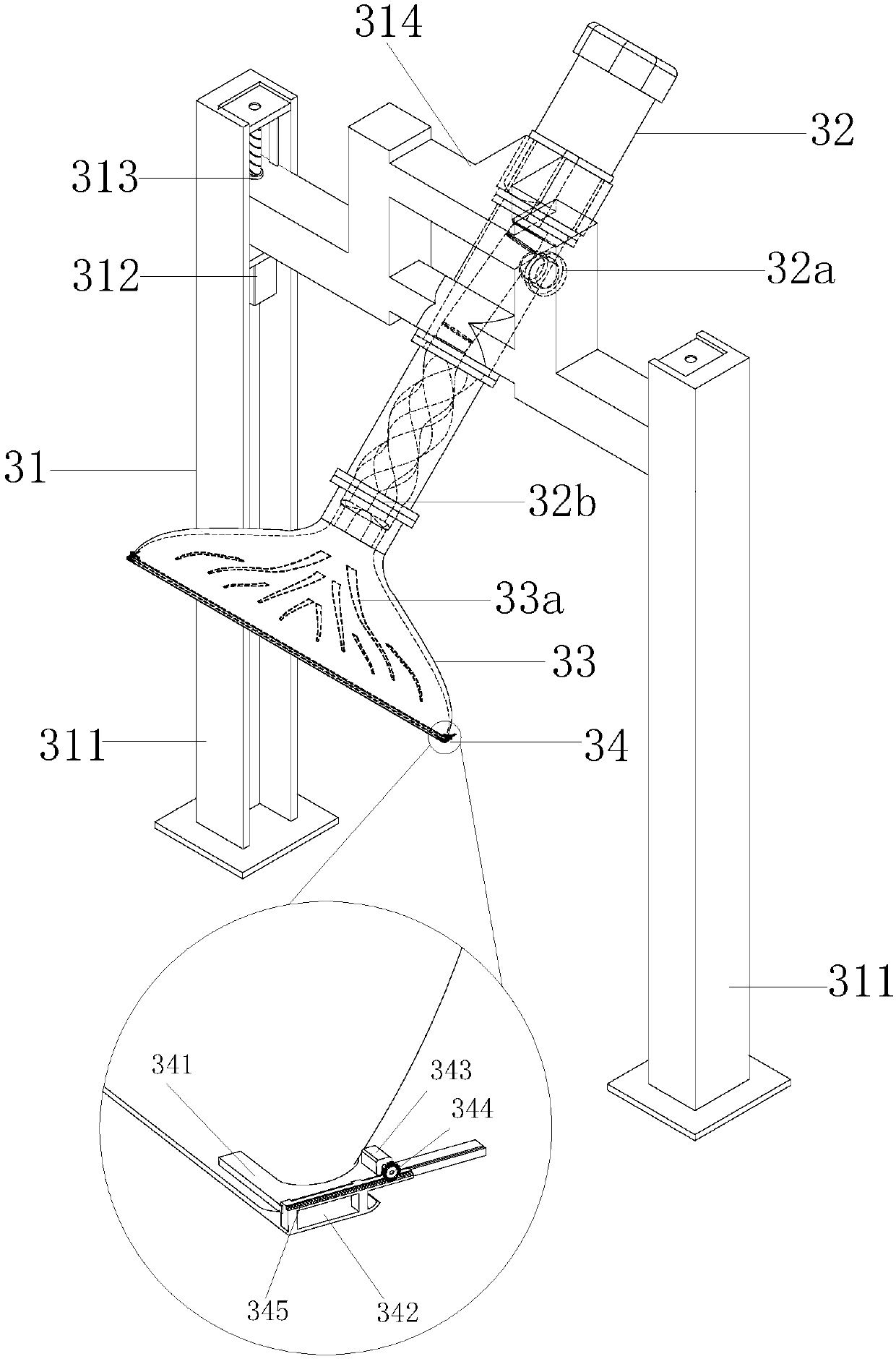

Device and method for testing exposure of precooled hydrogen

PendingCN113532843AMeet testing needsLower initial temperatureReactant parameters controlMachine valve testingMechanical engineeringStress sensors

The invention discloses a device and method for testing exposure of precooled hydrogen, and relates to the technical field of precooled hydrogen exposure testing. The device comprises a measurement and control system, and a supercharger, a hydrogen buffer gas tank, a heat exchanger, a pressure reducing valve, a to-be-tested valve and a hydrogen recovery system which are sequentially communicated through a high-pressure hydrogen pipe. The hydrogen recovery system comprises a recovery gas path A and a recovery gas path B which are connected in parallel. The measurement and control system comprises a PID controller. The PID controller is in electric signal connection with a pressure sensor c, a pressure sensor d and a flow value meter. The PID controller controls the opening degree of the valve element of the pressure reducing valve according to the front air pressure value, the rear air pressure value and the flow value so as to achieve the test pressure and the test flow required by the test of the to-be-tested valve, and meanwhile hydrogen is cooled through the porous heat exchanger; and the test requirements of low-temperature, continuous and high-flow hydrogen are met.

Owner:上海舜华新能源系统有限公司

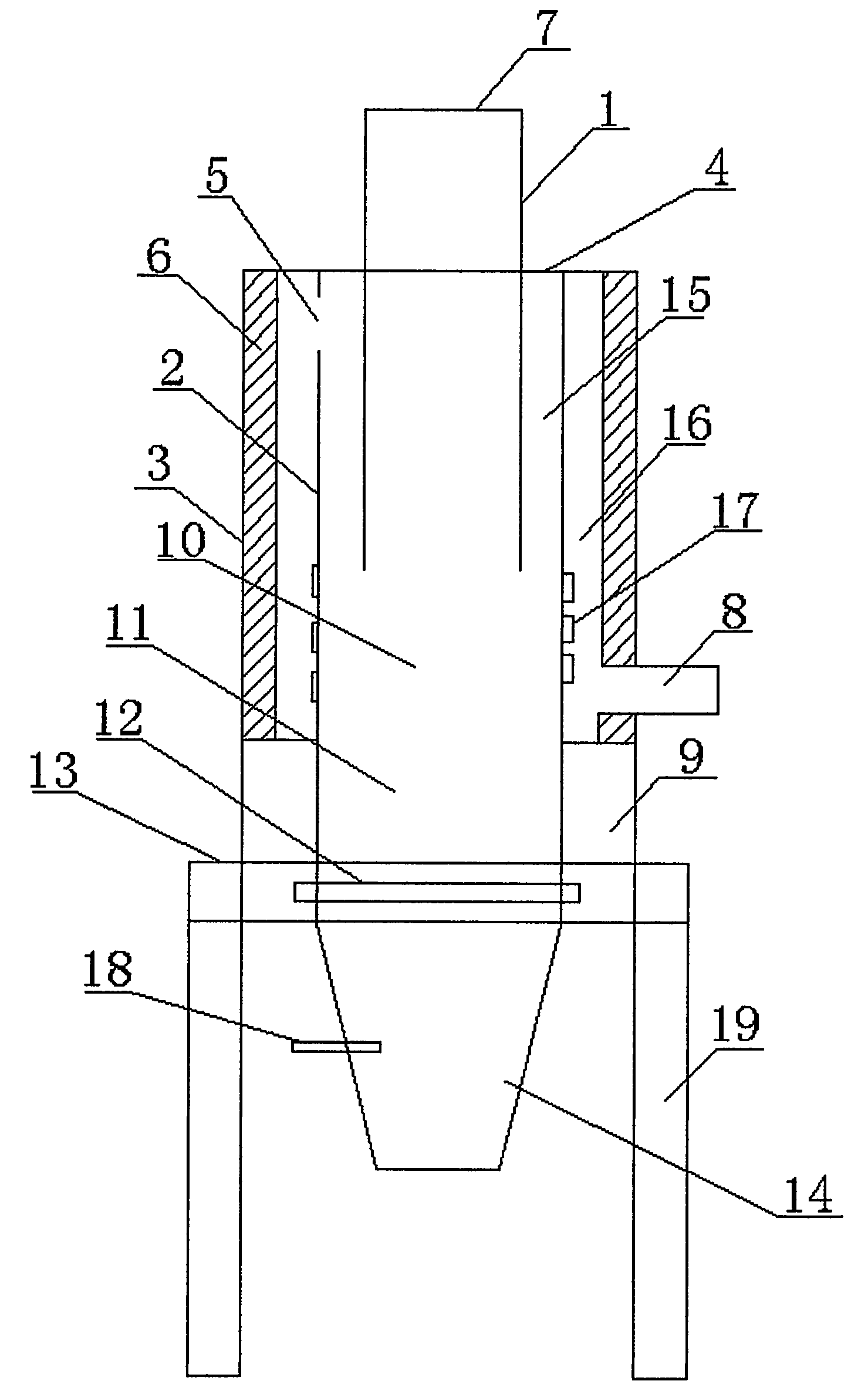

Up-draught biomass gasifier capable of heating fuel gas

ActiveCN104312631AIncrease temperatureLower initial temperatureCombustible gas productionFiltrationTar

The invention discloses an up-draught biomass gasifier capable of heating a fuel gas. The up-draught biomass gasifier capable of heating the fuel gas comprises an outer barrel, a middle barrel and an inner barrel. Fuel gas channels are formed among the barrels; the fuel gas generated by gasification flows to a fuel gas outlet through the fuel gas channels; heat transfer fins are disposed at the outside of the lower part of the middle barrel; and the fuel gas outlet is arranged at the lower part of the outer barrel. The temperature of the lower side of the middle barrel is relatively high, so that the fuel gas passing through the lower side of the middle barrel is heated continuously; the fuel gas can be kept at a relatively high temperature; tar in the fuel gas always exists in a gas state; and the problem of tar separation is overcome. Although an initial temperature of the fuel gas is reduced by increasing a material layer, the low-temperature fuel gas is heated to the relatively high temperature by the lower part of the middle barrel, so that the material layer of the gasifier can be thickened, thereby playing a better filtration effect for the fuel gas generated by the gasification and reducing generation of dust. The gasifier can keep the generated fuel gas at the relatively high temperature and reduce the generation of dust, and can solve corresponding problems existing in conventional up-draught biomass gasifiers.

Owner:上海艾耐基科技股份有限公司

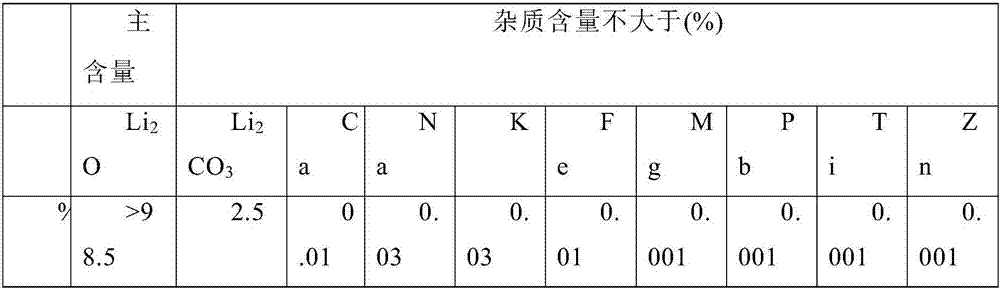

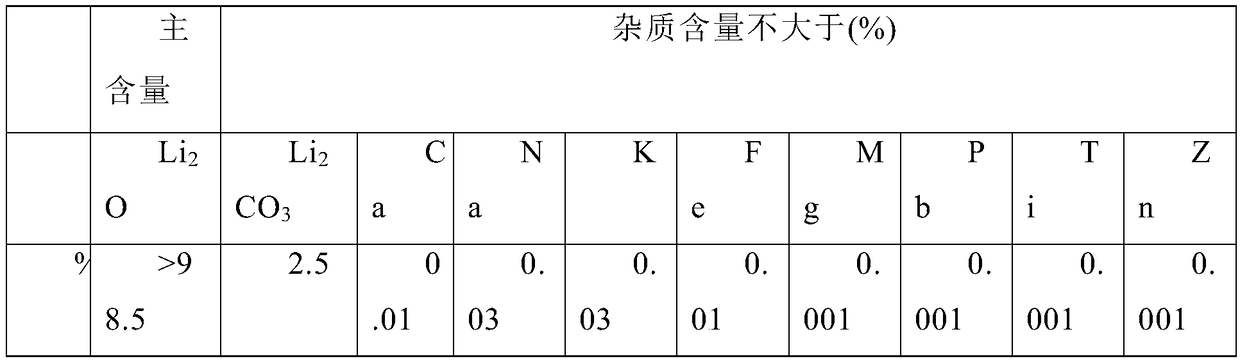

Method for preparing high-purity lithium oxide from lithium carbonate

The invention discloses a method for preparing high-purity lithium oxide from lithium carbonate. The method comprises the following steps: A, performing acidification neutralization, namely putting battery-grade lithium carbonate into a reaction container, adding concentrated nitric acid, dropwise adding lithium hydroxide and nitric acid, and controlling the pH value to 6-8; B, performing filtering decontamination, namely filtering a mixed solution, dropwise adding lithium hydroxide and nitric acid till the pH value is 11-13, filtering so as to obtain a secondary filtering solution, and dropwise adding lithium hydroxide and nitric acid into the secondary filtering solution till the pH value is 1-2 so as to obtain an adjusted solution; C, performing crystallization, separation and drying, namely performing evaporation crystallization on the adjusted solution, performing cooling centrifugal separation, and drying so as to obtain lithium nitrate; and D, performing high-temperature decomposition, namely putting the lithium nitrate into a decomposition furnace, vacuuming to minus 0.01MPa to minus 0.09MPa, rapidly heating to 500 DEG C within 2-3 hours, heating to 650-750 DEG C within 6-10 hours, keeping the temperature for 8-12 hours, and keeping a vacuum degree of minus 0.01MPa to minus 0.09MPa in the heating and temperature keeping process, thereby obtaining high-purity lithium oxide finally. The method disclosed by the invention is simple in process, low in cost of raw materials and the like, low in unit energy consumption, relatively thorough in decomposition, high in purity of the prepared lithium oxide, and high in production efficiency.

Owner:GANFENG LITHIUM CO LTD

Copper-based resin prepreg production equipment for mobile communication circuit boards

PendingCN109551247ASolve problems such as low production yieldLower initial temperatureOther manufacturing equipments/toolsEngineeringCopper foil

The invention relates to the technical field of copper-clad plate production for mobile communication circuit boards, in particular to copper-based resin prepreg production equipment for the mobile communication circuit boards. The equipment comprises a copper foil winding drum, a grinding device, a coating device and a cutting device, a drying device and a glue supply device, wherein the copper foil winding drum, the grinding device, the coating device and the cutting device are sequentially arranged from front to back, the drying device is installed below between the coating device and the cutting device, and the glue supply device is connected with the coating device through a conveying pipe. A copper-based resin prepreg produced by using the equipment and reinforcing materials are laminated at high temperature to manufacture a copper-clad plate, so that the problem that in the prior art, the yield of copper-clad plate production is reduced due to the fact that defects such as inclusion of bubbles, uneven composition of the prepreg are prone to occurring in the processes of gum dipping and curing of the reinforcing materials is solved.

Owner:XIAN HUAYUN TIANCHENG COMM TECH

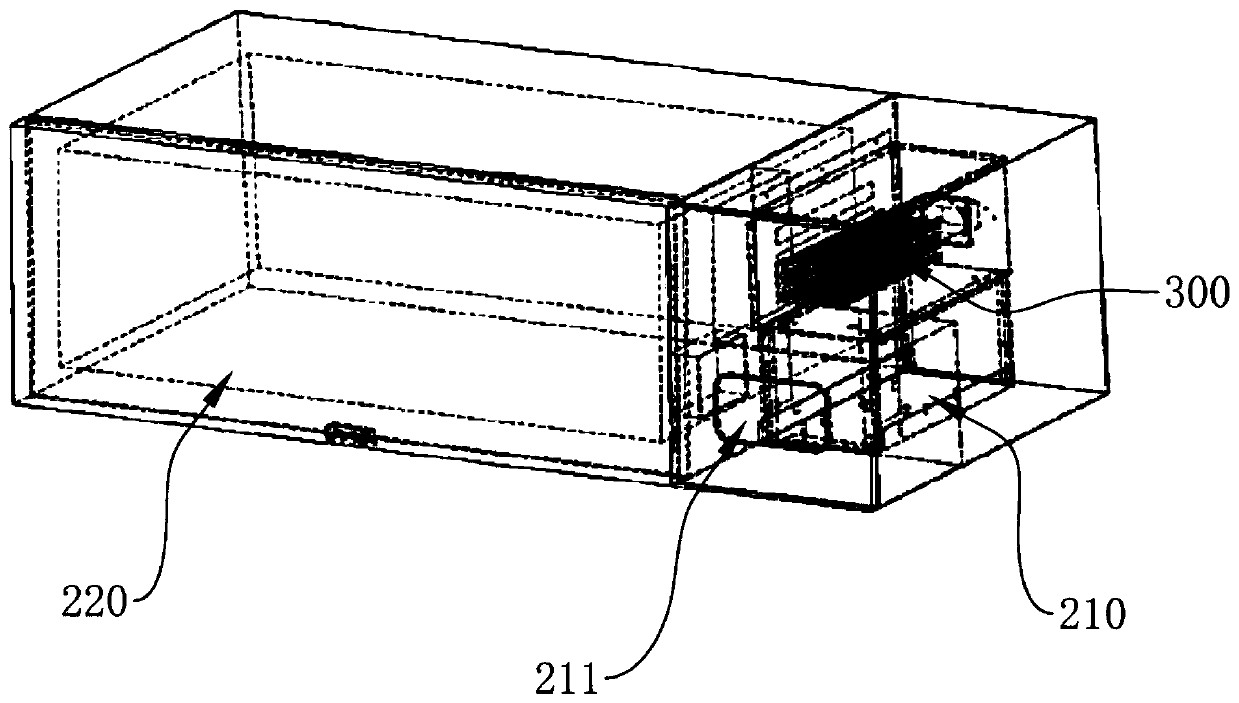

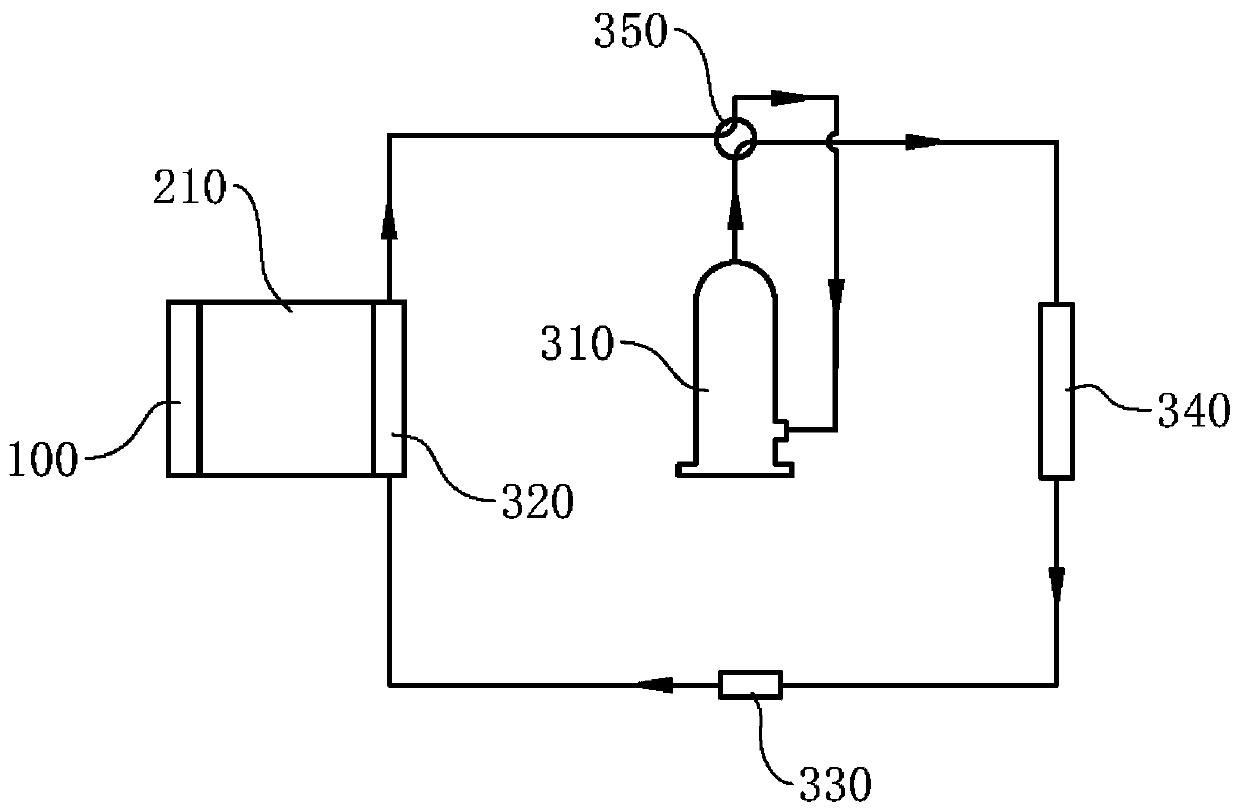

Cooling and heating integrated cabinet, temperature controlling method and unmanned vehicle

InactiveCN111578618ARaise the initial temperatureLower internal resistanceShow cabinetsMechanical apparatusTemperature controlEngineering

The invention provides a cooling and heating integrated cabinet, a temperature controlling method and an unmanned vehicle. The cooling and heating integrated cabinet comprises a heating chamber and aPTC heating element, and the PTC heating element is connected with the heating chamber in a thermal conductivity mode. The cooling and heating integrated cabinet further comprises a compression heating system, and the compression heating system comprises a compressor, a condenser, a throttling device and an evaporator. The compressor, the condenser, the throttling device and the evaporator are connected in series successively, and the condenser is connected with the heating chamber in a thermal conductivity mode. First, the compression heating system is turned on to heat the heating chamber, the temperature of the heating chamber is raised at a lower power, and then the PTC heating element is switched to heat the heating chamber to reduce energy consumption. The unmanned vehicle adopting the cooling and heating integrated cabinet can heat or cool goods, the energy consumption for heating is low and the time of endurance is long.

Owner:NEOLIX TECH CO LTD

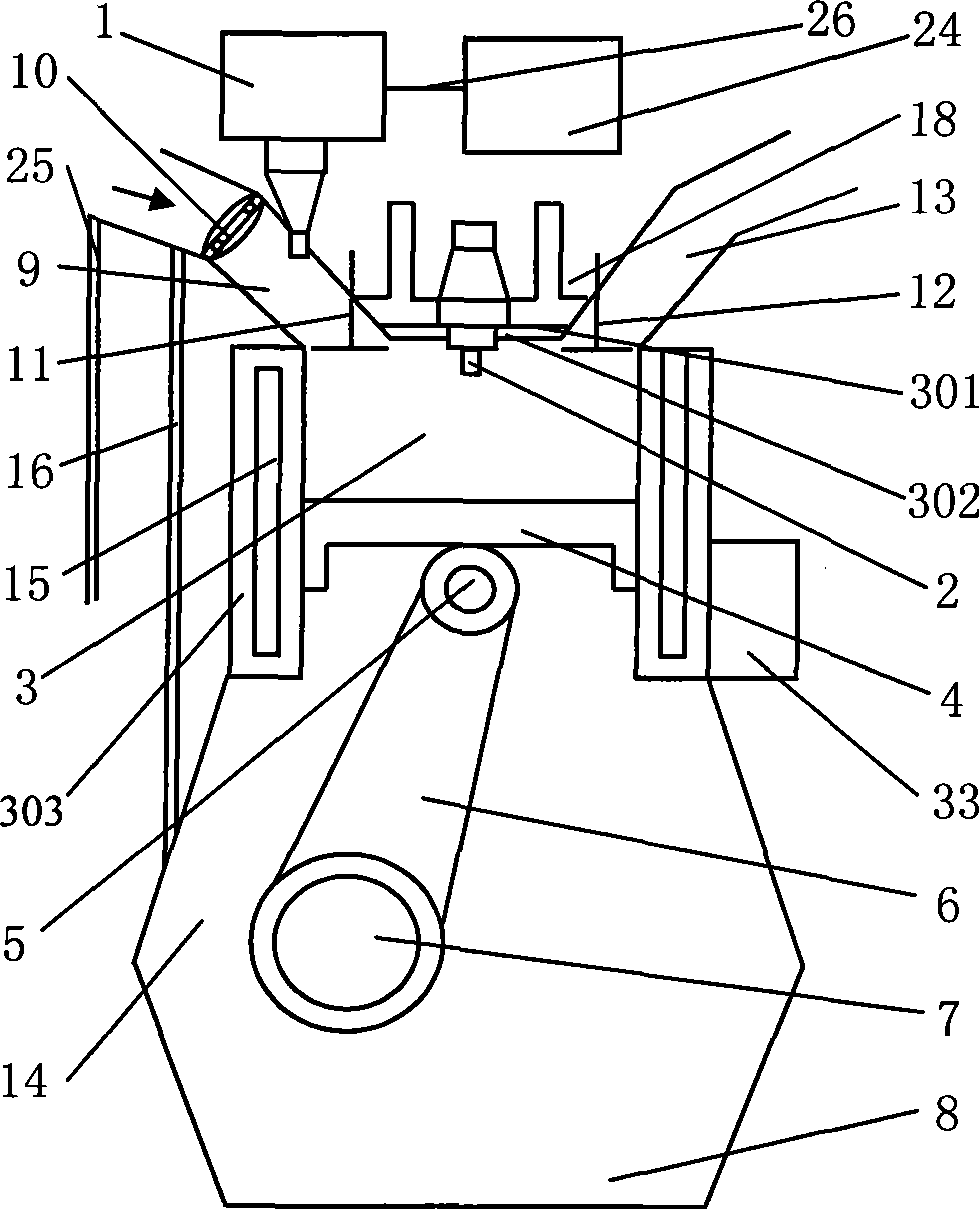

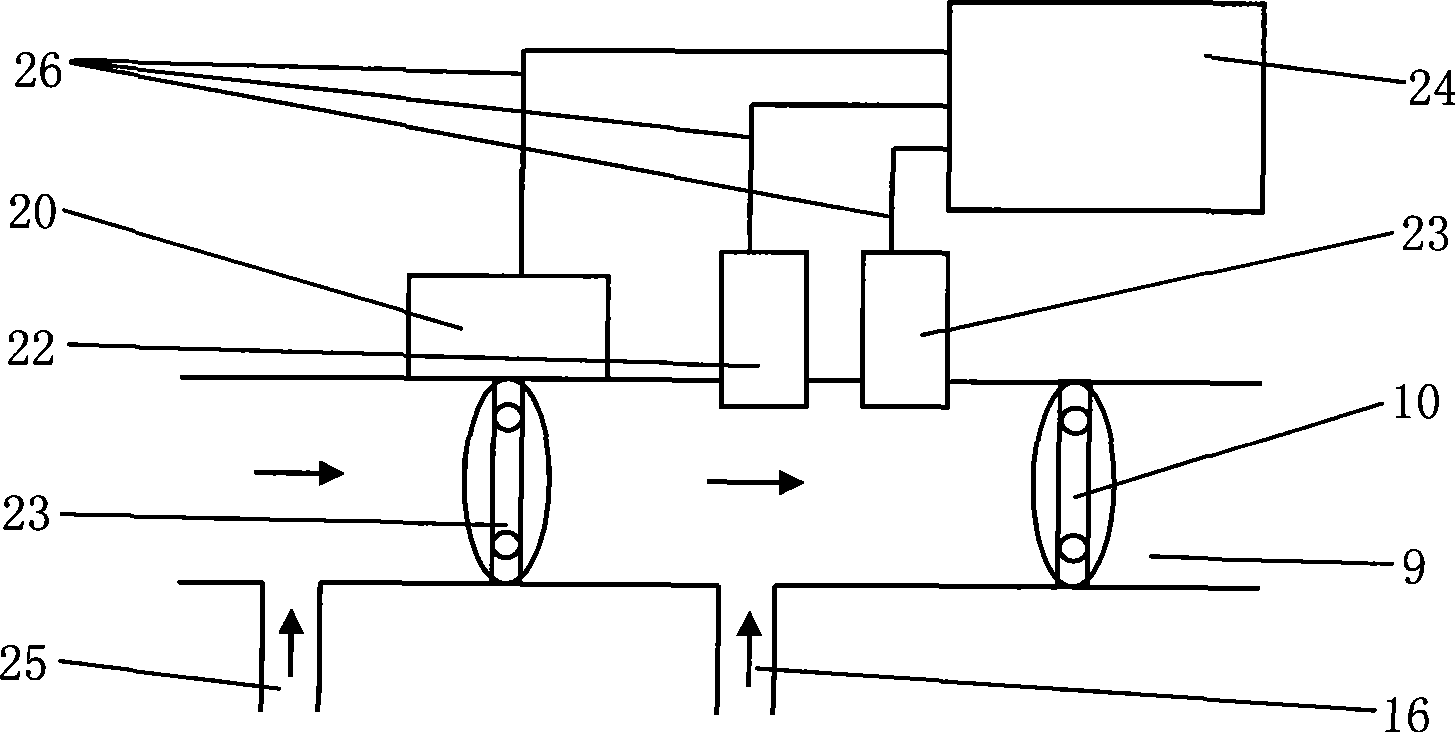

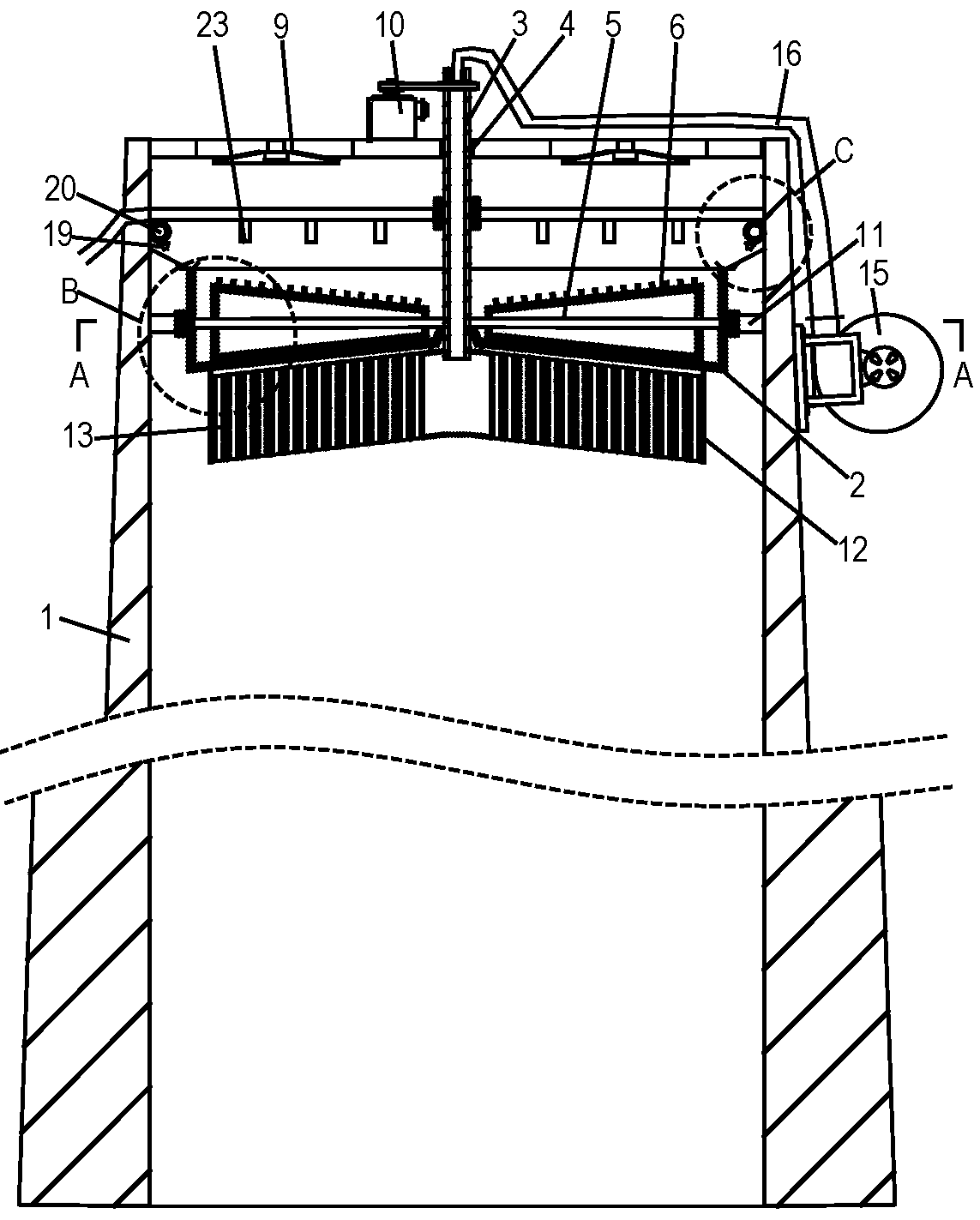

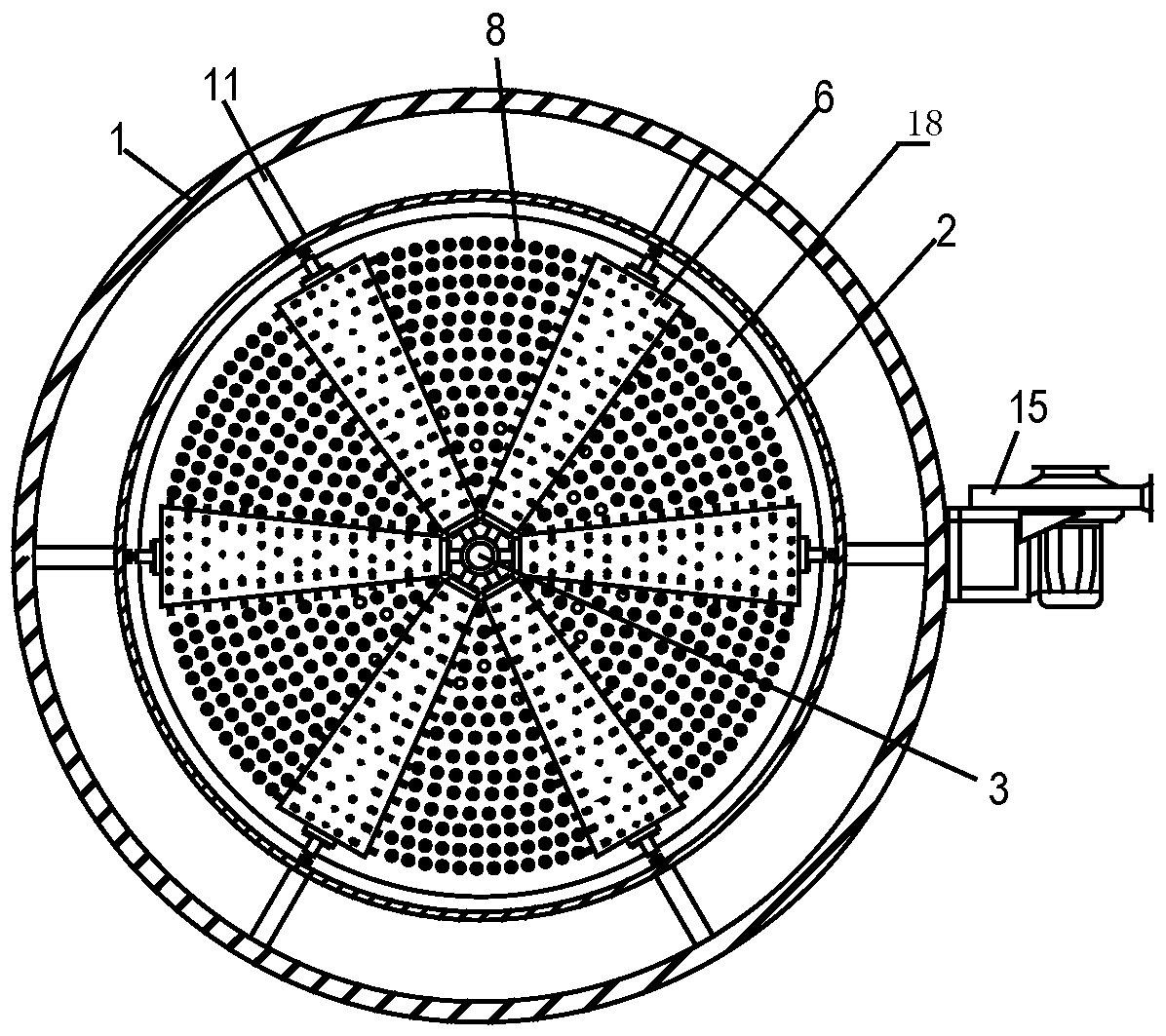

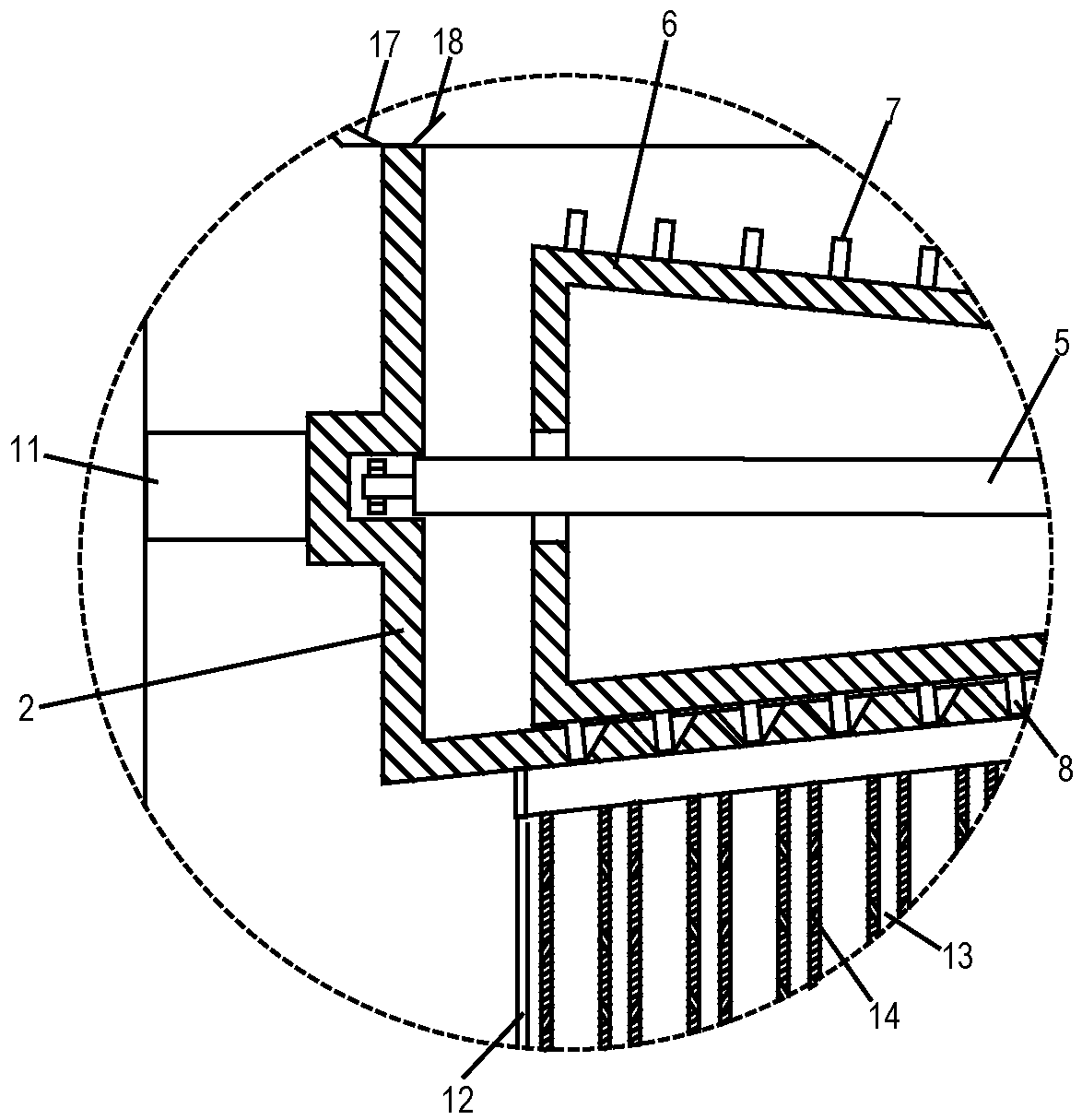

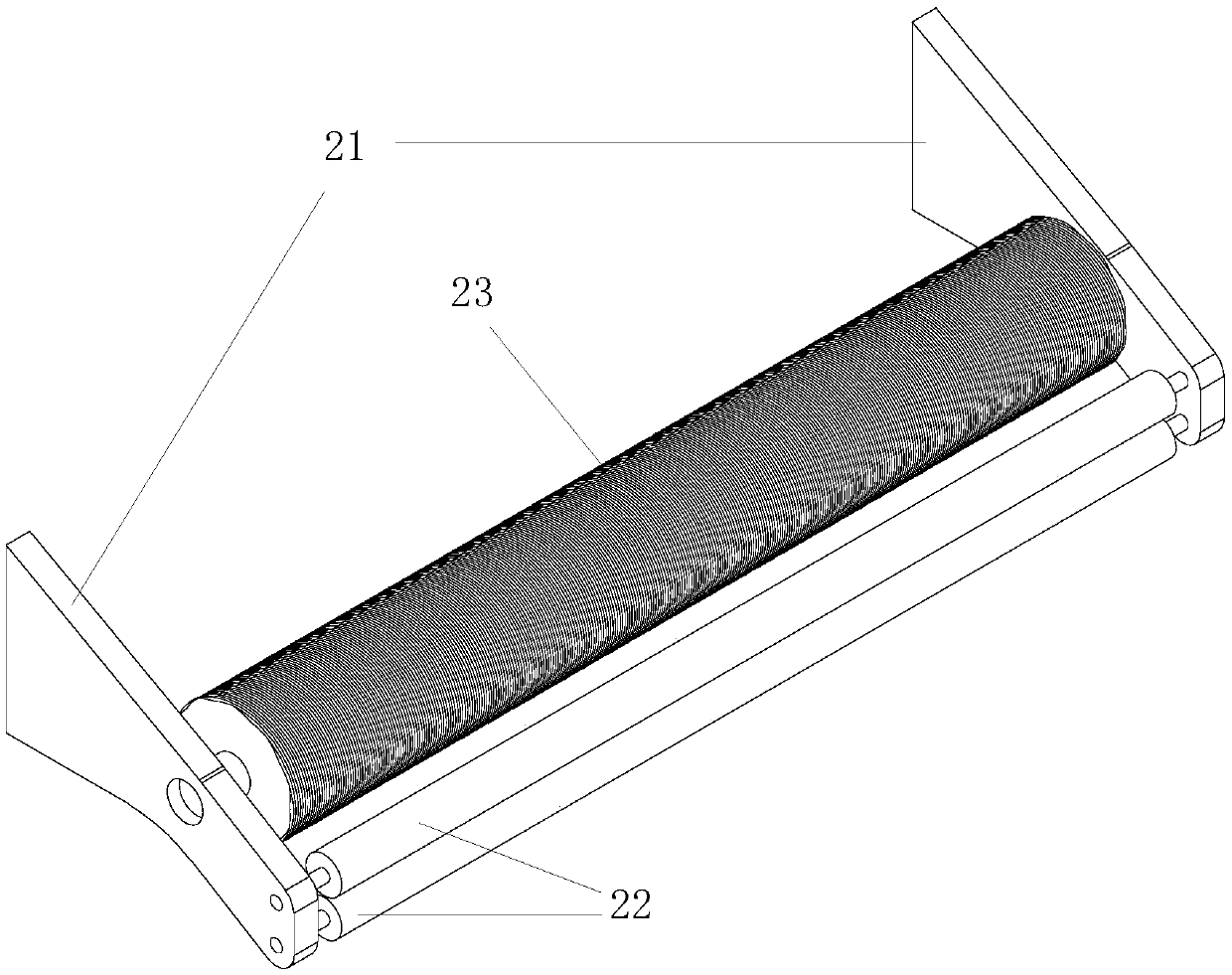

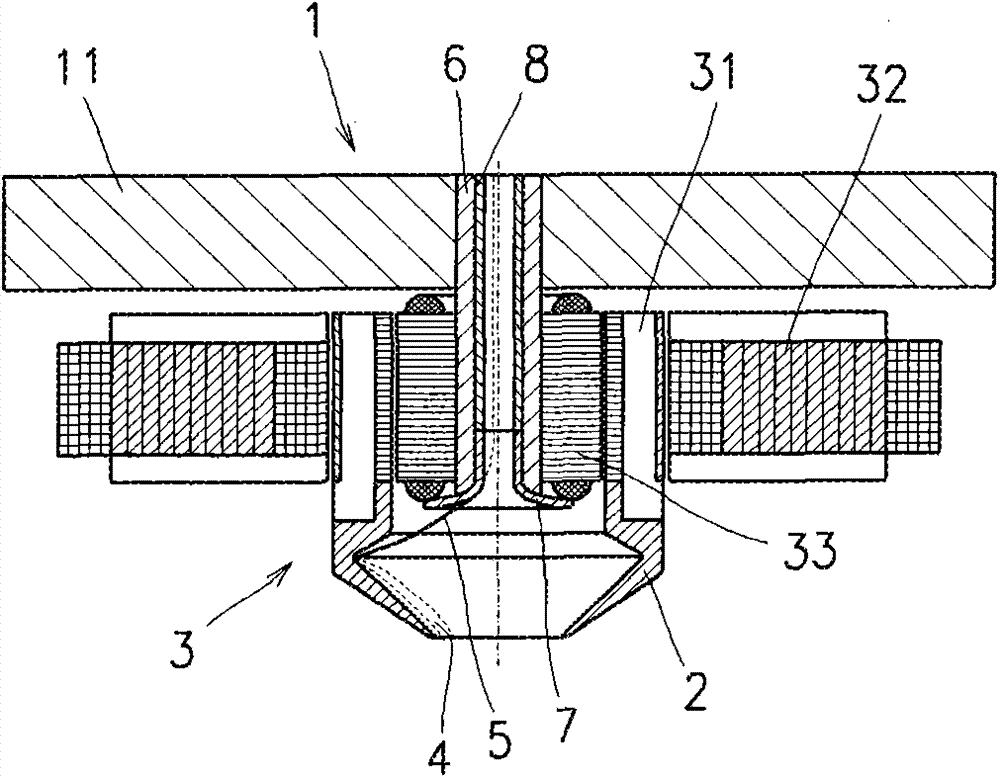

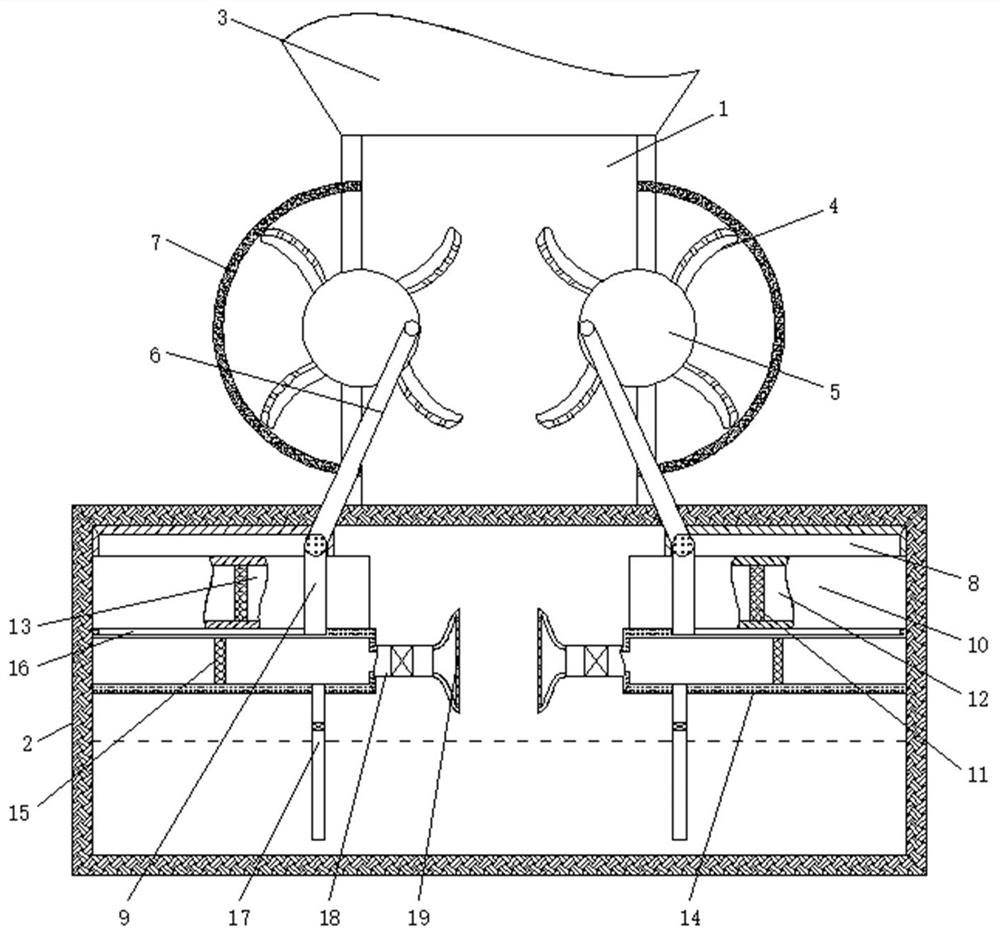

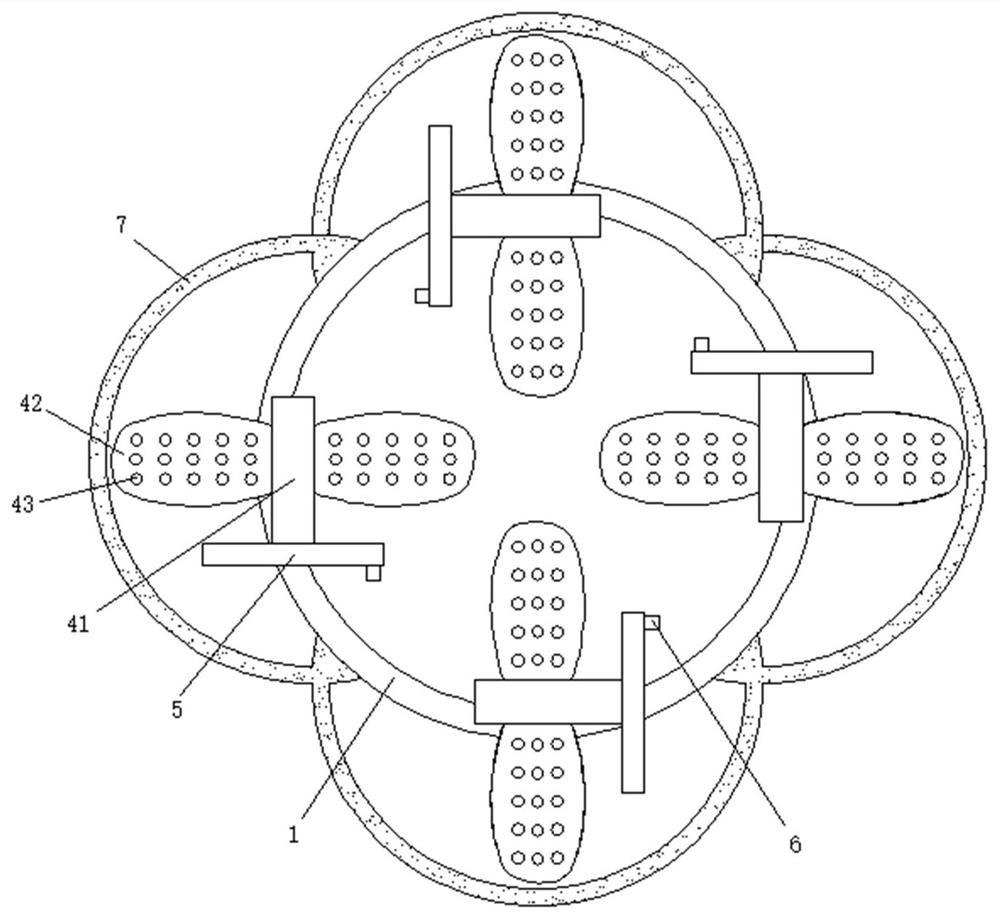

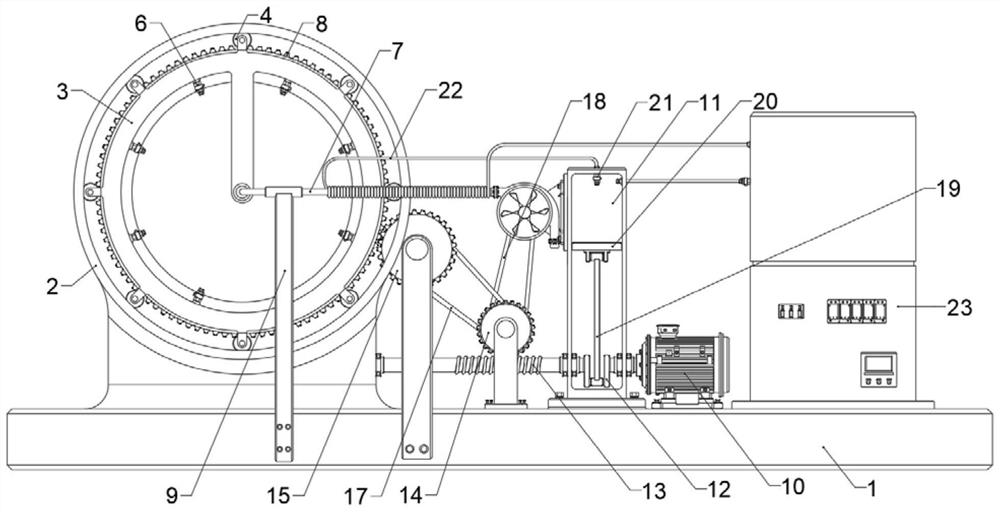

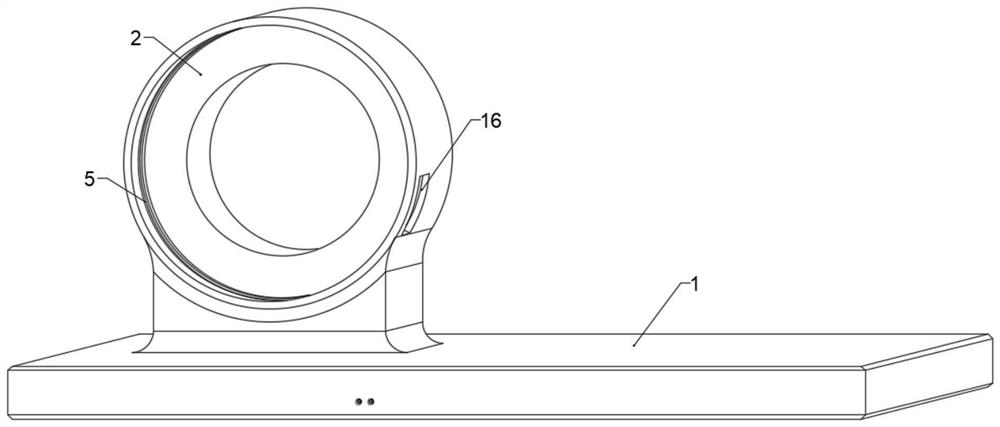

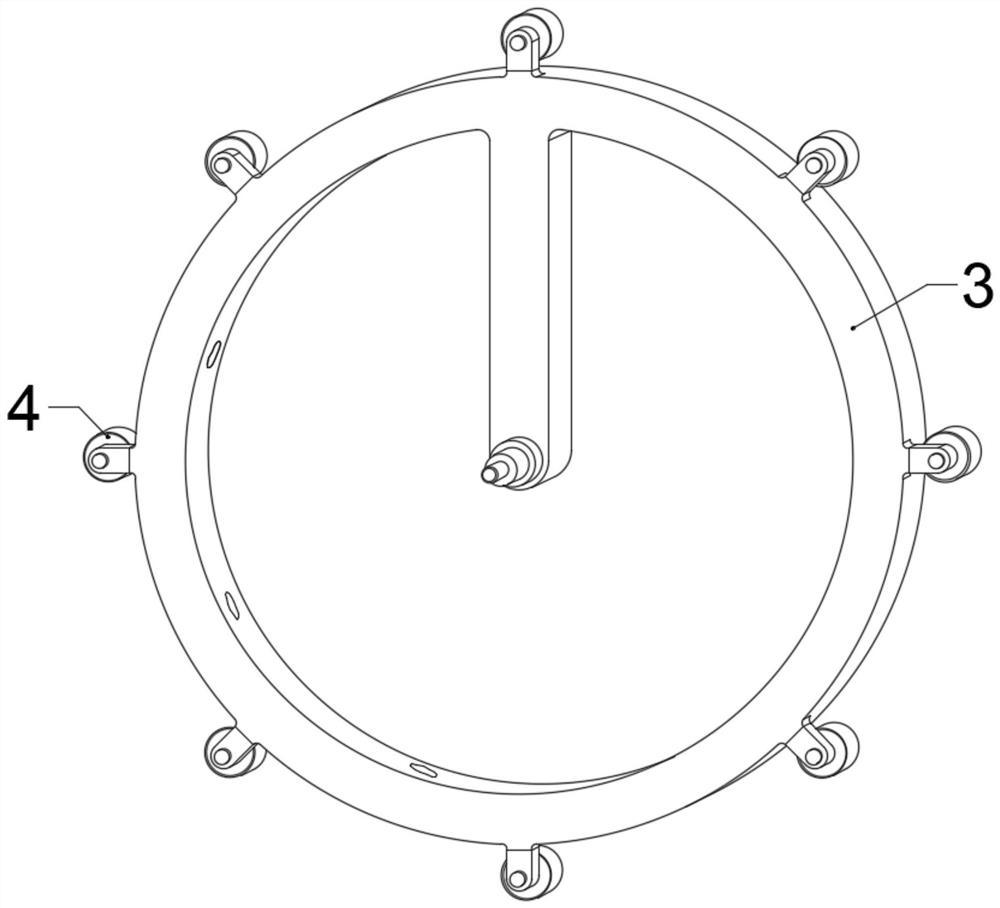

Spinning apparatus of rotor spinning machine

A spinning apparatus of a rotor spinning machine. The apparatus has spinning shells (2) with openings at two sides are coaxially mounted on a radial electromangeitc bearing, an electromagnetic bearing and an electromagnetic functional unit (31) of an electrical rotation drive of a driving system (3), the spinning shell (2) is provided with an inlet opening for entry of dissolved fibers (4) and an outlet opening for discharging a spun yarn (5), the outlet opening extends to an aperture formed in a stator (33) of the electrical rotation drive, a discharge chute (7) of the yarn is connected to the aperture in the stator of the electrical rotation drive, and the stator of the electrical rotation drive is supported in a cover (11) of a spinning unit (1). A discharge chute is supported in a bushing (6) made of heat conducting material, and the bushing is supported in the stator of the electrical rotation drive and in the cover of the spinning unit and used for dissipating heat from the stator of the electrical rotation drive to the cover of the spinning unit.

Owner:RIETER CZ AS

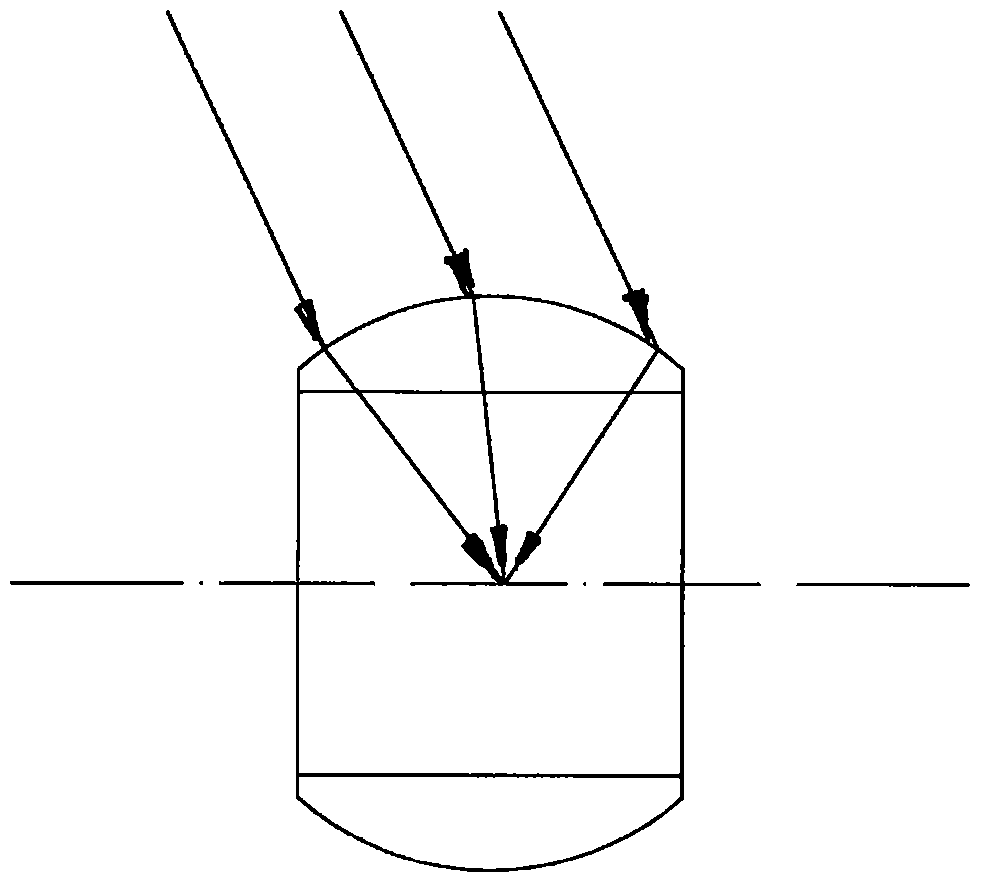

Annular convex lens and efficient light type solar water heater

PendingCN112178956AIncrease illuminationWith focus heat collection functionSolar heating energySolar heat collectors with working fluidsSolar lightSolar water

The invention provides an annular convex lens and an efficient light type solar water heater and belong to the solar water heaters. The annular convex lens is characterized in that an annular light-transmitting ring with a longitudinal focusing function is arranged on a glass evacuated tube in a sleeving manner, so that an evacuated tube collector only having a transverse focusing function also has the longitudinal focusing function, and the heat collecting efficiency is increased by multiple times; meanwhile, the light catching feature of the annular convex lens has high adaptability to the spatial movement of the solar light source; and in this way, the evacuated tube collector can be light and miniaturized, it can be achieved that the evacuated tube collector still keeps efficient lightcatching capacity, heat collecting capacity and heat supplying capacity when installed close to the facade of an outer wall, and therefore vast building residents can also use the solar water heater.Besides, the emission of carbon dioxide can be effectively reduced.

Owner:王振国

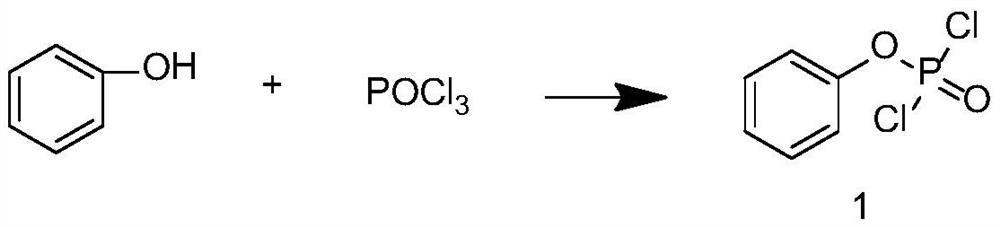

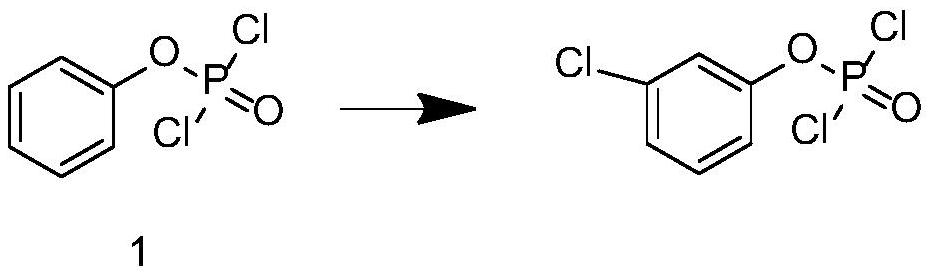

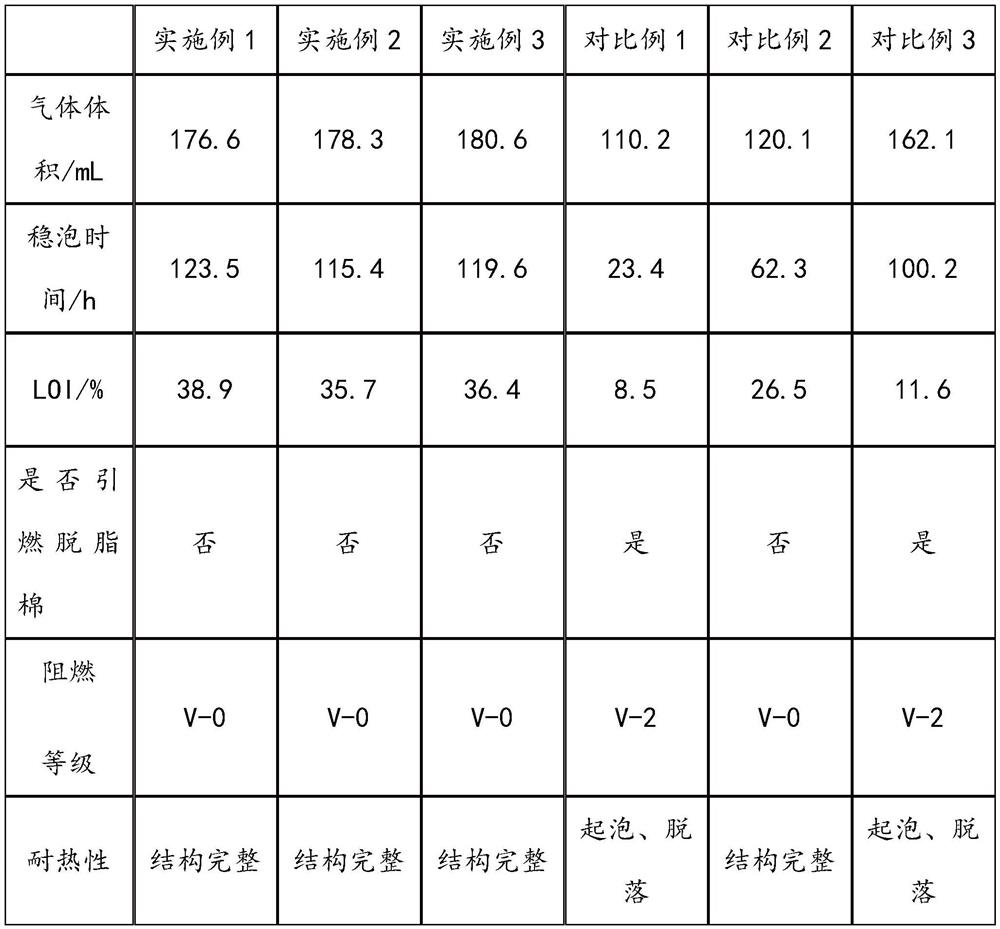

High-temperature flame-retardant foaming agent and preparation method thereof

The invention discloses a high-temperature flame-retardant foaming agent. The foaming agent is prepared from, by weight, 20 to 30 parts of azodicarbonamide, 10 to 15 parts of gelatin, 0.1 to 0.3 part of alkaline protease, 8 to 10 parts of flame-retardant mesoporous silicon dioxide and 15 to 25 parts of deionized water. The invention also discloses a preparation method of the high-temperature flame-retardant foaming agent. The azodicarbonamide and a protein type foaming agent are compounded according to a proper compatibility ratio, the defect that the foam stability of the azodicarbonamide is poor is effectively overcome, the composite organic foaming agent is loaded in the carrier mesoporous silica and can be uniformly dispersed in a polymer matrix, and the composite organic foaming agent is used as a bubble nucleation point to make particles of the foaming agent refined, so the problems that foam holes of a foam material prepared by the foaming agent are not uniform and the density of the foam holes is low are solved, and the foaming agent has flame retardance and high temperature resistance, so that the foaming agent has a certain application prospect and market value.

Owner:嘉善县纤明新材料有限公司

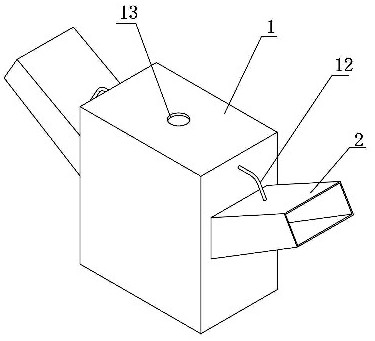

Water-cooling fire grate type biomass gasification furnace

ActiveCN113528193AReduced gravitational potential energyLower initial temperatureHollow bar grateGasification processes detailsWater vaporEnvironmental engineering

The invention relates to the technical field of biomass gasification, and discloses a water-cooling fire grate type biomass gasifier which comprises an ash passing channel, a water tank is fixedly installed at the bottom of the ash passing channel, an ash discharging hopper is fixedly installed at the upper end of the ash passing channel, and an energy reducing device is arranged on the inner side wall of the ash passing channel. A turntable is fixedly mounted in the middle of the energy reducing device. The energy reducing device is arranged in the ash passing channel, gravitational potential energy of ash is used as power for rotation of the fan blades to reduce the gravitational potential energy of the ash, meanwhile, the contact area of the fan blades and the ash is increased through the fan blades and the through holes of the fan blades, and heat of the ash passes through the eccentric rod and the heat conduction ring, the heat is used for the expansion effect of gas in the gas containing cavity to reduce the initial temperature of ash, the water impact phenomenon is reduced by reducing the potential energy and temperature of downward impact of the ash, the temperature of water vapor is reduced, and the impact phenomenon in the water tank is reduced.

Owner:赣州市怡辰宏焰能源科技有限公司

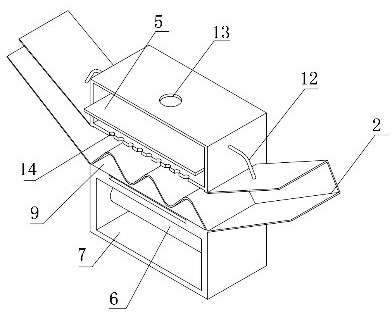

Processing, conveying and cooling equipment for gypsum production line

ActiveCN113405272ARealize rational utilizationLower initial temperatureConveyorsCompression machinesCold airProduction line

The invention discloses processing, conveying and cooling equipment for a gypsum production line. The processing, conveying and cooling equipment comprises a cooling box and a conveying hopper; a conveying belt used for conveying gypsum is arranged in the conveying hopper, the conveying hopper penetrates through the two side walls of the cooling box in a sealed mode, and a cooling through opening is formed in the position, located on the upper wall of the cooling box, of the conveying hopper in a penetrating mode; a processing space is formed in the part, located above the cooling through opening, of the cooling box; a connecting space is formed in the part, located below the conveying hopper, of the cooling box; a sealing plate is connected into the processing space in a sealed mode; and a cold air storage cavity is formed in the space, located below the sealing plate, of the processing space; the space, located above the sealing plate, of the processing space is arranged to be an excess material recycling cavity; a cooling structure is arranged in the cold air storage cavity; and a recycling structure is connected into the excess material recycling cavity. The equipment has the advantages that the rapid cooling process is better achieved, the tail gas absorption effect is achieved, and raw material waste and air pollution are avoided.

Owner:江苏思克赛斯机械制造有限公司

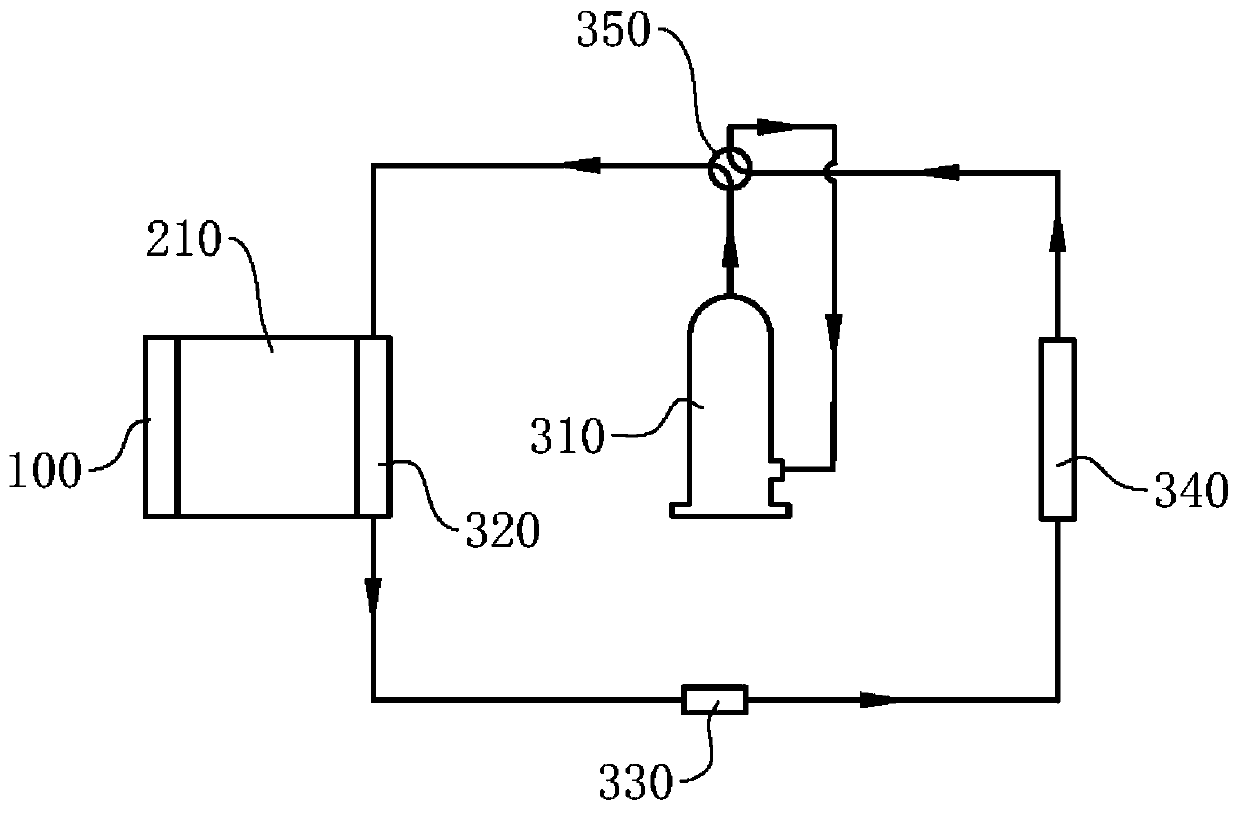

Fixed type water chiller capable of recycling waste heat

ActiveCN113280571AReduce the temperatureReduce energy consumptionDomestic cooling apparatusLighting and heating apparatusLiquid waterWater circulation

The invention discloses a fixed type water chiller capable of recycling waste heat. The fixed type water chiller comprises a machine shell and a bottom plate, wherein the bottom plate is fixedly connected with the outside ground through a plurality of bolts; a liquid tank is fixedly arranged at the bottom of the bottom plate; a refrigerating machine is fixedly arranged in the machine shell; a cooling liquid outlet pipe, a water inlet pipe, a water outlet pipe and a cooling liquid inlet pipe are arranged in the refrigerating machine respectively; the water outlet pipe is communicated with a material distribution box; the other end of the material distribution box is communicated with a plurality of backflow pipes; the plurality of backflow pipes penetrate through the bottom plate and are communicated with the interior of the liquid tank; and the backflow pipes are connected with a waste heat utilization structure and a cooling recycling structure. The fixed type water chiller has the advantages that a cooling medium and cooling liquid are cooled through an evaporation cooling process of low-boiling-point evaporation liquid and an air cooling process of heat dissipation blades respectively, and the problem that liquid water enters a cooling system is solved, so that the cooling efficiency is improved, the total amount of water in the water circulating flowing process is reduced, and resources are saved.

Owner:南通吉利新纺织有限公司

Cooling system device for magnetic axial bearing

InactiveCN112943807ALower initial temperatureAchieving Surround JetMagnetic bearingsBearing coolingMagnetic bearingEngineering

The invention discloses a cooling system device for a magnetic axial bearing. A rotating ring is rotatably arranged in an annular seat, and a plurality of snifting valves for cooling the magnetic bearing are arranged on the rotating ring along the circumference; a rotating mechanism is arranged on a mounting base, an air supply assembly used for pumping air into the rotating ring is further arranged on the mounting base, and a condensation assembly used for cooling the pumped air is attached to the air supply assembly; when a power device works, the air supply assembly and the condensation assembly are driven to work at the same time, wherein the air supply assembly continuously pumps air flow to an extending part of the rotating ring, and the fed air flow is sprayed to the magnetic bearing through the snifting valves distributed circumferentially; the condensation assembly is used for cooling the air flow passing through the air supply assembly, so that the air flow sprayed out of the snifting valves has a low initial temperature, and heat exchange with hot air around the magnetic bearing is achieved; and in addition, the air supply assembly drives a cargo transfer mechanism to act so as to drive the whole rotating ring to rotate.

Owner:廖加胞

Pipeline equipment for temperature control of phosphoric acid machine

ActiveCN109698148AEasy temperatureLower initial temperatureSemiconductor/solid-state device manufacturingPipeline systemsTemperature controlBuffer tank

The invention provides a piece of pipeline equipment for temperature control of a phosphoric acid machine. A first liquid inlet of a direct supply tank is connected with a liquid outlet of a first buffer tank. A liquid outlet of the direct supply tank is connected with a second liquid inlet thereof to constitute a main circulation loop in which a number of working chambers are connected. The working chambers are connected with first and second switching valves. The first switching valve is connected with a discharge outlet. The second switching valve is connected with a liquid inlet of a recovery tank. A liquid outlet of the recovery tank is connected with a liquid inlet of a second buffer tank. A liquid outlet of the second buffer tank is connected to a pipeline between the liquid outletof the first buffer tank and the first liquid inlet of the direct supply tank. A cooling device is arranged on a pipeline between the liquid outlet of the second buffer tank and the first liquid inletof the direct supply tank. By adding the cooling device on the pipeline between the liquid outlet of the second buffer tank and the first liquid inlet of the direct supply tank, the initial temperature of phosphoric acid entering the direct supply tank is reduced, the temperature difference between the buffer tanks and the direct supply tank is reduced, the temperature of phosphoric acid in the direct supply tank is controlled, and the alarm probability is reduced.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

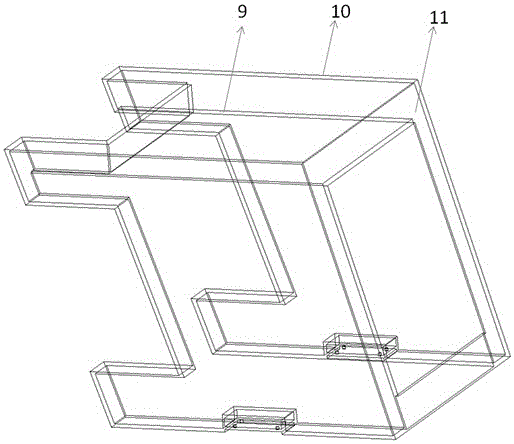

Combined hood for engineering machinery

ActiveCN104149859BImprove sound insulationImprove vibration resistanceSuperstructure subunitsPropulsion coolingMechanical engineeringPhysics

The invention discloses a combined hood for engineering machinery, which comprises an engine hood and a heat dissipation hood, and the heat dissipation hood is provided with an air intake grid and an exhaust grid; the heat dissipation hood is connected to the tail of the engine hood , the radiating cabin cover and the engine compartment cover are isolated by the tail end plate of the engine compartment cover; The outer cover is fixedly connected, and a first airtight cavity is formed between the engine compartment inner cover and the engine compartment outer cover; the heat dissipation compartment cover includes a heat dissipation compartment inner cover and a heat dissipation compartment outer cover positioned outside the heat dissipation compartment inner cover, and the heat dissipation compartment inner cover and The outer cover of the heat dissipation cabin is fixedly connected, and a second airtight cavity is formed between the inner cover of the heat dissipation cabin and the outer cover of the heat dissipation cabin. The combined hood has good sound insulation performance and anti-vibration performance.

Owner:JIANGSU NANGAO INTELLIGENT EQUIP INNOVATION CENT CO LTD

A kind of method utilizing lithium carbonate to prepare high-purity lithium oxide

Owner:GANFENG LITHIUM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com