Clothes drier

一种干燥装置、衣物的技术,应用在干衣机领域,能够解决致冷剂压力差大、难恢复暖风温度、升温慢等问题,达到减轻负担的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

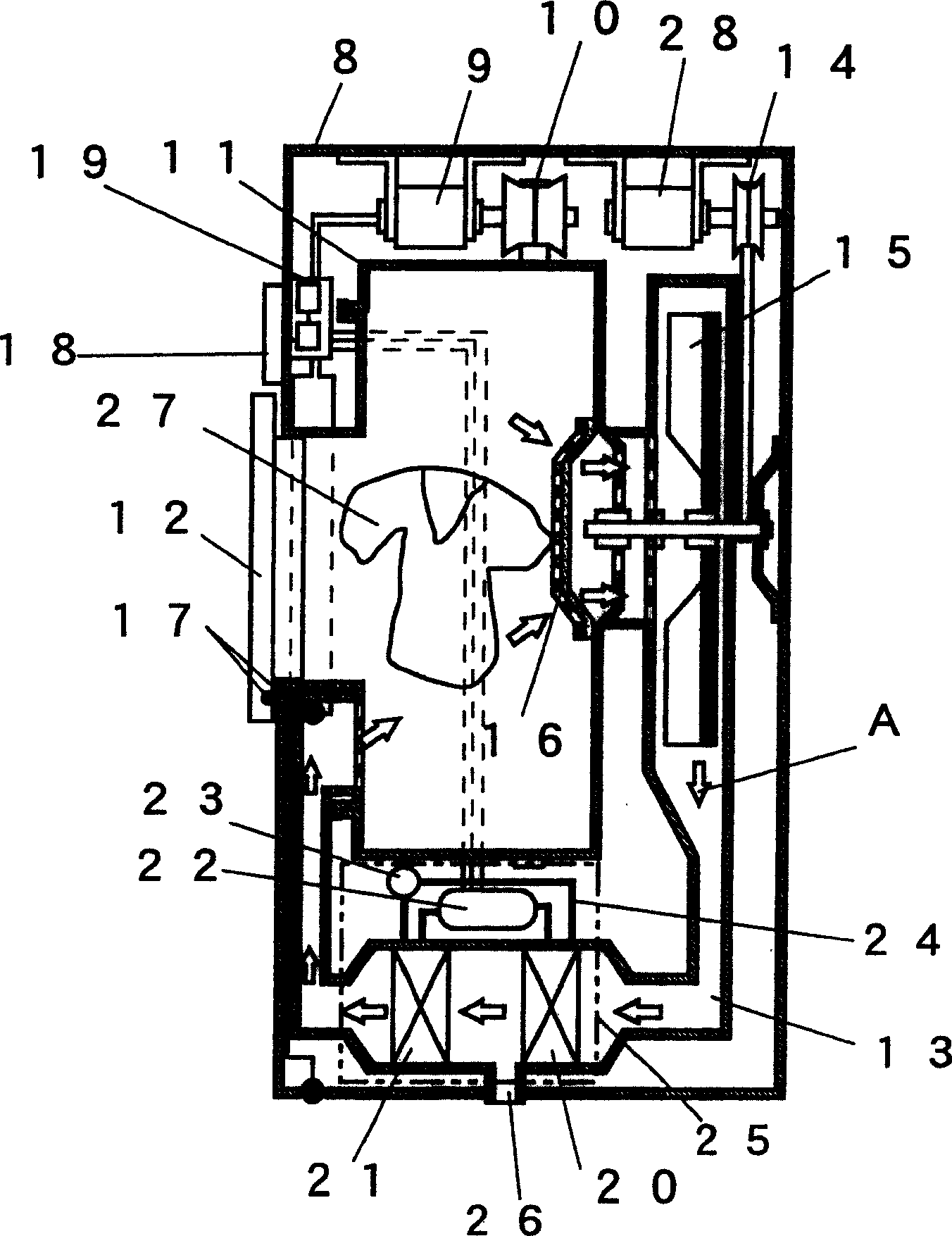

[0045] figure 1 It is a side sectional view of a clothes dryer equipped with the clothes drying device described in the first embodiment of the present invention. Such as figure 1 As shown in , the heat pump device 25 includes: a compressor 22 for compressing the refrigerant; a radiator 21 for releasing heat from the compressed high-temperature and high-pressure refrigerant; Pressure, thereby maintaining the pressure difference of the refrigerant capillary or other throttling device 23; The heat absorber 20 that takes away heat from the surroundings by the refrigerant that has been decompressed to a low pressure; and the above-mentioned components are connected so that The pipe 24 through which the refrigerant circulates.

[0046] Under the action of the blower 15, the air for drying clothes is guided from the drying room containing the clothes 27 to the rotating drum 11 of the stirring device through the air duct 13 to the heat absorber 20 and the heat radiator 21 of the ...

Embodiment 2

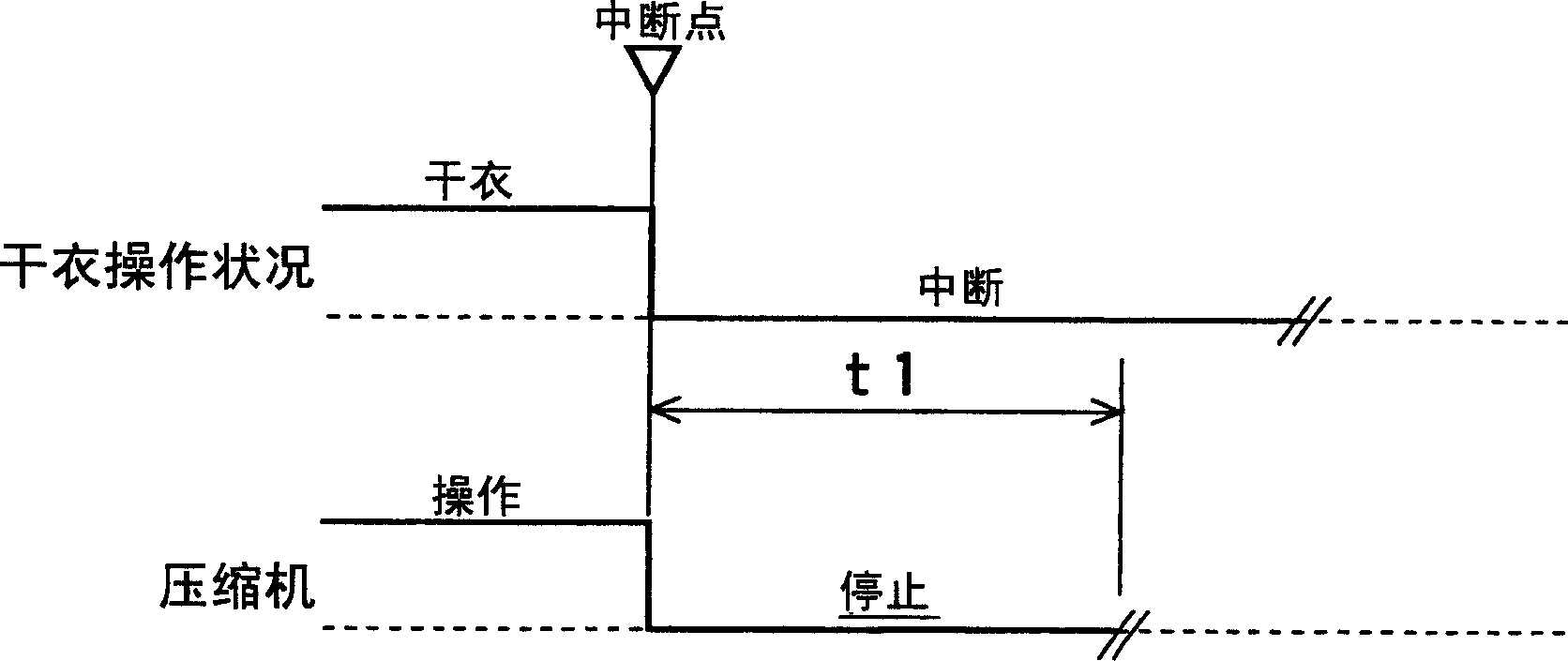

[0060] image 3 It is an operation timing chart when the drying operation of the clothes dryer equipped with the clothes drying apparatus according to the second embodiment of the present invention is interrupted. Here, since the basic operation and structure of the clothes dryer are the same as in Embodiment 1, a detailed description thereof will be omitted.

[0061] Such as image 3 As shown in , when the clothes drying operation is interrupted, the control device 19 restarts the compressor 22 after a predetermined time t1 has elapsed after the compressor 22 stops, and when the clothes drying operation is resumed.

[0062] In this way, by setting a prescribed stop time for the compressor 22, it is ensured that there is time to reduce the pressure difference of the refrigerant after the compressor 22 is stopped, thereby reducing the burden on the compressor 22 and preventing the compressor 22 from frequently operating in a short period of time. Stops and restarts are perfor...

Embodiment 3

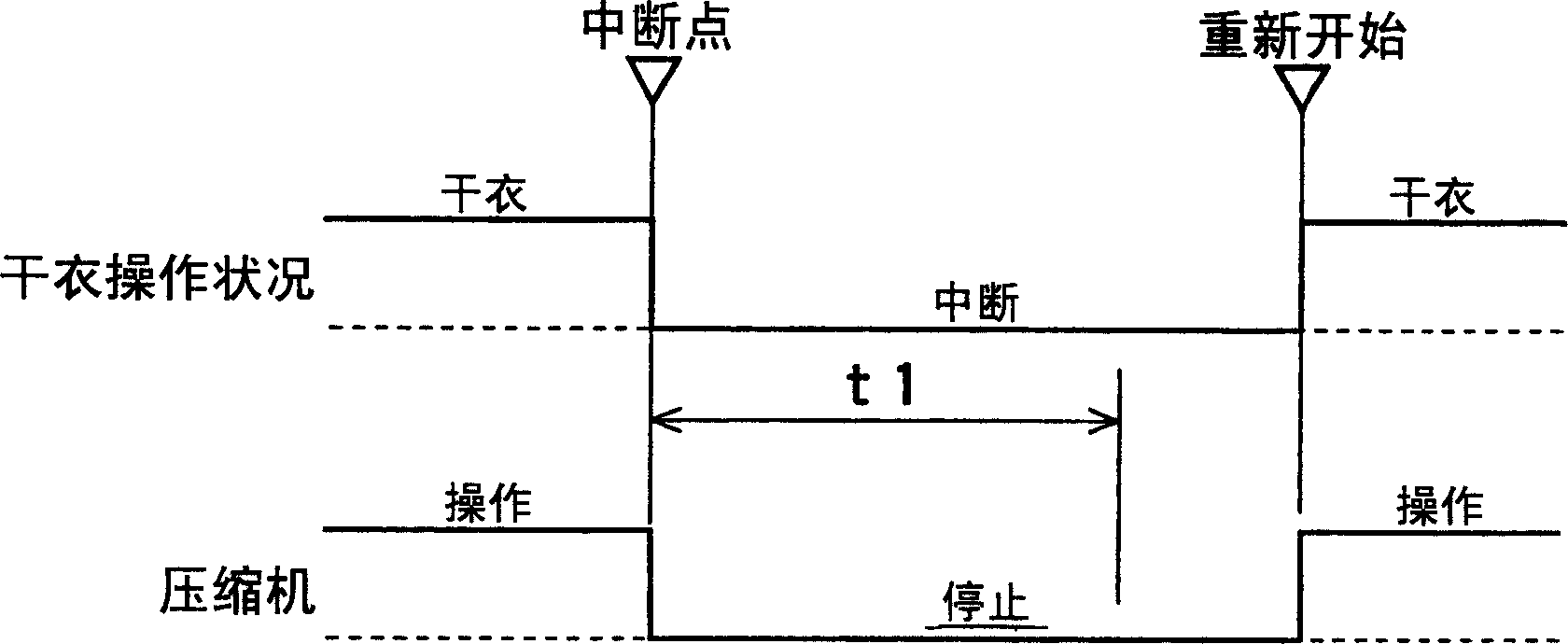

[0064] Figure 4 It is an operation timing chart when the drying operation of the clothes dryer equipped with the clothes drying apparatus according to the third embodiment of the present invention is interrupted. Here, since the basic operation and structure of the clothes dryer are the same as in Embodiment 1, a detailed description thereof is omitted here.

[0065] Such as Figure 4 As shown in , the drying operation starts before the predetermined time t1 elapses after the compressor 22 stops. Also in such a case, the control device 19 restarts the operation of the compressor 22 after the predetermined time t1 has elapsed.

[0066]In this way, by ensuring that the stop time of the compressor 22 reaches the prescribed time t1, the load on the compressor 22 can be reduced, and thus it is possible to cope with the interruption of the drying operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com