Patents

Literature

90results about How to "Fast migration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

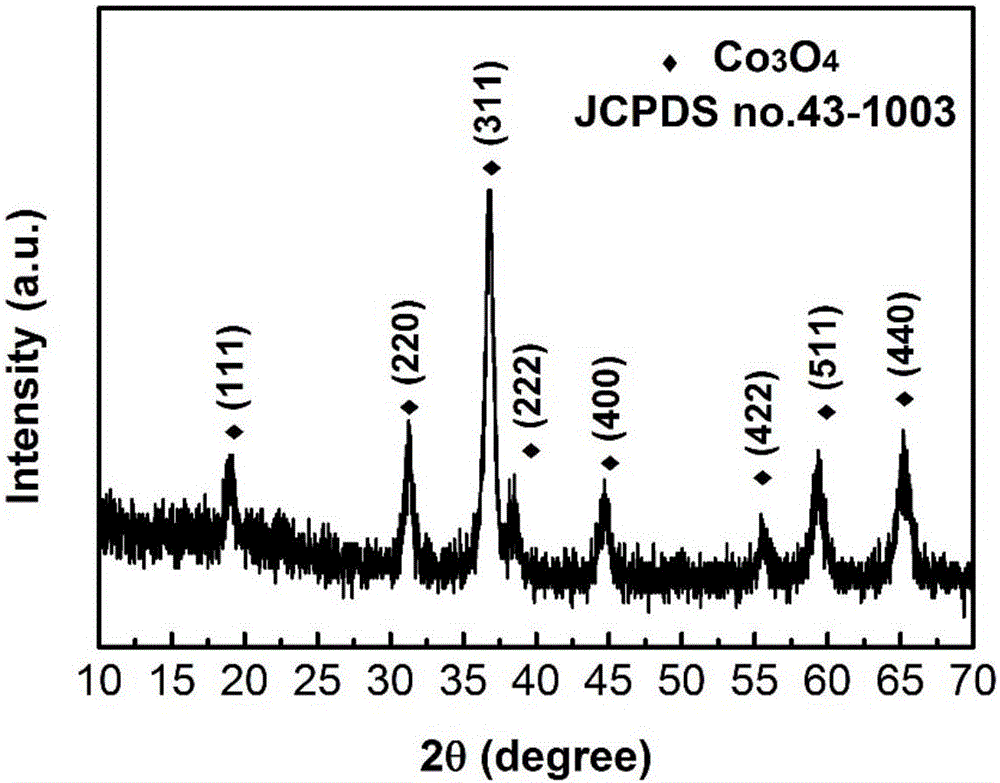

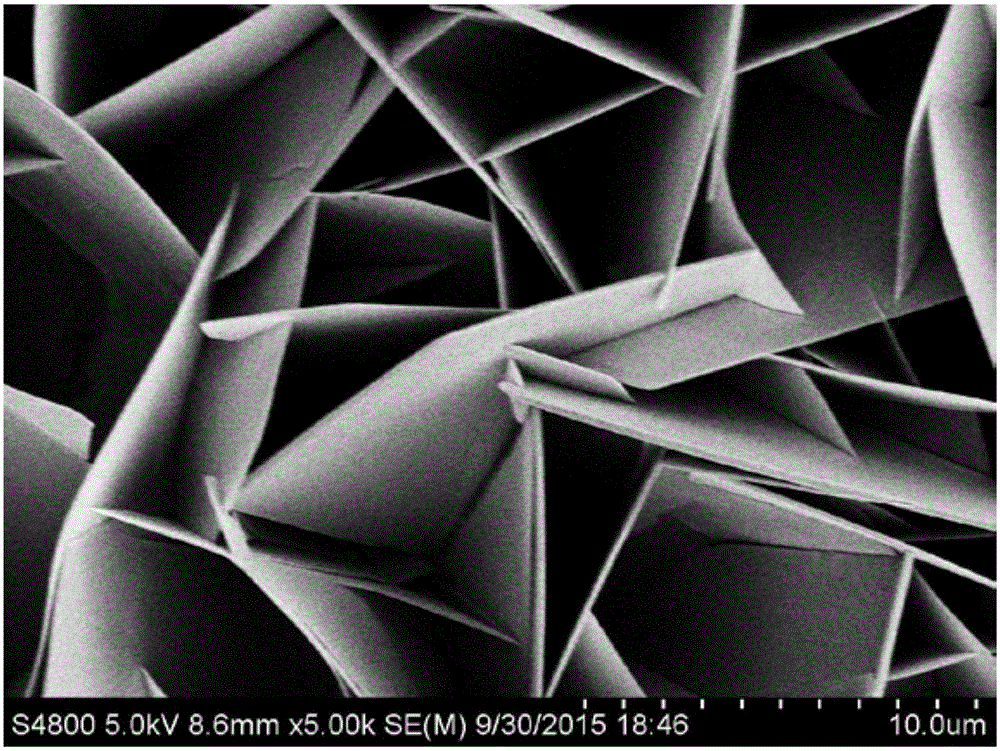

Cobaltosic oxide nanowire array, preparation method thereof as well as application of nanowire array as cathode of lithium ion battery

ActiveCN102556941AImprove performanceIncrease the areaDecorative surface effectsCell electrodesAcute angleCobalt(II,III) oxide

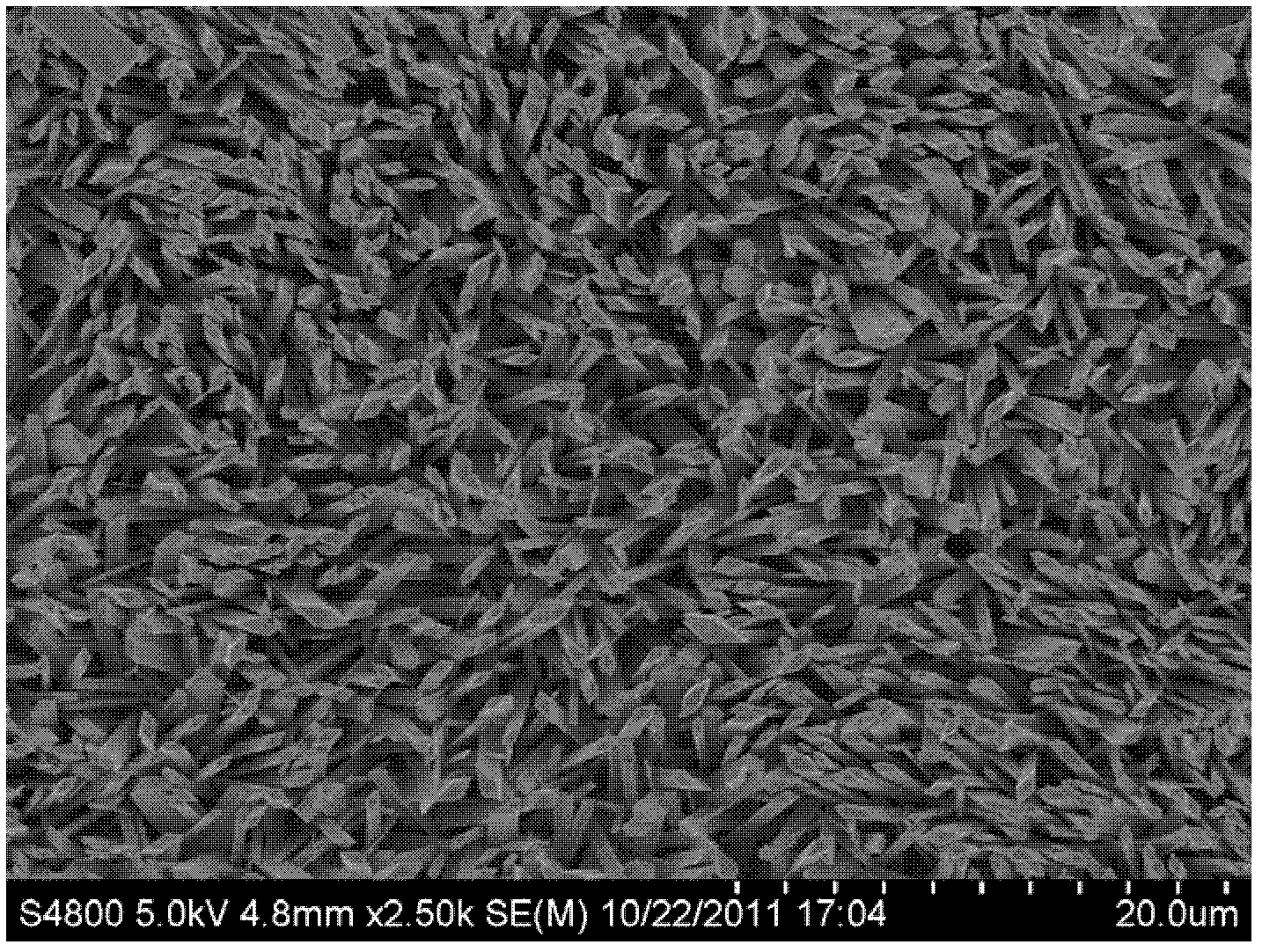

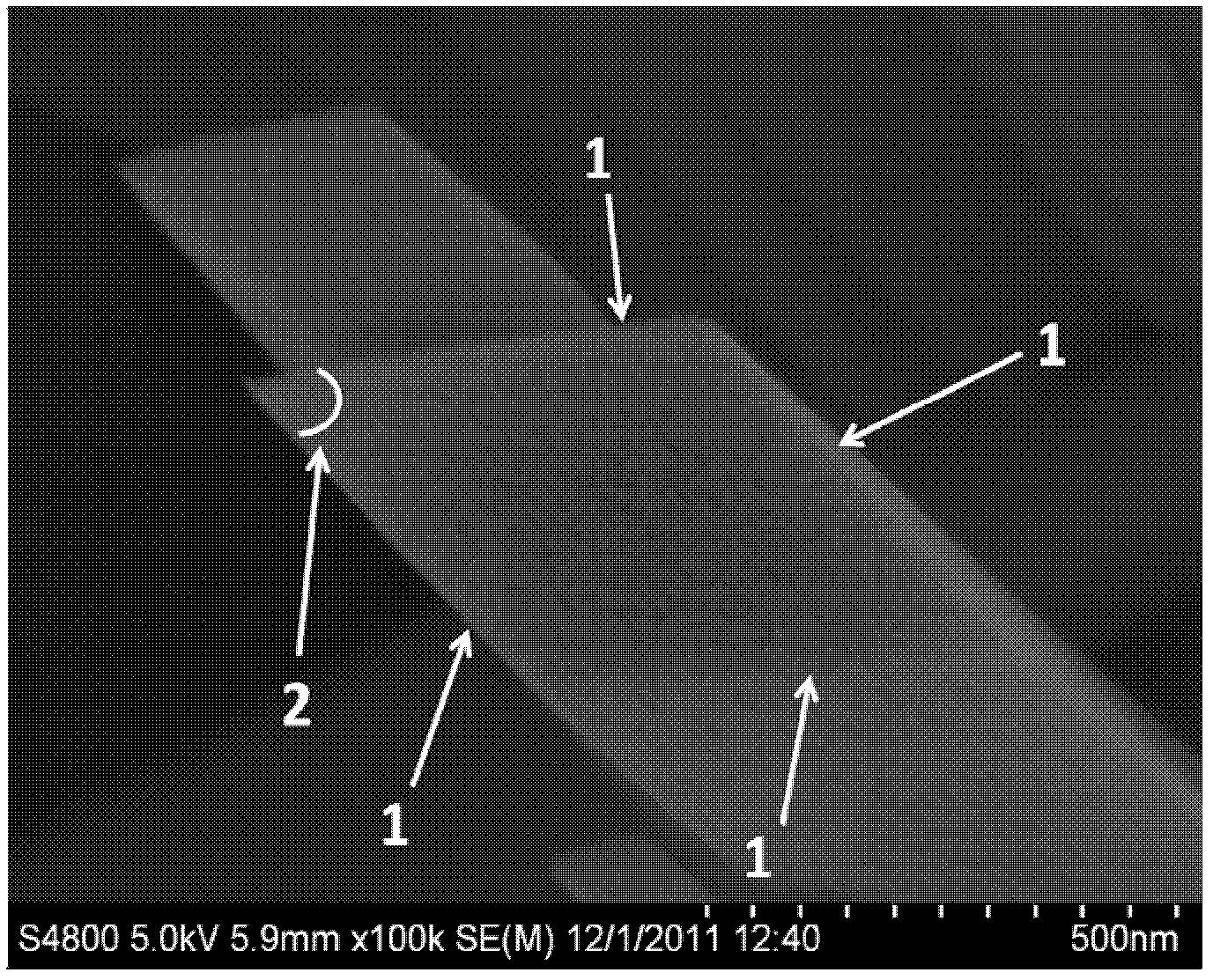

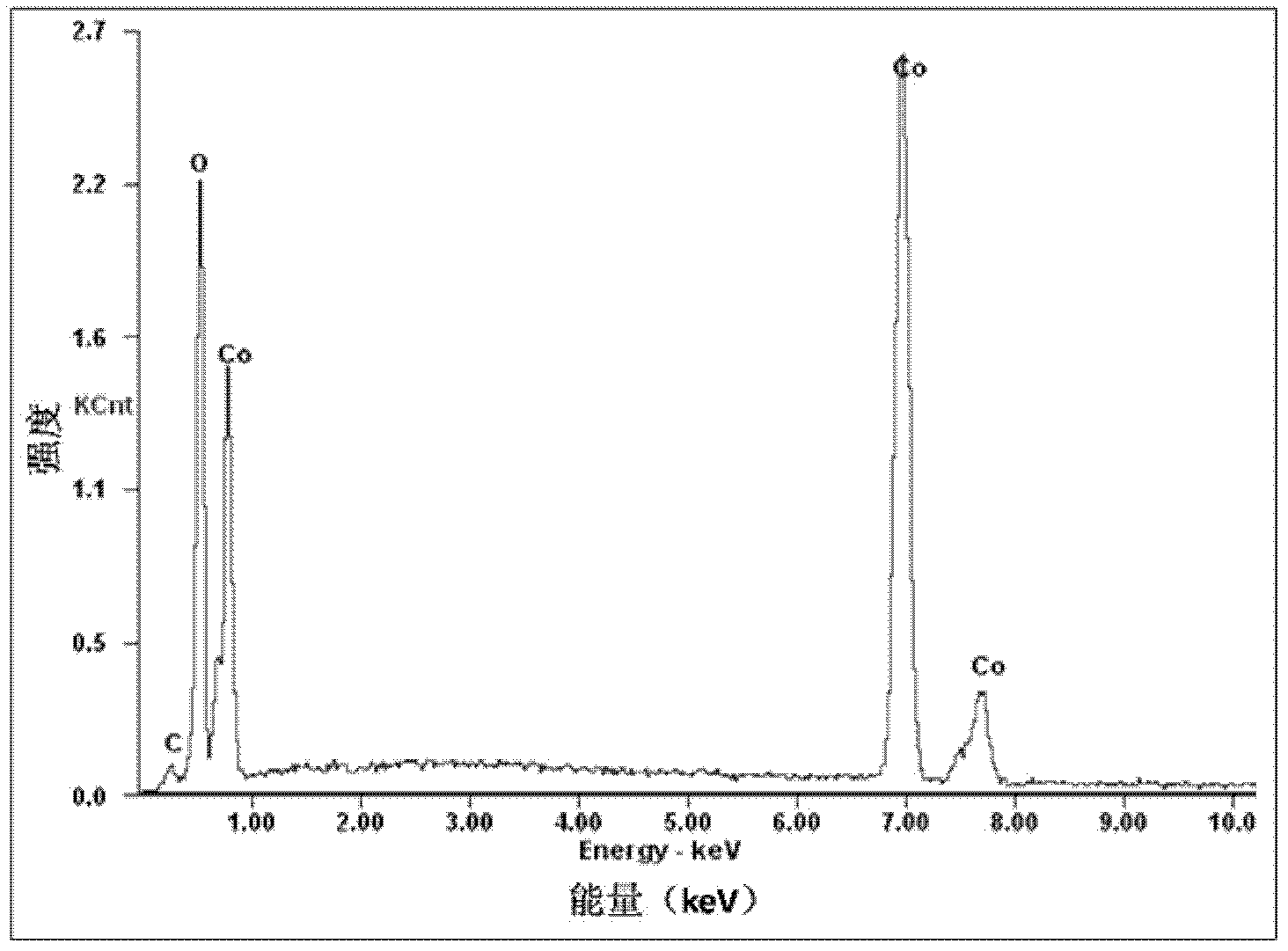

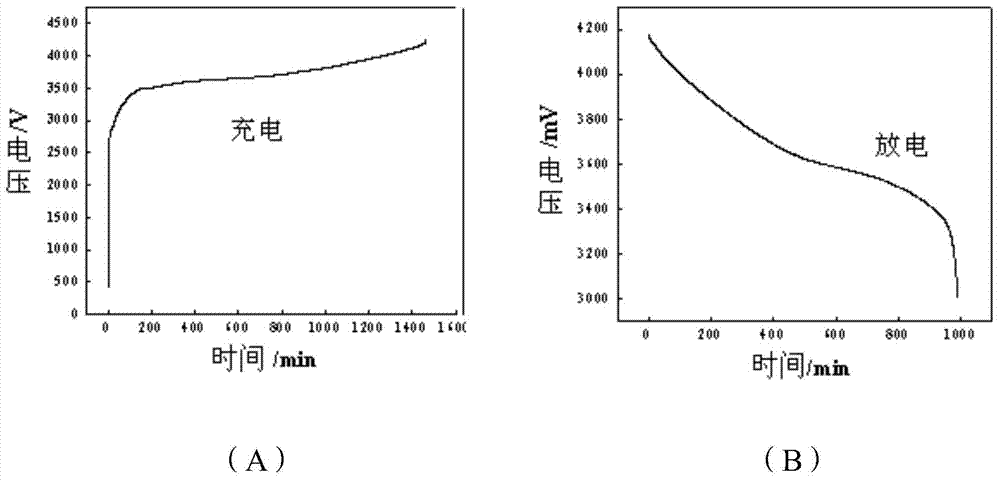

The invention relates to a cobaltosic oxide nanowire array, a preparation method thereof as well as an application of the nanowire array as a cathode of a lithium ion battery. The cobaltosic oxide nanowire array has a rhombus structure in appearance, the side length of the rhombus ranges from 100nm to 500nm, the acute angles of interior angles of the rhombus are 30-60 degrees, and the length of the array is 5-20 mu m. The invention further provides the preparation method of the cobaltosic oxide nanowire array, and the preparation method comprises the steps: mixing and stirring a cobalt salt, a chemical bonding agent, an alkaline reactant and water in certain molar ratio at normal temperature, transferring a uniformly mixed solution into a reaction kettle, placing a clean substrate into the solution for hydrothermal reaction, taking out the substrate, washing, and thermally treating the substrate in an inert atmosphere to obtain the cobaltosic oxide nanowire array. According to the invention, the cobaltosic oxide nanowire array can be directly used as the cathode of the lithium ion battery, can be used for obviously increasing the specific capacity and the cycle performance of the battery, has the discharge capacity up to more than 1000mAh / g, and is an ideal electrode material of the lithium ion battery.

Owner:ZHEJIANG UNIV

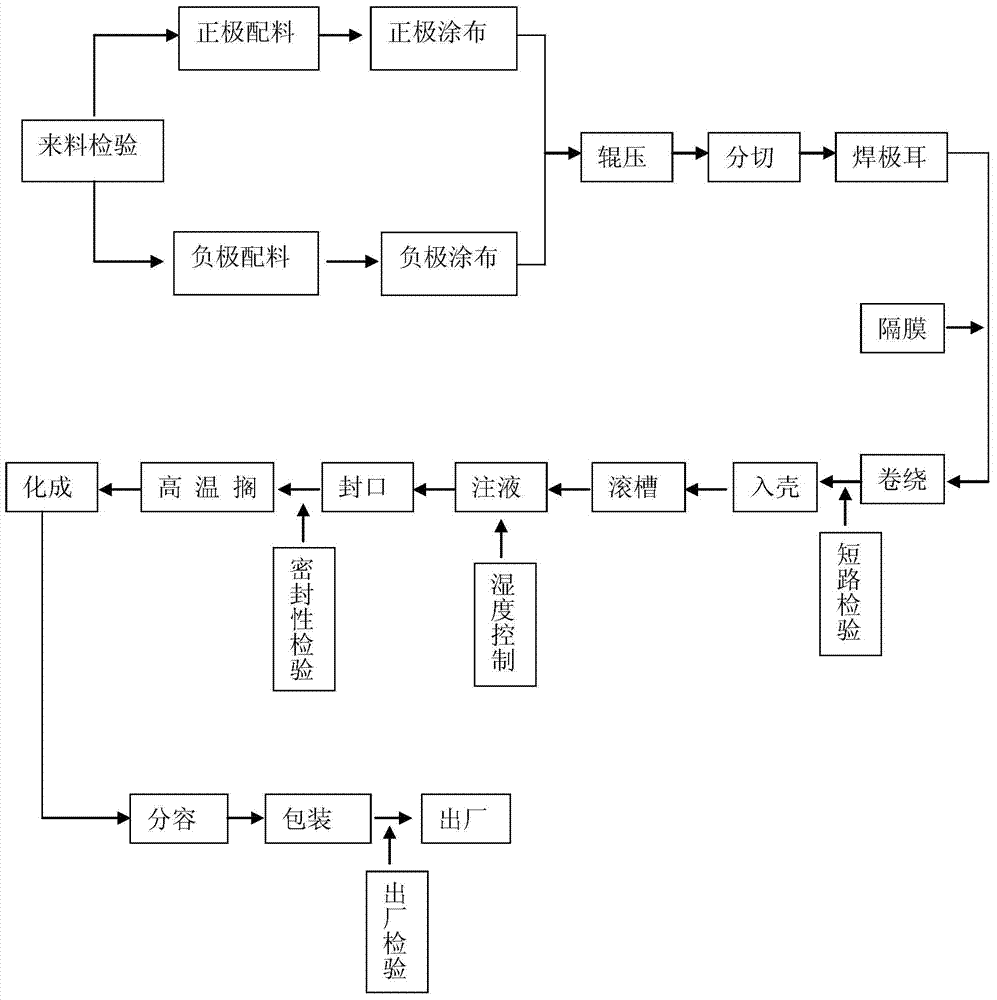

Positive slurry of lithium ion battery as well as preparation method and application of positive slurry of lithium ion battery

InactiveCN104332595AConductivity compensationIncrease electrolyte absorptionCell electrodesSlurrySodium-ion battery

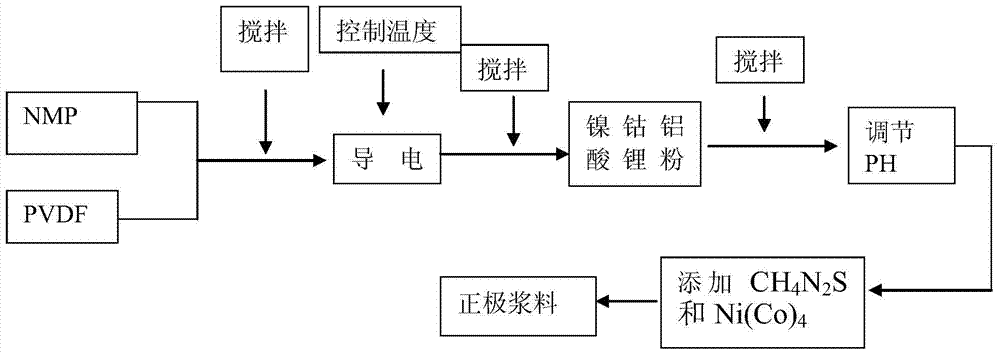

The invention provides positive slurry of a lithium ion battery as well as a preparation method and application of the positive slurry of the lithium ion battery. The preparation method of the positive slurry of the lithium ion battery comprises the following steps: (1) uniformly agitating and mixing a solvent and an oily binding agent to obtain a mixture A; (2) adding graphene into the mixture A at 25-40 DEG C and agitating uniformly to obtain a mixture B; and (3) adding nickel cobalt lithium aluminate powder into the mixture B; agitating to obtain the positive slurry; and during the agitating period, adding oxalic acid to adjust the pH value of the slurry to 8-9.5. The battery prepared from the positive slurry of the lithium ion battery has the excellent charging / discharging circulating service life and has the high power and safety performance. The battery prepared by the invention is applicable to the fields of hybrid electric vehicles, telecommunication networks, outer spaces, defending equipment and the like.

Owner:SHENZHEN MOTTCELL NEW ENERGY TECH CO LTD

Nano grade transition metal oxidation catalyst and its preparing method and use

InactiveCN1714936AHigh activityEnhanced anti-toxicityCatalyst carriersCatalyst activation/preparationMischmetalGranularity

The present invention is efficient oxidizing catalyst for organic waste water treating and its preparation process and application. The carrier prepared with composite powder of Ti, Si, Al and RE oxide and in the average granularity smaller than 100 nm is loaded with at least two kinds of transition metal to prepare the catalyst. The catalyst contains TiO2-SiO2-Al2O3 65-85 wt%, RE oxide 5-15 wt%, and transition oxide 5-30 wt%. The preparation process of the catalyst includes preparing carrier powder with the carrier components and through precipitation, homogenization, ageing, filtering, washing, pulping, dispersing, fluidizing at supercritical condition to eliminate water and activating; forming the carrier, soaking, fluidizing and drying, and activating to obtain the catalyst. The catalyst is used in acid organic waste water treatment and has COD degrading rate higher than 95 %, ammonia nitrogen oxidizing conversion rate higher than 99 % and chroma eliminating rate higher than 95 %.

Owner:CNPC JILIN CHEM GROUP CORP

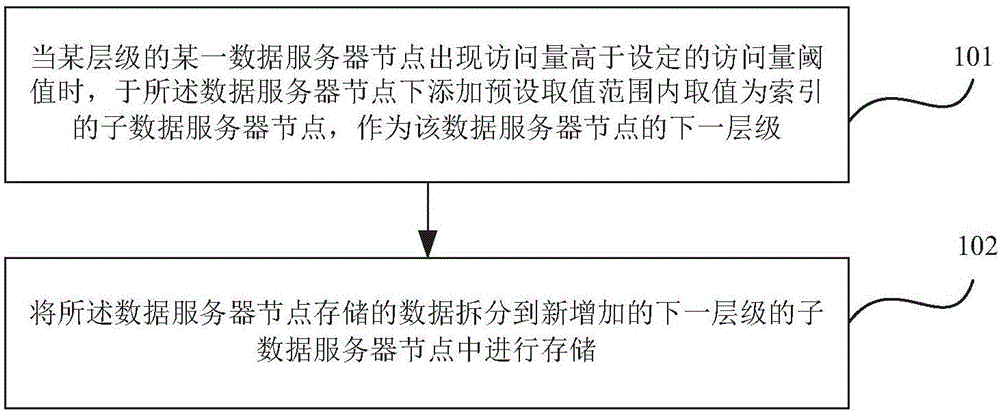

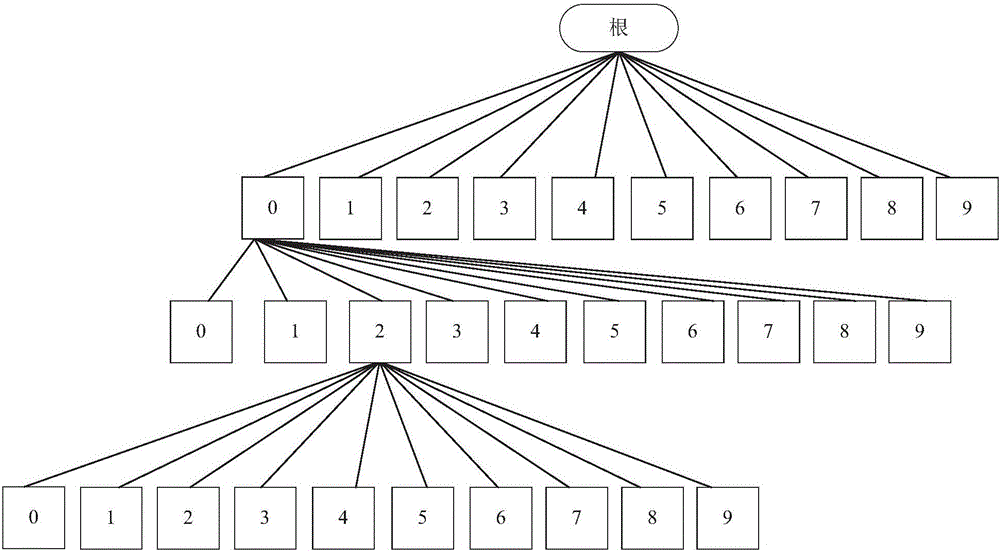

Method and system for achieving data division based on data server cluster

InactiveCN106202212AMeet the needs of split expansionMeet expansion needsTransmissionSpecial data processing applicationsPage viewData storing

The embodiment of the invention provides a method and system for achieving data division based on a data server cluster. Data server nodes in the data server cluster are distributed in a tree-like hierarchy mode. The method comprises the steps that when the page view of one certain data server node in one certain hierarchy is higher than a set page view threshold value, a sub data server node valued as an index within a preset value range is added under the data server node to be used as the lower hierarchy of the data server node; data stored by the data server node is divided into the sub data server node in the lower hierarchy for storage. According to the technical scheme, the method and system have the advantages that the single-node data server is further divided and expanded through the tree hierarchy expansion ability, the requirement of the data server with high page view for division and expansion is met, and overall data migration is not needed compared with a whole data cluster which is divided through a uniform Hash algorithm.

Owner:MICRO DREAM TECHTRONIC NETWORK TECH CHINACO

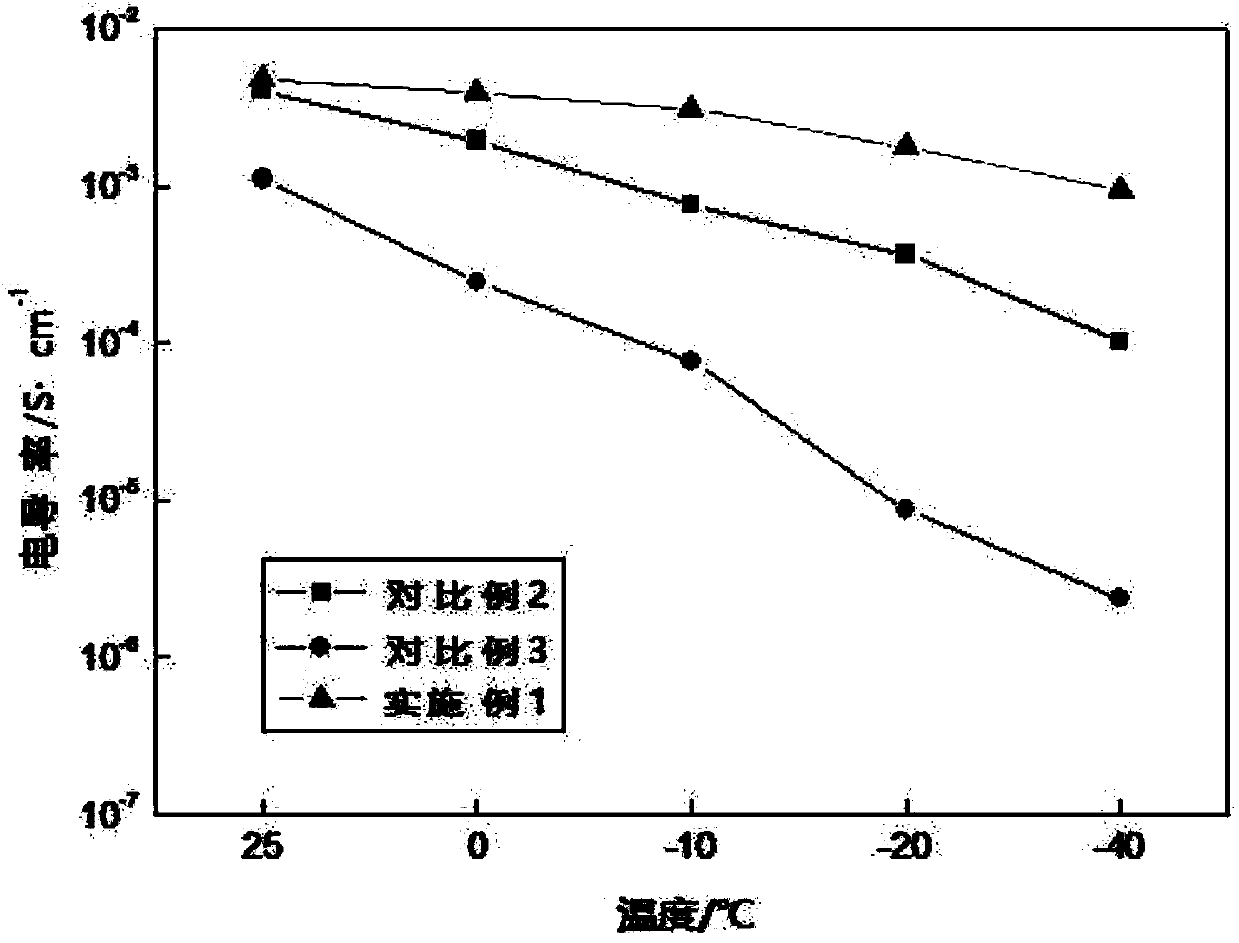

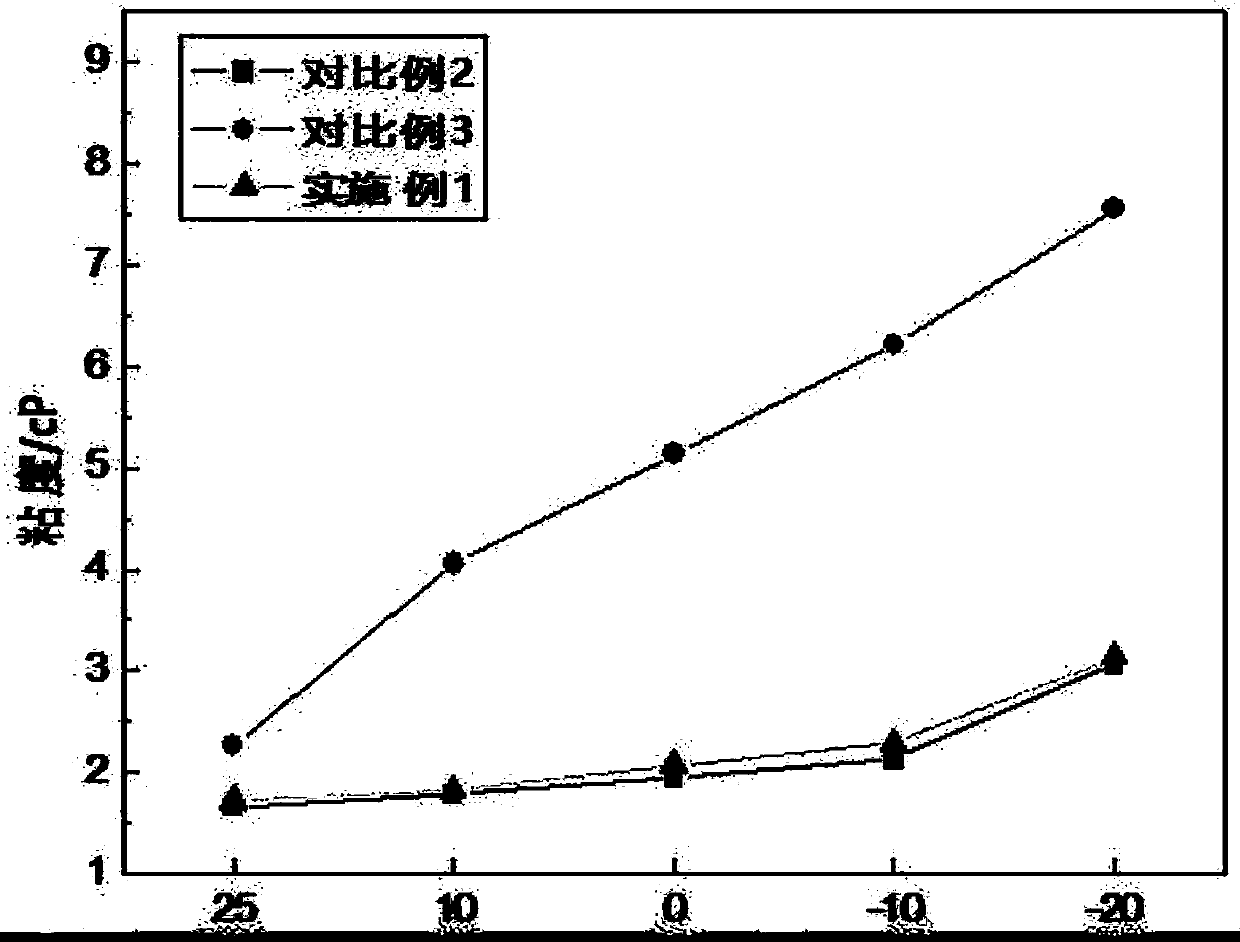

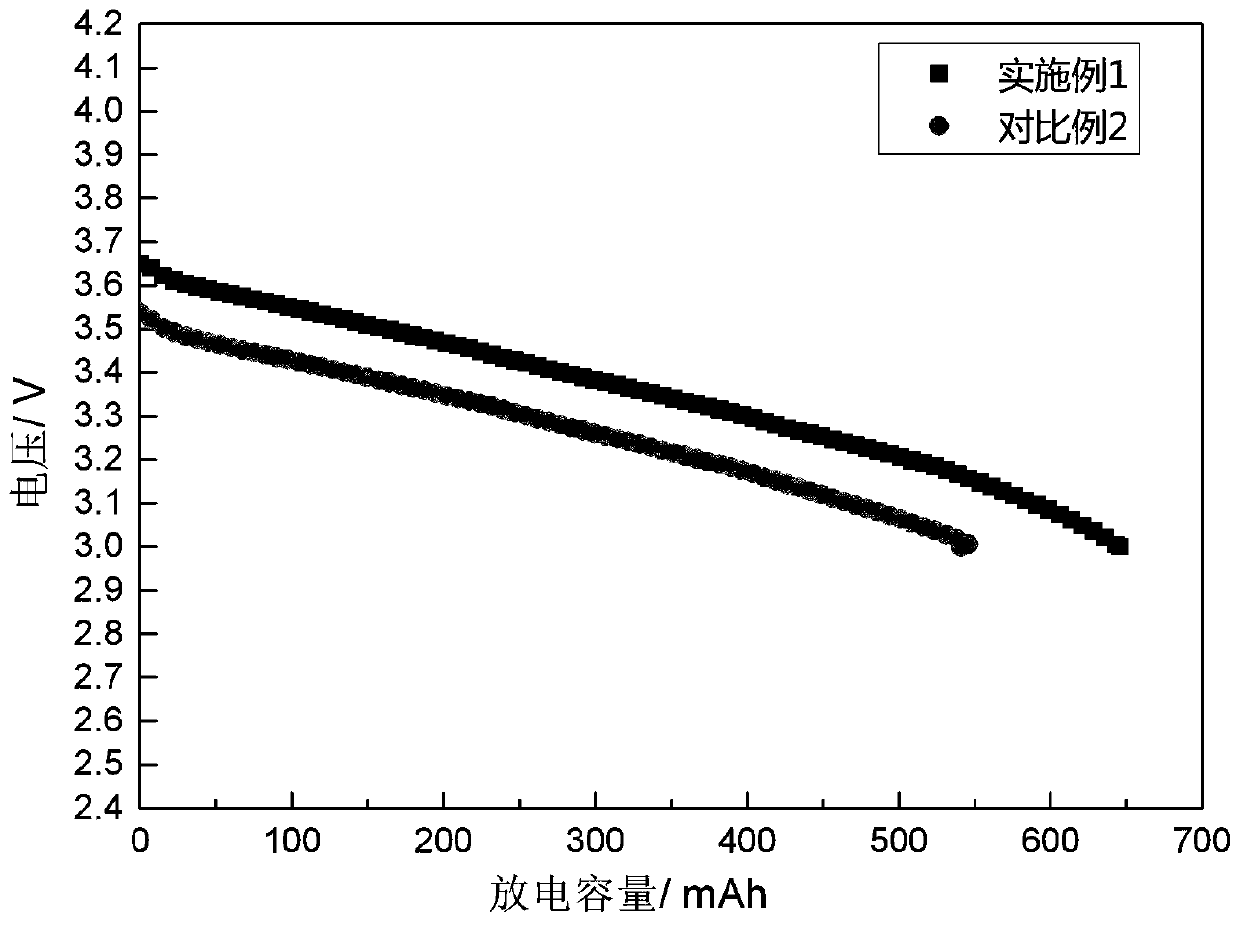

Electrolyte for improving low temperature performance of lithium ion battery and lithium ion battery comprising same

ActiveCN109860709APrevent the decomposition processImproved reversible capacity performanceSecondary cellsLithium electrodeNitrogen

The invention discloses an electrolyte for improving the low temperature performance of a lithium ion battery and a lithium ion battery comprising the same. The electrolyte comprises conductive lithium salt, a non-aqueous organic solvent, and additives, wherein the additives include a conventional negative electrode film forming additive, an additive with the structure of Formula I, and an anhydride-type compound additive with the structure of Formula II. According to the battery electrolyte provided by the invention, under synergistic effects among the additive with the structure of Formula I, the anhydride-type compound additive with the structure of Formula II, a nitrogen-containing lithium salt type additive and the conventional negative electrode film forming additive, the electrolytethus has excellent film forming performance on the electrode surface, the cycle performance and the rate performance of the lithium ion battery in a low temperature condition can be effectively improved, and the high temperature cycle performance and the storage performance of the battery are little affected.

Owner:SHANSHAN ADVANCED MATERIALS QUZHOU CO LTD

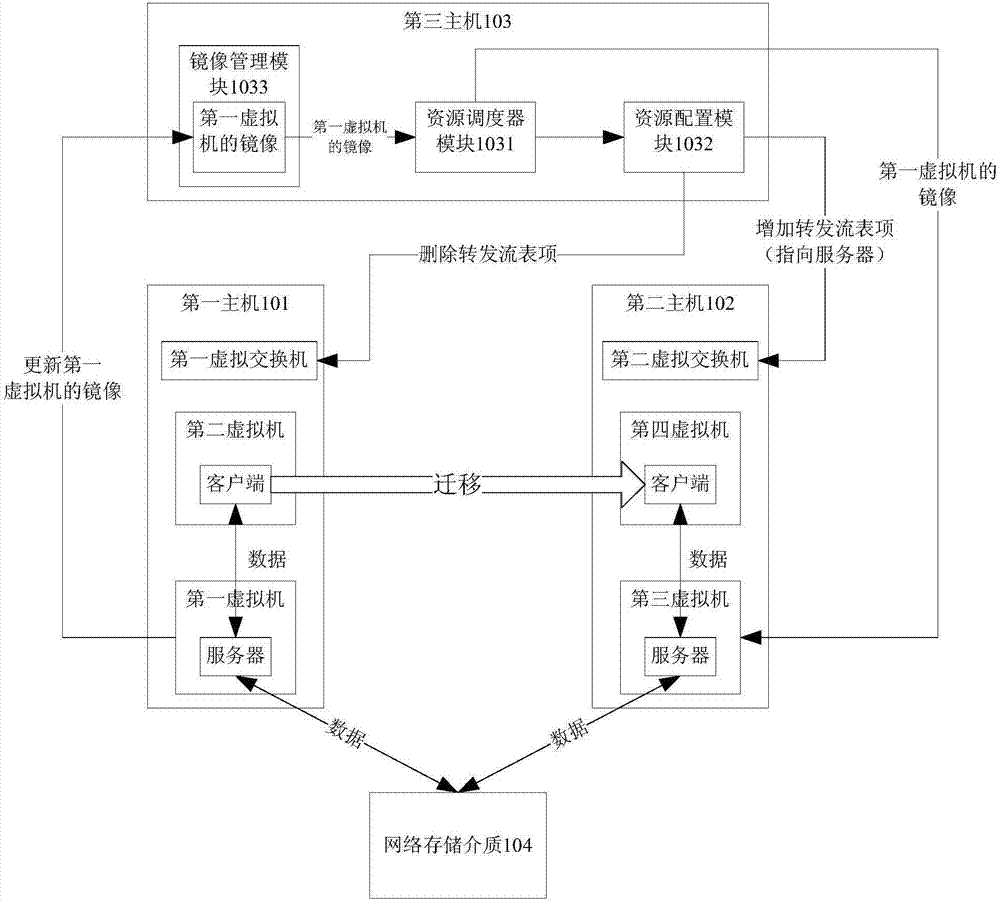

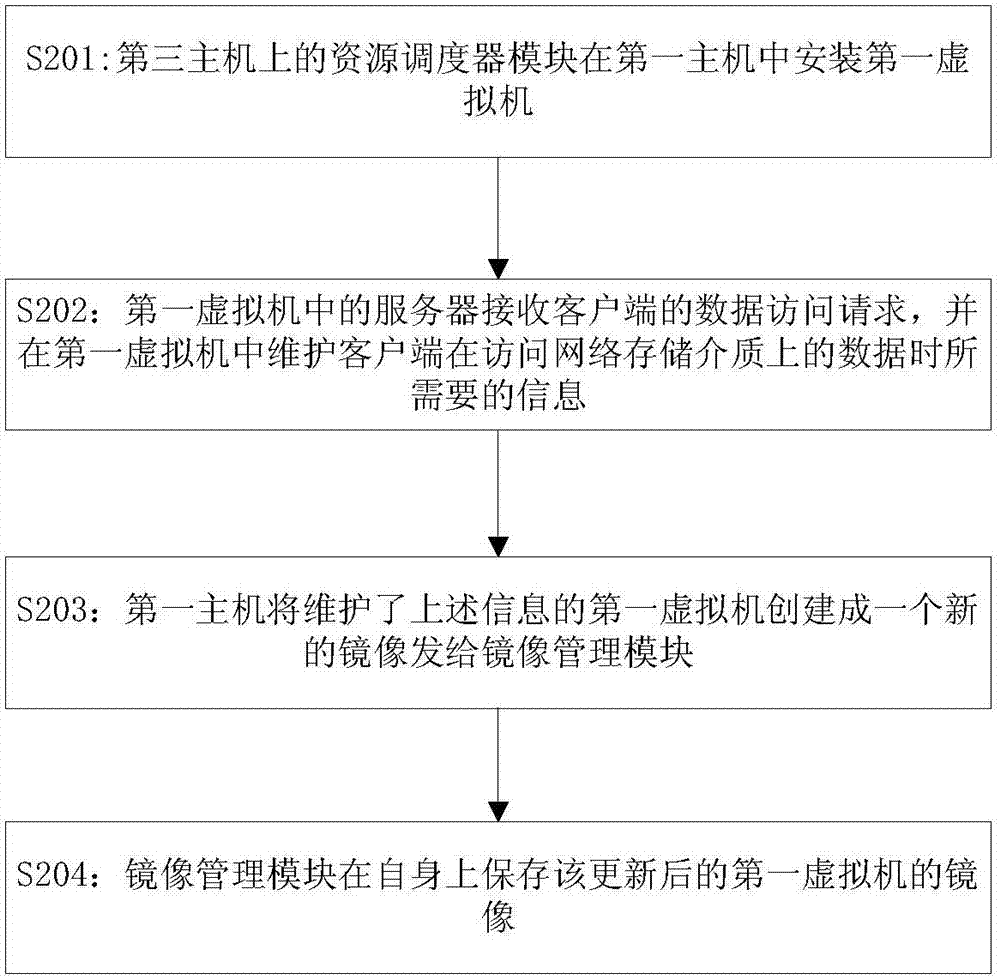

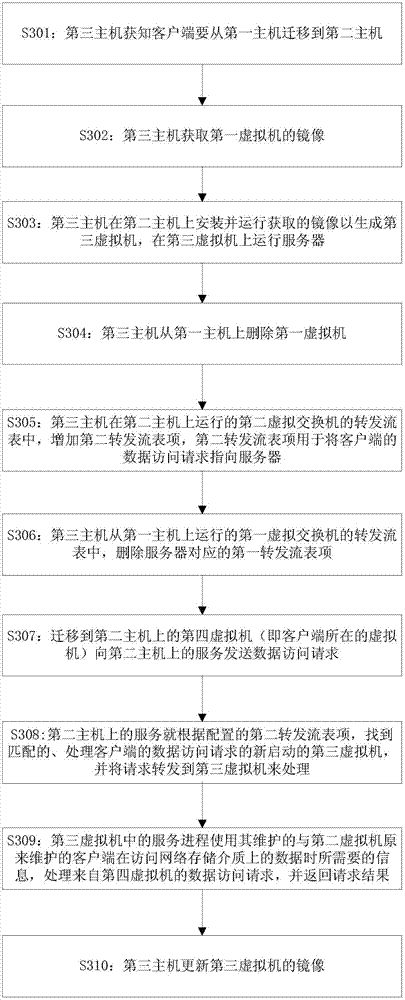

Apparatus and method for migrating virtual machine, where client is located, among different hosts

ActiveCN107368358AImprove resource usage efficiencySmall scaleProgram initiation/switchingTransmissionData accessClient-side

The invention discloses an apparatus and a method for migrating a virtual machine, where a client is located, among different hosts, and aims to ensure business continuity and shorten migration delay. The apparatus comprises a resource scheduler module and a resource configuration module, wherein the resource scheduler module is used for obtaining a mirror image of a first virtual machine located in a first host and running a server; the client runs in a second virtual machine of the first host; the obtained mirror image is installed and runs in a second host which the client is migrated to, thereby generating a third virtual machine; the server runs in the third virtual machine; and the resource configuration module is used for adding a forwarding flow entry in the second host. By installing and running the mirror image, information required for accessing data in a network storage medium by the client is migrated to the second host, and old information still can be used after the client is migrated, so that the business continuity is ensured; and by adding the forwarding flow entry, a data access request of the client is forwarded to a new virtual machine, and the client does not need to re-establish a connection with a new server, so that the migration duration is shortened.

Owner:HUAWEI TECH CO LTD

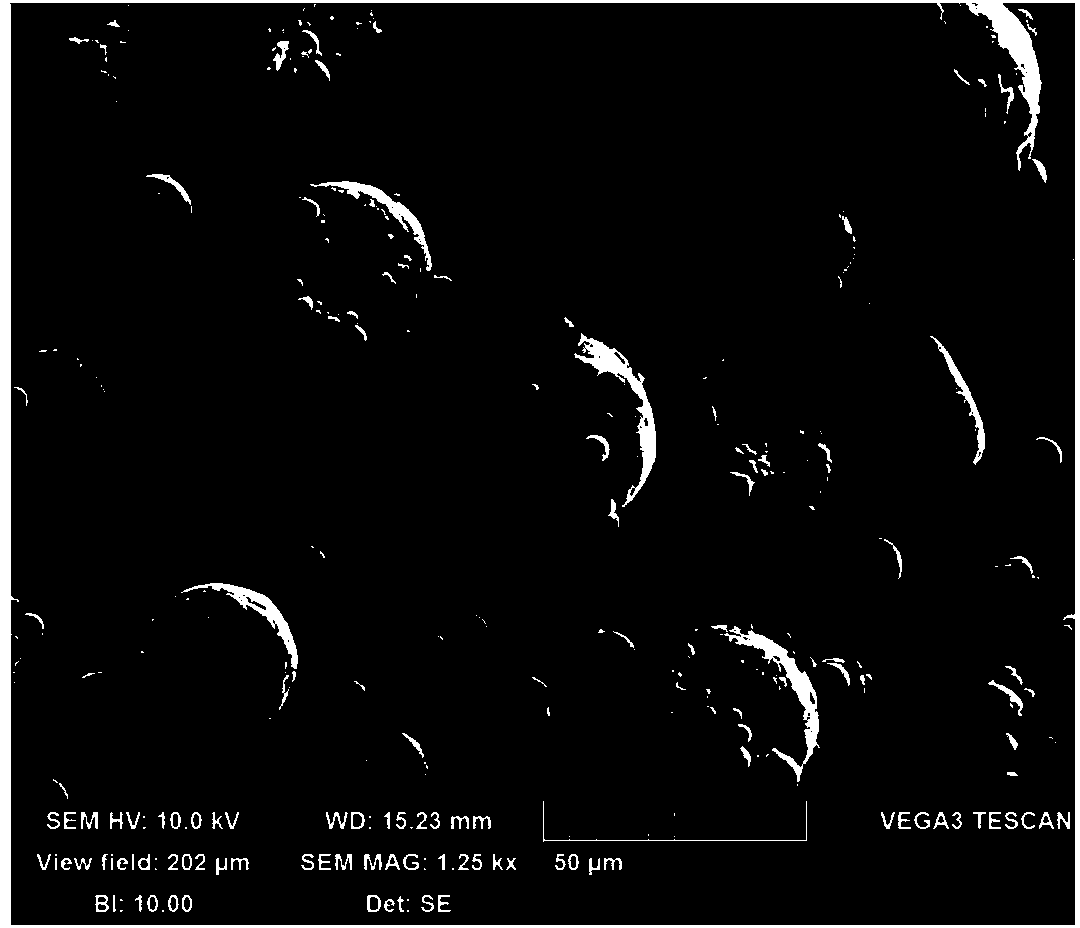

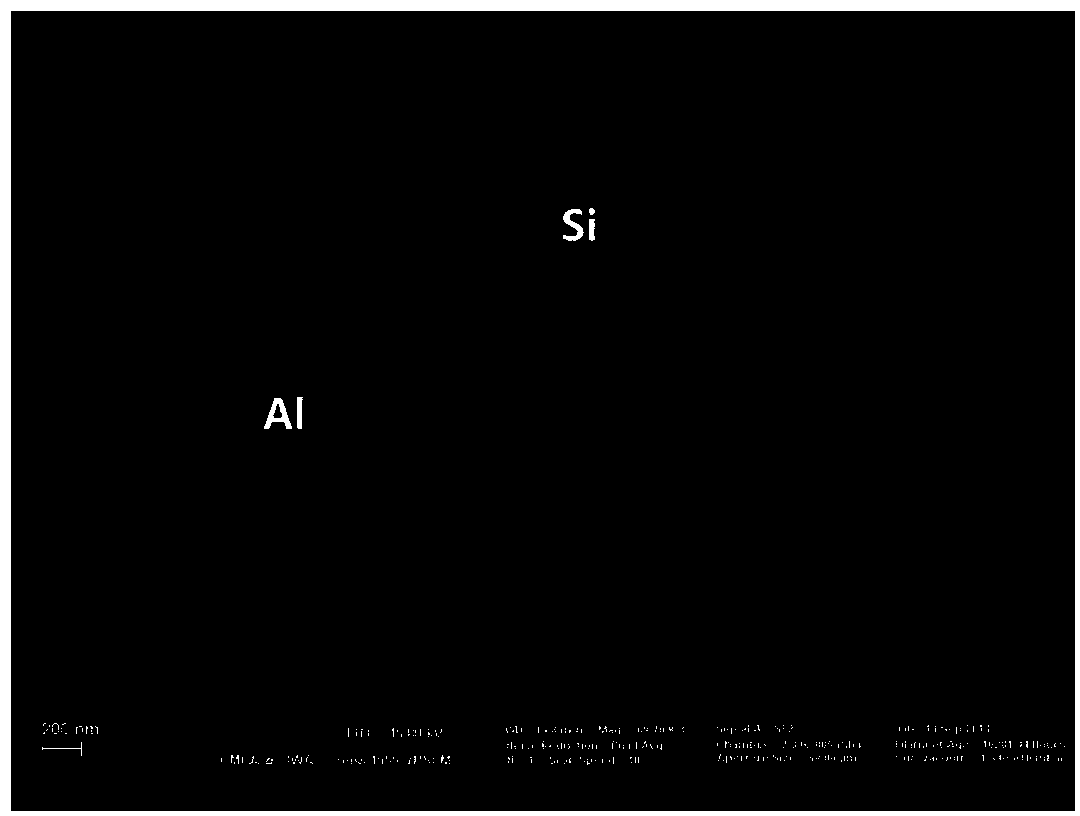

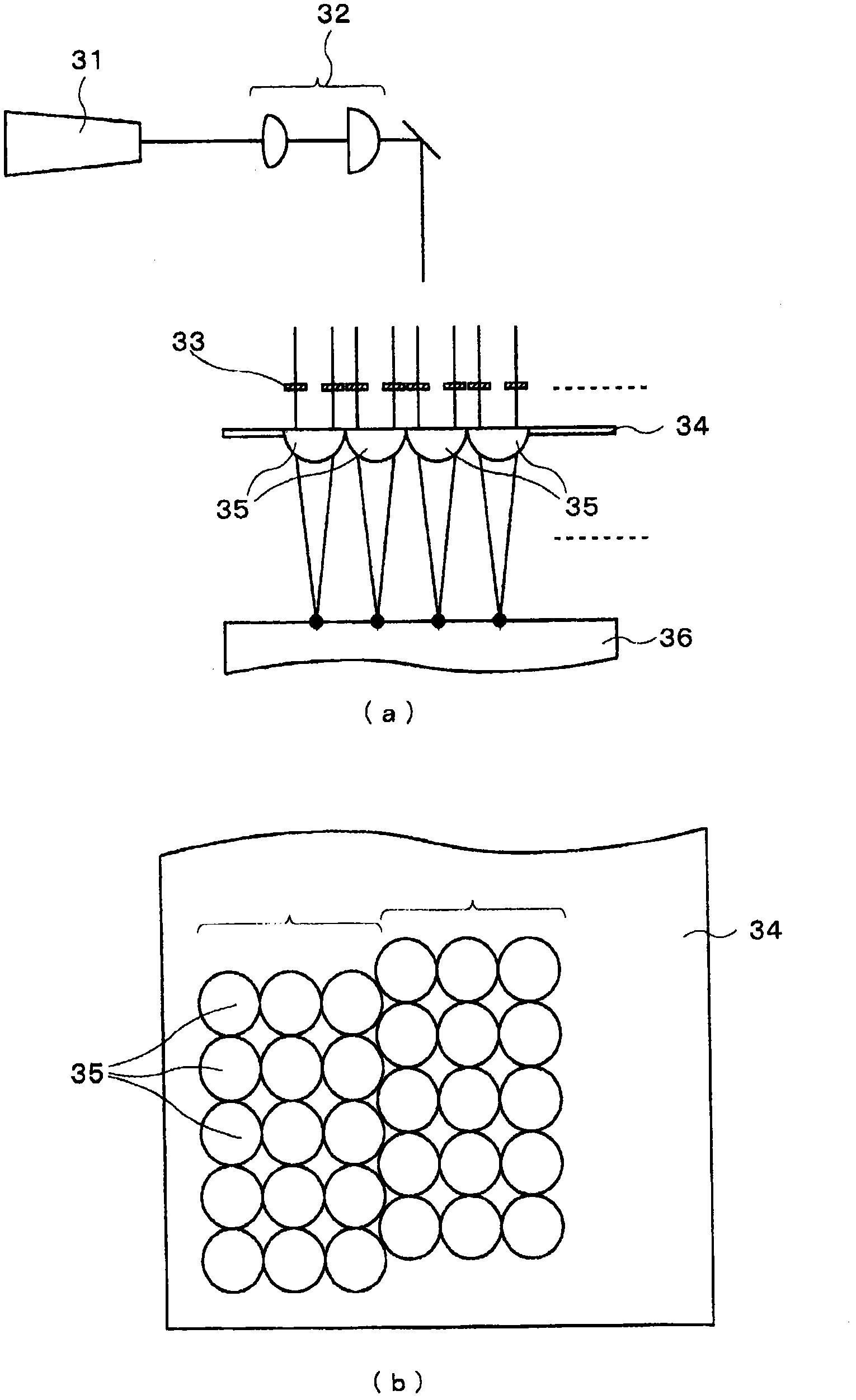

Method for preparing nanoscale spherical Si-phase Al-Si alloy through selective laser melting

InactiveCN104368815AImprove liquidityGuarantee the quality of powder coatingIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention relates to a method for preparing nanoscale spherical Si-phase Al-Si alloy through selective laser melting. The method comprises the steps that a CAD three-dimensional model for forming parts is designed, and is converted into a data format STL file capable of being slit, a supporting body of a certain height is built at the bottom of the three-dimensional model, the three-dimensional model and the supporting body are slit into a plurality of layers, technological parameter setting is carried out, and data and parameters are guided into SLM equipment; a sealing device is filled with inert gas for atmosphere protection after being vacuumized, a base plate is fixed to a work table capable of ascending and descending, a layer of Al-Si alloy powder is evenly laid on the base plate through a powder feeding system, corresponding cutting layers are selectively scanned according to guided-in parameter lasers, the base plate is lowered by the thickness of one layer, and a layer of new Al-Si alloy powder is evenly laid on the base plate until scanning of all the layers is finished. In the method, no mold is needed, the utilization rate of materials is high, the mechanical property of the Al-Si alloy can be improved, and the production cost of parts in a complex shape can be lowered.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

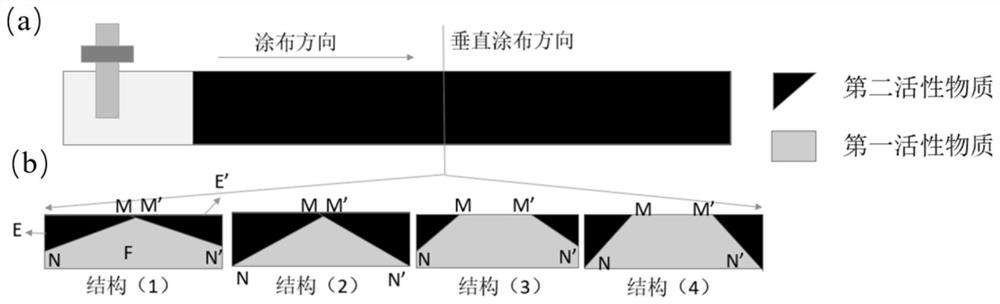

Positive plate and lithium ion battery containing positive plate

InactiveCN112310344AImprove cycle lifeAvoid security issuesSecondary cellsPositive electrodesEngineeringLithium-ion battery

The invention discloses a positive plate and a lithium ion battery containing the positive plate. The positive plate comprises a current collector and a coating located in a coating area of the current collector; the coating comprises a first coating area and a second coating area; the first coating area is located on the surface of the current collector coating area, and the contact surface of the first coating area and the current collector coating area completely covers the current collector coating area; the second coating area is located above the first coating area and comprises an areaE and an area E', the area E and the area E' are located on the long edge sides of the first coating area respectively, and the area E and the area E' are independent of each other or at least have one intersection point; and both the first coating area and the second coating area contain active substances. The problem of lithium precipitation in the edge area of the negative electrode is fully solved, a cruising ability of the lithium ion battery is improved, the problems of cyclic expansion and battery cell deformation are solved, and a safety risk is reduced.

Owner:ZHUHAI COSMX BATTERY CO LTD

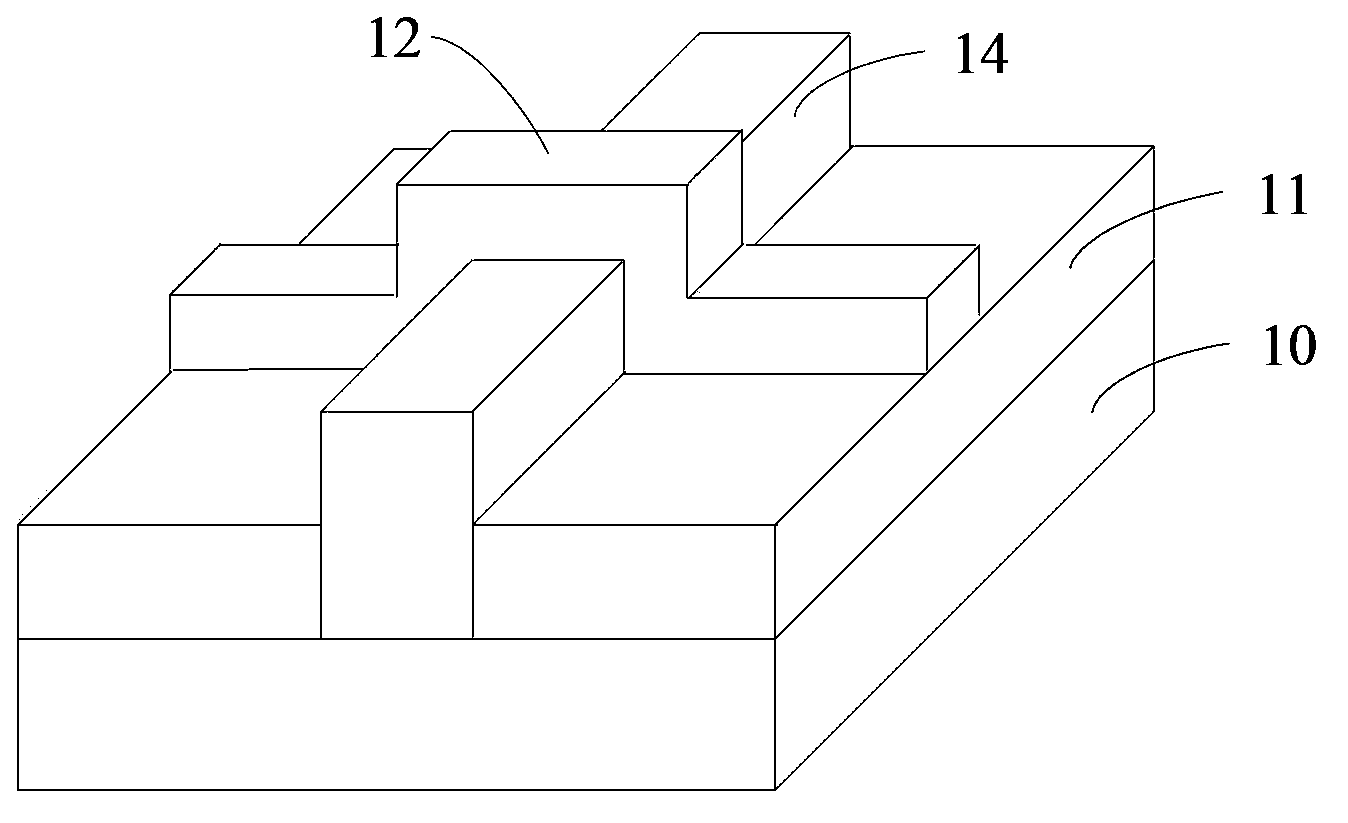

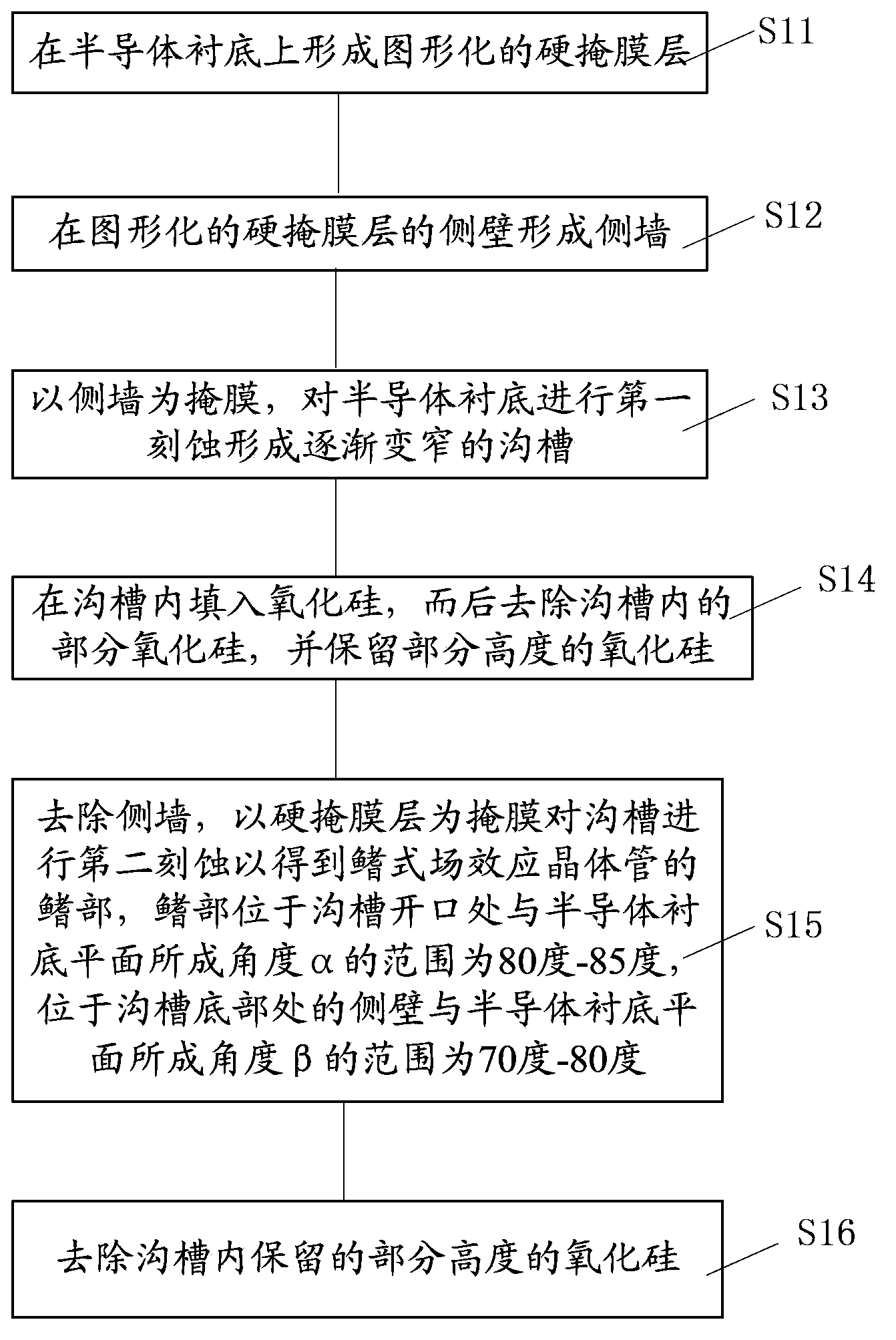

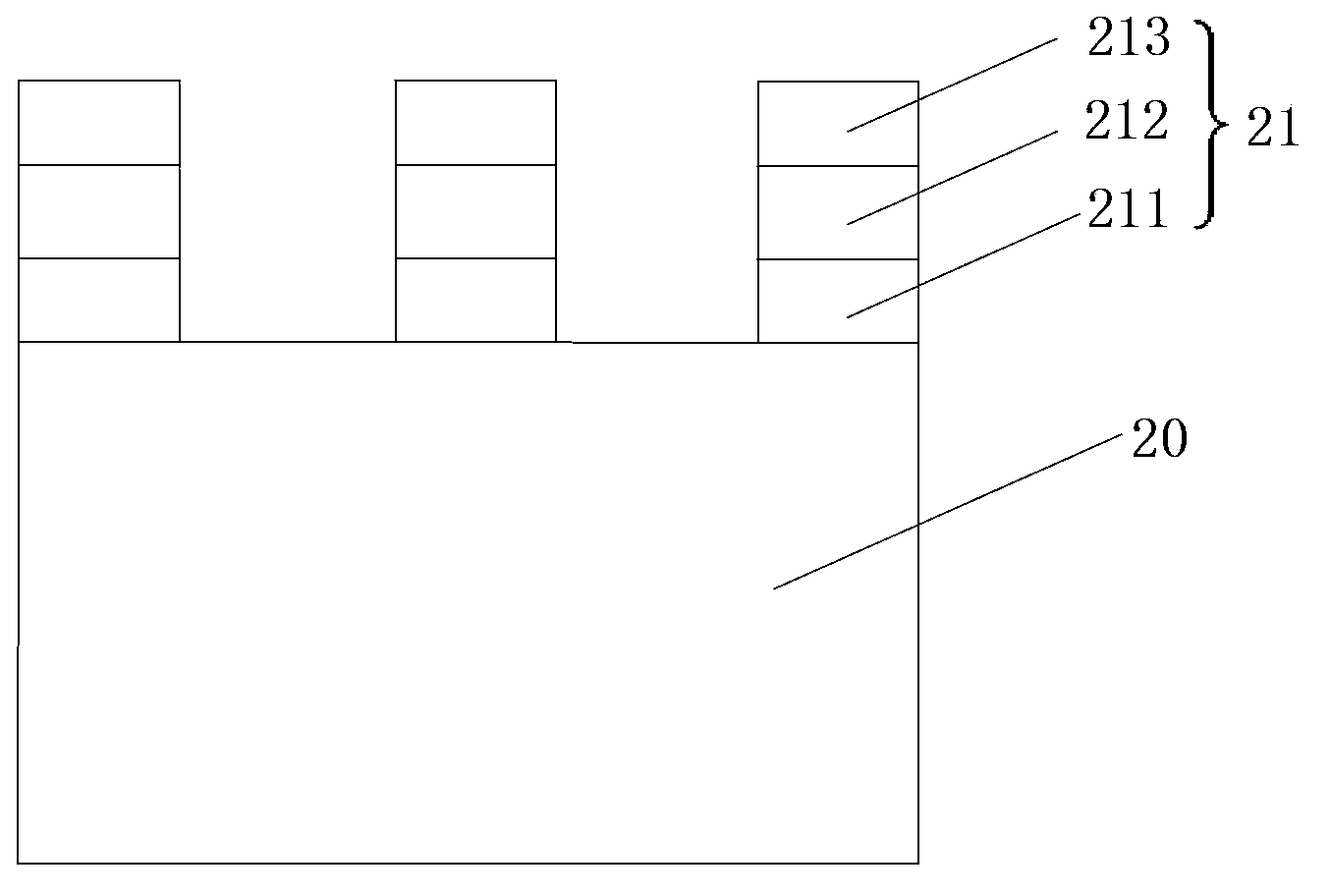

Fin portion manufacturing method and fin type field effect transistor and manufacturing method thereof

ActiveCN103811323AHighly controllableEasy to fillSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSilicon oxide

A fin portion manufacturing method comprises forming into an imaging hard mask layer on a semiconductor substrate; forming into a lateral wall on the lateral wall of the imaging hard mask layer; etching a semiconductor substrate for the first time to form into a gradually narrowed groove with the lateral wall serving as a mask; filling silicon oxide into the groove and removing partial silicon oxide inside the groove and reserving partial height of silicon oxide; removing the lateral wall, etching the groove for the second time to obtain the fin portion of the fin type field effect transistor with the hard mask layer serving as the mask. The range of the angle formed between the fin portion lateral wall at the groove opening and the semiconductor substrate plane is 80 to 85 degrees and the range of the angle formed between the fin portion lateral wall at the bottom and the semiconductor substrate is 70 to 80 degrees. The invention also provides a fin type field effect transistor and a manufacturing method thereof based on the fin portion manufacturing method. According to the technical scheme of the fin portion manufacturing method, the height of the fin portion is easy to control and the fin type field effect transistor response time is short.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

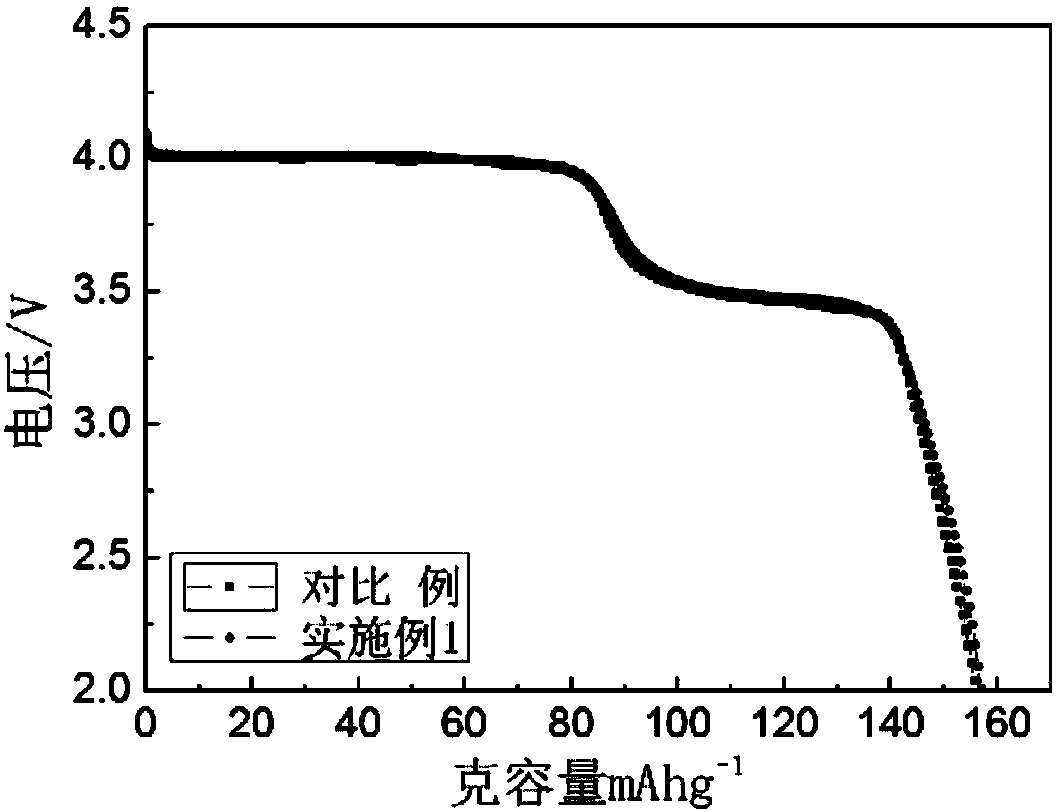

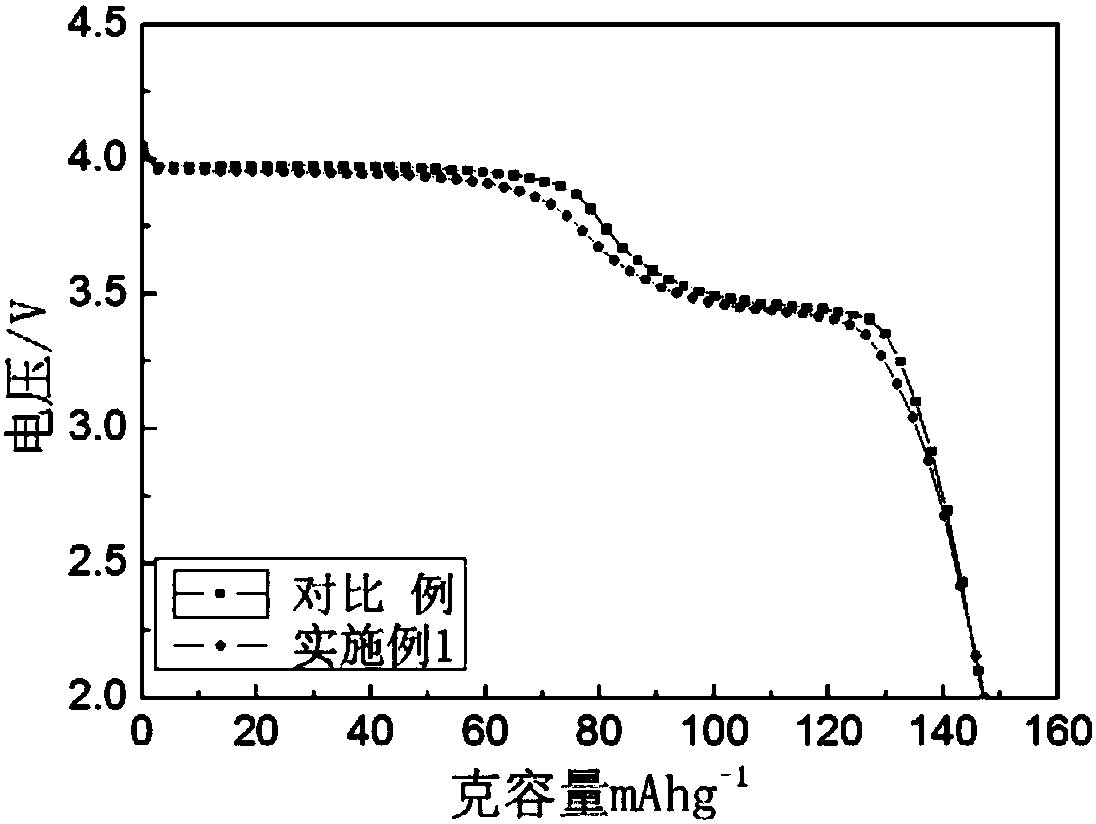

Three-dimensional porous nanocarbon composite lithium manganate spherical positive electrode material and preparation method thereof

InactiveCN103904322AExcellent high temperature cycle performanceExcellent high rate charge and discharge performanceCell electrodesSecondary cellsMicrosphereManganate

The invention discloses a three-dimensional porous nanocarbon composite lithium manganate spherical positive electrode material and a preparation method thereof. The preparation method comprises the following steps of adsorbing Mn<2+> ions onto a carbonyl (-COH-) group in a microgel three-dimensional macromolecular network by adopting poly(acrylamide, acrylic acid) microgel spheres as a template; increasing the pH value of the poly(acrylamide, acrylic acid) microgel spheres so as to in-situ hydrolyze the Mn<2+> ions to generate Mn(OH)2 crystal nucleus, depositing the Mn(OH)2 crystal nucleus into a space formed by the three-dimensional macromolecular network to form nano composite polymer microspheres; placing the obtained nano composite polymer microspheres into a tubular furnace to be calcined at a high temperature in an inert gas atmosphere to prepare the three-dimensional porous nanocarbon composite lithium manganate spherical positive electrode material. The positive electrode material has the advantages of excellent high-temperature cycling performance, large multiplying power charging-discharging performance and the like, and can be widely applied to the production of a lithium battery.

Owner:XIANGTAN UNIV

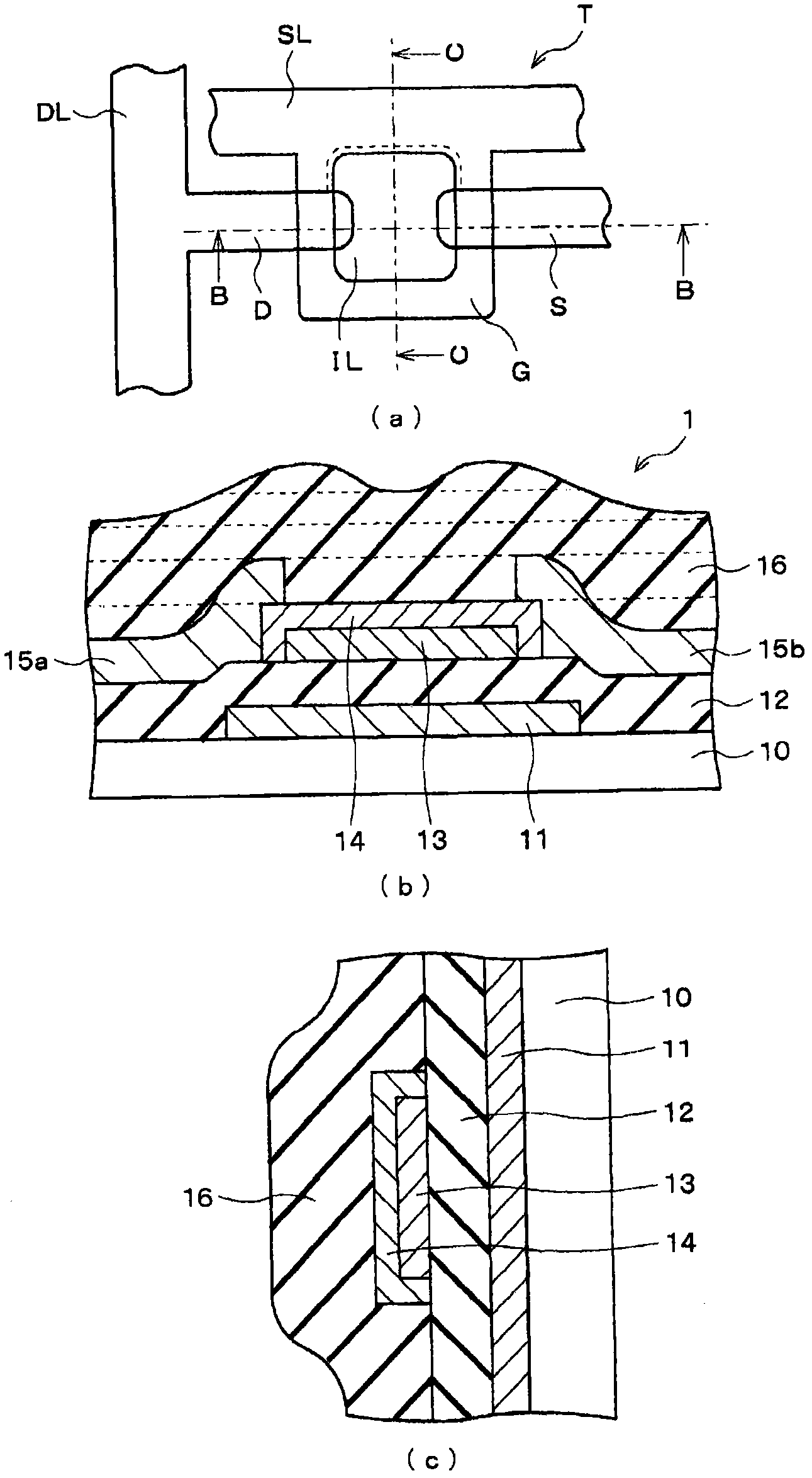

Thin-film transistor, manufacturing method therefor, and liquid-crystal display device

InactiveCN102576733AFast migrationIncrease the on-currentTransistorSemiconductor/solid-state device manufacturingPower flowLiquid-crystal display

Provided is a thin-film transistor comprising a low-temperature polysilicon transistor having a low off-current, excellent potential-holding characteristics, low power usage, and a high operating speed. Also provided are a liquid-crystal display device using said thin-film transistor and a method for manufacturing the thin-film transistor. The provided thin-film transistor uses an inversely staggered structure with a gate electrode, a gate insulation film, a channel region, and source / drain electrodes formed on top of a glass substrate. The channel region comprises a polysilicon film and an a-Si:H film that covers the top and sides of the polysilicon

Owner:V TECH CO LTD

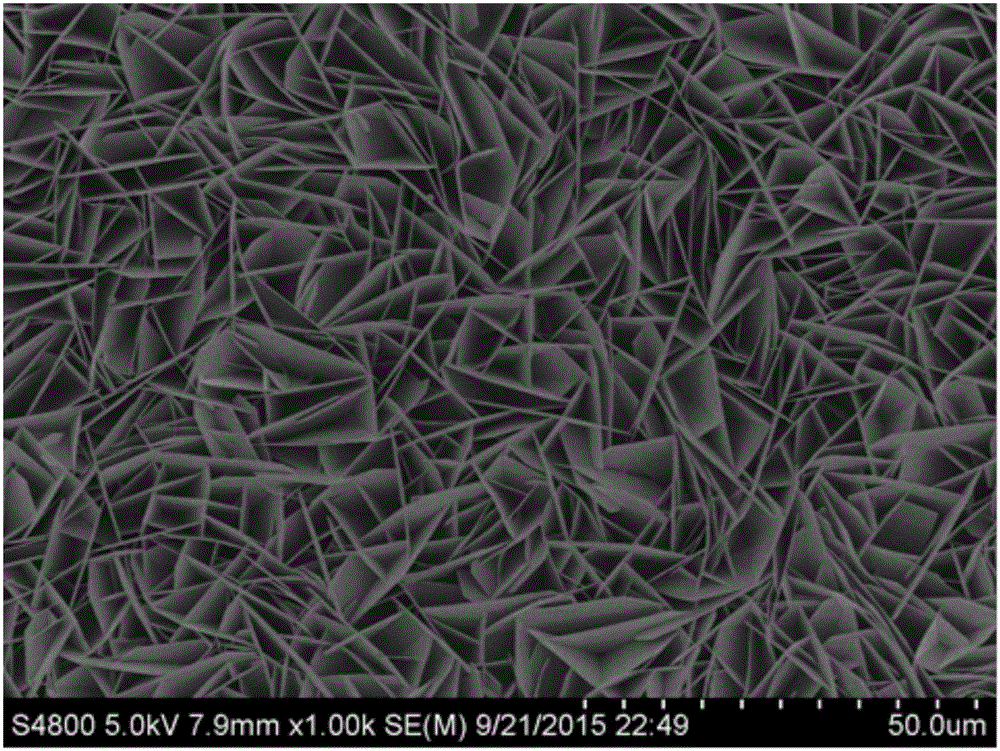

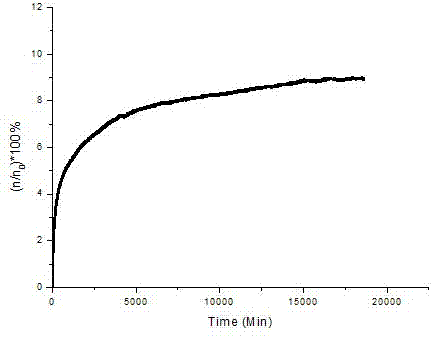

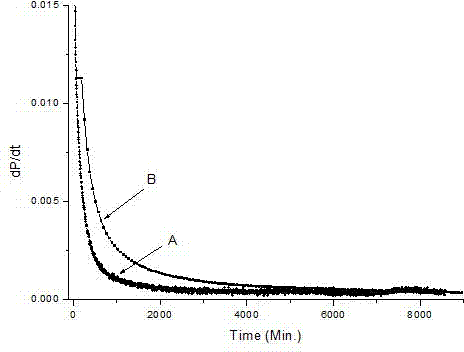

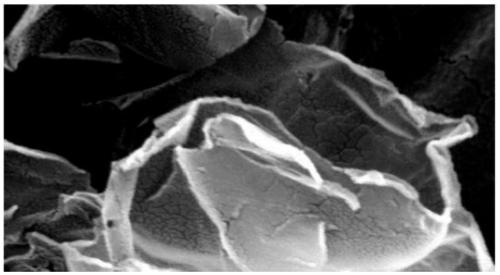

Cross cobalto-cobaltic oxide nanosheet array, gas sensor containing the array and application thereof

ActiveCN106066351AHigh sensitivityShorten reaction timeMaterial electrochemical variablesElectron mobilityChemistry

The invention discloses a cross cobalto-cobaltic oxide nanosheet array, a gas sensor containing the array and application thereof. The nanosheets in the special cross cobalto-cobaltic oxide nanosheet array cross with each other. The nanosheets have a mesoporous structure, and the highest sensitivity of 16.5 for selective detection of acetone at about 111 DEG C. The cross cobalto-cobaltic oxide nanosheet array overcomes the problem that traditional cobalto-cobaltic oxide nanosheet cannot directly generate array on an insulation substrate with only supporting effect, and has the advantages of low production cost, high efficiency, and simple and controllable operation. The cross cobalto-cobaltic oxide nanosheet array has open structure, large specific surface area and electron mobility, and can provide more space for the benefit of rapid adsorption and detachment of gas molecules, and significantly improve the gas sensitive properties of the material. The cross cobalto-cobaltic oxide nanosheet array has good stability; test is carried out every 3 days in 60 days; and after 20 times of test, the performance change rate is only + / - 8%. The invention is quite applicable to sensor, acetone detection and medical detection.

Owner:ZHEJIANG UNIV

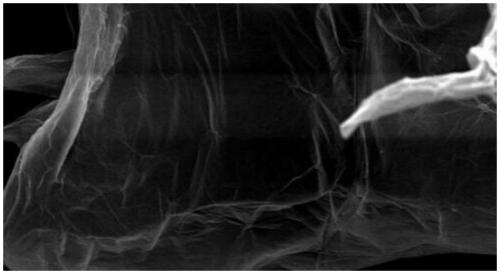

Nanocarbon material composite biomass hard carbon electrode material and preparation method and application thereof

ActiveCN113044827ALarge specific surface areaImprove conductivityCell electrodesSecondary cellsCarbon nanotubeCarbonization

The invention discloses a preparation method of a nanocarbon material composite biomass hard carbon electrode material. The preparation method comprises the following steps: with biomass as a raw material, primarily crushing, cleaning and drying the biomass; performing heating treatment with an alkali solution, performing secondary crushing after cleaning and drying, performing heating treatment with an acid solution, removing redundant inorganic salt impurity components, and performing cleaning and drying; adding a uniformly dispersed acid solution of graphene oxide and carbon nanotubes, conducting uniform stirring and mixing, performing treating by using a microwave hydrothermal method, carrying out drying, and performing crushing for the third time to obtain a composite biomass hard carbon precursor; and carrying out low-temperature pre-carbonization and high-temperature treatment on the composite biomass hard carbon precursor under the protection of an inert atmosphere to obtain the composite biomass hard carbon material. According to the nanocarbon material composite biomass hard carbon material, the crosslinking degree of a carbon structure is adjusted by controlling a pyrolysis speed, so the distribution, the number, the size and the like of holes are adjusted; and by adding the graphene and the carbon nanotubes, the specific surface area, the electrical conductivity and the thermal conductivity of the material are improved, and structural stability is enhanced.

Owner:昆山昆鹏利杰高分子材料技术有限公司

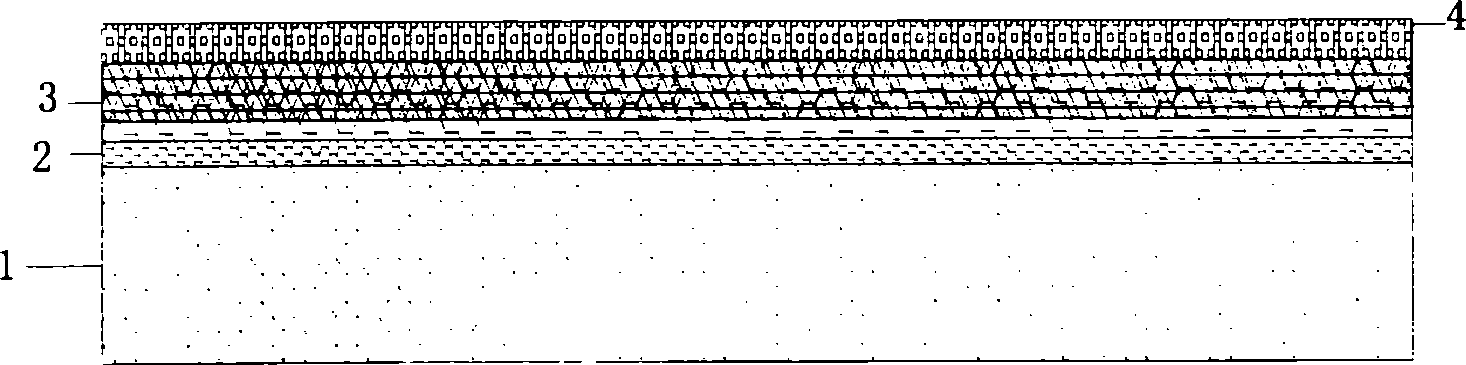

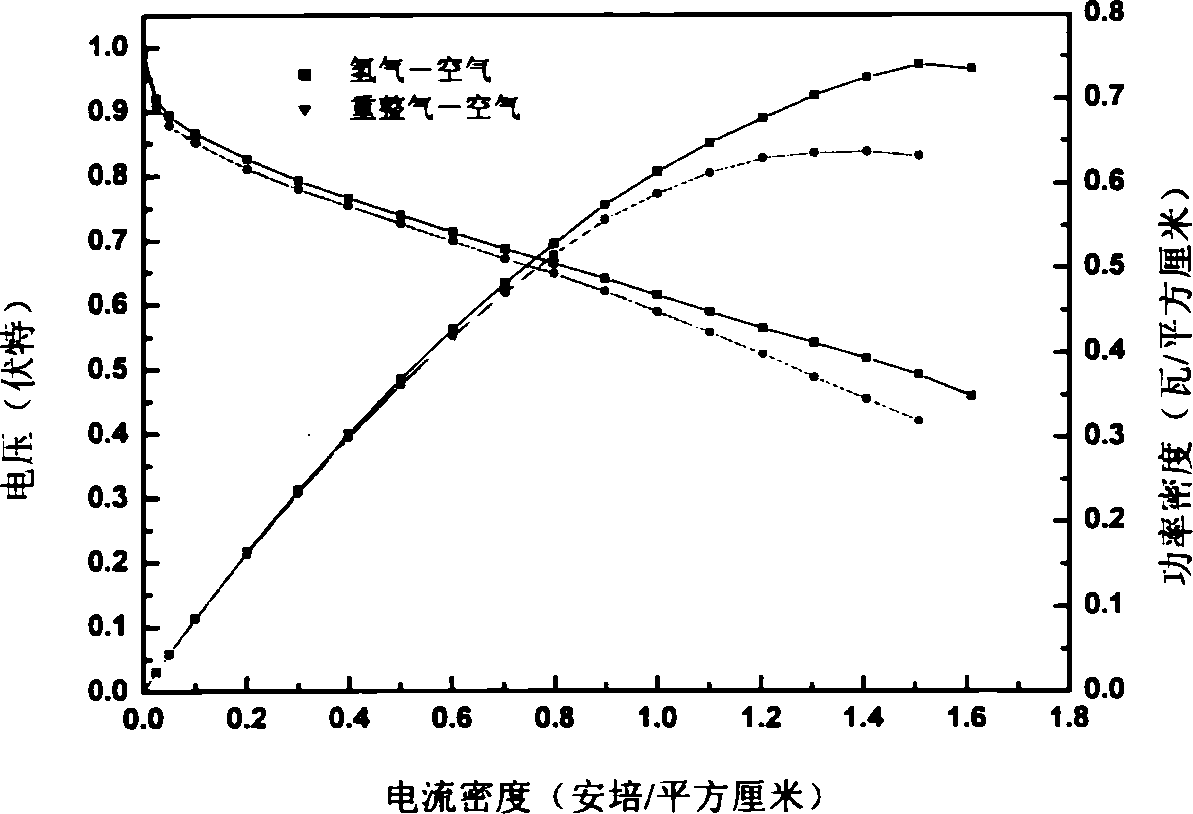

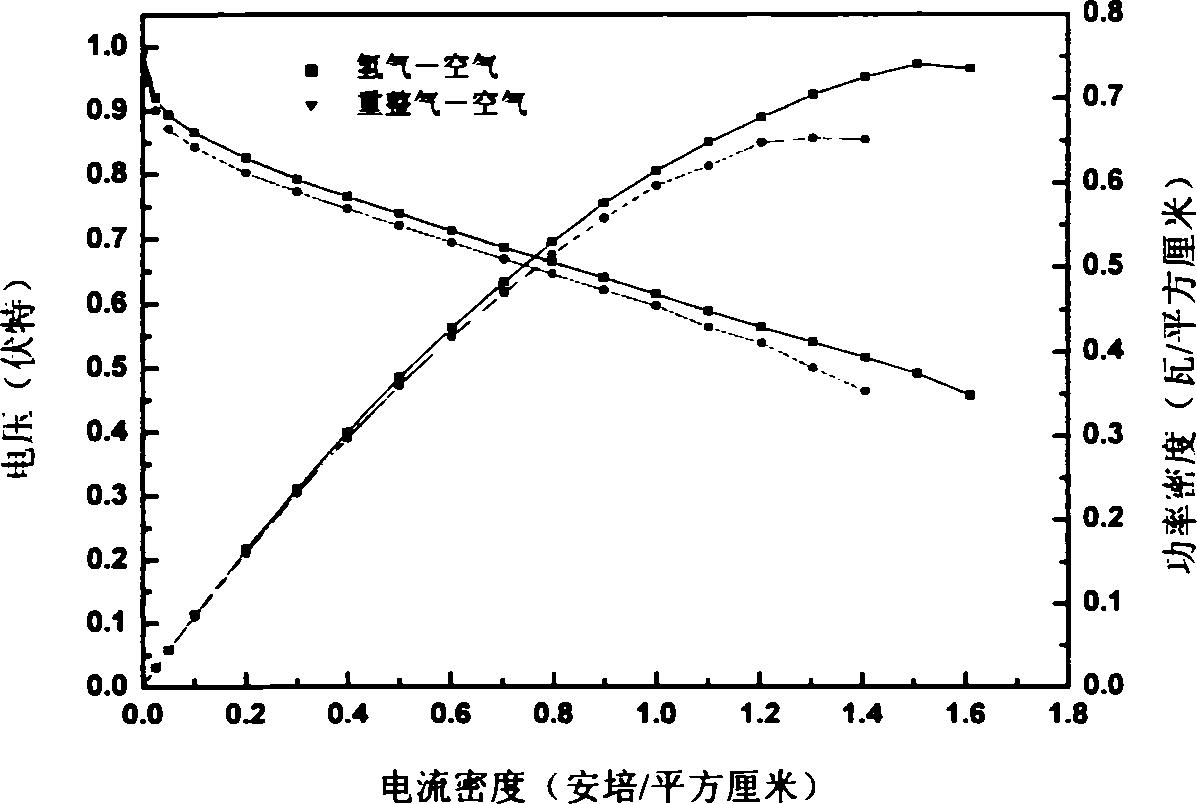

Anti-carbon monoxide composite anode electrode catalyst layer structure and preparation method

ActiveCN1885599AImprove utilization efficiencyImprove output power densityCell electrodesSolid electrolyte fuel cellsProtonProton exchange membrane fuel cell

The related preparation method for anti-CO composite positive electrode catalysis layer of proton-exchange member fuel cell comprises: with Pt / C or PtM / C(M is one or more of Ru, Mo, Sn, Ni, Au / Fe2O3,Au / Al2O3, Au / Co2O3, Fe, Co and W) as electric catalyst, a hydrophilic catalyst layer named inner catalyst layer with former catalyst and polymer solid as main components connected to the proton exchange member, a hydrophobic catalyst layer named outer catalyst layer with the catalyst and some hydrophober as main components connected to a diffused layer, and one or more middle catalyst layer with hydrophilic and hydrophobic feather gradient change. This invention has well performances.

Owner:SUNRISE POWER CO LTD

Solid powder multi-element composite infiltration agent and composite infiltration process

ActiveCN109468581AFast penetrationFine grainSolid state diffusion coatingRare earthOxidation resistant

The invention relates to a solid powder multi-element composite infiltration agent and a composite infiltration process, and belongs to the technical field of metal surface treatment. The composite infiltration agent is composed of a chromium source, a vanadium source, a boron source, nickel powder, an activating agent, a filling agent, an oxygen scavenger and a rare-earth infiltration enhancer. The composite infiltration agent has the effects of rapid infiltration speed, no pollution, improving the structural density of an infiltration layer, and avoiding the embrittlement of the infiltrationlayer. The composite infiltration process comprises the following steps of carrying out acid pickling activation pretreatment on a base body material, then burying the base body material into the composite infiltration agent, heating and preserving heat in a carbon-containing or nitrogen-containing atmosphere, and then carrying out quenching treatment after furnace cooling. According to the process, the method is simple, no pollution occurs, the infiltration speed is rapid, the infiltration agent is free of hardening, and the surface of an infiltrated workpiece is clean. The prepared composite infiltration layer is fine in the crystalline grains and compact in the structure, has a good gradient structure, has the toughness, the wear resistance, the corrosion resistance, the high-temperature oxidation resistance and the like, and can be applied to parts such as a tool, a mold, a bearing, and a gear.

Owner:GUANGDONG INST OF NEW MATERIALS

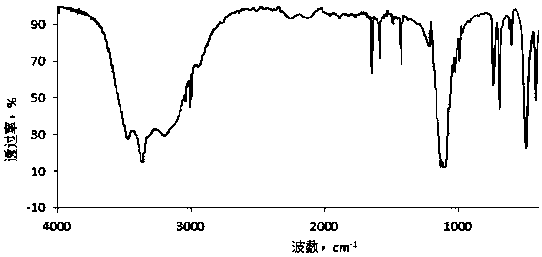

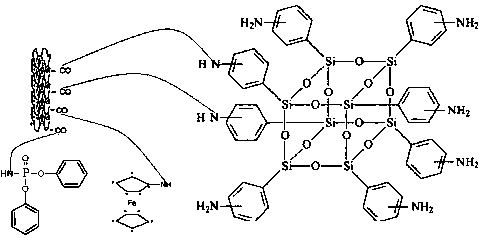

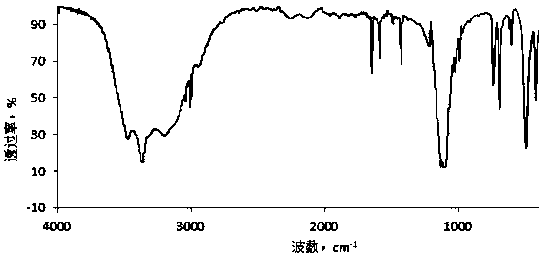

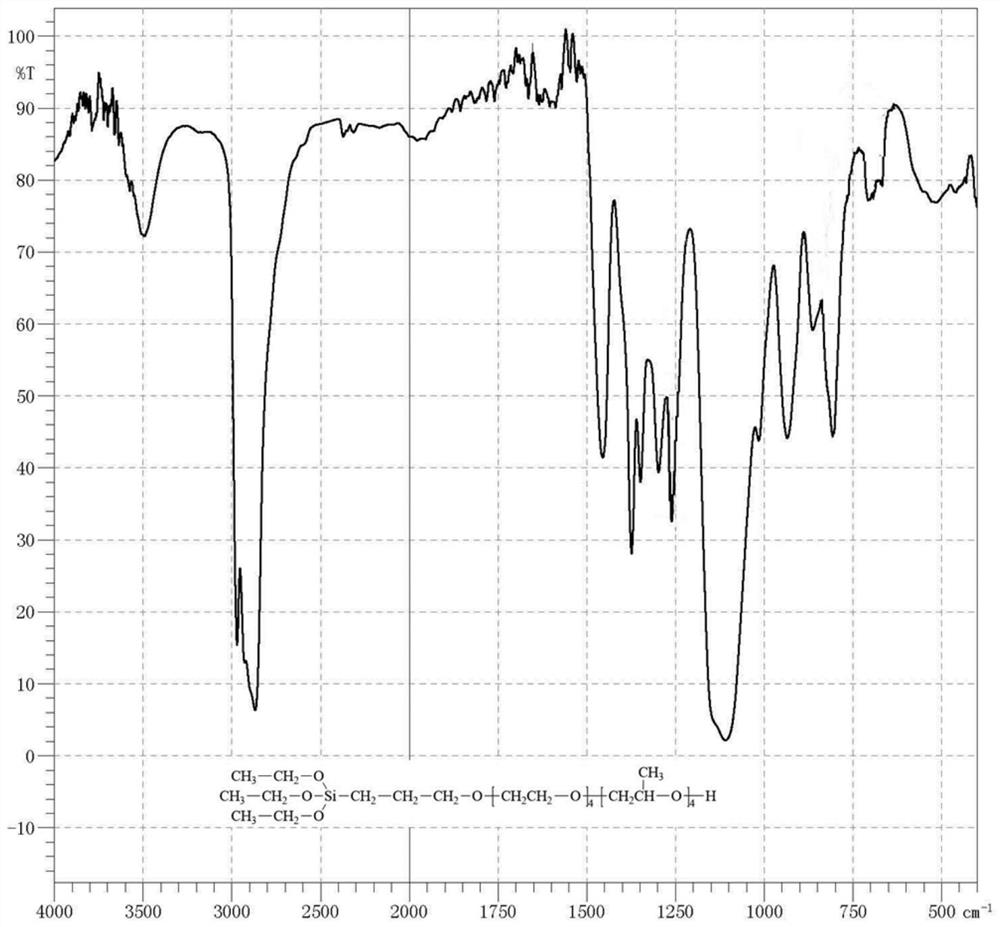

Preparation method of carbon nanotube amidation grafted polysilsesquioxane flame retardant

ActiveCN111171322ASolve the problem of high surface energy and easy agglomerationGood synergyPolymer scienceModified carbon

The invention relates to the field of preparation of new materials, in particular to a preparation method of a carbon nanotube amidation grafted polysilsesquioxane flame retardant. The preparation method comprises the following steps: surface modification is carried out on a carbon nano tube by adopting tetramethyl guanidino propyl trimethoxy silane; octaaminophenyl silsesquioxane, aminoferroceneand biphenyl phosphoramidate are grafted and introduced into the modified carbon nanotube material by adopting an amidation reaction, and high-heat-resistance and high-smoke-suppression cage-shaped polysilsesquioxane is obtained by virtue of a synergistic effect. The flame retardant has very excellent flame retardance, is used for polycarbonate products, and has the characteristics of small addition amount, strong carbon forming ability and high migration speed.

Owner:QUZHOU UNIV

Method for producing tritium-proof gloves

ActiveCN102922538AProtect the operatorReduce environmental pollutionManipulatorRubber layered productsThin membraneChemistry

The invention provides a method for producing a pair of tritium-proof gloves and belongs to the field of a radiation proof material. The method comprises the step of: preparing a three-layer compound rubber thin film by using a method of compounding layer by layer, wherein the outer layer is a rubber barrier layer which is good in hydrogen stopping property; the middle layer is a tritium absorption layer in which an organic hydrogen absorption agent prepared by DEB and a catalyst is dispersed; and the third layer is a rubber layer which is good in compatibility with the skin and is made of the same material as the outer layer. The gloves produced by using the method has the advantages that tritium permeating into each tritium-proof glove through surface layer rubber is fixed in the rubber layer of the middle layer of each glove, thereby achieving the tritium-proof effect; and the preparation process is simple, the tritium-proof effect is obvious and the tritium recycle and the environmental protection can be realized.

Owner:SICHUAN INST OF MATERIALS & TECH

Antistatic and antibacterial fabric master batch and preparing method thereof

InactiveCN109796753AInhibition of growth and reproductionImprove antibacterial propertiesFood additivePolymer science

The invention discloses an antistatic and antibacterial underwear fabric master batch and a preparing method thereof. Natural polymer material chitosan capable of serving as a food additive is adoptedas an antibacterial agent, and the antibacterial capacity of a chitosan composite material is improved by introducing zinc into amino and hydroxyl of three nucleophilic active functional groups of the chitosan. According to the antistatic and antibacterial underwear fabric master batch and the preparing method, three-dimensional graphene is used as an antistatic filler; the graphene has the advantages of being low in resistivity and high in electron transfer speed; agglomeration of the graphene can be avoided and overcome, and therefore the graphene can be dispersed in plastic; finally, as the three-dimensional graphene has the self-supporting effect, the three-dimensional graphene keeps the high specific surface area to serve as a carrier for the chitosan and the zinc, and the antibacterial performance of the chitosan and the zinc can be fully developed.

Owner:GUANGZHOU UNIVERSITY

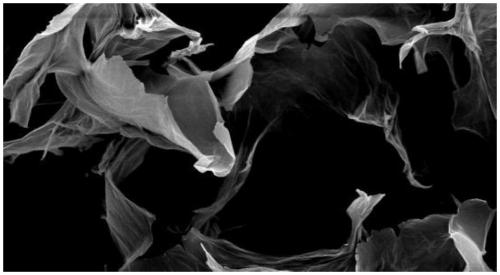

Application of graphene oxide conductive slurry in hole blackening direct electroplating

ActiveCN109811382ALow resistivityFast migrationElectrolytic inorganic material coatingPrinted circuit manufactureSlurryGraphene

The invention discloses application of graphene oxide conductive slurry in hole blackening direct electroplating. The application comprises the steps of preparing the graphene oxide conductive slurryand using the prepared graphene oxide conductive slurry to carry out hole blackening direct electroplating. According to the graphene oxide conductive slurry in hole blackening direct electroplating,the graphene oxide is modified to contain cyanate ester in the surface so that the graphene oxide conductive slurry has the very high mobility and the very high film forming property, an attached graphene oxide dense layer has stable continuity, the strength of the dense layer can be improved while the electric conduction capacity is improved, an electroplating plate is not prone to having littlecracks or being broken when deforms, and the service life of a conductive plate is prolonged; and according to the application of the graphene oxide conductive slurry in hole blackening direct electroplating, compared with a hole blackening direct electroplating technology in the prior art, the process step of using the graphene oxide conductive slurry in hole blackening direct electroplating is greatly simplified, the whole electroplating technology can be completed by repeating coating once, operation is easy to carry out, and the rate of finished products is high.

Owner:YANTAI HENGNUO CHEM TECH CO LTD

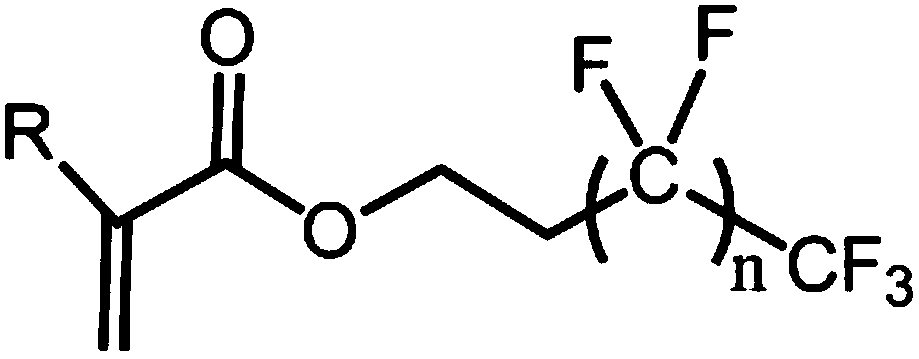

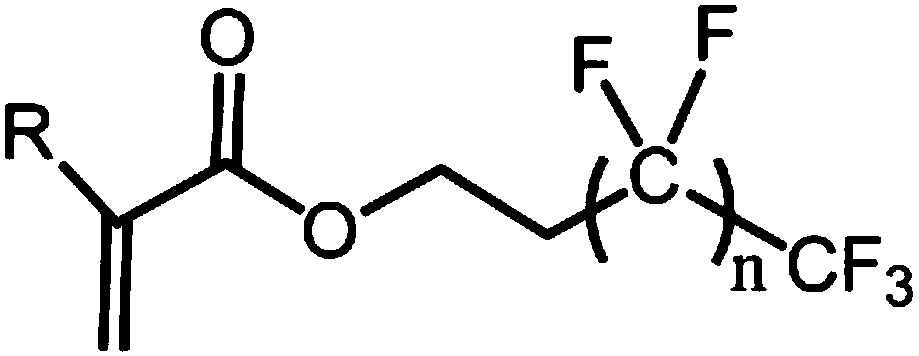

Fluorine-containing acrylate-based random copolymer, preparation method and uses thereof

ActiveCN109553715AAntifoamStrong fast defoaming performancePolyurea/polyurethane coatingsFoaming agentPlastic materials

The invention relates to a fluorine-containing acrylate-based random copolymer, which has a number average molecular weight of 20000-500000 and molecular weight distribution of 1.6-3, and is obtainedby carrying out free radical copolymerization on 40-80 wt% of a monomer component A and 20-60 wt% of a monomer component B, wherein the monomer component A is fluorine-containing (meth)acrylate, and the monomer component B is C8-C30 alkyl (meth)acrylate. The invention further relates to a preparation method of the fluorine-containing acrylate-based random copolymer, wherein the preparation methodcomprises: heating a solvent to a temperature of 80-140 DEG C, mixing the monomer component A, the monomer component B and an initiator to obtain a mixed solution, adding the mixed solution into the heated solvent in a dropwise manner within 1.5-3 h, and carrying out a copolymerization reaction to obtain the fluorine-containing acrylate-based random copolymer. The invention further relates to usesof the fluorine-containing acrylate-based random copolymer as an anti-foaming agent in coating materials, inks or plastic materials. According to the present invention, the fluorine-containing acrylate-based random copolymer has advantages of strong foam inhibition and defoaming performance and good system compatibility, the preparation is simple, and the continuous production can be achieved.

Owner:SANMING UNIV

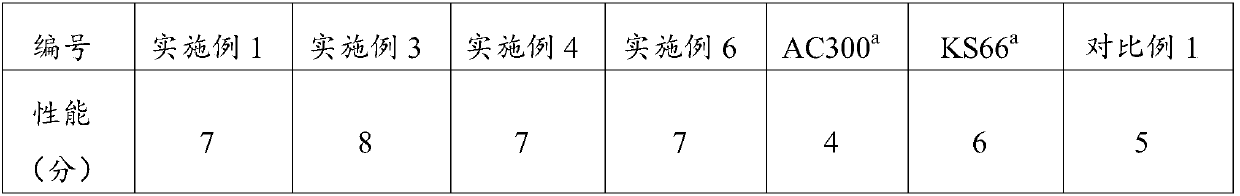

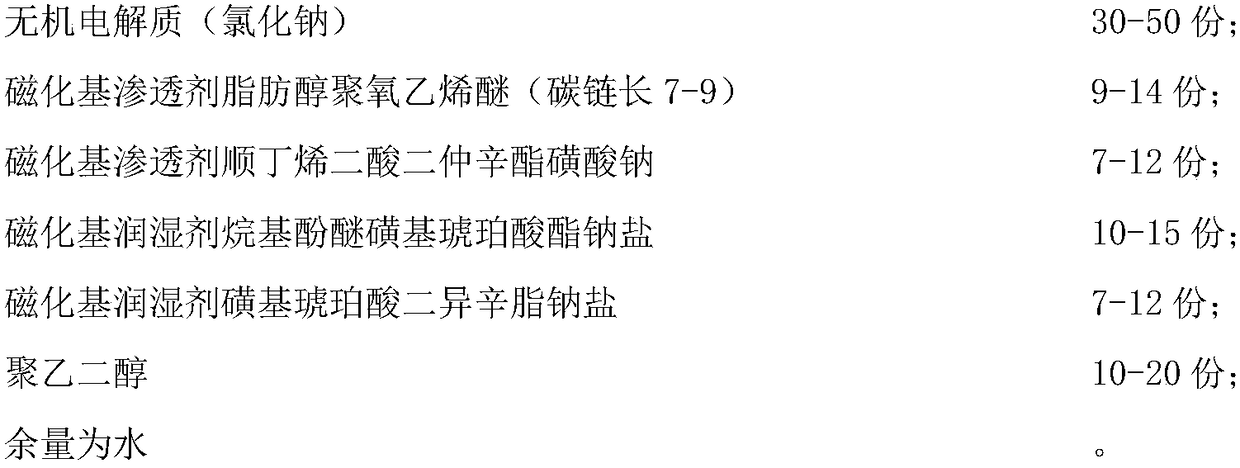

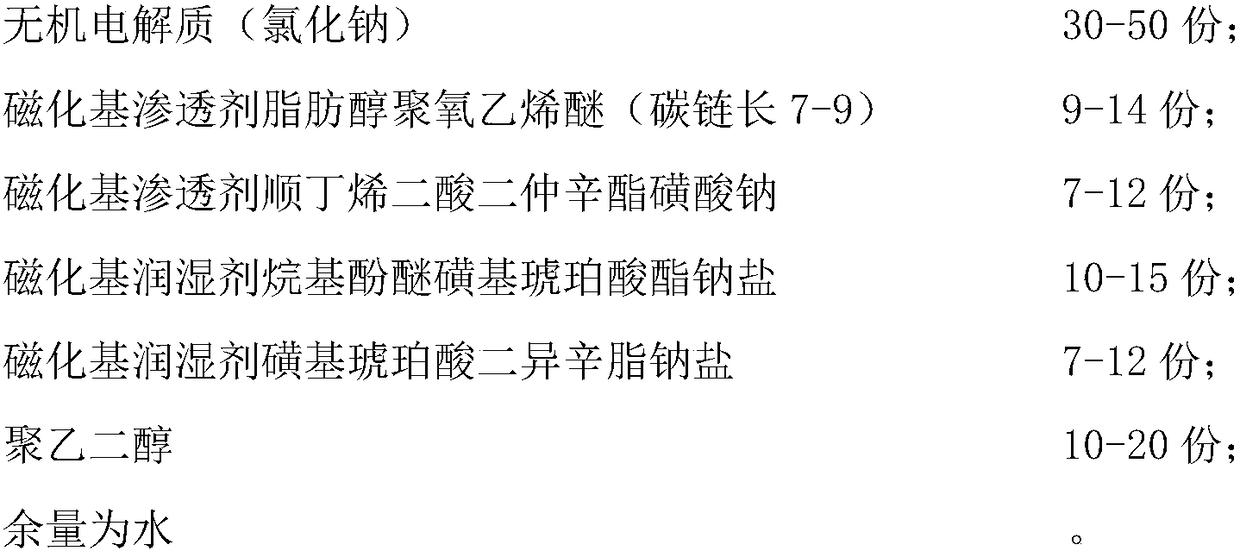

Magnetic anatonosis wetting agent capable of improving dust reduction effect of coal seam water injection

ActiveCN108084967AFast migrationReduce surface tensionOther chemical processesDust removalPolyethylene glycolAlkylphenol

The invention discloses a magnetic anatonosis wetting agent capable of improving a dust reduction effect of coal seam water injection. The magnetic anatonosis wetting agent is characterized by comprising the following components in parts by weight: 30-50 parts of inorganic electrolyte (sodium chloride), 9-14 parts of a magnetic penetrant fatty alcohol-polyoxyethylene ether (carbon chain length of7-9), 7-12 parts of a magnetic penetrant sodium diethylhexyl sulfosuccinate, 10-15 parts of a magnetic wetting agent alkylphenol ether sulfonylsuccinate sodium salt, 10-20 parts of polyethylene glycoland the balance of water. After the magnetic anatonosis wetting agent is injected into a coal seam, the water infiltration capability can be enhanced, the spreading range of water in the coal seam isexpanded, and the water injection effect is greatly improved. The magnetic anatonosis wetting agent is suitable for wide-range application to underground coal seam water injection due to the characteristics of simple and feasible preparation method, good dust reduction effect, convenient operation and low cost.

Owner:CHINA UNIV OF MINING & TECH

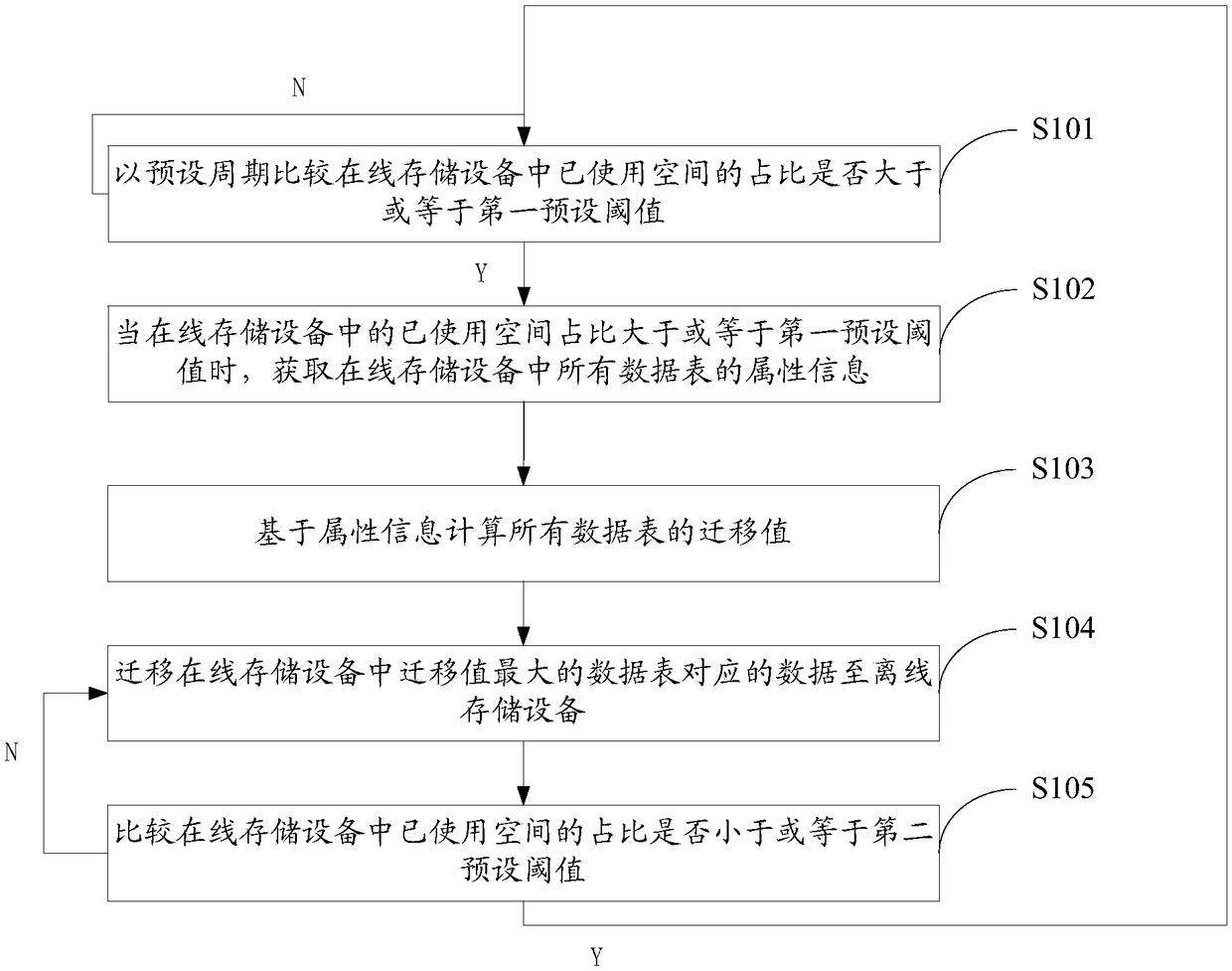

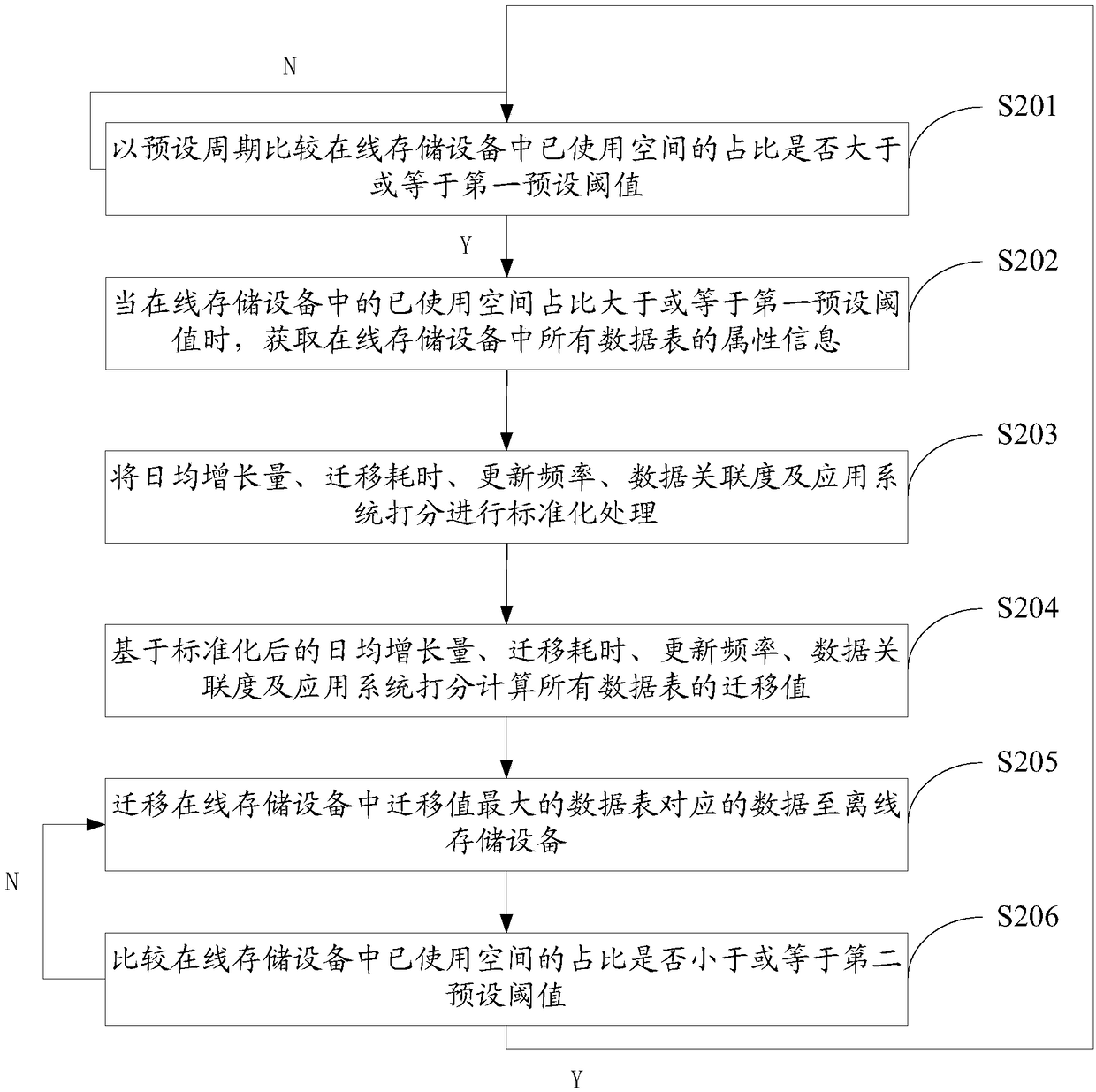

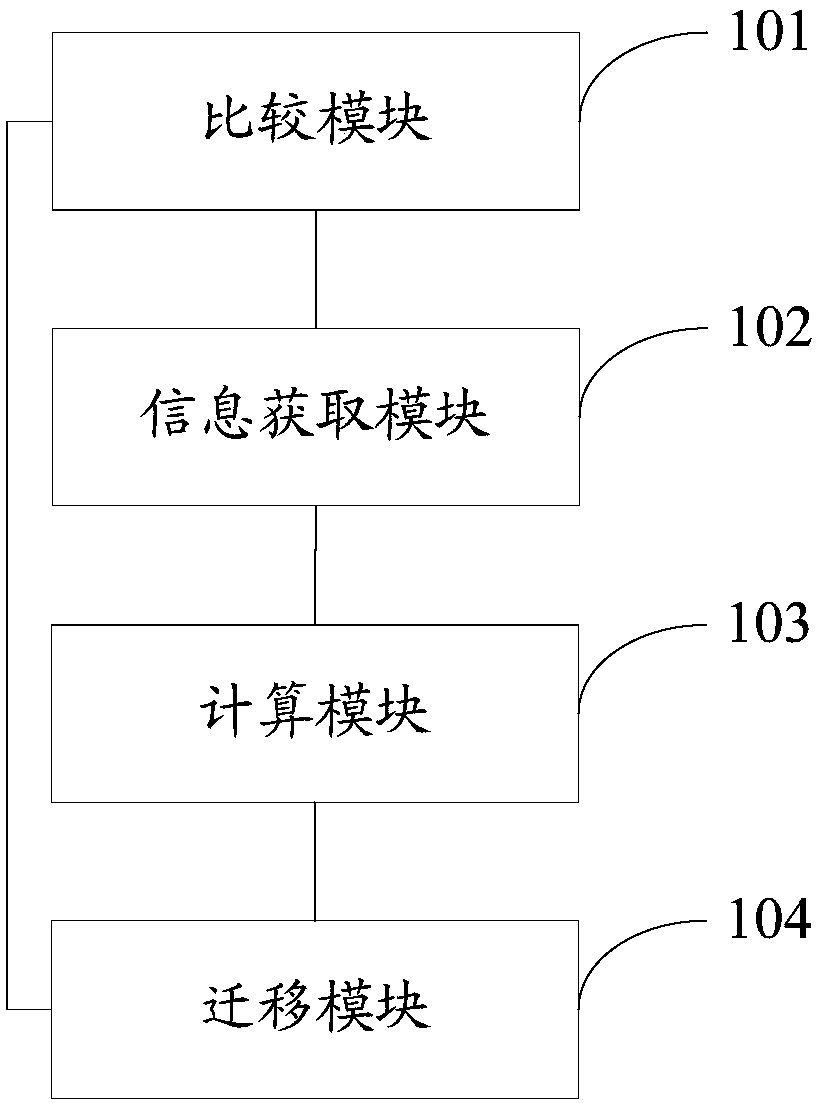

Data migration method and system used for hierarchical storage

InactiveCN108491165AIncrease free spaceSmall free spaceInput/output to record carriersSTEP-NCComputer science

The invention discloses a data migration method used for hierarchical storage. The method comprises the steps of A: comparing whether a proportion of used spaces in an online storage device is greaterthan or equal to a first preset threshold by a preset cycle, and if yes, executing the step B, otherwise, re-executing the step A; B: when the proportion of the used spaces in the online storage device is greater than or equal to the first preset threshold, obtaining attribute information of all data tables in the online storage device, and executing the step C; C: based on the attribute information, calculating migration values of all the data tables, and executing the step D; D: migrating data corresponding to the data table with a maximum migration value in the online storage device to anoffline storage device, and executing the step E; and E: comparing whether the proportion of the used spaces in the online storage device is smaller than or equal to the second preset threshold, and if yes, executing the step A, otherwise, executing the step D. The purposes of high migration speed, large released space, small influence range and high access efficiency are achieved.

Owner:AGRICULTURAL BANK OF CHINA

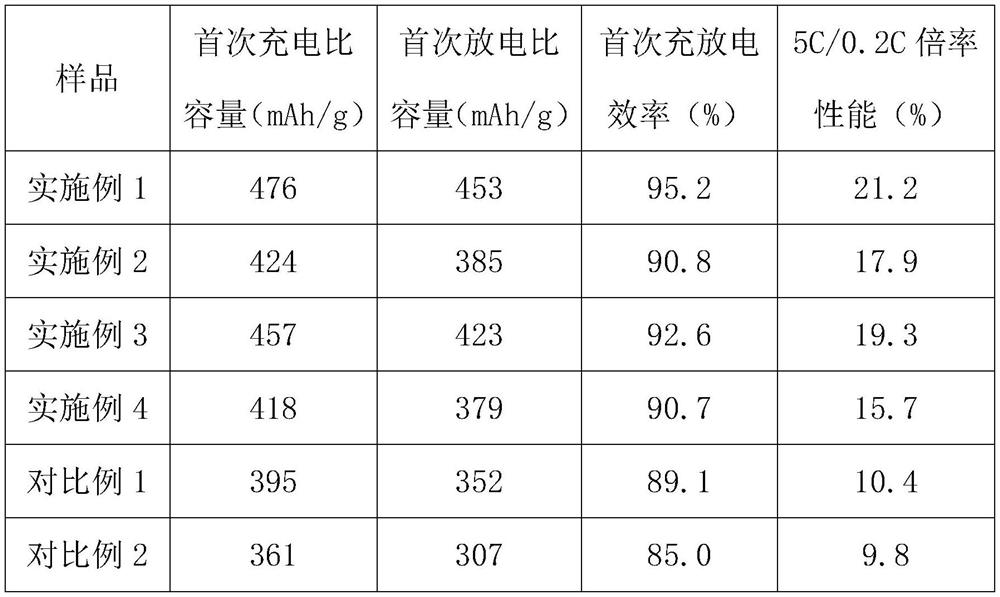

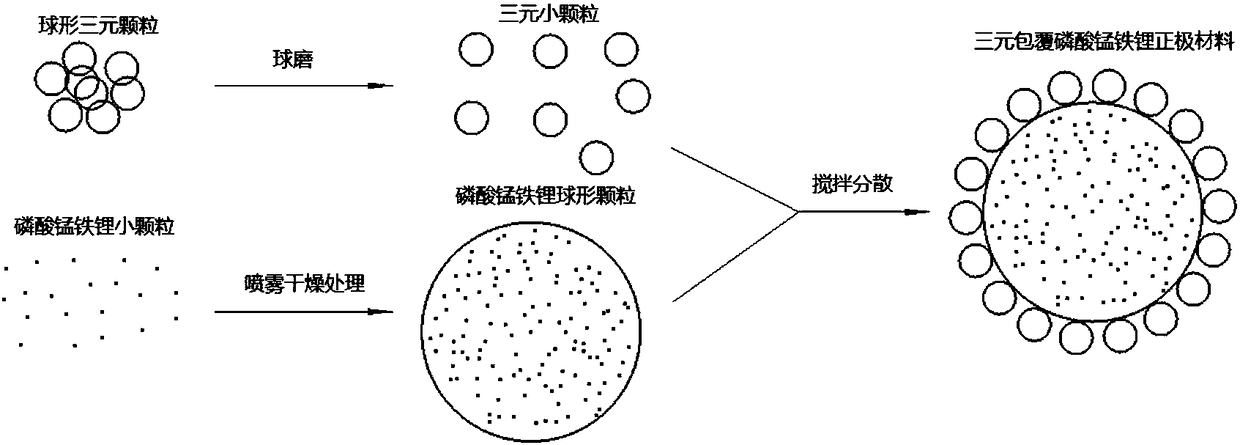

Lithium manganese iron phosphate-based composite positive electrode material and preparation method thereof

InactiveCN108598386AImprove internal electronic conductivityImprove conductivityCell electrodesSecondary cellsHigh rateHigh energy

The invention provides a lithium manganese iron phosphate-based composite positive electrode material. The lithium manganese iron phosphate-based composite positive electrode material adopts a core-shell structure, and comprises an inner core formed by lithium manganese iron phosphate and an outer shell for coating the surface of the inner core; and the outer shell adopts the material of lithium nickel cobalt manganate and / or lithium nickel cobalt aluminate. The lithium manganese iron phosphate-based composite positive electrode material provided by the invention has high energy density, highlow-temperature performance, high rate discharge performance and high cycle performance.

Owner:SHENZHEN DYNANONIC

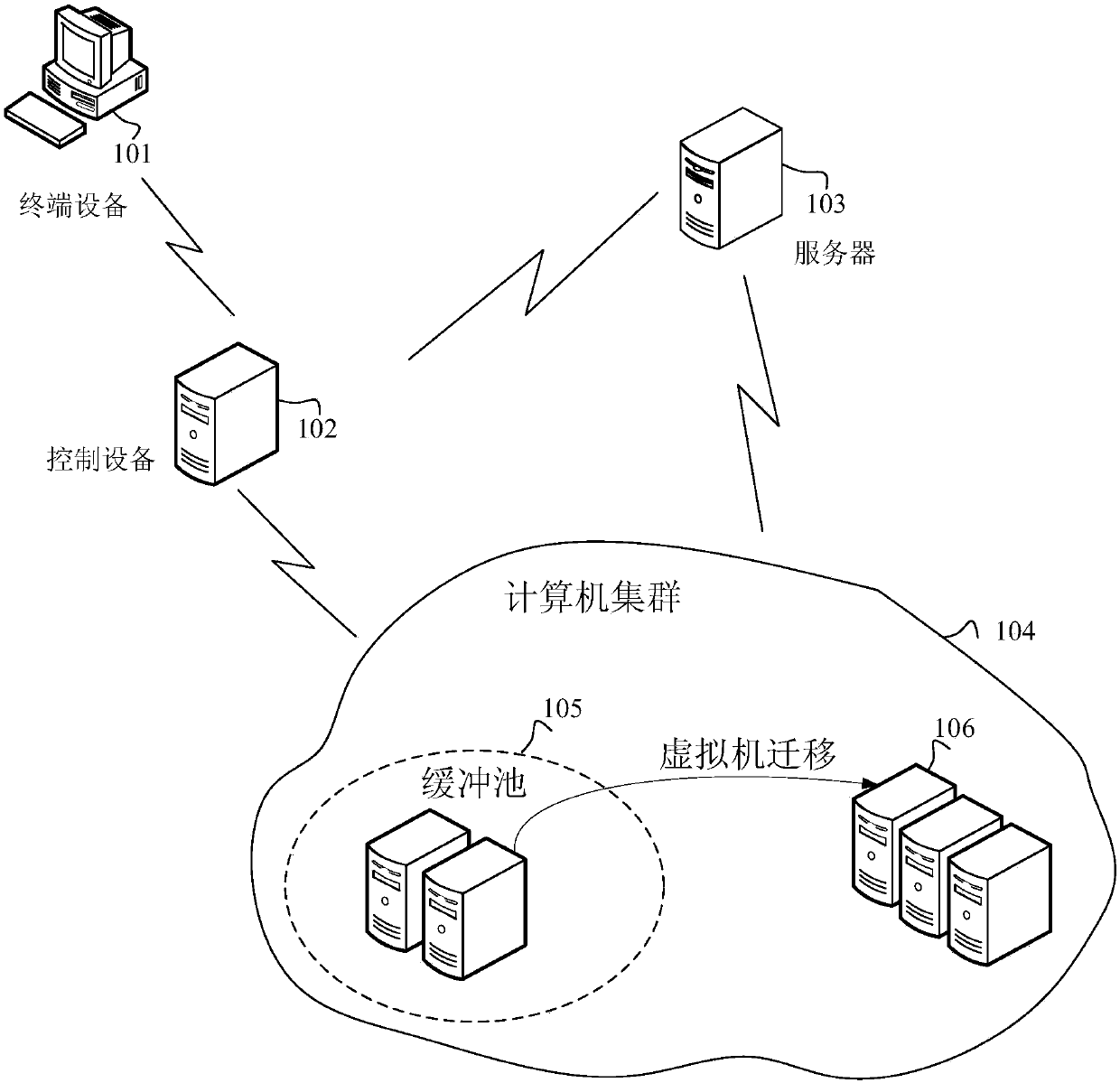

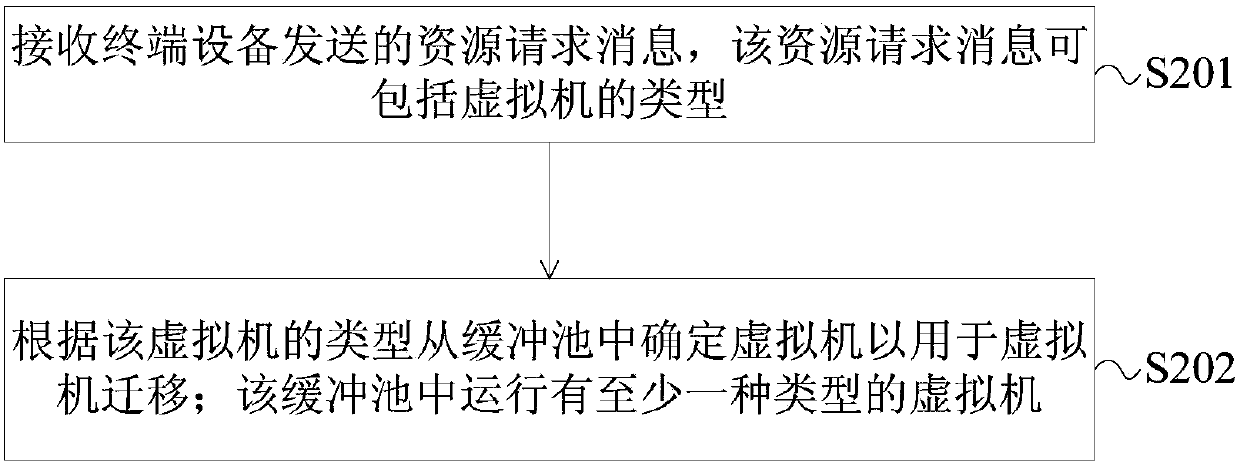

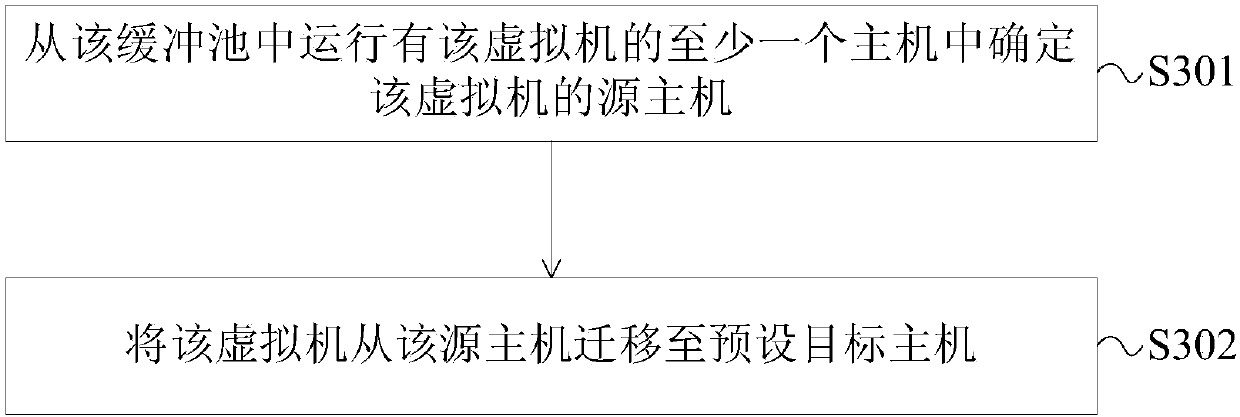

Virtual machine processing method and device and equipment

ActiveCN107807838AFast migrationSave payment timeSoftware simulation/interpretation/emulationTerminal equipmentComputer terminal

The invention provides a virtual machine processing method and device and equipment. The virtual machine processing method can comprise the steps that a resource request message sent by terminal equipment is received; the resource request message comprises a type of virtual machines; a virtual machine is determined from a buffer pool according to the type of the virtual machines to be used for virtual machine migration; and at least one type of virtual machines operates in the buffer pool. Through the virtual machine processing method and device and the equipment, delivery speed of the virtualmachine can be increased, delivery time is shortened, it is guaranteed that a user uses the requested virtual machine normally in time, and user experience is improved.

Owner:ALIBABA CLOUD COMPUTING LTD

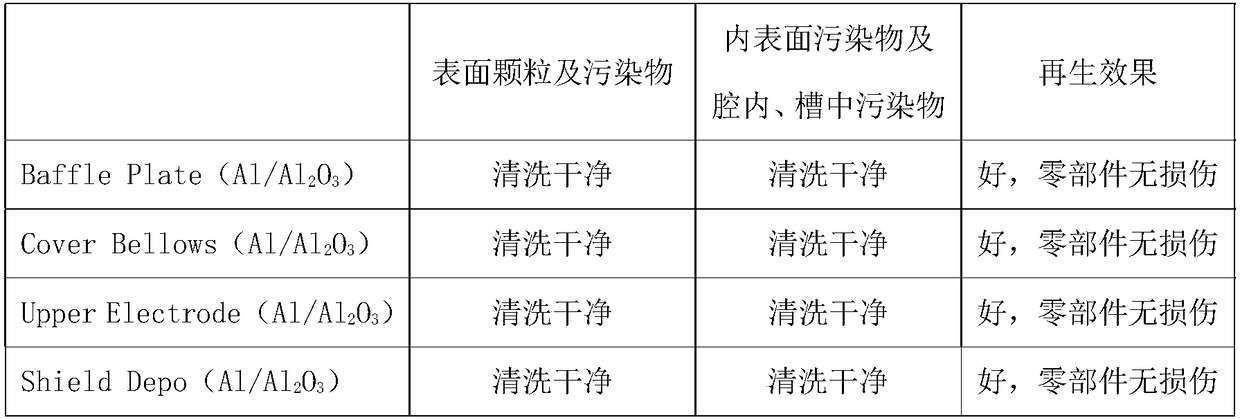

Regenerating method for Al/Al2O3 part of TD/DRM process of semiconductor 8-inch wafer film process

ActiveCN108573855AFast migrationLow viscositySemiconductor/solid-state device manufacturingEnvironmental resistanceThermal energy

The invention relates to a regenerating method for an Al / Al2O3 part of a TD / DRM process of a semiconductor 8-inch wafer film process. The method comprises the steps that dry ice particles are sprayedand cleaned to regenerate the surface of the part; local temperature difference change formed by thermal energy absorption of dry ice during a sublimation process is used to generate a 'shear stress'between a substrate and a cleaned object, and the cleaned object is quickly peeled off from the surface of the substrate; a Venturi nozzle can generate a carbon dioxide gas stream containing more dryice particles; ultrasonic assisted supercritical CO2 cleaning regenerates the inner surface, the chamber and the groove of the part; and supercritical CO2 easily penetrates into the micropores and thechamber or groove of the part to dissolve pollutants, so that the pollutants migrate fast in supercritical CO2 to achieve the purpose of cleaning. Ultrasonic assisting further improves the cleaning effect and efficiency. The regeneration time and cost are shortened. The regenerating method has the advantages of simple process, environmental protection, being pollution-free and good regeneration effect, does not damage the semiconductor part, and has no impact on the performance of the part.

Owner:苏州珮凯科技有限公司

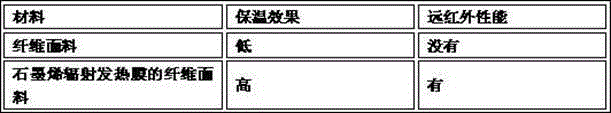

A kind of graphene radiation heating film and its preparation method and application

The invention relates to a graphene radiation heating film and the preparation method and application thereof. The graphene radiation heating film is formed by coating graphene sizing agent on a surface of fiber fabric; the graphene sizing agent is formed by mixing the following components in part by weight: 3 to 5 parts of graphene powder, 1 to 3 parts of far-infrared cast charge and 4 to 6 parts of bonding diluent; the preparation method comprises the following steps: weighting graphene powder of 3 to 5 parts by weight, far-infrared cast charge of 1 to 3 parts by weight and bonding diluent of 4 to 6 parts by weight, after mixing the graphene powder with far-infrared cast charge, stirring the mixture uniformly firstly, then adding bonding diluent and mixing, so as to form sizing agent; coating the sizing agent on the surface of the fiber fabric to form a film, and after the film is dried in the air or dried by baking, the graphene radiation heating film is formed. During use, the graphene radiation heating film emits heating by radiation under the effect of external temperature.

Owner:南京天脉健康科技发展有限公司

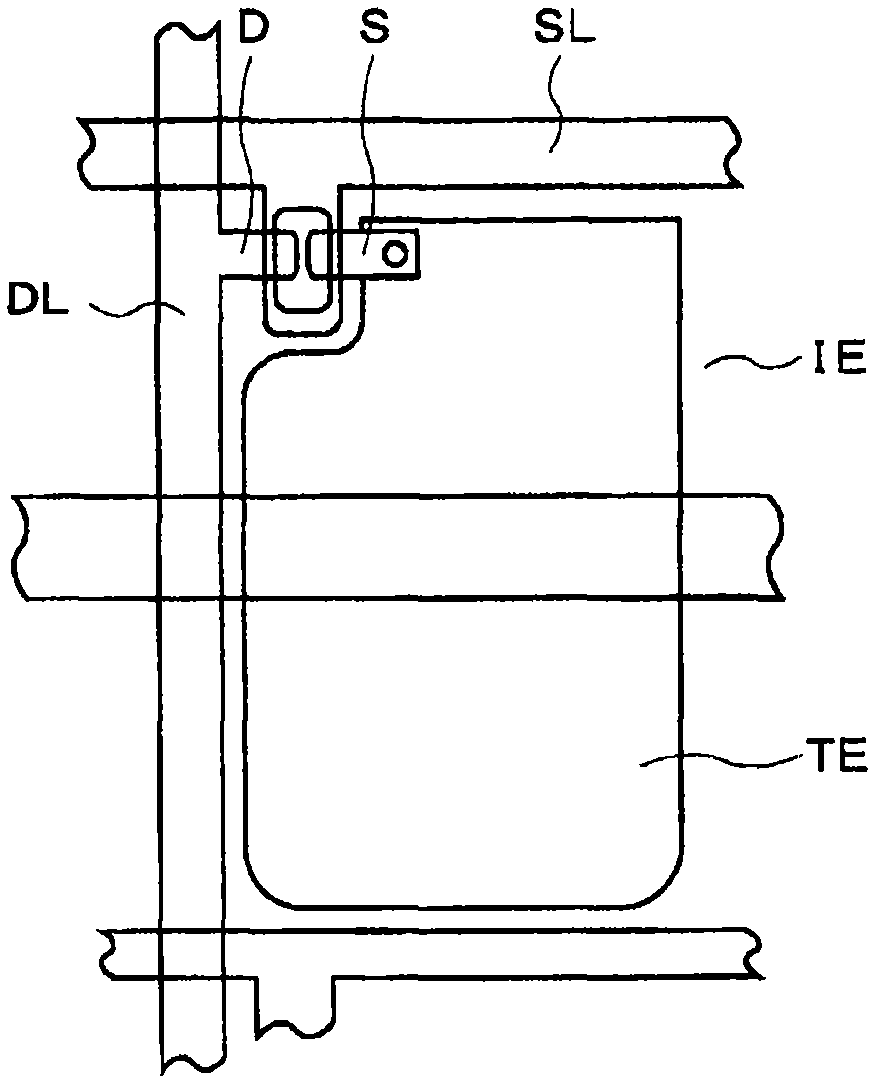

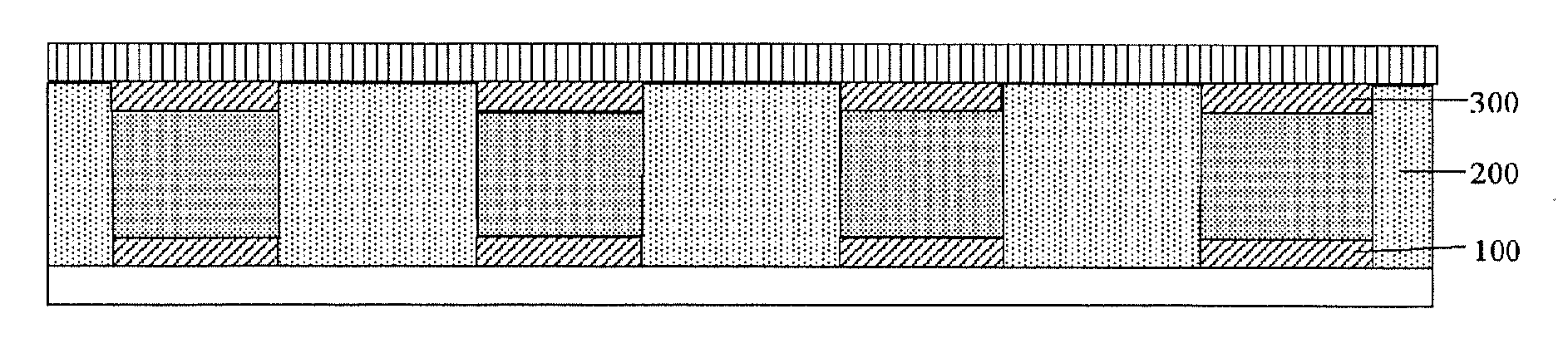

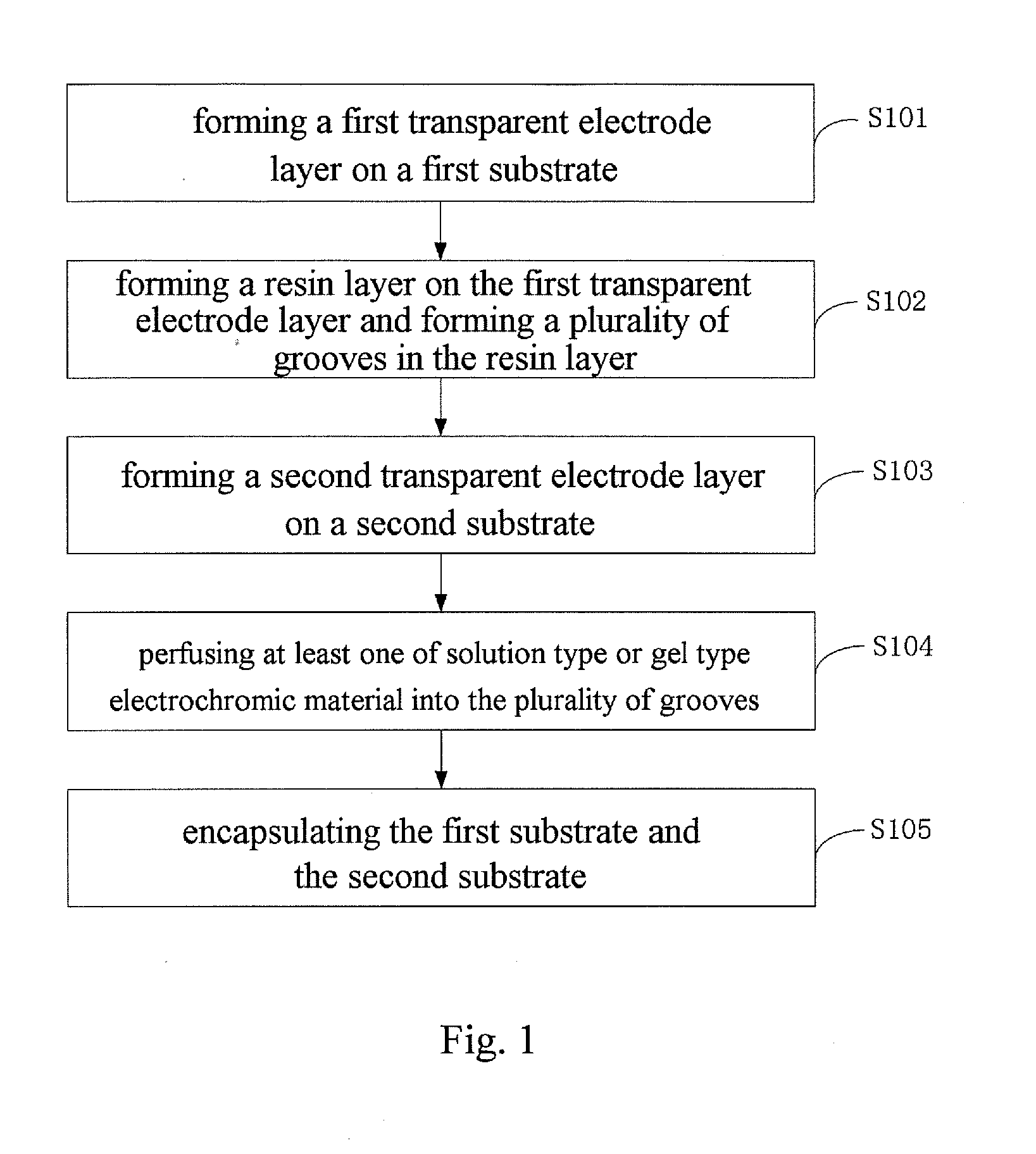

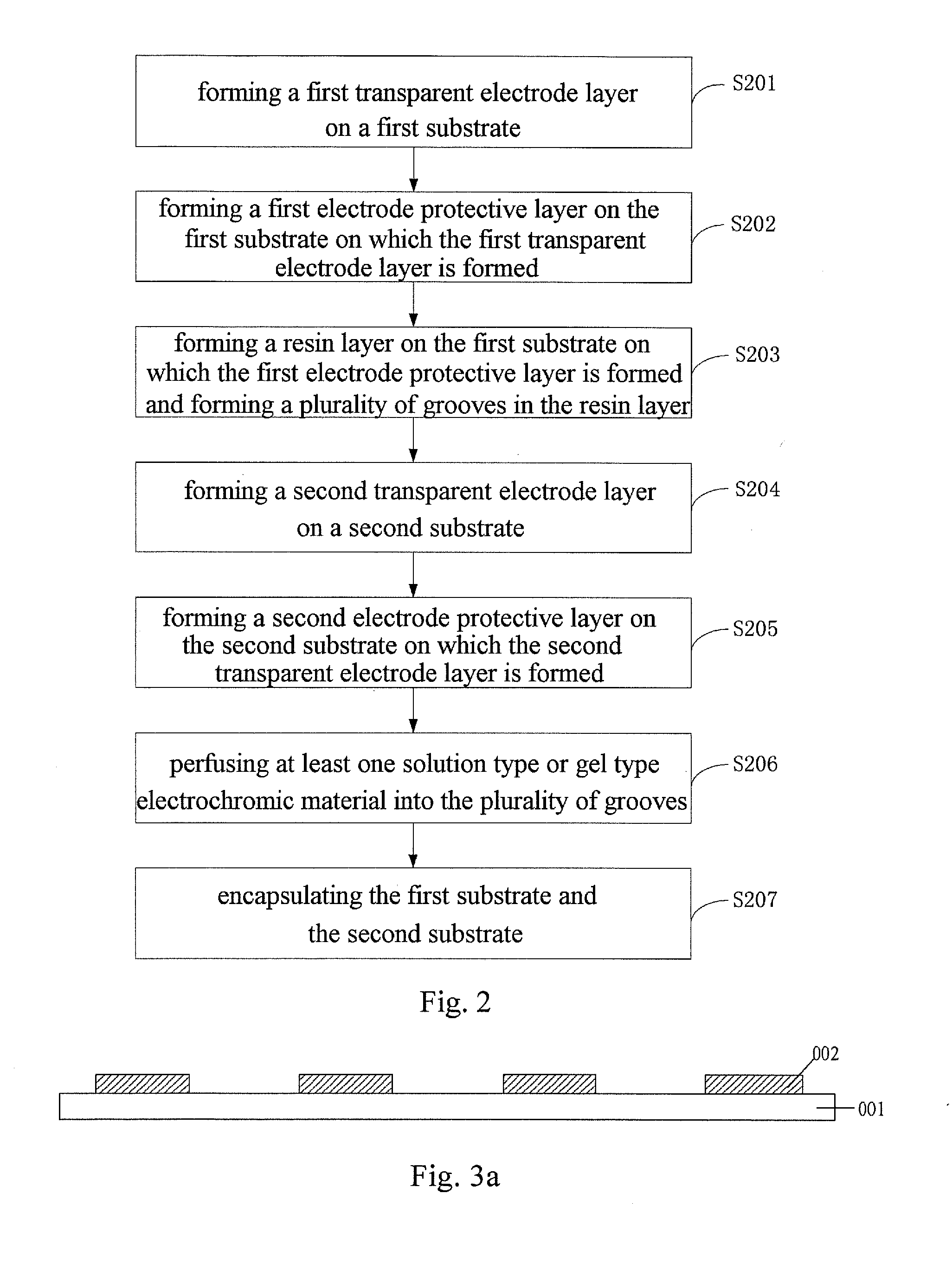

Electrochromic grating, manufacturing method thereof, display panel and display device

InactiveUS20160370679A1Increase contrastImprove the display effectNon-linear opticsOptical elementsElectricityGrating

The embodiments of the present invention disclose an electrochromic grating, a manufacturing method thereof, a display panel and a display device. The method of manufacturing the electrochromic grating comprises: forming a first transparent electrode layer on a first substrate; forming a resin layer on the first transparent electrode layer and forming a plurality of grooves in the resin layer; forming a second transparent electrode layer on a second substrate; perfusing at least one of solution type or gel type electrochromic material into the plurality of grooves; and then, encapsulating the first substrate and the second substrate. In this way, by using the at least one of solution type or gel type electrochromic material filled in the grooves, the conversion speed of the electrochromic grating between the transparent state and the colored state can be increased, the conversion response speed of the display panel between 2D picture and 3D picture can be further increased, so as to realize a higher contrast, thereby improving the display effect.

Owner:BOE TECH GRP CO LTD +1

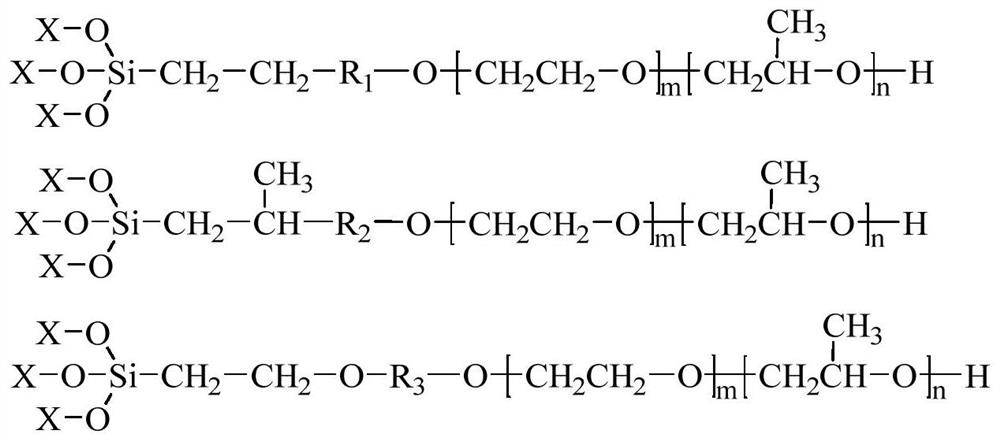

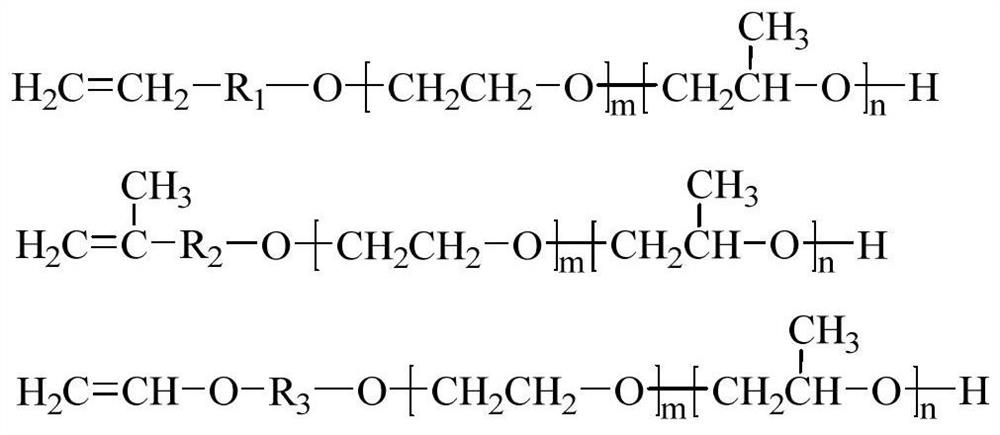

Water-based cutting fluid for diamond wire cutting and preparation method and use method thereof

ActiveCN112877124AAvoid disconnectionAvoid reunionFinal product manufactureLubricant compositionWire cuttingSilica fume

The invention relates to a water-based cutting fluid for diamond wire cutting and a preparation method and a use method thereof. The cutting fluid is mainly prepared from the following components in parts by weight: 8-33 parts by weight of silicone modified polyether; 3-7 parts by weight of a silane hydrolysis inhibiting stabilizer; and the balance of water, wherein the total weight part is 100. By implementing the embodiment of the invention, the cutting fluid has the following beneficial effects that the cutting fluid has a low-foam self-defoaming function, and a defoaming agent component does not need to be additionally added; the silicon modified polyether can be subjected to hydrolysis endothermic reaction on a cutting contact interface, and heat which cannot be taken away in time in the cutting process is balanced; meanwhile, the hydrolyzed silicon hydroxyl has a strong adsorption effect and can play roles in protecting the diamond wire, enhancing the lubricating property, reducing the cutting resistance and reducing the wire breakage probability; the dispersion of silicon powder is enhanced and the silicon powder is enabled not to be agglomerateand, active sites on the surface of the silicon powder are adsorbed and combined in time so that the problem of spontaneous combustion caused by high reaction activity of the filter-pressing silicon powder is avoided.

Owner:武汉宜田科技发展有限公司

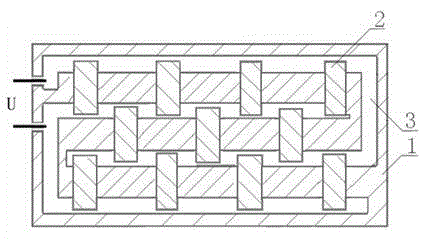

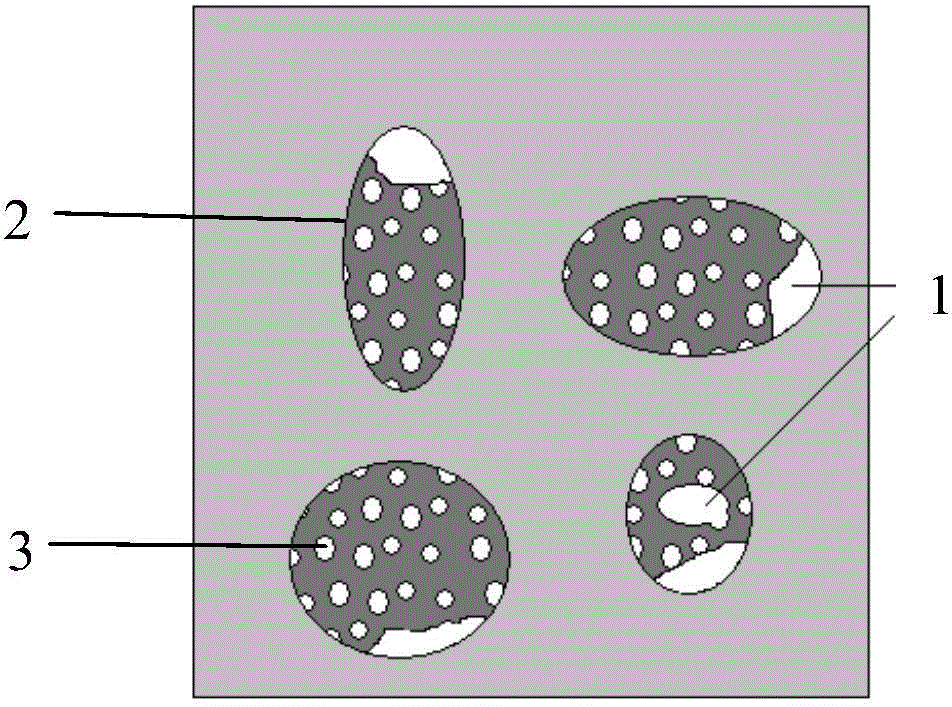

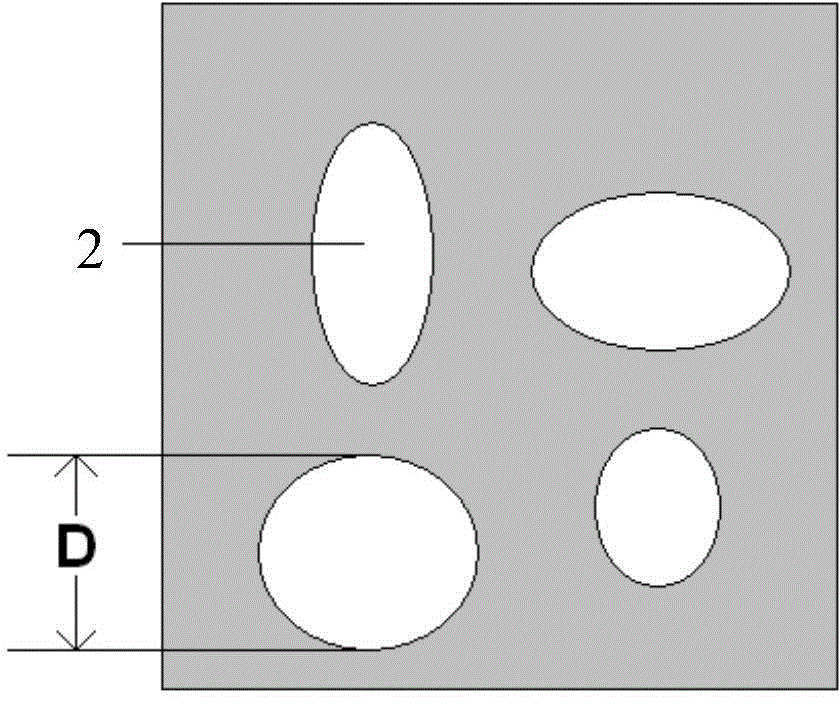

Multistage micropore composite electrode material and manufacturing method thereof

InactiveCN105280392AHigh specific surface areaHigh energy storage densityHybrid capacitor electrodesHybrid/EDL manufactureLarge poreCharge and discharge

The invention relates to a multistage micropore composite electrode material and a manufacturing method thereof. A structure is a three-dimensional pore structure. The material is characterized in that a small pore material possessing a three-dimensional mesh structure and a large pore material possessing the three-dimensional mesh structure are mutually wrapped; the small pore material is filled in pores of the large pore material and incompletely-filled gaps exist in the pores of the large pore material. The manufacturing method of the electrode material comprises the following steps that the large pore material possessing the three-dimensional mesh structure is dipped in a hydrogel solution so that the hydrogel solution is filled in large pores possessing the three-dimensional mesh structure; and then, the hydrogel is solidified so as to form a three-dimensional small gap material; during a solidified process, the size of the hydrogel is contracted to a certain degree so that unfilled gaps exist in the large pores. The material and the method have the advantages that the composite electrode material possesses a high specific surface area (high energy storage density) and rapid ion migration and diffusion speeds (short charge and discharge time); a manufacturing technology is simple and material cost is low.

Owner:黄辉 +2

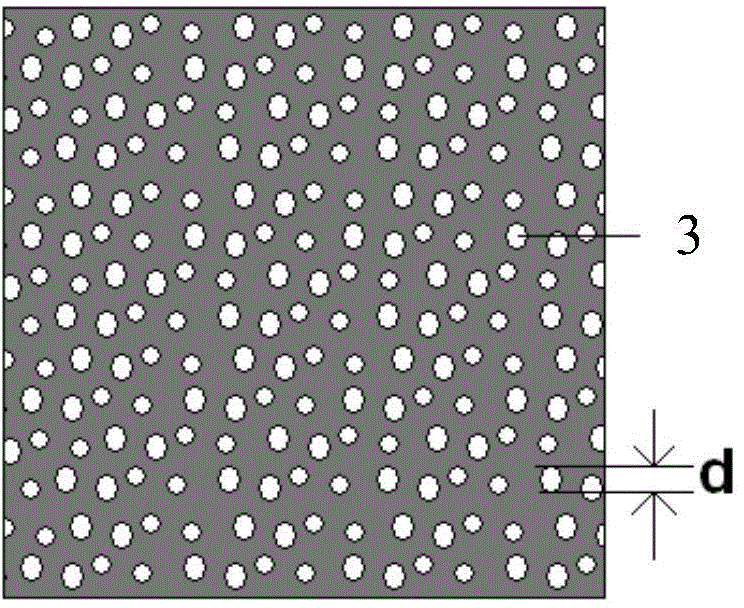

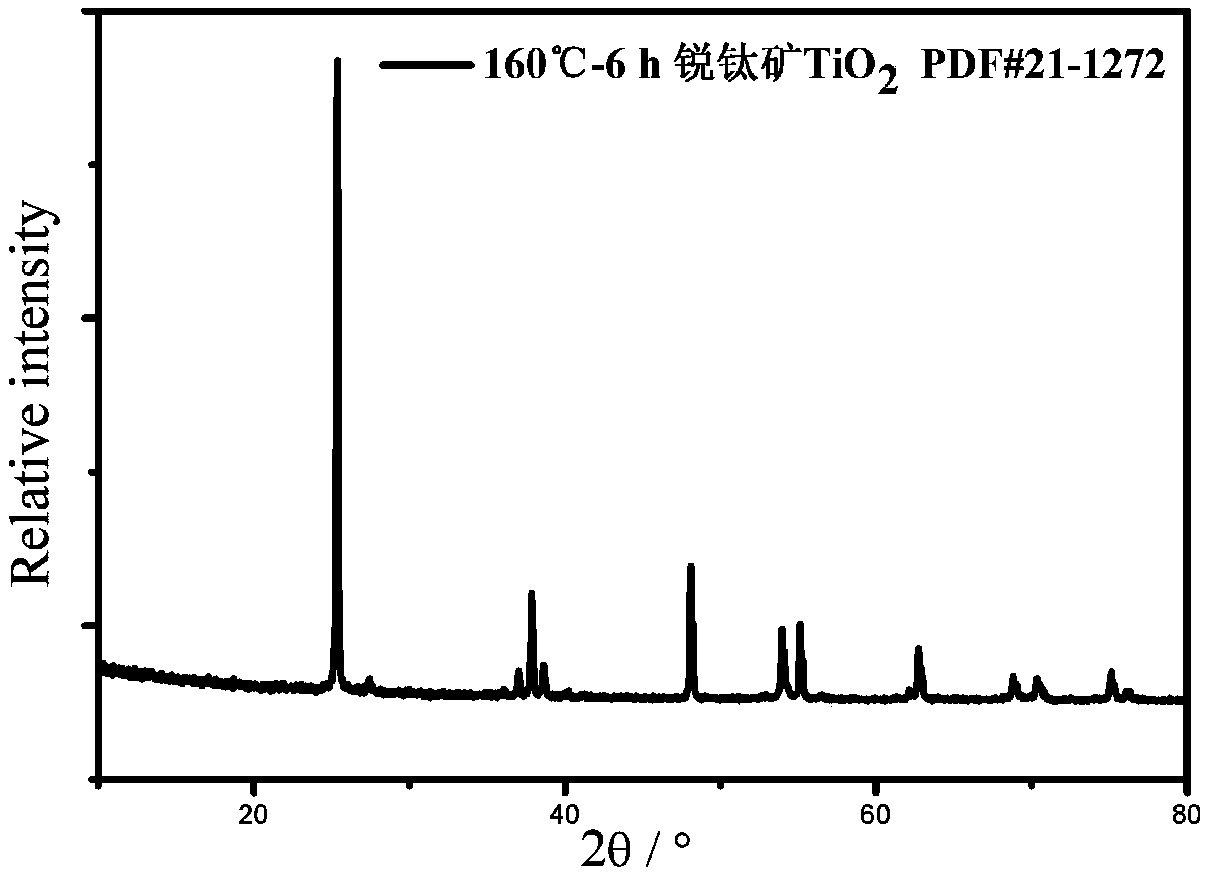

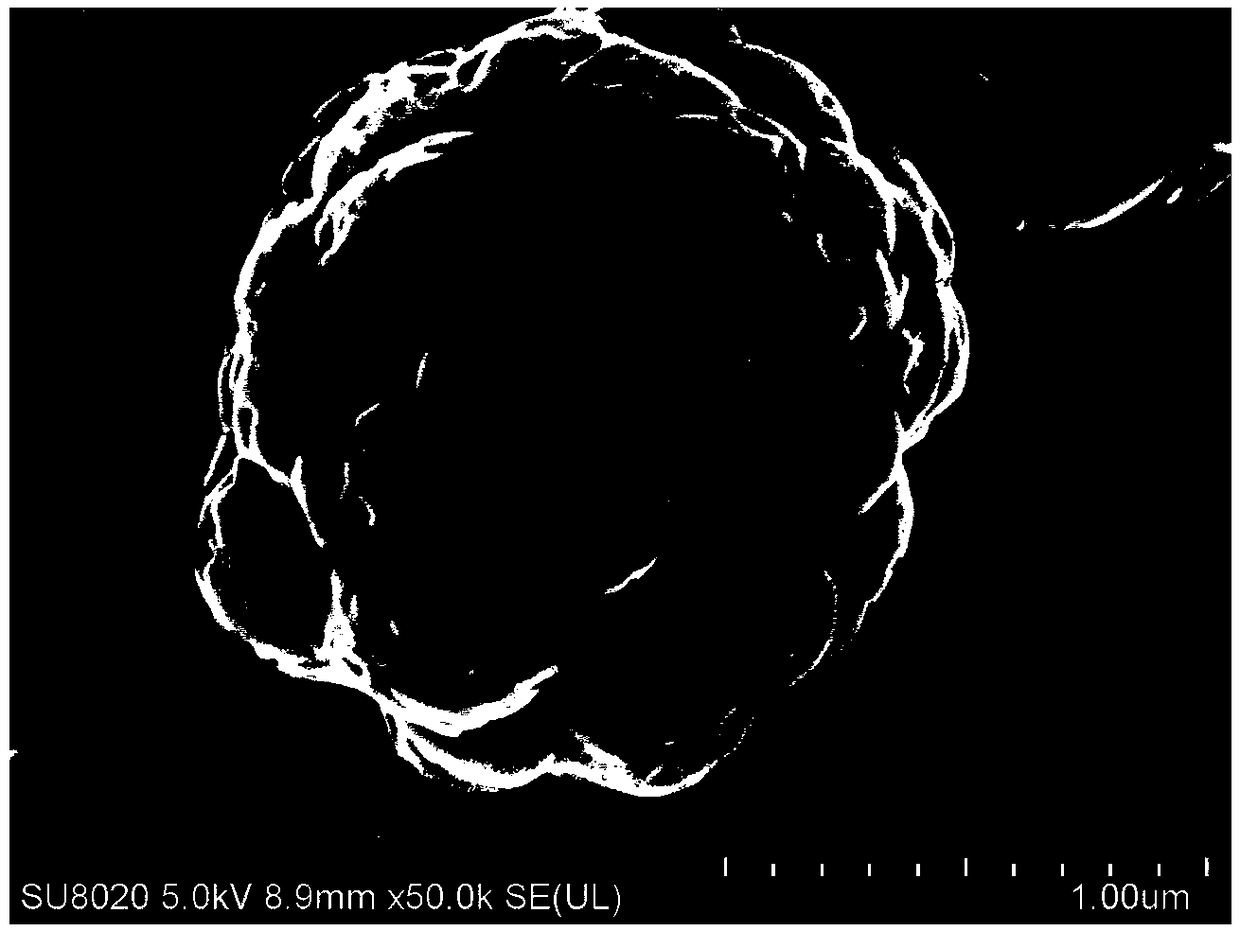

Porous flower-petal-shaped anatase TiO2 nano-crystal thin film and preparation method thereof

ActiveCN109046302AShape is easy to controlImprove bindingCatalyst activation/preparationPetalPhotoelectrochemistry

The invention relates to the technical field of preparation of nano-materials and photoelectrochemistry and in particular discloses a porous flower-petal-shaped anatase TiO2 nano-crystal thin film anda preparation method thereof. The porous flower-petal-shaped anatase TiO2 nano-crystal thin film is prepared by adopting hydrothermal synthesis and high-temperature crystallization methods; the prepared thin film is composed of porous TiO2 nano-crystals and has the advantages of large specific surface area and low compounding probability of photoelectron cavities; the TiO2 nano-crystal thin filmis an anatase phase and has a strong photoelectron cavity oxidization capability; the TiO2 nano-crystal thin film is obtained by direct hydrothermal growth of a Ti substrate and is combined with the substrate very well; the TiO2 nano-crystal thin film has relatively low charge migration resistance and the thin film does not easily fall off.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com