Defroster

A demister and blade technology, applied in the field of gas-liquid separation equipment, can solve the problems of demisting efficiency drop, secondary entrainment, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

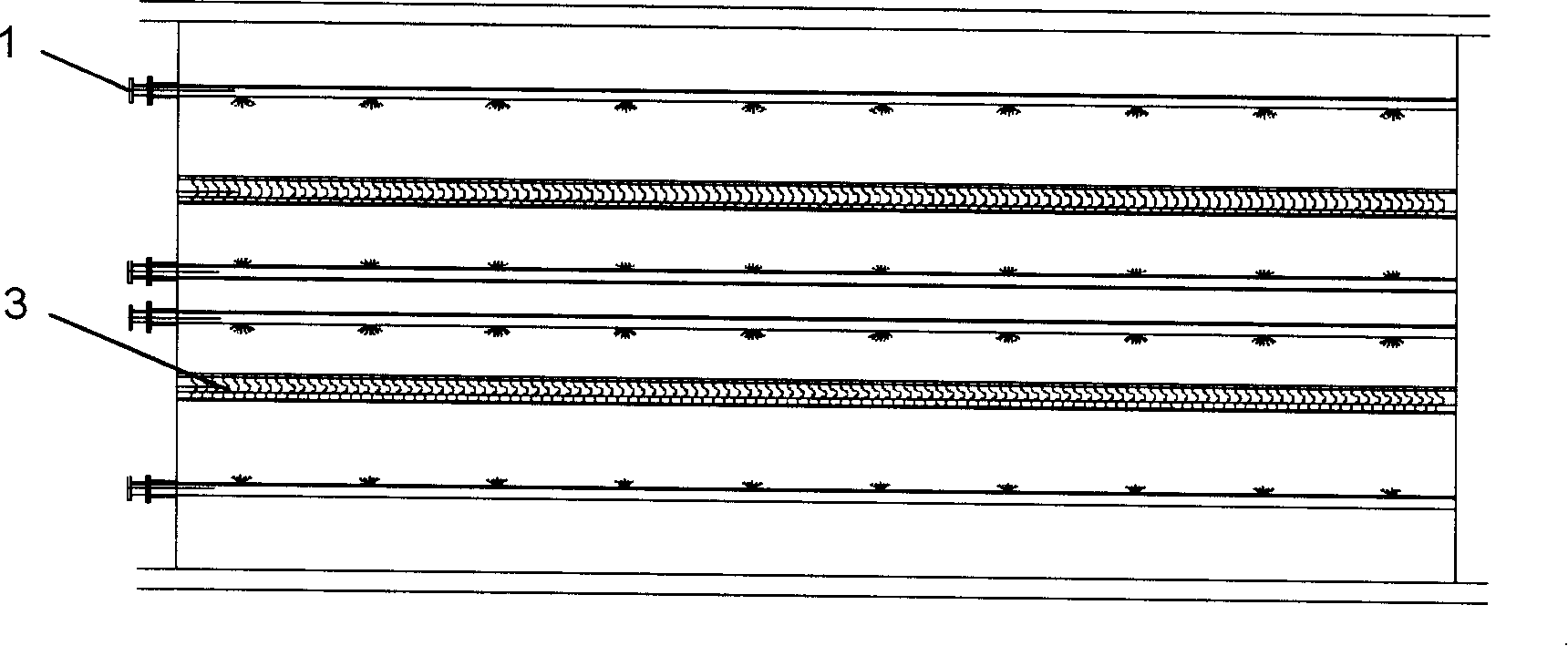

[0118] like Figure 4 As shown, the defogging unit 3 is a plurality of rows of circular blades 31 . Multiple rows of circular blades 31 are arranged in parallel to form the defogging unit 3 .

[0119] The circular defogging units 3 are arranged in a row on the section AA of the flue gas direction 5 . When the flue gas with liquid droplets passes through the lower half of the circular blade 311, due to the deflection of the streamline, the gas-liquid separation is realized under the action of inertial force, and some of the liquid droplets hit the blade and are captured. Equivalent to the role of a primary demister.

[0120] The remaining flue gas containing liquid droplets with smaller particle sizes passes through the upper half annular blade 312 for gas-liquid separation again, and the blade 31 is fixed by the fixing unit 2 .

[0121] A flushing water pipe 11 is arranged above the central point of the defogging unit blades 31, and nozzles (not shown) are evenly arranged d...

Embodiment 2

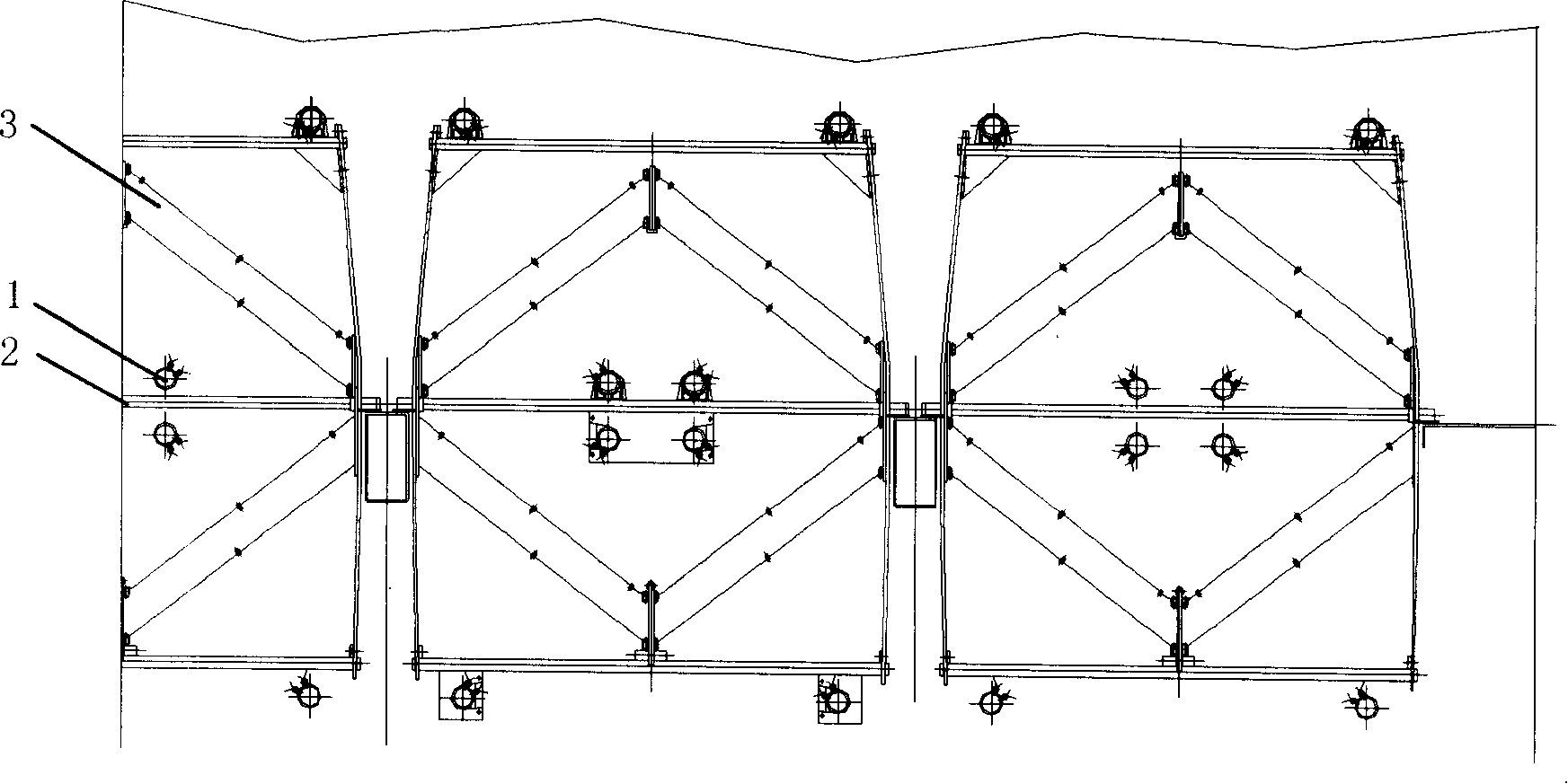

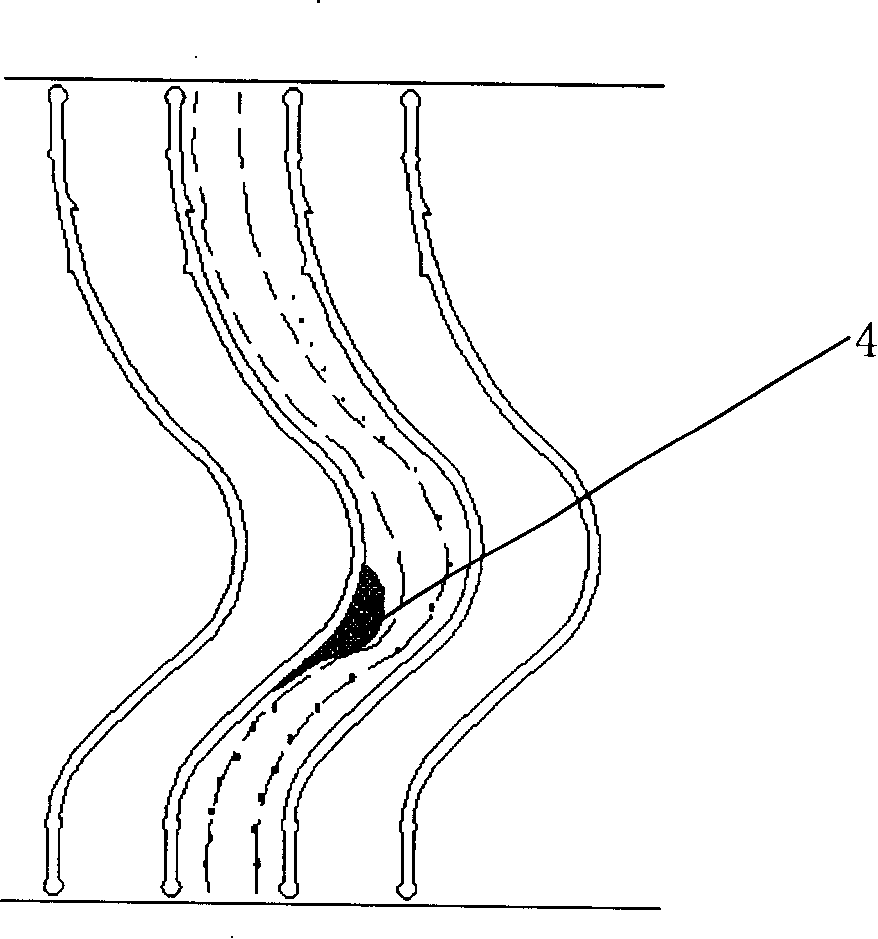

[0126] like Figure 5 As shown, the blade 31 of the defogging unit 3 includes an upper half blade 312 and a lower half blade 311 . Wherein the upper half blade 312 and the lower half blade 311 are formed by two sections of arcs with the same curvature respectively, so that the blades have the same cross section in the vertical direction, so as to ensure that the airflow has the same resistance in the vertical direction; The lower half of the blade is composed of two arcs with the same curvature.

[0127] The fixed unit 2 adopts a slot-type card structure.

[0128] like Image 6 As shown, since the lower half blade 311 has a smaller height h 2 and larger blade spacing d 2 , can remove larger particle size droplets, which is equivalent to the role of a coarse demister, and these droplets account for most of the droplets in the flue gas.

[0129] The upper half blade 312 has a greater thickness h 1 , blade spacing d 1 It is denser and can remove droplets with smaller parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com