Water-based cutting fluid for diamond wire cutting and preparation method and use method thereof

A diamond wire and cutting fluid technology, applied in the petroleum industry, climate sustainability, final product manufacturing, etc., can solve the problems of poor yield index of cutting silicon wafer line marks, difficulty in dispersing silicon powder, and dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

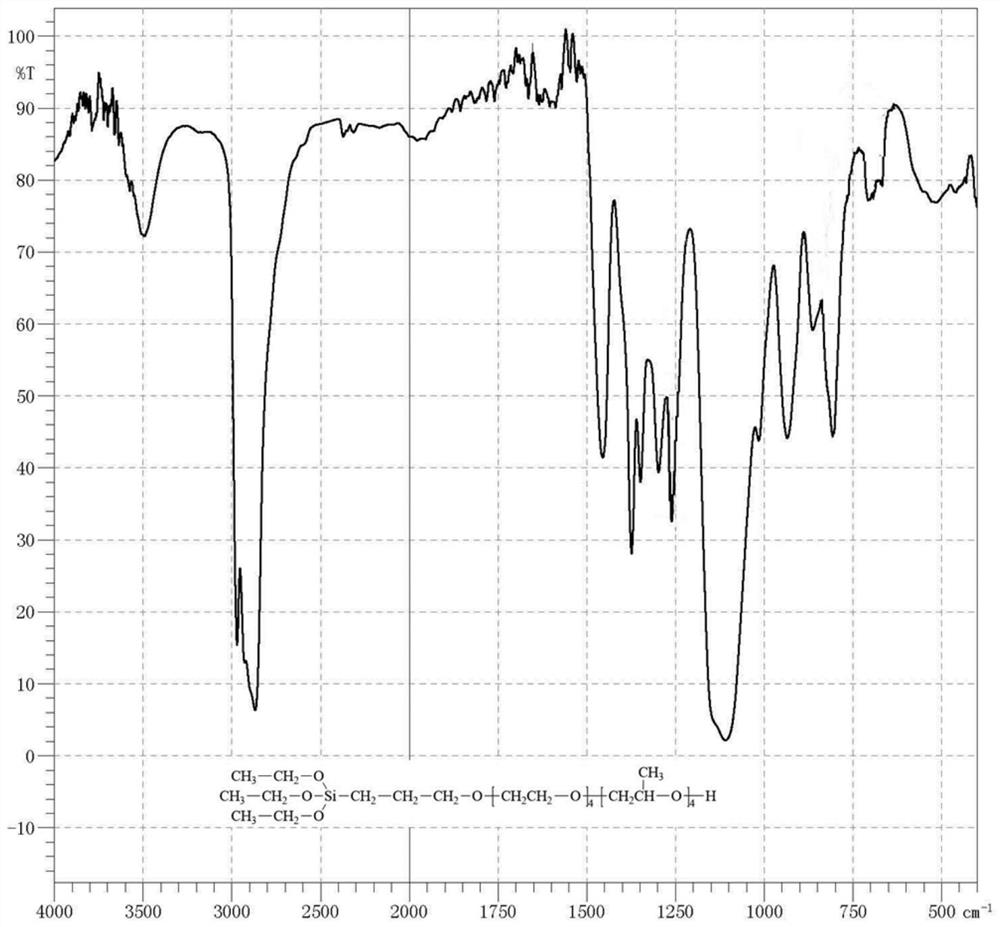

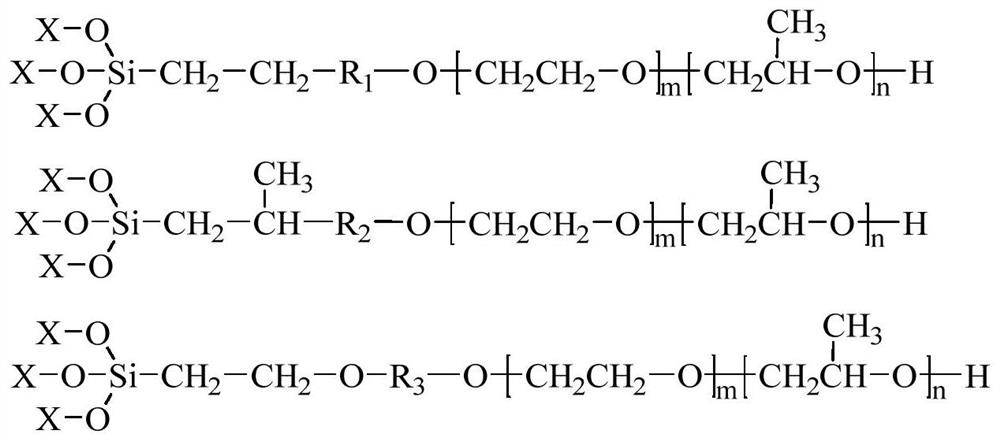

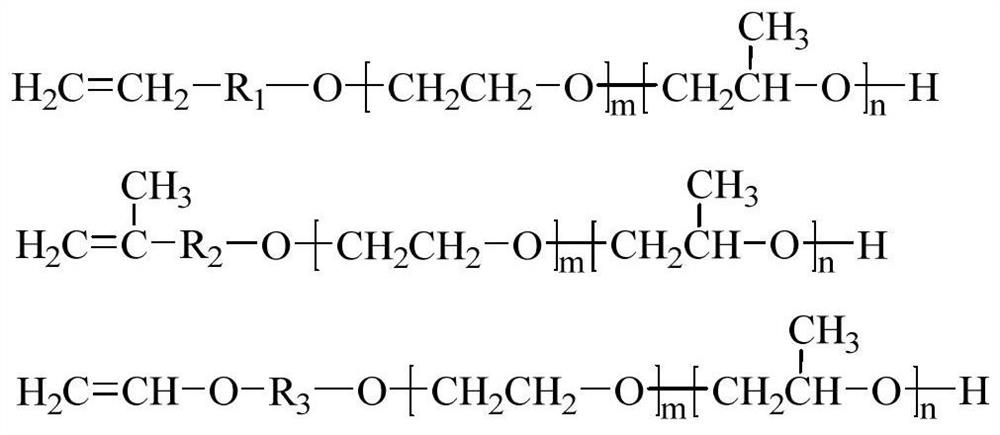

Method used

Image

Examples

Embodiment 1

[0025] The weight portion of formula is as follows (total weight portion is 100):

[0026] Silicon modified polyether: 22.5

[0027] Xylitol: 4.5

[0028] water: balance

[0029] The silicon modifier of the silicon-modified polyether is triethoxysilane, and the polyether is acryl polyoxyethylene polyoxypropylene ether (m=4, n=4).

Embodiment 2

[0031] The weight portion of formula is as follows (total weight portion is 100):

[0032] Silicon modified polyether: 18

[0033] Sorbitol: 6

[0034] water: balance

[0035] The silicon modifier of the above-mentioned silicon-modified polyether is triethoxysilane, and the polyether is methylenyl polyoxyethylene polyoxypropylene ether (m=4, n=6).

Embodiment 3

[0037] The weight portion of formula is as follows (total weight portion is 100):

[0038] Silicon modified polyether: 18.5

[0039] Glucitol: 5.5

[0040] water: balance

[0041] The silicon modifier of the silicon-modified polyether is triethoxysilane, and the polyether is vinyl butanediol ether polyoxyethylene ether polyoxypropylene ether (m=8, n=6).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com