Patents

Literature

573 results about "Black silicon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Black silicon is a semiconductor material, a surface modification of silicon with very low reflectivity and correspondingly high absorption of visible (and infrared) light. The modification was discovered in the 1980s as an unwanted side effect of reactive ion etching (RIE). Other methods for forming a similar structure include electrochemical etching, stain etching, metal-assisted chemical etching, and laser treatment (which is developed in Eric Mazur's laboratory at Harvard University), and FFC Cambridge process (an electrochemical reduction process). Black silicon has become a major asset to the solar photovoltaic industry as it enables greater light to electricity conversion efficiency of standard crystalline silicon solar cells, which significantly reduces their costs.

High-temperature (800 DEG C) wear-resistant paint and preparation method thereof

The invention discloses high-temperature (800 DEG C) wear-resistant paint and a preparation method thereof. The high-temperature wear-resistant paint comprises a component 1 and a component 2, wherein the component 1 is prepared by mixing a component A and a component B; the component A in the component 1 comprises the following components: black silicon carbide, fine-grain aluminum oxide, dispersing agent, zinc oxide, modified epoxy resin, flatting agent and an auxiliary material; the component B in the component 1 comprises the following components: organic silicon modified epoxy resin, a filler, antimony trioxide, film-forming assistant and thickener; and the component 2 is curing agent and coupling agent. The high-temperature (800 DEG C) wear-resistant paint is prepared by the following steps: mixing the component A and the component B in the component 1, and curing the component 1 with the component 2. The high-temperature wear-resistant paint is prepared by compounding the double components, has excellent high temperature resistance and wear resistance, and also has the fine properties of favorable hardness, high heat stability, ductility, workability and the like. The invention also designs the method for preparing the high-temperature wear-resistant paint. The preparation method is simple and low in cost.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

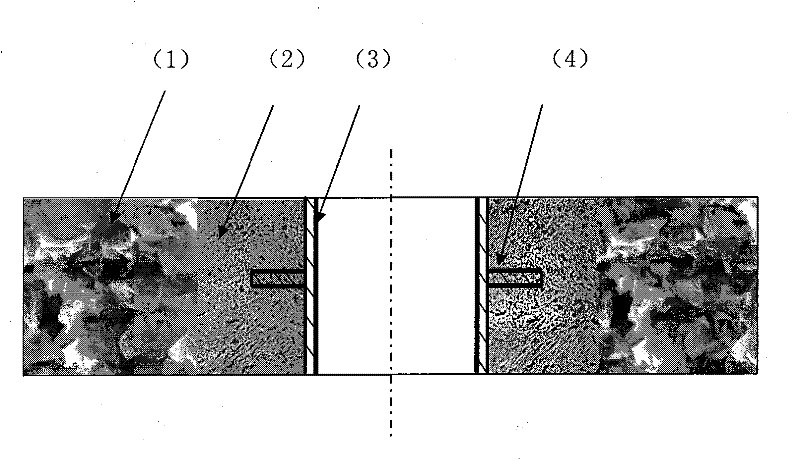

High-speed resin heavy-load grinding wheel

InactiveCN102161183AImprove mechanical propertiesImprove automationAbrasion apparatusGrinding devicesFiberZirconia alumina

Owner:江苏华东砂轮有限公司

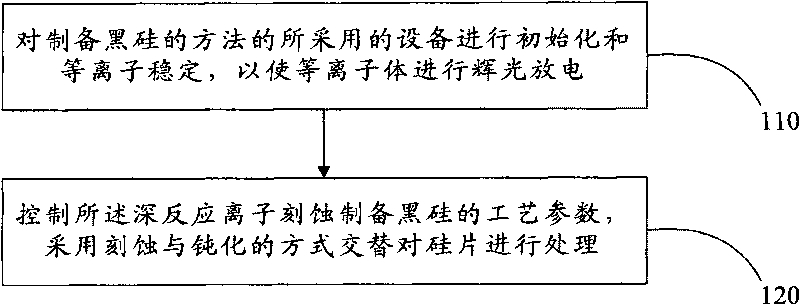

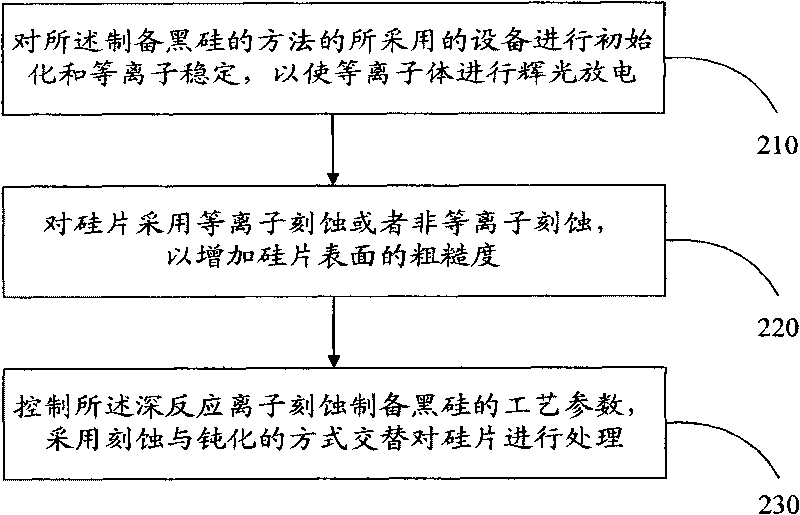

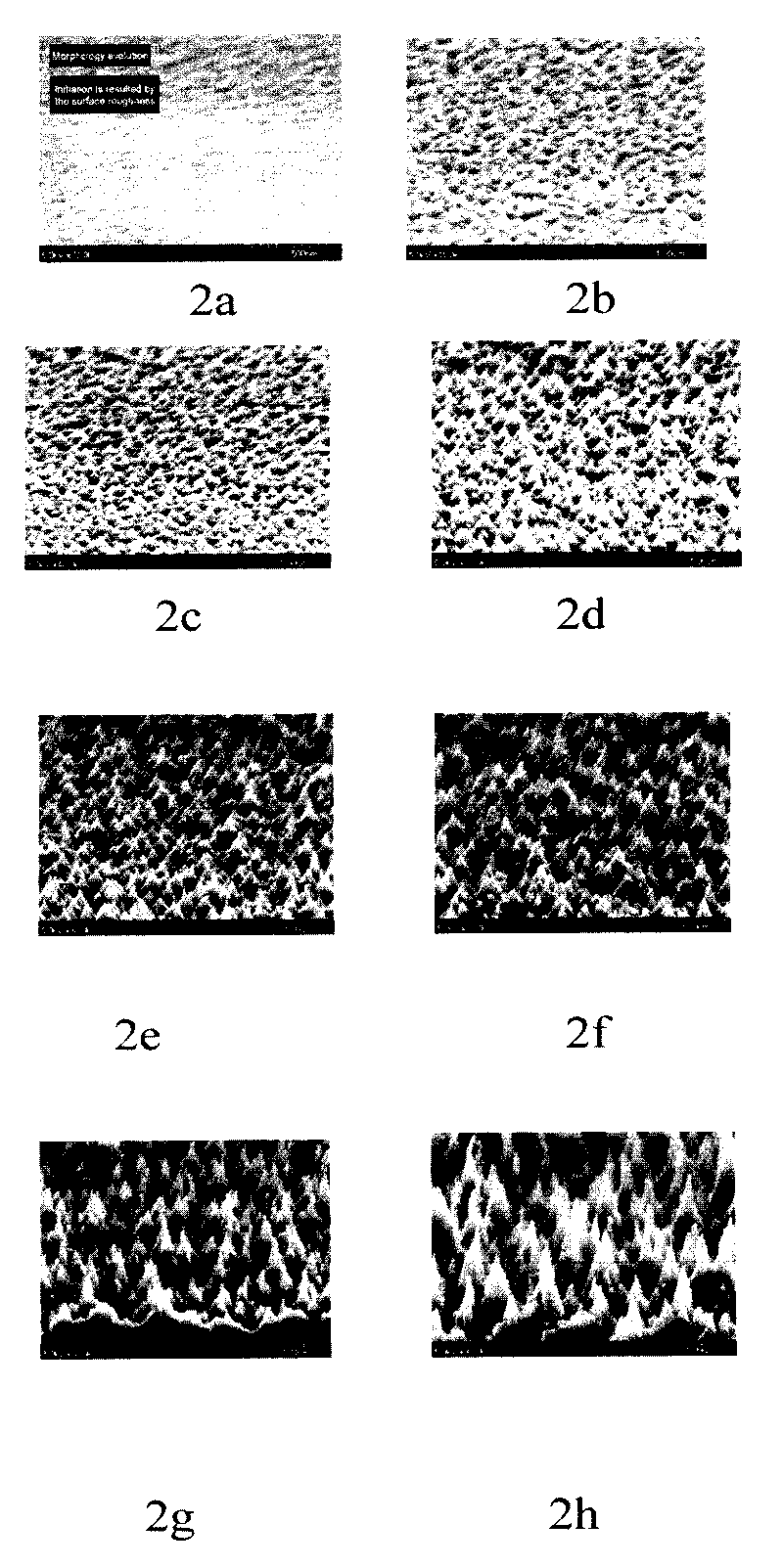

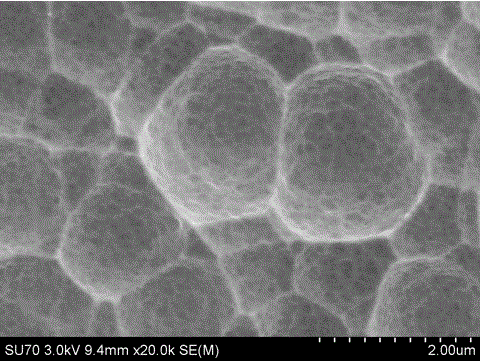

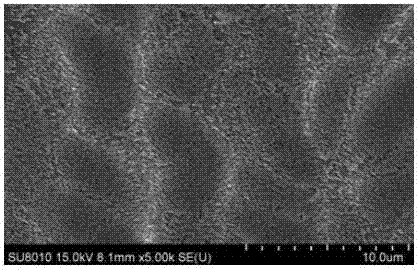

Maskless method for preparing black silicon by deep reactive ion etching

ActiveCN101734611AImprove efficiencyWon't breakNanostructure manufactureDecorative surface effectsNanostructureLarge range

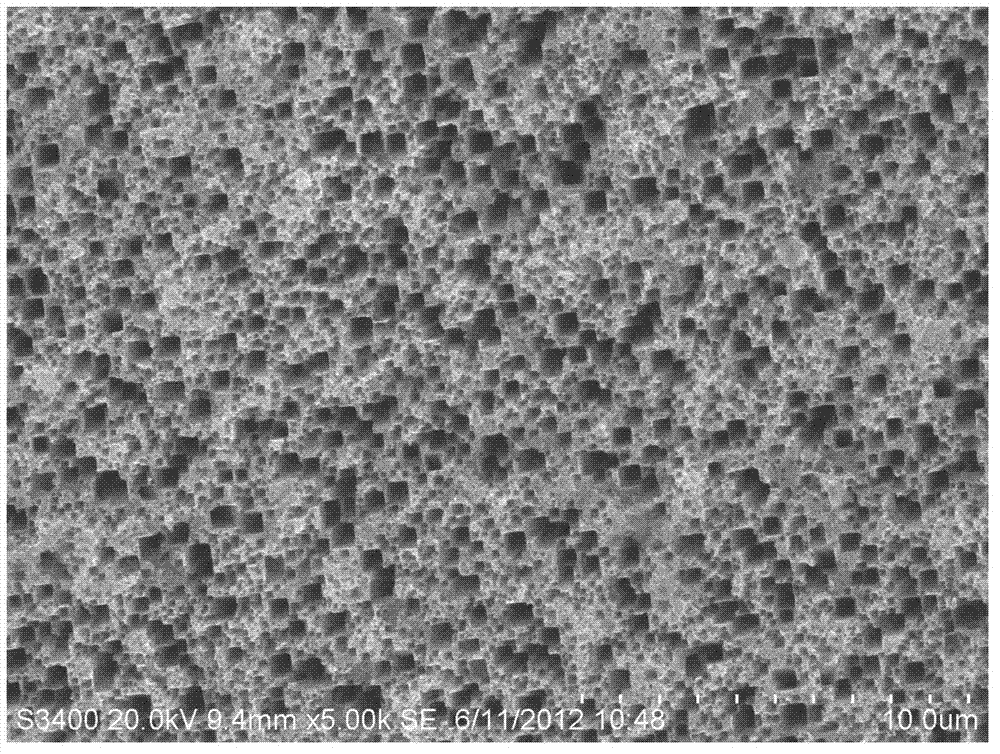

The invention discloses a maskless method for preparing black silicon by deep reactive ion etching, which comprises the following steps: performing initialization and plasma stability on equipment adopted by the method for preparing the black silicon so as to make plasma perform glow discharge; and controlling technological parameters for preparing the black silicon by deep reactive ion etching, and adopting etching and passivating modes to alternately process a silicon chip, wherein the parameters comprise plasma gas flow, panel etching power, panel passivating power, coil power, and etching and passivating cycle and temperature. The maskless method directly performs plasma processing on the surface of the silicon chip, and can generate large-range high-intensity nanostructures on the surface of the silicon chip in case of no nano mask by adjusting and selecting proper etching technological parameters. Meanwhile, the method for preparing the black silicon has high efficiency and low cost, and can be integrated with other micro-fabrication technology.

Owner:PEKING UNIV

Resin abrasive cutting wheel and manufacturing method thereof

ActiveCN102343558AHigh strengthImprove cutting effectBonded abrasive wheelsGrinding devicesCarbideGrinding wheel

The invention provides a resin abrasive cutting wheel and a manufacturing method thereof, belonging to the field of grinding tools. The resin abrasive cutting wheel solves the problem that the traditional brown corundum resin grinding wheel has low cost but bad cutting performance. The resin abrasive cutting wheel comprises a grinding body and a reinforcing sheet which is arranged inside the grinding body to reinforce the rotation strength of the grinding body, wherein the grinding body comprises the following raw materials in proportions by weight: 62-70% of brown corundum, 4-10% of black silicon carbide, 18-20% of phenolic resin and the balance of packing. The invention also provides a manufacturing method of the resin abrasive cutting wheel. According to the manufacturing method, the cutting performance of the abrasive cutting wheel is increased by increasing a special proportion of black silicon carbide under the condition that the cost is not increased.

Owner:NINGBO DAHUA GRINDING WHEEL

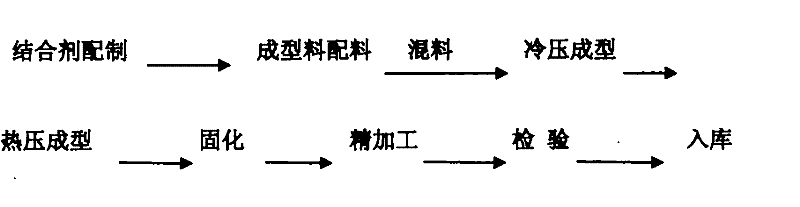

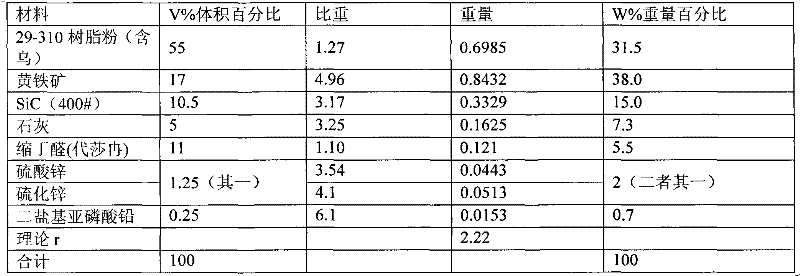

Large-standard high-speed resin heavy duty grinding wheel for grinding steel billet

ActiveCN104625978AHigh tensile and flexural strengthImprove the lubrication effectAbrasion apparatusGrinding devicesFiberMaximum diameter

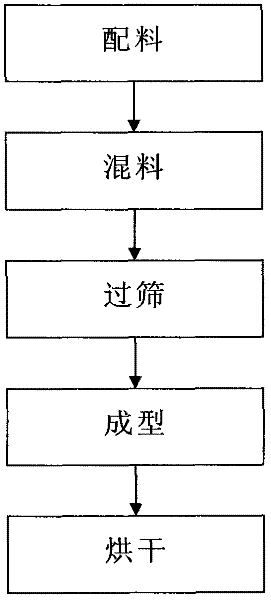

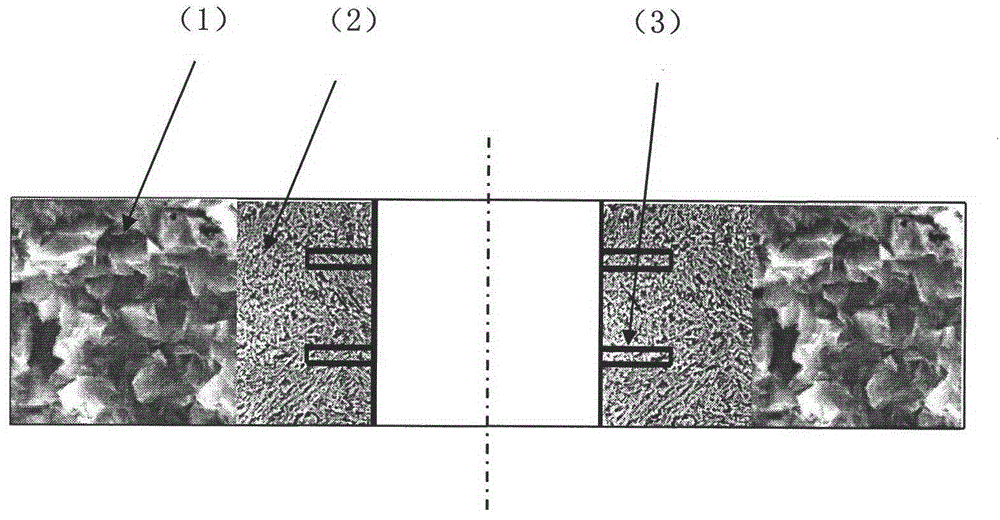

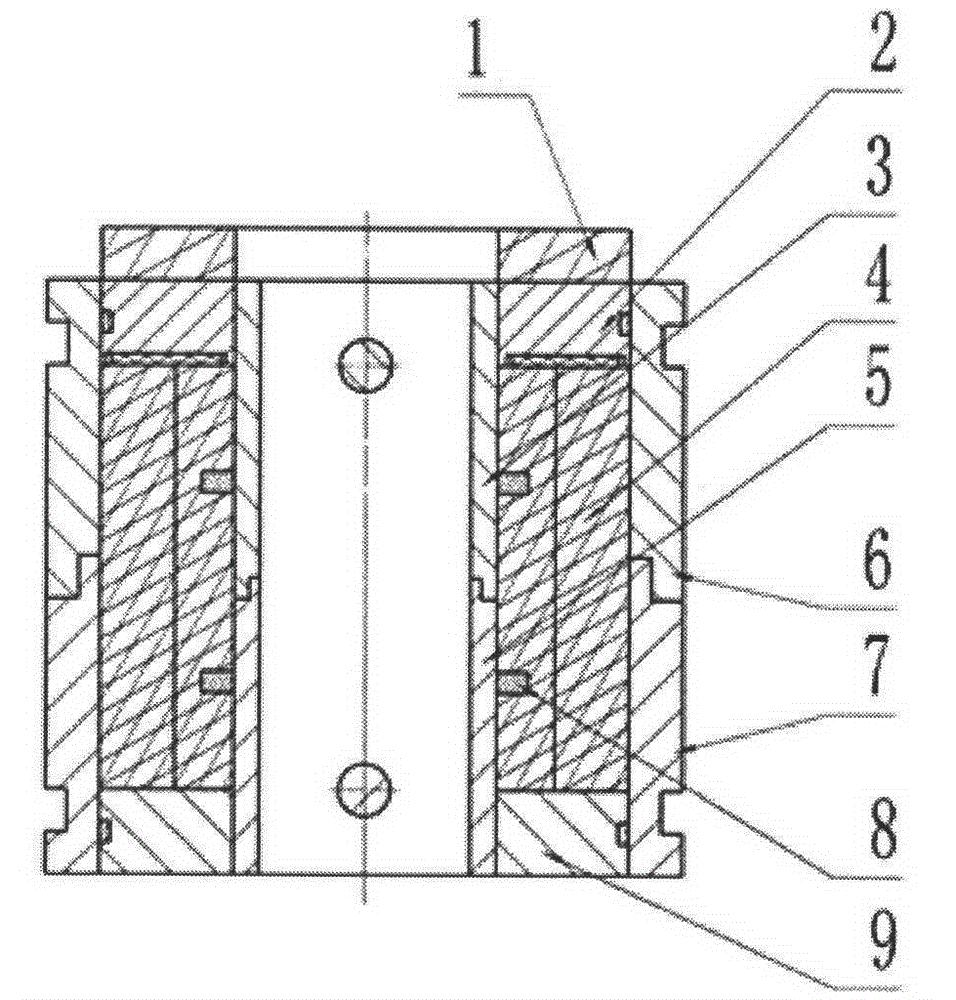

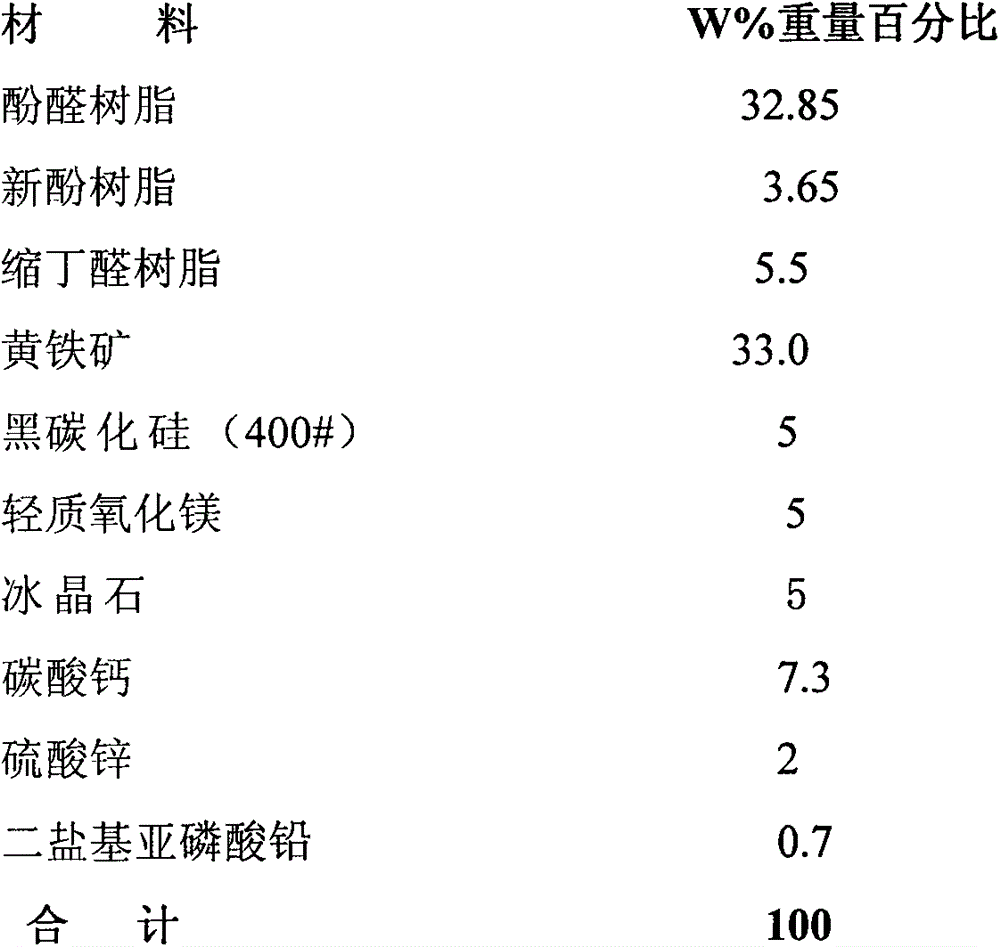

The preparation method for the large-standard high-speed resin heavy duty grinding wheel for grinding a steel billet comprises the steps that a dedicated binding agent for a high-performance modified high polymer matrix phenolic resin grinding wheel is prepared by using phenolic resin, xylok resin, butyral resin, iron pyrite, cryolite, light magnesium oxide, barite, 400 # carborundum and calcium carbonate, dedicated formulas for a grinding layer and a core layer are separately designed by using grinding materials such as fused alumina zirconia, aluminium oxide sintered corundum, black silicon carbide, furfural, dibutyl ester, fibers and steel rings, and the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is prepared by adopting a dual-phase reinforced composite technology and structure. According to the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet, the linear velocity is equal or greater than 90 m / s to 120 m / s, the maximum diameter is 925 mm, the thickness is 125 mm, and the tensile and breaking strength and the grinding efficiency of the grinding wheel are greatly improved. When the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is under heavy duty, the adaptability of the condition of grinding range is wide, and the linear velocity is high. The grinding efficiency reaches a thickness of 1 cm at a time, the problems that an existing grinding wheel cannot adapt to a steel billet, and the heavy duty grinding of steel is difficult are solved well, and the increasing development requirements of the iron and steel industry are met.

Owner:江苏华东砂轮有限公司

Silicon detector structure with broad spectral response and method of making same

InactiveCN102290481AWide spectral response rangeImprove absorption rateFinal product manufactureSemiconductor devicesSpectral responseSilicon detector

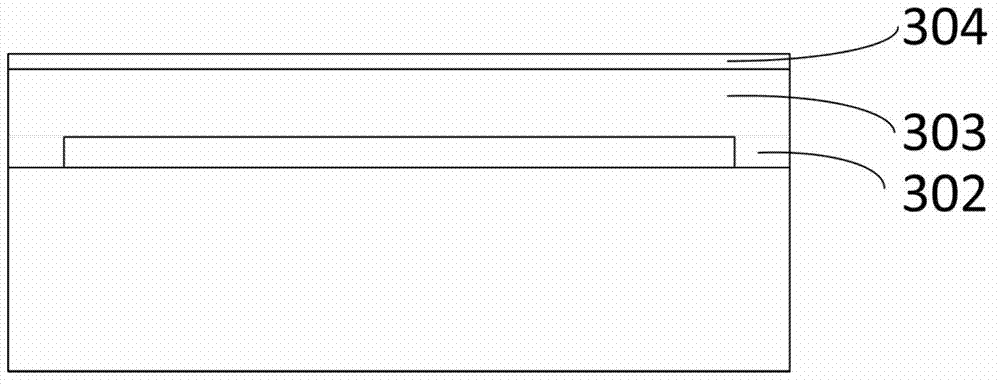

The invention relates to a silicon detector structure with a wide spectral response range, which comprises an n-type silicon substrate, a silicon dioxide medium masking layer, a p-type doping layer, a front surface contact electrode, an antireflection film layer, a broad-spectrum absorbing black silicon layer, a medium passivating layer and a back surface contact electrode, wherein a circular groove is arranged on the surface of the n-type silicon substrate; the silicon dioxide medium masking layer is formed around the circular groove on the surface of the n-type silicon substrate, and the middle of the silicon dioxide medium masking layer is an annular structure; the p-type doping layer is arranged in the circular groove of the n-type silicon substrate; the front surface contact electrode is produced on the inner wall of the annular structure of the silicon dioxide medium masking layer and covers the partial edge of the surface of the annular structure to form an annular structure; the antireflection film layer is produced in the annular structure of the front surface contact electrode and covers the surface of the p-type doping layer; the broad-spectrum absorbing black silicon layer is produced on the back surface of the n-type silicon substrate; the medium passivating layer is point-type and is formed on the surface of the broad-spectrum absorbing black silicon layer; and the back surface contact electrode is produced on the surface of the broad-spectrum absorbing black silicon layer and covers the point-type medium passivating layer.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

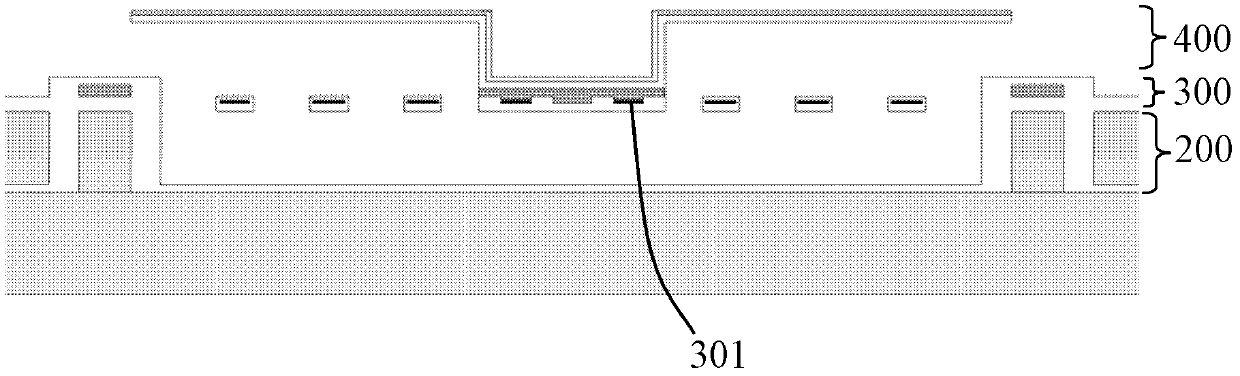

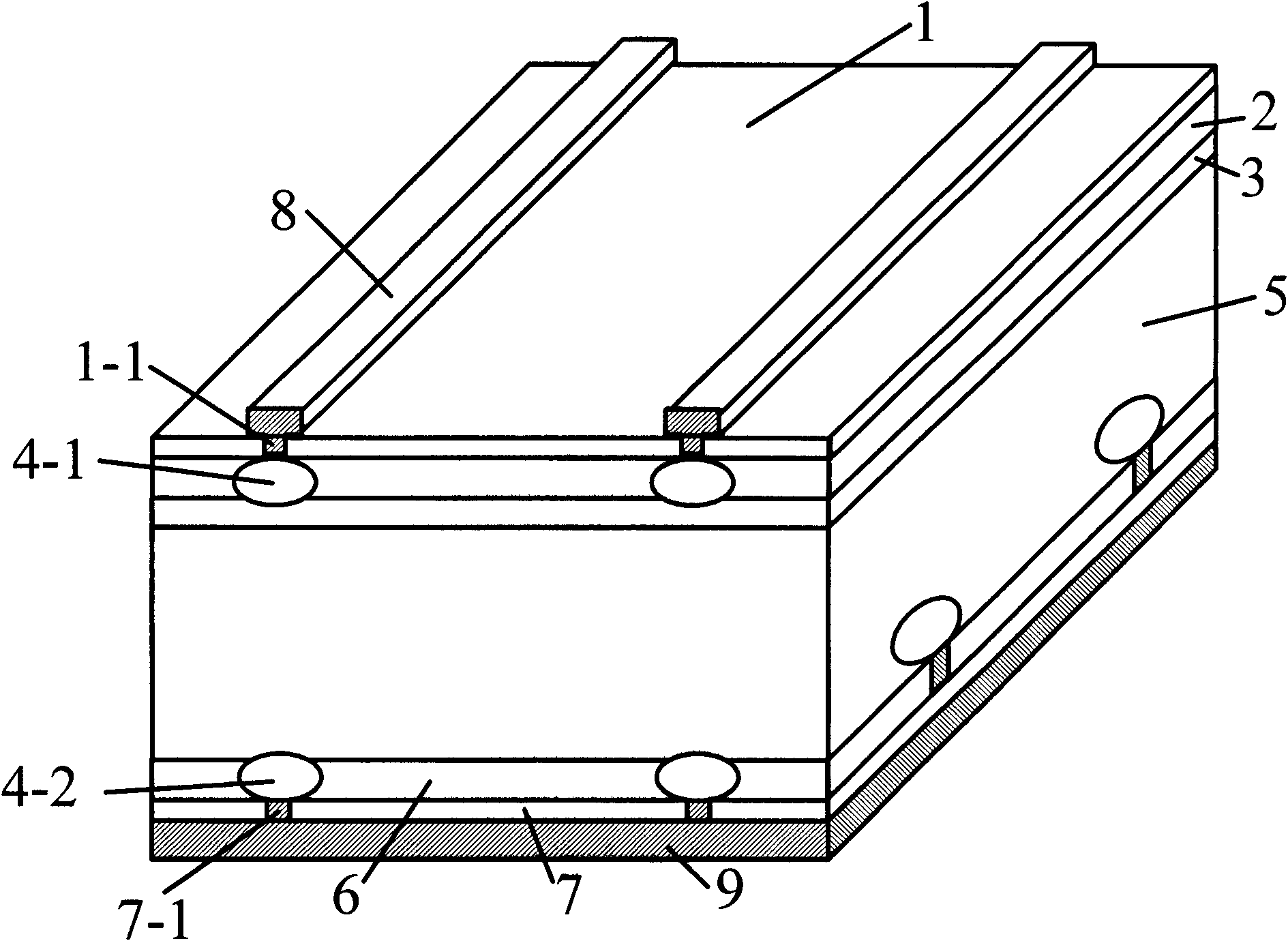

Thermopile infrared detector, array and preparation method of thermopile infrared detector

ActiveCN102901567AIncrease the absorption areaImprove response rateDecorative surface effectsCoupling light guidesThermopileThermocouple

The invention provides a thermopile infrared detector and an array thereof. The thermopile infrared detector comprises a supporting part, a thermocouple part and an infrared absorption part. The supporting part comprises a supporting column and a cavity, the thermocouple part is suspended above the supporting part, a cold end of the thermocouple part is connected with the supporting column, and the infrared absorption part is positioned above the thermocouple part and connected with a hot end of the thermocouple part. Correspondingly, the invention further provides a preparation method of the thermopile infrared detector. The infrared absorption part and the thermocouple part of the thermopile infrared detector are not coplanar, the area of the infrared absorption part is unlimited by thermocouple number, and the infrared absorption part can maximally cover the whole thermocouple part, so that infrared absorption efficiency can be improved. An infrared absorption layer is made of black silicon materials, the preparation method is compatible to semiconductor IC (integrated circuit) process, and accordingly preparation cost of the detector can be lowered.

Owner:中科芯未来微电子科技成都有限公司

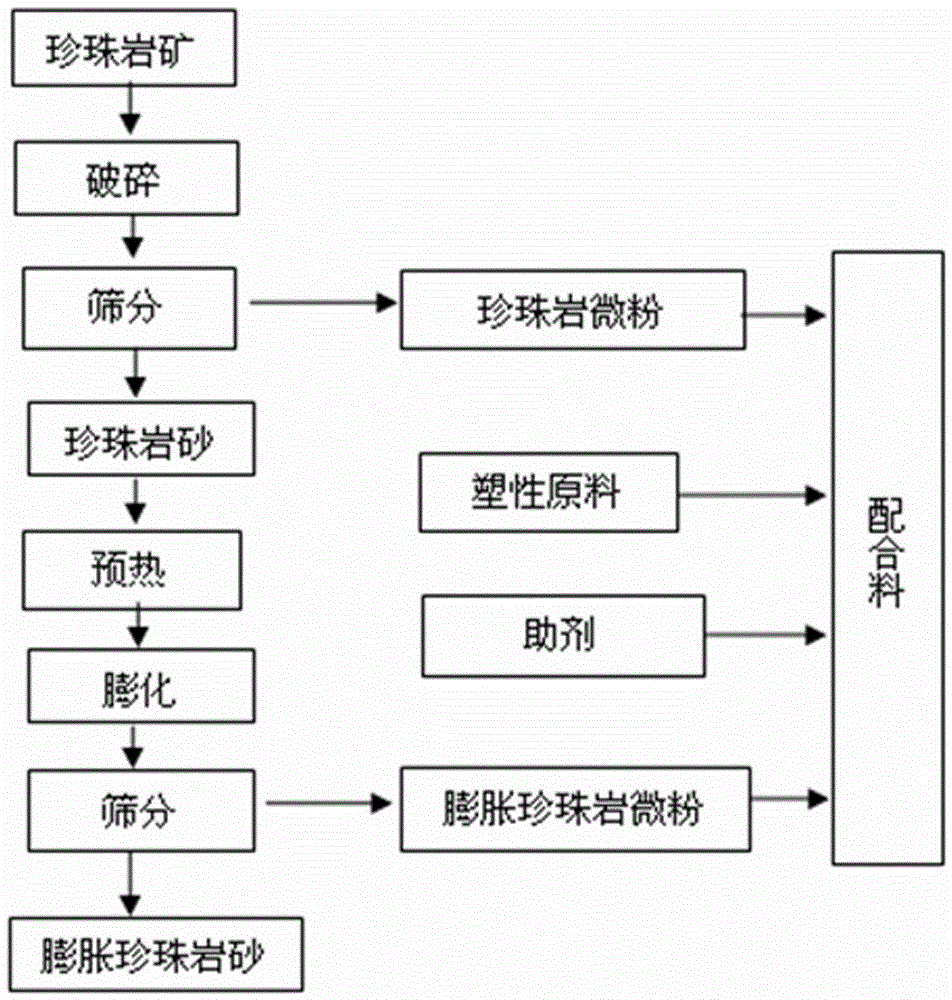

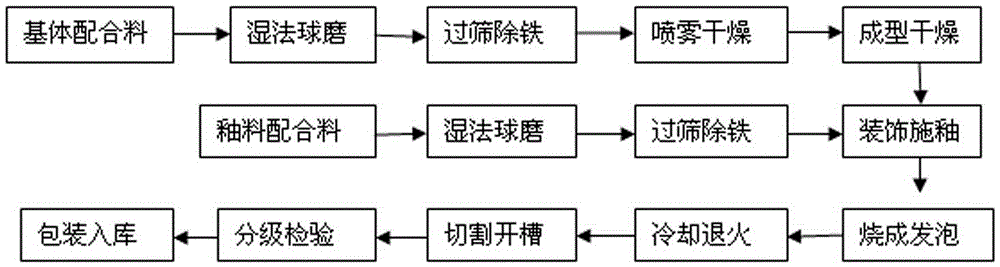

Thermal insulating decorative ceramic plate produced by comprehensive utilization of perlite waste and production method thereof

The invention discloses a thermal insulating decorative ceramic plate produced by comprehensive utilization of perlite waste and a production method thereof. A matrix formula consists of: 25%-100% of perlite micropowder, 20%-80% of expanded perlite micropowder, 2%-25% of Guangdong black mud, 0%-10% of limestone, 0.1%-5% of fluorite, 0.1%-2% of black silicon carbide, 0.5%-15% of bentonite, 0.1%-5% of sodium metasilicate nonahydrate, 0.1%-0.5% of sodium humate, and 0.1%-1.0% of sodium tripolyphosphate. A glaze formula consists of: 50-90% of expanded perlite powder, 50-90% of low temperature frit, 0.1-5% of zinc oxide, 0.1-5% of fluorite, 0-5% of apatite, 0.1-2.0% of sodium tripolyphosphate, 0.5-5% of kaolin, and 0.1-0.5% of sodium methyl cellulose. The production method is characterized by naked firing in a roller kiln at a low temperature of 900DEG C-1050DEG C. After firing, the thermal insulating decorative ceramic plate with a water absorption rate of less than 0.5%, a volume density of less than 500kg / m<3>, a rupture modulus of greater than 3.5Mpa, a thermal conductivity coefficient of less than 0.08 / W / (m.k), and a combustion level of A can be obtained.

Owner:XINYANG KEMEI NEW MATERIALS

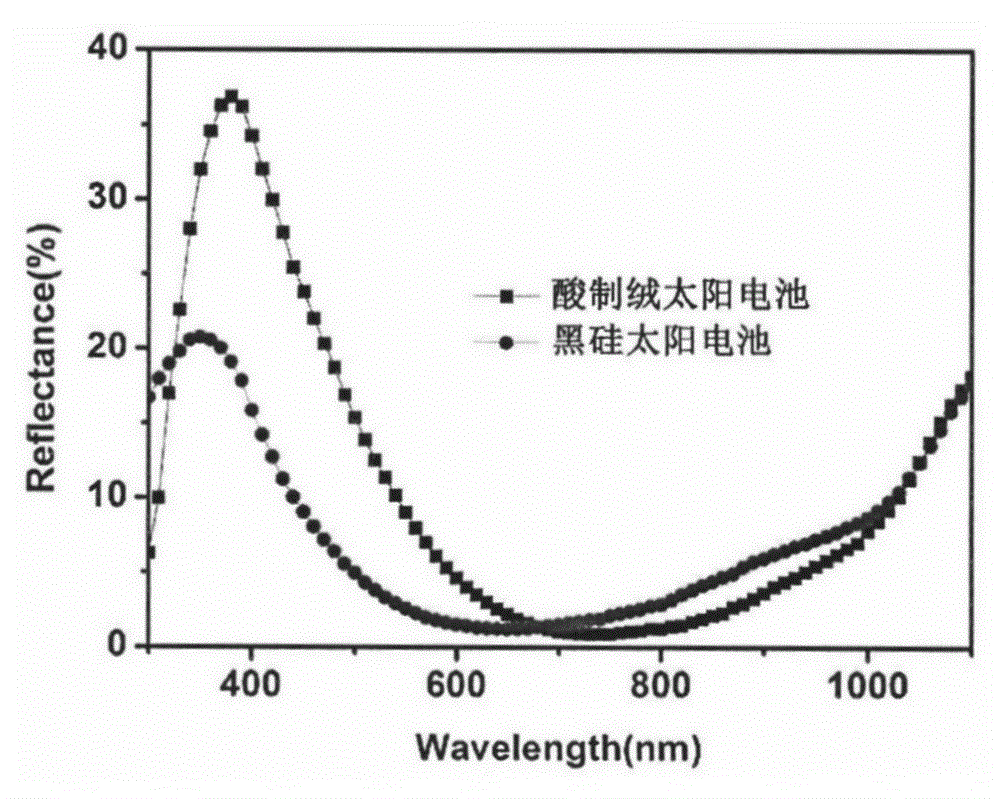

Method for preparing polycrystalline black silicon suede in single-sided by a metal catalytic chemical etching method

InactiveCN108179478AAbsorb moreImprove quantum efficiencyPolycrystalline material growthAfter-treatment detailsHigh surfaceSolar cell

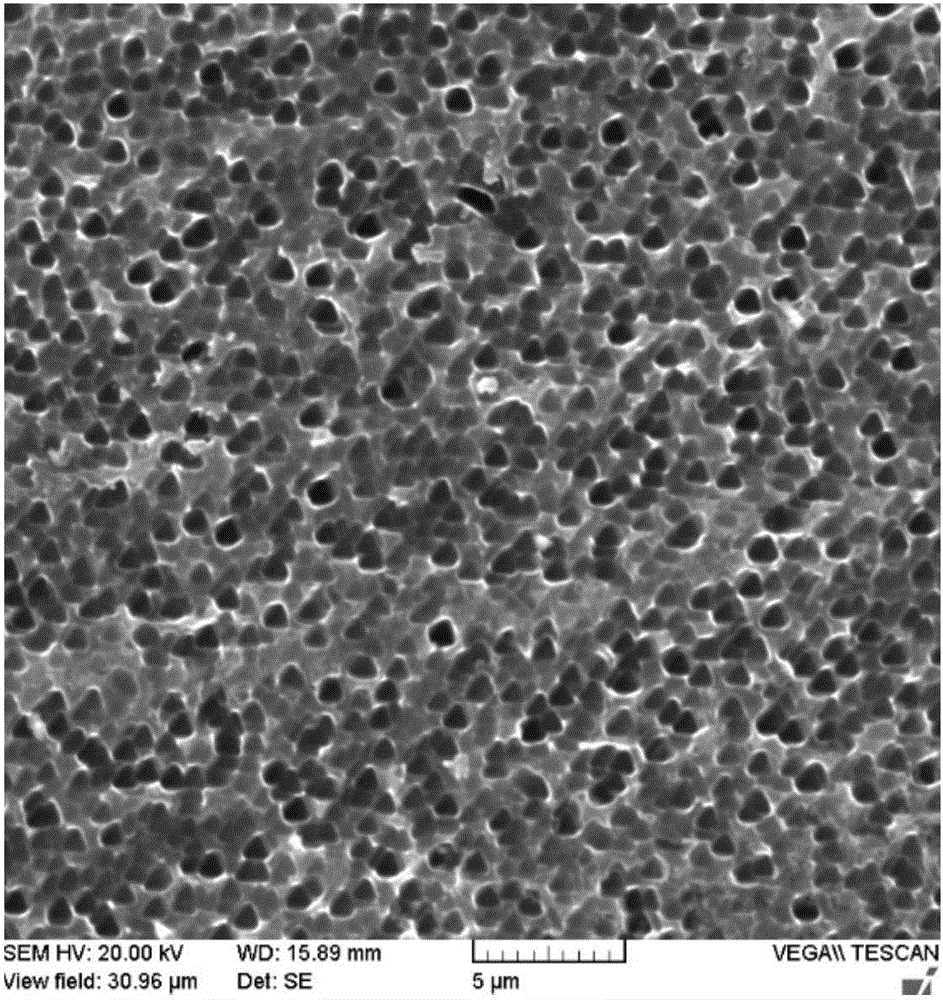

The invention relates to a method for preparing a polycrystalline black silicon suede in a single-sided by a metal catalytic chemical etching method. The method is characterized by comprising the following steps: (1) stacking two original silicon chips, and inserting in a same clamping groove; (2) removing a surface damage layer, and neutralizing in an acid pickling manner; (3) depositing silver particles in a hydrofluoric acid solution containing silver nitrate by using the silicon chips, corroding by using the hydrofluoric acid and hydrogen peroxide mixed solution, and forming a nanoscale hole on the crystal surface; (4) soaking the corroded silicon chip in the hydrogen peroxide and ammonia water mixed solution, and removing residual silver particles; (5) chambering the silicon chip in achambering solution, and expanding the nanoscale hole formed by the crystal surface to form a submicron order hole; (6) alkali cleaning, acid pickling, and cleaning the silicon chips, and separatingthe every two stacked silicon chips; and (7) acid pickling and cleaning the separated silicon chips, and drying the silicon chips. The suede structure obtained by the method provided by the inventionenables a battery to have an excellent antireflection effect, and by combining a passivation layer with high surface quality, an effective black silicon solar cell can be prepared.

Owner:WUXI SUNTECH POWER CO LTD

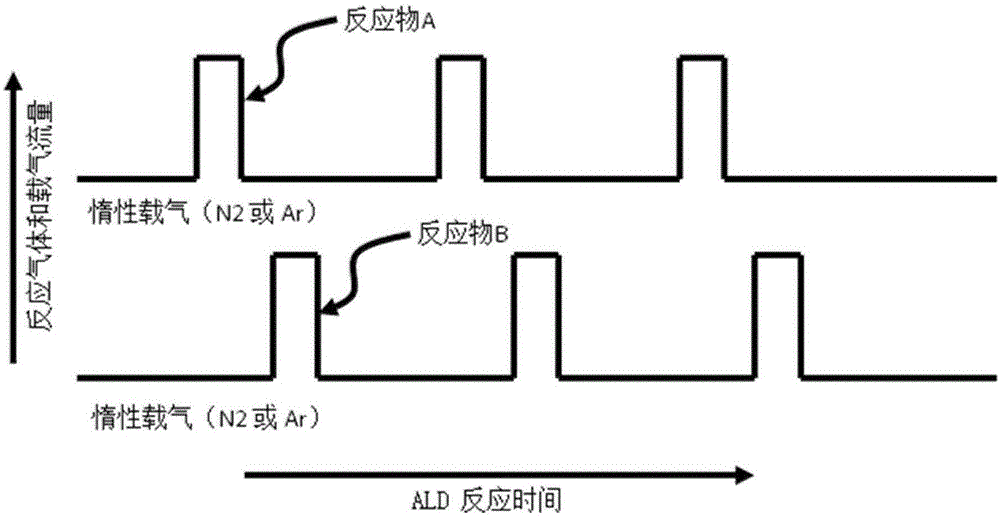

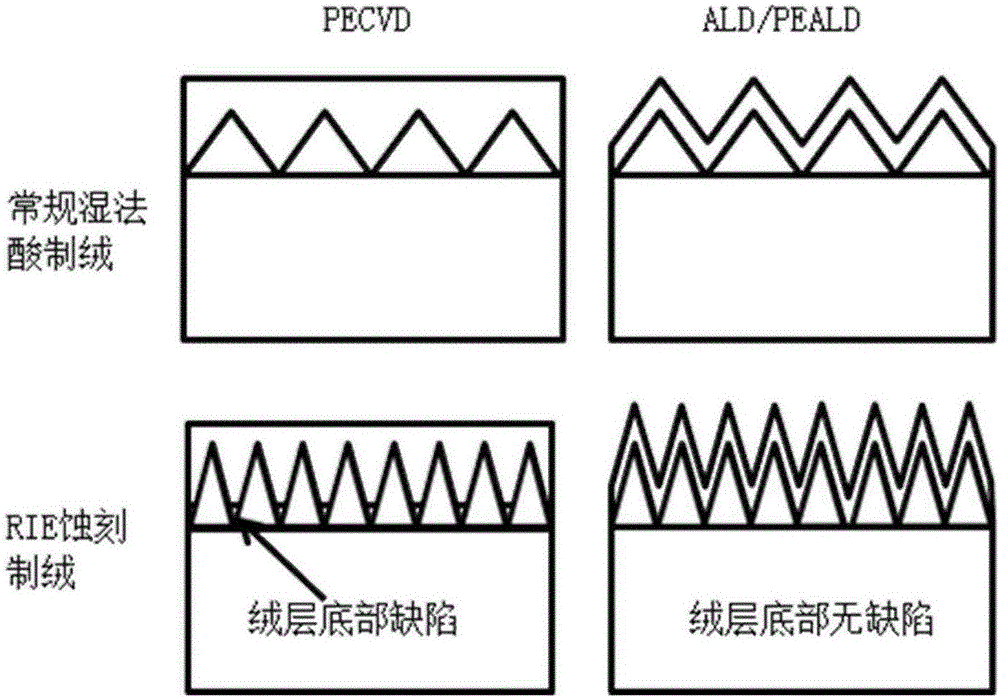

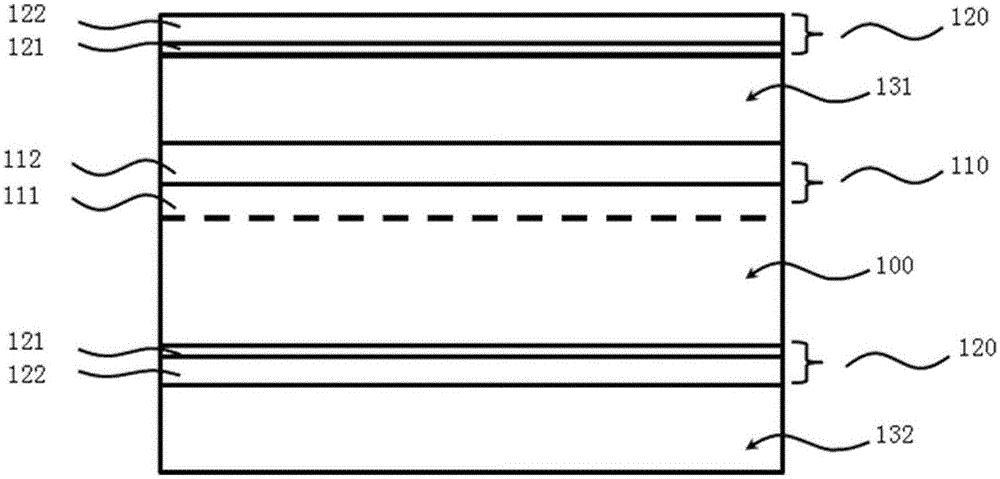

Fabrication process of crystalline silicon solar cell

ActiveCN105870249AImprove photoelectric conversion efficiencyExtend your lifeFinal product manufactureSemiconductor/solid-state device manufacturingCell fabricationMetallurgy

The invention relates to the field of fabrication of a solar cell, in particular to a surface passivation and anti-reflection technology of crystalline silicon cell for improving photoelectric conversion efficiency. Aiming at the existing cell technology process flow, nanometer lamination of a material such as SiO2, Al2O3 and SiNx and a composite material are fabricated by atomic layer deposition and plasma atomic layer deposition, passivation layer plating is carried out on the front surface and the back surface of the crystalline silicon cell, so that the minority carrier lifetime is prolonged, and the photoelectric conversion efficiency of the cell is improved; and SiNx anti-reflection layer plating can be continuously carried out after passivation layer plating, so that passivation and anti-reflection processes can be integrated in the same flow, the cost is reduced, and the yield is improved. The fabrication method is particularly and suitably used for combining with a black silicon technology, and multiple processes are avoided; and moreover, for a double-sided battery, the fact that double-sided passivation is carried out by using the fabrication method is a necessary choice.

Owner:JIANGSU MICROVIA NANO EQUIP TECH CO LTD

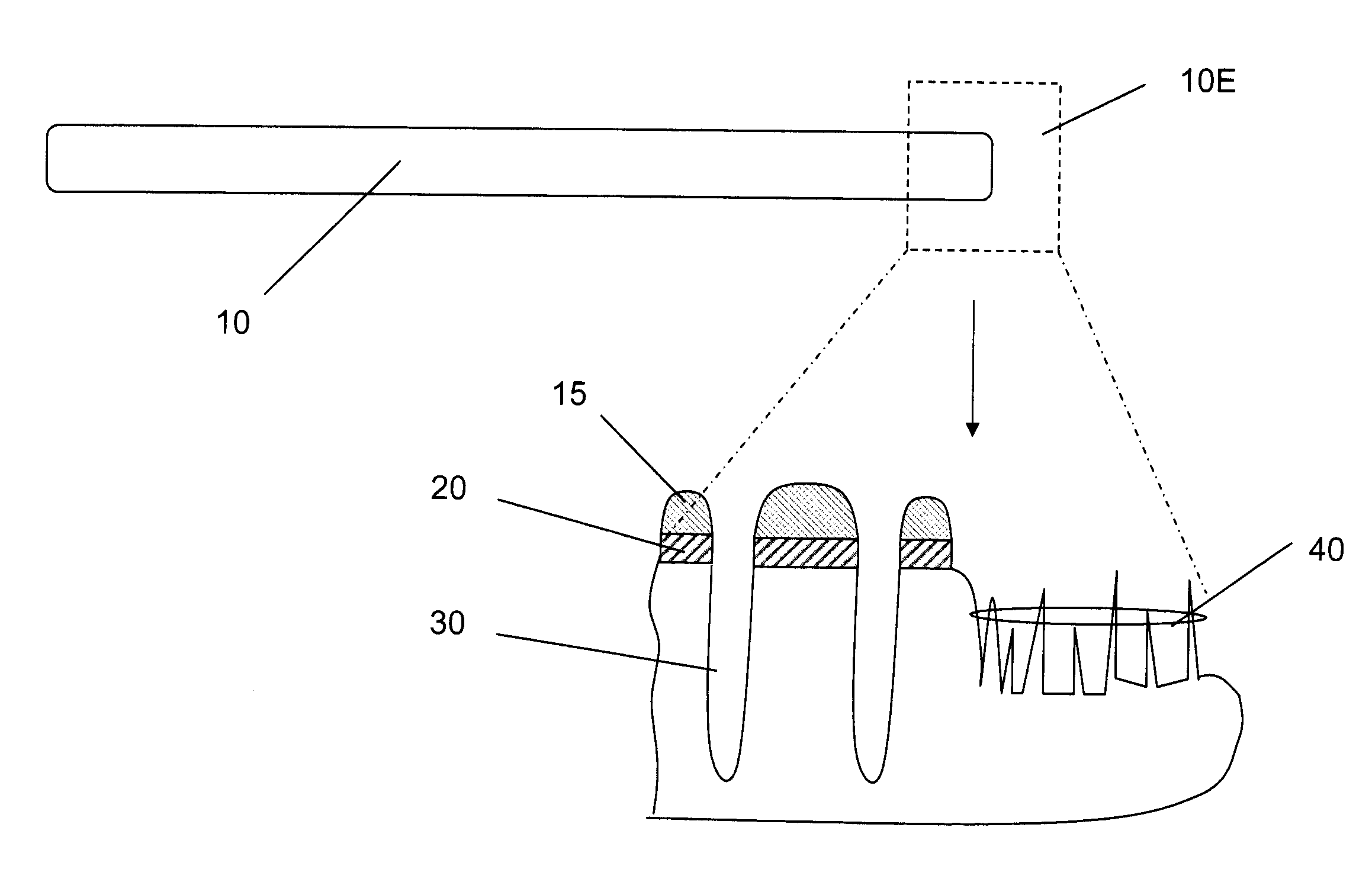

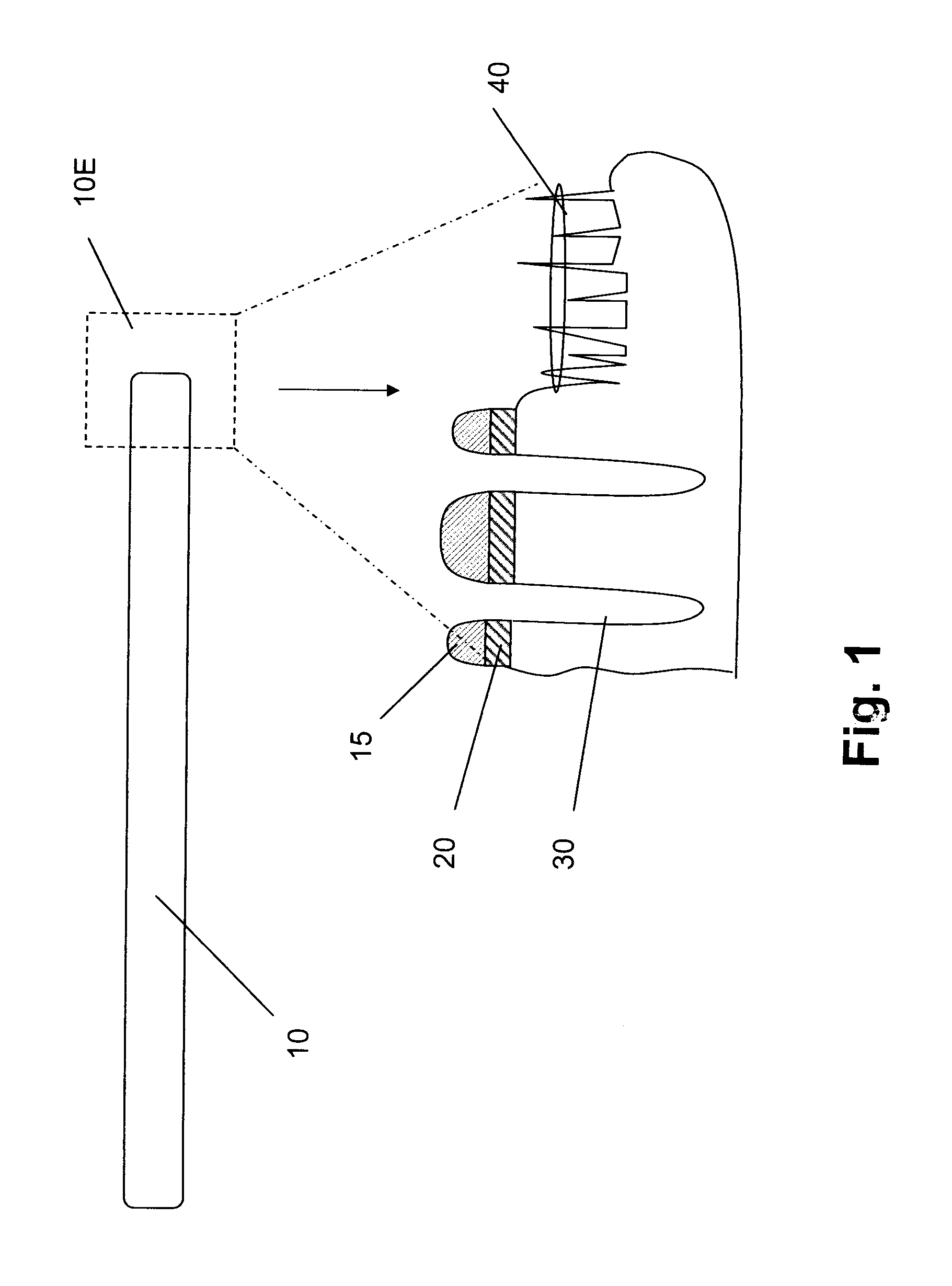

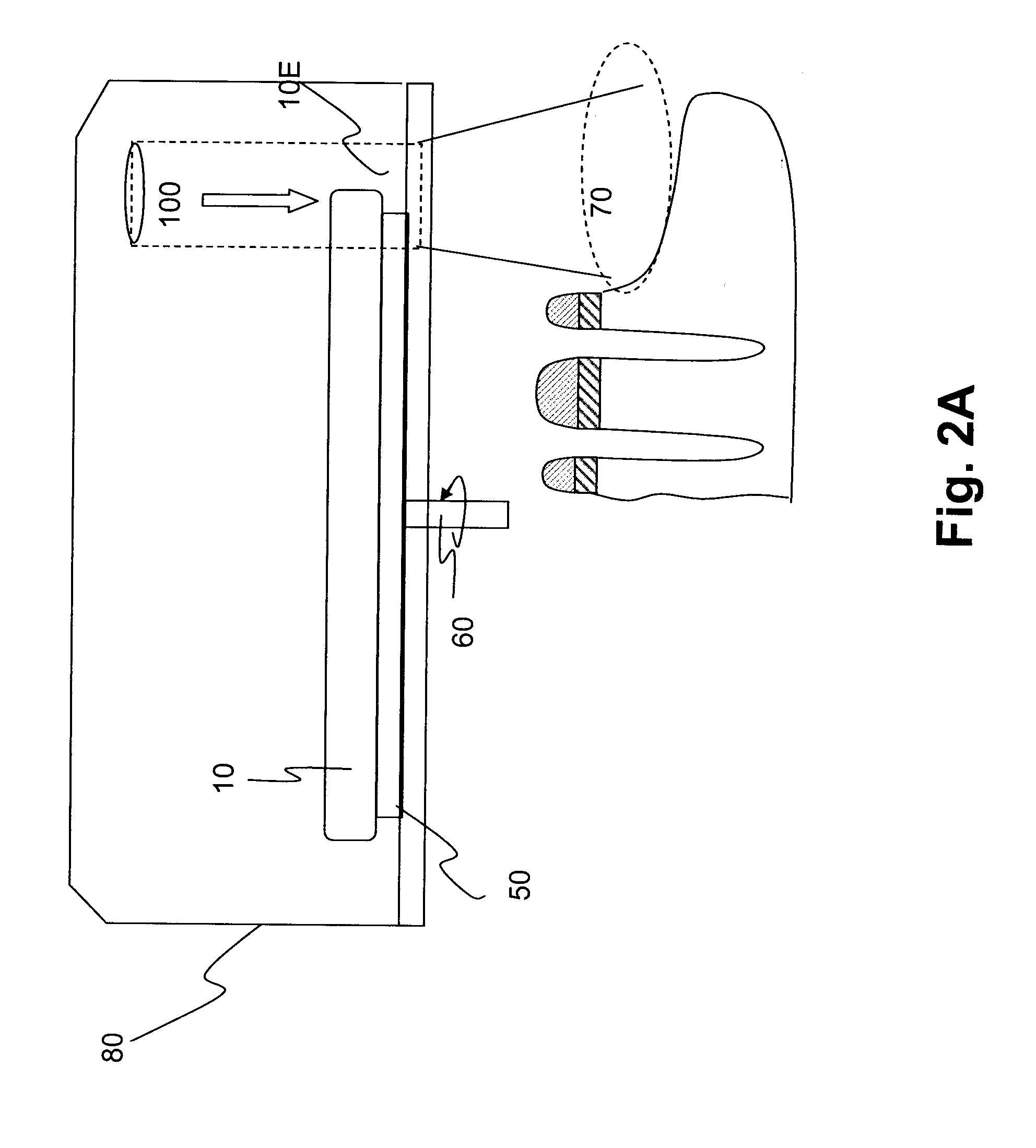

Method and apparatus for wafer edge cleaning

InactiveUS20080289651A1Minimally impactingEasy to disassembleSemiconductor/solid-state device manufacturingElectrostatic cleaningEngineeringIrradiation

A wafer edge cleaning system that includes a wafer dry etching chamber and one or more irradiation sources preferably positioned inside the wafer dry etching chamber. The irradiation source such as laser generates a beam aimed at the periphery of the wafer to melt any defects, in particular, black silicon at the edge of the wafer. Preferably, the wafer is mounted on a rotating platform. The invention further provides a method for removing black silicon at the edge of a semiconductor wafer that includes the steps of: patterning the wafer with a trench mask layer; etching the wafer to form a trench thereon; exposing the edge of the wafer to a laser beam to melt the black silicon thereon; stripping the mask and cleaning the wafer.

Owner:GLOBALFOUNDRIES INC

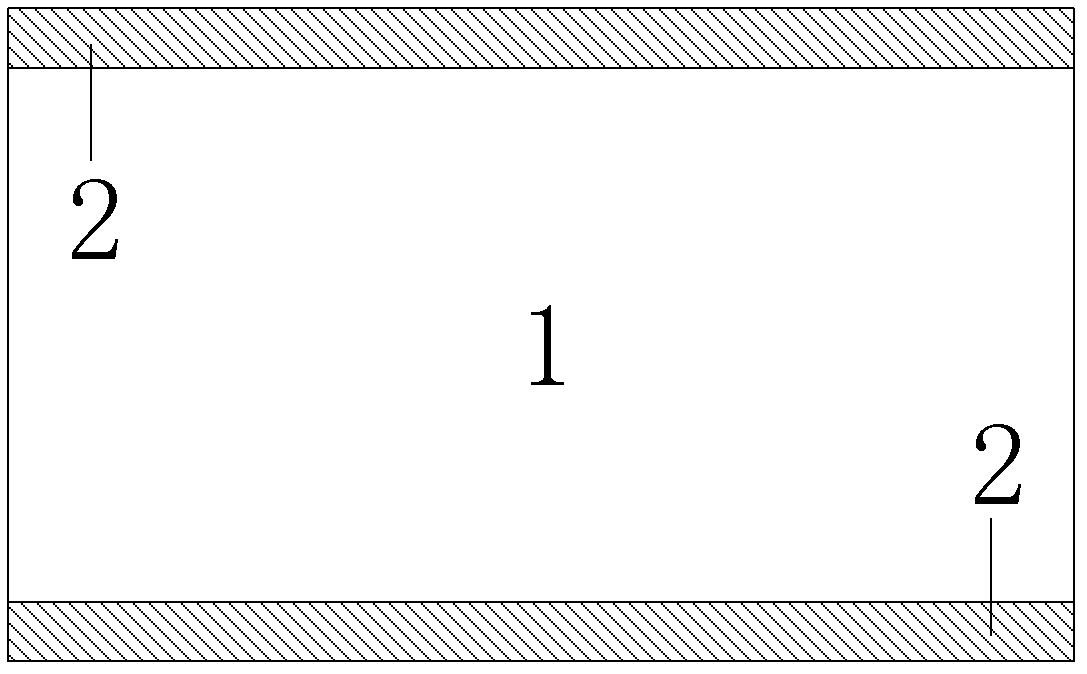

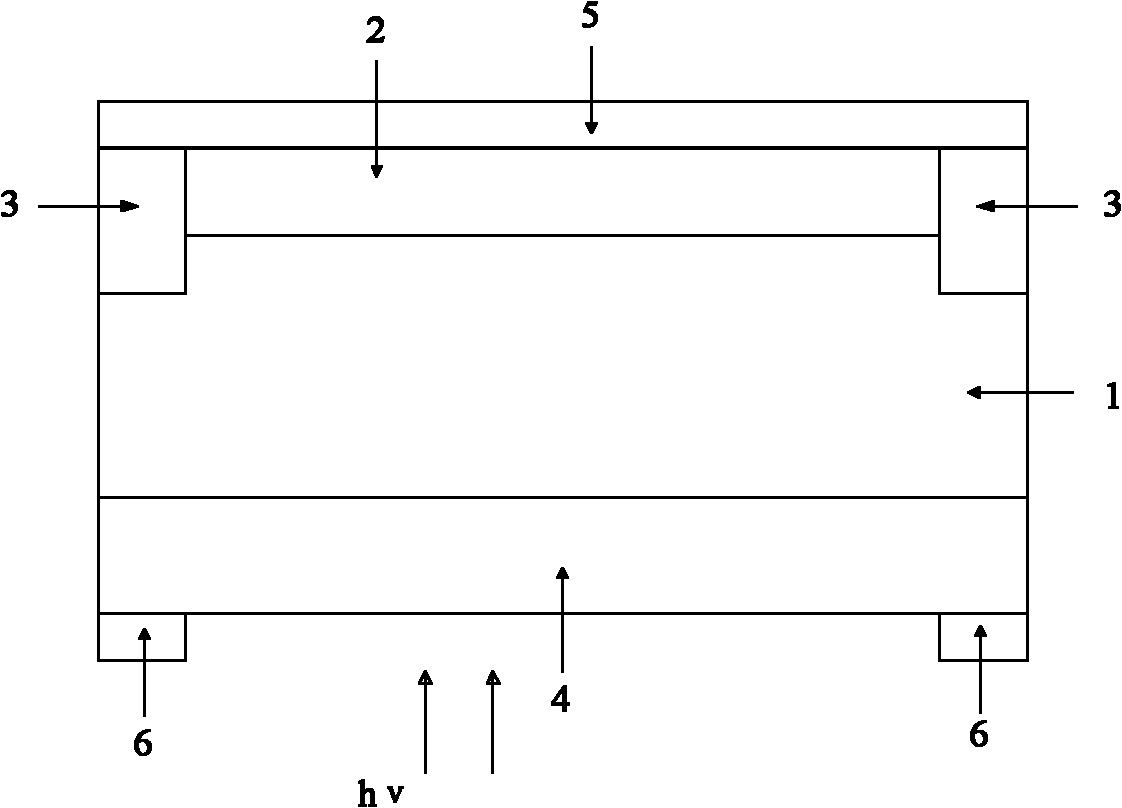

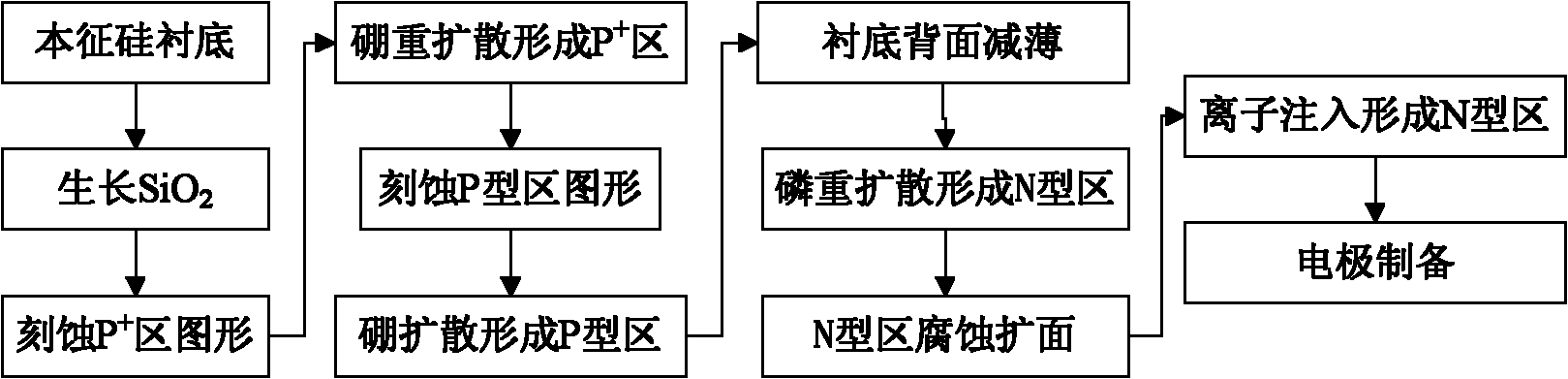

Back-illuminated Si-PIN photoelectric detector taking black silicon material as photosensitive layer and manufacturing method thereof

ActiveCN102176470AWide response bandImprove absorption rateFinal product manufacturePhotovoltaic energy generationPhotovoltaic detectorsIntrinsics

The invention discloses a back-illuminated Si-PIN photoelectric detector taking a black silicon material as a photosensitive layer and a manufacturing method thereof, belonging to the technical field of photoelectric detection. The photoelectric detector comprises a silicon intrinsic substrate, a P-type area located in the centre of the front surface of the silicon intrinsic substrate, an annularP+ area located around the front surface of the silicon intrinsic substrate, an N-type black silicon layer located on the back surface of the silicon intrinsic substrate, upper electrodes located on the upper surface of the P-type area and the P+ area, and lower electrodes located on the two sides of the lower surface of the N-type black silicon layer. According to the invention, the black silicon material is used as the photosensitive layer, and an annular P+ area 3 is increased around the P-type area 2 so that the back-illuminated Si-PIN photoelectric detector disclosed by the invention canabsorb light waves of near-infrared band and has higher light absorptivity and wider response band than a traditional Si photoelectric detector; the manufacturing process is relatively simple and hasthe characteristics of low cost, fast response speed, high responsiveness and wide response band, is easy to realize integration, and has obvious advantages in large-scale marketization.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

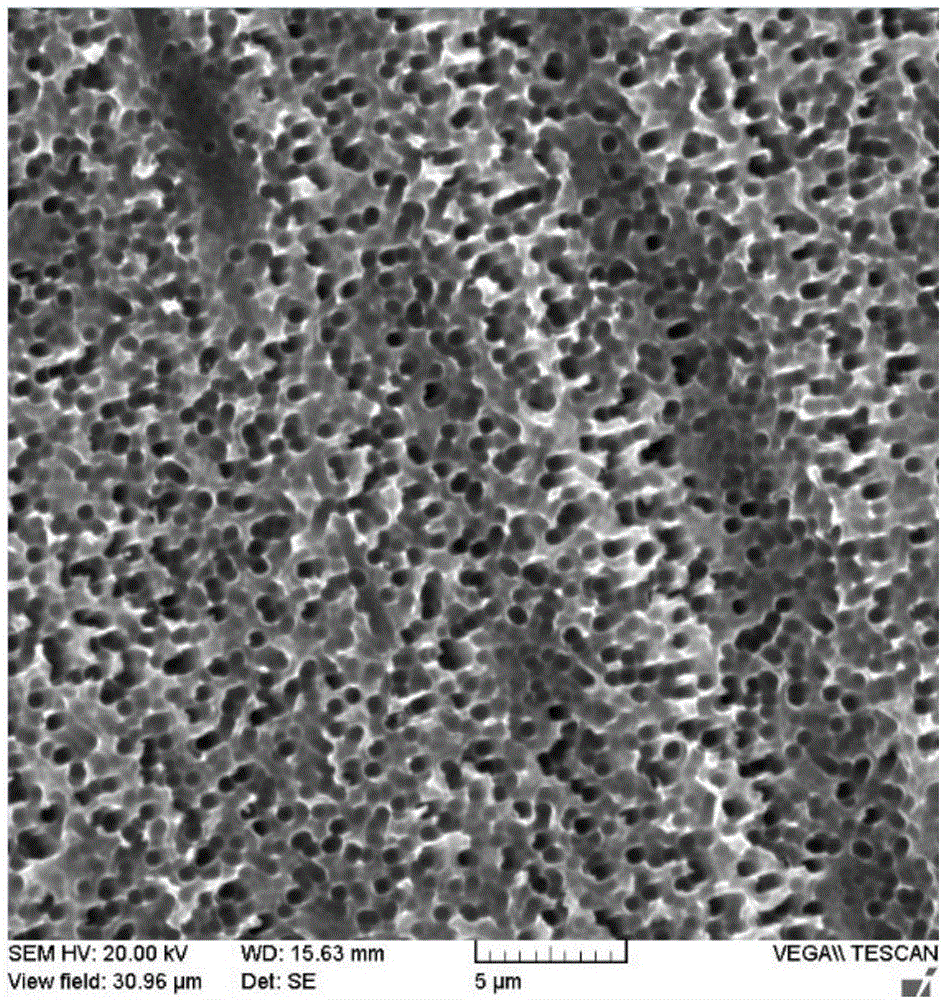

Method for preparing black silicon based on liquid-phase chemical reaction

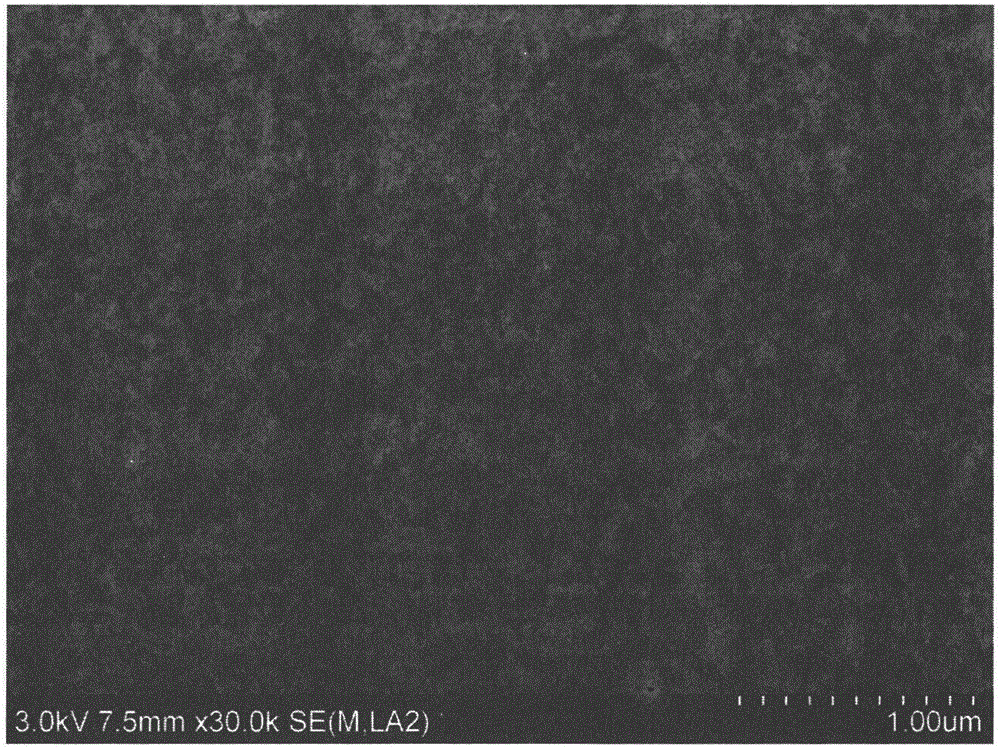

InactiveCN102051618AEnhanced light absorptionPromote absorptionAfter-treatment detailsChemical reactionSolar battery

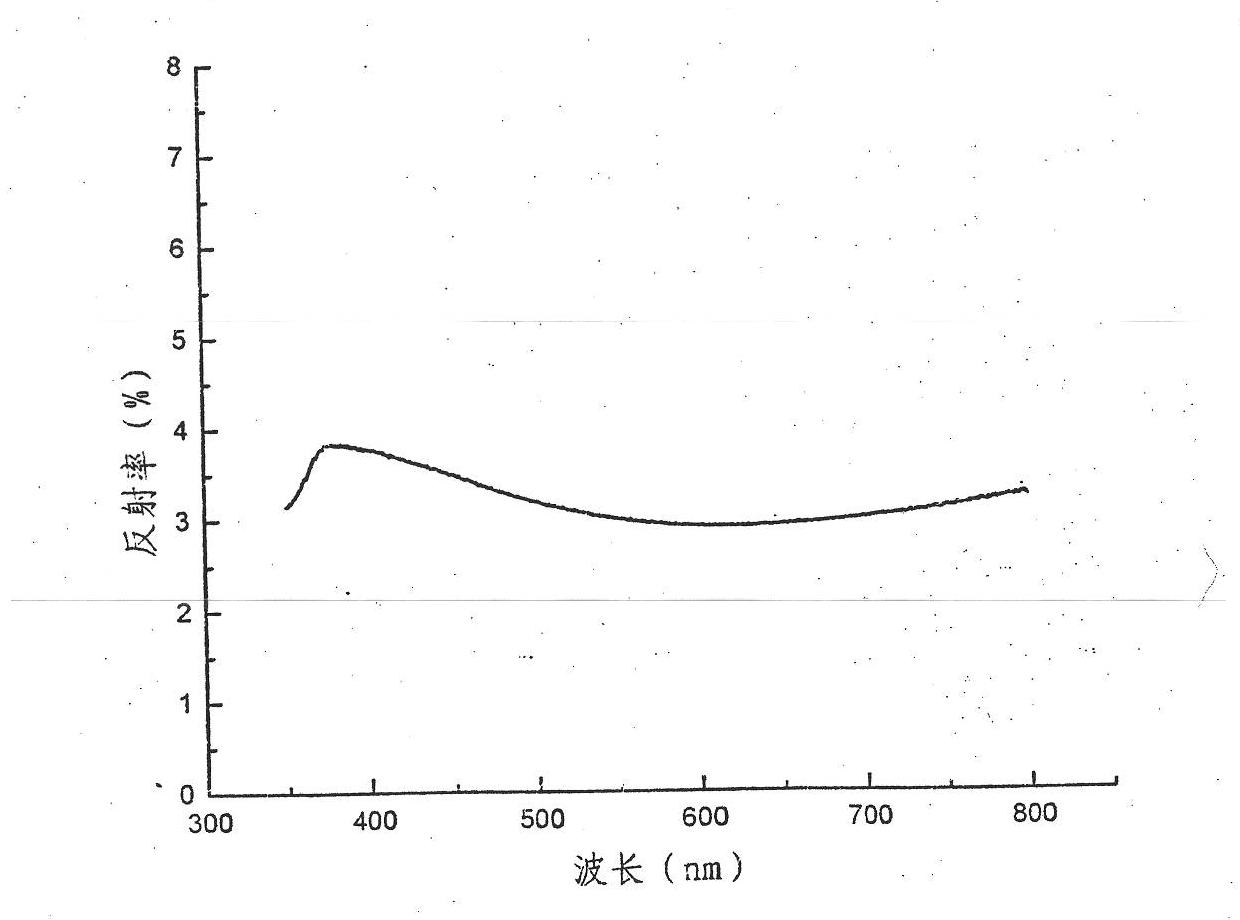

The invention relates to a method for preparing black silicon based on liquid-phase chemical reaction, comprising the following steps of: placing a silicon slice in a corrosive solution; then adding a metal compound to the corrosive solution; and carrying out texturing treatment on the surface of the silicon slice through ion etching reaction under catalysis to form a black silicon material with a microstructural surface. By carrying out surface texturing of a nano scale on the silicon surface, the band absorption and reflectivity of the product can be effectively controlled so that the conversion efficiency of a silicon-based solar battery can be improved. The method can be applied to preparing large-area black silicon material, and the surface of the prepared black silicon material contains microstructures, such as a silicon microcolumn, a silicon particle, silicon microholes and the like. The light absorption of the black silicon material in the wavelength range of 300-2000nm can be up to over 90%, and the light absorption in the wavelength range of 300-800nm can be up to over 95%.

Owner:YUNNAN NORMAL UNIV

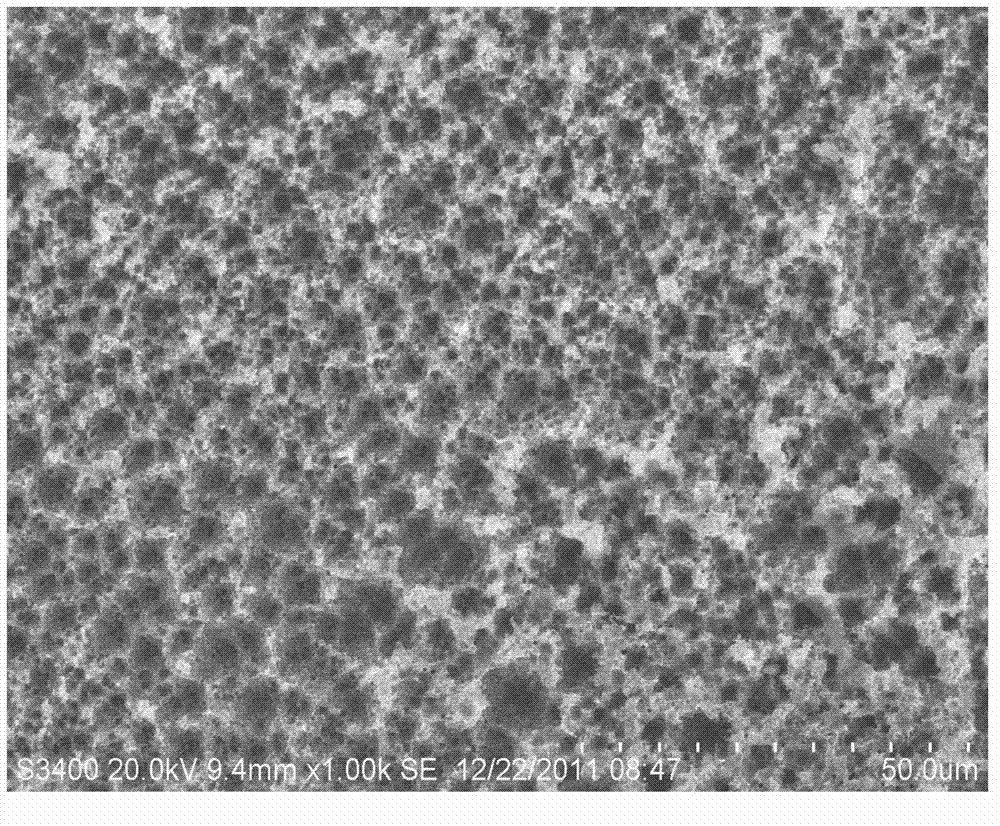

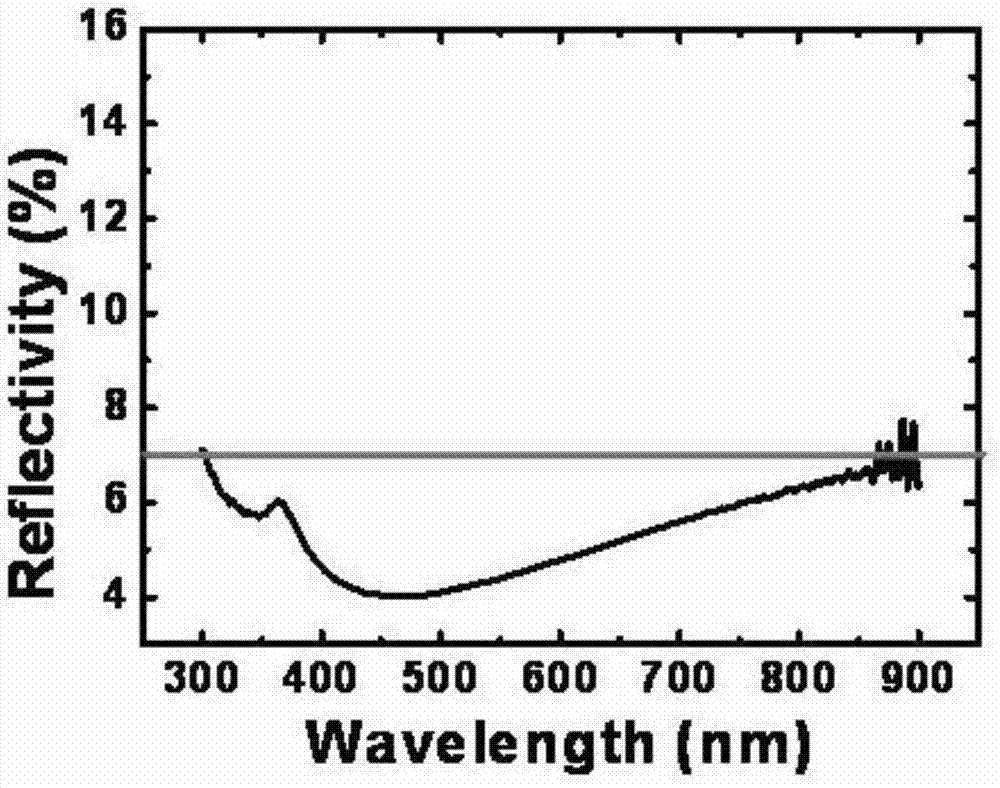

Method for preparing black silicon by metallic copper ion auxiliary etching

InactiveCN102768951AEasy to cleanAvoid residueSemiconductor/solid-state device manufacturingEtchingNanohole

The invention discloses a method for preparing black silicon by using metallic copper ion auxiliary etching, comprising the following steps of (1) preparing an etchant solution which is a mixed solution composed of hydrofluoric acid, hydrogen peroxide and cupric nitrate; (2) placing a monocrystalline or polycrystalline silicon wafer into the etchant solution which contains metallic copper ions, and controlling the temperature of the etchant solution and the reaction time; and (3) taking out the reacted silicon wafer, washing the silicon wafer with an oxidative acid liquor to remove metallic residues, washing, with ionized water, and drying the silicon wafer so as to obtain a black silicon material. Monocrystalline or polycrystalline silicon surfaces are etched in a texturing manner by the catalytic action of the metal copper ions, and the black silicon material with uniform nano-pores at the surface is prepared, so that the reflectivity of monocrystalline or polycrystalline silicon materials in a light absorption waveband is obviously reduced, and conversion efficiency of silicon-based solar cells is improved.

Owner:NANJING UNIV

Back-light black-surface silicon solar battery structure and production method thereof

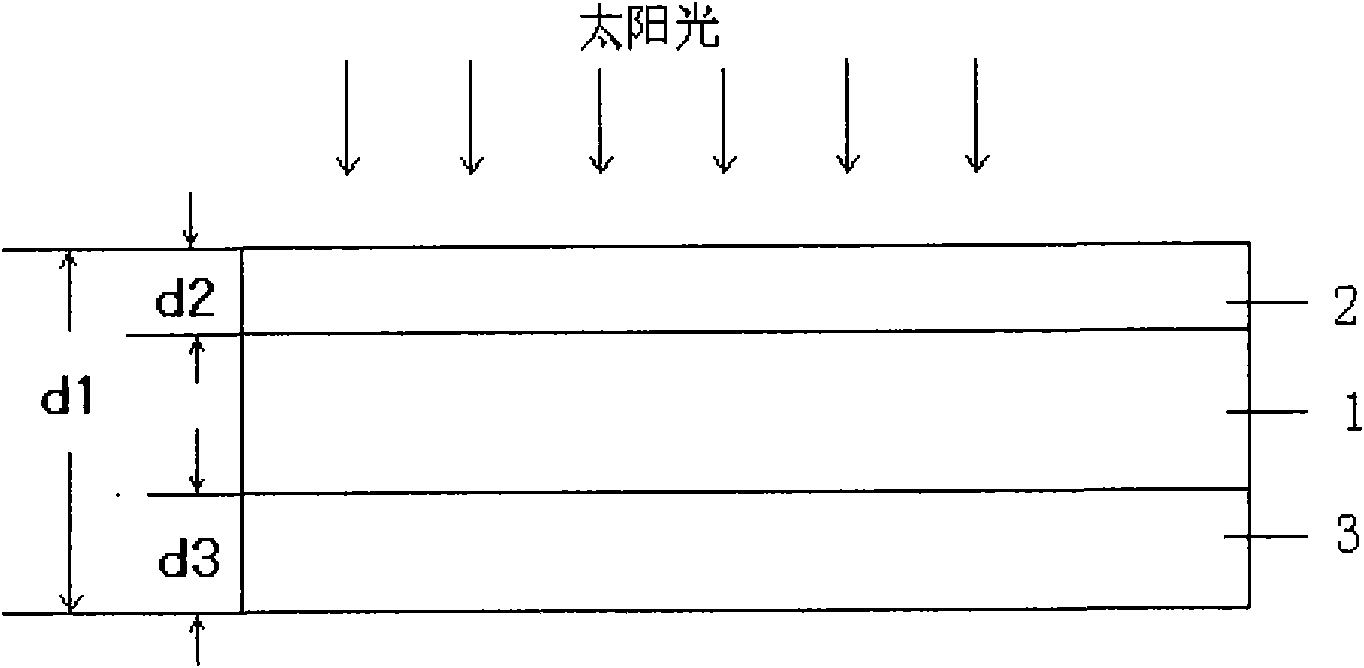

InactiveCN101807616AImprove photoelectric conversion efficiencyIncrease photocurrentFinal product manufacturePhotovoltaic energy generationTrappingSolar battery

The invention discloses a back-light black-surface silicon solar battery structure, which comprises a silicon-based substrate, a light trapping material layer which is formed at the front side of the silicon-based substrate and a broad-spectrum absorbing black silicon material layer which is formed at the back side of the silicon-based substrate. The invention further discloses a method for producing the back-light black-surface silicon solar battery structure. The invention can adequately use the characteristic of the broad-spectrum absorption of the black silicon material, thereby leading the sunlight which enters into the battery nearly to be completely absorbed, making a contribution to light current, solving the problem that the conventional silicon-based battery can not absorb and transfer solar spectrum with the wavelength which is more than 1.1mu m under the limitation of the infrared absorption, and effectively improving the photoelectric conversion efficiency of the silicon-based solar battery.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

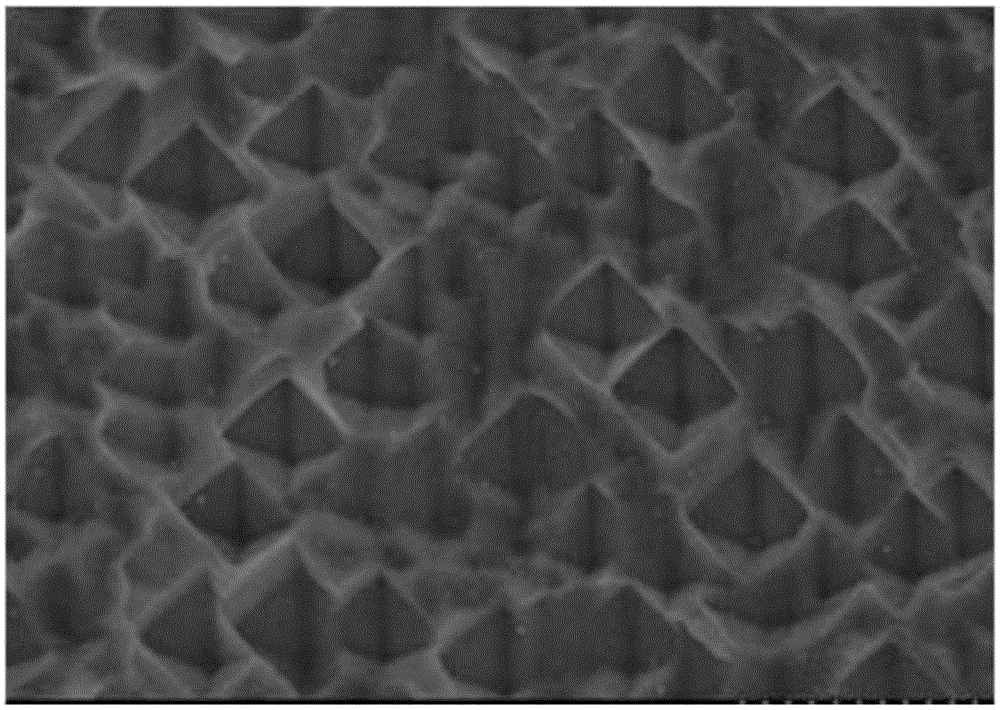

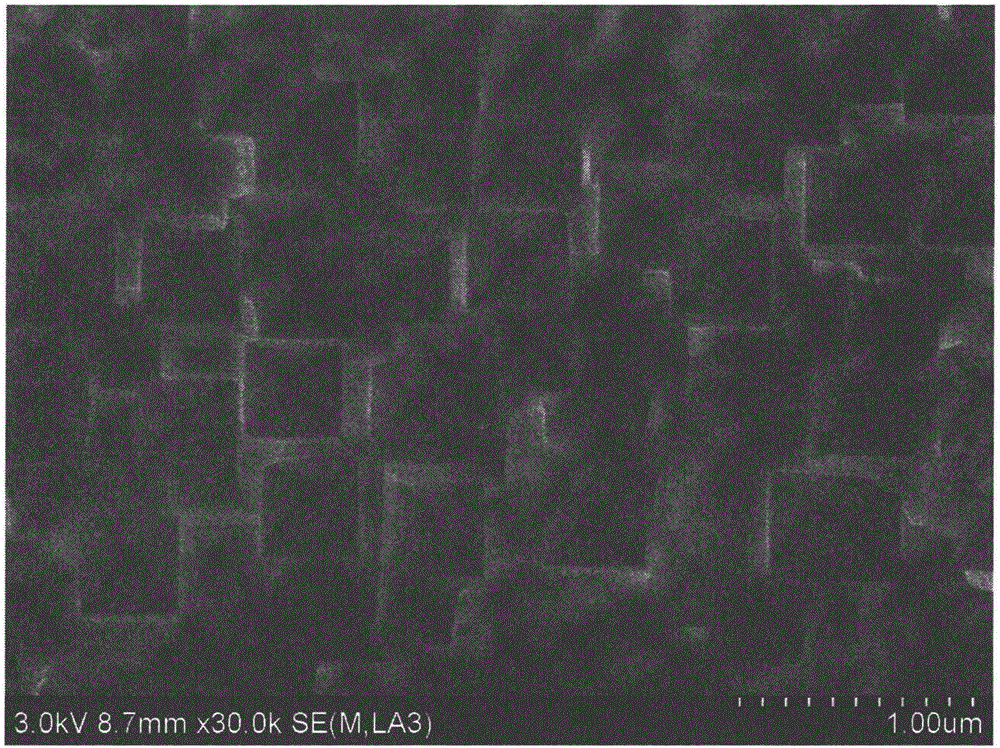

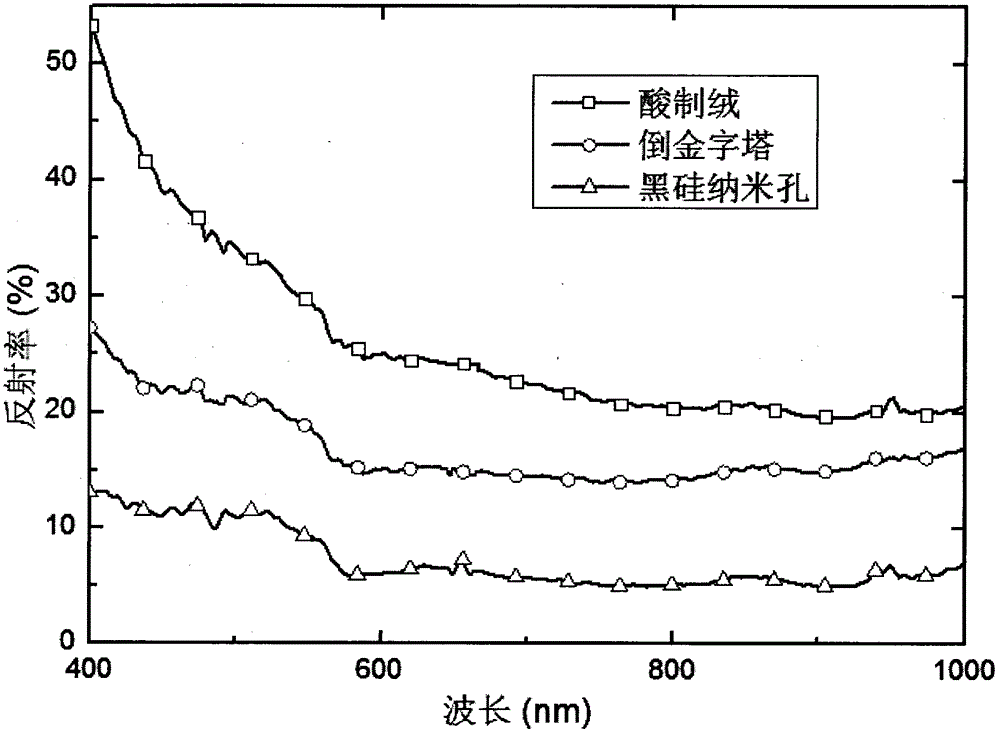

Preparation method, based on solution method, of polycrystalline solar cell

ActiveCN105070792AReduce reflectivityImprove conversion efficiencyMaterial nanotechnologyFinal product manufactureSilicon oxideSolar cell

The invention discloses a preparation method, based on a solution method, of a polycrystalline solar cell. The method includes the steps: (1) preparing a black silicon structure of the surface of a silicon oxide through a metal assisted chemical etching (MACE) technology; (2) performing optimized processing for the black silicon structure through a nano-structure rebuilding (NSR) solution so that an uniform reverse pyramid structure is formed; (3) changing the sheet resistance after diffusion and the thickness of a silicon nitride passive film on the nano-structure; and (4) forming a silicon oxide / silicon nitride dual-layer passive structure through liquid phase processing and PECVD. The prepared reverse pyramid anti-reflection structure has a better anti-reflection effect compared with a worm type structure formed by acid texturing, and is easier to passivate compared with a nano-black silicon structure, and is an ideal black silicon anti-reflection structure. The preparation method can prepare a polycrystalline solar cell that is low in reflectivity and high in conversion efficiency. Compared with a conventional cell process, the process of the method is simple, only adopts liquid phase processing, is low in cost, and is suitable for industrialized batch production.

Owner:江西汉可泛半导体技术有限公司

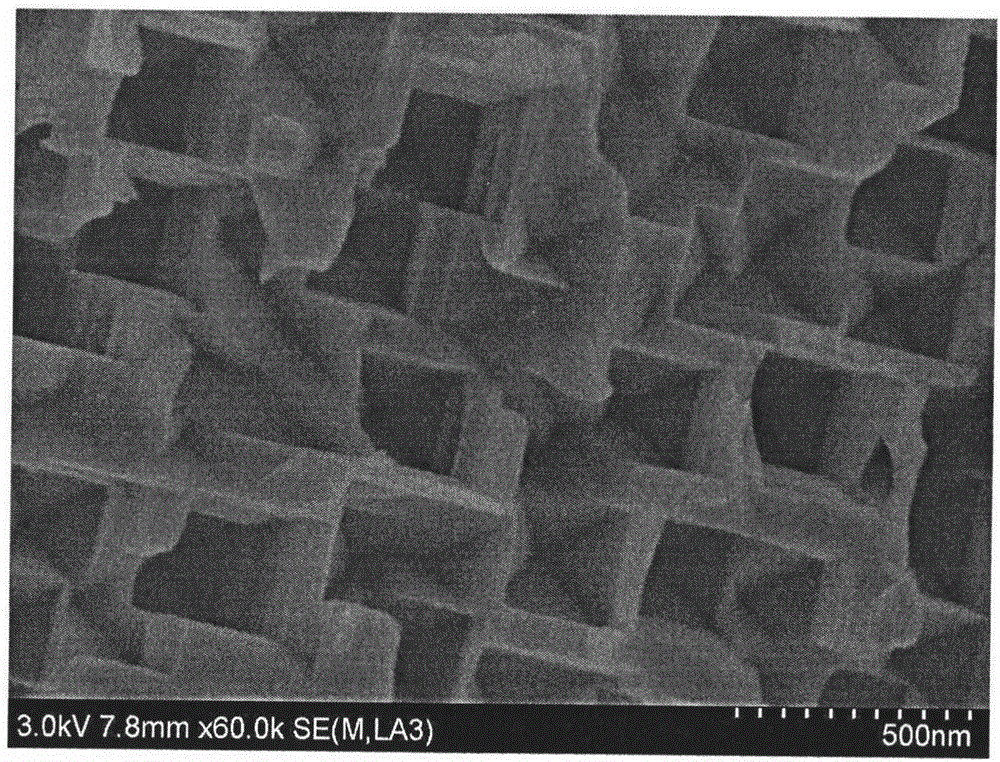

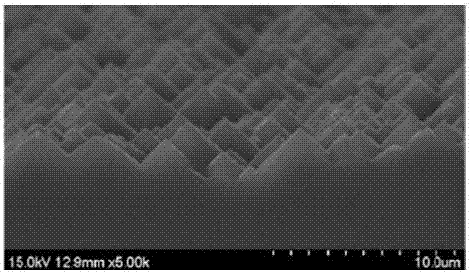

Inverted pyramid structure of polysilicon surface and fabrication method of inverted pyramid structure

InactiveCN105047734AReduce reflectivityImprove trapping effectFinal product manufacturePhotovoltaic energy generationNano structuringTrapping

The invention discloses an inverted pyramid structure of a polysilicon surface and a fabrication method of the inverted pyramid structure. The method comprises the following steps: preparing black silicon by different methods; rinsing a sample in a mixed liquid of hydrogen peroxide and ethanol amine; and carrying out retreatment on the washed black silicon in a mixed liquid of hydrogen peroxide, hydrofluoric acid, metaphosphoric acid and ammonium fluoride, so as to form the inverted pyramid structure of the polysilicon surface. A wet-chemical method which is different from acid and alkaline corrosion is adopted. According to the method, the effects of anisotropy can be reduced to the maximal extent; and the black silicon with different nano-structures can be corroded into a nano textured structure with a regular inverted pyramid structure through oxidation. Compared with the traditional polycrystalline silicon texture, the polysilicon inverted pyramid light-trapping structure disclosed by the invention is relatively high in light utilization rate and relatively low in reflectivity, so that the polysilicon inverted pyramid light-trapping structure has the characteristics of the inverted pyramid structure; compared with the traditional high surface recombination of a small and dense structure of the black silicon, the surface recombination is obviously reduced; and the efficiency of a solar cell is higher.

Owner:江苏辉伦太阳能科技有限公司

One-step wet black silicon preparation and surface treatment method

ActiveCN106024988AReduce the probability of electric leakageImprove absorption efficiencyAfter-treatment detailsFinal product manufactureSilicon cellPolymer

The invention provides a one-step wet black silicon preparation and surface treatment method, which comprises the steps of enabling a silicon wafer with a surface damage layer being removed to be immerged into a corrosive liquid so as to prepare black silicon through reaction, wherein the corrosive liquid is a mixed aqueous solution of a metal ion containing concentrated hydrofluoric acid, an oxidizing agent and a high-molecular polymer; and enabling the black silicon to be immerged into a surface treatment corrosive liquid so as to carry out surface optimization treatment, and acquiring a silicon wafer with a sub-micrometer structure and uniform texturing, wherein the surface treatment corrosive liquid is an additive containing mixed acid aqueous solution. The wet black silicon preparation method provided by the invention is simple in process and low in cost, the texturing surface of the black silicon after corrosion treatment is uniform and has no sharp boundary, and the reflectivity is 7-15%. The one-step wet black silicon preparation and surface treatment method greatly improves the absorption efficiency of a silicon cell for light, a solar cell prepared by using the black silicon prepared according to the method has low cell electric leakage rate, stable open-circuit voltage and high conversion efficiency.

Owner:湖州三峰能源科技有限公司

Method for manufacturing coated abrasive of finished superhard material

InactiveCN101780663AImprove stabilityAvoid the disadvantages of processing operationsAbrasion apparatusGrinding devicesPolyesterSuperhard material

The invention discloses a method for manufacturing a coated abrasive of a finished superhard material. The method comprises the following steps: singeing, rinsing, striking, soaking, coating, stretching and shaping, uncoiling, trade mark printing, primer coating, electrostatic sand-planting, pre-baking, composite adhesive coating, pre-drying, drying, coiling, flexing, shunt winding, slicing, adhesive coating, model loading, and shaping and curing. The substrate is made from polyester; substrate finishing agent is prepared from phenolic resin cementing agent and plenolic resin binder in the volume ratio of 180 to 100; the substrate is stretched while the substrate is dried at the temperature of between 200 and 220 DEG C; a grinding material is prepared from zirconia aluminum oxide and black silicon carbide; and the binder is prepared from phenol, 37 percent formaldehyde, 86 percent paraformaldehyde, NaOH and water in the volume ratio of 400 to 372 to 198 to 9.2 to 12. The method not only can save energy and reduce consumption, but also can improve the manufacture efficiency; and the coated abrasive tools of the finished superhard material manufactured by the method not only resists abrasion, but also has good stability of the substrate.

Owner:新沂市张氏磨具发展有限公司

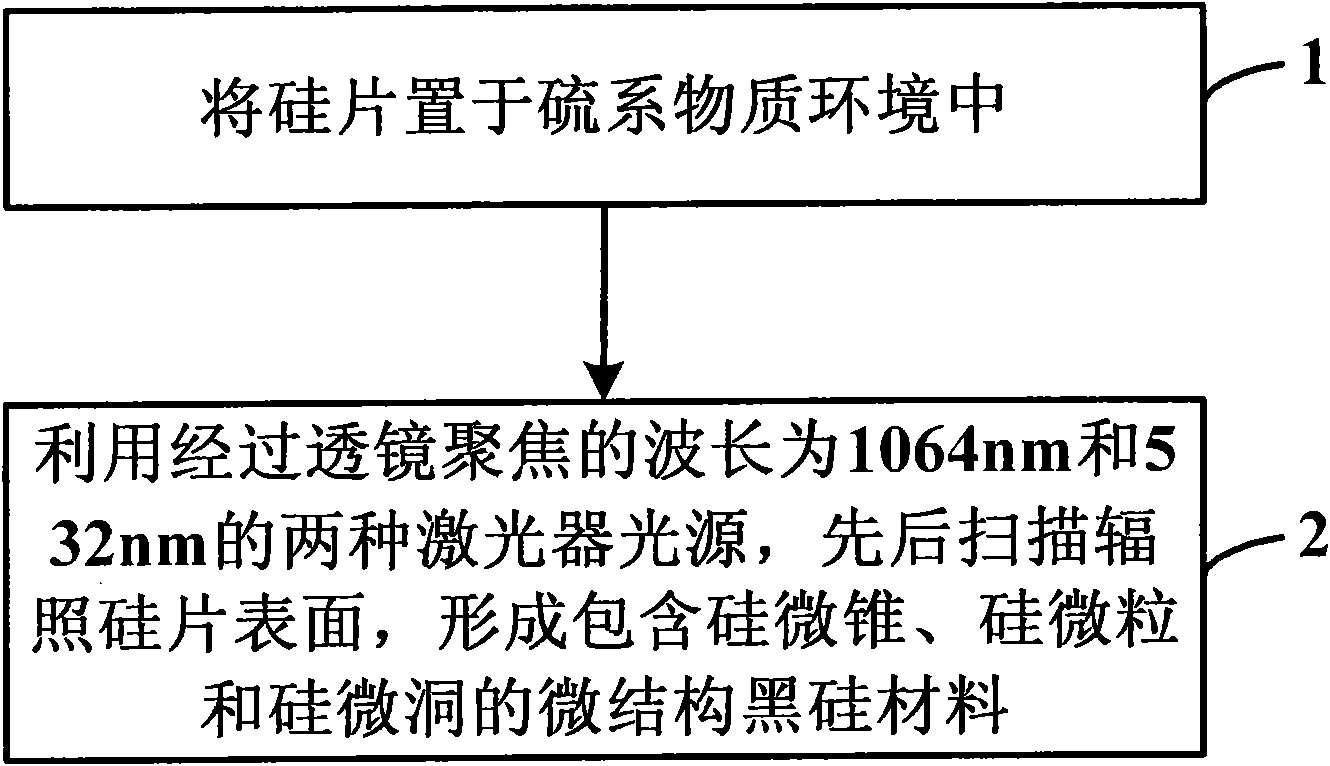

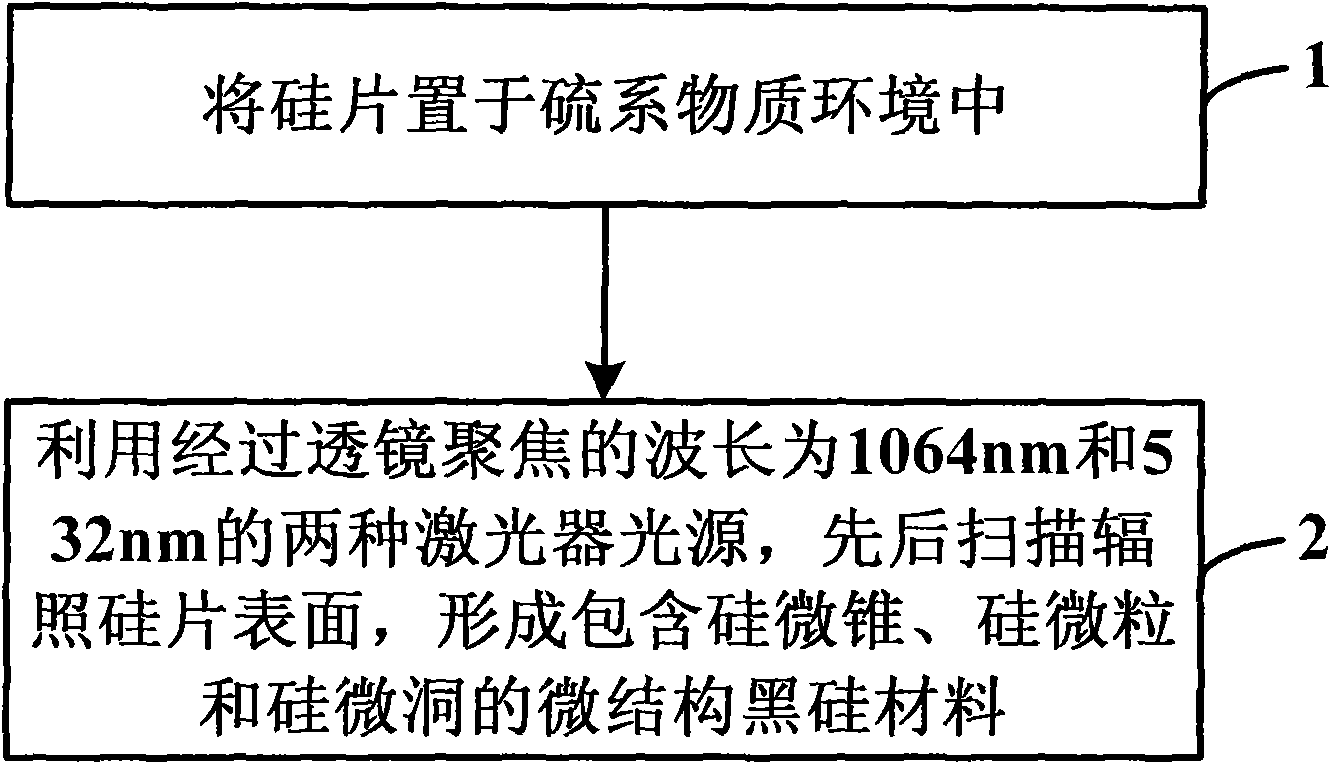

Method for manufacturing black silicon material

InactiveCN101824654AFully absorbedHigh absorption coefficientAfter-treatment detailsDiffusion/dopingParticulatesSurface layer

The invention discloses a method for manufacturing a black silicon material by utilizing the scanning of two laser light sources with the respective wavelengths of 1064nm and 532nm, which comprises the following steps: 1. placing a silicon sheet in a sulfur series substance environment; 2. sequentially scanning and irradiating the surface of the silicon sheet by utilizing the two laser light sources which are focused through a lens and respectively have the wavelengths of 1064nm and 532nm to form the microstructural black silicon material containing silicon microcones, silicon particulates and silicon microholes. The invention simultaneously integrates the characteristics that the action depth of the long-wave light source is deep and the action depth of the short-wave light source is shallow into the manufacture of the black silicon material and expands the ranges of a sulfur series doping substance, the silicon microcones, the silicon particulates and the silicon microholes on a surface layer, so that incident light can be more fully absorbed, and the absorption coefficient of the total solar spectrum is increased to more than 90 percent.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

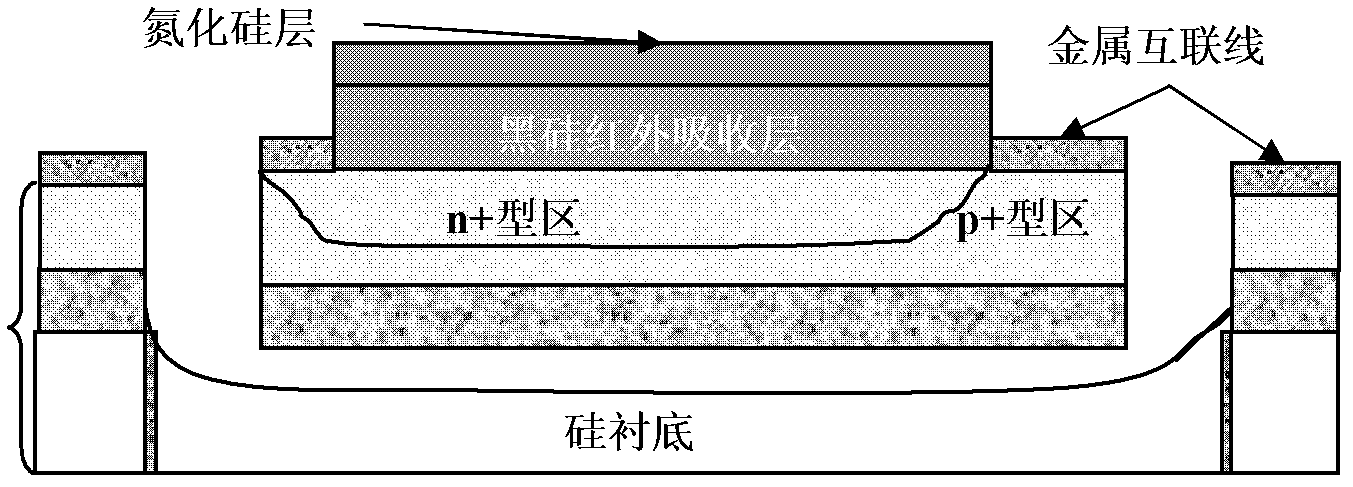

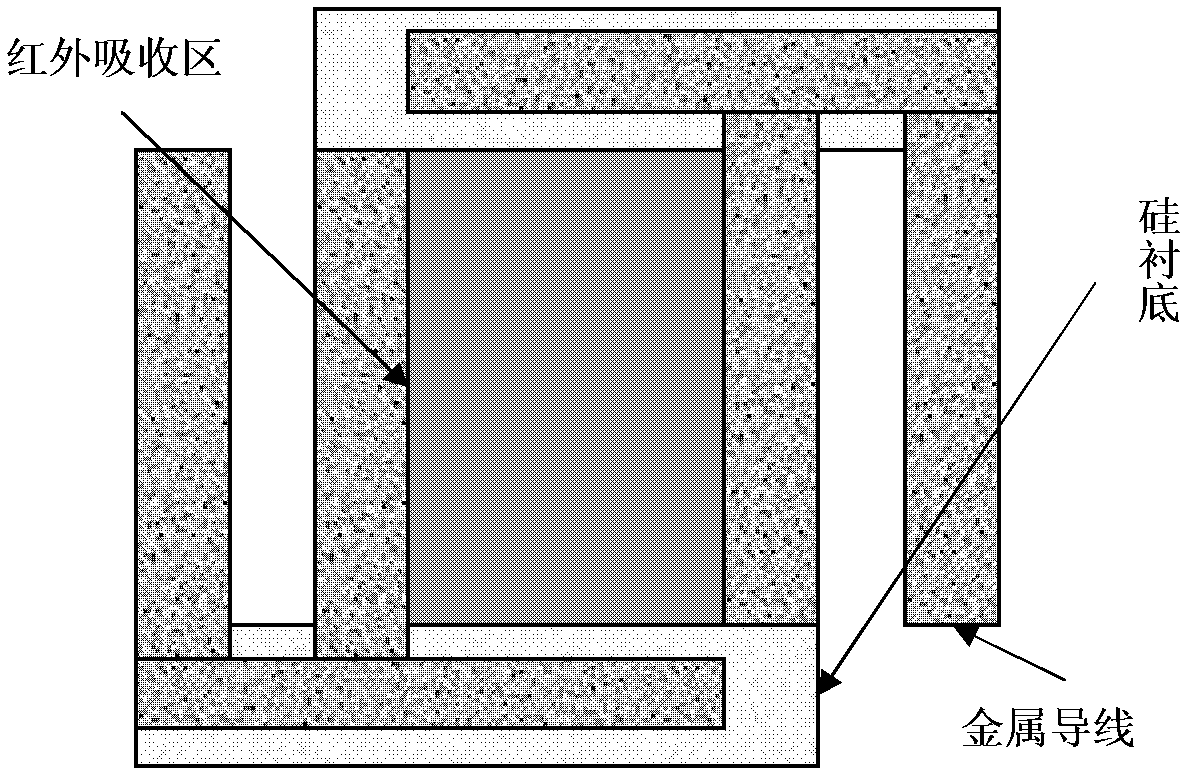

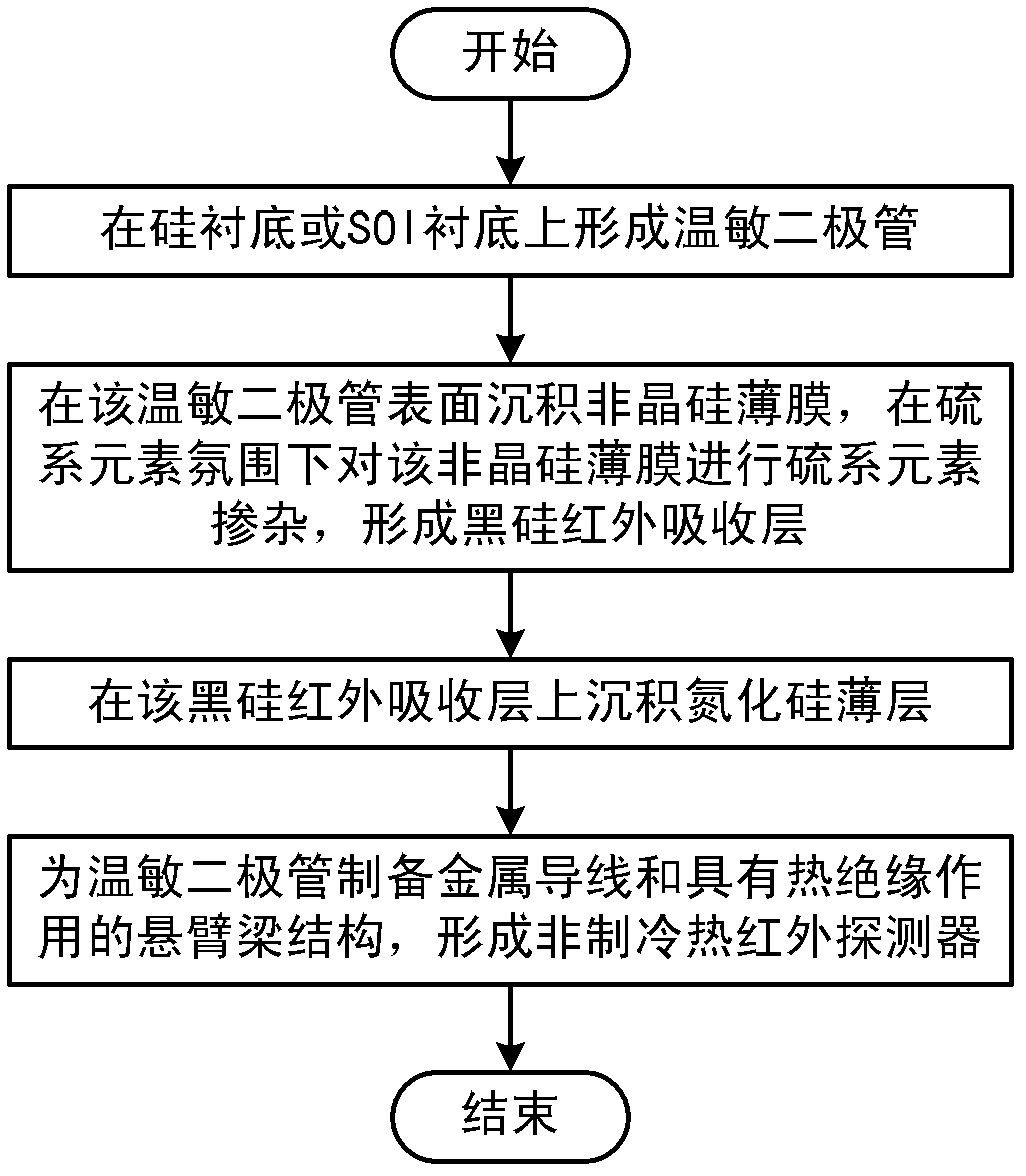

Method for manufacturing non-refrigerant thermal infrared detector based on black silicon material

InactiveCN102431957AHigh sensitivityLow costDecorative surface effectsChemical vapor deposition coatingThermal insulationThermal infrared

The invention discloses a method for manufacturing a non-refrigerant thermal infrared detector based on a black silicon material. The method comprises the following steps of: forming a thermosensitive diode on a silicon substrate or a silicon-on-insulator (SOI) substrate; depositing an amorphous silicon film on the surface of the thermosensitive diode, and performing sulfur element doping on the amorphous silicon film in an ultrafast laser irradiation mode or sulfur element ion implantation and ultrafast laser irradiation modes in the presence of sulfur elements to form a black silicon infrared absorbing layer; depositing a silicon nitride thin layer on the black silicon infrared absorbing layer to be used as a surface passivation layer; and preparing a metal conducting wire and a cantilever beam structure with a thermal insulation effect for the thermosensitive diode to form the non-refrigerant thermal infrared detector. In the method, the characteristics that the black silicon material has high infrared irradiation absorbability and is compatible with a micro-electronic processing process easily are fully utilized, and the manufactured thermal infrared detector has the advantages of high sensitivity and low cost and is easy to manufacture through an SOI complementary metal oxide semiconductor (CMOS) process and a CMOS process.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Additive for chambering acid liquid for texturing polycrystal black silicon and application of additive

ActiveCN106119976ACrystal flower improvementReactions become controllablePolycrystalline material growthAfter-treatment detailsPolyvinyl alcoholReaction rate

The invention provides an additive for chambering acid liquid for texturing polycrystal black silicon. The additive comprises the following components in percentage by mass: 0.5%-2% of polyvinyl alcohol, 1%-5% of triethanolamine, 1%-3% of tartaric acid, 0.5%-2% of a silane coupling agent and the balance of water. The invention further provides the chambering acid liquid adopting the additive and a method for texturing polycrystal black silicon. By adding the additive into the chambering acid liquid, the reaction of the chambering treatment can be decelerated, and the reaction rates of the chambering acid liquid on crystal surfaces of the polycrystal black silicon can be furthest kept consistent, so that the anisotropic corrosion is inhibited, crystal patterns of the polycrystal black silicon are obviously improved, and the appearance superiority and the performance superiority of the black silicon are embodied.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

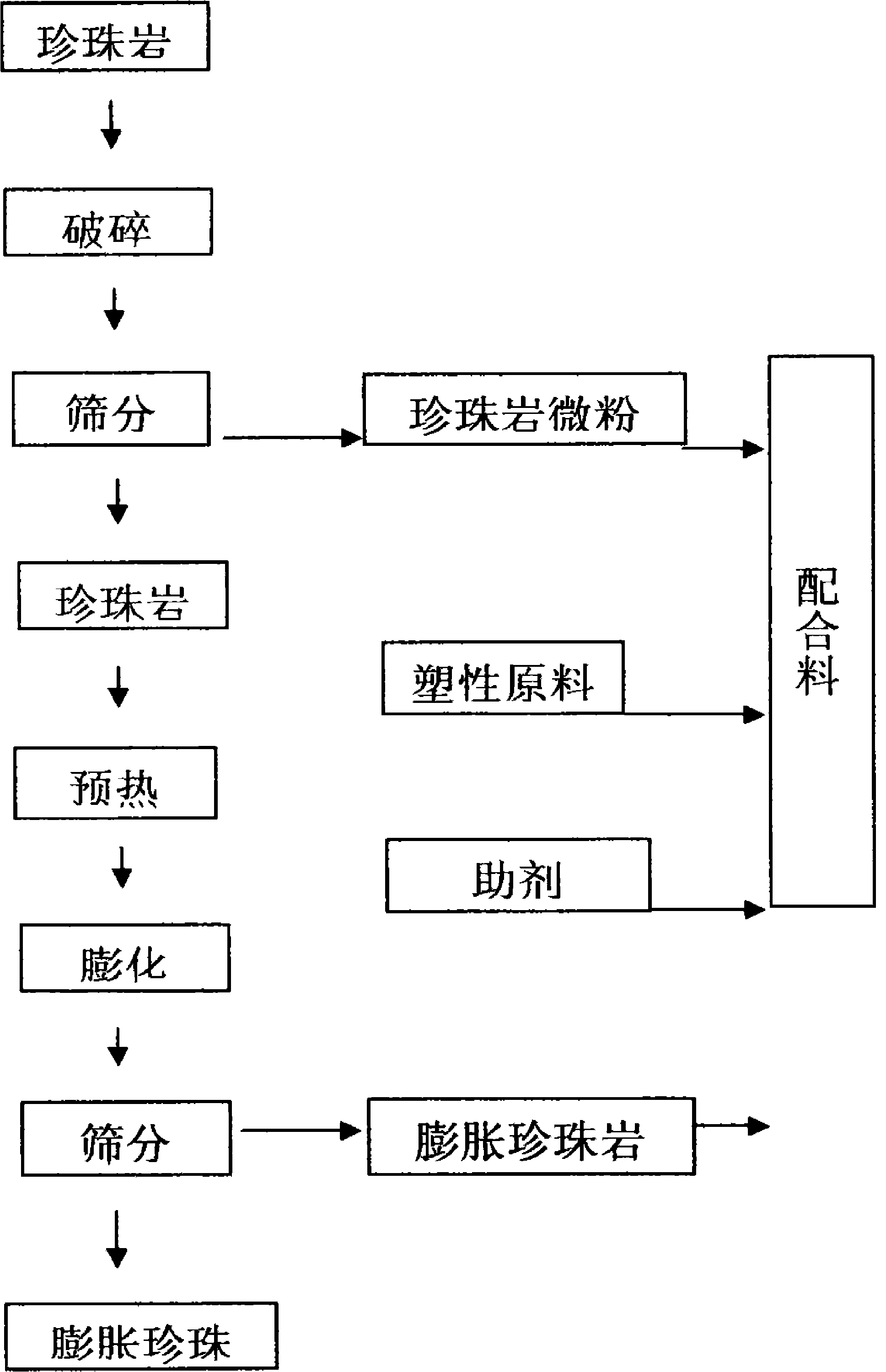

Method for producing light-weight heat-insulating decorative ceramic plate by using solid waste in production and processing course of expanded pearlite

InactiveCN103626476AIncreasing the thicknessLower firing temperatureCeramic materials productionCeramicwareSodium metasilicateSlurry

The invention provides a method for producing a light-weight heat-insulating decorative ceramic plate by using solid waste in the production and processing course of expanded pearlite. The light-weight heat-insulating decorative ceramic plate is prepared from the following materials: 25-100 percent of pearlite micro powder, 0-80 percent of expanded pearlite micro powder, 0-25 percent of Guangdong black clay, 0-10 percent of limestone, 0-5 percent of fluorite, 0.1-2 percent of black silicon carbide, 0-15 percent of bentonite, 0-5 percent of anhydrous sodium metasilicate, 0.1-0.5 percent of sodium humate and 0-1.0 percent of sodium tripolyphosphate. The batches are subjected to ball-milling and then slurry screening, slurry deironing, slurry aging, spray drying, powder aging, decorative distributing, dry-pressing forming, dry transporting and 900-1,050 DEG C oxidation burning are conducted to obtain the light-weight heat-insulating decorative integrated ceramic plate of which the water absorption is within 0.5%, the volume density is smaller than 500 kg / m<3>, the rupture modulus is more than 3.5 MPa, the heat conductivity is smaller than 0.08 / (m / k) and the burning level is A.

Owner:信阳方浩实业有限公司

Texturing method of diamond wire slice polycrystalline black silicon

ActiveCN106935669AEnsure uniformityGuarantee stabilityAfter-treatment detailsFinal product manufactureNanostructurePre deposition

The invention discloses a texturing method of diamond wire slice polycrystalline black silicon. The texturing method comprises the following steps in turn: a silicon chip is arranged in a solution containing nitric acid and hydrofluoric acid to be preprocessed; the preprocessed silicon chip is arranged in a solution containing metal salt to perform pre-deposition of oxidized metal nanoparticles; the silicon chip after pre-deposition is arranged in a solution containing hydrofluoric acid and an oxidizing agent to perform deposition of the oxidized metal nanoparticles; the silicon chip after deposition is arranged in a solution containing hydrofluoric acid, the oxidizing agent and metal salt ions to perform longitudinal and transverse broaching corrosion; the silicon chip after broaching is arranged in an acid solution to remove the metal ions; and the silicon chip of which the metal ions are removed is arranged in an alkaline solution containing a texturing additive to perform modification of the nanostructure so as to form the final textured surface. The non-uniformity and the chromatic aberration of the appearance after texturing can be effectively avoided.

Owner:江苏福吉食品有限公司

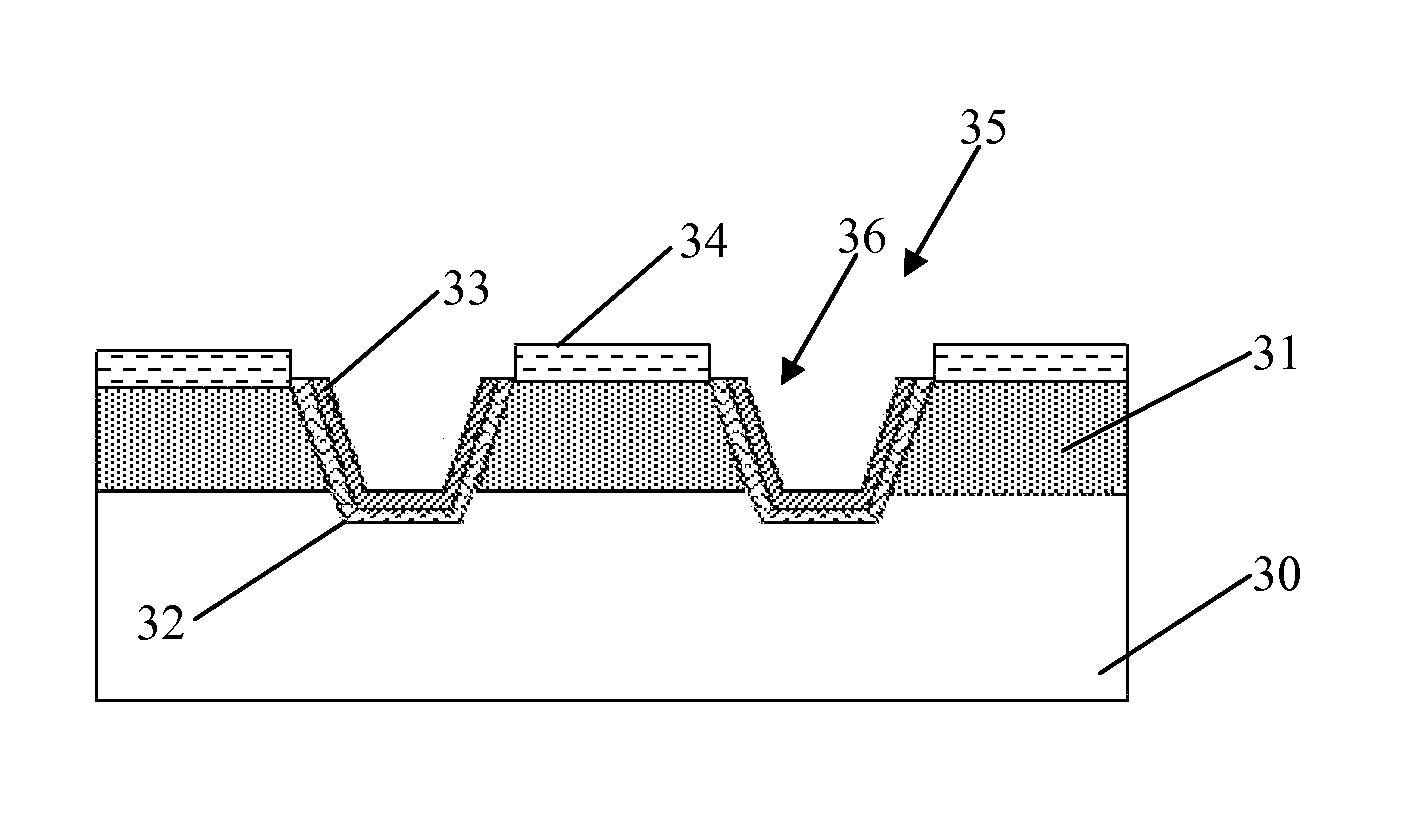

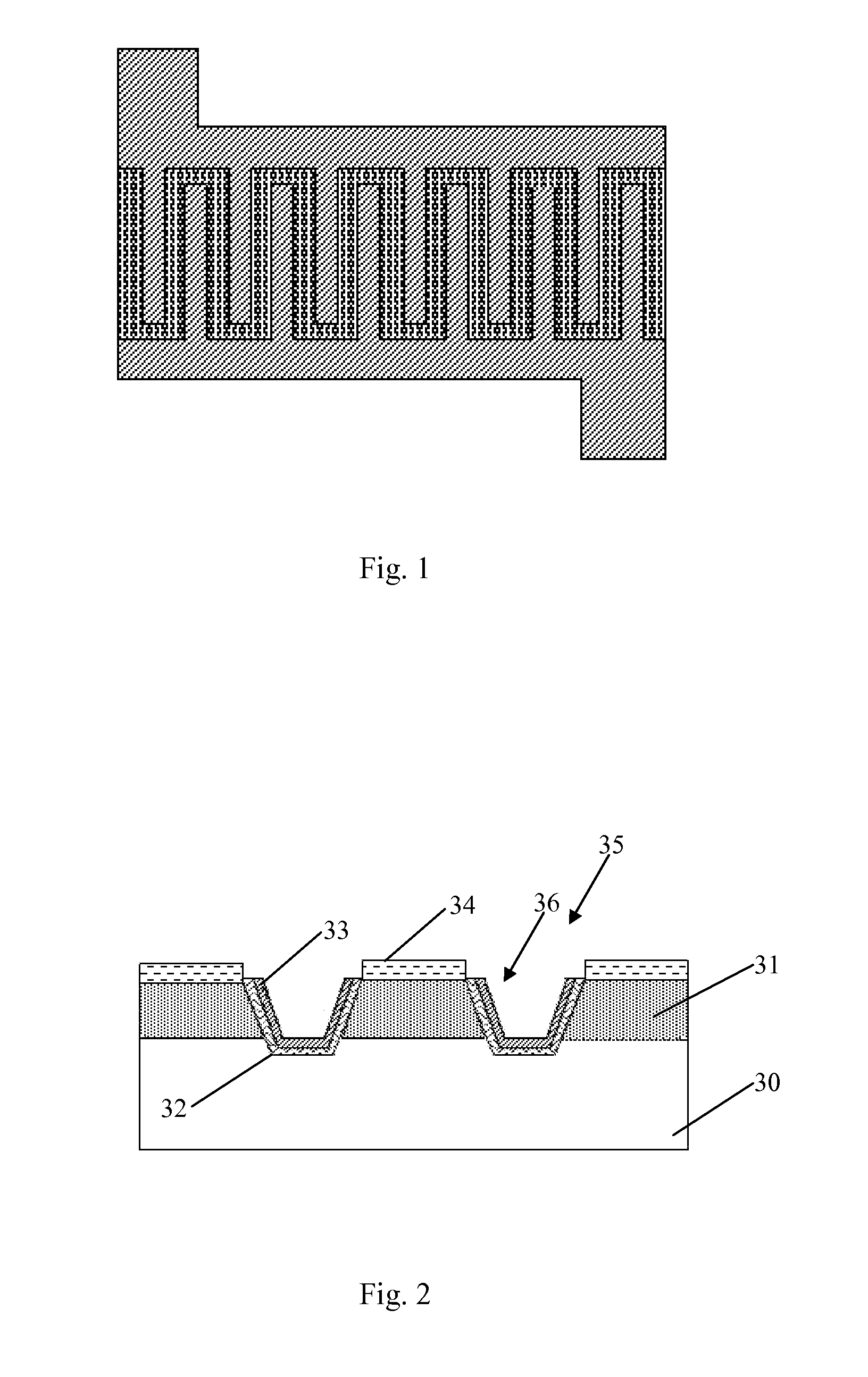

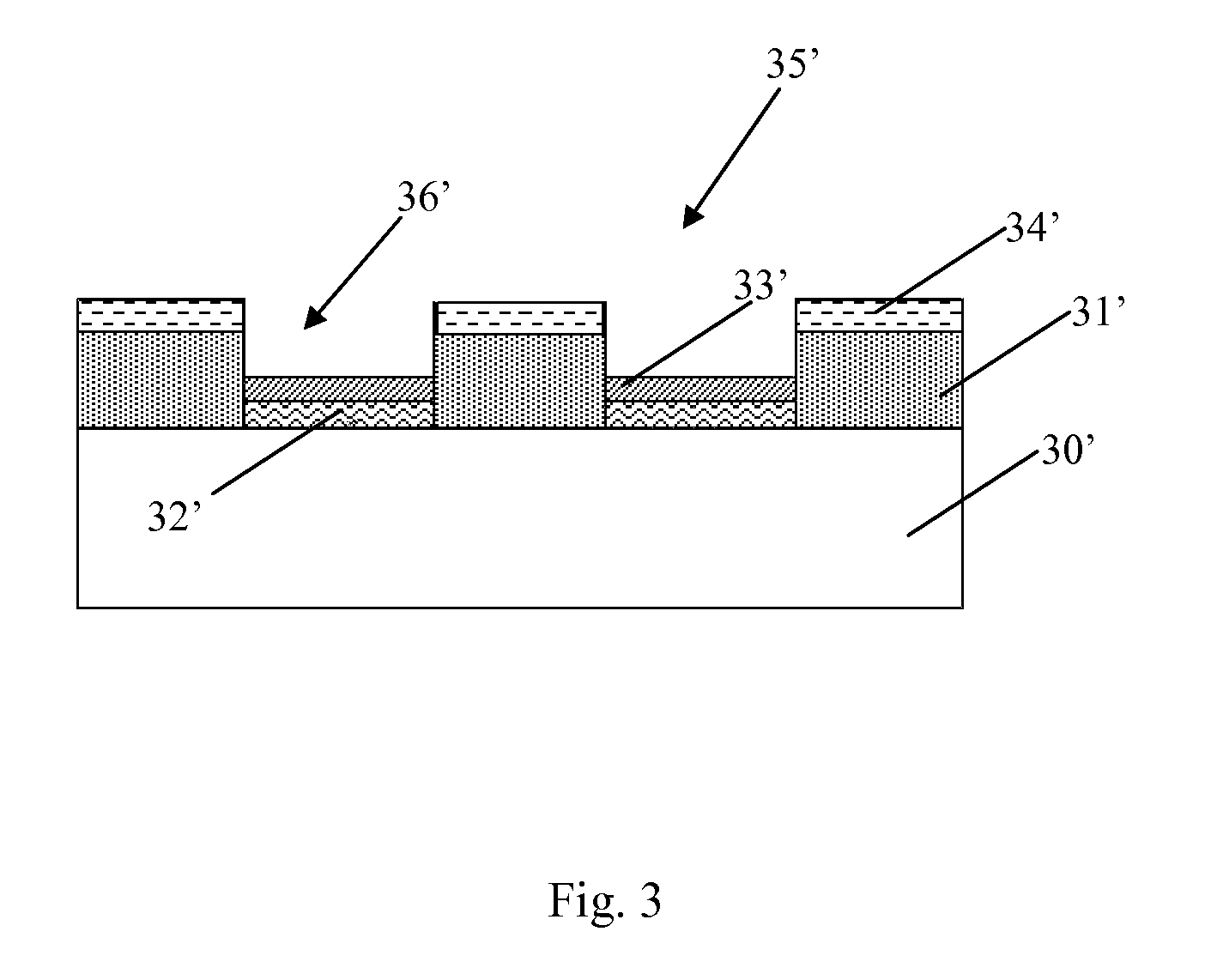

Black silicon based metal-semiconductor-metal photodetector

ActiveUS20120012967A1Design complexProcess complexFinal product manufactureSemiconductor/solid-state device manufacturingPhotodetectorInterdigitated electrode

A black silicon based metal-semiconductor-metal photodetector includes a silicon substrate and a black silicon layer formed on the silicon substrate. An interdigitated electrode pattern structure is formed on the black silicon layer, which can be a planar or U-shaped structure. A thin potential barrier layer is deposited at the interdigitated electrode pattern structure. An Al or transparent conductive ITO thin film is deposited on the thin potential barrier layer. A passivation layer is provided on the black silicon layer. In the black silicon based metal-semiconductor-metal photodetector, the black silicon layer, as a light-sensitive area, can respond to ultraviolet, visible and near infrared light.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

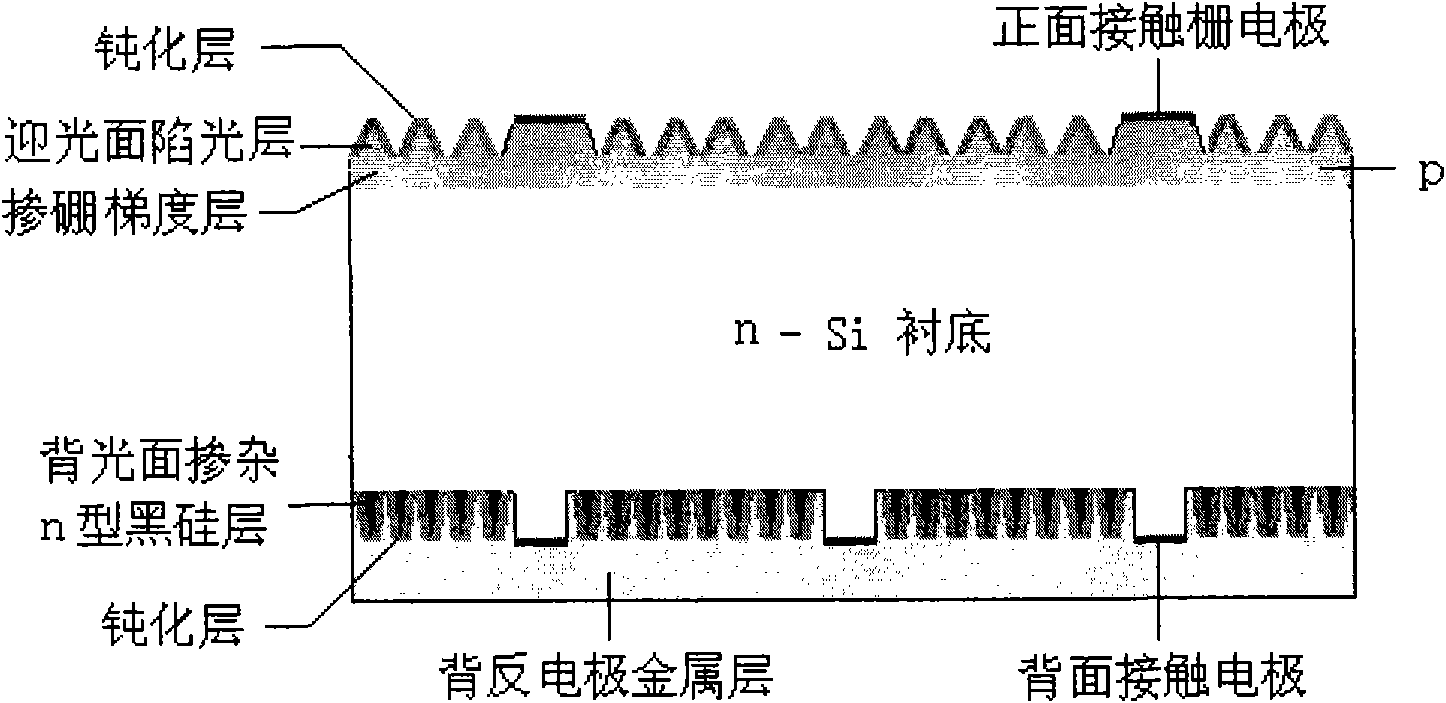

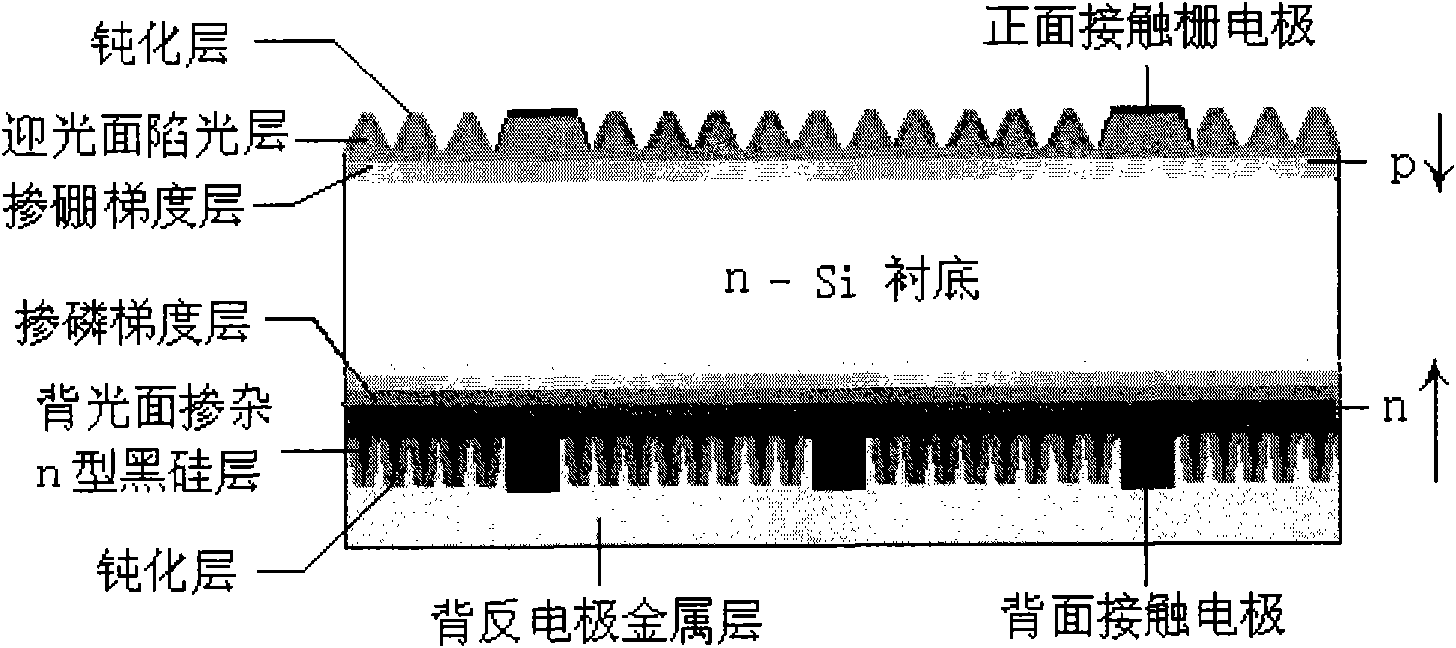

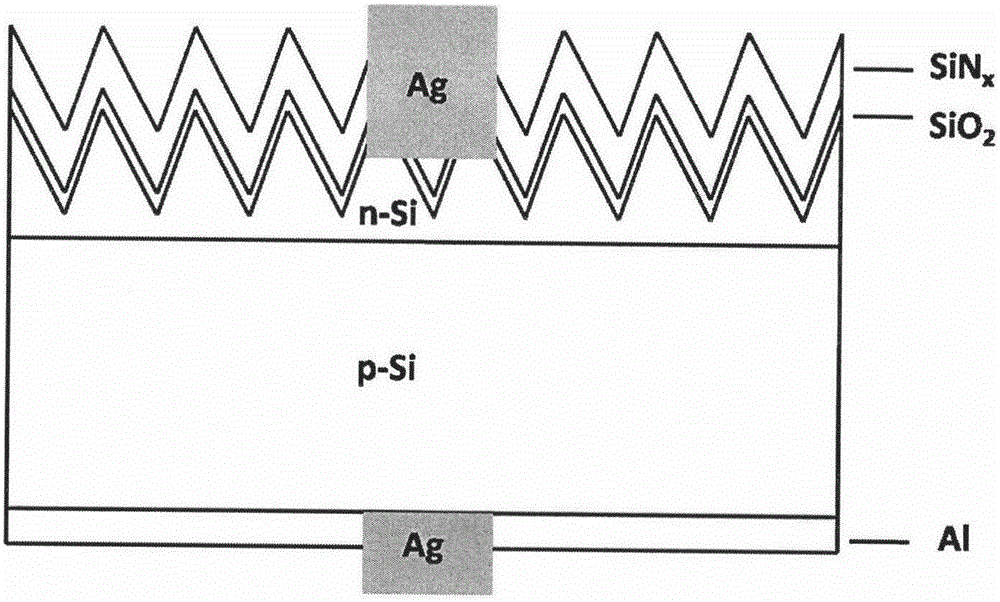

Solar cell having double-sided micro/nano composite structure and preparation method thereof

ActiveCN102110724AReduce reflectivityReduced characteristicsFinal product manufactureNanotechnologySolar cellReflective layer

The invention discloses a solar cell having a double-sided micro / nano composite structure and a preparation method thereof. The solar cell comprises a first micro / nano composite structure which is positioned on the front of the solar cell and a second micro / nano composite structure which is positioned on the back of the solar cell; the first micro / nano composite structure comprises a doped diffusion layer which is manufactured on the surface of a silicon-based substrate, a front micro-scale light absorption layer corroded on the doped diffusion layer, and a front nano-scale black silicon antireflection layer etched on the front micro-scale light absorption layer; the second micro / nano composite structure comprises a back micro-scale light absorption layer corroded on the lower surface of the silicon-based substrate, and a back nano-scale black silicon antireflection layer etched on the back micro-scale light absorption layer. The problems that a black silicon material layer replaces the micro-scale light absorption layer, and the absorption range of the solar spectrum is widened but the conversion efficiency is low in the traditional black silicon solar cell structure are solved.

Owner:PEKING UNIV

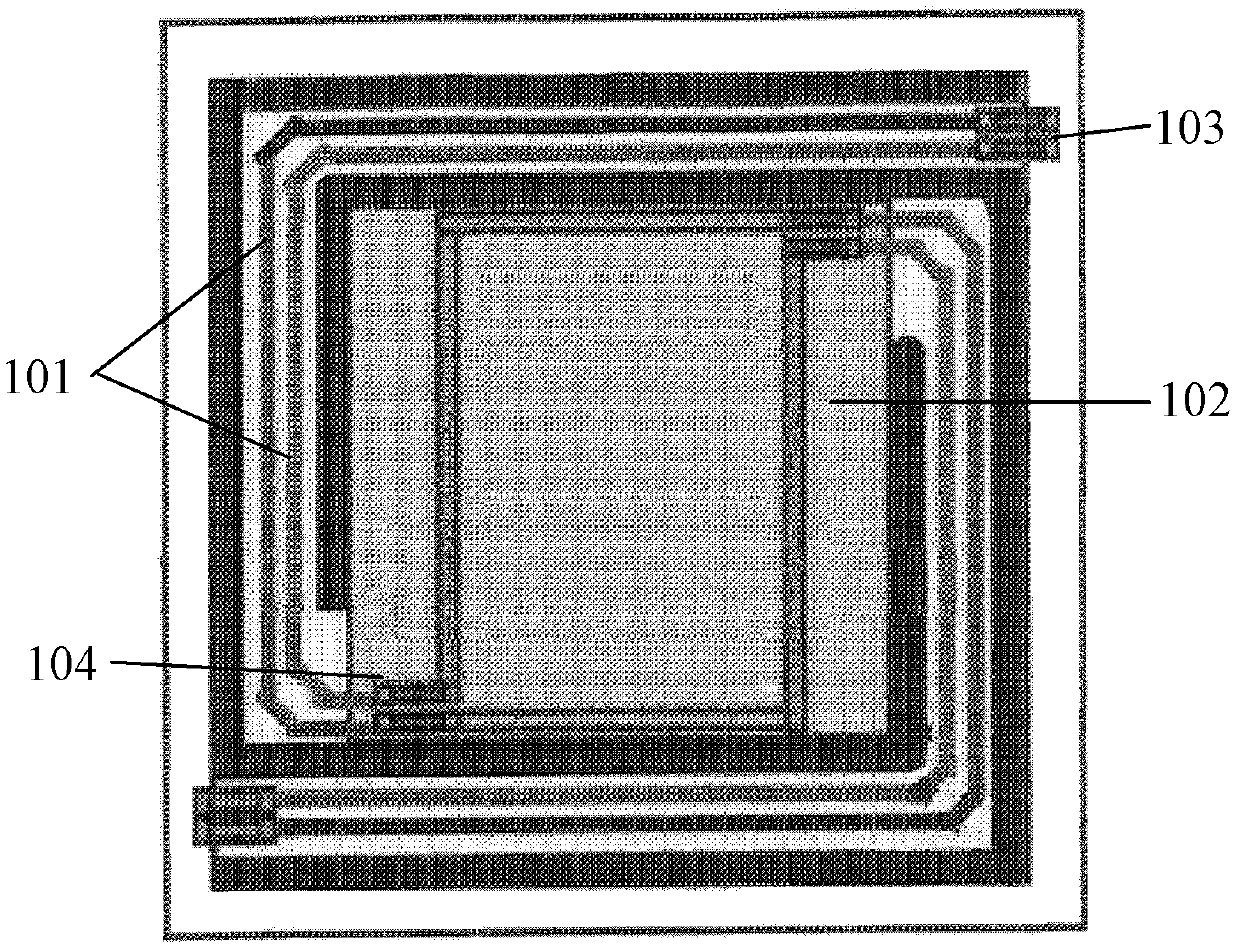

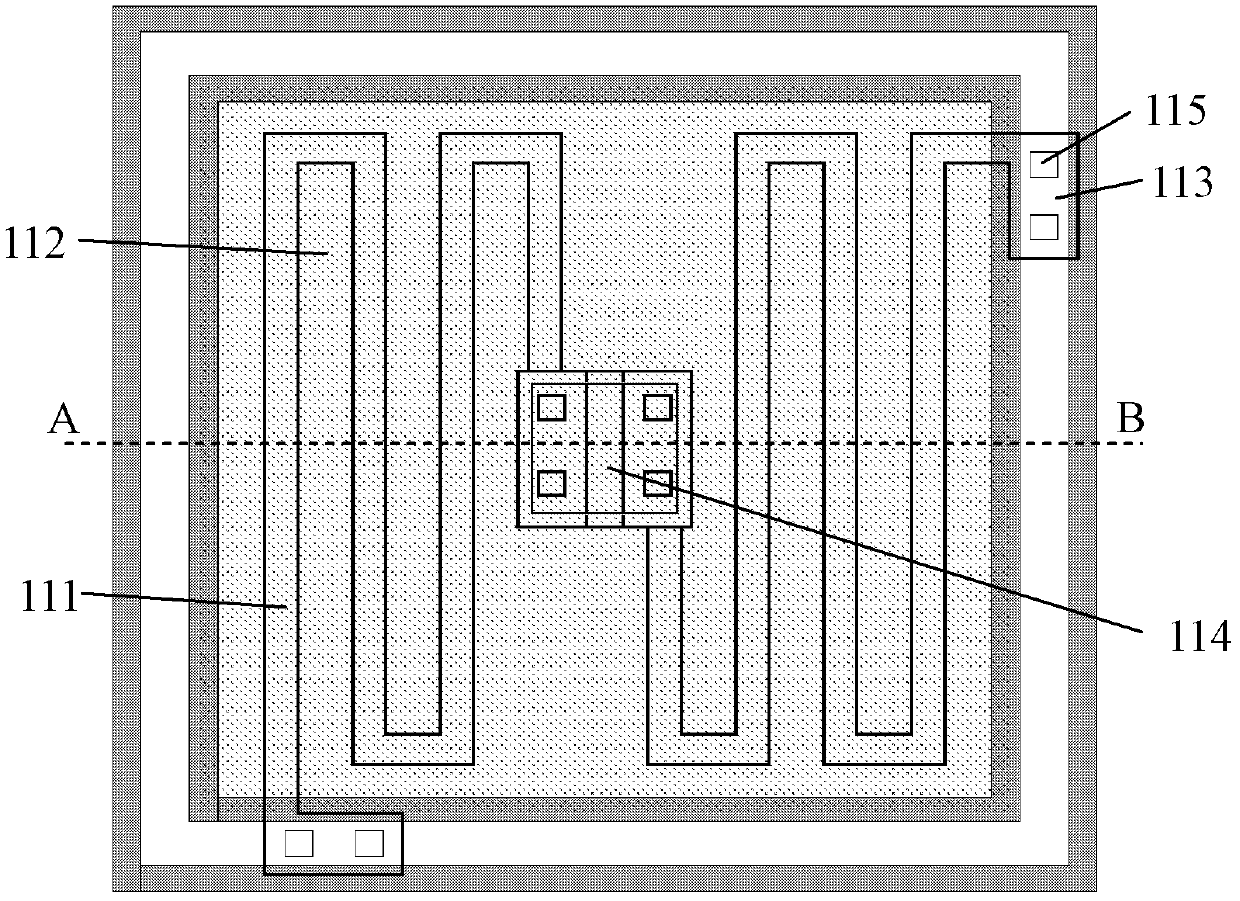

High-performance MEMS (Micro Electro Mechanical System) thermopile infrared detector based on black silicon and preparation method thereof

ActiveCN102829880AImprove response rateImprove the detection rateDecorative surface effectsChemical vapor deposition coatingThermopileEngineering

The invention relates to a high-performance MEMS (Micro Electro Mechanical System) thermopile infrared detector based on black silicon and a preparation method thereof. The high-performance MEMS thermopile infrared detector comprises a substrate, wherein the substrate is provided with a release barrier strip, a heat isolation cavity is arranged in the release barrier strip, a black silicon infrared absorption region is arranged above the heat isolation cavity, thermopiles are arranged on the outer side of the black silicon infrared absorption region, after the thermopiles on the outer side of the black silicon infrared absorption region are connected in series, the thermopiles are electrically connected to a whole body, and the thermopiles, which are connected in series, are provided with metal electrodes for outputting a detection result; the detection cold ends of the thermopiles are connected with the substrate through a first heat conduction and electric isolation structure, and a heat conductor is located on the outer side of a heat isolation cavity; and the detection heat ends of the thermopiles are in contact with the black silicon infrared absorption region through a second heat conduction and electric isolation structure. The high-performance MEMS thermopile infrared detector, provided by the invention, has the advantages of simple and easy implementation, convenience for monolithic integration, high response rate and detection rate, compatibility with a CMOS (Complementary Metal Oxide Semiconductor) process, wide application range, safety and reliable.

Owner:BEIJING ZHONGKE MICRO INVESTMENT MANAGEMENT CO LTD

Method for preparing black silicon structure by Ag-Cu (silver-copper) bimetallic MACE (metal-assisted chemical etching) type

ActiveCN106229386AGood repeatabilityReduce dosageAfter-treatment detailsFinal product manufactureEtchingSolar battery

The invention relates to a method for preparing a black silicon structure with low cost, and belongs to the technical field of photoelectricity. The method comprises the following steps of (1) precleaning a solution; (2) putting the cleaned silicon chip into a mixing solution of H2O2 (hydrogen peroxide), HF (hydrogen fluoride), AgNO3 (silver nitrate), Cu(NO3)2 (copper dinitrate) and ultrapure water, and etching, so as to prepare a black silicon nanometer antireflection structure; (3) optimizing the black silicon structure by a nanometer reconstruction solution, so as to form a uniform inverted pyramid-shaped structure. The method has the advantages that the polycrystalline silicon is performed with chemical etching by an Ag-Cu bimetallic assisting type; compared with the existing Ag-assisted chemical etching type, the consumption amount of AgNO3 is decreased by more than several dozens of times; the technology is simple, the preparation cost of black silicon is reduced, and the batch preparation of large-area black silicon is reduced; the black silicon structure is optimized by the nanometer reconstruction solution, and the huge application potential is realized in the preparation of black silicon solar batteries with high conversion efficiency.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

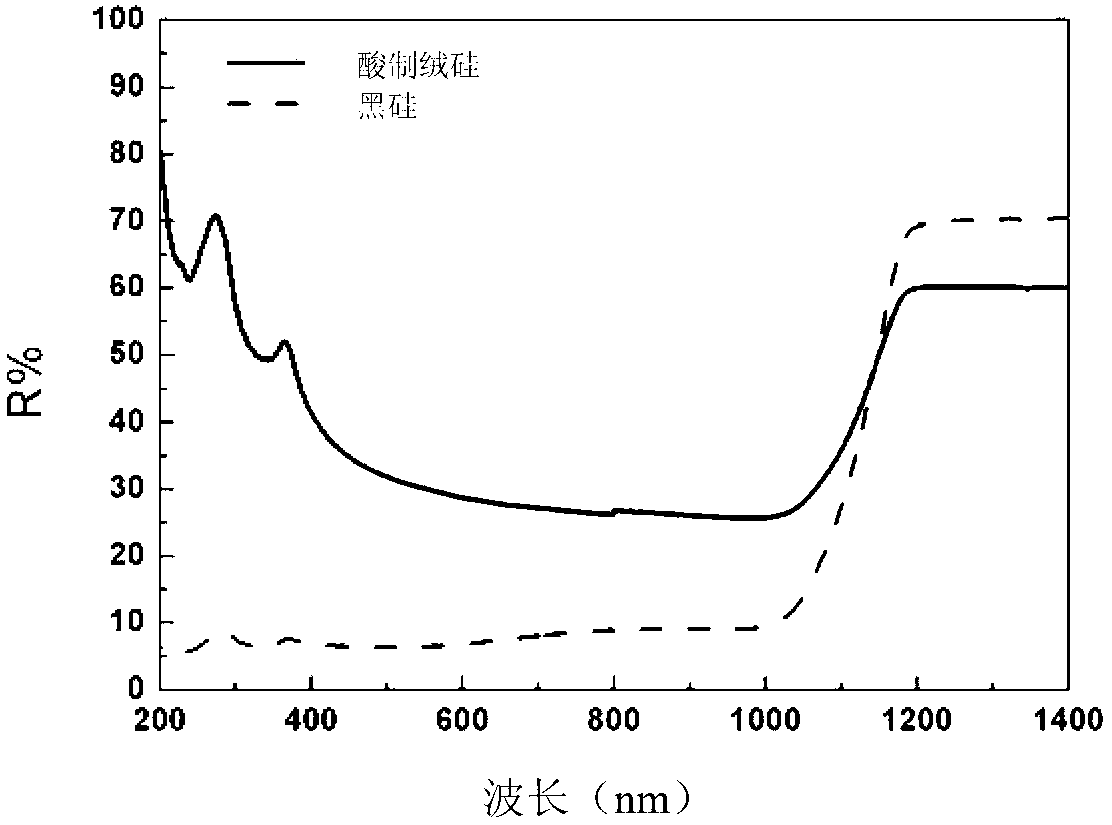

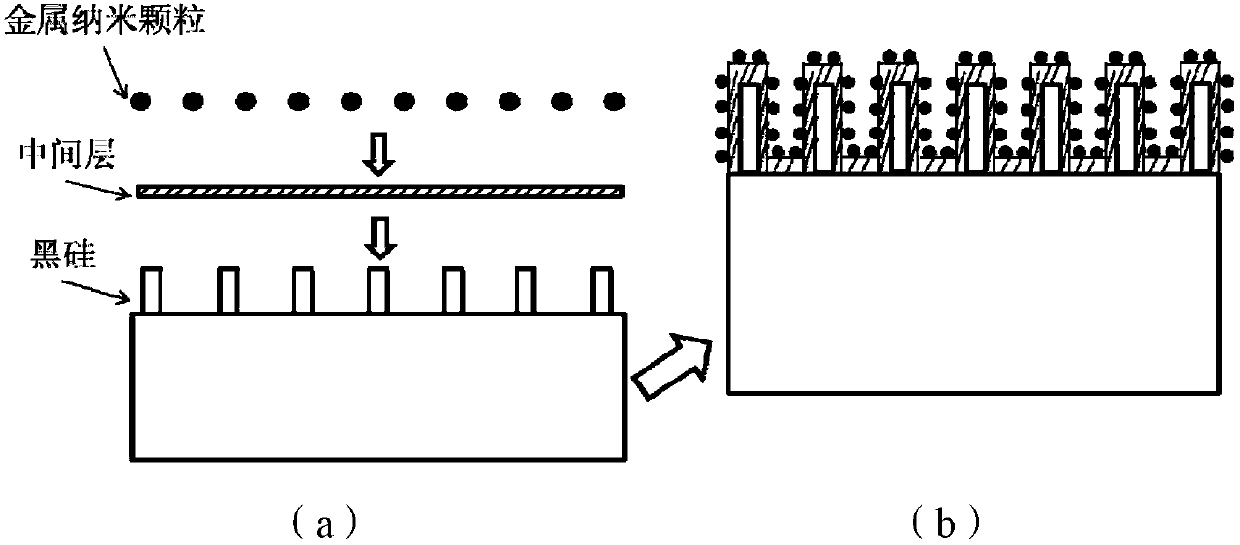

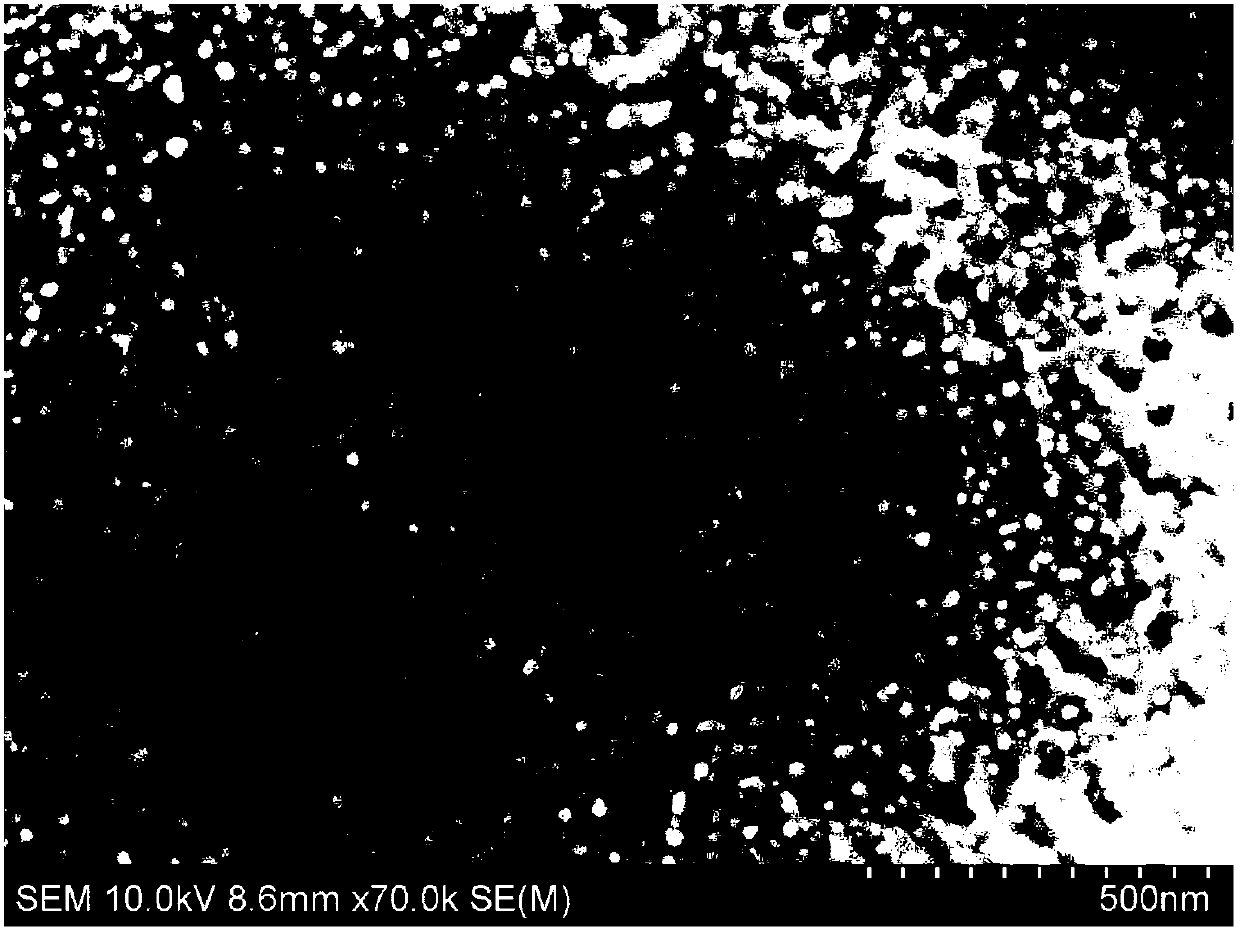

Method for reducing reflection of black silicon in wide band scope

ActiveCN102881769AInhibition reflexHigh outputFinal product manufactureSemiconductor devicesPlasma technologyTrapping

The invention provides a method for reducing reflection of black silicon in a wide band scope. The method comprises the following steps: 1) an intermediate layer is prepared on the surface of the black silicon, wherein the black silicon is silicon with a light trapping structure; 2) metal nanometer particles are deposited on the intermediate layer obtained in the step 1), and are not continuous or not in contact with one another; and 3) annealing processing is performed on a product obtained in the step 2). The method is simple in operation, low in cost, effectively combined with a black silicon technology, a surface isolation protection technology and a surface plasma technology to achieve a reflection reduction effect in the wide band scope, and conducive to the application in the industrial production of solar batteries.

Owner:深圳市石金科技股份有限公司

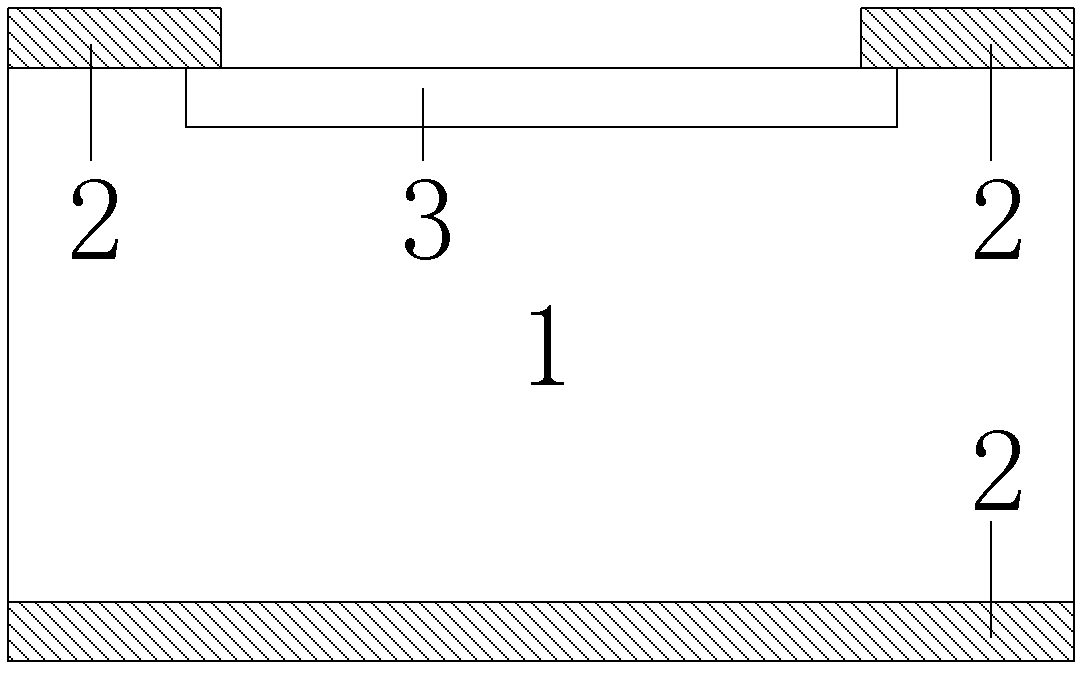

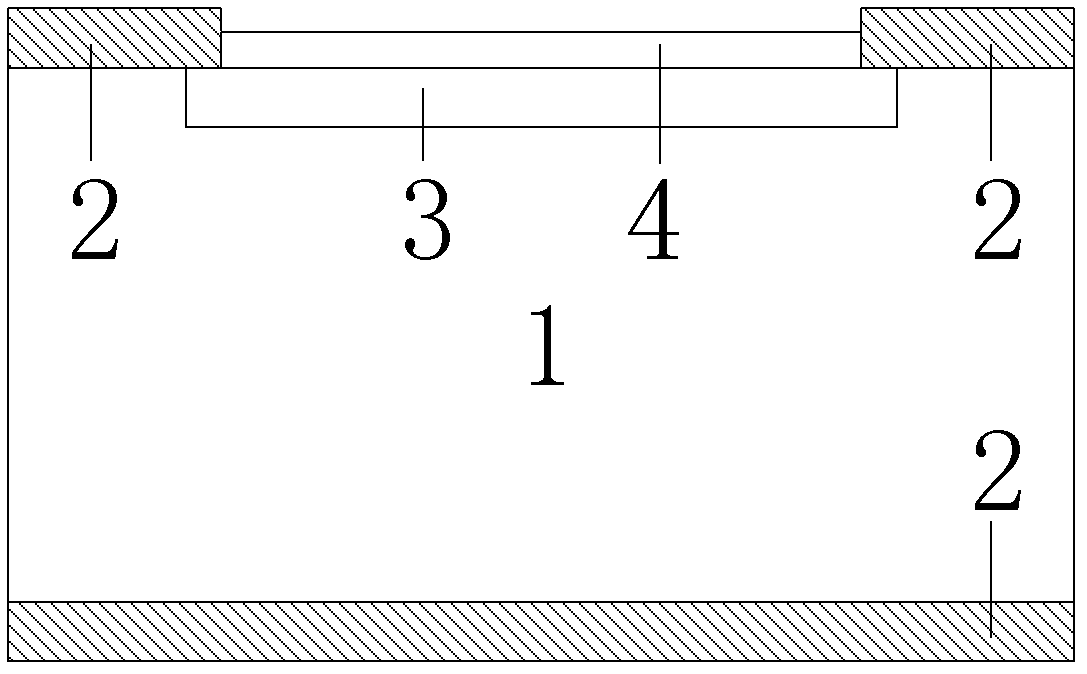

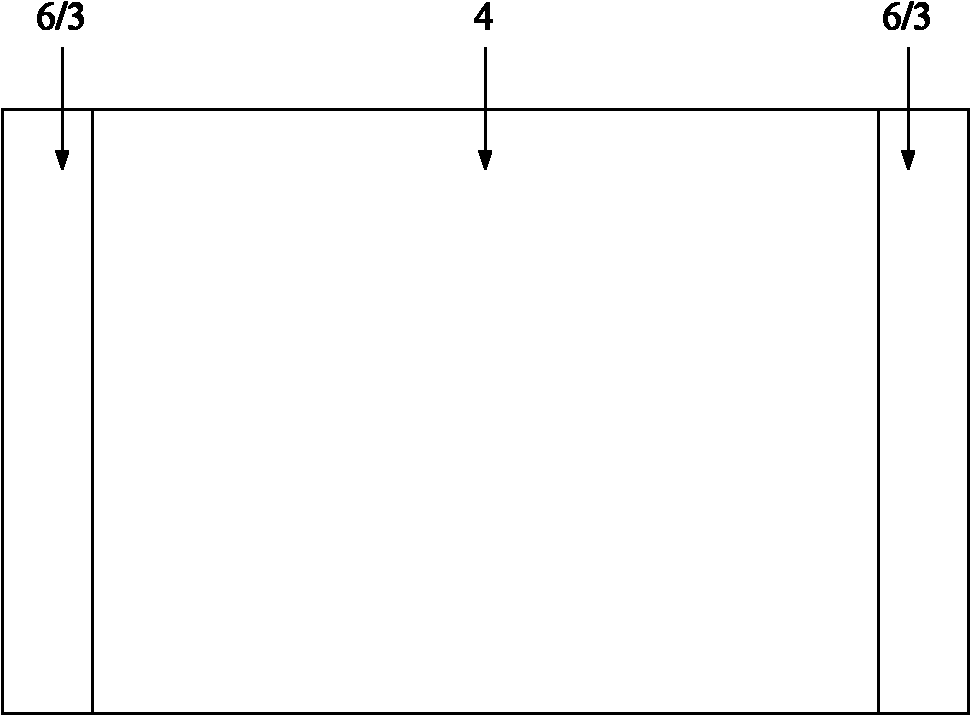

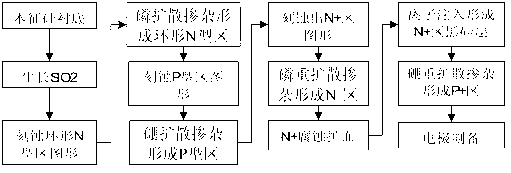

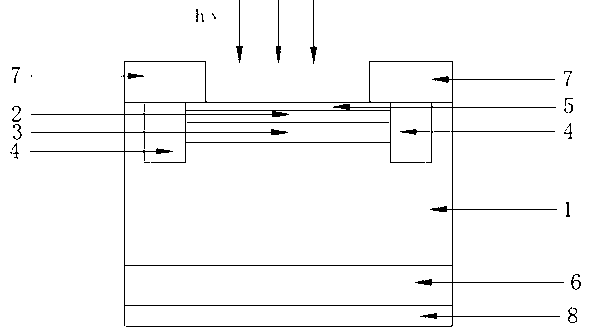

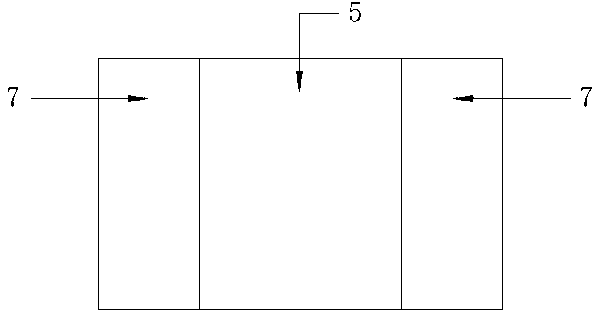

Silicon-avalanche photodetector (Si-APD) with black silicon as photosensitive layer and preparation method thereof

InactiveCN103137773ALarge light signal currentWide response bandRenewable energy productsSemiconductor devicesPhotovoltaic detectorsResponsivity

The invention discloses a silicon-avalanche photodetector (Si-APD) with black silicon as a photosensitive layer and a preparation method of the Si-APD with the black silicon as the photosensitive layer, and belongs to the field of photoelectric detection technology. The Si-APD comprises a silicon intrinsic substrate 1, an N<+> region 2, a P type region 3, an annular N type region 4, an N<+> region black silicon layer 5, a P<+> region 6, an upper electrode 7 and a lower electrode 8, wherein the N<+> region 2 is located in the middle of the upper surface of the silicon intrinsic substrate 1, the P type region 3 is located below the N<+> region, the annular N type region 4 is located on the periphery of the upper surface of the silicon intrinsic substrate, the N<+> region black silicon layer 5 is located on the upper surface of the N<+> region, the P<+> region 6 is located on the lower surface of the silicon intrinsic substrate, the upper electrode 7 is located on the upper surfaces of the N<+> region black silicon layer and the annular N type region, and the lower electrode 8 is located on the lower surface of the P<+> region. According to the Si-PAD, the black silicon material serves as the photosensitive layer, and meanwhile the annular N type region is additionally arranged on the peripheries of the N<+> region and the P type region. Thus, the Si-APD with the black silicon as the photosensitive layer can absorb light waves of a near-infrared band and have higher light absorptivity and a wider response wave band, the preparation technique is simple, the cost is low, and the Si-PAD has the advantages of being easy to integrate, quick in response speed, high in responsivity and wide in response wave band.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com