Back passivation solar cell back silver paste and preparation method thereof, and solar cell and preparation method thereof

A technology for solar cells and back silver paste, applied in the field of solar cells, can solve the problems of low adhesion strength between back electrodes and silicon, and the peeling test fails to meet industry requirements, and achieves the effect of improving photoelectric conversion efficiency and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

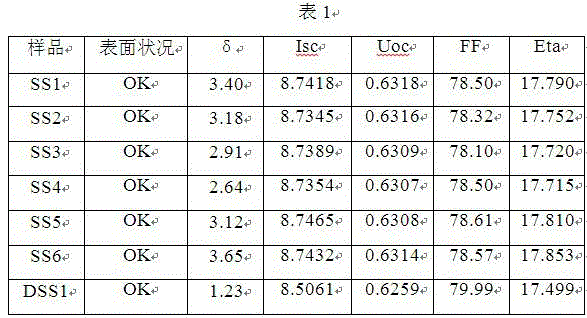

Examples

Embodiment approach

[0029] As a preferred embodiment of the present invention, the back passivation solar cell back silver slurry also contains dispersant, which promotes the uniform dispersing of each component in the back silver slurry.In the case of better selection, the backwipes of the back passivation solar cells are used as the benchmark, and the content of the dispersant is 0.1-1 weight.Among them, the dispersion agent can be selected from one or more of polyethylene pyrirol (PVP), polyacrylamide, cellulose derivatives, and triangular hex phosphates.

[0030] The present invention also provides a preparation method for the backwatch solar battery back silver pulp, including the dispersion of micron silver powder, nano silver powder, and inorganic glass powder in the organic carrier.material.

[0031] Because the back passivation solar battery back silver slurry provided by the present invention also contain nano -silver powder, and nano silver powder is prone to self -reunion due to its small...

Embodiment 1

[0046] (1) Preparation of inorganic glass powder SA1

[0047] Take 90 weight PBO, 10 weight B 2 O 3 Use the V -type hybrid machine to mix well, put it into the porcelain cricket, put it in a silicon carbon rod furnace, heat the heat to 550 ° C, heat preservation 0.5h, then rise to 1200 ° C, melted for 1.0 hours, water quenching, filtering, will get it will get it will get it.The glass beads are loaded into the ball mill, controlled the quality ratio, oxidized ball: glass beads: ion water = 4: 1.5: 0.6, the pot speed of 380 rpm, the ball grind for 6 hours, filter, dry, dry glass powder, get inorganic glass powderSA1, testing the particle size D 50 It is 1.50μm, D 100 For 8.28 μm, test the softening temperature on the expansion curve of the inorganic glass powder SA1 T f It is 300 ° C.

[0048] (2) Preparation of organic carriers

[0049] According to the quality ratio is butylka must be alcohol: butyl -oligraxinate: pine oil: diode (DBP) = 45: 30: 20: 5, the proportion of organic s...

Embodiment 2

[0055] The same steps are used to use the same steps 1, the difference is:

[0056] In the step (3), take 66 weights steps (2) prepared organic carrier, and then add 30 nano -silver powder and 4 -weight dispersion PVP, stir well, and then use a sand mill for sand grinding to test it to test it to test it to test it to test it to test it to test it to test it to test it.The fineness is less than 3 ~ 5 μm, that is, the nano silver slurry SB2;

[0057] In the step (4), the nano silver slurry SB1 is replaced by the nano silver slurry SB2.

[0058] Through the above steps, the back passivation solar battery back silver slurry of this embodiment is obtained as S2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com