Patents

Literature

1237results about How to "Reduce hindrance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

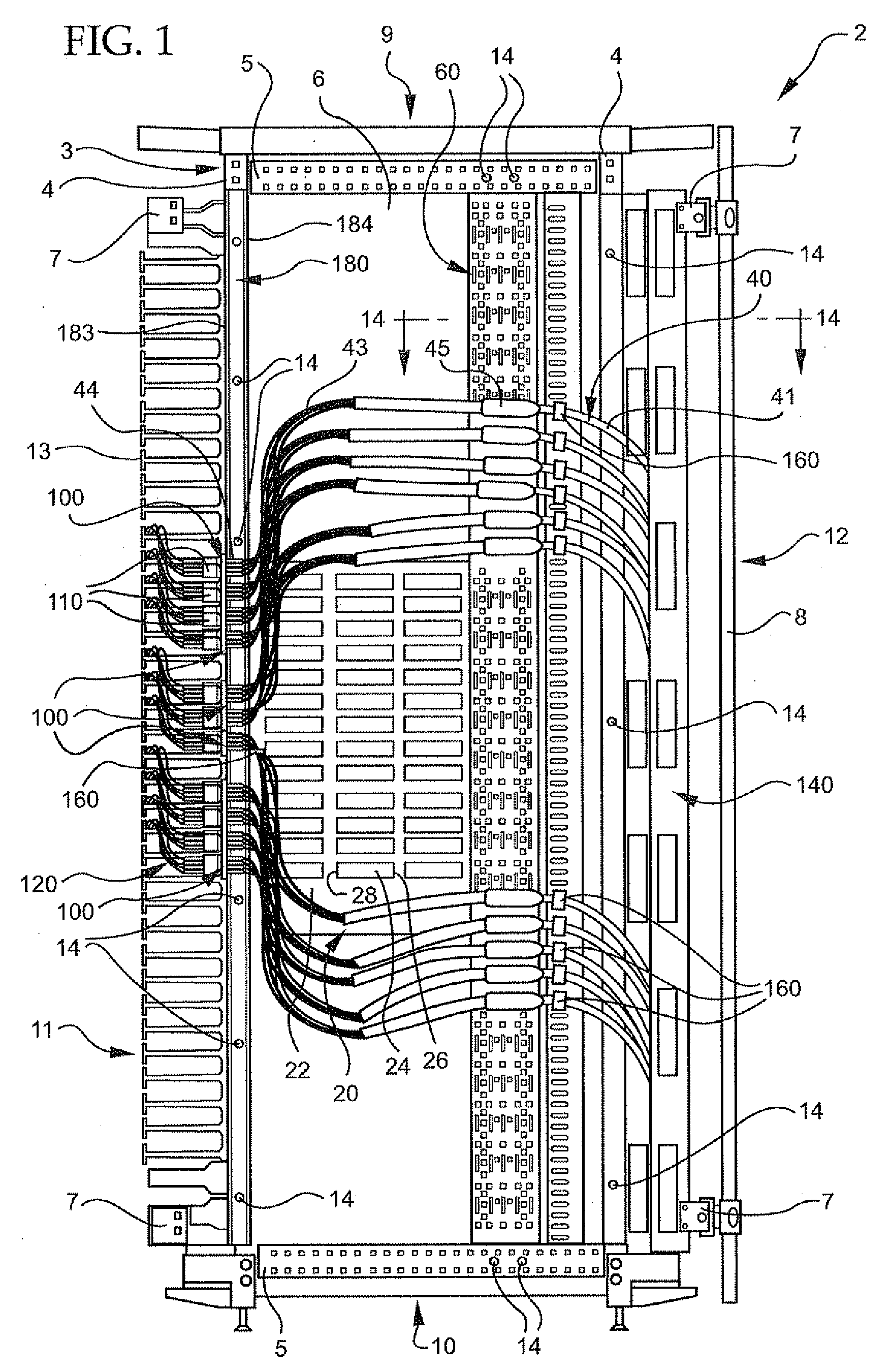

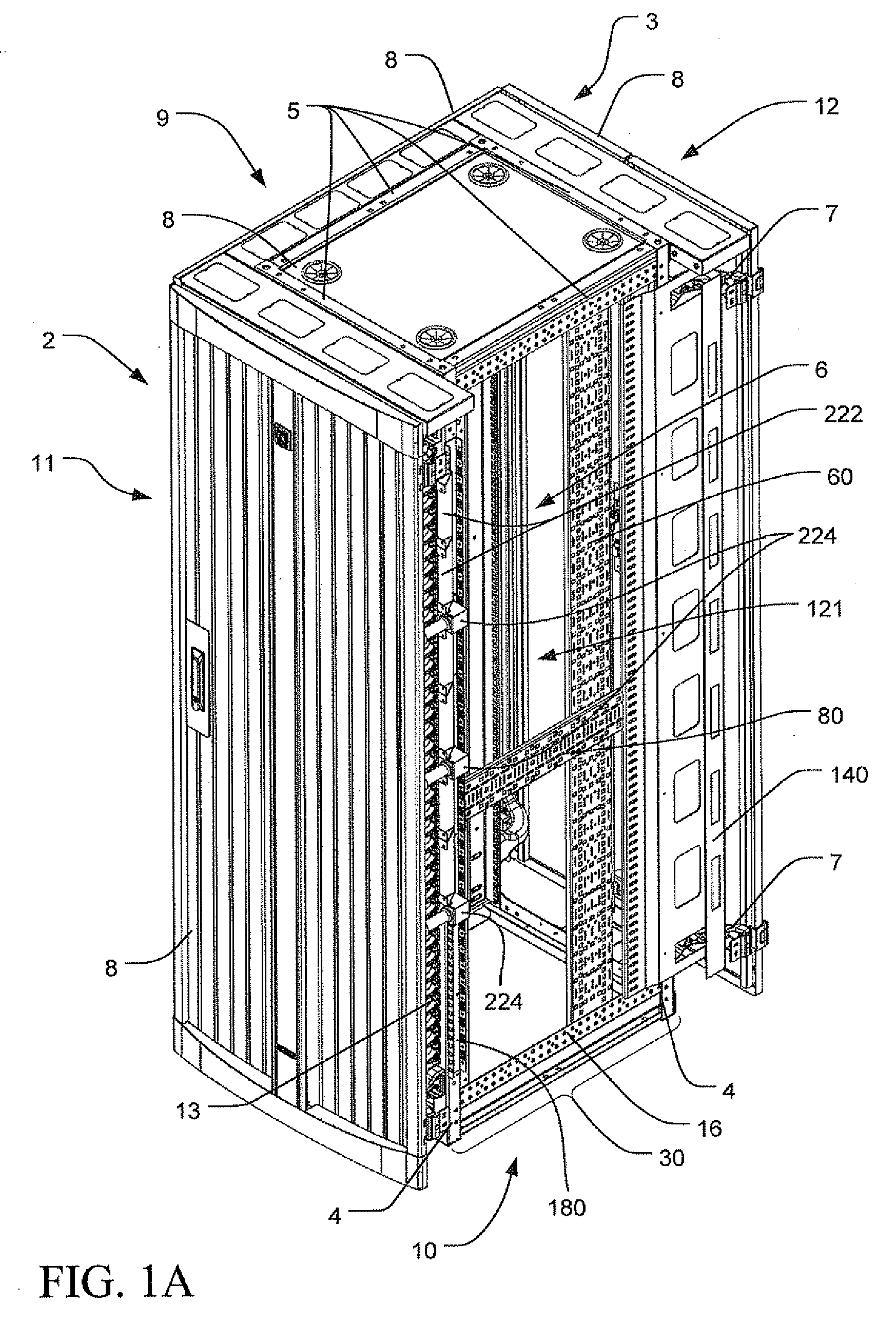

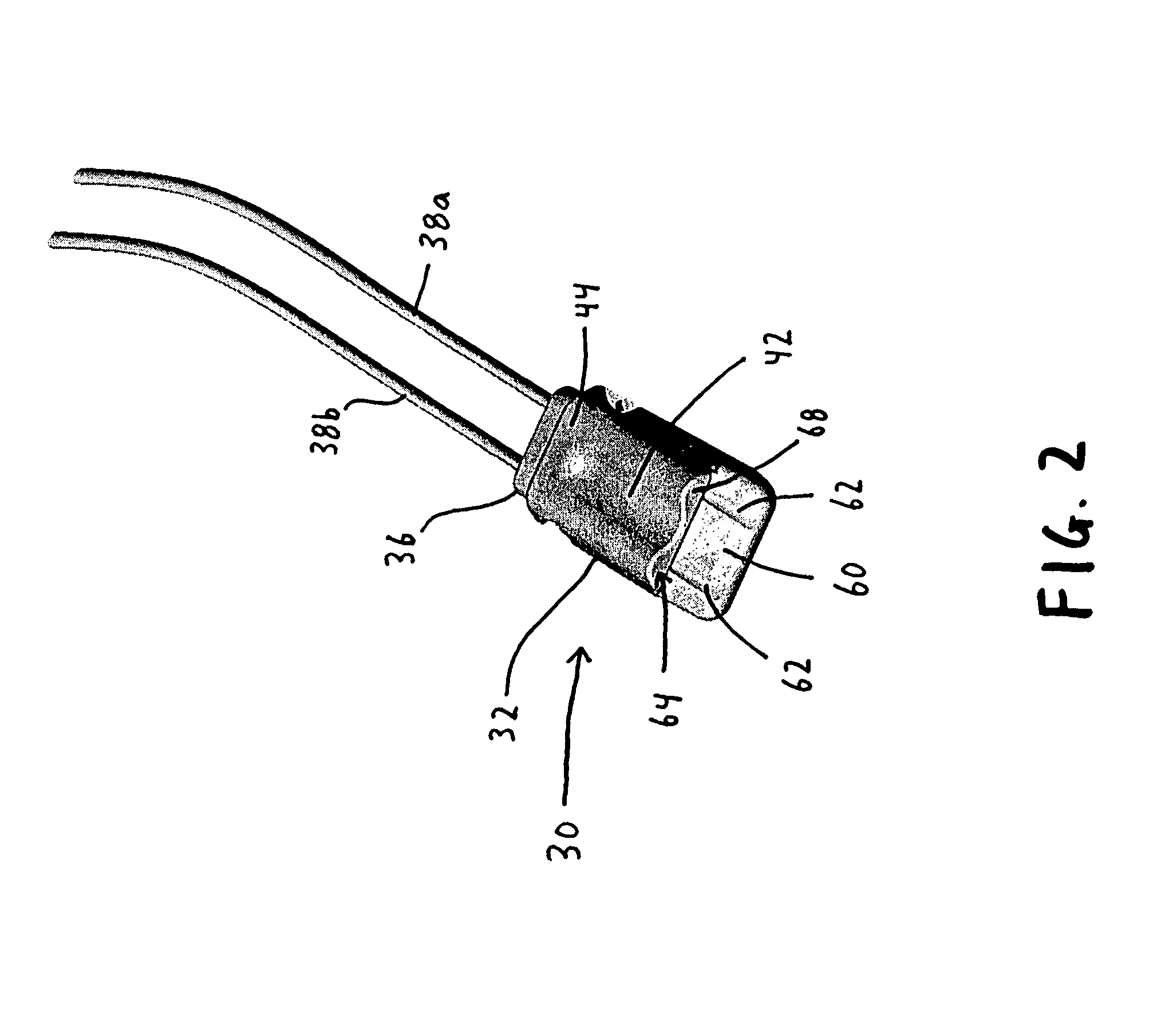

Apparatus and method for organizing cables in a cabinet

ActiveUS7974105B2Reduce hindranceEasy to installBus-bar/wiring layoutsOptical light guidesEngineeringCable management

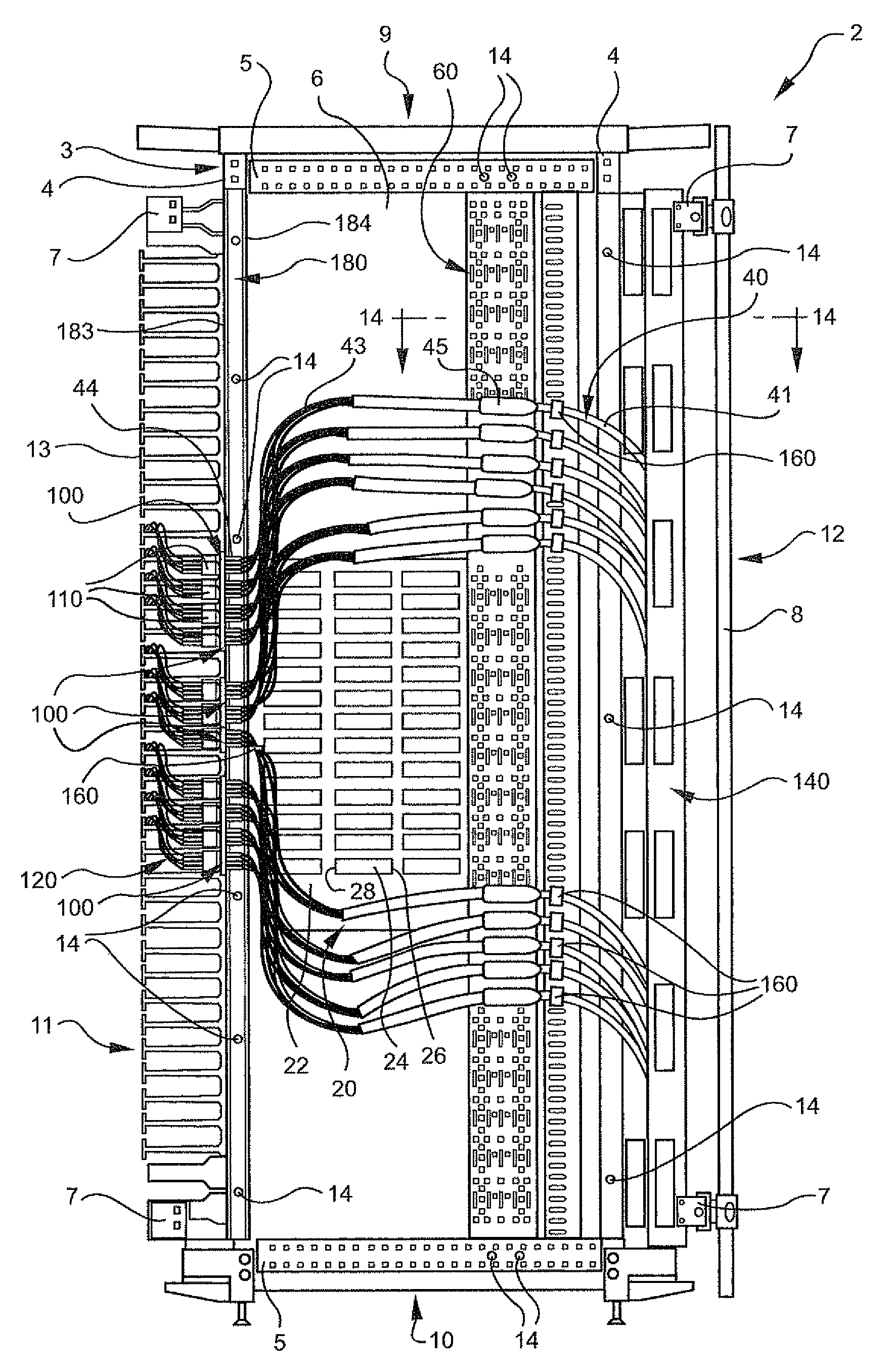

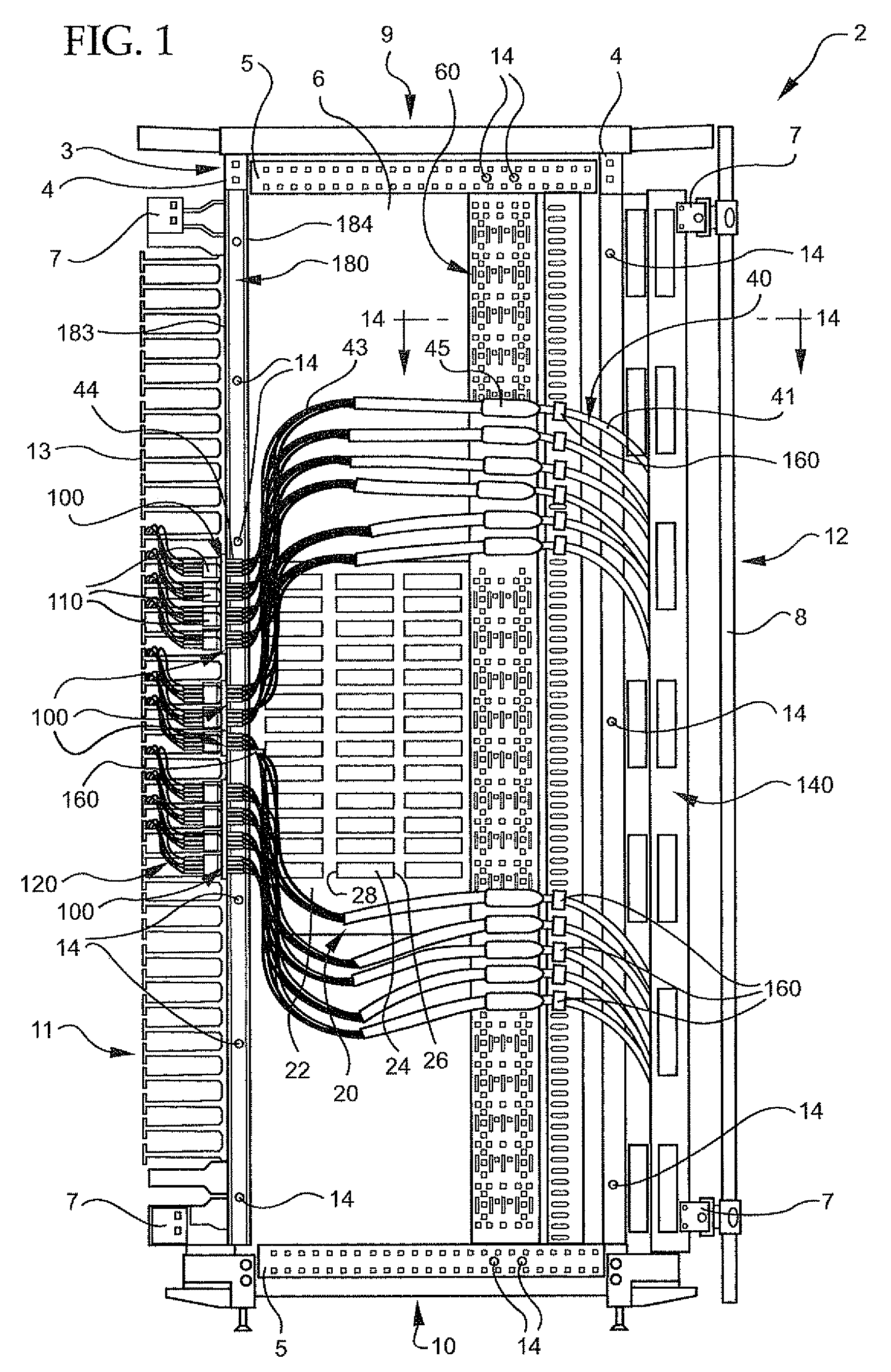

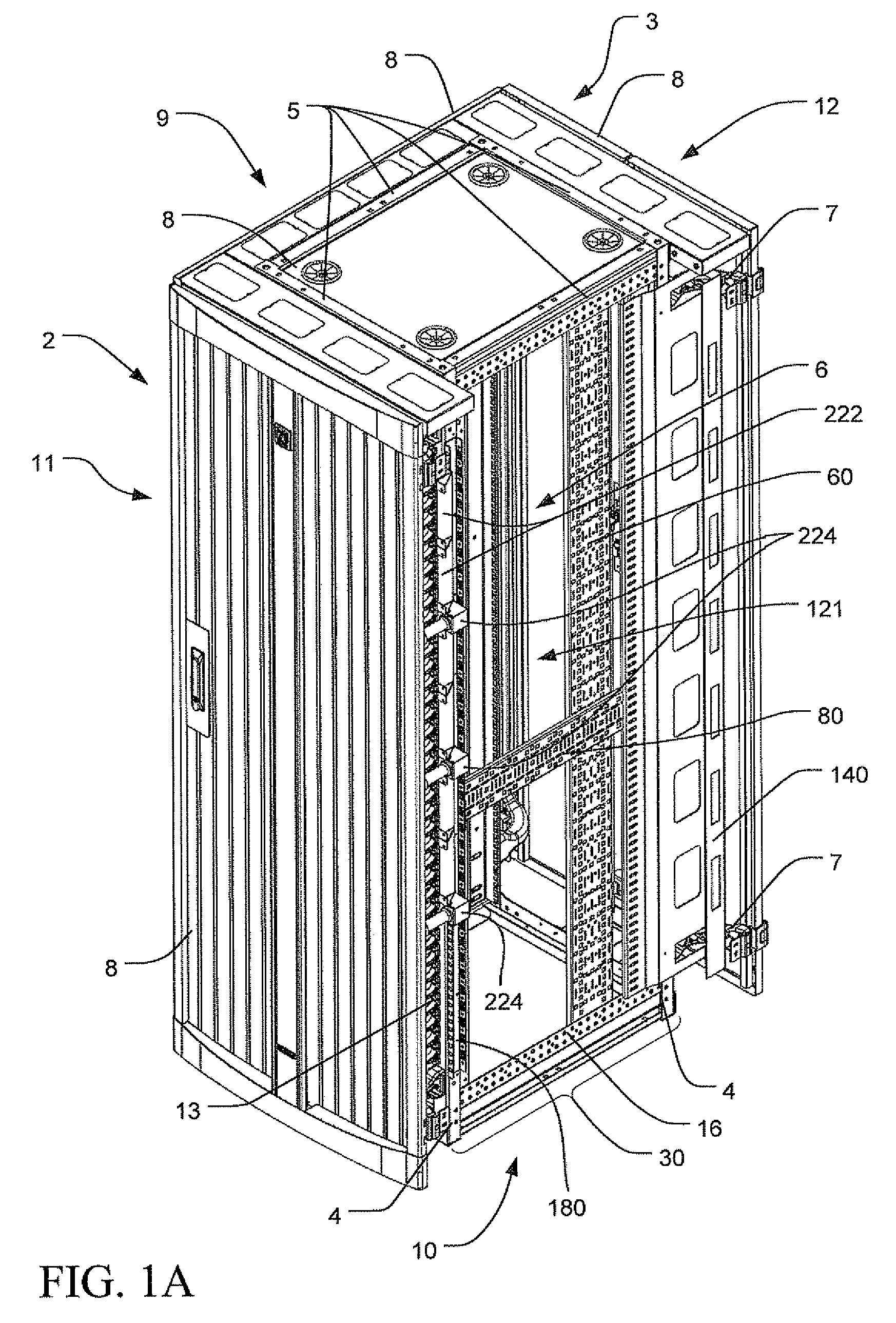

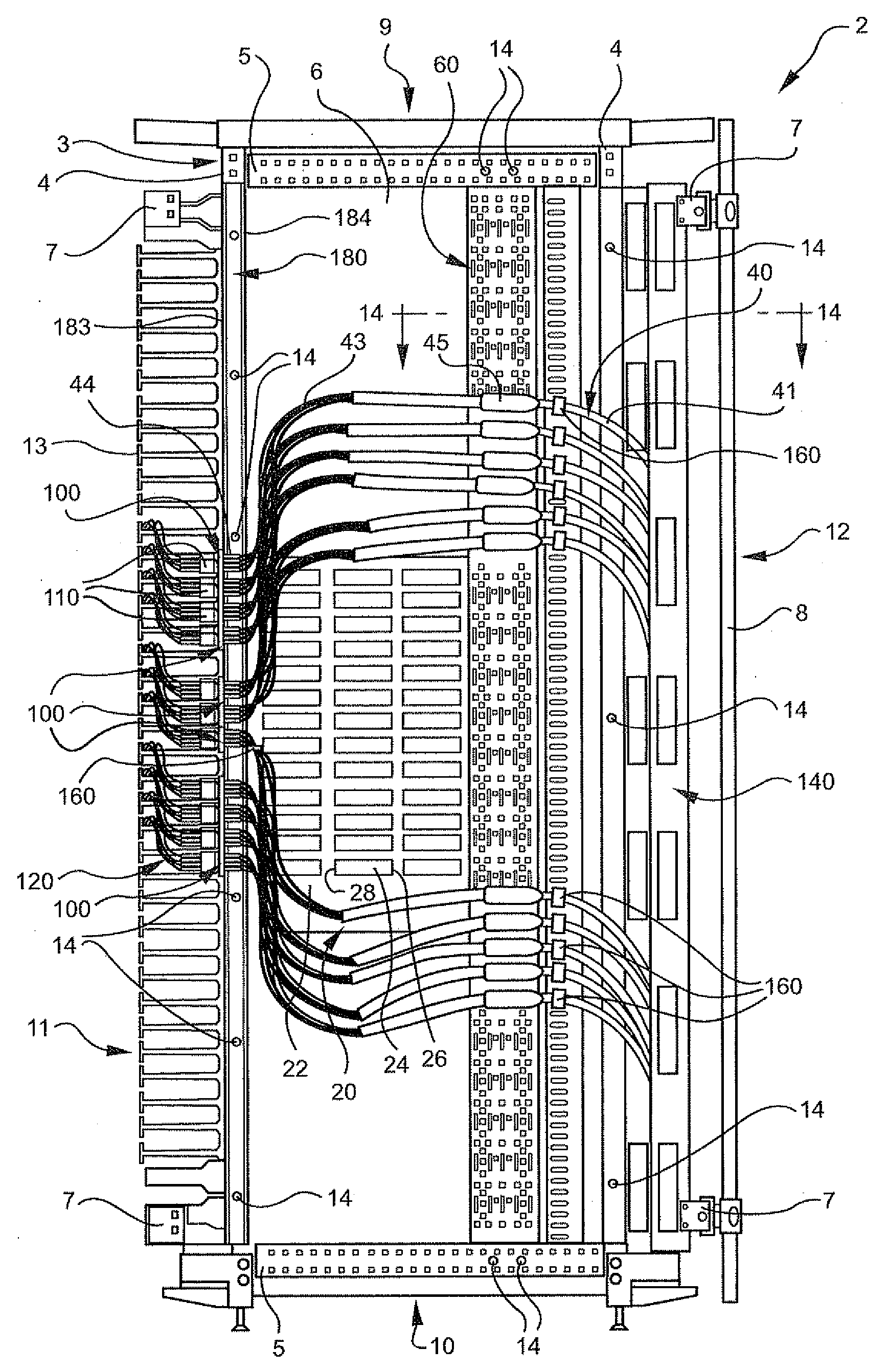

An equipment cabinet (2) includes an equipment rack (3) for mounting equipment (20), and includes organizational elements for organizing cables within the cabinet. The cables may be organized to reduce impeding airflow to or from the equipment, and / or to reduce unwanted bending of the cables themselves. The organizational elements may include one or more of: a trunk cable (40) including a furcation plug (45) and universal clip (47); a furcation bracket—either vertical (60) or horizontal (80); a termination panel (100); a trunk cable manager (140, 200); and / or an accessory bracket (180). The organizational elements may be used in various combinations with one another, and may be provided in a kit.

Owner:CHATSWORTH PROD INC

Apparatus and method for organizing cables in a cabinet

ActiveUS20090273915A1Improves optical fiber organizationReduces fiber congestionBus-bar/wiring layoutsOptical light guidesEngineeringCable management

An equipment cabinet (2) includes an equipment rack (3) for mounting equipment (20), and includes organizational elements for organizing cables within the cabinet. The cables may be organized to reduce impeding airflow to or from the equipment, and / or to reduce unwanted bending of the cables themselves. The organizational elements may include one or more of: a trunk cable (40) including a furcation plug (45) and universal clip (47); a furcation bracket—either vertical (60) or horizontal (80); a termination panel (100); a trunk cable manager (140, 200); and / or an accessory bracket (180). The organizational elements may be used in various combinations with one another, and may be provided in a kit.

Owner:CHATSWORTH PROD INC

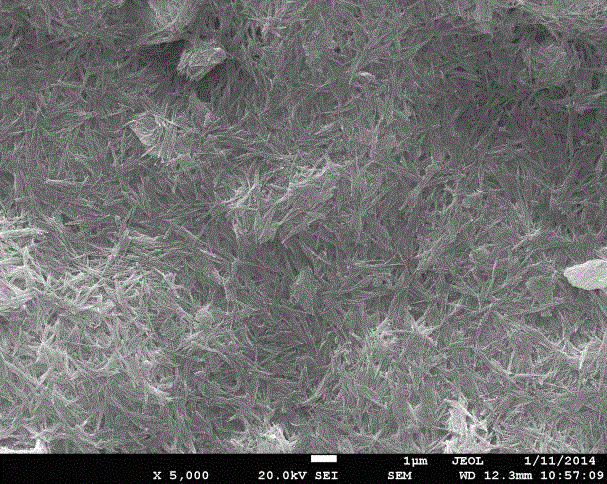

Anti-bacterial thermoplastic composite and preparation method thereof

The invention relates to an anti-bacterial thermoplastic composite, which comprises the following mixed components: 100 parts of thermoplastic by weight and 0.1-40 parts of composite antibacterial agent by weight, wherein the composite antibacterial agent comprises micronano inorganic / organic particles and guanidinesalt polymers which are coated on the surfaces of the micro / nano particles and / or embedded among pores and layers of the micronano particles; the weight ratio of the guanidinesalt polymers to the micro / nano particles is 1:1-1:50; and the micro / nano particles have at least a one-dimensional average size of 1nm-1000mum. The anti-bacterial thermoplastic composite is obtained by melting and mixing the components such as the thermoplastic, the composite antibacterial agent, and the like, therefore the antibacterial rate of the anti-bacterial thermoplastic composite is higher and the preparation method is simple.

Owner:CHINA PETROLEUM & CHEM CORP +1

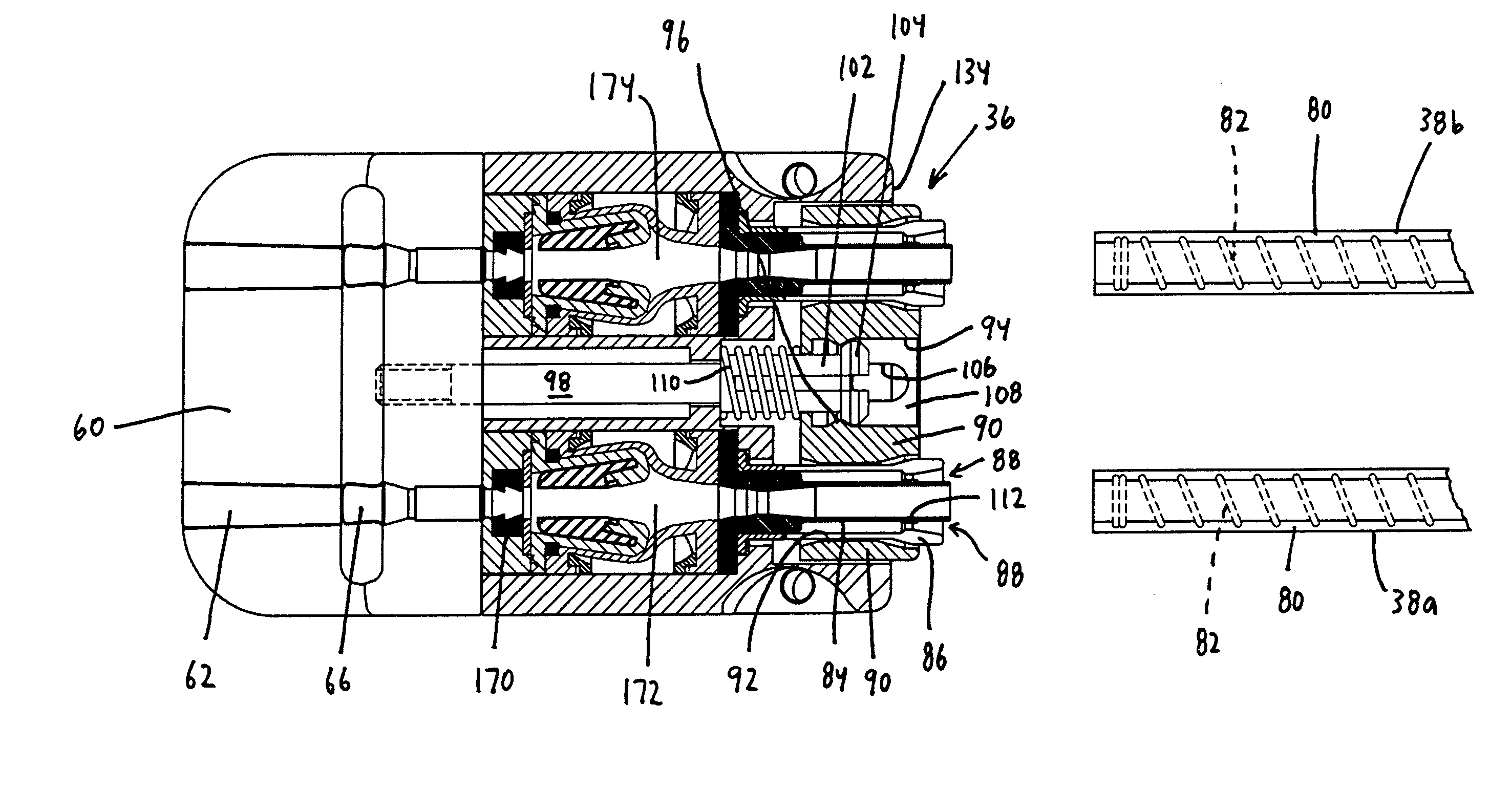

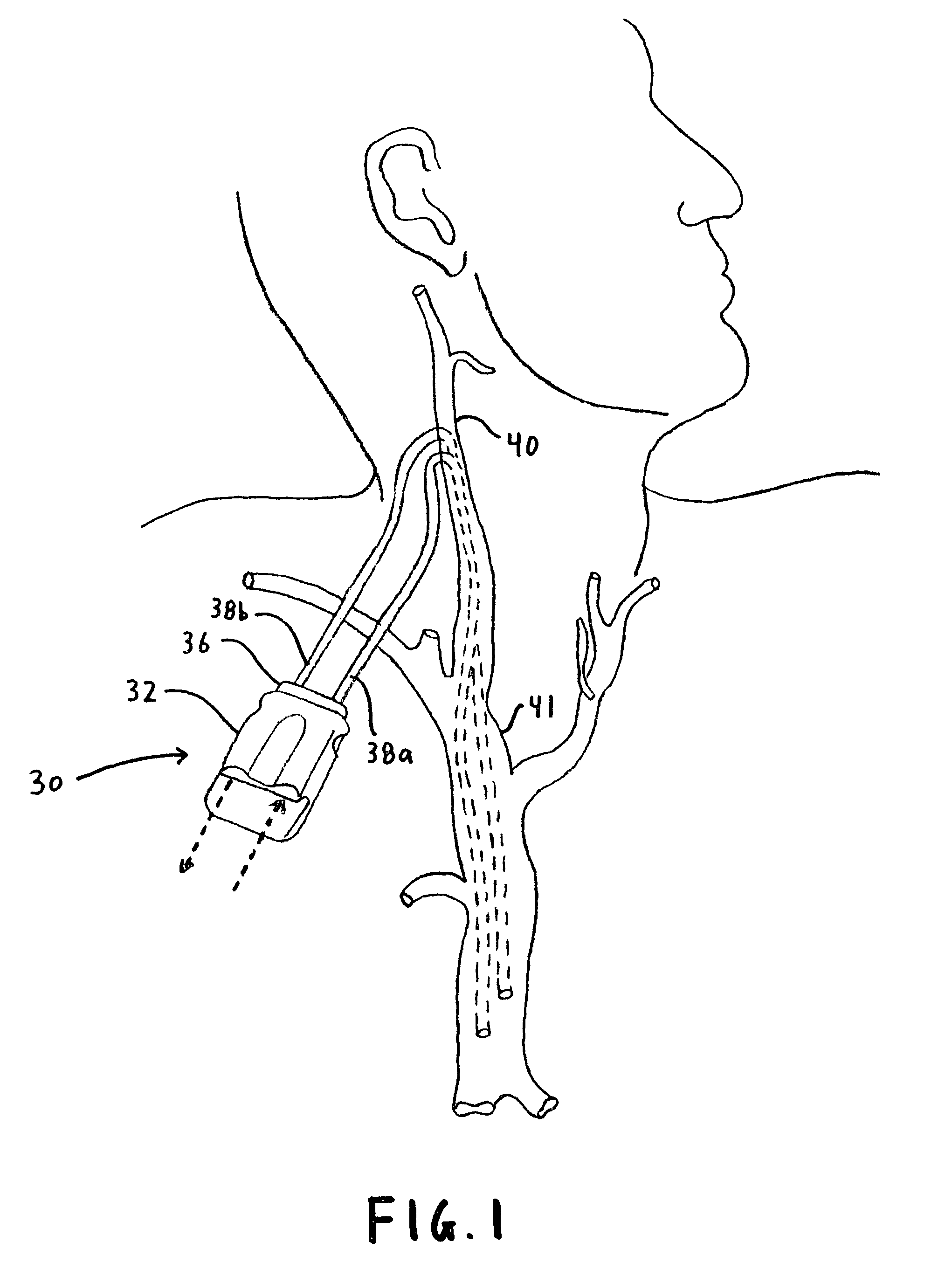

Port device for subcutaneous access to the vascular system of a patient

InactiveUS7131962B1Reduce the possibilityInhibition formationMedical devicesTube connectorsGuide tubeBiomedical engineering

A port device for implanting in a patient for subcutaneous access to the vascular system of the patient. The device includes a housing provided with apertures, each for receiving and retaining a needle. The housing is further provided with lock structure for locking catheters to the housing. The housing is configured internally to provide flow paths extending between needles disposed in the apertures and the catheters.

Owner:ND PARTNERS +1

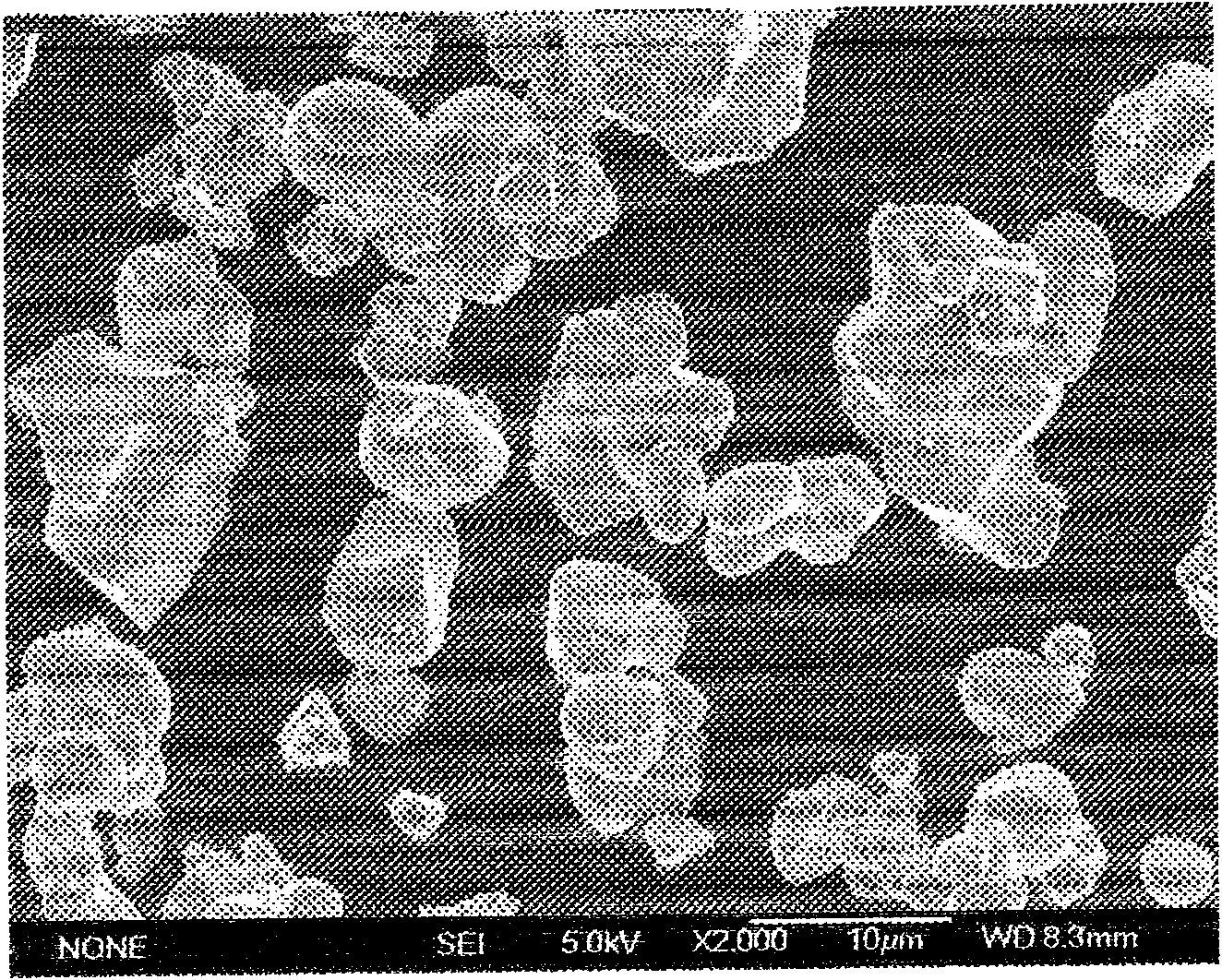

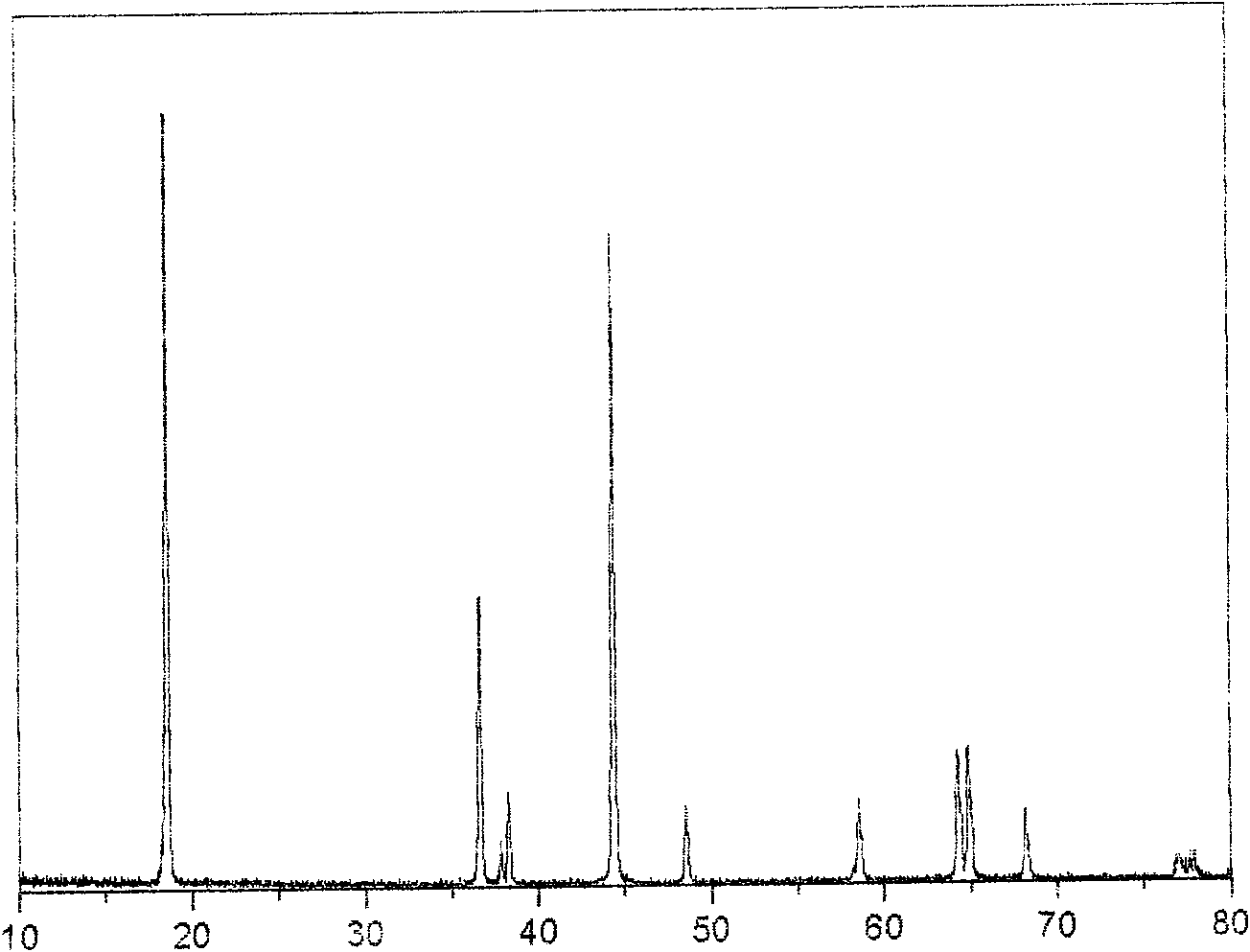

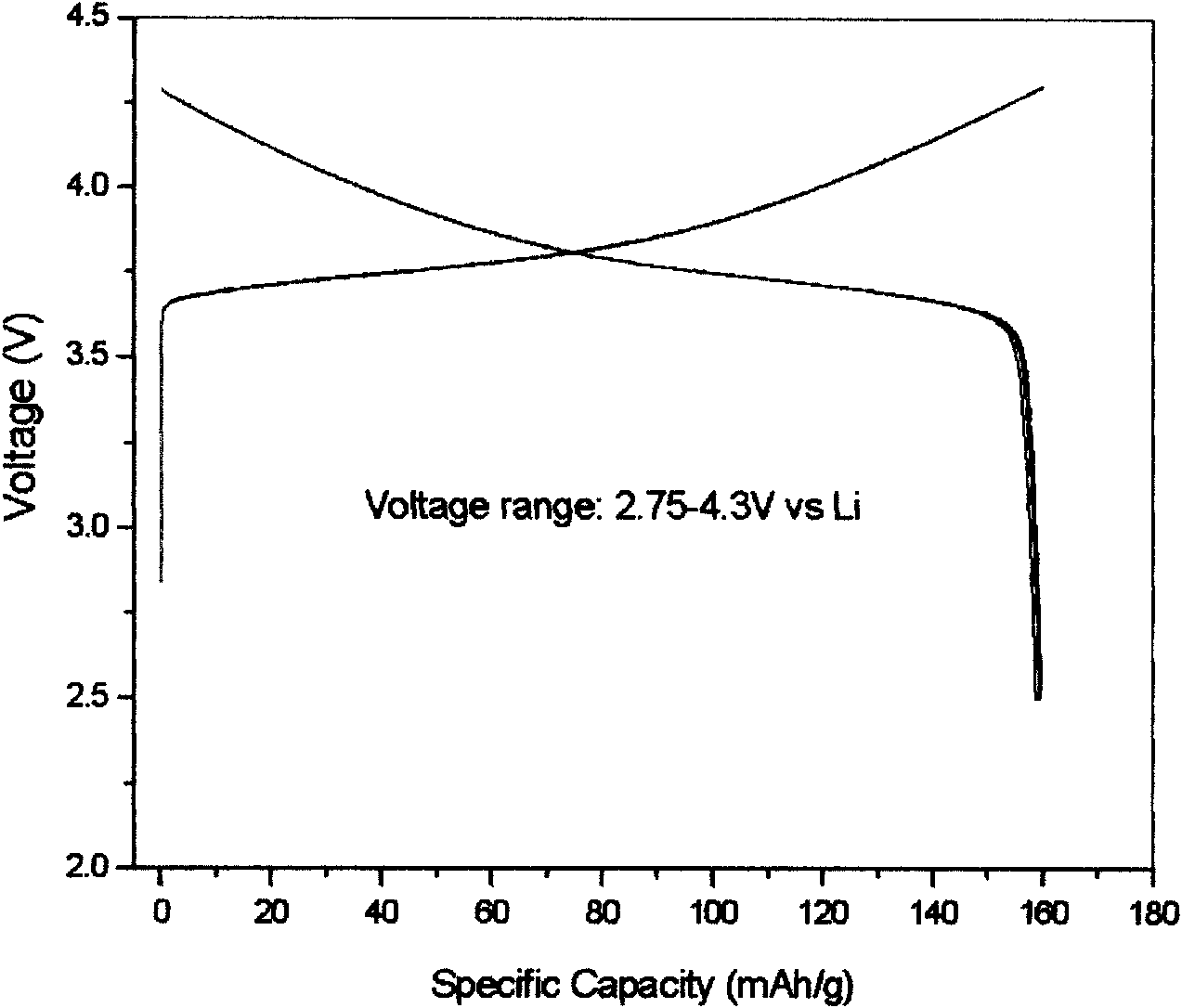

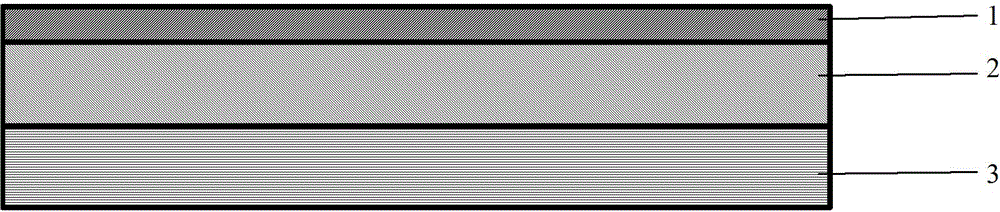

High-performance lithium ion battery cathode material and preparation method thereof

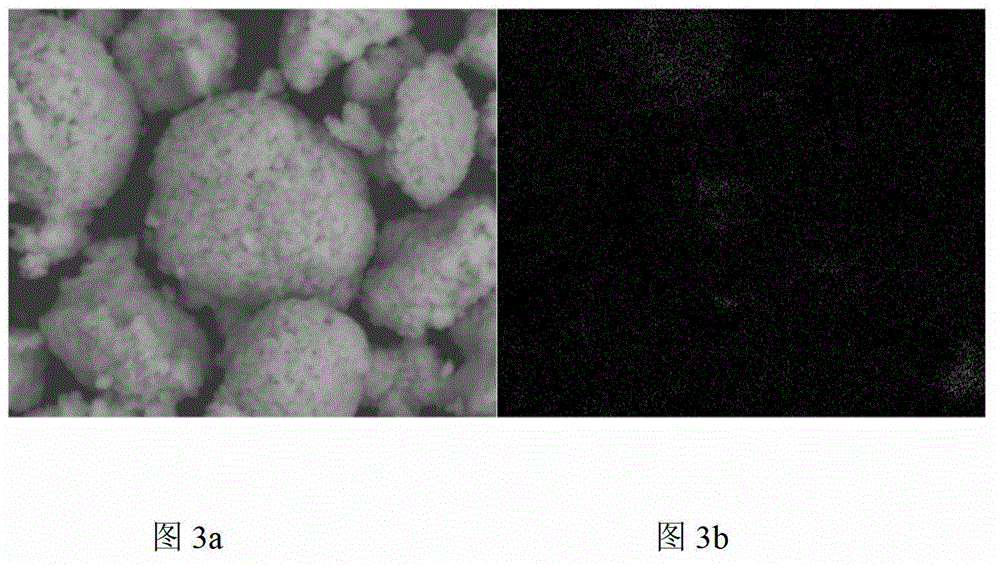

InactiveCN101847722AHigh tap densityImprove electrode processing performanceElectrode manufacturing processesNickel oxides/hydroxidesSingle crystalCobalt

The invention relates to a lithium ion battery cathode material LiNixCoyM1-x-yO2 prepared from micron-sized single crystal particles and a preparation method thereof, wherein x is greater than 0 and is not more than 0.8, y is greater than 0 and is not more than 0.5, and M is one or two of Li, Mn, Al and Mg. The invention is characterized in that (1) composite oxide or hydroxide of transition metal nickel, transition metal cobalt and modified metal M is used as a raw material, the composite oxide or hydroxide is porous aggregate comprising nanocrystals, the average size of the aggregate is 2-50 micrometers, and the specific surface area of the aggregate is greater than 15m<2> / g (measured by BET method); (2) the composite metal oxide or hydroxide and lithium salts are milled in a ball mill, the micron-sized composite metal oxide or hydroxide is converted into nanocrystal particles to obtain a nano-sized mixed precursor of the composite metal oxide or hydroxide and the lithium salts, and the mixed precursor is sintered at uniform temperature to obtain the required lithium ion battery cathode material; and (3) the prepared lithium ion battery cathode material LiNixCoyM1-x-yO2 is basically prepared from micron-sized single crystal particles, and the average size of the single crystal particles is 2-20 micrometers. In addition, the product has excellent physical and electrochemical properties, such as ultra-low specific surface area, reasonable particle size distribution, good electrode processing properties, ultra-long cycle life, excellent rate capability, obvious high and low temperature cycling and storing properties and excellent safety; and the product can be widely used as a high-performance lithium ion battery cathode material. The invention provides the high-performance lithium ion battery cathode material and the preparation method thereof.

Owner:QINGDAO LNCM

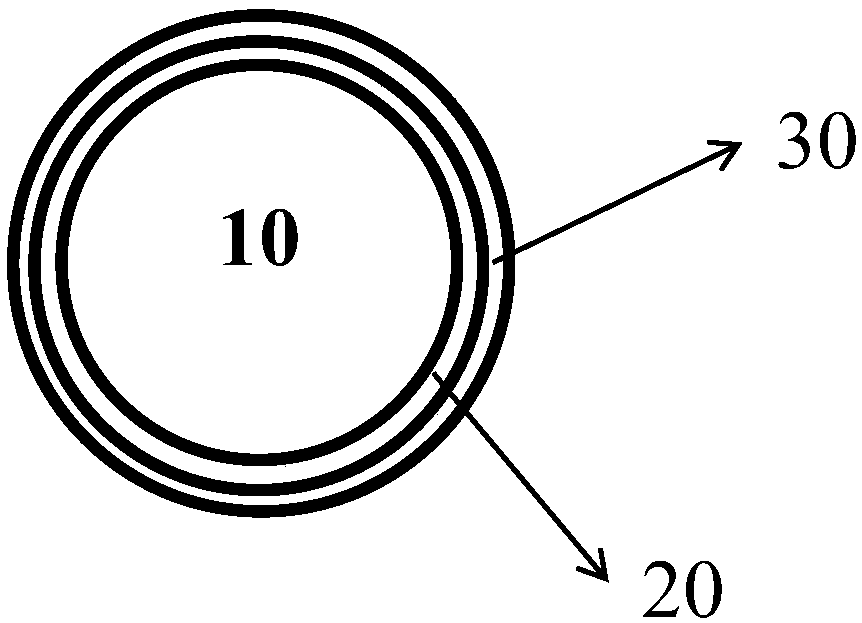

Three-layer core-shell structure positive electrode material, preparation method thereof and lithium ion battery

ActiveCN108598400AImprove ionic conductivityAvoid erosionCell electrodesSecondary cellsElectrical conductorLithium-ion battery

The invention relates to a three-layer core-shell structure positive electrode material. The three-layer core-shell structure positive electrode material comprises a three-layer structure, namely, a ternary positive electrode material inner core, an aluminum oxide layer and a rapid ion conductor layer, wherein the aluminum oxide layer wraps the ternary positive electrode material inner core, and the rapid ion conductor layer wraps the aluminum oxide layer. The invention also comprises a preparation method of the three-layer core-shell structure positive electrode material. Since the rapid ionconductor wrapping an outer layer of the three-layer core-shell structure positive electrode material has super strong ionic conductivity, the integral ionic conductivity of the Al2O3-coated positiveelectrode material can be improved, the electric energy loss is reduced, and the cycle property of a battery is improved; moreover, the aluminum oxide layer and the ternary positive electrode materialinner core form a Li-Al-Co-O co-melting body by high-temperature calcination during the preparation process, the ionic conductivity of the material can be further improved, and the electrical conductivity and the microstructure stability of the composite material are improved; and by the three-layer core-shell structure, the corrosion of an electrolyte to the ternary positive electrode material inner core can be reduced, and the battery safety is improved.

Owner:SOUNDON NEW ENERGY TECH CO LTD

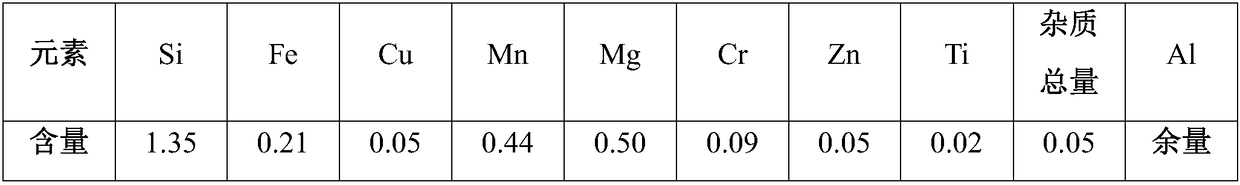

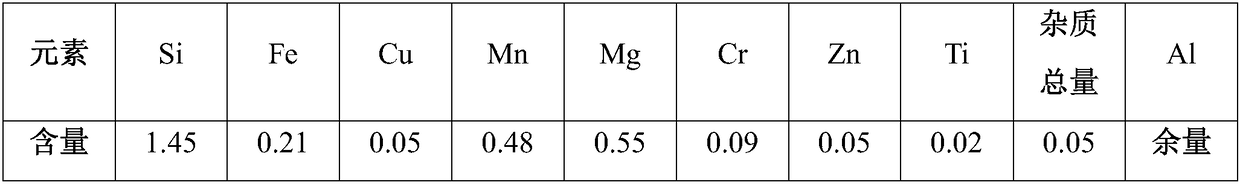

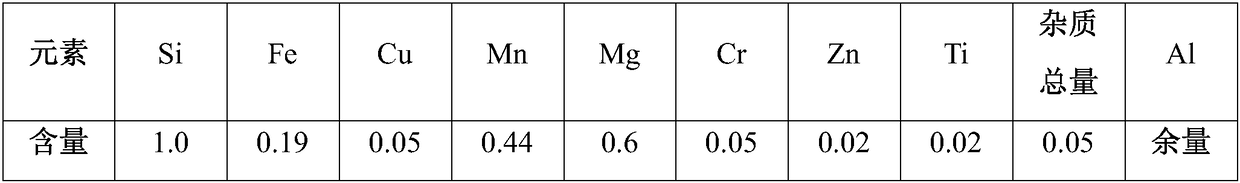

Production process of 6-series aluminum alloy ultra-thin round tube extrusion profile

The invention belongs to the technical field of aluminum alloy production, and relates to a production process of a 6-series aluminum alloy ultra-thin round tube extrusion profile, aluminum alloy rawmaterials comprise 1.35-1.45% of Si, 0.21% of Fe, 0.05 % of Cu, 0.44 to 0.48% of Mn, 0.50 to 0.55% of Mg, 0.09% of Cr, 0.05% of Zn, 0.02% of Ti, <= 0.05% of other single impurities, <=0.15% of total impurities, and balance of Al, an aluminum alloy ingot prepared by the formula is subjected to extrusion, on-line water mist quenching treatment, stretching and straightening, and artificial aging, andthe aging system for the artificial aging is 145+ / -5DEG C *11h, existing quenching method and aging system are changed, the size and the mechanical properties of a finally prepared aluminum alloy ultra-thin round tube can meet the requirements of production preparation, the aluminum alloy tube is thin in wall, and the elongation after fracture is greatly improved.

Owner:CHINA ZHONGWANG

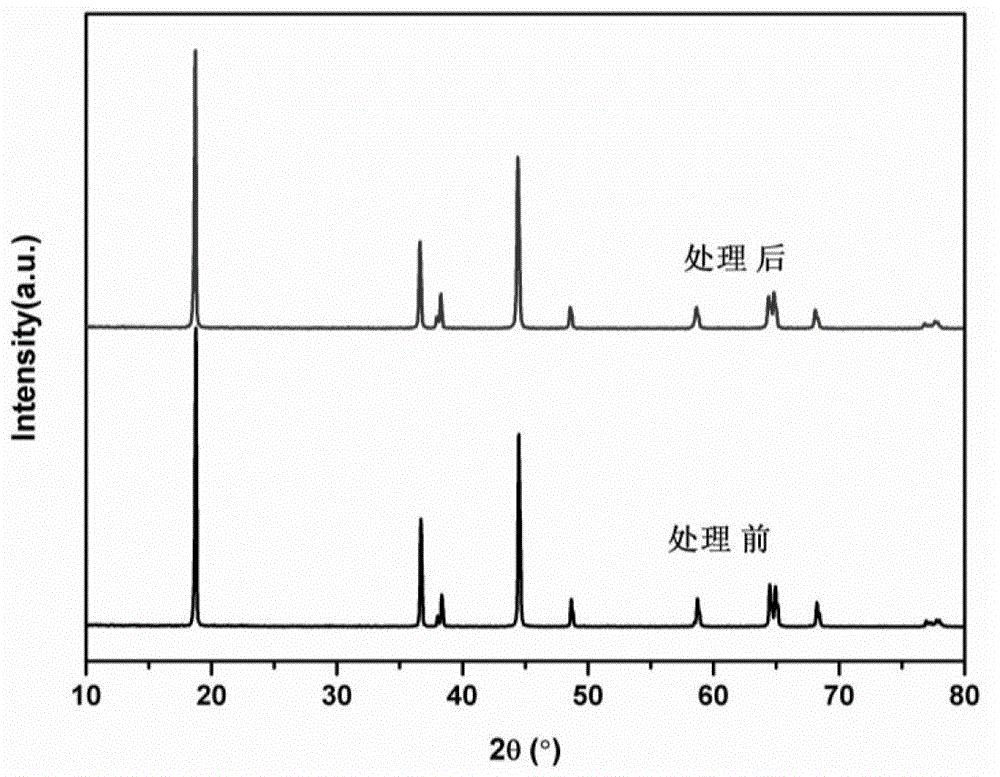

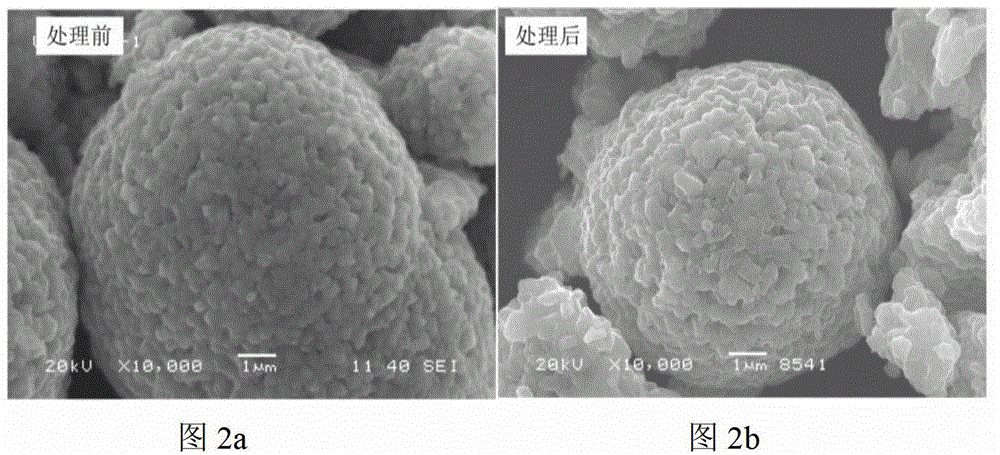

Method for removing lithium ion battery nickel-rich material surface lithium residues by liquid phase precipitation method

ActiveCN102881911ALow hygroscopicityGood hygroscopicityCell electrodesMoisture absorptionMaterial physics

The invention discloses a method for removing lithium ion battery nickel-rich material surface lithium residues by a liquid phase precipitation method. The method for removing the lithium ion battery nickel-rich material surface lithium residues by the liquid phase precipitation method includes the steps: dispersing lithium ion battery nickel-rich materials into phosphate solution, combining the nickel-rich material surface lithium residues with phosphate radical ions so as to form precipitation, nucleating on the material surface, and calcining so that a material with the surface wrapped with a compact Li3PO4 layer is obtained. The wrapping layer prepared by the method is more uniform and compact than a traditional wrapping layer, and storage performance of the material in air is obviously improved; and the moisture absorption performance of the nickel-rich materials can be improved while water brought into electrolyte by electrode materials is reduced, and structural stability of the material is enhanced. Moreover, Li3PO4 is better in stability in the electrolyte than in the battery materials, so that the comprehensive electrochemical performance of a positive electrode material can be effectively improved. The method for removing the lithium ion battery nickel-rich material surface lithium residues by the liquid phase precipitation method is simple in preparation process, short in flow path and low in production cost, and the prepared positive electrode material is excellent in physical performance and electrochemical performance.

Owner:CENT SOUTH UNIV

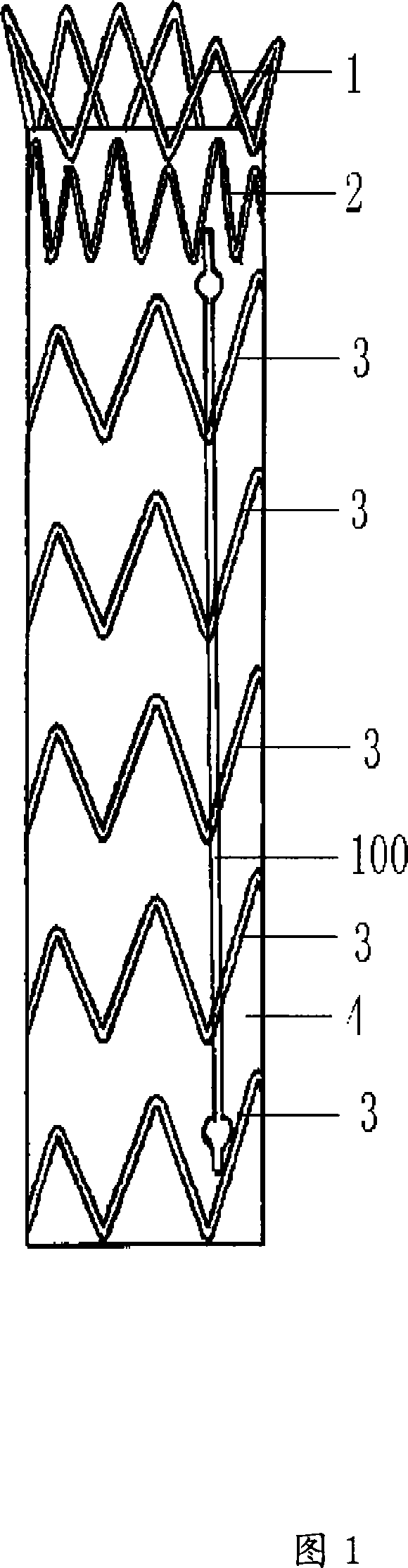

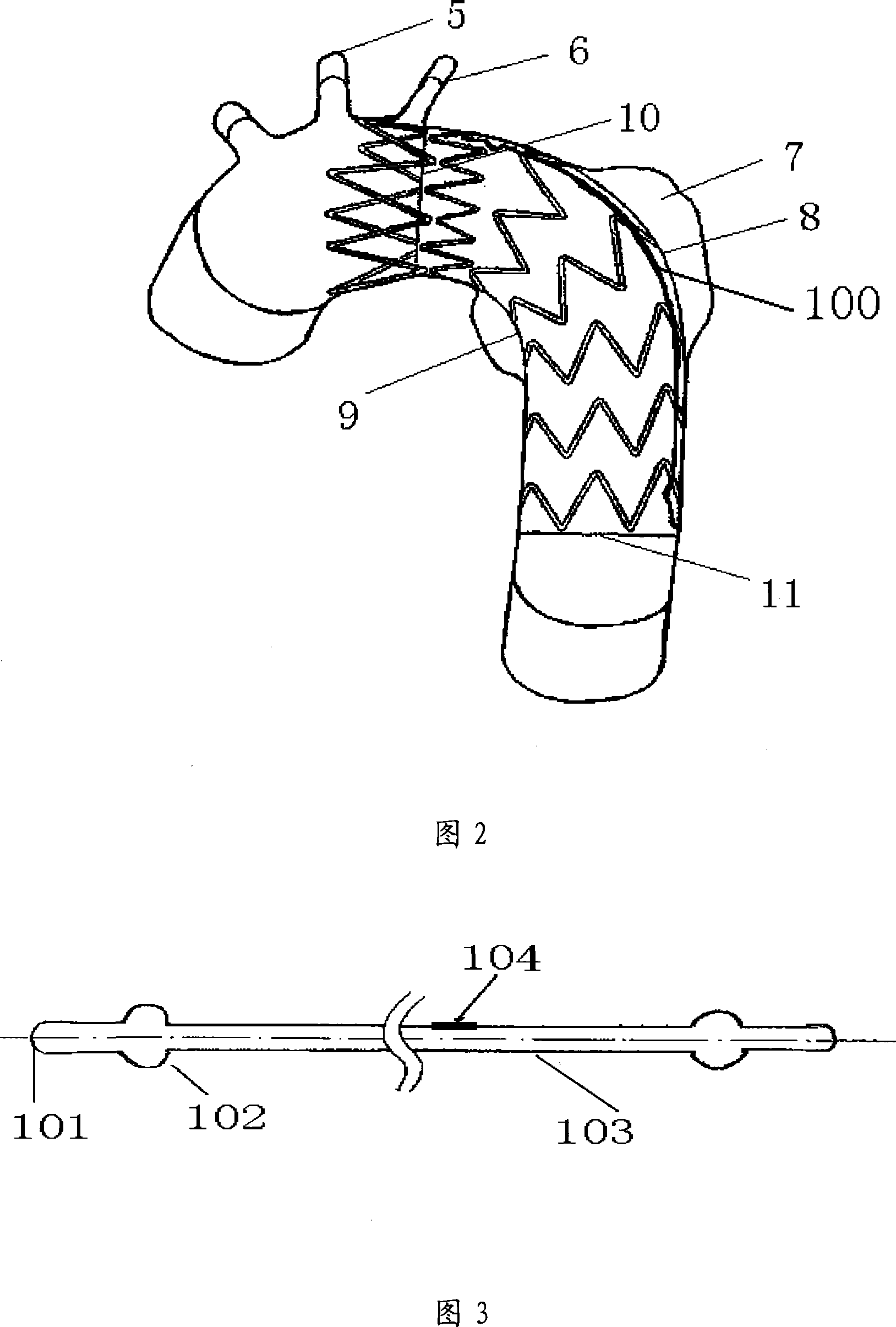

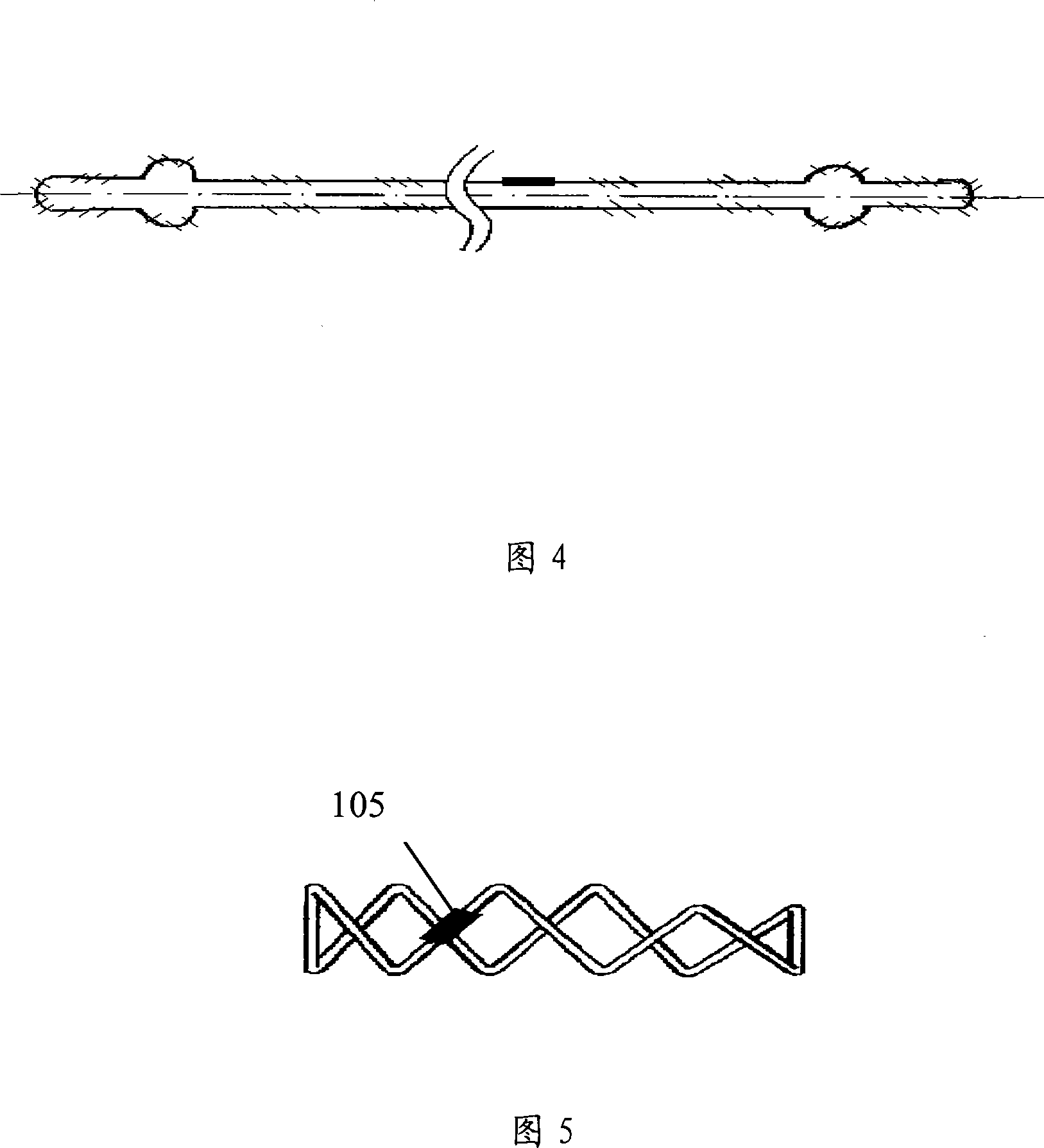

Tectorial bracket

ActiveCN101176686AReduced maximum outer profileEasy to installStentsSurgeryTectorial membraneLead blood

The invention discloses a coated stent, comprising a stent section, a coat and a reinforcement; wherein, two ends of a metal wire are connected to form the reinforcement which is fixed on the coat. The invention is characterized in that: since the coated stent adopts the independent reinforcement, the reinforcement is separated from the stent section, avoiding the risk that in prior art the integral connection of the reinforcement and the front and end stent sections can lead to fracture; furthermore, the hindrance produced in the course of releasing and assembling the whole stent is reduced,which is helpful for the releasing and assembling of the coated stent. The invention also discloses another coated stent comprising a stent section and a coat; wherein, two ends of a metal wire are connected by laser welding to form the stent section. Since two ends of the metal wire in each stent section are not fixedly connected, prior coated stent can lead blood damage; therefore, the risk is avoided.

Owner:SHANGHAI MICROPORT ENDOVASCULAR MEDTECH (GRP) CO LTD

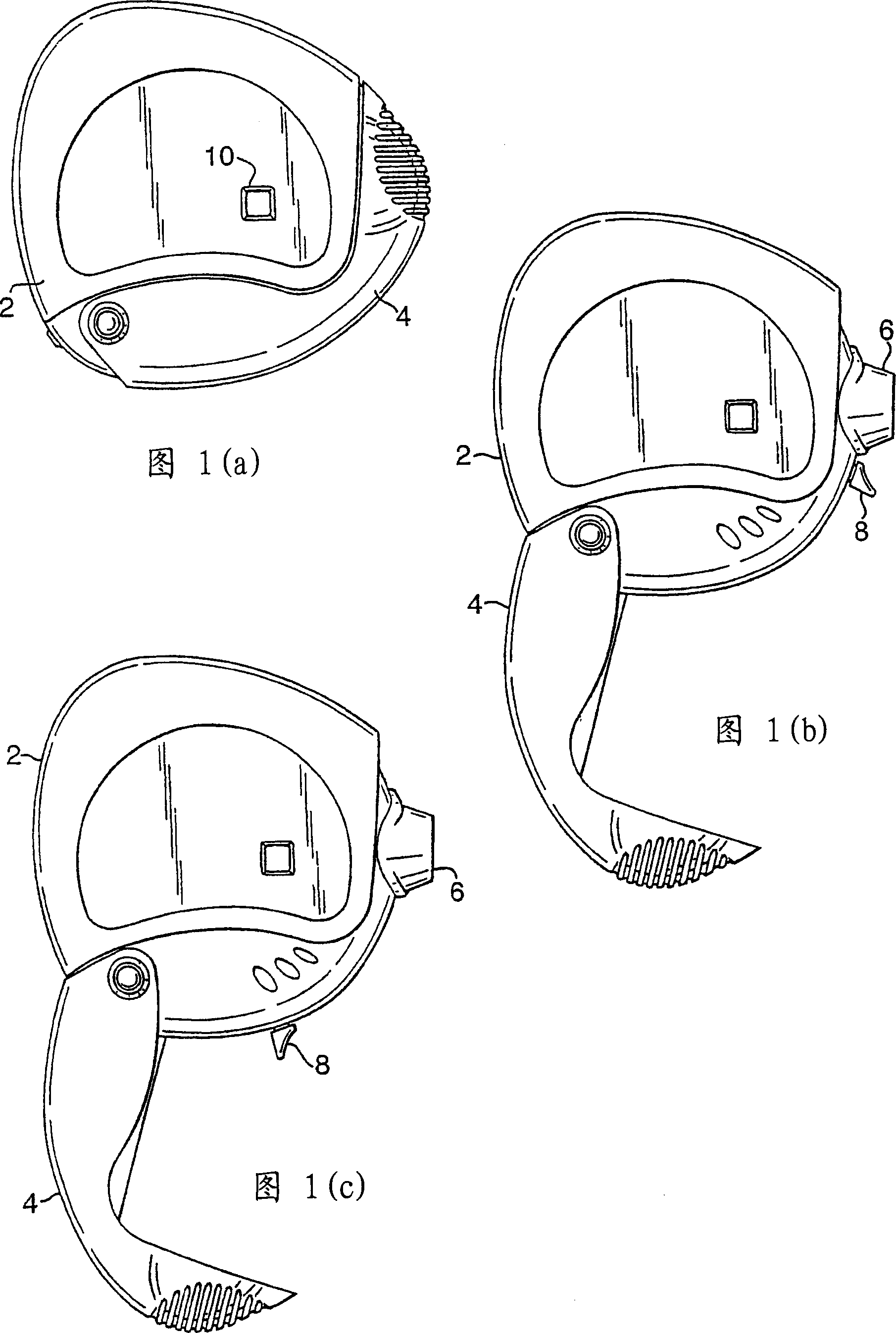

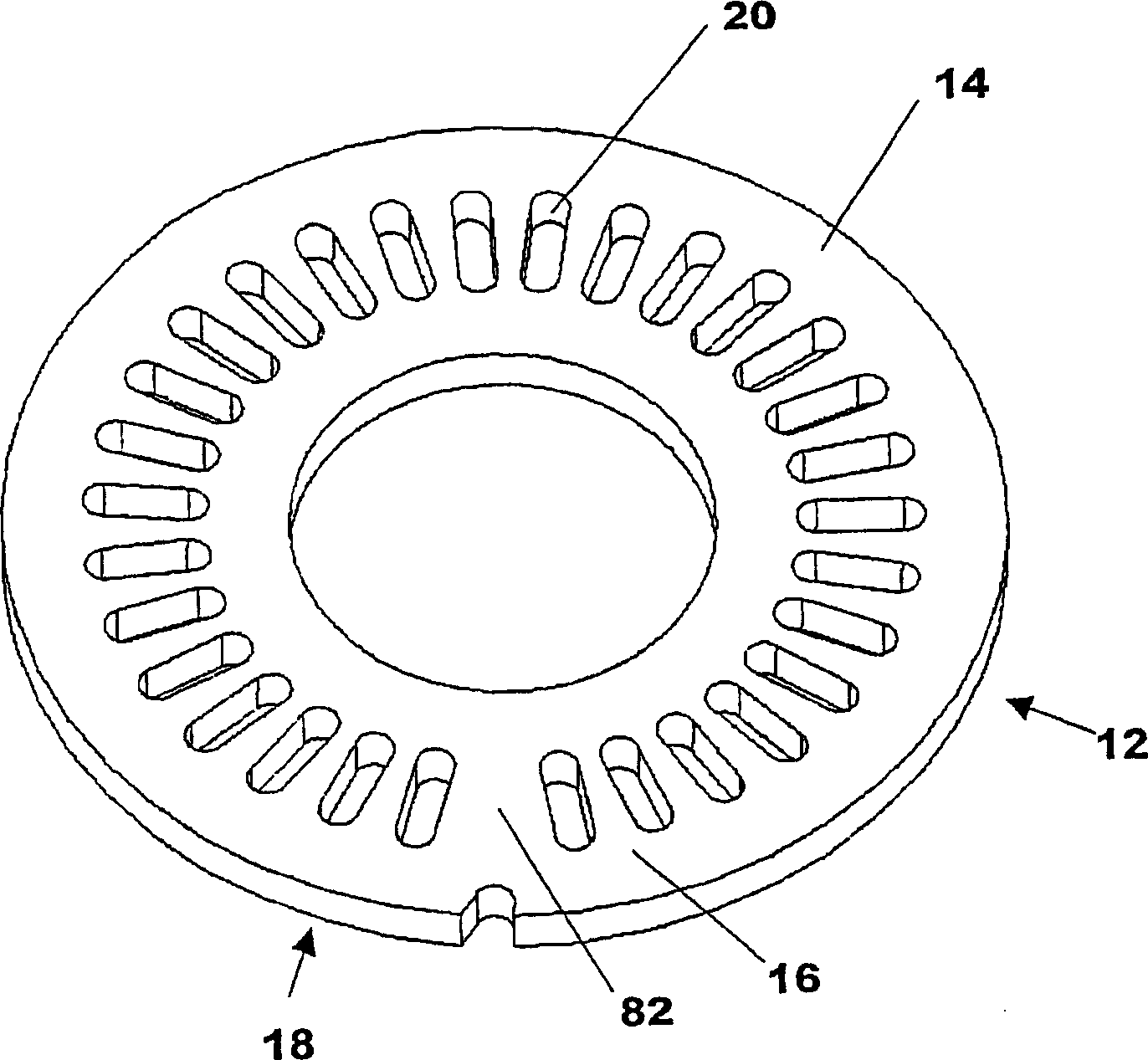

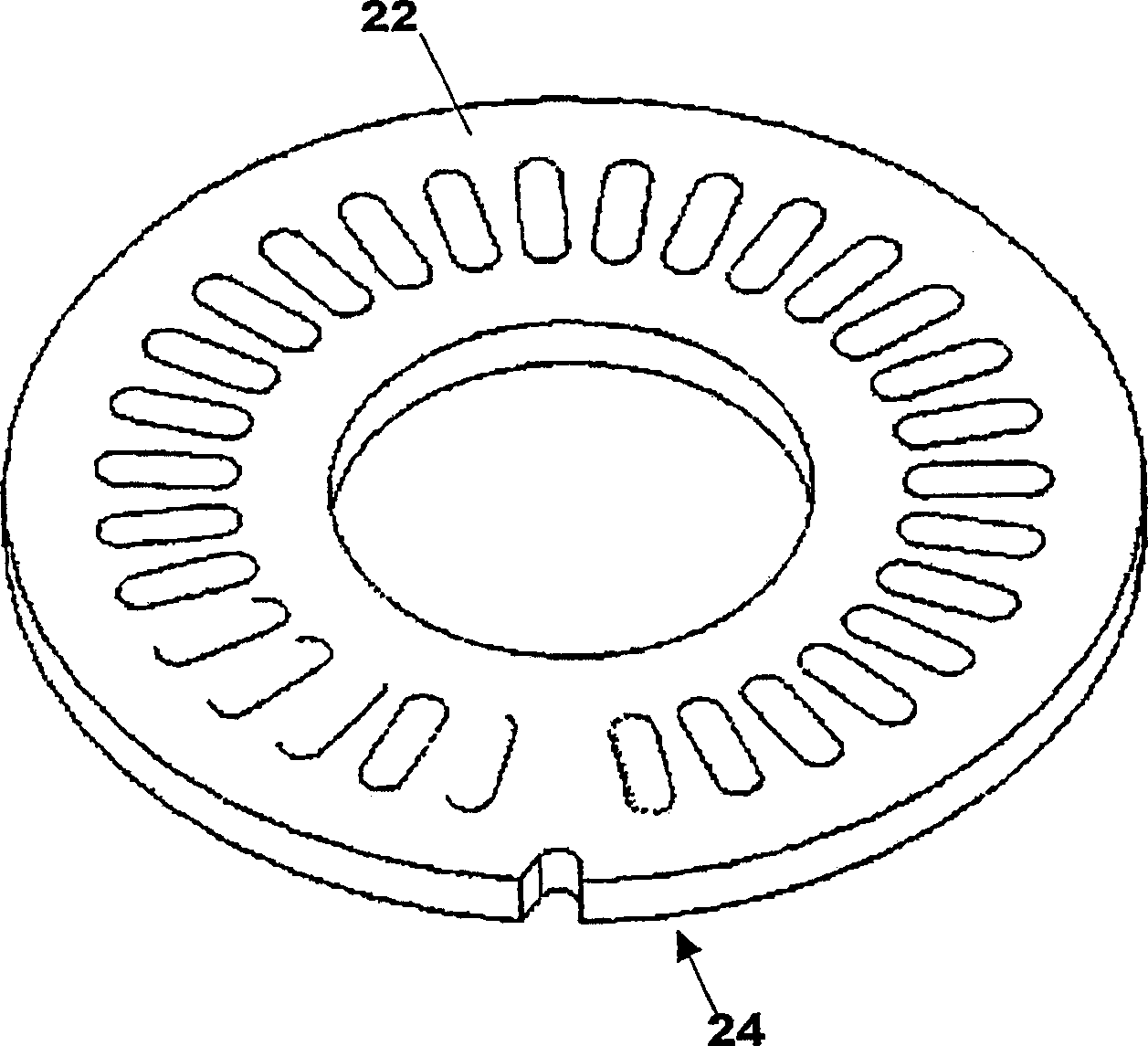

Dispensing device

ActiveCN1871044AReduce hindranceAvoid smallPowdered material dispensingMedical devicesIndividual doseEngineering

A device for dispensing individual doses of powder from respective pockets of a disc-shaped carrier by outwardly rupturing a lidding foil by means of pressure on an opposite side surface, the device providing individual respective deaggregation flow paths for each pocket, split airstreams allowing improved entrainment of powder, a cam mechanism for outwardly rupturing the pockets, an indexing mechanism linked to the cam mechanism and a dose counter.

Owner:PFIZER INC

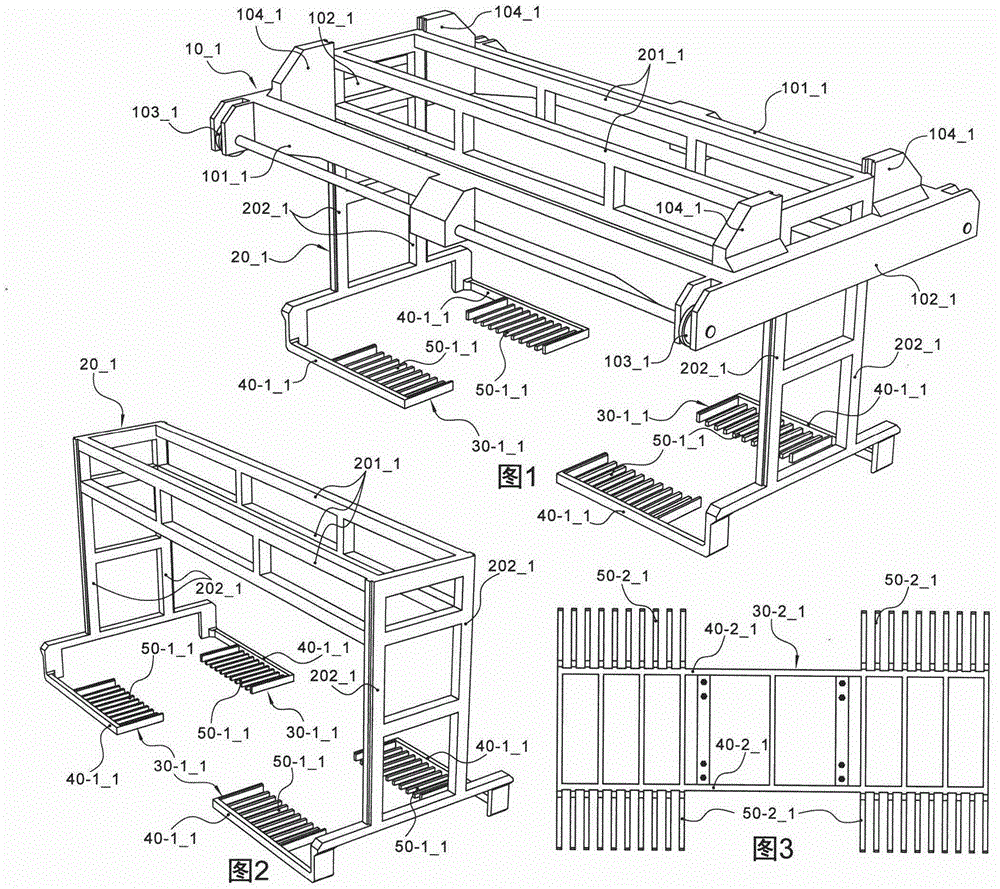

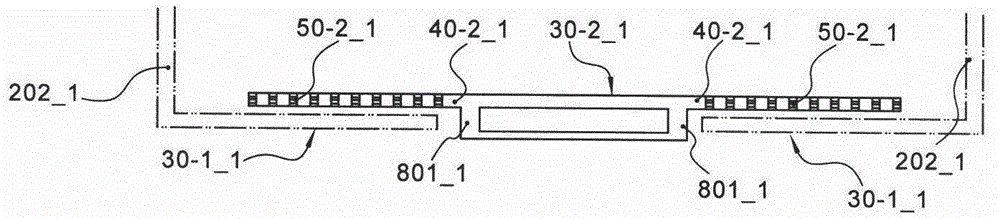

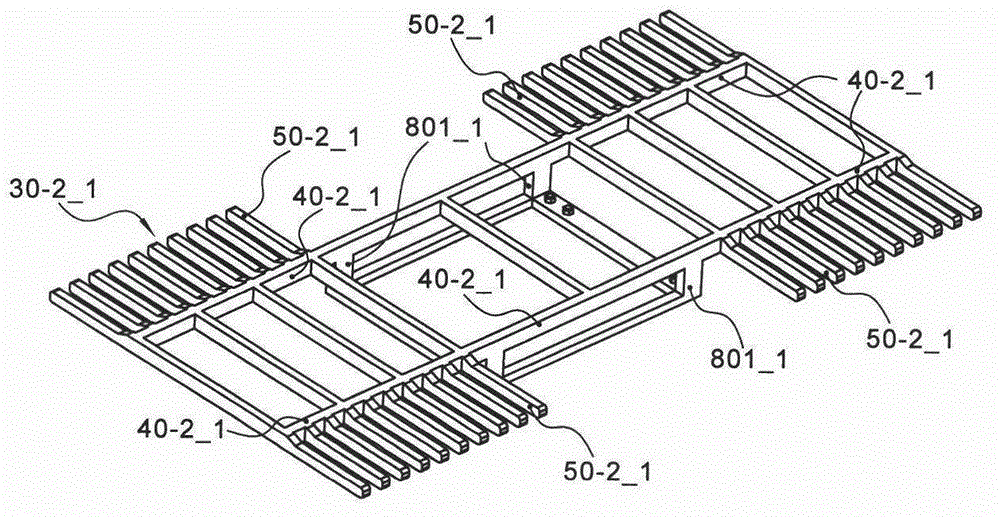

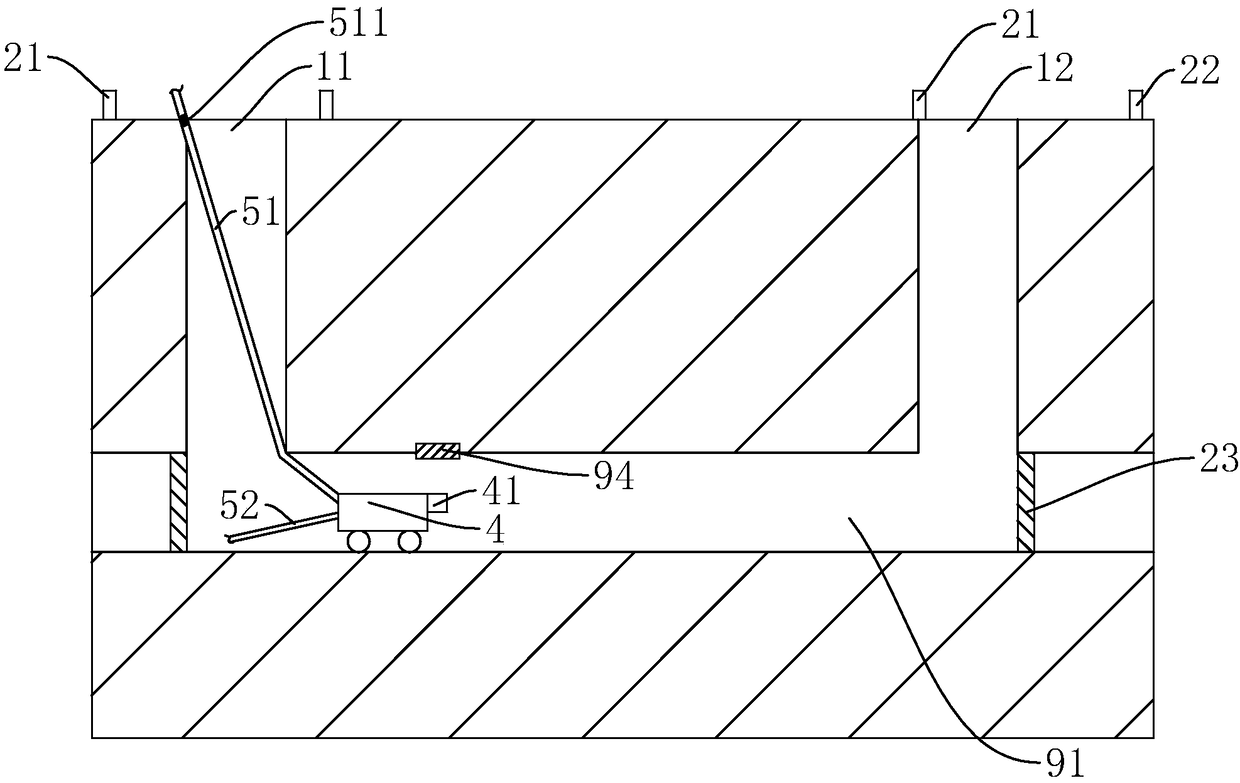

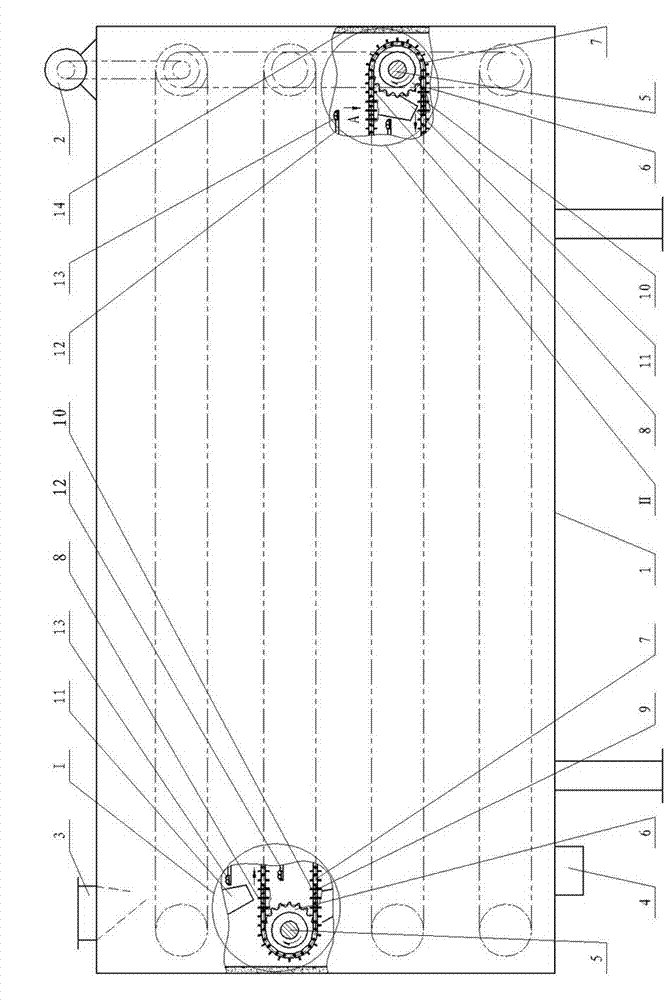

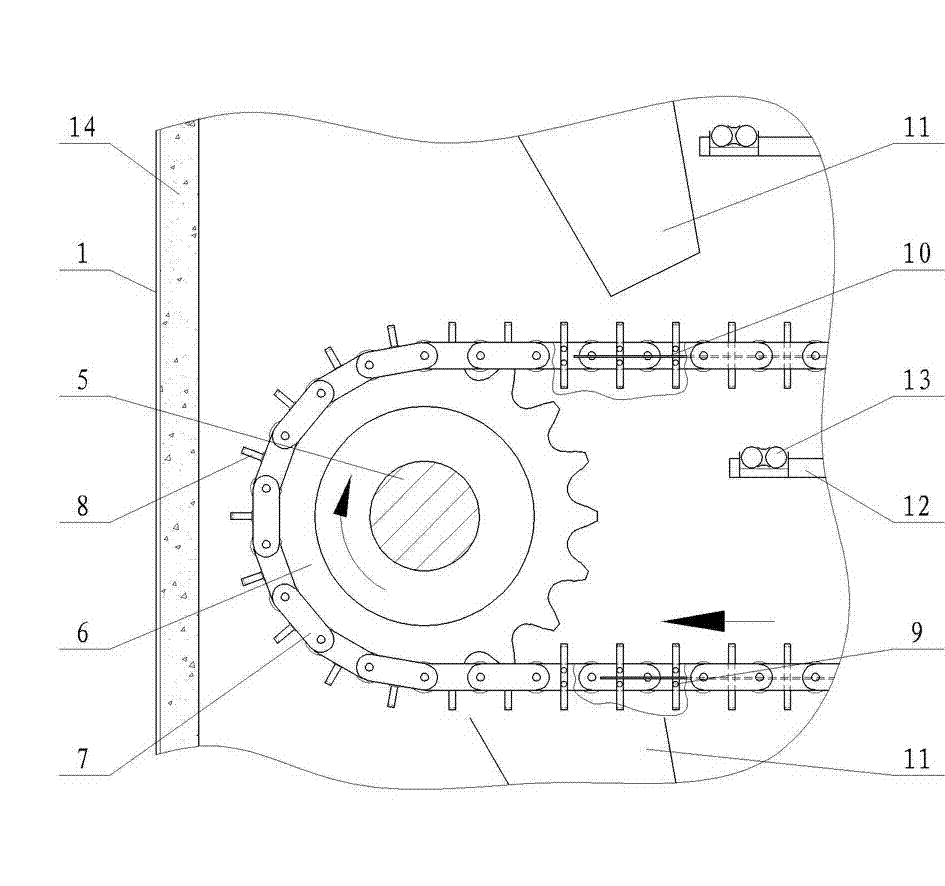

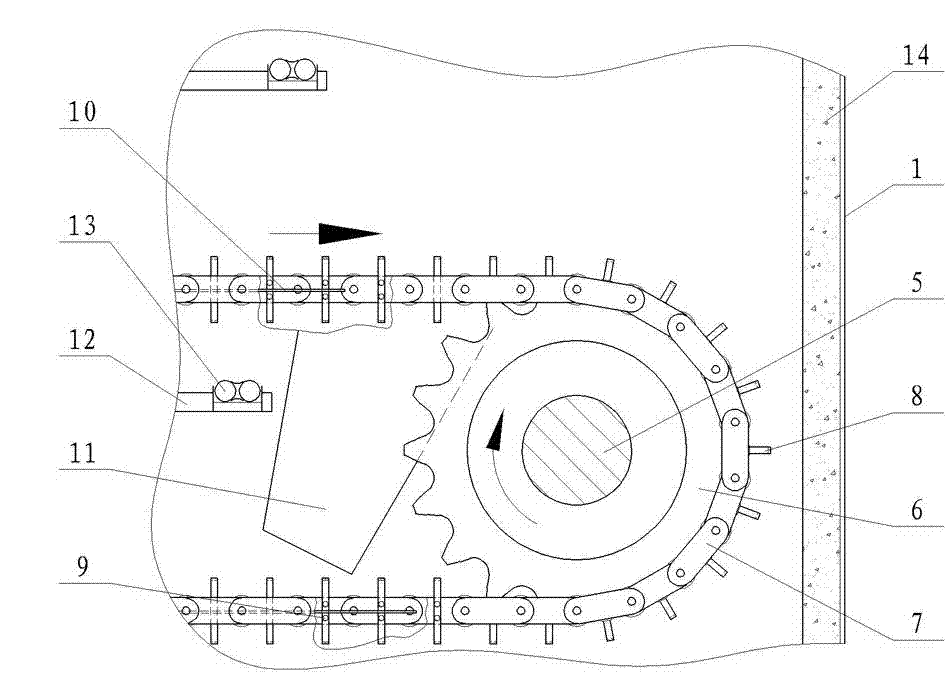

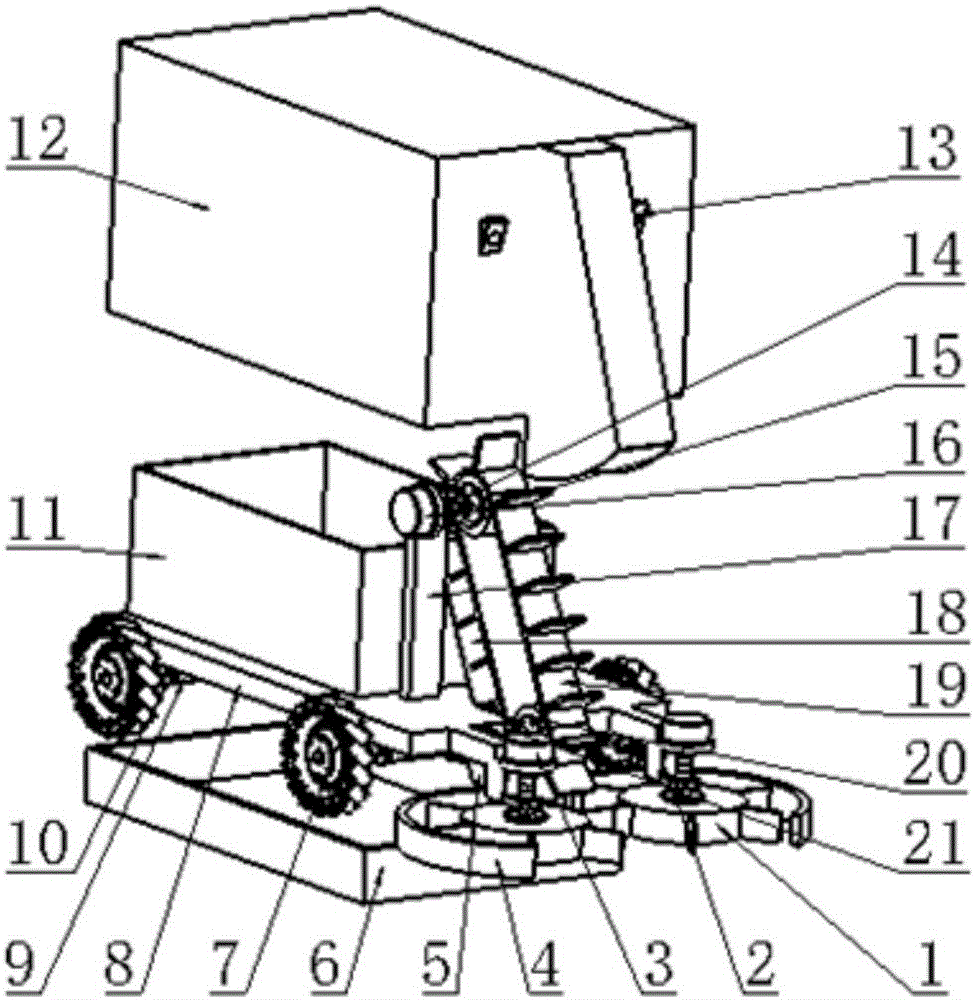

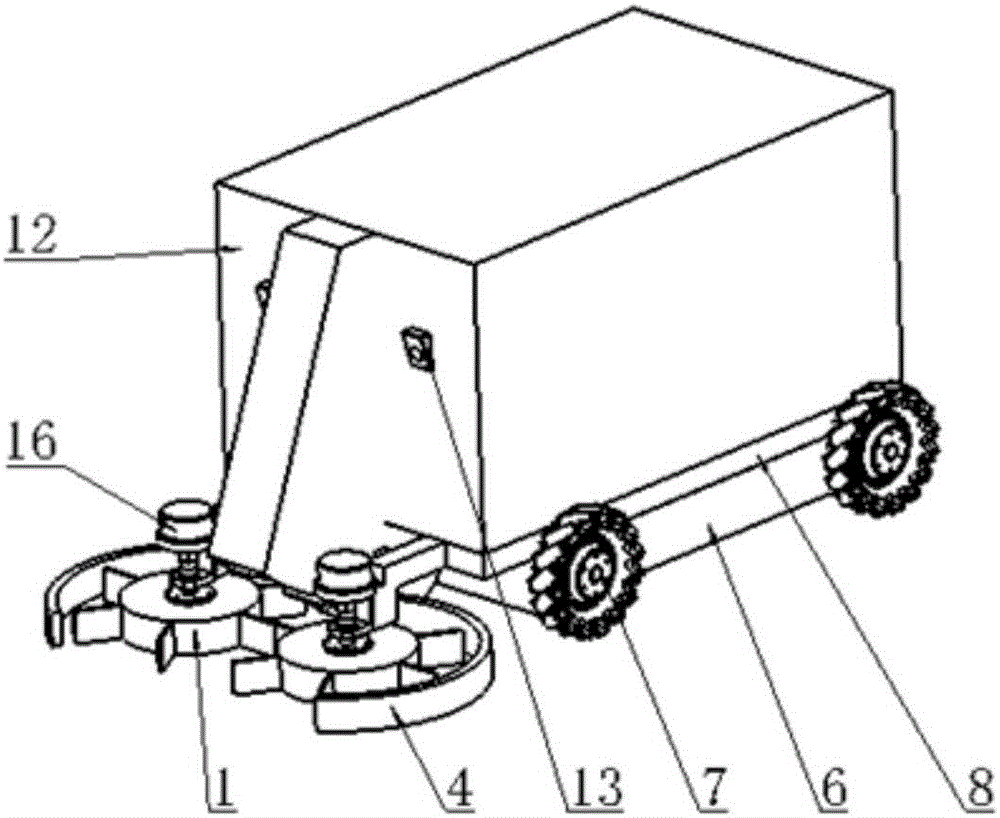

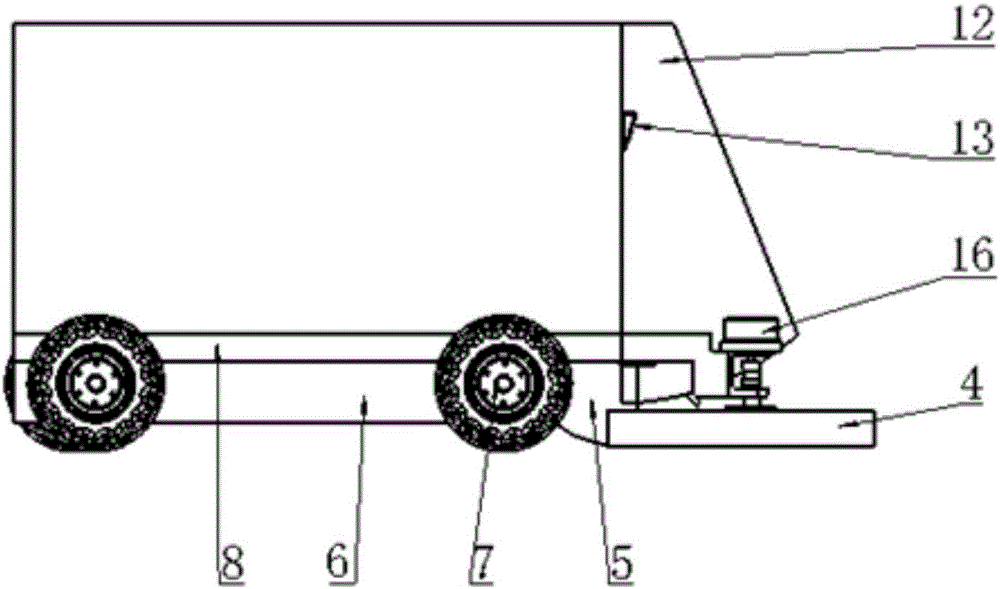

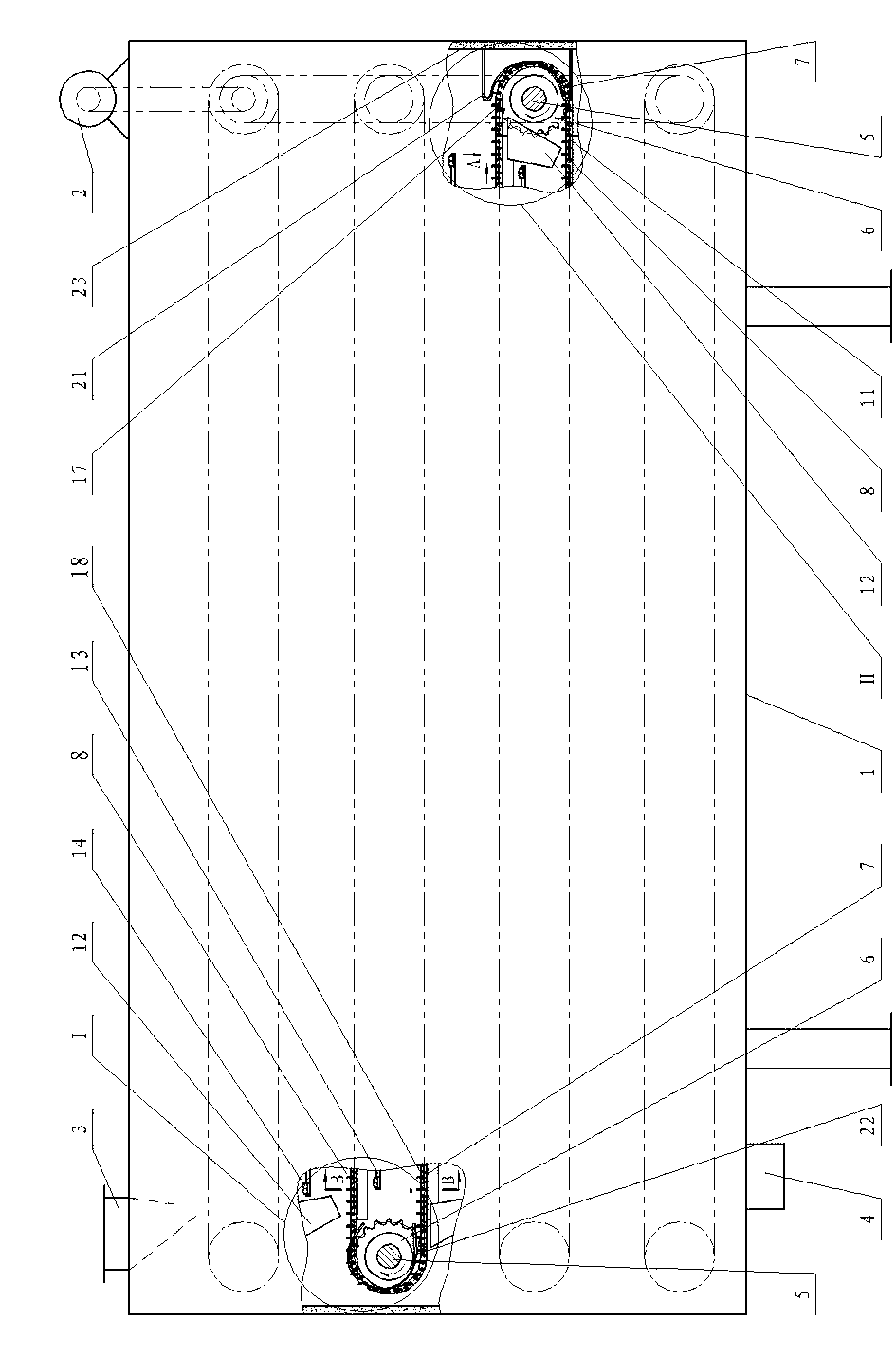

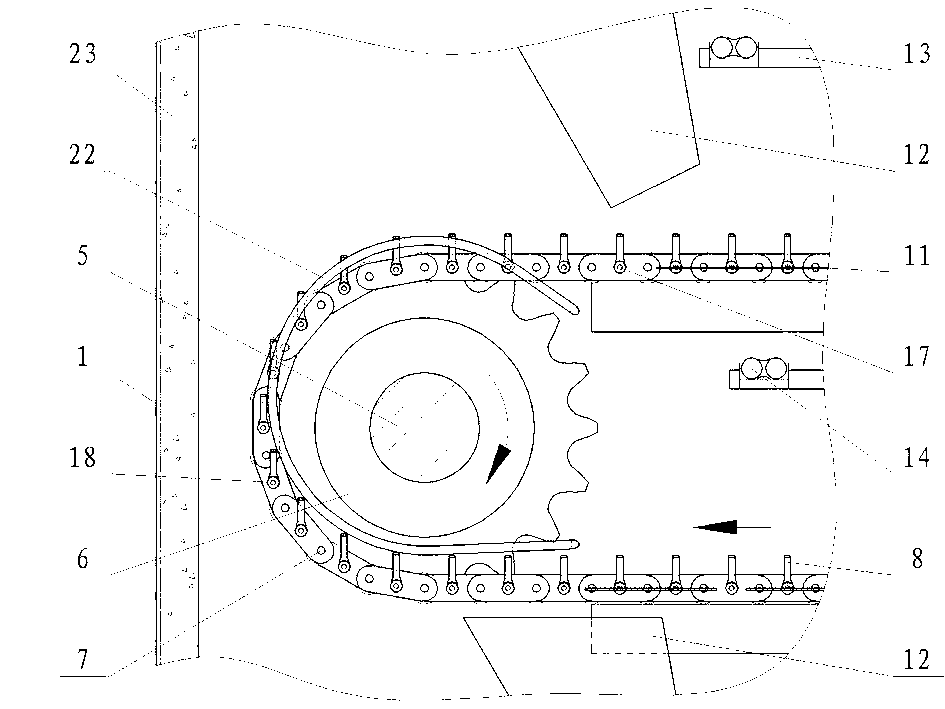

Parking device with comb teeth for supporting, storing and withdrawing vehicle

The invention provides a vehicle carrying scheme that lifting racks are used for lifting a vehicle above a vehicle top so as to perform leap-type translation in order to solve the problems that existing parking devices with the comb teeth for supporting, storing and withdrawing the vehicle are low in using ratio of the ground, inflexible in application, poor in storing and withdrawing efficiency and the like. Besides, by means of mutually communicated storing and withdrawing rack channels which are distributed below all comb-shaped parking racks of a parking queue, comb-shaped storing and withdrawing racks of carriers can directly and rapidly move and operate between each comb-shaped parking rack and vehicle storing and withdrawing port, the process of lifting and putting the road vehicle to a garage can be simply finished by the aid of comb-shaped lifting racks which are arranged at positions of the vehicle storing and withdrawing ports, a system is effectively simplified, and the efficiency is increased.

Owner:于君

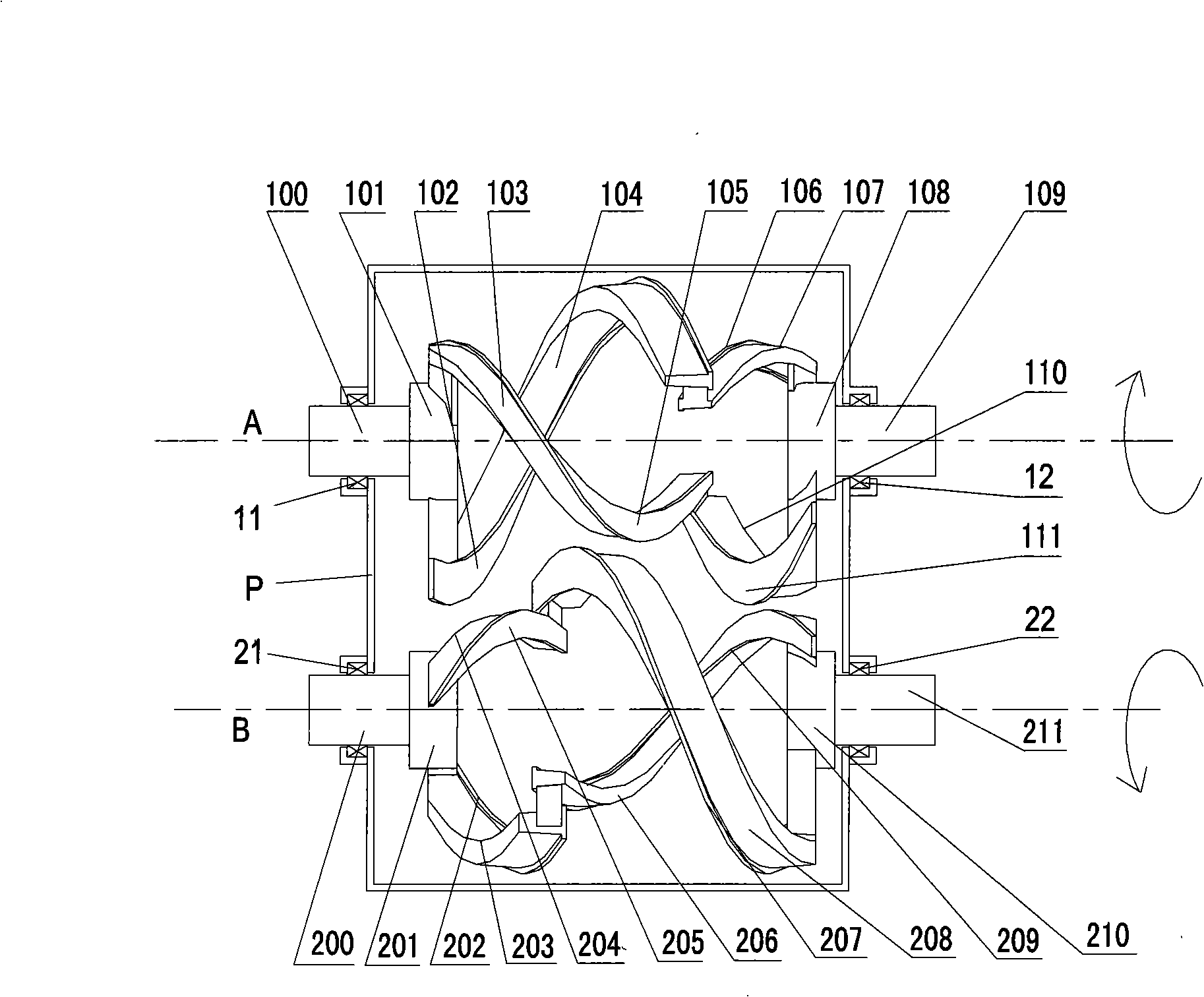

Double-helix shaft double-helical ribbon concrete batch plant

InactiveCN101347961ANot easy to hold the shaft and agglomerateSpeed up the flowCement mixing apparatusFistHorizontal axis

The invention relates to a double spiral axis double spiral ribbon concrete mixing plant, which relates to a mixer for clay or cement and other materials which turns around the horizontal or basically horizontal axis. The concrete mixing plant is provided with a machine body, a first agitation system and a second agitation system. The fist agitation system is provided with a left spindle head, a right spindle head and four spiral axes which are connected with the left and right spindle heads. The second agitation system is provided with the left spindle head, the right spindle and the four spiral axes which are connected with the left and right spindle heads. The direction of the spiral of an internal return unit shaft is opposite to that of the spiral of an internal feeding unit shaft; and the direction of the spiral of an external feeding unit shaft is opposite to that of the spiral of the external return unit shaft. The left and right spindle heads of the first agitation system and the second agitation system are connected with a bearing bracket arranged on the machine body. The speed at which the spindle axes move relative to materials is larger;, so the materials are subject to smaller resistance when being mixed in the mixer, the cement is difficult to curdle around the axes, and the materials flow smoothly in the mixer, thus ensuring that the mixer has .lower energy consumption and higher mixing efficiency, reducing cleaning time and increasing the service efficiency of the mixer.

Owner:蔡达棋

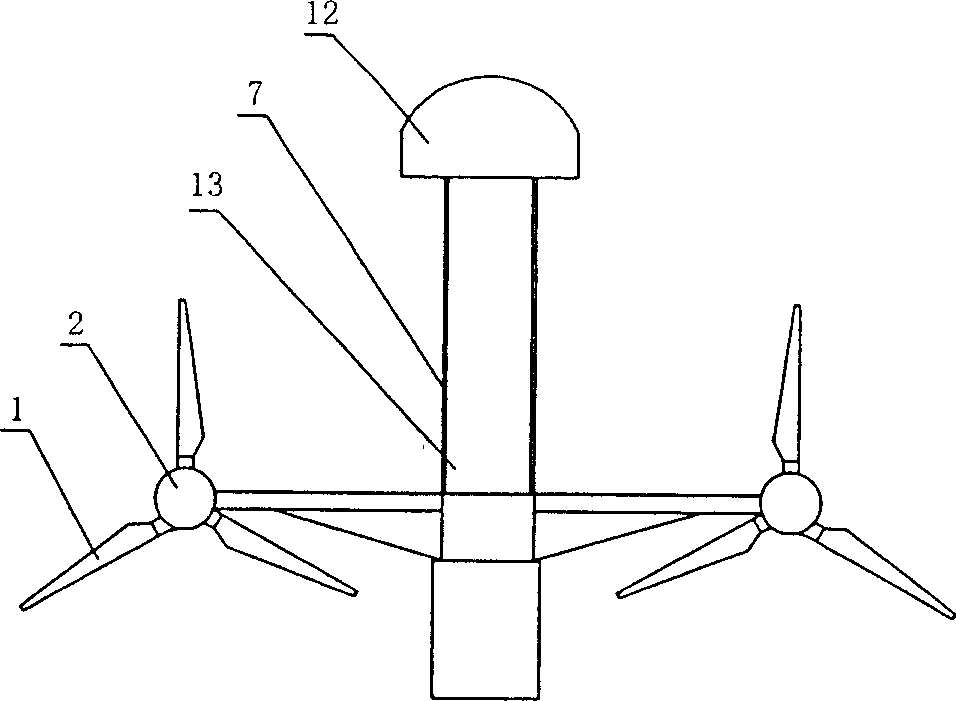

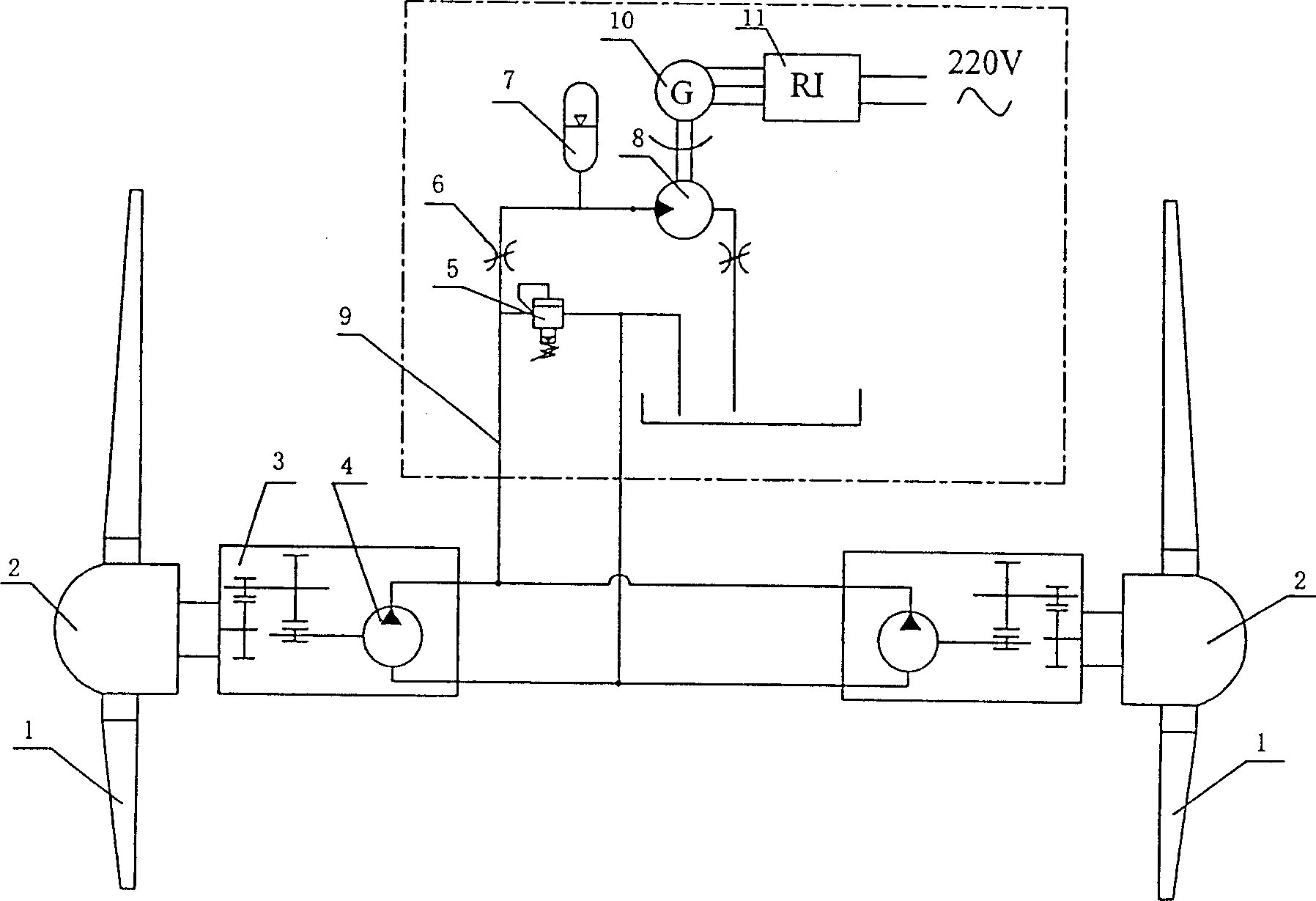

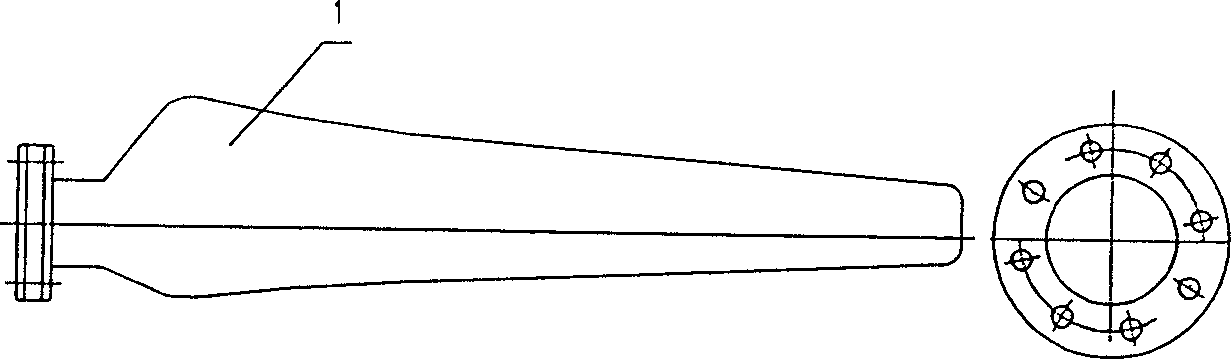

Hydraulic underwater windmill generator

The present invention discloses a kind of hydraulic type underwater windmill power generation equipment. It includes the following several portions: blade wheel, speed-increasing box, hydraulic pump, valve control mechanism, hydraulic motor, power generator, commutation storage excitation transformation controller, power generation platform and tower frame. Besides, said invention also provides the working principle of said hydraulic type underwater windmill power generation equipment and its concrete operation method.

Owner:ZHEJIANG UNIV

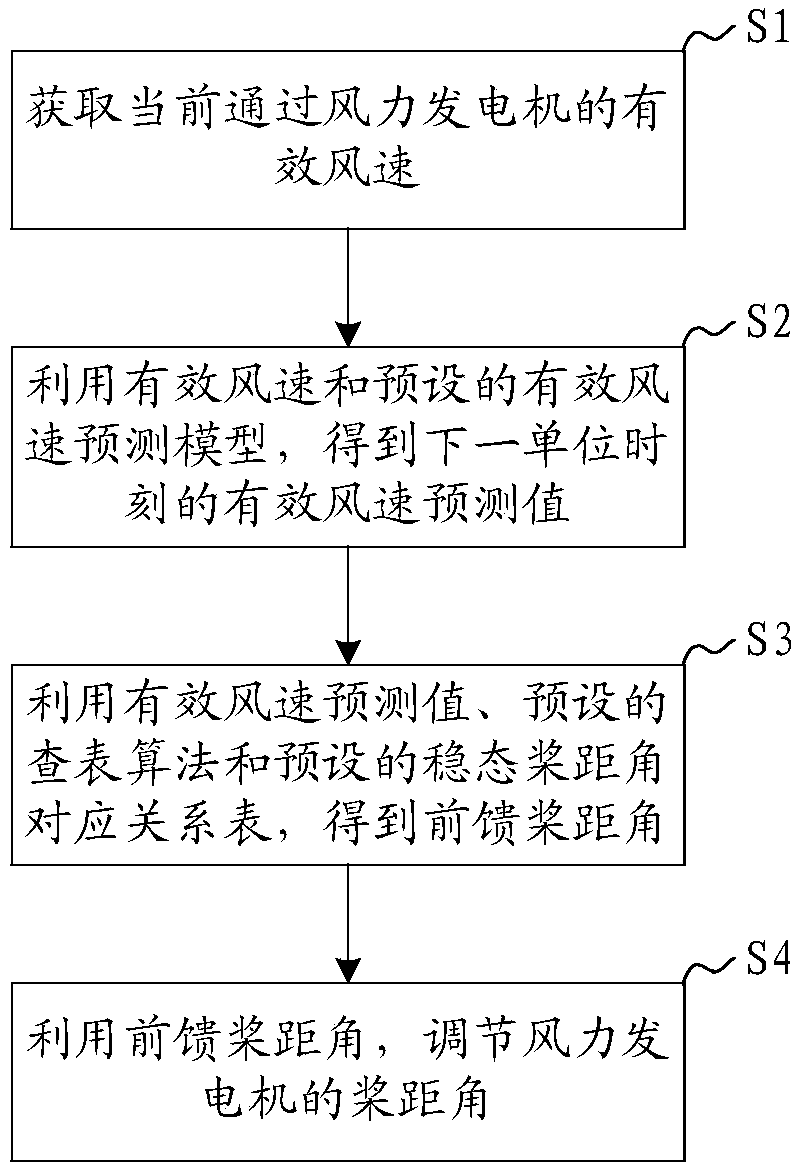

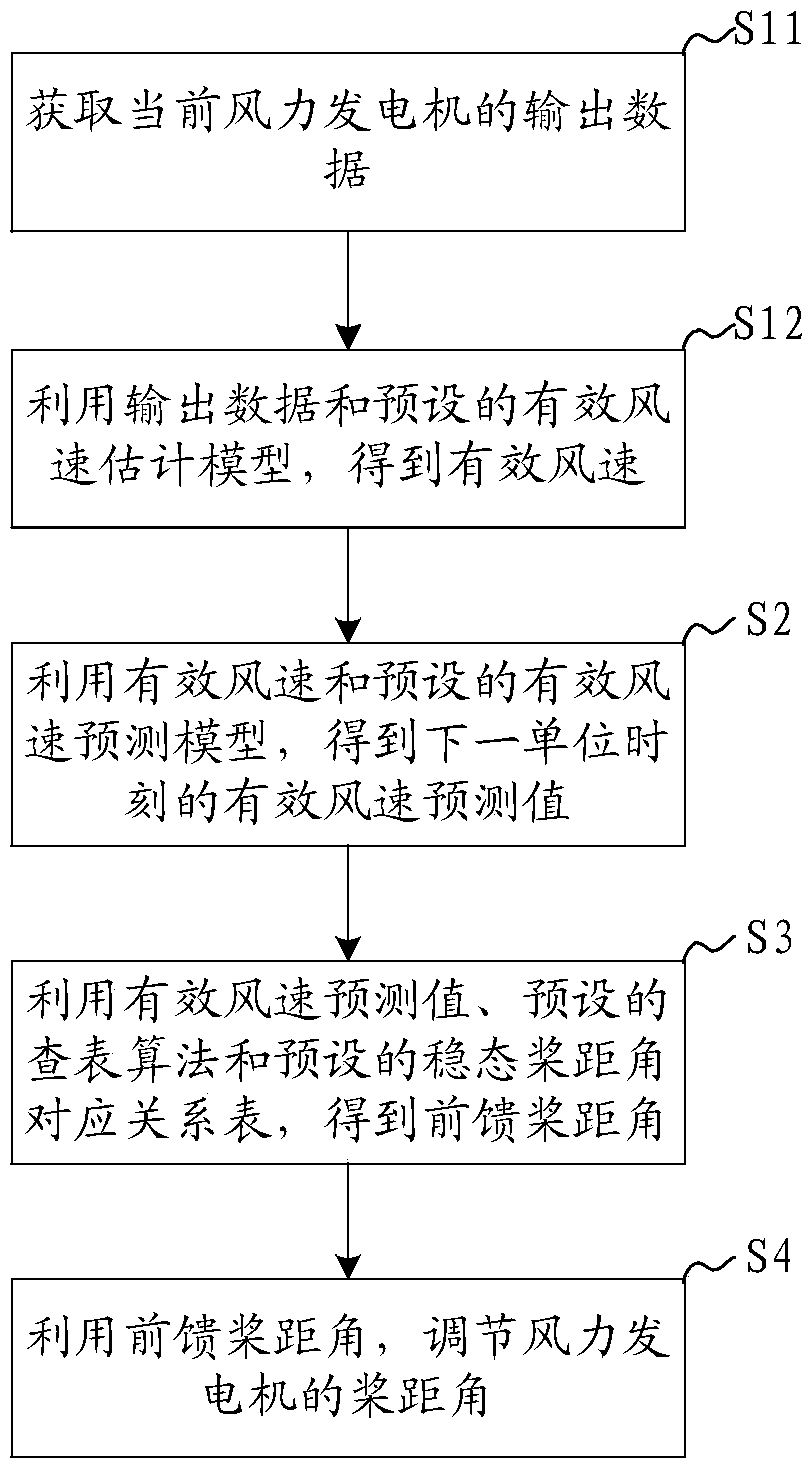

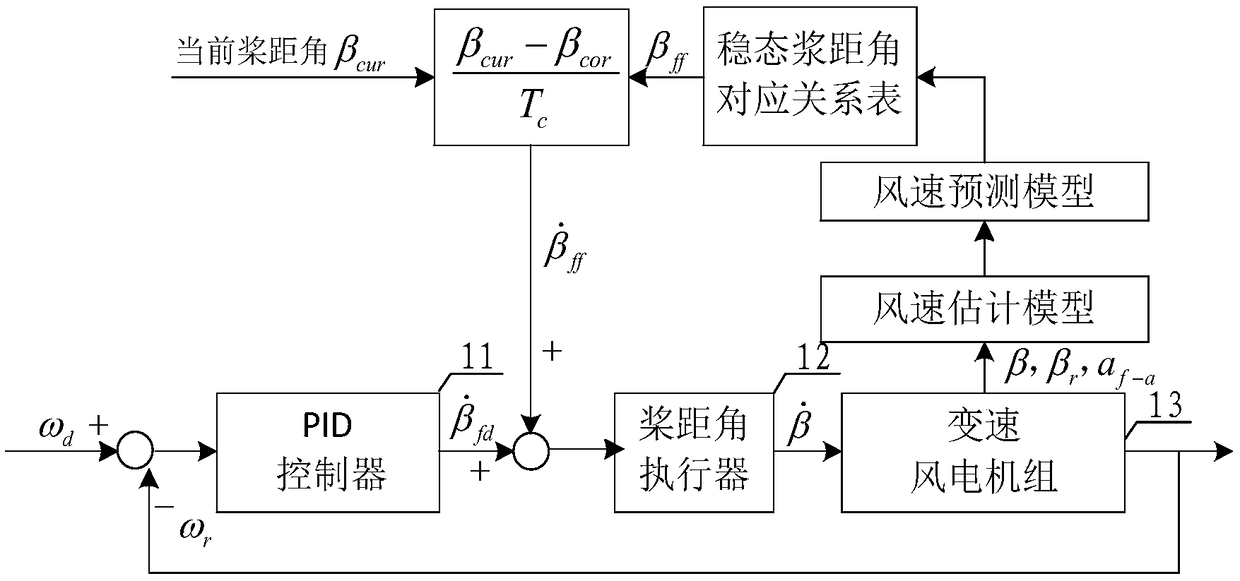

Wind driven generator pitch angle control method, system and device and readable storage medium

ActiveCN109185054AImplement early transformationIncrease transition timeWind motor controlClimate change adaptationEngineeringDynamo

The invention discloses a wind driven generator pitch angle control method, system and device and a computer readable storage medium. The method comprises the steps that the effective wind speed of awind driven generator at present is obtained; the effective wind speed predicted value in the next unit time is obtained through the effective wind speed and a preset effective wind speed prediction model; the feedforward pitch angle is obtained through the effective wind speed predicted value, the preset lookup algorithm and the preset steady pitch angle corresponding relation table; and throughthe feedforward pitch angle, the pitch angle of the wind driven generator is adjusted. According to the method, the effective wind speed predicted value of the current effective wind speed e in the next unit time is predicted in advance, through the effective wind speed predicted value, the feedforward pitch angle is looked up and worked out in the preset steady pitch angle corresponding relationtable, the pitch angle of the wind driven generator is adjusted, the pitch is changed in advance, the pitch change time is prolonged, the change rate is not too large, resistance of wind force to pitch change is reduced, the load of a pitch system is decreased, and the service life of the pitch system is prolonged.

Owner:ZHEJIANG WINDEY +1

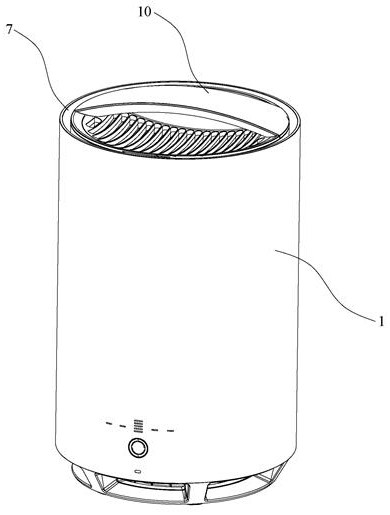

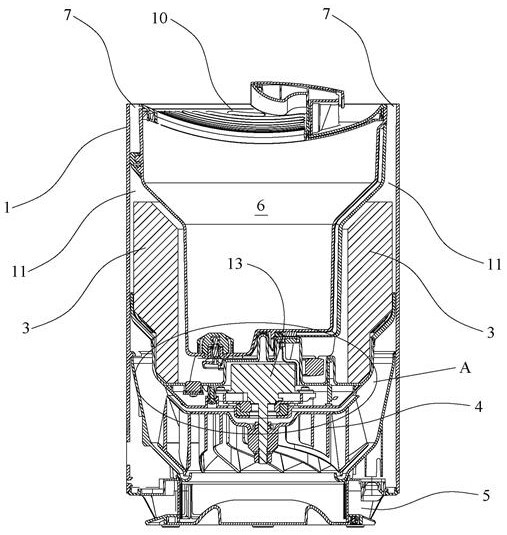

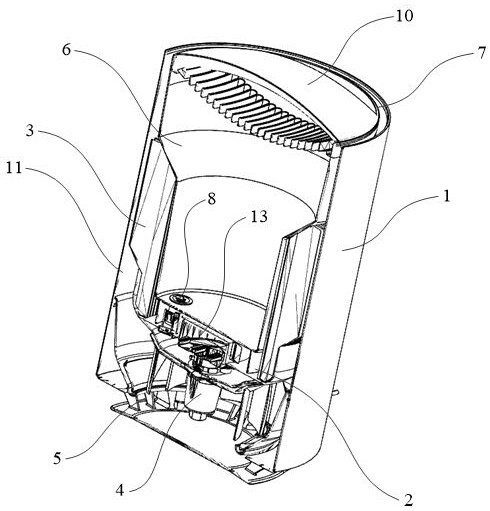

Vertical humidifier with variable-diameter evaporator

PendingCN111912069AReduce noiseEasy to humidifyMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsWater storage tank

The invention discloses a vertical humidifier with a variable-diameter evaporator, and belongs to an evaporative humidifier. The humidifier comprises a housing, wherein an evaporating water tank is arranged in the housing, an evaporator is arranged in the evaporating water tank, a fan is installed below the evaporator, and the air inlet end of the fan communicates with an air inlet of the housing;a water storage tank is further installed on the upper part of the evaporating water tank, the evaporator surrounds the lower part of the water storage tank, and the water storage tank further communicates with the evaporating water tank through a water inlet; and an air outlet is formed in the upper part of the housing, the air outlet communicates with the air outlet end of the fan, and the evaporator is arranged in an airflow channel between the air outlet and the air outlet end of the fan. The fan is installed on the lower part of the evaporator, so that operating noise waves pass throughthe evaporator and are reduced, and silence is realized; the turbulence and mass transfer effects of airflow can be increased by the variable-diameter evaporator with a tight lower end and a loose upper end, so that the humidification amount is effectively increased; and additionally, a vertical compact product structure surrounded by the variable-diameter evaporator is adopted, so that the size of the evaporator is smaller.

Owner:CHENGDU AIMBON INTELLIGENT TECH CO LTD

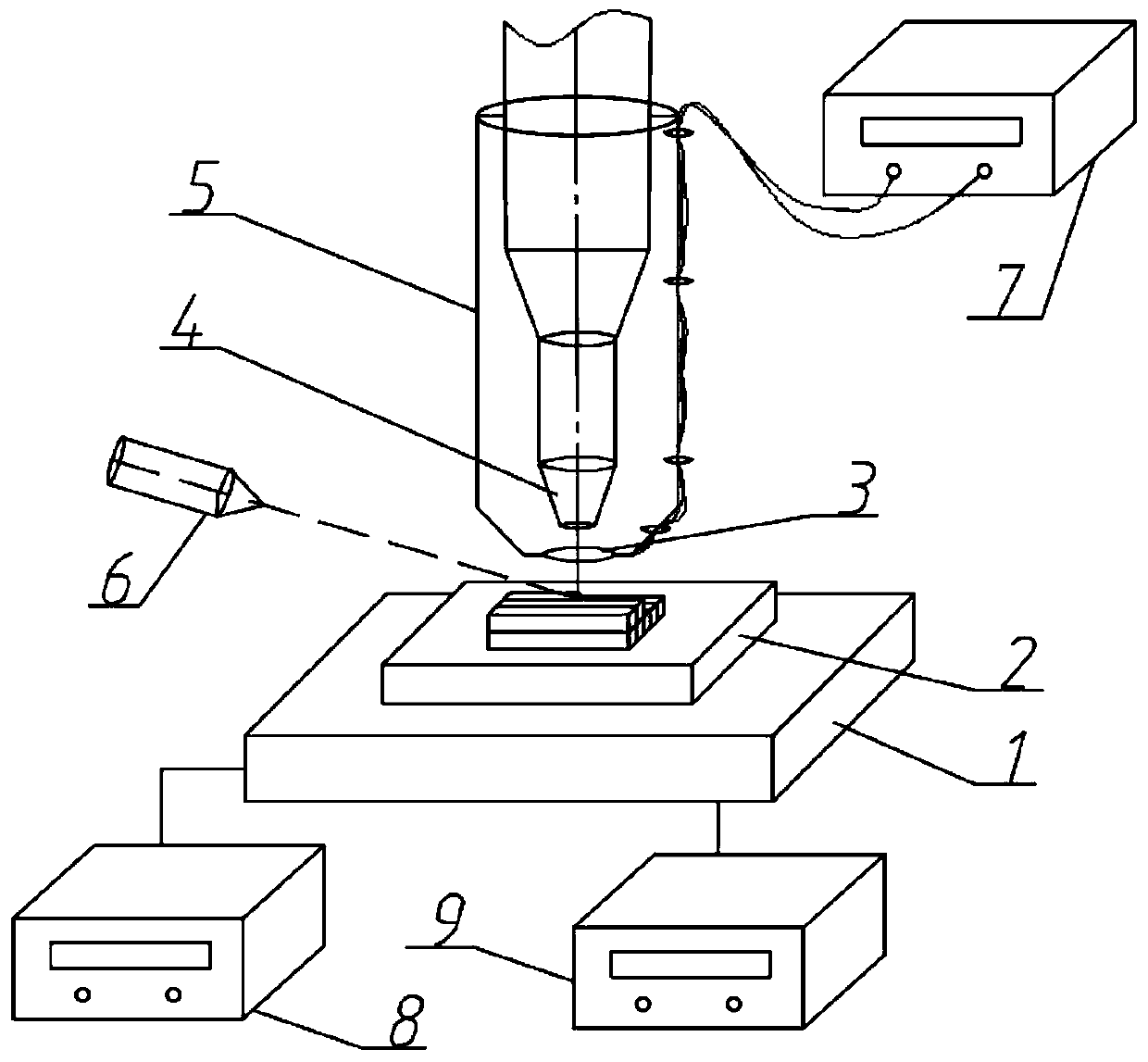

Inductance and ultrasound coupling-assisted method for direct laser deposition of metal material

ActiveCN110421167AAvoid interferenceProlong the action timeAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankMolten bath

The invention relates to an inductance and ultrasound coupling-assisted method for direct laser deposition of a metal material, belongs to the field of additive manufacturing and relates to a coupledenergy field. The energy field is obtained by coupling an inductance temperature field and an ultrasonic wave field. A follow-up electromagnetic induction device is suspended right below a laser headthrough an induction coil, so that the coil moves along with the laser head to preheat and slowly cool a round area around a molten bath. A bottom ultrasonic device is fixed between a worktable and abase plate, and ultrasonic waves are conducted to the molten bath upward through the base plate to impact and stir the molten bath and a solid-liquid interface. The coupled energy field makes up defects that a single inductance temperature field has no stirring effect to the molten bath and a single ultrasonic wave field which is short in action time to the molten bath is not obvious in effect. Induction heating plays a preheating and slow cooling role to reduce a temperature gradient and to reduce a thermal stress. The temperature field improves the impacting and stirring efficiency to the molten bath effectively by alleviating the solidification rate of the molten bath. The coupled energy field can reduce defects of cracks and pores, so that the mechanical properties of a metal materialformed part are improved.

Owner:DALIAN UNIV OF TECH

Process for applying hydrogen to deoxygenation of liquid steel

The invention relates to a process for applying hydrogen to deoxygenation of liquid steel. The invention adopts the technical scheme that: when the oxygen blowing decarbonization in a converter comes to an end, or when steel ladle is refined or when the oxygen blowing decarbonization for RH ultra-low-carbon steel production comes to an end, the mixed gas of H2 or Ar-H2 is blown into liquid steel for deoxygenation, the flowrate of the mixed gas ranges from 40 to 3000m3 / h, the pressure ranges from 0.5 to 2.0 MPa, and the time of blowing the mixed gas into the liquid steel ranges from 5 to 30min. When converter or steel ladle or RH hydrogen blowing deoxygenation comes to an end, hydrogen which is dissolved in the steel is removed by argon blowing and vacuum treatment, wherein the step of blowing the gas into the liquid steel for deoxygenation is that the gas is blown into the liquid steel for deoxygenation by a gas permeable brick from the bottom of a top-bottom combined blown converter or from the bottom of the steel ladle or from an RH ascending tube; and in the mixed gas of Ar-H2, the volume content of Ar ranges from 10 to 80 percent, and the volume content of H2 ranges from 20 to 90 percent. The invention has the advantages that the process is simple, and the pollution of the liquid steel caused by deoxygenation can be reduced. The process used for removing oxygen in the steel can effectively increase the cleaness of the liquid steel and the quality of steel products.

Owner:WUHAN UNIV OF SCI & TECH

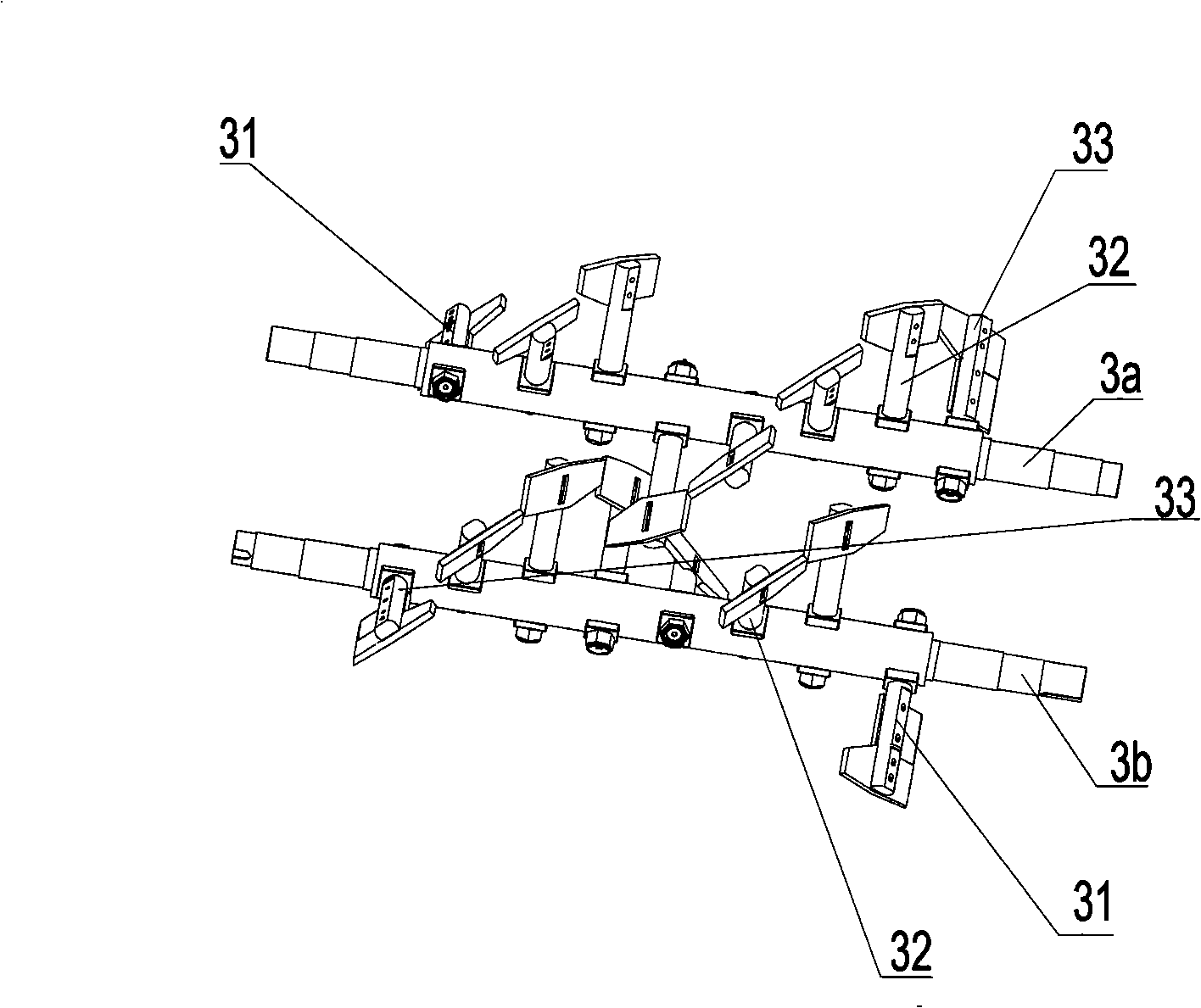

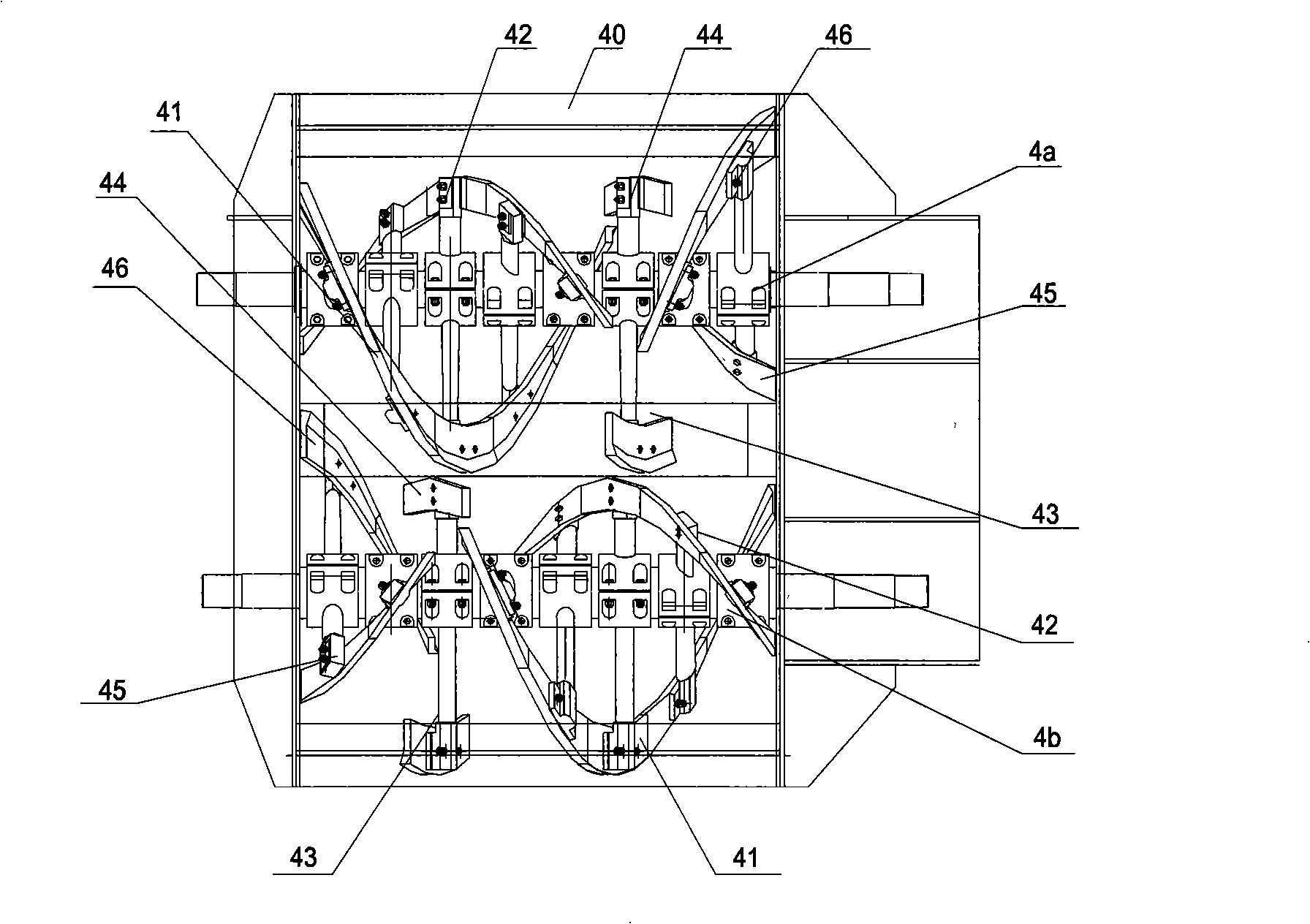

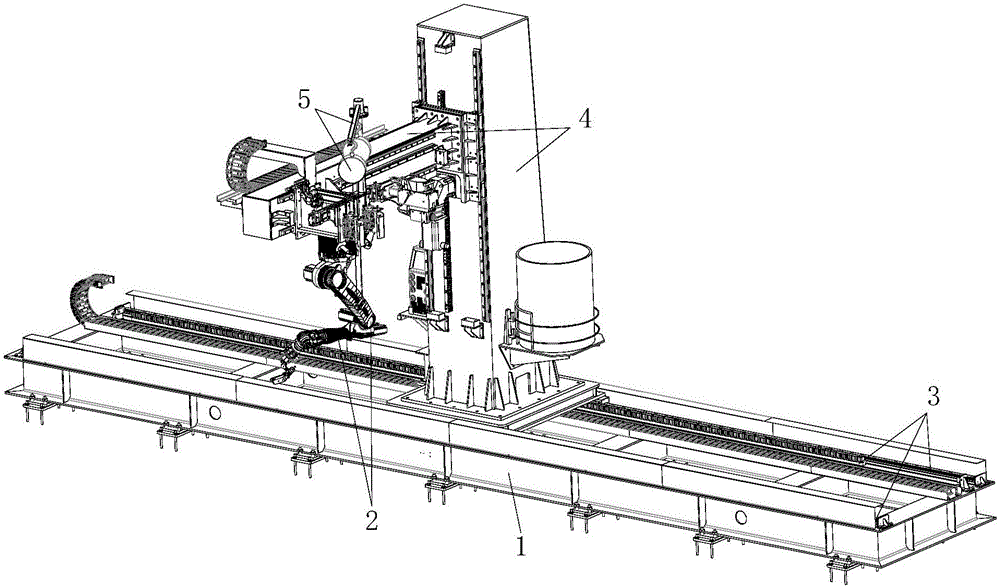

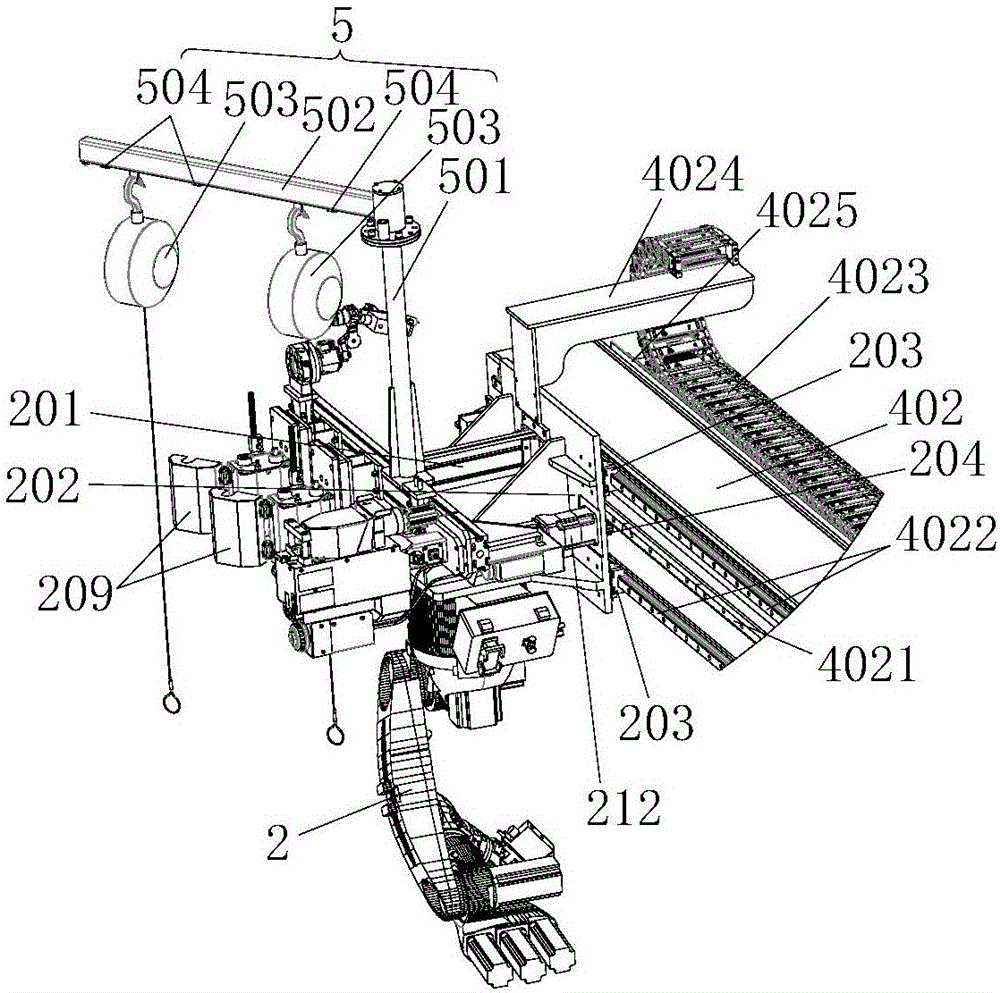

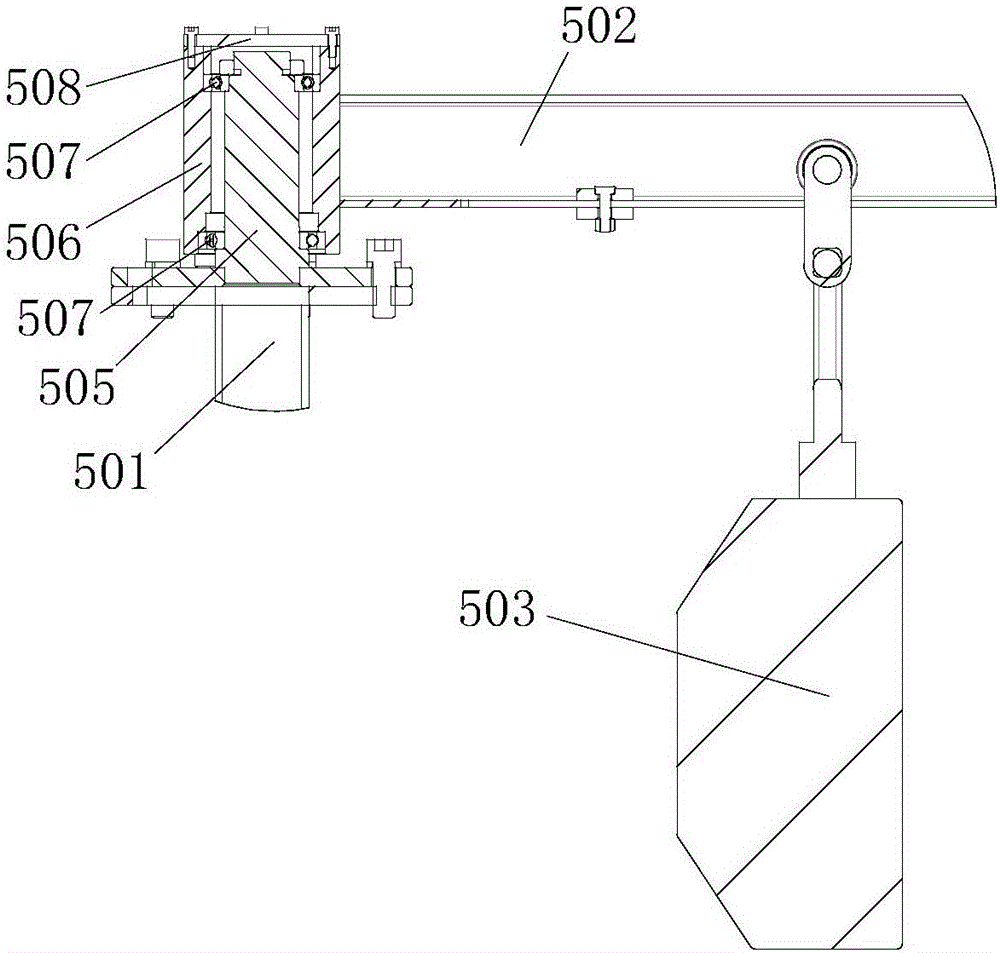

Robot welding working device

ActiveCN106271277AEnsure structural stabilityReduce hindranceWelding/cutting auxillary devicesAuxillary welding devicesHeavy loadControl theory

The invention discloses a robot welding working device. The robot welding working device comprises a fixing mechanism used for supporting and fixing bottom and a welding robot used for carrying out welding operation, wherein a walking ground rail which is used for providing a straight line walking track and protects a cable synchronously moving and a C-shaped frame device which is arranged on the walking ground rail, is used for controlling the welding robot to move and regulate along the vertical direction and move and regulate along the horizontal direction vertical to the walking track and protects the cable synchronously moving are arranged on the fixing mechanism; and a balance crane component used for automatically balancing the cable by virtue of sliding and rotation of a weight in a process of controlling the welding robot to move, regulate and carry out the welding operation. The robot welding working device disclosed by the invention has the advantages that free movement of the welding robot on a three-dimensional coordinate system along X axis, Y axis and X axis is realized; and stability when the welding robot moves and carries out welding operation is high. Therefore, the robot welding working device disclosed by the invention is applicable to automatic welding operation for workpieces which are in multiple varieties and structures and greatly different from each other.

Owner:CHANGSHA CTR ROBOTICS

Wall-mounted air conditioner indoor unit and air conditioner

ActiveCN105588190AEasy accessSmall pressure lossLighting and heating apparatusSpace heating and ventilation detailsAir volumeWall mount

The invention provides a wall-mounted air conditioner indoor unit and an air conditioner and relates to the technical field of air conditioners. According to the wall-mounted air conditioner indoor unit and the air conditioner, the air amount can be increased and the heat exchange efficiency can be improved. The wall-mounted air conditioner indoor unit comprises a machine shell and an evaporator arranged in the machine shell. Air inlets and air outlets are formed in the machine shell. The wall-mounted air conditioner indoor unit further comprises an axial fan. The axial fan is located in the machine shell. The machine shell comprises a front surface and a rear surface. The air outlets are formed in the front surface. The air inlets are formed in the rear surface. The machine shell is further provided with an installation base. The installation base is used for being fixedly connected with a wall. After the installation base is fixedly connected with the wall, gaps are formed between the air inlets and the wall. The wall-mounted air conditioner indoor unit provided by the invention is used for the air conditioner.

Owner:HISENSE (GUANGDONG) AIR CONDITIONER

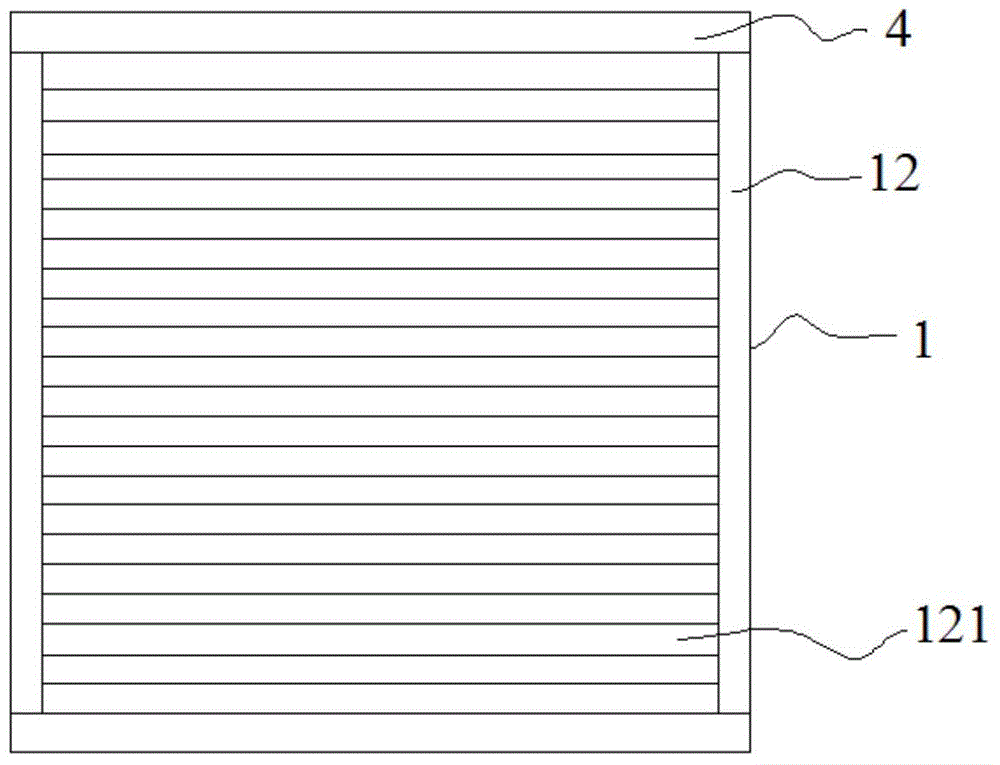

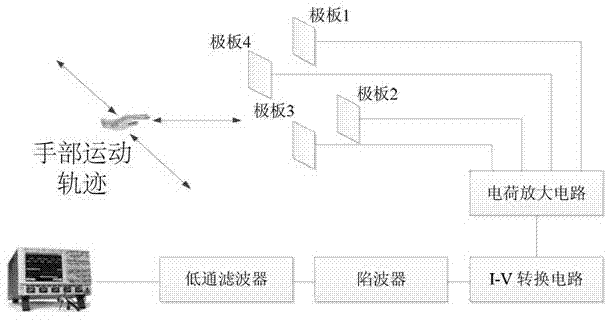

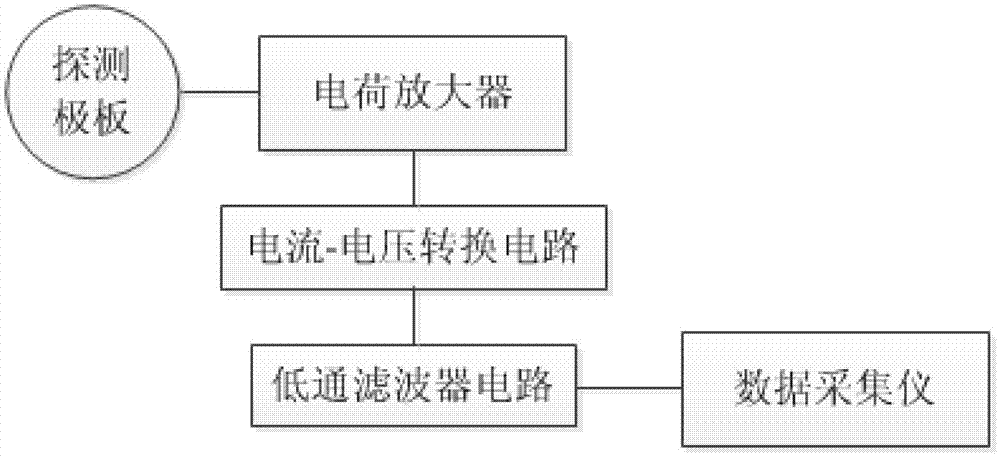

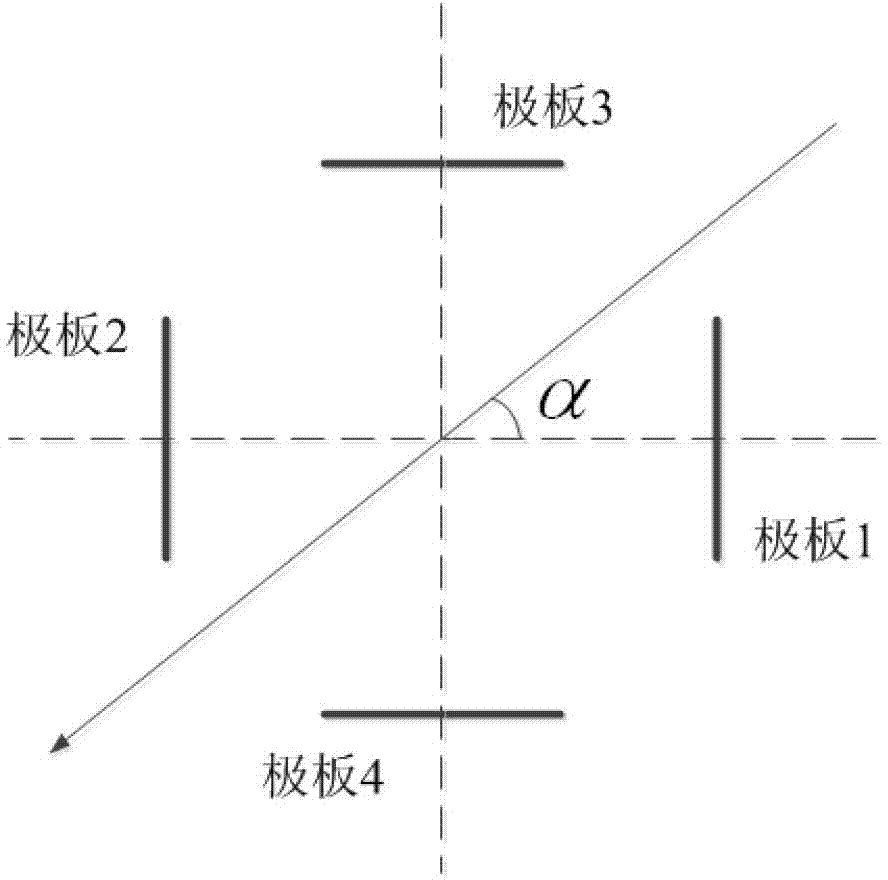

Non-contact electrostatic detection method for tracking human hand motion trajectory

InactiveCN102778581AReal-time trackingReduce hindranceIndication/recording movementDevices using electric/magnetic meansEngineeringMechanical engineering

The invention discloses a non-contact electrostatic detection method for tracking human hand motion trajectory, belongs to the field of electrostatic detection, and relates to a non-contact method for measuring hand motion speed. The non-contact electrostatic detection method comprises the following steps of distributing a multiple-electrode-plate detection array capable of detecting a human hand motion electrostatic signal; collecting an electrostatic signal in a monitoring environment; comparing the collected electrostatic induction signal potential value with a preset criterion; reading zero-passing time tightly following crest values on each electrode plate; and calculating human hand motion direction alpha and human hand motion speed V according to the detection results, and then tracking the human hand real-time motion trajectory. The invention further discloses a non-contact electrostatic detection method for measuring the human hand motion direction. By means of the non-contact electrostatic detection method, working corner areas of the technology for tracking the human hand motion trajectory can be reduced, and design complex degree of a human hand motion trajectory tracking detection system is reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

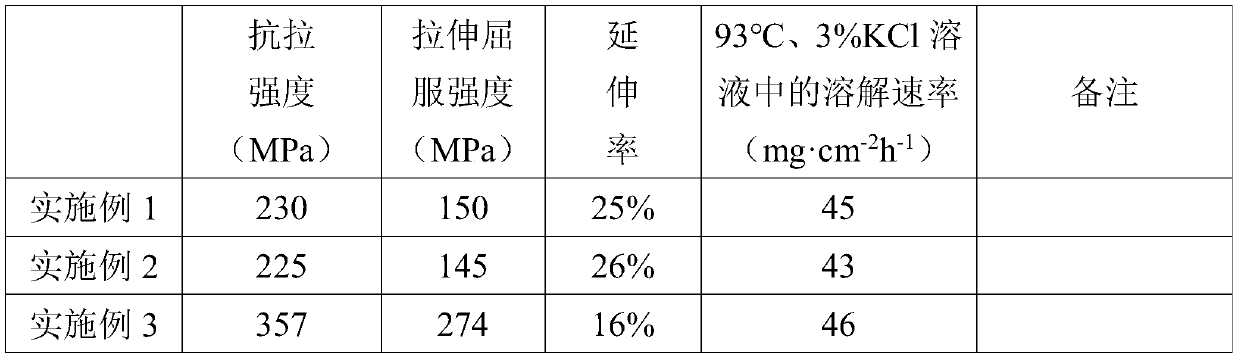

High-strength and high-ductility magnesium alloy capable of being dissolved rapidly and preparation method thereof

ActiveCN110184518AHigh strength and high elongation mechanical strength propertiesIncrease speedFluid removalSealing/packingDuctilityWater soluble

The invention provides a high-strength and high-ductility magnesium alloy capable of being dissolved rapidly and a preparation method thereof. The high-strength and high-ductility magnesium alloy capable of being dissolved rapidly comprises, by mass, 1.0%-22.0% of Gd, 0.001%-5.0% of Y, 0.001%-10% of Al, 0.001%-5.0% of Zn, 0.01%-1.0% of Zr, 0.0001%-1.0% of Sc, 0.01%-10.0% of Cu, 0.01%-3.0% of Li, 0.01%-3.0% of Ni, 0.01%-3.0% of Ga, 0.01%-3.0% of In, and the balance Mg and impurities, wherein the total content of Li, Ga and In is 0.1%-6.0%. The high-strength and high-ductility magnesium alloy capable of being dissolved rapidly can react with a water-soluble medium rapidly so as to be dissolved, has the mechanical strength properties of high strength and high ductility, and can meet the application requirements in various industrial fields.

Owner:FIVE STAR DOWNHOLE SERVICE INC

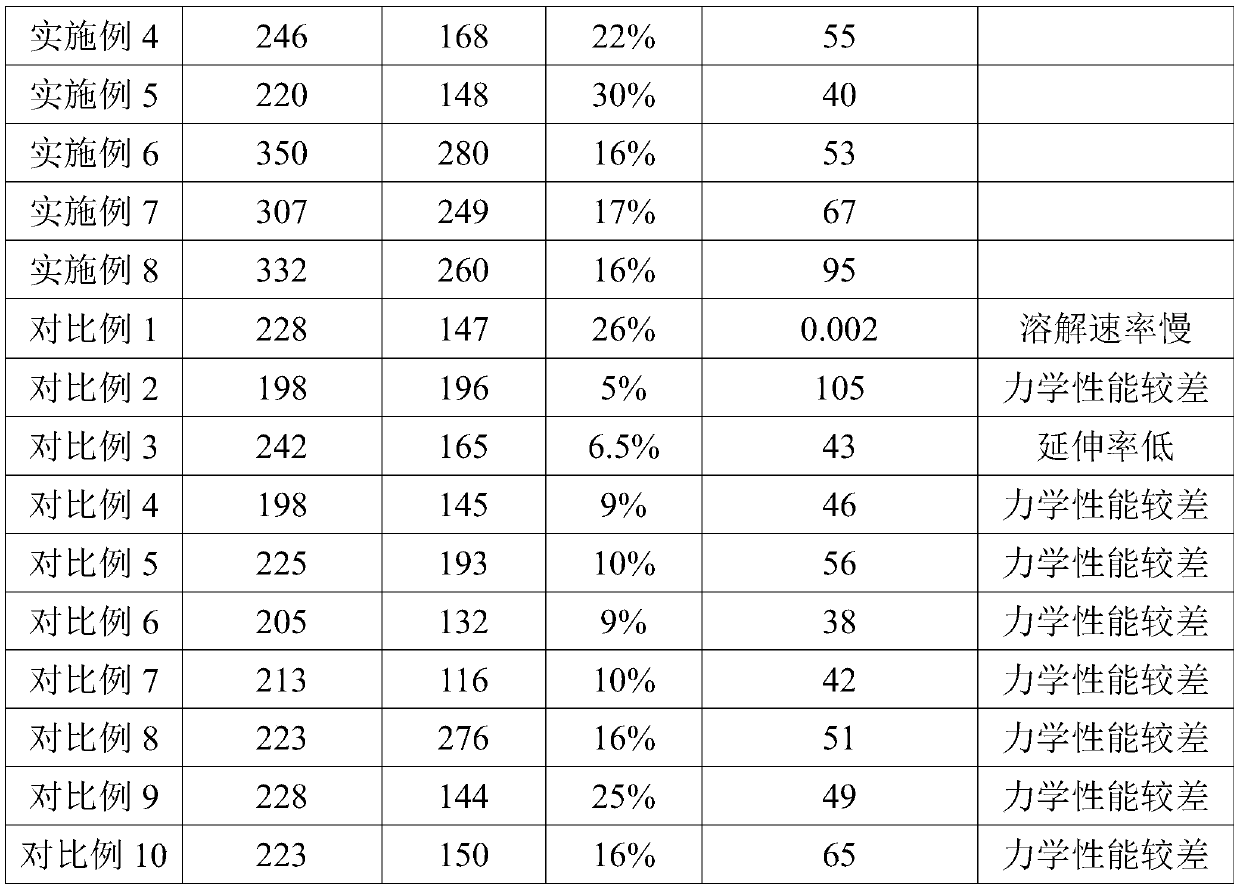

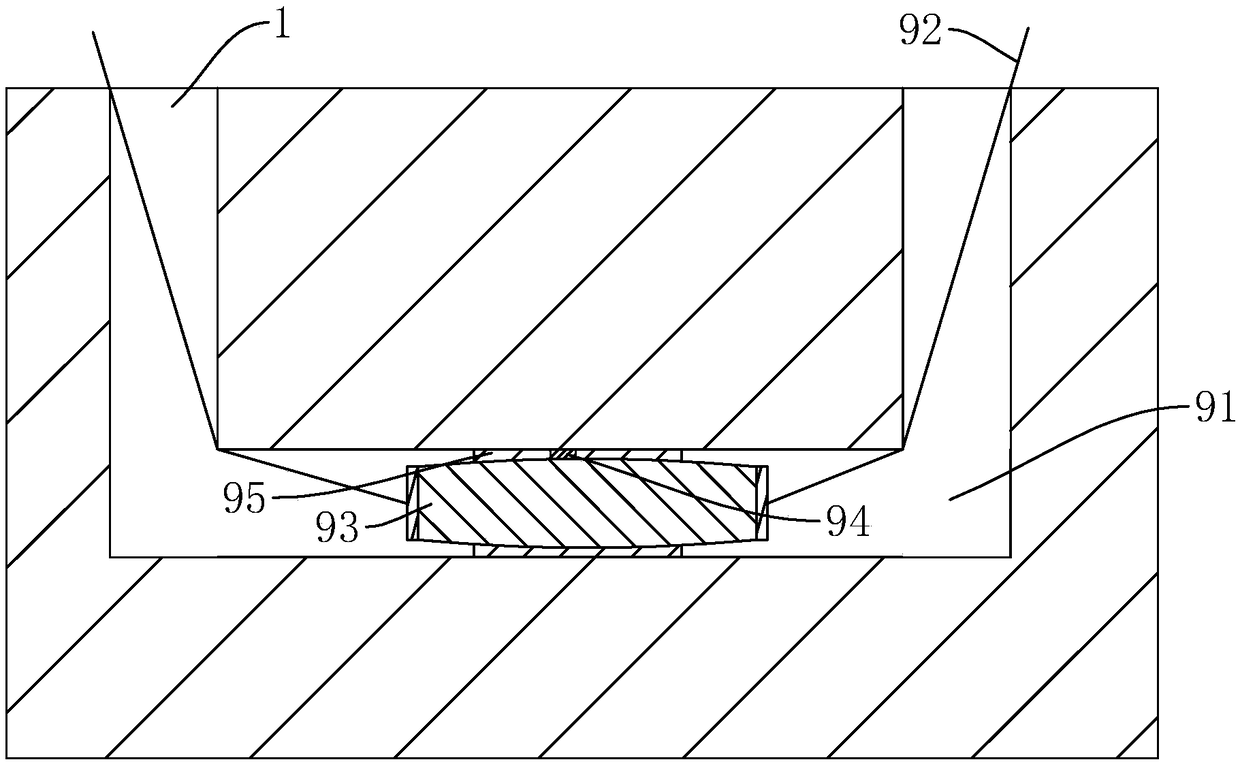

Positioning method of underground pipe non-excavation repair defect points

The invention discloses a positioning method of underground pipe non-excavation repair defect points, and solves the problem of a difficulty how to determine defect points of underground pipes alwaysin the repair process caused by people incapable of entering the pipes to examine the defect points. The positioning method comprises the following steps: a dredging car is cleaned; a connecting ropeis arranged on a remote control car provided with a camera, and the defect points in the pipes are searched through the camera; a first positioning mark is arranged in the position, positioned in an opening of a drainage well, of the connecting rope; a positioning rope is bound on a pipe repair airbag, and is provided with a second positioning mark corresponding to the first positioning mark; thesurface of the pipe repair airbag is coated with a repair material; after the second positioning mark is positioned in the opening of the drainage well, the pipe repair airbag is used for repair; andmultiple defect points can be once determined, and can be gradually repaired, so that the time and the times of the remote control car searching the defect points are saved, the working efficiency isimproved, and the repair flow is simplified.

Owner:浙江景迈环境科技有限公司

Continuous type infrared corncob drying machine

InactiveCN103081991ASolve the problem of high breakage rateImprove heat transfer efficiencyFood processingSeed preservation by dryingInfraredEngineering

The invention provides a continuous type infrared corncob drying machine which is characterized in that a box body is internally provided with a plurality of conveying devices driven by a transmission device to run, wherein I type and II type material pulling rods with two different lengths are fixedly arranged between two chains of the same conveying device at an interval; parts of each conveying device, which correspond to upper and lower sections of horizontal sections of the chains, are respectively provided with material supporting plates; material guide grooves are arranged below the tail ends of the material supporting plates; radiation devices are arranged above the material supporting plates; radiation racks of the radiation devices are suspended on the box body; the two ends of an infrared radiation element which downwards radiates infrared rays in a single direction are mounted on the radiation racks; and a feeding opening is arranged on the top of the box body, and a discharging opening is formed at the bottom of the box body. The continuous type infrared corncob drying machine disclosed by the invention has the advantages of high heat transferring efficiency, low energy consumption and good drying uniformity.

Owner:SHANDONG UNIV OF TECH

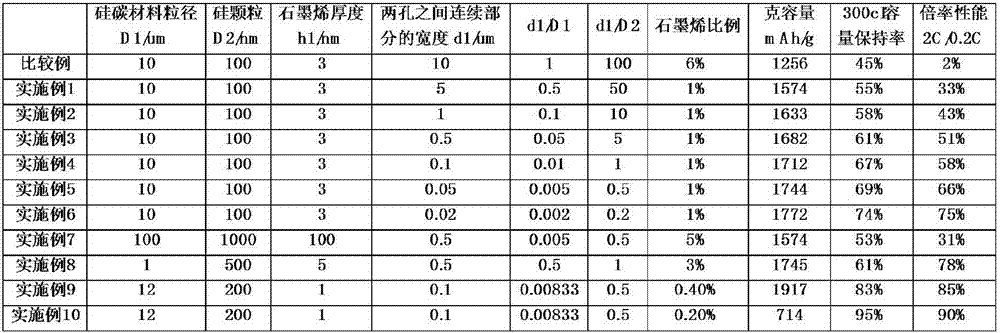

Silicon-carbon negative electrode material and preparation method thereof

The invention belongs to the field of energy storage research and particularly relates to a silicon-carbon negative electrode material. The silicon-carbon negative electrode material has a particle diameter D1 of 1 to 200 microns. The silicon-carbon negative electrode material has a secondary particle structure. The secondary particle is composed of a primary particle and an electron conduction component. The primary particle has a particle diameter D2 less than or equal to 0.5D1. The electron conduction component comprises a graphene sheet layer. The primary particles and the graphene sheet layers are uniformly dispersed. The graphene is porous graphene. The porous graphene sheet layer has thickness h1 less than or equal to 100 nm and a pore diameter D3. The width d1 of the continuous portion between the two pores is less than or equal to 0.5D1. Through the porous graphene, ions freely pass through two surfaces of graphene. The width of the continuous portion between the two pores does not exceed the radius of the secondary particle structure so that the two-dimensional graphene sheet has low inhibition effects on ion diffusion.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

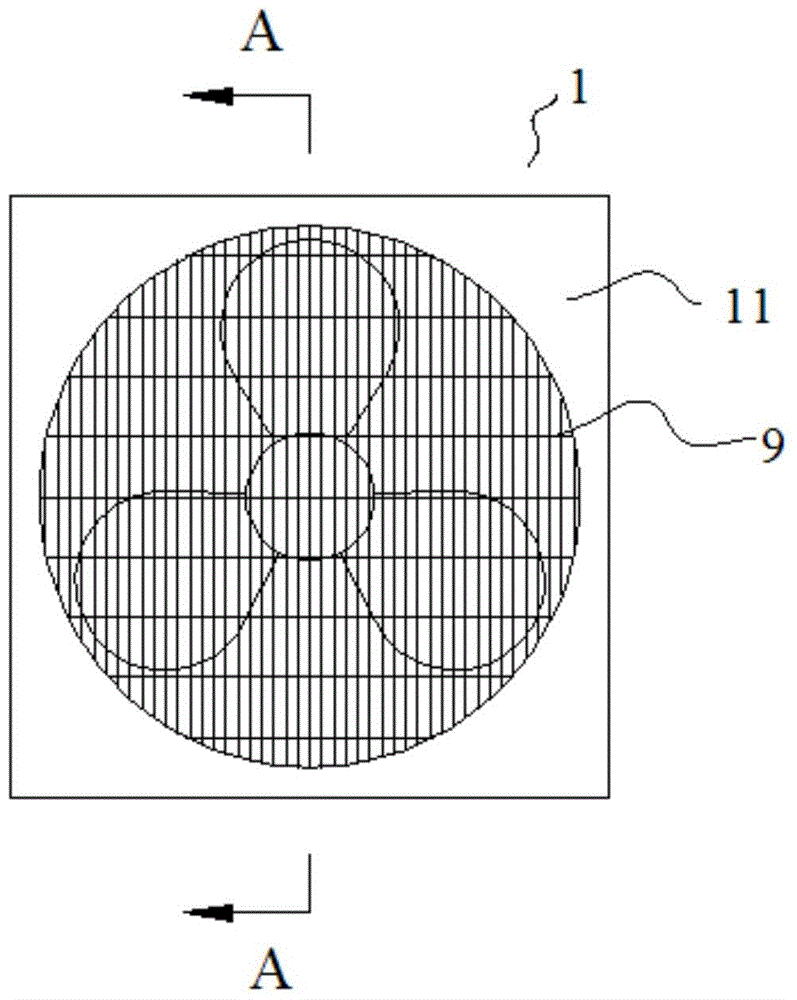

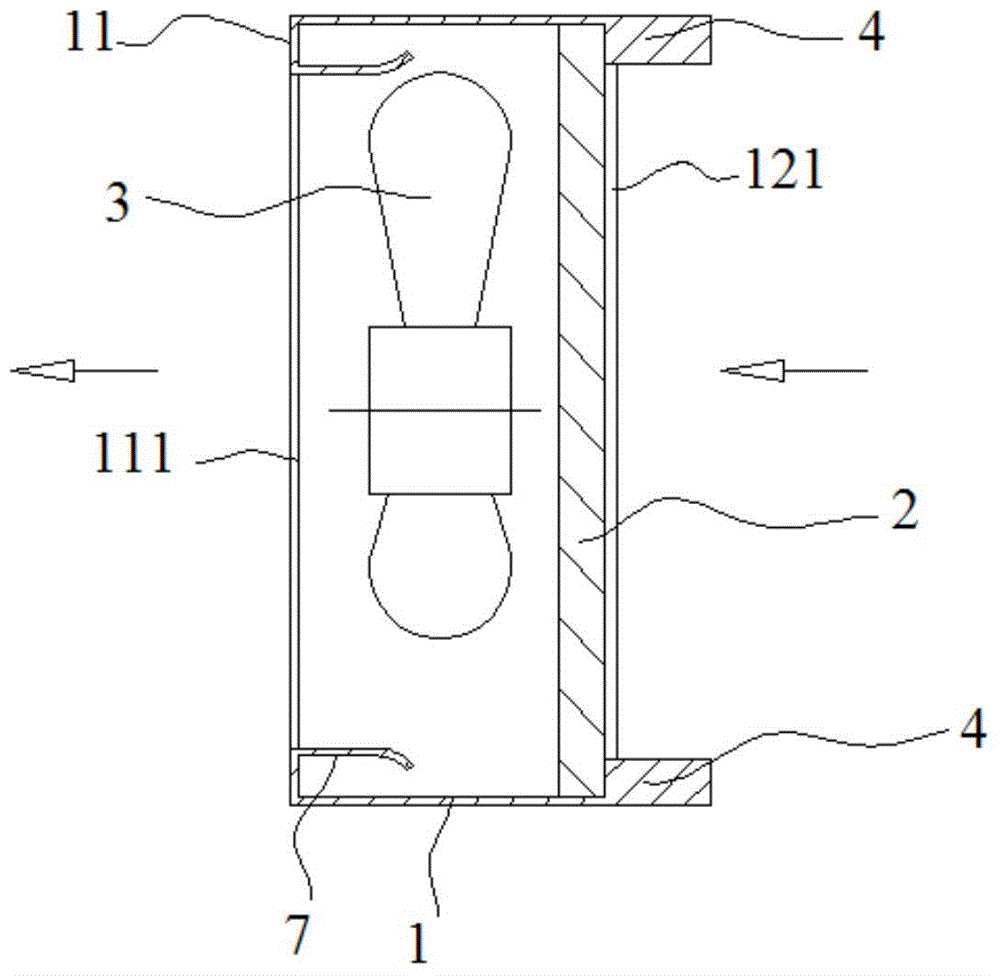

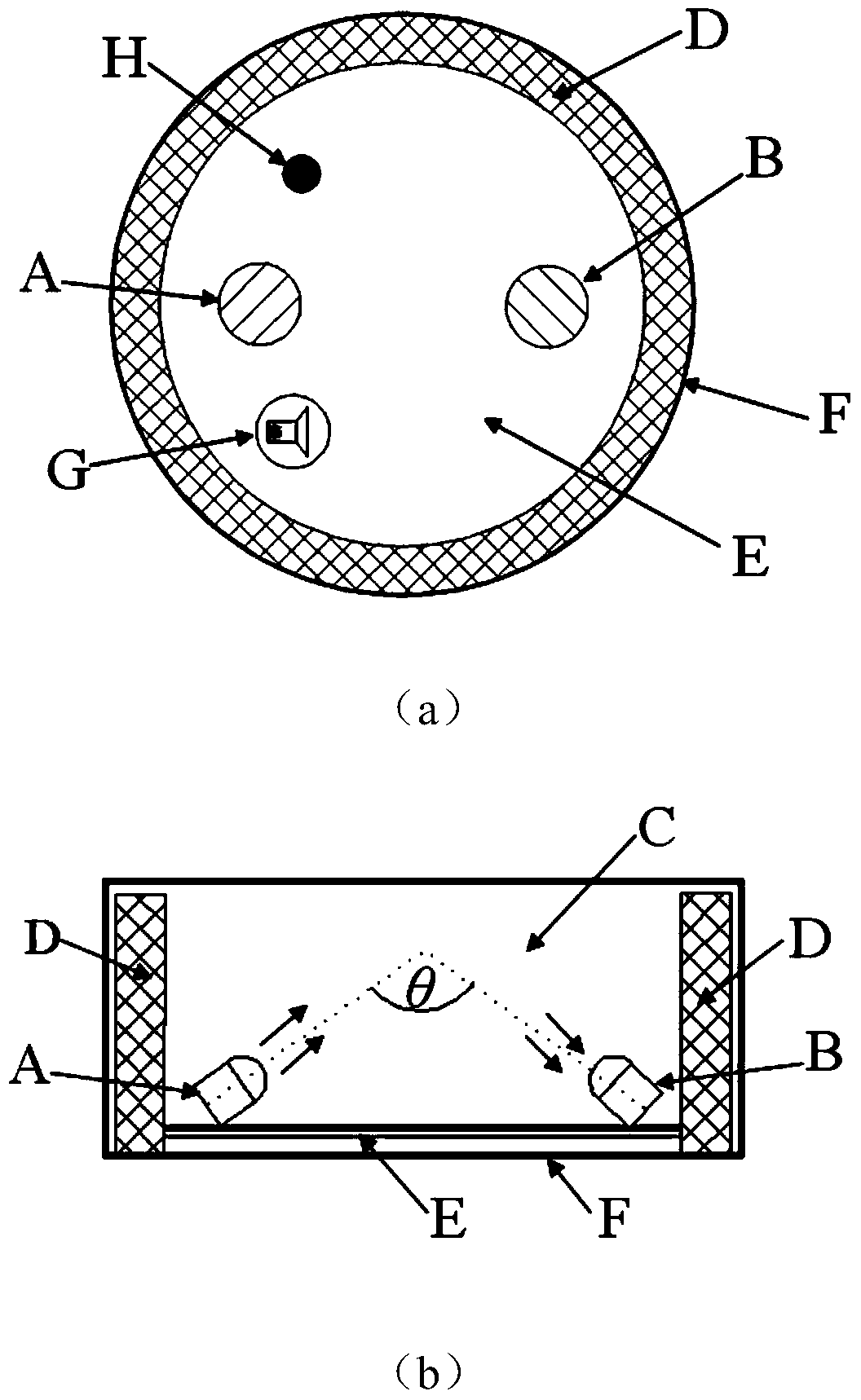

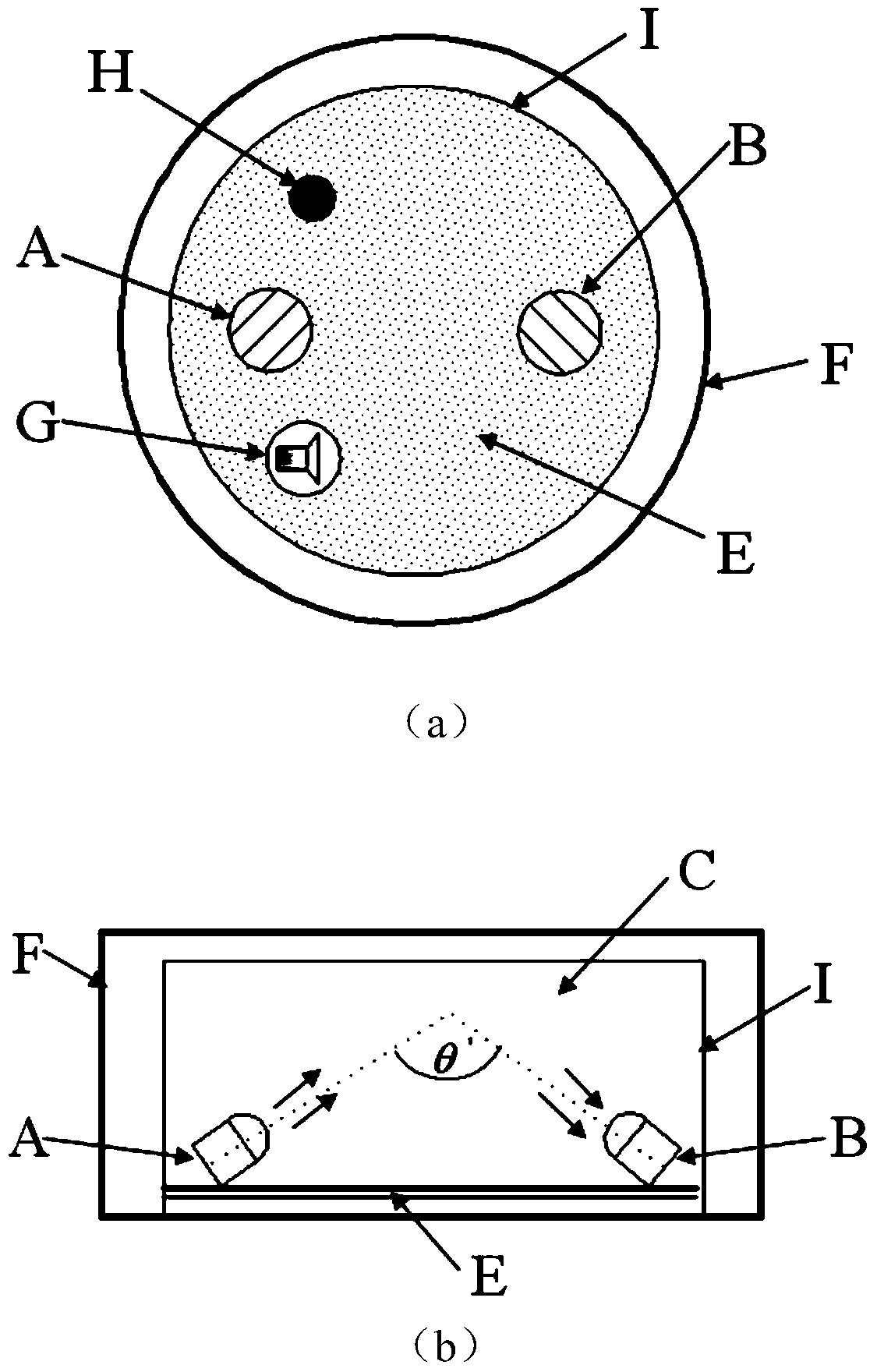

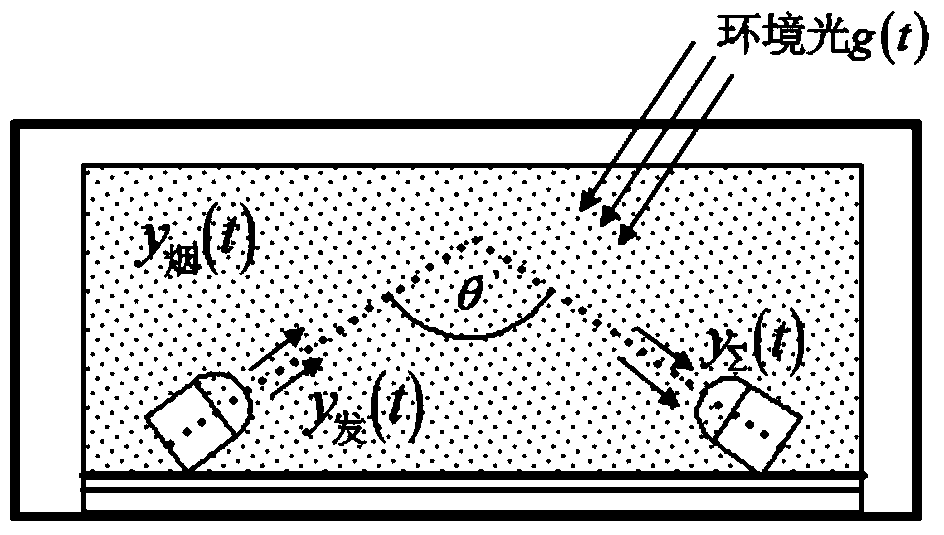

Point-shaped light scattering type smoke detector without optical labyrinth, and signal processing method

The invention discloses a point-shaped light scattering type smoke detector without an optical labyrinth, and a signal processing method. The point-shaped light scattering type smoke detector without the optical labyrinth comprises a photoelectric smoke detection part, a detection chamber (C), a filter screen (I), a signal processing unit (E), a housing (F), an alarm horn (G) and an indication lamp (H). According to the novel idea of the point-shaped light scattering type smoke detector without the optical labyrinth disclosed by the invention, the obstructions of smoke grains entering and exiting the detector are reduced, thus the flowing of smoke entering and exiting the chamber is smooth, and high response sensitivity and real-time performance are achieved. The function of the optical labyrinth structure is preventing an external environment light from entering the detection chamber, for this, the invention discloses a analysis and processing method for a signal containing functions of an environment light, a smoke and the like by virtue of an amplitude modulation and demodulation principle, provides an theoretical basis for the point-shaped light scattering type smoke detector without the labyrinth, and also provides a novel thought and research direction for research on improvement for the response sensitivity of the detector.

Owner:UNIV OF SCI & TECH OF CHINA

High-hardness and wear-resistant ball and preparation method thereof

ActiveCN104099531AEliminate internal stressIncrease internal stressFurnace typesMetallic material coating processesWear resistantHeat resistance

The invention discloses a high-hardness and wear-resistant ball. The high-hardness and wear-resistant ball comprises components of C, Mn, W, Si, Ni, Cr, Mo, V, Nb, Ca, Zr, Cu, Zn, S and P. The invention further discloses a preparation method for the high-hardness and wear-resistant ball, wherein a heat treatment process of the preparation method comprises the following steps: heating the temperature to 980-1030 DEG C, keeping the temperature for 50-80 min, and cooling to the room temperature; heating the temperature to 800-820 DEG C, keeping the temperature for 30-75 min, and cooling to the room temperature; heating the temperature to 500-530 DEG C, keeping the temperature for 130-150 min, and cooling to the room temperature. According to the preparation method, the surface of the wear-resistant ball is modified by using the reactive nitrogen arc cladding, and cladding powder is a composition of titanium powder and graphite powder, wherein the titanium powder comprises components of C, Mo, Si, Fe, Cl, N, O, H, and the balance Ti; the cladding current is 150-180 A; a nitrogen flow rate is 12-18 L / min. The wear-resistant ball provided by the invention has high hardness, and meanwhile, has excellent impact strength, heat resistance, wearing resistance and corrosion resistance.

Owner:宁国市宁武新材料科技有限公司

Mobile ball retrieving device

The invention discloses a mobile ball retrieving device. The device comprises a ball retrieving structure and a vehicle frame structure, wherein the ball retrieving structure comprises a dial plate, a first motor, a third motor, a first wheel axle, a motor base supporting rod, an oblique plate, a conveyer belt and a second wheel axle, the vehicle frame structure comprises a bottom cap, a universal wheel, a chassis, a second motor, a shell and a ball bin, a camera is installed at the front end of the shell, and a photoelectric sensor is installed on the top in the shell. Balls are quickly conveyed into the ball bin through coordinated rotation of the dial plate and the conveyer belt. Through omnidirectional movement of the universal wheel and detection of the sensor, balls can be retrieved more effectively.

Owner:SOUTH CHINA UNIV OF TECH

Harmless and resource utilization treatment method for bottom sludge of polluted water body

InactiveCN1807339ALarge specific surface areaHigh porositySludge treatmentCeramic materials productionAbsorption ratioVoid ratio

The treatment method with high performance and low cost for sediment in polluted water comprises: mixing the sediment with household sludge to extrusion form, then calcining for 20~40min at 1100~1300Deg. Wherein, the ceramsite in this invention has bulk specific gravity as 610-970kgíñm-3, particle bulk weight as 1932-2308 (kgíñm-3), water absorption ratio as 3-12%, void ratio as 46-65%, and specific surface area as 1. 82-3. 98(m2íñg-1), and fit to spread for application.

Owner:HARBIN INST OF TECH

Rotating rod type infrared corncob drier

InactiveCN103070458ASolve the problem of high breakage rateImprove heat transfer efficiencyFood processingSeed preservation by dryingInfraredAngular velocity

The invention provides a rotating rod type infrared corncob drier. The rotating rod type infrared corncob drier is characterized in that a plurality of conveying devices which are driven by a driving device to convey are arranged in a box body; one end of a bolt is screwed into a screw hole of a chain node on the inner side of a chain; the two ends of a material shifting rod are hollowly sleeved on the middle part of the bolt; a limit ring of which a deep concave hole contain steel balls keeps the steel balls to face the material shifting rod; the steel balls fall into a shallow concave hole of the material shifting rod and are loaded into the middle part of the bolt; each conveying device is respectively provided with material supporting plates corresponding to an upper horizontal section and a lower horizontal section of the chain; a material guide groove is formed below the tail ends of the material supporting plates; a radiating device which downwards radiates infrared ray in one direction is arranged above the material supporting plates; limit rods are arranged at the two ends of each conveying device, so that when the material shifting rod moves to a chain wheel to reverse, on one hand, the material shifting rod co-rotates along the chain wheel, on the other hand, the material shifting rod reversely rotates around the bolt at the speed equal to the co-rotation angular velocity; a material inlet is formed in the top of the box body; and a material outlet is formed in the bottom of the box body. The rotating rod type infrared corncob drier is high in heat transfer efficiency, good in drying uniformity, reasonable in structure, convenient to use and practical.

Owner:SHANDONG UNIV OF TECH

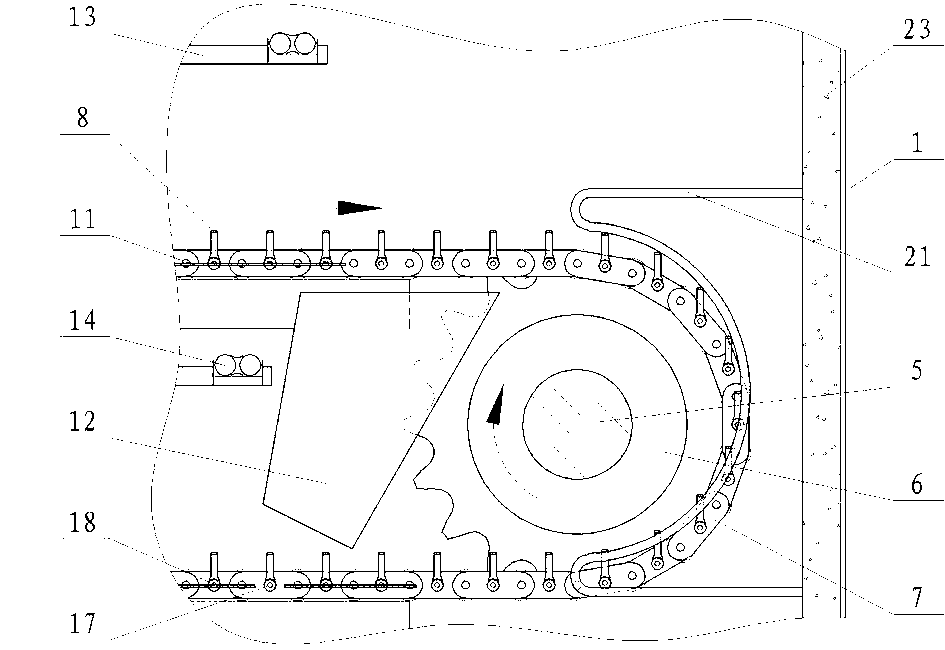

Multilayer composite positive pole piece, method for preparing pole piece and lithium ion battery applying multilayer composite positive pole piece

InactiveCN104466188AIsolated contactImprove immersionSecondary cellsNon-aqueous electrolyte accumulator electrodesPower batteryPole piece

The invention relates to the field of lithium ion batteries and in particular provides a multilayer composite positive pole piece, a method for preparing the pole piece and a secondary lithium ion battery applying the multilayer composite positive pole piece. The composite positive pole piece comprises a current collector layer, a positive active function layer and a safety protection layer formed on the positive active function layer. According to the positive pole piece disclosed by the invention, the condition that inner short circuit occurs because a negative pole material of the lithium ion battery is directly contacted with a positive active material is avoided, the safety performance is good, and the battery of the composite positive pole piece is applied to power batteries.

Owner:JIANGSU QINGTAO ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com