Tea drying device with deironing function

A technology of tea drying device and scraping device, which is applied in the direction of drying, drying machine, heating device, etc., which can solve the problems of high work intensity, lower tea grade, and low iron removal efficiency, so as to improve the effect and efficiency , the effect of preventing the growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

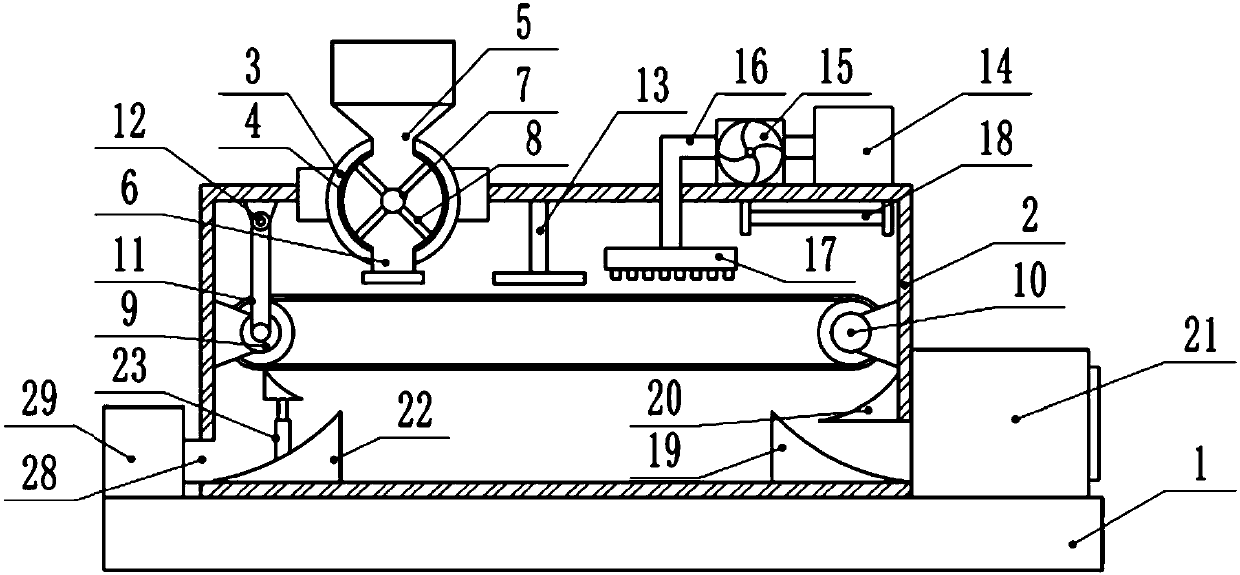

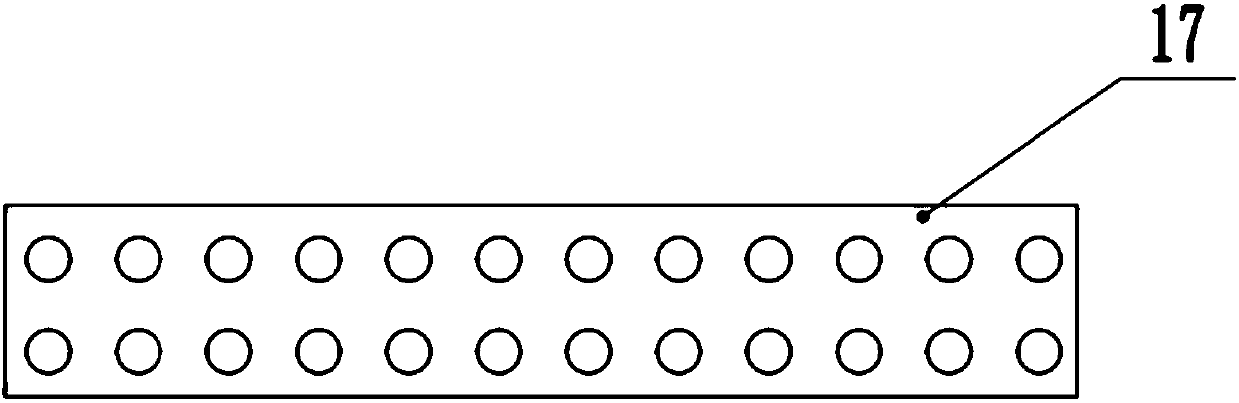

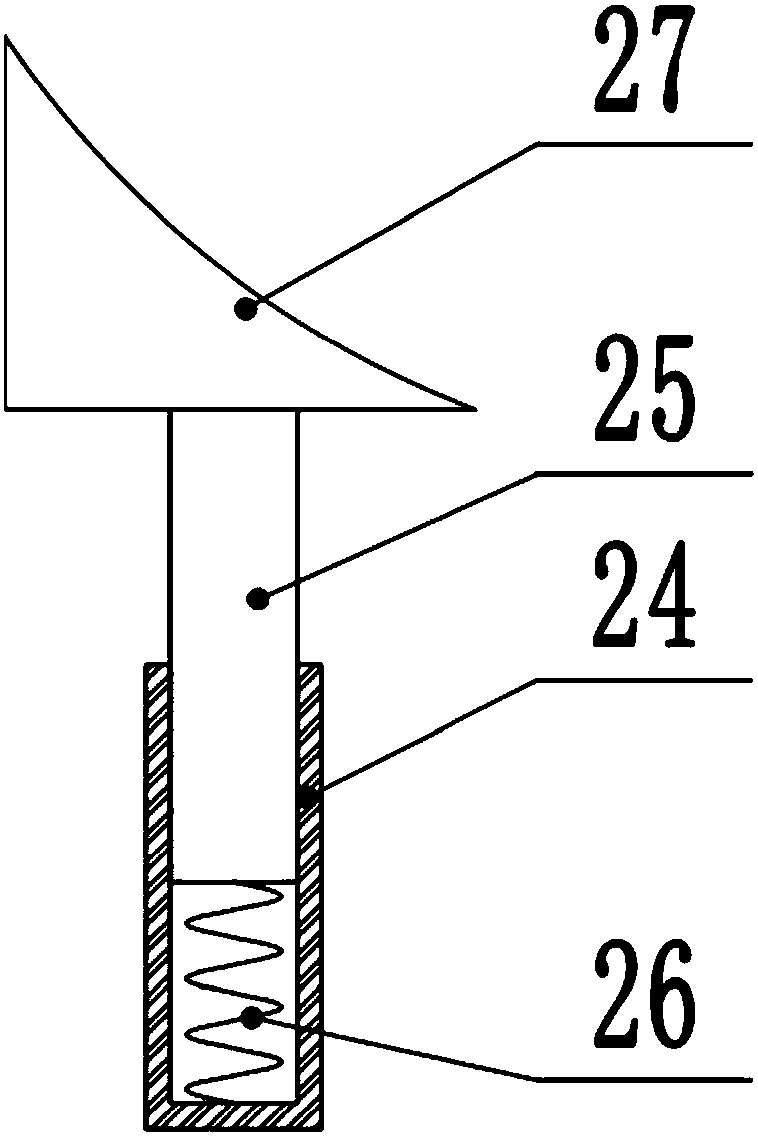

[0020] see Figure 1-3 , a tea drying device with its own iron removal function, comprising a base 1, a drying box 2, a preliminary drying drum 3, a flat plate 13, a drying fan 15, an ultraviolet germicidal lamp 18 and a scraping device 23, the The base 1 is provided with a drying box 2, and the drying box 2 is fixedly installed on the base 1 by bolts. The outer side of the drying box 2 is provided with an insulating layer, thereby effectively avoiding heat loss and improving energy utilization. The upper side of the dry box 2 is inlaid and fixed with a preliminary drying drum 3. The interior of the preliminary drying drum 3 is cylindrical and the preliminary drying drum 3 is provided with a heating layer 4. The heating layer 4 is provided with a heating wire inside. The wire is energized so as to heat the interior of the preliminary drying drum 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com