Patents

Literature

675 results about "Drying drum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rotary drum, also named rotary dryer, is a machine for drying process, which people call rotary drying. It’s a special kiln that usually co-works with burning system, like coal burner or oil burner. The heat goes through its inner cylinder, dehydrating the material inside. The materials can be added in and withdrawn during the drying process, so it can work continuously.

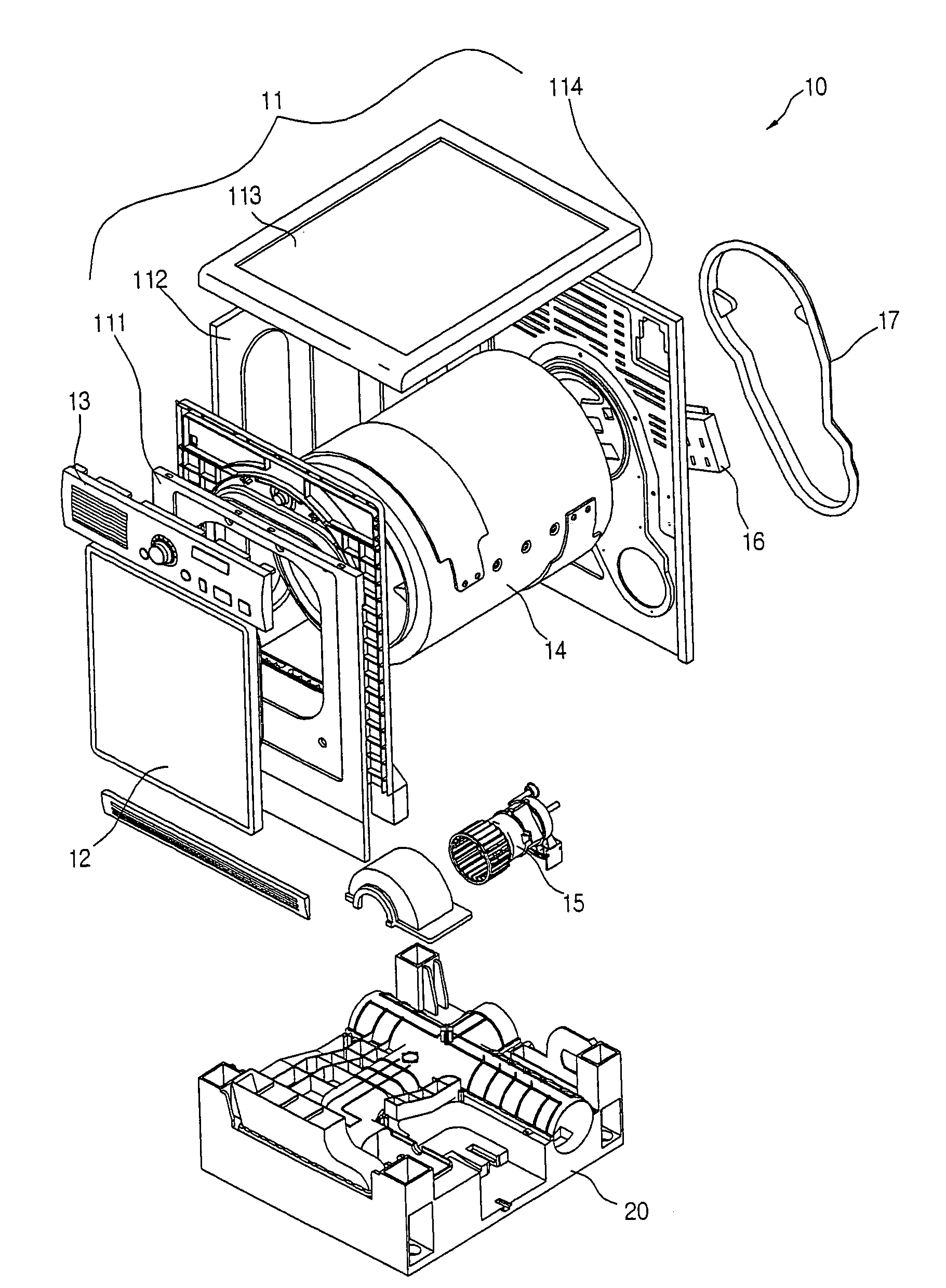

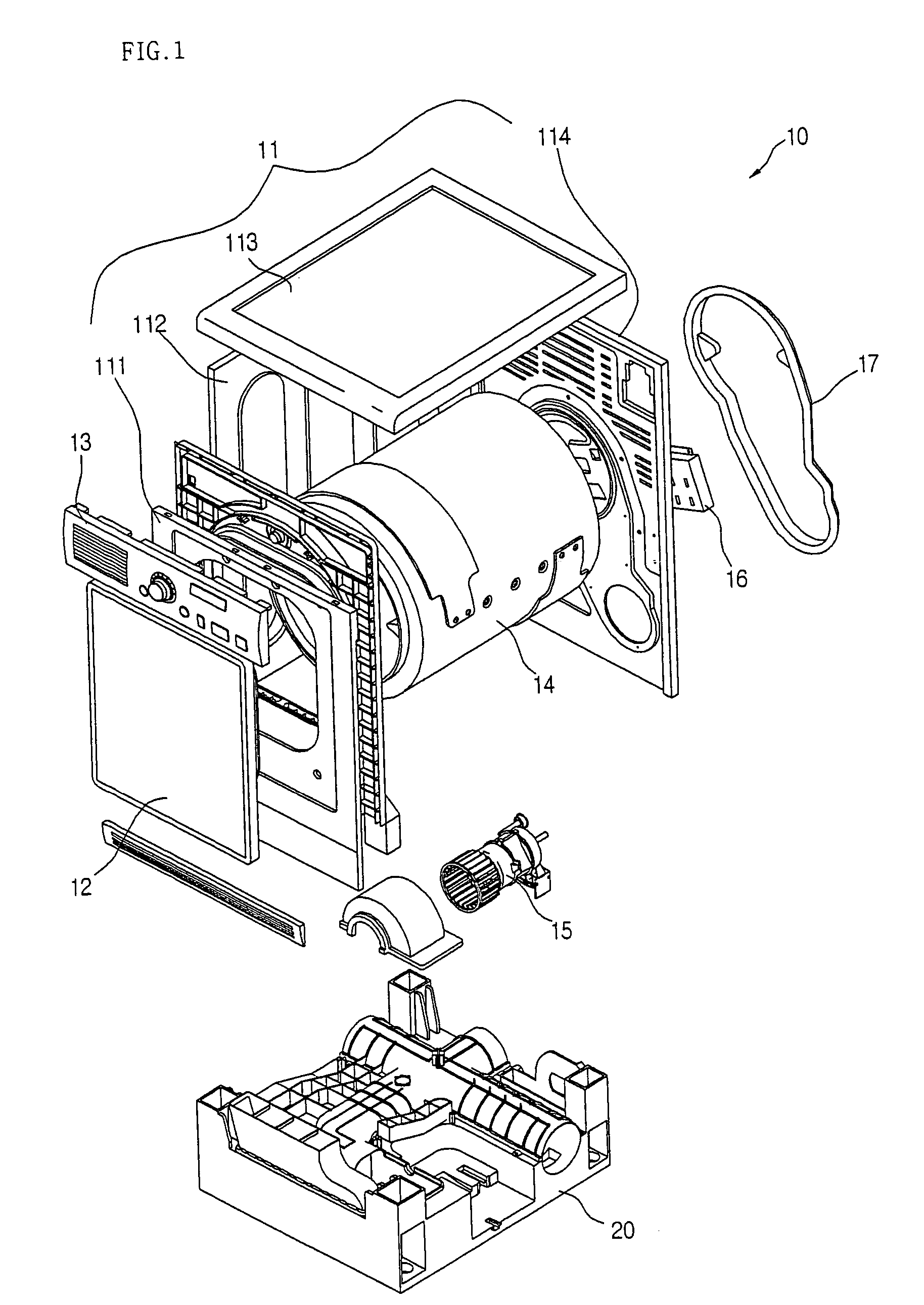

Operation method for combination dryer

InactiveUS20060112585A1Eliminate the problemDrying gas arrangementsOther washing machinesCyclic processRefresh cycle

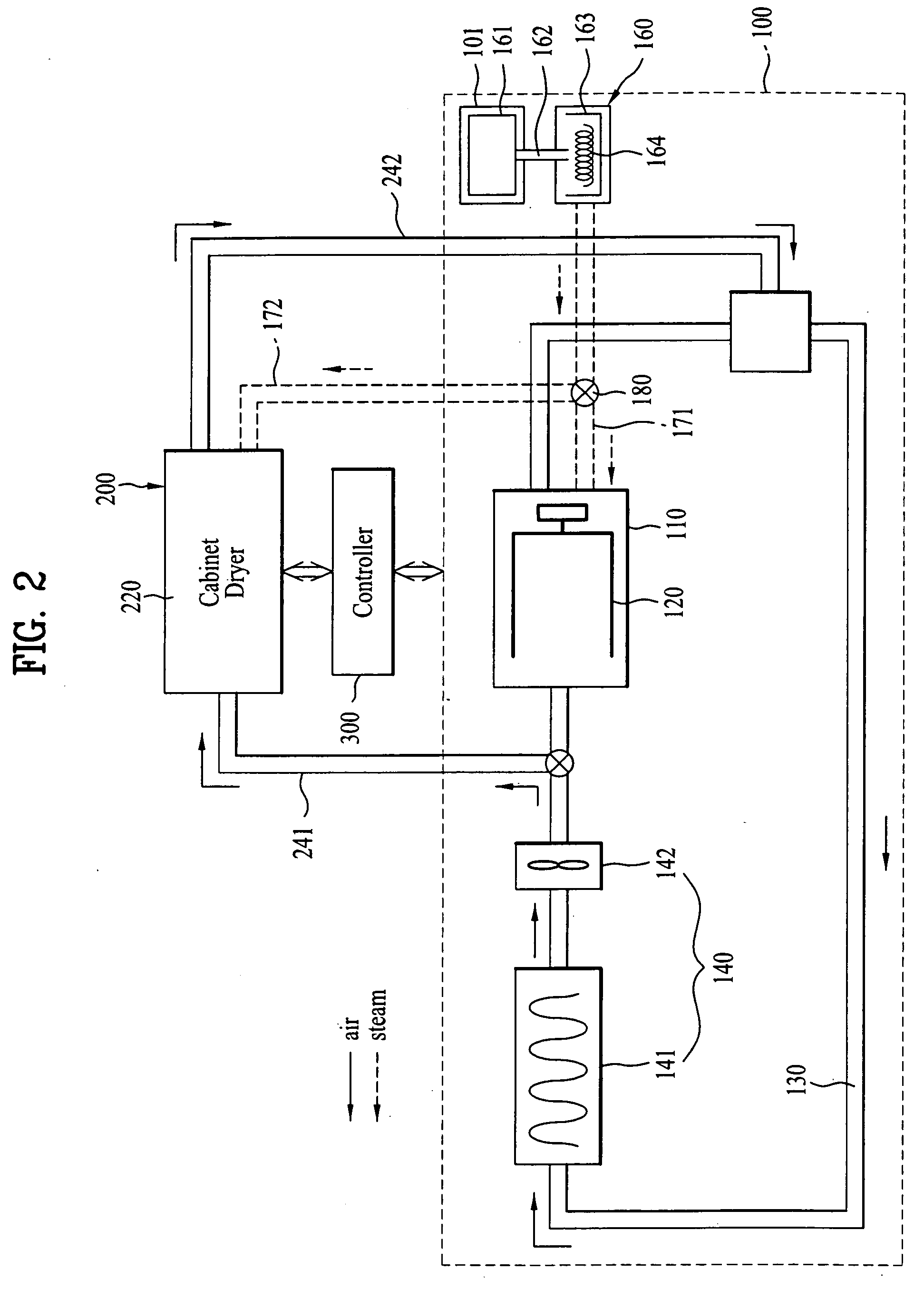

An operation method for a combination dryer is disclosed. The present invention relates to a combination dryer, and more particularly, to an operation method for a combination dryer which enables air in a drying drum and a cabinet for drying the laundry to circulate continuously and enables condensed water generated in the circulation process to perform a refreshing cycle by using the water.

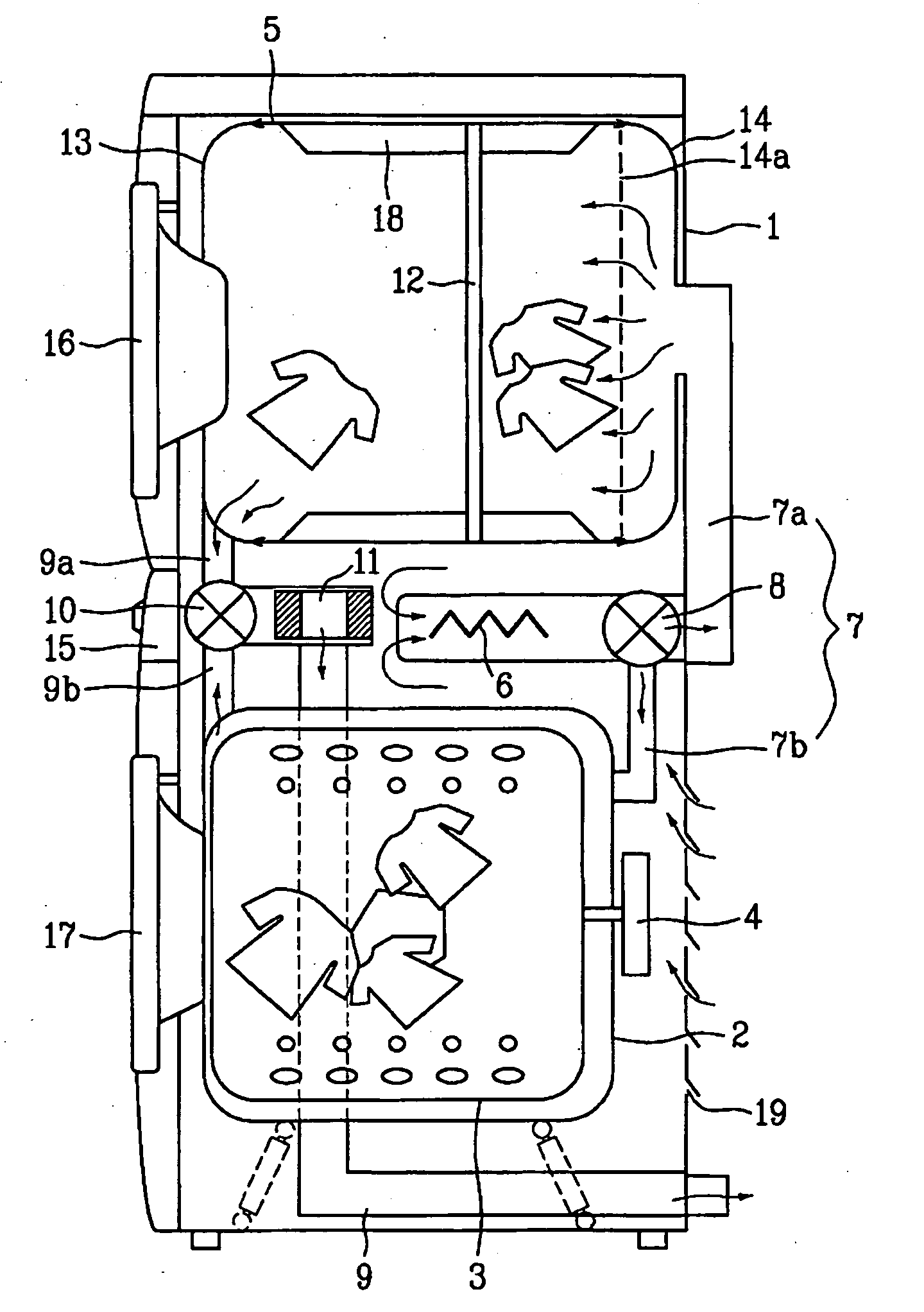

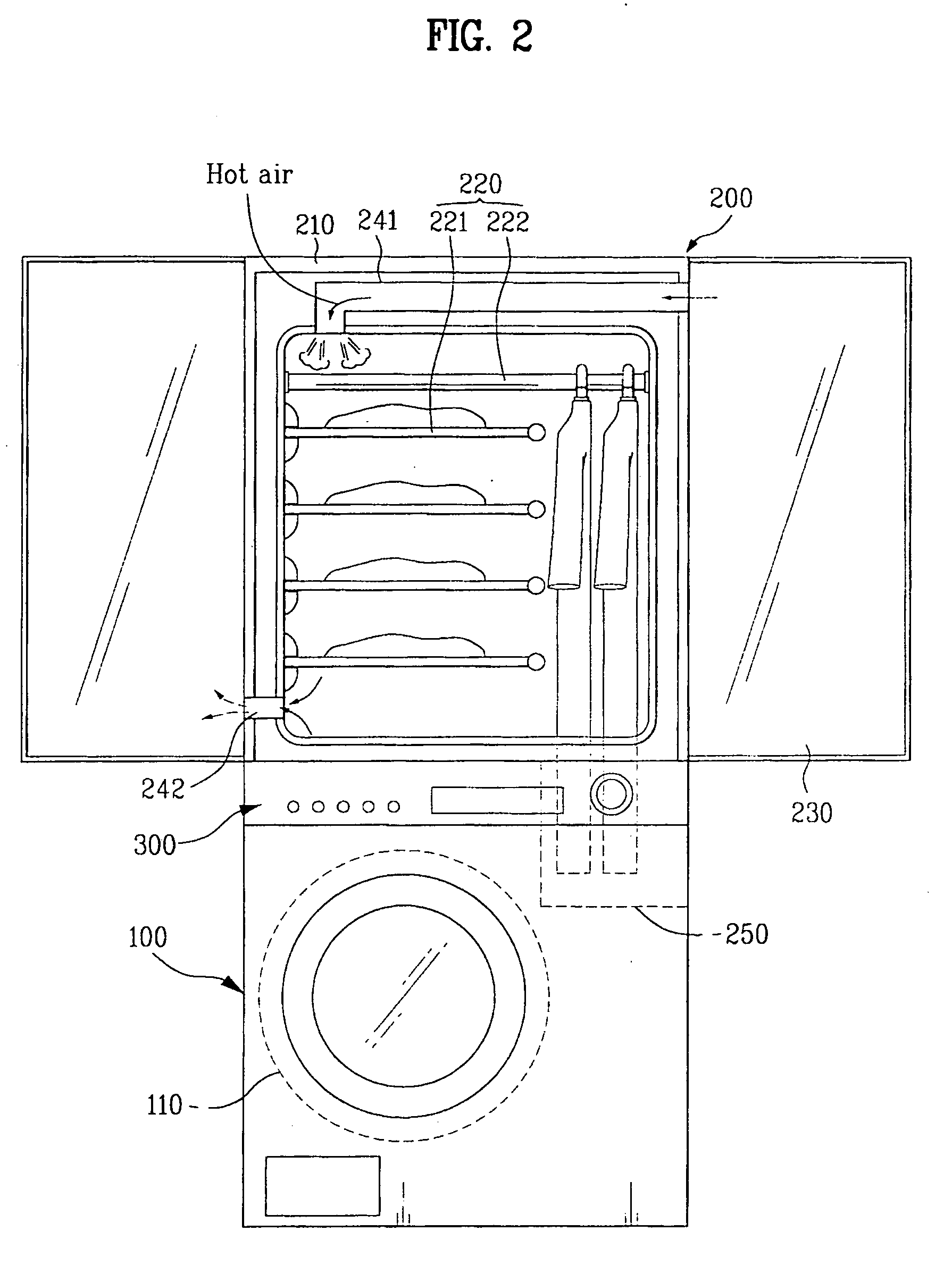

Single body washing machine and dryer device and a method for controlling the same

InactiveUS20070119072A1Other washing machinesDrying machines with non-progressive movementsEngineeringMechanical engineering

The present invention relates to a single body washing machine and dryer device, and more particularly, to a washing machine component and dryer component which are fabricated as a single body to enable the combination washing machine component and the dryer component to perform drying functions using a single heater that is shared between the two components. The single body washing machine and dryer device includes a cabinet for forming an inside space, a tub on one side of the inside space of the cabinet, a washing and drying combination drum rotatably mounted in the tub, a drying drum rotatably mounted on the other side of the inside space of the cabinet, and a heater for supplying hot air to the drying drum or the washing and drying combination drum selectively, or at the same time.

Owner:LG ELECTRONICS INC

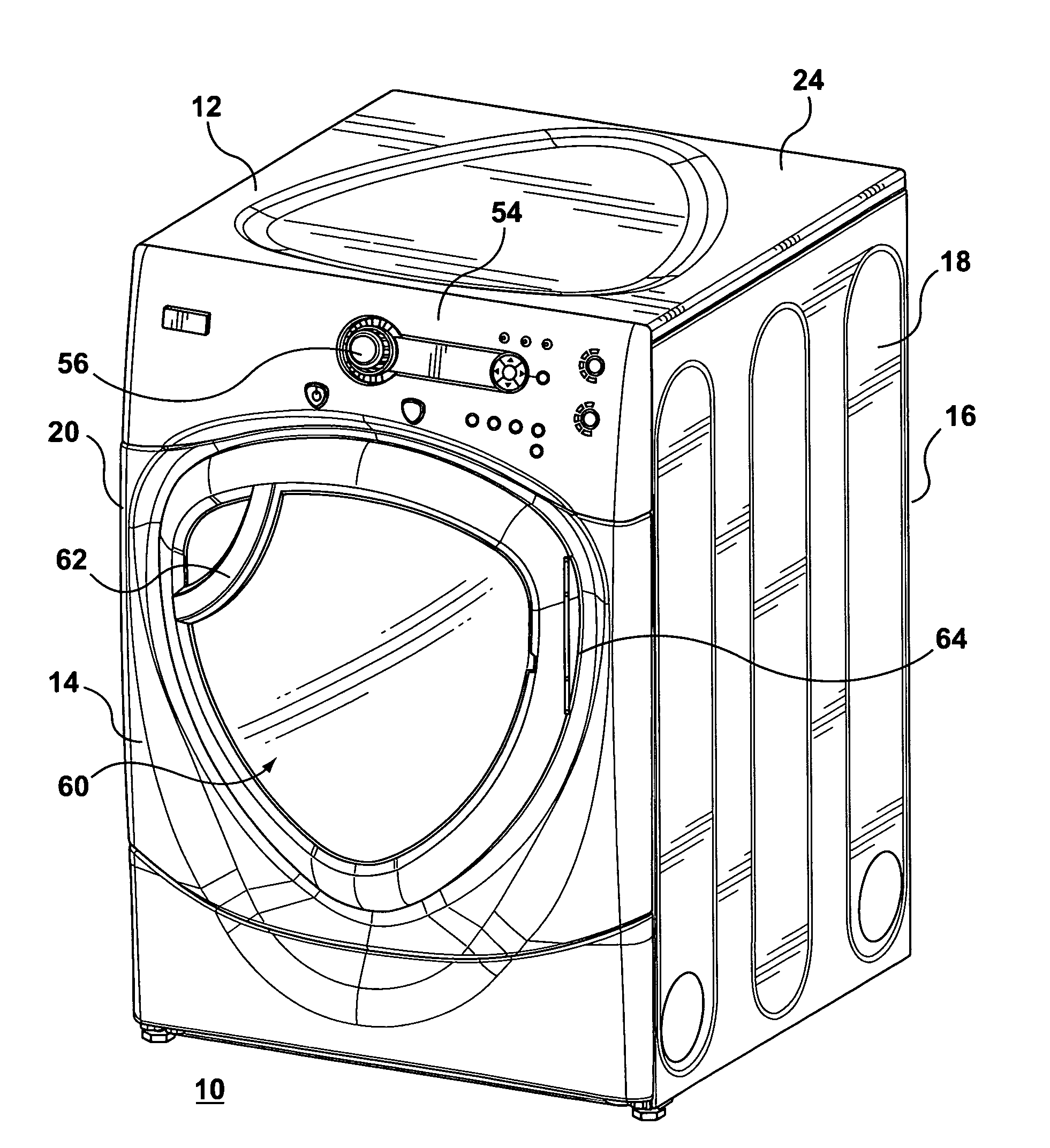

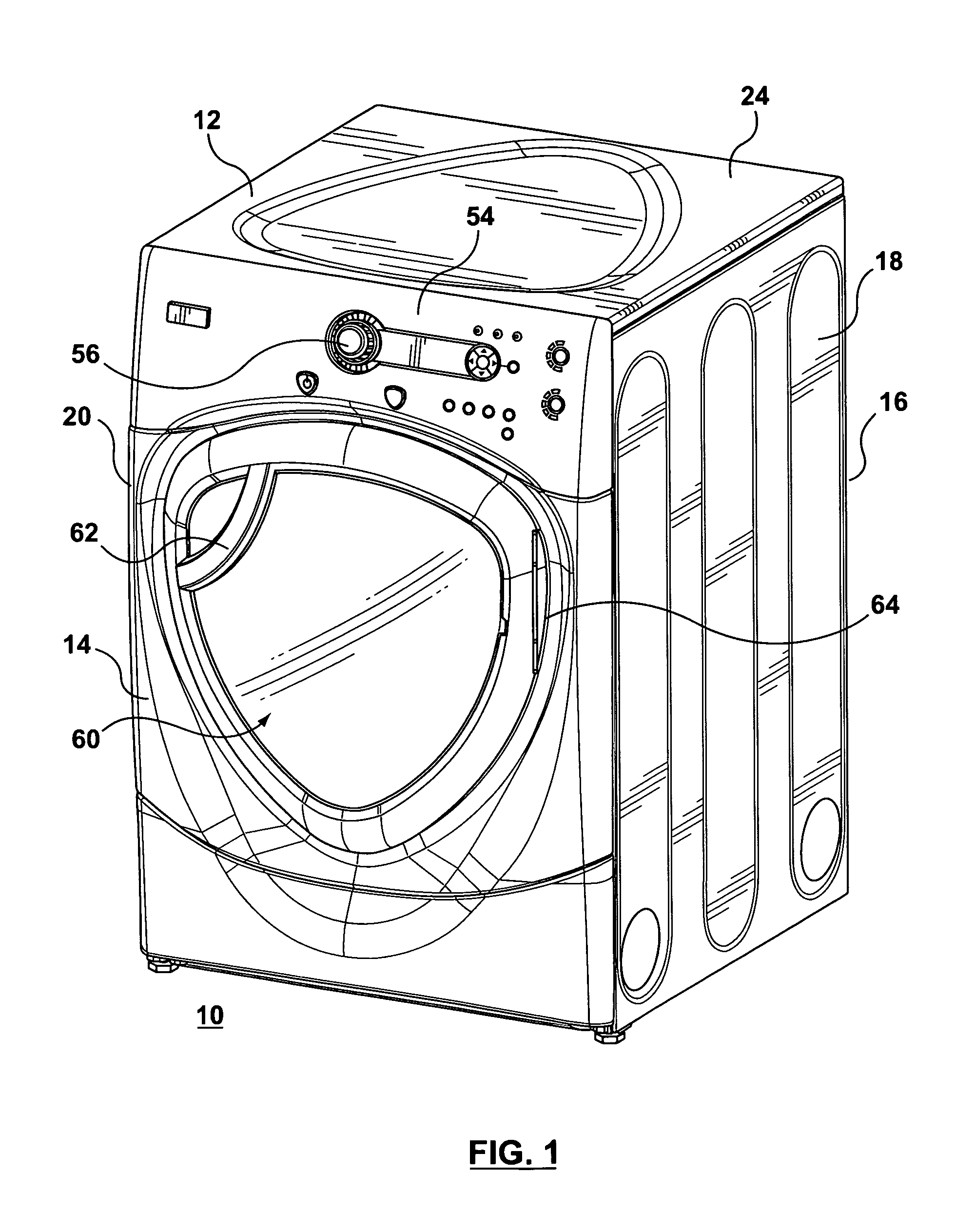

Clothes dryer apparatus and method for de-wrinkling clothes with reduced condensation

InactiveUS20100050464A1Reduce condensationReducing and eliminating wrinkleDrying using combination processesDrying gas arrangementsWrinkle skinProcess engineering

A clothes dryer has a drying drum with an airflow inlet and a motor for rotating the drum. A blower rotated by a fan motor flows air into, through, and out the drum. A refresh or touch-up de-wrinkle course is selected via a signal input on a control panel. Steam is supplied to the drum by a steam generating device, and heated air from a heater is supplied via the inlet. A controller operates the steam device and heater, in response to the course being selected, to supply to the drum a plurality of steam pulses of at least one first predetermined time and a heated air pulse after each steam pulse. Heated air pulses between steam pulses are intermediate pulses of at least one second predetermined time to reduce condensation in the dryer and the final pulse of heated air is of a duration to dry articles.

Owner:MABE CANADA

Combination dryer and method thereof

InactiveUS20060130354A1Avoid changeDrying using combination processesDrying gas arrangementsCyclic processRefresh cycle

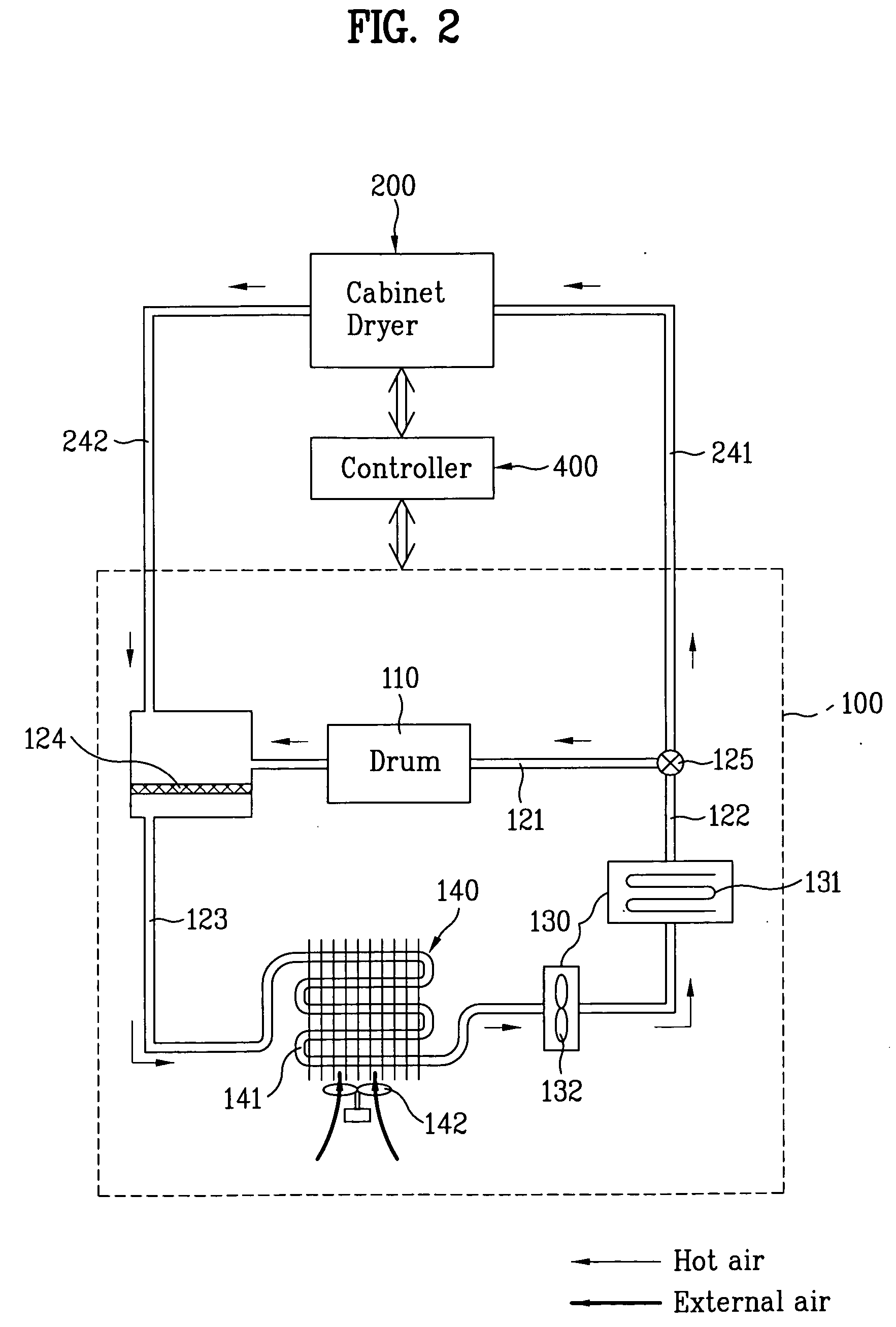

An operation method for a combination driver is disclosed. The present invention relates to a combination dryer, and more particularly, to an operation method for a combination dryer which enables air in a drying drum and a cabinet for drying the laundry to circulate continuously and enables water generated in the circulation process to perform a refreshing cycle by using the water.

Owner:LG ELECTRONICS INC

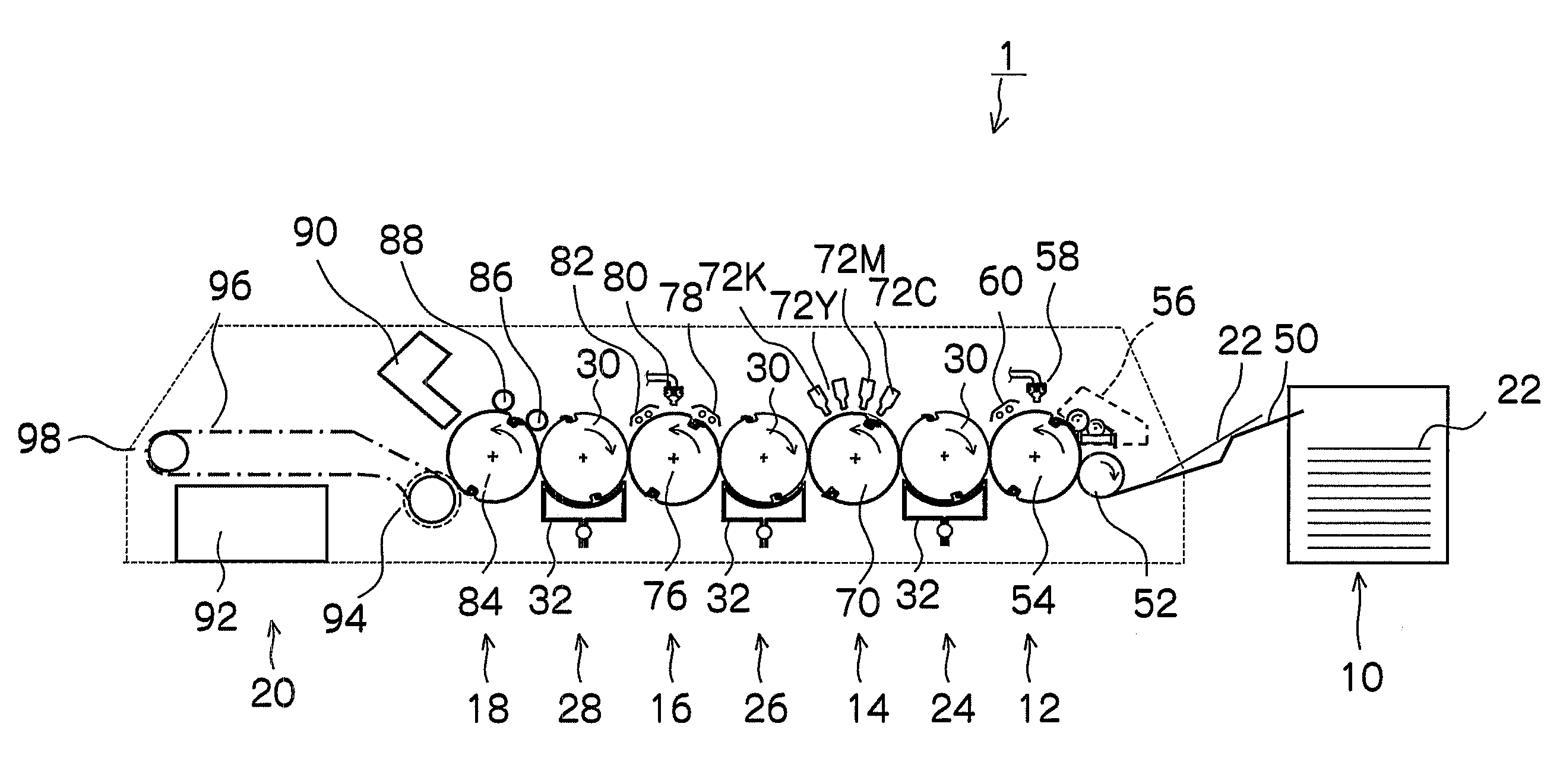

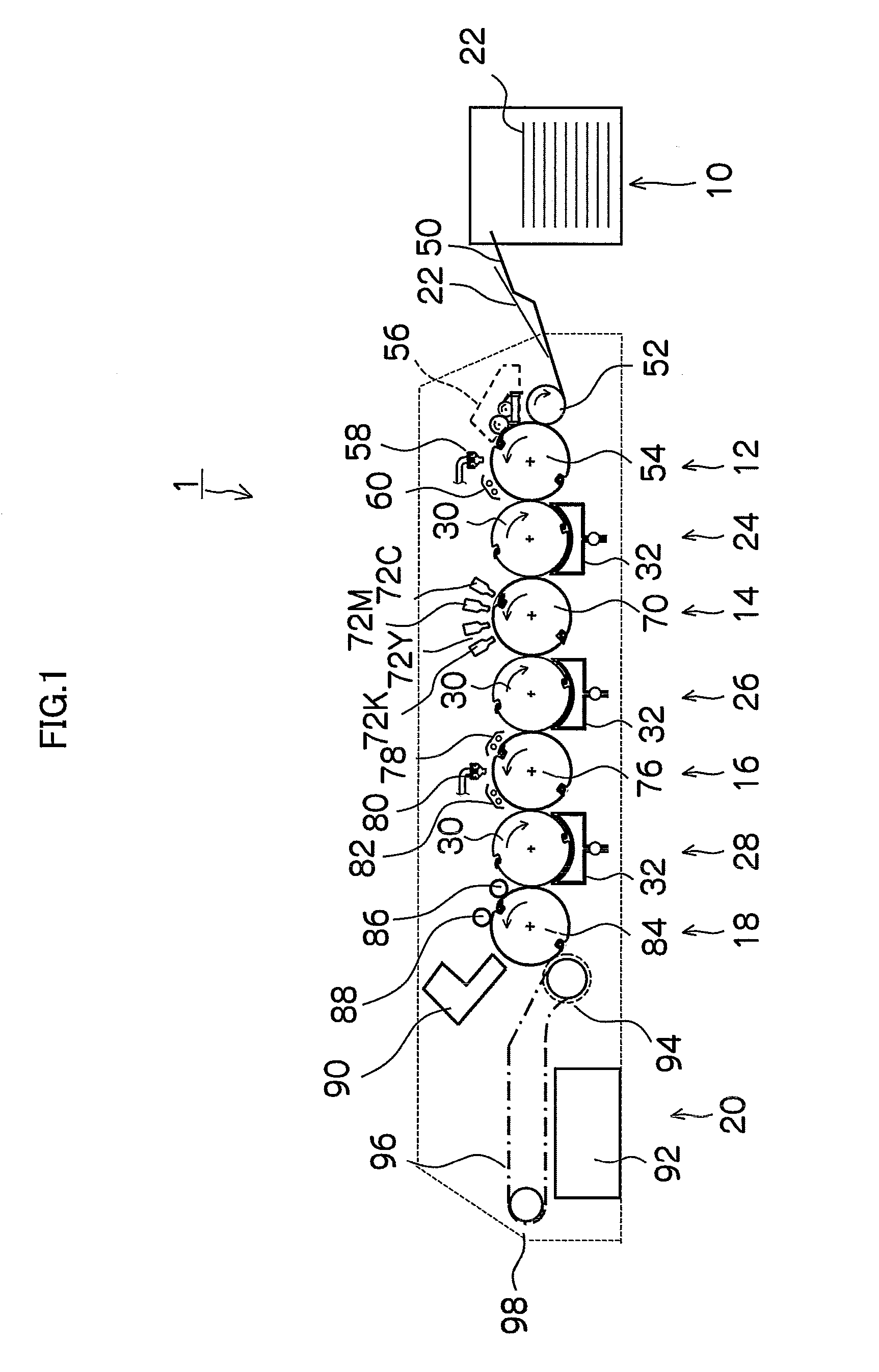

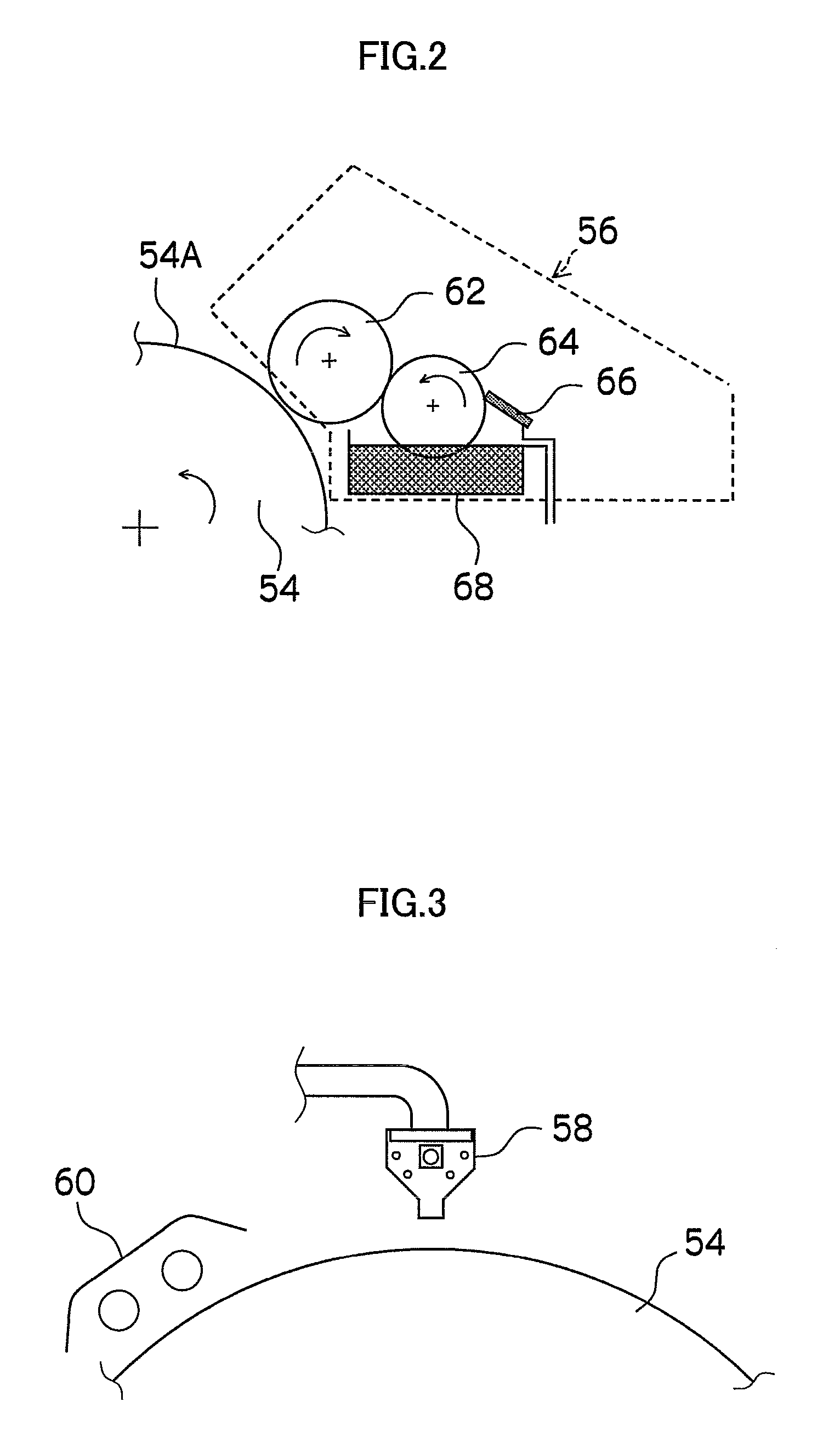

Inkjet recording method and apparatus

ActiveUS20090311426A1Improve image qualityCurl suppressionDuplicating/marking methodsPretreated surfacesSolid componentLiquid medium

The inkjet recording method includes: a treatment liquid depositing step of applying treatment liquid onto a recording medium while holding the recording medium on a circumferential surface of a treatment liquid drum and conveying the recording medium by rotating the treatment liquid drum, and drying at least a portion of a solvent in the treatment liquid; an image forming step of ejecting ink from a line type inkjet head to deposit the ink onto the recording medium on which the treatment liquid has been deposited, while holding the recording medium on a circumferential surface of an image formation drum and conveying the recording medium by rotating the image formation drum, the ink containing at least a resin dispersant (A), a pigment (B) that is dispersed by the resin dispersant (A), self-dispersible polymer micro-particles (C) and an aqueous liquid medium (D), the ink having one of a solid component that is aggregated upon making contact with the treatment liquid and a solid component that is precipitated upon making contact with the treatment liquid; and a drying step of drying a solvent in the ink having been deposited on the recording medium while holding the recording medium on a circumferential surface of a drying drum and conveying the recording medium by rotating the drying drum.

Owner:FUJIFILM CORP

Operating method of laundry device

InactiveUS20060137107A1Other washing machinesWashing machine with receptaclesRefresh cycleEngineering

An operating method of a laundry device is disclosed. The present invention relates more particularly, to an operation method for a combination dryer which enables air in a drying drum and a cabinet for drying the laundry to circulate continuously and enables water generated in the circulation process to perform a refreshing cycle by using the water.

Owner:LG ELECTRONICS INC

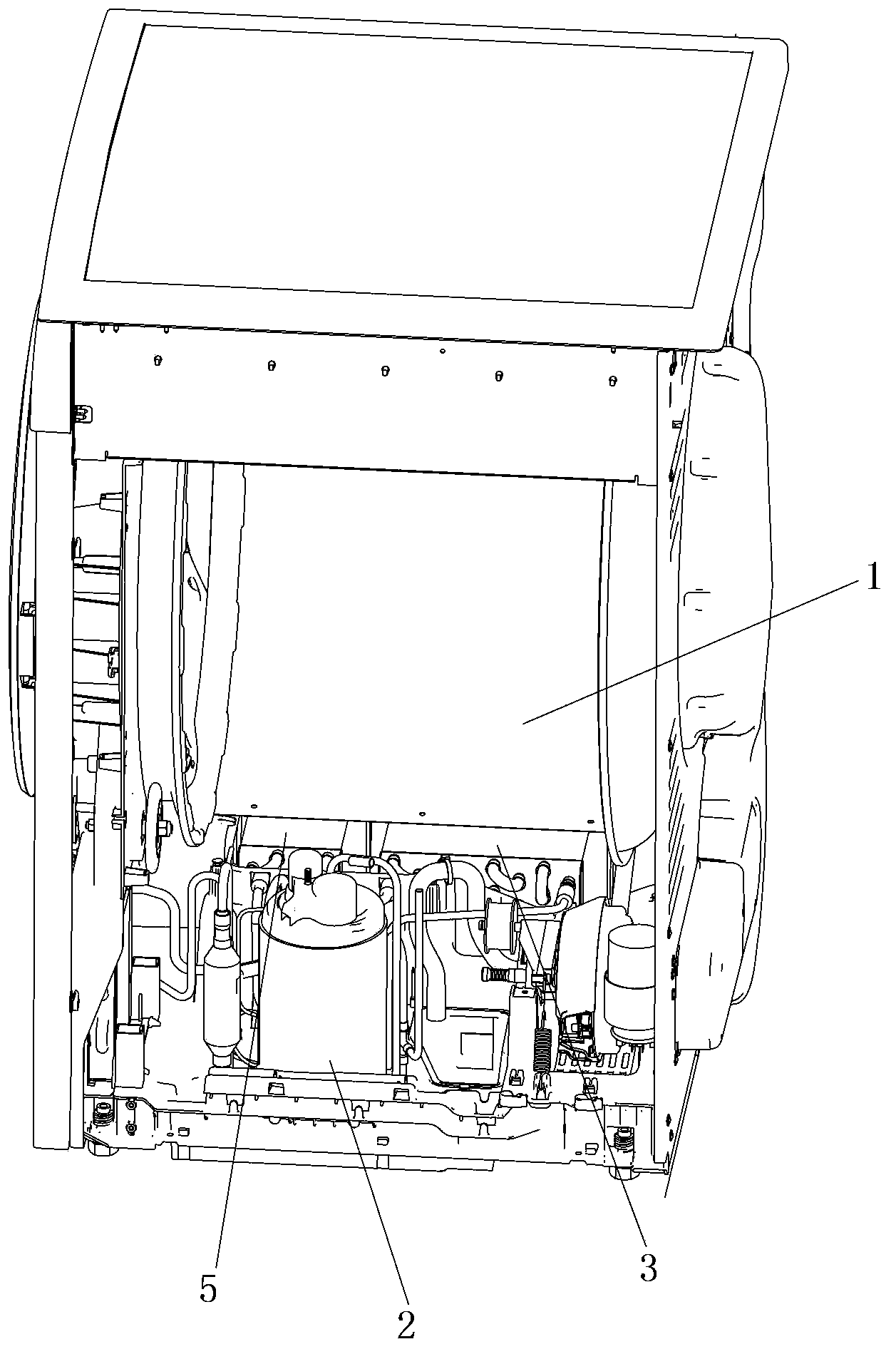

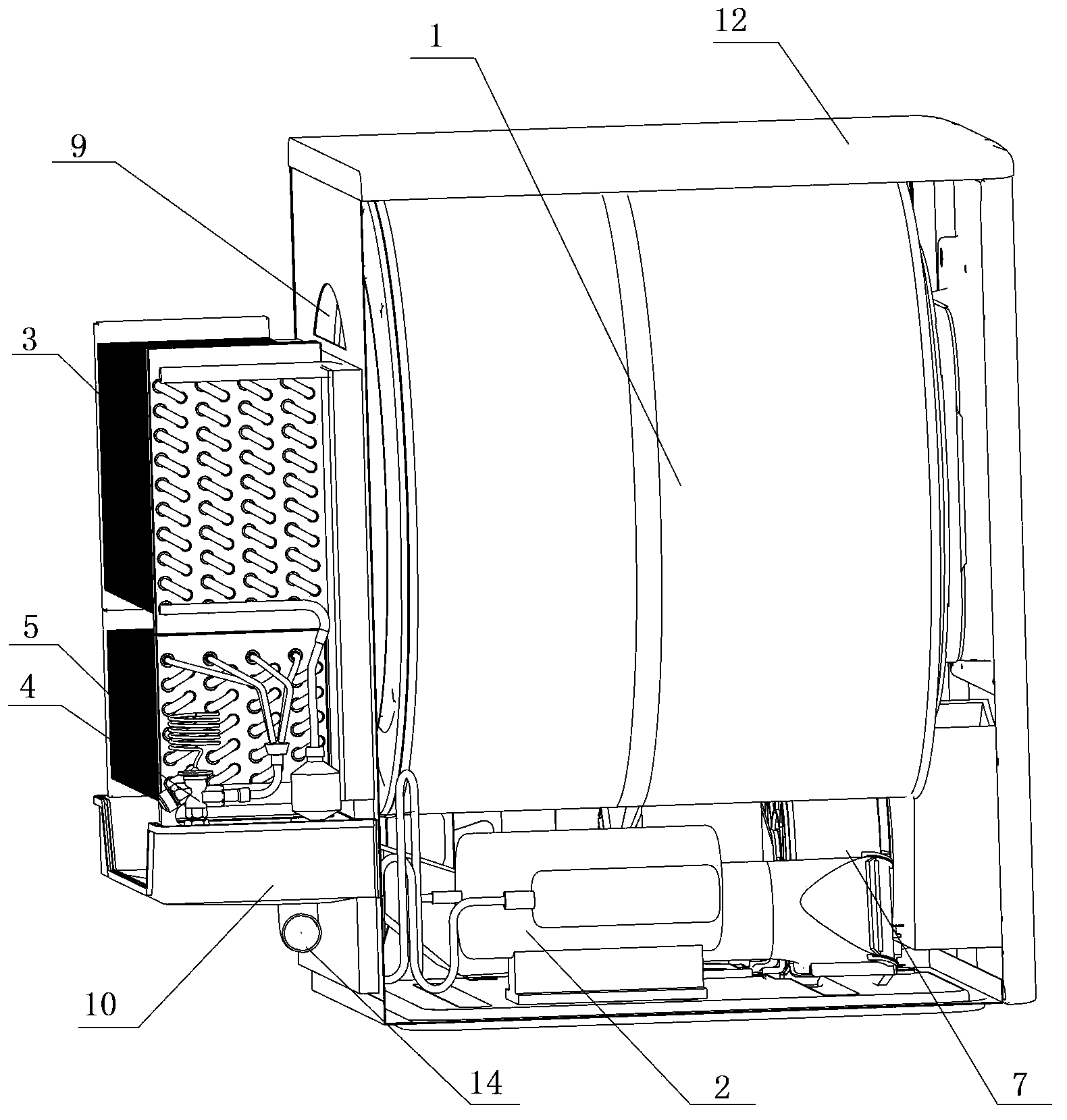

Clothes drier

ActiveCN1626724AReduce the burden onSuppress pressure riseTextiles and paperLaundry driersThermodynamicsEngineering

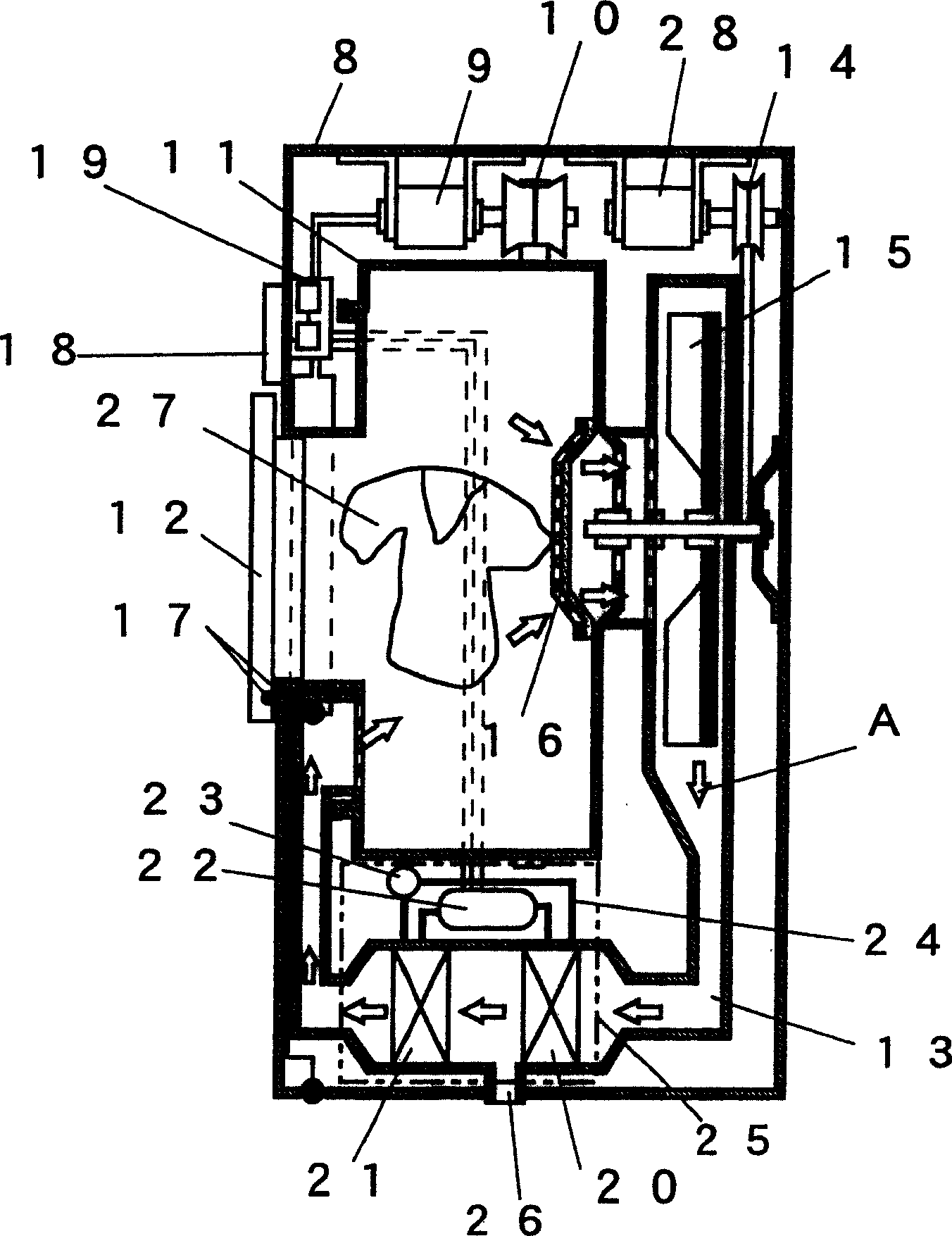

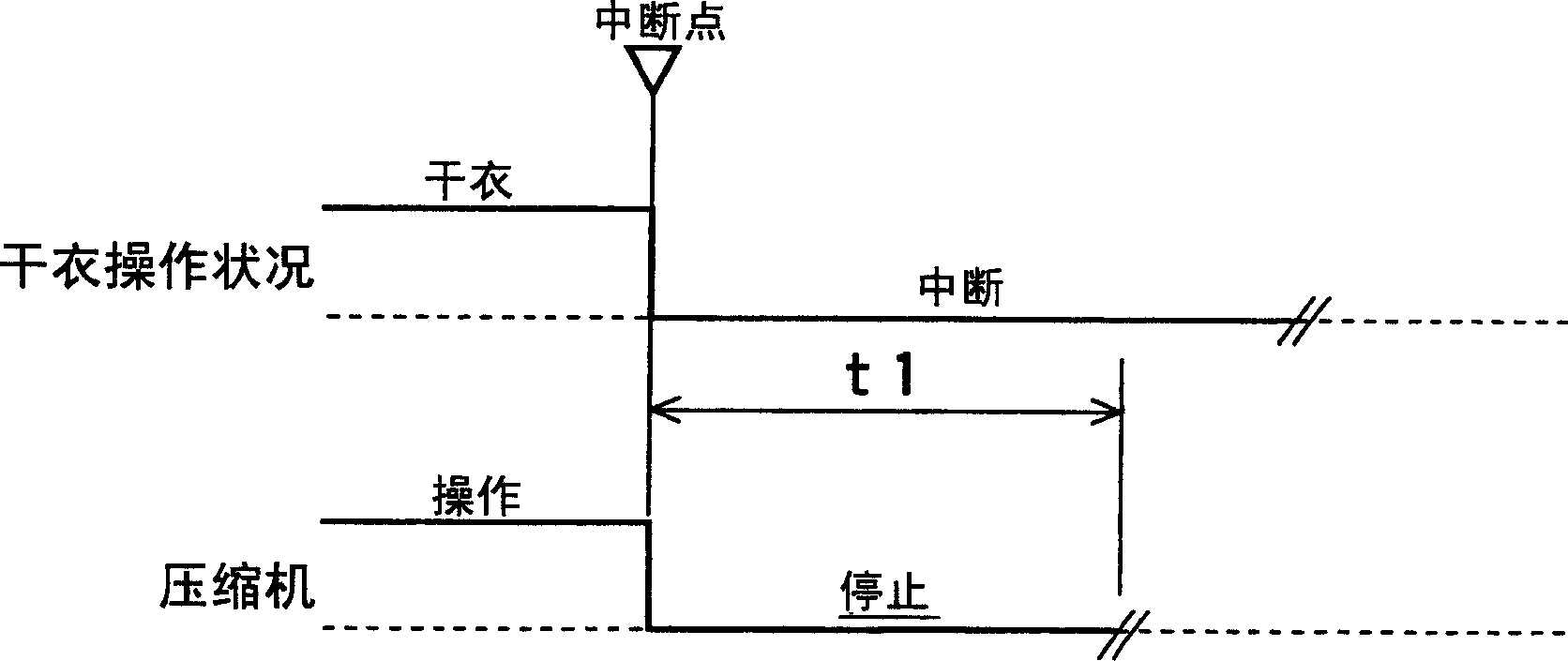

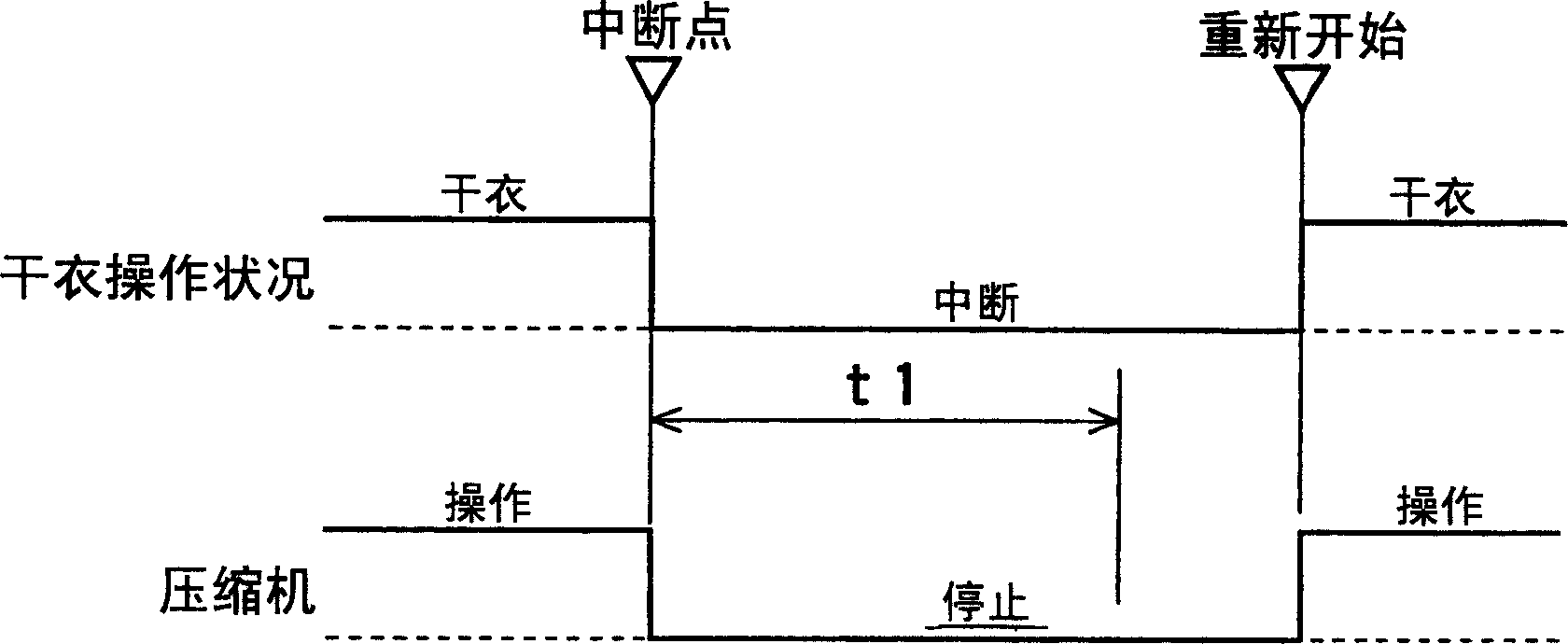

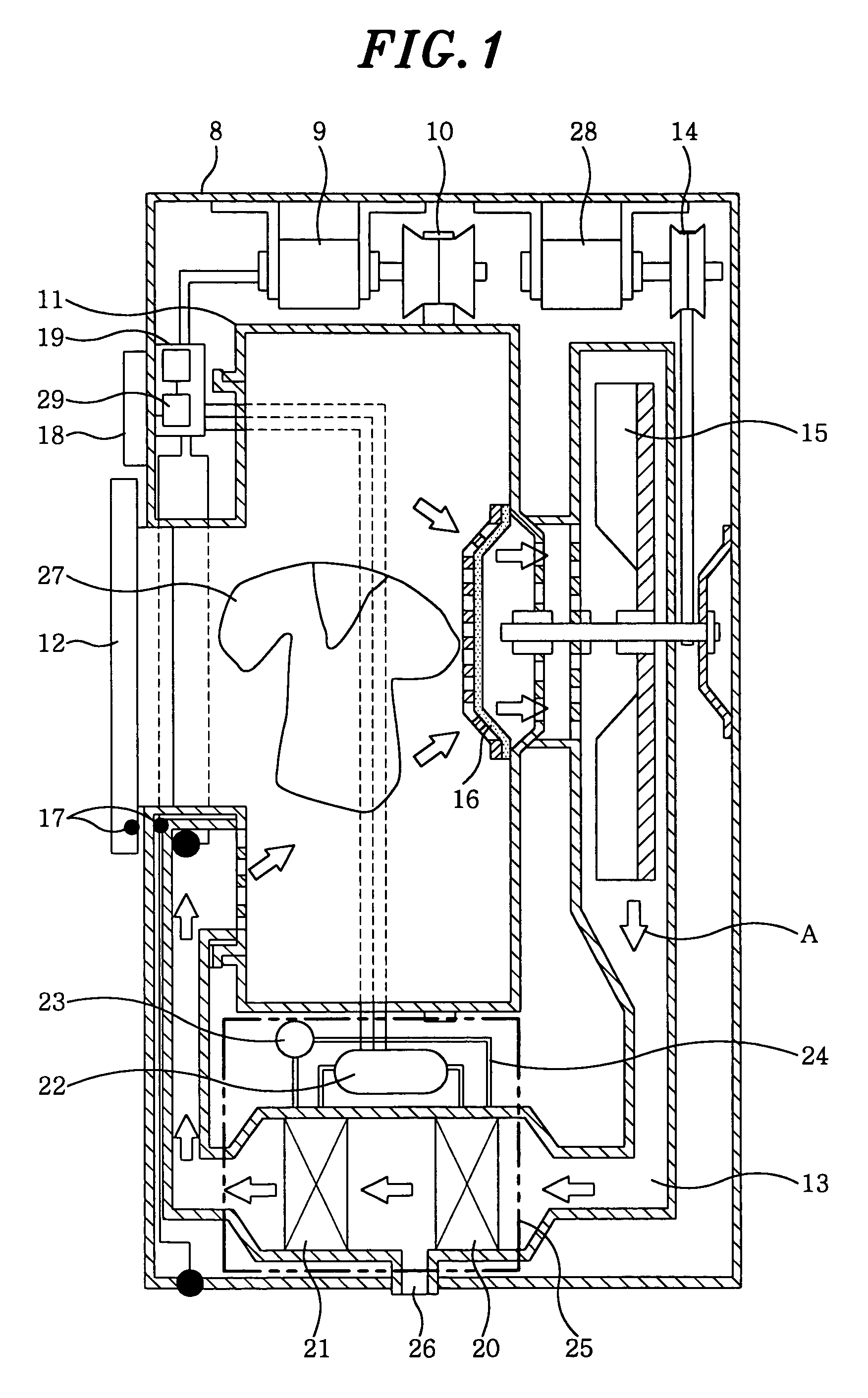

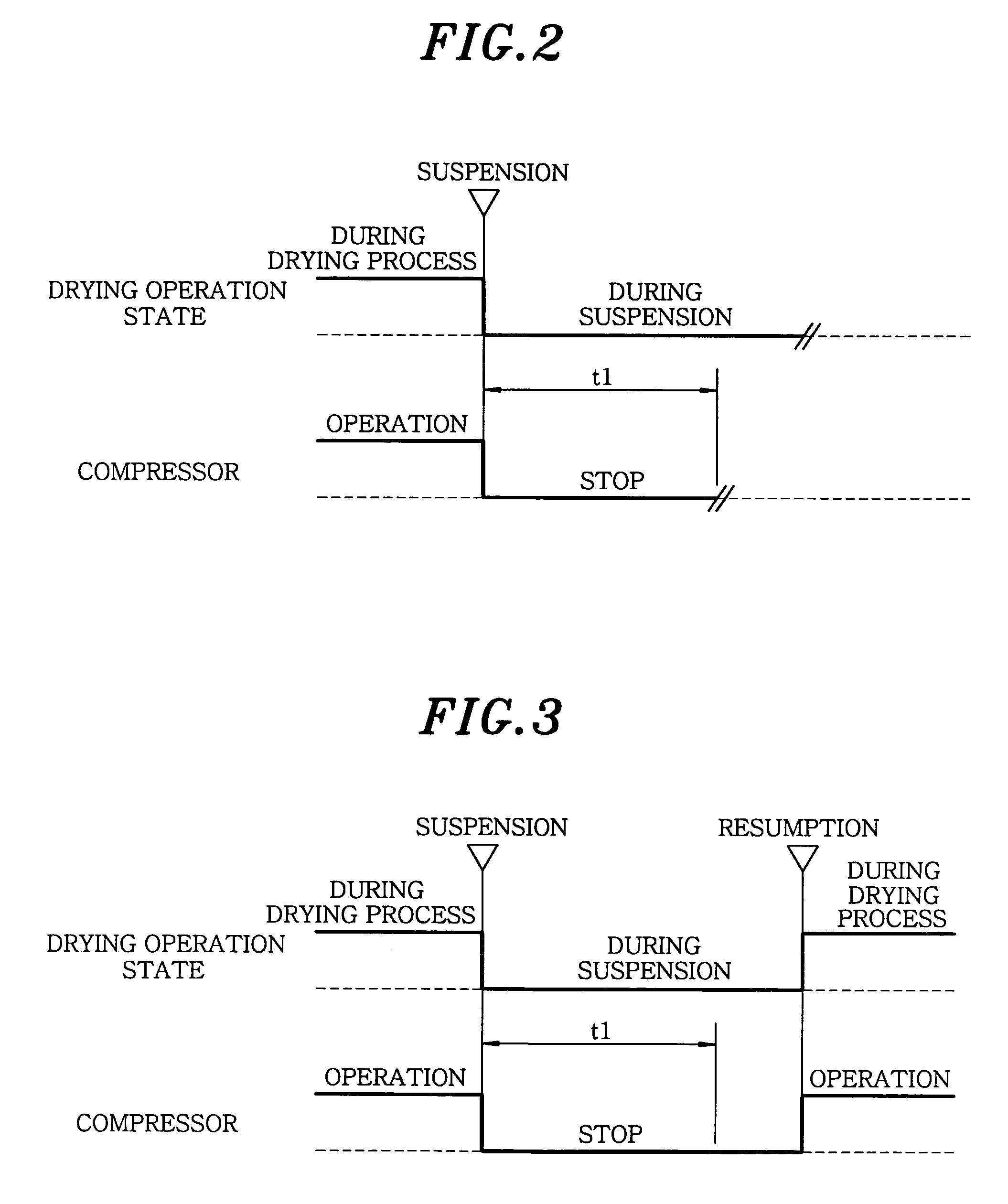

A clothes drying apparatus includes a heat pump mechanism (25), an air path (13) for guiding drying air into a drying drum (11) accommodating therein clothes (27), a blower (15) for supplying drying air to the air path (13), and a controller for controlling a driving of a compressor (22), wherein the controller operates the blower (15) and the compressor (22) during a drying operation; stops the compressor (22) in case the drying operation is suspended; and operates, in case the drying operation is resumed, the compressor (22) after a certain time period has elapsed since the compressor (22) had stopped. In case employing the heat pump mechanism (25) having the compressor (22) as a heat source, it is possible to reduce a load on the compressor (22) and allow temperature of warm air to rapidly return by using the heat pump mechanism (25). <IMAGE>

Owner:PANASONIC CORP

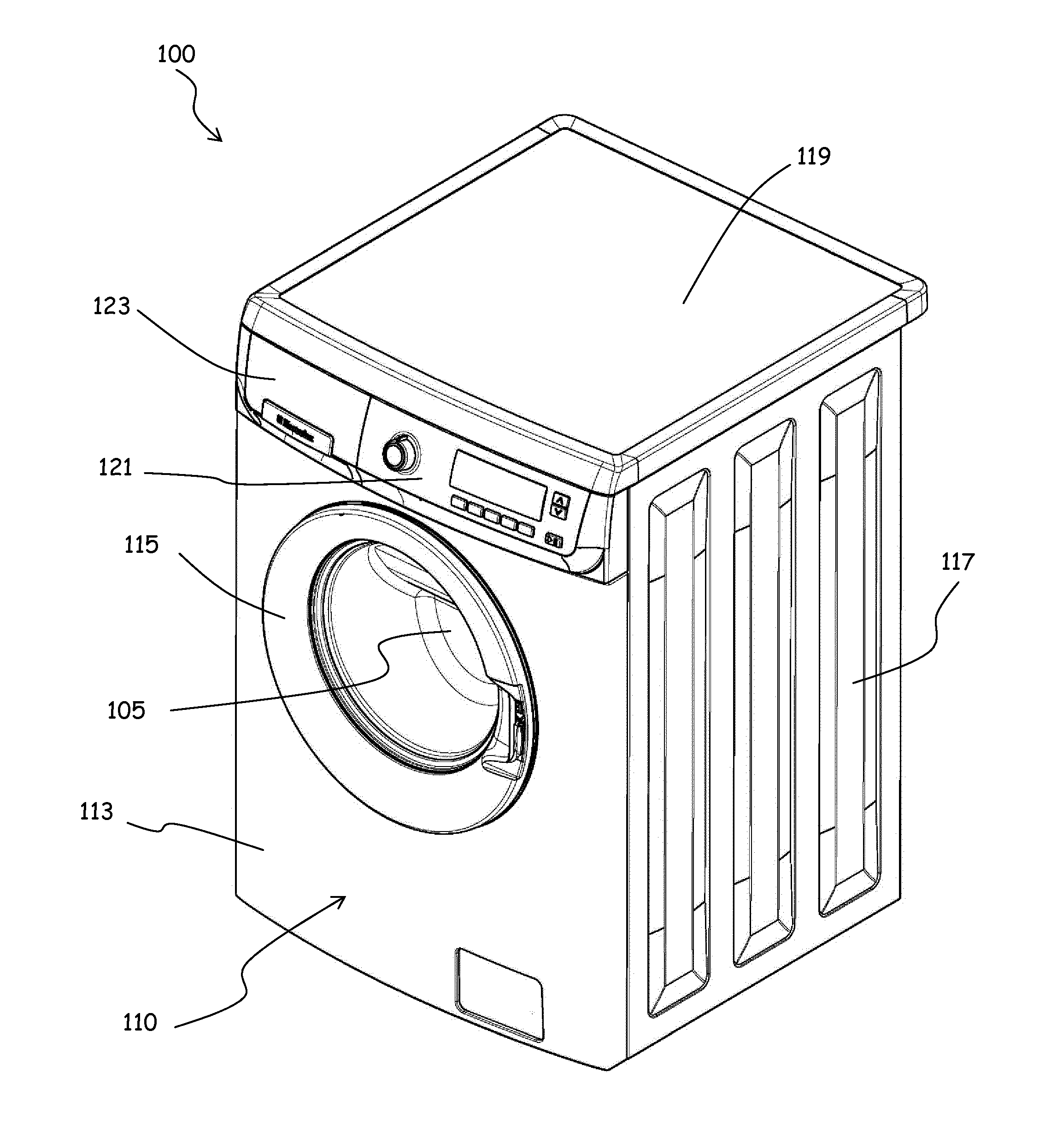

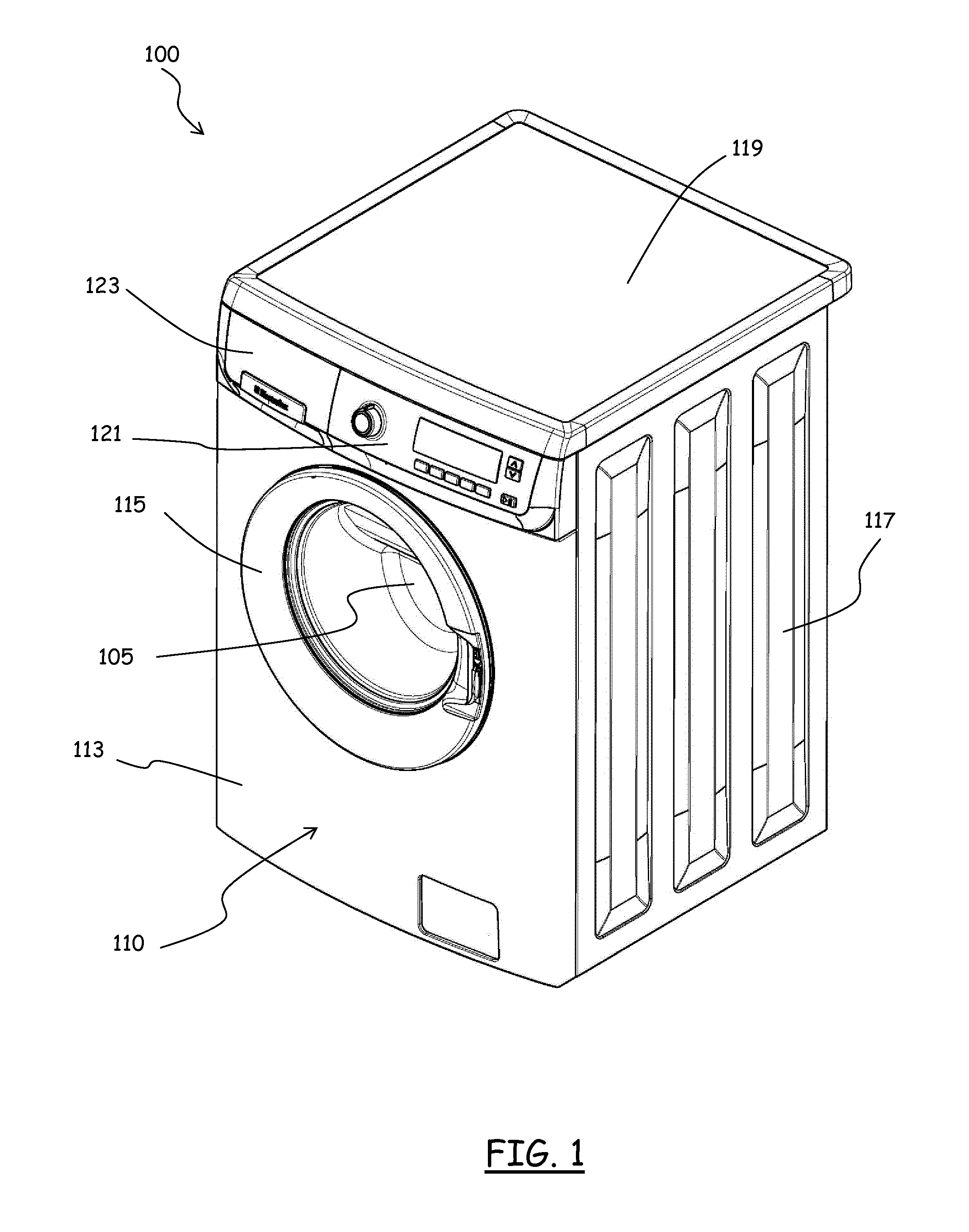

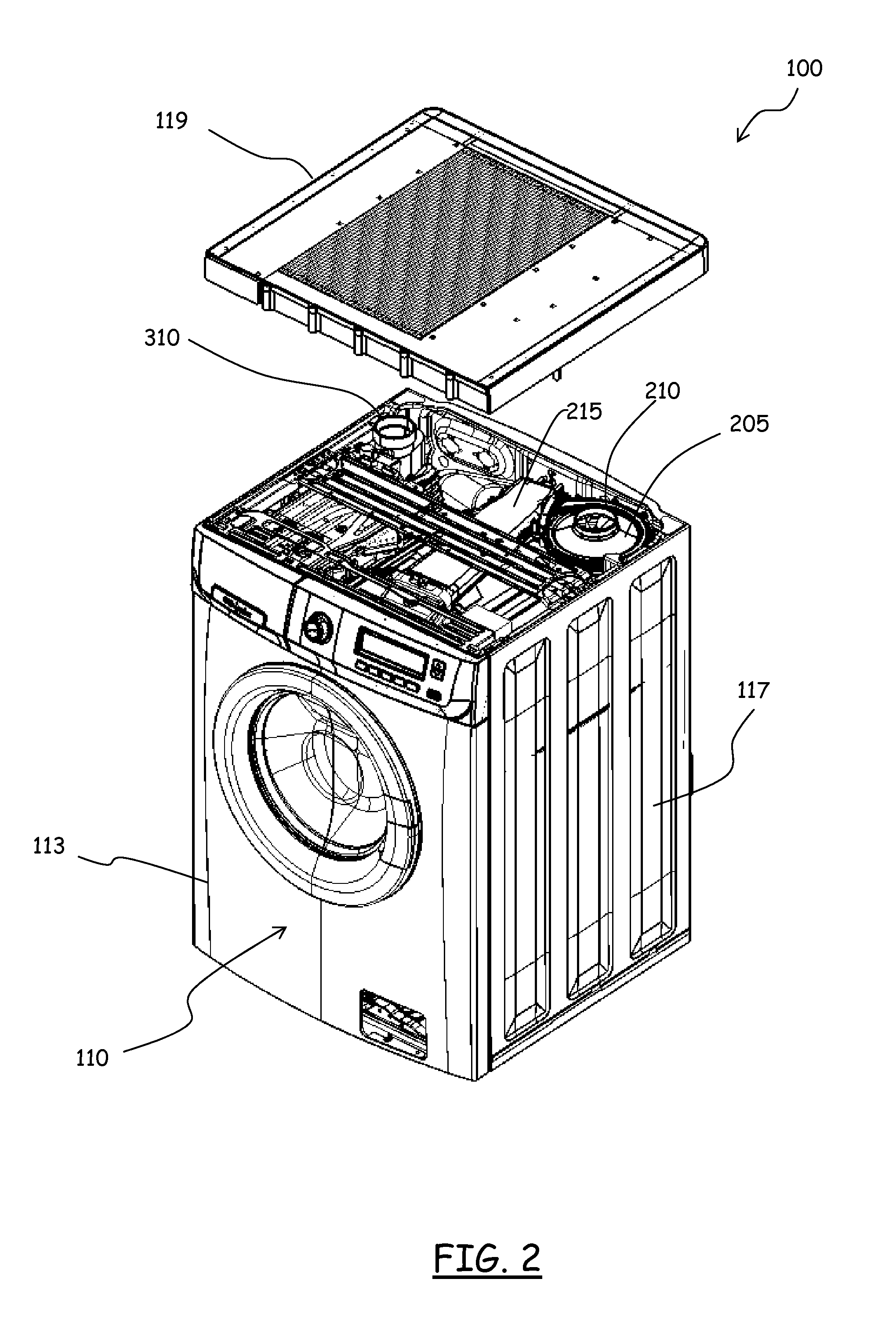

Appliance for drying laundry

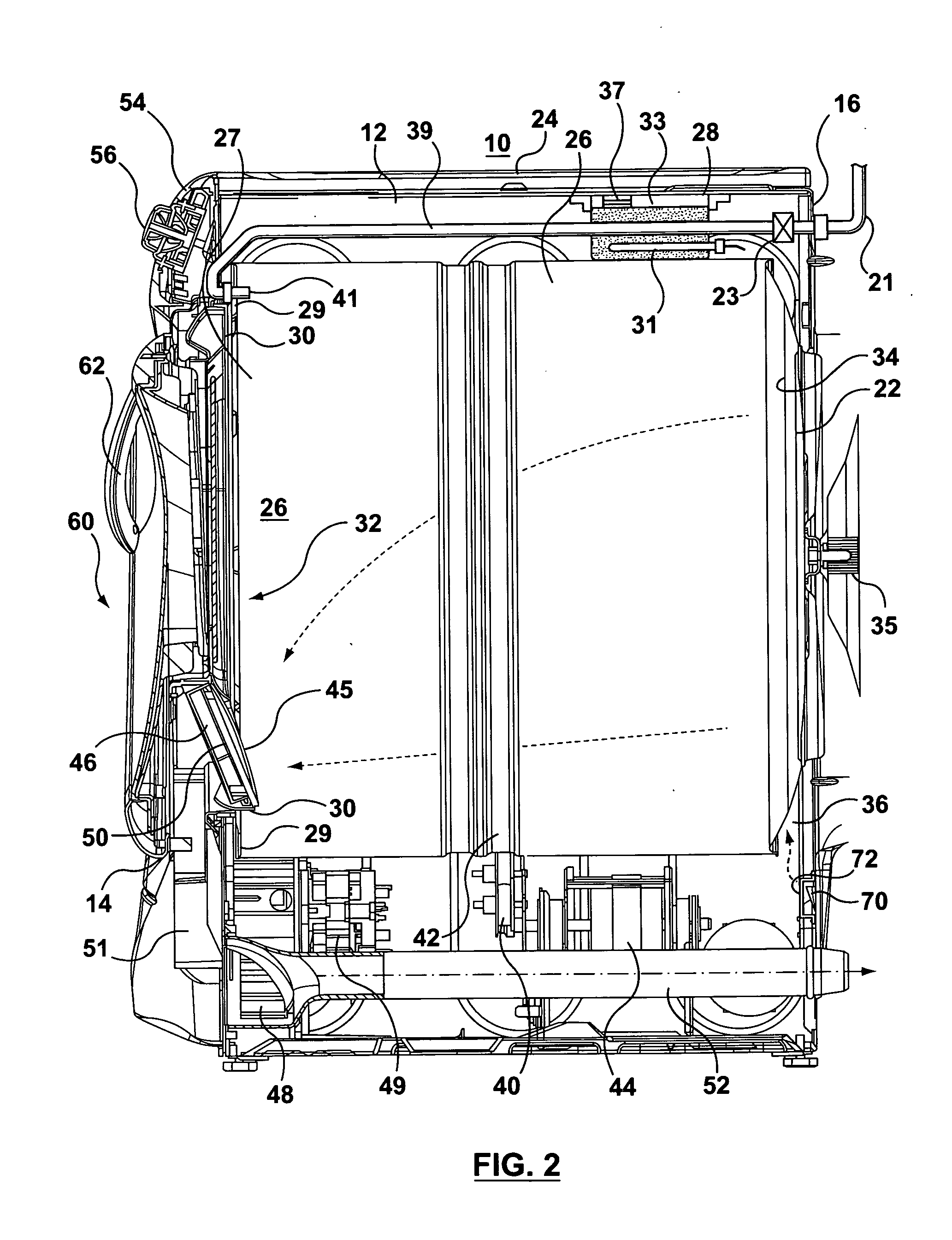

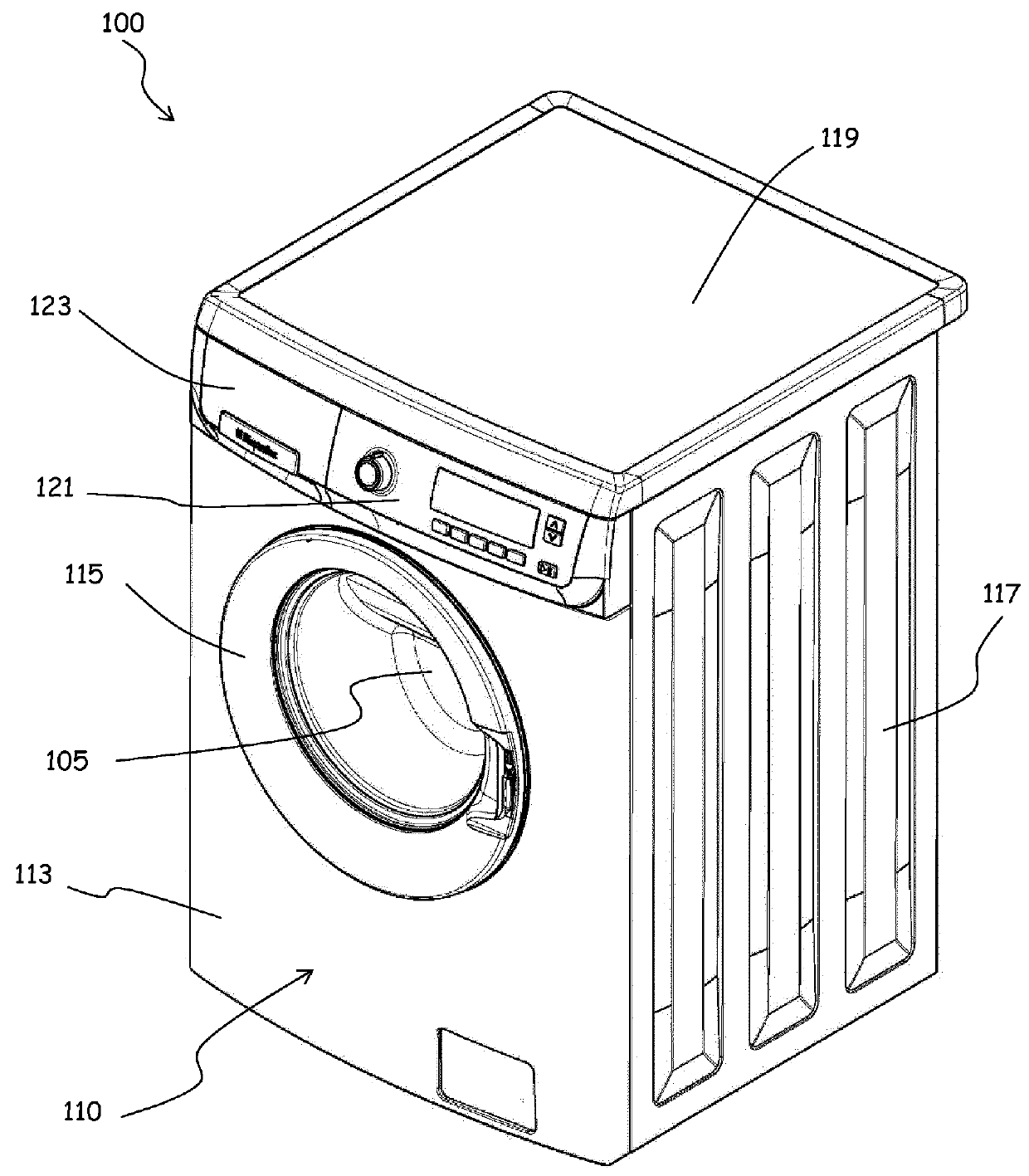

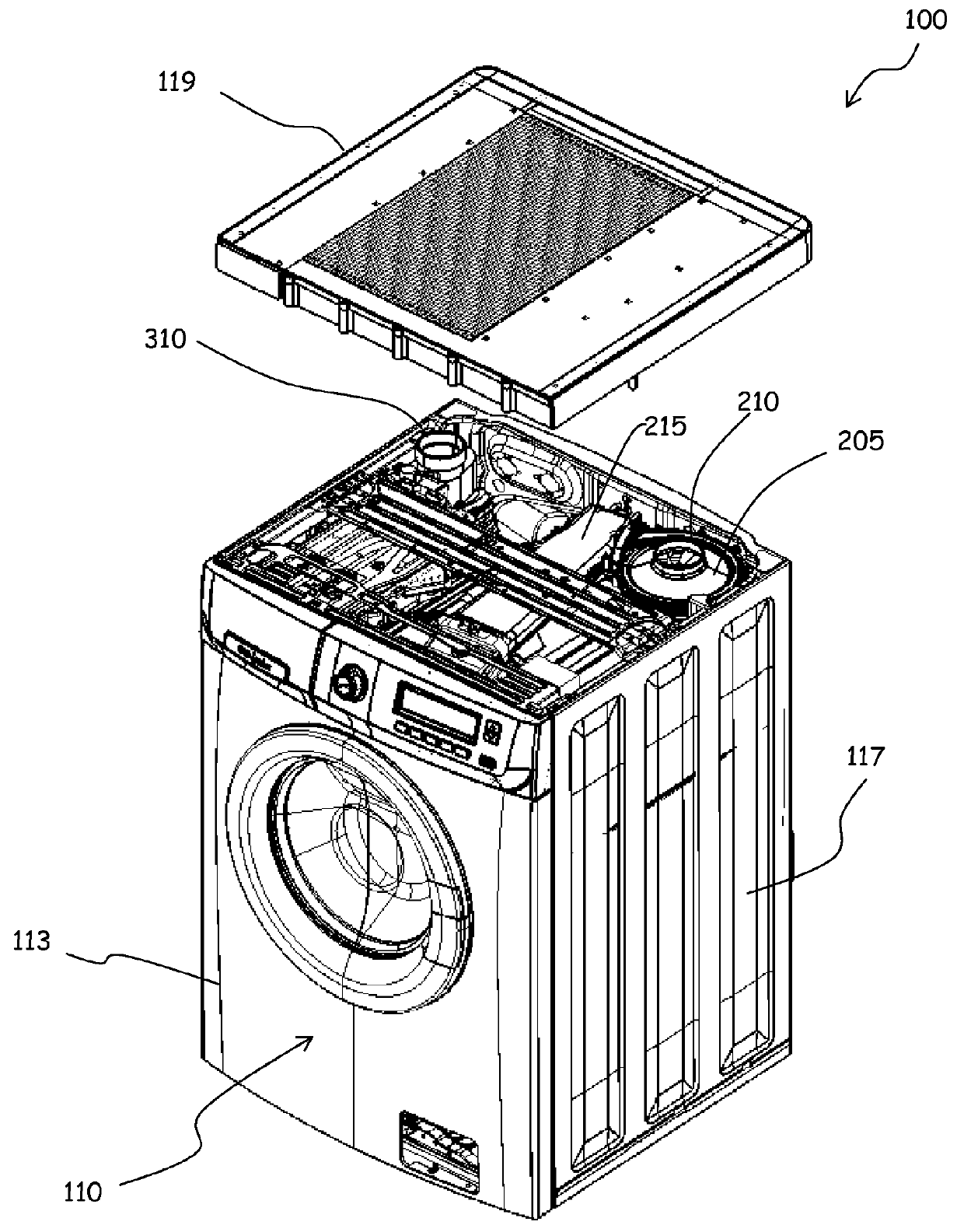

A top adapted to match and close from above a cabinet of a laundry drying appliance, is provided. The top is formed as a ready-to-mount part ready to be mounted to the cabinet and forming a moisture condensing module for dehydrating drying air used to dry laundry within a drying drum of the laundry drying appliance. The top has a drying air inlet for receiving moisture-laden drying air, a drying air outlet for delivering demoisturized drying air, fluid passageways defined thereinside from the drying air inlet to the drying air outlet for the passage of the drying air to be dehydrated and a moisture condenser arranged inside the fluid passageways. The top includes, integrally formed therein, at least one structural part of the appliance, the at least one structural part of the appliance having at least one a part of: a housing of a fan for propelling the drying air; a drying air delivery duct connectable to a drying air inlet of the drying drum for delivering the drying air into the drying drum; a seat for a container of detergents / softener for washing laundry; a condense water collector for collecting condense water released by the moisture-laden drying air; at least part of a condense water draining system; a support for at least one water inlet valve for selectively allowing the intake of water from a water main; and at least part of a water circuit for delivering water to wash the moisture condensing means.

Owner:ELECTROLUX HOME PROD CORP NV

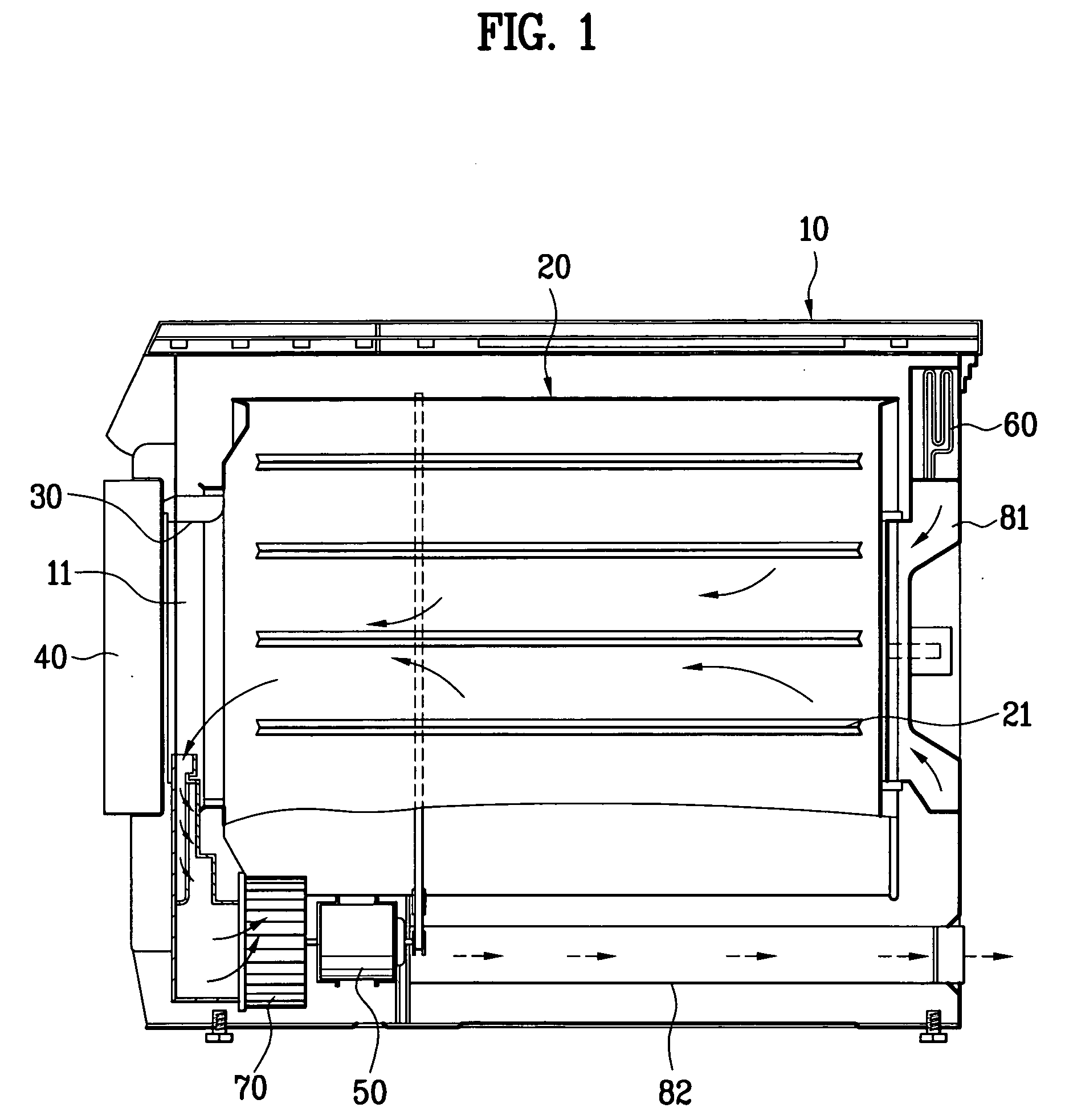

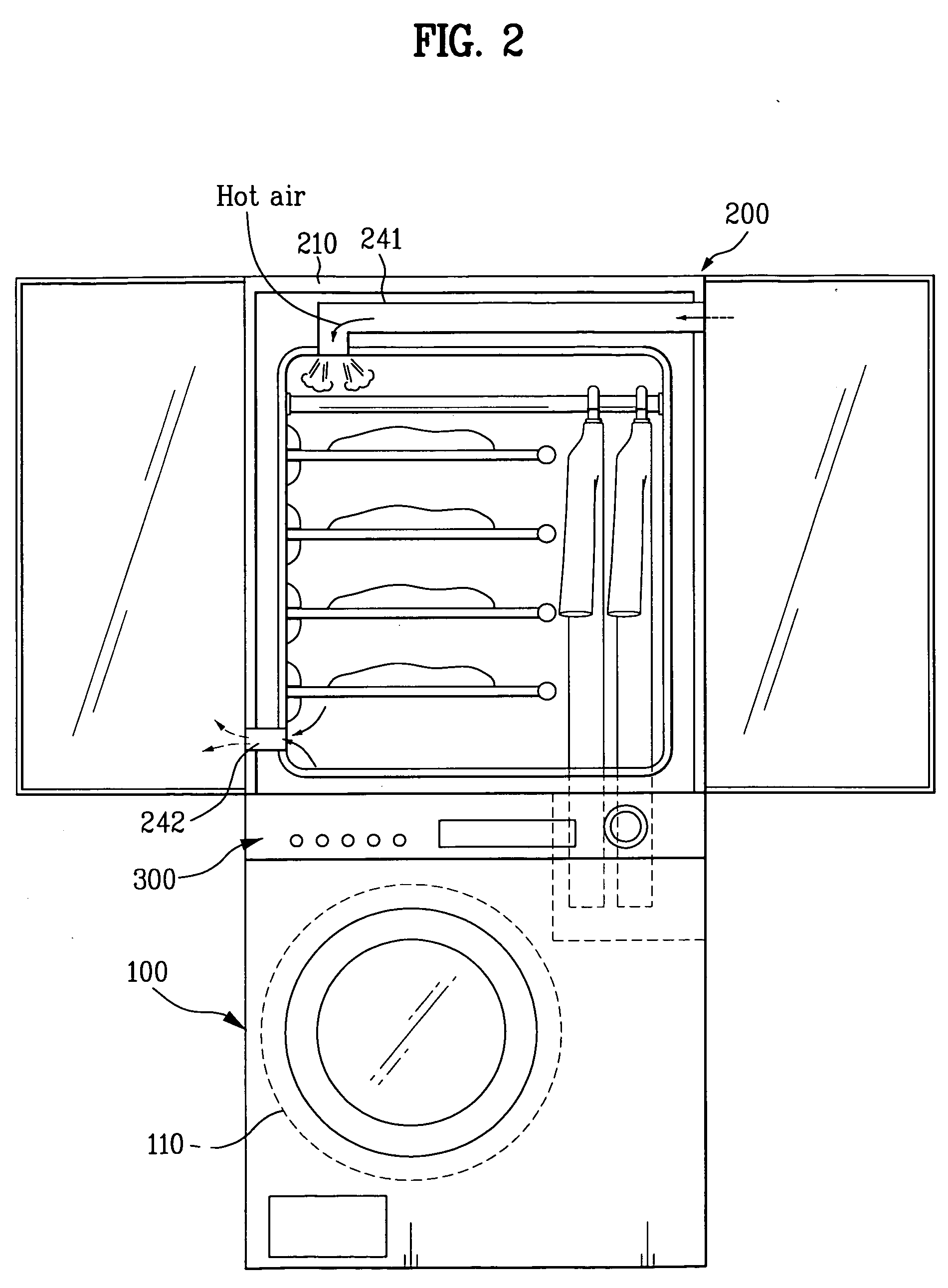

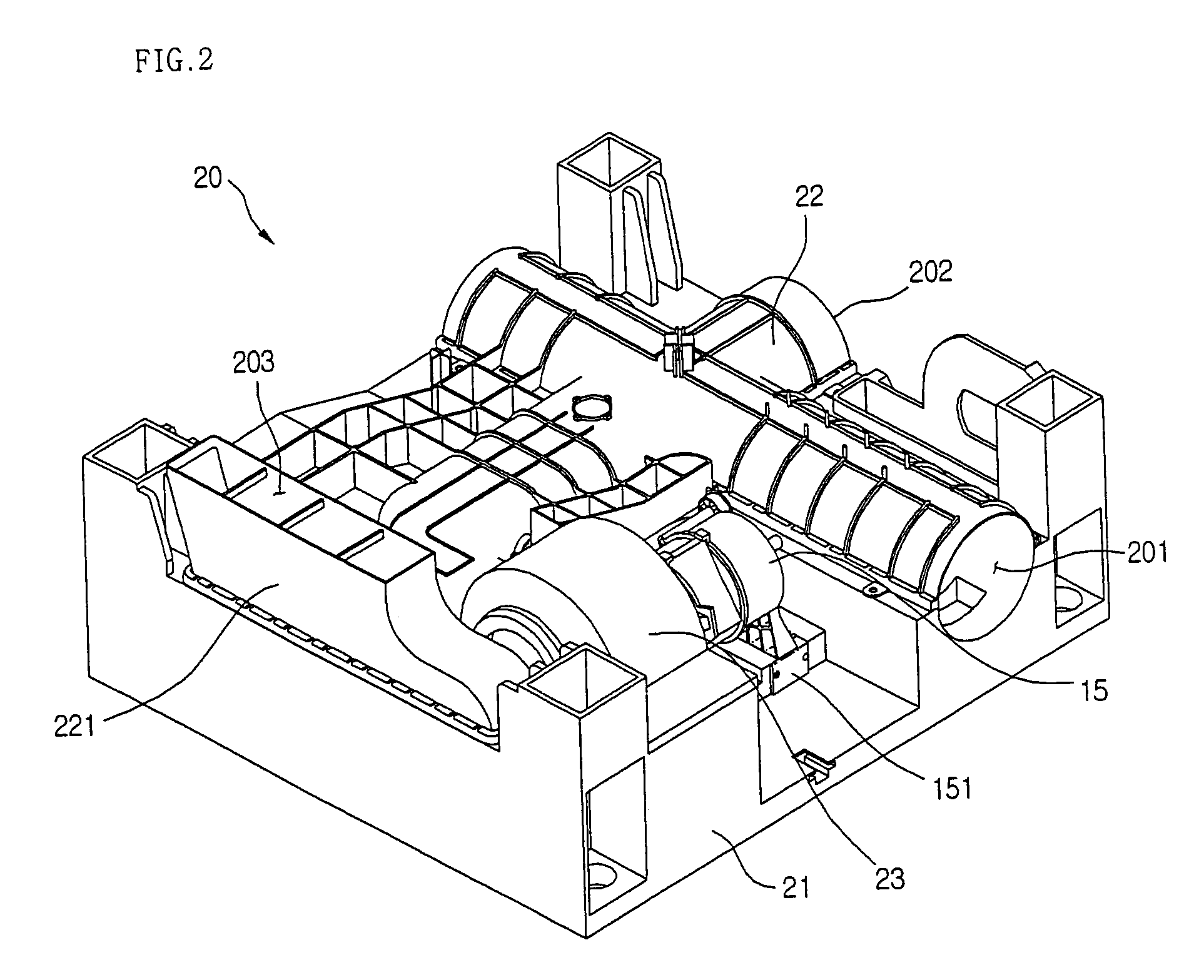

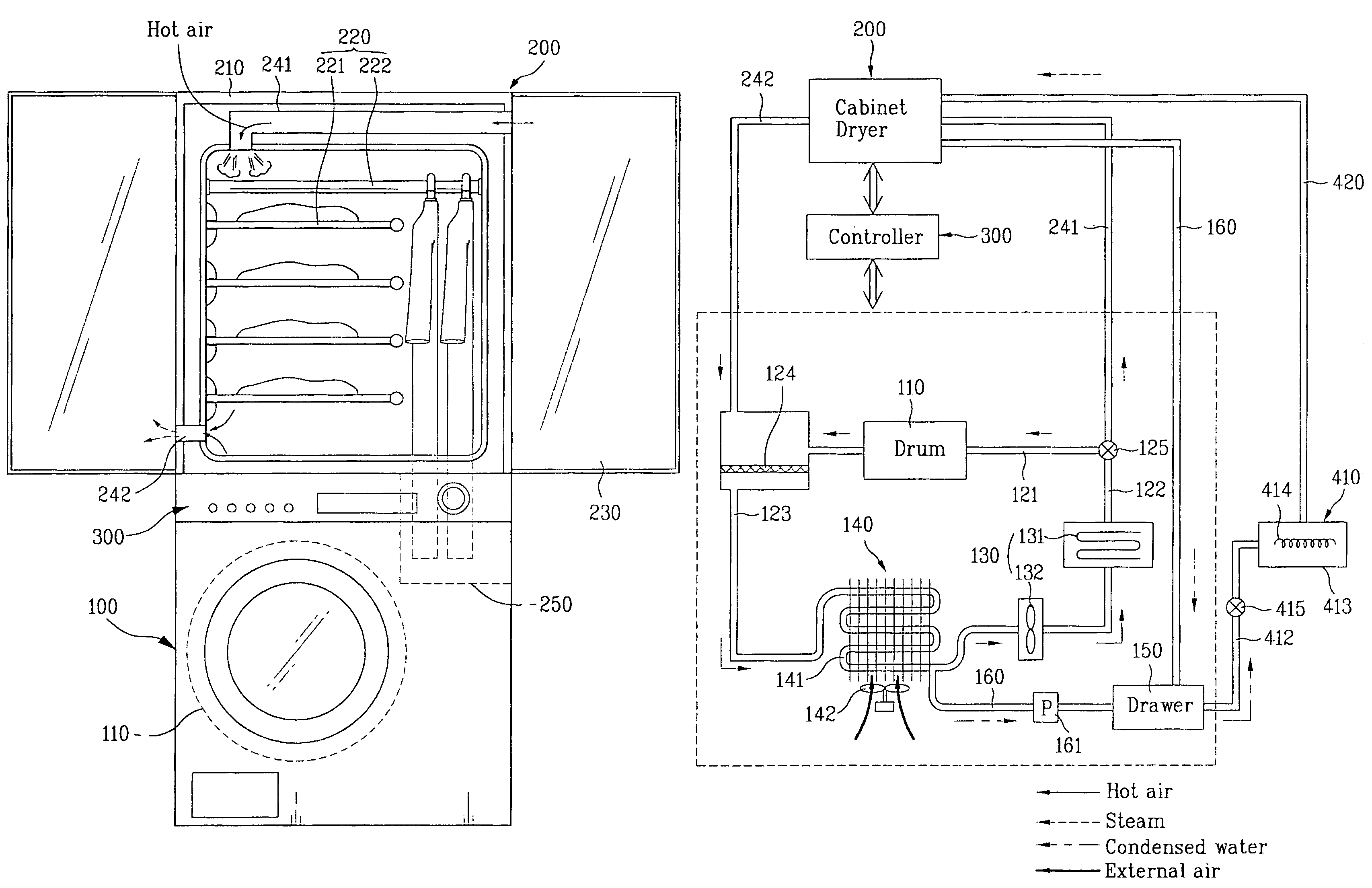

Composite washing system

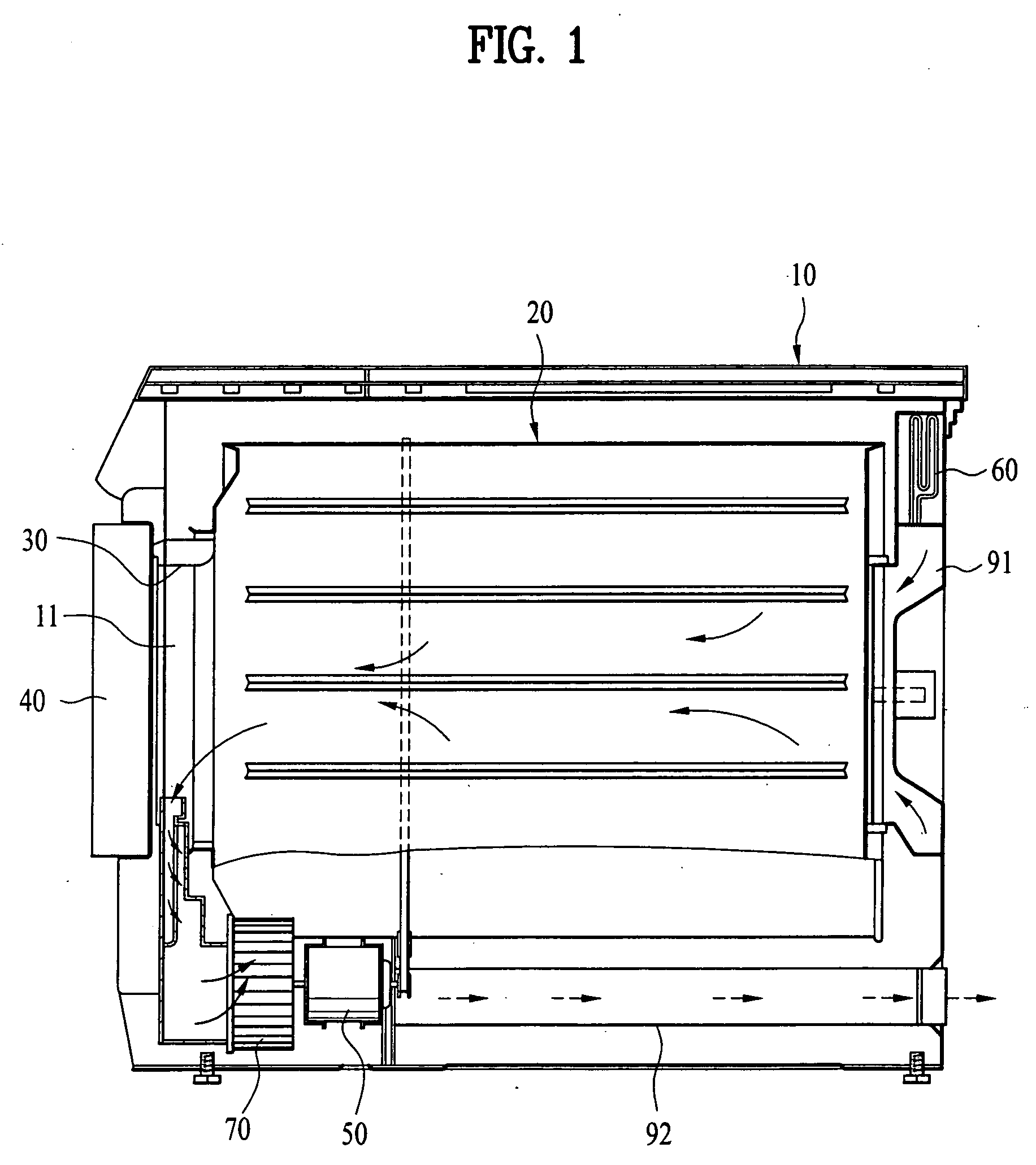

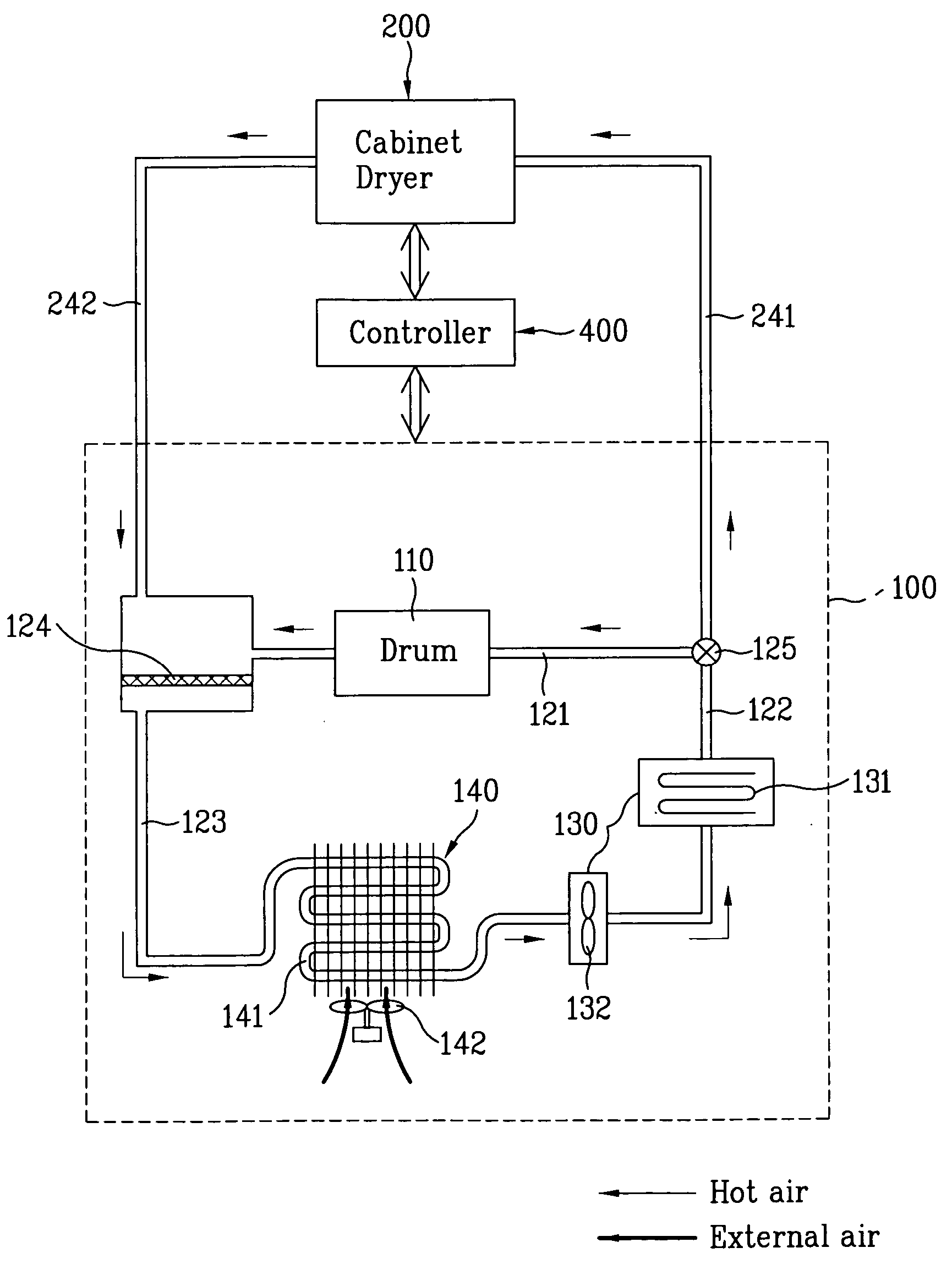

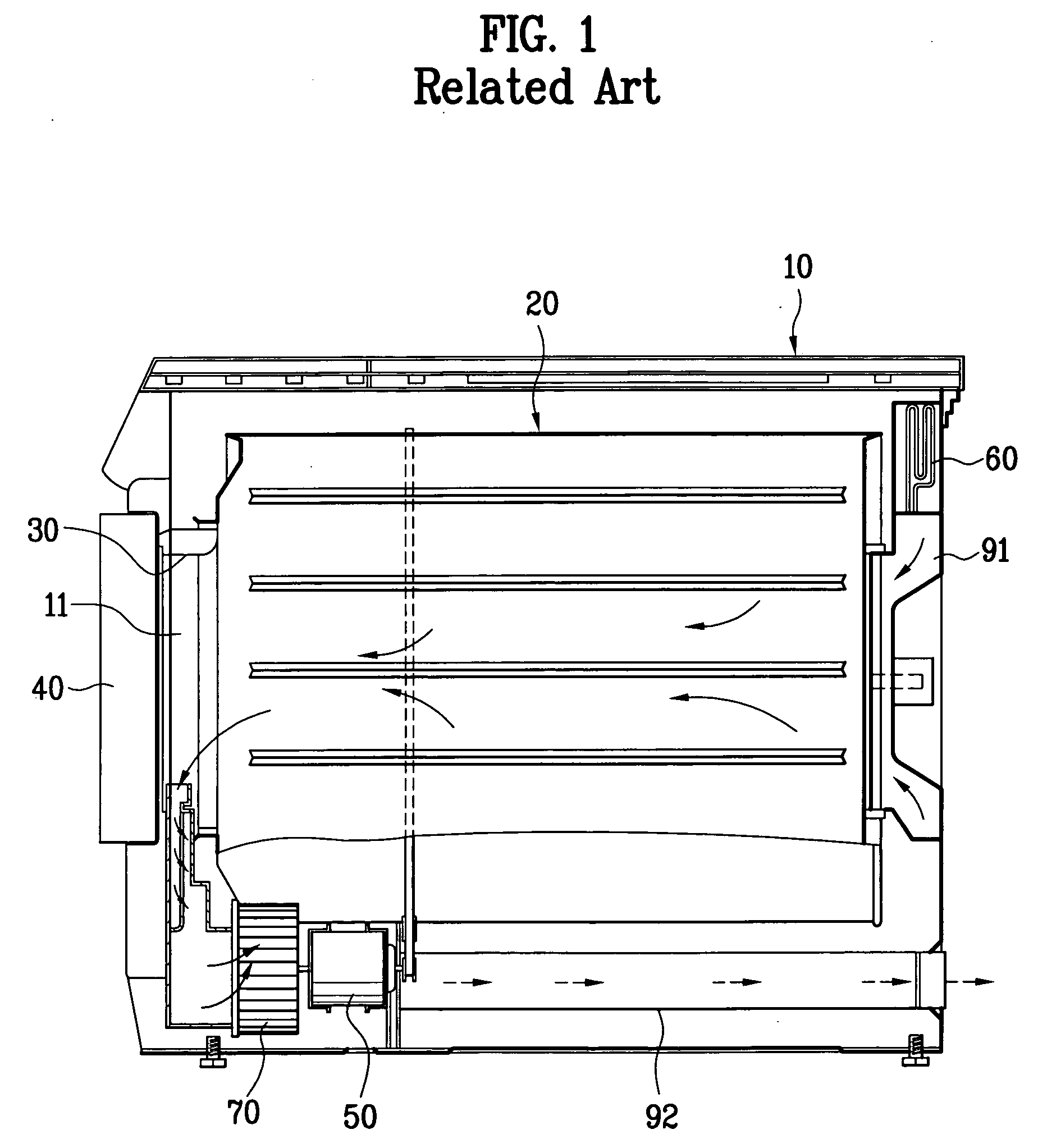

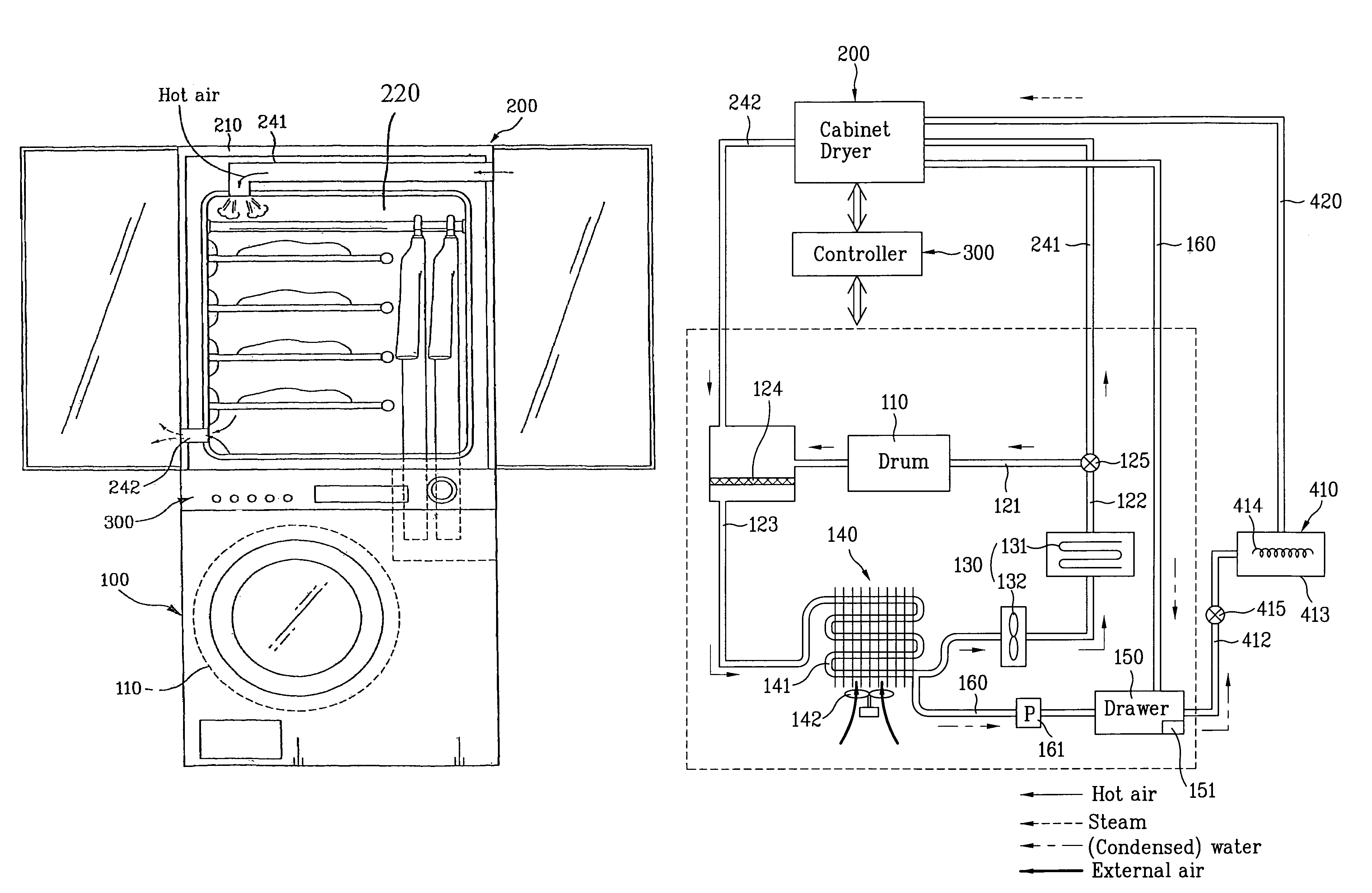

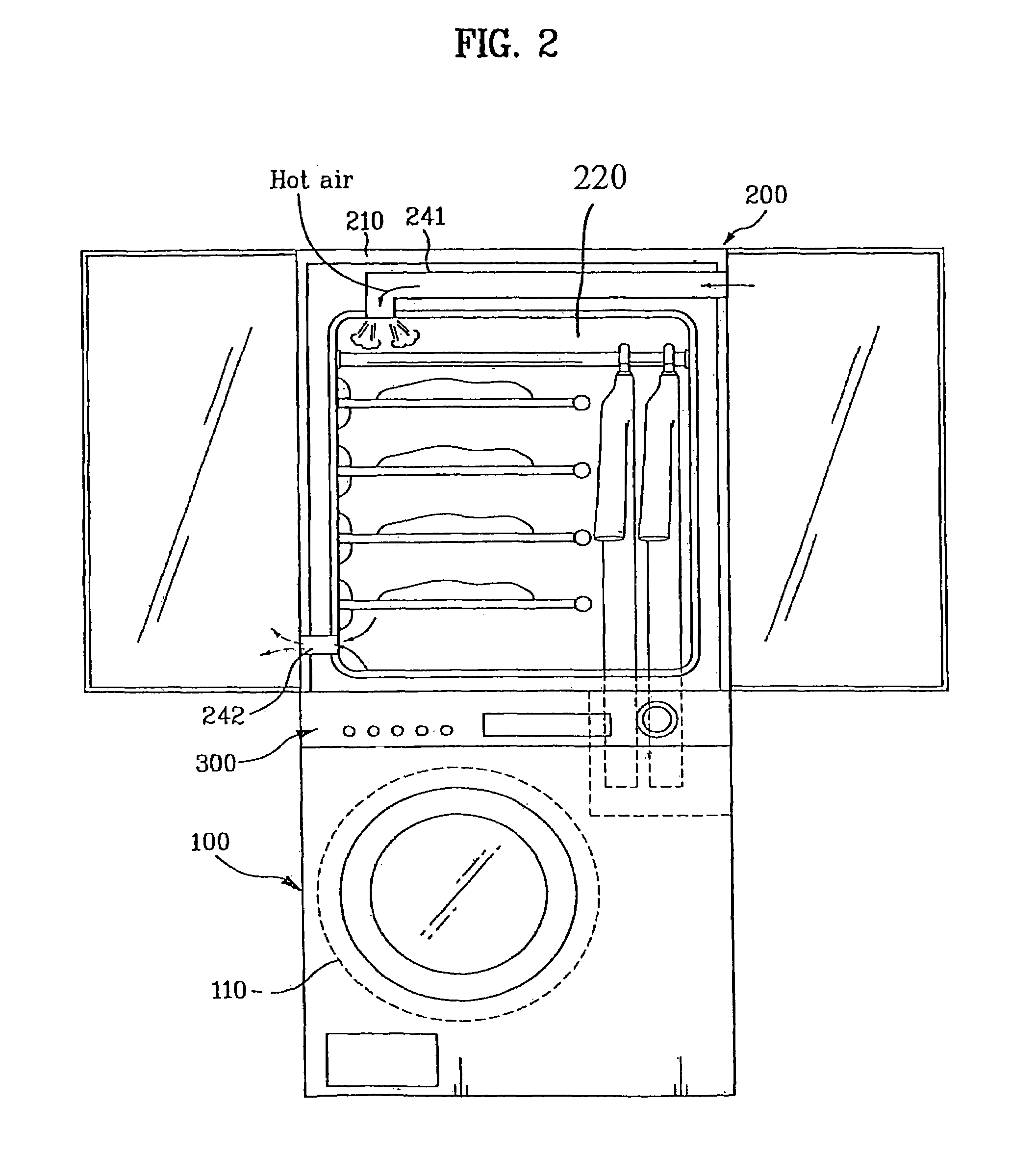

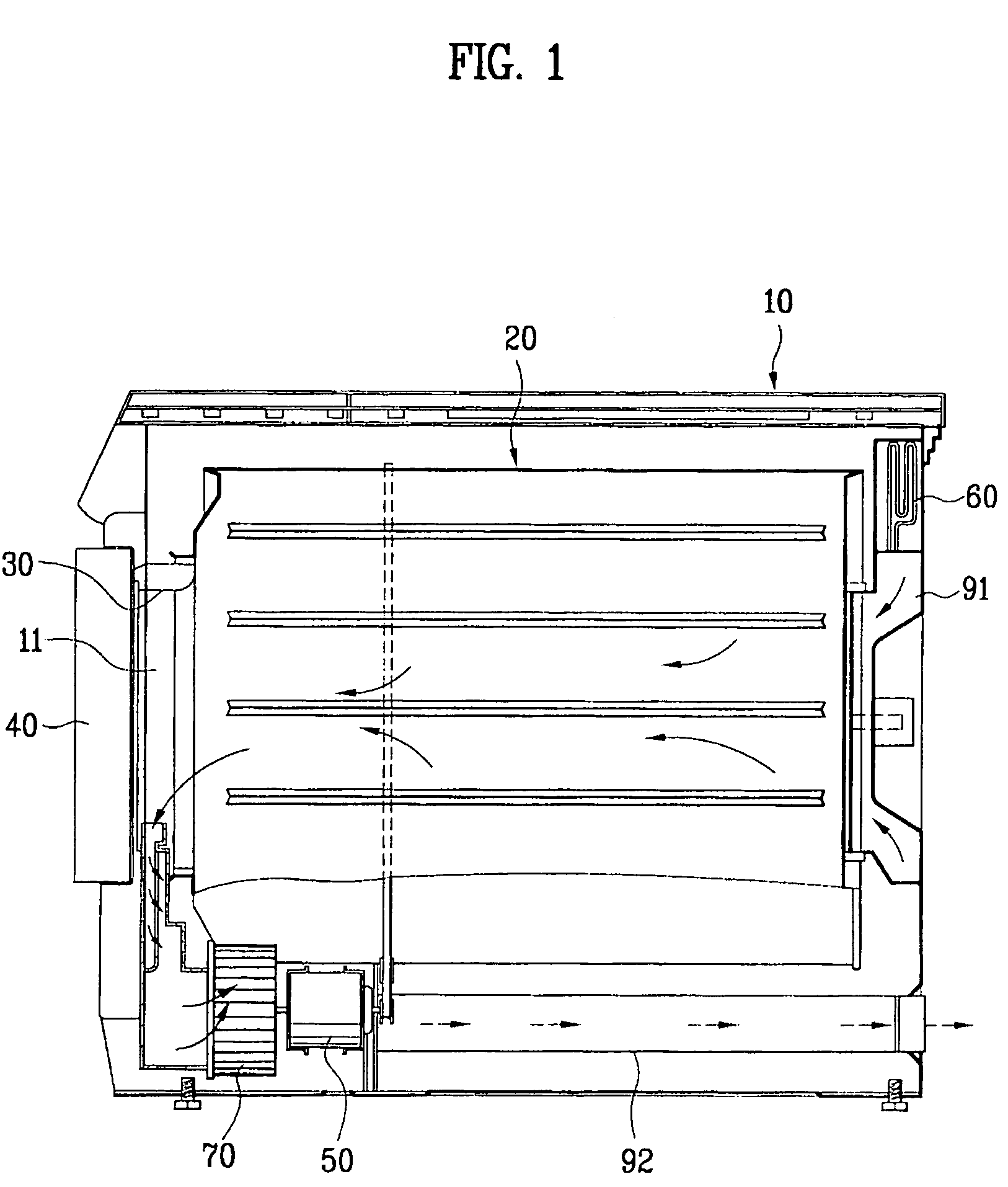

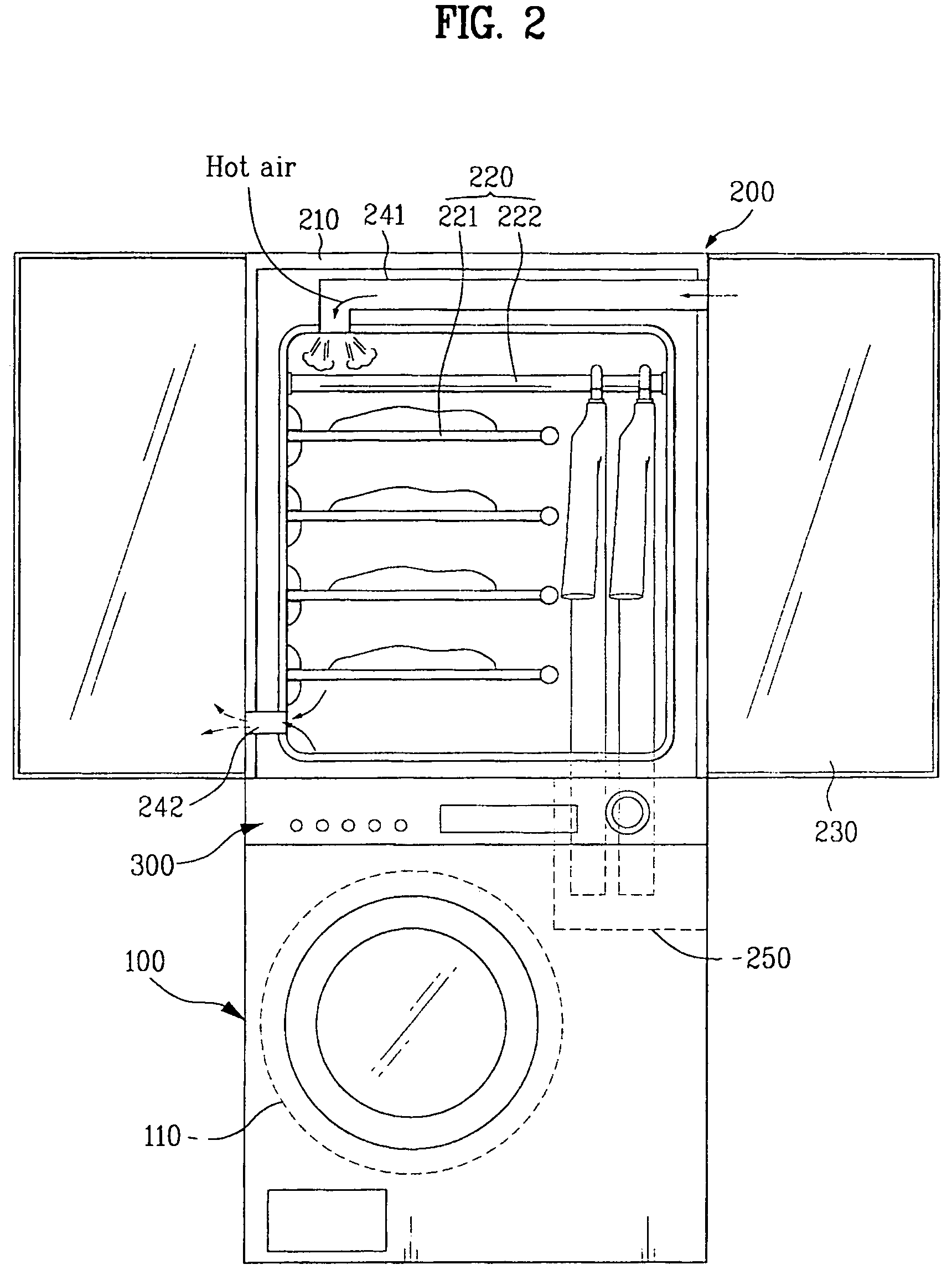

A composite washing system is disclosed which is capable of continuously circulating laundry-drying air through dryers while obtaining a more efficient drying effect, so that the composite washing system has a suitable built-in structure having minimal influence on the indoor environment. The composite washing system includes a drum dryer which dries laundry to be dried, and includes a drying drum adapted to receive the laundry, a hot air supply path adapted to guide a flow of hot air, a hot air supplier arranged in the hot air supply path to generate the hot air, and an air condenser adapted to condense the hot air, a cabinet dryer which is coupled to one side of the drum dryer, and is defined with a laundry receiving compartment, the cabinet dryer including a hot air inlet duct adapted to receive the hot air flowing through the hot air supply path, and a hot air supplying device which is arranged in the cabinet dryer to receive the hot air from the hot air inlet duct and to supply the received hot air to an inside of the laundry.

Owner:LG ELECTRONICS INC

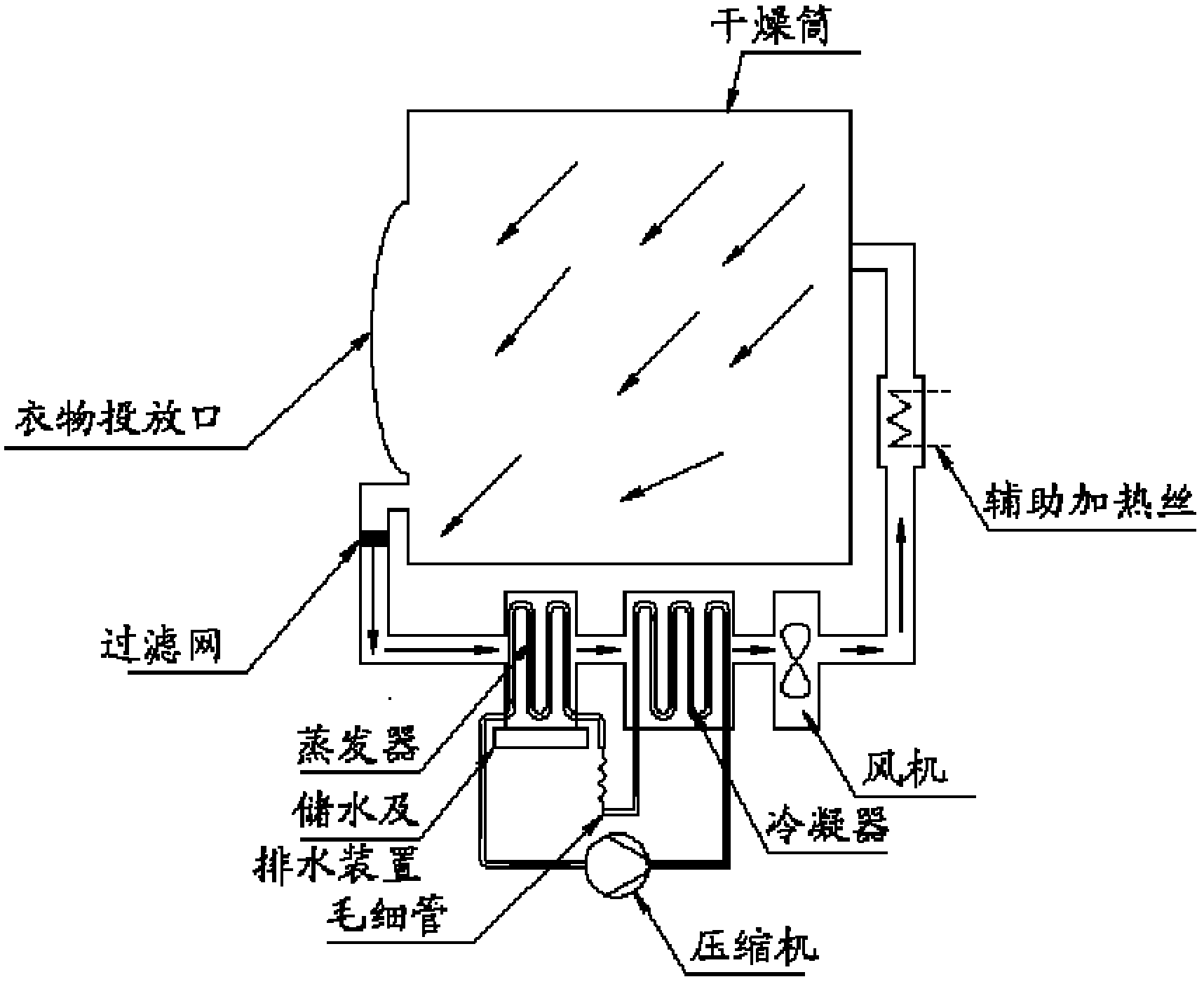

Clothes dryer and drying method thereof

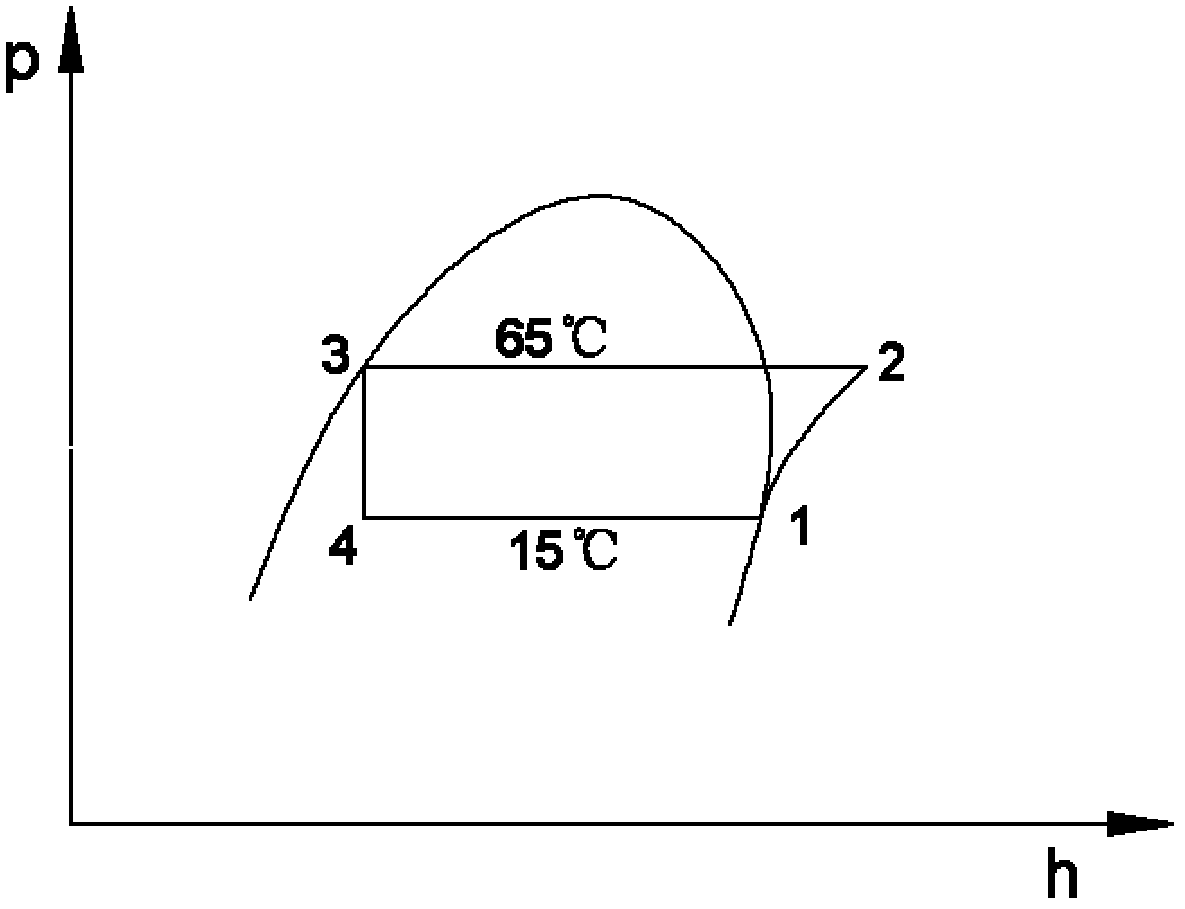

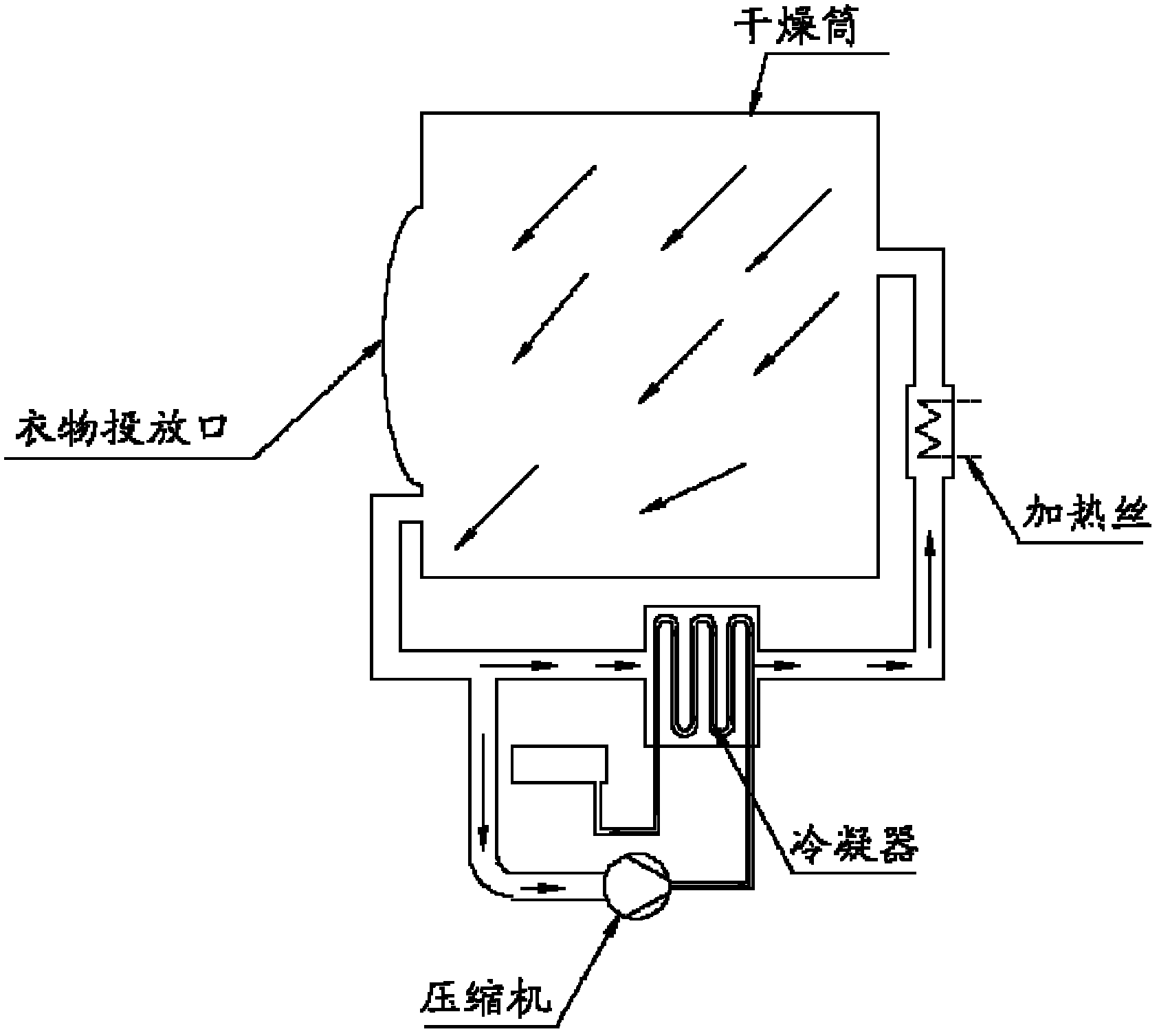

ActiveCN102677438AReduce power consumptionShorten drying timeTextiles and paperLaundry driersPulp and paper industryDrying time

The invention discloses a clothes dryer and a drying method thereof. The clothes dryer comprises a drying drum, a condenser, a steam compressor and heating wires. An air inlet end of the condenser is connected with an air exhaust end of the drying drum, an air exhaust end of the condenser is connected with an air inlet end of the drying drum, an air inlet end of the steam compressor is connected with an air exhaust end of the drying drum, an air exhaust end of the steam compressor is connected with a refrigerant inlet of the condenser, and the heating wires are arranged in a passage between the air exhaust end of the condenser and the air inlet end of the drying drum. The problem that drying time of a clothes dryer in the prior art is lengthened when energy consumption is reduced is solved, and power consumption of the clothes dryer is reduced, and drying time thereof is shortened.

Owner:HAIER GRP CORP +1

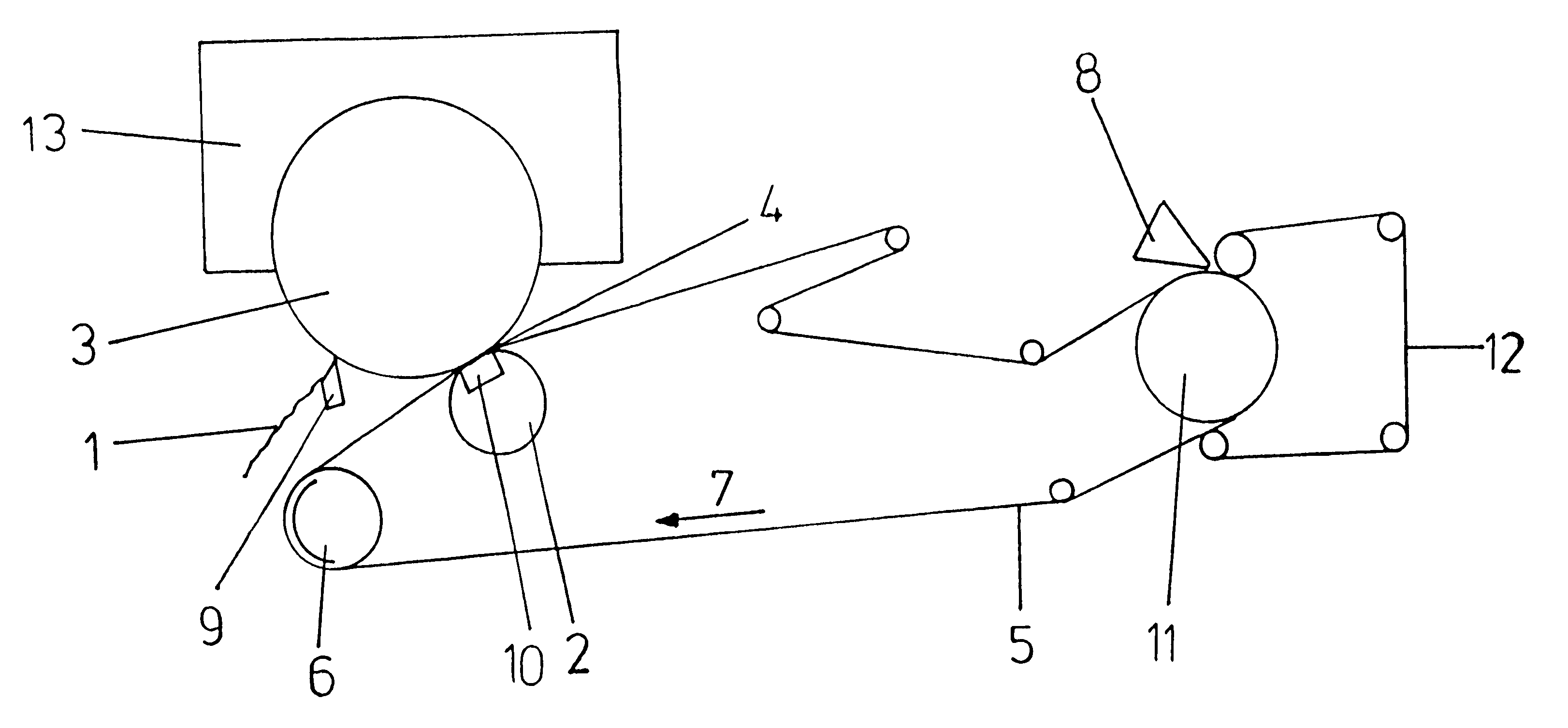

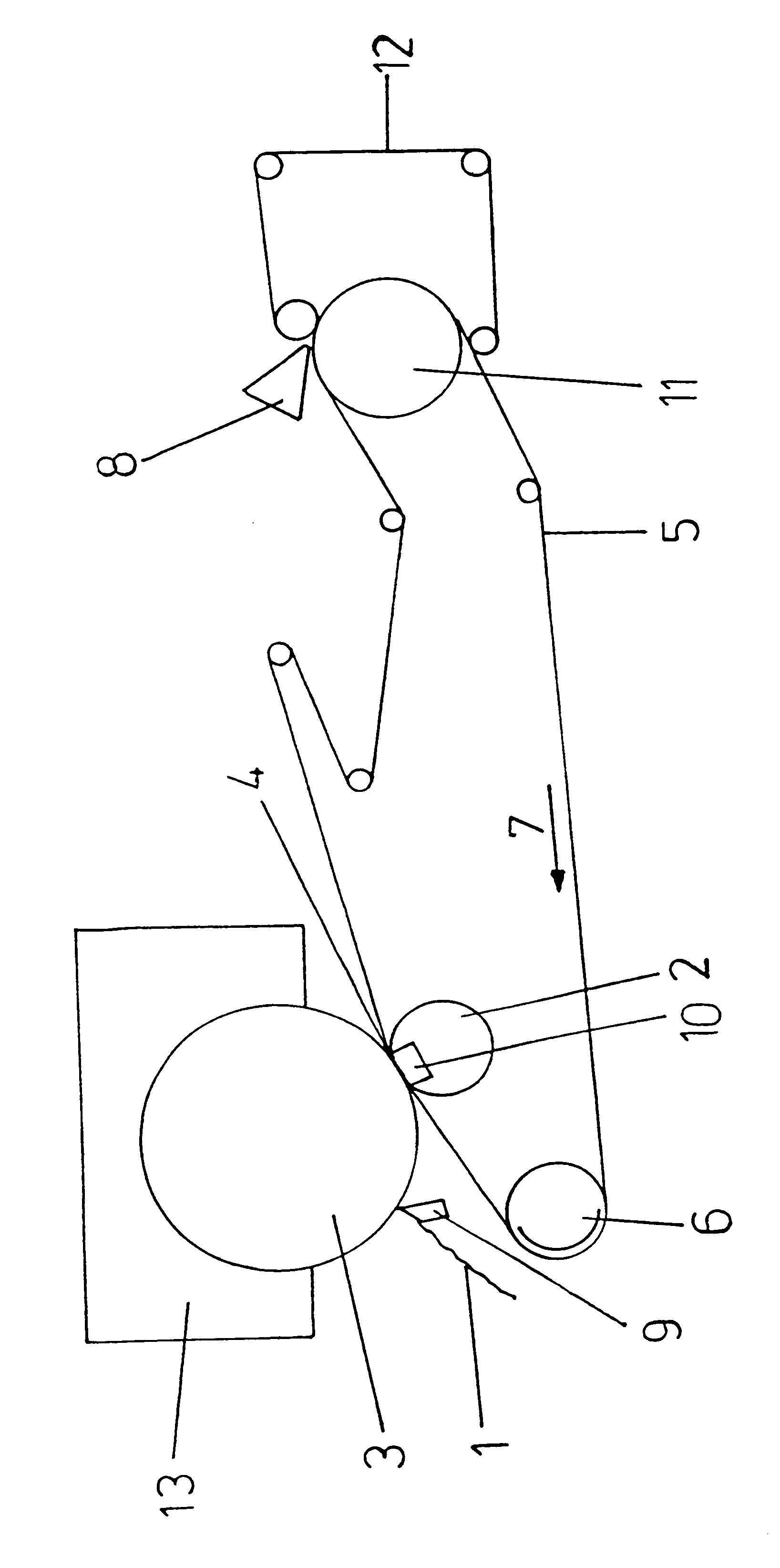

Machine and process for producing a fiber material web

InactiveUS6235160B1Reduce materialSimple designNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

Machine and process for producing a fiber material web that includes at least one press device having a shoe press unit and a drying drum, such that the shoe press unit and the drying drum are positioned to form an elongated press nip. The machine also includes at least one belt that is water-permeable and water-absorbent and that is adapted to guide the fiber material web through the press nip, and at least one suction device located ahead of the elongated press nip, relative to a belt travel direction. The at least one belt is guided over the at least one suction device. The process includes guiding the at least one belt over the at least one suction device and suctioning the at least one belt, such that moisture is removed from the at least one belt, and guiding the fiber material web and the suctioned at least one belt through the extended press nip.

Owner:VOITH PATENT GMBH

Operation method and device for combination dryer

An operation method for a combination dryer is disclosed. The present invention relates to a combination dryer, and more particularly, to an operation method for a combination dryer which enables air in a drying drum and a cabinet for drying the laundry to circulate continuously and enables condensed water generated in the circulation process to perform a refreshing cycle by using the water.

Owner:LG ELECTRONICS INC

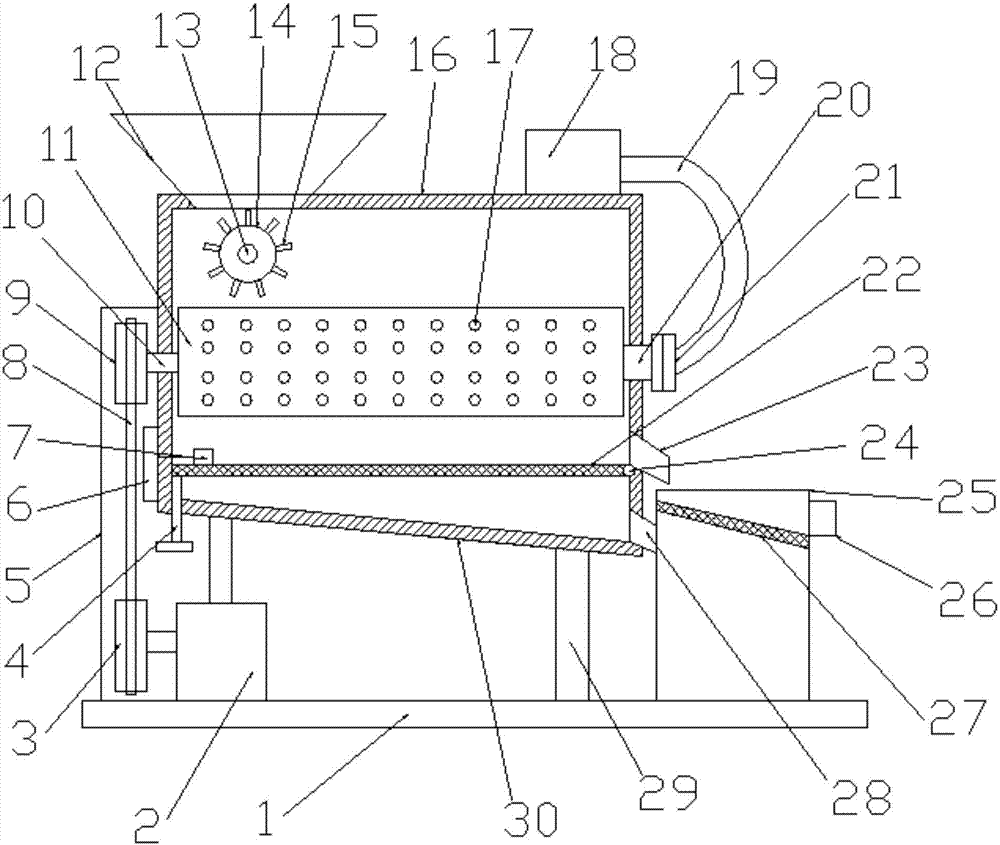

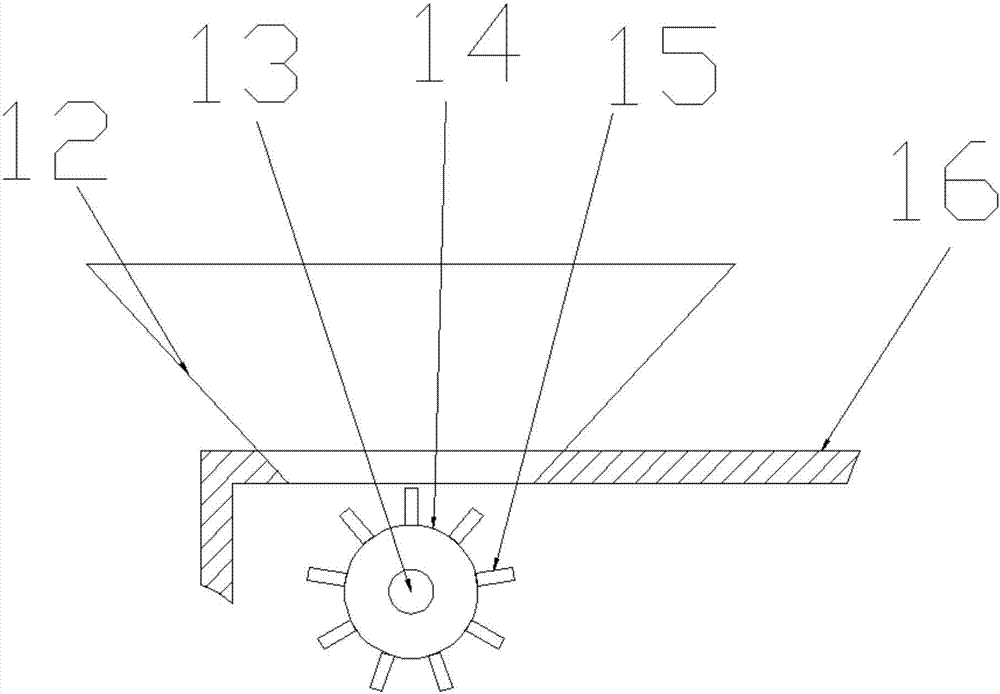

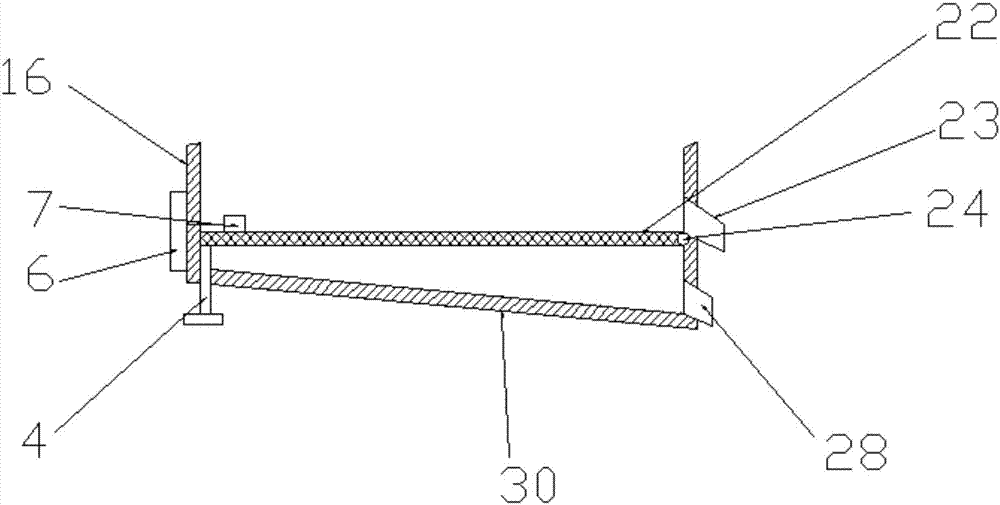

Leather drying machine

ActiveCN103451324AGuaranteed drying effectGuaranteed drying efficiencySkins/hides/leather/fur manufacturing apparatusLeather dryingEngineeringDrive motor

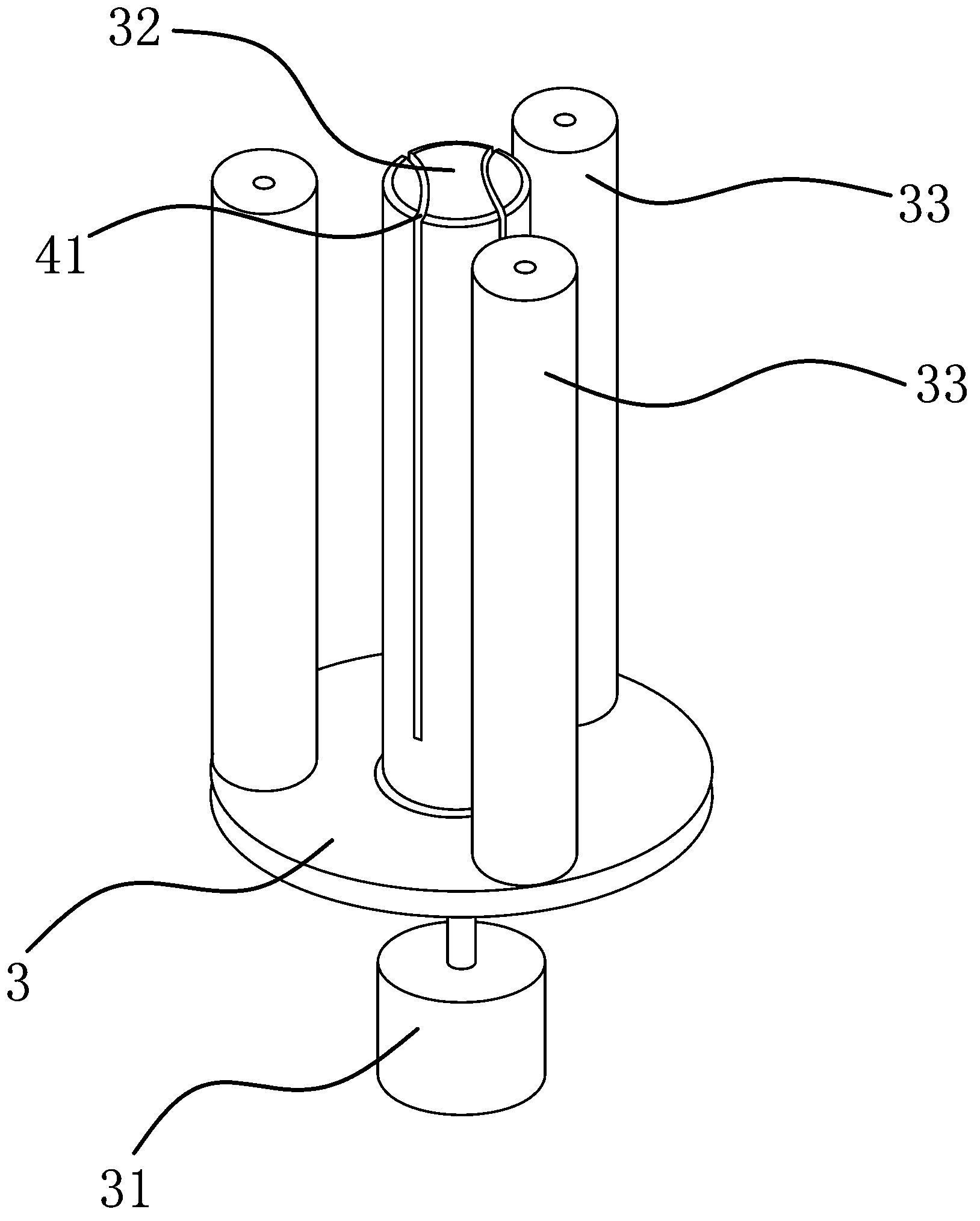

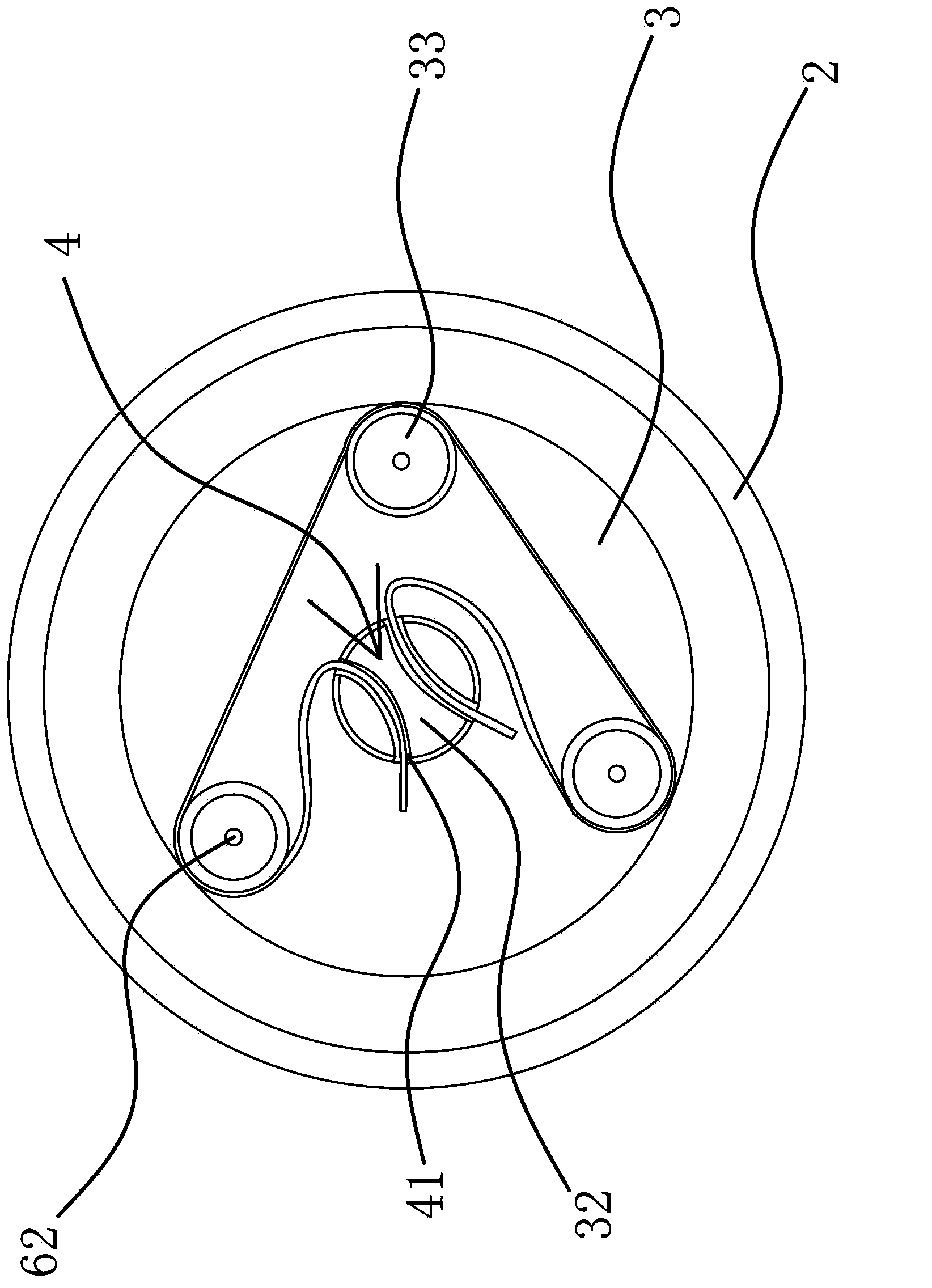

The invention provides a leather drying machine, which belongs to the technical field of leather production equipment and solves the technical problems of poor drying effect and the like of existing leather drying equipment. The leather drying machine comprises a base, wherein a drying drum with an opening at the upper end is fixedly arranged on the base; a driving motor is arranged at the bottom part of the drying drum; a rotating disc is connected onto an output shaft of the driving motor; a positioning shaft is arranged in the central position of the rotating disc and is provided with a clamping device which can fix two edges of leather on the positioning shaft; the rotating disc is also uniformly provided with three tensioning drums which abut against the leather and tension the leather; an air drum is arranged at the outer side of the drying drum, is internally provided with a fan and is communicated with the drying drum; the upper end of the drying drum is provided with a spongy water absorbing plate covering the opening; electric heating wires are arranged in the tensioning drum. The leather drying machine provided by the invention has the advantages of good drying effect and the like.

Owner:浙江富邦汽车内饰科技有限公司

Appliance for drying laundry

Owner:ELECTROLUX HOME PROD CORP NV

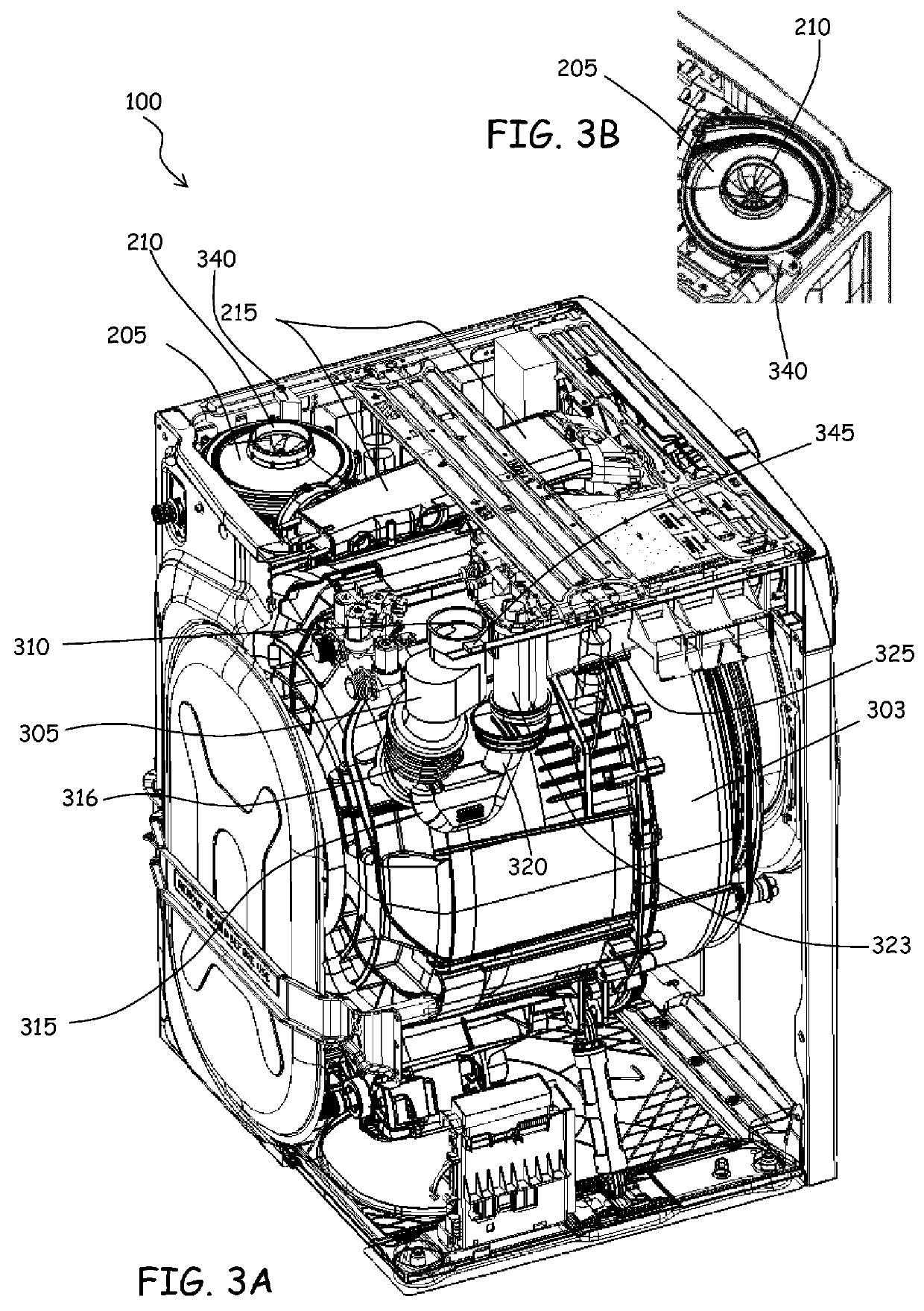

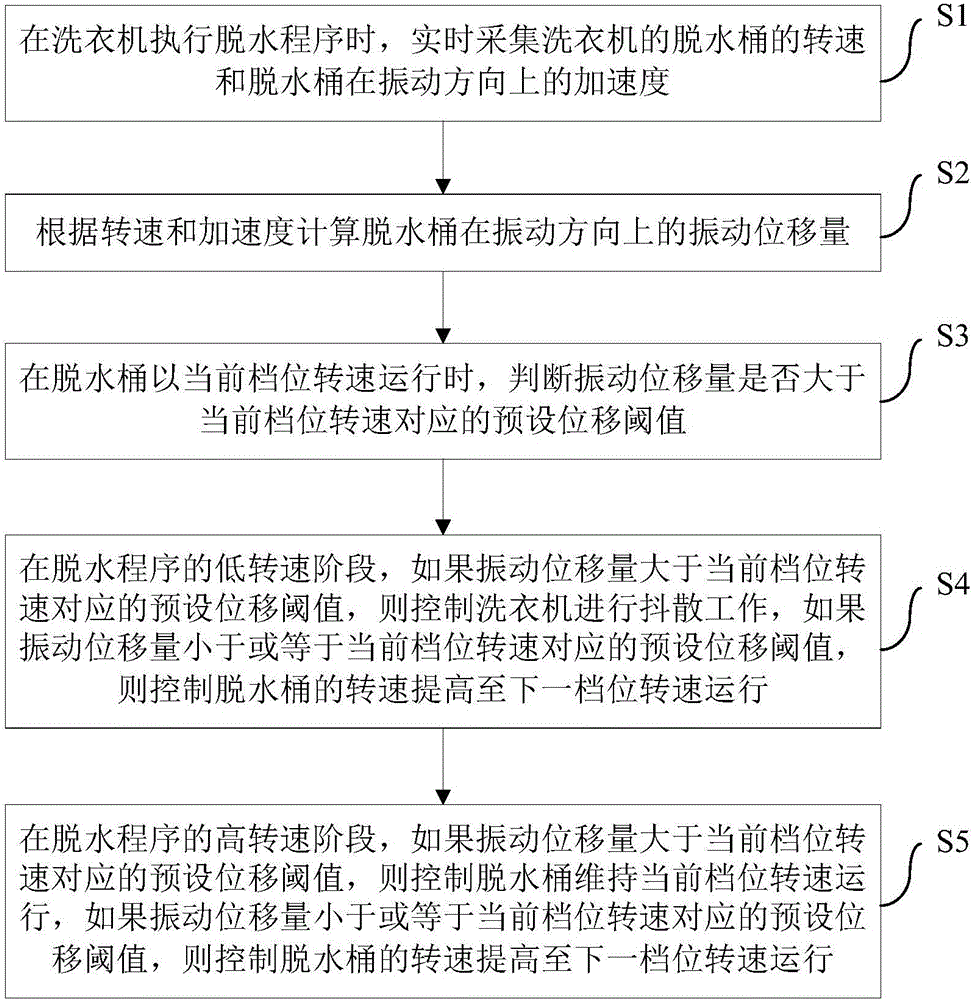

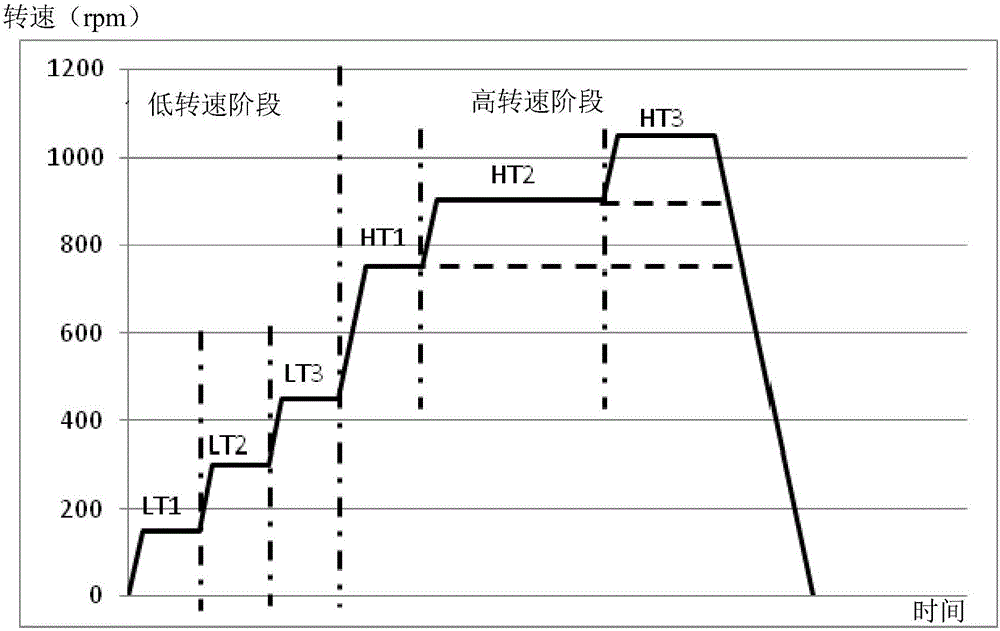

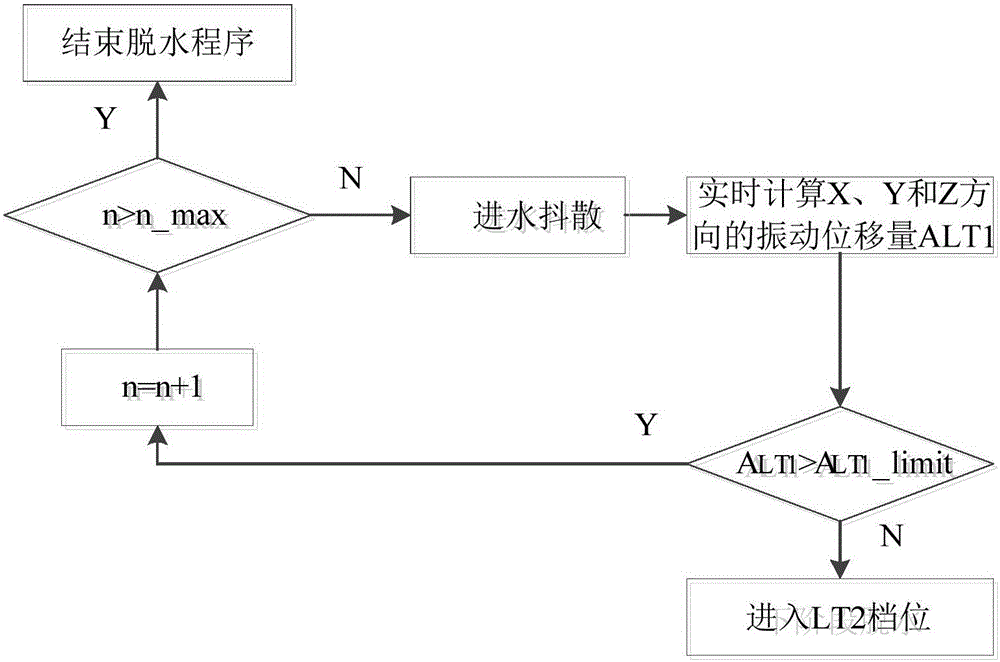

Spin drying control method and device of washing machine and washing machine

ActiveCN105951360AIncrease speedReduce high speed vibrationControl devices for washing apparatusTextiles and paperLow speedProcess engineering

The invention discloses a spin drying control method and device of a washing machine and the washing machine. The method comprises the following steps: when the washing machine executes a spin drying procedure, collecting the speed of a spin drying drum of the washing machine and the acceleration of the spin drying drum in the vibration direction in real time; calculating the vibration displacement of the spin drying drum in the vibration direction according to the speed and the acceleration; when the spin drying drum runs at the current-gear speed, judging whether the vibration displacement is greater than a preset displacement threshold corresponding to the current-gear speed; in a low-speed stage of the spin drying procedure, if the vibration displacement is greater than the preset displacement threshold corresponding to the current-gear speed, controlling the washing machine to perform loose shaking work; otherwise, controlling to increase the speed of the spin drying drum to the next-gear speed; in a high-speed stage of the spin drying procedure, if the vibration displacement is greater than the preset displacement threshold corresponding to the current-gear speed, controlling the spin drying drum to run at the current-gear speed; otherwise, controlling to increase the speed of the spin drying drum to the next-gear speed.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

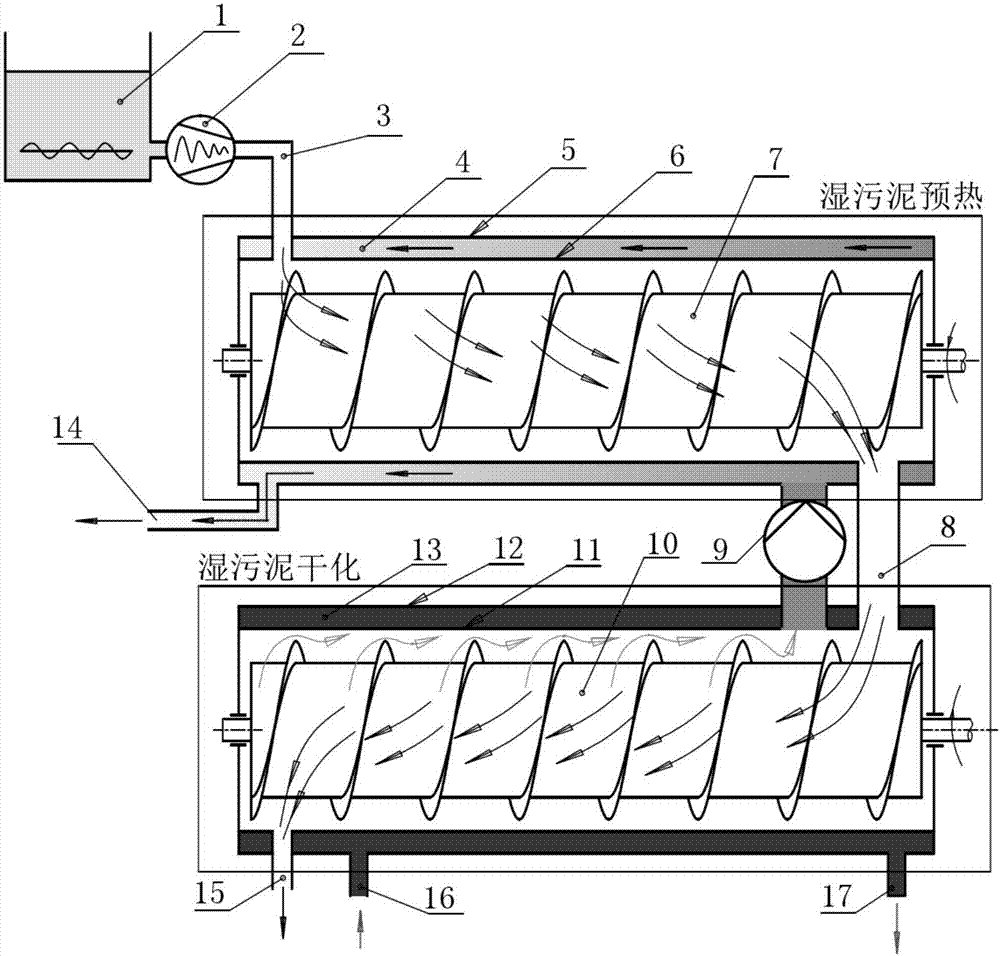

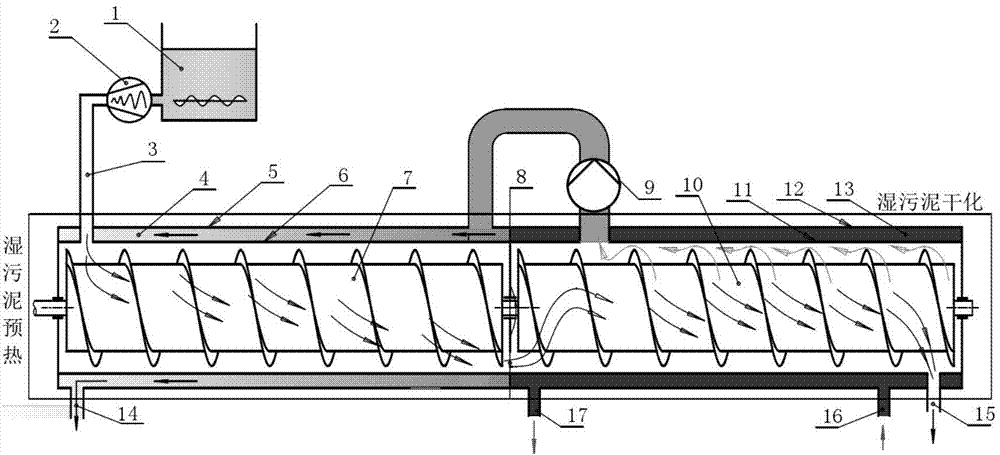

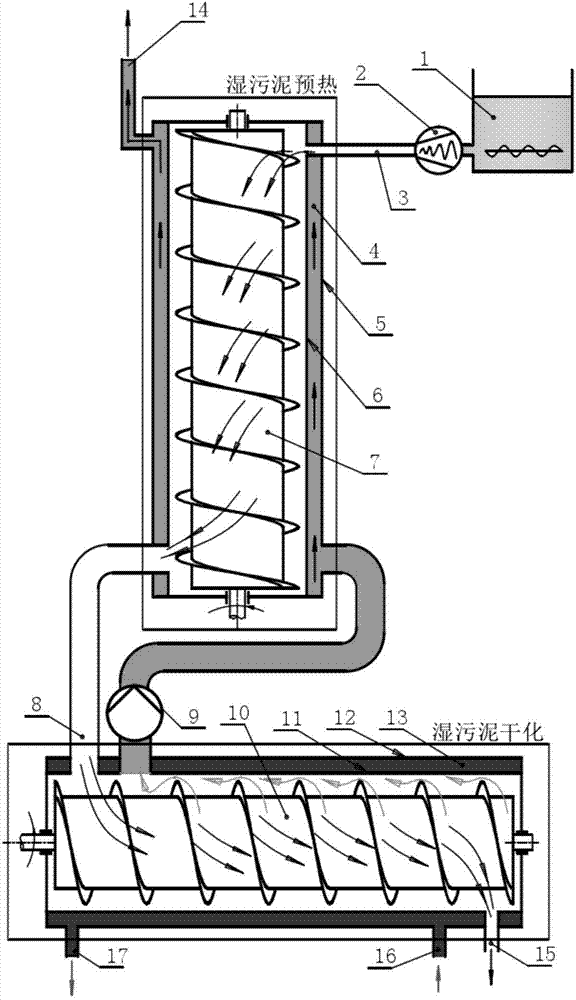

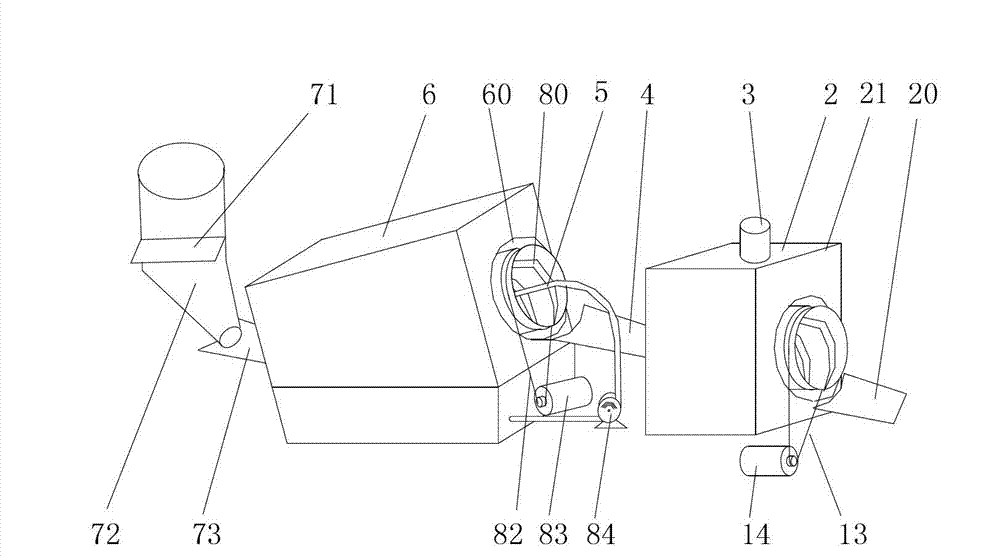

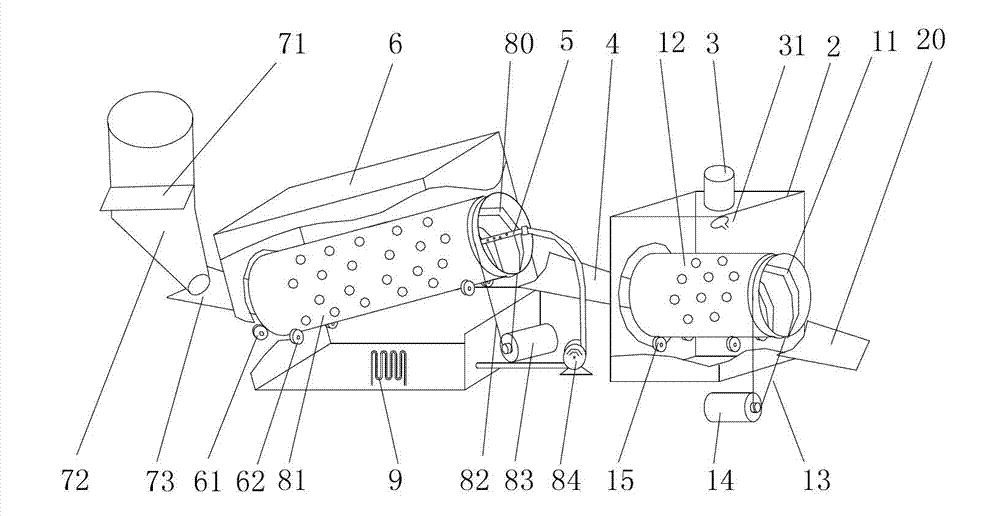

Binocular wet sludge drying equipment

InactiveCN103922557AHigh thermal efficiencyAchieve energy saving and emission reductionSludge treatment by de-watering/drying/thickeningSludgeEvaporation

The invention discloses binocular wet sludge drying equipment which is composed of a sludge pump (2), a wet sludge preheating drum, a wet sludge drying drum and a pipeline, wherein the wet sludge preheating drum is connected with the sludge pump (2) through the pipeline (3); the wet sludge drying drum is connected with the wet sludge preheating drum through a sludge blanking channel (8). According to the invention, steam latent heat for sludge drying is sufficiently utilized, and wet sludge entering into the wet sludge drying drum can rapidly enter into water evaporation stage because the steam latent heat preheats the wet sludge, so that the efficiency of sludge drying is improved, and energy conservation and emission reduction of sludge drying is realized; the wet sludge preheating drum is used as a direct heat exchanger between high-temperature steam and the wet sludge without auxiliary equipment such as a heat exchange fan, thereby improving the efficiency of heat exchange and simplifying the whole drying system.

Owner:CHONGQING UNIV

Clothes drier

InactiveUS7194823B2Reduce loadReducing effect of suspensionDrying gas arrangementsDrying machines with progressive movementsProcess engineeringHeat pump

A clothes drying apparatus includes a heat pump mechanism, an air path for guiding drying air into a drying drum accommodating therein clothes, a blower for supplying drying air to the air path, and a controller for controlling a driving of a compressor, wherein the controller operates the blower and the compressor during a drying operation; stops the compressor in case the drying operation is suspended; and operates, in case the drying operation is resumed, the compressor after a certain time period has elapsed since the compressor had stopped. In case employing the heat pump mechanism having the compressor as a heat source, it is possible to reduce a load on the compressor and allow temperature of warm air to rapidly return by using the heat pump mechanism.

Owner:PANASONIC CORP

Steel ball cleaning and drying equipment

ActiveCN103028565AImprove work efficiencyLow costCleaning using liquidsDrying machinesElectrical controlSteel ball

The invention discloses steel ball cleaning and drying equipment, which comprises a cleaning box body. An inclined cleaning drum is arranged in the cleaning box body. Through holes with diameter being smaller than the diameter of steel balls are arranged on the circumferential surface of the cleaning drum. A spiral plate for conveying the steel balls is fixedly arranged on the internal circumferential surface of the cleaning drum. A spray pipe is additionally arranged in the cleaning drum and is connected with a pump through a pipe. The inlet of the pump is communicated with cleaning solution at the lower part of the cleaning box body through a pipe. The steel ball cleaning and drying equipment additionally comprises an electric heating tube which is used for heating the cleaning solution, a drying box body, a drying fan which is arranged at the top and a drying heating tube which is arranged below the drying fan. A drying drum is horizontally arranged in the drying box body. Through holes with diameter being smaller than the diameter of the steel balls are arranged on the circumferential surface of the drying drum. A spiral plate for conveying the steel balls is fixedly arranged on the internal circumferential surface of the drying drum. An electrical control box supplies power to all electric appliances. The steel balls are fed from the bottom of the cleaning drum, are conveyed to the drying box body from the top and finally are output. The steel ball cleaning and drying equipment has the beneficial effects that the working efficiency is improved, the cost is reduced, the environmental pollution is reduced and the product quality is improved.

Owner:环驰云和钢球有限公司

Laundry drier

InactiveUS7694434B2Reduce manufacturing costSimplify the assembly processOther washing machinesDrying machines with non-progressive movementsEngineeringLaundry

A laundry drier is provided. The laundry drier includes a base, a drying drum, a front cover, a back cover, a top cover, and side covers. The base includes an air passage in the inside of the base, and at least one discharge port for discharging air that has flowed into the air passage. The drying drum is provided above the base and receives the laundry. The front cover is mounted in front of the drying drum, and the back cover is mounted in the rear side of the drying drum. The top cover is mounted above the drying drum, and the side covers are mounted in the lateral sides of the drying drum and have at least two discharge holes.

Owner:LG ELECTRONICS INC

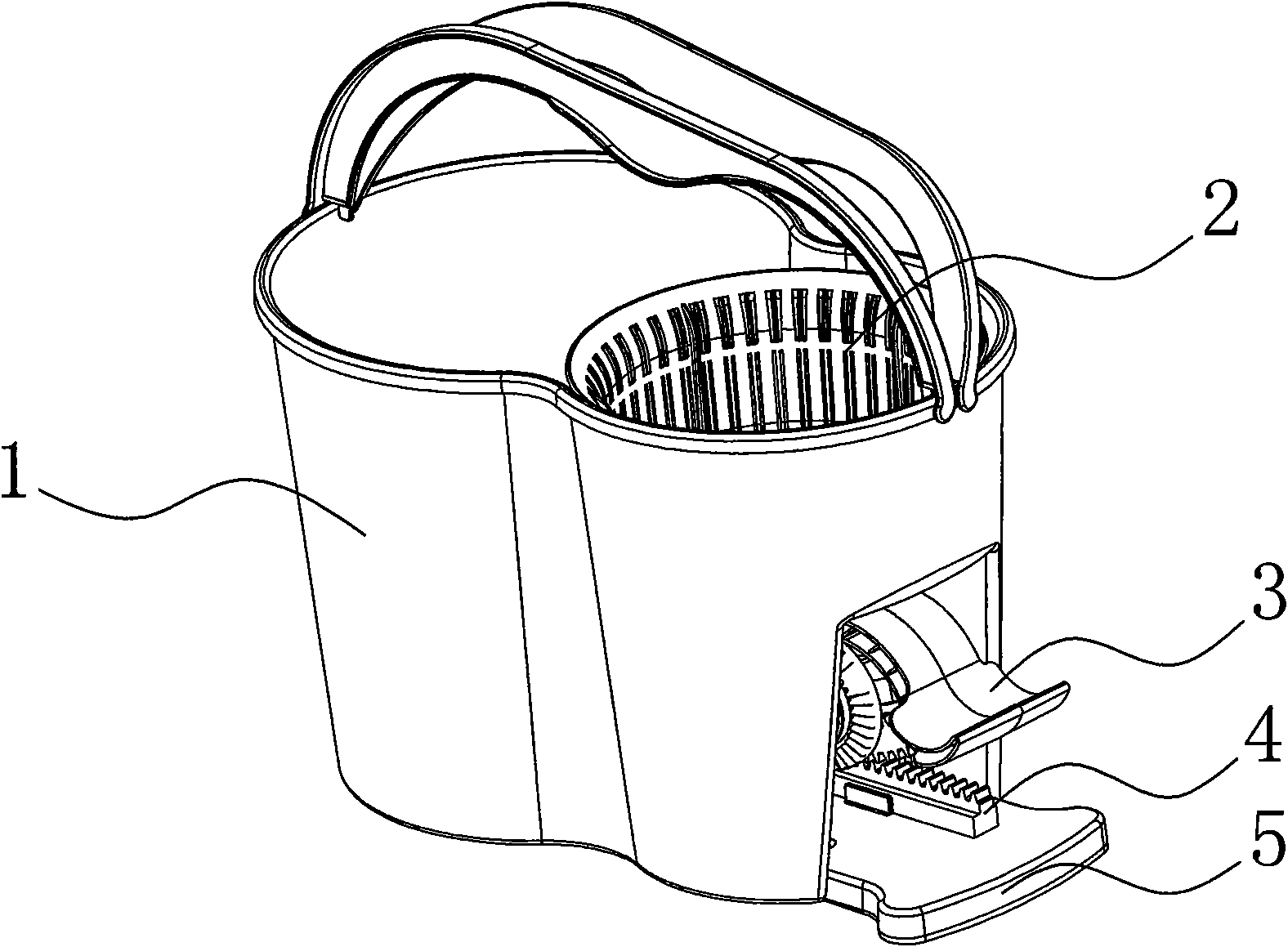

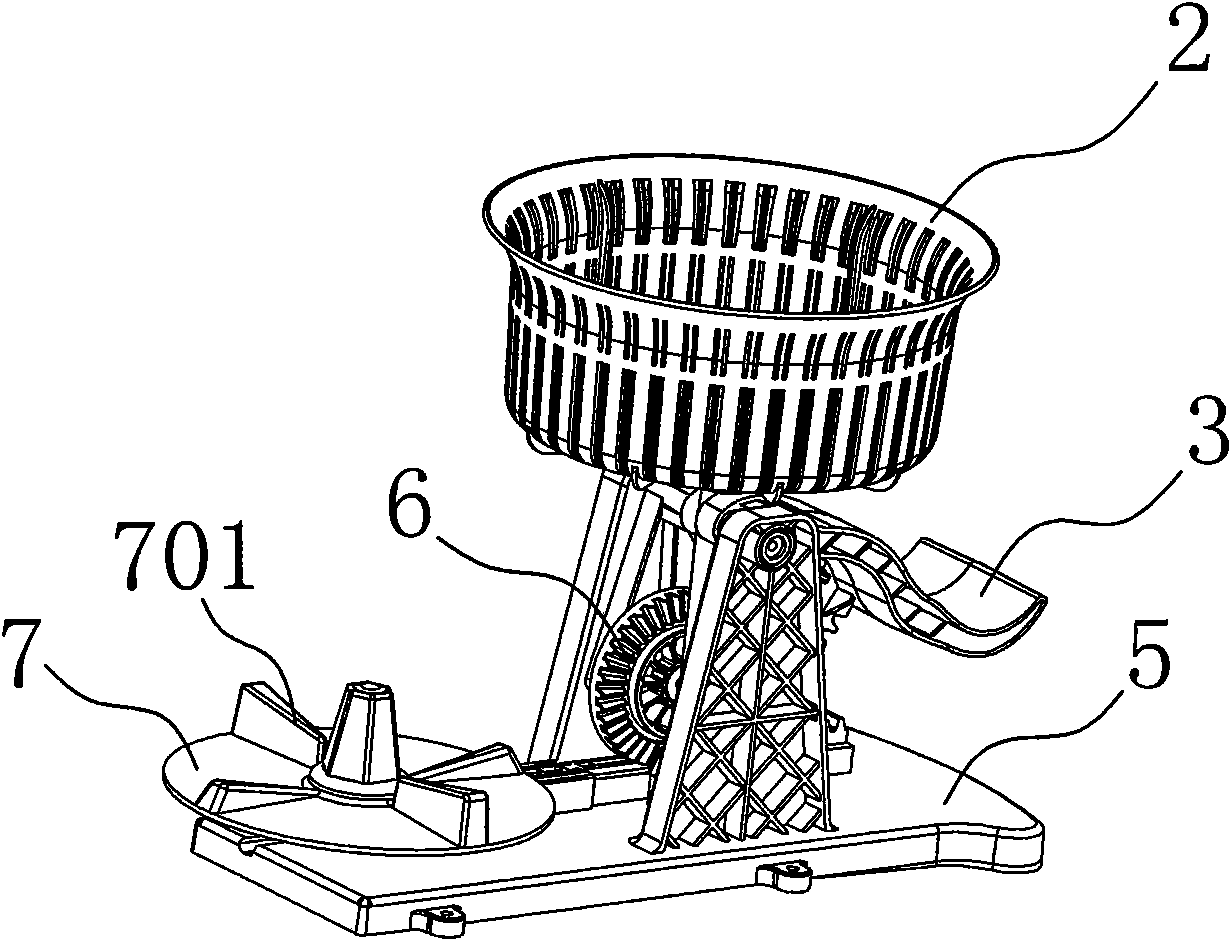

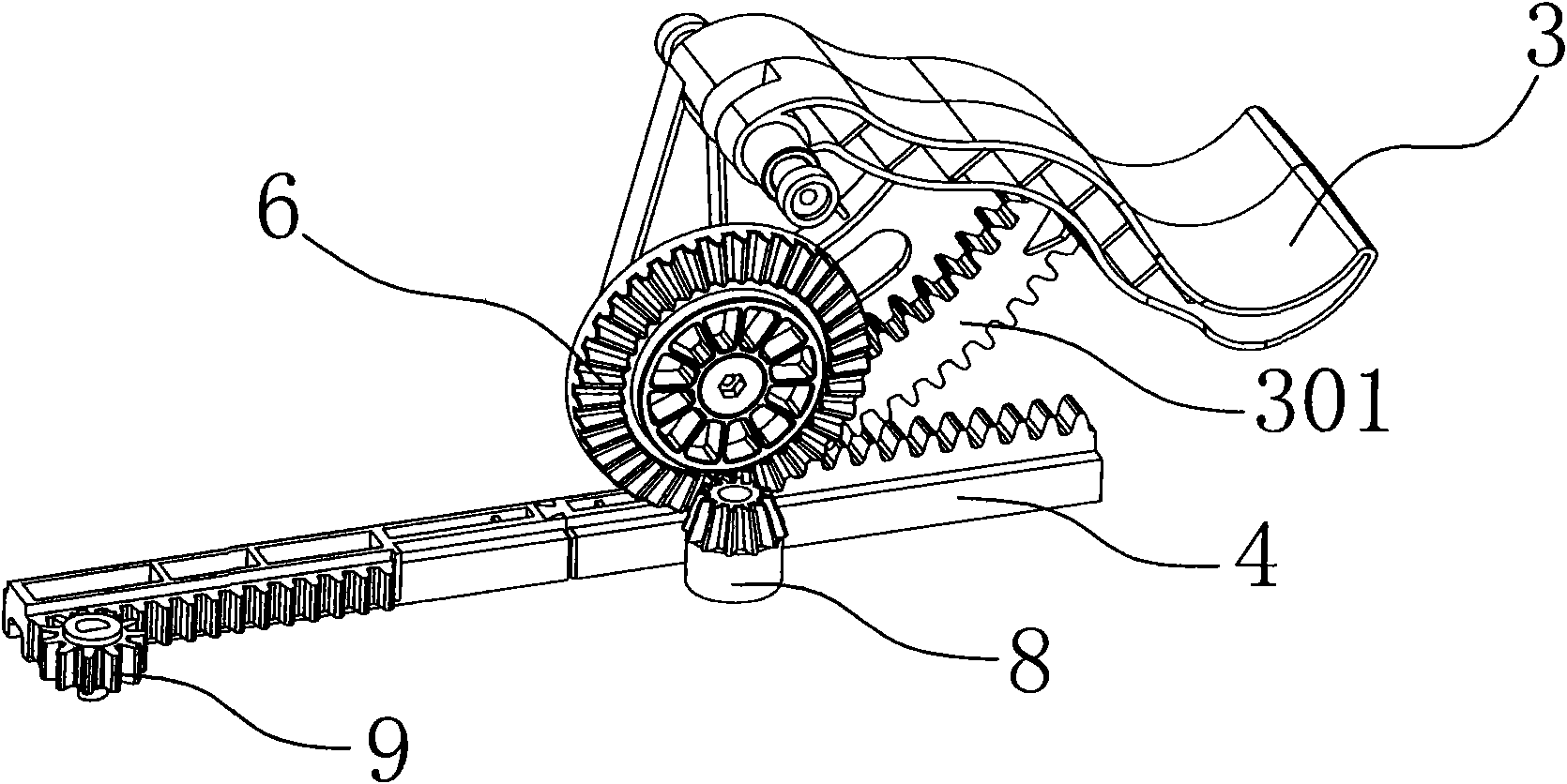

Mop cleaning and drying drum

InactiveCN101926634AEasy to cleanCompact structureCarpet cleanersFloor cleanersEngineeringBevel gear

The invention relates to sanitary cleaning appliances, in particular to a mop cleaning and drying drum. The mop cleaning and drying drum comprises a drum body, a water throwing-off frame, a stirring disk and a pedal mechanism, wherein the pedal mechanism is linked with the water throwing-off frame and the stirring disk; and the pedal mechanism comprises a pedal plate, a composite gear, a bevel gear, a rack, a stirring disk gear and a base. The design key points are as follows: the pedal plate is provided with a sector gear which is a two-sided gear; a large bevel gear, a small cylindrical gear and a spindle are connected into a whole to form the composite gear; the inner gear of the sector gear is engaged with the small cylindrical gear, and the outer gear of the sector gear is engaged with the rack; the rack is a combined type rack and is meshed with the stirring disk gear; and the stirring disk is provided with agitating vanes having different sizes and heights, and the improved stirring disk has better cleaning effect. The mop cleaning and drying drum has compact whole structure and convenient maintenance, uses the combined type rack, reduces maintenance cost, and is suitable for improving the structures of the existing similar products.

Owner:陆焕炯

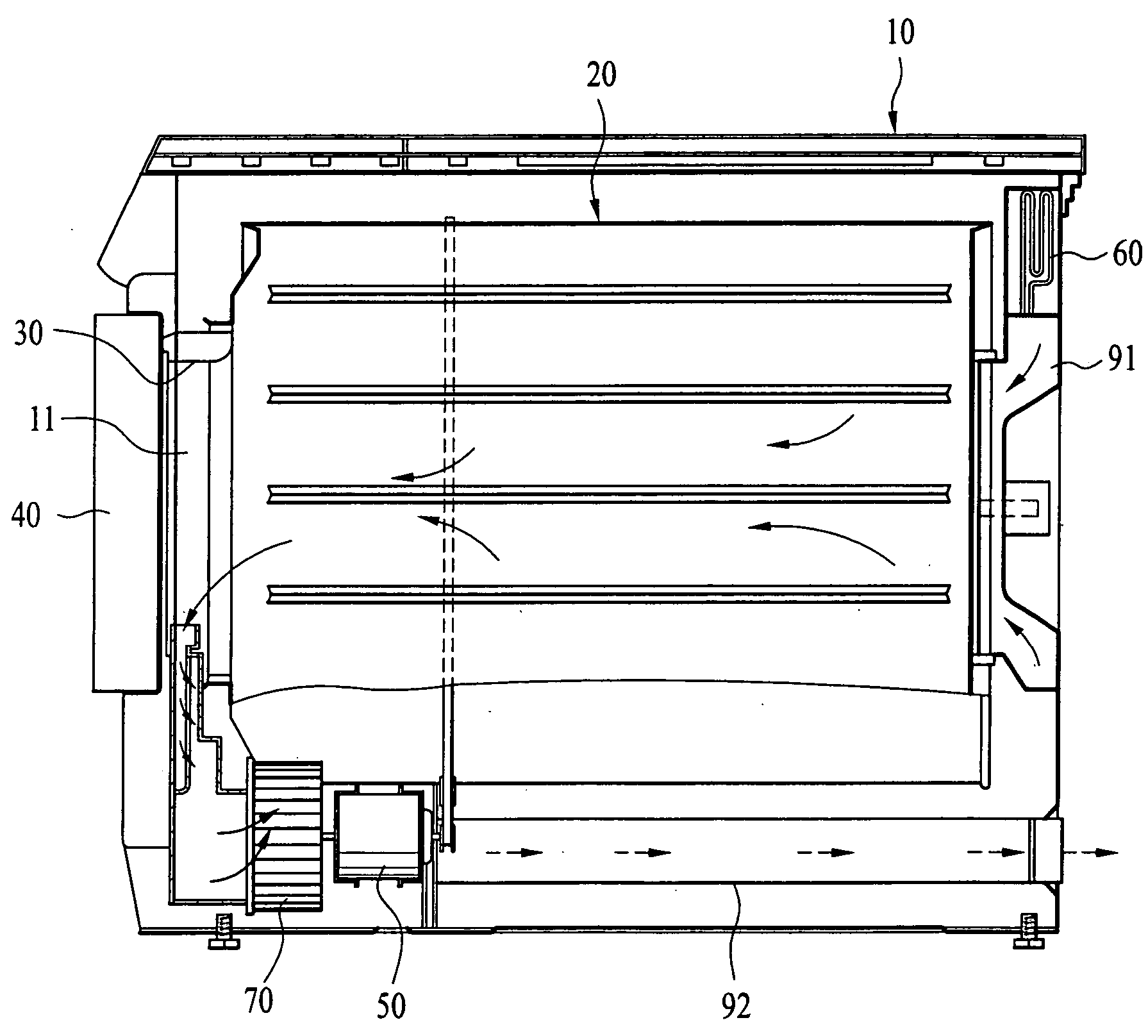

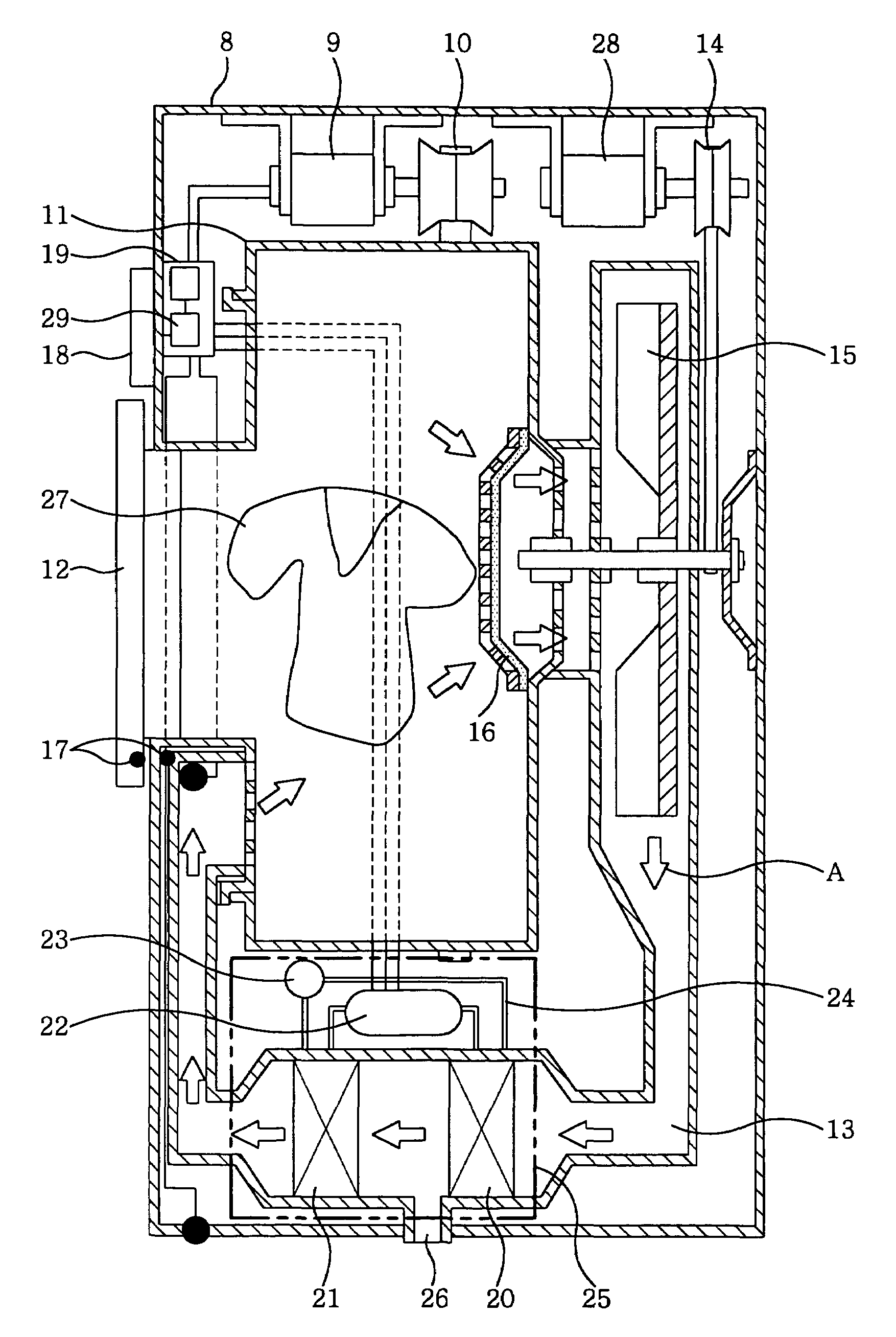

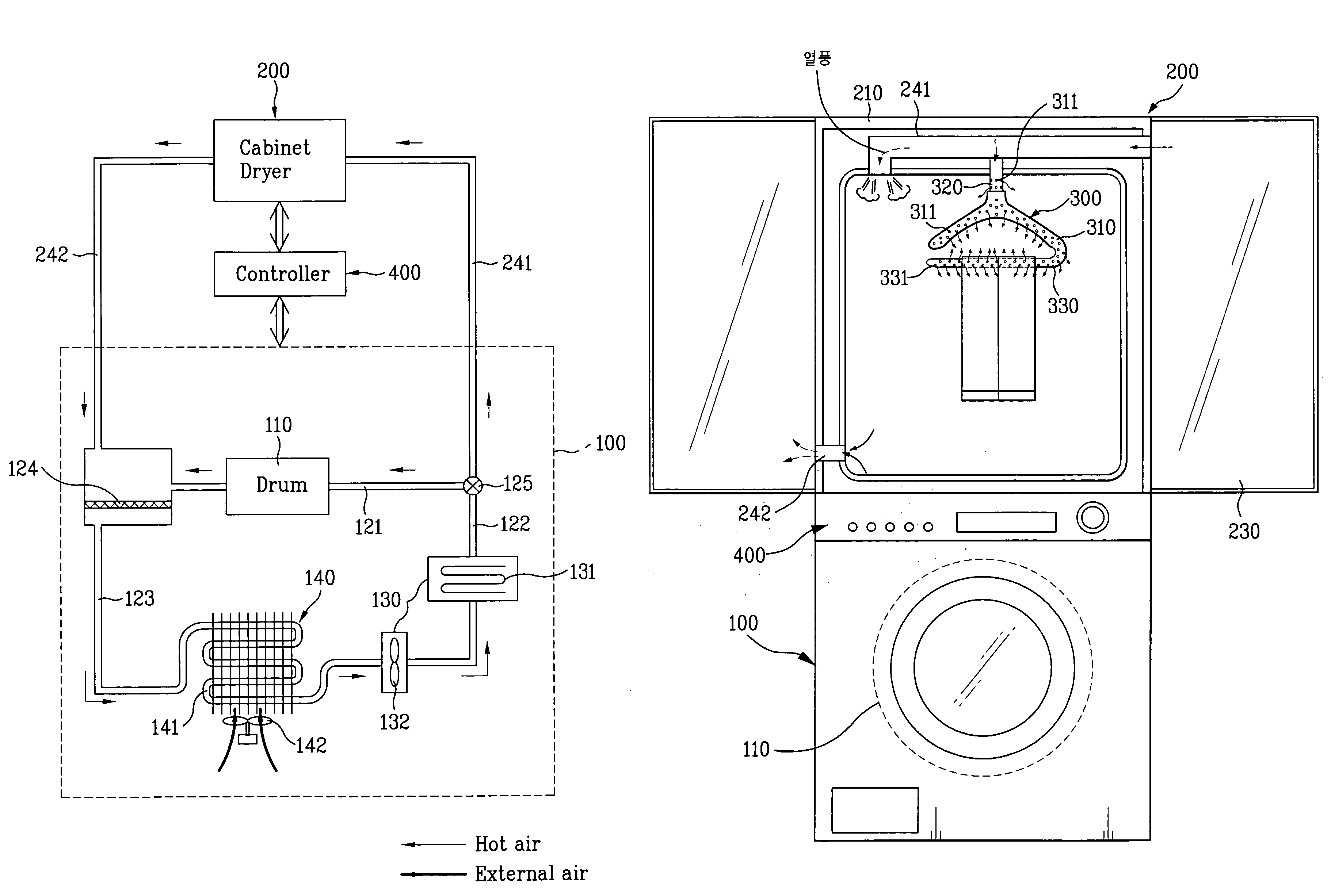

Composite washing system

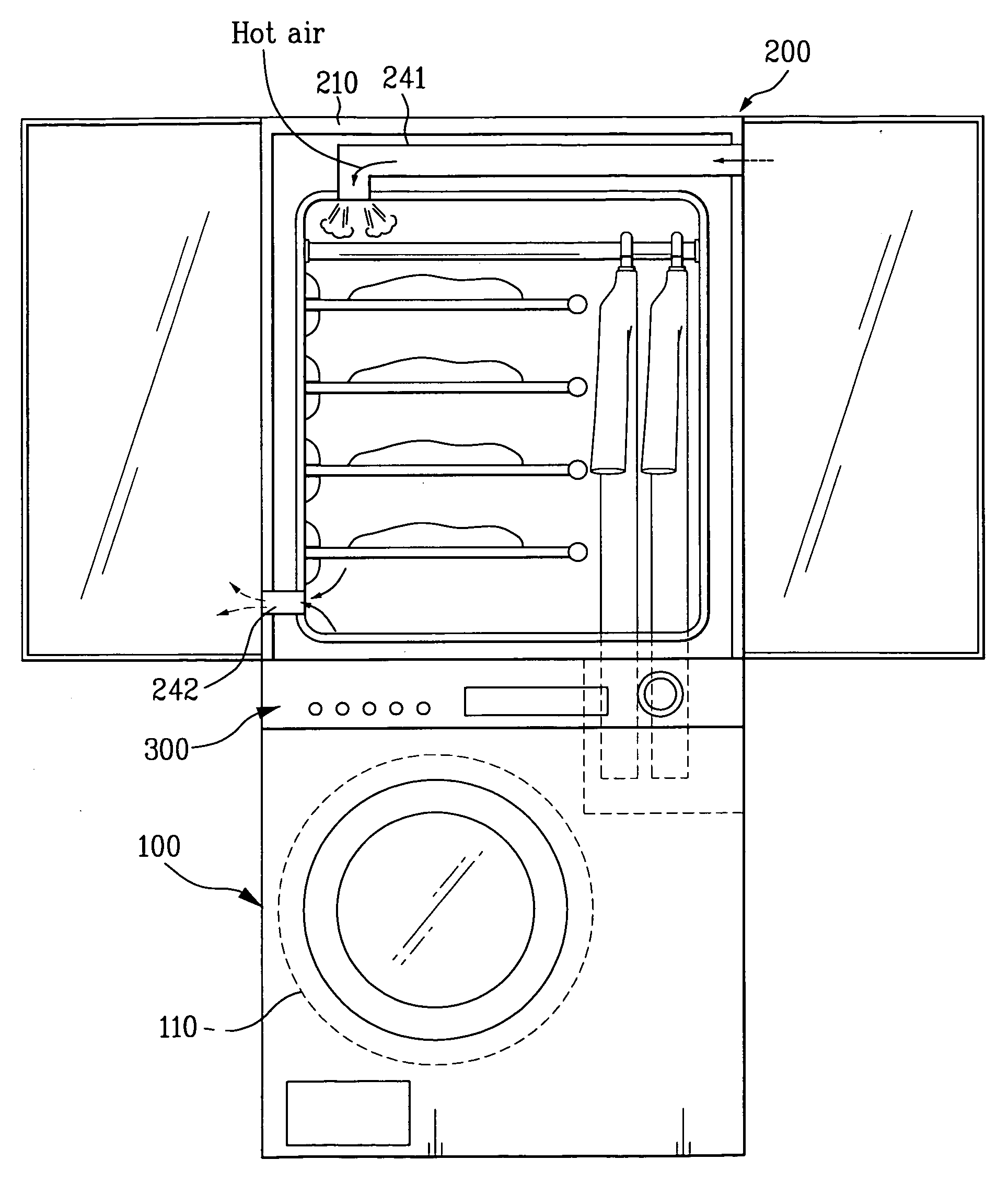

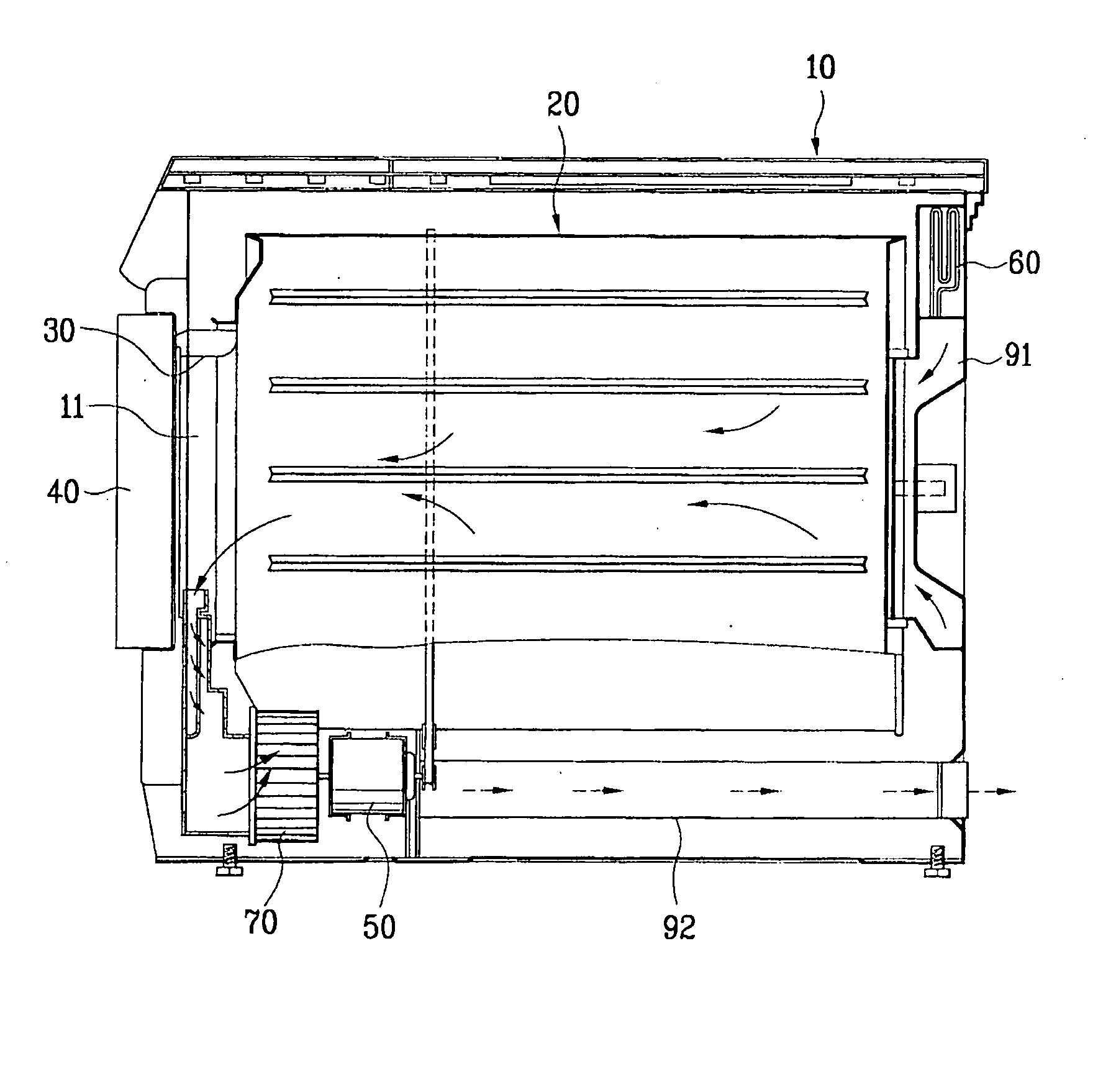

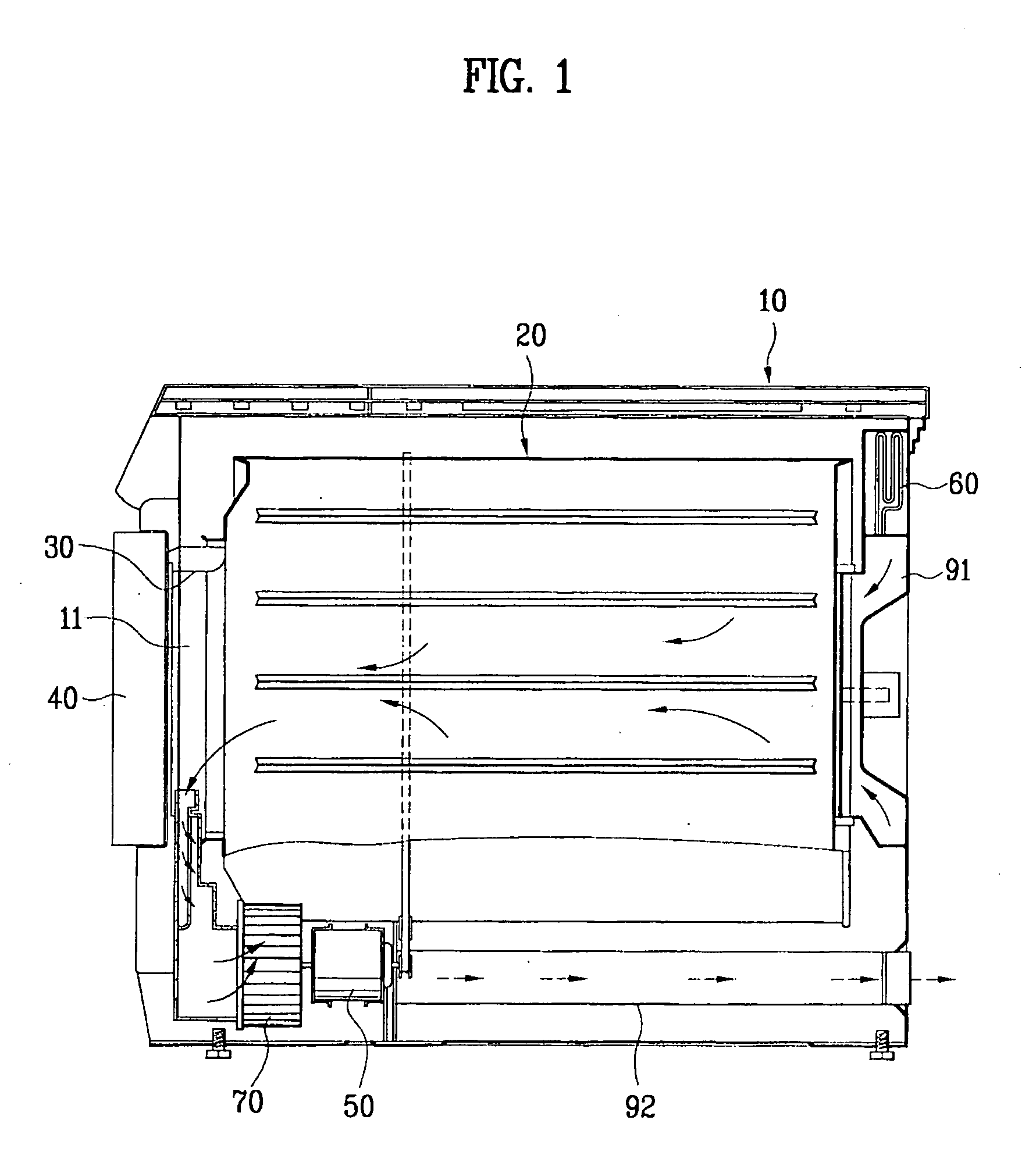

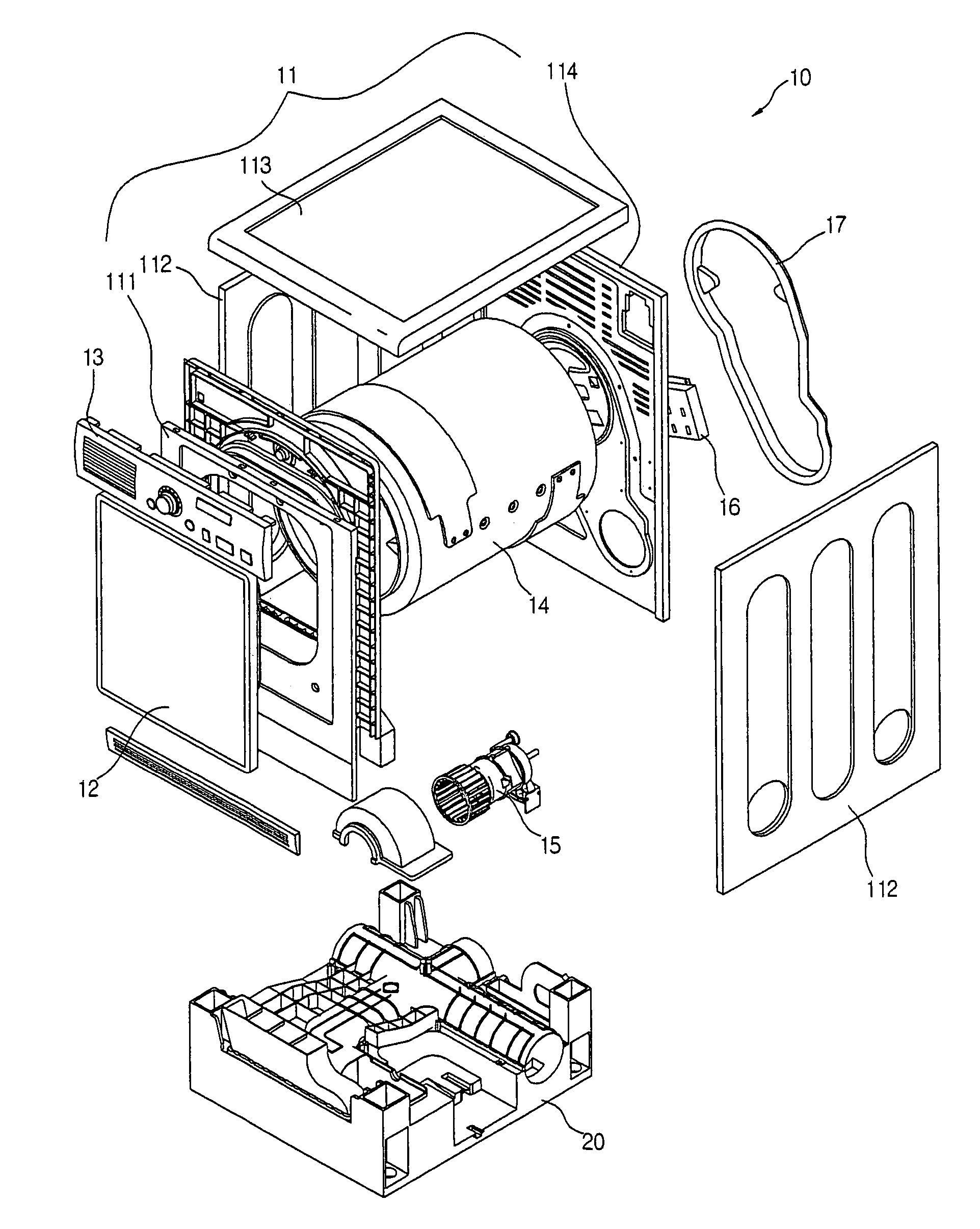

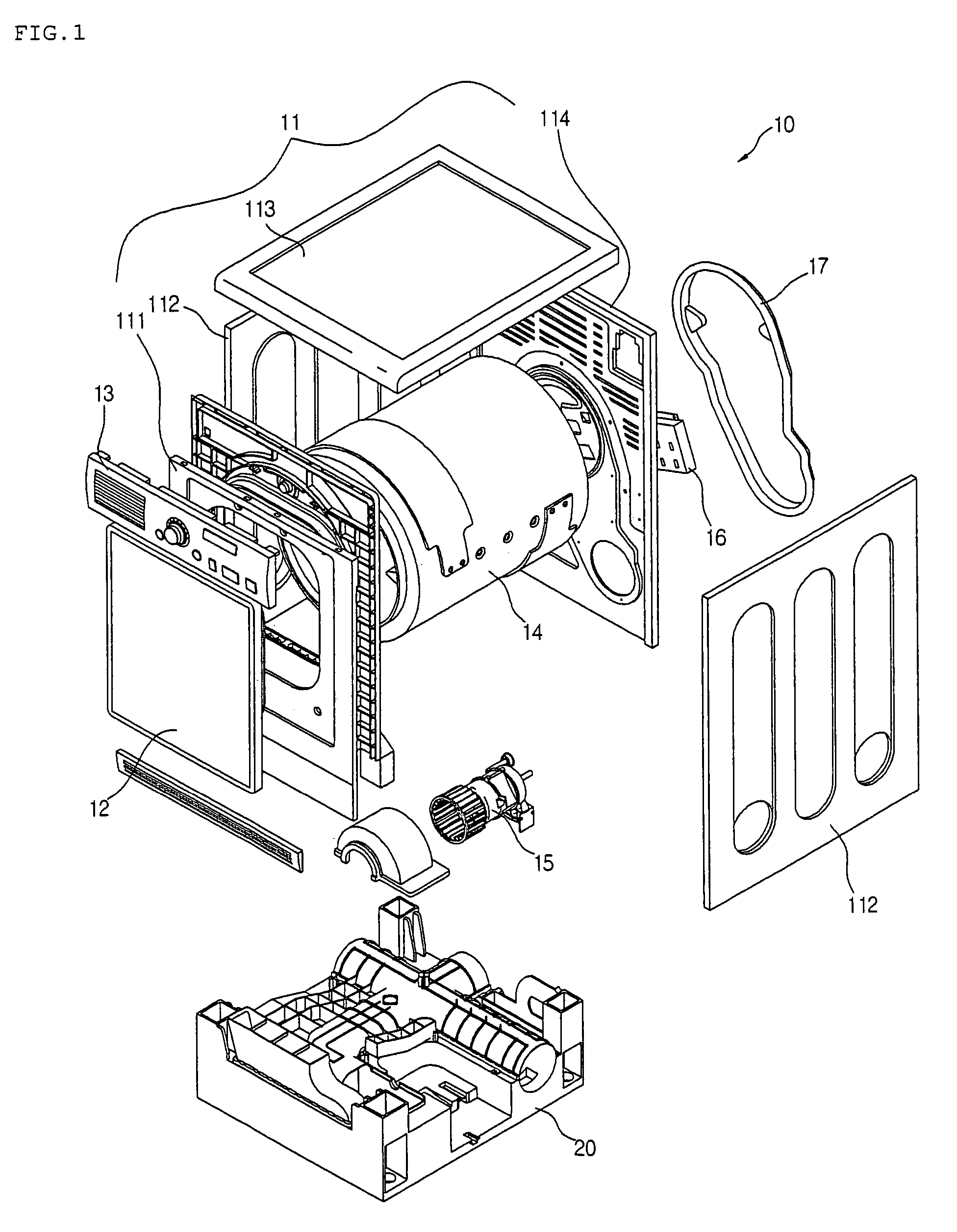

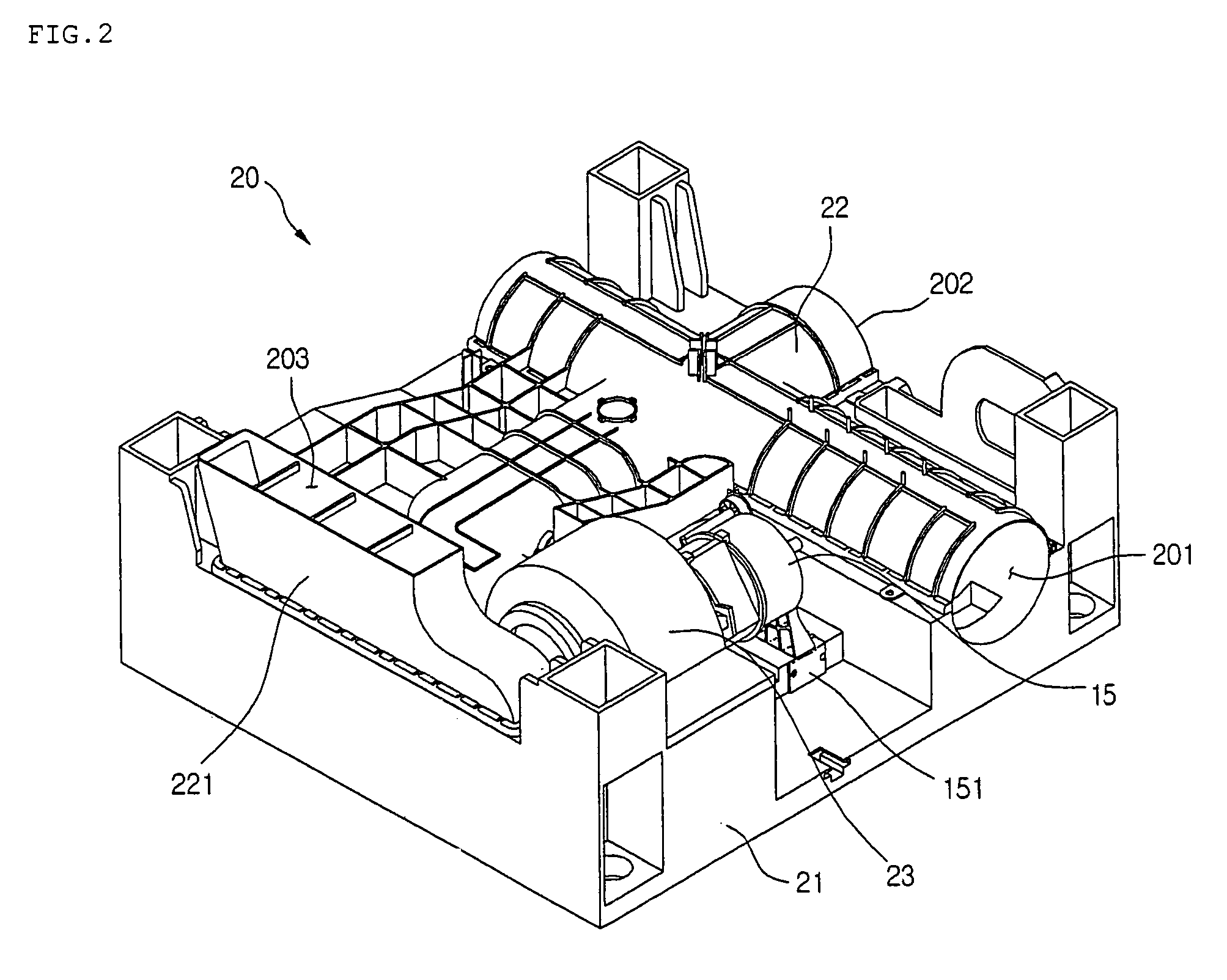

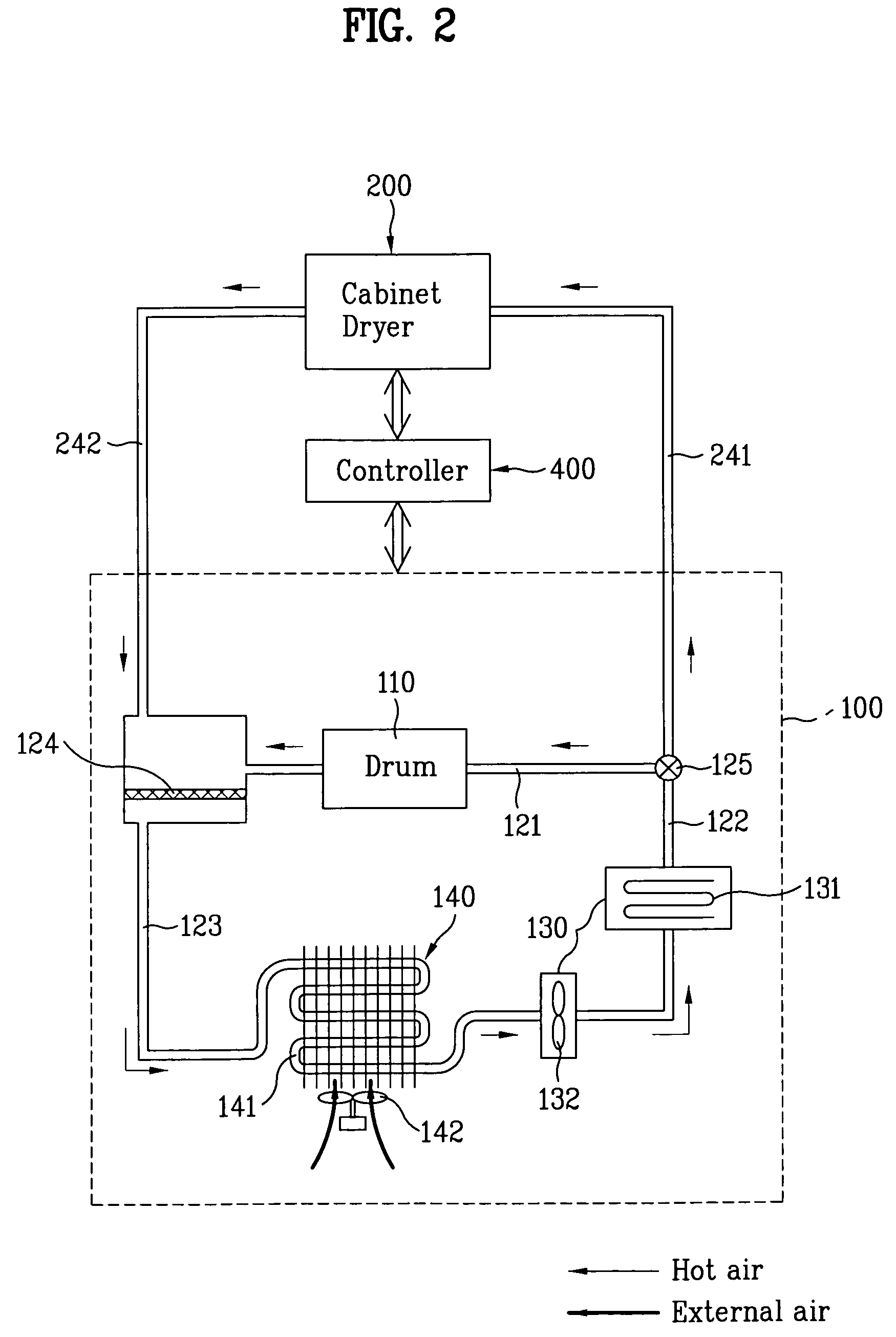

InactiveUS8695228B2Dry evenlyIroning apparatusDrying machines with non-progressive movementsHot blastWaste management

A composite washing system is disclosed which is capable of continuously circulating laundry-drying air through dryers while obtaining a more efficient drying effect, so that the composite washing system has a suitable built-in structure having minimal influence on the indoor environment. The composite washing system includes a drum dryer which dries laundry to be dried, and includes a drying drum adapted to receive the laundry, a hot air supply path adapted to guide a flow of hot air, a hot air supplier arranged in the hot air supply path to generate the hot air, and an air condenser adapted to condense the hot air, a cabinet dryer which is coupled to one side of the drum dryer, and is defined with a laundry receiving compartment, the cabinet dryer including a hot air inlet duct adapted to receive the hot air flowing through the hot air supply path, and a hot air supplying device which is arranged in the cabinet dryer to receive the hot air from the hot air inlet duct and to supply the received hot air to an inside of the laundry.

Owner:LG ELECTRONICS INC

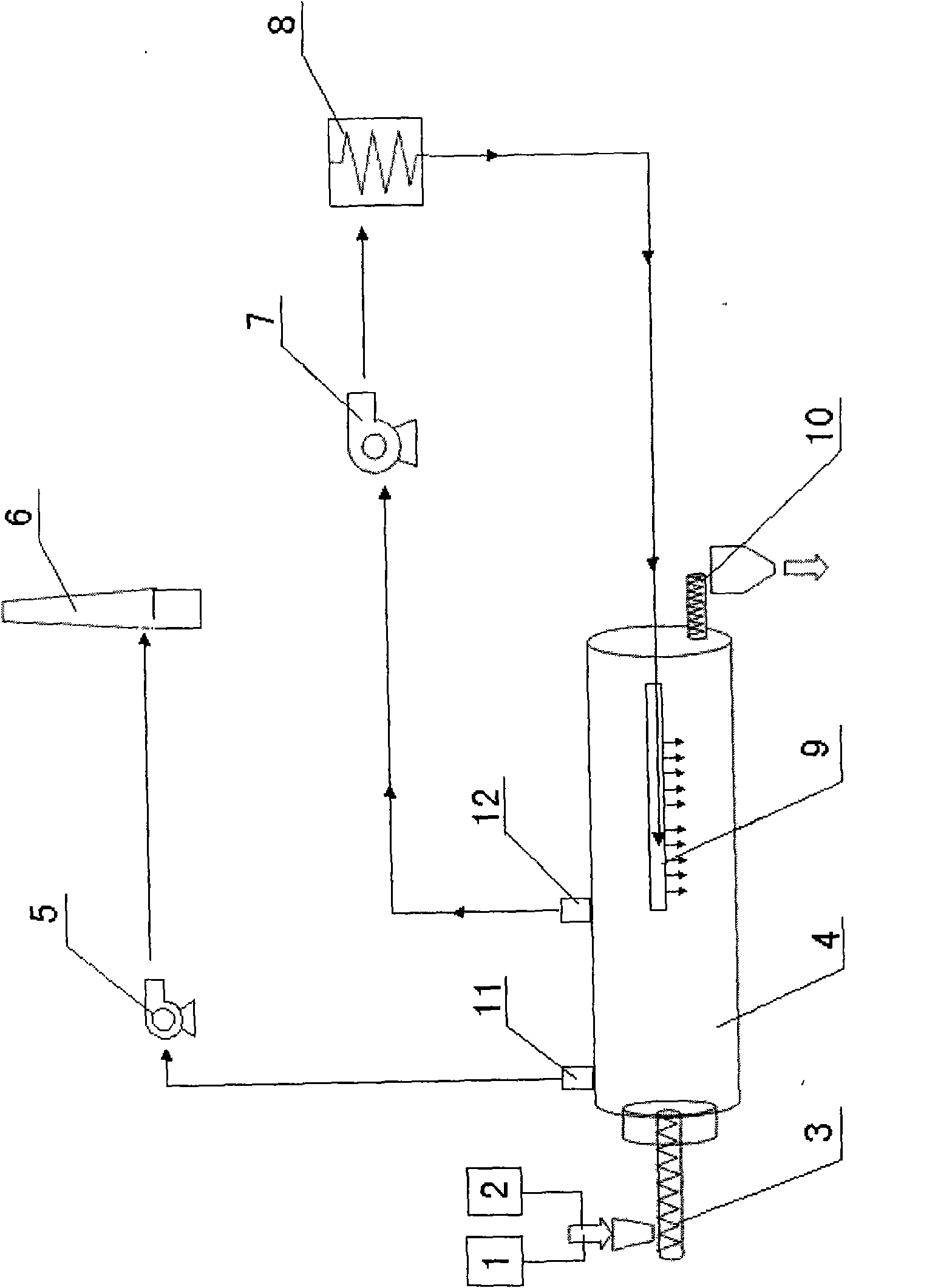

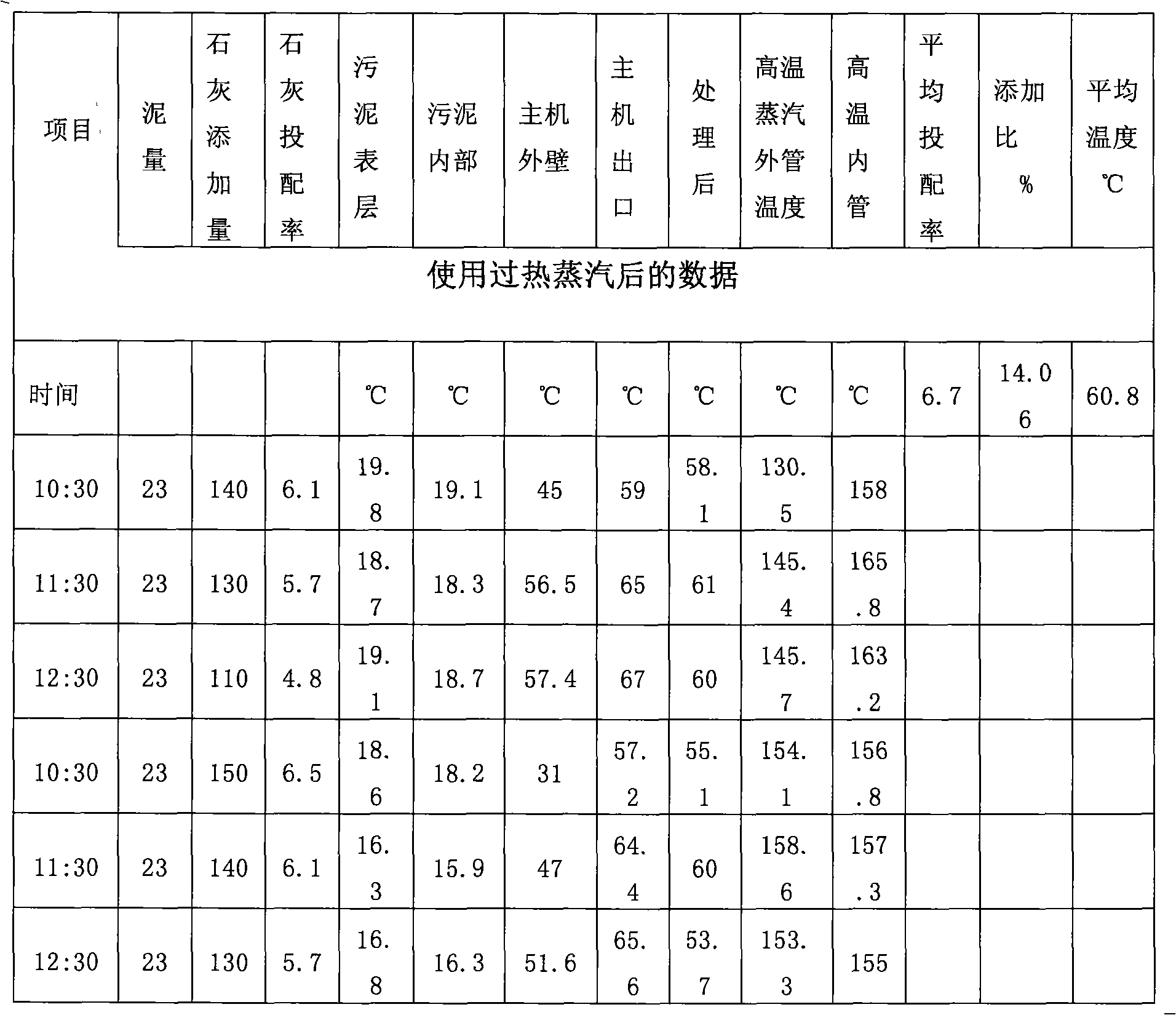

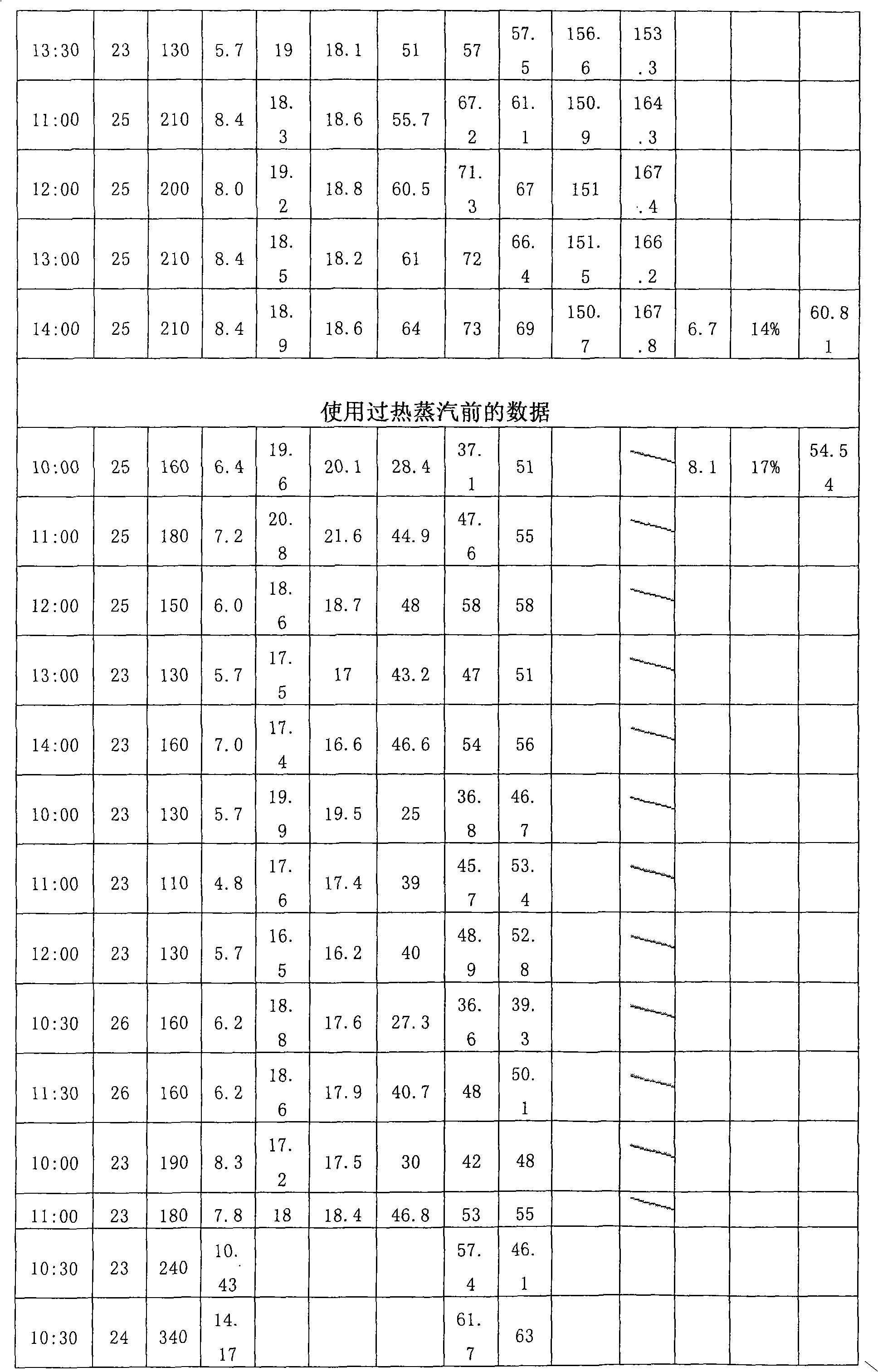

Method and device for drying sludge by utilizing high-temperature steam

InactiveCN101628779AFully dryReduce wasteSludge treatment by de-watering/drying/thickeningElectricityPulp and paper industry

The invention relates to a method and a device for drying sludge by utilizing high-temperature steam, belonging to the field of treatment of excess sludge after sewage treatment in a sewage treatment plant, river dredging sludge treatment and night soil sludge treatment. The method comprises the following steps: carrying out the primary drying of dehydrated organic sludge with water content more than 70 percent by a drying drum through external disposable energy sources or a chemical heat-generating agent, recycling saturated steam from the primary drying process in the drying drum, heating the saturated steam by a high-temperature heating device to form superheated steam, leading the superheated steam into the drying drum, and further carrying out the direct-contact secondary drying of the dehydrated organic sludge in the drying drum. After the superheated steam is used, the lime addition volume is reduced to 14.06 percent from 17 percent before reconstruction, the temperature of the drying drum is improved to 60.81 DEG C from 54.54 DEG C, the temperature of outlet materials is improved by 8 percent, and the electricity consumption used by the superheated steam is only 3kW / h per hour; therefore, the aims of energy saving and emission reducing are achieved, and the cost is greatly reduced.

Owner:PEKING UNIV +2

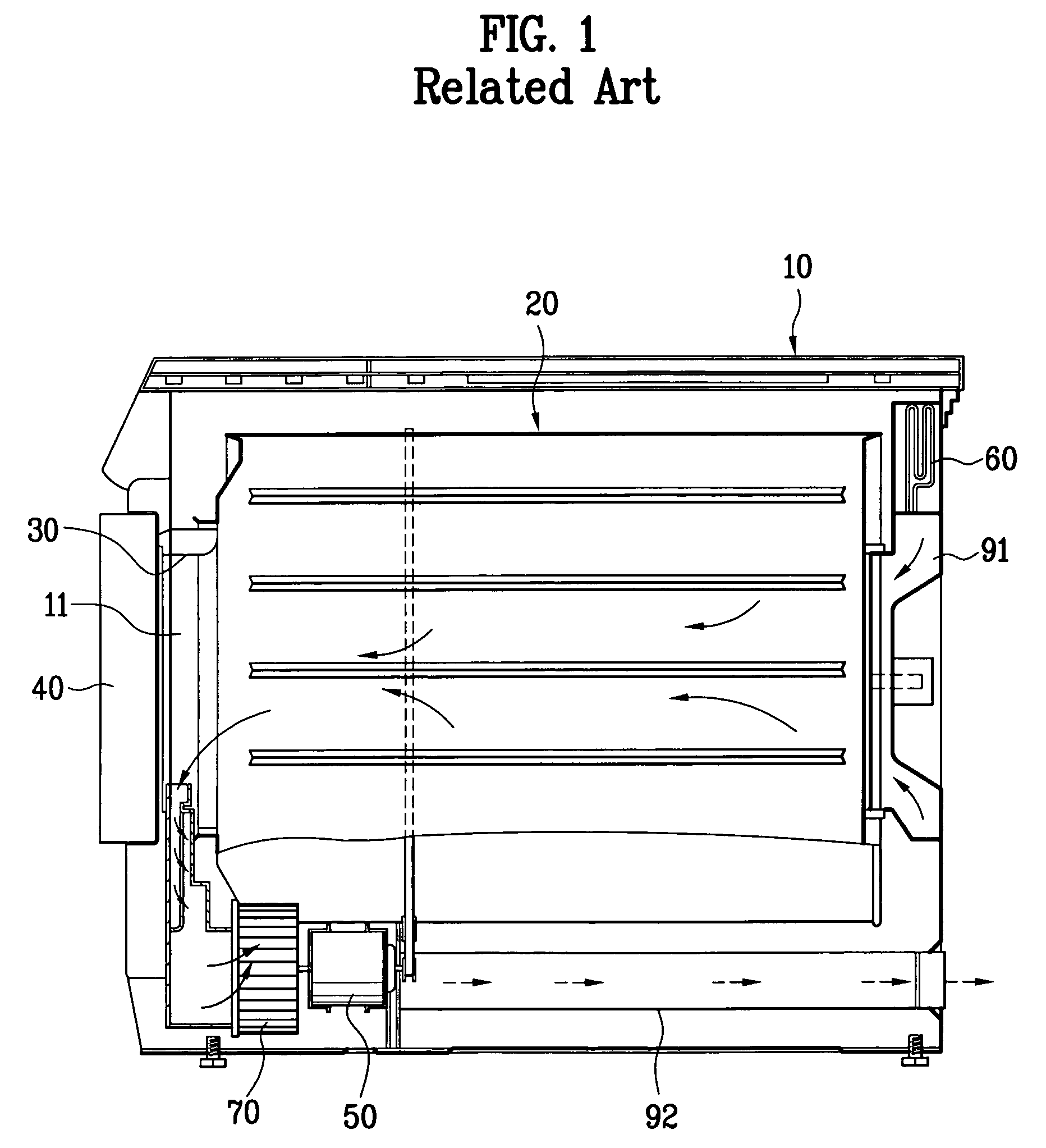

Laundry dryer and impurity entry preventing structure for the same

InactiveUS7640678B2Avoid impuritiesAvoid enteringDrying gas arrangementsDrying machines with non-progressive movementsEngineeringLaundry

Provided is a laundry dryer. The laundry dryer includes a drying drum for inserting laundry in, a base, and a cabinet enclosing the drying drum and the base. The base includes an outside air intake port that suctions indoor air, an air passage for moist air from the drying drum to pass through, and an impurity descending slot recessed a predetermined depth at a front of the outside air intake port for impurities to fall into.

Owner:LG ELECTRONICS INC

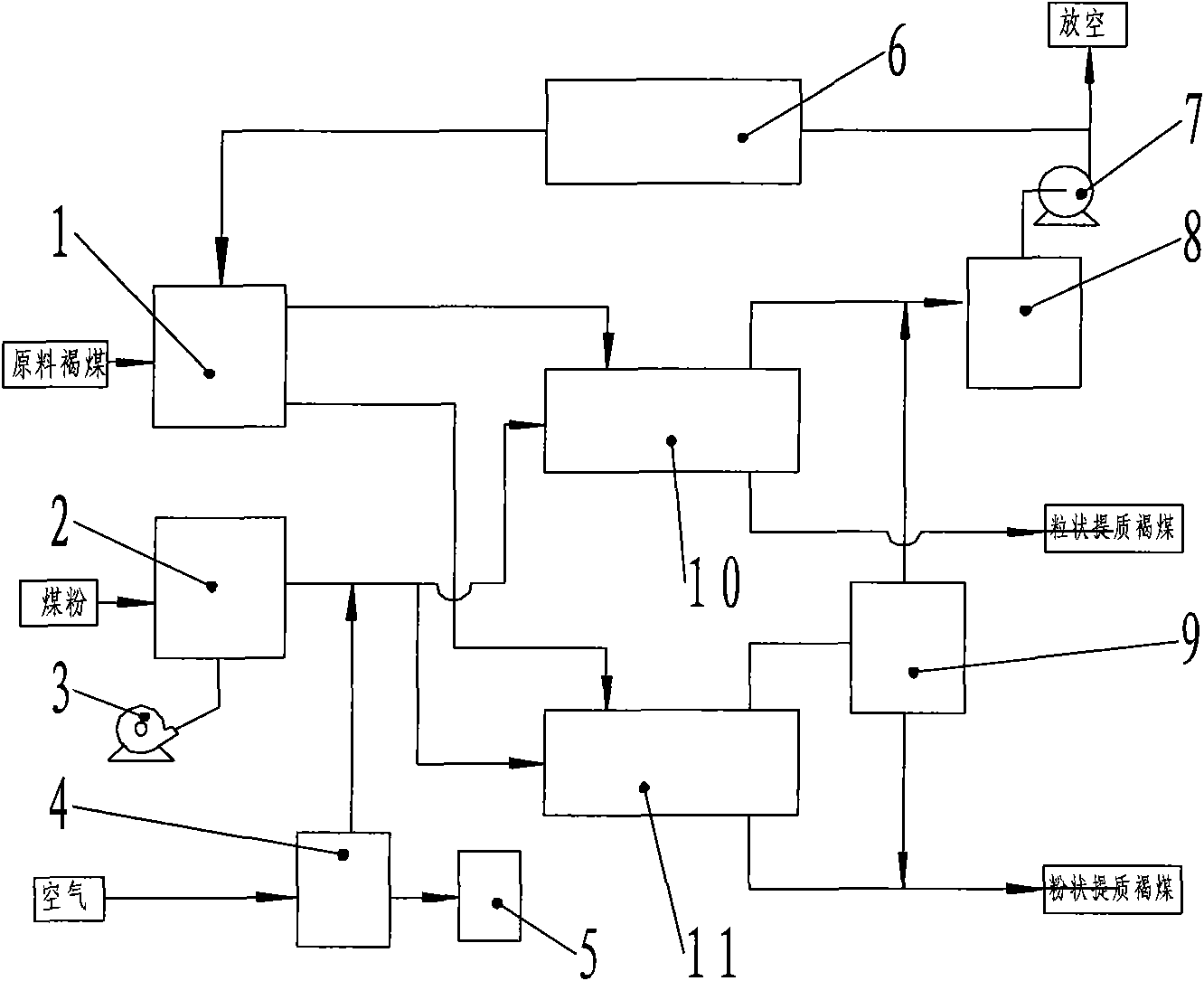

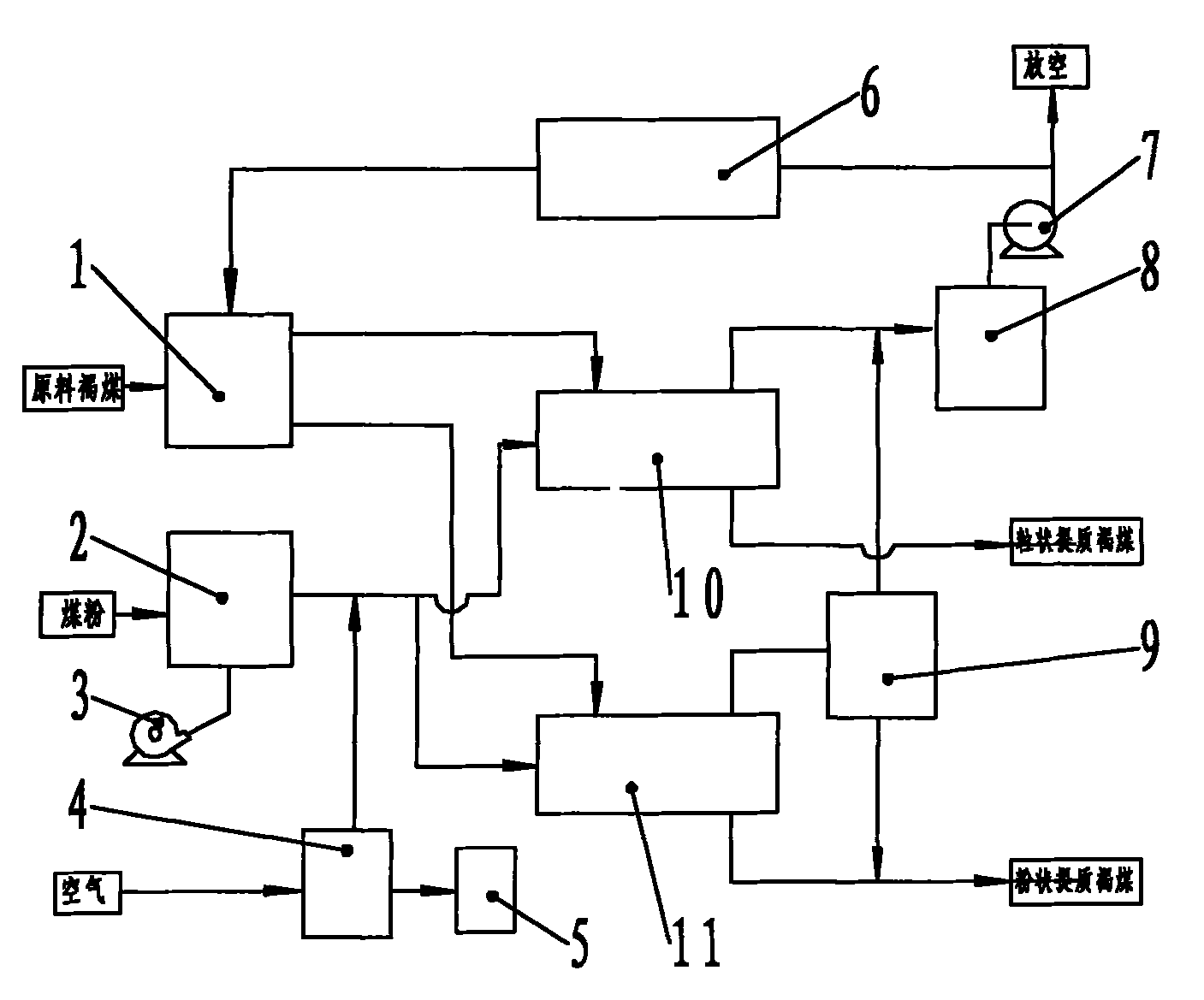

Method and device for drying and quality enhancement of lignite

InactiveCN101776370AImprove qualityIncrease useDrying solid materials with heatDrying machine combinationsLow oxygenCoal

The invention provides a method and a device for the drying and the quality enhancement of lignite. The device comprises a drying / sieving device, a preheating and drying / sieving device, a hot blast heater, a drying drum, a vibration fluidized bed, a cyclone separator, a defogger and a dust remover. The hot blast heater is respectively connected to the drying drum and the vibration fluidized bed, and an outlet of the preheating and drying / sieving device is respectively connected with the drying drum and the vibration fluidized bed. The preheating and drying / sieving device divides the lignite into two stages of big particle diameter and small particle diameter, high-temperature flue gas generated by the hot blast heater is used as a heating medium, the temperature of the flue gas is regulated by the residual low-oxygen gas after oxygen gas is separated by using an air separation system, the drying drum and the vibration fluidized bed are used for producing the quality-enhanced lignite with the big particle diameter and the small particle diameter, different production requirements are met, and part of exhausted tail gas is circularly used for preheating the raw materials of the lignite after being defogged. The invention respectively carries out drying and quality enhancement on the lignite according to the sizes of the particle diameters by grading equipment, eliminates the problem of uneven drying caused by different particle diameters, realizes the effective quality enhancement and the comprehensive utilization of coal resources, and is used for the large-scale process of drying and quality enhancement of the lignite.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

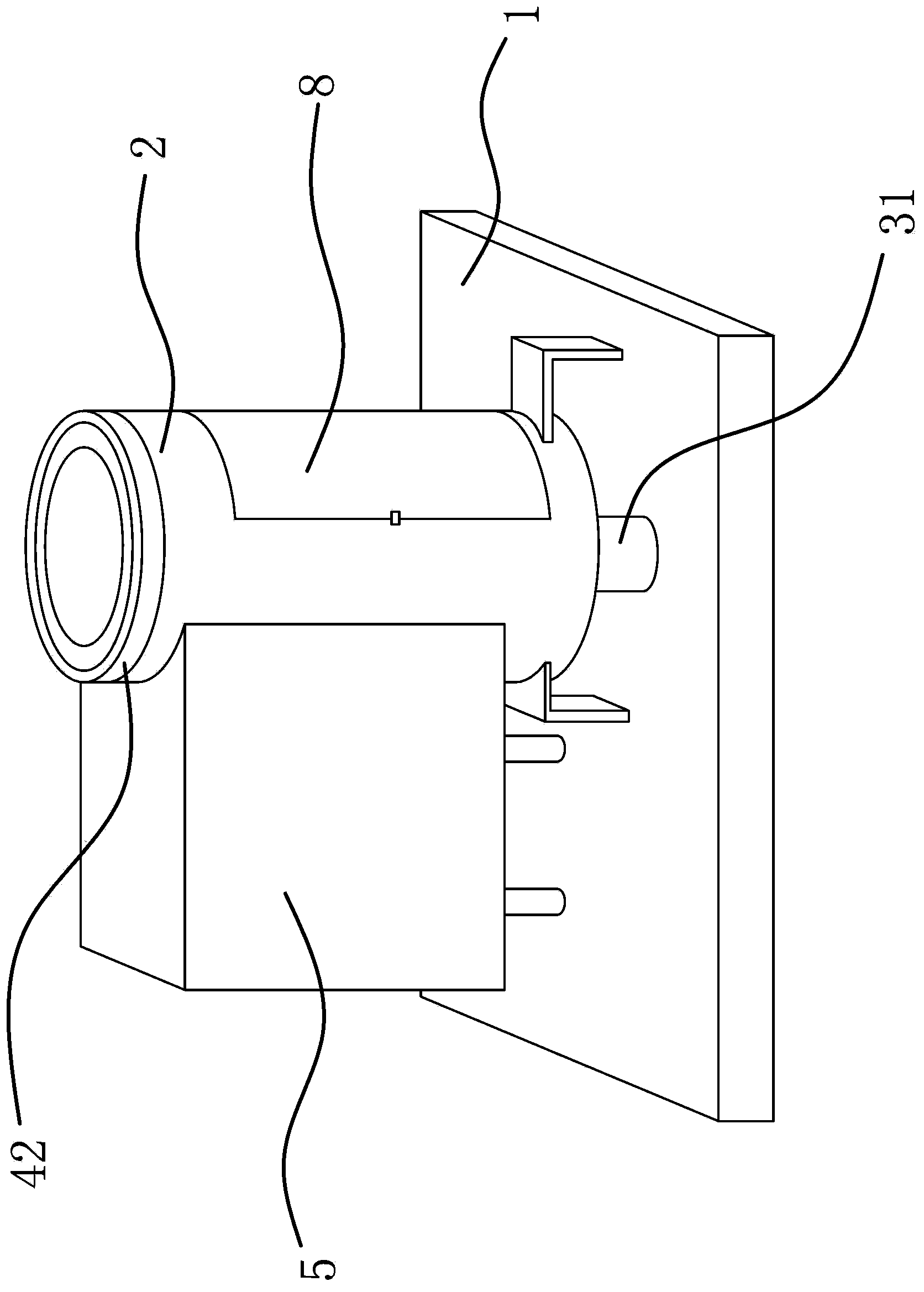

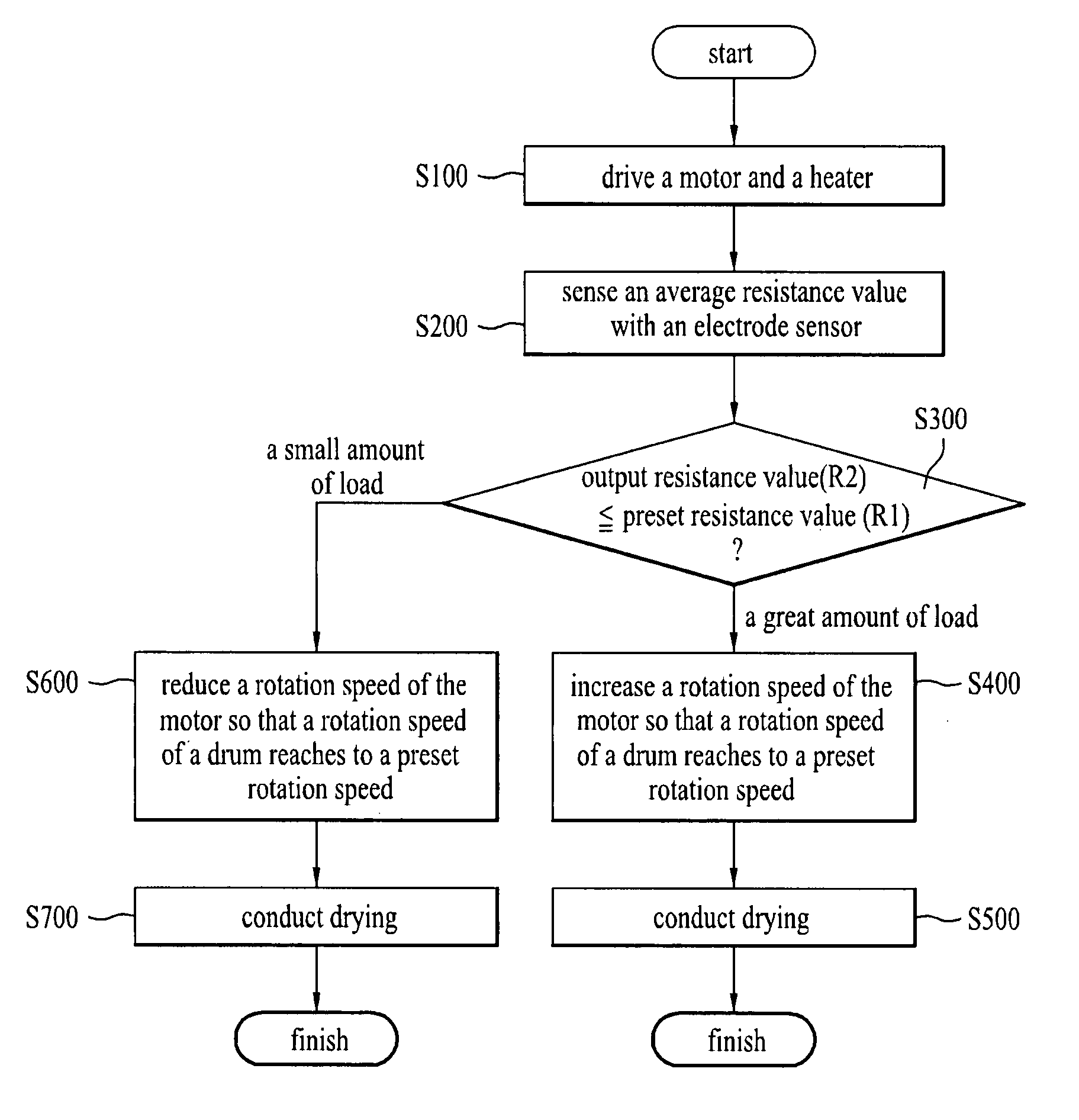

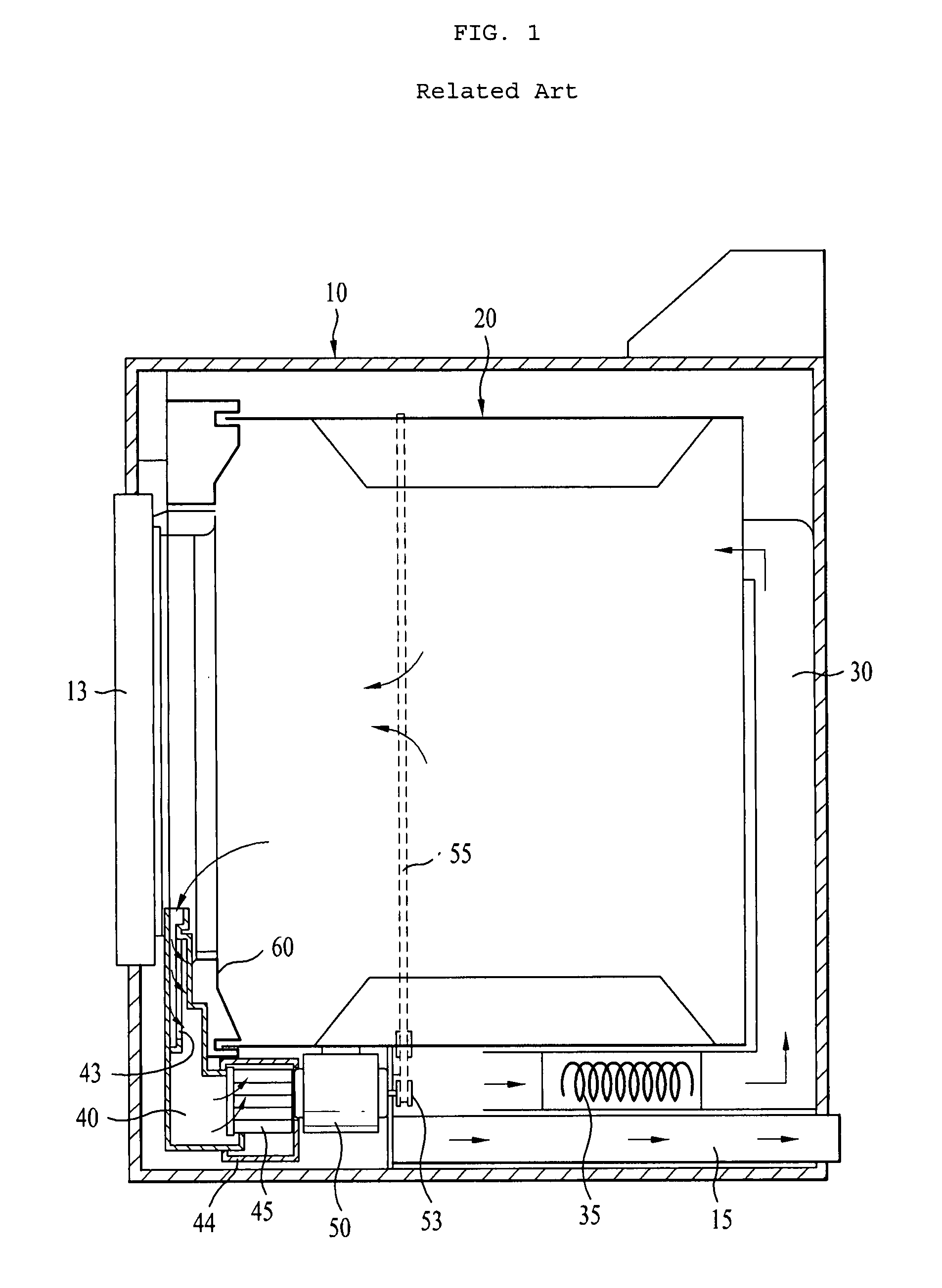

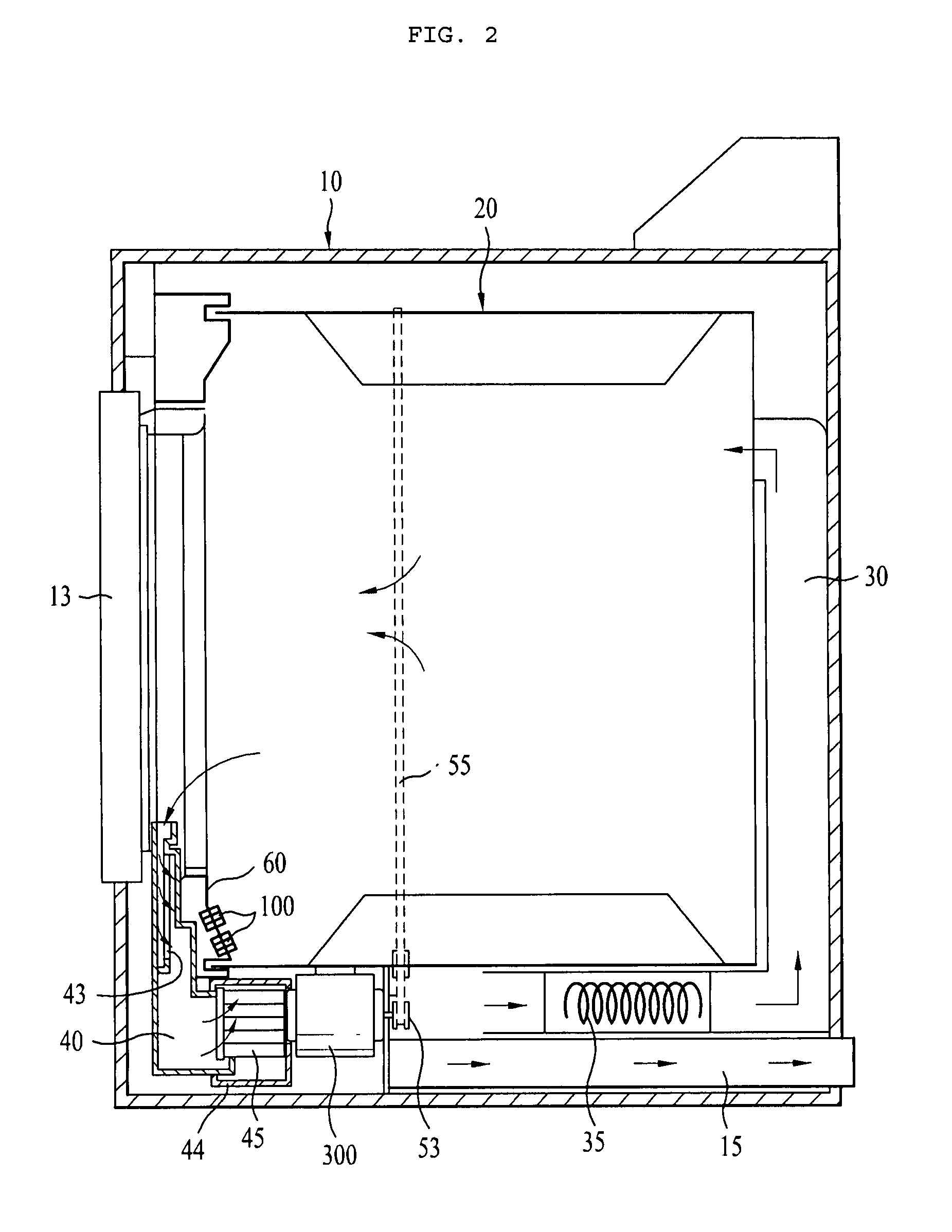

Dryer and method for controlling the same

InactiveUS20070251118A1Drying gas arrangementsDrying machines with progressive movementsRotation velocityEngineering

An object of the present invention is to provide a dryer and a method for controlling the same, in which a rotation speed of a drying drum is made to reach to a preset rotation speed regardless of a load of the drying object held in the drying drum. For this, the dryer includes a drying drum rotatably mounted in a body, a driving unit mounted to enable to vary a rotation speed of the drying drum, sensing means for sensing a load of the drying object in the drying drum, and a control unit for controlling the driving unit to vary a rotation speed of the driving unit proper to the load with reference to a sensing signal from the sensing means. For this, the method includes the steps of applying a drying course to start drying, sensing a load of a drying object with an electrode sensor after starting the drying course, and varying a rotation speed of the driving motor with the load sensed thus.

Owner:LG ELECTRONICS INC

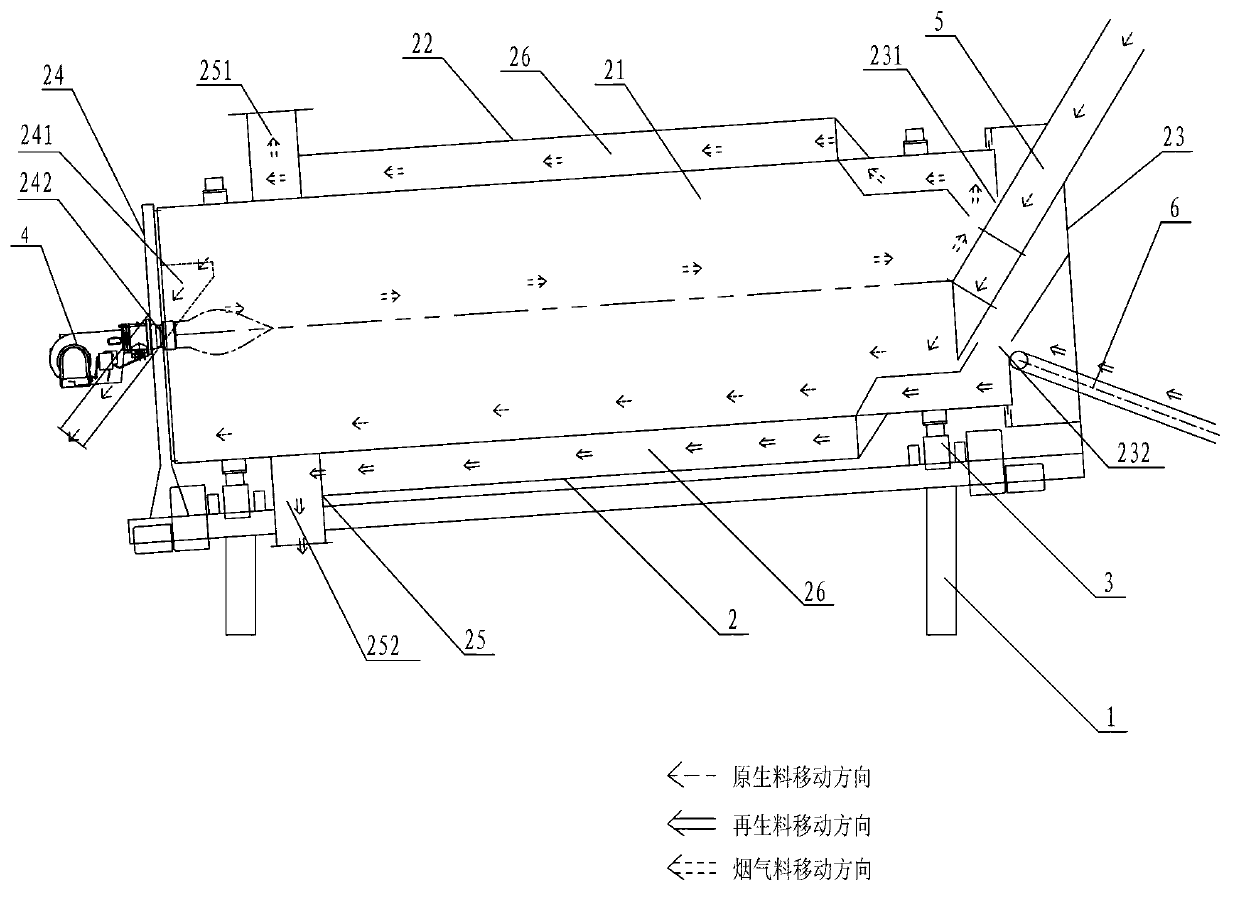

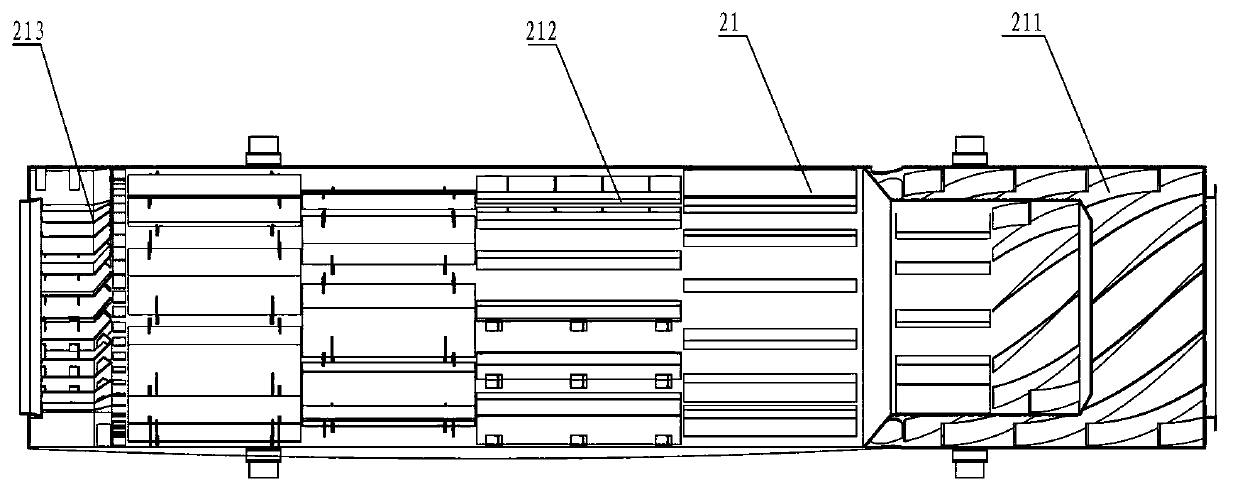

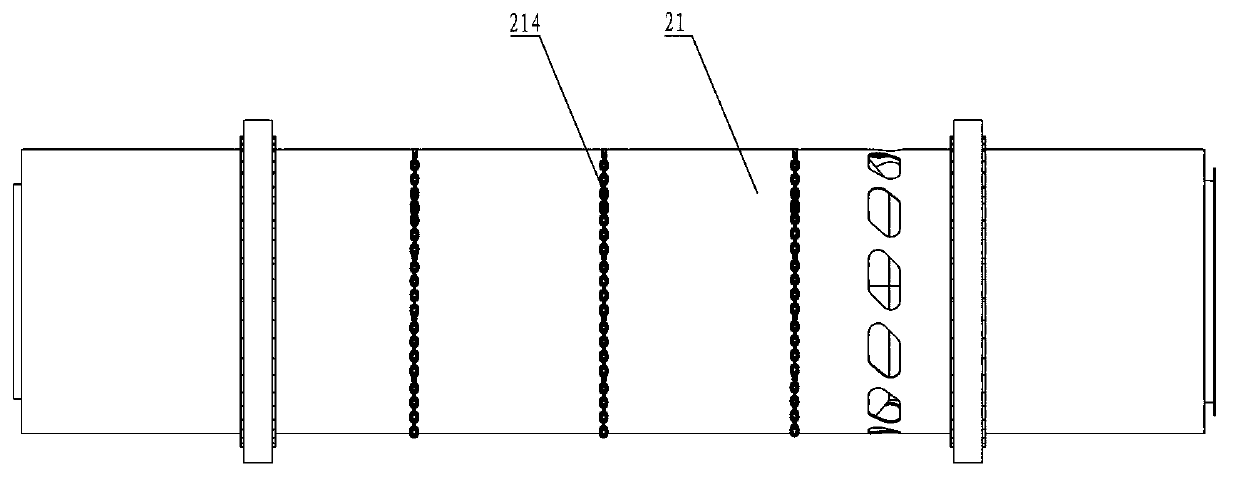

Asphalt mixture drying drum

InactiveCN103103908AImprove heating efficiencyAvoid heatingRoads maintainenceAsphalt concretePitch blende

The invention belongs to the technical field of asphalt concrete stirring, and in particular relates to an asphalt mixture drying drum capable of drying two kinds of asphalt materials at the same time. The drum comprises a drum body, a bracket, a driving device and a burner, wherein the drum body is arranged on the bracket through the driving device; the driving device can drive the drum body to rotate on the bracket; and the burner is connected with the drum body and is used for heating the interior of the drum body. The asphalt mixture drying drum is characterized in that the drum body is erected on the bracket, and is arranged in a manner of forming a certain included angle with the horizontal plane in the upper-lower direction; the high end of the drum body serves as a feed end, and the lower end of the drum body serves as a discharge end; the drum body comprises an internal drum body and an external drum body; the feed ends and the discharge ends of the internal drum body and the external drum body are respectively provided with feed ports and discharge ports; a material cavity for containing the asphalt materials is formed between the internal drum body and the external drum body; and the discharge port of the internal drum body is not communicated with the material cavity. The regeneration drum can dry the two kinds of asphalt materials at the same time, thus avoiding the problems of nonuniform heating, asphalt ageing and the like, and the heating efficiency is high.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

Combination dryer and method thereof

InactiveUS7418789B2Avoid changeDrying using combination processesDrying gas arrangementsCyclic processRefresh cycle

A combination dryer and operation method are disclosed. The combination dryer and operation method for a combination dryer enable air in a drying drum and a cabinet for drying the laundry to circulate continuously and enable water generated in the circulation process to be used to perform a refreshing cycle.

Owner:LG ELECTRONICS INC

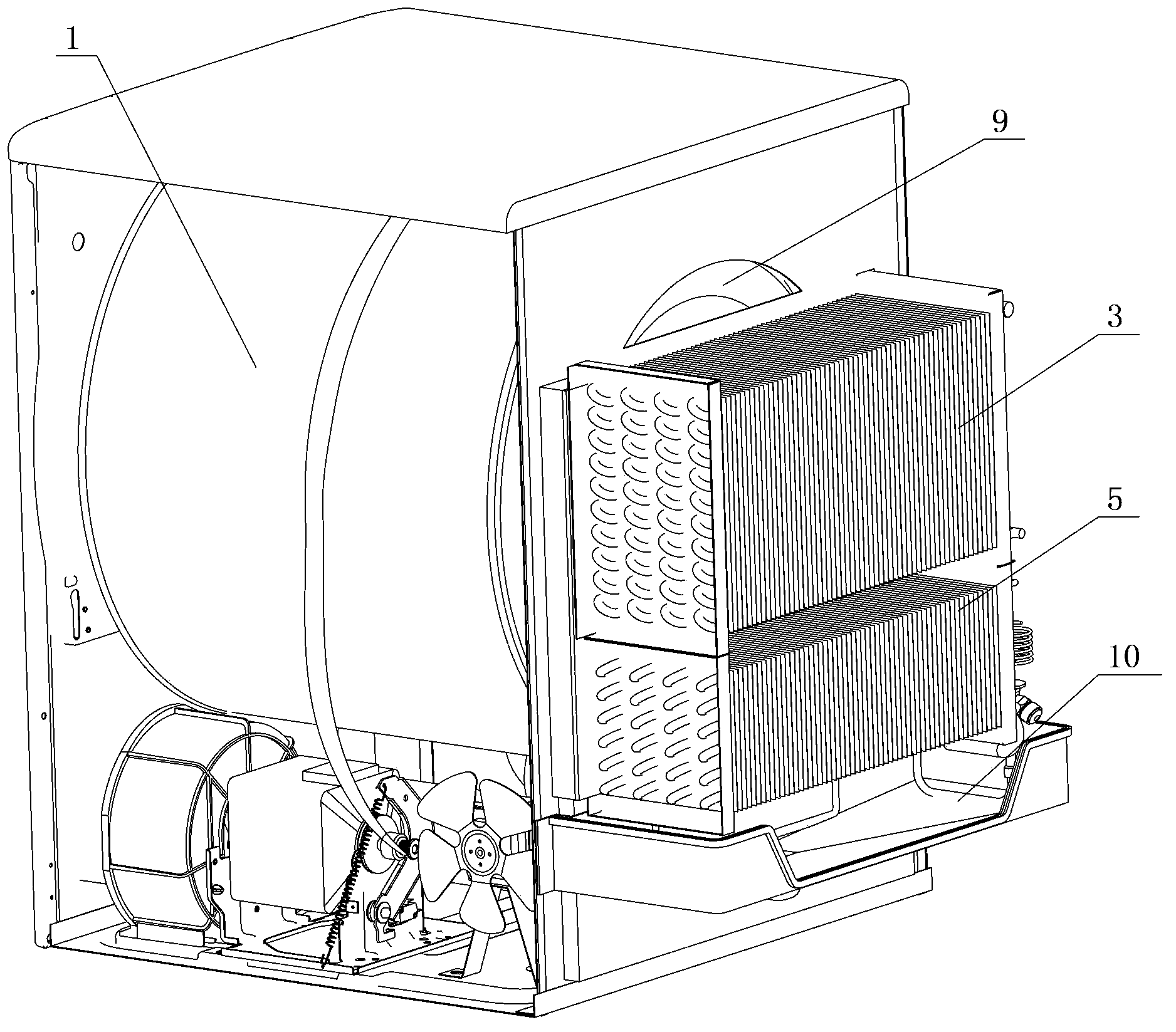

Heat-pump clothes dryer and clothes drying method

ActiveCN104233735AImprove the heating effectIncrease the areaTextiles and paperLaundry driersSteam condensationEngineering

The invention relates to a heat-pump clothes dryer and a clothes drying method. The heat-pump clothes dryer comprises a clothes drying drum, a heat pump system and a circulating air system. The heat pump system comprises a compressor, a condenser, a throttling device and an evaporator, and at least the condenser and the evaporator are arranged on the rear portion of the clothes drying drum. The evaporator is arranged below the condenser, and a windward side of the evaporator is arranged below the evaporator. Mounting space of the compressor is larger, the compressor can be a horizontal compressor with large capacity, clothes drying efficiency is improved, and drying time is shortened; condensed water after water steam condensation in operating current passing the evaporator flows from top to bottom, threads attached to the windward side of the evaporator can be flushed off, blockage of the evaporator by the threads and smoothness in flow of the operating flow are avoided, drying efficiency is reduced, heat exchange area of the condenser and the evaporator is sufficiently utilized, efficiency is improved and energy source is saved.

Owner:HAIER GRP CORP +1

Tea drying, sieving and separating device

InactiveCN107279332AEvenly heatedEasy to dropSievingPre-extraction tea treatmentDry structureTransducer

The invention discloses a tea drying, screening and separating device, which includes a fixed plate, an organic casing is arranged on the fixed plate, and a bracket is arranged at the bottom of the casing. The invention provides a tea drying, screening and separating device, which has a novel structure; The drying structure is ingeniously set, and the material distribution mechanism is set to make the raw materials evenly dispersed. The hot air in the inner chamber of the drying drum dries the tea leaves attached to the surface from the inside to the outside through the vent holes, and the heat is even. The tea leaves are fully heated to ensure the quality and high drying efficiency. In addition, it is convenient to drop the dried tea leaves for screening. The present invention drives the transducer set on the screen through an ultrasonic power supply, and attaches ultrasonic waves to the screen to make the fine powder accept The huge ultrasonic acceleration can suppress the blocking factors such as adhesion, friction, flat drop, wedging, etc., and can greatly improve the efficiency of screening and cleaning. In addition, the invention performs secondary screening to ensure the high quality of finished products.

Owner:银川金帮手信息科技有限公司

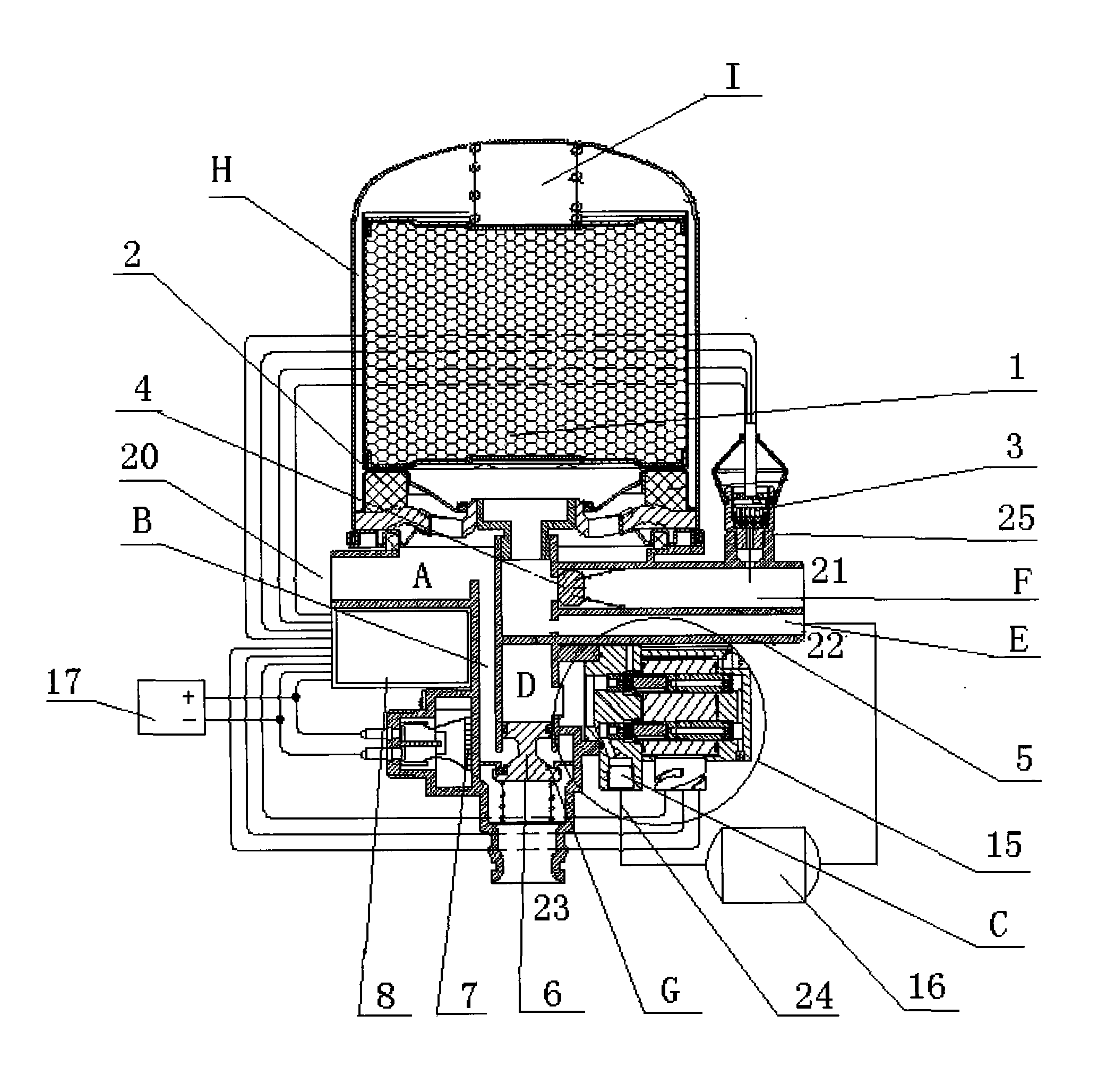

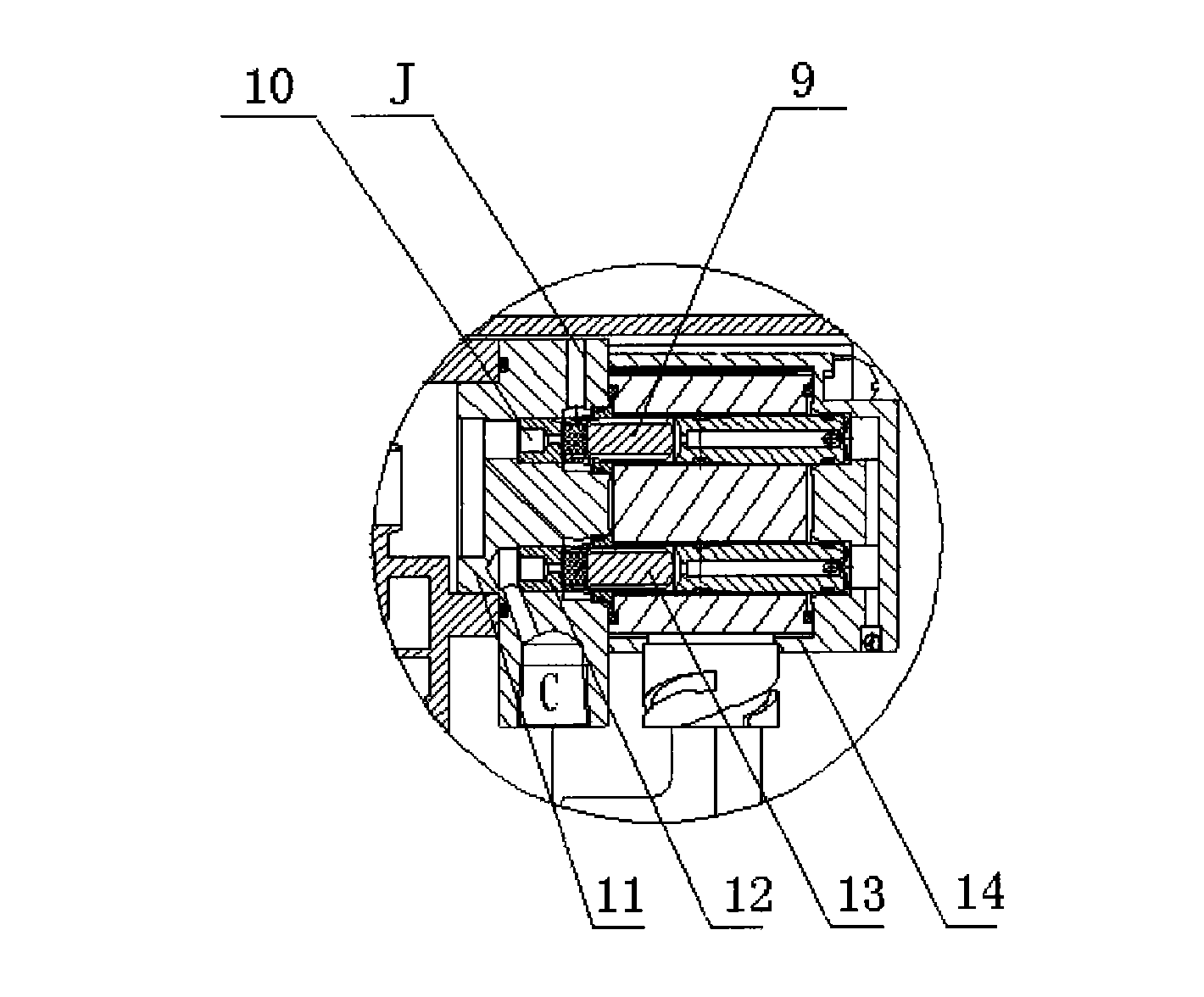

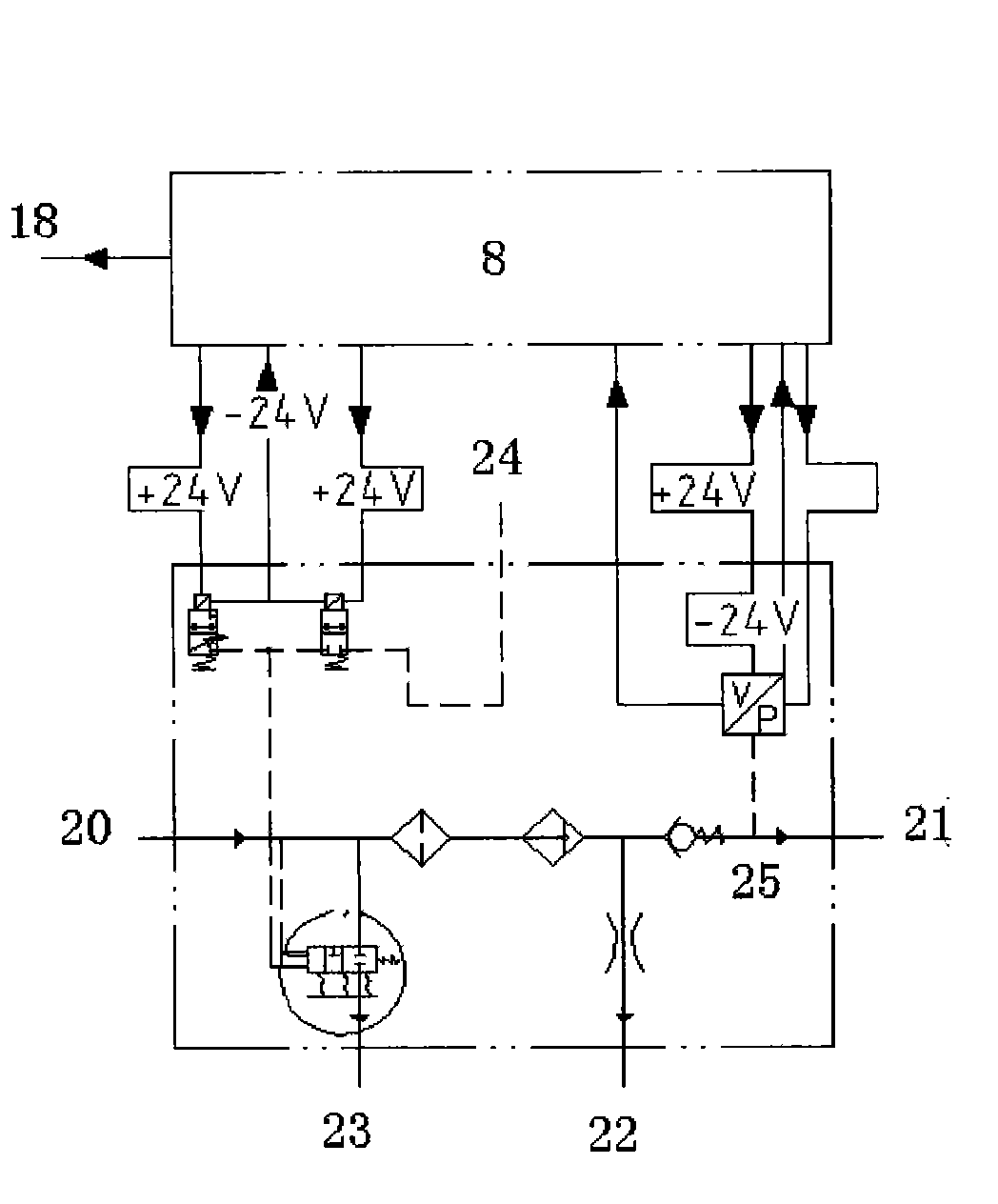

Intelligentized air dryer

ActiveCN101648106AExtend your lifeCompact structureDispersed particle separationControl systemDesiccant

The invention relates to an air dryer, in particular to an intelligentized air dryer which is suitable for an air control system and comprises a drying drum assembly and a base assembly, wherein the drying drum assembly is provided with a drying agent, a filter and an annular channel; the base assembly is provided with a dryer valve body, a heating device, a venting device and an electric controlsystem; and the electric control system is provided with a pressure reading device, an electric-control executing device and an ECU master control device. Compared with the prior air dryer, the intelligentized air dryer adopts the electric-control executing device, the ECU master control device and the pressure reading device to replace the traditional pressure adjusting valve device, thereby avoiding that a molecular sieve is difficult to recoil and regenerate caused by higher auxiliary gas consumption or normal gas consumption in an air system; in addition, the electric-control executing device, the ECU master control device and the dryer valve body are connected by a connecting plate and a pressing cover through bolts so that the intelligentized air dryer has more compact structure andsmaller volume on the basis of the traditional dryer.

Owner:RUILI GROUP RUIAN AUTO PARTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com