Patents

Literature

141results about How to "Turn over" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

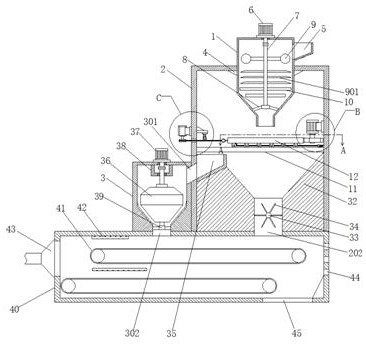

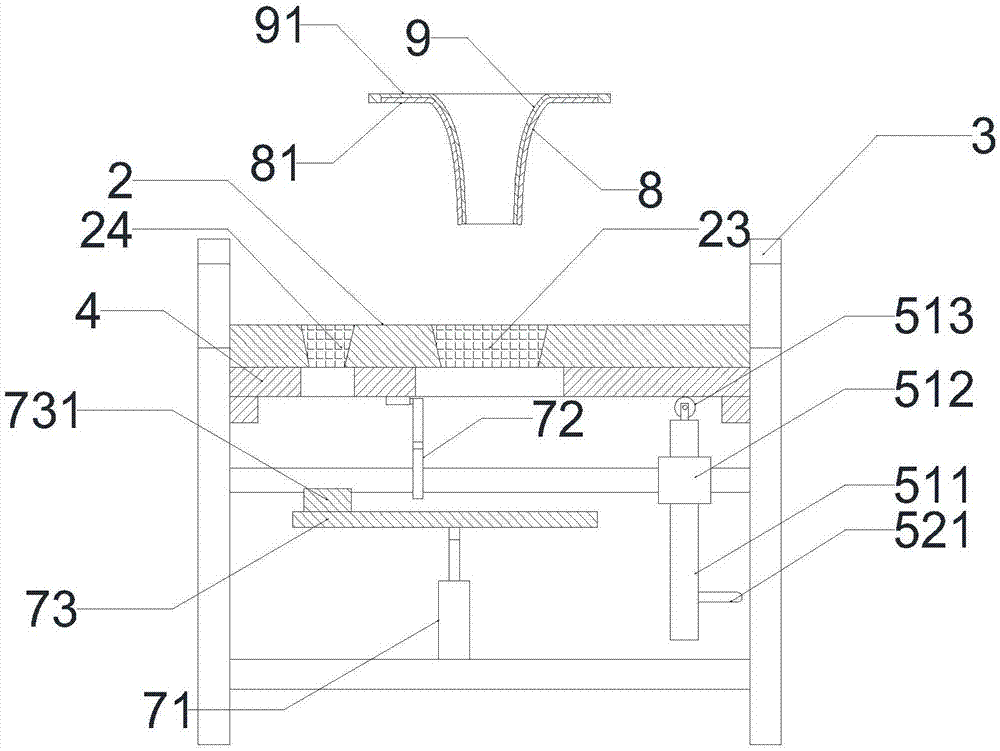

Efficient burning furnace with rotary fluidization grate

InactiveCN101532667ATurn overWith self-cleaning functionRevolving grateRocking grateCombustion systemFlue gas

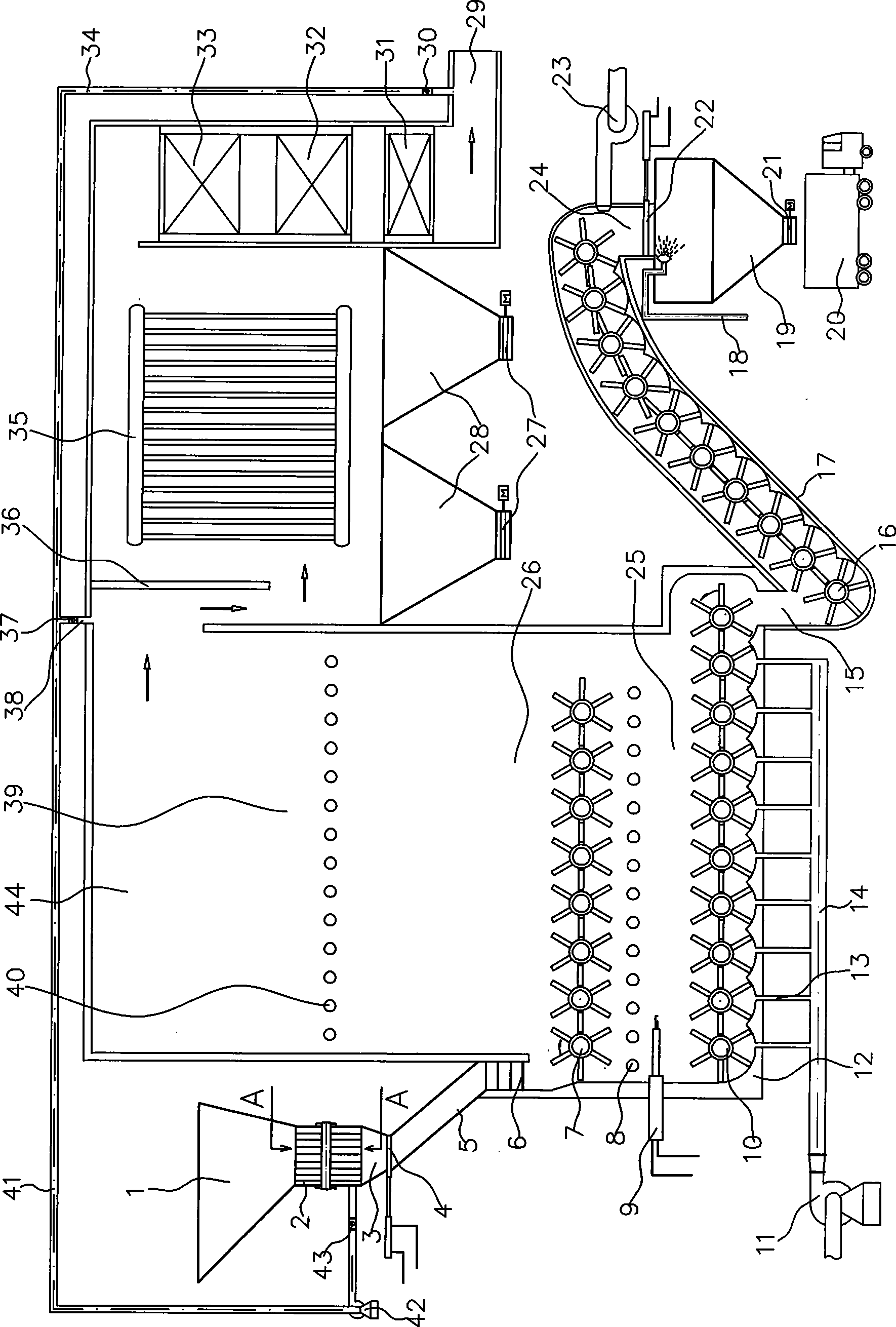

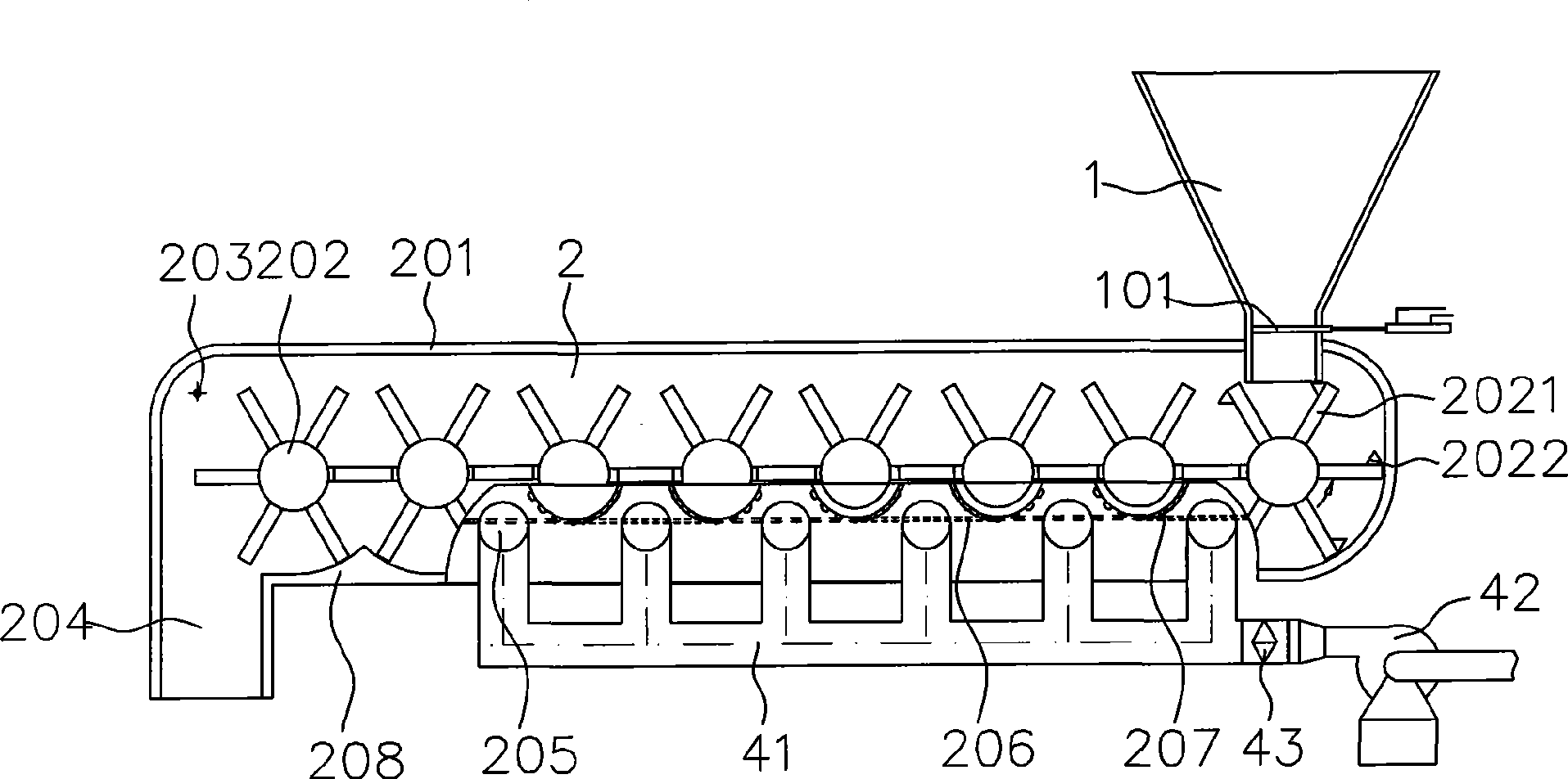

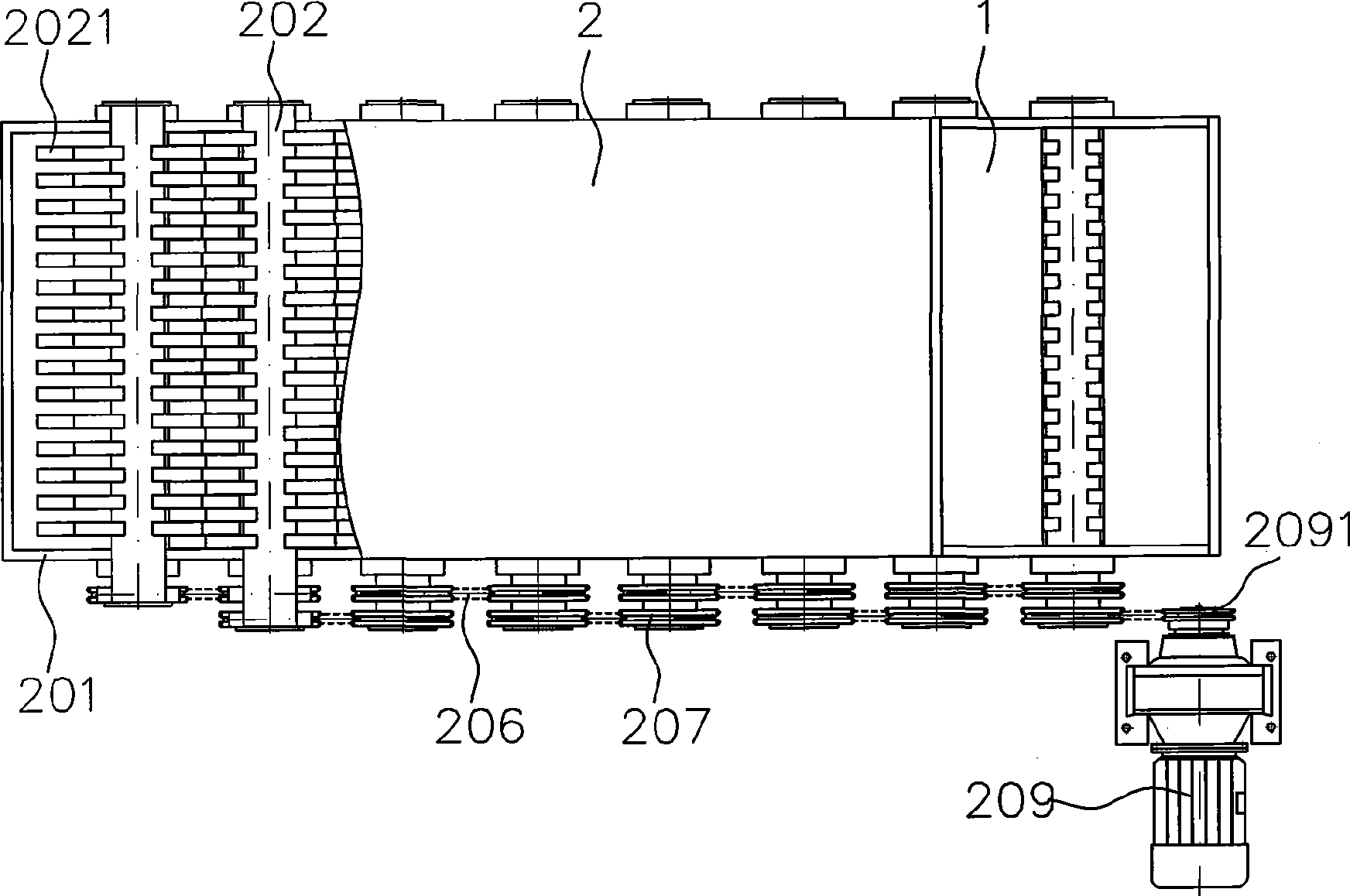

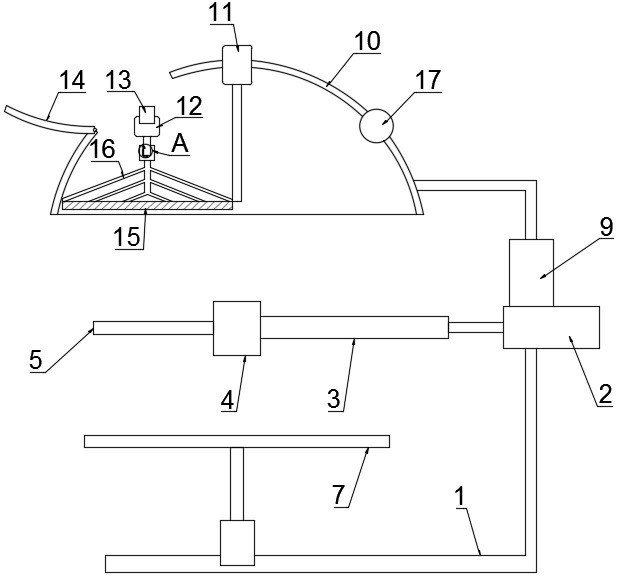

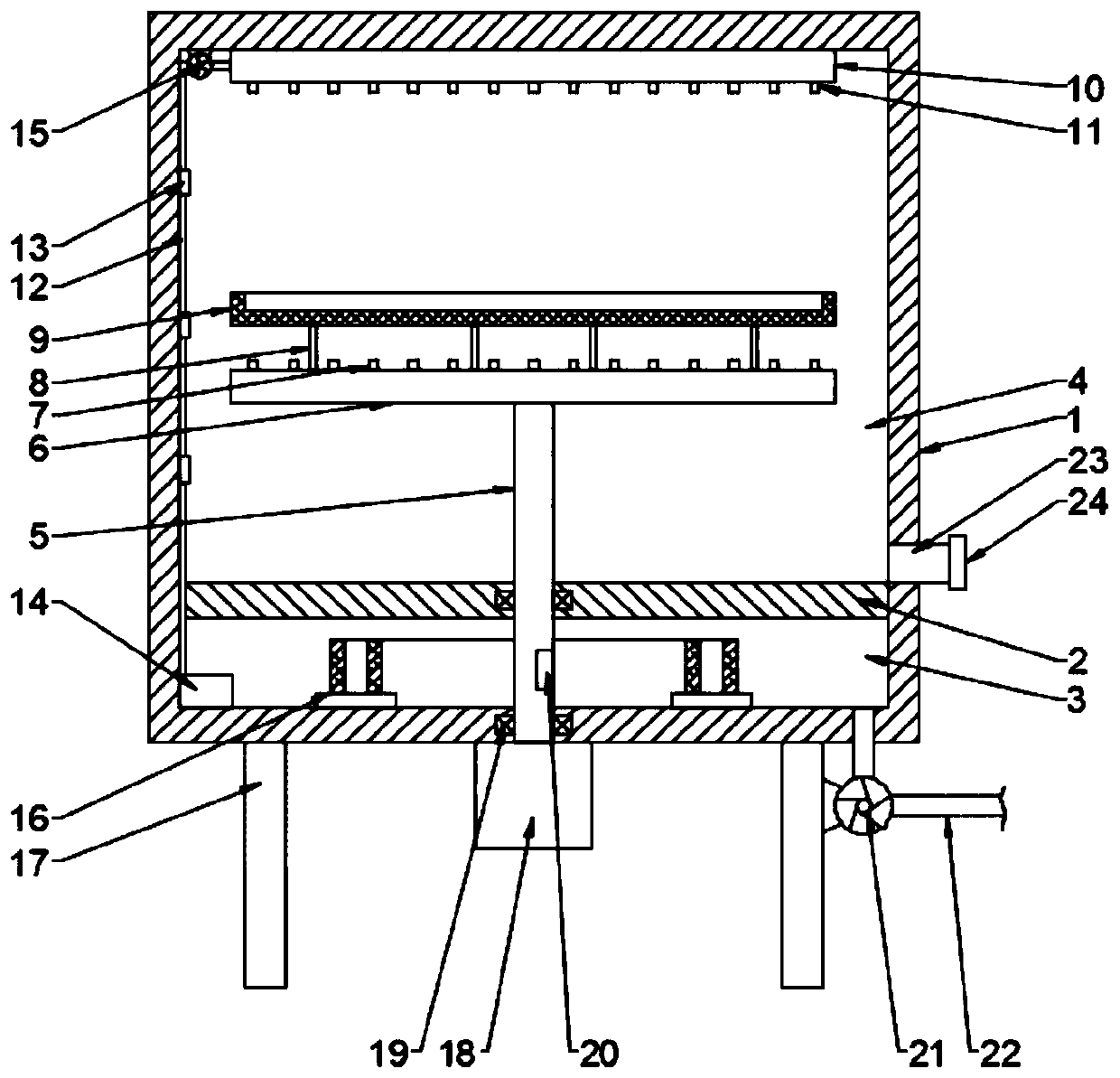

The invention relates to an efficient burning furnace with a rotary fluidization grate. The burning furnace with the rotary fluidization grate consists of a feeding system, a burning system and a slagging system; moreover, a waste heat boiler and a flue gas treatment system are connected with the burning furnace to form a complete garbage burning and generating system. The feeding system consists of a feeding hopper, a pre-drying conveying device, an aggregate bin, a chute and a charge distributor. The feeding hopper is a receiving opening for feeding garbage into the burning furnace and is arranged in a garbage storage pit close to one side of the burning furnace. An outlet of the feeding hopper is connected with an inlet of the pre-drying conveying device. A material level switch is arranged in the feeding hopper, and gives an alarm to prompt an operator to feed materials when the material level is lower than a set value so as to ensure that the hopper is not empty. The outlet of the hopper can be selectively provided with a feeding device. The burning furnace has the advantages of high burning speed, high burning efficiency, high slag burning degree, easy control, lower energy consumption, low pollution, low cost and investment conservation, and is applicable to domestic garbage with low thermal value and high moisture; and the garbage does not need to be pretreated.

Owner:新乡锅炉制造有限公司

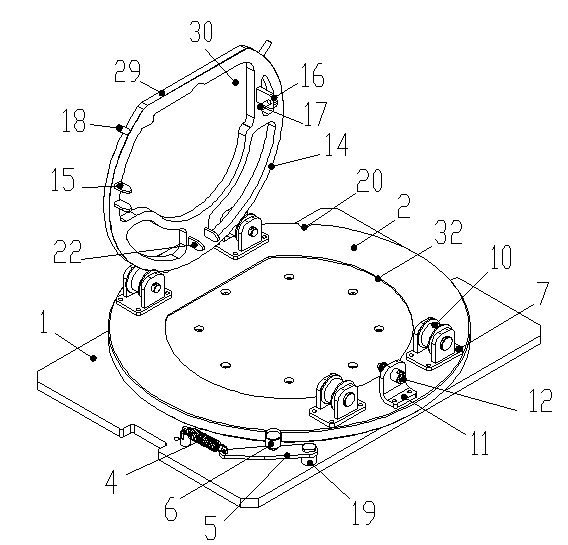

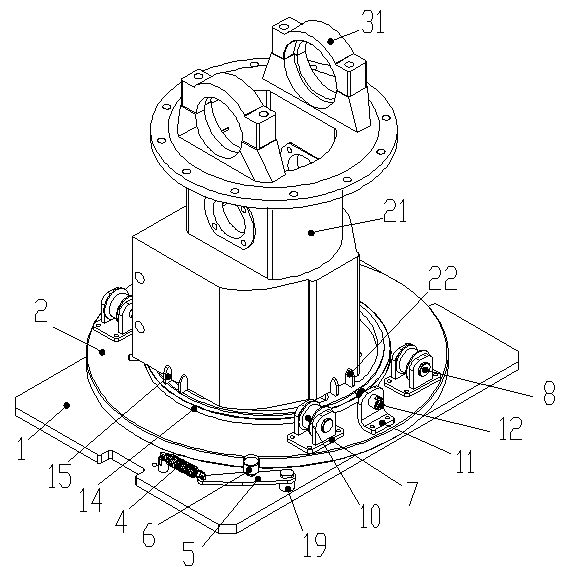

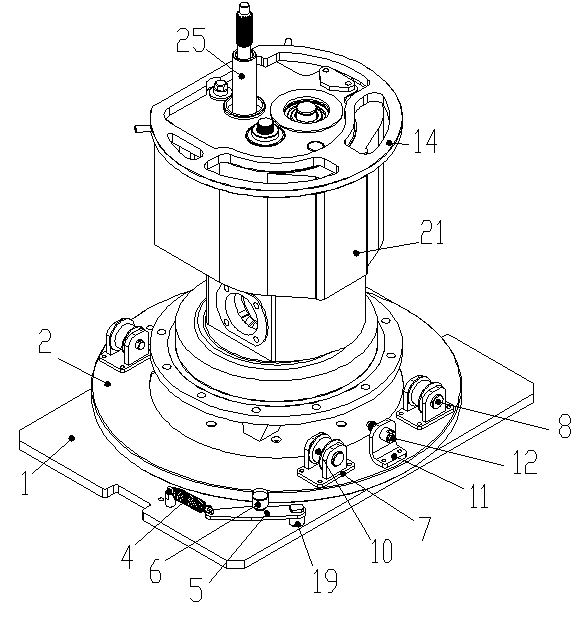

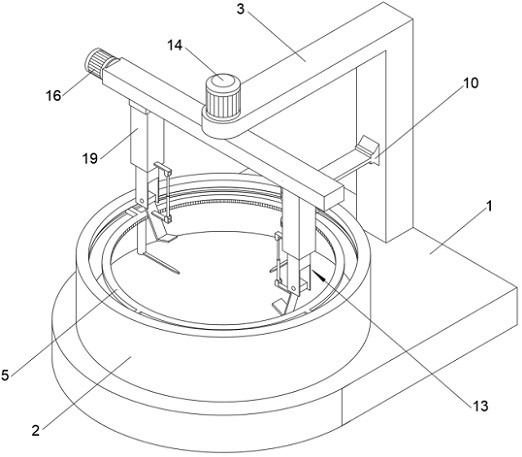

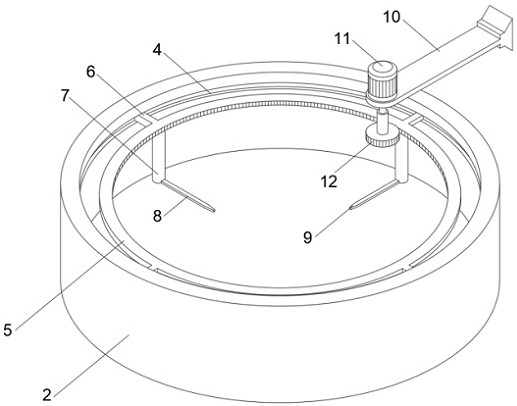

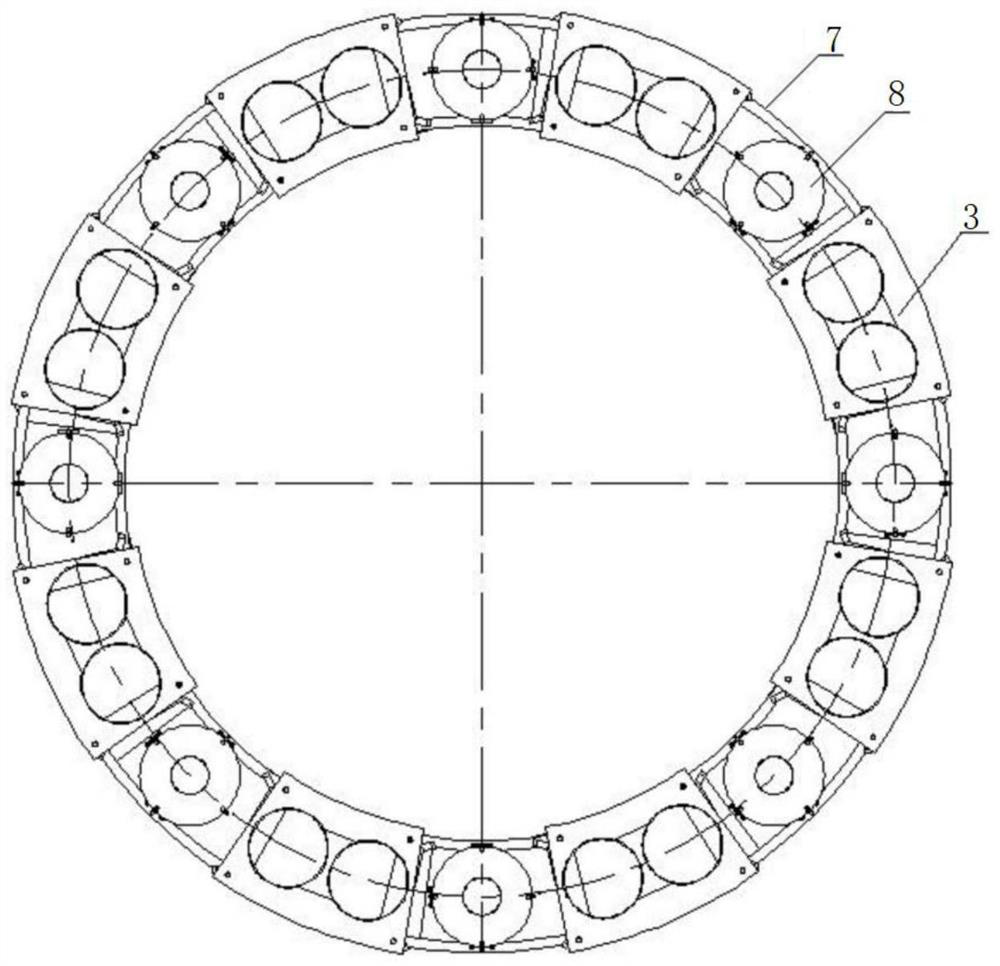

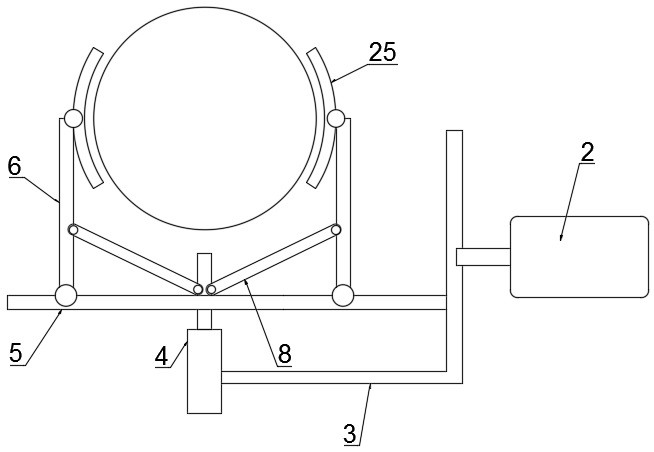

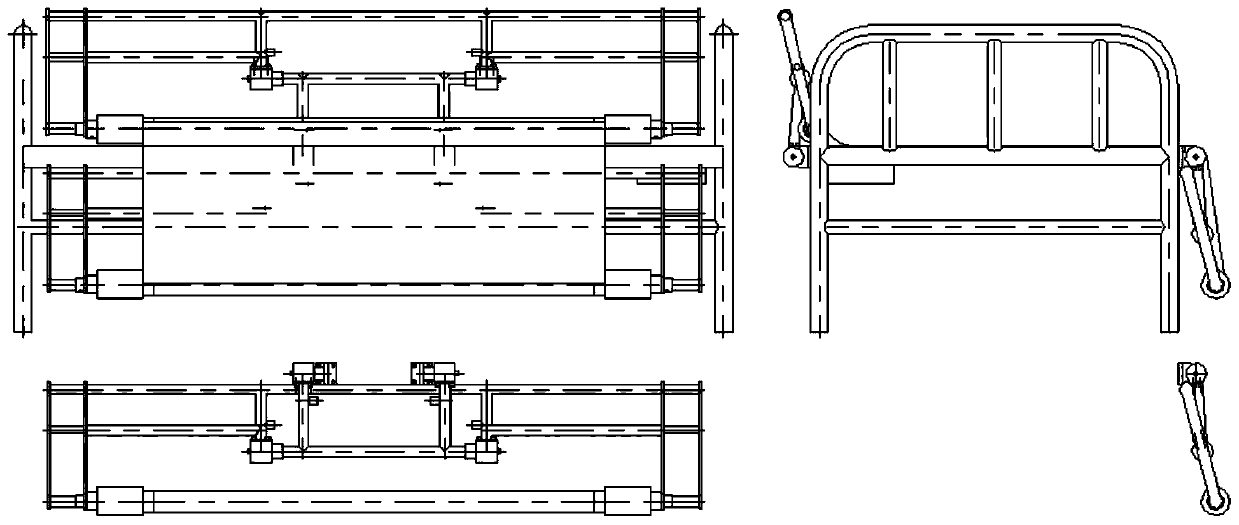

Rotary combined tray for forklift transmission assembly

ActiveCN103056657AWide applicabilityWith positioning functionAssembly machinesWork holdersEngineeringUltimate tensile strength

The invention discloses a tray for forklift transmission assembly. The tray is mainly formed by combining a main tray and an auxiliary tray, wherein the lower part of the main tray is provided with a double-layer horizontal rotating and positioning mechanism, and the upper part of the main tray is provided with a vertical rotating and positioning mechanism; and the auxiliary tray has a disc-shaped structure of which the diameter is the same as that of a flange disc on a transmission. The tray has the advantages of being wide in applicability, low in labor intensity, high in safety, high in efficiency and ensured in quality; the tray can be matched with assembly of five postures of multiple transmissions; the main tray and the auxiliary tray are matched, so that the transmissions can conveniently rotate along an axis of the flange disc, and the labor intensity is greatly reduced; the tray horizontally rotates, so that the forklift transmission operates on a single side is solved, and the position is not required to be changed back and forth; and due to the positioning function of the tray, online automatic press fitting, turning and screwing of the forklift transmission are guaranteed.

Owner:ANHUI HELI CO LTD

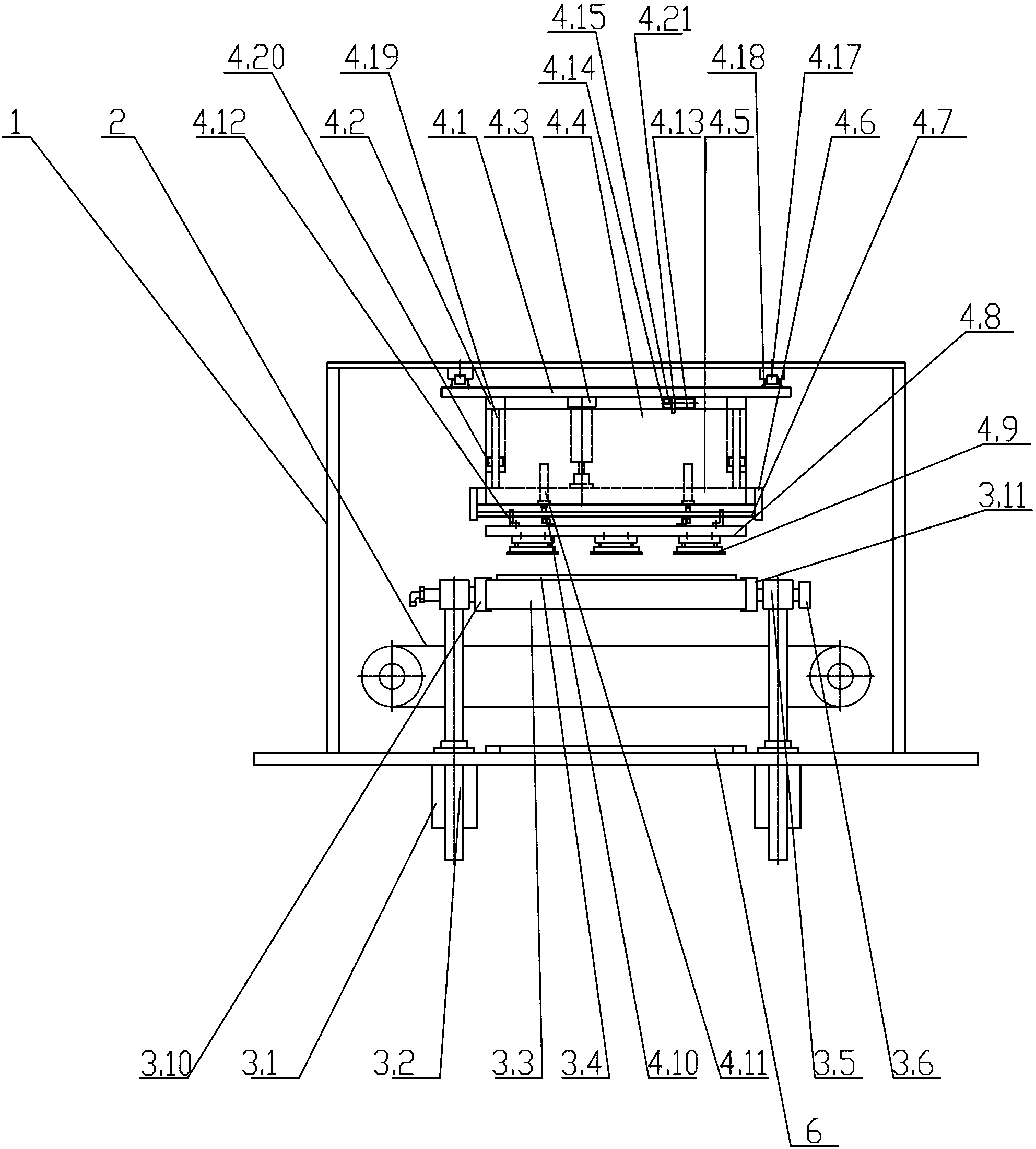

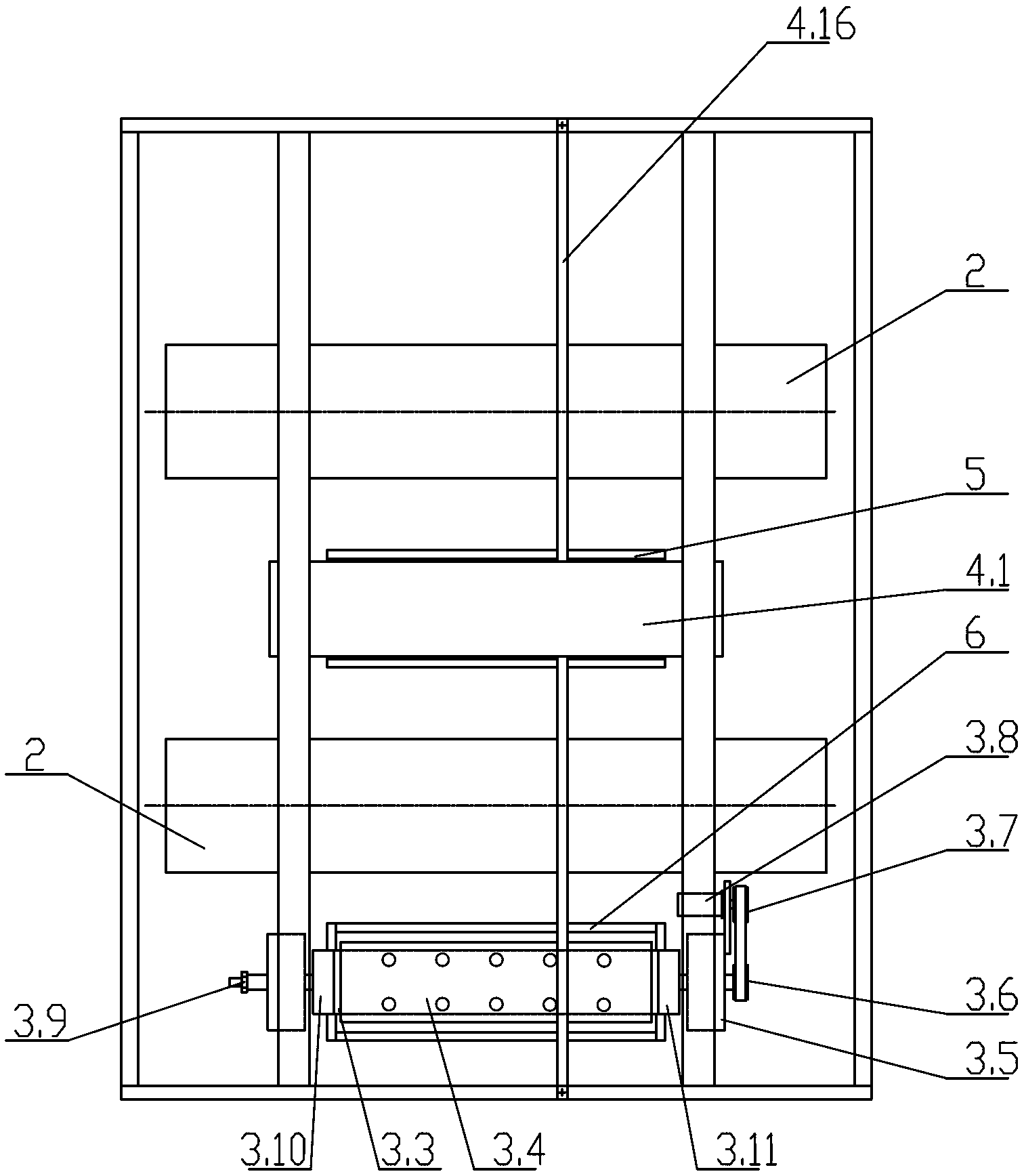

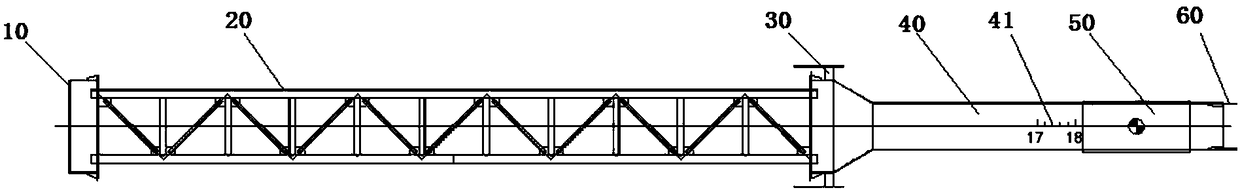

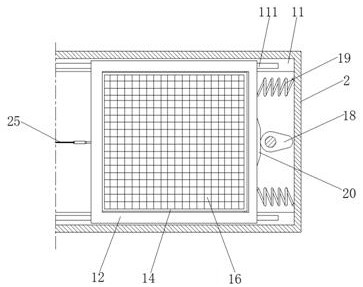

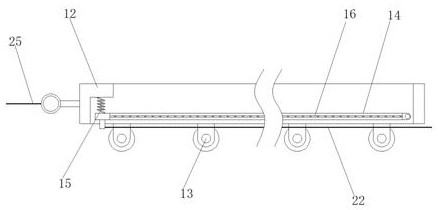

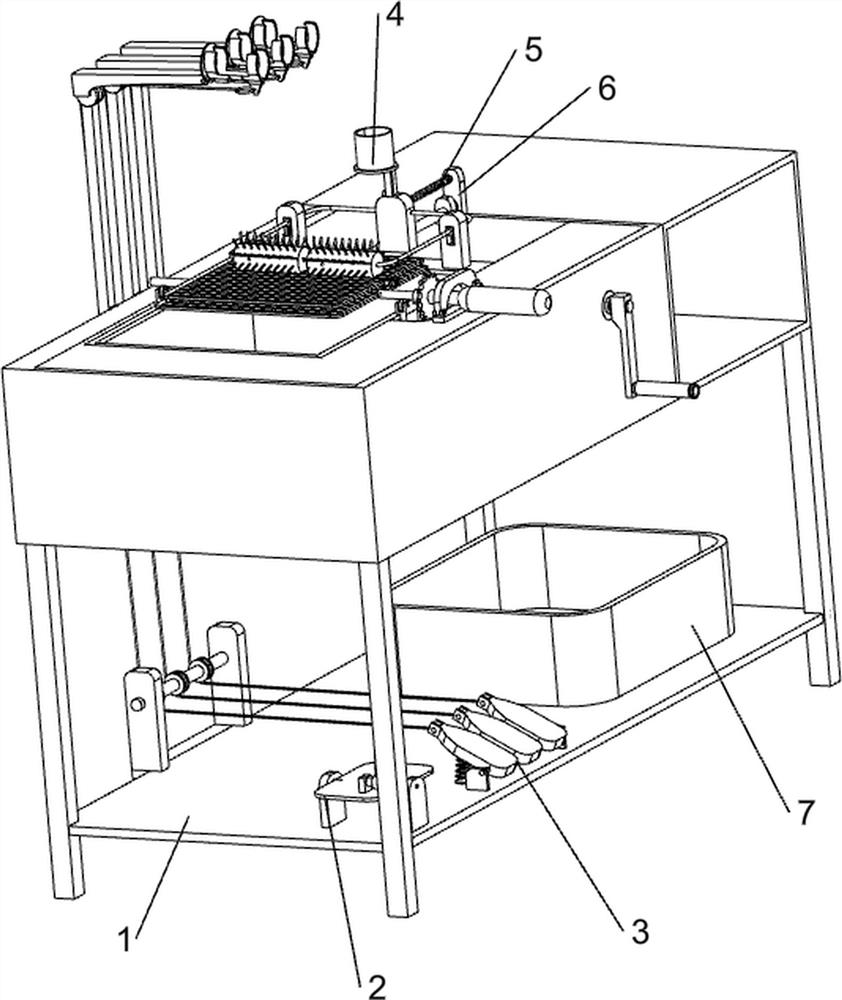

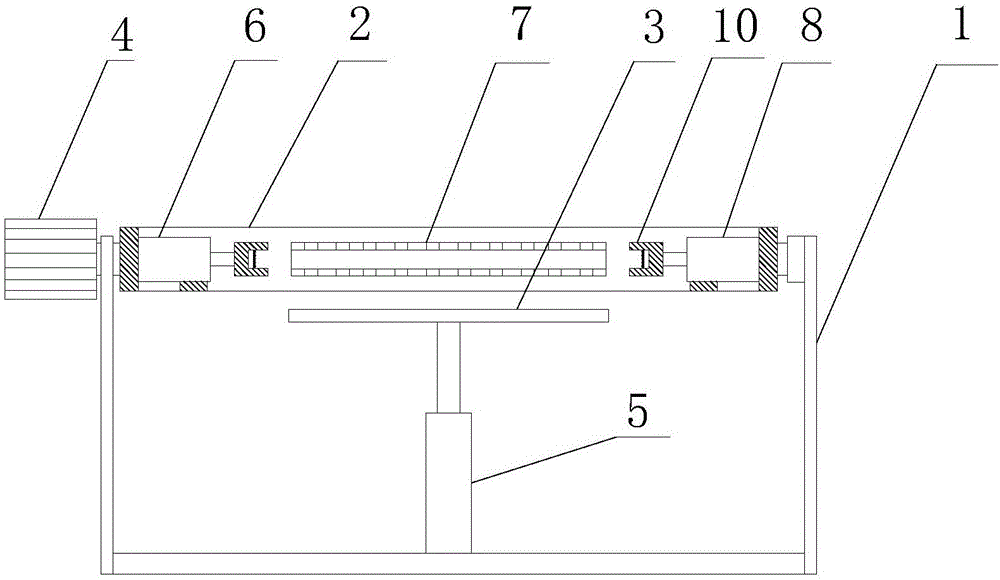

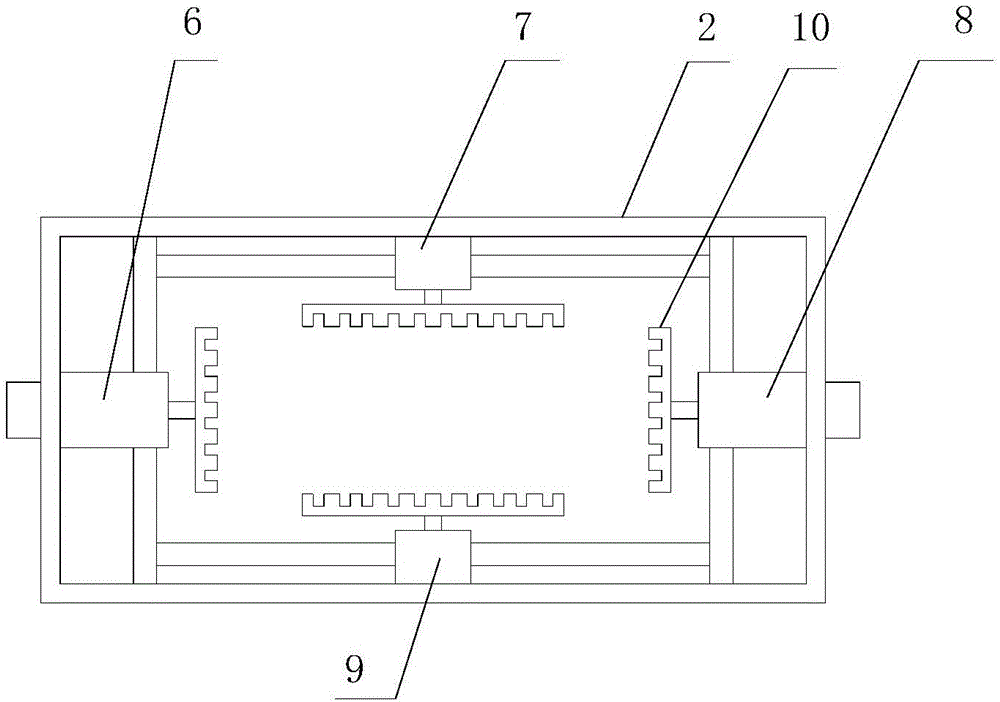

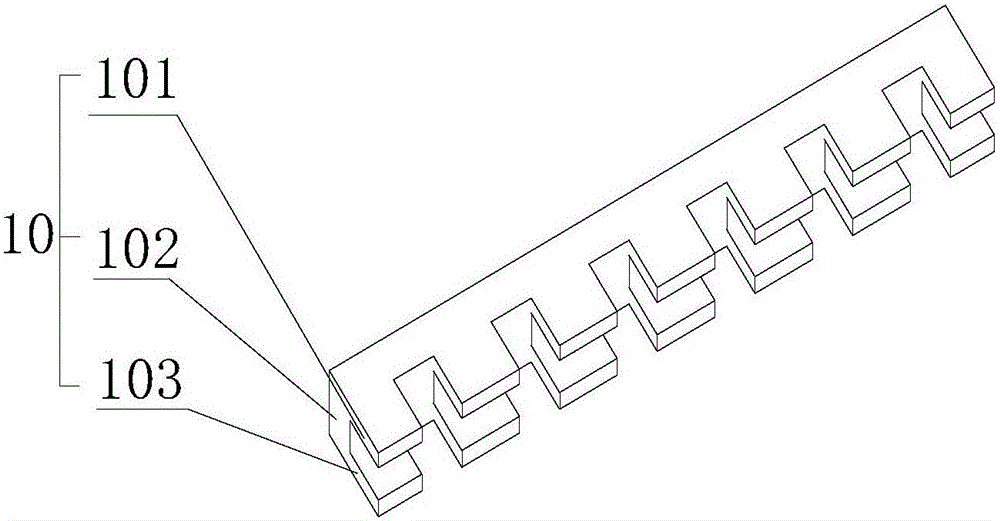

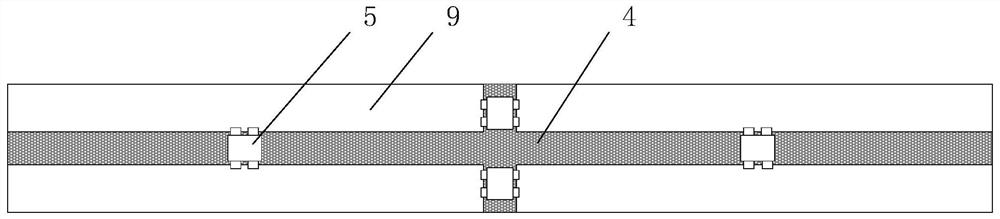

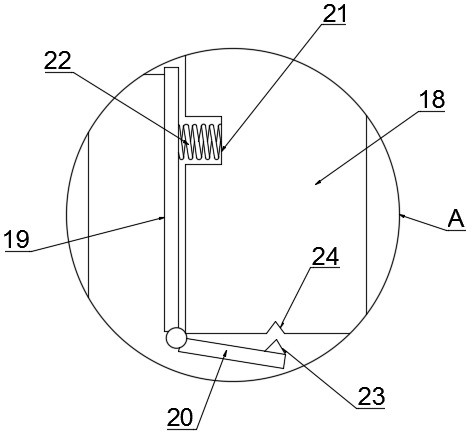

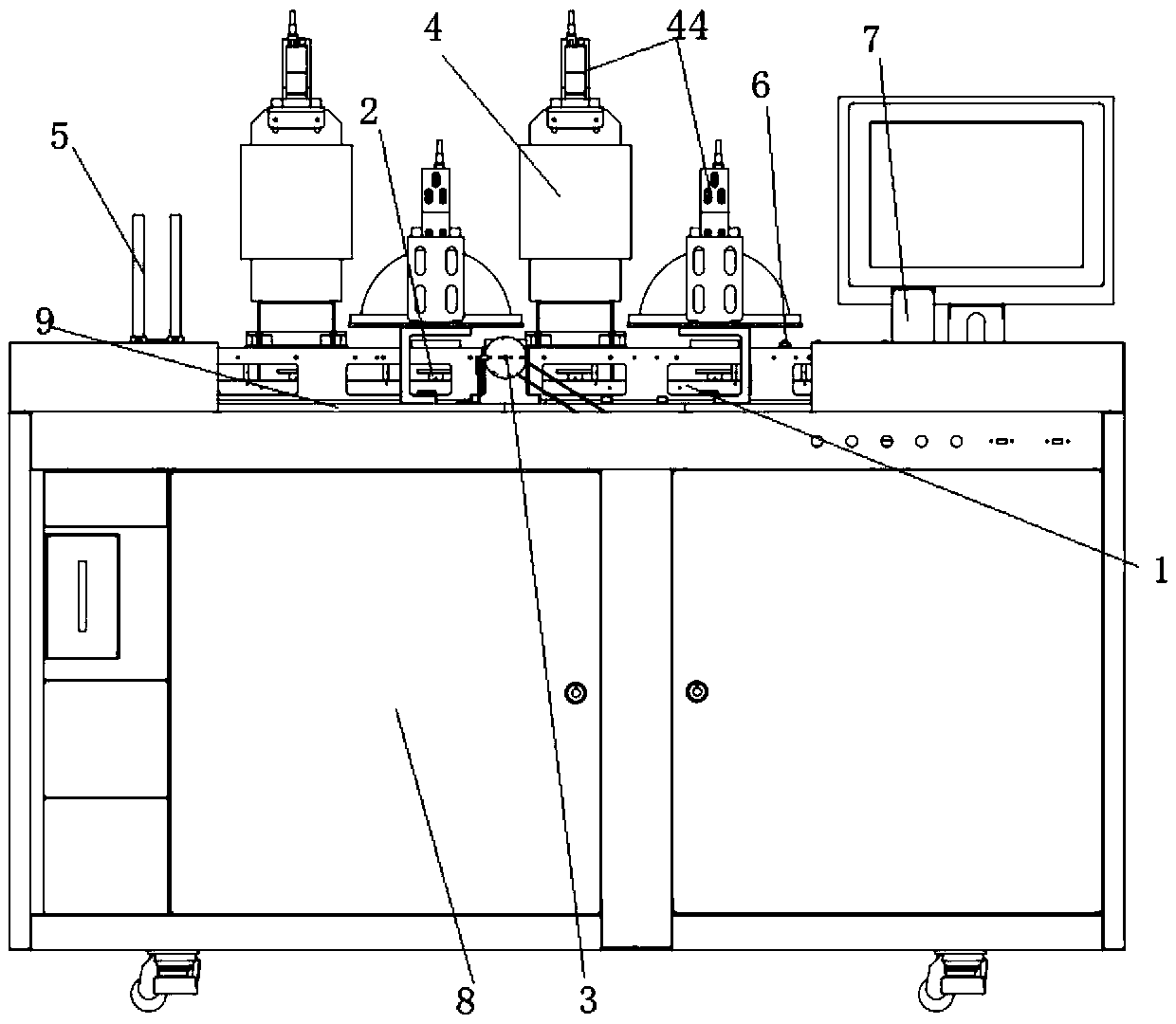

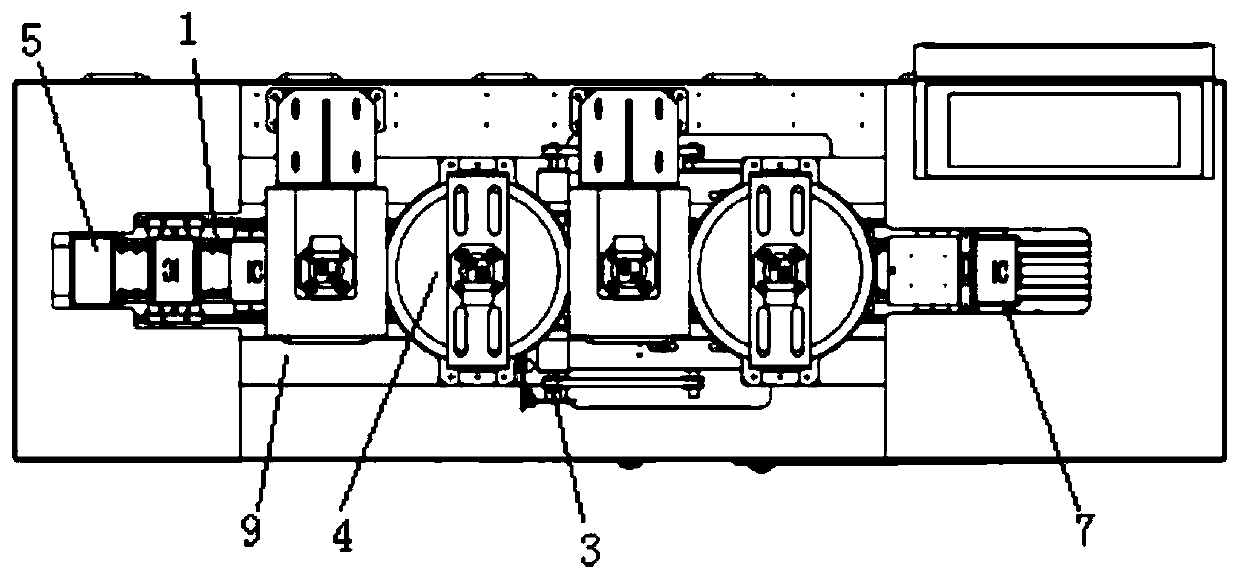

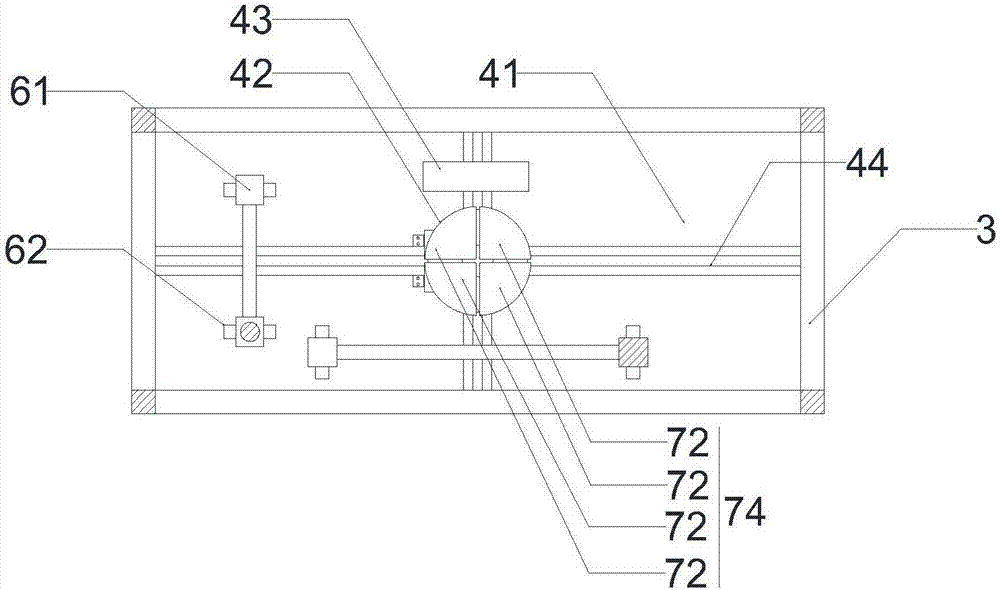

Carrying and screening device of battery packs and carrying and screening method

ActiveCN103227134AImprove handling efficiencyReduce breakage rateSemiconductor/solid-state device manufacturingConveyor partsScreening methodBelt conveyor

The invention relates to a carrying and screening device of battery packs and a carrying and screening method. The device comprises a rack, a belt conveyor, a waste placing table, a qualified product placing table, a carrying device, an auxiliary screening device and a turning over device, wherein the waste placing tale and the qualified placing table are arranged on the rack; the belt conveyor is mounted on a bottom plate of the rack; the carrying device comprises sucking discs, a first moving mechanism and a second moving mechanism; the first moving mechanism enables the sucking discs to move back and forth and conveys the sucking discs in which the battery packs are not absorbed to positions above the belt conveyor; the second moving mechanism enables the sucking discs to perform lifting movement; the auxiliary screening device comprises a first rotating mechanism fixedly connected onto the sucking discs, can drive the sucking discs to rotate for a certain angle, and can assist manual detection of the battery packs absorbed on the sucking discs; the turning over device is arranged above the qualified product placing table, and comprises an absorption plate, a second rotating mechanism and a lifting mechanism; the second rotating mechanism can drive the absorption plate to rotate by 180 degrees and achieve the turning over of the battery packs absorbed by the absorption plate; and the lifting mechanism can send the battery packs on the absorption plate onto the qualified product placing table.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

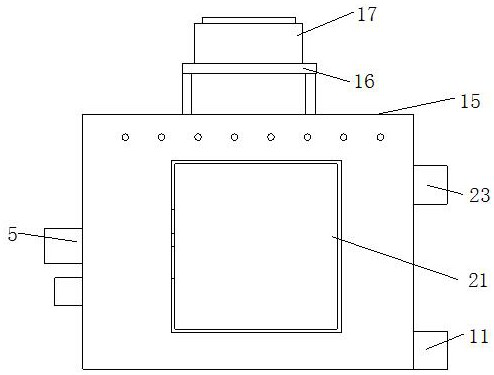

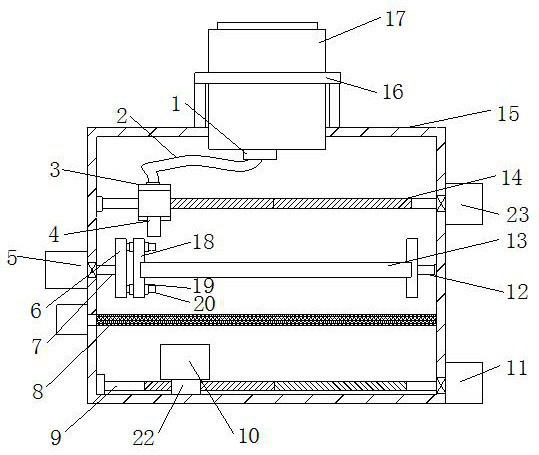

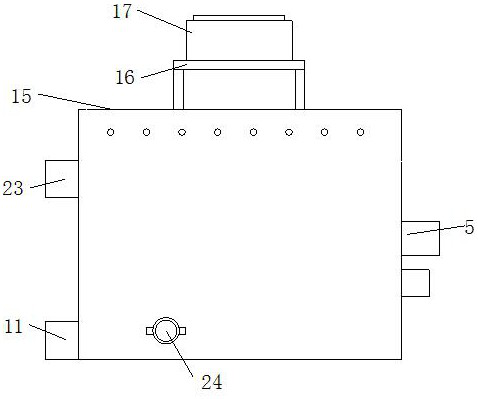

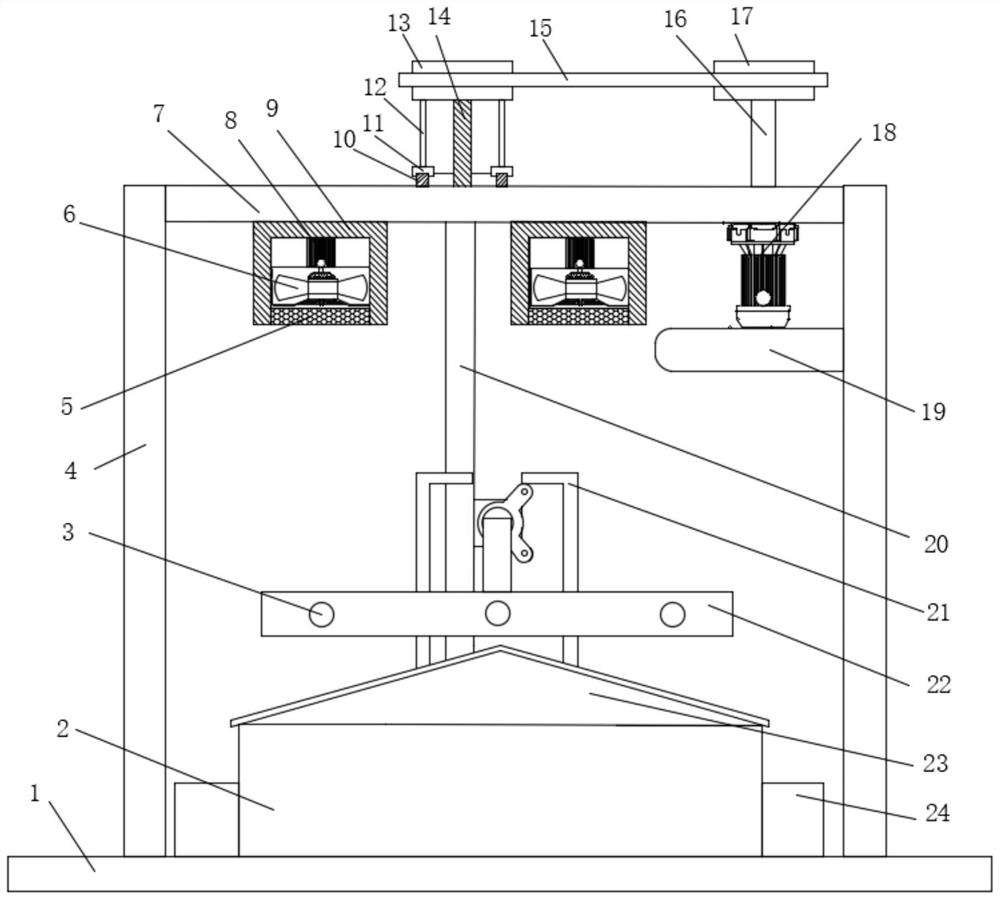

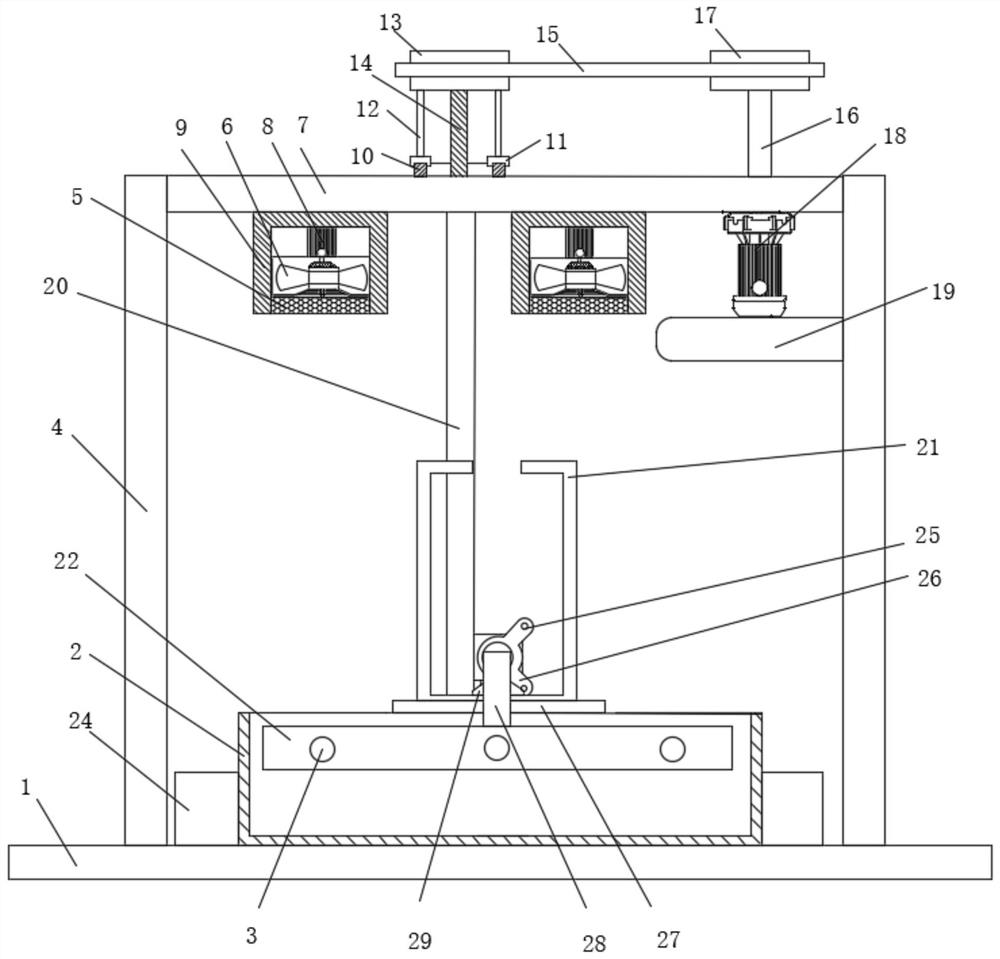

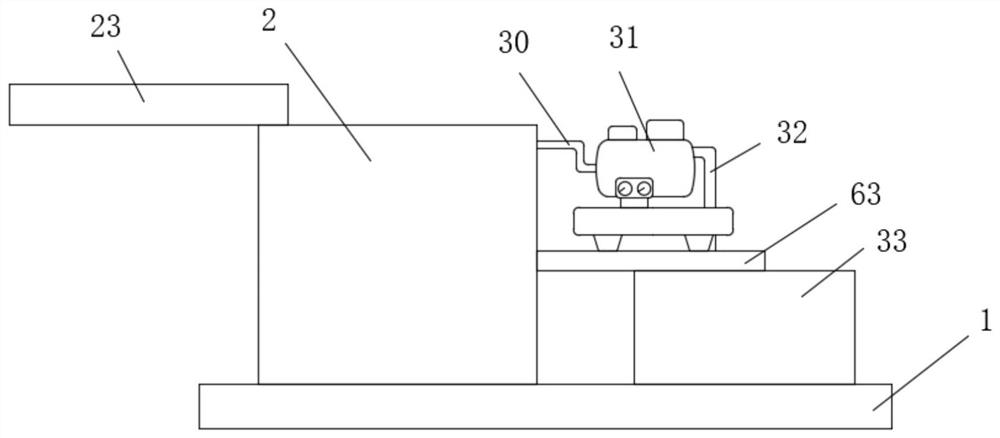

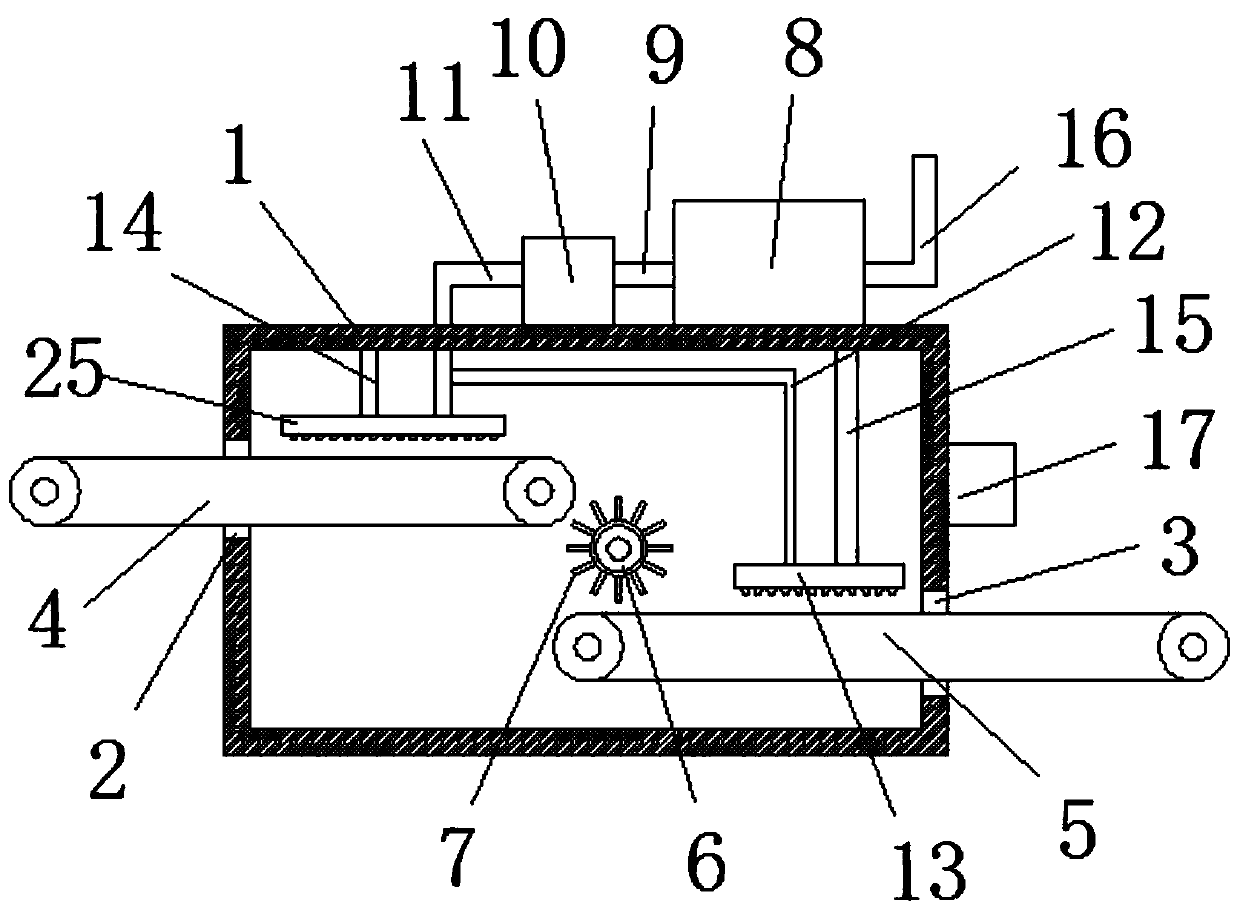

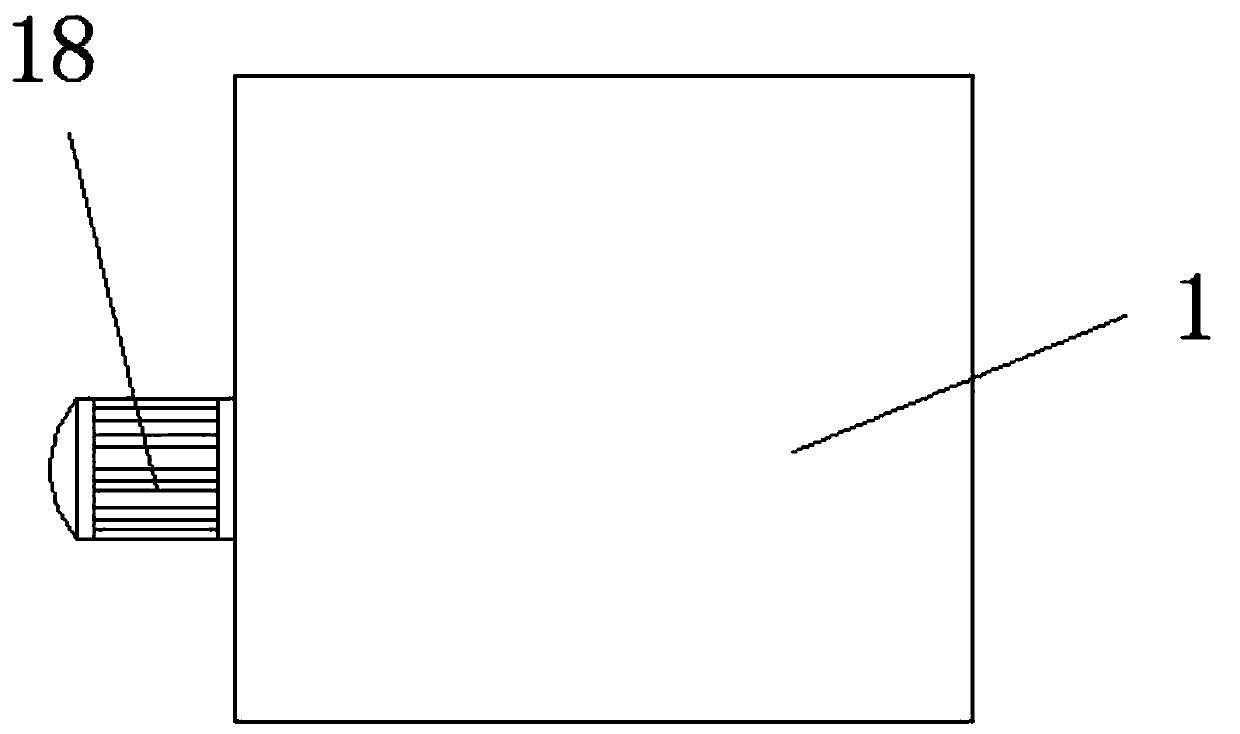

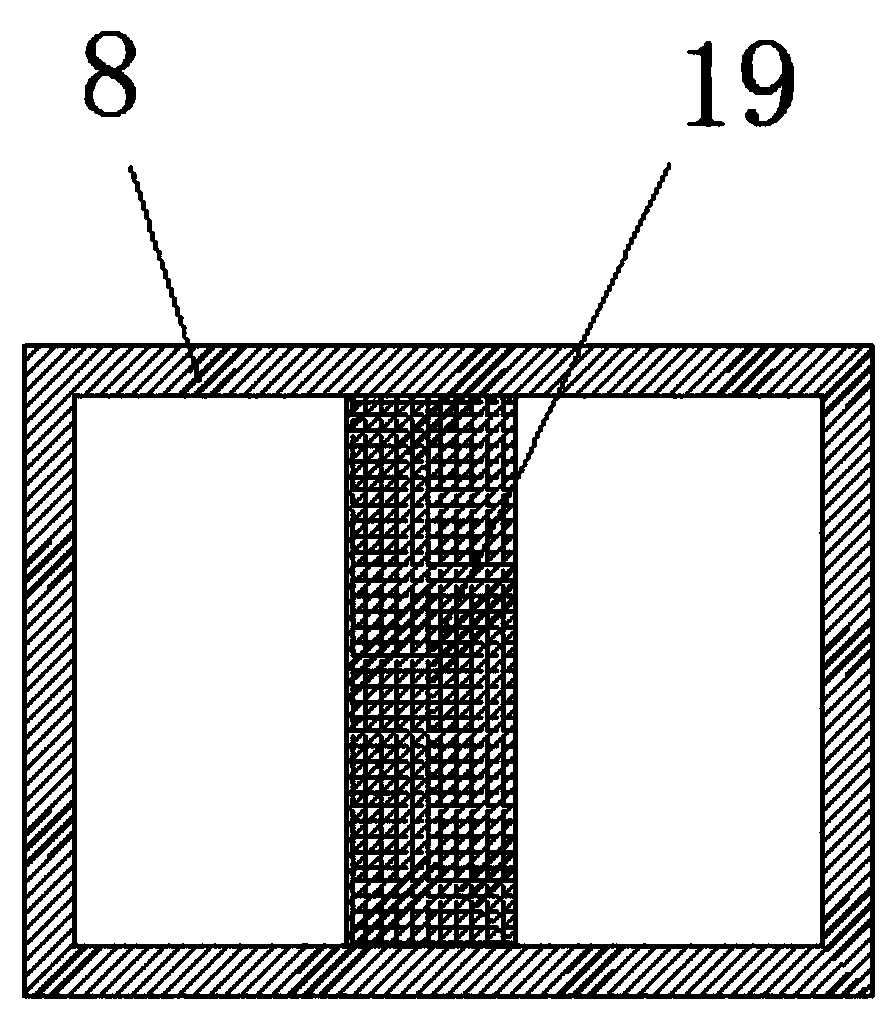

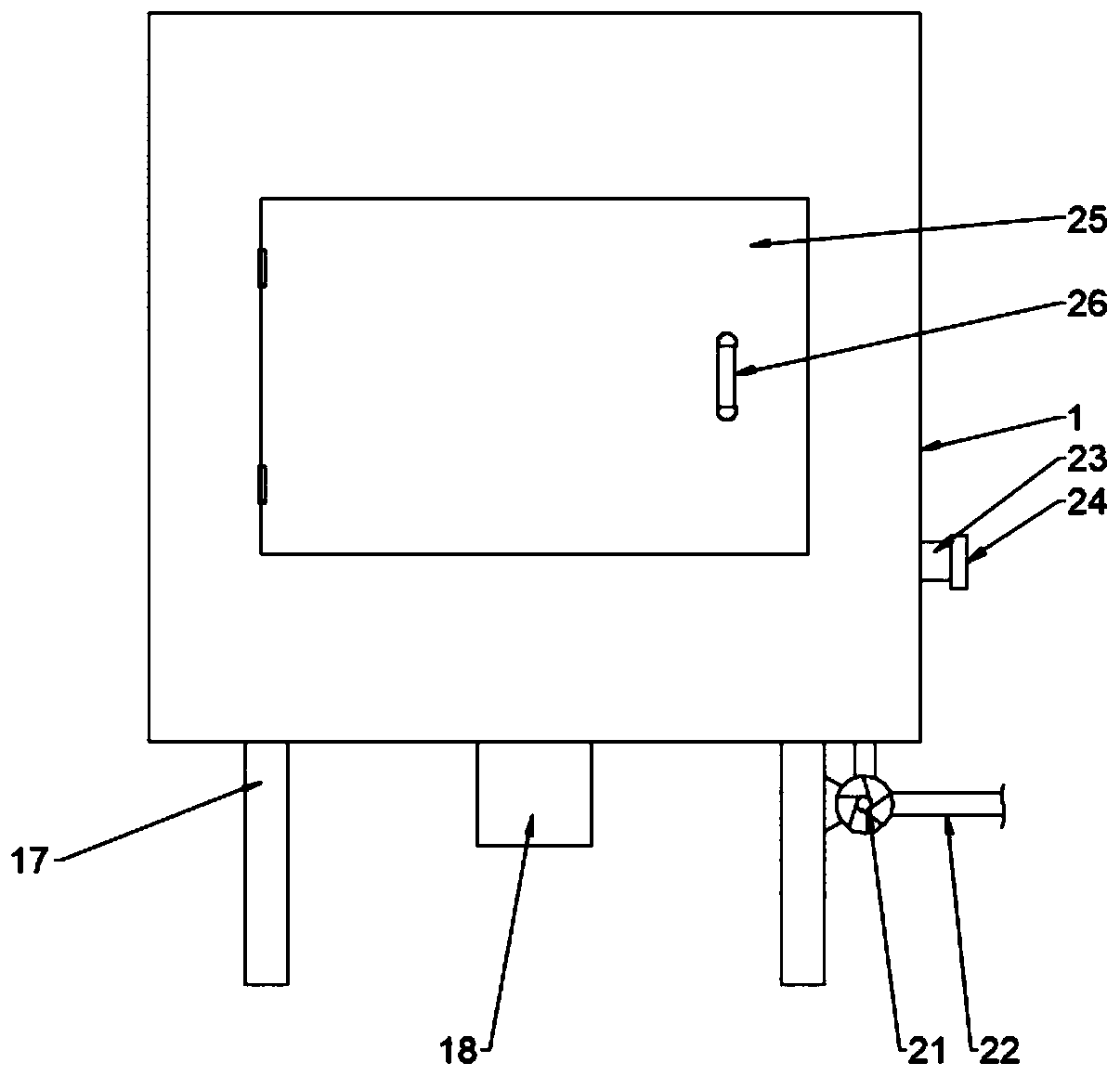

Dust removal device for cement packaging bag

InactiveCN108995911AEfficient removalTurn overDirt cleaningPackaging protectionAir blowerMaterials science

The invention discloses a dust removal device for a cement packaging bag in the technical field of cement processing. The dust removal device comprises a dust removal frame, wherein a cement bag inletis formed in the left side of the dust removal frame, a cement bag outlet is formed in the lower right side of the dust removal frame, and a feeding frame communicating with the cement bag inlet is arranged on the left side of the dust removal frame; a feeding conveyor belt driven by a conveyor motor is arranged on the left side of an inner cavity of the feeding frame in a penetrating manner; a discharging conveyor belt driven by the conveyor motor is arranged on the right side of the cement bag outlet in a penetrating manner; and a circular arc dust removal chamber is arranged at the top ofan inner cavity of the dust removal frame. The dust removal device is simple in structure and convenient to operate, dust on the cement packaging bag can be effectively removed, the cement bag can beturned over through rotation of cement bag supporting plates, dust removal of the cement bag is facilitated, the dust on the cement bag can be blown up by an air blower, the blown-up dust can be absorbed by a suction fan, and the purpose of dust removal is realized.

Owner:HUBEI BAIZHAOSHAN CEMENT CO LTD

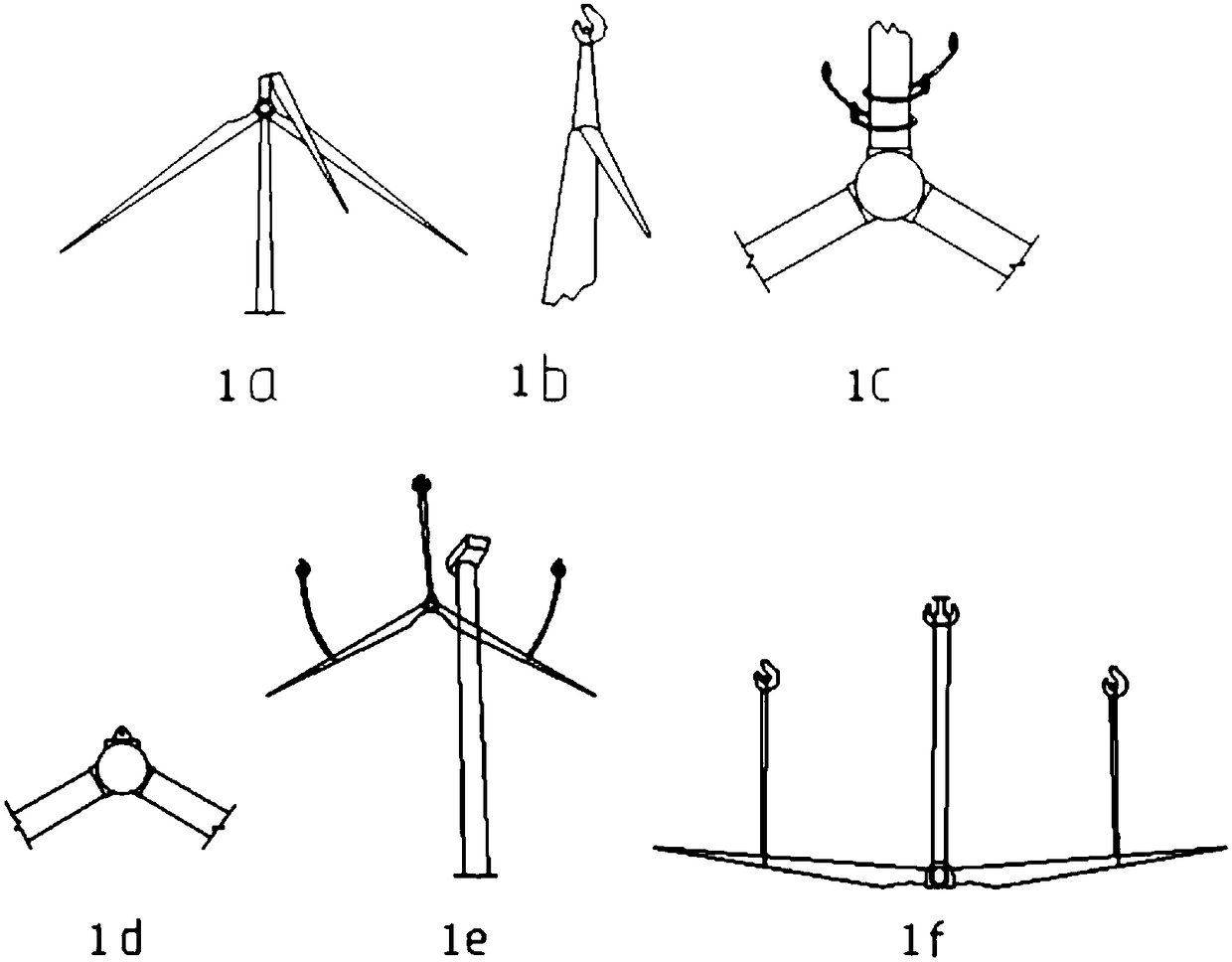

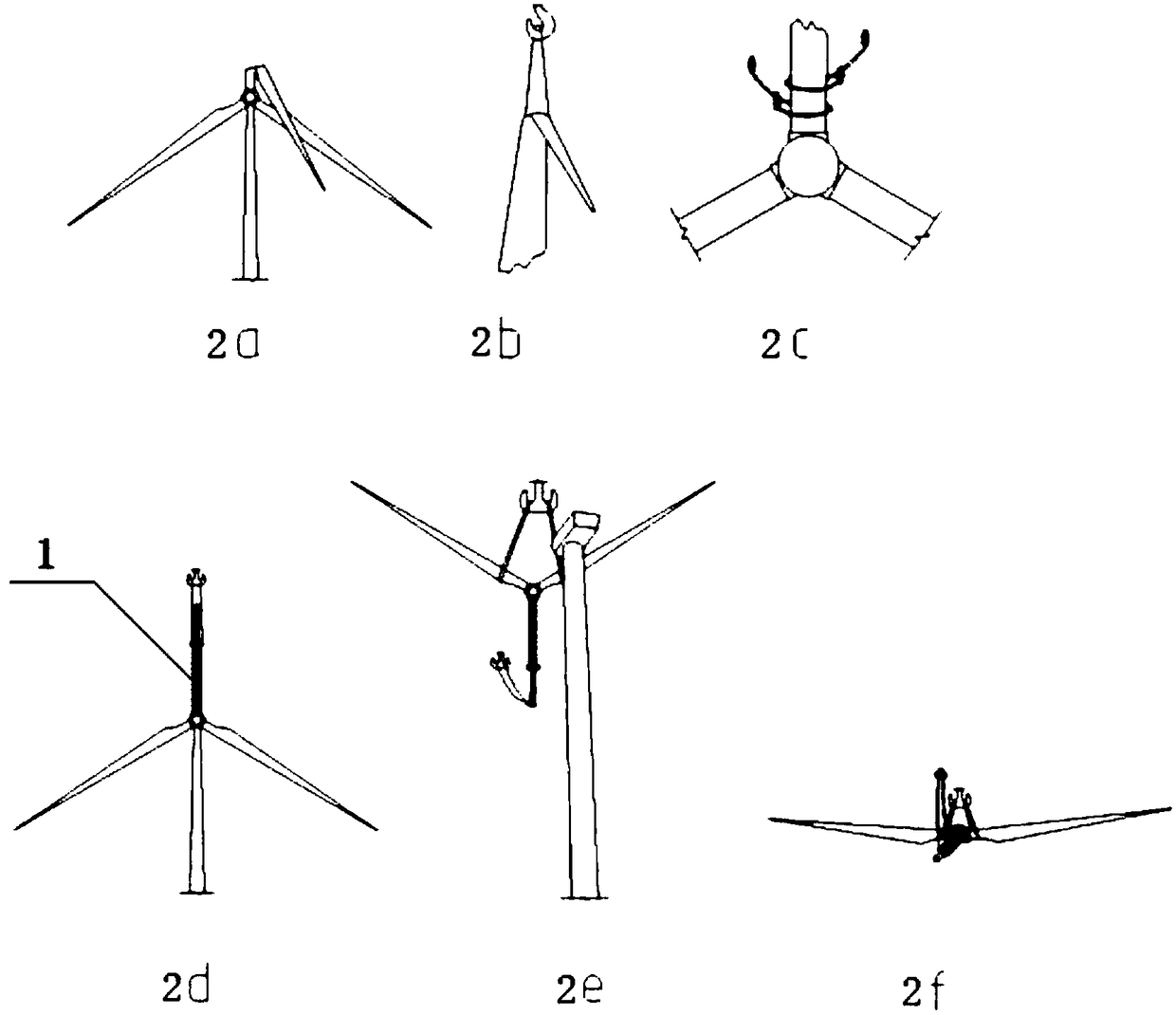

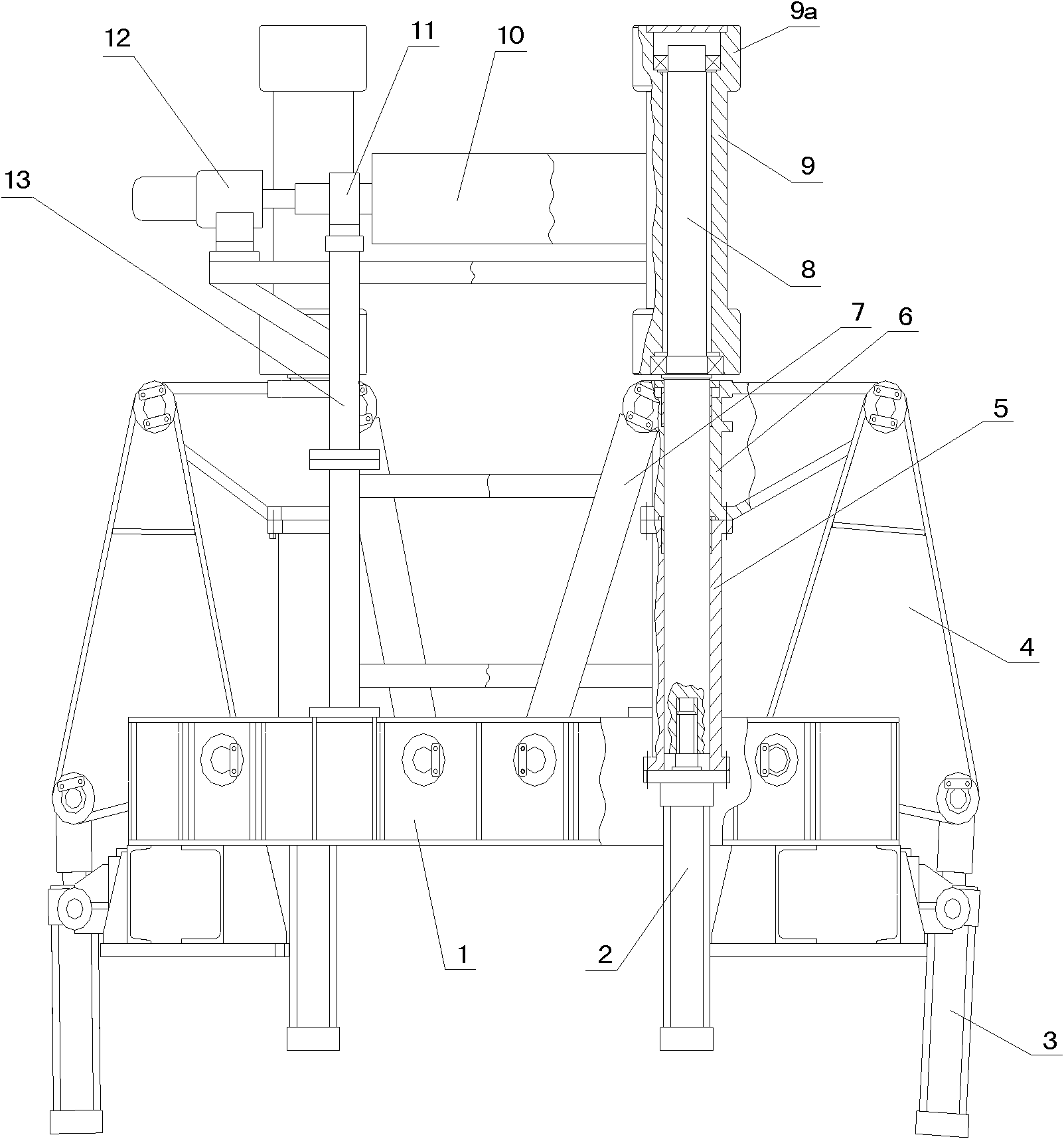

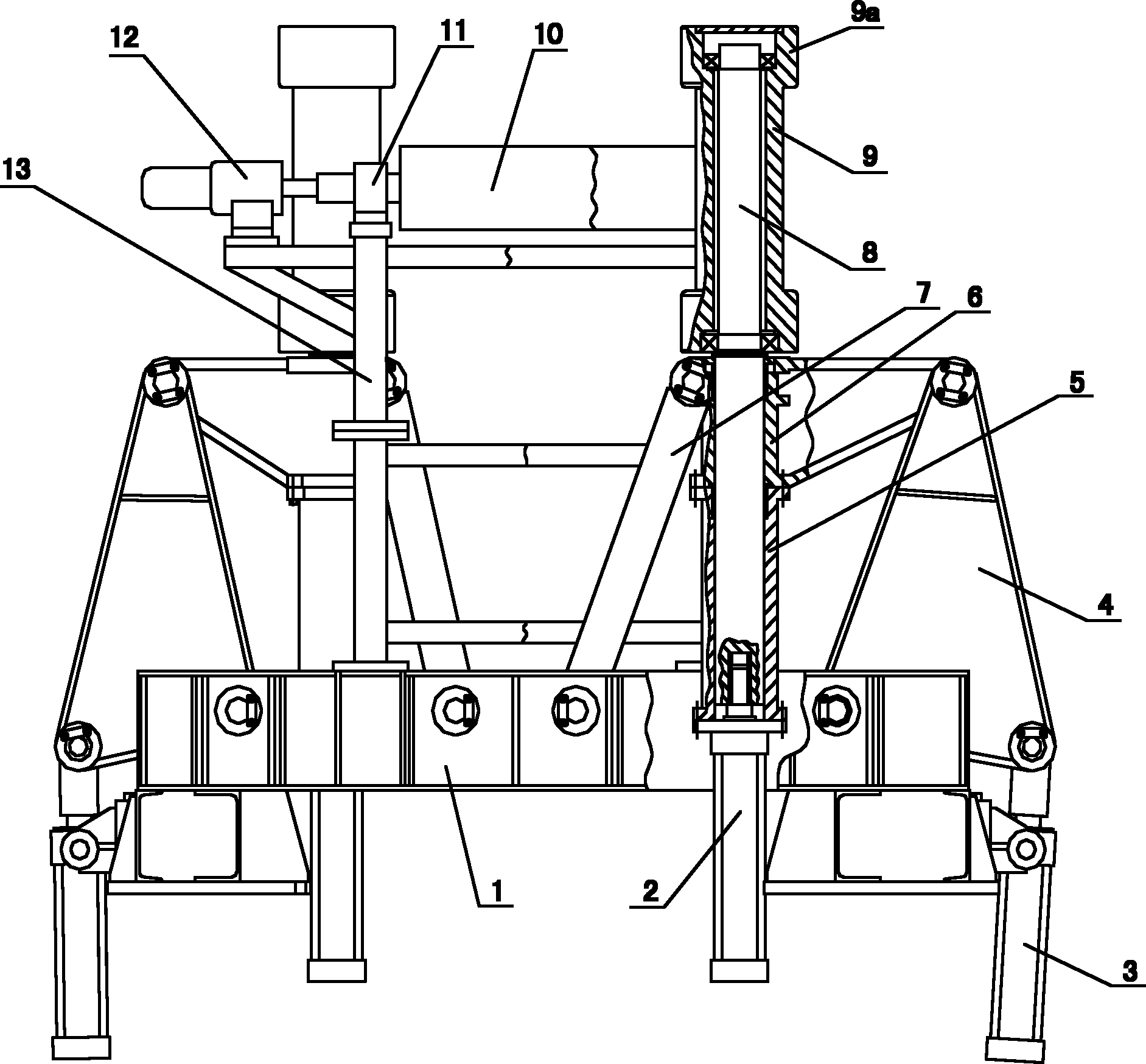

High-altitude dismantling method of offshore wind power impeller and gravity center adjustable type tool used for dismantling method of offshore wind power impeller

PendingCN108194285AAvoid damageAchieve disassemblyWind motor assemblyMachines/enginesImpellerElectricity

The invention provides a high-altitude dismantling method of an offshore wind power impeller and a gravity center adjustable type tool used for the dismantling method of the offshore wind power impeller. The high-altitude dismantling method comprises the following steps that (1), a blade tip and a blade root of a fractured fan blade are separated, and the blade tip is hoisted away by adopting a main crane; (2) the blade root is removed by adopting the main crane; (3) the main crane is adopted to hoist the gravity center adjustable type tool to replace the original fan blade, wherein the weightand the gravity center position of the gravity center adjustable tool are the same as those of the fan blade, and the gravity center adjustable type tool is mounted on the impeller; (4), the main crane is utilized to mount a blade root hoisting belt on two pieces of upward fan blades, and an auxiliary crane is utilized to be connected with a hoisting point on the gravity center adjustable type tool; and (5), a bolt between a hub and a power generator is removed, so that the hub is separated from the power generator, the impeller can be dismantled, the main crane and the auxiliary crane work simultaneously, an overturning action of the impeller is completed, and finally the impeller is slowly placed at a preset position. According to the high-altitude dismantling method, two hoisting points are used, dismantling and overturning of the impeller can be achieved, a crane ship does not need to be arranged additionally, and the repair cost is lowered.

Owner:CCCC SANHANG SHANGHAI NEW ENERGY ENG CO LTD +1

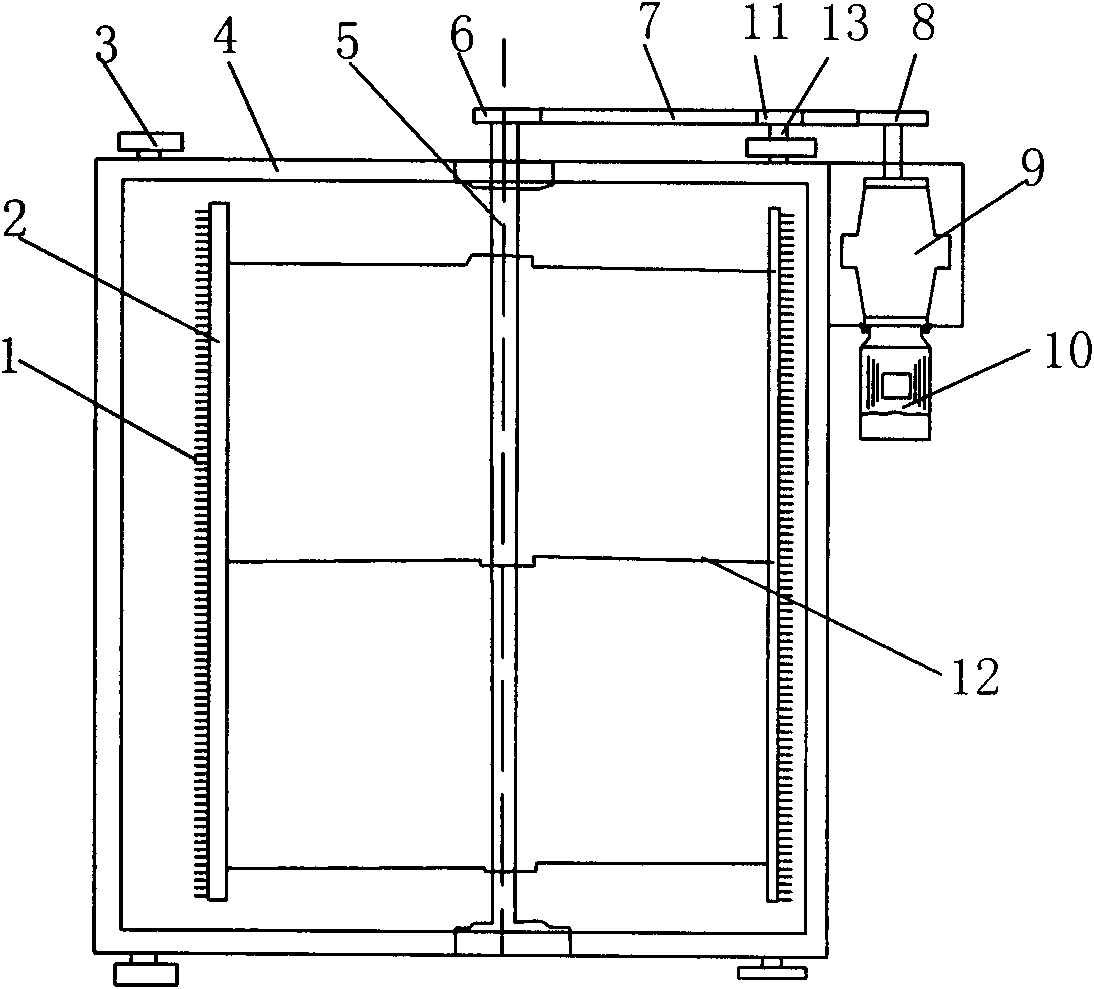

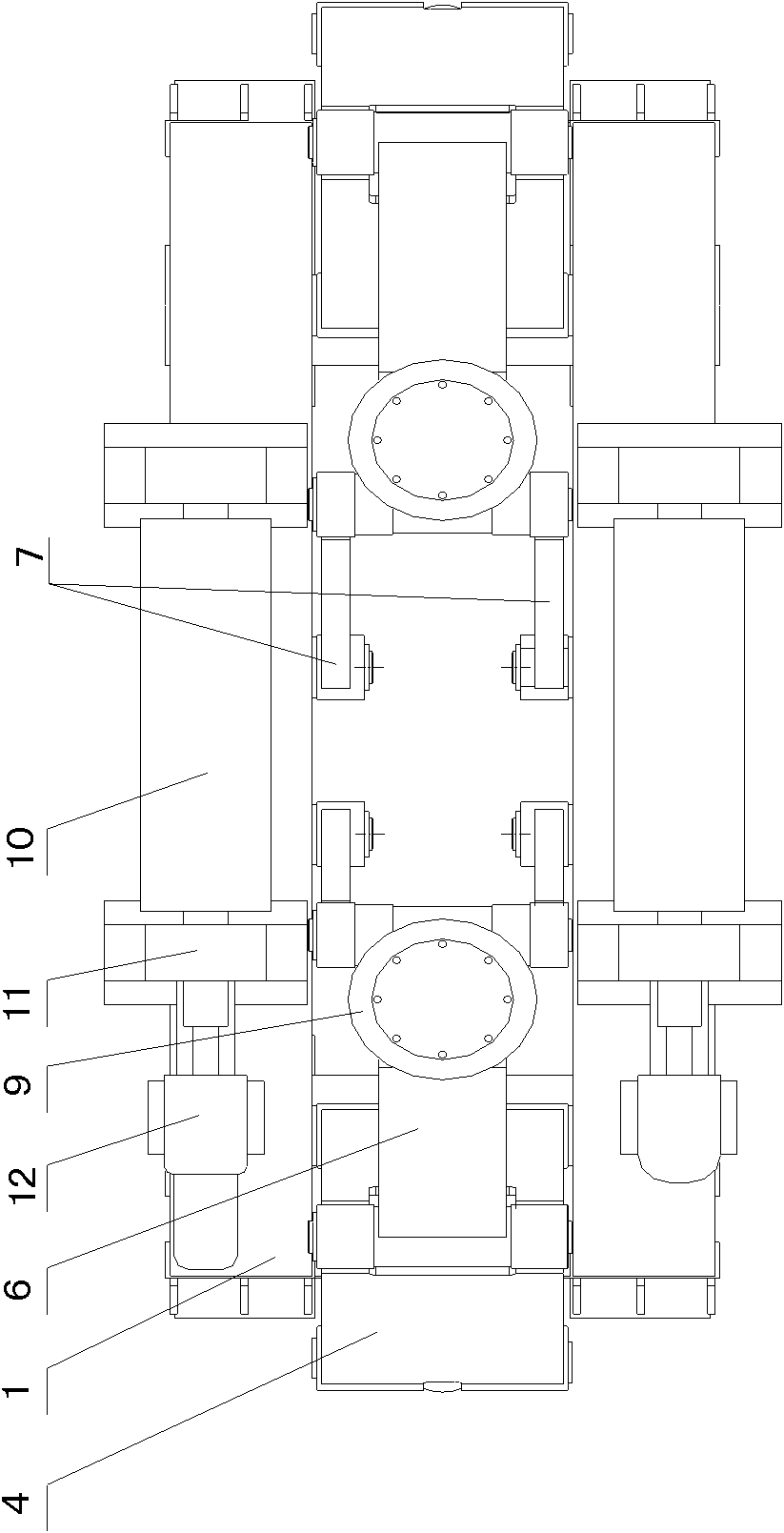

Chicken manure fermenting and turning machine

InactiveCN101913917AImprove turning efficiencyReduce labor costsClimate change adaptationExcrement fertilisersEngineeringMechanical engineering

The invention discloses a chicken manure fermenting and turning machine which comprises a framework [4], a turning wheel [12] and a driving device, wherein the framework [4] is provided with a plurality of roller wheels [3] which are flexibly connected on the framework [4] through a roller wheel spindle [13], a rotatable turning wheel spindle [5] is arranged in the framework [4], the turning wheel [12] is fixed on the turning wheel spindle [13], the outer circle of the turning wheel [12] is fixed with a plurality of turning plates [2] parallel to the center line of the turning wheel, and each turning plate [2] is fixed with turning teeth [1] for turning chicken manure; and the driving device drives the roller wheels and the turning wheel to rotate. The invention realizes mechanical chicken manure turning, raises the turning efficiency and lowers the labor cost.

Owner:铜陵正强禽业有限责任公司

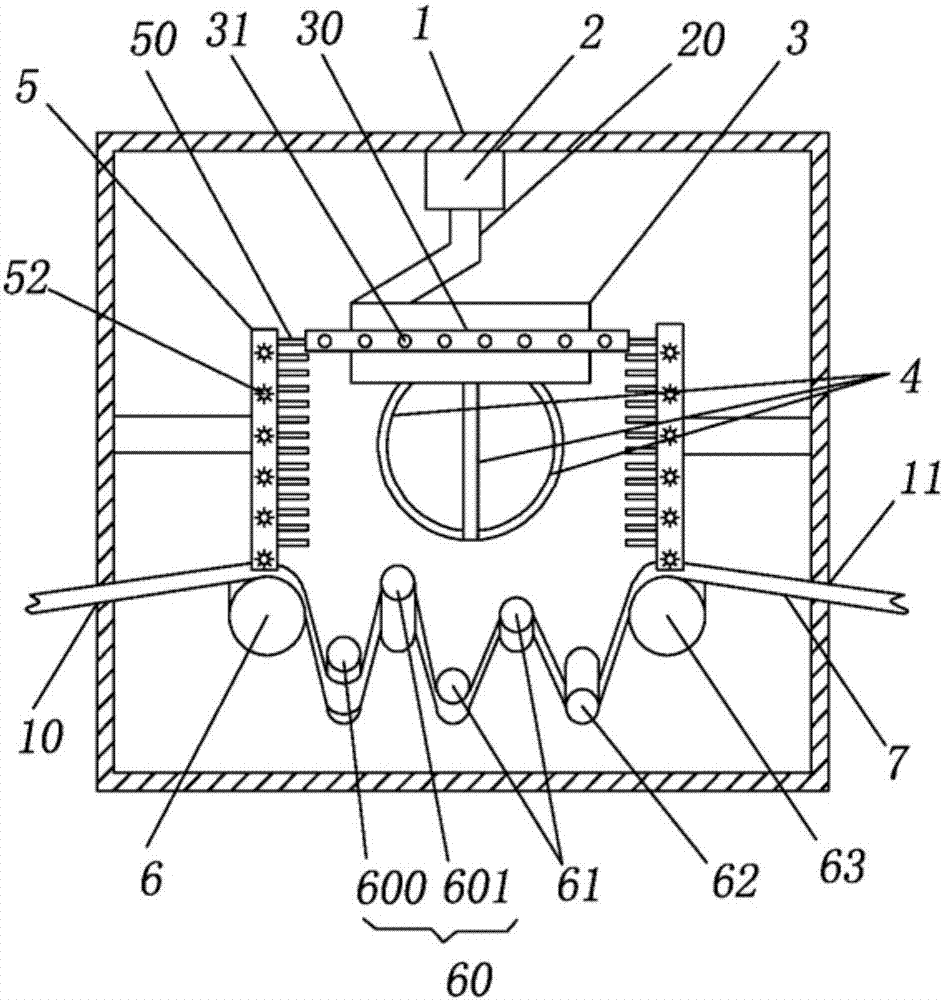

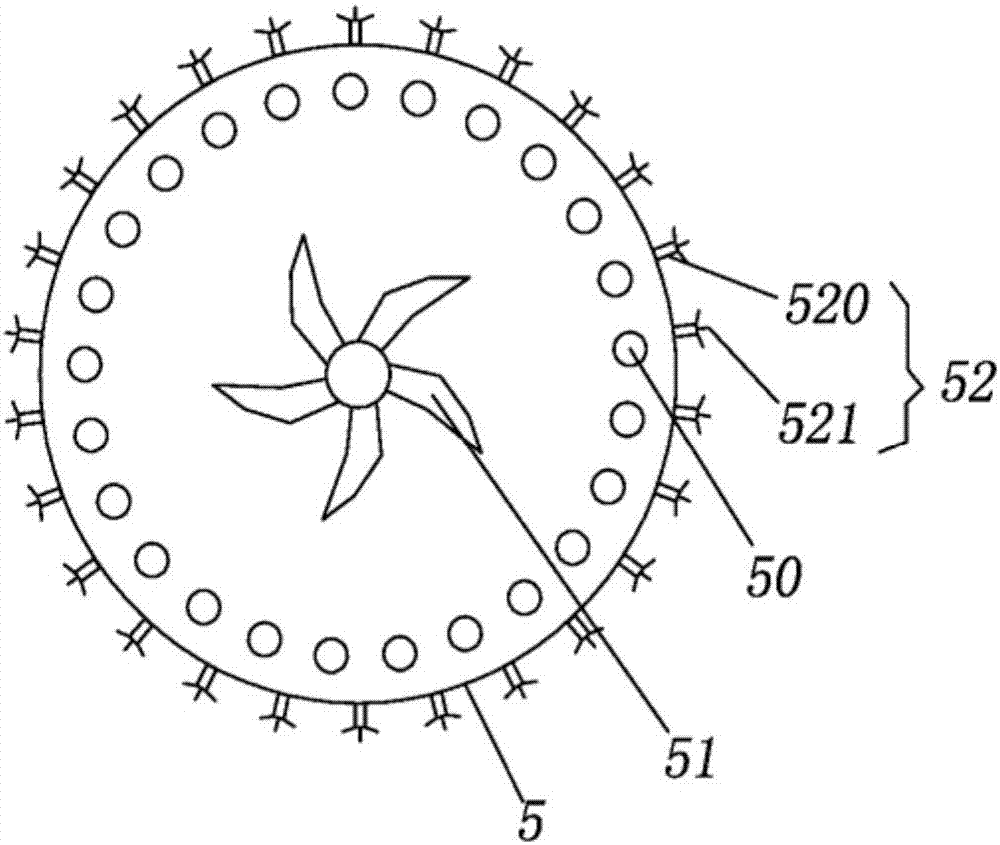

Textile sterilization device

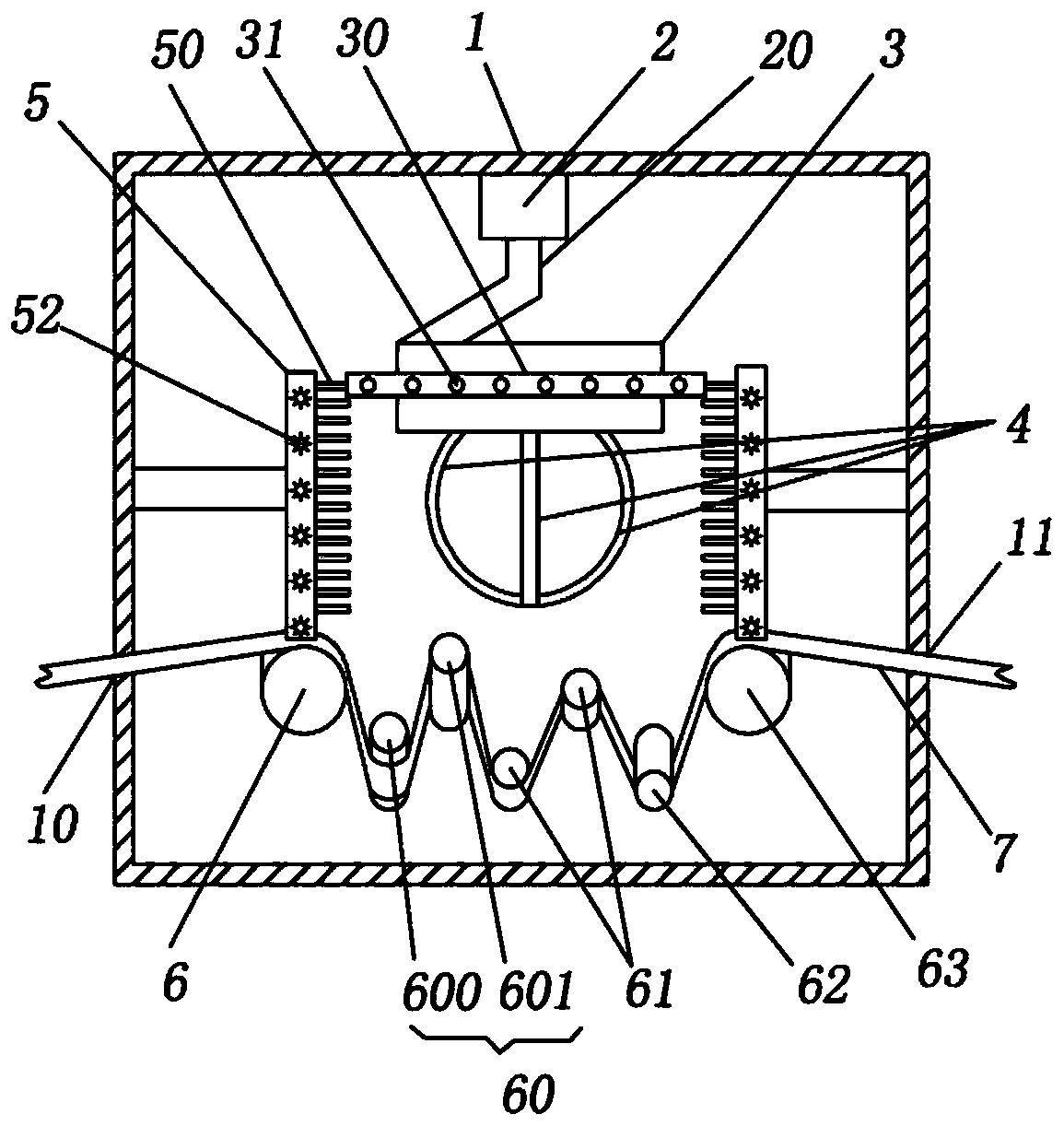

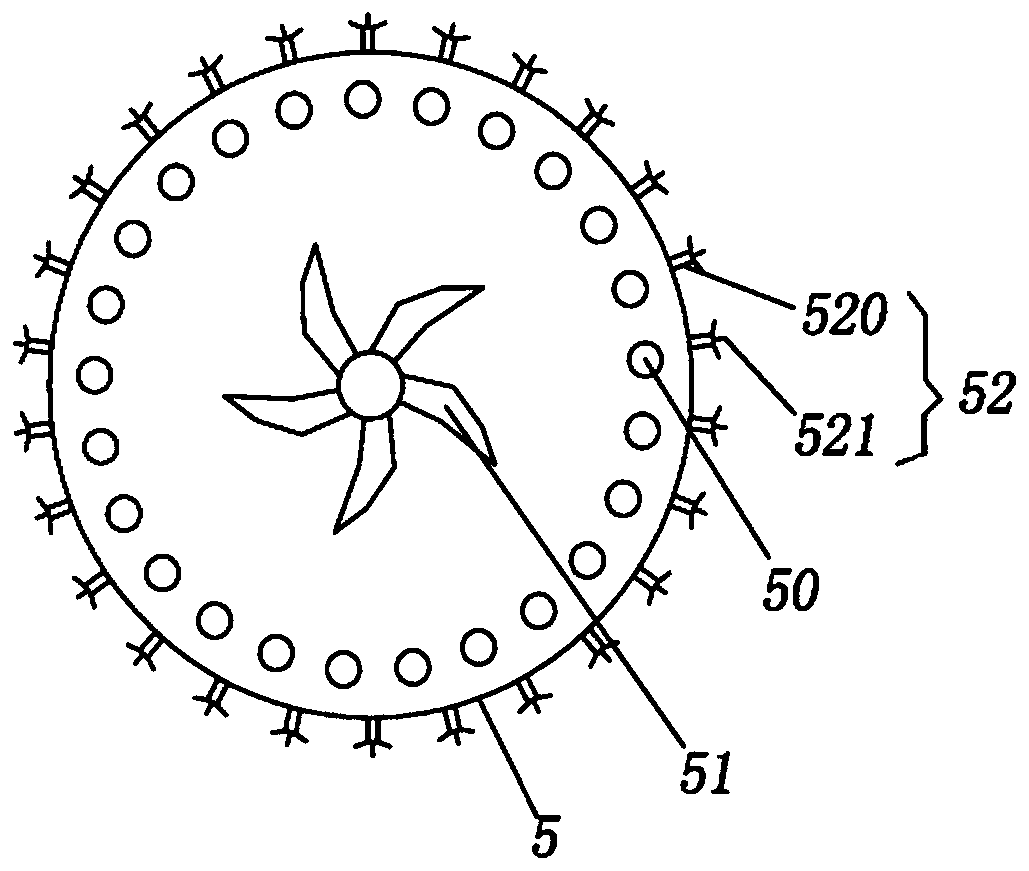

ActiveCN107952089AIncrease contact areaExpand the scope of sterilizationMechanical cleaningPressure cleaningTextile technologyEngineering

The invention belongs to the technical field of textiles, and particularly relates to a textile sterilization device. The device includes a sterilization chamber, the side wall of the sterilization chamber is provided with an feeding hole and a discharge hole, and the sterilization chamber is internally provided with a motor, a rotating disk, an ultraviolet lamp, a driving roller set and two cleaning disks symmetrically arranged on the two sides of the ultraviolet lamp; a motor is fixed in the sterilization chamber, an output shaft of the motor is fixedly connected with the rotating disk, therotating disk is fixedly connected with the ultraviolet lamp, the outer wall of the rotating disk is provided with a circular toothed ring, and a plurality of needle holes are formed in the circumferential direction of the toothed ring; the ultraviolet lamp includes a plurality of centrally symmetrical arc-shaped modulator tubes, the cleaning disks are rotatably connected with the side wall of thesterilization chamber, the surfaces of the cleaning disks are provided with a plurality of needle loops formed by convex needles, the convex needles are meshed with the needle holes, and the side walls of the cleaning disks are provided with a plurality of brushes used for cleaning the textiles; a drive roller set is located below the ultraviolet lamp, and the drive roller set includes a feedingroller, a discharging roller and a plurality of turning rollers used for turning the textiles. According to the scheme, the textile sterilization effect can be effectively improved.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

Cleaning device for plate processing

PendingCN111822417AAchieve clamping and fixingTurn overDrying gas arrangementsCleaning using liquidsElectric machineryWater storage tank

The invention discloses a cleaning device for plate processing, and relates to the field of plate processing. According to the cleaning device, the problem that an existing cleaning device cannot drya cleaned plate can be solved. By means of the following scheme, the cleaning device comprises a device shell, wherein a water storage tank is fixedly mounted at the upper end of the device shell; a first motor is fixedly mounted at the left end of the device shell; an output shaft of the first motor is connected with a drive shaft; the right end of the drive shaft passes through the device shelland extends to the inside of the device shell to be fixedly provided with connecting plates; a rotating shaft is rotationally mounted on the right wall inside the device shell; the left end of the rotating shaft is located in the device shell; clamping plates are installed at one ends, close to each other, of the rotating shaft and the connecting plate; inserting grooves are formed between the twoconnecting plates; and anti-skid patterns are arranged on the inner walls of the inserting grooves. The cleaning device for plate processing is good in cleaning effect, convenient to dry, high in automation degree, simple in operation and high in practicability.

Owner:何晓华

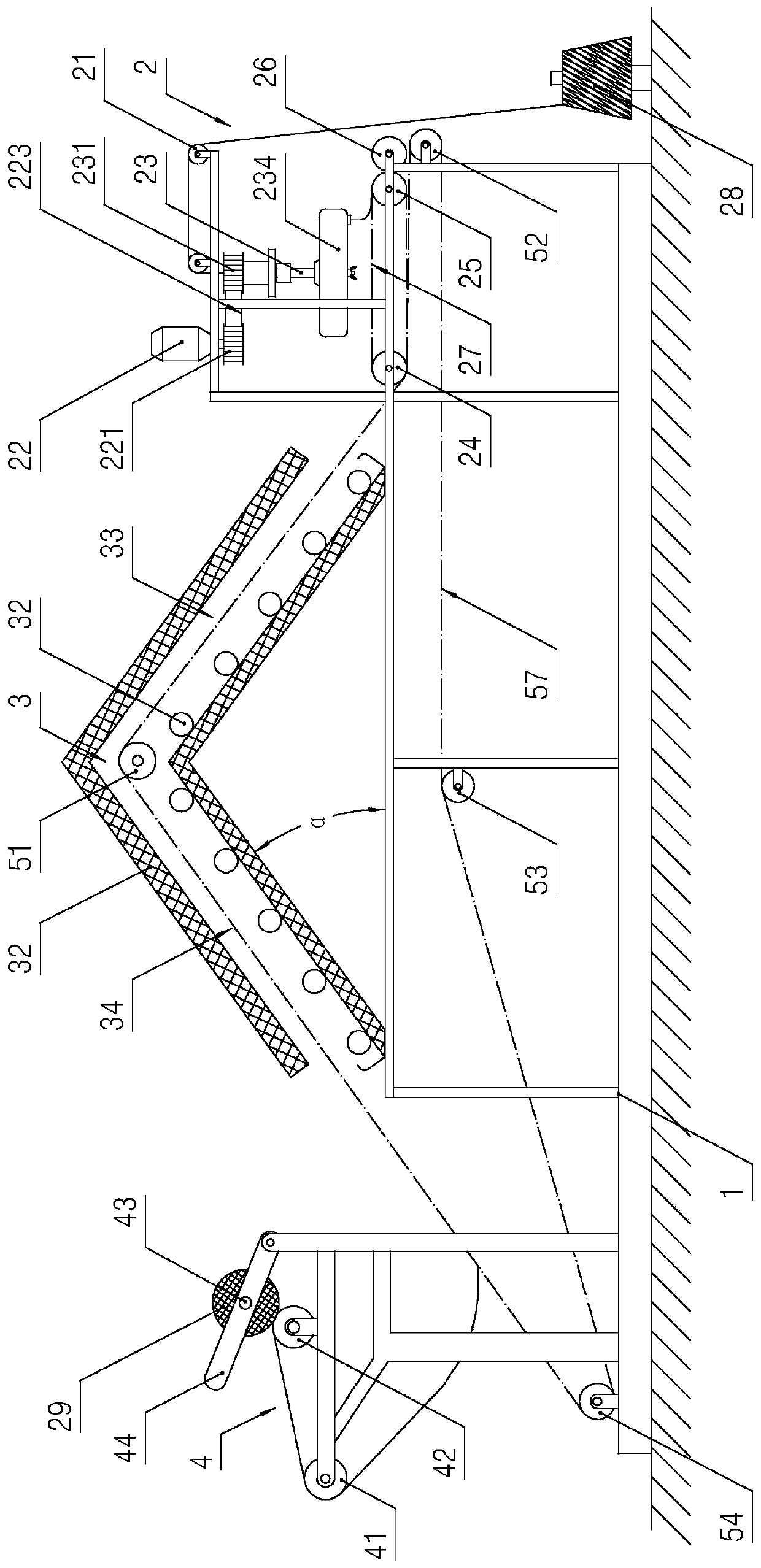

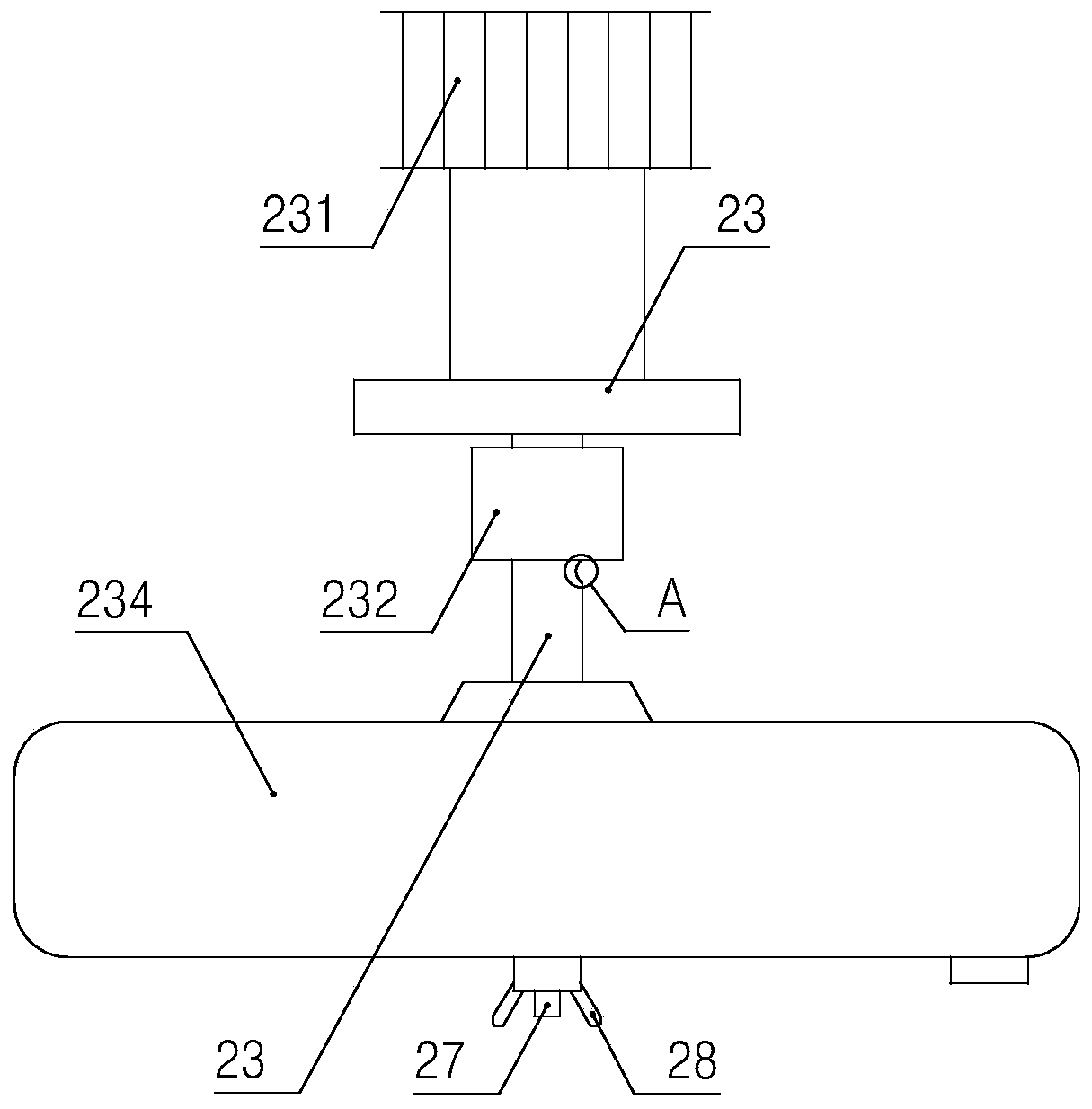

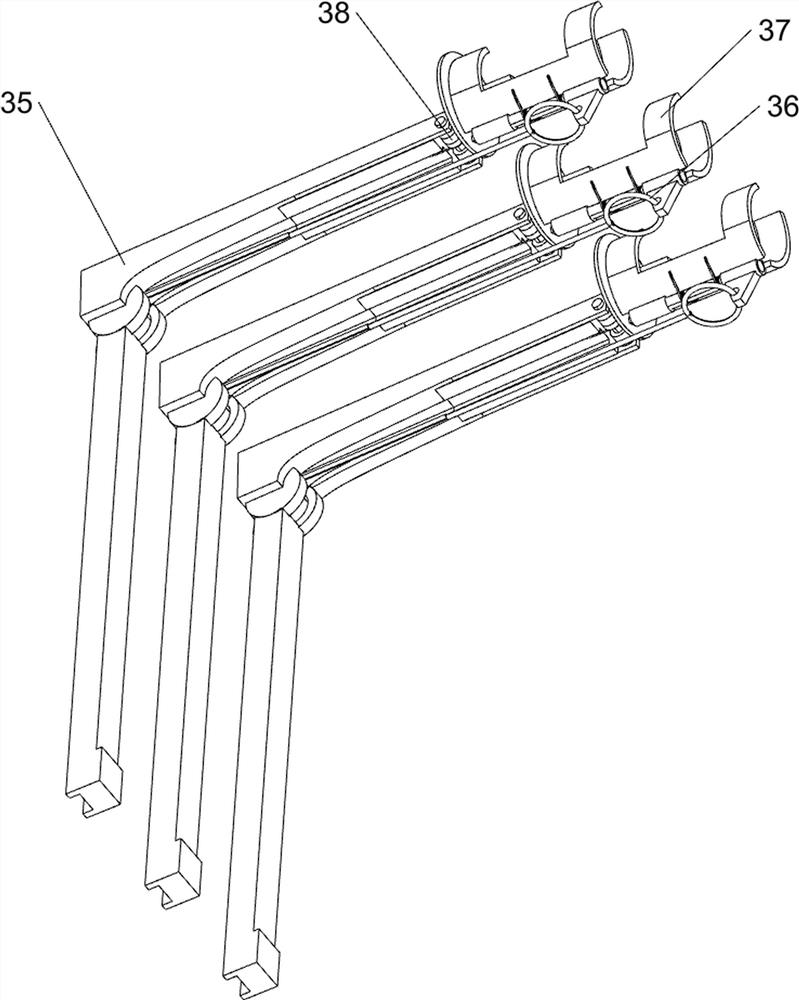

Yarn steaming and setting machine

PendingCN110016771ATurn overShorten the setting timeTextile treatment carriersLiquid/gas/vapor yarns/filaments treatmentYarnClosed loop

The invention discloses a yarn steaming and setting machine which conducts unwinding, yarn steaming and setting and winding synchronously. The yarn steaming and setting machine structurally comprisesa machine frame. A yarn unwinding device, a yarn steaming channel, a yarn winding device and a conveying belt penetrating through the yarn steaming channel are arranged on the machine frame. A yarn laying and transferring device is arranged on one side of the inlet of the yarn steaming channel on the machine frame. The yarn laying and transferring device comprises an inner transmission roller, anouter transmission roller and a transferring conveying belt, wherein the inner transmission roller and the outer transmission roller are matched with the yarn unwinding device and the conveying belt,and the transferring conveying belt is arranged on the inner transmission roller and the outer transmission roller through a closed loop. A turning clamping roller matched with the outer transmissionroller is arranged at the position, close to the outer transmission roller, of the machine frame. The conveying belt is located on the lower side of the transferring conveying belt and goes beyond thetransferring conveying belt, and the conveying belt is attached to the transferring conveying belt at the inner transmission roller. The yarn steaming and setting machine can be suitable for steamingand setting of various types of yarns.

Owner:张家港市德胜染整有限责任公司

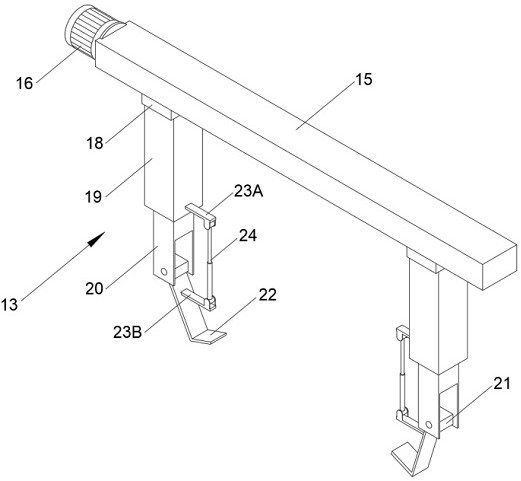

Automatic pancake overturning mechanism and automatic pancake preparation machine comprising same

PendingCN111657311ATurn overSmooth flipOil/fat bakingPancakes bakingEngineeringMechanical engineering

This application relates to an automatic cake overturning mechanism. The automatic cake overturning mechanism comprises supports, a first guide rail and a second guide rail; the supports are vertically arranged next to a griddle; the first guide rail and the second guide rail are horizontally installed on the supports in a vertical direction; the first guide rail is provided with an auxiliary rodperpendicular to the first guide rail; the auxiliary rod is glidingly connected with the first guide rail, so that the auxiliary rod can horizontally shift along the first guide rail and above the griddle; the second guide rail is provided with a mechanical arm; the tail end of the mechanical arm is equipped with a clamping jaw which can open and close; the clamping jaw is rotationally connected with the tail end of the mechanical arm, and an opening of the clamping jaw faces the surface of the griddle, so that the clamping jaw can clamp the edge of a pancake when closing; in the process thatthe mechanical arm horizontally shifts along the second guide rail, the clamping jaw can be driven to wind the pancake around the auxiliary rod, and during the horizontal shifting of the mechanical arm, the clamping jaw stretches the pancake to the edge of the griddle; and the edge of the pancake wound around the auxiliary rod is stretched to edge position of the other side of the griddle by the clamping jaw, thereby realizing overturning of the pancake.

Owner:北京味粒子科技有限公司

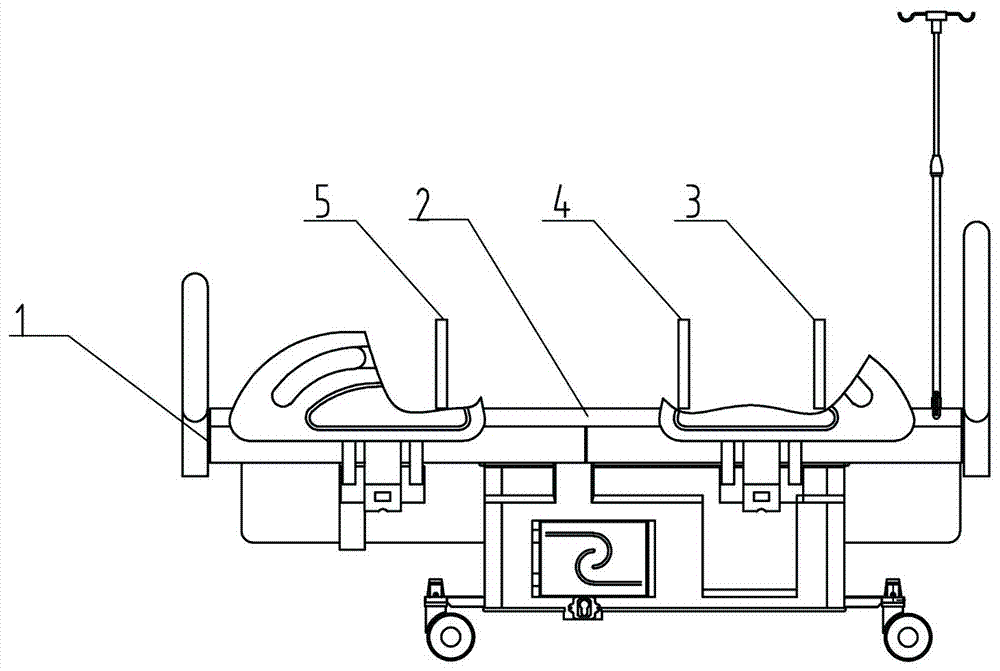

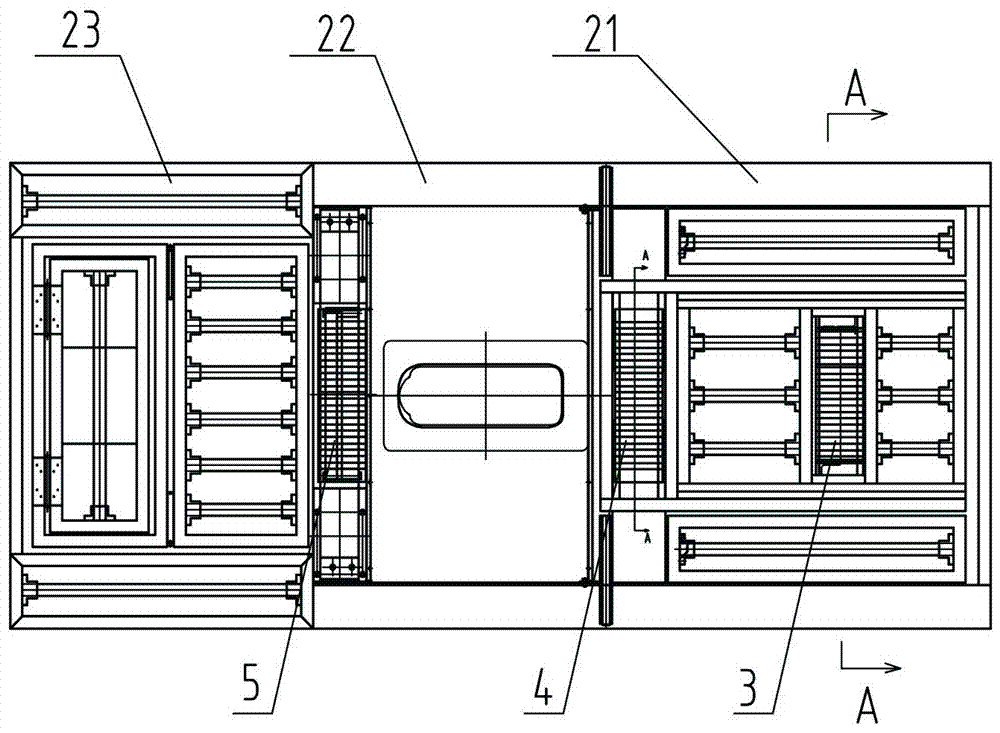

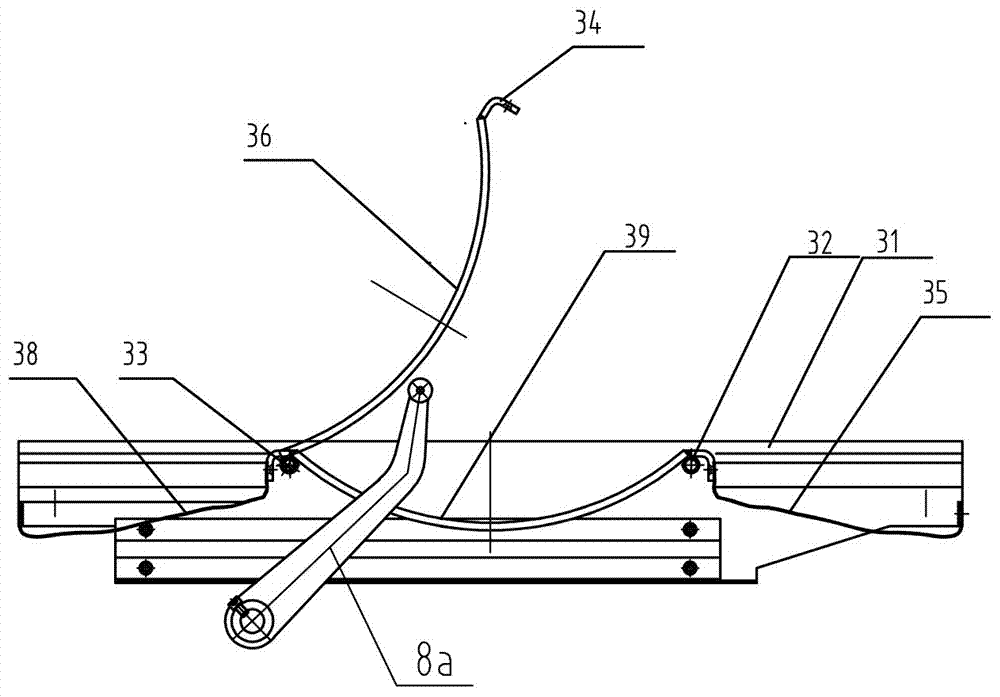

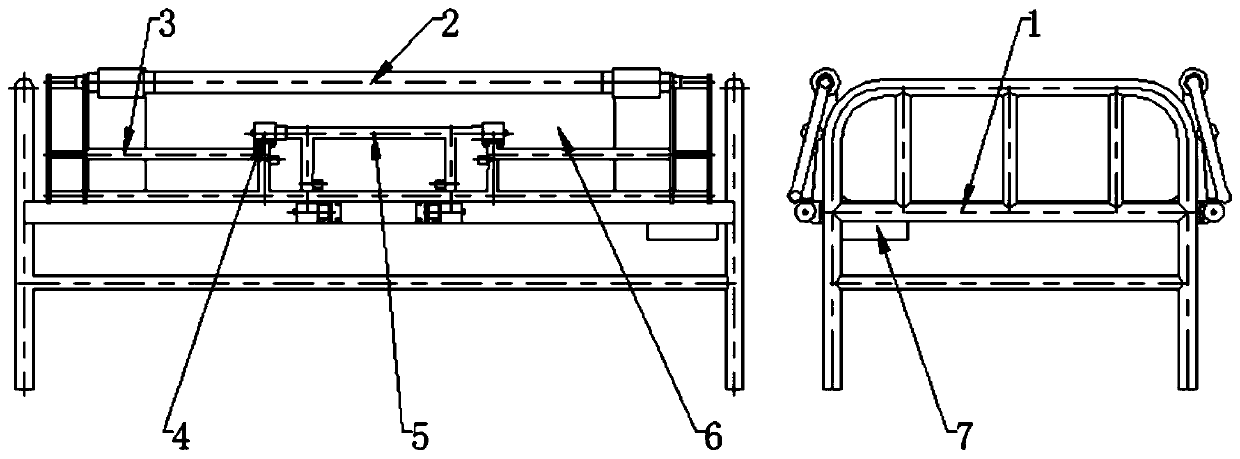

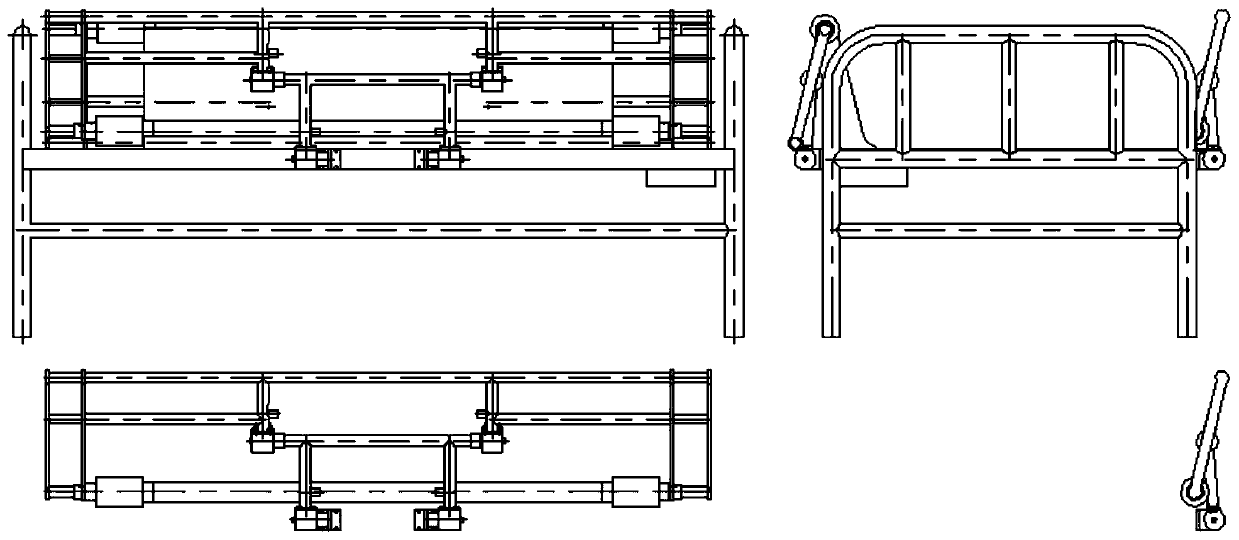

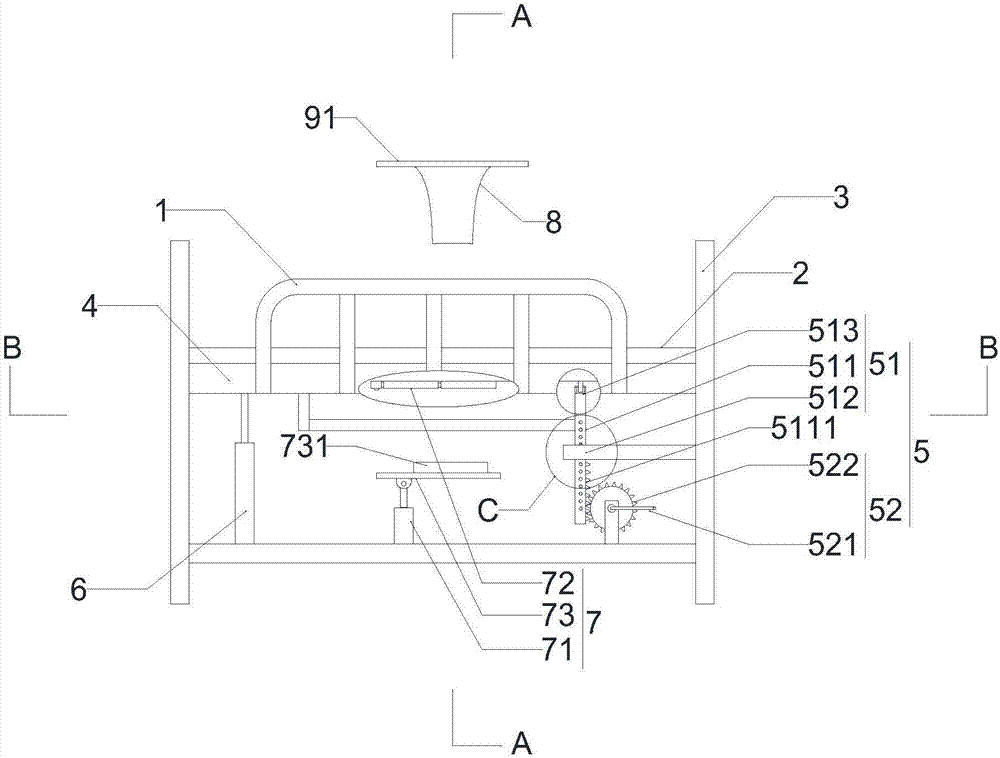

Turning-over system of nursing bed

InactiveCN107411905ATurn over coordinationPowerful turning overNursing bedsAmbulance serviceWhole bodyEngineering

The invention relates to a turning-over system of a nursing bed. The system comprises a back movable bed board, a middle bed board, a leg movable bed board and a bed frame and is characterized in that a shoulder turning-over component and a waist turning-over component are respectively arranged at the upper part and the lower part of the back movable bed board; a leg turning-over component is arranged at the upper part of the leg movable bed board; a driving mechanism used for driving the shoulder turning-over component, the waist turning-over component 4 and the leg turning-over component is arranged on a base plate of the bed. The turning-over system has the advantages that the three turning-over components can be rotated synchronously with the same angle by an electric push rod, so that a whole body is turned over on the nursing bed, therefore, a patient is more comfortable when in turning over of the body.

Owner:辽宁祥泽康养老产品制造有限公司

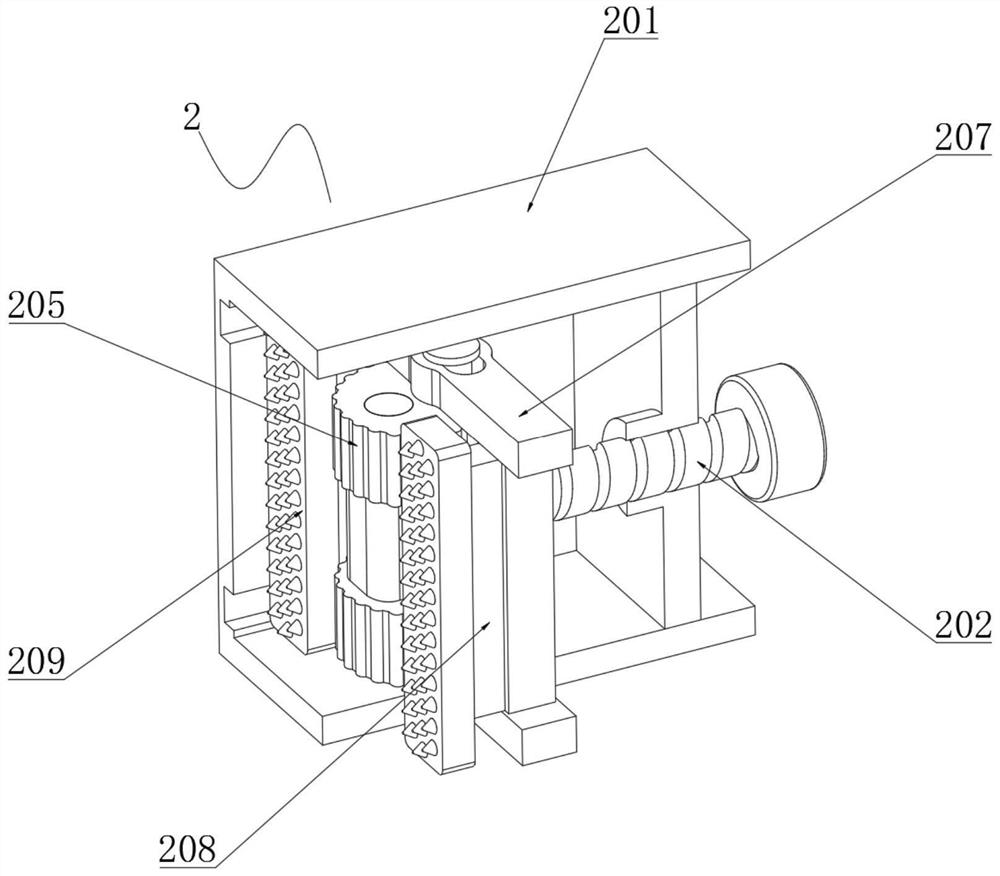

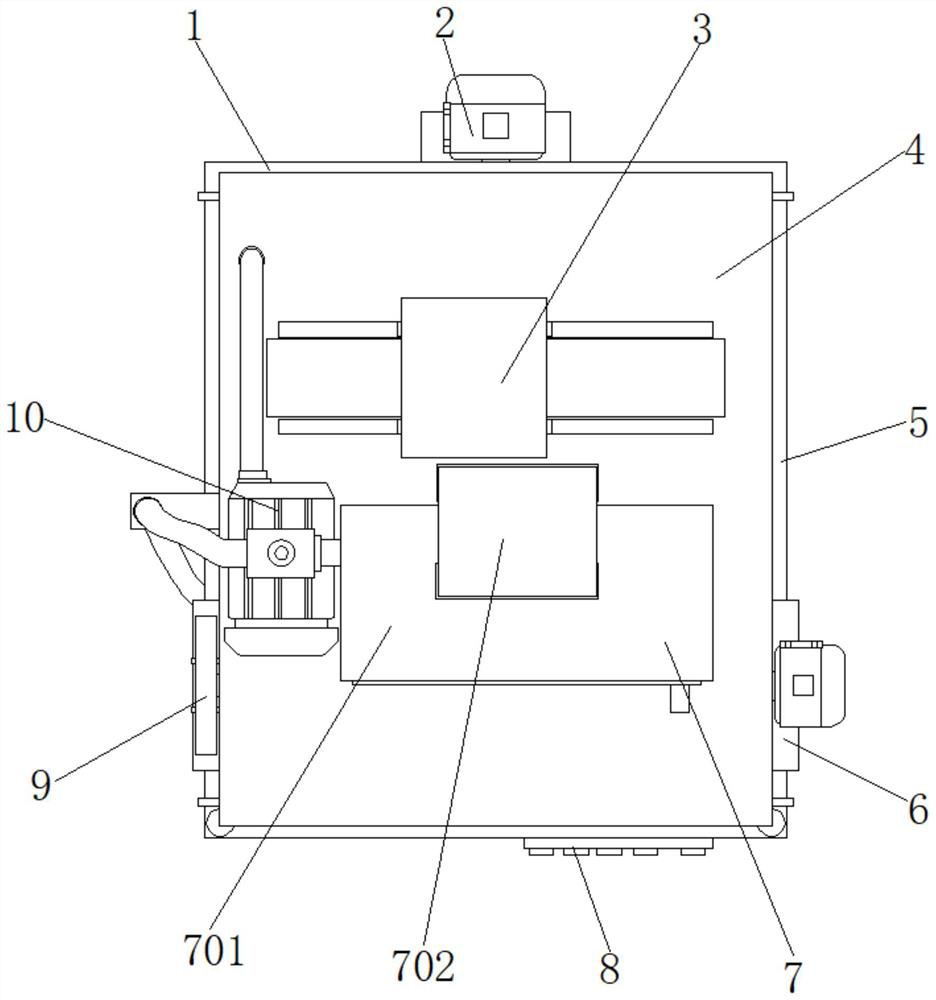

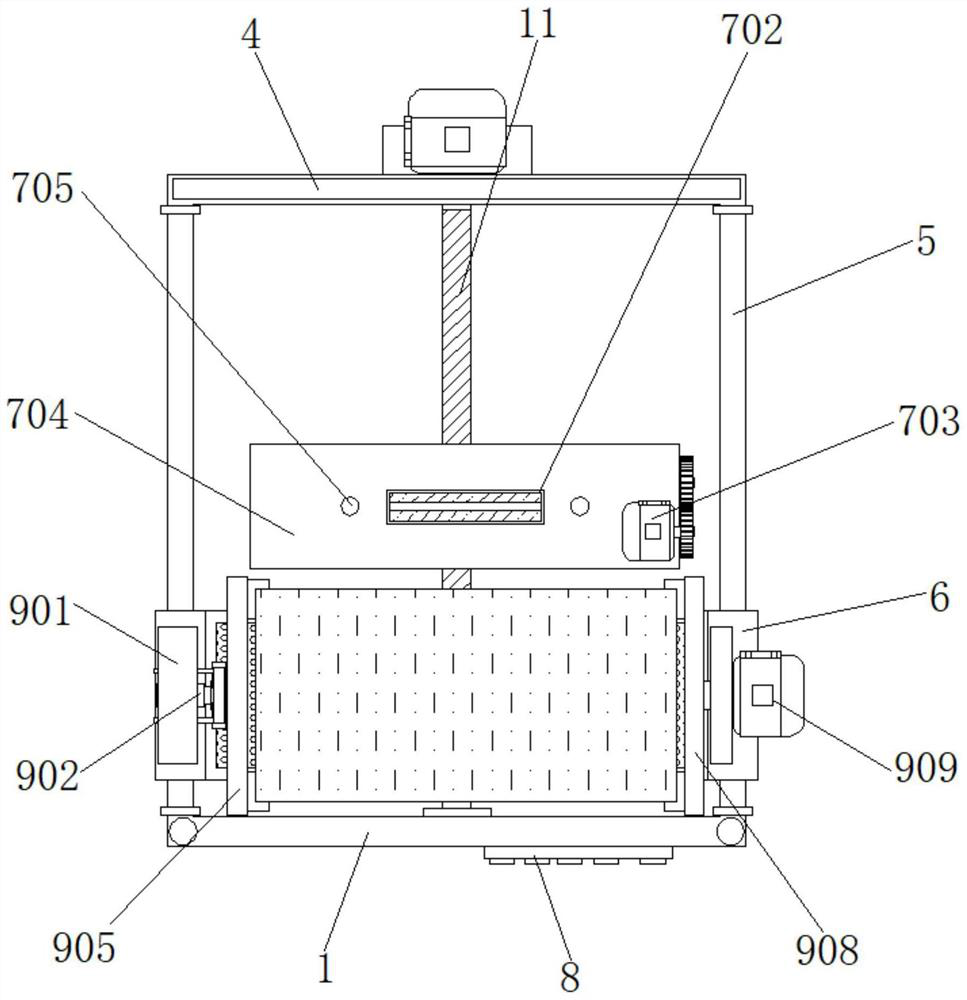

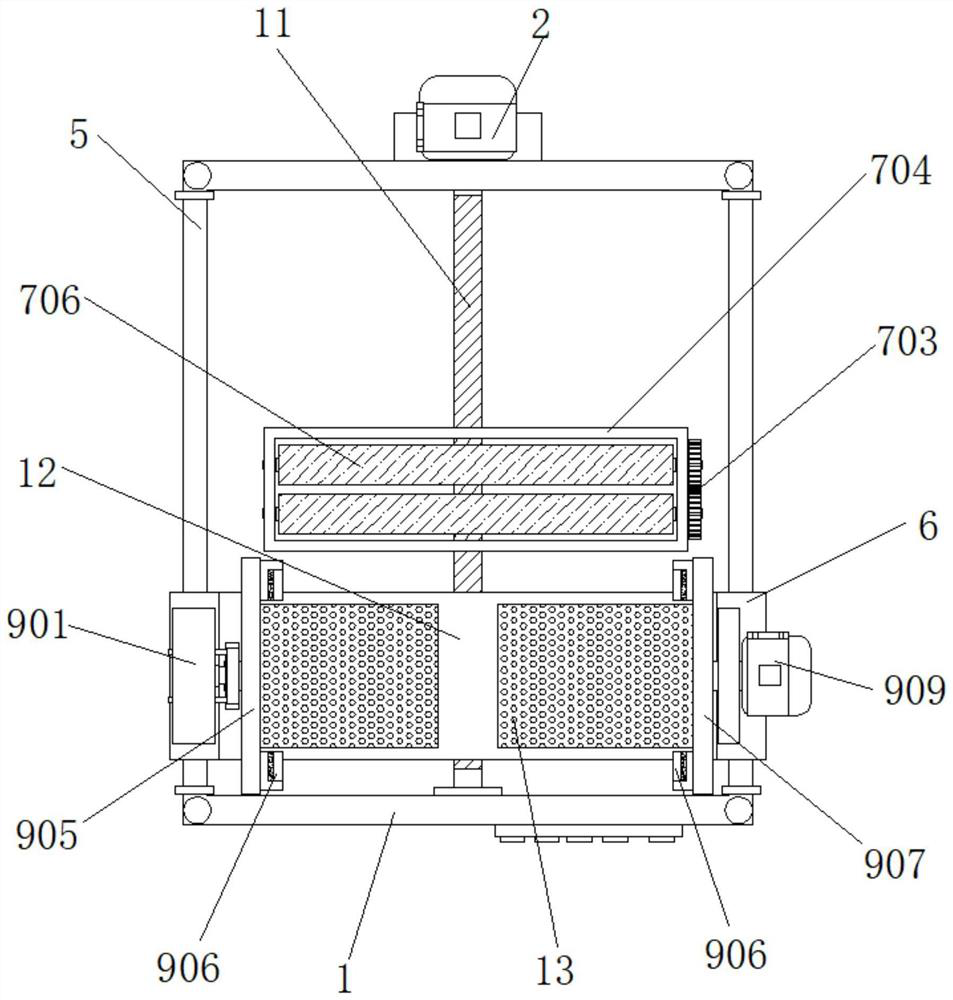

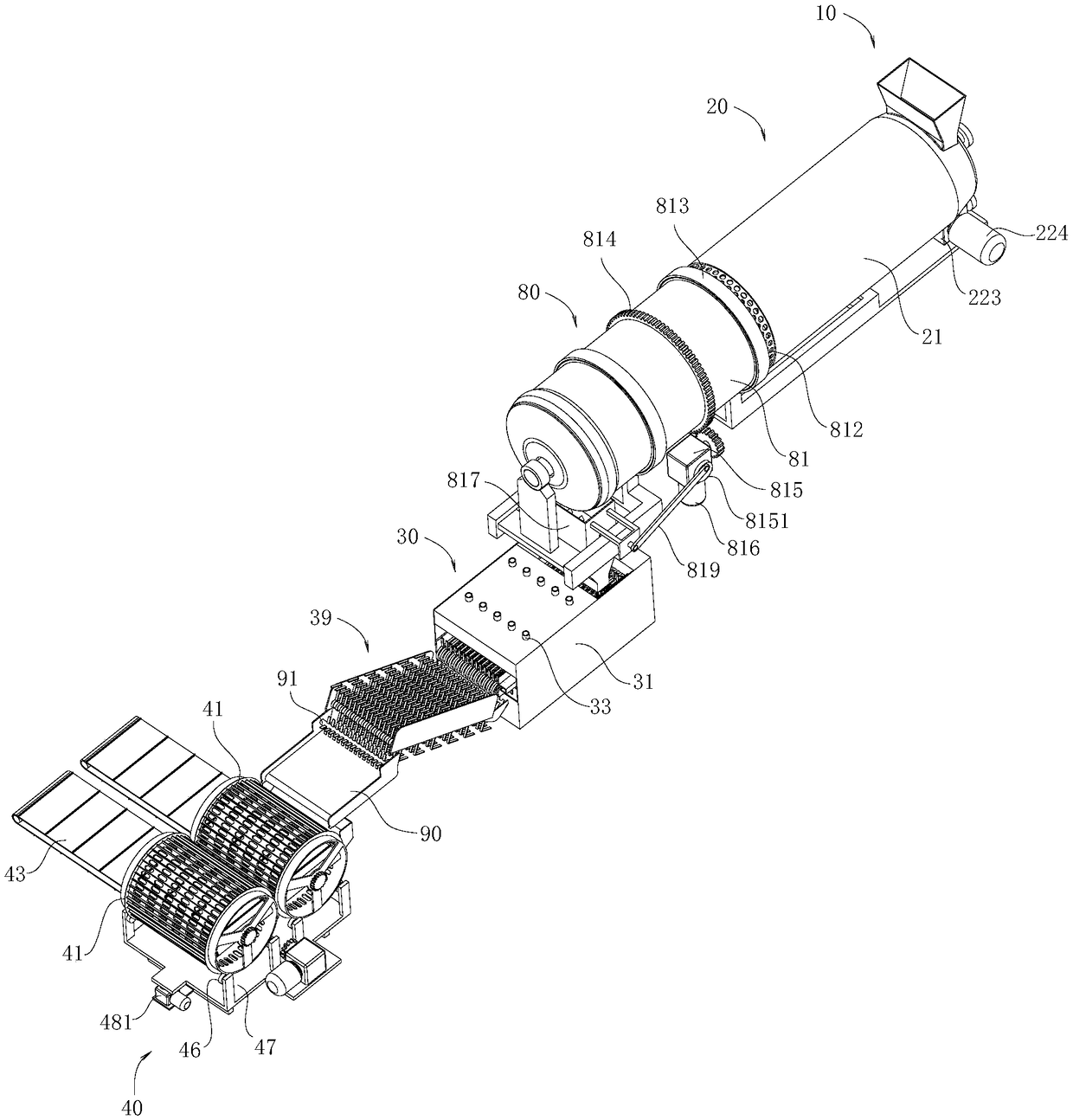

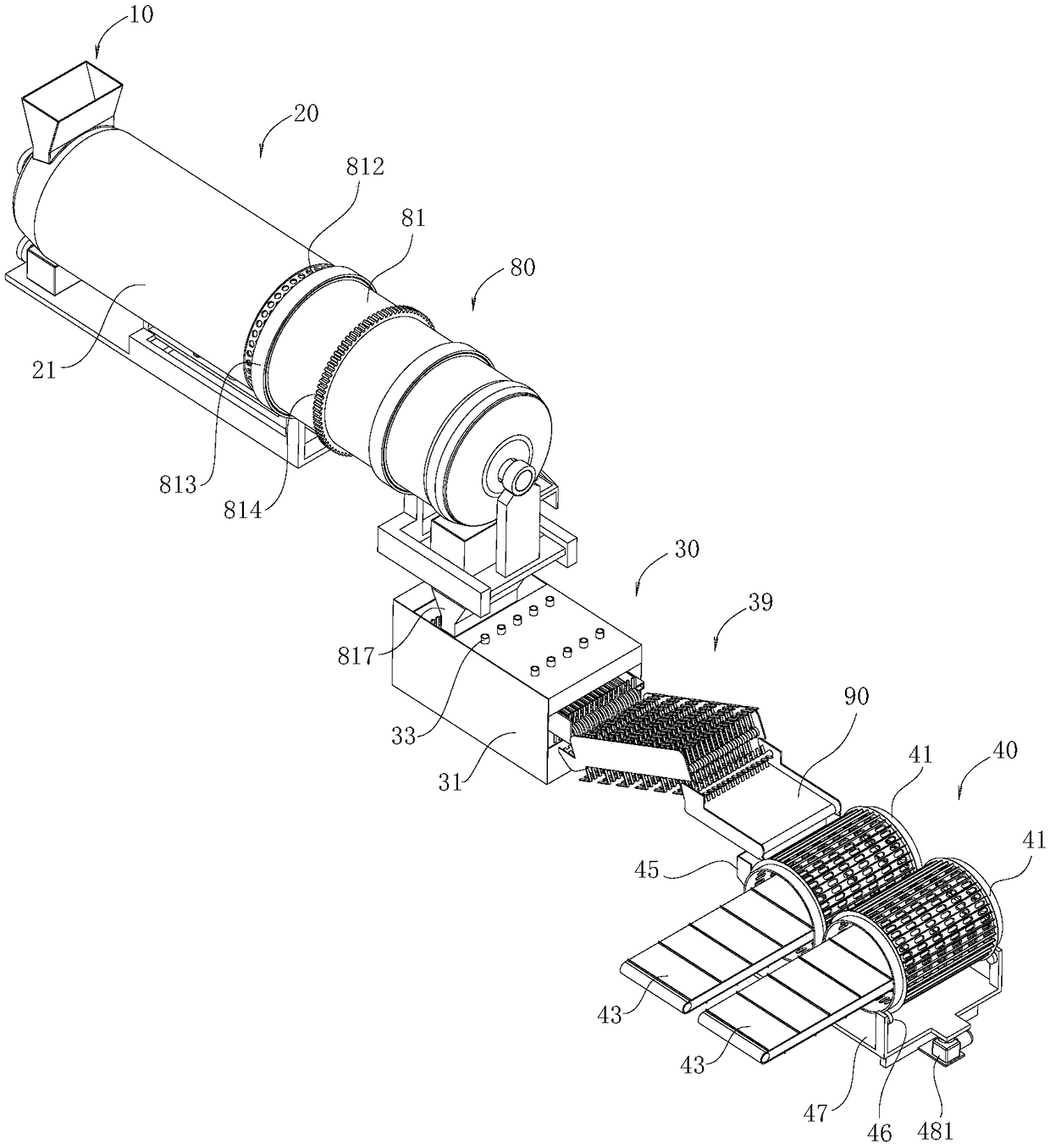

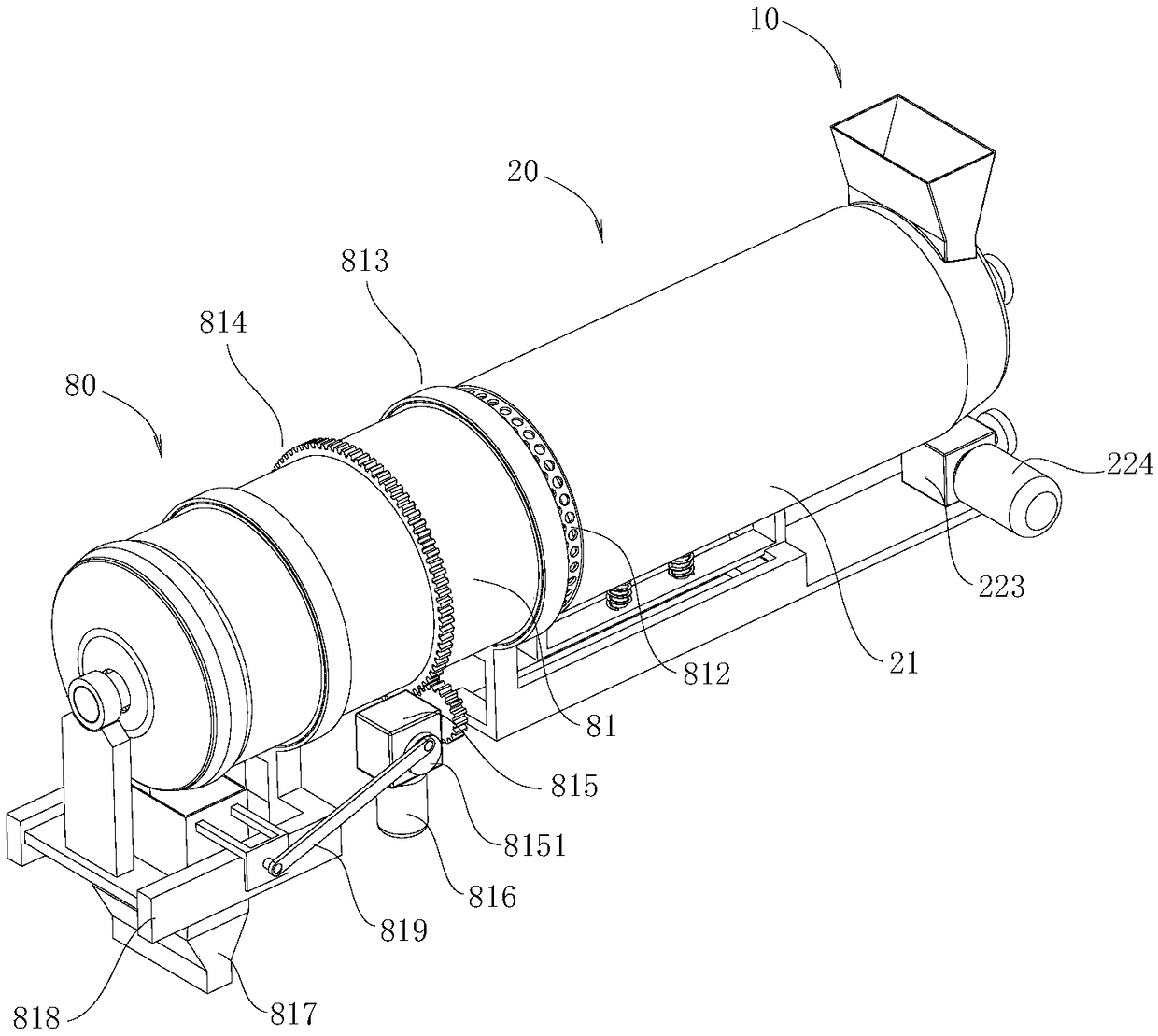

Secondary processing device for caking feed

ActiveCN112293772ASpeed up the sievingExcellent secondary processabilityFeeding-stuffDrying gas arrangementsProcess engineeringIdler-wheel

The invention relates to the technical field of feed processing, in particular to a secondary processing device for caking feed. The secondary processing device for the caking feed comprises a breaking barrel, a sieving box and a grinding barrel, wherein the front inner wall and the rear inner wall of the sieving box are independently provided with a horizontal cross bar; a rectangular frame is arranged above each horizontal cross bar; the lower surface of each rectangular frame is independently provided with idler wheels which move between left and right along a spacing groove; a sieving frame is arranged in each rectangular frame; the left end of the sieving frame and the rectangular frame are rotataly arranged; a first spring is connected between the right end of the sieving frame and the rectangular frame; and a screen mesh is arranged in the sieving frame. The whole device disclosed by the invention has an excellent secondary processing effect for the caking feed, the size of theprocessed feed can be guaranteed to be within a proper range, in addition, compared with the screening efficiency of a traditional screen mesh which is aslant arranged, the screening efficiency of thescreen mesh for feed discharged from the breaking barrel is higher, in addition, the caking feed which is not screened can be automatically added into the grinding barrel, and the secondary processing device disclosed by the invention has multiple functions, a high automation processing degree and an excellent secondary processing effect for the caking feed.

Owner:申亚生物科技股份有限公司

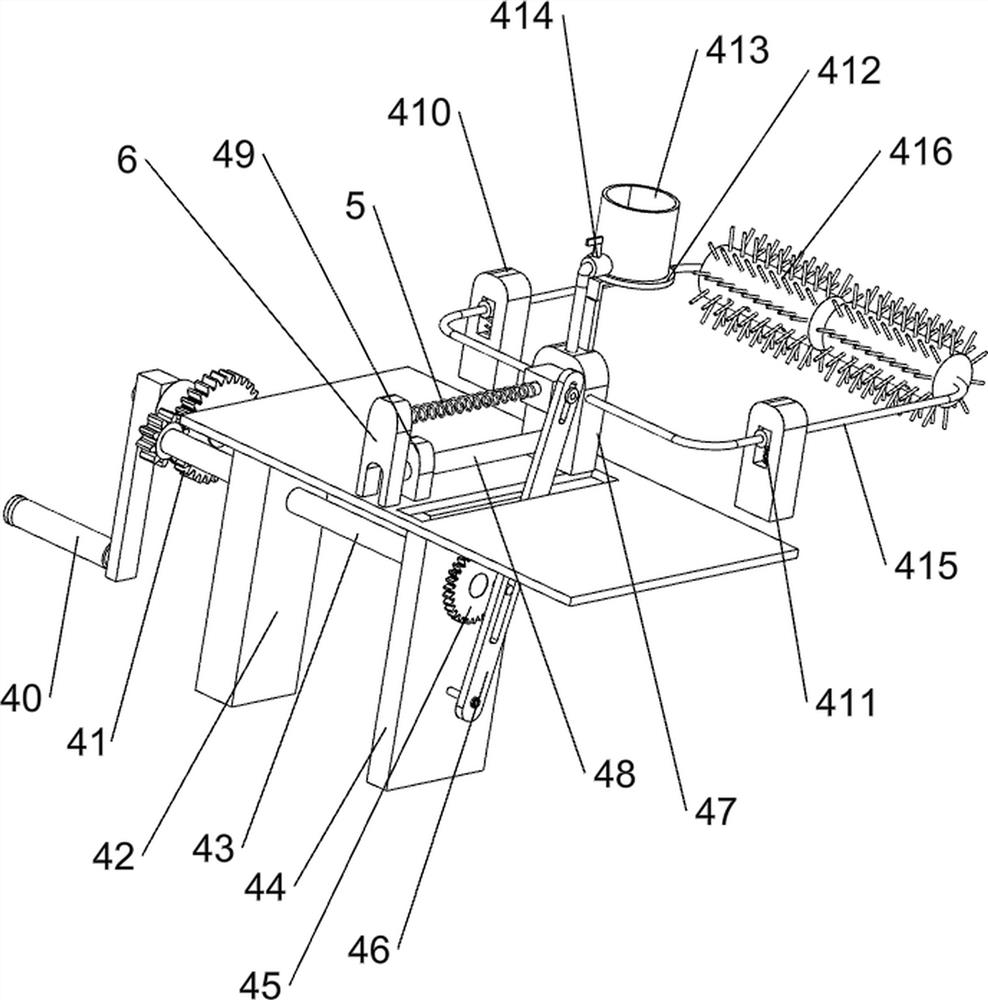

Hotpot condiment stir-frying device capable of conveniently detecting moisture content

The hotpot condiment stir-frying device comprises a supporting table, condiment containing pots and an L-shaped bearing beam, the condiment containing pots and the L-shaped bearing beam are fixedly installed on the two sides of the top face of the supporting table respectively, multiple sets of detection mechanisms used for detecting moisture are arranged in the condiment containing pots, and a pressure bearing frame rotating around a fixed axis is arranged in an inner cavity of each condiment containing pot; four bottom supporting columns distributed along the vertical center line of the material containing pot in a circumferential array mode are fixedly welded to the bottom face of the pressure bearing frame, and a mounting piece and a detection foot are sequentially and fixedly connected to the side, facing the center of the material containing pot, of each bottom supporting column; and a second motor is fixedly welded to the top face of one end of the bearing beam, a mounting frame is rotationally connected to the bottom face of the end of the bearing beam, two stir-frying mechanisms are symmetrically arranged below the mounting frame, and a driving assembly for adjusting the positions of the stir-frying mechanisms is further arranged on the bearing beam. According to the hotpot condiment stir-frying device capable of conveniently detecting the moisture content, condiments at all positions in the condiment containing pot are stir-fried more uniformly.

Owner:四川合合谷食品有限公司

Field manual barbecue device

The invention relates to a barbecue device, in particular to a field manual barbecue device. According to the field manual barbecue device, oil can be automatically smeared on food, the food can be turned over, and people can conveniently add seasonings to the food. The field manual barbecue device comprises a base support, a transmission mechanism arranged on the right front side of the base support, a seasoning mechanism arranged on one side, close to the transmission mechanism, of the base support, and a hand-cranking mechanism arranged in the middle of the upper portion of the base support; and components of the hand-cranking mechanism are matched with components of the transmission mechanism. Under the cooperation of the transmission mechanism, the seasoning mechanism, the hand-cranking mechanism, a third spring and a spring fixing block, people can turn over food conveniently during barbecuing, barbecue seasoning is added to the food, oil is brushed to the food, and people can bake the food more conveniently.

Owner:蔡亮

Circuit board processing table

ActiveCN106358371AReduce processing timeEasy to process on both sidesPrinted circuit manufactureRolloverEngineering

The invention discloses a circuit board processing table comprising a fixing frame, a moving frame, tray platforms, first driving mechanism, and second driving mechanism. Installed on the fixing frame, the moving frame comprises first side frame, second side frame, third side frame and fourth side frame connected from end to end in order. The first side frame, second side frame, third side frame and fourth side frame are installed with first clamping mechanism second clamping mechanism, third clamping mechanism and fourth clamping mechanism respectively inside; the first clamping mechanism second clamping mechanism, third clamping mechanism and fourth clamping mechanism comprise driving units mounted on the moving frame and clamping heads driven by the driving units to fore and aft motion; the tray platforms are arranged inside the first side frame, second side frame, third side frame and fourth side frame in a longitudinal way; the first driving mechanism is used for driving the moving frame to rotate; the second driving mechanism is used for driving the tray platforms to move upward an downward. The circuit board processing table realizes automatic circuit board clamping and rollover.

Owner:蚌埠市勇创机械电子有限公司

Steel turning device

ActiveCN102248089ATurn overReasonable structureMetal-working feeding devicesPositioning devicesHydraulic cylinderEngineering

The invention discloses a steel turning device and is characterized in that a turning mechanism which is arranged on a base comprises a pair of upright rollers which are arranged face to face, each roller is arranged at the upper end part of a vertical shaft and in rolling fit with the vertical shaft, each vertical shaft is arranged inside a guide sleeve, a first hydraulic cylinder is connected at the lower end of each guide sleeve, the piston rods of the first hydraulic cylinders are connected at the lower ends of the vertical shafts, a driving arm and the upper ends of a pair of connecting rods are hinged on the two sides of each guide sleeve, and each driving arm and the lower end of each connecting rod are hinged with the base; each guide sleeve combines with the base and driving arm and connecting rod which are hinged with the guide sleeve, to form a parallelogram four-link mechanism; and two second hydraulic cylinders are fixed on the two sides of the frame respectively, and thepiston rods of the two second hydraulic cylinders are hinged with two driving arms respectively. When a steel material passes through the space between the pair of rollers, the driving arms are pushed upwards by the two second hydraulic cylinders, so that the rollers move in the opposite direction to closely clamp the steel material, and then the rollers are driven by the two first hydraulic cylinders to reversely move in the vertical direction, as a result, the steel material is turned.

Owner:浩中机械(蚌埠)有限公司

Bridge swivel control system based on Beidou navigation system and application method thereof

PendingCN112411393AAutomate monitoringRealize informatizationMeasurement devicesBridge erection/assemblyControl systemStructural engineering

The invention belongs to the field of bridge construction, and particularly relates to an application method of a bridge swivel control system based on a Beidou navigation system, and the control system comprises a Beidou signal receiver, a control machine and a deviation rectification driver. The application method of the control system comprises the following steps: 1) setting an early warning threshold value and a deviation rectification value of a pier deflection angle; 2) starting the control system; 3) starting to rotate; 4) monitoring the swivel progress; 5) giving an alarm; 6) reducingthe pier deflection angle; 7) stopping alarming; and 8) ending swivel. The system is used for realizing automatic monitoring, automatic deviation correction and automatic stalling in the bridge swivel construction process, so that informatization of a construction site can be embodied, and the safety supervision efficiency of the construction site is remarkably improved.

Owner:中铁二十二局集团第一工程有限公司 +1

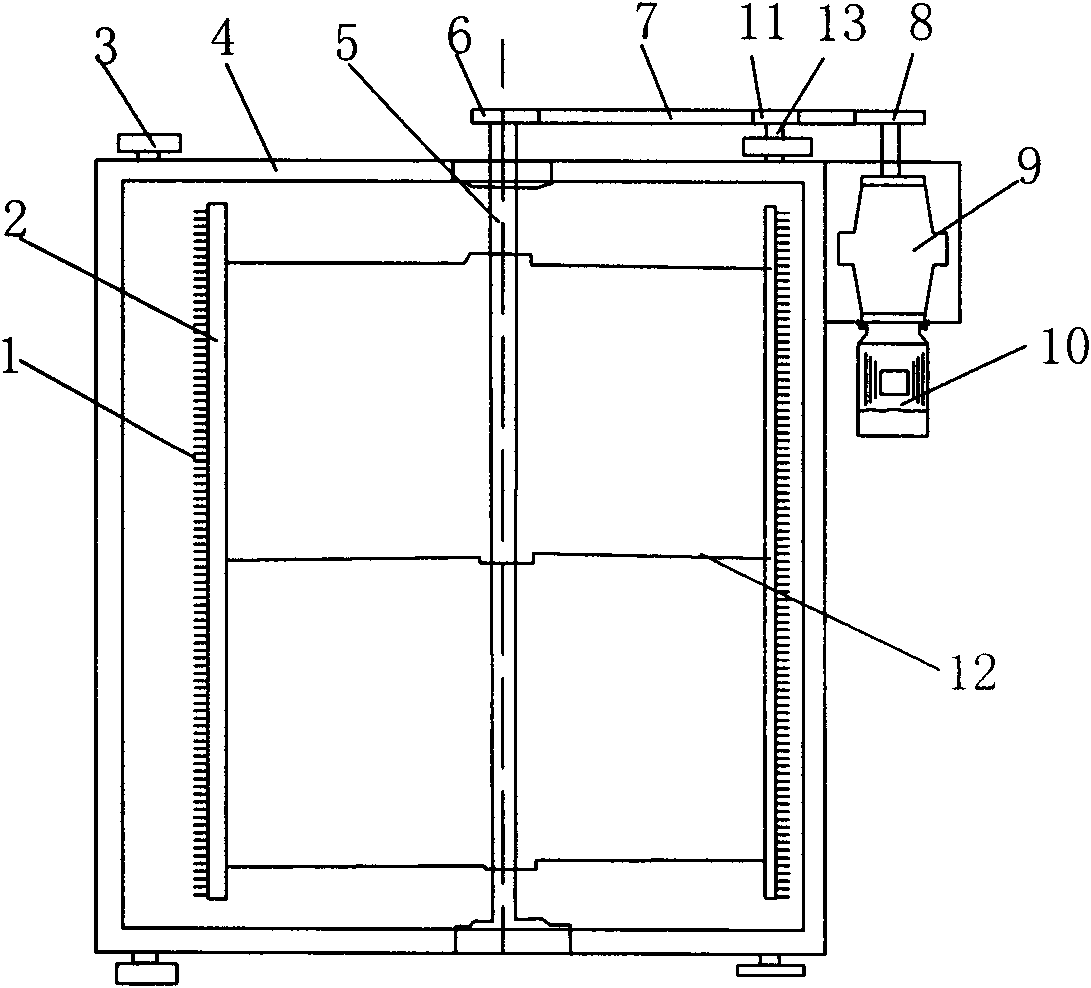

Motor rotor paint dipping device and using method thereof

ActiveCN111934504AEasy to impregnatePrevent fallingManufacturing dynamo-electric machinesElectric machineStructural engineering

The invention discloses a motor rotor paint dipping device. The motor rotor paint dipping device comprises a fixed base and a motor rotor body, and the top of the fixed base is fixedly connected withtwo symmetrically-arranged supporting columns. The tops of the sides, close to each other, of the two supporting columns are fixedly connected with the same first mounting plate; an air drying assembly used for air drying of the motor rotor body is arranged at the bottom of the first mounting plate, a paint dipping box is fixedly connected to the top of the fixed base, and a steering assembly usedfor turning over the motor rotor body and a paint supplementing assembly used for supplementing paint to the paint dipping box are placed on one side of the paint dipping box. The present invention further discloses a using method. The beneficial effects of the motor rotor paint dipping device and the using method thereof are that: through clamping of a placement assembly, motor rotors of different specifications can be subjected to paint dipping at the same time, then paint dipping operation is achieved through the lifting assembly, after paint dipping is completed, air drying is conducted through the air drying assembly, overturning is conducted through a steering assembly, the two faces of each motor rotor can be air-dried, efficiency is improved, the workload of workers is reduced, operation is convenient, and practicability is high.

Owner:绍兴市希多电机有限公司

Spraying device for automobile aluminum alloy hub

ActiveCN111715429AAvoid pollutionAvoid artificial flangingLiquid spraying apparatusElectric machineryStructural engineering

The invention discloses a spraying device for an automobile aluminum alloy hub. The spraying device comprises a base, wherein a motor I is fixedly connected to the upper side wall of the base, an L-shaped connecting plate is fixedly connected to the driving end of the motor I, and a telescopic rod I is fixedly connected to the end part of the connecting plate; a transverse plate is fixedly connected to the inner wall of the connecting plate, two rotating plates are rotationally connected to the side, away from the telescopic rod I, of the transverse plate, and arc-shaped plates are rotationally connected to the end parts of the rotating plates; and connecting rods are rotationally connected between the outer wall of the driving end of the telescopic rod I and the two rotating plates, a telescopic rod II is fixed to the inner bottom wall of the base, and the driving end of the telescopic rod II is vertically, downwards and fixedly connected with a supporting plate located on the lower sides of the two arc-shaped plates. According to the spraying device for the automobile aluminum alloy hub, by arranging a semicircular cover, environmental and equipment pollution caused by material flying out during spraying is avoided, and a clamped hub is driven to turn over through rotation of the motor I, so that spraying work on the two faces of the hub is achieved, and manual edge turnoveris avoided.

Owner:山西同誉金属材料科技有限公司

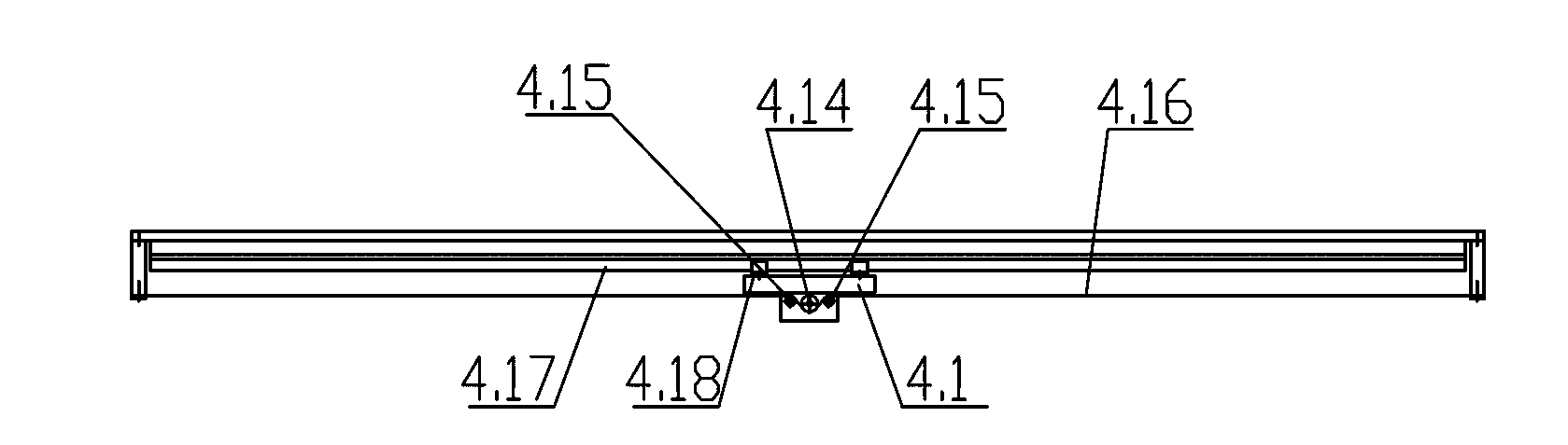

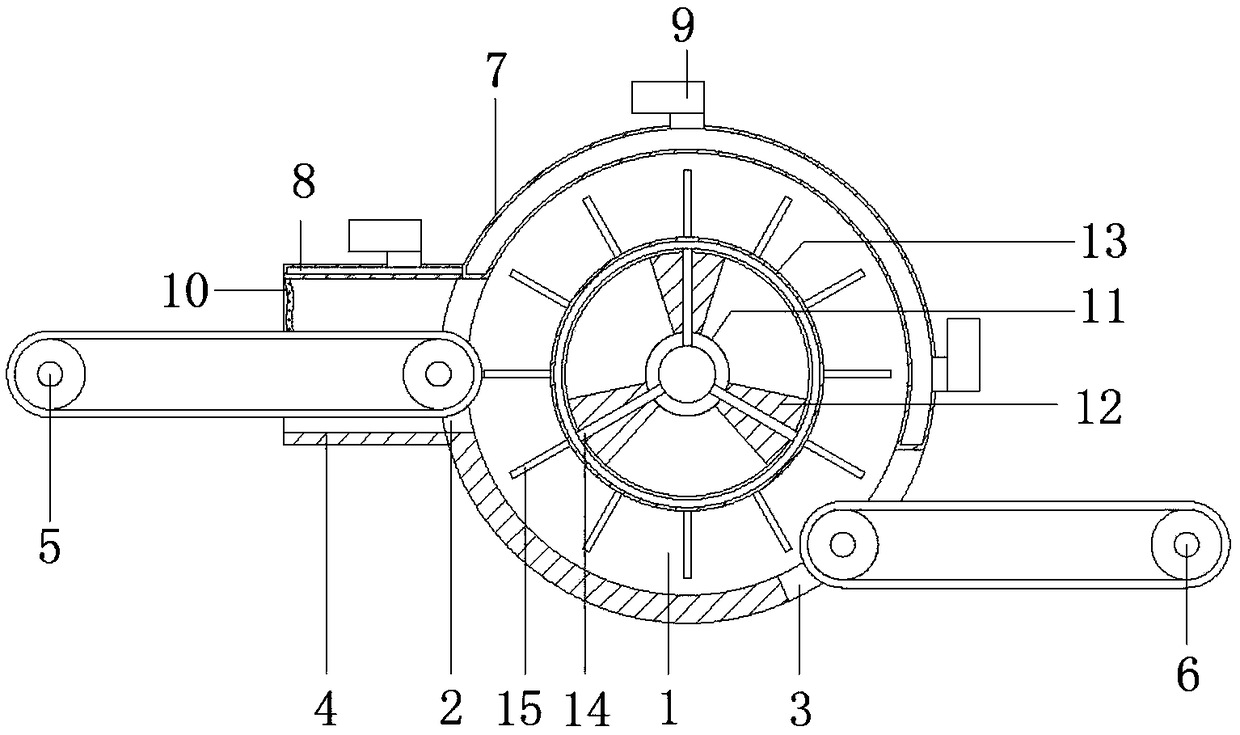

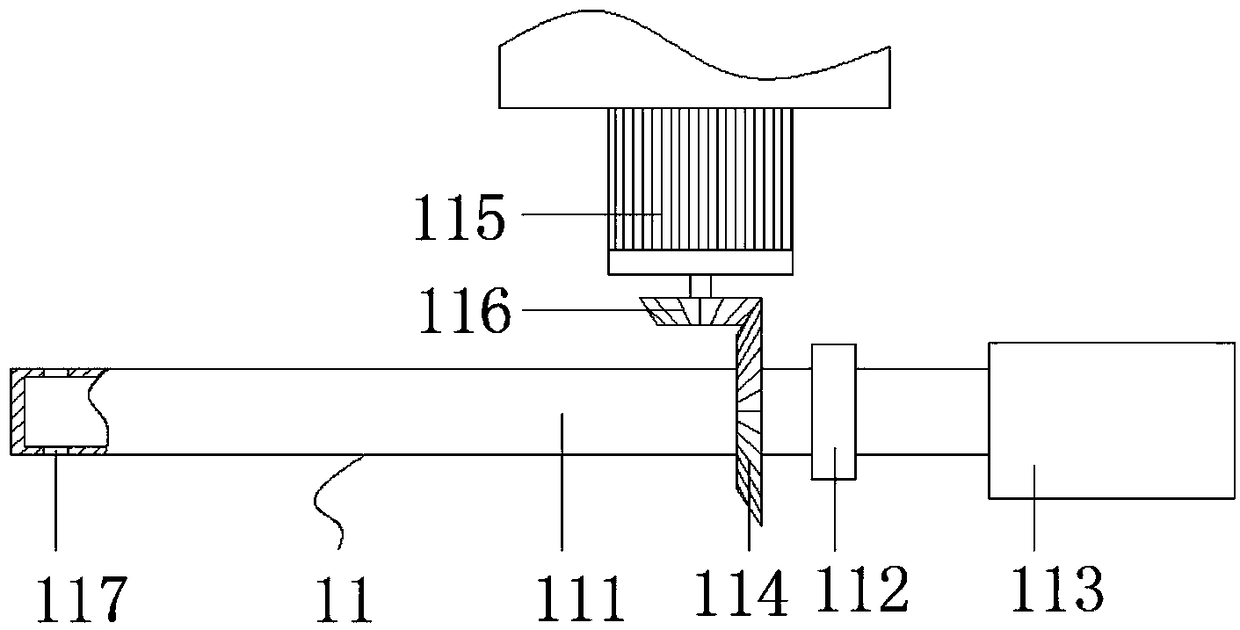

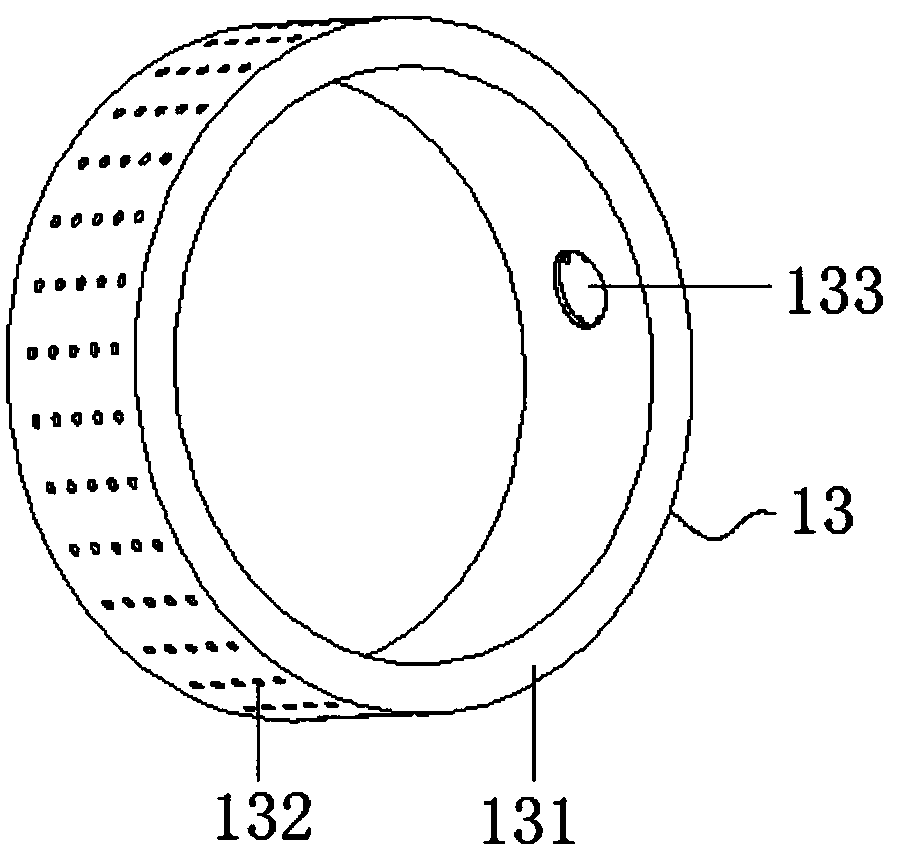

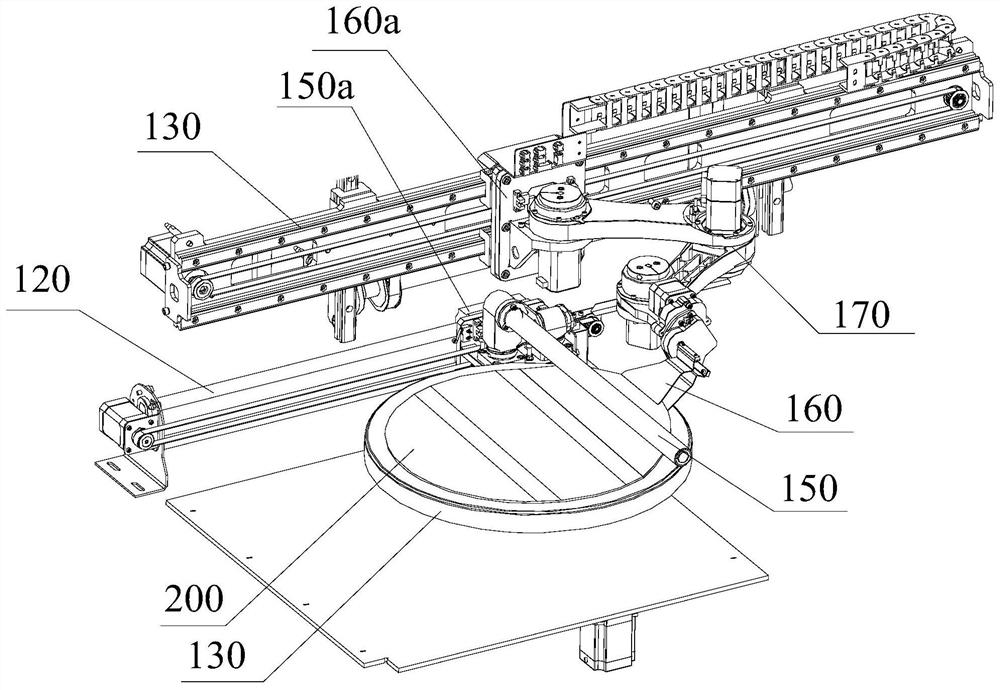

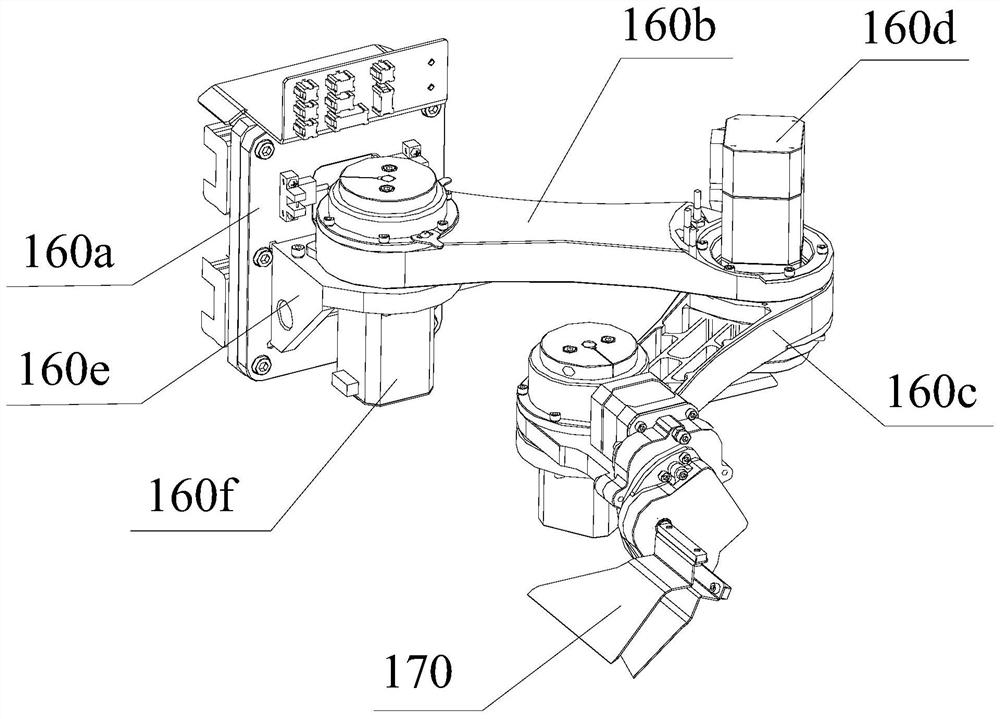

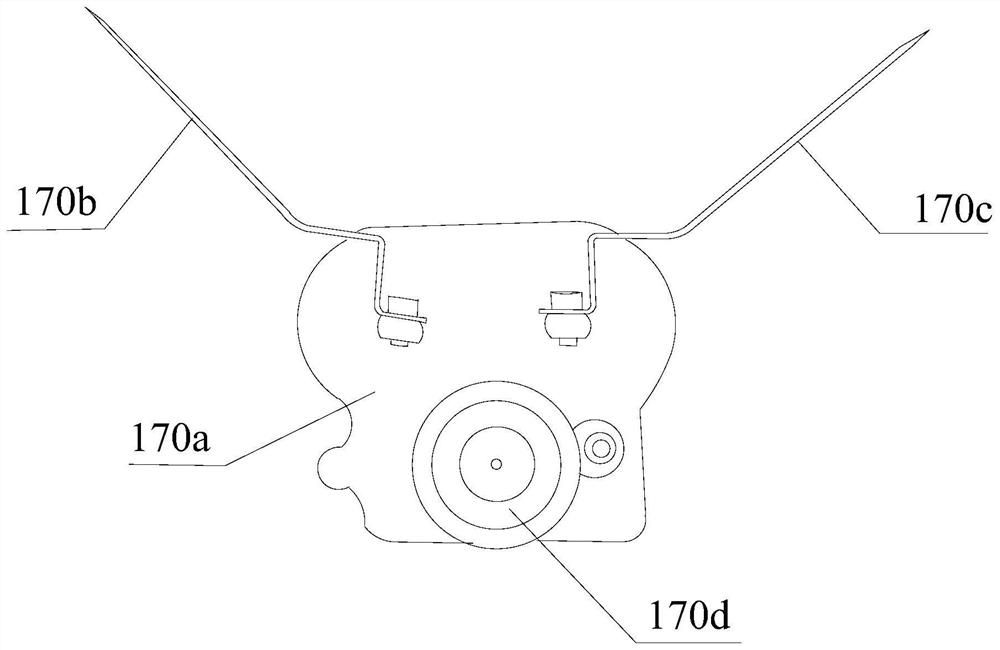

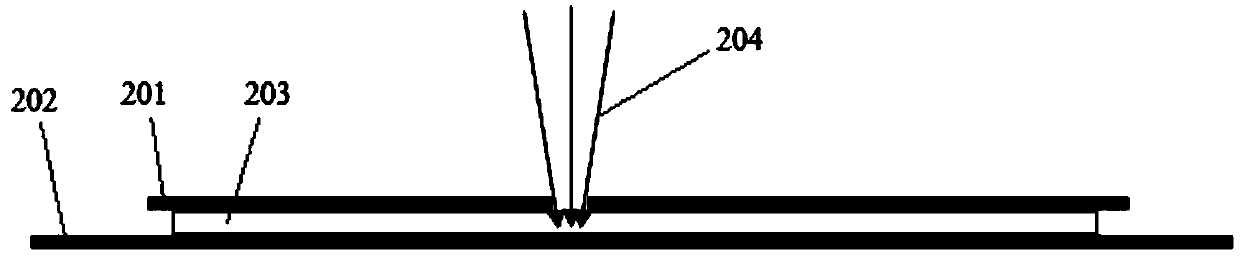

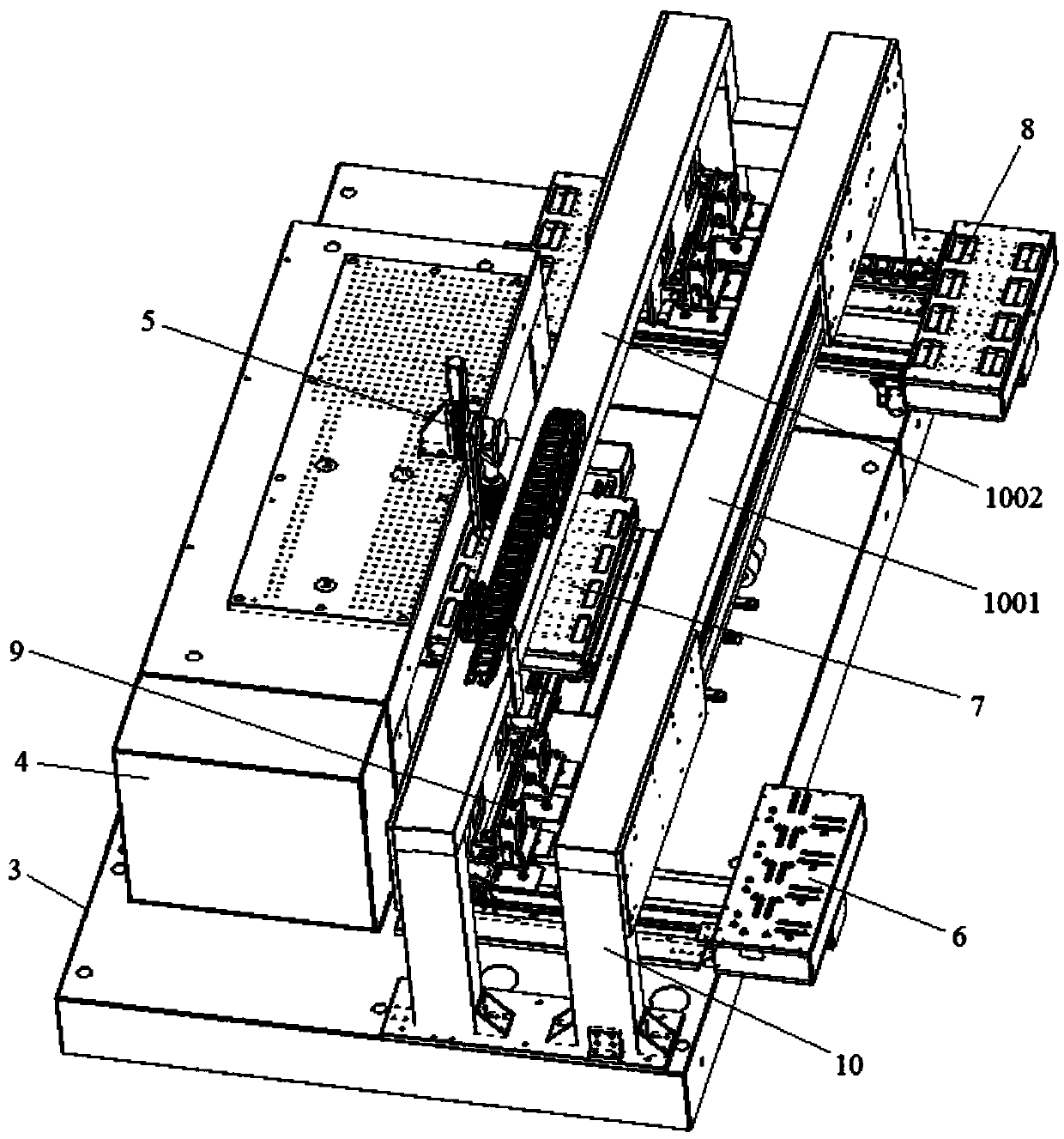

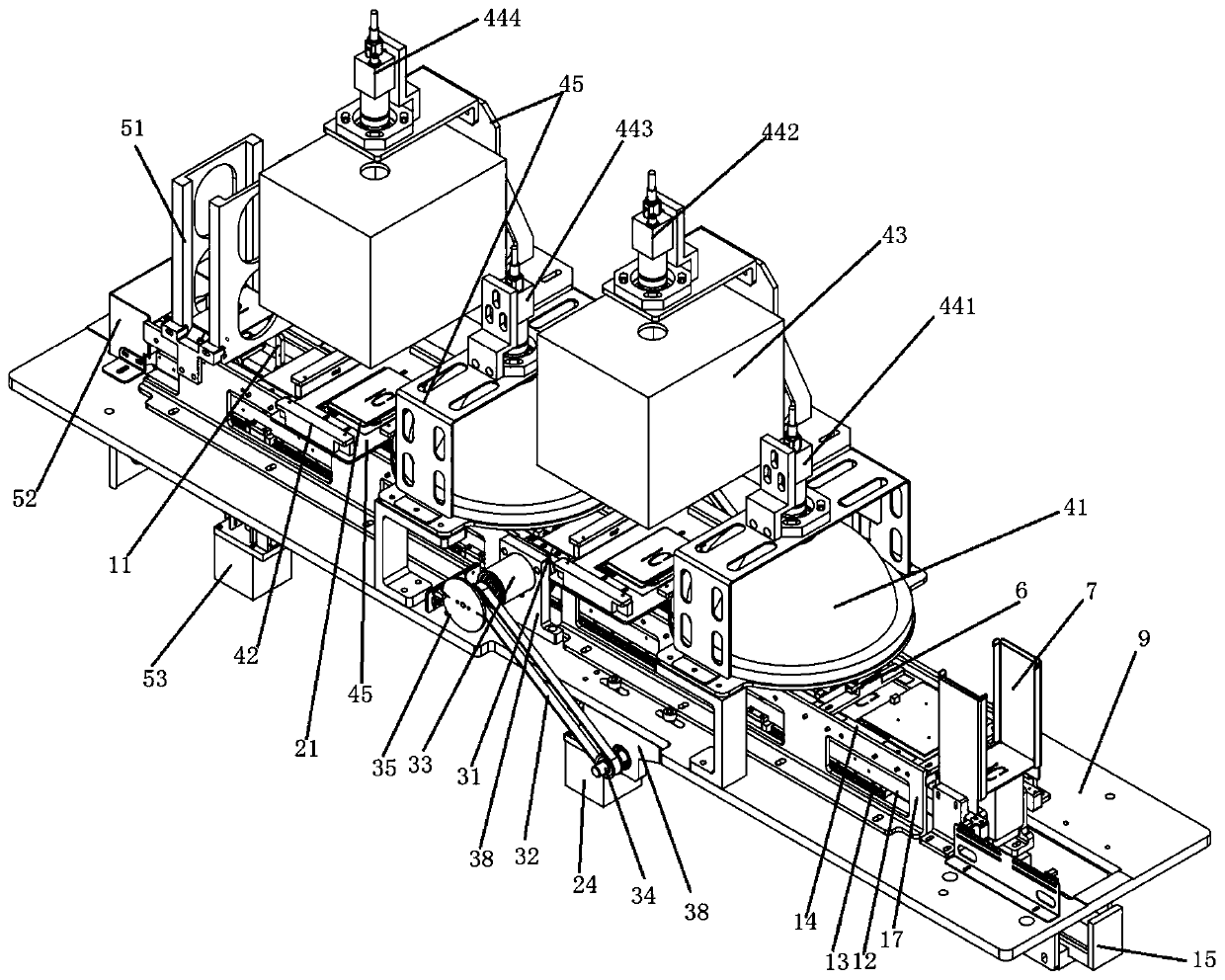

Device and method for laser processing of double-sided display screen

The invention discloses a device and method for laser processing of a double-sided display screen. The device comprises a base, a control system and optical equipment for processing the display screen; feeding equipment, processing equipment and discharging equipment are sequentially arranged on the base at intervals; a laser cutting head of the optical equipment is located above the processing equipment; a fixing frame stretching across the feeding equipment, the processing equipment and the discharging equipment is arranged on the base; overturning and moving equipment is arranged on the fixing frame; the control system is used for controlling the overturning and moving equipment to overturn the display screen and move the display screen, is used for controlling the optical equipment toprocess the display screen, is used for controlling the feeding equipment to perform feeding, is used for controlling the discharging equipment to perform discharging and is used for controlling the processing equipment to move to be aligned to the optical equipment. The moving equipment capable of performing overturning is arranged, all that is required for overturning of the display screen is toincrease two groups of rotating shafts on the fixing frame, additional stations are not required to be increased, the equipment size is not required to be increased, and the device is easy to operate.

Owner:WUHAN LINGYUN PHOTOELECTRONICS SYST

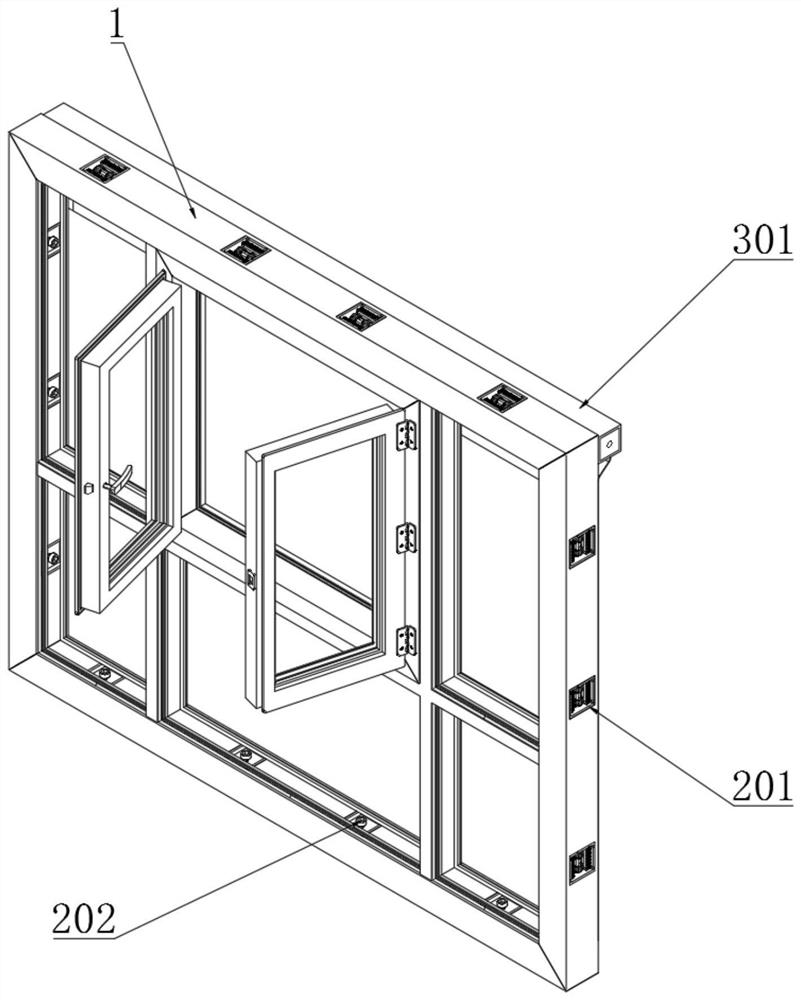

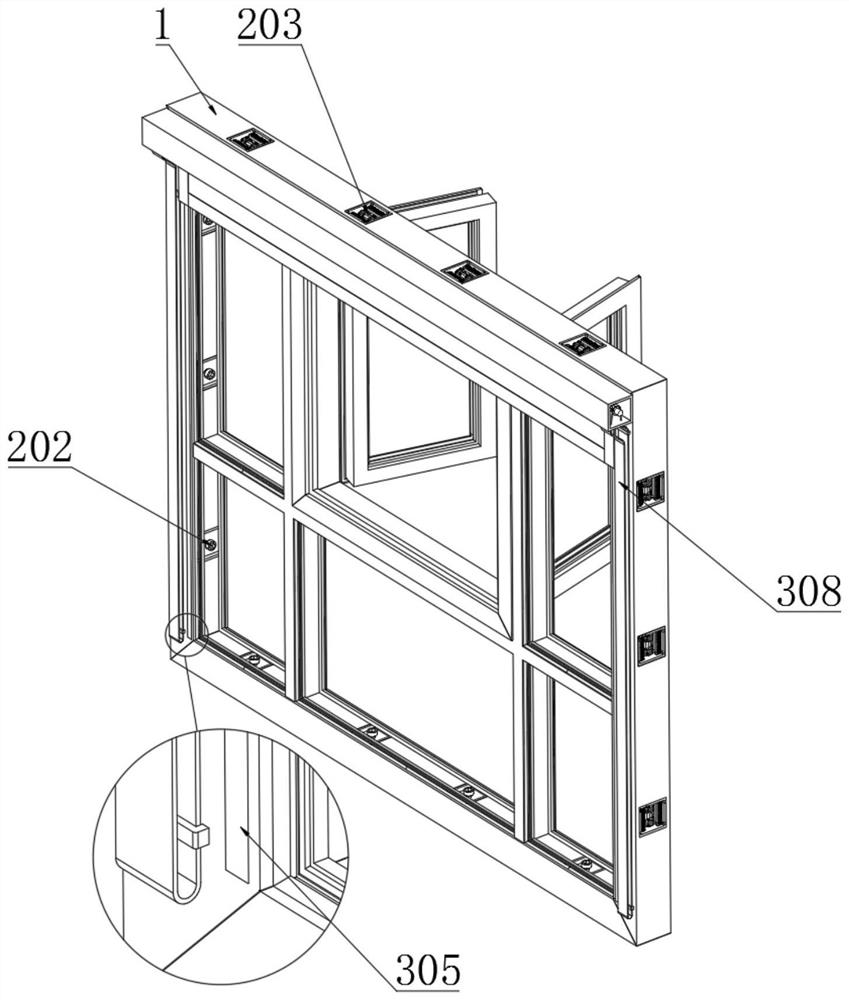

Convenient-to-assemble carved pattern type aluminum alloy door window

ActiveCN111691789AScientific and reasonable structureEasy to useFrame fasteningLight protection screensScrew threadSealant

The invention discloses a convenient-to-assemble carved pattern type aluminum alloy door window. The convenient-to-assemble carved pattern type aluminum alloy door window comprises an aluminum alloy window frame main body, four sides of the aluminum alloy window frame main body are all internally embedded with an assembling box, a middle part of one side of each assembling box is connected with anassembling bolt through a screw thread, one end of the assembling bolt is rotationally connected with a driving block at a position corresponding to an inner side of the assembling box, middle partsof two ends of the driving block both are rotationally connected with an assembling shaft, and eccentric assembling wheels are fixedly connected at positions, corresponding to two sides of the drivingblock, of an external side of the assembling shaft. According to the convenient-to-assemble carved pattern type aluminum alloy door window, by rotating the assembling bolt, the driving block, the assembling shaft and the eccentric assembling wheel are driven to move towards outside of the assembling box, after a side face of the eccentric assembling wheel and a wall are clamped together tightly,a gap between the aluminum alloy window frame main body and the wall is filled with sealant, thus, assembling of the aluminum alloy window frame is completed, an assembling process of the aluminum alloy window frame is optimized, and the aluminum alloy window frame can be assembled more simply and conveniently.

Owner:广东新伟信实业有限公司

Furniture production process based on paulownia wood material and intelligent production line

ActiveCN114030049AReduce the level of pollutionKeep healthyDispersed particle filtrationGrinding drivesWood dryingGrinding

The invention discloses a furniture production process based on paulownia wood and an intelligent production line, and is characterized in that the furniture production process comprises the following steps that firstly, specified paulownia wood is selected, the paulownia wood is cut into boards through a cutting device, and then the boards is dried in air for one to two days at normal temperature; and then the cut single wood boards are stacked in a layered mode and placed in corresponding wood drying machines, the drying temperature is controlled to be about 125 DEG C, and drying continues for two hours till the water content of the paulownia wood ranges from 10% to 15%. After the paulownia wood is placed in a first clamping groove and a second clamping groove, an electric push rod is controlled to extend, the paulownia wood is automatically and tightly clamped, then the surface of the wood is ground through a grinding and polishing assembly, after one face of the wood is ground, a second servo motor can be controlled to drive the wood to automatically and stably rotate by 180 degrees, the turning over of the paulownia wood is achieved, and the grinding treatment of the grinding and polishing assembly on the surface of the wood is facilitated.

Owner:徐夕华

Hard alloy screw cutting tool production raw material drying device

InactiveCN111457705ATurn overDry thoroughlyDrying gas arrangementsDrying chambers/containersAlloyCemented carbide

The invention belongs to the technical field of hard alloy screw cutting tool processing, in particular to a hard alloy screw cutting tool production raw material drying device. The hard alloy screw cutting tool production raw material drying device comprises a box body, a first conveyor belt and a second conveyor belt. A first through hole and a second through hole are separately formed in two side walls of the box body, the first conveyor belt and the second conveyor belt are separately mounted on two sides of an inner cavity of the box body, and the first conveyor belt and the second conveyor belt penetrate the first through hole and the second through hole separately and extend outside the box body. The hard alloy screw cutting tool production raw material drying device conveys a workpiece through the first conveyor belt and the second conveyor belt. In the conveying process, gas is blown to the surface of the workpiece to be dried through a first spray head and a second spray head. Meanwhile, the workpiece is limited by means of a limiting plate on the outer wall of a drum, so that the workpiece can be overturned to the surface of the second conveyor belt to be overturned, andtherefore, double sides can be dried, and the workpiece is dried more thoroughly.

Owner:扬州文丰机械制造有限公司

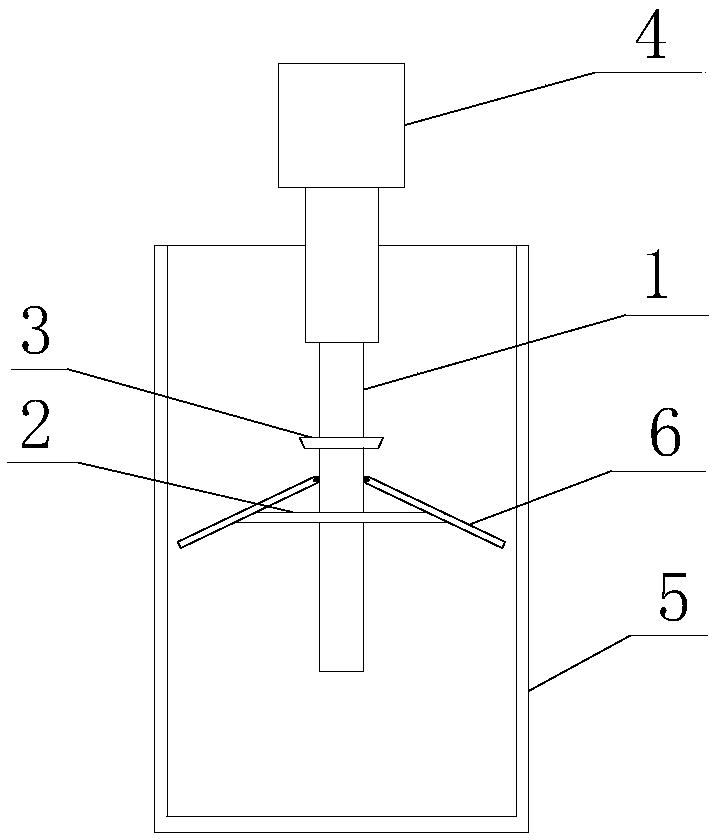

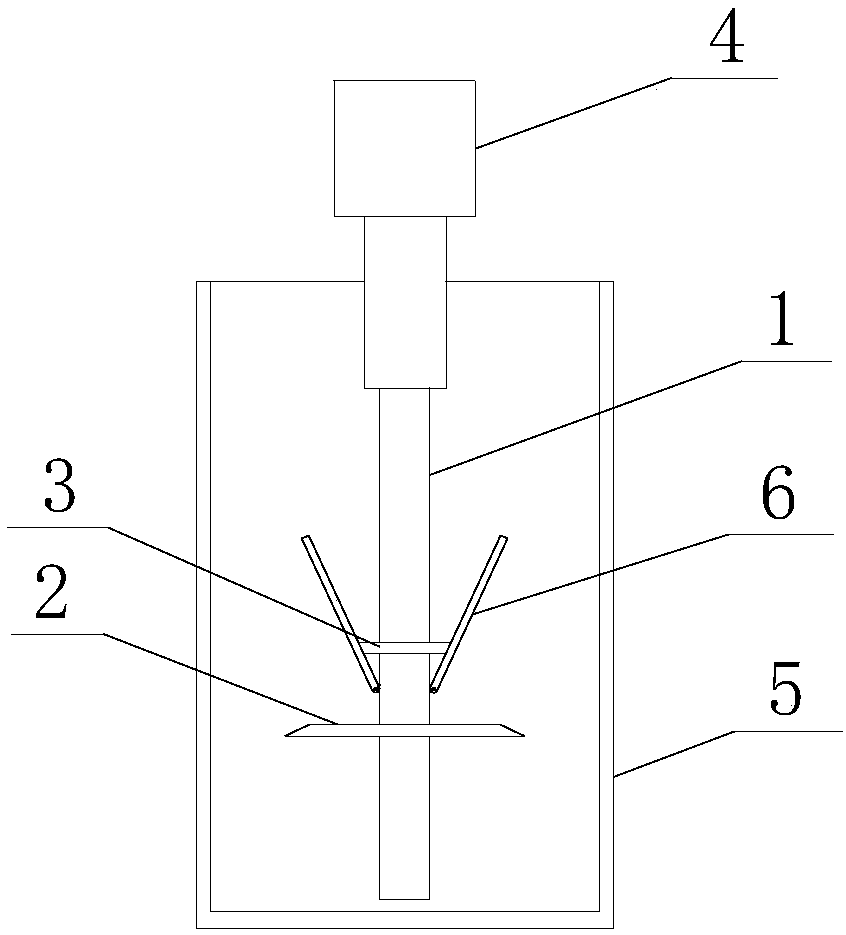

Medical testing and sterilization device based on opposite-injection spray-wash technology

InactiveCN109692836AComprehensive disinfectionGuarantee the quality of disinfectionLavatory sanitoryCleaning using liquidsMedical testingMedical device

The invention provides a medical testing and sterilization device based on opposite-injection spray-wash technology and particularly used for the technical field of medical sterilization. The medicaltesting and sterilization device comprises a box. A partition is arranged at the bottom of an inner cavity of the box. The inner cavity of the box is divided into a water inlet cavity and a sterilization cavity through the partition. A rotary shaft is embedded in the water inlet cavity and is fixedly connected with a spray-wash disc. A plurality of lower nozzles are evenly arranged at the top endof the spray-wash disc. A plurality of support leg rods are evenly arranged at the top end of the spray-wash disc. A tray is fixedly connected to the top ends of the support leg rods and is formed bynet weaving. A spray-wash device matched with the tray is arranged on the top wall of an inner cavity of the sterilization cavity. Through the spray-wash disc and the spray-wash device, a medical device in the tray is sterilized, sprayed and washed in the up and down directions simultaneously, a holding face of the medical device can be effectively sprayed and washed by the spray-wash disc, overall sterilization of the medical device is ensured, and sterilization quality is ensured. In addition, a motor is matched with the rotary shaft to drive the tray to rotate, thus the medical device is overturned, and omnibearing sterilization of the medical device is ensured.

Owner:太和县人民医院

Textile disinfection device

ActiveCN107952089BIncrease contact areaExpand the scope of sterilizationMechanical cleaningPressure cleaningTextile technologyEngineering

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

Cooking device

The invention relates to a mussel cooking device. The cooking device comprises a cooking box, wherein an oblique transfer belt is arranged in the cooking box and comprises multiple unit strips parallelly arranged at intervals, two closed ends of the oblique transfer belt are both provided with driving rollers, the lower-end side of the oblique transfer belt is located under a discharging port of agrading device, distributing strips are arranged in the peripheral directions of the unit strips at intervals, the distributing strips of the multiple unit strips are located on the same straight line, containing grooves for containing mussels are formed among the adjacent distributing strips, a material moving mechanism is arranged on the oblique transfer belt, and water is continuously boiled in the cooking box in advance, so that mussels are immersed in the cooking box on the oblique transfer belt, and initial mussel cooking is achieved. In addition, by utilizing the unit strips, the oblique transfer belt forms gaps for boiling water to pass so as to ensure that boiling water is fully in contact with the mussels, movement of transferred mussels is achieved through cooperation with thematerial moving mechanism so as to further achieve mussel turning, and smooth mussel opening is ensured.

Owner:王根节

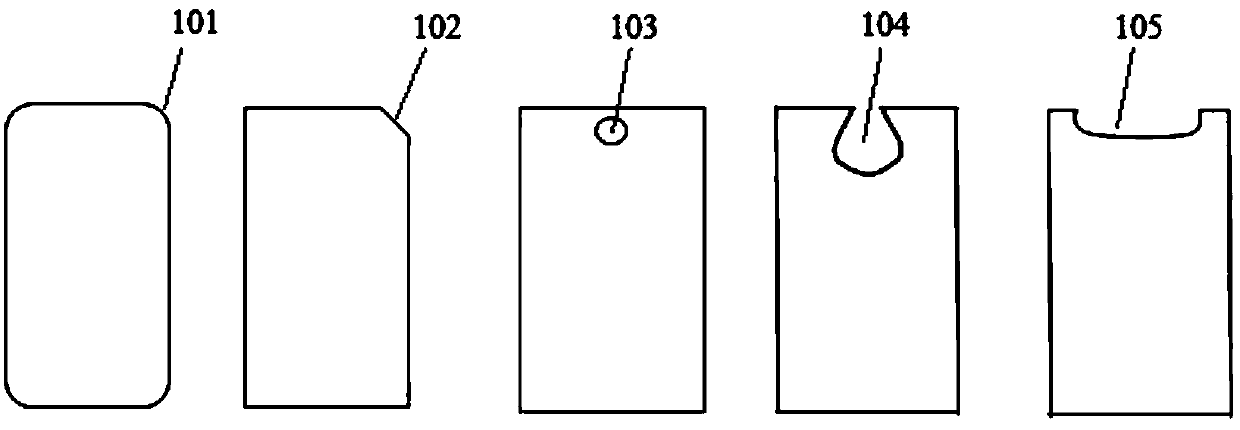

Identity card quality inspection device and using method thereof

PendingCN110501351AGuaranteed continuous transmissionRealize continuous detectionOptically investigating flaws/contaminationSortingSide informationControl system

The invention discloses an identity card quality inspection device. A card pushing plate in a card pushing mechanism is connected with a card pushing motor through a card pushing connecting plate. Card pushing slide rails are arranged on front and rear sides of the card pushing plate. A card supporting plate in a card supporting mechanism is connected with a lifting motor through a rising rod anda card supporting connecting plate. A U-shaped card supporting clamping plate in a turnover mechanism is arranged in the middle of the card supporting plate. A conveyor belt, a short rotating shaft, along rotating shaft and an overturning motor are connected. A bowl lamp, an annular lamp, a coaxial lamp and a camera in an image acquisition component are arranged right above the card supporting plate. A card distribution mechanism is located at a left end of the card pushing sliding rails, a card placing groove is located at a right end of the card pushing sliding rails, a card reader is located between the card placing groove and the card supporting plate. And a main control system is connected with the card pushing motor, the lifting motor, the overturning motor, a card sending motor, the camera and the card reader. Appearance quality of an identity card is determined and identity card printing information and chip storage information are verified by identifying front and reverse side information of the identity card, a structure is simple, efficiency is high, and accuracy is high too.

Owner:QINGDAO TONGCHAN SOFTWARE TECH

360-degree turnover sickbed

The invention provides a 360-degree turnover sickbed which comprises a bed frame, upper turnover bed frames, a lower turnover bed frame, rotary rolling shafts and a servo driver. The upper turnover bed frames are arranged on the left side and the right side of the bed frame through the lower turnover bed frame; the rotary rolling shafts are arranged on the upper turnover bed frames and can rotateunder the drive of the servo driver; two sides of a bed sheet are wound on the rotary rolling shafts on two sides of the bed frame; the upper turnover bed frames and the lower turnover bed frame are hinged; the lower turnover bed frame and the bed frame are hinged; hinged shafts are parallel to the rotary rolling shafts; and through the turnover of the upper turnover bed frames and the lower turnover bed frame, the rotary rolling shafts can be positioned at the position higher than a bed surface, located on two sides of the bed surface or positioned at the position lower than the bed surface.According to the 360-degree turnover sickbed provided by the invention, through the cooperation of the upper turnover bed frames and the lower turnover bed frame on two sides, a patient can turn overleft and right or lie on the bed under the drive of a moment motor, so that the skill requirements and the labor intensity of medical personnel can be reduced.

Owner:SHAANXI UNIV OF CHINESE MEDICINE

Chili bean processing mixer

PendingCN108745151ATurn overRealize the stirring actionShaking/oscillating/vibrating mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a chili bean processing mixer. The mixer comprises a stirring shaft, a paddle, a first limiting ring, a second limiting ring, a driving mechanism and a container for containinga material, wherein the stirring shaft is vertically arranged in the container with one end connected with the driving mechanism; the paddle comprises a plurality of blades of a strip structure and annularly arranged along the circumferential direction of the stirring shaft, and one end of each blade is movably connected to the stirring shaft so that the blade can swing up and down; the first limiting ring is located below the hinge portion of each blade and sleeves the stirring shaft; the second limiting ring is located above the hinge portion of each blade and sleeves the stirring shaft; the driving mechanism is used for driving the stirring shaft to move up and down in the container. The mixer can achieve mixing of the material without causing debris.

Owner:铜陵美子园农特产品加工有限公司

Medical nursing bed

The invention discloses a medical nursing bed. The medical nursing bed comprises a bed body and a mattress, and the bed body comprises a bed frame, a bed plate, a roll-over device and a sit-up device. The middle of the bed plate is provided with a first opening and a second opening; an opening-closing device for shielding the first opening and the second opening in closure is arranged on the lower surface of the bed plate; the mattress is provided with a third opening and a fourth opening corresponding to the first opening and the second opening of the bed plate in position; a first filler mat and a second filler mat are arranged in the third opening and the fourth opening respectively; a flexible waterproof supporting cushion in a funnel shape is arranged on the upper surface of the third opening of the mattress. Since the bed plate is formed by hinging of four steel plates, side face rotation and front face rotation of the bed plate can be realized, and rolling over and sitting up of a patient can be realized. Since each of the bed plate and the mattress is provided with two openings, the patient can conveniently defecate, and convenience in nursing, observation and cleaning is achieved. By the aid of the flexible waterproof supporting cushion, the mattress and the bed plate can be protected from being contaminated by excrement of the patient as far as possible.

Owner:重庆鬼谷子医疗器械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com