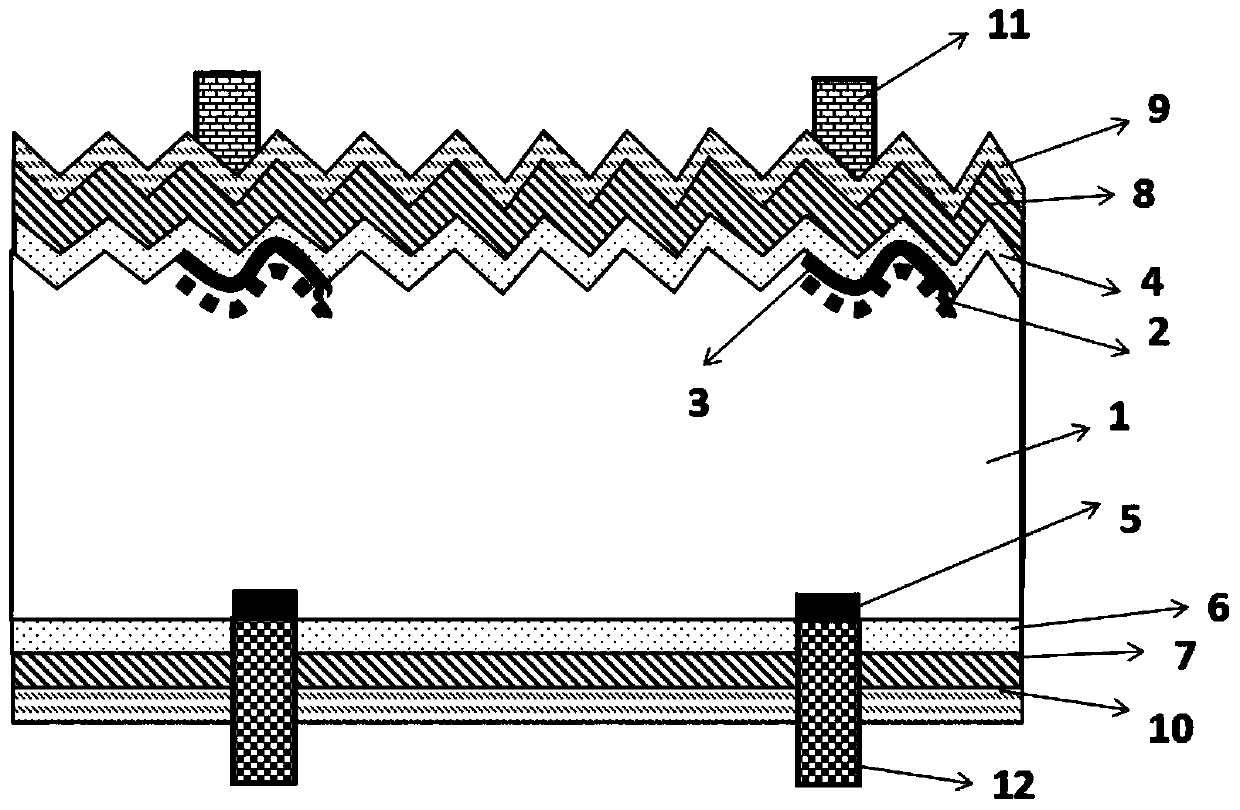

Double-sided selective emitter high-efficiency crystalline silicon cell and preparation method thereof

A technology of crystalline silicon cells and emitters, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of inability to passivate boron doping, difficult implementation, and immature technology, so as to avoid light absorption, improve Isc, and improve Effect of Surface Doping Concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A double-sided selective emitter extremely high-efficiency crystalline silicon battery specific battery manufacturing steps are as follows:

[0060] An N-type silicon wafer with a high minority carrier lifetime is used as the substrate (1), its resistivity is 0.8Ω.cm, and the minority carrier lifetime is >1ms.

[0061] (1) Double-sided texturing, in the groove machine, first use KOH:H 2 o 2 =1:3 for pre-cleaning 2min, the temperature is maintained at 75 ° C; then in KOH: additive = 8: 1 (the additive is composed as follows according to the number of parts: 5 parts of sodium lactate, 8 parts of surfactant (wherein, sodium hydroxide: poly Ether modified polysiloxane defoamer=1:2 (mass ratio)), 1 part of methyl glucose polyoxyethylene ether; 2 parts of glucose; 1 part of polyacrylamide; 83 parts of deionized water), the temperature is maintained at 80 ℃, time 7min for rapid texturing; the amount of thinning is controlled at about 0.55g.

[0062] (2) Intrinsic polysilico...

Embodiment 2

[0076] A double-sided selective emitter extremely high-efficiency crystalline silicon battery specific battery manufacturing steps are as follows:

[0077] An N-type silicon wafer with a high minority carrier lifetime is used as the substrate (1), its resistivity is 1.5Ω.cm, and the minority carrier lifetime is >1.5ms.

[0078] (1) Double-sided velvet, pre-cleaned for 2 minutes in the tank machine, KOH:H 2 o 2 =1:4, the temperature is maintained at 80°C; then in KOH: additive=7:1 (the composition of the additive is as follows according to the number of parts: 6 parts of sodium lactate, 9 parts of surfactant (sodium hydroxide: polyether modified silicone Alkanes antifoaming agent=1:2.5 (mass ratio)), 1.5 parts of methyl glucose polyoxyethylene ether; 2 parts of glucose; 1.5 parts of polyacrylamide; 80 parts of deionized water), the temperature was maintained at 75 ° C, and the time was 7 minutes. Fast velvet. The amount of thinning is controlled at about 0.5g;

[0079] (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com