Patents

Literature

212 results about "Defogger" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A defogger, demister, or defroster is a system to clear condensation and thaw frost from the windshield, backglass, or side windows of a motor vehicle. It was invented by German automobile engineer Heinz Kunert.

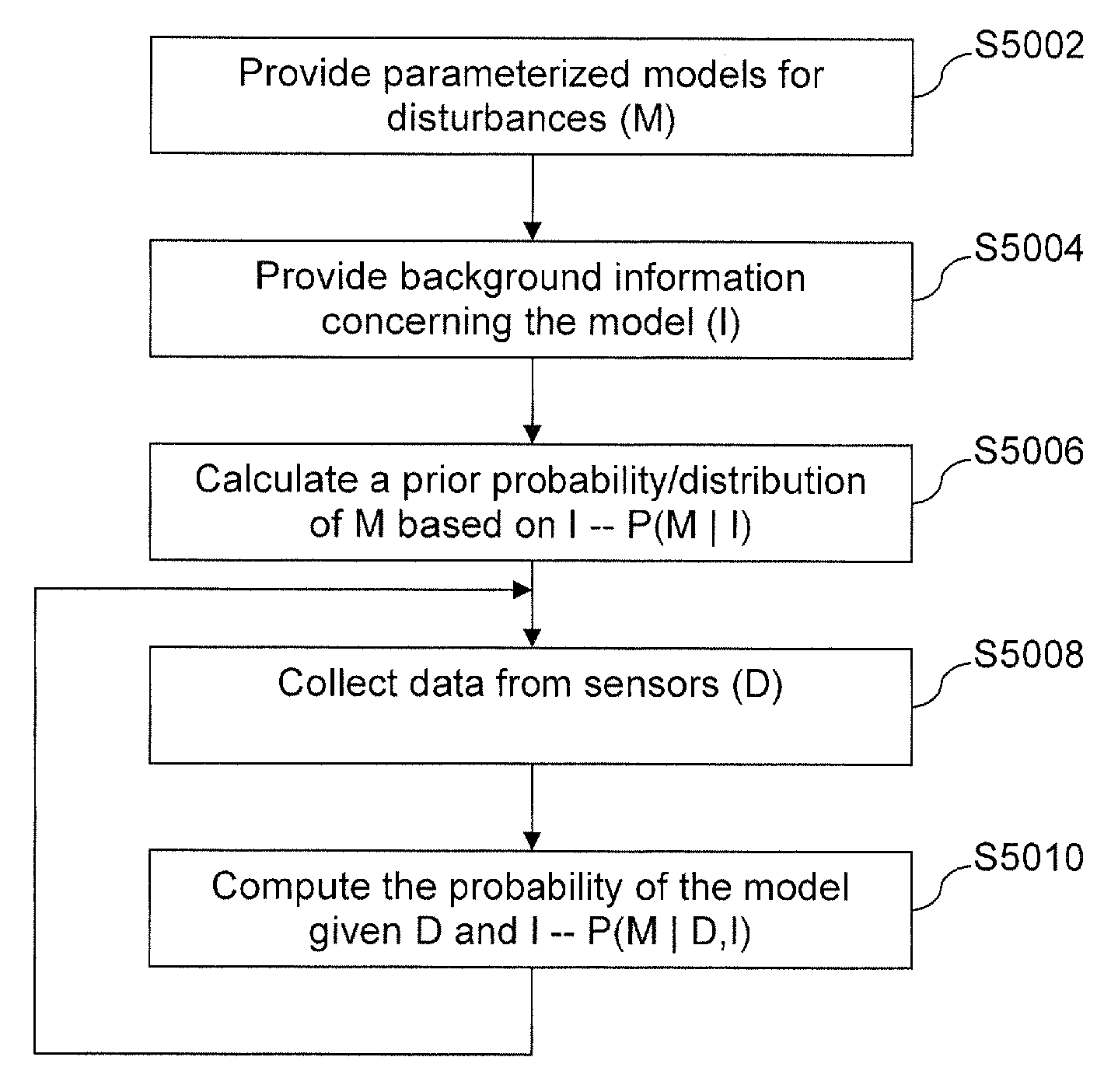

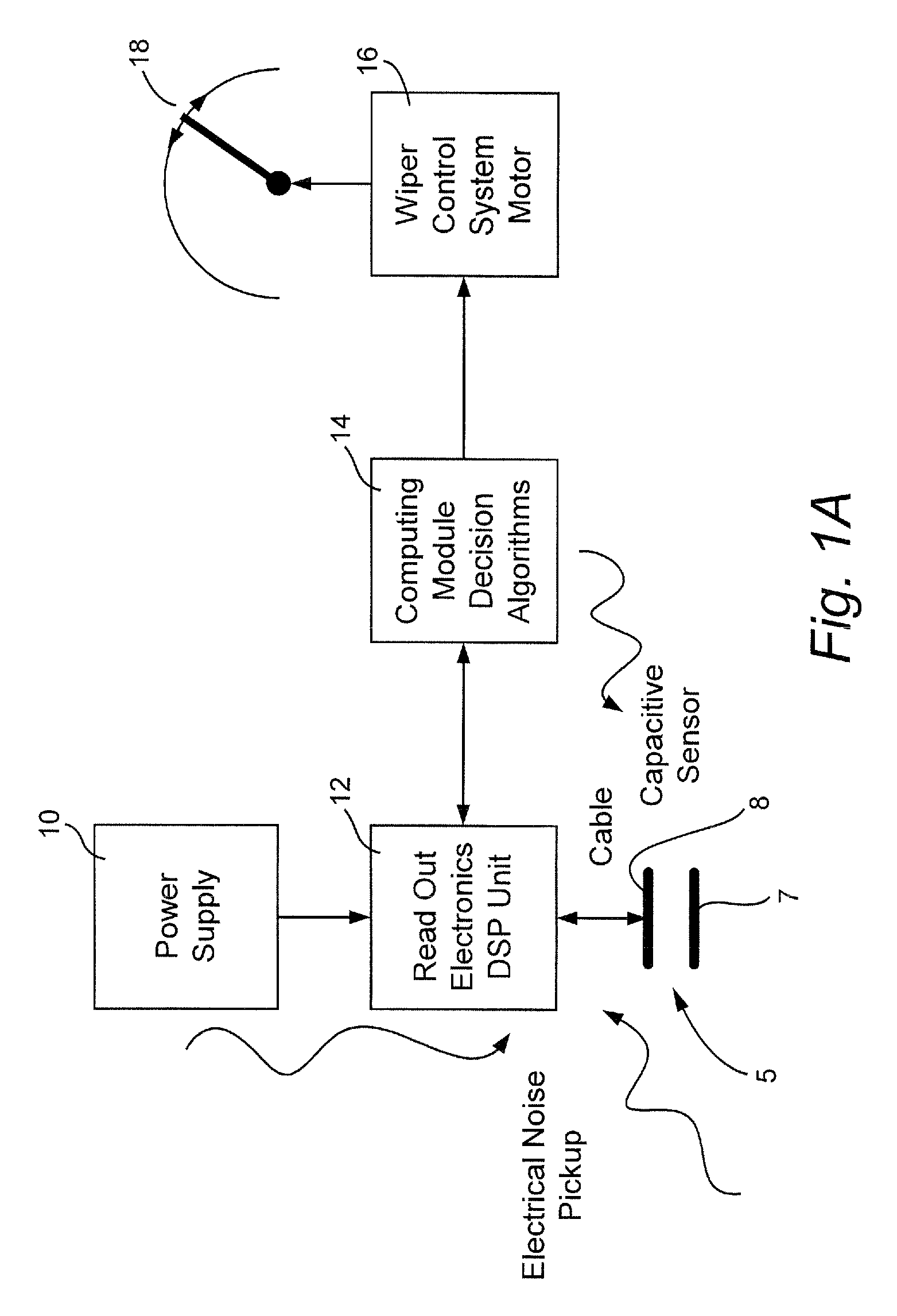

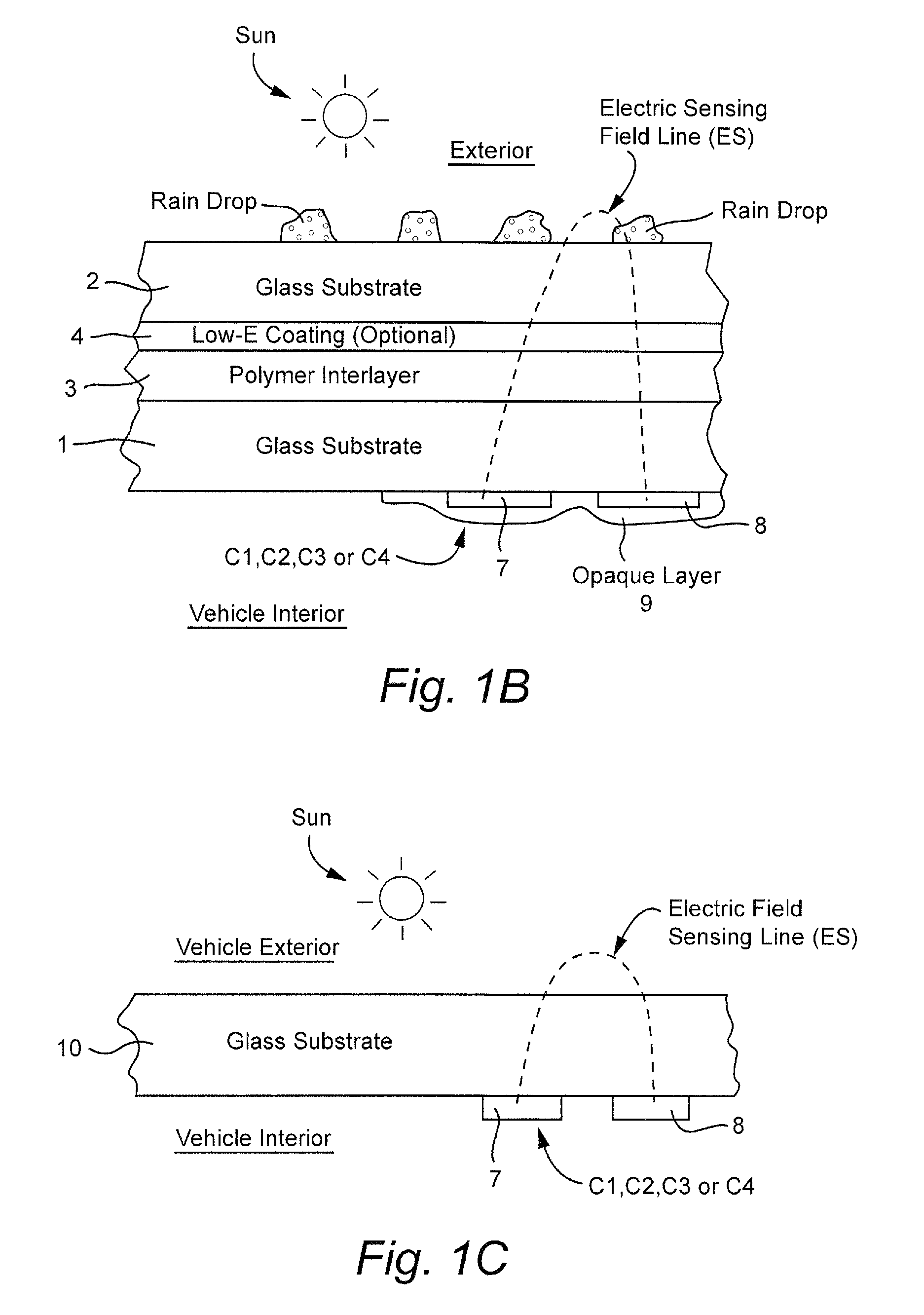

Moisture sensor and/or defogger with bayesian improvements, and related methods

ActiveUS20130024169A1Hazard reductionReduce distractionsMathematical modelsVehicle headlampsEngineeringMoisture sensor

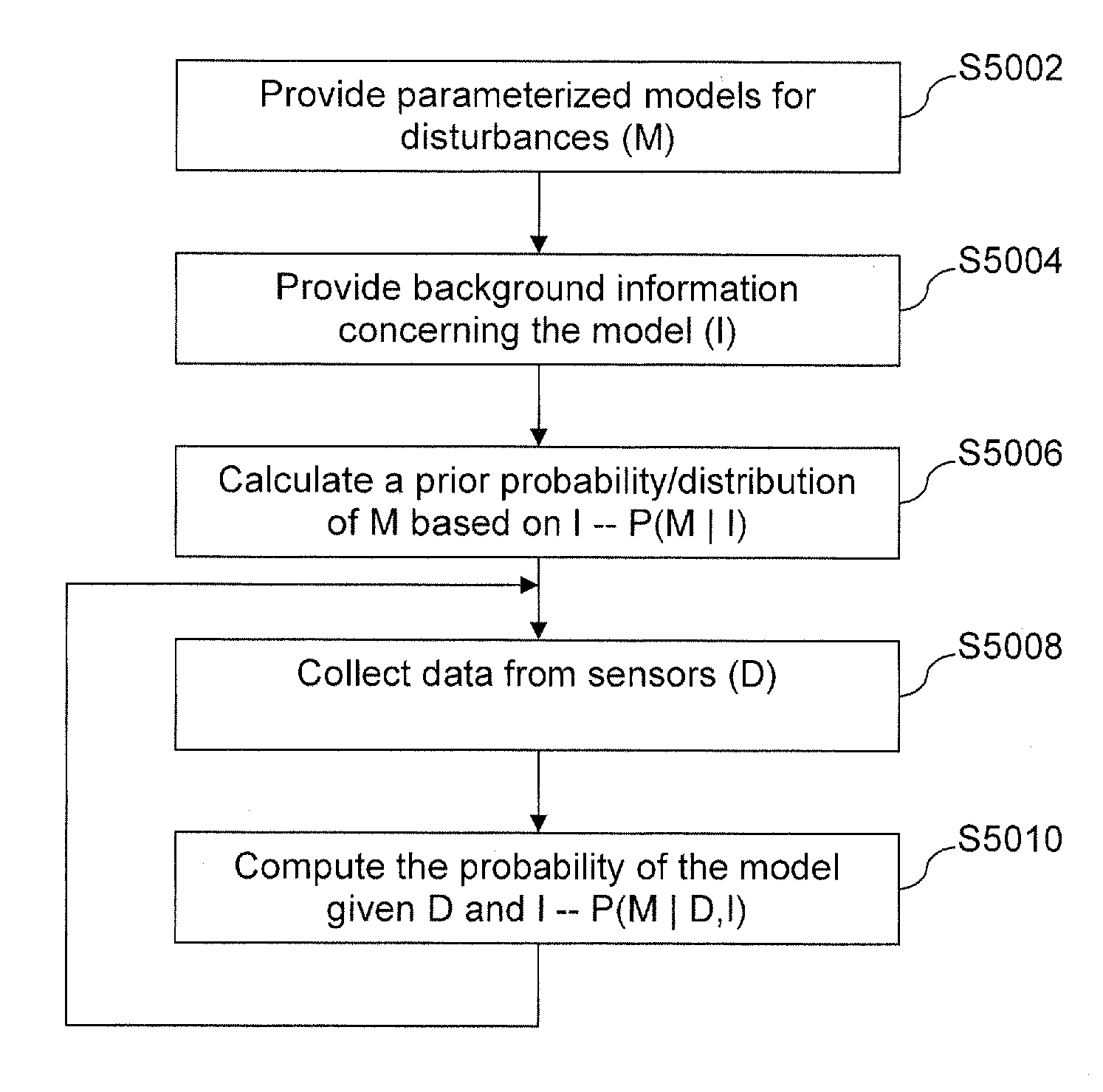

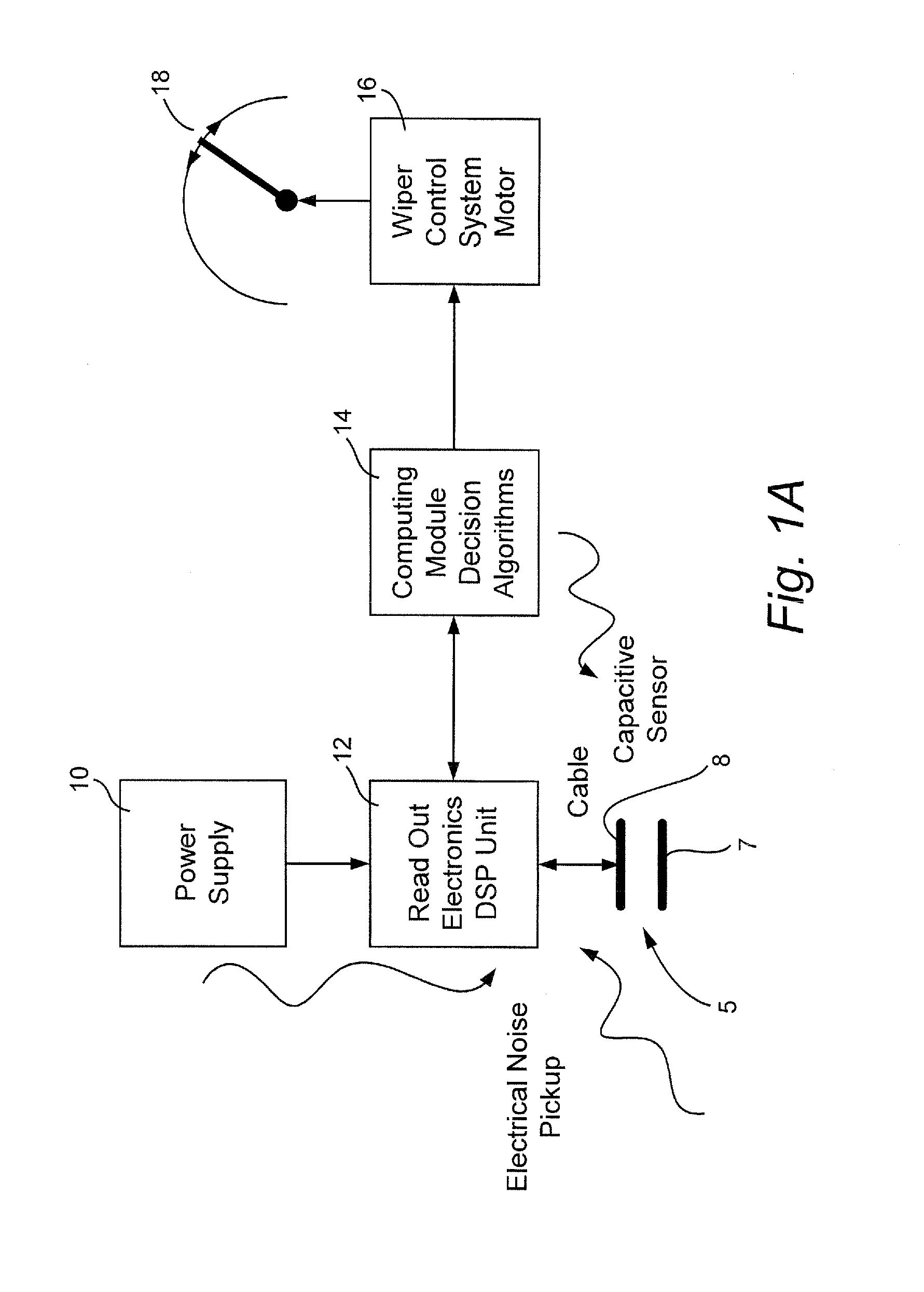

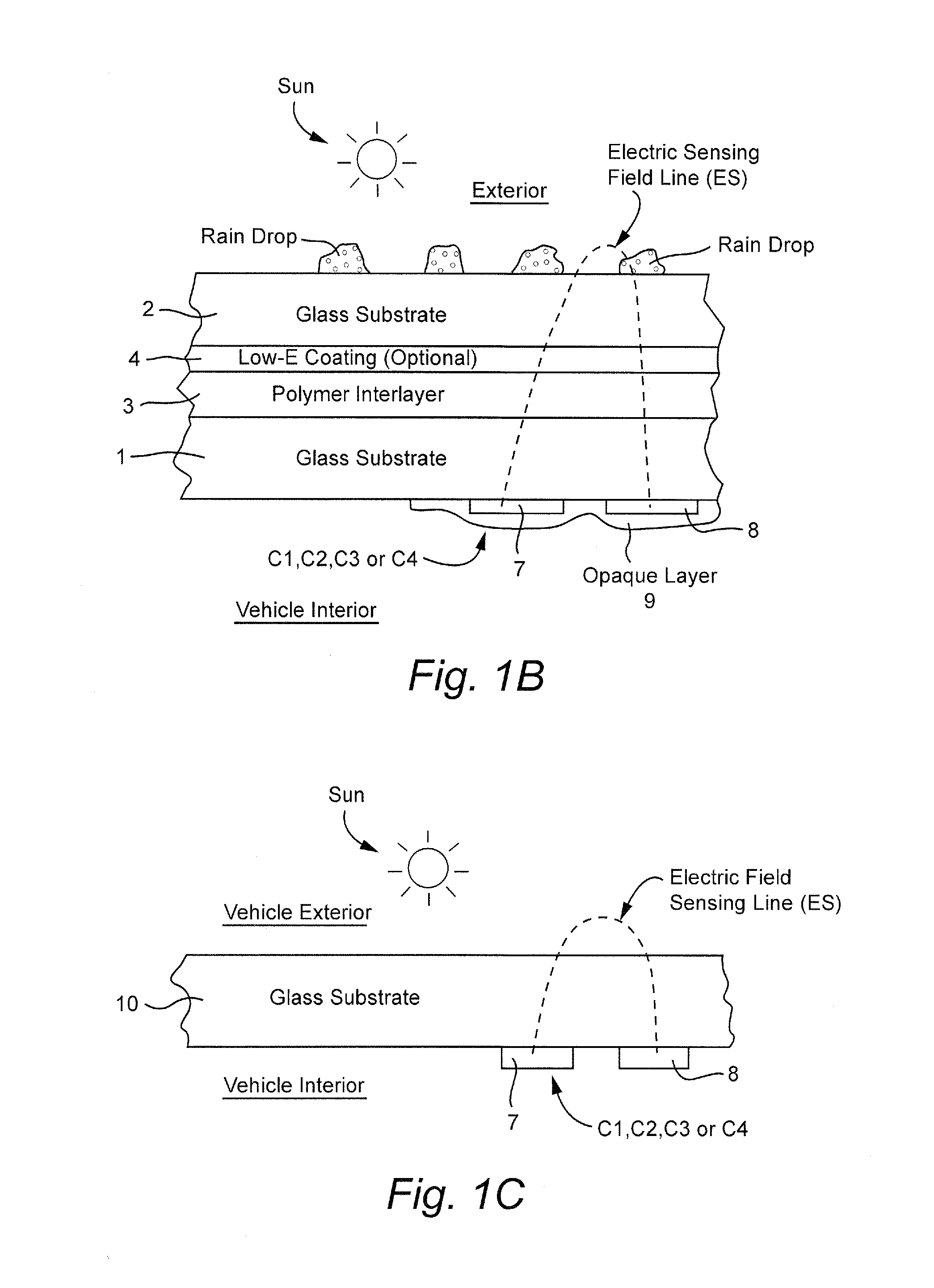

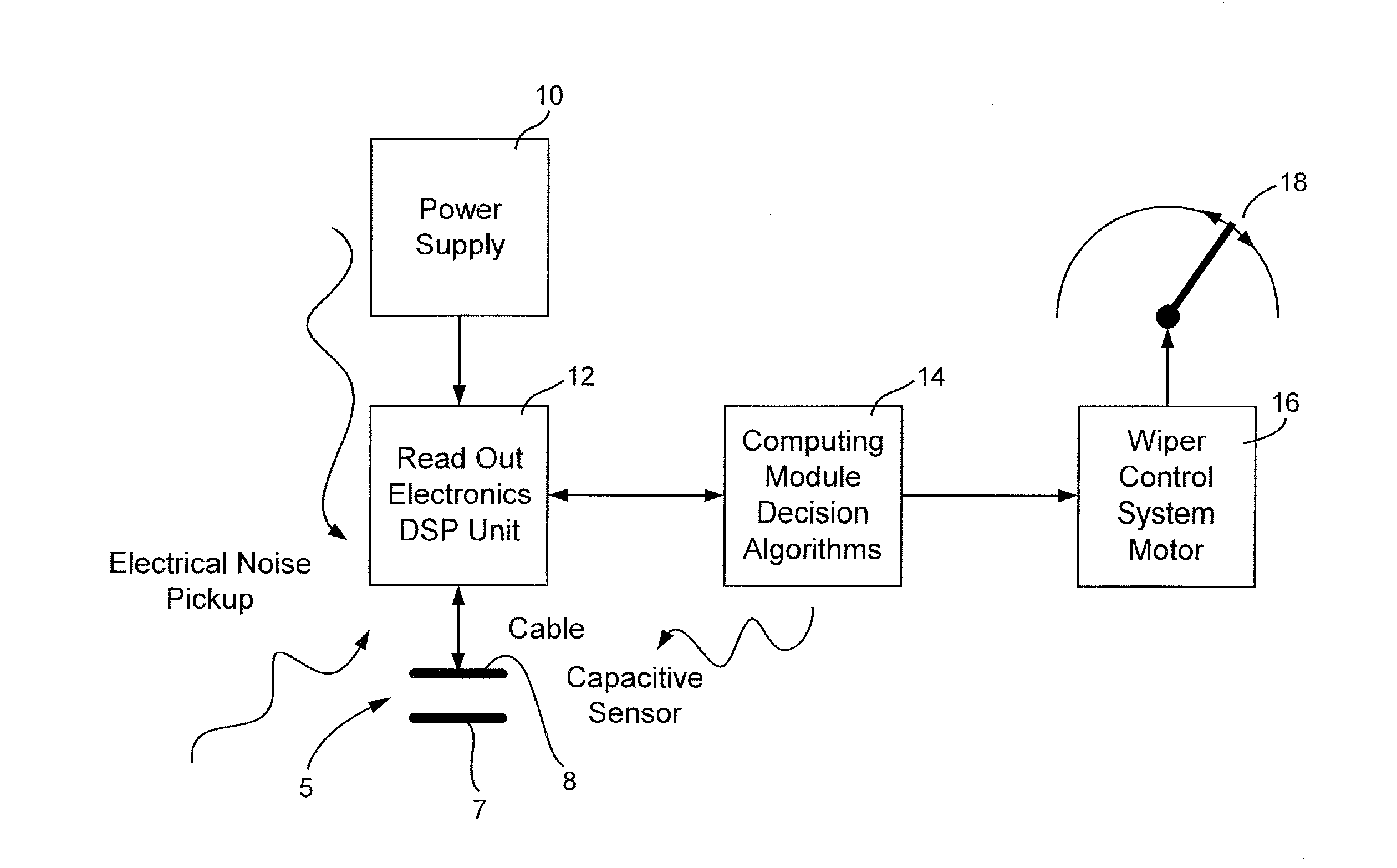

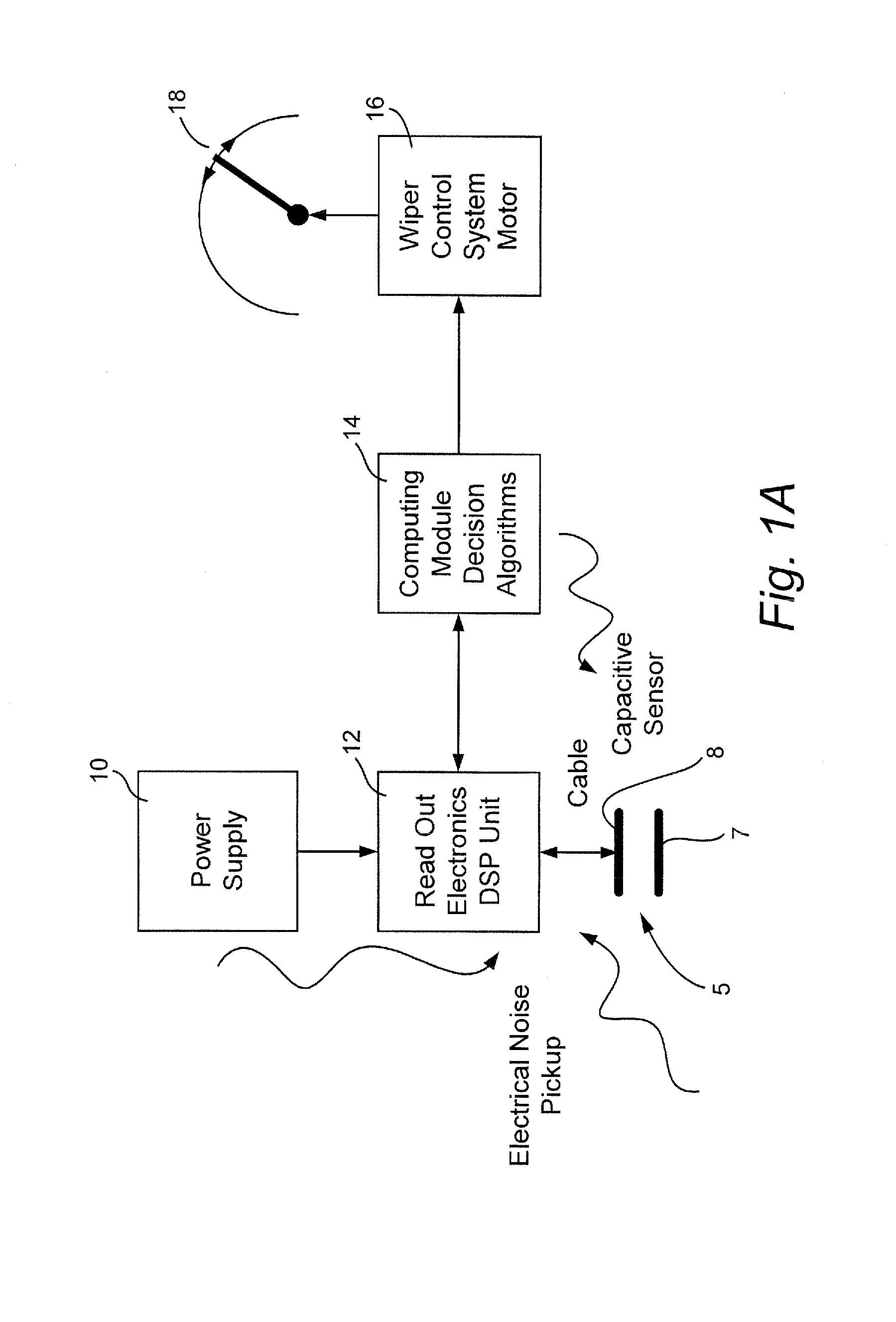

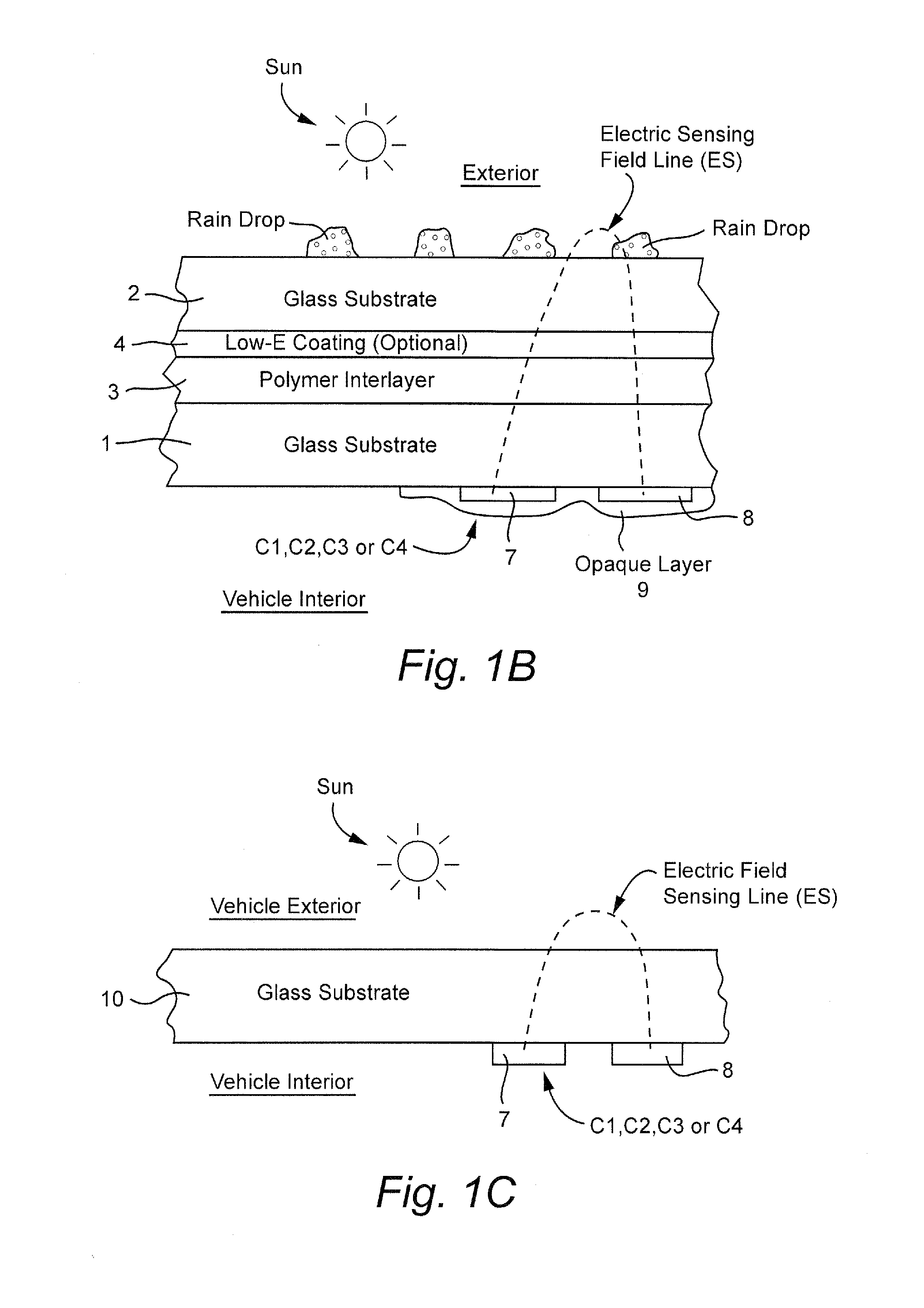

In certain example embodiments, moisture sensors, defoggers, etc., and / or related methods, are provided. More particularly, certain example embodiments relate to moisture sensors and / or defoggers that may be used in various applications such as, for example, refrigerator / freezer merchandisers, vehicle windows, building windows, etc. When condensation or moisture is detected, an appropriate action may be taken (e.g., actuating windshield wipers, turning on a defroster, triggering the heating of a merchandiser door or window, etc.). Bayesian approaches optionally may be implemented in certain example embodiments in an attempt to improve moisture detection accuracy. For instance, models of various types of disturbances may be developed and, based on live data and a priori information known about the model, a probability of the model being accurate is calculated. If a threshold value is met, the model may be considered a match and, optionally, a corresponding appropriate action may be taken.

Owner:GUARDIAN GLASS LLC

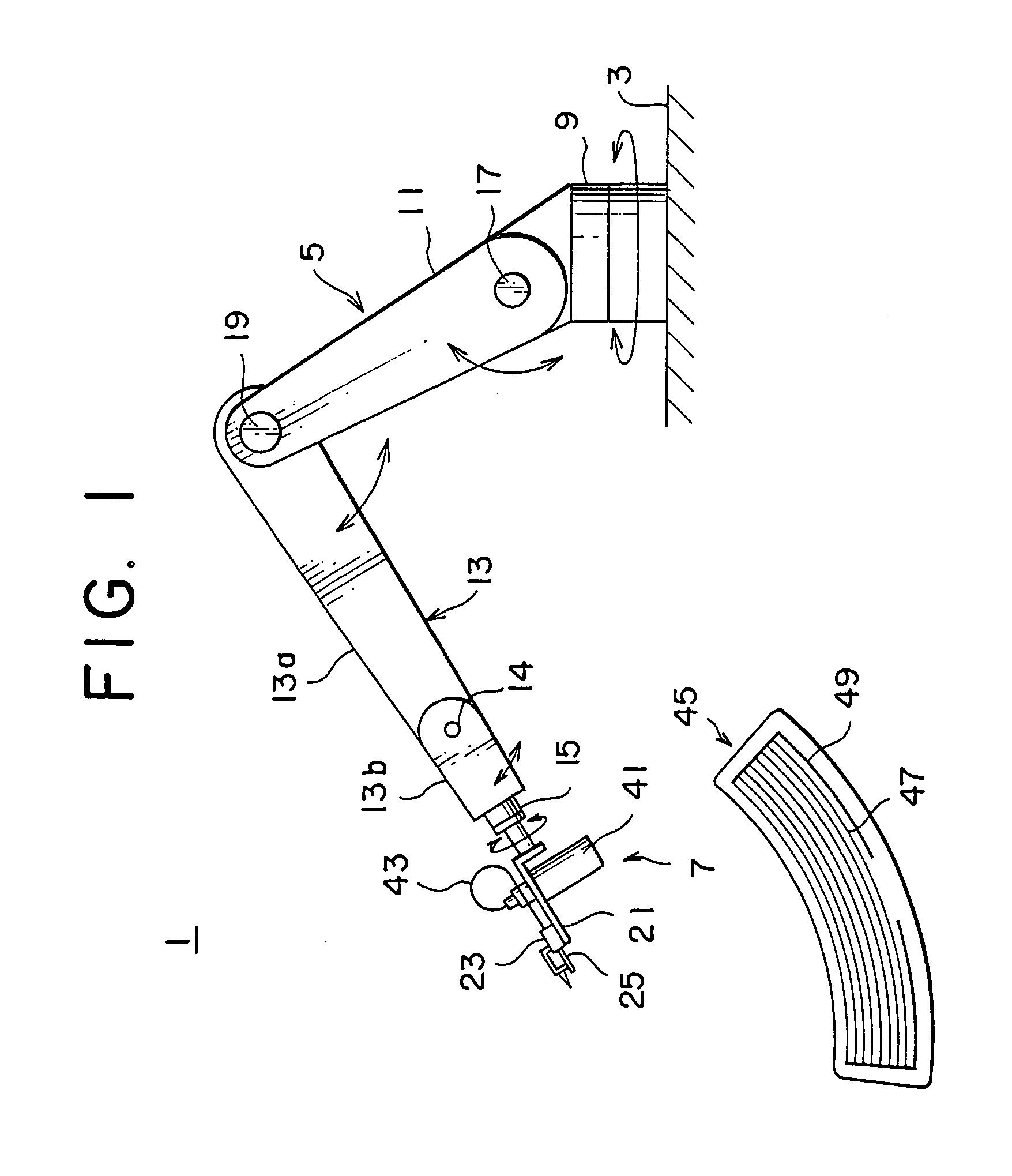

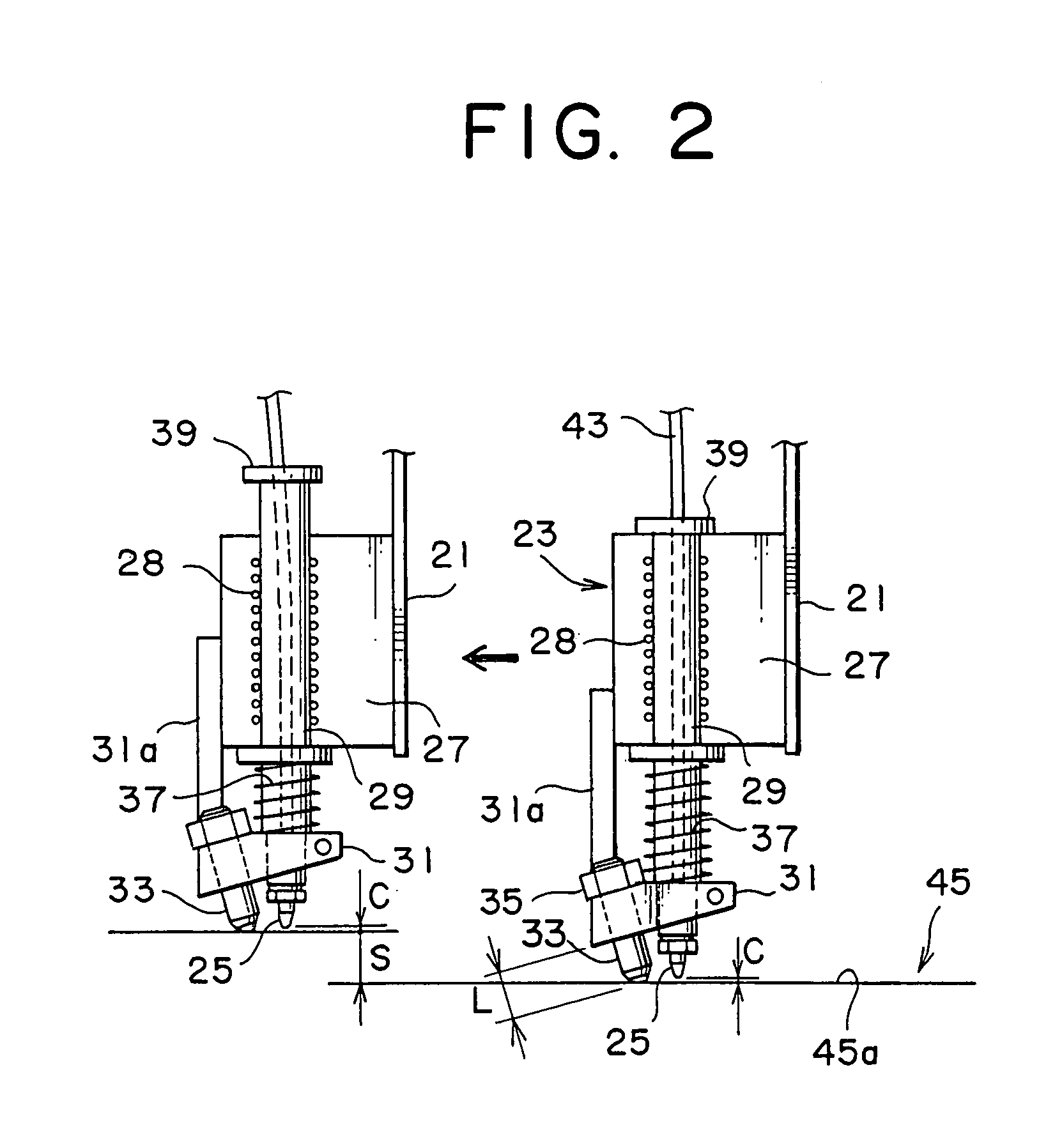

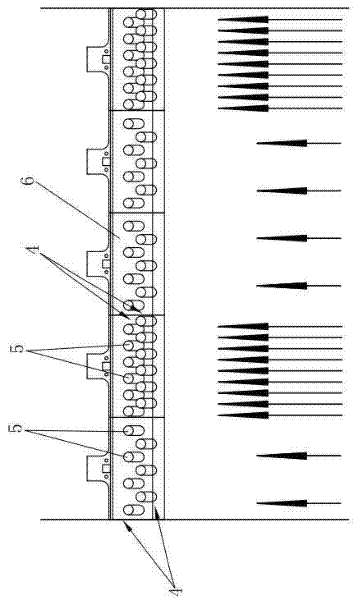

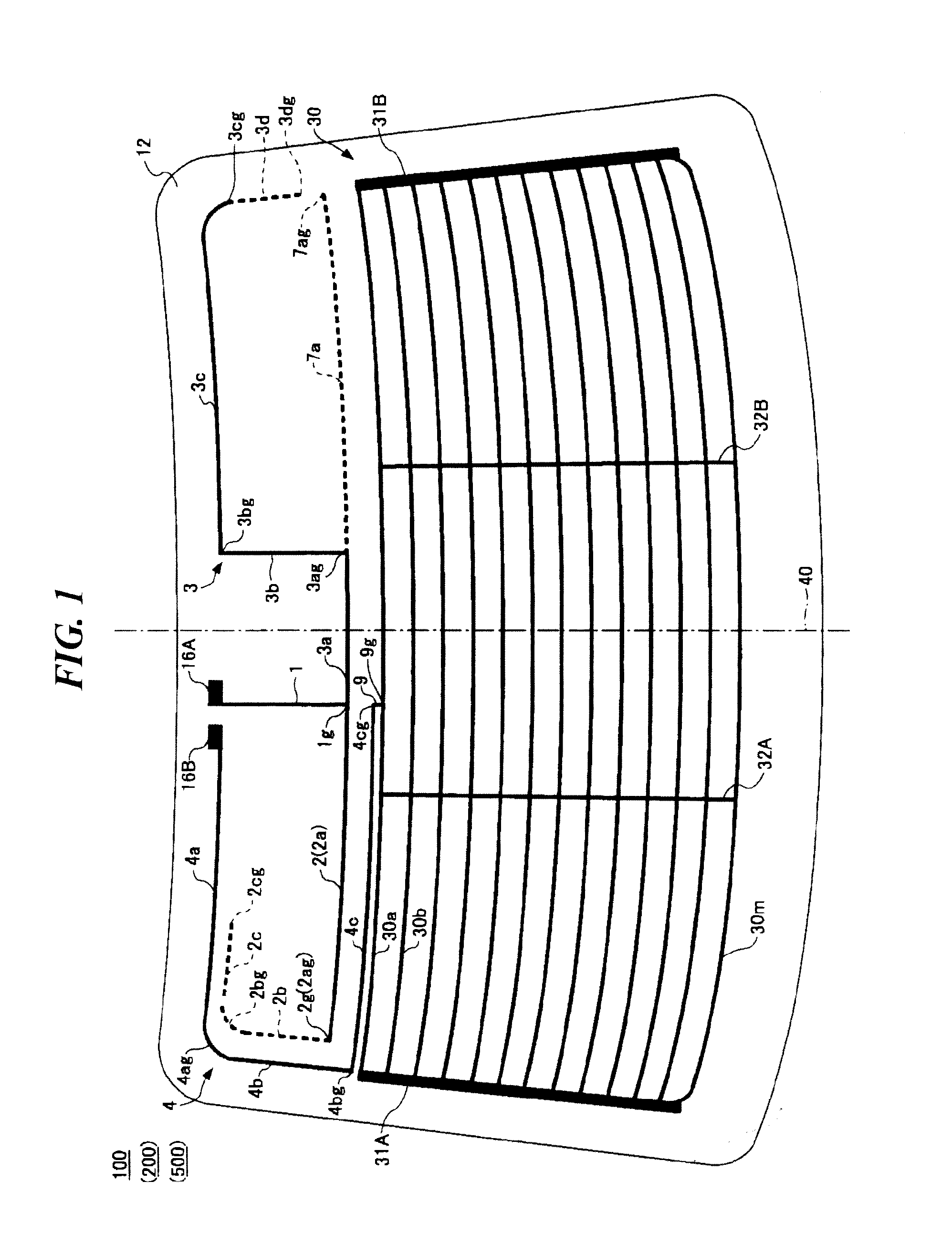

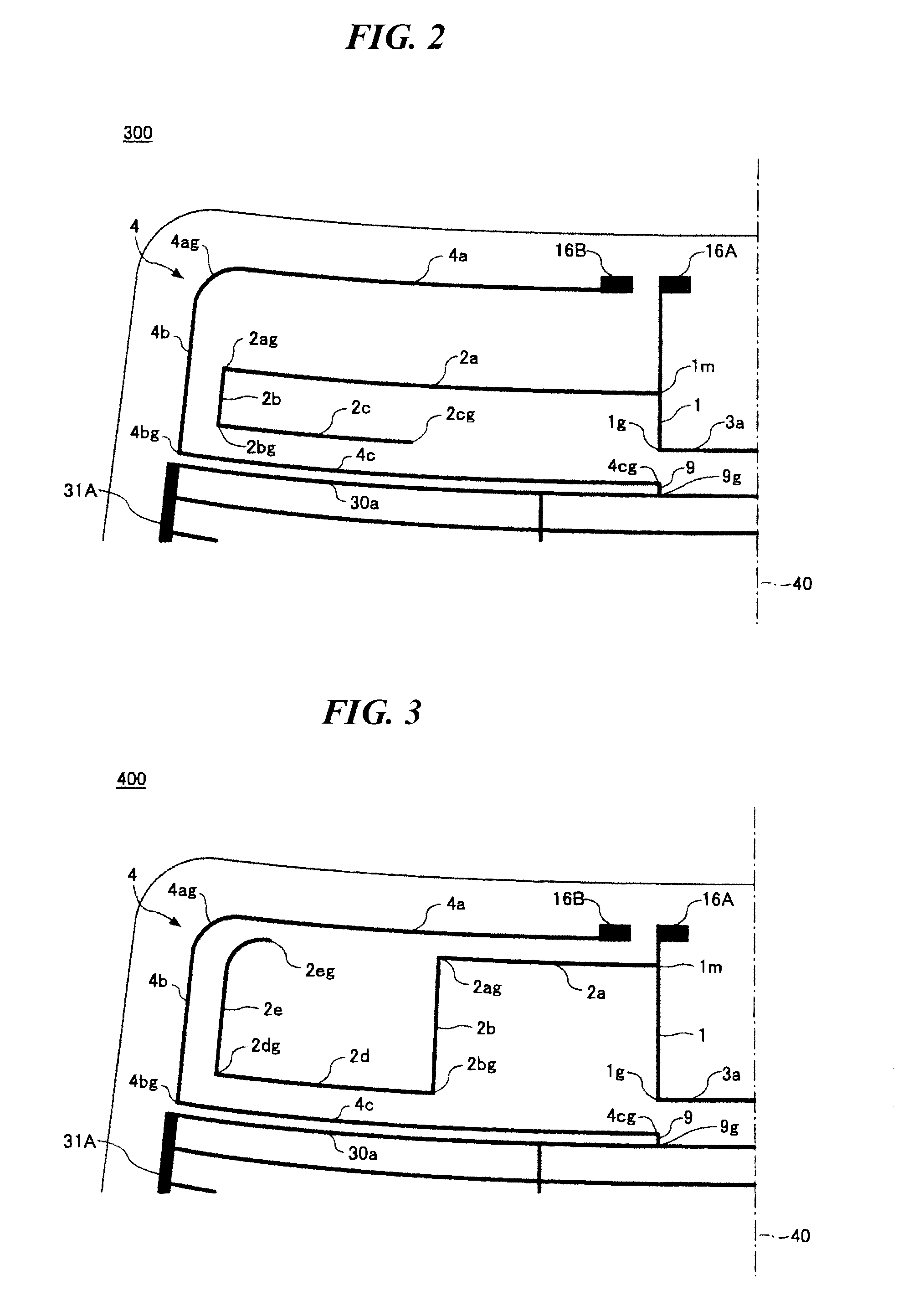

Defogger line forming device

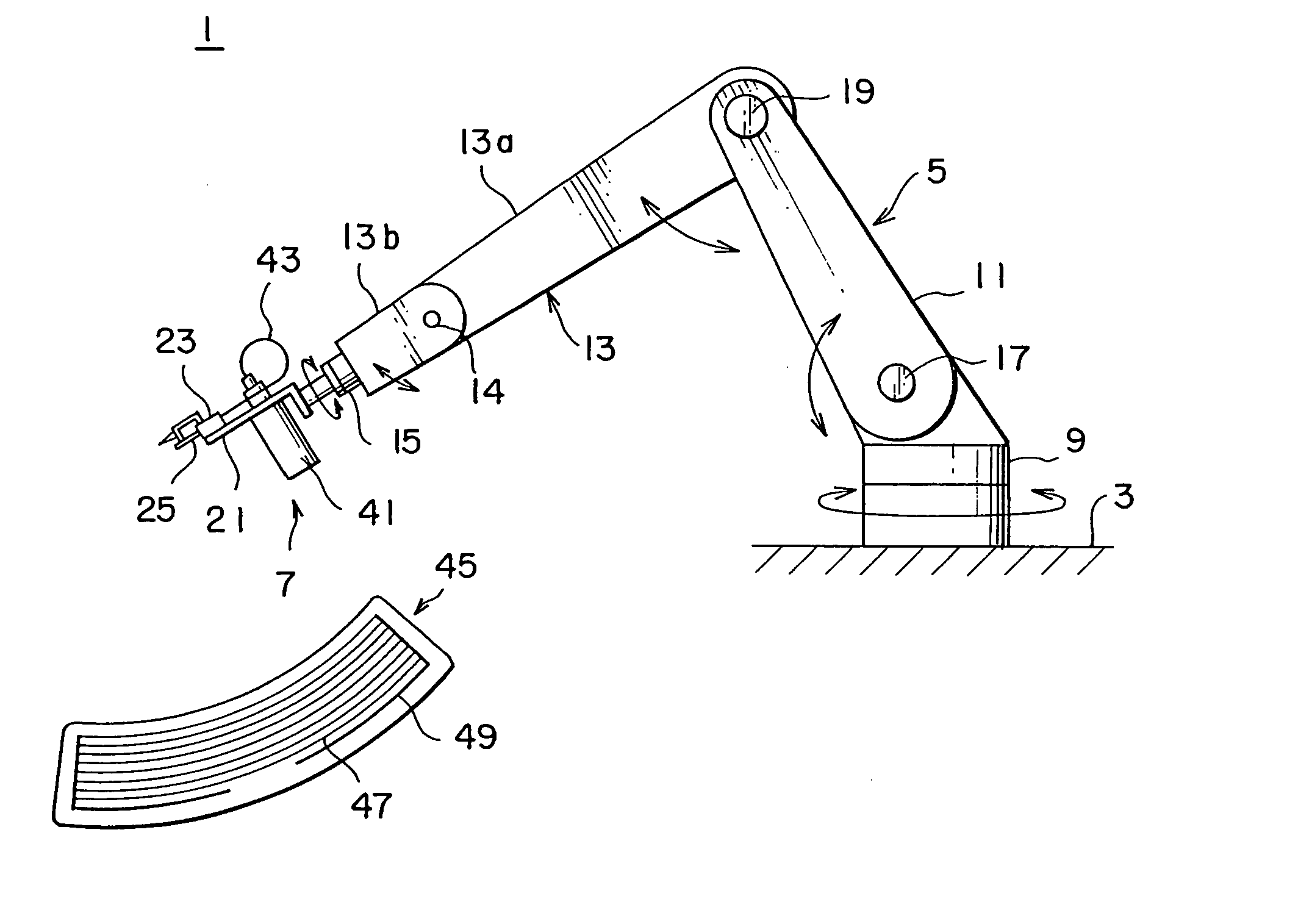

A defogger line forming device is equipped with a nozzle for applying conductive paste to a curved surface resin glass constituting a resin window, a robot arm for moving the nozzle along the window, a contact member provided so as to be movable integrally with the nozzle and adapted to come into contact with the resin window to maintain a fixed distance between the resin window and the nozzle, a volume measurement type supply device for supplying the conductive paste to the nozzle, and a hose communicating with the nozzle and the supply device. More specifically, the nozzle and the contact member are mounted to a bracket at the distal end of the robot arm so as to be slidable in a direction crossing the window, and the supply device is integrally fixed to the bracket.

Owner:TOYOTA IND CORP

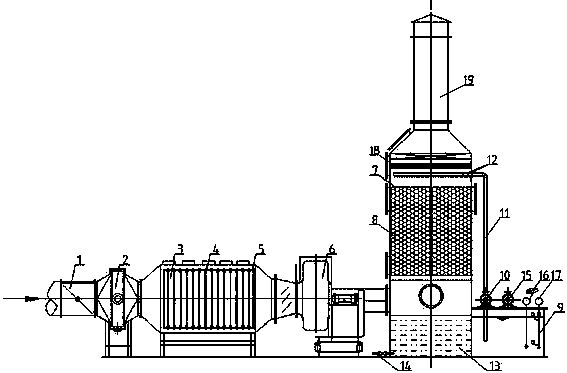

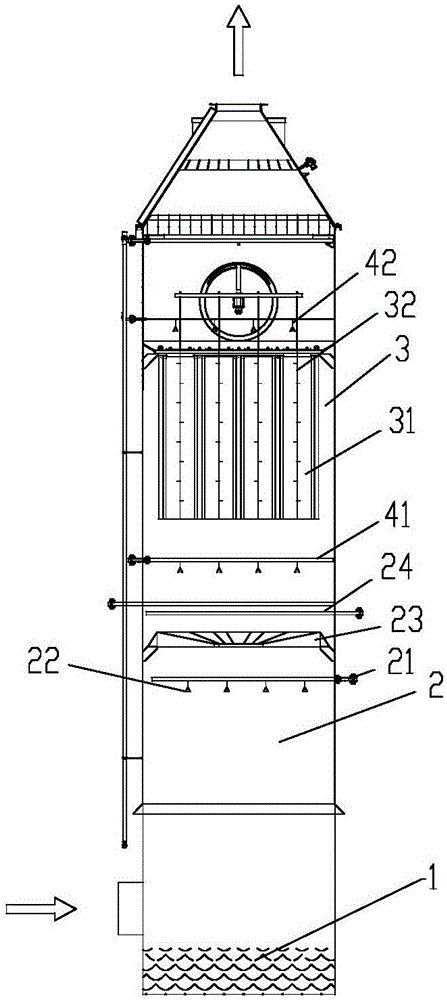

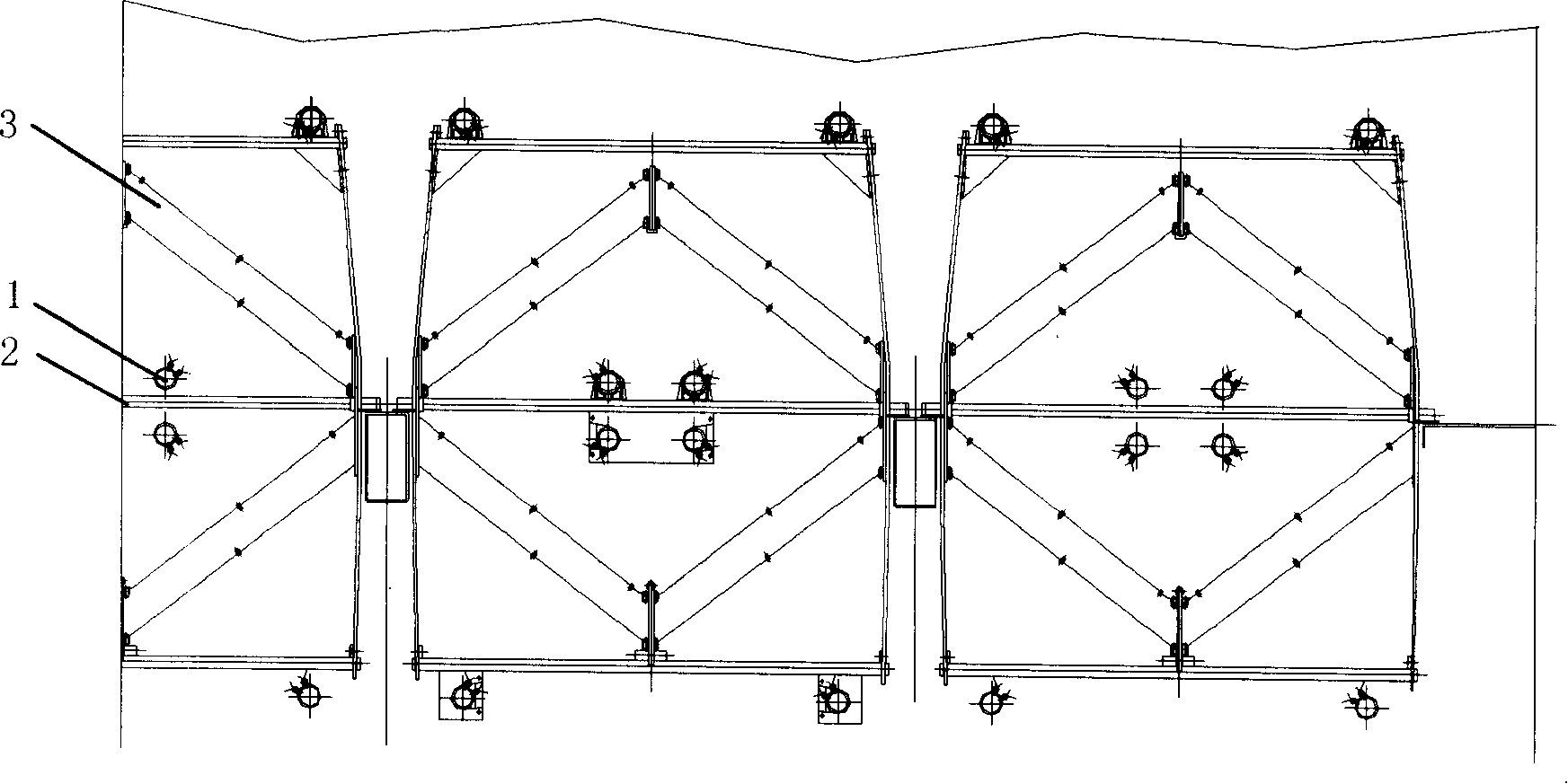

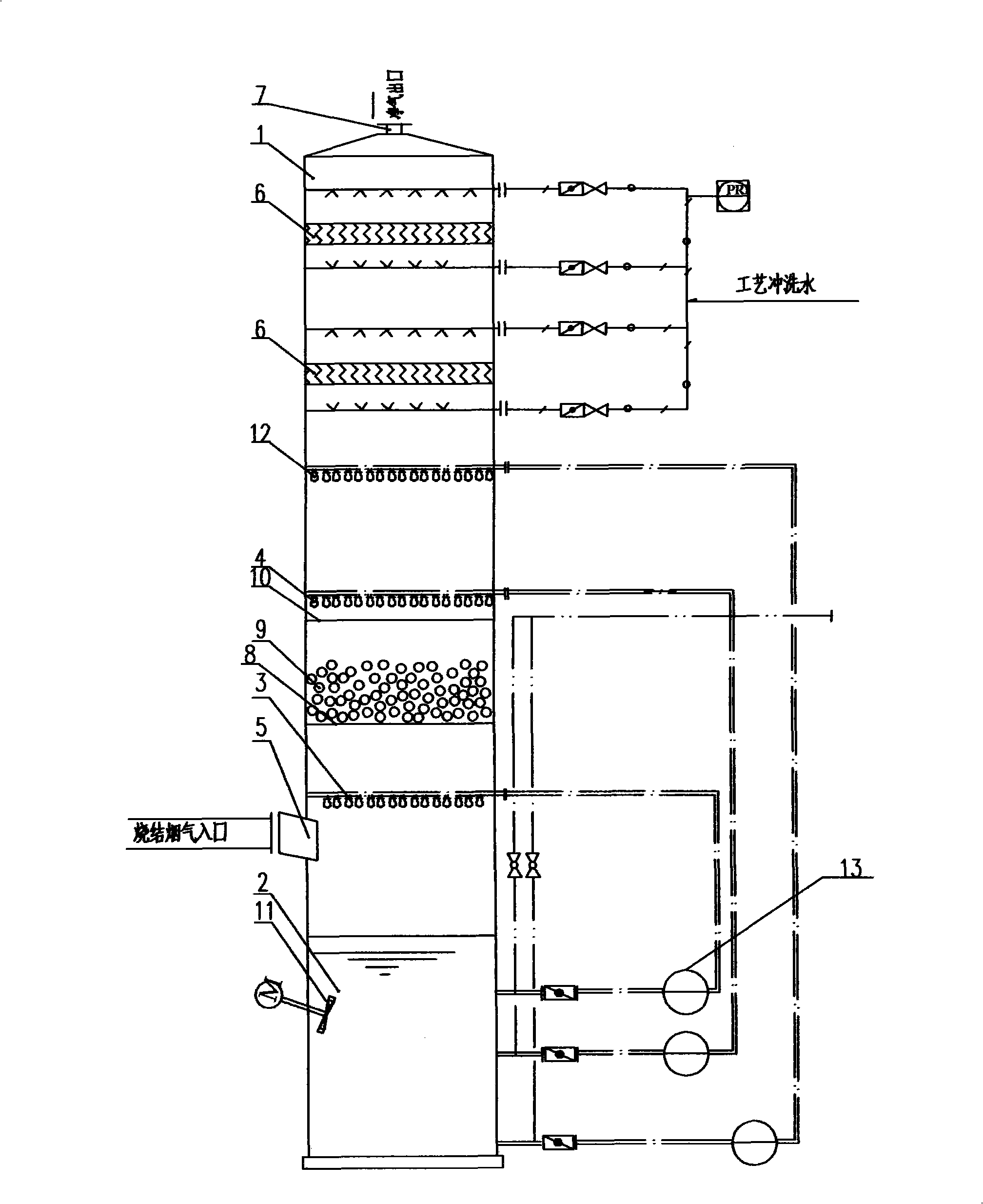

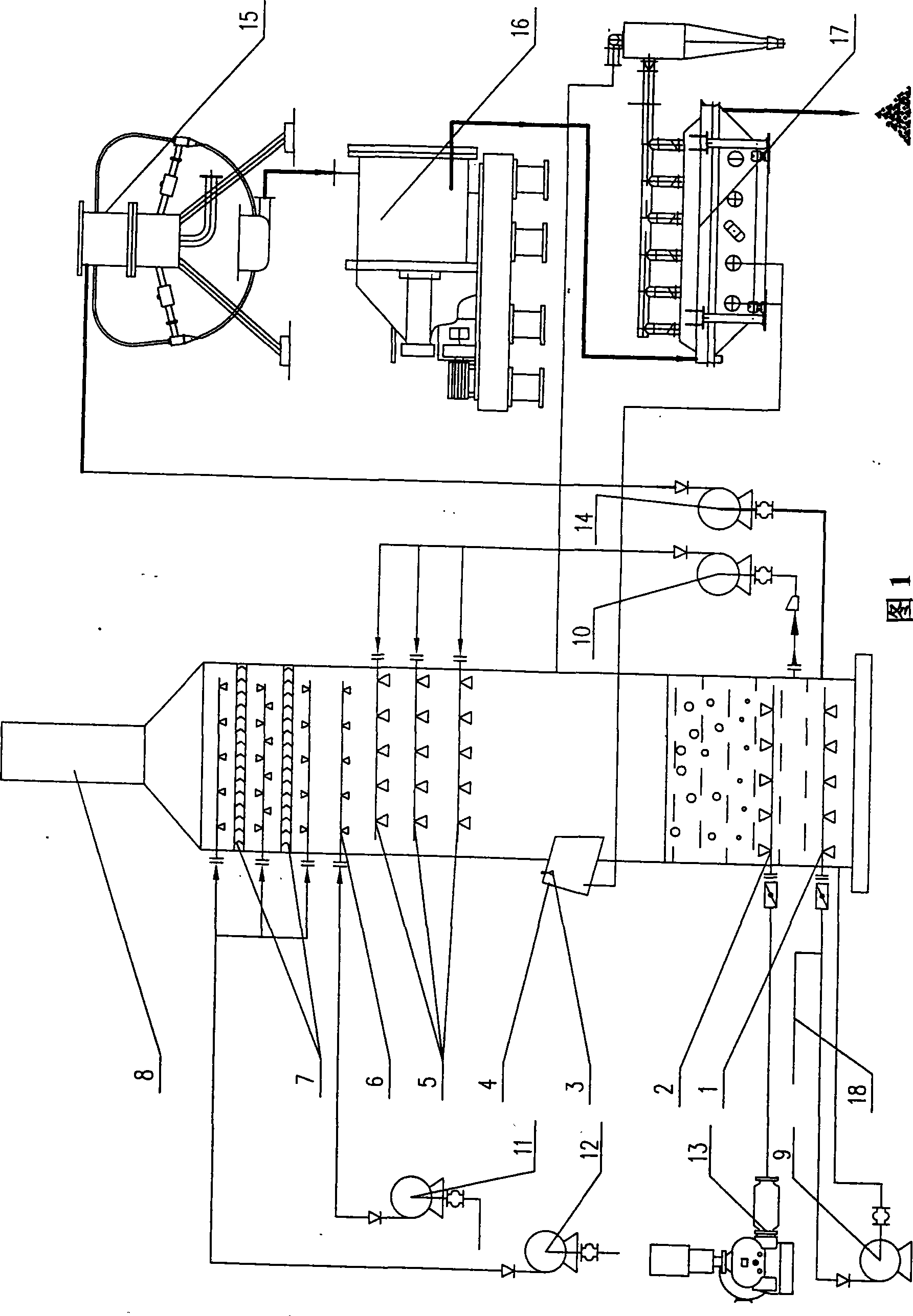

Gas outburst spinning dive desulfurization dust cleaning apparatus

ActiveCN101229478AGuaranteed thermal safetyImprove removal efficiencyUsing liquid separation agentCycloneFlue gas

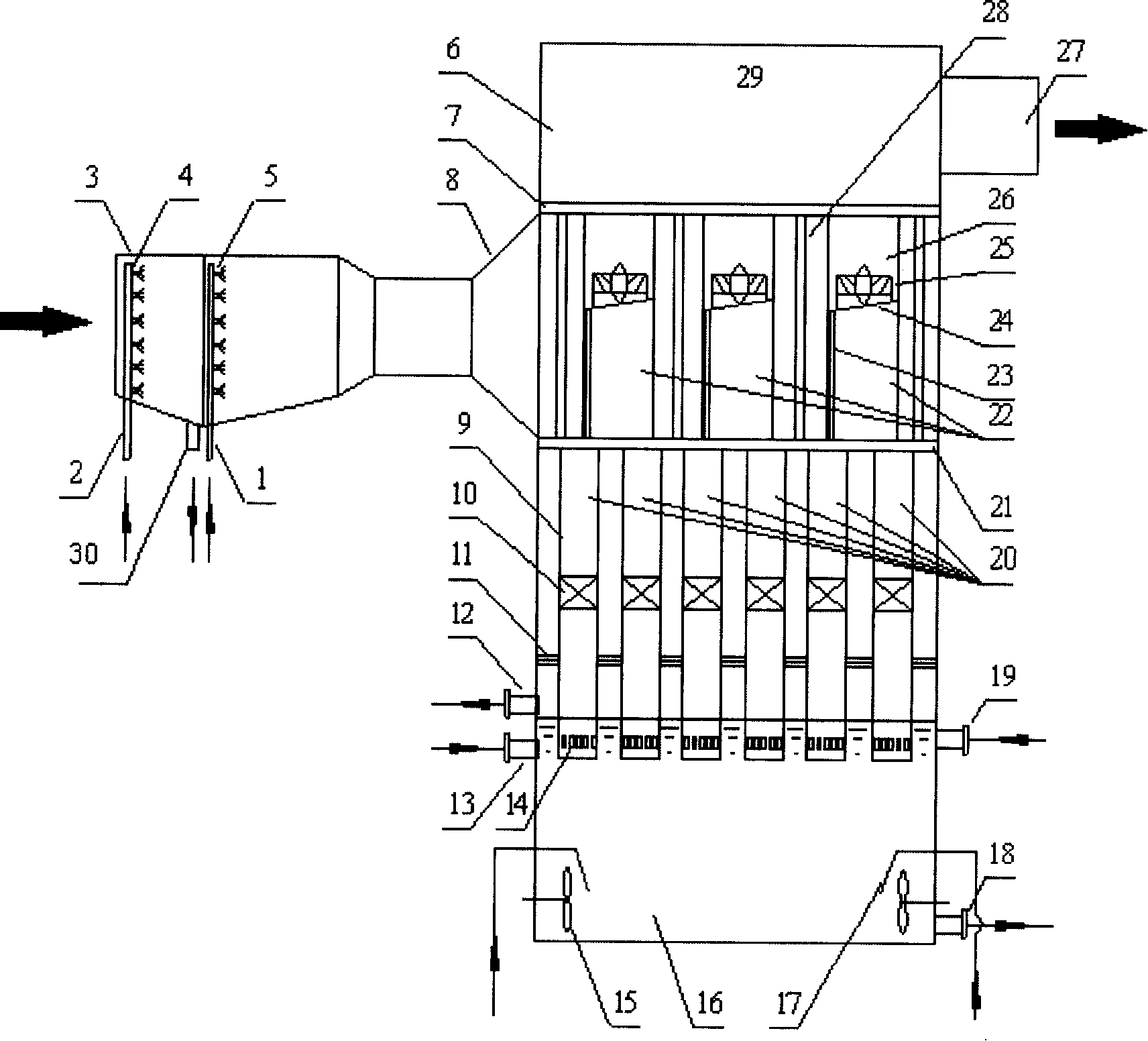

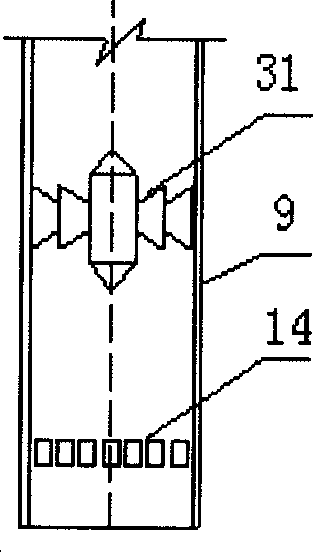

The invention discloses a gas outburst cyclone desulfurization dust removal device, comprising a cooling defluorination device, a desulfuration absorbing tower and a defogger. The flue gas containing SO2 is first introduced into the cooling defluorination device to be eliminated most of HF gas by the sprayed alkaline liquor spray and fresh water, and the temperature is then reduced to below 80 DEG C. The cooled defluorination flue gas is sent into the desulfuration absorbing tower; after obtaining strong rotating momentum in a cyclone gas outburst pipe with a cyclone device, the flue gas is dashed into a slurry pond in tangential direction of the vents at the bottom of the pipe; the optimally distributed array form enhances the effect of rotary gas spraying into slurry liquid, strengthens the process of gas and liquid transformation, improves efficiency of desulfurization dust removal and reduces resistance loss. The flue gas after purification is emitted out after a multi-pipe cyclone centrifugal defogger. The gas outburst cyclone desulfurization dust removal device can realize efficiency of desulfurization above 95 percent and dust removal efficiency of higher than 90 percent, which can be used in purification process of flue gas in power plant, sintering smoke and other gases containing SO2.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Multi-mode moisture sensor and/or defogger, and related methods

InactiveUS20130019618A1Hazard reductionReduce distractionsVehicle headlampsCorrosion preventionEngineeringMoisture sensor

In certain example embodiments, moisture sensors, defoggers, etc., and / or related methods, are provided. More particularly, certain example embodiments relate to moisture sensors and / or defoggers that may be used in various applications such as, for example, refrigerator / freezer merchandisers, vehicle windows, building windows, etc. When condensation or moisture is detected, an appropriate action may be taken (e.g., actuating windshield wipers, turning on a defroster, triggering the heating of a merchandiser door or window, etc.). Bayesian approaches optionally may be implemented in certain example embodiments in an attempt to improve moisture detection accuracy. For instance, models of various types of disturbances may be developed and, based on live data and a priori information known about the model, a probability of the model being accurate is calculated. If a threshold value is met, the model may be considered a match and, optionally, a corresponding appropriate action may be taken.

Owner:GUARDIAN GLASS LLC

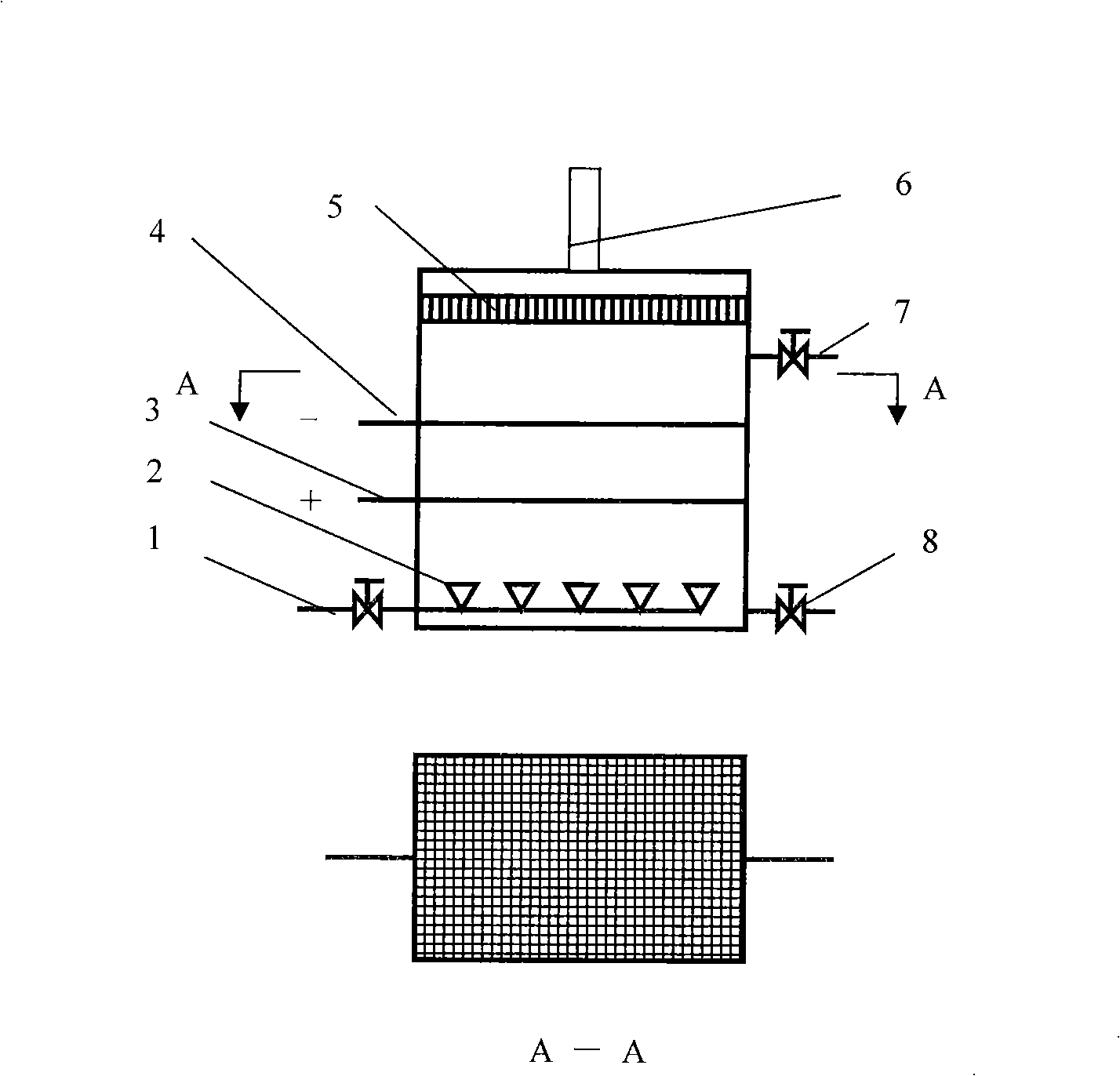

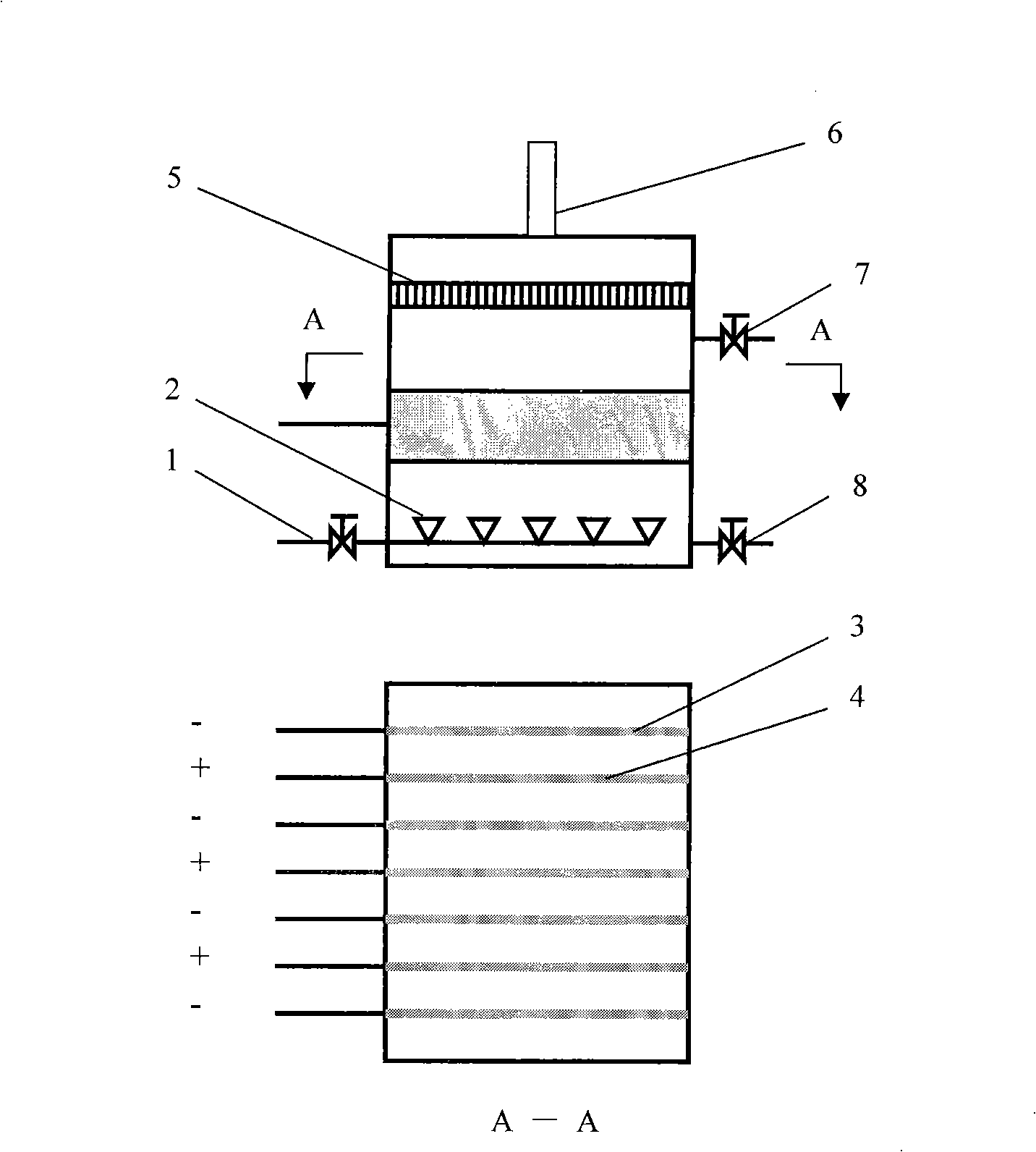

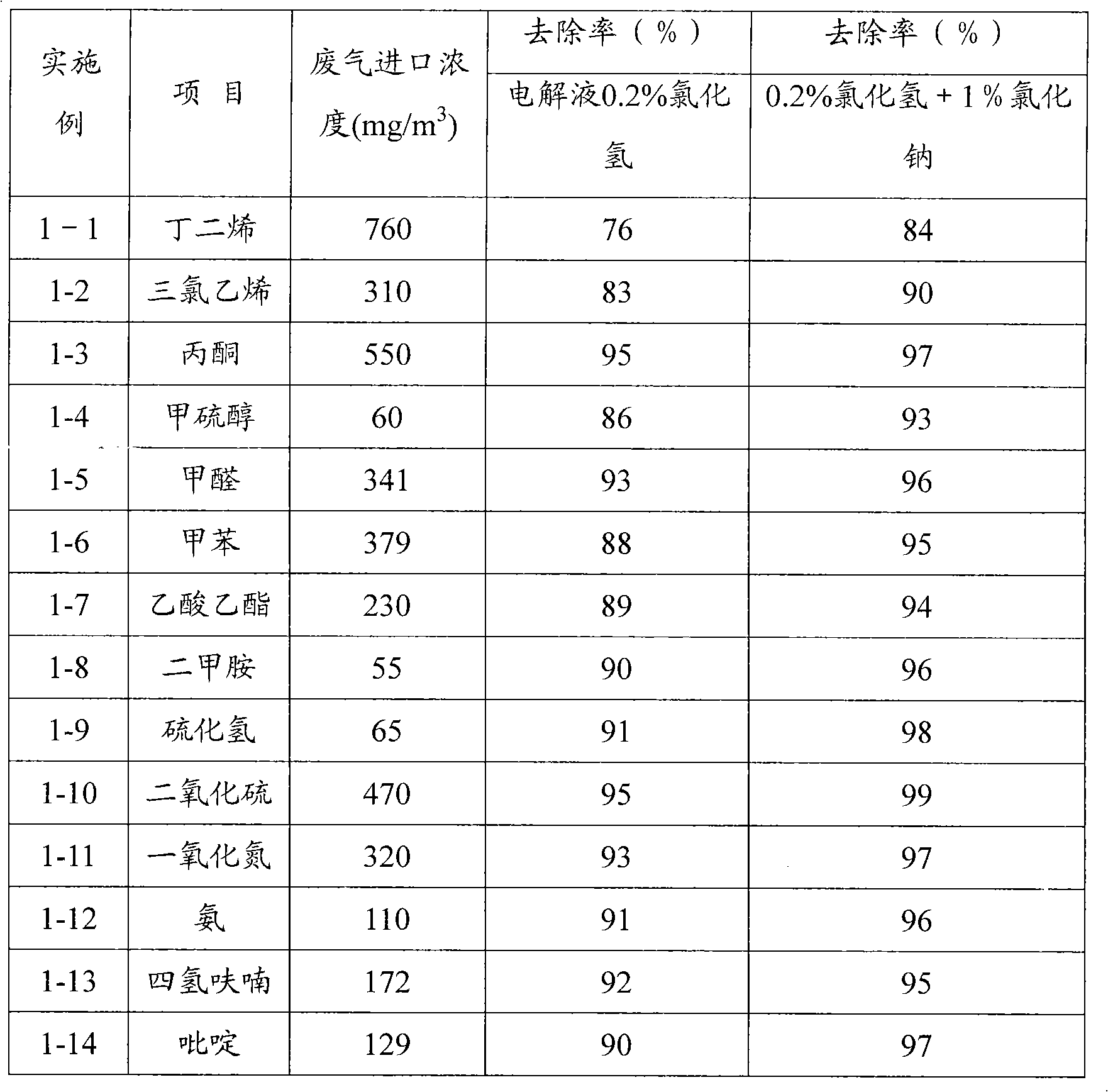

Electrolysis reactor for removing gaseous noxious pollutant from airflow and method of use thereof

InactiveCN101347705ALow running costApplicable treatmentDispersed particle separationElectrolysisEngineering

The invention discloses an electrolytic reactor for removing gaseous harmful pollutants from air currents and an application method thereof; the bottom of the electrolytic reactor is provided with an inlet of the gas to be treated and a liquid drainage port, the top thereof is equipped with an purified gas outlet, the electrolytic reactor is internally provided with an electrode, the electrode includes an electrode unit, a negative plate and a positive plate of which are arranged in an interlaced and parallel way; the negative plate and the positive plate in the electrode are arranged in an interlaced and parallel way, a gas distributor which is communicated with the inlet of the gas to be treated is arranged below the electrode, a defogger is arranged between the electrode and the purified gas outlet and a liquid filling port is arranged between the electrode and the defogger. The electrolytic reactor is used for eliminating gaseous harmful pollutants from air currents, chlorine hydride water solution or the mixed water solution of chlorine hydride and salt is taken as electrolytic solution of electrolytic reaction, and when harmful gas passes through the electrolytic reactor in the acid environment, the harmful gas can be oxidized by hypochlorous acid which is generated in electrolysis of chlorine hydride, thus the electrolytic reactor can effectively eliminate gaseous harmful pollutants and has low running cost and positive significance.

Owner:黄立维

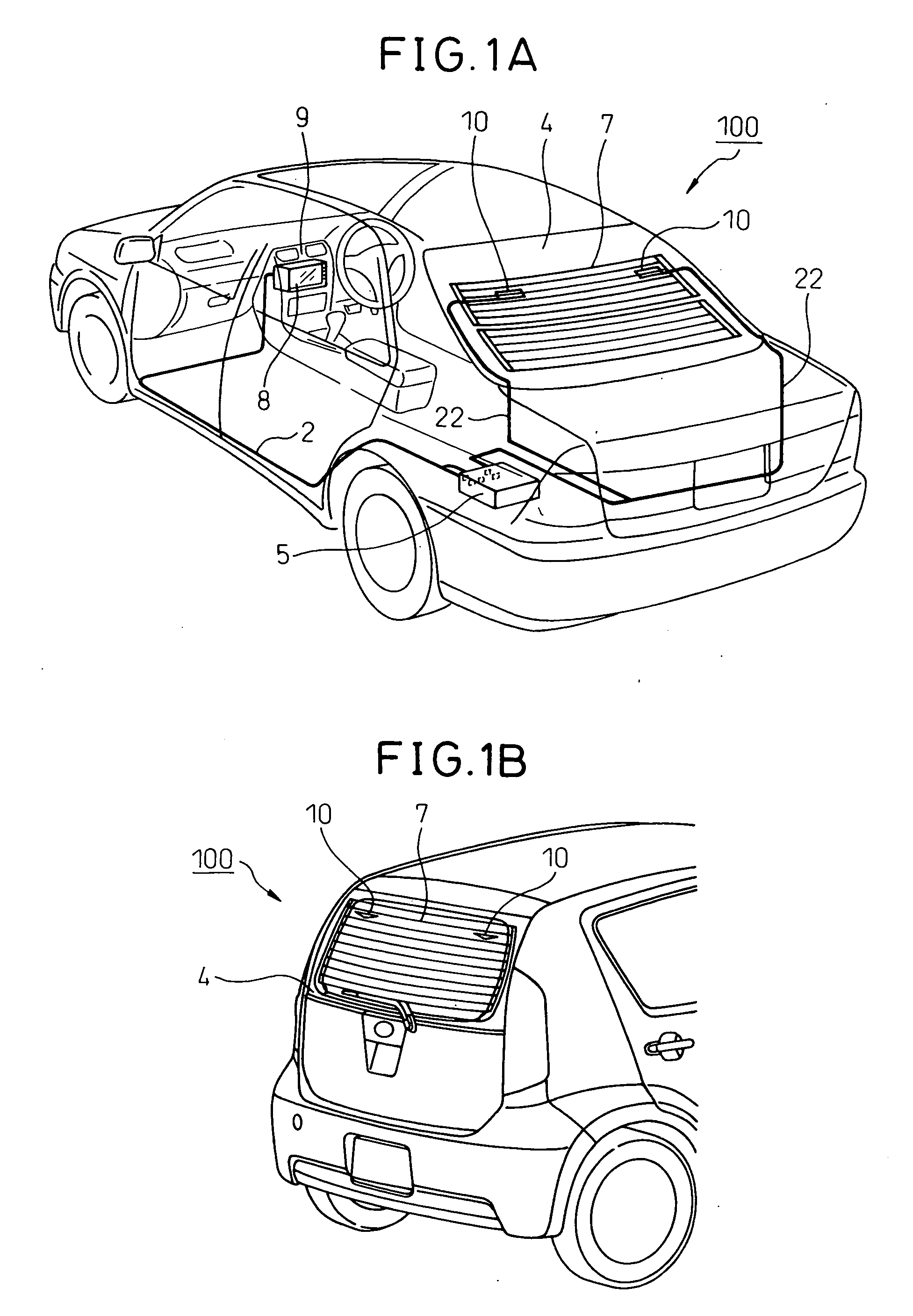

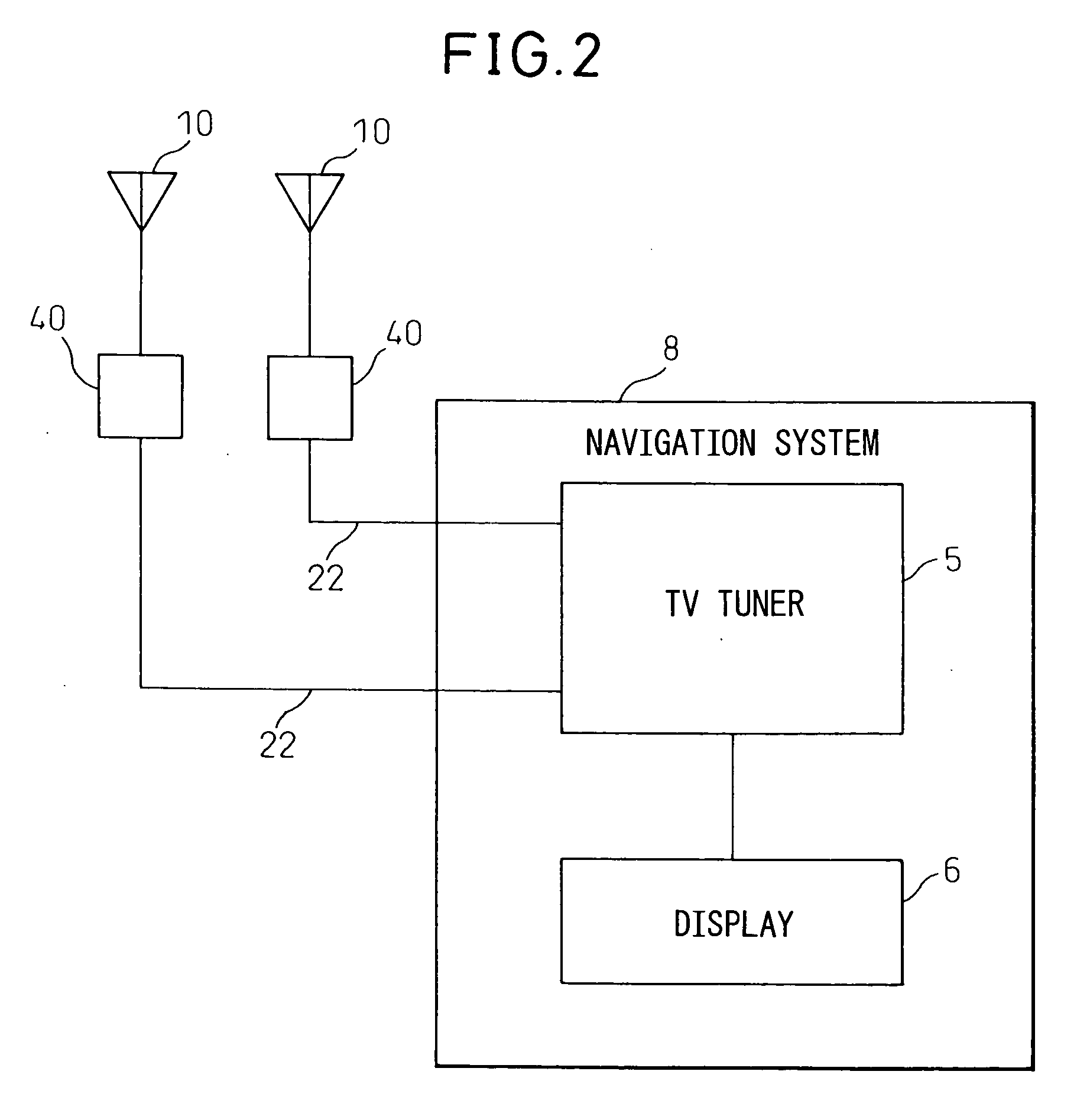

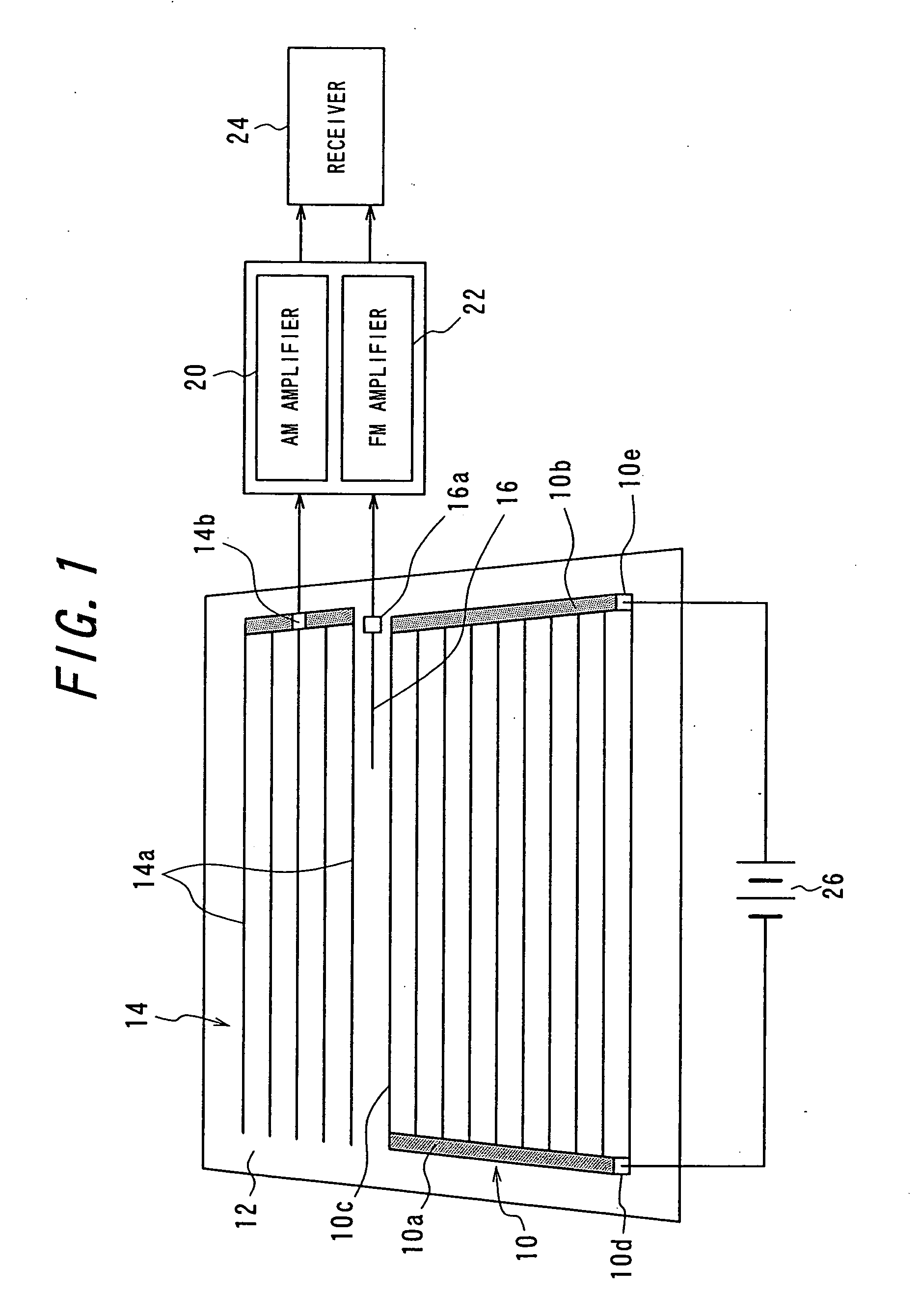

Loop antenna attached to rear window of vehicle

InactiveUS20070120756A1Without impairing performanceLittle degradation of performanceAntenna adaptation in movable bodiesLoop antennasAntenna elementDefogger

A loop antenna able to be mounted on the rear window of a vehicle provided with a defogger, that is, a loop antenna to be mounted on a rear window provided with a defogger having electrodes arranged in the vertical direction at the two ends and a plurality of electrical heating wires bridging the electrodes in the horizontal direction, wherein an antenna element forming a loop is made polygonal in shape, two power feed terminals of the loop antenna are provided at positions a predetermined distance away from the midpoint of the bottom of the antenna element, constituted by one side, in the vertical direction, a distance between the power feed terminals and bottom is formed smaller than the distance between adjoining electrical heating wires of the defogger, and the loop antenna is mounted on the rear window between the adjoining electrical heating wires. The polygonal shape may be a triangular shape.

Owner:FUJITSU GENERAL LTD

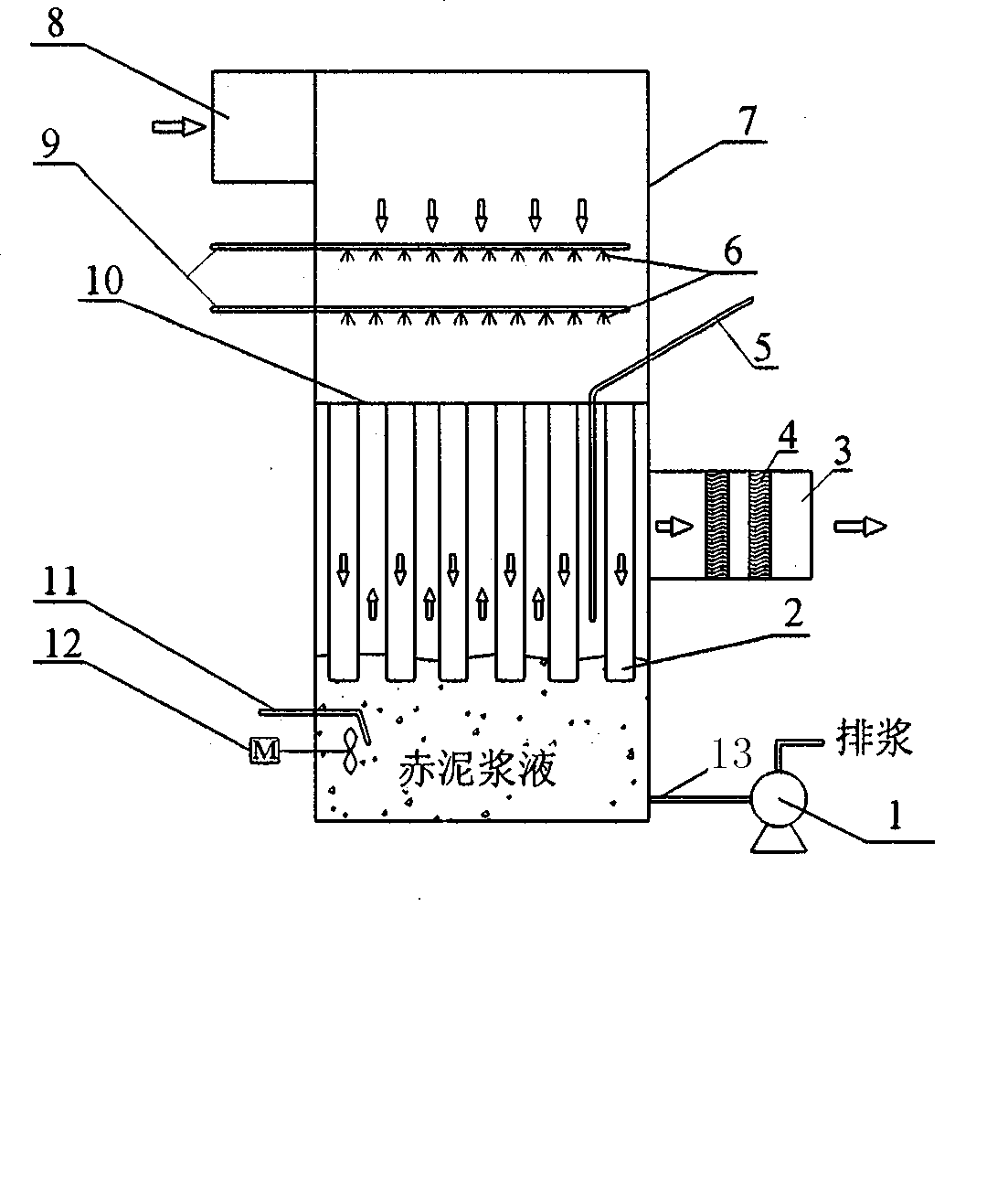

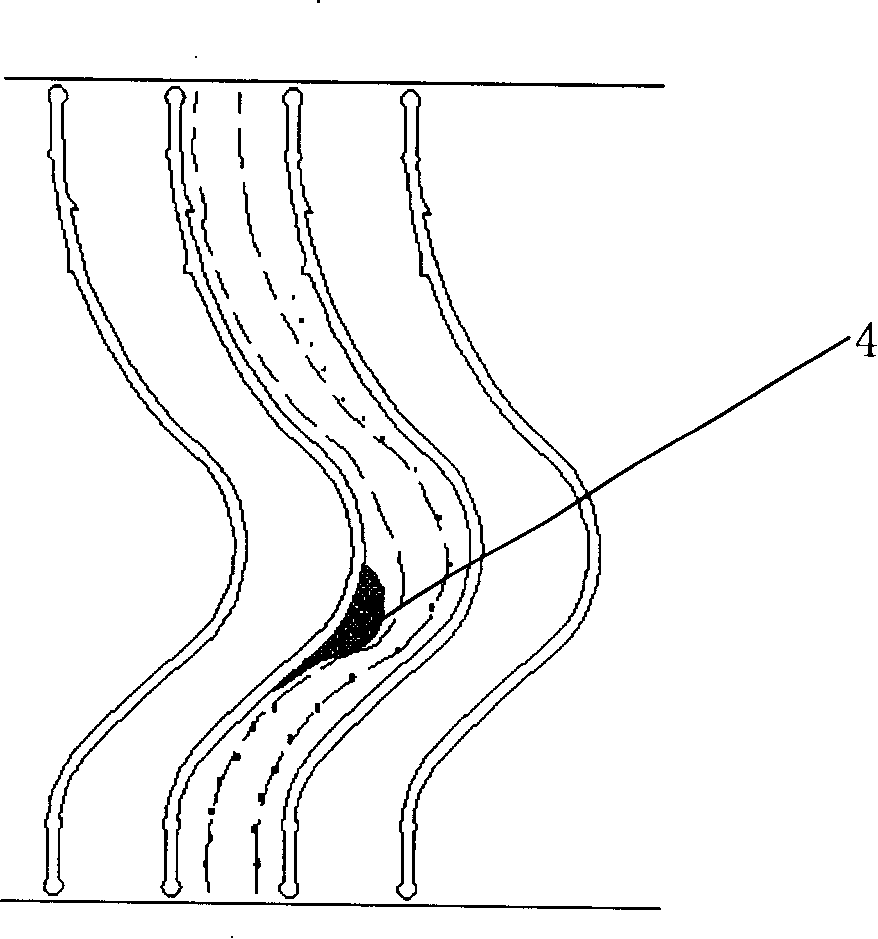

Bubble tower as desulfurizer and use thereof

The invention provides a bubble tower that is used for removing acid gas in pollution gas. The bubble tower includes: a tower body (7); an air inlet (8) that is set on the tower body for leading into pollution gas; one layer or multi-layer spraying mains (9) located below the air inlet for spraying liquid, wherein, multiple nozzles are set on each spraying main; a clapboard (10) located below the spraying mains; a spraying tube (2) that is located below the clapboard and one end is immerged into liquid; a supplying liquid tube (5) that passes through the clapboard and one end is located below the clapboard for adding or supplying liquid; a defogger (4) that is set on middle / down part of the tower body and connects with the tower body side wall; an air outlet (3) that is set behind the defogger for removing purified gas; an oxidizing wind tube (11) that one end is immerged into liquid for leading into oxidizing gas; a beater (12) for beating liquid; a discharge liquid tube that is set under the tower body for discharging liquid in tower, the discharge liquid tube is communicated with a slurry pump (1). The invention also provides uses of the bubble tower for removing SO2, SO3, HF, HCL or other acid gas or other mixer in pollution gas, wherein, red mud is used as absorbent.

Owner:BEIJING BOOTES ELECTRIC POWER SCI & TECH

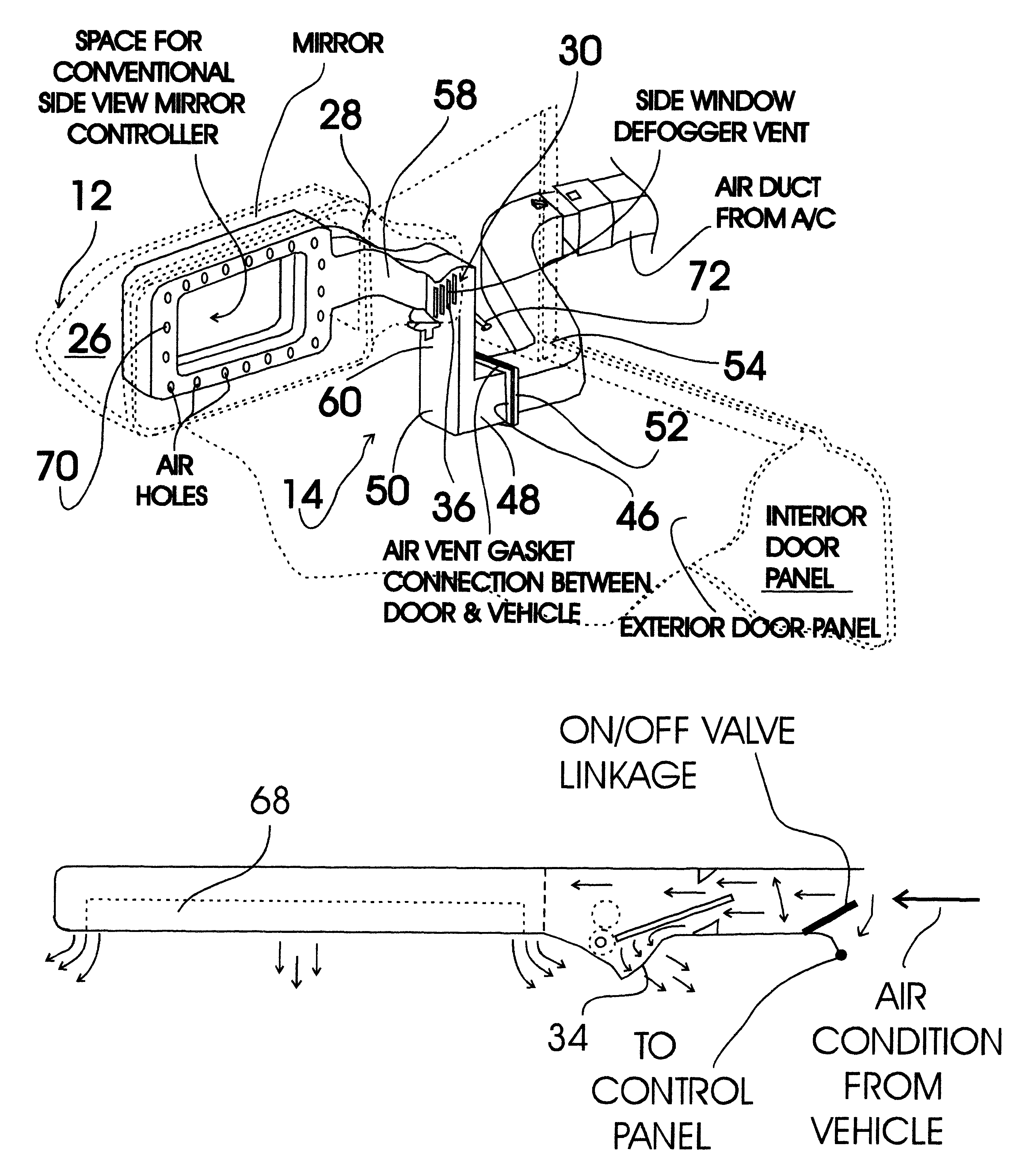

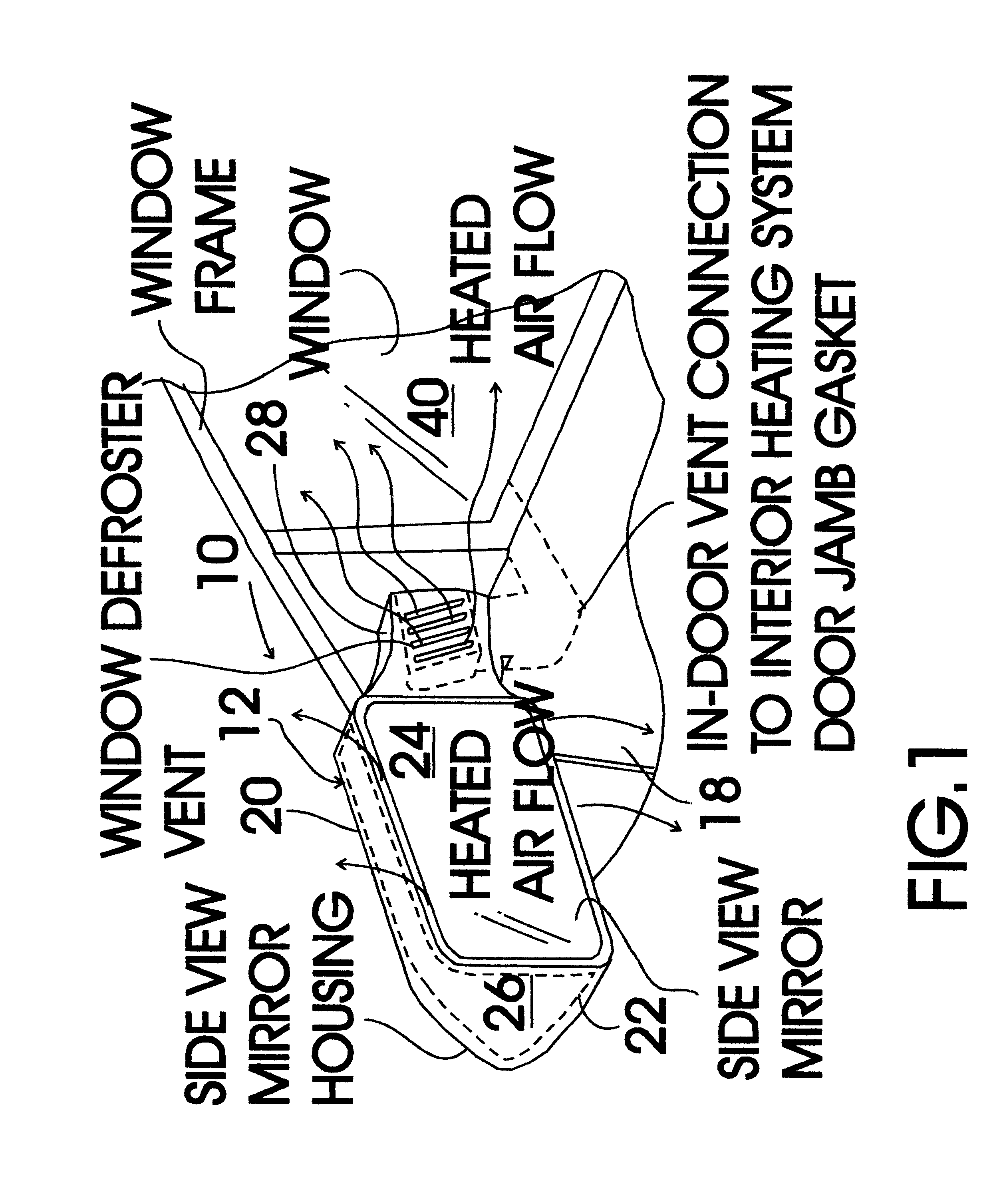

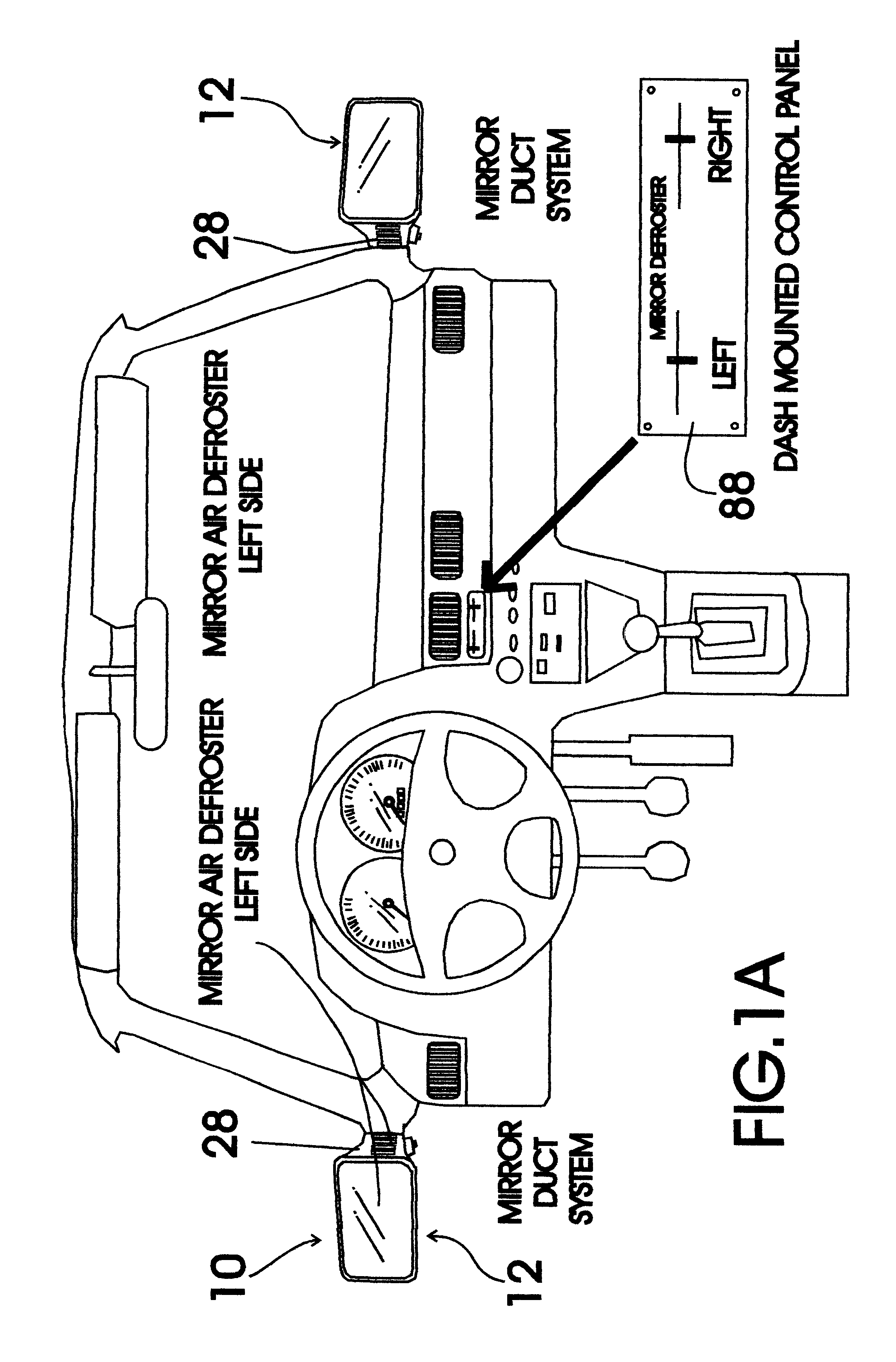

Exterior side view mirror and side window defogger system

InactiveUS6267664B1Appropriate proportionAir-treating devicesVehicle heating/cooling devicesEngineeringDefogger

A system including a defrosting mechanism in the form of an air stream directed against the side view mirror of a vehicle as well as an air stream directed against the side window of the vehicle adjacent to the side view mirror. The side view mirror and side window defogger system for vehicles also includes one or more adjustment mechanisms to allow the user to optimize the defogging air streams directed toward the side view mirror and the side window.

Owner:VANDALE ALPHONSE J +1

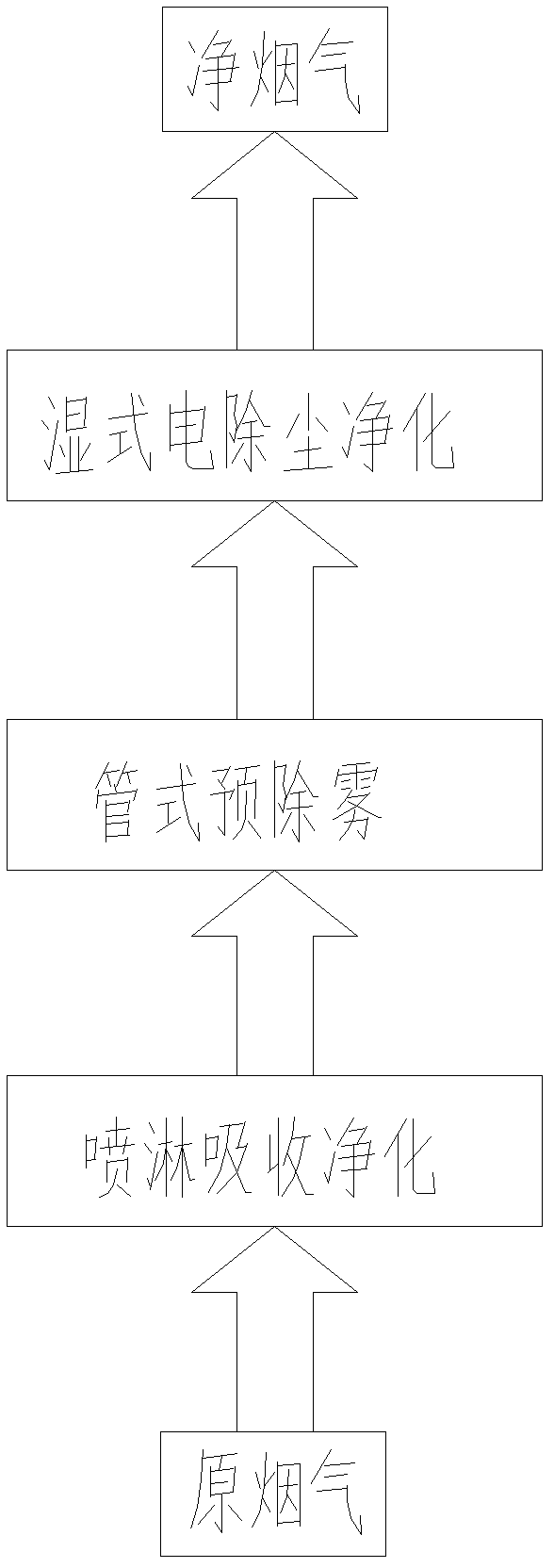

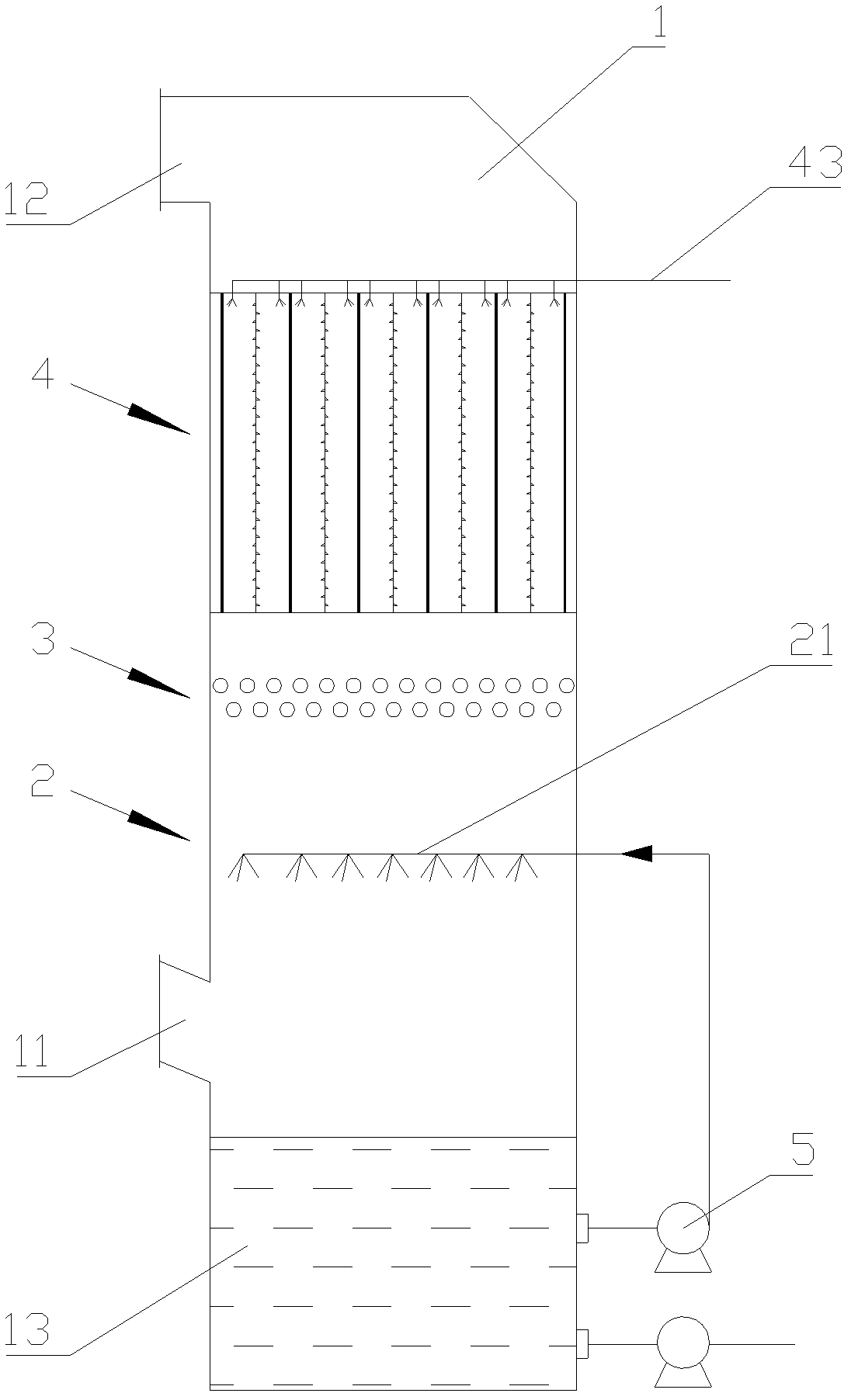

Process and device for removing combined pollutants

The invention discloses a process for removing combined pollutants. The process for removing the combined pollutants comprises the following steps of: 1) spraying, adsorbing and purifying; 2) carrying out tubular pre-defogging; and 3) carrying out wet electric dedusting for purifying. In addition, the invention also provides a device for removing the combined pollutants for implementing the process for removing the combined pollutants, wherein the device for removing the combined pollutants comprises a removal tower of which the bottom is provided with a smoke inlet and the top is provided with a smoke outlet, a desulfurization spraying layer, a tubular defogger and an electric dust catcher are orderly arranged between the smoke inlet and the smoke outlet from bottom to top in the removal tower, and a slurry pond for storing limestone slurry is arranged under the smoke inlet. According to the invention, three process steps are integrated in one removal tower, so that a top defogger in the traditional desulfurizing tower is omitted, PM2.5 tiny dust and SO3 acid mist aerosol are removed efficiently and a 'gypsum rain' phenomenon is avoided effectively.

Owner:浙江菲达脱硫工程有限公司 +1

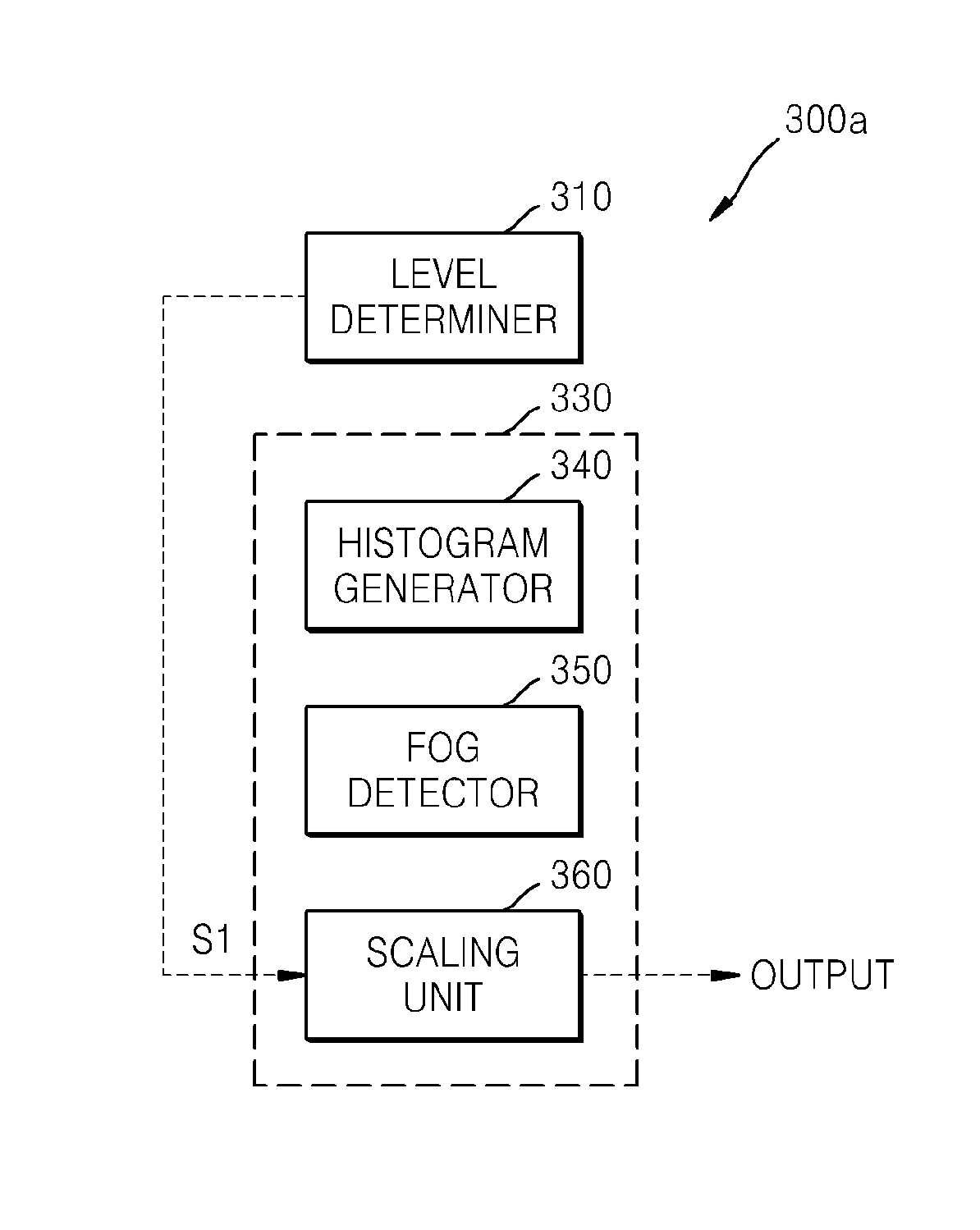

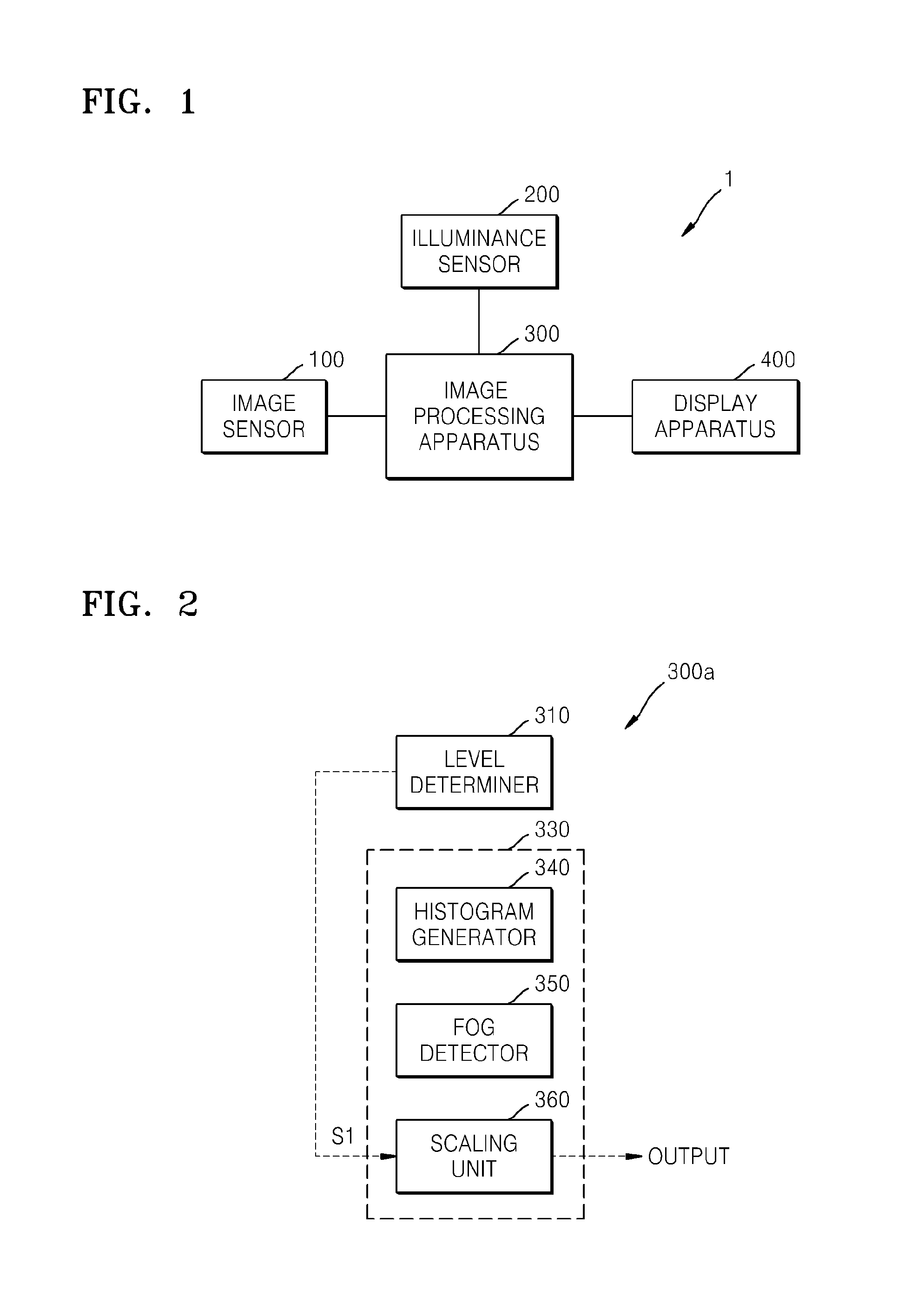

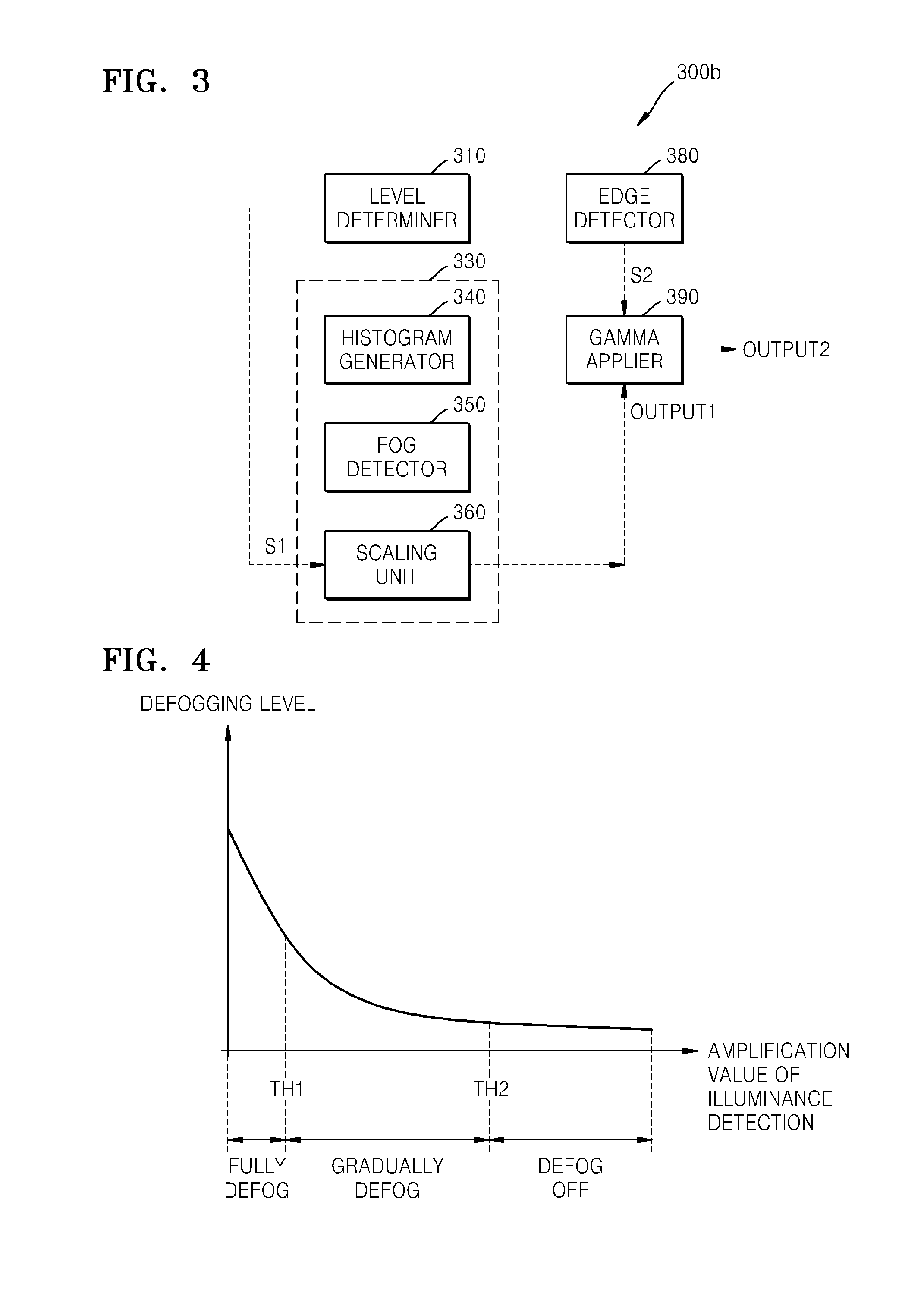

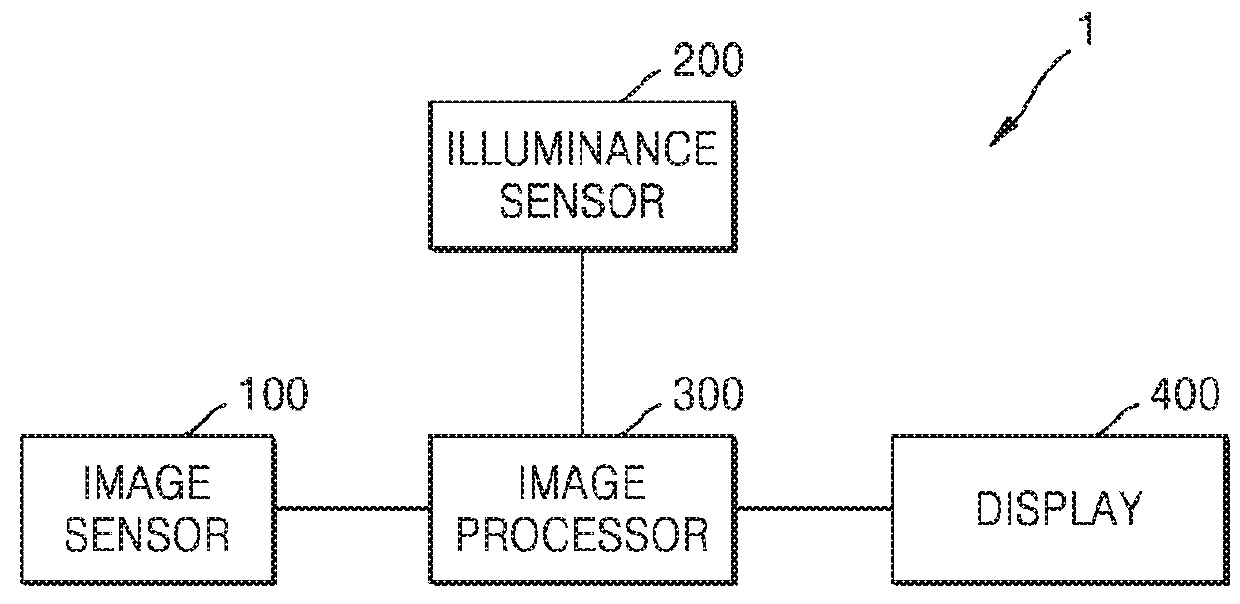

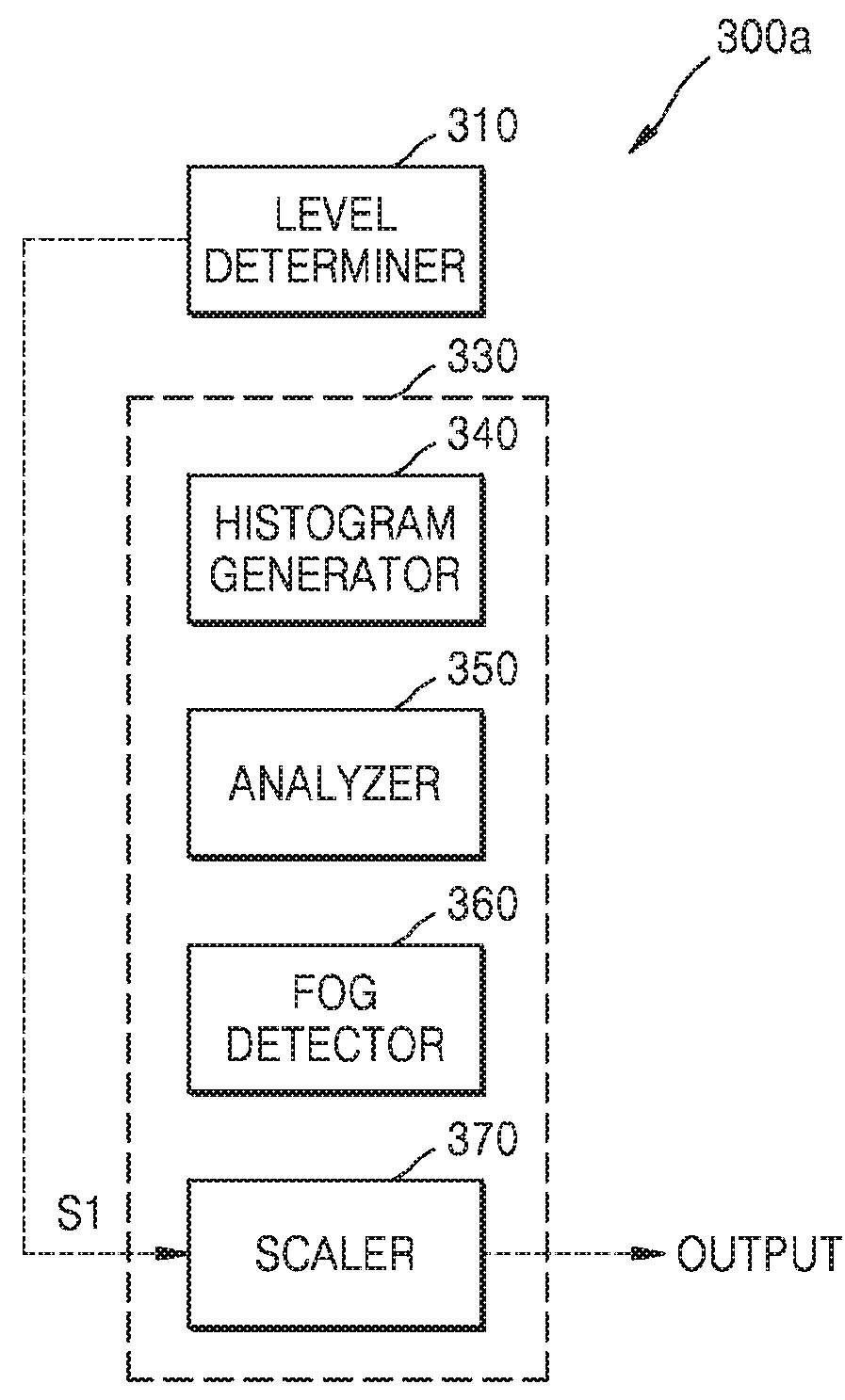

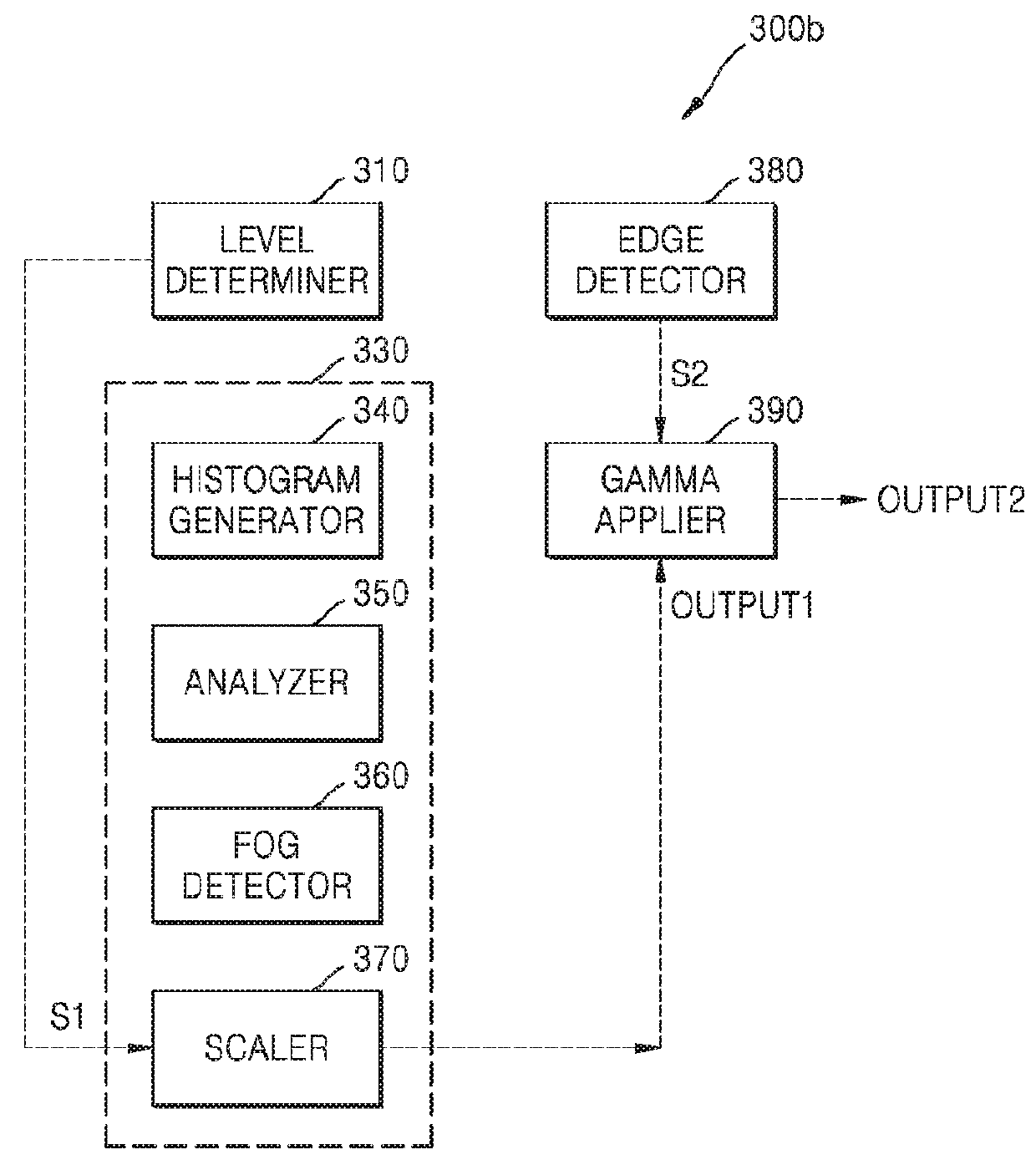

Defogging system and defogging method

ActiveUS20150279011A1Lower Level RequirementsIncrease contrastImage enhancementImage analysisIlluminanceHistogram

Provided are a defogging system and a defogging method. The defogging system includes: an illuminance sensor configured to detect a surrounding illuminance; a level determiner configured to determine a defogging level of the input image based on the detected surrounding illuminance; and a defogger configured to determine a fog state of the input image based on a histogram of the input image, and adaptively defog the input image according to the determined fog state and defogging level.

Owner:VISIONEXT CO LTD +1

Malodorous gas and industrial waste gas purifying treatment device

InactiveCN103521049AEfficient removalStrong combinationDispersed particle separationHigh concentrationToxic industrial waste

The invention relates to a malodorous gas and industrial waste gas purifying treatment device, and belongs to the technical field of environment-protection devices. The device is characterized in that: in an UV photolysis device, a throttle communicates with an inlet of an UV photolysis device box through a defogger; an outlet of the UV photolysis device box communicates with an inlet of a spraying deodorizing tower through a centrifugal induced draft fan; and an UV lamp is fixed in the UV photolysis device box through a support. In the spraying deodorizing tower, the bottom of the spraying deodorizing tower is a water tank body; the middle part of the spraying deodorizing tower is a filling material zone; an agent-spraying device nozzle and a deodorizing device are sequentially arranged on the upper part of the spraying deodorizing tower; an air-discharge pipe is arranged on the top of the spraying deodorizing tower; and the agent-spraying device nozzle communicates with an acid-alkali tank through a circulation pump. The device has the advantages that: 1, the device has high odor-removing effect, wherein a treatment efficiency can be higher than 99%; 2, the process is simple, device operation is simple and convenient, and special management is not needed; 3, the device has high adaptability, and can be adapted to high concentrations; and also the running of the device is stable and reliable; 4, running cost is low; and 5, the device causes no secondary pollution residue; malodorous substances are converted into H2O, CO2, and the like through the photolysis device, such that environment-protection and modern management requirements are satisfied.

Owner:吉林省拓达环保设备工程有限公司

Defog system and defog method

A defog system and a defog method are provided. The defog system includes an illuminance sensor configured to detect ambient illuminance, and at least one processor to implement a level determiner configured to determine a defog level of an input image based on the ambient illuminance. The at least one processor further implements a defogger configured to determine whether to defog the input image based on skewness and kurtosis of a histogram of the input image, and, in response to the defogger determining to defog the input image, determine a fog condition of the input image based on a cumulative probability of the histogram, and defog the input image based on the defog level.

Owner:HANWHA TECHWIN CO LTD

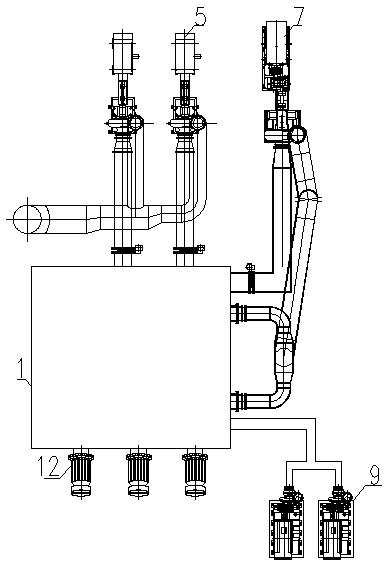

Method and system for deeply removing dust from flue gas after wet desulfurization

InactiveCN106621680ASolve the particle size is too smallSolve the problem that is difficult to chargeGas treatmentAuxillary pretreatmentElectricityParticulates

The invention discloses a method and system for deeply removing dust from flue gas after wet desulfurization. The method comprises the following steps: performing coagulation on PM2.5 fine particles in flue gas after desulfurization to magnify the particles by steam, and then performing wet electrostatic precipitation. The system for deeply removing dust from flue gas disclosed by the invention comprises a phase change condensing chamber, a condensing defogger and an electrostatic precipitator, wherein the phase change condensing chamber is abutted against the flue gas desulfurization system; a plurality of steam nozzles are arranged in the phase change condensing chamber; the steam nozzles are connected with the steam system through a steam distribution pipe; the electrostatic precipitator is abutted against the outlet of the phase change condensing chamber; and the condensing defogger is arranged on a passage between the phase change condensing chamber and the electrostatic precipitator. The method and system for deeply removing dust from flue gas after wet desulfurization disclosed by the invention effectively solve the problem that the particle sizes of inlet particulate matters of a wet electrostatic precipitator is small, so that the charging is difficult, the dust removal efficiency is improved and deep dust removal is realized.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

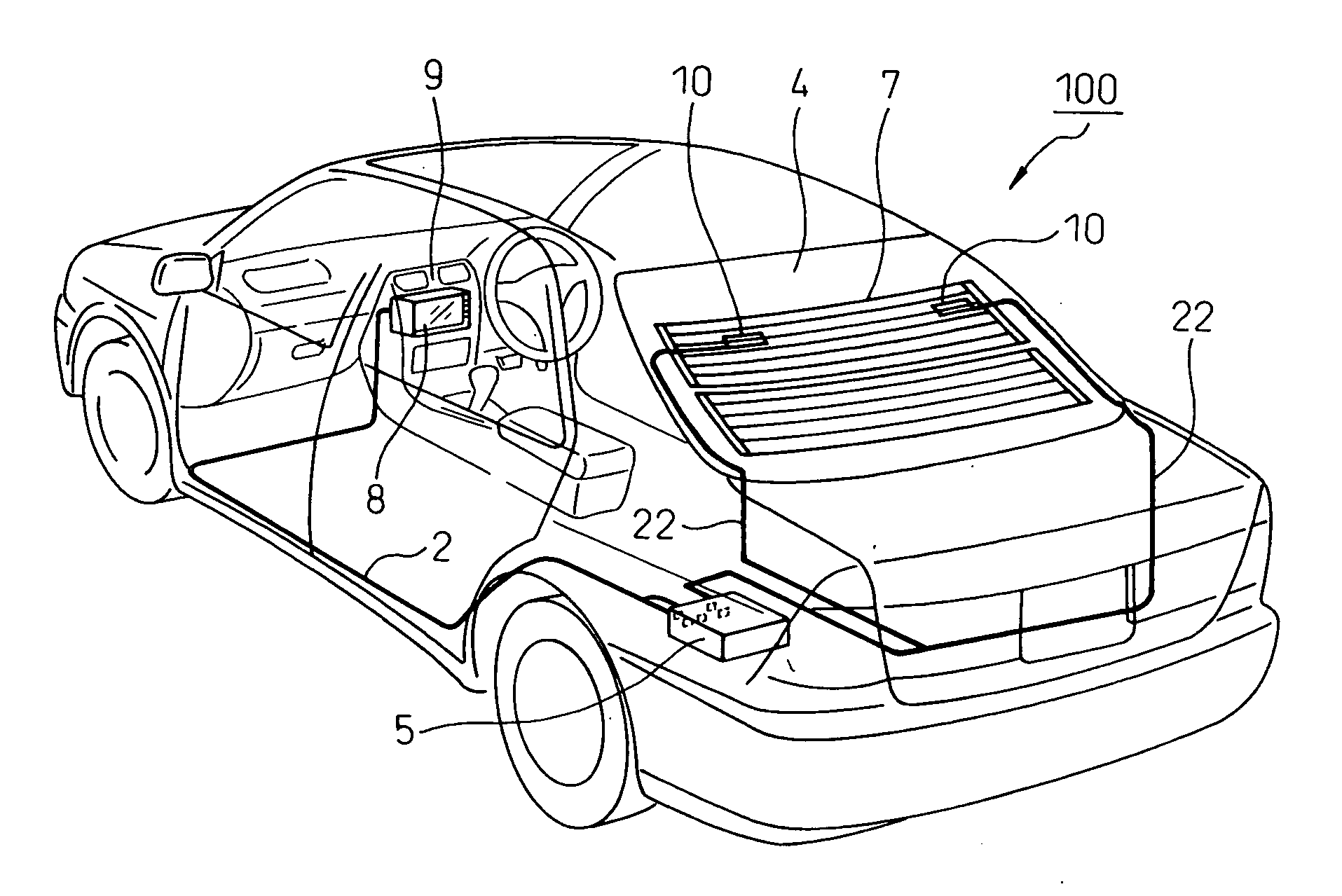

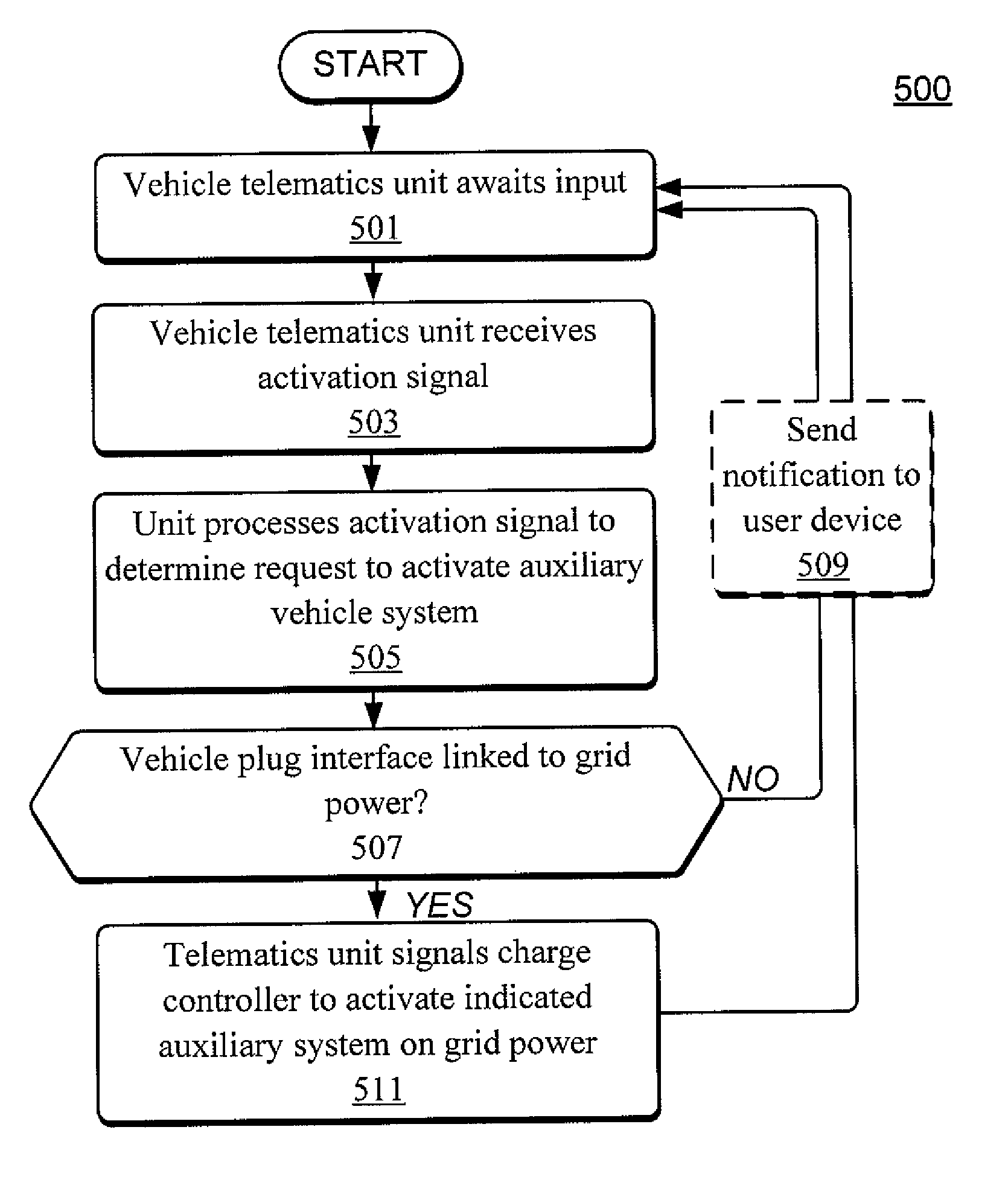

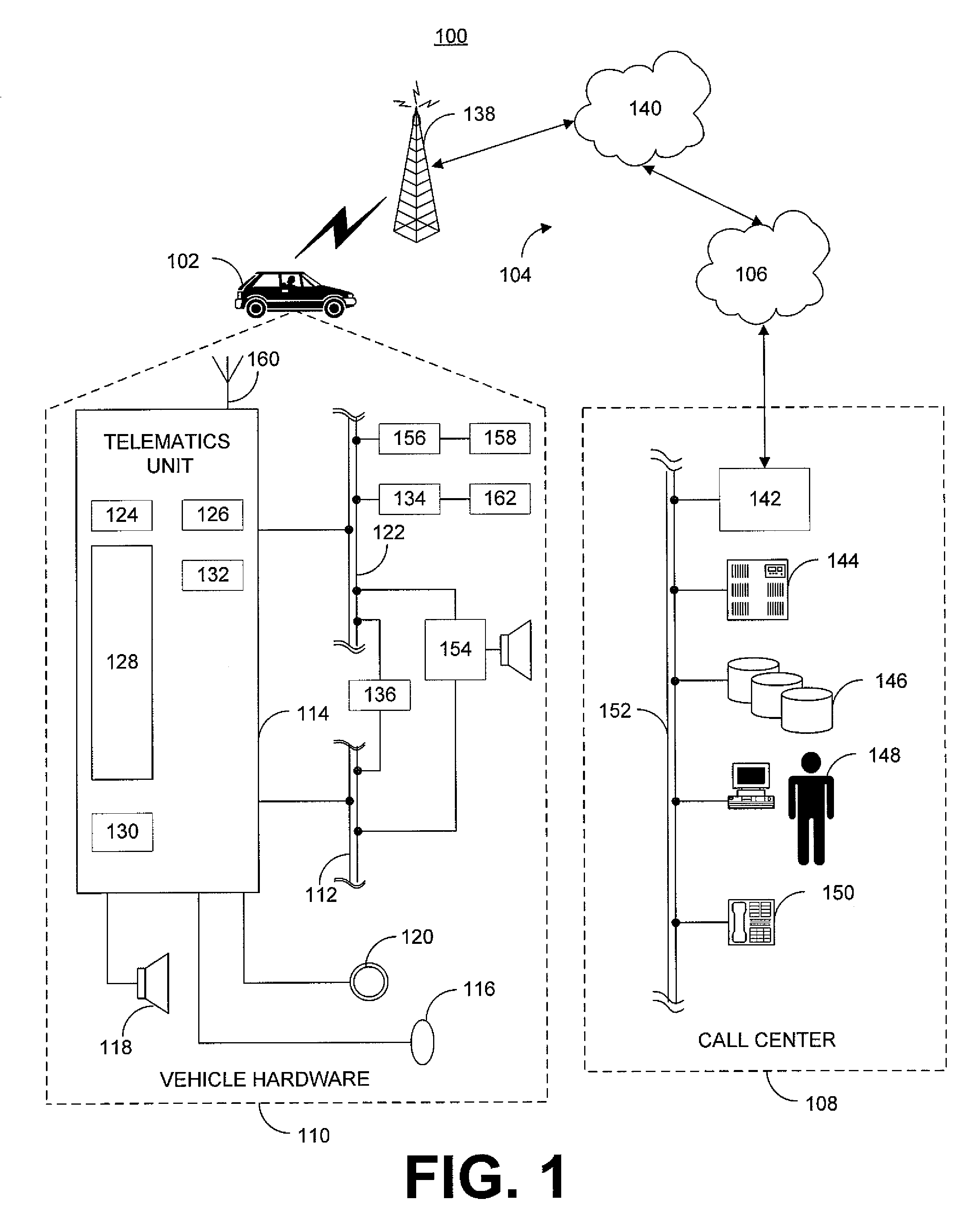

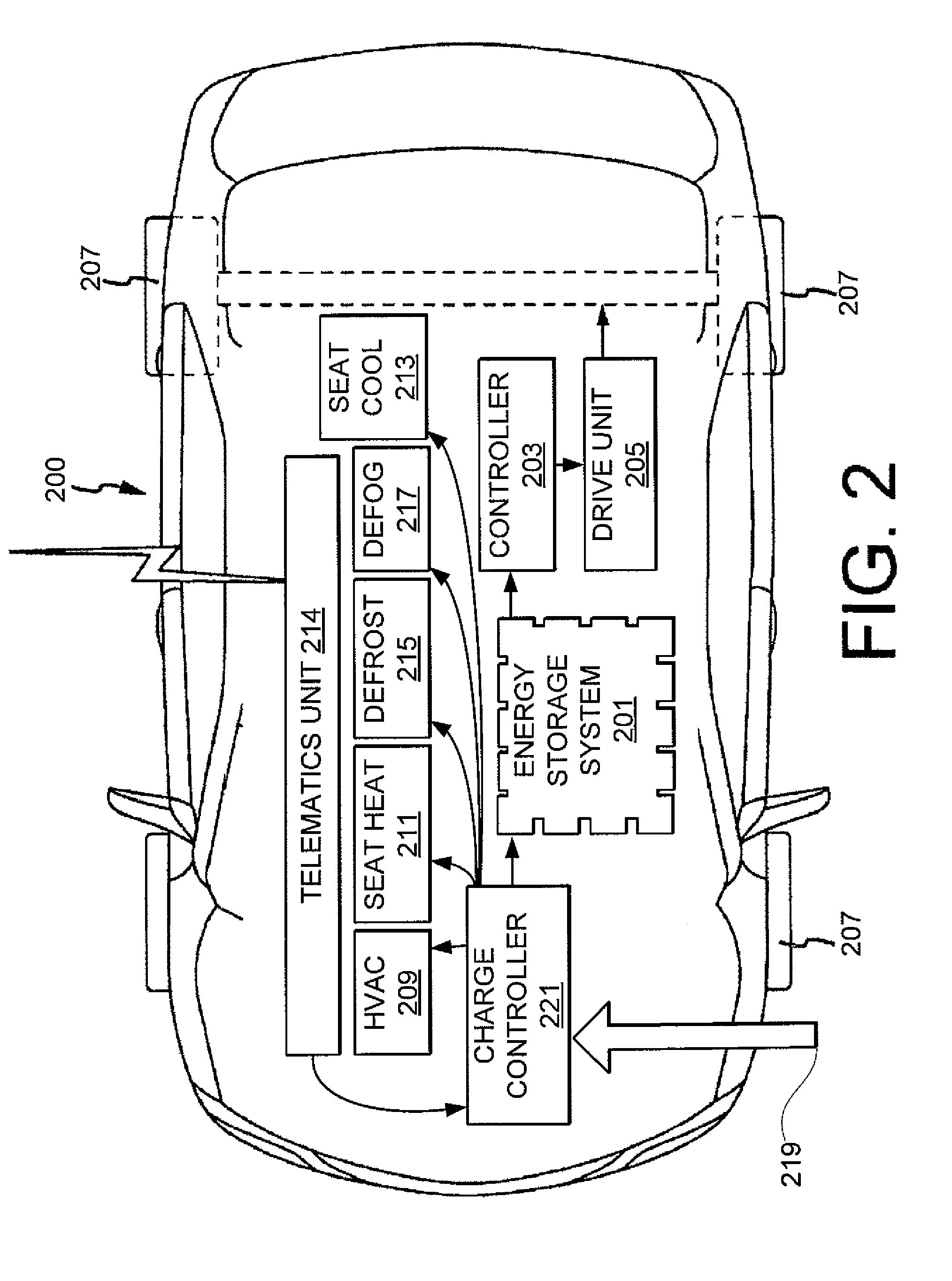

Remote trigger of an alternate energy source to power a vehicle system

ActiveUS8326470B2Increase rangeDigital data processing detailsRailway vehiclesOn boardElectric power

The described method and system improve electric-power driving range for electric vehicles, i.e., electric-only, hybrid electric, and other vehicles that draw electrical power from an on-board storage system for propulsion and auxiliary functions such as HVAC, defroster, defogger, seat heaters, seat coolers, etc. The described system uses an alternate energy source off-board of the vehicle, e.g., the municipal power grid, to power and run vehicle systems while the vehicle is plugged into the grid. The system also provides the user with the ability to remotely choose via an electronic medium or telematics system among multiple available alternate sources of energy to power vehicle systems. The user may remotely trigger the use of the selected source and may also remotely activate and deactivate vehicle systems powered by the alternative energy source.

Owner:GENERA MOTORS LLC

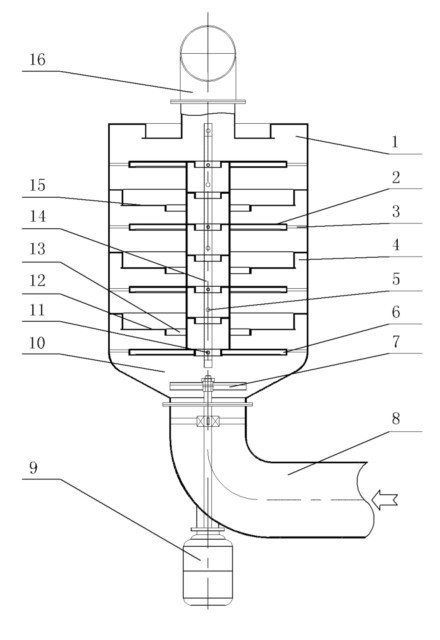

Defroster

InactiveCN101209387AIncrease contact areaImprove defogging efficiencyDispersed particle separationBiochemical engineeringDefogger

The invention provides a defogger which comprises a cleaning unit which is used for cleaning the defogger, a defogging unit which is used for separating air and liquid, a fixing unit which is used for fixing the defogging unit, wherein, the defogging unit is an array or a plurality of arrays of blades, and the blade takes an annular shape. The defogger of the invention reduces secondary entrainment and improves defogging efficiency; meanwhile, the defogger has simple structure and convenient installation, maintenance and operation.

Owner:SHANGHAI HUOLIN ENG PLASTICS

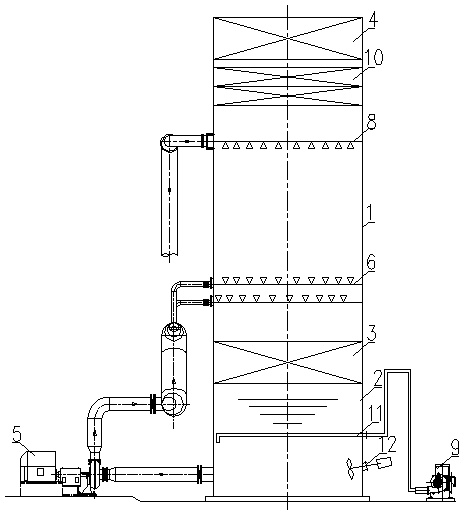

Desulfurizing tower for wet fuel gas desulfurizing system

ActiveCN101259373AExtended service lifePlay the role of current equalizationDispersed particle separationFlue gasSlurry

The invention discloses a desulfurization tower used for a wet flue gas desulfurization system which includes a tower body (1); the bottom part of the tower body (1) is provided with a slurry pool (2); a first spraying layer (3) and a second spraying layer (4) are arranged above the serum pool (2) and spaced from up to down; a waste gas inlet (5) is arranged on the wall of the tower body (1) between the slurry pool (2) and the first spraying layer (3); a defogger (6) is arranged above the second spraying layer (4); the top part of the tower body (1) is provided with a waste gas outlet (7); a supporting plate (8) is arranged between the first spraying layer (3) and the second spraying layer (4); the surface of the supporting plate (8) is provided with a through hole; a plurality of hollow balls (9) are arranged on the supporting plate (8); a limit plate (10) is arranged below the second spraying layer (4) and a through hole is arranged on the limit plate (10). The desulfurization tower not only has high desulfurization efficiency, but also can be suitable for the desulfurization of the high flue gas generated by the techniques of making steel and making iron, etc.

Owner:HUATIAN ENG & TECH CORP MCC

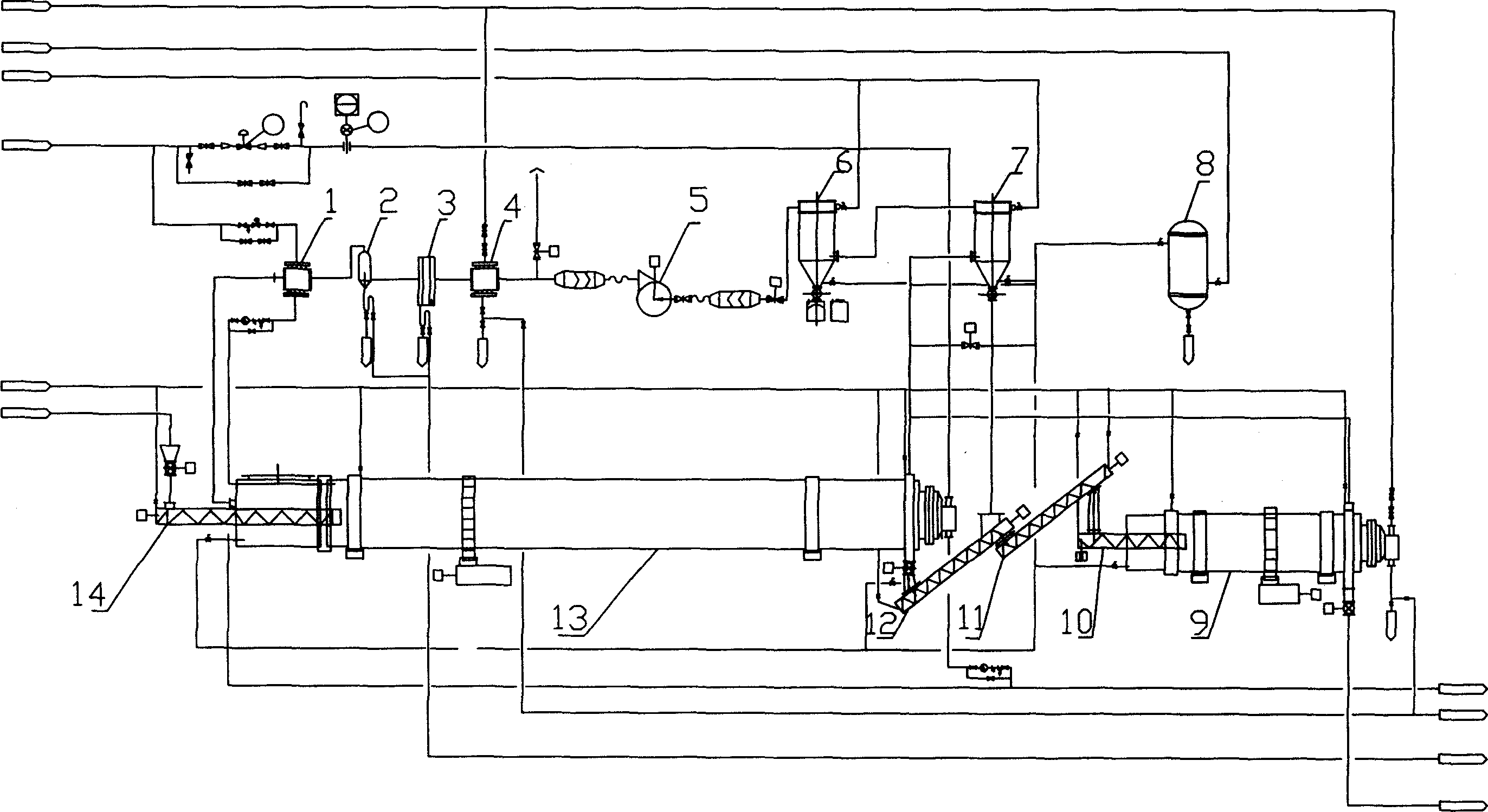

High volatile coal dust rotary drying process

ActiveCN1928477AEasy to operateReduce dosageDrying solid materials with heatDrying machines with non-progressive movementsBaghouseCoal dust

The invention relates to a high volatile drying technique for coal powder. Steam is thermal source and steam pipe is contacted with wet coal powder directly. Dry and hot coal powder, in which water is vaporized out by heating, is sent to revolving cooling machine by auger and is cooled in the revolving cooling machine, regular coal powder is sent into coal powder tank; water vaporized is carried out by watercarrying nitrogen. Watercarrying nitrogen is heated and sent into drier and passes through first grade fabric filter with partial coal powder; in first grade fabric filter most coal powder is settled down and residual coal powder is settled down through second grade fabric filter; almost clean nitrogen is sent into table cooler and cooled by cycle air-blower, water is eliminated by defogger and the nitrogen is sent back to nitrogen tank with closed cycle. In the whole drying process it is the nitrogen circumstance entirely so that the explosive risk is avoided and by closed cycle the cost is saved with little nitrogen amount.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Moisture sensor and/or defogger with Bayesian improvements, and related methods

ActiveUS9371032B2Hazard reductionReduce distractionsMathematical modelsVehicle headlampsEngineeringMoisture sensor

In certain example embodiments, moisture sensors, defoggers, etc., and / or related methods, are provided. More particularly, certain example embodiments relate to moisture sensors and / or defoggers that may be used in various applications such as, for example, refrigerator / freezer merchandisers, vehicle windows, building windows, etc. When condensation or moisture is detected, an appropriate action may be taken (e.g., actuating windshield wipers, turning on a defroster, triggering the heating of a merchandiser door or window, etc.). Bayesian approaches optionally may be implemented in certain example embodiments in an attempt to improve moisture detection accuracy. For instance, models of various types of disturbances may be developed and, based on live data and a priori information known about the model, a probability of the model being accurate is calculated. If a threshold value is met, the model may be considered a match and, optionally, a corresponding appropriate action may be taken.

Owner:GUARDIAN GLASS LLC

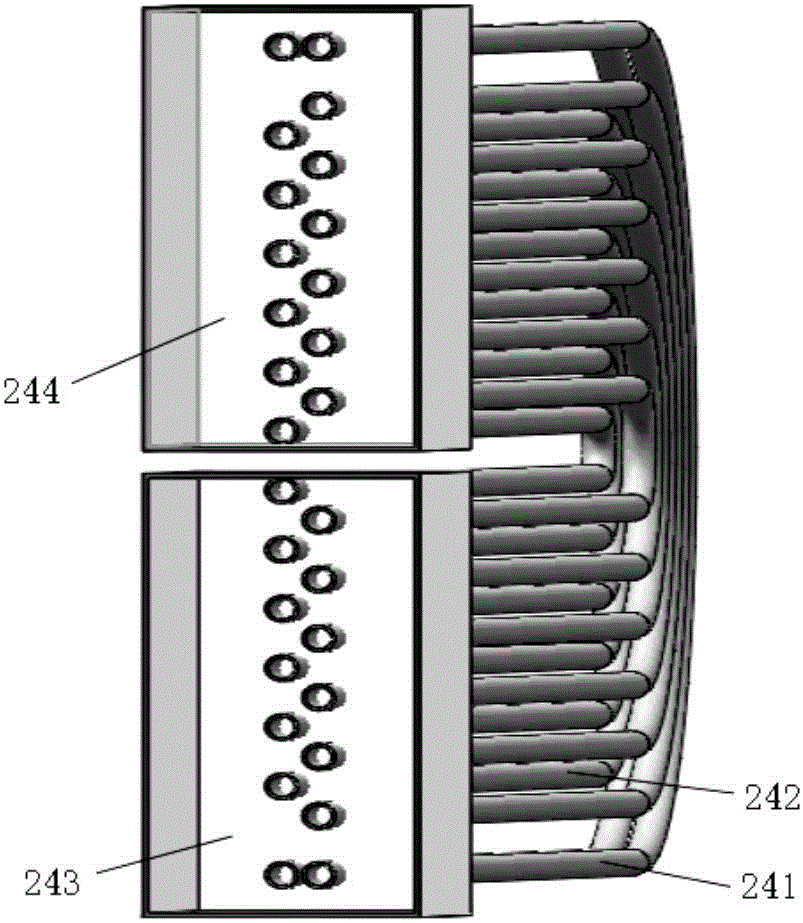

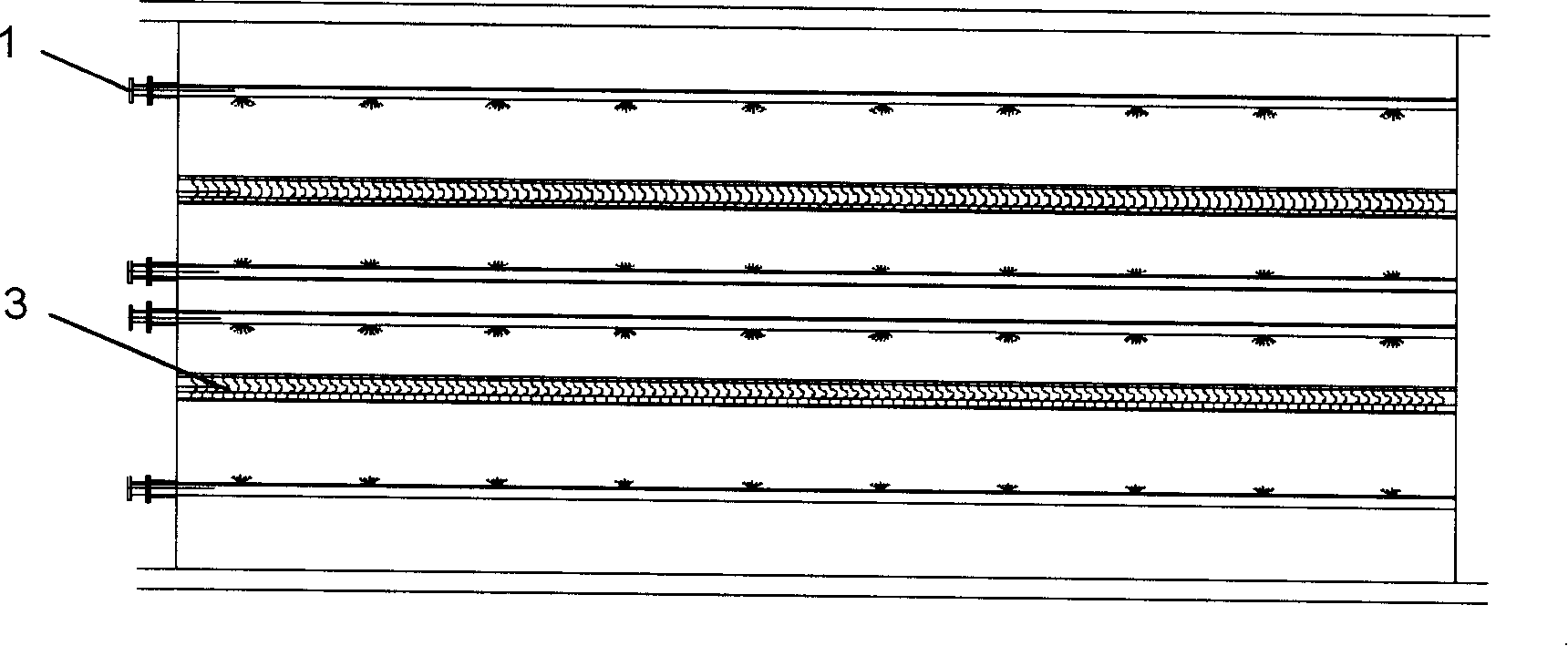

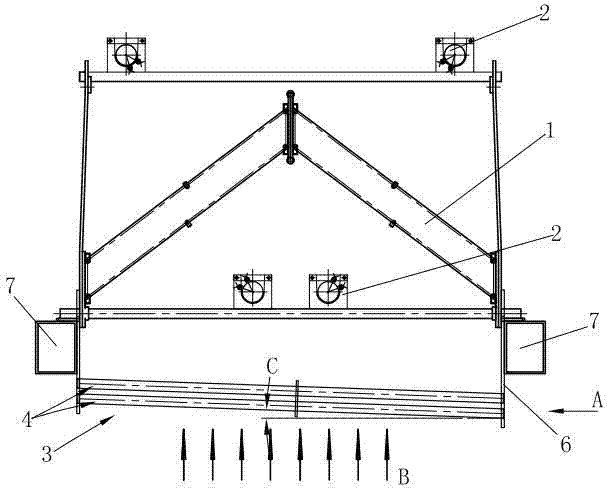

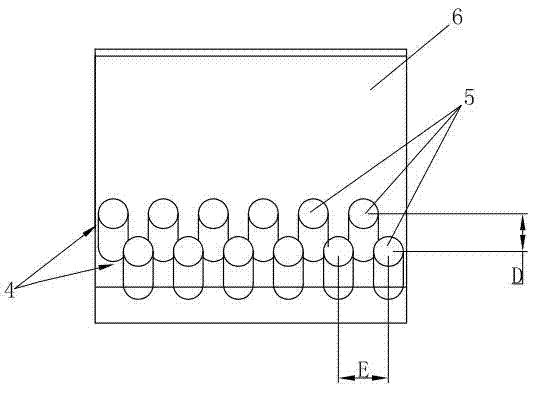

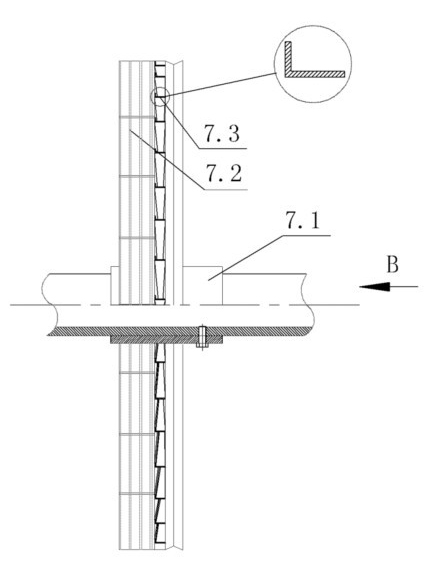

Defogging device for absorption tower

InactiveCN102527193AReduce processingImprove defogging efficiencyDispersed particle separationEngineeringTower

The invention relates to a defogging device for an absorption tower. The defogging device comprises at least one of a flat plate defogger, a ridge defogger or a diamond defogger, and is characterized in that a pre-defogger is arranged at the upstream position relative to the defogger in the flow direction of smoke gas and comprises at least two layers of pipe rows which are arranged in parallel, wherein the pipe rows consists of circular pipes which are arranged in parallel; the circular pipes in the two adjacent layers of pipe rows are arranged in a staggered mode; and the circular pipes in the pipe rows of the pre-defogger are tilted relative to a horizontal plane. According to the defogging device, the pre-defogger is arranged in front of the defogger, part of fog drips in the smoke gas is removed, the treatment capacity of the defogger in the rear is relieved, and smoke gas flow fields in a flue are distributed uniformly by arranging intervals of the pipe rows and intervals of the circular pipes reasonably, so that the defogging efficiency is improved, and the phenomena of carrying and gypsum rain are avoided; and aggregated water drops can be discharged quickly along the circular pipes, so that the water drops which are dripped directly are prevented from being winded up again by the smoke gas or blocking the flowing of the smoke gas.

Owner:江苏德克环保设备有限公司

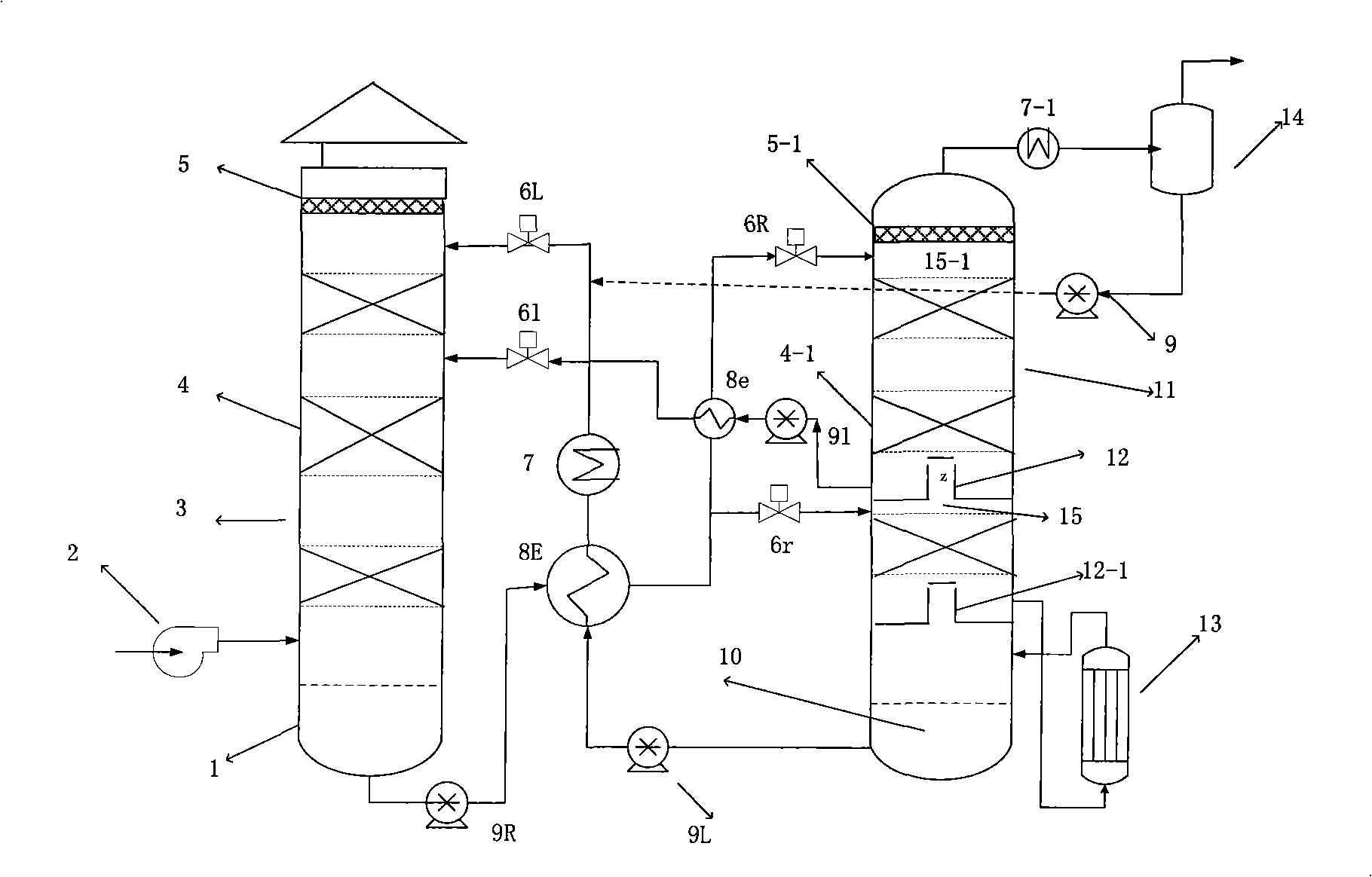

Flue gas decarbonization system of stepped absorption and regeneration

A flue gas decarbonization system of stepped absorption and regeneration belongs to the technical field of clean coal and comprises two parts of an absorption system and a regeneration system. The absorption system comprises a pregnant solution tank, an absorption tower, filling, a defogger and two barren liquor inlets; and the regeneration system comprises a regeneration tower, a barren liquor tank, two barren liquor accumulating tanks, a defogger, a solution boiler, a regeneration gas cooler, and the like. The flue gas decarbonization system adopts the new technology of two-stage absorption and stepped regeneration, can adapt to the absorption characteristic of absorbent, obviously optimizes the system, lowers the energy consumption and the electricity consumption of regeneration, and is suitable to the decarbonization of the coal-fired power plant and the chemical field.

Owner:XIAN THERMAL POWER RES INST CO LTD

In-hollow column intercrystalline ammonia process of desulfurization, recovery system and method thereof

The invention relates to a crystallization ammonia process desulfurization and recycling system in an empty tower and a method thereof, which belong to the technical field of environment-friendly equipment. The system comprises a sprinkling desulfurizing tower, a hydrocyclone, a centrifuger, and a vibrating fluidized bed dryer. The method comprises the following steps: hot flue gas enters the middle part of the sprinkling desulfurizing tower, reaches the optimal temperature for ammonia process desulphurization after being cooled by process water sprinkling at the inlet of the tower, and then is subjected to absorption by a sprinkling layer, and finally gets rid of most of free water which is removed by a defogger; clean flue gas is directly sent out by a steel chimney on the top of the sprinkling desulfurizing tower; absorption liquid in a stock tank at the lower part of the tower reaches the state of supersaturation after being subjected to circulating absorption a plurality of times, is forced to be oxidized by oxygen in air and flue gas in the bottom of the tower, and finally produces an ammonium sulphate saturated solution containing a certain amount of solid; the ammonium sulphate saturated solution containing a certain amount of solid is further concentrated by a water cyclone; the concentrated solution forms powder through the centrifuger; and after being dried by the drier, ammonium sulphate products with water content of less than 0.3% can be obtained.

Owner:北京中大能环工程技术有限公司

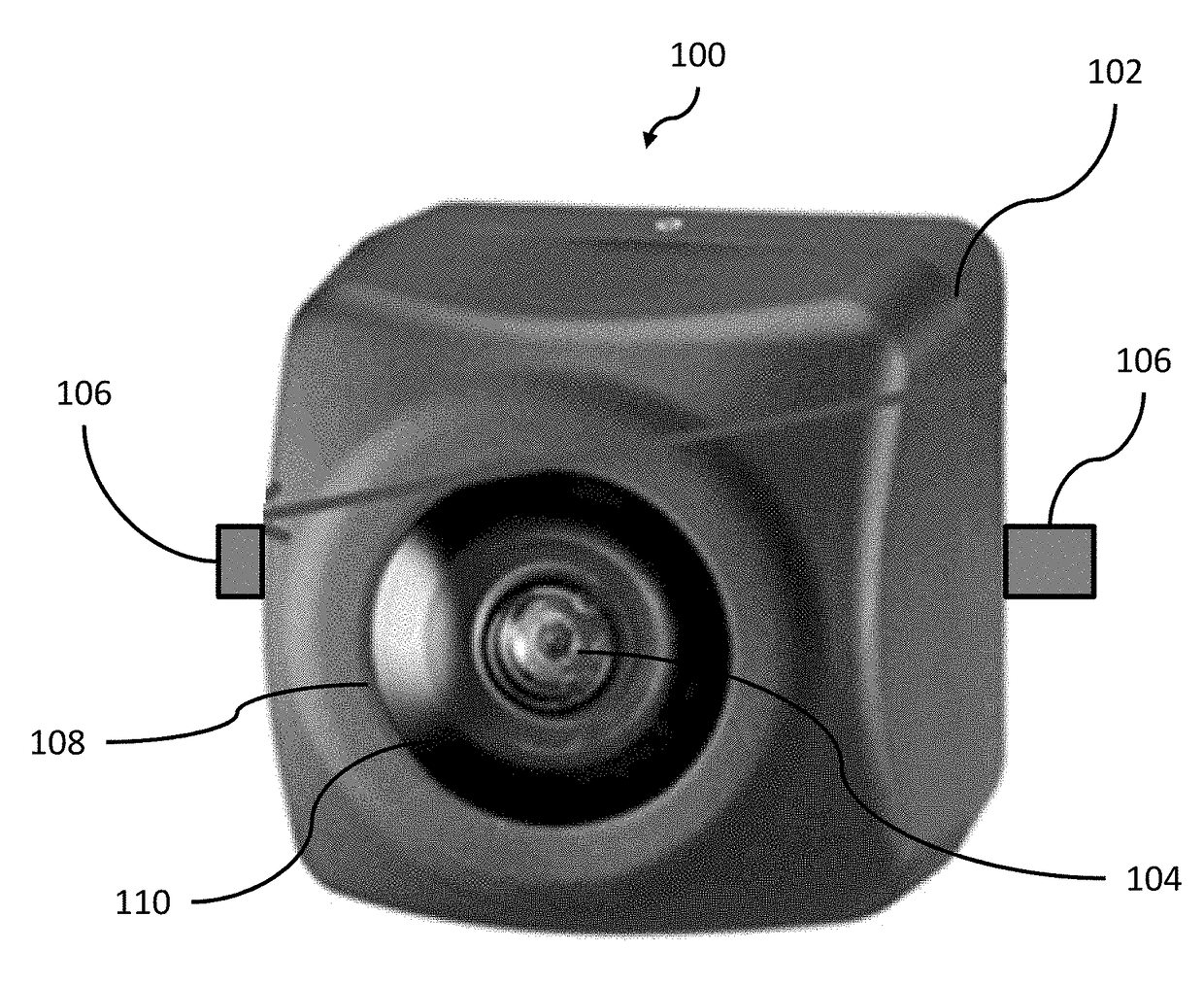

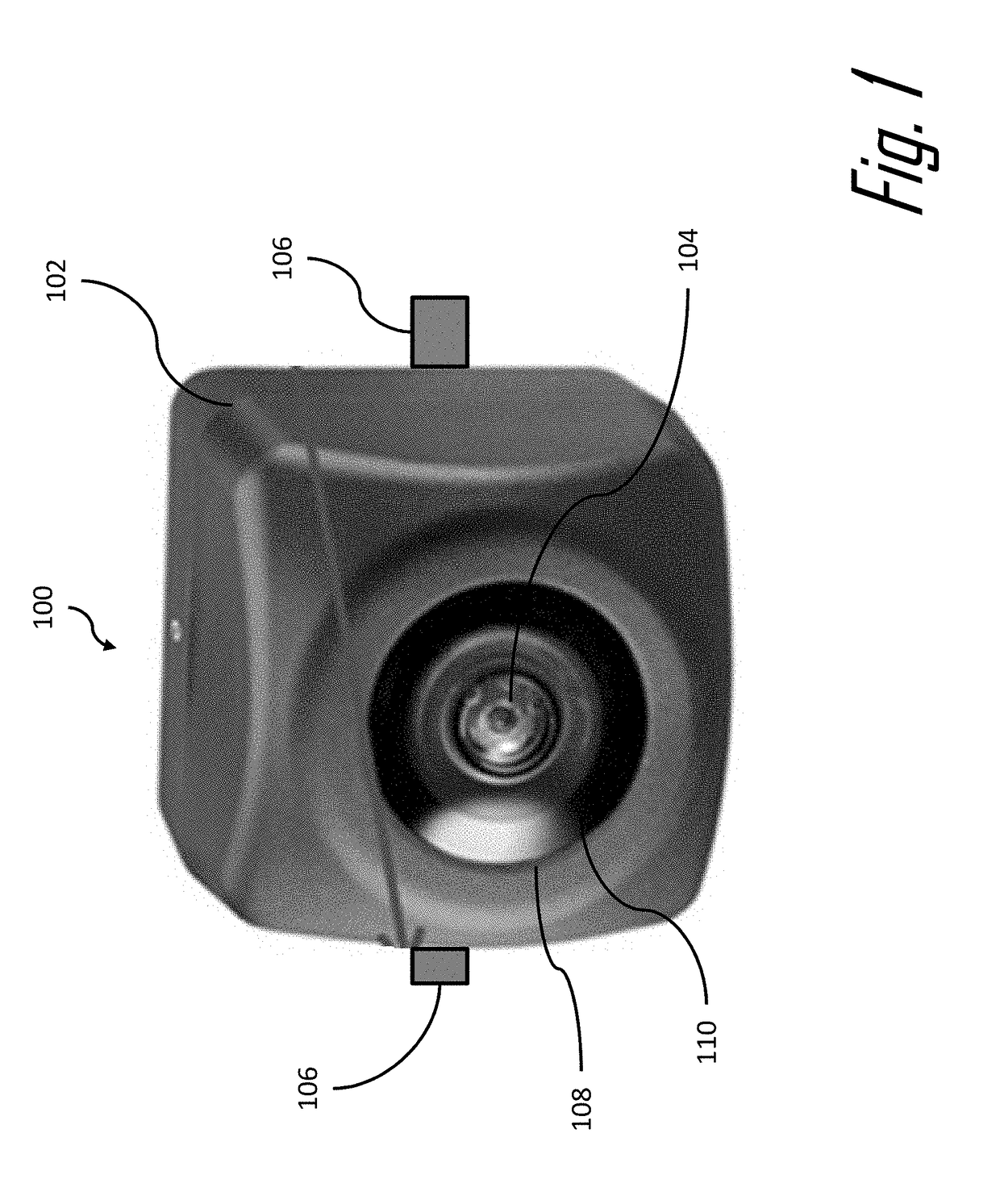

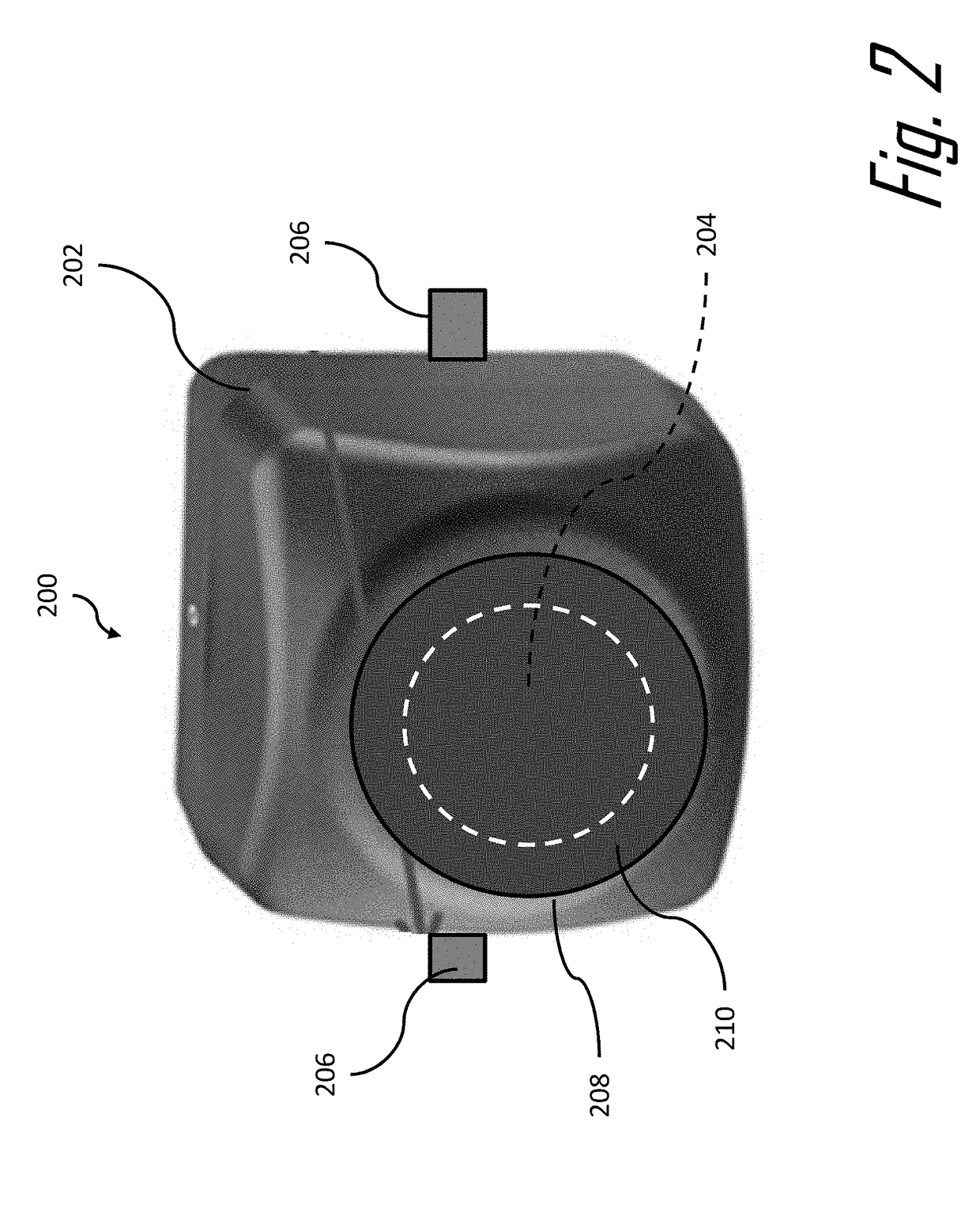

Sensor assembly with integral defroster/defogger

ActiveUS20180263082A1Wave based measurement systemsTransparent/reflecting heating arrangementsLane departure warning systemTransceiver

A sensor assembly configured for use in a motor vehicle is presented. The sensor assembly includes a sensor device such as a camera, LIDAR, RADAR, or ultrasonic transceiver, and a housing that is at least partially formed of an electrically conductive polymeric material. The housing has a pair of electrically conductive terminals connected to the electrically conductive polymeric material. The pair of electrically conductive terminals are configured to be interconnected with an electrical power supply. When the terminals are connected to the power supply, the housing heats to remove snow, ice, frost and / or condensation from the sensor assembly. The sensor assembly is suitable for use with a back-up camera, blind spot warning system, lane departure warning system, adaptive cruise control system and / or autonomous driving control system.

Owner:APTIV TECH LTD

Desulfurizing absorption tower

InactiveCN103120894AIncrease the liquid to gas ratioIncrease contact areaDispersed particle separationFlue gasContact time

The invention relates to a desulfurizing absorption tower which comprises an absorption tower; a flue gas outlet is formed in the top of the absorption tower; a tower body is provided with a flue gas inlet; a size tank is arranged on the bottom of the tower; a gas desulfurizing layer is arranged between the flue gas outlet and the flue gas inlet, and is provided with a size spraying layer and a size injecting layer below the size spraying layer; a spray nozzle of the size spraying layer is arranged downwards; the spray nozzle of the size spraying layer is arranged upwards; and flue gas is firstly in contact with the size injecting layer so as to be desulfurized after entering from the flue gas inlet, then is in contact with the size spraying layer so as to be desulfurized, and is discharged out from the flue gas outlet after fog drops in the flue gas is removed through a defogger above the spraying layer. According to the desulfurizing absorption tower, two different kinds of spraying modes are adopted for desulfurizing the flue gas; the contact area and the contact time of the flue gas and size are enlarged; the mixing degree of the flue gas and the size and the liquid-gas ratio of the absorption tower are improved; the desulfurizing efficiency is improved; and the pollution to the environment is lowered.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG

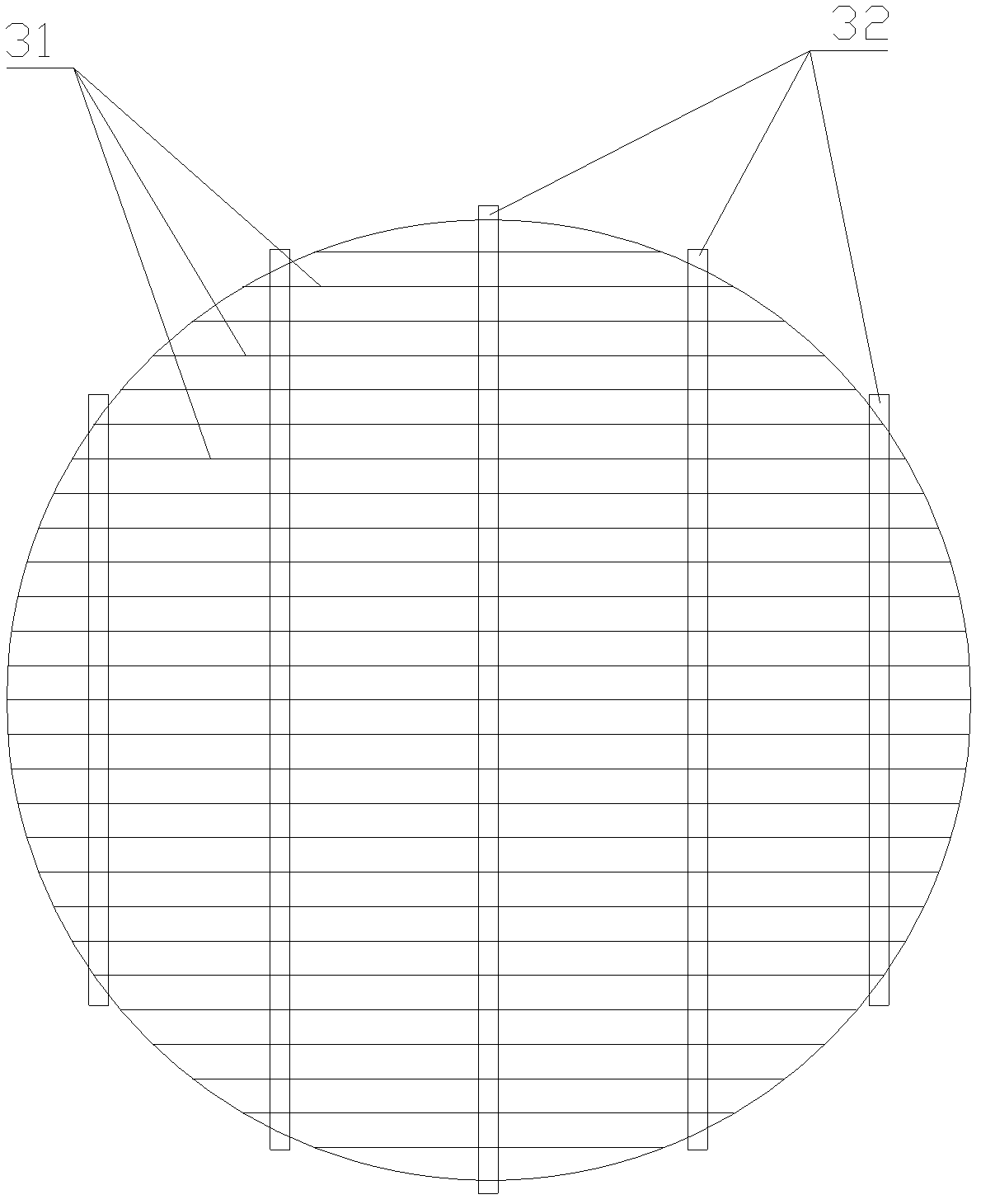

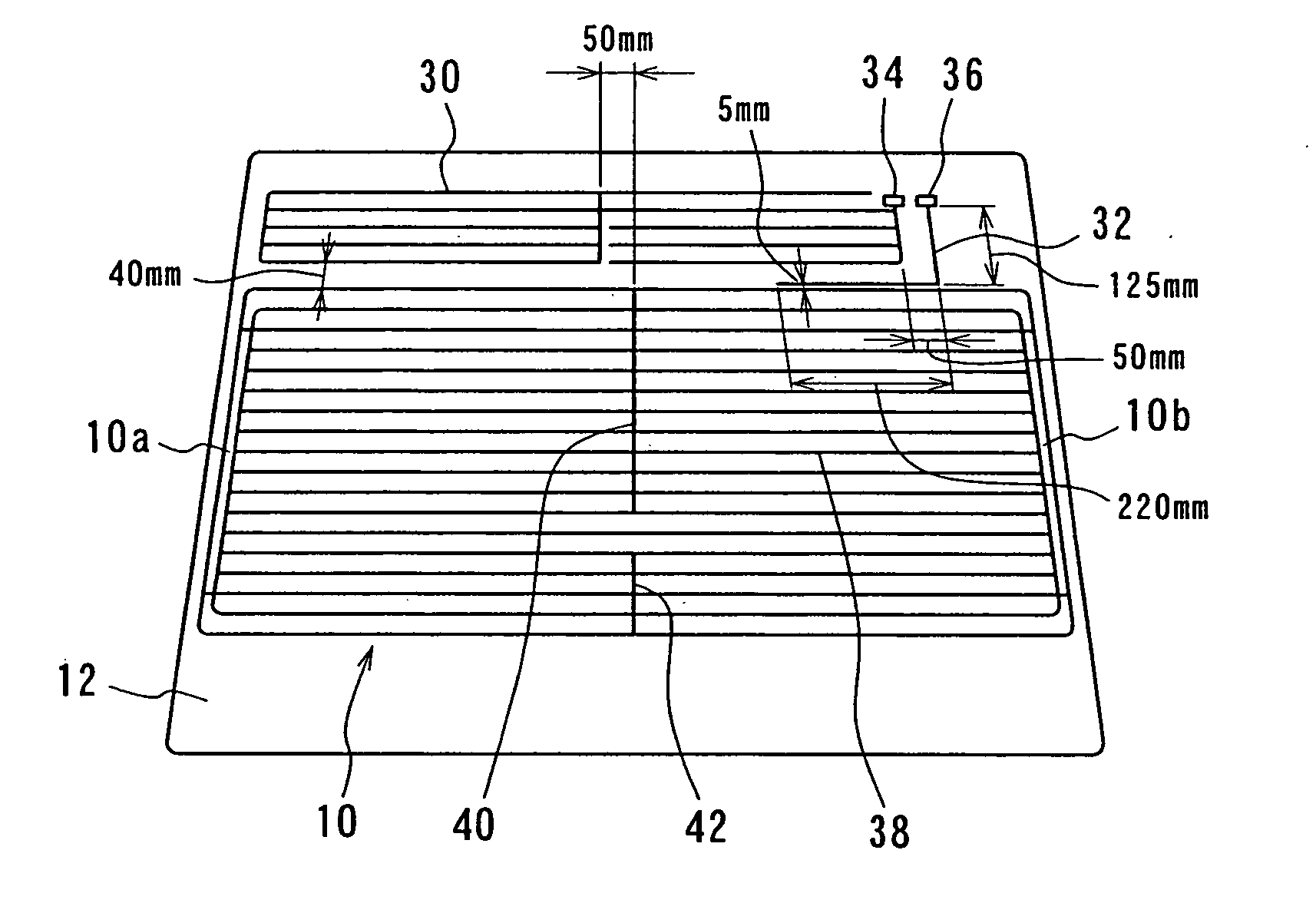

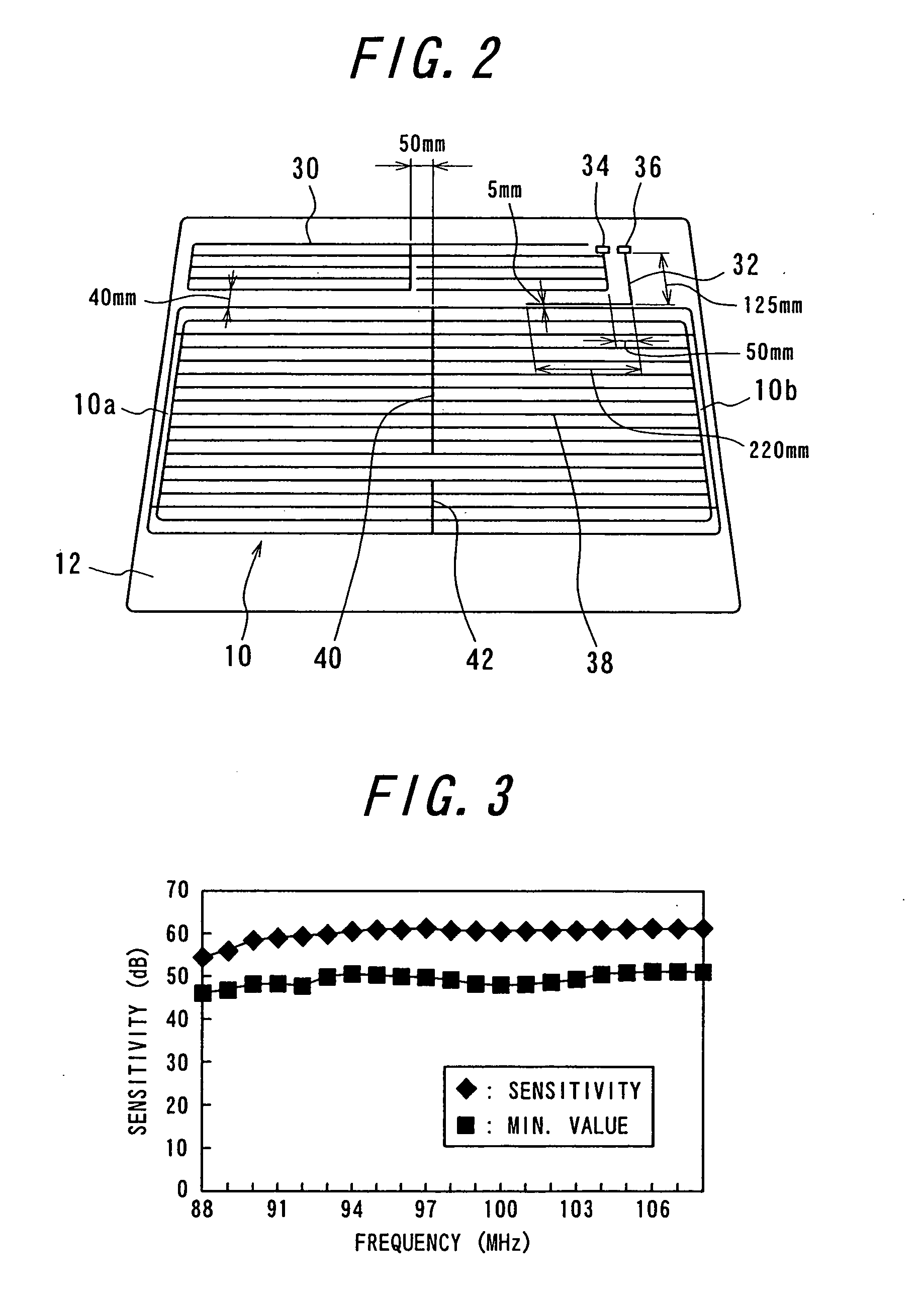

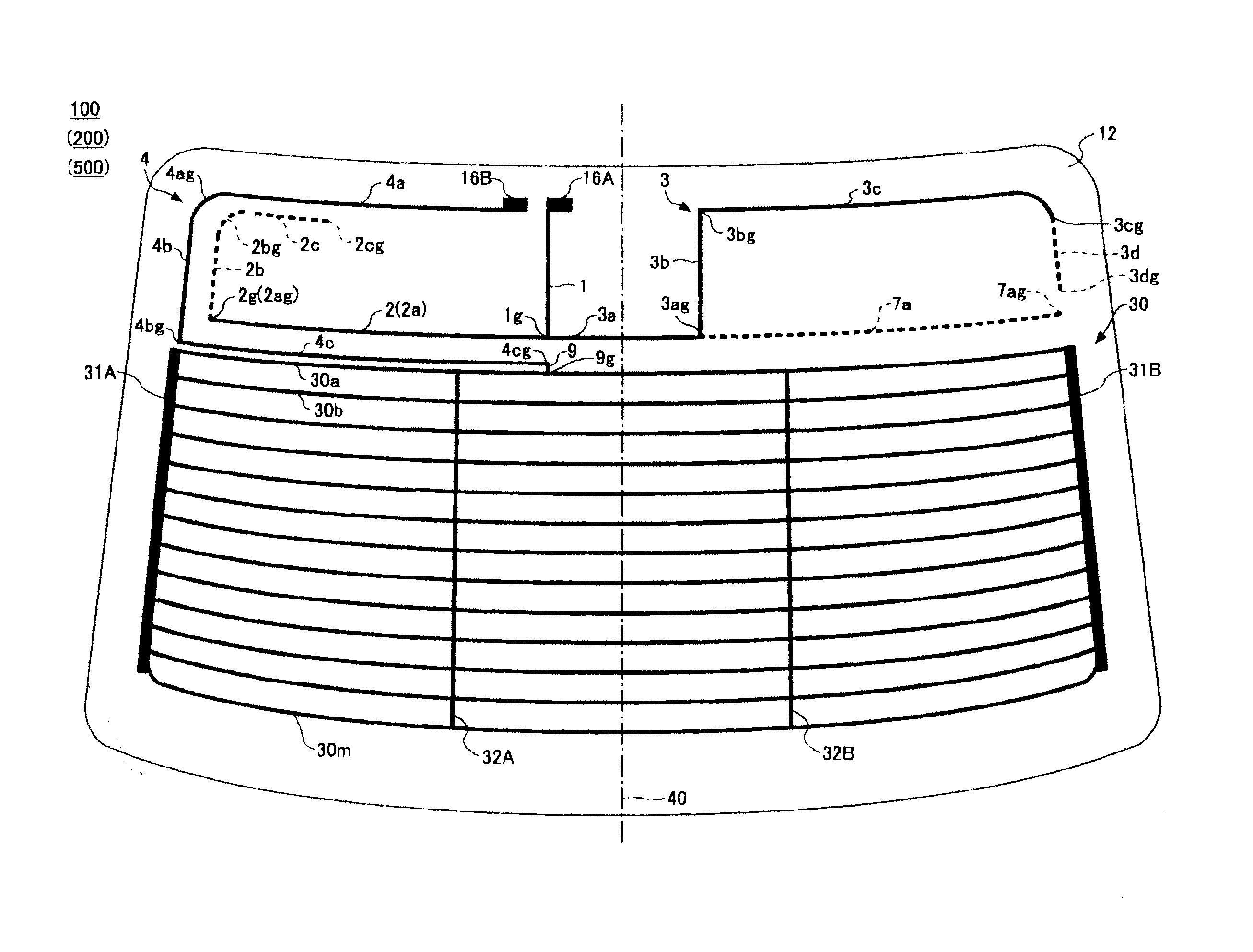

Heating line pattern structure of defogger

InactiveUS20060077109A1Reduce sensitivityDe-icing/drying-out arrangementsElectrical conductorEngineering

A structure of a heating line pattern of a defogger for improving the directivity of an FM antenna in an antenna for a motor vehicle comprising AM and FM antennas formed on a rear window glass panel. A heating line pattern structure comprises two bus-bars formed on both sides of the rear window glass panel, a plurality of heating lines arranged in parallel in a horizontal direction between the two bus-bars, and first and second linear conductors formed in a line in a vertical direction at the central portion of the defogger.

Owner:NIPPON SHEET GLASS CO LTD

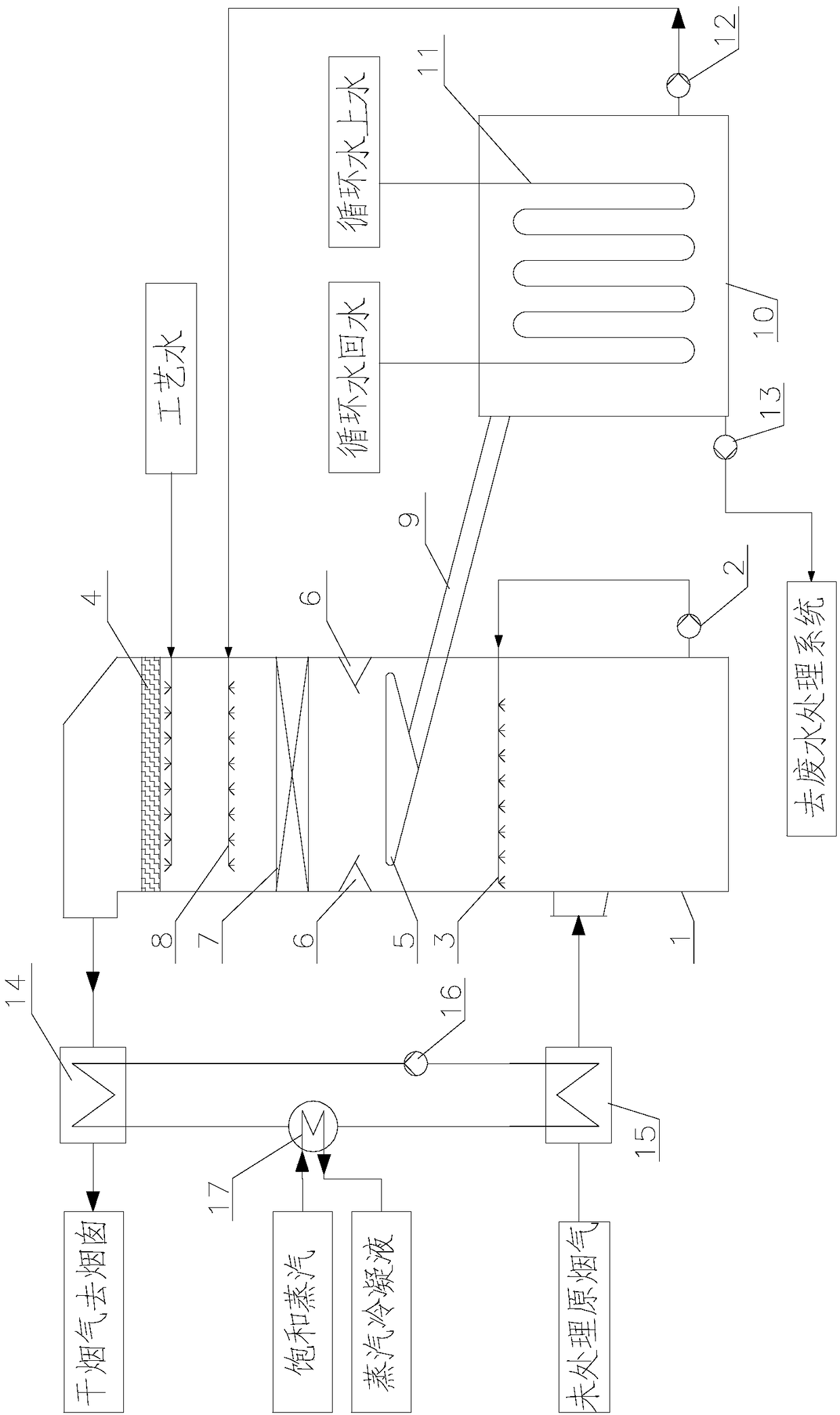

Device and method for eliminating colored smoke plume generated during wet desulphurization

PendingCN109126331AReduce moisture contentReduce heat loadUsing liquid separation agentSlurryEngineering

The invention relates to a device and a method for eliminating colored smoke plume generated during wet desulphurization. The device comprises a wet desulfurization absorption tower, a wash-cooling system and a smoke heat exchange system. By arranging the wash-cooling system between a spray layer of a traditional wet desulfurization absorption tower and a defogger, smoke in the wet desulfurizationabsorption tower is washed and cooled, temperature of clean smoke at an outlet of the wet desulfurization absorption tower is lowered, and humidity of saturated smoke is decreased. By arranging the smoke heat exchange system at an inlet and the outlet of the wet desulfurization absorption tower, clean smoke at the outlet of the wet desulfurization absorption tower is heated by heat of raw smoke generated before desulphurization, temperature of exhaust smoke is enabled to be 10 DEG C higher than a dew point temperature, and no forming of colored smoke plume or gypsum rain is ensured. The device and the method for eliminating the colored smoke plume generated during wet desulphurization have the advantages that desulphurization efficiency is increased, the carried fluid in the smoke is reduced, dedusting efficiency of the wet desulfurization absorption tower is increased, exhaust smoke humidity is decreased, and the exhaust smoke is free from colored smoke plume or gypsum rain.

Owner:武汉华德环保工程技术有限公司

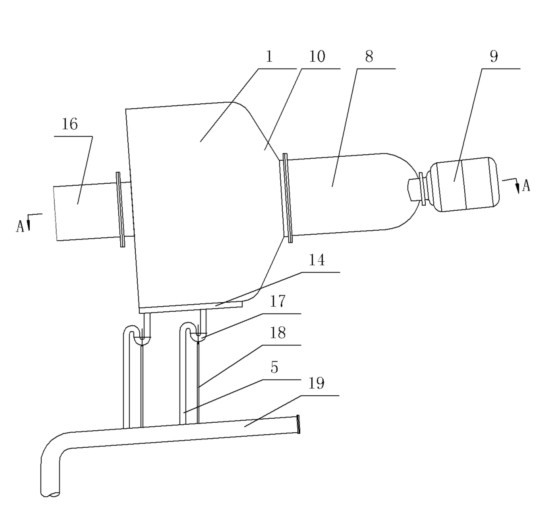

Horizontal type defogger

InactiveCN102188859ALow costImprove purification effectDispersed particle separationToxic materialFront edge

The invention relates to a horizontal type defogger, comprising a cylinder body which is transversely arranged and connected with an air inlet pipeline and an air outlet pipeline, wherein a defogging motor is arranged on the bent part of the air inlet pipeline; defogging blades are arranged on the output shaft of the defogging motor; the bottom side of the cylinder body is provided with a drainage groove; a drainage pipe is arranged on the bottom of the drainage groove; at least one inner damping plate and at least one outer damping plate are arranged in the cylinder body; the inner damping plates and the outer damping plates are arranged at intervals; the front edges of the inner damping plates are extended forwardly, and bent inwardly to form an inner backwater groove; and an outer backwater groove which is concave backwardly is arranged between the side edges of the outer damping plates and the inner wall of the cylinder. The horizontal type defogger is used for defogging for an atomization dust removal device, mixed water fog and tail gas are fed from the air inlet pipeline by virtue of a draught fan, the soot, dust and toxic substances in the tail gas are mixed in the water fog, the water fog is separated from the airflow through the defogging blades and the inner and outer damping plates, then the condensed water flows into the drainage groove, and the pure air is exhausted from the air outlet pipeline. The horizontal type defogger provided by the invention has the advantages of low cost and obvious purification effect.

Owner:张宏生

Moisture sensor and/or defogger with bayesian improvements, and related methods

InactiveUS20160275409A1Hazard reductionReduce distractionsVehicle headlampsOptical signallingEngineeringMoisture sensor

In certain example embodiments, moisture sensors, defoggers, etc., and / or related methods, are provided. More particularly, certain example embodiments relate to moisture sensors and / or defoggers that may be used in various applications such as, for example, refrigerator / freezer merchandisers, vehicle windows, building windows, etc. When condensation or moisture is detected, an appropriate action may be taken (e.g., actuating windshield wipers, turning on a defroster, triggering the heating of a merchandiser door or window, etc.). Bayesian approaches optionally may be implemented in certain example embodiments in an attempt to improve moisture detection accuracy. For instance, models of various types of disturbances may be developed and, based on live data and a priori information known about the model, a probability of the model being accurate is calculated. If a threshold value is met, the model may be considered a match and, optionally, a corresponding appropriate action may be taken.

Owner:GUARDIAN GLASS LLC

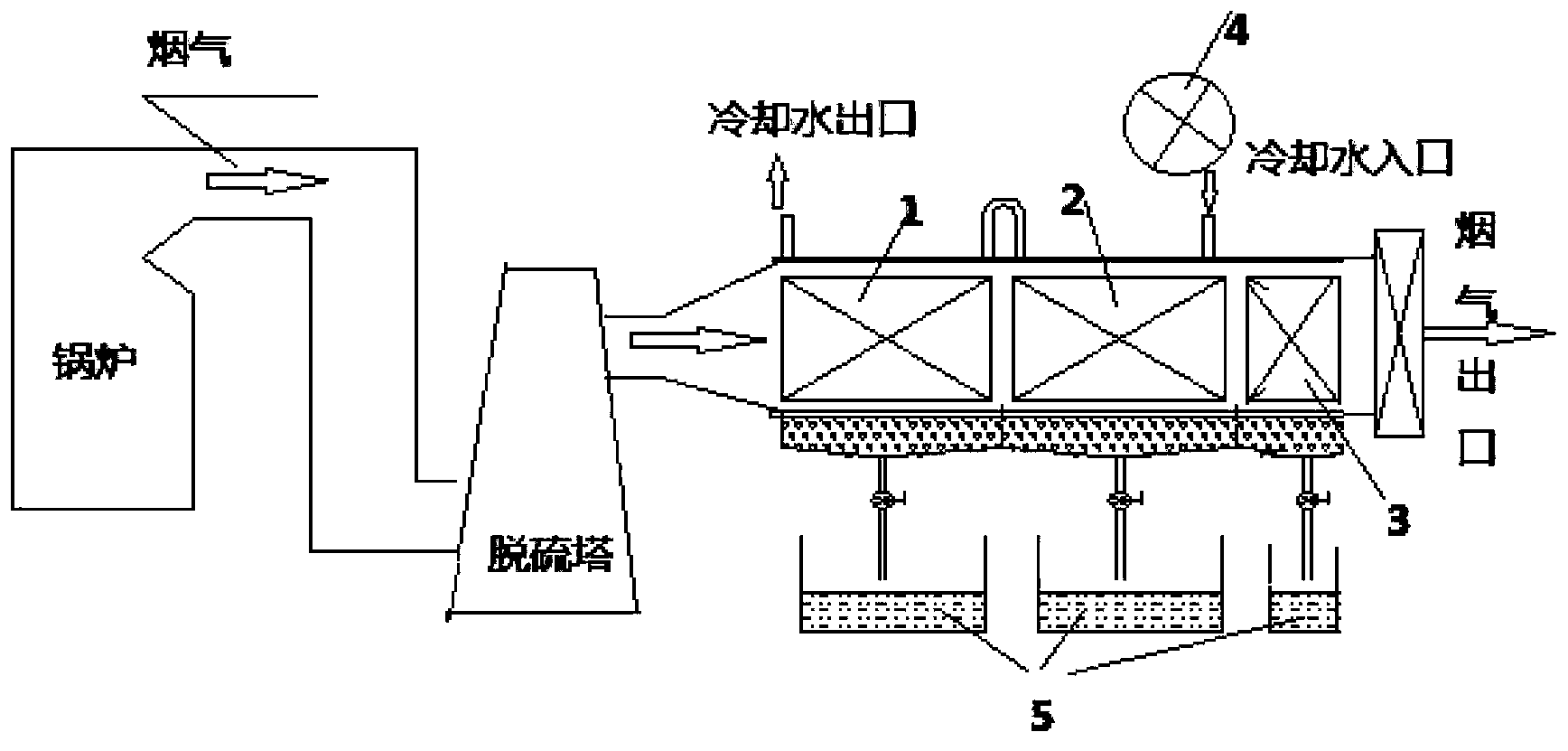

System for recycling afterheat and condensed water of desulfurized tail flue gas

InactiveCN103353120ALighting and heating apparatusCombustion technology mitigationFlue gasNuclear engineering

The invention discloses a system for recycling afterheat and condensed water of desulfurized tail flue gas. The system for recycling the afterheat and the condensed water of the desulfurized tail flue gas comprises a first condensing heat exchanger and a second condensing heat exchanger which are arranged on a desulphurizing tower outlet flue, wherein an efficient defogger is arranged behind the second condensing heat exchanger; a circulating cooling water pump is connected onto the second condensing heat exchanger; a cooling water outlet is connected onto the first condensing heat exchanger; condensed water recyclers are connected to the bottoms of the first condensing heat exchanger, the second condensing heat exchanger and the efficient defogger respectively; cooling water conveyed by the circulating cooling water pump enters the second condensing heat exchanger from the upper part, of the second condensing heat exchanger to be in a countercurrent contact with desulfurized flue gas for heat exchange, is drained from the cooling water outlet on the first condensing heat exchanger, and is finally drained through the efficient defogger. The system can be used for recycling the afterheat and the condensed water of the desulfurized tail flue gas in a power plant, so that the system has a great significance in water conservation and energy conservation of the power plant.

Owner:NORTH UNITED POWER CO LTD +3

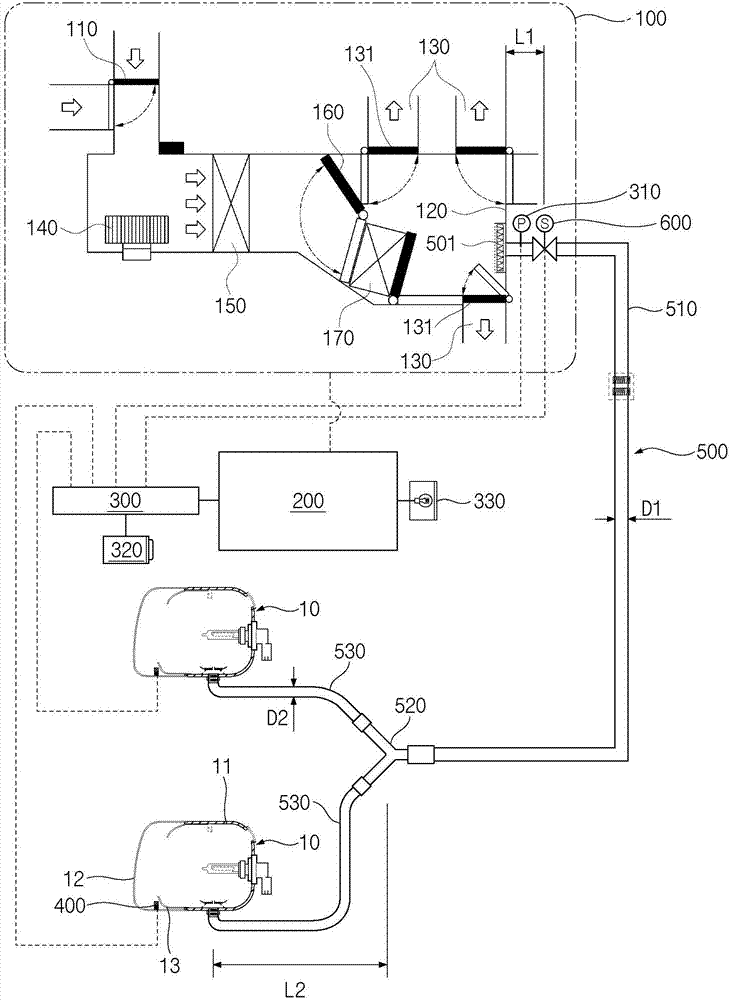

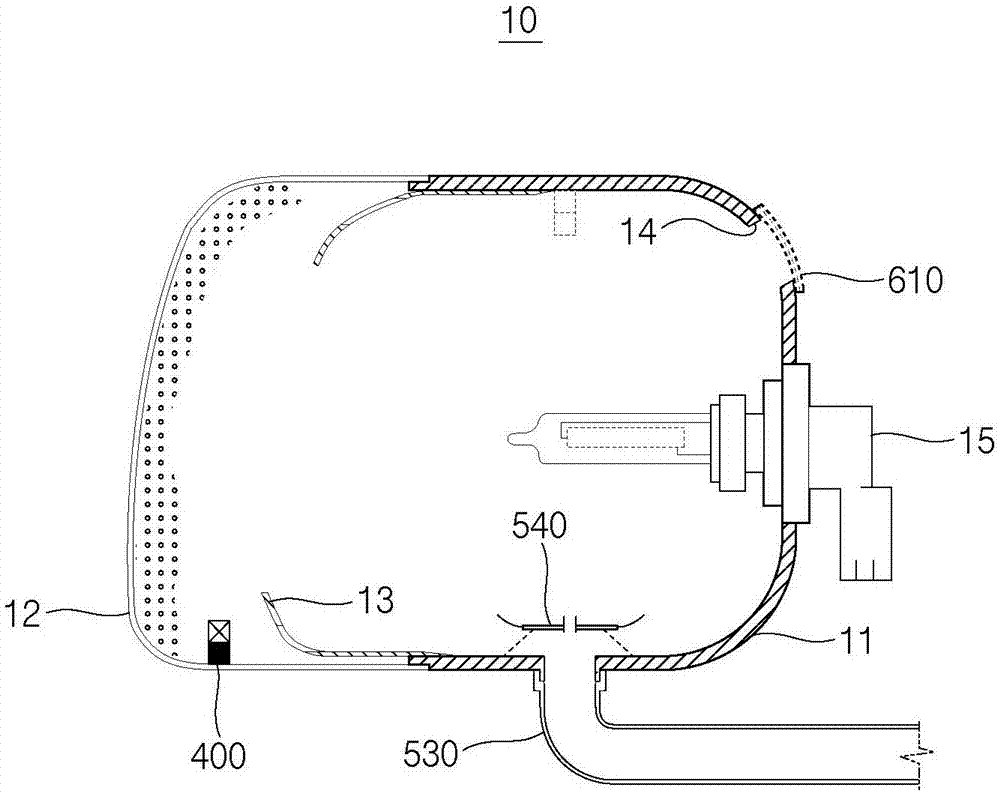

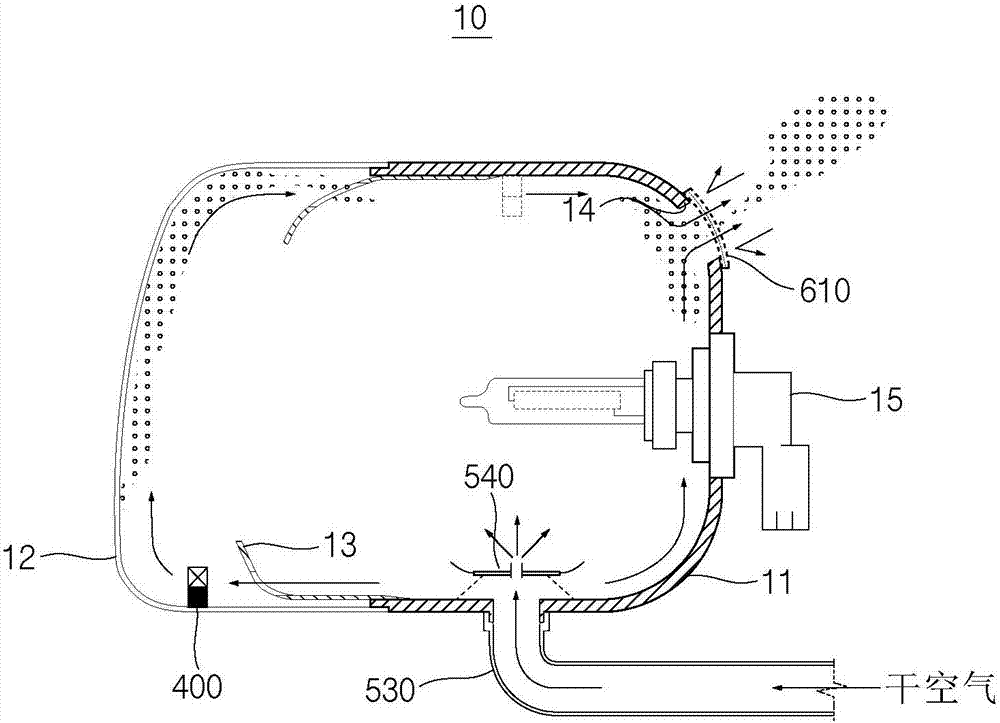

Active lamp defogger and humidity removal method thereof

ActiveCN107084350AInhibition of inflowBest supply conditionsGas-tight/water-tight arrangementsSignalling/lighting devicesControl theoryCheck valve

The invention relates to an active lamp defogger and humidity removal method thereof, and the fog in a lamp can be removed and restrained through controlling dew point in the lamp by dry air or reducing absolute humidity of the air in the lamp. The active lamp defogger comprises: an active defogging controller which is connected with an electronic control unit for controlling an HVAC device of a vehicle, a humidity detection sensor which is connected with the active defogging controller and is arranegd in the lamp of the vehicle to detect the humidity in the lamp, a dry air supply line which forms a moving path of the dry air of the HVAC device from the HVAC device to the lamp, and a check valve which is arranged on the dry air supply line and is closer to the HVAC device than the lamp. Then the active lamp defogger can rapidly reduce the absolute humidity in the lamp under the dew point temperature to defog or restrain the fog occuring.

Owner:HYUNDAI MOBIS CO LTD

Glass antenna and window glass for vehicle

ActiveUS20100321259A1High gainGains of the antenna conductors are highAntenna adaptation in movable bodiesMechanical engineeringDefogger

A glass antenna for a vehicle includes a first to fourth elements, a connection element and a first and second feeding portions. The first element is elongated from the first feeding portion in a first direction. The second element is elongated from the first element in a second direction. The third element includes: a first partial element which is elongated from the first element in a third direction; a second partial element which is elongated from the first partial element in a fourth direction; and a third partial element which is elongated from the second partial element. The fourth element is elongated from the second feeding portion in the second direction, and detours the second element in the second direction, on a side of the second direction to be elongated in the third direction. The connection element connects the fourth element to a defogger.

Owner:ASAHI GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com