Method for removing front polycrystalline silicon winding plating

A technology of polycrystalline silicon and polycrystalline silicon layer, applied in the field of solar cells, can solve the problems of increasing process cost, narrow process window, increasing machine equipment, etc., and achieve the effect of reducing production cost, increasing reaction window, and meeting mass production requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

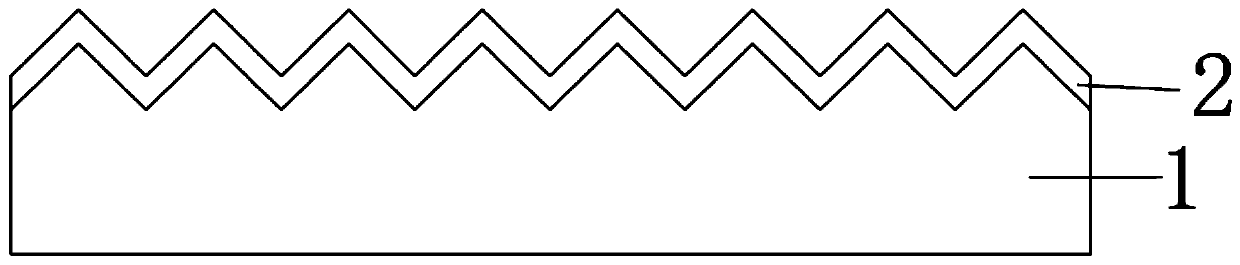

[0076] (1) Take a silicon substrate 1 with a resistivity of 1Ω·cm and a thickness of 160 μm, and place the silicon substrate 1 with a resistivity of 1Ω·cm and a thickness of 160 μm in an alkaline solution, so that the back surface and the front surface of the silicon substrate 1 The surface is made of suede.

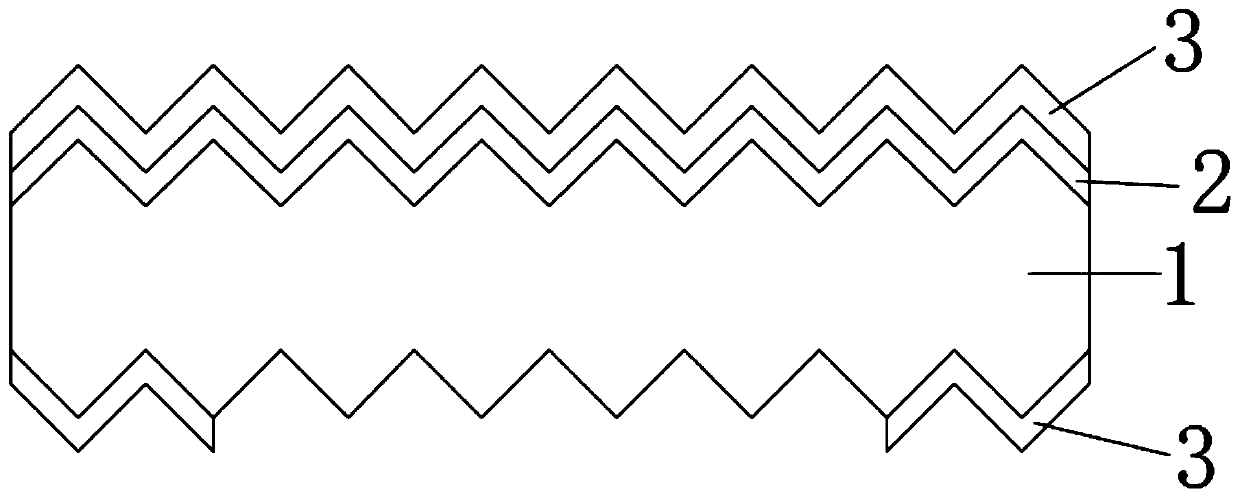

[0077] (2) Boron diffusion is carried out on the front side of the silicon wafer after alkali texturing to form the p+ emitter 2 and the front borosilicate glass layer 3 on the front side of the silicon wafer; during the boron diffusion process, part of the boron atoms diffuse to the back edge of the silicon substrate 1 area, and form the back borosilicate glass layer 3 in the edge area. Complete the battery structure of this step as figure 1 shown.

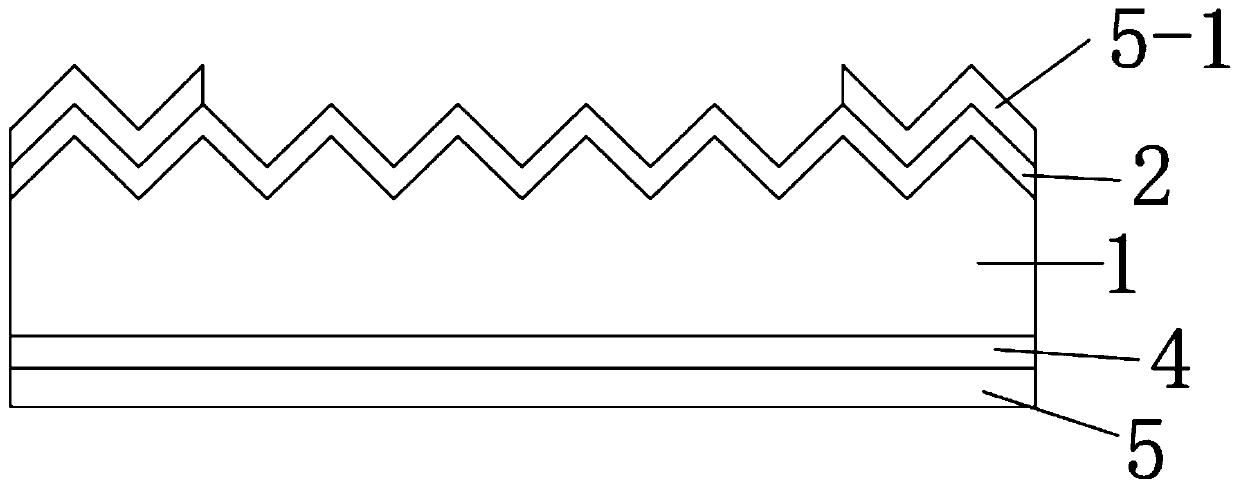

[0078] (3) Place the backside of the silicon wafer treated in step (2) in a mixed acid system of hydrofluoric acid and nitric acid for wet etching. The textured surface on the back of the silicon wafer is etched into a p...

Embodiment 2

[0088] (1) Take a silicon substrate 1 with a resistivity of 0.3Ω·cm and a thickness of 90 μm, and place the silicon substrate 1 with a resistivity of 0.3Ω·cm and a thickness of 90 μm in an alkaline solution, so that on the back of the silicon substrate 1 Both the surface and the front surface form a textured surface.

[0089] (2) Boron diffusion is carried out on the front side of the silicon wafer after alkali texturing to form the p+ emitter 2 and the front borosilicate glass layer 3 on the front side of the silicon wafer; during the boron diffusion process, part of the boron atoms diffuse to the back edge of the silicon substrate 1 area, and form the back borosilicate glass layer 3 in the edge area. Complete the battery structure of this step as figure 1 shown.

[0090] (3) Place the backside of the silicon wafer treated in step (2) in a mixed acid system of hydrofluoric acid and nitric acid for wet etching. The textured surface on the back of the silicon wafer is etched...

Embodiment 3

[0100] (1) Take a silicon substrate 1 with a resistivity of 10Ω·cm and a thickness of 300 μm, and place the silicon substrate 1 with a resistivity of 10Ω·cm and a thickness of 300 μm in an alkaline solution, so that on the back surface and the front surface of the silicon substrate 1 The surface is made of suede.

[0101] (2) Boron diffusion is carried out on the front side of the silicon wafer after alkali texturing to form the p+ emitter 2 and the front borosilicate glass layer 3 on the front side of the silicon wafer; during the boron diffusion process, part of the boron atoms diffuse to the back edge of the silicon substrate 1 area, and form the back borosilicate glass layer 3 in the edge area. Complete the battery structure of this step as figure 1 shown.

[0102] (3) Place the backside of the silicon wafer treated in step (2) in a mixed acid system of hydrofluoric acid and nitric acid for wet etching. The textured surface on the back of the silicon wafer is etched int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com