Patents

Literature

532 results about "Boron doping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Doping means the introduction of impurities into a semiconductor crystal to the defined modification of conductivity. Two of the most important materials silicon can be doped with, are boron (3 valence electrons = 3-valent) and phosphorus (5 valence electrons = 5-valent).

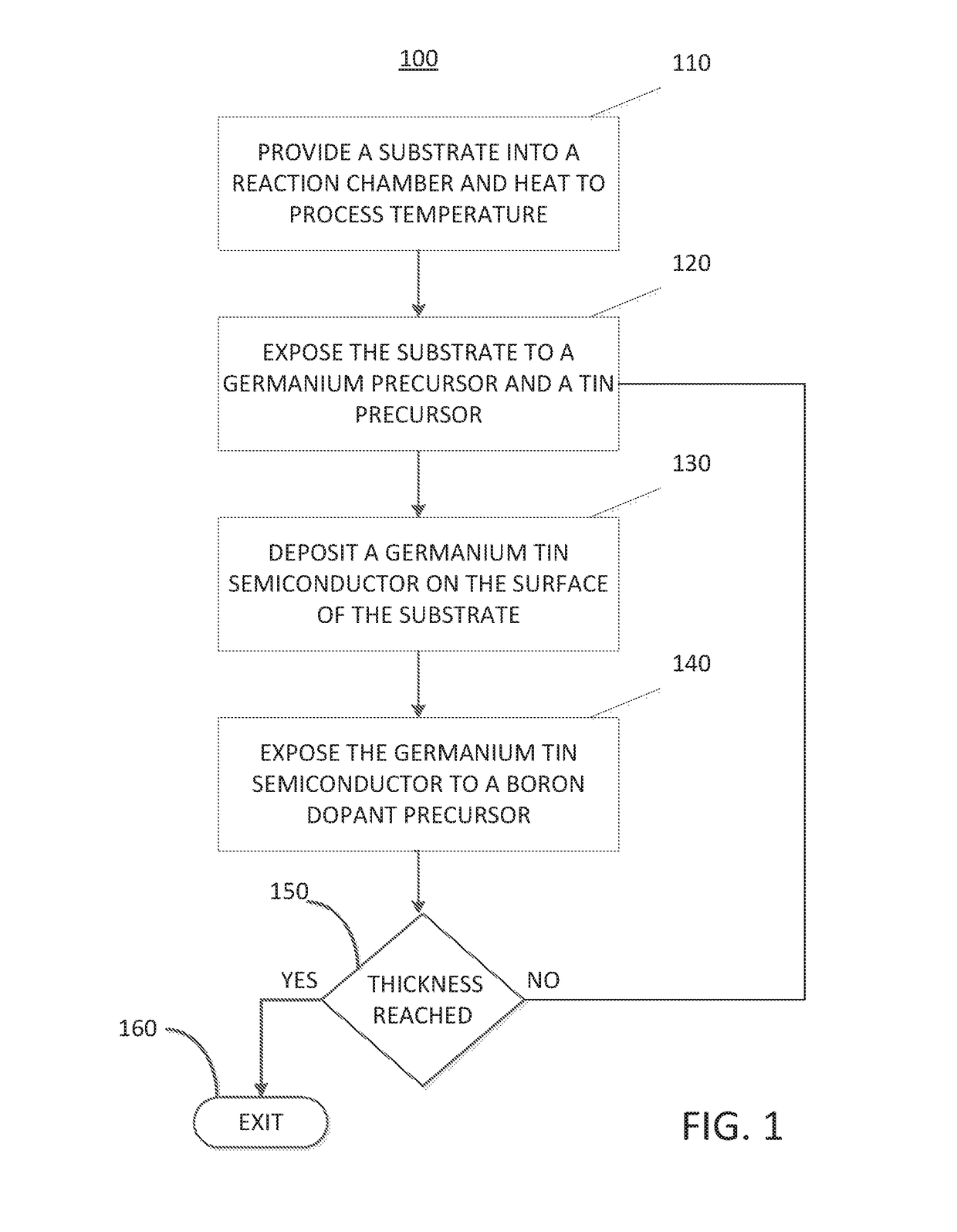

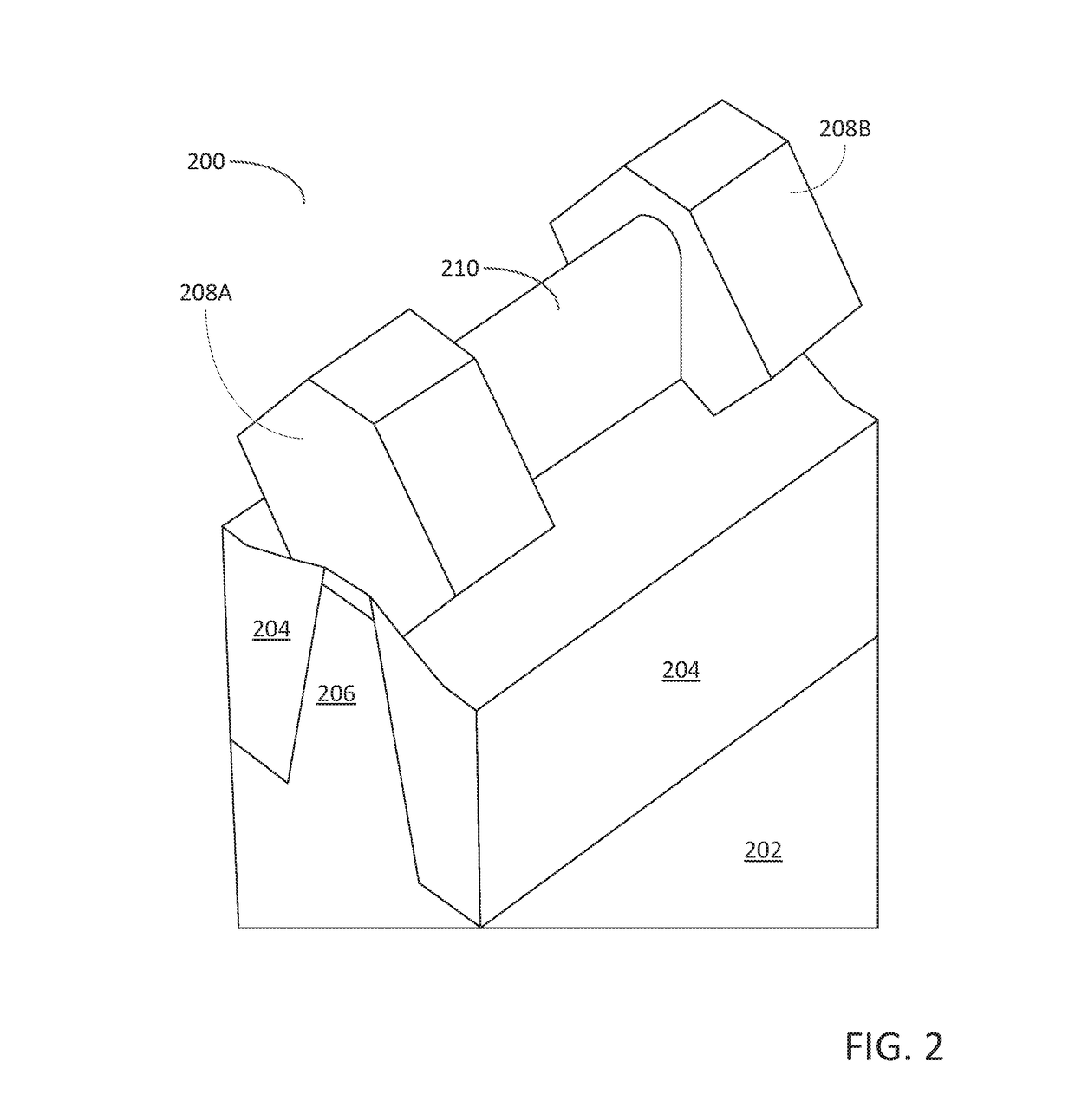

Methods for depositing a doped germanium tin semiconductor and related semiconductor device structures

ActiveUS10236177B1Polycrystalline material growthAfter-treatment detailsDopantDeposition temperature

A method for depositing a germanium tin (Ge1-xSnx) semiconductor is disclosed. The method may include; providing a substrate within a reaction chamber, heating the substrate to a deposition temperature and exposing the substrate to a germanium precursor and a tin precursor. The method may further include; depositing a germanium tin (Ge1-xSnx) semiconductor on the surface of the substrate, and exposing the germanium tin (Ge1-xSnx) semiconductor to a boron dopant precursor. Semiconductor device structures including a germanium tin (Ge1-xSnx) semiconductor formed by the methods of the disclosure are also provided.

Owner:ASM IP HLDG BV

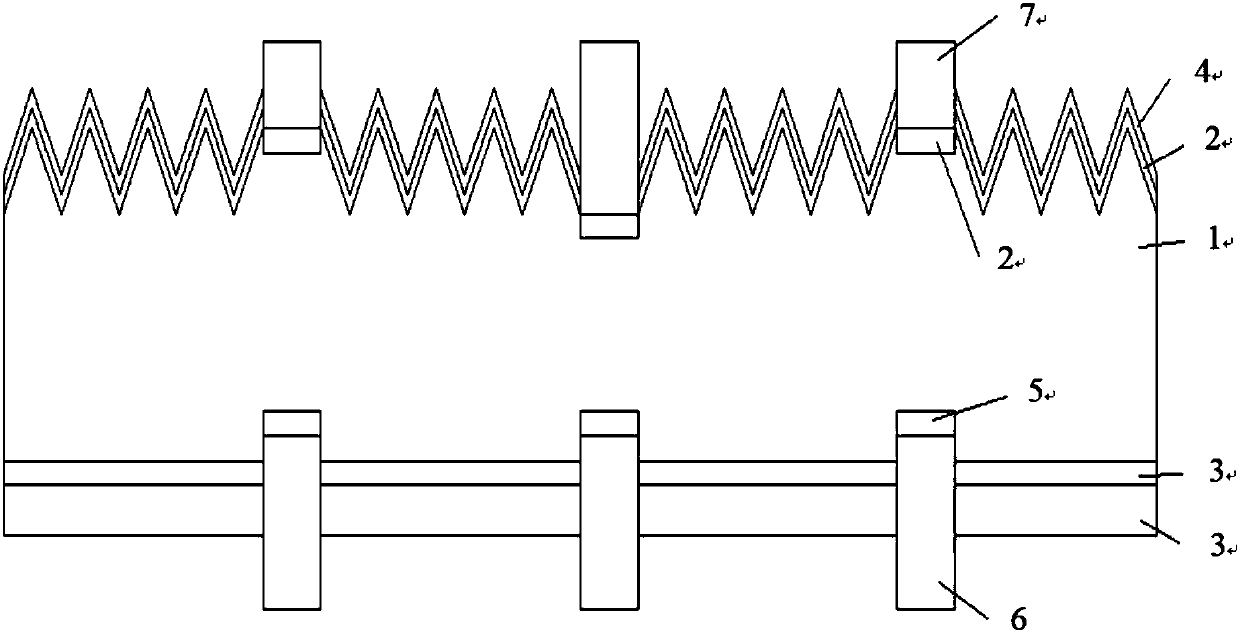

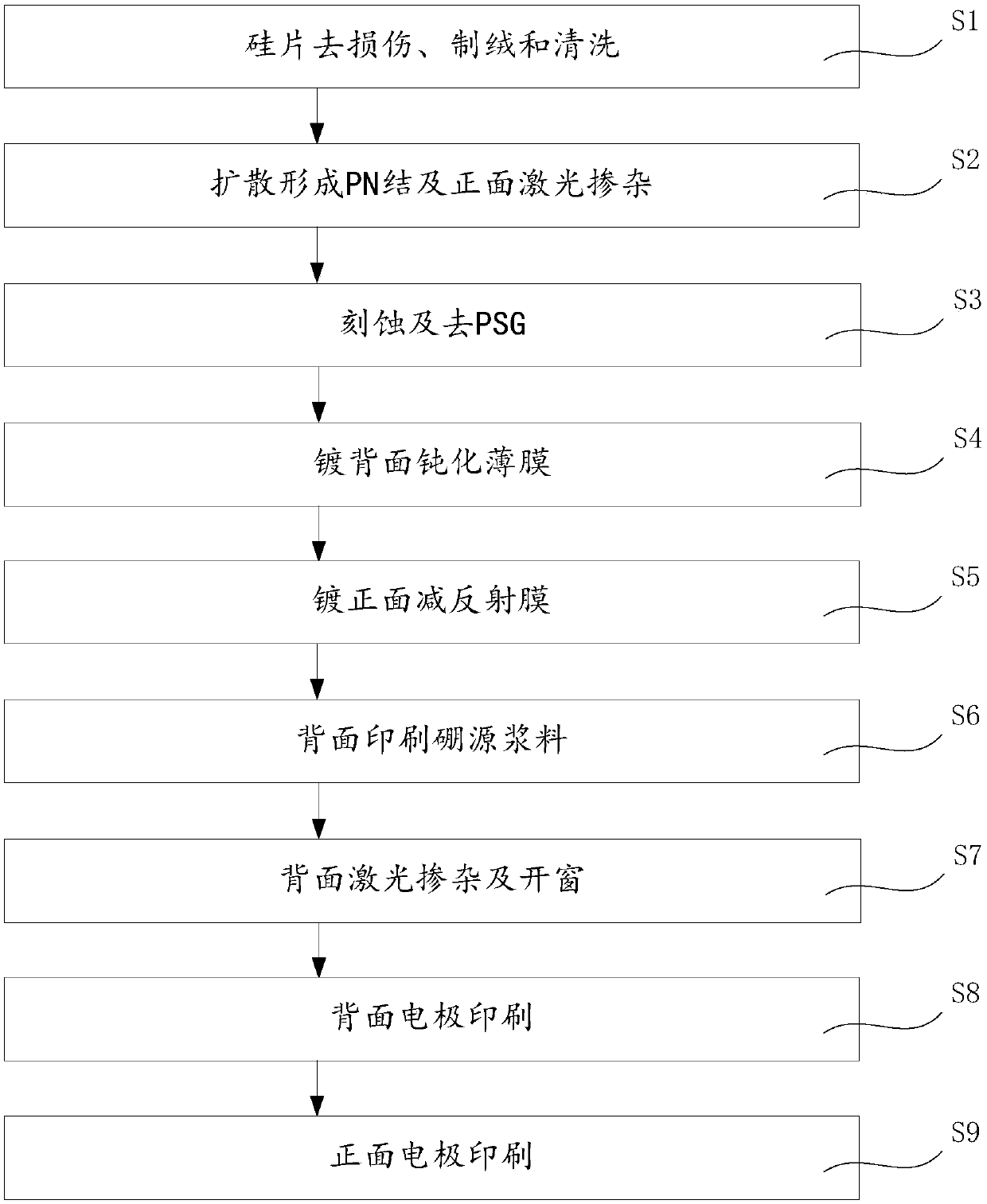

Fabrication method of double-side PERC crystalline silicon solar cell

InactiveCN107863419AImprove conversion efficiencyImplement backside metallizationFinal product manufactureSemiconductor/solid-state device manufacturingScreen printingSilicon solar cell

The invention discloses a fabrication method of a double-side PERC crystalline silicon solar cell. The fabrication method comprises the following steps of (1) removing damage of a silicon wafer, and performing texturing and cleaning; (2) performing diffusion to form a pn junction and performing front-surface laser doping; (3) etching and removing PSG; (4) plating a back-surface passivation thin film; (5) plating a front-surface anti-reflection film; (6) printing boron source paste on a back surface; (7) performing back-surface laser doping and windowing; (8) performing back-surface electrode printing; and (9) performing front-surface electrode printing. A laser doping technology is applied to a process of a selective emitter formed on a front surface and local boron doping on the back surface, only two processes of laser doping and boron source paste printing are added on the basis of a conventional PERC battery process, and the conversion efficiency of the double-side PERC cell is greatly improved; moreover, with the adoption of a secondary printing alignment laser printing MARK point mode, the back-surface metallization of the double-side PERC cell is achieved; and by the method,the problem of difficulty in alignment of a back-surface aluminum grid line to a laser windowing grid line of the silk-screen printed double-sided PERC cell is completely solved.

Owner:SPIC XIAN SOLAR POWER CO LTD

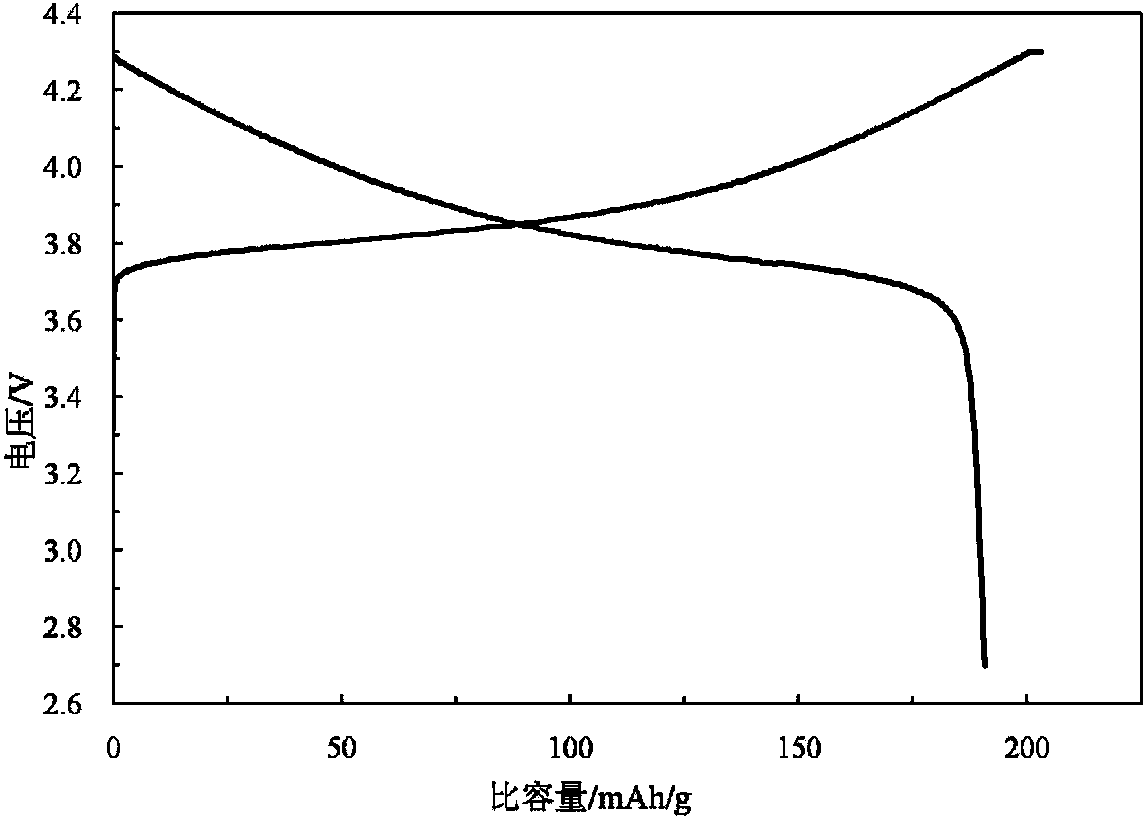

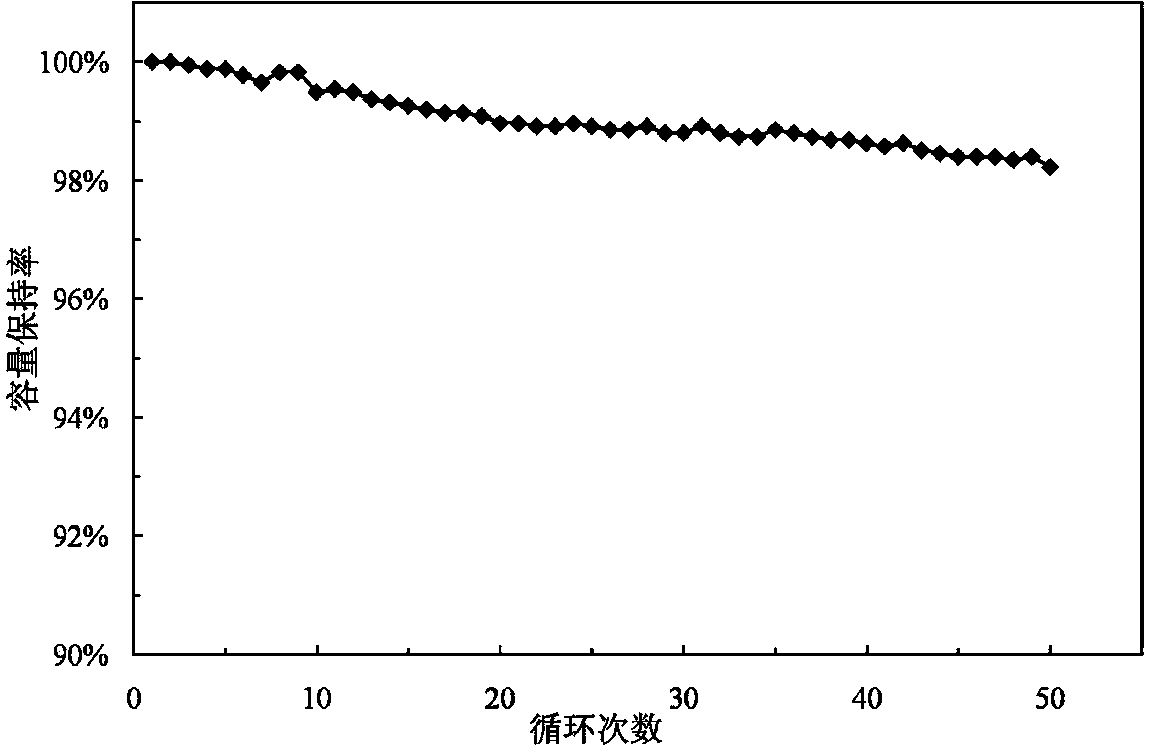

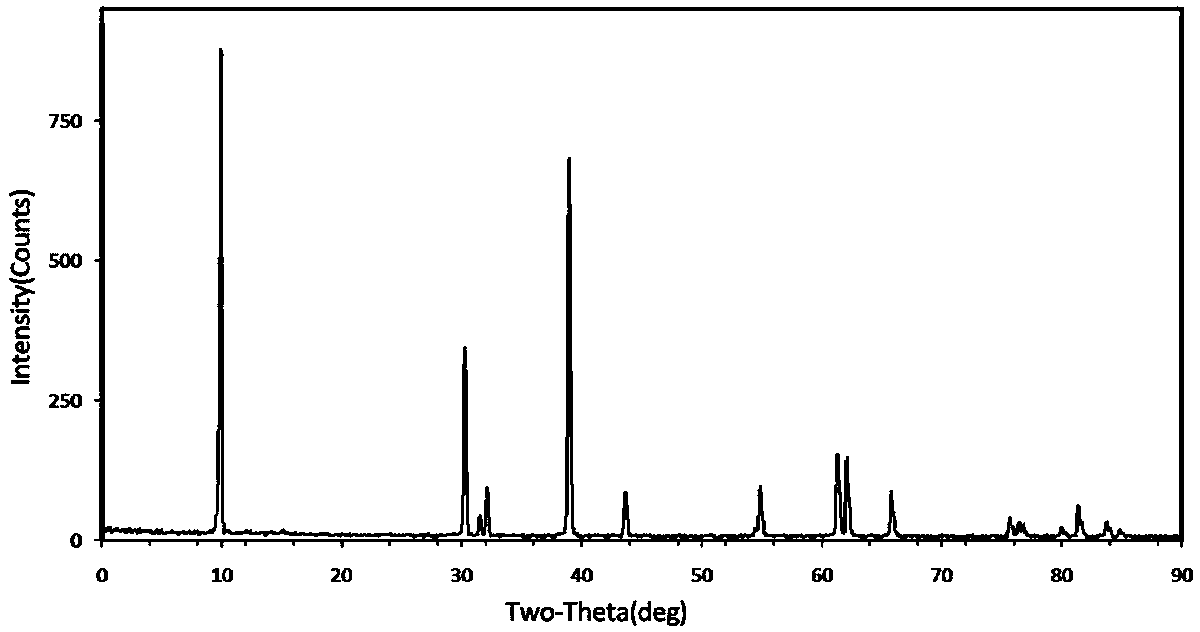

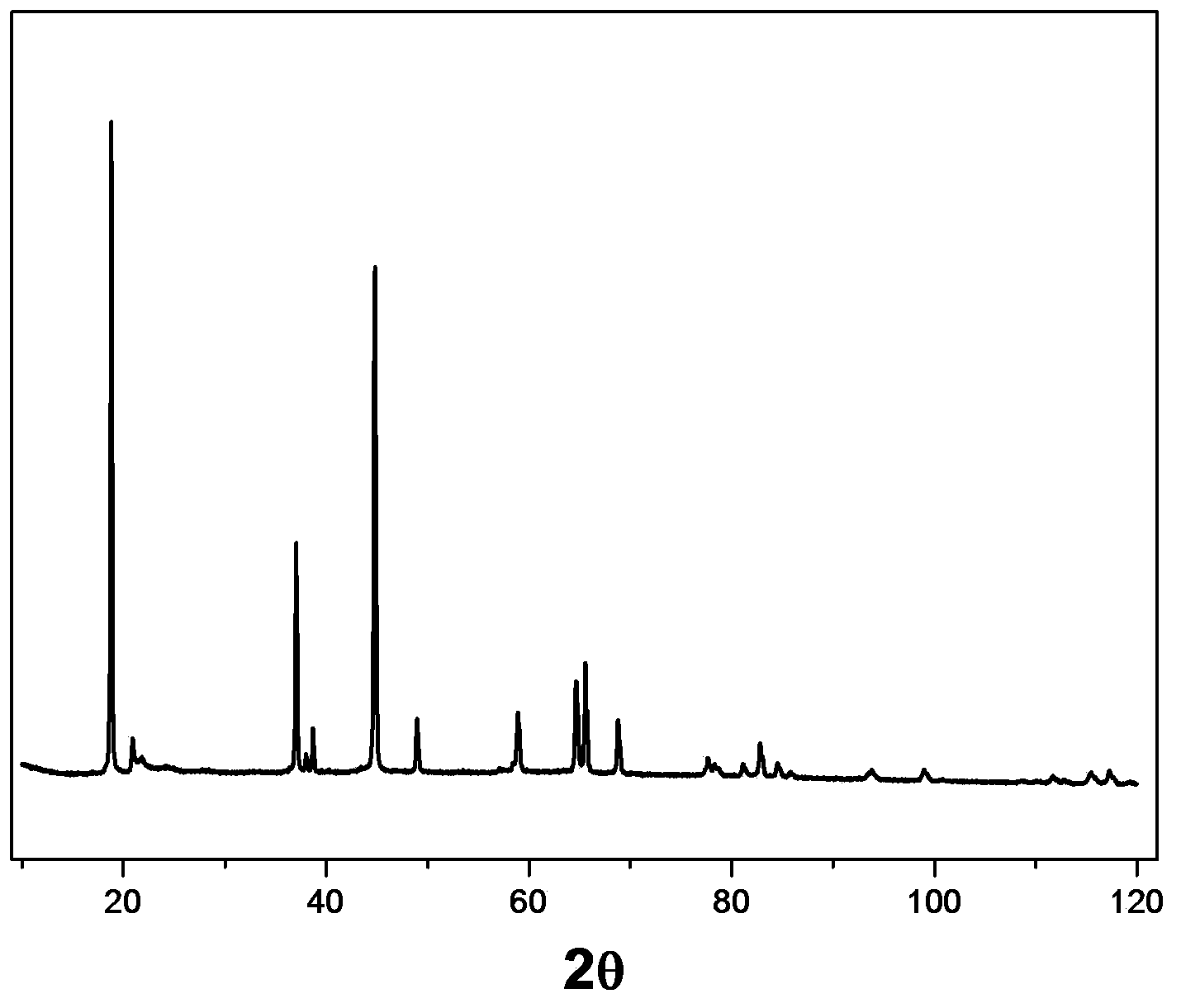

Modified lithium ion battery ternary positive electrode material and preparation method thereof

InactiveCN103855387ALower sintering temperatureHigh tap densityCell electrodesSecondary cellsAir atmosphereNickel salt

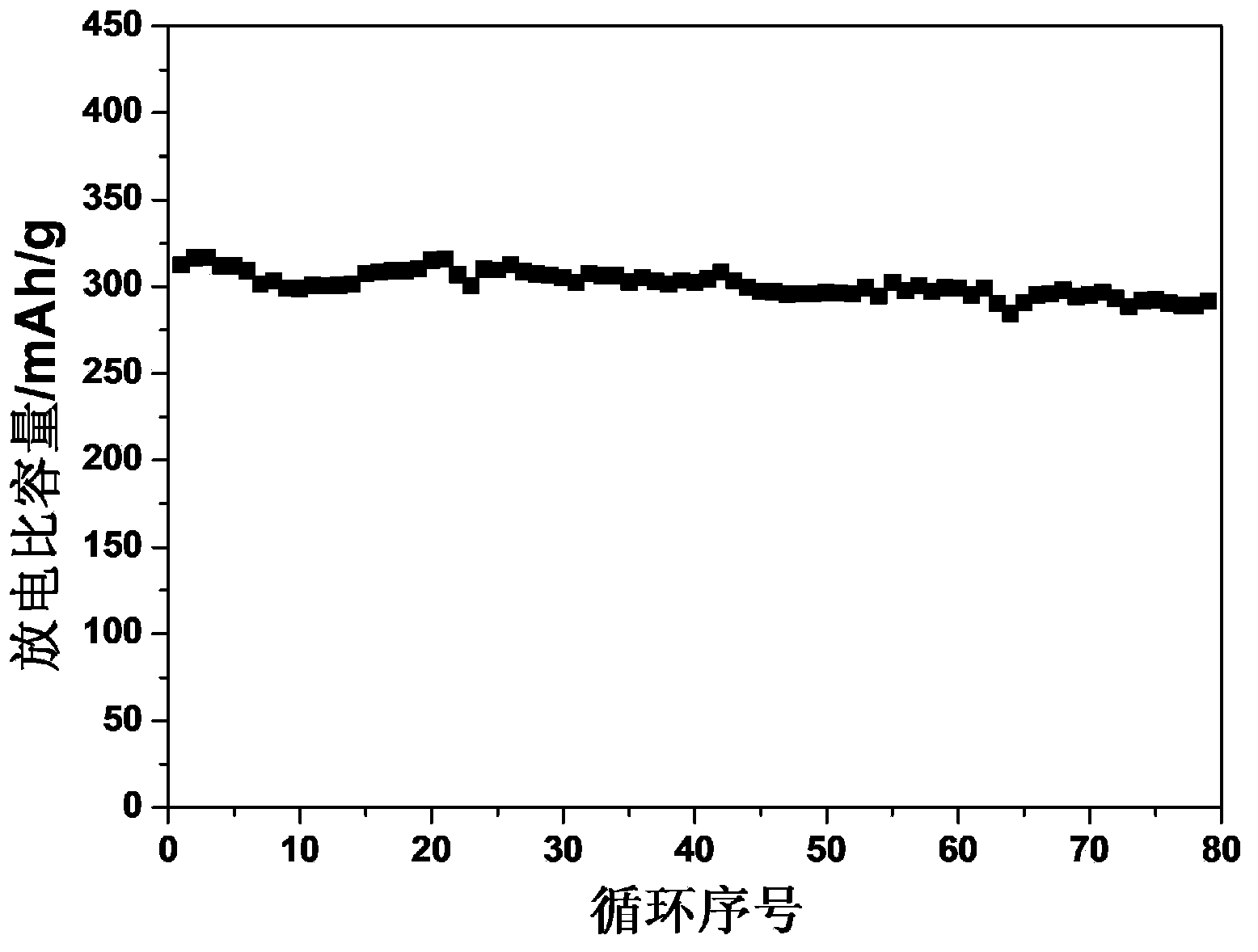

The invention relates to a modified lithium ion battery ternary positive electrode material and a preparation method of the modified lithium ion battery ternary positive electrode material. The chemical generation formula of the material is as follows: LiNiaCo<1-a-b>MnbBxO2 / TiO2, wherein a is more than 0 and less than 1, b is more than 0 and less than 1, (1-a-b) is more than 0 and less than 1, x is more than 0.005 and less than 0.1, and the TiO2 is a cladding layer. The soluble nickel salt, cobalt salt and manganese salt are prepared into a mixed salt solution, the mixed salt solution is reacted with a mixed alkaline solution prepared by mixing the NaOH and ammonium hydroxide, after being filtered, washed and dried, the reaction product is mixed with a boronic compound and roasted for 4h to 12h at the temperature of 300 to 800 DEG C under an air atmosphere, then the roasted product is ball milled with the lithium salt to be uniformly mixed together, the mixture is coated with titanium dioxide after being calcined at the high temperature to obtain the modified lithium ion battery ternary positive electrode material. The prepared boron doping modified ternary positive electrode material is high in specific capacity and good in cycling performance.

Owner:ZHEJIANG MEIDARUI NEW MATERIAL TECH CO LTD

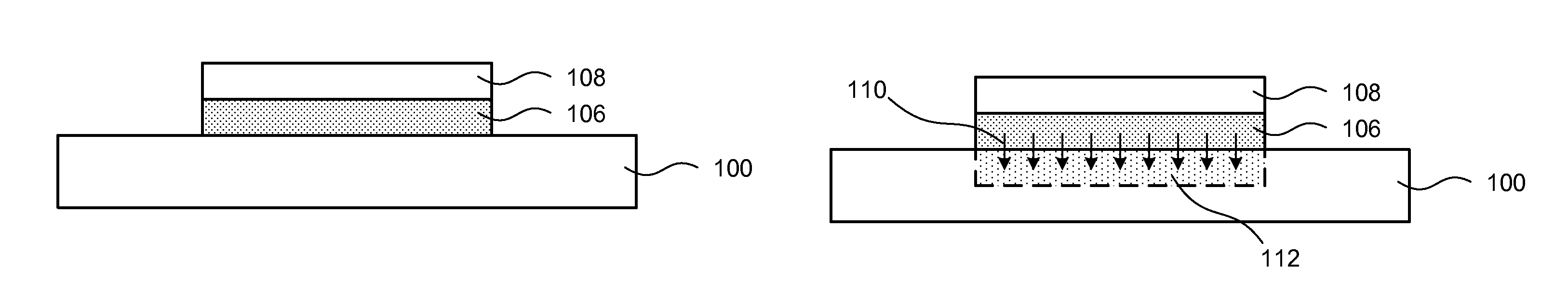

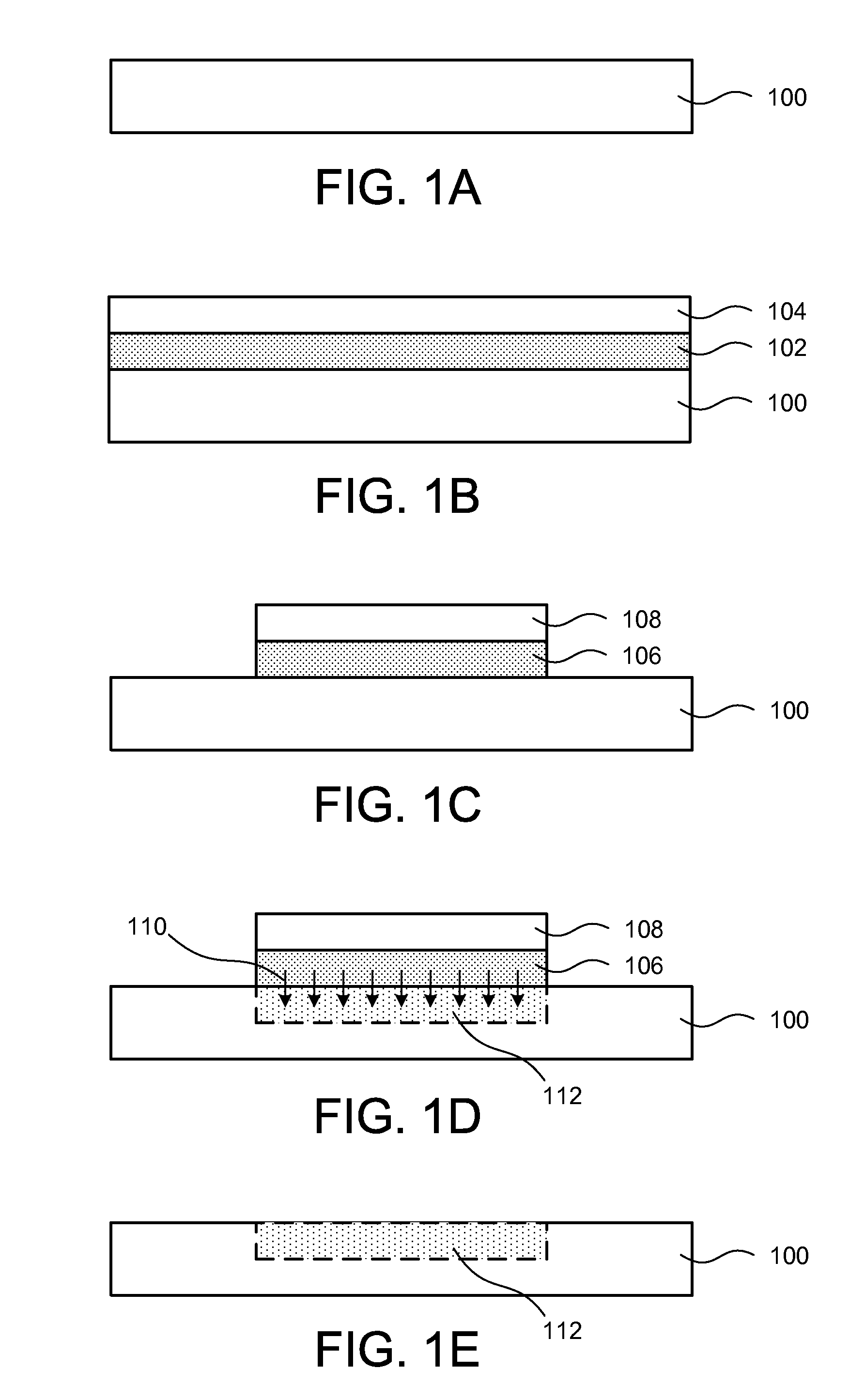

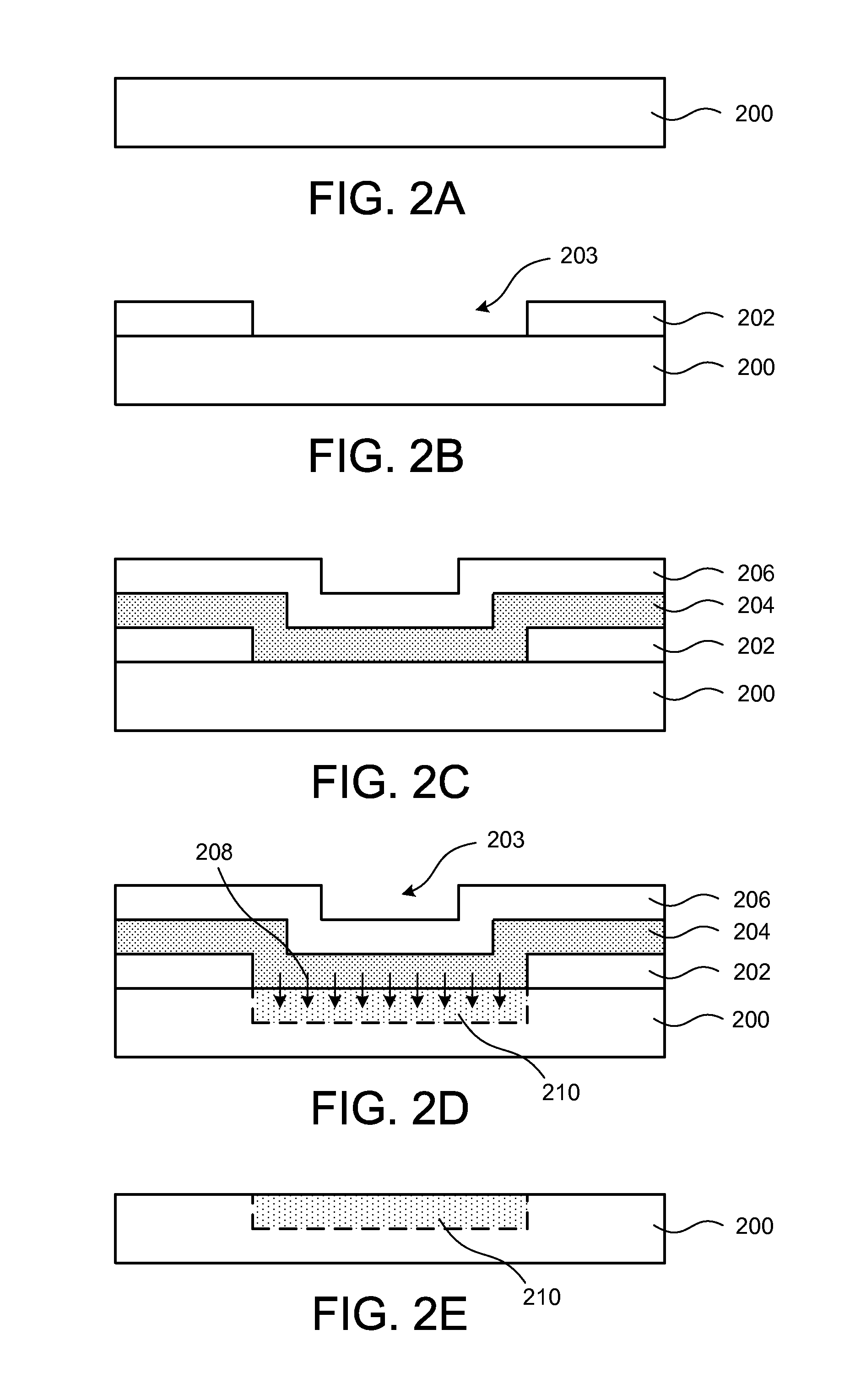

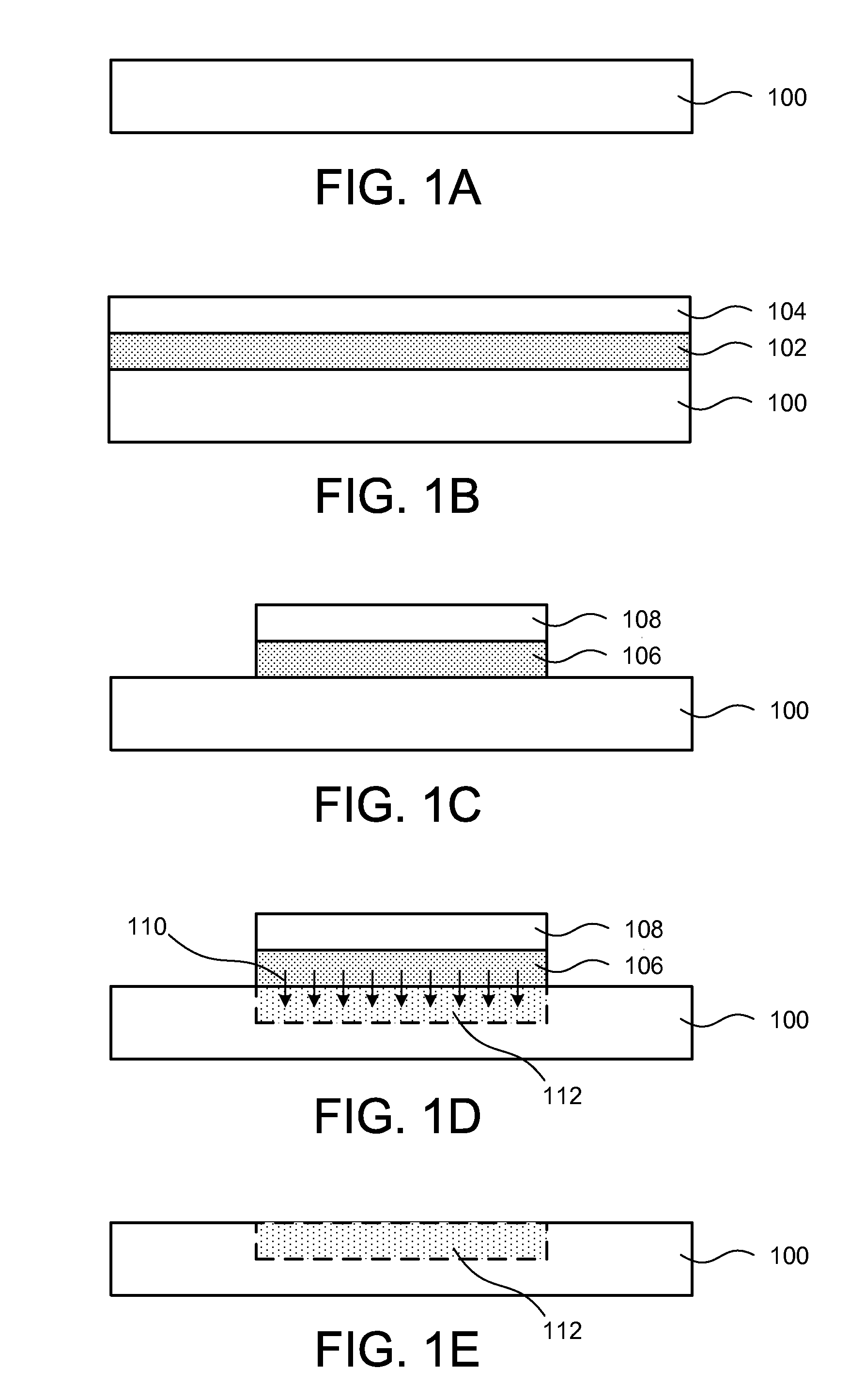

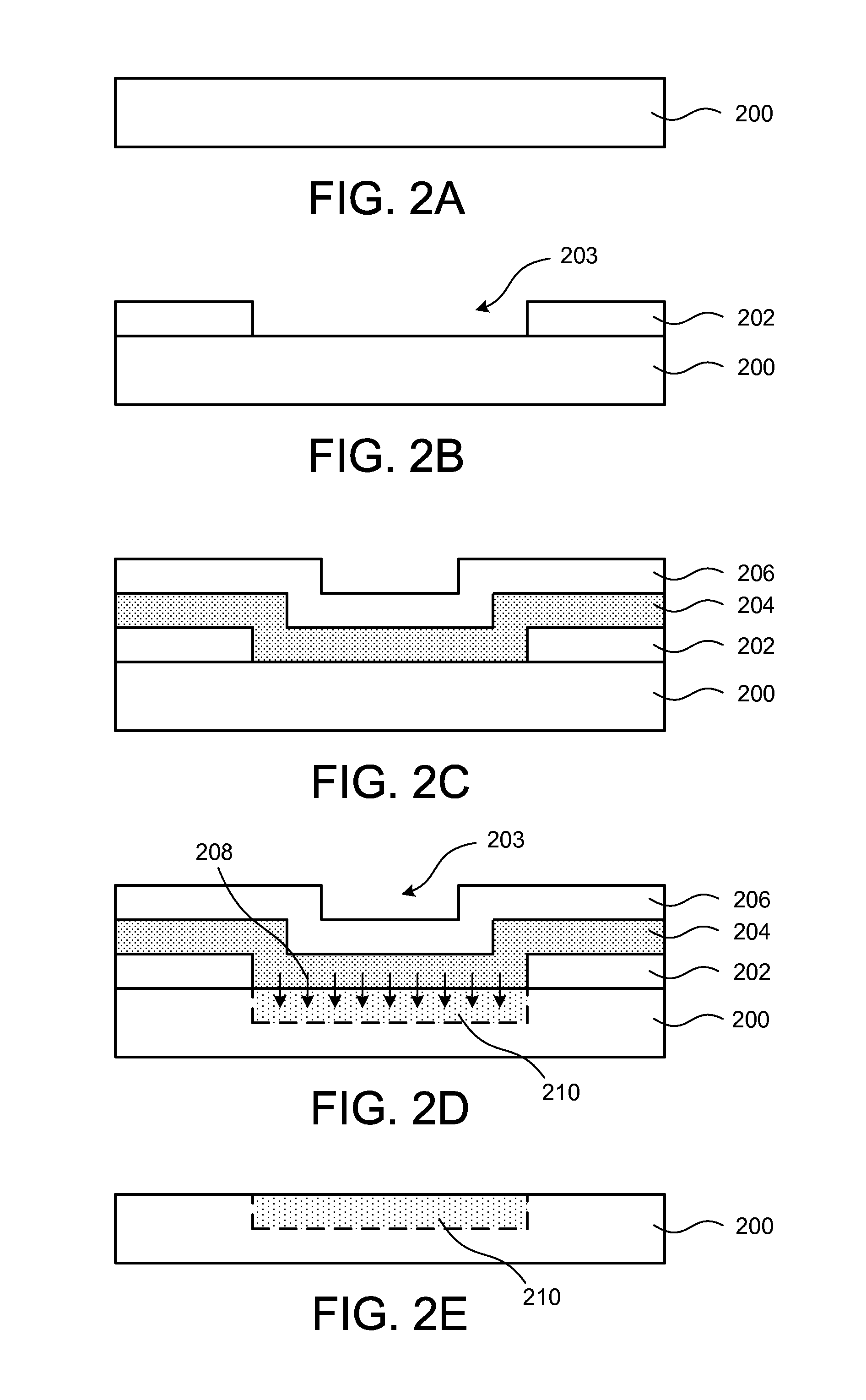

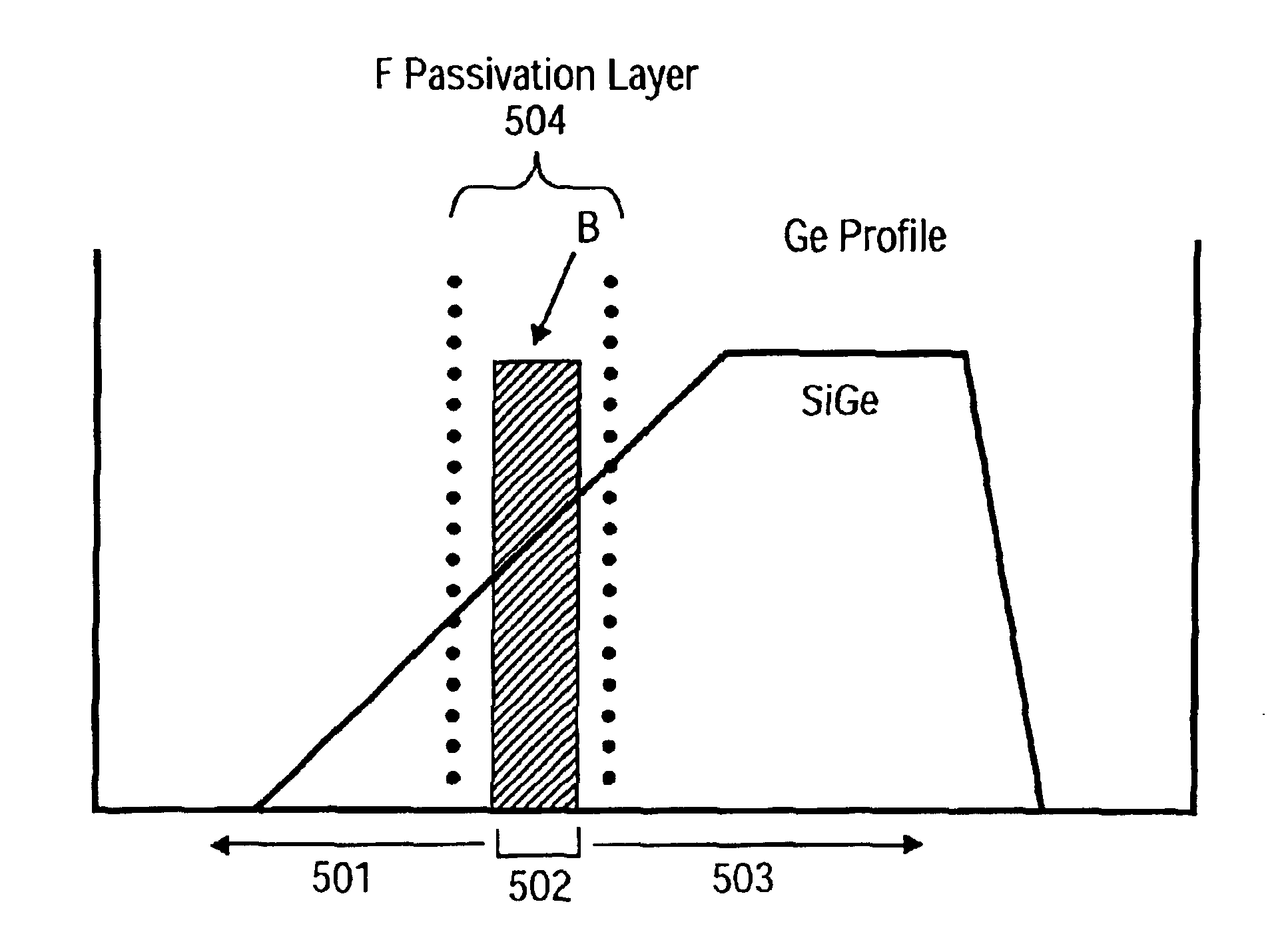

Method for forming ultra-shallow boron doping regions by solid phase diffusion

A method for forming an ultra-shallow boron dopant region in a substrate is provided. In one embodiment, the method includes depositing, by atomic layer deposition (ALD), a boron dopant layer in direct contact with the substrate, where the boron dopant layer contains an oxide, a nitride, or an oxynitride formed by alternating gaseous exposures of boron amide precursor or an organoboron precursor and a reactant gas. The method further includes patterning the dopant layer and forming an ultra-shallow dopant region in the substrate by diffusing boron from the boron dopant layer into the substrate by a thermal treatment.

Owner:TOKYO ELECTRON LTD

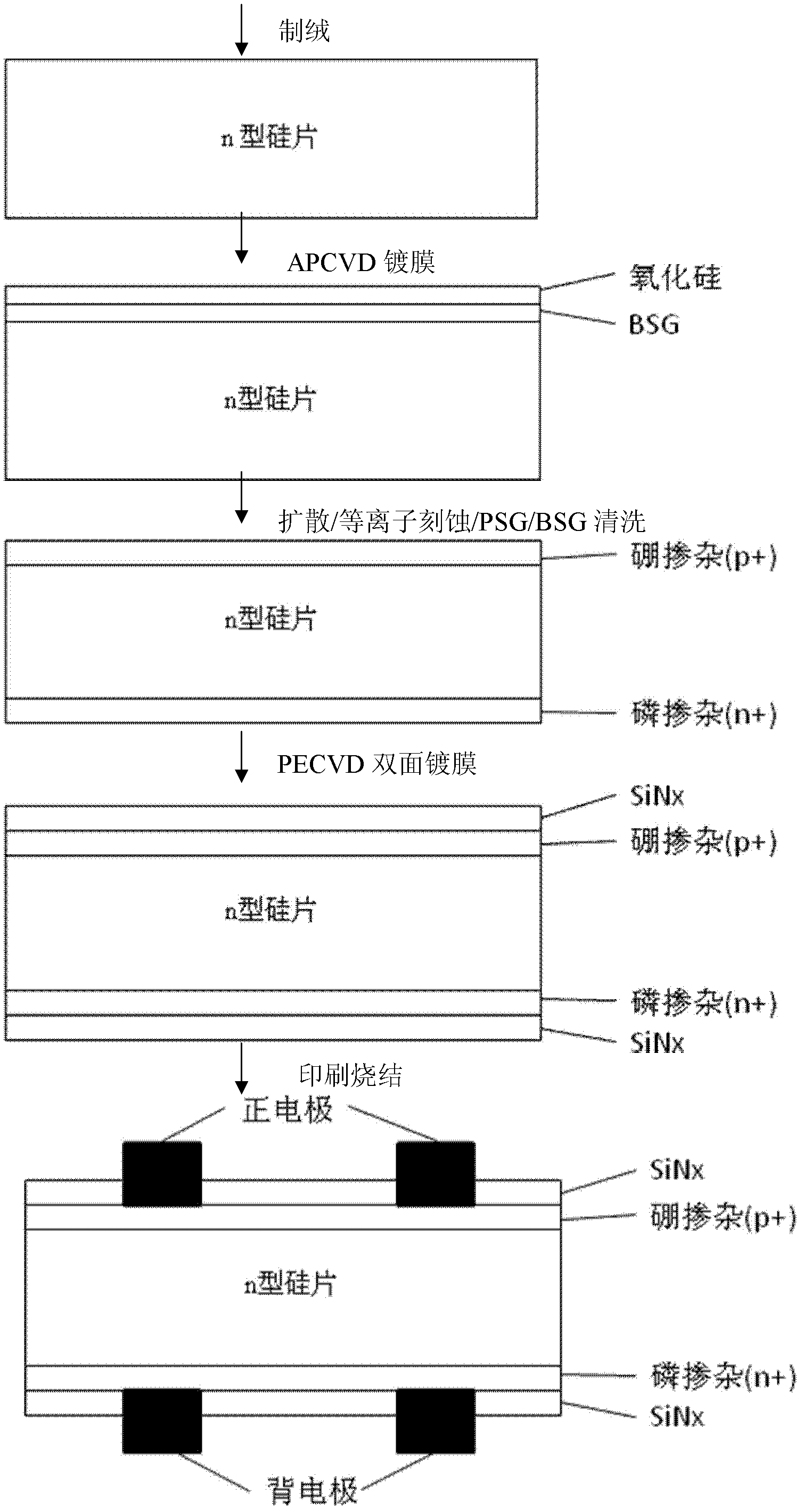

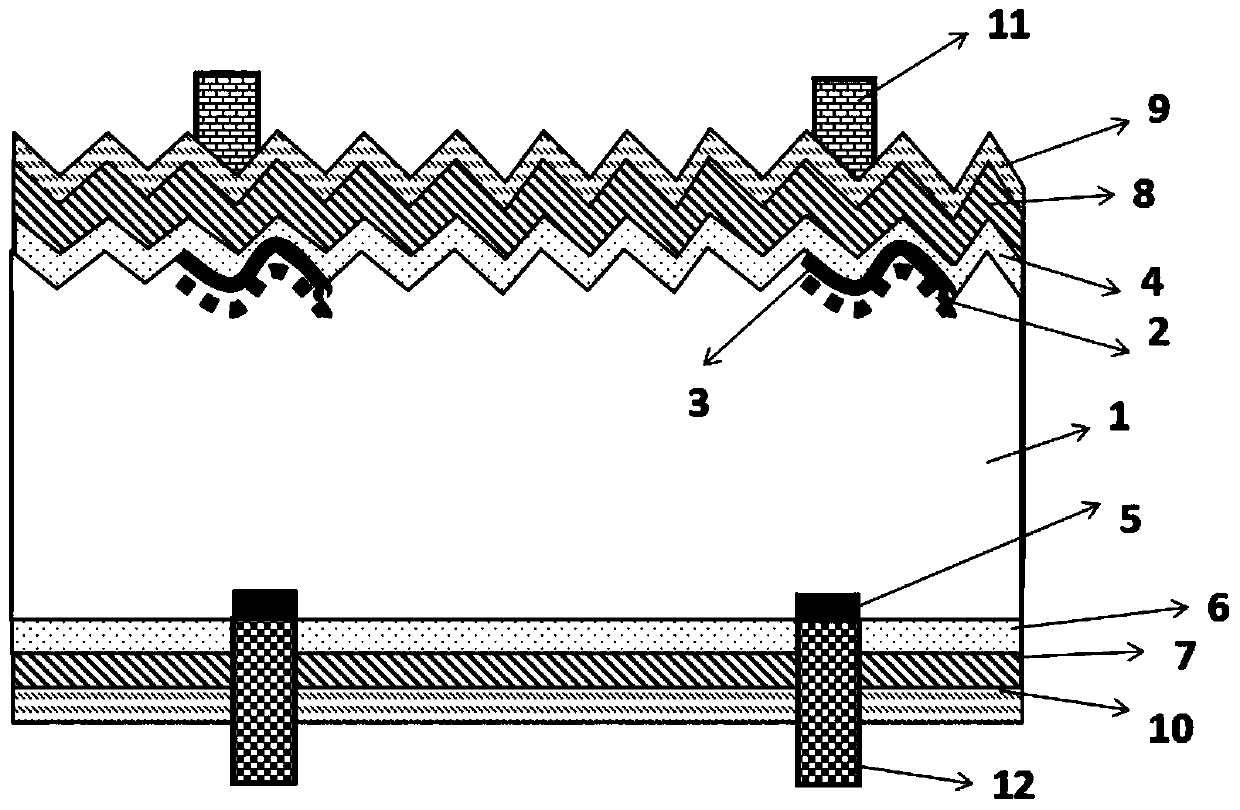

High efficiency N-type double-faced solar cell and preparation method thereof

ActiveCN104733555AIncrease the open circuit voltageInhibited DiffusionFinal product manufacturePhotovoltaic energy generationPhosphorSilicon dioxide

The invention relates to a high efficiency N-type double-faced solar cell and a preparation method thereof. The structure of the solar cell comprises an N-type silicon slice substrate, a front side boron doping layer, a back side phosphor doping layer, double-faced silicon dioxide passivation layers, doubled-faced silicon nitride antireflection layers and double-faced electrodes. The invention further discloses a preparation method for the solar cell, the preparation method particularly comprises the first step that double-faced texturization is conducted; the second step that front side boron diffusion is conducted; the third step that front side film masking is conducted; the fourth step that back side washing is conducted; the fifth step that back side phosphorus diffusion is conducted; the sixth step that a mask film is removed; the seventh step that double-faced passivation is conducted; the eighth step that double-faced film coating is conducted; the ninth step that the front side electrodes and the back side electrodes are formed; the tenth step that laser edge carving is conducted. According to the high efficiency N-type double-faced solar cell and the preparation method thereof, knots are formed on both the front side and the back side of the N-type silicon slice, the front side and the back side both have high photoelectric converting rates, the output power of an assembly of the high efficiency N-type double-faced solar cell is 20% higher than the output power of a common solar cell, and meanwhile the high efficiency N-type double-faced solar cell is applicable to large-scale industrial production due to the fact that the preparation technology is simple and practical.

Owner:常州顺风太阳能科技有限公司

Method for forming ultra-shallow boron doping regions by solid phase diffusion

A method for forming an ultra-shallow boron dopant region in a substrate is provided. In one embodiment, the method includes depositing, by atomic layer deposition (ALD), a boron dopant layer in direct contact with the substrate, where the boron dopant layer contains an oxide, a nitride, or an oxynitride formed by alternating gaseous exposures of boron amide precursor or an organoboron precursor and a reactant gas. The method further includes patterning the dopant layer and forming an ultra-shallow dopant region in the substrate by diffusing boron from the boron dopant layer into the substrate by a thermal treatment.

Owner:TOKYO ELECTRON LTD

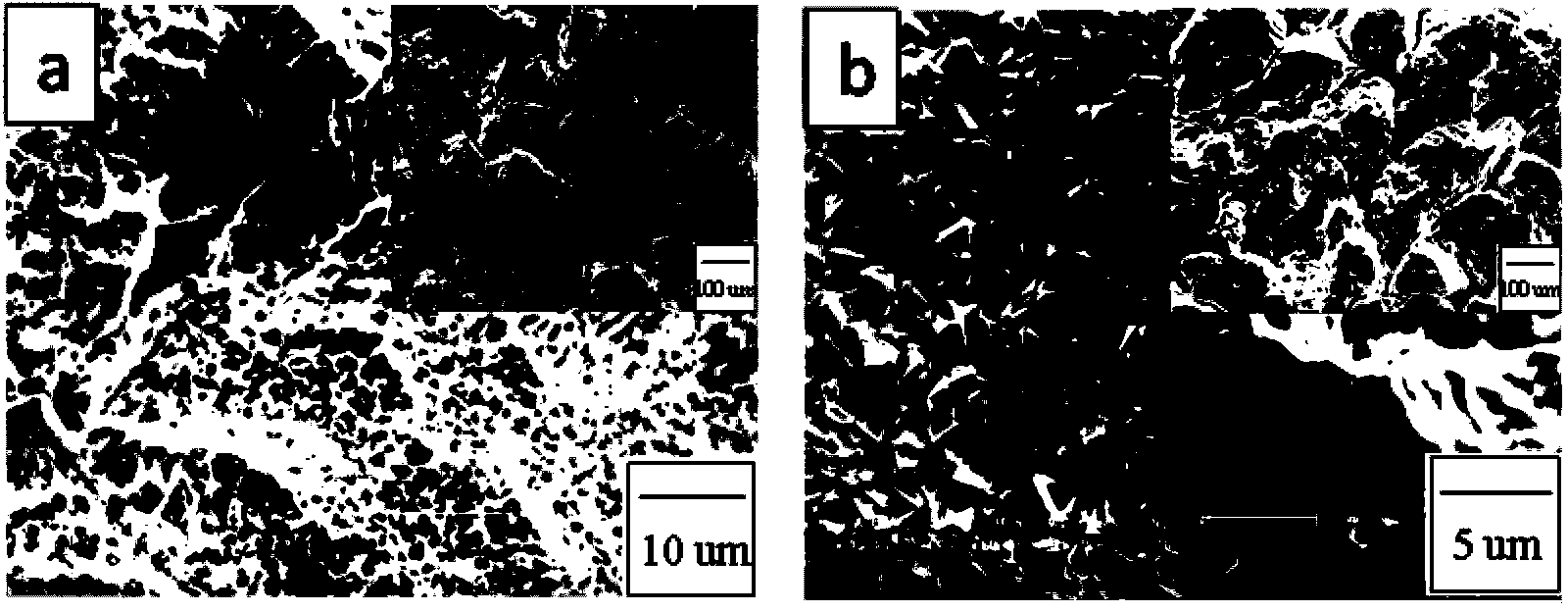

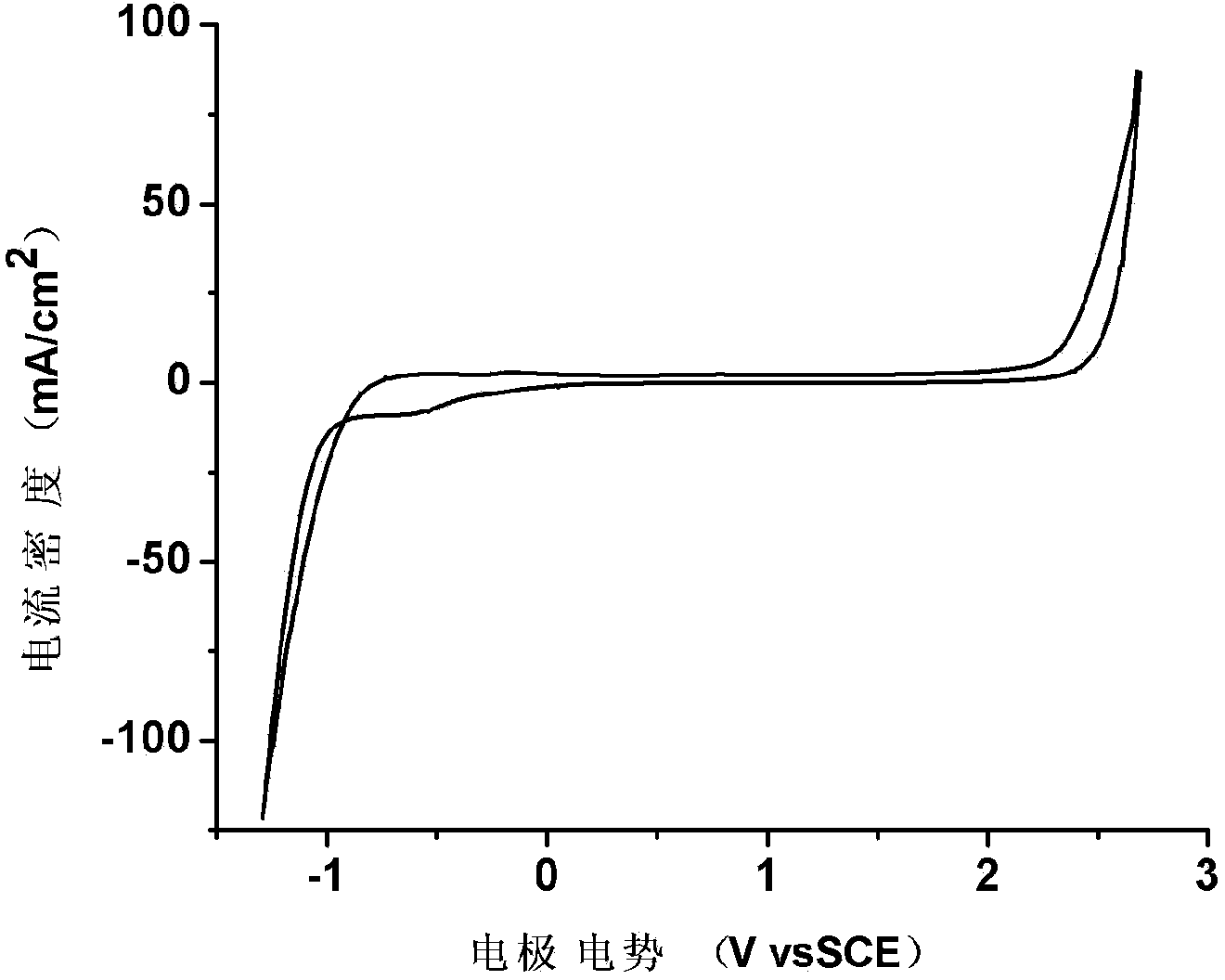

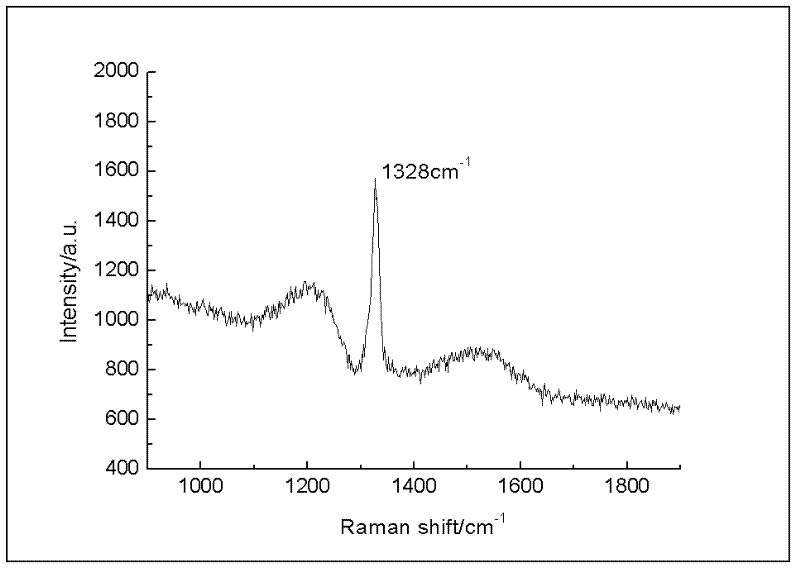

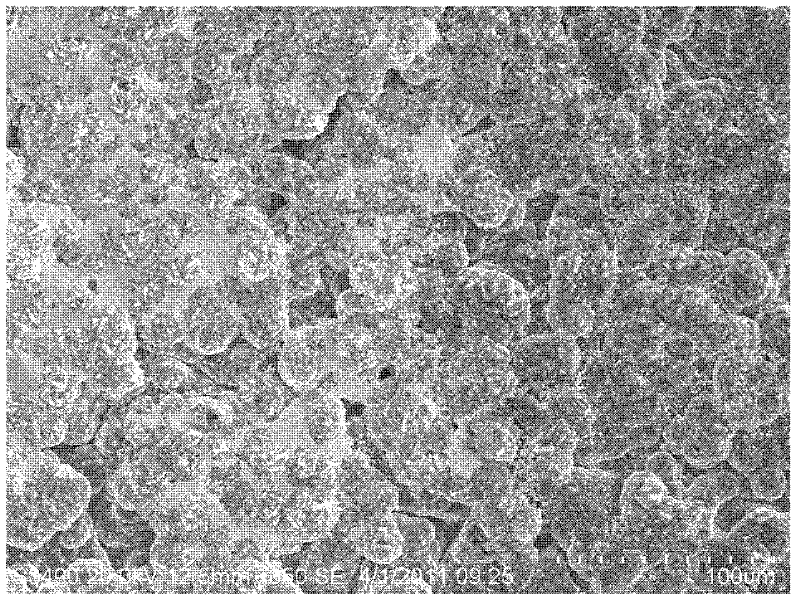

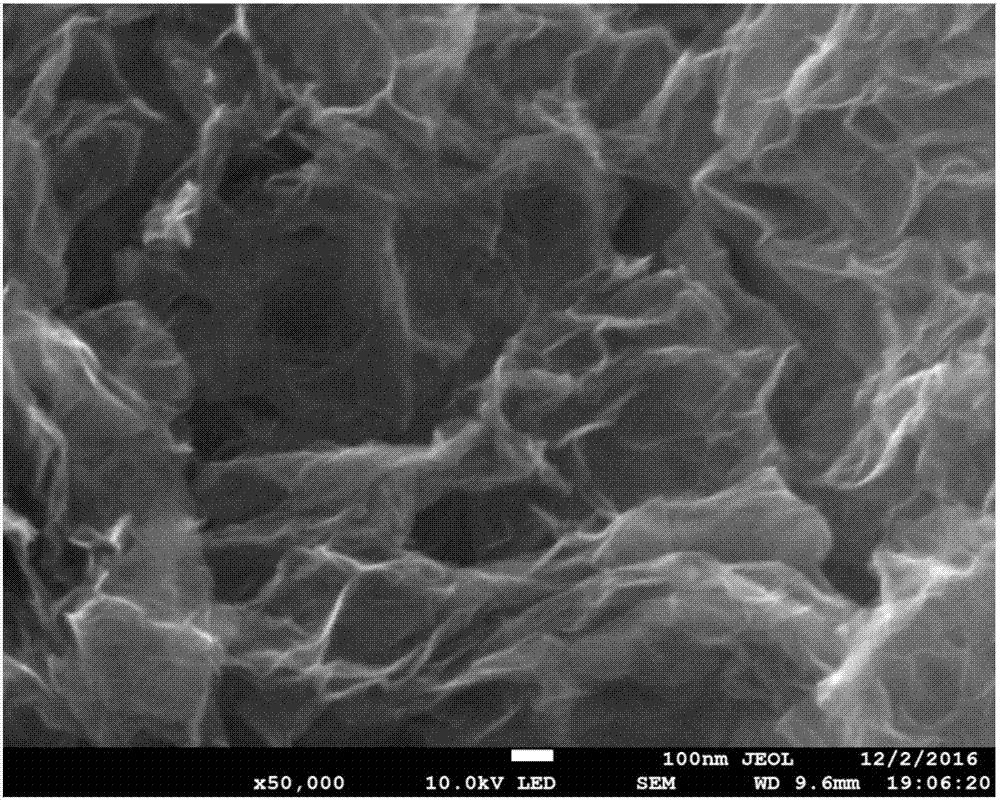

Preparation method of boron-doped diamond film electrode taking porous titanium as matrix

InactiveCN103643219AIncrease growth rateImprove stabilityChemical vapor deposition coatingGas phaseChemical vapor deposition

The invention discloses a preparation method of a boron-doped diamond (BDD) film electrode taking porous titanium as a matrix. The preparation method is characterized in that the titanium matrix is a porous titanium material with the porosity of 20-50%, hot filament chemical vapor deposition equipment is adopted, and a porous titanium base BDD electrode is prepared through chemical vapor deposition by using a second-order boron concentration control mode. By adopting the method, the generation capacity of TiC is controlled by adjusting boron source concentrations of different stages during chemical vapor deposition, namely the formation of TiC is inhibited by using high boron doping at the initial stage to improve the bonding force between a base and a film, and the boron source concentration is reduced in the later period of reaction to perform low boron doping. The porous titanium base BDD electrode prepared by the method disclosed by the invention is uniform and compact in diamond grain, and the porous titanium matrix is completely covered by a diamond film, so that the electrode has good stability and a relatively wide potential window.

Owner:JILIN UNIV

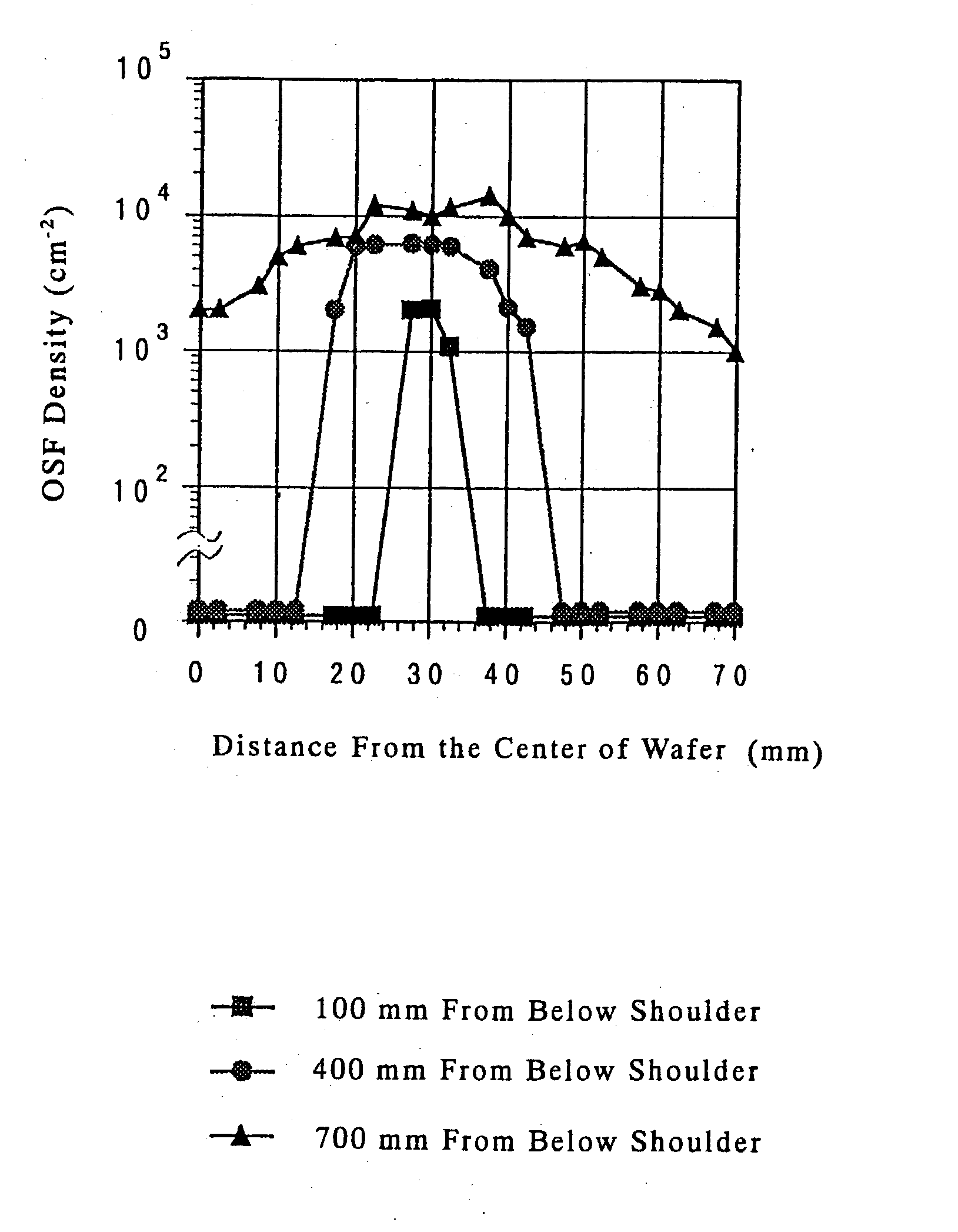

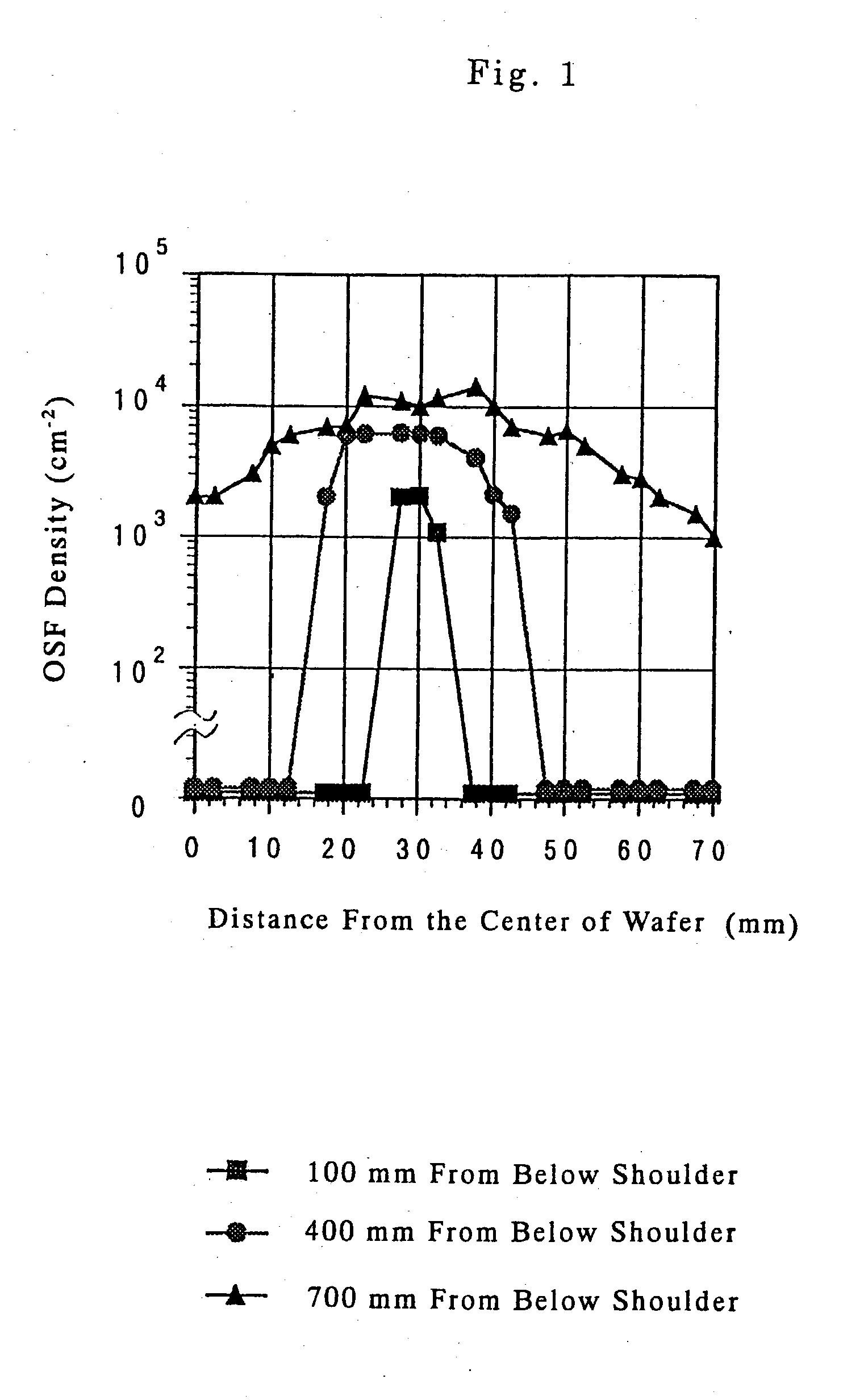

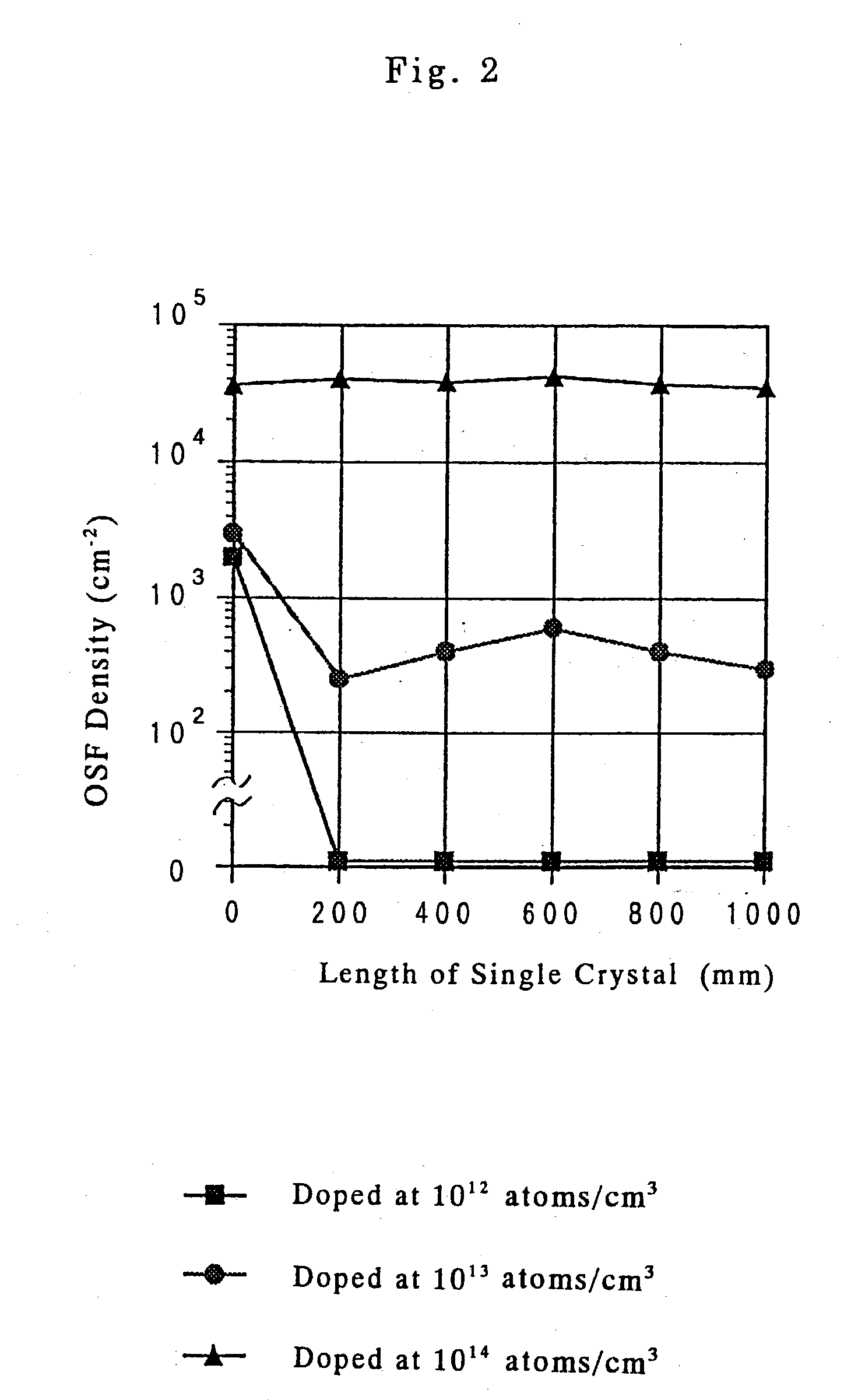

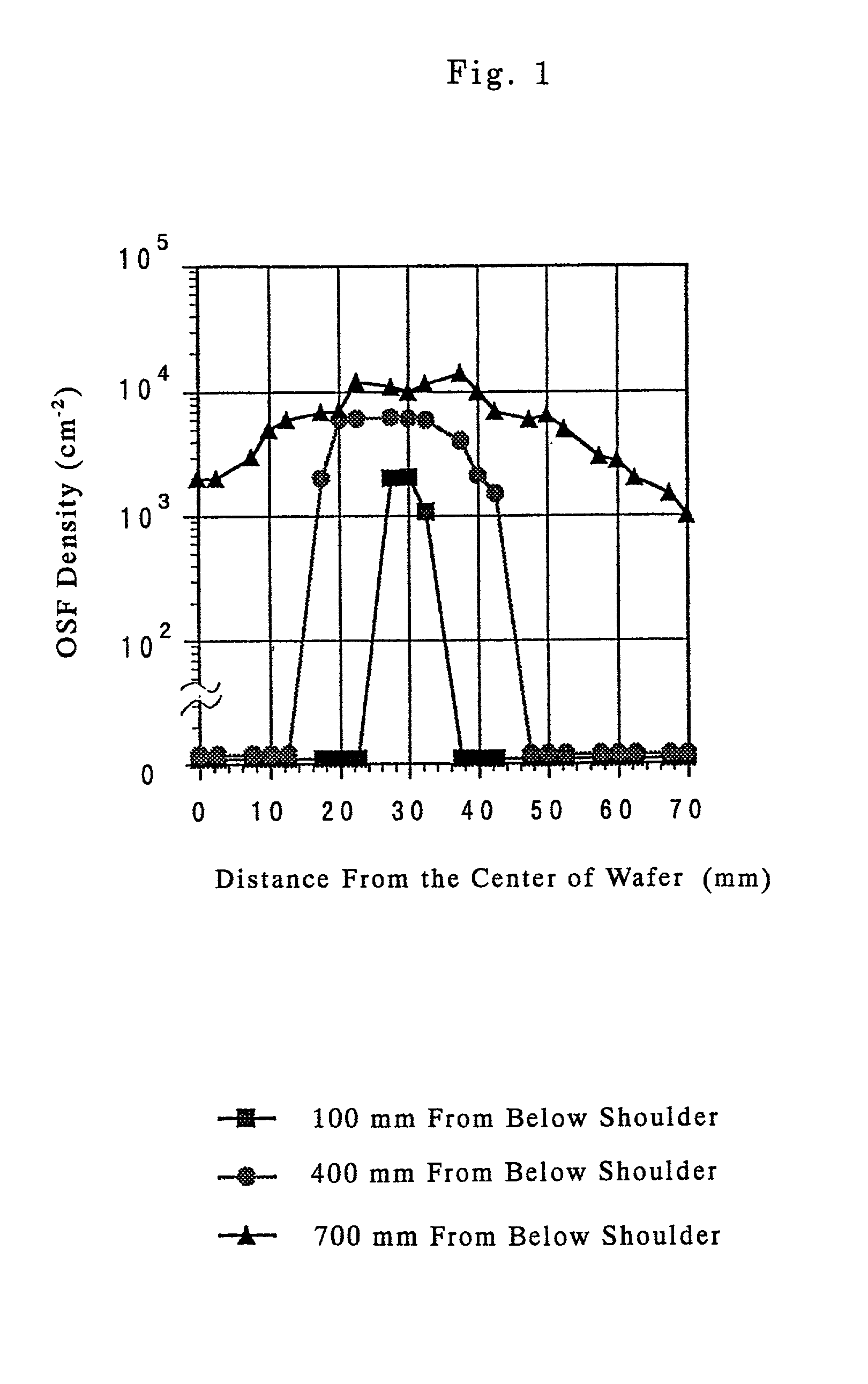

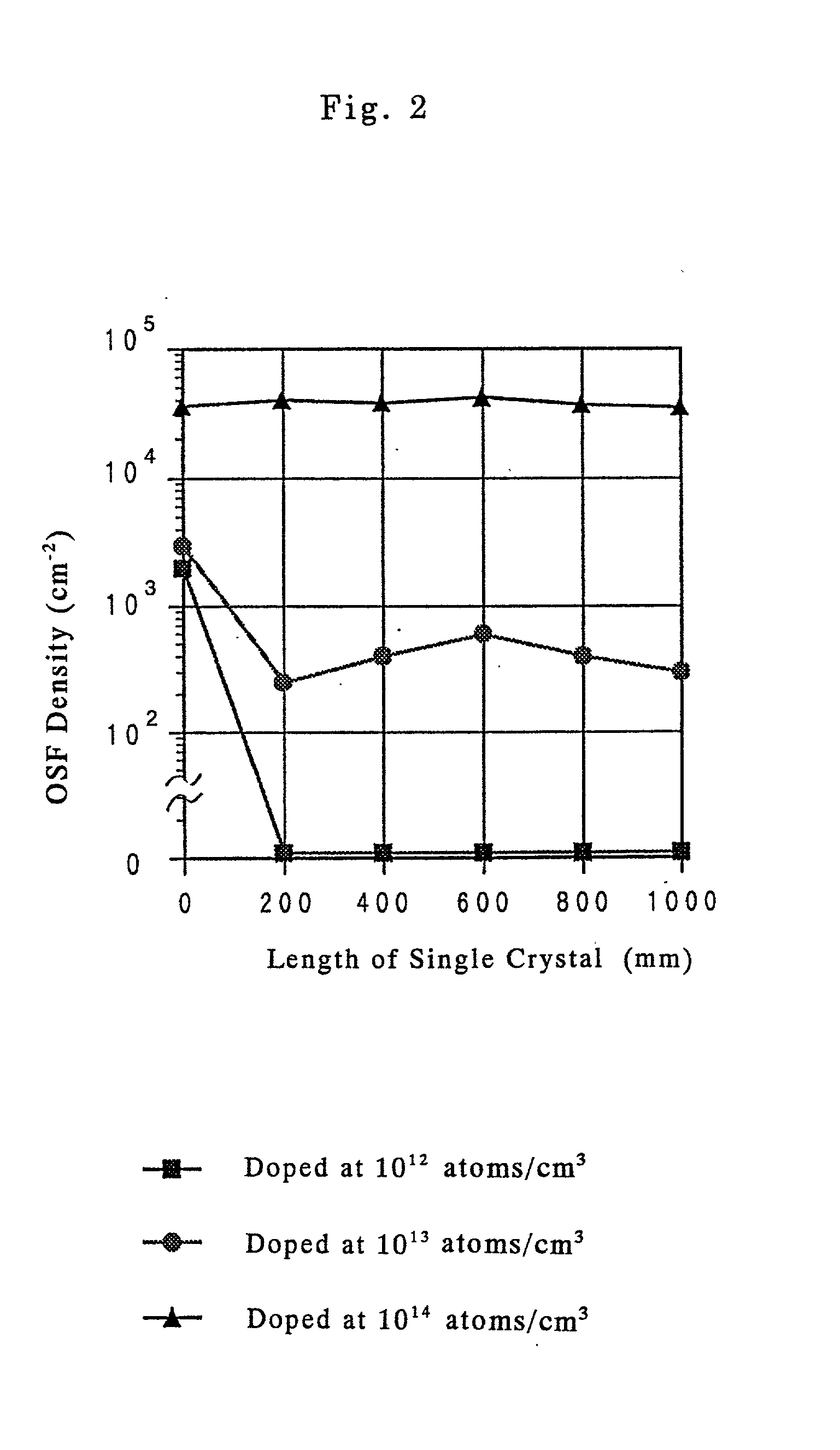

Silicon single crystal, silicon wafer, and epitaxial wafer

InactiveUS20030175532A1Increase widthFew surface defectPolycrystalline material growthSiliconWaferingSingle crystal

Owner:SUMITOMO MITSUBISHI SILICON CORP

Silicon single crystal, silicon wafer, and epitaxial wafer.

InactiveUS6641888B2Increase widthEnhance formation rate and growth ratePolycrystalline material growthSiliconSingle crystalMaterials science

Owner:SUMITOMO MITSUBISHI SILICON CORP

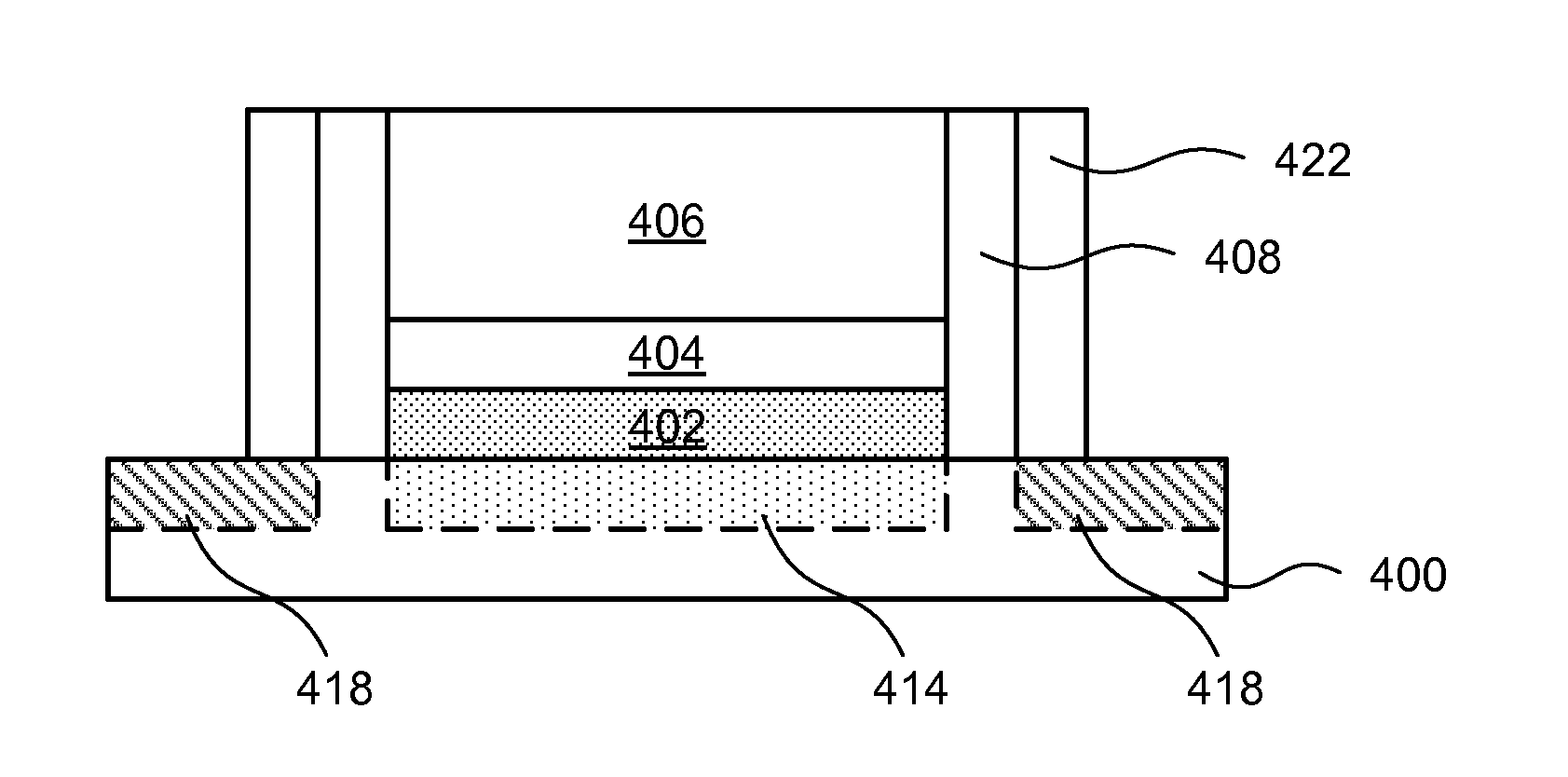

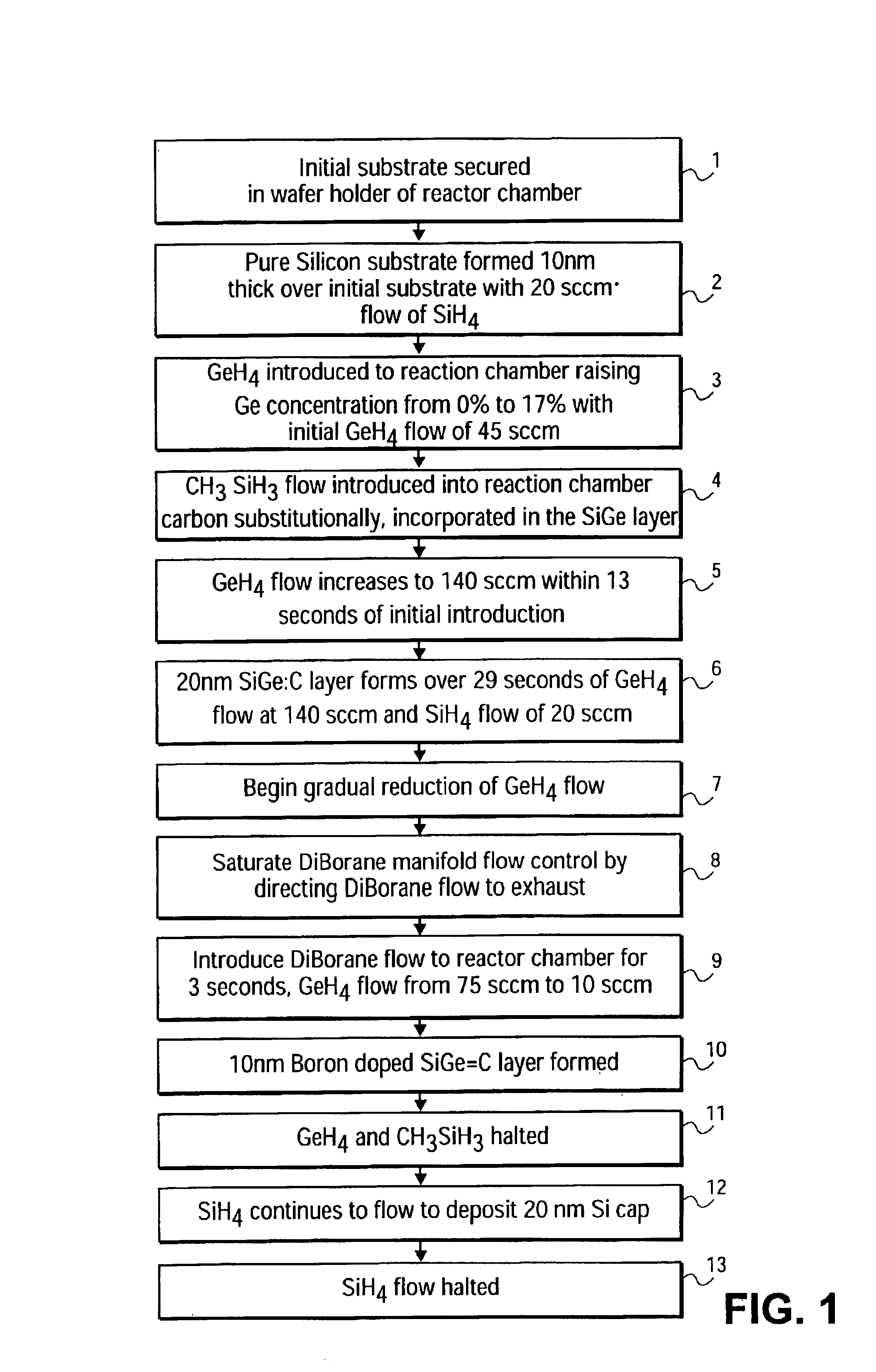

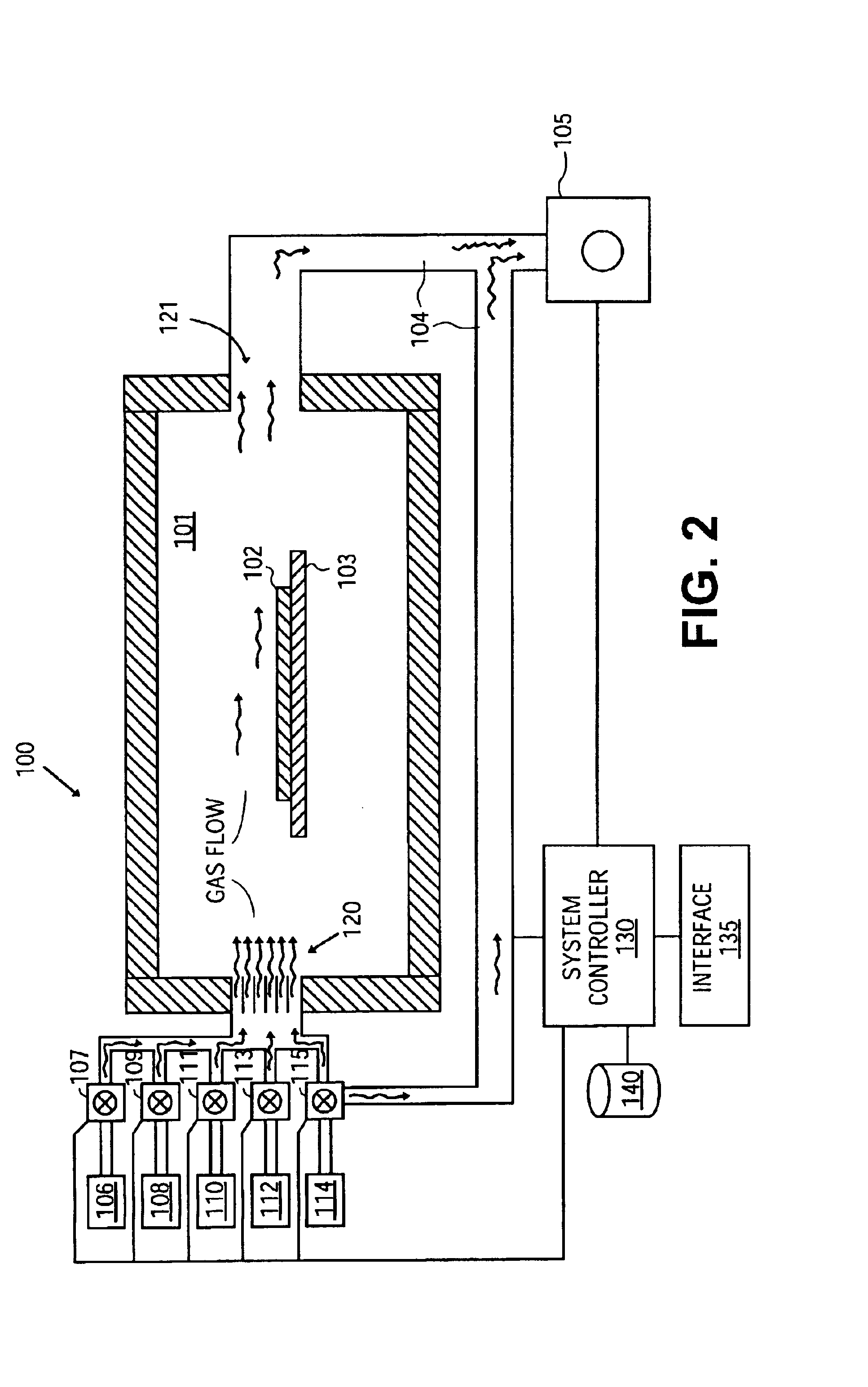

Method for fabricating a bipolar transistor base

InactiveUS6927140B2Semiconductor/solid-state device manufacturingSemiconductor devicesMetallurgyTransistor

A method for forming a base of a bipolar transistor. A narrow base is formed using a flash of boron doping gas in a reaction chamber to create a narrow base with high boron concentration. This method allows for reliable formation of a base with high boron concentration while maintaining manageability in controlling deposition of other materials in a substrate.

Owner:INTEL CORP

Boron-doped lithium-rich anode material for lithium ion batteries and preparation method of material

ActiveCN103413931AMinimal dosageHigh tap densityOxygen/ozone/oxide/hydroxideElectrode thermal treatmentElectrical batteryPhysical chemistry

The invention discloses a boron-doped lithium-rich anode material for lithium ion batteries and a preparation method of the material. The chemical formula of the material provided by the invention is Li[LiaMnbCocNidBx]O2, wherein the sum total of a, b, c, d, and x equals 1, a, b and x are greater than 0, c is greater than or equal to 0, and the sum total of c and d is greater than 0. The material, provided by the invention and prepared through a coprecipitation method and a sol-gel method, is doped with a relatively small amount of boron element but achieves a very remarkable effect, and the stability of the material can be greatly improved just by doping 2% boron; meanwhile, the tap density of the material is increased due to the doping of boron; the coprecipitation method for synthesizing the material is convenient for industrial mass production; the sol-gel method has simple steps, the granules of the synthesized product are uniform and fine.

Owner:PEKING UNIV

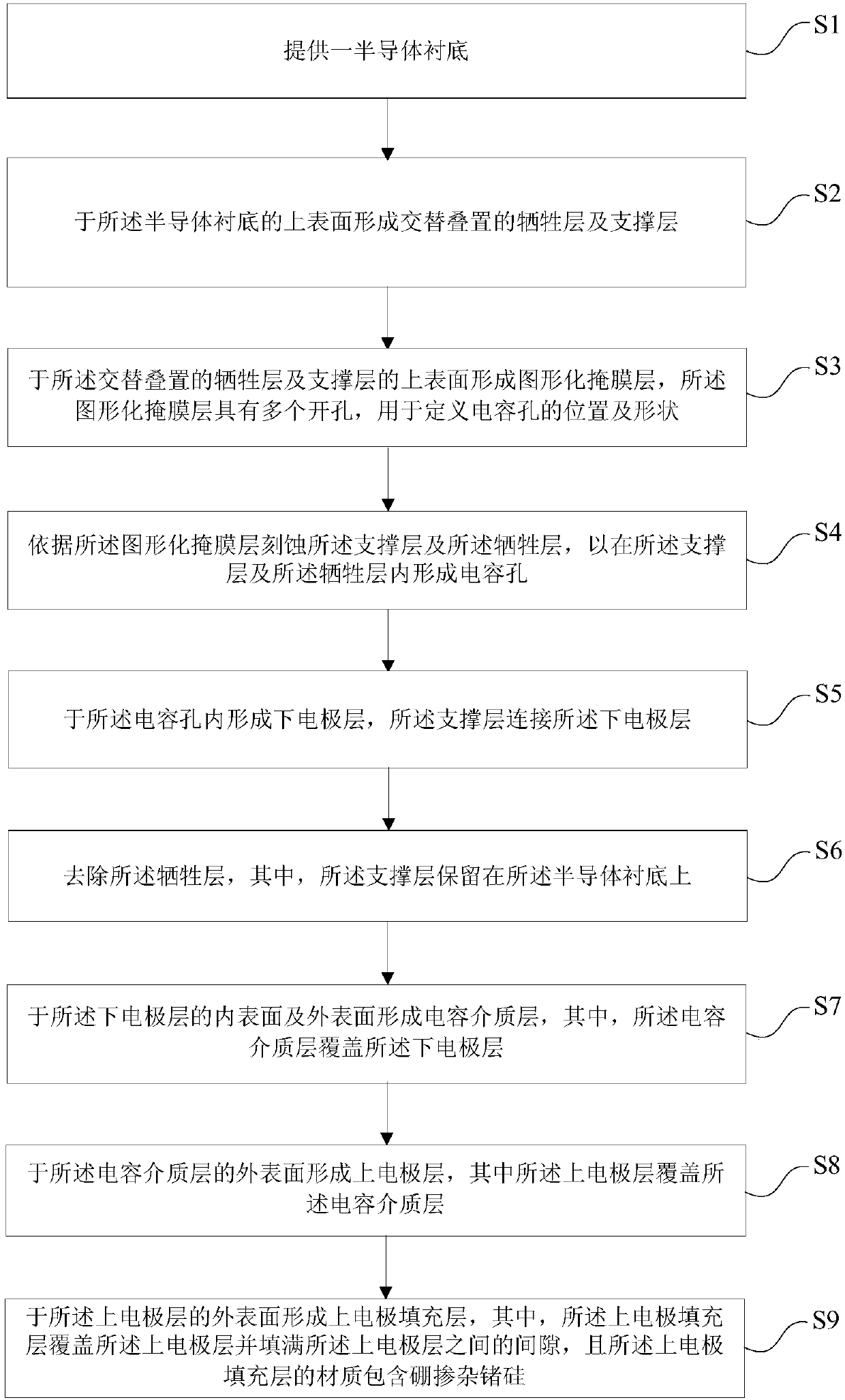

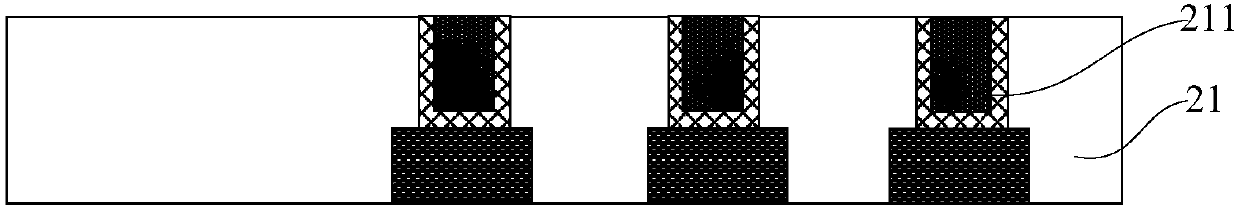

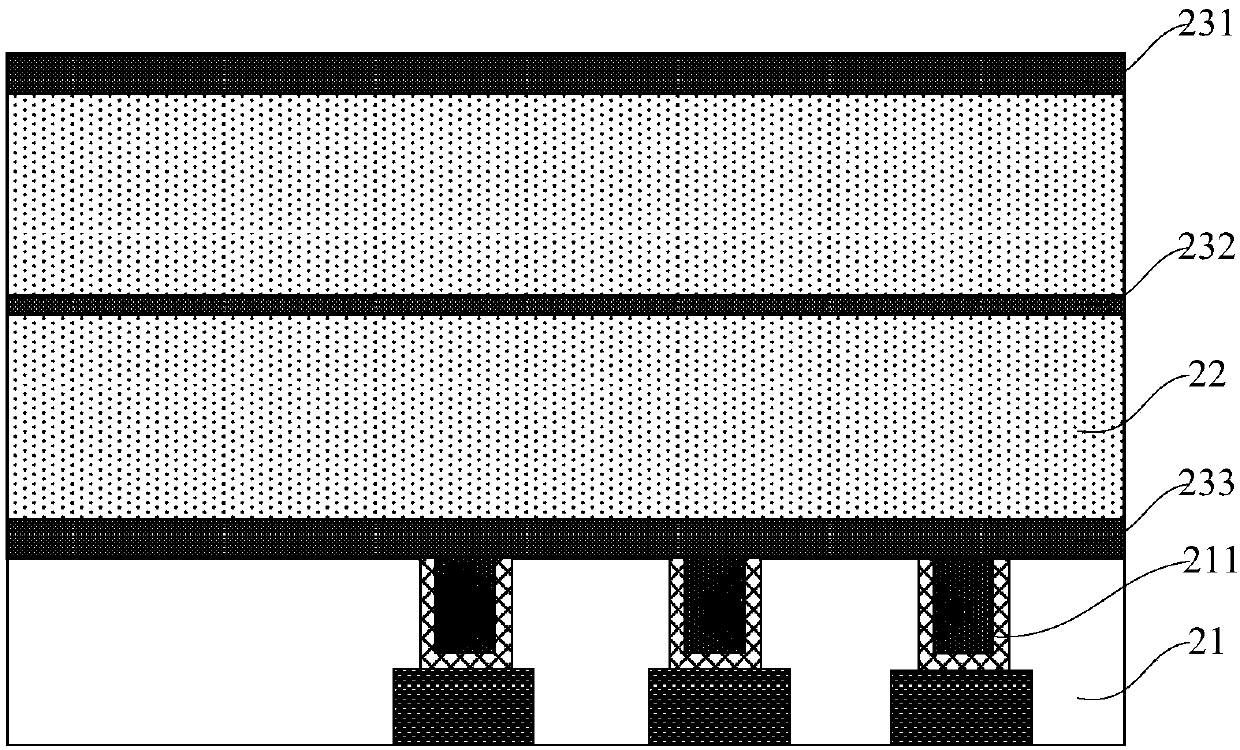

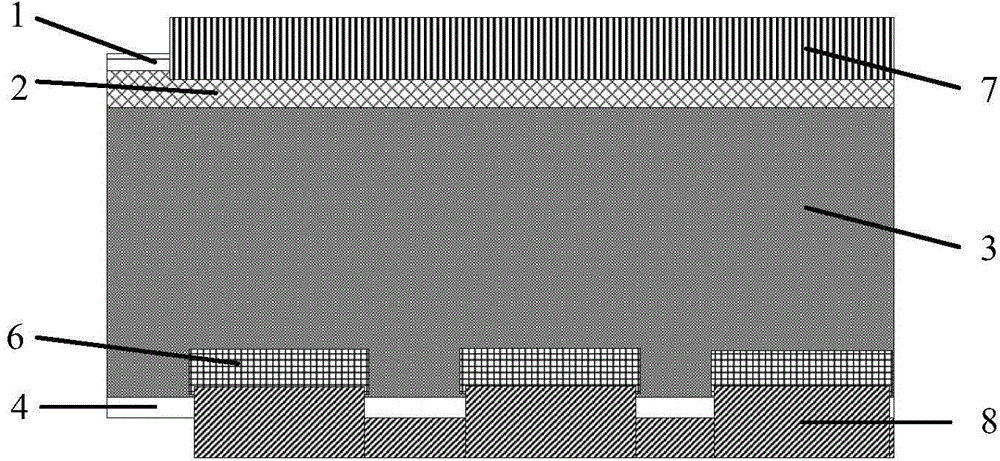

Capacitor array structure and manufacture method thereof

PendingCN107910327ALower the resistance valueReduce the impactTransistorSemiconductor/solid-state device detailsCapacitanceEngineering

The invention provides a capacitor array structure and a manufacture method thereof. The method includes 1) providing a semiconductor substrate; 2) forming sacrificial layer and support layers in an alternating and stacking manner on the upper surface of the semiconductor substrate; 3) forming graphic mask layers on the upper surfaces of the sacrificial layer and support layers arranged in an alternating and stacking manner, wherein the graphic mask layers have a plurality of holes; 4) forming capacitance holes in the support layers and the sacrificial layers; 5) forming lower electrode layersin the capacitance layers; 6) removing the sacrificial layers and remaining the support layers on the semiconductor substrate; 7) forming capacitance medium layers on the inner surfaces and the outersurface of the lower electrode layers; 8) forming upper electrode layers on the outer surfaces of the capacitance medium layers; 9) forming upper electrode filling layers on the outer surface of theupper electrode layers, wherein the material of the upper electrode filling layers contains boron doped germanium-silicon. According to the invention, temperature of a formation technique can be reduced, so that influence on the capacitance medium layers by thermal budge can be reduced. At the same time, current carrier moving rate can be improved, so that the resistance value of the filling layers can be reduced.

Owner:CHANGXIN MEMORY TECH INC

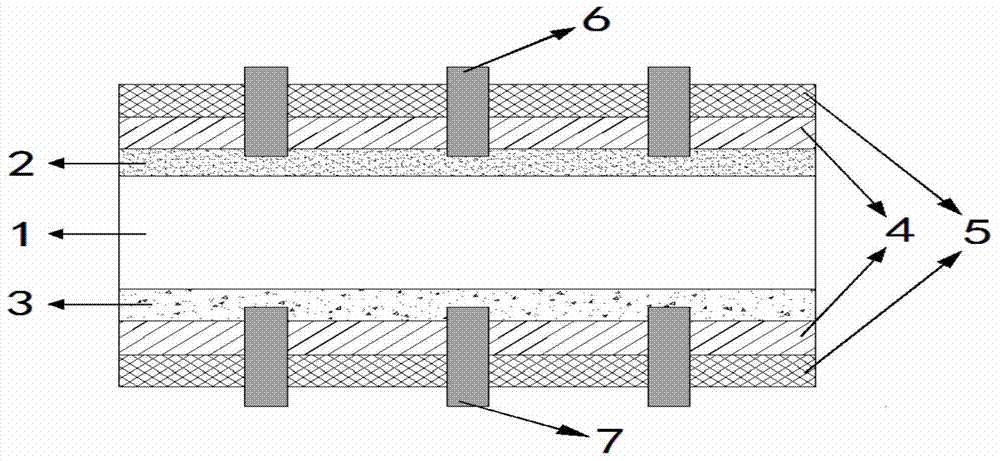

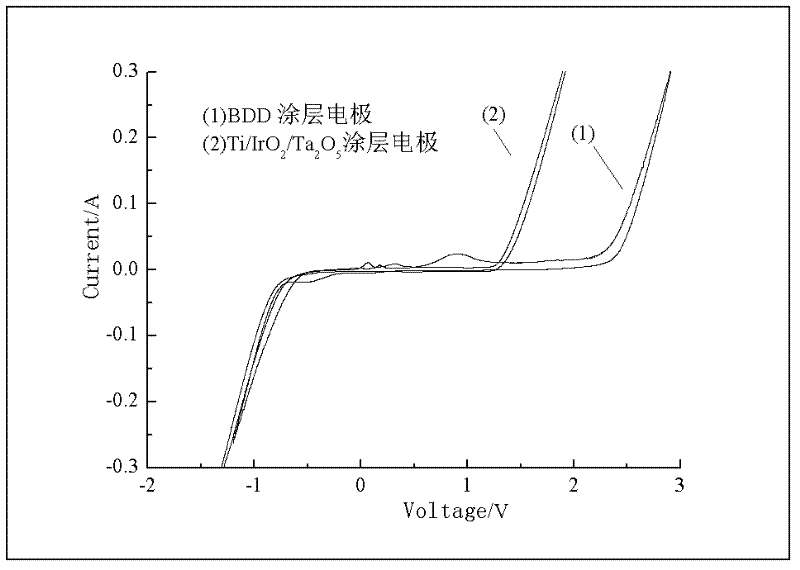

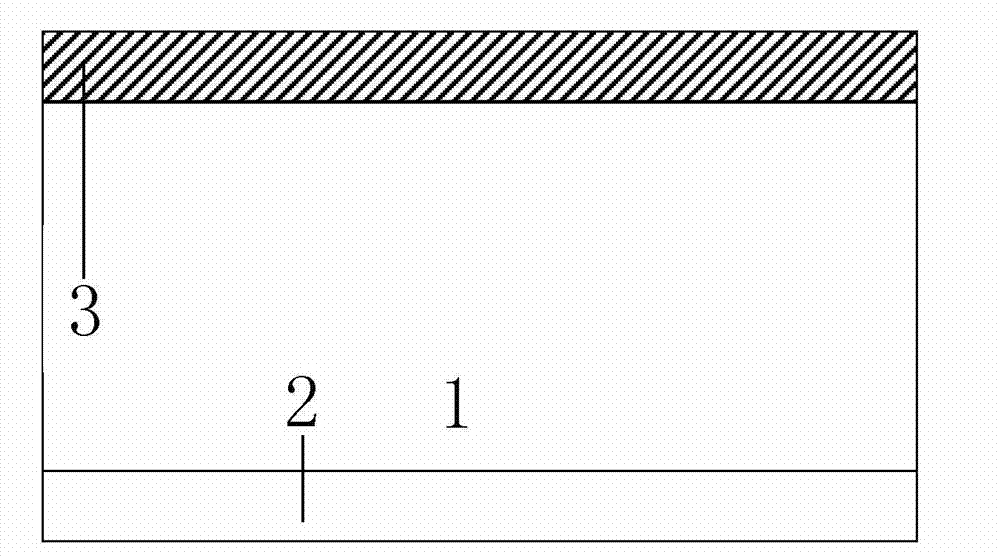

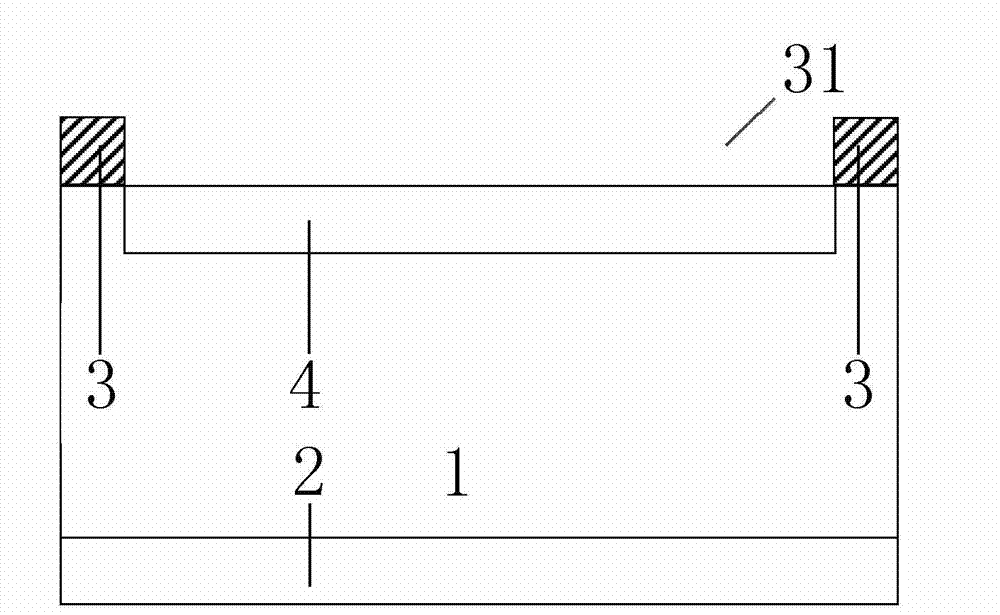

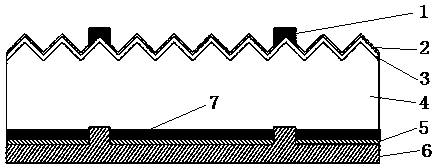

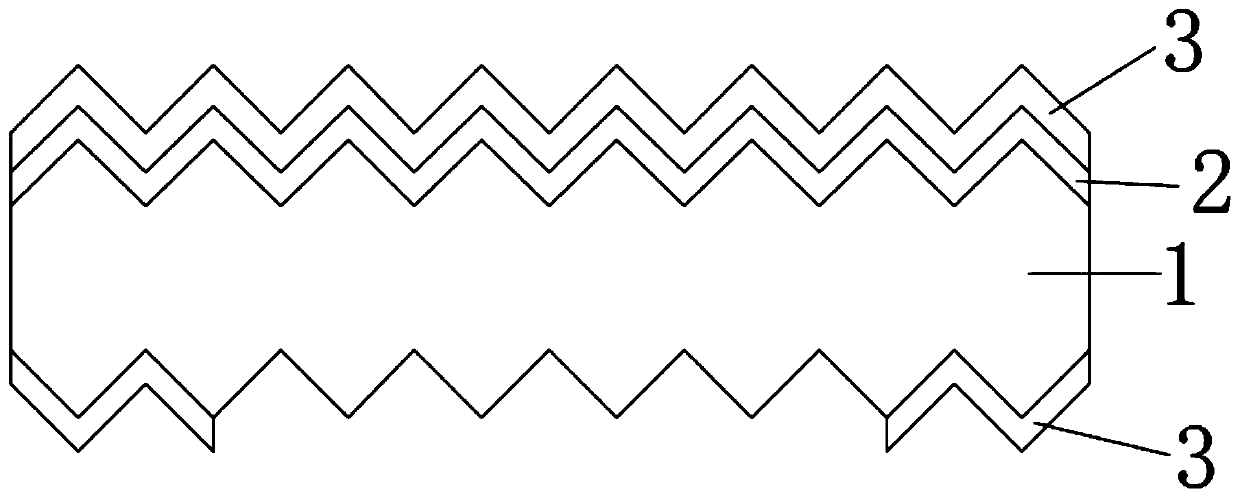

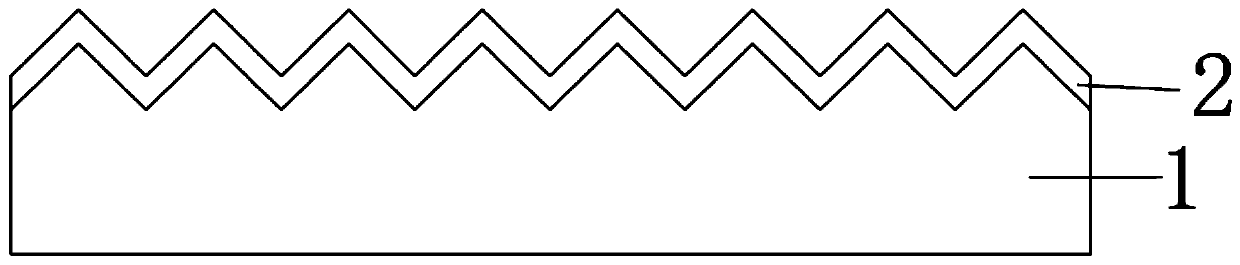

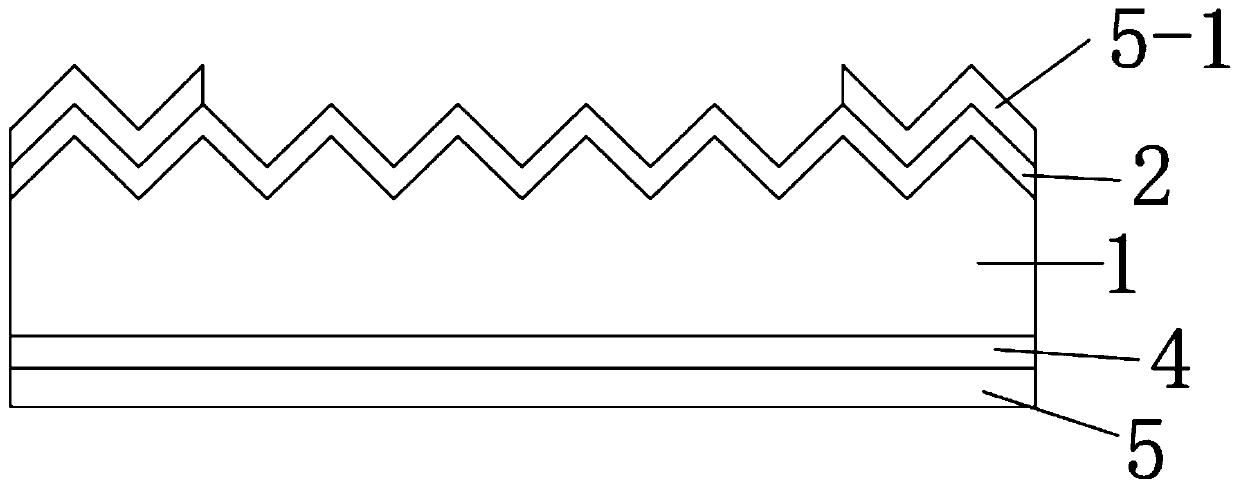

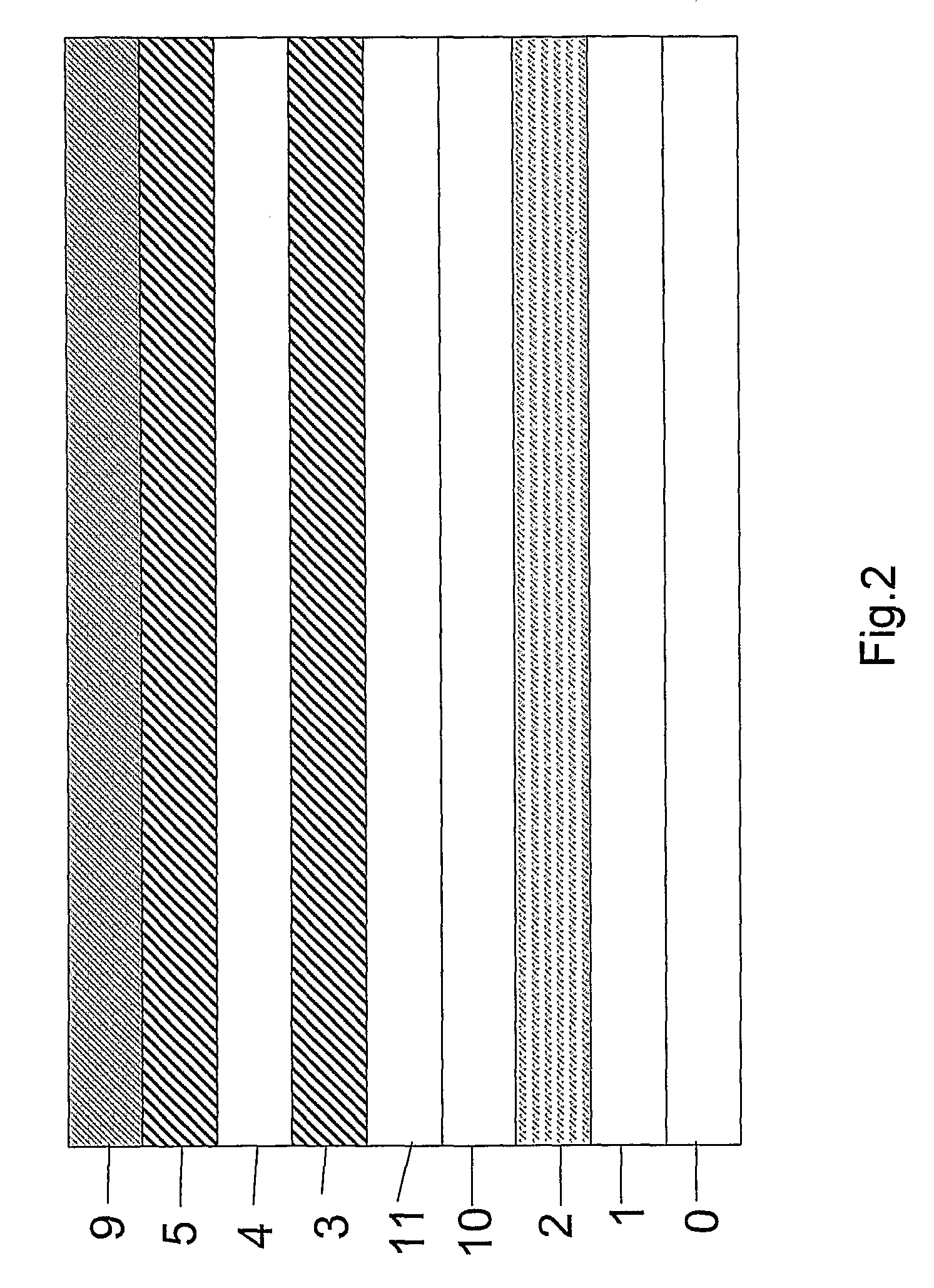

Production method of titanium-based boron-doping diamond coating electrode

InactiveCN102242374ALow costEasy to operateWater/sewage treatmentChemical vapor deposition coatingSputteringNiobium

The invention relates to a production method of titanium-based boron-doping diamond coating electrode, the invention is characterized in that the method is realized by sputtering a transition layer on a substrate material and then depositing the boron-doping diamond coating by a CVD method. The electrode is composed of a substrate (1), a transition layer (2) and a diamond layer (3), and is characterized in that the substrate is titanium, the transition layer is niobium or tantalum through magnetron sputtering, and the boron-doping concentration used in the CVD technology is 6000 - 10000 ppm. The invention provides a production method of BDD electrode with long service life and high electrolytic efficiency, and has the advantages of low cost and high repeatability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

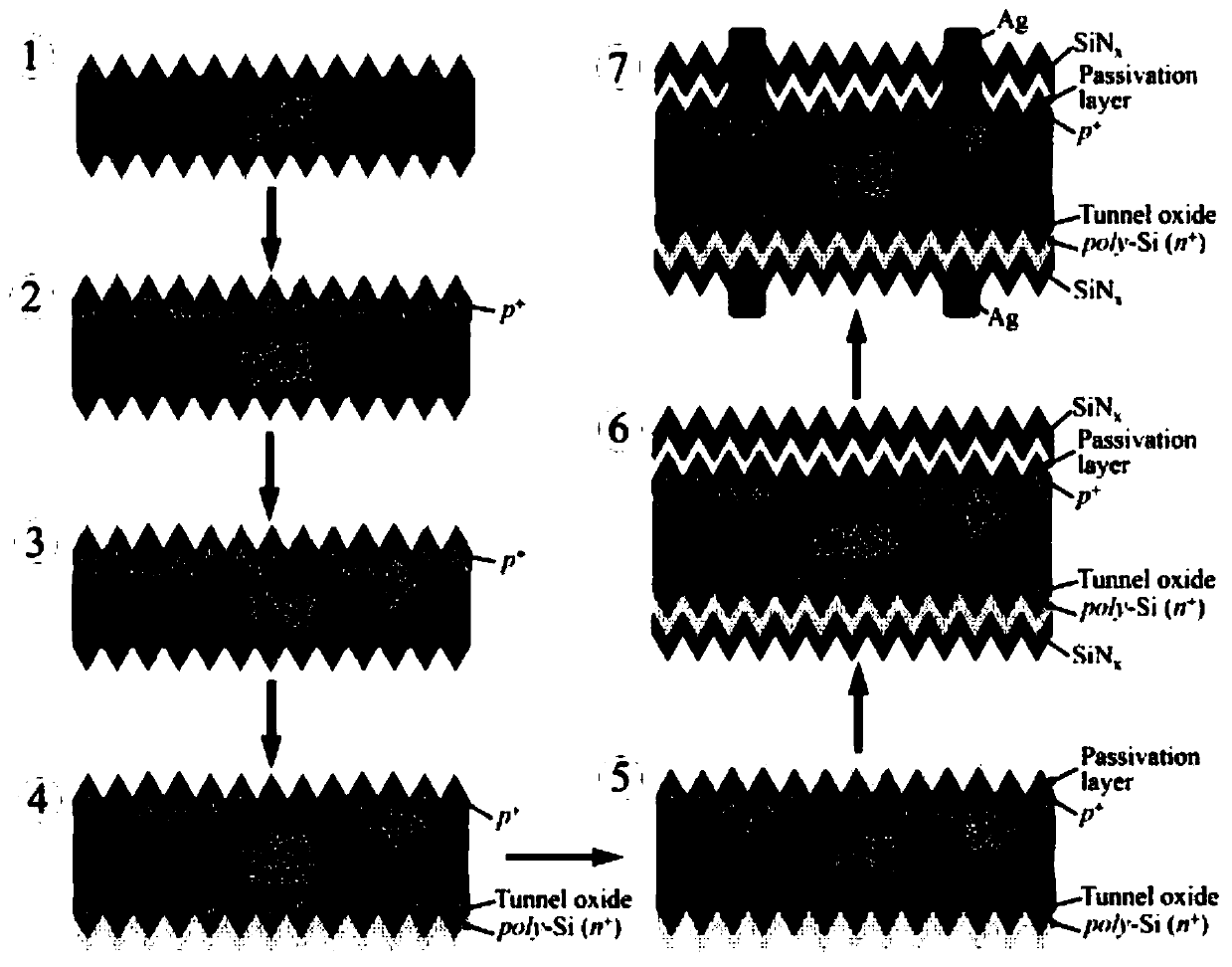

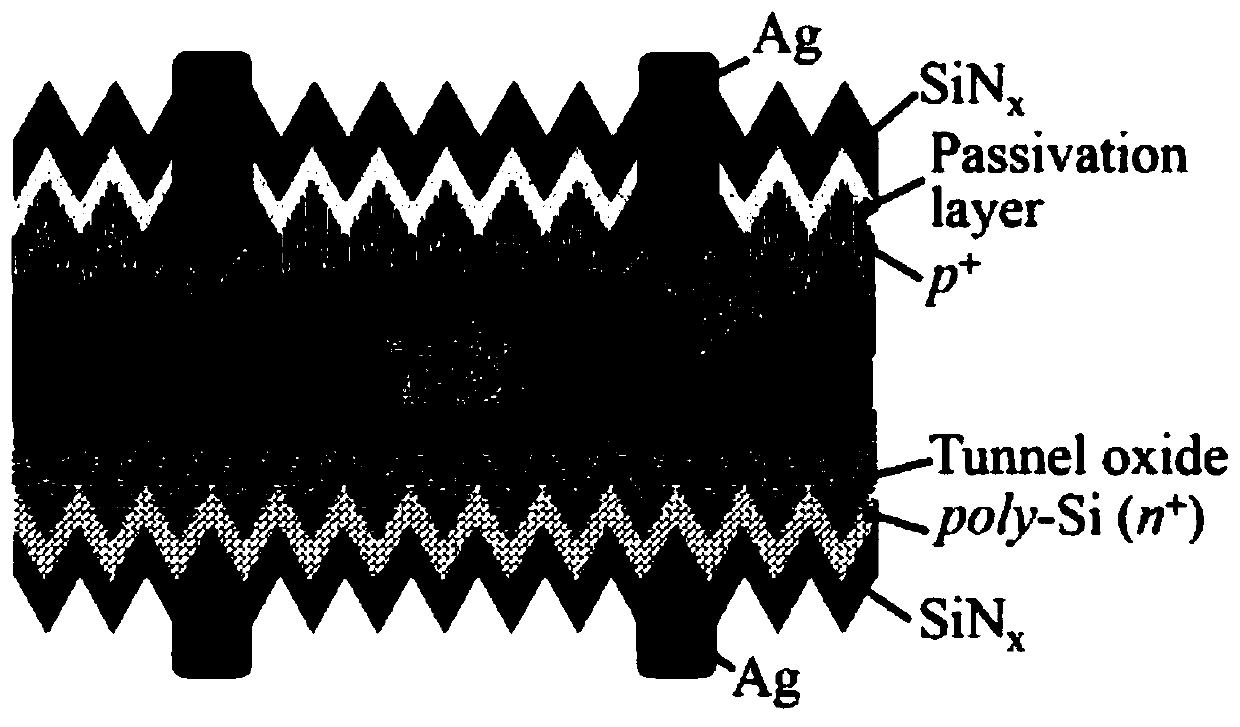

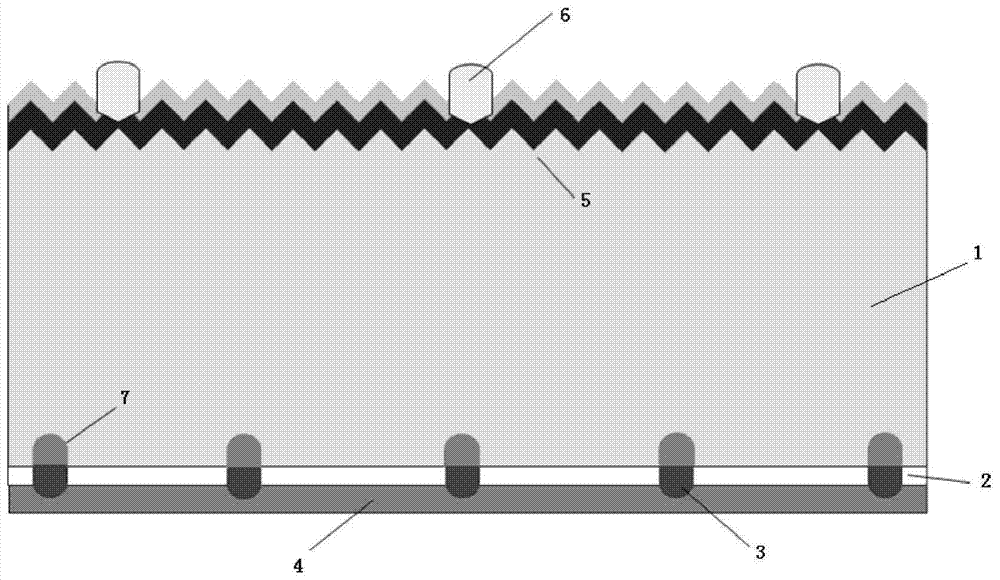

Fabrication method of P-type back-surface tunneling oxide passivation contact solar cell

InactiveCN110233180AAvoid secondary diffusionEasy to operateFinal product manufacturePhotovoltaic energy generationOperabilitySilicon thin film

The invention provides a fabrication method of a P-type back-surface tunneling oxide passivation contact solar cell. The method comprises the steps of performing previous process processing on a frontsurface and a back surface of a P-type single-crystal silicon wafer; oxidizing the back surface to form an ultrathin tunneling oxide layer and fabricate a boron-doping silicon thin film layer; performing phosphorus diffusion on the front surface of the single-crystal silicon wafer, and fabricating a selective emitter; and printing metal electrodes on surfaces of a first passivation anti-reflection layer on the back surface and a second passivation anti-reflection layer on the front surface of the single-crystal silicon wafer, and forming favorable contact between the metal electrodes and thesingle-crystal silicon wafer, thereby obtaining P-type back-surface tunneling oxide passivation contact of the solar cell. The invention provides a complete and practical P-type tunneling oxide passivation contact solar fabrication process circuit, a process method of first back-surface boron-doping poly-silicon thin film and then front-surface phosphorus diffusion, secondary phosphorus diffusioncan be effectively prevented, so that a phenomenon that square resistance is not matched is generated, and the operability is high.

Owner:SUZHOU TALESUN SOLAR TECH CO LTD

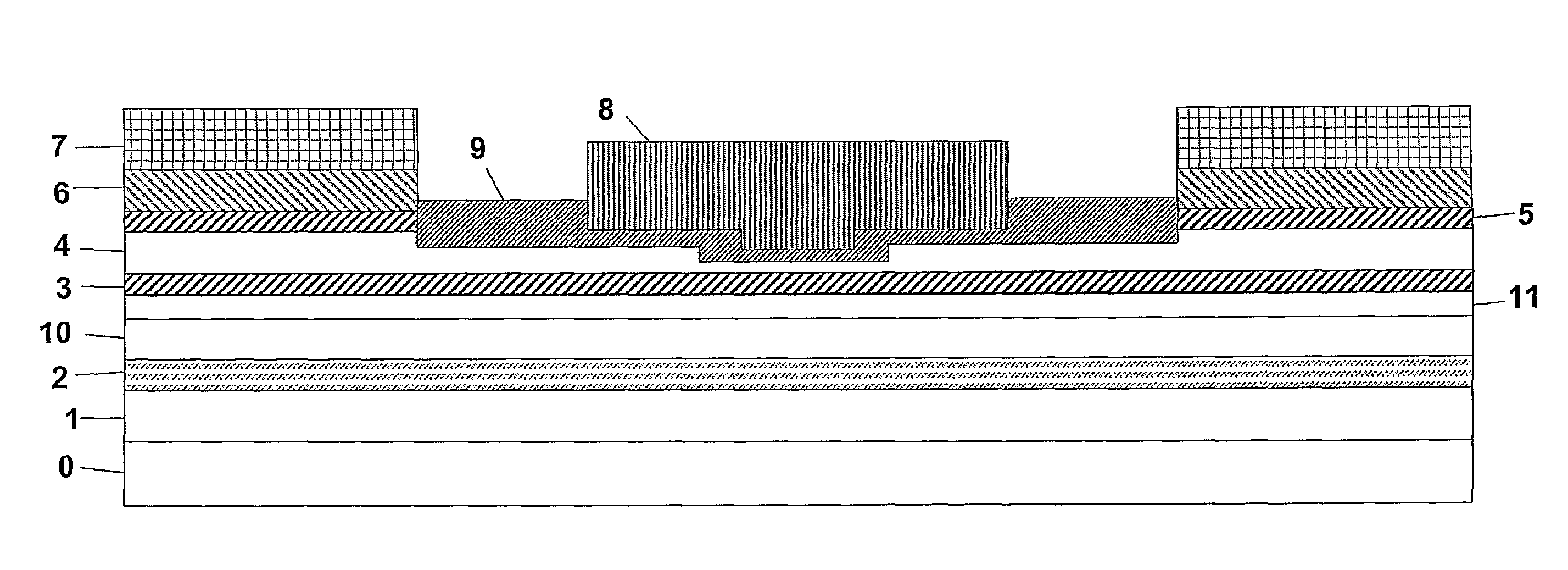

Silicon-based near infrared photoelectric detector structure and manufacturing method thereof

InactiveCN102903781AEasy to operateSimple processFinal product manufactureSemiconductor devicesPhotovoltaic detectorsSulfur

The invention discloses a silicon-based near infrared photoelectric detector structure which comprises an n type silicon substrate, a phosphorus back field, a sulfur element doping layer, a p type boron doping layer, a see-through surface masking layer, an antireflection film layer, a front contact electrode and a back contact electrode, wherein two layers of step-shaped circular grooves are downwardly arranged above the n type silicon substrate; the phosphorus back field is arranged below the n type silicon substrate; the sulfur element doping layer is arranged in the lower circular groove above the n type silicon substrate; the p type boron doping layer is arranged in the upper circular groove above the n type silicon substrate; the see-through surface masking layer is arranged around the upper circular groove above the n type silicon substrate and covers the periphery of the p type boron doping layer; a circular hole is formed in the middle of the see-through surface masking layer; a ring-shaped groove is arranged at the periphery of the circular hole and the outer diameter of the ring-shaped groove is smaller than the diameter of the upper circular groove above the n type silicon substrate; the antireflection film layer is arranged in the circular hole in the middle of the see-through surface masking layer; the front contact electrode is arranged in the ring-shaped groove on the see-through surface masking layer; and the back contact electrode is arranged below the phosphorus back field. According to the silicon-based near infrared photoelectric detector structure, the difficulty that the traditional silicon photoelectric detectors have weak response to the near infrared lights with wavelengths greater than 1100nm can be solved, and particularly, the high-sensitivity near infrared photoelectric detection for the silicon-based photoelectric detectors can be realized.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Method for boron doping of crystalline silicon solar battery

InactiveCN102437238ALow costFast coating speedFinal product manufactureSemiconductor devicesSilicon oxideOptoelectronics

The invention discloses a method for boron doping of a crystalline silicon solar battery, which comprises the following steps that: a first layer of film-boron doped silicon oxide film is deposited on the surface of a silicon chip after the wool making, a second layer of film-silicon oxide film is deposited on the first layer of the film to be used as a barrier layer, then the silicon chip is processed at high temperature, so boron atoms can be diffused into a silicon basic body to form a boron doped layer. Due to the adoption of the method, a boron transmission electrode (p+) can be prepared on an n-type silicon chip, or a boron back surface (p+) is formed on a p-type silicon chip. Through the barrier layer, single-faced boron doping can be realized, and a boron source is free from being sucked into a diffusion furnace tube, so the corrosion of the furnace tube can be reduced, and the service life can be prolonged; and if a phosphorus source is introduced during the high-temperature annealing process, the boron doping and phosphorus doping can be respectively realized on two sides of the silicon chip.

Owner:JA SOLAR TECH YANGZHOU +1

Laser boron doped selective emitter TOPCon structure cell and preparation method thereof

ActiveCN110299422AIncrease the open circuit voltageImprove fill factorFinal product manufacturePhotovoltaic energy generationSurface concentrationScreen printing

The invention discloses a laser boron doped selective emitter TOPCon structure cell and a preparation method thereof. The method comprises the following steps: cleaning and texturing an n-type siliconwafer; during boron diffusion, promoting the formation of a P++ layer with high boron surface concentration without an oxidation process; promoting the doping in a grid line region by laser; after cleaning, putting the n-type silicon wafer back to a diffusion furnace for oxidization to form a selective emitter; removing BSG and a P+ layer on the back, and preparing a tunneling oxide layer and a doped film silicon layer on the back; removing the polycrystalline silicon produced by roll plating on the front and the BSG obtained in step II, and depositing a passivation layer and a SiNx antireflection film on both sides; and screen-printing a double-sided electrode. The preparation method of the invention can not only improve the open circuit voltage of the cell, but also improve the fillingfactor of the cell and finally improve the conversion efficiency of the Topcon solar cell.

Owner:TRINA SOLAR CO LTD +1

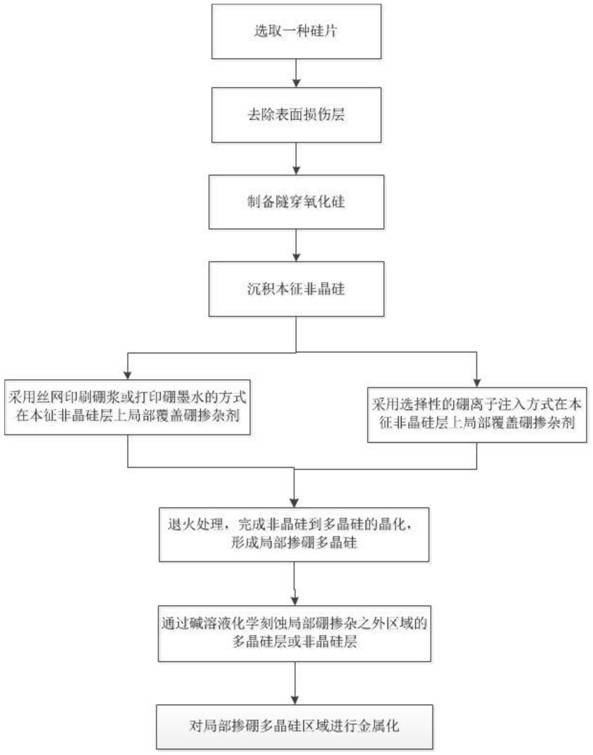

Preparation method of local boron back surface passive field solar cell

InactiveCN104752562ALow costImprove fill factorFinal product manufacturePhotovoltaic energy generationElectrical resistance and conductancePower flow

The invention discloses a preparation method of a local boron back surface passive field solar cell. The preparation method of the local boron back surface passive field solar cell includes following steps: (1) selecting a p type single crystal silicon wafer, and covering the back surface of the p type single crystal silicon wafer with a passive layer after pretreatment; (2) arranging a boron source on the passive layer; (3) using a laser to enable the boron source to penetrate through the passive layer, and then mingling the boron source into a silicon substrate so as to generate local boron doping; (4) arranging sizing containing silver above a local boron doping area; (5) completely covering the back surface of the p type single crystal silicon wafer with an aluminum layer, and obtaining the local boron back surface passive field solar cell through subsequent processing. The preparation method of the local boron back surface passive field solar cell can decrease the back metallization contact area, reduces back surface recombination, lateral resistance and contact resistance, increases electric current opening voltage and fill factors of the local boron back surface passive field solar cell and components, and improves photoelectric conversion efficiency of the local boron back surface passive field solar cell and the components.

Owner:JA SOLAR TECH YANGZHOU +1

Double-sided selective emitter high-efficiency crystalline silicon cell and preparation method thereof

ActiveCN111524983AAvoid the disadvantage of high surface concentrationPlay a passivation effectFinal product manufacturePhotovoltaic energy generationPhotovoltaic industrySilicon oxide

The invention belongs to the field of solar photovoltaic industry and particularly provides a double-sided selective emitter efficient crystalline silicon cell and a preparation method thereof. The double-sided selective emitter efficient crystalline silicon cell is characterized in that a double-sided selective emitter structure is adopted, a boron-doped heavily-doped region is a polycrystallinesilicon structure in which aluminum oxide replaces silicon oxide to serve as a tunneling layer, a constant surface concentration increase fill factor (FF) exceeding 1E20atom / cm <3> can be achieved, alightly-expanded region is pure boron doping, a heavily-expanded boron doping process and a lightly-expanded boron doping process can be realized in one step, and the process is simplified. Silicon oxide is adopted as a tunneling layer for a phosphorus-doped region, a heavily-doped region is of a double-layer poly structure, the surface concentration is high, metallization contact is improved, a lightly-expanded region is of a single-layer lightly-doped poly structure, and then the open-circuit voltage (Voc) is increased. The formation of the double-sided selective emitter effectively utilizesa mask etching mode. The double-sided selective emitter efficient crystalline silicon cell is advantaged in that the structure can effectively improve battery efficiency, and is suitable for batch production.

Owner:CHANGZHOU UNIV +1

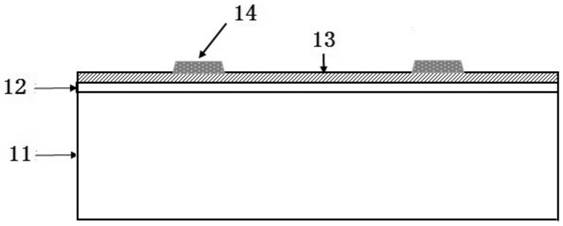

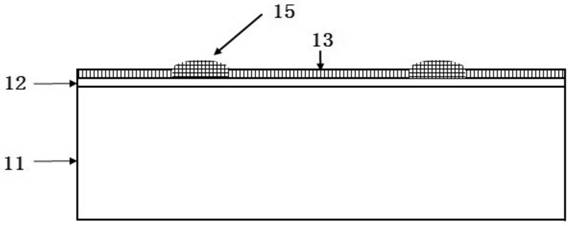

Method for realizing hole local passivation contact, and crystalline silicon solar cell and preparation method thereof

InactiveCN111628049ASimple processLow costFinal product manufacturePhotovoltaic energy generationEtchingSilicon solar cell

The invention discloses a method for realizing hole local passivation contact, which can realize selective boron doping by adopting printing boron slurry or printing boron ink, and can also realize selective boron doping by selective boron ion implantation, and the boron surface concentration of the formed local boron-doped polycrystalline silicon is not lower than 7E19cm <-3>; and the polycrystalline silicon or amorphous silicon thin film region without local boron doping is etched through alkaline solution chemical etching, and the local boron-doped polycrystalline silicon region is metalized to form the hole local passivation contact structure. Furthermore, the invention also discloses a crystalline silicon solar cell with the hole local passivation contact structure and a correspondingcell preparation method. According to the preparation method of the hole local passivation contact and the preparation method of the corresponding crystalline silicon solar cell, the process is simple, the cost is low, and the industrial potential is good.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

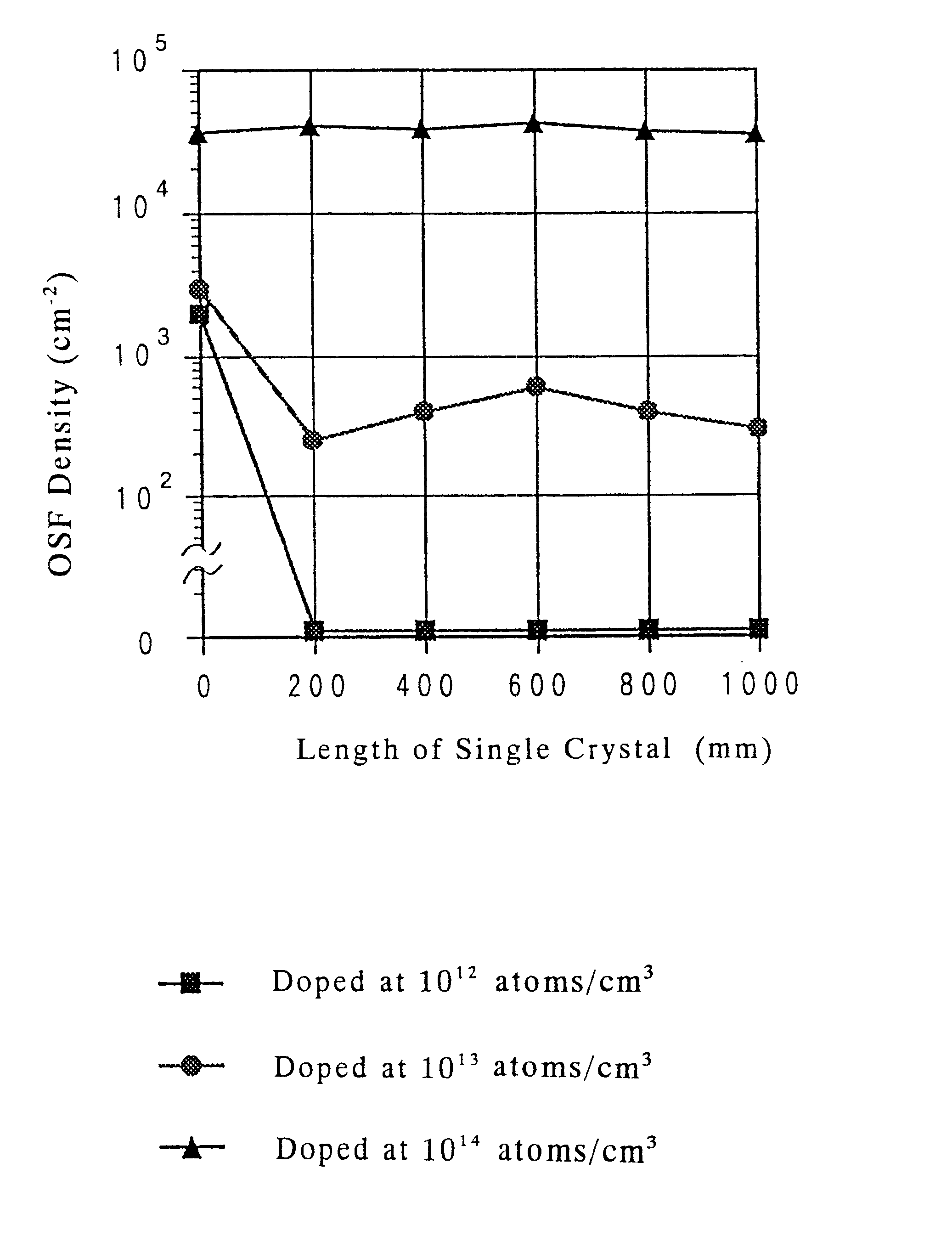

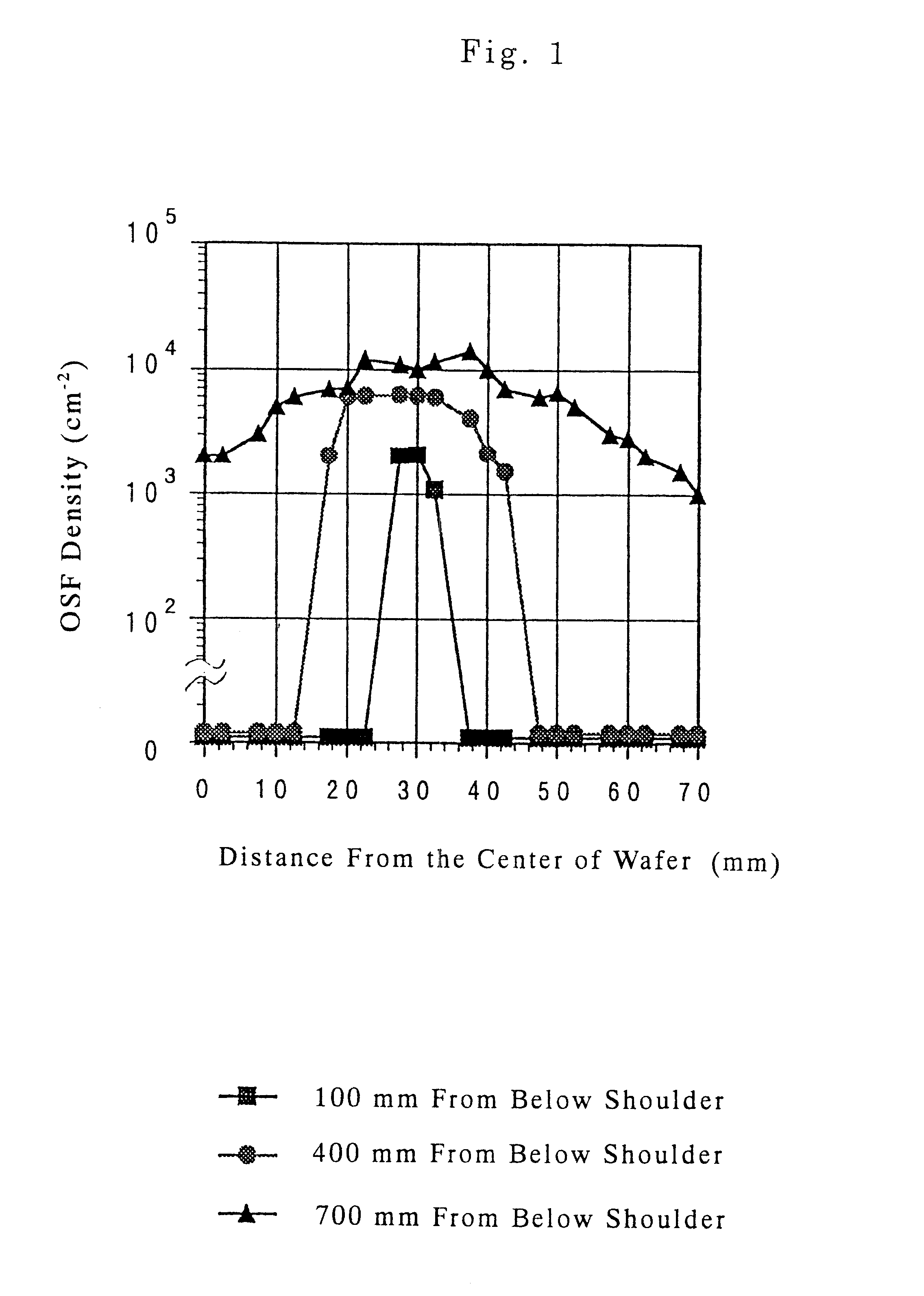

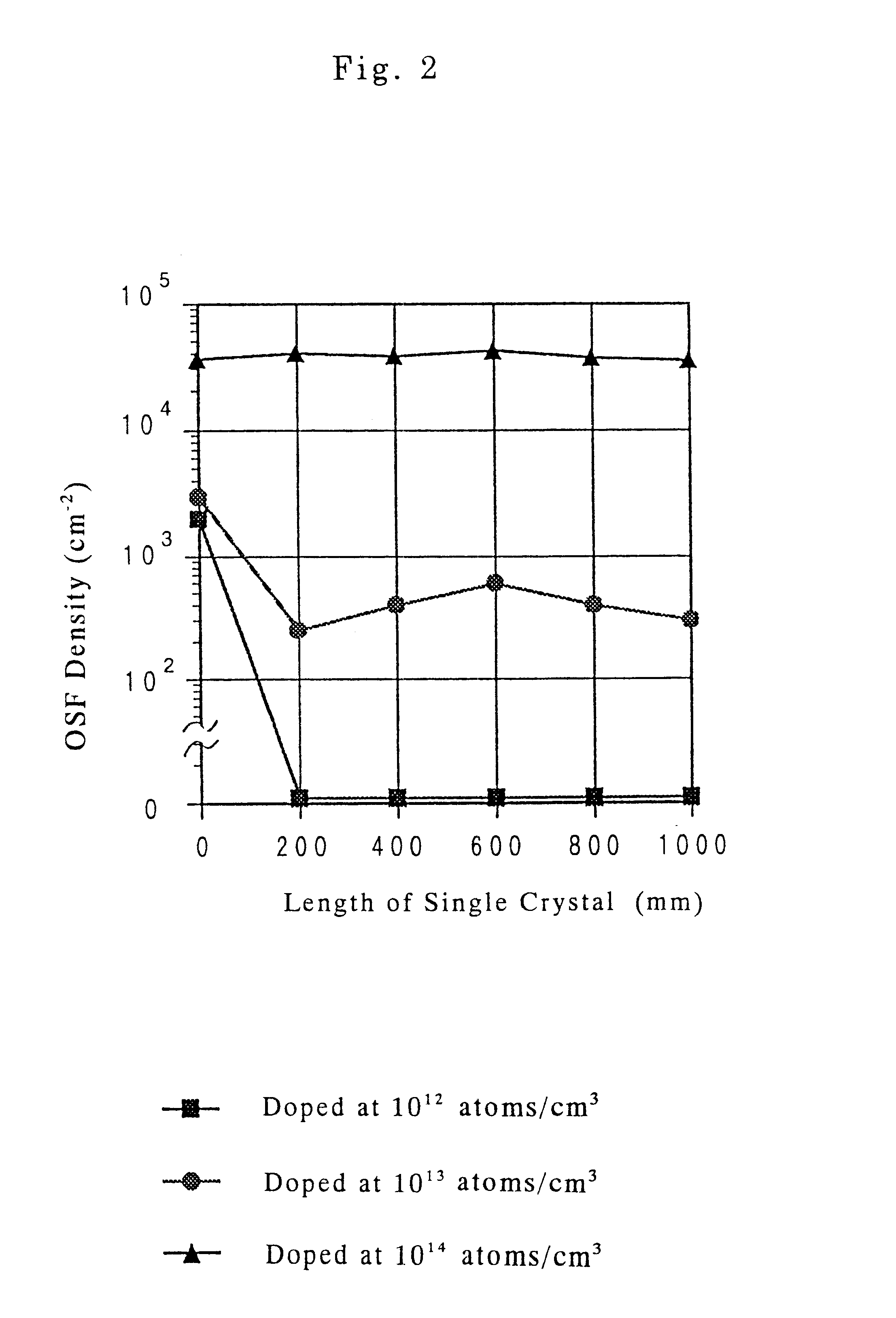

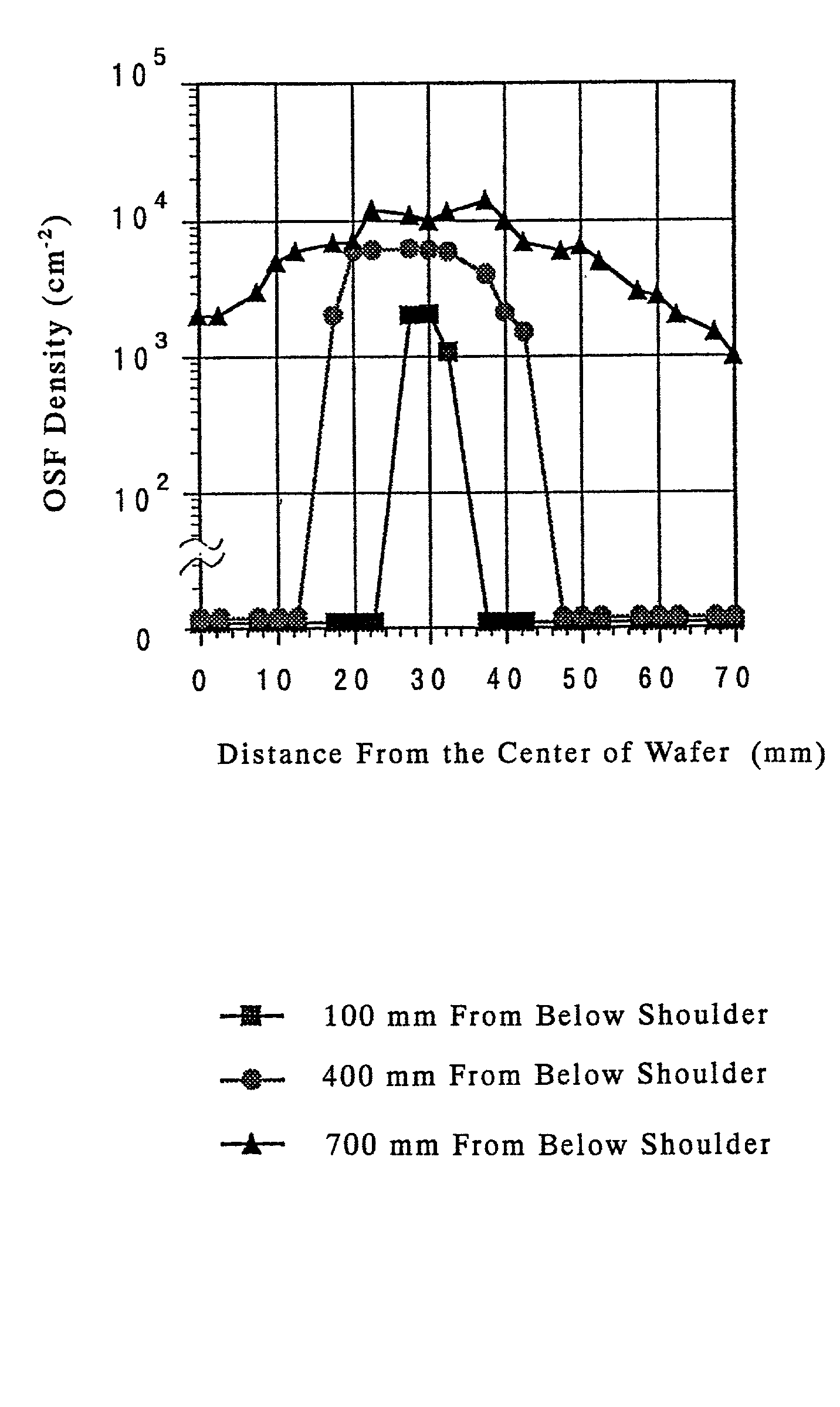

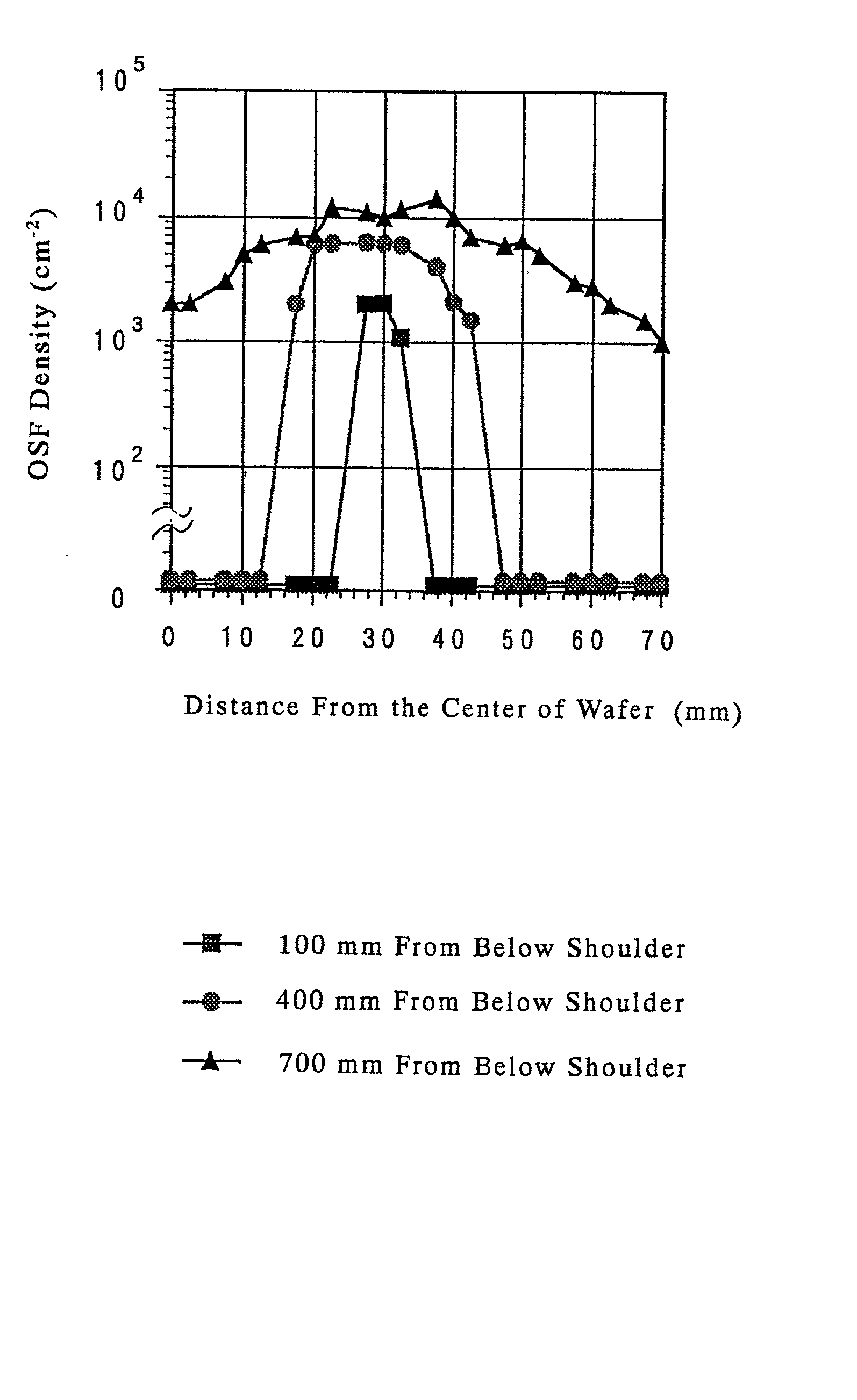

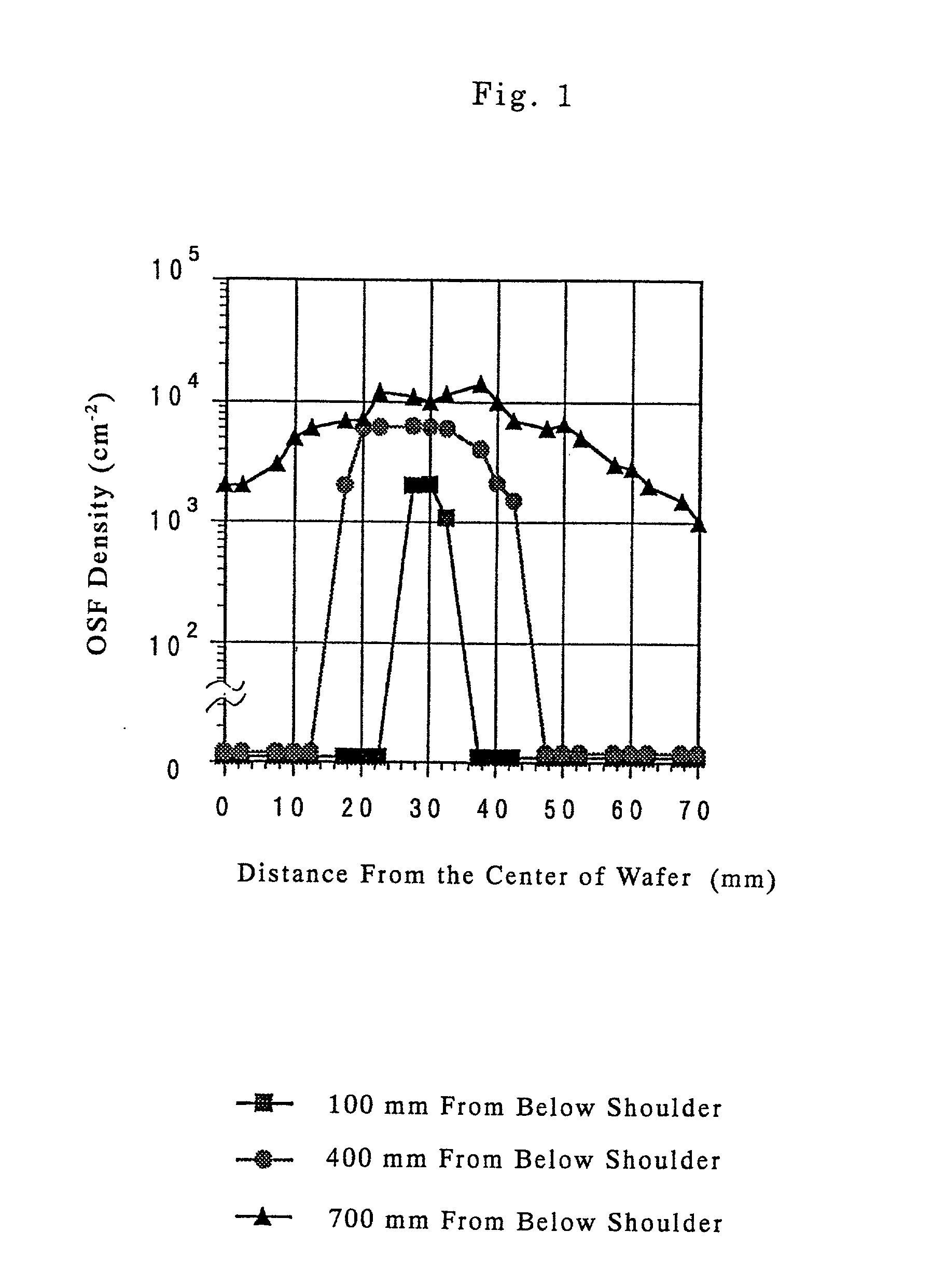

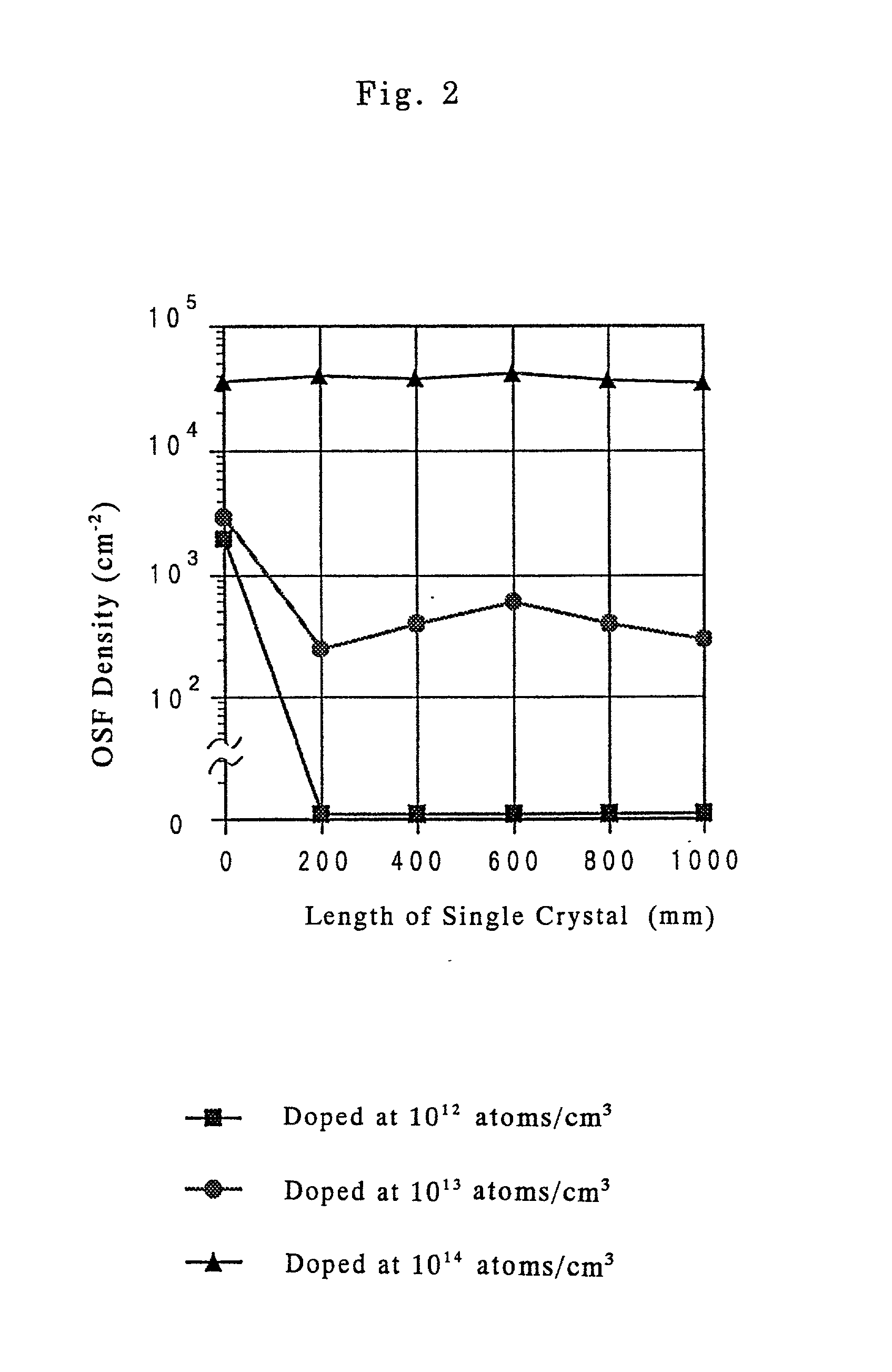

Silicon single crystal, silicon wafer, and epitaxial wafer

InactiveUS20020142171A1Increase widthFew surface defectPolycrystalline material growthSiliconSingle crystalBoron doping

There are provided silicon single crystal, silicon wafer, and epitaxial wafer having a sufficient gettering effect suitable for a large-scale integrated device. The silicon single crystal which is suitable for an epitaxial wafer is grown with nitrogen doping at a concentration of 1x1013 atoms / cm3 or more, or with nitrogen doping at a concentration of 1x1012 atoms / cm3 and carbon doping at a concentration of 0.1x1016-5x1016 atoms / cm3 and / or boron doping at a concentration of 1x1017 atoms / cm3 or more. The silicon wafer is produced by slicing from the silicon single crystal, and an epitaxial layer is grown on a surface of the silicon wafer to produce the epitaxial wafer. The present invention provides an epitaxial wafer for a large-scale integrated device having no defects in a device-active region and having an excellent gettering effect without performance of an extrinsic or intrinsic gettering treatment, which is a factor for increasing the number of production steps and production costs.

Owner:SUMITOMO MITSUBISHI SILICON CORP

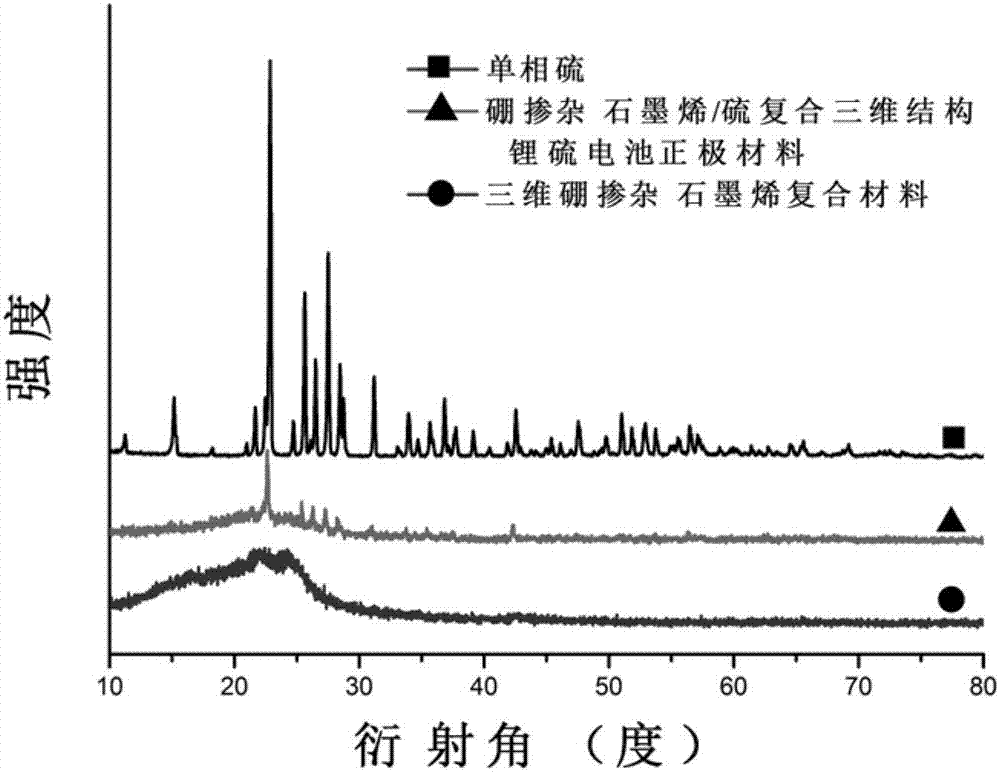

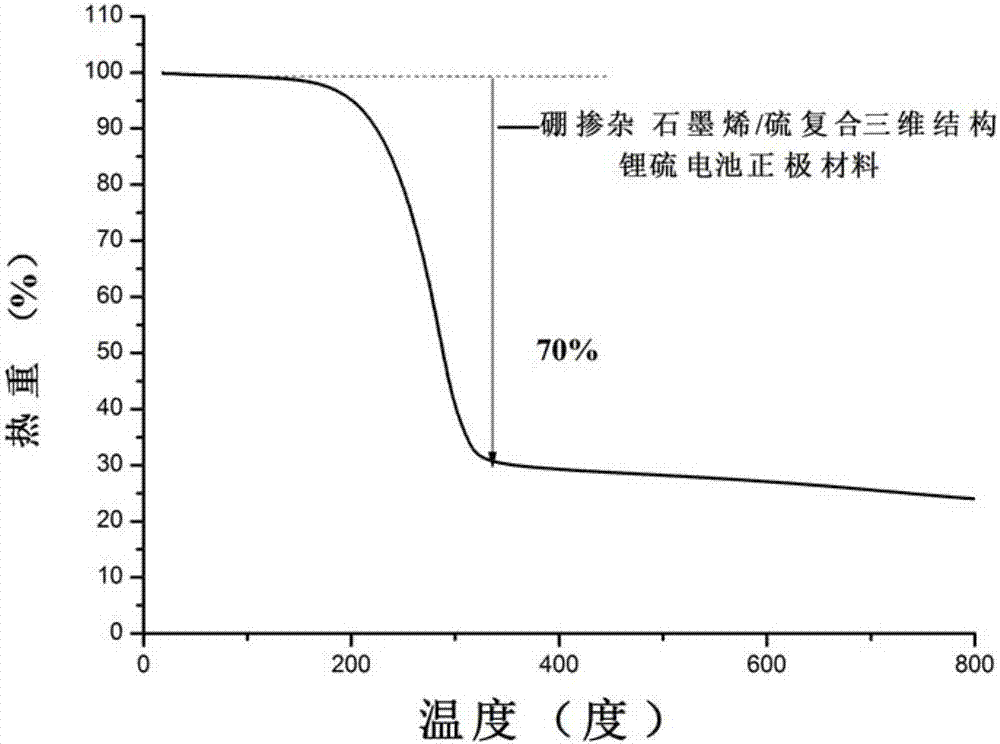

Method for preparing cathode material of lithium-sulfur battery

ActiveCN106876685AHighlight substantive featuresImprove cycle performanceCell electrodesLi-accumulatorsDoped grapheneLithium–sulfur battery

The invention relates to a method for preparing a cathode material of a lithium-sulfur battery, and relates to an electrode formed by an active material. The method is characterized in that the graphene oxide reduction, boron doping and solvent thermal reaction are completed by one step, and the cathode material of the lithium-sulfur battery with a boron-doped graphene / sulfur composite three-dimensional structure is prepared by a one-step method. The defects that the cathode material of the lithium-sulfur battery has small and uneven sulfur load content, and low active material load and utilization rate, resulting in poor electrochemical performance of the lithium-sulfur battery in the prior art are overcome.

Owner:HEBEI UNIV OF TECH

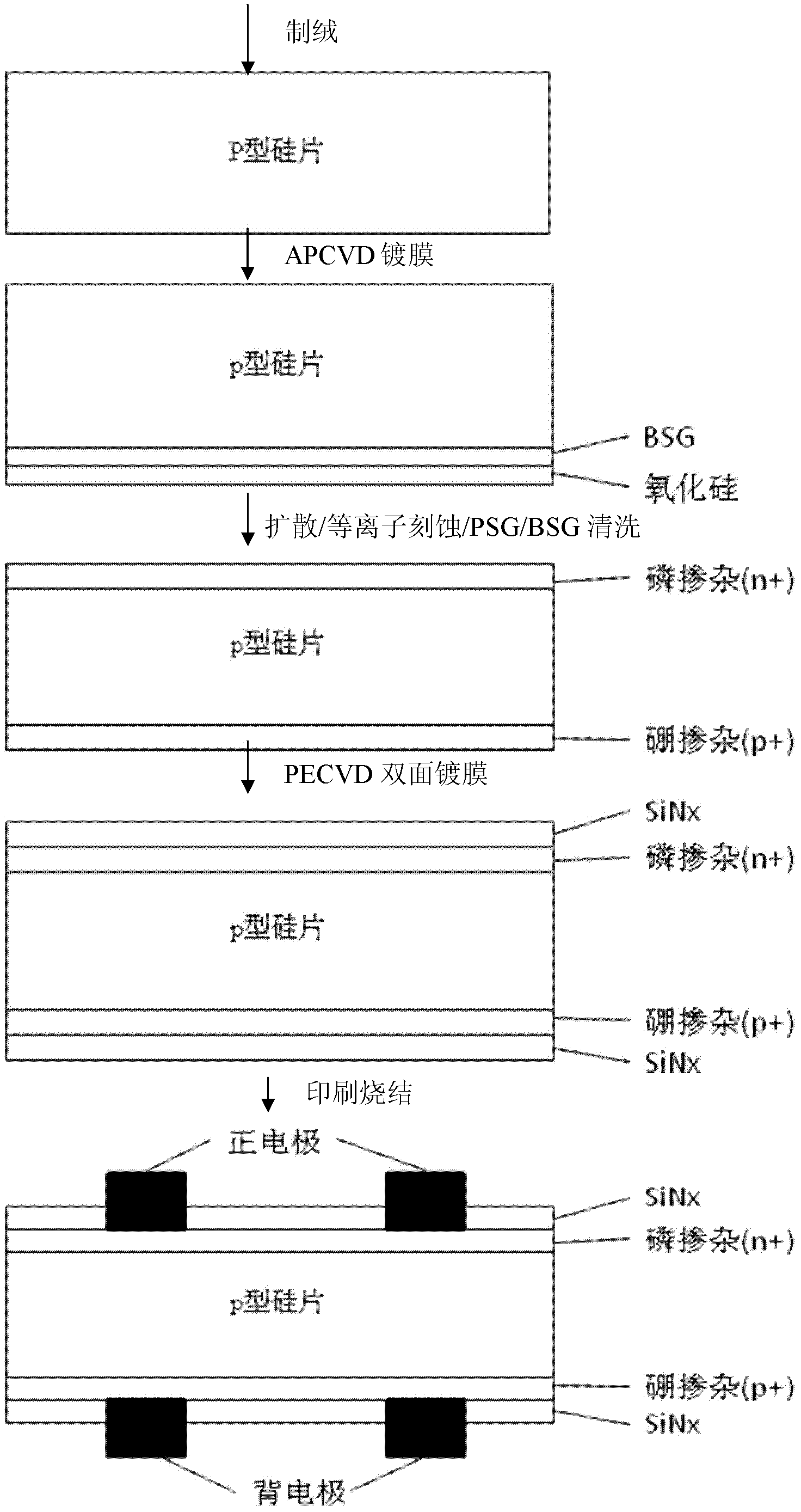

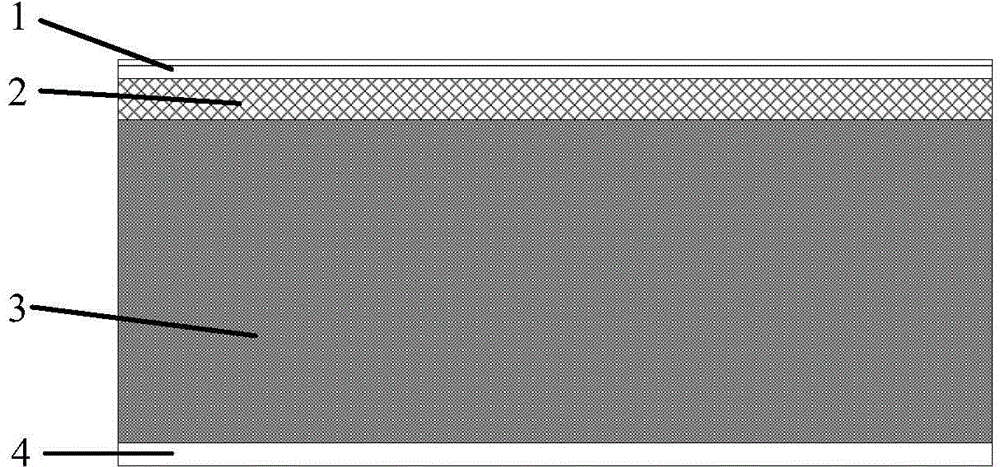

Method for manufacturing PERT crystalline silicon solar battery by adopting novel doping mode

InactiveCN103996744AReduce manufacturing costSimple stepsFinal product manufacturePhotovoltaic energy generationEtchingIndustrial equipment

The invention provides a method for manufacturing a PERT crystalline silicon solar battery by adopting a novel doping mode. The method comprises the steps that texturing is carried out on the single face of a silicon chip, cleaning is carried out, phosphorosilicate glass deposits on the front, borosilicate glass deposits on the back, high-temperature annealing is carried out, n doping layers are formed on the front, p doping layers are formed on the back, plasma edge etching is carried out, the phosphorosilicate glass and the borosilicate glass remaining on the surface of the silicon chip are cleaned and removed, an aluminum oxide / silicon nitride laminating film deposits on the single face of the back, a silicon nitride antireflection film deposits on the front, the film is partially opened from the back so that the boron doping layers can be exposed, a back electrode and an aluminum layer are printed on the back, a silver grid line is printed on the front, and sintering and testing are carried out. The preparing method is simple in step, easy to operate, and capable of efficiently manufacturing the crystalline silicon solar battery in a mass mode, and has the advantages that on the basis of commercialized industrial equipment, conventional battery production equipment possessed by an enterprise production line at present is fully utilized, the equipment investment is greatly reduced, and the manufacturing cost of per watt of the battery is not increased.

Owner:ALTUSVIA ENERGY TAICANG

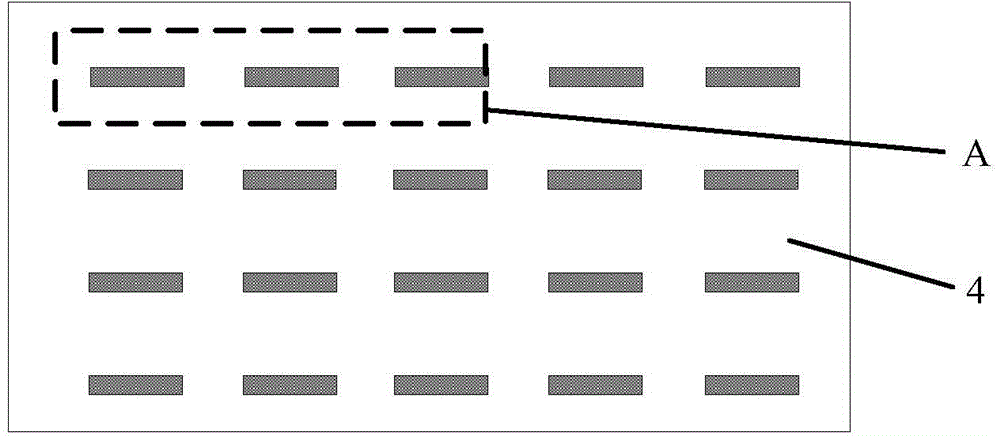

Distributed local boron-doped double-face photoreceptive crystalline silicon solar cell and preparation method thereof

ActiveCN104091842AIncrease the doping concentrationIncrease doping depthFinal product manufacturePhotovoltaic energy generationCrystalline siliconBoron

The invention discloses a distributed local boron-doped double-face photoreceptive crystalline silicon solar cell and a preparation method of the distributed local boron-doped double-face photoreceptive crystalline silicon solar cell. The cell comprises a silicon substrate, an N-type doping region is arranged on the front face of the silicon substrate, a front anti-reflection passivation coating is arranged on the N-type doping region, and a back passivation coating is arranged on the back face of the silicon substrate. The preparation method includes the following steps that part of the back passivation coating is removed on the back passivation coating through distributed short line patterns, the silicon substrate is exposed, and then a plurality of removal passageways are formed; then boron-silicon paste is locally printed so as to cover the removal passageways; then a back electrode layer and a front electrode layer are respectively printed and dried; high-temperature sintering is conducted, the boron-silicon paste in the passageways is removed, a distributed P-type boron heavy doping region is formed on the contact interface of the removal passageways and the silicon substrate, and then a P-type boron heavy doping layer is formed; in the high-temperature sintering process, the front electrode layer and the back electrode layer are formed at the same time. The recombination rate of minority carriers on the contact interface are reduced, open-circuit voltages and conversion efficiency of the cell can be improved, the coating opening area is reduced, and the surface recombination rate is further reduced, wherein the minority carriers are arranged on the back face of the solar cell.

Owner:TRINASOLAR CO LTD

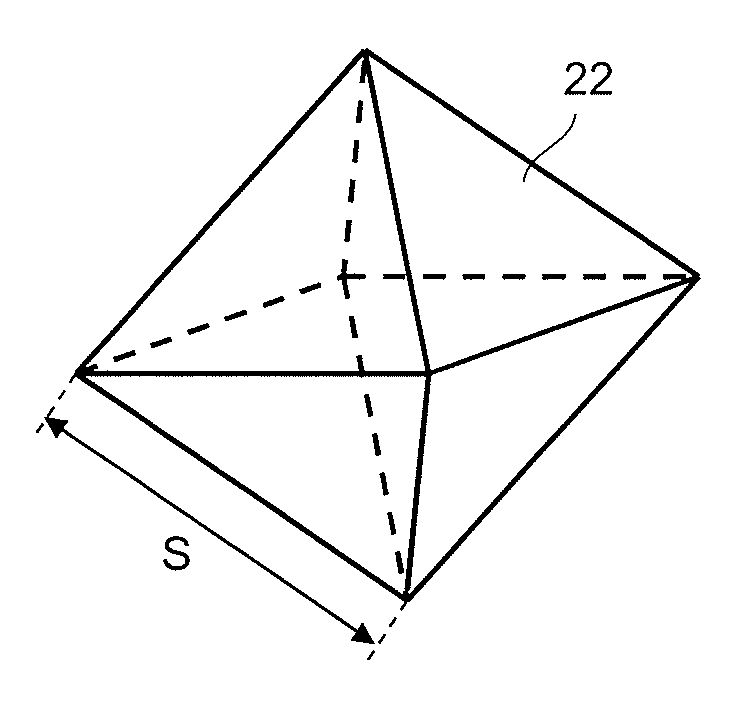

Silicon single crystal, silicon wafer, and epitaxial wafer

InactiveUS20020142170A1Increase widthFew surface defectPolycrystalline material growthBy pulling from meltWaferingSingle crystal

There are provided silicon single crystal, silicon wafer, and epitaxial wafer having a sufficient gettering effect suitable for a large-scale integrated device. The silicon single crystal which is suitable for an epitaxial wafer is grown with nitrogen doping at a concentration of 1x1013 atoms / cm3 or more, or with nitrogen doping at a concentration of 1x1012 atoms / cm3 and carbon doping at a concentration of 0.1x1016-5x1016 atoms / cm3 and / or boron doping at a concentration of 1x1017 atoms / cm3 or more. The silicon wafer is produced by slicing from the silicon single crystal, and an epitaxial layer is grown on a surface of the silicon wafer to produce the epitaxial wafer. The present invention provides an epitaxial wafer for a large-scale integrated device having no defects in a device-active region and having an excellent gettering effect without performance of an extrinsic or intrinsic gettering treatment, which is a factor for increasing the number of production steps and production costs.

Owner:SUMITOMO MITSUBISHI SILICON CORP

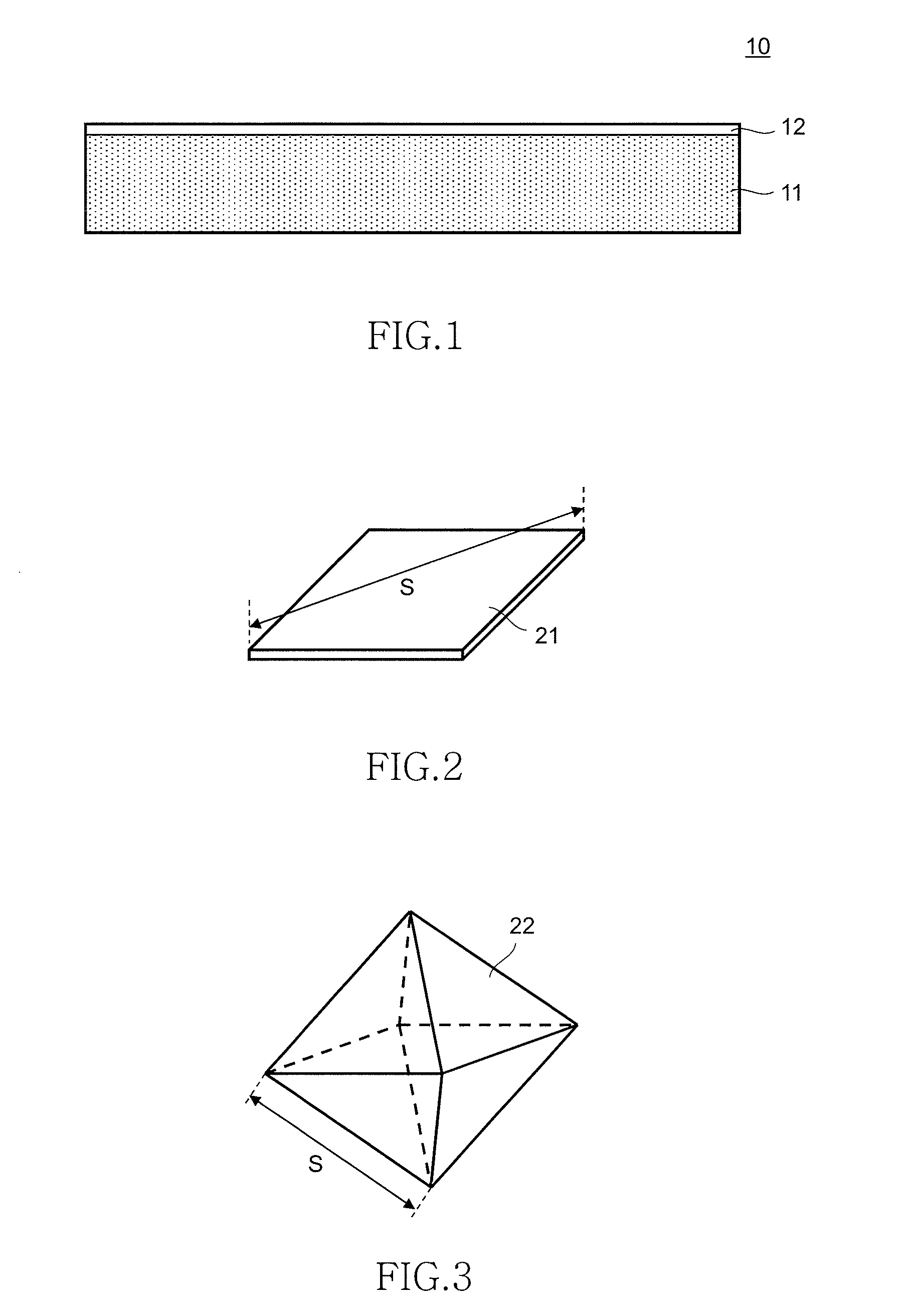

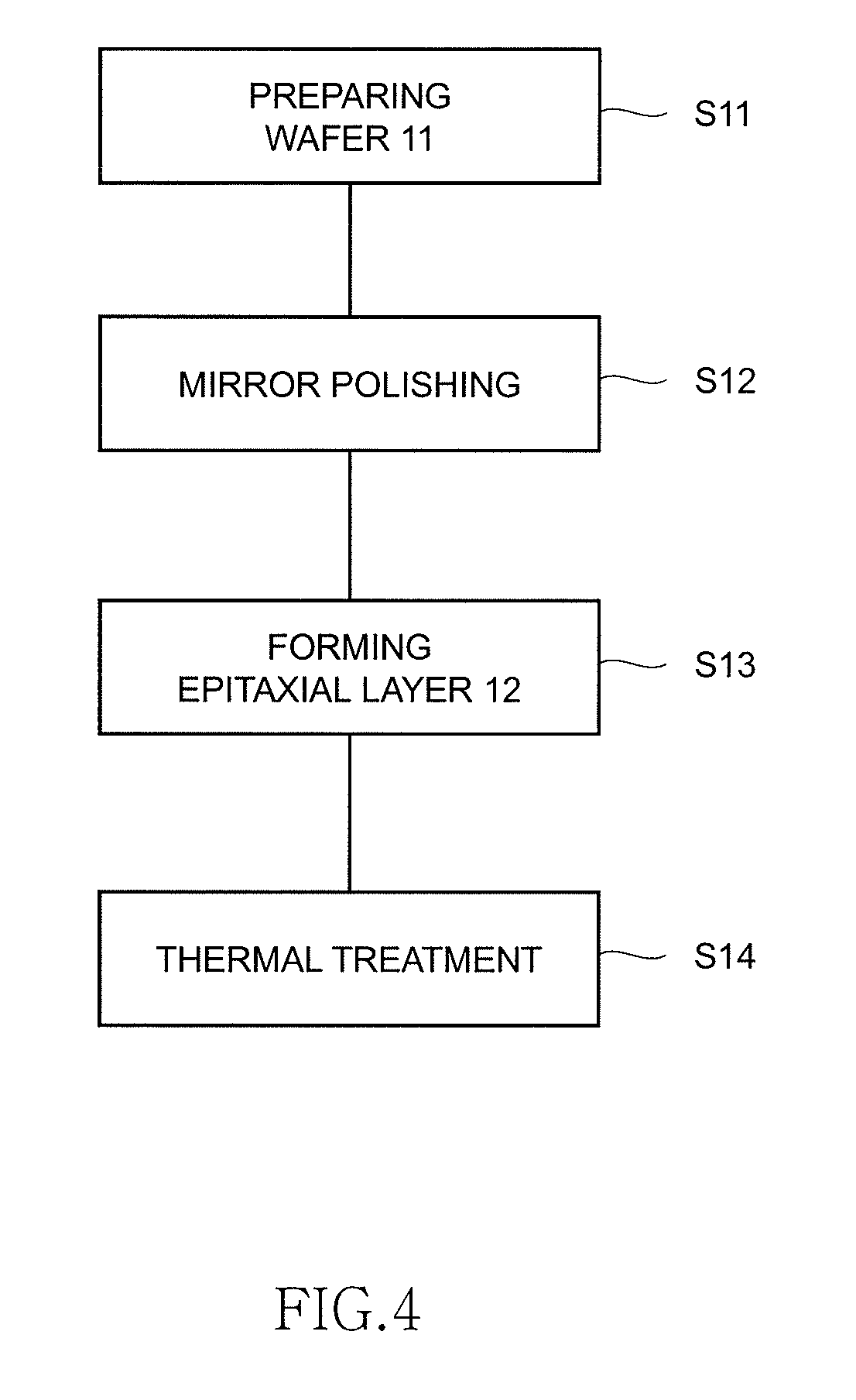

Silicon wafer and method of manufacturing thereof, and method of manufacturing semiconductor device

ActiveUS20120306052A1Avoid misalignmentAvoid it happening againSemiconductor/solid-state device manufacturingSemiconductor devicesNitrogenOxygen precipitates

An object of the present invention is to provide an epitaxial wafer on which dislocation is preventable even when a LSA treatment is performed in device processes. An epitaxial wafer according to the present invention includes a wafer 11 whose nitrogen concentration is 1×1012 atoms / cm3 or more or whose specific resistance is 20 mΩ·cm or less by boron doping, and an epitaxial layer 12 provided on the wafer 11. On the wafer 11, if a thermal treatment is performed at 750° C. for 4 hours and then at 1,000° C. for 4 hours, polyhedron oxygen precipitates grow predominantly over plate-like oxygen precipitates. Therefore, in the device processes, plate-like oxygen precipitates cannot be easily formed. As a result, even when the LSA treatment is performed after various thermal histories in the device processes, it is possible to prevent the dislocation, which is triggered by oxygen precipitates, from generating.

Owner:SUMCO CORP

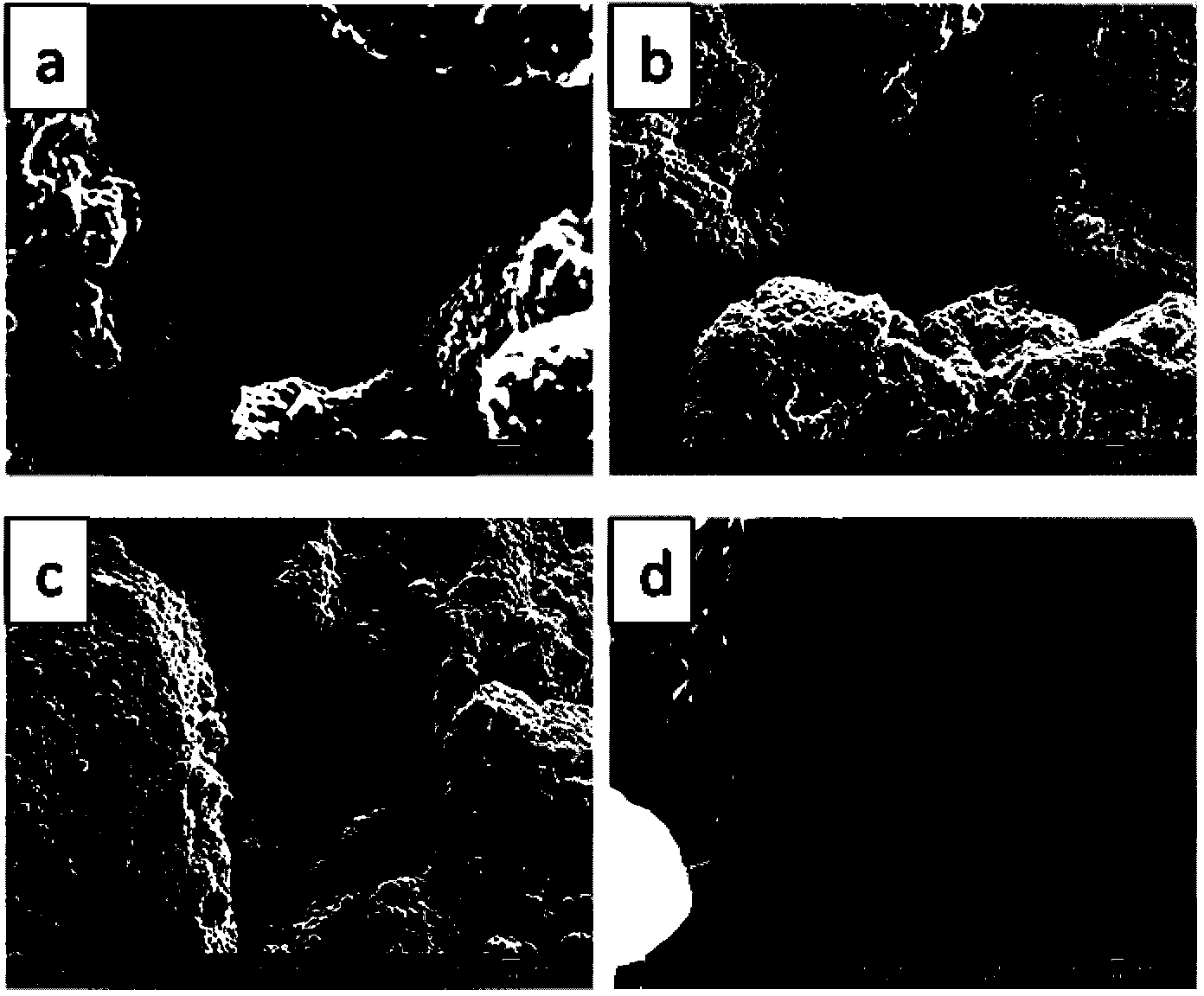

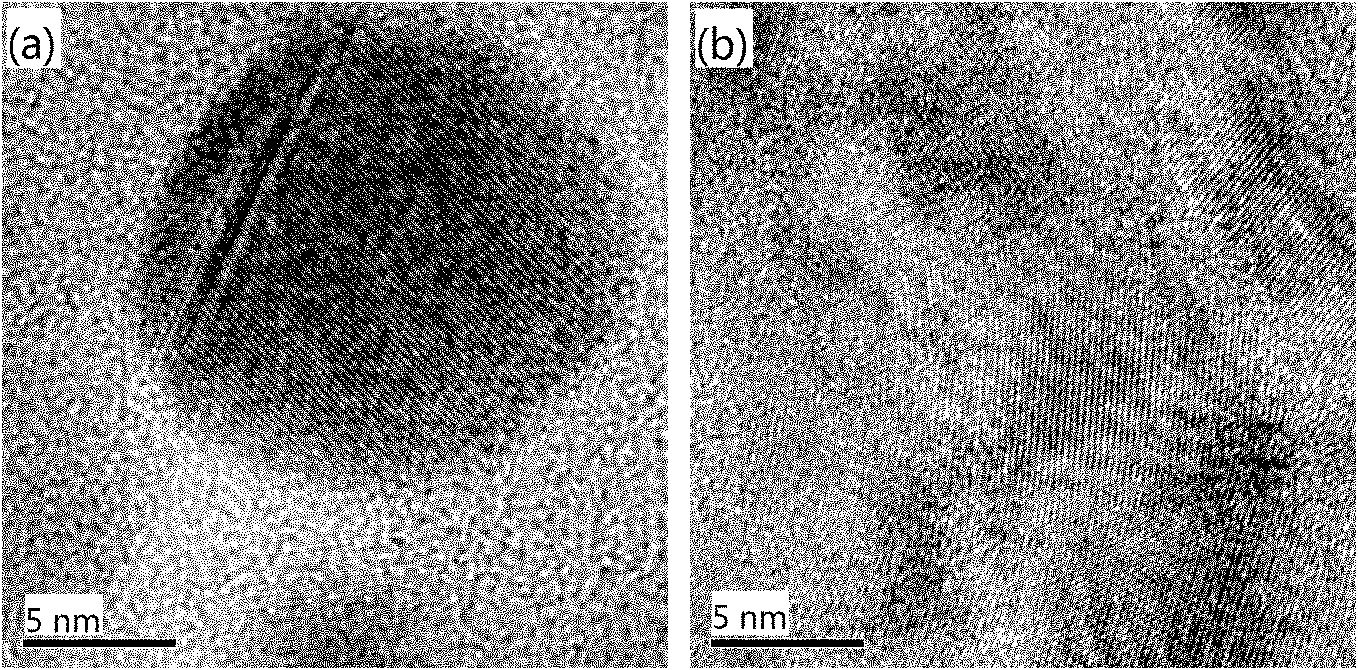

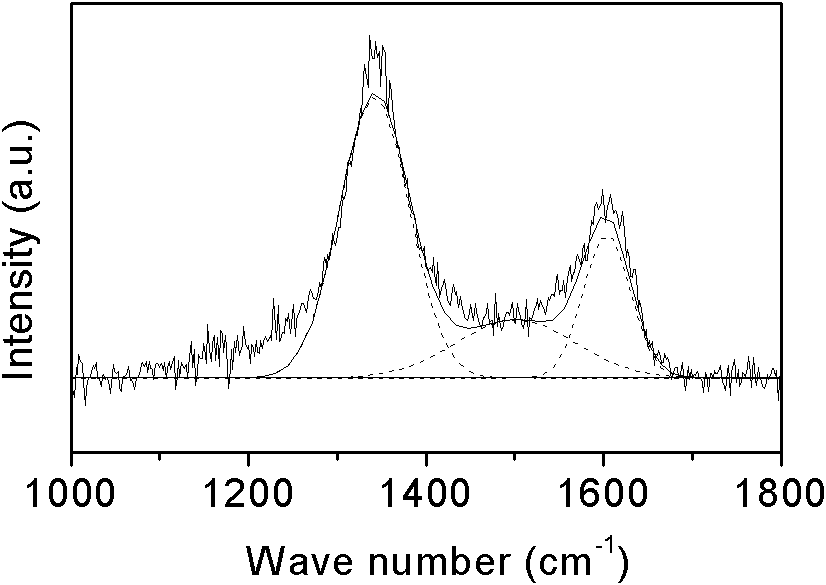

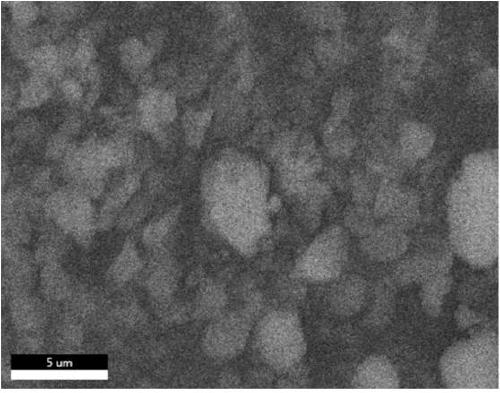

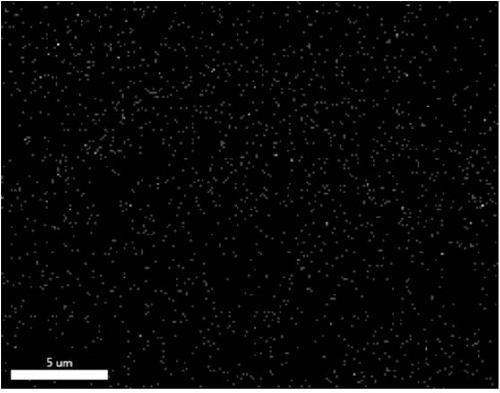

Boron-doped nanocrystalline diamond film and preparation method thereof

InactiveCN101956178AImprove electrochemical performanceImprove conductivityChemical vapor deposition coatingBoron atomElectrochemistry

The invention provides a boron-doped nanocrystalline diamond film. The boron-doped nanocrystalline diamond film is prepared by using the following steps of: preparing a boron-doped nanocrystalline diamond film on a monocrystalline silicon substrate by adopting a CVD (Chemical Vapor Deposition) method and annealing the film in vacuum at 800-1200 DEG C for 30-60 min to obtain the boron-doped nanocrystalline diamond film. By using the vacuum annealing method, the invention ensure that boron atoms aggregated on a grain boundary of the nanocrystalline diamond film are dispersed into nanocrystalline diamond grains and the amount of trans-polyacetylene on the grain boundary is greatly reduced, thereby effectively improving the p-type conductive performance and the electrochemical performance of the boron-doped nanocrystalline diamond film. The invention has very important scientific meaning and engineering values to the application of the boron-doped nanocrystalline diamond film in nano-electronic devices and the electrochemical field, such as water treatment, heavy metal detection, and the like.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of boron-doping carbon nitride as well as product and application thereof

ActiveCN109569691AEvenly dopedImprove photocatalytic performanceWater/sewage treatment by irradiationWater treatment compoundsChemical reactionBoron doped carbon

The invention relates to a preparation method of boron-doping carbon nitride as well as a product and application thereof. By virtue of a hydrothermal reaction way of melamine and boric acid, on one hand, boron atoms have chemical reaction with melamine, so that the boron and carbon-nitrogen elements are mixed in an atomic level; on the other hand, the hydrothermal reaction is performed for the melamine in an acid environment, so that a supermolecule-like structure is formed, and the separation of a carbon nitride lamina structure in the subsequent roasting process can be facilitated; and a precursor synthesized in the reaction is roasted to prepare boron-doped carbon nitride which is uniform in doping and has a thinner lamina structure. The boron-doping carbon nitride prepared by adoptingthe preparation method of the invention is uniform in element doping, thinner in lamina, better in optical catalysis, simple in preparation operation, low in difficulty and suitable for enlarged production.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Method for removing front polycrystalline silicon winding plating

ActiveCN111341881AControl reaction rateMeet mass production needsFinal product manufacturePhotovoltaic energy generationAmorphous siliconSingle crystal

The invention relates to a method for removing front polycrystalline silicon winding plating. The method comprises the following steps: (1) performing boron diffusion on the front surface of a siliconwafer to form a p + emitter and a front borosilicate glass layer; (2) etching the back surface of the silicon wafer, etching the back surface into a plane, removing the boron-doped layer and the borosilicate glass layer on the back surface and the periphery, and removing the front borosilicate glass layer; (3) growing a tunneling oxide layer and an intrinsic amorphous silicon layer on the back surface of the silicon wafer, and forming a front winding polycrystalline silicon layer on the edge region of the front surface of the silicon wafer; (4) carrying out ion implantation on the intrinsic amorphous silicon layer to form a phosphorosilicate glass layer, and performing annealing to form a phosphorus-doped polycrystalline silicon layer; (5) plating a silicon nitride layer on the phosphorus-doped polycrystalline silicon layer; (6) placing the silicon wafer in a mixed solution of alkali and a single crystal additive to remove the front winding polycrystalline silicon layer; and (7) plating aluminum oxide layers on the two sides of the silicon wafer, and plating a passivation antireflection film layer on the aluminum oxide layer on the front side. According to the method, the reactionrate of the alkali liquor in the alkali winding plating solution and the winding plating polycrystalline silicon can be well controlled, and reaction windows can be increased.

Owner:TAIZHOU ZHONGLAI PHOTOELECTRIC TECH CO LTD

Diamond transistor and method of manufacture thereof

InactiveUS7981721B2Reduce surface roughnessReduce step heightTransistorPolycrystalline material growthDelta dopingEngineering

A method of manufacturing a transistor, typically a MESFET, includes providing a substrate including single crystal diamond material having a growth surface on which further layers of diamond material can be deposited. The substrate is preferably formed by a CVD process and has high purity. The growth surface has a root-mean-square roughness of 3 nm or less, or is free of steps or protrusions larger than 3 nm. Further diamond layers are deposited on the growth surface to define the active regions of the transistor. An optional n+ shielding layer can be formed in or on the substrate, following which an additional layer of high purity diamond is deposited. A layer of intrinsic diamond may be formed directly on the upper surface of the high purity layer, followed by a boron doped (“delta doped”) layer. A trench is formed in the delta doped layer to define a gate region.

Owner:DIAMOND MICROWAVE DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com