System for recycling afterheat and condensed water of desulfurized tail flue gas

A recovery system and flue gas waste heat technology, applied in the field of energy conservation and environmental protection, can solve problems such as low desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

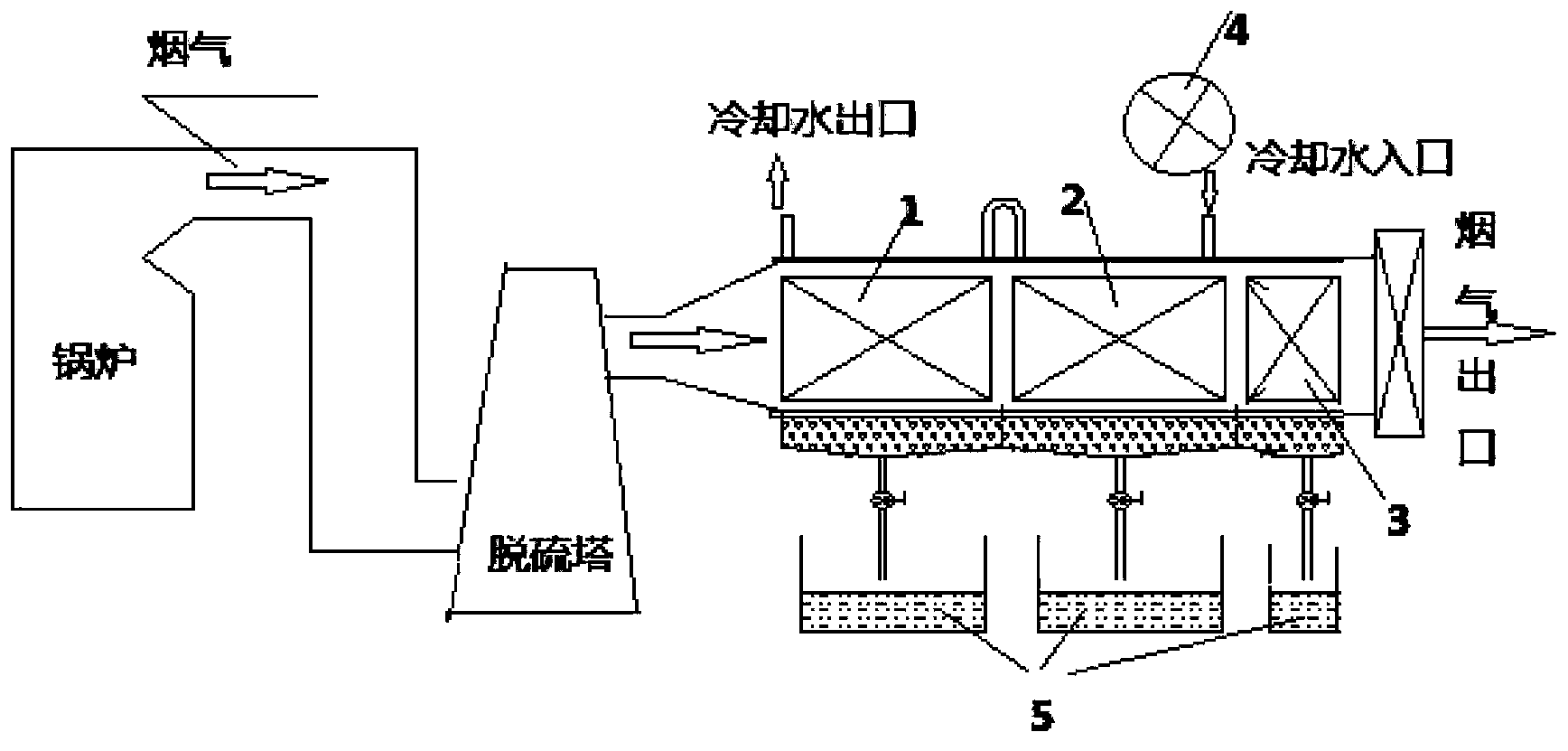

[0009] The technical idea of the present invention is to install a waste heat and condensate recovery system in the outlet flue of the desulfurization tower to reduce the flue gas temperature and condense water vapor at the same time, and the water can be recovered through a special device.

[0010] see figure 1 , this embodiment presents a specific structure of a desulfurization tail flue gas waste heat and condensate recovery system, including a first condensing heat exchanger 1 and a second condensing heat exchanger 2 arranged on the outlet flue of the desulfurization tower, and the second condensing heat exchanger A high-efficiency demister 3 is arranged behind the heat exchanger 2, a cooling circulating water pump 4 is connected to the second condensing heat exchanger 2, and a cooling water outlet is connected to the first condensing heat exchanger 1; the first condensing heat exchanger 1 , The bottom of the second condensing heat exchanger 2 and the high-efficiency dem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com