Desulfurizing tower for wet fuel gas desulfurizing system

A wet flue gas desulfurization and desulfurization tower technology, which is applied in the field of flue gas desulfurization, can solve the problems of insufficient mixing of flue gas and absorbent slurry, low flow rate of spray tower, and large floor area, etc., so as to improve service life, High desulfurization efficiency and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

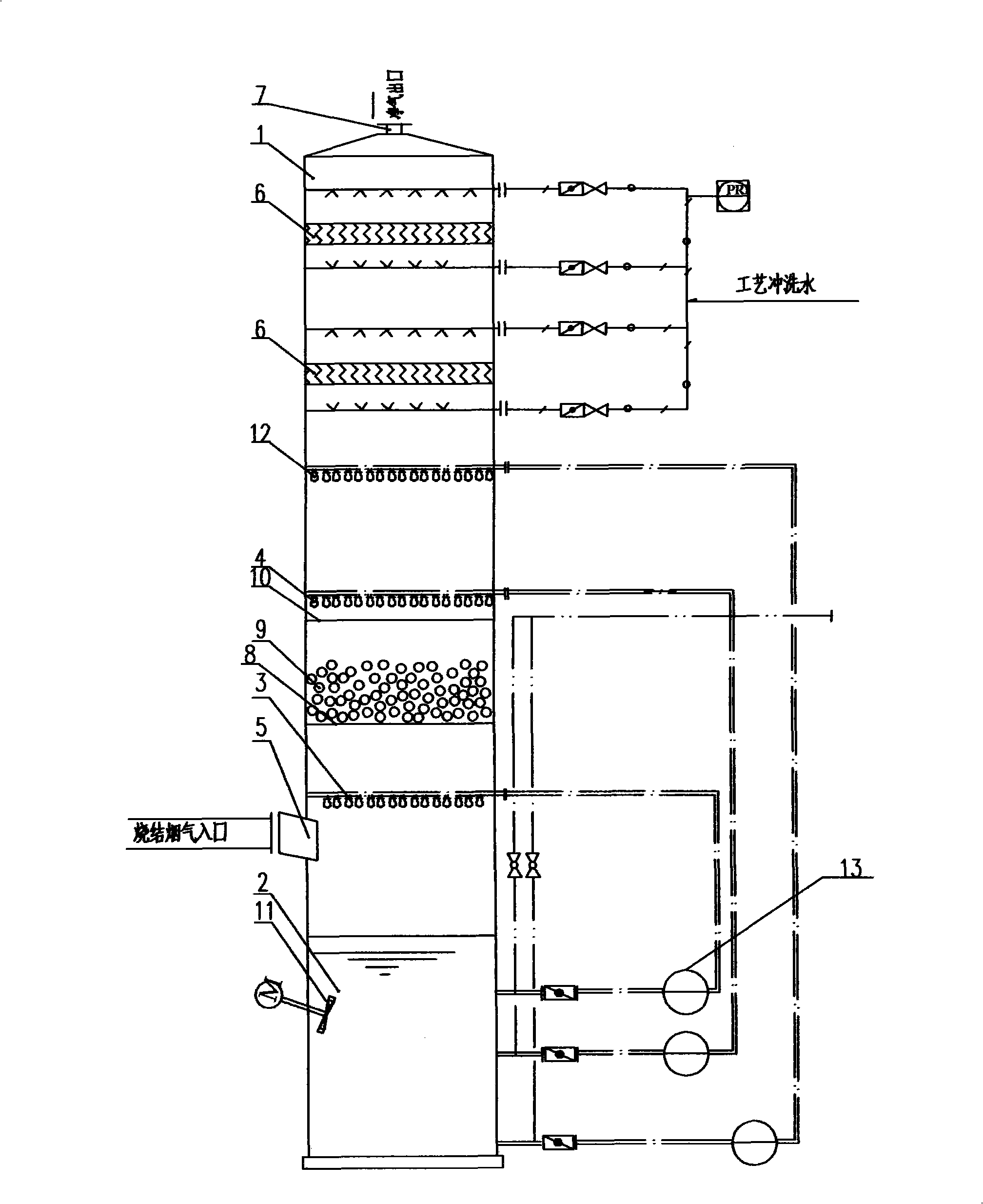

[0016] figure 1 The desulfurization tower for the wet flue gas desulfurization system shown includes a tower body 1, a slurry pool 2 is provided at the bottom of the tower body 1, and a first spray layer 3 and a first spray layer 3 are arranged at intervals above the slurry pool 2 from bottom to top. The second spray layer 4, the above-mentioned first spray layer 3 and the second spray layer 4 are respectively supplied with slurry by a set of pipelines, and the tower body 1 between the slurry pool 2 and the first spray layer 3 A waste gas inlet 5 is provided on the wall, a demister 6 is provided above the second spray layer 4, a waste gas outlet 7 is provided on the top of the tower body 1, and between the first spray layer 3 and the second spray layer 4 Support plate 8 is arranged between, and the surface of support plate 8 is provided with through hole, and several hollow balls 9 are placed on support plate 8, and the bottom of second spraying layer 4 is provided with limiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com