Patents

Literature

70results about How to "Reduce migration speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

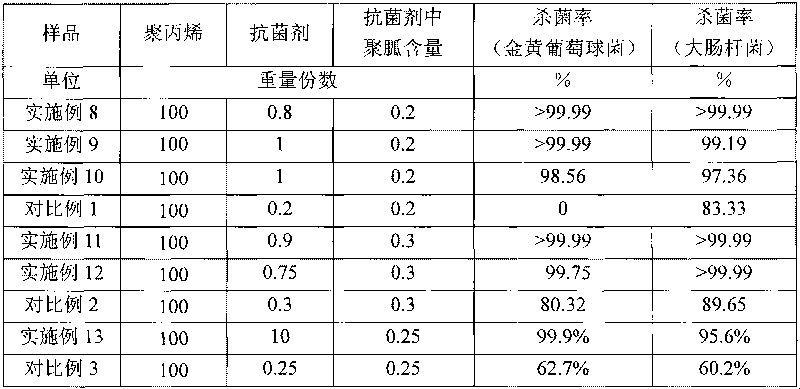

Anti-bacterial thermoplastic composite and preparation method thereof

The invention relates to an anti-bacterial thermoplastic composite, which comprises the following mixed components: 100 parts of thermoplastic by weight and 0.1-40 parts of composite antibacterial agent by weight, wherein the composite antibacterial agent comprises micronano inorganic / organic particles and guanidinesalt polymers which are coated on the surfaces of the micro / nano particles and / or embedded among pores and layers of the micronano particles; the weight ratio of the guanidinesalt polymers to the micro / nano particles is 1:1-1:50; and the micro / nano particles have at least a one-dimensional average size of 1nm-1000mum. The anti-bacterial thermoplastic composite is obtained by melting and mixing the components such as the thermoplastic, the composite antibacterial agent, and the like, therefore the antibacterial rate of the anti-bacterial thermoplastic composite is higher and the preparation method is simple.

Owner:CHINA PETROLEUM & CHEM CORP +1

Compound antimicrobial and preparation method thereof

The invention provides a compound antimicrobial and a preparation method thereof. The compound antimicrobial comprises micro-nano particles and guanidine polymers by the weight ratio of 1:1 to 1:50, wherein the micro-nano particles at least have the one-dimensional average dimension of 1nm to 1000 mu m; the guanidine polymers are coated on the surfaces of the micro-nano particles and / or embedded in holes or among layers of the micro-nano particles; inorganic or organic particles comprising micro-nano particles are added to a solution of the guanidine polymers; organic alkali is added or not added; the particles and the solution are uniformly mixed and dried for obtaining the compound antimicrobial. When applied to plastics, fibers and rubber, the antimicrobial has high sterilization efficiency, also largely reduces the processing cost of antibacterial materials, and has simple and convenient preparation method.

Owner:CHINA PETROLEUM & CHEM CORP +1

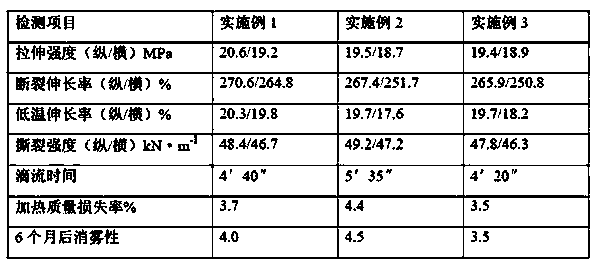

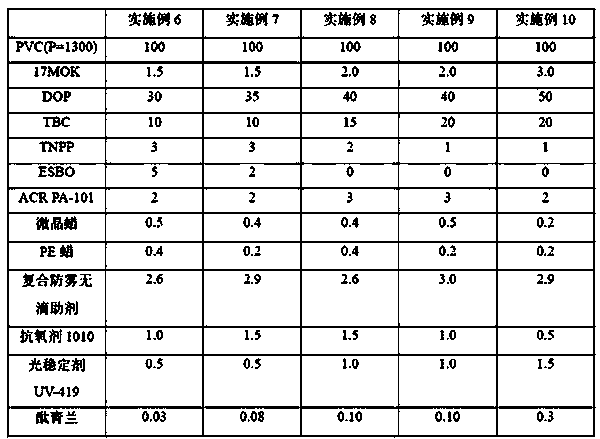

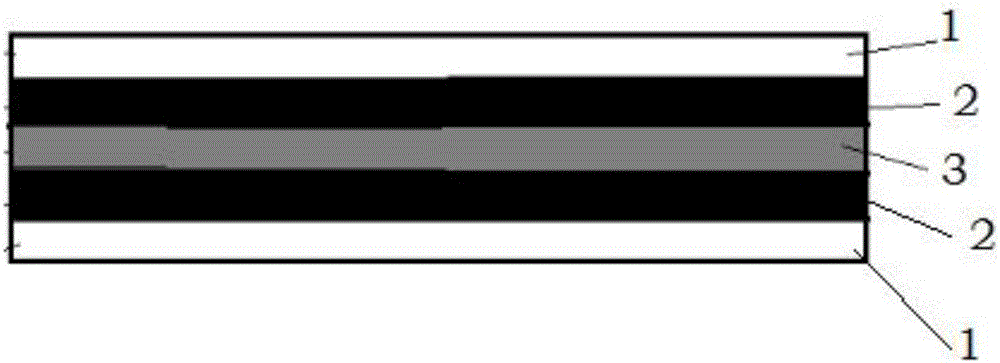

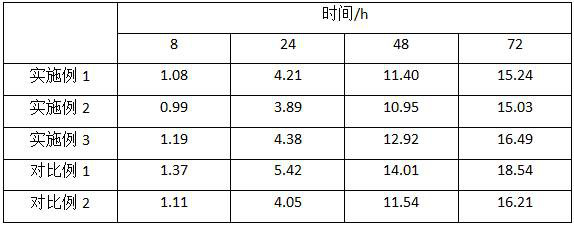

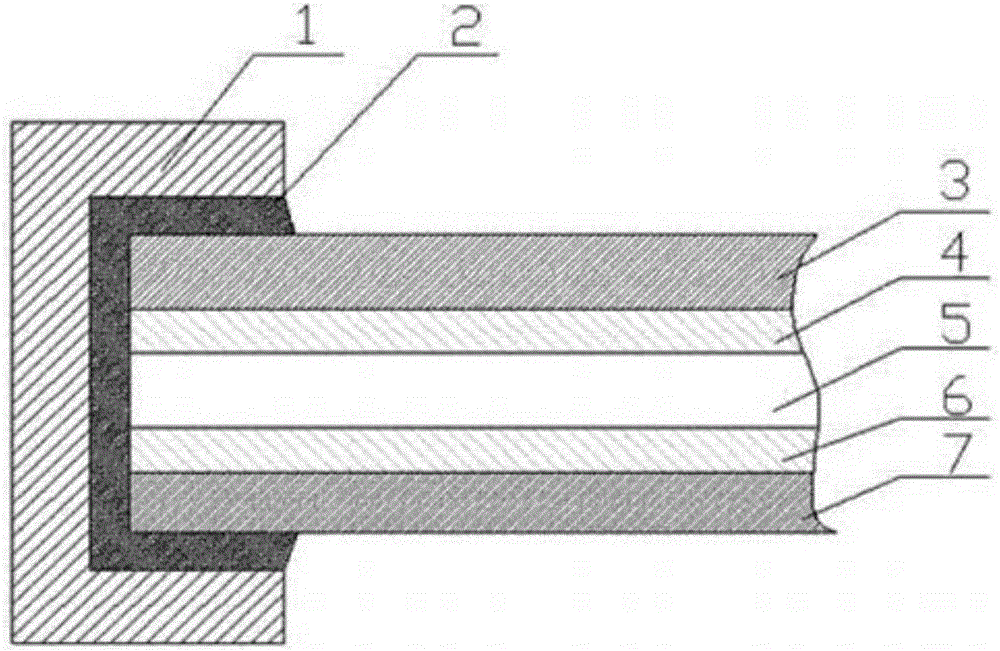

Fog-dissipation and anti-dropping polyvinyl chloride greenhouse film and preparation method thereof

ActiveCN104249522AExtended use timeReduce migration speedSynthetic resin layered productsLaminationIntercalation reactionSurface layer

The invention relates to a fog-dissipation and anti-dropping polyvinyl chloride greenhouse film and a preparation method thereof, and belongs to the technical field of polymer materials. The preparation method is characterized in that 100 parts by weight of a polyvinyl chloride resin is adopted as the main raw material, 2.5-5.0 parts by weight of a composite anti-fogging and anti-dropping additive is added, and a three-layer co-extruding composite calendering process is adopted to prepare the greenhouse film with a three-layer composite structure, wherein the concentration of the composite anti-fogging and anti-dropping additive in the middle layer is 1.5-2.5 times the concentration of the composite anti-fogging and anti-dropping additive in the surface layer, the thickness of the middle layer is 2-3 times the thickness of the surface layer, and the composite anti-fogging and anti-dropping additive is formed by carrying out an intercalation reaction on 10-15 parts by weight of a composite anti-fogging agent, 25-50 parts by weight of a composite anti-dropping agent, and 40-80 parts by weight of a slow-release agent. The durable fog-dissipation and anti-dropping polyvinyl chloride greenhouse film preparation method is the intercalation-material matching and mixing-calendering process of the anti-fogging agent, the anti-dropping agent and the slow-release agent. The fog-dissipation and anti-dropping polyvinyl chloride greenhouse film has effects of fog-dissipation and anti-dropping.

Owner:CHINA PETROLEUM & CHEM CORP

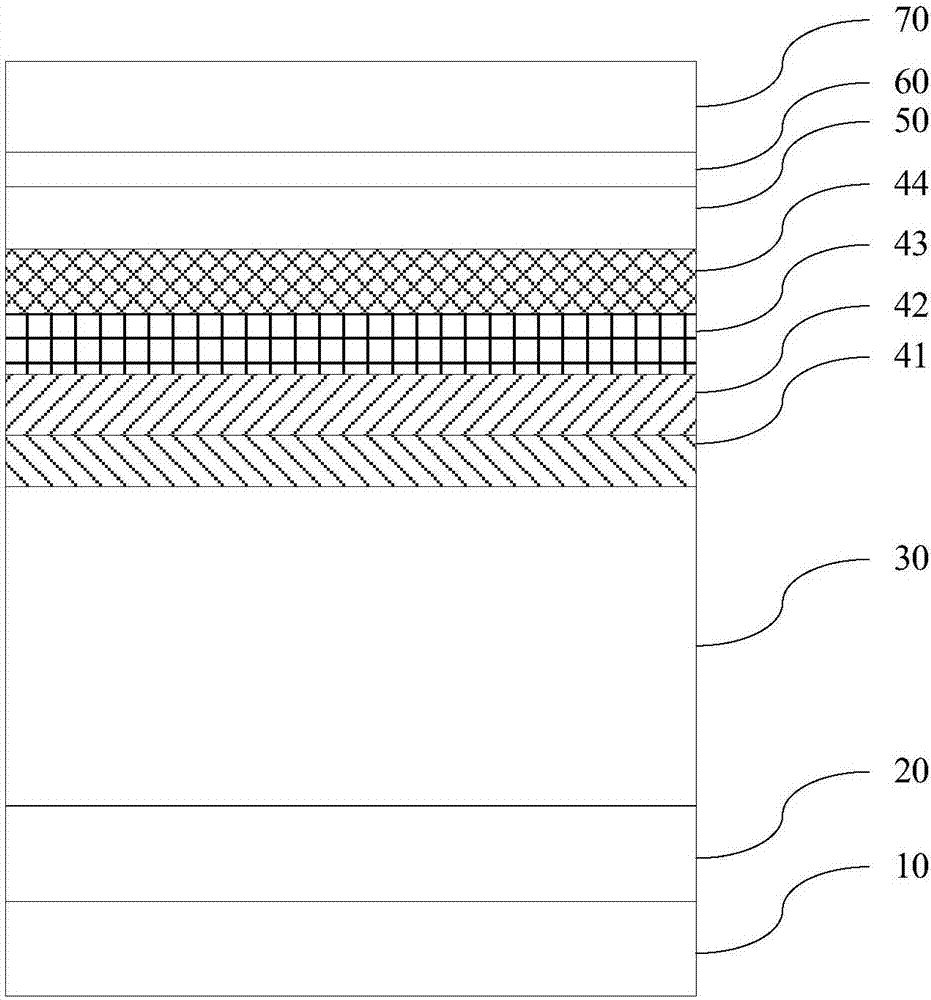

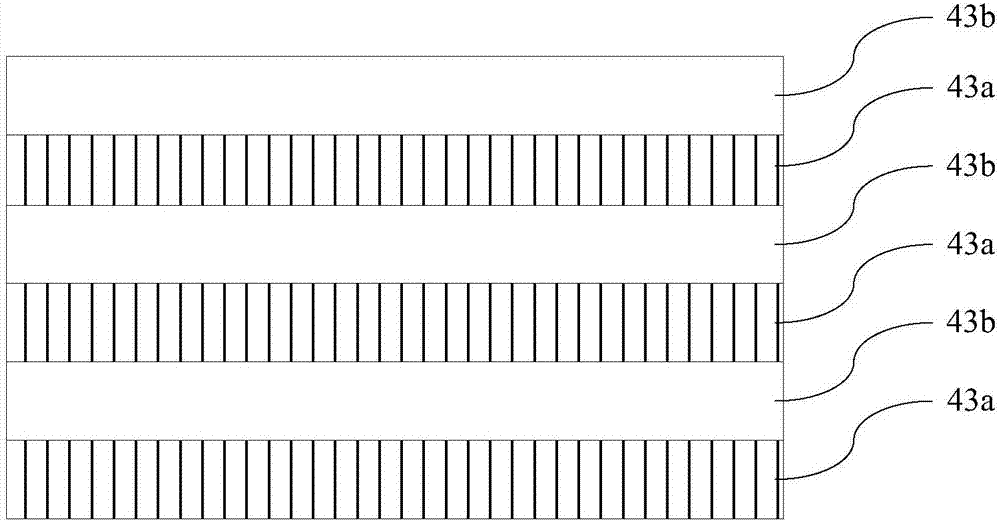

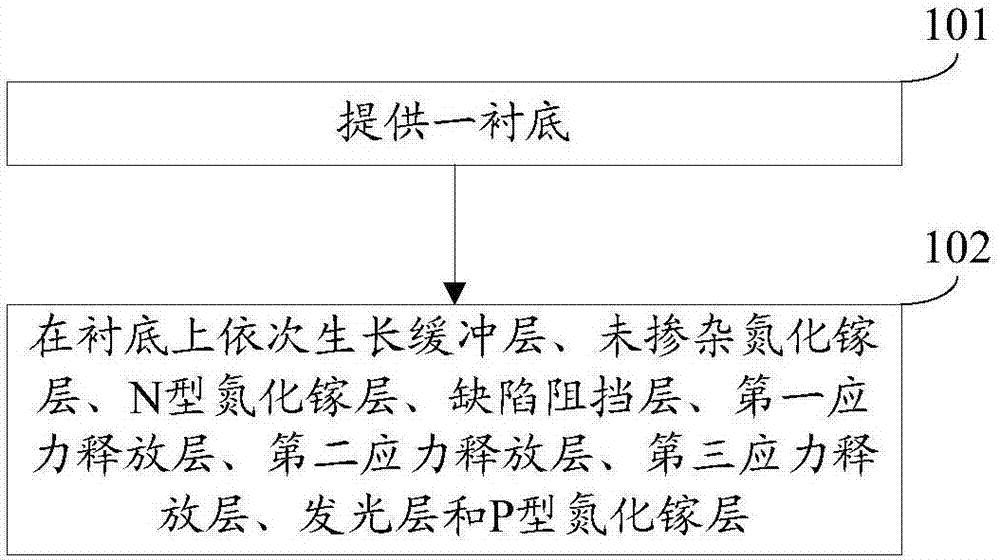

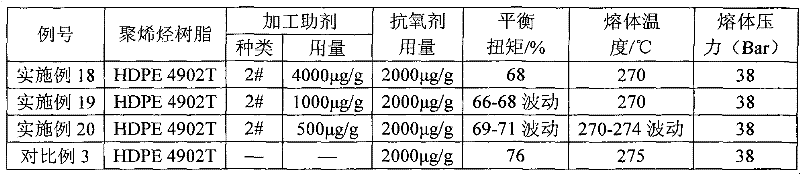

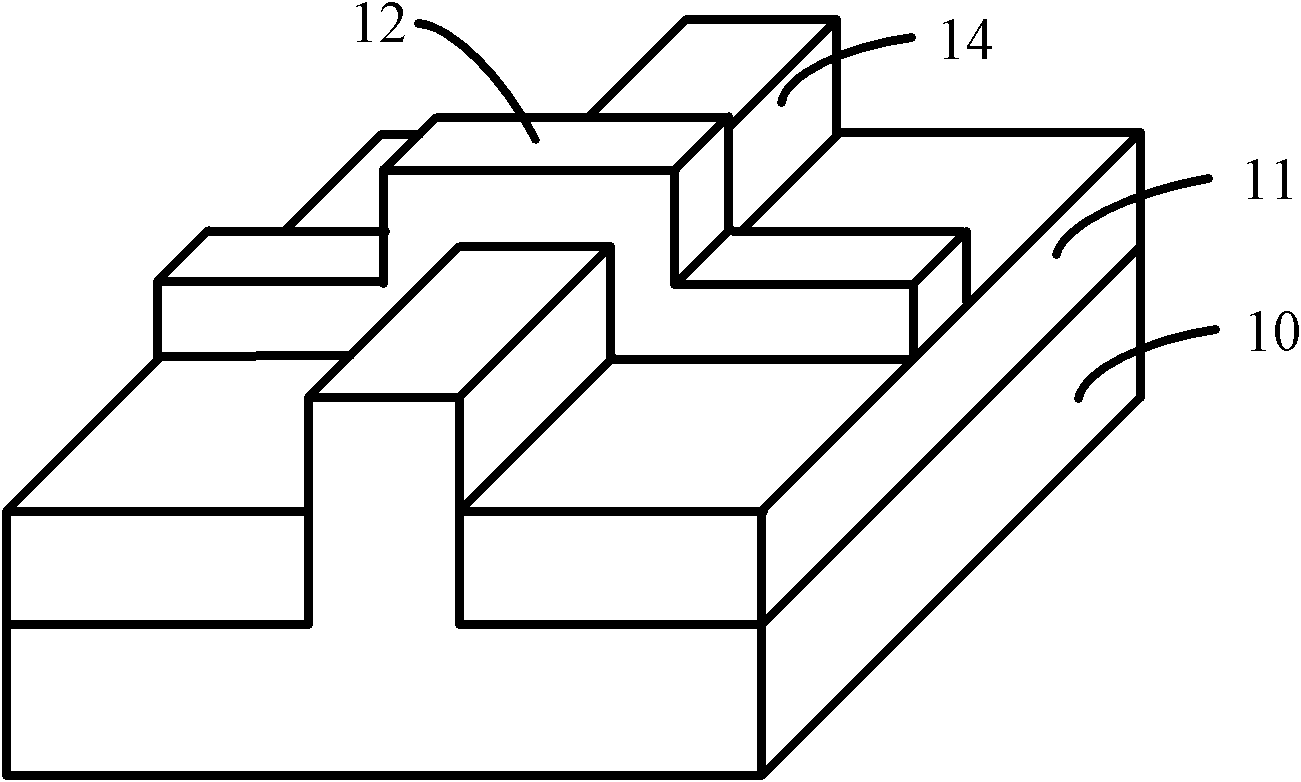

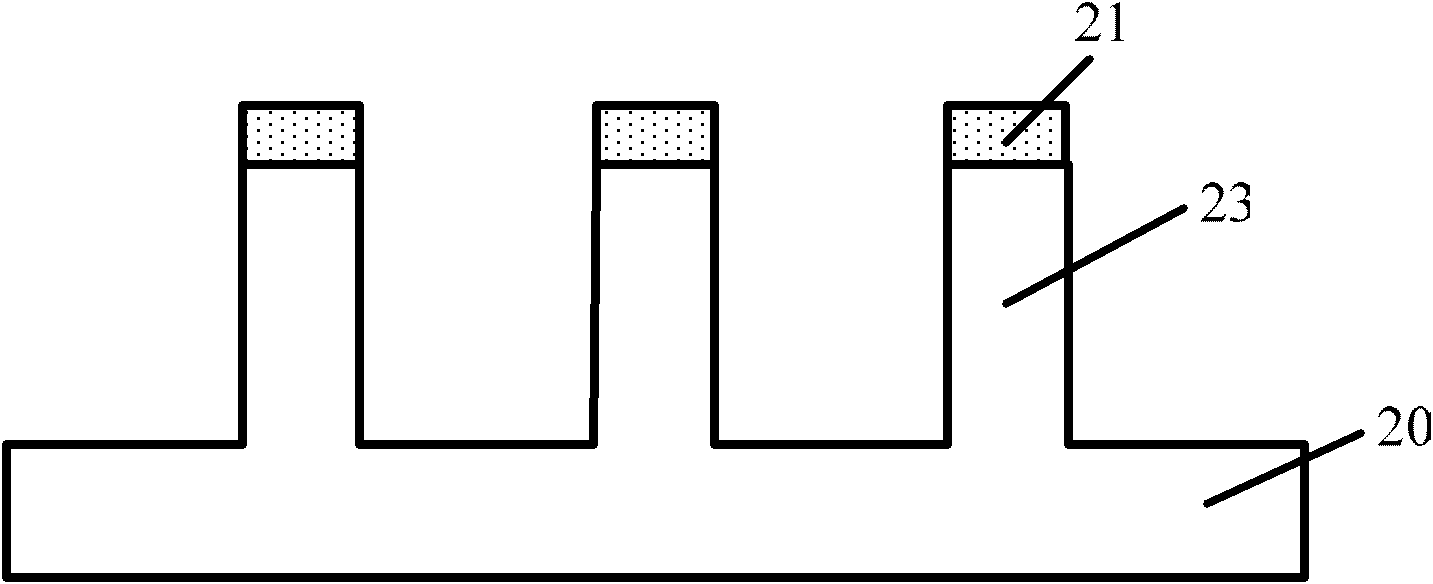

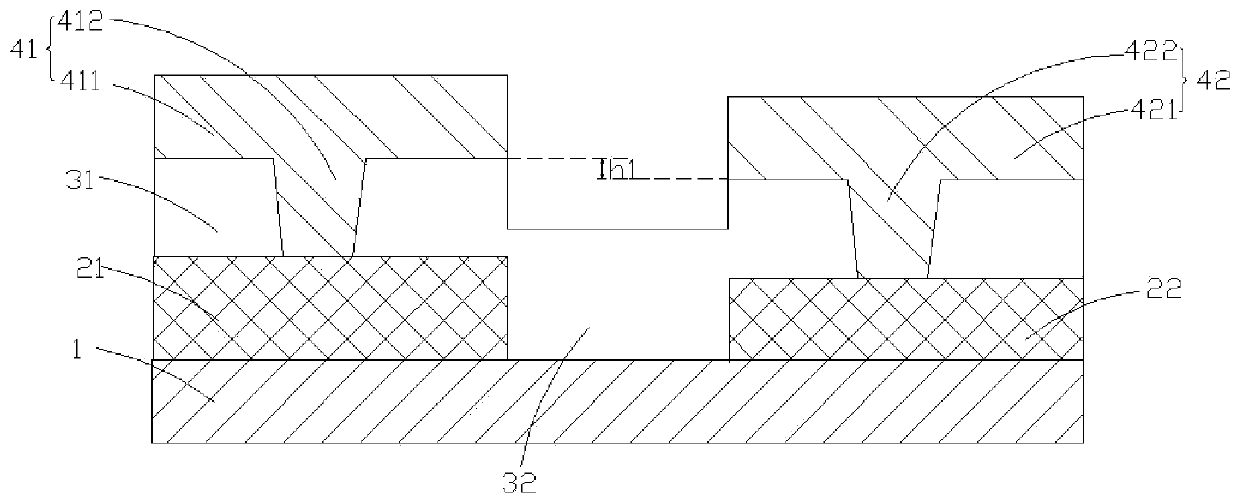

Epitaxial wafer of light-emitting diode and preparation method thereof

ActiveCN107331745AReduce stressReduce mismatchSemiconductor devicesGallium nitrideLight-emitting diode

The invention discloses an epitaxial wafer of a light-emitting diode and a preparation method thereof, and belongs to the technical field of semiconductors. The epitaxial wafer comprises a substrate, a buffer layer, an undoped gallium nitride layer, an N-type gallium nitride layer, a defect blocking layer, a first stress release layer, a second stress release layer, a third stress release layer, a light emitting layer and a P-type gallium nitride layer, and is characterized in that the buffer layer, the undoped gallium nitride layer, the N-type gallium nitride layer, the defect blocking layer, the first stress release layer, the second stress release layer, the third stress release layer, the light emitting layer and the P-type gallium nitride layer are sequentially laminated on the substrate, the defect blocking layer is a silicon-doped aluminum gallium nitride layer, the first stress release layer is a silicon-doped gallium nitride layer, the second stress release layer comprises a plurality of first sub-layers and a plurality of second sub-layers which are arranged in an alternately laminating manner, the first sub-layers are undoped InGaN layers, the second sub-layers are silicon-doped gallium nitride layers, and the third stress release layer is a silicon-doped InGaN layer; and the doping concentration of silicon in the defect blocking layer is lower than that of the first stress release layer, the doping concentration of silicon in the first stress release layer is higher than that of each second sub-layer, and the doping concentration of silicon in each second sub-layer is lower than that of the third stress release layer. The light emitting efficiency can be improved according to the invention.

Owner:HC SEMITEK ZHEJIANG CO LTD

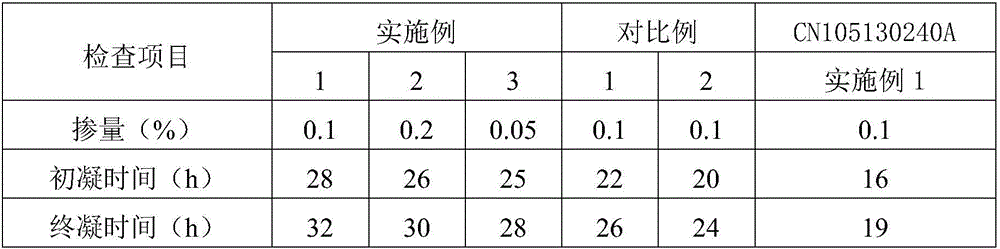

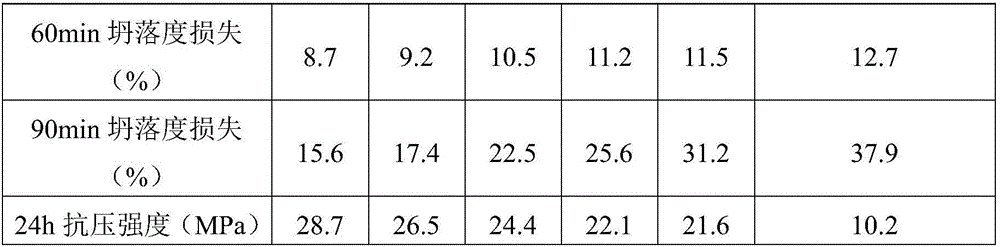

Concrete retarder

The invention discloses concrete retarder. The concrete retarder comprises, by weight, 2-4 parts of sodium borate, 3-7 parts of monopotassium phosphate, 4-8 parts of calcium sulfate, 6-8 parts of etidronic acid, 3-5 parts of ethylene diamine tetraacetic acid, 1-4 parts of sorbitol, 25-30 parts of bentonite, 10-15 parts of vermiculite powder, 4-6 parts of a water reducing agent, 1-3 parts of a dispersing agent and 0.4-0,8 part of a surface active agent. The concrete retarder has the advantages of good retarding effect, high strength, free of pollution and the like, and is a concrete additive which is quite promising.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

High-toughness high-water-steam-baffled completely-biodegraded composite multilayer film and preparation method thereof

InactiveCN106393919AHigh water vapor barrierImprove toughnessSynthetic resin layered productsFlat articlesWater vaporUltimate tensile strength

The invention relates to the technical field of polymer materials, and specifically relates to a high-toughness high-water-steam-baffled completely-biodegraded composite multilayer film and a manufacturing method thereof. The film comprises a structure from the second layer to the seventh layer and is composed of a PBAT based high-toughness high-barrier biodegradable material (A), a high-weatherability high-barrier biodegradable material (B), and a high-toughness functional biodegradable material layer (C). A multi-layer co-extrusion film blowing technology is adopted. Multiple material layers are compounded to prepare the film. The film is highly tough, the tensile strength can reach 18 MPa, the horizontal / vertical breaking elongation rate can reach more than 500%, no prominent difference exists in the vertical direction and the horizontal direction, the water steam baffling performance is strong, the water steam penetration rate of the film with a thickness of 10 [mu]m is 240 g / m2.24h; the processing performance is good, the minimal thickness of the film can reach 5 [mu]m; the processing equipment does not need frequent adjustment, and the film is used as a package film, an agricultural cover film, and the like.

Owner:SHANGHAI HONGRUI CHEM PROD CO LTD

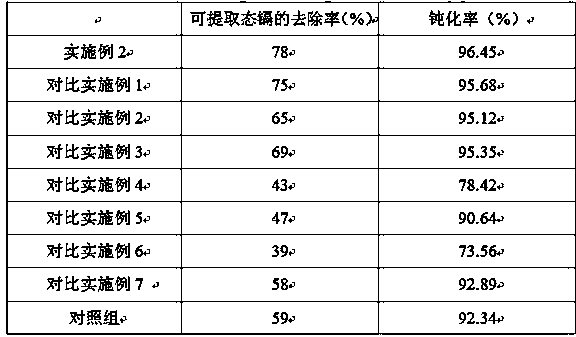

Preparation method of montmorillonite-modified soil remediation agent

InactiveCN109370605ASolve pollutionImprove adsorption capacityContaminated soil reclamationSilicon compoundsSoil remediationSoil heavy metals

The invention discloses a preparation method of a montmorillonite-modified soil remediation agent. The preparation method of the montmorillonite-modified soil remediation agent comprises the followingsteps of (1) preparation of modified montmorillonite, (2) preparation of biomass charcoal, (3) raw material weighing and (4) preparation of finished products. The prepared montmorillonite-modified soil remediation agent can effectively absorb soil heavy metal, greatly reduce the migration speed of heavy metal elements and well solve the problem of soil heavy metal pollution, thereby having high marketing values.

Owner:马步华

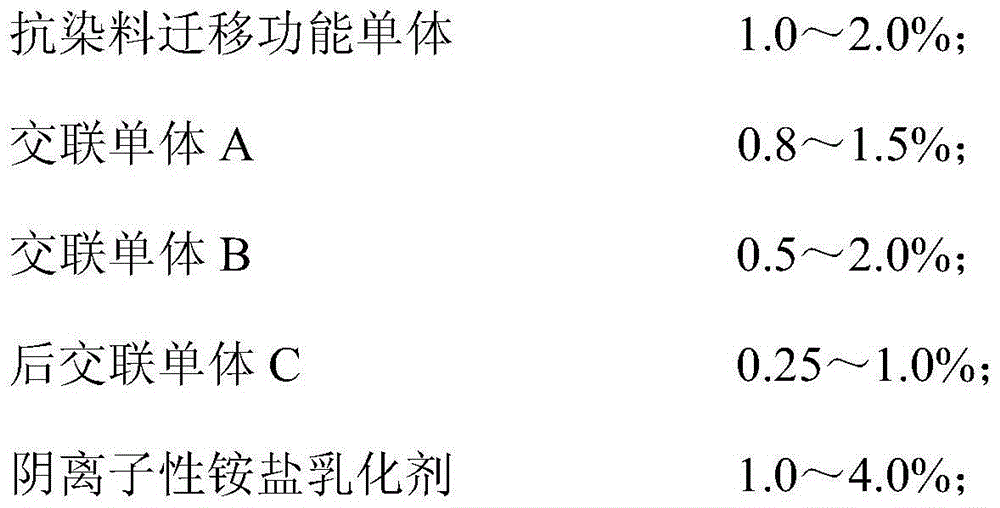

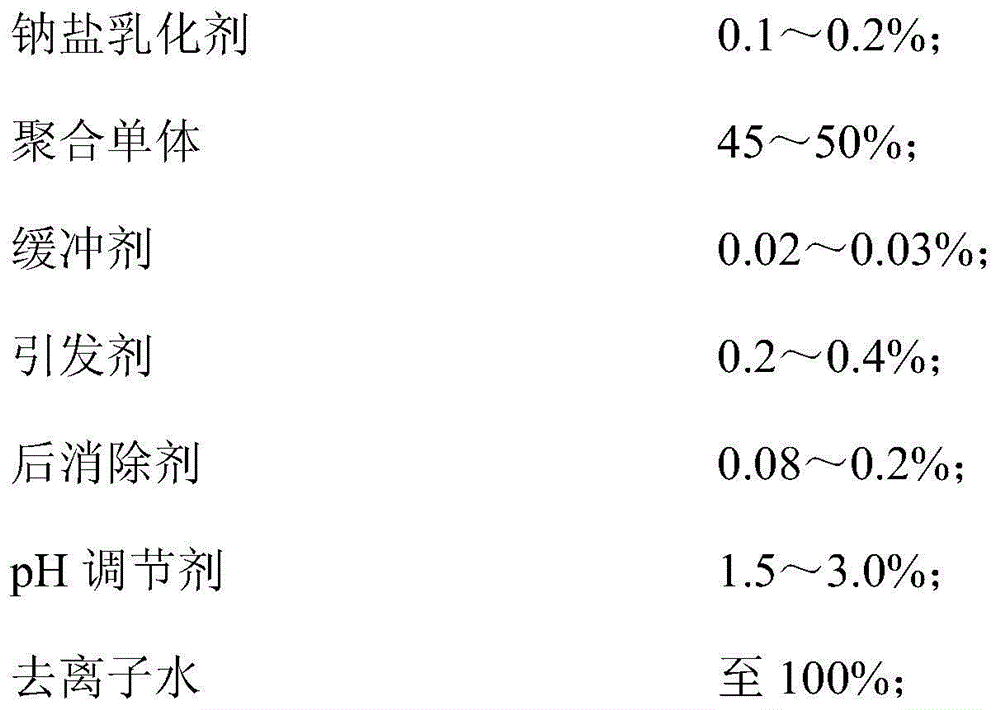

Polyacrylate emulsion capable of postponing dye transfer and preparation method thereof

ActiveCN104910319AIncrease the speed of self-crosslinkingReduce migration speedDyeing processMethacrylateTextile printer

The invention relates to a polyacrylate emulsion capable of postponing dye transfer, which comprises an anti-dye-transfer functional monomer, a crosslinking monomer A, a crosslinking monomer B, a post-crosslinking monomer C, an anionic ammonium salt emulsifier, a sodium salt emulsifier, a polymerizable monomer, a buffering agent, an initiator, a post remover, a pH regulator and deionized water, wherein the crosslinking monomer B is any one or at least two of ethyl acetoacetate methacrylate and diacetone acrylamide; and the post-crossliking monomer C is any one or at least two of diamidohydrazine adipate and hexamethylendiamine. By using the polyacrylate emulsion capable of postponing dye transfer, the printing coat can not generate color spots or stripes due to dye transfer on terylene and other fabrics with severe dye transfer in the textile use period; and the polyacrylate emulsion can keep the color completeness of the coat, and has favorable application prospects in the fields of leather, textiles, paints and the like.

Owner:DONGGUAN CTL NEW MATERIAL TECH

Halogen-free flame-retarded cross-linked polyethylene cable insulating material with low smoke

InactiveCN104479210AReduce migration speedReduce dosagePlastic/resin/waxes insulatorsInsulated cablesAluminium hydroxideLead phosphate

The invention discloses a halogen-free flame-retarded cross-linked polyethylene cable insulating material with low smoke. The insulating material is prepared from the following raw materials in parts by weight: 80-150 parts of cross-linked polyethylene, 10-30 parts of magnesium hydroxide, 5-9 parts of aluminium hydroxide, 1-2 parts of lead sulfate tribasic, 0.5-0.9 part of dibasic lead phosphate, 0.3-0.7 part of paraffin, 20-50 parts of phthalate and 5-15 parts of nano-montmorillonite. The insulating material provided by the invention has the advantages of being light in weight, good in toughness, small in flame and low in burning speed, having no molten drop and less smoke, being anti-migration, good in char forming characteristics, easy in processing and the like.

Owner:GUIZHOU MINGHCOO WIRE & CABLE CO LTD

Method for producing latex foamed product by using low-protein latex

PendingCN110982131AReduce allergies and other hazardsImprove foam stabilityPolymer scienceFoaming agent

The invention relates to the technical field of latex foamed products, in particular to a method for producing a latex foamed product by using low-protein latex. The natural latex foamed product is prepared from the following raw materials in parts by weight: 100 parts of latex, 2-5 parts of a vulcanizing agent, 0.5-6 parts of a foaming agent, 1-5 parts of a foam stabilizer, 0.5-1.5 parts of a gelatinizing agent, 3-5 parts of an active agent, 3-12 parts of an auxiliary agent and 1-15 parts of a filler. The natural latex in the preparation raw materials of the natural latex foamed product provided by the invention is low-protein natural latex, and has the characteristics of nature, environmental protection, no pollution, no toxicity, antianaphylaxis and the like. Proper amounts of the foamstabilizer and the active agent are added in the production and preparation process of the latex foamed product; meanwhile, the production process parameters are changed, so that the prepared latex foamed product has good foam stability, uniform foam pore size, regular and stable pore structure, few internal defects and the like, the prepared foamed product has good resilience, and the tensile strength, elongation at break, resilience rate and the like are remarkably improved.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

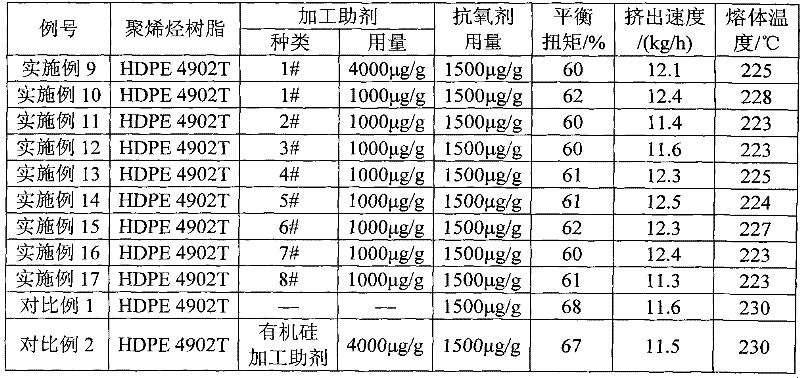

Processing assistant for polyolefin granulation process, and preparation method and application thereof

The invention relates to a processing assistant for a polyolefin granulation process, and a preparation method and application thereof. The processing assistant comprises the following blended components: low polymers and polybasic acid, wherein the mol ratio of low polymers to polybasic acid is 1:(0.1-10); the low polymers are linear or short-branched-chain low polymers of which the molecular weight is 2000-20000, and at least one end of the molecular chain has a terminal polar group; and the polybasic acid is an inorganic polybasic acid or organic polybasic acid. The processing assistant can be used in the polyolefin granulation process, can have a good viscosity breaking effect under the condition of small addition amount, and can lower the processing torque and melt temperature, thereby achieving the functions of lowering the energy consumption and reducing the abrasion.

Owner:CHINA PETROLEUM & CHEM CORP +1

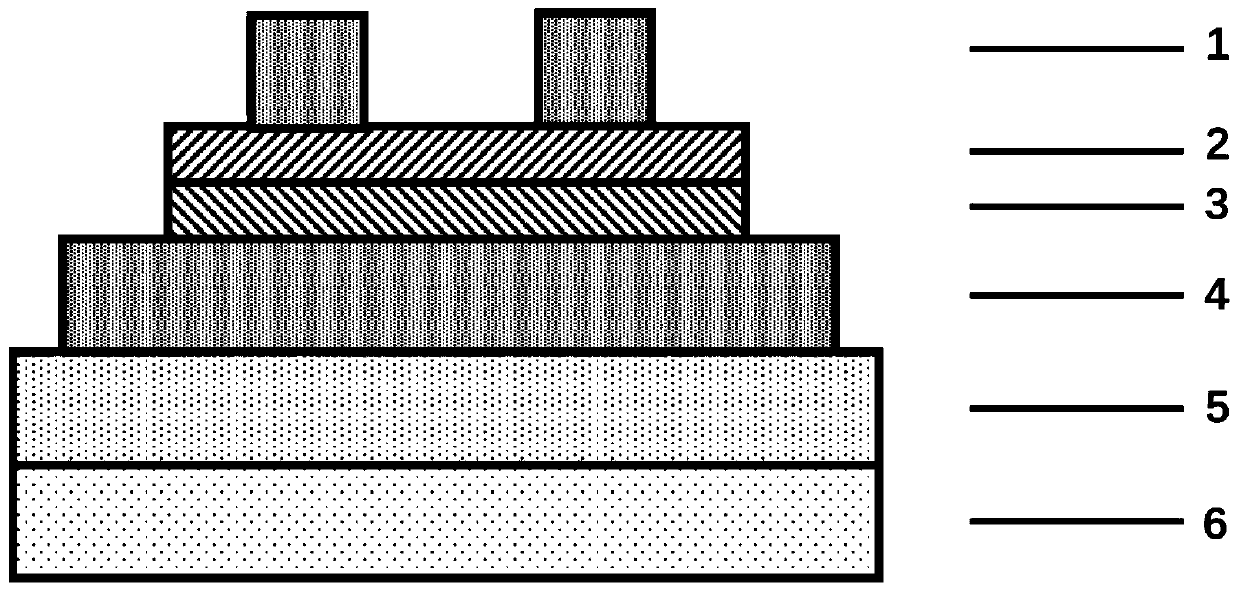

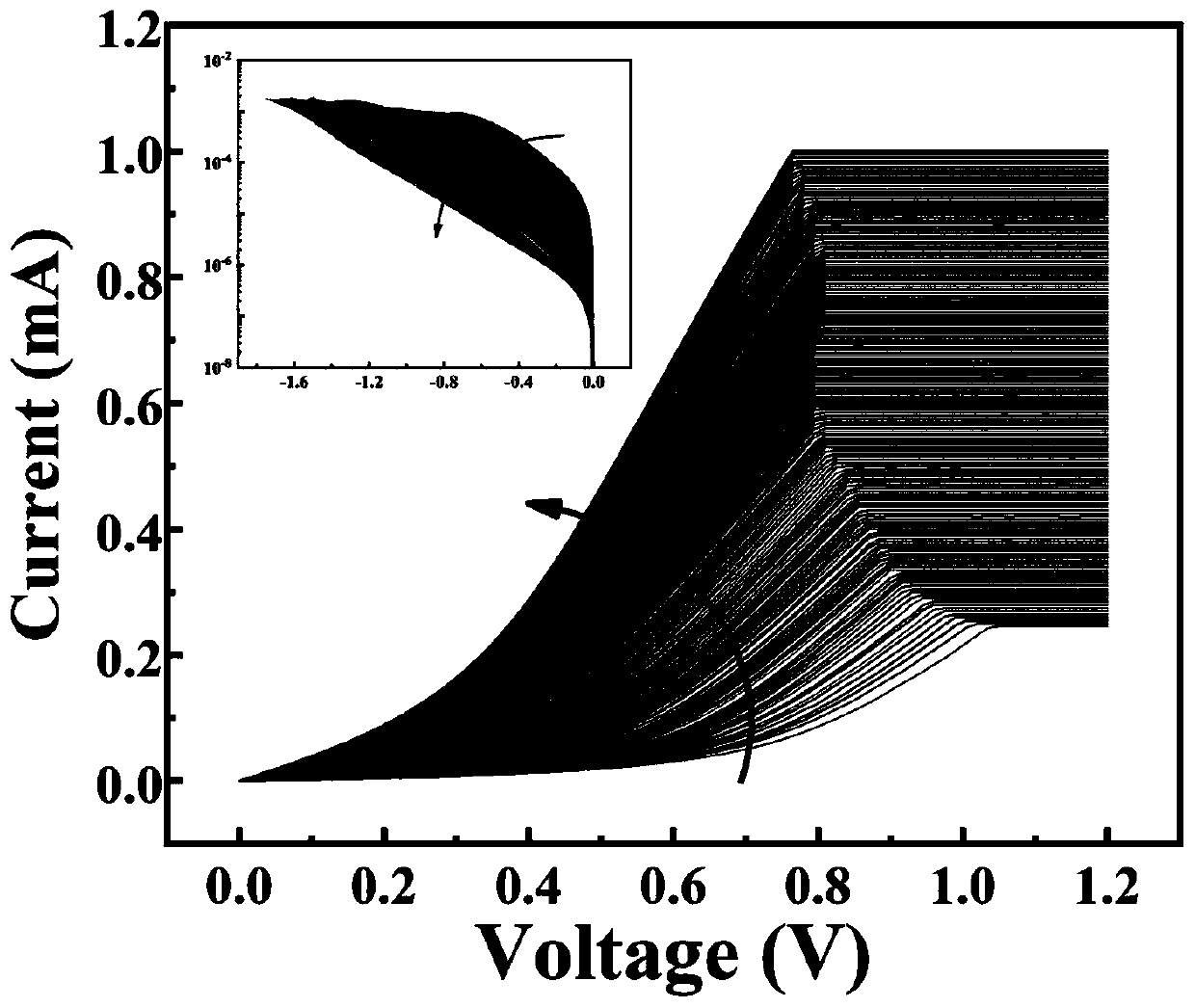

Analog HfOx/HfOy homojunction memristor and regulation and control method thereof

ActiveCN110911559AHigh oxygen vacancy mobilityLower resistanceSemiconductor/solid-state device testing/measurementDigital storageElectronic synapseCondensed matter physics

The invention belongs to the technical field of microelectronic devices. The invention discloses an analog HfOx / HfOy homojunction memristor and a regulation and control method thereof. The homojunction memristor comprises a lower electrode layer, a functional layer and an upper electrode layer which are sequentially stacked from bottom to top, and the functional layer is an HfOx / HfOy homojunctionfunctional layer formed by stacking an HfOx layer and an HfOy layer from bottom to top; for the HfOx / HfOy homojunction functional layer, 1.6<x<1.8, 1.9<y<2, and the thickness of the HfOx layer is larger than that of the HfOy layer. According to the invention, the key device structure, especially the functional layer composition and the like, is improved; the hafnium oxide lamination with high / lowoxygen vacancies grown in a stacked manner is used as the resistive function layer, and compared with the prior art, the technical problems of small resistance gradual change window, low operation speed and poor consistency of an analog memristor and an electronic synaptic bionic device based on the analog memristor can be effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH

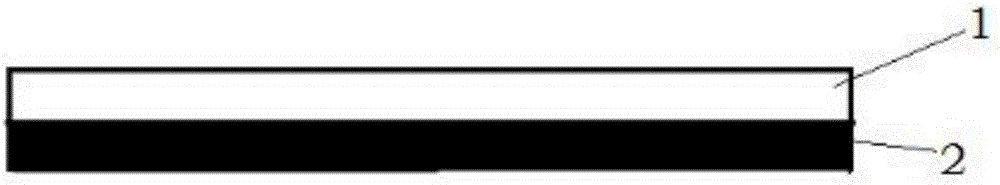

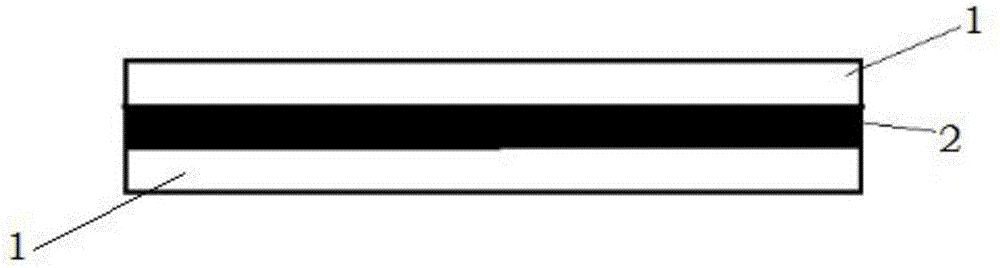

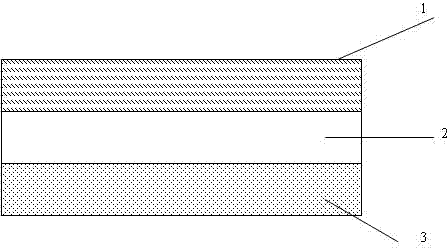

A kind of encapsulation adhesive film for solar cell module

ActiveCN103421443BAvoid PID phenomenaPrevent penetrationFilm/foil adhesivesPhotovoltaic energy generationPolyolefinSolar cell

The invention discloses a packaging adhesive film for a solar cell module. The packaging adhesive film for the solar cell module comprises a blocking layer, a first adhesive layer and a second adhesive layer, wherein the first adhesive layer and the second adhesive layer are located at the two sides of the blocking layer, the blocking layer is a polyolefin blocking layer containing ethylene-a-olefin polymer. The adhesive film is good in blocking performance and capable of effectively avoiding the PID phenomenon of the solar cell module under the high-pressure, damp and hot environment, the adhering performance between the packaging adhesive film and a glass substrate and between the packaging adhesive film and a cell sheet is good, and the service life of the solar cell module is prolonged.

Owner:乐凯胶片股份有限公司

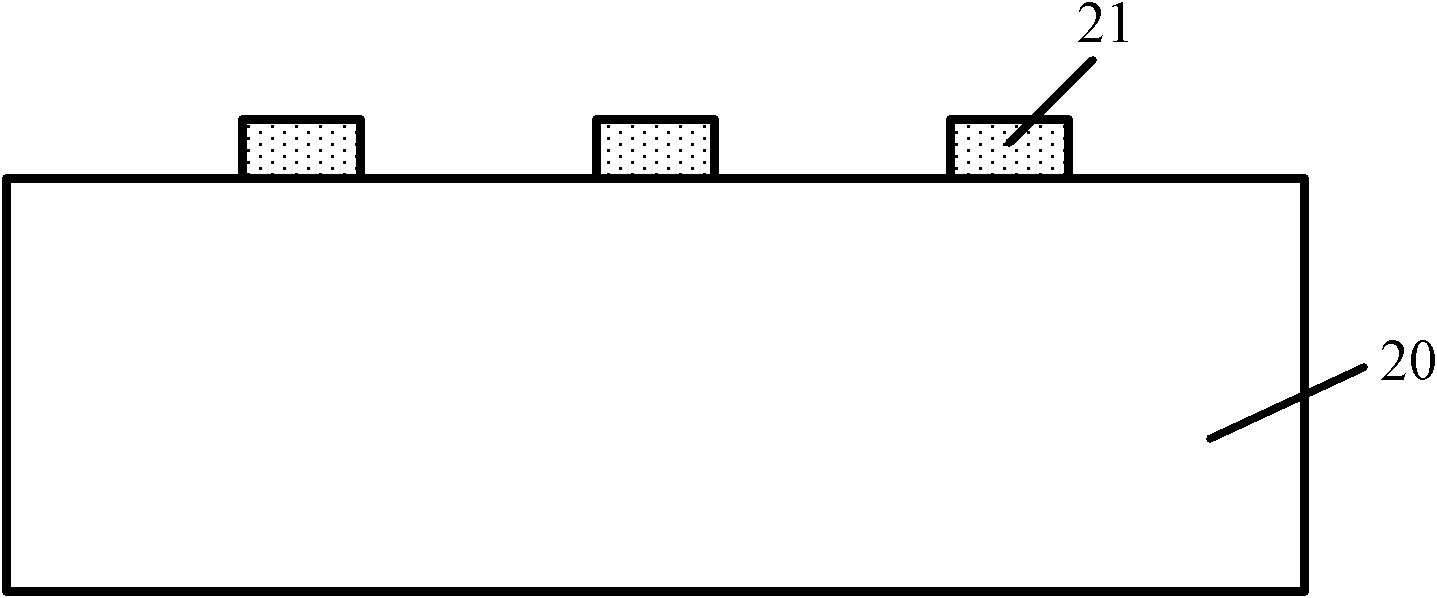

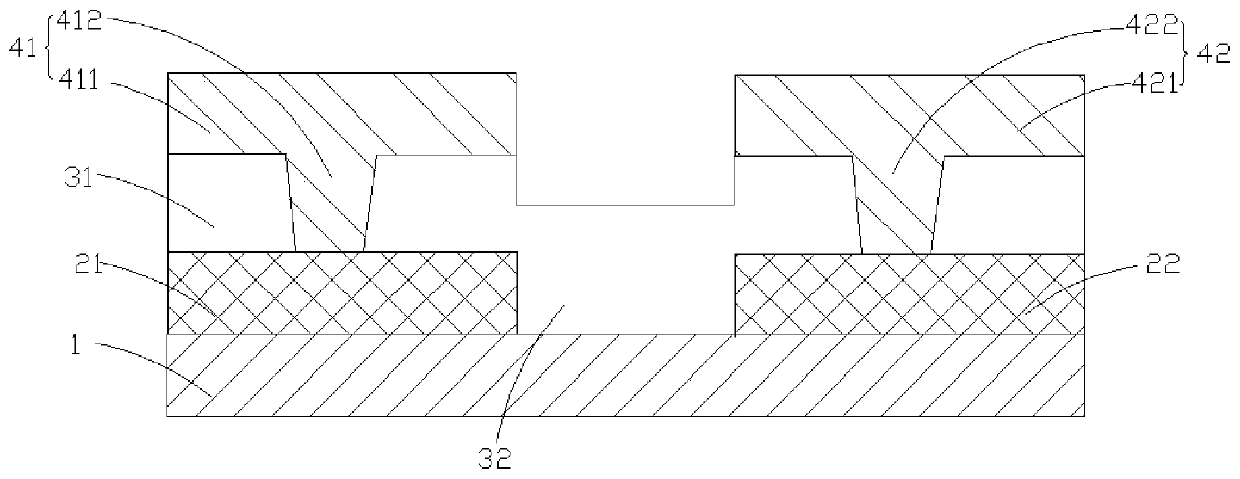

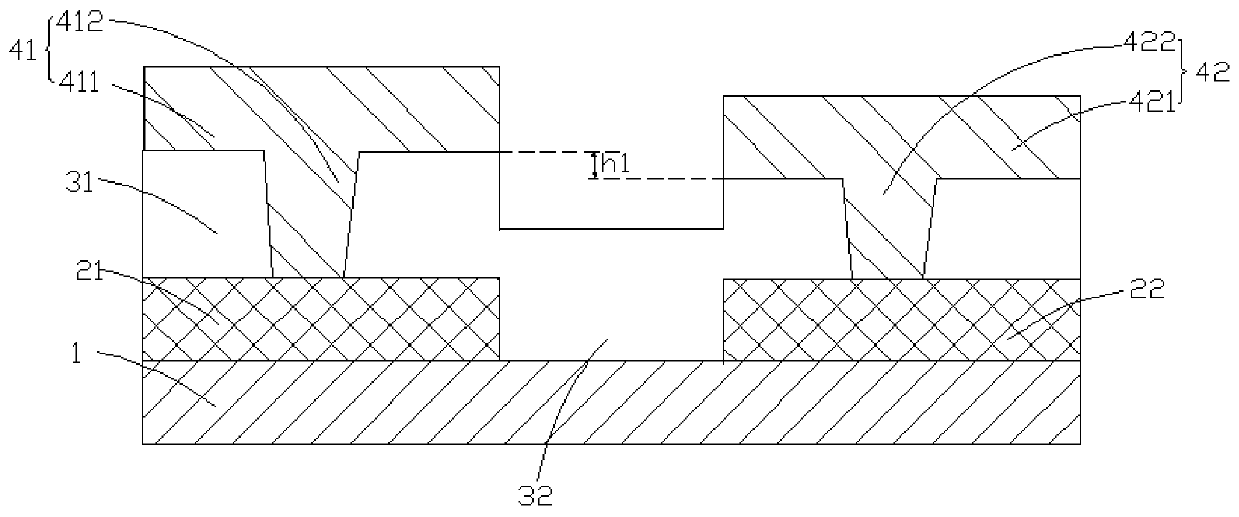

Semiconductor structure, formation method of semiconductor structure, complementary metal-oxide-semiconductor transistor (CMOS) and formation method of CMOS

ActiveCN103187439AFast migrationSlow migrationTransistorSolid-state devicesCMOSSemiconductor structure

The invention discloses a semiconductor structure, a formation method of the semiconductor structure, a complementary metal-oxide-semiconductor transistor (CMOS) and a formation method of CMOS. The semiconductor structure comprises a semiconductor substrate, first side stress walls and second side stress walls, wherein a fin part is arranged on the surface of the semiconductor substrate, the first side stress walls are positioned on the surface of the semiconductor substrate and on the two sides of the bottom of the fin part, the second side stress walls are positioned on the two sides of the top of the fin part, and the stress types of the first side stress walls and the second side stress walls are contrary. The electrical properties of the semiconductor structure and the CMOS are good, and the technological windows of the semiconductor structure formation method and the CMOS formation method are large.

Owner:SEMICON MFG INT (SHANGHAI) CORP

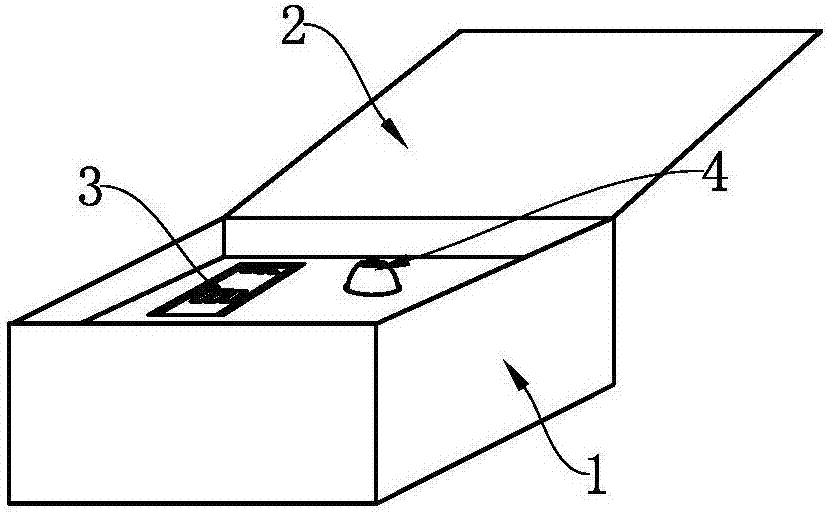

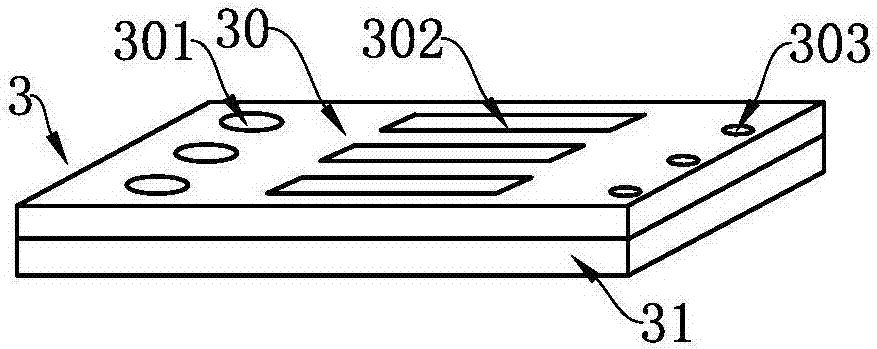

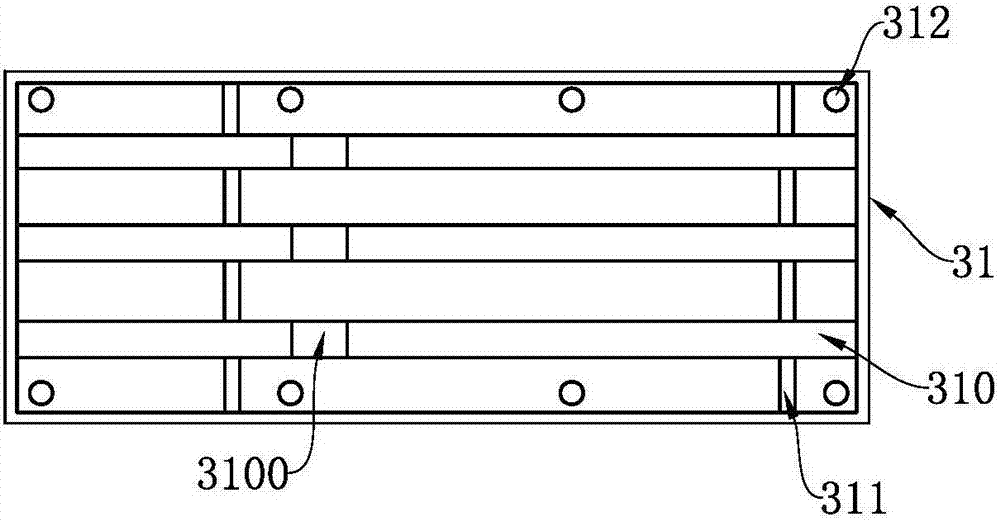

Multiple-detection kit for vaginitis, and preparation method thereof

PendingCN107389940AImprove hydrophilicityImprove reagent sensitivityMaterial analysisGardnerella vaginalis DNABiology

The invention relates to the technical field of in vitro diagnosis, and concretely relates to a multiple-detection kit for vaginitis. The kit comprises a kit body and a kit cover, a detection card and a sample processing solution bottle are arranged in kit body, the detection card comprises a card cover and a card body, a Gardnerell avaginalis test strip, a Candida albicans test strip and a Trichomonas vaginalis test strip are arranged in the card body, and each of the Gardnerell avaginalis test strip, the Candida albicans test strip and the Trichomonas vaginalis test strip is provided with a first sample pad layer and a second sample pad layer treated with the sample pad treatment fluid. The kit can decompose and filter out interfering substances in vaginal secretions, so the sensitivity of the kit is improved.

Owner:山东康华生物医疗科技股份有限公司

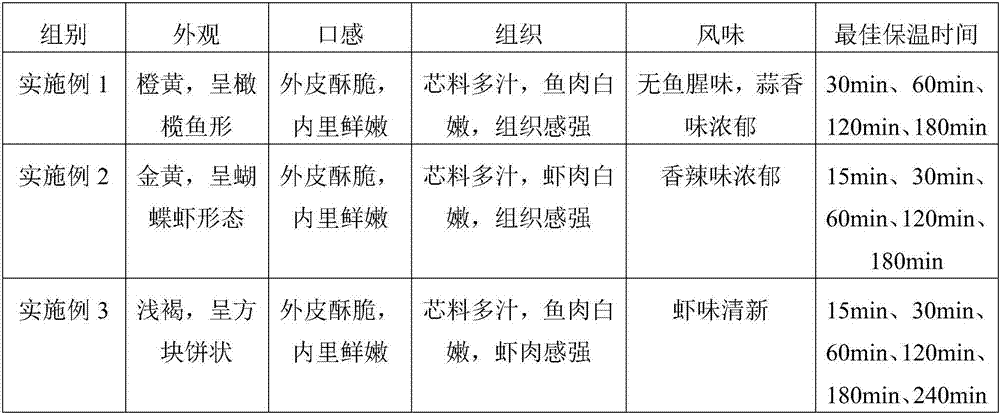

Frozen pre-deep-fried fish and shrimp type powder-coating food and preparation method thereof

InactiveCN106858411AGood lookingGreat tasteFood ingredient as thickening agentYeast food ingredientsFlavorShrimp

The invention belongs to the field of food processing, and discloses a frozen pre-deep-fried fish and shrimp type powder-coating food. The frozen pre-deep-fried fish and shrimp type powder-coating food comprises the following components in parts by weight: 50-60 parts of core materials, 2-6 parts of pre-coating powder, 15-25 parts of coating starch, 13-22 parts of bread crumbs and 2-4 parts of palm oil. The invention further discloses a preparation method of the frozen pre-deep-fried fish and shrimp type powder-coating food. According to the frozen pre-deep-fried fish and shrimp type powder-coating food and the preparation method disclosed by the invention, fish meat and shrimp meat are used as main raw materials for making the powder-coating deep-fried foods, and nutritive white meat protein is provided; besides, the compounding ratio of optimal water retention auxiliary materials of the core materials, the compounding ratio of flavor, and the type of outer-layer starch bran are improved, seasoning water retention slurry is mixed, bran is coated, after deep-frying is performed, freezing is performed, and packaging is performed so that the frozen pre-deep-fried fish and shrimp type powder-coating food which is good in appearance, good in mouth feel, good in tissue, good in flavor, capable of being subjected to microwave treatment and resistant to heat preservation can be obtained. The frozen pre-deep-fried fish and shrimp type powder-coating food can be heated from a frozen state through a commercial or household microwave oven, and then the heated frozen pre-deep-fried fish and shrimp type powder-coating food can be subjected to heat preservation in a hot cabinet for 2-4 hours for sale and supply.

Owner:SHENZHEN ALLIED AQUATIC PROD DEV LTD

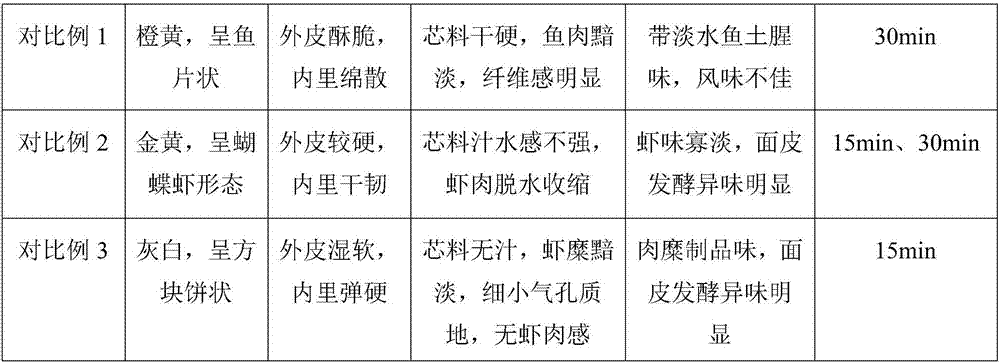

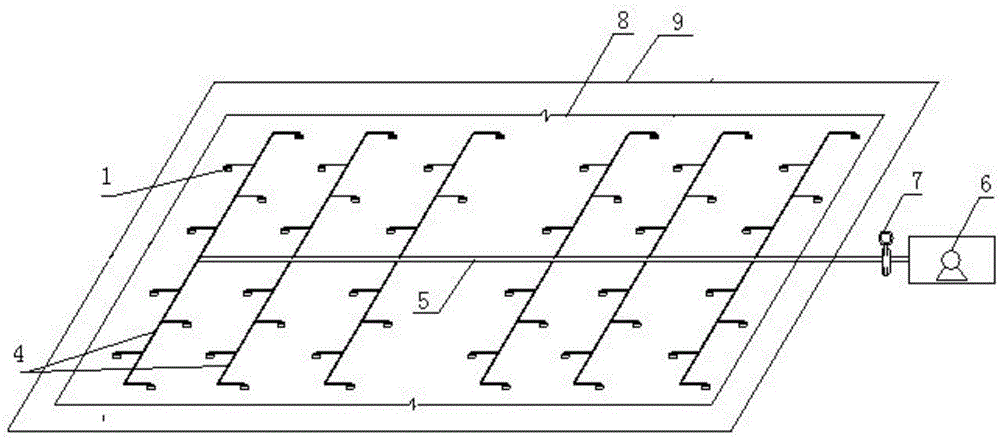

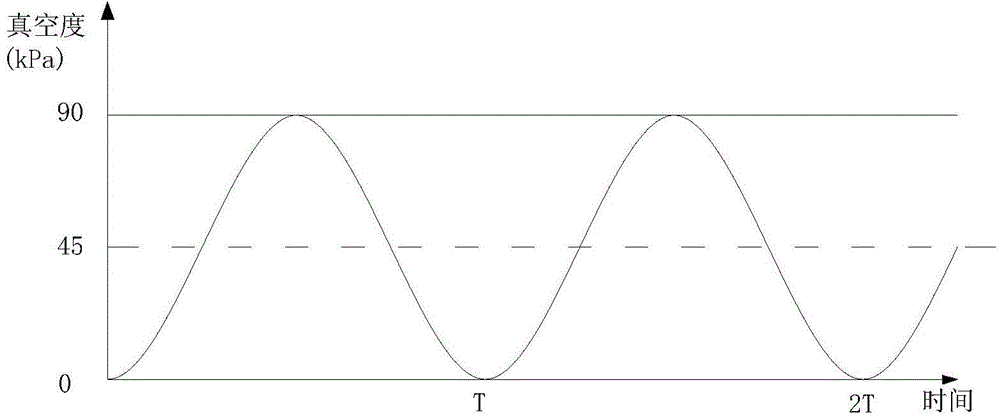

Intermittent vacuum precompression device and soft foundation treatment method of intermittent vacuum precompression device

ActiveCN104452736AReasonable structural designEasy to operateSoil preservationEngineeringSoil material

The invention discloses an intermittent vacuum precompression device and a soft foundation treatment method of the device. The intermittent vacuum precompression device comprises vertical drainage bodies (1), direct connecting joints (2) connected with the vertical drainage body (1), connecting pipes (3) connected with the direct connecting joints (2), discharge branches (4) connected with the connecting pipe (3), a drainage collector (5) connected with the discharge branches (4), a jet pump (6) connected with the drainage collector (5), and a valve (7) mounted between the drainage collector (5) and the jet pump (6). The device can delay aggregation of clay fine particles during drainage via short-period variation of a vacuum degree in an early drainage stage, alleviate clogging of the drainage bodies due to clay particle migration under the condition of applying a constant vacuum degree and therefore delay the clogging of a drainage pipeline and a neighbouring soil body. The device can solve the problem of too early clogging of a drainage channel due to soil material migration in the existing vacuum precompression process, and has an important application value.

Owner:NANJING HYDRAULIC RES INST

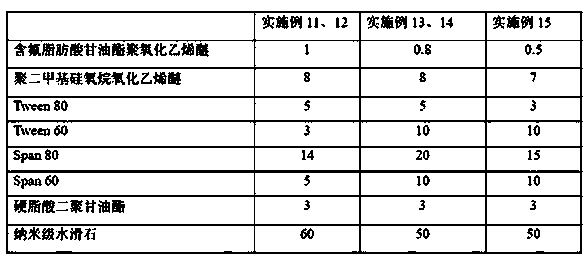

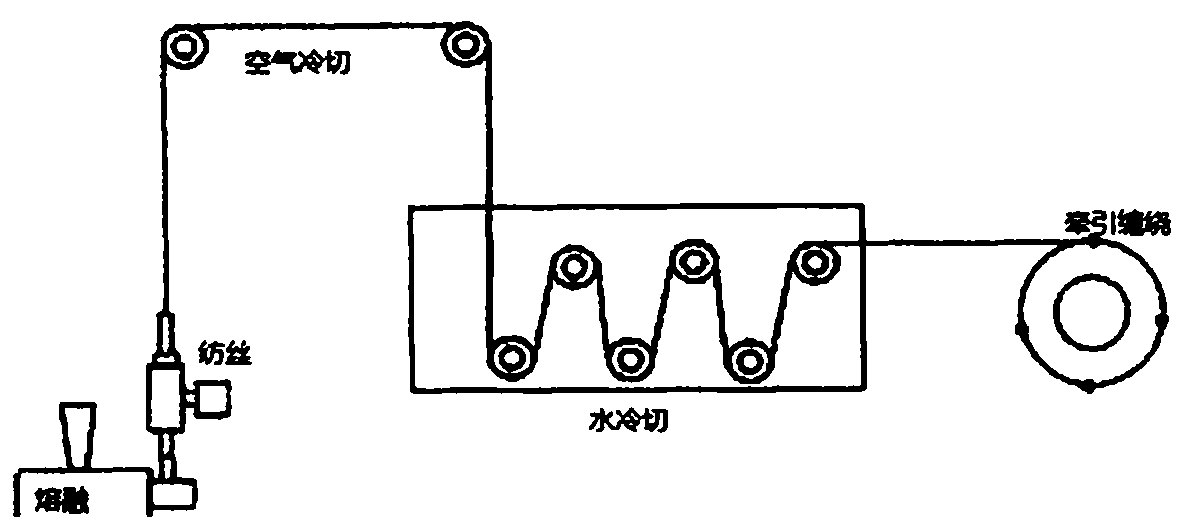

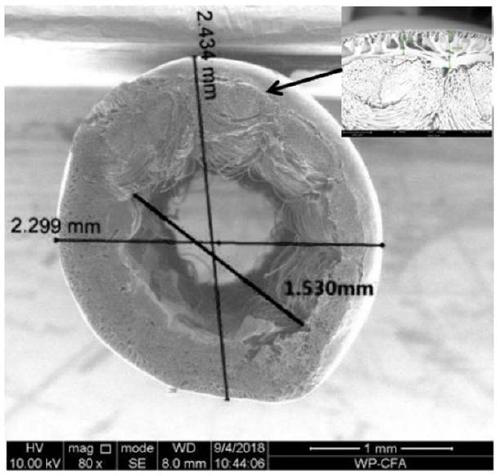

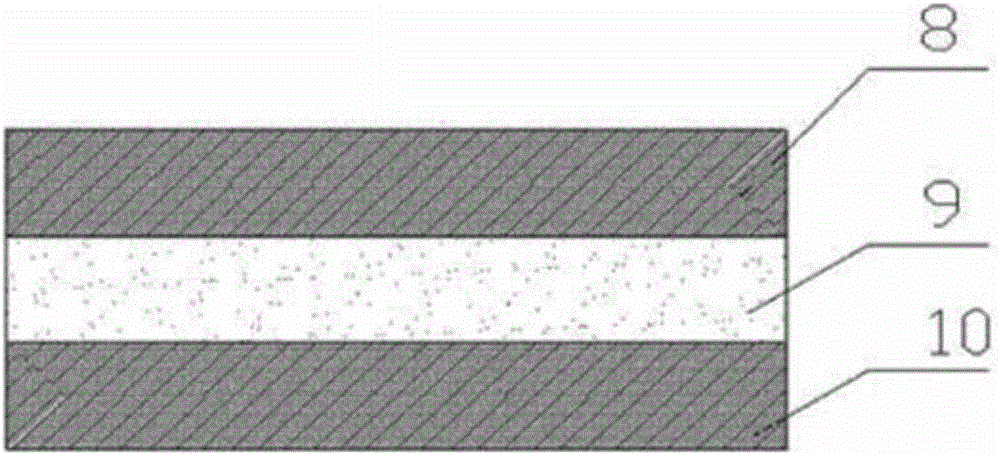

Antibacterial multilayer composite hollow fiber membrane material and preparation method thereof

InactiveCN111235687AImprove thermal stabilityOvercoming problems such as failureHollow filament manufactureFilament/thread formingGrapheneAnti bacterial

The invention discloses an antibacterial multilayer composite hollow fiber membrane material and a preparation method thereof. According to the material, graphene / chitosan intercalated zirconium phosphate is adopted to prepare and obtain a new modified antibacterial agent, and then the antibacterial agent is melt-blended with PP resin, PVB resin, PVDF resin, a compatilizer, a lubricant, an antioxidant and other processing auxiliaries to obtain the antibacterial multilayer composite hollow fiber membrane material. The prepared antibacterial multilayer composite hollow fiber membrane material overcomes the problems of antibacterial agent failure and the like caused by high temperature in a traditional antibacterial material processing process. By lowering the release speed of the antibacterial agent, long-time bacterial resistance and bacteriostasis of the composite material are realized.

Owner:泉州嘉宸科技有限公司

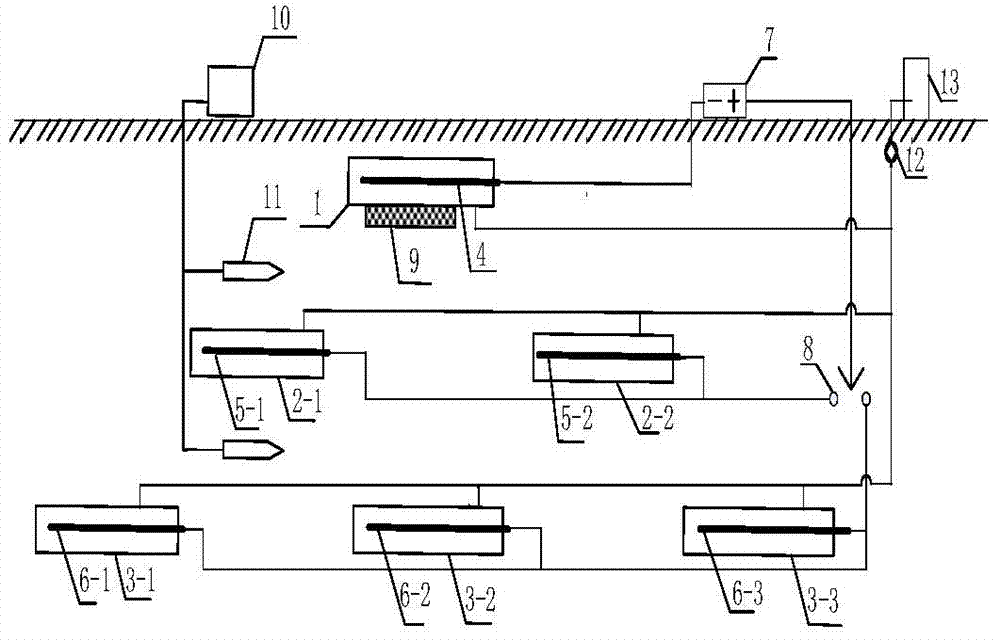

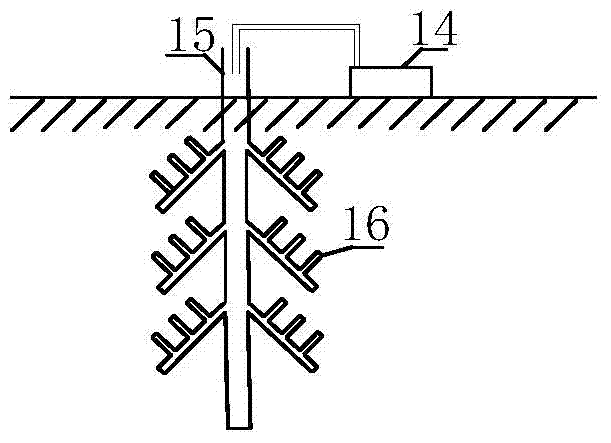

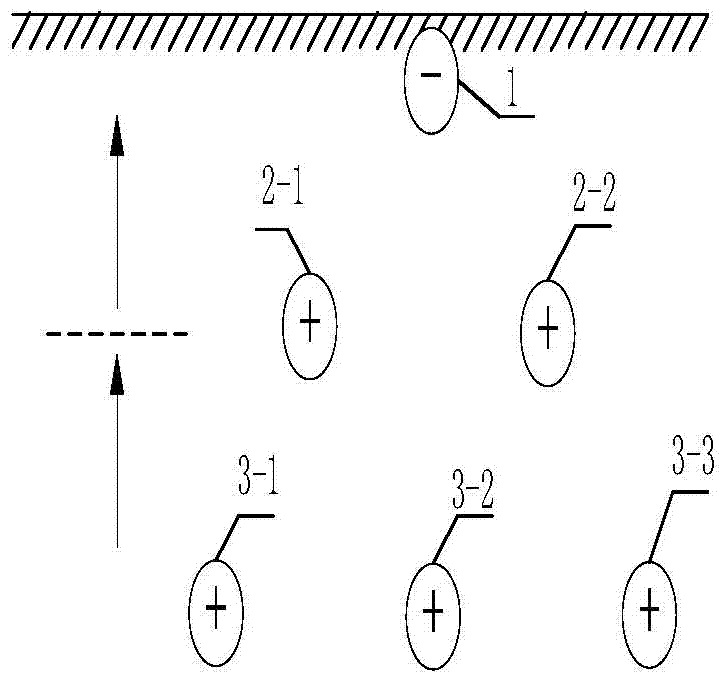

Device and method for repairing contaminated soil through combination of focusing type hierarchical electric method and injected solution

InactiveCN104259190AImprove migration speedReduce migration speedContaminated soil reclamationChemical agentTreatment system

The invention discloses a device and method for repairing contaminated soil through the combination of a focusing type hierarchical electric method and an injected solution. The repairing device comprises a focusing type hierarchical electric treatment system and an automatic injection control treatment system; a chemical agent is injected into the soil by using the automatic injection control treatment system so as to completely decompose various combination states of radioactive element-strontium; in the focusing type electrode repairing, contaminants in the deep soil is gradually focused to a central region of a surface layer at a certain angle, so that the containment area is reduced; the hierarchical electrode repairing not only can transport and enrich the containments to the surface layer, but also can lower the energy consumption, shorten the treatment time and improve the processing efficiency. The device and the method can increase the repairing speed, has the good repairing effect and is capable of effectively removing strontium containments.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Concrete air-entraining agent

InactiveCN104446109AImprove workabilityIncreased durabilityCamellia oleiferaEnvironmental engineering

The invention discloses a concrete air-entraining agent, comprising the following components in parts by weight: 56-70 parts of camellia saponin water aqua, 8-22 parts of sodium dodecyl benzene sulfonate and 10-23 parts of lignin calcium carbonate water reducer calcium lignosulphonate. According to the concrete air-entraining agent disclosed by the invention, through compounding of the camellia saponin water aqua, the sodium dodecyl benzene sulfonate and the lignin calcium carbonate water reducer calcium lignosulphonate, a good effect is obtained; the concrete air-entraining agent is high in gas production rate, and small in mixing amount; introduced bubbles are not communicated, and are small in interval and aperture; and the durability, the permeability resistance, the freezing resistance and the erosion resistance of concrete can be improved, and the working performance, such as easiness in mixing, of the concrete can be improved.

Owner:HUNAN CONSTR ENG GRP COR +1

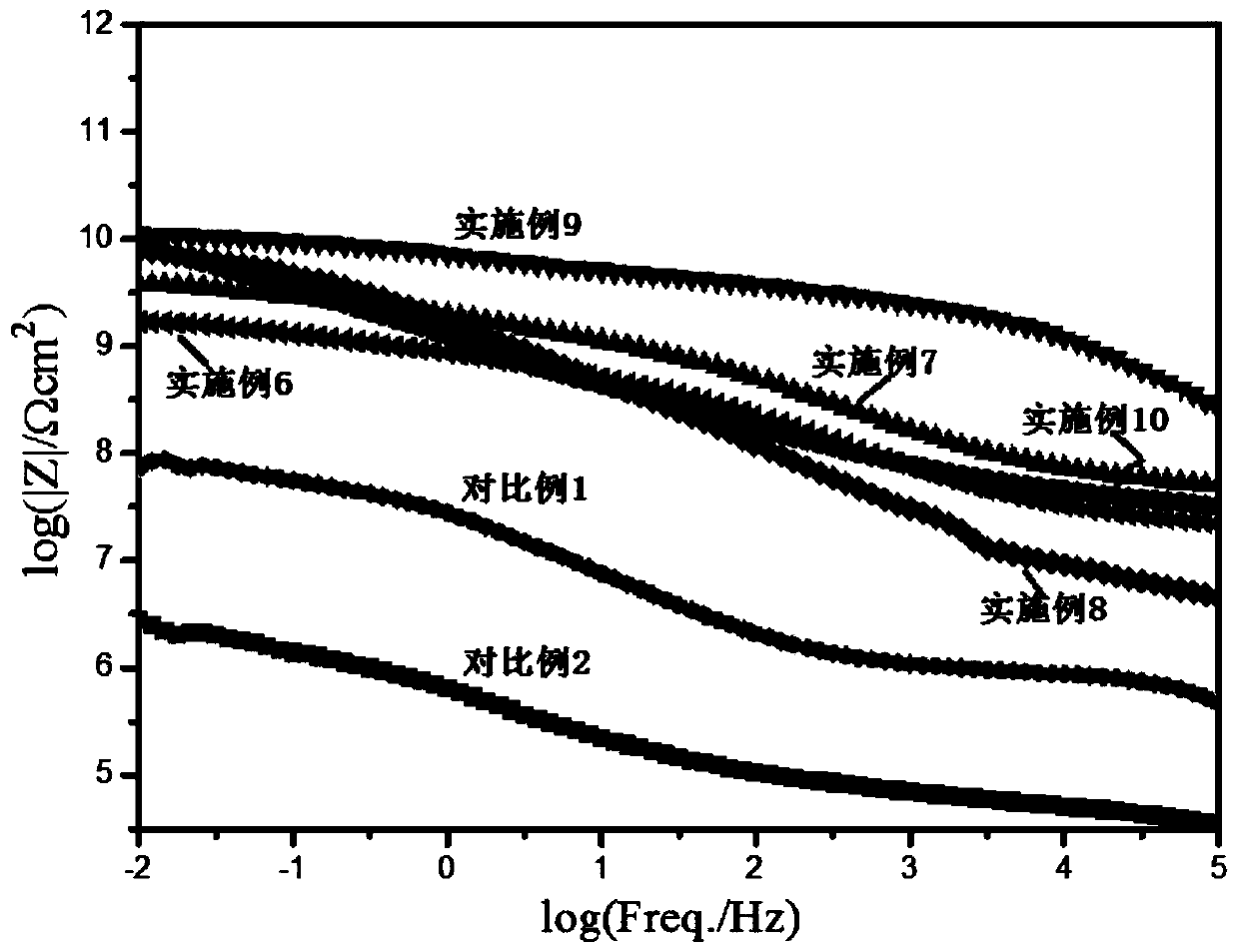

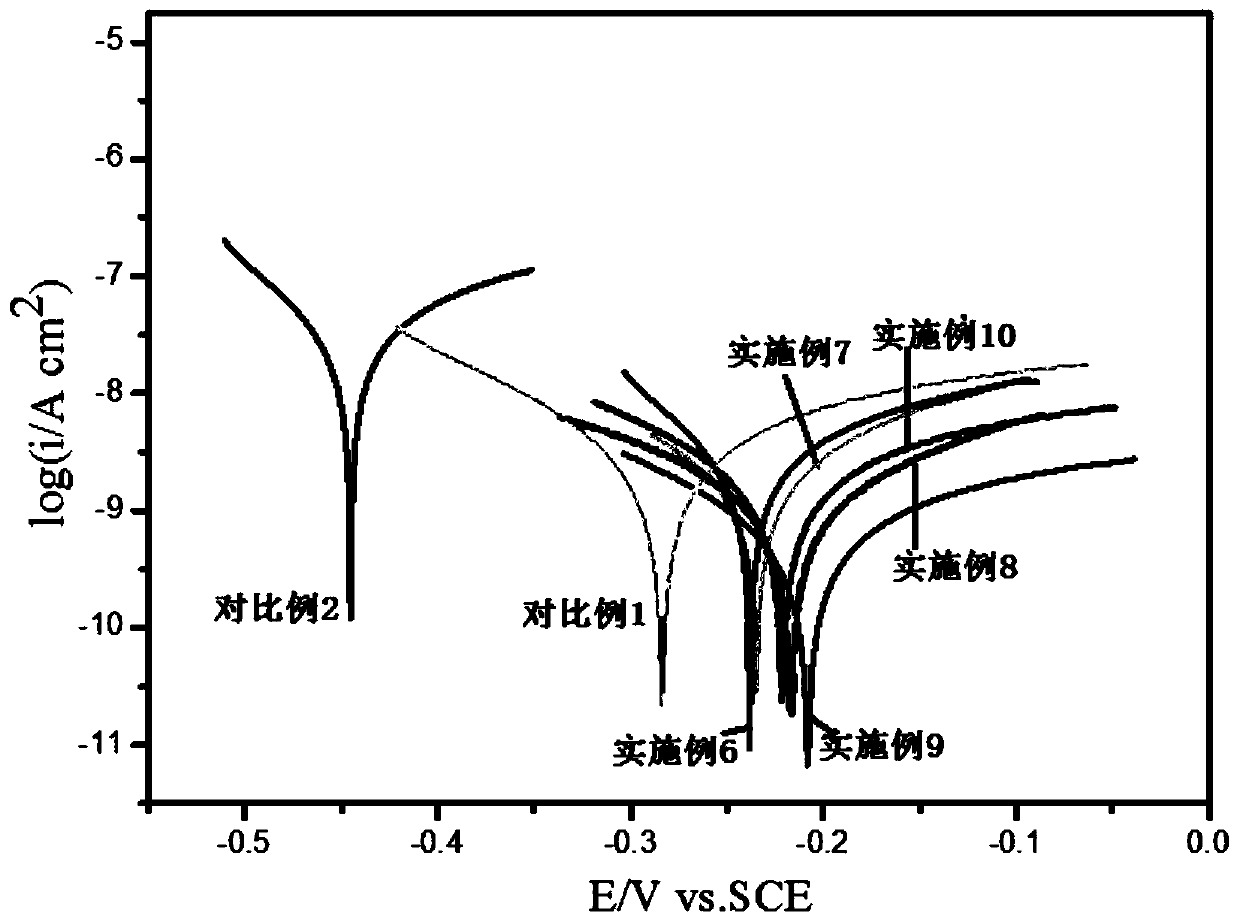

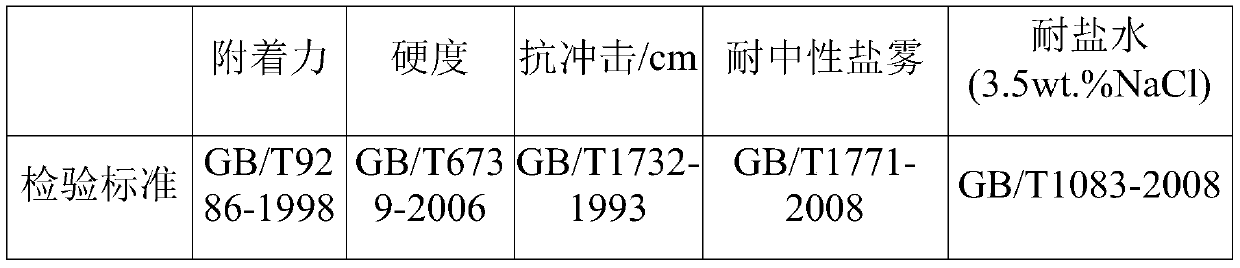

Composite material, waterborne anticorrosive paint and preparation method thereof

InactiveCN110511602APlay an isolation roleImprove compactnessAnti-corrosive paintsEpoxyAcrylic resin

Relating to the technical field of corrosion prevention, the invention particularly discloses a composite material, a waterborne anticorrosive paint and a preparation method thereof. The composite material is prepared from g-C3N4 and sepiolite in a mass ratio of 1:0.5-10. The waterborne anticorrosive paint comprises a component A and a component B. Specifically, the component A comprises: the composite material, a curing agent, an anti-settling thixotropic agent, an anti-flash-rust agent and deionized water; the component B comprises: waterborne epoxy acrylic resin, a defoaming agent, a wetting dispersant, a levelling agent, an adhesion promoter and a curing agent. The anticorrosive paint prepared from g-C3N4 and modified sepiolite as the anticorrosive components has excellent salt spray resistance.

Owner:SHIJIAZHUANG TIEDAO UNIV

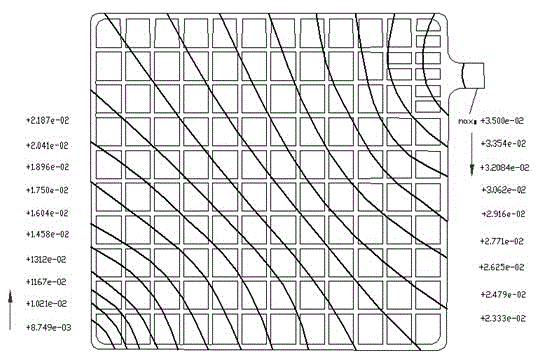

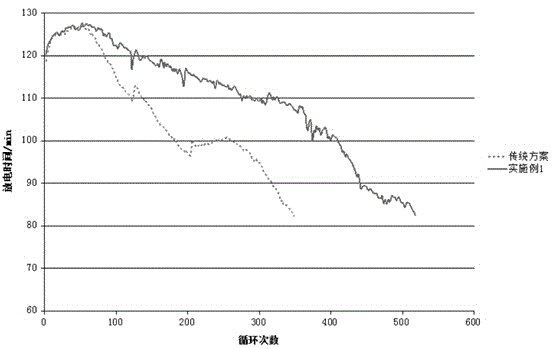

Novel power lead acid battery

InactiveCN104993151AGuaranteed concentrationReduce migration speedFinal product manufactureElectrode carriers/collectorsGratingElectrical battery

The invention discloses a novel power lead acid battery with long service life, stable working performance, strong versatility and high production efficiency. The battery comprises a battery shell, battery electrode groups, an extraction electrode and an electrolyte, the battery shell comprises a battery jar, a battery cover and a battery cover plate, each of the electrode groups is composed of positive electrode plates, negative electrode plates, a separator plate and a lead part, Sb alloy is electroplated or chemically plated on the surface of the positive electrode grating of the battery, the content of Sb in the Sb alloy is 1-100%, the gamma value of the grating structure of the battery is 0.30-0.40g / cm<2>, and the length-to-width ratio of the grating structure is 1.0-1.2. The battery can well solve the disadvantages of poor electric conduction performance, short cycle life, low versatility and large influences on the stability of a vehicle of previous electric vehicle batteries, and is a novel power battery with the advantages of high efficiency, long life and low cost.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD

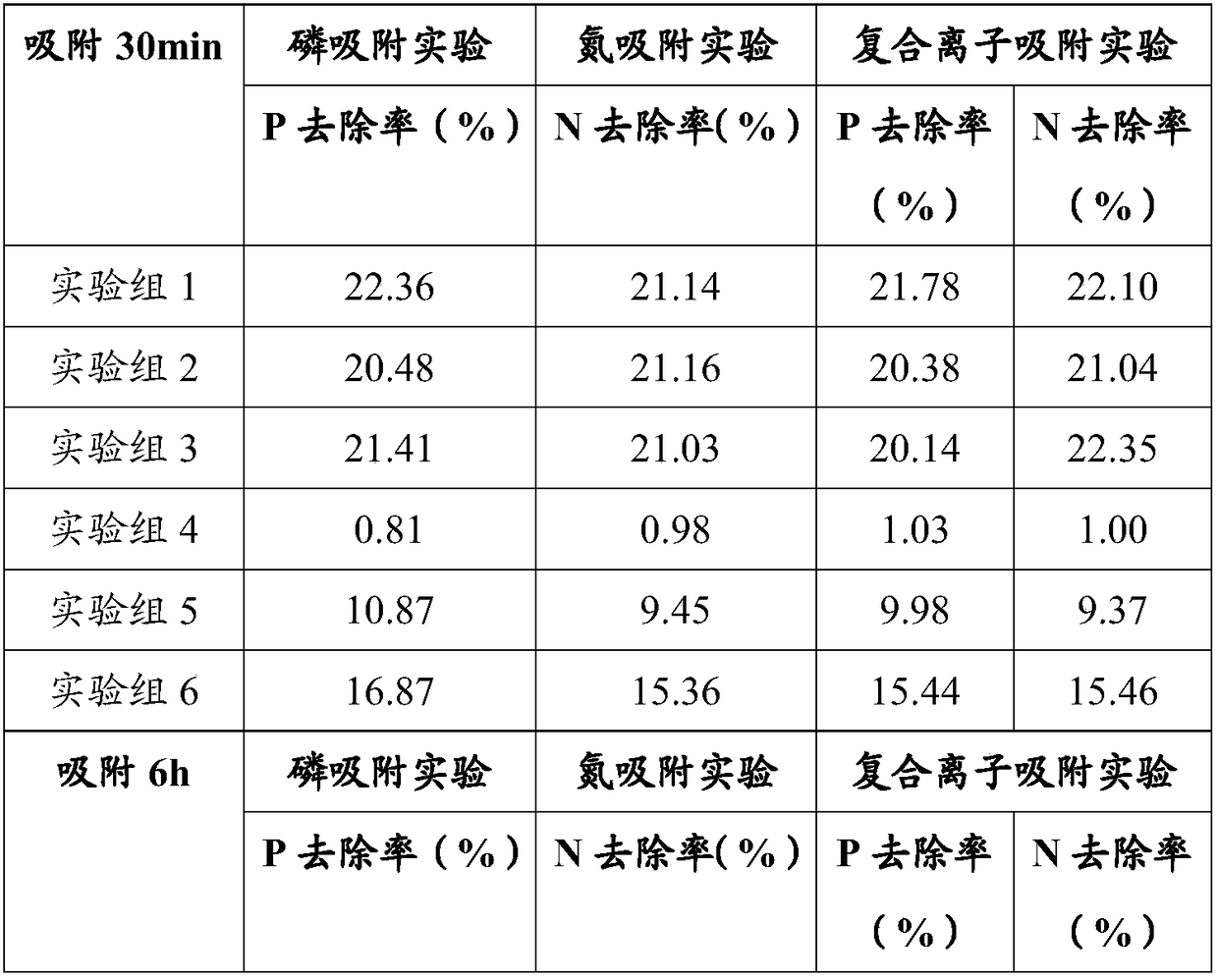

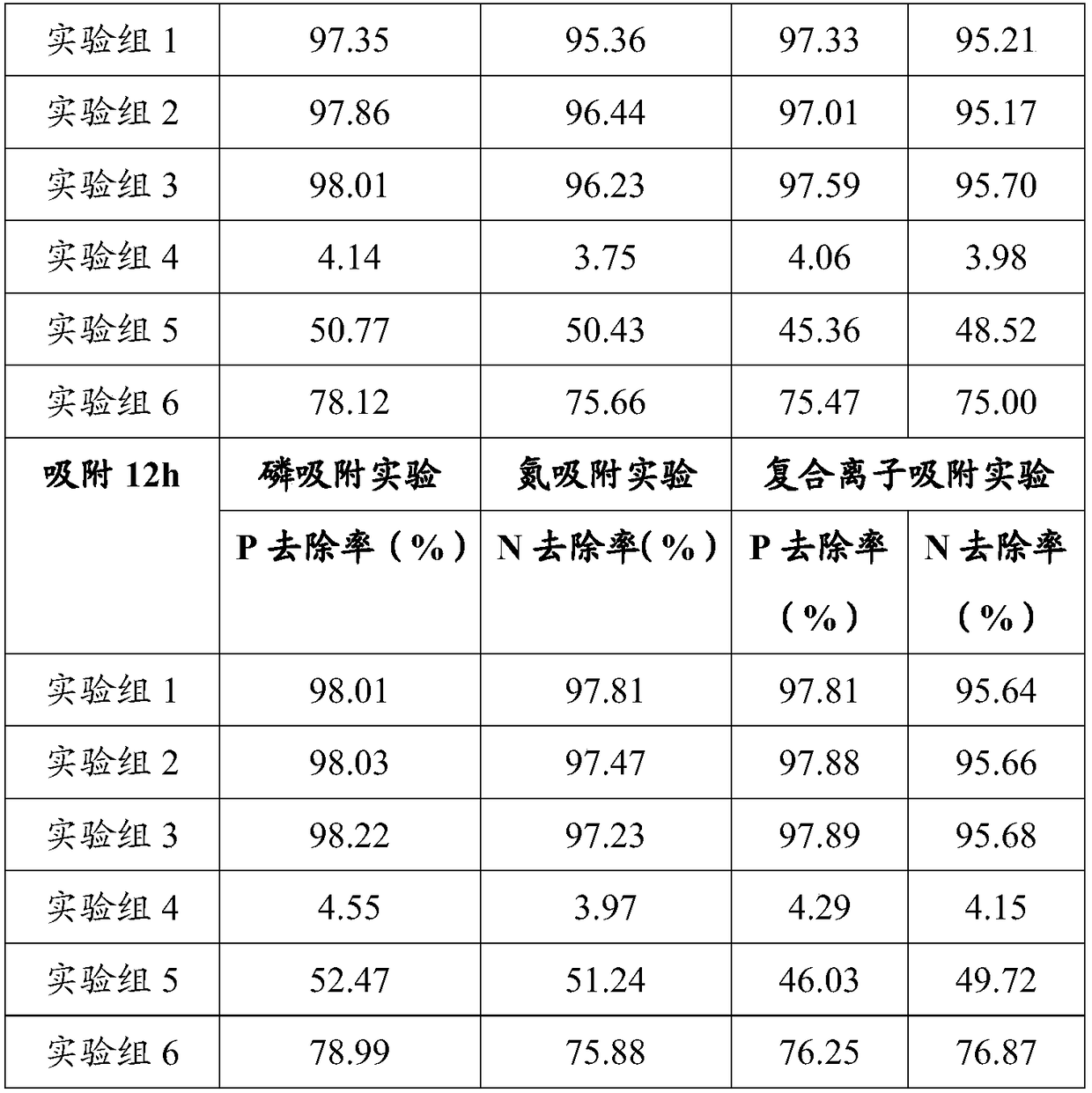

Cornstalk biochar with capacity of repairing nitrogen and phosphorus non-point source pollution and repairing method

InactiveCN108636356APollution efficientImprove adsorption capacityOther chemical processesContaminated soil reclamationMicrobial agentPollution

The invention belongs to the technical field of non-point source pollution repairing and particularly relates to cornstalk biochar with capacity of repairing nitrogen and phosphorus non-point source pollution and a repairing method. The cornstalk biochar is prepared from raw material components in parts by weight as follows: 50-200 parts of cornstalk charcoal and 0.1-0.5 parts of a microbial agent. The repairing method comprises steps as follows: preparation of the cornstalk biochar, application of the cornstalk biochar, crop planting and the like. The cornstalk is pretreated with a calcium chloride solution, so that the adsorptive property of the cornstalk is improved, nitrogen and phosphorus adsorbed on the stalk are subjected to concentrated treatment and degraded under the action of the microbial agent and microorganisms in soil, and the nitrogen and phosphorus non-point source pollution is efficiently repaired. According to the repairing method, the cornstalk biochar is adopted toperform partitioning interception on soil of an excrement accumulation area and farmlands surrounding the excrement accumulation area, the migration rate of nitrogen and phosphorus in the soil is reduced, and the problem of pollution is solved from the soil source.

Owner:JILIN AGRICULTURAL UNIV

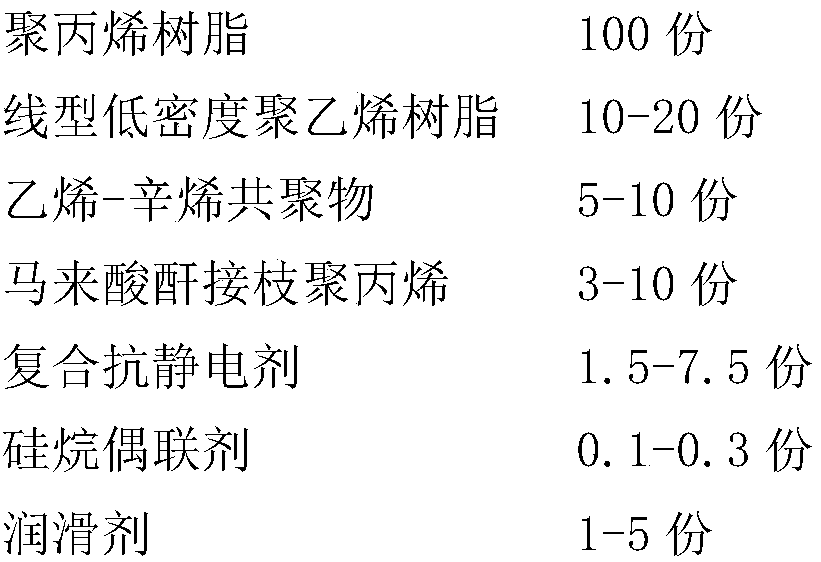

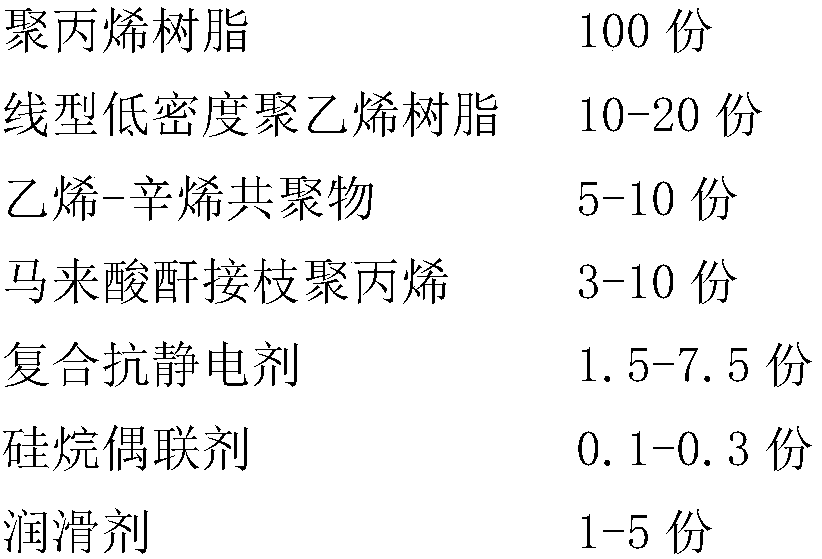

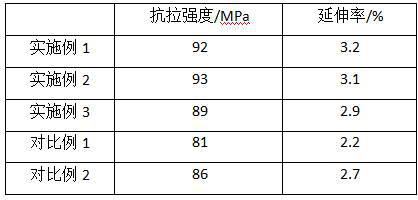

Antistatic reinforced polypropylene plastic packing barrel

ActiveCN109679211AReduce migration speedImprove release efficiencyLow-density polyethyleneLinear low-density polyethylene

The invention discloses an antistatic reinforced polypropylene plastic packing barrel. The packing barrel is prepared from the following components in parts by weight: 100 parts of polypropylene resin, 10-20 parts of linear low-density polyethylene resin, 5-10 parts of ethylene-octene copolymers, 3-10 parts of maleic anhydride grafted polypropylene, 1.5-7.5 parts of a composite antistatic agent, 0.1-0.3 parts of a silane coupling agent and 1-5 parts of a lubricant, wherein the composite antistatic agent is prepared from the following components in parts by weight: 2-10 parts of conductive mesoporous nano titania and 1-10 parts of a small molecule antistatic agent. The conductive mesoporous nano titania supported small molecule antistatic agent is taken as a composite antistatic agent and matched with linear low-density polyethylene resin and the ethylene-octene copolymers as toughening agents, the prepared polypropylene plastic packing barrel has comprehensive effects of excellent antistatic effect, high mechanical strength, ultraviolet shielding and aging resistance, long service life and the like.

Owner:CHANGZHOU CENTRWAY PLASTICS

Aluminum-plastic composite bag for food packaging and processing method thereof

ActiveCN113637879AImprove corrosion resistanceAvoid crackingSynthetic resin layered productsDomestic articlesAdhesiveBoPET

The invention discloses an aluminum-plastic composite bag for food packaging and a processing method thereof, and belongs to the technical field of food packaging. The innermost layer of the aluminum-plastic composite bag is an aluminum foil layer, a biaxially oriented polypropylene layer and a heat sealing film layer are sequentially arranged outwards, and the layers are bonded through an adhesive. The aluminum foil layer is 1235 double-zero foil with the thickness of 0.008 to 0.009 mm and is prepared from the following raw materials in parts by weight: 0.086 percent to 0.10 percent of Si, 0.37 percent to 0.43 percent of Fe, 0.005 percent to 0.01 percent of Cu, 0.005 percent to 0.01 percent of Mn, 0.005 percent to 0.01 percent of Mg, 0.005 percent to 0.01 percent of Cr, 0.005 percent to 0.01 percent of Zn, 0.02 percent to 0. 03 percent of V, 0.013 percent to 0.030 percent of Ti, less than or equal to 0.01 percent of other single impurities, less than or equal to 0.05 percent of total impurities and the balance of Al; and the aluminum foil layer is formed by casting, saw milling, soaking, hot rolling, primary cold rolling, primary annealing, secondary cold rolling, foil rolling and finished product annealing. The tensile strength and the elongation of the aluminum foil processed by the method provided by the invention are improved to different degrees, the corrosion resistance is improved, the metal element migration speed of the aluminum-plastic composite bag is low when the aluminum foil is applied to food packaging, and the preservation time of food is prolonged.

Owner:滨州宏展铝业科技有限公司

PID effect resistant solar cell module

InactiveCN106469762ASolving Potential-Induced Decay PhenomenaExtended service lifePhotovoltaic energy generationSemiconductor devicesPolyolefinEngineering

The invention relates to a PID effect resistant solar cell module, and the module comprises a module frame, solar cell glass, a cell piece and a back plate, wherein the solar cell glass, the cell piece and the back plate are disposed in an installation groove of the module frame and are sequentially stacked. The interior of the installation groove is provided with sealing glue, and a first packaging layer is disposed between the solar cell glass and the cell piece. A second packaging layer is disposed between the cell piece and the back plate, and the first and second packaging layers are made of the same material. Each packaging layer comprises a blocking layer, a first adhesive layer and a second adhesive layer, wherein the first and second adhesive layers are disposed at two sides of the blocking layer, and the blocking layer is a polyolefin blocking layer made of ethylene-alpha-olefin polymer. Each adhesive layer is made of ethylene-vinyl acetate copolymer, and the cell piece is a back contact solar cell. According to the invention, the blocking layer can block steam from entering the solar cell module through the back plate. The structure can slow down the migration of sodion. The module solves a problem of potential induced attenuation in a wet and hot environment from two aspects, and prolongs the service life.

Owner:梁结平

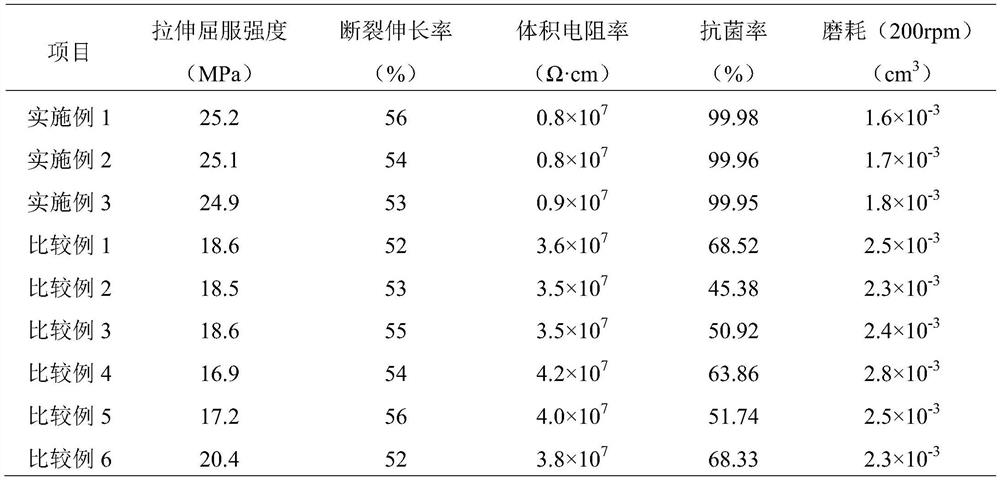

Antistatic bacteriostatic ultra-high molecular weight polyethylene fiber and preparation method thereof

PendingCN112663162AGood antibacterial effectSmall mechanical propertiesElectroconductive/antistatic filament manufactureFlame-proof filament manufactureFiberPolymer science

The invention belongs to the technical field of ultra-high molecular weight polyethylene fibers, and particularly relates to an antistatic antibacterial ultra-high molecular weight polyethylene fiber. The antistatic antibacterial ultra-high molecular weight polyethylene fiber is composed of the following components of, in parts by weight, 100-200 parts of ultra-high molecular weight polyethylene, 1-3 parts of an antioxidant, 3-5 parts of an antistatic agent, 20-50 parts of an antibacterial agent, 1-10 parts of a macromolecular compatilizer, 0.2-1.4 parts of a coupling agent, 4-8 parts of a surfactant, 0.1-1 part of a synergist and 450-1,000 parts of a solvent. According to the antistatic bacteriostatic ultra-high molecular weight polyethylene fiber and the preparation method thereof, a reasonable formula is selected, and all the components have a synergistic effect, so that the overall performance of the UHMWPE fiber is effectively improved, particularly, the UHMWPE fiber has stronger antistatic and antibacterial properties, excellent mechanical properties of the material can be maintained, the stability is high, the service life of the UHMWPE fiber is prolonged, and the use cost is reduced.

Owner:九江中科鑫星新材料有限公司

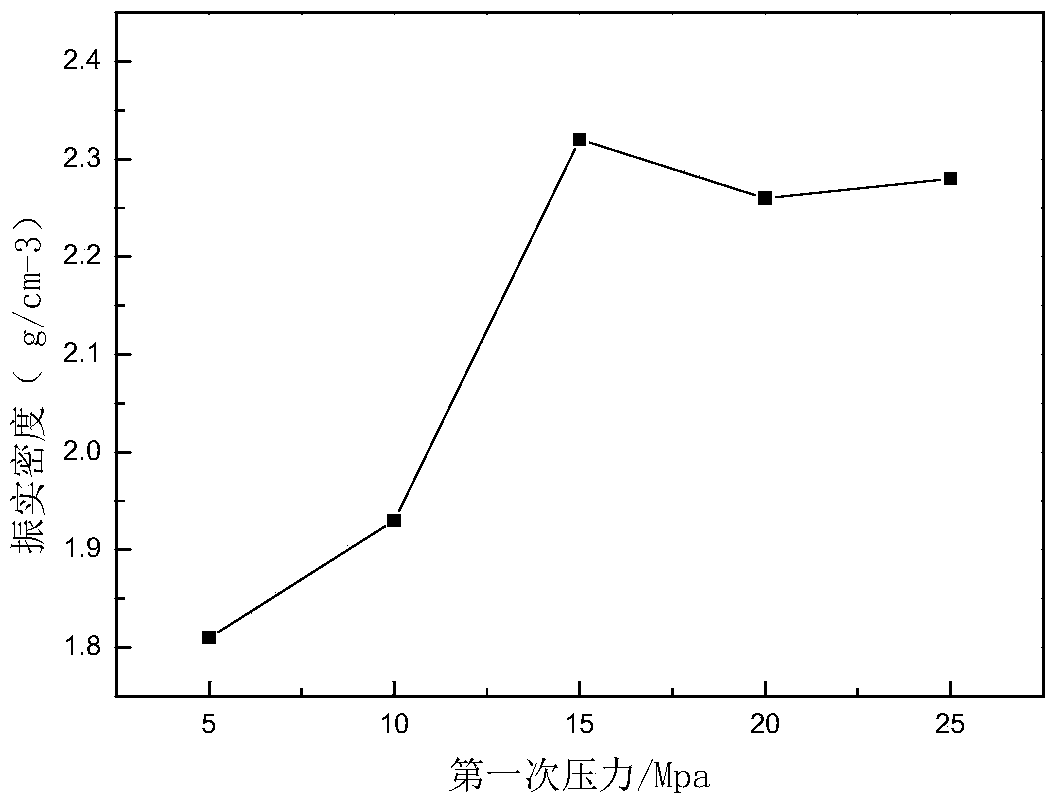

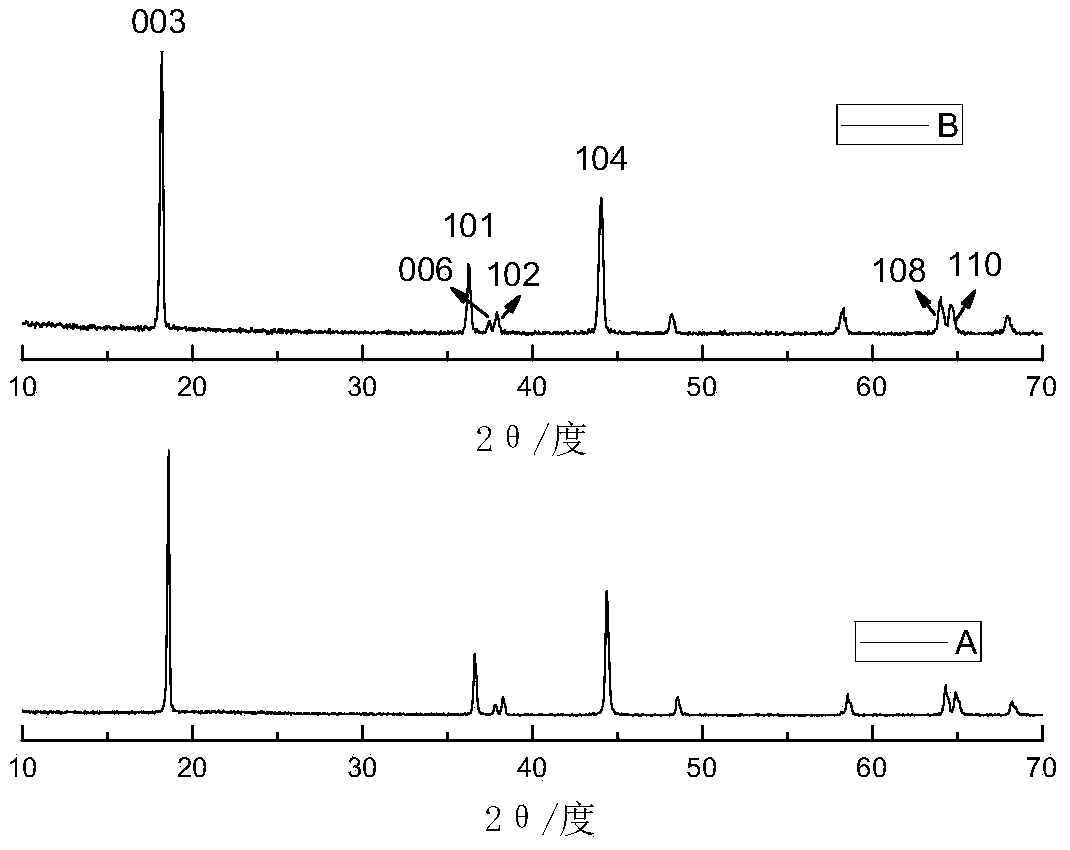

Synthetic method for improving tap density of LiNi0.5Co0.3Mn0.2O2 positive electrode material

InactiveCN103928677AHigh charge and discharge capacityImprove cycle performanceCell electrodesSecondary cellsStored energyEngineering

The invention provides a synthetic method for improving the tap density of a LiNi0.5Co0.3Mn0.2O2 positive electrode material. According to the method, the tap density of the synthesized positive electrode material is high, the specific discharge capacity of the material is high, and the cycling stability is good. The LiNi0.5Co0.3Mn0.2O2 positive electrode material prepared through the method has high charge-discharge specific capacity and good cycle performance, and can be used as the positive electrode material of a stored energy lithium ion battery. The method of changing different compressed tablets is used for improving the tap density of the positive electrode material, operation is simple, the effect is obvious, no additional chemical substances are needed, a good effect can be achieved, novel impurities can be prevented from being led in, and thus good economic value is achieved.

Owner:NANJING UNIV OF TECH

Anti-bacterial thermoplastic composite and preparation method thereof

Owner:CHINA PETROLEUM & CHEM CORP +1

Display substrate, display device and preparation method of display substrate

ActiveCN110993650AIncrease distanceReduce electric field strengthSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceElectrical connection

The embodiment of the invention relates to the technical field of display, and discloses a display substrate. The display substrate comprises: a first metal layer and a second metal layer which are arranged on a substrate at intervals, a first insulating layer located on the sides, away from the substrate, of the first metal layer and the second metal layer; and a first bonding pad and a second bonding pad which are arranged at an interval, wherein the first bonding pad comprises a first flat part located at one side, far away from the first metal layer, of the first insulating layer, the first flat part is electrically connected with the first metal layer, the second bonding pad comprises a second flat part positioned on one side, far away from the second metal layer, of the first insulating layer, the second flat part is electrically connected with the second metal layer, and the bottom surface of one side of the first flat part facing the first metal layer is higher than the bottomsurface of one side of the second flat part facing the second metal layer. According to the display substrate, the display device and the preparation method of the display substrate provided by the embodiment of the invention, the risk of short circuit between the two bonding pads arranged at intervals is reduced, and the reliability of bonding pads in a binding area is improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com