Preparation method, based on solution method, of polycrystalline solar cell

A solar cell, solution method technology, applied in nanotechnology, circuits, photovoltaic power generation and other directions for materials and surface science, can solve the problems of low conversion efficiency of black silicon cells, achieve low reflectivity, low solution cost, temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

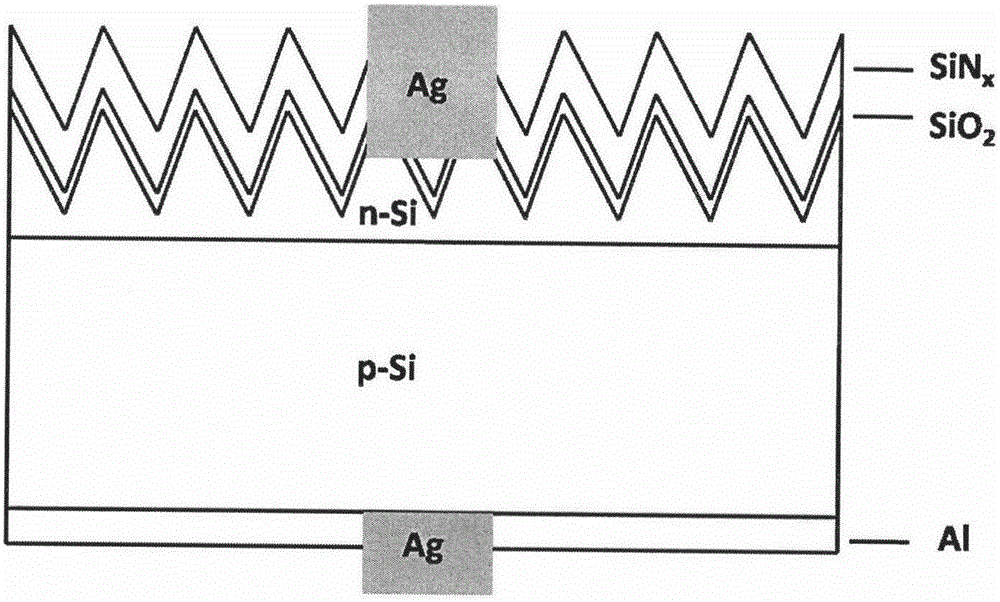

[0026] In order to control the preparation cost of black silicon and improve the conversion efficiency of black silicon cells, an embodiment of the present invention provides a method for preparing polycrystalline solar cells based on a solution method, including:

[0027] (1) cleaning the surface of the silicon wafer;

[0028] (2) Deposit silver nanoparticles on the surface of the silicon wafer, and catalyze and corrode the black silicon nanoporous structure;

[0029] (3) Cleaning the prepared black silicon with NSR and hydrogen peroxide solution to form an inverted pyramid anti-reflection structure on the surface of the silicon wafer;

[0030] (4) After cleaning before diffusion, diffusion is performed in a diffusion furnace to form a PN junction;

[0031] (5) Then wet etching process is used to etch the back junction and edge junction of the diffused silicon wafer, and remove the surface phosphosilicate glass and the diffusion dead layer;

[0032] (6) The silicon oxide in...

Embodiment 1

[0038] (1) In the volume ratio HF (40%): HNO 3 (70%): H 2 Etching was carried out in a solution of O=1:3:2, the time was 3 min, and the temperature was room temperature. The concentration of NaOH solution used to remove the porous silicon is 1%, the time is 30 s, and the temperature is room temperature.

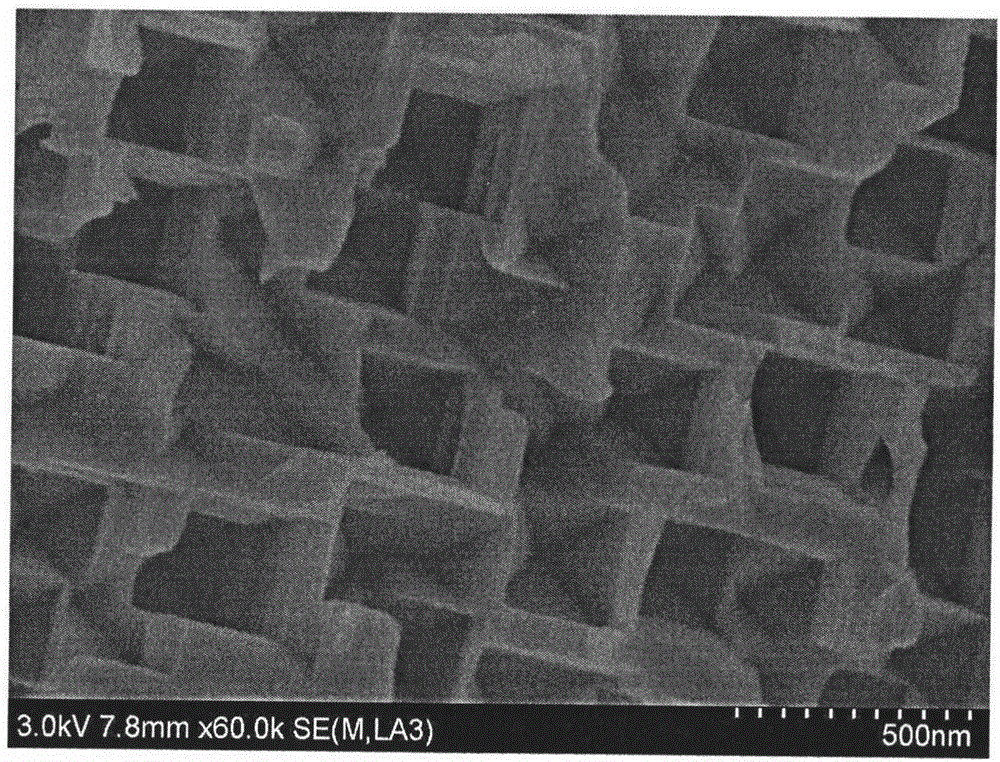

[0039] (2) Deposit a layer of silver nanoparticles on the surface of the silicon wafer immersed in the solution, 0.002MAgNO 3 +4MHF, response time 50s;

[0040] (3) Immerse the silicon wafer deposited with silver nanoparticles in the solution for corrosion, 0.3MH 2 o 2 +1.5MHF to obtain nano-hole structure, the reaction time is 180s. ;

[0041] (4) immerse the etched black silicon wafer in the solution for cleaning, remove residual silver nanoparticles, H 2 o 2 : NH 4 OH=1:3, the reaction time is 180s;

[0042] (5) Immersing the prepared black silicon into the solution for etching to prepare an inverted pyramid black silicon structure. Utilizing the anisotropic cor...

Embodiment 2

[0045] Prepare a solar cell with the structure described in Example 1:

[0046] Pre-cleaned in HCl and HF solutions, the N-type emitter in the PN junction is made of POCl 3 It is obtained by diffusion, the diffusion temperature is 825°C, and the rear resistance of diffusion is 70Ω / sq; the wet etching process mainly uses HF and HNO 3 solution to etch the back junction and edge junction, and then use dilute HF solution to remove the surface phosphosilicate glass; in HNO 3 (69%): H 2 O=1:3 solution in a water bath for 30 minutes at a temperature of 80°C to prepare a very thin inner layer of silicon oxide passivation layer; then PECVD deposited 85nm SiN x , deposited onto the black silicon emitter surface. When screen-printing electrodes, the back side is made of aluminum paste, and the front and back grid electrodes are made of silver paste. Finally, a rapid heat treatment is carried out in a chain sintering furnace.

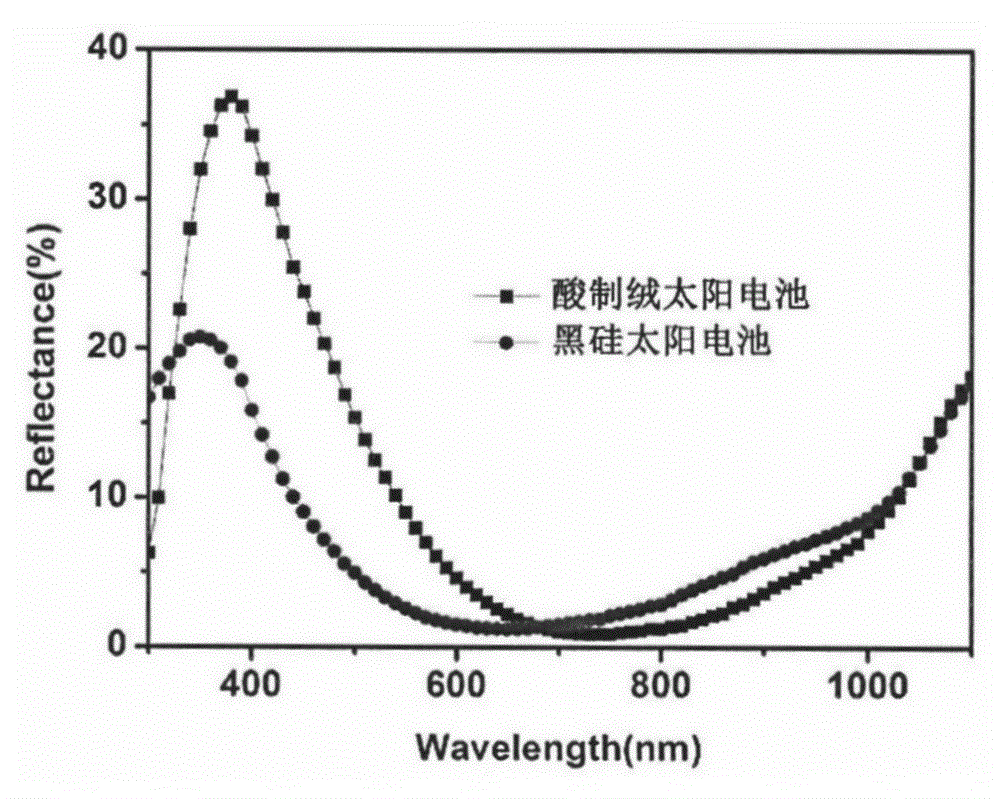

[0047] The result of the embodiment: compared with the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com