Defogging device for absorption tower

A technology of demisting device and absorption tower, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc. It can solve the problems of power plant chimney floating, high flue gas flow rate, and blockage of demisters, so as to reduce the phenomenon of carrying , Improve the efficiency of defogging and reduce the effect of gypsum rain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

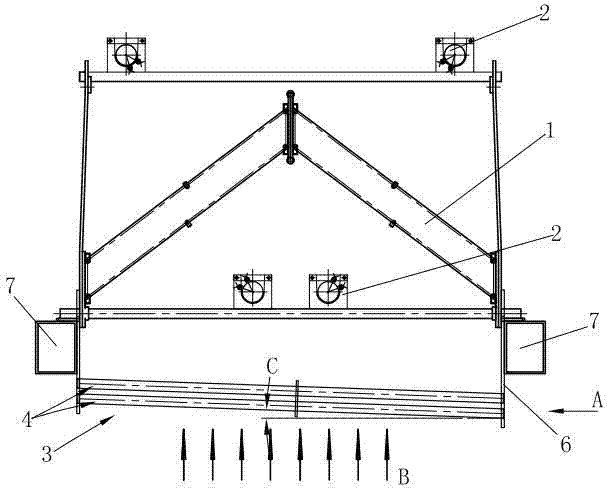

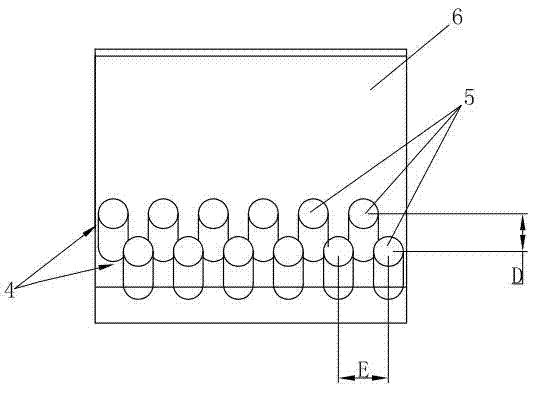

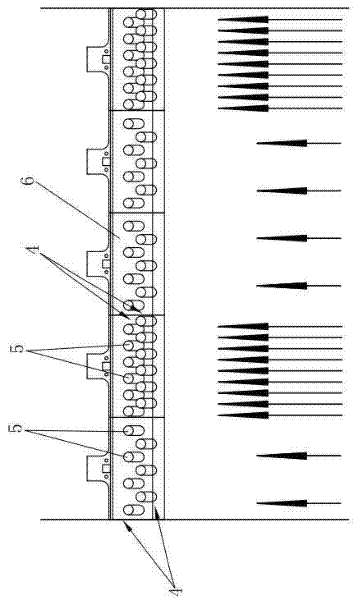

[0019] Such as figure 1 , 2 As shown, the present invention includes at least one of a flat plate demister, a roof demister or a diamond demister installed in a vertically erected absorption tower, figure 1 The middle is the roof type mist eliminator 1, and the cleaning device 2 is arranged on the roof type mist eliminator 1, in the direction of the flue gas flow ( figure 1 Middle arrow B) A pre-mist eliminator 3 is provided upstream of the roof-type demister 1. The pre-mist eliminator 3 includes two layers of pipe rows 4 arranged in parallel, and the pipe row 4 consists of several round pipes 5 arranged in parallel Composition, the round tubes 5 of two adjacent tube rows 4 are arranged in a staggered manner, the round tubes 5 of the pre-mist eliminator tube row are usually PP tubes, and the two ends of the round tubes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com