Process and device for removing combined pollutants

A pollutant removal technology, applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as clogging, fine dust, acid mist aerosol cannot be removed, etc., to improve collection capacity, reduce load, avoid The effect of plaster rain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

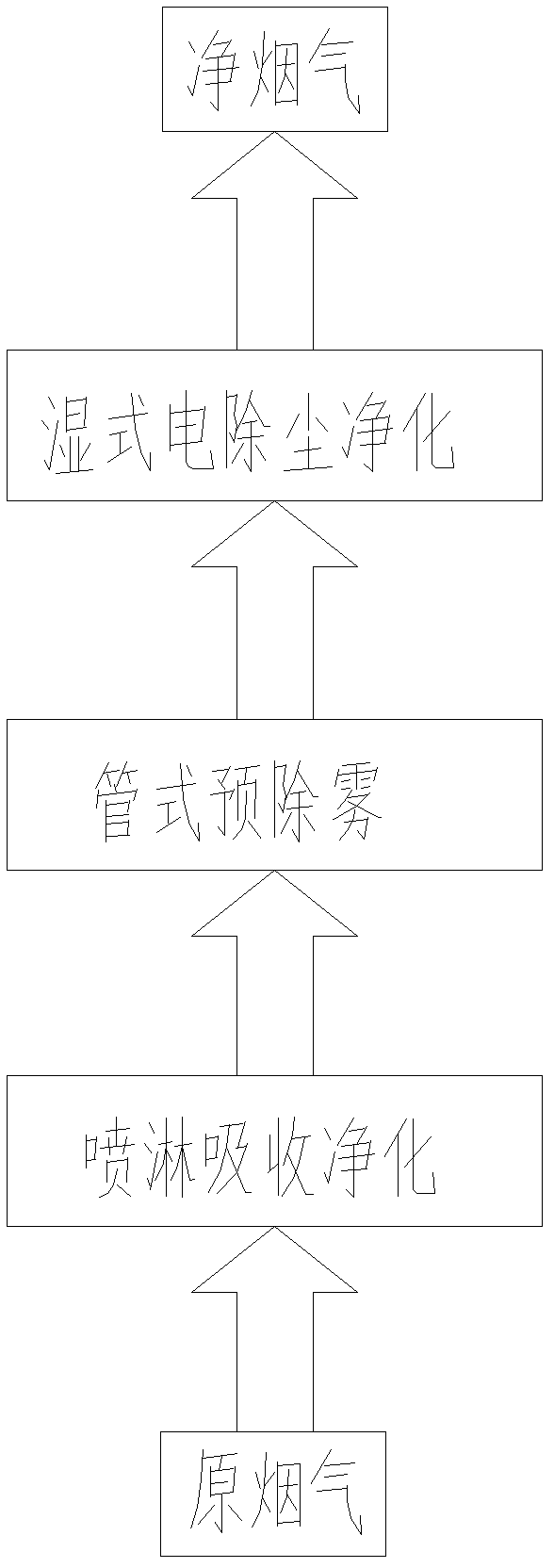

[0029] Such as figure 1 The flow chart of a kind of complex pollutant removal process of the present invention shown, a kind of composite pollutant removal process comprises the steps:

[0030] 1) Spray absorption purification step: After the original flue gas is sprayed through limestone slurry, SO 2 Such acid gas can be absorbed, and a large number of gypsum slurry droplets and water droplets are produced;

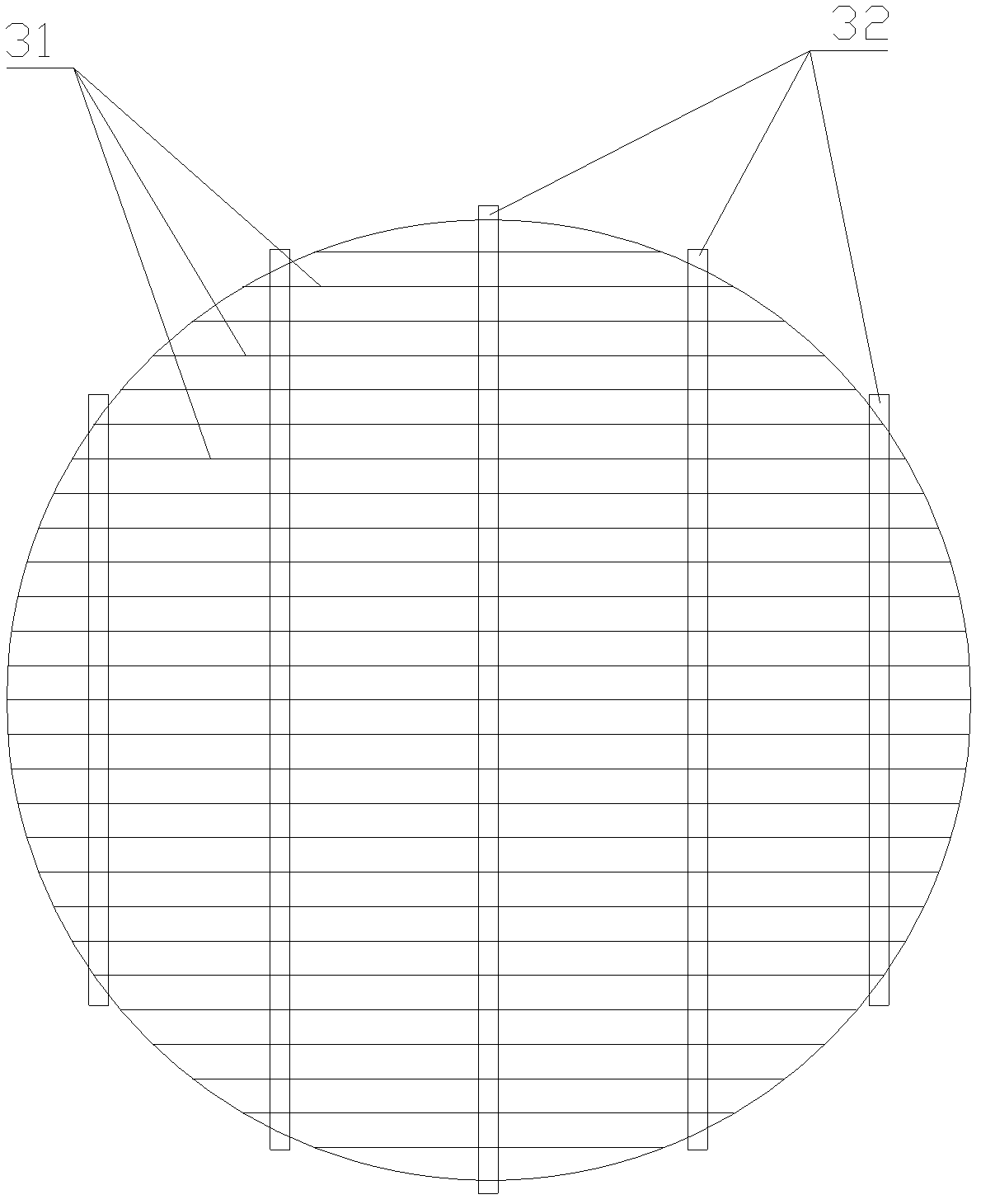

[0031] 2) Tubular pre-defogging step: remove larger gypsum slurry droplets and water droplets in the flue gas through the collision mechanism, and uniformly distribute the flue gas flow field;

[0032] 3) Purification step of wet electrostatic precipitator: make PM 2.5 Dust, SO 3 Acidic aerosols and fine slurry droplets are charged and settled on the dust collector to purify the flue gas.

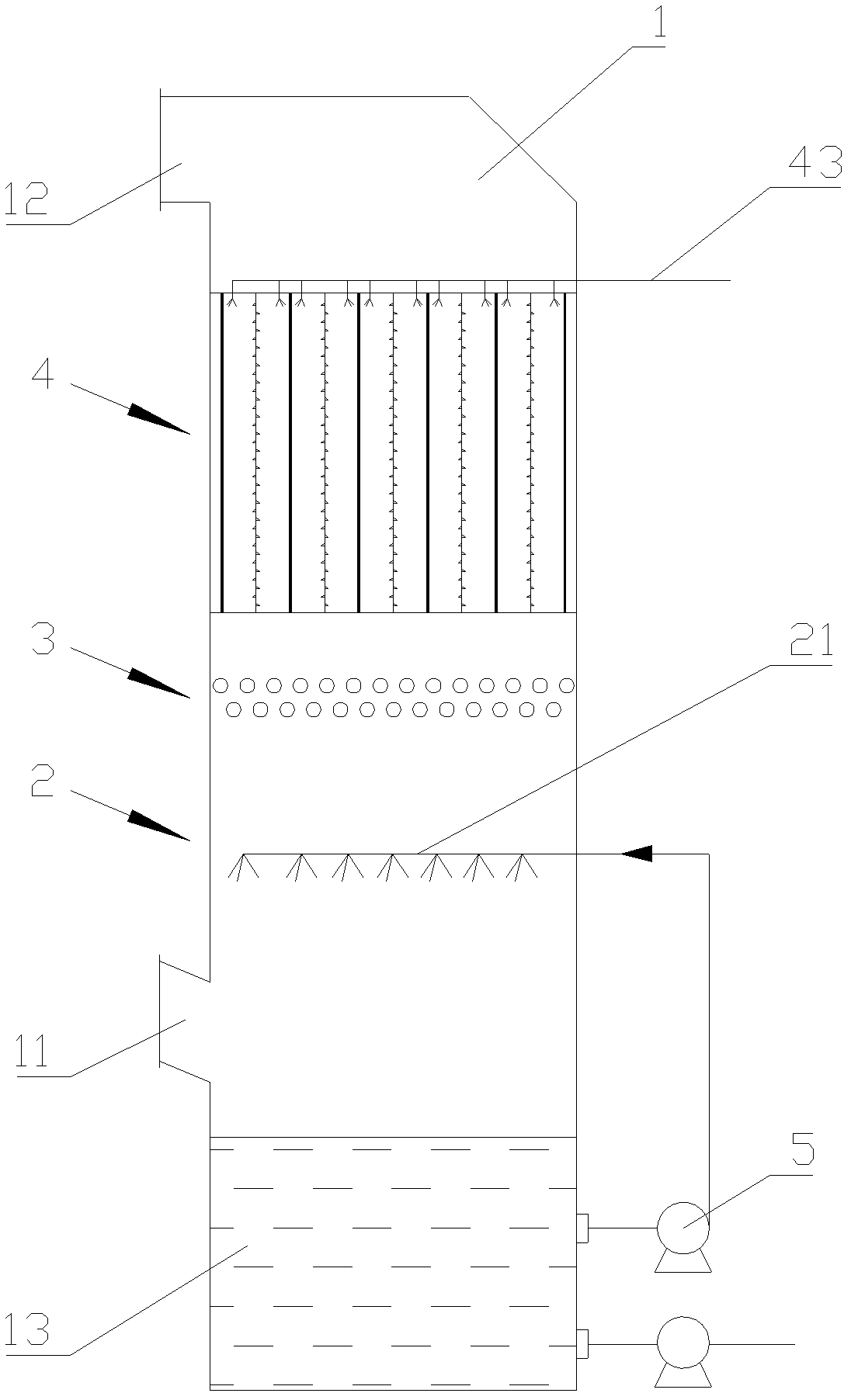

[0033] In addition if figure 2 As shown, the present invention also provides a kind of composite pollutant removal device that realizes above-mentioned composite pollutant remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com