Production method of titanium-based boron-doping diamond coating electrode

A boron-doped diamond, coating electrode technology, applied in metal material coating process, electrode, coating and other directions, can solve the problem of corrosion resistance, easy passivation, poor bonding performance between boron-doped diamond coating and substrate, easy to fall off, cost Low cost, to achieve the effect of cost saving, excellent bonding performance of film base and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing a titanium-based boron-doped diamond coated electrode, comprising the following steps:

[0030] First, use diamond sandpaper with a particle size of 40 microns and 10 microns to polish the surface of the pure titanium plate as the base material 1 for 5-10 minutes respectively;

[0031] Secondly, the polished pure titanium plate is ultrasonically cleaned in alcohol for 2-3 times for 10 minutes each time to complete the sputtering pretreatment of the dull titanium plate;

[0032] Third, place the blunt titanium plate pretreated by sputtering in a sputtering device for sputtering, and form a sputtering transition layer 2 with a thickness of 100-500 nanometers on the surface of the blunt titanium plate; DC magnetron sputtering is used during sputtering sputtering technology, the sputtering target is niobium or tantalum, the magnetron sputtering parameters are: current 0.5~1.5A, voltage 100~140V, background vacuum 0.001~0.01Pa, working gas is argon, ga...

Embodiment 1

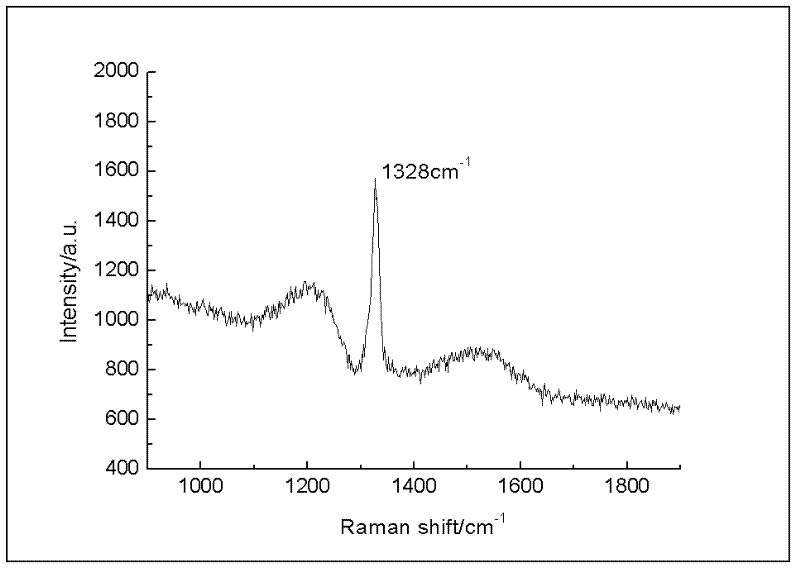

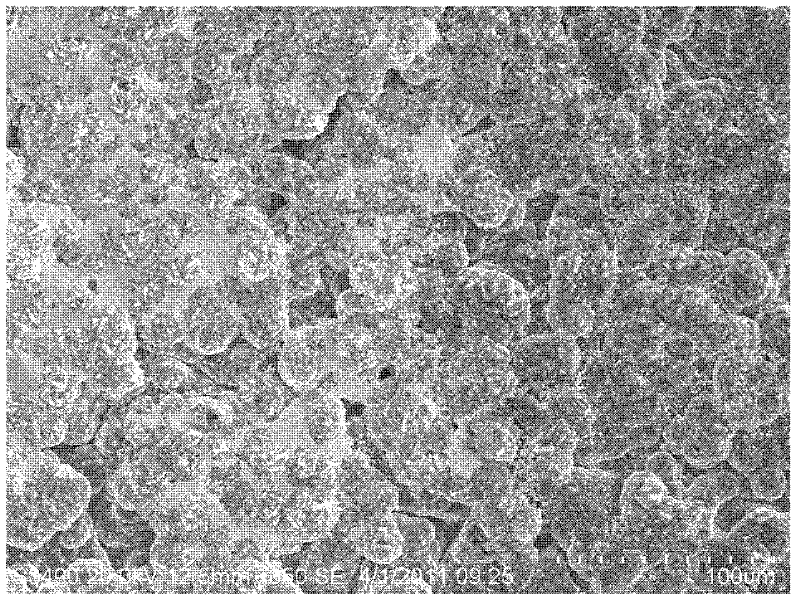

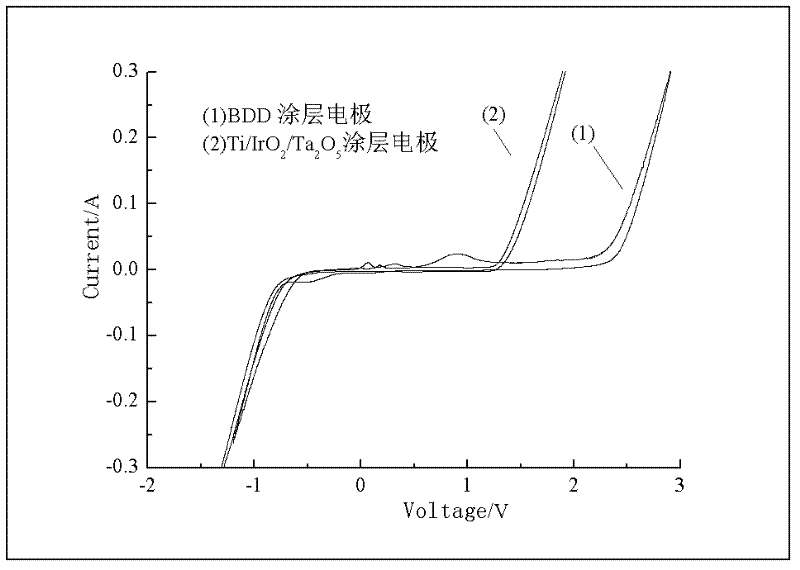

[0040]Grind the titanium plate with W40 and W10 sandpaper for 5~10min respectively, and ultrasonically clean it with alcohol for 10min, twice. A tantalum transition layer of 400 nm was sputtered on titanium by DC magnetron sputtering. The sputtering parameters were the substrate temperature of 400 °C, the current of 1.2 A, the voltage of 110 V, the background vacuum of 0.005 Pa, the working gas of argon, and the pressure of 1.5 Pa. . The samples obtained by sputtering were pickled in 5 mol / L HCl solution, the temperature of the constant temperature water bath was set at 70-90 ℃ for 30 minutes, and then ultrasonically cleaned in the alcohol suspension prepared by W0.5 and W0.2 diamond mixed powder 30min for pretreatment, seeding, and then ultrasonic cleaning with alcohol for 2-3 minutes, 2-4 minutes each time. The BDD coating was deposited on the transition layer by HFCVD. The deposition parameters were the distance from the hot wire to the substrate 6 mm, the hot wire tempera...

example 2

[0045] Grind the titanium plate with W40 and W10 sandpaper for 5~10min respectively, and ultrasonically clean it with alcohol for 10min, 3 times. A 100nm niobium transition layer was sputtered on titanium by DC magnetron sputtering. The sputtering parameters were substrate temperature of 600°C, current of 0.5A, voltage of 100V, background vacuum of 0.001Pa, working gas of argon, and pressure of 0.4Pa. . The samples obtained by sputtering were pickled in 10mol / L HCl solution, the temperature of the constant temperature water bath was set at 70-90℃ for 30min, and then ultrasonically cleaned in the alcohol suspension prepared by W0.5 and W0.2 diamond mixed powder After 30min seed crystal pretreatment, ultrasonic cleaning was carried out in alcohol solution 2-3 times for 4 minutes each time. The BDD coating was deposited on the transition layer by HFCVD. The deposition parameters were the distance from the hot wire to the substrate 8m, the hot wire temperature 2500℃, the substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com