Biomass furnace and device for removing nitric oxide in same

A biomass combustion furnace and nitric oxide technology, applied in the combustion chamber, combustion method, combustion equipment, etc., can solve the problems of lack of a retaining wall at the tail and a secondary ash pushing system, pollution of combustion efficiency, and lack of temperature control devices. Achieve the effects of no secondary pollution operability, high combustion efficiency and strong economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

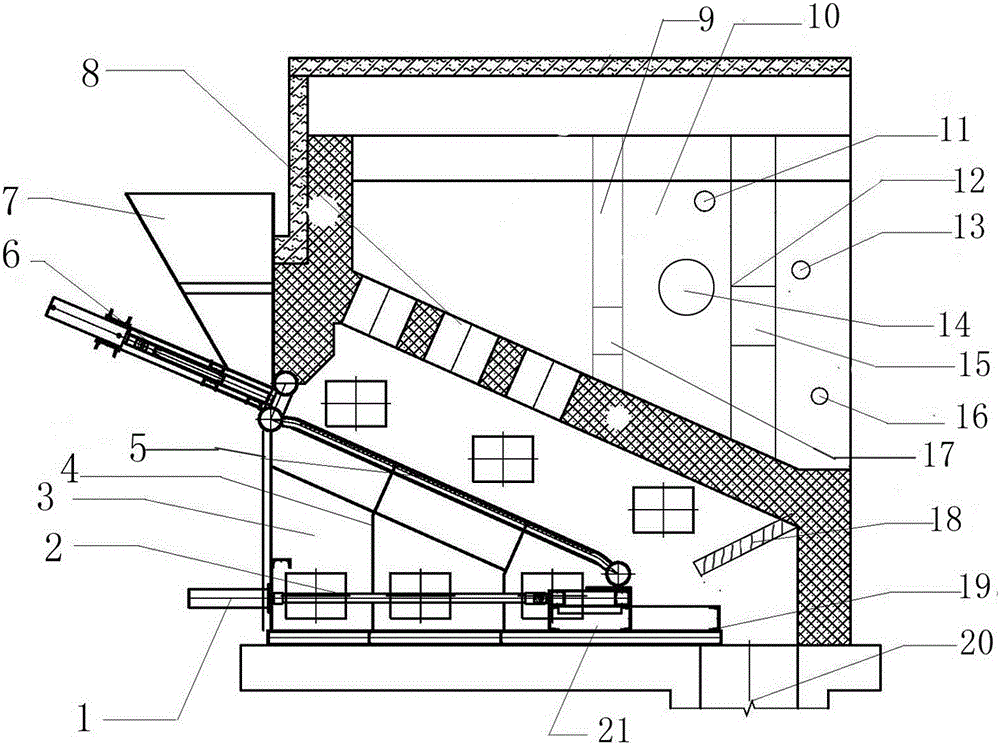

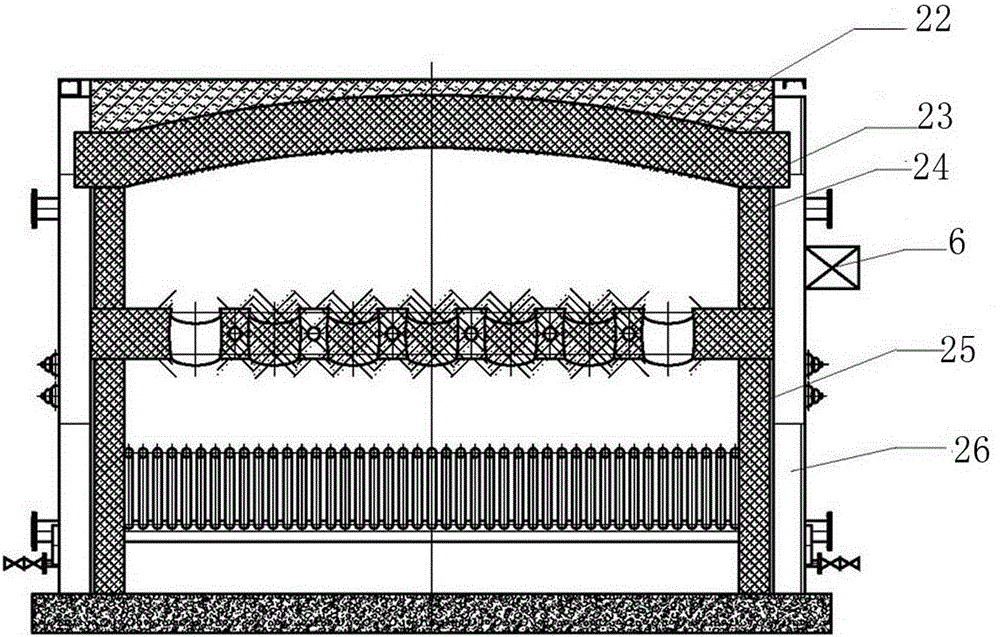

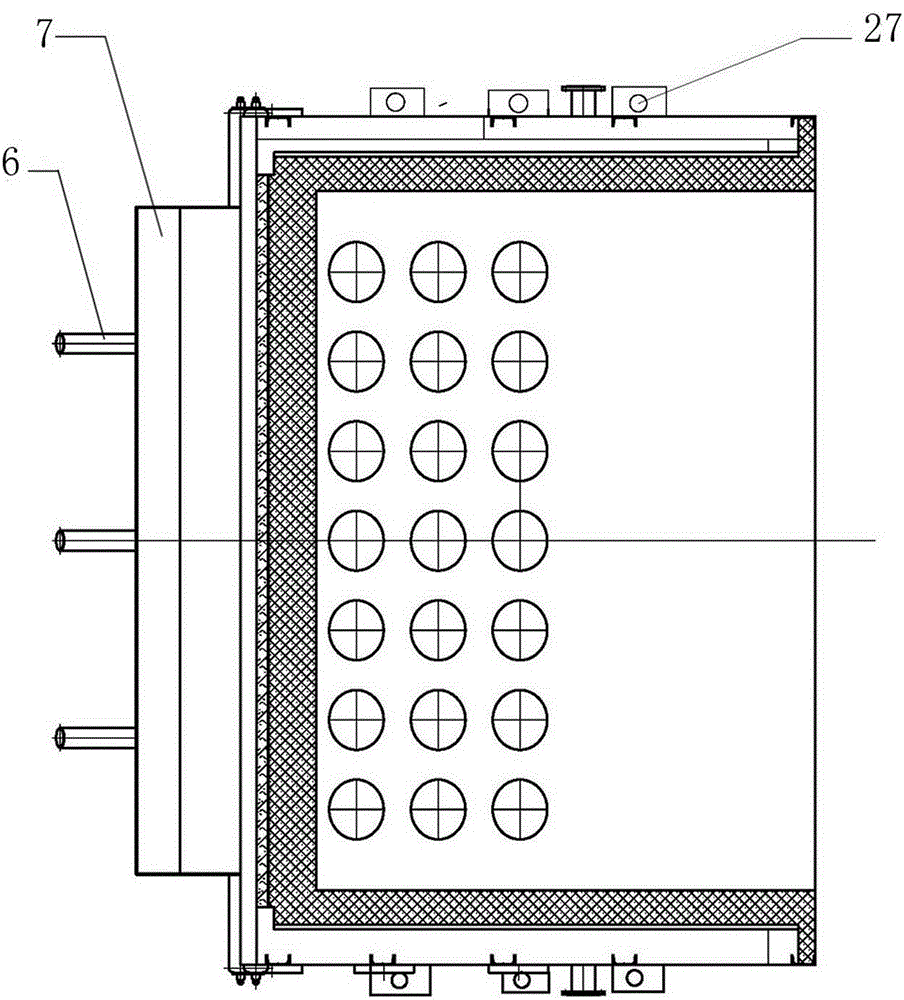

[0013] Such as Figure 1-3 As shown, a biomass combustion furnace and a device for removing nitric oxide in the furnace include a furnace body, a furnace arch 8, a hopper 7 and a feeding device 6. The slope-shaped furnace arch 8 is located in the middle of the furnace body, and the furnace arch 8 It is a flower arch structure, and the opening of the flower arch is evenly arranged in a circular shape. There is a water-cooled fire grate 5 parallel to the furnace arch below the furnace arch. A retaining wall 18 is installed at the junction between the furnace arch and the furnace side wall 24 . The retaining wall 12, the furnace arch 8 and the water-cooled fire grate 5 form a relatively closed circulating combustion chamber; a slag removal pit 20 is arranged under the front end of the ash collecting platform 19, and the ash generated by combustion is pushed into the slag removal pit; There is a retaining wall 18 above the slag removal pit to prevent biomass from being blown dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com