Patents

Literature

419 results about "Photovoltaic industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photovoltaic industry. Photovoltaics (PV) convert solar energy into direct current electricity using semiconducting materials that exhibit the photovoltaic effect. A photovoltaic system employs solar panels composed of a number of solar cells to supply usable solar power.

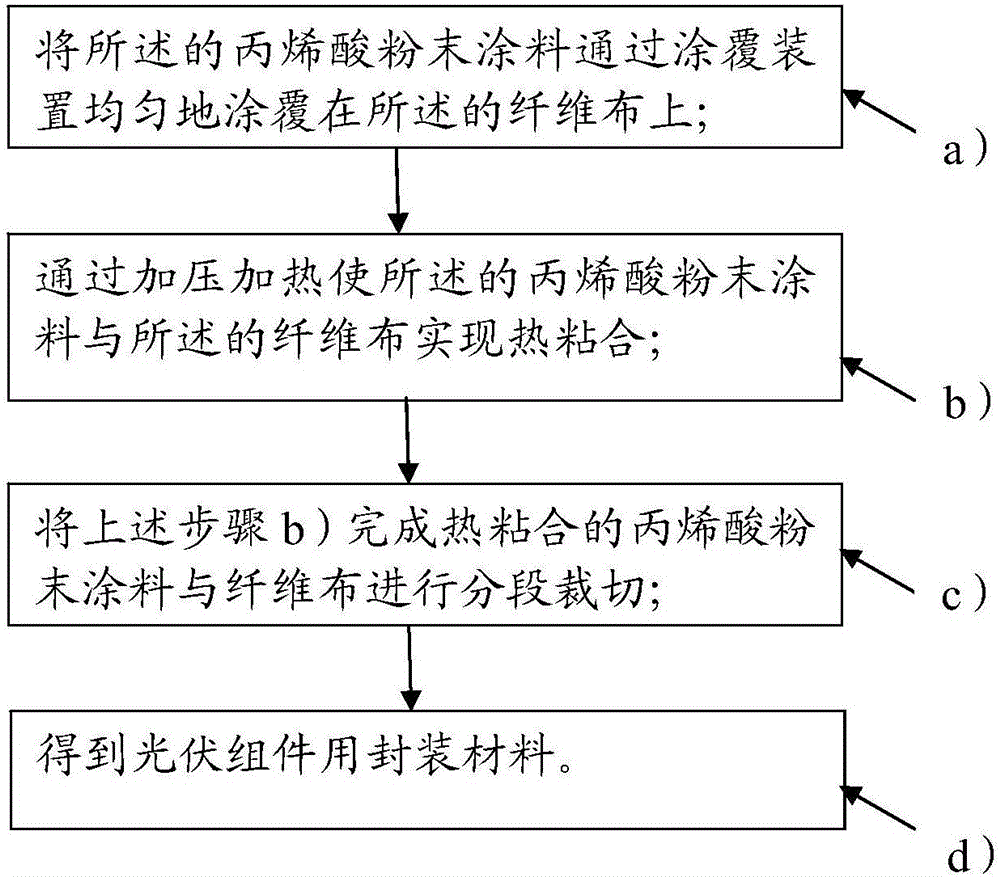

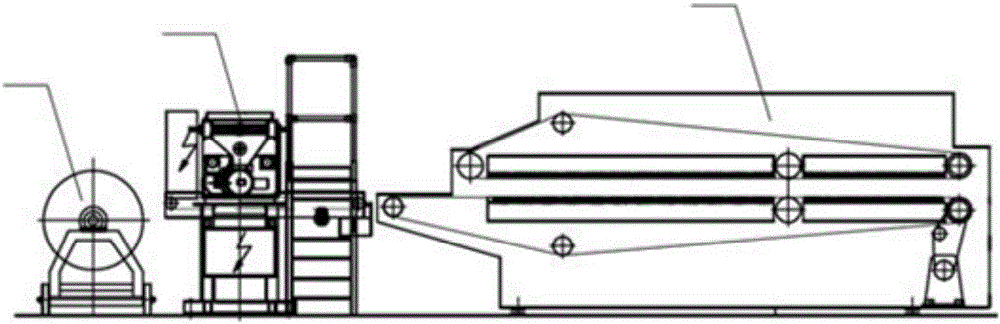

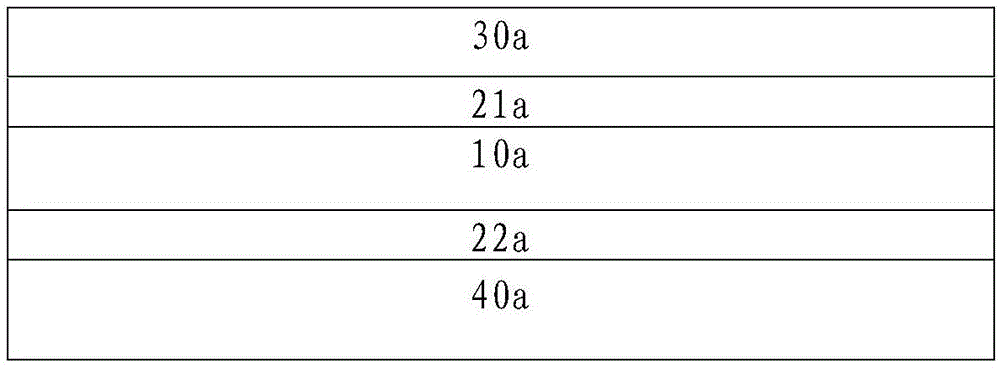

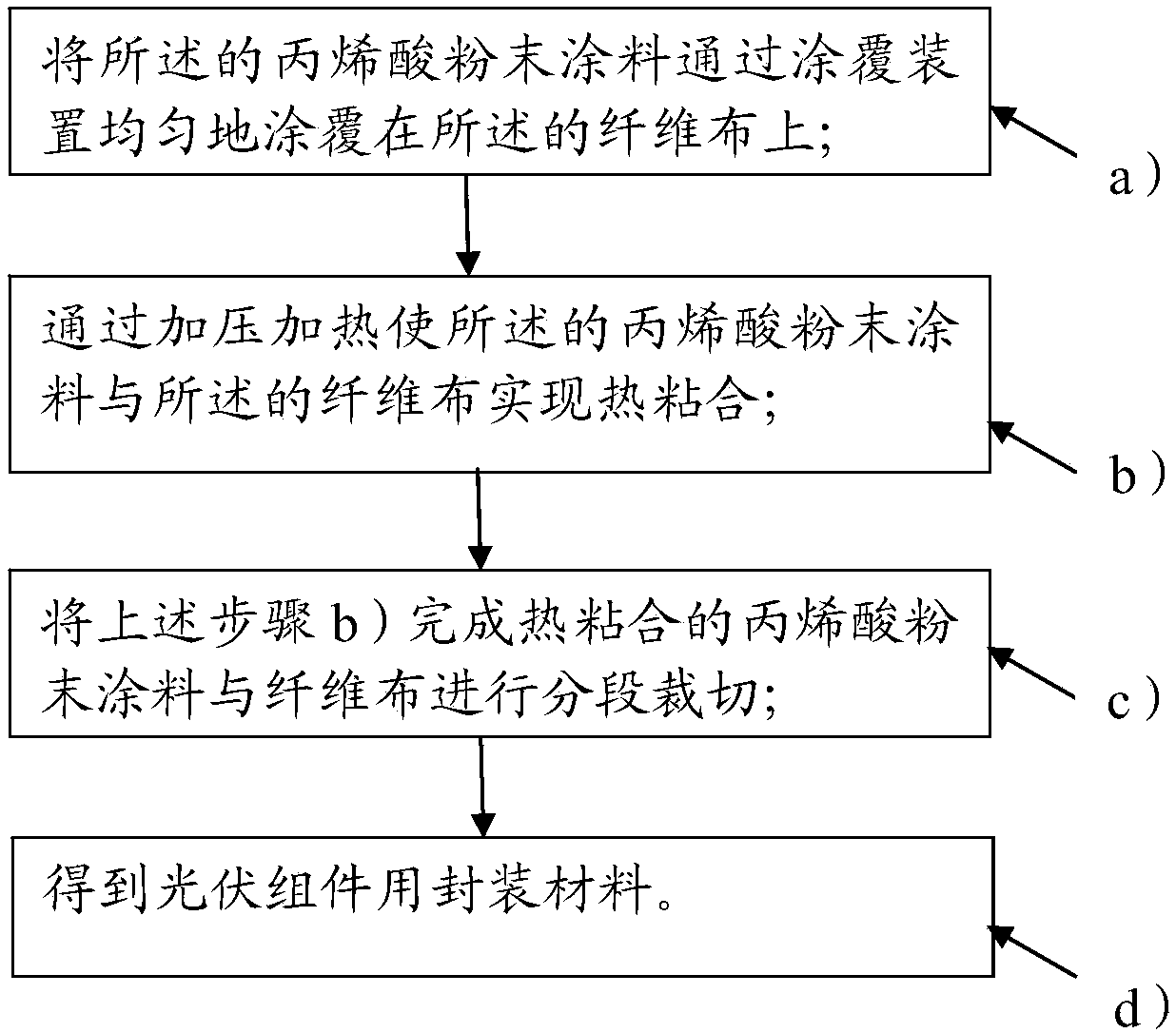

Packaging material for photovoltaic module and preparation method of the packaging material

ActiveCN106299000AReduce weightReduce installation costsFinal product manufactureFibre treatmentFiberPhotovoltaic industry

The invention discloses a packaging material for a photovoltaic module. The packaging material comprises the following raw materials in parts by weight: 30-50 parts of fiber cloth produced from fiber material through weaving; and 50-70 parts of acrylic powder coating including acrylic resins and a curing agent. The acrylic powder coating is evenly spread on the fiber cloth. The packaging material is low in manufacturing cost. While meeting the prerequisites of resistance to ultraviolet, aging, impact and fire which are standard requirements of the photovoltaic industry, the packaging material solves the problem of lightweight photovoltaic module packaging material, makes installation more convenient, reduces the installation cost, and thus is very suitable for large-scale promotion and application in the photovoltaic field. The invention also discloses a preparation method of the packaging material for a photovoltaic module. The method meets installation requirement for changing the packaging size of a photovoltaic module at will to adapt to different buildings and thus further facilitates installation and application of photovoltaic modules.

Owner:TIGER DRYLAC TAICANG +1

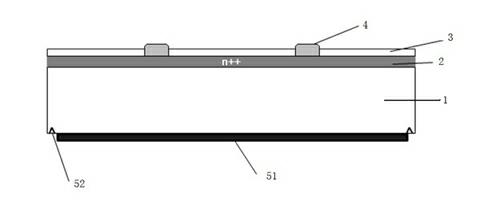

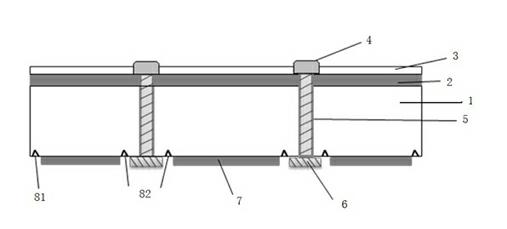

Preparation method of MWT (Metal Wrap Through) solar cell

ActiveCN102208486AImprove efficiencyBusbarPhotovoltaic energy generationSemiconductor devicesPhotovoltaic industryChemical solution

The invention discloses a preparation method of an MWT (Metal Wrap Through) solar cell, comprising the following steps of: (1) carrying out phosphorous diffusion by using a p-type crystal silicon substrate; (2) etching one surface of the crystal silicon substrate by using a chemical solution to remove a phosphorous diffused layer so as to form a polished surface; (3) depositing a passivated antireflective film on the other surface of the crystal silicon substrate to form a light receiving surface; (4) forming a conductive through hole on the crystal silicon substrate by using laser lights; (5) filling a conductive silver paste into the conductive through hole by using a wire mesh on the polished surface so as to form an emitter contact electrode; (6) printing an aluminum paste on the polished surface by using a wire mesh so as to form a base contact electrode; (7) printing a silver contact grid line on the light receiving surface and connecting the silver contact grid line with the conductive through hole; and (8) forming the ohmic contact between a metal and the silicon substrate through sintering so as to finish the solar cell making process. The preparation method of the MWT (Metal Wrap Through) solar cell, disclosed by the invention, has the advantages of simple process flow and easiness in operation, is completely compatible with a solar cell production line widely applied in the current photovoltaic industry and is suitable for mass production.

Owner:JA SOLAR TECH YANGZHOU

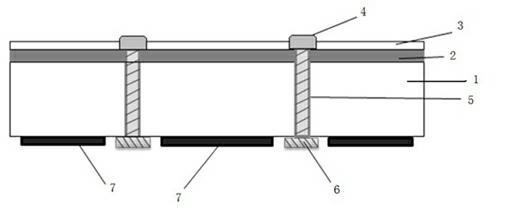

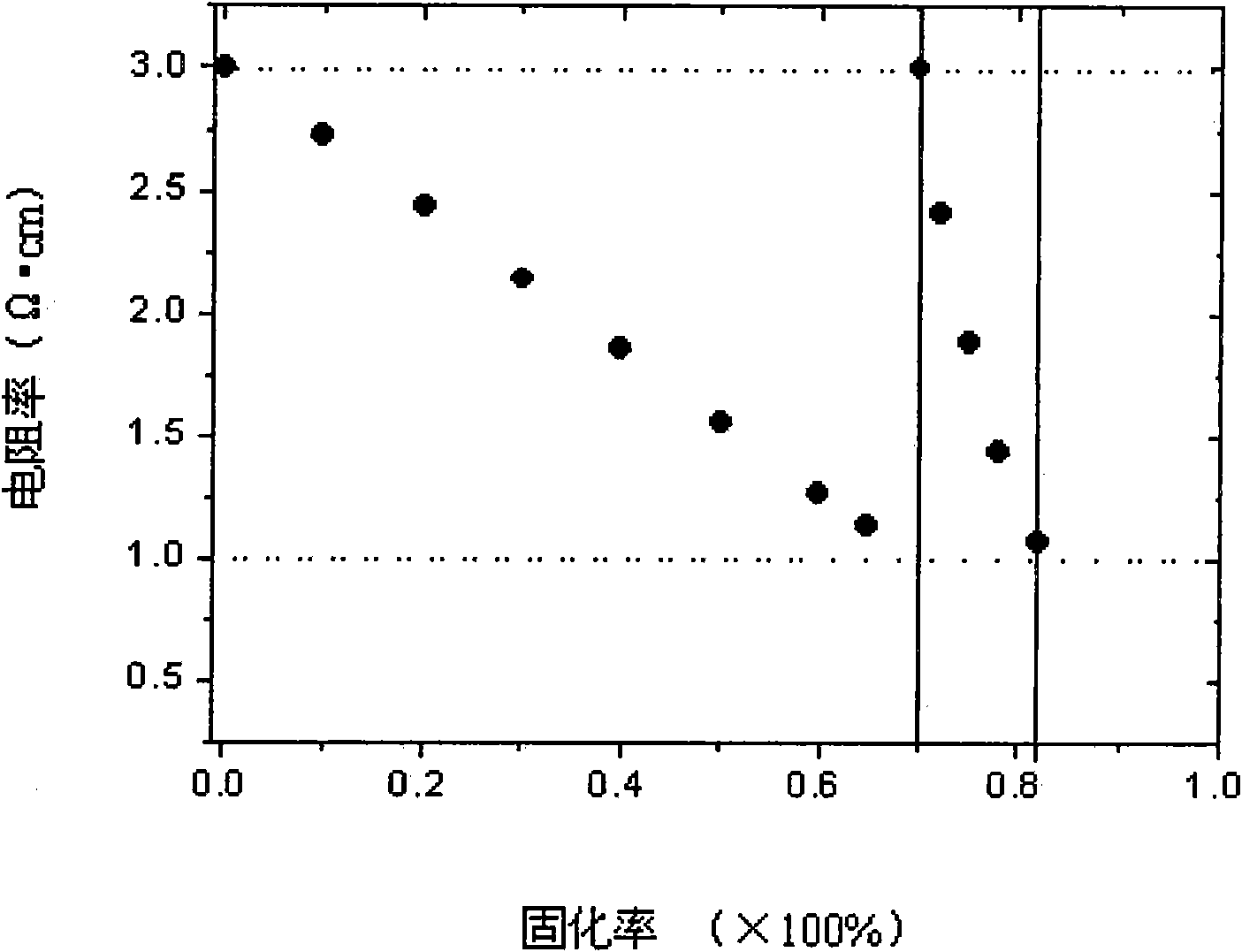

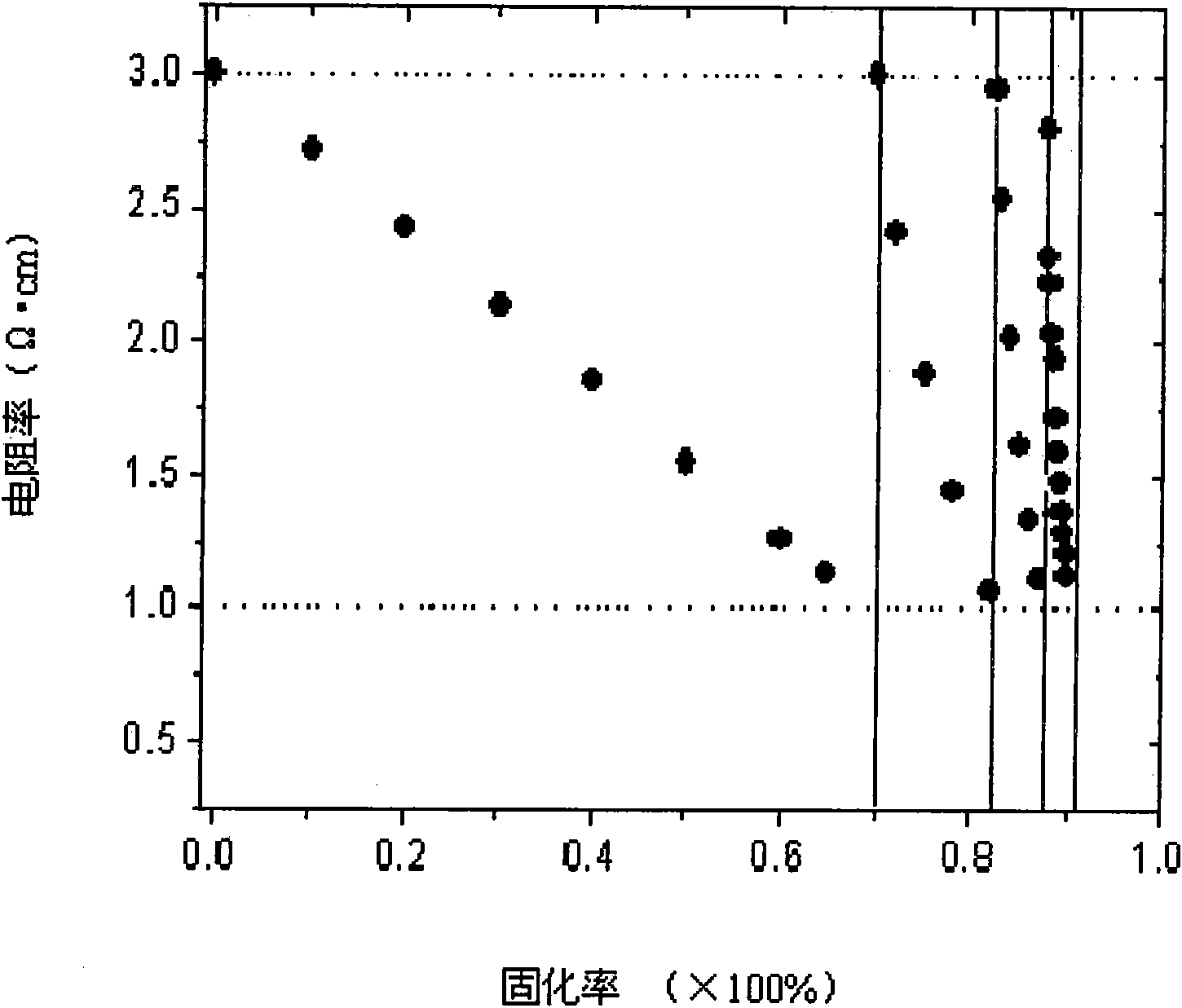

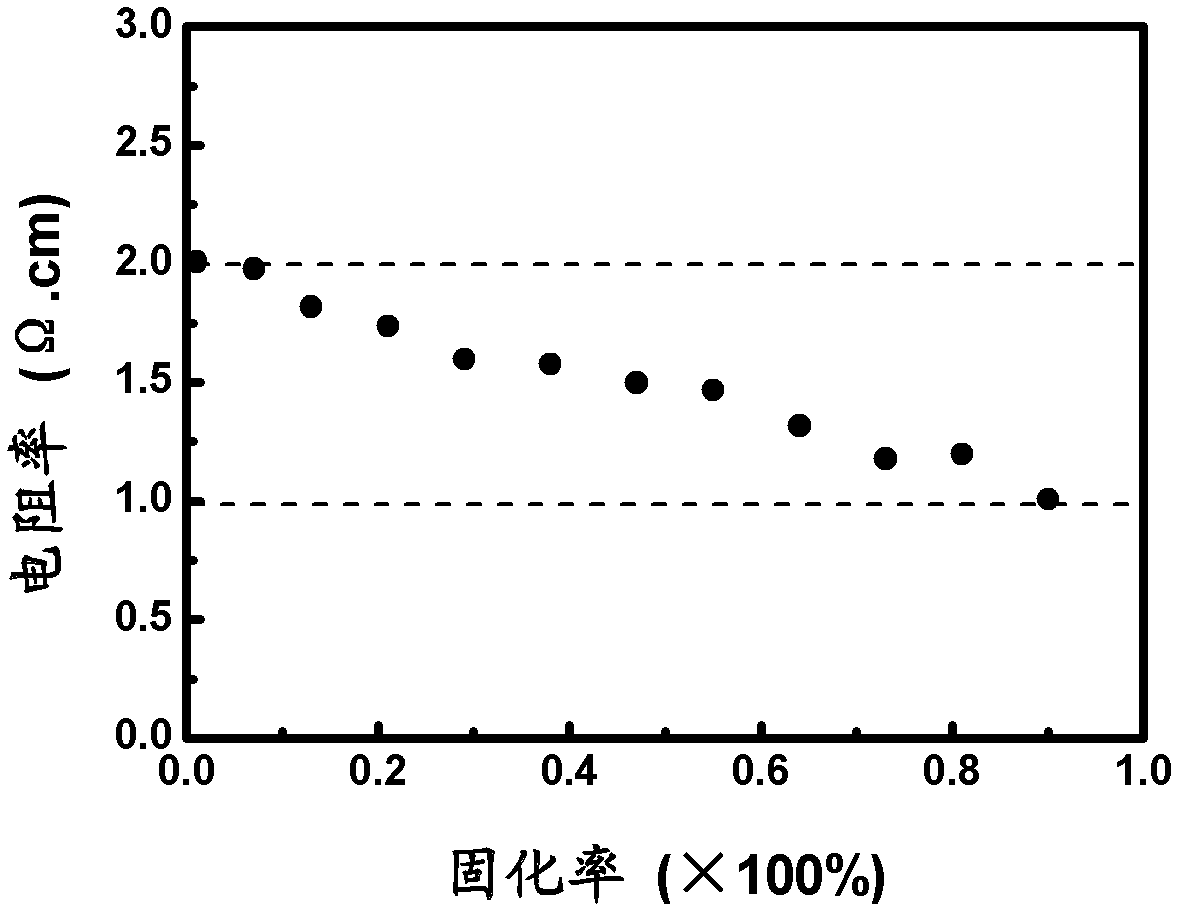

Method for controlling specific resistance of gallium-doped Czochralski silicon in crystal growth process

InactiveCN101654804AIncrease profitReduce manufacturing costBy pulling from meltDopantPhotovoltaic industry

The invention discloses a method for controlling the specific resistance of gallium-doping Czochralski silicon in the crystal growth process, which comprises the following steps: melting multi-crystalsilicon in vacuum or under the protection of argon, melting gallium in the silicon solution to form a gallium-doping silicon solution, and growing the single crystal of the Czochralski silicon; in the crystal growth process, when the specific resistance of the crystal is 1.2-1.0 omega cm, doping the n type dopant-phosphorus with certain concentration in the residual gallium-doping silicon solution to form a phosphorus and gallium-doped silicon solution for continuously growing, and enabling the specific resistance of the crystal to be regulated to 3.0 omega cm again; and when the curing ratioof the crystal reaches 80-90%, stopping the growth. The phosphorus doping process in the residual gallium-doped silicon solution can be carried out many times. The invention can control the specificresistance of the back half part of the single crystal of the gallium-doped Czochralski silicon in the range of 1-3 omega cm to be favorable for increasing the utilization ratio of silicon materials in the process of preparing high-efficiency solar batteries, thus the manufacturing cost of the high-efficiency batteries is greatly reduced, and the method has simple operation and can be easily applied to the photovoltaic industry in a large scale.

Owner:ZHEJIANG UNIV

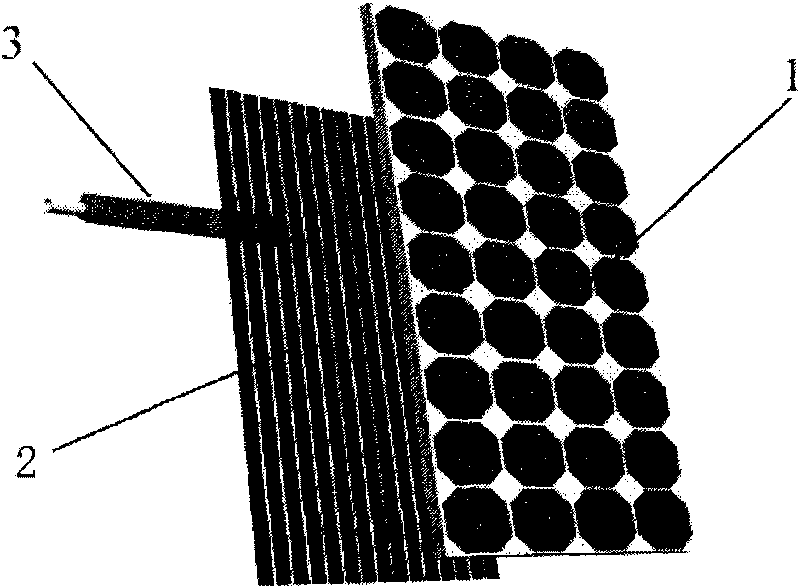

High-efficient solar photovoltaic cell heat dissipating device and electricity and heat cogeneration system

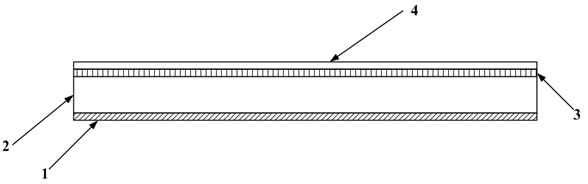

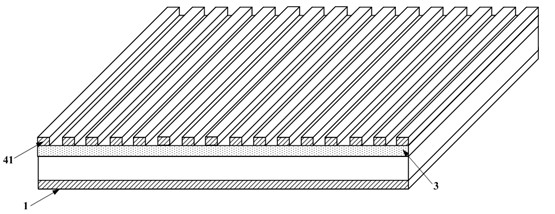

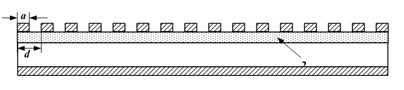

ActiveCN101764167AIncrease temperatureImprove utilization efficiencySolar heating energySolar heat devicesPhotovoltaic industryCells panel

The invention discloses a high-efficient solar photovoltaic cell heat dissipating device and an electricity and heat cogeneration system, which relates to the solar utilization technology. The high-efficient solar photovoltaic cell heat dissipating device is used for the heat dissipation of a solar photovoltaic cell panel. The high-efficient solar photovoltaic cell heat dissipating device is characterized in that the device comprises a flat heat pipe and a tube-on-sheet heat exchanger; the flat heat pipe comprises a front panel and a rear panel; the front panel is directly or indirectly clung to the backboard of the cell panel and covers the whole backboard of the cell panel; the tube-on-sheet heat exchanger is attached to the rear panel of the flat heat pipe; in case of having no influence on the combination of the cell panel and the building surface and of being used as building member, the high-efficient solar photovoltaic cell heat dissipating device can rapidly transfer away the heat of the cell panel, which is rapidly absorbed by a heat absorption plane of the flat heat pipe, from a through pipe by a cooling medium, i.e. water or antifreeze solution and the like, through the tube-on-sheet heat exchanger so as to effectively prevent the temperature rise of the cell panel; and the high-efficient solar photovoltaic cell heat dissipating device can also form the electricity and heat cogeneration system to effectively utilize the transferred heat to output hot water so as to sufficiently improve the solar utilization efficiency and reduce the cost of the solar photovoltaic industry.

Owner:CHANGZHOU HETONG PURUN ENERGY TECH CO LTD

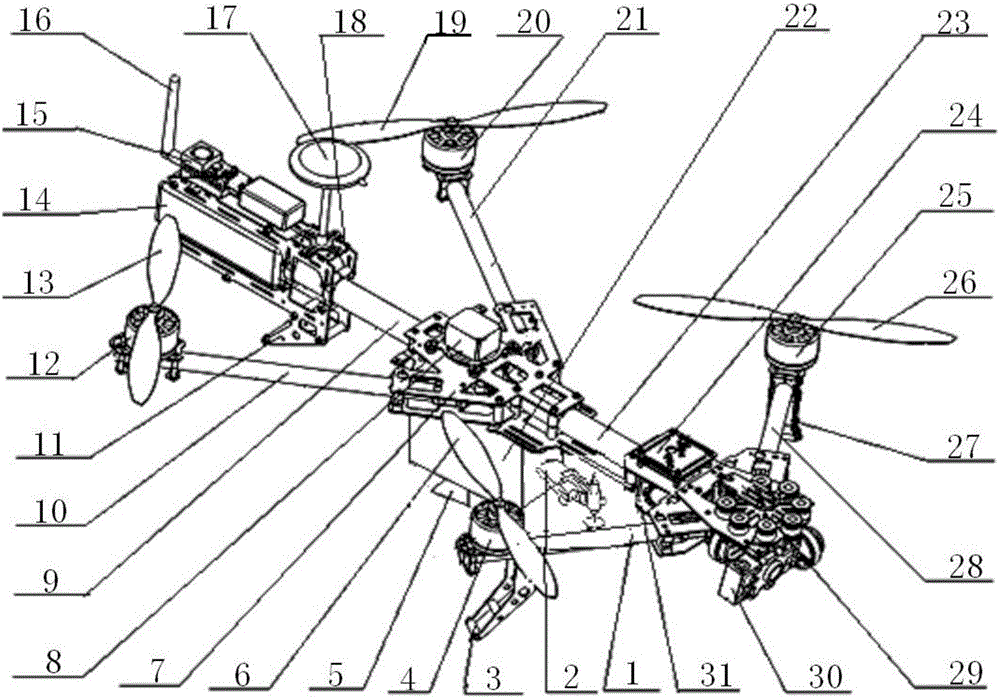

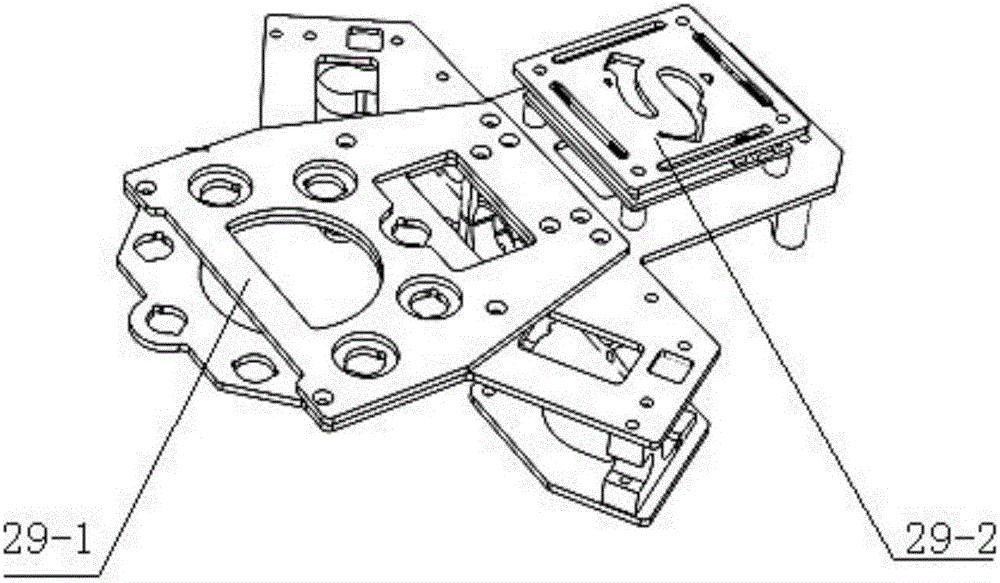

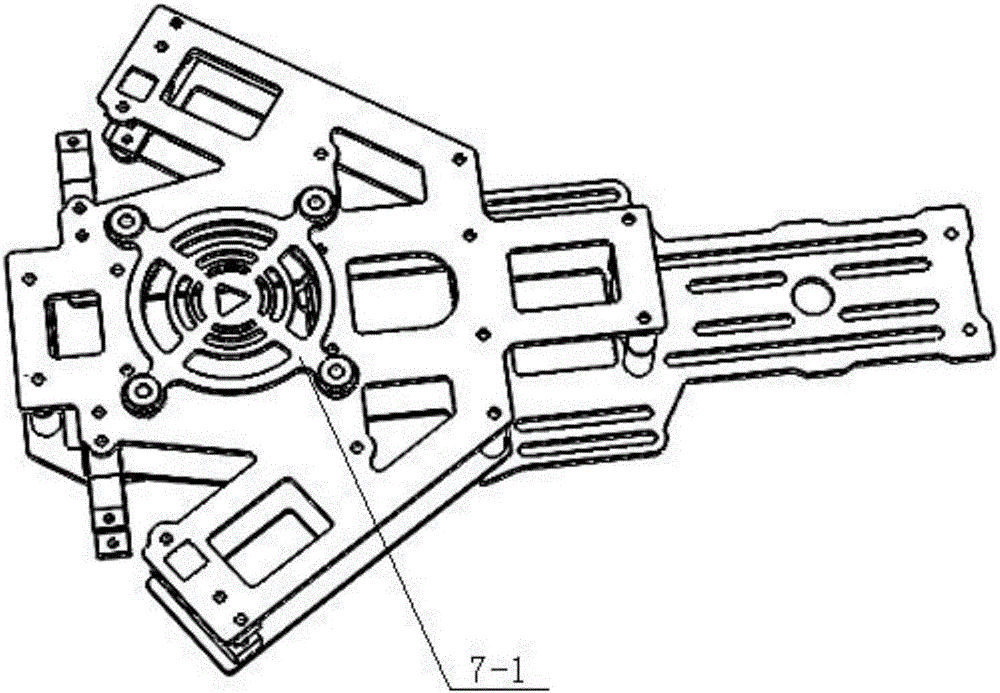

Photovoltaic panel monitoring and cleaning aerial robot system and photovoltaic panel cleaning method

ActiveCN105799910AMonitor Surface CleanlinessRealize real-time wireless monitoringCleaning using toolsCleaning using gasesPhotovoltaic industryTransceiver

The invention relates to a photovoltaic panel monitoring and cleaning aerial robot system and a photovoltaic panel cleaning method. The system comprises a quadrotor unmanned aerial vehicle, a cleaning device, a monitoring device, a wireless transceiver, a GPS positioning device, a main controller and a remote controller, wherein the monitoring device is composed of a camera, a cradle head and a cradle head controller, the cleaning device is composed of a robot arm and an electric nozzle, a lithium battery, the wireless transceiver, an airborne antenna and the GPS positioning device are integrated on the tail portion, the lithium battery and the wireless transceiver are both connected with the main controller, and a flight remote control handle, a cleaning remote control handle and an LCD are arranged on the remote controller. The unmanned aerial vehicle airborne wireless telemetry technology and the cleaning robot arm are combined, the clean states of photovoltaic cell panels are monitored through the remote control device, the photovoltaic cell panels needing to be cleaned are cleaned with an airborne cleaning robot, targeting property is high, cleaning efficiency can be improved greatly, and a big problem in the photovoltaic industry is solved.

Owner:辽宁宏成电力股份有限公司

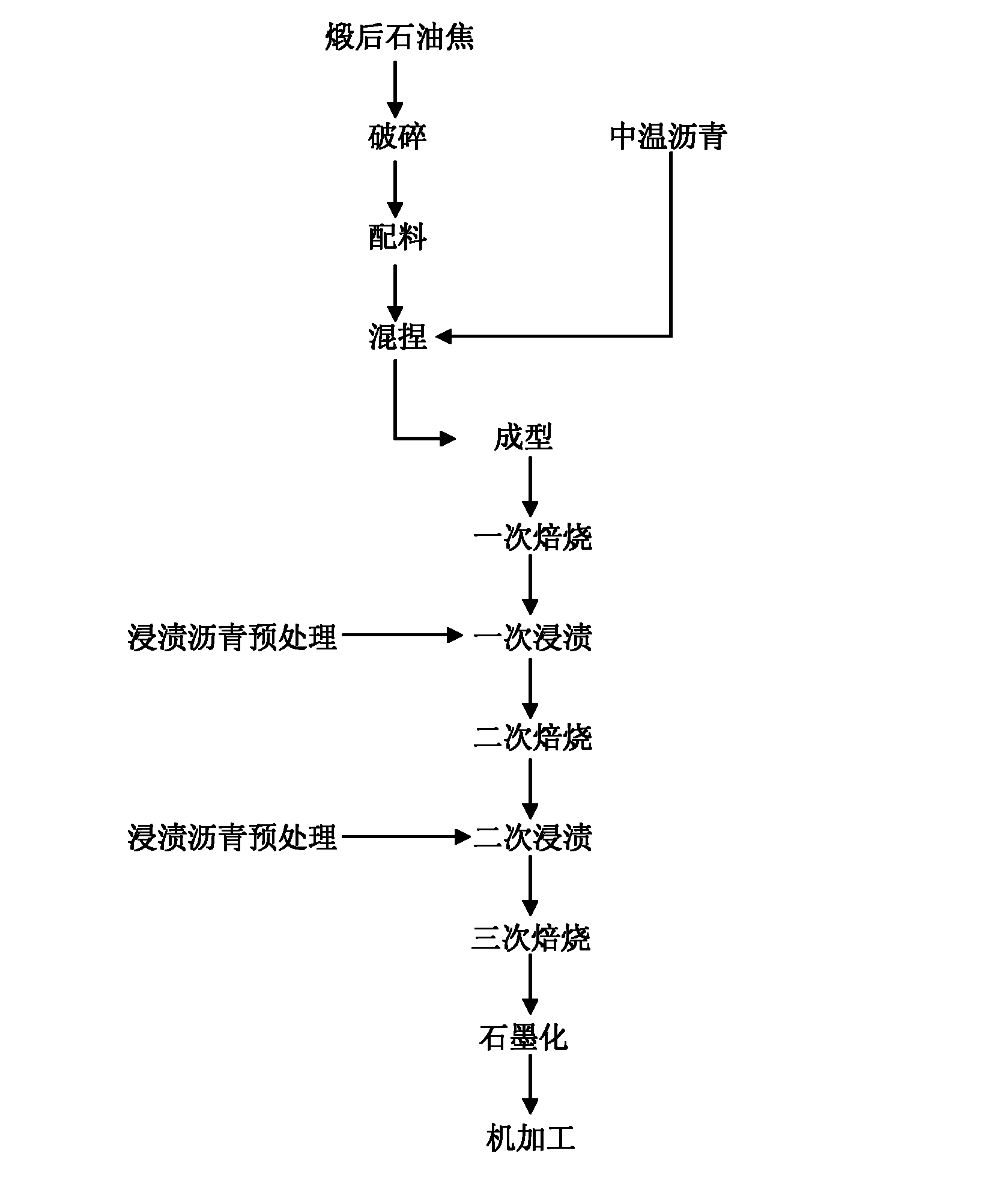

Graphite material for monocrystalline silicon growth thermal field in solar photovoltaic industry and production method thereof

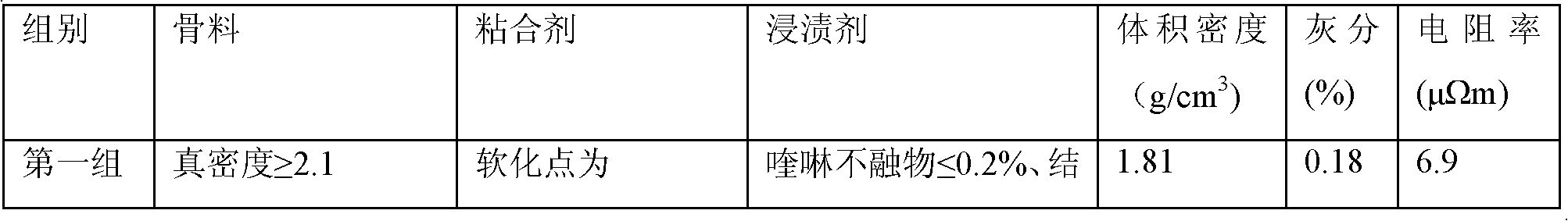

The invention relates to a graphite material for a monocrystalline silicon growth thermal field in a solar photovoltaic industry. In the graphite material, an aggregate is calcined petroleum coke, wherein the true density of the calcined petroleum coke is more than or equal to 2.1g / cm <3>, and the ash content of the calcined petroleum coke is less than or equal to 0.3%; a binder is medium temperature pitch, wherein the softening point of the medium temperature pitch is 83-86 DEG C, and the coking value of the medium temperature pitch is more than or equal to 49%; and the volume density of the graphite material is larger than or equal to 1.80g / cm<3>, the resistivity of the graphite material is less than or equal to 7.0 mu omega m, the compression strength of the graphite material is larger than or equal to 38Mpa, the rupture strength of the graphite material is more than or equal to 18Mpa, the porosity of the graphite material is less than or equal to 14%, the ash content of the graphite material is less than or equal to 0.2%, and the thermal expansion coefficient of the graphite material is less than or equal to 2*10<-6> / DEG C. The preparation method of the graphite material comprises the following steps: smashing raw materials, sieving, burdening, kneading, molding, primarily roasting, secondarily roasting, secondarily dipping, and thirdly roasting; and graphitizing, thus obtaining a finished product.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

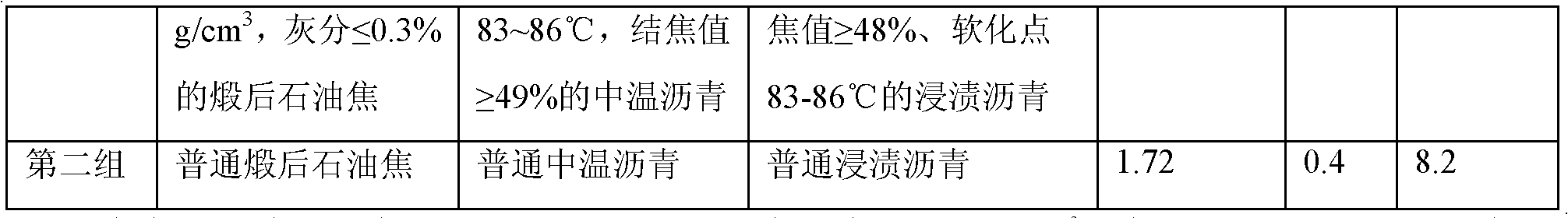

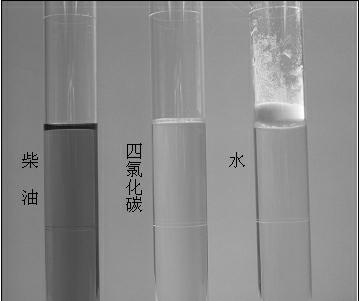

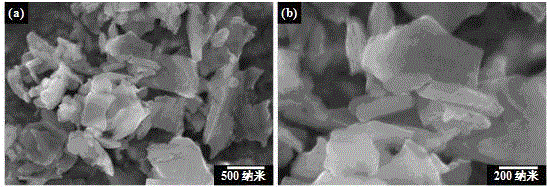

Preparation method of hydrophobic nano-silica

ActiveCN102502663AAvoid reunionImprove hydrophobicitySilicaNanotechnologyPhotovoltaic industryHydrolysis

The invention belongs to the technical field of nanometer material, particularly relates to a preparation method of hydrophobic nano-silica. Silicon tetrachloride is added to alkaline solution to perform a hydrolysis reaction so as to prepare silica, and organic modifiers are added to liquid reactant for reaction; then hydrophobic nano-silica is obtained through water washing and drying; or the organic modifiers are added for reaction after the liquid reactant is processed through water washing, and then hydrophobic nano-silica is obtained through drying. The preparation method effectively solves the utilization problem of a by-product that is silicon tetrachloride in photovoltaic industry and other industrial productions, is simple, fast, safe and controllable, achieves lower cost, and can process silicon tetrachloride massively.

Owner:河南海博瑞硅材料科技有限公司

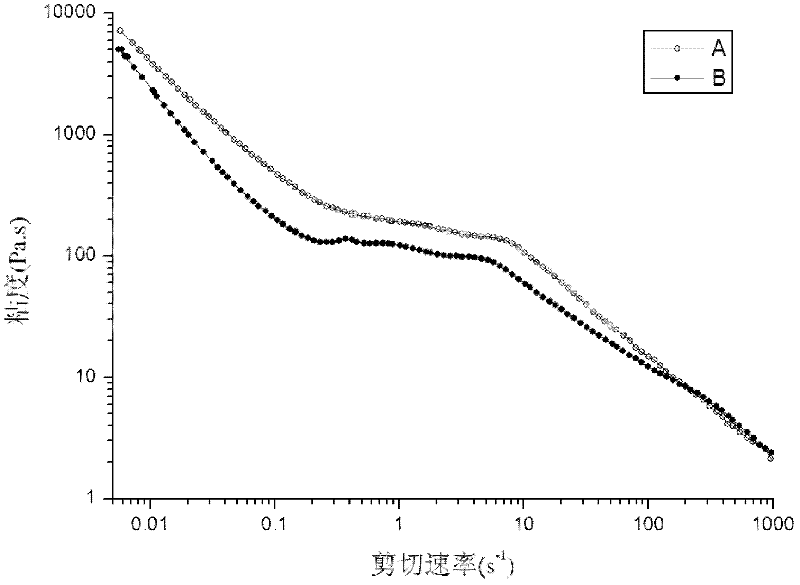

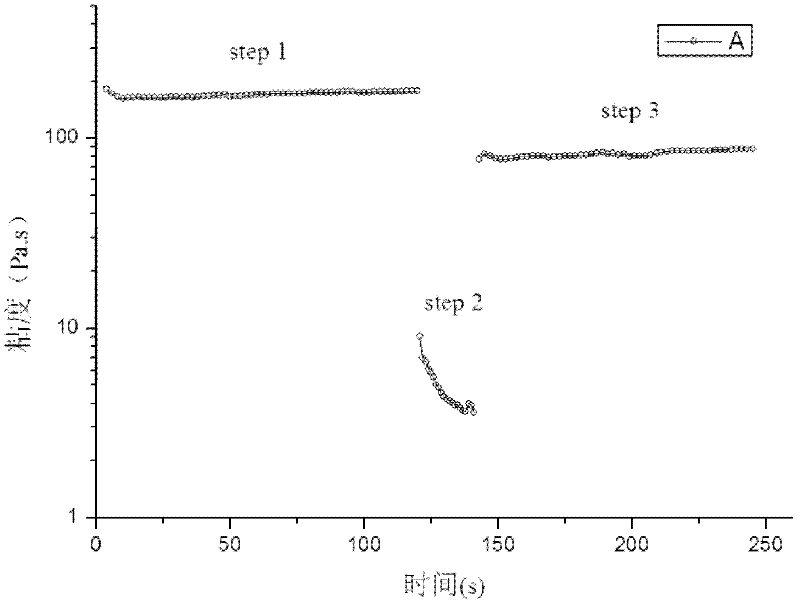

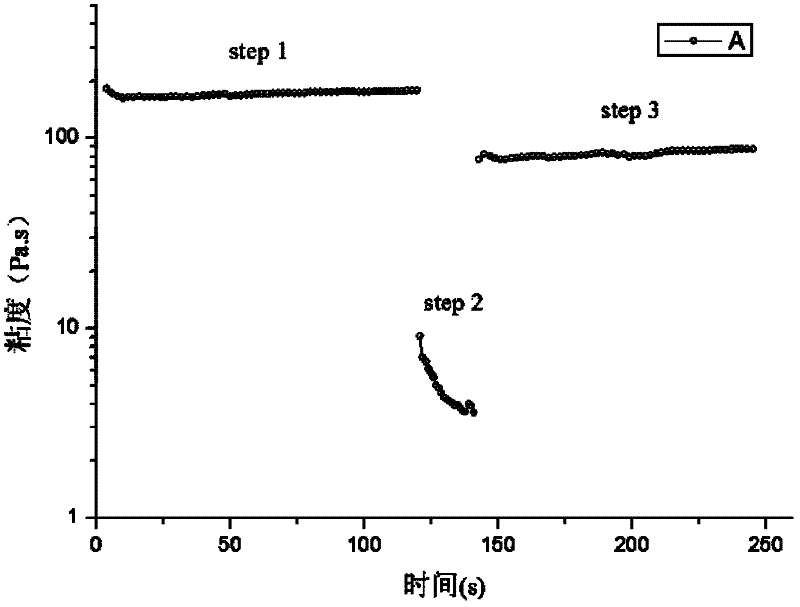

Method for testing rheological property of conductive slurry

InactiveCN102393348AComprehensive Rheological CharacterizationRheological CharacterizationFlow propertiesTemperature controlPhotovoltaic industry

The invention relates to the photovoltaic industry and in particular relates to a method for testing the rheological property of a conductive slurry. The method comprises the following steps: calibrating the instrument accuracy; setting a temperature; selecting and calibrating a clamp; loading and testing a sample; and determining the rheological property. Compared with a viscometer, the test method provided by the invention has a measurement accuracy which is one order of magnitude higher than that of the viscometer, needs a few samples, can be used for realizing accurate temperature control and quick experiment operations, and can represent the rheological property of the conductive slurry more comprehensively.

Owner:TRINA SOLAR CO LTD

Method for preparing graphene composite thin film on surface of silicon slice

InactiveCN102584334AImprove the interface binding forceImprove photoelectric conversion efficiencyPhotovoltaic industryComposite film

The invention relates to a method for preparing a graphene composite thin film on the surface of a silicon slice. The method comprises the following steps of: performing surface treatment on the silicon slice with a PN node; preparing amino silane on the surface of the silicon slice by adopting a self-assembly method by taking the silicon slice as a substrate material; putting the substrate into a graphene oxide dispersing solution; and preparing the graphene oxide composite thin film on the surface of the substrate. Compared with the prior art, the method has the advantages that: the process is simple, the cost is low, the photoelectric performance of a solar battery can be improved, and the graphene composite thin film is expected to be an ideal photoelectric conversion material of a photovoltaic industry.

Owner:SHANGHAI JIAO TONG UNIV

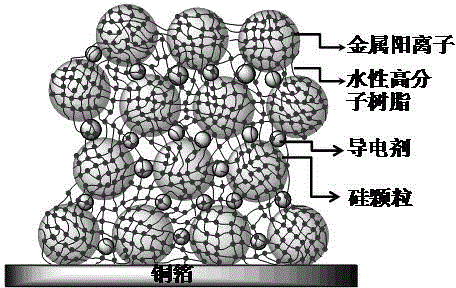

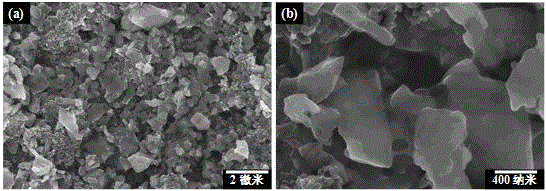

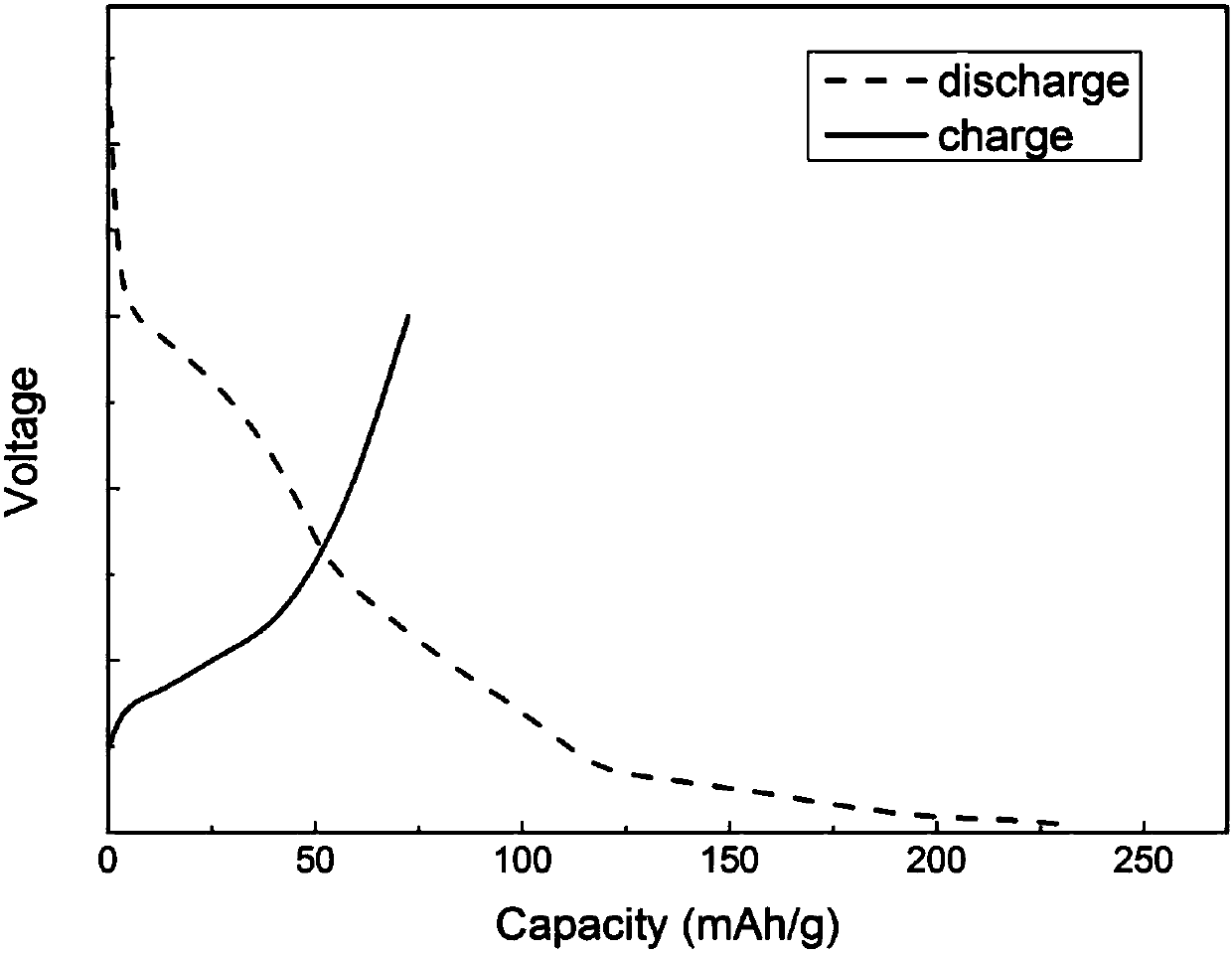

Preparation method and application for lithium ion battery negative electrode material based on photovoltaic silicon waste material

ActiveCN105336922APrecisely control the average particle size rangeImprove electronic conductivityCell electrodesPhotovoltaic industryEtching

The invention provides a preparation method and an application technology for a lithium ion battery negative electrode material based on a photovoltaic silicon waste material. By performing serial purification (including cleaning, high temperature impurity-removing and the like) on high-purity silicon waste material generated by cutting silicon wafers in the photovoltaic industry, and by performing regulation and control (including wet etching, in-situ graphite carbon coating and mixing with conventional graphite negative electrode based on a certain proportion) on the structure and composition, a micro or submicro silicon or silicon-graphite mixing material is obtained; then by developing a three-dimensional high-strength binder system and optimizing an electrode processing technology, the strong volume effect of the silicon material being used as the lithium ion negative electrode material in the charging / discharging processes is reduced to enable the silicon material to achieve the demand on the service life of the negative electrode material by the lithium ion battery; the silicon material can be assembled with the corresponding positive electrode material to form a whole battery with high specific energy; and in addition, the high cost of the existing silicon negative electrode material can be reduced greatly, and the efficient recycling utilization of the photovoltaic silicon waste material can be realized as well, so that the preparation method and the application technology are quite high in the economic and social value.

Owner:江苏载驰科技股份有限公司

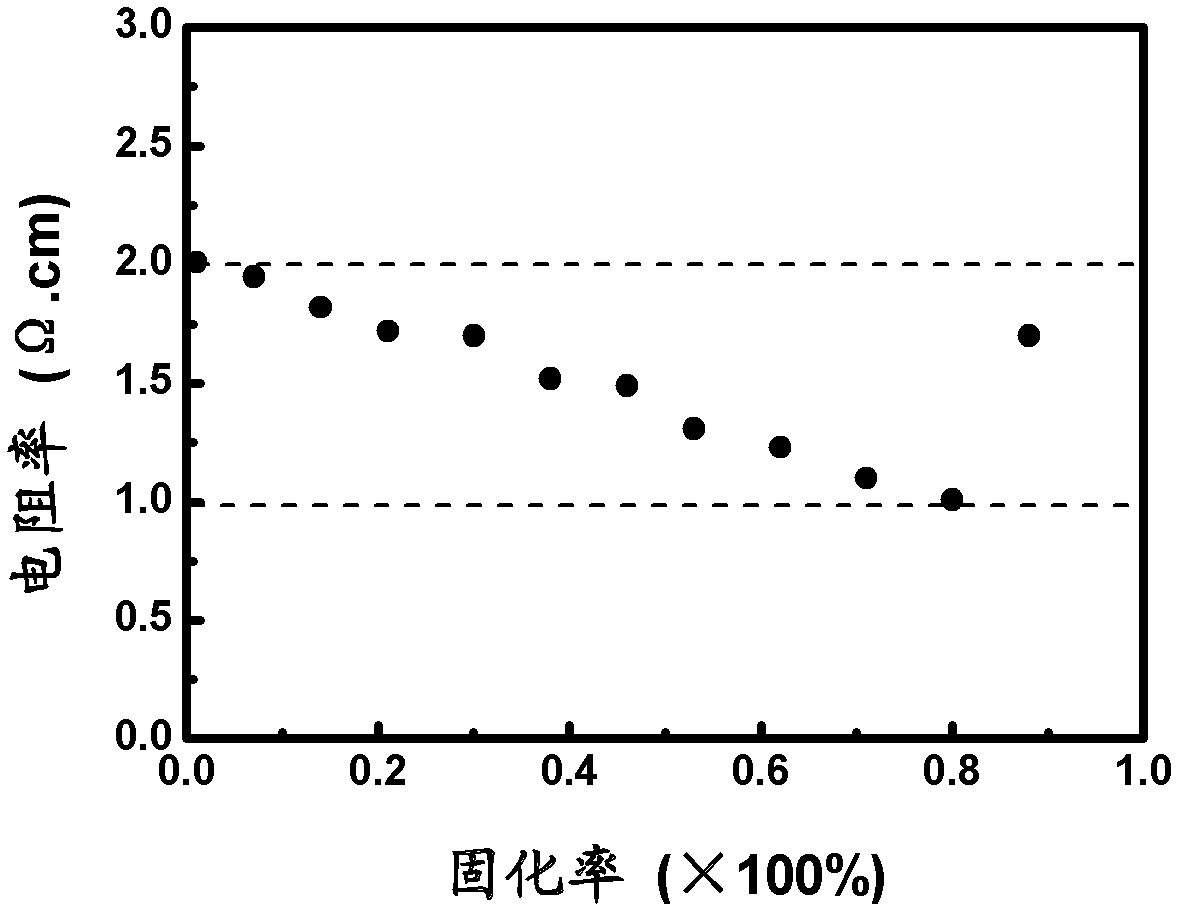

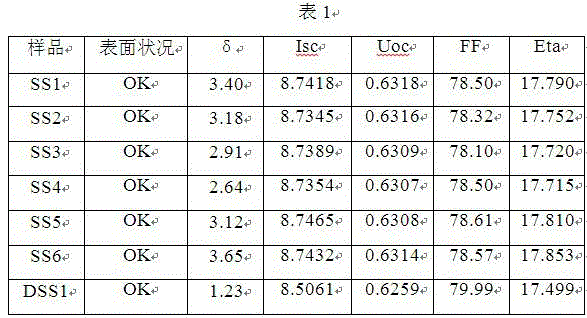

N-type casting policrystalline silicon with uniform doping resistivity and preparation method thereof

ActiveCN102560641AIncrease profitReduce manufacturing costPolycrystalline material growthSingle crystal growth detailsPhotovoltaic industryIngot

The invention discloses an N-type casting policrystalline silicon with a uniform doping resistivity and a preparation method thereof. The preparation method comprises the following steps of: mixing a polycrystalline silicon material, a phosphorus doping agent and gallium; then fusing; and growing a polycrystalline silicon body by using a casting method. According to the N-type casting policrystalline silicon with the uniform doping resistivity, the resistivity of about 90% N-type phosphorus doping phosphorus doping cast ingots can be controlled in the range of 1.0-2.0 omega.cm, therefore, the utilization rate of the N-type polycrystalline silicon crystal in the process of manufacturing an efficient solar cell is beneficially improved, the manufacturing cost of the efficient solar cell is remarkably lowered, the preparation method is simple to operate and easy to popularize and use in the photovoltaic industry.

Owner:ZHEJIANG UNIV

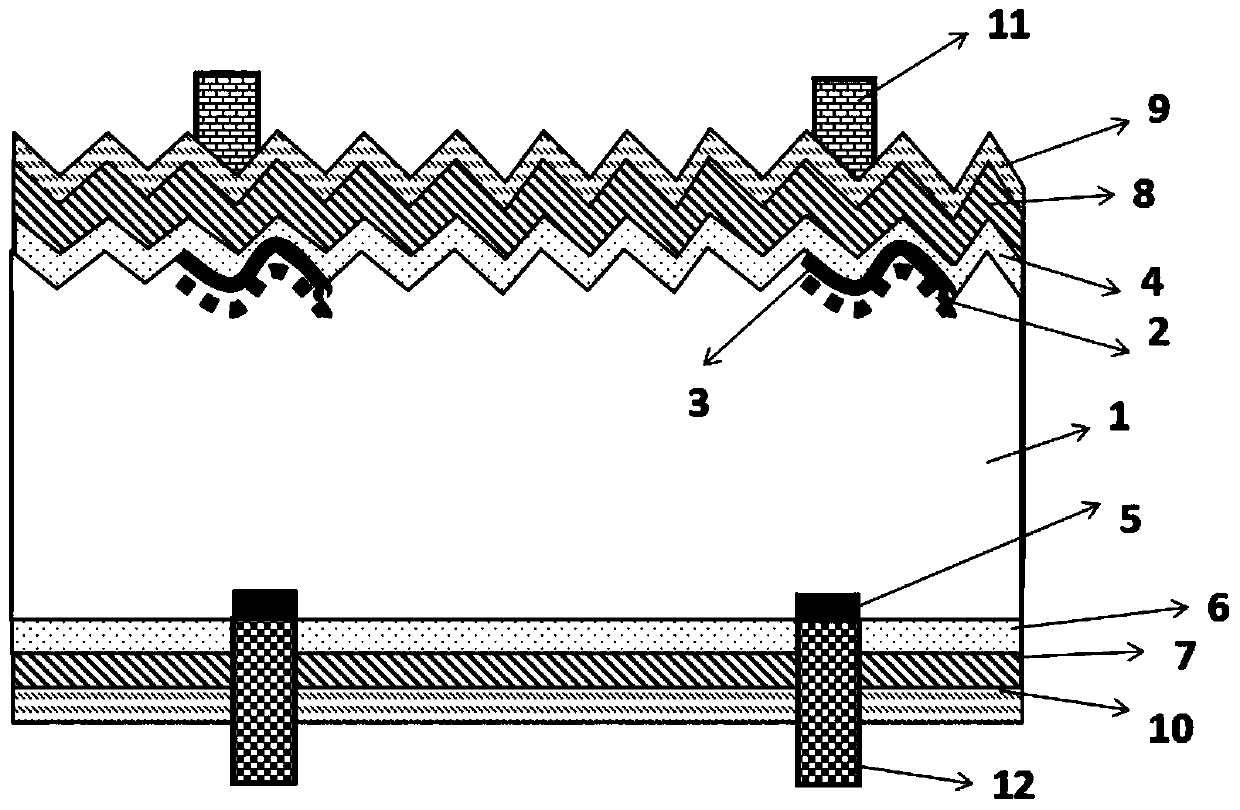

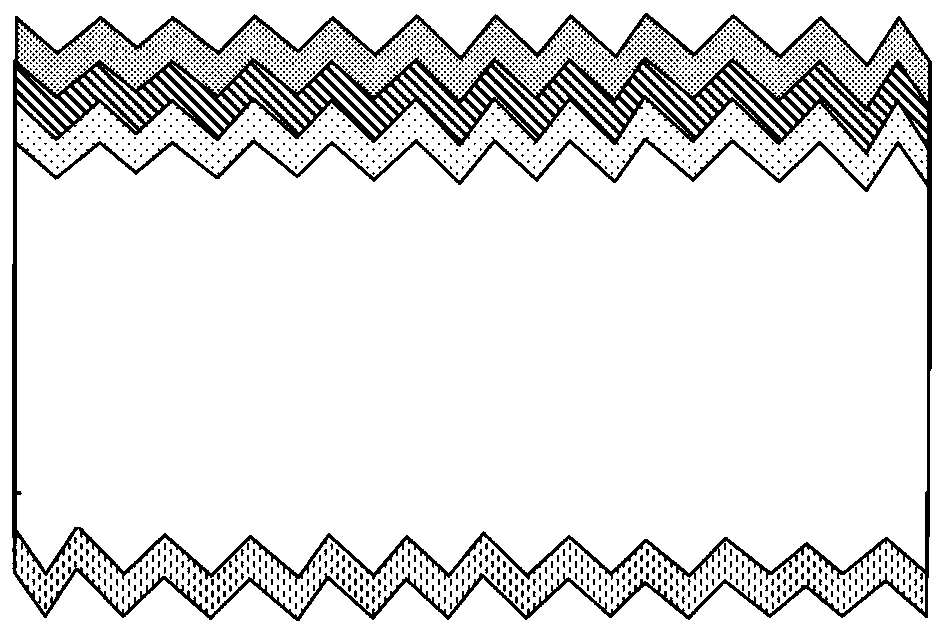

Serially connected type perovskite/homojunction silicon laminated solar cell and preparation method thereof

PendingCN110246923ALow costImprove efficiencyFinal product manufactureSolid-state devicesPhotovoltaic industrySilicon solar cell

The invention discloses a serially connected type perovskite / homojunction silicon laminated solar cell and a preparation method thereof. The laminated solar cell comprises an n-type homogeneous crystalline silicon solar cell serving as a bottom cell based on a PERC (passivated emitter rear contact cell) structure. A perovskite solar cell with a transparent electrode serves as a top cell. The structure of the laminated solar cell sequentially comprises a metal bottom electrode, a bottom electrode opened passivation layer, a local or all n-type heavily doped layer, n-type silicon, a p-type heavily doped emitter, an emitting electrode passivation layer, a tunneling layer, an electron transport layer, a perovskite absorption layer, a hole transport layer, a top electrode buffer layer, a transparent electrode, a metal grid line electrode and an antireflection film from bottom to top. The laminated solar cell is based on the mainstream homojunction PREC solar crystalline silicon cell in the current photovoltaic industry, and is simple in preparation process, low in preparation cost, high in light conversion efficiency and suitable for large-scale industrial production.

Owner:深圳黑晶光电技术有限公司

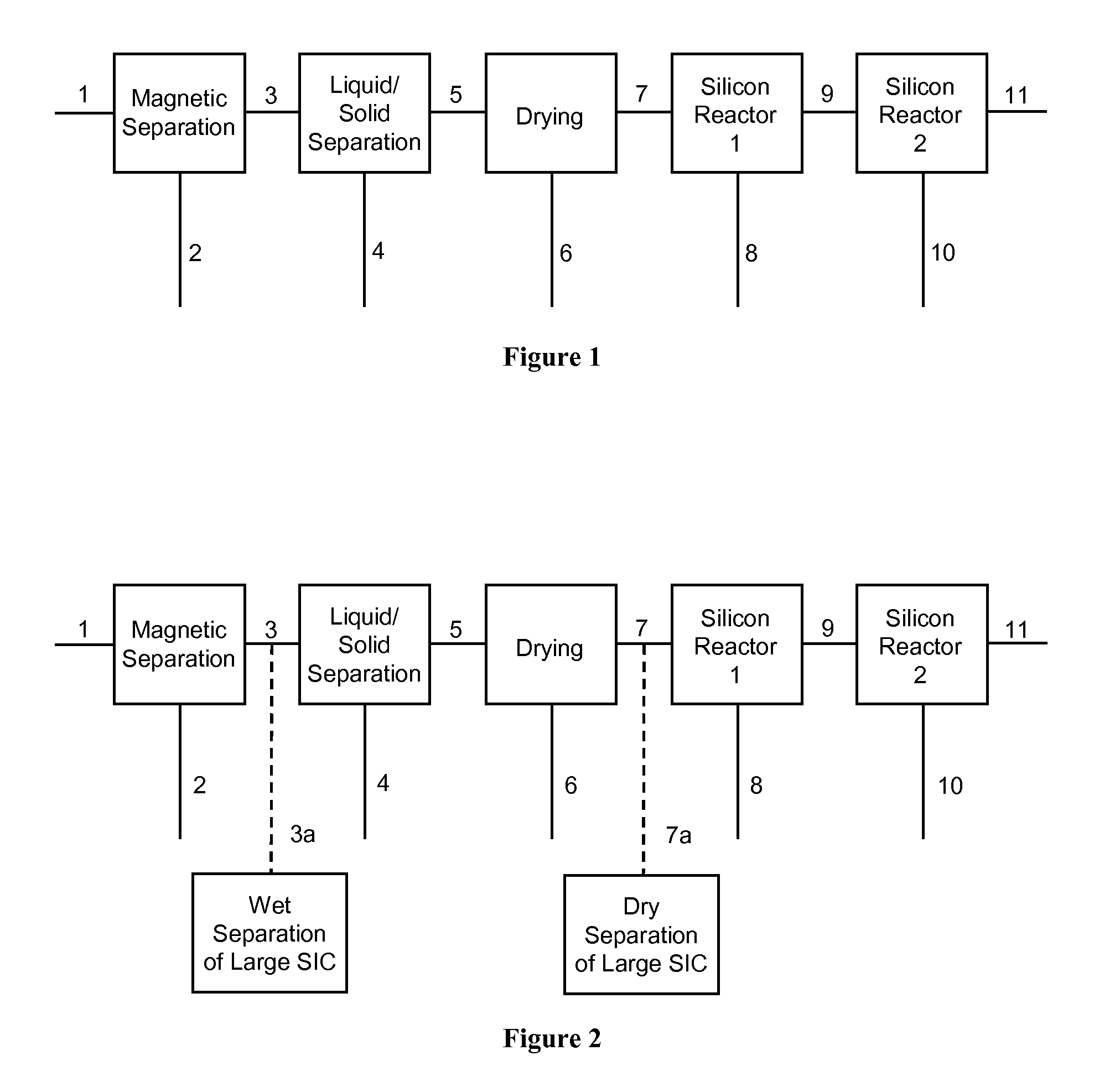

Methods and apparatus for recovery of silicon and silicon carbide from spent wafer-sawing slurry

InactiveUS20110059002A1Reduce contentHigh puritySiliconOther chemical processesPhotovoltaic industryWafering

Methods, systems, and apparatus are disclosed herein for recovery of high-purity silicon, silicon carbide and PEG from a slurry produced during a wafer cutting process. A silicon-containing material can be processed for production of a silicon-rich composition. Silicon carbide and PEG recovered from the silicon-containing material can be used to form a wafer-saw cutting fluid. The silicon-rich composition can be reacted with iodine containing compounds that can be purified and / or used to form deposited silicon of high purity. The produced silicon can be used in the photovoltaic industry or semiconductor industry.

Owner:QUIXOTIC SYST

Ultra clear float solar battery glass production process and product thereof

ActiveCN103253864AHigh light transmittanceReduce reflectivityGlass severing apparatusPhotovoltaic industryEngineering

The invention belongs to the technical field of special glass production, and provides an ultra clear float solar battery glass production process and a product thereof. The process comprises the following steps: (1) preparing raw materials, (2) feeding and melting, (3) carrying out clarification, (4) carrying out homogenization, (5) carrying out tin stripping molding, (6) annealing, and (7) cutting. With the ultra clear float solar battery glass production process, ultra clear float solar battery glass with a thickness of 2.5 mm can be produced, wherein the glass has characteristics of high transmittance, low reflectivity and light unit weight, and is applicable for photovoltaic industry to be adopted as a photoelectric conversion substrate and a light-heat conversion panel so as to be used for solar battery manufacturing. In addition, with application of the process to produce the ultra clear float solar battery glass, the production cost is low so as to reduce a production cost of the whole photovoltaic industry chain.

Owner:XINYI PHOTOVOLTAIC IND (ANHUI) HLDG CO LTD

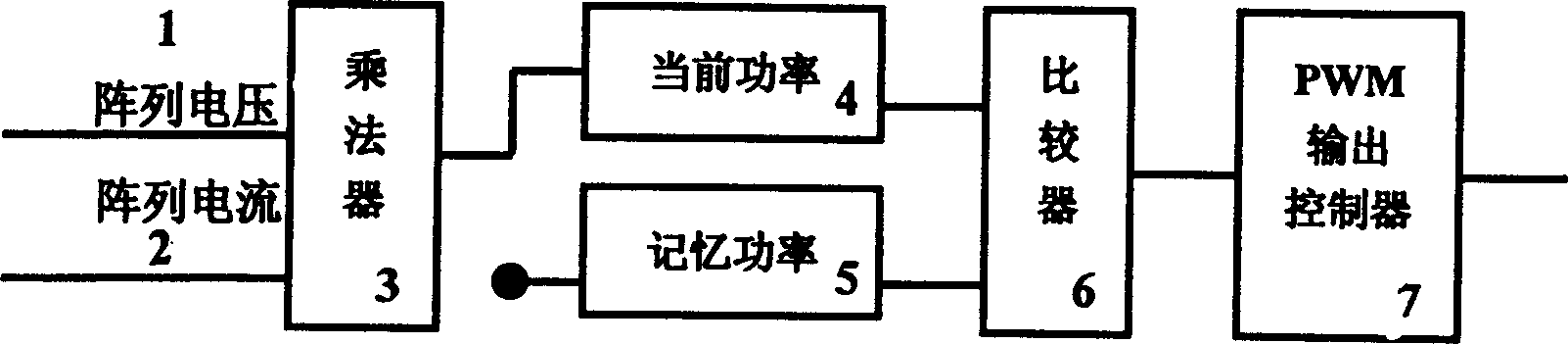

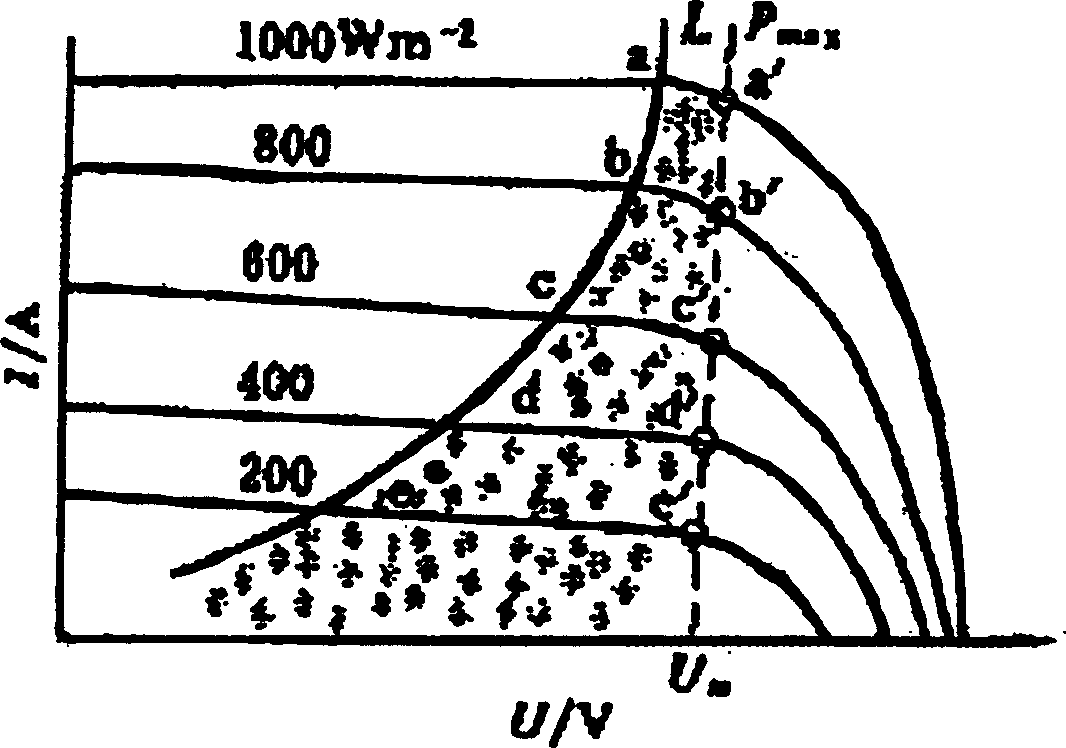

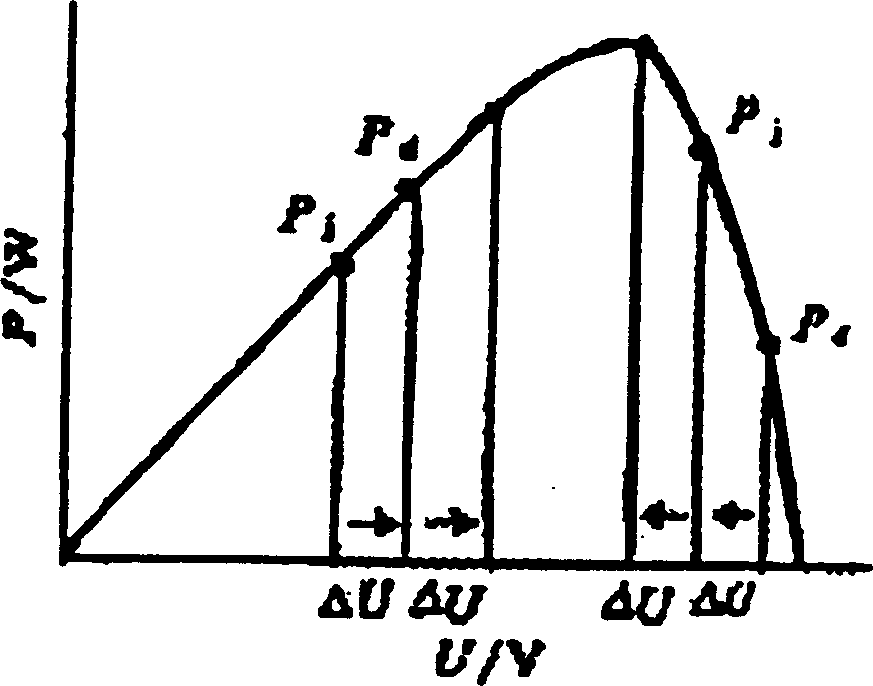

Self optimization maximum power point tracing device and method

InactiveCN1556584AImplement trackingImprove tracking speedLight radiation electric generatorElectric variable regulationSquare arrayPhotovoltaic industry

The invention relates to a optimization self-searching maximal power point tracing device and a method, especially relates to a control device and method for solar energy photovoltaic industry electric generating system. The device is made of solar battery square array, control device, multiplier and comparator, the output end of the multiplier is connected with the input end of the current power model, the output end of the current power model is connected with the input end of the comparator, the output end of the comparator is connected to the input end of pulse modifying PWM output controller, the memory power model output end is connected to the input end of the comparator in parallel. The merits of the invention is: it can realize the tracing to the maximal output power point of the solar battery, the working point of the battery can point to the maximal power point always; it uses special maximal power dynamic comparing technology, it also uses special technology in aspect of power calculation, noise filtering. Thus the tracing speed and the accuracy are upgraded greatly.

Owner:SHANGHAI CHENGYI ELECTRIC CO LTD +1

Pressure-sensitive adhesive and preparation method thereof

InactiveCN102850972AGood weather resistanceReduce surface tensionMonocarboxylic acid ester polymer adhesivesFilm/foil adhesivesCross-linkPhotovoltaic industry

The invention relates to the field of adhesives and particularly relates to an acrylate pressure-sensitive adhesive with high weather resistance and low surface tension and a preparation method thereof. The pressure-sensitive adhesive comprises, by weight, 60 to 100 parts of a soft monomer, 30 to 90 parts of a hard monomer, 2 to 10 parts of a cross-linking monomer, 0.5 to 1 part of an initiator and 120 to 250 parts of an organic solvent, and the pressure-sensitive adhesive is prepared by using such a formula system. According to the invention, the pressure-sensitive adhesive has excellent weather resistance, low surface tension and accordingly improved insulating performance, water resistance and alkali resistance, and can be used in places and industries in which environment is harsh and requirements on weather resistance or aging resistance are strict, e.g., the solar photovoltaic industry and the automobile industry.

Owner:YANTAI DARBOND TECH

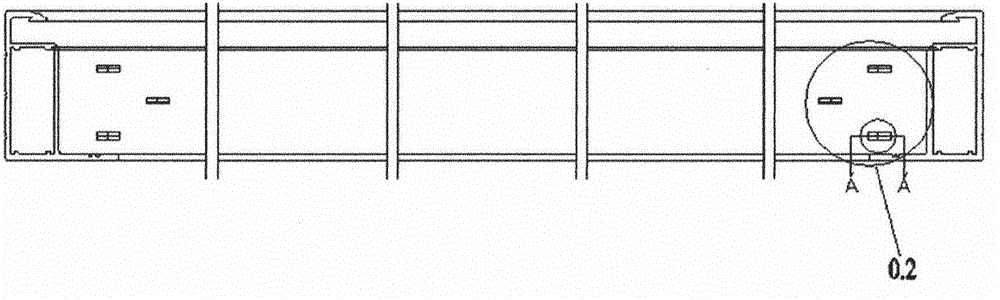

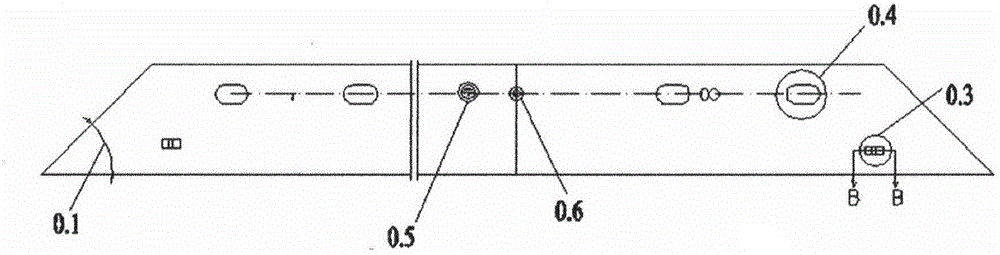

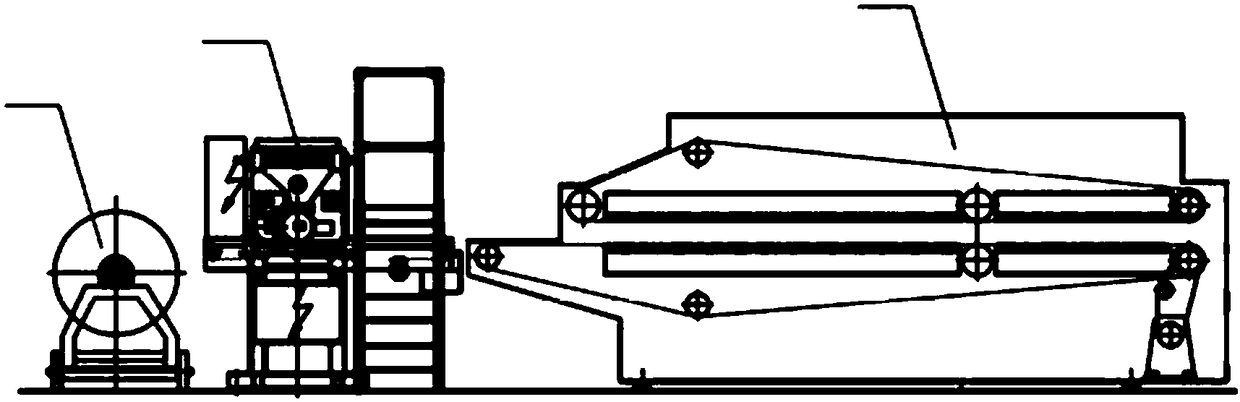

Flexible automatic machining unit of photovoltaic module aluminum frame

ActiveCN104924091AImprove consistencyQuality improvementShaping toolsOther manufacturing equipments/toolsPhotovoltaic industryControl system

The invention discloses a flexible automatic machining unit of a photovoltaic module aluminum frame, and relates to the technical field of manufacturing related photovoltaic module aluminum frame in the photovoltaic industry. A feeding system, a blanking system, an angle code pressing system, a water falling hole stamping system, a mounting hole and landmark stamping system, a material supplying system and a hydraulic system are all connected with a control system; and the hydraulic system, the angle code pressing system, the water falling hole stamping system and the mounting hole and landmark stamping system are connected with a hydraulic execution part through hydraulic pipelines. The flexible automatic machining unit is good in product consistency, high in precision, and good in quality; a mould replacement process is simple and efficient; and the unit is high in automation level, high in machining production efficiency and low in manufacturing cost.

Owner:山东金博利达精密机械有限公司

Double-sided selective emitter high-efficiency crystalline silicon cell and preparation method thereof

ActiveCN111524983AAvoid the disadvantage of high surface concentrationPlay a passivation effectFinal product manufacturePhotovoltaic energy generationPhotovoltaic industrySilicon oxide

The invention belongs to the field of solar photovoltaic industry and particularly provides a double-sided selective emitter efficient crystalline silicon cell and a preparation method thereof. The double-sided selective emitter efficient crystalline silicon cell is characterized in that a double-sided selective emitter structure is adopted, a boron-doped heavily-doped region is a polycrystallinesilicon structure in which aluminum oxide replaces silicon oxide to serve as a tunneling layer, a constant surface concentration increase fill factor (FF) exceeding 1E20atom / cm <3> can be achieved, alightly-expanded region is pure boron doping, a heavily-expanded boron doping process and a lightly-expanded boron doping process can be realized in one step, and the process is simplified. Silicon oxide is adopted as a tunneling layer for a phosphorus-doped region, a heavily-doped region is of a double-layer poly structure, the surface concentration is high, metallization contact is improved, a lightly-expanded region is of a single-layer lightly-doped poly structure, and then the open-circuit voltage (Voc) is increased. The formation of the double-sided selective emitter effectively utilizesa mask etching mode. The double-sided selective emitter efficient crystalline silicon cell is advantaged in that the structure can effectively improve battery efficiency, and is suitable for batch production.

Owner:CHANGZHOU UNIV +1

Method for producing chromium-based iron alloys through cutting wastes by crystalline silicon

The invention belongs to the metallurgical field, and concretely relates to a new method for directly producing chromium-based iron alloy products in a metallurgical furnace by using a special furnace charge prepared through cutting wastes and chromium concentrate powder by monocrystalline or polycrystalline silicon. The method comprises the following steps: adding a certain amount of monocrystalline or polycrystalline silicon cutting waste powder to the chromium concentrate powder, processing through using a ball press or a disc pelletizer to prepare the spherical or block metallurgic furnace charge, and smelting in an induction furnace or an electric furnace to obtain medium-and-low-carbon ferrochrome, silicon-chromium-iron alloy and other chromium-based iron alloy products. The method reasonably and efficiently utilizes metallic silicon, silicon carbide and other high-quality high temperature metallurgical reducing agents contained in photovoltaic cutting wastes, directly uses the chromium concentrate powder, and adopts an electric-silicothermic metallurgy process through a one step technology. Compared with traditional methods, the method has the advantages of energy consumption saving, and solving of the pollution of solid wastes formed in the photovoltaic industry to the environment.

Owner:UNIV OF SCI & TECH BEIJING

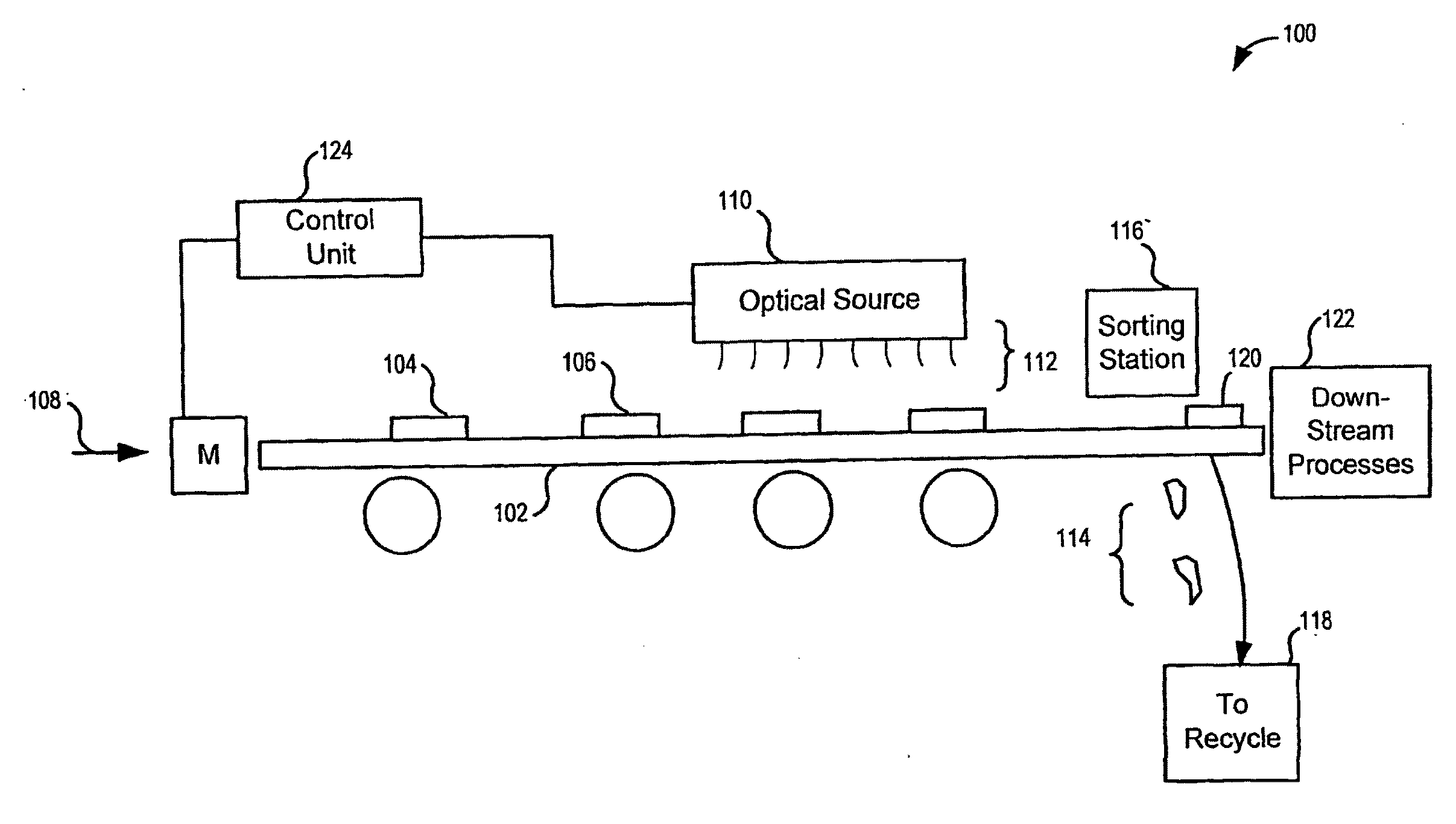

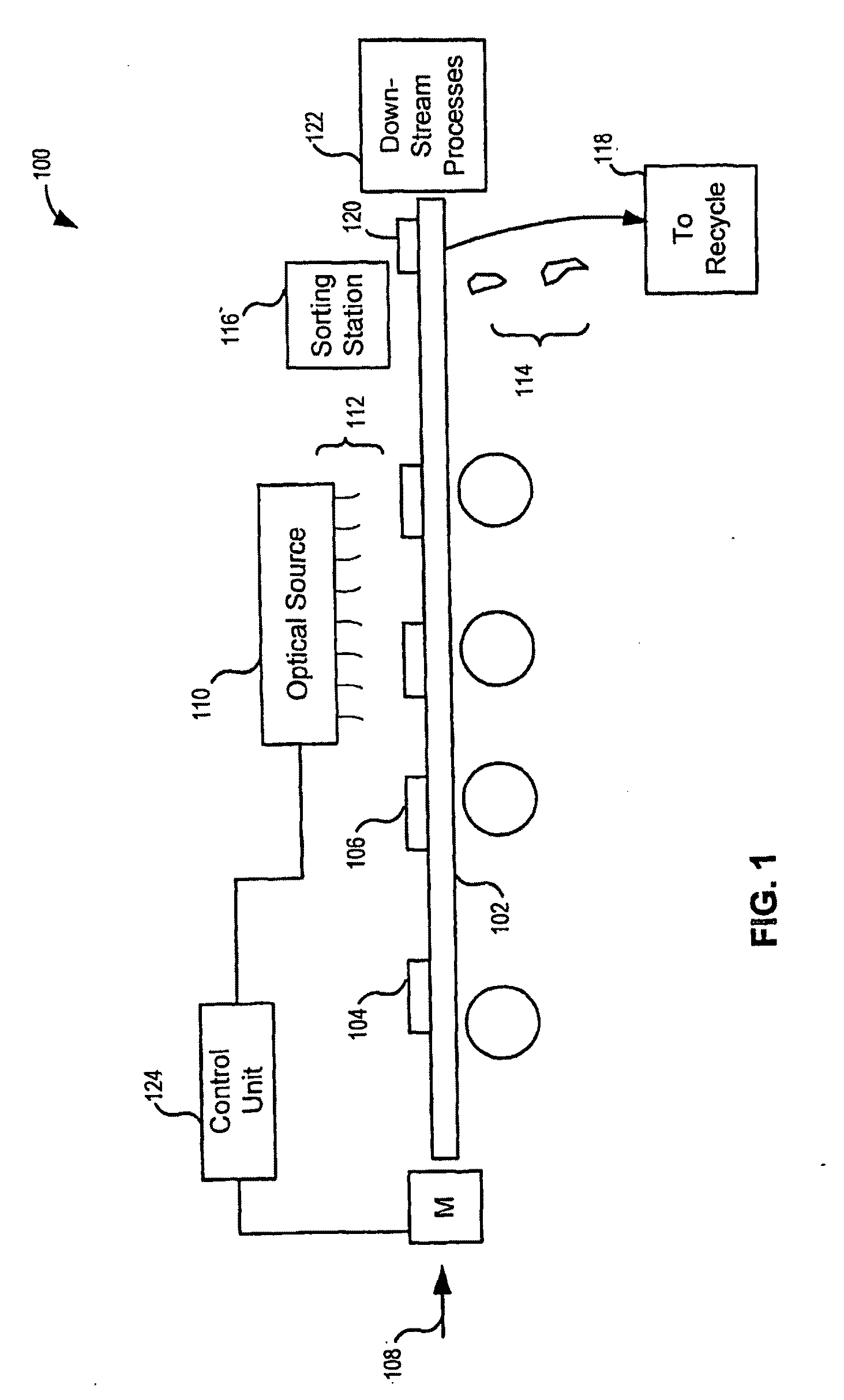

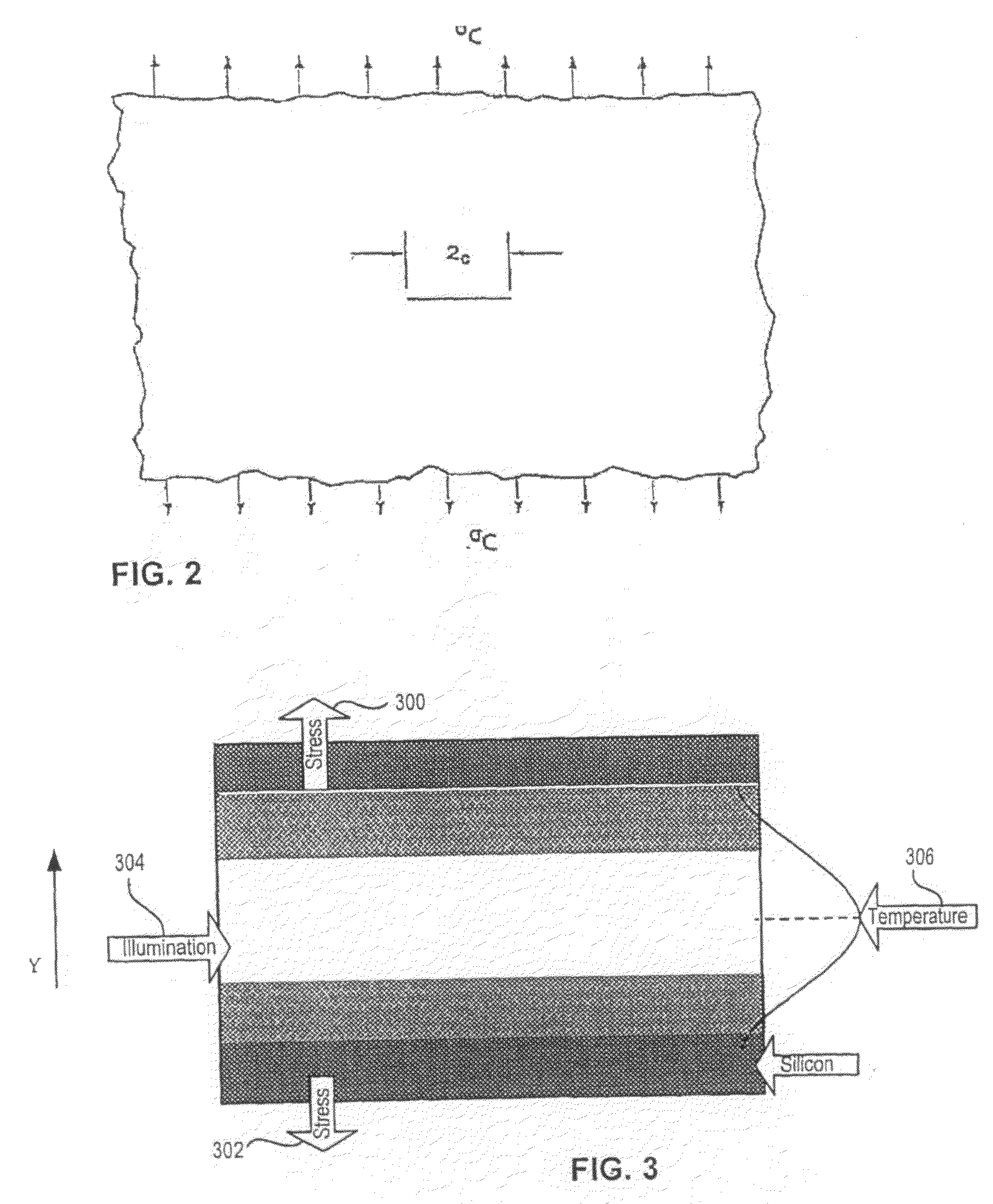

Screening of Silicon Wafers Used in Photovoltaics

InactiveUS20100136715A1Liquid surface applicatorsSemiconductor/solid-state device testing/measurementPhotovoltaic industryElectrical and Electronics engineering

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

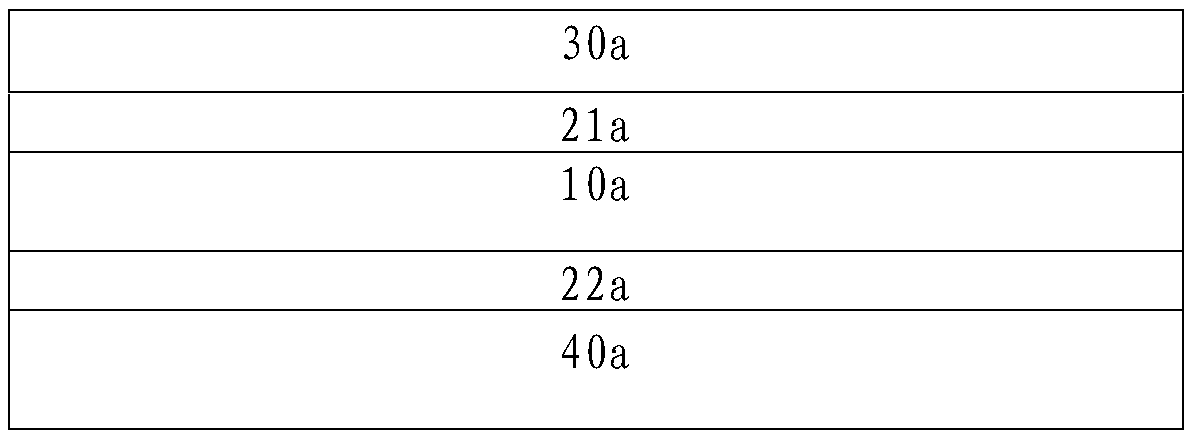

Back passivation solar cell back silver paste and preparation method thereof, and solar cell and preparation method thereof

ActiveCN105374412AImprove photoelectric conversion efficiencyStrong adhesionFinal product manufactureNon-conductive material with dispersed conductive materialSilver pastePhotovoltaic industry

The invention provides a back passivation solar cell back silver paste and a preparation method thereof. The paste includes micrometer silver powder, nanometer silver powder, inorganic glass powder, and an organic carrier, the inorganic glass powder is formed by a 80-92 wt% component X and a 8-20 wt% component Y, the component X is PbO and / or Bi2O3, and the component Y is B2O3. According to the back passivation solar cell back silver paste and the preparation method thereof, the back silver paste is printed on the backside of a back passivation silicon substrate, a smooth and compact back electrode can be formed, the adhesion between the back electrode and the silicon substrate is good, a welding pulling force test with a photovoltaic welding strip is in accordance with the requirement of the current photovoltaic industry, and the photoelectric conversion efficiency of solar cells prepared by employing the back silver paste is effectively improved.

Owner:BYD CO LTD

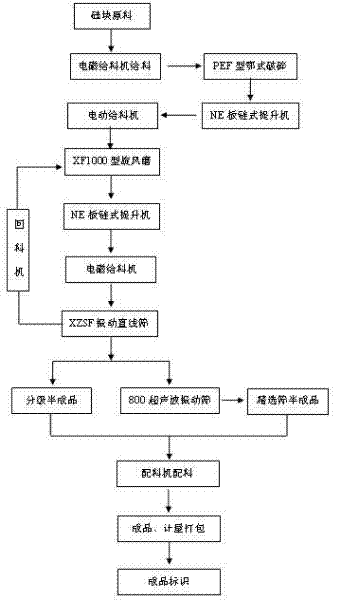

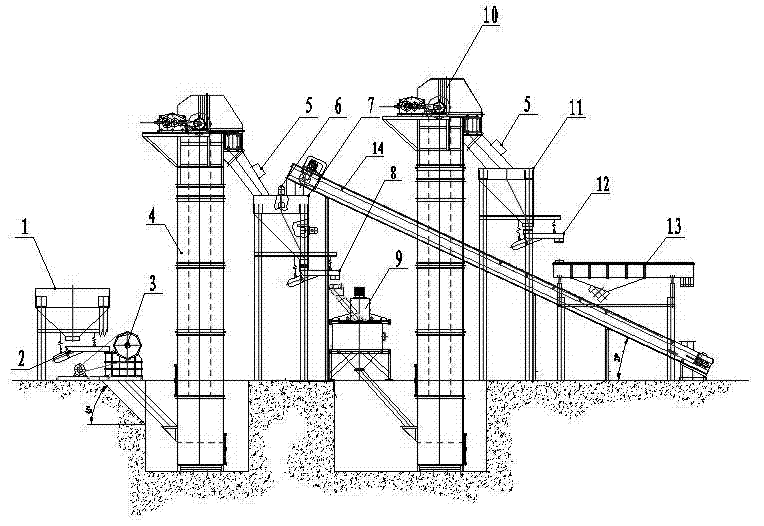

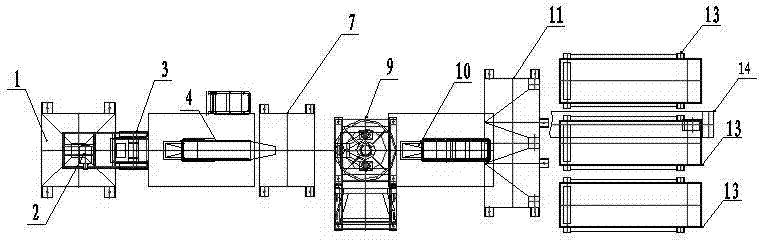

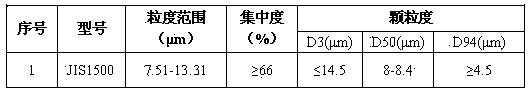

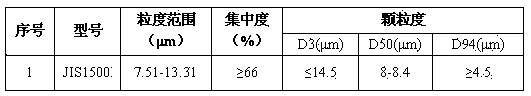

Preparation process of silicon metal powder with high chemical activity and low fine powder rate and special equipment

InactiveCN102218364AHigh chemical activityReduce manufacturing costGrain treatmentsPhotovoltaic industryCombined method

The invention particularly relates to a preparation process of silicon metal powder with high chemical activity and low fine powder rate specific to the photovoltaic industry, and belongs to the field of processing of silicon materials. In the preparation process, a jaw crusher is firstly used for crushing raw materials for the first time till the diameter of the crushed raw materials reaches 2 to 5 centimeters; after the materials is deironization, the materials are conveyed to a cyclone mill and crushed for the second time to prepare semi-finished silicon powder with the particle size of 700 to 50 Mum; after re-deironization, according to the requirement on particle size of a finished product, the semi-finished silicon powder is screened by a vibrating screen of a screening machine into a larger-particle-size powder section, a finished product section and a smaller-particle-size powder section in terms of particle size sections; the powder of the larger-particle-size powder section is re-crushed; and the semi-finished powder of the finished product section and the smaller-particle-size powder section are proportioned to prepare the finished product finally. In the preparation process of the silicon metal powder disclosed by the invention, a revolving type silicon metal crushing technology is adopted, a wind power-mechanical power combined method is utilized to drive the silicon metal to move at a high speed automatically and be crushed mutually into powder, thus the specific surface area of metal silicon powder reaches 0.69 square meters per gram, and the fine powder rate is reduced within 8 percent simultaneously.

Owner:抚州聚源新材料有限公司

Encapsulation material for photovoltaic module and preparation method of the encapsulation material

ActiveCN106299000BReduce weightReduce installation costsFinal product manufactureFibre treatmentFiberPhotovoltaic industry

The invention discloses a packaging material for photovoltaic modules. The packaging material includes the following raw materials in parts by weight: 30-50 parts of fiber cloth, the fiber cloth is made of fiber materials; 50-70 parts of acrylic powder coating, and 50-70 parts of acrylic powder The coating includes an acrylic resin and a curing agent; wherein, the acrylic powder coating is evenly coated on the fiber cloth; the invention not only has low manufacturing cost, but also satisfies the requirements of photovoltaic industry technical standards such as anti-ultraviolet, anti-aging, impact resistance, and fire prevention. It effectively solves the problem of reducing the weight of the photovoltaic module packaging material, improves the convenience of installation, and reduces the installation cost, which is very suitable for large-scale promotion and application in the photovoltaic field; The package size of photovoltaic modules can be changed arbitrarily to meet the installation requirements of different buildings, which further facilitates the installation and application of photovoltaic modules.

Owner:TIGER DRYLAC TAICANG +1

Silicon wafer cutting technology

ActiveCN103522431AIncrease usage ratioReduce pollutionWorking accessoriesFine working devicesPhotovoltaic industryProcess engineering

The invention relates to a silicon wafer cutting technology, in particular to a monocrystal silicon and polycrystalline wafer cutting technology suitable for the solar photovoltaic industry. In the silicon wafer cutting technology, main auxiliary materials used for silicon wafer cutting are mortar, waste mortar is recycled, the matching of the mortar is adjusted, and parameters in the cutting technology are adjusted on the basis. The silicon wafer cutting technology has the advantages that the motor is separated and recycled, the use ratio of recycled sand and the use ratio of recycled liquid are improved in the production process, waste materials are recycled, environmental pollution can be reduced, the production cost can be reduced, the photovoltaic industry is accordingly promoted, the solar energy resources are effectively used, and the use number of the non-renewable resources is reduced; the cutting technology is adjusted, the defect that the cutting capacity of the recycled sand and the cutting capacity of the recycled liquid are insufficient is overcome, the silicon wafer cutting pass percent is higher than 92%, the production cost is reduced, and meanwhile discharging of solid waste is reduced.

Owner:SHANXI LUAN PHOTOVOLTAICS TECH

Preparation method of N-type crystalline silicon back emitter junction solar battery and corrosive liquid

InactiveCN102593263AImprove efficiencyEasy to operateFinal product manufactureSurface treatment compositionsAcetic acidProduction line

The invention discloses a preparation method of an N-type crystalline silicon back emitter junction solar battery and corrosive liquid. The preparation method comprises the following steps of adopting the corrosive liquid to conduct chemical thinning on an N-type crystalline silicon sheet and enabling the thickness to be reduced to 50-150 mum, and then using a standard process to prepare the solar battery. The corrosive liquid used in the preparation method of the N-type crystalline silicon back emitter junction solar battery is further disclosed. The corrosive liquid is composed of nitric acid, hydrofluoric acid, water and / or acetic acid. The N-type crystalline silicon back emitter junction solar battery prepared by using the method is high in battery efficiency, when the substrate material is the polycrystalline silicon sheet or low-weight monocrystalline silicon sheet, the battery efficiency is obviously promoted, related process equipment is all existing equipment on a P-type solar battery production line, no big cost needs extra investing, operation is simple, and the preparation method and the corrosive liquid are favorable for large-scale application in the photovoltaic industry.

Owner:ZHEJIANG UNIV

Solar cell with high conversion efficiency

InactiveCN102097497AChange light absorptionEnhanced light absorptionPhotovoltaic energy generationSemiconductor devicesAnti-reflective coatingPhotovoltaic industry

The invention discloses a solar cell with high conversion efficiency, which belongs to the field of semiconductor material application. The solar cell is formed by forming a periodical nanostructure such as a nano wire grating and a nanopore array in a conventional antireflection coating of the solar cell. The nanostructure can reduce an effective refractive index of the antireflection coating, and makes a refractive index of the antireflection coating matched with a substrate so as to improve the reflection resistance of the coating and enhance the light absorption of the solar cell to further improve the conversion efficiency of the solar cell. Theoretical analysis shows that the conversion efficiency of the solar cell adopting the antireflection coating with the nanostructure is relatively more improved at 400 to 1,000 nm, and particularly is greatly improved at short-wave bands. The nanostructure can be realized only by using photoetching and etching based on a conventional solar cell processing technique, and the processing technique is compatible with the conventional solar cell processing technique, and can be widely applied to the photovoltaic industry.

Owner:CHONGQING UNIV

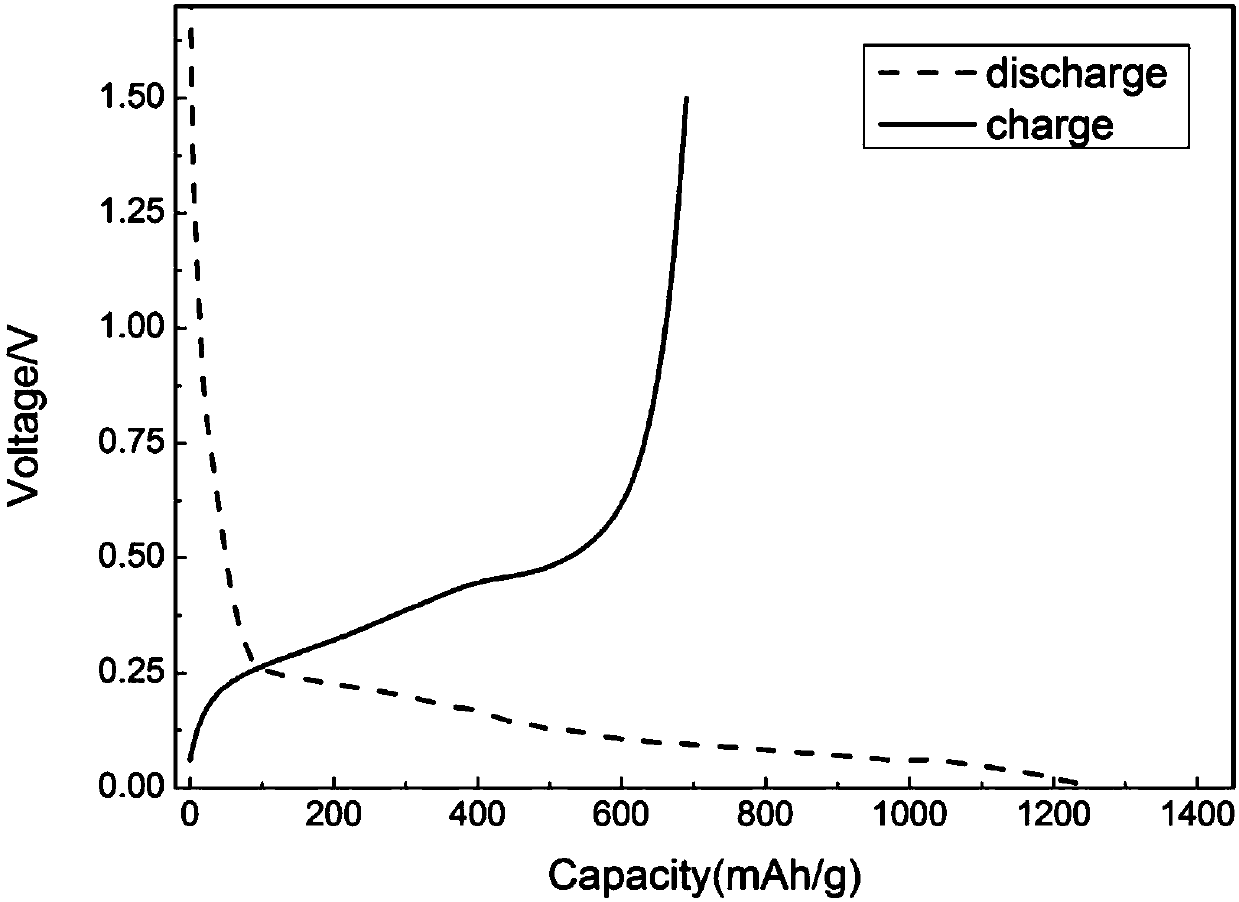

Method for preparing lithium ion battery negative electrode material from photovoltaic industry wastes

InactiveCN107732200AReduce manufacturing costEfficient Development StrategyCell electrodesPhotovoltaic industrySolvent

The invention discloses a method for preparing a lithium ion battery negative electrode material from photovoltaic industry wastes. The method comprises 1) pretreating photovoltaic industry wastes toobtain silicon powder, and 2) preparing a lithium ion battery negative electrode material through 2.1), adding the prepared silicon powder and a dispersant into a solvent according to a mass ratio of4 to 1 and carrying out dispersion to obtain uniformly dispersed nano-silicon particles, 2.2), adding an initiator ammonium persulfate into the solution obtained by the step 2.1) and carrying out ultrasonic dispersion, 2.3), acidifying the solution and adjusting the pH of the solution to 1-3, 2.4), then dropwisely adding monomers into the silicon particles for coating and stirring the mixture fora reaction in an ice bath for 8-12h, and 2.5) after the reaction, centrifuging the liquid, washing the liquid to pH of 7, then carrying out vacuum drying and carrying out grinding to obtain the lithium ion battery negative electrode material. Through treatment on photovoltaic industry wastes, the silicon raw material is modified through the simple and easy industrial use method and the commercialapplication of the silicon negative electrode is promoted.

Owner:XI AN JIAOTONG UNIV

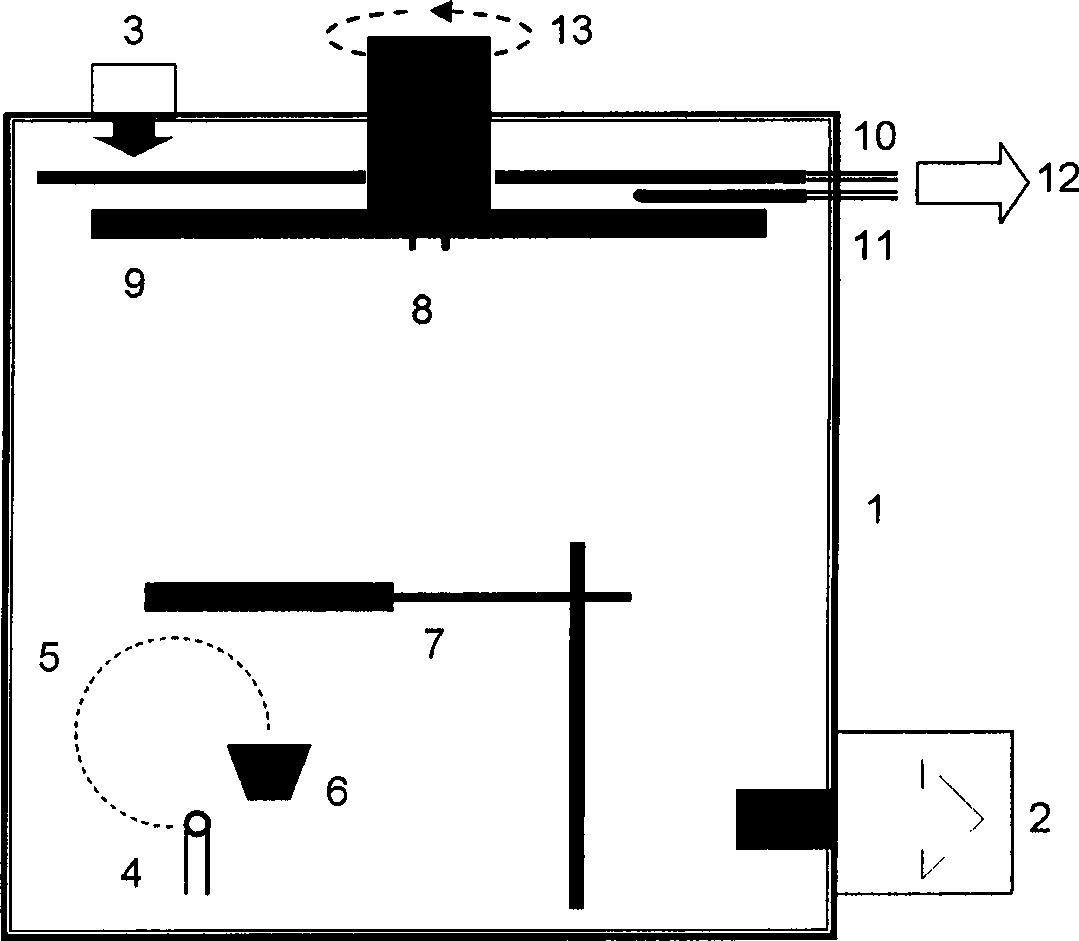

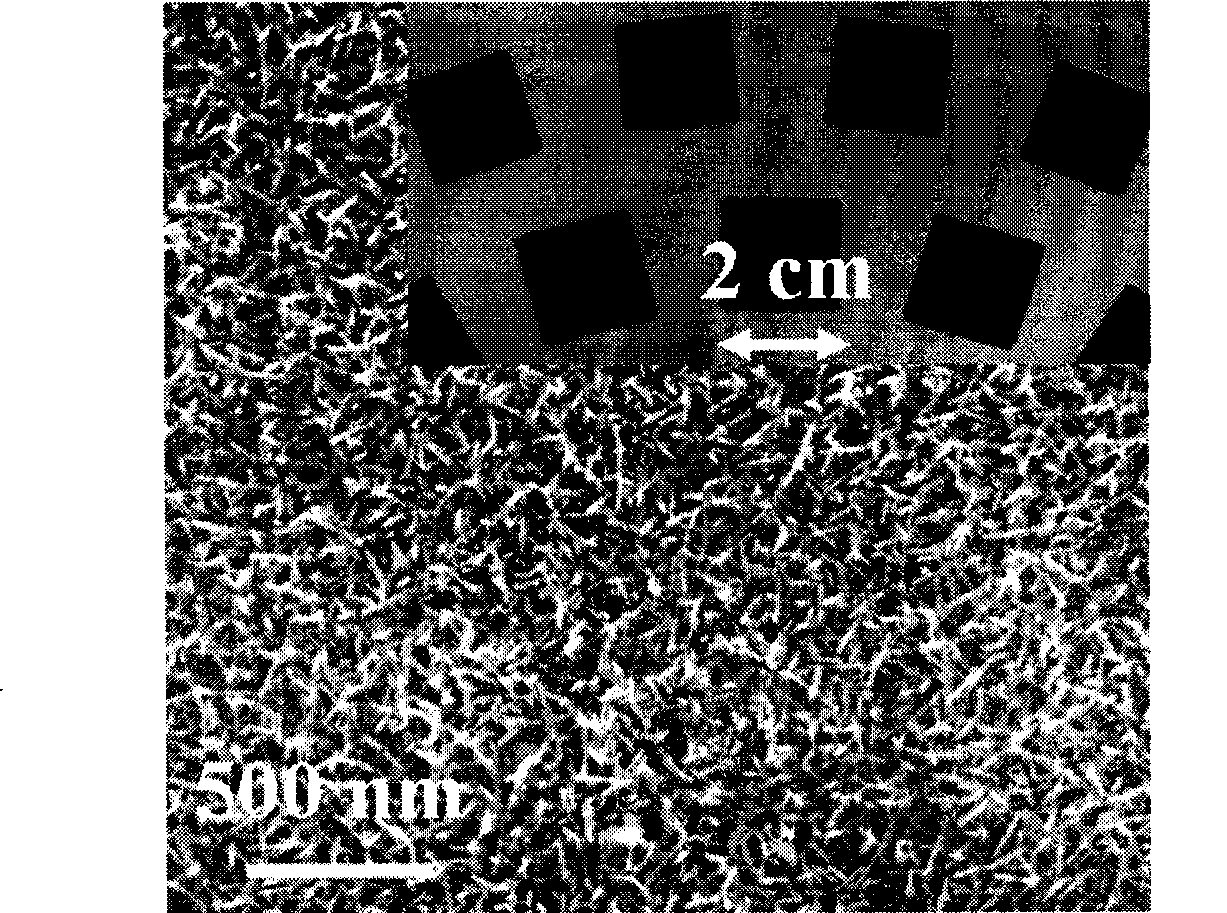

Method for producing small-sized tin indium oxide nano-wire material in low-temperature

InactiveCN101509123ASmall sizeReduce the temperaturePolycrystalline material growthVacuum evaporation coatingIndiumNanowire

The invention relates to a method for preparing small size indium tin oxide nanowire materials at low temperature, belonging to the technical field of photoelectronic device materials. The method mainly comprises the following steps: a target and a substrate are installed in a cavity of an electron beam evaporimeter; the cavity is closed, vacuumized and baked; electron beam spots are adjusted to shine on the surface of the ITO target and the electron beam current is adjusted so that the deposition rate of the target on the substrate is 0.2-0.5nm / s after evaporation; the evaporation is stopped when the depth of the deposition on the substrate meets the requirement, and the preparation is finished after cooling. The method utilizes the conventional electron beam evaporation device to prepare the small size ITO nanowire materials at low temperature. The obtained nano materials not only have good field emission characteristics and anti-reflection characteristics, but also are even, controllable and low in price, can realize preparation in large area and need no catalysts, thus can be applied in illuminating, illustrating and photovoltaic industries.

Owner:NANJING UNIV

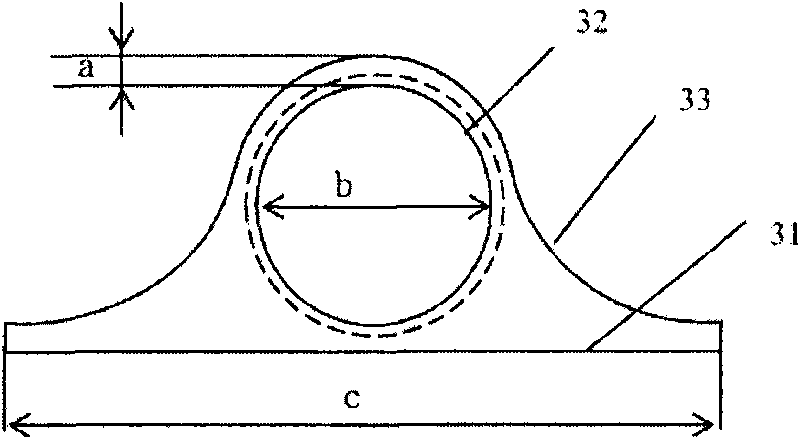

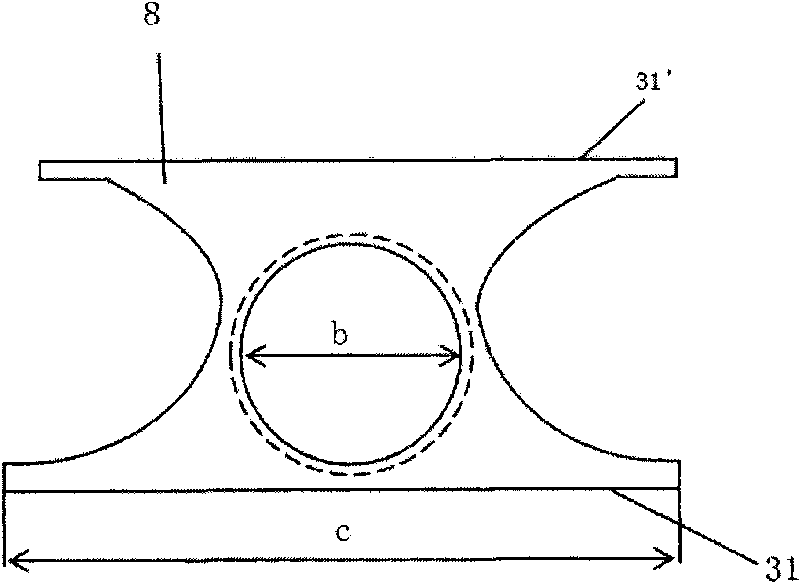

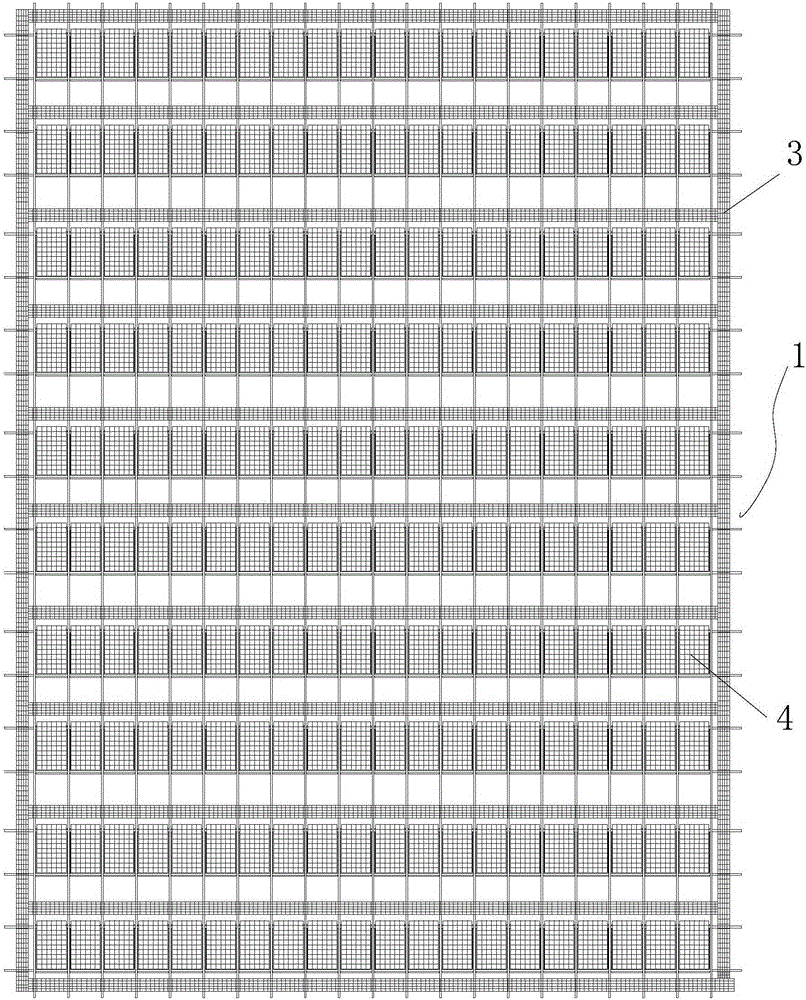

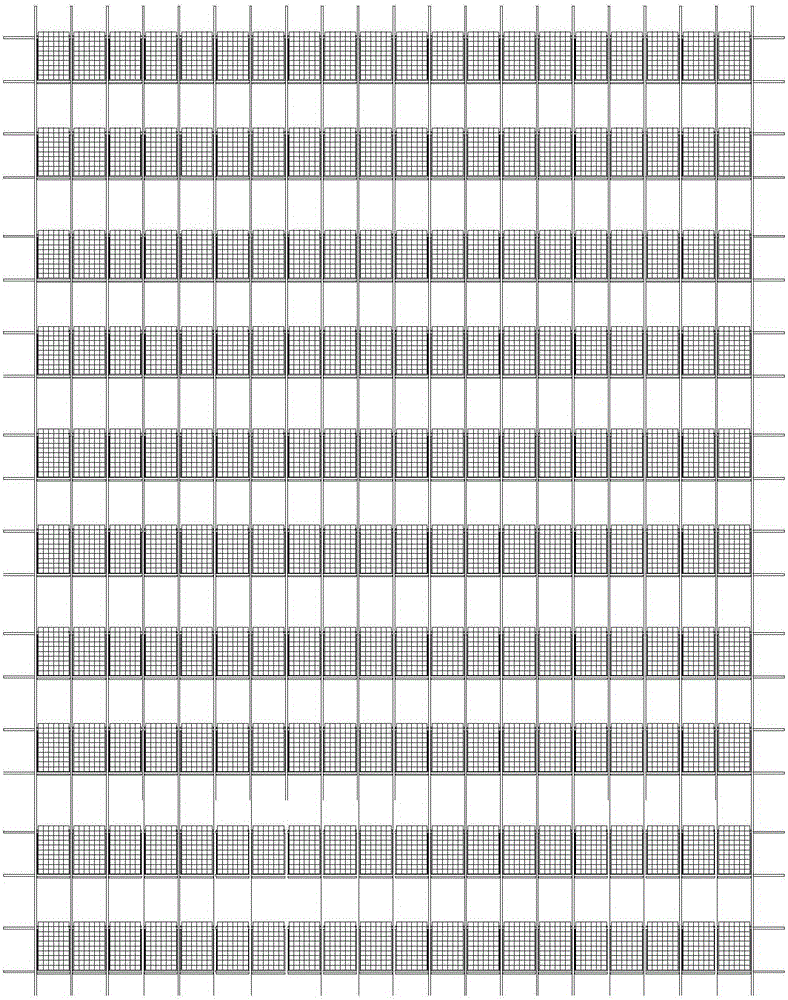

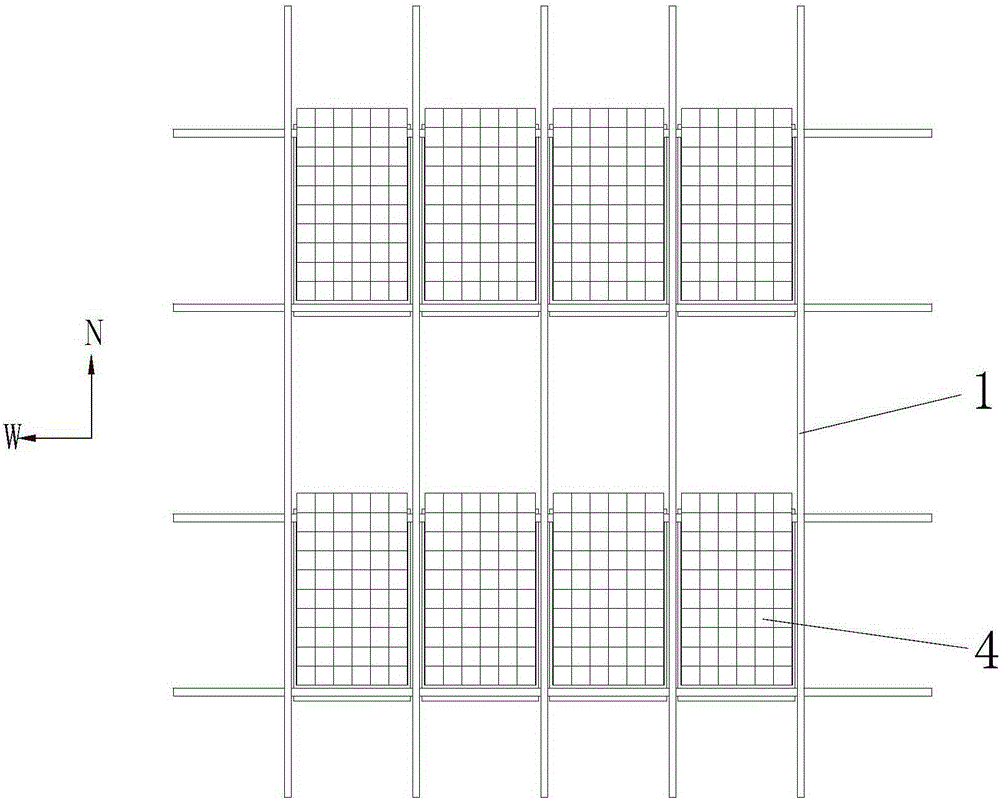

Floating structure of surface photovoltaic power station and construction process thereof

ActiveCN105356827AThe floating structure is novel and simpleThe shape of the space is novel and peculiarPhotovoltaic supportsWaterborne vesselsPhotovoltaic industryMarine engineering

The invention provides a technical scheme of a floating structure of a surface photovoltaic power station. The floating structure comprises a plane fixation structure, support floating bodies, a walkway plate, and photovoltaic assemblies arranged on the support floating bodies. The plane fixation structure is a meshed or aperture grid-shaped cell structure; and the space inside meshes or aperture grids is used for accommodating and fixing support floating bodies. Under the joint effect of the multiple support floating bodies, the plane fixation structure and the support floating bodies float on the water surface. The space shapes of the support floating bodies are novel and peculiar and the support floating bodies serve as key function components for the overall floating structure. The support floating bodies play a role in supporting the plane fixation structure upwardly and supporting the photovoltaic assemblies upwardly and directly. In addition, the invention also provides a corresponding construction process method; floating plastic support floating bodies are produced in situ at the construction site, thereby reducing the logistics transportation cost substantially and lowering the overall engineering cost. Therefore, the feasibility objective of the technical economy of the surface photovoltaic power station is achieved and the development process of the national photovoltaic industry is promoted.

Owner:张庆中

Preparation method for ultra pure silicon material used in solar energy photovoltaic industry

ActiveCN102225766ASimple processFinal product manufactureSilicon compoundsChemical treatmentPhotovoltaic industry

The invention discloses a preparation method for an ultra pure silicon material used in solar energy photovoltaic industry. The method is characterized by comprising the steps of ore dressing, quartz ore cleaning, primary selection, first chemical treatment, secondary selection, first high temperature treatment, third selection, magnetic separation treatment, multielement chemical treatment, ultrasonic treatment, treatment with a flotation machine, high temperature chlorination treatment, centrifuge dewatering and drying, deshydroxy treatment and magnetic separation. The ultra pure silicon material prepared by the method provided in the invention can be used to fabricate solar energy photovoltaic products; therefore, developmental demands in domestic solar energy photovoltaic industry andother high and new technology industries are satisfied, and the passive situation that ultra pure silicon materials used in the solar energy photovoltaic industry are depended on import is changed.

Owner:JIANGSU SHENGDA QUARTZ PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com