Patents

Literature

153results about "Hollow bar grate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

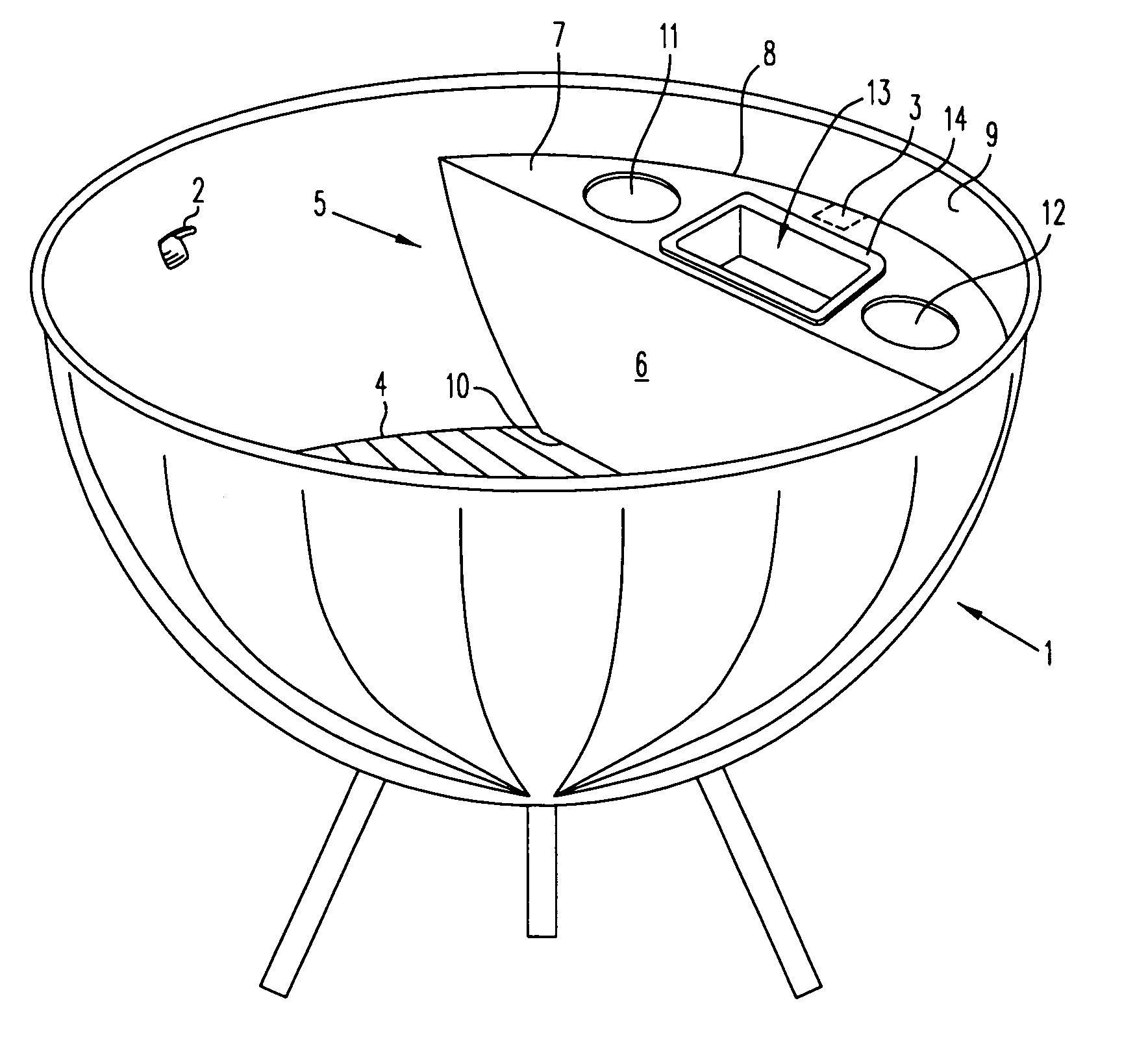

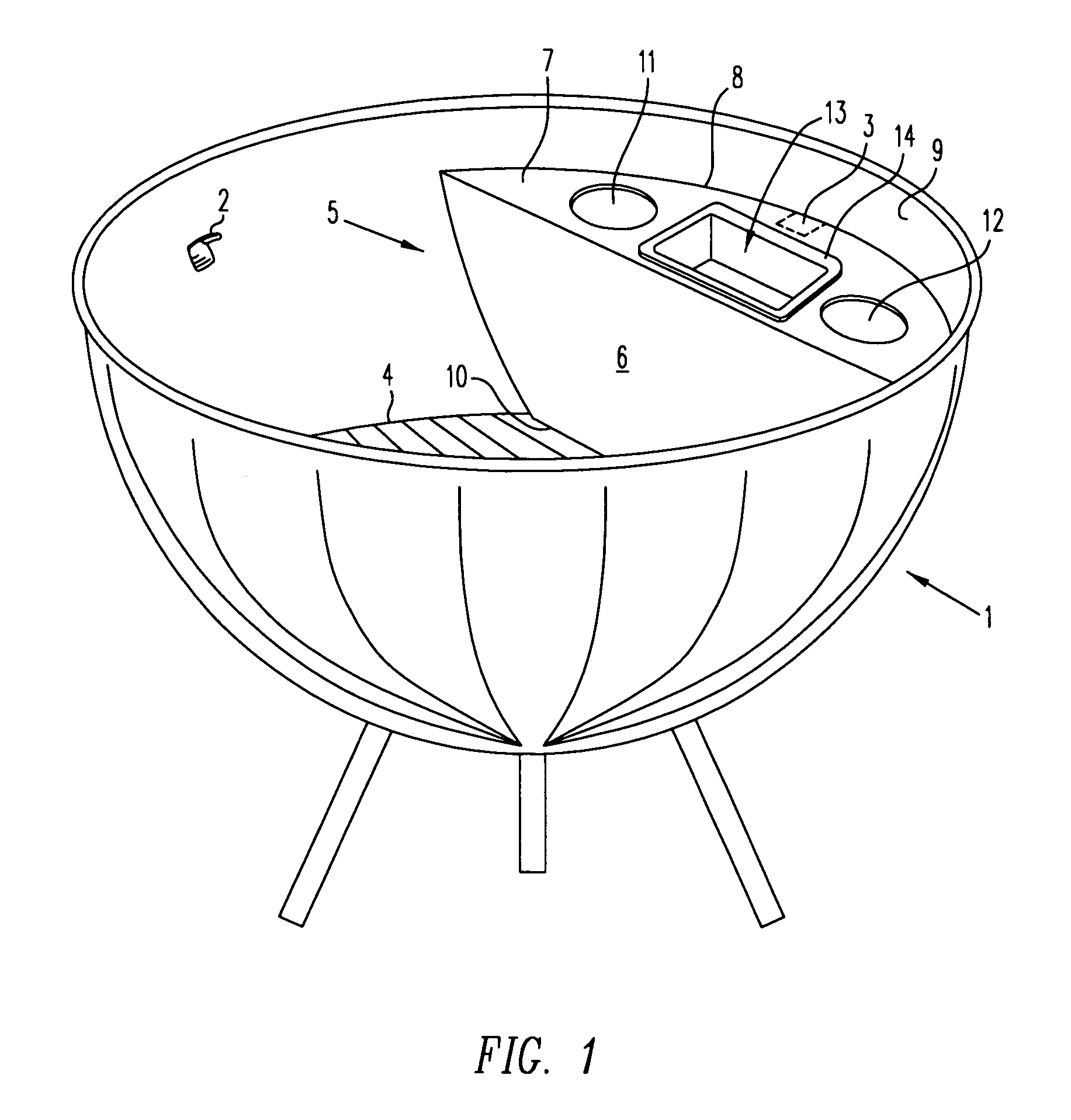

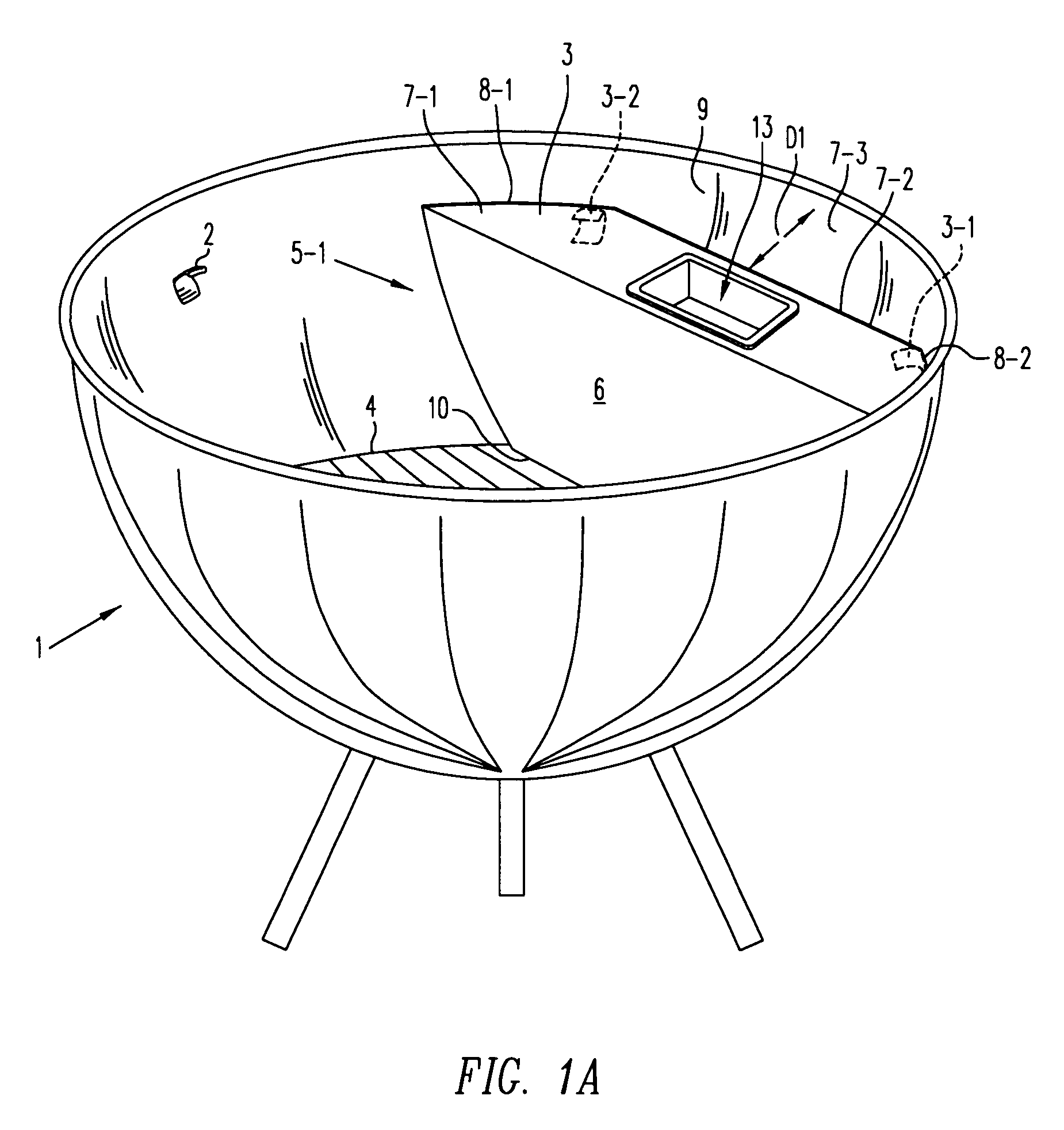

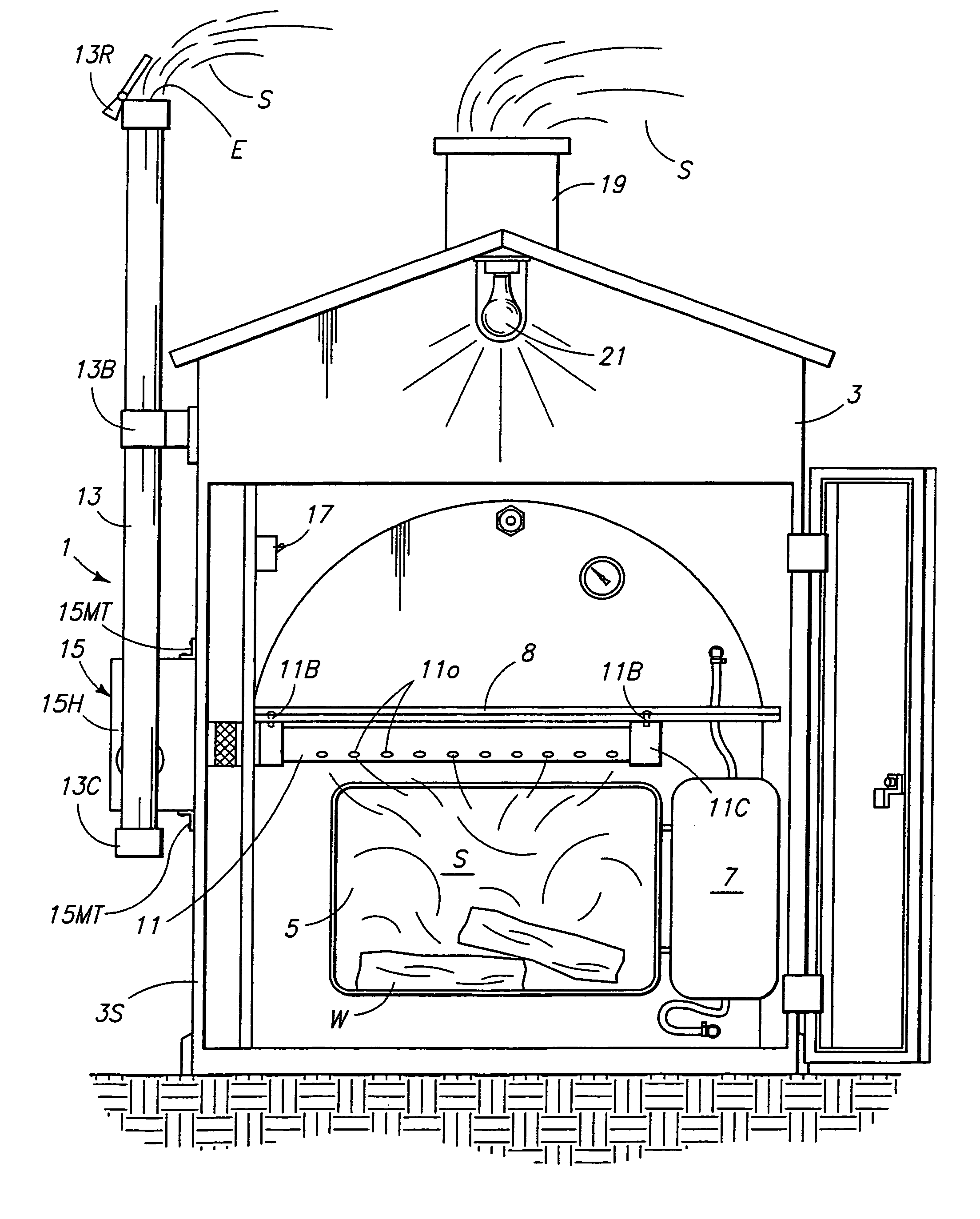

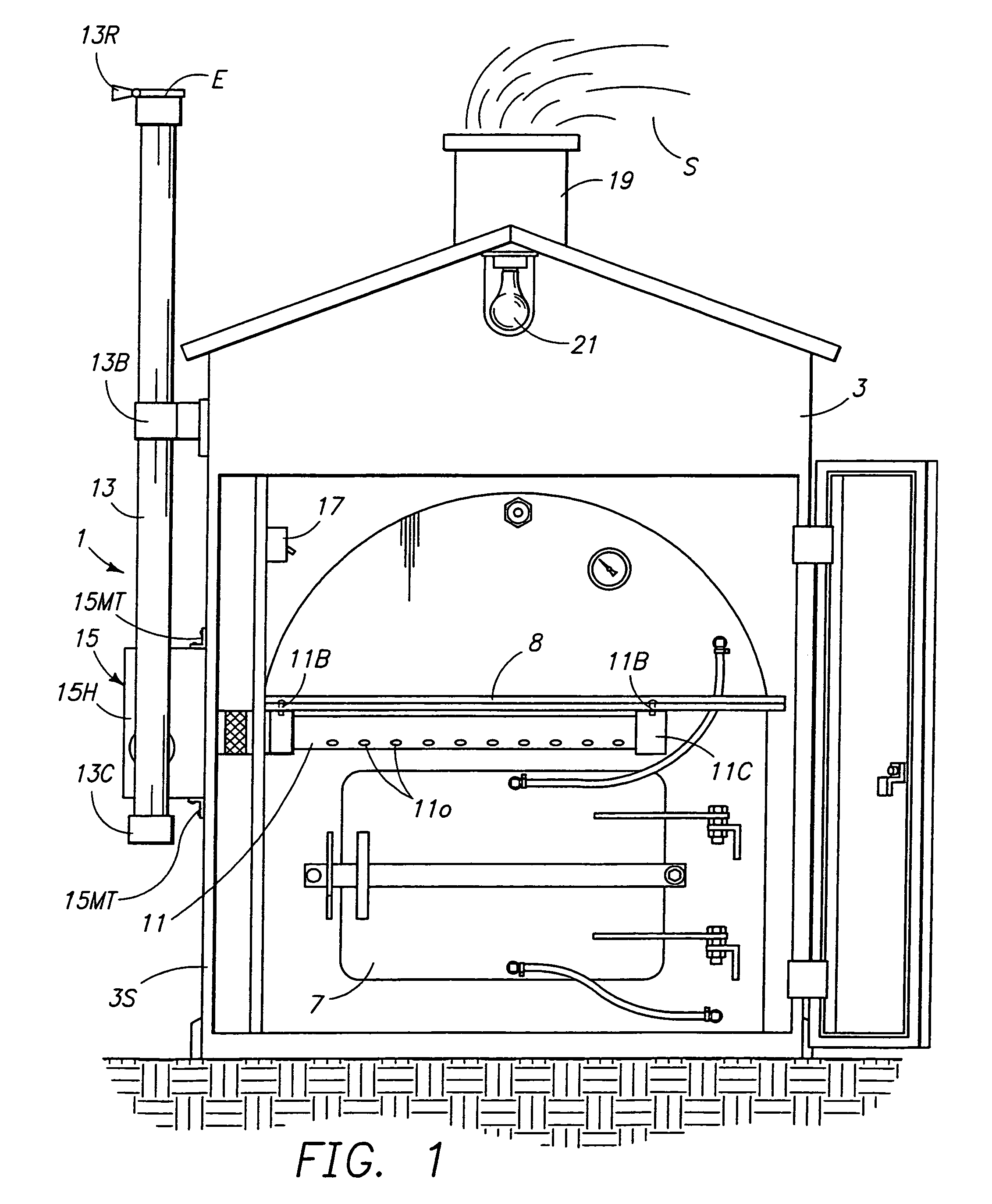

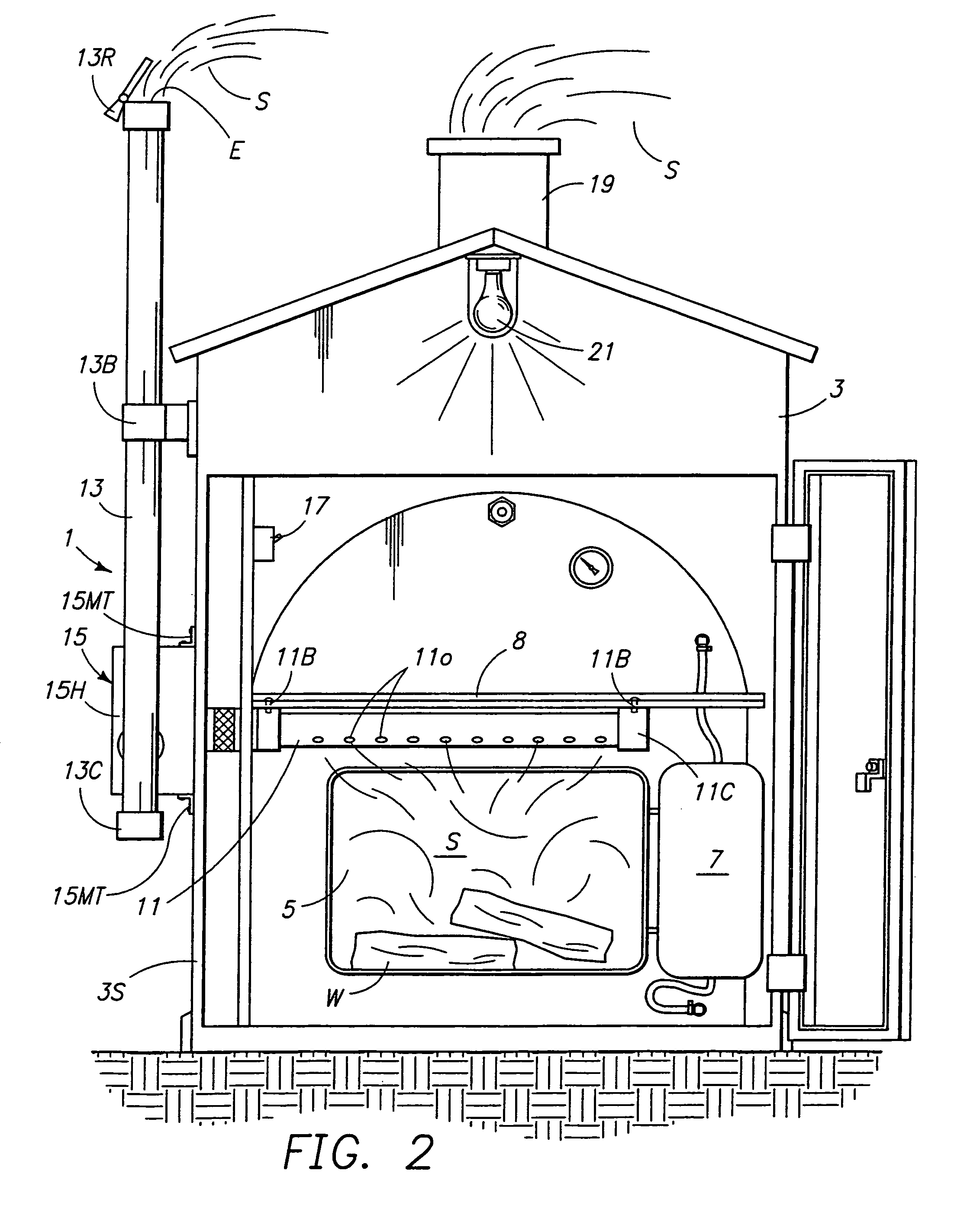

Cooker to smoker adapter

ActiveUS7832330B1Reduce heatConveniently addedAir-treating devicesMilk treatmentNuclear engineeringCooker

A cooker to smoker adapter is provided, and in one embodiment the cooker to smoker adapter includes first and second walls constructed to cooperate with a wall of a cooker to provide a fuel containment zone for receipt of fuel to be used in a smoking process. In another embodiment, one of the walls includes at least one aperture to readily permit the addition of fuel to the fuel containment zone. In yet another embodiment, a second aperture is provided in one of the walls, this aperture being adapted to receive a reservoir for a liquid. In a further embodiment, a liquid holding reservoir is provided integral with one of the walls. In another embodiment, stand-alone structures are provided to define a fuel containment zone to permit the burning of fuel while avoiding direct radiant transmission of heat from the fuel containment zone to a food which is being smoked. In one embodiment, the stand-alone structure is adapted to receive a reservoir for water. In a further one of the stand-alone embodiments, a cap is provided on the cooker to smoker adapter structure. In the stand-alone cooker to smoker adapters an aperture is included in the walls to permit the addition of fuel into a fuel containment zone. In the free-standing cooker to smoker adapters, a chute may also be provided to facilitate the addition of fuel into the fuel containment zone.

Owner:AFC BUSINESS VENTURES

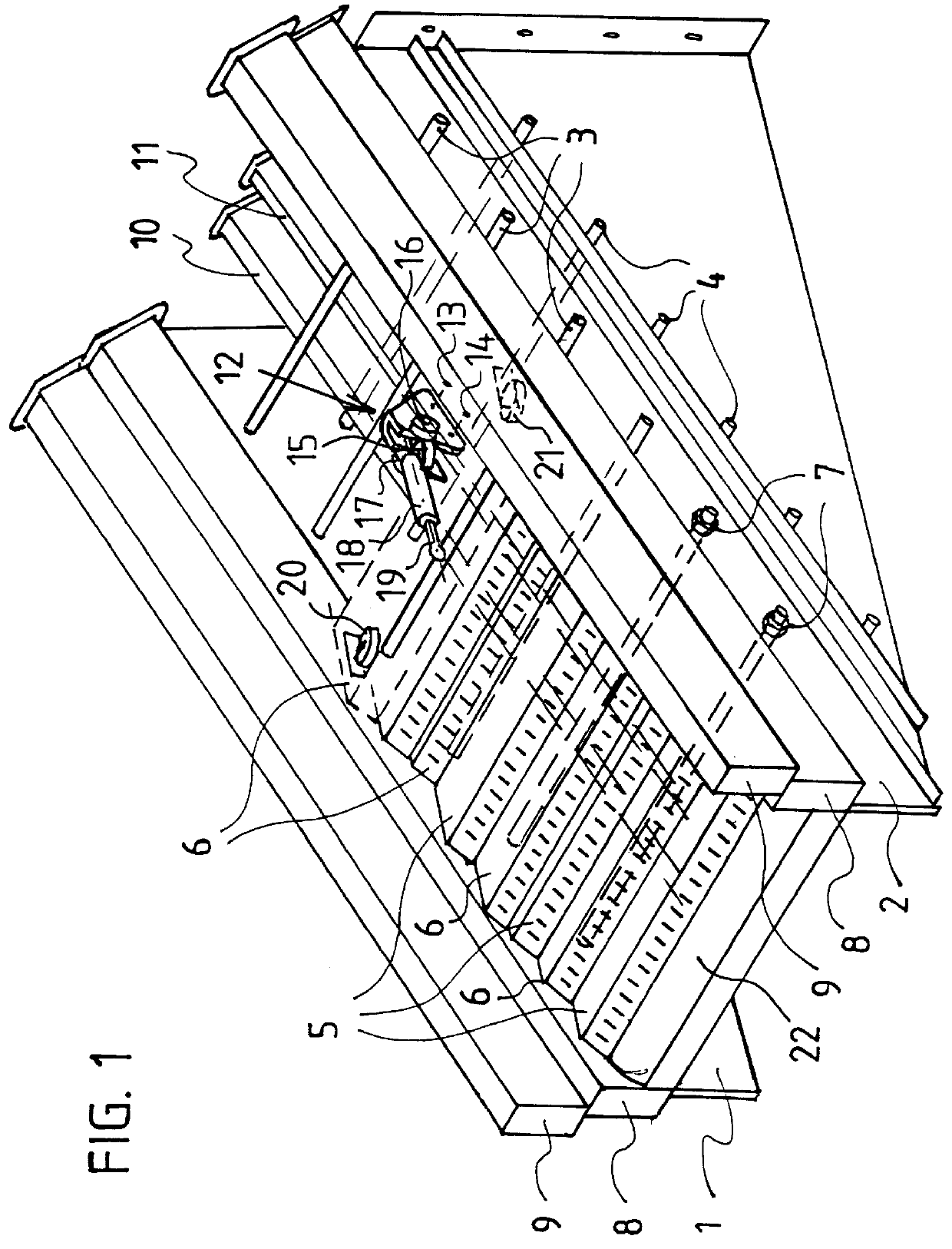

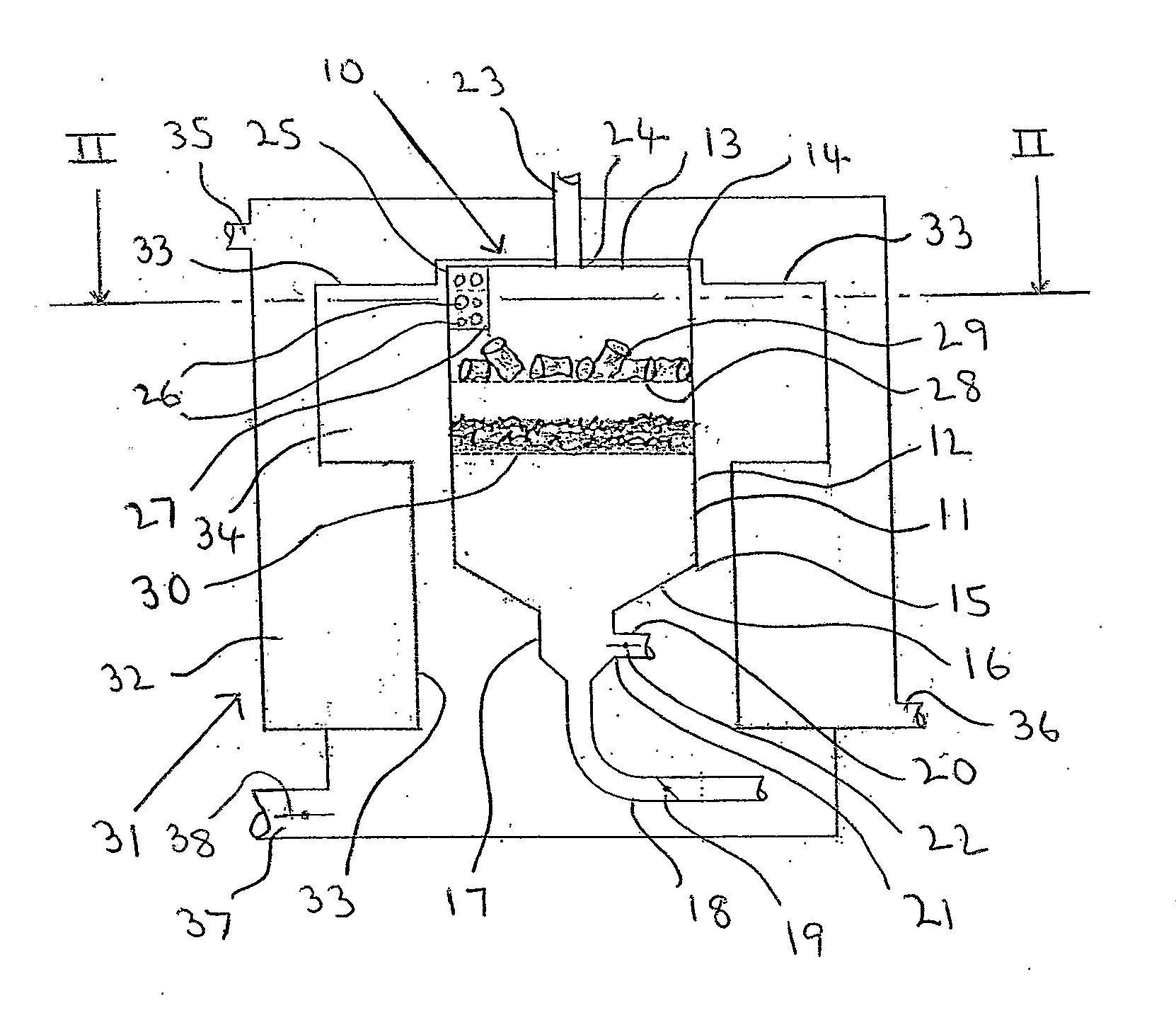

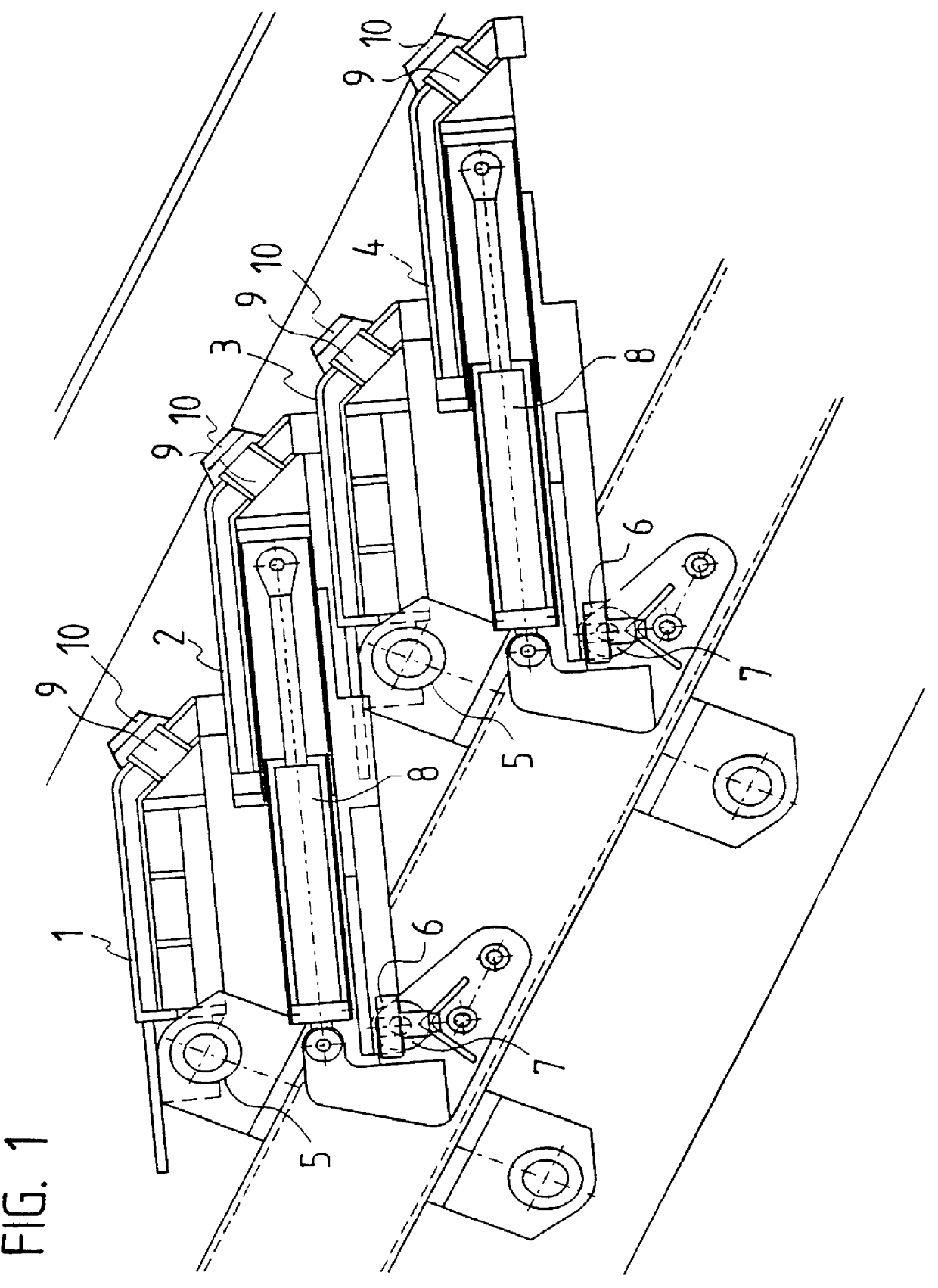

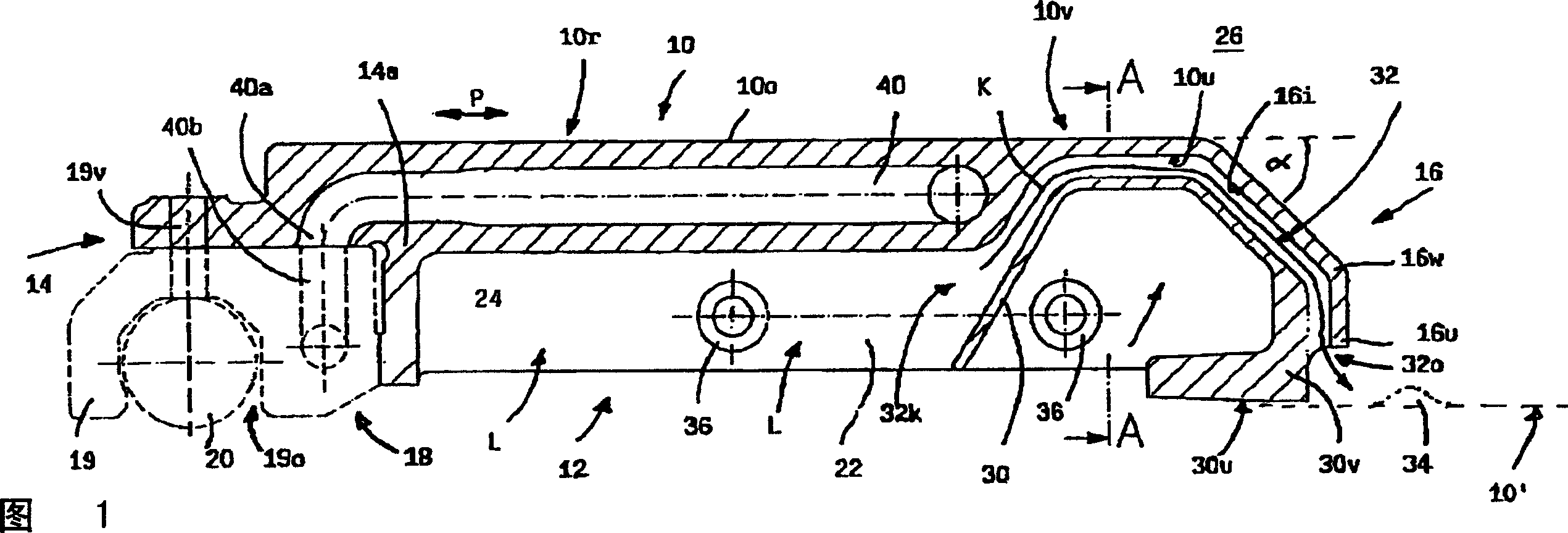

Water-cooled thrust combustion grate

A thrust combustion grate for burning refuse having altemately stationary (5) and movable (6) hollow grate plates (5,6) in a stairway formation, that rest on each other with their front underedge. The grate plates extend across the entire width of the grateway. The movable grate plates (6) are each driven by a hydraulic cylinder-piston unit (18,19). To the sides, the grateway is limited by panels of water-cooled conduits (8,9), which, in the longitudinal direction, each consist of at least two sections sealingly flanged together. The panels are rigidly screwed to each other by a plurality of horizontally disposed distancing bars (3,4) running perpendicular thereto. Running between the panels are two additional conduits (10,11) flanged together in the same way, for feeding primary air and cooling water, which are fixed to certain individual distancing bars (3,4). The back sides of the stationary grate plates (5) each rest on one distancing bar (3) while the back sides of the movable grate plates (6) rest on at least one steel roller (16,17) with a horizontal axis, with each side of their front sides being guided along a steel roller (20,21) whose axis runs perpendicular to the grate plate (6). The front portions of the grate plates (6) form by primary air slots (25).

Owner:DOIKOS INVESTIMENTS LTD

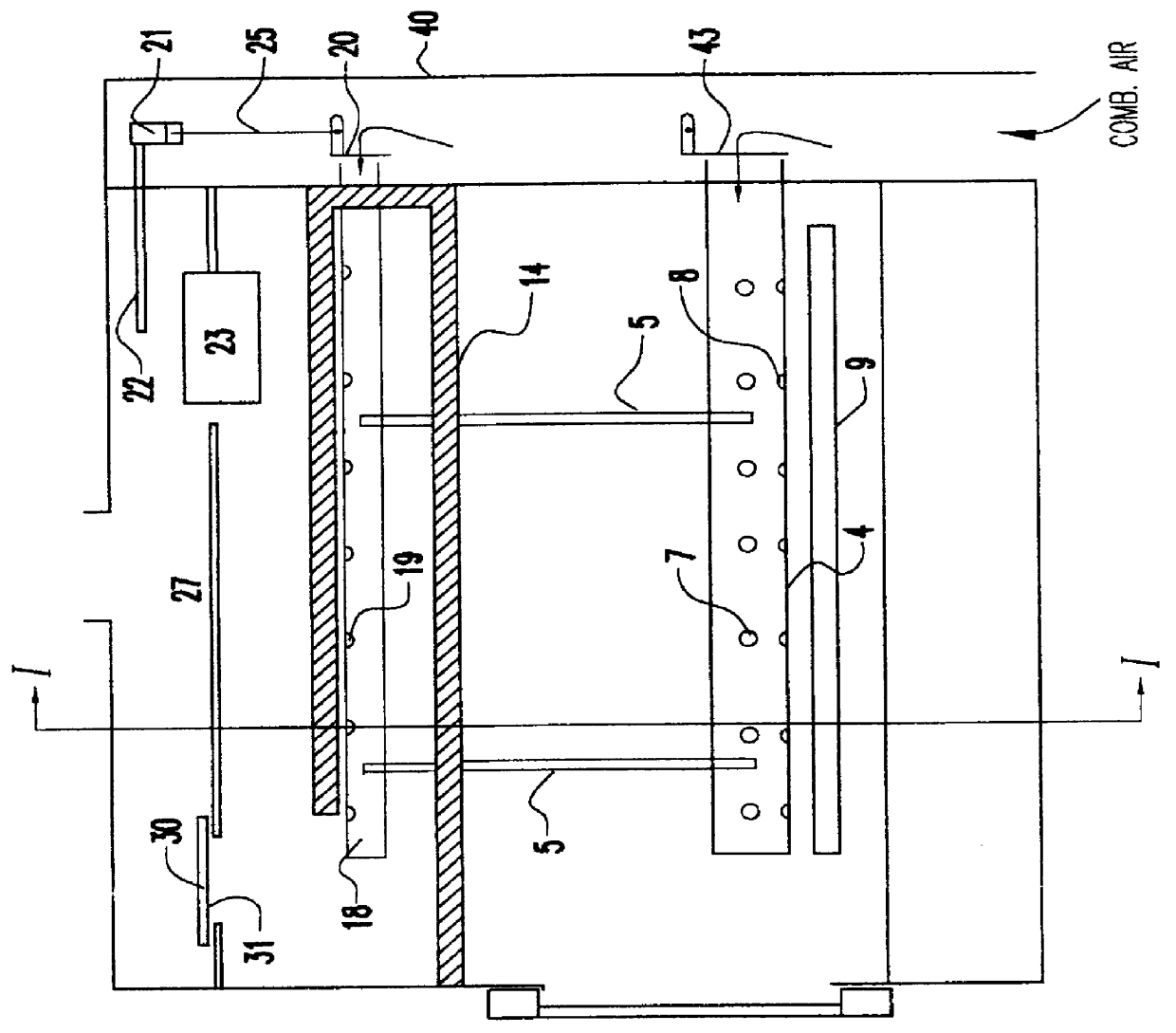

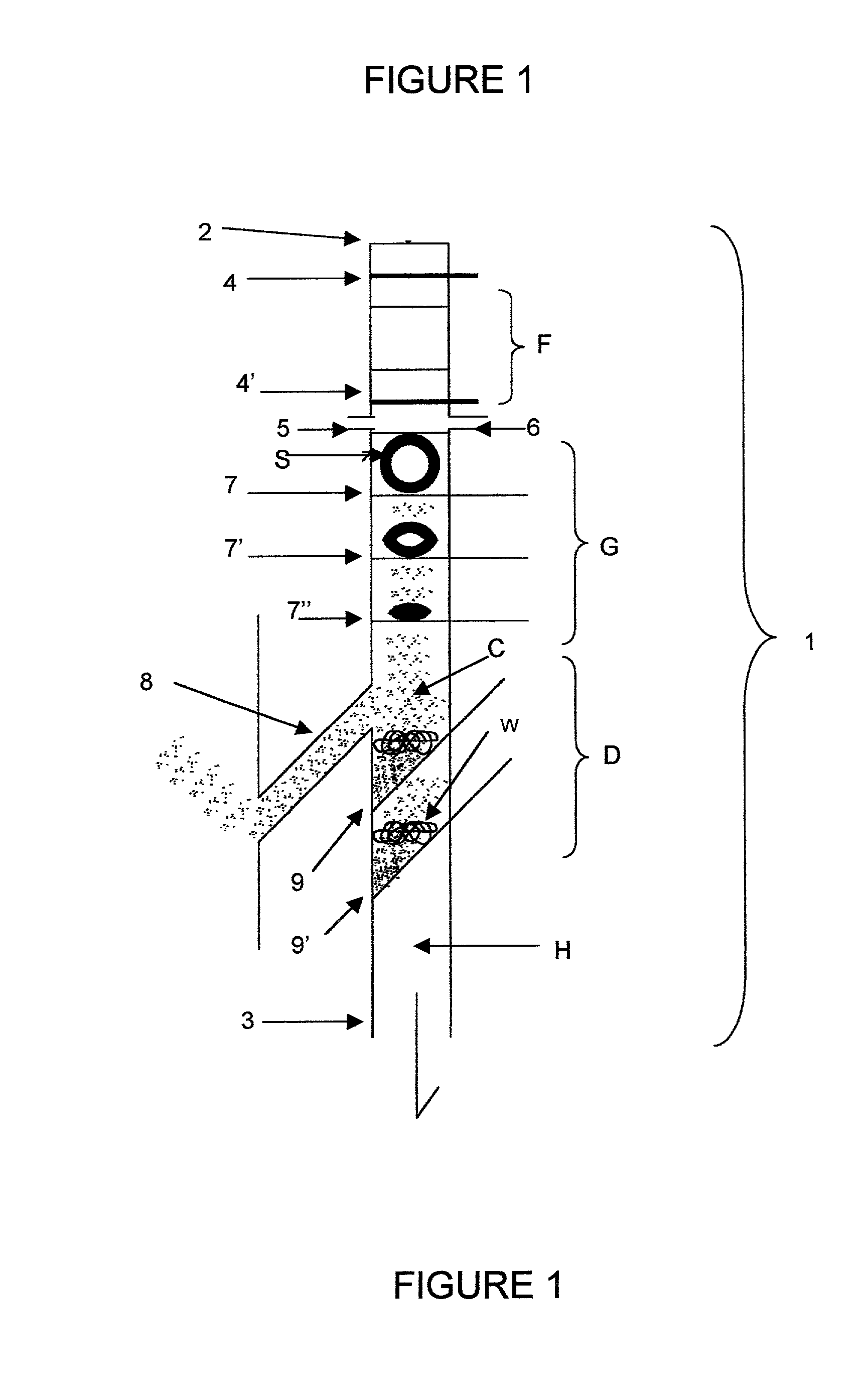

Combustion system

InactiveUS6067979AAvoid quenchingIncrease gasification rateSolid bar grateCombustion-air/flue-gas circulation for stovesCombustion systemCombustion chamber

A combustion system includes a primary combustion chamber divided into left and right sides by fuel-retaining standards defining a canyon or void extending into a secondary combustion chamber is provided. The floor of the primary combustion chamber and the fuel-retaining standards direct the burning solid fuel toward the lower part of the canyon, while at the same time retaining the non-burning solid fuel on either side of the fuel-retaining standards. The combustion system further includes an air delivery system having a lower air tube supplying high and low velocity air and an upper air tube. The lower air tube is positioned proximate to a firebox floor, while the upper air tube is positioned within the secondary chamber. Automatic air setting mechanisms are provided so that proper air settings can be maintained during various phases of a fire. The combustion system further includes a loading door having openings and a bypass system preventing the loading door from being fully closed unless the bypass is in the completely closed position. The secondary combustion chamber includes at least fuel protecting baffles and a secondary combustion chamber ceiling which extends partially over the entire length of the secondary combustion chamber or includes openings. A catalyst mounting system which minimizes canning and masking and a radiant catalyst heating system are also provided.

Owner:JAASMA DENNIS R

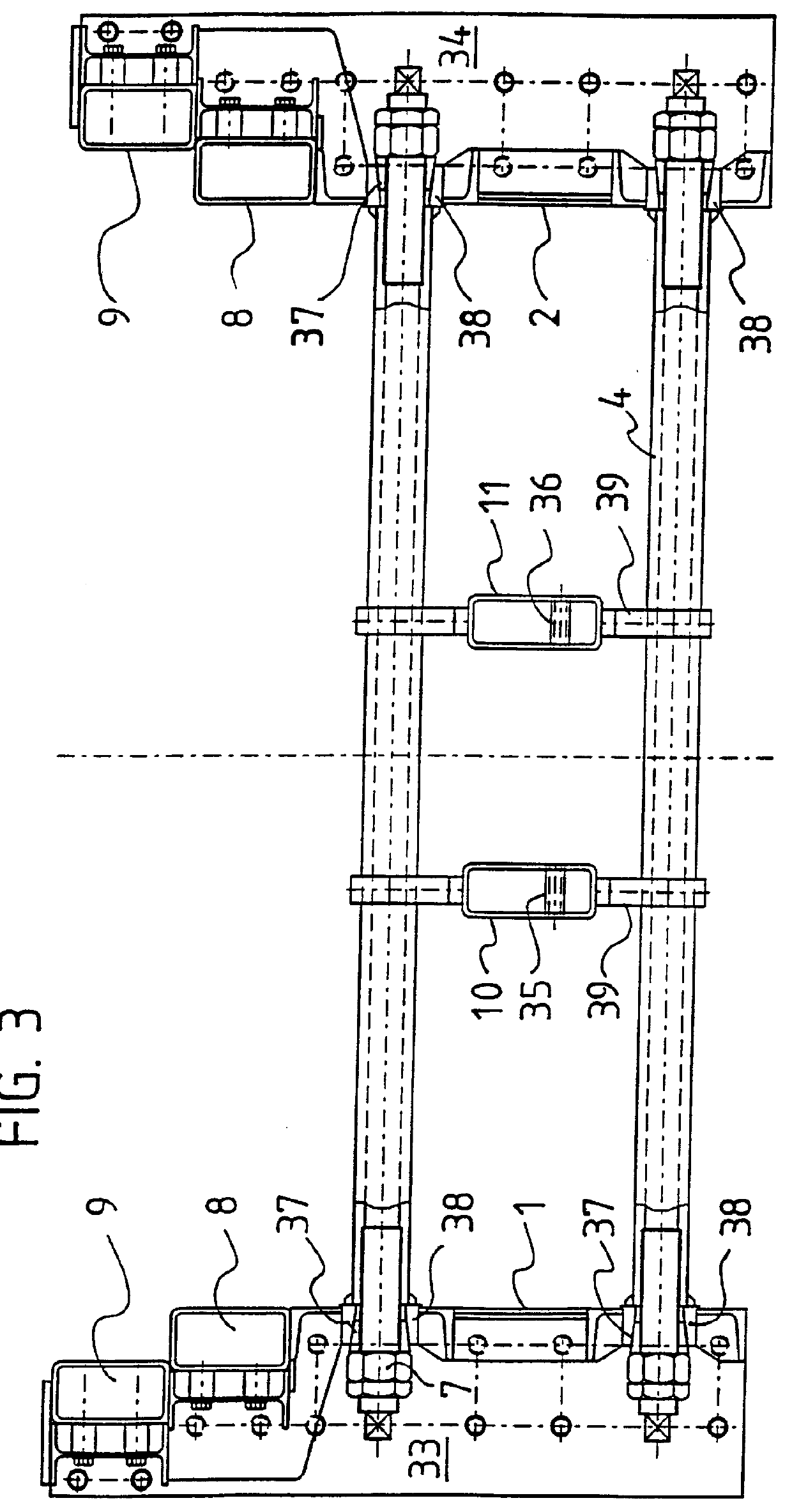

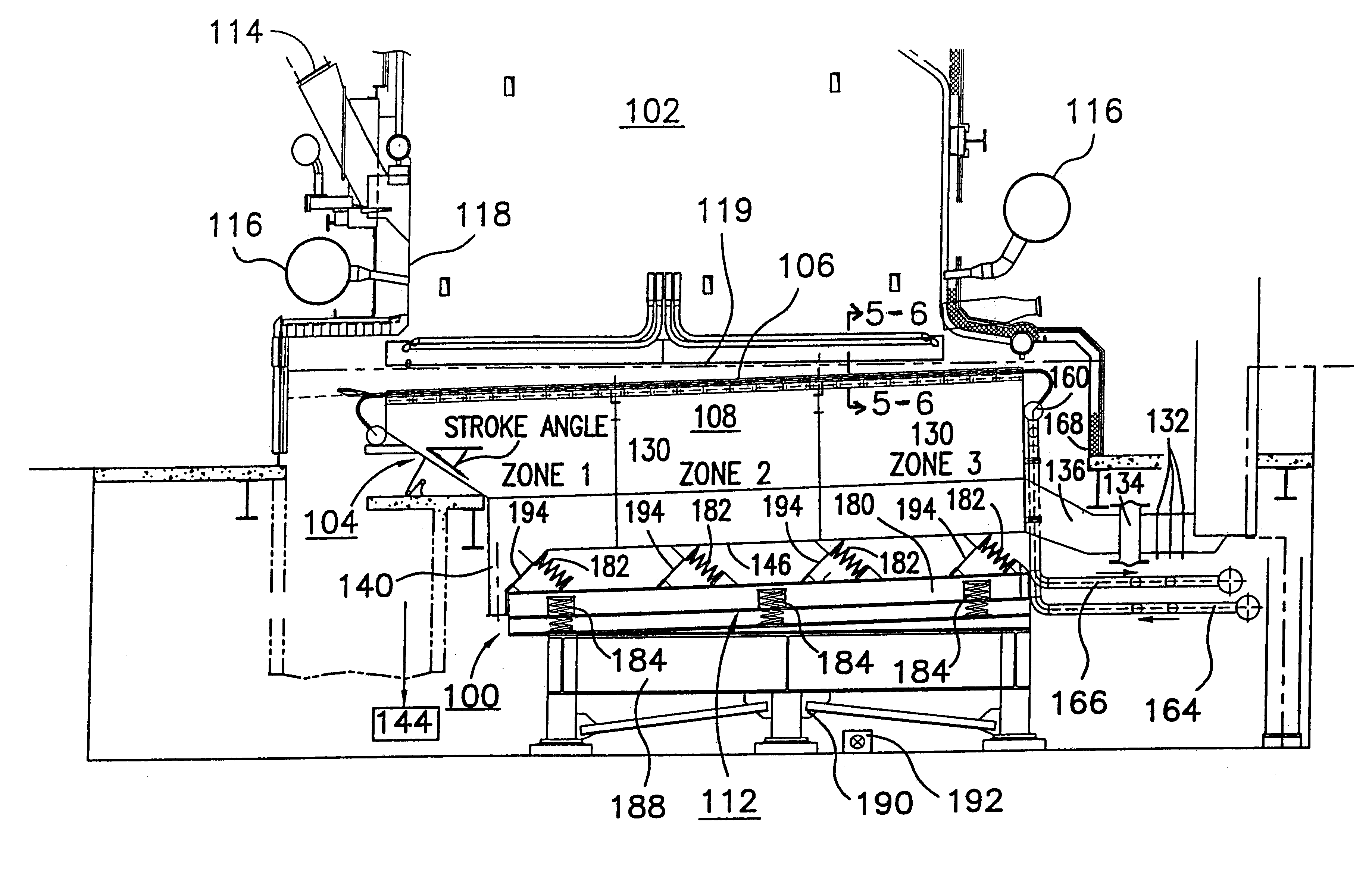

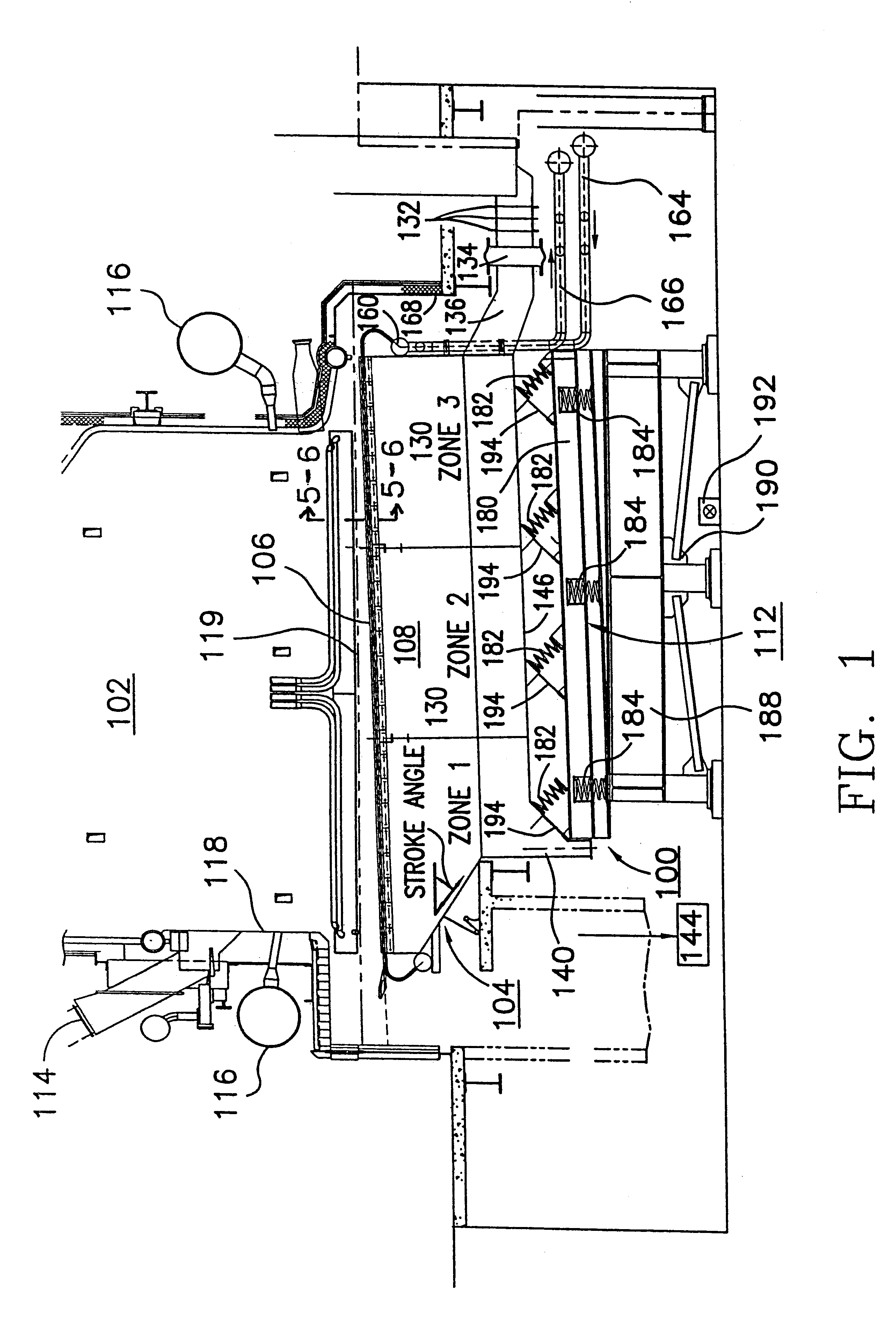

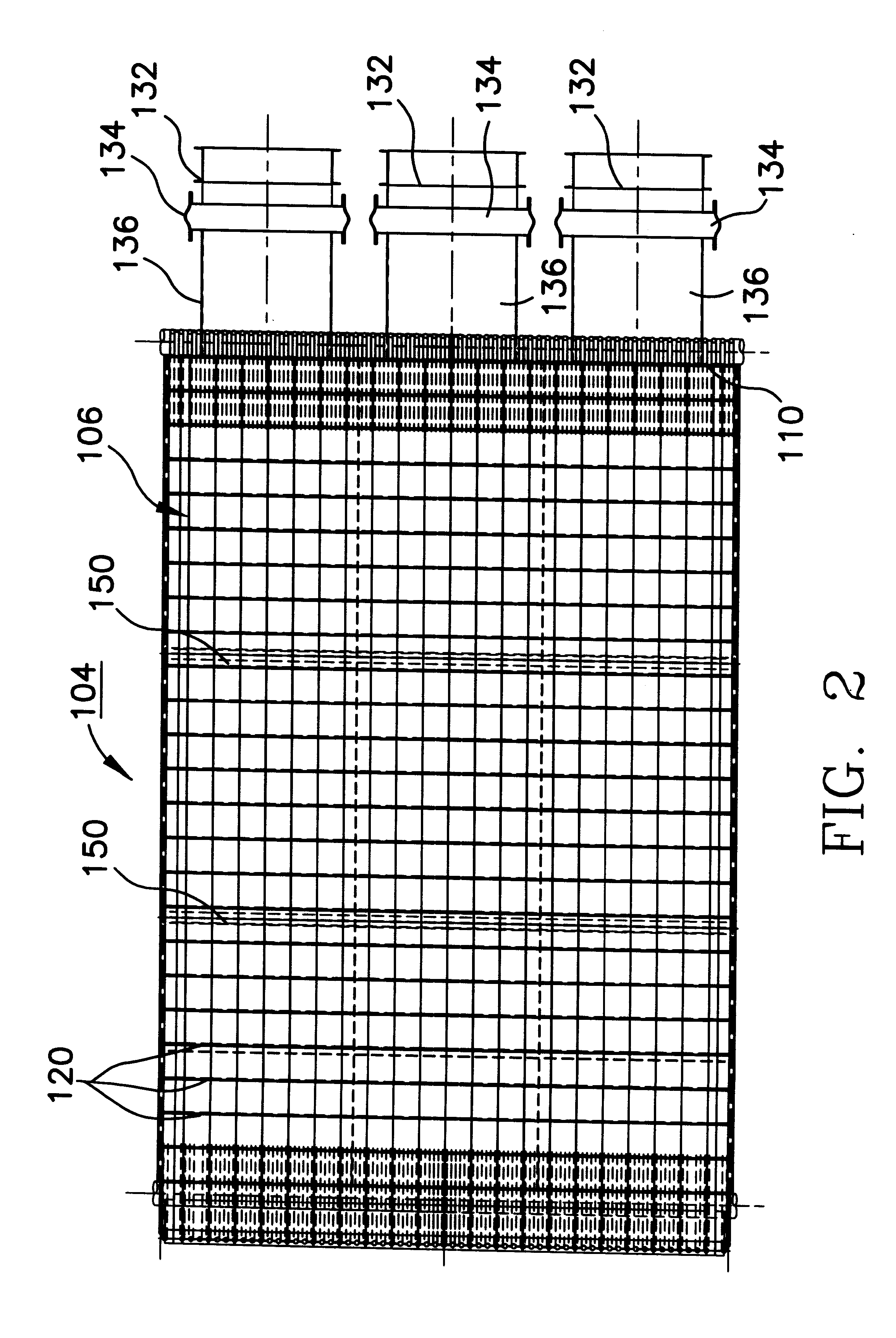

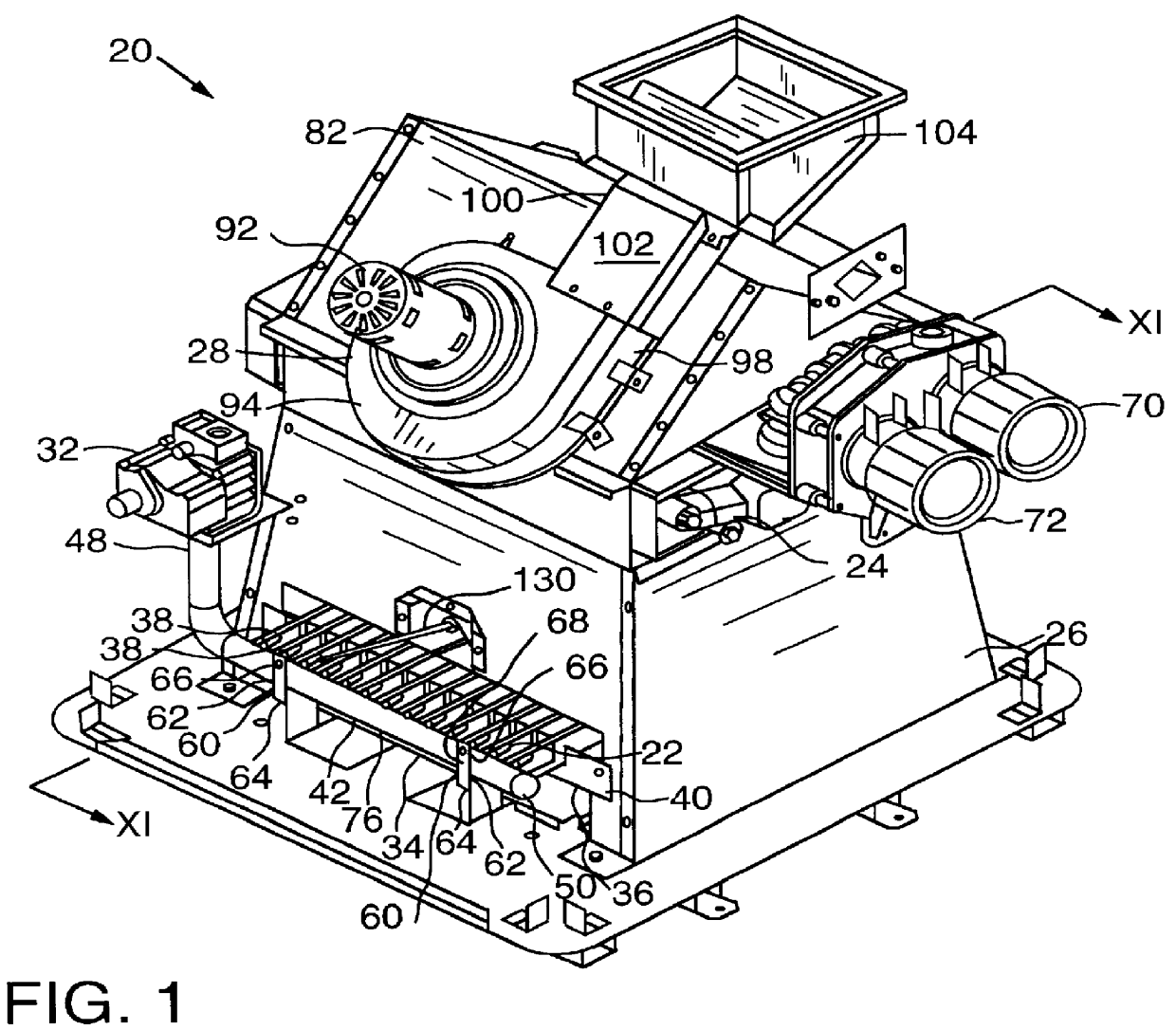

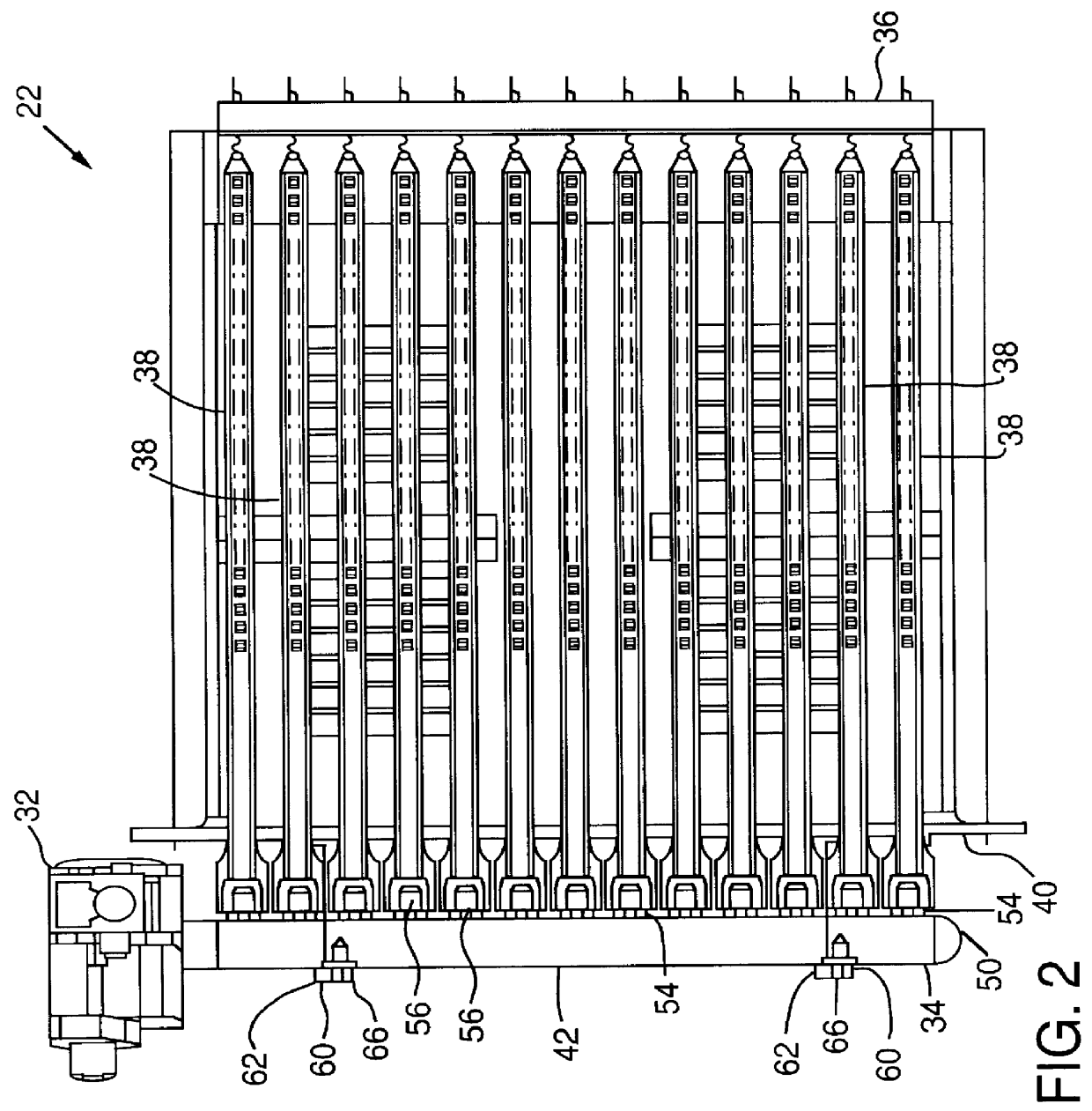

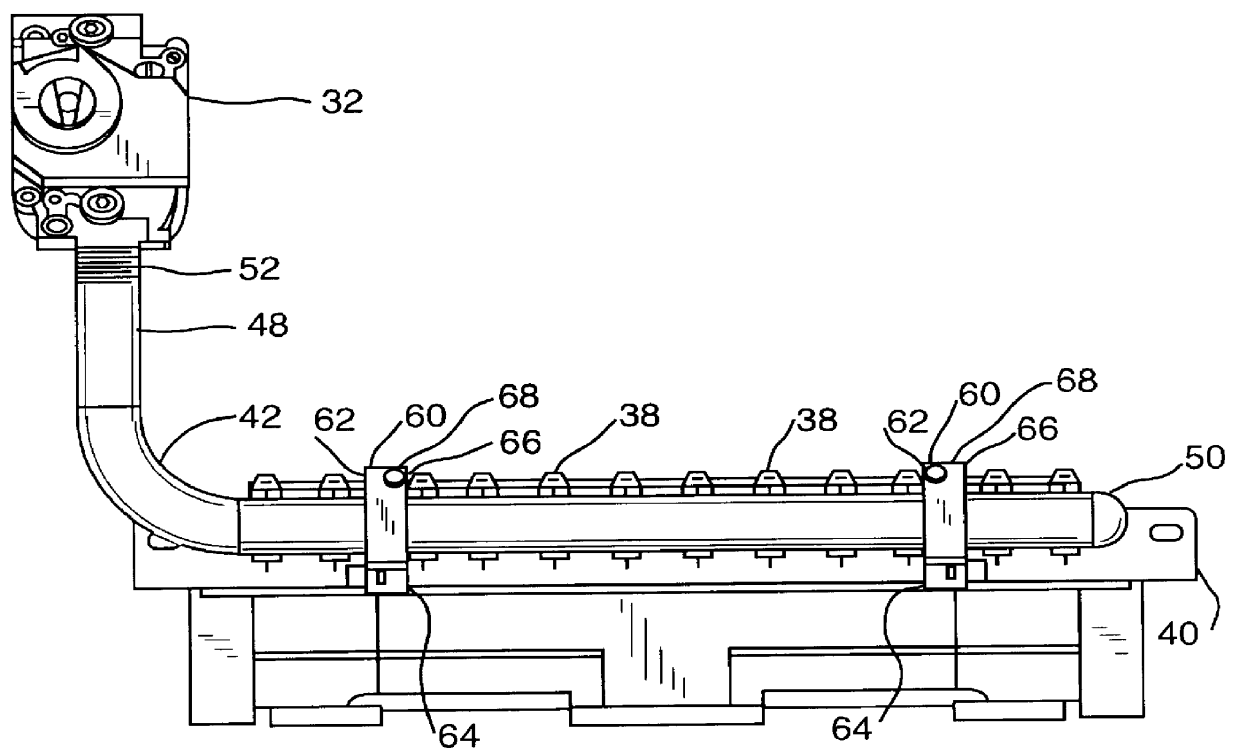

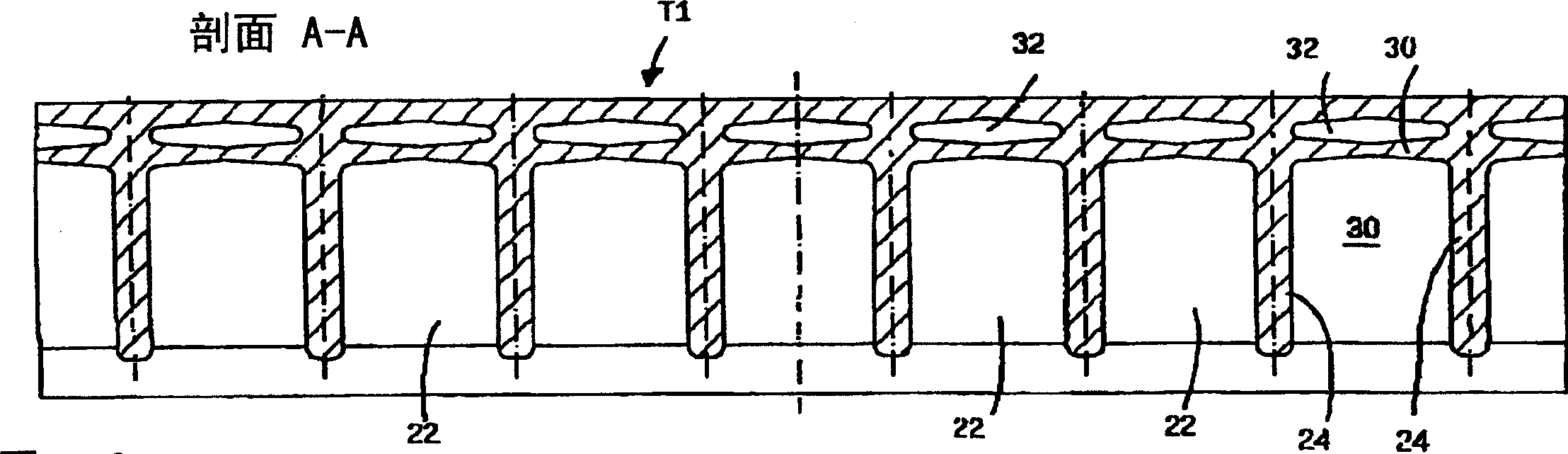

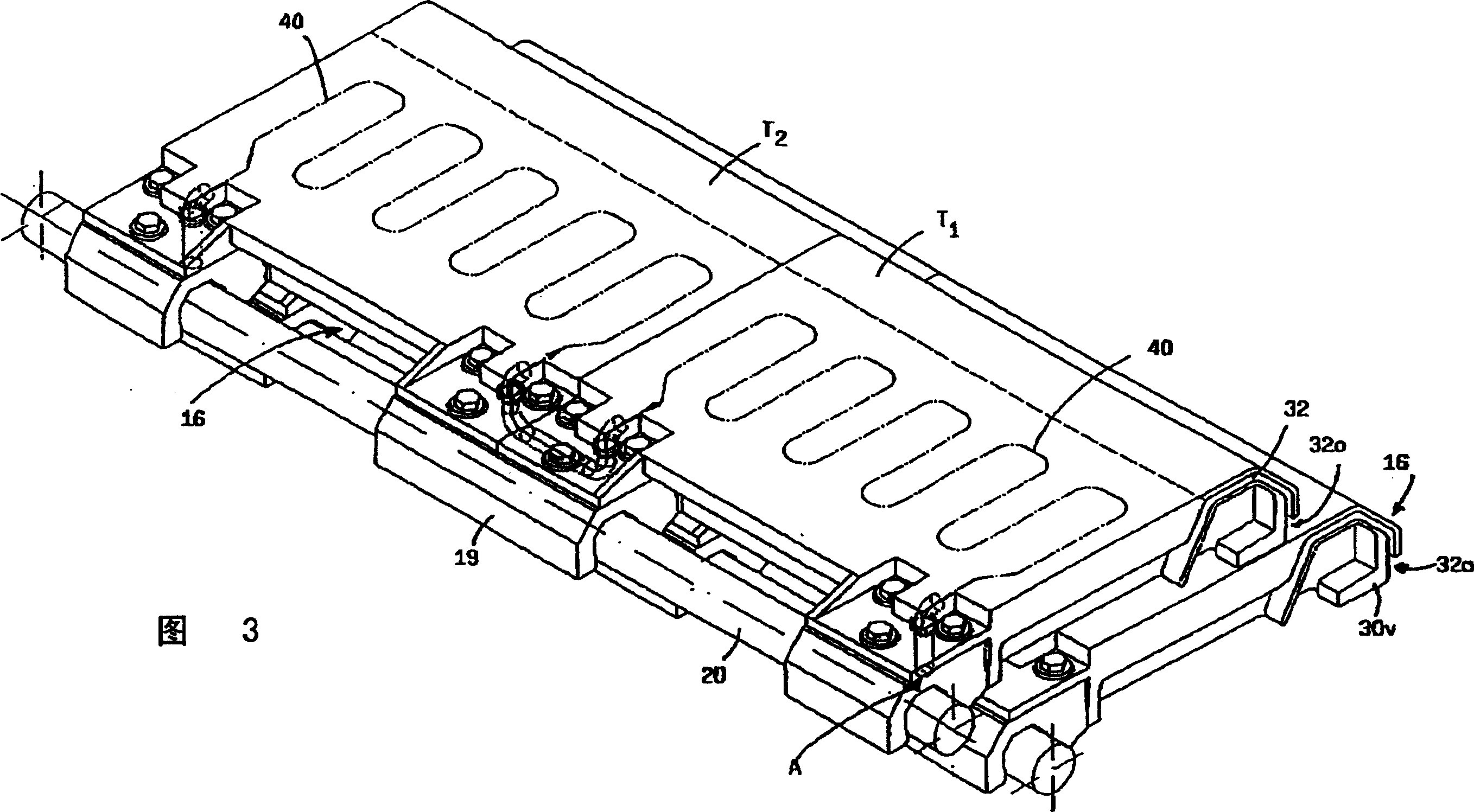

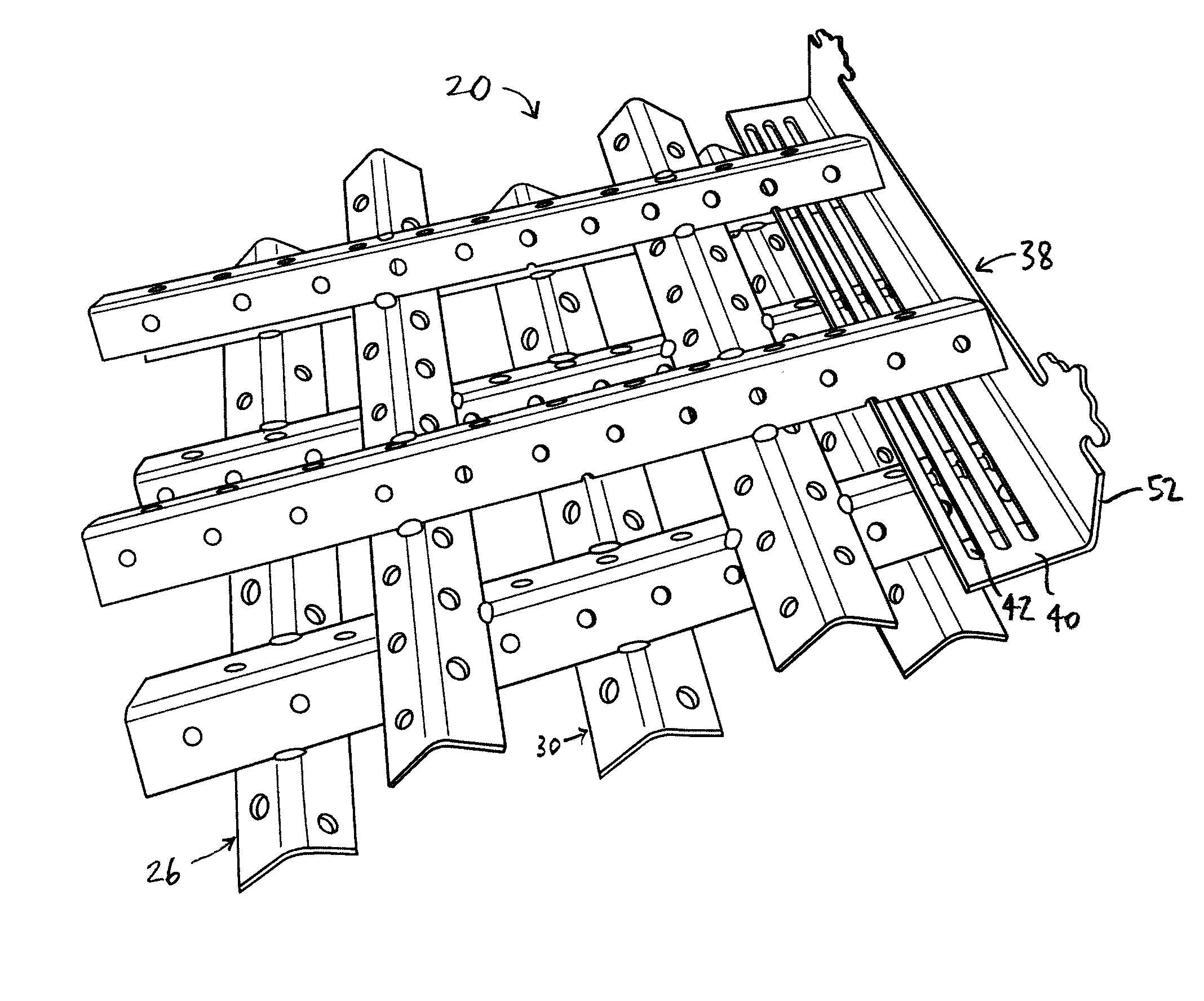

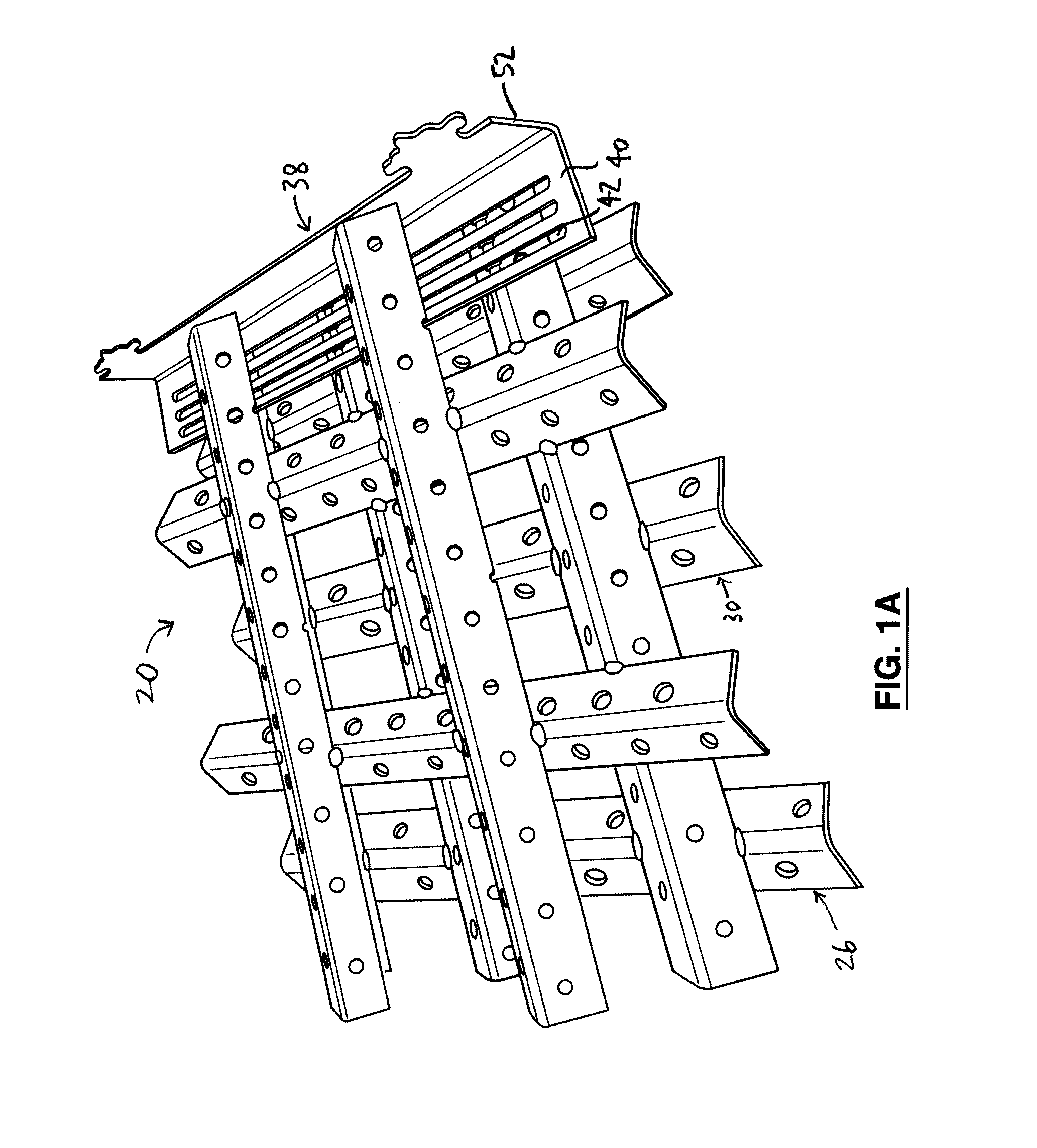

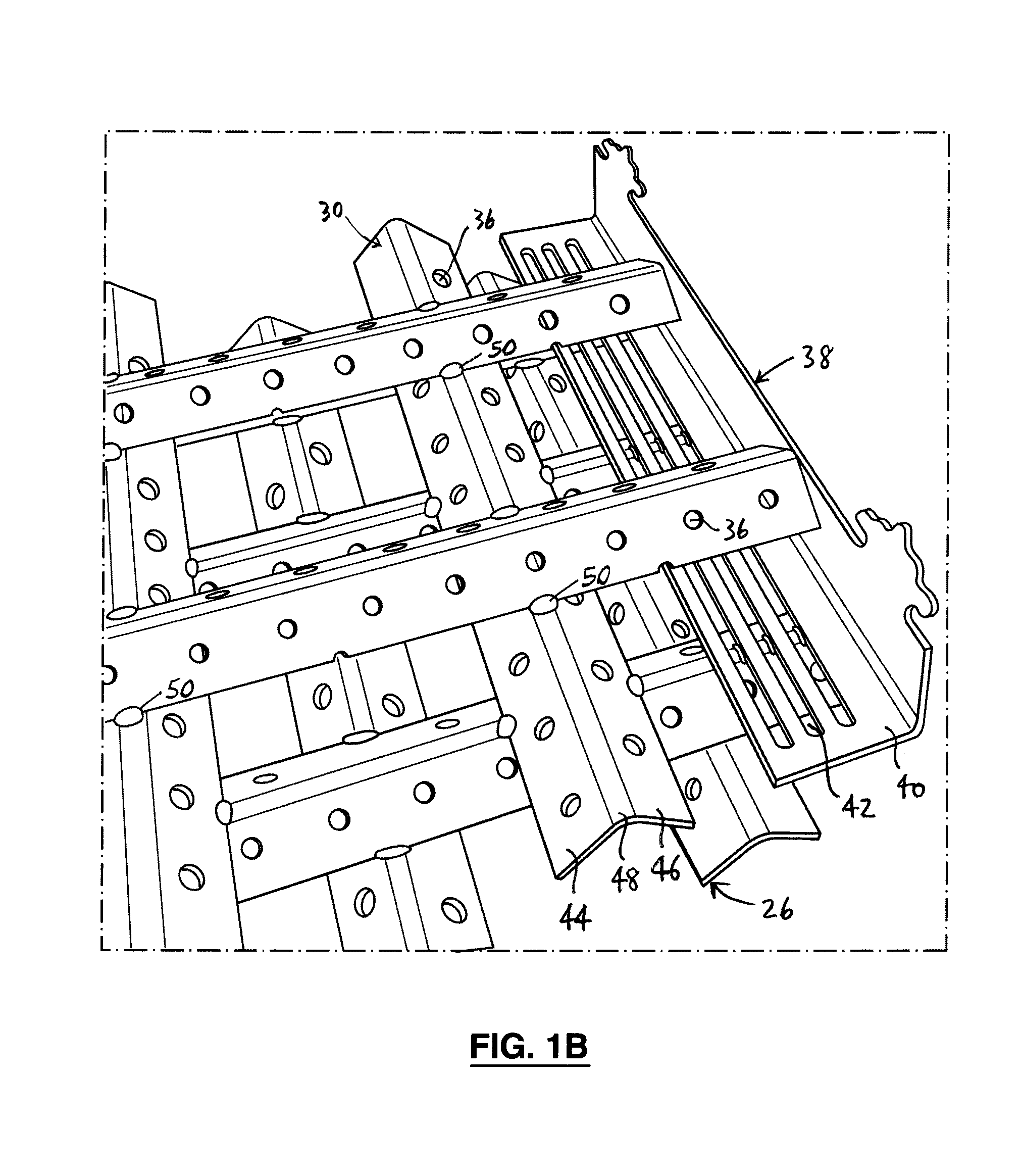

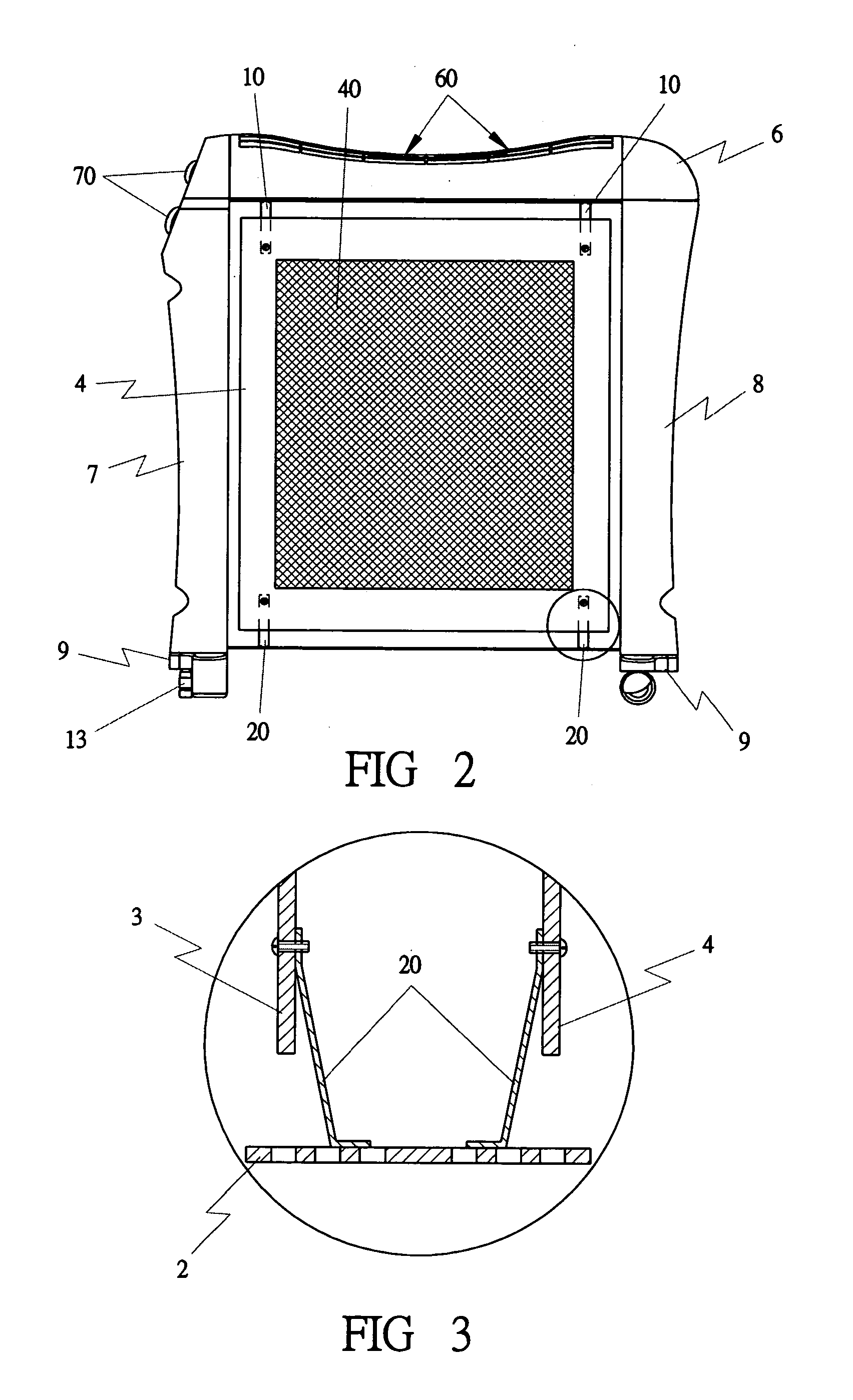

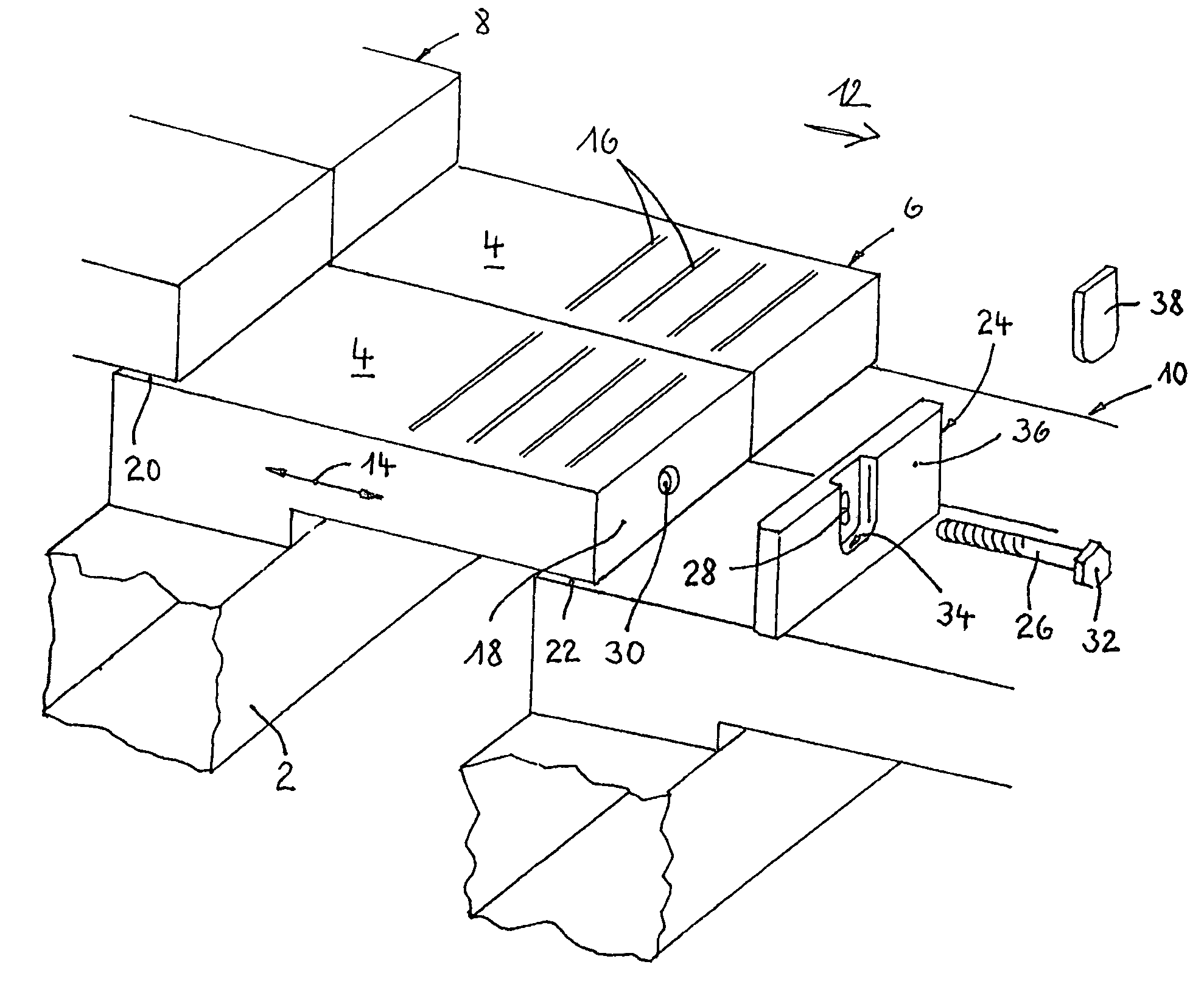

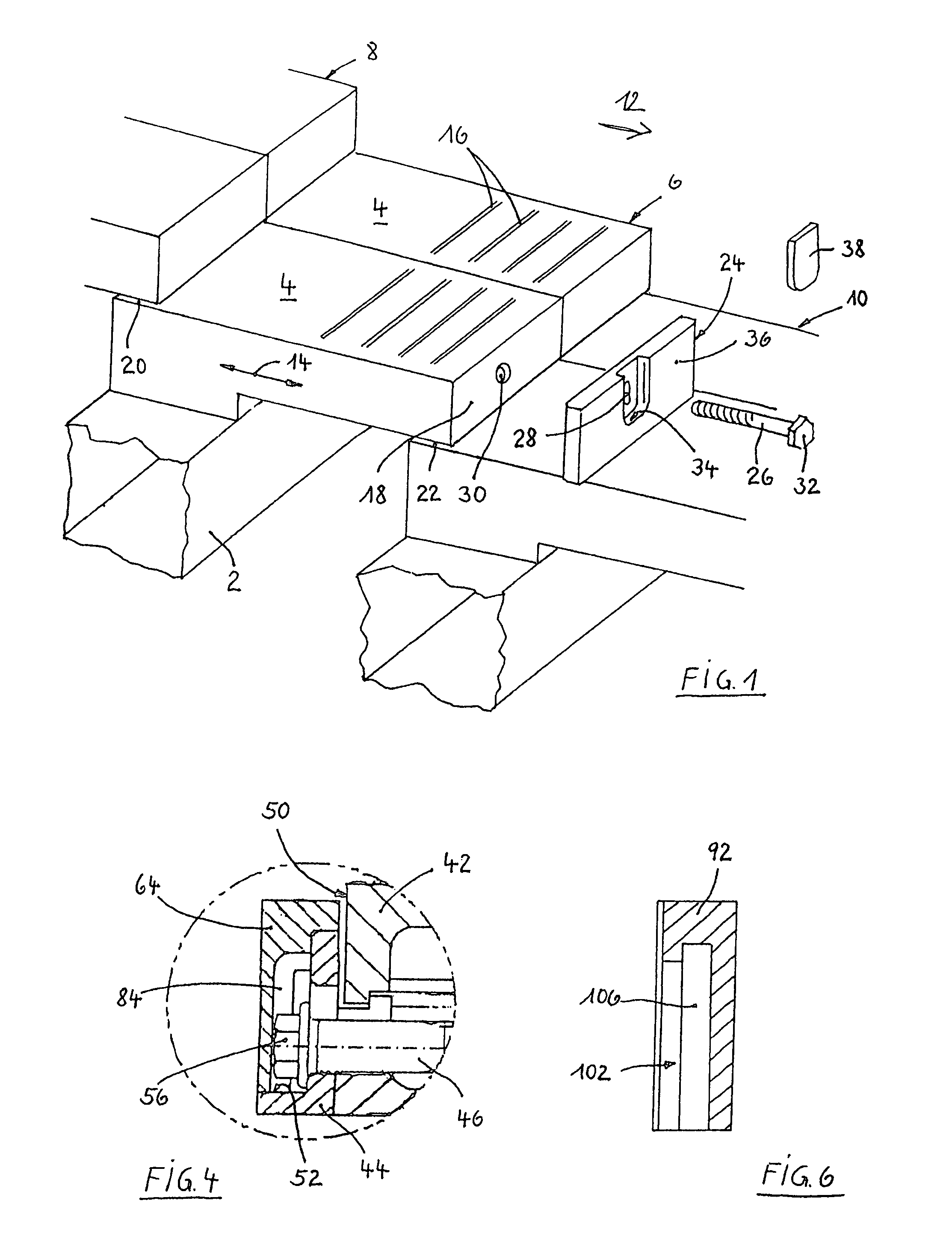

Water-cooled oscillating grate system

InactiveUS6220190B1Minimize under grate air leakageEffective and efficient and reliable operationHollow bar grateSpeed sensing governorsCombustionWater source

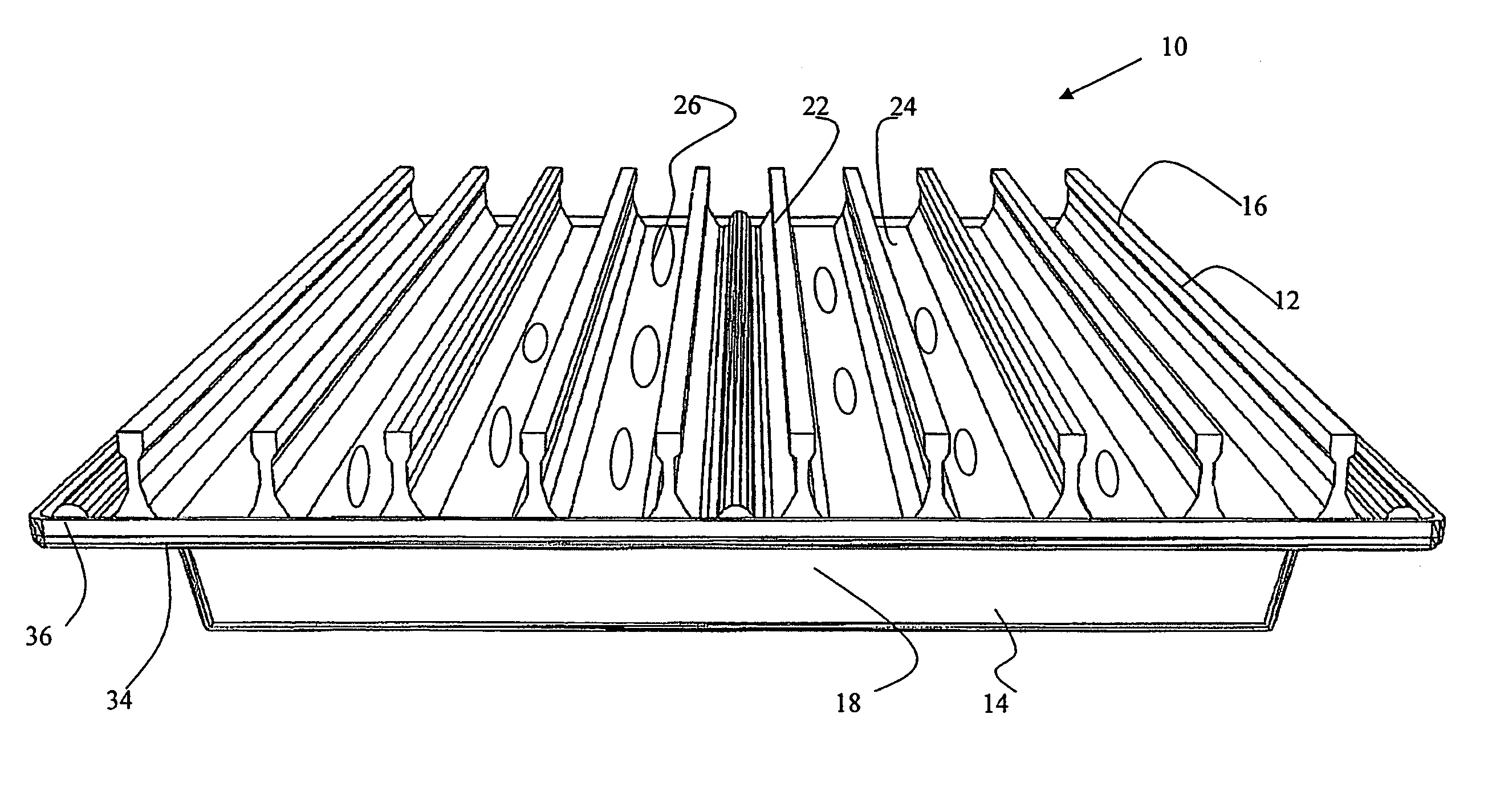

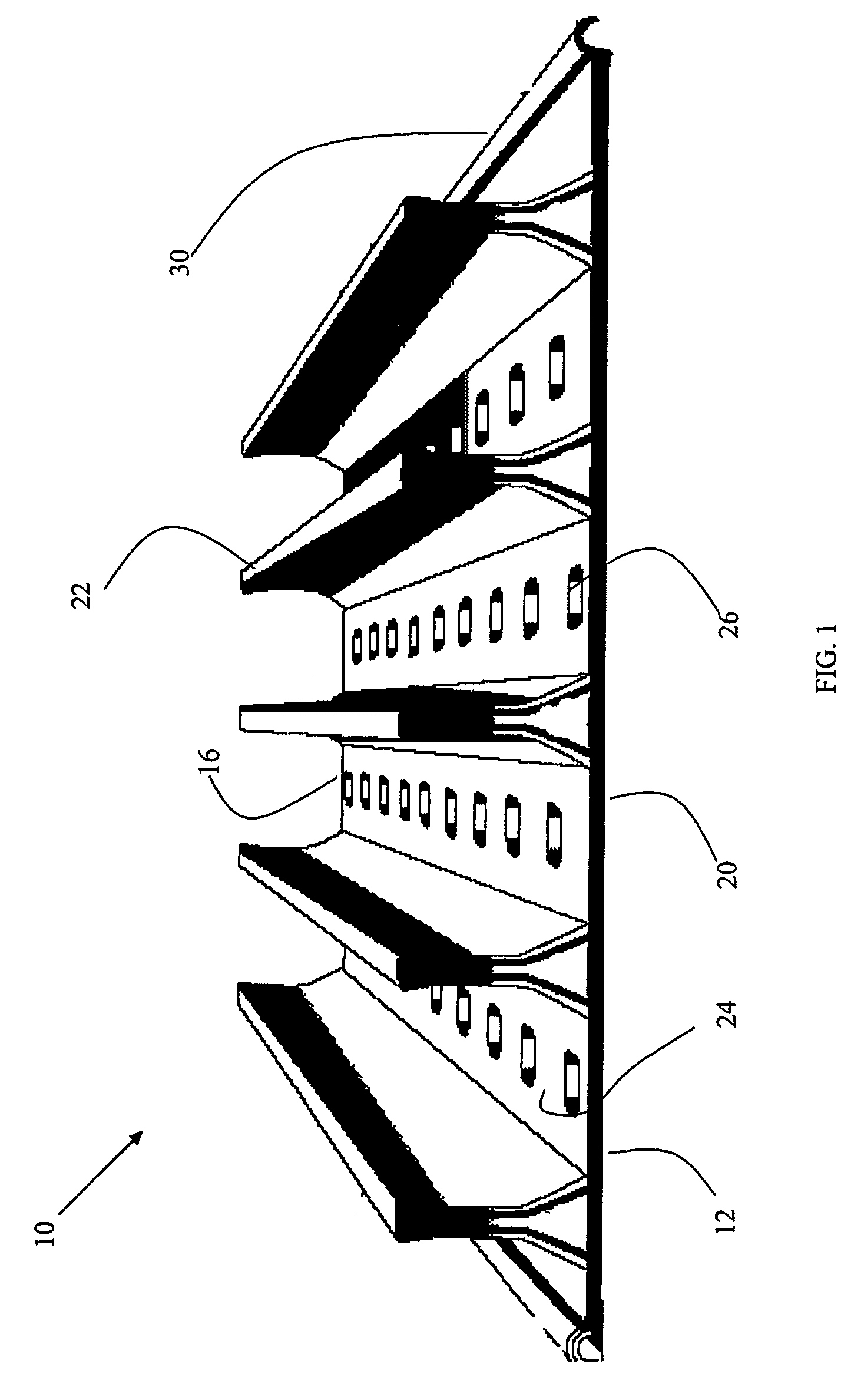

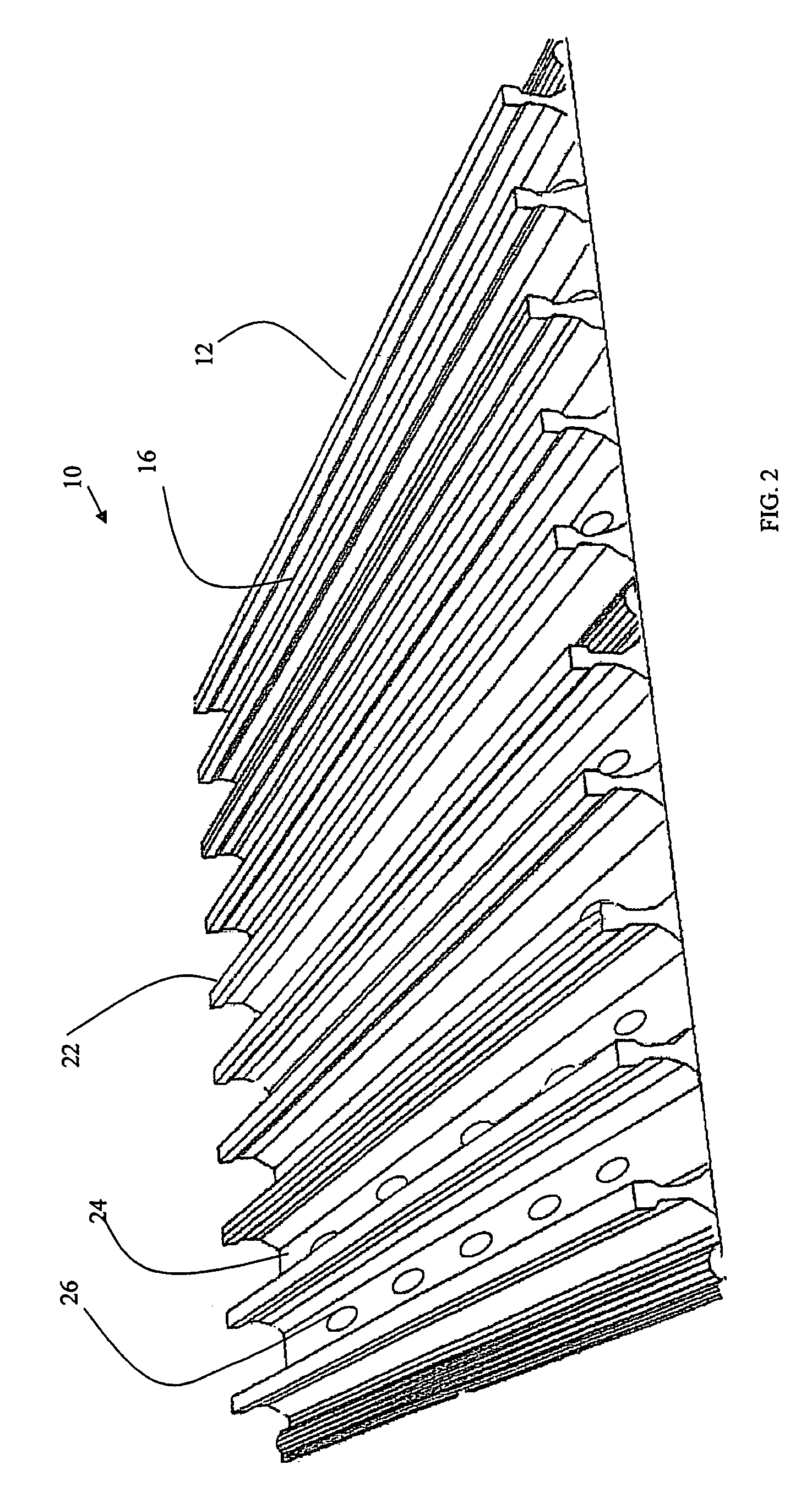

An integral water-cooled, air permeated, vibrating grate system for combusting biomass and other fuels in a boiler includes a grate top surface having air-flow apertures extending therethrough. The grate top surface is supported by a plurality of water-cooling pipes which arc coupled to a water supply. An enclosed air plenum unit is positioned under and attached directly to the grate top surface. The air plenum unit is coupled to an air supply for providing combustion air through the top grate surface air-flow apertures. The air plenum unit includes multiple zones, each of which zones has an associated air flow control damper so that the flow of combustion air can be controlled. Ash siftings formed on the grate top surface when the biomass or other fuel is combusted fall into the air plenum unit and flow toward at least one ash-siftings discharge opening at a discharge end of the air plenum when the grate top surface and the air plenum is vibrated. The grate top surface and the air plenum are vibrated together by a vibratory drive-isolation assembly which includes a longitudinally extending counterbalance member. A plurality of drive springs are supported by the counterbalance member. The drive springs are distributed across the width and the length of the top grate surface and at least one vibratory motor or mechanism is associated with the counterbalance member so that the vibration can be adjustably controlled.

Owner:RILEY STOKER

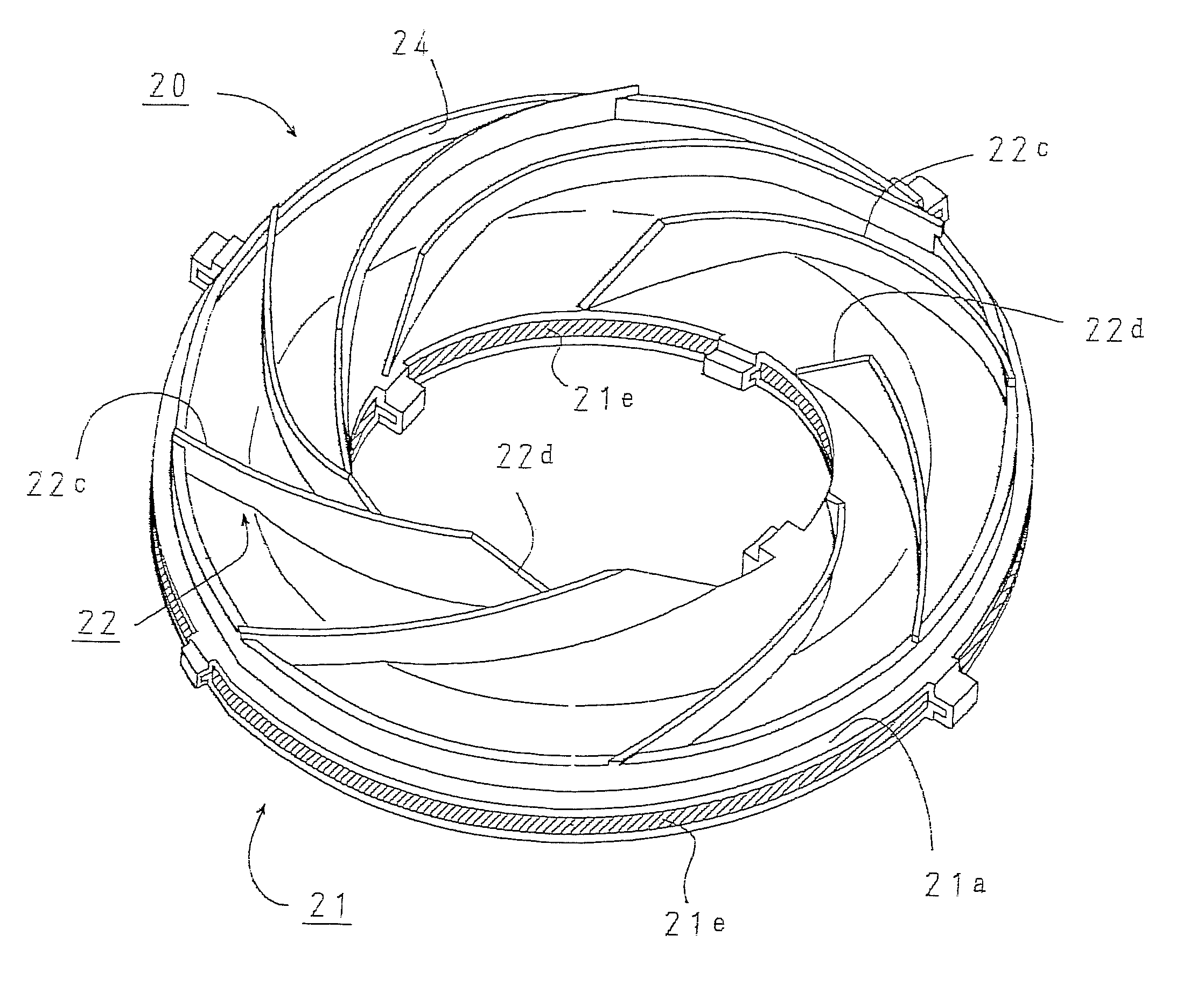

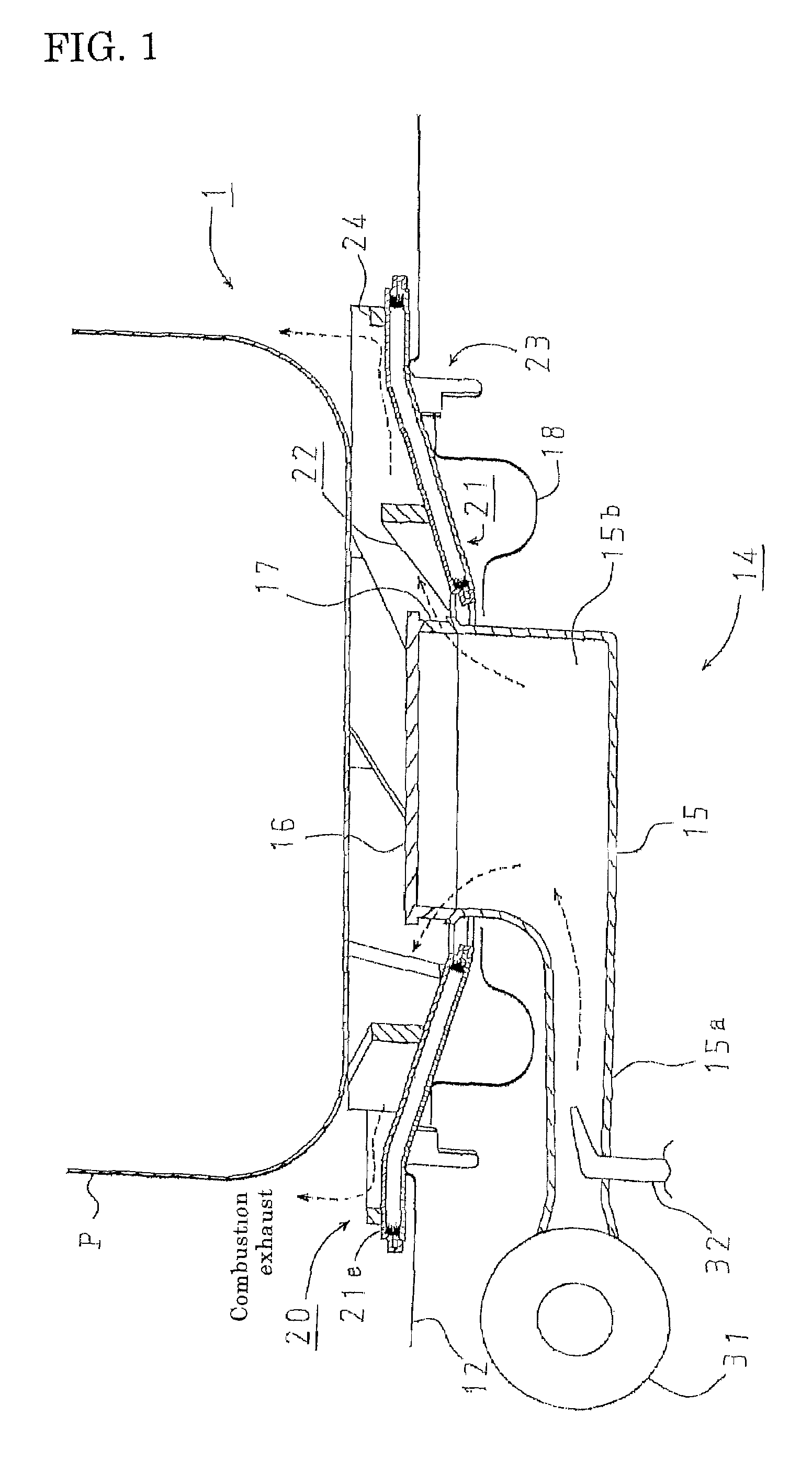

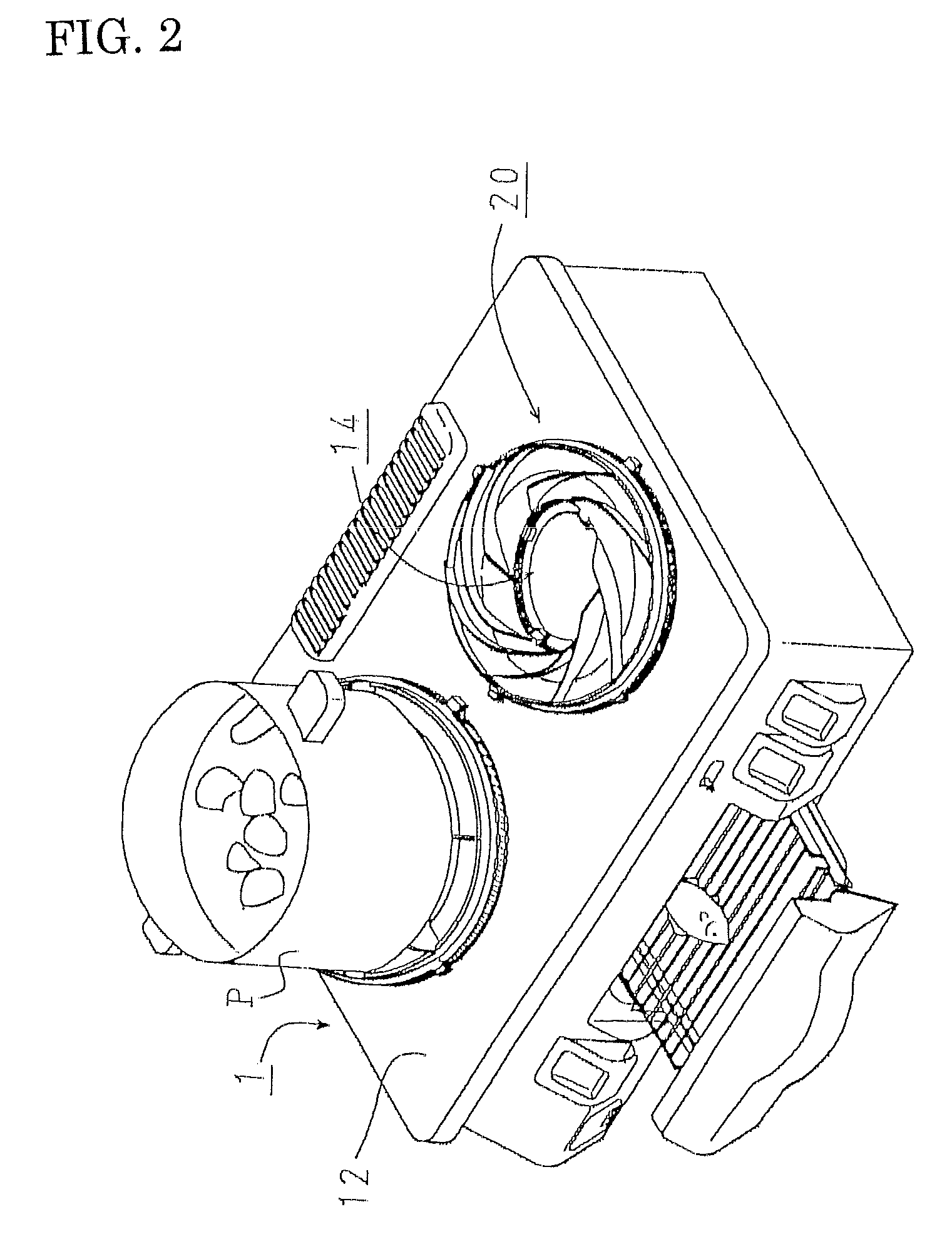

Cooking stove

InactiveUS7721727B2Improve heating efficiencyAvoid environmentDomestic stoves or rangesSolid bar grateCombustorHeat transmission

According to a gas table 1, combustion gas (including the flame) is jetted from a flame port 17 of a burner 14 diagonally upward entirely twisted in the burner circumferential direction. The combustion gas flows into plural combustion gas routes sectioned into spiral shape, and hits trivet claws 22, and goes through. That is, the combustion gas is guided in spiral shape by the trivet claws 22, and exhausted along a cooking container P bottom surface toward the outer circumferential direction. As a result, in the combustion gas route, the combustion gas is always subject to direction changing force and the flow thereof is disturbed, and accordingly, a heat transmission border film is unlikely to be formed on the cooking container P bottom surface, and the heat of the combustion gas is transmitted to the bottom surface of the cooking container P preferably.

Owner:PALOMA IND LTD

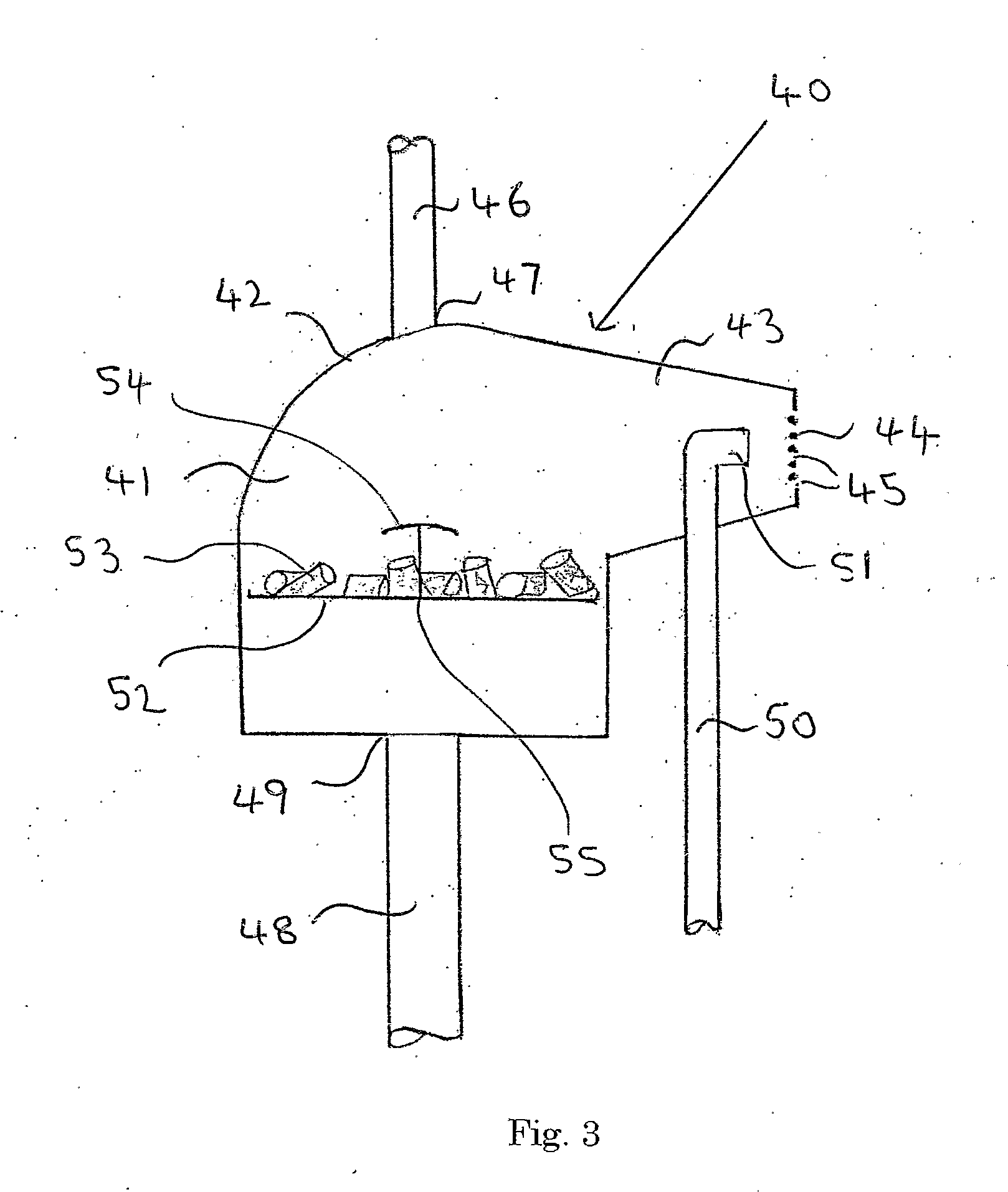

Apparatus and method for fractionating alternative solid fuels

An apparatus and a method for fractionating alternative solid fuels, specially whole tires, into volatiles and coal, to be used as alternative fuels, and metal, the apparatus comprising: a feeding zone wherein the solid fuels are feed to the apparatus, a gasifying zone into which the solid fuels are processed, obtaining a gaseous fraction, coal and metal; cooled grills controlling the bed permeability and permanence time of the solid fuels at the gasifying zone; and a discharging zone into which the resultant coal and metal are discharged.

Owner:CEMEX DE C V

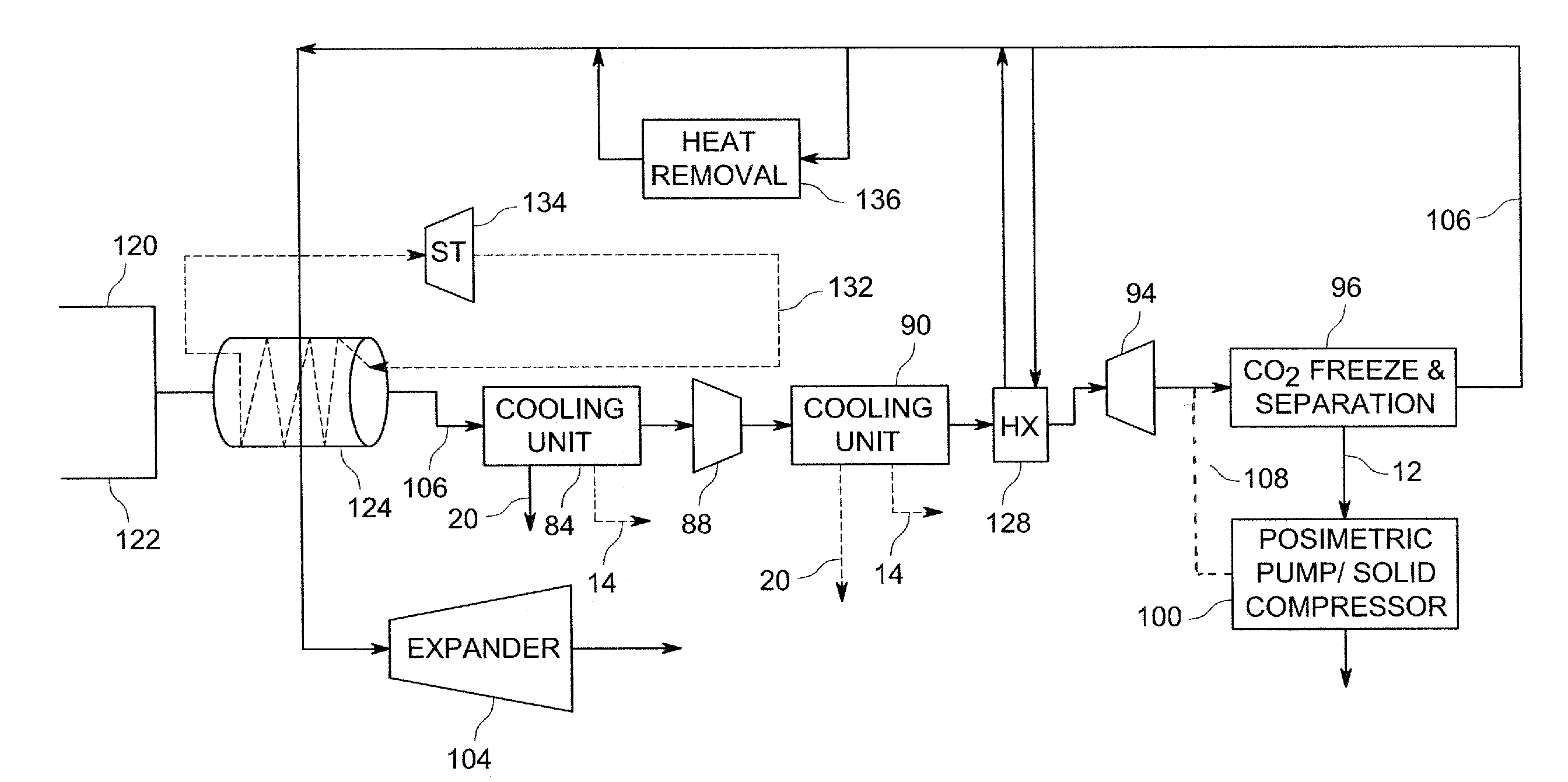

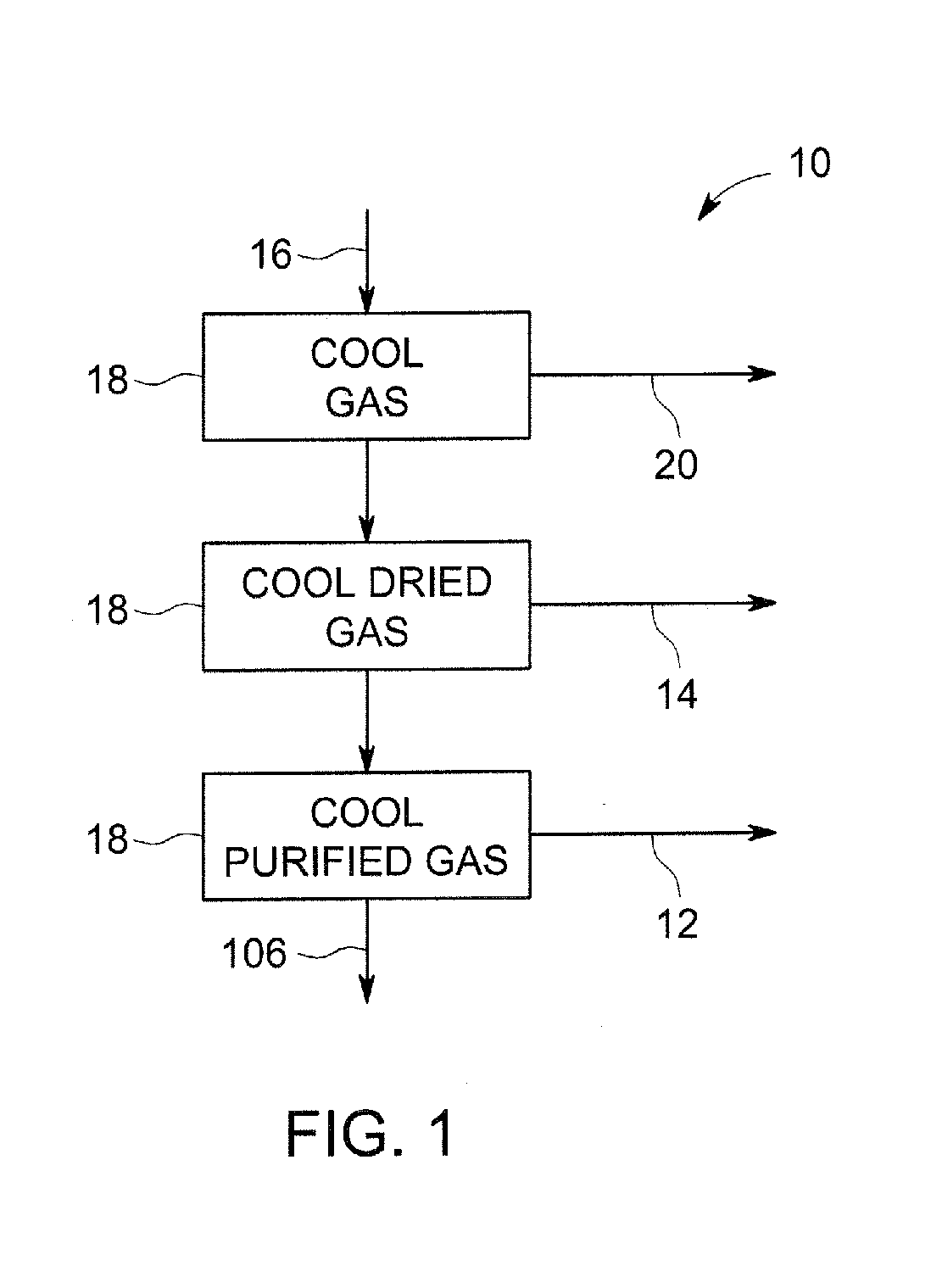

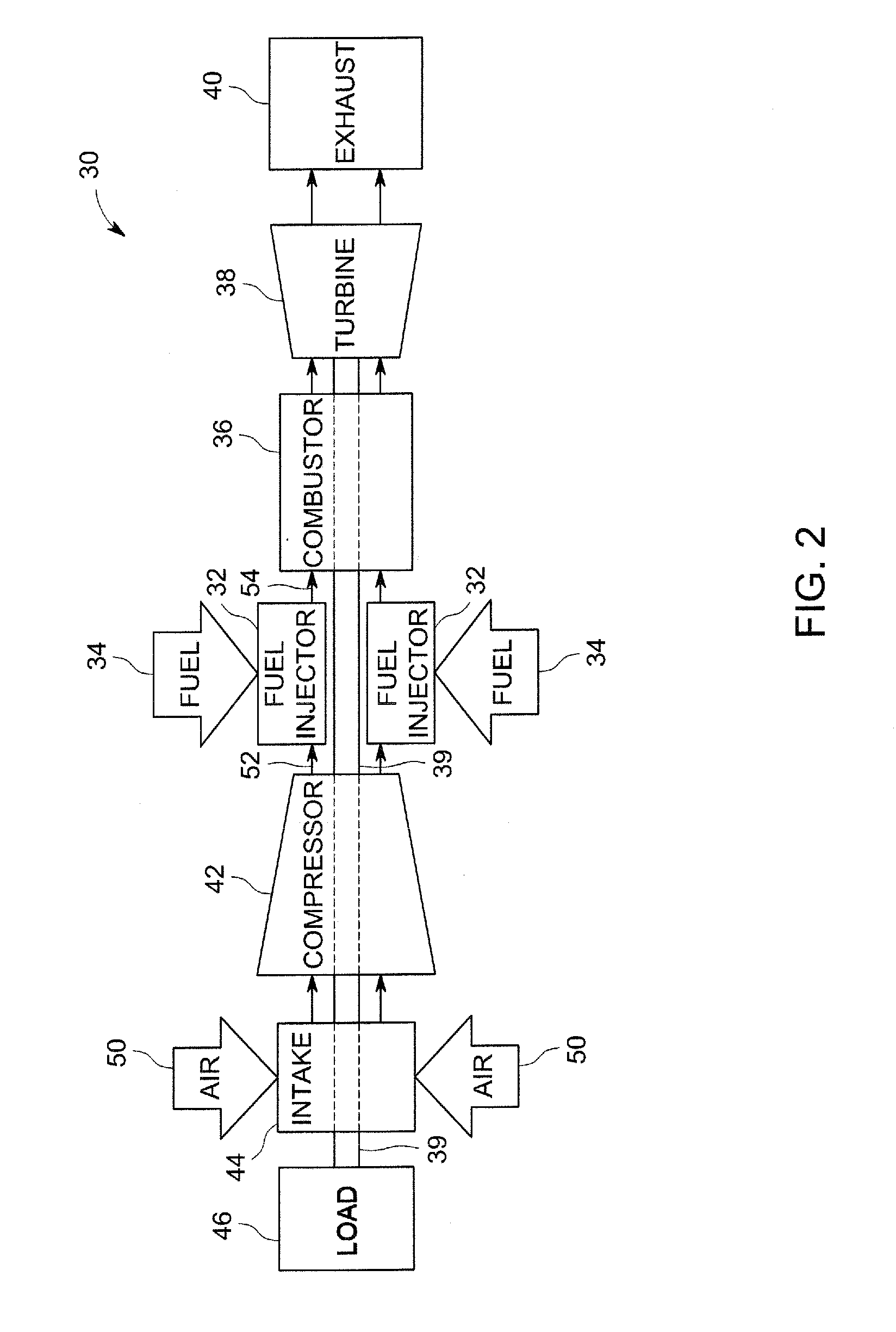

Systems and methods for co2 capture

The present disclosure relates to the separation of CO2 from a gas mixture. The CO2 may be removed by cooling the gas mixture such that the CO2 can be removed as a solid or liquid. In various embodiments the gas mixture from which the CO2 is removed may include exhaust gases generated as part of a combustion process, such as may be employed in a power generation process, though the gas mixture may be any gas mixture that includes CO2.

Owner:GENERAL ELECTRIC CO

Direct fired outdoor heater and heating method

InactiveUS6138666AReduced service lifeIncrease temperatureDomestic stoves or rangesBoiler water tubesCombustionEngineering

A heater includes a housing having an angled top, a fan having a discharge disposed parallel to the angled top of the housing, and a baffle for laminarizing airflow through the heater. The heater may also create airflow through a cover, across a housing, a heat sensitive component, and / or a raceway, and into a housing inlet. The heater may include a manifold having at least one coupling member that slidingly engages and disengages a burner. Methods for propelling combustion air through a heater, laminarizing combustion airflow in a heater, improving the efficiency of a heater, and converting a heater to make it compatible with a different fuel are also disclosed.

Owner:ZODIAC POOL SYST

System and device for grilling foods

A system of modular, interlocking, raised-rail grate panels and a complementarily-shaped basin for supporting and peripherally-containing the base of the grate panels while continuing to allow the passage of gasses lengthwise between the raised rails and the passage of gases and liquids through the base of the grate panels, such that delivery of searing and reflective heat to a cooking food is facilitated, wherein the grate panels and basin are coated with an abrasion-resistant, high-temperature, easy-to-clean, non-stick coating for ease of use, and wherein accessory features such as integrated, stylized food branding irons and raised-rail adaptive cooking tools are optionally provided.

Owner:AHV HLDG LLC

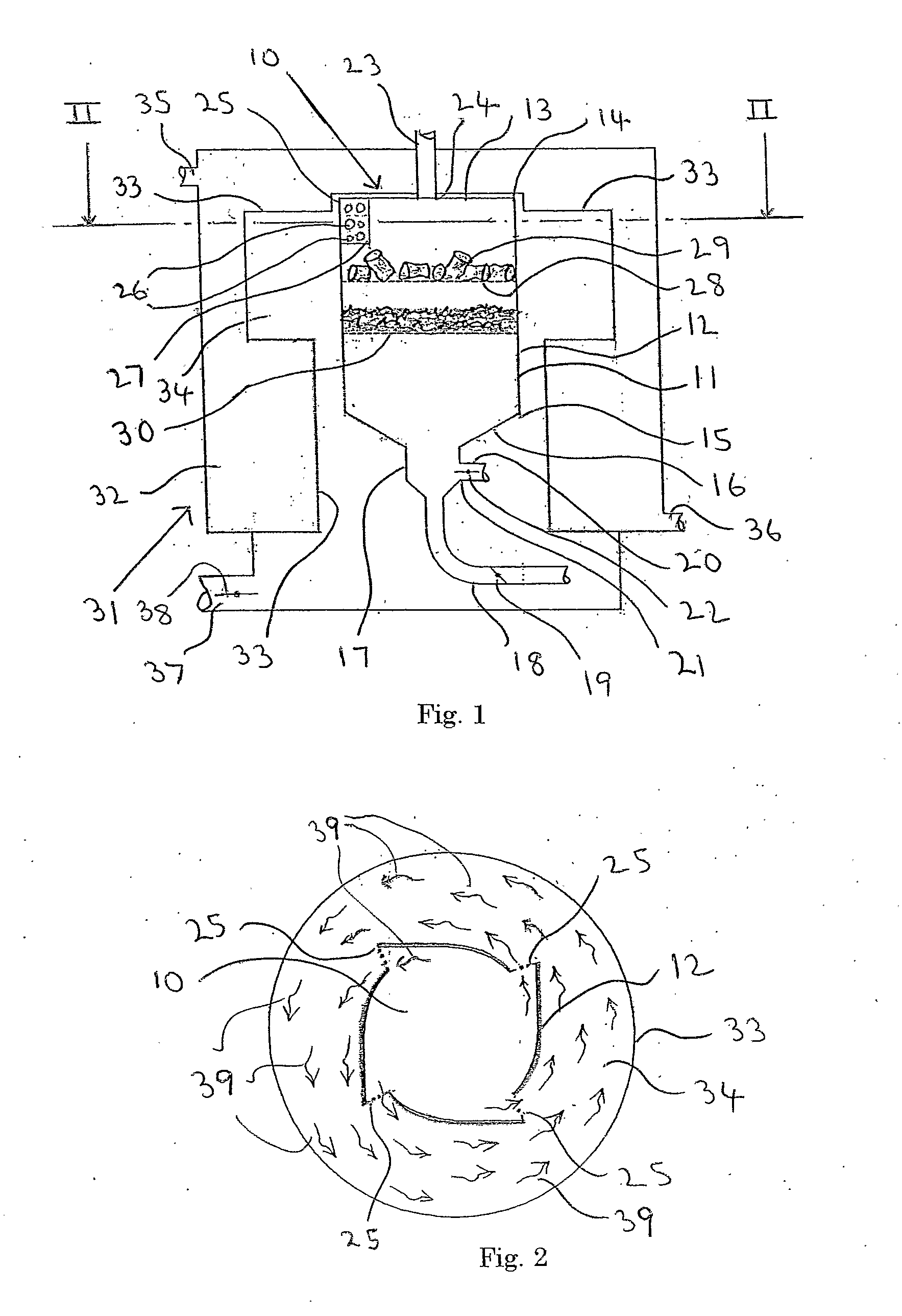

Combustion Chamber for Burning Solid Fuels

ActiveUS20100037806A1Close movementControl flowHollow bar grateSolid fuel combustionVolatilesCombustion chamber

A combustion chamber (10) for burning solid fuels having a high volatiles content has a hollow body (11) with a cylindrical wall section (12) and a top section (13) located at end (14) of the cylindrical wall section (12). The hollow body (11) has a primary air inlet (20), a fuel inlet (23) and four volatiles outlets (25) (one shown), mounted therein. Each volatiles outlet (25) has a plurality of apertures (26) of differing sizes arranged in a plate (27). In use, the burning volatiles exit the apertures (26) in a turbulent flow resulting in efficient combustion of the volatiles. Additionally, a heat transferring surface (33) on a water jacket (32) is shaped around the combustion chamber (10) so as to define a channel (34) there between. This arrangement results in an efficient transfer of heat from the turbulent flow of volatiles, which is forced to circulate around the channel (34).

Owner:DUIGNAN FRANCIS DONAL +1

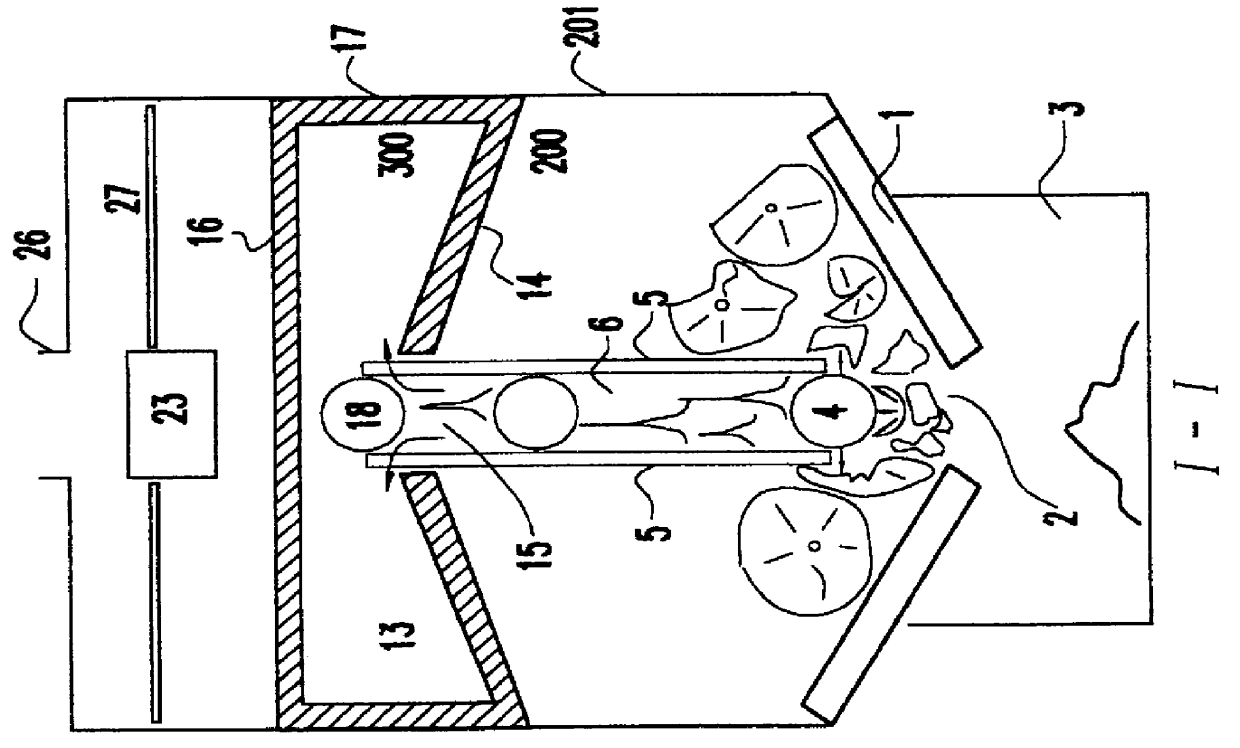

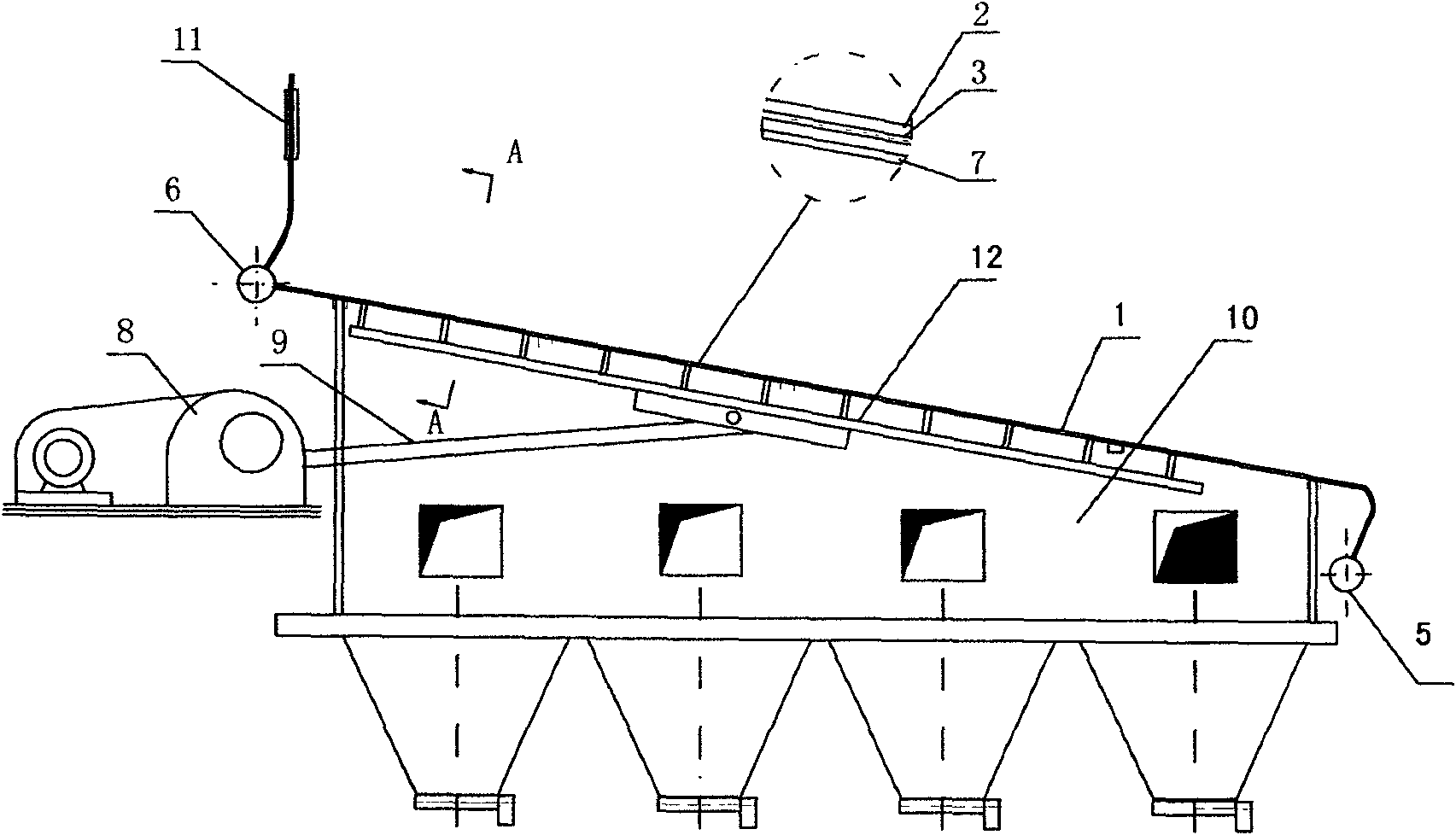

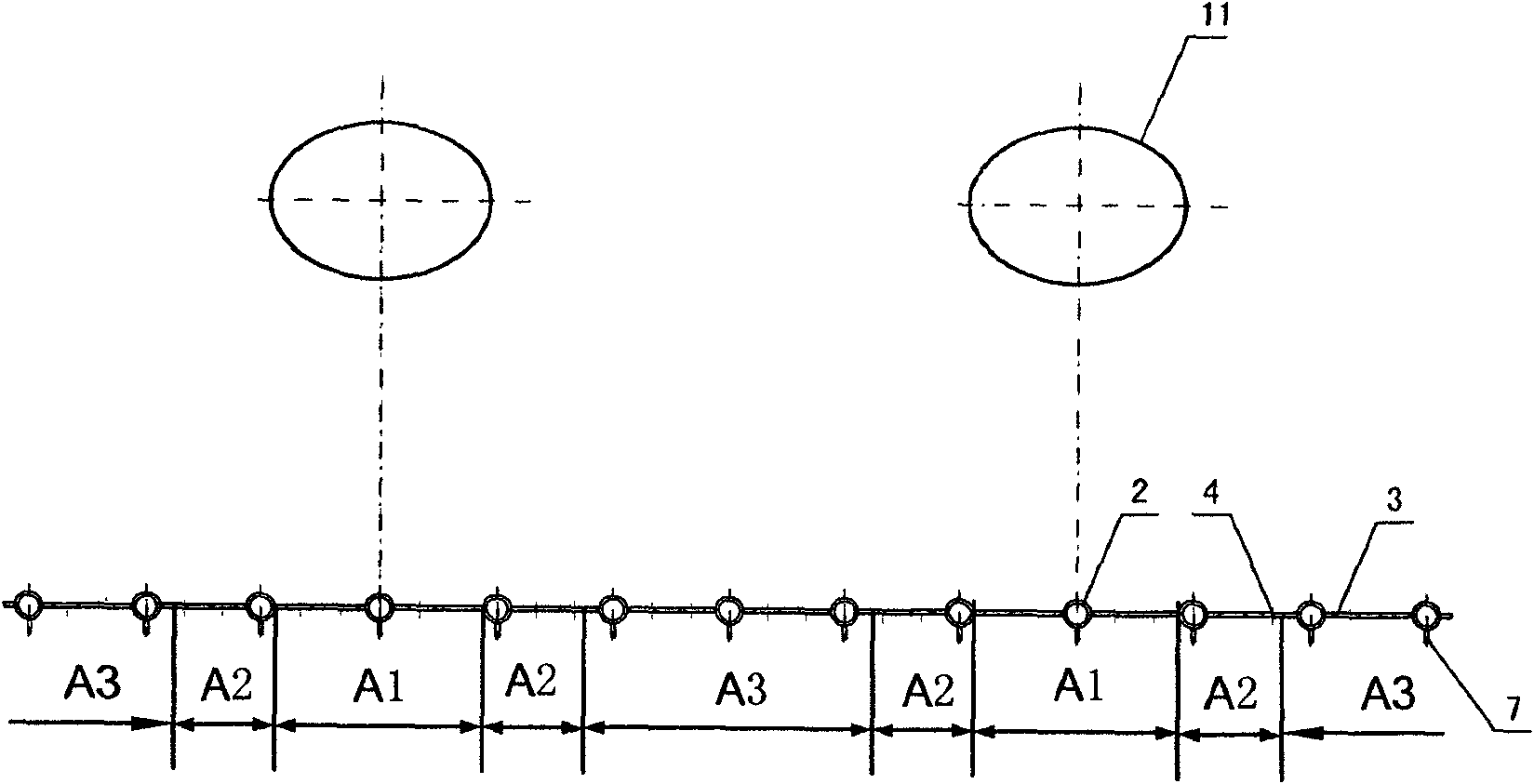

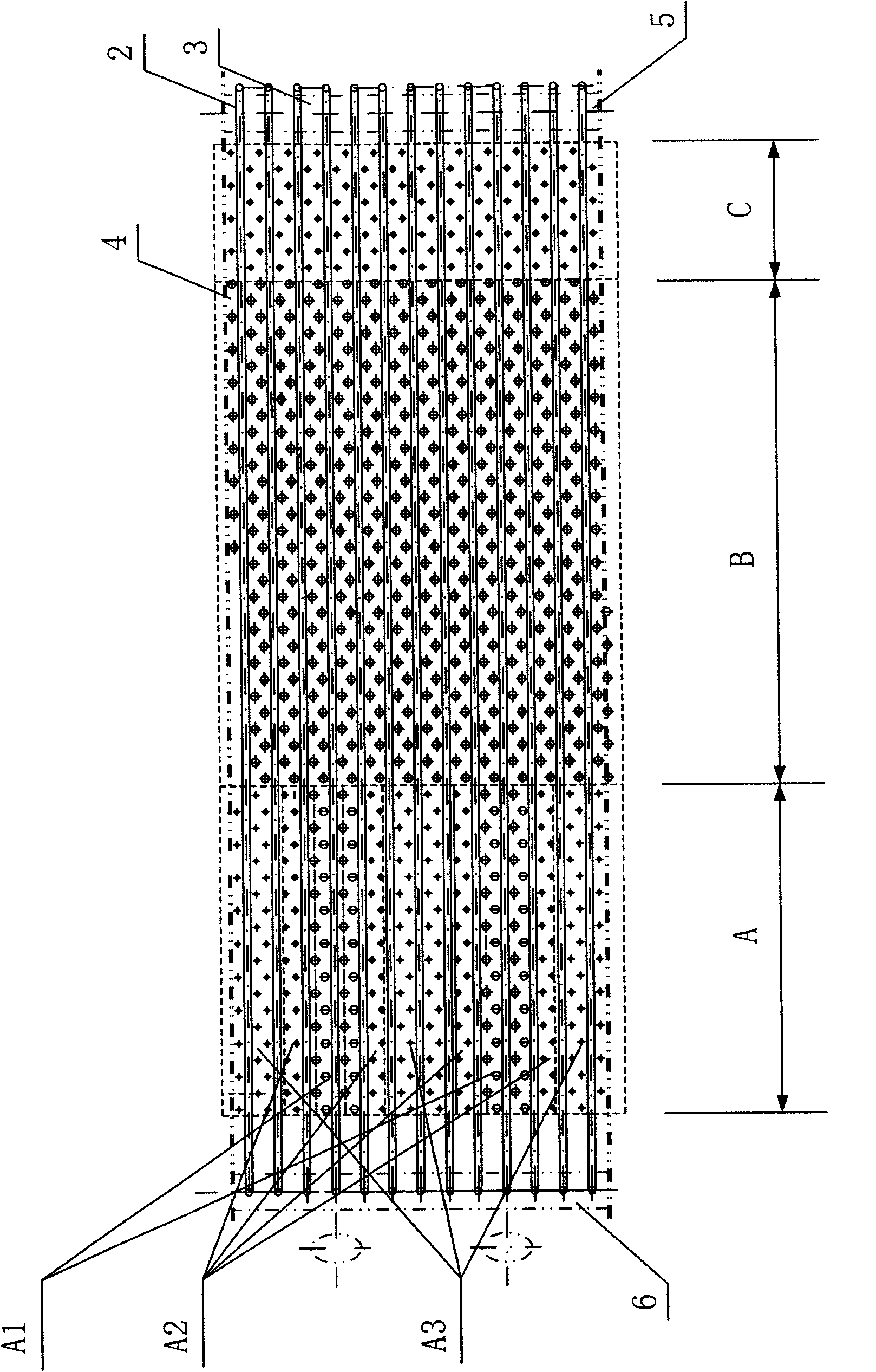

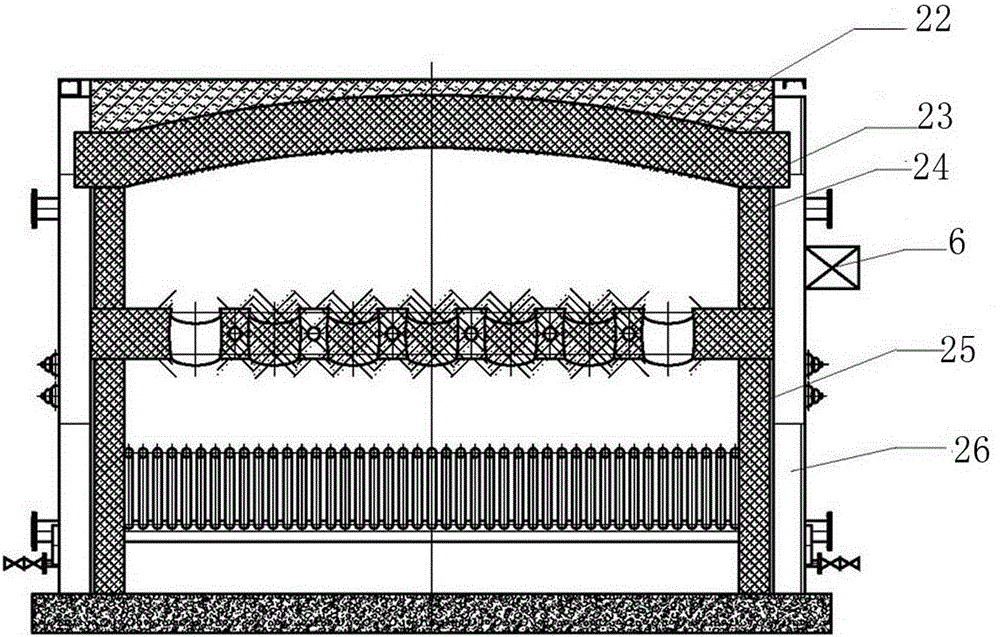

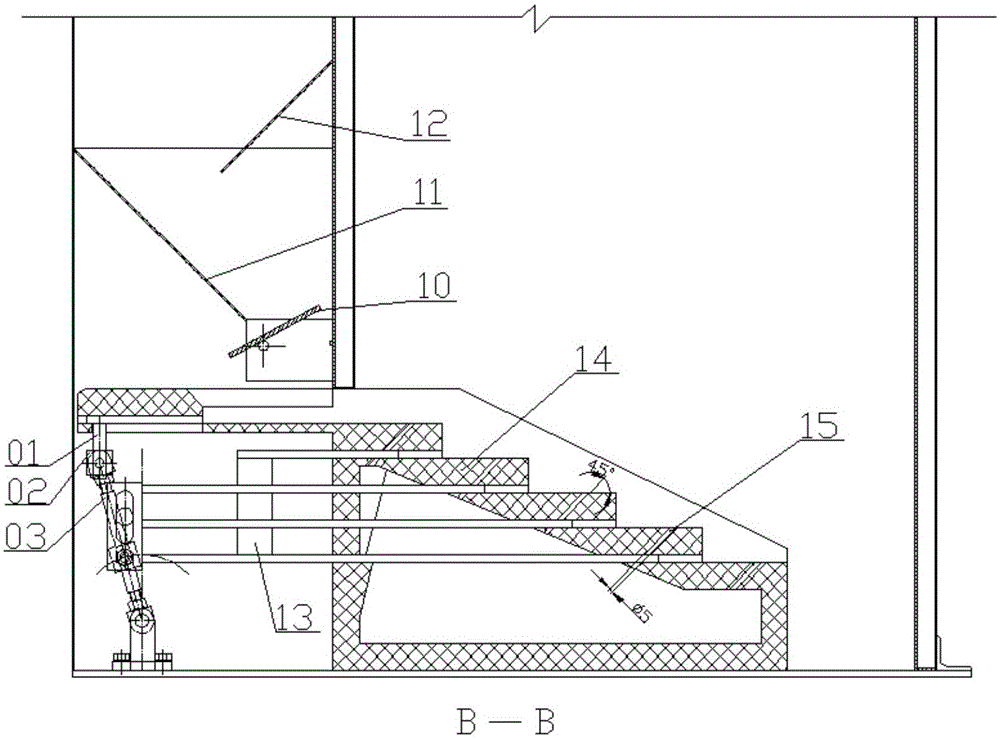

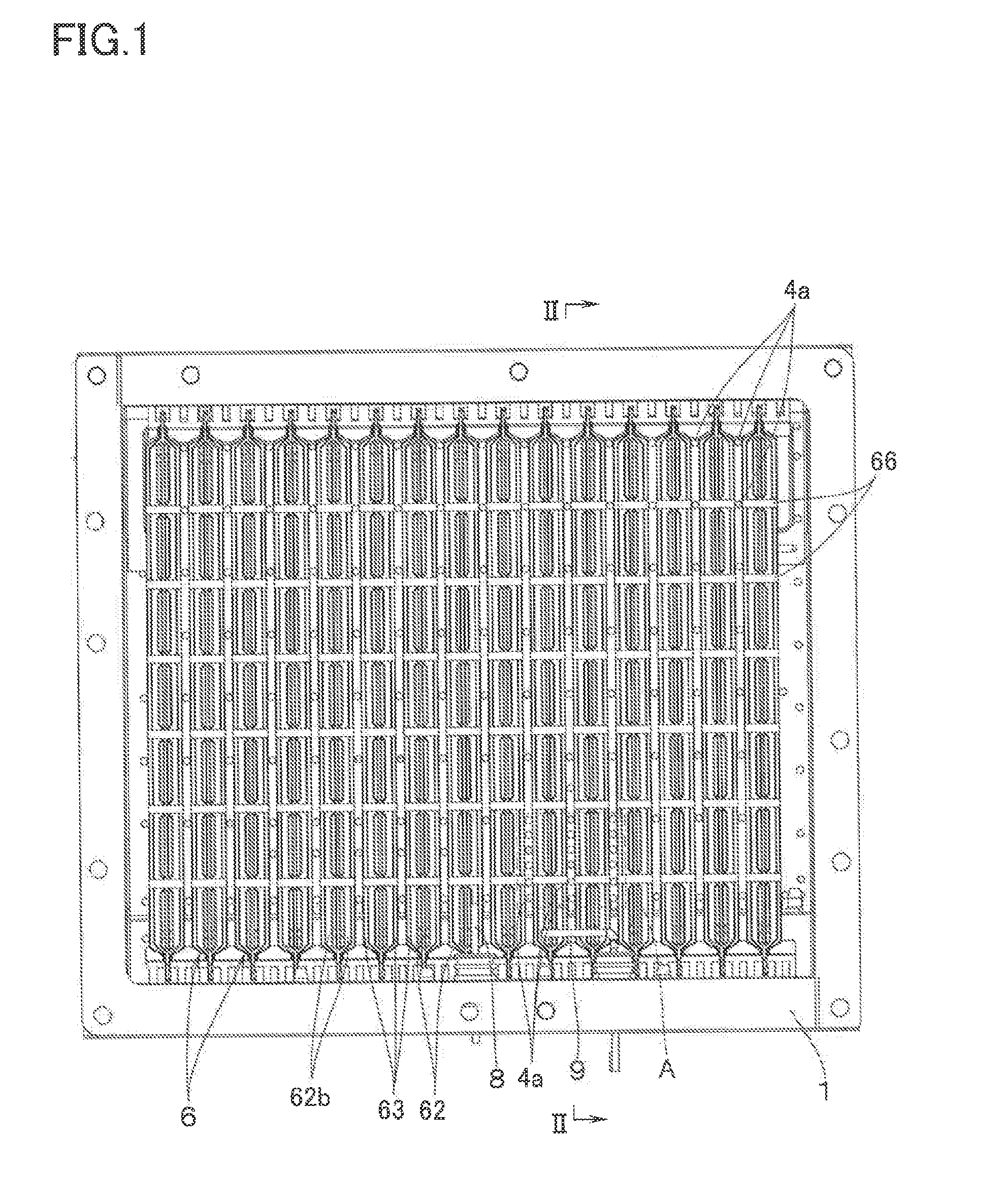

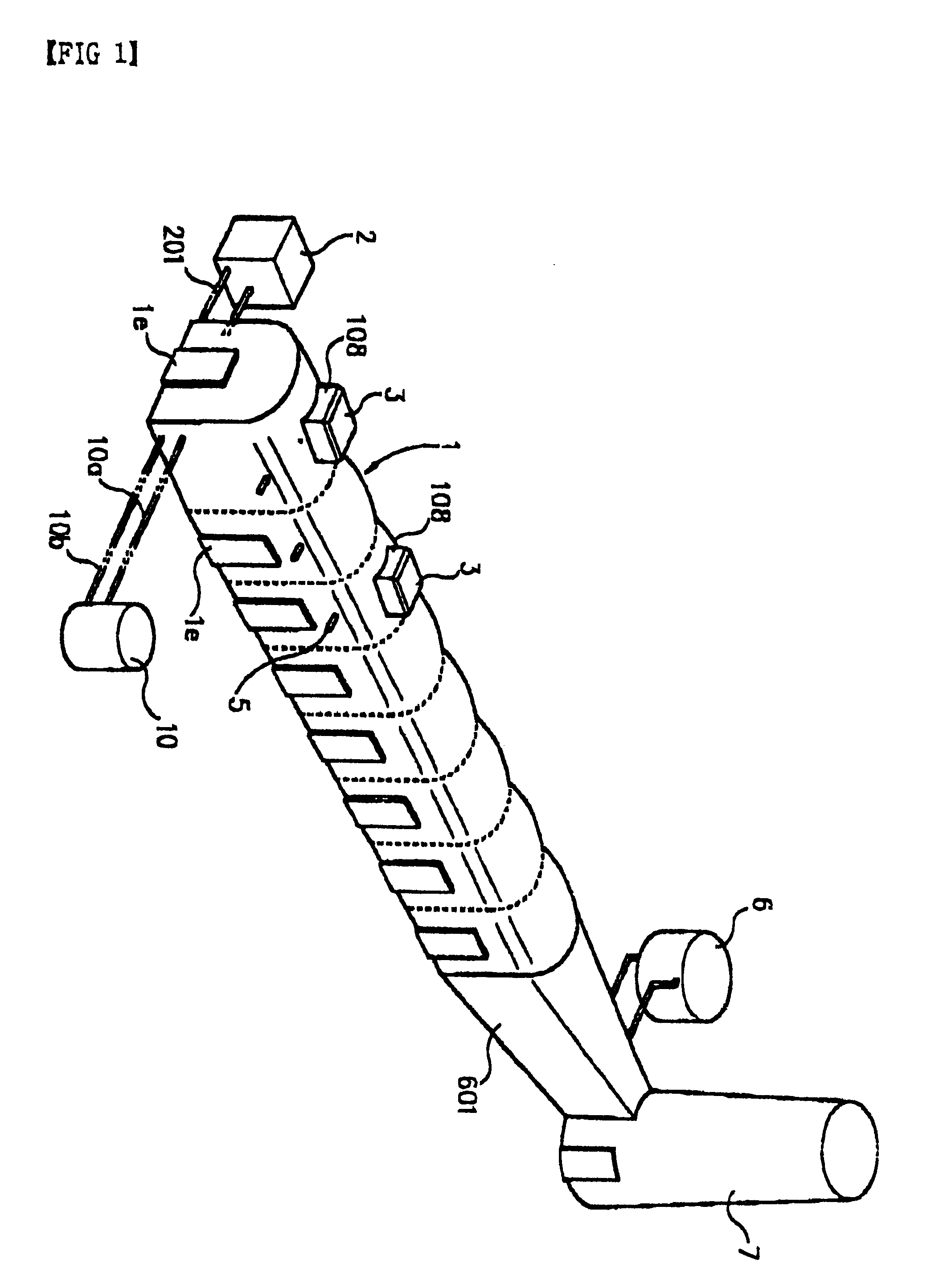

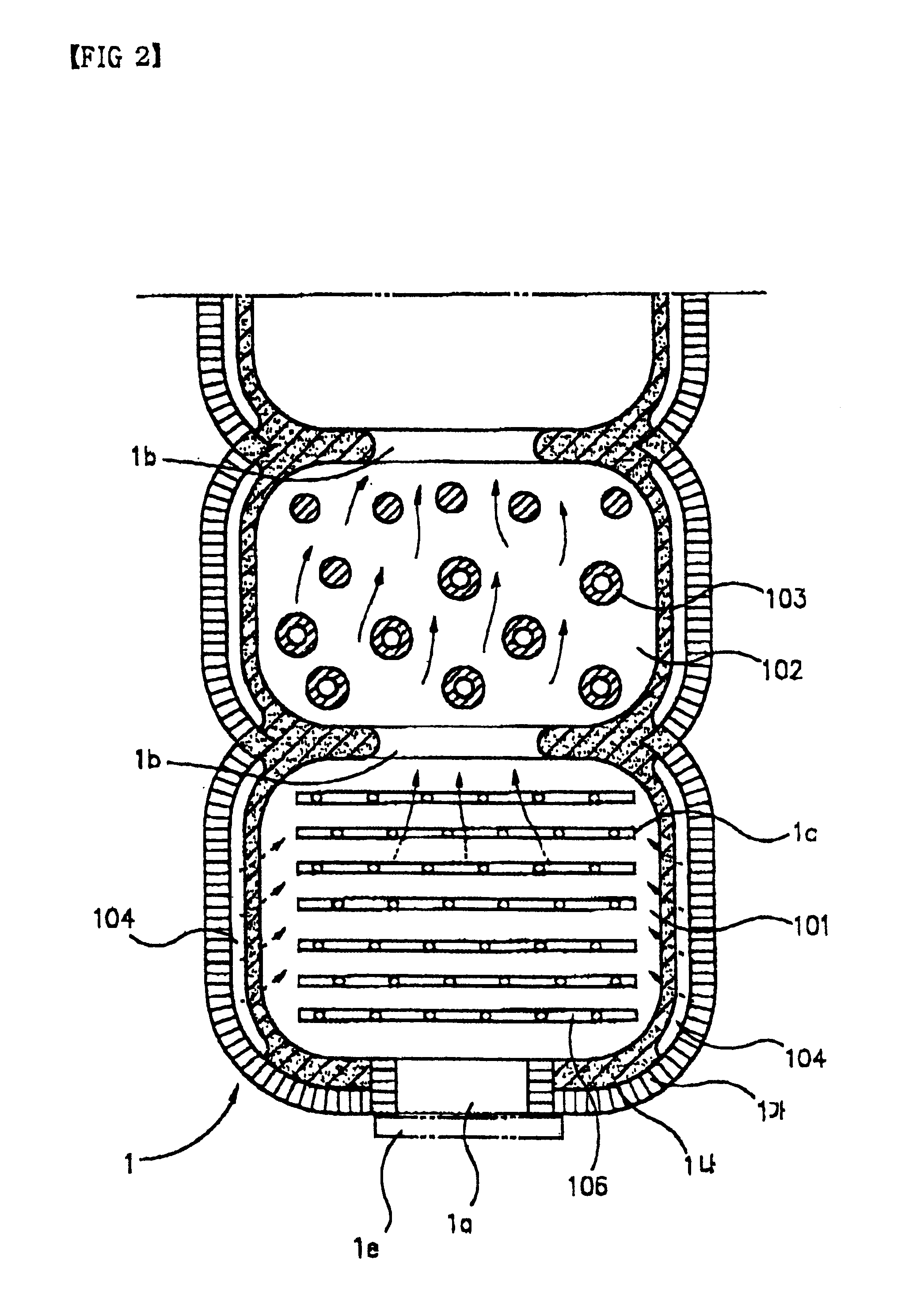

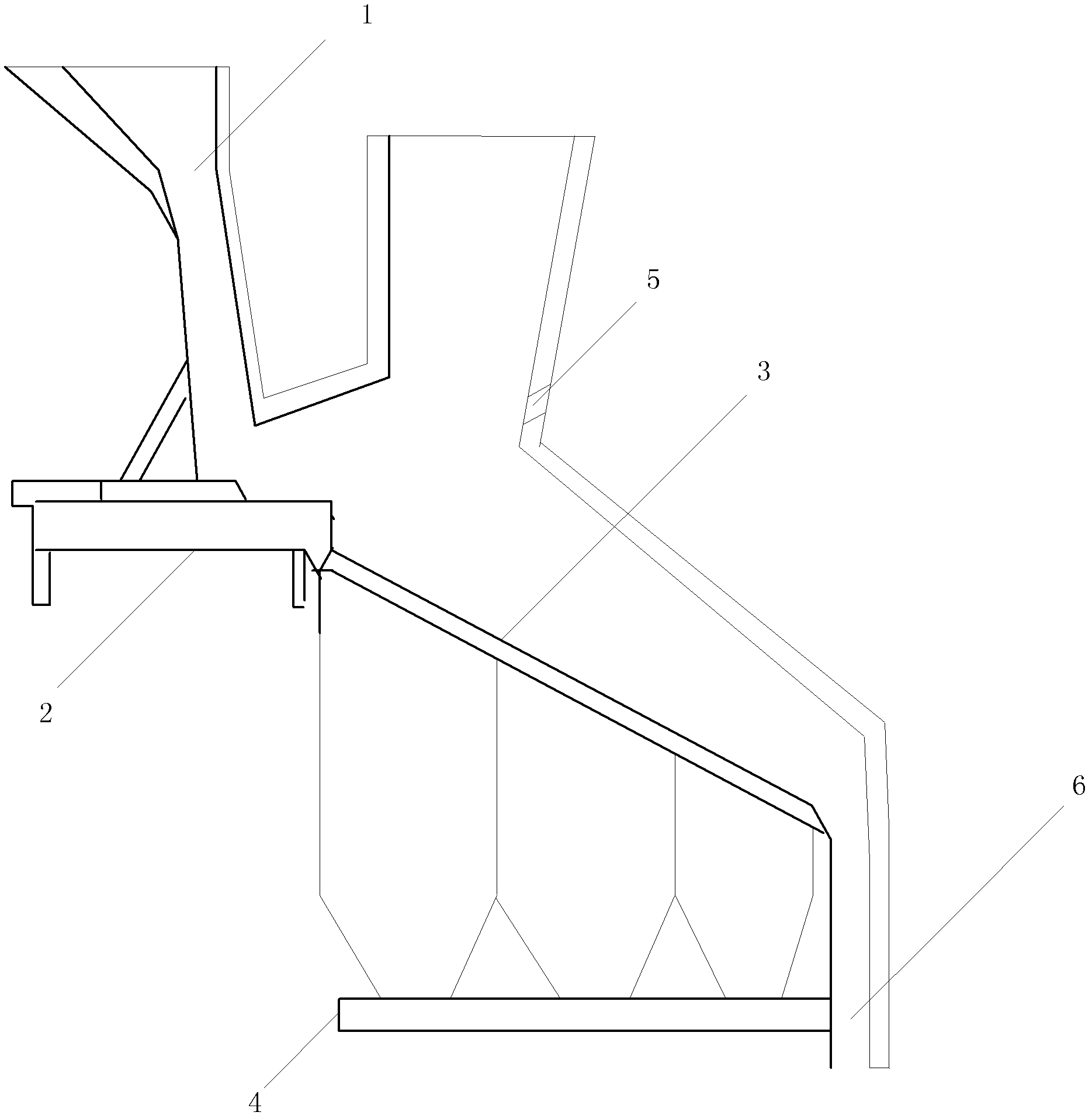

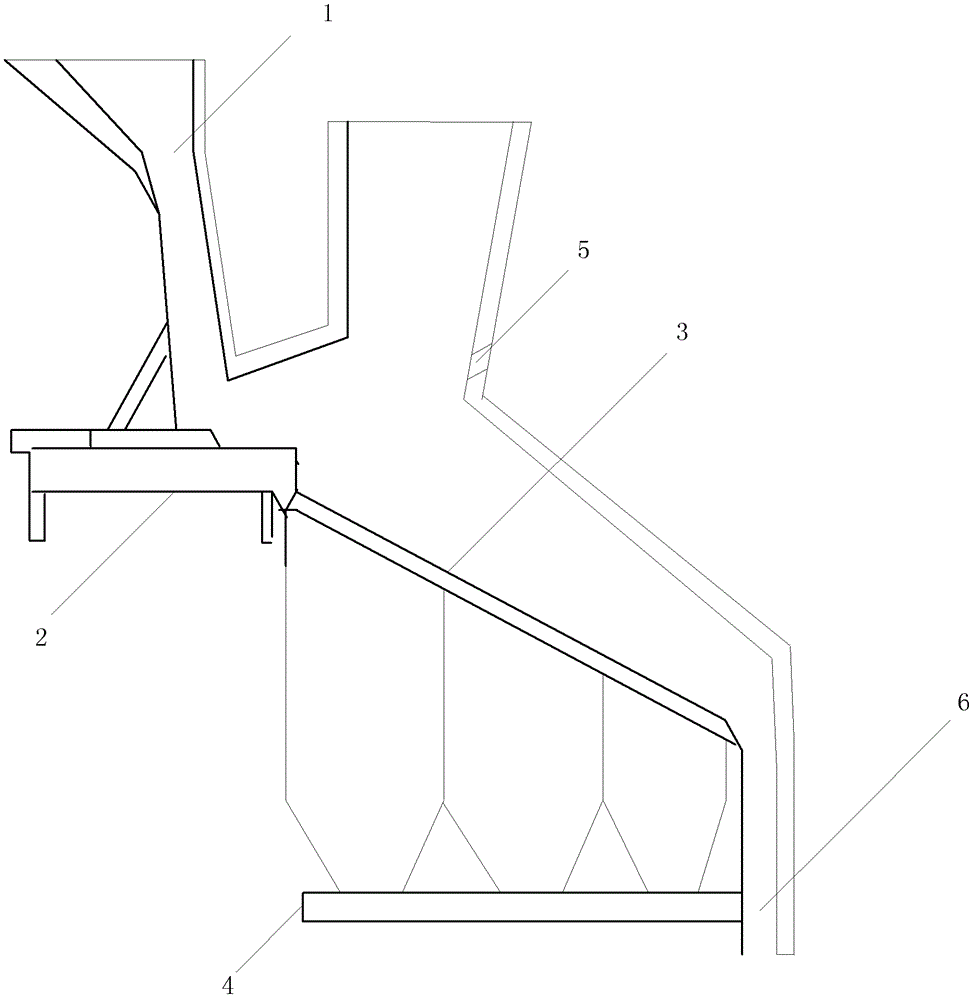

Bidirectional non-uniform matching air distributing water-cooled vibration grate of biomass direct-combustion boiler

InactiveCN101625126ASimple structureWide adaptabilityHollow bar grateRevolving grateDirect combustionEngineering

The invention relates to a bidirectional non-uniform matching air distributing water-cooled vibration grate of a biomass direct-combustion boiler, comprising a grate (1) formed by arranging a plurality of inclined water-cooled pipes (2) in parallel at predetermined intervals, wherein the grate (1) is fixed on a support frame (12); an air chamber (10) is arranged below the support frame (12); a discharge hole (13) is arranged below the air chamber (10); the water-cooled pipes (2) are connected with each other by a membrane (3) which is provided with an air inlet hole (4); an inlet end of the water-cooled pipe (2) is connected with an inlet collection tank (5); an outlet end of the water-cooled pipe (2) is connected with an inlet collection tank (6); and a driving device (8) is connected with the support frame (12) at the lower part of the grate (1) through a connecting rod (9) to provide vibration for the grate (1). A drying initial combustion zone, a primary combustion zone and an after-combustion zone are divided in the moving direction of biomass with different aperture ratios for each zone. In addition, the drying initial combustion zone is divided into three sub-zones according to the feeding amount of biomass with larger aperture ratio closer to the sub-zone of a feeding inlet.

Owner:SOUTHEAST UNIV

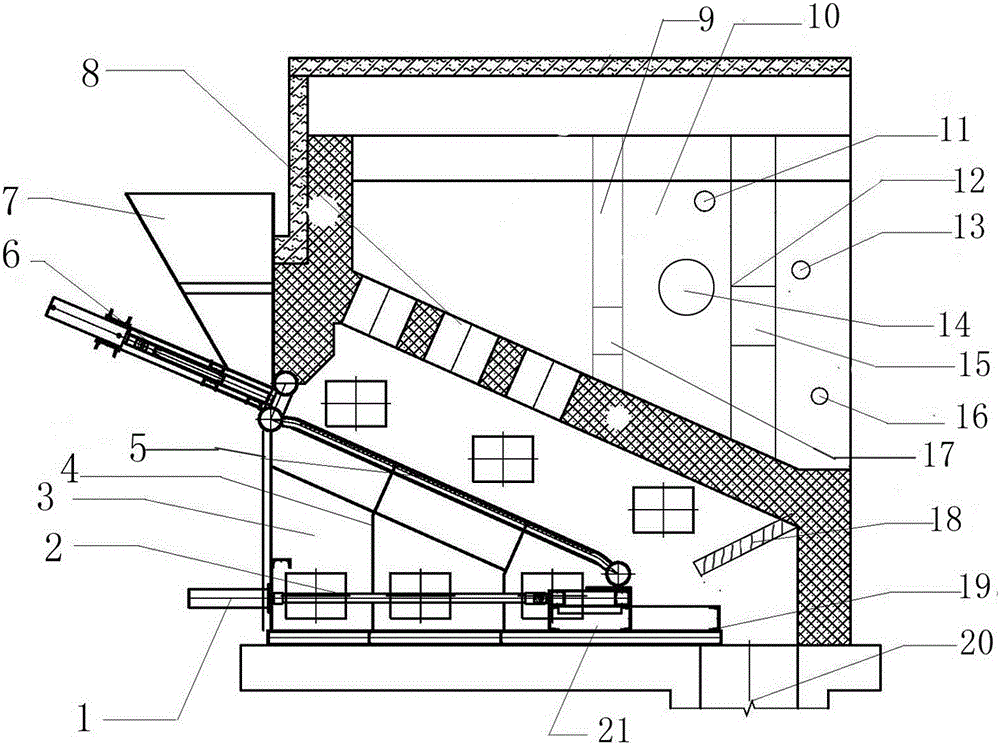

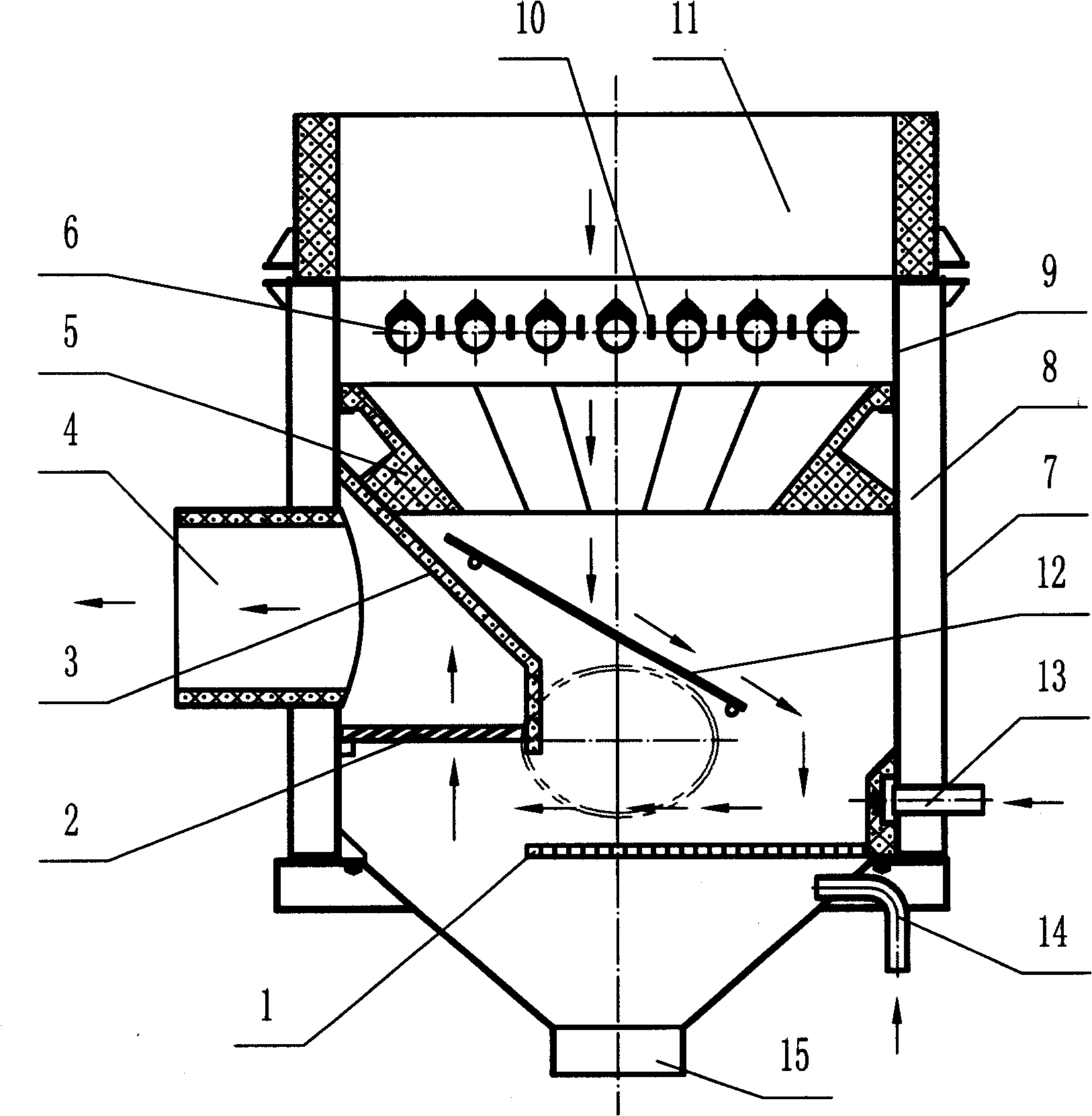

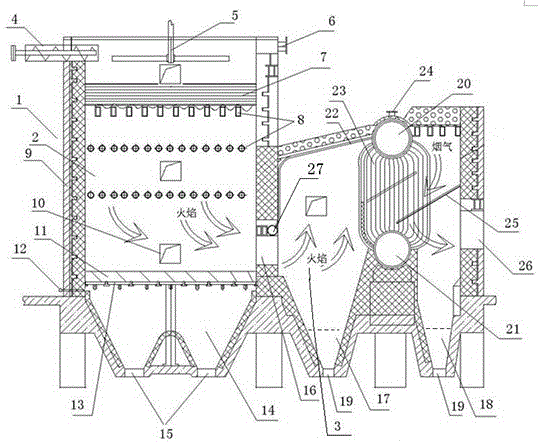

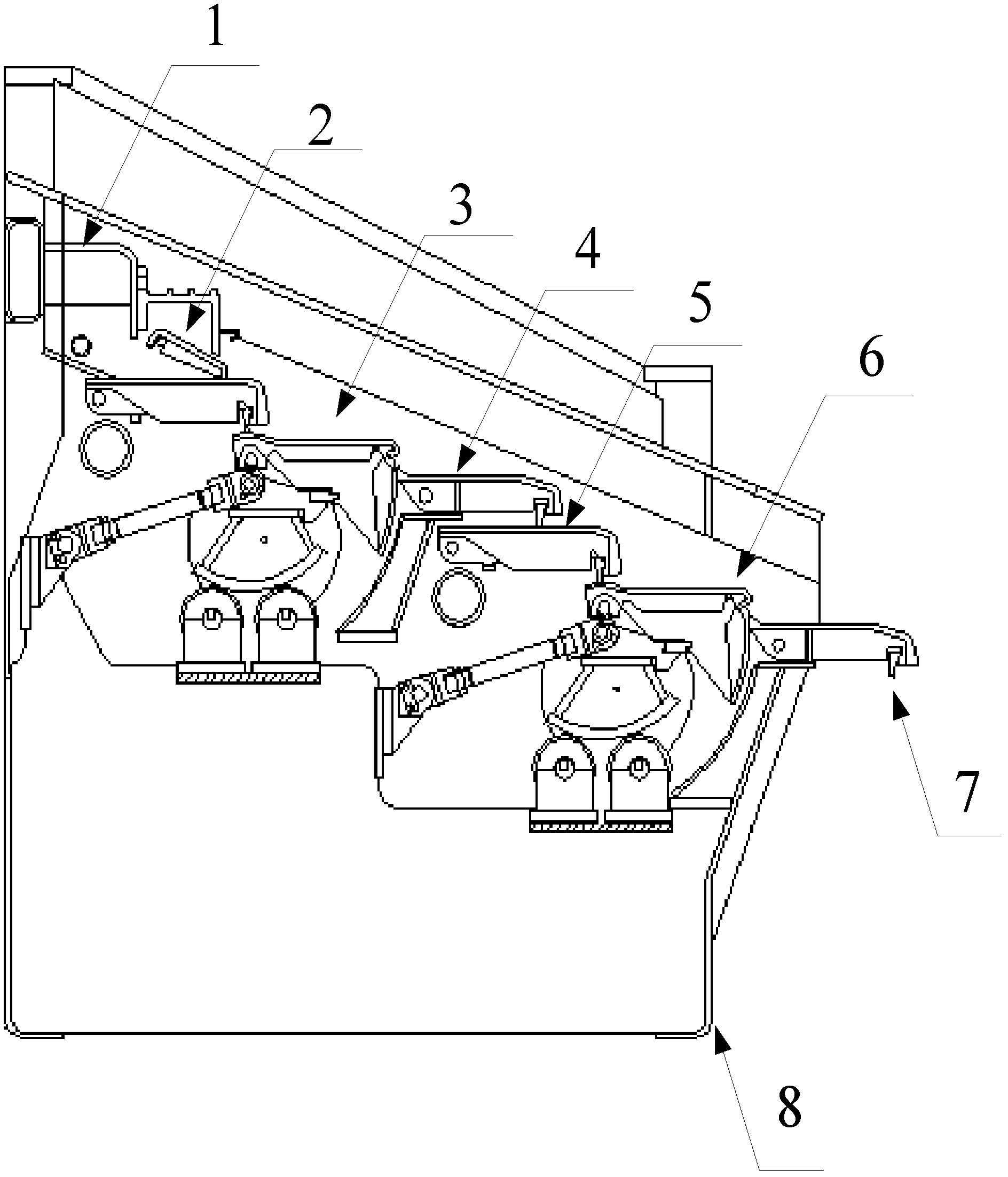

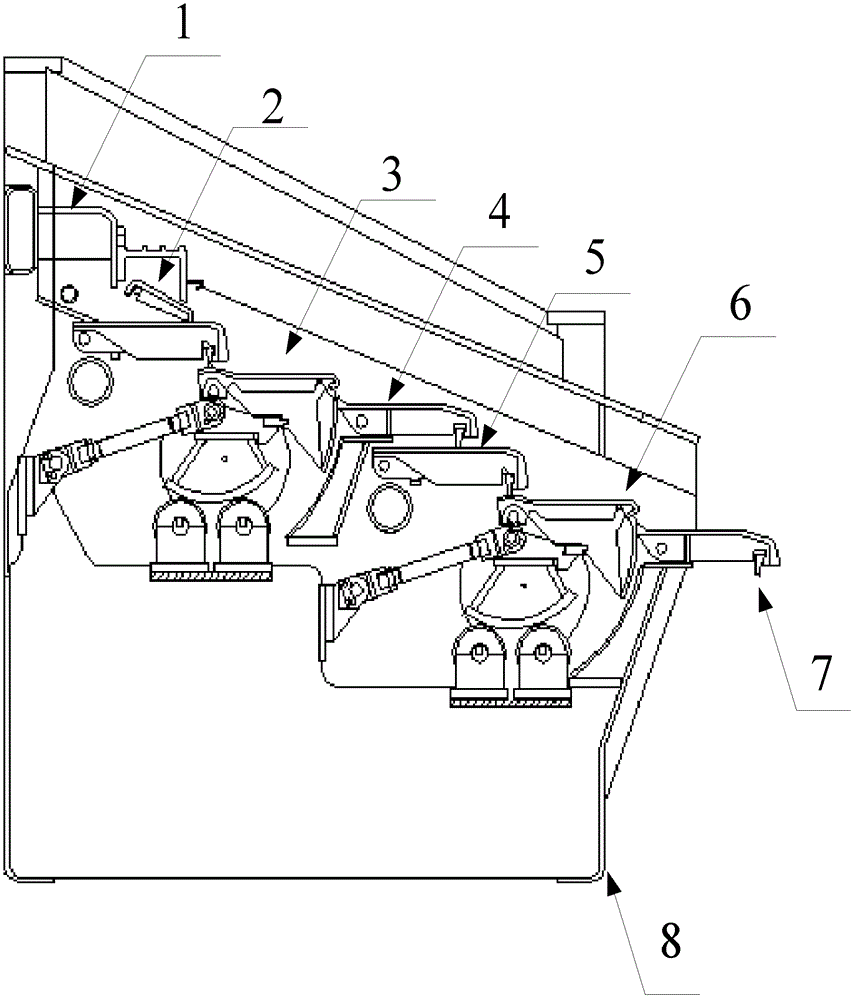

Multistage hydraulic mechanical garbage incinerator and control method for same

ActiveCN102607037AImprove combustionImprove burnout rateHollow bar grateInclined grateHydraulic machinerySteel frame

The invention provides a multistage hydraulic mechanical garbage incinerator and a control method for the same. The multistage hydraulic mechanical garbage incinerator comprises a feeding port, a feeding fire grate, an incinerating fire grate, a primary air supply system and a secondary air supply system. The incinerating fire grate is longitudinally divided into five units, wherein the first unit, the second unit, the third unit and the fourth unit are standard units, the fifth unit is a tail end lengthened unit, each unit comprises a plurality of sliding fire grate segments, turning fire grate segments and fixed fire grate segments, and the incinerating fire grate is integrally and longitudinally divided into a drying section, a burning section and a burnout section by the five units. The multistage hydraulic mechanical garbage incinerator is characterized in that the fire grate segments in each row of the incinerating fire grate are transversely driven by a shaft and transversely supported by a steel frame at three positions at the least. By the aid of the multistage hydraulic mechanical garbage incinerator, the shortcomings of an existing garbage incinerator are improved, and burnout ratio of garbage incineration is increased.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECHCAL DEV BEIJING +1

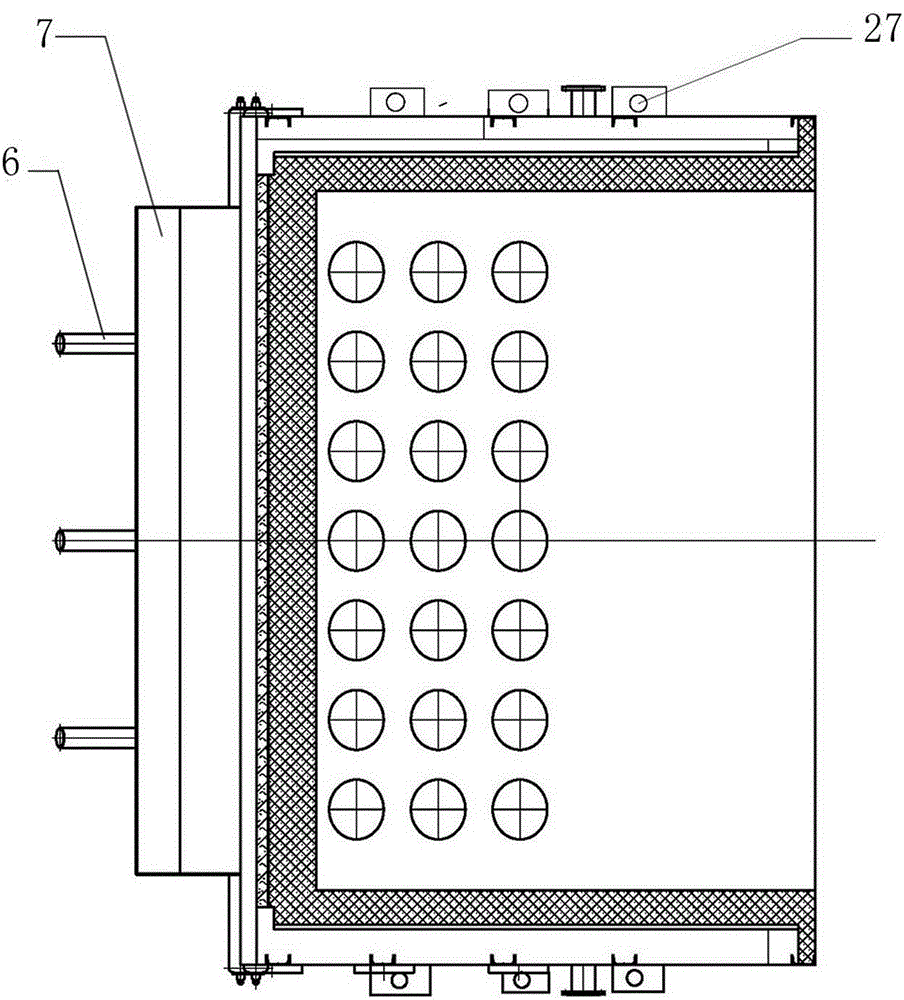

Biomass furnace and device for removing nitric oxide in same

InactiveCN105003911AImprove combustion efficiencyEasy to burnHollow bar grateSolid fuel combustionCombustionEngineering

The invention relates to a biomass furnace and a device for removing nitric oxide in the furnace. The middle part of the furnace is provided with a furnace arch in a slope shape. A water-cooled stocker in parallel with the furnace arch is arranged below the furnace arch. The bottom of the front end of the stocker is provided with an ash collecting platform. A material retaining wall is arranged above the platform. A deslagging pit is arranged below the front end of the ash collecting platform, and the rear end is provided with an ash pushing device. The furnace arch, a furnace wall above the furnace arch, and two fir barriers form a denitration cavity. The furnace wall on a side of the cavity is provided with a feeding device. The furnace wall above the feeding device is provided with a blowhole. The device is characterized by simple structure, good economical efficiency, no secondary pollution, good maneuverability, and easy monitoring, and combustion efficiency of the furnace is not reduced. The device improves combustion efficiency of biomass. Under the condition of ensuring enough output of the furnace, a problem that combustion generates nitric oxide pollution is solved.

Owner:冯之军

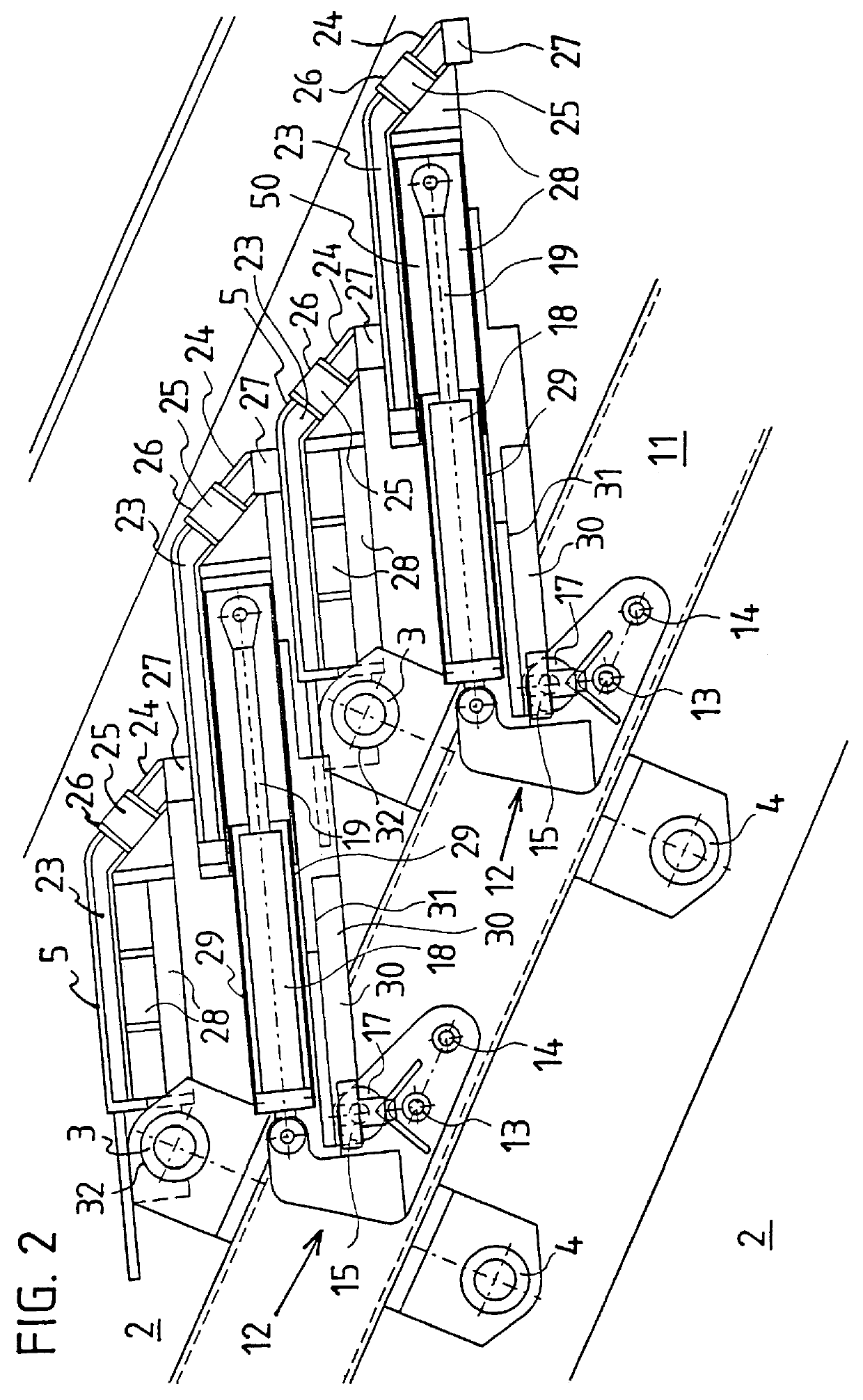

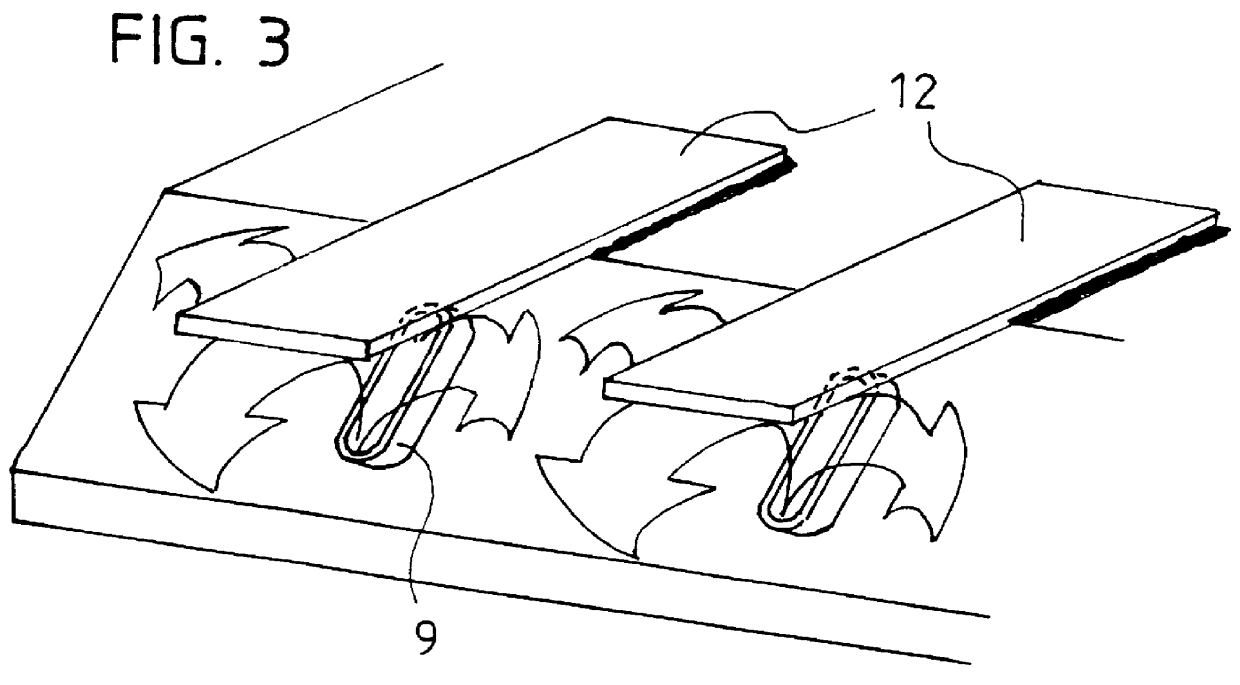

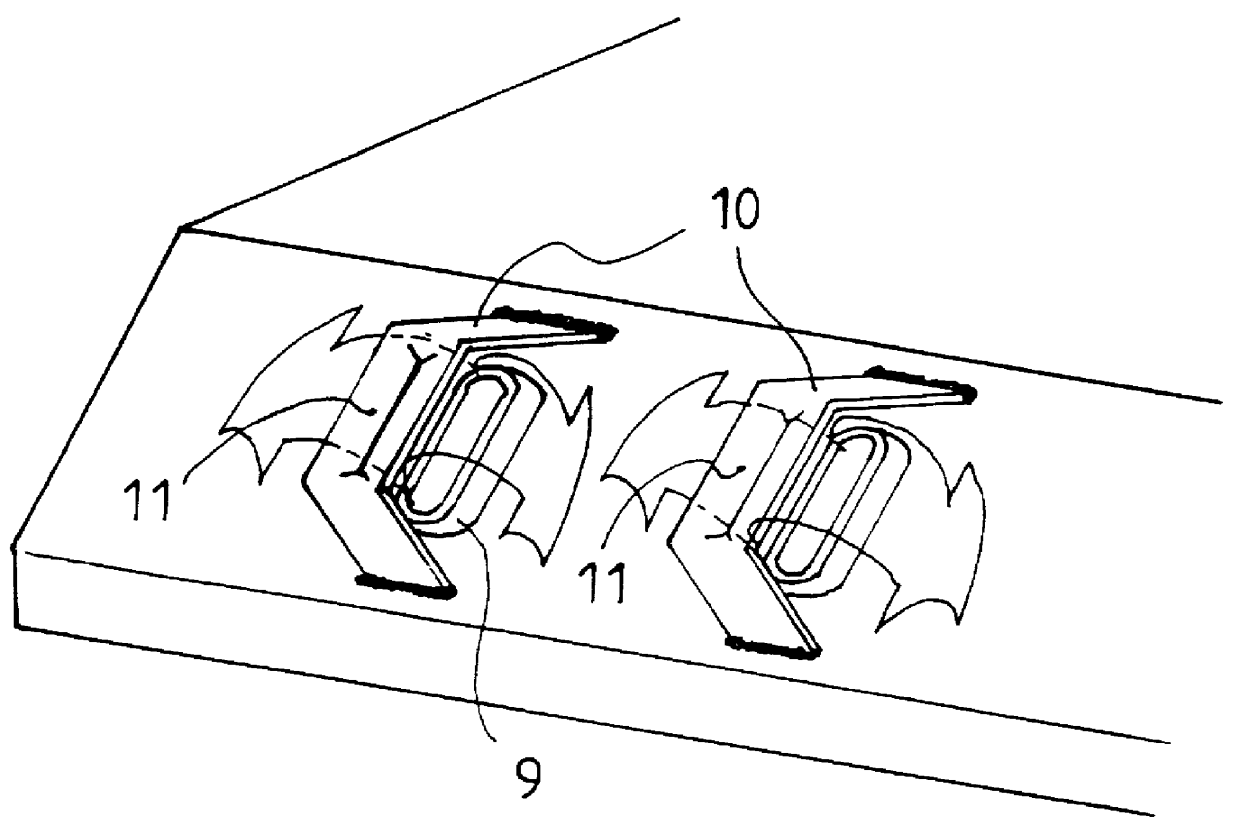

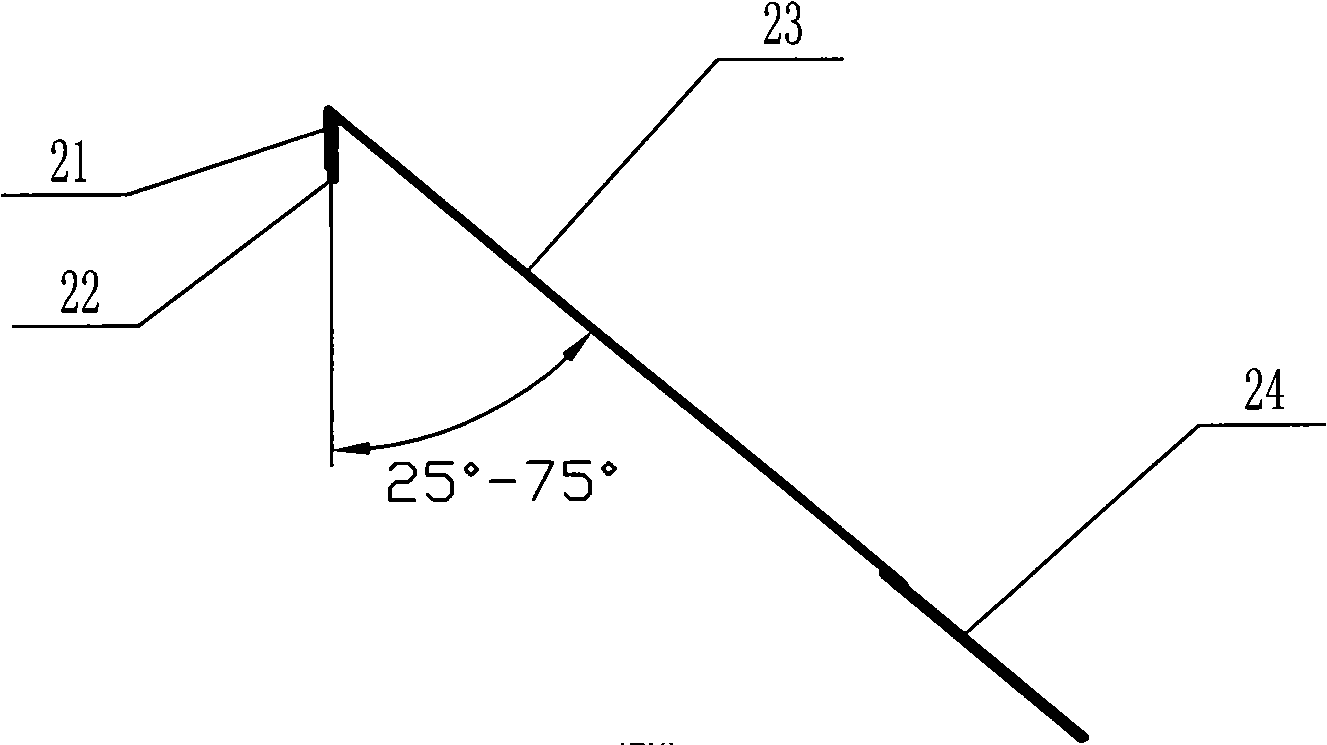

Process for incinerating solids on a water-cooled thrust combustion grate, and a grate plate and grate for accomplishing the process

A process wherein primary air supplied to the combustion bed through the thrust combustion grate is deflected after exiting from a surface of the thrust combustion grate by deflector elements mounted on the surface of the thrust combustion grate. The grate required for this purpose has grate plates made from a permeable hollow element with connection pieces for supplying and draining cooling water, with primary air supply ducts that run through the grate plate from a bottom to a top. Deflector elements against which the primary air exiting the outlet is intended to impact, are disposed over openings of the primary air supply ducts.

Owner:DOIKOS INVESTIMENTS LTD

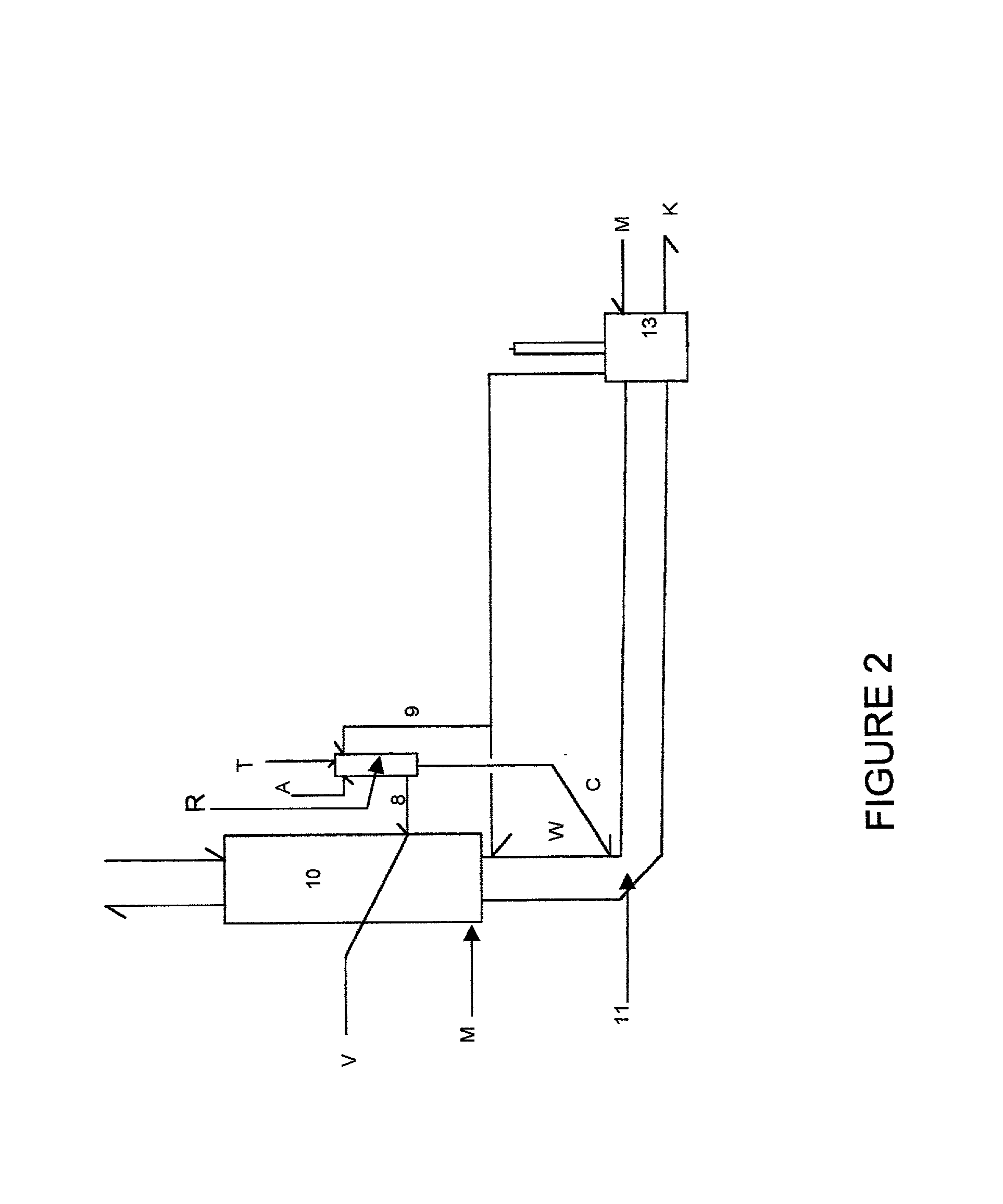

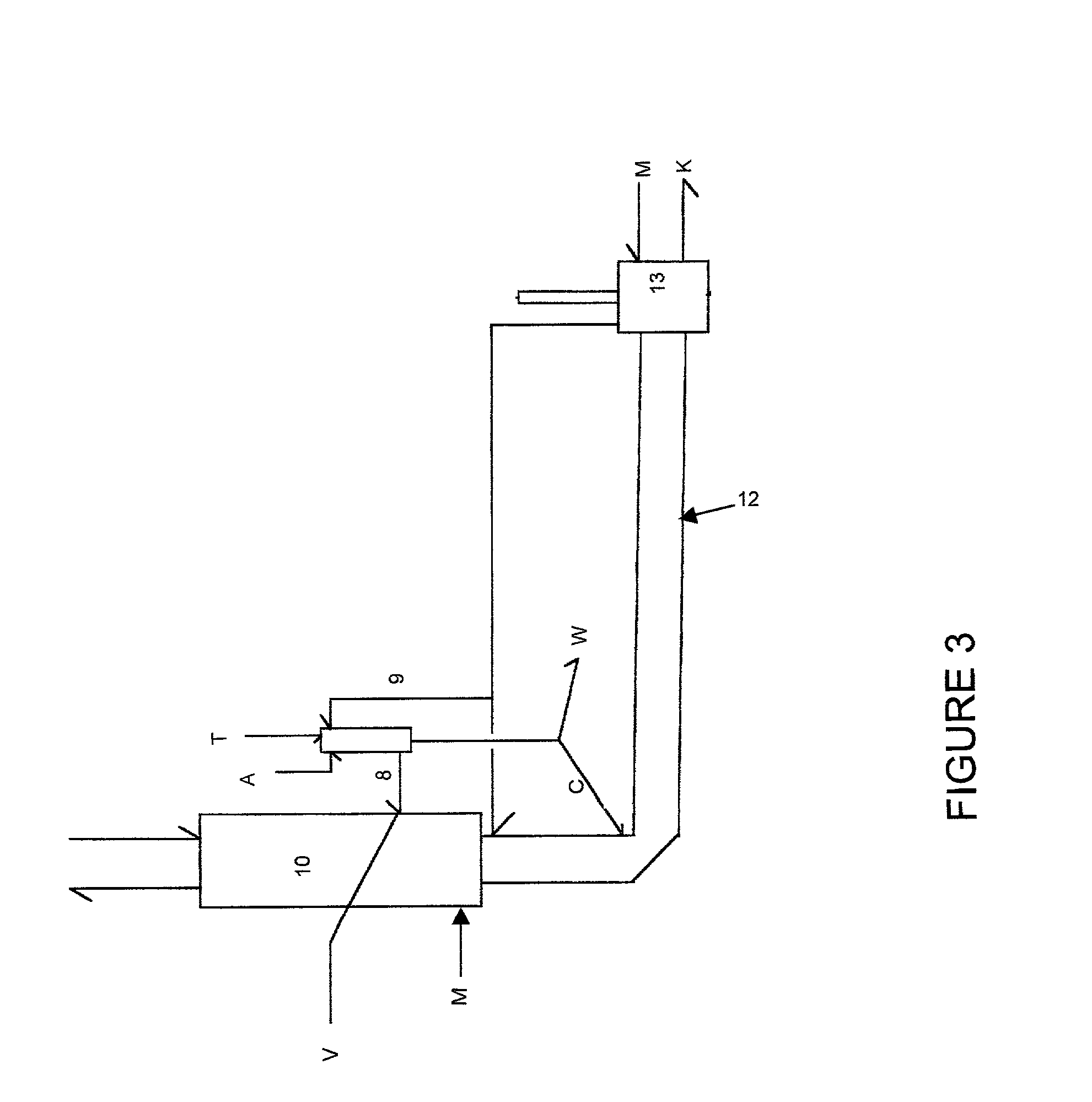

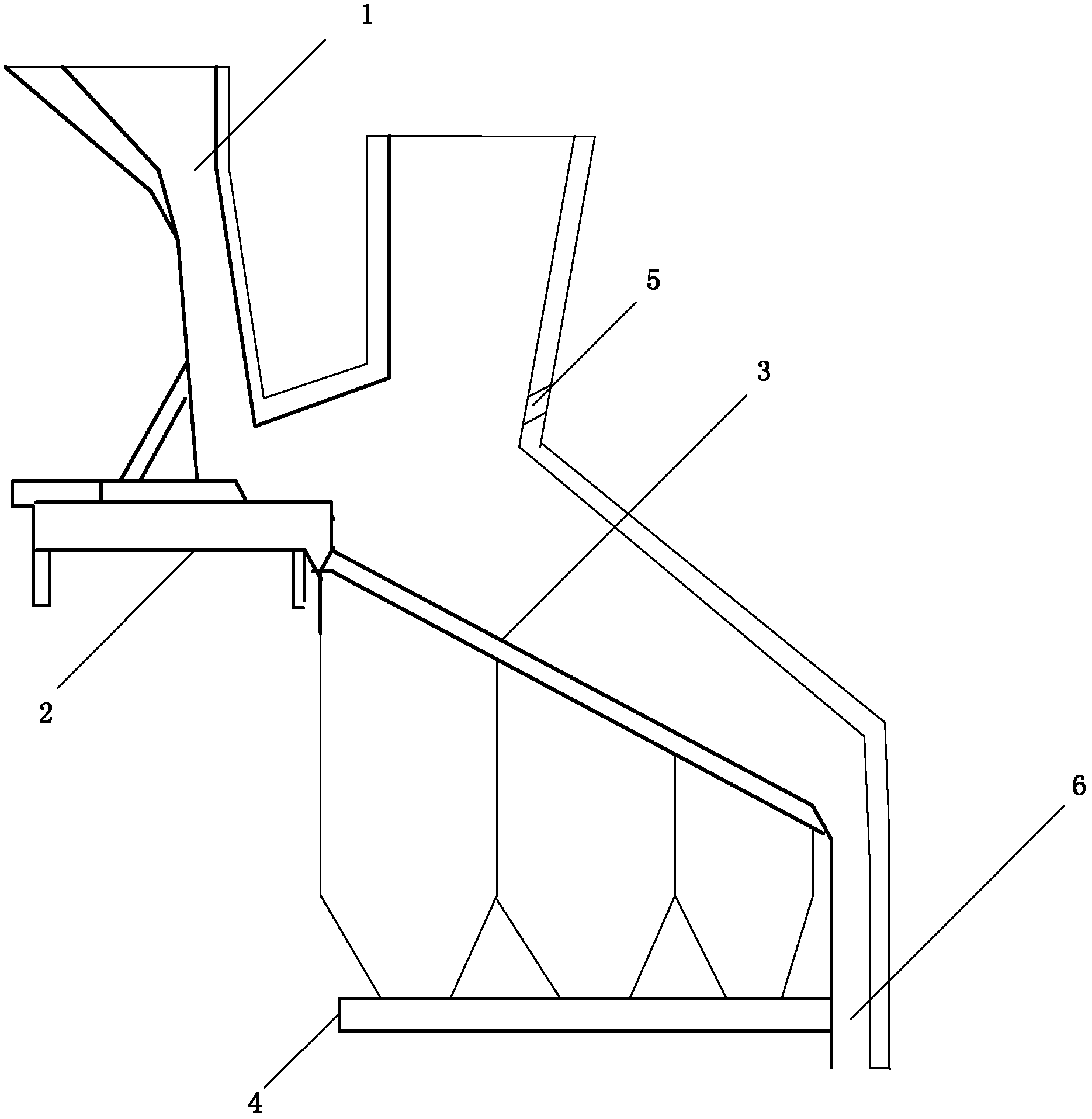

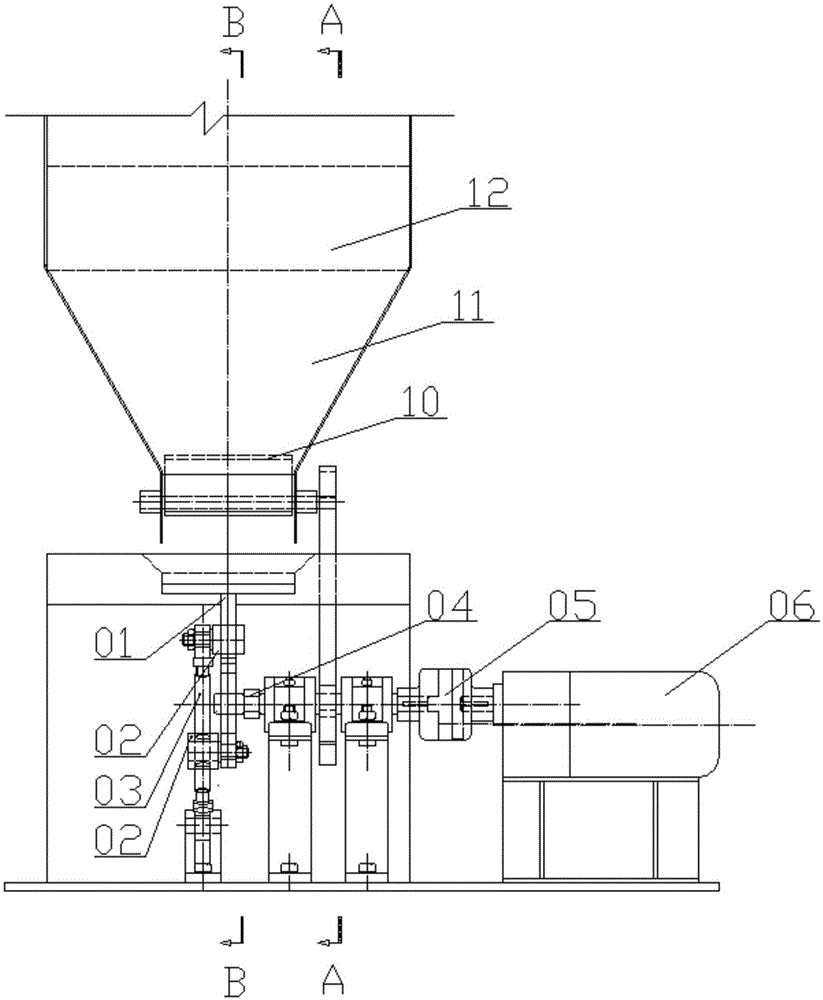

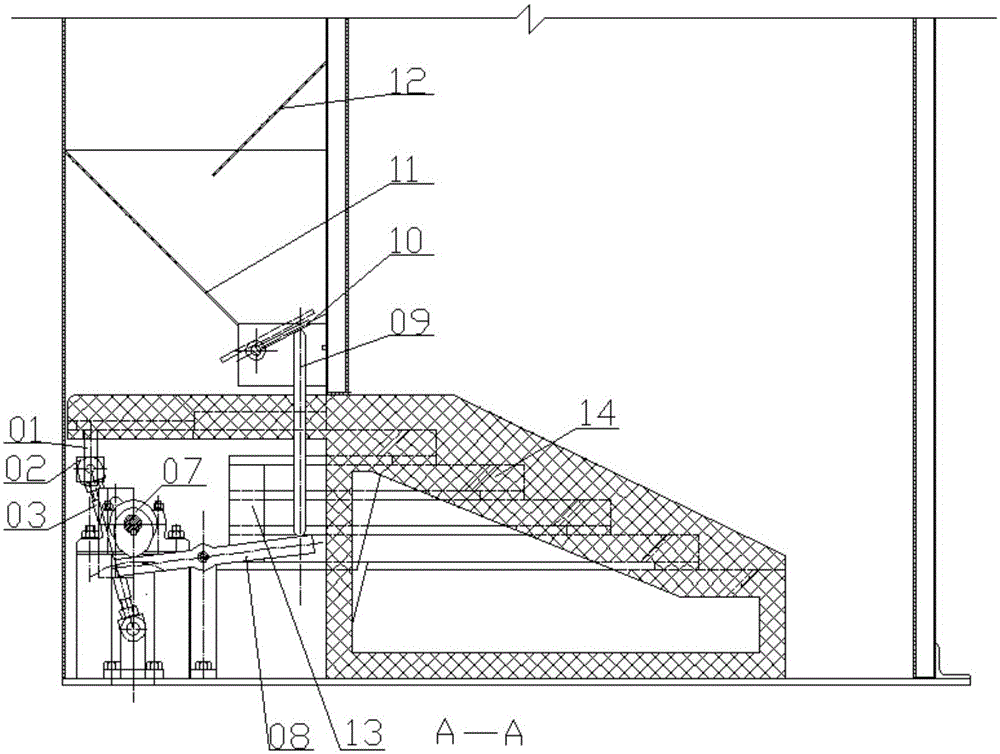

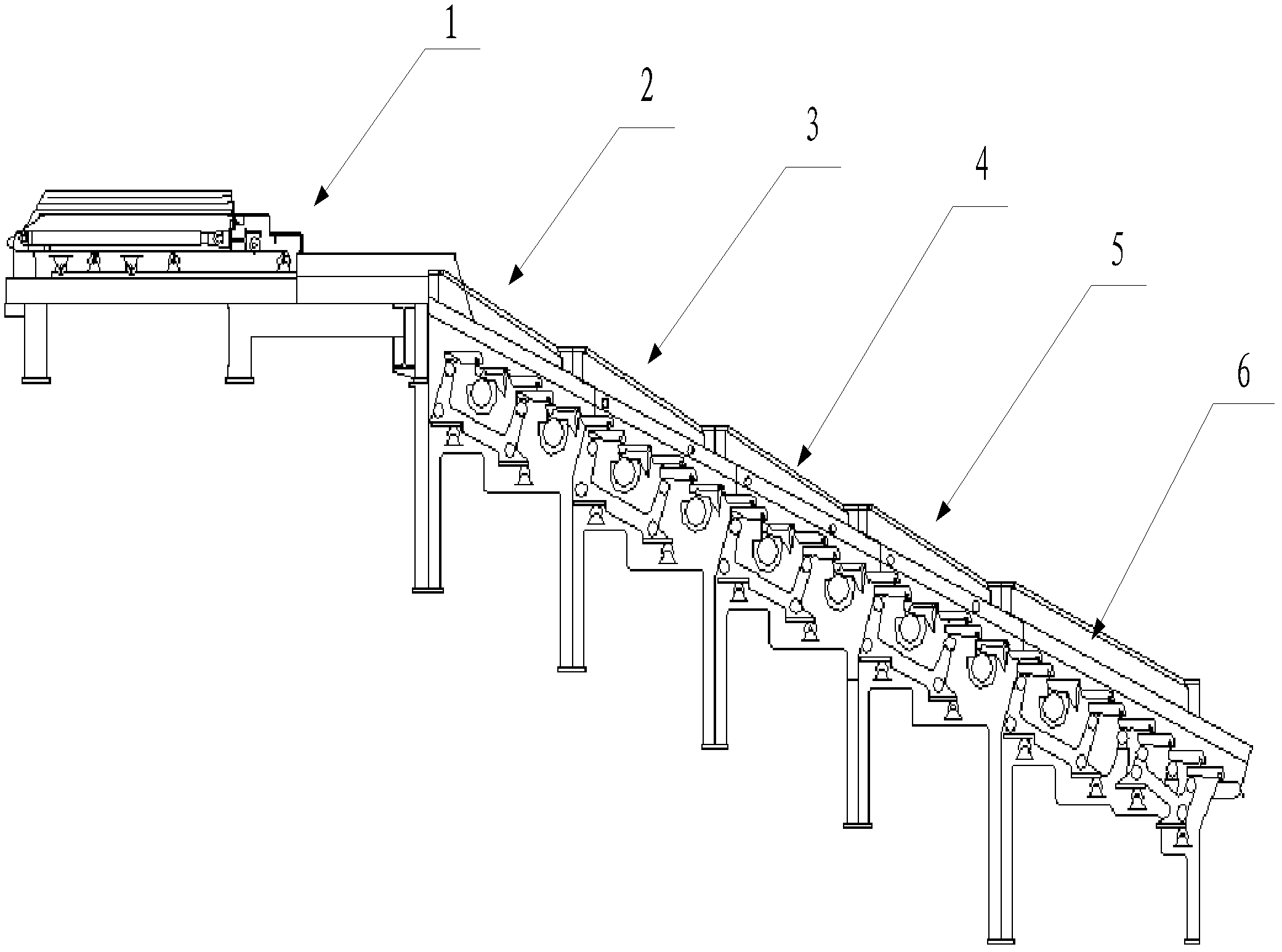

Feeding device for small biomass granular fuel boiler

InactiveCN105135461APrecipitation is stableRealize the problem of string burning to the silo and continuous fireHollow bar grateLump/pulverulent fuel feeder/distributionEngineeringPellet fuel

The invention relates to a biomass fuel boiler and in particular to a feeding device for a small biomass granular fuel boiler. The feeding device comprises a storage bin driven by a motor, a feeding mechanism, a push mechanism, a poking mechanism and a step-like fire bed. A feeding overturning plate in the feeding mechanism is arranged at the lower end of the storage bin. One side of the feeding overturning plate is hinged to the storage bin, and the other side of the feeding overturning plate is clamped to an edge protrusion of the storage bin. The push mechanism is arranged on a first layer of step of the step-like fire bed and can slide on the first layer of step. The feeding mechanism is hinged to the push mechanism. The poking mechanism is arranged on the lower portion of the storage bin and connected with the feeding mechanism in a transmission manner. According to the feeding device for the small biomass granular fuel boiler, the flow property and the pile angle feature of biomass granular fuel are utilized, and automatic discharging is achieved; the problem that flame in a hearth spreads and burns the material bin, and fire spreading is caused is prevented; besides, ash loosening and fire poking functions are achieved, and coking is prevented; a fire bed storage furnace supplies heat, radiates heat and carries out heat convection; and one-time wind-fire bed surface supply is achieved, a granular fuel solid part is fully burned, and therefore the burn-out rate is increased.

Owner:JILIN UNIV

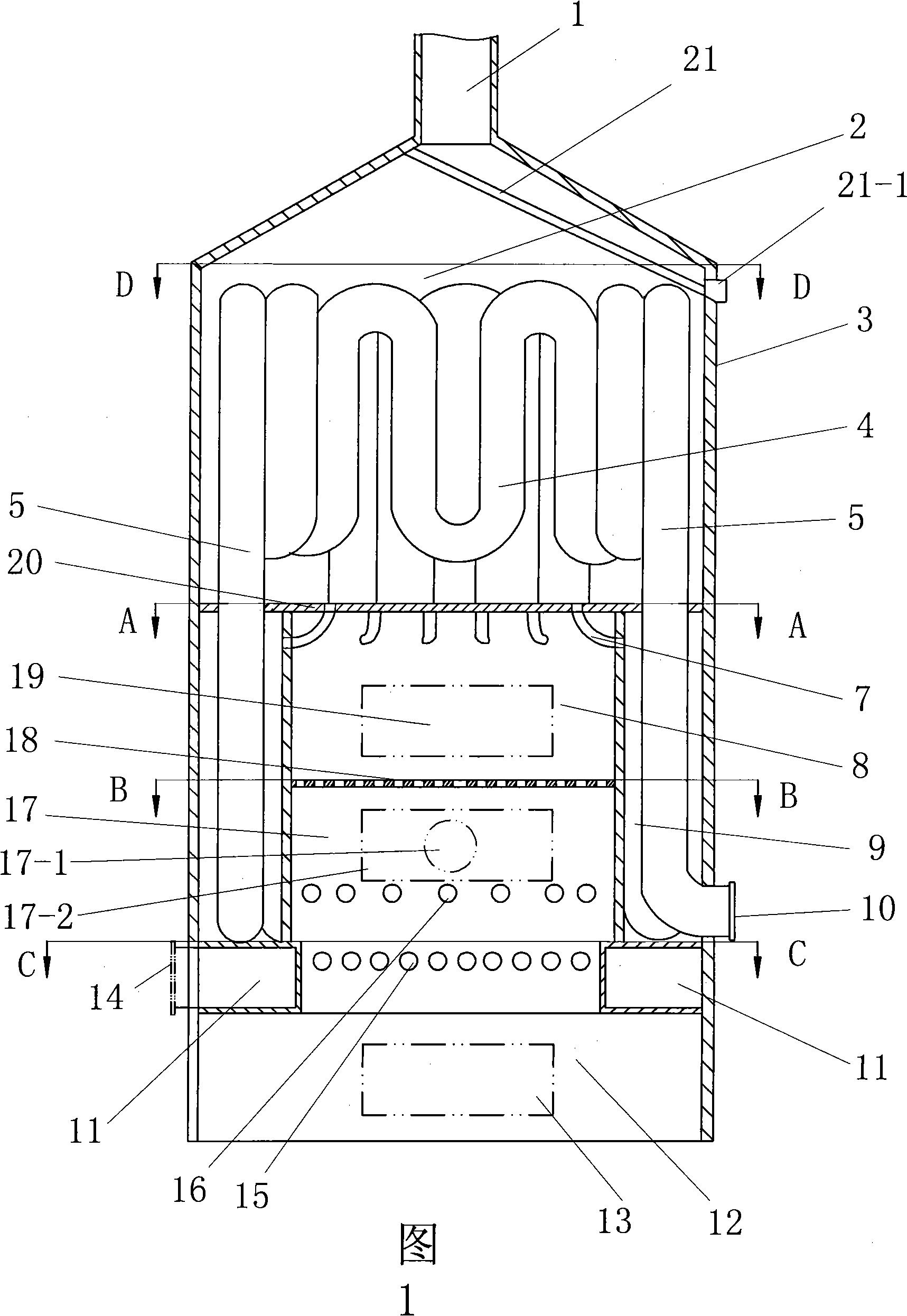

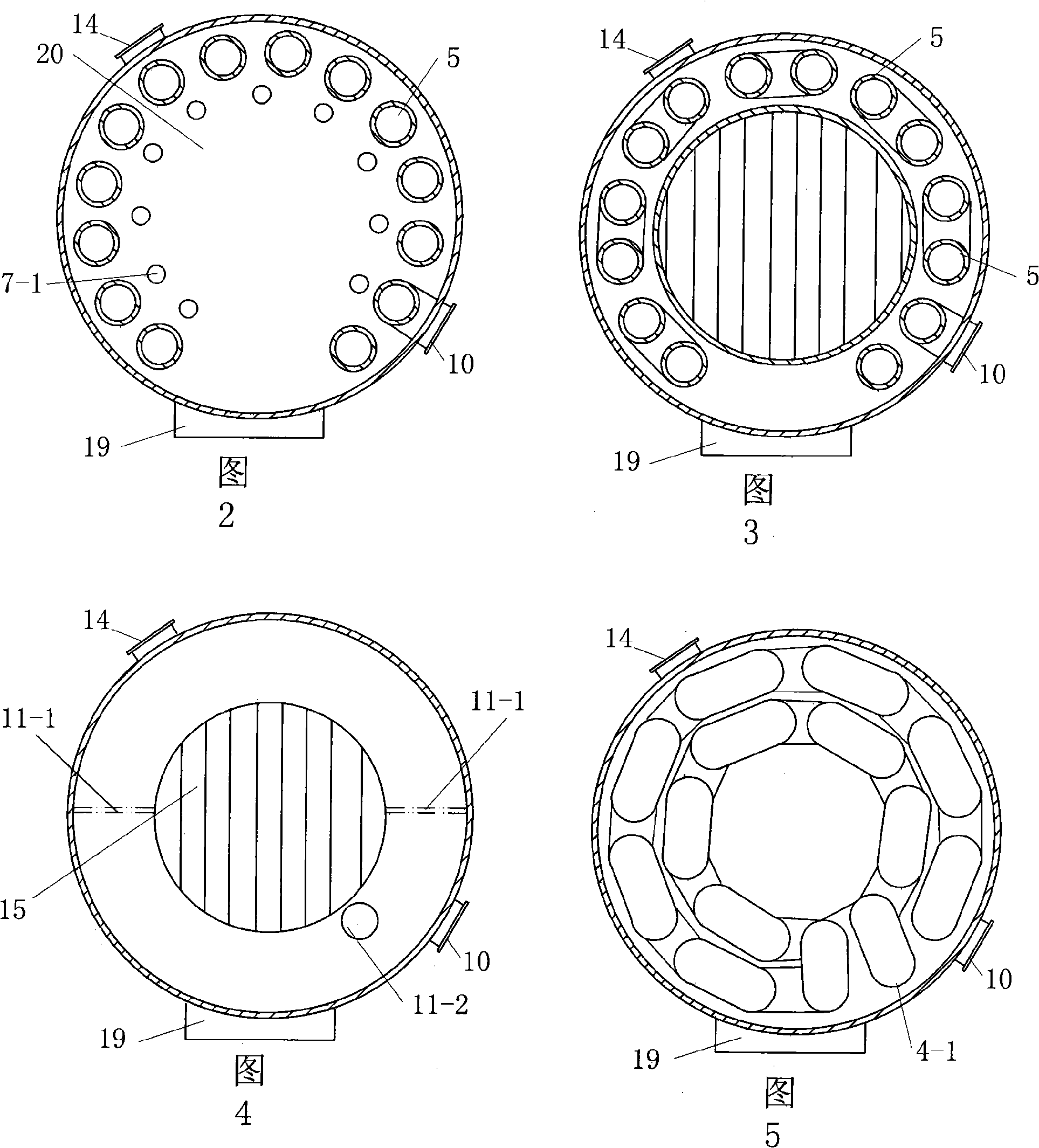

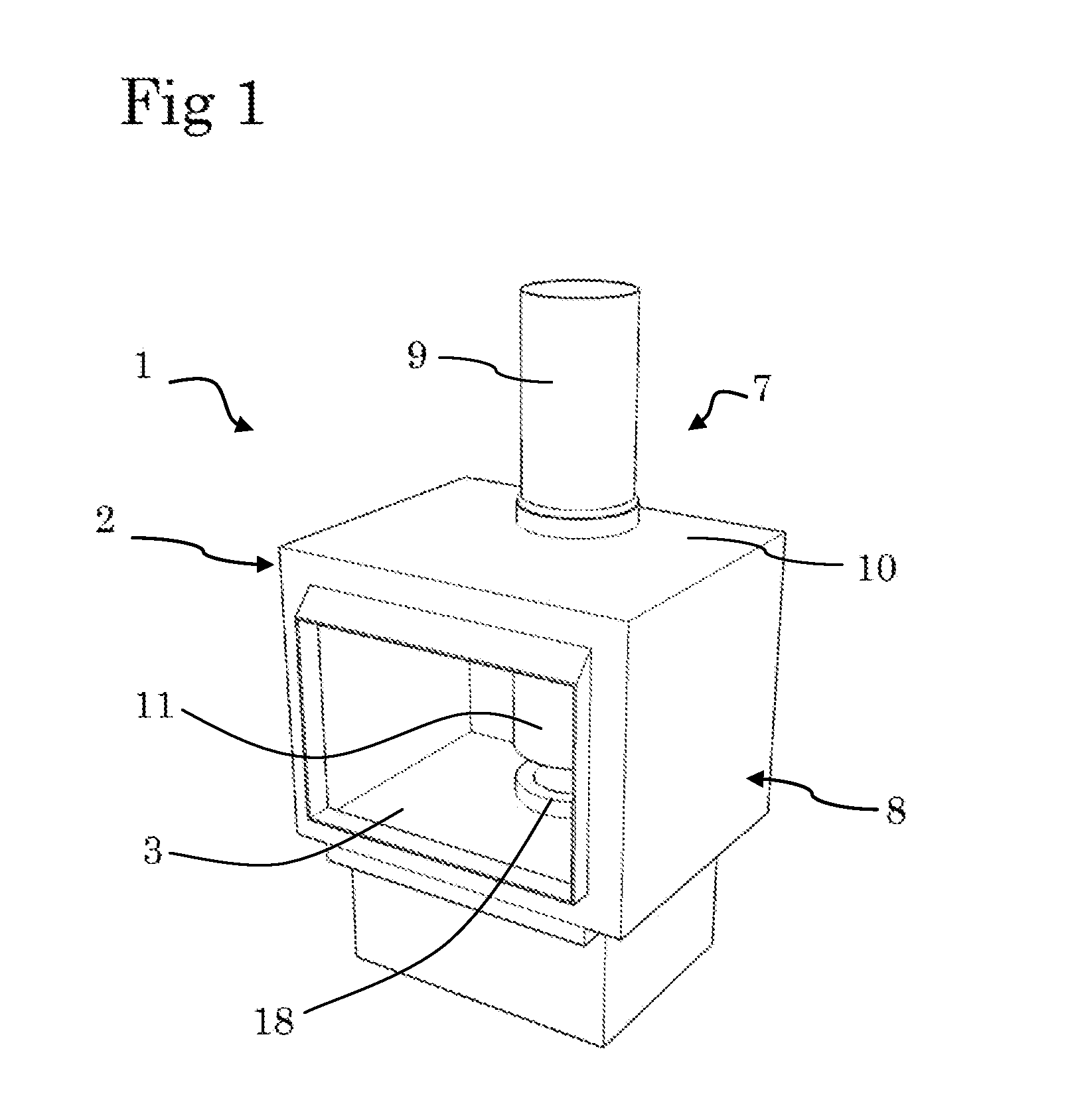

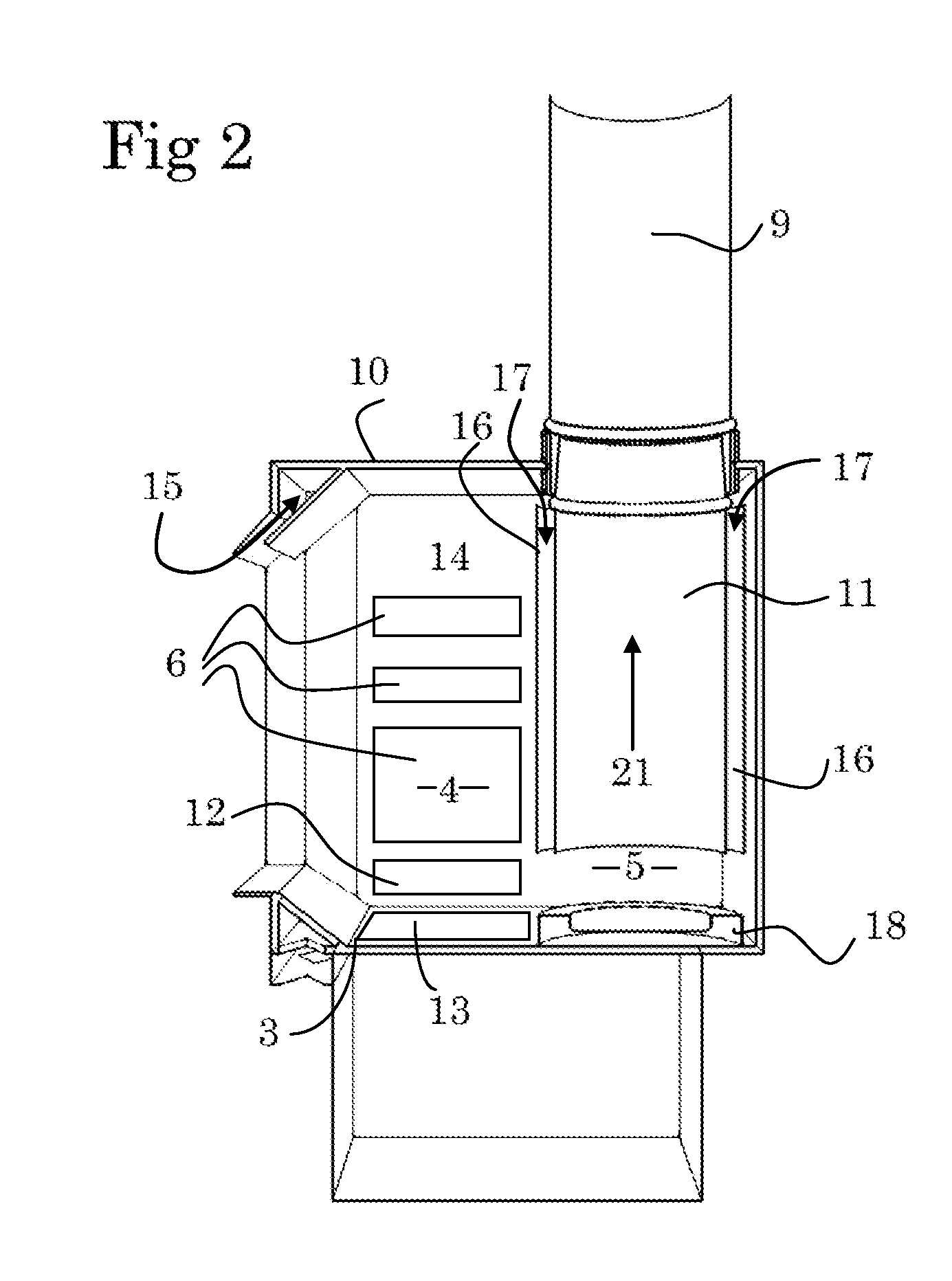

Hot-air stove

InactiveCN101307953AExtended stayExtend heating timeHollow bar grateAir heatersCombustion chamberHigh energy

The invention relates to a hot blast producer. The technical problem to be solved is to provide a hot blast producer which has the characteristics of high energy utilization rate, clean discharged waste, clean acquired hot blast without smoke smell and low production cost. The invention adopts the technical proposal that: the hot blast producer comprises a chimney on the top and a producer body arranged vertically; the middle of the producer body is provided with a heating chamber and a combustion chamber which are arranged up and down; the combustion chamber and a secondary combustion chamber under the combustion chamber form a closed cylinder body the peripheral wall of which is provided with an air course; a heat absorbing air pipe is arranged zigzag between the heating chamber and the secondary combustion chamber; the peripheral wall of the secondary combustion chamber is also provided with a group of heatconducting holes; the combustion chamber is also provided with a group of syphons, each syphone is respectively communicated with through holes on the peripheral wall and on a top plate; grates on the bottom of the cylinder body consist of hollow pipes, two ends of the hollow pipes are respectively communicated with an annular channel which winds into circles along the peripheral wall of the producer body; and the annular channel is respectively communicated with an inner air pipe outlet and a hot blast outlet.

Owner:王德金

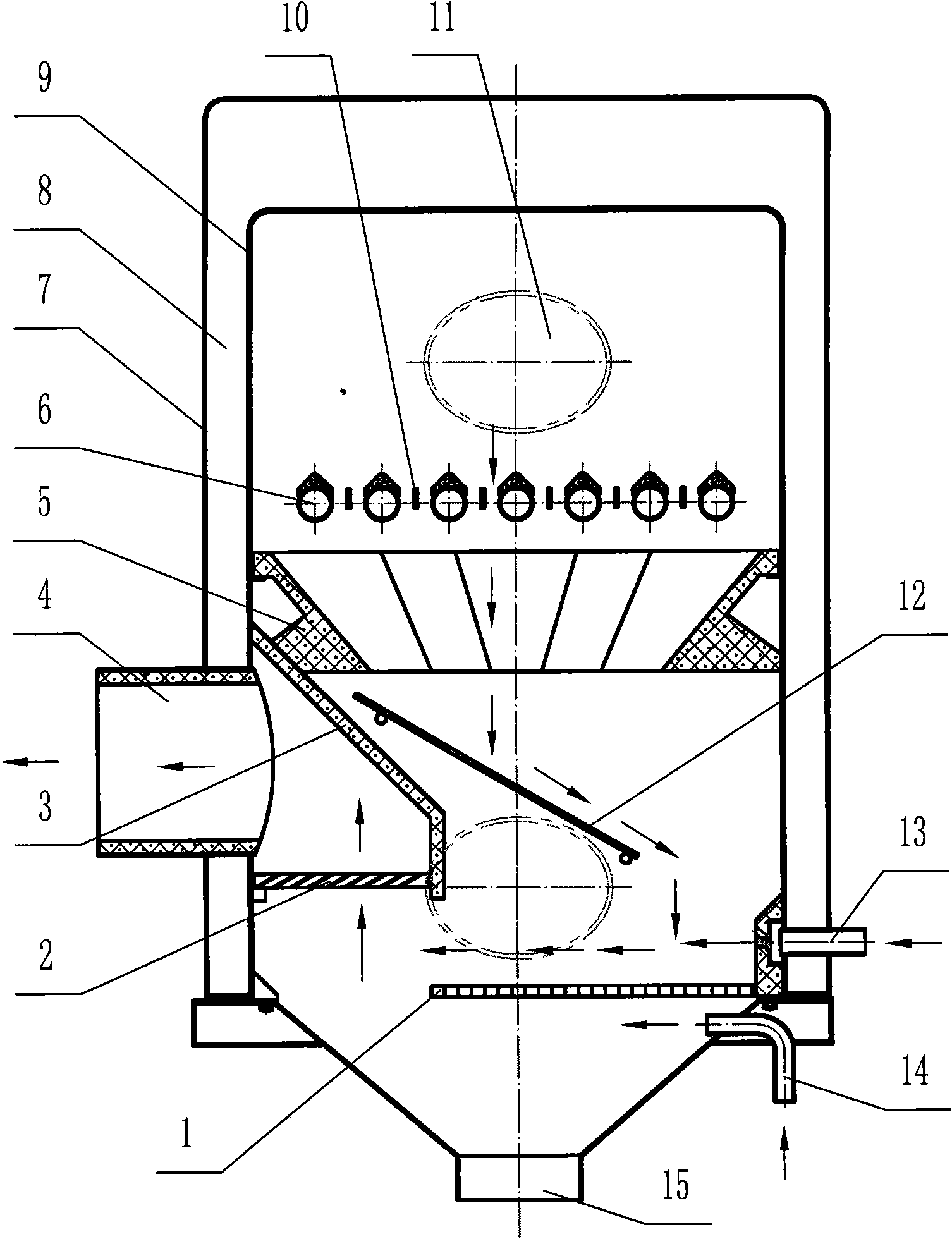

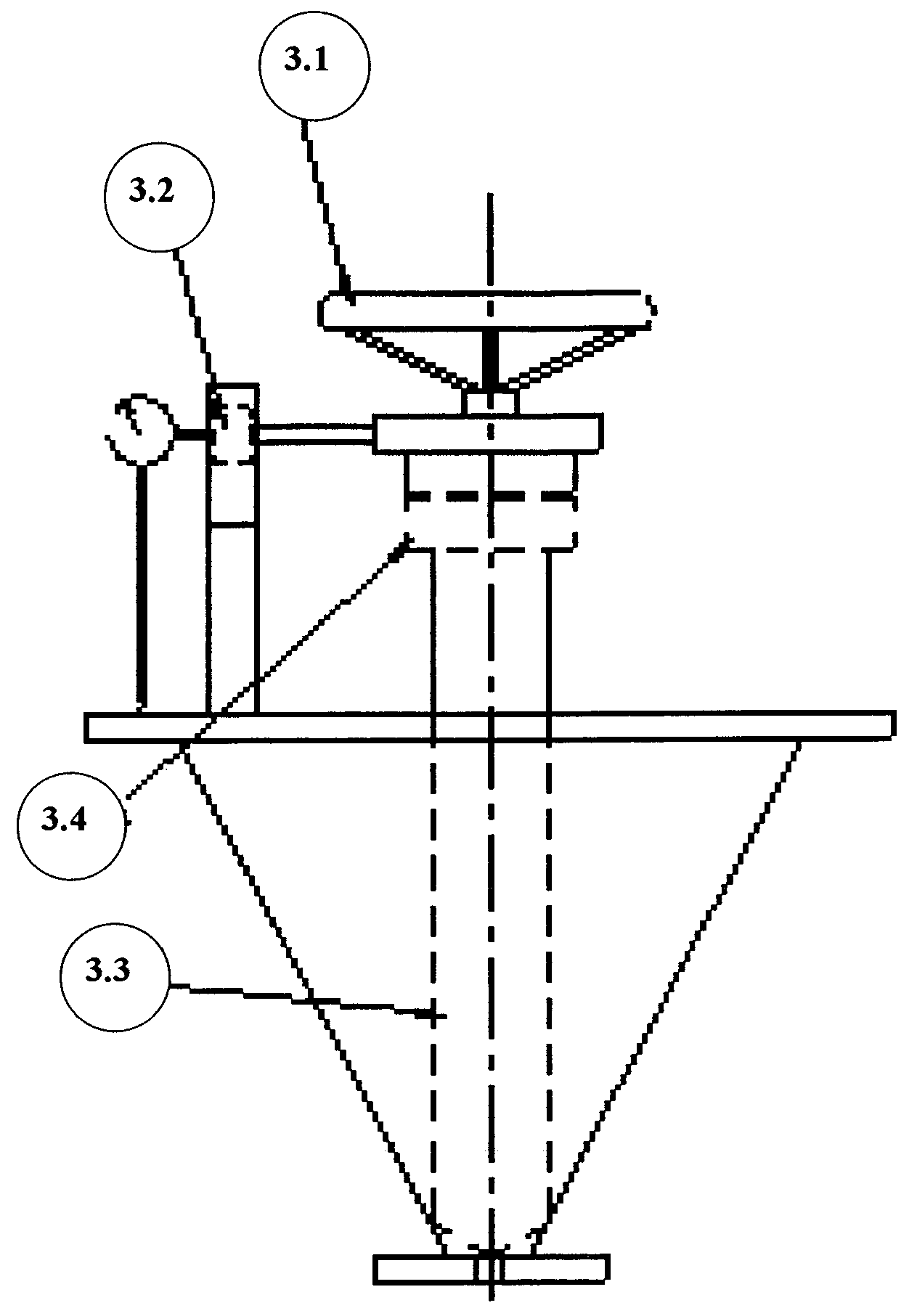

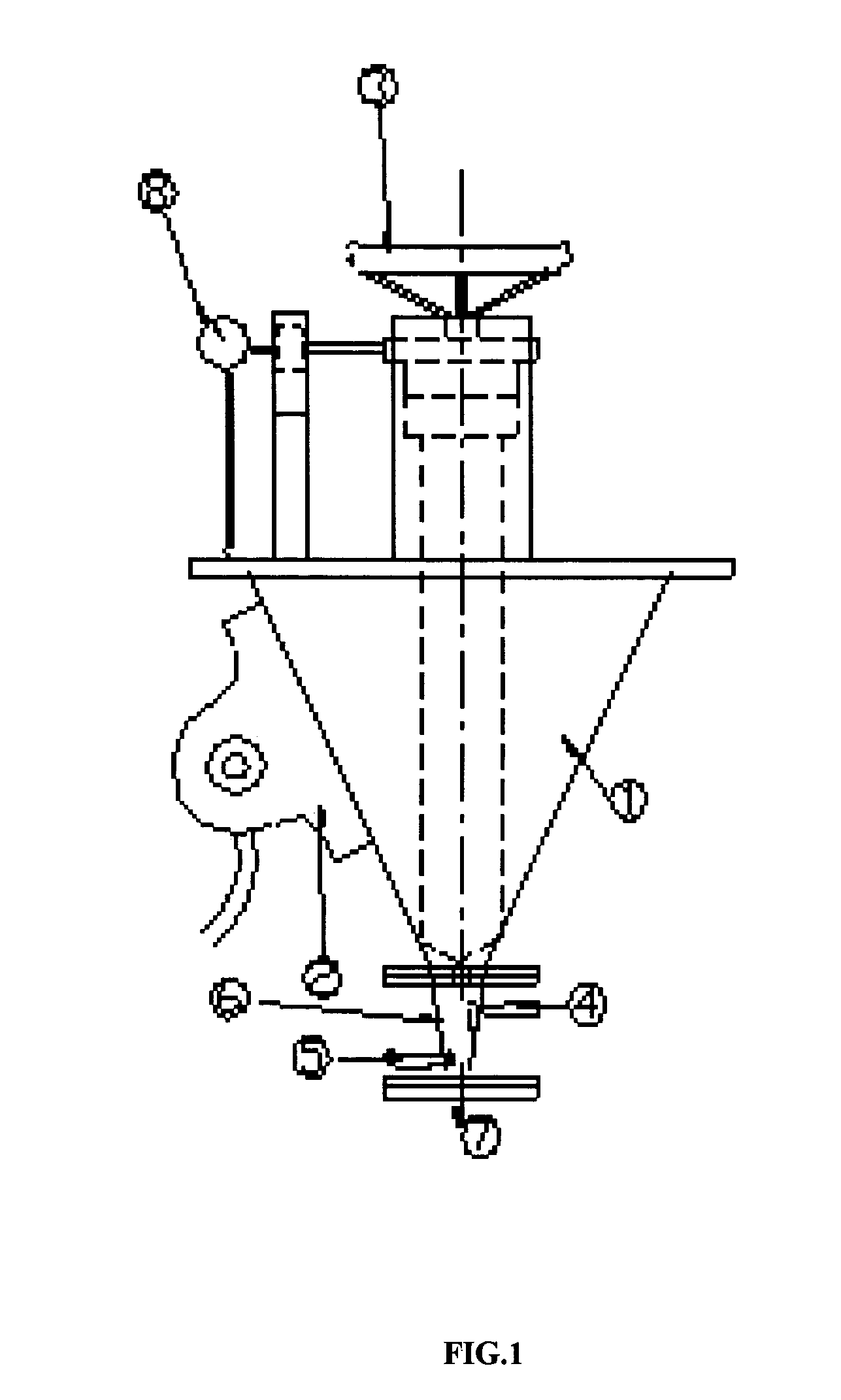

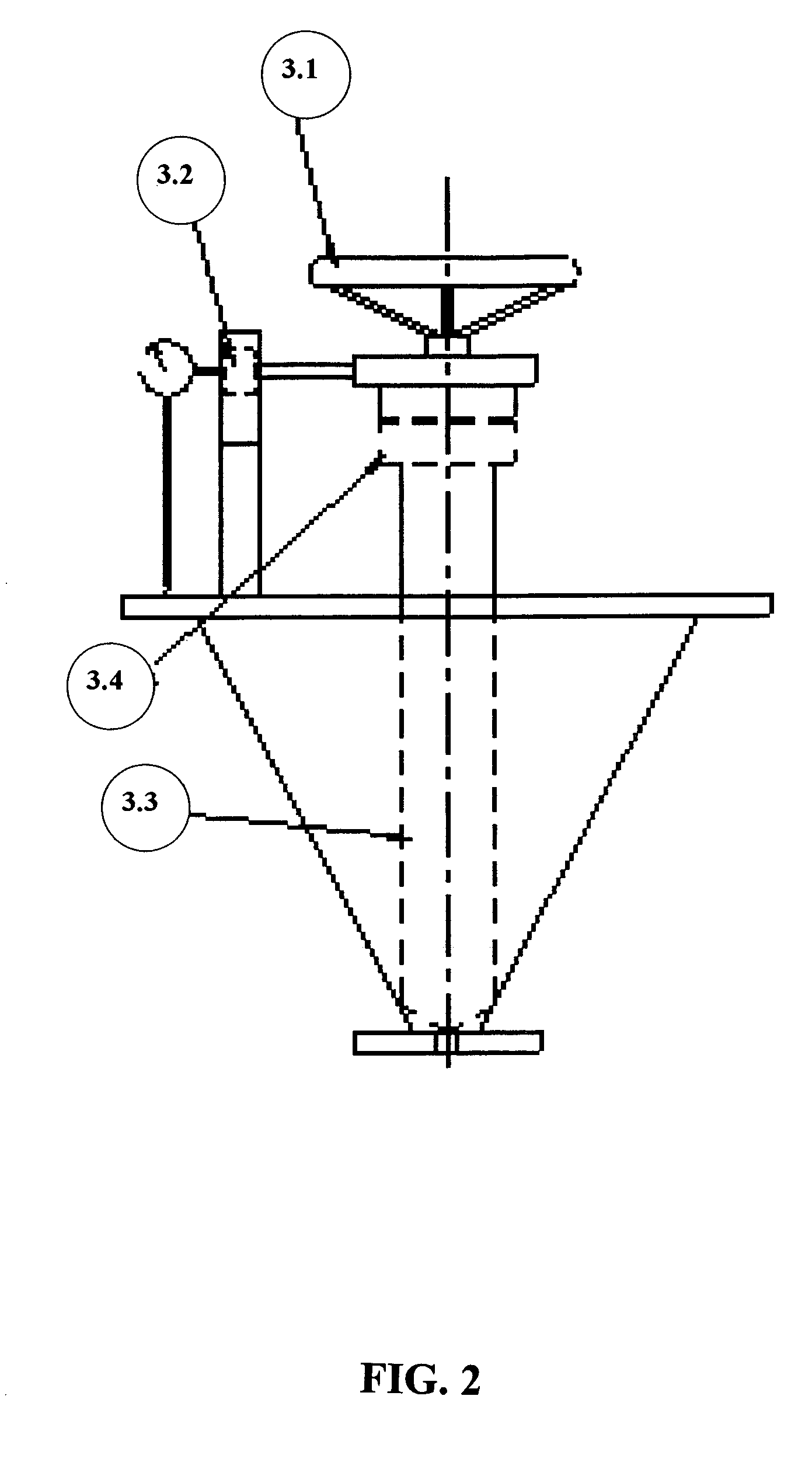

High-temperature combustion-supporting device and special combustion device for inverse combustion type biomass fuel

InactiveCN101315195ASolve combustion problemsBurn completelyHollow bar grateWater heatersCombustionEconomic benefits

The invention discloses a high-temperature combustion-supporting device and a backfire biomass fuel dedicated combustion device. The high-temperature combustion-supporting device comprises a ring-shaped body. The inner surface of the ring-shaped body is inverted-cone-shaped or inverted-regular-pyramid-shaped, the outer circumferential surface thereof matches the inner shell shape of the combustion device. The ring-shaped body has integrated structure or combined structure. The dedicated combustion device comprises an inner shell, a water jacket and an outer shell. An upper grate and a lower grate are arranged inside the inner shell. A feed port and a high-temperature fume outlet penetrate the inner shell, the water jacket and the outer shell. An ash outlet is formed at the lower part of the inner shell. The high-temperature combustion-supporting device is arranged on the inner shell wall below the upper grate. A dedusting shroud is arranged on the inner shell relative to the high-temperature fume outlet. A dedusting mesh is arranged at the lower port of the dedusting shroud. A secondary air inlet penetrates the inner shell, the water jacket and the outer shell. The high-temperature combustion-supporting device and the backfire biomass fuel dedicated combustion device have the advantages of reasonable design, complete combustion, suitability for various fuels and good social and economic benefits.

Owner:HENAN DERUN BOILER

Fire grate plate and corresponding incinerate fire grate and refuse incinerate equipment

The invention relates to a grate plate used for burning grates, including a burning grate of the grate plate and solid waste burning equipment which is equipped with the burning grate.

Owner:DOOSAN LENTJES GMBH

Auxiliary smoke arresting unit

InactiveUS8011359B1Safe openDomestic stoves or rangesCombustion ventilatorsPulp and paper industryWood burning

Smoke escaping from an outdoor wood burning furnace may be effectively arrested with a smoke arresting unit. By mounting a smoke gathering manifold above the furnace door operatively connected to a vacuum source for drawing smoke discharging from the furnace chamber through an open furnace door, the gathered and arrested smoke may be discharged through a separate discharging chimney. The vacuum source may be activated when the furnace fan is switched off and the furnace door is opened for refueling.

Owner:SCHULTZ CHRISTOPHER T

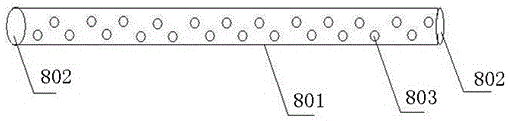

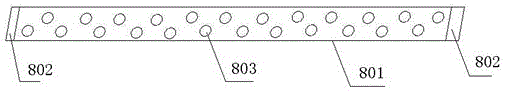

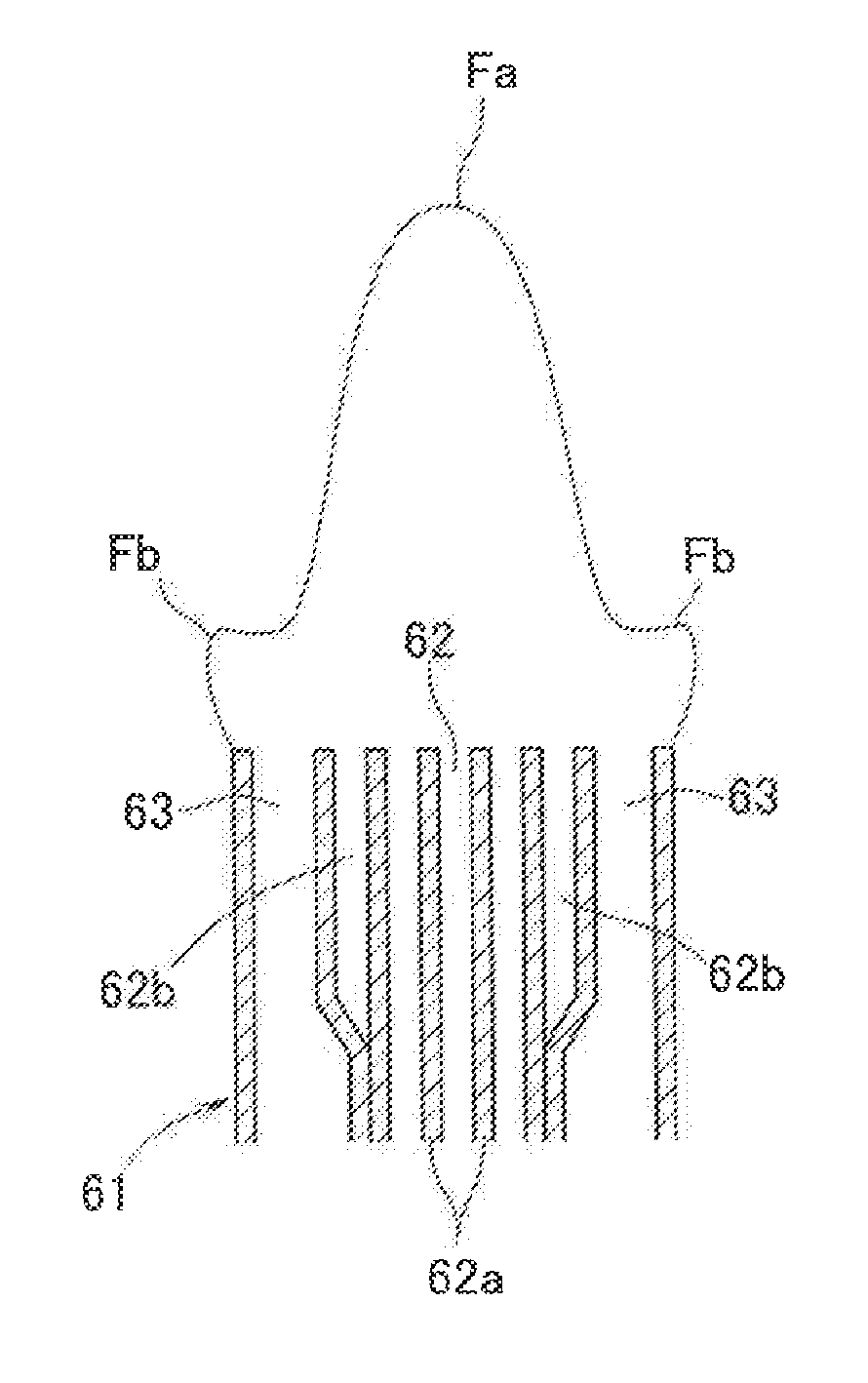

Flute-shaped grate, application thereof and flute-shaped grate boiler

InactiveCN105066152AReasonable designReasonable design and reasonable structureHollow bar grateSolid fuel combustionFluteCombustion

The invention discloses a flute-shaped grate. A flute-shaped pipe body is hollow, and the two ends of the flute-shaped pipe body are provided with air inlets. One face of the flute-shaped pipe body is provided with one or two rows of circular air outlets. The number and the diameter of the air outlets and the distance between every two adjacent air outlets are set according to different fuel materials. The invention further discloses a boiler with the flute-shaped grate. The flute-shaped grate is widely applied to the fields of stoves, steam boilers, hot water boilers and industrial kiln stoves and is reasonable in design, simple in structure and low in manufacturing cost. The flute-shaped grate boiler with the flute-shaped grate adopts a new combustion way, uses biomass energy and waste as fuel, achieves sufficient combustion, and is environmentally friendly, free of pollution and suitable for being used and popularized.

Owner:胡乐鹏

Grate assembly

A grate assembly for guiding air into a pile of combustible wood pellets for combustion thereof. The grate assembly includes a structural subassembly having at least two sets of elongate members, a first one of the two sets forming a lower layer for at least partially supporting a second one of the two sets forming an upper layer. The grate assembly also includes a support element attached to the structural subassembly. Each member includes a body at least partially defining one or more channels and a number of holes in fluid communication with the channel(s) to guide air into the pile of the wood pellets. The support element includes a base portion with a plurality of apertures, for ignition of the pellets therethrough

Owner:PALMER BRADLEY C

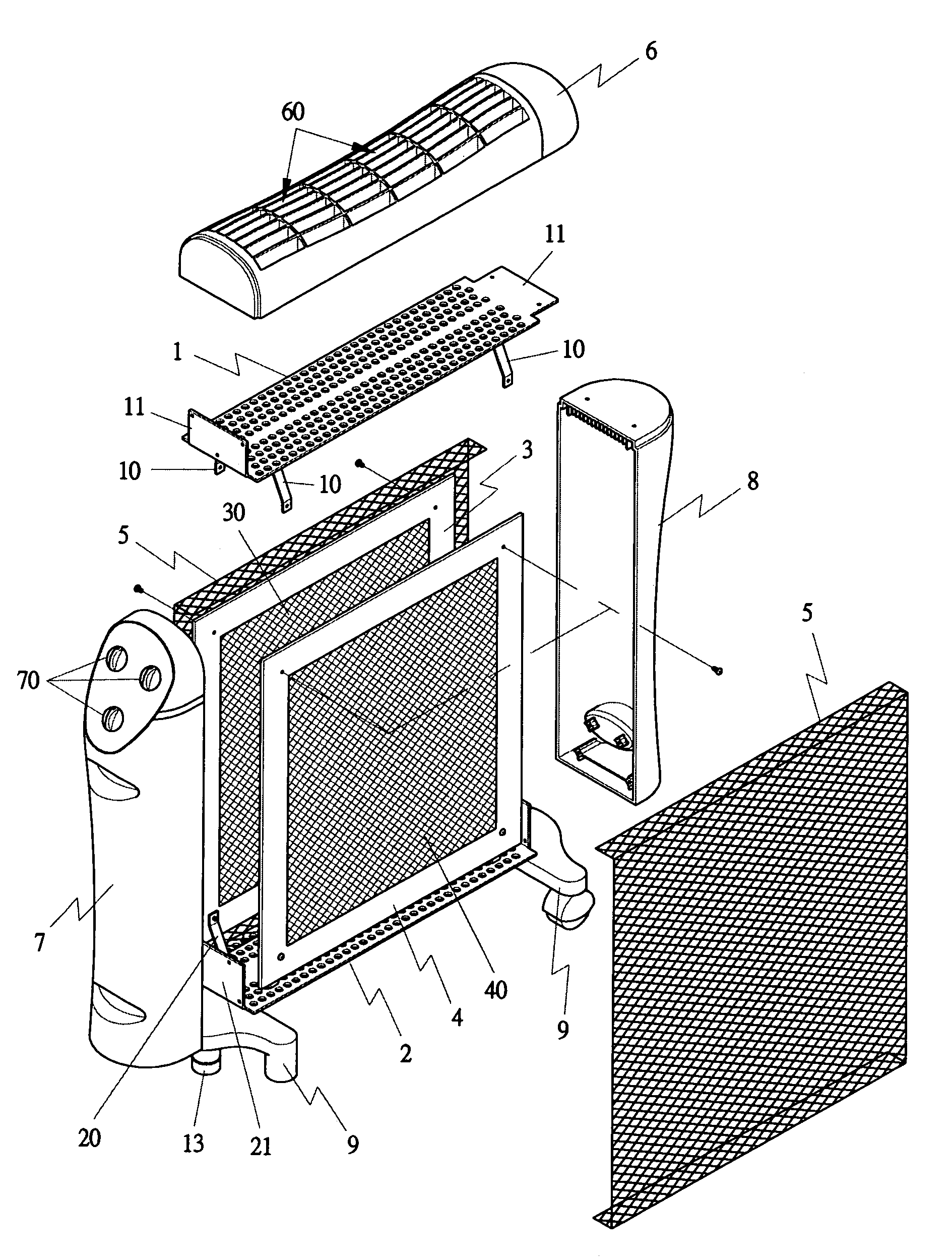

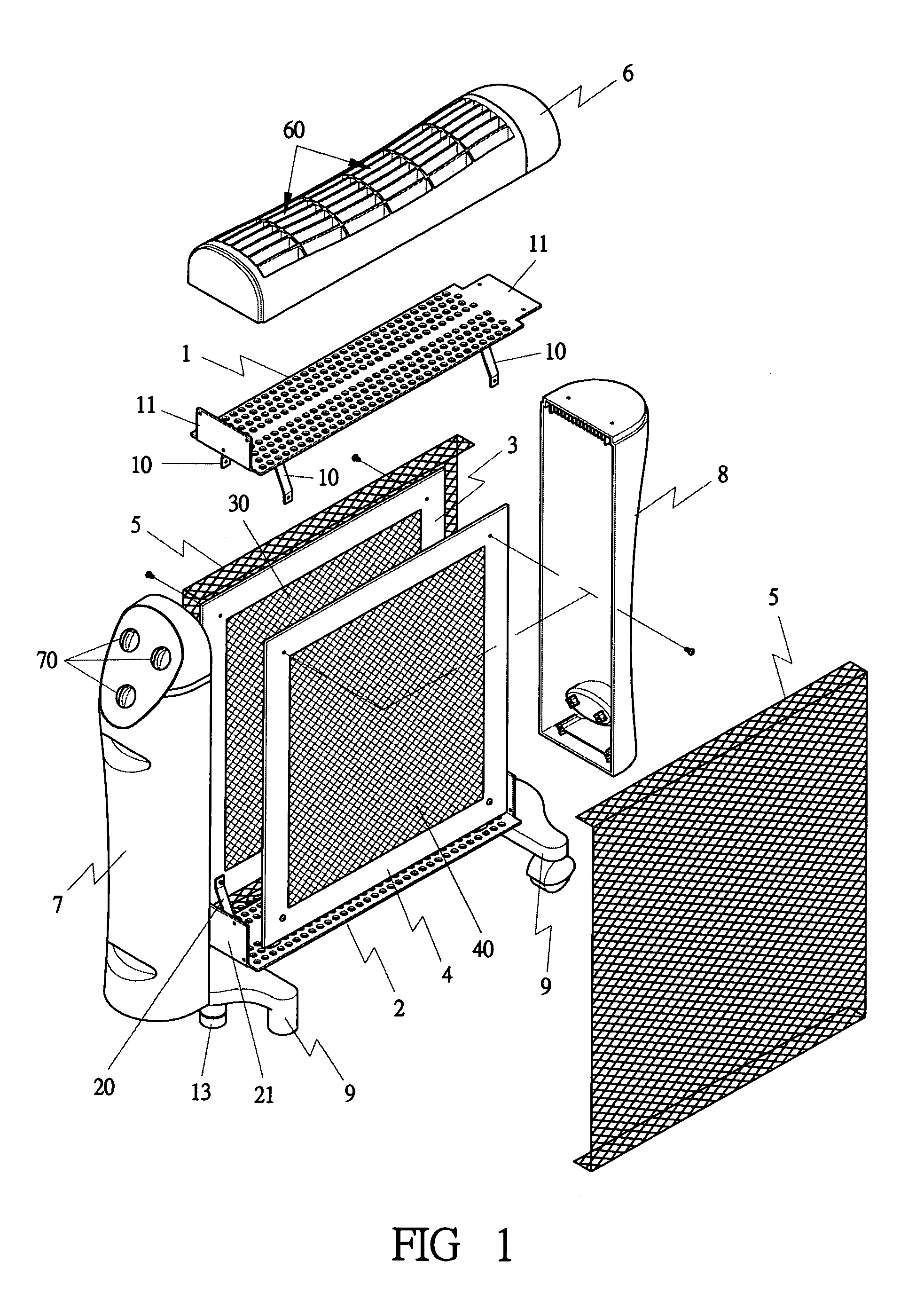

Convectional radial electric warmer

A conventional radial electric warmer includes an upper and a lower support base, plural heaters, a protective net, and an upper, a front and a rear cover. The upper and the lower support base respectively have a fixing frame for the heaters, and plural holes for hot air to flow out. The heaters respectively consist of plural heating pieces secured at the outside of the upper and the lower support base with the fixing frames with bolts. The protective net is secured at the front side of the heaters, secured stably by the upper and the lower support base. The upper, the front and the rear cover are respectively secured at the upper side, the front side and the rear side of the upper and the lower support base. Further, two foot frames are fixed under the lower support base to keep the warmer standing on the ground. Then the warmer is very safe to use and highly effective.

Owner:HUANG CHUAN PAN +1

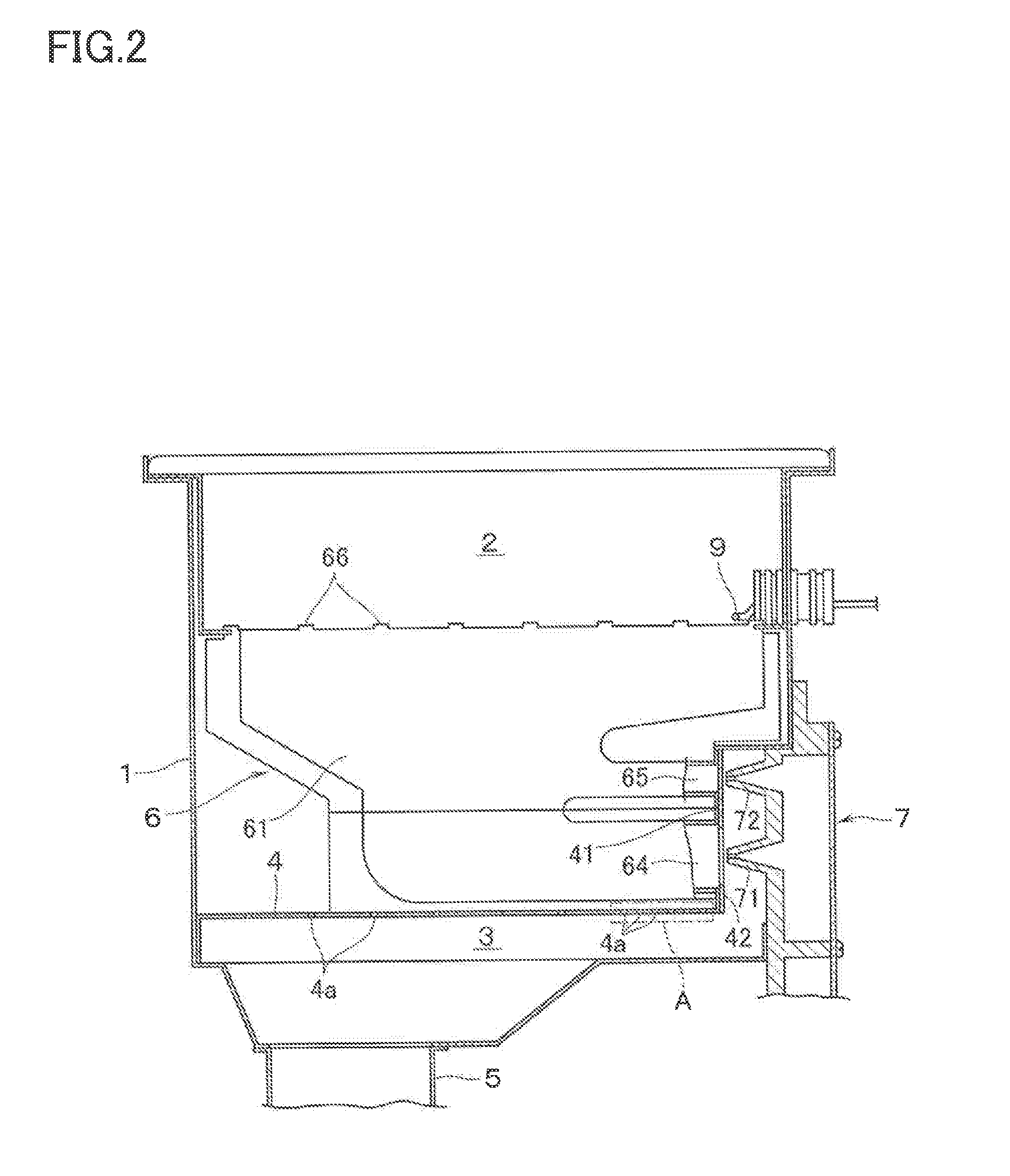

Combustion apparatus

InactiveUS20110297059A1Combustion velocityEasy to liftSolid bar grateHollow bar grateCombustion chamberLeft direction

A combustion apparatus has: a combustion housing; a partition plate provided in the combustion housing to partition a space in the combustion housing into a combustion chamber and an air supply chamber; and a plurality of rich-lean burners arranged in a right-left direction of the combustion chamber. A multiplicity of distributed holes are formed in the partition plate through which distributed holes secondary air is supplied from the air supply chamber to the combustion chamber. A flame rod facing to an upper side of a part of the rich-lean burners stops combustion when the flame rod does not detect any flames owing to a flame lift at a time of an oxygen deficiency. A supply quantity of the secondary air to the part of the rich-lean burners to which part the flame rod faces is larger than those to other parts.

Owner:RINNAI CORP

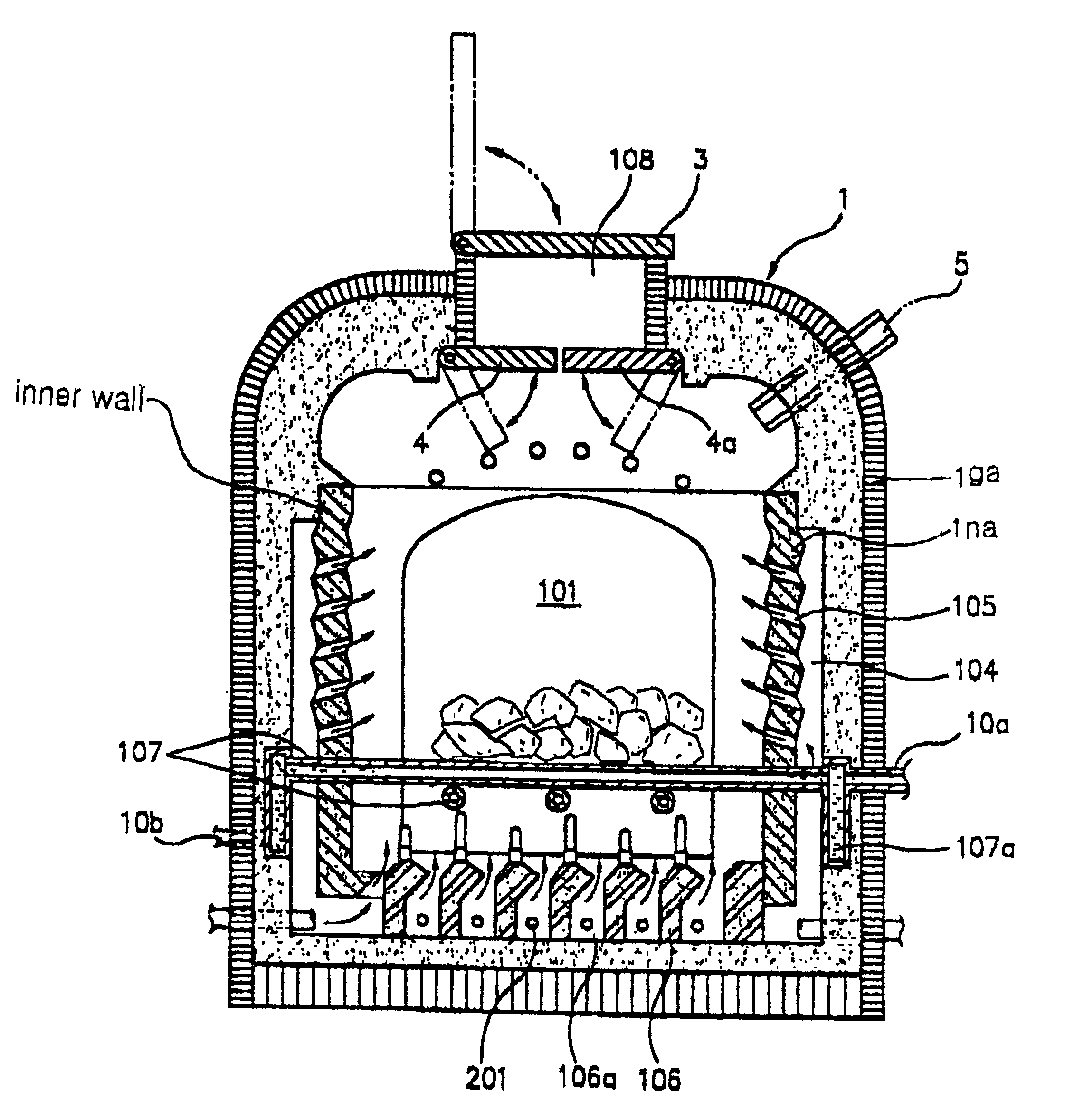

Safety incinerator for rubbish in volume and flammable waste

This invention is a mass incinerator for burning various rubbishes (life rubbishes, industry wastes, hospital rubbishes and like) and flammable wastes (hospital wastes, poison material and like) under high temperature atmosphere. In particularly; to an incinerator in which the combustion chambers 101 constructed in a dome form and the auxiliar combustion chambers 102 are connected alternately to form a tunnel shape. An air supply chamber 104 is formed between the outside wall and the inside wall of the combustion chamber 101. The materials being burned are inputted through the double hinged gate so that the soot or the dust is not scattered outward. The input during the combustion process is possible to improve the treating whereby rubbishes or wastes are completely burnt to prevent the environmental pollutant such as heavy metal material or dioxin as well as soot from discharging. Also, the hot water produced by the heat generated from the combustion process is supplied for agriculture, industry and home and used for generating electricity.

Owner:YANG DAE YOUN

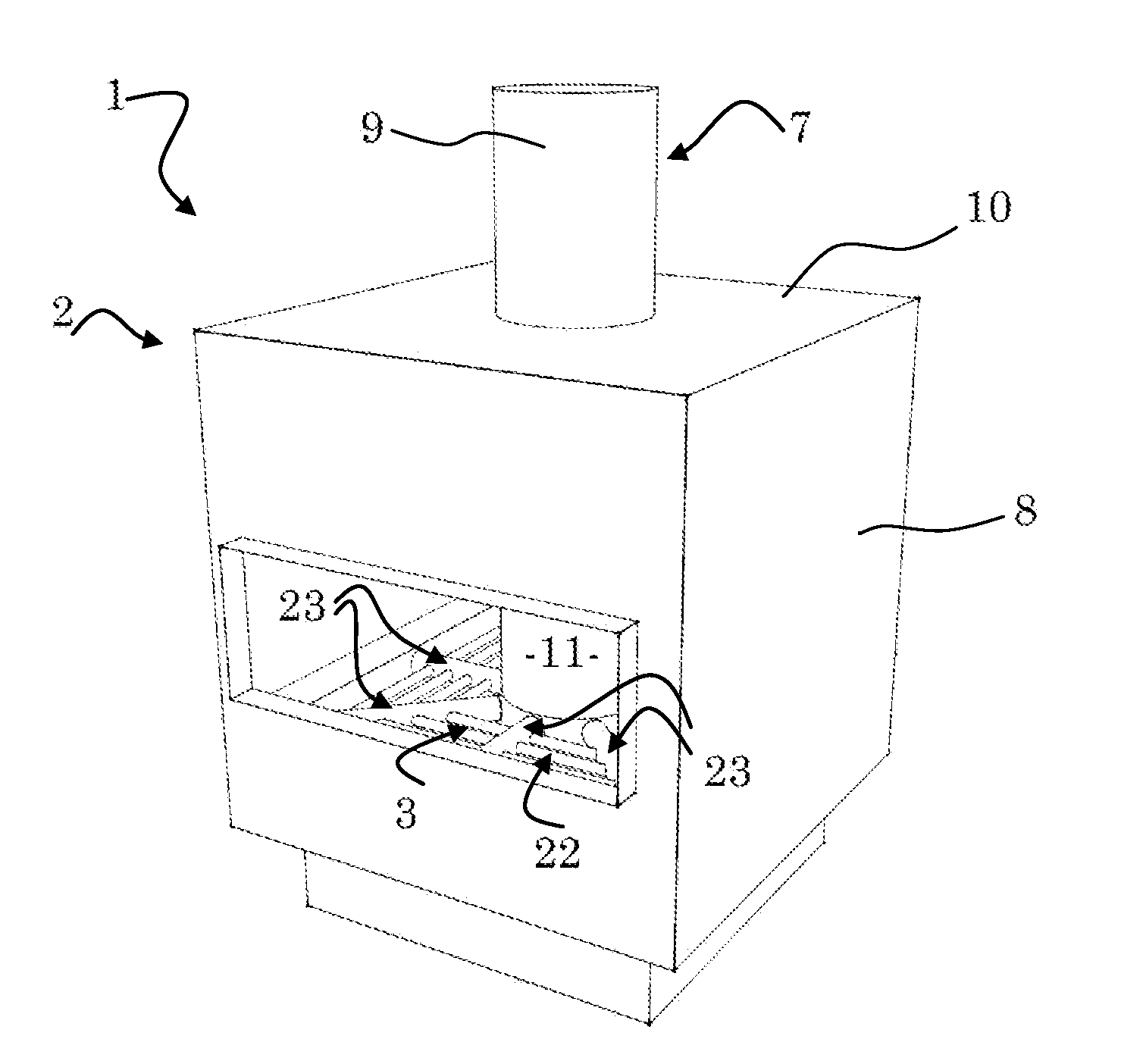

A Combustion System

ActiveUS20140196637A1Extension of timeIncrease temperatureDomestic stoves or rangesHollow bar grateCombustion systemProduct gas

This invention relates to a combustion system. The combustion system includes a fireplace which has a fire base, a primary combustion zone for pyrolysising and / or combusting a biomass fuel, and a secondary combustion zone for combusting gases and / or particulate matter produced from the pyrolysis and / or combustion of the biomass fuel. The combustion system also includes an exhaust flue, the exhaust flue extending to a position near to, or adjacent, the secondary combustion zone and / or the fire base. The invention may be particularly suitable for use in relation to wood burners, either by retrofitting to existing wood burners or by incorporating into new wood burners.

Owner:STEWART JASON JOREN JENS

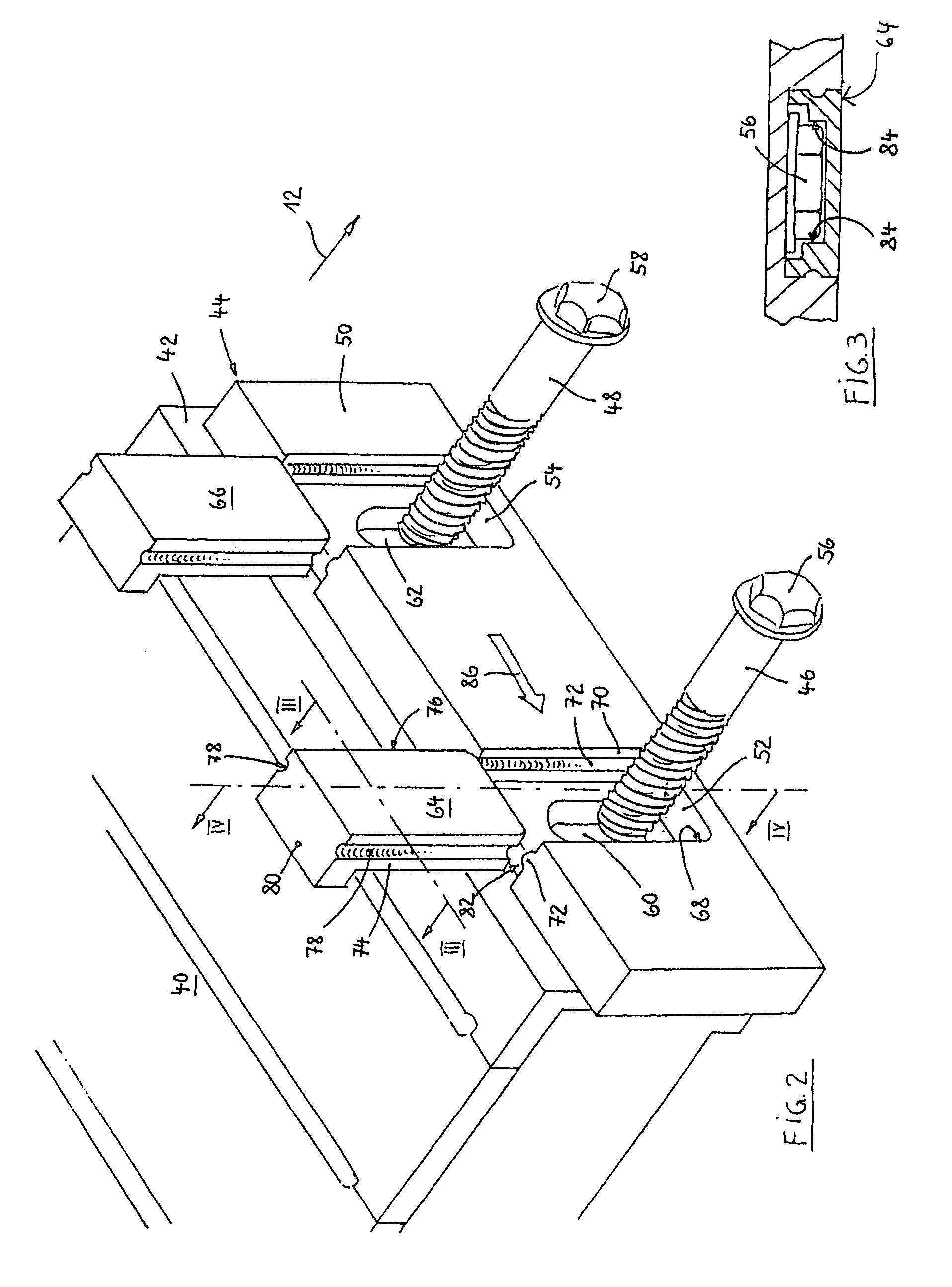

Grate plate arrangement for step plates

InactiveUS7219610B2Easy to disassembleUnnecessary useConveyorsHollow bar grateEngineeringMechanical engineering

Owner:IKN GMBH

Integrated water-cooled grate

InactiveCN108443892AReduce replacement rateSolve the problem that the connection cannot be sealed wellHollow bar grateIncinerator apparatusHydraulic cylinderEngineering

The invention discloses an integrated water-cooled grate. Fixed water-cooled grate bodies and movable air-cooled grate bodies are arranged on a machine body. Each movable air-cooled grate body is arranged between every two fixed water-cooled grate bodies, the movable air-cooled grate bodies are positioned above or below the fixed water-cooled grate bodies, the fixed water-cooled grate bodies and the movable air-cooled grate bodies are alternately arranged, a water-cooled grate support frame is arranged below each fixed water-cooled grate body, an air-cooled grate support mechanism is arrangedon the lower part of each movable air-cooled grate body, a hydraulic actuating mechanism is arranged on the side face of each movable air-cooled grate body, and a hydraulic cylinder is arranged at thelower end of each hydraulic actuating mechanism. According to the integrated water-cooled grate, the problem that the connection between a movable water pipe which is connected with a current water-cooled grate and moves along with the current water-cooled grate and a fixed water cannot be well sealed due to the motion / movement of the current water-cooled grate is solved, and the problems of leakage of cooling water and high cost caused by the high breakage and replacement rate of water-cooled grate segments are solved. Due to the adoption of the grate segments of the integrated water-cooledgrate, the replacement rate of the grate segments can be reduced by 2 / 3.

Owner:西格斯先进技术有限公司

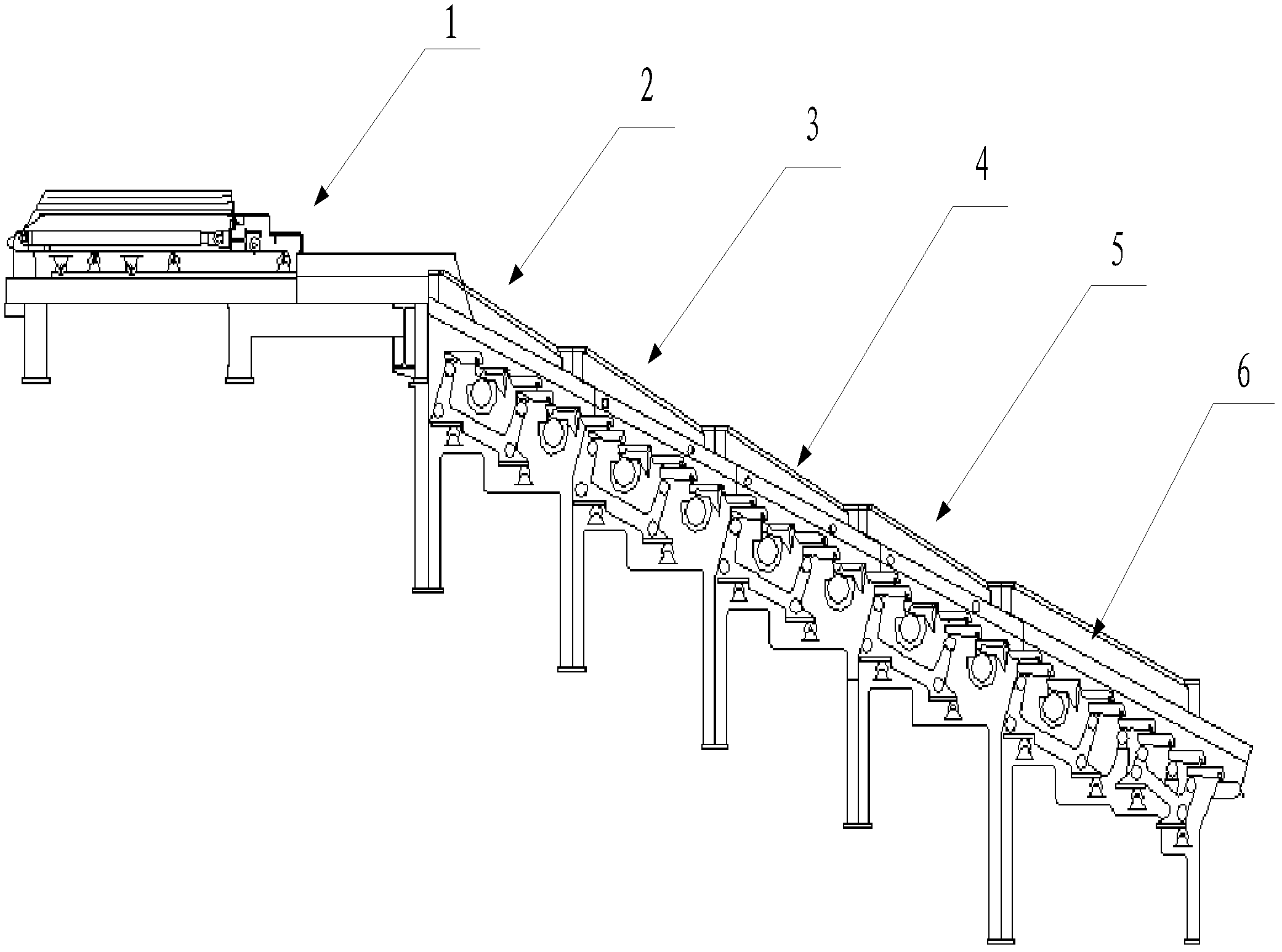

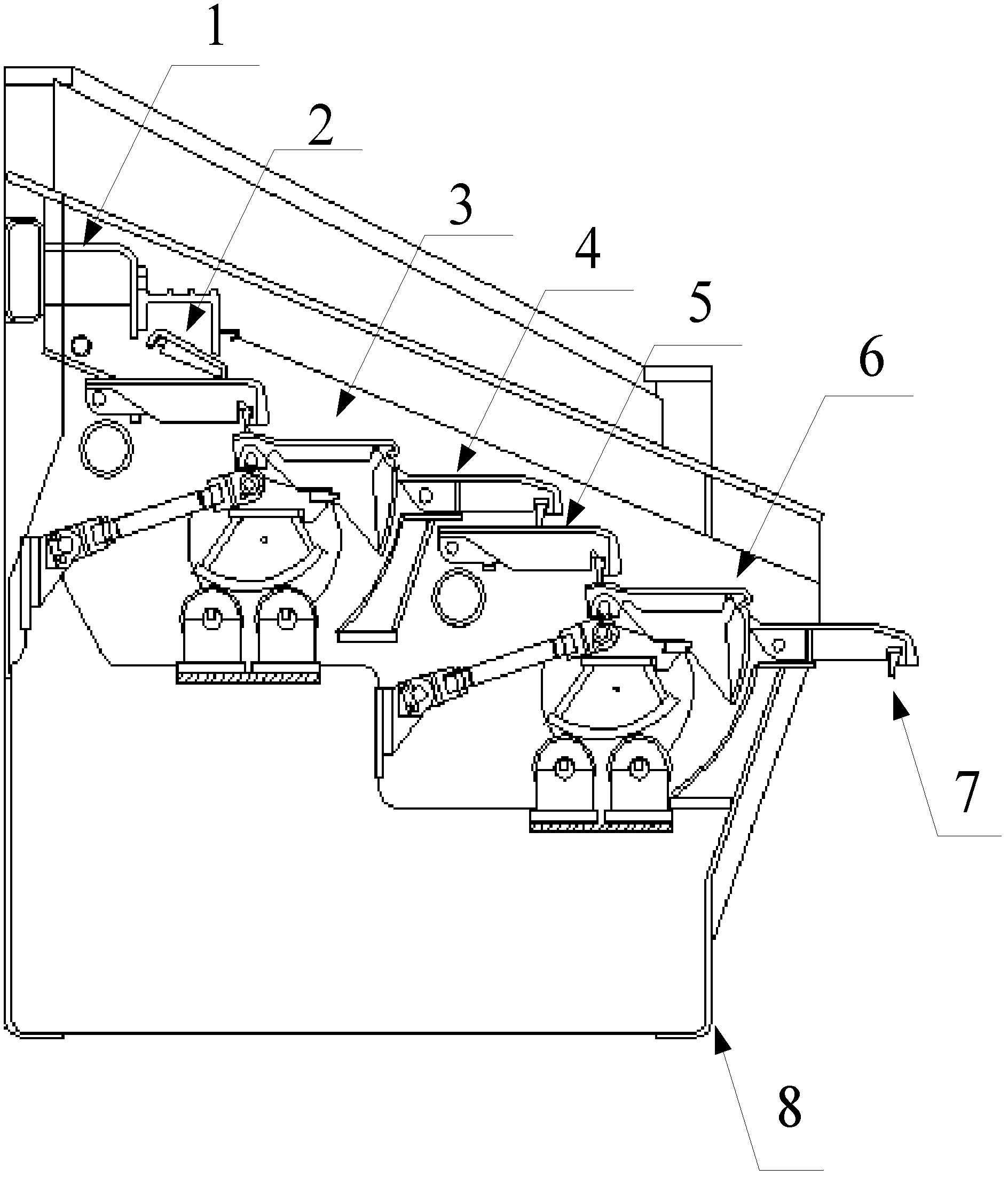

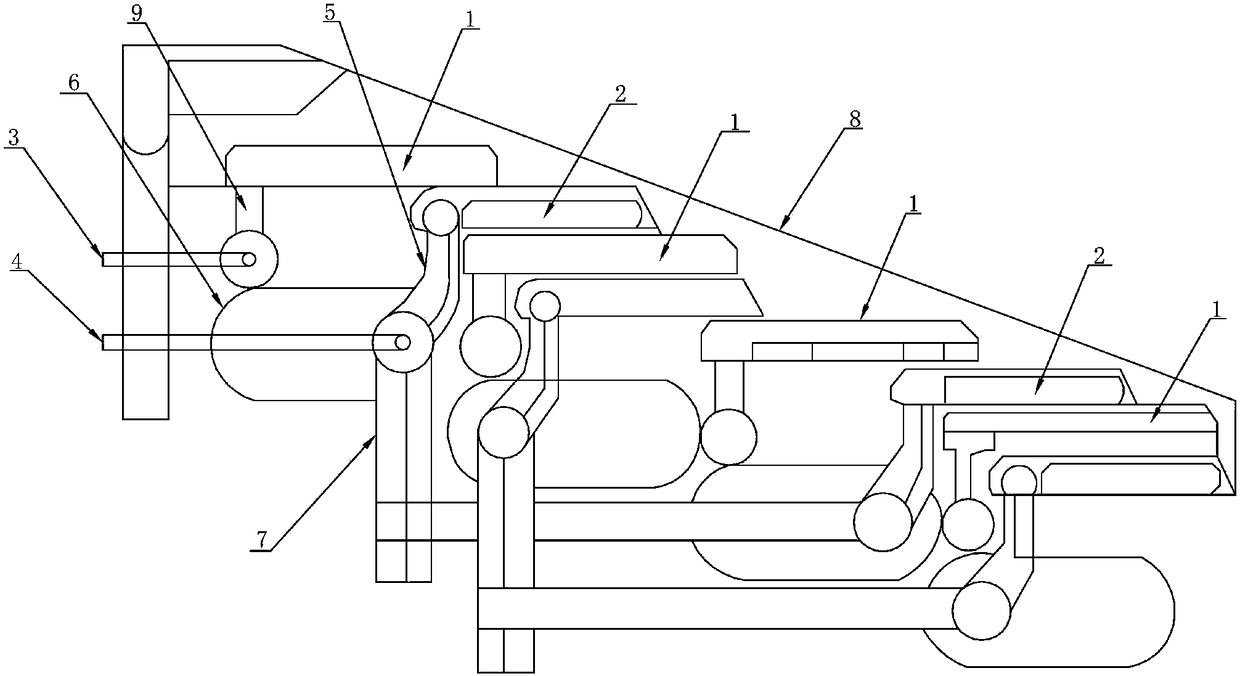

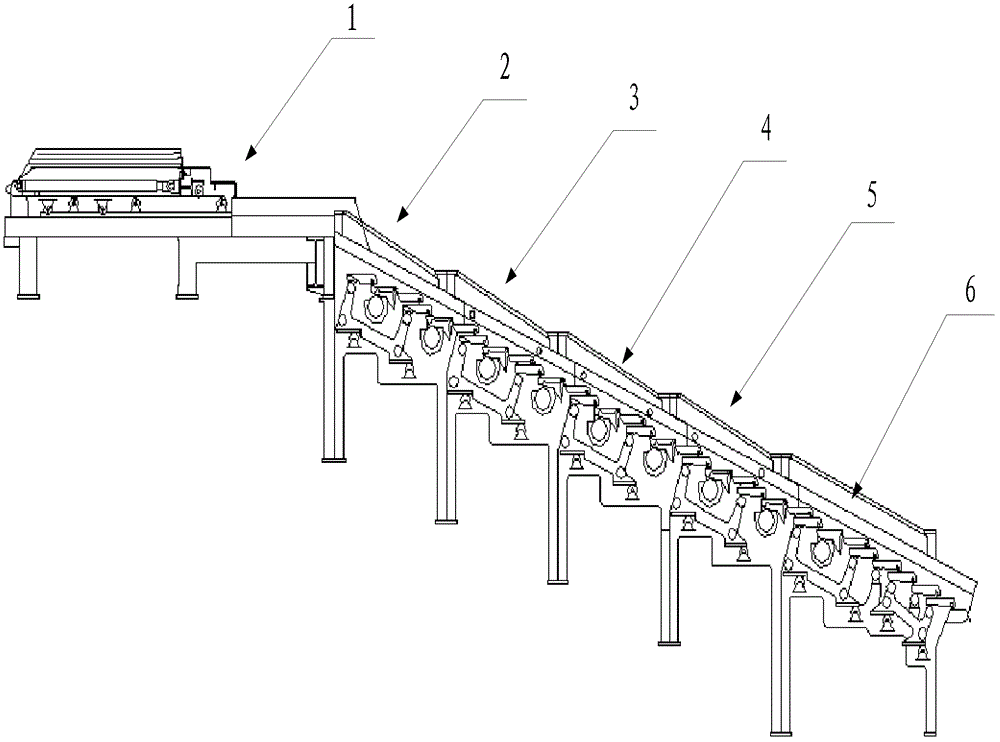

Multistage hydraulic mechanical garbage incinerator

ActiveCN102607036ASolve technical problemsGuaranteed uptimeHollow bar grateInclined grateHydraulic machineryIncineration

The invention provides a multistage hydraulic mechanical garbage incinerator, which comprises a feeding port, a feeding fire grate, an incinerating fire grate, a primary air supply system and a secondary air supply system. The incinerating fire grate is longitudinally divided into five units, wherein the first unit, the second unit, the third unit and the fourth unit are standard units, the fifth unit is a tail end lengthened unit, each unit comprises a plurality of sliding fire grate segments, turning fire grate segments and fixed fire grate segments, and the incinerating fire grate is integrally divided into a drying section, a burning section and a burnout section by the five units along the garbage moving direction. The multistage hydraulic mechanical garbage incinerator is characterized in that a limiting support device for limiting a feeding trolley to move upward is arranged on the upper surface of a tail of the feeding trolley of the feeding fire grate. By the aid of the multistage hydraulic mechanical garbage incinerator, the shortcomings of an existing garbage incinerator are improved, and burnout ratio of garbage incineration is increased.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECHCAL DEV BEIJING +2

Device for feeding pulverized coal to furnace

ActiveUS6928936B1Stable flow rateEasy to operateHollow bar grateLump/pulverulent fuel feeder/distributionMicrometerEngineering

The present invention provides a device for feeding pulverized coal to a furnace, such as a drop tube furnace. The feeding system consists of a feed hopper, a pneumatic vibrator positioned on the periphery of the feeder hopper, a needle valve arrangement in the said feed hopper, a depth gauge micrometer, a distribution chamber with primary and secondary airline at the bottom of the said feed hopper. Adjusting the pressure of compressed air allows setting of the frequency of vibration of the pneumatic vibrator. The needle valve arrangement in conjunction with the vibratory hopper controls the feed rate. The rate of coal flow is measured by the depth gauge micrometer. The distribution chamber with primary and secondary airline at the bottom of the said feed hopper allows uniform mixing of air with coal before being charged into the furnace reactor.

Owner:COUNSCIL OF SCI & IND RES

Multistage hydraulic mechanical garbage incinerator

ActiveCN102607036BImprove combustionImprove burnout rateHollow bar grateInclined grateCombustionHydraulic machinery

A multi-stage hydraulic mechanical garbage incinerator comprising a material inlet, a material-feeding grate (4), an incineration grate, a primary air supply system, and a secondary air supply system. The incineration grate is divided along the longitudinal direction into five units, where the first to the fourth of the units are standard units, and where the fifth unit is an end extension unit, while each unit consists of several sliding grate plates, flipping grate plates, and fixed grate plates. The five units divide the entire incineration grate along a direction of garbage movement into a drying section, a combustion section, and a burnout section. A limiting support apparatus (2) for use in limiting upward movement of a material-feeding trolley (3) of the material-feeding grate (4) is provided on the upper surface at the tail part of the material-feeding trolley (3).

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECHCAL DEV BEIJING +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com