Patents

Literature

708results about How to "Dry thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

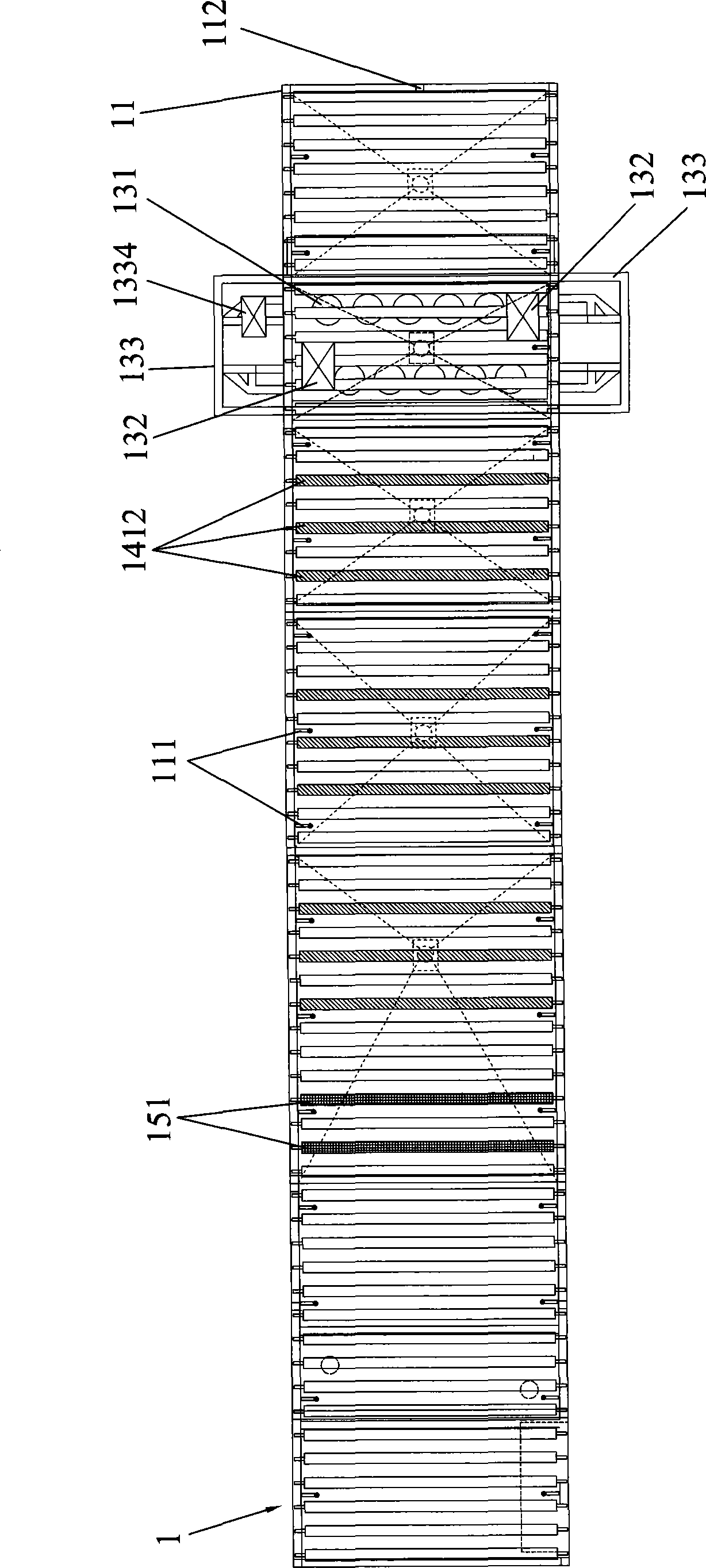

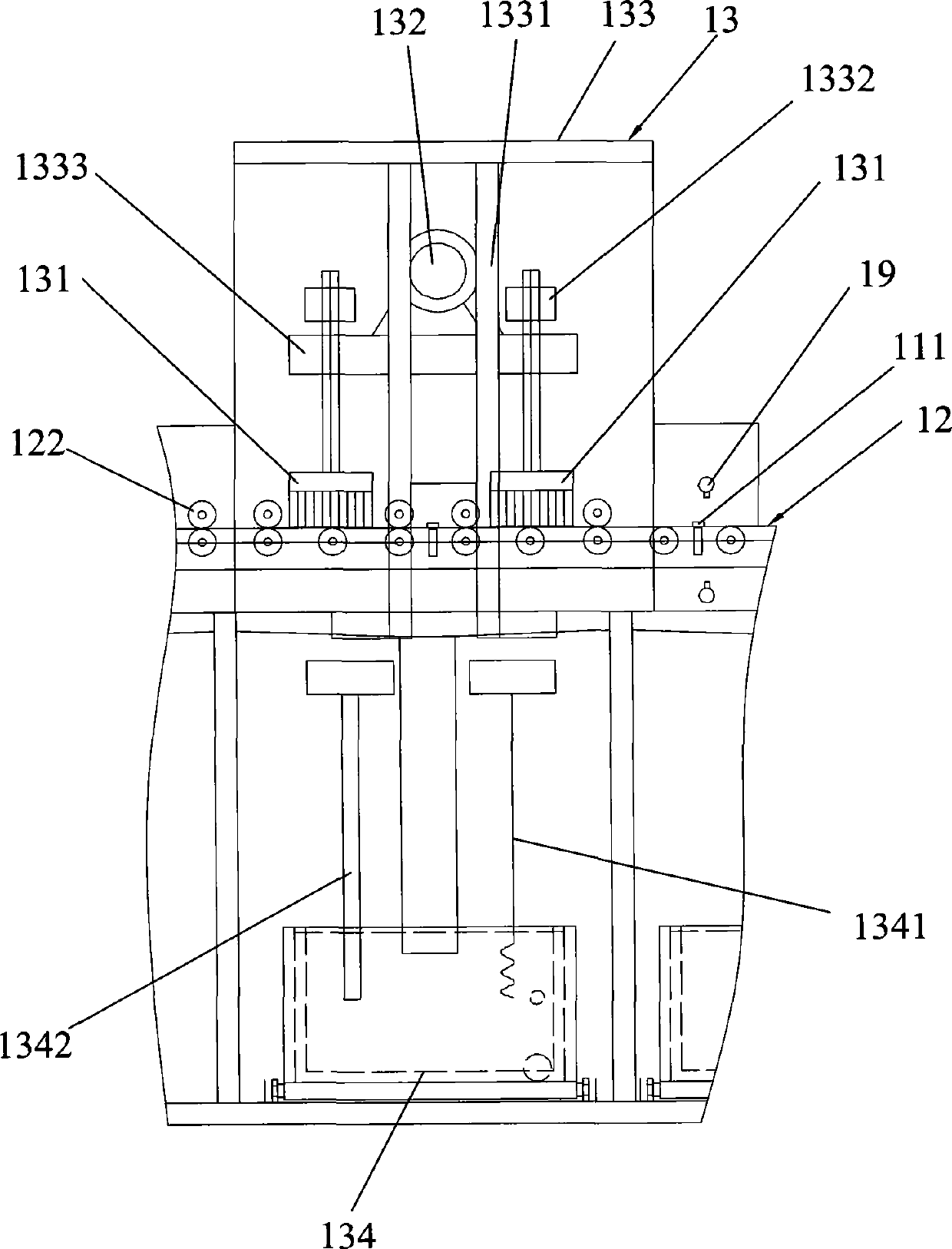

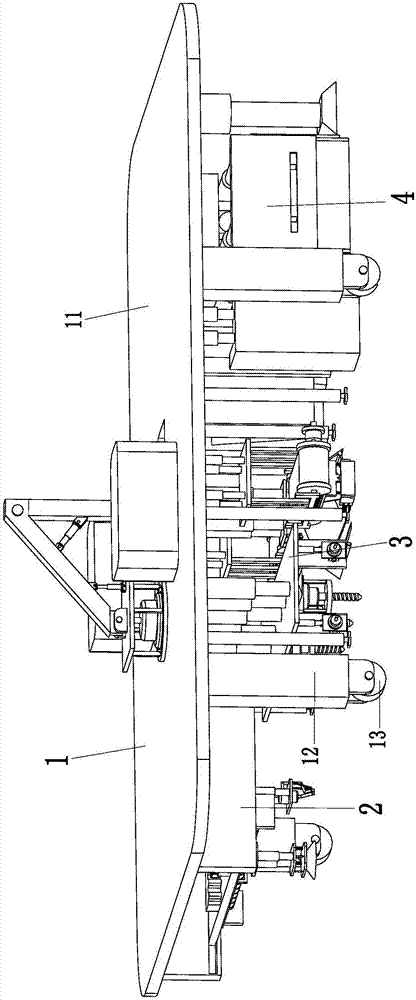

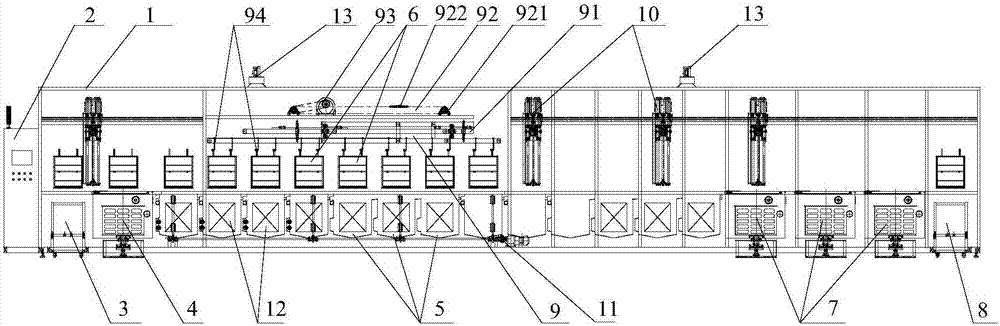

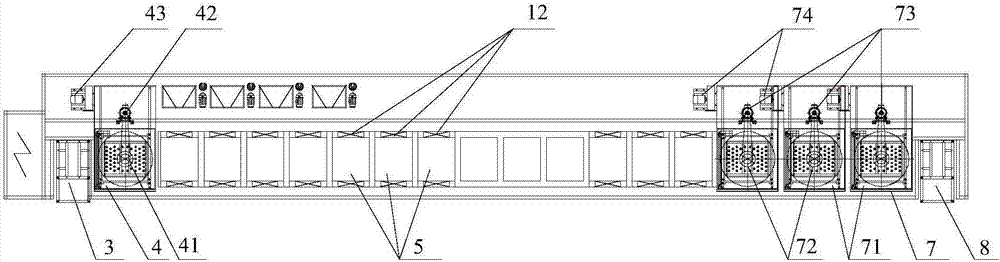

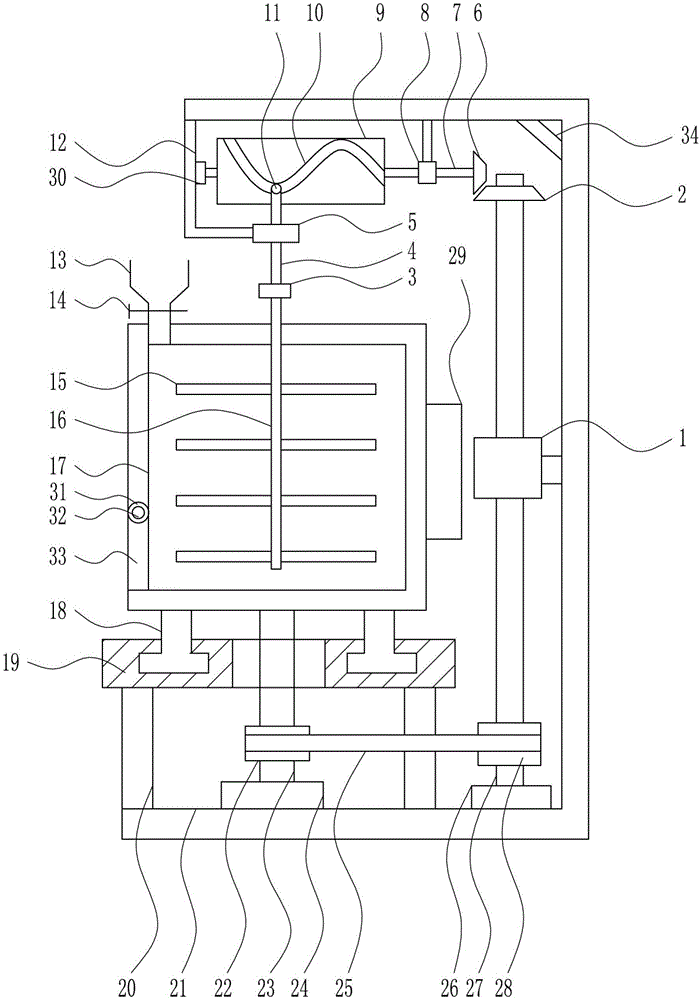

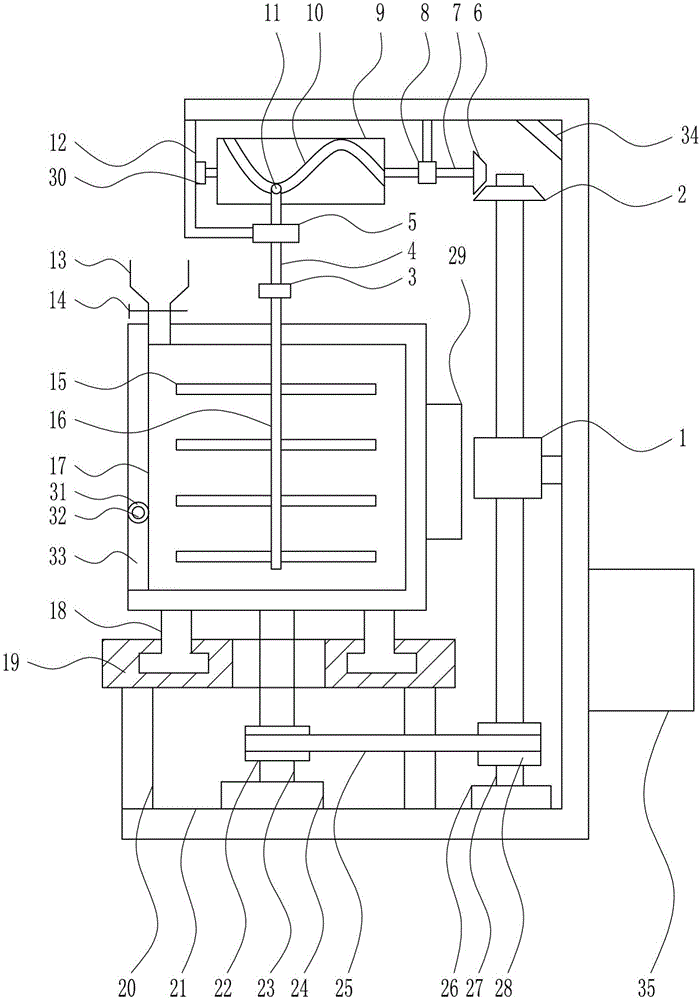

Glass-cleaning and drying device

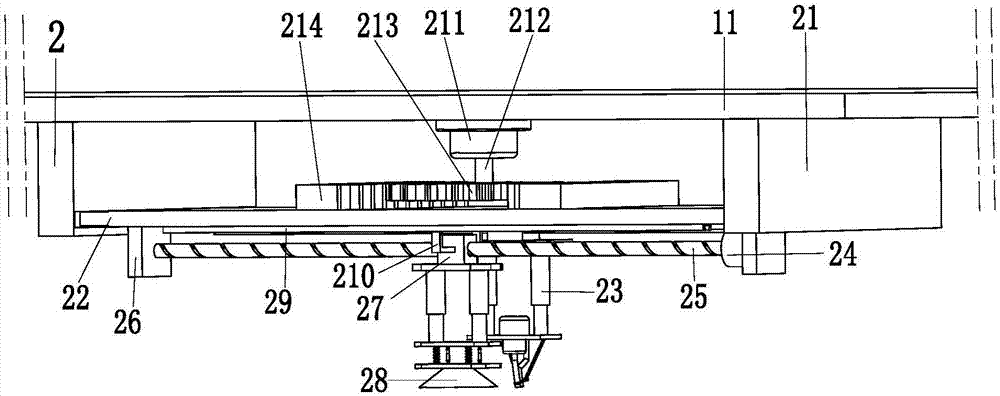

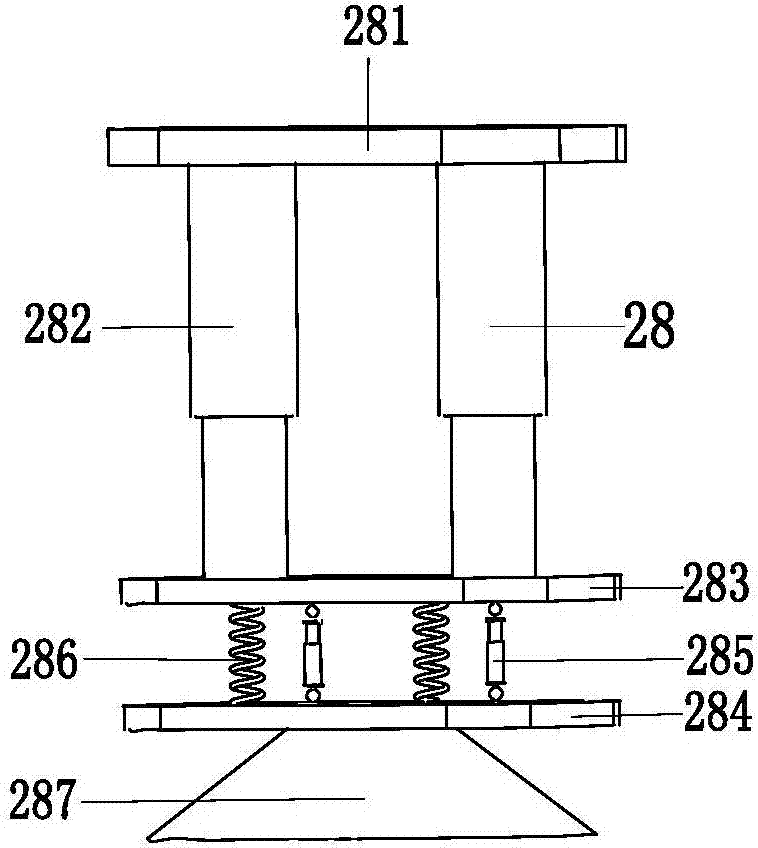

The invention provides a glass-cleaning and drying device suitable for cleaning and drying coated glass. The glass-cleaning and drying device comprises a stand, a conveying mechanism, a tray brush device, a brush device, a water-absorbing component, a drying device and a heat drying device. The conveying mechanism comprises a driving motor and a plurality of conveying rollers arranged in a line, wherein the driving motor drives the conveying rollers to convey coated glass; the tray brush device comprises a lifting mechanism, a plurality of tray brushes and a tray brush driving mechanism; the lifting driver of the lifting mechanism drives the tray brushes to move up and down relative to the coated glass; the tray brush driving mechanism drives the tray brushes to rotate; the clamped transmission roller group of the brush device is arranged between the tray brush device and the brush device for conveying the coated glass in a clamping mode and expelling moisture on the coated glass; the water-absorbing component comprises a water-absorbing roller group which comprises water-absorbing rollers with water absorption in vertical two-to-two correspondence; the drying device comprises air knives and a blower; and the air knives respectively face to the upper surface and the lower surface of the coated glass.

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD

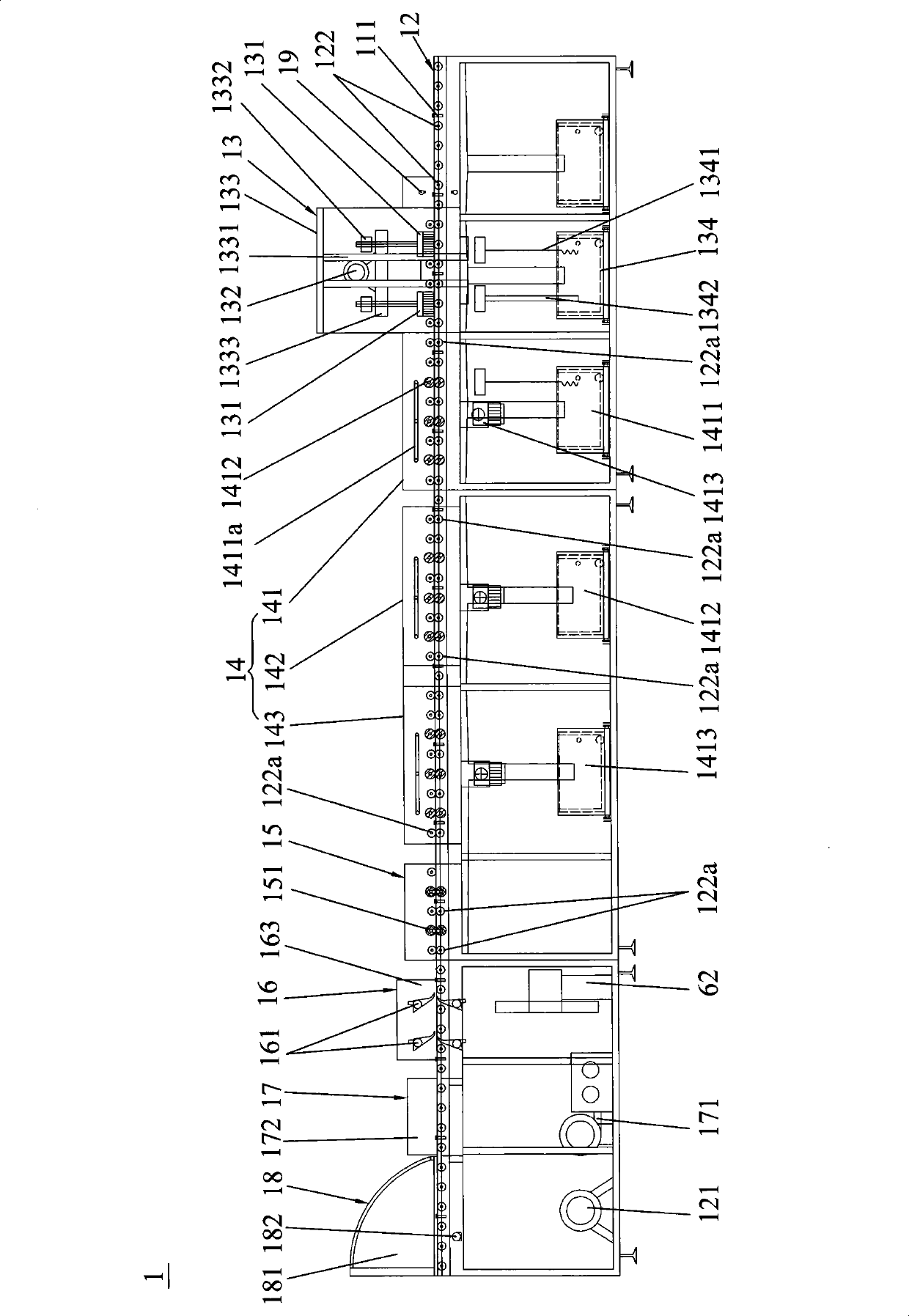

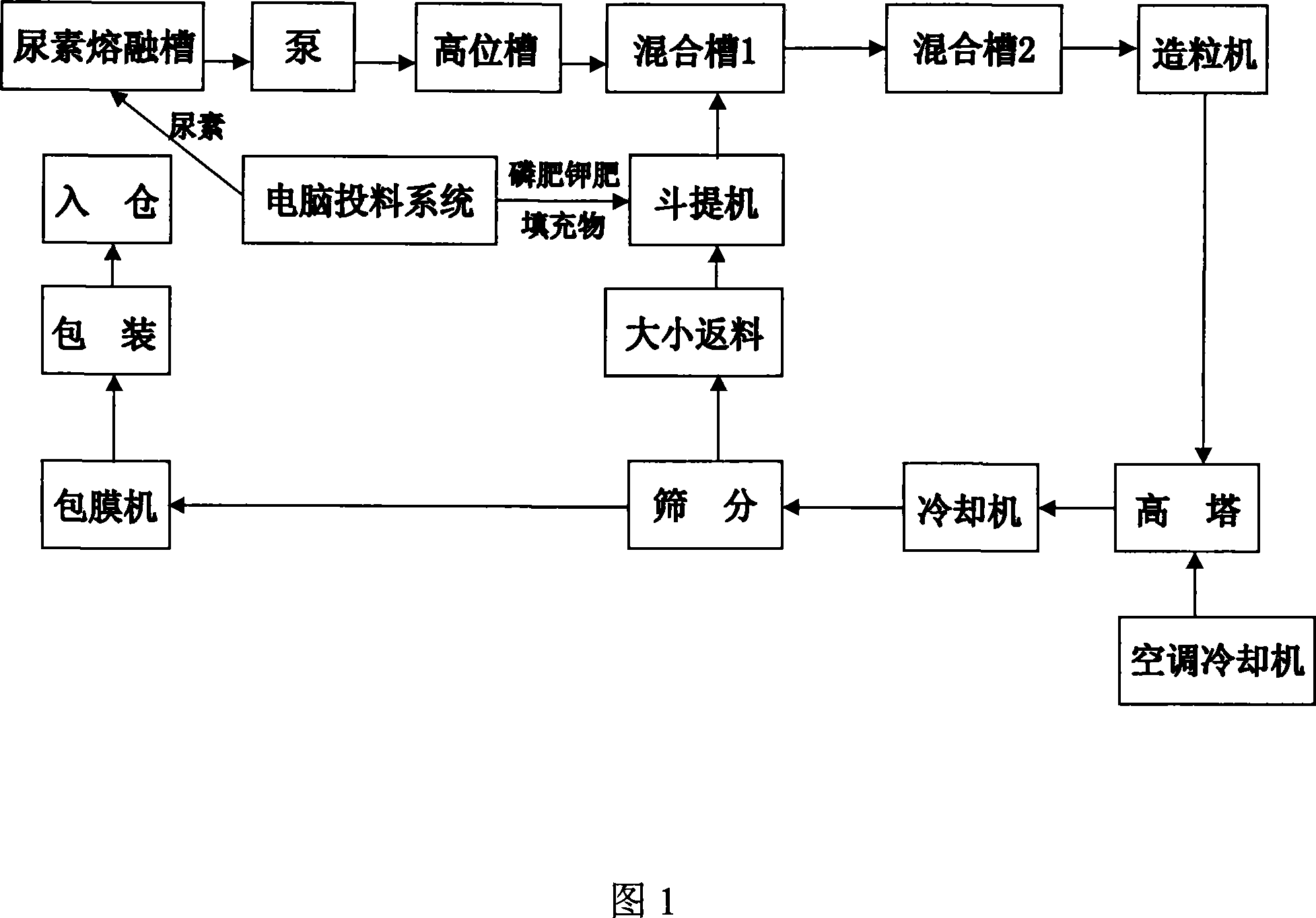

Process for producing compound fertilizer by tower granulation

The invention discloses a high tower making grain technics for producing compound fertilizer, which is characterized in that the urea saltpeter ammonium phosphorus is smelted under the tower through measuring, then enters the mixing reacting groove on the tower top by a pump, then is mixed with measured monoammonium phosphate, potassium chloride, lemery, filler, middle microelement and paint, finally, enters the granulator to be granulated. The invention makes use of the pump to put the urea (saltpeter ammonium phosphorus) material serum to the top of the tower, thereby, saving energy, decreasing investment, being convenient for service and saving cost.

Owner:GUANGDONG DAZHONG AGRI SCI CO LTD

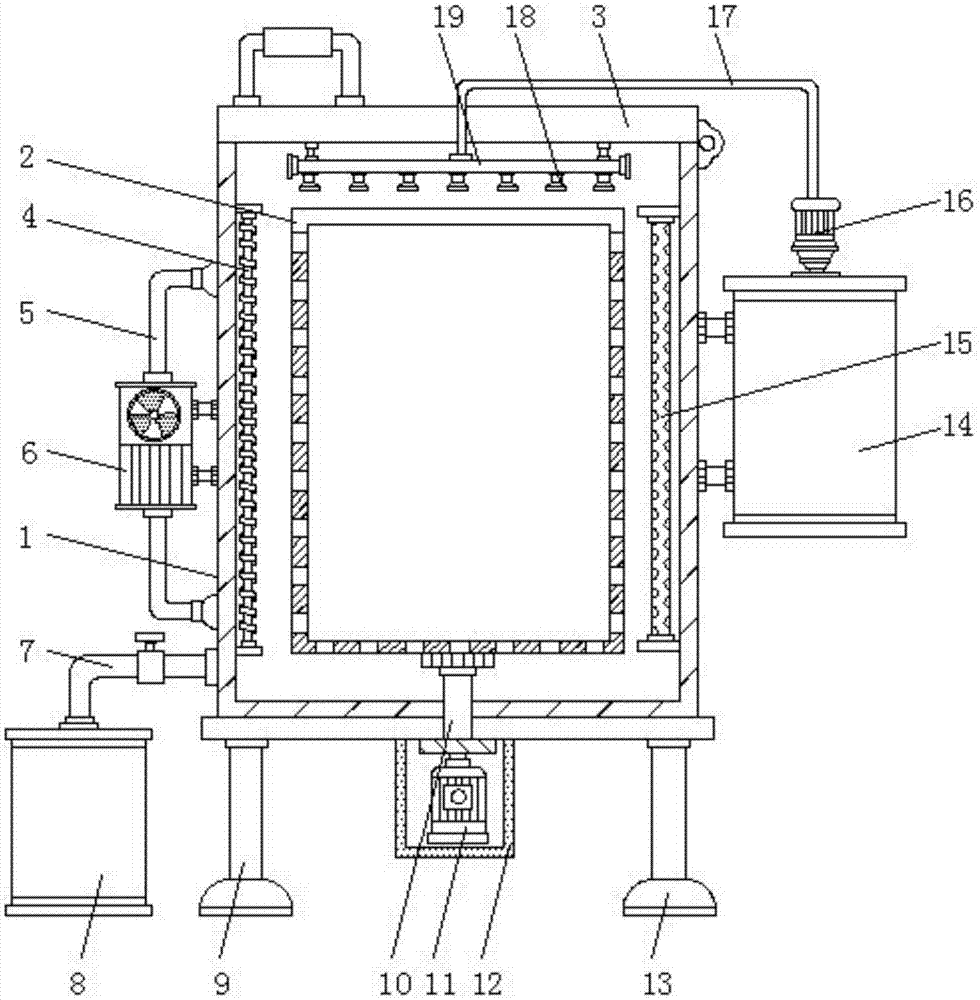

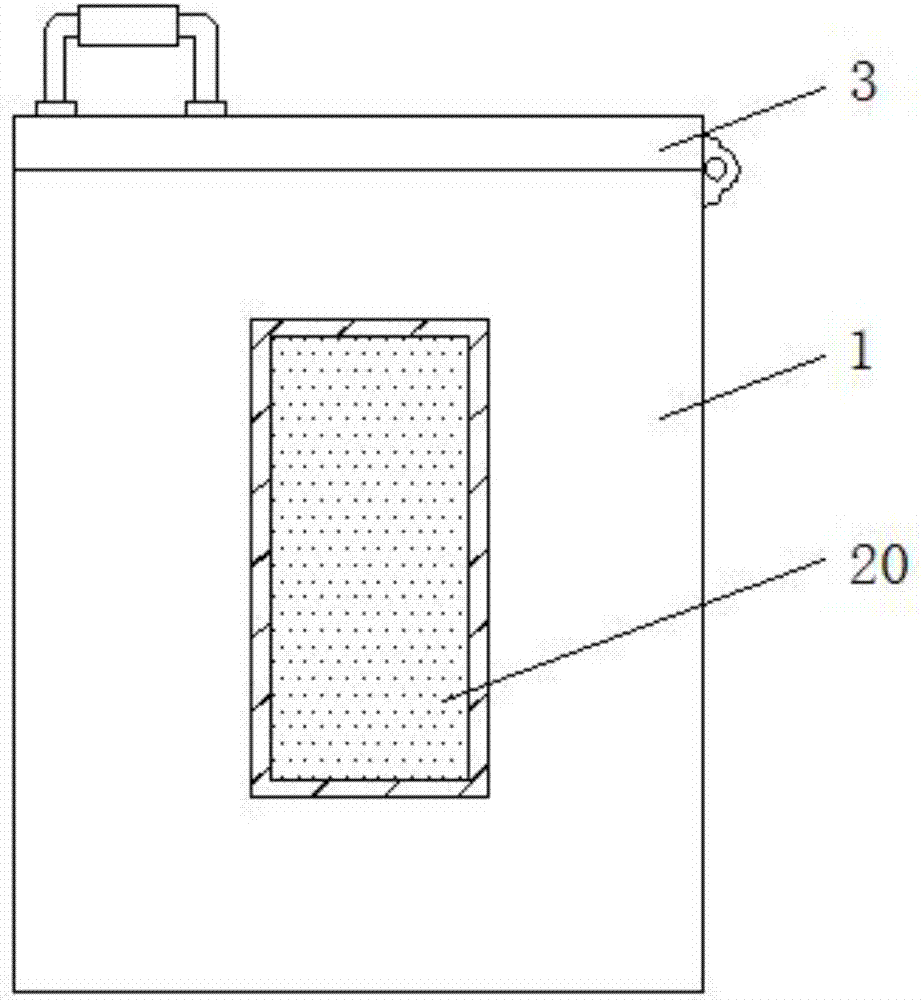

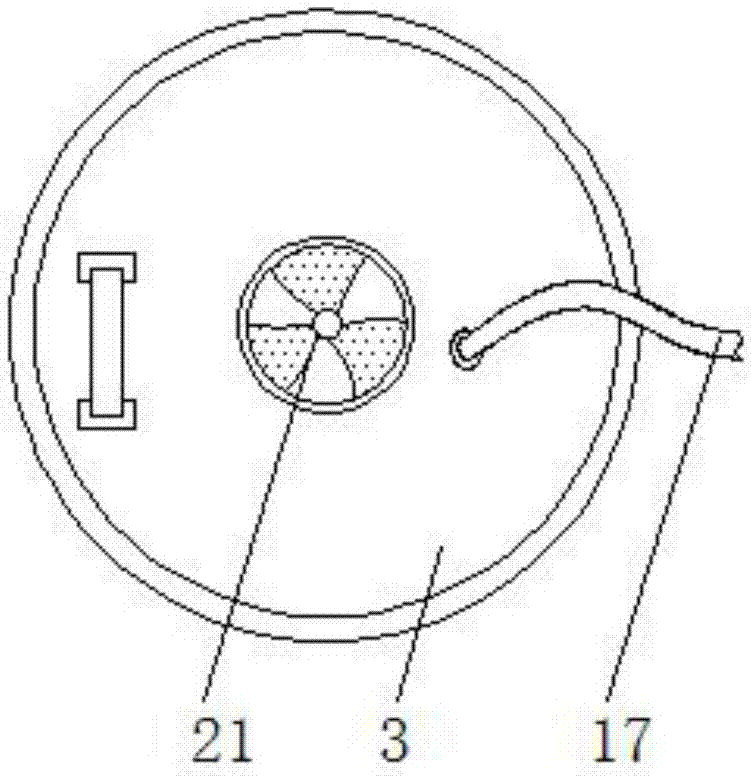

Tea cleaning and drying device

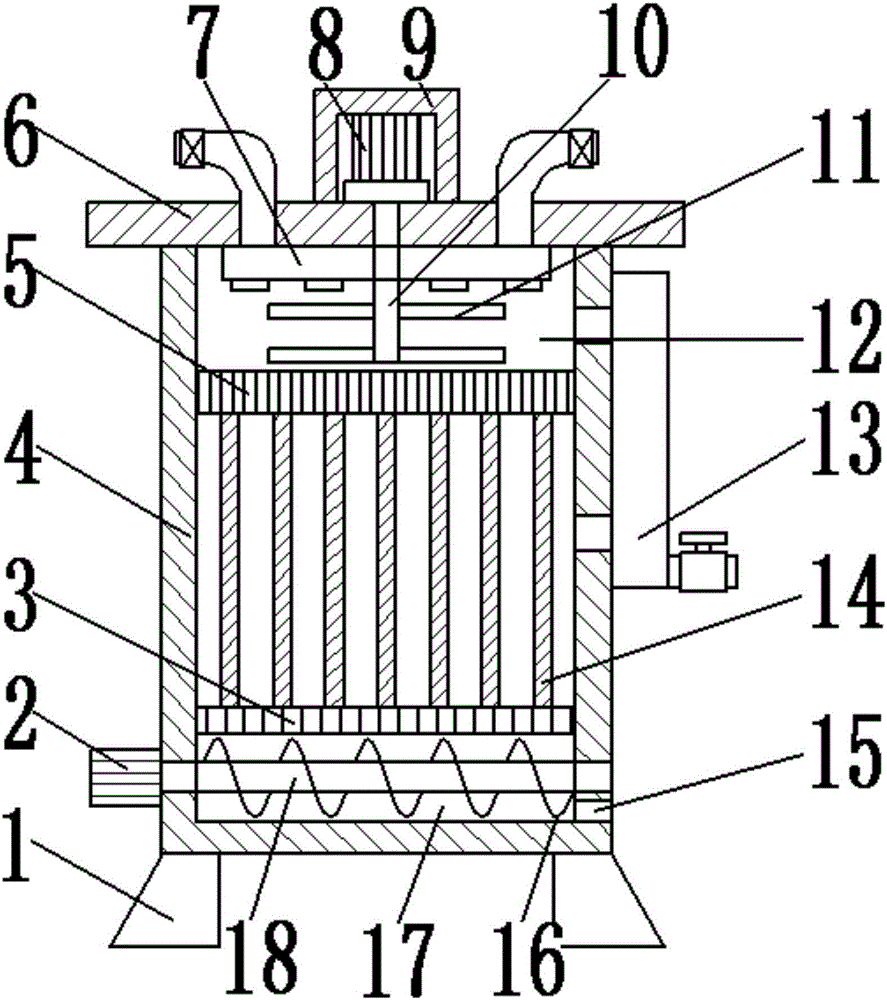

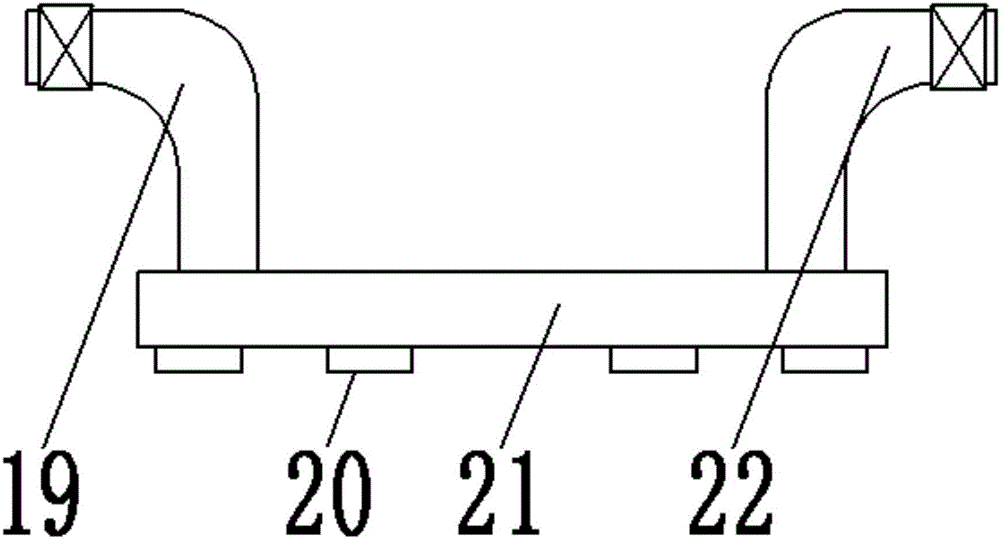

InactiveCN107965989ARealize the function of cleaning and removing impuritiesSpeed up the flowPre-extraction tea treatmentDrying gas arrangementsWater resourcesAgricultural engineering

The invention discloses a tea cleaning and drying device which comprises a drying box, a rotating tube and a seal cover. The bottom of the drying box is provided with a rotating motor, the rotating motor is connected with the rotating tube through a rotating shaft, two inner walls, close to the rotating tube, of the drying box are provided with a heating pipe and an ultraviolet ray lamp pipe correspondingly, the outer wall, close to the heating pipe, of the drying box is provided with an air blower, the bottom of one side of the drying box is connected with a waste water treatment box througha pollution discharge pipe, the top of the seal cover is provided with an air exhaust fan, and the bottom of the seal cover is provided with a water spray pipe. By means of the tea cleaning and dryingdevice, before agricultural and sideline products are dried, cleaning and impurity removing functions performed on the agricultural and sideline products can be realized, and the quality of dried products is improved; by means of the arrangement of the waste water treatment box, the waste water after cleaning can be filtered and purified, and the recycling of water resources is facilitated; and the tea cleaning and drying device is simple in structure, the efficiency of drying performed on the agricultural and sideline products is high, and the drying is performed more thoroughly.

Owner:WUZHOU YAZHENG AGRI TECH CO LTD

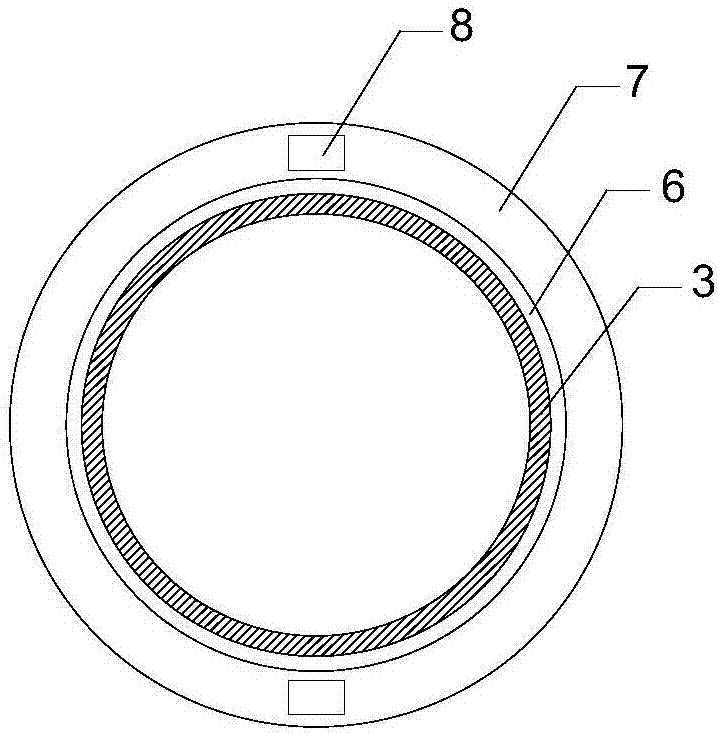

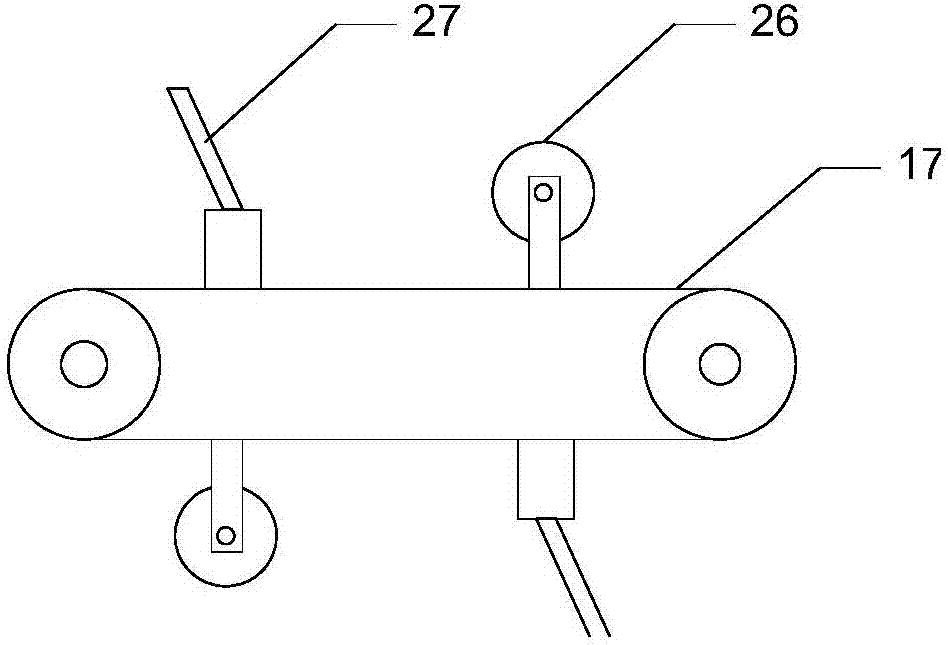

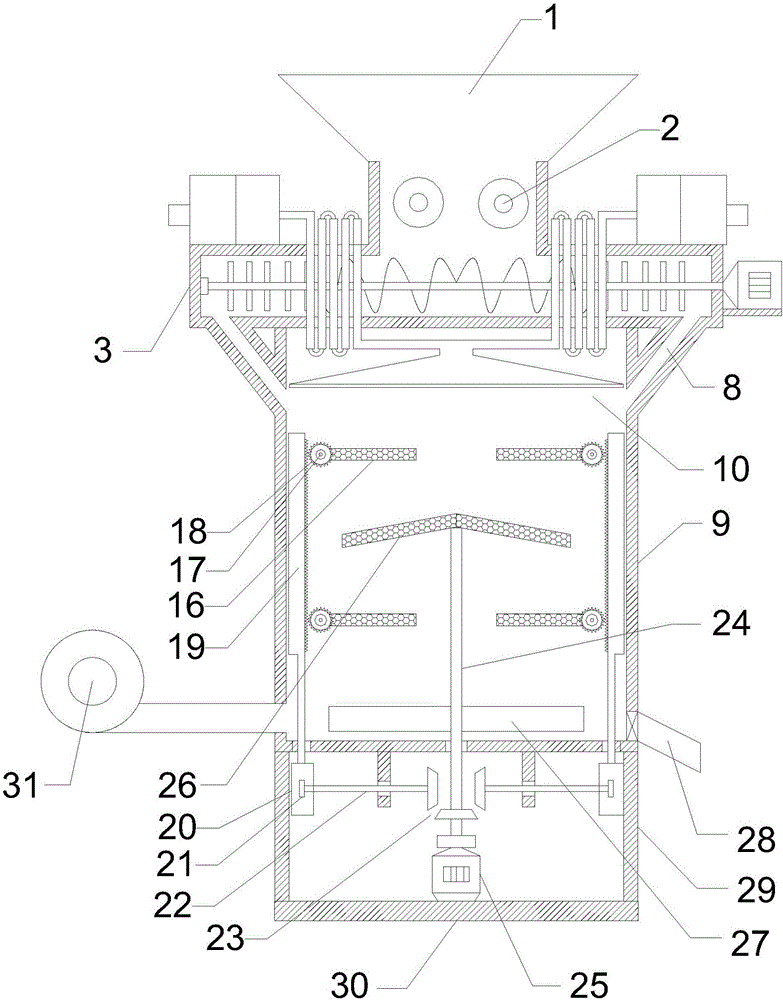

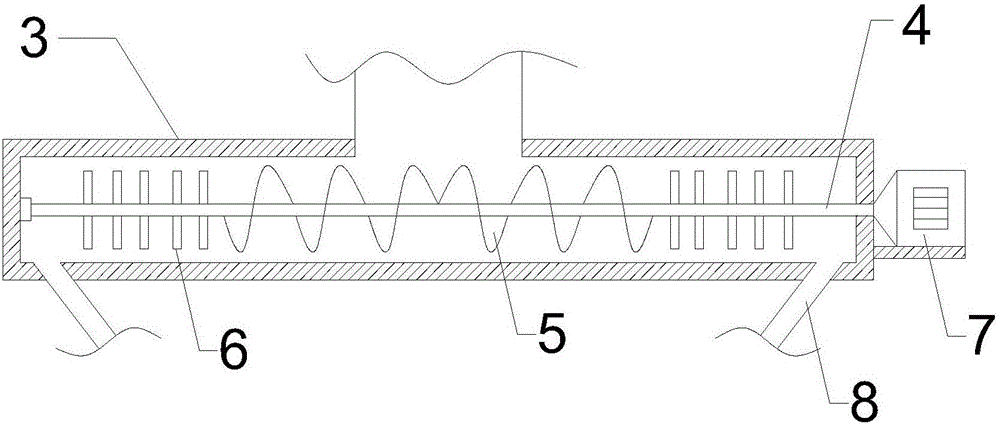

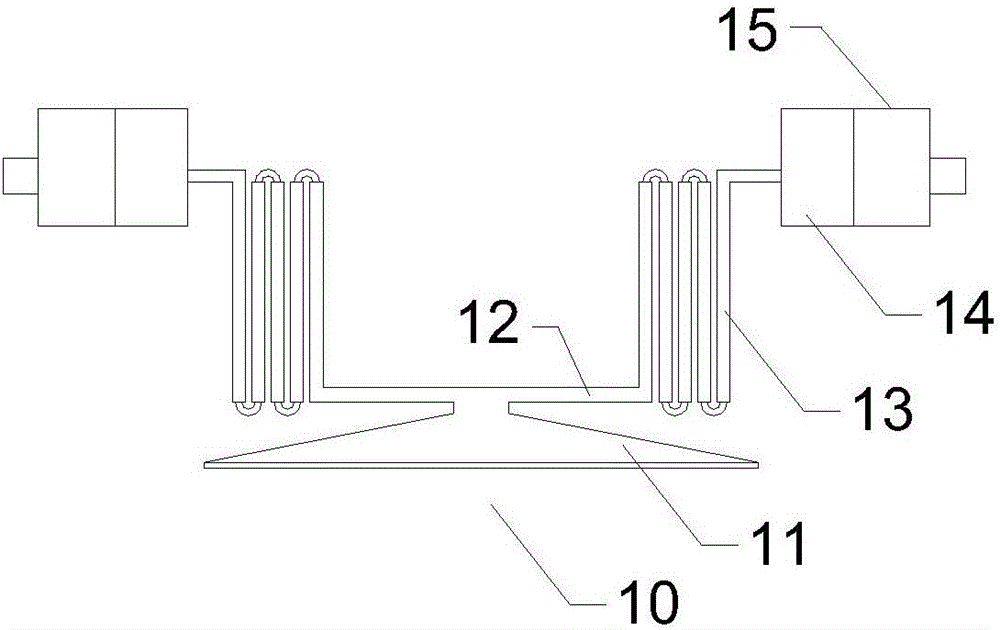

Continuous sludge treatment device

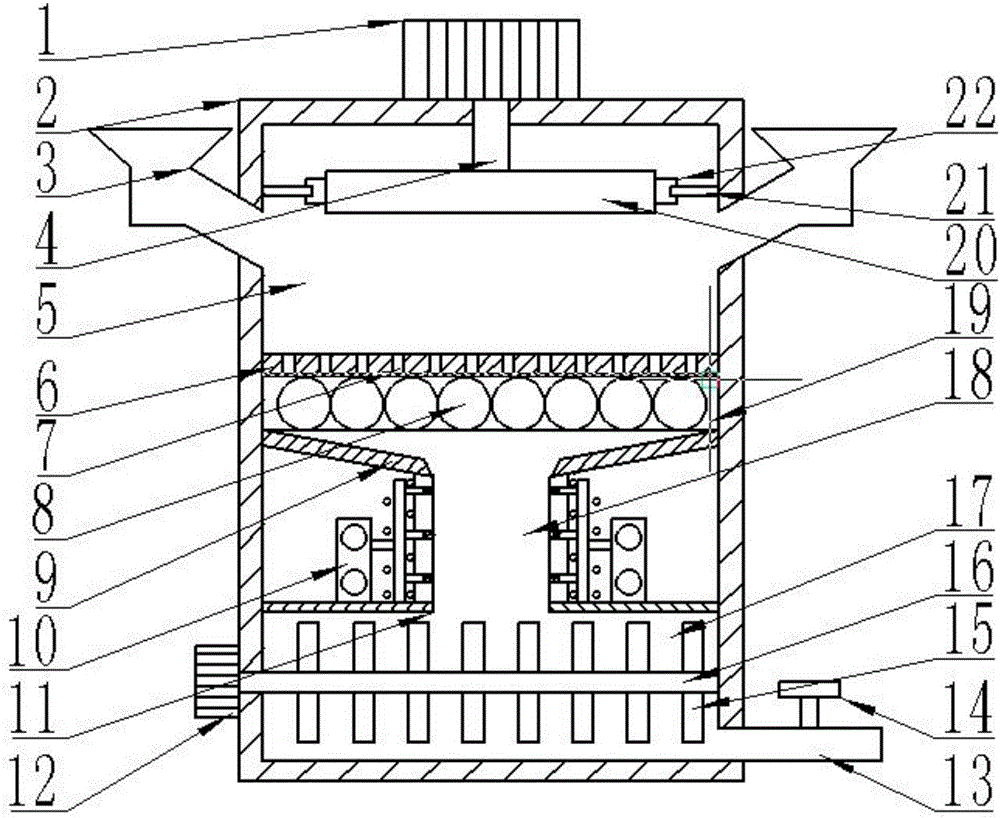

InactiveCN107176780AAvoid cloggingEfficient heatingSludge treatment by de-watering/drying/thickeningSludgePulp and paper industry

The invention discloses a continuous sludge treatment device. The continuous sludge treatment device comprises a feeding hopper, a first driving motor and a second driving motor, wherein the feeding hopper is communicated with a dewatering box, a screen drum is arranged in the dewatering box and sleeved with a rack ring, and the rack ring is rotationally connected with the screen drum through a bearing; strip-shaped brushes which are symmetrically arranged are fixedly connected with the right side wall of the rack ring; a drying box is communicated with the right side of the screen drum through a sludge pipe. With the arrangement of a screw extrusion dewatering device provided with the rotating brushes, sieve meshes are prevented from being blocked, continuous dewatering work is guaranteed, and the continuous sludge treatment device has higher dewatering efficiency; the continuous sludge treatment device is equipped with a drying device consisting of a heating plate, flat spreading rollers and scrapers, therefore, sludge is efficiently and uniformly heated, and drying efficiency is improved; an auxiliary drying device consisting of hot air spray nozzles, smashing blades and a turning plate is arranged, so that the sludge is thoroughly dried, and the drying effect is guaranteed.

Owner:李群珍

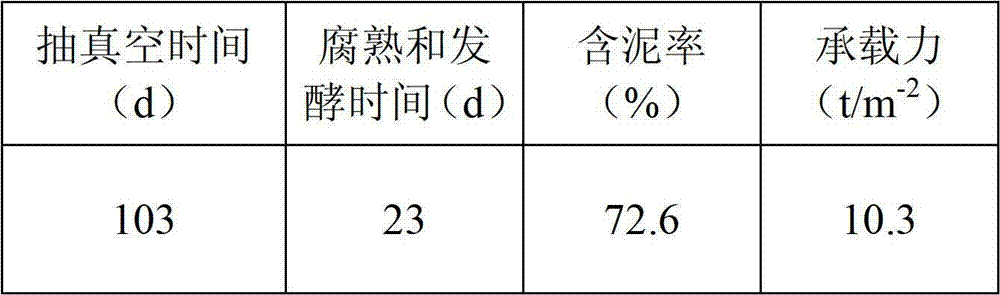

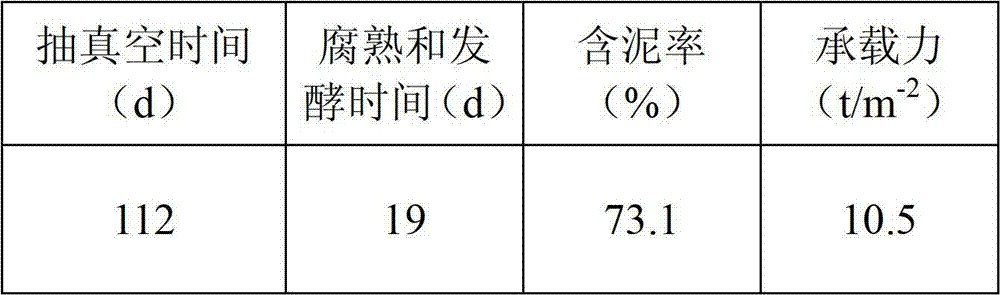

Method for promoting rapid drying of dredged silt by microorganism

ActiveCN102815854ARapid flocculation sedimentation concentrationLow costSludge treatment by de-watering/drying/thickeningBiological sludge treatmentLife activityDecomposition

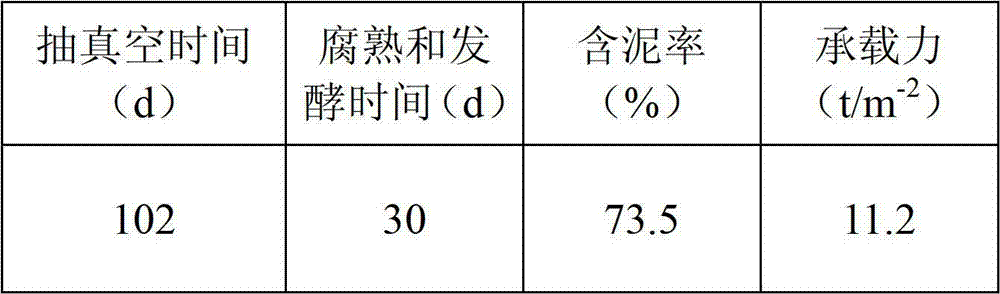

The invention relates to a method for promoting rapid drying of dredged silt by a microorganism. The method includes: taking straw and other organic matters as a substrate, conducting anaerobic fermentation and decomposition, burying the substrate in a silt storage yard, pre-burying a vacuum pumping pipe network system, inputting dredged silt, and then adding a flocculant and a coagulant aid to perform initial concentration, vacuum pumping, compression and other processes. The method for promoting rapid drying of dredged silt by a microorganism makes use of life activities of the microorganism and the produced gas to change the compact silt state formed during vacuum pumping, makes the silt become loose and porous, promotes flow of moisture, thereby improving the water pumping and drainage effect of vacuum preloading, and transforming the dredged silt from a fluid state to a plastic state or semi-solid state rapidly. Thus, the method realizes rapid dewatering and drying of dredged sludge, and has the characteristics of low cost and short construction period.

Owner:JIANGSU JIANGDA ECOLOGICAL SCI & TECHCO

Efficient feed crushing and drying equipment

InactiveCN107525389AAvoid stickinessImprove drying efficiencyFeeding-stuffDrying solid materialsEngineeringAir heater

The invention discloses efficient feed crushing and drying equipment. The equipment comprises a feeding hopper and a drying box; throwing plates are peripherally distributed on the inner wall of the drying box; an air heater communicates to the lower end of the left side of the drying box; a discharge pipe is arranged at the lower end of the right side of the drying box; and a valve is arranged in the discharge pipe. The equipment is provided with a crushing roller and a double-channel crushing cylinder for two-stage crushing of feeds to achieve high processing efficiency; the equipment is provided with a hot gas utilization device for efficiently using waste gas heat to improve the heat utilization; meanwhile, the bonding of the feeds in the crushing cylinder is prevented, so that the waste of raw materials is prevented; as a turntable and the throwing plates are provided for throwing the feeds into the air for hot gas drying; meanwhile, caked feed blocks are collided with the inner wall of the drying box for scattering through the turntable, so that the feed drying efficiency is improved, and the drying is more thorough; and through a scraper, the discharge is more thorough.

Owner:周建明

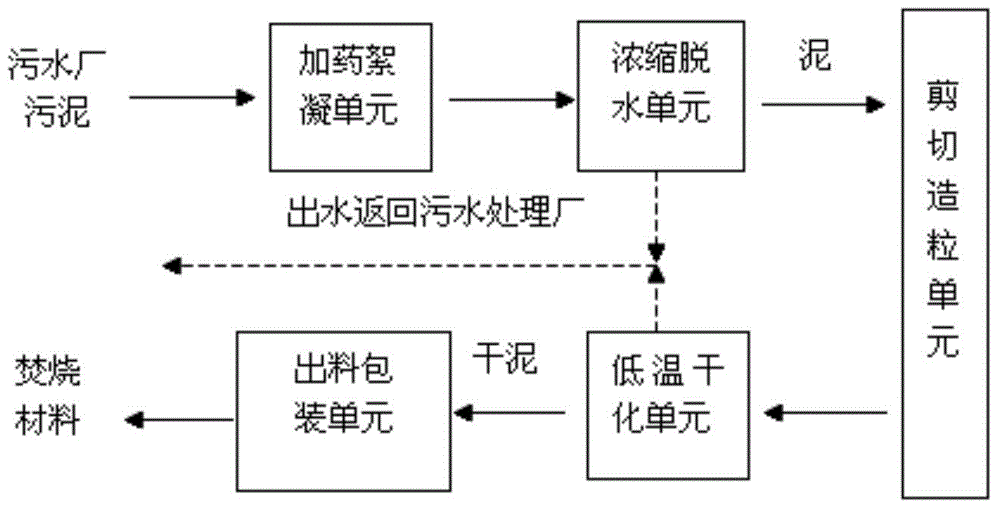

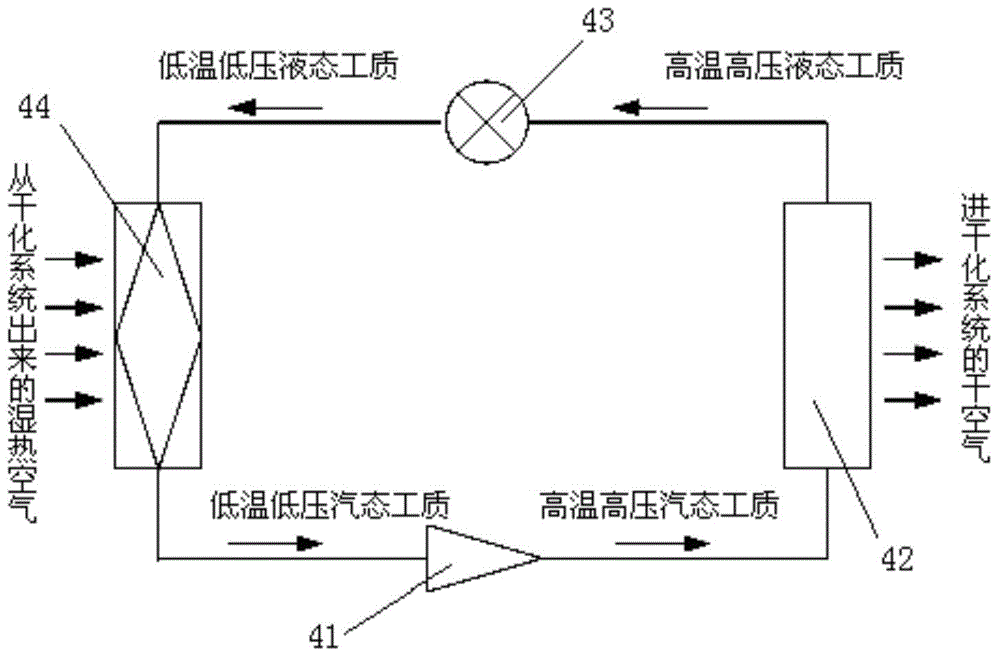

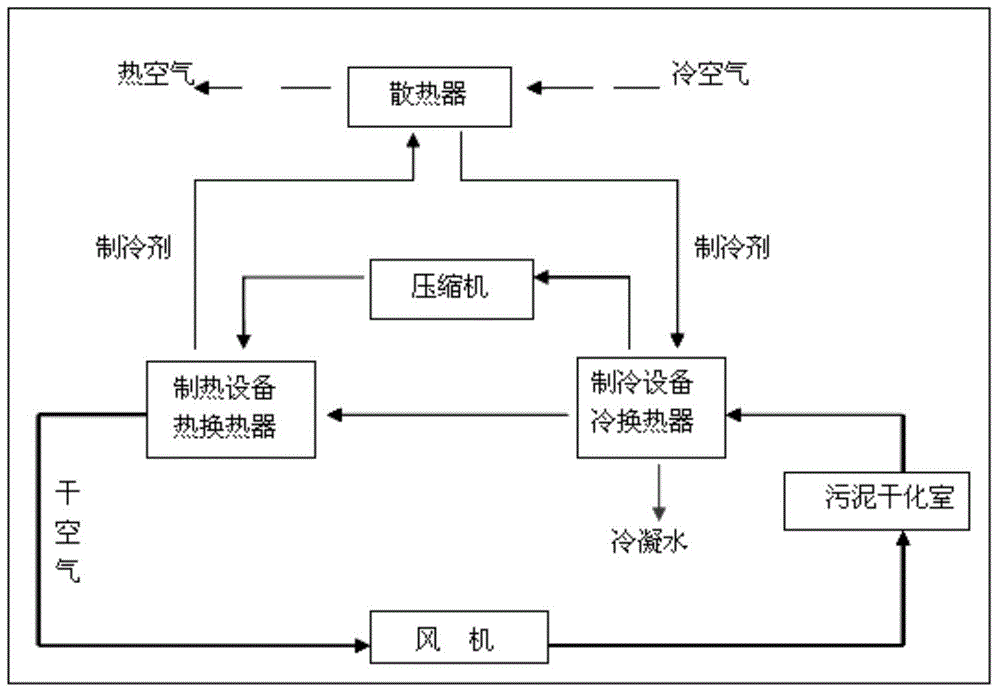

Low-temperature sludge drying treatment system and technology

ActiveCN103553291AReduce energy consumptionHigh degree of integrationSludge treatment by de-watering/drying/thickeningFlocculationDewatered sludge

The invention discloses a low-temperature sludge drying treatment system. The low-temperature sludge drying treatment system comprises a dosage and flocculation unit, a condensation and dewatering unit, a shearing and granulation unit, a low-temperature drying unit and a discharging and packaging unit which are sequentially connected, wherein the dosage and flocculation unit comprises a flocculation tank and a stirring device arranged in the flocculation tank, the condensation and dewatering unit comprises a sludge dewatering machine, the shearing and granulation unit comprises a shearing and granulator, the low-temperature drying unit consists of a low-temperature sludge drying machine, a fan and a heat pump system. The technology comprises the treatment steps of 1) feeding a flocculating agent into sludge so as to promote the dewatering property; 2) dewatering the flocculated sludge; 3) performing shearing and granulation treatment on the dewatered sludge; 4) performing low-temperature drying treatment on the granulated sludge at 50-100DEG C; 5) performing vacuum bagged packaging on the dried sludge. The treatment system is less in occupied area, high in equalization degree, low in energy consumption, and incapable of producing secondary pollution in the treatment process.

Owner:BEIJING BIOTECHINA ENVIRONMENT CORP

Conveniently instant tomato and bean curd soup

ActiveCN101669658AThe selection of raw materials is scientific and reasonableRich and balanced nutritionFood preparationConvenience foodInstant tea

The invention provides a conveniently instant tomato and bean curd soup, belonging to the technical field of convenient foods; main component materials of the soup comprise tomato, bean curd, and other minor ingredients; prepared soup base is poured into a traying of a blocky groove; more than 99% of moisture is stripped down by a vacuum freeze-drying technology, and simultaneously cooked solid block is formed to obtain the conveniently instant tomato and bean curd soup. The conveniently instant tomato and bean curd soup solves defects that in the prior art, semi-finished puree is inconvenientto eat, has short shelf life, single taste and the like; the prepared conveniently instant tomato and bean curd soup has rich ingredients, delicious taste, high nutrition value, long shelf life, simple and practicable manufacture, does not contain preservative, and is applicable to large-scale popularization and application.

Owner:福建省新闽商业运营管理有限公司

Method for preparing high-purity chicory and helianthus tuberosus fructo-oligosaccharide in coproduction of polyfructosan

The invention relates to the technical field of extraction and preparation of saccharides, and in particular relates to a method for preparing high-purity chicory and helianthus tuberosus fructo-oligosaccharide in coproduction of polyfructosan. The method comprises the steps of cleaning, slicing, drying and grinding chicory root or helianthus tuberosus tuber, and implementing continuous countercurrent ultrasonic extraction by an alkaline extraction solution to obtain an inulin solution; classifying the inulin solution through an ultra-filtration member to separate macromolecular filtrate and micromolecular filtrate; implementing enzymolysis on the micro-molecular filtrate, condensing after enzymolysis, implementing chromatographic separation, decoloring, transforming, condensing and drying to obtain fructo-oligosaccharide; and decoloring, transforming, condensing and drying the macromolecular filtrate to obtain the polyfructosan. The method realizes coproduction with the polyfructosan and obviously improves raw material utilization rate; the method saves time and improves extraction rate, and can realize continuous production and greatly improve production efficiency.

Owner:BAOLINGBAO BIOLOGY

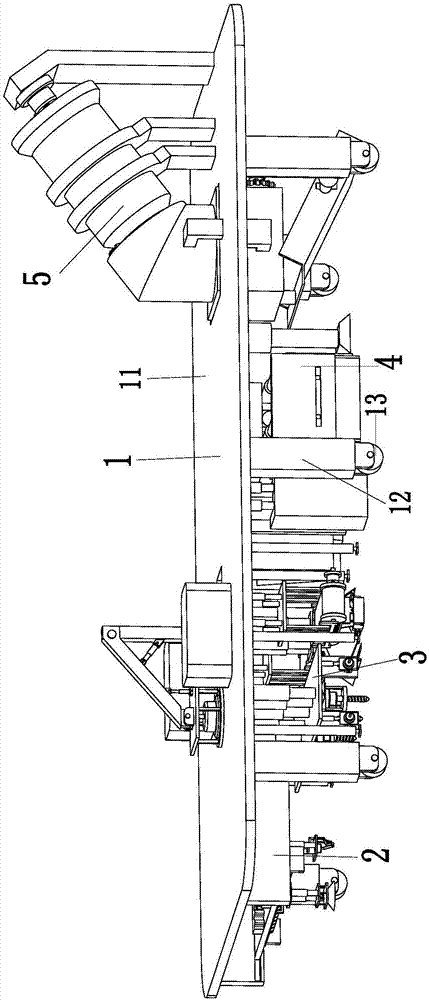

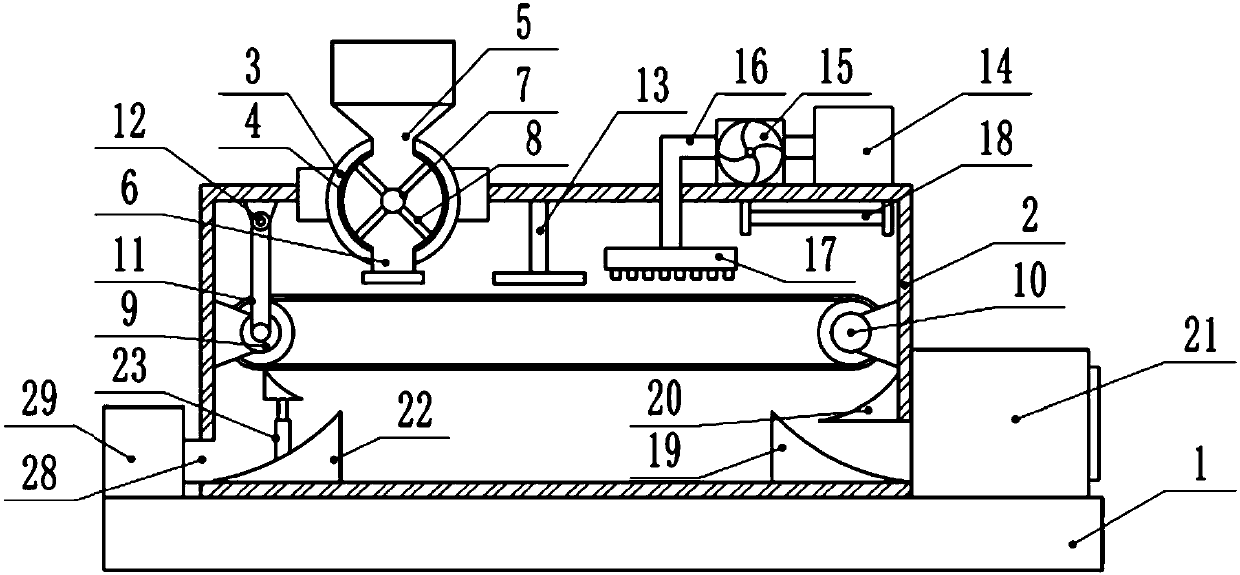

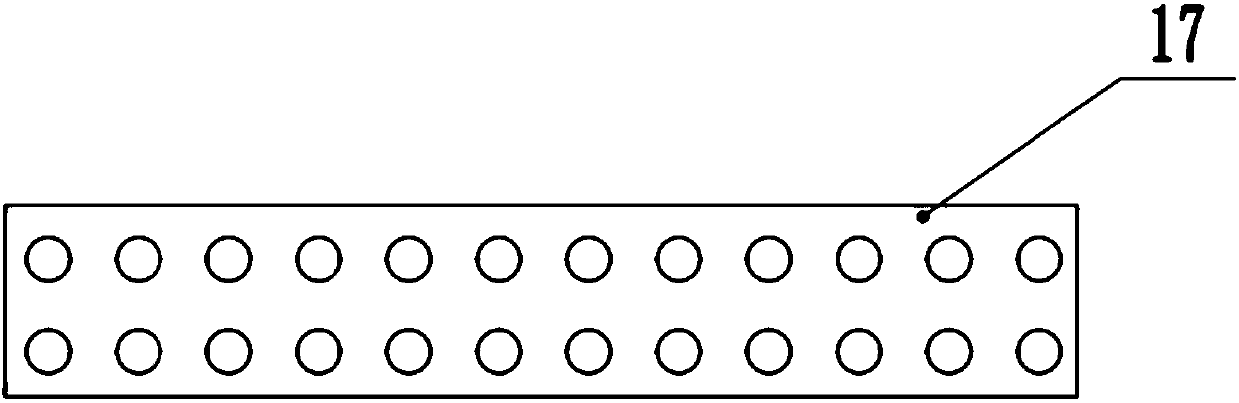

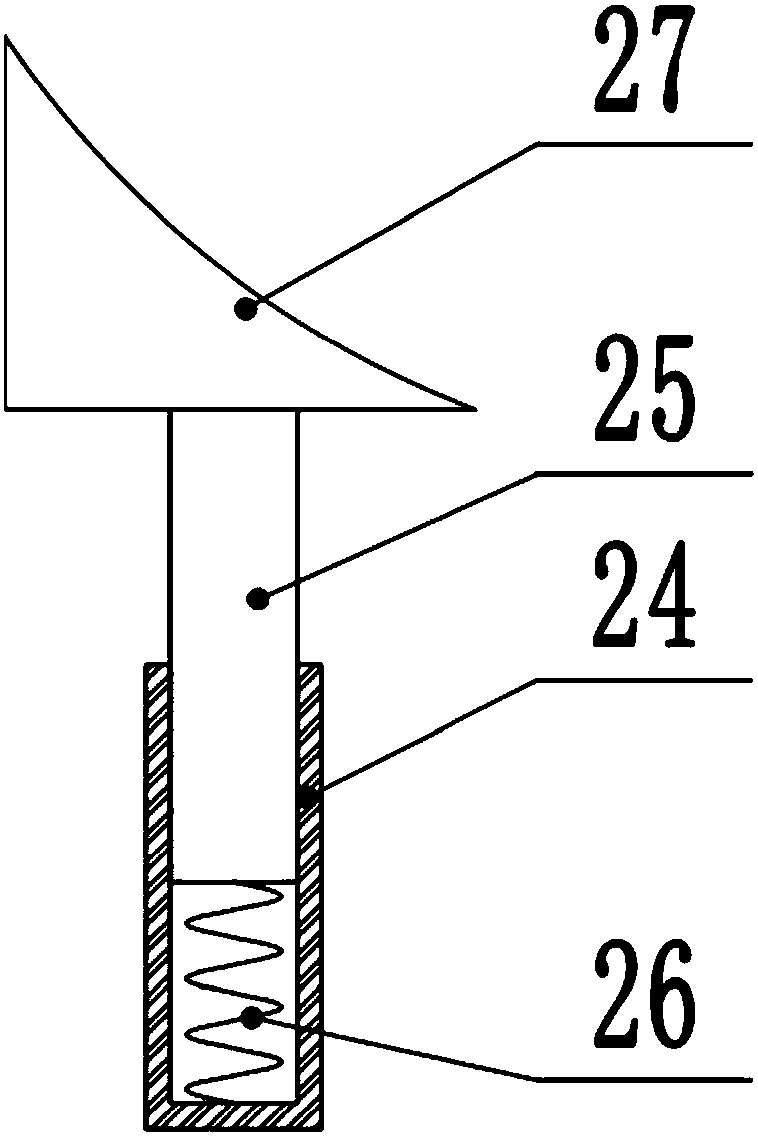

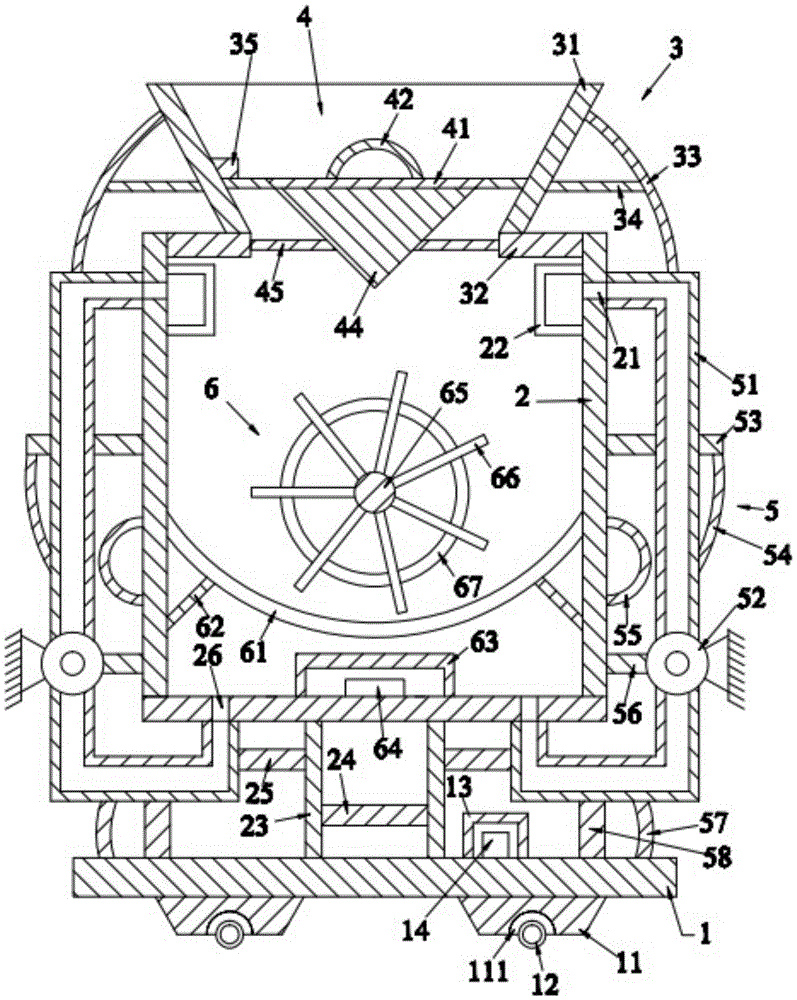

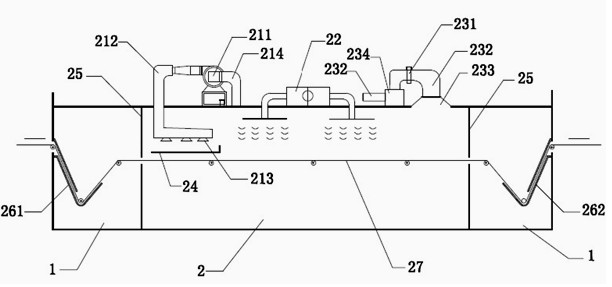

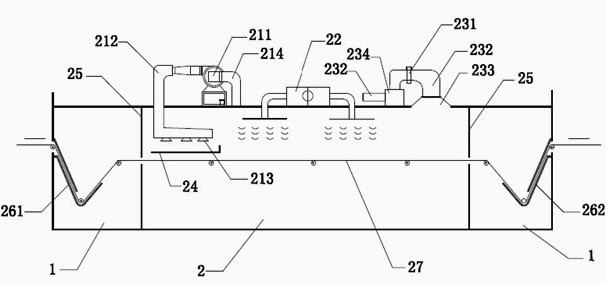

Bituminous concrete pavement renovation and construction all-in-one machine for road

InactiveCN107988884ADry thoroughlyProvides thorough drying in all directionsUsing liquid separation agentRoad cleaningRoad surfaceBituminous concrete

The invention relates to a bituminous concrete pavement renovation and construction all-in-one machine for a road. The bituminous concrete pavement renovation and construction all-in-one machine comprises a supporting device, a drying device, a shoveling device, a cleaning device and a paving device, wherein the drying device is mounted at the bottom of the left end of the supporting device; the shoveling device is mounted at the bottom of the supporting device; the shoveling device is located on the right side of the drying device; the cleaning device is mounted at the middle part of the supporting device; the paving device is mounted at the right end of the supporting device. The bituminous concrete pavement renovation and construction all-in-one machine for the road can solve the problems that a pavement cannot be dried completely, pavements with different slopes and gradients cannot be dried, pavements on two sides of the road cannot be dug, gravels on the road are difficult to grab, gravels on the side walls of a dug roadbed cannot be effectively cleared away, the dug roadbed is cleaned incompletely, bituminous concrete is stirred incompletely, and the bituminous concrete cannot be uniformly spread on the dug roadbed.

Owner:倪立秧

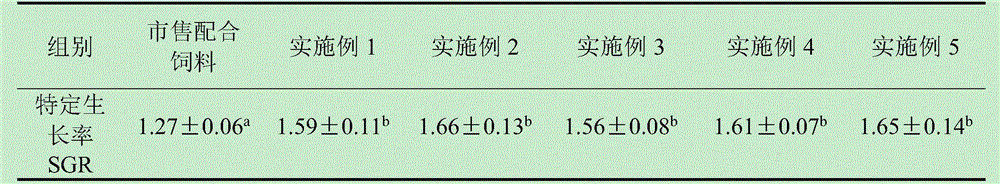

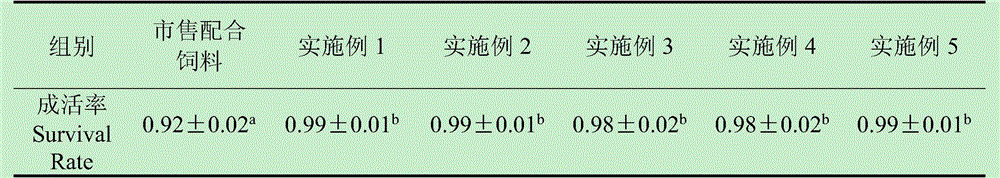

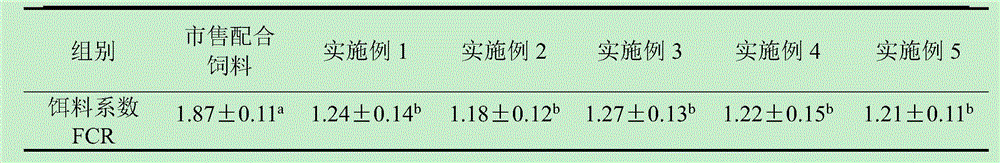

Tilapia mossambica compound feed and preparation method thereof

The invention relates to a compound feed of aquaculture animals and particularly relates to a tilapia mossambica compound feed. The invention further relates to a preparation method of the tilapia mossambica compound feed. The tilapia mossambica compound feed is prepared from the following components in parts by mass: 15-25 parts of wheat bran, 10-20 parts of enteromorpha powder, 10-20 parts of kelp powder, 8-16 parts of rice bran, 8-16 parts of cottonseed meal, 8-14 parts of sweet potato flour, 6-10 parts of dried potato powder, 4-8 parts of alfalfa meal, 4-8 parts of agar, 4-8 parts of dried carrot powder, 4-6 parts of shell powder, 4-6 parts of purslane, 2-4 parts of houttuynia cordata, 1-2 parts of mints, 1-2 parts of ginger, 1-2 parts of honey, 2-4 parts of fish oil and 1-3 parts of soybean oil. The tilapia mossambica compound feed has the advantages of low cost and low feed coefficient; and after tilapia mossambica is fed with the feed, the specific growth rate of the tilapia mossambica is high and the survival rate is high.

Owner:QINGDAO HAIZHIXING BIOLOGICAL SCI & TECH

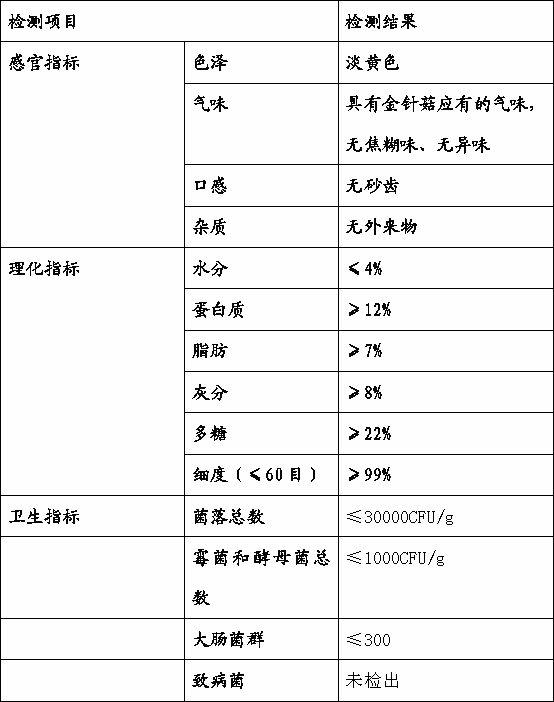

Method for processing golden mushroom root powder

The invention belongs to the field of processing agricultural products, in particular to a method for processing golden mushroom root powder. In the method, fresh golden mushroom roots serving as a raw material undergo boiling, dehydration, drying, grinding and sterilization to prepare the golden mushroom root powder, wherein in the drying step, the two-step drying method is adopted, so that the golden mushroom roots can be fully dried without damaging nutritive matters. The method has the advantages that: the golden mushroom roots which are discarded in the processing of golden mushrooms are used as a raw material, the waste golden mushroom roots are recycled, the source is wide, and the cost is low; and by processing the golden mushroom roots into the golden mushroom root powder, the wastes are changed into the valuables, and the problem that the discarded golden mushroom roots pollute the environment is solved.

Owner:山东创新源农业技术开发有限公司

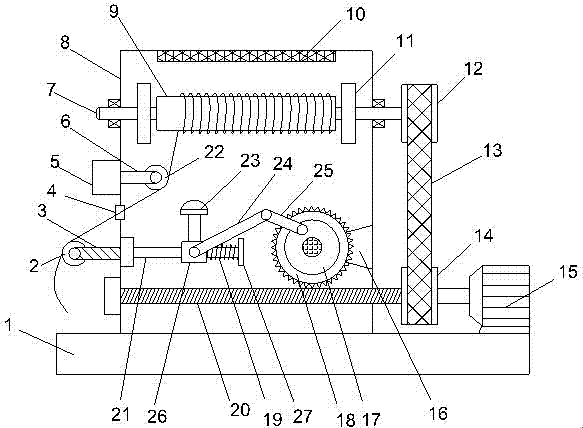

Chemical fiber winding device with drying function

InactiveCN107352324ADry thoroughlyImprove drying rateDrying solid materials with heatFilament handlingFiberDrive wheel

A chemical fiber winding device with a drying function, comprising a base, a drying chamber is arranged on the base, a driven shaft is arranged horizontally in the drying chamber, a driving motor is arranged on the base, and a driving wheel is fixedly installed on the motor shaft of the driving motor. There is a transmission belt on the pulley and the driven wheel; a worm is fixedly installed on the coaxial line on the driving wheel, a baffle is set at the right end of the cantilever beam, a slider is slidably installed on the cantilever beam, and a fan is installed on the top of the slider. There is a first connecting rod hinged; a bracket is provided on the inner wall on the right side of the drying chamber, and a worm gear is rotated on the bracket, and the worm gear is connected with the worm. While winding, the slider reciprocates on the cantilever beam, so that the fan can reciprocate left and right, and blows and dries the chemical fibers wound on the winding roller. The winding and drying are carried out synchronously, and the chemical fiber Drying is more thorough and the rate of drying is greatly increased.

Owner:盐城千之诺机械有限公司

Production technology of white microsphere high-strength white carbon black

The invention discloses a production technology of white microsphere high-strength white carbon black, which takes sodium silicate and concentrated sulfuric acid as the main raw materials, uses the steps of dissolving, synthesizing, filter pressing, slurrying, drying and the like, and especially adopts the mode of adding aluminum oxide in the slurring step and combining the pressure type drying with fluidized bed secondary drying in the drying step to produce the white microsphere high-strength white carbon black with high strength, low broken rate, environment protection and easy dispersion. The microsphere high-strength white carbon black is very suitable for tire industry, can enhance fluidity and improve mixing capability of rubber.

Owner:WUXI HENGCHENG SILICON IND CO LTD

Expressway broken concrete pavement automatic cleaning device

The invention relates to an expressway broken concrete pavement automatic cleaning device. The expressway broken concrete pavement automatic cleaning device comprises a supporting device, a drying device, a shoveling device and a sweeping device. The drying device is installed at the bottom of the left end of the supporting device, the shoveling device is installed at the bottom of the supportingdevice and located on the right side of the drying device, and the sweeping device is installed at the right end of the supporting device. The expressway broken concrete pavement automatic cleaning device can solve the problems that in the existing pavement construction process, pavements are not completely dried, the pavements with different gradients and slopes cannot be dried, the pavements onthe two sides of a road cannot be excavated, road fragments are difficult to grab, fragments of the side walls of an excavated roadbed cannot be effectively cleaned away, and the excavated roadbed isnot completely swept; and the functions that in the pavement construction process, the pavements can be thoroughly dried in all directions and excavated, and the fragments generated after excavationcan be thoroughly cleaned away can be achieved.

Owner:刘静

Tea drying device with deironing function

InactiveCN107660623ADry thoroughlyAvoid accumulationPre-extraction tea treatmentDrying machine combinationsPulp and paper industryAir blower

The invention discloses a tea drying device with a deironing function. The tea drying device comprises a base, a drying box, a primary drying roller, a flatly laying plate, a drying fan, an ultraviolet sterilization lamp and a scraping device, wherein the drying box is arranged on the base; the primary drying roller is fixedly arranged at the upper side of the drying box in an embedded way; a magnetic material is coated on the upper surface of the conveying belt; the flatly laying plate is also arranged inside the drying box; a heating box is fixedly arranged at the upper side of the drying box; the drying fan is also arranged at the left side of the heating box; the scraping device is arranged on a chip guide plate. The drying device can be used for performing primary drying and secondarydrying on the tea, so that the drying of the tea can be more thorough; the ultraviolet sterilization lamp performs sterilization on the tea; the residual germ growth on the surface of the tea can beprevented; the quality of the tea is improved; the shelf life of the tea is improved; meanwhile, iron chips in the tea can be removed through suction; the iron chips can be automatically scraped awaythrough the scraping device; simplicity and effectiveness are realized.

Owner:葛善文

Production technology of white microbead-shaped white carbon black

The invention relates to a production technology of a white microbead-shaped white carbon black. In the production technology, sodium silicate or concentrated sulfuric acid are used as the main raw materials and the steps such as dissolution, synthesis, filter pressing, slurrying, drying and the like are employed; in particular, in the process of drying, the pressure type drying technology and the fluidized bed drying technology are employed, so that the microbead-shaped white carbon black which is environment-friendly and extremely easily dispersive is obtained.

Owner:WUXI HENGCHENG SILICON IND CO LTD

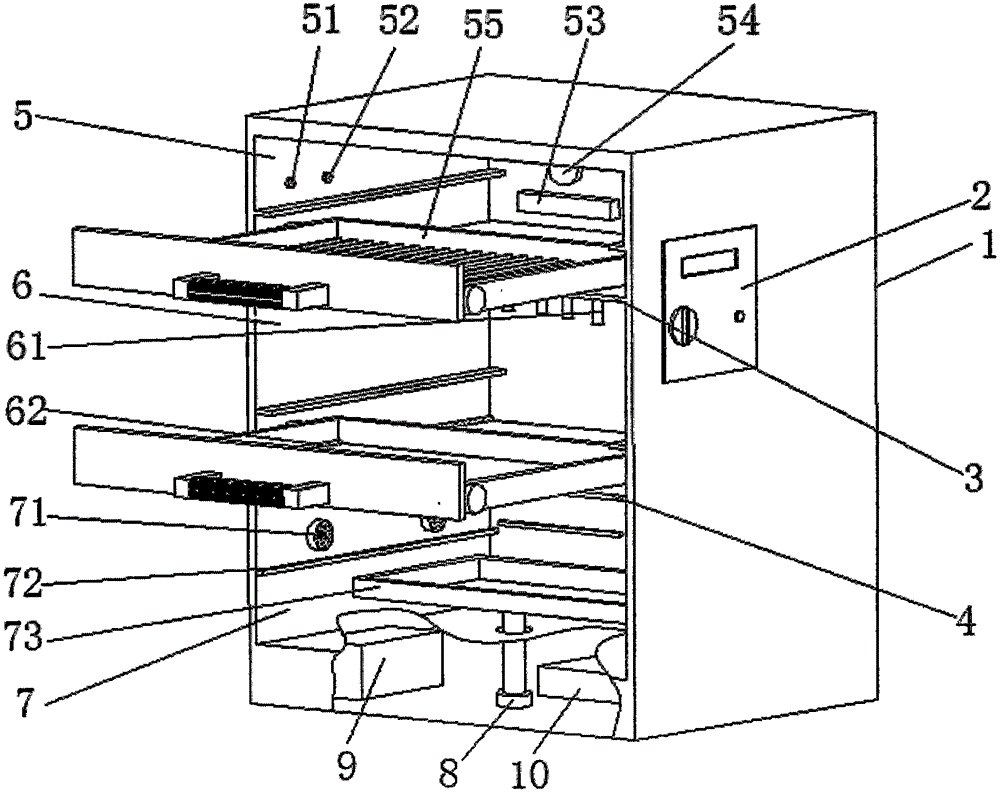

Endoscopic disinfection device for otolaryngological department

InactiveCN105343907ANeat and orderly dischargeEnsure hygiene and safetyLavatory sanitoryHeatWater leakageDisinfectant

The invention discloses an endoscopic disinfection device for the otolaryngological department. The endoscopic disinfection device comprises a shell, a sealing door is hinged to the side face of the shell, the middle of the sealing door is provided with a transparent observation window, the side face of the shell is provided with a control panel, an inner cavity of the shell is divided into a sterilizing room, a cleaning room and a storage room from top to bottom through a first partition plate and a second partition plate, the surface of the second partition plate and the surface of a sliding plate located in the cleaning room are high in the middle and low on the two sides, the bottom of the shell is provided with an equipment mounting cavity, the equipment mounting cavity is provided with a drive motor, a warm air machine and a liquid storage tank, and the liquid storage tank is internally provided with a booster pump; a control panel is electrically connected with the drive motor, the warm air machine and the booster pump. By means of the endoscopic disinfection device, heating sterilization or ultrasonic sterilization can be selected for endoscopes which are difficult to sterilize thoroughly according to requirements, or heating sterilization and ultrasonic sterilization are combined to conduct sterilization, and sterilization is made to be more thorough; sterilization waste water can be drained through water leakage tanks and cleaning spray heads, meanwhile disinfectant can be cleaned away, and subsequent use cannot be affected.

Owner:徐建华

Method for processing thunberg fritillary bulb

InactiveCN101878807AShort drying cycleDry thoroughlyFruits/vegetable preservation by dehydrationNutrientChemistry

The invention discloses a method for processing thunberg fritillary bulb, which comprises the following steps of: cleaning the picked fresh thunberg fritillary bulb; airing the surface of the thunberg fritillary bulb; slicing the aired thunberg fritillary bulb; performing microwave drying on the sliced thunberg fritillary bulb by adopting microwave drying equipment; spreading the thunberg fritillary bulb subjected to microwave drying; drying the thunberg fritillary bulb which is spread for a certain period of time in a drying oven; cooling the dried thunberg fritillary bulb to normal temperature; and performing vacuum packaging. The method for processing the thunberg fritillary bulb has the advantages of no toxin or pollution, capacity of maintaining original flavor of the thunberg fritillary bulb without consuming plenty of water for soaking, capacity of maintaining nutrient components of the thunberg fritillary bulb to the greatest degree, complete dryness, long quality guarantee period, difficult deterioration, and short production cycle.

Owner:戴永峰

Textile drying device

InactiveCN105674705ASimple structureEasy to useDrying gas arrangementsDrying machines with non-progressive movementsAgricultural engineeringElastic rods

A textile drying device, comprising a bottom plate, a frame body, a feeding device, a cover plate device, an air circulation device, and a heating device. The bottom plate is provided with a first support block, a first roller, a fixed frame, and a power supply. There are a first through hole, a filter frame, a first support rod, a first cross bar, a second cross bar and a second through hole, and the feeding device includes a feed hopper, a horizontal plate, a first bending rod, a third cross bar and The first fixed block, the cover plate device includes a cover plate, a grip ring, a diverter block and a first horizontal plate, and the air circulation device includes a pipe, a fan, a fourth horizontal bar, a second bending bar, an elastic bar, a first connecting bar, The third bending rod and the second supporting rod, the heating device includes an iron net, an inclined rod, a heat dissipation frame, a heating rod, a rotating shaft, a rotating rod and a supporting ring. The present invention can thoroughly dry the textiles with high drying efficiency. And the drying effect is good.

Owner:RUIAN AOYA CLOTHING CO LTD

Device for crushing, drying and stirring building material

InactiveCN106621991AEasy to mix and pourEasy to filterRotary stirring mixersTransportation and packagingSlide platePulp and paper industry

The invention discloses a device for crushing, drying and stirring a building material. The device comprises a tank body, a rolling bin, an extruding bin, a blanking channel and a stirring bin; the tank body is provided with a first drive motor and a feed hopper; the rolling bin is internally provided with a sieve plate and a pressing plate; a telescopic shaft is arranged at the upper end of the pressing plate; connecting pieces are arranged at the two ends of the pressing plate; the extruding bin is arranged at the lower end of the sieve plate; an extruding roll is arranged in the extruding bin; the blanking channel is arranged at the lower end of the extruding bin; the blanking channel is provided with a slide plate, a drying device and a support plate; the drying device is arranged at the lower end of the slide plate, and comprises a heating tube, an air outlet cavity and an air blower; the stirring bin is arranged at the lower end of the blanking channel; the stirring bin is internally provided with a discharge tube and a stirring shaft; the stirring shaft is connected with a second drive motor; a stirring rod is arranged on the stirring shaft; and the second drive motor is fixed at the left end of the tank body. The device integrates crushing, drying and stirring, the efficiency is high, the crushing and the screening are conducted, the crushing is thorough, the material is convenient to dry, and the drying speed is high.

Owner:河南常青藤信息科技有限公司

Coating drying technology and device thereof

The invention discloses a coating drying technology and device thereof. The technology is used for drying a coating by combining a microwave drying technology with a circulating air-supply type drying technology, and a mode of heating the microwave dried coating from inside to outside is combined with a mode of drying the microwave dried coating with circulating air from outside to inside so that the purpose of more rapidly thoroughly drying the coating is achieved. The coating drying technology disclosed in the invention has the characteristics of uniform heating, high drying speed, high heat efficiency, good product quality and the like; and the circulating air can be used for immediately eliminating a solvent evaporated by the coating in a microwave heating process, thus the problems of local overheating caused by high microwave heating speed and incapability of immediately eliminating the solvent is avoided, the quality of the coating is ensured, and the thorough and uniform drying effect is obtained. The device has simple structure, can obtain better drying effect of the coating, and can improve the drying speed, thereby greatly saving the production period, improving the production efficiency and being capable of effectively avoiding microwave leakage.

Owner:惠州市德赛聚能电池有限公司

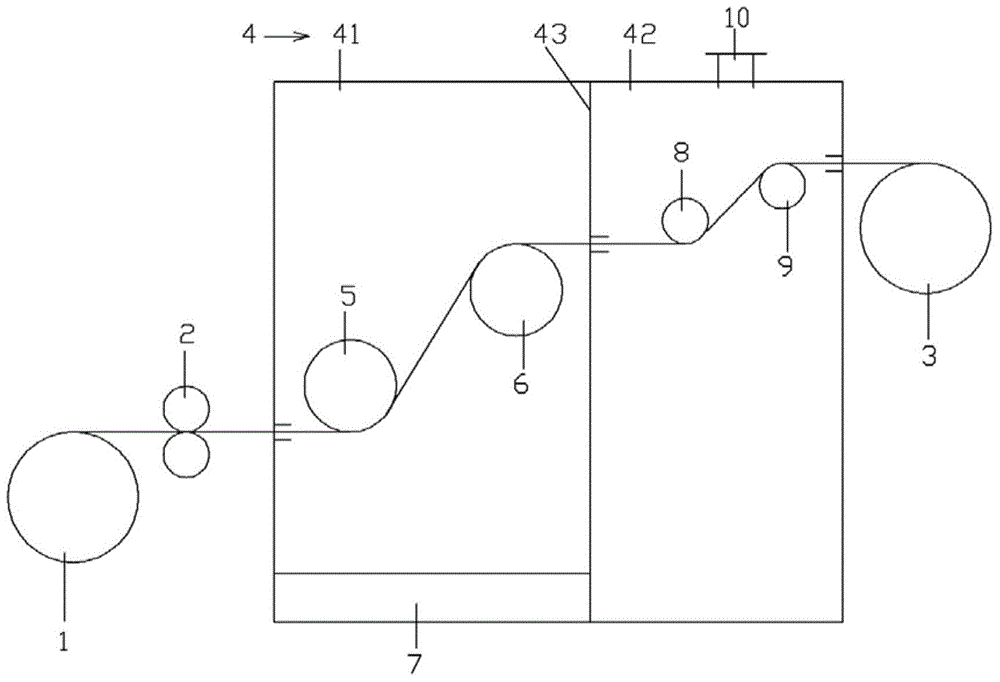

Drying device for water jet loom

ActiveCN103983093AFor long-term storageSmall footprintDrying machines with progressive movementsDrying solid materialsPulp and paper industryElectromagnetic heating

Provided is a drying device for a water jet loom. A first front drying roller and a first reverse side drying roller are installed in a main drying chamber, a second front drying roller and a second reverse side drying roller are installed in an auxiliary drying chamber, the lower portion of the main drying chamber is provided with a water receiving groove, and the auxiliary drying chamber is provided with an air outlet to be communicated with the outside of the chamber. The first front drying roller, the first reverse side drying roller, the second front drying roller and the second reverse side drying roller are identical in structure and are electromagnetic heating rollers, and cloth is released through a cloth inlet roller, sequentially passes across a cloth inlet press roller, the first front drying roller, the first reverse side drying roller, the second front drying roller and the second reverse side drying roller and then is wound through a cloth collecting roller. An electromagnetic coil is adopted for heating, a boiler for heat supply and drying is not needed, an occupied space of the device is small, and the device dries the cloth more thoroughly and is favorable for long-term storage of a cloth roll.

Owner:刘骏

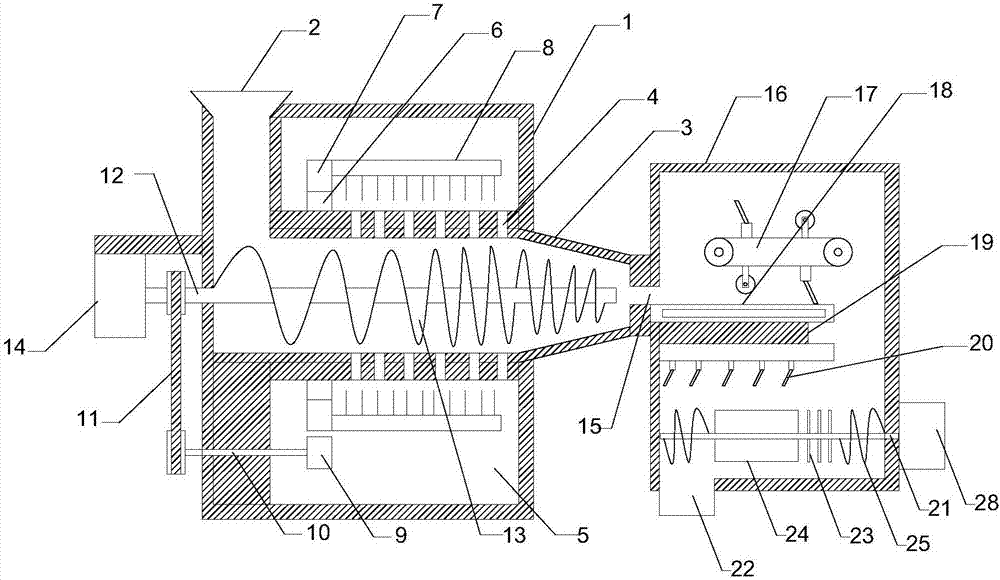

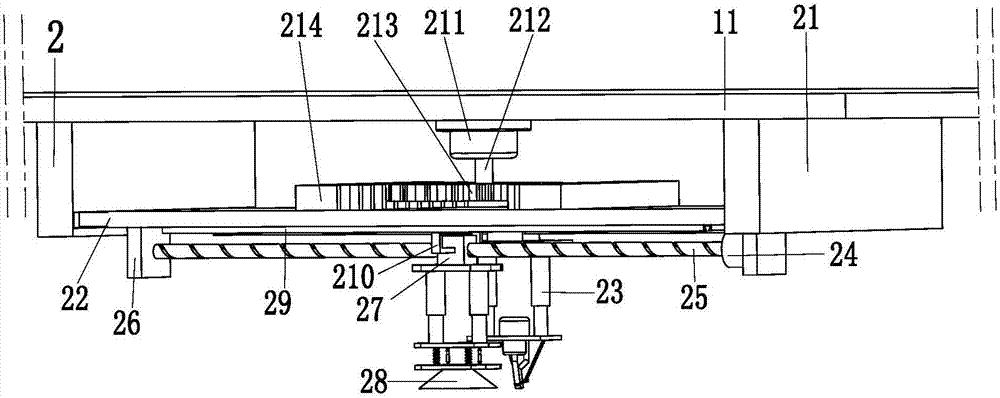

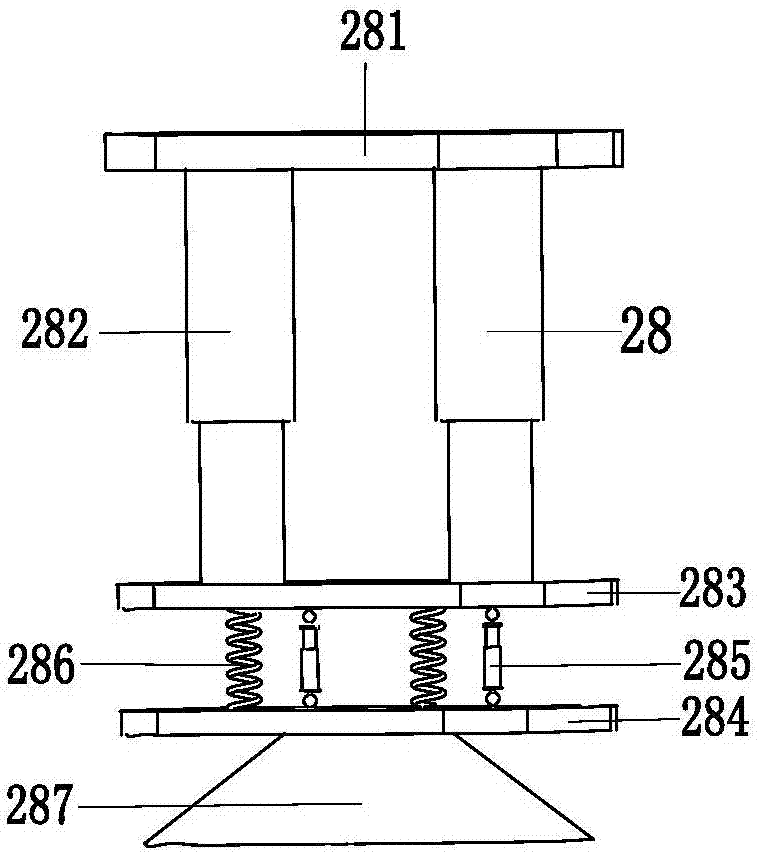

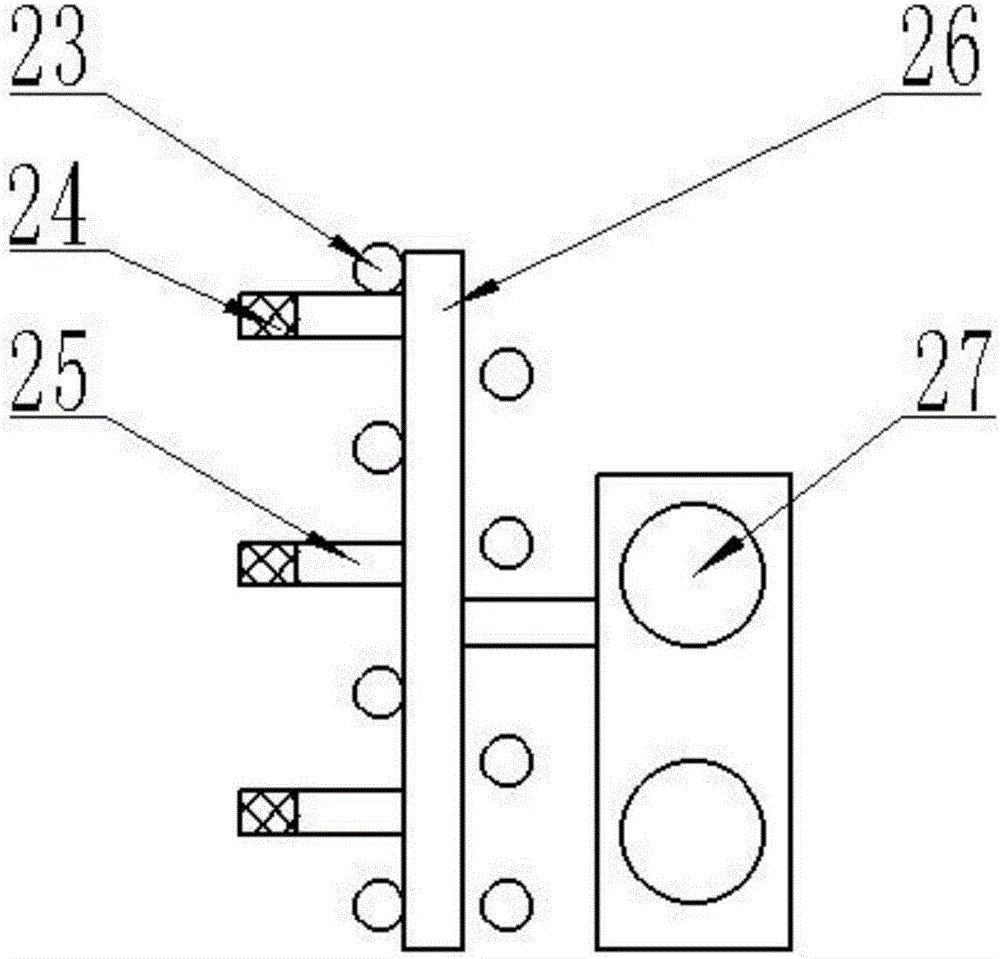

Full-automatic power shell ultrasonic cleaning machine

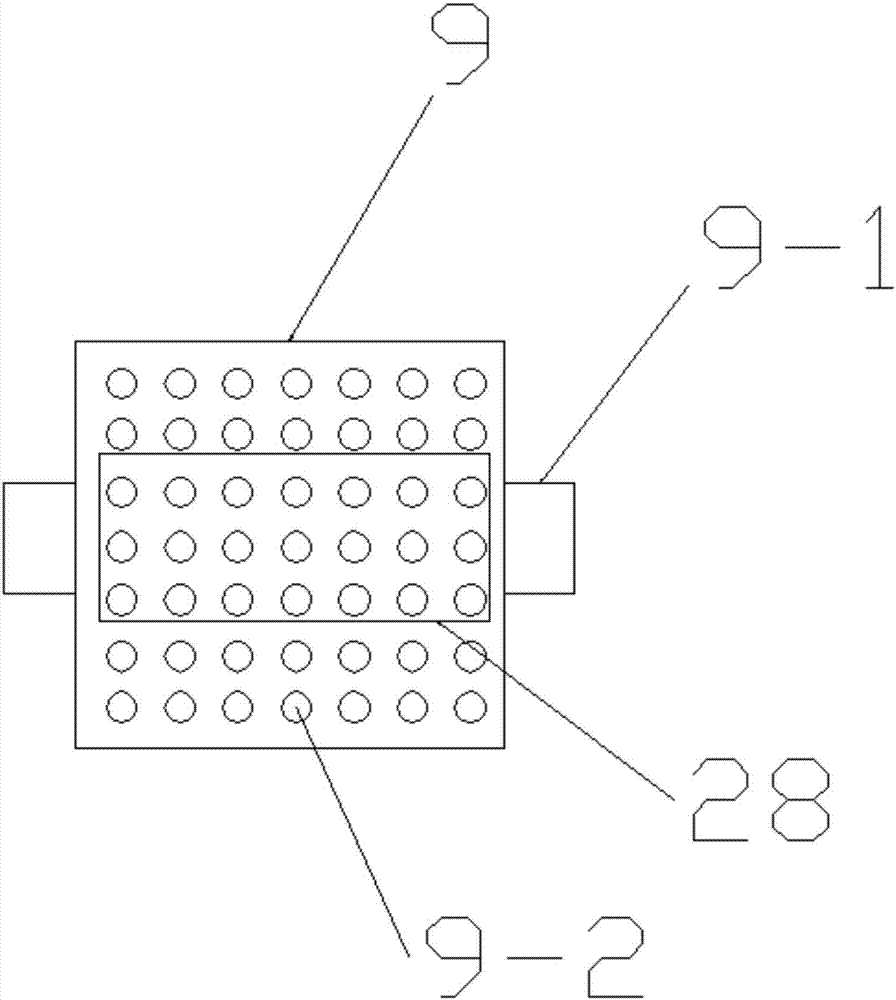

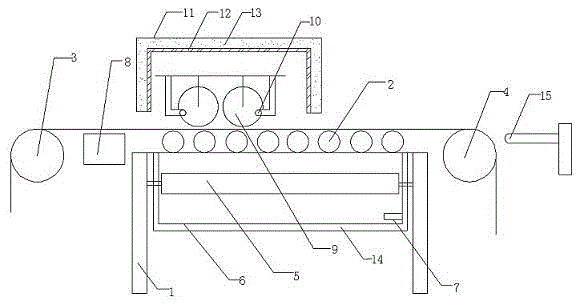

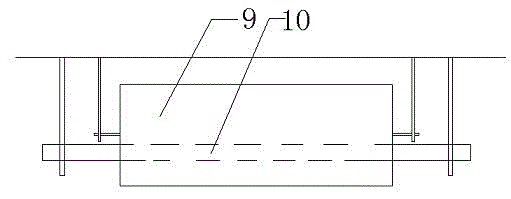

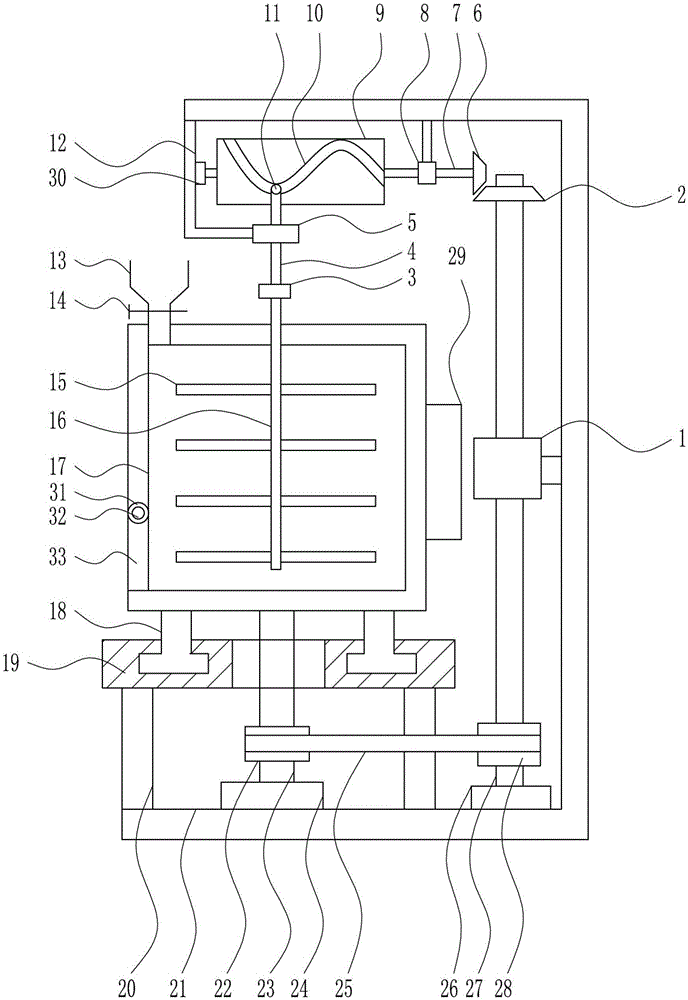

PendingCN106964598ADry thoroughlyResidue reductionDrying solid materials without heatCleaning using liquidsPhysicsElectric machinery

The invention discloses a full-automatic power shell ultrasonic cleaning machine. The ultrasonic cleaning machine comprises a frame, and a loading table, at least one cleaning tank for holding cleaning liquid, spin-dry tanks and an unloading table arranged on the frame in a feeding direction in sequence. The ultrasonic cleaning machine further comprises cleaning containers with hollowed surfaces for loading workpieces, and a driving mechanism arranged on the frame for driving the cleaning containers to move in the feeding direction; the driving mechanism is also used for driving the cleaning containers to lift in the vertical direction; and the spin-dry tanks comprise tank bodies, first centrifugal cylinders arranged in the tank bodies for driving the cleaning containers to centrifugally rotate, and first centrifugal motors for driving the first centrifugal cylinders to rotate. According to the full-automatic power shell ultrasonic cleaning machine, the centrifugal cylinders are arranged in the spin-dry tanks; and the centrifugal motors drive the centrifugal cylinders to rotate for centrifugal spin-dry of cleaned workpieces, so that the workpieces are dried more thoroughly, the cleaning liquid residues are reduced, the workpiece quality is improved, and the cost is saved.

Owner:ZHANGJIAGANG KEYUXIN ULTRASONIC

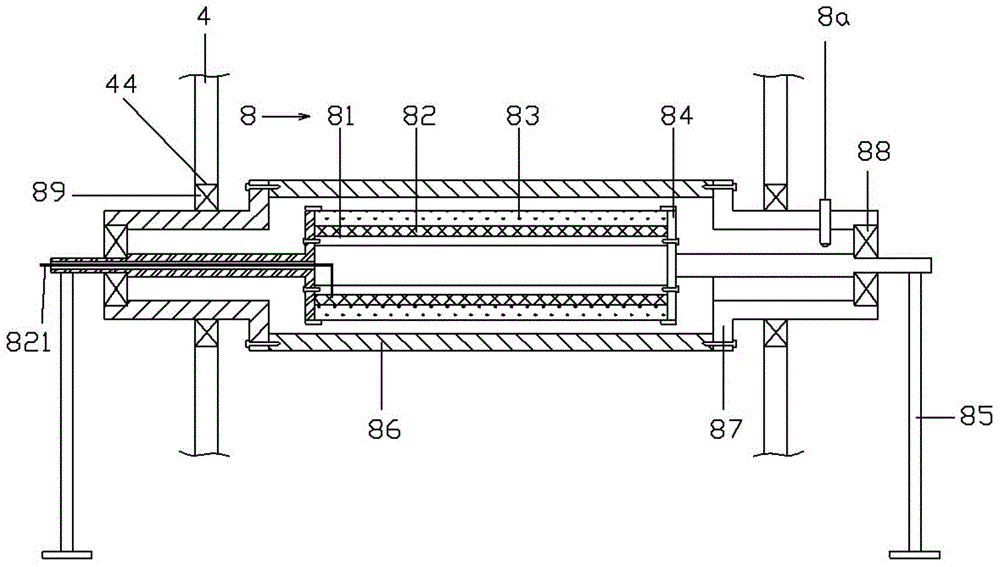

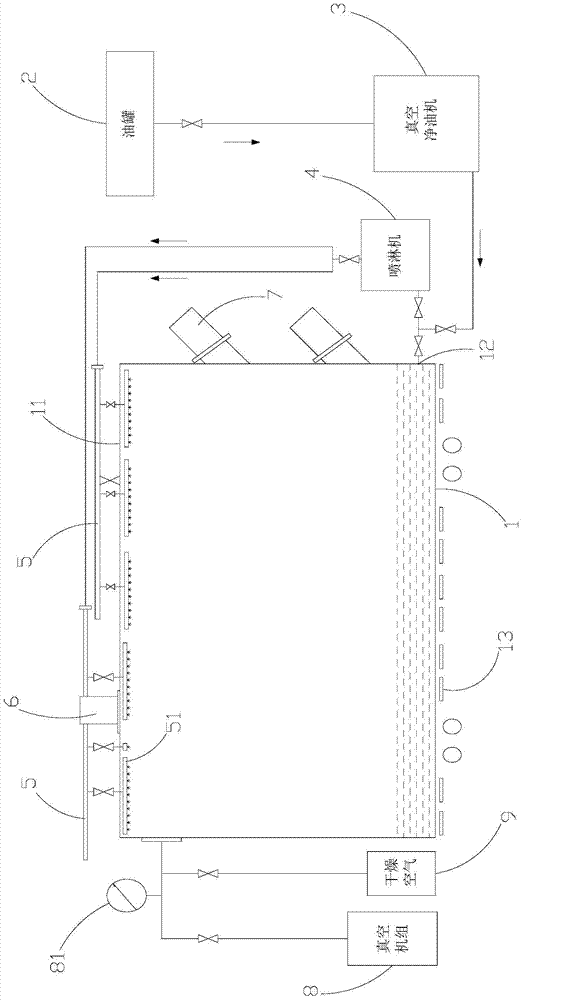

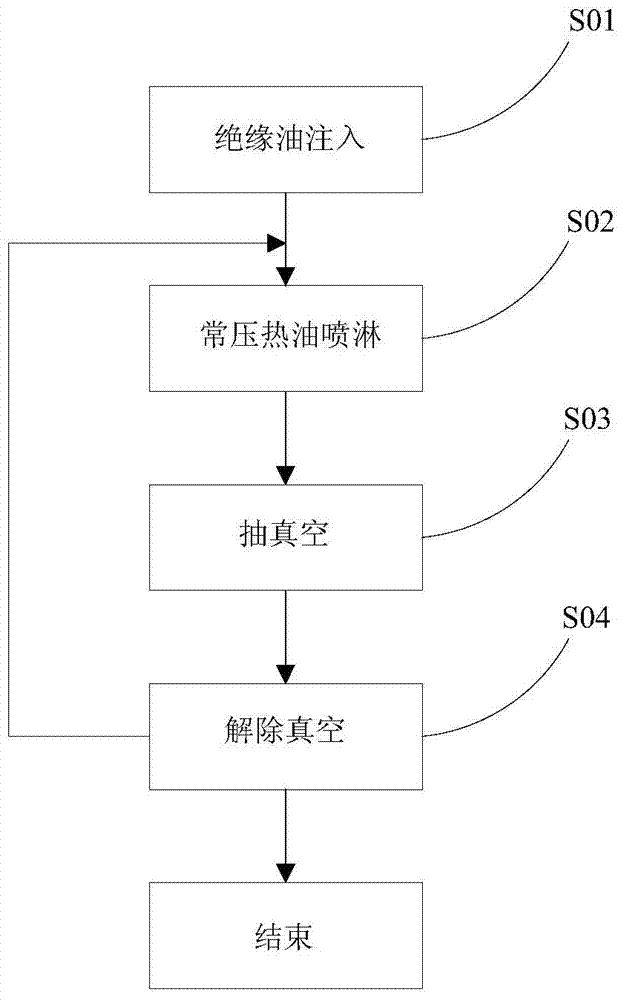

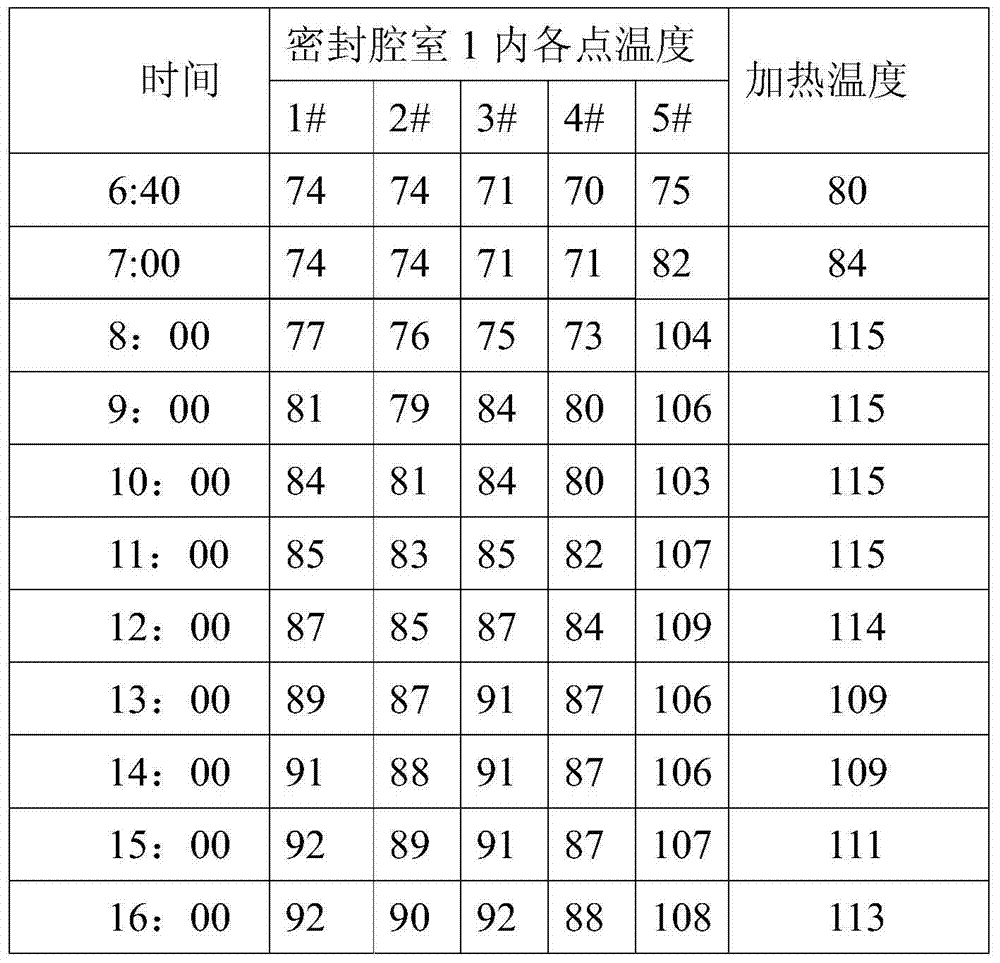

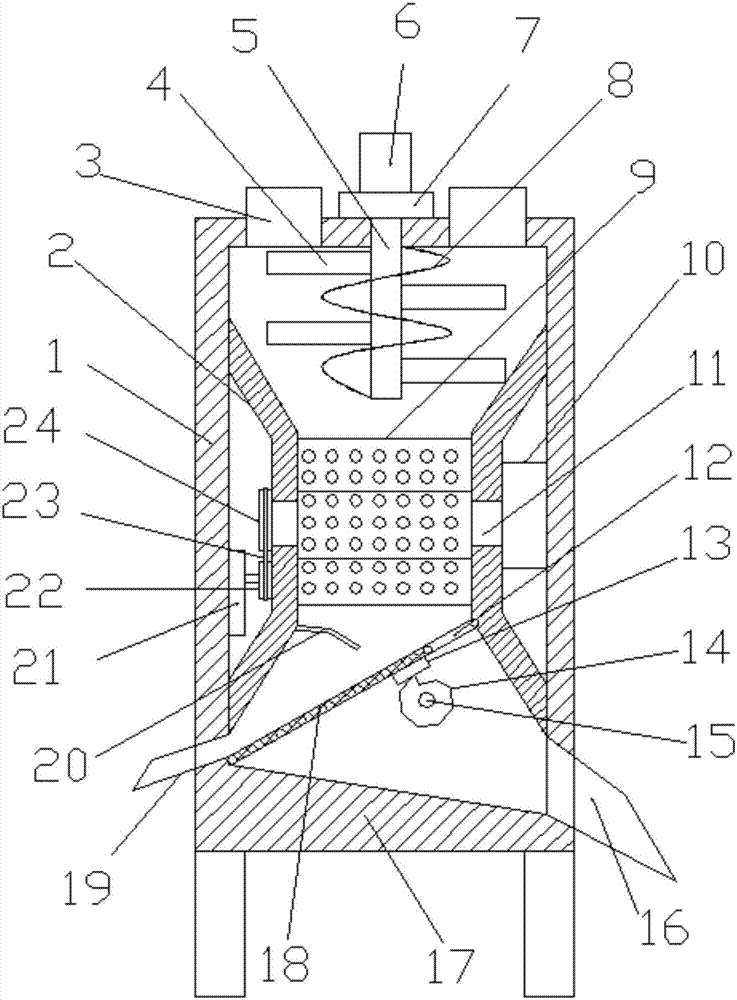

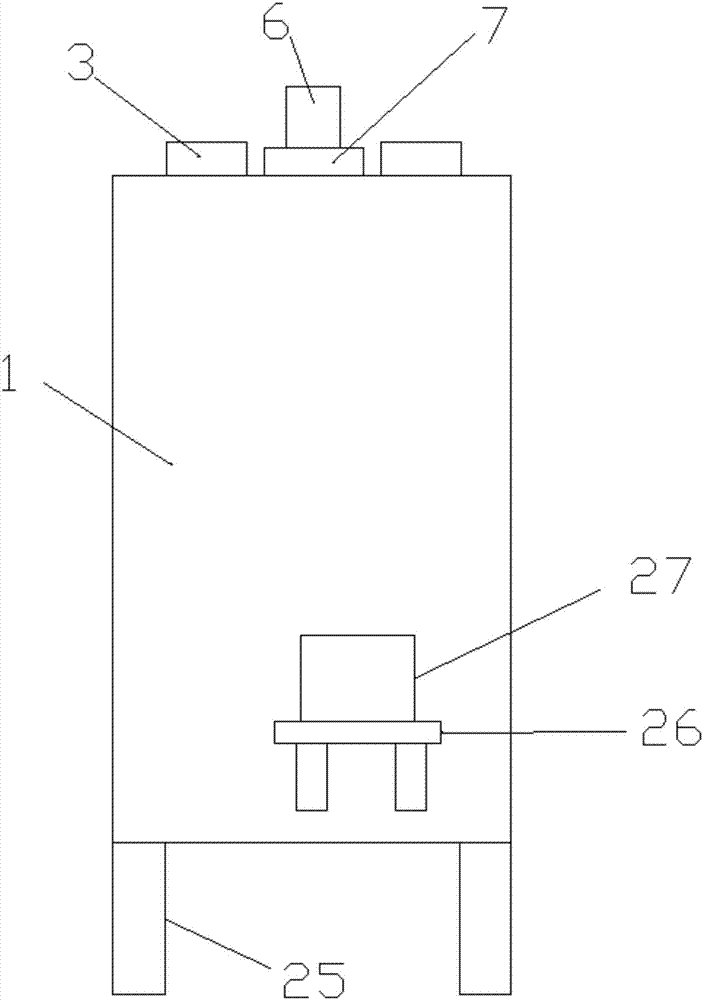

Hot oil spray and drying device and method for converter transformer

InactiveCN104332284ASimple on-site operationGood rheological drying effectDrying using combination processesTransformers/inductances coolingVacuum pumpingTransformer

The invention discloses a hot oil spray and drying device for a converter transformer. The hot oil spray and drying device for the converter transformer comprises an oil supply device, a spray pipe, a vacuum unit, a drying air generator and a converter transformer body, wherein a sealing chamber is arranged on the periphery of the converter transformer body, the sealing chamber comprises an upper cover installed on the upper side, a spray pipeline is installed on the upper cover and is respectively communicated with the oil supply device and the sealing chamber, the vacuum unit and the drying air generator are respectively communicated with the sealing chamber, three insulating pieces which are used for inspecting the drying effect of the sealing chamber are installed in the sealing chamber, the insulating pieces are respectively installed at the bottom of a tap switch of the converter transformer, the bottom of windings and the top of the windings, and a heating plate is installed on the lower side of the sealing chamber. The invention further discloses a hot oil spray and drying method of the converter transformer, which comprises the steps of insulating oil filling, normal-pressure hot oil spray, vacuum pumping and vacuum release. The hot oil spray and drying device and method for the converter transformer have the advantages of quick spray speed, thorough drying, high reliability and practicability and easiness in field operation.

Owner:TIANSHENGQIAO BUREAU CSG EHV POWER TRANSMISSION CO

Peanut butter and preparing method thereof

The invention belongs to the technical field of food processing, and in particular relate to peanut butter and a preparing method thereof. The peanut butter comprises the following main ingredients in parts by weight: 5-20 parts of peanut kernel, 20-60 parts of peanut protein powder, and 100-300 parts of water; and the peanut butter comprises accessory materials in parts by weight: 2-8 parts salt, 1-8 parts of dextrin, 1-5 parts of a sweetening agent, 5-10 parts of peanut oil, red kojic rice with the weight accounting for 0.1-0.4% of the weight of the peanut protein powder, 1-3 parts of white spirit, 8-12 parts of white sesame seed, 2-8 parts of garlic, 2-8 parts o fginger, and 1-4 parts of paprika powder. According to the peanut butter and a preparing method, the peanut protein powder is taken as the raw material, and the peanut oil and the roasted peanut kernel are taken as the accessory materials and added into the peanut butter in various forms, so that the peanut butter has a pure flavor, and an enhanced mouthfeel; and in addition, the preparing method disclosed by the invention adopts the method, in which the peanut protein powder is dried to be used for directly preparing the peanut butter, which is different from the traditional method in which the peanut kernel is dried and then grinded. The peanut butter and the preparing method provided by the invention have the advantage that the peanut protein powder is dried completely, so that the flavor completely emits out, and the peanut butter has delicate and pure mouthfeel.

Owner:SHANDONG GAOTANG LANSHAN GRP CORP

Rapid efficient melon seed drying and screening device

The invention discloses a fast and high-efficiency melon seed drying and screening device, which comprises a casing, the bottom of the casing is symmetrically arranged with supporting feet; Enclosing the machine room, a roller is arranged between the two convex folded plates, and a plurality of ventilation holes are evenly arranged on the circumferential side wall of the roller, and the rollers at both ends of the roller are set in the middle position of the convex folded plates. On the shaft bearing, the roller shaft at the left end of the drum extends into the machine compartment on the left side, and the end is fitted with a driven pulley. A transmission belt is set between the pulleys. The invention provides a fast and efficient melon seed drying and screening device with a novel structure; the invention cleverly arranges a uniform mechanism and a drying mechanism so that the drying is more uniform and the drying efficiency is high. In addition, the invention The vibrating screening mechanism is cleverly set up to achieve high screening efficiency, and at the same time, the melon seeds are further dried thoroughly.

Owner:叶有福

Fabric desizing and drying device

ActiveCN104457187ADry thoroughlyAvoid distributingDrying machines with progressive movementsDrying solid materialsElectric heatingHeater Rod

The invention provides a fabric desizing and drying device. The fabric desizing and drying device comprises a support. Multiple rollers are arranged on the support, a cloth feeding roller is arranged on one side of the support, and a cloth collecting roller is arranged on the other side of the support. An electric heating plate is arranged at the portion, below the rollers, of the support, the electric heating plate is covered with a protective cover, a temperature sensor is arranged in the protective cover, a far infrared heating plate is arranged below the portion between the cloth feeding roller and the support, an air blower is arranged on one side of the cloth collecting roller, two pressing rollers of hollow structures are arranged above the rollers, and a heating rod is inserted into each pressing roller. The fabric desizing and drying device is simple in structure and reasonable in design, hardened parts in fabric can be dried, the drying quality of the fabric is guaranteed, the drying speed is high, and work efficiency is improved.

Owner:苏州泳坤纺织后整理股份有限公司

Animal husbandry bio-organic fertilizer efficient drying device

InactiveCN106196946AEasy to operateEasy to useManure dryingDrying machines with non-progressive movementsOrganic manureEngineering

The invention relates to an animal husbandry bio-organic fertilizer drying device, in particular to an animal husbandry bio-organic fertilizer efficient drying device. The technical problem to be solved by the invention is to provide the animal husbandry bio-organic fertilizer efficient drying device with convenience for operation, quick drying and thorough drying. In order to solve the technical problems, the animal husbandry bio-organic fertilizer efficient drying device comprises a first bearing, a first motor, a lifting rod, a guide sleeve, a second bevel gear, an electric control valve, a stirring blade, a rotating rod, a drying box, a slide block, a circular slide rail, support rods, a mounting frame, a small belt wheel, a second rotating shaft, a third bearing base, a flat belt and the like; and the support rods are symmetrically arranged on the left side of the bottom in the mounting frame. The animal husbandry bio-organic fertilizer efficient drying device achieves the effects of convenience for operation, quick drying and thorough drying, is low in manufacturing cost, reasonable in structure, easy to maintain and convenient for use, reduces the investment of manpower and material resources, and reduces the cost.

Owner:陈朝阳

Chemical raw material drying device with spiral discharge device

ActiveCN106369953AEasy dischargeKeep dryDrying solid materialsDrying machines with local agitationWater vaporEngineering

The invention discloses a chemical raw material drying device with a spiral discharge device. The chemical raw material drying device comprises a base; a discharge bin is arranged on the top of the base; a heating filter plate is arranged on the top of the discharge bin; a drying box is arranged on the top of the heating filter plate; a drying plate is arranged inside the drying box; the bottom of the drying plate is connected with the heating filter plate; the top end of the drying plate is connected with a flow-splitting plate; the flow-splitting plate is arranged on the top of the drying box; a charge bin is arranged on the top of the flow-splitting plate; and a crushing shaft, crushing blades and a charge device are arranged inside the charge bin. The chemical raw material drying device disclosed by the invention is simple in structure, is reasonable in design and is convenient to use; the flow-splitting plate is arranged, so that chemical raw materials can be uniformly discharged and are not input to be clustered, and therefore, the drying device can be used for drying more conveniently; a gas exhaust device is arranged, so that water vapor generated in a drying process can be exhausted; and a drying plate and a drying box can be arranged for drying materials, so that the materials are dried completely.

Owner:JIANSU JINSHAN BEER RAW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com